Page 1

ZIP CUT 28 MITER BANDSAW

Bandsaw Operations Manual

DAKE

724 Robbins Rd

Grand Haven MI. 49417

Phone 800-937-3253 Fax 800-846-3253

www.dakecorp.com

Page 2

Section Page

1. Machine placement / set up / installation: 3

1.1 Base set up 3

1.2 Saw Assembly 3

1.3 Anchoring base 3

1.4 Installing saw to base 4

1.5 Power connections 4

1.6 Accessory installation 4,5

2. Component features, functions and adjustments 5,6,7

3. Safety: 7

4. Machine operation: 8

4.1 Set up 8

4.2 Operation 8

5. Changing the blade: 8,9,10

6. Guide and preset calibrations: 9,10

7. Maintenance and routine adjustments 11

7.1 Maintenance Daily 11

7.2 Weekly Maintenance 11

7.3 Monthly Maintenance 11

7.4 Routine Adjustments: 11

8. Blades: 12

8.1 Simplified selection chart 12

8.2 Blade Break In 12

9. Specifications: 14

10. Drawings: Electrical / Exploded Views / Part Numbers 15-18

11. Trouble Shooting: 19-22

TABLE OF CONTENTS

MACHINE MODEL

SERIAL NUMBER

DATE OF PURCHASE

2

Page 3

MACHINE SET UP / INSTALLATION

1. Machine assembly / set up installation:

1.1 Saw base / pedestal:

1. Remove preassembled base from shipping container. Check for loose parts and

discard container.

1.2 Saw assembly:

1. Carefully remove the saw from the shipping container. Take care not to damage any

components, check for any loosen items. Discard container.

1. Machine Placement:

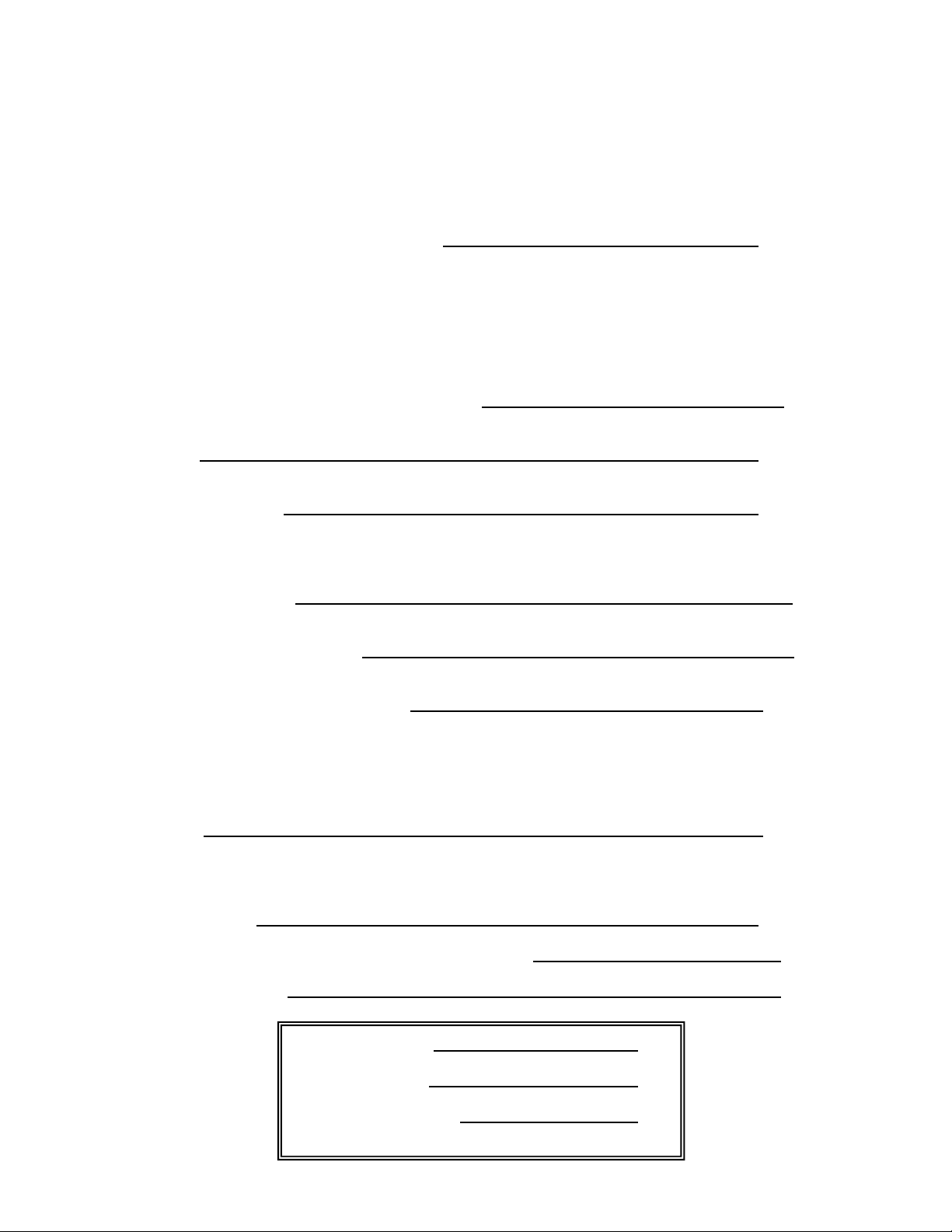

1.3 Anchoring the machine:

NOTE: Machine must be located away from, congested areas, traffic areas, close

proximity to where others will be working!

Bandsaw should always be positioned so operator can be accessible to all sides and

that there are no trip hazards or liquids present. Keep sides of saw area clear so there is

enough room to feed material into the saw. Keep the back of the saw 32” away from

walls.

Saw must be anchored on a level hard surface! Machine must be removed from the

pallet. Anchoring of the machine must be done to prevent movement of the unit during

operation. The base is supplied with two mounting holes one on the front and one on the

rear of the saw. (Figure 1) Anchoring must be done in a suitable fashion.

Figure 1 figure 2

3

Page 4

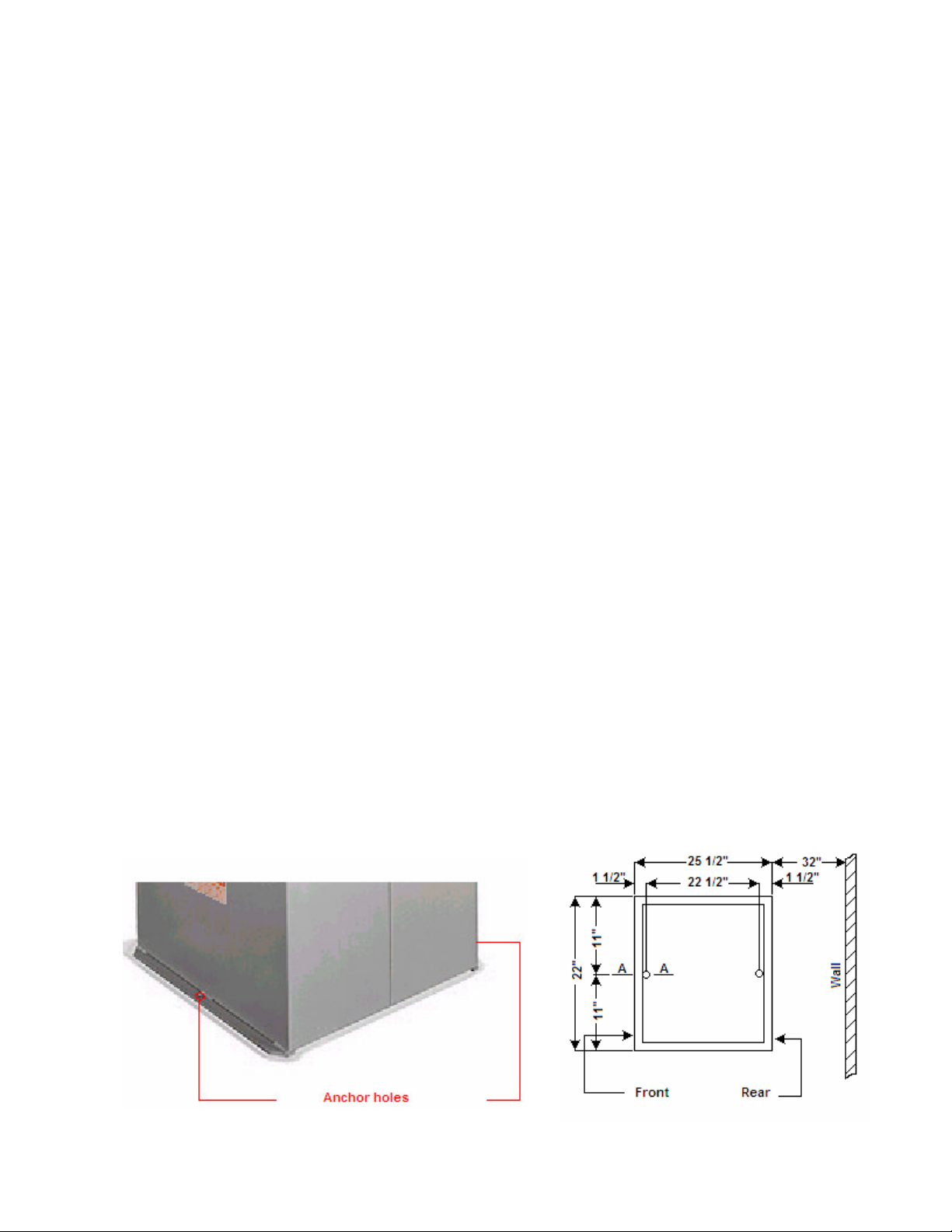

1. Installing machine to base:

1.4 Carefully strap the saw as shown in drawing figure 3. Lift the saw and set carefully onto the

base that is anchored to the floor. With straps still on the saw remove the front blue access panel.

(Figure 4) With the panel removed and using the 4 supplied bolts, bolt the machine onto the base and

tighten bolts securely.

Replace the access panel.

Figure 3 figure 4

1. Power connections:

NOTE: before connecting power make sure main power is OFF and make sure there are no

damaged parts on the machine, and that all components move freely and are not rubbing,

binding etc.!

1.5 Connection of power to this machine must be done by a qualified electrician. Machine

is supplied with a power cord that can have a plug (20 amp) installed or can be hardwired into a

suitable power source. Minimum 20 amp service is recommended for this machine.

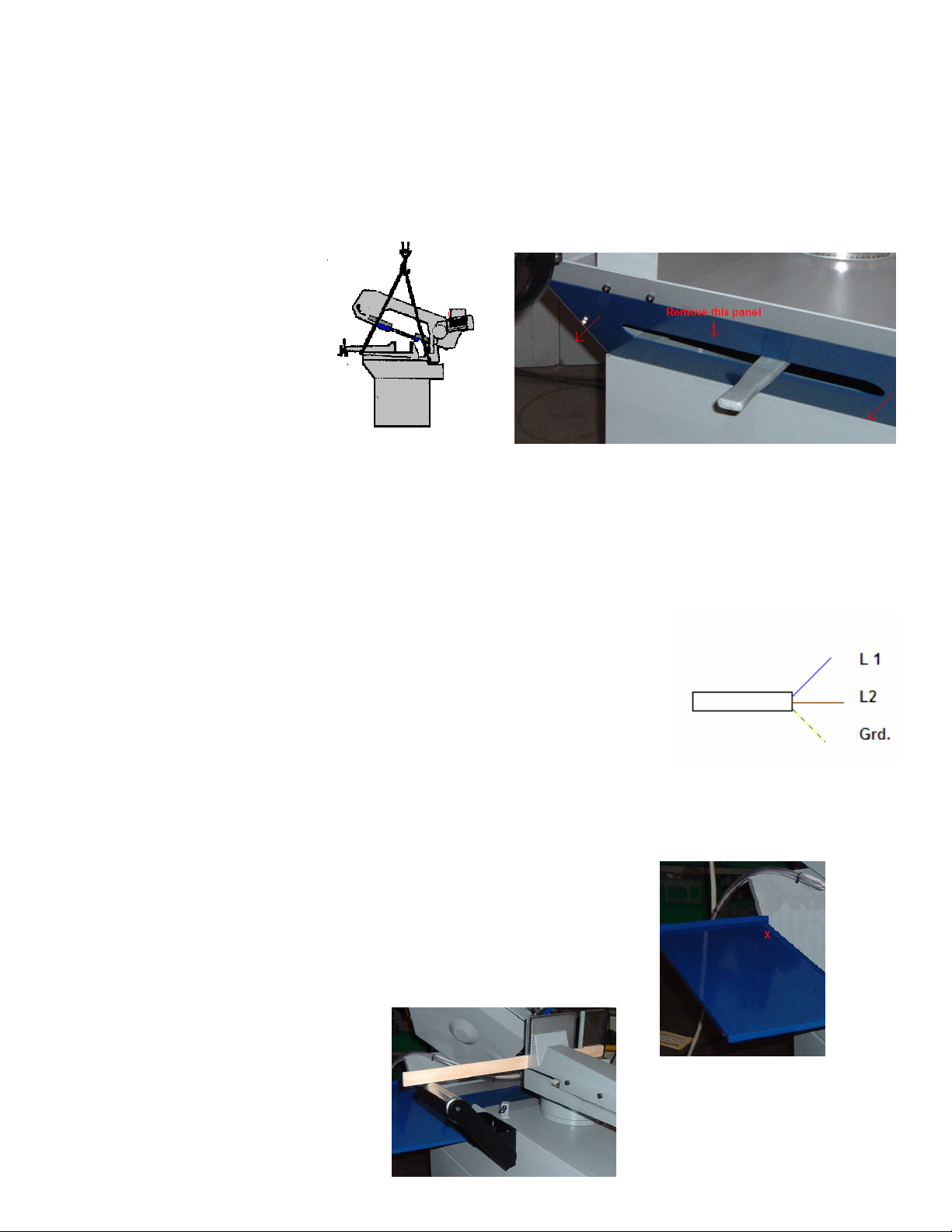

1. Accessory installation:

1.6 Installation of the drip tray, roller support and stock stop can be done at this time.

1. The drip tray is mounted to the left rear of the saw to prevent coolant from dripping onto the

floor while cutting miters. On the back left hand side of the saw (Approx. by the red X see figure

5) is a bolt, remove this bolt. Fit the tray with the folded lip over the saw edge and align the hole

in the lip of the tray with the bolt hole. Install bolt and snug up.

2. Roller assembly is mounted just in front of the drip tray on the

Left hand side of the machine. This roller is bolted to the machine using

The bolts and washers supplied and that are screwed in the saw at the

Mounting point. Remove the bolts and install the roller only figure

tightening the bolts. Using a straight piece of material clamped in the

Vise flat on the table, adjust the roller up to this material and tighten

Bolts. (See figure 6) Check the

Level of the roller both rear and

Front. Both must be at the same

Height.

Figure 5

Figure 6

4

Page 5

3. Stock stop installation can be done at any time. This is used to deadhead your material against

for cutting repeat lengths. This can be removed if not being used. The stock stop screws into the

vise base on the right hand side of the vise. (Figure 7) The stop is measured using a tape or

template from the blade to the face of the stock stop. It is adjusted by loosening the pinch bolts

on the stop block.

Figure 7

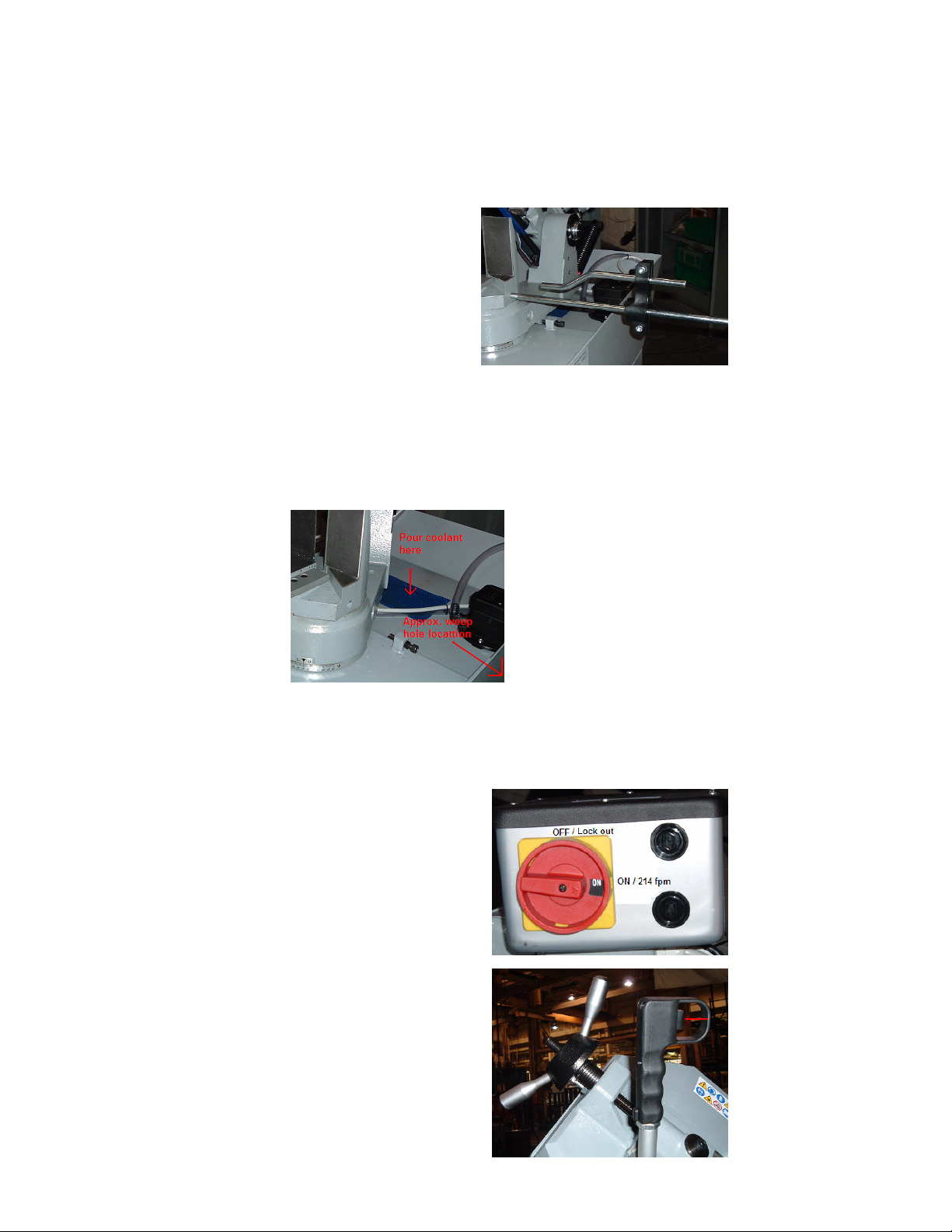

4. Add coolant. Mix the coolant as outlined in the instructions furnished with the coolant

concentrate. Usually mixed 10:1. Use only a high quality water soluble coolant. NOTE: Do not

use cutting oils!

Premix the coolant and pour small amounts directly into the blue filter screen on the back of the

saw. (Approx. 3 gallons) Do not over fill because on the right rear side there is a weep hole that

excess coolant will flow out of onto the floor. Slowly add coolant and check in the weep hole

using a small wire or pencil and stop filling when you are about ¼” from the weep hole. (Figure 8)

Figure 8

2. Component features, functions and adjustments:

A. Electrical Box. Off with lock out / on @ 214 fpm.

NOTE: With switch on the motor does not run!

B. Trigger Switch. Dead man style safety switch.

Trigger is pulled to make motor run.

(Both blade and coolant motors)

5

Page 6

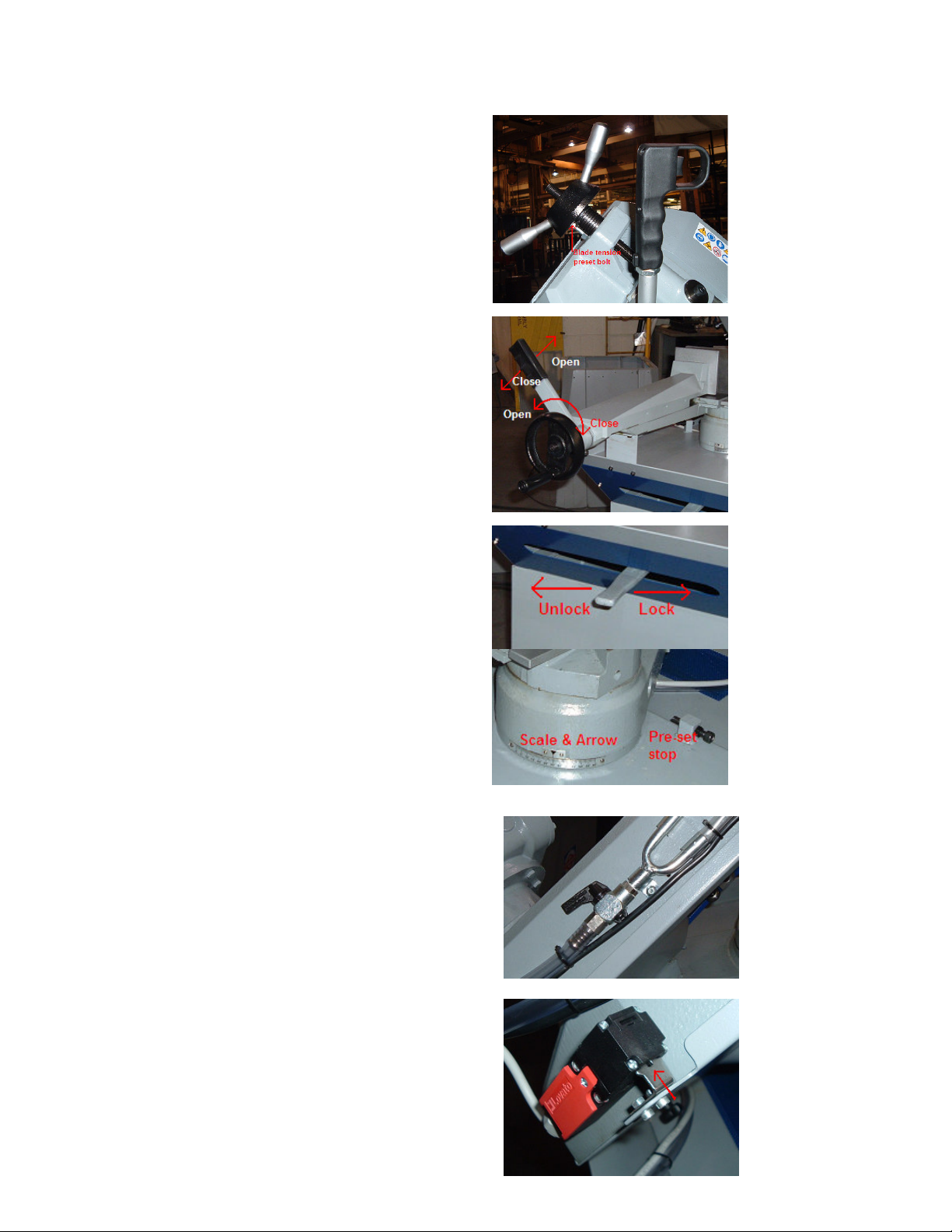

C. Blade tensioning handle. Mechanical

Blade tensioning handle is turned clockwise

To tighten blade; Handle will hit preset bolt

At the proper tension for the blade size.

NOTE: If different size blade is used, length or

Thickness this bolt will need to be re-calibrated

Using a blade pressure gauge to achieve proper

Preset tension.

D. Quick Release Vise. Using the handle wheel

Adjustment of the material can be made by

Opening or closing the vise up to the material.

Once the vise jaws come with-in a 1/16 – 1/8”

Of the material the quick release cam handle

Can be used to open or close the vise to the

Material for fast action.

E. Head Lock Lever. The head lock lever

When released allows the rotation of the

Cutting head up to 60° for mitering. Move

The lever to the left to unlock the head and

Right to lock it at any angle. For angle set

Up align arrow to the angle required on

The scale at the bottom of the rotation

Point of the vise. There is preset

Adjustable stops at 90° (0°) and 60°

These can be calibrated by turning the

Stop bolts in or out to get correct angle.

F. Coolant Flow Control. This valve is located on the

Bandsaw cutting head on the top of the casting

Towards the rear of the saw head. This valve controls

The amount of coolant distributed during cutting.

When adjusting be sure coolant flow is sufficient to

Both guides.

G. Interlock. This interlock is mounted on the rear of

The cutting head and will disable the saw when the

Blade cover is open. This prevent accidental starting

Or running of the machine during blade changes.

6

Page 7

H. Guide Arms. The guide arms are horizontally

Opposed for great rigidity. The outward arm is

Adjustable in and out allowing for close proximity

To the material when cutting different diameters.

By loosen the locking bolt knob the guide will

Slide in and out for the different size materials being

Cut. You always want the guides as close to the

Material as possible. NOTE: When moving this

Arm make sure the arm rail is seated into the way

Fully before tightening locking knob.

I. Throat Filler Plate. This filler plate is bolted to the

V groove in the vise. This filler plate takes up

Room in the V when straight cutting, allowing for

Cutting shorter lengths without the part falling

Under the blades path, and giving a larger support

Area. When miter cutting this filler plate can be

Unbolted and removed to allow cutting of miters

Without damaging the plate.

3. Safety:

NOTE: Do not operate this machine until all adjustments have been made and you have

read the safety instructions!

1. Wear approved safety glasses with side shields..

2. Wear non-slip foot ware. Do not over reach! Keep a safe footing.

3. Wear a dust mask if material being cut is dusty or lets off particles such as fiberglass.

4. Wear hearing protection.

5. Keep guards in place and in good condition. Lock machine out if guards or components are

broken or missing. Replace any worn or broken parts without delay.

6. Make sure the incoming power supply is up to codes and kept in good condition.

7. Always wait until blade has stopped completely before opening covers / doors, reaching into

point of operation or making adjustments.

8. Use good quality blades of the correct tooth configuration for the material being cut and of

the right size. Change blades when needed. If the blades are worn, burnt, cracked, and

missing teeth they must be changed. Dispose of discarded blades properly.

9. Handle blades with care! They can cut, even through gloves.

10. Keep hands away from the blade and parts of material being cut? The parts may be hot and

can burn you.

11. Keep all work clean. Monitor coolant regularly and replenish or change as necessary.

12. Keep area of machine well lit.

13. Keep all visitors and children a safe distance from machine.

14. Anchor the machine to a solid level floor.

15. Do not wear loose clothing, jewelry, neck ties, rings, loose long hair, and gloves.

16. Do not force the work. Too much pressure or hard jabs can cause injury, ruin the blade,

create excessive heat.

17. Do not operate the machine if under the influence of drugs, alcohol, or medications.

18. Do not use machine for purposes that it was not intended for. Do not force the material.

19. Do not leave the machine running unattended. Always turn off machine and wait for it to

stop before walking away.

NOTE: Turn off power and lock out when ever changing or installing the blade

Always use high quality blades of the correct size!

7

Page 8

WARNING: Never let the pull down handle go at the end of the cut. The cutting head is under

spring tension and will return upward rapidly and could cause serious injury. Always keep

hands on the pull down handle.

Always cut with arm extended, never put face over the cutting head return path!

4. Machine operation:

4.1 Set-up

1. Select cutting speed by placing the switch on control box to the ON position. (Paragraph A in

section 2)

2. Set length. Using the stock stop, tape measure or line on the material place the part under

the blade at desired length. (Figure 4)

3. Clamp the material into the vise. Make sure material is supported and level with the cutting

table using the hand wheel run the vise jaw just up to the material leaving approx. 1/16” –

1/8” gap. Move the quick release vise lever down until part is firmly held in place. (Paragraph

D in section2)

4. If miter is required loosen the head lock lever and rotate cutting head to desired angle and

lock in place. NOTE: For some miters the throat filler plate must be removed. Do so before

material is clamped. (Paragraph E , I in section 2)

5. Adjust guide arm distance if needed. You want to maintain close proximity to the material if

possible. (Paragraph H in section 2)

4.2 Operation:

1. With all set up complete, turn the start switch to the ON position making sure you have a

firm footing and a comfortable grasp of the pull down handle, squeeze the trigger to start the

blade. Take note while the blade is running but not in the work of the coolant flow. You want

a steady but not excessive flow from both guides. If flow is not suitable adjust the flow

control valve before continuing. (Paragraph F in section 2)

2. Slowly pull the cutting head down allowing the rotating blade to make light contact with the

material. When contact with material is made increase the pressure and continue with the

cut. When the cut is finished with the blade still running raise the blade up just past the

material and release trigger to stop the blade. Keeping the blade running while raising the

blade prevents the blade from catching the material and damaging the blades teeth.

Continue to lift the head all the way back up keeping control of the cutting heads return rate.

NOTE: Never let go of the pull down handle before it reaches its up most rest position!

NOTE: New blades must be broke in properly for best performance and blade life. See the

blade selection section in this manual for break in and optimum cutting hints.

5. Changing the blade:

Handle blades with caution they are sharp and can cause serious injuries!

1. Turn power off and lock out machine. (Paragraph A in section 2)

8

Page 9

2. Remove four knobs that hold blade cover in place. (Figure 9) Hold onto the cover to

prevent it from falling. Remove the cover and

Set out of your way.

3. With the cover removed, remove blade

Guard from the moveable guide arm and

Set it aside. (Figure 10)

Figure 9

Figure 10

4. Using a pair of heavy gloves that are not prone to snagging, hold the top of the blade

while loosening (counter-clockwise) the blade tension handle, until blade is slackened.

(Paragraph C in section 2)

Slowly and carefully lower the top of the blade downward (off the wheels) in the direction

it will want to go. (Figure 11) While holding the top of the blade and it being laid

downward, push the blade downward out of the guides. (Figure 11) Remove, coil and

discard safely.

Figure 11

5. Install new blade in reverse order. Carefully uncoil the blade. NOTE: Do not toss the

blade on the ground to uncoil. This is a very dangerous and

Damaging practice! Read the instructions on the blade box.

Remove the plastic teeth protection strip from blade if so

Equipped. With blade laid flat insert the blade between the

Guide rollers and push upward until the fully seat into the

Guides and guide pads. Make sure the blade contacts

The upper blade guide. See photo

9

Page 10

With the blade being held in the guides, loop the blade over the drive wheel and front idle

wheels. Apply a slight amount of tension to the blade with the blade tensioning handle,

enough to hold the blade onto the wheels. Check that the blade is still fully in the guides

and push the blade up against the back lips of the wheels. Tighten blade tensioning

handle until it dead heads the preset bolt. (Paragraph C in section2)

NOTE: Before installing the blade check the blade because at times the blade will

reverse it self while uncoiling, make sure teeth are facing the rear of the machine

or in the direction the blade travels. If blade is reversed carefully twist the blade to

reverse the teeth direction.

6. Replace the blade guard; make adjustments so it does not rub on the blade.

7. Replace rear blade cover. Make sure interlock switch in engaged. (Paragraph G in

section 2)

8. Restore power to the machine and jog the blade a few times to make sure the blade is

seated into the guides.

6. Calibrating blade guides and tensioning preset bolt for different size blades.

NOTE: It is recommended that the same size of blade be used as originally equipped. Dake is

not responsible for any of the following changes that may be required for blades of different

specifications.

1. The machine is calibrated for a bi-metal blade that is 97 ½” long, 1” wide and 0.035 thick.

Never use blades that are wider than 1” or narrower than 1”. Damage may occur to guides

and blade.

If a blade is used that is either longer, shorter or of a different thickness re-calibration may

be necessary to the preset bolt or blade guides.

2. Preset tension bolt can be adjusted inward or outward for shorter or longer blades. To

calibrate the bolt should be screw inward to allow installation on the new blade. With the

blade installed is should be tensioned according to the manufactures specifications using

a tension gauge. With proper tension applied adjust the preset bolt out until it dead heads

the tensioning handle. Lock in place with the jam nut. (Paragraph C in section 2)

3. For a blade of a different thickness, thinner or thicker the guide pads may require

adjustment.

Loosen nut C, screw B and set screw D

Widening the distance between pads.

Loosen nuts H, and set screws I and

Rotate the eccentric pins E-G to widen

Clearance between bearings F.

Mount new blade and place the blade

Against pad A, adjust set screw D until

You have approx. 0.010 – 0.015 of

Clearance to blade. Lock screw a in place

with nut C.

Rotate eccentric pins E-G until bearings have a slight drag on the blade then tighten nuts

H and set screws I. Do not place too much drag on these bearings.

10

Page 11

7. Maintenance and routine adjustments.

7.1 Maintenance Daily:

1. Top off coolant as needed.

2. General cleaning of machine. Clean chips and debris from machine.

3. Check condition of the saw blade.

4. Check all guards and interlocks.

7.2 Weekly Maintenance:

1. Clean all chips from coolant filter cover. (Blue cover on top rear of machine)

2. Clean band wheels.

7.3 Monthly Maintenance:

1. Check tightness of band wheel bolts.

2. Check guides for wear debris for adjustment.

3. Check guards and interlocks.

4. Replace coolant. Clean coolant reservoir and pump pick up screen.

NOTE: Gear box is maintenance free.

7.4 Routine Adjustments:

1. If slop develops in vise, tighten vise slide screws.

2. Calibration of guides or preset tensioning bolt. (See 6.1 –3)

3. Head height and depth of cut.

Per photo on the right there are two

Adjusting screws with lock nuts. One

Bolt in the back is for setting max.

Height of the head return. This can

Be set so the head does not go up

As high, if material being cut is

Smaller diameters. The other bolt

In the front limits the depth of cut,

And can be set to prevent cutting

Into the vise casting. Simply loosen

Lock nuts adjust bolts to where you need them and tighten lock nuts down.

4. Angle stop calibration see paragraph E in section 2.

5. If head lock lever is loose and will not tighten head in position remove from access panel

(As you did during mounting of saw to base) set the lever in the tighten position. With the

lever all the way to the right loosen the large clamp bolt on the locking lever casting. Drop

handle down slightly on the shaft and move toward the left a very small amount. (A

couple of teeth on the shaft are sufficient), push the lever back up onto the shaft and

tighten clamp bolt. Reinstall access panel.

11

Page 12

8. Blades:

8.1 Simplified selection chart at right.

1. Rules of thumb for blade selection

Four important numbers to keep in mind are the

Rule of thumb numbers. These numbers are

3, 6, 12 and 24:

Number 3: Represents the minimum

Number of teeth you want working at one

time. If the blade is too coarse for the work,

The teeth can straddle the work; this will strip

Teeth from the blade.

Number 24: The maximum number of teeth you would want in the cut at one time. Too fine a

tooth blade will clog with chips again resulting in stripped teeth.

Number 6 to 12: The ideal number of teeth working at one time.

8.2 Blade breaks in:

1. It is recommended that the blade manufactures break procedure is followed.

Proper blade break-in is as important to good blade life as choosing the right blade. The best

analogy I have heard for blade break-in is the pencil story. If you sharpen a pencil to a nice

sharp point and attempt to write with it, the lead breaks off because it is too sharp to glide

over the paper. If you take the same pencil with the same sharp point and lightly rub it over

the paper you hone or soften the point, resulting in a pencil that can be used for a long period

of time.

The same is true with a bandsaw blade.

When it is new it has very sharp point over

the length of the blade that will tear the

material, chatter and chip or round off the

teeth in a hurry. Breaking in the blade

allows for tips of the teeth to be honed into

a usable tooth that produces good cuts and

longevity.

Blade break-in will vary depending on the

type of material you are cutting. Softer

materials such as carbon steel or aluminum

will require a longer break-in cycle than that of harder materials. Structurals and pipe will

require a longer break-in period because the actual square inches are reduced due to the

interruptions of the material. From the charts listed earlier you can determine if the break-in

will be for softer or harder material

A simplified rule of thumb break-in procedure that applies to most applications:

1. Set blade speed to normal cutting fpm.

12

Page 13

2. Figure out number of square inches the material is, e.g. 4” x 4” solid = 16 sq inches.

3. Decrease your head feed pressure to ½ of normal cutting rate - “soft material” and ¾ of the

normal cutting rate for “hard material”.

4. Start machine cutting. Increase speed slightly when blade has cut distance equal to the width

of the blade.

5. Increase speed again slightly as the blade reaches the halfway point of the cut. Finish the

cut without increasing feed again.

6. Start the next cut with the same feed rate as you ended the last cut. Increase the feed rate

again before reaching the halfway point.

7. Repeat step 7 until the blade has cut the recommended number of square inches determined

from the graph below. The cutting time at this point should be at the recommended cutting time,

but adjust if needed.

Total area required for blade break-in can be figured using this

graph, e.g. 4” x 4” = 16 sq. inches of 1020 mild steel cut at 214 fpm

requires 30 square inches of material to be cut at break-in speeds

(dotted line). Dividing the recommended square inches of material

area needed for break-in by the square inches of material will tell

you how many pieces to cut at the break-in speeds. Approximately

2 pieces will need to be cut at break-in speeds in this example.

Determine cutting speeds and feeds by the chip.

1. Look at the sample chip drawing to determine optimum cutting parameters.

Long spiral-shaped chips indicate ideal cutting.

Very fine or pulverized chips indicate lack of feed

And/ or cutting pressure.

Thick and/ or blue chips indicate overload or the

Blade or too much cutting pressure.

13

Page 14

9. Specifications:

Capacities:

@ 90° 8 ¾” 7 ¾” 10” x 6”

@45° 6 ¼” 6” 10 ¼” x 3 1/8”

@60° 4” 4” 4” x 4”

Horse Power 2 HP max.

Gear Reduction 28:1

Wheel Dia. 11 ½”

Blade Size 97 ½” x 1” x 0.035

Blade Speed 214 fpm

Max. Vise Opening 10 ½”

10. Drawings: Electrical / Exploded Views / Part Numbers

Contactor Part number 301457

14

Page 15

Ref #

Dake Part #

1 010A0009

2 99200002

3 99200003

4 99200004

5 NOT AVAILABLE

6 9920006

7 86005005

8 84320017

9 D80A0011

Ref #

Dake Part #

10 99200010

12 88140020

13 88600000

14 69501000

15 49001003

16 D80A1006

17 99200017

18 99200018

15

Page 16

Ref #

101 99200101

102 99200102

103 99200103

104 99200104

105 99200105

106 86002004

107 AFC10047

108 230B0001

109 AFC40109

Dake Part #

Ref #

111 050B0012

113 99200113

114 99200114

115 AGB80031

116 84310015

117 NOT AVAILABLE

118 99200118

119 9920019

120 99200120

Dake Part #

16

Page 17

Ref # Dake Part #

201 99200201

202 99200202

204 99200204

205 81700035

206 53500112

207 53500128

208 D80C0083

209

210 76200003

Ref # Dake Part #

212 99200212

213 82502082

214 82502082

215 84101054

216 AFC40052

217 AGC40051

218

219

220 99200220

Ref # Dake Part #

221 99200221

222 99200222

223 99200223

224 82505101

225 99100046

226 AFC40144

227 44600001

228 99200228

229 AFC40146

17

Page 18

Ref # Dake Part #

230 99200230

231 86005005

232 84320014

233 81700025

234 44114512

235

236 99200236

237 AF750030

238 99200238

Ref # Dake Part #

239 72212000

240

241

242

243 160C0030

244 100C0005

245 AF750147

246 AF750147

247 AF750146

Ref # Dake Part #

248 AF75B148

249 AF750148

250 84113010

252 AFC40145

18

Page 19

11. Trouble Shooting:

19

Page 20

20

Page 21

21

Page 22

NOTES:

22

Loading...

Loading...