Page 1

DAKE VDL-18

ASSEMBLY AND INSTRUCTIONAL MANUAL

WARNING! Read and understand all instructions and responsibilities before

operating. Failure to follow safety instructions and labels could result in

serious injury.

Dake Corporation Phone: 800.937.3253 www.dakecorp.com

1809 Industrial Park Dr. customerservice@dakecorp.com

Grand Haven, MI 49417

Page 2

Dake Corporation

1809 Industrial Park Dr

Grand Haven, MI 49417

www.dakecorp.com

Table of Contents

DAKE Standard Limited Warranty ..................................................................................................... 3

Finished Machines ............................................................................................................................ 3

Parts .................................................................................................................................................. 3

Sale of Service (Repairs)................................................................................................................... 3

Warranty Process .............................................................................................................................. 3

Warranty Exceptions ......................................................................................................................... 4

Return & Refund Policy ...................................................................................................................... 4

Returns .............................................................................................................................................. 5

Refunds ............................................................................................................................................. 5

Specifications ...................................................................................................................................... 6

Machine Specifications ...................................................................................................................... 6

Safety Warnings .................................................................................................................................. 7

Safety Labels: .................................................................................................................................. 10

Introduction - Assembly of components-Before starting……………………………………………….11-25

Blade install - tracking - tensioning ………………………………………………………………….26-28

Ceramic Guide Adjustment …..……………………………………………………………………….29-33

General Instructions: ....................................................................................................................... 33

Blade Guidepost Adjustment: .......................................................................................................... 34

Table Tilt: ......................................................................................................................................... 34

Fence Assembly Adjustment: .......................................................................................................... 35

Maintenance ...................................................................................................................................... 35

Trouble Shooting: ....................................................................................................................... 36-37

Parts List....................................................................................................................................... 38-57

Parts list & Exploded diagrams …………………………………………………………..…………..38-57

1VDL-18 Wiring Diagram:................................................................................................................ 58

Order Information ............................................................................................................................. 59

Part# VDL-18 2 REV#082020

Page 3

DAKE Standard Limited Warranty

Finished Machines

- Dake warrants to the original purchaser the finished machine manufactured or distributed

by it to be free from defects in material and workmanship under normal use and service

within 1 year (12 months) from the delivery date to the end user.

Parts

- Dake warrants to the original purchaser the component part manufactured or distributed

by it to be free from defects in material and workmanship under normal use and service

within 30 days from the delivery date to the end user.

- The standard limited warranty includes the replacement of the defective component part

at no cost to the end user.

Sale of Service (Repairs)

- Dake warrants to the original purchaser the component part repaired by Dake

Corporation at the manufacturing facility to be free from defects in material and

workmanship under normal use and service within 90 days from the return date to the

end user, as it pertains to the repair work completed.

- The standard limited warranty includes repair of the defective component part, at no cost

to the end user.

Warranty Process

- Subject to the conditions hereinafter set forth, the manufacturer will repair or replace any

portion of the product that proves defective in materials or workmanship. The

manufacturer retains the sole right and option, after inspection, to determine whether to

repair or replace defective equipment, parts or components. The manufacturer will

assume ownership of any defective parts replaced under this warranty.

- All requested warranty claims must be communicated to the distributor or representative

responsible for the sale. Once communication has been initiated, Dake Customer Service

must be contacted for approval:

Part# VDL-18 3 REV#082020

Page 4

• Phone: (800) 937-3253

• Email: customerservice@dakecorp.com

When contacting Dake, please have the following information readily available:

- Model #

- Serial #

- Sales Order #

Purchasers who notify Dake within the warranty period will be issued a Case number and/or a

Return Material Authorization (RMA) number. If the item is to be returned per Dake’s request,

the RMA number must be clearly written on the exterior packaging. Any item shipped to Dake

without an RMA will not be processed.

Warranty Exceptions

The following conditions are not applicable to the standard limited warranty:

(a) Part installation or machine service was not completed by a certified professional,

and is not in accordance with applicable local codes, ordinances, and good trade

practices.

(b) Defects or malfunctions resulting from improper installation or failure to operate or

maintain the unit in accordance with the printed instructions provided.

(c) Defects or malfunctions resulting from abuse, accident, neglect, or damage outside

of prepaid freight terms.

(d) Normal maintenance service or preventative maintenance, and the parts used in

connection with such service.

(e) Units and parts which have been altered or repaired, other than by the manufacturer

or as specifically authorized by the manufacturer.

(f) Alterations made to the machine that were not previously approved by the

manufacturer, or that are used for purposes other than the original design of the

machine.

Return & Refund Policy

- Thank you for purchasing from Dake! If you are not entirely satisfied with your

purchase, we are here to help.

Part# VDL-18 4 REV#082020

Page 5

Returns

- All Dake manufactured / distributed machines, parts and couplings include a 30-day return

option. These policies are valid from the date of final shipment to the end user. To be

eligible for a return, the item must be unused and in the same condition as received. All

requested warranty claims must be communicated to the distributor or representative

responsible for the sale. Once communication has been initiated, Dake Customer Service

must be contacted for approval:

- Phone: (800) 937-3253

- Email: customerservice@dakecorp.com

- Once the return request has been approved by Customer Service, a representative will

supply a Return Material Authorization (RMA) number.

- The returned item must have the provided RMA number clearly marked on the outside

packaging. Any item received without an RMA number clearly visible on the packaging

will not be processed.

- An RMA number can only be provided by the Dake Customer Service team and must

be obtained prior to the return shipment.

Refunds

- Once the item has been received and inspected for damages, a representative will

notify the requestor referencing the provided RMA number. If the return is approved, a

refund will be issued to the original method of payment, less a 20% restocking fee.

- The restocking fee may be waived if an order is placed at the time of return with like-

value merchandise. Transportation costs are the responsibility of the end user and will

not be credited upon return approval.

- Any item that is returned after the initial 30 days or has excessive/obvious use will not

be considered for a full refund.

Part# VDL-18 5 REV#082020

Page 6

Specifications

VDL-18 Bandsaw

Description

Dimensions

Motor Voltage/HP

115/ 230V (prewired 115V)/ 1-3/4HP

Breaker

15 amp for both 115V and 230V

Throat

18 7/32" (463mm)

Table cast iron

20" x 26" (508mm x 660mm)

Front table to center of blade

11" (280mm)

Table tilt

- 6 degrees + 45 degrees

Miter slot

3/8" x 3/4" (9.525mm x 19.05mm)

Table height

38" (965mm)

Fly wheel

Cast iron

Resaw capacity

16" (406.4mm)

Minimum blade length

143 3/4" (3,651mm)

Maximum blade length

145 1/2" (3,695mm)

Maximum blade width

1-1/4" (31.75mm)

Minimum blade width

1/8" (3mm)

Guides

Laguna ceramic

Blade speeds (FPM)

Variable speeds

Low: 100-290

High: 1200-3500

Dust chute diameter (OD)

4" x 2

Height

77 3/4" (1,975mm)

Machine dimensions (W x D) Base

footprint

36 3/16" x 36" (919mm x 915mm)

27" x 19 2/3" (688mmx500mm)

Machine dimensions with mobility kit (W

x D)

Base footprint with mobility kit

43" x 36" (1093mm x 915mm)

37 3/8" x 24 11/32" (949mm x 618mm)

Weight gross

515 lbs (234 kg)

Weight net

480 lbs (218 kg)

Package size (W x D x H)

81 1/2" x 33 7/8" x 30-1/4"

(2070mm x 860mm x 770mm)

Variable Foot Brake

Disk Rotor

Mobility kit

Optional

Industrial work-light

Optional

Machine Specifications

Part# VDL-18 6 REV#082020

Page 7

- In the space provided record the serial number and model number of the machine. This

information is only found on the black Dake tag. If contacting Dake this information must be

provided to assist in identifying the specific machine.

Model No:

Part No:

Serial No:

Date of Purchase:

Safety Warnings

BEFORE USE, ALL SAFTEY INSTRUCTIONS MUST BE READ

- As you know, the vertical bandsaw is a universal saw for contour cutting. Blade selection is

important and by choosing the right blade, you can make most any pattern cutting on most any

material with this machine. However, the most important thing is to realize how to operate it in

a safe and correct way and how to maintain it.

- We have tried to supply you all the information about these. Please be sure to look

through all the contents in this manual so that you may obtain the maximum efficiency

and the longest machine life with minimum expense.

Part# VDL-18 7 REV#082020

Page 8

- The specifications and information in this manual were current at the time this

manual was approved for printing. Dake, whose policy is one of continuous

improvement, reserves the right, however, to change specifications or design at any

time without incurring obligations.

- Always include the part number, model number, and parts description, for parts

orders or correspondence concerning your bandsaw, so we can supply you a

rapidly after-sales service.

▲WARNING

1. Read the operator’s manual carefully. Learn the tools applications and limitations, as

well as the specific potential hazards peculiar to it.

2. Always wear approved safety glasses/face shields while using this machine.

3. Make certain the machine is properly grounded.

4. Before operating the machine, remove tie, rings, watches, other jewelry, and roll up

sleeves above the elbows. Remove all loose clothing and confine long hair. DO NOT

wear gloves when operating.

5. Keep the floor around the machine clean and free of scrap material, oil and grease.

6. Always keep machine guards in place when the machine is in use. If removed for

maintenance purposes, use extreme caution, and replace the guards immediately.

7. DO NOT overreach! Always maintain a balanced stance. Do not fall or lean against

blades or other moving parts.

8. Use only sharp blades. Dull blades are dangerous.

9. Make all machine adjustments or maintenance with the machine unplugged from the

power source.

10. Use the right tool. DO NOT force a tool or attachment to do a job which it was not

designed for.

11. DO NOT make cuts requiring more power than is available on the machine.

12. Replace warning labels if they become obscured or removed.

13. Make certain the motor switch is in the OFF position before connecting the machine to

power.

14. Give your work undivided attention. Looking around, carrying on a conversation. And

“horse-play” is careless acts that can result in serious injury.

Part# VDL-18 8 REV#082020

Page 9

15. Make a habit of checking to see that keys and adjusting wrenches are removed before

▲ WARNING

All electrical connections must be done by a qualified electrician. Failure to comply

may cause serious injury!

All adjustment or repairs must be done with the machine disconnected from the power

source. Failure to comply may result in serious injury!

turning on the machine.

16. Keep visitors a safe distance from the work area.

17. Use recommended accessories; improper accessories may be hazardous.

18. Never place hands directly in line with the saw blade.

19. Always use push sticks when cutting small material.

20. Raise or lower the blade guide only when the machine has been turned off and the blade

has stopped moving.

21. Read and understand warnings posted on the machine.

22. DO NOT use attachments for any other purpose than for what they were designed for.

Failure to comply with all these warnings could lead to serious injury.

This is the safety alert symbol.

- When you see this symbol on your press be alert to the potential for personal injury.

Part# VDL-18 9 REV#082020

Page 10

Safety Labels:

Label Part # 84605 Label Part # 84395 Label Part # 84605

Label Part # 84604 Label Part # 82199

Part# VDL-18 10 REV#082020

Page 11

This bandsaw is designed to give you years of safe service. Read this owner’s

Introduction to Bandsaws.

manual in its entirety before assembly or use.

The bandsaw is generally defined as a saw blade in the form of an endless steel band

that rotates around two or more wheels. This blade is a continuous metal band with

teeth on one side. As the wheels rotate, so does the band, which creates the

continuous sawing action.

Because the direction of the blade is always downward toward the table, there is little

danger (except for special cuts) that the material will be thrown back at the operator,

which is called a kickback.

The unique feature of the bandsaw is that the work piece can be rotated around the

blade creating a curve. It is the tool most often used when curves have to be cut in

Part# VDL-18 11 REV#082020

Page 12

wood or metal.

What you will receive with your Bandsaw.

Because the bandsaw blade is fairly thin, it can cut thick stock with a minimum of

horsepower. For this reason, the bandsaw is often the machine of choice.

Fence

Fence parts

Part# VDL-18 12 REV#082020

Page 13

Fence guide bar

Table ratchet handles & washers Rubber feet and hardware

Fence stop

Table

Part# VDL-18 13 REV#082020

Fence guide bar attachment parts

T bar

Page 14

Note: The mobility kit and light are optional.

1. Tension indicator window

10. Rip fence assembly

2. Switch

11. Dust port 4”

3. Motor

12. Quick-release blade tension lever

4. Frame

13. Blade tracking knob

5. Blade tension handle

14. Optional mobility kit

6. Blade tracking window

15. 110v power socket

7. Cast iron table

16. Blade guide shaft lock

8. Blade guide adjustment hand wheel

17. Flywheel

9. Blade guide

18. Brake foot pedal

Parts of the Bandsaw.

The bandsaw has many parts. The major parts are discussed in this manual. If you are not familiar

with the bandsaw, take the time to read this section and become familiar with the machine.

Part# VDL-18 14 REV#082020

Page 15

4. Frame.

1.

Tension indicator

Tension indicators are designed to indicate the compression of a

spring. As a rule, the greater the spring compression, the

greater the tension on the blade. The tension scale does not

register until the blade is relatively taut and is located on the

inside of the body of the bandsaw. The tension scale is a

general reference and not a rule. The tension indicator is visible

with the upper door closed by looking through the tension

indicator window.

2.

Switch.

To start the machine press the "I" button on the start stop

switch. To shut off the machine press the "O" on the start stop

switch. When the safety switch is pressed it stops the power to

the motor. To reset it, twist and it will pop out and allow power to

be supplied to the motor.

3.

Motor.

The bandsaw is supplied with a 120V motor. It drives the lower

flywheel through a drive belt.

Emergency stop button

Start / Stop buttons

The frame of the bandsaw is a U-shaped frame, which houses all the parts of the

machine. This is the heart of the bandsaw and must be very rigid, as it takes the

strain of the blade being tensioned.

5. Blade tension handle.

The blade tension handle moves the blade tension and tilt assembly vertically. The

vertical action compresses a spring that ensures that the blade tension is constant

and will not change dramatically as the blade length increases due to the heat

generated by the cutting action.

Part# VDL-18 15 REV#082020

6. Blade tracking window.

There is a blade tracking window on the side of the frame that allows the edge of

the upper flywheel to be viewed. This allows the tracking of the blade to be

achieved with the door closed.

7. Cast iron table.

The table supports the work piece and can tilt (-6 degrees to +45 degrees) to produce

cuts at various angles. It has a groove to the right-hand side of the blade, which is

used to guide the miter gauge. In the center there is a table insert which the blade

passes through. Should the blade wander off center, this table insert will protect the

Page 16

blade from damage, as it is soft and should not damage the blade. The table also

supports the adjustable fence, which is used for parallel cuts. There is a nut and bolt

that joins both sides of the table and stops the table from warping. The nut and bolt

must always be fitted in the table and only removed when removing or fitting a blade.

8. Blade guide adjustment hand wheel.

The upper blade guides are attached to the blade guide shaft. The shaft is vertically

adjustable with a hand wheel. The guides should be adjusted so the guides are just

above the wood being cut. This gives the blade maximum stability and is also the

safest way to operate the bandsaw.

9. Blade guides.

There are two sets of blade guides, one above and one below the table. The function

of the guides is to give the blade stability and ensure that the blade movement

left/right, forward/back is kept to a minimum. The guides above the table are fitted to a

shaft that has vertical adjustment. The upper guides are adjustable so that the guides

are held just above the job being cut. This gives the blade the maximum amount of

stability and also keeps the amount of blade that is exposed to a minimum. The

guides have ceramic inserts that can be adjusted for almost zero clearance.

10. Rip fence assembly.

The rip fence assembly consists of a guide rail, cast knuckle, fence attachment

casting, rule and a high-low fence. The guide rail is attached to the table side. It guides

the fence assembly across the table. The cast knuckle slides on the guide rail and is

lockable in any position to suit the width of cut. The fence attachment casting is

attached to the cast knuckle with three screws that when loosened allow the fence to

be adjusted for drift. The fence is attached to the fence attachment casting with two

studded knobs that allow the fence to be adjusted laterally across the table to suit the

job being cut. The fence can be fitted in the low position or the vertical (7 1/4" height)

position.

There is a rule that is fitted to the side of the table and can be used as a quick guide

on the distance that the fence is from the blade. The Fence Stop can be used for non

through cuts and can be set on any length of the fence with the quick release handle.”

Note. The rule will have to be adjusted each time the fence is adjusted for drift, as this will

change the distance the fence is from the blade

11. Dust ports 4".

The bandsaw produces a lot of sawdust, so extraction is very important. This is

achieved by connecting a 4" dust extraction hoses with a minimum capacity of 1,000

CFM to the two dust ports located at the back of the machine. The stronger the suction

Part# VDL-18 16 REV#082020

Page 17

from the dust collector, the better for you and the machine.

12. Quick-release blade tension lever.

There is a quick-release tension lever at the back of the bandsaw. The lever is a

convenient way of quickly releasing the tension on the blade and speeds up blade

change dramatically.

13.Blade-tracking knob.

The blade-tracking knob is located at the back of the bandsaw and is used to adjust the blade

tracking. The knob must be locked once the adjustment is completed

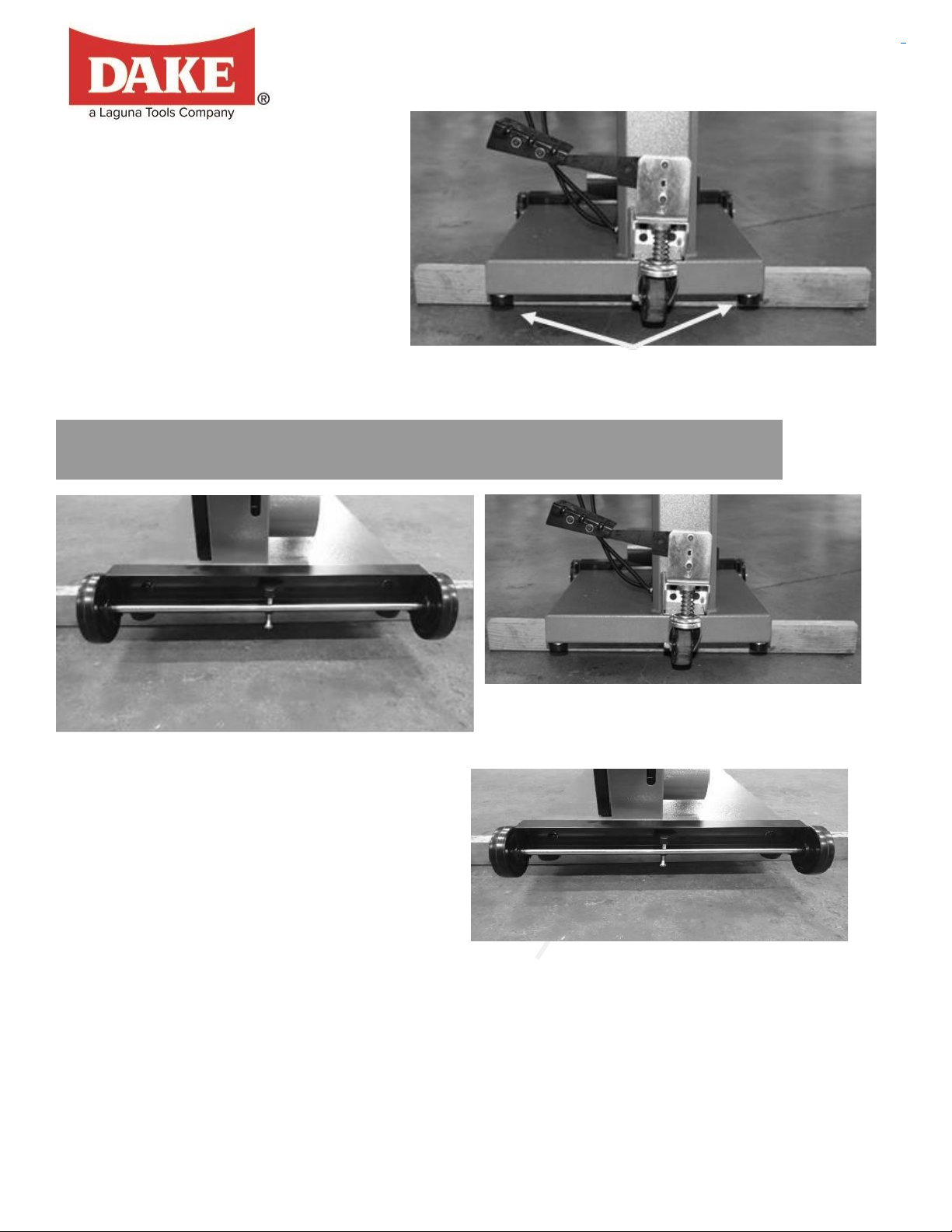

14. Optional mobility kit.

The optional mobility kit is fitted to the base of

the bandsaw and consists of two fixed wheels at

the front of the bandsaw and a swivel wheel at

the back of the band saw. The swivel wheel is

activated and deactivated with a foot lever. With

the swivel wheel deactivated, the bandsaw sits on

two rubber feet.

15. Optional light.

The optional light is fitted with four screws through

pre-drilled holes at the top of the bandsaw.

The bandsaw is provided with a 120V socket that

the light can be connected to.

16. Blade guide shaft lock

The upper blade guide is fixed to the blade guide shaft, which is vertically adjustable. Once the

guides have been adjusted vertically; the shaft is locked in position with the lock knob

17. Flywheel.

The blade is suspended over two wheels that are covered with rubber called a "tire". The tire

cushions the blade and protects the teeth from coming in contact with the metal of the

flywheel. The lower wheel is the drive wheel and is attached to the motor with a rubber drive

belt. The lower flywheel powers the blade and pulls the blade down through the work piece.

The top wheel has two functions. One function is to balance or track the blade on the wheels,

and the second one is to tension the blade. Both functions are adjustable.

Part# VDL-18 17 REV#082020

Page 18

18. Brake.

Assembly and set up.

Assembling the rubber feet.

The bandsaw is provided with a brake that is operated by

applying the foot pedal. When the foot pedal is applied, the

power is interrupted from the motor and the flywheel is slowed

by the disc brake.

19.Guards

When running, the blade can be very dangerous, and the

amount of blade that is exposed must be kept to a minimum.

Disc brake on flywheel

The machine is supplied with a number of guards, all of which MUST be installed and used

while the machine is running. There is a guard that is attached to the lower door and is

adjustable vertically once the door is closed. There is a guard on the guide vertical adjustment

shaft

20. Blade tilt and tension mechanism.

The upper wheel is attached to the tilt and tension mechanism. This mechanism adjusts the

wheel so that the bandsaw blade can be adjusted for blade tracking. This is achieved by a

screwed handle at the back of the machine that pushes on the mechanism and adjusts the

axis of the wheel so that it runs true with the lower wheel. The second function is to tension the

blade, which is achieved by adjusting the upper flywheel vertically. A handle is located below

upper flywheel and, when rotated, will move the wheel up or down. The machine has a quickacting blade release mechanism that is located at the back of the machine and will remove the

tension from the blade to speed the removal and fitting of blades. The mechanism has a

spring, which helps to keep the tension constant as the blade expands and contracts with the

heat generated by the cutting action.

21. Electrical connection.

The bandsaw is provided with a cord and a 120v plug.

Part# VDL-18 18 REV#082020

Page 19

Rear swivel wheel

Front wheels Locking screw

Bandsaw supported on wooden block

Method 1.

Assembling the optional mobility kit

Fit the rubber feet to the bandsaw

prior to removing it from the

packaging.

Method 2.

1.Support the bandsaw on

wooden blocks.

2.Assemble the rubber feet with

the hardware provide both at front and Rubber feet

back of the bandsaw.

1.

Support the bandsaw on wooden blocks.

2.

Fit the swivel assembly to the back

of the bandsaw with the provided

bolts.

3.

Fit the front wheels to the front of the

bandsaw with the bolts provided and

remove the two rubber feet that are

close to the front wheels.

Note. Never operate the bandsaw with

the mobility kit engaged or the front wheel

assembly locking screw engaged.

Part# VDL-18 19 REV#082020

Page 20

.

Trunion clamp stud

Tilt stop bolt

Fitting the table.

It is possible to fit the table to the bandsaw with one person but far easier if you have two people, one to lift

the table and one to guide the trunion clamp studs

Tilt blanking disc Table tilt hole

Tilt stop bolt Tilt blanking disc

The table has a reference stop bolt that is used to quickly align the table after tilting.

The stop bolt hits the tilt-blanking disc when it is positioned over the table tilt hole.

When the tilt blanking disc is moved away from the hole, it allows the tilt stop bolt to

pass through the table tilt hole, and the table can be moved to the maximum amount

of tilt (-6 degrees).

Part# VDL-18 20 REV#082020

Page 21

Table mounted to the bandsaw

Trunion clamp stud

Ratchet handle

With the table fitted to the trunions, assemble the two ratchet handles and flat washers.

How to adjust the table for square to the blade. This will be detailed later in the manual.

Table rule with fixings

Table with rule mounted

Attach the rule to the table with the hardware supplied. Do not

fully tighten the bolts, as the position of the rule will have to be

adjusted to suit the blade, which will be detailed later in the

manual.

Rule adjustment slot

Part# VDL-18 21 REV#082020

Page 22

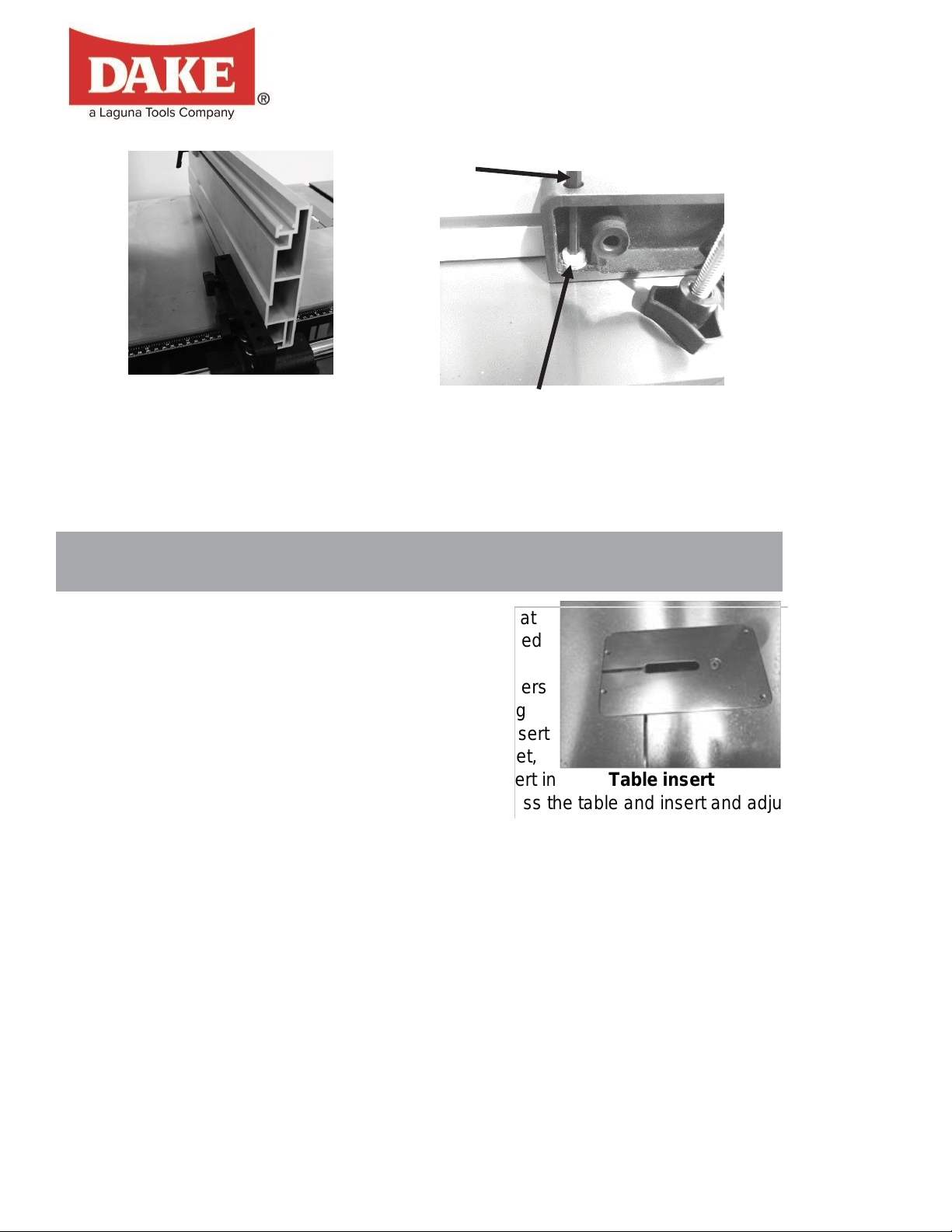

1. Fit the fence bar to the table with the screws and spacers supplied.

Note. The distance between the fixing holes and the end of the bar is not symmetrical, and

the end that has the longest distance must be at the back of the bandsaw (closest to the

column).

2. Slide the fence support onto the fence bar and fit the fence support clamp screw.

3. Slide the fence onto the clamping strip.

4. Lift the fence just clear of the table and secure it in position with the clamping screws.

Spacer

Fence bar

Fence support

Fence support

Fence support lock knob

Lock knob

Fitting the fence.

Fence in low position Fence clamped in low position

Part# VDL-18 22 REV#082020

Page 23

The fence support and the fence are held off the table with a nylon-support Allen

Fence in high position

Allen key

Support Allen screw

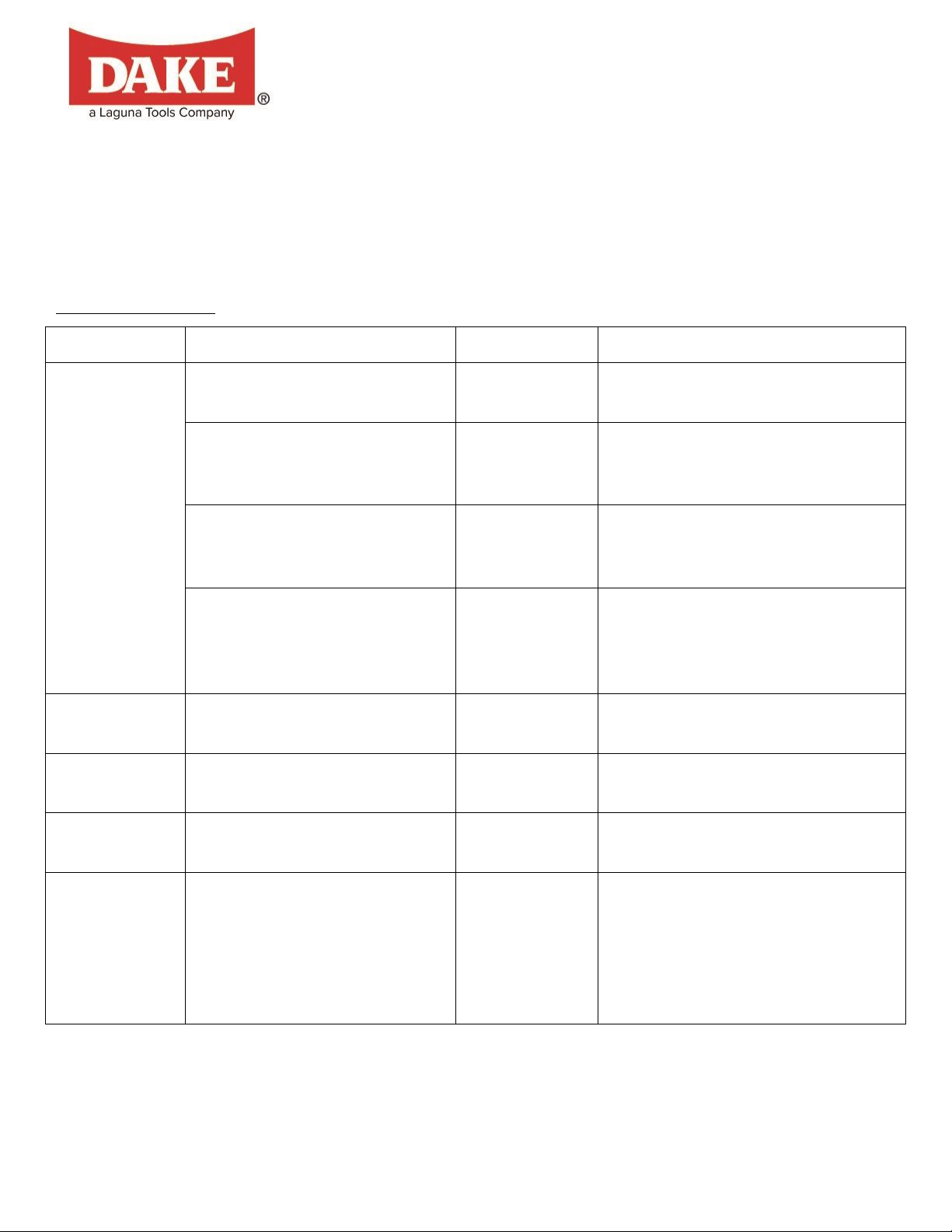

Fitting the table insert and Fence Stopper

screw. This screw ensures that the fence and the fence support do not damage the

table. The screw is adjustable to compensate for wear.

The machine is supplied with a removable table insert that

is held in position with a screw. The table insert is removed

when blades are removed or fitted to the machine. The

insert is made of soft aluminum so that if the blade wanders

and contacts the insert, there is less chance of damaging

the blade. Adjusting screws are provided to adjust the insert

vertically level with the table. The insert comes factory set,

but should adjustment become necessary, place the insert in Table insert

the table with the screw fitted. Place a straight edge across the table and insert and adjust the screws

so that the table insert is level with the top of the table.

Fitting the Fence Stop

The fence stopper can be used to control the length of cut for non through cuts. To set the stop in

place, the scale should be attached into the T-slot on top of the fence when it is on the vertical

position. The “0” on the scale should be adjusted and set to be align up to the front tip of the blade.

Then refer to the scale, slide the fence stopper to the desired cutting length behind the front tip of the

blade as shown in the scale, then fix the fence stopper in place by tightening down the quick release

handle.

Part# VDL-18 23 REV#082020

Page 24

Fixing screws and cable clips Light fitted in position

Fitting the optional light.

Part# VDL-18 24 REV#082020

Page 25

Suggested cable route

Light plugged into

socket

The light is fitted to the top of the bandsaw as shown. The light is supplied with a plug 120V. The

Before starting the bandsaw.

cable must be held in position with the clips provided and positioned so that the cable is safe and will

not in any way come close to the blade or cabinet door. Above is the suggested cable route. Use the

sticky cable clamps to secure the cable along the top of the bandsaw. Ensure that the cable is not

over the vertical shaft hole, as it could be damaged when the shaft exits the hole.

Read and understand the instruction manual before operating the saw.

1.

If you are still not thoroughly familiar with the operation of the bandsaw, get

advice from a qualified person.

2.

Make sure the machine is properly grounded and that the wiring codes are followed.

3.

Do not operate the bandsaw while under the influence of drugs, alcohol or

medicine or if tired.

4.

Always wear eye protection, safety glasses or a safety shield, and hearing protection.

5.

Wear a dust mask; long-term exposure to the fine dust created by the

bandsaw is not healthy.

6.

Remove your tie, rings, watch and all jewelry. Roll up your sleeves; you do

not want anything to get caught in the saw.

7.

Make sure that the guards are in place and use them at all times. The guards

protect you from coming in contact with the blade.

8.

Make sure that the saw blade teeth point downward toward the table.

9.

Adjust the upper blade guard so that it is just clearing the material being cut.

10.

Make sure that the blade has been properly tensioned and tracked.

11.

Stop the machine before removing the scrap piece from the table.

12.

Always keep your hands and fingers away from the blade.

Part# VDL-18 25 REV#082020

Page 26

13.

A lot of people do not like to change the blades and go to great lengths to avoid doing it. To

use the bandsaw to its greatest advantage, you will have to use the appropriate blade and

track it quickly. This is a habit that can be easily developed. If you use a step-by-step method

of tracking and tensioning, the procedure should only take a minute or two. Be careful when

using blades, especially wide ones. Always use gloves and safety glasses.

Clamp screw

Throat plate

Table split clamp screw

Table split clamp slot

Blade in table split

Plastic blanking block

Make sure that you use the proper size and type of blade.

14.

Hold the work piece firmly against the table. Do not attempt to saw stock that

does not have a flat surface facing down, unless a suitable support is used.

15.

Use a push stick at the end of a cut. This is the most dangerous time because

the cut is complete, and the blade is exposed. Push sticks are commercially

available.

16.

Hold the wood firmly and feed it into the blade at a moderate speed.

17.

Turn off the machine if you must back the material out of an uncompleted or

jammed cut.

Disconnect the power from

the bandsaw.

1.

Remove the throat plate

by removing the clamp

screw.

Part# VDL-18 26 REV#082020

Page 27

2.

Tracking the blade.

Remove the table split clamp

ratchet handle.

3.

Remove the plastic blanking plate.

4.

Adjust the side guide and back guide out as far as they will go (both upper and lower guides).

This will ensure that they do not interfere with the blade while you are installing, tracking and

tensioning the blade.

5.

Uncoil the blade. Remember to use gloves and safety glasses. The blade may have dirt or oil

on it, so use a clean rag to clean the blade by pulling rearwards so that the cloth does not hook

on the teeth

6.

Inspect the teeth and the general condition of the blade. If the teeth are pointing in the wrong

direction when you hold the blade up to the machine, you will have to turn it inside out. To do

this, hold the blade with both hands and rotate.

7.

Slide the blade through the table split.

8.

Open the blade guard door. Slide the blade over the top flywheel and feed through the slot at

the side of the vertical column. Then feed the blade into the blade guard slot and close the

blade guard door.

9.

Deactivate the quick action blade tension lever and rotate the blade tension wheel so that the

blade can fit over the lower flywheel.

10.

Activate the quick action blade tension lever.

11.

Apply light tension to the blade with the blade tension wheel.

1.

To track the blade, start rotating the wheels by hand in the normal direction. As you do this,

watch the blade to determine where the blade wants to track. If the blade is tracking too far

forward or backward, make small adjustments with the tracking adjustment knob located at the

back of the bandsaw while still rotating the wheel. Once the blade is tracking in the correct

position, fully tension the blade and re-track. Lock the tracking adjustment handle.

Note: The blade must be fully tensioned for final tracking.

Note: Never track the blade with the saw running.

Part# VDL-18 27 REV#082020

Page 28

Lock knob

Tensioning the blade.

Blade guard door

Tracking window

Tracking knob Blade in column slot

Blade tension wheel

1.Deactivate the quick action blade tension lever and

rotate the blade tension wheel so that the blade can fit

over the lower flywheel.

2. Activate the quick action blade tension lever.

3. Apply light tension to the blade with the blade tension

wheel.

4.The scale inside the top half door of the bandsaw is

a good reference to use determining what tensions are

good based off the width of the blades for many

applications Quick action tension lever (activated)

.

Blade tension indicator

.

Part# VDL-18 28 REV#082020

Page 29

Introduction.

Welcome to a new era in bandsawing. You have purchased a bandsaw with a revolutionary blade

guide system that is designed to give you years of safe, high-quality bandsawing. Most blade guides

are designed to support the blade on the sides and either above or below the side guides at the back

of the blade. This can allow the blade to twist as pressure from the material being cut pushes against

the back-blade guide. The Ceramic Guide eliminates this by supporting the blade above and below

the back blade guide, giving the blade unsurpassed stability. The Ceramic Guide also incorporates

patented ceramic as the blade support material. The advantage of this material is its ability to resist

wear, and with care it should give years of safe service.

Please read the following notes as they will assist you in getting the optimum performance

from your ceramic guide system.

As with the roller guide systems, the ceramic guide system will damage your blade if it is not adjusted

correctly. The guide blocks must not come in contact with the teeth of the blade. It is advisable to run

the blade by hand with the guide blocks completely clear of the blade, and only when you are

completely sure that the blade is running consistently in the correct position, you may then adjust the

surround guide blocks as detailed in this manual.

Note on using the ceramic guide system.

1.

When fitting a blade to your bandsaw, adjust the guide blocks as detailed later and run the

blade by hand through the guide blocks for at least two complete revolutions.

2.

The weld on a new blade may not be perfectly aligned, and the misalignment could hit the

ceramic blocks (side and back), causing damage to the blocks or the blade. If the blade has a

bad weld, return it to your blade supplier or side dress and file the back of the blade as needed.

3.

The back blade guide is manufactured from ceramic, so as the blade pushes against it, friction

between the blade and the ceramic occurs. This action generates a certain amount of sparks.

This is normal and will become less with time as the back of the blade guide smoothes out the

back of the blade.

4.

The back blade guide will slowly form a small grove as the blade is used (this is normal). It is

recommended that for approximately every 8 hours of use, the guide be rotated 15 degrees.

Part# VDL-18 29 REV#082020

Page 30

This will ensure that the groove does not become too deep and will greatly extend the life of

your guide.

5.

The ceramic guide system can be used with 1/8” to 1-1/4” blades.

6.

The ceramic guide system uses ceramic to support and guide the blade. This has

many advantages (very poor conductor of heat, very resistant to wear, etc.). The

disadvantage is that it is very brittle, so the guides must never be dropped, exposed

to hard knocks, hit with hard objects or used with badly welded blades. Any of the

above actions may cause the ceramic to chip or break and will detract from the

performance of the ceramic guide system. Any mistreatment of the guide system

will render the warranty void.

7.

The side guide blocks must be tightened before running the machine to avoid

jamming the blade and damaging the machine and/or guide blocks.

8.

When cutting gummy material, the blade can become covered with resin. You will

find that the surround guide system ceramic blocks remove the resin as the blade is

moved through the guide blocks and keep that part of the blade clean. For this

reason, it is recommended that the blocks be adjusted as close to the gullet as

possible, but the teeth must not come in contact with the blocks, as they will become

damaged. Although the guide blocks clean the blade, some materials will still gum

the blade and the resin will have to be removed with solvent.

Side guide clamp screw

The blade should run through the

center of the rear blade guide, and the

side guides should be parallel with the

blade. If they have been moved out of

adjustment, adjust as follows:

Top Upper Side Guides Parallel Adjustment.

Loosen the side guides and move out as far as

possible. Loosen the guide assembly and

move back away from the blade.

Move the back blade guide forward so it just

touches the back of the blade and lock in

position.

Back guide clamp screw

Part# VDL-18 30 REV#082020

Page 31

Loosen the guide clamp screw that allows the

side guides to move forward and back. Adjust

so that the ceramic blocks are just behind the

gullet of the teeth and are parallel to the blade.

Retighten the clamp screws.

Gently push one side guide so that it touches

the blade and lock it in position. Bring the other

guide toward the blade so that there is minimal

clearance between the blade and the guide. You

can put a thin piece of paper to put between the

blade and the guide to obtain the correct. Back guide touching back of the blade

clearance until you gain experience. Tighten the

clamp screws and remove the paper. Rotate the

blade by hand, ensuring that the weld of the

blade does not hit the ceramic blocks, as this

will cause damage.

Lower blade guide

The lower blade guides have two locking screws

that, when released, allow the guide assembly to

be moved forward and back. Rotate the blade by

hand and ensure that it is tracking consistently

in the correct position

Loosen the side guides and move out from the

blade. Loosen the two clamp screws that allow

the guide assembly to move forward and back.

Adjust it so that the ceramic blocks are just

behind the gullet of the blade and retighten the

clamp screws.

Place a dollar bill or piece of paper of similar thickness

between the guide blocks and the blade. Gently bring both side

guides toward the blade so that slight pressure is exerted

on the blade. Tighten the clamp screws and remove the

paper.

Rotate the blade by hand, ensuring that the weld of the

blade does not hit the ceramic block

Part# VDL-18 31 REV#082020

Page 32

Loosen the rear guide clamp screw and push

the guide forward so that it just touches the

back of the blade. Tighten the guide in position.

Rotate the blade by hand and check to see that the

back of the blade does not hit the blade guide with a

bad weld..

Note: You will probably find that the guides can be

adjusted more easily by tilting the table to 45

degrees.

Note: Rotate the back guide by approximately 15

degrees after every 8 hours of use. This will greatly

extend the life of the back-blade guide, as it will

even out the wear

Before you cut any metal or wood, read the safety

rules at the front of this manual

Table tilted 45 degree

Part# VDL-18 32 REV#082020

Page 33

General Instructions:

Below are some basic instruction to properly operate the VDL-18 bandsaw machine.

1. Make sure the blade is properly adjusted for tension and tracking.

2. Adjust blade guide assembly so that the guide guides are just above the workpiece (about

3/16”) allowing minimum exposure to the blade.

3. If using the fence, move it into position and lock it to the guide rail. If you are using the miter

gauge for a crosscut, the fence should be moved safely out of the way.

4. Turn the machine on and wait a few seconds for the machine to fully get up to speed.

5. Place the straightest edge of the workpiece against the fence and push the workpiece slowly

into the blade. Do not force the workpiece into the blade. Let the blade do the work.

NOTE: (DO NOT over feed that bandsaw blade. This will reduce blade life and have a greater

chance of breaking the blade).

6. When cutting long stock, the operator should use roller stands, support tables, or an assistant

to help stabilize the workpiece.

7. When cutting at an angle with a tilted table, provide a guide against which the material being

cut can rest. Freehand cutting at an angle can result in injury, and maintaining an accurate cut

is difficult.

9. Deactivate the quick action blade tension lever and rotate the blade tension wheel so that the

blade can fit over the lower flywheel.

10. Activate the quick action blade tension lever.

11. Apply light tension to the blade with the blade tension wheel.

12.The scale inside the top half door of the bandsaw is a good reference to use determining what

tensions are good based off the width of the blades for many applications.

High to Low Setting & FPM setting:

- First will explain the procedure to change the VDL-18 from high gear to low gear or vice versa.

The same procedure applies both ways.

Disconnect the machine from the power source before making any adjustments.

1. Turn the machine off and unplug from the power source.

NOTE: (The motor MUST BE OFF before going to the next step)

2. Once the motor is completely off, slide the lever to the desired high to low setting. You

may run into situations where the lever does not fully go into low or high. If so, carefully

Part# VDL-18 33 REV#082020

Page 34

rotate the blade while trying to put the motor into gear. The lever will fully go into to

Blade Speed Ranges (FPM)

High Gear Range

1200 – 3500 FPM

Low Gear Range

100 – 290 FPM

gear.

- Below is the procedure to change the FPMs of the bandsaw (SAW ON, AND RUNNING).

-

1. To change to the desired RPM on the bandsaw, the bandsaw MUST be on and the

blade rotating in the required gear prior changing the speed.

2. Locate the motor locking level located on the back side if the bandsaw near the bottom

by the motor. Loosen the lever handle.

3. The adjuster hand wheel located on the bottom right of the bandsaw adjusts the blade

speed. referencing to the dial located on the back of the motor.

4. Slowly rotate the handwheel CW to increase the blade speed, or CCW to decrease the

blade speed.

5. Tighten the motor locking lever back in place immediately.

USE CAUTION: Never start the VDL-18 bandsaw with any slack in the drive belt. Doing so

can cause machine damage as the belt is forced to pull through the slack.

Blade Guidepost Adjustment:

- The following steps are to properly adjust the Blade Guidepost height on the VDL-18 Bandsaw.

1. Locate the guidepost locking screw located on the rear top half go the bandsaw. To make

any adjustments, loosen the locking screw to allow the blade guidepost to freely move

horizontally.

2. The hand wheel located above the blade guidepost on the side of the machine adjusts the

horizontal movement of the guidepost.

NOTE: (Maintain a clearance of 3/16 inch between the blade guidepost and the

workpiece to allow minimum exposed blade to prevent injury).

3. After correctly adjusting the height of the blade guidepost, ALWAYS tighten the guidepost

screw for the guide will stay in the desired position.

Table Tilt:

- The following steps are to properly adjust the Table Tilt angle on the VDL-18 Bandsaw.

1. For tilting the table to right (max. 45º), you have to loosen the two ratchet handles, then tilt

the table to your desired angle.

Part# VDL-18 34 REV#082020

Page 35

2. For tilting the table to left (max. -6º), the table has a reference stop bolt that is used to

quickly align the table after tilting. The stop bolt hits the tilt-blanking disc when it is

positioned over the table tilt hole. When the tilt blanking disc is moved away from the hole,

it allows the tilt stop bolt to pass through the table tilt hole, and the table can be moved to

the maximum amount of tilt (-6 degrees).

Tilt stop bolt Tilt blanking disk

Tilt blanking disc Table tilt hole

Fence Assembly Adjustment:

- The following steps are to properly adjust the Fence Assembly Adjustment on the VDL-18

Bandsaw. This will change the accuracy length cut of the workpiece. Check the clearance

between the table and the fence. The fence should not rub against the table surface but be

slightly above it. This gap should be the same at the front of the table as it is at the rear.

1. Loosen the fence locking wheel located on the fence assembly.

2. The fence is now free to move vertically along the worktable.

3. Once in the desired spot, lock the fence in place by tightening the locking screw.

Maintenance

Before performing any maintenance to the machine, make sure to unplug the cord from

the power source before cleaning.

- Maintain bearing guides clean and free of build-up.

- Check that the cleaning brush over the band wheel is working properly and remove any

deposits from the band wheels to avoid vibration and blade breakage.

- The table surface should be always kept clean and free of rust for best results. talcum powder

applied with a blackboard eraser rubbed in vigorously once a week; this will fill casting pores

and form a moisture barrier. This method provides a tabletop that is slick and allows rust rings

to be easily wiped from the surface.

Part# VDL-18 35 REV#082020

Page 36

- Clean and grease all mechanical movement components such as gears, bars, if it becomes

Item

Action

Interval

Maintenance

Saw Blade

Listen for sound of missing

teeth.

Whenever

operating saw

Replace blade when teeth are

broken.

Observe cutting action for

cleanness and accuracy.

Whenever

operating saw

Replace blade when bent or worn;

use a wider blade for more accurate

straight cuts.

Listen for a poor weld – a “click”

as it passes through the guide

bearings.

When changing

blade

Use a different blade or dress the

weld with a grinder.

Watch for signs of slippage on

the drive wheels (blade

occasionally slows or comes to

a stop while sawing).

Whenever

sawing

Be sure you are using the correct

blade tension; check rubber tires for

cleanliness and adherence to drive

wheel – replace if necessary.

Lower Drive

Wheel

Check bearing area for leakage

of lubricant.

Monthly

Replace bearing if leakage occurs.

Upper Drive

Wheel

Check bearing area for leakage

of lubrication.

Monthly

Replace bearing if leakage occurs.

Drive Wheel

Rubber Tires

Check for cleanliness.

Daily and when

changing blade

Wipe or brush clean.

Drive Belt

Check for smooth surfaces and

adherence to drive wheel.

Check for glazing.

Monthly or when

blade slippage

occurs Monthly,

or when slippage

occurs

(squealing belt)

Clean when necessary – replace if

damaged or excessively worn.

Replace a glazed belt – DO NOT

USE BELT DRESSING.

difficult to adjust.

- Clean and oil the tensioning mechanism if it becomes difficult to adjust.

- Check the drive V-belt for cracks overtime. Replace if any irregular wear is present.

Trouble Shooting:

Part# VDL-18 36 REV#082020

Page 37

Part# VDL-18 37 REV#082020

Gearbox

Check sight glass for level –

should be to halfway point on

sight glass.

Daily

Annually

Fill up to halfway point on sight glass

with 90 wt. gear oil.

Drain and refill.

Blade Support

Bearings

Check for wear, damage, or

lubricant leakage.

Monthly and

when changing

blade

Replace when necessary.

Carbide Blade

Guides

Check for excessive wear.

When changing

blade

Replace if excessively worn.

Page 38

Parts List

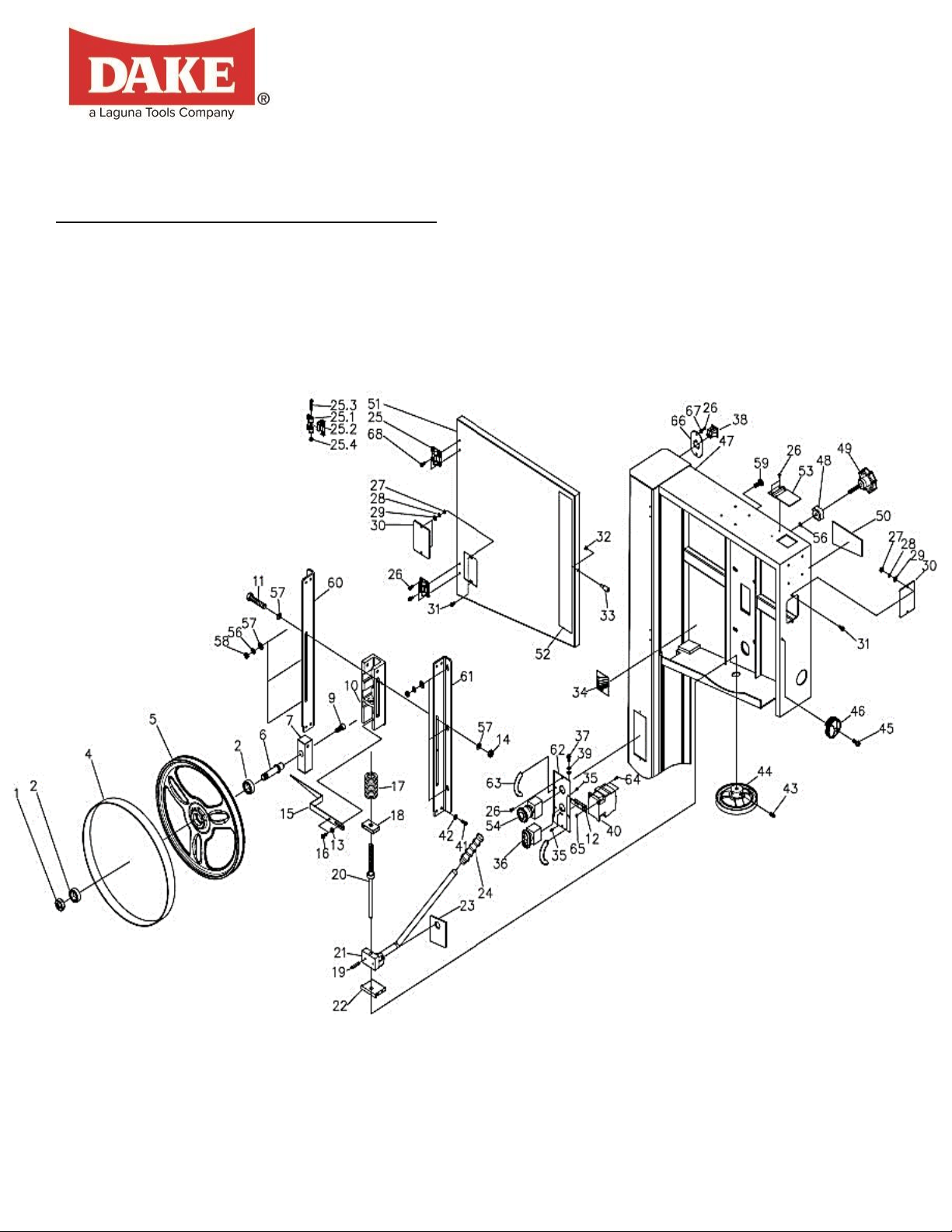

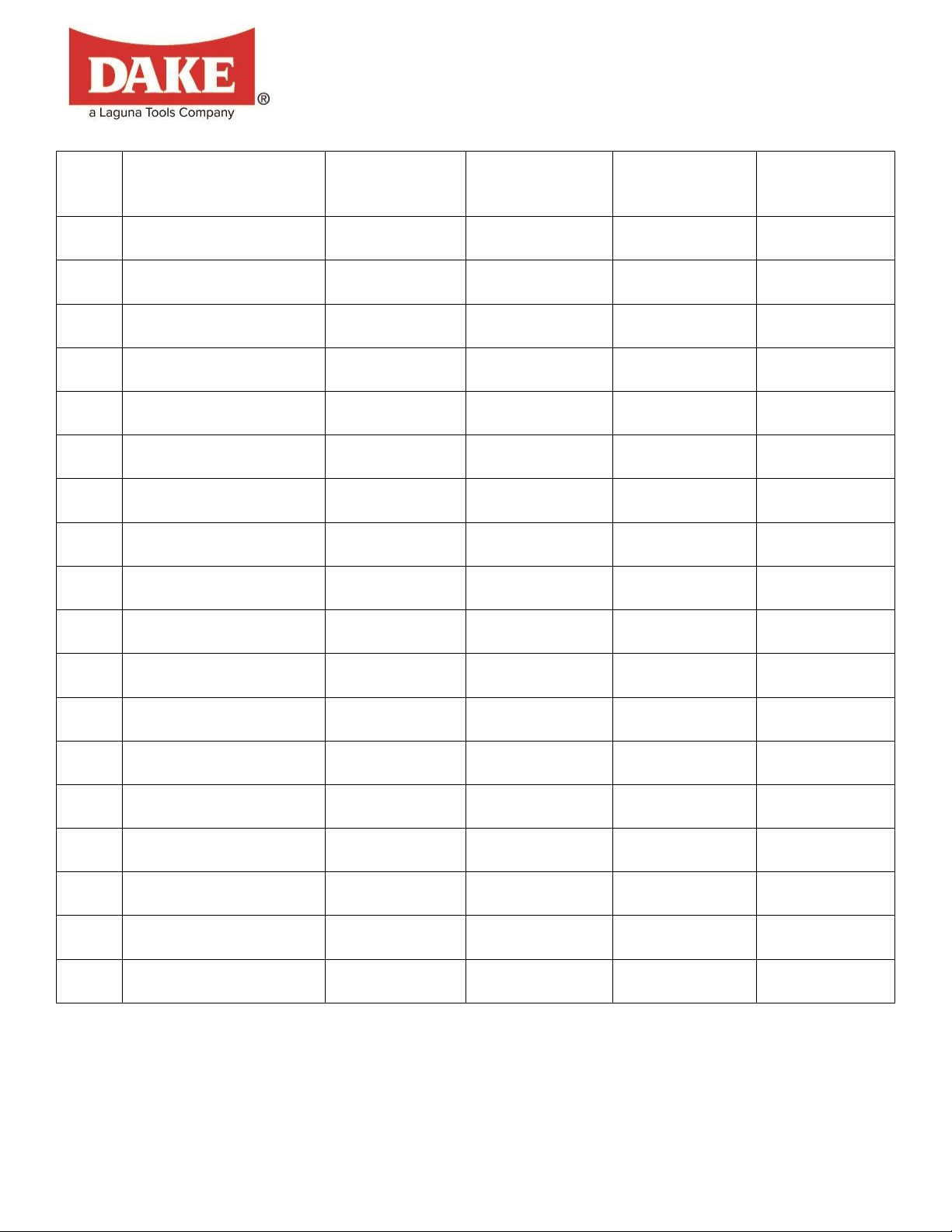

Upper Wheel Assembly: (Parts List Below)

Part# VDL-18 38 REV#082020

Page 39

Part# VDL-18 39 REV#082020

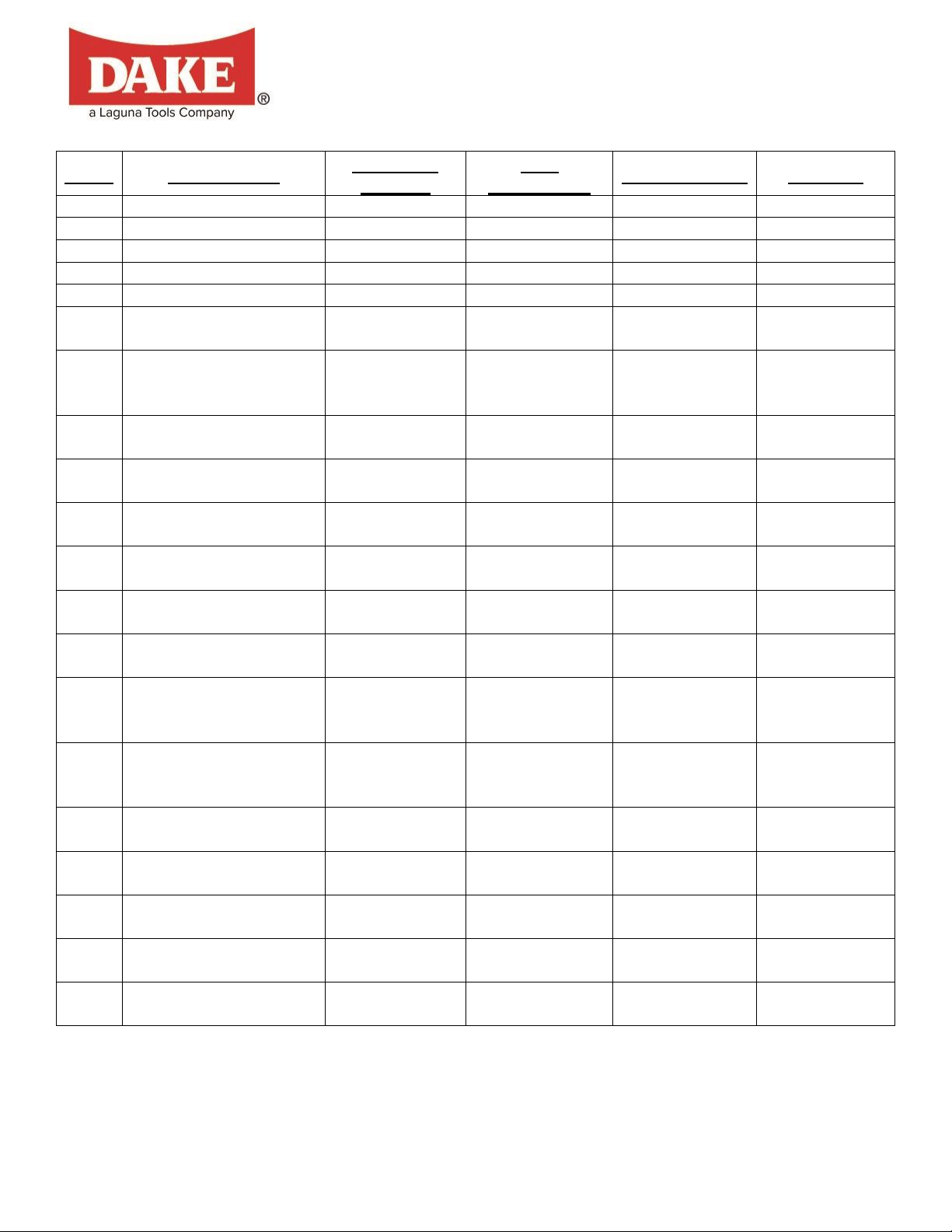

Upper Wheel Assembly

Index

Part Number

Item

Description

Specifications

Quantity

Dake Part

Number

1

PBAND18BX2203-1

Hex Nut

5/8-18UNF-LH

1

2

PBAND18BX2203-2

Ball Bearing

6204LLU

2

4

PBAND18BX2203-4

PU Tire

1

5

PBAND18BX2203-5

Upper Wheel

1

6

PBAND18BX2203-6

Upper Wheel

Shaft

1

7

PBAND18BX2203-7

Upper Wheel

Shaft Bracket

1

9

PBAND1412-175-9

Socket Head

Cap Screw

3/8”-16x5/8"

1

10

PBAND18BX2203-10

Sliding Bracket

1

11

PBAND18BX2203-11

Hex Cap Screw

M8x80

1

12

PBAND1412-175-170

Switch Plate

1

13

PBAND18BX2203-13

Bushing

1

14

PBAND18BX2203-14

Nylon Inserted

Lock Nut

M8

1

15

PBAND18BX2203-15

Pointer

1

16

PBAND18BX2203-16

Special Bolt

2

17

PBAND18BX2203-17

Spring

1

18

PBAND18BX2203-18

Bracket

1

19

PBAND1412-175-19

Pin

Ø4x20

1

20

PBAND18BX2203-20

Adjusting Screw

1

21

PBAND18BX2203-21

Blade Tension

Arm Assembly

1

22

PBAND18BX2203-22

Support Block

1

23

PBAND1412-175-23

Plate

1

24

PBAND1412-175-24

Handle

1

25

PBAND1412-175-25

Door Hinge Set

2

25.1

PBAND1412-175-25-

1

Door Hinge,

Left

2

25.2

PBAND1412-175-25-

2

Door Hinge,

Right

2

Page 40

25.3

PBAND1412-175-25-

3

Socket Head

Cap Screw

M5x0.8x35

2

25.4

PBAND1412-175-25-

4

Nylon Inserted

Lock Nut

M5x0.8

2

26

PBAND1412-175-26

Screw

M3.5x10mm

10

27

PBAND1412-175-27

Hex Nut

#10-24

4

28

PBAND1412-175-28

Lock Washer

#10

4

29

PBAND1412-175-29

Flat Washer

#10

4

30

PBAND1412-175-30

Tracking

Window

2

31

PBAND1412-175-31

Screw

#10-24×1/2"

4

32

PBAND1412-175-32

Hex Nut

1/4”-20

1

33

PBAND1412-175-33

Door Stud

1

34

PBAND18BX2203-34

Tension Gauge

1

35

MBAND14BX110-

175-35

Phillips Flat

Head Screw

M3x6

6

36

MBAND14BX110-

175-36

ON/ OFF

Switch

1

37

PBAND1412-175-37

Screw

M5x0.8x16

2

38

PBAND1412-175-38

Outlet

1

39

PBAND1412-175-39

Washer, Lock-

Int. Tooth

M5

3

40

MBAND14BX110-

175-40

Contactor

1

41

PBAND1412-175-41

Hex Cap Screw

1/4"-20x5/8"

4

42

PBAND1412-175-42

Lock Washer

1/4"

4

43

PBAND1412-175-43

Set Screw

1/4"-20x3/8"

2

44

PBAND18BX2203-44

Handwheel

1

45

PBAND1412-175-45

Screw

1/4"-20x3/4"

1

46

PBAND1412-175-46

Lock Knob

1

47

PBAND18CX110175-

47

Saw Body

1

48

PBAND1412-175-48

Lock Knob

1

49

PBAND1412-175-49

Adjusting Knob

1

50

PBAND1412-175-50

Tension Label

1

51

PBAND18BX2203-51

Upper Door

1

52

PBAND18CX110175-

52

Logo Label

1

53

PBAND1412-175-53

Hinge Cover

1

Part# VDL-18 40 REV#082020

Page 41

54

MBAND14BX110-

175-54

Emergency

Stop

1

55

PBAND1412-175-55

Warning Label

1

56

PBAND1412-175-2-

13

Lock Washer

5/16"

7

57

PBAND1412-175-2-

11

Flat Washer

5/16"

8

58

PBAND1412-175-3-

38

Hex Nut

5/16"-18

6

59

PBAND18BX2203-59

Carriage Bolt

5/16-18x1"

6

60

PBAND18BX2203-60

Upper Wheel

Bracket- Left

1

61

PBAND18BX2203-61

Upper Wheel

Bracket- Right

1

62

PBAND18CX110175-

62

Control Panel

1

63

MBAND14BX110-

175-63

Handle

2

64

MBAND14BX110-

175-64

Hex Cap Screw

M4x0.7x12

2

65

MBAND14BX110-

175-65

Hex Nut

M4x0.7

2

66

MBAND14BX110-

175-66

Plate

1

67

MBAND14BX110-

175-67

Washer, Lock-

Int. Tooth

M4

2

68

MBAND14BX110-

175-68

Screw

M4x0.7x8

4

Part# VDL-18 41 REV#082020

Page 42

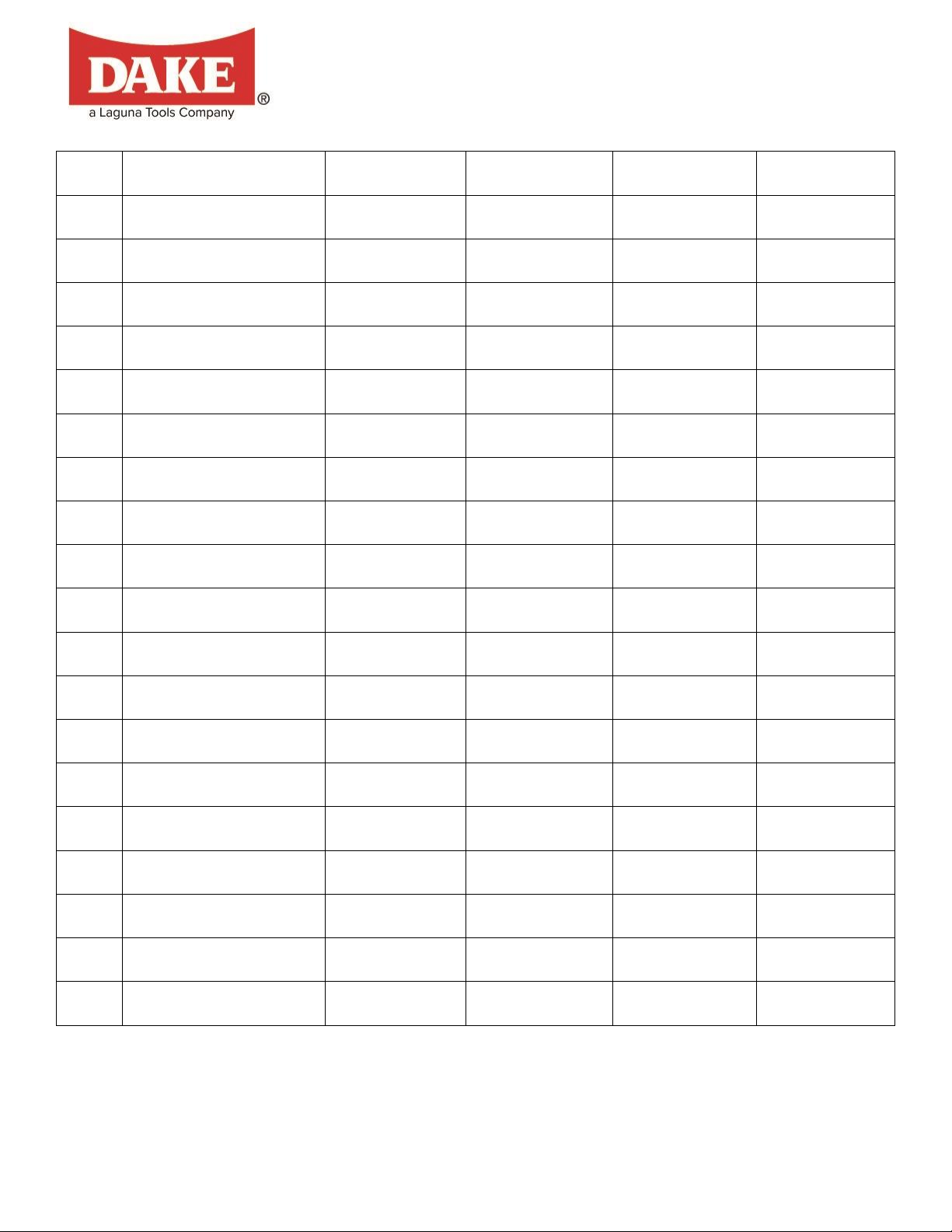

Table and Fence Assembly: (Parts List Below)

Part# VDL-18 42 REV#082020

Page 43

Table & Fence Assembly Parts List

Index

Part Number

Dake Part

Number

Item

Description

Specifications

Quantity

1

PBAND18BX2203-

3-1

Aluminum

Fence

1

2

PBAND1412-175-3-

2

Plastic

Adjusting

Screw

1

3

PBAND1412-175-3-

3

Fence Body

1

4

PBAND1412-175-3-

4

Lock Knob

2

5

PBAND1412-175-3-

5

Socket Head

Cap Screw

5/16"-18x3/4"

3

6

PBAND1412-175-2-

13

Lock Washer

5/16"

10

7

PBAND1412-175-3-

7

Fence Head

1

8

PBAND18BX2203-

3-8

Lock Knob

1

9

PBAND1412-175-3-

9

Lock Bar

1

10

PBAND1412-175-3-

10

Set Screw

M4x0.7x4

4

11

PBAND1412-175-3-

11

Table Insert

1

12

PBAND18BX2203-

3-12

Table

1

13

PBAND18BX2203-

3-13

Scale

1

14

PBAND18BX2203-

3-14

Scale Plate

1

15

PBAND1412-175-3-

15

Hex Cap

Screw

M5x0.8x10

2

16

PBAND1412-175-29

Flat Washer

M5

2

17

PBAND1412-175-3-

17

Bushing

2

18

PBAND1412-175-3-

18

Socket Head

Cap Screw

5/16"-18x2-

1/2"

2

Part# VDL-18 43 REV#082020

Page 44

19

PBAND18BX2203-

3-19

Steel Tube

1

20

PBAND1412-175-3-

20

Scale

1

21

PBAND1412-175-3-

21

Trunnion

2

22

PBAND1412-175-3-

22

Hex Cap

Screw

M10x1.5x50

2

23

PBAND1412-175-3-

23

Slide Block

2

24

PBAND1412-175-3-

24

Flat Washer

1/4"

6

25

PBAND1412-175-2-

42

Lock Washer

1/4"

6

26

PBAND1412-175-3-

26

Socket Head

Cap Screw

M6x1x16

6

27

PBAND1412-175-3-

27

Pointer

1

28

PBAND1412-175-3-

28

Screw

M5x0.8x8

1

29

PBAND1412-175-3-

29

Bracket

1

30

PBAND1412-175-2-

42

Flat Washer

3/8"

2

31

PBAND1412-175-3-

31

Lock Handle

2

32

PBAND1412-175-3-

32

Hex Cap

Screw

5/16"-18x1-

1/4"

3

33

PBAND1412-175-3-

33

Set Screw

5/16"-18x5/8"

2

34

PBAND1412-175-3-

34

Hex Cap

Screw

5/16"-18x1-

3/4"

3

35

PBAND1412-175-3-

35

Hex Cap

Screw

3/8"-16×2"

1

36

PBAND1412-175-3-

36

Hex Nut

3/8"-16

1

37

PBAND1412-175-3-

37

Phillips Flat

Head Screw

M4x0.7x8

1

38

PBAND1412-175-3-

38

Hex Nut

5/16"-18

1

Part# VDL-18 44 REV#082020

Page 45

Part# VDL-18 45 REV#082020

39

PBAND1412-175-2-

11

Flat Washer

5/16"

1

40

PBAND1412-175-3-

40

Lock Handle

1

41

PBAND18BX2203-

3-41

Nylon Inserted

Lock Nut

5/16-18UNC

1

42

PBAND1412-175-3-

42

Set Screw

1/4"-20x1/4"

2

43

PBAND18BX2203-

3-43

Fence Stop

Hinge

1

44

PBAND18BX2203-

3-44

Lock Handle

1

45

PBAND18BX2203-

3-45

Fence Stop-A

1

46

PBAND18BX2203-

3-46

Fence Stop-B

1

47

PBAND1412-175-6-

26

Bushing

2

48

PBAND18BX2203-

3-48

Socket Head

Cap Screw

5/16-

18UNCx2"

1

49

PBAND18BX2203-

3-49

Square Nut

1/4-20UNC

1

50

PBAND18BX2203-

3-50

Screw

M3x0.5x4

2

51

PBAND18BX2203-

3-51

Scale

1

Page 46

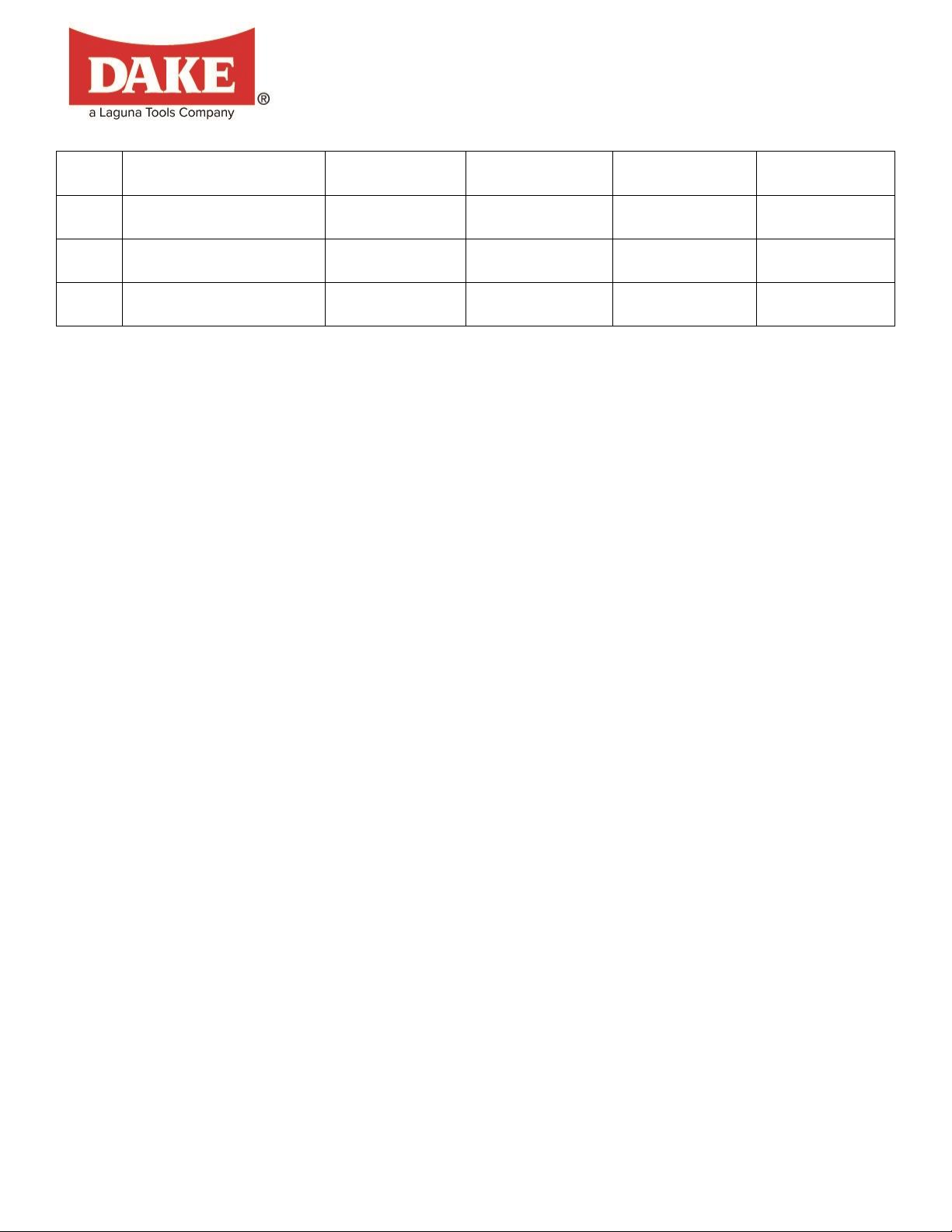

Upper & Lower Blade Guides Assembly: (Parts List Below)

Part# VDL-18 46 REV#082020

Page 47

Part# VDL-18 47 REV#082020

Upper & Lower Blade Guides Assembly Parts List

Index

Part Number

Dake Part

Number

Item

Description

Specifications

Quantity

1

PBAND1412-175-

4-1

Lock Knob

1

2

PBAND1412-175-

2-8

Set Screw

5/16"-18x3/8"

2

3

PBAND1412-175-

43

Set Screw

1/4"-20x3/8"

1

4

PBAND1412-175-

4-4

Hand wheel

1

5

PBAND1412-175-

4-5

Handle

1

6

PBAND18BX2203-

4-6

Pointer

1

7

PBAND1412-175-

4-7

Screw

1/4"-20x3/8"

1

8

PBAND18BX2203-

4-8

Upper Blade

Guard

1

9

PBAND18BX2203-

4-9

Height Scale

1

10

PBAND18BX2203-

4-10

Magnet

1

11

PBAND1412-175-

4-11

Guide Bar

Bracket

1

12

PBAND1412-175-

4-12

Socket Head

Cap Screw

5/16"-18x1-

1/4"

2

13

PBAND1412-175-

4-13

C-Ring

S12

2

14

PBAND1412-175-

4-14

Worm

1

Page 48

Part# VDL-18 48 REV#082020

15

PBAND1412-175-

4-15

E-Ring

E8

2

16

PBAND1412-175-

4-16

Gear Base

1

17

PBAND1412-175-

4-17

Bushing

1

18

PBAND1412-175-

4-18

Shaft

1

19

PBAND1412-175-

4-19

Gear

1

20

PBAND1412-175-

4-20

Plate

1

21

PBAND1412-175-

4-21

Socket Head

Button Screw

5/16"-18x1/2"

4

22

PBAND18BX2203-

4-22

Guide Bar

1

23

PBAND1412-175-

4-23

Socket Head

Cap Screw

1/4"-20x5/8"

4

24

PBAND1412-175-

42

Lock Washer

1/4"

2

25

PBAND1412-175-

4-25

Lock Knob

4

26

PBAND1412-175-

4-26

Ceramic

Guide

8

27

PBAND1412-175-

4-27

Adjusting

Block

4

28

PBAND1412-175-

4-28

Fixed Block

2

29

PBAND1412-175-

4-29

Lock Knob

1

30

PBAND1412-175-

4-30

Ceramic

Guide

2

31

PBAND1412-175-

4-31

Support Shaft

1

32

PBAND1412-175-

4-32

Guide Bracket

1

33

PBAND1412-175-

4-33

Lock Handle

1

34

PBAND1412-175-

4-34

Support Shaft

1

Page 49

35

PBAND1412-175-

4-35

Lock Knob

1

36

PBAND1412-175-

4-36

Socket Head

Button Screw

1/4"-20x1/2"

2

37

PBAND18BX2203-

4-37

Base

1

38

PBAND1412-175-

4-38

Special Bolt

2

39

PBAND1412-175-

2-11

Flat Washer

5/16"

4

40

PBAND1412-175-

4-40

Hex Cap

Screw

5/16"-18x1"

4

41

PBAND1412-175-

2-13

Lock Washer

5/16"

4

Part# VDL-18 49 REV#082020

Page 50

Lower Wheel & Motor Assembly: (Parts List Below)

Lower Wheel & Motor Assembly Parts List

Part# VDL-18 50 REV#082020

Page 51

Part# VDL-18 51 REV#082020

Index

Part Number

Dake Part

Number

Item

Description

Specifications

Quantity

1

PBAND18BX2203-1

Hex Nut

5/8-18UNF-LH

1

2

PBAND18BX2203-2

Ball Bearing

6204LLU

2

3

PBAND18BX2203-2-3

Plate

1

4

PBAND18BX2203-4

PU Tire

1

5

PBAND18BX2203-2-5

Lower Wheel

1

6

PBAND18CX110175-

2-6

V-Belt

1

7

PBAND18CX110175-

2-7

Motor

Pulley,Variable

Speed

1

7A

PBAND18CX110175-

2-7A

Motor

Pulley,Cover

1

7B

PBAND18CX110175-

2-7B

Motor

Pulley,Holder

1

7C

PBAND18CX110175-

2-7C

Motor

Pulley,Slide

1

7D

PBAND18CX110175-

2-7D

Motor

Pulley,Spring

1

7E

PBAND18CX110175-

2-7E

Motor

Pulley,Bushing

1

7F

PBAND18CX110175-

2-7F

Motor

Pulley,Coupling

1

7G

PBAND18CX110175-

2-7G

Motor

Pulley,Plastic

Support Post

3

7H

PBAND1412-175-2-8

Motor

Pulley,Set

Screw

5/16"-18x3/8"

4

7I

PBAND18CX110175-

2-7I

Motor

Pulley,Pin

6x16

2

7J

PBAND18CX110175-

2-7J

Motor

Pulley,Pin

5x10

1

7K

PBAND18CX110175-

2-7k

Motor

Pulley,Pin

6x12

2

8

PBAND18CX110175-

2-8

Hex Cap Screw

3/8-16UNCx1-

3/4"

1

9

PBAND18CX110175-

2-9

Key

7x7x100

1

Page 52

10

MBAND14BX110-

175-2-10

Flat Washer

1/4"

2

76

PBAND1412-175-2-

11

Flat Washer

5/16"

2

12

PBAND18CX110175-

2-12

Spindle Pulley

1

13

MBAND14BX110-

175-2-13

Plate

1

14

MBAND14BX110-

175-2-14

Phillips Flat

Head Screw

5/16"-18x1-

1/2"

3

15

PBAND18BX2203-2-

15

Lower Spindle

1

16

PBAND1412-175-2-

16

Hex Cap Screw

M5x0.8x30

2

17

PBAND1412-175-29

Flat Washer

M5

6

18

PBAND1412-175-2-

18

Brush

1

19

PBAND1412-175-2-

19

Hex Nut

M5x0.8

4

20

PBAND1412-175-2-

20

Insert Block

1

21

PBAND1412-175-2-

21

Shelf

1

22

PBAND1412-175-2-

22

Hex Cap Screw

M5x0.8x12

2

23

PBAND1412-175-26

Screw

M3.5x10mm

6

24

PBAND18BX2203-2-

24

Lower Door

1

25

PBAND1412-175-25

Door Hinge Set

2

25.1

PBAND1412-175-25-

1

Door Hinge,

Left

2

25.2

PBAND1412-175-25-

2

Door Hinge,

Right

2

25.3

PBAND1412-175-25-

3

Socket Head

Cap Screw

M5x0.8x35

2

25.4

PBAND1412-175-25-

4

Nylon Inserted

Lock Nut

M5x0.8

2

26

PBAND1412-175-2-

26

Lock Knob

2

Part# VDL-18 52 REV#082020

Page 53

Part# VDL-18 53 REV#082020

27

PBAND18BX2203-2-

27

Lower Blade

Guard

1

28

PBAND1412-175-2-

28

Screw

1/4"-20x3/4"

1

29

PBAND1412-175-2-

29

Plate

1

30

PBAND1412-175-32

Hex Nut

1/4”-20

1

31

PBAND1412-175-33

Door Stud

1

32

PBAND1412-175-2-

32

Flat Washer

1/4”

1

33

PBAND1412-175-2-

33

Nylon Inserted

Lock Nut

1/4”-20

1

34

PBAND1412-175-46

Lock Knob

1

35

PBAND1412-175-45

Screw

1/4"-20x3/4"

1

36

PBAND1412-175-2-

36

Plate

1

37

PBAND1412-175-2-

37

Screw

#10-24×3/8"

2

38

PBAND1412-175-2-

38

Strain Relief

6N-4

4

39

MBAND14BX110-

175-2-39

Motor Cord

1

40

MBAND14BX110-

175-2-40

Power Cord

1

41

MBAND14BX110-

175-2-76

Bushing

2

42

PBAND1412-175-2-

42

Flat Washer

3/8"

7

43

PBAND1412-175-8

Lock Washer

3/8"

5

44

PBAND18BX2203-2-

44

Hex Nut

3/4"-16UNF

1

45

PBAND18CX110175-

2-45

Motor

1

MBAND14BX110-

175-2-45MF

Motor Fan (not

shown)

1

MBAND14BX110-

175-2-45MFC

Motor Fan

Cover (not

shown)

1

MBAND14BX110-

175-2-45JB

Junction Box

(not shown)

1

Page 54

Part# VDL-18 54 REV#082020

MBAND14BX110-

175-2-45JBC

Junction Box

Cover (not

shown)

1

46

PBAND1412-175-2-

46

Spindle Holder

1

47

PBAND1412-175-2-

47

Adjusting

Screw

4

48

PBAND1412-175-2-

48

Hex Cap Screw

3/8"-16×1-3/4"

5

49

PBAND18BX2203-2-

49

Flat Washer

3/4"

1

50

PBAND18BX2203-2-

50

Switch Cover

1

51

MBAND14BX110-

175-2-51

Hex Nut

M6x1.0

2

52

MBAND14BX110-

175-2-52

Limited Switch

Cord

1

53

MBAND14BX110-

175-2-53

Hex Cap Screw

3/8"-16×3/4"

3

54

MBAND14BX110-

175-2-54

Hex Cap Screw

M6x1.0x35

2

55

PBAND1412-175-3-

36

Hex Nut

3/8"-16

4

56

PBAND18CX110175-

2-56

Foot Brake

1

57

MBAND14BX110-

175-2-57

Hex Cap Screw

5/16-

18UNCx1/2

1

58

MBAND14BX110-

175-2-58

Hex Cap Screw

3/8-16UNCx1-

1/4"

1

59

MBAND14BX110-

175-2-59

Spring

1

60

MBAND14BX110-

175-2-60

Limited Switch

1

61

MBAND14BX110-

175-2-61

Screw

M3×20mm

2

62

MBAND14BX110-

175-2-62

Screw

1/4"-20x3/8"

2

63

MBAND14BX110-

175-2-63

Brake

Assembly

1

Page 55

MBAND14BX110-

175-2-63P

Brake Pad (not

shown), 2

pieces

64

MBAND14BX110-

175-2-64

Disc

1

65

MBAND14BX110-

175-2-65

Inner Cable

1

66

MBAND14BX110-

175-2-66

Housing

1

67

MBAND14BX110-

175-2-67

Plate

1

68

MBAND14BX110-

175-2-68

Socket Head

Button Screw

3/8"-16 x1"

4

69

MBAND14BX110-

175-2-69

Rubber Pad

4

70

MBAND14BX110-

175-2-70

Socket Head

Button Screw

M5x0.8x12

3

71

MBAND14BX110-

175-68

Screw

M4x0.7x8

4

72

MBAND14BX110-

175-2-72

Spacer

2

73

MBAND14BX110-

175-2-73

Plate

1

74

PBAND1412-175-4-

40

Hex Cap Screw

5/16-

18UNCx1"

4

75

PBAND1412-175-2-

13

Lock Washer

5/16"

4

76

PBAND1412-175-2-

11

Flat Washer

5/16"

4

77

PBAND18CX110175-

2-77

spacer sleeve

1

78

PBAND18CX110175-

2-78

Phillips Flat

Head Screw

3/8-16UNCx1-

1/2"

2

79

PBAND18CX110175-

2-79

Gear Plate

1

80

PBAND18CX110175-

2-80

Carriage Bolt

3/8-16UNCx1-

1/4"

1

81

PBAND18CX110175-

2-81

Flat Washer

3/8"

7

Part# VDL-18 55 REV#082020

Page 56

82

PBAND18CX110175-

2-82

Lock Handle

1

83

PBAND18CX110175-

2-83

Gear Box

Assembly

1

84

PBAND18CX110175-

2-84

Nylon Inserted

Lock Nut

3/8-16UNC

3

85

PBAND1412-175-43

Set Screw

1/4"-

20UNCx3/8"

1

86

PBAND18CX110175-

2-86

Handwheel

1

87

PBAND18CX110175-

2-87

Knob

1

88

PBAND18CX110175-

2-88

Hex Cap Screw

5/16-

18UNCx5/8"

4

89

PBAND18CX110175-

2-89

Flat Washer

5/16"

4

90

PBAND18CX110175-

2-90

Pointer

1

91

PBAND18CX110175-

2-91

Worm Gear

Assembly

1

91A

PBAND18CX110175-

2-91A

Worm

1

91B

PBAND18CX110175-

2-91B

Ball Bearing

6801ZZ

3

91C

PBAND18CX110175-

2-91C

spacer sleeve

2

91D

PBAND18CX110175-

2-91D

Gear

1

91E

PBAND18CX110175-

2-91E

spacer sleeve

1

91F

PBAND18CX110175-

2-91F

Key

4x4x8mm

1

91G

PBAND18CX110175-

2-91G

Key

4x4x18mm

1

91H

PBAND18CX110175-

2-91H

Shaft

1

91I

PBAND18CX110175-

2-91I

Ball Bearing

6802ZZ

1

91J

PBAND18CX110175-

2-91J

Gear Bracket

1

Part# VDL-18 56 REV#082020

Page 57

91K

PBAND18CX110175-

2-91K

Nylon Inserted

Lock Nut

M12x1.75

1

92