Page 1

724 Robbins Road

Grand Haven, Michigan 49417

616-842-7110 Phone 800-937-3253

616-842-0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

Dura Press Models

FORCE 10 & FORCE 20

Use and Maintenance Manual

Hydraulic Press-Manual Pump

Model No: _________________

Serial No: _________________

Force 10M /Force 20M1

1 06/10

Page 2

Section I

INTRODUCTION

1. This manual has been created by DAKE to give the Customer all the necessary

information for regular use and correct maintenance of the hydraulic presses in

the DURA PRESS series. It contains the use and maintenance instructions as

well as the safety and calibrating instructions requiring your direct action.

2. It is advised to keep this publication in a good condition and somewhere easily

accessible to enable rapid reference in case of need or work.

3. Starting checks and maintenance must be carried out assuring the safety of the

operators; precautions are highlighted by the symbol.

4. Periodical and punctual written notes on what has been carried out in the

maintenance phase indicates meticulousness, but above all it becomes a clear

diary of what has been done and what will have to be done at the next

maintenance deadline.

5. For further information, please do not hesitate to call our Dake Technical Service

department at 1-800-846-3253, remembering to give the model name and serial

number of your press for faster response.

6. It is strictly forbidden to modify or tamper with the machine.

7. Removal, modification or tampering with the guards and safety devises of the

press will automatically forfeit warranty and relieve the manufacturer of all liability

for any damage to things and/or persons.

8. THE PRESS IS DESIGNED EXCLUSIVELY TO BE USED BY JUST ONE

OPERATOR.

9. It is advised to read the next section carefully: List of safety checks.

Force 10M /Force 20M2

2 06/10

Page 3

Section II

LIST OF SAFETY CHECKS

ALWAYS ACT WITH

CAUTION

ATTENTION

PRECAUTION

Read the rest of this section very carefully before proceeding to read the

following sections.

CAUTION general

When working always pay attention and be alert. Be careful. Be aware of possible

hazards.

CAUTION regulations

Observe the law and regulations of the premises regarding you and your machine.

CAUTION clothing

Injury may occur if you do not wear suitable clothing. Loose clothing may get caught up

in the machinery. Wear protective clothing suitable for the work. Examples: rigid

helmet, safety shoes, safety earmuffs, close-fitting overalls, industrial gloves, etc. Keep

cuffs buttoned. Do not wear a tie or scarf, or long hair.

ATTENTION tools

Always check that your tools are in good condition and that the tools are suitable for the

work to make (ex. don’t use the pliers as hammers etc.)

ATTENTION repairs

Don’t make repairs or any other service that you are not familiar with.

ATTENTION tampering

It is severely forbidden to modify or to tamper with press parts that can alter the

standard working.

CAUTION hydraulic hoses

Hydraulic hoses may be the cause of accidents. Regularly check such hoses looking

for:

Damaged fittings

Outer coverings worn by rubber

Swollen outer coverings

Bent or crushed hoses

And anything else that may be a hazard.

Force 10M /Force 20M3

3 06/10

Page 4

CAUTION pressure pipes

The flexible or metal pipes of a system may hold fluids under pressure even with the

system switched off. Before dismantling them, check on the diagram whether the

section could be under pressure. In any case, loosen the fittings slowly.

CAUTION hydraulic oil

Very fine jets of high-pressure hydraulic oil can penetrate the skin: do not use your

fingers to detect any leaks of hydraulic oil, neither put your face close to them, but use a

piece of cardboard to check for any leaks on them.

If hydraulic oil penetrates into your skin, get treatment from a doctor immediately.

CAUTION o-rings and gaskets

Gaskets and o-rings fitted incorrectly, damaged or worn may cause leaks and

accidents. Do not use thinners, solvents or acids close to o-rings and gaskets.

CAUTION operator

For no reason whatsoever must the operator have their hands in the area of the ram

during the pressing operation, on the equipment used.

According to new legislation, the employer will have to check that the operator

has understood these notices.

Force 10M /Force 20M4

4 06/10

Page 5

Section III

TABLE OF CONTENTS

SECTION I INTRODUCTION

SECTION II LIST OF SAFETY CHECKS

SECTION III TABLE OF CONTENTS

SECTION 1.0 GENERAL SAFETY INSTRUCTIONS

1.1 General instructions and definitions

1.2 Description

1.3 Use

1.4 Press identification

1.5 Safety labels

1.6 General safety instructions

SECTION 2.0 TECHNICAL DATA SHEET

2.1 Cylinder and spare parts section

2.2 Manual pump and spare parts section

SECTION 3.0 UNPACKING

3.1 Disposing of the packing

SECTION 4.0 HANDLING, TRANSPORTING AND POSITIONING

4.1 Notices for handling and transporting

4.2 Positioning the press

SECTION 5.0 COMMISSIONING AND START-UP

5.1 Filling the press with oil

5.2 Starting the machine

5.3 Discharging the air

5.4 Maximum pressure adjustment

SECTION 6.0 SAFETY INSTRUCTIONS

SECTION 7.0 OPERATION

7.1 Controls

7.2 Mobile table height adjustment

SECTION 8.0 MAINTENANCE

SECTION 9.0 MALFUNCTIONING, CAUSES AND REMEDIES

9.1 Cylinder malfunctioning

SECTION 10.0 PUTTING OUT OF SERVICE

SECTION 11.0 DEMOLITION AND DIVISION OF MATERIALS

Force 10M /Force 20M5

5 06/10

Page 6

Section 1.0

1.1 GENERAL INSTRUCTIONS AND DEFINITIONS

This handbook is an integral part of the product; IT MUST be carefully conserved for

future reference.

FOR ANY REQUEST FOR CLARIFICATION, ASK YOUR EMPLOYER OR THE

DAKE TECHNICAL SERVICE, AVOIDING ANY PERSONAL INITIATIVE THAT

COULD CAUSE VERY SERIOUS OR FATAL ACCIDENTS.

Before using the machine, read the warranty carefully.

DEFINITIONS:

- In this manual “right-hand side”, “left-hand side”, “forwards”,

“backwards”, “top” and “bottom” refer to the operator situated in

front of the press with the power unit to his right.

- In this manual, the units of measurement are expressed in the

international system SI (e.g. liquid capacity is expressed in liters).

1.2 DESCRIPTION

The machine described in this manual denominated HYDRAULIC PRESS Model

Dura Press has been specifically designed for use in operations where it is

necessary to use a force of compression that can be moved into different positions

even on the same part:

1. The PRESS BODY, made of high tensile carbon steel and thanks to its

monolithic structure, has considerable bending strength.

2. The HAND PUMP, placed on the right of the press allows with facility to reach

the work pressure.

3. The HYDRAULIC CYLINDER specially designed for the specific requirements

of use of the press. In addition to the special care for the internal surfaces

and of the rod, special low-friction gaskets have been used in it to optimize

the operations where special precision in the pressing action is required.

1.3 USE

The DURA PRESS/FORCE series press is mainly designed for operations of

straightening out sheet metal, profiles, and metal structures, in addition it can be

used to insert inserts (e.g. bushes, bearings, bushings, etc.), to remove inserts,

calking and all the operations where bending or cutting metal materials are not

carried out.

Other uses are not allowed unless the manufacturer expressly authorizes them.

The substance of the above mentioned operation will always be subordinate to the

maximum working capacity of the press.

THIS MACHINE IS DESTINED ONLY FOR THE USE IT HAS BEEN DESIGNED

FOR, ANY OTHER USE IS TO BE CONSIDERED IMPROPER AND THEREFORE

THE MANUFACTURER CANNOT BE HELD LIABLE FOR ANY DAMAGE

CAUSED BY ANY IMPROPER USE OR USE NOT EXPRESSLY MENTIONED IN

THIS USER’S MANUAL.

Force 10M /Force 20M6

6 06/10

Page 7

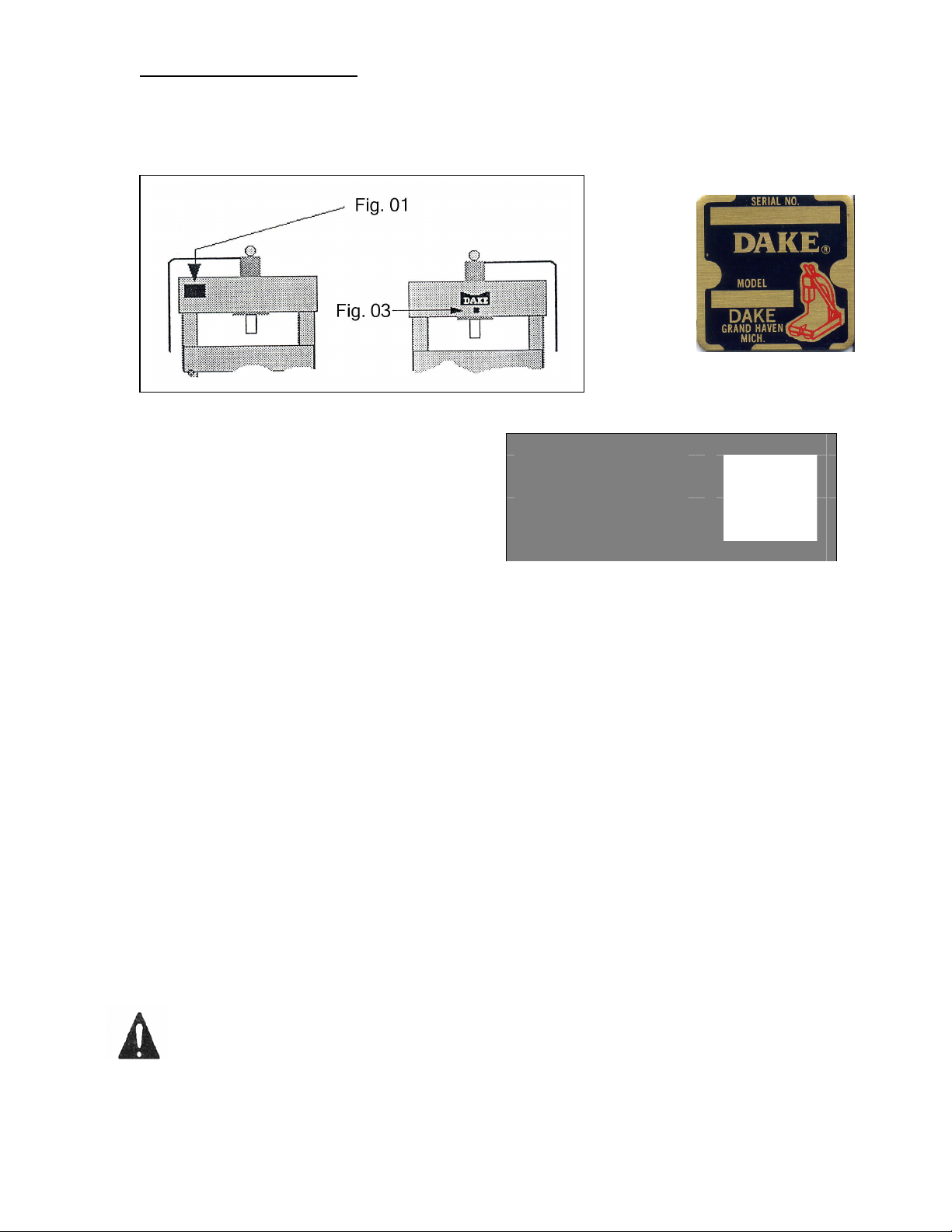

1.4 PRESS IDENTIFICATION

Fig. 03A

The press is fitted with a rating plate fixed in a visible manner on the rear as shown

in Fig. 01 below. Dake part number and serial number on front name plate shown in

Fig. 03

The rating plate (Fig. 02/03A)

shows the identification data:

- Press model

- Max. tonnage

- Max. pressure

- Press serial number/ Year of

Manufacture

- Dake part number (Tag 03)

- Serial number (Tag 03)

FOR EVERY COMMUNICATION, REQUEST FOR SERVICE OR SPARE PARTS, IT IS

ALWAYS ESSENTIAL TO QUOTE ALL THE DATA GIVEN ON THE RATING PLATE.

1.5 SAFETY LABELS

The labels on the machine highlight particular risks or provide necessary instructions

for particular operations to be carried out in safety.

Here we reproduce the labels affixed to the press and indicate their location. The

operator will have to check that these labels are present on the machine and fixed in

a stable manner. In the event of any of them missing or having deteriorated it will be

necessary to immediately notify the person in charge of safety and to forward a

request to the manufacturer.

MODEL

TON MAX

PRESSURE MAX

SERIAL NO.DAKE

Fig. 02

Part No. 607

PSS

20

200

023.98

WARNING LABELS

To the left is the safety Alert symbol. When you see these safety alert symbols on

your press, be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

Carefully read all safety messages in these instructions and on your press

safety signs. Keep safety labels in good condition. Replace missing or damaged

safety labels. This machine is intended to be operated by one person. This person

should be conscious of the press ram movement not only for himself but also for persons in

the immediate area of the machine.

Force 10M /Force 20M7

7 06/10

Page 8

Label 300168

Label 84487

Label 84399

Label 607

Force 10M /Force 20M8

Label Placement View

84399

8 06/10

Page 9

1.6 GENERAL SAFETY INSTRUCTIONS

Use of the press is allowed exclusively for trained and authorized

personnel.

When you leave the machine, even if only for a moment, make sure it is not

in the pressing phase, dangerous for you and for others.

In the event of confusion or uncertainty in the manner of operation to be

made, refer to the user’s manual or call qualified personnel to resolve your

doubts.

Operate the manual pump only from the working position that is in front of

the hydraulic power unit.

It is forbidden to use equipment or carry out operations that may have even

the slightest chance of projecting splinters or parts of equipment.

Section 2.0

2.0 TECHNICAL DATA SHEET

Below we give a table summarizing the technical-dimensional particulars of the

DURA series Presses.

Model

Dura

Press

Force 10 10 20” 4” 6” 36” 31 x 19” 71” 350

Force 20 20 20” 4” 6” 36” 31 x 19” 71” 485

Ton

Max.

Width

between

Uprights

Width

between

Table

Channels

Max.

Ram

Travel

Max.

Ram to

Table

Base

(w x d)

Height Weight

lbs

Model

Dura

Press

Force 10 60 mm 12 mm

Force 20 80 mm 12 mm

Bore Thread Hole

size

MAXIMUM OPERATING PRESSURE FOR ALL MODELS 350 bars.

Force 10M /Force 20M9

9 06/10

Page 10

2.1 CYLINDER AND SPARE PARTS SECTION

Model Force 10M & Force 20M Breakdown

1

3

2

Item

No

1 Gauge Bar 300357 300358

Gauge in tons 301723 301722

2 Hand Pump - Complete 300366 301485

Hydraulic Cylinder

3

Complete

4 Piston Gasket 300796 301558

5 Spring 300797 301560

6 Head Scraper 300798 301561

Fitting for gauge 301888 301888

Description

Part Number

Force

10M

300652 301343

Force

20M

Force 10M /Force 20M10

10 06/10

Page 11

Model Force 10M & Force 20M Breakdown

Hand Pump Assembly

Item No Description

12 Piston Pump 302367 302367

2 Handwheel 302368 302368

20:29 Valve 302369 302369

31-32-33 Valve 302370 302370

30 Filter N/A N/A

34 Rod assembly 302373 302373

6 Spring 302372 302346

5 Cap 302371 302371

25 Tap Screw N/A N/A

Complete Pump 300366 301485

Gasket Repair Kit 301327 301542

Linkage Assembly (Item 9,10,11,15,16,34)

Relief Valve (Item 1,2,3,4,5) 301576 -Relief Valve 4NV -- 301573

* If n/a is shown must replace entire pump

Section 3.0

Force 10M Force 20M

Part Number

301575 301574

Force 10M /Force 20M11

11 06/10

Page 12

3.0 UNPACKING

If the machine is supplied wrapped in plastic sheet, any accessories, spare parts

and expendables are packed in cardboard boxes and positioned on top of the

worktable.

To remove the packing, cut the plastic wrap, taking care not to damage the machine

or cardboard box.

Remove any accessories from on top of the worktable, check the contents

correspond to the order and to the accompanying documentation.

After removing the plastic, unbolt the lag bolts from the skid.

For handling and transport, please refer to Section 4.0.

3.1 DISPOSING OF THE PACKING

The packing will have to be disposed of by the purchaser in compliance with their

local regulations.

The elements comprising the packing (e.g. plastic bags, polystyrene, nails, nylon,

etc.) MUST NOT be left within the reach of children as they are a source of danger

for them.

CLAIMS SHALL NOT BE ACCEPTED IN THE EVENT OF THE GOODS NOT

BEING IN CONFORMITY WITH THE ORDER OR WITH THE ACCOMPANYING

DOCUMENTS IF THEY ARE NOT NOTIFIED WITHIN FIVE DAYS OF THE

DATE OF RECEIVING THE GOODS.

Force 10M /Force 20M12

12 06/10

Page 13

Section 4.0

4.0 HANDLING, TRANSPORT AND POSITIONING

For handling the packed machine, as described above

(see section 3.0), it is necessary to use special lifting

equipment whose maximum lifting capacity must be no

lower than the total weight of the press.

THE TOTAL WEIGHT OF THE PRESS PLUS PACKING

IS SHOWN ON THE ADHESIVE TABS PLACED ON

THE PACKING AND ON THE ACCOMPANYING

DOCUMENTS.

For loading and unloading the machine, lifting straps are

to be used positioned as shown in Fig. 04.

4.1 NOTICES FOR HANDLING AND TRANSPORT

Loading and unloading will have to be done with lifting straps in conformity with and

according to the instructions of the above paragraph, in addition check:

Check that the straps are made in conformity with safety regulations and they

have attached the relative plates certifying they are in conformity with the standards.

CHECK THAT THE MAXIMUM CAPACITY OF EACH STRAP IS GREATER

THAN THE TOTAL WEIGHT OF THE PRESS.

Check that the straps are in a good state of repair.

It is forbidden for things and/or persons to stand close to the machine, the

unloading or loading area, and the means of transport during the loading and

unloading phases.

Do not make any sudden movements with the lifting equipment while lifting or

lowering the load.

Pay the utmost attention during all handling operations so that the press and in

particular the hydraulic power unit does not get damaged.

Observe the in-house provisions concerning lifting and handling.

IT IS FORBIDDEN TO APPROACH OR PASS UNDER HANGING LOADS.

THE MANUFACTURER DECLINES ALL LIABILITY FOR ANY DAMAGE CAUSED

BY ANY ACTION DURING THE PHASE OF UNLOADING AND LOADING THE

PRESS.

Force 10M /Force 20M13

13 06/10

Page 14

4.2 POSITIONING THE PRESS

Simple precautions are necessary for correctly positioning the press. Always

consider the safety aspect not only in relation to the work carried out with the press,

but also to the dangers originated by the other machines in the workplace. Before

positioning, check that

- The floor is suitable for positioning the press that is it has no holes or

subsiding portions, and that its capacity is sufficient to sustain the

weight of the press plus the weight of the accessory parts and of any

piece to be processed if of large dimensions, considering an

appropriate coefficient of safety.

- Do not do the positioning on unstable or non-compact surfaces

(e.g. on gravel or grit, beaten earth, sand, etc.).

- PAY THE UTMOST ATTENTION TO OVERHEAD ELECTRICITY

LINES.

- Check beforehand the position of any overhead electricity lines

and mark them with special warning cards.

- Always consider a suitable distance from the sliding paths for the

means of transport, elevators, transpallets, etc., sudden and

unexpected sources of danger.

- Check that the position identified is always served by adequate lifting

systems.

- Pay the utmost attention to handling the lifting systems (e.g. overhead

traveling cranes, hoists, transpallets, fork-lift trucks, cranes, jib cranes,

etc.)

After identifying the most suitable place for positioning, follow the instructions for

handling of Section 5.0, mark a square on the floor with YELLOW paint (highly

resistant to abrasion) around the perimeter of the press as shown by the diagram

in Fig. 06.

The area highlighted in this way will indicate the area of caution for the lifting

equipment and the personnel nearby.

Force 10M /Force 20M14

14 06/10

Page 15

Section 5.0

5.0 COMMISSIONING AND STARTING

This section describes the operations to be followed on commissioning along with

some advice for starting the machine for the first time.

5.1 FILLING THE PRESS WITH OIL

To fill the press, use exclusively the oils indicated in the table or ones of equivalent

reliability. The choice must be made considering the environmental conditions and

the operating features of the press.

Manufacturer

Mobil DTE 24 DTE 25 DTE 26

DIN 51524 H-LP 32 H-LP 46 H-LP 68

Castrol Hysoin AWS 32 Hysoin AWS 46 Hysoin AWS 68

ESSO Nuto H 32 Nuto H 46 Nuto H 68

Shell Tellus 32 Tellus 46 Tellus 68

Chevron EP Hydr. Oil 32 EP Hydr. Oil 46 EP Hydr. Oil 68

A B C

Choose the type of oil (column A, B, C) on the basis of the average working

temperature, for temperate climates the reference column in “B”. For operating

conditions in colder climates user column “A”, for warmer climates select column “C”.

5.2 FIRST STARTING

The press was shipped without oil.

After you have filled up the tank you have to stroke the hand pump until the ram is

fully extended out of the cylinder, release the wheel under the pump to return the

ram. You have to verify the oil level in the tank and if needed refill the tank. You

have to repeat the above-mentioned operation sometimes to bleed the air from the

system. See Air Discharge Section 5.3.

The level of oil in the tank may fall on starting, because of:

- absorption of volume by the cylinder

- absorption of volume by the pumping unit

- discharge of air bubbles remaining in the piping

It is necessary to top off the level of oil bringing it up to the correct height.

Force 10M /Force 20M15

15 06/10

Page 16

5.3 AIR DISCHARGE

After the first start-up, or after maintenance carried out on elements of the system

(e.g. cylinders, filters, pipes, changing oil) a considerable quantity of air may be

present in the circuit.

Irregular operation, noise, and/or uneven cylinder movement highlight the presence

of air.

It is necessary to discharge the air as follows:

- Pump ram down to the maximum stroke.

- Loosen the upper nipple of the press cylinder and wrap it in a cloth to

avoid oil splashes.

- Stroke the hand pump to remove the air.

- Verify that all the air has been bled out of the system when only oil is

expelled from the fitting.

- Tighten the nipple.

This operation must be continued until oil is completely free of air bubbles or froth.

After discharging the air, it is necessary to top off the oil level in the unit.

5.4 MAXIMUM PRESSURE ADJUSTMENT

The maximum work pressure of the press is adjusted by pressure regulator valve

suitably set and sealed with lead.

DAKE DECLINES ALL LIABILITY FOR DAMAGE TO THINGS AND/OR

PERSONS CAUSED BY TAMPERING WITH THE PRESSURE CONTROL VALVE

FITTED ON THE UNIT.

Force 10M /Force 20M16

16 06/10

Page 17

Section 6.0

6.0 SAFETY INSTRUCTIONS

THE MANUFACTURER DECLINES ALL LIABILITY FOR

DAMAGE TO THINGS OR PERSONS CAUSED BY NONOBSERVANCE OF THE SAFETY INSTRUCTIONS GIVEN IN

THIS MANUAL WHICH SUPPLEMENT THE CURRENT LEGAL

REGULATIONS IN WORKPLACES.

IT IS EXTREMELY IMPORTANT FOR THE OPERATOR TO UNDERSTAND ALL

THE SAFETY INSTRUCTIONS LISTED BELOW IN ORDER TO PREVENT

DAMAGE TO THEMSELVES, TO THINGS OR TO OTHERS.

A machine not subject to regular maintenance is a danger for the operator

and for the persons working nearby. To ensure safe and efficient operation of

the machine, check that the maintenance schedule is regularly observed.

It is strictly forbidden to tamper with, modify, or elaborate parts of the

machine that alter its regular operation.

The press is designed exclusively for use by a single operator.

Use of the press is reserved exclusively for authorized and qualified

personnel informed about the risks deriving from its use.

Before operating the machine, the operator will check that there is no

equipment or persons in the immediate vicinity of the machine whose

presence may be dangerous for themselves and for others.

All work requiring the piece to be pressed to be supported by the operator

is forbidden.

It is necessary to arrange suitable supporting and positioning equipment

for the pieces to be pressed.

It is strictly forbidden to press, cut, draw, and do anything else with pieces

whose dimensions or physical nature may explode or product splinters.

In the event of there being the slightest possibility of the pressed piece

exploding the user is obliged to arrange a protective barrier of adequate

dimensions and substance (e.g. polycarbonate) all around the press to protect

the personnel present, and to position an additional partition between the

control area and the work area to protect the operator.

Force 10M /Force 20M17

17 06/10

Page 18

Section 7.0

7.0 OPERATION

Before starting any operations, make sure there are no other persons in the

immediate vicinity of the machine.

IT IS STRICTLY FORBIDDEN TO PASS UNDER THE WORK TABLE.

7.1 CONTROLS

To make the press work you have to stroke the pump control lever.

The feed speed of the cylinder and the pressure will depend on the driving speed of

the pump control lever. The pressure starts to rise when the cylinder shaft is in

contact with the piece of press, continuing with the pump action the pressure rises

until to have the necessary valve to make the operation.

For the ram to retract, loosen the valve placed under the pump control lever. The

cylinder is equipped with a spring for the ram return.

7.2 HEIGHT ADJUSTMENT OF THE MOVABLE BASE

To get very good use of the press it is necessary to place the worktable at a correct

height depending on the operation to make and on the tooling to use.

1. To the size of the part to be pressed.

2. To any tooling placed on the movable table.

3. With the help of a second worker to lift the movable table.

4. To take away the pins and to place them in the holes of the correct height.

5. To lower slowly the worktable onto the pins.

6. To verify the positioning of the table and of the pins.

If the work position you wish corresponds with the max. width of the work size it is

not necessary to place the pins (that will be placed in a dry place) because we have

foreseen and prepared stops suitably welded to the stanchions.

Force 10M /Force 20M18

18 06/10

Page 19

Section 8.0

8.0 MAINTENANCE

AUTHORIZED AND TRAINED PERSONNEL MUST CARRY OUT ROUTINE

MAINTENANCE OPERATIONS.

ALL MAINTENANCE OR CLEANING OPERATIONS MUST BE DONE WITH THE

MASTER SWITCH OFF. (IF EQUIPPED)

SPECIAL MAINTENANCE OPERATIONS (REPAIRS) MUST BE CARRIED OUT BY

THE MANUFACTURER’S PERSONNEL ON THE PREMISES OF THE

MANUFACTURER OR BY SUITABLY TRAINED AND SPECIALIZED PERSONNEL

UPON AUTHORIZATION BY THE MANUFACTURER.

Routine maintenance operations apply to the mechanical part of this appliance, the

only special prescriptions concern checking the oil level, the characteristics of the

fluid used (and possible replacement in the case of its deterioration).

It is a good rule to take note of maintenance work to help you remember all the

work carried out on the unit.

8.1 OIL LEVEL

Check the level of oil every month through the oil fill cap hole on the top of the oil

tank. Visual inspection of the oil level should be approximately ½” below the top of

the tank.

Any topping off has to be done with the same type of and clean oil used in the filling

phase of the system and with the same procedures as regards cleaning the fluid.

It is advised to note the type of oil used on a card affixed onto the unit or on the last

few pages of this manual, containing pre-printed tables to be filled in.

If topping off turns out to be too frequent, check for leaks in the system.

8.2 CHANGING AND DISPOSING OF THE OIL

The oil will have to be changed periodically every 2000 operating hours or at

least once a year.

Changing the oil, and therefore disposing of it, will have to be done in conformity

with the law as hydraulic oil is considered special waste. Call authorized firms for

the disposal of special wastes.

DO NOT DISPERSE SPENT OIL INTO THE ENVIRONMENT

Take care while handling oil, excessive or extended contact can cause irritation. In

this case, wash the area involved with plenty of water and soap or special detergent.

Force 10M /Force 20M19

19 06/10

Page 20

8.3 CLEANING

CARRY OUT THE CLEANING OPERATIONS EVERY WEEK.

It is a good rule to carry out periodical cleaning of the press in order to eliminate

foreign bodies (e.g. dust, extraneous and dirty substances, etc.).

Eliminate all foreign bodies from the piston rod that could damage both the surface

of the rod and the cylinder gaskets.

While cleaning, use detergent substances that are not harmful, do not pollute and

are in conformity with the law.

While cleaning, prevent shaking with hands, wear protective gloves and use brushes

or oilers to lubricate the guides.

Do not use solvents or aggressive acids.

Section 9.0

9.0 MALFUNCTIONING, CAUSES and REMEDIES

9.1 CYLINDER MALFUNCTIONING

MALFUNCTION ORIGIN REMEDY

The cylinder moves

irregularly

Cylinder will not move - Cylinder gaskets

Cylinder leaks oil - Head gasket damaged or

Cylinder will not press - Lack of pressure from

Force 10M /Force 20M20

- Air in the pump

- Air in the circuit

- Damage cylinder gaskets

- Damage or worm pump

- Sequence valve jammed

- Delivery pipe clogged or

choked.

completely damaged

- Blocked distributor

- Damaged pump

worn

pump

- Pressure control valve set

low

* Call Dake Technical Service 1-800-937-3253

20 06/10

CYLINDERS

- Bleed the air

- Bleed the air

- Replace the gaskets

- Replace the pump

- Recondition seq. valve

- Check pipes

- Replace

- Recondition distributor

- Recondition or replace

- Replace

- Recondition pump

- Set valve

*

*

*

*

*

Page 21

Section 10.0

10.0 PUTTING OUT OF SERVICE

In the case of putting away for a long period it is necessary to empty the unit of oil

and protect it suitably so there is no dust, moisture, or other foreign bodies, exposed

to the unit that can damage the parts of the unit.

When putting into operation after a period of storage, meticulously follow ALL

the indications of Section 5.0.

Section 11.0

11.0 DEMOLITION AND DIVISION OF MATERIALS

If you are not going to use the appliance any more, it is recommended to make it

inoperative by removing the oil contained in the tank and eliminating the oil

remaining in the cylinder, pipes, pump body and valves.

When going for demolition the press must be treated as special waste, it must

therefore be split up into its homogeneous parts, these parts must be separately

disposed of in conformity with the laws in force.

724 Robbins Road

Grand Haven, Michigan 49417

616-842-7110 Phone 800-937-3253

616-842-0859 Fax 800-846-3253

Web: www.dakecorp.com

E-mail : customerservice@dakecorp.com

technicalsupport@dakecorp.com

Force 10M /Force 20M21

21 06/10

Page 22

Gauge Conversion 10 ton

Bore 60 mm = 2.362”

10 Ton 302 bar 4565 PSI

5 Ton 151 bar 2282 PSI

4 Ton 121 bar 1825 PSI

3 Ton 90 bar 1369 PSI

2 Ton 60 bar 913 PSI

1 Ton 30 bar 456 PSI

Gauge Conversion 20 ton

Bore 80 mm = 3.149”

20 Ton 340 bar 5136 PSI

15 Ton 255 bar 3852 PSI

10 Ton 170 bar 2568 PSI

5 Ton 85 bar 1284 PSI

4 Ton 68 bar 1027 PSI

3 Ton 51 bar 770 PSI

2 Ton 34 bar 514 PSI

1 Ton 17 bar 257 PSI

Force 10M /Force 20M22

22 06/10

Loading...

Loading...