Page 1

7/21/08

JOHNSON VERTICAL BAND SAWS

INSTRUCTION MANUAL AND PARTS LIST

SECTION I – Manual

FOR MODELS

E-16 (And Old Style V-16)

V-16

V-24

VH-24

V-40

VH-40

MODEL: ________________________________________

SERIAL NUMBER: ________________________________

N MANUAL AND PARTS LIST

DATE PURCHASED: ______________________________

Manual V-16, V-24, VH-24, V-40 & VH-40

1 – Section I

DAKE Division of JSJ

724 Robbins Road

Grand Haven, Michigan 49417

616.842.7110 Phone 800-937-3253

616.842.0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

Page 2

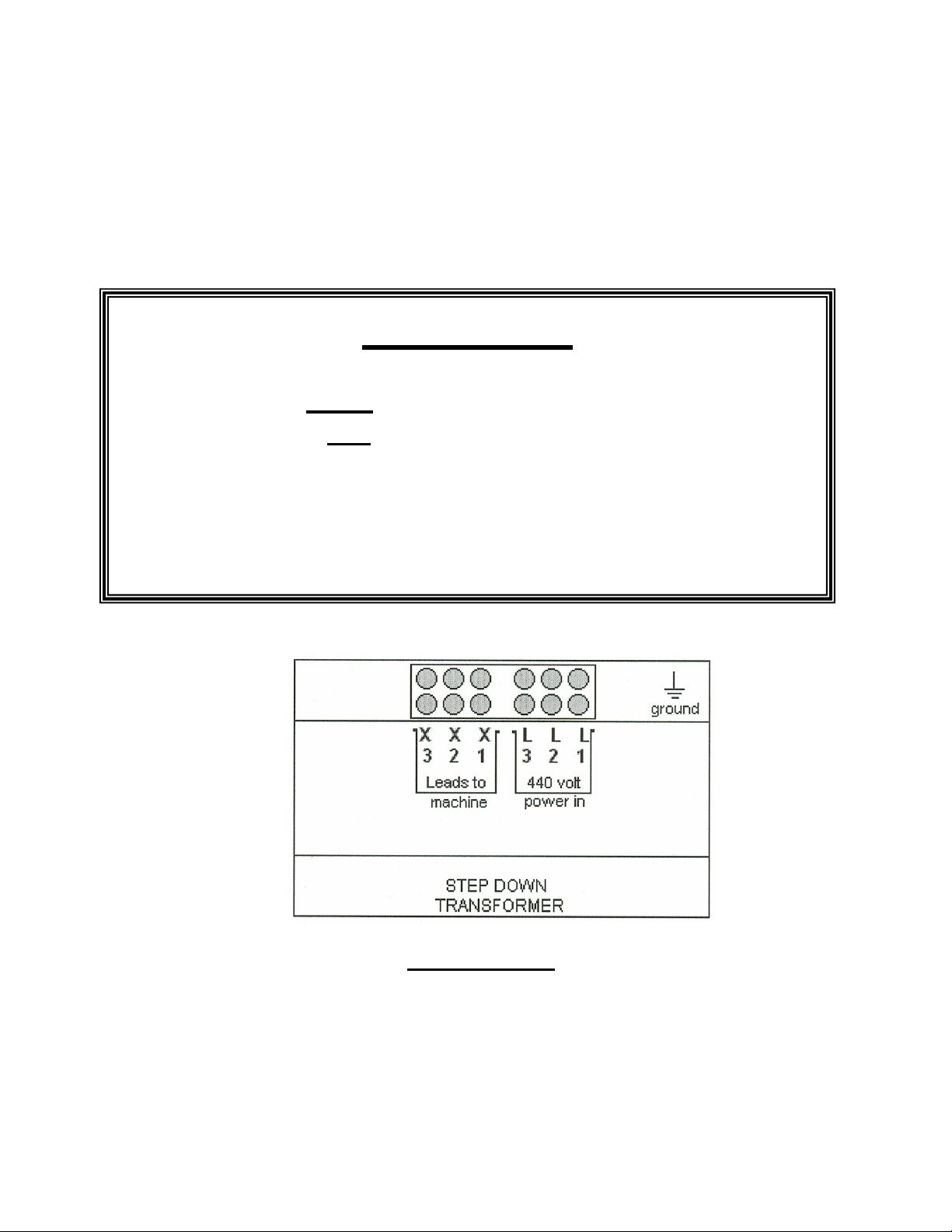

If machine is to be operated

At 440 volt 3 phase power, please

7/21/08

read the following warning.

This machine must be wired by a qualified

electrician. Do not connect 440-volt power directly

to this machine. You must use the optional step

down transformer (part no 300674) available at

Dake. Failure to do so may affect warranty, if

damage occurs from improper wiring.

WARNING!

FOREWORD

These instructions cover the installation and operation of vertical band saws. Attention

to maintenance and service will afford many years of trouble free operation. We suggest that

these instructions be retained by the department or individual responsible for the machine and

kept in a readily accessible location for reference purposes.

Manual V-16, V-24, VH-24, V-40 & VH-40

2 – Section I

Page 3

SECTION I - TABLE OF CONTENTS

Specifications ....................................................................................... 4

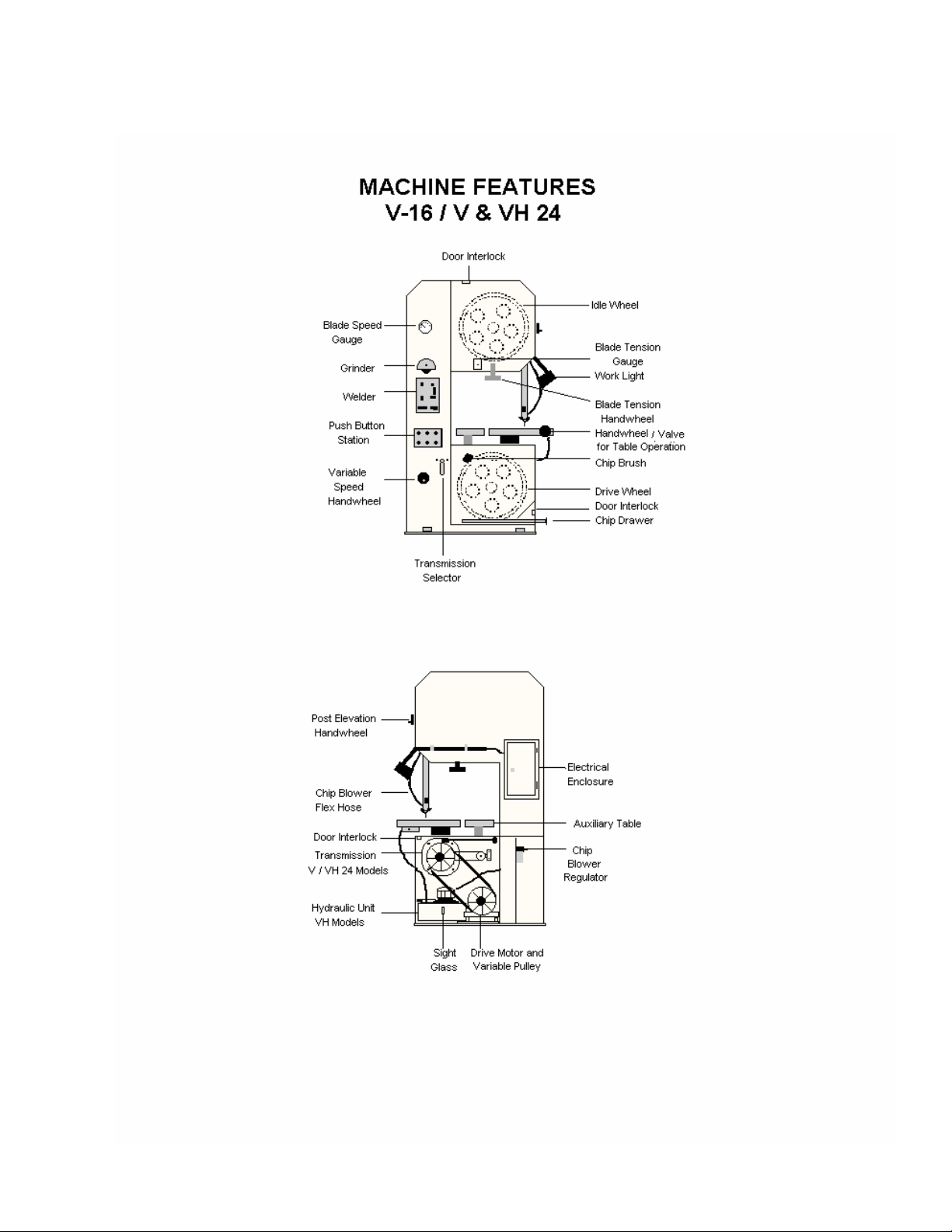

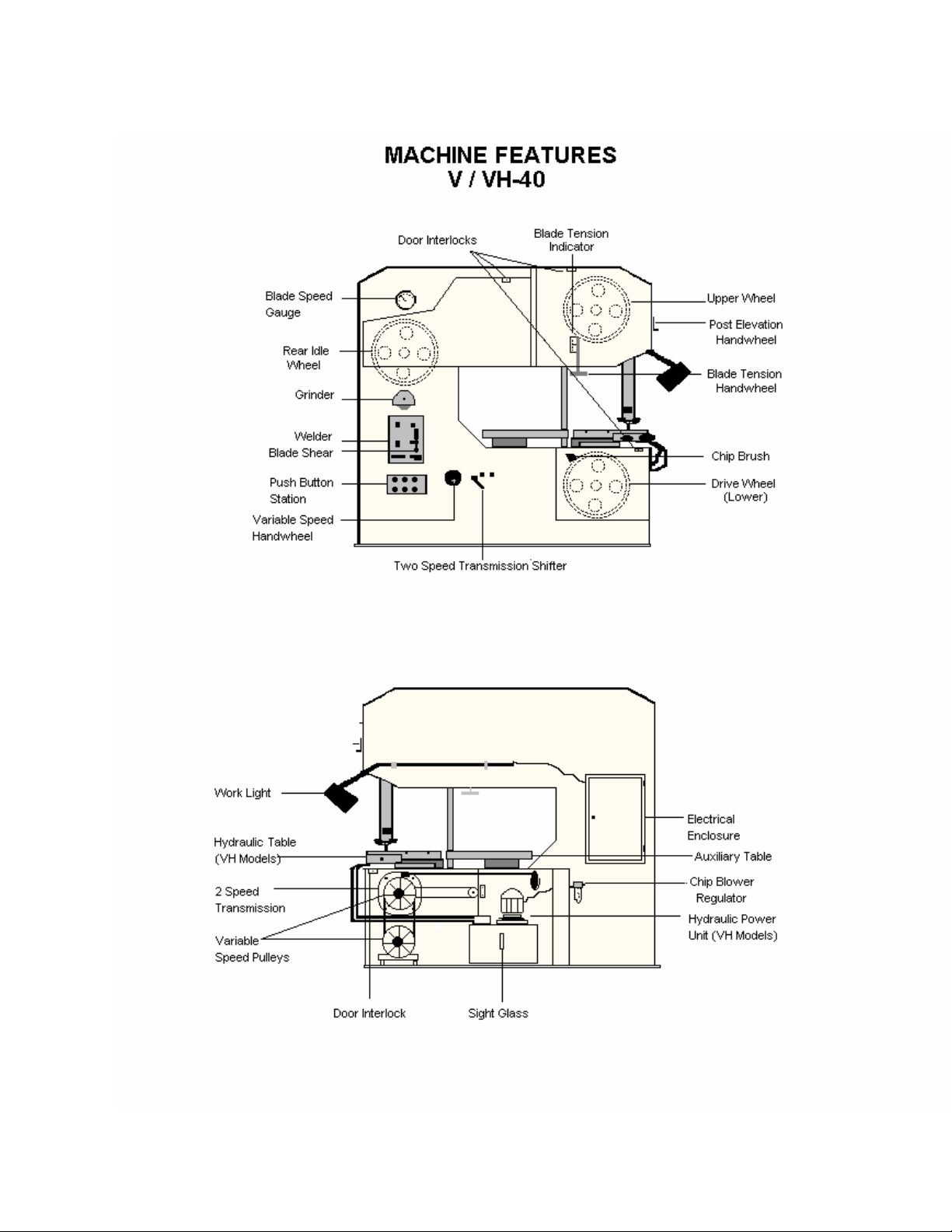

Machine Features ................................................................................ 5-6

Unloading ............................................................................................. 7

Installation ............................................................................................ 7

Electrical .............................................................................................. 7

Filling Speed Regulator ………………………………………………….. 8

Machine Operation .............................................................................. 8

Wheel Alignment ................................................................................. 9

Blade Installation ................................................................................. 9

Blade Tensioning ................................................................................ 10

Blade Guides / Adjustment .................................................................. 10-14

Band Speed Selection ......................................................................... 14

Saw Blade Selection……………………………………………………… 15-16

Blade Break-in…………………………………………………………….. 15

Speeds & Feeds ................................................................................. 16-20

Rate Reduction Matrix For Hard Material ........................................... 20

Hydraulic Feed Table ……………………………………………………. 21

Welding Instructions ............................................................................ 21

Blade Preparation For Welding ........................................................... 21-22

Clamping / Welding / Annealing ......................................................... 22-23

Re-Finishing the Weld (Grinding) ....................................................... 23

Welder Layout & Maintenance ........................................................... 23

Poor Welds & Trouble Shooting ......................................................... 23-24

Machine Maintenance ........................................................................ 24

Use Of Standard Accessories ..……………........................................ 24-25

Manual V-16, V-24, VH-24, V-40 & VH-40

3 – Section I

7/21/08

Page 4

7/21/08

SPECIFICATIONS

Model Number:

V-16 V-24/VH-24 V-40/VH-40

Capacity:

Throat Inches 16 23-1/2 41

Work Height Inches 11 12-1/2 12-1/2

Table:

Work Table Inches 23-1/2 x 23-1/2 26-3/8 x 26-3/8 26-3/8 x 26-3/8

Auxiliary Inches -- 9 x 22-3/8 15-1/2 x 21-1/2

Height from Floor Inches 38 42 41

Travel-Manual or Hydraulic Inches -- 10 10

Tilt-Left Degree

Tilt-Right Degree

10 10 10

30 30 30

Table Weight Capacity Lbs. 850 850 850

Blade:

Width Minimum Inches 1/8 1/8 1/8

Width Maximum Inches 5/8 1 3/4

Length Minimum/Maximum Inches 128/133 178/187 134/140

wheels)

Length Minimum/Maximum Inches -- -- 186/189 (

wheels)

(2

3

Wheel Diameter Inches 16-1/2 24-1/2 16-1/2

Band Speed:

Low Range FPM 60 to 590 50 to 425 50 to 425

High Range FPM -- 425 to 4250 425 to 4250

Drive Motor HP 1 2.2 2.2

Welder Capacity: Inches

1/8 – 5/8 1/8 – 1 1/8 – 1

VH models equipped

with hydraulic table

Hydraulic Motor: HP -- 1/3 1/3

Height of Machine: Inches 72 90 78

Floor Space: Inches

38 x 25 60 x 60 72 x 60

Shipping Weight:

Manual Table Lbs. 1000 2025 2025

Hydraulic Table Lbs. -- 2225 2395

Manual V-16, V-24, VH-24, V-40 & VH-40

4 – Section I

Page 5

Manual V-16, V-24, VH-24, V-40 & VH-40

7/21/08

5 – Section I

Page 6

Manual V-16, V-24, VH-24, V-40 & VH-40

7/21/08

6 – Section I

Page 7

7/21/08

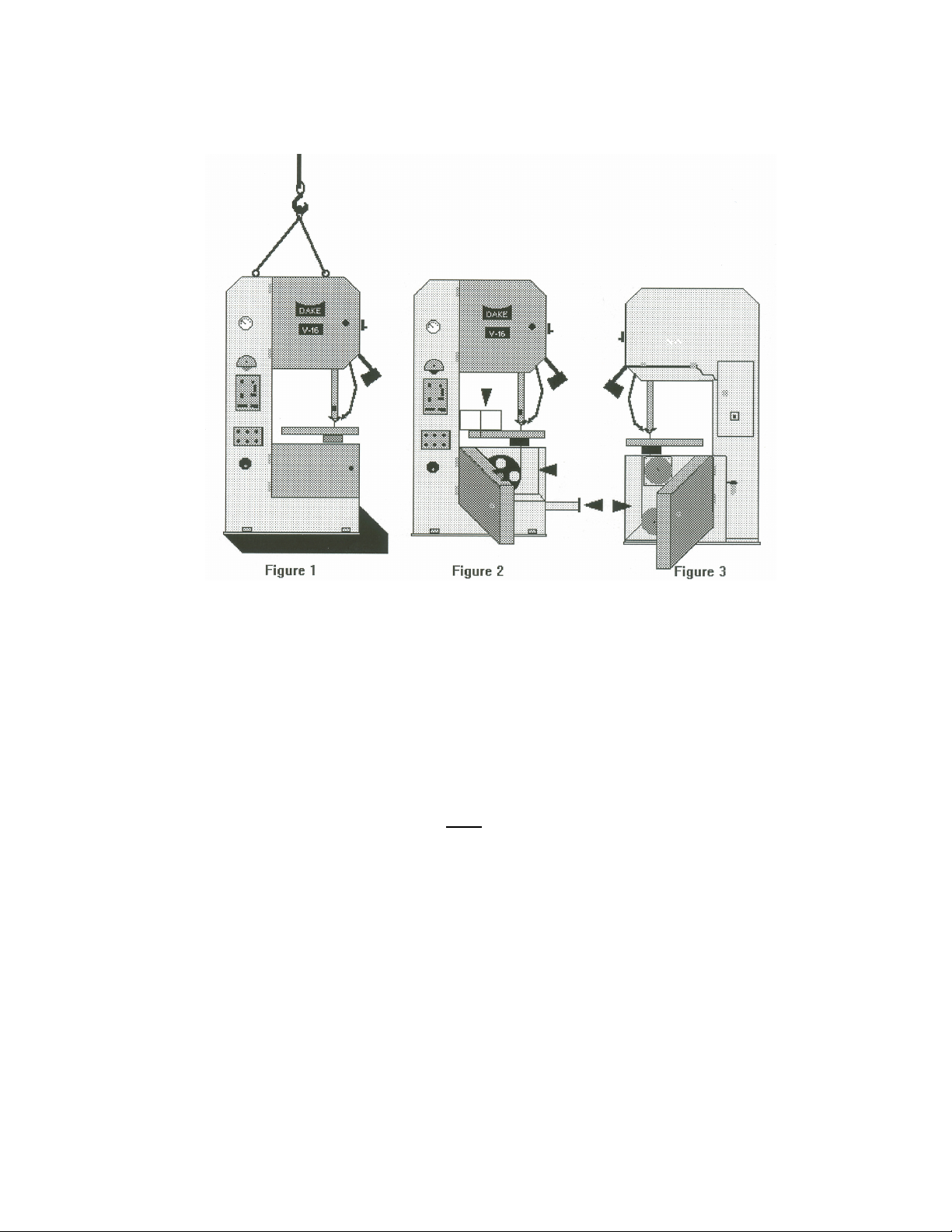

MACHINE UNPACKING AND INSTALLATION

UNLOADING:

surfaces, electrical or hydraulic parts. Carefully inspect the machine for physical damage. If

damage is noted, notify the truck line at once. They may require inspection, and that a claim is

filed. Check that all standard accessories are with the machine. Some accessories may be boxed or

placed behind access doors or chip drawer. (See figure 2 & 3) The band saws are provided with lifting

eyes that screw into the top of the machine. These lifting eyes may be located in any of the

compartments shown by arrows in figure 1 & 2 above. Particular care should be taken in selecting

areas of the machine for handling, as electrical components and adjustment knobs can be marked up

or damaged. WARNING: Machine table may NOT be used as a lifting point. Damage to the saw

and alignment problems could result. Remove the mounting bolt nuts from the machine. Using the

lifting eyes, remove the machine from the skid and put in place. (See figure 1)

Remove the shrink-wrap covering the machine, carefully as not to damage painted

INSTALLATION:

large work pieces. The machine is provided with holes in the base to anchor the unit to the floor.

Shims should be used to properly level the unit. The saw is shipped with an anti-rust protective coating

on machined metal surfaces. Surfaces should be cleaned with the appropriate solvent and then coated

with a light film of oil.

Location of the machine should take into consideration the ability to traverse

ELECTRICAL:

(+/- 10%) or with a Dake external step down transformer from 460v to 230v. If any adjustments or

changes are needed a qualified electrician should perform them. See detailed information as provided

in a circuit diagram #80587.

The machine is wired to be operated with an input voltage of 230, 3 phase, 60 htz

Manual V-16, V-24, VH-24, V-40 & VH-40

7 – Section I

Page 8

7/21/08

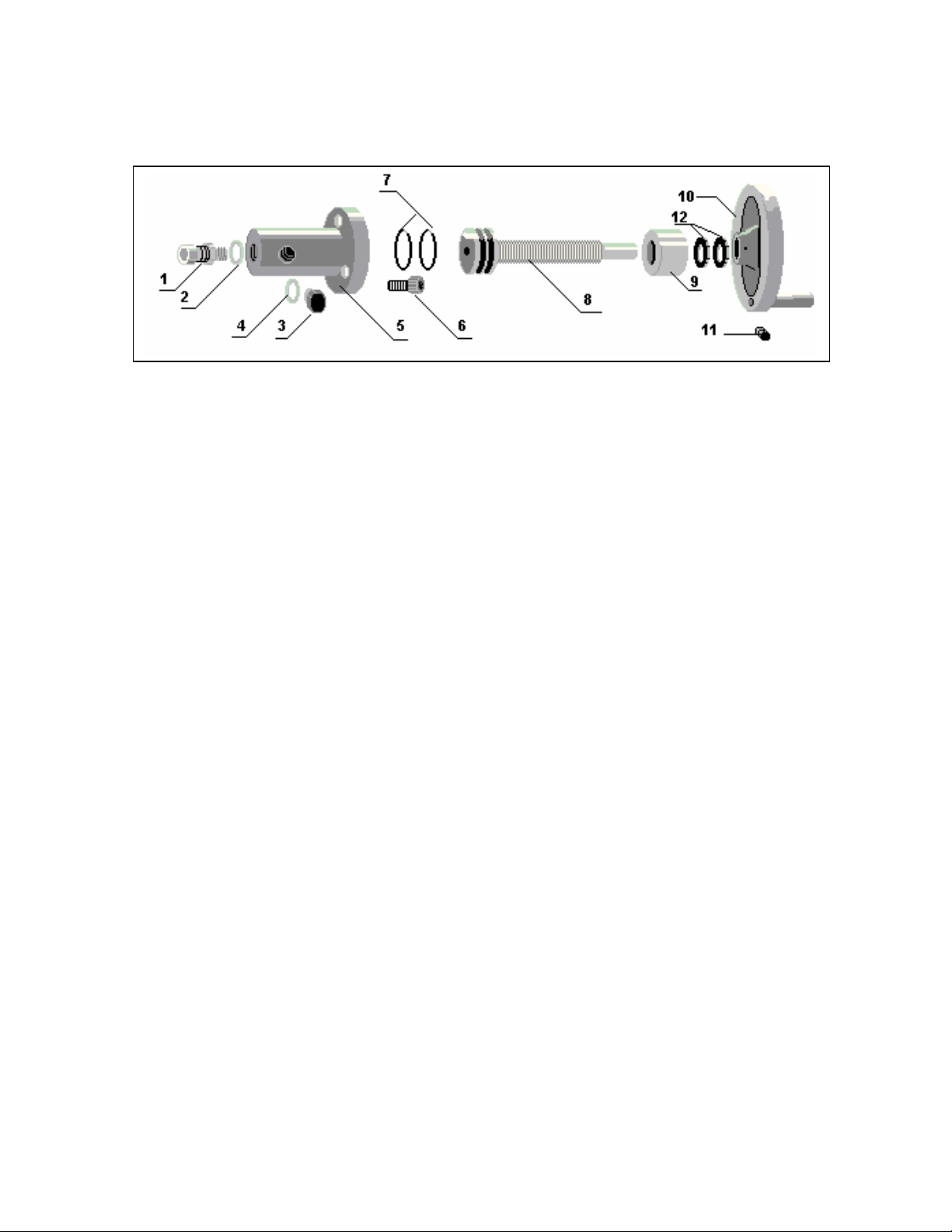

FILLING THE SPEED REGULATOR

This is pre filled at the factory

These instructions are for future use

2. Screw the hand wheel in.

3. Turn the saw off once hand wheel is in.

4. Remove the mounting screws (item 6).

5. Remove the plug from the cylinder (Item 3).

6. Turn screw out.

7. Add oil (Lightweight hydraulic oil) slowly while turning the wheel out.

8. When it is completely full, replace the plug (Item 3).

9. Re-mount the cylinder to the saw body.

10. Turn on the saw and adjust to the desired speed.

11. When saw is at maximum RPM, re-adjust the lock nuts on Item 8

1. Turn the saw on.

MACHINE OPERATION

Prior to performing any cutting with the machine, it is recommended that the personal become

familiar with the various controls and accessories.

PRECAUTIONS

• No loose clothing.

• Eye protection should be worn.

• All guards must be in position.

• Table is secured in place and locked. Table load capacity should be noted and not exceeded.

• Extra supports may be required for large or cumbersome components.

• Irregular shapes and small objects should be secured by means of a clamp or suitable fixture.

• Machine and surrounding should be kept free of tools, scrap and foreign objects.

• Machine should be locked out before making any adjustments.

• Care in uncoiling, and coiling and installation of blades should be observed. Gloves recommended.

• Storage of blades in an area near the machine will allow operating personal, to use the proper

blade for each operation.

•

Machine is furnished with electrical door interlocks. These interlocks should periodically be checked

for proper operation.

Manual V-16, V-24, VH-24, V-40 & VH-40

8 – Section I

Page 9

7/21/08

WHEEL ALIGNMENT

V-16 & V / VH-24

Note: This alignment is factory set, but may need adjustment when replacing blade.

Two wheel machines have a bottom wheel that drives the saw blade and a top idle wheel that is

adjustable to facilitate blade tracking. The edges of the wheels are fitted with a composite material to

accommodate the tooth set.

The idle wheel may be adjusted by loosening the knurled locking collar and turning the black knob in

the center of the wheel. Turning the knob in a clockwise manner runs the blade toward the back edge

of the band wheel. A counter clockwise movement will move the blade toward the front edge of the

band wheel.

Correct tracking takes place when the blade runs approximately in the center of the wheel.

NOTE: The main casting with adjusting screws have been preset at the factory during assembly

utilizing special fixtures. No adjustment should be attempted.

V-40 / VH-40

Machines with two idle wheels in addition to the drive wheel possess tracking control on each wheel.

The top band wheel is set at the factory and no future adjustment should be necessary. *All

adjustments should be performed utilizing the third band wheel. If difficulty is encountered in tracking,

the top wheel may be reset as if the machine were to be used in the two wheel mode.

NOTE: With the V / VH-40 machines, it is possible to

have the blade appear to be tracking properly but in

actuality the two band wheels can be adjusted so they

form an intersecting planes, rather than a common plane

or parallel plane. This will result in excessive wear on

the crown on the band wheel by the blade teeth, and

severe cases, the composite material will shred or

actually come loose from the band wheel.

*If the blade does not track properly against the back up

guide bearing, there is a small amount of lateral

adjustment in the top wheel. (See figure 5) Loosen the

set screws and slide the yoke to make the blade line up

properly with the backup guide bearing.

BLADE INSTALLATION

Blade selection is based on the many factors and complexity of the work to be cut.

The blade placed on the band wheels with teeth facing toward the operator and down toward the top of

the worktable. Tension the blade to remove slack. Rotate the wheels by hand to ensure tracking is

correct, and blade will not “pop” off when machine is started. If tracking is incorrect, adjust before

starting machine.

Manual V-16, V-24, VH-24, V-40 & VH-40

9 – Section I

Page 10

7/21/08

BLADE TENSIONING

The blade indicator is located inside the upper wheel compartment, on the lower left side of the idle

wheel. (See machine features graphic) The indicator has an arrow mounted on the horizontal plane,

with a corresponding scale for blade tensioning. The scale has two legends, one reads inches from 0 1”, and the second reads mm 0 - 25 mm. This allows tensioning either standard or metric blade widths.

With out tension on the blade, the indicator should read zero. As tension is applied to the blade the

needle will move accordingly, and should be tightened until the correct blade width is indicated on this

gauge. Example: Installing a 1/2” blade on the machine, tighten the hand wheel until the indicator’s

arrow is pointing to the 1/2” mark on the scale. Before starting the machine check the blades tracking

by hand as described in an earlier section.

This indicator has been calibrated at the factory. If recalibration is ever needed follow the steps below.

Using a blade tension gauge, (many times the

company that you purchase blades from can furnish

you with this gauge) tension the blade to the proper

PSI. The PSI will very from blade types (carbon, Bimetal) and blade widths. This information can be

obtained from your blade supplier. When proper

tension is achieved, loosen the setscrew in the collar

on the tensioning wheel shaft. (See figure 6) Adjust

this collar up or down on the shaft until the arrow is

pointing to the corresponding blade width. on the

indicator, Tighten setscrew.

Note: It is better to over tension the blade than to

run it under tensioned.

BLADE GUIDES

Your machine has come equipped with a set of interchangeable “V” type blade guides. A set of

guides consist of two each left hand and two each right hand guide inserts. The standard

guides furnished are 10 / 12 mm guides. Other sizes are optional, and can be purchased

separately, or as a five piece set. The five-piece set includes 3 / 4 mm (1/8 - 1/4”) 6 / 8 mm

(5/16 - 3/8”) 10 / 12 mm (standard set 1/2 - 5/8”) 16 / 20 mm (3/4”) and 25 / 32 mm (1”)

blade width will dictate the size blade guide to be used.

The

Note: Never use blades larger than the rated capacity of the machine. Never use blades

narrower than guide insert. Damage will occur to guide insert and blade. Blade insert must

correspond with blade width.

Manual V-16, V-24, VH-24, V-40 & VH-40

10 – Section I

Page 11

7/21/08

An analysis of the work to be performed should be made and the proper

blade selected. The blade should always be inspected before installing

on the machine. Things to look for should be the smoothness on the

sides and back edge of the weld, look for any missing teeth, or

impacted chips. The blade guides may now be selected and inserted

into both the upper and lower guide holders. Proper adjustment of these

guides takes place when they form a complete “V” shape (see graphic

below) and support the blade equally on each side. A couple of

thousands on each side of the blade will provide the running clearance

and support for contour sawing.

Note: Blade guides should be cleaned of chips each blade

change or more frequently if required.

BLADE GUIDES

The back end roller that supports the back of the blade on each guide holder contains a hardened cap

over a set of ball bearings. This should be checked periodically for free movement so it is allowed to

rotate freely as the back of the blade comes in contact with the face of this roller. Noticeable friction in

this assembly indicates it should be replaced. This can be done by removing the right hand guide

insert, moving the left hand guide up away from the bearing face. Loosen the setscrew on the bottom

of the guide holder and sliding the old bearing and shaft out and a new one in. Tighten the setscrew

and re-adjust the guides. See graphic below.

The “V” type solid blade guides and holder assemblies as furnished standard with the machine are

recommended for the majority of cutting applications. This is true for the cutting of materials at blade

speeds in the low range.

If the machine is operated in the high range, it should be operated with the high-speed roller guides,

supplied with this machine, installed.

NOTE: If machine is operated in excess of above, abnormal blade wear and breakage may

occur, due to the increased heat developed with the standard solid guides.

Manual V-16, V-24, VH-24, V-40 & VH-40

11 – Section I

Page 12

HIGH SPEED ROLLER GUIDES

Applications and Advantages:

Friction and abrasive cutting, filing operations, aluminum and woodcutting.

These guides eliminate having to change inserts when changing to blades of different widths.

Requirements for Installation:

These roller guides must be installed using a new 1/2” blade width band for proper alignment.

The 1/2” band should be tracked within the approximate center line of the band wheels.

Note: Be certain band wheels are clean are free of any foreign material build up before

proceeding.

Tools / Hardware Required:

Drill - 7/16”

Drill and tap for ¼” 20 set screw

¼” 20 set screw 1/4 - 3/8” long

Upper Guide Installation:

1: Remove the existing guide holder assembly (part A)

via the 2 countersunk socket head cap screws located

on the backside of the moveable guide arm post. (Part

B) Store the original guide holder assembly for future

use. Remove the lower (red painted, part C) hold

down foot located at the bottom of the movable guide

arm post. (See graphic below)

7/21/08

2: With a 7/16” drill the bottom guide-mounting hole

out. Drill from the front of the guidepost, to a depth of

approx. 1”. The hole should be just deep enough to

stop short of breaking through the countersunk portion

of the hole.

3: Drill and tap a hole for a ¼” 20 set screw approx. ½ - ¾” back from the front edge of the guidepost.

This hole must be centered (intersect) with the 7/16” hole. As shown above.

Manual V-16, V-24, VH-24, V-40 & VH-40

12 – Section I

Page 13

7/21/08

4: Insert the mounting stud (B) into the guide casting (A). Keep the stud

flush with the front of the casting. Keeping the mounting stud flat area

on the bottom, tighten securely the set screw (C) on the bottom of the

casting.

5: Insert this stud and guide assembly into the 7/16” hole in the guidepost. Make sure upper roller guide

is plumb with the guidepost. Lightly tighten set screw you installed in the guidepost.

Lower Guide Installation:

6: Remove lower blade guide. Replace this guide with the high

speed guide containing the

mounting bracket with slotted hole, reusing existing nuts /

bolts.

Position assembly upward along the slotted bracket, so that

the guide body casting has enough clearance to allow the

work table to be tilted for angle cutting. Tighten the socket

head cap screw or nut.

Note: Make certain that if a socket head cap screw is

used, it does not bottom out into the main saw casting

item 1. Shorten the cap screw if necessary

7: Alignment of Upper / Lower Guides:

With blade properly tensioned and tracked, position the

back-up roller by loosening the set

screw (A) on the front of the guide casting, and move the

knurled knob left to right until blade is in alignment with

the groove in the bearing. Rotate the knurled knob until

you have approx. 1/16” clearance from the back of the

blade to the front edge of the back-up roller. Tighten set

screw (A).

The two roller bearings below the back up bearing can

be adjusted in and out, left and right. Loosen the set screws that retain the bearing stems into the

casting. Using the single bearing assembly, position these bearings approx. 1/16” behind the deepest

gullet of the blade.

The single bearing assembly along with the adjustably of the upper guide roller will service blades from

¼” to ¾” The double roller set is used only when blade of ½” to 1” are used. Note: The adjustments

are the same for both single and double bearing assemblies.

Rotate eccentric bearing stems until both blade and the back up bearing groove are parallel with each

other. Set screws should be just snug up until actual alignment is confirmed.

Manual V-16, V-24, VH-24, V-40 & VH-40

13 – Section I

Page 14

7/21/08

Repeat this process for the lower guide assembly.

Note: Upper guide stud may be adjusted in or out in the guide post to allow proper clearance for

blade, and for alignment with lower guide.

Align backup bearing as previously described for upper guide. Tighten both set screws when alignment

is confirmed.

Re-adjust side rollers. (Graphic in previous column) Set the side clearance distance between rollers

and saw blade, leaving about a .004 gap.

Note: If the adjustment setting for side clearance

between roller and blade is not enough, the side

rollers will cause the blade to miss-track or be

pushed outward from the guide rollers.

Note: If blade alignment from band wheel to

roller guides is necessary, do so by rotating

eccentric shafts on the roller guides. Then

lock them in place with the set screws.

After all adjustments have been made, tighten

all components tight.

BAND SPEED SELECTION

The saw blade is driven by a single speed transmission on the 16” machine and dual speed

transmissions on the 24” and 40” machines. The shifting lever on the larger models has three positions.

(Figure 1) The center being the neutral position, for set up. With the machine off, move the shift lever to

the left for low speed range (50-500 FPM) and to the right for the high speed range. (500-5000 FPM)

To shift the machine the shift lever handle must be pulled outward and then shifted left or right. (Figure

2)

WARNING: NEVER SHIFT WHILE THE MOTOR IS RUNNING. THIS WILL CAUSE EXTENSIVE

DAMAGE TO THE DRIVE TRAIN.

Manual V-16, V-24, VH-24, V-40 & VH-40

14 – Section I

Page 15

7/21/08

Note: Occasionally the drive wheel may have to

be jogged by hand to engage the transmission

lever.

The variable speed is achieved through the use of a

variable regulator. (Figure 3) This is turned clockwise

or counter- clockwise to obtain an increase or

decrease in blade speed, in either range. Adjust until

desired speed is reached as read on the blade

speed gauge.

WARNING: DO NOT ADJUST THE VARIABLE SPEED CONTROL (FIGURE 3) SPEED UNLESS

THE MACHINE IS IN OPERATION! FAILURE TO DO SO WILL CAUSE SEALS TO FAIL, AND

RENDER THE UNIT INOPERABLE.

SAW BLADE SELECTION

There are numerous types of saw blades available depending upon the application. Tooth pitch, form,

tooth set, and blade composite make up all contribute to the desired cut. Blade speeds and feed are

also a factors. The complexity of the subject cannot be properly detailed in this manual, and it is

suggested that you contact your local blade supplier for more detailed information and

recommendations for the application.

Below is a chart that can be used as a guide line for blade selection and a percentage chart for

determining the speeds and feeds for material after determining the Rockwell hardness.

The chart below shows material shape and sizes of square solid, round solid, and tubing, channel, and

angle. The size range from 0” - 12” is diameter; the column under the shapes gives recommendation of

a vari-tooth blade. Example: 4” round solid, will require a 3/4 pitch blade.

Note: For structurals and tubing, determine the average width of cut.

Blades must be broke in properly, for longest life and best cut finish. Break in cutting should be

done at 1/3-1/2 normal cutting rate, for the 50-100 square inches.

NOTE: Below are the three most commonly used types of blades. The Bi-Metal blade is the most durable, for standard types of cutting

applications. The teeth are made of high speed steel and welded to a backing material. The cutting edge contains 8% cobolt with a Rc of 64

to 68. (These blades are more difficult to weld than standard carbon.) The carbon blade is the least expensive with reduced blade life. The

back of the blade is made of hardened material with a Rc of 31 to 37 and tooth hardness of 64 to 66. The carbide tipped blade has carbide

inserts welded to the blade teeth with a Ra rating of 92

Manual V-16, V-24, VH-24, V-40 & VH-40

15 – Section I

Page 16

7/21/08

SAW BLADE SELECTION

MATERIAL SHAPE MATERIAL SHAPE MATERIAL SHAPE

MATERIAL IN

INCHES TOOTH SELECTION TOOTH SELECTION TOOTH SELECTION

0 14 / 18 14 / 18 14 / 18

.1 14 / 18 14 / 18 14 / 18

.2 14 / 18 14 / 18 14 / 18

.3 10 / 14 14 / 18 10 / 14

.4 8 / 12 10 / 14 8 / 12

.5 8 / 12 8 / 12 6 / 10

.6 6 / 10 8 / 12 5 / 8

.7 6 / 10 6 / 10 5 / 8

.8 5 / 8 6 / 10 5 / 8

.9 5 / 8 5 / 8 5 / 8

1 5 / 8 5 / 8 4 / 6

1 1/4 4 / 6 5 / 8 4 / 6

1 1/2 4 / 6 4 / 6 4 / 6

1 3/4 4 / 6 4 / 6 4 / 6

2 4 / 6 4 / 6 3 / 4

2 1/4 4 / 6 4 / 6 3 / 4

2 1/2 3 / 4 4 / 6 3 / 4

2 3/4 3 / 4 4 / 6 3 / 4

3 3 / 4 3 / 4 3 / 4

3 1/4 3 / 4 3 / 4 3 / 4

3 1/2 3 / 4 3 / 4 3 / 4

3 3/4 3 / 4 3 / 4 2 / 3

4 3 / 4 3 / 4 2 / 3

5 2 / 3 3 / 4 2 / 3

6 2 / 3 3 / 4 2 / 3

7 2 / 3 2 / 3 1.4 / 2.5

8 1.4 / 2.5 2 / 3 1.4 / 2.5

9 1.4 / 2.5 2 / 3 1.4 / 2.5

10 1.4 / 2.5 1.4 / 2.5 1.4 / 2.5

11 1.4 / 2.5 1.4 / 2.5 1.4 / 2.5

12 1.4 / 2.5 1.4 / 2.5 1.4 / 2.5

SPEEDS AND FEEDS

As important as proper blade selection, is proper feeds and speeds for the different materials to be cut.

It is impossible to determine absolute rates for each material and machine, below is a chart that will

give you staring points for most applications; keeping in mind these are only approximations.

The left hand column, labeled Material tells you the family, the column Alloy lists the types that are

within that family of material. The top six columns give material dimensions. Below these column are

listed the recommended FPM and SIPM for that material type. Example: Carbon steel with a alloy make

up classified as 1030, with a diameter of 4” will be cut at 329 FPM and SIPM of 14, shown as fpm 329

sipm 14.

Manual V-16, V-24, VH-24, V-40 & VH-40

16 – Section I

Page 17

7/21/08

MATERIAL ALLOY 1/2" 1" 2" 4" 7" 12"

1100,2011,2017,2024 fpm 568 sipm 7 fpm 577 sipm 11 fpm 536 sipm 16 fpm 498 sipm 21 fpm 451sipm 23 fpm 389 sipm 24

ALUMINUM ALLOY 3003,5052,5086,6061 fpm 568 sipm 7 fpm 577 sipm 11 fpm 536 sipm 16 fpm 498 sipm 21 fpm 451sipm 23 fpm 389 sipm 24

6063,6101,6262,7075 fpm 568 sipm 7 fpm 577 sipm 11 fpm 536 sipm 16 fpm 498 sipm 21 fpm 451sipm 23 fpm 389 sipm 24

356,360 fpm 511 sipm 7 fpm 501 sipm 10 fpm 482 sipm 14 fpm 448 sipm 19 fpm 406 sipm 21 fpm350 sipm 22

353 fpm 454 sipm 6 fpm 445 sipm 8 fpm 429 sipm 12 fpm 399 sipm 17 fpm 361 sipm 19 fpm311 sipm 19

1452,187 fpm 426 sipm 6 fpm 418 sipm 8 fpm 402 sipm 12 fpm 374 sipm 16 fpm 338 sipm 18 fpm 292 sipm 18

380,544 fpm 397 sipm 5 fpm 390 sipm 7 fpm 375 sipm 11 fpm349 sipm 15 fpm 316 sipm 16 fpm 272 sipm 17

173,932 fpm 358 sipm 5 fpm 351 sipm 7 fpm 338 sipm 10 fpm 314 sipm 13 fpm 284 sipm 15 fpm 245 sipm 15

330,365 fpm 324 sipm 4 fpm 317 sipm 6 fpm 305 sipm 9 fpm 284 sipm 12 fpm 257 sipm 13 fpm 222 sipm 14

COPPER ALLOY 623,624 fpm 301 sipm 4 fpm 295 sipm 6 fpm 284 sipm 8 fpm 264 sipm 11 fpm 239 sipm 12 fpm 206 sipm 13

230,260,272 fpm 278 sipm 4 fpm 273 sipm 5 fpm 263 sipm 8 fpm 244 sipm 10 fpm 221 sipm 11 fpm 191 sipm 12

280,464,632,655 fpm 278 sipm 4 fpm 273 sipm 5 fpm 263 sipm 8 fpm 244 sipm 10 fpm 221 sipm 11 fpm 191 sipm 12

101,102,110,122,172 fpm 267 sipm 3 fpm 262 sipm 5 fpm 252sipm 7 fpm 234 sipm 10 fpm 212 sipm 11 fpm 183 sipm 11

1751,182,220,510 fpm 267 sipm 3 fpm 262 sipm 5 fpm 252 sipm 7 fpm 234 sipm 10 fpm 212 sipm 11 fpm 183 sipm 11

625,706,715,934 fpm 267 sipm 3 fpm 262 sipm 5 fpm 252 sipm 7 fpm 234 sipm 10 fpm 212 sipm 11 fpm 183 sipm 11

630 fpm 261 sipm 3 fpm 256 sipm 5 fpm 246 sipm 7 fpm 229 sipm 10 fpm 207 sipm 11 fpm 179 sipm 11

811 fpm 244 sipm 3 fpm 239 sipm 5 fpm 230 sipm 7 fpm 214 sipm 9 fpm 194 sipm 10 fpm 167 sipm 10

12L14 fpm 483 sipm 6 fpm 473 sipm 9 fpm 455 sipm 13 fpm 424 sipm 18 fpm 383 sipm 20 fpm 321 sipm 20

1213,1215 fpm 454 sipm 6 fpm 445 sipm 8 fpm 429 sipm 12 fpm 399 sipm 17 fpm 361 sipm 19 fpm 311 sipm 19

RESULFURIZED 1117 fpm 386 sipm 5 fpm 379 sipm 7 fpm 364 sipm 11 fpm 339 sipm 15 fpm 307 sipm 16 fpm 265 sipm 16

CARBON STEEL 1137 fpm 329 sipm 4 fpm 323 sipm 6 fpm 311 sipm 9 fpm 289 sipm 12 fpm 262 sipm 14 fpm 262 sipm 14

1141,1144 fpm 318 sipm 4 fpm 312 sipm 6 fpm 300 sipm 9 fpm 279 sipm 12 fpm 253 sipm 13 fpm 218 sipm 13

1144 HI STRESS fpm 318 sipm 4 fpm 312 sipm 6 fpm 300 sipm 9 fpm 279 sipm 12 fpm 253 sipm 13 fpm 218 sipm 13

1030 fpm 375 sipm 5 fpm 367 sipm 7 fpm 254 sipm 10 fpm 329 sipm 14 fpm 298 sipm 15 fpm 257 sipm 16

1008,1015,1020,1025 fpm 363 sipm 5 fpm 356 sipm 7 fpm 343 sipm 10 fpm 319 sipm 14 fpm 289 sipm 15 fpm 249 sipm 15

1035 fpm 352 sipm 5 fpm 345 sipm 7 fpm 332 sipm 10 fpm 309 sipm 13 fpm 280 sipm 14 fpm 241 sipm 14

1018,1021,1025 fpm 341 sipm 4 fpm 334 sipm 6 fpm 321 sipm 9 fpm 299 sipm 13 fpm 271 sipm 14 fpm 234 sipm 14

CARBON STEEL 1026,1513 fpm 341 sipm 4 fpm 334 sipm 6 fpm 321 sipm 9 fpm 299 sipm 13 fpm 271 sipm 14 fpm 234 sipm 14

A36 (SHAPES),1040 fpm 307 sipm 4 fpm 301 sipm 6 fpm 289 sipm 8 fpm 269 sipm 12 fpm 243 sipm 13 fpm 210 sipm 13

1042,1541 fpm 284 sipm 4 fpm 278 sipm 5 fpm 268 sipm 8 fpm 249 sipm 11 fpm 225 sipm 12 fpm 195 sipm 12

1044,1045 fpm 250 sipm 3 fpm 245 sipm 5 fpm 236 sipm 7 fpm 219 sipm 9 fpm 198 sipm 10 fpm 171 sipm 11

1060 fpm 227sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

1095 fpm 210 sipm 3 fpm 206 sipm 4 fpm 198 sipm 6 fpm 184 sipm 8 fpm 167 sipm 9 fpm 144 sipm 9

8615,8620,8622 fpm 273 sipm 4 fpm 267 sipm 5 fpm 257 sipm 7 fpm 239 sipm 10 fpm 216 sipm 11 fpm 187 sipm 12

NI-CR-MO 4340,E4340,8630 fpm 250 sipm 3 fpm 245 sipm 5 fpm 236 sipm 7 fpm 219 sipm 9 fpm 198 sipm 10 fpm 171 sipm 11

ALLOY STEEL 8640 fpm 227 sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

E9310 fpm 199 sipm 3 fpm 195 sipm 4 fpm 188 sipm 5 fpm 174 sipm 7 fpm 158 sipm 8 fpm 136 sipm 8

TOOL STEEL L-6 fpm 216 sipm 3 fpm 212 sipm 4 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

SHOCK RESISTING S-1 fpm 227 sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

TOOL S-5 fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 126 sipm 7 fpm 109 sipm 7

STEEL S-7 fpm 142 sipm 2 fpm 139 sipm 3 fpm 134 sipm 4 fpm 125 sipm 5 fpm 113 sipm 6 fpm 97 sipm 6

Manual V-16, V-24, VH-24, V-40 & VH-40

17 – Section I

Page 18

7/21/08

MATERIAL ALLOY 1/2" 1" 2" 4" 7" 12"

A-6 fpm 227 sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

COLD-WORK A-2 fpm 204 sipm 3 fpm 200 sipm 4 fpm 193 sipm 6 fpm 179 sipm 8 fpm 162 sipm 8 fpm 140 sipm 9

TOOL STEEL A-10 fpm 182 sipm 2 fpm 178 sipm 3 fpm 171 sipm 5 fpm 159 sipm 7 fpm 144 sipm 7 fpm 125 sipm 8

D-2 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

HOT-WORK TOOL H-11,H-12,H-13 fpm 216 sipm 3 fpm 212 sipm 4 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

OIL HARDENING 0-1 fpm 227 sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

TOOL STEEL 0-6 fpm 216 sipm 9 fpm 212 sipm 12 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

WATER-HARD

TOOL STEEL W-1 fpm 256 sipm 3 fpm 251 sipm 5 fpm 241 sipm 7 fpm 224 sipm 10 fpm 203 sipm 11 fpm 175 sipm 11

HIGH-SPEED TOOL M-1 fpm 125 sipm 2 fpm 122 sipm 2 fpm 118 sipm 3 fpm 110 sipm 5 fpm 99 sipm 5 fpm 86 sipm 5

STEEL M-2,M-42,T-1 fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

T-15 fpm 79 sipm 1 fpm 78 sipm 1 fpm 75 sipm 2 fpm 70 sipm 3 fpm 63 sipm 3 fpm 54 sipm 3

A242(1) COR-TEN A fpm 341 sipm 4 fpm 334 sipm 6 fpm 321 sipm 9 fpm 299 sipm 13 fpm 271 sipm 14 fpm 234 sipm 14

ALLOY A242(2) COR-TEN B fpm 307 sipm 4 fpm 301 sipm 6 fpm 289 sipm 8 fpm 269 sipm 8 fpm 243 sipm 13 fpm 210 sipm 13

STEEL 300M,HY-80,HY-100 fpm 182 sipm 2 fpm 178 sipm 3 fpm 171 sipm 5 fpm 159 sipm 7 fpm 144 sipm 7 fpm 125 sipm 8

HP 9-4-20,HP 9-4-25 fpm 119 sipm 2 fpm 117 sipm 2 fpm 113 sipm 3 fpm 105sipm 4 fpm 95 sipm 5 fpm 82 sipm 2

MN ALLOY 1330 fpm 250 sipm 3 fpm 245 sipm 5 fpm 236 sipm 7 fpm 219 sipm 9 fpm 198 sipm 10 fpm 171 sipm 11

STEEL 1345 fpm 238 sipm 3 fpm 234 sipm 4 fpm 225 sipm 7 fpm 209 sipm 9 fpm 189 sipm 10 fpm 163 sipm 10

41L40 fpm 312 sipm 4 fpm 306 sipm 6 fpm 295 sipm 9 fpm 274 sipm 12 fpm 248 sipm 13 fpm 214 sipm 13

4130 fpm 307 sipm 4 fpm 301 sipm 6 fpm 289 sipm 8 fpm 269 sipm 12 fpm 243 sipm 13 fpm 210 sipm 13

CR-MO e.t.d.'150 fpm 284 sipm 4 fpm 278 sipm 5 fpm 268 sipm 8 fpm 249 sipm 11 fpm 225 sipm 12 fpm 195 sipm 12

ALLOY STEEL 4140,4142 fpm 284 sipm 4 fpm 278 sipm 5 fpm 268 sipm 8 fpm 249 sipm 11 fpm 225 sipm 12 fpm 195 sipm 12

4145 fpm 238 sipm 3 fpm 234 sipm 4 fpm 225 sipm 7 fpm 209 sipm 9 fpm 189 sipm 10 fpm 163 sipm 10

4150 fpm 227 sipm 3 fpm 223 sipm 4 fpm 214 sipm 6 fpm 199 sipm 9 fpm 180 sipm 9 fpm 156 sipm 10

5160 fpm 250 sipm 3 fpm 245 sipm 5 fpm 236 sipm 7 fpm 219 sipm 9 fpm 198 sipm 10 fpm 171 sipm 11

CR ALLOY STEEL 6150 fpm 238 sipm 3 fpm 234 sipm 4 fpm 225 sipm 7 fpm 209 sipm 9 fpm 189 sipm 10 fpm 163 sipm 10

E52100 fpm 182 sipm 2 fpm 178 sipm 3 fpm 171 sipm 5 fpm 159 sipm 7 fpm 144 sipm 7 fpm 125 sipm 8

420 fpm 216 sipm 3 fpm 212 sipm 4 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

430 fpm 170 sipm 2 fpm 167 sipm 3 fpm 161 sipm 5 fpm 149 sipm 6 fpm 1235sipm 7 fpm 117 sipm 7

CR STAINLESS 410,502 fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 126 sipm 7 fpm 109 sipm 7

STEEL 414 fpm 131 sipm 2 fpm 128 sipm 2 fpm 123 sipm 4 fpm 115 sipm 5 fpm 104 sipm 5 fpm 90 sipm 6

431 fpm 108 sipm 1 fpm 106 sipm 2 fpm 102 sipm 3 fpm 95 sipm 4 fpm 86 sipm 4 fpm 74 sipm 5

440C fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

MOLD STEEL P-20 fpm 261 sipm 3 fpm 256 sipm 5 fpm 246 sipm 7 fpm 229 sipm 10 fpm 207 sipm 11 fpm 179 sipm 11

STAINLESS STEEL CUSTOM 450,456 fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

304,324 fpm 136 sipm 2 fpm 134 sipm 3 fpm 129 sipm 4 fpm 120 sipm 5 fpm 108 sipm 6 fpm 93 sipm 6

304L fpm 131 sipm 2 fpm 128 sipm 2 fpm 123 sipm 4 fpm, 115 sipm 5 fpm 104 sipm 5 fpm 90 sipm 6

347 fpm 125 sipm 2 fpm 122 sipm 2 fpm 118 sipm 3 fpm 110 sipm 5 fpm 99 sipm 5 fpm 86 sipm 5

AUSTENITIC 316,316L fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

STAINLESS STEEL 18-18-2,309 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

310 fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

22-13-5 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NITRONIC 50,60 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

Manual V-16, V-24, VH-24, V-40 & VH-40

18 – Section I

Page 19

7/21/08

MATERIAL ALLOY 1/2" 1" 2" 4" 7" 12"

MARTENSITIC

STAINLESS STEEL GREEK ASCOLOY fpm 108 sipm 1 fpm 106 sipm 2 fpm 102 sipm 3 fpm 95 sipm 4 fpm 86 sipm 4 fpm 74 sipm 5

416 fpm 216 sipm 3 fpm 212 sipm 4 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

FREE MACHINING 440 F fpm 182 sipm 2 fpm 178 sipm 3 fpm 171 sipm 5 fpm 159 sipm 7 fpm 144 sipm 7 fpm 125 sipm 8

STAINLESS STEEL 203 EZ,430 F fpm 170 sipm 2 fpm 167 sipm 3 fpm 161 sipm 5 fpm 149 sipm 6 fpm 135 sipm 7 fpm 117 sipm 7

303,303 PB,303 SE fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 126 sipm 67 fpm 109 sipm 7

416 fpm 216 sipm 3 fpm 212 sipm 4 fpm 204 sipm 6 fpm 189 sipm 8 fpm 171 sipm 9 fpm 148 sipm 9

FREE MACHINING 440 F fpm 182 sipm 2 fpm 178 sipm 3 fpm 171 sipm 5 fpm 159 sipm 7 fpm 144 sipm 7 fpm 125 sipm 8

STAINLESS STEEL 203 EZ,430 F fpm 170 sipm 2 fpm 167 sipm 3 fpm 161 sipm 5 fpm 149 sipm 6 fpm 135 sipm 7 fpm 117 sipm 7

303,303 PB,303 SE fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 126 sipm 67 fpm 109 sipm 7

FERRITIC FERRALIUM 255 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

AUSTENITIC S.S. 2205 fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

15-5 PH fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

PRECIPITATION 17-4 PH,17-7 PH fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

HARDENABLE AM 350,AM 355 fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

STAINLESS STEEL PH 13-8 MO fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

PH 14-8 MO fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

PH 15-7 MO fpm 85 sipm 1 fpm 84 sipm 2 fpm 80 sipm 2 fpm 75 sipm 3 fpm 68 sipm 4 fpm 58 sipm 4

MAGNESIUM AZ31B MAG-

ALLOY NESIUM ALLOY fpm 568 sipm 7 fpm 557 sipm 11 fpm 536 sipm 16 fpm 498 sipm 21 fpm 451 sipm 23 fpm 389 sipm 24

IRON BASE PYROMET X-15 fpm 136 sipm 2 fpm 134 sipm 3 fpm 129 sipm 4 fpm 120 sipm 5 fpm 108 sipm 6 fpm 93 sipm 6

SUPER ALLOY A286 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

INCOLOY 800,801 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

COBALT BASE ASTROLOY M fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

ALLOY WF-11 fpm 74 sipm 1 fpm 72 sipm 1 fpm 70 sipm 2 fpm 65 sipm 3 fpm 59 sipm 3 fpm 51 sipm 3

TI-3A1-8V-6CR-4MO-4Zr fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1

TI-8Mo-8V-2Fe-3Al fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1 fpm 91 sipm 1

TI-2Al-11Sn-5Zr-1Mo fpm 85 sipm 1 fpm 84 sipm 2 fpm 80 sipm 2 fpm 75 sipm 3 fpm 68 sipm 4 fpm 58 sipm 4

TITANIUM ALLOY TI-5Al-2.5Sn fpm 85 sipm 1 fpm 84 sipm 2 fpm 80 sipm 2 fpm 75 sipm 3 fpm 68 sipm 4 fpm 58 sipm 4

TI-6Al-2Sn-4Zr-2Mo fpm 85 sipm 1 fpm 84 sipm 2 fpm 80 sipm 2 fpm 75 sipm 3 fpm 68 sipm 4 fpm 58 sipm 4

TI-6Al-4V fpm 79 sipm 1 fpm 78 sipm 1 fpm 75 sipm 2 fpm 70 sipm 3 fpm 63 sipm 3 fpm 54 sipm 3

TI-7Al-4Mo fpm 74 sipm 1 fpm 72 sipm 1 fpm 70 sipm 2 fpm 65 sipm 3 fpm 59 sipm 3 fpm 51 sipm 3

TI-8Al-1Mo-1V fpm 74 sipm 1 fpm 72 sipm 1 fpm 70 sipm 2 fpm 65 sipm 3 fpm 59 sipm 3 fpm 51 sipm 3

NICKEL ALLOY NICKEL 200,201,205 fpm 97 sipm 1 fpm 95 sipm 2 fpm 91 sipm 3 fpm 85 sipm 4 fpm 77 sipm 4 fpm 66 sipm 4

INCONEL 625 fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

INCOLOY 802,804 fpm 102 sipm 1 fpm 100 sipm 2 fpm 96 sipm 3 fpm 90 sipm 4 fpm 81 sipm 4 fpm 70 sipm 4

MONEL R405 fpm 97 sipm 1 fpm 95 sipm 2 fpm 91 sipm 3 fpm 85 sipm 4 fpm 77 sipm 4 fpm 66 sipm 4

NICKEL BASE 20CB3 fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

ALLOY MONEL 400,401 fpm 85 sipm 1 fpm 84 sipm 2 fpm 80 sipm 2 fpm 75 sipm 3 fpm 68 sipm 4 fpm 58 sipm 4

(*HASTELLOY) *B,B-2,C,C-22 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

*C-276,C-4 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

*F,G,G-2,3,G-30 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

*N,S,W,X , INCOLOY

825

fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

Manual V-16, V-24, VH-24, V-40 & VH-40

19 – Section I

Page 20

7/21/08

MATERIAL ALLOY 1/2" 1" 2" 4" 7" 12"

INCONEL 751,X750 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

NICKEL BASE WASPALOY fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1 fpm 79 sipm 1

ALLOY MONEL K500 fpm 74 sipm 1 fpm 72 sipm 1 fpm 70 sipm 2 fpm 65 sipm 3 fpm 59 sipm 3 fpm 51 sipm 3

(*HASTELLOY) INCOLOY 901,903,926 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

INCONEL 600,718 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NI-SPAN-C 902 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NIMONIC 263 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

RENE 41,UDIMET 500 fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

NIMONIC 75 fpm 57 sipm 1 fpm 56 sipm 1 fpm 54 sipm 2 fpm 50 sipm 2 fpm 45 sipm 2 fpm 39 sipm 2

ASTM A220 (50005) fpm 273 sipm 4 fpm 267 sipm 5 fpm 257 sipm 7 fpm 239 sipm 10 fpm 216 sipm 11 fpm 187 sipm 12

CAST IRONS ASTM A220 (60004) fpm 193 sipm 3 fpm 189 sipm 4 fpm 182 sipm 5 fpm 169 sipm 7 fpm 153 sipm 8 fpm 132 sipm 8

PEARLITIC ASTM A220 (70003) fpm 165 sipm 2 fpm 161 sipm 3 fpm 155 sipm 5 fpm 144 sipm 6 fpm 131 sipm 7 fpm 133 sipm 7

MALLEABLE ASTM A220 (80002) fpm 142 sipm 2 fpm 139 sipm 3 fpm 134 sipm 4 fpm 125 sipm 5 fpm 113 sipm 6 fpm 97 sipm 6

ASTM A220 (90001) fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

ASTM A436 (1B) fpm 170 sipm 2 fpm 167 sipm 3 fpm 161 sipm 5 fpm 149 sipm 6 fpm 135 sipm 7 fpm 117 sipm 7

GRAY IRON ASTM A436 (2) fpm 159 sipm 2 fpm 156 sipm 3 fpm 150 sipm 4 fpm 140 sipm 6 fpm 125 sipm 7 fpm 109 sipm 7

AUSTENITIC ASTM A436 (2B) fpm 142 sipm 2 fpm 139 sipm 3 fpm 134 sipm 4 fpm 125 sipm 5 fpm 133 sipm 6 fpm 97 sipm 6

DUCTILE ASTM A439 (D-2) fpm 91 sipm 1 fpm 89 sipm 2 fpm 86 sipm 2 fpm 80 sipm 3 fpm 72 sipm 4 fpm 62 sipm 4

AUSTENITIC ASTM A439 (D2-B) fpm 68 sipm 1 fpm 67 sipm 1 fpm 64 sipm 2 fpm 60 sipm 3 fpm 54 sipm 3 fpm 47 sipm 3

MALLEABLE ASTM A47(50&53ksi) fpm 341 sipm 4 fpm 334 sipm 6 fpm 321 sipm 9 fpm 299 sipm 13 fpm 271 sipm 14 fpm 234 sipm 14

ASTM A48 (20ksi) fpm 261 sipm 3 fpm 256 sipm 5 fpm 246 sipm 7 fpm 229 sipm 10 fpm 207 sipm 11 fpm 179 sipm 11

GARY IRON ASTM A48 (40ksi) fpm 204 sipm 3 fpm 200 sipm 4 fpm 193 sipm 6 fpm 179 sipm 8 fpm 162 sipm 8 fpm 140 sipm 9

ASTM A48 (60ksi) fpm 114 sipm 1 fpm 111 sipm 2 fpm 107 sipm 3 fpm 100 sipm 4 fpm 90 sipm 5 fpm 78 sipm 5

ASTM A536 (60-40-18) fpm 409 sipm 5 fpm 401 sipm 8 fpm 396 sipm 11 fpm 359 sipm 15 fpm 325 sipm 17 fpm 280 sipm 17

DUCTILE ASTM A536 (88-55-06) fpm 273 sipm 4 fpm 267 sipm 5 fpm 257 sipm 7 fpm 239 sipm 10 fpm 216 sipm 11 fpm 187 sipm 12

ASTM A536 (100-70-03) fpm 210 sipm 3 fpm 206 sipm 4 fpm 198 sipm 6 fpm 184 sipm 8 fpm 167 sipm 9 fpm 144 sipm 9

ASTM A536 (120-90-02) fpm 136 sipm 2 fpm 134 sipm 3 fpm 129 sipm 4 fpm 120 sipm 5 fpm 108 sipm 6 fpm 93 sipm 6

RATE REDUCTION FOR HARD MATERIALS

Below is a matrix for speed reduction for hard materials. Find the material hardness, either Rockwell

(Rc) or Brinell (Bhn), and reduce both band speed and cutting rate by the percentage shown.

HARDNESS (Rc) HARDNESS (Bhn) SPEED / CUTTING

Rockwell Brinell

Up to 20 226 0%

22 237 5%

24 247 10%

26 258 15%

28 271 20%

30 286 25%

32 301 30%

34 319 33%

36 336 35%

38 353 40%

RATE REDUCTION

Manual V-16, V-24, VH-24, V-40 & VH-40

20 – Section I

Page 21

7/21/08

HYDRAULIC FEED TABLE

Machines equipped with a hydraulic feed table (VH models) have a pumping unit in the base. The

system has an adjustable relief valve, which is factory preset at 400 p.s.i. The systems oil level must be

checked periodically to assure the oil levels are maintained at the full level of the sight glass.

The feed table regulator will provide a smooth movement to the table. If the feed appears to be

intermittent it is probably due to air in the system. This is normally exhausted by running the table in

and out a few times.

To move the feed table, push the “hydraulic start” button on the control panel then, rotate the handle on

the front of the table to the right to start or increase the table feed rate. To move the table back to the

starting position rotate the handle to the left, there is only one speed for the reverse movement (see

diagram below).

WELDING INSTRUCTIONS

GENERAL DESCRIPTION

Note: Always wear eye protection when

using this welder or grinder!

Your Dake vertical band saw is equipped

with a “resistance-type” butt welder. The

two clamp jaws of the welder hold the

blade ends together. When the welding

start knob is turned fully clockwise past the

zero setting, electric current flows through

the blade ends creating enough heat to

soften and join them.

Note: This welder is suitable to weld

Metal blades 3 x 0.5 - 25 x 0.8mm

bi-metal blades 6 x 0.9 - 25 x 0.9mm

Manual V-16, V-24, VH-24, V-40 & VH-40

21 – Section I

BANDSAW WELDING

6 x 0.9 1 - 2 1 2.5 DARK RED 15

10 x 0.9 1 - 2 1 3.0 DARK RED 15

12 x 0.6 1 - 2 1 3.0 DARK RED 15

12 x 0.9 1 - 2 1 3.0 DARK RED 15

13 x 0.7 1 - 2 1 - 2 3.0 DARK RED 15

16 x 0.7 1 - 2 1 - 2 3.0 DARK RED 15

19 x 0.9 1 - 2 1 - 2 3.0 DARK RED 15

25 x 0.9 1 - 2 1 - 2 3.5 DARK RED 15

CURRENT

mm step *) step *) mm COLOR TIME SEC.

UPSETTING

PRESSURE

UPSETTING

WAY

ANNEALING ANNEALING

Page 22

7/21/08

This welder should not be used for welding 2% and 3% tungsten-alloyed metal cutting blades or HSS

blades.

The approximate valves for bi-metal blades are indicated in the matrix in the next column

.

Note: * The weld current step and upsetting pressure step have to be increased with some saw

manufactures. The saw blade has to be metallically clean and no tooth may enter into the welding

seam.

1. PREPARATION OF BLADE

Before welding the blade ends should be cleaned or rubbed with emery cloth on both sides of the blade

to a length of 1”, until they are metallically clean over the enter width.

Cut the blade ends accurately and at right angles. (See graphic below) Check

abutment against the stop for a cut at right angles. Proper welding can only

be achieved if the blade ends are cut with out a burr and at right angles. (Also

see trouble shooting section)

2. ADJUSTMENT

The initial jaw gap and upset force must be adjusted and

proportioned to the cross sectional area of the blade

being welded. A greater jaw gap will allow a wider or

thicker blade to reach proper welding temperature. A

greater upset pressure produces the same unit pressure

in welding a wider or thicker blade.

Set the welding current switch (1 figure 1), upsetting

pressure switch (2 figure 1) and the upsetting way switch

(3 figure 1) to the blade width to be welded. In view of

the wide range of material qualities and thickness scale

values are only guide values, which have been

calculated for commercial blades of 0.65 mm thick. Trial

welds should determine the correct settings for different steel qualities and thickness. Particularly thin

blades (0.4 mm) should be welded with a short upsetting way, high current and weak upsetting

pressure. Example: Blade width is 1/2”. Current switch is set to 1/2” (number 1) position. The upsetting

pressure switch is set to 1/2” (number 1) position. The upsetting way switch is set to the 1/2” position.

3. CLAMPING THE BLADE ENDS

Insert the blade ends in the clamping jaws so that the joist is exactly in the center of the jaws. To

protect the jaws the blades should be inserted so the teeth are aligned at the front stops. Only blades

without teeth should be aligned at the rear stops. Leave slack in the blade coil, the blade must be free

so it can move easily during welding.

4. WELDING

Manual V-16, V-24, VH-24, V-40 & VH-40

22 – Section I

Page 23

7/21/08

Turn the upsetting switch (3 figure 1) past the position (5 figure 1) to welding (6 fig. 1) and lock it for

about 3 seconds until the welding is completed. The current is switched off automatically.

Sparks spray out during welding, therefore stand at the side of the machine.

WARNING: BLADE WILL BE HOT!

5. ANNEALING

When the blade is heated in the butt welding process, the steel at the point of the weld “air hardens”

and becomes brittle. The anneal on/off knob is used to anneal the weld by reheating it. This returns the

blade close to its original condition.

After welding loosen the pressure clamps (7 fig. 1) and set the jaws to the wide annealing position by

turning the upsetting pressure switch (2 fig. 1) counter clockwise. Re-clamp the blade so that the weld

is in the center between the jaws. Operate the annealing switch (8 fig.1) until the weld becomes dark

cherry red. This will take from 1 to 5 seconds depending on the blade width. Allow blade to cool until

the blade returns to a dark color. Repeat this process at least three times. Some brittle alloys require

more annealing than the standard carbon blades.

Note: It is difficult to weld and anneal bi-metal blades due to the make up of this type of blade. It

will take some practice to successfully achieve a suitable weld.

WARNING: BLADE WILL BE HOT!

After annealing bend test your weld:

6. RE-FINISHING THE WELD

Welding burr (flash) can be removed by finishing with a grinding wheel above the welder. Grind in a

longitudinal direction, other wise transverse fractures may occur. The proper finish of the blade after

grinding, a tempered steel-blue coloring.

Note: Do not over grind, into the blade facing. Remove any burr on the back edge of the blade

.

WELDER LAYOUT AND CONTROLS

7. WELDER MAINTENANCE

If the clamping areas of the jaws are dirty or deformed so they so not clamp

evenly, good welds cannot be made. Any dirt or metallic debris must be

removed from the jaws. The jaws should never be filed. It should only be

polished with a proper cleaning material and if absolutely necessary polished

with fine emery cloth held on a flat piece of bar stock. The uniformity of current

flow and contact pressure can be checked by putting the welder in the

annealing position and clamping a piece of blade stock with out a weld in the

jaws. When the annealing switch is turned to the heating position the blade

should heat uniformly over its entire width. (See fig. 2) If the heating is not

uniform the clamping devices should be checked for dirt or misalignment.

figure 2

Manual V-16, V-24, VH-24, V-40 & VH-40

23 – Section I

Page 24

7/21/08

8. POOR WELDS / TROUBLE SHOOTING

If the welded seam contains holes, the upsetting pressure should be increased, the welding current

reduced or both settings changed. We must emphasize once again that proper welds cannot be

made if the blade ends are not cut square, and properly cleaned. Welding of blades may take

practice, do not be discouraged if your welds are not perfect at first.

Avoid overlapping when welding thin blades. If welder does not give suitable weld, check in coming

voltage to the machine. If voltage is low, use next blade size setting. Example: 220 volt machine,

incoming voltage is 208 volt, to weld 1/2” blade use 5/8” settings.

If incoming voltage is high reverse this procedure.

If incoming voltage is low, the welder transformer has taps that can be set to a 10% increase or

decrease. SHOCK HAZARD! ONLY A QUALIFIED ELECTRICIAN SHOULD ATTEMPT THIS.

ALWAYS CONTACT DAKE BEFORE REMOVING THE WELDER.

If the welder does not shut off, after the welding cycle, or will not start the welding cycle, a limit switch

adjustment is needed.

THE WELDER MUST BE REMOVED FOR THIS ADJUSTMENT. SHOCK HAZARD! ALWAYS

CONTACT DAKE BEFORE REMOVING THE WELDER OF MAKING INTERNAL ADJUSTMENTS. A

QUALIFIED ELECTRICIAN MUST DO THESE ADJUSTMENT.

MACHINE MAINTENANCE

The maintenance of the machine is naturally based on the usage rather than a time element.

The following is a recommendation based-on-average usage, and adjustment to the frequency

can be made on an individual basis. See below graphic for locations.

• Chip Pan - clean - as required.

• Band wheel tires - remove embedded chips -

weekly.

• Blade guide assemblies - clean - weekly.

• Gear box - drain and refill - yearly

• Monitor Hydraulic Reservoir.

• Drain water from water trap on air regulator

weekly.

Note: If raising the guide post more than half way up

from the table, and guide post cranks up hard, the

upper blade guard must be removed. See figure A&B

Blade will still be contained in the upper position.

Manual V-16, V-24, VH-24, V-40 & VH-40

24 – Section I

Page 25

USE OF STANDARD AND OPTIONAL

ACCESSORIES

CIRCLE CUTTING (OPTIONAL) (figure 1)

(Assembly part number 714801)

The device is used for cutting out perfectly round

objects. Insert the round bar into the corresponding

hole in the guide post, secure with set screw.

Gross radius changes are made moving the cast

assemblies on the round bar, fine adjustments are

done with the thumb wheel.

RIP FENCE Standard all models (figure 2)

(Part number 714805 – Model 24/40/F-16)

(Part number 714869 – Model E-16 only)

Used for cutting material in accurate straight lines. To

attach, insert T-bolt provided in the T-slot in the front of

the table. Slide into the desired position and tighten

handle.

PROFILE CUTTING ATTACHMENT Standard on VH-24 / VH-40 models (figure 3)

(Part number 714821)

This device is used for cutting irregular shapes with

the hydraulic table. Set the chain up as shown in

figure 3. Set the material in the holder and guide with

the hand wheel on the right side of the table. The

excess chain should be coiled out of the way, while

operating the machine.

Note: When chain is not engaged in the rear

sprocket the angle of cut is controlled by guiding

the handles on the holder.

PROTRACTOR HEAD

Standard on 24/40 models. Optional for 16 models

(figure 4)

(Assembly Part number 714800 24/40/F-16 Models)

(Assembly Part number 75561 E-16 Model)

Used for cutting angles 90 degrees to 45

degrees in relation to the blade. It is fastened to

the table by means of T-bolts. The L-shaped bar

is used for additional support of the work. This is

not factory bent.

Manual V-16, V-24, VH-24, V-40 & VH-40

25 – Section I

7/21/08

Page 26

T-SLOTS

T-slots are machined into the work table for your use

with fixturing or other accessories. The dimensions

of these T-slots are furnished to the right.

7/21/08

Manual V-16, V-24, VH-24, V-40 & VH-40

26 – Section I

Loading...

Loading...