Dakota Digital SERIES II STR3D, SERIES II STR4D, SERIES II STR5D, SERIES II STR6D User Manual

Page 1

VACUUM FLUORESCENT DIGITAL DASHBOARD

SERIES II

The latest in digital dashboard technology for the

street rodder, car, and truck enthusiast.

INSTALLATION AND OPERATION MANUAL

Please read this before beginning installation or wiring.

MODELS STR3D, STR4D, STR5D, & STR6D

3421 W. Hovland Ave.

Sioux Falls, SD 57107

Phone: (605) 332-6513

FAX: (605) 339-4106

Page 2

Thank you for purchasing the Vacuum Fluorescent Digital Dashboard from DAKOTA

DIGITAL, the leader in custom automotive electronics. Representing the latest electronics

dashboard technology for the street rodder, car, and truck enthusiast alike, the digital

instrumentation uses state of the art vacuum fluorescent display technology to give the driver

up to date and accurate information on the operation of his or her vehicle. As used in several

production automobiles, vacuum fluorescent displays give superior performance and visual

appeal over LCD or LED display systems. Emitting a blue/green light that can be filtered to a

wide variety of colors, the VFD system boasts excellent daytime visibility and while under

computer control, automatically dims for nighttime driving. Using microprocessor technology,

the digital dashboard gives the driver additional features and benefits not typically found on any

other brand or type of instrumentation. Digital accuracy and solid state reliability will give you,

the driver, quality service for miles down the road.

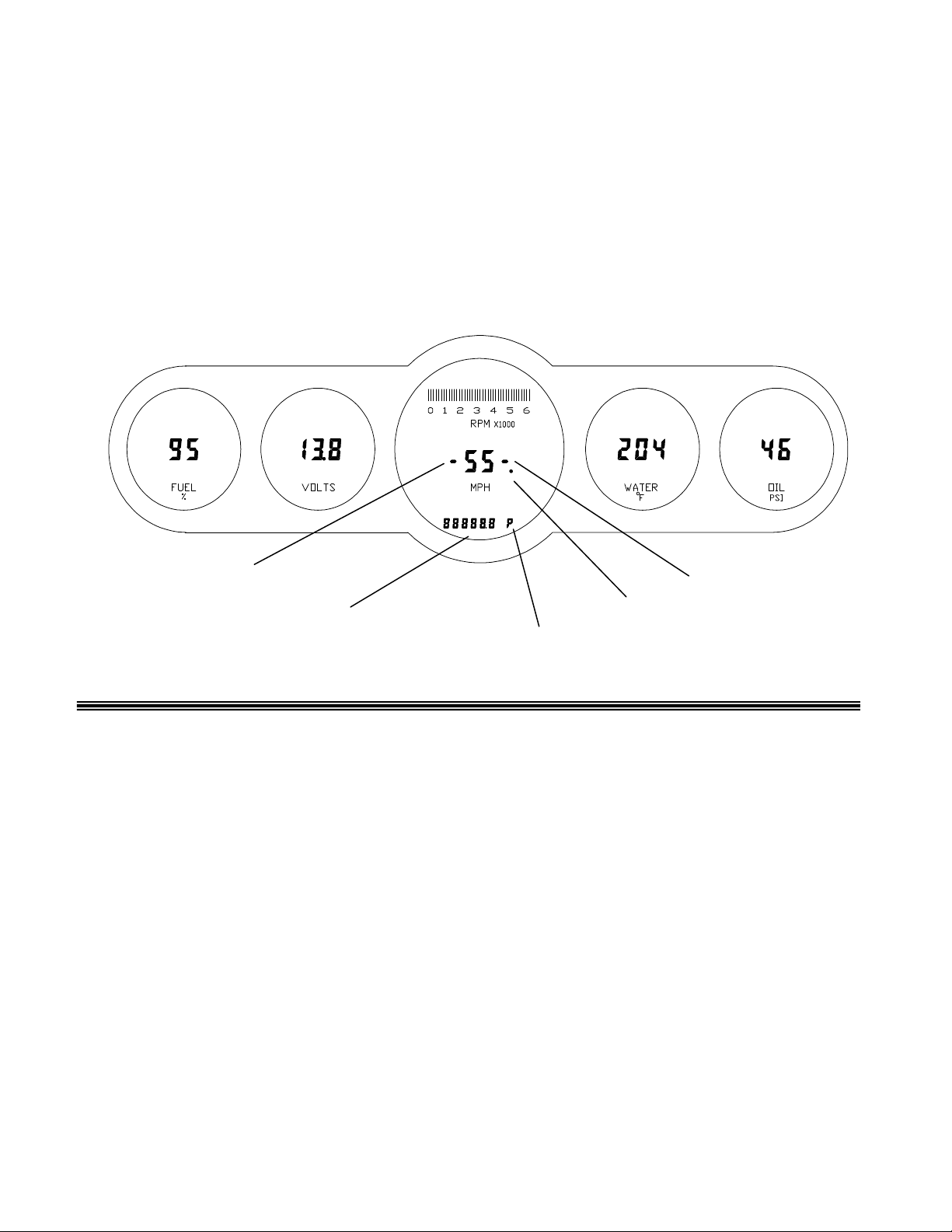

Left turn signal Right turn signal

High beam indicator

Odometer/trip odometer

Gear shift indicator (requires optional sender)

DISPLAY FEATURES

Your DAKOTA DIGITAL instrumentation panel has many features, some of which you

will not be able to see until the instrumentation is completely wired and installed. The turn

signals and the high beam indicators are part of the digital speedometer display therefore you

will not see them before the instrumentation is installed. If your panel is a year specific street

rod panel you may also have additional green and or red LED's which also can be used for turn

signals and high beam indicators. These panels allow you to use either the indicators that are a

part of your speedometer, or the LED's.

The odometer is the bottom display of the speedometer area. This is the same display

that will function as the resettable trip-odometer. The digit furthest to the right of the odometer

will become your gear shift indicator if you purchased the optional gear shift sending unit. Every

DAKOTA DIGITAL instrumentation panel is equipped with this indicator. If you did not originally

order a gear shift sending unit, and would like to have a gear shift indicator, you may order the

sending unit at anytime and when properly installed, the gear shift indicator will operate.

A demonstration mode or “show” mode is also built into the system. Pressing and

holding the TRIP switch for 7-8 seconds with power on will start the gauges going in an

animated sequence. Pressing the RESET switch will exit the demonstration mode.

2

Page 3

WARNING

The vacuum fluorescent displays are made of glass and should be handled with care. Use

extreme care around the glass evacuation tubes (small tubes at the bottom of each

display) as bumping them may cause breakage and render the display useless.

MOUNTING DISPLAY SYSTEMS WITH SUBPANELS

When mounting instrumentation systems mounted to a Lexan subpanel, begin by

removing the subpanel from the aluminum. Cut an opening in the dash just smaller than the

outer dimensions of the aluminum panel. Remove all nuts and washers from the studs on the

back side of the panel and insert into the hole. Next, install four washers or clips and secure

with a nut on each. This is what holds the panel to the dashboard. Now, install a nut on each

stud and set the display panel in place over the studs. If the studs were bent slightly inward

from securing the aluminum panel, you may have to bend them outward to line up with the holes

on the lectern subpanel. Always lay the display panel aside when not in use to avoid

accidentally damaging the displays. Once aligned, secure it with an additional four nuts. Leave

a gap of no less than 1/8" between the display glass and the front lens material. Be careful not

to compress the glass against the front lens. Again, note that the displays are glass and should

be handled with care. Use extreme care around the glass evacuation tubes (small tubes at the

bottom of each display) as bumping them may cause breakage and render the display useless.

MOUNTING SYSTEMS WITH DISPLAYS MOUNTED TO ALUMINUM

When mounting year specific aluminum panel, cut an opening into the dashboard if

necessary and secure the entire panel with the instrumentation using the appropriate mounting

hardware. Some panels are set into the front of the dash while others are installed from the rear

of the dash. The exact mounting configuration will depend on what year car and panel you are

installing.

MOUNTING SINGLE LENS SYSTEMS

Your DAKOTA DIGITAL single lens system will come to you with a single plexiglass lens

and instrumentation that is mounted in an aluminum case. The lens and the instrumentation

have corresponding mounting holes. After you have affixed the mounting studs of your choice

to the backside of your dash, the lens piece should be slid over the studs followed by the display

system. The lens can be secured with either washers and nuts, or by a bead of RTV around the

back side of the lens and case. If RTV is used, the system will need to be held in place until it

has had time to cure. The lens should be tight against the aluminum display case.

3

Page 4

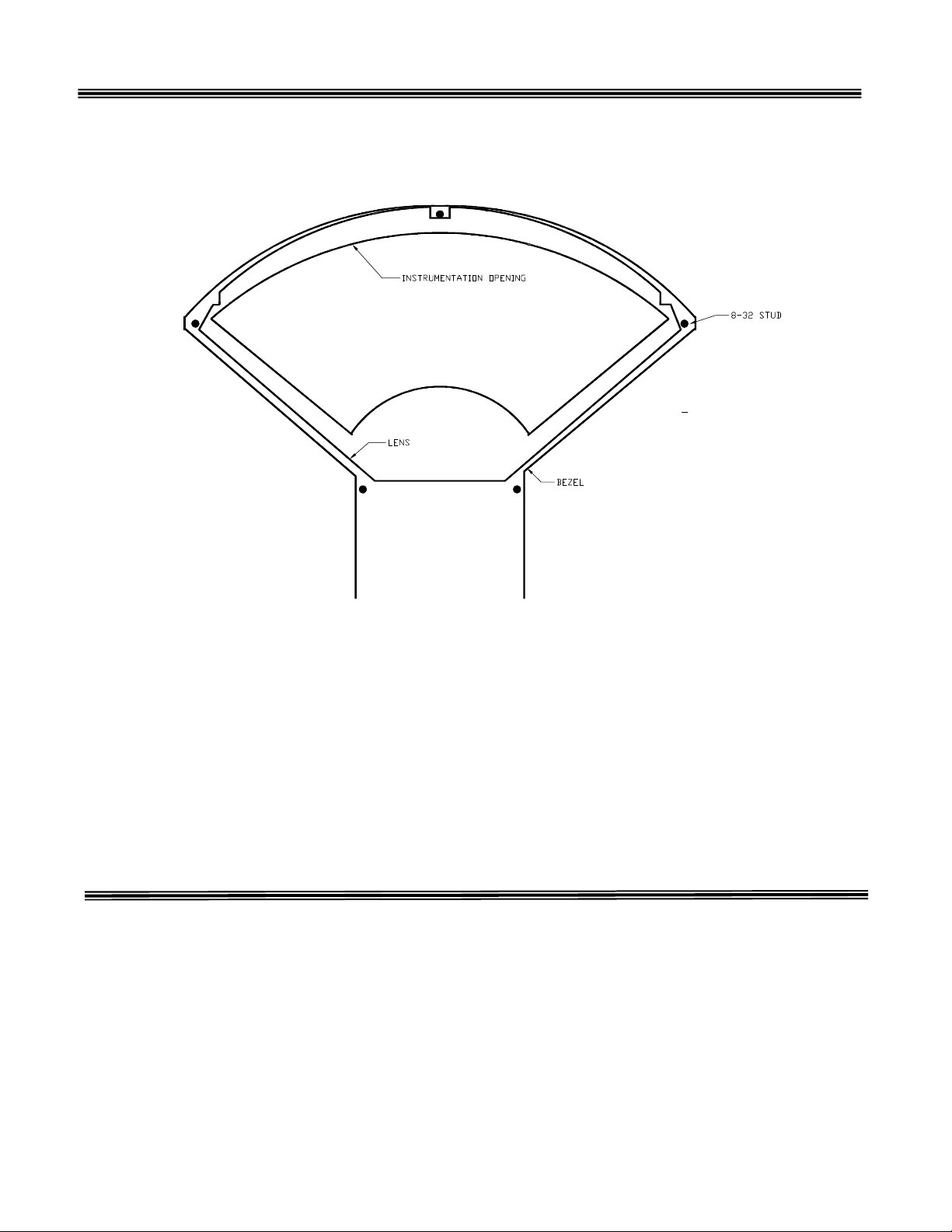

MOUNTING KITS INTO ORIGINAL DASHES

When installing the display system into the original bezel, several steps must be taken to

prepare the bezel. The first is to remove the cluster from the dashboard and all instrumentation

from the bezel. You should essentially be left with a bare chrome or metal bezel. Remove all

felt inserts from the back side of the bezel that sit between the lens and the chrome.

55-56 Chevy car chrome bezel shown with lens and display opening outlines.

Next, take the supplied lens, with the lettering facing the front of the dash and place it in

the chrome bezel. Lay a bead of RTV around the back side of the lens to secure it in place.

After the RTV has cured, the display panel is ready to be placed on the bezel. If studs were

supplied with the panel, screw them into the bezel and place a nut on them before placing the

display system on it.

Be very careful not to hit the displays against anything as they are glass and will break.

Adjust the height of the panel so that the glass displays are 1/8" away from the front lens.

Applying a lock washer and nut to the studs behind the display panel, secure the display panel

to the bezel. If screws were provided with the panel, secure them through the display panel and

into the bezel. No additional holes should need to be drilled. All holes in the display systems

are pre-drilled at the factory.

CONTROL BOX

Once the display panel is in place, mount the control box within the connecting cable's

distance (approximately 3 feet) and secure to the underside of the dashboard. This case does

not have to be mounted to metal, but by doing so you will provide a better ground to the control

box. When connecting the display cable to the unit, be very sure to pay attention to the "up"

side of the connector. Align the connector in the socket and press firmly into the control box.

The connector locks will secure the connector. Some systems also have a 2-wire connector

from the display panel that must also be connected. This plugs in next to the flat gray cable.

4

Page 5

Wiring the control box into the vehicle.

+12V

Connect the +12V terminal to accessory power from the fuse panel or vehicle wiring

harness. This terminal should have power when the key is on or in accessory position. In

addition to powering the display system, this is also where the voltmeter gauge senses the

vehicle electrical system voltage.

Use 20 AWG or larger wire to ensure the system gets good power.

Never connect this to a battery charger alone. It needs to have a 12 volt battery

connected to it. Battery chargers have an unregulated voltage output that will cause the system

to not operate properly.

GROUND

This is the main ground for the display system. A wire should be run from this terminal to

the vehicle’s main ground location at the chassis or engine block. This ground wire should also

be connected to the control box case. One of the mounting screws or case lid screws can be

used for this. Do not use the dash or a dash support brace for the ground connection.

Use 18 AWG or larger wire to ensure sufficient grounding. Proper vehicle grounding is

extremely important for the gauges to read and operate correctly. The engine block should

have heavy ground cables to the battery, frame, firewall, and body. Failure to properly ground

the engine block or the control box can cause incorrect or erratic operation.

DIMMING

The gauges are designed to dim down when the headlights are turned on. This is to

reduce the display intensity at night so the gauges do not cause eye strain or reduced night

vision. Connect this to the tail light or parking light circuit so that it has 12 volts whenever the

headlights are on. When this terminal does not have power the display system will be at full

brightness. When power is applied, the display dims to an adjustable level. The night

brightness level is adjustable two different ways.

The default method is to have the system to dim to a preset level when the lights are

turned on. This brightness is adjusted by turning the shaft protruding from right side of the

control box, next to the display system connector. Turning the shaft clockwise will decrease the

brightness. The shaft will rotate ¾ turn from stop to stop. Do not attempt turn it past the stops.

See DIM ADJ for a description of the second method.

DIM ADJ

The second method allows you to have a dash mounted control to vary the brightness

while the headlights are on. This requires a 10k potentiometer or Dakota Digital’s DIM-1 kit. A

stock headlight rheostat will not work. The dash mount dimmer has two wires, one connects to

the DIM ADJ terminal and the other connects to ground. To allow the dash mount dimmer to

have full control, the shaft on the side of the control box must be turned fully counter-clockwise.

The dash mount dimmer will only vary the display brightness when the DIMMING terminal has

power.

5

Page 6

SPEED

The vehicle speed sensor (VSS) connects to this to tell the system how fast the vehicle is

moving. For two wire speed sensors, like the one Dakota Digital supplies with this system, the

polarity of the wires does not matter. Connect one wire to ground and the other to the speed

terminal. The speed sensor ground wire should be brought back to the control box to ensure a

proper signal is received. Twisting the ground and signal wires around each other provides an

additional level of interference protection. The speed signal wire should not be routed along

side ignition or other high current or high voltage wires.

For vehicles which already have a vehicle speed signal, tap into the VSS wire and

connect it to the speed terminal. You may have to consult a vehicle service manual or wiring

diagram to determine wire color and location.

This system can accept 4000 ppm – 128000 ppm speed signals. The sensor that Dakota

Digital provides is an 8000 ppm type. The speedometer is fully adjustable and calibration is

discussed in a later section. Failure to calibrate the speedometer may cause your odometer mileage to

increase very rapidly if the speedometer is reading too fast.

TACH

Depending on the type of system that you have there may be no tachometer, a bar graph

tachometer, a digital tachometer, or both bar graph and digital readouts. Connect the tach

terminal to the ignition system. On vehicles using a separate ignition coil, connect to the

negative side of the coil. The negative side of the coil will be the wire that goes to the points or

electronic ignition module. For GM HEI ignition equipped motors, connect the tach terminal to

the terminal marked “TACH” or on some systems, to a single white wire with a spade terminal

on it. On MSD ignition systems, connect to the TACH output terminal. With magneto system

connect to the kill wire for the tach signal. Do not connect the TACH terminal to the secondary,

or high voltage side, of the ignition coil. To ensure that the ignition system does not interfere

with any other dashboard functions, do not run the tachometer wire along side any other sender

or input wires. DO NOT USE SOLID CORE SPARK PLUG WIRES WITH THIS DASHBOARD

SYSTEM. Solid core ignition wires cause a large amount of electromagnetic and radio

frequency interference which can disrupt the system operation.

The tachometer is compatible with 4, 6, 8, and 10 cylinder gasoline engines. There are

DIP programming switches inside the control box that set the number of cylinders, tach bar

graph full scale range, and tach display type. These settings are discussed later in the section

on internal adjustments. If a diesel engine is being used and the alternator has a tach output,

then Dakota Digital’s DSL-1 interface will convert the alternator signal to operate the

tachometer.

WATER

The water temperature sender included with this system must be used. Other senders

will cause incorrect readings. The sender mounts on the engine block or into the intake

manifold so that the end of the sensor is in the engine coolant flow. The sender gets its

electrical ground connection to the engine block through its threads. Do not use Teflon tape or

thread sealant on the sender threads. Doing so can cause incorrect readings or cause the

gauge to display an out of range indication. A sender with 3/8 NPT thread size is normally

included and 1/8 NPT thread size is available. If the engine you have requires a different thread

size you will need to use an adapter to convert the thread size. Adapters can be found at your

local auto parts dealer or hardware store.

6

Page 7

A single wire should be run from the terminal on top of the water sender to the control

box terminal marked WATER. If your wiring harness already has a wire routed through the

vehicle for the water temperature then it may be used. Do not route the water sender wire along

side a spark plug wire or other high current or high voltage wires. Doing so can cause incorrect

or erratic gauge readings.

If the water display shows “---“ this indicates that the control box is sensing a short to

ground or out-of-range error from the sender or sender wire. If the water display shows “EEE”

this indicates that the control box is sensing an open circuit or out-of-range error from the

sender or sender wire. If either indication remains on the display, inspect the sender wire for

damage, check the routing of the sender wire, check the sending unit grounding, and check that

the correct sending unit is connected. The sending unit should be stamped with “VDO” and

“150°C”.

Replacement sender part numbers are:

Dakota Digital VDO equivalent

1/8” NPT SEN-04-1 323 057

3/8” NPT SEN-04-2 323 059

½” NPT SEN-04-4 323 060

12mm SEN-04-6 323 092

OIL

The oil pressure sender included with this system must be used. Other senders will

cause incorrect readings. If the sender mounting location is too small or is restricted, then pipe

fittings may be required to move the sender away from the restrictions. Oil pressure line may

also be used to remote mount the sender to the fire wall. The sender gets its electrical ground

connection to the engine block through its threads. Do not use Teflon tape or thread sealant on

the sender threads. Doing so can cause incorrect readings or cause the gauge to display an

out-of-range indication. If the sender is being remote mounted away from the engine, make

sure the sender case is ground well. The sender has 1/8 NPT thread size. If the engine you

have requires a different thread size you will need to use an adapter to convert the thread size.

Adapters can be found at your local auto parts dealer or hardware store.

A single wire should be run from the terminal on top of the oil sender to the control box

terminal marked OIL. If your wiring harness already has a wire routed through the vehicle for

the oil sender then it may be used. Do not route the oil sender wire along side a spark plug wire

or other high current or high voltage wires. Doing so can cause incorrect or erratic gauge

readings.

If the oil display shows “—“ this indicates that the control box is sensing a short to ground

or out-of-range error from the sender or sender wire. If the oil display shows “EE” this indicates

that the control box is sensing an open circuit or out-of-range error from the sender. If either

indication remains on the display, inspect the sender wire for damage, check the routing of the

sender wire, check the sending unit grounding, and check that the correct sending unit is

connected.

Replacement sender part numbers are:

Dakota Digital VDO equivalent

100 psi 150015 360 086

FUEL

The fuel gauge sending unit is not normally supplied with the system. The display

system will usually use the fuel sending unit that is already in the tank. The sending units that

are compatible with this system are as follows: GM, Ford, VDO, and Stewart Warner. The

Stewart Warner sender type is used by most after-market gauges. The DIP programming

switches inside the control box must be set to indicate which sender type you are using.

7

Page 8

A single wire should be run from the fuel sender to the control box terminal marked FUEL. If

your wiring harness already has a wire routed through the vehicle for the fuel sender then it may

be used. If using a wire from an existing harness, make sure that the wire does not have power.

The fuel sender gets power from the control box only. Fuel senders get their ground from the

sender mounting plate. Make sure that a ground wire is connected from one of the sender

mounting bolts to the vehicle frame.

The fuel sender type is selected using the DIP programming switches located inside the

control box. The settings are discussed later in the section on internal adjustments.

If the fuel display shows “—“ this indicates that the control box is sensing a short to

ground or out-of-range error from the sender or sender wire. If the fuel display shows “EE” this

indicates that the control box is sensing an open circuit or out-of-range error from the sender. If

either indication remains on the display, inspect the sender wire for damage, check the routing

of the sender wire, check the sending unit grounding, and check that the DIP programming

switches are set correctly for the sending unit that is connected.

TRIP

The TRIP terminal is used for the trip odometer function, for setting the oil warning set

point (see WRN), and for speedometer calibration (see SPEEDOMETER CALIBRATION). The

TRIP input is activated by a ground connection. The push button switch supplied (or any

normally open switch) is wired by connecting one terminal to TRIP and the other terminal to a

ground. When the trip button is pressed, the odometer display will switch from full odometer

mileage to the trip mileage or from the trip mileage to the full odometer mileage. When the trip

mileage is shown a lower case “t” will be displayed to the left of the trip meter reading. “t 000.0”

Pressing and holding the trip button for 7-8 sec. will enter the demonstration mode.

RESET

The RESET terminal is used for the trip odometer function, for setting the water warning

set point (see WRN), and for the speedometer calibration (see SPEEDOMETER

CALIBRATION). The RESET input is activated by a ground connection. The push button

switch supplied (or any normally open switch) is wired by connecting one terminal to RESET

and the other terminal to a ground. When the reset button is pressed and held for a few

seconds, the trip miles will be reset to zero. This will not affect the full odometer mileage.

Pressing the reset button will also exit the demonstration mode.

CHECK

The check engine terminal is used with fuel injection ECM’s

to display engine problems and trouble codes. The CHECK input

is activated by a ground signal from the ECM. Whenever the

check input is grounded the system will display a lower case “c” to

the left of the speedometer. When the ECM is placed into

diagnostic mode trouble codes can be read by counting the

flashes. Consult a service manual for the fuel injection system that

you have for further information on trouble codes.

With some ECM’s a 12 volt light bulb may need to be

connected in addition to our CHECK input in order to provide

proper current loading. In this case both the bulb and our display system indicator would both

come on when the check engine wire was set.

8

Page 9

BRAKE

The BRAKE terminal can be used as a brake system warning

indicator. The BRAKE input is activated by a ground signal from the

brake pressure switch on the master cylinder or from the parking

brake set switch. Connect a wire from this terminal to the pressure

switch on the master cylinder or consult a vehicle service manual to

determine color and location of an existing wire. Whenever the

BRAKE input is grounded the system will flash a “b” to the right of

the speedometer.

HI BEAM

The HI BEAM terminal is activated by a 12 volt signal from the headlight high beam wire.

When the terminal has 12 volts, a dot will light up to the lower right of the speedometer display.

An existing wire from the vehicle for the high beam indicator can be used or a new wire can be

connected from the high beam side of the hi beam/low beam switch.

LEFT

The LEFT terminal is activated by a 12 volt signal from the turn signal switch. When this

terminal has 12 volts, a dash will light up to the left of the speedometer display. An existing wire

from the vehicle for the left turn indicator can be used or a new wire can be connected from the

turn signal switch.

RIGHT

The RIGHT terminal is activated by a 12 volt signal from the turn signal switch. When

this terminal has 12 volts, a dash will light up to the right of the speedometer display. An

existing wire from the vehicle for the right turn indicator can be used or a new wire can be

connected from the turn signal switch.

WRN

The WRN terminal is a dual function input and output. The output is ground-activated

when the preset rpm limit is exceeded. This output can turn on a 4 Watt or smaller 12 volt bulb

or can activate a relay to turn on a larger bulb. To wire a warning light to this output, connect

one wire from the bulb to 12 volt accessory power and connect the other wire to the WRN

terminal.

The input is used to set the water, oil, and rpm warning set points. See the Gauge

Warning section for a description of how to set these.

9

Page 10

MPH/KPH

The MPH/KPH terminal is activated by a 12 volt signal from a push button or toggle

switch(not supplied). When the display system is in English mode (MPH & °F) by placing DIP

programming switch #7 off, applying 12 volts to this terminal will convert the speed reading from

MPH to KPH. The odometer will continue to accumulate miles correctly, but will display dashes.

The bar speed display, if present, will not be affected.

When the display system is in Metric mode (KPH & °C) by placing DIP programming

switch #7 on, applying 12 volts to this terminal will convert the speed reading from KPH to MPH.

The odometer will continue to accumulate kilometers correctly, but will display dashes. The bar

speed display, if present, will not be affected.

This input is provided to allow a convenient method of switching from MPH to KPH or

from KPH to MPH while crossing borders or driving in areas with different speed markings.

GEAR SHIFT INDICATOR INPUTS

The PARK, REVERSE, NTRL, OVRDRV, DRIVE, 2nd,and 1st terminals are used for the

gear shift indicator. The inputs are activated be a 12 volt signal from a gear shift sending unit.

The indicator is built into every system but it will not light up

unless a Dakota Digital GSS-1000 or compatible gear shift

sending unit is connected to tell it what gear the

transmission is in. The gear shift sending unit is not

included with the system and must be purchased separately.

When the gear shift sending unit is connected, a letter

will light up to the right of the odometer to indicate what gear

the transmission is in. Below is a chart showing the display

indicators for each of the gears and a wiring diagram using

Dakota Digital’s GSS-1000 adjustable gear shift sending

unit. If you have a different gear shift sending unit, consult

the wiring instructions supplied by the manufacturer.

GSS-1000

DECODER

Backup

Park

Dim

Reverse

Neutral

Drive

HI

First

Overdrv

Signal

Second

Ground

to Chassis Ground

to sensor BLACK wire

to sensor GREEN wire

to sensor RED wire

to control box FIRST terminal

to control box SECOND terminal

to control box DRIVE terminal

to control box OVERDRIVE terminal

to control box NEUTRAL terminal

to control box REVERSE terminal

to control box PARK terminal

(optional)

(optional)

+12V

do not connect

Power

Safety

10

Page 11

Insert cable with red stripe to right side.

Optional display power connector found on some systems.

11

Page 12

Setting up the control box

SPEEDOMETER CALIBRATION

The speedometer calibration is done using the TRIP and RESET switches. There are

two different ways to calibrate the speedometer. The first method control box uses an auto-cal

mode where you drive one mile (1 km for metric) and the system automatically adjusts the

speedometer calibration. The second method allows you to adjust the speedometer up or down

as you drive.

To enter the auto-calibration mode, begin with the key off. Press and hold both the trip

and reset switches at the same time while the vehicle is being started. The speed will display

“CAL”. Once the switches are released the control box will begin measuring. As you drive the

odometer will display the number of pulses received from the sensor. If the reading stays at

zero as you drive, then check the vehicle speed sensor and speed sensor wiring. Once you

have driven exactly one mile (or km) press and hold both of the switches again. The system will

calculate and store the new speed calibration. Once the switches are released the system will

restart and go back to normal operation.

While the system is in the auto-cal mode the voltage, fuel, oil, and water gauges will

remain blank will not change until the speed calibration is completed.

To enter the speedometer adjust mode, press and hold both the trip and reset switches at

the same time while the system is on and operating. The switches will need to be held for about

4-6 seconds. The odometer will display “AdJUSt” and the other gauges will function normally.

Release the switches. Pressing and holding the TRIP switch will increase the speedometer

reading. Pressing and holding the RESET switch will decrease the speedometer reading.

Pressing and holding both the TRIP and RESET switches at the same time will store the current

speed calibration and exit the speed adjust mode. While the system is in speed adjust mode

the odometer will continue to accumulate normally, even though it is not displayed.

FUEL DIP SWITCH SETTINGS

The control box can read 5 different types of fuel senders. The DIP programming

switches are located inside the control box, so the cover must be carefully removed to get

access to the switches. Make sure the key is turned off before opening up the control box so

that there is no power to the system. The switches labeled 1, 2, and 3 are used to select the

different sender types. Once the switches have been set, replace the cover before turning the

system on. The sender types are listed below, along with their corresponding empty and full

resistance readings. If you do not know what type of sender you have, use an ohmmeter to

measure the fuel sender resistance when it is full and empty.

Sender type Empty R Full R Switch #1 Switch #2 Switch #3

GM 0-30 ohm 0 ohms 30 ohms ON ON OFF

GM 0-90 ohm 0 ohms 90 ohms OFF ON OFF

GM 40-250 40 ohms 249 ohms ON ON ON

FORD 73 ohms 10 ohms OFF OFF ON

VDO 10 ohms 180 ohms OFF OFF OFF

SW/SUN 240 ohms 33 ohms OFF ON ON

SW/SUN is the default setting when systems are shipped.

12

Page 13

TACHOMETER DIP SWITCH SETTINGS

The control box will work with 4, 6, 8, and 10 cylinder ignition systems. The DIP

programming switches are located inside the control box, so the cover must be carefully

removed to get access to the switches. Make sure the key is turned off before opening up the

control box so that there is no power to the system. The switches numbers 5 and 6 select the

number of engine cylinders. The settings are as follows:

Engine cylinders Switch #5 Switch #6 Bar tach Switch #4

4 ON ON 6000 rpm

6 OFF ON 8000 rpm

8 ON OFF

OFF

ON

10 OFF OFF

The default setting when systems are shipped from the factory is 8 cylinder.

Tachometer display type Switch #8

Bar tach only (no digital numbers) OFF

Both a digital and bar tach display ON

In addition, the tachometer bar graph can be set to read 6000 rpm at full scale(switch #4

OFF) or 8000 rpm at full scale(switch #4 ON). This option would have been specified when the

order was originally placed and the switch should be set to match the display system lens

engraving. Systems with both a digital and bar graph tachometer are always set for 8000 full

scale(switch #4 ON).

Because some systems have a digital speedometer with a bar graph tachometer directly

above it(55 Chevy car) and some systems a have separate digital speedometer and digital

tachometer, each having their own bar graph readout(73 Chevy pickup), switch #8 selects which

style display system is being used. For 5-gauge systems with a bar graph tachometer directly

above the speedometer, turn switch #8 OFF. For 6-gauge systems with a bar graph

speedometer directly above the digital speedometer, turn switch #8 ON. This is set correctly at

the factory before shipping to match the display system that it is paired with.

METRIC SELECTION DIP SWITCH SETTINGS

Switch #7 selects whether the temperature will be displayed in °F or °C and also sets the

speedometer for MPH or KPH. For MPH/°F turn switch #7 OFF. For KPH/°C turn switch #7

ON. Changing switch #7 does not change the speedometer calibration. Speedometer

calibration is discussed in another section. This switch will be set from the factory to match the

display system lens engraving. If this is changed, a new lens should be purchased so that the

labeling matches the gauge readings.

13

Page 14

GAUGE WARNING FEATURE

The gauges have the built in feature to alert you when they are outside their normal

operation range. The fuel display will flash whenever the fuel level is below 10% to indicate low

fuel. The voltage gauge will flash whenever the system voltage is below 11.0 volts and the

engine is running. The water gauge will flash whenever the temperature is higher than the water

warning set point. The oil gauge will flash whenever the oil pressure is below the oil warning set

point and the engine is running. The WRN output will be activated whenever the rpm warning

set point is exceeded. A single. lit bar on the right half of the rpm bar display shows the current

rpm warning set point. The rpm warning set point can either be used as a shift indication or as a

red line indication. The rpm warning output is triggered off the bar tach and is updated every 1/8

second.

The water, oil, and rpm warning set points are user adjustable. They are preset at the

factory to 250 for water, 10 for oil, 4560 for 6000 bar tachs, and 6080 for 8000 bar tachs. The

warning set points are adjusted using the TRIP, RESET, and WRN terminals.

To enter the warning adjust mode, ground the WRN terminal while the system is being

turned on. The speedometer will display “AdJ”. Release the ground from the WRN terminal.

The current warning set points will be displayed. The RESET, TRIP, and WRN inputs adjust the

water, oil, and rpm warning set points respectively. Once the set points have been changed, if

an input is not activated for 8 seconds the values will be saved and the system will begin

operating normally.

To change the water warning set point, press and hold the RESET button until the

desired value is shown. The range is from 194 – 254°F in 2° increments (90 – 123°C).

To change the oil warning set point, press and hold the TRIP button until the desired

value is shown. The range is from 2 – 30 psi in 2 psi increments.

To change the rpm warning set point, ground the WRN terminal until the desired value is

displayed. For 0-6000 bar tachs, the range is from 2160-5760 rpm in 120 rpm increments. For

0-8000 bar tachs, the range is from 2880-7680 rpm in 160 rpm increments.

GAUGE SPECIFICATIONS

Gauge Minimum reading Maximum reading Resolution Accuracy

WATER 0°F (0°C) 302°F (150°C) 1 - 2° ±5°F(±3°C)

OIL 0 psi 99 psi 1 psi ±3

FUEL 0% (empty) 99% (full) 1 - 3% ±5 -- ±15

VOLT 8.0 volts 18.0 volts 0.1 volt ±0.1

SPEED 0 mph (kph) 255 mph (kph) 1 ±1%

ODOMETER 00000.0 miles (km) 99999.9 miles (km) 0.1 ±0.5%

TRIP METER 000.0 miles (km) 999.9 miles (km) 0.1 ±0.5%

TACH bar 400 rpm 6000 rpm or 8000 rpm 120 or 160 ±80 rpm

TACH digital 400 rpm 9990 rpm 10 ±40 rpm

Power requirements: 11 – 15 volts dc

(Battery chargers cannot be used for powering or testing this system.)

14

Page 15

WIRE COLOR CODE FOR GM WIRING HARNESS

On the connector that originally plugged into the instrument cluster:

Function Color

------------------------------------------------------------------ +12 volt Pink/Black or Pink

Ground Black

Oil sender Tan or no wire if mechanical

Water sender Dark green

Fuel sender Pink or light brown (should not have power)

Left turn Light blue

Right turn Dark blue

High beam Light green

Brake warn Tan/white or tan

WARRANTY

All DAKOTA DIGITAL instruments are warranted free of defects in material and

workmanship for the life of the vehicle in which they are originally installed. In the event of a

problem with one of our products, DAKOTA DIGITAL will replace or repair the instrument at no

charge. (The decision to repair or replace is solely that of DAKOTA DIGITAL. DAKOTA

DIGITAL is not responsible for shipping costs of products returned under warranty or for labor

charges for product installation and removal.) This warranty becomes invalid if the product is

misused, altered or installed incorrectly.

The above warranties, both expressed and implied, do not cover damages caused by

improper assembly, misuse, abuse, fire, unauthorized modifications, floods or acts of God, or

reimbursement of customer or shop time. The extent of the warranty is limited only to the

product and does not cover any loss or damaged to vehicle, equipment, or non-DAKOTA

DIGITAL products.

SERVICE AND REPAIR

DAKOTA DIGITAL offers complete service and repair of its product line. In addition, free

technical consultation is available to help you work through any questions or problems you may

be having installing one of our units.

Should you ever need to send the unit back for repairs, please package the product in a

good quality box along with plenty of packing material. Ship the product by UPS or insured

Parcel Post. Be sure to include a complete description of the problem, your full name and

address (street address preferred), and a telephone number where you can be reached during

the day. An authorization number for products being return for repair is not needed. Do not

send any money. We will bill you for the repair charges.

15

Page 16

TROUBLESHOOTING GUIDE

This is a list of some problems and their solutions which may be encountered when installing your

instrumentation system. If you cannot determine what the problem is or how to solve it, please call our

technical assistance line (605) 332-6513 or email to dakotasupport@dakotadigital.com.

* A note on vehicle grounding. *

The most common cause of problems with electric gauges is poor ground connections. The

engine block has the highest ground currents of any point in the vehicle. The ignition system, electric

gauge senders, starter, alternator, etc. all use the engine block for a ground point. Since the alternator is

grounded directly to the engine block all ground currents in the entire vehicle must pass through the

engine block while the engine is running. A weak or loose connection can cause all kinds of random

problems that may difficult to track down. The engine block should have heavy ground straps to both the

chassis and the body. The main negative cable from the battery should be connected directly to the

engine block.

Symptom Possible Problem Solution

----------------------------------------------------------------------------------------------------------------------------------System does not light up. Control box may not be getting Check if the control box has

power. 12 volts connected to it.

Do not use a battery charger to

power the system.

Check the fuse on the control

box. If it is blown, replace with a

2 amp fuse.

The display system may not be Insert the connector on the

getting power. display system wiring harness

into the slot on the side of the

control box. Be sure the pins

line up properly.

Check the display system wiring

harness for broken or cut wires.

The control box may have Return the control box to Dakota

an internal problem Digital with a description of the

problem and a phone number.

The speed and tach light, Display power harness is not Plug the 2-wire harness into the

but the fuel, volt, oil, and connected. control box. The mating connector

water do not. is located next to the fuse.

One display does not The display panel Return the display panel to

light up at all, all others corner of the display is white, Dakota Digital for repair. Include

work correctly. the display is cracked or broken a phone number and address.

The tachometer will not The control box is not connected Make sure the control box is

show a reading. to the engine properly connected to your particular

ignition system properly.

The control box is not set up Make sure switch #8 is OFF if

correctly for your display system you have a bar graph only.

16

Page 17

Symptom Possible Problem Solution

----------------------------------------------------------------------------------------------------------------------------------The tachometer reading The tachometer signal wire is Check the connections at both

is incorrect. loose or broken. ends of the wire.

The control box is not set up for Refer to the Internal Adjustments

the proper number of cylinders section of the installation manual

or the proper tach range. to set the control box properly.

The speedometer will The speed sending unit is not Check that both speed sending

not show a reading. connected to the control box unit wires are connected to the

properly. control box properly.

The speed sending unit being Use the speed sending unit

used is not compatible with the supplied with the display

control box. system.

The speed sending unit is not Check that sender is mounted

connected to the transmission properly.

properly. Check that transmission has the

appropriate internal parts.

The sending unit wire is picking Isolate the sending unit wire from

up noise from nearby wires. motor and ignition wires.

The speedometer is reading The speedometer is not calibrated. Refer to the Speed Calibration

too fast or too slow. section of the installation manual.

With the engine running and A tachometer wire is too close to Reroute or isolate the tachometer

the vehicle sitting still, the to the speed sensor wire. wire away from the speed wire.

speedometer reads higher There is a ground problem between Make certain the ground wire for

than zero. the speed sensor and the control the speed sensor is connected

box. directly to the control box ground.

A display shows “EE” Sending unit for that gauge Check the wire from sending unit

is not connected to the control to the control box for breaks.

box. Make sure that the sending unit is

wired to the correct terminal.

Sending unit is not getting Make sure the sending unit is

grounded. grounded properly.

Make sure the water and oil senders

have clean threads.

On the water or oil, the sending Use the water and oil senders that

unit is not the correct type. were supplied with the system.

On the fuel, the control box may be Refer to “Fuel DIP switch settings”

set for the wrong fuel sender. section of the installation manual

to ensure that the settings match

your fuel sender.

A display shows “- -“ The sending unit wire for that Repair or replace shorted wire.

gauge is shorted to ground.

Fuel displays “FL” The control box is set to an invalid Refer to “Fuel DIP switch settings”

fuel sender setting. section of the installation manual

to ensure that the settings match

your fuel sender.

17

Page 18

Symptom Possible Problem Solution

----------------------------------------------------------------------------------------------------------------------------------The fuel display reads The control box may be set for Refer to “Fuel DIP switch settings”

backwards, incorrectly, the wrong type of fuel sender. section of the installation manual

or does not change. to ensure that the settings match

your fuel sender.

The fuel sender may not be Check the connections at both

connected to the control box ends of the fuel sender wire.

properly. Make sure the fuel sender is

grounded properly.

The fuel sender may not be Check the fuel sending unit with

operating properly. a mechanical gauge or an

electrical multi-meter.

The fuel sender may have a If the proper resistance range

non-standard resistance setting is not available with

range. the control box settings, replace

the fuel sender with a different

style.

The oil or water display The engine block may not be Use heavy ground cables from the

reading is incorrect. grounded to the chassis frame battery to the engine block.

or body properly. Make sure both ends of the cable

have clean metal-to-metal

connections.

Use a braided ground strap to

ground the engine block to the

chassis.

Use a large braided ground strap

to ground the engine block to

the body or fire wall.

The threads are not grounding to Make sure no thread sealant is used

the engine block. on any of the threads.

The sending unit wire is picking Isolate the sending unit wire from

up noise from nearby wires. motor and ignition wires.

The sending unit is not Use the sending unit provided

compatible with the control box the display system.

The sending unit has failed. Return the sending unit to

Dakota Digital for replacement.

18

Page 19

Symptom Possible Problem Solution

----------------------------------------------------------------------------------------------------------------------------------The gear shift indicator The optional gear shift sending Connect the sending unit to the

does not light up. unit is not connected to the control box using the

control box. instructions supplied with the

sending unit.

The gear shift indicator The gear shift sending unit Check the connections to the

does not operate is not connected properly. transmission linkage and to

properly. the control box.

Connect 12 volts to the sending

unit power wire.

The colored bulbs in The LED bulbs are not Connect the wires found on the

the display panel for connected into the auto's back of the aluminum panel

turn signals and high electrical system. to your cars electrical system

beam do not light up. (these are not wired into the as explained in the Optional

(not found on all units) display system control box) Indicators section of the manual.

The internal turn signal The control box is not connected Check the wires connected to the

and high beam to the vehicle's electrical HIGH, LEFT, and RIGHT

indicators do not light up. system properly. terminals on the control box.

The check engine The control box is not connected This feature is designed to work

indicator does not to a TPI control module. with engine control systems that

operate properly. provide an active low signal.

The check engine The Engine Control Module Connect a light or similar load

indicator stays on (ECM) needs to see the to the ECM along with the

all of the time. load of a light connected to it. control box.

Trip select and trip reset Select and reset switches are Momentary push-button or toggle

functions do not operate not connected to the control switches must be connected to

properly. box. the TRIP and RESET terminals

as described in the Trip meter

section of the installation manual

The wrong type of switch is The switch terminal connected

being used. to the control box should

normally be open. When the

the switch is activated, the

terminal should make contact

to ground.

The display system starts The TRIP terminal is constantly Disconnect or replace the trip

up in the demonstration connected to ground. select switch.

mode and remains in it.

The speed always shows The WRN terminal is constantly Check wiring to the WRN

“AdJ”. connected to ground. terminal for a short to ground.

19

Page 20

CLOCK

Wiring instructions for VFD systems with a clock built in.

Introduction:

The clock displays the current time in 12 hour format with an AM/PM indicator. The AM/PM indicator

appears as a dot that will be displayed in the upper left corner. The dot will be on every other 12 hour period (on

during AM and off during PM). The high brightness display matches our other Odyssey and STR series gauges

and has the same night brightness dimming capability. Features included are:

• Quartz accuracy.

• Night dimming feature.

• Very low standby power to prevent battery drain.

• High Visibility VFD display for sunlight readability.

Operation:

The gauge needs the red, orange, and black wires connected to operate. The red wire should have

switched 12 volt power from an ACC. point on the fuse panel. The orange wire should have constant 12 volt

power. The black wire should be connected to a good ground point. When the blue wire has 12 volts, it will dim the

display for night viewing.

Setting the time:

Using a small, thin object such as a pen or hairpin, press “set” buttons through front lens access holes.

The access holes are on the right side of the lens. Top “set” button advances hours, bottom “set” button advances

minutes.

Wiring:

BLACK - connect to a good ground point in the vehicle.

RED - connect to switched 12 volt power point.

(An accessory terminal will work for this.)

ORANGE - connect to a constant 12 volt power point.

(This will keep the correct time.)

BLUE - connect to the tail light circuit.

DAKOTA DIGITAL, INC. * 3421 W. Hovland Ave. * Sioux Falls, SD 57107 * (605) 332-6513

www.dakotadigital.com

dakotasupport@dakotadigital.com

20

Loading...

Loading...