Page 1

IMPORTANT NOTE:

The +12V for the

off.

controller should NOT

be taken from the same

circuit as the Fan Power

12V as this can cause

the fan to cycle on and

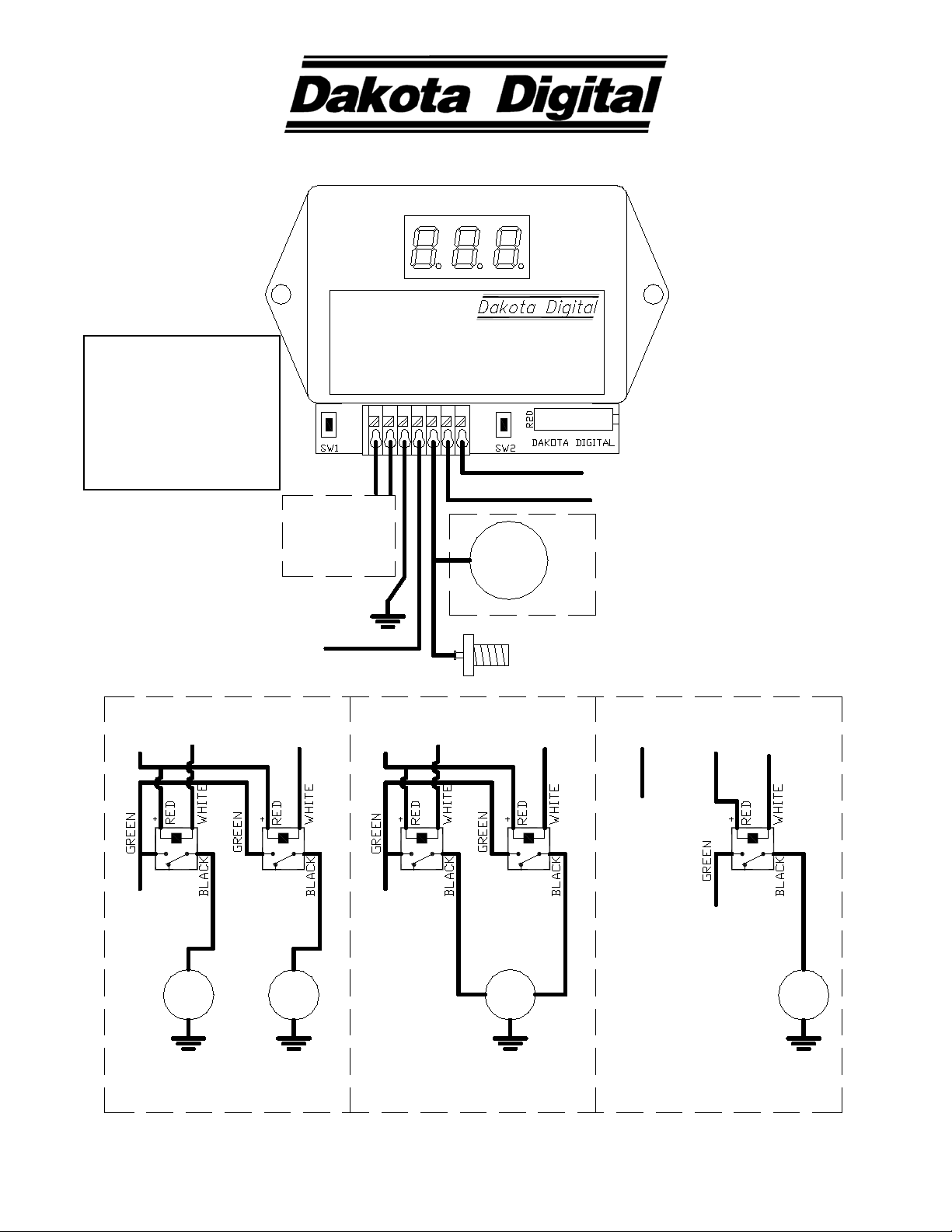

PAC-2700

ELECTRIC COOLING FAN CONTOLLER

PAC-2700

FAN CONTROLLER

CUSTOM

A/C

SW1

FAN HIGH

SENDER

+12v

GND

FAN LOW

IGNITION

ADJUSTMENT

SW2

+12V with key ON

A/C clutch cycle switch

Choose

option

below

GAUGE

Not used in

sender only

application

(+12v trigger)

Fused battery 12V

+12V

Fan PWR +12V

two separate fans dual speed fan

Fan

High

FAN2

Fan

Low

FAN1

+12V

Fan PWR +12V

Fan

High

HIGH

SENDER

Fan

Low

FAN

LOW

Fan

High

NOT

CONNECTED

+12V

Fan

PWR

+12V

single fan

Fan

Low

FAN

MAN# 650264:B

Page 2

Operation

The electric cooling fan controller provides a way to run up to two electric engine cooling fans or one two speed cooling

fan. (A second relay, sold separately, is required for two speed or dual fan operation). The controller monitors the engine

temperature using a dedicated sender, or a gauge and its sender. When the engine temperature goes above a user

adjustable set point, the fan is turned on with a relay. When the engine has cooled below a user selectable off

temperature, the fan is shut off. Separate on and off temperatures can be set for the high and low fan outputs. The

controller will also run the fan when the air conditioner requires, by detecting when the air conditioning clutch is engaged.

The unit can be set to keep the fan running (if the engine is hot enough) after the key is turned off. Several delay times are

available from no delay to five minutes. The display will countdown the seconds left before the fan is turned off. If the

battery voltage drops too low, the fan will be turned off and a “Lo bAt” message will display for the remainder of the time.

Settings for several gauge systems are included to make installation with a gauge easier. The included gauges are

Stewart Warner, Classic Instruments, VDO, and Autometer. If the gauge being used isn’t included, a custom calibration

option allows the system to be calibrated to any gauge with clear numerical temp markings. This is accomplished by

setting the controller to match the marks on the gauge with a few steps described in detail in the installation instructions.

IMPORTANT NOTE!!!: If using a gauge with this unit, always ensure that your gauge is working properly. If the gauge is not reading

correctly, the fan control unit will not hav e correct temperature information and cannot be guaranteed to properly control the fan,

possibly leading to overheatin g and engine dam age.

If the gauge uses a two-wire temperature sender (such as Autometer full sweep) use of a dedicated Dakota Digital sender is

required.

If a gauge is not used, ONLY a Dakota Digital 300ºF sender should be used. Other senders may not give a correct reading to

the control unit.

Custom gauge calibration requires numerical marks, stock “C-NORMAL-H” type gauges cannot be accurately calibrated to.

Required components for installation:

The PAC-2700 is shipped with necessary components for use with a single fan on a gauged system. These parts include:

1 PAC-2700 module

1 RLY-3 relay with wiring harness

1 Instruction manual

For some options of the PAC-2700, additional components are required. These are listed below.

- Second RLY-3 assembly (needed for dual fan or two speed fan operation)

- 300ºF sender Dakota Digital temp sender (for operation without a gauge)

Installation

Note: Mount ONLY in vehicle cabin. Controller is not designed for engine compartment mounting.

The terminal strip on this unit has 6 connections:

1. Fan high relay Connect to the white wire on the high fan relay assembly

(for single fan applications leave unconnected)

2. Fan low relay Connect to the white wire on the low fan relay assembly

3. Ground Connect to a good chassis ground

4. Power Connect to a fused 12V battery

5. Sender Connect to the engine temperature sender wire.

6. A/C clutch Connect to the cycle switch on systems with air conditioning

(on systems without air conditioning leave unconnected)

7. Ignition Connect to a circuit which has +12V only with the ignition key ON. (switched power)

Relay wiring:

White Connect to control unit

Green Connect to fused 12V battery circuit that can run cooling fan

Red Connect to fused 12V battery

Black Connect to cooling fan

Factory Presets

This controller comes preset to use a dedicated sender as follows:

Dakota Digital Sender only (no gauge, see above for 300ºF sender opt ions )

One single speed fan

205ºF on temperature

200ºF off temperature

30 sec Fan off delay

If the factory settings don’t fit your application, you will need to go through the setup procedure on the following page. At

anytime during the setup procedure, the key may be turned off and the settings up to that point will be saved.

MAN# 650264:B

Page 3

Set Up

1. Press and hold SW2, then turn the key on.

2. Release SW2, then press and release SW1 to move onto the next step.

3. To select temperature scale to use, press and hold SW1 to select (Fahrenheit)

or press and hold SW2 for

scale is selected, the display will flash and go on to next setting.

(Celsius). Hold the switch for longer than one sec to select. Once a temperature

4. Display will now read indicating low fan on temperature is to be set. Use SW1 or SW2 to select the

temperature at which the fan should turn on. Press both switches to save the setting. Display will flash once

setting is saved.

Note: SW1 increases the temperature, while SW2 decreases the temperature.

5. Display will now read indicating low fan off temperature is to be set. Again, use SW1 or SW2 to set the

temperature at which the fan should turn off. Press both switches to save the setting.

6. If two fan or dual speed fan mode was previously selected, temperature settings for the high fan output are at this

point in setup for convenience. If single fan mode is set up, setup will skip high temp settings and go to step 7.

6a. Display will no w rea d indicating high fan on temperature is to be set. Use SW1 or SW2 to set the

temperature at which the fan should turn on. Press both switches to save the setting.

6b. Display will now read indicating high fan off temperature is to be set. Use SW1 or SW2 to set the

temperature and press both switches to save the setting.

7. Display will read Use SW1 or SW2 to cycle through the following options. Press both switches to select an

option.

Display Option

Fan will turn off when key is turned off.

If fan was running at key off, it will continue to run for 30 seconds after key is turned off.

If fan was running at key off, it will continue to run for 45 seconds after key is turned off.

If fan was running at key off, it will continue to run for 1 minute after key is turned off.

If fan was running at key off, it will continue to run for 2 minutes after key is turned off.

If fan was running at key off, it will continue to run for 3 minutes after key is turned off.

If fan was running at key off, it will continue to run for 5 minutes after key is turned off.

8. Display will read indicating fan type is to be set. Use SW1 or SW2 to select the fan type used. Press both

switches to save setting.

Display Option

one single speed fan (only low fan output used)

two single speed fans (high and low fan outputs both on for high temp,

& some dual spd fans only low fan output on for low temp)

one dual speed fan (high fan output on, low fan off for high temp,

high fan off, low fan on for low temp)

Note: If two fan or dual speed are selected and high fan temp setting was not set before, setup will return to step

6 to allow temp settings to be made.

9. Display will read signaling to select a sender type. Press SW1 to move through

list forward, press SW2 to back up. Press both switches to save setting. The supported

senders are listed below with the display that represents each option.

Display Option

No gauge, dedicated Dakota Digital sender only

Dakota Digital individual temp gauge with sender

Dakota Digital instrument cluster with control box (ver. STR-D or later, older versions use CUS)

Stewart Warner gauge and sender

Classic gauge and sender

VDO gauge and sender

Autometer gauge and sender

Custom calibrated gauge

Custom calibration (for gauge sets not listed above)

10. If your gauge is not supported in one of the options above, you will need to custom calibrate the controller for your

gauge. (if CUS is selected and calibration has not been done, the calibration sequence will automatically be

started). The following is the procedure for custom calibration. If your gauge system is listed above, skip this

portion and continue at step 11.

MAN# 650264:B

Page 4

Custom Calibration

Note 1: If your engine is warm you may need to disconnect the wire from your sender in order get to the lower

points on the gauge.

Note 2: If the key is turned off in custom setup, the previous gauge setting will be used and the custom gauge will

not be saved.

Note 3: If your gauge does not have defined ticks with numerical temp readings, it is highly recommended to use

CC1. Select in Step 9 above. Display will read .

a dedicated sender as calibration to the gauge is very inaccurate or impossible without temp markings.

CC2. Turn the potentiometer on the lower right corner of the unit (marked CUSTOM ADJUSTMENT) with a

small flat screw driver. While doing so, watch your temp gauge and line up the ne edl e with the lowest

temperature tick on the gauge. Custom gauge must be calibrated starting at cold temperatures and

moving to hot temperatures.

Note: Turning potentiometer clockwise increases temperature reading.

CC3. Once the gauge is set to a tick, press SW1 or SW2. A temperature reading will appear on the display.

Scroll to the temp reading that matches the tick temperature reading on the gauge using SW1 to increase

and SW2 to decrease. Press both buttons to save the number. Display will again read

.

CC4. Repeat steps CC2 and CC3 with the next lowest tick on gauge until al l the ticks on your gauge have been

set. (up to 6 but no less than 4 points). Press both SW1 and SW2 at

to stop setting points if there

are less than 6 points on your gauge. If there are more than 6 points on your gauge, select points over

the full range of the gauge (cold to hot). This will give a better match to your gauge.

11. Unit will flash

to indicate set up is complete. The unit now has been set up. If the wiring and setup have

been properly completed the unit should begin normal operation at this point.

Resetting Factory presets

This procedure will return the device to the original factory presets and clear custom calibration settings.

NOTE: Calibration data for the custom gauge setup will be lost when reset to factory presets.

1. Turn key off.

2. Press and hold SW1 and SW2 and turn key on.

3. Display will read for reset

4. Display will flash to indicate unit is reset. Factory reset values are listed at the

beginning of the setup portion of this manual.

Checking set up (diagnostic mode)

This unit comes with a feature to allow you to mimic normal operating temperatures using the

adjustment pot. This can allow you to test the installation before ever starting the engine. Just

follow these steps.

1. Turn the key on.

2. Press SW1 and SW2 at the same time and hold. A number representing the temperature will come up on the

display. This number will blink once to indicate that the unit has entered diagnostic mode. SW1 and SW2 may

now be released and the unit will remain in diagnostic mode until the key is turned off.

3. Adjust the potentiometer on the left side of the unit while watching the display and listening for the fan. The fan

should start when the display reads hotter than the set ON temp. It should again shut off when the display reads

lower than the OFF temp.

4. You may also look at your water temperature gauge (if unit is using a gauge) and compare the temperature

reading of the unit to the gauge. The temperatures should be within a few degrees. If not, the wrong gauge may

be selected in the setup routine. Go through setup again by turning off the ignition, pressing and holding SW2 and

turning ignition back on. If a selection cannot be found that closely matches your gauge you may have to custom

calibrate to your gauge. (see step 10 in setup)

Checking the current reading

The current temperature reading can be displayed on the unit at anytime during normal operation without going into the

diagnostic mode. Simply press and hold SW1 while the key is on and the PAC-2700 is not in setup or diagnostic mode.

The current temperature will be shown on the display until the SW1 is released.

MAN# 650264:B

Page 5

PROBLEM

CAUSE

SOLUTION

Display reads “Er0”

(lost memory)

Setup memory lost, unit needs to be

recalibrated

Go through setup procedure, (see setup in this manual)

Display reads “Er1”

Wrong gauge selected

Unit not connected to sender

Select proper gauge in setup or use custom cal if

Connect SENDER terminal on unit to sender circuit

Display reads “Er2”

Wrong gauge selected

Unit not connected to sender

Use setup to select proper gauge, or use custom cal if

Connect SENDER terminal on unit to sender circuit

Display reads “Er3”

Setup data is out of valid range

Go through setup again, custom cal may be incorrect

Display reads “bAt”

into setup

+12v terminal does not have

Connect +12v terminal to fused battery connection. This

Display alternates

Battery voltage dropped too low

Ensure battery is fully charged. Check and replace weak

battery drain.

compensate.

Fan runs constantly

Controller has an error

Check display for error message

your gauge is not supported.

TROUBLESHOOTING

(shorted sender)

(open sender)

when attempting to go

between “Lo” and “bAt”

Fan turns on late, or

not at all

Gauge disconnected from sender

(gauge option only)

Sender is shorted

Sender not connected

constant power

during key off extended fan on time

Unit has no power

Broken/shorted wire to sender

Wrong gauge is selected

(gauge setup)

Wrong sender used

(for no gauge setup)

On temperature in setup is too high

Fan not connected properly

Alternator overcharging

(Analog gauge applications only)

needed

Reconnect gauge to sender

Check sender wire for short to ground, look for pinched

sender wire or bare connection touching ground

needed

Reconnect wire to sender

terminal should have constant power at all times.

battery. Shorten fan delay time to prevent excessive

With key on, hold SW1, if the display doesn’t show a

temperature after a few seconds, check battery and

ground connections.

Check wire to sender for breaks or shorts and repair.

Hold SW1, if temperature read is lower than expected or

doesn’t match gauge, redo setup.

For sender only applications ONLY a Dakota Digital

300ºF sender can be used. Other senders may not give

a correct temperature reading.

Hold SW1, if temperature read is above the desired on

temperature, and fan is not running, redo setup.

Remove fan output from unit and short wire to ground. If

fan does not run, check relay and fan connections.

Use a voltmeter to measure the voltage at the battery

while the engine is running. If this voltage is above 15v

the unit may turn the fan on later than expected. Either

correct overcharging problem or set on temp lower to

Fan off temp too low

Broken/shorted wire to sender

Wrong gauge is selected

MAN# 650264:B

Increase off temp in setup

Check wire to sender for breaks or shorts and repair.

Select appropriate gauge in setup, or custom calibrate if

Page 6

TROUBLESHOOTING (continued)

PROBLEM

CAUSE

SOLUTION

Custom gauge setup

Not enough points used

Point entered twice

Make sure that at least 4 points of gauge are set

Each point set must be different that the poi nt bef or e it

On/off set point

displays “Err” and

returns to “Snd” setup

option

Fans cycle on-off

especially when engine

temp is close to

Points not input in correct order

+12v for controller taken from same

circuit as the fan power +12V (green

wire on relays)

Set gauge points in order from cold points to hot points

Connect the +12V for the controller to a different circuit

separate from the circuit connected to fan relays.

SERVICE AND REPAIR

problems you may be having installing one of our products. Please read through the Troubleshooting Guide. There, you will find the solution to most problems.

Should you ever need to send the unit back for repairs, please call our technical support line, (605) 332-6513, to request a Return Merchandise Authorization

number. Pack ag e the pro duc t in a good quali t y box alon g with plenty of packing material. Ship the product by UPS or insured Parcel Post. Be sure to include the RMA

number on the package, and include a complete description of the probl em wit h R MA numb er , your full nam e an d add ress (s t re et add ress preferred), and a telep ho ne num b er

where you can be reached during the day. Any returns for warranty work must include a copy of the dated sales receipt from your place of purchase. Send no money. We will

bill you after repair.

DAKOTA DIGITAL offers complete service and repair of its product line. In addition, technical consultation is available to help you work through any questions or

Dakota Digital 24 Month Warranty

workmanship within 24 MONTHS FROM THE DATE OF PURCHASE, such defect(s ) will be rep ai r ed or re placed at Dakota Digital’s opti on .

apply to any product or part thereof which in the opinion of the Company has been damaged through alteration, improper installation, mishandling, misuse, neglect, or

accident.

the duration of this written warranty. Any action for breach of any warranty hereunder, including any implied warranty of merchantability, must be brought within a period of 24

months from date of original purchase. No person or representative is authorized to assume, for Dakota Digital, any liability other than expressed herein in connection with

the sale of this product.

DAKOTA DIGITAL warrants to the ORIGINAL PURCHASER of this product that should it, under normal use and condition, be proven defective in material or

This warranty does not cover nor extend to damage to the vehicle’s systems, and does not cover removal or reinstallation of the product. This Warranty does not

This Warranty is in lieu of all other expressed warranties or liabilities. Any implied warranties, including any implied warranty of merchantability, shall be limited to

4510 W. 61ST St. N., Sioux Falls, SD 57107

Phone: (605) 332-6513 FAX: (605) 339-4106

www.dakotadigital.com

dakotasupport@dakotadigital.com

©Copyright 2010 Dakota Digital Inc.

MAN# 650264:B

Loading...

Loading...