Page 1

Operator’s Manual Text

Section I

Model LE-13A

Dake/Johnson Horizontal Band saw

Fully Automatic

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecorp.com

12/10/07 Model LE13A Text 1

Page 2

FOREWORD

NOTE:

This manual has been prepared to acquaint you with the operation,

maintenance, and serviceable components of your Dake/Johnson machine.

We urge that you read it carefully before operating your machine. Please refer

to the manual when contacting the factory regarding parts, schematic or

when you have other questions.

As Dake’s policy is one of continuous development for each range of

machine, the contents of this manual, though completely up to date when

issued, are subject to change without notice.

For your information and future reference, data concerning your machine

may be inserted in the space provided below.

Machine Model LE 13A_____________________

Serial Number ___________________________

Date Received ___________________________

Voltage 220 Volt _________________________

Phase 3______ Cycle 60_____ Motor H.P.3_____

Please give the machine model and serial number in correspondence and include

the part numbers on part orders.

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecorp.com

Use only genuine Dake/Johnson replacement parts and optional equipment. Use of

substitutes or imitations may cause damage to the machine. This may void the warranty,

and may cause injury.

12/10/07 Model LE13A Text 2

Page 3

CONTENTS

SECTION 1 – Safety

1.1 General Product specifications

1.2 General Safety Instructions

1.3 Location of Safety Labels

SECTION 2 – Description

2.1 Machine Life

2.2 Intended Use

2.3 Noise Level

SECTION 3 – Transportation & Installation

3.1 Transportation

3.2 Preparation for Installation

3.3 Inspection before trial run

3.4 Environment requirement

3.5 Dismantling

SECTION 4 – Machine operation

4.1Control Panel Description

4.2 Blade Change

4.3 Manual operation Instructions

4.4 Blade speed change

4.5 Automatic operation instructions

4.6 Part length set part length

4.7 How to set piece counter

4.8 Bundle attachment installation

4.9 Cutting data

5.0 Lubrication and maintenance

6.1 Trouble shooting

12/10/07 Model LE13A Text 3

Page 4

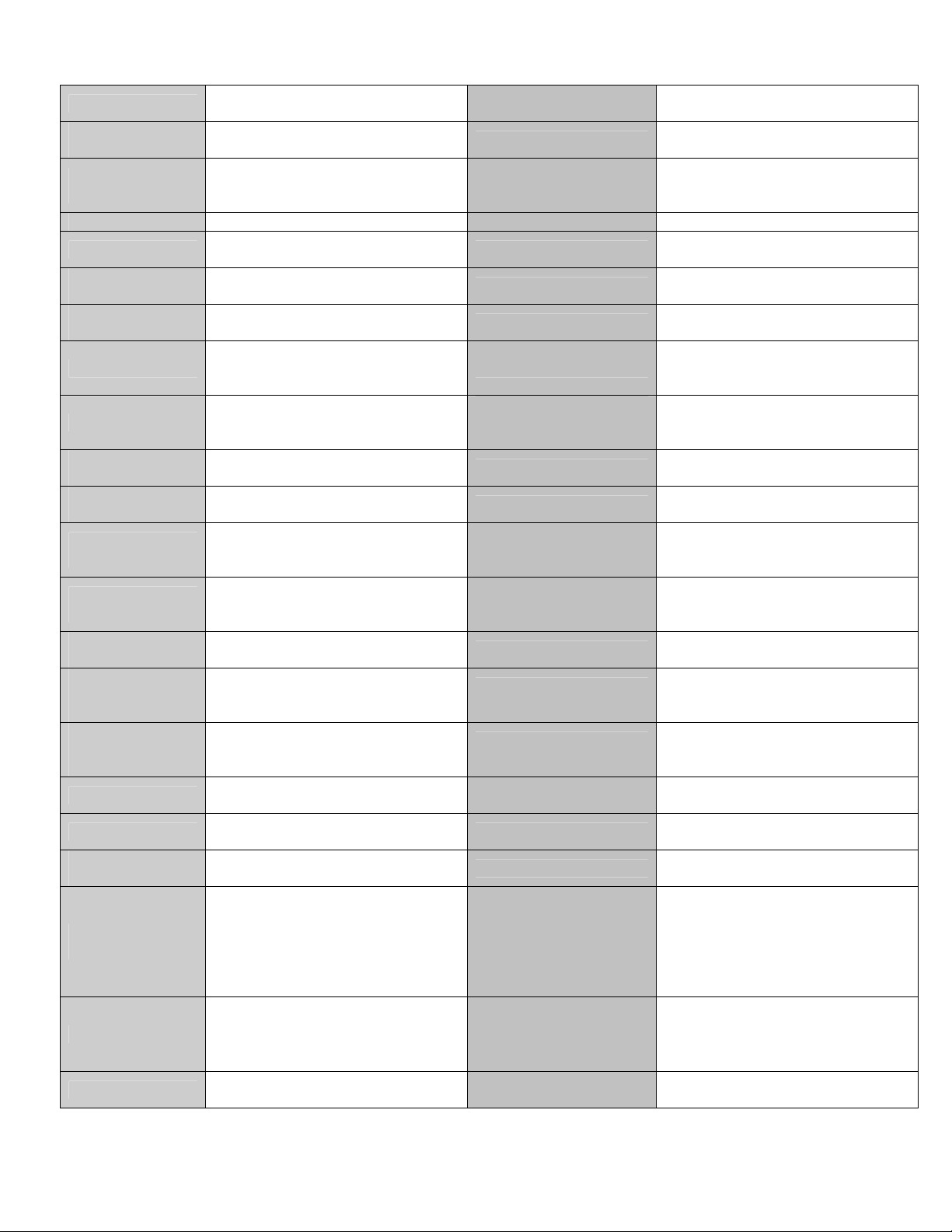

Machine Type

Capacity

Bundled

Drop Length

Possible

Blade Size

Blade Speeds

Feed Stroke

(Single)

Multiple

Stroke

Feed Type

Length Set Up

Horse Power

Blade Motor

Hydraulic

Pump HP

Coolant Pump

Type & HP

Hydraulic Oil

Capacity

Coolant

Capacity

Vises (Quick

set ratchet

type)

Vise

Clamping

Pressure

Vise Ways

Work Table

Hitch Feed

Capacity

Hydraulic

Pump

Head Feed

Piece Counter

1.1 General Product Specifications

Horizontal scissors type

8.5” wide, 6.5 “ high

Less than 2 inches

150 inches x 1 1/4 inch

88 / 130 / 177 / 223 / 262

F.P.M.

3/8 inch minimum – 16 inch

maximum – 141.5”

9 times

Hydraulic hitch feed with vertical

rollers, feed speed 16 inches in

6 seconds

Front mounted hand wheel, and

DRO with large numeral digits.

5 H.P.

1 H.P.

1/8 H.P.

1.2 gallons

10 gallons

Hydraulic with blade forward

clamping for minimized burr and

with 1” throw

600 pounds

Precision ground and hardened

Machined with chip clearance

inserts

2790 pounds with use of roller

table

Hydraulics on demand (HOD)

with minimum pressure start up

Hydraulic regulation with RPM

compensation feed back

9,999 piece with auto shut off

Rapid Head

Approach

Blade Tensioning

Electrical

System Control

Warning Light

Auto Shut Off

Chip Brush

Foot Print

Roller Support w/

vertical roller

dimensions

Work Height

Weight

Tool Kit

Spare Parts

Work Light

Machine Support

Pads

Collective Hour

Timer

Auger Style Chip

Removal System

Guarding

Lubricant

Voltage

AMP

Operating

Temperature

Sure stop hydraulically

controlled

Mechanical with preset locking

ring

CE approved / Thermo

overload, low voltage

protection, 110 control voltage

PLC

Yes

Pieces reached, out of stock,

blade slippage/breakage

Speed synchronized

76 inches x 75 inches (76

inches deep without roller

support)

72 inches long x 16 inches wide

inches

3196 pounds

Standard – Includes screw

drivers, wrenches and Allan

keys

Standard – Includes chip

brushes and guide bearing

replacements

Standard

Standard

Standard

Standard

Full hinged

Flood type unit built into the

machine (Electric)

• Available 230-volt three phase

• Available 460-volt three phase

(external transformer)

Machine should be wired to

main service by a qualified

Electrician.

• 20-amp service for 230-volt

machine

• 16-amp service for 460-volt

machine

No special operating

temperature level

12/10/07 Model LE13A Text 4

Page 5

SECTION 1

1.2 General Safety Instruction

Read and understand the instruction manual and warning signs before operating this

machine. Failure to follow these instructions and warnings can result in serious injury or

death.

1. Always wear eye protection.

2. Do not wear gloves, neckties, loose clothing or jewelry while operating machine.

3. Keep fingers out of path of the blade.

4. Do not remove jammed or cut-off pieces until blade had completely stopped.

5. Check blade tension and adjust blade guide before starting.

6. Always clamp stock firmly in place before cutting and use auxiliary support for long

material.

7. Disconnect machine power from source before making repairs or adjustments.

8. Guards should be in place and used at all times.

9. Keep machine and chip collections system clean.

10. Never operate the machine when guarding is removed.

11. Do not touch the blade or place any body parts into the vice area when machine is

in operation.

12/10/07 Model LE13A Text 5

Page 6

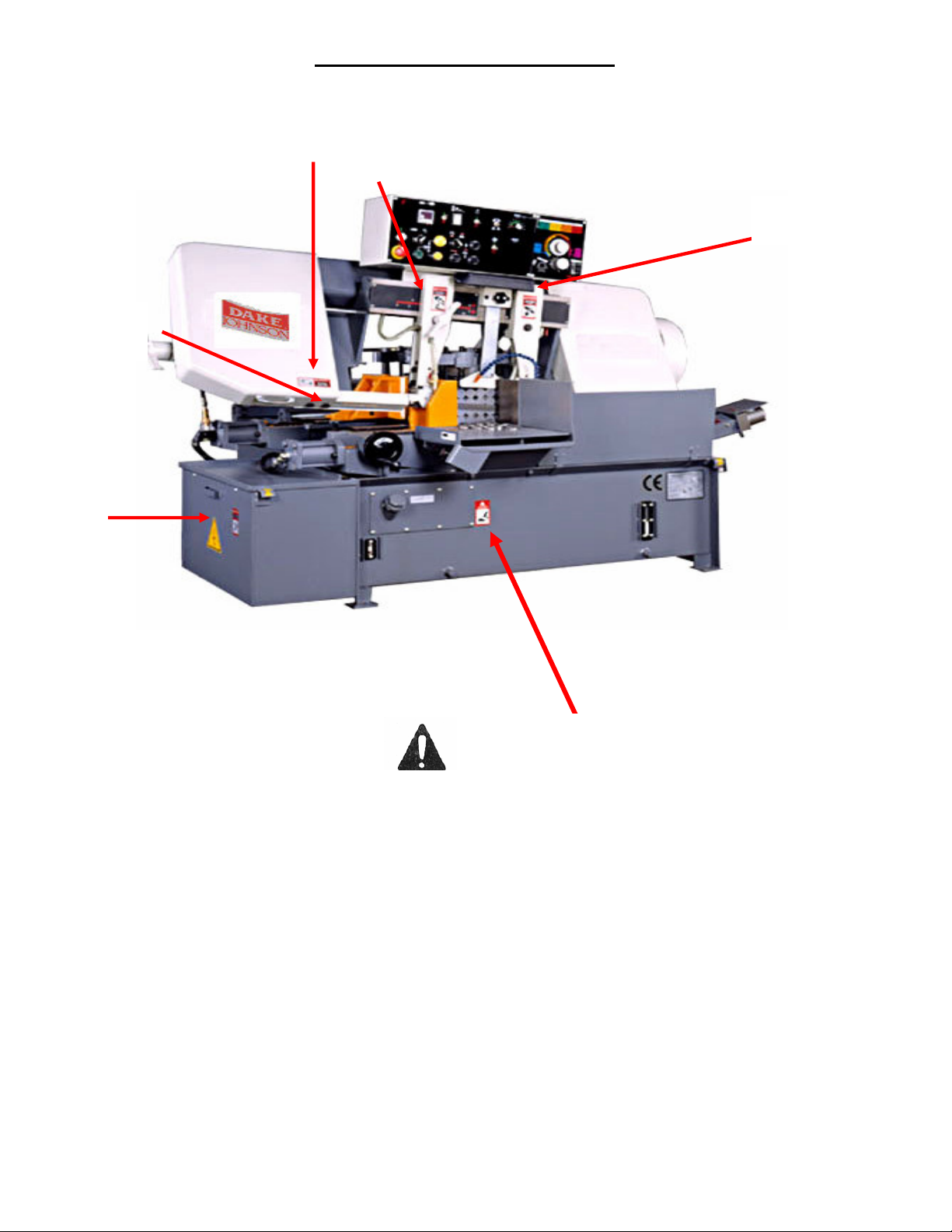

Location of Safety Labels 1.3

1

3

2

4

5

6

SAFETY

be alert to the potential personal injury.

Follow recommended precautions and safe operating practices. Carefully read all

safety messages in these instructions and on your saw safety signs. Keep safety

labels in good condition.

Label 1 – DANGER – KEEP THE COVERS CLOSED WHEN SAW BLADE IS IN

MOTION

Label 2 – DANGER – KEEPS HANDS OFF DURING SAWBLADE OPERATION

Label 3 – DANGER – KEEP BODY PARTS AWAY FROM MOVING PARTS

DURING MACHINE OPERATION

Label 4 – DANGER – DO NOT STEP ON THE ROLLERS ON FEED TRACK

Label 5 – DANGER – THIS MACHINE ELECTRICITY MUST BE LOCKED OUT

BEFORE SERVICING.

Label 6 – DANGER – STEEL TOE SAFETY SHOES MUST BE WORN WHEN

OPERATING THIS MACHINE

12/10/07 Model LE13A Text 6

you see this symbol on your saw,

Page 7

2.1 Machine Life

The intended life limit of this machine is ten years under normal operating

conditions and with good maintenance. The intended life of this machine is

calculated by: 8 hours x 5 days x 52 weeks x 10 years = 20,800 hours.

2.2 Intended Use

The LE10A is an automatic hydraulic band saw machine. It is designed and

constructed for metal sawing only. It is not intended to cut other materials for

example: meat, wood, stone, plastic, Mg and analogous materials.

For safety, it is designed with safety guarding to protect from the moving elements

while operating.

The interlock devices of the wheel guards are hardwired to stop the spindle

revolution of the drive and drive wheel.

This machine has three operation modes:

(1) Automatic Mode

(2) Single Cycle Mode

(3) Manual Mode

It is designed for a trained and skilled person to operate this machine; they must be

trained until they know how to operate it safety.

It is designed that this machine can not be used in a potential explosive

environment.

2.3 Noise Level

The LE13A have a noise level below 75dB (For detailed information, please refer to

the TECHNICAL Section)

SECTION 3

3.1 Transportation

Use a forklift to move the

crated machine. When moving

the machine with a forklift, be

sure the load is safely balanced

personal injury or damage to the

machine can result. Below is the

requirements for lifting:

12/10/07 Model LE13A Text 7

Page 8

Item Metric English

Machine

Weight W

Capacity, T 2 ton 2 ton

Length of the

Fork, L1

Distance

between fork,

L2

1492

meters

meters

Kg

1.5

1.2

LE13A

3,290

lbs

59.06“

47.24”

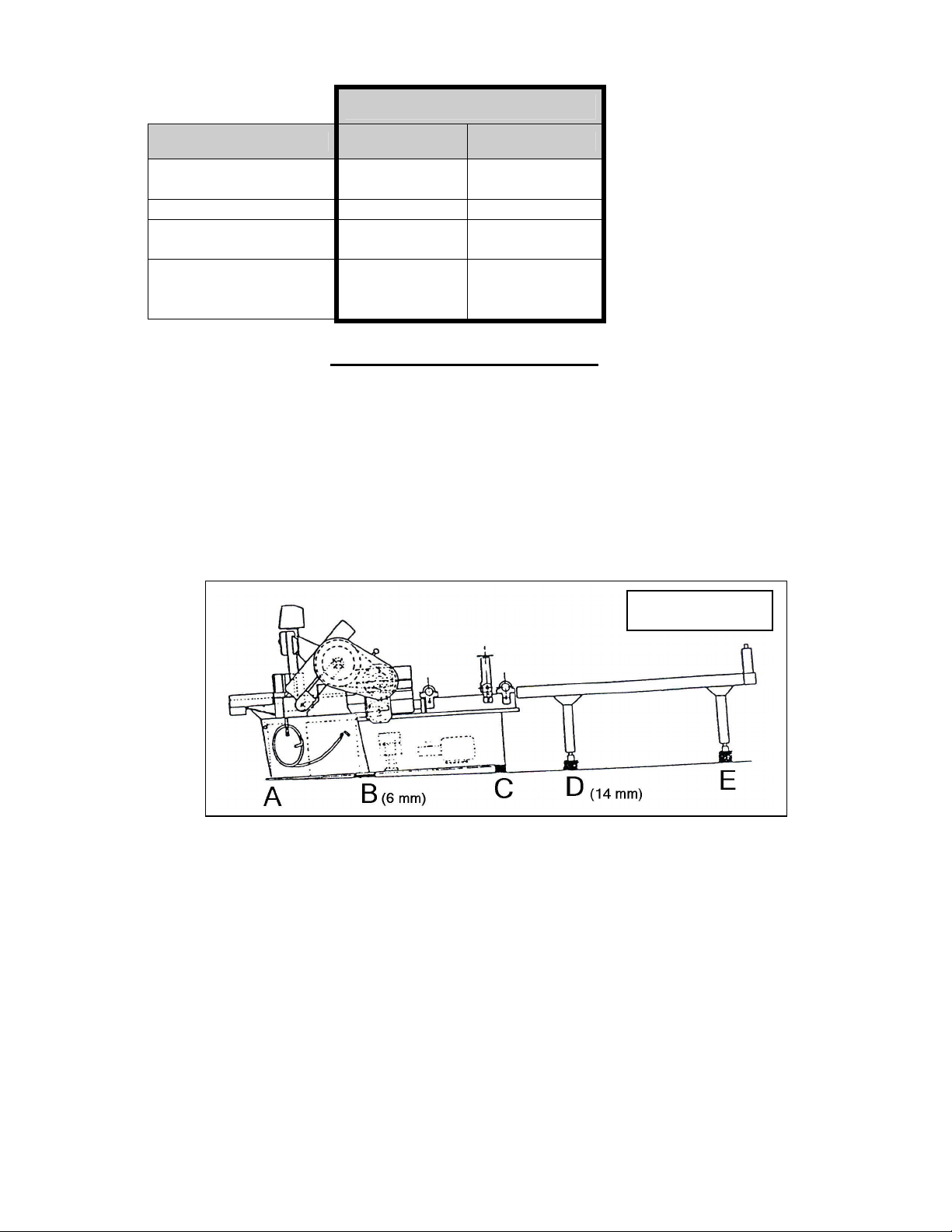

3.2 Preparation for installation

1. LEVELING: It is important to install the machine so that the rear most portion of

the main body table, feed table and roller bed is slightly raised. This prevents

cutting fluid from flowing backward along the material to be cut, especially long

material, and draining on the floor.

See Figure 3.3

Shim section B thicker than section A by 6mm. Shim section D thicker than section

E by 14mm. Horizontally, the table should be level or a little lower on the right.

FIGURE 3.3

If the table is higher on the right, recovery of the cutting oil will be slowed. The

height of the roller table, which is factory-adjusted, need not be re-adjusted. Be sure

the roller table is on the same level as the upper face of the feed table. Use a

straight edge to determine this. The roller face should be level with the feed table or

up to 0.12mm higher.

After the leveling is complete, check to make sure none of the steel sheets fail to

touch the floor due to overload.

REMOVING BRACKET FOR TRANSPORTATION: This bracket must be removed

before operating machine. Keep the bracket for use in moving the machine in the

future.

12/10/07 Model LE13A Text 8

Page 9

This red bracket

must be removed

before the

electrical is

connected.

Figure 3.4

Warning!!!!

Failure to remove this bracket could cause damage to the machine and void the

warranty.

INITIAL OILING: Clean the machine thoroughly. Be sure anti-corrosion additives

applied to sliding parts are removed with cleaning oil. When making a test run refer

to the instructions on 8-1 for proper oiling.

Be sure the cutting fluid is full before operating. This machine was shipped with oil

in it. Use the oil gauge to check oil and cutting fluid level in the machine.

Warning!!!!!

Do not start the motor without oil; damage to the pump will result.

WARNING!!!!

Only a licensed electrician who follows local and state laws is authorized to

connect power to this machine.

The power supply cord will need to come out of the electric box located on the left

side of the machine. Connect power source to the terminals on this cord. Once

connected, turn the main power on (on the left side of machine). The green lamp

should now be on.

Attach grounding terminal located beside the power cord to the factory ground line.

OIL FILL

OIL GAUGE

12/10/07 Model LE13A Text 9

Page 10

CAUTION!!!!!

THE GROUND WIRE MUST BE CONNECTED; FAILURE TO CONNECT THE

GROUND WIRE CAN DAMAGE THE MACHINE AND VOID THE WARRANTY.

Next, make sure the emergency stop button is not activated and that item 4 on

page 11 is to the right. Now press the LIFT button (see picture item 6 on page 11);

lifting starts in one or two seconds after the emergency button is released, the head

continues in the up direction as long as the button is held down. If the head does

not go up, immediately turn the power off, consult your electrician.

3.3 Inspections for Trial Run

After the saw has been installed, this inspection should be performed. The following

checklist will locate any items that may need further attention.

Connect the power (only a qualified electrician)

Coolant fluid is full (only water based coolant)

Hydraulic oil level is full

Check for loose components, guards or panels

Tools and other materials left on saw, remove all tools that are not

part of the machine.

3.4 Environment Requirement

1. Keep the machine on a dry, shaded place to prevent damage to the electrical

components.

2. Storage condition:

Temperature: -20°C 75°C

Humidity: 10% 90%

3. Operation condition:

Temperature: 0°C 55°C

Humidity: 10% 90%

3.5 Dismantle

1. Turn the power OFF.

2. Disconnect the power supply.

3. Drain the hydraulic oil and coolant.

4. Reverse the procedure of installation for this machine.

12/10/07 Model LE13A Text 10

Page 11

15

SECTION 4

12

4.1 Control Panel Description

13 14

16

1

6

7

8

9

2

3

4

1. POWER LIGHT

This light will come on when the circuit breaker is ON.

2. EMERGENCY STOP BUTTON

When this button is depressed, all machine operations will stop.

3. BLADE DRIVE BUTTON

When this button is depressed, the saw blade motor, cutting fluid pump and the

chip removal system will begin to operate and the saw head begins to descend.

The saw head descends quickly until the quick approach arm makes contact with

the work and thereafter, it will descend at the designated cutting speed.

NOTE:

a. On the manual operation, if the front vise is not closed, the saw blade motor

will not operate and saw head will not descend even if the button is

depressed.

b. With the rear vise stop position switch set at

depressing this button will not operate the saw blade motor unless the rear

vise is at the forward limit position. (Manual Operation)

5

11

10

12/10/07 Model LE13A Text 11

Page 12

Front vise

Rear vise

4. AUTO-MANUAL SELECTOR

For Continuous cutting, turn this selector to

To individually operate each function, turn this selector to the hand picture

(MANUAL).

5. QUICK APPROACH BUTTON

When this button is pressed the head will move in the downward position until the

quick approach arm touches the material.

6. RAISE BUTTON

When this button is pressed the blade motor stops and the saw head moves in the

upward position. When the button is released the head will stop moving.

7. VISE CLAMP BUTTON

When this button is pressed and held, one vise will open and the other vise will

close

8. VISE CLAMP SELECTION

When this selector is turned to the left (see picture to the right) with the automanual selector (4) turned to MANUAL the front vise opens and the rear vise

closes; when the selector is turned to the picture (on the lower left of this

paragraph) the rear vise opens and the front vise closes.

(AUTO).

opens

NOTE: On the manual operation, if this selector is

Not turned to the “Rear vice open” the saw blade motor will not operate even if the

drive button (3) is depressed.

9 & 10 REAR VISE FORWARD AND BACKWARD BUTTONS

When the forward button (9) is depressed with the auto-manual selector turned to

“MANUAL” the rear vise moves forward; when the backward button (10) is

depressed, the rear vise moves backward. The rear vise stops moving when the

button is released.

11. CUTTING FLUID PUMP SWITCH

When this switch is set at “|” the cutting fluid pump operates and the cutting fluid will

be on even though the saw blade motor is not in operation. Use this switch when

removing saw chips with the cutting fluid (without the blade operation).

12. CUTTING PIECE COUNTER

This counter is used to press the number of cuts required on the automatic

operation. When the counter reaches the preset number, the machine automatically

stops. To activate the counter, set the counter ON/OFF witch at “| “

opens

12/10/07 Model LE13A Text 12

Page 13

13. Vise shut off switch.

When this switch is off the counter will not work.

14. FEEDING-TIMES PRESET COUNTER

When a cutting length of more than 23” (600mm) is required, preset the required

number of feeds on this counter. The counter is capable of being set to the

maximum of nine feeds. 9*15.74=141.66 (9 x 400mm = 3600mm)

15. WORKING LIGHT

Turn this knob to the left to have the work light on, turn the knob to the right to have

the work light off.

16. REAR VISE STOP POSITION SWITCH

For bundle cutting, set this switch to the multiple picture, so that the rear vise

remains at the forward limit position. For single cutting, set this switch to the single

picture, so that the rear vise stays at the backward limit position.

NOTE: When the switch is set for bundle cutting, the blade will not start

unless the rear vise is at the forward limit positionBLADE SPEED ADJUSTING

BUTTON (Not Shown)

17

18

17. Blade feed

When this control is turned clockwise, the cutting feed is increased. When turned

counter clockwise the feed will decrease. Align the feed control with the zone which

corresponds to the materiel on the work piece to be cut.

18. CUTTING PRESSURE CONTROL & FLOW CONTROL.

When this control is turned clockwise, the cutting force of the saw blade increases;

when it is turned counterclockwise, the cutting force decreases. Align the pressure

control with the zone which corresponds to the material on the work piece to be cut.

12/10/07 Model LE13A Text 13

Page 14

4.2 Blade change

1. Select the saw blade best suited for the work piece to be cut. Size and

shape of the work piece and type of material should all be considered when

selecting the saw blade to be used.

2. Saw blade change.

Warning!!!!!

Always wear gloves, safety glasses and other protective equipment

to prevent injury when changing the saw blade. The power must be

locked out before changing the saw blade.

a. Turn on the main power on the left side of the machine.

b. Press the hydraulic ON button to start the hydraulic pump motor.(item

6 page 11)

c. Turn the auto-manual selector to manual position (the hand item 4

page 11)

d. Press the raise button (item 6 pages 11) to raise the saw head until it

is above the vise.

e. Push the emergency stop button and turn off the main power on the

machine.

Warning!!!!!

Never change the blade with the power on.

f. Remove the blade safety cover.

g. Open both the drive wheel and idle wheel covers.

h. Turn both the left and right insert lock levers counter clockwise to

loosen the inserts.

i. Turn the blade tension selector to “LOOSEN” to move the driven

wheel toward the idle wheel, this will loosen the blade.

j. Remove the band saw blade.

k. Place the saw blade onto both the drive and idle wheels.

l. Insert the saw blade into both the left and right inserts so that the

back edge of the saw blade touches the back-up tip of each insert.

m. To properly position the saw blade on the drive wheel, insert so that

the back edge of the saw blade makes contact with the flange of the

drive wheel.

n. Turn the blade tension handle clock wise to tighten the blade (about

ten clicks)

3. Adjust the position of the wire brush.

a. Loosen the lock lever for the wire brush case.

b. Manually move the brush case so that the wire brush contacts the

saw blade properly.

12/10/07 Model LE13A Text 14

Page 15

4. Properly position the blade guide according to the diameter (or the width) of

the work piece to be cut.

a. Pull the left insert lock lever down to loosen the insert.

b. Loosen the lock lever of the blade guide, and manually move the

blade guide and align the indicator of the blade guide with the scale

of the guide bar, depending upon the size of the work piece.

c. After adjusting the blade guide position tighten the lock lever of the

blade guide.

d. Push the insert lock lever up to tighten the insert.

4.3 Manual Operation Instructions

MANUAL OPERATION

1. Properly place the work piece on the work feed table.

e. Depress the raise button to raise the saw head until it is at the highest

position.

f. Manually disengage the pawls from both the front and rear vise racks,

and open the front and rear vise completely.

g. Loosen the lock handles of the vertical roller guides to completely

open the vertical roller guides.

h. Set the rear vise stop position switch so that the rear vise stays at the

backward limit position.

i. Carefully place the work piece onto the work feed table so that is

extends approximately 2.5” (60mm) beyond the rear vise.

2. Determine the proper position of the work piece for cutting.

j. Turn the vise clamp selector to “rear vise open”.

k. Manually move the rear vise until it pushes against the work piece.

Then engage the pawl with the rack.

l. Turn the vise clamp selector to “front vise open”, so that the work

piece is securely clamped with the rear vise.

m. Push the vertical roller guides against the work piece and tighten the

guides with the lock handles.

n. Depress the rear vise forward button until the rear vise moves to the

forward limit position.

o. Manually move the front vise until it pushes against the work piece

then engage the pawl with the rack.

p. Turn the vise clamp selector to “rear vise open” so that the work

piece is securely clamped with the front.

q. Depress the rear vise backward button until the rear vise moves to

the backward limit position.

r. Turn the vise clamp selector to “front vise open”.

s. Lower the saw blade by depressing the quick approach button, until

the quick approach feeler is just above the work piece.

t. Depress the rear vise forward button to move the work piece forward

until the cutting position of the work piece is aligned with the saw

blade. If necessary, press the rear vise backward button so that the

work piece is accurately positioned.

12/10/07 Model LE13A Text 15

Page 16

u. After properly adjusting the position of the work piece, turn the vise

clamp selector to “back vise open”, so that the work piece is securely

clamped with the front vise.

v. Adjust the blade speed to the proper speed section 4.4

w. Turn on the coolant by turning the coolant switch. The flow of cutting

fluid should be adjusted, depending upon the material.

x. When the blade drive button is pressed, the cutting fluid pump begins

to operate causing the cutting fluid to flow out the coolant lines. Adjust the

cutting fluid flow with the fluid controls so that the proper amount of fluid will flow

from the blade inserts, the quick approach and the wire brush case.

Saw chips which are fine and curve require an increase in the amount of

cutting fluid.

Saw chips which are fine and grained require a reduction in the amount of

cutting fluid.

5. Adjust both the cutting force and the descending speed of the saw blade and

begin cutting the work piece by pushing the green blade drive button.

a. Turn the cutting pressure control (page 13 for description) to the zone

corresponding to the material (or shape) of the work piece to be cut.

When the work piece is large (or difficult to cut), turn the control to the

right end of the corresponding zone. When the work piece is small (or

easy to cut), turn the control to the left end of the corresponding zone.

Always turn the cutting pressure control to the point most suitable for

the work piece to be cut.

b. Slowly turn the feed control clockwise from zero to the point just

before the blade begins to vibrate. As the flow control is turned, the

saw blade begins to descend and the actual cutting of the work piece

begins. After completion of the cutting, the saw blade stops at the

lower limit position.

4.4 Automatic operation instructions

Set part length (section 4.6). Follow instructions for manual operation. The only thing

that will be different is after you push the green start button turn the manual /

automatic switch to automatic (see section 4.1).

Warning!!!!!

Always turn the machine power off before changing the blade

speed.

12/10/07 Model LE13A Text 16

Page 17

4.5 Blade speed change

3. Adjust the saw blade speed.

c. There is a handle just to the right of the motor, when loosened the

motor can be moved up and down. Move the motor up and move the

belt to the desired speed.

d. It is necessary to properly adjust the saw blade speed, depending

upon the material and shape of the work piece to be cut.

e. The blade drive uses a V-Belt: A-47 (60 Hz) and A-48 (50 Hz).

Blade speeds are 27, 40, 54, 68 and 80m/min

4.6 Part length set up and automatic operation

How to set the required cutting length on the cutting length counter.

WARNING!!!!!

Do not change the numerals (number of feeds) on the feeding times

preset counter during operation.

a. Loosen the hand-wheel lock screw.

b. Turn the hand-wheel to set the required cutting length on the cutting

length counter.

12/10/07 Model LE13A Text 17

Page 18

NOTE:

1. When setting the cutting length, be sure to turn the hand wheel

clockwise past the desired length, then turn it counter clock wise to

the desired length to prevent error due to the backlash.

c. Tighten the hand-wheel lock screw

Hand wheel

4. If the required cutting length exceeds the maximum cutting length of 23.6 inches

(600mm), feed the work piece as many times as necessary, using the feed

times preset counter (item 14 page 11). For example: if a cutting length of 31.5

inches (800mm) is required.

a. Divide 31.5 by 2 =15.75

b. This will be the length of cut needed to make 31.5 inches.

c. Set the feed times counter at 2.

d. Now the material will be pushed forward two times, each time moving the

material forward 15.75 inches.

NOTE:

i. The cutting length preset device is factory adjusted to compensate

for the set width of the saw blade.

ii. When the feeding times preset counter is not in use, set it a 1.

iii. The feeding times preset counter is capable of feeding the work

piece nine times, up to a maximum cutting length of 212.5 inches

(5400mm).

5. How to set the number of required cuts on the cutting piece counter.

Warning!!!!!

Do not change the number of cuts during cutting operation.

a. Set the cutting piece counter switch (item 12 page 11) at “o” (OFF).

b. Press the reset button (on the bottom of the readout) to reset all white

numerals to zero.

c. On the top of this read out there are five black buttons, each button is a

different digit. Push these buttons to desired amount of pieces to be cut.

d. After the number of cuts has been set.

e. Set the counter ON/OFF switch at “| “(ON).

12/10/07 Model LE13A Text 18

Page 19

6. Turn the auto-manual selector to AUTO and press the blade drive button. The

blade will run and the automatic operation will begin.

7. After the required number of cuts have been completed, the saw blade will stop

in the lower position and all machine operations will stop.

NOTE:

i. During automatic operation, shifting the auto-manual selector to

MANUAL will cause the saw blade to stop in the lower position,

after completion of the cutting operation on which the selector was

shifted.

NOTE:

If the machine does not start be sure the vise switch (item 8 in the control panel

description) is turned to the left.

4.7 How to install bundle attachments

How to use the bundle cutting attachments

WARINING!!!!!

Never install the bundle attachments while the machine is in

operation. This machine electricity must be locked out before

installing bundle attachments.

WARNING!!!!!

Keep fingers clear of vise, personal injury could occur.

This multi-vise is used when bundle cutting is performed. To perform bundle cutting,

proceed as follows:

1. Install the stud bolts on the front and rear vises and position the multi-vise on

the front and rear vises.

2. Connect the multi-vise hoses to their quick connectors at the front and rear vise

cylinders.

3. Attach the bundle cutting fence to the work tray. The fence is designed to

prevent the cut pieces from spreading out across the work tray. Adjust the width

of the fence so that it equals the width of the bundle.

12/10/07 Model LE13A Text 19

Page 20

4. Set the switch to bundle cutting (item 13 pages 11).

CORRECT

INCORRECT

5. Position the work piece for bundle cutting.

Allowable clamping width: 7 inches (180mm)

6. Roughly align the center of the multi-vise cylinders with the center of the work

pieces to be cut and tighten the lock nuts.

7. Turn the multi-vise handles so that there is 1/4” of clearance between the work

retaining plate and the material.

8. For subsequent operations, refer to the instructions for manual operation and

automatic operation, and perform the bundle cutting.

EXAMPLE:

BLADE BREAK IN OPERATION

When a new saw blade is used, be sure to first break in the blade before using it for

actual extended operation. Failure to break in the blade will shorten the life of the

blade and result in less than optimum efficiency. To break in the blade, proceed as

follows:

1. Lengthen the time required for cutting 2-3 times that of normal.

12/10/07 Model LE13A Text 20

Page 21

2. The break-in operation can be considered sufficient if all unusual noises

or metallic sounds have been eliminated. (For instance, to completely

break in the blade, a minimum of five complete cuts of a 200mm (7.9 in)

diameter work piece will be required.)

3. After the break-in operation has been completed, return the blades speed

and descending speed to their normal settings

4.8 Cutting Data

12/10/07 Model LE13A Text 21

Page 22

6.2 Lubrication

Description

Hydraulic Oil DTE 24 Hydraulic oil

Gearbox Oil 80/90 Synthetic gear lube

Drive wheel Shell Alvania EP Grease 2 or Mobilplex 48

Idle Wheel Shell Alvania EP Grease 2 or Mobilplex 48

Blade Tension Device Shell Alvania EP Grease 2 or Mobilplex 48

Worm Shaft Shell Alvania EP Grease 2 or Mobilplex 48

Cutting Fluid Water based coolant

Lubricant

Section 7 – MAINTENANCE

7.1 Periodic Maintenance

After use for the day, clean out saw chips that have accumulated in the machine. To do

this, set the cutting fluid pumps switch at “|”and wash saw chips away with the discharging

cutting fluid.

Before beginning operation for the day, perform the following maintenance operations:

1. Check the hydraulic oil level, adding oil if necessary.

2. Check the cutting fluid level, adding fluid as

necessary. If the fluid appears contaminated or

deteriorated, drain and replace it.

3. Check the saw blade to ensure that it is properly

positioned on both the drive, idle wheels and in the left

and right inserts.

4. Check the wire brush for proper contact with the saw

blade. If it is worn, replace.

5. Check the urethane rope (used on the idle wheel) for

Grease Fittings

wear. If they are broken, replace.

6. Lubricate the following points:

a. Front vise slide plates

b. Rear vise slide plates

c. Feed cylinder guide shaft.

7.2 Six Month Maintenance

Check the following once every six months:

1. Clean the filters in the cutting fluid tank.

2. Replace the transmission oil (recommended oil: 80/90

synthetic) after the first three months or 600 hours of

operation and every six months or 1200 hours of

operation (whichever occurs first) thereafter.

3. Replace the hydraulic oil.

12/10/07 Model LE13A Text 22

Page 23

SECTION 8 – TROUBLE SHOOTING CHART 8.1

Machine has power but will not start cut in Semi-Auto mode

Vibration during cutting or excessive noise

Yellow warning light flashes

Material will not feed

Blade cuts crooked or unsure

Hydraulic pump runs when head button pushed but machine will not run

Will not cut in automatic mode

Will not cut to length set on digital readout

Blade Stalls in cut

Use of blade with incorrect pitch. Call blade supplier.

Failure to break in blade. Perform break-in (first 12 cuts 1/3 slower

than normal cut rate).

Excessive blade speed. Reduce speed.

Insufficient blade speed. Increase blade speed.

Excessive chip load (blade loads up

with chips, too fine).

Wire chip brush worn/improperly

adjusted.

Blade improperly held by insert.

Carbide pads too loose.

Roller table in true alignment with

feeder unit.

Belt slipping stalling blade. Belt is loose on pulley. Loosen motor

Guide arms set too far apart. Move guide arms closer together. Use

Limit switches on doors and pulley

(open).

Fuse blown in machine or wall

service.

Insufficient blade tension. Tighten blade a half to a full turn beyond

Out of stock or end of program Estop pushed in.

Blade too narrow/too wide (out of

capacity) too long.

Coolant mixed incorrect, or no

coolant used.

Front vise not closed. Jog the vise selector switch and bump

Zero parts entered in piece counter

or zero strokes.

Not in automatic mode. Reset

piece counter bottom button.

Part moved during cut. Check clamping of part. Use bundle

Movement detector on idle wheel

out of adjustment.

Length set up wheel backed up

during set up.

Reduce load cut slower or coarser blade,

adjust chip brush for cleaning blade.

Readjust or replace (just touch blade).

Tighten the 2 knurled knobs on guide

arms as tight as possible to reduce pad

clearance, or replace.

Not set straight to machine feed system.

Sits too high or low to the feed roller.

Adjust

lock handle, push down on motor and

tighten. Replace belt is worn.

indicator marks on guide arm rail for

proper spacing.

Check all doors are closed. Check limit

adjustment, make sure cotter pin is not

interfering with limit activation.

Check and replace fuses as needed.

when tensioner lock ring clicks.

Press reset button on counter. Make

sure you have stock. Reset number of

pieces in counter check E-stop.

Use only blade within cap. .035-.045

thickness. Use blade or correct length &

width.

Mix coolant to manufactures specs. (10-

1) Increase coolant flow.

vise close button. This will close vises.

Reset # in piece counter. Must have at

least 1 stroke entered. Out of stock limit

tripped. Feed limit failure.

Reset piece counter. Check that

machine is in automatic cycle. Vises are

closed.

cutting option for multiple piece cutting.

Adjust red LED illuminates as wheel

passes by it.

Set to length without going beyond

length, and backing up. Backlash is

screw will cause

12/10/07 Model LE13A Text 23

Page 24

8.1 Minor trouble shooting

Symptom Probable Cause Corrective Action

Hydraulic pump motor

does not run even

though hydraulic on

button is depressed.

Saw blade motor does

not run even when

blade drive button is

depressed.

a. Power line disconnected

b. Circuit protector OFF

c. Thermal relay activated

d. Loose terminal retaining

e. Out-of-stock limit switch

a. Terminal relay activated

b. Vise clamp selector set at

c. Rear vice stop position

screw

activated

switch

set at

a. Connect

b. Turn ON

c. Push reset button

d. Tighten

e. Set vise clamp selector at

a. Push reset button

b. Set vice clamp selector at

c. Move rear vise to its

forward limit position

(when performing bundle

cutting)

d. Set rear vise stop position

switch at (when

performing single cutting)

Rear vice does not

move forward or

backward even when

its forward or

backward button is

depressed.

Front or rear vise does

not open or close even

though vise clamp

selector is manipulated

For problems not indicated on the above chart, refer to the electrical circuit and

hydraulic circuit diagrams (provided inside the electrical enclosure).

a. Auto-Manual selector set at

b. Saw head not at its UP

position

a. Auto-Manual selector set at a. Change auto-Manual

a. Set auto-manual selector

b. Raise saw head to its UP

position

selector setting.

For original Dake replacement parts contact us at:

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecorp.com

12/10/07 Model LE13A Text 24

Loading...

Loading...