Page 1

USE AND MAINTENANCE MANUAL

SAR 440 SA GDS

01/2006

THOMAS S.p.A. - Via Pasubio, 32 - 36033 Isola Vicentina (VI) - Telephone 0444 / 97.61.05 - Fax 0444 / 97.69.34

Registro Imprese n. 4272//VI116 REA n. 93906/Vicenza

Page 2

Contents

SAR 440 SA GDS

Contents........................................................................... " 2

Ordering spare parts........................................................" 2

Guarantee ........................................................................" 2

Machine certification and identification marking............." 3

CHAPTER 1

Reference to accident-prevention regulations .................." 4

1.1 - Advice for the operator ............................................. " 4

1.2 - Location of shields against accidental contact with

the tool..................................................................... " 4

1.3 - Electrical equipment according to European

Standard "CENELEC EN 60 204-1"............................ " 4

1.4 - Emergencies according to European Standard

"CENELEC EN 60 204-1" .........................................." 4

CHAPTER 2

Recommendations and advice for use .............................." 4

2.1 - Recommendations and advice for using the machine........ " 4

CHAPTER 3

Technical characteristics ................................................." 5

3.1 - Table of cutting capacity and technical details ............" 5

CHAPTER 4

Machine dimensions - Transport - Installation

Dismantling ...................................................................... " 5

4.1 - Machine dimensions ................................................. " 5

4.2 - Transport and handling of the machine ....................." 6

4.3 - Minimum requirements for the premises

housing the machine................................................. " 6

4.4 - Anchorage of standard machine ..............................." 6

4.5 - Instructions for electrical connection ........................." 6

4.6 - Instructions for assembly of the loose parts and

accessories .............................................................." 6

4.7 - Disactivating the machine ........................................." 6

4.8 - Dismantling .............................................................." 6

CHAPTER 5

Machine functional parts.................................................." 7

5.1 - Operating head or saw frame ...................................." 7

5.2 - Vice.........................................................................." 7

5.3 - B e d .......................................................................... " 7

CHAPTER 6

Description of the operating cycle ...................................." 8

6.1 - Starting up and cutting cycle ..................................... " 8

CHAPTER 7

Regulating the machine ...................................................." 9

7.1 - Blade tension assembly...........................................“ 10

7.2 - Blade guide blocks .................................................. “ 10

7.3 - Vice ......................................................................... “ 11

7.4 - Regulating the cutting angle .....................................“ 11

7.5 - Blade-cleaning brush ...............................................“ 11

7.6 - Regulating the height of the cut ................................ “ 11

7.7 - Regulating the cutting speed ...................................." 11

7.8 - Changing the blade .................................................." 12

CHAPTER 8

Routine and special maintenance................................. " 12

8.1 - Daily maintenance ..................................................." 12

8.2 - Weekly maintenance ..............................................." 12

8.3 - Monthly maintenance ..............................................." 12

8.4 - Six-monthly maintenance......................................... " 12

8.5 - Oils for lubricating coolant........................................ " 12

8.6 -Oil disposal ................................................................" 12

8.7 - Special maintenance................................................" 12

CHAPTER 9

Material classification and choice of tool ..................... " 13

9.1 - Definition of materials............................................... " 13

9.2 - Selecting blade ........................................................ " 13

9.3 - T eeth pitch ............................................................... " 13

9.4 - Cutting and advance speed ....................................." 14

9.5 - Blade running-in ....................................................... " 14

9.6 - Blade structure ........................................................" 14

9.7 - Blade type ............................................................... " 14

T eeth shape and angle............................................. " 14

Set..........................................................................." 15

9.7.1 - T a ble of recommended cutting parameters ................... " 15

CHAPTER 10

Machine components .................................................... " 16

10.1- List of spare parts .................................................... " 16

CHAPTER 11

Wiring diagrams ............................................................ " 21

Schema elettrico idraulico ............................................ " 23

CHAPTER 12

T roub leshooting ............................................................ " 24

12.1- Blade and cutting diagnosis ..................................... " 24

12.2- Electrical components diagnosis.............................. " 28

CHAPTER 13

Noise tests ..................................................................... " 28

Plates and labels............................................................ " 29

Ordering spare parts

- When ordering spare parts you must state:

MACHINE MODEL

SERIAL NUMBER

PART REFERENCE NUMBER

Without these references WE WILL NOT SUPPLY the spares. See point 10.1 - list of spare parts -

Guarantee

- The Company guarantees that the machine to which this manual refers has been designed and built to comply with safety regulations and

that it has been tested for functionality in the factory.

- The machine is guaranteed for 12 months: the guarantee does not cover the electric motors, electric components, pneumatic components

or any damage due to dropping or to bad machine management, the failure to observe maintenance standards or bad handling by the

operator.

- The buyer has only the right to replacement of the faulty parts, while transport and packing costs are at his expense.

- The serial number on the machine is a primary reference for the guarantee, for after-sales assistance and for identifying the machine for any

necessity.

2

Page 3

Machine certification and identification marking

MACHINE LABEL

via Pasubio, 32 36033 ISOLA VIC. - ITALIA

SAR 440 SA GDS

MODEL

TYP

SERIAL NUMBER

YEAR OF MANUFACTURE

SAR

440 SA GDS

(Space reserved for the NAME and STAMP of the DEALER and/or IMPORTER)

3

Page 4

SAR 440 SA GDS

REFERENCE TO ACCIDENT - PREVENTION REGULATIONS

1

This machine has been built to comply with the national and community accident-prevention regulations in force. Improper use

and/or tampering with the safety devices will relieve the manufacturer of all responsibility.

1.1 - Advice for the operator

- Check that the voltage indicated on the plate, normally fixed to the machine motor, is the same as the line voltage.

- Check the efficiency of your electric supply and earthing system; connect the power cable of the machine to the socket and the earth

lead yellow-green in colour) to the earthing system.

- When the saw frame is in suspend mode (up) the toothed blade must not move.

- Only the blade section used for cutting must be kept unprotected. Remove guarding by operating on the adjustable head.

- It is forbidden to work on the machine without its shields (these are all blue or grey in colour).

- Always disconnect the machine from the power socket before blade change or carrying out any maintenance job, even in the case

of abnormal machine operation.

- Always wear suitable eye protection.

- Never put your hands or arms into the cutting area while the machine is operating.

- Do not wear loose clothing with sleeves that are too long, gloves that are too big, bracelets, chains or any other object that could get

caught in the machine during operation; tie back long hair.

- Keep the area free of equipment, tools or any other object.

- Perform only one operation at a time and never have several objects in your hands at the same time. Keep your hands as clean as

possible.

- All internal and/or internal operations, maintenance or repairs, must be performed in a well-lit area or where there is sufficient light

from extra sources so as to avoid the risk of even slight accidents.

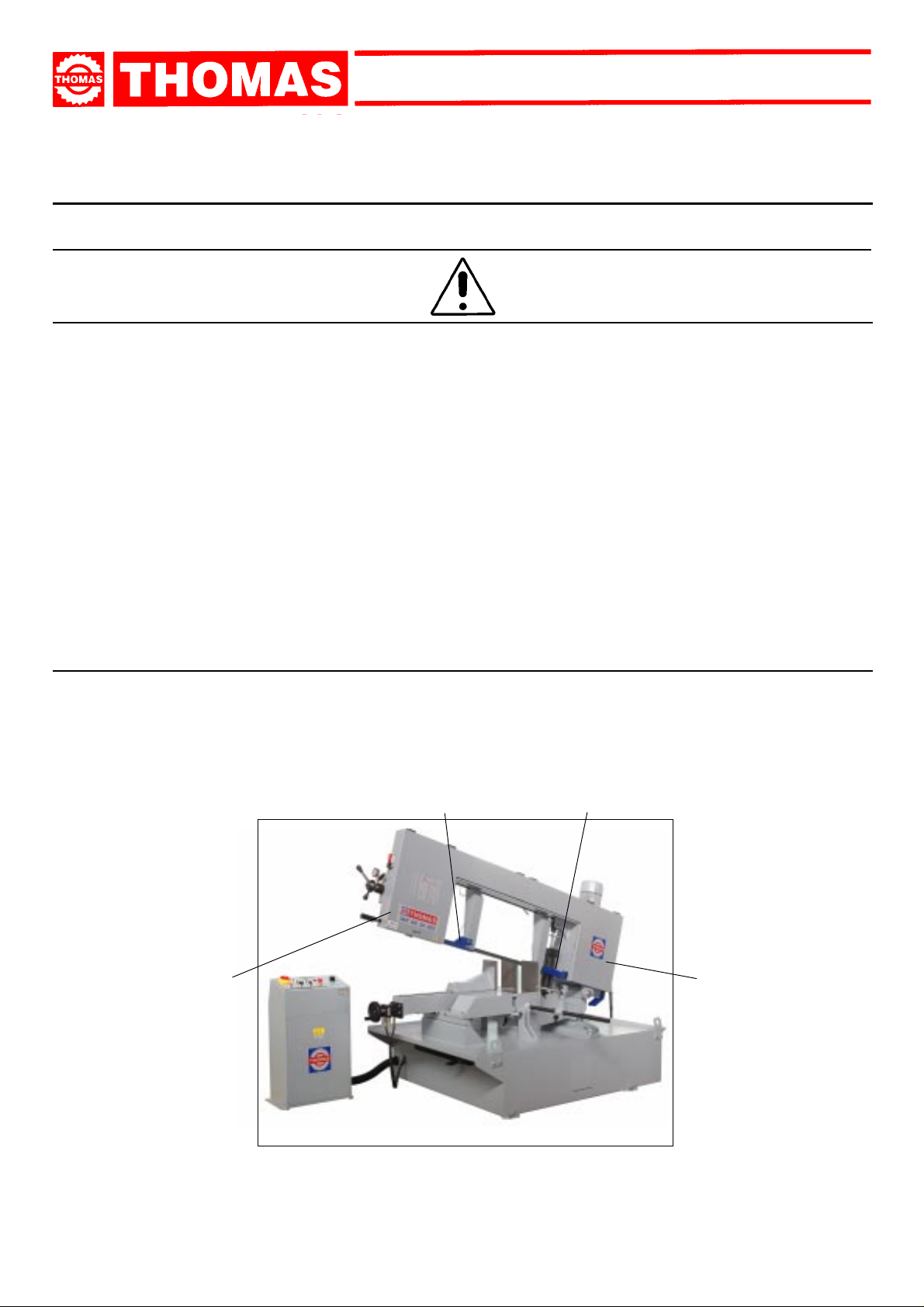

1.2 - Location of shields against accidental contact with the tool

- Blue or grey metal shield fixed frontally with screws to the fixed blade-guiding block ( Ref. A ).

- Blue or grey metal shield fastened on the front with screws onto the blade guide adjustable head to ensure maximum covering of

blade and piece to be cut ( Ref. B ).

- Grey metal guards fastened to the saw frame with knobs, protecting the blade driving flywheels ( Ref. C ).

B

C

A

C

4

Page 5

SAR 440 SA GDS

1.3 - Electrical equipment according to European Standard "CENELEC EN 60 204-1" which assimilates,

with some integrating modifications, the publication "IEC 204-1"

- The electrical equipment ensures protection against electric shock as a result of direct or indirect contact. The active parts of this

equipment are housed in a box to which access is limited by screws that can only be removed with a special tool; the parts are fed

with alternating current at low voltage (24 V). The equipment is protected against splashes of water and dust.

- Protection of the system against short circuits is ensured by means of rapid fuses and earthing; in the event of motor overload,

protection is provided by a thermal relay.

- In the event of a power cut, the specific start-up button must be reset.

- The machine has been tested in conformity with point 20 of EN 60204.

1.4 - Emergencies according to European Standard "CENELEC EN 60 204-1"

- In the event of incorrect operation or of danger conditions, the machine may be stopped immediately by pressing the red mushroom button.

- The casual or voluntary removal of the protection shield of the flywheels causes the stepping-in of a microswitch that automatically

stops all machine functions.

- In case blade breaks, the band tightening microswitch/pressure switch disconnects all machine.

NOTE:Resetting of machine operation after each emergency stop is achieved by reactivating the specific restart button.

RECOMMENDATIONS AND ADVICE FOR USE

2

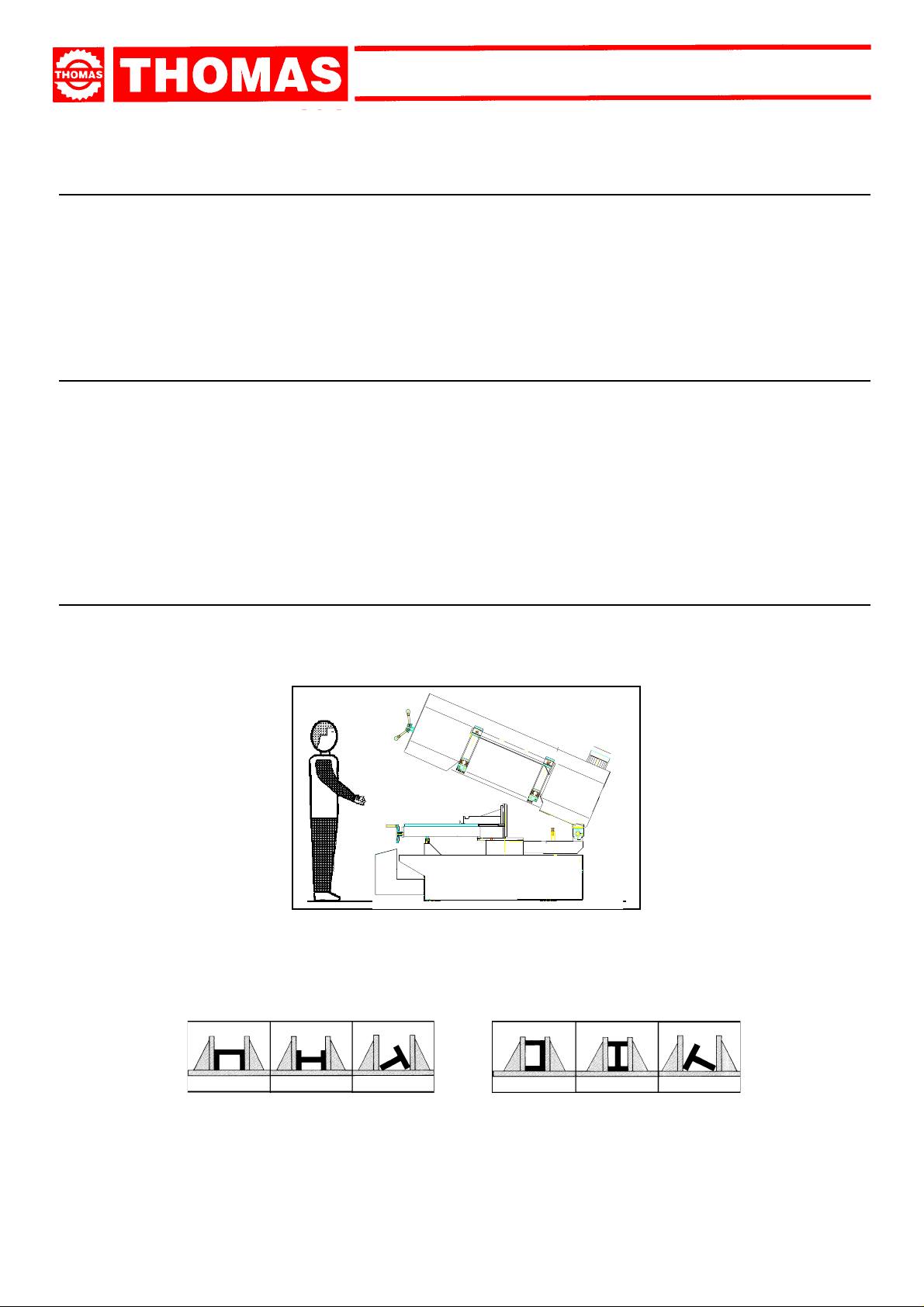

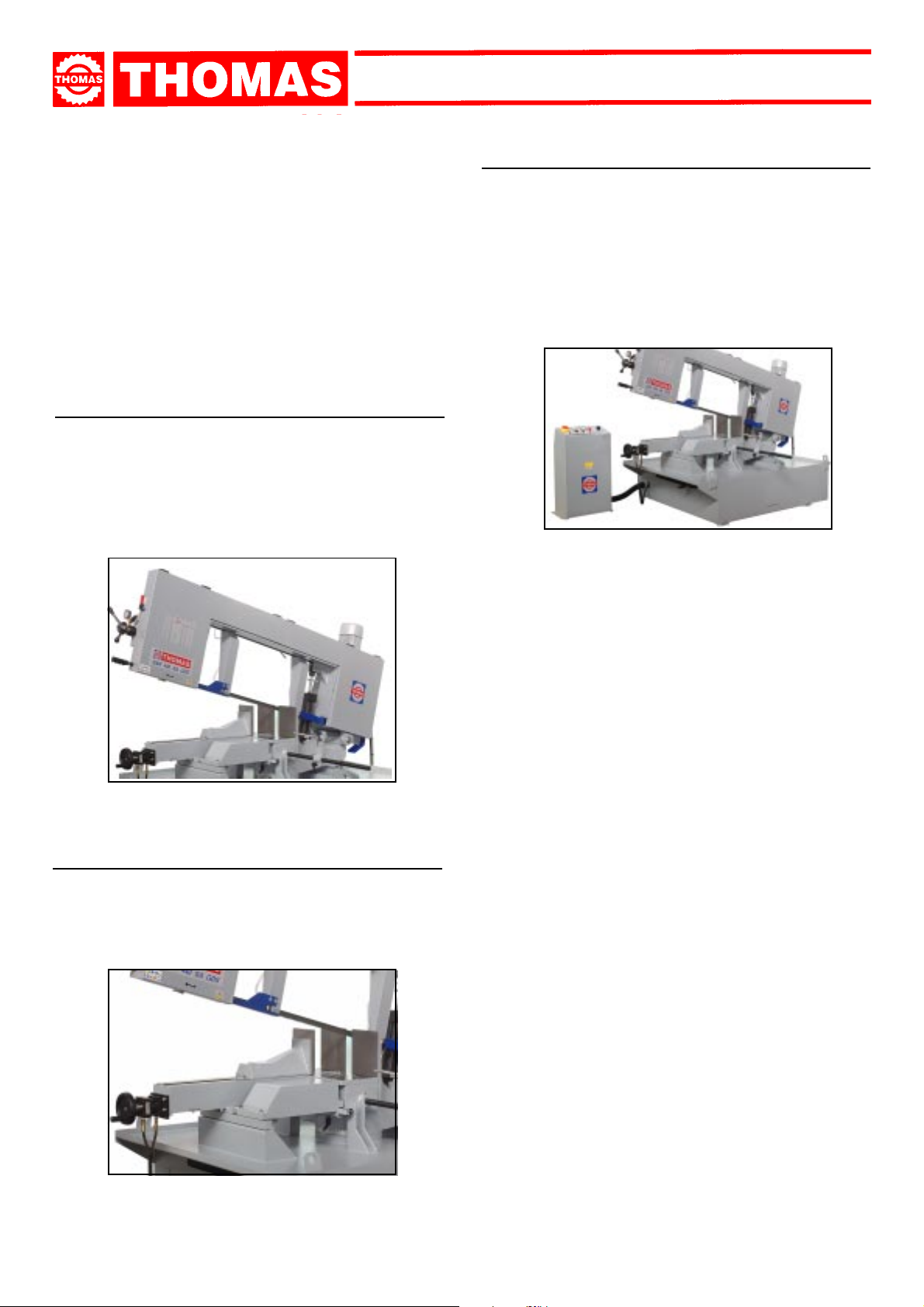

2.1 - Recommendations and advice for using the machine

- The machine has been designed to cut metal building materials, with different shapes and profiles, used in workshops, turner’s

shops and general mechanical structural work.

- Only one operator is needed to use the machine, that must stand as shown in the picture.

- Before starting each cutting operation, ensure that the part is firmly gripped in the vice and that the end is suitably supported.

These figures show examples of suitable clamping of different section bars, bearing in mind the cutting capacities of the machine in

order to achieve a good efficiency and blade durability.

- Do not use blades of a different size from those stated in the machine specifications.

- If the blade gets stuck in the cut, release the running button immediately, switch off the machine, open the vice slowly, remove the

part and check that the blade or its teeth are not broken. If they are broken, change the tool.

- Check saw frame return spring to ensure proper balancing.

- Before carrying out any repairs on the machine, consult the dealer or apply to THOMAS.

5

Page 6

SAR 440 SA GDS

TECHNICAL

3

CHARACTERISTICS

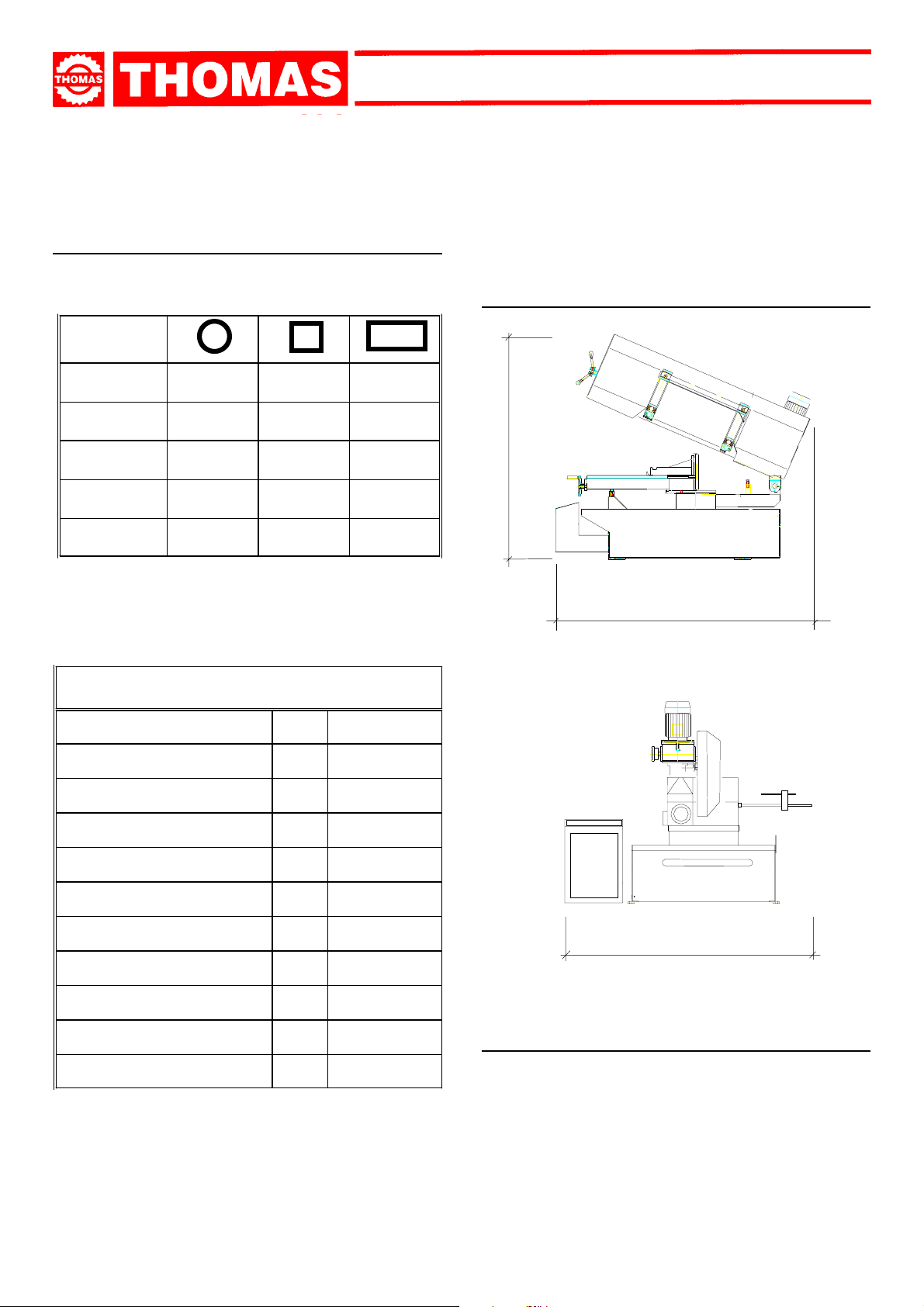

3.1 - Table of cutting capacity and technical details

0° 440 440 610 x 440

45° DX 440 440 500 x 230

45° SX 440 440 500 x 230

60° DX 320 300 320 x 245

60° SX 340 320 340 x 250

MACHINE DIMENSIONS

TRANSPORT

4

INSTALLATION

DISMANTLING

4.1 - Machine dimensions

2500

TE CHNICAL DATA

ELECTRIC MOTOR - 3-PHASE

HYDRA ULIC PUMP MOTOR

COOLANT PUMP MOTOR

FLYWHEEL Ø

BLADE DIMENSIONS

VARIABLE BLADE SPEED

VICE OPENING

SAW F RAME INCL INA TION

WORKING TA BLE HEIGHT

MA CHINE DIME NS IONS

kW 2,2

kW 1,1

kW 0,18

mm 455

mm 5200 x 34 x 1,1

m/min 28 ÷ 140

mm 615

°0

mm 750

mm 2500x 3000x2500

3000

2400

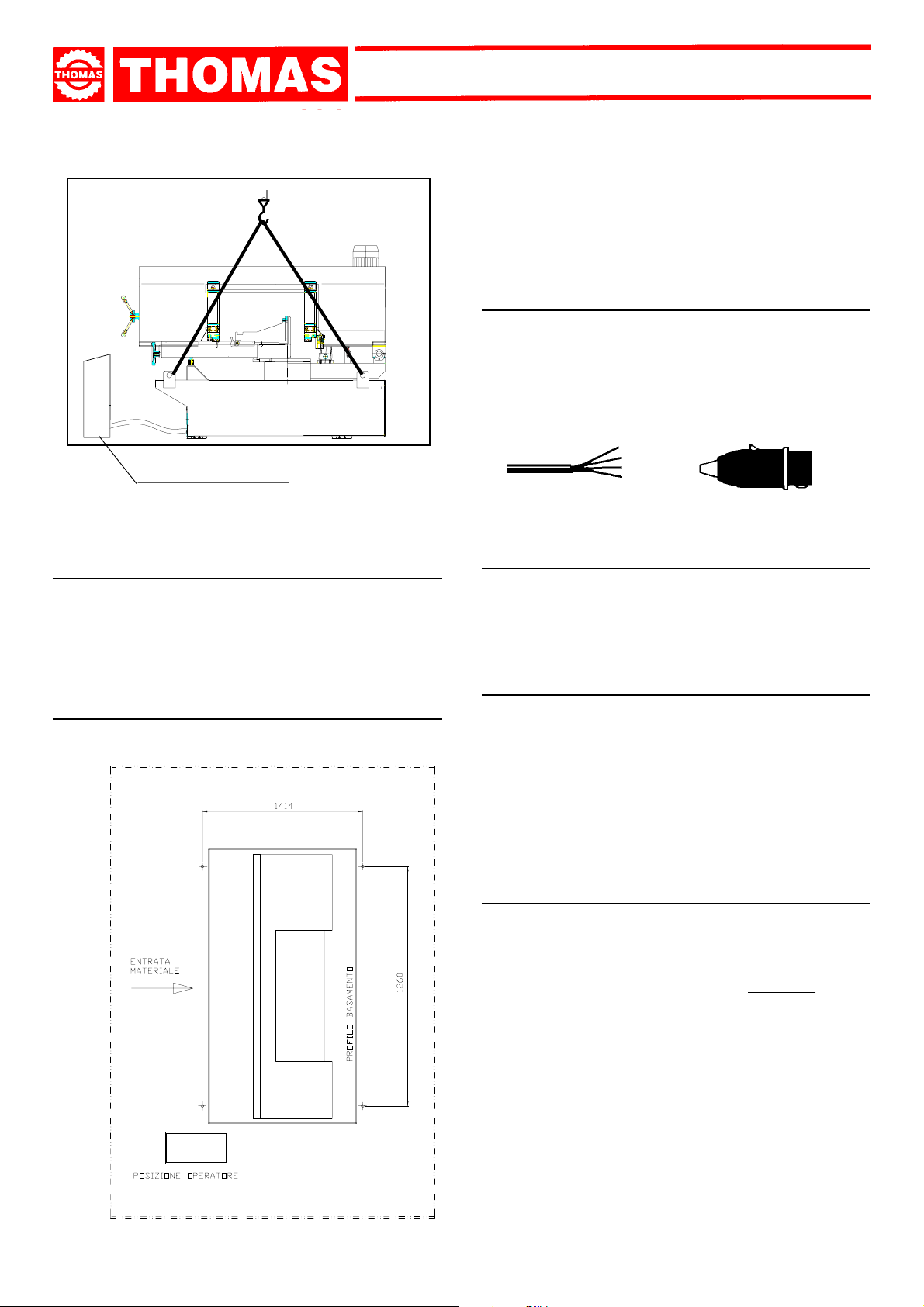

4.2 - Transport and handling of the machine

MACHINE WE IG HT

6

Kg 1570

In case of transportation in its own packing, use a fork-lift truck.

Sling the machine with special straps as illustrated making

sure that the control panel has been securely placed on the

machine base

Page 7

QUADRO ELETTRICO

SAR 440 SA GDS

- Position the machine on a firm cement floor, maintaining, at the

rear, a minimum distance of 1000 mm from the wall; anchor it to

the ground as shown in the diagram, using screws and expansion

plugs or tie rods sunk in cement, ensuring that it is sitting level.

4.5 - Instructions for electrical connection

- The machine is not provided with an electric plug, so the customer

must fit a suitable one for his own working conditions:

1 - WIRING DIAGRAM FOR 4-WIRE SYSTEM FOR THREE-

PHASE MACHINE - SOCKET FOR A 16A PLUG

R = L1

S = L2

T = L3

PE = GND

4.3 - Minimum requirements for the premises

housing the machine

- Mains voltage and frequency complying with the machine motor

characteristics.

- Environment temperature from -10 °C to +50 °C.

- Relative humidity not over 90%.

4.4 - Anchorage of standard machine

INGOMBRO OPERATIVO = mm 2400

INGOMBRO OPERATIVO = mm 3000

4.6 - Instructions for assembly of the loose parts and

accessories

Fit the components supplied as indicated in the photo:

- Mount the stock stop.

- Mount the coolant liquid holder.

4.7 - Disactivating the machine

- If the sawing machine is to be out of use for a long period, it is

advisable to proceed as follows:

1) detach the plug from the electric supply panel

2) loosen blade

3)empty the coolant tank

4)carefully clean and grease the machine

5)if necessary, co ver the machine .

4.8 - Dismantling

(because of deterioration and/or obsolescence)

General rules

If the machine is to be permanently demolished and/or scrapped,

divide the material to be disposed of according to type and composition, as follows:

1) Cast iron or ferrous materials, composed of

ondary raw materials, so they may be taken to an iron foundry

for re-smelting after having removed the contents (classified in

point 3);

2) electrical components, including the cable and electronic ma-terial

(magnetic cards, etc.), fall within the category of material classified as being assimilable to urban waste according to the laws of

the European community, so they may be set aside for collection

by the public waste disposal service;

3) old mineral and synthetic and/or mixed oils, emulsified oils and

greases are special refuse, so they must be collected, transported

and subsequently disposed of by the old oil disposal service.

metal alone, are sec-

NOTE:since standards and legislation concerning refuse in gen-

7

Page 8

SAR 440 SA GDS

eral is in a state of continuous evolution and therefore

subject to changes and variations, the user must keep

informed of the regulations in force at the time of disposing

of the machine tool, as these may differ from those

described above, which are to be considered as a general

guide line.

MACHINE FUNCTIONAL

5

PARTS

5.1 - Operating head or saw frame

- Machine part consisting of the members that transfer the motion

(gearmotor, flywheels), the tightening/guiding (blade guide arms,

blade tightening slide) and the tool lowering control.

5.3 - Bed

- Structure supporting the HEAD OR SAW FRAME, the VICE, the

SWIVEL DEVICE with relative locking system, the ELECTRICALS,

the BAR STOP and housing the coolant TANK for cut and pump.

5.2 - Vice

- Hydrailic locking system for cutting material. This de vice allows

for the quick shifting of the vice and the possibility to cut

inclinations to the left and right.

8

Page 9

SAR 440 SA GDS

DESCRIPTION OF THE

6

OPERATING CYCLE

Before operating, all the main organs of the machine must be

set in optimum conditions (see the chapter on “Regulating the

machine”).

6.1 - Getting started

DESCRIPTION OF THE CUTTING PROCESS:

- Start the cutting cycle

- Automatic closure of the vice;

- Lowering of the sawframe ( blade );

- Lifting of the sawframe ( using selector );

- Opening of the vice.

PRELIMINARY OPERATIONS:

- Ensure that the machine is not on emergency stop; in which case

free the red, mushroom shaped, button ( 1 ) on the panel of commands.

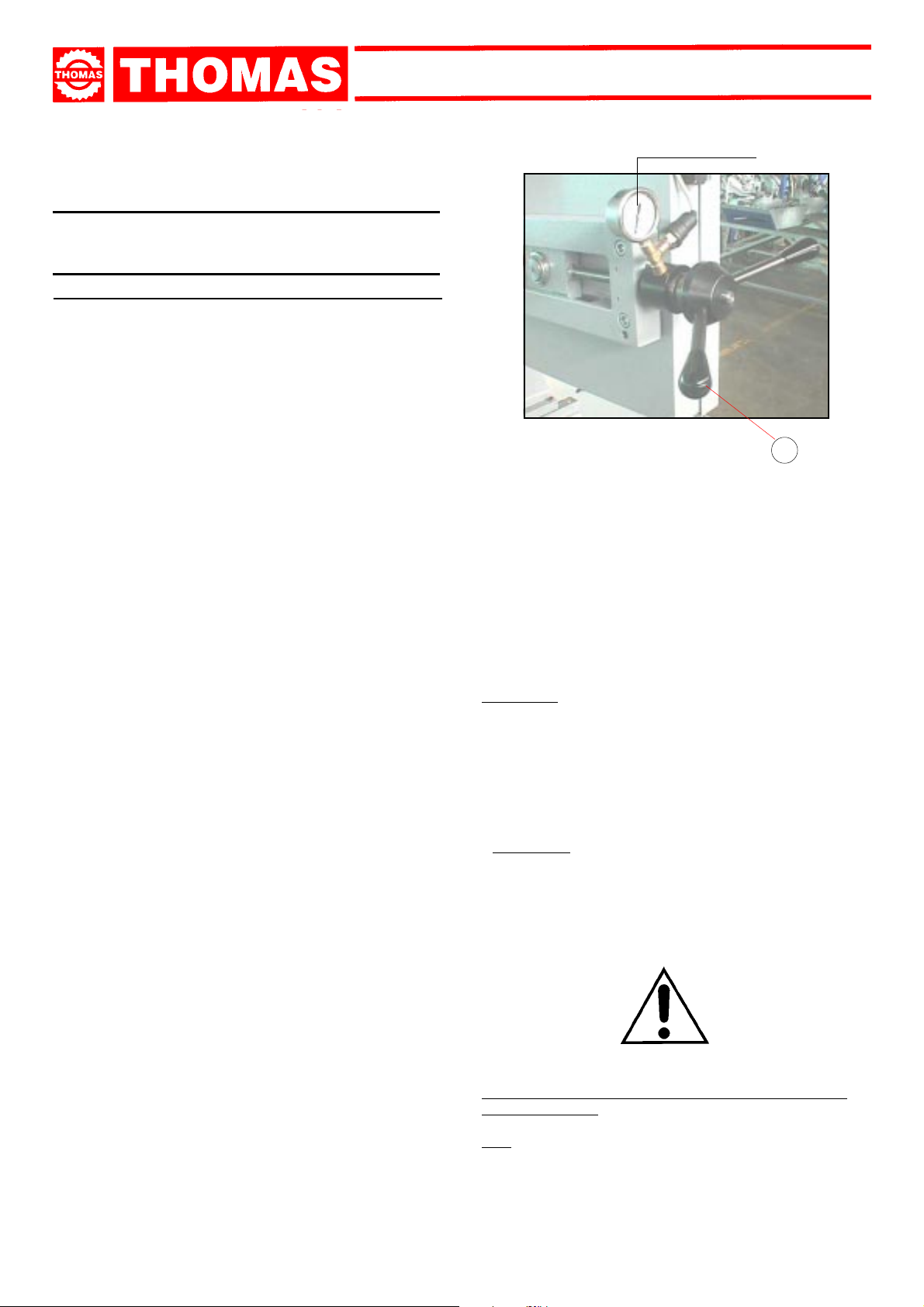

- Rotate the blade tension handwheel ( 8 ) until the blade tension

pressure reaches 160 Bars.

- Rotate the main switch ( 2 ) in position 1.

- Press the illuminated button ( 3 ) and ensure that the relative

light is lit.

- Rotate the selector ( 5 ) to activate the lifting of the sawframe.

N.B.: if the lifting process does not occur, invert the electric

alimentation phase ( this operation is only to be done during installation ).

Service pressure of the hydraulic unit should be approx. 50

BAR.

WARNING: always ensure that the vice is positioned to the

extreme left or right of the counter vice to avoid accidental

contact with the structure of the sawframe.

- Turn selector ( 9 ) to open the vice.

160 BAR

8

- Activate the hand wheel of the gear and set the speed control

to suit the characteristics of the material to be cut. ( do not

regulate when the motor is off ).

To regulate the desired speed refer to the plaque .

- In case of a wrong manoeuvre or to stop the cutting cycle,

press the STOP button ( 10 ).

- At the end of the cutting cycle, the sawframe will stop in the

inferior position. Rotate the selector ( 5 ) to activate the lifting of

the sawframe.

- Turn selector ( 9 ) to open the vice.

ATTENTION:

- The cutting cycle can be executed even if the selector ( 9 ) has

been switched for the open vice.

In fact, as you press START ( 3 ) the vice will close automatically .

To open the vice again you will have to turn the selector ( 9 )

first to close the vice and then to open the vice.

- Once the cut has been executed the hydraulic pump will keep

running for 20 seconds.

- Position the vice according to the dimension of the material to

cut.

- Put the material to be cut in the vice, and approach the vice

jaw up to 3 - 4 mm with the handwheel.

- Ensuring that the latch is in place on the rack.

- Load the material to cut at the required cutting length and turn

the selector ( 9 ) to lock the material in the vice.

- Bring the mobile blade guiding arm as close as possible to

the object to be cut.

- Ensure that the cutting index correspond with the inclination

desired and that the device is blocked.

- Before starting the cutting process, it is advisable to advance

the blade to more or less 10 mm from the object to be cut,

pressing, if necessary, selector ( 5 ).

- Press regulator ( 6 ) to the ideal cutting speed to suit the

characteristics of the material. It is recommend that one always

start off slowly, increasing the speed if necessary.

- Press button ( 4 ) to initiate the cutting cycle: control that the

blade turns in the correct direction and that the cooling liquid

flows sufficiently.

ATTENTION: Soon after the automatic shut off of the hydraulic

pump, press the button ( 4 ) to open the vice automatically if

the selector ( 9 ) was switched to vice open during the cutting

phase.

Note: It is recommend not to use the saw to its maximum

capacity for the first 50 working hours.

It is absolutely forbidden to approach the hands to

the cutting area.

Note: for a proper lubrication and cooling during the cut, we

recommend to use a mixture of 9 parts of water and one of oil.

9

Page 10

SAR 440 SA GDS

10

2

1

4

3

5

9

1

6

10

nim/m

F

EROTAIRAVONITNALOV

DNAH-ROTAIRAV

LEEHW

°N.SOP

DEEPSGNITTUC

89 01112131415161718191021222324252627282

OILGATID'ATICOLEV

5.72235.635.14641565165.66275.77389859101701311021721331041

Page 11

SAR 440 SA GDS

- the CUTTING SPEED and the TYPE of BLADE - combined

with a suitable lowering of saw frame - are of decisive importance for cutting quality and for machine performance (for

further details on this topic, see below in the chapter on “Mate-

rial classification and blade selection”).

- When starting to cut with a new blade, in order to safeguard its

life and efficiency, the first two or three cuts must be made

while exerting a slight pressure on the part, so that the time

taken to cut is about double the normal time (see below in the

chapter on “Material classification and blade selection” in the

section on

- Press the red emergency button ( 1 ) when there are conditions of

danger or malfunctions in general, so as to stop machine operation immediately.

CUTTING DIRECTION

Blade running-in

).

7.2 - Blade-guide head

Blade guiding is obtained by means of plates which are regulated

during the testing phase according to blade thickness.

B

A

A

REGULATING

7

THE MACHINE

7.1 - Blade tension assembly

The ideal blade tension is obtained by rotating the hand wheel belt

tensioner until the blade tension pressure reaches 160 Bars

otherwise the saw will not operate.

N.B.: when the saw is not in use it is recommend to loosen the

blade tension.

It is always recommend to use the blade sizes suggested in

this manual.

160 BAR

8

AB

C

When replacing a blade, ensure that the belts are 1,1 mm thick as

the guiding blade pads have been adjusted to this size. If using

different size toothed belts, it will be necessary to proceed with a

new registration as follows:

- Loosen the screws ( B ) and loosen dowels (A ) widening the

passage between the plates.

- Loosen the dowels ( C ) and rotate the pins to widen the passage

between the bearings.

- Mount the new blade and rotate the hand wheel belt tensioner

until the relative dip-switch is activated.

- Tighten the dowels ( A ) and then loosen them to allow a play of

0,04 mm to ensure the smooth running of the blade and fasten

the screws ( B ).

- Rotate the pins until the bearings rest on the blade and block the

screws ( C ).

- Ensure that between the blade and the superior bearings there

are 0,2 - 0,3 mm of play; if necessary, loosen the screws ( D )

that block the heads and execute the necessary registration.

11

Page 12

SAR 440 SA GDS

7.3 - Vice

-- The rapid advancement of the vice to the object to be cut is

obtained by manually moving the vice and lifting the latch ( F ).

Before blocking the object to be cut with the hand wheel check

that the latch is gripped to the rack.

- The vice unit can be positioned to the left or right of the blade.

Ensure that this positioning has been executed correctly in order

to avoid irreparab le damage to the saw .

- It is recommended to keep the vice guide and ribbon clean and

oiled at all times.

F

7.5 - Blade-cleaning brush

Ideal for the cleaning of the blade during its cutting cycle.

Periodically check the integrity of the brush and if necessary

proceed to an ulterior regulation to guarantee cleansing of

the blade.

7.6 - Regulating the height of the cut

It is an accessory that permits the execution of lifting and/or nearing of the arch.

- Operate the selector button ( H ) to move the arch up and

down to the desired position.

1

H

6

7.4 - Regulating the cutting angle

- Lift the sawframe.

- Operate the Lever ( G ) to release the rotation of the device.

- Rotate the sawframe to the desired angle referring to the

graduated sector.

- Tighten the lever ( G ) to block the device from rotating.

7.7 - Regulating the cutting speed

Regulation of the cutting speed can only be done with the motorbelt in motion.

T o change the running speed, adjust with hand wheel and refer to

the plaque.

V

TABELLA LUBRIFICANTI

COMPONENTE

PART.

LUBRIFICANTE

OIL TYPE

QUANTITA'

KG

12

G

INDICE

RIDUT T ORE

REDUCT OR

VARIATORE

VARIATOR

SHELL

TIVELA S320

SHELL

DO NAX T A

1,6

1,2

Page 13

SAR 440 SA GDS

BEFORE PERFORMING THE FOLLOWING OPERATIONS,

THE ELECTRIC POWER SUPPLY AND THE POWER CABLE

MUST BE COMPLETELY DISCONNECTED.

7.8 – Replacing the blade

- Lift the sawframe in upright position.

- Loosen the blade with the hand wheel, remove the shield of the

mobile blade guide and the shield of the belt cleaning brush.

- Open the posterior and anterior carter flywheels and extract the

old blade from the flywheels and from the blade guide blocks.

- Insert the new blade inserting it between the plaques and then

on the flywheel holder, taking note of the direction of the teeth in

respect to the direction of the cut (refer to diagram below).

- Replace the tension of the blade checking that it is housed

perfectly within the flywheels.

- Re-assemble the shields of the mobile guide blade and of the

belt cleaning brush and close the carter flywheels cover, checking

that the safety dip-switch is activated otherwise the machine will

not operate when it is switched on.

WARNING: alwa ys use blades having dimensions spcified

in this manual and for which the blade guide heads have

been set: otherwise, see chapter on "Description of the

operating cycle" in the section Starting-up..

CUTTING DIRECTION

8.2 - Weekl y maintenance

- More accurate general cleaning of the machine to remove shavings, especially from the lubricant fluid tank.

- Removal of pump from its housing, cleaning of the suction filter

and suction zone.

- Clean the filter of the pump suction head and the suction

area.

- Cleaning with compressed air of blade guide arms (guide bearings, pads and drain hole of the lubricating cooling).

- Cleaning flywheel housings and blade sliding surfaces on flywheels.

- Check condition of the blade cleaning brushes.

- Greasing of motor flywheel bearings.

8.3 - Monthly maintenance

- Check the tightening of the motor flywheel screws.

- Check that the blade guide bearings on arms are perfect running

condition.

- Check the tightening of the screws of the gearmotor, pump and

accident protection guarding.

8.4 - Six-monthly maintenance

REDUCTION UNIT

-

we suggest to make the first oil replacement after about 300

working hours and wash internal parts carefully.

Use synthetic oil SHELL TIVELA OIL 320 type or equiv alent.

-

The following oil replacement should be made after about 2000

working hours.

V ARIATOR UNIT

-

Make the oil replacement after about 2000 working hours using

the SHELL DONAX TA type or equivalent.

PROBABLE REPLACEMENT OF OTHER PARTS –

REDUCTION GEAR OR SPEED CONTROL, MOTOR PUMP

AND ELECTRICAL COMPONENTS – TO BE EXECUTED BY

SPECIALISED AND COMPETENT PERSONNEL.

ROUTINE

AND SPECIAL

8

MAINTENANCE

THE MAINTENANCE JOBS ARE LISTED BELOW, DIVIDED INTO

DAILY, WEEKLY, MONTHLY AND SIX-MONTHLY INTERVALS. IF

THE FOLLOWING OPERATIONS ARE NEGLECTED, THE RESULT

WILL BE PREMATURE WEAR OF THE MACHINE AND POOR

PERFORMANCE.

8.1 - Daily maintenance

- General cleaning of the machine to remove accumulated shavings.

- Clean the lubricating coolant drain hole to avoid excess fluid.

- Top up the level of lubricating coolant.

- Check blade for wear.

- Rise of saw frame to top position and partial slackening of the

blade to avoid useless yield stress.

- Check functionality of the shields and emergency stops.

WARNING : absolutely do not mix synthetic oil and mineral oil.

Replace the oil in the hydraulic unit ad least once a year using

SHELL HYDRAULIC OIL 32 type or equiv alent.

- The saw with the ascending arch device, a complete oil change

is advisable once a year using SHELL HYDRAULIC OIL 32 or

similar.

- Continuity test of the equipotential protection circuit.

8.5 - Oils for lubricating coolant

Considering the vast range of products on the market, the user

can choose the one most suited to his own requirements, using as

reference the type SHELL LUTEM OIL ECO.

THE MINIMUM PERCENTAGE OF OIL DILUTED IN W ATER IS

8 - 10 %.

8.6 - Oil disposal

The disposal of these products is controlled by strict regulations.

Please see the Chapter on “Machine dimensions - Transport - In-

stallation” in the section on

Dismantling

.

8.7 - Special maintenance

Special maintenance operations must be carried out by skilled personnel.

However, we advise contacting THOMAS or their dealer and/or importer. Also the reset of protective and safety equipment and devices, of the reducer, the motor, the motor pump and electric components is to be considered extraordinary maintenance.

13

Page 14

SAR 440 SA GDS

MATERIAL

CLASSIFICATION AND

9

CHOICE OF TOOL

Since the aim is to obtain excellent cutting quality, the various

parameters such as hardness of the material, shape and thick-

ness, transverse cutting section of the part to be cut, selec-

tion of the type of cutting blade, cutting speed and control of

saw frame lowering.These specifications must therefore be har-

moniously combined in a single operating condition according to

practical considerations and common sense, so as to achieve

an optimum condition that does not require countless operations to prepare the machine when there are many variations in

the job to be performed.The various problems that crop up from

time to time will be solved more easily if the operator has a good

knoledge of these specifications.

WE THEREFORE RECOMMEND YOU TO ALWAYS USE

GENUINE SP ARE BLADES THAT GUARANTEE SUPERIOR

QUALITY AND PERFORMANCE.

9.1 - Definition of materials

The table at the foot of the page lists the characteristics of the materials to be cut, so as to choose the right tool to use.

9.2 - Selecting blade

be cut, according to these criteria:

- parts with a thin and/or variable section such as profiles, pipes

and plate, need close toothing, so that the number of teeth used

simultaneously in cutting is from 3 to 6;

- parts with large transverse sections and solid sections need widely

spaced toothing to allow for the greater volume of the shavings

and better tooth penetration;

- parts made of soft material or plastic (light alloys, mild bronze,

teflon, wood, etc.) also require widely spaced toothing;

- pieces cut in bundles require combo tooth design.

9.3 - Teeth pitch

As already stated, this depends on the following factors:

- hardness of the material

- dimensions of the section

- thickness of the wall.

BLADE TEETH SELECTION TABLE

THICKNESS MM

TILL 1.5 14 10/14

FROM 1 TO 2 8 8/12

FROM 2 TO 3 6 6/10

FROM 3 TO 5 6 5/8

FROM 4 TO 6 6 4/6

MORE THAN 6 4 4/6

Z CONTINUOUS

TOOTH DESIGN

Z COMBO

TOOTH DESIGN

First of all the pitch of the teeth must be chosen, in the other words,

the number of teeth per inch (25,4 mm) suitable for thematerial to

TYPES OF STEEL CHARACTERISTICS

USE

Construction

steels

Carbon

steels

Spring

steels

Alloyed steels for

hardening and

tempering and for

nitriding

Alloyed

casehardening

steels

Alloyed for

bearings

Tool steel

Stainless

steels

Copper alloys

Special brass

Bronze

Cast iron

I

UNI

Fe360

Fe430

Fe510

C20

C40

C50

C60

50CrV4

60SiCr8

35CrMo4

39NiCrMo4

41CrAlMo7

18NiCrMo7

20NiCrMo2

100Cr6 100Cr6 100C6 534 A 99 52100 207 95 690÷980

52NiCrMoKU

C100KU

X210Cr13KU

58SiMo8KU

X12Cr13

X5CrNi1810

X8CrNi1910

X8CrNiMo1713

Aluminium copper alloy G-CuAl11Fe4Ni4 UNI 5275

Special manganese/silicon brass G-CuZn36Si1Pb1 UNI5038

Manganese bronze SAE43 - SAE430

Phosphor bronze G-CuSn12 UNI 7013/2a

Gray pig iron G25

Spheroidal graphite cast iron GS600

Malleable cast iron W40-05

56NiCrMoV7C100K

D

DIN

St37

St44

St52

CK20

CK40

CK50

CK60

50CrV4

60SiCr7

34CrMo4

36CrNiMo4

41CrAlMo7

----

21NiCrMo2

C100W1

X210Cr12

----

4001

4301

----

4401

F

AF NOR

E24

E28

E36

XC20

XC42H1

----

XC55

50CV4

----

35CD4

39NCD4

40CADG12

20NCD7

20NCD2

----

----

Z200C12

Y60SC7

----

Z5CN18.09

----

Z6CDN17.12

GB

SB

---43

50

060 A 20

060 A 40

----

060 A 62

735 A 50

----

708 A 37

----

905 M 39

En 325

805 H 20

----

BS 1

BD2-BD3

----

----

304 C 12

----

316 S 16

USA

AISI-SAE

----

----

---1020

1040

1050

1060

6150

9262

4135

9840

---4320

4315

----

S-1

D6-D3

S5

410

304

----

316

S = THICKNESS

Hardness

BRINELL

HB

116

148

180

198

198

202

202

207

224

220

228

232

232

224

244

212

252

244

202

202

202

202

220

140

120

100

212

232

222

Hardness

ROCKWELL

HRB

67

80

88

93

93

94

94

95

98

98

99

100

100

98

102

96

103

102

94

94

94

94

98

77

69

56,5

96

100

98

R=N/mm²

360÷480

430÷560

510÷660

540÷690

700÷840

760÷900

830÷980

1140÷1330

1220÷1400

780÷930

880÷1080

930÷1130

760÷1030

690÷980

800÷1030

710÷980

820÷1060

800÷1030

670÷885

590÷685

540÷685

490÷685

620÷685

375÷440

320÷410

265÷314

245

600

420

14

Page 15

SAR 440 SA GDS

SOLID Ø OR L MM

TILL 30 8

FROM 30 TO 60 6

FROM 40 TO 80 4 4/6

MORE THAN 90 3 3/4

Z CONTINUOUS

TOOTH DESIGN

Ø = DIAMETER L = WIDTH

Z COMBO

TOOTH DESIGN

5/8

4/6

9.4 - Cutting and advance speed

The cutting speed (m/min) and the advance speed (cm2/min = area

travelled by the disk teeth when removing shavings) are limited by

the development of heat close to the tips of the teeth.

- The cutting speed is subordinate to the resistance of the material

(R = N/mm

widest section.

- Too high an advance speed (= lowering of the saw frame) tends to

cause the disk to deviate from the ideal cutting path, producing

non rectilinear cuts on both the vertical and the horizontal plane.

The best combination of these two parameters can be seen directly

examining the chips.

Long spiral-shaped chips indicate ideal cutting.

2

), to its hardness (HRC) and to the dimensions of the

9.7 - Blade type

They differ essentially in their constructive characteristics, such as:

- shape and cutting angle of tooth

- pitch

- set

Shape and angle of tooth

REGULAR TOOTH: 0° rake and constant pitch.

Most common form for transversal or inclined cutting of solid small

and average cross-sections or pipes, in laminated mild steel and

grey iron or general metal.

POSITIVE RAKE TOOTH: 9° - 10° positive rake and constant pitch.

positive

Particular use for crosswise or inclined cuts in solid sections or large

pipes, but above all harder materials (highly alloyed and stainless

steels, special bronze and forge pig).

Very fine or pulverized chips indicate lack of

feed and/or cutting pressure.

Thick and/or blue chips indicate overload of

the blade.

9.5 - Blade running-in

When cutting for the first time, it is good practice to run in the

tool making a series of cuts at a low advance speed

(= 30-35 cm

to the cutting capacity and solid section of normal steel with R =

410-510 N/mm

2

/min on material of average dimensions with respect

2

), generously spraying the cutting area with lu-

bricating coolant.

9.6 - Blade structure

Bi-metal blades are the most commonly used. They consist in a silicon-steel blade backing with electron beam or laser welded high speed

steel (HHS) cutting edge. The type of stocks are classified in M2,

M42, M51 and differ from each other because of their major hardness due to the increasing percentage of Cobalt (Co) and molybdenum (Mo) contained in the metal alloy.

COMBO TOOTH: pitch varies between teeth and consequently varying teeth size and varying gullet depths. Pitch varies between teeth

which ensures a smoother, quieter cut and longer blade life owing to

the lack of vibration.

Another advantage offered in the use of this type of blade in the fact

that with an only blade it is possible to cut a wide range of different

distance between teeth

materials in size and type.

COMBO TOOTH: 9° - 10° positive rake.

positive

This type of blade is the most suitable for the cutting of section bars

and large and thick pipes as well as for the cutting of solid bars at

maximum machine capacity. Available pitches: 3-4/4-6.

15

Page 16

SAR 440 SA GDS

Set

Saw teeth bent out of the plane of the saw body, resulting in a wide

cut in the workpiece.

REGULAR OR RAKER SET: Cutting teeth right and left, alternated

by a straight tooth.

Of general use for materials with dimensions superior to 5 mm. Used

for the cutting of steel, castings and hard nonferrous materials.

WAVY SET: Set in smooth waves.

This set is associated with very fine teeth and it is mainly used for

9.7.1 - RECOMMENDED CUTTING PARAMETERS

the cutting of pipes and thin section bars (from 1 to 3 mm).

ALTERNATE SET (IN GROUPS): Groups of cutting teeth right and

left, alternated by a straight tooth.

This set is associated with very fine teeth and it is used for extremely

thin materials (less than 1 mm).

ALTERNATE SET (INDIVIDUAL TEETH): Cutting teeth right and left.

This set is used for the cutting of nonferrous soft materials, plastics

and wood.

STEEL C UTTING SPEED LUBRICATION

CONSTRUCTION 60/80 EMULSIFIABLE OIL

CEMENTATION 40/50 EMULSIFIABLE OIL

CARBON STEEL 40/60 EMULSIFIABLE OIL

HARDENING A ND TE MPE RING 40/50 EMULSIFIABLE OIL

BEARINGS 40/60 EMULSIFIABLE OIL

SPRINGS 40/60 EMULSIFIABLE OIL

FOR TOOLS 30/40 EMULSIFIABLE OIL

FOR VALVES 35/50 EMULSIFIABLE OIL

STAINLESS STEEL 30/40 EMULSIFIABLE OIL

SPHEROIDAL GRAPHITE 20/40 EMULSIFIABLE OIL

CAST IRON 40/60 EMULSIFIABLE OIL

16

ALUMINIUM 80/600 KEROSENE

BRONZE 70/120 EMULSIFIABLE OIL

HARD BRONZE 30/60 EMULSIFIABLE OIL

BRASS 70/350 EMULSIFIABLE OIL

COPPER 50/720 EMULSIFIABLE OIL

Page 17

SAR 440 SA GDS

10

MACHINE COMPONENTS

10.1 - List of spare parts

REFERENCE N° DENOMINATION

1 Bedframe

2 Electric box

3 Electric parts housing guard

4 Revolving arm lock lever

5 Arm lock bush

6 Machine hoisting hook

7 Lateral guard

8 Stroke-end stop

9 Adjustable bracket

10 Refrigeranting liquid tank

11 Electropump

12 Bar stop body

13 Bar stop push rod

14 Bar stop rod

15 Revolving arm pin

16 Countervice pin

17 Revolving arm

18 Bearing 32008 X

19 Bushing

20 Screw

21 Hinge pin protection

22 Bearing 32008 X

23 Hinge pin spacer

24 Hinge pin

25 Ring nut guk M 40x1,5

26 Countervice r.h. ja w

27 Countervice l.h. jaw

28 Interchangeable plate

29 Countervice

30 Countervice anterior guard

31 Pieces support

32

33 Vice support

34 Rack

35 Rack support

36 Vice

37 Vice screw

38 Handwheel

39 Pin

40 Pawl

41 Vice jaw

42 Crucible

43 Ring NILOS 32008 XAV

REFERENCE N° DENOMINATION

44 Bearing fork

45 Bearing SKF NATV 17 PPI

46 Pin

47 Bearing protection

48 Hydraulic vice cilinder

49 Hinge pin support

50 Sheath

51 Saw frame cylinder support

52 Bush

53 Pin

54 Handle

17

Page 18

SAR 440 SA GDS

REFERENCE N° DENOMINATION

60 Sawframe

61 Electric motor

62 Speed variator

63 Speed variator handwheel

64 Ring nut guk M 40x1,5

65 Speed reducer

66 Spacer

67

68 Cylinder joint

69 Cylinder superior pin

70 Microswitch

71 Plate

72 Plate

73 Sawframe cylinder

74

75 Adjustable screw

76 transmission flywheel pin

77 Ring nut guk M 45x1,5

78 Blade tightening slide

79

80

81 Handle

82 Blade tightening handwheel

pin

83 Pin

84 Blade tightening Cylinder

85 Bracket

86 Ring NILOS 32209 XAV

87 Bearing 32209 XAV

88

89 T ransmission flywheel

90 Ring nut guk M 45 x 1,5

91 Bearing 3309 2RS

92 Ring NILOS 3309 AV

93 Bearing protection

94 Motor flywheel shaft

95 Motor flywheel

96 Cone clamping

EUROCONIC

97 Blade guide protection

98 Microswitch

99 R.h Flywheel protection

100 L.h. Flywheel protection

101 Blade guide arm guide

10 2 L.h. adjustable blade guide

arm

10 3 R.h. adjustable blade guide

arm

104 Hand lever

105

106 Additional protection

REFERENCE N° DENOMINATION

107 Spacer

108 Bearing 51204

109 Spring washer

110 Manometer

11 1 Pressure switch

112 Rear crucible

113

11 4 Blade guide bearing pin

11 5 Bearing 6200 2RS

11 6 Ring seeger Ø 10

11 7 Upper blade guide pad

11 8 Lateral blade guide pad

119 Hinge

120 Middle protection

121 Brush

12 2 Brush support

12 3 Bearing 626 2RS

12 4 Brush ring

125 Blade protection

126 Auxiliary blade protection

127

130 Distributor block

131 Coupling

132 Cooling liquid cock

133

134 Flexible tube

135 Handgripp

18

Page 19

10

SAR 440 SA GDS

42

6

53

52

51

21

49

22

18

25

20

19

24

43

27

26

43

23

44

47

28

17

45

46

14

11

13

29

16

15

12

30

7

8

8

9

54

31

34

35

6

5

4

1

50

2

33

41

36

37

39

3

48

38

19

Page 20

20

81

82

83

109

108

110

84

78

77

107

ZOOM - 2

133

131

76

111

75

85

130

86

132

72

87

131

70

73

98

71

134

68

69

64

63

65

66

61

62

101

60

98

91

93

92

94

112

95

96

SAR 440 SA GDS

135

89

87

86

90

120

100

Page 21

104

102

104

103

124

SAR 440 SA GDS

126

125

97

115

114

116

ZOOM 1

117

118

106

118

117

123

ZOOM 2

122

121

114

115

116

21

Page 22

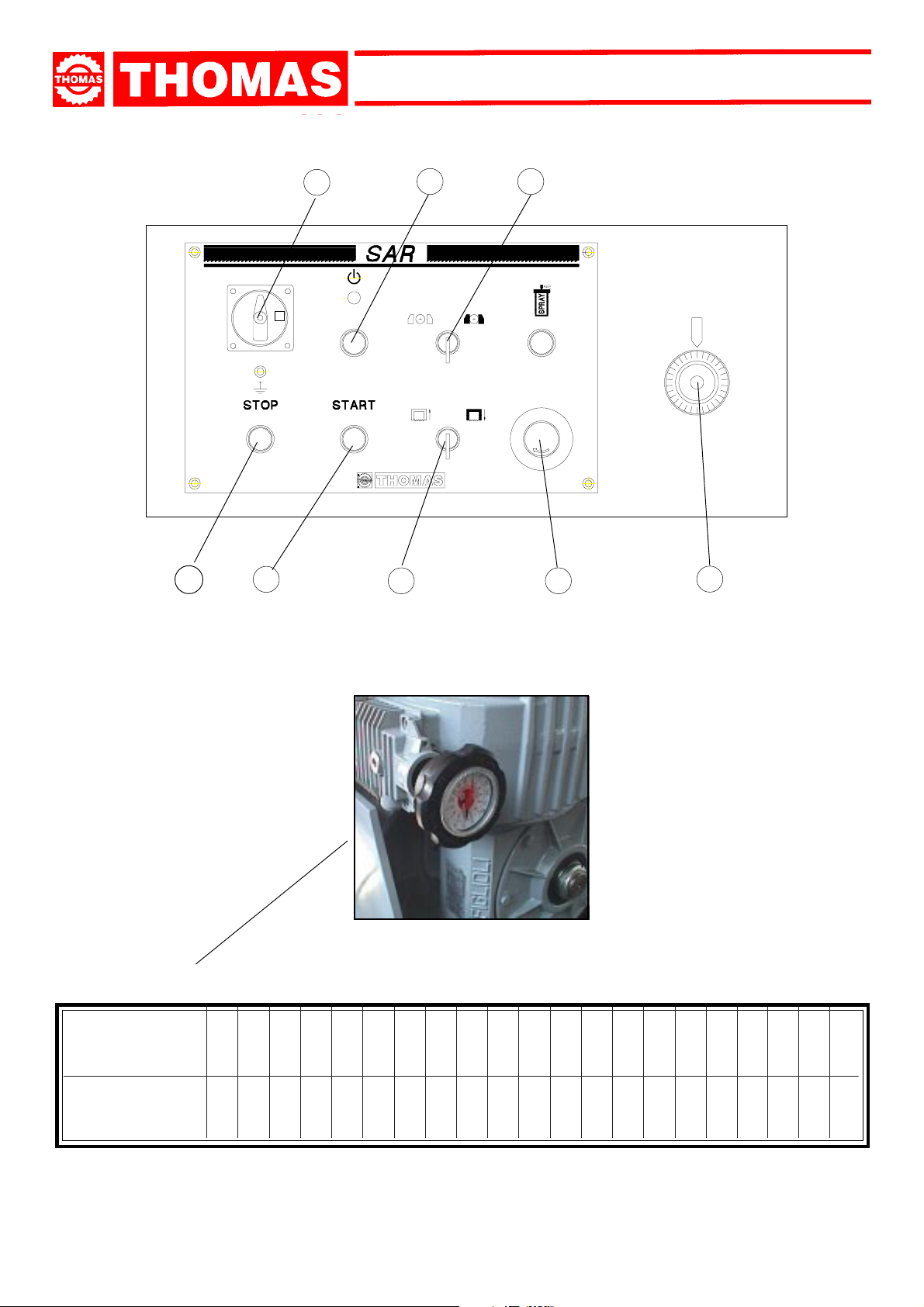

SAR 440 SA GDS

KEY:

401 Main switch

402 Arch movement selector

403 Emergency switch

404 STOP button

405 Regulator arch descent

406 On-line button

407 Start button

408 Vice selector

KEY:

401

404

406

1

407 402

408 405

403

410 Transformer

411 Fuse cartridge

412 Relay ( Kb )

413 Remote switch

414 Thermal motor

415 Remote switch

416 Timer

417 Thermal motor

KEY:

421 Motor gear case id.

422 Vice electrovalve-solenoid

423 Gear case tank id.

424 Sawframe electrovalve-solenoid

411 413 417 414 415 410 412 416

22

421

424

423422

Page 23

SAR 440 SA GDS

11

11.1 - Three-phase electric diagram

ELECTRIC DIA GRAM

THOMAS

THOMAS

QS1 Main switch

FU1 Fuse cartridge

KM1 Central motor control switch id.

KM2 Motor belt control switch

FR2 Thermal motor belt

M1 Motor gear case id.

M2 Belt motor

M3 Motor pump

FU2 Fuse cartridge

TC1 T ransformer

23

Page 24

SAR 440 SA GDS

THOMAS

THOMAS

24

Page 25

11.2 - Hydraulic electric diagram

SAR 440 SA GDS

01 Sawframe downfeed regulator

02 Sawframe lifting speed

regulator

04 Electric valve

05 Valve

06 Valve

DATA: 20/01/06

ELENCO COMPO NENTI ELETTRICI SCH. 1

MOD.: S AR 440 SA GDS OP TIONAL:

RIF. DES CRIZIONE CARATTERISTICHE QUANTITA FO RNITORE ART.

QS 1 INTERUTTO RE GE NERALE 20 A 600 V, TRIFA SE 1 GIOVE NZANA P20 0003 R1

P-FU1 PO RT. X M OTORI CE NTRALINA IDRAUL. 32 A 600 V 3 FASI 1

FU1 FUSIB. PROT MOTORE IDRAULICO 10 A 600 V 10 X 38 3

P FU2 PORT X PROT MOT. NASTRO E POM PA 32 A 600 V 3 FASI 1

FU2 FUS.PROT MOT. NASTRO E POMPA 16 A 600 V 10 X 38 3

P-FU3 PORT. X PROT TRASF. 32 A 600 V 2 FASI 1

FU 3 FUS IBILIP RO TEZ, TRAS F OR M ATO RE 1A 600 V 10 X 38 2

P-FU4 PORT. X PROT SECOND. 32 A 600 V 1 FASI 1

FU 4 FU S. P R OT C IR. AUS ILIA RIO 4A 600 V 10 X 38 1

TC1 TRASFORMATO RE AUS, 75 VA USCITA 24 VOLT 1 F.M.T. 75 VA 24 V. SEC

KM 1 TELERUTTORE CEN TR. IDRAULICA 25A 600V 24V 1 C.G.E. CL00A 310 T1

KM 2 TELERUTTORE M OTORE NA STRO 25A 600V 24V 1 C.G.E. CL00A310 T1

FR1 TERMICO PROT.MOT. CENTRAL. IDR. 10 A 750 V N.C. 2,5-4 A 1 C.G.E. RT1 K

FR 2 TERM ICO PR OT.M O TORE NA S TRO 10 A 750 V N.C . 4-6 A 1 C.G .E . RT1 L

M1 M OTORE CENTRALINA IDRA ULICA KW 1,1 1400 GIRI 1 TES SA RO

M2 MOTORE NASTRO KW 2,2 1400 GIRI 1 TESSARO

M3 POMPA ACQUA KW 0,11 2800 GIRI H 120 1 SACEMI TRIFASE

KA1 RELE AUSILIARIO + ZOCCOLO 7A 250 V. 2CONT. SCAMBIO 1 FINDER 55.32 024 +9472

KA2 RELE AUSILIARIO + ZOCCOLO 5A 250 V. 4CONT. SCAMBIO 1 FINDER 55.34 024 +9474

HL SPIA LINEA 24 V. NEON FASTOM V. 1 SIGNALUX TB F SC1 VE 24V.

SB1 PULSANTE EMERGENZA 3 A 250 V N.C. 1 TELEMECANIQUE ZB4 BS 844 + BZ102

SB2 PULSANTE LINEA 10A 690 V N.O. 1 LOVATO 8LM 2 TB108

SB3 PULSANTE INIZIO CICLO 10A 690 V N.O. 1 LOVATO 8LM2 TB103

SB4 PULSANTE STOP CICLO 10A 690 V N.C. 1 LOVATO 8LM2 ?

SA1 SELETTORE MPV. ARCO 10A 690 V + 2 N.O 1 LOVATO 8LM2 TS231

SA 2 SE LE TTO RE M ORS A 10A 690 V+ 2N.O.+ 2 N.C 1 LOV ATO 8LM 2 TS220

YV I----4 VA LVOLE IDRAULICHE SU CENTRALINA 4 L-C- 21,5 V DC RAC 24 V

SQ 2 M ICRO RIP ARO NASTRO 3 A 250 V CON CHIAV E 1 REITE R RS2 10 11 D

SQ 3 M ICRO RIP ARO NASTRO 3 A 250 V CON CHIAV E 1 REITE R RS2 10 11 D

SQ1 MICRO ARCO BASSO 3A 400 V NC+NO 1 PIZZATO FR 4501

P PRESSOSTATO TENS. LAM A 0.5 A 250 V 300 BAR N.O 1 ELETTROTEC PMN 14K T 90D

X 1 S CA TOLA DE R IV A ZIO NE 6 V IE 1 P A LAZZOLI TAIS 101061

X2 M ORS E TTI CONN ES SIONE 2,5 MM 800 V 47 S IE M E NS 8W A 11 011 DF11

X3 MORSETTI CONNESSIONE TE RMINALI 2 W EIDMULLER EW 35

KTC TEM PORIZZATORE + ZOCCOLO 2 C. SCAMBIO 300 SEC 1 CROUZET TOP 36 24 V+ 9026

KM 1-C CONTATTO AUS. CENTRALINA 1 NC+ 1 NO 10A 750 V. 1 C.G.E. BCLF 10+BCLF01

KM2-C CONTATTO AUS. NA STRO 1 NC + NO 10 A 750 V. 1 C.G.E. BCLF 10+BCLF01

WEBER

WEBER

WEBER

WEBER

WEBER

WEBER

WEBER

WEBER

PCH 3 X 38

CH10 X 30 10 A

PCH 3 X 38

CH 10 X 38 16 A

PCH 2 X 38

CH 10 X 38 1AM

PCH 1 X 38

CH 10 X 38 4A

25

Page 26

SAR 440 SA GDS

12

This chapter lists the probable faults and malfunctions that could occur while the machine is being used and suggests possible remedies for

solving them.

The first paragraph provides diagnosis for TOOLS and CUTS, the second for ELECTRICAL COMPONENTS.

TROUBLESHOOTING

12.1 - Blade and cut diagnosis

FAULT PROBABLE CAUSE REMEDY

TOOTH BREAKAGE

Too fast advance

Wrong cutting speed

Wrong tooth pitch

Chips sticking onto teeth and in the gullets or material that gums

Defects on the material or material too

hard

Ineffective gripping of the part in the vice

Decrease advance, exerting less cutting

pressure. Adjust the braking device if

mounted on the machine.

Change speed and/or type of blade.

See chapter on “Material classification and

blade selection”, in the section

tion table according to cutting and feed

speed.

Choose a suitable blade. See Chapter “Ma-

terial classification and blade selection”.

Check for clogging of cooling liquid drain

holes on the blade-guide pads and that flow

is plentiful in order to facilitate the removal

of chips from the blade.

Material surfaces can be oxidised or covered

with impurities making them, at the beginning of the cut, harder that the blade itself,

or have hardened areas or inclusions inside

the section due to productive agents used

such as casting sand, welding wastes, etc.

Avoid cutting these materials or in any case

perform cutting with extreme care, cleaning and removing such impurities as quickly

as possible.

Check the gripping of the part.

Blade selec-

26

The blade gets stuck in the material

Starting cut on sharp or irregular section bars

Poor quality blade

Previously broken tooth left in the cut

Cutting resumed on a groove made pre-

viously

Vibrations

Wrong tooth pitch or shape

Insufficient lubricating refrigerant or

wrong emulsion

Teeth positioned in the direction opposite the cutting direction

Reduce feed and exert less cutting pressure.

Pay more attention when y ou start cutting.

Use a superior quality blade.

Accurately remove all the parts left in.

Make the cut elsewhere, turning the part.

Check gripping of the part.

Replace blade with a more suitable one.

See “Material classification and blade

selection” in the

Adjust blade guide pads.

Check level of liquid in the tank. Increase the

flow of lubricating refrigerant, checking that

the hole and the liquid outlet pipe are not

blocked.

Check the emulsion percentage.

Turn teeth in correct direction.

Blade Types

section.

Page 27

FAULT PROBABLE CAUSE REMEDY

SAR 440 SA GDS

PREMATURE BLADE WEAR

Faulty running-in of blade

Teeth positioned in the direction opposite the cutting direction

Poor quality blade

Too fast advance

Wrong cutting speed

Defects on the material or material too

hard

Insufficient lubricating refrigerant or

wrong emulsion

See “Material classification and blade se-

lection” in the

Turn teeth in correct direction.

Use a superior quality blade.

Decrease advance, exerting less cutting

pressure. Adjust the braking device if

mounted on the machine.

Change speed and/or type of blade.

See chapter on “Material classification and

blade selection”, in the section

Blade running-in

section.

Blade selection table according to cutting and feed

speed.

Material surfaces can be oxidised or covered

with impurities making them, at the beginning of the cut, harder that the blade itself,

or have hardened areas or inclusions inside

the section due to productive agents used

such as casting sand, welding wastes, etc.

Avoid cutting these materials or in any case

perform cutting with extreme care, cleaning and removing such impurities as quickly

as possible.

Check level of liquid in the tank. Increase the

flow of lubricating refrigerant, checking that

the hole and the liquid outlet pipe are not

blocked.

Check the emulsion percentage.

BLADE BREAKAGE

Faulty welding of blade

Too fast advance

Wrong cutting speed

Wrong tooth pitch

Ineffective gripping of the part in the vice

Blade touching material at beginning of

cut

The welding of the blade is of utmost importance. The meeting surfaces must perfectly

match and once they are welded they must

have no inclusions or bubbles; the welded

part must be perfectly smooth and even.

They must be evenly thick and have no bulges

that can cause dents or instant breakage

when sliding between the blade guide pads.

Decrease advance, exerting less cutting

pressure. Adjust the braking device if

mounted on the machine.

Change speed and/or type of blade.

See chapter on “Material classification and

blade selection”, in the section

Blade selection table according to cutting and feed

speed.

Choose a suitable blade. See Chapter “Ma-

terial classification and blade selection”.

Check the gripping of the part.

At the beginning of the cutting process,

never lower the saw frame before starting

the blade motor.

27

Page 28

FAULT PROBABLE CAUSE REMEDY

SAR 440 SA GDS

STREAKED OR ETCHED BANDS

Blade guide pads not regulated or dirty

because of lack of maintenance

Blade guide block too far from material

to be cut

Improper position of blade on flywheels

Insufficient lubricating refrigerant or

wrong emulsion

Damaged or chipped blade guide

pad

Tight or slackened blade guide bearing

Check distance between blocks (see “Ma-

chine adjustments” in the

Blocks

section): extremely accurate guiding

may cause cracks and breakage of the tooth.

Clean carefully.

Approach head as near as possible to material to be cut so that only the blade section

employed in the cut is free, this will prevent

deflections that would excessively stress the

blade.

The back of blade rubs against the support

due to deformed or poorly welded bands (tapered), causing cracks and swelling of the

back contour.

Check level of liquid in the tank. Increase the

flow of lubricating refrigerant, checking that

the hole and the liquid outlet pipe are not

blocked. Check the emulsion percentage.

Replace it.

Adjust it (see Chapter “Machine adjust-

ments” in

Blade guide

Blade Guide

section).

CUTS OFF THE STRAIGHT

Blade not parallel as to the counter-vice

Blade not perpendicular due to the excessive play between the guide pads

and maladjustment of the blocks

Too fast advance

Blade guide block too far from material

to be cut

Worn out blade

Wrong tooth pitch

Check fastenings of the blade guide blocks

as to the counter-vice so that they are not

too loose and adjust blocks vertically; bring

into line the position of the degrees and if

necessary adjust the stop screws of the

degree cuts.

Check and vertically re-adjust the blade guide

blocks; reset proper side guide play (see

Chapter “Machine adjustments” in

guide

section).

Decrease advance, exerting less cutting

pressure. Adjust the braking device if

mounted on the machine.

Approach it as near as possible to material

to be cut so that only the blade section employed in the cut is free, this will prevent deflections that would excessively stress the

blade.

Replace it.

Blade with major density of teeth is being

used, try using one with less teeth (see Chapter “Material classification and blade se-

lection” in the

Blade Types

section).

Blade

28

Page 29

FAULT PROBABLE CAUSE REMEDY

SAR 440 SA GDS

FAULTY CUT

STREAKED CUTTING SURFACE

Broken teeth

Insufficient lubricating refrigerant or

wrong emulsion

Worn out flywheels

Flywheel housing full of chips

Too fast advance

Poor quality blade

Worn out blade or with chipped and/or

broken teeth

Wrong tooth pitch

Blade guide block too far from material

to be cut

Irregular work of the blade due to the lack of

teeth can cause deflection in the cut; check

blade and if necessary replace it.

Check level of liquid in the tank. Increase the

flow of lubricating refrigerant, checking that

the hole and the liquid outlet pipe are not

blocked.

Check the emulsion percentage.

The support and guide flange of the band

are so worn out that they cannot ensure

the alignment of the blade, causing faulty

cutting; blade rolling and drawing tracks can

have become tapered. Replace them.

Clean with compressed air.

Decrease advance, exerting less cutting

pressure. Adjust the braking device if

mounted on the machine.

Use a superior quality blade.

Replace it.

Blade used probably has too large teeth; use

one with more teeth (see “Material classi-

fication and blade selection” in the

Types

section).

Approach it as near as possible to material

to be cut so that only the blade section employed in the cut is free, this will prevent deflections that would excessively stress the

blade.

Blade

NOISE ON GUIDE BLOCKS

Insufficient lubricating refrigerant or

wrong emulsion

Chipped bearings

Worn out or damaged pads

Check level of liquid in the tank. Increase the

flow of lubricating refrigerant, checking that

the hole and the liquid outlet pipe are not

blocked.

Check the emulsion percentage.

Dirt and/or chips between blade and guide

bearings. Replace them.

Replace them.

29

Page 30

12.2 - Electrical components diagnosis

FAULT PROBABLE CAUSE REMEDY

SAR 440 SA GDS

MACHINE DOES NOT WORK

Power supply

Main disconnect switch

Fuses " FU 1 "

" SQ 1 " safety microswitch

Blade tightening microswitch

Emergency button " SB 1 " on

Cycle reset or line button " SB 2 "

Thermal relay of main motor

Transformer " TC 1 "

Fuse " FU 2 - FU 3 "

Check: - phases

- cables

- socket

- plug

Voltage must arrive upstream from the fuses

(terminal board).

It must be turned to ON position.

Check electrical efficiency. Check power line

connections and relative terminals.

Check electrical efficiency and check for

shorts that trigger these protections on the

power side of the circuit.

Check closing of the flywheel guard. Check

the efficiency of the device; replace it if damaged.

Make sure to have tightened the blade with

the relevant handwheel and to have actuated

the microswitch.

Ensure that it is off and that its contacts are

unbroken.

Check mechanical efficiency; replace if damaged.

Check that thermal relay protecting main

motor is correctly connected.

Check that the supply voltage is the same

as the line voltage and that it gives a value of

24 V at output.

Check fuse efficiency and ensure there are

no short circuits causing the protection on

the control side of the circuit.

Microswitch " SQ 2 "

MOTOR STOPPED WITH PILOT LIGHT

“HL” LIT

13

In accordance with point 1.7.4.f of the Machines Directive EEC 98/37

2 measurements with the machine operating unloaded.

- The microphone was been located close to the operator's head, at medium height.

- The weighted equivalent continuous acoustic pressure level was 65,4 dB (A).

- The maximum level of the WEIGHTED instantaneous acoustic pressure C was always less than 130 dB.

NOTE: with the machine operating, the noise level will vary according to the different materials being processed. The user must there-fore

assess the intensity and if necessary provide the operators with the necessary personal protection, as required by Law 277/1991.

NOISE TESTS

Remote-control switch " KM "

Motor " M 1 "

After having raised the saw frame, check

that the microswitch is not engaged and if

necessary check operating efficiency.

Check that phases are present at both input and output; ensure that it is not blocked,

that it closes when fed, that it does not cause

short circuits; otherwise change it.

Check that it is not burnt and that it turns

freely.

It may be rewound or changed.

30

Page 31

PLATES AND LABELS

SAR 440 SA GDS

31

Page 32

THOMAS S.p.A. - Via Pasubio, 32 - 36033 Isola Vicentina (VI) - Telephone 0444 / 97.61.05 - Fax 0444 / 97.69.34

Loading...

Loading...