Page 1

INSTRUCTIONS AND PARTS

LIST FOR MODEL

FORCE 10DA and FORCE 25DA

(Double Acting, Electrically-Operated Hydraulic Press)

Thank you for buying Dake !!!!

We hope you enjoy many years of using your new Dake hydraulic press. We hope you find these instructions

helpful, if you have any questions please give us a call, or just stop by for a factory tour.

724 Robbins Road

Grand Haven, MI 49417

Phone: 616-842-7110 800-937-3253

Ordering information

Please order all parts by part number and name; also mention model number as shown

on plate attached to the frame of the press.

Note: This press is not intended for stripping operations! Personal injury or

machine damage can result.

Press set-up

Installation Instructions

Your new Dake Press has been packaged in a manner to prevent damage to any critical components; some

assembly may be required. All parts in the accessory box are critical to the function of your press. Some

presses may come completely assembled.

NOTE: FOR EASE OF ASSEMBLY LEAVE THE PRESS FRAME MOUNTED ON THE SHIPPING

SKID

1. Remove plastic from the machine.

2. Open the box and you will see a pumping unit, with the press still

laying on its side. Locate the four holes on the side of the press facing

up.

3. Place the pumping unit on the side of the press with the mounting

bracket facing down, making sure the holes all line up.

4. There are four bolts, washers and nuts in a bag, in the box. Put the

bolts in the holes using the washers and nuts. Make sure all nuts and

bolts are tight.

5. With the press lying on its side fill the reservoir with DTE 24 Mobile oil

or equivalent with 2 gallons of oil.

Force 10DA & Force 25DA

1

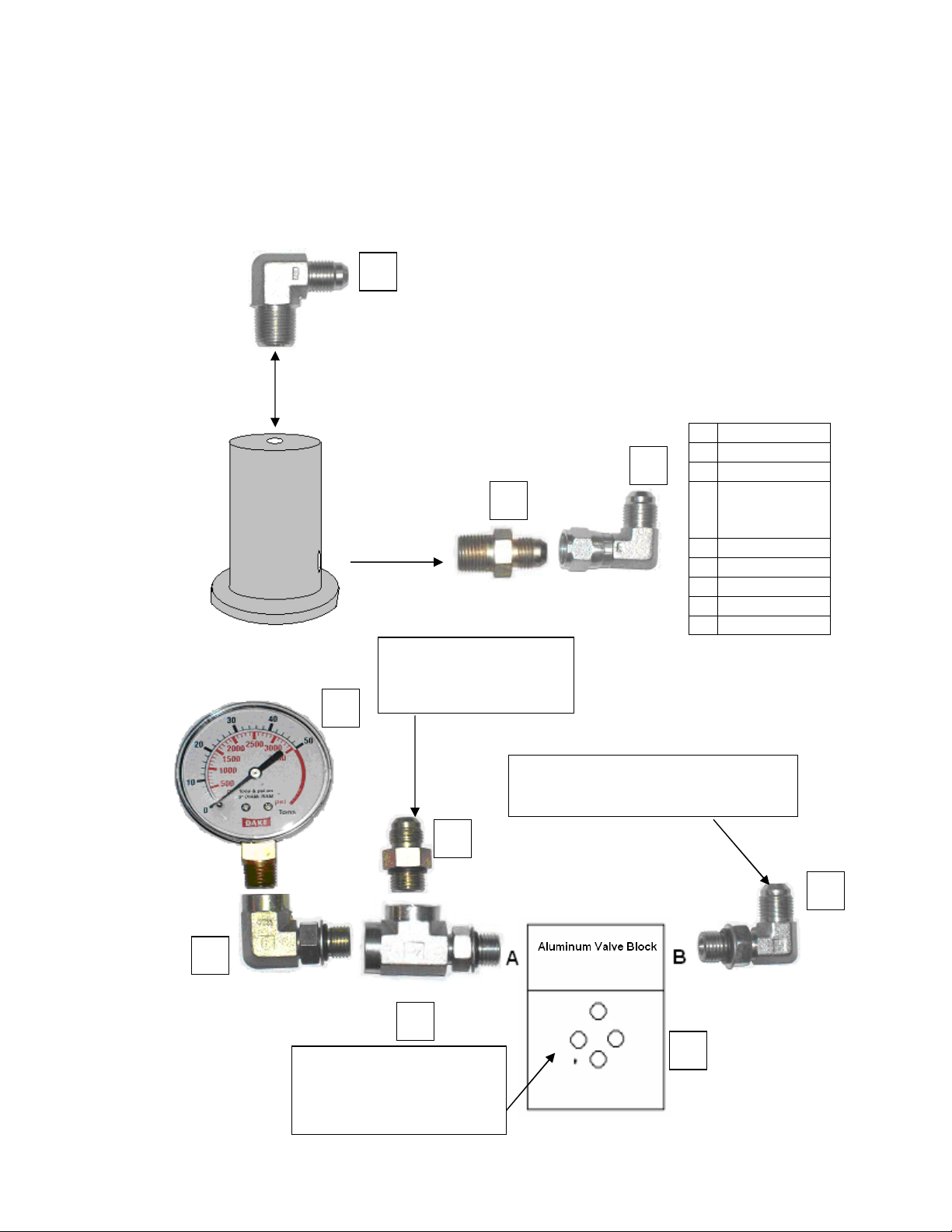

Page 2

2

3

5

6

7

8

WARNING!!!!

Be sure all bolts and fittings are tight before operating this pumping unit,

personal injury could result.

How to install the fittings on your new hydraulic press

1

A Port

B Port

Cylinder

1 72050

3

2

73425

72047

4 10 ton 301315

25 ton 301316

50 ton 302179

69671

72402

302183

302061

9 302224

Hydraulic hose connects

here and to the A port.

4

5

8

Force 10DA & Force 25DA

Joy stick valve mounts here. It

only fits one way. Part

number 302224

7

2

Hydraulic hose connects here and to the B

port.

6

9

Page 3

WARNING!!!

Be sure all fittings and bolts are tight.

Do not over tighten fittings or bolts.

Wiring Instructions

WARNING!!!!

A licensed qualified electrician that follows all state and local laws must wire and

install the electrics on this machine.

110 Volt

1. For 110 volts this machine is ready to plug in. The machine can be wired 220 volt single phase.

Always follow the wiring diagram provided in the motor cover when converting to 220 volt single

phase. A cord and plug that is rated for the specified voltage and amperage must be used. This

rating is located on the motor.

WARNING!!!!

It is the responsibility of the installer to make sure the motor is wired correctly for the voltage needed.

Damage to motor could result.

220 Volt single phases

WARNING!!!!

A licensed qualified electrician that follows all state and local laws must wire and

install the electrics on this machine.

WARNING!!!!!

This Machine new is shipped out as a 110 volt machine. If the wiring must be changed to

suit 220 volts single phase.

1. The leads on the motor must be changed to fit 220 volts, follow the diagram on the motor.

2. Install plug and wire that fits the rating on the motor, this plug and wire must be rated for

the voltage and amperage listed on the motor.

Operation

1. Fill the reservoir with 2 gallons of Mobil DTE 24 hydraulic fluid or its equivalent AW 32.

2. Turn the on / off power switch (toggle switch) to the “on” position (up).

3. Move the control lever down, this will advance the ram in the downward position.

4. Release the control lever and the ram will stop moving.

5. Move the control lever handle to the up position and the ram will move up.

6. When the press is new be sure to move the ram up and down to work out any air that

may be in the system.

Force 10DA & Force 25DA

3

Page 4

Lubrication

Keep all working parts of the press well oiled for easier operation. Also, keep a light film

of oil over the entire surface of the ram to prevent rust.

WARNING!!!!

This press is not intended for stripping operations! Personal injury or machine

damage can result.

WARNING!!!!

Only use Hydraulic oil in this machine DTE 24 hydraulic oil is recommended.

Do not use transmission fluid in this press, the warranty will be void and this fluid

will damage the seals.

Force 10DA & Force 25DA

4

Page 5

Ram moves in the neutral

position

Ram runs jerky while moving

up and down

Machine will not build desired

pressure

Pins are shearing or bending Relief valve needs to be reset Remove octagon cap from back of

Oil leaks around the ram Cylinder seals need replacing Replace cylinder seals

Oil leaks around holes other

than the ram

Ram will not extend the full 10

inches.

Hydraulic gauge will not read

pressure

Motor will not start No power to it, Power switch

Motor overheats and shuts

down

Motor runs but ram will not

move

Force 10DA & Force 25DA

PROBLEM & SOLUTIONS

4-way valve is not functioning

correctly

Air in the system Self-bleeding system. Continue to

Relief valve needs to be reset

Hydraulic hoses connected

incorrectly or in reverse

Bolts need to be tightened. Tighten bolts around the ram.

Oil level is too low. Re-fill the reservoir with oil or add

Hydraulic gauge is bad

Hydraulic hoses connected in

reverse

is bad

Duty cycle time is exceeded

Too long of extension cord is

being used.

Motor runs in reverse rotation Check motor wiring diagram on

5

Test 4 way valve for proper

function

run ram up & down aprox. 15

times.

Remove octagon cap from back of

manifold and adjust set screw to

correct pressure. WARNING – Do

not exceed 2413 PSI for 10 tons

and 3145 psi for 25 tons. Make

sure the hose on top of the

cylinder is connected on the left

side of the valve by the gauge.

manifold and adjust set screw to

correct pressure. WARNING – Do

not exceed 2413 PSI 10 tons and

3145 psi for 25 tons

oil up to the fill hole with the elbow

removed.

Replace the hydraulic gauge

Switch the hydraulic lines

Double check the electrical cord.

Trouble shoot power switch

Check the duty cycle time on the

motor.

Extension cord will lower the

Amps and will cause overheating

of the motor. Remove cord.

motor and correct motor rotation

with the yellow arrow on the motor

Page 6

Force 10DA & Force 25DA

6

Page 7

ITEM

1 Frame 1 86517 86684

2 1/2" - 13NC x 2 3/4" 4 43355 43355 LG. Hex Cap Screw

3 1/2" Channel Washer 4 43657 43657

4 Workhead Assembly 1 716514 716640

5 1/2" Lock Washer 4 43647 43647

6 1/2" - 13 Hex Nut 4 43916 43916

7 Base Angle 2 85189 978

8 1/2" - 13NC LG. 4 43349 43347 Hex Cap Screw

9 Table Pin 2 86520 85407

9A Retaining Ring 2 43975 76818

11 Table Channel 1 86692 86682

12 1/2" Lock Washer 4 43647 43644

13 1/2" - 13 Hex Nut 4 43916 43916

20 Nose Piece 1 86691 86683

23 Hydraulic Power Unit 1 300266PU 300265PU

Gauge, Fittings, Hoses and

Valve

24 5/16" - 18NC x ½" 4 43313 43313 LG. Hex Cap Screw

25 5/16" Flat Washer 4 43632 43631

27 Warning Label 1 84487 84487 (See Page 10)

28 Warning Label 1 84399 84399 (See Page 10)

29 3-IN-1 Warning Label 1 300168 300168 (See Page 10)

30 Safety Instructions 1 76462 76462 (See Page 10)

31 Warning Label 1 84395 84395 (See Page 10)

32 DAKE Name Plate 1 86533 86534 (See Page 10)

33 Made In USA Plate 1 76936 76936 (See Page 10)

34 Table Plates 2 85427 85508

Conversion tons to psi Label 1 79955 79964 CONVERSION CHART LABEL

DESCRIPTION QTY

1 300266KIT 300265KIT Gauge, Fittings, Hoses and Valve

10DA

Part No.

25DA

Part No.

REMARKS

does not include Gauge, Fittings,

Hoses and Valve

PARTS NOT ILLUSTRATED

Breather Vent and elbow 1 300267 300267

Eyebolts 2 N/A 300284

Triangular Snap Hooks 4 N/A 300285

Coil Chain 2 N/A 78477

Gauge 1 301315 301316 Reads in tons / psi

Gauge 1 301315 300268 Reads in bar / psi

Reservoir 1 300269 300269

Optional check valve 1 302071 302071

Optional relief valve 1 301949 301949

Optional relief valve 1 302197 302197

Bolts 4 43401 43401

Bolts 4 76749 76749

Bolts 4 302221 302221

Reservoir fill port

2 gallon

Check valve

290-3625 psi or 20-250 bar

43.5-435 psi or 3-30 bar

Mounting bolts for valve only

Mounting bolts for valve and relief

valve or check valve

Mounting bolts for valve, check

valve and relief valve.

Force 10DA & Force 25DA

7

Page 8

Force 10DA & Force 25DA

8

Page 9

ITEM

DESCRIPTION

A Piston 86690

B Cylinder Flange 86689

C Cylinder 86688

ITEM

D Socket Head Cap Screw 43450

A Piston 86463

E O-Ring 78483

B Cylinder Flange 86462

F Seal 78484

C Cylinder 86461

G Wear Ring 78485

D Socket Head Cap Screw 43471

H Wear Ring 78486

E O-Ring 79881

J O-Ring Seal 78487

F Seal 79880

Complete Workhead Assembly 716514

G Wear Ring 78486

Cylinder Repair Kit

H Wear Ring 79840

(Includes items E, F, G, H, J)

J O-Ring 79882

Complete Workhead Assembly 716640

Cylinder Repair Kit

(Includes items E, F, G, H, J)

DESCRIPTION

PART

NO.

PART

NO.

716699

716698

Force 10DA & Force 25DA

9

Page 10

Force 10DA & Force 25DA

FORCE 10DA - Specifications

10

Page 11

FORCE 25DA

- Specifications

Force 10DA & Force 25DA

11

Page 12

Part No: 84399

Part No: 84487

Par

t No: 84395

Safety

This is the safety alert symbol; follow recommended precautions and safe operating

practices. When you see this symbol on your press be alert to the potential for personal injury.

Carefully read all safety messages in these instructions and on your press safety signs.

Keep safety labels in good condition. Replace missing or damaged safety labels

This machine is intended to be operated by one person. This person should be conscious

of the press ram movement not only for himself but also for persons in the immediate area of

the machine.

Part No: 76462

Force 10DA & Force 25DA

This machine is not designed for

stripping operations. Personal injury

or machine damage can result.

Please contact factory for current prices.

724 Robbins Road

Grand Haven, MI 49417

Phone: 616-842-7110 800-937-3253

Fax: 616-842-0859 800-846-3253

Web: www.dakecorp.com

E-mail: customerservice@dakecorp.com

12

technicalservice@dakecorp.com

Loading...

Loading...