Page 1

DAKE VERTICAL BAND SAW

Model V-16

INSTRUCTION MANUAL

Please record your saws information

DAKE (Division of JSJ)

724 Robbins Road

Grand Haven, Michigan 49417

616.842.7110 Phone 800-937-3253

616.842.0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

Page 2

- 1 -

DAKE V-16 TABLE OF CONTENTS

Forward ................................................................................................ 2-3

Installation and setup............................................................................ 3-4

Specifications ....................................................................................... 4-5

Operational Controls ............................................................................. 6-7

Operation: Blade installation ... ............................................................ 7

Blade Tracking...................................................................................... 8

Guide Post Adjustment......................................................................... 8

Guide Adjustment / Holder and Guide.................................................. 9-10

Blade Selection / Type of Blades ......................................................... 10-11

Tooth Shapes ....................................................................................... 11

Set Types .............................................................................................. 11

Blade Selection Chart ........................................................................... 12

Saw Speed & Pitch Selector ................................................................. 13

Welder Operation .................................................................................. 14

Blade Cutting / Tooth Spacing............................................................... 14

Welding of the Blade ............................................................................. 15

Annealing (Carbon)................................................................................ 15

Annealing (Bi-Metal) ............................................................................. 16

Blade Dressing (Grinding) ..................................................................... 16

Weld Inspection .................................................................................... 17

Blade Weld Trouble Shooting ............................................................... 17-18

Trouble Shooting Chart / Saw /Blade / Cutting ..................................... 18-20

Maintenance.......................................................................................... 20

Exploded Diagrams and Parts Lists ...................................................... 21-25

Electrical Drawing ................................................................................. 26

Page 3

- 2 -

FOREWARD

First of all, we would like to take this opportunity to thank you for selecting our Dake V-16

model vertical Bandsaw.

As you know, the vertical bandsaw is a universal saw for contour cutting. Blade selection is

important and by choosing the right blade, you can make most any pattern cutting on most

any material with this machine. However, the most important thing is to realize how to

operate it in a safe and correct way and how to maintain it.

We have tried to supply you all the information about these. Please be sure to look through

all the contents in this manual so that you may obtain the maximum efficiency and the

longest machine life with minimum expense.

The specifications and information in this manual were current at the time this manual was

approved for printing. Dake, whose policy is one of continuous improvement, reserves the

right, however, to change specifications or design at any time without incurring obligations.

Always include the part number, model number, and parts description, for parts orders or

correspondence concerning your bandsaw, so we can supply you a rapidly after-sales

service.

1. Read the operator’s manual carefully. Learn the tools applications and limitations, as well

as the specific potential hazards peculiar to it.

2. Always wear approved safety glasses/face shields while using this machine.

3. Make certain the machine is properly grounded.

4. Before operating the machine, remove tie, rings, watches, other jewelry, and roll up

sleeves above the elbows. Remove all loose clothing and confine long hair. DO NOT

wear gloves when operating.

5. Keep the floor around the machine clean and free of scrap material, oil and grease.

6. Keep machine guards in place at all times when the machine is in use. If removed for

maintenance purposes, use extreme caution and replace the guards immediately.

7. DO NOT over reach. Maintain a balanced stance at all times so that you do not fall or

lean against blades or other moving parts.

8. Use only sharp blades. Dull blades are dangerous.

9. Make all machine adjustments or maintenance with the machine unplugged from the

power source.

10. Use the right tool. Don’t force a tool or attachment to do a job which it was not designed

for.

▲WARNING

Page 4

- 3 -

11. DO NOT make cuts requiring more power than is available on the machine.

12. Replace warning labels if they become obscured or removed.

13. Make certain the motor switch is in the OFF position before connecting the machine to

power.

14. Give your work undivided attention. Looking around, carrying on a conversation. And

“horse-play” is careless acts that can result in serious injury.

15. Make a habit of checking to see that keys and adjusting wrenches are removed before

turning on the machine.

16. Keep visitors a safe distance from the work area.

17. Use recommended accessories; improper accessories may be hazardous.

18. Never place hands directly in line with the saw blade.

19. Always use push sticks when cutting small material.

20. Raise or lower the blade guide only when the machine has been turned off and the

blade has stopped moving.

21. Read and understand warnings posted on the machine.

22. DO NOT use attachments for any other purpose than for what they were designed for.

23. Failure to comply with all of these warnings could lead to serious injury.

INSTALLATION

WARNING!!!

The machine table must NOT be used as a lifting point. Damage to the saw could

occur.

UNLOADING: Remove the shrink-wrap covering the machine, careful not to damage

painted surfaces. Carefully inspect the machine for physical damage. If damage is

noted, notify the truck line at once. They may require inspection, and that a claim be

filed. Check that all standard accessories are with the machine. Some accessories may be

boxed or placed behind the rear access door. The band saw is provided with a lifting eye

that is screwed into the top of the machine. This lifting eye may be located in the rear

compartment.

Particular care should be taken in selecting areas of the machine for handling, as electrical

components and adjustment knobs can be marked up or damaged. Remove the mounting

bolts holding the machine to the skid, using the lifting eye, remove the machine from the

skid and set in designated area.

Page 5

- 4 -

CLEANING

1. Remove anti-rust oil.

2. Remove the coating with a clean brush applied with appropriate solvent.

3. When the coating has been softened, remove it with clean rag.

POWER SUPPLY

1. Shut off the main power switch

before connecting cable.

2. Check motor voltage against

supply voltage.

3. Make sure the power supply is

connected to comply with the

local safety regulations.

4. Your saw may be pre-wired with

a power cable attached. This

cable can be hard wired or the

preferred method of installing a

properly rated quick disconnect.

▲ WARNING

All electrical connections must be done by

a qualified electrician. Failure to comply

may cause serious injury!

All adjustment or repairs must be done with

the machine disconnected from the power

source. Failure to comply may result in

serious injury!

5. The leads connect to L1, L2, and L3 and ground. The bandsaw must be grounded.

6. Check that the blade is running in the correct clockwise direction. If the blade runs

backwards, disconnect the power. Then reverse any two of the three L1, L2, and L3

leads. Do not reverse the ground.

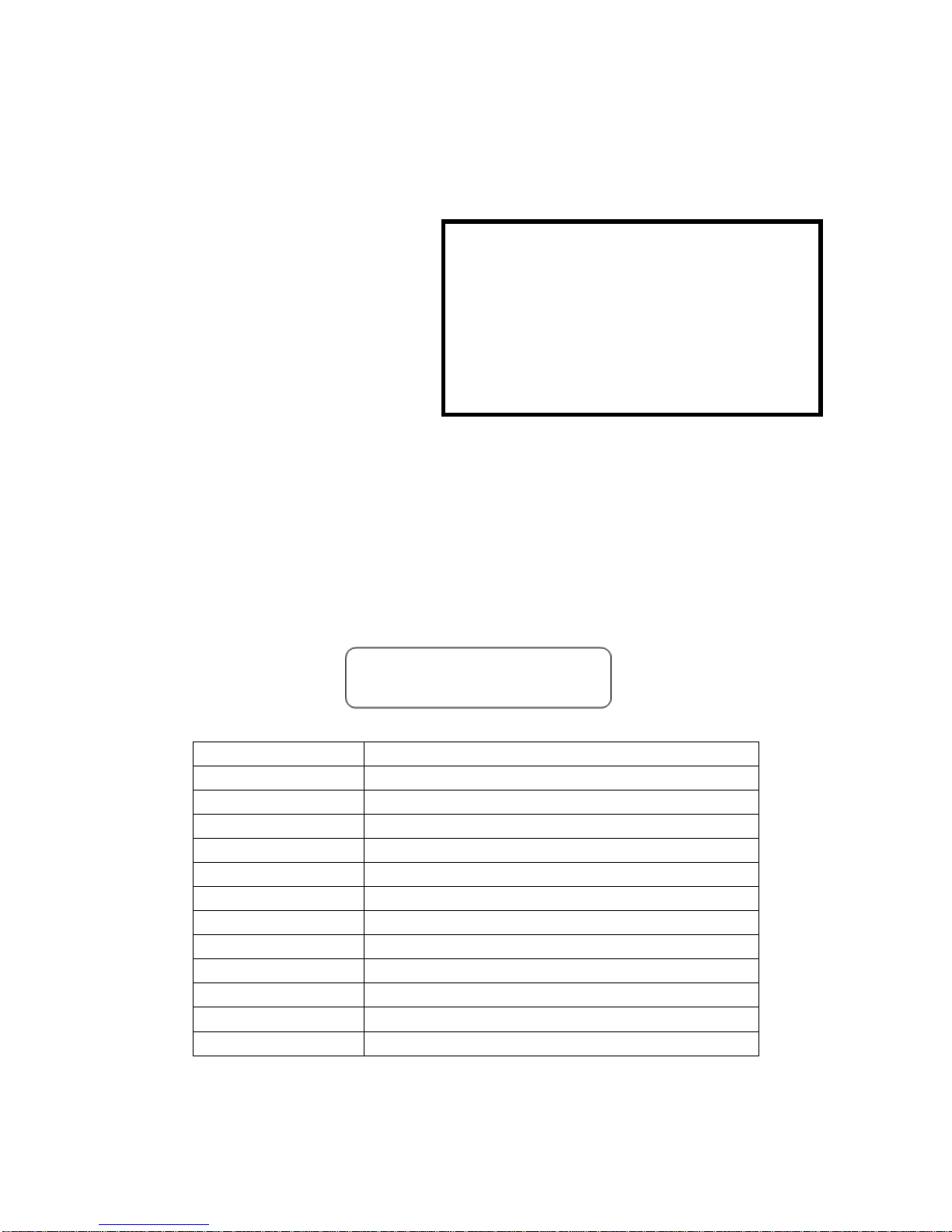

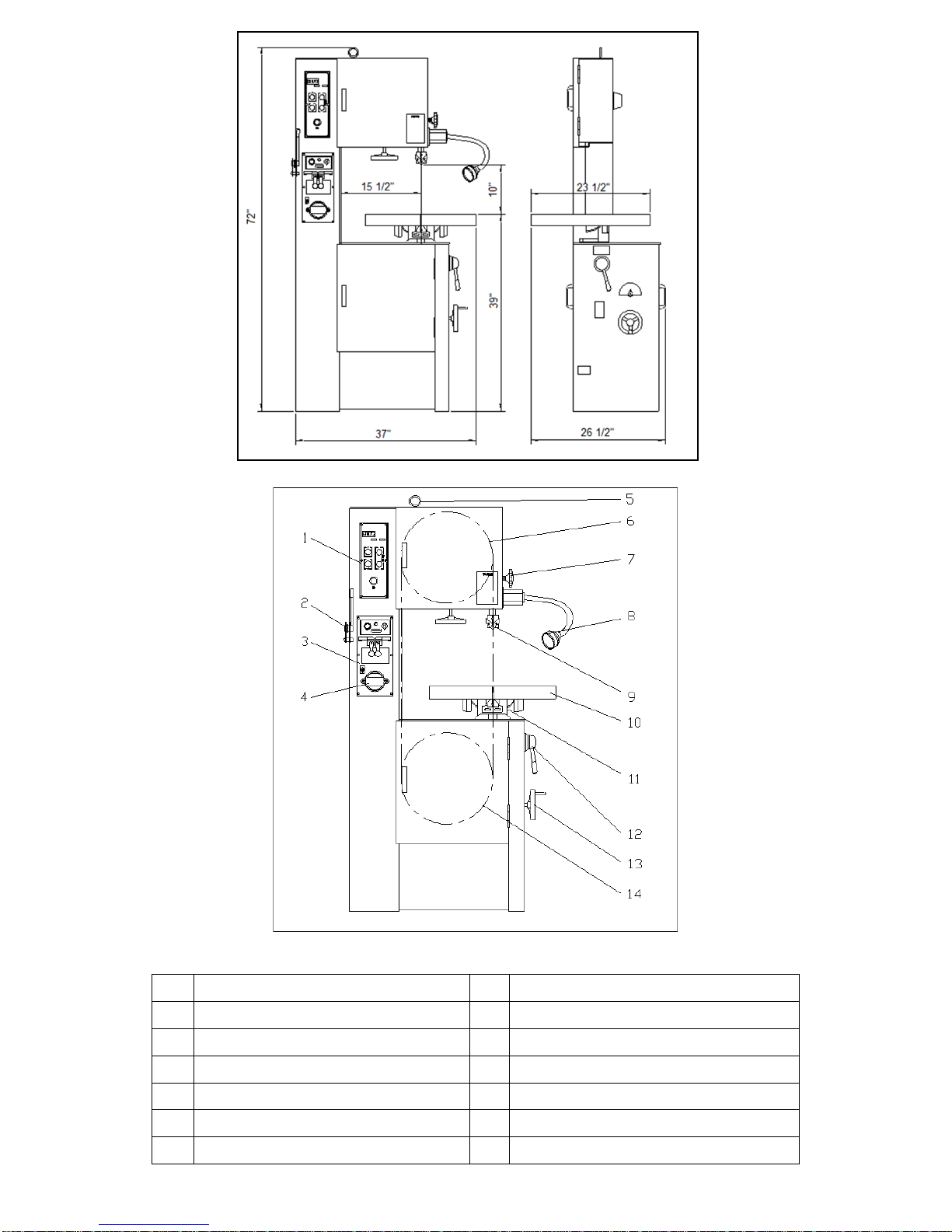

SPECIFICATIONS

Capacity

15 ½” X 10”

Blade Width Cap.

1/8” ~ 5/8”

Blade Speed

82-3,950 fpm

Table Size

21.5" x 24"

Table Tilt

R-15 ゚, L- 12゚, 8 ゚ Each F & B

Main Drive Motor

230 volt 3 Phase, 2 HP

Grinder Motor

110V, 1 Phase, 0.04 KW

Blade Length

123 ½”

Blade Welder Cap

2.4 KVA, 1/8” ~ 5/8”

Band Wheel Diameter

16”

Table Height

39”

Dimension

37” (Length) 26 ½” (Width) 72” (Height)

Mach. Weight

904 lbs.

Page 6

- 5 -

1

Control Panel

8

Work Lamp

2

Blade Shear

9

Blade Guide Supports

3

Welder Panel

10

Work Table

4

Grinding Wheel Motor

11

Table Support Housing

5

Lifting Eye

12

Low/High Range Shift Lever

6

Upper Wheel

13

Variable Speed Hand Wheel

7

Guide Post Lock Knob

14

Lower Wheel

Page 7

- 6 -

Low/High Range Shift Lever –

Located on right side of machine base. Pull toward the front of the machine to shift into the

low speed range. Push toward the rear of the machine to shift into the high-speed range.

Caution: Do not change the speed range while the machine is running. Adjust only when

the machine is stopped NOTE: If the lever will not mesh the speed range, slightly rotate the

band wheel and the lever will go into gear.

Variable Speed Hand Wheel –

Located below the worktable on right side of machine base. Turn clockwise to increase

speed and counter-clockwise to decrease speed.

Caution: Do not turn handle while machine is stopped. Adjust speed only when machine is

running. RPMs will be displayed on the control panels digital readout.

Upper Guide Post Lock Knob –

Located on right side of upper frame. Turn counter-clockwise to loosen and clockwise to

tighten. Always support the guide post when adjusting this knob to prevent unexpected

dropping of the guide post.

Work Lamp Switch – Turn lamp on and off. Caution must be used as light will be hot.

Blade Shear Lever –

Located on upper left hand side of the column. Lever up position allows insertion of the

blade into the shear. Pull lever downward to cut the blade. (This shear unit must be

mounted during set up)

Grinder Toggle Switch –

Located on the blade welder panel found on columns front. Flip switch up to start grinder;

flip down to stop grinder. This motor has temperature protection which will turn off the

power automatically when the motor is over-hearting. Motor will reset once it cools down.

Weld Button –

Located on the blade welders panel found on the front of the column. Depress and hold to

start welding. Shuts off automatically when weld is done. Release when weld is completed

Anneal Button –

Located on the blade welders panel found on the front of the column. Depress and hold to

anneal blade, release to stop.

Blade Clamp Pressure Knob –

Located on the blade welders panel found on front of the column. Sets pressure for different

width blades.

Blade Clamps –

Located on the blade welder panel found on the front of the column. Down position allows

insertion of the blade into the clamp. Up position locks blade

Blade Tension Hand Wheel –

Located on underside of the upper frame. Turn clockwise to tension the blade;

counter-clockwise to release tension on the blade.

Blade Tracking Hand Wheel –

Located at the upper rear of the saw. Turn clockwise to track the blade toward front of the

blade wheel Turn counter-clockwise to track blade toward rear of the blade wheel. (Do not

let the blade ride up onto the wheel lip)

▲CONTROLS

Page 8

- 7 -

.

Table Tilt Mechanism –

Located under worktable. To tilt table left or right, loosen hex cap screws at the rear of the

mechanism. Always tighten table bolts before operating the saw.

Power indicator Light –

Indicates that power to the control panel is on.

Key Lock Switch–

Turn the key to the 12 o’clock position and remove key to lock out power from the control

panel.

System Fuse Holder –

Holds the fuse that renders the saw inoperable when blown.

Main Motor Start Switch –

Depress to start bandsaw.

Main Motor Stop Switch –

Depress to stop bandsaw.

Emergency Stop Switch –

Press to stop the machine. Turn knob 90° to reset.

OPERATIONS

BLADE INSTALLATION

1. Install the blade as illustrated through the guides and onto the upper and lower wheels.

Replace any guarding that was removed after blade is installed.

2. Adjust blade tension per the tension scale by turning the blade tension adjustment hand

wheel. The scale is visible from the rear side.

3. Jog the machine to see if the blade tracks properly, adjust blade tracking by turning the

tracking adjuster when it is necessary. (See blade tracking section on next page for

further details)

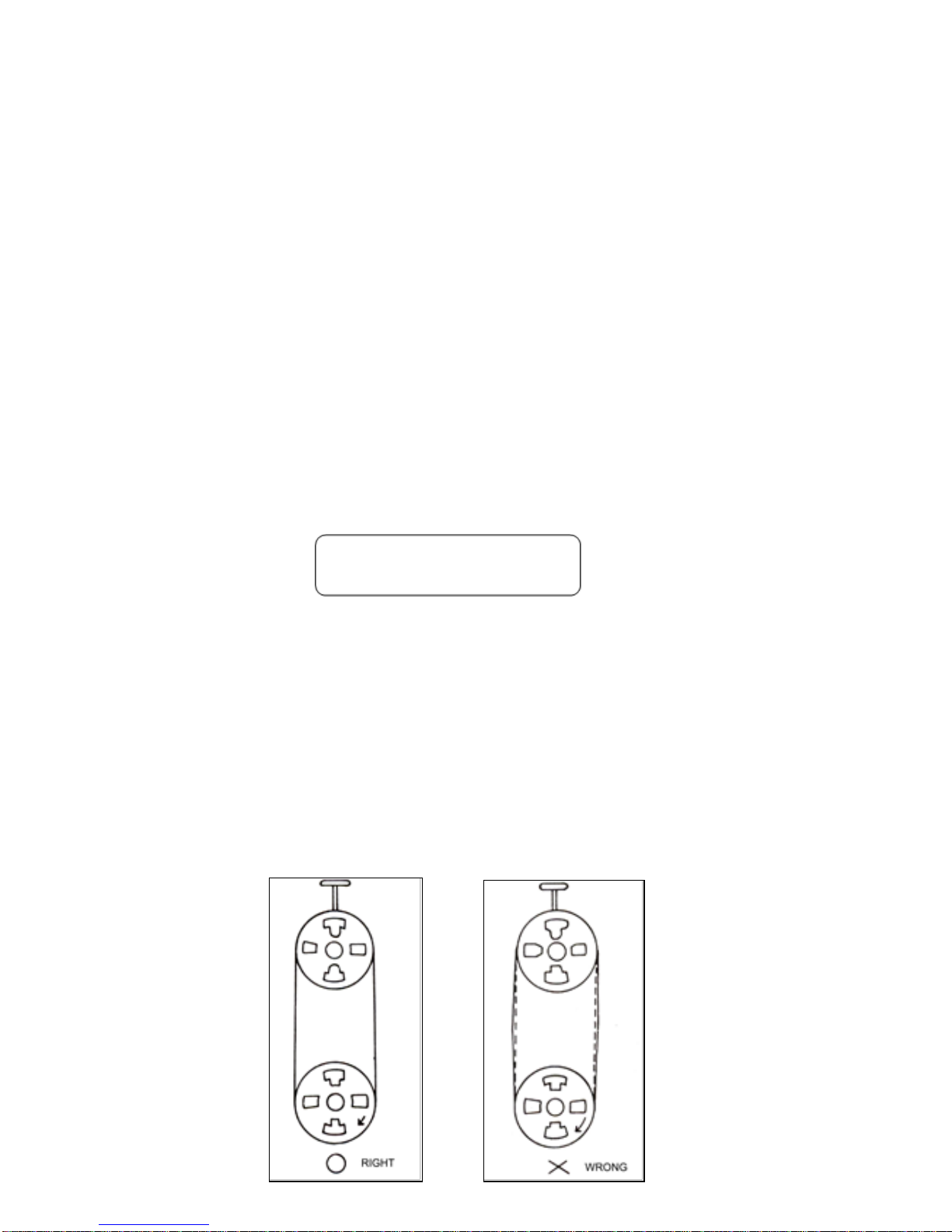

Proper tensioning Improper tensioning

Page 9

- 8 -

BLADE TRACKING

Blade tracking may be required from time to time depending on the blade size and tension.

Disconnect the machine from the power source and open both blade wheel doors. Shift the

high-low gearbox lever into the neutral position. Turn the upper blade wheel by hand while

observing blade position on the upper blade wheel to determine if adjustment is necessary:

a. Turn blade tracking knob clockwise to track

blade toward front of blade wheel.

b. Turn counter-clockwise to track blade toward

rear of blade wheel. Blade should be tracked

as close of the center of the top blade wheel

as possible. Do not allow blade to run on the

wheel lip.

▲Note: Upper and lower blade guides should be

moved away and left loose from the blade while

tracking adjustments are being made.

GUIDE POST ADJUSTING

1. Loosen the guide post locking knob. Always

support the guide post when loosening the

guide post to prevent it from unexpectedly

falling. (Figure A next page)

2. The height of the upper guide post setting is in

relationship to the height of the material. The

height between the material and the blade

guide end is suggested to be about 1/4”. (See

figure B illustration on next page)

3. Lock the guide post tightly.

▲ WARNING

All adjustment or repairs to the machine must

be done with the power off and the machine

disconnected from the power source. Failure to

comply may result in serious injury!

Page 10

- 9 -

Figure A Figure B

▲ It may be necessary to open the blade guides, before you adjust the guide post to

allow free movement of the guide post.

GUIDE HOLDER ADJUSTMENT

1. Loosen the inner hex screws

located at the right lower side of

guide post with an “L” shaped allen

wrench.

2. Adjust the guide holder forward or

backward according to the blade

width. The front edge of the blade

guides must be adjusted about 1/8”

behind the blade teeth. (see figure B

next page)

3. Tighten the screws securely.

BLADE GUIDE ADJUSTING

1. Loosen the inner hex screws of the blade guide with an “L” shaped allen wrench.

2. Adjust the blade guides very close to the blade but not touching the guide faces. (approx.

thickness of a business card)

3. With blade tight allow guides to ride up to the blade not forcing them off center. Tighten

the blade guides securely. (See figure A next page)

NOTE: There are a total of four blade guides and two guide holders located above the

table and under the table, all to be adjusted to the same position.

Page 11

- 10 -

Figure A Figure B

The blade guides will wear after time at the

front faces. If the blade guides become hard

to be properly adjusted, turn the left blade

guide over to the right side, as illustrated in

the right illustration, and turn the right-side

blade guide over to the left side as well. The

blade guides can then be used on both sides

getting more mileage out of the guides.

The backup blade guide button will wear over

time as friction from the saw blade may cause

a worn line on its surface. If this is found to

happen, loosen the lower guide holder bolt

and turn it to rotate the button shaft to change

the buttons position on the saw blade.

▲ CAUTION

Blade guide must be properly adjusted

or damage may occur to the blade and/or

the guides.

BLADE SELECTION

To get the most satisfactory work from your saw, it is important to choose a blade that is

correct for the work. Blade life, cut straightness, finishing quality and sawing efficiency is all

related to the choice of blade. Blade breakage, teeth stripping, crooked cuts, and other

common complaints are, in most instances, caused by using the wrong blades. Blades are

classified by materials, tooth shapes, and types of set.

Page 12

- 11 -

TYPES OF BLADES

Bandsaw blades are available in specific sizes, or in 100 feet coils. They are made from

several different metals:

1. Carbon Steel Blade: which are widely used because of their general adaptability for all

types of work and the low cost. They are excellent for cutting nonferrous metals and

plastics.

2. High-Speed Steel Blade: which resist heat generated in cutting to far greater extent than

carbon steel blades. They are best suited for cutting ferrous metals.

3. Alloy Steel Blade: which are tougher and more wear resistant than either of the above.

They will cut faster and longer than blades of carbon or high-speed steel.

4. Carbide-Tipped Blade: which are best used for cutting unusual materials such as

uranium, titanium, and beryllium. These metals are difficult to cut with other types of

blades.

TOOTH SHAPES

The regular or standard tooth is preferred for all ferrous metals and general-purpose cutting.

The skip-tooth blade has widely spaced teeth to provide the added chip clearance needed

for cutting softer nonferrous materials. The hook, or saber tooth blades has a 10°undercut

which permits better feed and chip removal, it is best for the harder nonferrous alloys.

SET TYPES

Regular or rake set is generally furnished on saws that have 2 to 24 teeth per inch. These

blades have one tooth set to left, one to right, and one unset tooth called a rake. This set is

used when material is to be contour cut. Wavy set is furnished on saws that have 8 to 32

teeth per inch. This set has groups of teeth bent alternately to left and right, which greatly

reduce the strain on individual teeth. Saws with wavy set are used where tooth breakage is

a problem, such as in cutting thin stock or where a variety of work is cut without changing

blades.

Of the three common set patterns, only raker and wave are now used in metalworking.

Always use rake set except:

For work of varying cross

section use wave set.

When one blade must be

used for a range of material

sizes use wave set

Page 13

- 12 -

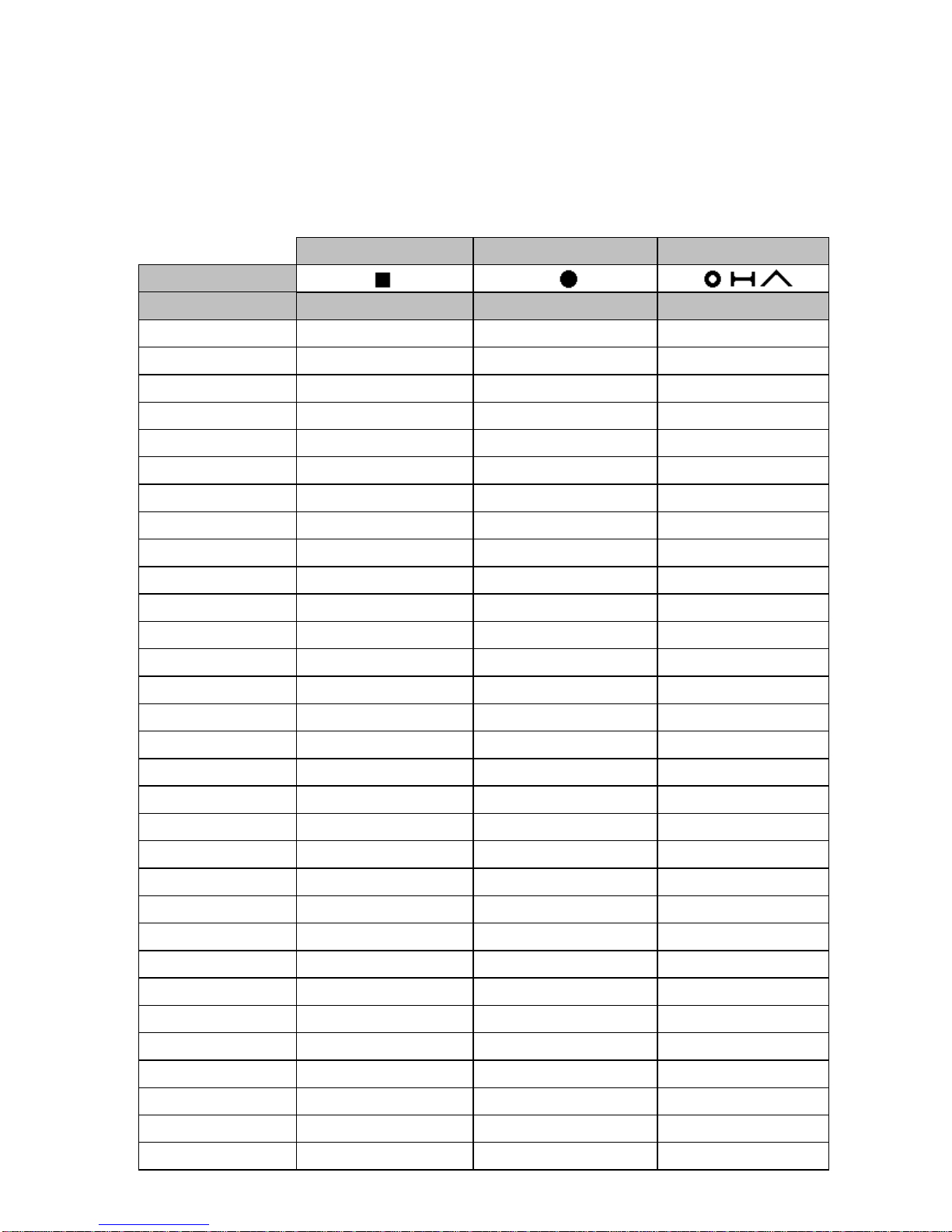

▲ PLEASE NOTE THAT CORRECT BLADE SELECTION IS VERY IMPORTANT TO

BANDSAW OPERATING AT FULL POTENTIAL. ALWAYS SELECT A BLADE

ACCORDING TO THE MATERIAL SHAPE AND THICKNESS OF THE WORK

Always break in the blade per blade manufactures recommendations.

SAW BLADE SELECTION

MATERIAL SHAPE

MATERIAL SHAPE

MATERIAL SHAPE

MATERIAL IN

INCHES

TOOTH SELECTION

TOOTH SELECTION

TOOTH SELECTION

0

14 / 18

14 / 18

14 / 18

.1

14 / 18

14 / 18

14 / 18

.2

14 / 18

14 / 18

14 / 18

.3

10 / 14

14 / 18

10 / 14

.4

8 / 12

10 / 14

8 / 12

.5

8 / 12

8 / 12

6 / 10

.6

6 / 10

8 / 12

5 / 8

.7

6 / 10

6 / 10

5 / 8

.8

5 / 8

6 / 10

5 / 8

.9

5 / 8

5 / 8

5 / 8

1

5 / 8

5 / 8

4 / 6

1 1/4

4 / 6

5 / 8

4 / 6

1 1/2

4 / 6

4 / 6

4 / 6

1 3/4

4 / 6

4 / 6

4 / 6

2

4 / 6

4 / 6

3 / 4

2 1/4

4 / 6

4 / 6

3 / 4

2 1/2

3 / 4

4 / 6

3 / 4

2 3/4

3 / 4

4 / 6

3 / 4

3

3 / 4

3 / 4

3 / 4

3 1/4

3 / 4

3 / 4

3 / 4

3 1/2

3 / 4

3 / 4

3 / 4

3 3/4

3 / 4

3 / 4

2 / 3

4

3 / 4

3 / 4

2 / 3

5

2 / 3

3 / 4

2 / 3

6

2 / 3

3 / 4

2 / 3

7

2 / 3

2 / 3

1.4 / 2.5

8

1.4 / 2.5

2 / 3

1.4 / 2.5

9

1.4 / 2.5

2 / 3

1.4 / 2.5

10

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

11

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

12

1.4 / 2.5

1.4 / 2.5

1.4 / 2.5

Page 14

- 13 -

Please refer to the “Speed & Pitch Selector wheel that is supplied on your saw for speeds

and feeds, radius cutting and blade pitch selection.

Select saw blades in relationship to the thickness of materials. The following suggestions

are a rule of thumb to consider when selecting a blade.

A. Select a larger pitch blade for a thicker material.

B. Select a smaller pitch blade for a thicker material.

C. Use a smaller pitch blade to obtain a smooth cutting surface.

D. Use a larger pitch blade to obtain a faster cutting speed.

E. It is important to have different blades for different applications

Page 15

- 14 -

WELDER OPERATION

This welder is for occasional use for blade repair and is not intended for welding blades on a regular basis

from bulk stock. This welder is best suited for carbon bands but with practice both carbon and bi-metal can

also be welded.

BLADE CUTTING

1. Cut the blade to the length of the

machine. Using the blade shear will insure

that the blade ends are cut flat, square and

smooth.

2. Place the back edge of blade against the

square cutting guide of the shear and firmly

pull the cutting lever down to shear the

blade. Both ends of the blade must be

sheared to allow for a good butt weld.

3. Keep the shear blade clean and free from

blade end pieces that can get trapped in the

shear.

Using the Blade Shear.

TOOTH SPACING

1. On fine-pitched blades, one or more teeth on each side of the cut must be removed by

grinding so that the cross section of the weld area of the blade is uniform. Following

these guidelines will help make the teeth uniformly spaced after the weld.

Page 16

- 15 -

▲CAUTION: If the saw blade is rusty, the rust must be ground off before the blade is welded.

WELDING

1. Turn pressure knob to “0” position.

2. Butt blade ends together and locate joint in the center between the two

electrodes.

3. Set pressure knob to blade width. (Due to the different materials and thickness of

blade, please pay especial attention to the pressure adjustment. Thicker the

blade higher the pressure setting.)

4. Press and hold welder button. Do not release until the blade joint is “red” hot.

The switch is automatic and will shut welder off after a preset time of 3 or 4

seconds and the blade returns to original color. Note: The weld joint may throw

sparks during welding so wear safety glasses and proper apparel.

ANNEALING (Carbon Blades)

1. Turn pressure knob to “0” position.

2. Release blade and center the weld joint at the front of the electrodes. (At the wider part)

3. Press and jog the annealing switch button until the weld is a “dull cherry” to “cherry red”

color. Allow the blades to cool slowly by decreasing the jogging frequency.

4. Perform the annealing operations 4 or 5 times, gradually reducing the heat each time.

5. Remove any welding dust or scale from the joint and anneal 2 or 3 more times,

successively at lower temperatures. (quicker series of press and release of annealing

button)

Page 17

- 16 -

ANNEALING (Bi-Metal)

Set up blade for annealing as mentioned above for carbon blades steps 1 & 2.

Heat the band slowly by jogging the

annealing switch button until the weld

just begins to emit light (this would be

the dullest red color) or minute puff of

smoke. The desired color may not be

visible in normal room light. Always

shade the weld area with your hand.

Cool the weld quickly by releasing the

annealing button. Repeat this

operation 4 or 5 times.

▲NOTE: This procedure should be followed both before and after grinding

BI-METAL Blades.

GRINDING THE WELDED BLADE

▲ WARNING

Keep hands away from rotating grinding wheel. When not in use make, sure

wheel is covered with built in cover

After welding, the blade must be dressed to remove excess metal or flash from the weld.

Grind the welded area down to the same thickness as the rest of the band. Handle the blade

carefully.

Grind Carefully: do not hit the teeth; or grind deeper than the thickness of the blade; or

overheat the weld area. Be sure to remove flash from the back edge of the blade. Any flash

or “stub” teeth that project beyond the normal set or height of the other teeth must be

ground off.

Anneal the welded area that was ground again. Anneal 2 or 3 times using a lower

temperature. (Just as area starts to emit light)

Page 18

- 17 -

INSPECION OF THE WELD

When the blade is removed from the

welder it should be inspected

carefully.

The spacing of the teeth should be

uniform and the weld should be

located in the center of the gullet.

Major jaw misalignment is easily

noted at this time from the weld

appearance. See the trouble shooting

chapter if the weld is imperfect.

▲CAUTION: This welder is designed for intermittent use. Repeated welding

within a short period of time may cause the welder to overheat.

TROUBLE SHOOTING

MISALIGNED WELD

(1) Dirt or scale on jaws or blade.

(2) Blade ends not cut off square.

(3) Blade ends not correctly aligned when clamped in jaws.

(4) Worn jaws or inserts.

(5) Jaws are not aligned correctly.

Page 19

- 18 -

MISALIGNED WELD-BLADE ENDS ARE OVERLAPPED

(1) Jaw Upset Force Control set for wider blade than used, re-adjust correctly.

(2) Blade ends or jaws not aligned correctly.

WELD BREAKS WHEN USED

(Joint is not complete, “blow holes” in joint)

(1) Weld not annealed correctly.

(2) Weld has been ground too thin.

(3) Weak “Incomplete” weld.

INCOMPLETE WELD (Items 3 – 8 requires welder removal)

(1) Incorrect Initial Set-Up:

(a) Initial jaw gap (weld lever position) not set correctly.

(b) Upset force control not set correctly.

(2) Improper clamping procedures.

(3) Defective cut-off switch may not break the circuit at end of welding operation.

(4) Cut-off Switch not adjusted correctly.

(5) Points of cut-off switch welded together.

(6) Slide Rod sticking because of rust or dirt. Clean and oil the rod.

(7) Slide Rod movement obstructed because the stop screw too tight on the Rod.

(8) Jaw movement obstructed by kinked jaw cable or tangled wires. Bend cable and

untangle wires.

BRITTLE WELDS

Weld has not been annealed correctly; see “Annealing” in operation chapter. Poor

annealing can be caused by:

1. Incorrect annealing heat. Bring weld up to correct color as described under “Annealing”

in welder operations chapter.

2. Scale or oil on weld can cause poor annealing.

TROUBLE SHOOTING

PROBLEM

CAUSE

SOLUTIONS

The Weld could not be made,

the Jaws do not move

A. The wire connection is poor, the

connecting point of welding

switch is bad

B. The transformer is burnt out

C. Some oil is on the blade

D. Some rust is on the blade

ends

E. The adjustment of the welding

pressure is incorrect

A. Change the welding switch.

B. Change the transformer.

C. Remove the oil

D. Grind off the rust

E. Loosen the adjusting screw

that is in center of it

The weld area melts the blade

not welds it when welding

switch is pushed

A. The welding switch cut off too

late

B. The Welding Pressure is too

weak

C. The jaw movement is too slow

A. Screw the welding switch

Connecting Nut tight

B. Turn the welding pressure

adjuster clockwise

C. Put some oil on the rear side

of the welding lever jaws

Page 20

- 19 -

The annealing job cannot be

made when pushing the anneal

button

A. The connection of annealing

switch is loose or broken

B. The fuse is blown

C. The connection of the

electrodes to blade is poor

A. Change an anneal switch

B. Change a fuse

C. Clean electrode surfaces

The grinder is not running when

the grinder switch on

A. The grinder motor is defective

B. The grinder switch is defective

A. Replace the grinder

B. Replace the switch

The blade can not be tightly

clamped with the jaw clamps

A. The jaw clamps are burnt or

defective

B. The lower jaw inserts defective

C. The Jaws are burnt or eroded

A. Change clampers

B. Change lower jaw Inserts

C. Change jaws

The annealing button will not

release to neutral position

Some dust or debris around the

anneal button restricting movement

Release the anneal button by

gently pulling it to the

neutral position

Clean out any dust or debris

Blade tooth broken

A. Incorrect pitch for the application

B. Brittle blade improper annealing

C. Inferior blade

A. Select a right pitch blade

B. Re-weld and anneal

C. Decrease feeding rate

D. Change to high quality blade

Blade damaged

A. Brittle blade improper annealing

B. Blade tension out of adjustment

C. Too Fast feeding

D. Blade teeth hitting guides.

E. Cannot cut radius without blade

twisting.

A. Decrease the annealing

temperature

B. Adjust blade tension

C. Decrease feed rate

D. Adjust a proper gap

between the blade and the

guide insert

E. Change to a narrower blade

PROBLEM

CAUSE

SOLUTIONS

Saw blade is twisted

A. Improper weld

B. Blade installed in improper way

C. Blade tension too loose

D. The blade is being over fed

A. Re-weld the blade again

B. Set the guide inserts closer

C. Increase blade tension

D. Decrease the feeding rate

when starting the cut

E. Use a proper width blade for

radius cutting

The sawing direction deviates

A. The blade tooth is not on even

or warn unevenly.

B. The blade tension is too loose

C. The guide post was set too high

A. Make sure a good blade is

used without damaged teeth

B. Increase blade tension

C. Set the guide post to be

within a ¼” of the work

D. Decrease feeding rate

Saw blade walks off

A. Blade tension is too loose

B. Blade is not tracked properly

A. Increase blade tension

B. Adjust the wheel alignment

Page 21

- 20 -

The blade dulling prematurely

A. The blade speed is too fast

B. The selection of blade is

improper

C. Feeding rate too fast

A. Slow down the blade speed

B. Use a proper blade for the

application

C. Decrease feeding rate

The blade is not cutting straight

vertically

A. The blade dull

B. The guide post is not properly

fixed

C. The blade tension is too loose

D. The blade is not exactly 90°to

the table

A. Change to a new blade

B. Fix the guide post properly ¼”

above material

C. Increase blade tension

D. Adjust it to be 90°

Excessive noise when machine

is running

A. The variable speed pulley is

damaged

C. The saw is not sitting flat on the

floor

A. Change a new pulley

B. Reposition the machine on a

flat even hard floor

MAINTENANCE

PART OR PLACE TO BE

OILDED OR GREASED

TYPE OF OIL

OR GREASE

LUBRICATING

PERIOD

REMARKS

Bearings

Gear oil

every 6 months

Gear Box:

Guide post sliding part

Grease

weekly

#1350 & #1360

Speed Change handle

Grease

every 6 months

#0600,# 0740, #7120 & #7290

Gear and thread

Grease

every 3 months

#7080 & 7110

Variable pulley

Grease

every 100 hours

#9995: V-16 only

Table slide shaft

Machine oil

N/A

Upper wheel slide block

Machine oil

monthly

#3100 & #3110

Blade Tension Screw

Grease

monthly

#3110 & #3120

Welder Jaw

(clean up daily)

Rubber Tire

(clean up daily)

Work Table Assembly

(clean up daily)

Page 22

- -

Page 23

GEAR BOX COMPONENT

GUIDE POST COMPONENT

0500

1

GEAR BOX

1311

1

UPPER GUIDE SUPPORT,

0510

1

GEAR BOX COVER

1312

1

LOWER GUIDE SUPPORT,

0520

1

GEAR

1320

4

BLADE GUIDE

0521

1

GAER

1330

2

BLADE STOPER

0530

1

SCREW NUT

1350

1

BLADE GUIDE POST

0531

1

SCREW NUT

1360

1

GUIDE POST HOUSING

0540

1

GEAR

1361

1

POST CLAMPING SPRING

0550

1

GEAR SHAFT

1370

1

BLADE GUARD, LEFT

0560

1

SHAFT COVER

1381

1

BLADE GUARD, RIGHT CE TYPE

0570

1

GEAR

1390

1

POST HOUSING PIN

0580

1

MAIN SHAFT

9015

1

GUIDE POST LOCKER

0591

1

MAIN SHAFT COVER

9210

1

HANDLE KNOB

0600

1

SPEED CHANGING SHAFT

0610

1

SPEED CHANGING ARM

0611

1

SHAFT STOPPER

0612

1

SPRING

0620

1

SLIDE BLOCK

MAIN DRIVE

0630

1

CRUTCH

0631

2

BRASS BRACKET

2000

1

MAIN DRIVE MOTOR

0632

1

BRASS BRACKET

2010

1

MOTOR PULLEY

0700

1

SPEED CHANGING LEVER

2020

2

MOTOR SUSPENSION ARM

0740

1

SHAFT HOUSING

B3310

1

V-BELT, 2010+VARIATOR

0790

1

SPEED LEVER RIGHT

BM22

1

V-BELT, 2010+4040

7070

1

PULLEY

9220

1

LEVER KNOB

B3520

1

V-BELT, 7070+VARIATOR

G6008

1

BALL BEARING

G6206

1

BALL BEARING

WHEEL COMPONENT

G6303

1

BALL BEARING

G6304

1

BALL BEARING

3010

1

LOWER WHEEL

L4030

1

OIL SEAL

3020

2

RUBBER TIRE

L5230

1

OIL SEAL

3030

1

TAPER SLEEVE

L5840

1

OIL SEAL

3040

1

WHEEL LOCKING NUT

3050

1

UPPER WHEEL

3060

2

UPPER WHEEL LOCKOR

WORK TABLE COMPONENT

3080

1

SLIDE BLOCK HOUSING

3090

1

SLIDE BLOCK SEAT

1010

1

WORK TABLE

3100

2

SLIDE BLOCK GUIDE

1021

1

TABLE SUPPORT FRAME

3110A

1

UPPER WHEEL SLIDER

1031

2

TABLE BRACKET

3116

1

SLIDER SCREW SHAFT

1060

2

WASHER, 1/2”

3120

1

WHEEL ELEVATE SHAFT

1071

4

TUBE SCREW

3121

1

SPRING

1080

2

BLADE GUARD

3150

1

WASHER

1090

1

TABLE SUPPORT HOUSING

3180

3

INDICATOR RING

1100

1

GUIDE SUPPORT HOUSING

3190

1

TENSION INDICATOR

1550

1

RIP FENCE + LOCKER

3200

1

WHEEL TILT ADJUSTER

3220

1

WHEEL TILT CONNECTER

3240

1

CONNECTER WASHER

3250

1

CONNECTER HOUSING

9030

1

HANDWHEEL

9060

1

TILT ADJUST HANDWHEEL

G6205

2

BALL BEARING

3100A

1

UPPER WHEEL SLIDER

3111

1

SLIDER COVER

3116

1

SLIDER SCREW SHAFT

3120

1

WHEEL ELEVATE SHAFT

3121

1

SPRING

Page 24

AIR PUMP COMPONENT

VARIATOR COMPONENT

4010

1

AIR PUMP HOUSING

7400

1

SPEED CHANGE SHAFT

4020

1

AIR PUMP COVER

7410

1

SHAFT BLOCK

4030

1

AIR PUMP SHAFT

7420

1

SPEED INDICATE SHAFT

4040

1

AIR PUMP PULLEY

7430

1

GEAR SHAFT ARM

4050

4

AIR PUMP LEAVE

7440

1

INDICATE GEAR SHAFT ARM

4060

1

AIR PUMP SEAT

7450

1

SPEED SHAFT HOUSING

4140

1

AIR OUTLET

7451

1

WASHER TUBE

4150

1

AIR INLET

7460

1

PUELLY SHAFT ARM

4170

1

AIR NOZZLE

7470

1

VARIABLE PULLEY SHAFT

4180

1

AIR NOZZLE CLIPPER

7500A

1

VARIABLE PULLEY

BM22

-

V-BELT, 2010 + 4040

9030

1

HAND WHEEL

G6201

2

BALL BEARING

9230

1

HAND WHEEL KNOB

9995

1

GEAR NOZZLE

B3310

-

V-BELT, 2010+VARIATOR

MAIN BODY & MISCELLANCEOUS

B3520

-

V-BELT, 7070+VARIATOR

5000

1

MAIN BODY

5100

1

REAR DOOR, RIGHT

5120

1

LOWER DOOR

8200

1

SPEED AND PITCH SELECTOR

5140

1

UPPER DOOR

8201

1

SPEED AND PITCH SELECTOR

8092

1

LUBRICATE INSTRUCTION

8202

1

SPEED AND PITCH SELECTOR

8111

1

CONTROL PLATE

8203

1

BRASS BOLT

8204

1

BRASS HANDLE

8422

1

GEAR BOX INSTRUCTION

8205

1

SELECTOR BUSHING

8712

1

INDICATOR PLATE

8743

1

TILT INDICATOR, L & R

8771

1

TILT INDICATOR, F & B

9300

2

UPPER DOOR HINGE

9310

4

HINGE

9500

6

SPRING PLATE

9590

3

HANDLE ARM

9600

1

CHIP STOPPER

9700

2

INDICTOR NEDDLE

9900

1

MAGNIFIYING GLASS

9780

1

BRUSHER BRACKET

9790

1

CHIP BRUSHER

9999

1

EYE BOLT

CONTROL SWITCH COMPONENT

6600

1

PUSH BUTTON, ON

6602

1

PUSH BUTTON, OFF,

6610

1

EMERGENCY SWITCH

6650

1

KEY SWITCH

6713

1

MAGNETIC SWITCH

6723

1

OVERLOAD STARTER

6741

1

PILOT LIGHT

6745

1

VOLTAGE REDUCER

6750

1

FUSE SEAT

6755

1

FUSE

6772

1

WIRE HOUSING

6773

2

WIRE HOUSING

6799

1

WIRING PLATE

6620

2

LIMIT SWITCH

7310

1

SPEED READOUT DETECTOR

7330

1

DIGITAL TACHOMETER

Page 25

-

Page 26

WELDER COMPONENT

6800 WORK LAMP COMPONENT

6010

3

LIMIT SWITCH

6802

1

WORK LAMP COMPONENT

6011

1

INSULATOR

Bulb - MR 16 12v 20w

6020

1

GUIDE BLOCK

6021

1

SPRING BRACKET

6030

1

GUIDE CASTING

6040

1

HOUSING

6050

1

STATIONARY JAW

6051

1

INSULATOR

6052

3

INSULATING TUBE

6053

3

WASHER, INSULATE

6054

3

SPACER

6060

2

ECCENTRIC SHAFT

6070

1

CLAMP LEVER, RIGHT

6071

1

CLAMP LEVER, LEFT

6100

1

CLAMP SUPPORT, RIGHT

6101

1

CLAMP SUPPORT, LEFT

6110

1

CLAMP PLATE, RIGHT

6111

1

CLAMP PLATE, LEFT

6120

2

CAM

6130

1

MOVING JAW

6150

1

WELD BUTTON

6161

1

LIMIT SWITCH BRACKET

6170

1

PRESSURE ADJUST KNOB

1900 SHEAR COMPONENT

6180

1

SHAFT

6200

1

CAM

1910

3

SPINDLE BUSHING

6210

1

WELD TENSION ARM

1920

1

SPINDLE LIFT

6211

1

BUSHING

1930

1

BLADE SHAFT

6220

1

SPRING, SHORTER

1940

2

VANED IRON PLATE

6230

1

SPRING, LONGER

1950

2

LOWER BLADE

6240

1

TRANSFORMER

1960

1

UPPER BLADE

6250

1

SWITCH

1970

1

JOINT PLATE, LEFT

6260

1

GRINDER MOTOR

1980

1

CHAIN JOINT, RIGHT

6270

1

SPACER

1990

1

HANDLE BAR

6280

1

GRINDER WHEEL

9210

1

KNOB

6281

1

1/4" WASHER, FLAT

6282

1

6 mm-1.0 HEX NUT

6290

1

GRINDER GUARD

6291

1

GRINDER COVER

6330

1

WELDER NAME PLATE

6340

1

INSTRUCTION LABLE

6350

1

GRINDER LABLE

6420

1

ANNEAL BUTTON

9290

2

KNOB

6170

1

PRESSURE ADJUST KNOB

6180

1

SHAFT

Page 27

Loading...

Loading...