Page 1

INSTRUCTIONS AND PARTS LIST

POWER HAMMER

10/09/07

Dake Power Hammer

DAKE (Division of JSJ)

724 Robbins Road

Grand Haven, Michigan 49417

616.842.7110 Phone 800-937-3253

616.842.0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

1

Page 2

A

Set up and Operation of the Dake Power Hammer

Once you remove the power hammer from the packaging you will need to install the shaping dies to be

used and the wheels.

WARNING !!!

Unplug the power hammer from the electrical source before changing the dies.

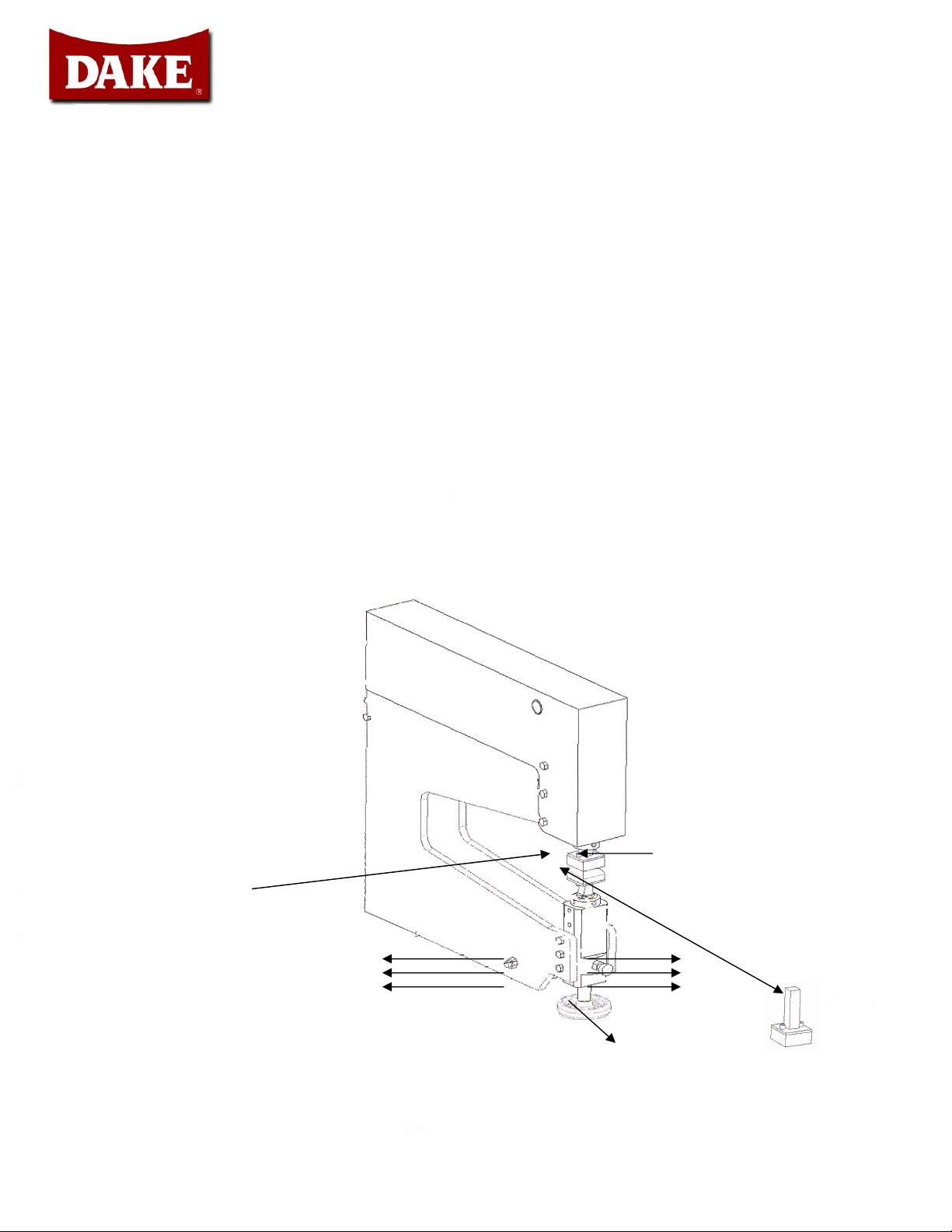

A. Remove the 6 bolts from the adjustable bottom sleeve.

B. Remove the adjustable bottom sleeve from the side plates.

C. Insert die holder with the desired die attached into the slider. Make sure the die holder is

bottomed into the slider.

D. Tighten the two hex socket set screws to secure the upper die holder.

D

A

D

C

B

10/09/07

Dake Power Hammer

2

Page 3

Set up and Operation of the Dake Power Hammer

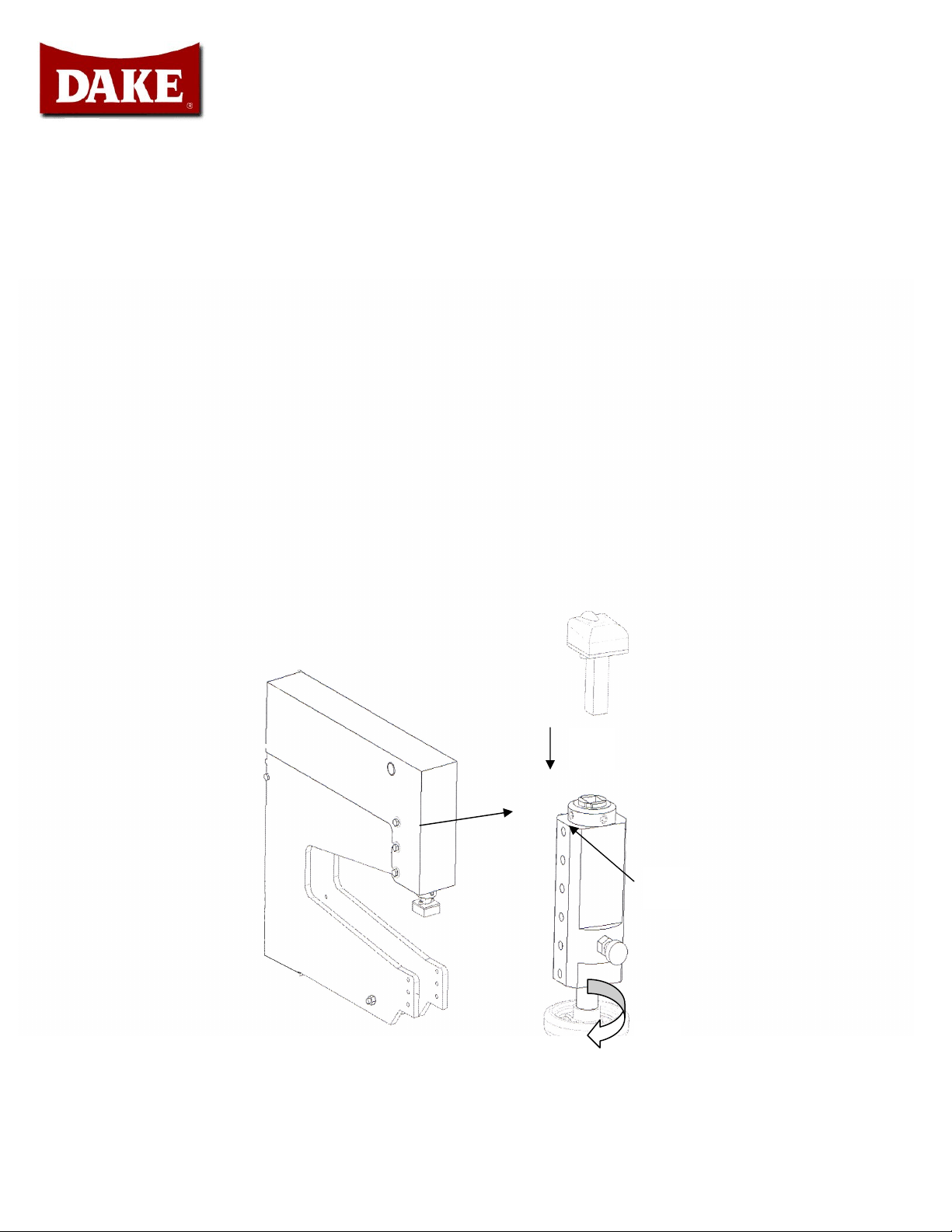

E. Rotate the adjusting screw handle to move the bottom adjustment rod down.

F. Insert the die holder with the desired die attached into the adjustable bottom sleeve. Make

sure the die holder is bottomed into the adjustable bottom sleeve.

G. Snug up the two hex socket set screws on the adjustable bottom sleeve to hold the die holder

firmly but still allow it to move up by turning the adjusting screw handle.

F

G

E

10/09/07

Dake Power Hammer

3

Page 4

I

Set up and Operation of the Dake Power Hammer

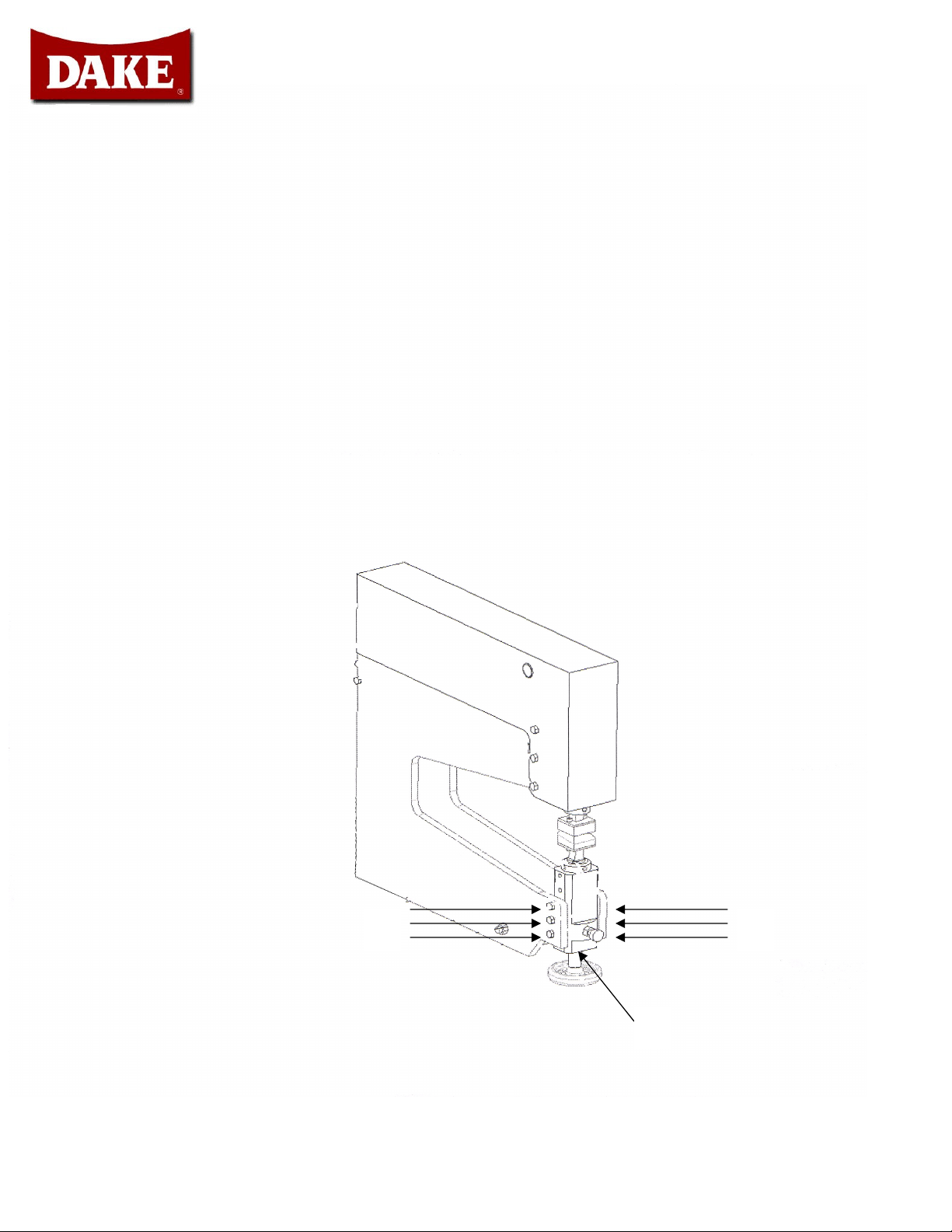

I. Insert adjustable bottom sleeve (B) and attach six bolts through the side plates and into the

adjustable bottom sleeve.

I

B

10/09/07

Dake Power Hammer

4

Page 5

J

Set up and Operation of the Dake Power Hammer

J. Make sure the lock screw on the adjustment bottom sleeve is loose.

K. Rotate adjusting screw handle to move the lower die to the upper die.

WARNING !!!!

For safe operation and possible die damage always adjust the gap between the upper die half and the

work piece to a minimum of ¼” before starting motor.

K

¼” minimum gap

before starting motor

10/09/07

Dake Power Hammer

5

Page 6

M

Set up and Operation of the Dake Power Hammer

L. Check the two set screws on the die holder to see if they are tight. These hold the lower die firmly

in place.

M. The upper and lower dies need to be lined up. If they do not line up, loosen the bolts holding the

dies to the die holders and align the dies. Don’t forget to retighten these bolts.

L

10/09/07

Dake Power Hammer

6

Page 7

Set up and Operation of the Dake Power Hammer

WARNING !!!

Before turning on power to your Dake power hammer be sure to review all safety stickers and

warnings.

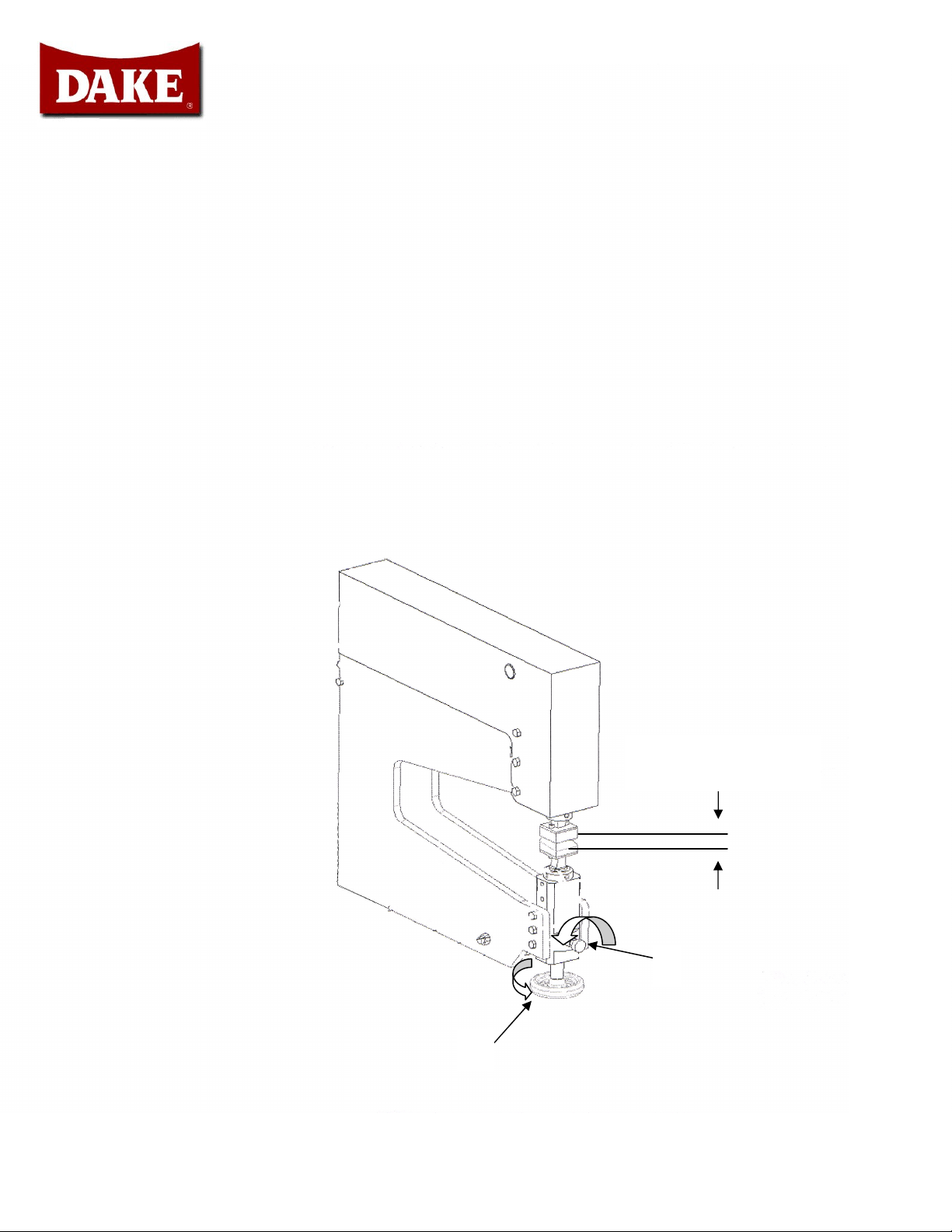

N. With the motor turned on, the upper die holder will begin to oscillate. Rotate the adjusting screw

handle to move the lower die up until just before it touches the upper die. This is a good initial

setting to try shaping with.

O. With the die gap set to your desired setting, tighten the lock screw on the adjustable bottom sleeve

to lock in the gap setting. Repeat steps N and O for any future gap adjustments, up or down.

N

O

10/09/07

Dake Power Hammer

7

Page 8

10/09/07

Dake Power Hammer

8

Page 9

Item # Part description Qty Part #

1 Side Plate 2 87160

2 Rear spacer Plate 1 87153

3 Front Mount Plate 1 87155

5 2 Bolt Flange Bearing 2 301907

6 Offset Shaft (27”) 1 301908

7 Connecting Rod 1 87157

8 Cast Bronze Bushing 1 301943

9 Slider 1 87156

10 Top Collet 1 87150

12 Slide Gulide & Bushing 1 87158

13 Shoulder Bolt 1 301909

14 Bearing 1 301939

15 Washer (center hole 5/16 bolt) 1 301910

16

Socket head cap screw 5/16-18UNC X 1

1 43434

17 Bottom Collet 1 87159

19 Bottom Adjustment Rod 1 87149

20 Hand Wheel 1 87173

21 Die Holder 2 87152

22 Upper Die 1

23 Lower Die 1

24

25 Knurled Head Screw 1-1/2” 1 301946

26 Alignment Key 1 87151

27 Support Key 1 87148

28 Top Cover (Red) 1 301891

29 Belt Cover Inner (Red) 1 301890

30 Cover Belt (Red) 1 301892

31 Top Pulley 1 301953

32 Bottom Pulley 1 301947

33 Belt 1

34 Electric Motor 1 10079-

07

35 Grease Zerk (1/4 x 28 straight) 1 301912

36

37

Nut 1/2-13 UNC

3 301913

38

39

40 Socket head Cap Screw 6-32 x ½ 2 301914

41 Half Dog Hex Socket Set Screw 3/8-16

6 301915

UNC x ½

42 Nut 5/8-11 UNC 1 301916

43 Socket Head Cap Screw 3/8-16 UNC x 1 2 43451

10/09/07

Dake Power Hammer

9

Page 10

½

44 Grade 8 Hex Cap Screw 3/8-16 UNC x 1

1-1/4

45 Grade 8 Hex Head Cap Screw 5/8-11

UNC X 1-1/4

46 Socket Head Cap Screw ¼-20 x 3/8 1 43411

47 Key Stock 3/16 x 3/16 1 386?

48 Socket Head Cap Screw ¼-20 x ¾ 10 43414

49

50 UHMW Poly Rod 1

51

52

53

54

55

56 Grade 8 Hex Bolt 5/16-18 x 1 4 301929

57 Bottom Sleeve 1 87147

58 Cross Brace 2 301893

59

60 RivNuts ¼-20 6

61 Grade 8 Washer 3/8 12 301933

62

63

64 Bottom Spacer, Base 1 87162

67

68

69

70 Grade 8 Nut 5/16 4 301934

71 Grade 8 Hex Bolt ½-13 x 8 2 301935

72 Belt 1 301936

73 Grade 9 Lock Washer 3/8 6 301937

74 Finishing Plug 3 301948

75

76 Washer 5/16 Grade 8 8 301938

Parts Not Shown Qty Part #

Stand 1 716552

Caster Standard 300lbs. Capacity 2 301931

Caster Swivel, Total Locking 300 lbs. 2 301932

20 301917

4 301918

10/09/07

Dake Power Hammer

10

Page 11

You are now ready to start shaping metal

Everyone has their own technique when it comes to shaping and you will need to find your own. So,

practice, think , practice and think some more before practicing again. We have found that like

forming by hand, it is easier to get the desired shape using the Dake power hammer by using several

steps to “sneak up” on the final shape, versus trying to get the shape in one step.

A good source of information on how to use a power hammer type machine like this , is reading any

of the several books on sheet metal shaping currently available.

Have fun and be safe!!!!!

Dake

Maintenance

You need to maintain your Dake power hammer as you would any other piece of shop equipment.

More use requires more maintenance. This should include, but not limited to checking and greasing

bearings and bushings regularly. Check for any loose components, lines and connections and replace

as needed.

10/09/07

Dake Power Hammer

11

Page 12

Safety stickers that are located on the Dake power Hammer

WARNING!!!!

Review all safety stickers before operating this machine.

Part number Part number Part number Part number

301889 85425 300168 84395

Part number

76462

10/09/07

Dake Power Hammer

12

Page 13

110 volt Machine

10/09/07

Dake Power Hammer

13

Page 14

220 volt single phase machine

10/09/07

Dake Power Hammer

14

Loading...

Loading...