Page 1

BENCH AND FLOOR MODEL PRESSES

10 Ton single acting manual hydraulic press

FOR YOUR OWN SAFETY AND

OPTIMUM OPERATION READ

INSTRUCTION MANUAL BEFORE

OPERATING PRESS

RETAIN THIS MANUAL FOR

FURTHER REFERENCE.

10 TON BENCH PRESS 10 TON FLOOR PRESS

# 972200 #972210

Page 2

1

TABLE OF CONTENTS

• Model specifications page 2

• Placement of press page 2

• Safety points page 3

• Warning labels page 4

• Assembly instructions page 5

• Assembly instructions page 6

• Assembly instructions page 7

• Assembly instructions page 8

• Operation instructions page 8

• Maintenance page 9

• Trouble shooting page 9

• Parts list for bench press page 10

• Exploded diagram for bench model page 11

• Parts list for floor press page 12

• Exploded diagram for floor model page 13

Page 3

2

When transporting the machine please use caution. If using a sling

After installing the press, use the kerosene or degreasing product

rust oil which was applied at the factory. Then

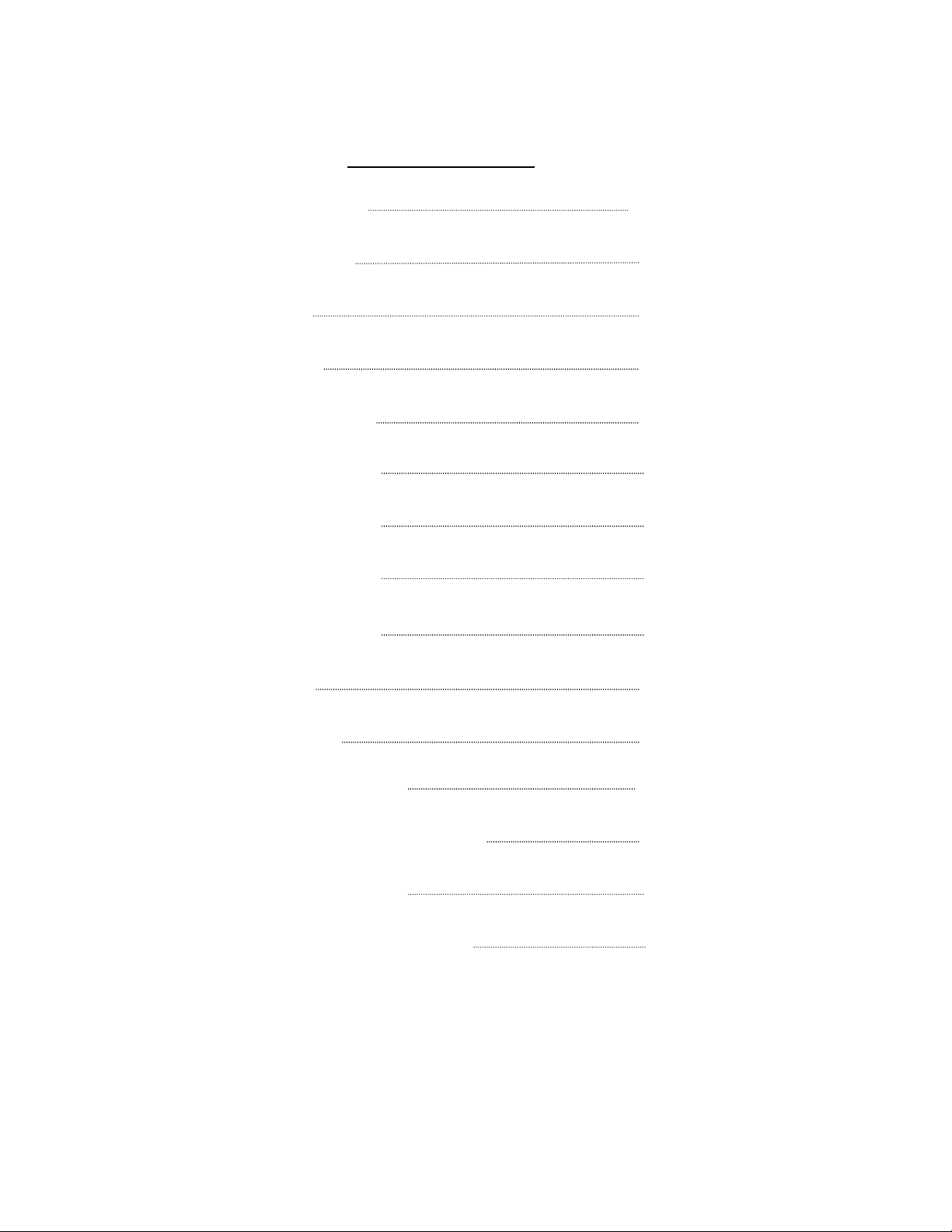

SPECIFICATIONS

Machine

Specifications: 10 TON UTILITY BENCH 10 TON UTILITY FLOOR

Press Type Manual 10 ton Bench Manual 10 ton Floor

Cylinder Type Single Acting Single Acting

Max. Press Capacity 10 ton 10 ton

Ram Diameter 1 ½" 1 ½”

Ram Stroke 6” 6”

Head Travel Left / Right of center Left / Right of center

Travel Per Stroke 1/8” approx. 1/8” approx.

Width between uprights 16 ¾” 16 ¾”

Width between channels 3” 3”

Max. Ram to Table 16” 38”

Overall Height 36” 60”

Weight 132 lbs. 149 lbs.

1. INSTALLATION PLACEMENT:

INSTALLATION OF PRESS

PRESS PLACEMENT SELECTION

CAUTION

1. Location of press should be in a well lit area that will not interfere

with other machines or operations.

2. Carefully unbox machine components from shipping carton.

Inspect all packing as not to throw out any parts or manuals.

3.

have someone steady the machine while transporting it.

4. Install your press on a sturdy level floor surface, or work bench.

The machine must be anchored to the floor or workbench

securely.

5.

to clean off the antiwipe machined surfaces (such as ram) with a light coating of

lubricant oil.

Page 4

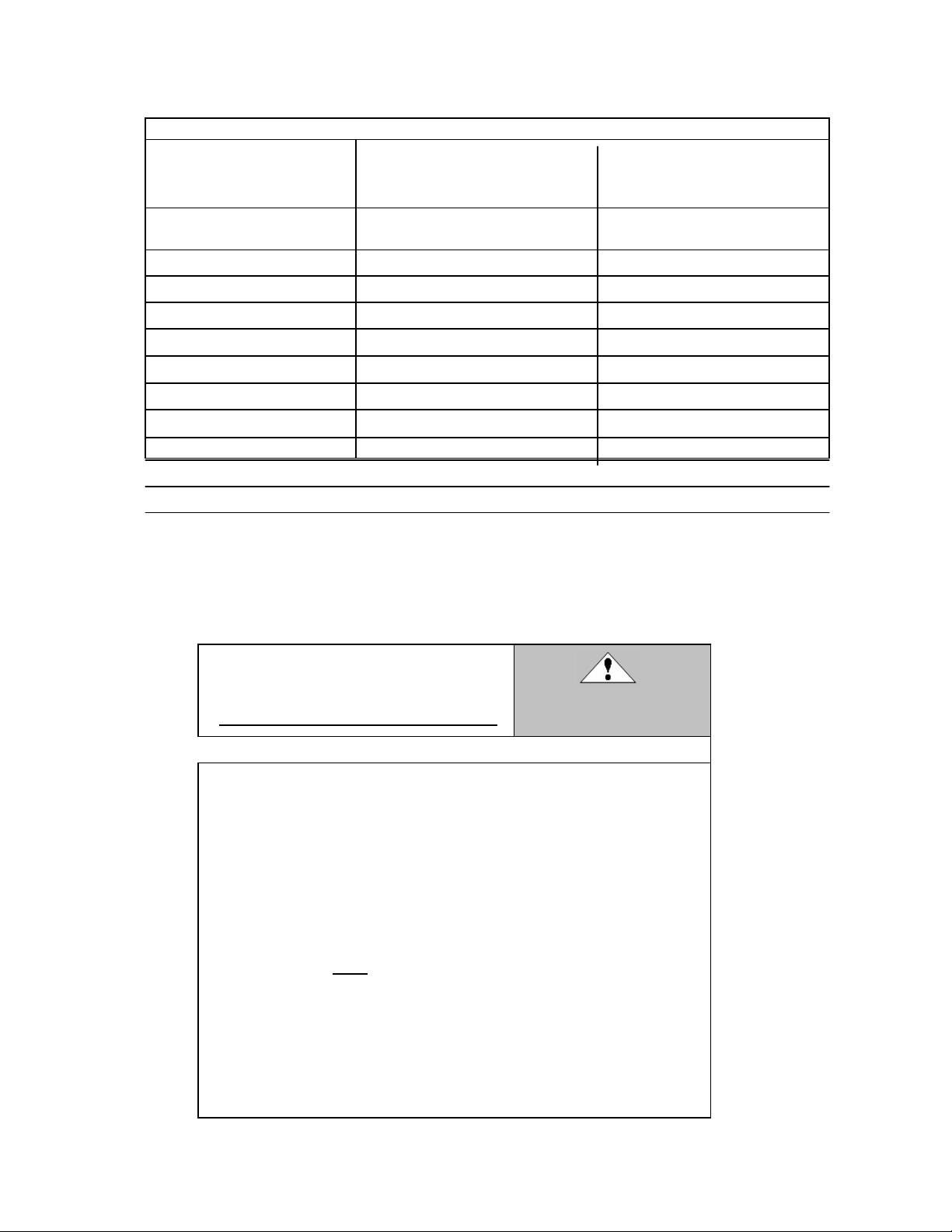

3

• SAFETY POINTS

BEFORE USE, ALL SAFETY POINTS MUST BE READ AND UNDERSTOOD!

Before the PRESS is used, the instruction manual with this machine must be read and

understood. This manual offers safe operation instructions. Offered below are safety

instructions designed for the press and general safety instructions that apply to

most machinery

.

Operation of the press incorrectly, or in a dangerous

fashion can result in serious injury or death.

Operation of the press incorrectly, or in a dangerous

fashion can result in damage to machine or it’s

components and to the cutting tool.

Instructions

Intend use :

This machine is intended to be operated by one person. This person should be

conscious of the press ram movement not only for himself but also for persons in the

immediate area of the machine. Caution is required when operating the press because

it can be dangerous due to the high pressures exerted from the ram. Operation

hazards such as pinching, ejection of parts are always present. Please think about the

safety warnings in the instruction manual before operating the machine.

Misuse of this machine will void warranty and cause unsafe working conditions.

for safe press use.

2. FOR SAFE OPERATION

For your own safety read the instruction manual before operating your single

acting hydraulic press.

1. Keep hands out of point of operation.

2. Never hold part while pressing.

3. Always wear the eye protection.

4. Clamp work piece or brace when pressing.

5. Never place fingers in pin holes.

6. Always use nose piece when pressing. Never press using the end of the

ram, damage to ram or threads can occur.

7. Never use a press that is not fastened securely to the floor or workbench.

8. Always used table pins and accessories furnished with press.

Page 5

4

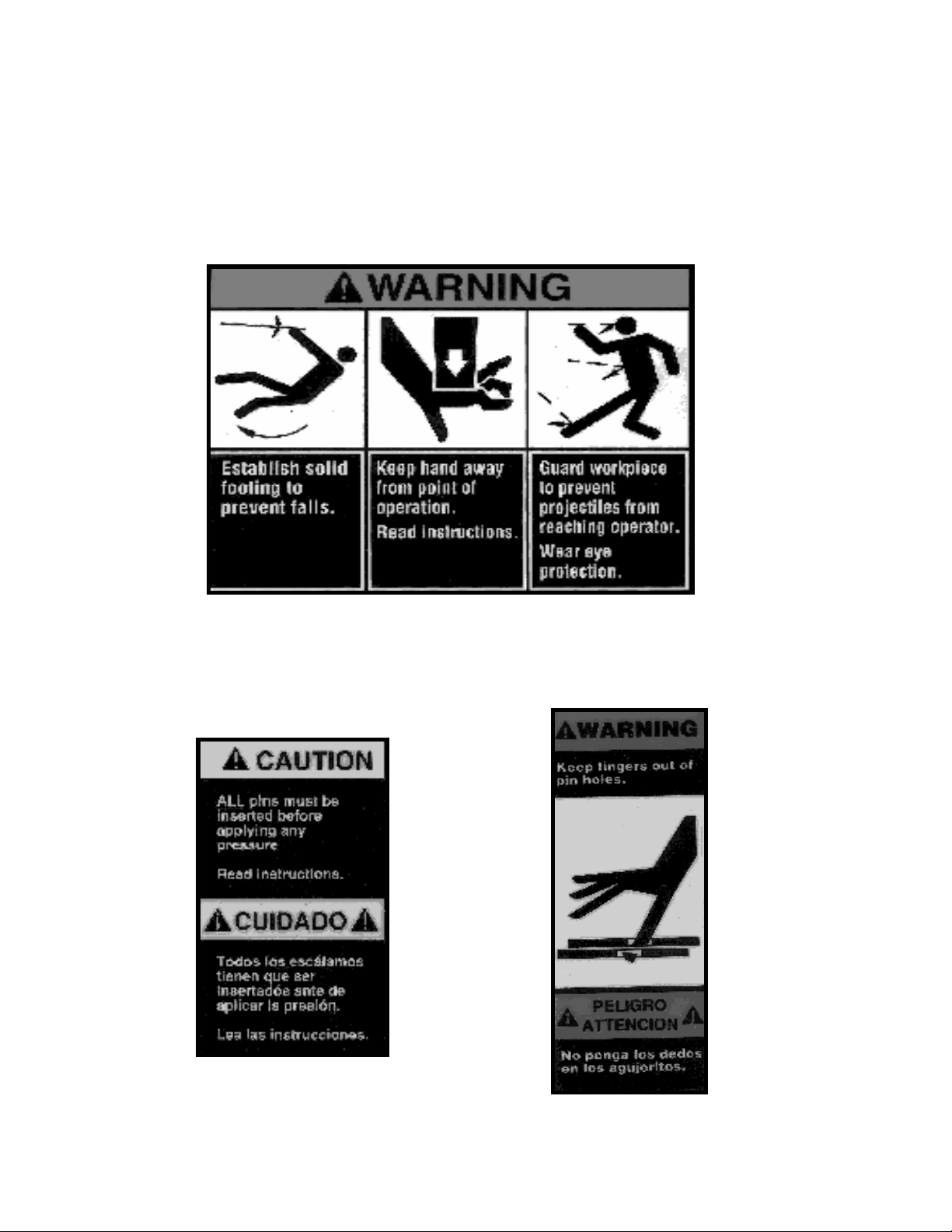

3. WARNING LABELS:

READ AND UNDERSTAND THESE WARNING LABELS PLACED ON THIS

MACHINE BEFORE OPERATING. MAKE SURE ALL PERSONS IN THE AREA

OF THE PRESS ARE AWARE OF THESE WARNINGS.

UNDER NO CIRCUMSTANCES SHOULD THESE LABELS BE REMOVED!

Establish solid footing Keep hands away Guard workpiece to

To prevent falls from point of prevent projectiles

operation from reaching operator

WEAR EYE PROTECTION

All pins must be inserted before

applying any pressure

Keep finger out of pin holes

Page 6

5

4.

ASSEMBLY INSTRUCTIONS

:

FOR DAKE MODEL UTILITY 10 TON BENCH AND FLOOR MODEL PRESSES.

Your new Dake Press has been packaged in a manner to prevent damage to any critical

components, some assembly will be required. All parts in the accessory box are critical to

the function of your press. Please review the list of materials to insure you have all

components required. Please refer to the parts list and exploded diagrams on pages 10-13

of this owners manual.

Your press head frame, uprights and head traverse ram plate has been pre-assembled at

the factory. You will be required to install the worktable, ram, pumping unit and base angles.

Follow the simple instructions below for quick assembly. Assembly may be made easier if

the frame is laid down flat with the front facing upward.

STEP 1: Bench model:

Using (2) M8 x 20mm bolts, nuts and washers install the union support to the bottom from of

the upright channels. (Pump hanger bracket on the right hand side of the upright.) Angle is

to face outward see drawing below on right.

Hand tighten.

Pump hanger bracket

Union support

STEP 1. Floor model:

Install the union support to the inside of the upright channels and base angles, using the 4 of

the M8 x 25mm bolts, nuts and washers provided. Place union support in-between the

channels, and install the 2 base angles to the frame through the union support and install

nuts. Base angles face outward (See drawing below) Hand tighten.

Base angle

Union support

Union support

Base angle

Page 7

6

STEP 2. Floor model: (Bench model skip this step)

Install the diagonal support straps. Using 4 M8 x 25mm bolts, nuts and washers. Install the

support straps to the inside of the base angles then to the frame as shown. Finger tighten.

Diagonal support

straps

STEP 3:

Carefully stand the unit upright. Making sure all components are square to each other,

tighten all nuts and bolts securely.

STEP 4: Floor model: (Bench model skip this step)

Install pump mounting plate on the side of the upright channel using the 3 M10 x 25mm

bolts, nuts and washers.

Mount Head ram

traverse plates. The

side with two bars

welded to them go

inside the frame, with

Pump mounting plate

the thick threaded

plate on the bottom.

Using two 10mm x 120

Mounting bolts, nuts washers

mm bolts, washers and

nuts snug only enough

To allow plate to travel

STEP 5. Floor model: (Bench model skip this step)

Install the pumping unit to the mounting plate using 2 M10 x 25mm bolts, nuts and washers.

Make sure pump is centered on this mounting plate.

Pumping unit

Page 8

7

STEP 6:

With press standing upright and all bolts tightened install the worktable. Insert two table pins

in the two lowest holes. Take the worktable and tilt it at a sharp angle and insert it in the

uprights. (NOTE: The gussets welded to the table are at slight angles. The narrowest

dimension of these gussets go down. See drawing) (Step 1) Once worktable is in the

uprights turn it level and lower down and set it on the table pins. (Step 2) Take care when

doing this, a helper would be advised.

Gussets inside table

Step 1

Lower

Narrowest dimension

Step 2

STEP 7:

Locate the cylinder and remove the plastic protective cap on the end of the ram. (If

applicable) Carefully screw the cylinder from the top into the head traverse ram plate. Screw

this in as tight as possible while keeping the cylinders hydraulic hose fitting facing to the left.

(Cylinder may not be totally tight while keeping the fitting facing this way, but it will not effect

the presses operation.)

Using Teflon tape install the gauge to the

top of the cylinder facing forward.

Gauge

Hose fitting

STEP 8:

On the bench model hang the pumping unit in its holder bracket on the side of the frame.

Remove the plastic protective cap from the end of the hydraulic hose. Screw the hydraulic

hose onto the cylinder hose fitting. The fitting has a knurled collar that you can tighten by

hand. (Do not use a wrench because damage may occur to the fitting) The hose has a check

valve that prevents oil from escaping so if hose is ever removed air will not get in the system.

Install a nose piece and use table blocks when operating this machine.

Page 9

8

Nose piece

Table block

NOTE:

System is filled with oil and may take a few pumps to fill all lines.

Close the pump valve and pump to check for piston action, and for

leaks.

If air appears to be in the system, open the valve handle and pump

vigorously about a dozen times. Close valve and try again.

STEP 9:

Chose location placement as described on page 2. Mount the press securely.

You are now ready to use the press.

5. OPERATION (PROCEDURE)

Always use the supplied nose pieces. The flat nose piece will be good for most pressing and

flattening operations. The step style nose piece will work well for pressing bearing, bushing

and parts that have a hole that the nose piece will fit into. This nose piece will help support or

hold the piece during pressing operations.

There are two table plates that should always be used as a backing plate during pressing

operations. You will find notches in these table plates to allow you to use the press as a

straightening press for axles, shafts, etc and most round stock.

When using your press always use the highest table setting to minimize the stroke distance

of the ram. Note: Only use supplied table pins. Do not weld or pin table. Once a part is put in

the press and is clamped or braced securely, close the pumping unit release valve handle.

(Clockwise). Pump the handle to lower the ram. Pump until pressing operation is completed.

If you need to maintain pressure leave the valve on the pumping unit closed. When

operation is complete, turn the valve counter-clockwise to release pressure and raise the

ram. Once the ram has been raise just above the work close valve again and repeat

operation on the next part. There is no need to raise the ram all the way to the top each time.

If pressing application requires a certain tonnage, press until the gauge reads the

Page 10

9

If oil is ever needed, remove plug from the top of the pumping unit

appropriate tonnage then stop. Release pressure and repeat operation.

NOTE: Never pump the ram down fully and dead head the ram in the cylinder. Only build

pressure when using the table plates or a part is being pressed. Failure to do this may cause

ram seal damage and leaking.

If the application requires off center pressing, loosen the head ram traverse plate bolts and

slide head left or right to the area where pressing is required. You may now proceed with the

operation. When head is returned to the center position snug these bolts up to prevent

unexpected movement.

Always make sure you are

pressing with the whole ram.

Center ram over the work, do

not press with only the edge

of the nose piece. This can

cause injury by ejecting the

part, or damage to the ram.

6. MAINTENANCE OF MACHINE

MAINTENANCE!

1. On a regular basis wipe the enter press. Keep ram free from

debris and abrasive materials (Frequency depends on

environment the machine is in)

2. A light oil applied to the ram will help to keep the surface clean.

3. If the hydraulic hose or table pins are worn or cut, or damaged in

any way, have it replaced immediately.

4.

and add hydraulic jack oil. Bleed the system by pumping the

handle repeatedly about a dozen time with the relief valve open.

Close valve and check that air has been bled.

Page 11

10

7. TROUBLE SHOOTING:

Problem Solution

Oil leaking around ram.

Ram is jerky or sluggish With release valve open repeatedly pump the handle to bleed air from lines.

Ram does not return fully Open and close release valve several times. If continues contact Dake.

Pump will not pump Make sure valve is fully closed. Contact Dake.

Leaking by gauge Place Teflon tape to threads and reinstall.

Leaking by hoses Check all fitting, make sure they are tight. Look for hole or abrasions.

Will not reach max. tonnage Check that the valve is closed fully. Bleed system, Contact Dake.

Will not hold pressure Some bleed off will occur over time. Check valve is closed fully

Put ram under full pressure for 24 hours. If problem continues contact Dake

Page 12

11

8. PARTS LIST

10 TON BENCH UTILITY PRESS PARTS LIST

Ref # Dake Part # Description Qty.

1 301139 Frame upright channel 2

2 301138 Head frame channel 2

3 / 19 301137 / 301133 Head ram traverse plates 1 upper & lower

4 301136 Bolt M12 x 110mm 6

5 301135 Lock washer 12mm 6

6 301134 Nut M12 x 4 6

7 301132 Union support 1

8 301131 Base angle 2

9 301130 Bolt M8 x 20 6

10 301129 Lock washer 8mm 6

11 301128 Nut M8 6

12 301127 Flat nose piece 1

13 301126 Step nose piece 1

14 301125 Table pin 2

15 301124 Table plate 2

16 301123 Work table 1

17 301122 Ram / Cylinder 1

18 301121 Pumping unit 1

20 301150 Bolt M10 x 140 2

21 Washer 10mm 2

22 301149 Lock washer 10mm 2

23 301141 Nut 10mm 2

24 301120

25 Ring 1

Gauge 1

Spare seals should be stored in safe location out of direct sunlight if future is

required.

Page 13

12

10 TON BENCH UTILITY PRESS

Page 14

13

301120

10 TON FLOOR UTILITY PRESS PARTS LIST

Ref # Dake Part # Description Qty.

1 301154 Frame upright channel 2

2 301153 Head frame channel 2

3 / 4 301152 / 301151 Head ram traverse plates 1 upper & lower

5 301150 Bolt M10 x 120mm 2

6 301149 Lock washer 10mm 2

7 301148 Union Support 1

8 301147 Base angle 2

9 301146 Bolt M8 x 25 12

10 301129 Lock washer 8mm 12

11 301128 Nut M8 12

12 301145 Angle support strap 4

13 301144 Pump support bracket 1

14 301143 Bolt M10 x 25 5

15 301142 Lock washer 10mm 4

16 301141 Nut M10 4

17 301123 Work table 1

18 301124 Table plate 2

19 301127 Flat nose piece (1-5/8 – 12) 1

20 301126 Step nose piece (1-5/8 – 12)

21 301140 Ram / Cylinder 1

22 301121 Pumping unit 1

23 301125 Table pin 2

24 301136 Bolt M12 x 110mm 4

25 301135 Lock washer 12mm 4

26 301134 Nut M12 4

27 Bolt M8 x 25 4

28

29 Ring 1

Gauge 1

1

Spare seals should be stored in safe location out of direct sunlight if future is

required.

When ordering parts have model and date of purchase information ready.

For assistance call Dake Service at 1-800-937-3253 or fax to 1-800-846-3253

e-mail to customerservice@dakecorp.com

Page 15

14

10 TON FLOOR UTILITY PRESS

Loading...

Loading...