Page 1

Phone: 800.937.3253

www.dakecorp.com

DAKE DRILL PRESS

TB16, SB16, SB25, & SB32

INSTRUCTIONAL MANUAL

WARNING!

Read and understand all instructions and responsibilities before operating. Failure to follow

safety instructions and labels could result in serious injury.

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

Fax: 800.846.3253

customerservice@dakecorp.com

Page 2

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

TABLE OF CONTENTS

DAKE STANDARD LIMITED WARRANTY ............................................................ 2

RETURN & REFUND POLICY .............................................................................. 4

SPECIFICATIONS ................................................................................................ 5

SAFETY ................................................................................................................ 6

SET UP ................................................................................................................. 8

UNCRATING AND INSTALLATION ............................................................. 8

GROUNDING INSTRUCTIONS ................................................................... 9

OPERATION ......................................................................................................... 9

DRILL/CHUCK INSTALLATION ................................................................... 9

INSTALLATION OF DRILL BIT .................................................................. 10

TOOLING REMOVAL................................................................................. 10

TABLE HEIGHT ADJUSTMENT ................................................................ 10

TABLE SWING ADJUSTMENT .................................................................. 11

FEED DEPTH ADJUSTMENT .................................................................... 11

WORK HOLDING ....................................................................................... 12

SPEED ADJUSTMENT .............................................................................. 12

SAFETY FEATURES ................................................................................. 14

MAINTENANCE .................................................................................................. 15

TROUBLESHOOTING ........................................................................................ 16

ELECTRICAL DIAGRAMS .................................................................................. 17

EXPLODED VIEWS & PART LISTS .................................................................... 18

ORDERING INFORMATION ............................................................................... 23

1 REV012019

Page 3

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

DAKE STANDARD LIMITED WARRANTY

Finished Machines

Dake warrants to the original purchaser the finished machine manufactured or distributed by it to

be free from defects in material and workmanship under normal use and service within 1 year

(12 months) from the delivery date to the end user.

Parts & Couplings

Dake warrants to the original purchaser the component part or coupling manufactured or

distributed by it to be free from defects in material and workmanship under normal use and

service within 30 days from the delivery date to the end user.

The standard limited warranty includes the replacement of the defective component part or

coupling, at no cost to the end user.

Warranty Process

Subject to the conditions hereinafter set forth, the manufacturer will repair or replace any portion

of the product that proves defective in materials or workmanship. The manufacturer retains the

sole right and option, after inspection, to determine whether to repair or replace defective

equipment, parts or components. The manufacturer will assume ownership of any defective

parts replaced under this warranty.

All requested warranty claims must be communicated to the distributor or representative

responsible for the sale. Once communication has been initiated, Dake Customer Service must

be contacted for approval:

Phone: (800) 937-3253

Email: customerservice@dakecorp.com

When contacting Dake, please have the following information readily available:

- Model #

- Serial #

- Sales Order #

Purchasers who notify Dake within the warranty period will be issued a Case number and/or a

Return Material Authorization (RMA) number. If the item is to be returned per Dake’s request,

the RMA number must be clearly written on the exterior packaging. Any item shipped to Dake

without an RMA will not be processed.

2 REV012019

Page 4

Grand Haven, MI 49417

Warranty Exceptions:

The following conditions are not applicable to the standard limited warranty:

(a) Part installation or machine service was not completed by a certified professional, and

is not in accordance with applicable local codes, ordinances and good trade practices.

(b) Defects or malfunctions resulting from improper installation or failure to operate or

maintain the unit in accordance with the printed instructions provided.

(c) Defects or malfunctions resulting from abuse, accident, neglect or damage outside of

prepaid freight terms.

(d) Normal maintenance service or preventative maintenance, and the parts used in

connection with such service.

(e) Units and parts which have been altered or repaired, other than by the manufacturer

or as specifically authorized by the manufacturer.

Dake Corporation

724 Robbins Road

www.dakecorp.com

(f) Alterations made to the machine that were not previously approved by the

manufacturer, or that are used for purposes other than the original design of the

machine.

3 REV012019

Page 5

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

RETURN & REFUND POLICY

Thank you for purchasing from Dake! If you are not entirely satisfied with your purchase, we are

here to help.

Returns

All Dake manufactured / distributed machines, parts and couplings include a 30-day return

option. These policies are valid from the date of final shipment to the end user.

To be eligible for a return, the item must be unused and in the same condition as received.

All requested warranty claims must be communicated to the distributor or representative

responsible for the sale. Once communication has been initiated, Dake Customer Service must

be contacted for approval:

Phone: (800) 937-3253

Email: customerservice@dakecorp.com

Once the return request has been approved by Customer Service, a representative will supply a

Return Material Authorization (RMA) number. The returned item must have the provided RMA

number clearly marked on the outside packaging. Any item received without an RMA number

clearly visible on the packaging will not be processed.

An RMA number can only be provided by the Dake Customer Service team and must be

obtained prior to the return shipment.

Refunds

Once the item has been received and inspected for damages, a representative will notify the

requestor referencing the provided RMA number.

If the return is approved, a refund will be issued to the original method of payment, less a 20%

restocking fee. The restocking fee may be waived if an order is placed at the time of return with

like-value merchandise.

Transportation costs are the responsibility of the end user and will not be credited upon return

approval.

Any item that is returned after the initial 30 days or has excessive/obvious use will not be

considered for a full refund.

4 REV012019

Page 6

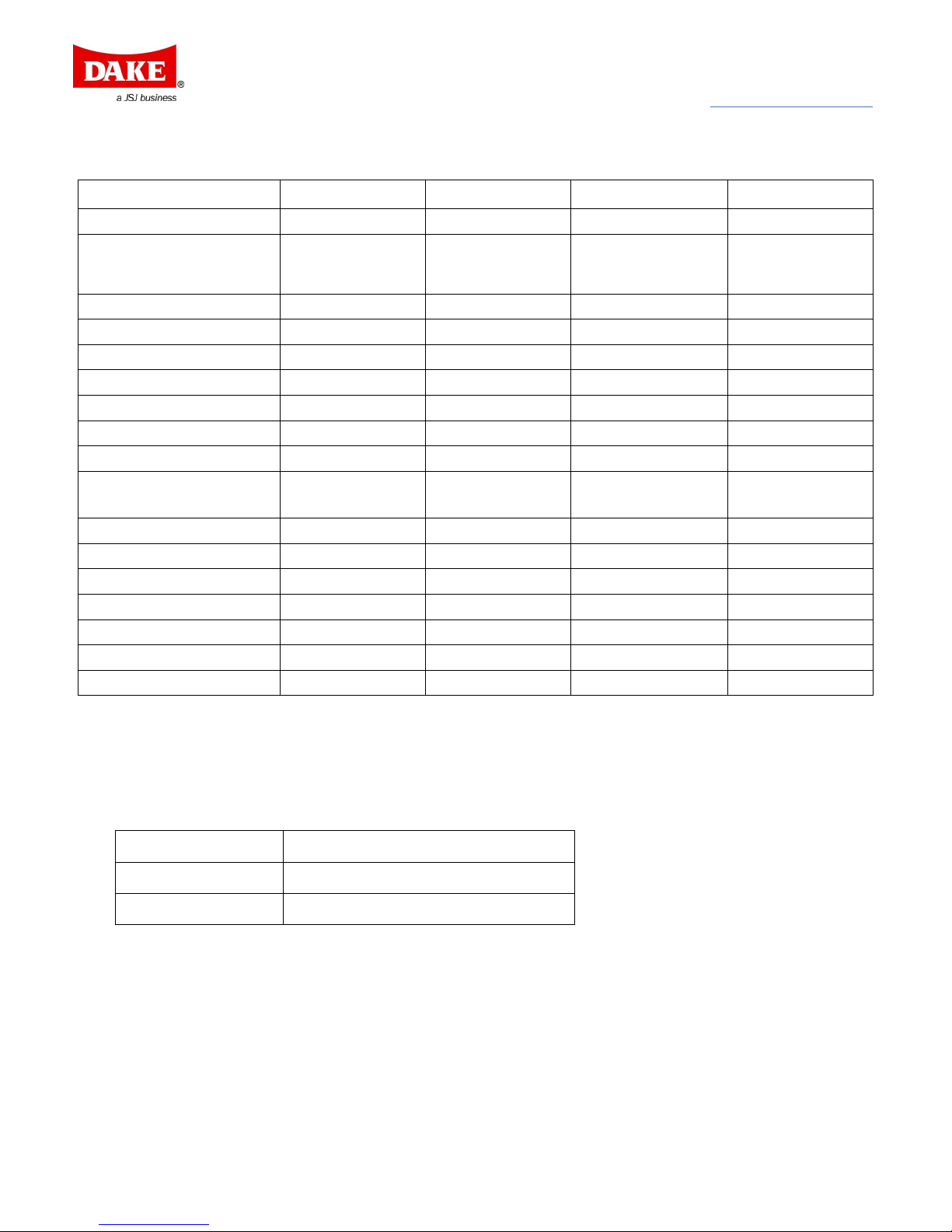

SPECIFICATIONS

Model

TB-16

SB-16

SB-25

SB-32

Number

977100-1

977200-1

977300

977400-2

110V Single

220V 3-Phase

Horsepower

1/2 HP

1/2 HP

2 HP

2 HP

Drill Type

Bench

Floor

Floor

Floor

Max. Drill Capacity

5/8”

5/8”

1”

1-1/4”

Spindle Taper

MT2

MT2

MT3

MT4

Spindle Travel

3-1/8”

3-1/8”

5”

5-1/4”

Max. Work Diameter

14-1/8”

14-1/8”

18”

18”

Speeds (Step Pulley)

9 9 9

9

Range

Column Diameter

3-1/8”

3-1/8”

3-5/8”

4”

Table

11-3/4” x 11-3/4”

11-3/4” x 11-3/4”

13-3/4” x 13-3/4”

15-3/4” x 15-3/4”

Base

17-3/4” x 12-1/4”

19-5/8” x 12-1/2”

23-5/8” x 15”

23-5/8” x 15”

Spindle to Table

16-1/2”

28-1/2”

28-3/8”

26-1/8”

Spindle to Base

26-1/2”

49-1/4”

50”

50”

Overall Height

42-1/2”

64”

71”

71”

Weight

175 lbs.

230 lbs.

397 lbs.

483 lbs.

Serial No.

Model No.

Date Purchased:

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Voltage

Spindle Speed

120V 110V/220V

240-3400 RPM 240-3400 RPM 270-2000 RPM 270-2290 RPM

Phase,

220V

3-Phase

In the space provided record the serial number and model number of the machine. If contacting

Dake this information must be provided to assist in identifying the specific machine.

5 REV012019

Page 7

Dake Corporation

Label Part No.

84395

Label Part No.

76462

Label Part No.

82199

Label Part No.

300168

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

SAFETY

This is the safety alert symbol. When you see this symbol on your machine be alert to

the potential for personal injury.

Carefully read all safety messages in these instructions and on your machine safety

signs. Keep safety labels in good condition. Replace missing or damaged labels.

Employer is responsible to perform a hazard/PPE assessment before work activity.

Additional Safety Warnings:

• Operation of the drill press incorrectly, or on a dangerous fashion can result in serious

injury or death, damage to the machine, it’s components, or cutting tool.

• The drill press is designed for drilling and boring operations. Cautions is required when

operating the drill press because it can be dangerous due to the high spindle rotation

speed.

• Guards such as pully cover and chuck guard must be in place and in working condition to

prevent hazard.

• Switch the power off before setting, inspecting, lubricating, cleaning, or changing the drill

bit.

• Always wear eye protection.

6 REV012019

Page 8

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

• Do not wear gloves, neckties, necklaces, rings, or loose clothing. Non-slip footwear is

recommended. Wear protective hair covering to contain long hair.

• To clamp work piece to brace against column to prevent material rotation.

• Using recommended speed for drill bit, and work piece material.

• Remove adjusting key and wrenches. Be in the habit of checking to see that keys and

adjusting wrenches are removed from tool before turning the machine on.

• Keep work area clean. Cluttered areas and benches invite accidents.

• All visitors should be kept a safe distance from work area.

• Make workshop kid proof with padlocks, master switches, or by removing the starter key.

• Do not force tool. Machine will do a better and safer job at the rate for which it was

designed.

• Use the right tool. Do not force the tool or use the machine to do a job for which it was

not designed.

• Use recommended speed for drill accessories and workpiece material.

• Use a face or dust mask if cutting operation is dusty.

• Secure work. Use clamps or a vise to hold work, do not hold part with hands.

• Do not overreach. Keep proper footing and balance at all times.

• Maintain tool with care. Keep tools sharp and clean for best and safest performance.

• Disconnect drill press from power before servicing or changing accessories.

• Reduce the risk of accidental starting. Make sure switch is in off position before plugging

in.

• Use recommended accessories. The use of improper accessories may cause risk of

injury.

• Never stand on machine for risk of serious injury.

• Check for damaged parts. Before further use of machine, a guard or other part that is

damaged should be replaced or repaired. Carefully check to determine that it will operate

properly and perform its intended function. Check alignment of moving parts, binding of

moving parts, breakage of parts, mountings, and any other conditions that affect its

operation.

• Never leave tool running unattended. Turn power off. Do not leave machine until it comes

to a complete stop.

• Adjust the table or depth stop to avoiding drilling into the table, shut off the power.

Remove the drill bit or cutting tool, and clean the table before leaving the machine.

• Do not operate until completely assembled and installed according to the instructions.

• If any part of your drill press is malfunctioning, has been damaged, or broken do not

operate until the part is properly repaired or replaced.

• Never place your fingers in positions where they could contact the drill or other cutting

tool if the work piece should unexpectedly shift.

• Never perform any operation by moving the head or table with respect to one another. Do

not switch machine on or start any operation before checking that the head and table lock

7 REV012019

Page 9

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

handle are clamped tight to the column, and head and table support collars are correctly

positioned.

• Before switching the power on be sure the belt cover is down, and the bit is installed

properly in the chuck.

• Lockout the motor switch when leaving the drill press. Don’t perform layout, assembly, or

setup work on the table while the cutting tools rotating.

Voltage Warning:

• Before connecting the machine to a power source know your incoming voltage.

• At power source with voltage greater than that specified for the machine can result in

serious injury to the user and can damage the machine.

• Using a power source with voltage less than that of the machines rating can damage the

motor and other components.

• If you are unsure of the voltage rating do not use the machine.

SET UP

UNCRATING AND INSTALLATION

1. Location of the drill press should be in a well-lit area with correct power supply and that

will not interfere with other machines or operations.

2. Carefully uncrate machine and inspect all packing to make sure no parts are manuals

are thrown out.

3. When transporting the machine please use caution. If using a sling have someone

steady the machine while moving.

4. Install your drill press on a sturdy level floor surface, or workbench. The machine must

be anchored to the floor or workbench securely, the machine is top heavy.

5. Connect appropriate power to the machine. Make sure circuit breakers are suitable for

the machine. Consult local codes for proper installation of machine. Always route power

cables in a safe manner away from traffic areas, damp areas, heat, and moving parts.

6. After installing the drill press, use the kerosene or degreasing product to clean off the

anti-rust oil which was applied at the factory. Then wipe machined surfaces with a light

coating of lubricant oil (way oil).

7. Check for damaged parts before further use of the machine. A guard or other part that is

damaged should be replaced or repaired before use. Carefully check to determine that it

will operate properly and perform its intended function. Check for alignment of moving

parts and binding od moving parts. Breakage of parts or mountings and or any other

conditions that could be affect its operation.

8 REV012019

Page 10

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk or electrical shock. This machine is equipped with an electric

cord must be used with a matching outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

• Do not modify the plug provided. If it will not fit the outlet have the proper outlet installed

by a qualified electrician.

• Improper connection of the equipment grounding can result in a risk of electrical shock.

The conductor with insulation having an outer surface that is green with yellow stripes is

equipment grounding conductor. If repair or replacement of the electric cord or plug is

necessary, do not connect the equipment grounding conductor to a live terminal.

• Check with a qualified electrician or serviceman if the grounding instructions are not

completely understood, or if in doubt as whether the machine is properly grounded.

• It is not recommended to use an extension cord on the machine. If one must be used,

use only a grounded cord on the machine and length of run needed.

• Repaired or replace damaged or worn cords immediately.

OPERATION

DRILL/CHUCK INSTALLATION

1. Before inserting drill bits, chucks, or arbors always clean out the spindle hole and taper

hole with a clean cloth.

2. Open chuck jaws completely by turning attached chuck key counter-clockwise until the

jaws are fully opened.

3. To install the chuck to the arbor tightly, slide the chuck into the taper forcing it into the

spindle with by handle.

4. Place a block of wood on the table then lower the spindle to contact the wood and press

the chuck tightly into the spindle taper.

5. Install a taper shaft drill into the taper the same way as you would the chuck. If an

adaptor is used it must fit the taper correctly and the bit must fit snug in the adaptor.

9 REV012019

Page 11

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

INSTALLATION OF DRILL BIT

A drill bit with a shaft of at least 1” long should be used to allow correct chuck jaw contact. If the

shaft is under 1” do not insert bit as far into the chuck where it allows jaw contact with the drill

flutes.

Center drill bit into the chuck and tighten the chuck securely with the chuck key.

Note: Always use sharp, straight bits. Never use bits with turned down shafts. Never exceed the

maximum shaft diameter bit size for the machine.

TOOLING REMOVAL

1. Before removing the chuck or bit form the machine be sure the spindle has come to

complete stop and power is off.

2. If needed rotate spindle by hand to align the spindle and quill openings.

3. Insert the wedge removal tool while supporting the tooling tap the wedge to remove the

tooling.

TABLE HEIGHT ADJUSTMENT

1. Loosen the clamp bolt then adjusting the table with the bracket handle to desired work

height.

2. Retighten the clamp securely when table is adjusted to desired height.

Note: Keep table adjustment rack clean from debris. Never attempt to move table with clamp

bolt tightened.

10 REV012019

Page 12

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

TABLE SWING ADJUSTMENT

1. To swing the table up to 360°, loosen the clamp release bolt and swing the table to the

desired position.

2. After table is in the correct position, tighten clamp release bolt securely.

Note: Never swing the table if any material or fixturing is on it. Only adjust when table is free

of loose articles.

FEED DEPTH ADJUSTMENT

1. Setting the feed depth adjustment is done by loosening the clamp bolt on the spindle

depth index sleeve.

2. Rotate to desired length, and securely tighten the clamp bolt.

Note: Never make this adjustment while machine is running.

11 REV012019

Page 13

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

WORK HOLDING

When drilling directly on the table surface it is recommended that a piece of wood or plywood be

clamped securely to the table under the work piece. This will minimize splintering or burring as

the drill breaks through the work. It will minimize drill bit and table damage. Clamp work piece to

the table whenever possible. The table has “T-slots” that allow for many different clamping

configurations. When part cannot be affixed to the table a drill vise that is bolted to the table

must be used to hold the work piece safely.

SPEED ADJUSTMENT

WARNING: Wait until the machine had come to a complete stop and power is

disconnected before proceeding with changing the speed!

1. Open the pulley cover to expose the pulleys and drive belts.

2. Loosen the tension lock handles.

3. Choose the proper speed for drilling operation, refer to “Speed Adjustment Guide”, next

in this manual.

4. Move belt to the correct step pulleys for desired speed.

5. Push the motor backwards until proper blade tension is applied, about 1/2" of deflection,

see illustration below.

6. Retighten belt tension lock handle.

Note: If center pulley bracket does not move freely loosen spring loaded bolts 1/2 to 3/4 of a

turn.

12 REV012019

Page 14

1 – 7

240 RPM

270 RPM

270 RPM

1 – 6

420 RPM

400 RPM

410 RPM

2 – 7

450 RPM

450 RPM

450 RPM

1 – 5

660 RPM

550 RPM

600 RPM

2 – 6

760 RPM

660 RPM

690 RPM

3 – 7

780 RPM

720 RPM

720 RPM

2 – 4

1980 RPM

1270 RPM

1410 RPM

3 – 5

2100 RPM

1460 RPM

1620 RPM

3 – 4

3400 RPM

2000 RPM

2290 RPM

Speed Adjustment Guide:

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Pulley Steps TB-16 & SB-16 SB-25 SB-32

Proper belt tension is approximately 10 lbs, or 1/2" of deflection.

13 REV012019

Page 15

Proper drill speed for a given drill bit size:

Material Type

Alum. &

Copper

Drill Dia.

RPM

1/16”

2,445

3,665

4,890

6,110

12,225

1/8”

1,220

1,831

2,445

3,055

6,110

3/16”

815

1,220

1,630

2,035

4,075

1/4"

610

915

1,220

1,530

3,055

5/16”

490

735

980

1,220

2,445

3/8”

405

610

815

1,020

2,035

7/16”

350

525

700

870

1,745

1/2"

305

460

610

765

1,530

5/8”

245

365

490

610

1,220

3/4"

205

305

405

510

1,020

7/8”

174

261

348

435

762

1”

153

229

306

382

668

1-1/8”

136

204

272

340

595

1-1/4”

122

167

244

306

535

Cast Steel Tool Steel Cast Iron Mild Steel

TB-16

&

SB-16

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

SB-15

SB-32

SAFETY FEATURES

14 REV012019

Page 16

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

MAINTENANCE

Before performing any maintenance ensure that the machine is LOCKED OUT and

unplugged.

Special maintenance operations must be carried out by skilled personnel. However, we advise

contacting DAKE. The term special maintenance also covers resetting of protection/safety

equipment and devices.

• On a regular basis, blow out any dust that may accumulate inside the motor (frequency

depends on environment the machine is in).

• A coat of automotive wax needs to be applied to the table and column to help keep the

surface clean.

• If the power cord is worn, cut, or damaged in any way have it replaced immediately.

• All ball bearings are packed with grease at the factory and require no further lubrication.

• Periodically lubricate the gear and rack table elevation mechanism, the spindle splines

and rack (teeth on quill).

• After each use the machine should be cleaned.

• Weekly lubrication of all sliding or moving parts with light weight or way oil is

recommended.

15 REV012019

Page 17

TROUBLESHOOTING

SYMPTOM

CAUSE

SOLUTION

Machine not plugged in

Plug in to proper receptacle

Clear error by turning drill off

and back on

Too long or not correct

extension cord

Remove extension cord and

plug directly in to receptacle

Emergency stop button is

activated

Belt cover is open

Close belt cover

Adjust tension, see “Speed

manual

Check for wear or if pulley

can be tightened

Spindle bearing worn

Replace bearing

Rust inhibitor, dirt, debris in

or on quill or spindle taper

Check belt for damage and

of this manual

Debris in quill

Clean quill and teeth

See “Feed Depth Adjustment”

in this manual

Tighten belt tension, see

of this manual

Belt is broken or worn

Replace belt

Taper is slipping in spindle

Clean chuck and quill

Troubleshoot motor or

contact DAKE

Machine does not turn on

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Frequency drive has an error

Deactivate emergency button

Noisy Operation

Chuck or quills fall out

Spindle does not move up or

down

Spindle does not rotate

Incorrect belt tension

Loose spindle or motor pulley

Belt is broken or slipping

Feed depth adjustment is set

Belt tension is too loose

Adjustment” section of this

Clean chuck and quill

replace if needed. Check for

proper belt tension, see

“Speed Adjustment” section

“Speed Adjustment” section

16 REV012019

Motor is not rotating

Page 18

ELECTRICAL DIAGRAMS

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

17 REV012019

Page 19

EXPLODED VIEWS & PART LISTS

TB-16 & SB-16:

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

18 REV012019

Page 20

TB-16 & SB-16:

1

Base

301002

301001

2

Flange

301003

301004

3

Spring Washer (4x)

13mm

13mm

4

Screw (M13 x 16mm L)

300999

300999

5

Column

301005

301006

6

Rack

301007

301007

7

Handle

301008

301008

8

Clamp Bolt

301009

301009

9

Clamp Bolt

301010

301010

10

Table Arm

301011

301011

11

Table Bracket

301012

301012

12

Worm

301056

301056

13

Collar

301013

301013

14

Feed Handle (3x)

301014

301014

15

Lock Handle

301070

301070

15A

Lock Screw

302818

302818

16

Feed Head

301016

301016

17

Spindle Scale

301017

301017

18

Feed Shaft

301018

301018

19

Belt Adjust Handle

301019

301019

20

Wing Bolt (M10 x 35mm L)

301077

301077

21

Road – B

301022

301022

22

Motor Plate

301021

301021

23

Road – A

301020

301020

24

Head

301023

301023

25

Motor

300993

300993

26

Switch

301024

301024

27

Spring & Cap Base

301025

301025

28

Motor Pulley

301026

301026

29

Belt A28

301027

301027

30

Screw (4x)

300998

300998

31

Pulley Cover

301028

301028

32

Insert Pulley Nut

301029

301029

33

Spindle Pully

301030

301030

34

Insert Pulley Shaft

301031

301031

Item No. Part Description TB-16 SB-16

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

19 REV012019

Page 21

Dake Corporation

35

Middle Pulley

301032

301032

36

Screw & Spring (2x)

301033

301033

37

Belt A23

301093

301093

38

Middle Pulley Shaft

301034

301034

39

Bearing 6203Z

300987

300987

40

Bearing 6203Z

300987

300987

41

Table

301035

301035

42

Quill (1.85”)

301036

301036

43

Bearing 6003Z

300988

300988

44

Spindle

301037

301037

45

Arbor

301038

301038

46

Wedge

301039

301039

47

Belt Cover Interlock Switch

300992

300992

48

Plexiglass Chuck Guard

300997

300997

N/A

Chuck (13mm)

301870

301870

N/A

Key (13mm)

301968

301968

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Item No. Part Description TB-16 SB-16

Please contact factory for current prices.

ORDERING INFORMATION

Parts are available for direct purchase from Dake or through a distributor. When placing a parts

order, you will need to provide the part number, name of part, and model number. All parts

shipped F.O.B. Factory in Grand Haven, MI

20 REV012019

Page 22

SB-25 & SB-32:

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

21 REV012019

Page 23

SB-25 & SB-32:

1

Base

301040

301041

2

Flange

301042

301043

3

Spring Washer (4x)

13mm

13mm

4

Screw (M13 x 16mm L)

300999

300999

5

Column

301044

301045

6

Rack

301047

301046

7

Handle

301048

301048

8

Clamp Bolt

301049

301049

9

Clamp Bolt

301051

301051

10

Table Arm

301052

301053

11

Table Bracket

301055

301054

12

Worm

301056

301056

13

Collar

301057

301058

14

Feed Handle (3x)

301059

301059

15

Lock Handle

301070

301070

15A

Lock Screw

302818

302818

16

Feed Head

301069

301069

17

Spindle Scale

301071

301072

18

Feed Shaft

301073

301074

19

Belt Adjust Handle

301075

301076

20

Wing Bolt

301077

301078

21

Road – A

301079

301080

22

Motor Plate

301081

301081

23

Road – B

301082

301083

24

Head

301060

301084

25

Spring Base

N/A

N/A

26

Switch

301061

301062

27

Spring & Cap

301063

301064

28

Motor Pulley

301065

301065

29

Belt

301066

301066

30

Screw (4x)

300998

300998

31

Pulley Cover

301067

301068

32

Insert Pulley Nut

301085

301086

33

Spindle Pulley

301088

301087

34

Insert Pulley Shaft

302218

302217

Item No. Part Description SB-25V SB-32V

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

22 REV012019

Page 24

Dake Corporation

35

Middle Pulley

301089

301090

36

Screw & Spring (2x)

301092

301092

37

Belt A23

301093

301093

38

Middle Pulley Shaft

301094

301094

39

Bearing 6203Z

300987

300987

40

Bearing 6203Z

300987

300987

41

Table

301095

301096

42

Quill

301098

301097

43

Bearing

300990

300990

43

Bearing

300989

300989

44

Spindle

301099

301100

45

Arbor

301101

301102

46

Seal

N/A

N/A

47

Wedge

301104

301103

48

Belt Cover Interlock Switch

300992

300992

49

Motor

300996

300994

50

Plexiglass Chuck Guard

300995

300995

N/A

Chuck (16mm)

301966

301966

N/A

Key (16mm)

301967

301967

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Item No. Part Description SB-25V SB-32V

Please contact factory for current prices.

ORDERING INFORMATION

Parts are available for direct purchase from Dake or through a distributor. When placing a parts

order, you will need to provide the part number, name of part, and model number. All parts

shipped F.O.B. Factory in Grand Haven, MI

23 REV012019

Loading...

Loading...