Page 1

724 Robbins Road

Grand Haven, Michigan 49417

616-842-7110 Phone 800-937-3253

616-842-0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail: customerservice@dakecorp.com

technicalsupport@dakecorp.com

Dura Press Models

FORCE 40, 70 & 100

Dual voltage machines for 220 / 440 volts

Use and Maintenance Manual

Model No: _________________

Serial No: _________________

Force 40 70 100 Ton

1

Page 2

Model

84935

FORCE

40 40 35" 8" 19" 37" 68 ipm 7 ipm 63" x 27" 88"

FORCE

70 70 35" 8" 19" 37" 42 ipm 4 ipm 63" x 27" 88"

FORCE

100

Max

Ton

100 41" 10" 19" 39" 52 ipm 3 ipm 75" x 33" 90"

Width

between

uprights

Width

between

table

channels

Max.

Ram

travel

Max.

Ram

to

table

Ram

rapid

advance

Ram

pressing

speed

Base

(W x D) Height Weight

Maximum operating pressure for all models 280 bars

Sound pressure maximum 78,6 db

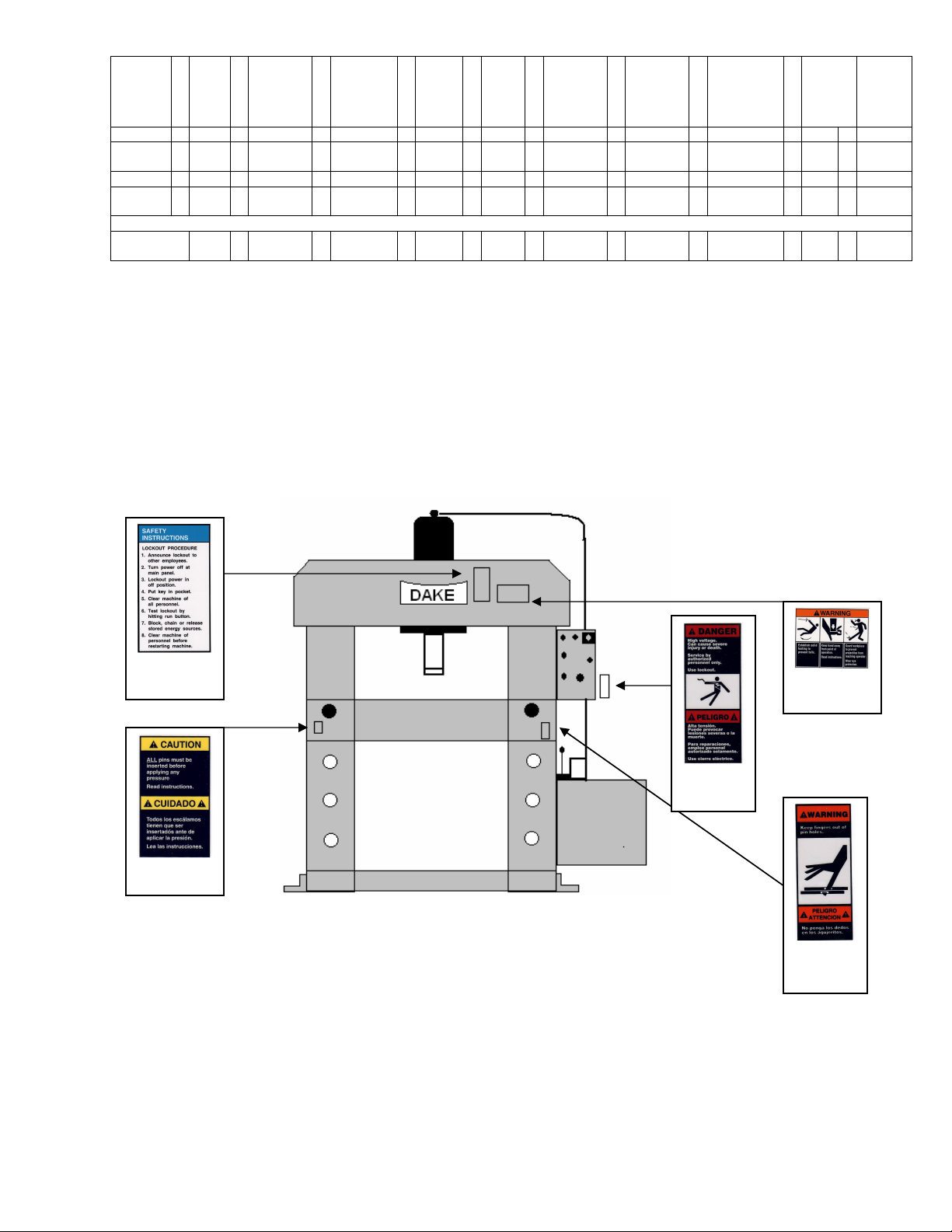

For the safety of the operator/owner it is your responsibility to review the follow warnings

and safety labels located in this manual and on the machine. It is the responsibility of the

operator/owner to understand these labels. If there are any questions regarding these labels

call Dake at 1-800-937-3253.

Below is a diagram of where the safety labels are required.

880

lbs.

1100

lbs.

2200

lbs.

Part number

76462

Part number

84487

Part

number

Part number

300168

Part

number

84399

If at any time these safety stickers need to be replaced or are missing lock out the machine and

contact Dake immediately.

Force 40 70 100 Ton

2

Page 3

The operator and owner must read and understand all of the following warnings. It is the

responsibility of the employer to check that the following warnings have been understood

by the operator and maintenance personnel.

WARNING!!!!

Operator must never place hands in the area of the ram during pressing operations.

Do not use this press for pulling.

A machine not subject to maintenance and periodic structural inspection is a danger for

the operator and the persons working near by.

It is strictly forbidden to tamper with, modify or elaborate parts of the machine that alter

its regular operation.

During the phases of maintenance requiring guards to be removed, machine must be

locked out according to local and state laws.

This press is designed for one operator.

All work requiring the piece to be pressed to be supported by the operator is forbidden.

It is strictly forbidden to press, cut, draw and do anything else with pieces whose

dimensions or physical nature may explode or produce splinters.

DEFINITIONS

In this manual “right side”, “left side”, forwards, backwards, top and bottom refer to the operator

situated in front of the press with the power unit to there right.

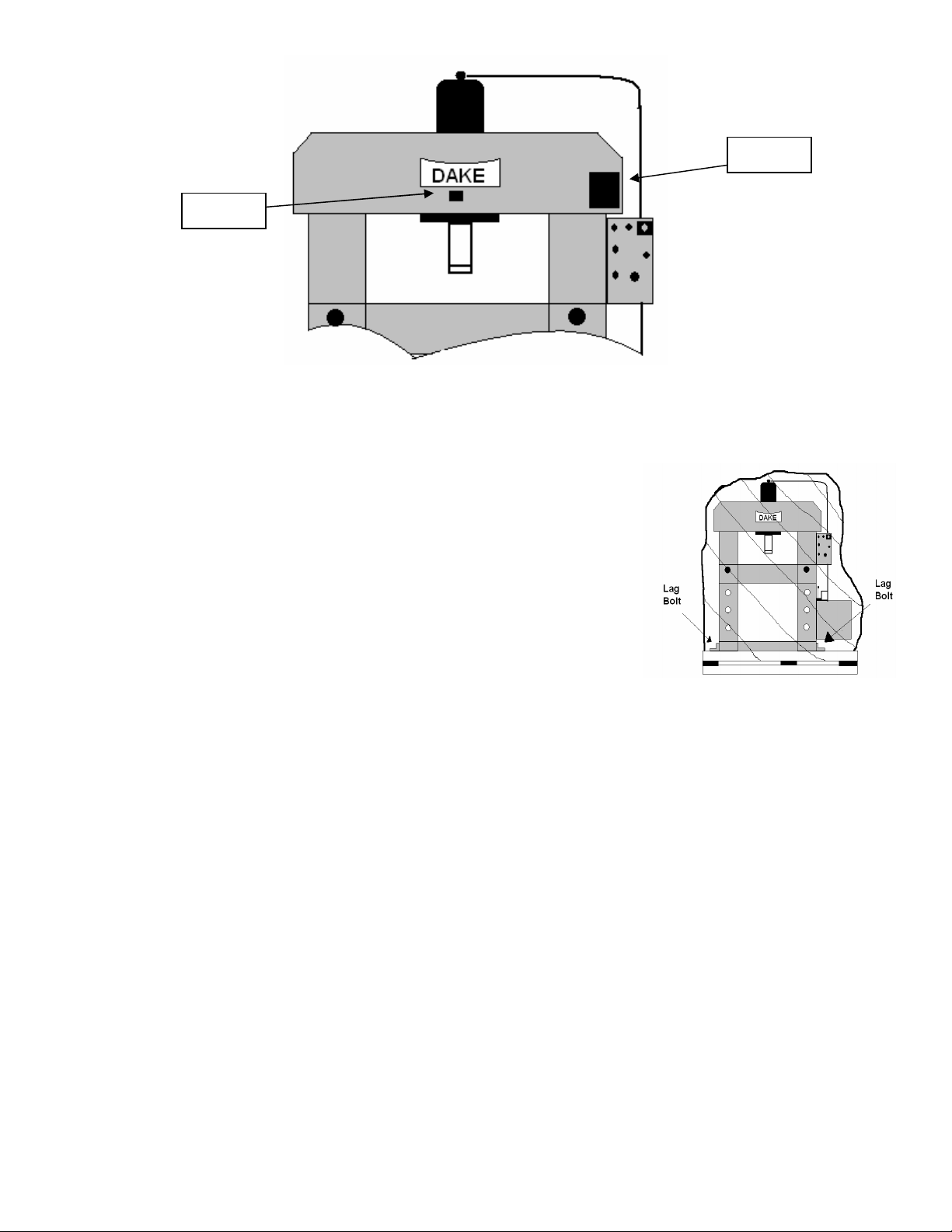

Press Identification

The press is fitted with a rating plate fixed in a visible manner on the front as shown in Fig. 1

item 1 on next page. The Dake part number and serial number on the front name plate shown in

Fig. 1 item 2.

Force 40 70 100 Ton

3

Page 4

Item 1

Item 2

Fig. 1

Unpacking

The machine has shrink wrap on it and any accessories, spare part may be

Packed in cardboard boxes and positioned on top of the work table.

To remove the packing, cut the plastic wrap, taking care not to damage the

Machine or any part of it. Remove the accessories from the top of the work

table, check the contents correspond to the order and to the accompanying

documentation. Remove the lag bolts that hold the press to the skid.

Disposing of the packaging

Fig. 3

The packing will have to be disposed of be the purchaser in compliance with the current

regulations.

Claims shall not be accepted in the event of the goods not being in conformity with order or

with the accompanying documents if they are not notified within five days of the date of

receiving the goods.

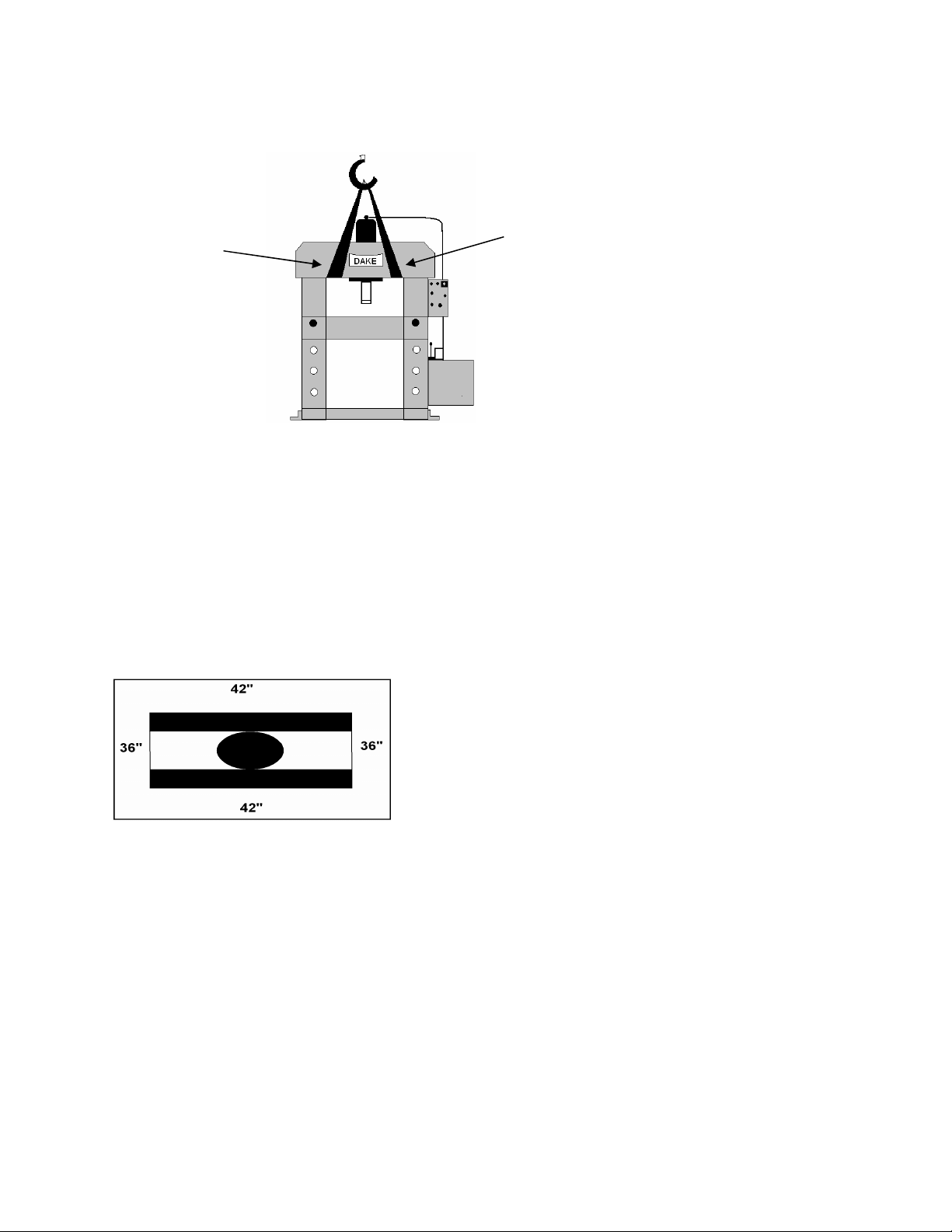

Handling and transport and positioning

For handling the machine it is necessary to use special lifting equipment whose maximum lifting

capacity must be no lower than the total weight of the press which can be found on page 2 of this

manual.

Loading and unloading the machine

Use lifting straps are to be used to position as shown below in Fig 4.

WARNING!!!

Be sure the maximum capacity of each strap is greater than the total weight of the press.

Force 40 70 100 Ton

4

Page 5

Do not make sudden movements when transporting the machine.

The manufacturer is not responsible for damage to the machine while loading or unloading the

press.

Pick up

here

Pick up

here

Fig. 4

Positioning the press

Simple precautions are necessary for correctly positioning the press always consider the safety

aspect not only in relation to the work carried out with the press, but also to the dangers

originated by the other machines in the workplace.

Do not position on unstable or unleveled floor.

Below in fig. 4 is the allowable distance from the wall, other machines or other objects.

Fig. 4

Commissioning and Starting

Electrical connection

This machine is dual voltage 220 3 phase / 440 3 phase. The amp rating on these machines are

6.8 amps on 220 volt 3 phase and 3.4 amp on 220 volt 3 phase.

WARNING!!!

Only a certified electrician that follows local and state laws is authorized to perform any

type of electrical connection on this machine. The electrical power supply voltage must be

made in compliance with local and state laws.

Force 40 70 100 Ton

5

Page 6

For proper operation it is necessary to ensure constant voltage and it must not exceed or be lower

than 5% of the rated value.

Before making any electrical connection confirm voltage rating of the machine. There is a black

plastic box mounted on top of the reservoir.

WARNING!!!

Be sure there is no power to the machine before checking the following connections. It may

be necessary to lock out the machine for proper power disconnection.

Remove the two mounting screws that hold this box in place. Under this box you will see one of

the following possibilities in fig. 5. After confirming or changing this to the correct voltage

mount the cover with the two screws. Now, open the electrical panel on the transformer be sure it

is set for the correct output voltage.

Fig. 5

220 Volt connection 440 volt connections

WARNING!!!

Any damage caused by a faulty electrical connection is not covered by warranty.

Filling the pumping unit

To fill the pumping unit, use exclusively the oils indicated in the table on the next page or

equivalent. The environmental conditions must be considered before purchasing oil. To transfer

the oil from the container to the tank use an external filter as shown in Fig. 6 in order to prevent

the introduction of foreign material or liquids at the time of filling.

The amount of oil required for each model is described in the chart below.

40 Ton 10.5 Gallons

70 ton 10.5 Gallons

100 Ton 15.5 Gallons

A - Oil B - Pump C - Filter D - Press Oil

Force 40 70 100 Ton

6

Page 7

Fig. 6

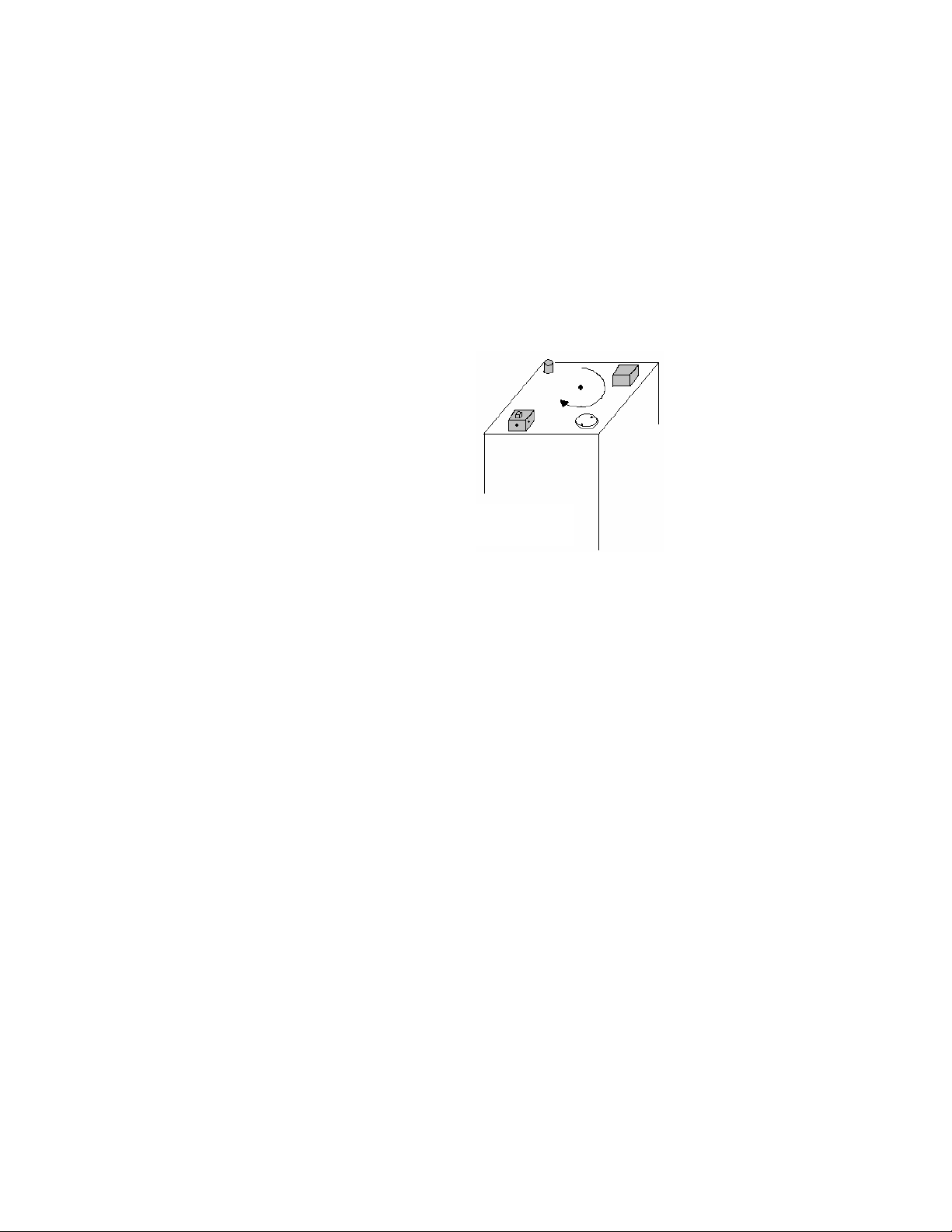

Pump rotation

After making the electrical connections to the press it is necessary to make a visual check on the

direction of rotation of the electric motor.

Before checking the direction of rotation of the pump, fill the reservoir with oil see Fig. 6

1. Unscrew the inspection cap.

2. Identify a reference point on the drive shaft.

3. Power up the motor for Max. 1-2 seconds.

4. Check that the rotation of the shaft coincides with that of the arrow shown on the top of

the unit see Fig 7.

5. Screw down inspection cap.

If the motor rotates in the wrong direction:

See your electrician.

Fig. 7

Any damage caused by wrong electrical connection is not covered by warranty

Force 40 70 100 Ton

7

Page 8

DTE Oil No.

Gravity 31 26

Maximum Pour

Flash Point

Viscosity @ 100F.

Viscosity @ 130F.

Viscosity @ 210F.

Color 3 Max. 3.5 Max.

Viscosity Index 95 Min. 95 Min.

Also Passes ASTM Rust

Test Yes Yes

Oiliness Additive Yes Yes

Competitive Oils

Equivalent to above

specifications

24

20F. 20F

395F 400F.

145-160 290-310

84.5 144

44 53

DTE Oil No.26

Cities Service Pacemaker Oil

Exxon Co. Nuto H32 Nuto H68

Gulf Oil Co. Harmony No.

Pure Oil Co. Puropale Rx

Shell Oil Tellus Oil No.

Sinclair Oil Duro Oil

Standard Oil Rycon Indl Oil

Sun Oil Co. Sunvis No.

Sunray DX Oil Co. No. 475

Texaco Rando Oil No.

NO. XD 15

43 AW

Anti Wear No.

150

32

AW16

No. 15

706 No. 816

WR

Diamond Roza

L

HD-32

Pacemaker Oil

No. XD30

Harmony No.

54AW

Puropale Rx Anti

Wear No. 300

Tellus Oil No. 68

Duro Oil AW31

Rycon Indl Oil

No. 31

Sunvis No. 754

No. 831 WR

No. 477

Diamond Roza H

Rando Oil No.

HD-68

To obtain best results oil temperature should not exceed 140F. When using DTE No. 26 as an

Alternative for DTE No. 24 there might be a slight variation in the ram speeds.

First starting

After filling the reservoir through the fill cap it is necessary to prime the pump. Check that all the

valves and distributors are in the rest position, at the time of starting do not operate any

movement.

To obtain starting it may be necessary to press the reset button in the electrical panel.

Force 40 70 100 Ton

8

Page 9

WARNING!!!

This press is exclusively prepared to be used only by one operator.

To prime, jog the start button (electric motor). When the unit emits a dull sound with no jumps

and the sound of the pump is constant. An uneven “tinny” noise indicates there is air in the

pump.

The oil in the reservoir may fall on start up due to:

1. absorption of volume by the cylinder

2. Absorption of volume by the pumping unit.

3. Discharge of air bubbles remaining in the piping.

It is necessary to top off the level of oil bringing it up to the correct height, by checking the level

gauge. The level should be about half way up the stick.

Operation

Before starting any operations make sure there are no other persons in the immediate vicinity of

the machine.

It is strictly forbidden to pass under the work table.

To operate the cylinder, activate the master switch, and then operate the distributor lever Fig. 8.

Pulling - the lever toward the operator (Pos. 2) the piston rod lowers.

Pushing - the lever from the opposite side to the operator (Pos. 3) the piston rod will go up.

Releasing - the lever will return to the neutral position stopping the ram from moving (Pos. 1).

With the hand wheel positioned on the side of the distributors (Fig. 8 Pos. 4) it is possible to

adjust the operating pressure continually and therefore the pressing force of the cylinder. The

pressure gauge (Fig. 7 Pos. 5) allows displaying the pressure during the working phases.

Adjustment of the maximum pressure must be made starting from the lower value and gradually

increasing to reach the pressure necessary to perform the operation to be carried out.

Dake declines all liability for damage to things and/or persons caused by tampering with

the pressure control valve fitted on the unit.

Force 40 70 100 Ton

9

Page 10

Fig. 8

Work table height adjustment

To optimize the use of the press it is necessary to set the work table at a convenient height in

relation to the operation to be carried out and to the equipment to be used.

Before proceeding to lift the mobile table, check that:

- The eyebolts fixed to the work table are fully tightened Pos. 01.

- The eyebolt support (nose piece) is properly screwed onto the cylinder ram (Pos. 2)

- The eyebolts fixed to the nose piece are fully tightened.

1. Hook the chains (Pos. 5) to the respective eyebolts and lift the cylinder ram until the

chains are set under tension but, do not lift the table.

2. Check the chain connections to all eyebolts to ensure a safe secure connection.

3. When the connection is safe, lift the table just above the desired table height.

4. Take the split pins (Pos. 6) off the pins then remove the pins.

5. Insert the pins to the desired work table height pin location then, insert the split pins.

6. Slowly move the table down until it rests on the table pins.

7. Check to be sure the position and the assembly of the pins are correct.

8. Unhook the chains and leave them hang in a downward position (Pos. 5).

Pos. 2

Pos. 6

Pos. 3

Pos. 1

Pos. 5

Force 40 70 100 Ton

10

Page 11

Operating Temperature

After the machine has been put into operation at full rate, check that the oil temperature does not

exceed 140 F.

If the above described conditions are exceeded, check that the fluid used is not too viscous

(replace with more suitable fluid).

Using the unit with temperatures above those indicated above automatically forfeits

warranty.

Maintenance

Routine Maintenance operations must be carried out by authorized and trained personnel.

All maintenance or cleaning operations must be done with the machine properly locked out

in accordance with OSHA regulations.

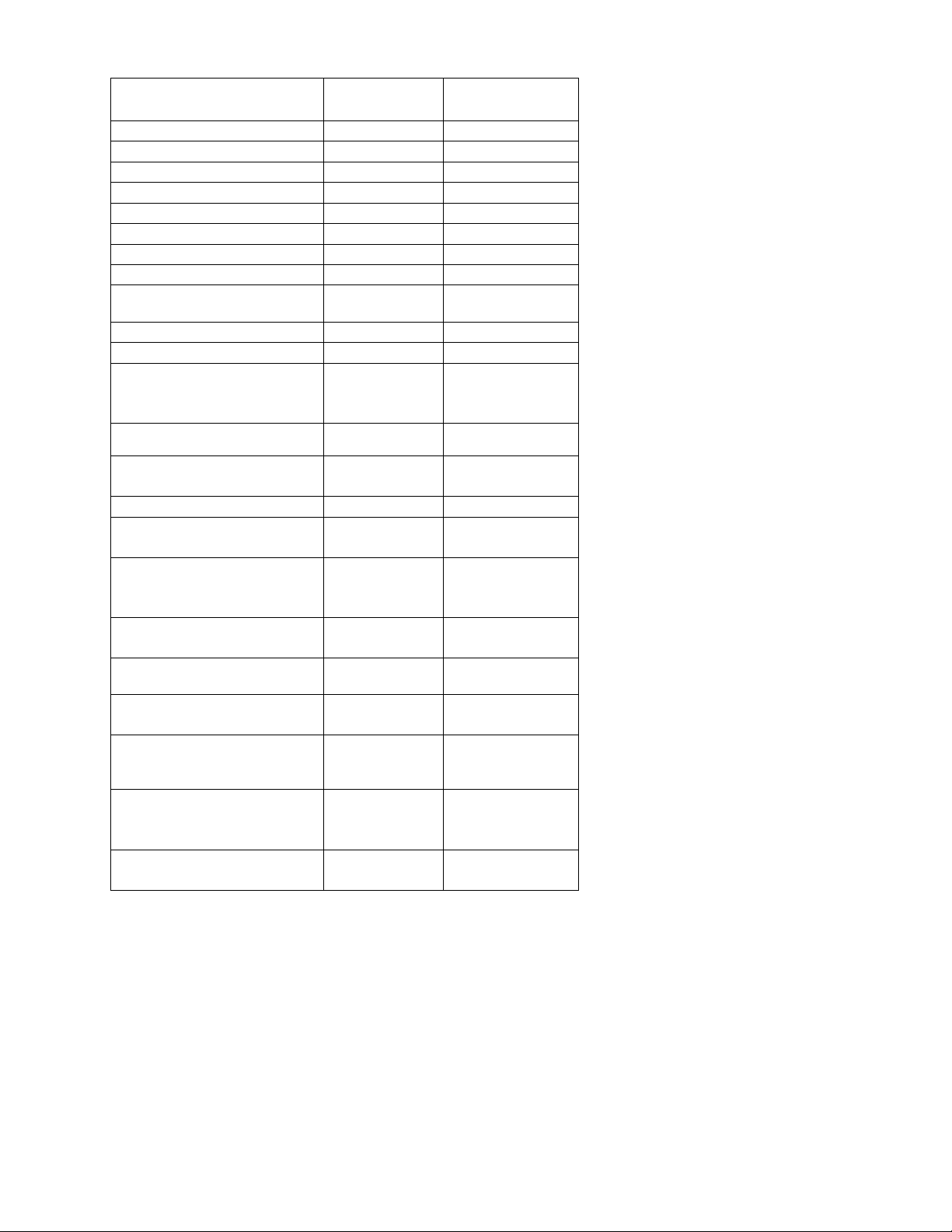

Below is a table with the normal times for maintenance work:

HOURS

50

100

300

500

1000

1500

2000

CHECK OIL

FILTER

YES

YES

YES YES

YES YES

YES YES YES

YES YES

YES YES YES

CHECK

OIL

CHANGE

OIL

CHANGE OIL

FILTER

CHANGE AIR

FILTER

Changing the oil

The oil will have to be changed periodically every 2000 operating hours or at least once a year.

Empty the unit tank by arranging a container of an adequate capacity to contain the quantity of

oil to be removed under the drainage plug at the bottom of the tank.

Remember to tighten the plug before filling the tank.

Disposing of the oil will have to be done in conformity with local and state laws along with

OSHA regulations. Hydraulic oil is considered special waste.

Filters

The filter must be frequently replaced during the first period of operation of the press and then at

regular intervals of time to be defined according to the conditions of use and the environment

where the machine is located.

It is recommended to change the filter after the first 100 hours of operation. After that

approximately every 500-600 hours.

Force 40 70 100 Ton

11

Page 12

On this unit there are three filters:

- Oil outlet filter

- Oil inlet filter

- Air inlet filter

Replacing the filters will help give the pump, oil and generally all the moving components longer

service life.

Failure to comply with the maintenance table in changing the filter will forfeit the

warranty.

Force 40 70 100 Ton

12

Page 13

Malfunction Origin Remedy

Cylinder moves

slow

Air in the pump.

Air in the circuit

Damaged cylinder gaskets

Damaged or worn pump

Sequence valve jammed

Delivery oil line clogged or

choked

Bleed the air

Bleed the air

Replace the gaskets

Replace the pump

Recondition seq. valve

Check hydraulic lines

Piston will not

move

Cylinder leaks oil

Piston ram will not

build pressure

Pump Cavitation

Foam forms in the

fluid

Pumps

Pressure relief

valves

Pumps deliver little

or no oil

Pump will not turn

Unstable valves

Valve parts

jammed

Piston moves

irregularly or will

not move

Electric motor will not turn

Piston gaskets completely

Damaged

Blocked distributor

Damaged pump

Head gaskets damaged or worn Replace

Lack of pressure from pump

Pressure control valve set low

Filter Suction clogged

Fluid too viscous

Fluid level too low

Fluid unsuitable

Fittings or joints let air in

Air discharge in the circuit

Worn or damaged Recondition or replace

Operating instability Replace or recondition

Pumps worn or damaged Replace and recondition

Pump joint broken or undone Check or replace

Valve seat damaged

Pressure not constant

Dirty fluid Drain off fluid clean system and

Lack of pressure from the pump

Pressure adjustment valve set

low

The translating cylinder is

damaged

Translating wheels or guides

dirty or blocked

Check motor

Replace

Recondition distributor

Recondition or replace

Recondition pump

Set valve

Clean or replace

Replace

Bring back up to correct level

Replace with suitable fluid

Replace or tighten fittings

Discharge the remaining air from the

system

Replace or recondition

Check pump or pressure relief valve

components refill with clean and filtered

fluid

Recondition the pump

Set the valve

Check and recondition

Clean or replace parts

Excessive wear on

parts

Force 40 70 100 Ton

Oil containing abrasives

Insufficient lubrication

High operating pressure

Foreign bodies in the oil not held

back by the filter

13

Replace the fluid

Poor quality oil

Lowe the setting of the pressure relief

valve

Insufficient filtering, replace the filters

Page 14

Putting out of service

In the case of not operating for a long period it is necessary to disconnect the press from the

sources of electrical power supply.

Empty the unit of oil and protect it suitably so there is no dust, moisture or other foreign bodies

that can damage the parts of the unit.

Demolition and division of materials

If you are not going to use the machine any more, it is recommended to make it inoperative by

removing the oil contained in the tank and eliminating the oil remaining in the cylinder,

hydraulic lines, pump body and valves.

When going for demolition the press must be treated as special waste, it must therefore be split

up into its homogeneous parts, these parts must be separately disposed of in conformity with

local and state laws along with all OSHA regulations.

Force 40 70 100 Ton

14

Page 15

Electrical box Parts breakdown

1 2 3

4 5

6 7

Part

Item # Part Name

1 Pump Start button 716542 1

2 Stop button 716539 1

3 Start button 716556 1

4 Emergency button 300351 1

5 Power light 300298 1

6 Main power switch 80554L 1

7 Elect. Box lock 300628 1

7A Door key 80511

8 Female plug 1

N/A Male plug 301547 1

Electrical box w/ all

N/A

N/A

components

Electrical box w/ no

components 300389 1

number Qty.

300387 1

8

Force 40 70 100 Ton

15

Page 16

Electrical box components parts

1

2

3

4 5 6

Item # Part Name 40 Ton

1 Contactor

2 Transformer 300842

3 Overload 220 volt 302187

3 Overload 440 volt 302189

3A N.O. contact block 302192

4 Relay 72300000

5 Fuse block 300843

5B Fuse 2 amp 77523

6 Terminal block ground

6A Terminal block black

70 Ton 100 Ton

300842 300842

302187 302187

302189 302188

302192 302192

72300000 72300000

300843 300843

77523 77523

Qty

1

1

1

1

1

1

1

3

2

3

Force 40 70 100 Ton

16

Page 17

2.6 Exchange valve

Item # Part Name

1 Complete relief valve

O-ring kit spring

N/A

N/A Valve handle

washer

Part #

40 Ton

300178 300178 300178

301393 301393 301393

Part #

70 Ton

Part #

100 Ton Qty

1

1

1

Force 40 70 100 Ton

17

Page 18

2.5 Distributor section

Part

Item # Part Name

N/A Complete valve assembly 300179

1, 2, 3, 4, 5 Knob lever pin fork powder

scraper 302211

Shaft group cap group main

6, 9, 10

Not shown

7

8

11, 12, 13

Back valve body entry

collector body max valve 302208

body 302210

Relief valve 300852

Cover Body 302209

Gasket Set 300886

number Qty

1

1

1

1

1

1

1

Force 40 70 100 Ton

18

Page 19

6

Cylinder breakdown

8

7

4

1

2

Item # Part Name

1 Piston Gasket 300609 301195 301189 1

2 Piston 0-ring 300610 301196 301186 1

3 Head guide rings 300647 301197 301187 1

4 Head o-ring 300648 301198 301188 1

5 Head gasket 300649 301199 301185 1

6 Head scraper 300650 301200 301184 1

7 Washer Washer comes with fitting 2

8 Hose fitting top 301390 301390 301390 2

8A Hose fitting bottom 301390 301390 301390 2

Complete cylinder 300698 300642 SS100C00 1

Not

shown

Not

shown

Not

shown

Gauge 300359 300360 1

Hydraulic hose B

port 300382 300382 1

Hydraulic hose A

port 300383 300383 1

3

Part#

40 Ton

Part#

70 Ton

5

Part#

100 Ton

Qty

Force 40 70 100 Ton

19

Page 20

2.4 Hydraulic pumping unit

Part #

Item # Part Name

1 Complete power unit 300633 300633 79937 1

1 Tank cover 301388 301388 301391 1

2 Electrical cover 300388 300388 300388 1

3 Fill cap 302055 302055 302055 1

4 Air filter 300391 300635 300224 1

5 Drain filter 300392 300392 300223 1

6

7 Back motor bearing 1

*8 Motor rotor 301848 301848 1

*9 Driving shaft 1

8 9 11 Drive shaft assembly 302200 302200

10 Front motor bearing 1

*11 Pump motor 1

12 Blade 302056 302056 1

13 Pumping bearing 1

14 Eccentric 1

15 Roller bearing 1

16 High pressure pump group 301115 301115 301115 2

Outlet filter / on bottom of

N/A

pump 300393 300393 300394 1

40 Ton

Part#

70 Ton

Part #

100 Ton Qty

Force 40 70 100 Ton

20

Page 21

Hydraulic diagram

Force 40 70 100 Ton

21

Page 22

Electrical schematic

Force 40 70 100 Ton

22

Page 23

DURA PRESS

Gauge Conversion

Force 40

Bore 120 mm = 4.73 =

40 Tons = 314 Bar = 4555 PSI

35 Tons = 275 Bar = 3986 PSI

30 Tons = 235 Bar = 3416 PSI

25 Tons = 196 Bar = 2847 PSI

20 Tons = 157 Bar = 2277 PSI

15 Tons = 117 Bar = 1708PSI

10 Tons = 78 Bar = 1138 PSI

5 Tons = 39 Bar = 569 PSI

1 Ton = 7.8 Bar = 114 PSI

Force 40 70 100 Ton

23

Page 24

DURA PRESS

Gauge Conversion

Force 70

Bore 160 mm = 6.299

70 Tons = 299 Bar = 4493 PSI

65 Tons = 278 Bar = 4172 PSI

60 Tons = 256 Bar = 3851 PSI

55 Tons = 235 Bar = 3530 PSI

50 Tons = 214Bar = 3209 PSI

45 Tons = 192 Bar = 2888 PSI

40 Tons = 171 Bar = 2567 PSI

35 Tons = 150 Bar = 2246 PSI

30 Tons = 128 Bar = 1925 PSI

25 Tons = 110 Bar = 1605 PSI

20 Tons = 88 Bar = 1284 PSI

15 Tons = 66 Bar = 963 PSI

10 Tons = 44 Bar = 642 PSI

5 Tons = 22 Bar = 321 PSI

1 Ton = 4.4 Bar = 64 PSI

Force 40 70 100 Ton

24

Page 25

DURA PRESS

Gauge Conversion

Force 100

Bore 180 mm = 7.086 =

100 Tons = 350 Bar = 5074 PSI

95 Tons = 332 Bar = 4820 PSI

90 Tons = 315 Bar = 4566 PSI

85 Tons = 297 Bar = 4312 PSI

80 Tons = 280 Bar = 4058 PSI

75 Tons = 262 Bar = 3805 PSI

70 Tons = 245 Bar = 3551 PSI

65 Tons = 227 Bar = 3298 PSI

60 Tons = 210 Bar = 3044 PSI

55 Tons = 192 Bar = 2790 PSI

50 Tons = 175 Bar = 2536 PSI

45 Tons = 157 Bar = 2283 PSI

40 Tons = 135 Bar = 2028 PSI

35 Tons = 122 Bar = 1775 PSI

30 Tons = 105 Bar = 1522 PSI

25 Tons = 87 Bar = 1268 PSI

20 Tons = 70 Bar = 1014 PSI

15 Tons = 52 Bar = 761 PSI

10 Tons = 35 Bar = 507 PSI

5 Tons = 17 Bar = 253 PSI

1 Ton = 3.4 Bar = 50 PSI

Force 40 70 100 Ton

25

Loading...

Loading...