Page 1

FORCE 50 DA HYDRAULIC PRESS

INSTRUCTIONS AND PARTS LIST

Ordering information

Please order all parts by part number and name; also mention model number as shown on plate attached to the

frame of the press. Prices do not include freight and handling charges.

724 Robbins Road

Grand Haven, MI 49417

Phone: 616-842-7110 800-937-3253

Fax: 616-842-0859 800-846-3253

Web: www.dakecorp.com

E-mail: customerservice@dakecorp.com

3/29/2010 1

technicalservice@dakecorp.com

Page 2

Thank you for buying Dake !!!!

We hope you enjoy many years of using your new Dake hydraulic press. We hope you find these instructions

helpful, if you have any questions please give us a call, or just stop by for a factory tour.

724 Robbins Road

Grand Haven, MI 49417

Phone: 616-842-7110 800-937-3253

3/29/2010 2

Page 3

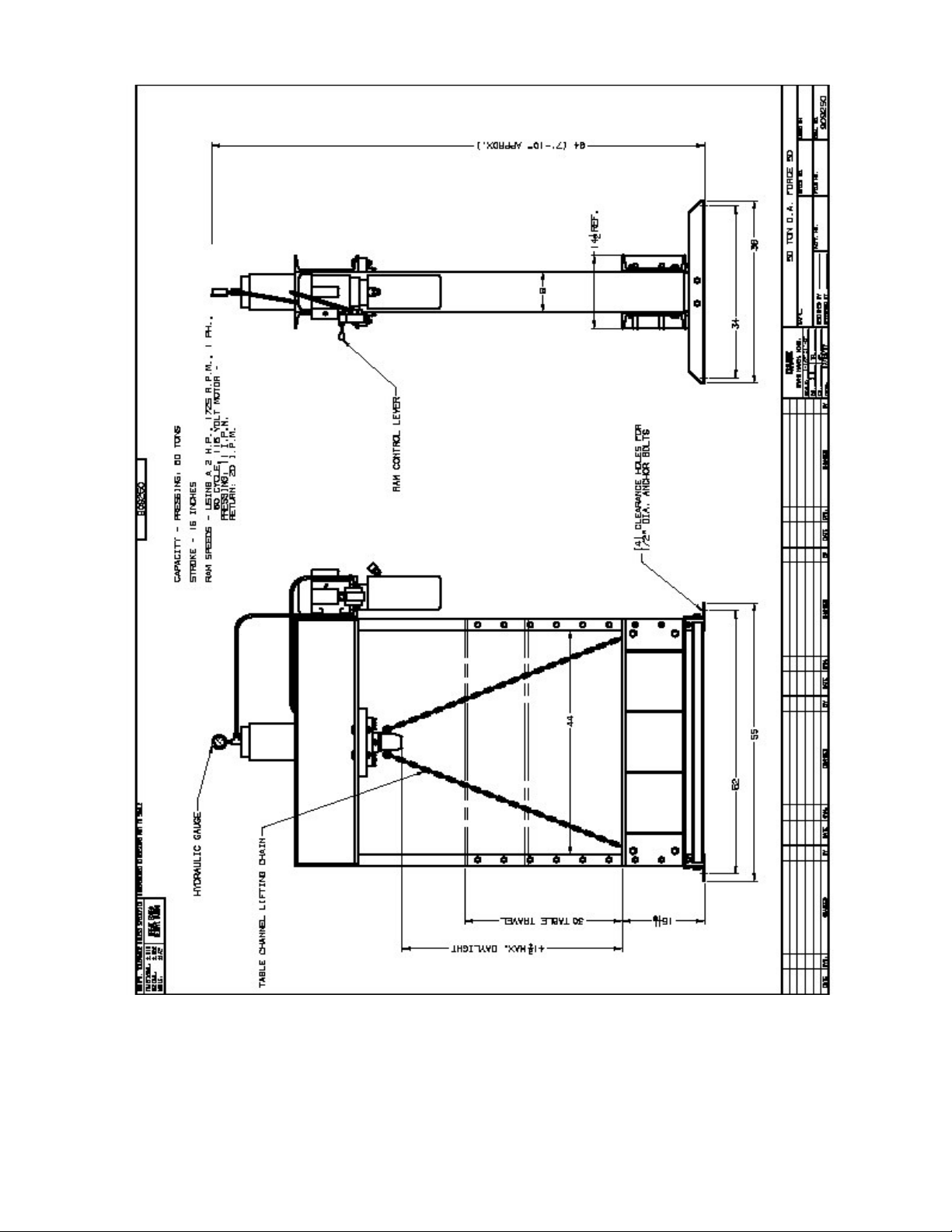

Dimensional drawing of 50 ton press

3/29/2010 3

Page 4

MACHINE SPECIFICATIONS

Tons 50

Stroke 16 inches

Pressing speed 11 Inches per minute

Return speed 20 Inches per minute

Daylight 41 3/4

Table travel 30 Inches

Between channels 44 Inches

Motor

1725 R.P.M

Weight 1200 lbs.

Approx. height 7’ 10” / 94”

1. Remote relief valve part number 301949. This will make the tonnage adjustable from 290 – 3537

p.s.i.

2. Check valve makes the press hold pressure part number 302071

3. Side mounted arbor part number 02007. This press will mount on the left side of the 50 DA press.

2 horse power / 60

cycle / 115/220 Volt

Optional side mounted arbor

Options

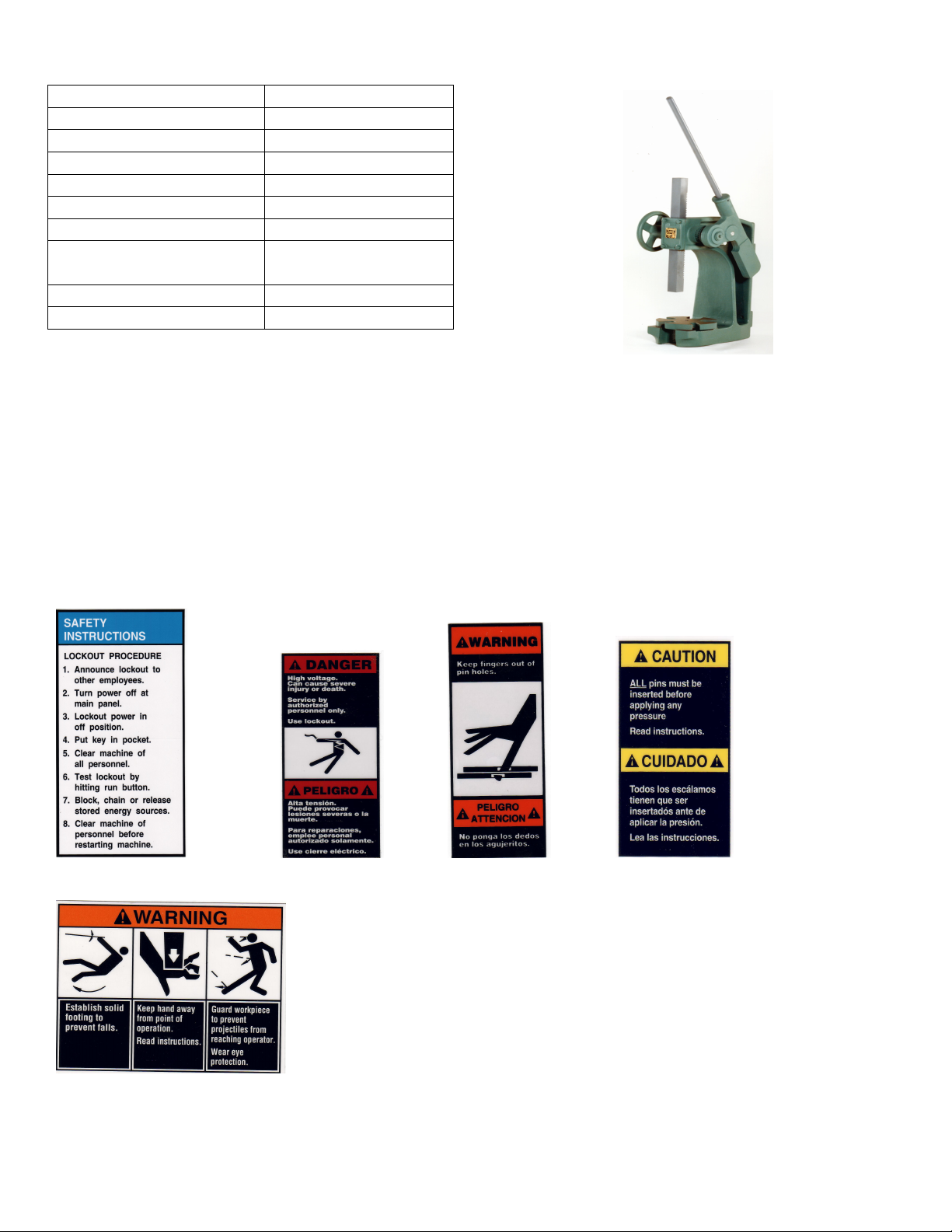

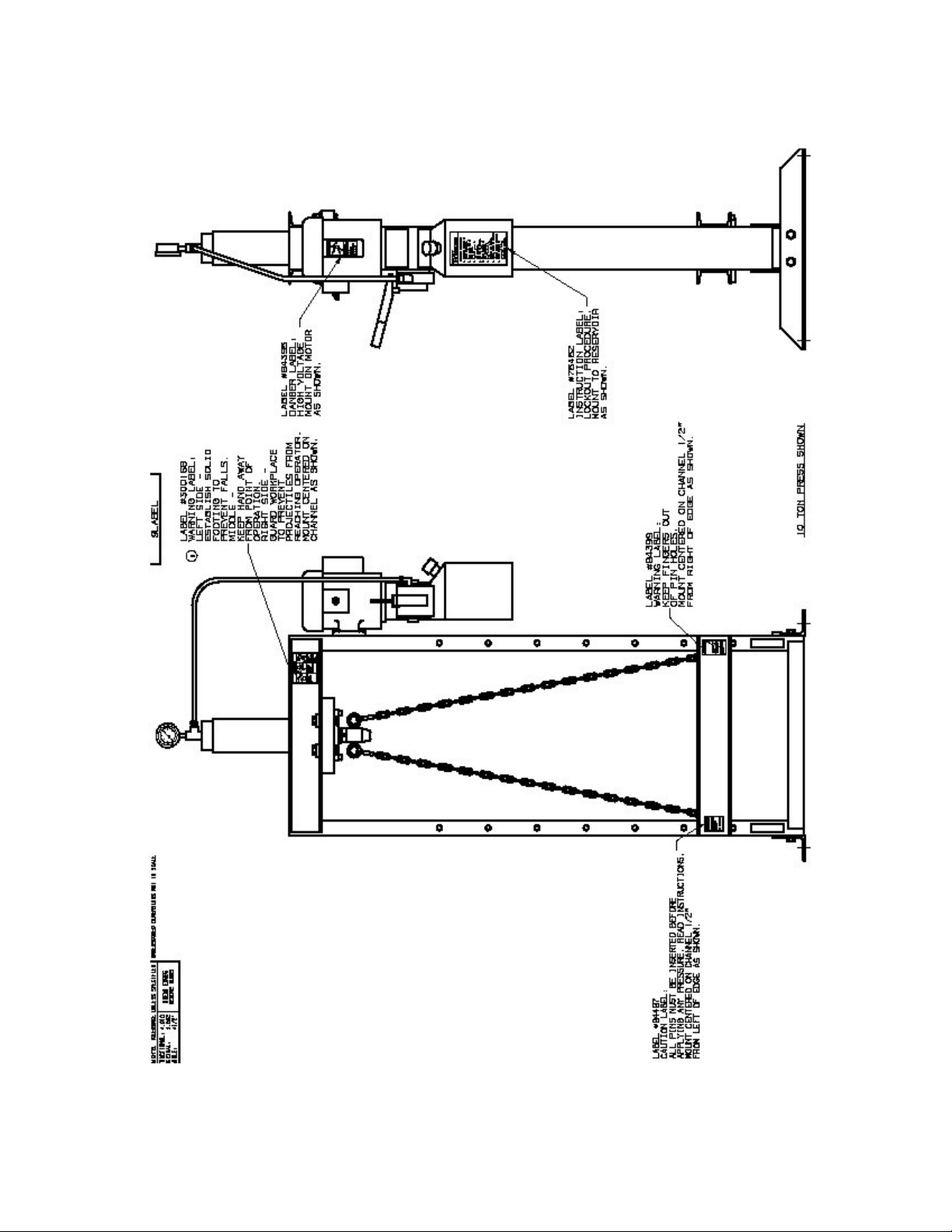

Part Number 76462 Part Number 84395 Part Number 84399 Part Number 84487

Part Number 300168

3/29/2010 4

Page 5

Below is a drawing showing the location of all safety labels on this press.

3/29/2010 5

Page 6

This machine is not designed for stripping operations. Personal injury or machine

damage can result.

Press set-up

Installation Instructions

Your new Dake Press has been packaged in a manner to prevent damage to any critical components; some

assembly will be required. All parts in the accessory box are critical to the function of your press. Some presses

may be pre assembled.

NOTE: FOR EASE OF ASSEMBLY LEAVE THE PRESS FRAME MOUNTED ON THE SHIPPING SKID

1. Remove plastic from the machine.

2. Open the box and you will see a pumping unit, with the press still laying on its side. Locate the four holes

on the side of the press facing up.

3. Place the pumping unit on the side of the press with the mounting bracket facing down, making sure the

holes all line up.

4. There are four bolts, washers and nuts in a bag, in the box. Put the bolts in the holes using the washers

and nuts. Make sure all nuts and bolts are tight.

5. With the press lying on its side fill the reservoir with DTE 24 Mobile oil or equivalent.

6. Look at picture on the next page to install all the fittings.

WARNING!!!!

Be sure all bolts and fittings are tight before operating this pumping unit, personal injury could result.

3/29/2010 6

Page 7

How to install the fittings on your new hydraulic press

the A port.

1

Cylinder

4

A Port

B Port

Hydraulic hose

connects here and to

2

Hydraulic hose connects here and

to the B port.

3

1 72050

2 73425

3 72047

4 10 ton 301315

25 ton 301316

50 ton 302179

5 69671

6 72402

7 302183

8 302061

5

6

8

WARNING!!!

Be sure all fittings and bolts are tight.

Do not over tighten fittings or bolts.

Joy stick valve mounts

here. It only fits one

way.

7

3/29/2010 7

Page 8

Wiring Instructions

WARNING!!!!

A licensed qualified electrician that follows all state and local laws must wire and install the electrics on

this machine.

110 Volt

WARNING!!!!!

This machine must have a designated 30 amp drop for 110 volts.

1. For 110 volts this machine is ready to plug in. The machine can be wired 220 volt single phase. Always

follow the wiring diagram provided in the motor cover when converting to 220 volt single phase. A cord

and plug that is rated for the specified voltage and amperage must be used. This rating is located on the

motor.

WARNING!!!!

It is the responsibility of the installer to make sure the motor is wired correctly for the voltage needed.

Damage to motor could result.

220 Volt single phases 17.2 amps

WARNING!!!!

A licensed qualified electrician that follows all state and local laws must wire and install the electrics on

this machine.

WARNING!!!!!

This Machine new is shipped out as a 110 volt machine. If the wiring must be changed to suit

220 volts single phase.

1. The leads on the motor must be changed to fit 220 volts 17.2 Amps, follow the diagram on the

motor.

2. Install plug and wire that fits the rating on the motor, this plug and wire must be rated for the

voltage and amperage listed on the motor.

Operation

WARNING!!!!!!

If a 110 volt power supply will be used. A designated 30 amp drop must be supplied; this press will not

operate correctly without the 30 amps.

1. Fill the reservoir with 3 gallons of Mobil DTE 24 hydraulic fluid or its equivalent AW 32.

2. Turn the on / off power switch (toggle switch) to the “on” position (up).

3. Move the control lever down, this will advance the ram in the downward position.

4. Release the control lever and the ram will stop moving.

5. Move the control lever handle to the up position and the ram will move up.

3/29/2010 8

Page 9

6. When the press is new be sure to move the ram up and down to work out any air that may be in the system.

Lubrication

Keep all working parts of the press well oiled for easier operation. Also, keep a light film of oil over the entire

surface of the ram to prevent rust.

WARNING!!!!

This press is not intended for stripping operations! Personal injury or machine damage can result.

WARNING!!!!

Only use Hydraulic oil in this machine DTE 24 hydraulic oil is recommended.

Do not use transmission fluid in this press, the warranty will be void and this fluid will damage the seals.

3/29/2010 9

Page 10

3/29/2010 10

Page 11

1

1

4

4

4

4

1

1

4

4

4

4

2

4

4

1

6

1

6

1

2

1

4

1

4

1

4

1

4

1

2

2

2

2

4

1

2

FORCE 50 DA HYDRAULIC PRESS

PARTS LIST

Item # Qty Description Part # Item # Qty. Description Part #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Frame 50 Ton 87137 20

Hex Cap Screw 1/2"-13x3 1/4" lg 43356 21

Channel Washer 1/2" 43657 22

Work head Assembly 716547 23

Lock Washer 1/2" 43647 24

Hex Nut 1/2"-13 43916 25

Base Angle 566 26

Hex Cap Screw 1/2"-13NC X 1

1/2" lg 43349 27

Table Pin 569 28

Retaining Ring 43980 29

Table Channel 706945 30

Lock Washer 1/2" 43647 31

Hex Nut 1/2"-13 43916 32

Table Bolts 79983 33

Table Spacer 86488 34

Shackle 301884 35

Chain 301881 36

Spring Snap 301882 37

Eye Bolt 301880

Nose Piece 87138

Lock Washer 5/8" 43648

Hex Nut 5/8"x11 43917

Hydraulic Power Unit 301856

Hex Cap Screw 5/16"18 NCx1/2"lg

Lock Washer 5/16" 43644

Hex Nut 5/16"-18 43911

Label 301879

Label 84487

Label 84399

Label 300168

Label 76462

Label 84395

Name Plate 301856

Label 76936

Table Plate 702

V-Block 336

Dake Name Plate 81002

43313

3/29/2010 11

Page 12

3/29/2010 12

Page 13

3/29/2010 13

Page 14

3/29/2010 14

Loading...

Loading...