Page 1

INSTRUCTIONS

SECTION I – Text

MODELS

Euromatic 370 S

Euromatic 370 S-L

Euromatic 370 PP

Euromatic 370 PP-L

MODEL: ________________________________________

SERIAL NUMBER: ________________________________

DATE PURCHASED: ______________________________

724 Robbins Road

Grand Haven, Michigan 49417

616-842-7110 Phone 800-937-3253

616-842-0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

370 S 370 S L 370 PP 370 PP L

1

Page 2

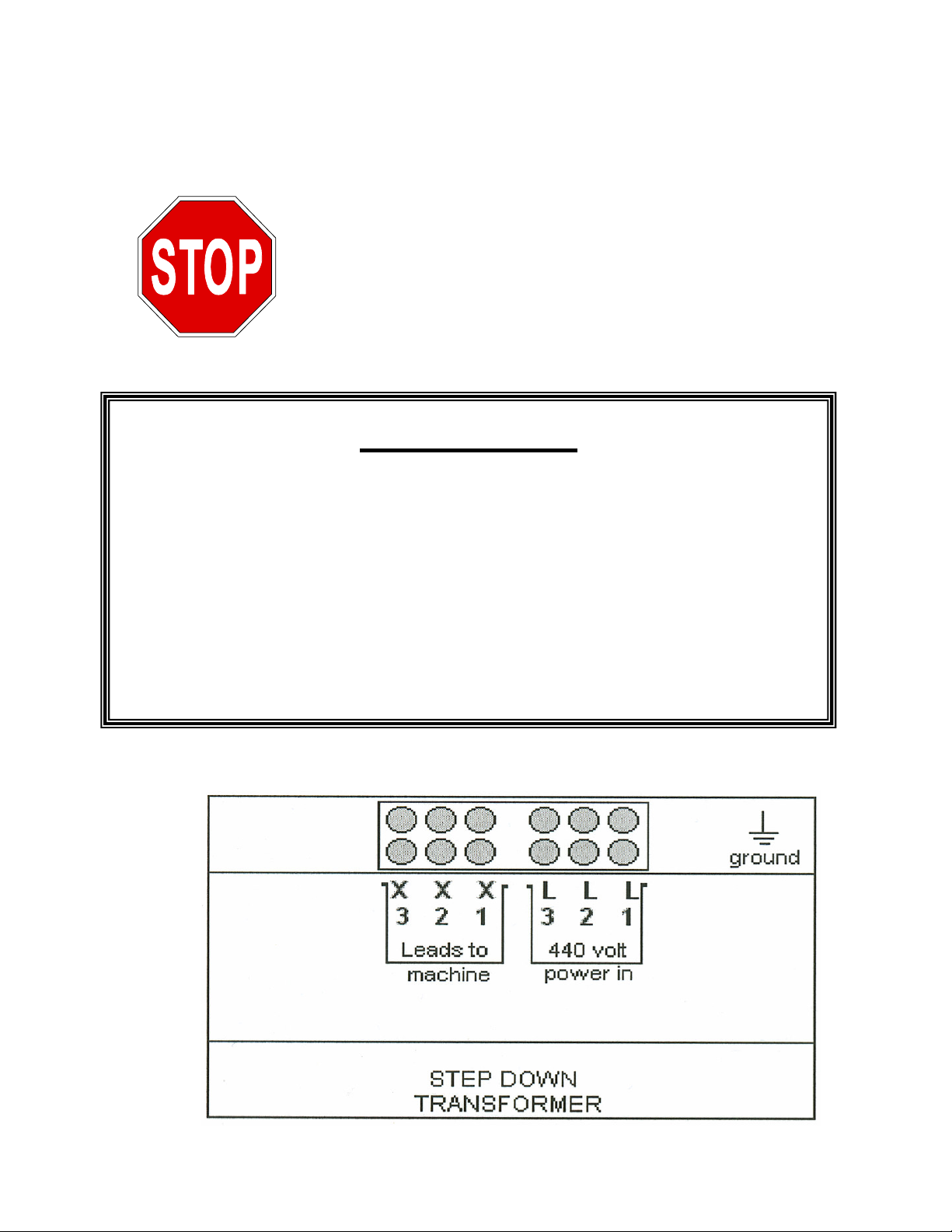

If machine is to be operated

at 440 volt 3 phase power,

please read the following

warning.

WARNING!

This machine must be wired by a qualified electrician. Do not

connect 440-volt power directly to this machine. The use of a

step down transformer, Must be used with this machine.

Failure to do so may affect warranty.

Call Dake if a transformer is needed 1-800-937-3253

370 S 370 S L 370 PP 370 PP L

2

Page 3

EUROMATIC 370 PP AUTOMATIC & SEMI-AUTOMATIC

Specifications and Capacities

TECHNICAL DATA 4-5

Unpacking and Installation

UNPACKING THE MACHINE 6

LIFTING THE MACHINE 6

BLADE INSTALLATION 7-8

9-10

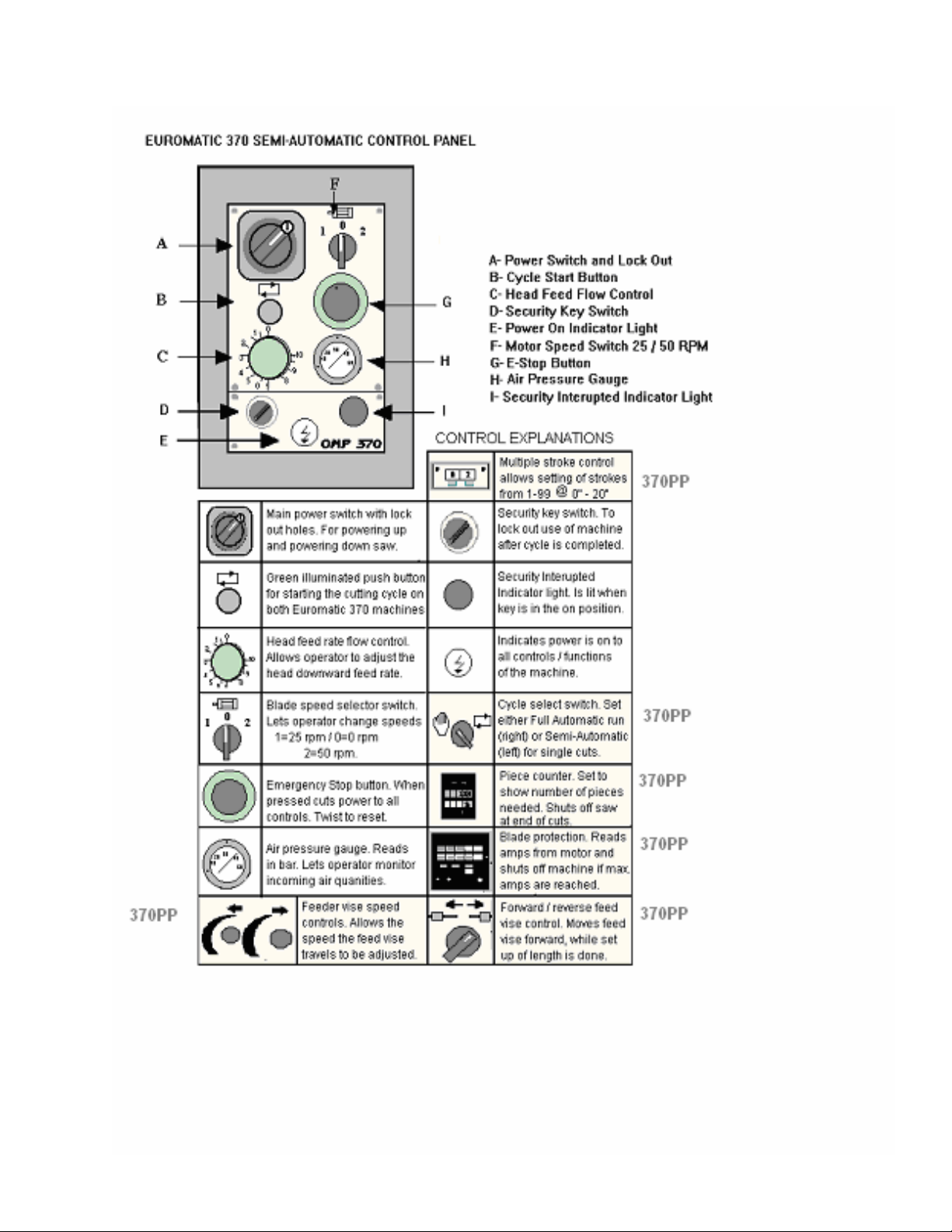

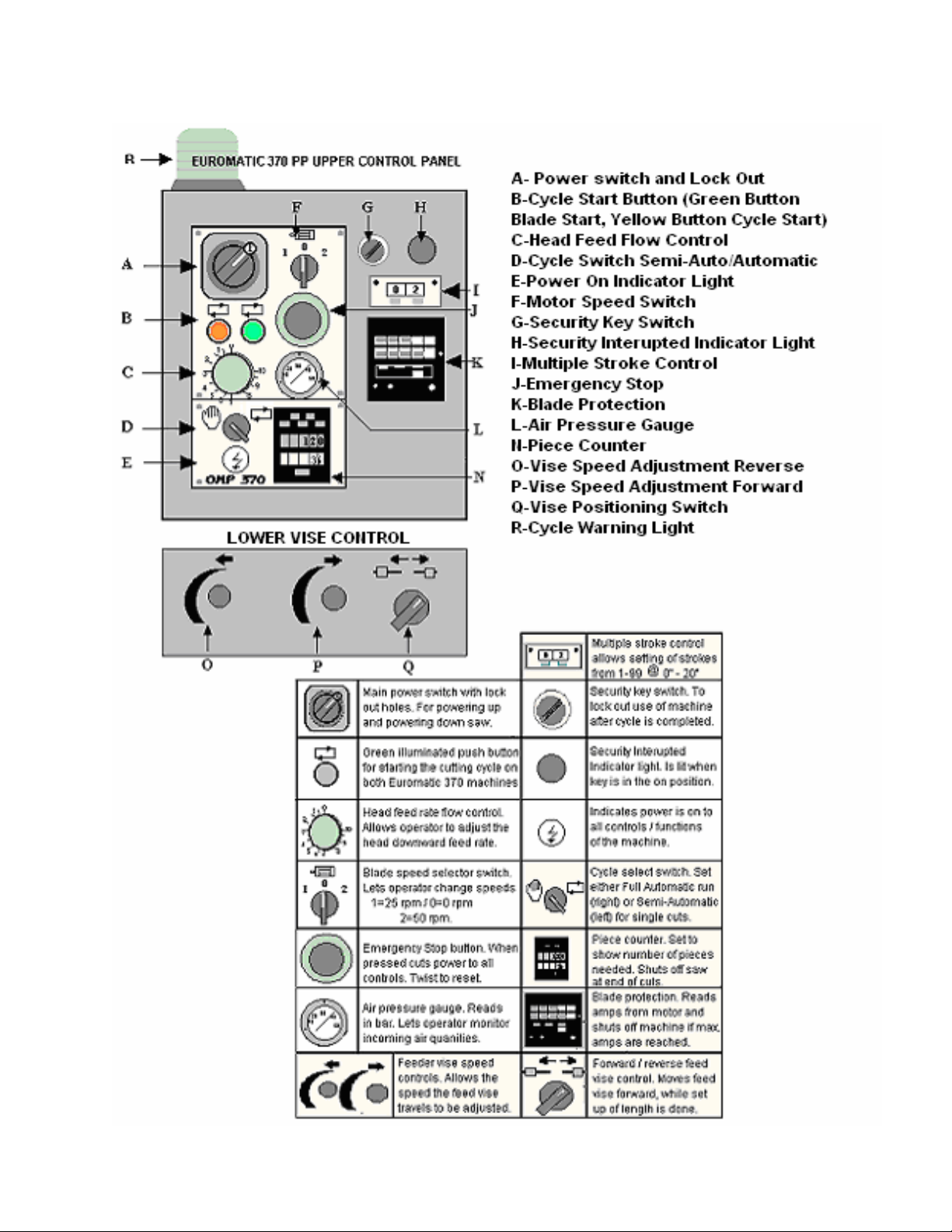

Getting to Know the Control Panel

THE CONTROL PANEL FOR S MODEL 9

THE CONTROL PANEL FOR PP MODEL 10

Blade Selection, Speeds and Feeds

HOW TO USE YOUR SAW PITCH CALCULATOR 13

BLADE SELECTION FOR NON-FERROUS 13

BLADE SELLECTION FOR FERROUS 11

Set Up Parameters

SETTING THE HEAD PARAMETERS 15

SETTING UP THE VISES FOR CLAMPING 16

SEMI-AUTOMATIC CUTTING 370PP/S 17

VISE ADJUSTMENT FOR MITER CUTTING 18

VERTICAL HOLD DOWN VISE 19-20

HEAD DOWN FEED REGULATOR 21

BLADE PROTECTION DEVICE SET UP AND FEATURES 21

BLADE PROTECTION CALIBRATION 22-23

DRO Set Up (PP Models)

SETTING CUTTING LENGTH W / DRO 24-25

PROGRAMMING FOR MULTIPLE INDEXING 25-26

SETTING THE PIECE COUNTER 27

Operational and Cutting Tips

CUTTING TIPS 27-28

HEAD CHANGING INSTRUCTIONS 30-33

Gib Block Adjustment

GIB ADJUSTMENT 34

Maintenance Schedule

MAINTENANCE SCHEDULE FOR FEROUS HEAD 35

MAINTENANCE SCHEDULE FOR NON-FEROUS HEAD 36

Trouble Shooting Matrix

PROBLEMS, THINGS TO CHECK, SOLUTIONS 37

Technical Data Ferrous

370 S 370 S L 370 PP 370 PP L

3

Page 4

Blade Specifications Unit Value

Max. Blade Diameter Mm/inches 370mm/14.5 Inches

Min. Blade Diameter Mm/inches 300mm/12 inches

Max. Blade Thickness HSS (STANDARD) Mm/inches 3.5MM/.137 inch

Min. Blade Thickness HSS (usable range) Mm/inches 2mm/.098 inches

Blade Arbor Hole Mm/inches 32mm/1.25 inches

Drive Pin Spacing Mm/inches 2/10/63mm/.078/.393/2.48 inches

Cutting Speeds

2 Speeds (standard) RPM 25 RPM/ 50RPM

Head Decent

Max. Head Stroke Mm/inches 228.6mm/9 inches

Head Down stroke Adjustable

Head Feed System Air over Hydraulic

Power consumptions

Drive Motor HP 4.5

COOLANT Pump HP 1/3

Electrical Service 220 volt Volts/Amps 220/20

Electrical Service 440 Volts Volts/Amps 440/16

Air Requirements (PP has accumulator) PSI/CFM 90-100/6

Vises

Main Vise (adjustable) Power Pneumatic

Feed Vise (adjustable) Power Pneumatic

Max Vise Opening Mm/inches 228.6/9

Vise Jaw Height Mm/inches 69.85/2.75

Feed Cylinder (370PP) Mm/inches 508/20

Multiple Stroke Capacity Digital Counter 999 Times

Capacities

Coolant Liter/Gallon Approx. 22.7/5

Gear Box Oil Liter/Gallon Approx. 4.5/1

Piece Counter Range Piece 1-99,999

Blade Protection/Amp Meter Range Adjustable

Miter Capacities

Miter Left Degrees 0-90

Miter Right Degrees 0-45

Machine Weight

370PP Kilograms/Pound 778/1716

370S Kilogram/Pound 598/1320

Cutting Capacity

370PP/370S 101.6mm/4inches 98.42/3 7/8

90 Degrees 45 Degrees

370 S 370 S L 370 PP 370 PP L

4

Page 5

Technical Data Non-Ferrous head

has accumulator)

Blade Specifications Unit Value

Max. Blade Diameter Mm/inches 370mm/14.5 Inches

Min. Blade Diameter Mm/inches 300mm/12 inches

Blade Type Mm/inches Carbide

Blade Arbor Hole Mm/inches 32mm

Cutting Speeds

2 Speeds (standard) RPM 1500 RPM/ 3000RPM

Head Decent

Max. Head Stroke Mm/inches 228.6mm/9 inches

Head Down stroke Adjustable

Head Feed System Air over Hydraulic

Power consumptions

Drive Motor HP 4.5

COOLANT Pump HP 1/3

Electrical Service 220 volt Volts/Amps 220/20

Electrical Service 440 Volts Volts/Amps 440/16

Air Requirements (PP

Vises

Main Vise (adjustable) Power Pneumatic

Feed Vise (adjustable) Power Pneumatic

Max Vise Opening Mm/inches 228.6/9

Vise Jaw Height Mm/inches 69.85/2.75

Feed Cylinder (370PP) Mm/inches 508/20

Multiple Stroke Capacity Digital Counter 999 Times

Capacities

Coolant Liter/Gallon Approx. 22.7/5

Gear Box Oil Liter/Gallon Approx. 4.5/1

Piece Counter Range Piece 1-99,999

Blade Protection/Amp Meter Range Adjustable

Miter Capacities

Miter Left Degrees 0-45

Miter Right Degrees 0-12 1/2

Machine Weight

370PP Kilograms/Pound 778/1716

370S Kilogram/Pound 598/1320

Cutting Capacity 90 Degrees 45 Degrees

370PP/370S 101.6mm/4inches 98.42/3 7/8

PSI/CFM 90-100/6

370 S 370 S L 370 PP 370 PP L

5

Page 6

UNPACKING AND INSTALLATION

Unpacking

A: Remove box or shrink wrap. Carefully inspect the machine for any physical damage. If damage is noted, notify the

truck line at once. They may require an inspection and a claim to be filed.

B: Remove the metal banding that holds the machine to the skid.

WARNING!!!!!

The banding can be sharp and cause injury.

C: Check that all standard parts and optional accessories are with the machine. Some accessories may be located in

chip drawer or behind access doors. Each machine should include one blade, one gallon of coolant, tool kit, owner’s manual,

and saw pitch calculator.

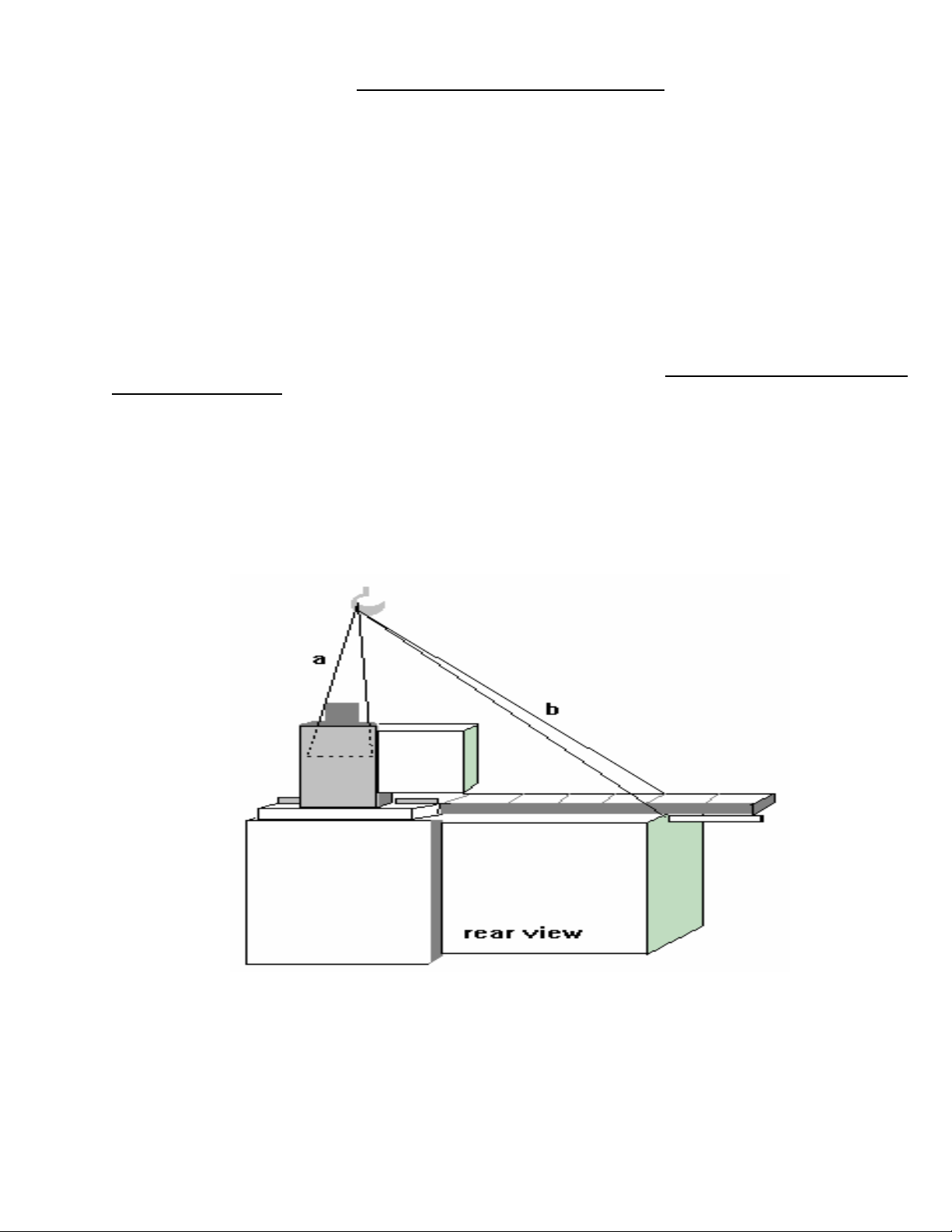

D: Remove the machine from the skid. If using an over head hoist, place a sling (part “A” shown below) around the

gear box Put the sling (part “B” shown below) around the feeder portion of the machine. DO NOT PLACE SLING AROUND

THE FEED CYLINDER! The sling is to stabilize the machine while lifting, and is not intended for lifting a large load.

When lifting the 370 Semi-Automatic saw, use only one sling around the gear box. Always take proper precautions

when lifting these machines. If the machine slips or moves while lifting injury may occur. If a fork lift is used to move

the machine, make sure the weight is distributed evenly and the forks are all the way through before lifting.

E: Set the machine in the location where it will be operated. Make sure saw is located in such a way that it will not

interfere with surrounding equipment. The machine must not be in a location where unsafe working conditions may

exist.

F: Discard packing materials in a safe manner. Make sure all the accessories and literature have been removed.

Installation

A: Clean off all surfaces that have been greased or coated with rust inhibitor.

B: After machine is in place on a level flat surface, adjust leveling bolts located in the foot flange of the machine base.

Adjust the machine so that it does not rock from floor irregularities.

C: From the main power, source connects power to the machine. This power source must supply the machine with a

separate breaker of proper amperage. For a 220 volt machine a 20 amp service is recommended. For a 440 volt machine a

370 S 370 S L 370 PP 370 PP L

6

Page 7

16 amp service is recommended. Machines are rated at +/-10%. The wires are connected to the terminal block inside the control

cabinet.

WARNING!!!!!

All electrical connections should only be made by a qualified electrician. Before turning on power,

check that all electrical components are in place. They may have come loose in shipping. If you have

any questions please call Dake or consult your electrician.

D: Locate the air regulator on the rear of the vertical column. With a quick disconnect or hard plumb air to the

regulator. It is recommended to have an emergency air shut off valve. Once all the fittings are secure, turn the air supply on to

the machine. The gauge should read at 90 PSI. If the reading is more or less adjust the regulator to 90 PSI.

Incoming air

from the air compressor must be clean and dry. Use all precautions and water traps as necessary.

E: If loading or unloading tables were ordered install them now. Make sure the tables are level and in precise

alignment with the feeder unit.

WARNING!!!!!

Failure to align tables and level to the correct height of the feeder may cause material to roll or

catch on other components.

Continuation of the set up is on page 9.

INSTALLATION OF THE BLADE

WARNING!!!!!

Before performing the following operations, the electrical supply must be LOCKED OUT.

Installing the blade (Ferrous head)

Open the Plexiglas cover. Open the magnetically latched blade guard. Remove the spindle flange bolt using the socket wrench

provided with the saw. (Standard threads) Remove the blade flange, and wipe the blade surface of the flange and spindle clean.

Carefully slide the blade up through the coolant distribution tubes. Take care not to bend these tubes. With a rolling motion of

the blade counter clockwise, push against the chip brush and slide blade over the spindle shoulder. Rotate the blade on the

shoulder to align the two large drive pin holes. Insert the flange pins through the drive pin holes and insert bolt, finger tighten at

this point. The back lash must be removed from the blade. This is done by pushing the blade against rotation, until it

bottoms out on the drive pins. (Push Downward) While holding the blade against the pins tighten the spindle bolt securely.

Failure to remove the back lash may result in blade breakage and personal injury!

BLADE INSTALLATION

A: Clean spindle and flange faces, so there are no chips on the faces.

B: Install blade on the spindle shaft shoulder, so the teeth are facing down, for clockwise rotation, and install blade

flange. Take care that you do not hit any machine parts with the carbide tips; this may affect the blade performance.

C: Screw the spindle bolt in finger tight

D: Holding the spindle shaft with the wrench tighten bolt securely.

E: Close blade cover.

Continued on page 11

370 S 370 S L 370 PP 370 PP L

7

Page 8

WARNING!!!!!

Before performing the following operations, the electrical supply must be LOCKED OUT.

NEVER ATTEMPT TO CUT STEEL OR FERROUS MATERIALS WITH THE NON-FERROUS

HEAD INSTALLED. IT MAY CAUSE SERIOUS INJURY, OR FIRE!

CAUTION!!!!

USE CARE, CARBIDE TIPS ARE SHARP.

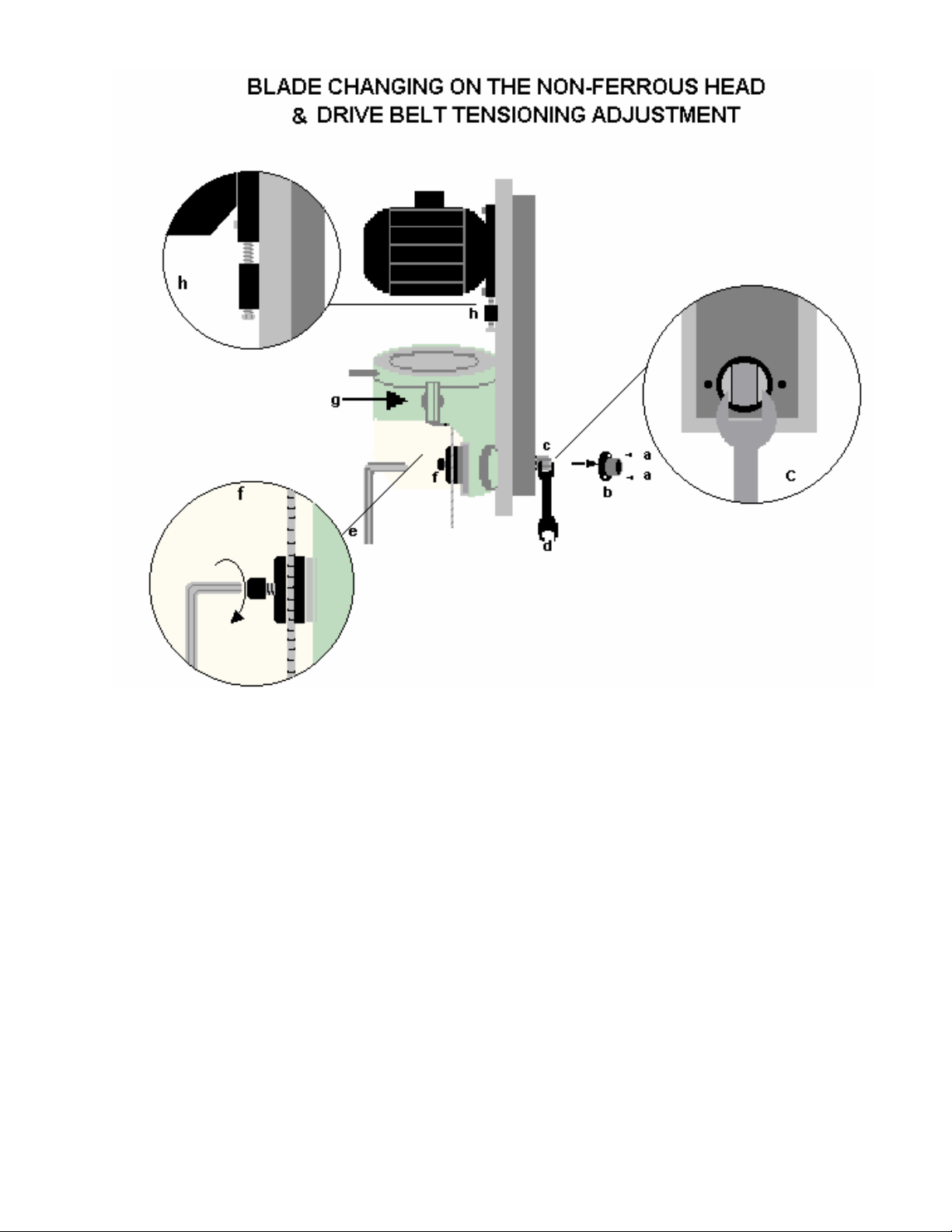

BLADE INSTALLATION

A: Clean spindle and flange faces, so there are no chips on the faces.

B. Remove item B using wrench d, put wrench D on shaft C. Then use wrench E to remove bolt F. (Left Hand

Threads).

C: Install blade on the spindle shaft shoulder, so the teeth are facing down, for clockwise rotation, and install blade

flange. Take care that you do not hit any machine parts with the carbide tips; this may affect the blade performance.

D: Screw the spindle bolt in finger tight

E: Holding the spindle shaft with the wrench tighten bolt securely.

F: Close and tighten blade cover.

NOTE: The blade pins may have been removed from your blade flange, to allow easier blade sizing, and safety. If you

reinstall the pins for carbide blade or HSS blade cutting, backlash must be removed from the blade while installing. See the

section on blade installation on page 0 of this manual.

Continued on page 11

370 S 370 S L 370 PP 370 PP L

8

Page 9

370 S 370 S L 370 PP 370 PP L

9

Page 10

370 S 370 S L 370 PP 370 PP L

10

Page 11

Close the safety guard then turn on the power to the machine. Close the head feed control knob to the “0” setting. (

370PP Place the Automatic / Semi-Automatic switch in the Semi-Auto mode The hand symbol). Make sure head is in the up

position (making contact with the upper parameter limit, this limit is the bottom one). Place the speed selector switch on either

“1” or “2”. Press the start button (370PP the green button 370S the yellow button) and take notice of the blade rotation, to stop

the blade rotation press the emergency stop button.

If properly wired the blade will rotate: (in accordance with the arrow on the blade guard)

Ferrous Head in a Counter Clockwise direction

Non-Ferrous Head in a Clockwise direction

If rotation is incorrect consult your electrician.

Add coolant to the machine. Using the coolant supplied with your saw (or any water Soluble coolant concentrate) mix

per manufactures instructions (normally 10 to 1) in a container or bucket. Next pour the mixed coolant into the machine coolant

pan, which can be pulled outward to fill. With the machine in Semi-Auto mode, (be sure the head feed control knob is set at

“0”) press the start button. (With the 370PP you will have to push the yellow button after pushing the green button for the

coolant to come on). This will start the motor and the coolant will flow. The valve right above the blade guard on the right will

allow you to regulate the flow of coolant. This can be varied to the type of cutting you doing.

Do not use cutting oil in this machine!!!

I:

out procedures. These procedures should be followed at all times maintenance is performed, including blade changes.

K:

the page 9 and 10.

Proper Blade Selection 370PP 370S

The most important decision you will make on your machine is selecting the Right Blade for the Material. The larger

the part, the more coarse of blade. The smaller or thinner the part the less coarse of bladeAn improper blade will sacrifice the

quality of cut, safety and blade life. When in doubt use the slide pitch calculator provided with the machine. If you are not sure,

do not hesitate to call DAKE for a recommendation.

Familiarize your self with all the warning labels

. Check with your safety committee on the proper lock

Take time now to familiarize your self with the control panel’s functions, using the graphic on

BLADE SELECTION SPEEDS AND FEEDS

Warning!!!!!!

Never use a blade that is cracked, dull, or missing teeth

Different blade types

There are many different grinds that can be put on a blade. A special grind may work for you. Call Dake for

information on these blades. Special coated blades are also available, such as cobalt. These blades can increase blade life

considerably on certain applications. The blade thickness can affect the way the blade will cut. A thinner blade may work better

for you if you are cutting thin wall tubing. The thinner blade has to remove less kerf, meaning the blade cuts less material, and

cuts faster without out distorting the tube. A thicker blade such as a 3mm is more rigid and will flex less cutting heavy material.

Each high speed steel blade can be reground up to about 20 times. If done properly.

CAUTION!!!!

Always have blades reground by a qualified professional. Always use blade with proper pin hole

spacing.

Speeds and feeds

The best way for determining this, is by sound, and chip appearance. With the proper blade the machine will cut

smooth and throw a curly chip. The chip should be shinny, curly, and cool to the touch. If the chip is bent into a curl, discolored

and/or hot, the feed rate may be too fast. If the chip is powdery or splintered the feed rate may be too fast, too slow or the

incorrect blade is being used. Rule of thumb, if it sounds good and the chips look good you have it set right.

370 S 370 S L 370 PP 370 PP L

.

11

Page 12

Spindle speeds

The larger or harder the material the slower the speed. The thinner or softer the material the faster the spindle speed.

2" Solid stainless 25 RPM

2" X 1/8" wall tubing 50 RPM

2" Solid aluminum 50 RPM

Blade Selection

For Non-Ferrous Cutting Head

Example:

3" Solid cold rolled 25 RPM

Same rules apply as with the Ferrous cutting head. Your selection of teeth configurations are more limited with

carbide. For solid material from 2" to 4" (non ferrous) a 14" X 60 tooth blade is recommended.

Solid material from 1" to 2" a 14" X 84 tooth blade is recommended. For materials less than 1" a 14" X 100 tooth blade is

recommended.

Warning!!!!!

Never use a blade that is cracked, dull, or missing teeth

Different blade types

There

are different types of grinds for carbide, Positive pitch and negative pitch. You may select a positive pitch blade for

more aggressive cutting And a negative pitch for thinner material.

How to use the saw pitch calculator (Graphic on following page

Look at side1, select type of material to be cut from the vertical window on the left side of the material menus. Slide

the inner portion so the arrow lines up with the size being cut. The horizontal window will display the

Blade pitch. Knowing the pitch turn over and read side 2. In the left hand column find the

pitch from the other side. Slide the arrow to this pitch number. Above the horizontal

Window is displayed different blade sizes. Select blade size wanted, and read the

Number below it this is the number of teeth needed.

Example

Material 2 1/2" round solid mild steel. See figure 1 inset A

The pitch is 14mm. See figure 1 inset B

The blade diameter needed is 14". (Use this diameter for 14 1/2”) See figure 2 inset C

The number of teeth will be 80. See figure 2 inset D

Normally when cutting harder materials like stainless steel, you will use a pitch of 1 or 2 smaller. For softer materials like

aluminum, a pitch of 1 or 2 larger.

When miter cutting the next larger pitch blade may be needed.

If the chip packs into the gullet, slow feed down or use coarser blade.

:

.

)

370 S 370 S L 370 PP 370 PP L

12

Page 13

BLADE SELECTION FOR NON-FERROUS HEAD

Proper Blade Selection 370 Non-Ferrous

Same rules apply as with the ferrous head in selecting the "Right Blade for the Material". The larger the part the more

coarse teeth. The smaller or thinner the part, the more fine the teeth. An improper blade will sacrifice the cut safety and blade

life

Although the selection of teeth configurations, are more limited with carbide, here is a brief description of blade

recommendations for certain size materials.

1. For solid material from 2” to 4” (non-ferrous material) a 14” X 60th blade is used.

2. Solids from 1” to 2” a 14” X 84th blade is recommended.

3. For cutting material less than 1” a 14” X 100th is recommended.

4. Large extrusion with relief an 84th may be used.

5. Any thin wall tubing or small extrusions with relief should be cut with a 100th blade

WARNING!!!!!

Never use a blade that is cracked, dull or with chipped or missing teeth.

370 S 370 S L 370 PP 370 PP L

13

Page 14

Different blade types

There are many different grinds for carbide. Positive pitch and negative pitch. You may select a positive pitch blade for more

aggressive cutting. A negative pitch for the more thin material. Also, different thicknesses for the blade are available. The same

rule applies here as for the Ferrous head, that high speed steel blade are available for the non-ferrous cutting head. These blades

may work better for some applications. And are normally run at the 1500 rpm setting.

C: Precision ground carbide blades can be purchased for the non-ferrous head that will give you superior finish. A

standard ground carbide blade is cut with a double beveled tooth and a straight rake tooth and so on around the circumference

of the blade. A precision ground blade is beveled left, beveled right, and a double beveled tooth, around the blade without the

straight ground “rake” tooth, you eliminate much of the kerf marks a special grind may work for you. Call factory for

information on these blades.

The blade thickness can affect the way the blade will cut. A thinner blade may work better for you if you are cutting

thin wall tubing. The thinner blade has to remove less kerf, meaning the blade cuts less material.

CAUTION!!!!

Carbide blades should be reground only by a qualified professional.

Speeds and feeds

If the saw cuts without laboring through the cut the feed is correct the chip created on non-ferrous normally will not curl, Rule

of thumb if it sounds good and the chips look good you have it set right.

Note: 3000 rpm is the normal cutting speed for non-ferrous material with a carbide blade.

WARNING!!!!!

PROPERLY ADJUST ALL VISES BEFORE CUTTING. MAKE SURE THE BLADE WILL NOT STRIKE ANY

STEEL PARTS OF THE MACHINE. IF DEEP MITER CUTS ARE BEING MADE, LOWER WEAR PLATES MAY

NEED TO BE REPLACED WITH ALUMINUM PLATES, OR REMOVED AND A CLEARANCE CUT MADE INTO

THE PLATES WITH STEEL CUTTING SAW.

370 S 370 S L 370 PP 370 PP L

14

Page 15

SETTING THE HEAD PARAMETERS

Warning!!!!!

Never depress the limit switches with your finger. Your finger could be crushed or amputated

between the limit switch and cam block.

Setting the head parameters

This is quite simple and very dependable method of reducing “dead air” cutting. The above graphic illustrates the four

basic parts of the head positioning system.

A is the lower limit, adjustable cam block.

B. is the machined T-slot way that the cams move vertically in.

C. is the upper head limit, adjustable cam block.

D. is the limit switch that will control the lower setting. When this switch is activated the blade stops and the head

returns to the upper setting.

E. This is the upper limit switch; this controls the head on the return stroke and stops it in the upper setting.

The gear box is on the left, and the vertical column is on the right side, as looking at the adjustments.

To set these parameters move the cams to the extreme positions and snug down. (The top cam up and the lower cam

down)

1. Power up the machine, and check that you have air pressure on the gauge.

2. Turn the speed selector switch to the “0” setting.

3. Place material in the main vise, and up to the blades path. Do not place under the

Blade path. move the head feed control valve to zero.

4.Make sure the emergency button is not engaged. On automatic machines (370 PP) place the cycle selector switch to the

“semi-auto” mode (hand symbol). Press the green cycle button (370S Yellow Button) (370PP push the green button then push

the yellow button) and slowly open the head feed valve. As the head descends downward toward the material, close the head

370 S 370 S L 370 PP 370 PP L

15

Page 16

feed flow control valve to stop the head just above the material. Never have the blade adjusted closer than ½” to the

material to allow proper clearance.

5. After stopping the head, loosen the upper head setting cam. (the cam block on the bottom) Now raise this cam up to where it

just touches the limit switch without depressing the limit switch button. Securely tighten this cam down. (the power of the head

feed cylinder will actually move this limit if the cam is not securely tight)

Warning!!!!!

Never lock the cam locks half on or half off the T-slot.

6.Now adjust the lower cam block (top block) to the highest position. Then, open the head feed flow control valve and

let the head descend just past the lowest point of the material, and close the valve. Now slide the lower parameter cam setting

block (cam block on the top) down to the limit switch. Holding the cam tight activate this limit switch button. This must be

done before the head returns to the upper position. Be sure the cam is tight.

Warning!!!!!

Never make these adjustments with the blade rotating.

VISE ADJUSTMENTS

Proper vise set up and adjustments are very important for quality and safe cutting.

WARNING!!!!!

KEEP FINGERS AWAY FROM THE VISE OPENING, IT MAY CAUSE PERSONAL INJURY.

With the vise in the open position, turn the hand wheel until you are a 1/16” to 1/8” away from the material. Push the

emergency stop button to activate the vise to see if the material is properly clamped. To deactivate the vise turn the emergency

stop button to the right.

This will be the proper setting. (Push the emergency stop button to test clamping)

Note: The main vise can be moved left and right via T-slots. This allows you to clamp close to the blade even when making

miter cuts.

Now adjust the anti-burr arm to a setting that will clamp the material in the rear vise jaw. This is done by loosening the bolt that

holds the anti-burr arm bracket.

Note: The anti-burr arm is not designed for clamping, but to hold the piece from moving when the blade exits the cut.

The anti-burr arm might need to be removed for some miter cutting.

For the 370 PP

Loosen the large bolt on the rear feeder vise block, Then clamp the material in the main vise manually (Do Not use the

emergency stop button). Move rear vise feeder jaw so that it lightly touches the material (the jaw should be parallel with the

main vise). Tighten the bolt on the rear feeder vise block. Now, loosen the large bolt on the front block of the feeder vise, slide

the jaw toward the material and set as above 1/8” from the material.

Note: The rear vise on the feeder also moves. With the material clamped in the main vise loosen the rear vise block

bolt, and adjust so the jaw is parallel with the main vise.

Note: If vises crush the material you are cutting increase the gap in the vise dimensions.

370 S 370 S L 370 PP 370 PP L

machine, the feeder vise must also be adjusted. This is done to the same dimensions as the main vise.

16

Page 17

The air pressure can also be reduced by turning the main incoming air regulator down. Turning this down will also

slow the operation of the machine.

WARNING!!!!!

BE SURE CAM IS TIGHT; DAMAGE TO THE MACHINE AND/OR PERSONAL INJURY MAY

OCCUR

Warning!!!!!

Never depress the limit switches with your finger. Your finger could be crushed or amputated

between the limit switch and cam block.

SEMI-AUTOMATIC CUTTING

370 PP / S

Running in the Semi-Auto mode

WARNING!!!!

Always close the safety guard when the machine is in operation.

A: Turn on the main power to the saw.

B: With the 370 PP model turn the cycle selector switch to the semi-auto selection (hand symbol)

C: Turn the security key to the on position (LEFT)

D: Set up and adjust your vises to the material being cut. (See vise set up section)

E: Set up your head parameters. (See head limit section)

F: Place part against positive stop, or position material for correct length to be cut.

WARNING!!!!!

NEVER MOVE THE BLADE SPEED SELECTION KNOB WHILE THE MACHINE IS IN

OPERATION OR WHILE THE GREEN OR YELLOW LIGHT IS ON, IT MAY DAMAGE THE

MACHINE.

G: Select speed. 25 or 50 RPM for ferrous material, 15000 or 3000 for non-ferrous material

H: Close head feed flow control.

I: Press the green start button. (370PP you will need to press the orange button after pushing the green button) Adjust

the head feed rate, and coolant flow to the material being cut.

WARNING!!!!!

if this is not followed, causing possible blade and/or machine damage, or may result in personal injury.

The following steps will be executed

1. Vises close and clamp the part.

2. Motor starts, coolant flow starts. Head will descend and make cut.

3. Motor stops, coolant flow stops. Head will return to the preset height.

4. Vise will unclamp part.

Miter cutting and Squaring

The 370 PP and 370 S have a scale scribed into the front of the rotating portion of the cutting head (0 to 60 degrees.)

On the stationary portion of the cutting head casting is a scribed line. Any angle can be set by loosening the lock handle. This

handle is located front and center of the cutting head.

Loosen the locking handle, this handle can be pulled and repositioned to clear the coolant tube.

370 S 370 S L 370 PP 370 PP L

Make sure head feed control is closed before starting cycle. Head could overfeed into the part

VISE SET-UP AND MITER CUTTING

FERROUS HEAD

17

Page 18

Loosen this handle and position it in an upwards position so it will not hit the casting while you rotate the head.

With the handle loose turn the cutting head, using the rotation handle, to the angle needed, and lock down tightly when

the angle is set.

WARNING!!!!!

HEAD MUST BE LOCKED IN POSITION, MAY CAUSE DAMAGE TO THE MACHINE.

There are preset stops at 90 and 45 degrees. Remove the positive stop on the left hand side of the cutting head to go

beyond 45 degrees. This will allow you to miter in both directions and allow placement of the head for slot cutting.

The saw can be squared up on the horizontal plane with the two adjusting bolts in the positive stop block located on

the left side of the cutting head. Loosen the lock nuts and adjust the stop bolts in or out against the positive pin stops to achieve

square ness.

Adjust main vise as close to the blade as possible (in the “T” slots) without interfering with the cutting.

Some applications may require repositioning of the rear vise jaws, for proper clamping. This can be done by loosening

the locking bolts on the jaw, and moving closer to the blade.

Some miter cuts will require removal of the anti burr arm. Vises may need to clamp tighter for mitering some

materials. As you cut on an angle, the part may be pulled toward the blade if the vises are loose. Normally, when mitering go to

the next larger tooth size. You are increasing the cross section and may need a coarser blade.

Caution!!!!

Always clamp parts properly, the blade can throw a loose pieces from the machine and cause injury.

NOTE: FOR SETUP OF THE VERTICAL HOLD DOWN VISE SEE PAGE 18

OPTIMUM CUTTING POSITION

BLADE ROTATION

NON-FERROUS HEAD

the material being cut.

To maintain this cutting position, adjustment of the rear vise will be necessary.

This adjustment is made by loosening the rear vise and sliding it in the “T” slots forward or backward to reach the

optimum position.

370 S 370 S L 370 PP 370 PP L

The optimum cutting position as shown above will put the center line of the blade 35 mm in front of the center line of

18

Page 19

This adjustment is necessary when ever a different blade size is used on the machine. With a different blade size the

center line of the blade will change.

By adjusting this rear vise you may also achieve a more or less aggressive cut position.

NOTE: When ever the rear vise is moved the feeder vise must also be adjusted, on the 370 PP

.

VERTICAL HOLD DOWN VISE

EUROMATIC 370 PP

Your machine may be equipped with a vertical hold down vise. This vise will help hold the material flat on the

machines bed, and assist in bundle cutting, by keeping the material grouped.

Note: This vise should never be used with out the main vise.

SET-UP:

A: Set material vises (feed and main) for proper clamping.

B: Choose the clamping foot most suited for your application. (Figure 1 items A & B)The long foot should be used for

smaller or flat material. The shorter feet will be used for larger diameter material.

This foot will screw on and off the piston of the cylinder. (Figure 1 item C)

C: Loosen the large mounting nut (figure 1 item D) from the bottom of the cylinder slide bracket. (Figure 1 item F)

With the cylinder nut loose, move the hold down foot over to the center of the material being cut. (Figure 2 item 4) In

some cases this foot may be positioned over a different area of the part for more control in clamping.

D: After foot and cylinder is centered over the material, tighten this nut. Hand tight usually will hold the cylinder

sufficiently in place. With this adjustment done, the foot should be above the material to be cut.

Note: In some applications the material size or shape will not allow the vertical hold down to be used.

E: With vise adjusted, you may begin cutting.

Note: The design of this cylinder will not allow over exertion of pressure to the part and will not affect the cylinder if the piston

does not fully stroke (Full stroke approx. 1 1/4”).

Other items shown are in Figure 1 item E is the electrical panel, figure 2 item 1 is rear feeding vise, item 2 vertical

hold down vise item 3 main clamping vise and item 4 material.

Note: Vertical vise will only activate during the automatic run cycle!

NOTE: THE VERTICAL HOLD DOWN VISE MUST REMOVED TO ACCESS THE BLADE. REMOVE

THE VISE AND CAREFULLY LAY OUT OF THE WAY WHILE CHANGING THE BLADE. TAKE CARE NOT TO

DAMAGE THE TUBING OR THE CYLINDER!

FOR EXTREME MITERING CUTTING TO THE LEFT, THE VERTICAL HOLD DOWN VISE AND

BRACKET MUST BE REMOVED.

370 S 370 S L 370 PP 370 PP L

19

Page 20

WARNING!!!!!

DO NOT LET THE FEEDER VISE HIT THE VERTICAL HOLD DOWN DURING THE FEED

CYCLE, THIS MAY CAUSE EXTENSIVE DAMAGE TO THE VERTICAL HOLD DOWN.

ALWAYS CENTER THE HOLD DOWN FOOT IN-BETWEEN THE FEEDER VISE JAWS

HEAD DOWN FEED REGULATOR

EUROMATIC 370 PP

Your 370 PP may be equipped with the head feed regulator feature. This feature allows you to control the head feed

pressure for cutting tubes and structural steel, at a faster rate. By regulating the head feed pressure you will be able to cut

through the thickest mass of the material at a normal or reduced rate. When the blade enters the interrupted section of the

material the head will speed up and cut faster. This will allow quicker cutting time on these materials.

Note: When cutting solid materials this regulator will not activate and increase rate.

This regulator will also allow you to control the head return rate, making for quicker cycle times.

ADJUSTING THE REGULATOR.

A: Using the large gray adjusting knob on the regulator body, pull out and turn it clockwise to slow the descent rate

down. Turning this knob counter-clockwise will increase the feed rate through the material. (Figure 1 item B)

B: To increase the head return rate, the slotted adjusting screw in the top of the bleeder body can be adjusted. Clock

wise will slow the return rate down, and counter-clockwise will increase the return rate. (Figure 1 item C)

Note: Common sense must be practiced when adjusting the return rate. Slamming the head upward can damage the

machine.

If cutting solids the down feed pressure may need to be adjusted in a way that maximum pressure is applied. (Figure 1

item A represents the head feed cylinder)

!

Gauge is for pressure reference, or showing the amount of pressure exerted to the cylinder.

370 S 370 S L 370 PP 370 PP L

20

Page 21

SETTING THE BLADE PROTECTOR PARAMETERS

370PP

CONTROL FUNCTIONS

A. This scale shows the actual amps being drawn by the motor, during operation via LEDS.

B. This scale allows you to program shut off amps. Wet approx. 2 amps higher than the freewheeling amps. (amp draw

while machine is running, but not cutting)

C. Write in area for recording parameters such as min. amp draw, blade shut off setting, max. Amp draws during cutting

cycle and average constant amp draw.

D. Test switch, for testing the scales LED’s. (Factory preset no adjustment needed)

E. LED is illuminated when ever preset shut off amps have been met and the blade shuts off.

F. Press this button when preset amps have been met and the LED is illuminated. Press this button to reinstate power to

the controls, allowing restart of the cycle.

G. Knob to set your preset shut off amps. This controls the LED’s on the bottom scale.

H. Calibration adjusting screw. (Factory preset and no adjustment needed)

Features

Operator sets shut off amps, 2 amps above free wheeling amps. If blade is dull, wrong for the material being cut or the head

feed is excessive. The amps will peak to your preset amps and shut the saw off. This prevents damage to the blade, saw and

material, this will prevent over feeding that can give you a poor finish and shorten blade life.

You can monitor blade life by recording the amps being drawn, while cutting and using a new blade. When the blade dulls the

amps increase.

The shut off amp settings are adjustable and allows adjustments for different materials and different blades.

Warning!!!!!

Setting amps too high may cause motor to over heat, machine or blade damage.

BLADE PROTECTION CALIBRATION

370 S 370 S L 370 PP 370 PP L

21

Page 22

On occasion you may need to recalibrate your blade protection device. Common problems that may create the need for

recalibration may be.

A: Low incoming voltage. When your incoming voltage is below the specified machine voltage, your amps being

consumed by the machine will increase. This will not effect the operation of the machine, but it may cause the blade protection

device to activate premature.

B: Voltage fluctuation of incoming power.

Warning signs of the need to recalibrate will be.

A: The blade protection will shut machine down when ever blade is started.

B: The blade protection device will active as soon as blade contacts work.

C: The blade protection device will active, while cutting, assuming the blade speed, blade pitch, blade condition, and

head feed rate is correct, and amp setting is set sufficient.

D: Another key to determine is if low incoming voltage is present is if machine will not stay powered up after turning

on the main power switch of the machine.

Note

: If the condition described in “D” above exists, another adjustment may be required. In the electrical panel you will find

a thermo overload. The overload will have a small adjusting wheel with amp rating shown on it. This overload (using this

adjusting wheel) will need to be adjusted. Moving this wheel one indicator line at a time will Increase the overload until

machine will power up normally.

CAUTION!!!

Do not mistake vise timers for this over load. (You will find the two vise timers mounted side by side, and should not be

adjusted, unless there is a need to speed up or slow down the timing of the vises.)

CALIBRATION

To calibrate the device, you will need to open the rear access door of the electrical panel. In the middle of the door

panel you will find a square inductive pick up, with a hole in the middle of this block that has wire running through the hole.

(See figure below) On the side of this block you will find two wires, connected to two of the four taps. To calibrate remove the

bottom wire only (wire B on the illustration), and place it on tap labeled 3. Start the saw and watch the LED’s on the device.

With the amp setting set at approx. halfway, the amp reading on the top line should be approx. two LED’s lit on the low speed.

If the amps on the top line are still too high move the tap to the number 4 tap.

adjustment during severe operation, recalibrate to the next lowest tap number.

Note

: Move the wire to the higher numbered taps, only as much as needed. If device does not activate after

Setting Length with the DRO 370PP

Note: Power to the DRO module is battery powered. This battery has a 7 to 10 year life expectancy. This battery can be

purchased at most electronics store. If display blinks, or does not display replace battery.

Step 1.Setting the counter (DRO) at zero

Switch the cycle mode switch to the semi-automatic mode.

370 S 370 S L 370 PP 370 PP L

22

Page 23

Warning!!!!

The feeder vise must be placed in the forward position (This switch is located on the far right hand

side of the lower control panel)

Loosen the lock handle located by the bearing support. See Figure 1 below.

Turning the feeder vise hand wheel in a counter clockwise direction, “dead head” the feeder vise against the screws end limit.

The digital counter can now be set at zero with the feeder vise “dead headed” loosen the set screw in the collar of the counter.

Rotate the collar until there are all zeros in the counter window. Tighten set screw (Figure 4).

Figure 1

Adding blade thickness in counter (DRO)

Note: By entering the blade thickness to the counter the need to add this thickness dimension to the cut length can be

eliminated.

When ever the blade is changed it is recommended to check the thickness, as it may change after resharpening.

This parameter setting only needs to be added once.

Move the feeder vise to the forward position.

Loosen the lock handle, located by the bearing support. See Figure 1.

Turn the feeder vise hand wheel in a counter clockwise direction, “dead head” the feeder vise against the screws end limit.

Determine the thickness of the blade, back the feeder vise off (turning the adjusting wheel clockwise) until the LCD reads the

blade thickness. When this dimension has been met, Loosen the set screw in the collar (Figure2) and rotate the collar (Figure 3)

until the display reads all zeros in the counters window. Tighten this set screw. You now have the blade thickness added in the

length of cut equation.

370 S 370 S L 370 PP 370 PP L

23

Page 24

Figure 2 Figure 3

Set screw

EXAMPLE:

The thickness of the blade you are using is .098. The counter is zeroed out. This will become your true zero point of the feeder.

If the length of the part you cut is 10”, the feeder will feed the part 10.098” The counter will have a negative number of -.098.

Note: The length of cut is figured from the right hand side of the blade. If you now “dead head” the feeder you will have a

negative number -.098.

Step 3 Length compensation

If you find your cut dimension is too long or short you can compensate for this error without having to rezero your counter. On

the counter you have a * key. When you press this key twice you will get zero reading. You may now from this zero reading

adjust +/- the length of error.

Note: You will only be able to move the feeder 10” with this value displayed.

Note: If you are using the multiple stroke features, divide the blade thickness for multiple strokes accordingly.

Step 4: Setting up length for cut

While reading the DRO turn the adjusting hand wheel clockwise until desired length is obtained and displayed on the LCD

readout.

Example: The length needed is 7.125” the adjusting wheel was turned until the DRO red 7.125.

Note: The encoder is very sensitive, so take care when you release the adjusting wheel that the length does not change.

Step 5 Start cycle

Tighten the handle locking knob securely. Taking note that the length does not change, while tightening.

Place the cycle selector switch to the automatic position.

Turn the vise position to the backward position (switch is located on the lower control panel right hand side). When this switch

is activated, the vise will move to the stop, take note the length does not change.

Load stock and start cutting (See cutting in automatic section). During the cutting cycle the speed of the feeder vise forward and

backward cut may be adjusted to suit your needs.

Dake will not be responsible for any parameter changes made by the customer to this unit.

MULTIPLE STROKE PROGRAMMING

Most automatic machines on the market today offer multiple strokes indexing for longer piece part cutting. These

multiple indexing features normally allow the indexing up to 9 individual strokes. The Dake Euromatic optional multiple

indexing, is a simple electronic push button with analog programming, with function LED, to let the operator see where the

machine is at, during the feed cycle. The limits of this counter are extreme, allowing you set 0 - 99 individual indexes. This

wide range gives the machine the capability of cutting lengths up to 1980 inches long.

370 S 370 S L 370 PP 370 PP L

24

Page 25

PROGRAMMING FOR MULTIPLE INDEXING

A: Three things that must be determined before programming for multiple indexing.

1. Length of cut needed. How many equal strokes must be carried out to achieve this length Example: The length of

cut needed is 42.75”. We know a single maximum feed index is 20”. The length we need will require us to index the piece 3

times.

2. Now that we have established that 3 indexes are needed, we divide our length by 3. In the example our length is

42.75” divided by 3 gives us a length setting of 14.250”

Note: You may be tempted to feed the part at a shorter length, thinking it will feed faster at a short stroke. Example: The length

needed being 42.75” indexed 6 times at 7.125” With the variable feed speed adjustments, this will allow you to feed longer

lengths at very quick speeds, meaning 3 long indexes will happen in less time than 6 short indexes.

3. Last we must figure what the true blade thickness is. This should be done by checking the blade kerf with a caliper.

The example we will use here is a blade thickness of 0.096”. Knowing we must index our part 3 times to accomplish

our length, we must divide our blade thickness by 3 times, giving us a blade thickness of 0.032”

This is programmed into the equation as described in the DRO length set up chapter.

TIP: A shallow test cut into a scrap piece of material, then checking this cut with a caliper, will give you an

accurate measurement. This will show the thickness of the blade, plus any run out that may occur. All blades will have a

certain amount of run out, and this gives you the most accurate blade dimensioning.

This example is shown in the illustration below.

NOTE: A parameter of at least one must be entered into the multiple index counters, for the machine to cycle

in the automatic mode. If machine does not feed, make sure a digit is entered.

CUTTING IN THE AUTOMATIC MODE FOR THE 370PP

SETTING THE PIECE COUNTER

A: Power up the machine.

B: Place selector switch into the semi-auto position (hand symbol)

C. Place vise position switch (switch on the lower control panel, far right side item Q on page 9) to forward.

CAUTION!!!

This is very important. If this is not done, the feed vise will slam back and continue back until the

end of the cylinders stroke, when lock bolt is loosened. This may cause severe damage to the feeding

cylinder, and possible injury to the operat

D: Loosen the large lock handle on the feed cylinder, and set your length of cut. Please read the section on setting

your length with the DRO section before proceeding.

E: With your length set, adjust your vises as described in the vise set up section.

F: Adjust your head positioning as described in the head limit section.

370 S 370 S L 370 PP 370 PP L

25

Page 26

G: On the piece counter, clear out the previous number that has been cut. Press the lower centered button to clear this

number out. See graphic A this page.

H: Enter into the counter the number of parts you need to cut. (If you run out of stock before this amount has been met,

the machine will shut off) See figure B

I: Example: Clear counter. Pressing individual buttons enter the number to be cut which shown here is 632 pieces.

I: Place your material in position for cutting.(If vises are clamped turn off the security key) Move the material

up to the blades path Keep the material as close to this point as possible, this will be your first cut piece. No face cut

will be made.

K: Switch cycle selector to automatic mode.

L: Switch the vise position switch on lower control panel to backward.

M: Select speed.

N: Close head feed flow control valve.

O: Check setting on motor protection, that it is set correctly. (If machine does not start check the reset button

on blade protection device.) Turn the security key to the ON posit

P: Press green start button. There will be a slight delay before machine starts. This is a safety feature built into

the machine.

Q: Adjust head feed flow control.

R: Adjust your coolant flow.

S: Adjust the feeder speeds, forward and backwards. This allows you to adjust the rate of time it takes to feed the

material in both forward and backward motion. Do not set this feed rate excessive or damage may occur and

tolerances may slip.

WARNING!!!!!

Make sure head feed control is closed before starting cycle. Head could overfeed into the part if this

is not followed, causing possible blade, or machine damage, or may result in personal injury.

These are the operations that will be carried out.

1. Feeder advances material.

2. Vises clamp part.

3. Motor starts, coolant flow starts and head descends.

4. Part is cut, coolant flow stops. Registers part a 1 piece cut.

5. Head returns to upper preset.

6. Main vise unclamps, feed vise clamps.

7. Feeds material forward and cycle repeats, until preset numbers have been cut or material runs out.

Set up for face cut

Follow the instructions listed above with the exception of material placement and cycle mode and feed vise position settings.

The material must be placed under the blade, the thickness of the face cut wanted. When the cycle starts, the cycle switch must

be in semi-automatic. The feed vise position switch must be set in the forward position. Once the cycle start button has been

pressed, turn the cycle mode switch to the automatic position and the feed vise position switch to the rear position. Now the

machine will complete the automatic program after making your face cut.

Note: Failure to follow the above procedure may result in the first cut piece being out of tolerance.

OPERATIONAL AND CUTTING TIPS

Blade Tips

A: Always inspect blade before installing on machine. If questionable don't use.

370 S 370 S L 370 PP 370 PP L

26

Page 27

B: Check gullets of the blade. Check teeth and surface of blade. If a chip is packed or welded in the gullets do not use,

a blade in this condition will "thump" each time the blade passes through the part and could cause breakage. This condition

normally is evident when an over feeding conditions exists or when a blade is too fine for the material. The side of the blade

should not have any type of smear or build up on it. This happens when you cut too slow (some material like aluminum will do

this but will not affect the blades performance)

C: Always remove the back lash from the blade.

D: Always cut with coolant if possible. It is better to use too much coolant than not enough, it is better to mix your

coolant on the heavy side. This way you can add plain water to bring it up to level. Plus the rust inhibitors have a better chance

to work.

E: Select your blade properly. Using your calculator or contacting your blade supplier. If you are cutting tubing and

are having a problem with chatter, go to a finer tooth. Rule of thumb if you have to change blades or go to a finer tooth for

tubing. For solids use a heavier tooth blade.

F: Keep your blades sharp. Don't squeeze a few more cuts out of a dull blade. This may damage the blade and your

part. It also puts undue stress on the machine.

G: Always have your blade sharpened by a qualified professional. A cheap regrind will not give you good results. If

you need a blade resharpend and do not know of a reputable business, contact Dake. We will be happy to refer you to someone.

H: Never use a blade smaller or larger then stated in our specifications. Always use a blade with the correct pin hole

spacing and arbor size.

Cutting

A: Watch the chip. This will tell you all you need to know. A curly, silver colored, cool chip is what you want. If Chip

is different from this description change blade speed, head feed speed, or blade. Also make sure you have a sufficient supply of

coolant flowing on the part.

B: If the blade bucks or chatters, check your blade for conditions described above.

C: On material you have not cut before, make trial cuts. Always start out at a slow speed. Increase from here until it

sounds smooth cutting, at the fastest possible rate.

Operational

A: All doors and covers must be closed before machine will operate.

B: If machine stops in the cut you are in blade protection shut off mode. Check the following. Head feed rate to high,

incorrect blade (too fine), or the blade is dull. Correct problem and press the reset button on blade protection device, to

restart operations.

C: Always set the vises correctly.

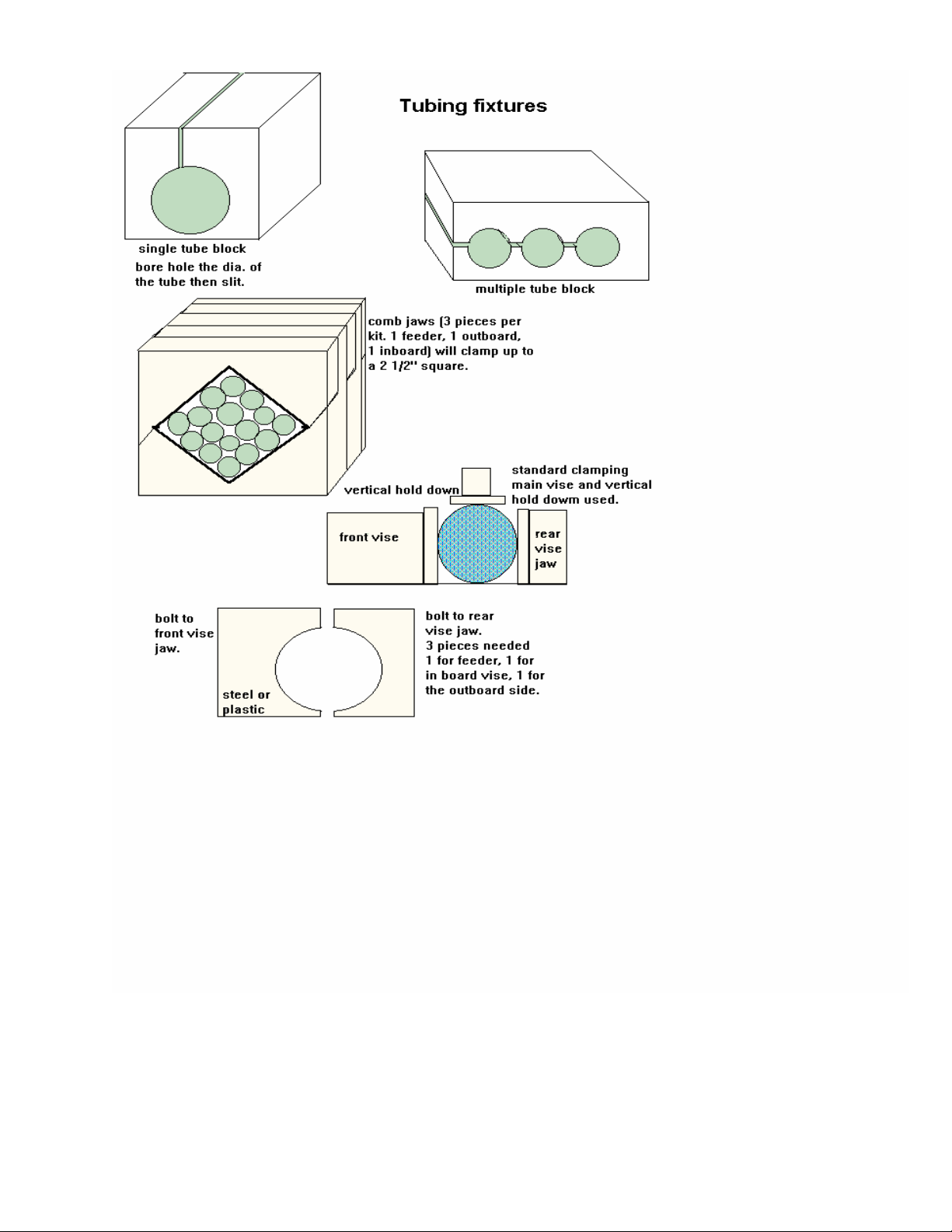

D: Some material that is an unruly shape may require fixturing.

E: If bundle cutting round stock with out comb jaws, tack welding the end of the bundle will prevent parts form

spinning.

F: Thin wall tube may be crushed when clamping. A block with a hole bored through it then slit length wise, will hold

the tube with out crushing it. See next page for examples.

G: If you want to continuously feed one length after another, simply tape the pieces together end for end.

Injury Do not misuse this machine!!!!!!

Always operate machine in a safe manner. Safety first to prevent personal

370 S 370 S L 370 PP 370 PP L

27

Page 28

These are only examples of different types of fixtures, Dake does not manufacture these.

370 S 370 S L 370 PP 370 PP L

28

Page 29

HEAD CHANGE INSTRUCTIONS

(Initial set-up and adjustments)

If you have purchased the optional ferrous or non-ferrous cutting head for your machine, there may be a few

modifications needed for your machine. These modifications should be needed only once, during your initial set up.

GUARD MODIFICATION

If your machine was purchased as a ferrous machine, your Plexiglas guard will need to be relocated. You will need to

unbolt the guard from its mounting, and shift the guard over to the right approx 2”. New holes (in hood brackets) will need to

be drilled to fasten this in its new position. The reason for this modification is due to the fact, the mounting plate and spindle

cap extends out from the head farther than ferrous head.

If you are installing a ferrous head onto a non-ferrous machine, this is modification may not be necessary. If it does

require moving the guard, complete the steps above only to the left.

INSTALLATION TIPS

A. Remove blade from cutting head before removal

B. Always mark the gib blocks when removed from head, to indicate where they came from.

Example: Left rear, right rear, side.

Note: Always place these gib blocks in safe place to prevent damage to the gib blocks.

C. If changing heads will be done frequently, quick disconnects for the electrical may be installed. Each time the head

is to be changed, the motor must be unwired and then rewired when the other head is installed. To eliminate time and the need

for an electrician to complete this task, a short length of cord with a quick disconnect plug may be wired to each motor. A cord

from the machine will have a mating plug attached to it.

When ever a head is changed a simple twist of the plug and the motor is disconnected.

Note: If this system is used, make sure the plugs on the heads are wired for proper rotation. Clockwise for the nonferrous and counter clockwise for the ferrous head.

D: Always store the unused head upright and in a safe location.

HEAD REMOVAL

WARNING!!!!!

THE POWER AND AIR MUST BE LOCKED OUT BEFORE PERFORMING THIS

PROCEDURE.

Step 1: Guard removal (Power must be off, and locked out)

A. Open the Plexiglas hood and safely hold it open. Having a helper or using a hoist to hold the hood open, remove the

clips holding the gas shocks to the hood. Lower the hood.

B. Lock the head in place (approx. half way down the column) using the upper and lower limit cams. Bring these cams

to a setting where the upper and lower limits both are being activated at the same time. This will hold the head while you

disconnect the air line.

C. Remove any tubing, wires, etc. Remove the way oilier tubing from head fittings, and anything that runs over the top

of the hoods brackets. Remove hood limit switch if applicable.

D. Remove the mounting bolts and remove the hood from the machine. Set it in a safe location.

WARNING!!!!!

THE POWER AND AIR MUST BE LOCKED OUT BEFORE PERFORMING THIS

PROCEDURE.

Step 2: Replacing the gib plates. (Figure A on page 32)

A. Disconnect the wiring from the motor. (If quick release plug is used, disconnect it now) (ref. 1) B. Remove the rear

column cover plate, from the column casting. Place the six screws out of the way. (Two different covers are used for ferrous

and non-ferrous. The plate furnished on the machine will work for either head, unless you choose to connect a chip collection

370 S 370 S L 370 PP 370 PP L

29

Page 30

system for the non-ferrous head, using a ferrous cover plate. This plate will need to be modified, adding a discharge tube

connection. (Ref 2)

WARNING!!!!!

ONLY A SLING APPROVED BY OSHA AND THAT IS RATED FOR THIS WEIGHT SHOULD

BE USED.

C. Move all tubing and wiring clear of the head, and CAREFULLY AND SAFELY place a sling or strap around the

head. This sling will be used in lifting the head from the column, so take care in placing this strap.(Figure B ref 3)

Step 3: Removing the gib plates. (Figure B ref 5/6)

A. With the head securely strapped, loosen and remove booth head lever cams from the “T” slot in the head. (Ref 4)

B. Remove the set screw from the lower lock nut on the head feed cylinder piston. (See gib plate detail drawing. ref A)

If this screw and nut are behind an obstruction, remove the upper and lower air lines, from the fittings on the head feed

cylinder. Place a compressed air nozzle in the upper or lower fitting on the cylinder, and move head up or down to

clear obstruction. (Move hoist with the strap to allow movement.)

C. Remove the lower locking nut from the head feed cylinder piston. (Ref b on gib plate detail drawing)

D. With the head disconnected from the head feed cylinder, gently lower the head down using the strap and hoist.

Lower until head has cleared the piston.

E. Eight allen head bolts hold the two gib plates to the head. From the back of the column remove these eight bolts.

(Ref C on gib plate detail drawing) Note: These bolts may be quite tight. An impact wrench may be useful for this.

Note: Step 6 may need to be repeated to raise or lower the head to allow access to the bolts.

F. With the eight bolts removed, carefully remove the two gib plates from the machines, and place in a safe location

where no damage will come to them. (Mark left top / right top for future installation)

Step 4: Removing the head.

A With all tubes, wires, etc. clear from the head, pull the head away from the column, (figure C ref 7) using a strap and

hoist. (Fork lift or engine hoist can be used)

Warning!!!!!

Head may be difficult to balance. Take caution when lifting the head

B Using extreme care set the head in a safe location in an upright position.

REPLACEMENT HEAD INSTALLATION

Installing head onto the column

A. Wipe all way surfaces clean of debris. Wipe the rear machined surfaces and oil galley rings of the head, clean of

debris.

B. With the replacement head carefully strapped and hooked to a hoist etc., lift the head to the column, and insert

between ways (figure D).

Note: When placing the replacement head keep it low on the column, below the cylinder piston threads.

Installing the gib plates

A. The gib plates that came with this head may need some grinding or adjusting. This procedure is a one time

operation, and will not be needed on future installations.

B. Bolt the two gib plates to the back of the head in reverse order from above. (Figure E ref 5)

C. Attempt to wobble these gib plates while on the machine. If they are tight, grasp the head and try to move it side to

side. Watch for gaps at the ways when moving the head side to side.

D. If there is slight movement, tighten the gib blocks up a half turn at a time. Adjustments are made with the screws

threaded into the top of the gib block, as shown in gib plate detail drawing ref e. (The two rear plates will show gaps

when the head is moved front to back, (Adjust the back gibs) the gib plate on the side will be responsible for side to

side movement. (Adjust these gibs for side to side movement)

Note: Refer to gib block adjustment.

E After any gib block adjustments are made, the head must be tested for free travel. Using the strap raise and lower the

head on the column and check that the head travels the full length of the column, without binding or jerking. There will be a

370 S 370 S L 370 PP 370 PP L

30

Page 31

certain amount of jerking without the cylinder connected, this is normal. If the head jerks excessively future adjustments will be

needed.

Note: If cylinder piston restricts your from moving the head the full length of the column, remove the bottom air line from the

cylinder, using compressed air, blow into the fitting and the piston will retract.

F. If the gib blocks are too tight and can not be adjusted, it is recommended that the gib block faces be surface ground.

(Gib detail drawing ref d) After they are ground check fit, and adjust as needed or surface grind again, until gibs can be

adjusted.

G. Run the head feed cylinder piston through the head casting mounting hole a install the locking nut. (Figure E ref 6)

Tighten securely and replace the set screw in the lock nut and tighten.

H. With the upper and lower tube lines removed form the cylinder and using compressed air run the head up and down

on the column. The head will now travel without jerky movements or hesitation. If these conditions still exist readjust the gib

blocks.

I. Replace the head limits cams into the “T” slots in the head. (Figure F ref 4)

J. Connect power back to the motor.

K. Replace rear column cover.

L. Reconnect any tube lines, wires, etc., that may have been removed before removing the head.

M. Reinstall Plexiglas hood in the correct position, and connect gas shocks, limit switch, etc. (If hood modifications

have not yet been made, do this modification now.)

Note: Once these adjustments and modifications have been made, and parts are replaced in original position, these

adjustments / modification will not be needed again.

Once these adjustments are made it should be a simple change.

1. Remove hood.

2. Disconnect electrical to motor and tubing etc.

3. Remove rear cover unbolt gib plates, and cylinder.

4. Remove head, put on replacement head.

5. Install gib plates, replace nut on cylinder piston.

6. put on rear cover, rewire, and connect all tubes.

7. Replace hood.

8. Start cutting!

370 S 370 S L 370 PP 370 PP L

31

Page 32

370 S 370 S L 370 PP 370 PP L

32

Page 33

370 S 370 S L 370 PP 370 PP L

33

Page 34

EUROMATIC 370 PP / S MAINTENANCE SCHEDULE

FERROUS HEAD

370PP /S

A: Gear box. Maintain safe level of oil. Oil should be visible through sight glass on the right side of the gear box

when machine is running. Note: Oil will appear foamy during operation. When running at high speed oil may weep from

filler cap. This is normal and will subside once machine has expelled out the excess oil in gear box.

B: Air oiler Located on the air regulator.

Air must be dry and clean. Use appropriate measures to

insure this, before it enters the machine.

WARNING!!!!!

LOCK OUT AIR SUPPLY TO THE MACHINE BEFORE REMOVING OIL RESIVOIR PLUG.

C: Head feed cylinder. The oil reservoir is mounted into the cylinder. The reservoir is clear and you can visually

inspect the amount. When oil level is approximately a depth of 1/4” oil must be added

To fill reservoir, remove brass cap on top and add oil into the reservoir until full cycle head to bleed.

D: Chip drawer. Located behind the front access door, This drawer pulls easily out for cleaning.

E: Coolant. This pan is located under chip drawer. The coolant should be kept clean. When coolant needs changing,

remove the drain plug from the pan.

F: Way Oiler. This reservoir is on the back of the column. This reservoir should be kept topped off. At the beginning

of each shift, this should be pumped twice to maintain good lubrication for the ways.

G: Gib blocks. This acts as an adjustable guide for the gear box. If adjustment is needed

See the gib block adjustment section in this manual

H: Vise gib can be adjusted by loosening the lock nuts and turning the set screws equally.

This should be done when ever vise shifts left or right when clamping.

I: Chip brush. Replace as needed.

J: Excessive backlash. This can be reduced, by removing the spindle shaft cover plate on the lower right hand side of

the gear box. Using the set screws in plate, loosen mounting bolt and tighten set screws tightening these set screws will pull the

plate away for gear box and allow removal of the plate. With plate removed tighten spindle nut and replace plate in reverse

order. Proper backlash will be approximately. 1/16” to 1/8” play in spindle with blade on the spindle.

Maintenance Schedule

Item Model Daily Weekly Monthly 100 Hours 6 Months

Gear Box Oil 370 PP / S change after first

Air Regulator oiler 370 PP / S check / add

Head Feed Cylinder Oil 370 PP / S add as needed

Coolant Water based 370 PP / S check / add change

Chip Drawer 370 PP / S empty

Gib Adjustment (Head) 370 PP / S check as needed

Vise Gib Adjustment 370 PP / S check as needed

Way Oiler 370 PP / S 2 pumps check / add

DRO Magnetic Strip 370 PP wipe / clean

DRO Reader Adjustment 370 PP check / set if needed

Lube Types Head Feed Cylinder.-DTE 24

Hydraulic Oil

change

370 S 370 S L 370 PP 370 PP L

34

Page 35

Gear Box- 80 / 90 Gear Oil Way Oiler-Light Weight Way Oil

Air Oiler - Tool Oil Clean DRO Strip-Clean Dry Rag

EUROMATIC 370 PP / S MAINTENANCE SCHEDULE

NON-FERROUS HEAD

370PP/S

A Gear boxThe gear box does not require any oil. The horizontal spindle shaft has zerk fittings provided for

lubrication. The spindle should be greased with a high quality, high temperature grease.

B Air oiler Located on the air regulator must be dry and clean. Use appropriate measures to insure, before it

enters the machine.

C Head feed cylinder. The oil reservoir is mounted into the cylinder. The reservoir is clear and you can visually

inspect the amount. When oil level is approximately depth of 1/4” oil must be added

To fill reservoir remove brass cap on top and add oil into the reservoir until full Cycle head to bleed.

D Chip drawer Located behind front access doorThis drawer pulls easily out for cleaning. If a chip collection unit has

been installed to the back of the machine, it should be emptied at regular intervals.

E Coolant pan is located under chip drawer. The coolant should be kept clean. When coolant needs changing, remove

the drain plug from the pan.

F Way Oiler. This reservoir is on the back of the column. This reservoir should be kept topped off. At the beginning of

each shift, this should be pumped twice to maintain good lubrication for the ways.

G Gib blocks. This acts as an adjustable guide for the gear box. If adjustment is needed see the gib block adjustment

section in this manual

H Vise gib can be adjusted by loosening the lock nuts and turning the set screws equally. This should be done when

ever vise shifts left or right when clamping.

I clean frequently any chips that build up within the vertical column.

J Belt tensioning should be done as needed.

BELT TENSION ADJUSTMENT

A: To adjust loosen the four motor mounting bolts. (Loosen slightly)

B: Using the adjusting bolt threaded into the block on the motor panel (H) adjust as needed.

C: Tighten motor mounting bolts securely.

Note: If you find no adjustment left in the threads, the belt may be stretched and in need of replacement. Belt tension

should have approx. 1/4 - 3/8” deflection.

On occasion if adjustment is not possible, loosen the motor mounting bolt and reposition the motor and try adjustment.

Maintenance Schedule

Item Model Daily Weekly Monthly 100 Hours 6 Months

Spindle grease 370 PP / S as needed

Air Regulator oiler 370 PP / S check / add

Head Feed Cylinder Oil 370 PP / S add as needed

Coolant 370 PP / S check / add change

Chip Drawer 370 PP / S empty

Gib Adjustment (Head) 370 PP / S check as needed

370 S 370 S L 370 PP 370 PP L

35

Page 36

Vise Gib Adjustment 370 PP / S check as needed

Way Oiler 370 PP / S 2 pumps check / add

DRO Magnetic Strip 370 PP wipe / clean

DRO Reader Adjustment 370 PP check / set if needed

Lube Types Head Feed Cylinder.-DTE 24

Spindle Grease -Hi Temp. Way Oiler-Light Weight Way Oil

Air Oiler - Tool Oil Clean DRO Strip-Clean Dry Rag

Hydraulic Oil

TROUBLSHOOTING GUIDE

FERROUS & NON-FERROUS HEAD

PROBLEM THINGS TO CHECK SOLUTION

Blade chatters while cutting Blade pitch, gullets are packed Replace blade, regrind, clean gullets

Part moves while cutting Check how parts are clamped, rear vise Reclamp or fixture as needed

Par has hanging burr Part distorted while clamped, anti burr

vise

Part has burr on exit of cut Lack of support on short pieces Add solid wear plate to support part

Rough or scored finish Blade dull, incorrect blade, tooth

missing

Blade Breaks Backlash, dull blade, part moved in

vise

Motor/Gear box noise Low oil, excessive backlash Add oil, adjust backlash

Head is jerky Binding components, air in system If oil is full, bleed head cylinder

Motor hums or runs slow Check Power source fuses, hood

interlock

Motor runs backwards Leads on incoming power are incorrect Have qualified electrician make a

No power to the machine Check power source fuses, hood

interlock

Vises do not operate or are slow Incoming air pressure, regulator

pressure

Head stops down feeding Lack of air, flow control valve

adjustment

Head returns slow Gib strip adjustment, air return valve

closed

Tolerances slipping Feeder too fast, blade, overfeeding Slow feeder, adjust blade thickness

Unsquare cutting Wrong, dull blade thickness

adjustment

Will not feed material (370PP) Multiple stroke counter, vise position

reversed

Motor runs hot Incoming voltage too high Power should be +/- 10%

Head crashes down Low or no oil in head feed cylinder

leakage

Machine stops (370PP) Blade protection stops operation Correct problem and reset calibration

Machine will not restart Security locked out, piece counter not

cleared

Machine will not start E-stop activated, out of stock Reset E-stop, check feed vise clearance

* Parts may come off hot, this is normal with non-ferrous cutting.

Adjust anti burr arm or outboard vise

Replace blade, Reclamp part

Replace blade, Reclamp part

Replace fuses, close hood

change

Replace fuses, close hood

Increase air pressure, set higher

Increase air pressure, adjust valve

Adjust gib, open-air return valve more

Slow feeder, adjust blade thickness

Multiple stroke set at 0, switch forward

Add oil to cylinder as outlined repair

leak

unit

Turn key to on position, clear counter

370 S 370 S L 370 PP 370 PP L

36

Loading...

Loading...