Page 1

*** PLEASE NOTE****

This manual is for Dake Johnson manufactured J & JH horizontal bandsaws from 1985 to

current.

If your model is prior to 1985, please contact the factory for manual and parts information.

1938 - 1965 Johnson manufactured J saws.

1965 - 1984 Kysor/Johnson manufactured J & JH saws.

6/02

1

Page 2

Operator’s Manual and Part’s List

Model J-10 & JH-10

Dake/Johnson Horizontal Bandsaw

6/02

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecorp.com

2

Page 3

6/02

FOREWORD

This manual has been prepared to acquaint you with the operation, maintenance, and

serviceable components of your Dake/Johnson machine. We urge that you read it carefully

before operating your machine. Please refer to the pertinent sections when contacting the

factory regarding parts, schematics…or when you have other questions.

As Dake’s policy is one of continuous development for each range of machine, the contents

of this manual, though completely up to date when issued, are subject to change without

notice.

For your information and future reference, pertinent data concerning your machine may be

inserted in the space provided below.

Machine Model ___________________________

Serial Number ___________________________

Date Received _________________

Voltage ___________________________

Phase _______ Cycle _______ Motor H.P. ______

Please give the machine model and serial number in correspondence, and include the parts

numbers on parts orders to speed the filling of your requirements and to minimize your

inconvenience.

FACTORY: DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecorp.com

NOTE: Use only genuine Dake/Johnson replacement parts and optional equipment. Use of

substitutes or imitations may cause damage to the machine, void the warranty, and may

cause injury.

3

Page 4

CONTENTS

GENERAL

Basic Machine Data ……………………………………. 4

Specifications …………………………………………….. 4

Machine Installation ……………………………………… 4

Safety Information………………………………………… 5-6

Electrical Diagrams ………………………………………. 7-9

Machine Features ……………………………………….. 10

SECTION 1

OPERATION

Controls and Operation ………………………………….. 11

Standard Drive …………………………………………… 12

Blade Selection ………………………………………….. 13

Blade Removal/Installation ……………………………… 13-14

Blade Guide Adjustment ………………………………… 14-15

Balance Spring Adjustment …………………………….. 15

Feed Cylinder Bleeding …………………………………. 15

SECTION 2

MAINTENANCE

Lubrication ………………………………………………… 16

Sawing Problems and Solutions ………………………… 17

SECTION 3

ASSEMBLIES & PARTS LISTS

Machine Assembly (Front View) ………………………… 18-19

Machine Assembly (Top View) ………………………….. 20

Gear Box Assembly ………………………………………. 21

Hydraulic Assembly ………………………………………. 22-23

Guide Arm Assembly ……………………………………... 24

Vise Unit ……………………………………………………. 25

6/02

4

Page 5

6/02

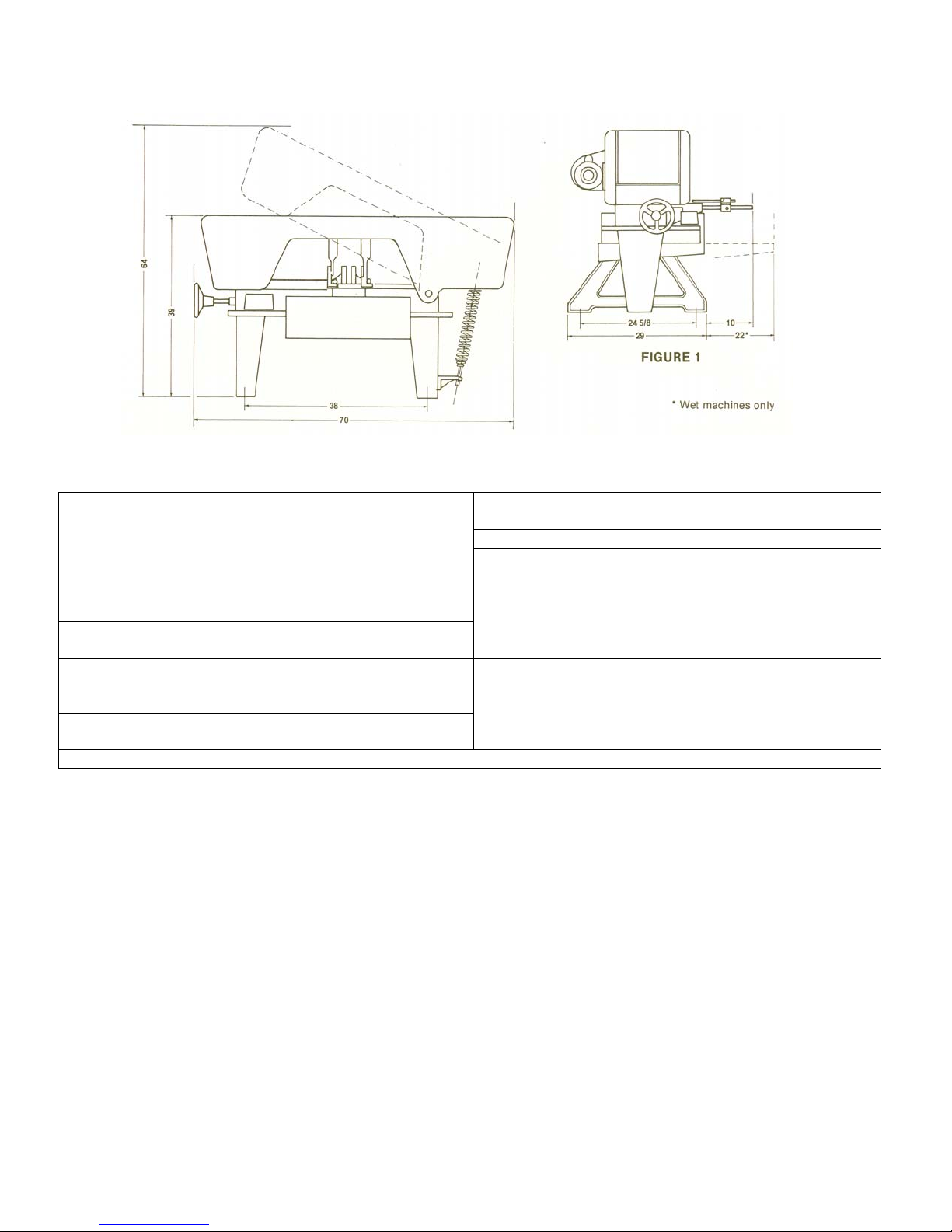

BASIC MACHINE DATA

SPECIFICATIONS

Capacity………...10” (25cm) rounds, 18” (46cm) flats Floor Space ……………… 29” (74cm) x 70” (178com)

Blade Size (Part Numbers: 75958 (3/4”) OR 75957 (1”) Height, Closed* …………………………….. 39” (99cm)

J-10 ……………………… ¾” (2cm) x 137” (348cm) Height, Open* ……………………………... 64” (163cm)

JH-10……………………... 1” (3cm) x 137” (348cm) Floor to Bed* …………………………….. 23 ¾“ (60cm)

Blade Speeds Net Weight

………………………………50, 90, 160 and 270 fpm J-10 Dry …………………………. 812 lbs (368 kgs)

………………………………..15, 29, 49 and 82 mpm J-10 Wet ..……………………….. 845 lbs (383 kgs)

Bed Work Area. ……..……… 11” (28cm) x 18” (46cm) JH-10 Dry ……………………..… 817 lbs (371 kgs)

Vise Size ………………………. 5” (13cm) x 11” (28cm) JH-10 Wet ……………………….. 850 lbs (386 kgs)

Drive Motor Gross Weight

J-10 ………………………………….…. 1 hp (.75kw) J-10 Dry …………………….…… 896 lbs (406 kgs)

JH-10 …………………………………... 1 hp (.75kw) J-10 Wet ……………………..….. 929 lbs (409 kgs)

Electrical System, specify …....110/230V, 1 PH, 60 Hz JH-10 Dry …………………..…… 901 lbs (409 kgs)

208/230/460V, 3 PH, 60 Hz JH-10 Wet ..……………………….934 lbs (424 kgs)

Coolant Capacity …………………………...… 3 gallons Water-soluble only – do not use oil.

INSTALLATION

UNCRATING :

machine has been moved to its approximate location.

CAUTION: BE SURE ELECTRICAL CHARACTERISTICS OF MOTOR AND SWITCH

CORRESPOND WITH ELECTRICAL POWER SUPPLY.

!!!ATTENTION!!! DO NOT ATTEMPT TO RUN THIS SAW UNTIL THE BLADE ALIGNMENT HAS

BEEN CHECK AS PER THE OWNER’S MANUAL AND THE BLADE HAS BEEN PROPERLY RETENSIONED.

LEVELING: Position machine reasonably level, shim under legs if necessary. Wet machines

should be more carefully leveled to be certain that the coolant intake remains submerged.

CONNECT INCOMING POWER TO THE STARTER PER APPLICABLE DIAGRAM, AND IN

ACCORDANCE WITH ALL LOCAL CODES.

Remove crating carefully. For ease in handling do not remove from skid until

5

Page 6

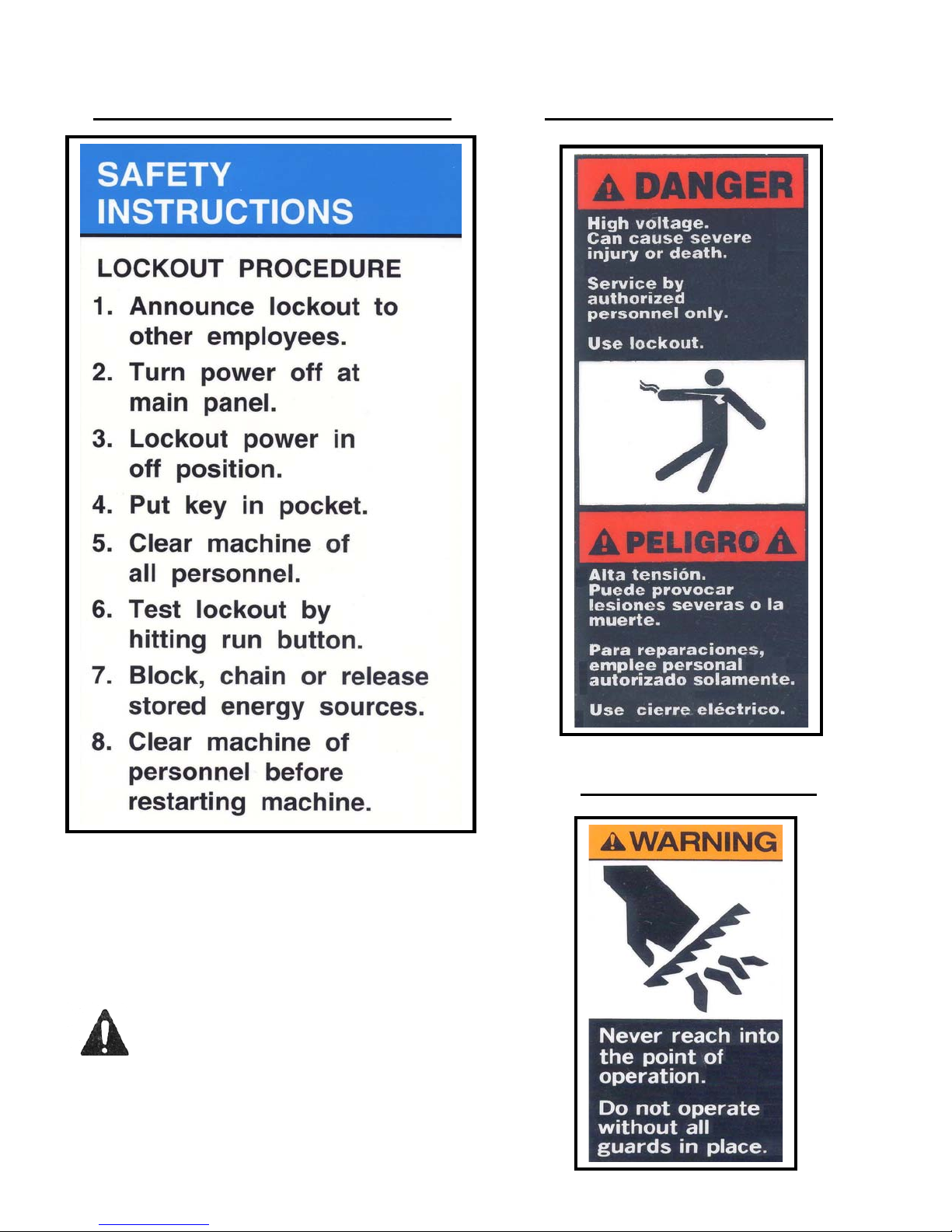

SAFETY INFORMATION

LABEL

84605

LABEL

84604

LABEL

84395

LABEL

76462

LABEL 84605 – SAFETY INSTRUCTIONS

6/02

SAFETY

This is the safety alert symbol. When

you see this symbol on your saw, be alert to

the potential for personal injury.

Follow recommended precautions and safe

operating practices. Carefully read all safety

messages in these instructions and on your saw

safety signs. Keep safety labels in good

condition. Replace missing or damaged safety

labels.

6

Page 7

LABEL 84604 – SAFETY INSTRUCTIONS LABEL 84395 – DANGER LABEL

LABEL 84604 – WARNING

Follow recommended precautions and safe operating

practices. Carefully read all safety messages in these

instructions and on your saw safety signs. Keep safety

labels in good condition. Replace missing or damaged

safety labels.

6/02

SAFETY

This is the safety alert symbol. When you see this

symbol on your saw, be alert to the potential for

personal injury.

7

Page 8

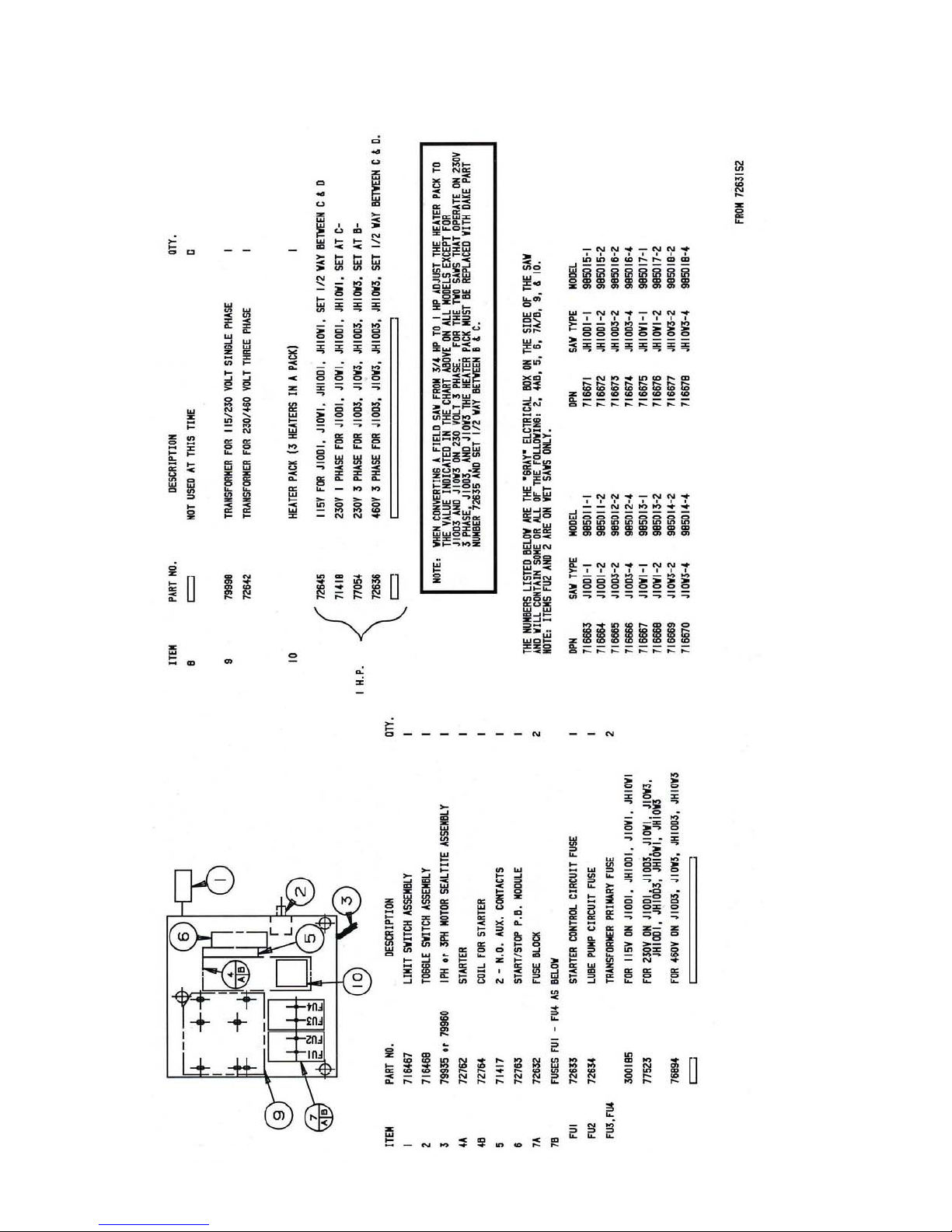

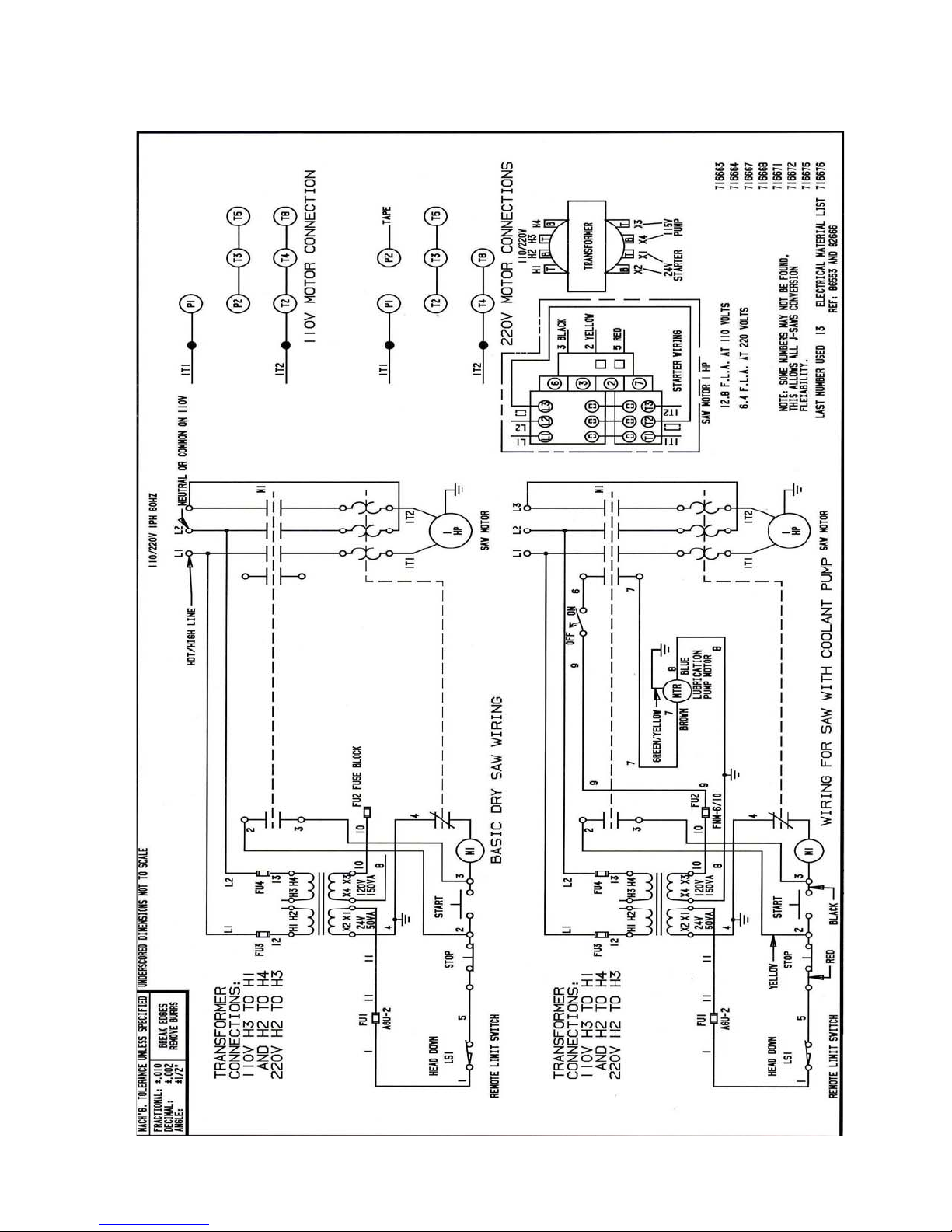

ELECTRICAL CONTROL DIAGRAMS

6/02

8

Page 9

SINGLE PHASE ELECTRICAL DIAGRAM

6/02

9

Page 10

THREE PHASE ELECTRICAL DIAGRAM

6/02

10

Page 11

Vise

Handwheel

Head Feed

Control

MACHINE FEATURES

Blade

Tension

Handle

Guide Arm

Stock

Stop Gauge

SECTION 1

6/02

Off-On

Switch &

Starter

Balance

Spring

11

Page 12

OFF/ON SWITCH

All J-saw machines are equipped with a manual starter with low voltage, dropout protection

and a limit switch. When the machine frame reaches the end of its down travel it contacts the

limit switch, turning off the machine.

HYDRAULIC CONTROL

The hydraulic control cylinder mounted on the rear of the machine is operated by a control

valve mounted on the front of the machine head. To close valve, turn the control to the right.

When the valve is completely closed, the frame will remain stationary at the desired position.

To open valve, turn control to the left. Opening of the valve will control the speed of descent

of frame (or head) and does not control frame weight. This control is mainly used in cutting

pipe or thin-walled tubing, structurals, etc., to prevent plunging of the saw blade.

VISE

The vise can be positioned straight for a 90º cut or at any angle to 45º. The vise swivel jaw

adjusts automatically to any position of the stationary jaw.

VISE QUICK-RELEASE

Consists of the vise half-nut, vise lift, lift handle and a sliding hold-down block to which the

swivel jaw is attached. Move the vise lift handle toward front of the machine to disengage the

vise nut from the vise screw; this allows the swivel jaw to be moved freely. Move the lift

handle towards the rear of the vise to engage the vise nut when clamping.

VISE HANDWHEEL

Used to open and close the vise jaws…vise nut must be fully engaged. Turn handwheel

counterclockwise to open the vise, clockwise to close the vise.

BLADE TENSION HANDLE

Turn the screw handle clockwise as tight as possible. Check every eight operating hours and

retighten to compensate for possible stretching of blades. Consult your blade manufacturer

for the proper PSI tension.

GUIDE ARMS

Loosen the handle on the left guide arm to slide arm along the top of the frame. Guide arms

should be set as close as possible to the work, without interfering.

STOCK STOP GAUGE

Consists of a stock stop assembly and a mounting bar installed in the tip-off block on front of

the machine. The stop assembly can be moved along the bar to indicate correct length for

duplicate cuts. Stock stop rod has a cap screw in the end for making fine adjustments. Turn

rod to extended position (rotated to the right) when measuring stock, and retract the rod

(rotate to left) when cutting.

OPERATING INSTRUCTIONS

6/02

OPERATION

12

Page 13

6/02

1. Raise frame and close feed cylinder valve to hold frame in elevated position.

2. Loosen the vise nut and open the vise. Place work in vise and slide the vise swivel jaw

against the work piece. Engage the vise nut and tighten the vise screw to clamp the work

securely.

3. Slowly open feed cylinder valve and lower the frame until the blade almost touches the

work. CAUTION: IF BLADE SHOULD REST UPON THE WORK BEFORE MOTOR IS

STARED THE BLADE TEETH CAN BE DAMAGED- IF BLADE IS DROPPED ONTO THE

WORK THE BLADE MIGHT BREAK. MAKE SURE BLADE IS PROPERLY BROKEN IN

PRIOR TO CUTTING.

4. Move the adjustable guide arm as close as possible to the work to provide maximum

blade rigidity.

5. Check the blade tension. Consult blade manufacturer for proper PSI tension.

6. Turn coolant valve on (wet machines only). CAUTION: DO NOT OPERATE MACHINE

WITHOUT SUFFICIENT COOLANT IN TANK. COOLANT MUST BE WATER-SOLUBLE

DO NOT USE OIL.

7. Check blade speed for material you are cutting. Refer to blade manufacturer for proper

speeds for the material you are cutting.

8. To change blade speed, loosen thumbscrew on right end of machine and raise the pulley

guard. Move drive belt to proper grooves in both pulleys for desired blade speed, (see fig. 3).

Replace guard.

9. Start motor.

10. Open feed cylinder valve to the proper setting. “Proper” setting depends upon type of

material, hardness and thickness of stock and desired accuracy and finish. Soft materials

require less feed than hard materials. Thin cross-sections require less feed than solid crosssections. Generally, reduced feed pressure will result in a straighter more accurate cut.

13

Page 14

6/02

BLADE SELECTION

Saw blades should be selected by choosing the blade that will give the best results at the

lowest cost. Type of material and the speed at which it must be sawed determine the choice.

Listed below are general factors affecting blade selection.

1. Blade Type.

(a) Carbon Steel – Can be used to cut all types of ferrous, non-ferrous and

composition materials except alloys containing high percentage of chrome and

nickel. Limiting factor: low resistance to heat.

(b) Bi-Metal – Designed for cutting ferrous metals in production cut-off

applications. Developed to saw high alloy materials that cannot be cut

economically by other means. Can be operated at higher speeds and greater

feed pressures than carbon steel blades.

2. Tooth Style.

(a) Standard – Zero degree rake angle and full round gullets. Best suited for

cutting ferrous and non-ferrous materials.

(b) Skip Tooth – Basically the same as standard except for more widely spaced

teeth. Provides added chip room when cutting non-ferrous materials.

(c) Hook Tooth – Similar to skip tooth except teeth have positive rake. Effective

in sawing non-ferrous metals and large ferrous sections when heavy feed

pressures are required. Fast cutting.

3. Tooth Spacing.

Tooth spacing is determined by hardness of material and/or the cross-section.

The harder the material, the more teeth per inch. Thin cross-sections require

more teeth to avoid straddle. Rule: at least 3 teeth in contact with work.

4. Tooth Set.

(a) Raker – Most widely used. Consists of a repeated pattern of one tooth set

left, one right and one tooth straight. Recommended for production cutting

where material is of uniform size, shape and type.

(b) Wavy – Has groups of teeth set alternately to the left and to the right forming

a wave-like pattern. Used for cutting thin stock or where the work varies such

as in pipe, angles, channels and extrusions.

BLADE REMOVAL

1. Raise frame a few inches above bed and close feed cylinder valve to hold frame up.

2. Remove necessary guarding and blade cleaning brushes.

3. Turn blade tension screw counterclockwise and pull idle wheel toward center of machine.

4. Push blade down out of blade guides and remove blade from machine.

BLADE INSTALLATION

14

Page 15

6/02

1. Raise frame a few inches above bed and close feed cylinder valve to hold frame up.

2. Remove necessary guards and blade cleaning brushes.

3. Turn blade tension screw counterclockwise and pull idle wheel toward center of machine.

4. Grasp blade in center forming two loops. From rear of machine place blade loops under

wheels and rest the near portion on right front blade guard. CAUTION: BE SURE TO

WEAR GLOVES WHEN HANDLING BLADES.

5. Push blade up into blade guides. CAUTION: BE AWARE OF HYDRAULIC & COOLANT

LINES.

6. Fit blade up against flanges of the idle and drive wheels and tighten tension screw enough

to hold blade in place. Depress side of blade near rear blade guard to hold blade on

wheels while tightening tension screw.

7. Check to see that the blade is positioned correctly and tighten screw. Consult blade

manufacturer for proper PSI tension.

8. Install blade cleaning brushes and guards that were removed earlier.

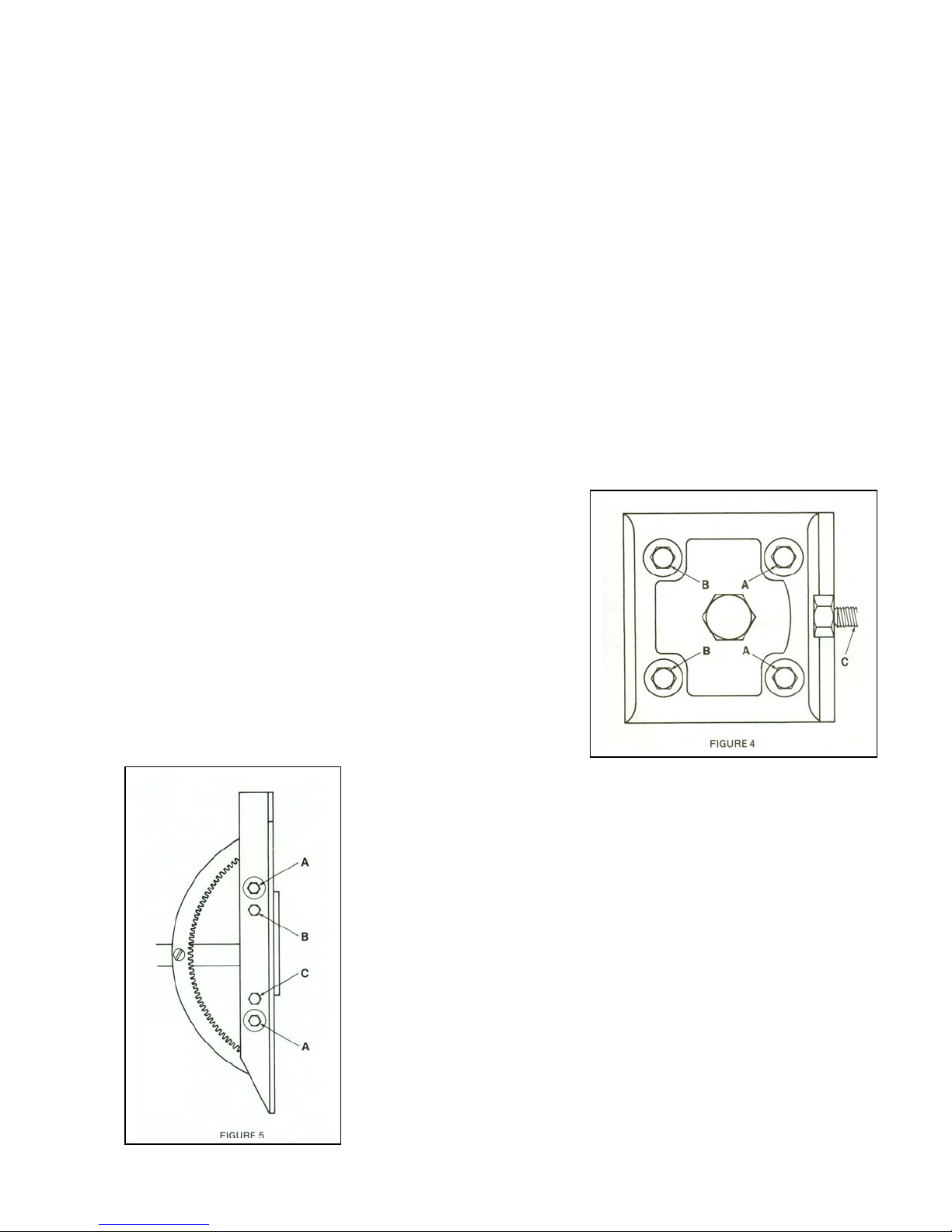

BLADE TRACKING ADJUSTMENT

Saw blade should track on each wheel with the back of blade up to, but not riding on, the

wheel flange. Adjust as follows:

1. Idle Wheel.

Open top cover on left end of machine to gain

access to idle wheel. Idle wheel is mounted on a

slide block, which contains the blade height

adjustment screws. To raise the blade, loosen the

two screws toward center of machine (A, Fig. 4)

one-half turn and tighten the other two screws (B)

one-half turn. Be sure tension screw (C) is properly

tightened. Reverse procedure to lower blade. Care

must be taken not to over adjust. Check by running

machine after each adjustment.

2. Drive Wheel.

(a) To raise the blade, loosen two cap screws (A, Fig. 5) and

tighten screws (B and C). All four screws must be turned

equally and in small increments (about ½ turn) to avoid overadjustment; check by running machine after each adjustment.

(b) To lower blade, reverse above procedure – loosen screws

(B and C) and tighten screw (A).

15

Page 16

6/02

E

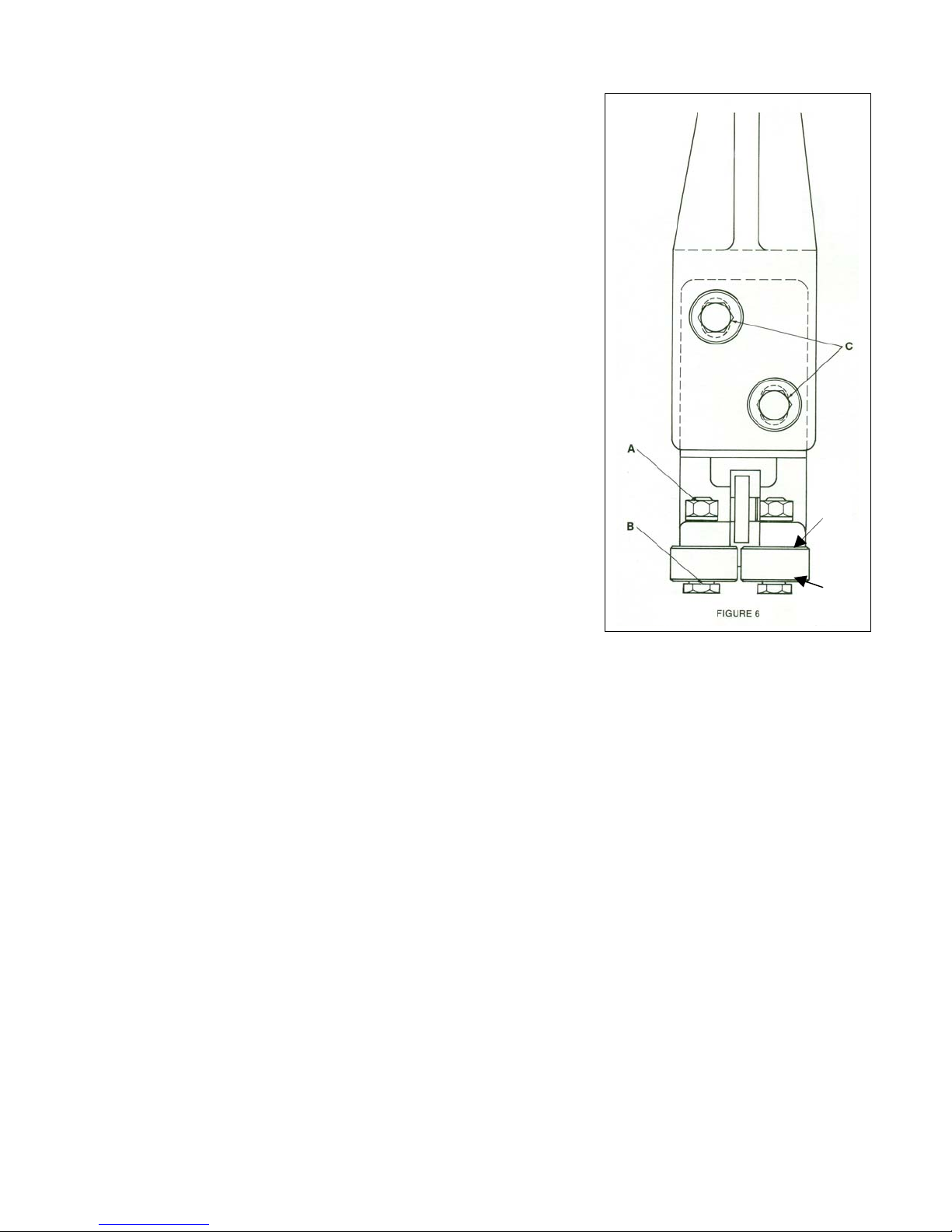

BLADE GUIDE ADJUSTMENT

NOTE: The following instructions are for one

guide arm; procedure is same for both. Left hand

guide arm is shown in Figure 6.

1. Loosen nut (A, Fig. 6) and turn eccentric axle (B)

until there is no light gap between rollers and

blade…do not pinch the blade. Tighten nut (A).

2. Vertical and radial adjustment is provided by the

clearance in the guide mounting holes (C, Fig. 6).

This allows squaring of the blade to the bed, and

holding the blade in the natural blade line.

3. Proper guide adjustment may require adding or

removing washer (shims) (D, Fig. 6) for correct

bearing height (E, fig. 6)

D

FRAME BALANCE SPRING ADJUSTMENT

To check for proper balance spring adjustment, lift frame at eh handle with an extension type

scale (fish scale). Frame should weigh 12-15 pounds; if no, adjust by turning nut on the tension

screw at bottom of spring.

FEED CYLINDER BLEEDING

Air trapped in the hydraulic cylinder can cause the down feed of the machine head to be

erratic or “bouncy”. Before taking corrective steps observe CAUTION.

CAUTION: UNDER NO CIRCUMSTANCES SHOULD THE HYDRAULIC TUBING CONNECTIONS

BE LOOSENED OR DISCONNECTED WITH THE MACHINE HEAD IN THE UP POSITION.

Bleed the hydraulic cylinder circuit as follows:

1. Place a long neck funnel in the oil cup (diameter of funnel neck must be almost the same

size of the fill cup.

2. Pour oil into the funnel. *Make sure there is a sufficient amount of oil in the funnel so that

air does not get drawn into cylinder.

3. With head feed valve open, raise and lower head about four times.

4. Pour more oil into the funnel.

5. Close head feed valve.

6. Raise head.

7. Open feed valve and lower head.

8. Repeat 5,6 & 7 several times.

9. Remove funnel.

16

Page 17

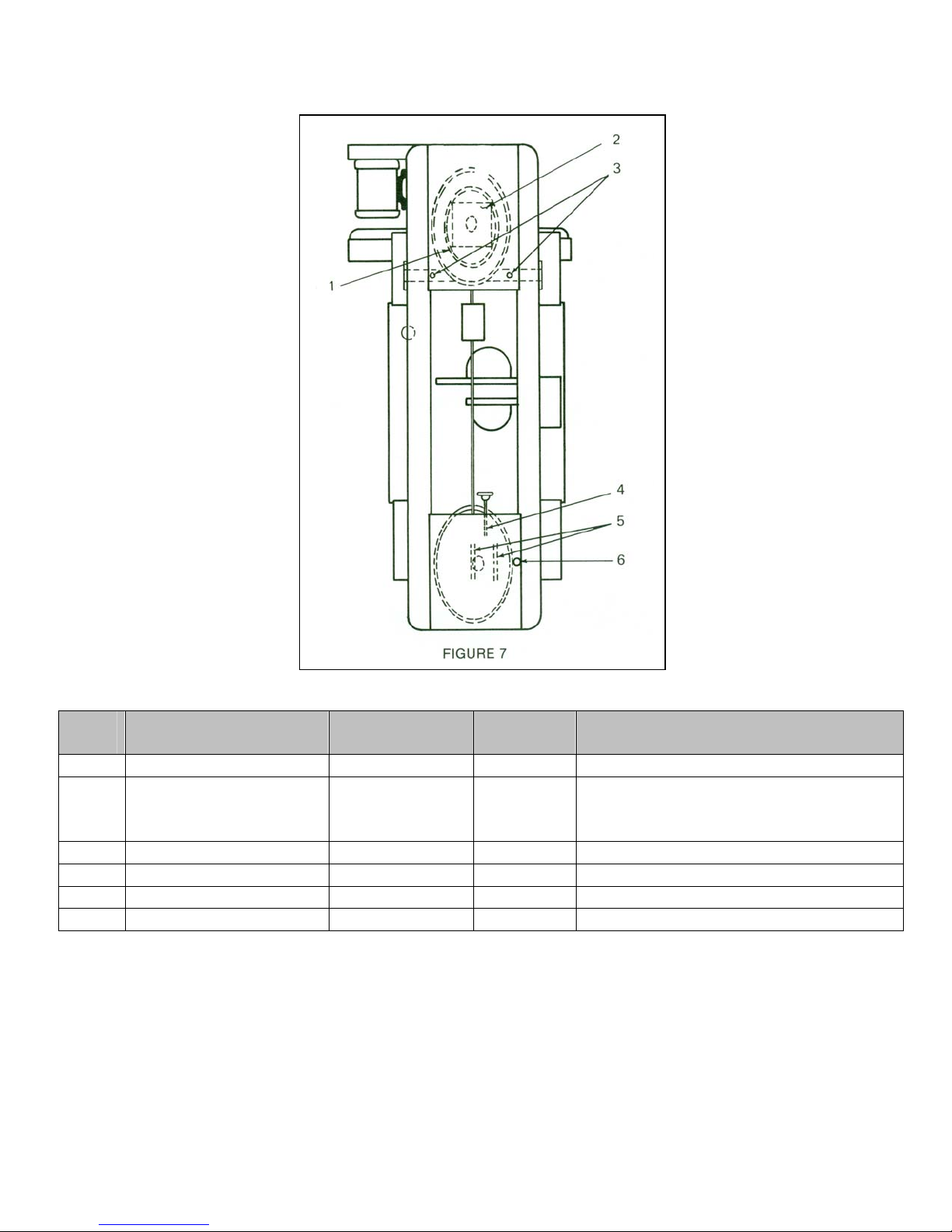

MAINTENANCE

LUBRICATION

Lube

Point

1 Drive wheel ring gear 6 months

2 Gear box Maintain level

3 Pivot bar (2 fittings) Monthly

4 Tension screw 6 months

5 Idle wheel slide ways 6 months

6 Feed cylinder Maintain level

A – Mobil DTE 24 or 26 oil. Viscosity range 310SSU @ 100ºF.

B – Gear oil 80/90. Mobil SHC635 synthetic gear lube.

C – General purpose grease. Viscosity range NLGI-2.

D – Open gear lubricant.

Description

RECOMMENDED LUBRICANTS

Interval

Lubricant

D

B

C

C

C

A

Instructions

Clean thoroughly before lubricating.

Maintain level at 2 to 3 ounces.

Drain and refill yearly. Capacity 3

ounces.

Use grease gun.

Clean threads before lubricating.

Clean thoroughly before lubricating.

Maintain level at top of oil cup.

6/02

17

Page 18

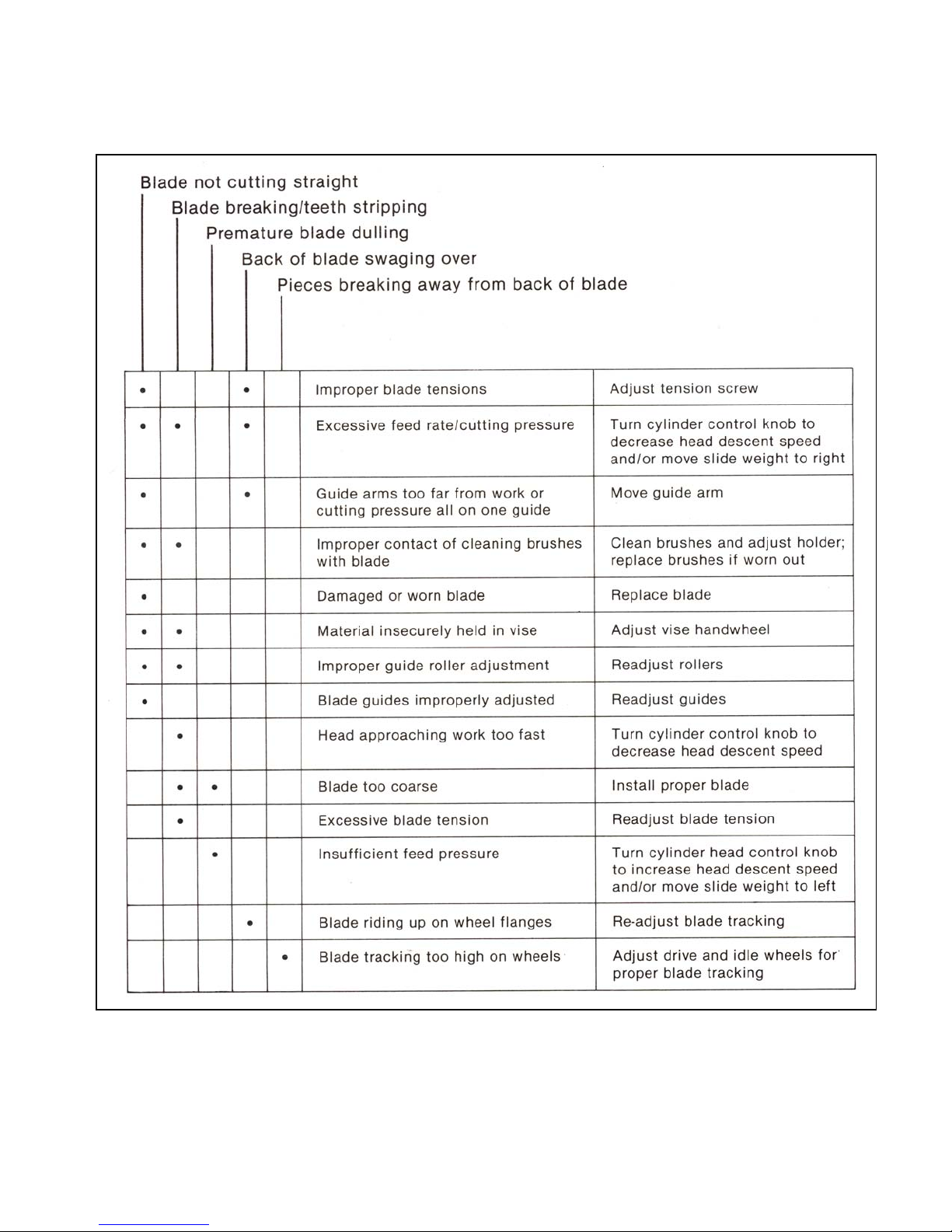

SAWING PROBLEMS & SOLUTIONS

6/02

18

Page 19

Section 3

ASSEMBLIES AND PARTS LIST

6/02

19

Page 20

6/02

MACHINE ASSEMBLY, Front View

ITEM PART NO. DESCRIPTION QTY

1 10002-01 Front Frame 1

2 10003-01 Rear Frame 1

3 10001-00 Bed 1

4 10066-00 Pivot Bar 1

5 13010-08 Shaft Locking Collar 2

6 10004-02 Right Leg 1

7 10005-02 Left Leg 1

8 10070-00 Balance Spring - includes carriage bolt and nut 1

9 10100-01 Spring Perch 1

10 10101-01 Outboard Bearing Casting – (uses 3/8” bolt – lockwasher - nut) 1

11 5527-00 Stock Stop Assembly 1

11A 5027-00 Holder Casting 1

11B 5213-00 Rod 1

11C 5028-00 Spring 1

11D 5200-00 Handle 1

12 5027-01 Stock Stop Mounting Bar 1

13 10006-01 Tip-off Block 1

14 10269-00A Coolant Drawer Pan 1

15 300405A Left Hand Blade Guard 1

16 300404A Right Hand Blade Guard 1

17

18 10268-06A Left Leg Pan 1

19 10268-05A Right Leg Pan 1

20 10093-00 Frame Handle 1

21 10229-00 Brush holder Guard 1

22 72295 Dake/Johnson Name Plate 1

23 71541 Submersible Coolant Pump – Electric 110 volt 1

PARTS NOT ILLUSTRATED

PART NO. DESCRIPTION QTY

10079-05 Motor, 230/460 volt, 60 Hz, 3 phase – 1 H.P. 1

10079-07 Motor, 110/230 volt, 60 Hz, 1 phase – 1 H.P. 1

10042-10 Motor Pulley – 5/8” Bore 1

10077-10 Drive Belt 1

10223-10A Pulley Guard 1

5107-00 Motor Hanger Base 1

5106-02 Frame Hanger Motor Base 1

5106-03 Motor Mounting Pin 1

300403A Frame Covers (Left and Right Hand Sides) 2

10230-10A Rear Frame Blade Guard 1

10271-00A Drive Wheel Drip Pan 1

10287-00 Strap, Wheel Pan 1

10286-00 Bar, Wheel Pan 1

70295 Thumb Screw – Drive Wheel Drip Pan 2

10209-01 Spring Bracket Top 1

10126-13A Lower Left Front Cover 1

10091-10 Frame Rest 1

300407A Drive Wheel Cover 1

300408A Idle Wheel Cover 1

300409A Drive & Idle Wheel Spoke Guards 2

300246 Wire Ties 12

20

Page 21

6/02

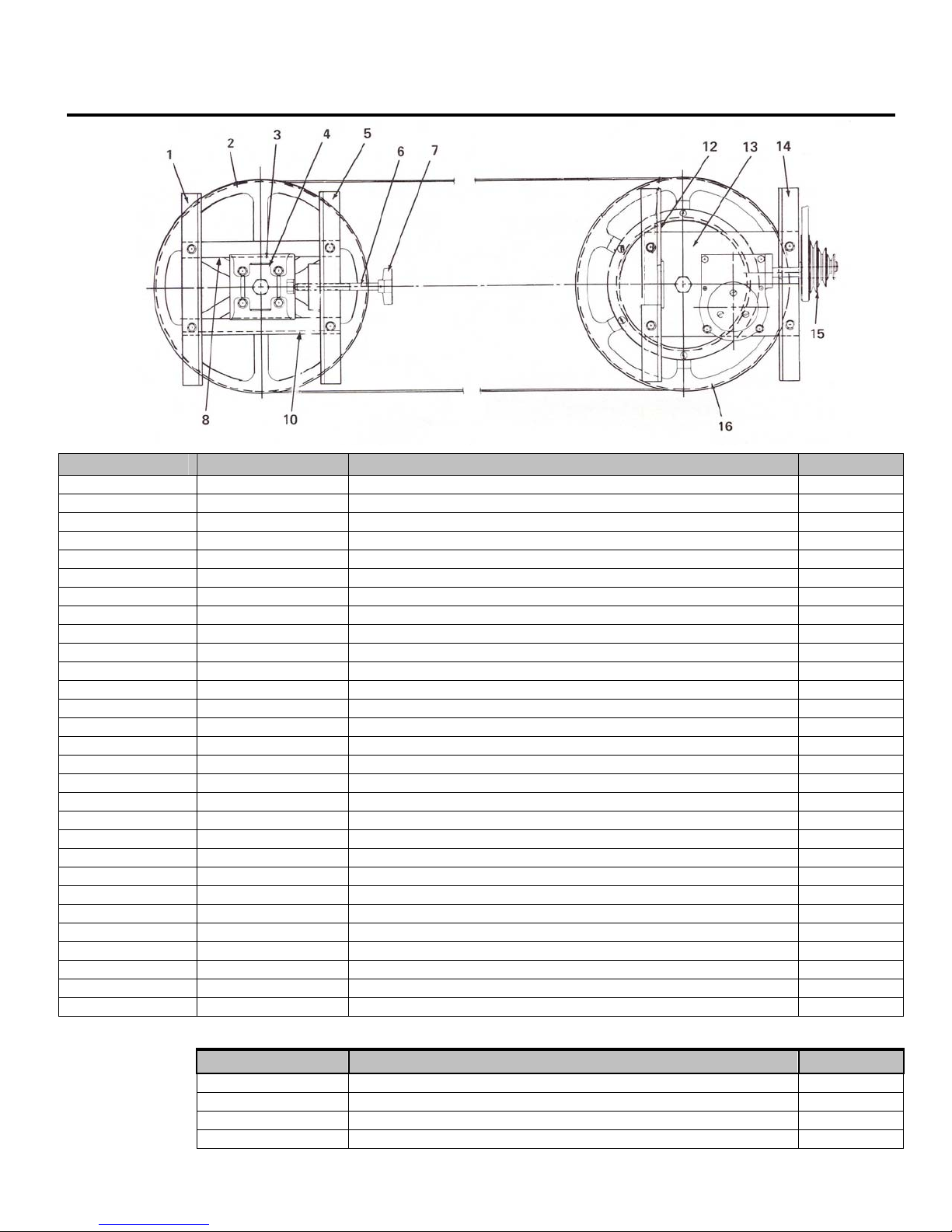

MACHINE ASSEMBLY, Top View

ITEM PART NO. DESCRIPTION QTY

1 10064-09 Idle Wheel and Frame Mounting Bracket (Outboard) 1

2 10510-02 Idle Wheel Assembly (J-10) 1

10010-02 Idle Wheel Only (J-10) 1

10510-04 Idle Wheel Assembly (JH-10) 1

13035-01 Idle Wheel Only (JH-10) 1

10062-00 Wheel Axle (J-10 & JH-10) 1

10134-01 Bearing Cup (J-10 & JH-10) 2

10134-02 Bearing Cone (J-10 & JH-10) 2

10135-00 Dust Collar (J-10 & JH-10) 2

10136-00 Snap Ring (J-10 & JH-10) 1

3 & 4 5011-01 Slide & Rocker Block Assembly 1

5 10064-08 Idle Wheel and Frame Mounting Bracket (Inboard) 1

6 & 7 10125-01 Tension Screw Assembly 1

8 10210-00 Slideway – Top 2

10 10067-00 Slideway – Bottom 1

12 10064-10 Drive Wheel and Frame Mounting Bracket (Inboard) 1

13 10063-00 Gear Box Mounting Plate 1

14 10064-06 Drive Wheel and Frame Mounting Bracket (Outboard) 1

15 10043-10 Driven Pulley – 3/4" Bore (Key – Part No. 71061) 1

16 10510-01 Drive Wheel Assembly (J-10) 1

10010-01 Drive Wheel Only (J-10) 1

10052-00 Ring Gear (Used on J-10 and JH-10) 1

10510-03 Drive Wheel Assembly (JH-10) 1

10010-03 Drive Wheel Only (JH-10) 1

10062-00 Wheel Axle (J-10 & JH-10) 1

10134-01 Bearing Cup (J-10 & JH-10) 2

10134-02 Bearing Cone (J-10 & JH-10) 2

10135-00 Dust Collar (J-10 & JH-10) 2

10136-00 Snap Ring (J-10 & JH-10) 1

PARTS NOT ILLUSTRATED

PART NO. DESCRIPTION QTY

70346 Wheel Mounting Bolt (3/4" – 16 x 1¼”) 2

14123 Wheel Mounting Bolt Nut (1" – 14) 2

70296 Wheel Mounting Bolt Lock Nut (1" – 14) 2

5143-00 Grease Fitting 1

21

Page 22

6/02

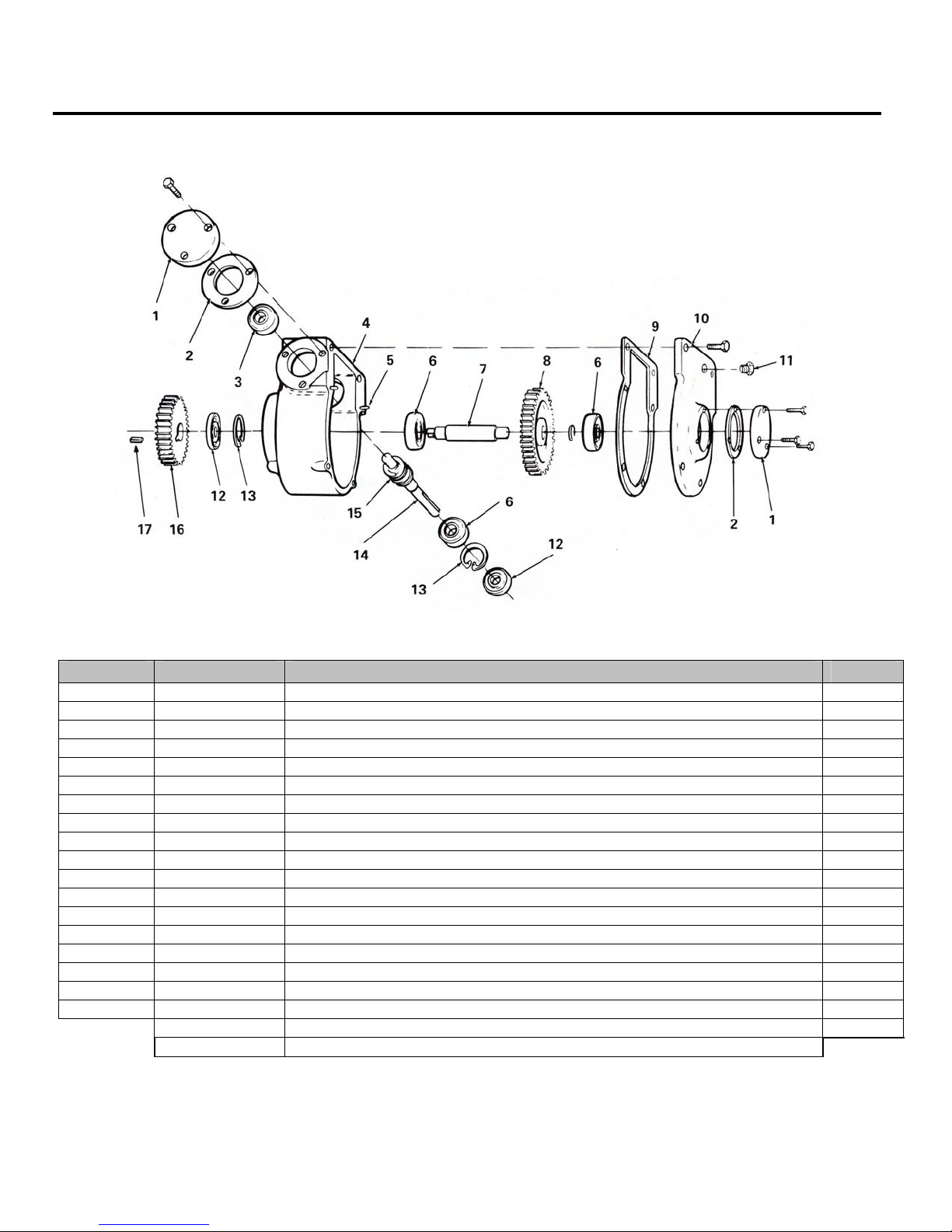

GEARBOX ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 5047-00 Bearing Cap 2

2 5138-00 Cap Gasket 2

3 5073-00 Bearing 1

4 5044-00 Gear Case 1

5 5142-00 Dowel Pin 2

6 5072-00 Bearing 3

7 10049-00 Worm Gear Shaft 1

8 & 15 10051-51 Worm – Steel Worm & Gear Bronze Assembly (10051-00 & 10050-00) 1

9 13080-01 Cover Gasket 1

10 5045-00 Gear Case Cover 1

11 7368 Breather Vent 1

12 5137-22 Oil Seal 2

13 5136-00 Snap Ring 2

14 5048-00 Worm Shaft 1

15A 71061 Key (3/16 x 3/16 x 1¾”) 1

16 10053-00 Spur Gear (Set Screw – Part No. 43558) 1

17 10047-01 Key (3/16 x 3/16 x ½”) 1

26189 Woodruff Key (Not Shown) 2

10544-00 Gear Case Assembly Complete 1

714706 Bearing & Seal Kit (Includes Items 2,3,6,9,12 & 13)

22

Page 23

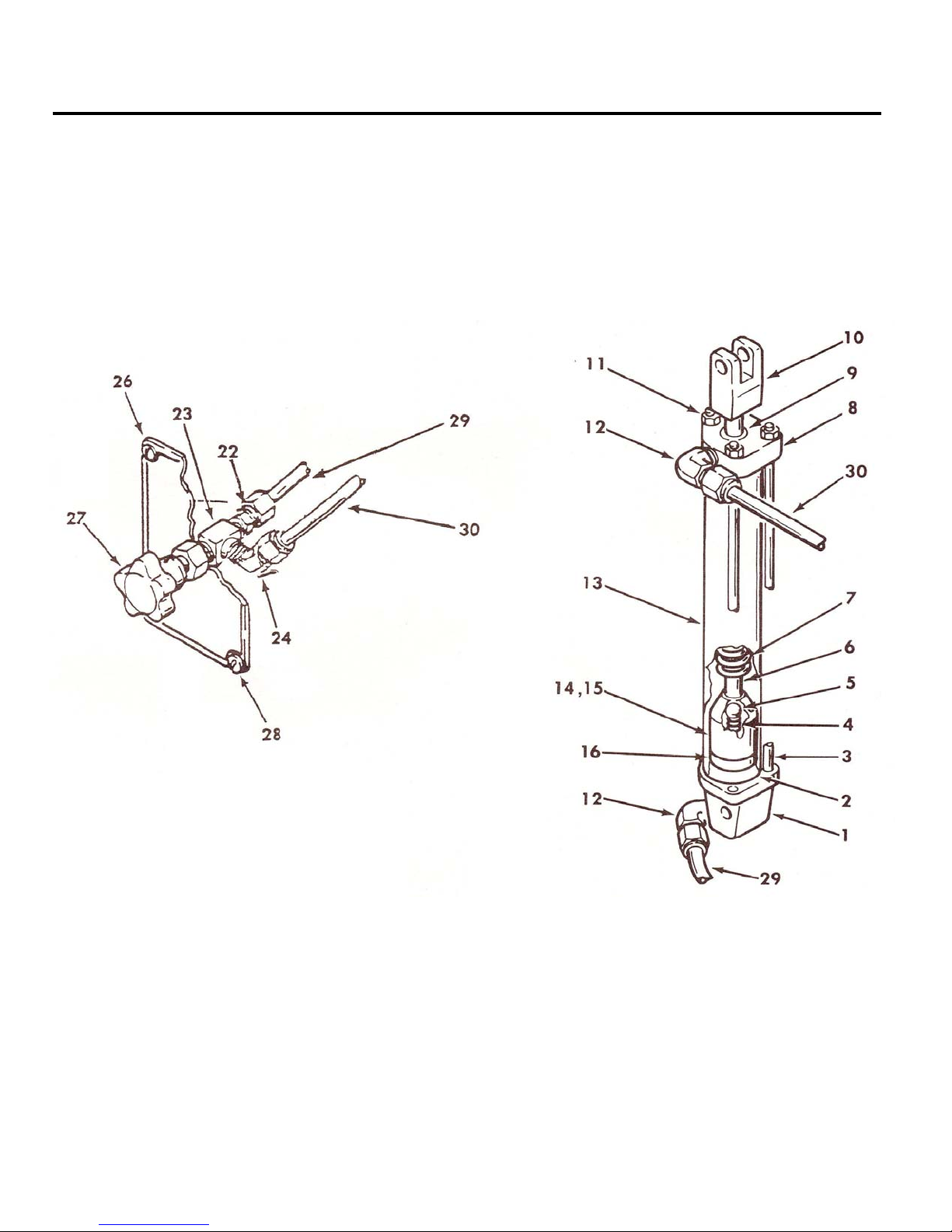

HYDRAULIC ASSEMBLY

6/02

23

Page 24

6/02

ITEM PART NO. DESCRIPTION QTY

1 10031-00 Cylinder Base 1

2 10203-03 Fiber Seal 2

3 10205-02 Tie Rod 3

4 5129-00 Spring 1

4A 5116-00 Spring – R Style included in repair kit. 1

5 17817 3/8 inch Ball 1

6 10204-02 Piston Rod 1

7 10033-00 Head Stop Spring 1

8 5030-10 Cylinder Head 1

9 10115-02 Head Seal (O-Ring) – New Models 1

9A 10115-03 Older Models Garlock Shaft Seal (1/2” ID x 7/8” OD x 1/8” Thick) 1

9B 13080-03 Older Models Garlock Shaft Seal (1/2” ID x .801” OD x 1/8” Thick) 1

10 10013-00 Yoke 1

11 43905 10-24 Nut 3

12 71357 Elbow (Includes furrow and nut) 2

13 10203-02 Cylinder Body 1

14 5119-00 Piston 1

15 5120-00 Piston Nut 1

16 5130-00 Leather Cup 1

10530-08 Control Valve Assembly 1

17 40600-00 Straight Fitting 2

18 1738 Nipple 1/4 x 2-1/2 1

19 70466 Reducer 3/8 x ¼ 1

20 588 3/8 Pipe Plug 1

21 1115 Tee ¼ 1

22 70465 Coupler 1/4 x 1/8 2

23 5131-00 Valve 1

24 44143

25 1329 1/8 Close Nipple 2

26 10030-00 Face Plate 1

27 13018-14 Knob 1

28 44349 8 x 32 Screw 4

29 40515-00 5/16 Tubing 7 ft. 1

30 40515-00 5/16 Tubing 8 ft. 1

31 5032-00

10530-10 Hydraulic Assembly (Includes Control Valve Assembly) 1

10530-09 Cylinder Assembly (Only) 1

90° St. Elbow

Oilier (Not Shown) *Note: Items 18-21 are not needed when saw is

equipped with oilier

714717

10530-01 Rod & Piston Assembly (Includes Items 4,5,6,14,15 & 16)

Hydraulic Cylinder Repair Kit (Includes Items 2, 4, 4A, 5, 9, 9A,

9B & 16)

1

1

24

Page 25

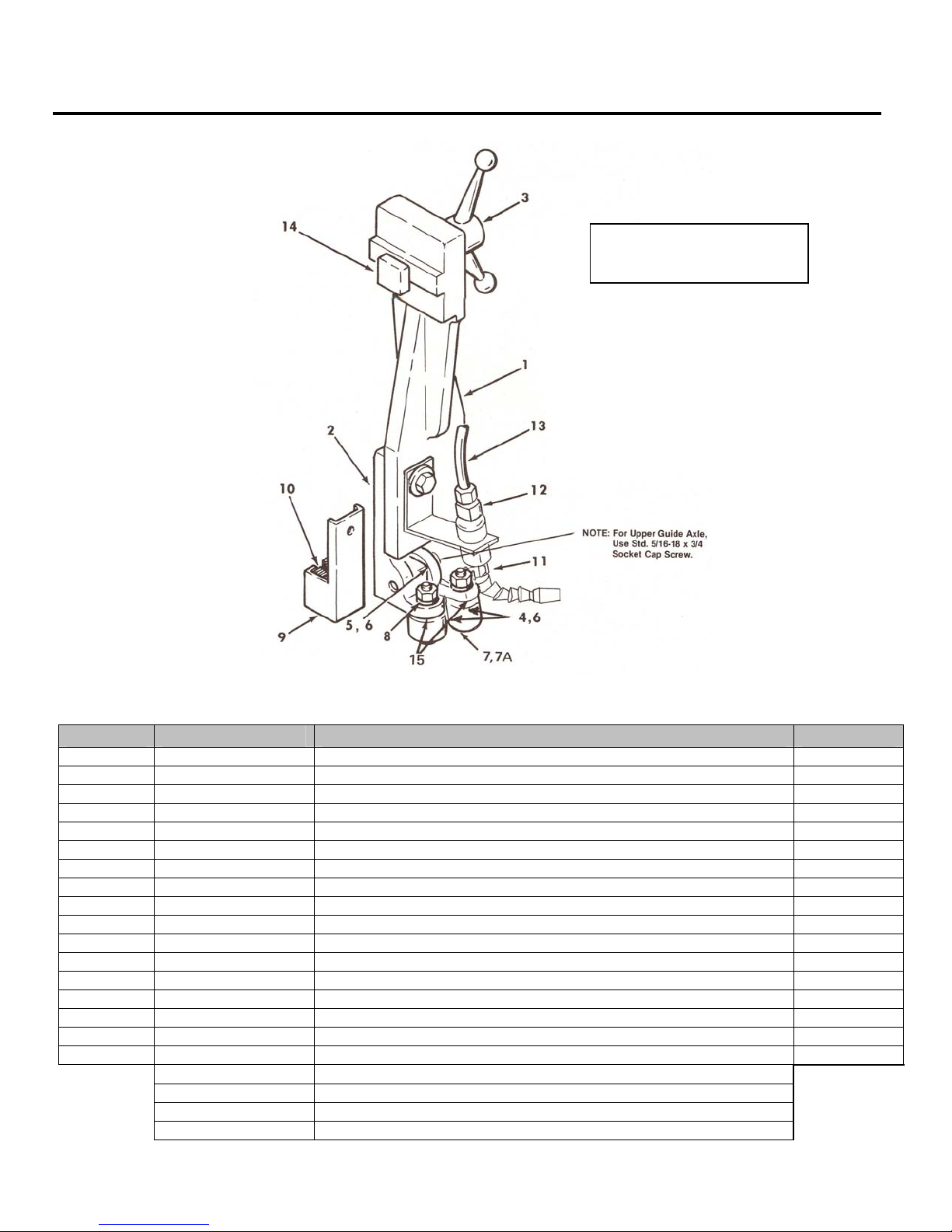

6/02

GUIDE ARM ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 10019-10 Guide Arm LH & RH 1

2 10020-10 Guide Holder 1

3 10084-01 Guide Arm Tightening Handle 1

4 10025-01 Side Guide Bearing 2

5 5026-00 Upper Guide Bearing 1

6 5023-01 Upper Guide Bushing 1

7 10022-02 Inside Concentric Axle with Nut & Washer 1

7A 5075-00 Side Guide Bushing 1

8 10022-10 Outside Eccentric Axle with Nut & Washer 1

9 5122-00 Brush Holder 1

10 5133-S Blade Cleaning Brush Kit – 6 Pairs 1

11 715342 Coolant Nozzle Assembly 1

12 34528 Tube Fitting, Poly-Tite 1

13 67762 Tubing 10 ft.

14 10512-10 T-Bolt 1

15 70462 Spacer Washer (JH Model Only) 8

10519-10 Guide Arm Assembly Complete LH & RH 2

10520-10 Guide Holder Assembly (Includes Items 2, 4, 5, 6, 7, 8 & 15)

715104 Guide Bearing Kit (Includes Items 4, 5, 6&7A) Will outfit 2 arms

75958 Blade, J-Saw – 3/4” x 137” x .035” 5/8 VP – Bi-Metal

75957 Blade, JH-Saw – 1” x 137” x .035” 5/8 VP – Bi-Metal

T-slot Dimension

5/8” New Style

25

Page 26

6/02

VISE UNIT

ITEM PART NO. DESCRIPTION QTY

1 10007-00 Hold Down Block 1

2 10099-00 Vise Lift 1

3 5200-00 Handle 1

4 10008-00 Movable Vise Jaw (Bolt – Part No. 43348) 1

5 10009-00 Stationary Vise Jaw (Bolt – Part No. 43348) 1

7 10116-00 Lift Pin 1

8 10201-00 Vise Nut Plate (Self Tapping Screw (10-24) – Part No. 43882) 2

9 10016-00 Vise Nut 1

10 10015-10 Vise Screw 1

11 10014-00 Handwheel 1

12 70464 Stop Collar 1

13 70287 Drive Pin 1 or 2

26

Page 27

Metal Band Saws & Cold Saws for Precise,

p

Low-Cost Service Free Sawing.

Horizonal Bandsaws, Vertical Bandsaws and Cold Saws

competitively priced.

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 1-800-937-3253 616-842-7110

Fax: 1-800-846-3253 616-842-0859

E-mail: customerservice@dakecorp.com

technicalservice@dakecorp.com

Web: www.dakecor

.com

6/02

Arbor and Hydraulic Presses for All Your

Application needs.

A complete line of Arbor, H-Frame and custom engineered

Hydraulic Presses for production, maintenance and

research work.

27

Loading...

Loading...