Page 1

VERTICAL BAND SAWS

INSTRUCTION MANUAL AND PARTS LIST

MODEL 14-10

DAKE/PARMA

WHEN ORDERING PARTS

GIVE COMPLETE SERIAL NUMBER OF MACHINE

GIVE PART NUMBER AND NAME

GIVE AMOUNT REQUIRED

MODEL: 14-10________________________________

SERIAL NUMBER: _____________________________

DATE PURCHASED: ___________________________

DAKE Division of JSJ

724 Robbins Road

Grand Haven, MI 49417

Phone: 616-842-7110 800-937-3253

Fax: 616-842-0859 800-846-3253

E-mail: technicalservice@dakecorp.com

Website: www.dakecorp.com

5/13/07

Model 14-10 1

Page 2

5/13/07

Table of Contents

Specifications ………………………………… Page 3

Features ………………………………………. Page 3

Adjustments ………………………………….. Page 4

Lubricating …………………………………… Page 4

Blade Selection ……………………………… Page 5

Parts List …………………………………….. Pages 6-13

Model 14-10 2

Page 3

5/13/07

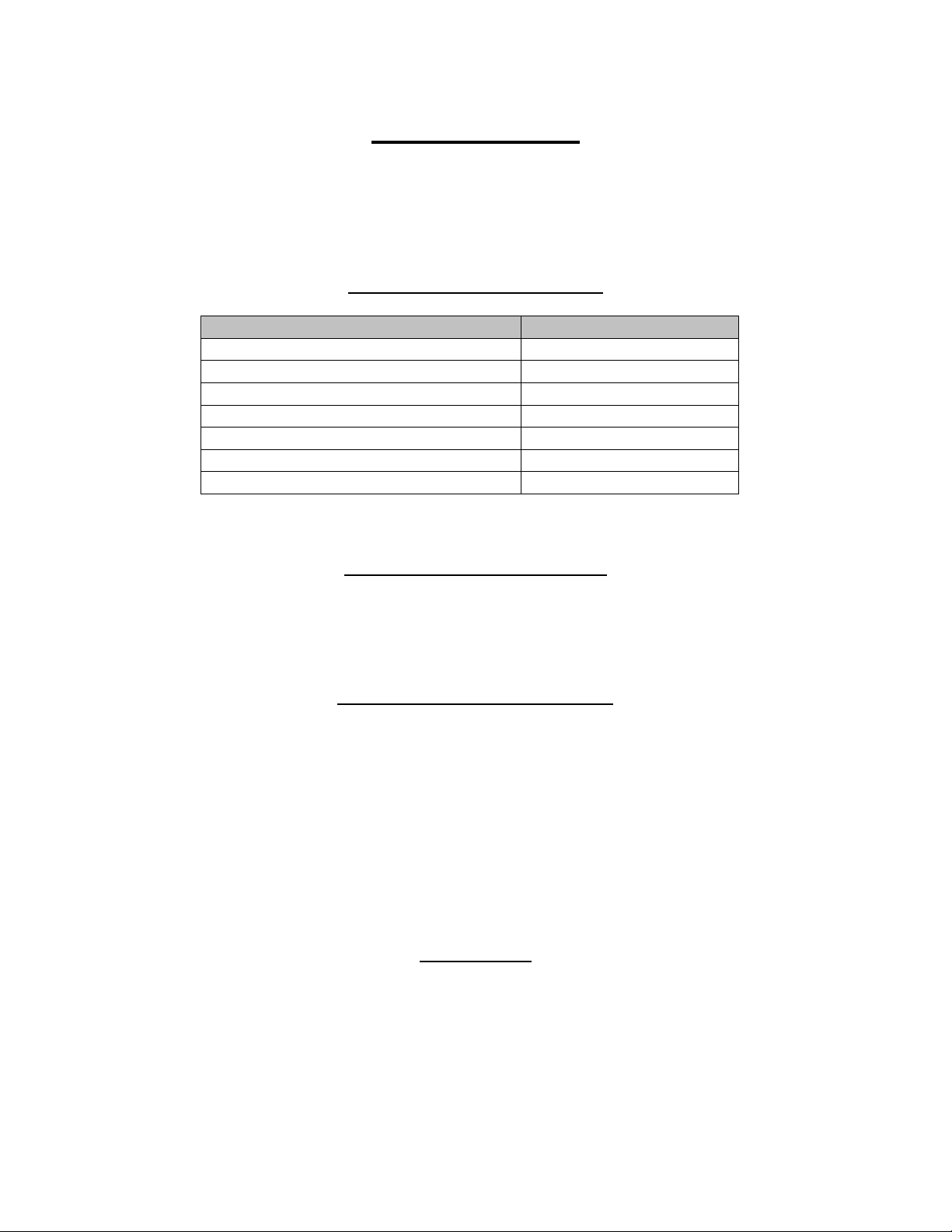

Specifications

Part Number 988050 / 988051

Blade Width ¼-½ inches

Blade Length 120 inches

Blade Speed 70/140/270/540

Band Wheels 2

Band Wheel Size 14 inches

Horsepower 1 h.p.

Throat Size (band to column) 14 inches

Maximum work height 10 inches

Worktable Dimensions 15 x 16 inches

Worktable Tilt 5º left / 45º right

Worktable Height 42 ½ inches

Machine Height 76 inches

Machine Floor Space 24 x 28 inches

Weight 500 pounds

Features

Designed for high performance at a low price

Blade changes are quick and easy.

4 speeds that are easily adjustable.

Model 14-10 3

Page 4

5/13/07

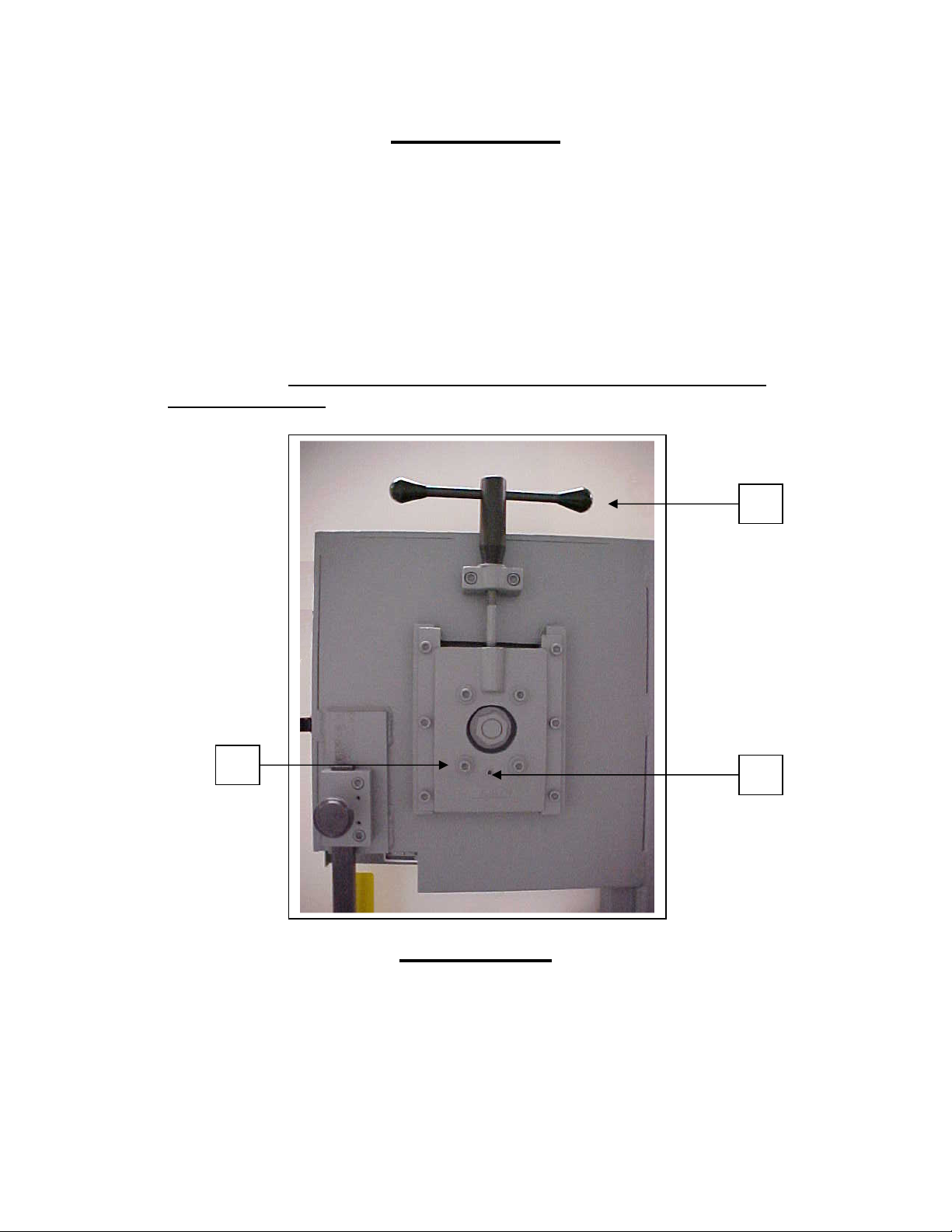

Adjustments

Blade Tension Handle (Item A) – Used to remove and install saw blade.

Also used to set the correct blade tension – Be sure blade is tight.

Upper Blade Wheel Cant Adjustment (Items B&C) – If your saw should

get out of adjustment and the blade runs off the wheel or runs back

against the lip, loosen the two bottom bolts on the wheel slide. Turn the

set screw in or out to make the blade run approximately 1/32” away from

the lip on the back of the wheel. Tighten the two wheel slide bolts.

IMPORTANT: If the blade is allowed to run against the lip on the wheel it

will wear the lip off.

A

B

C

Lubricating

Gear Box: Your 14-10 gearbox is filled at the factory. Check the fluid

level on arrival, and then check every six months thereafter. Use 90

weight gear lube to maintain fluid level at the fill / check pipe plug.

Model 14-10 4

Page 5

5/13/07

Blade Selection

For Operator convenience, a blade selector chart is located inside the saw

cover. It provides recommended blade speeds, required teeth per inch,

and minimum cutting radius for various blade widths. The following chart

can be used to select the blade needed:

Standard Tooth Applications

Thickness of Material Teeth per Inch

Up to 1/8” 18 Teeth

1/8” to 1/4" 14 Teeth

1/4" to 1/2" 10 Teeth

1/2" to 1” 8 Teeth

1” to 3” 6 –4 Teeth

3” to 6” 4-6 Teeth

6” and longer 3H

Note: 1) You must have at least 3 teeth into your work or blade damage will result.

2) For straight cuts, a 3/4" inch blade is best.

Blade Speed (feet per minute)

To change blade speeds, lift the motor and move the v-belt to one of the

three speeds offered: 70/140/270/540. Refer to the blade selector chart

inside the cover on your 14-10 for the appropriate speed.

Blade Removal and Installation

To remove the blade, release the blade tension handle. (Item A on page

4). Remove the blade.

To install the blade, place the blade over the bottom wheel, then on the

top wheel. Teeth must point down toward the table. Tighten the blade

tension handle enough to hold the blade firmly in place, and the push the

blade into the guide inserts. Turn the machine on to allow the blade to

position itself and then finish tightening the blade. IMPORTANT: Blade

must be tight to insure straight cut.

Please Note:

The most common causes for your 14-10 not cutting straight are:

1) Blade tension is too low.

2) The blade is either dull or worn on one side.

3) The blade is upside down. The teeth must point down toward

the table.

Model 14-10 5

Page 6

5/13/07

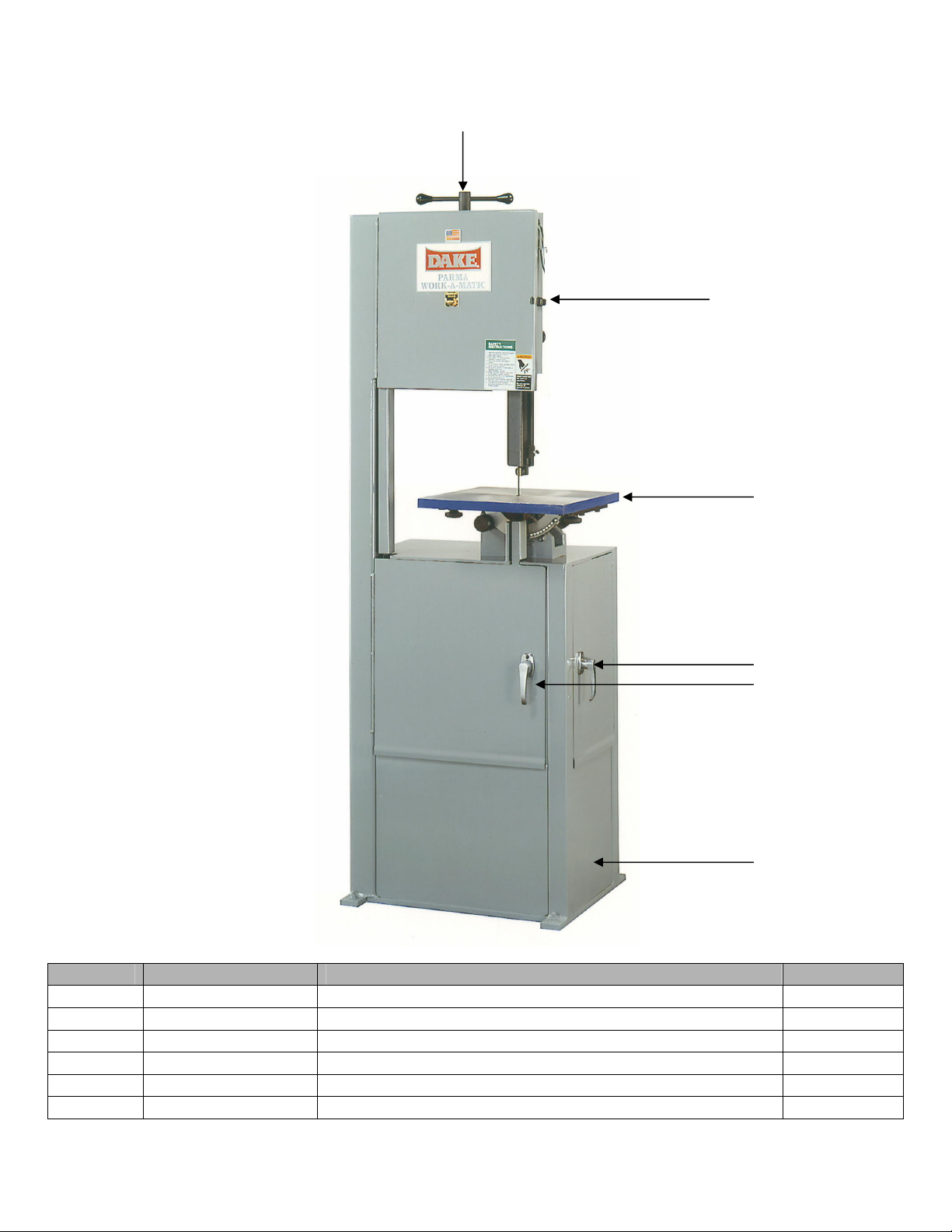

1

Item Part Number Description Quantity

1 716716 Tension Handle Assembly 1

2 86747 Door Latch 1

3 87088 Table 1

4a 300568 Door Handle 2

4b 300569 Door Latch 2

5 716745 Frame Assembly 1

2

3

4

5

Model 14-10 6

Page 7

5/13/07

4

Item Part Number Description Quantity

1 716716 Tension Handle Assembly 1

86828 Tension Handle Body 1

87104 Tension Handle 2

2 716705 Wheel Assembly 2

300459 Band, Blade Wheel 1

300466 Retaining Ring 2

300693 Bearing, Wheel 2

86795 Wheel Blade – Lower/Upper 1

86803 Axle Wheel Lower/Upper 1

86804 Stud – Wheel 1

3 300917 & 300918 Blade Guard 1

300342 Thumb Screws 2

4 300585 Speed Selector Label 1

1

2

3

2

Model 14-10 7

Page 8

5/13/07

1

2

10

11

12

13

3

4

5

6

7

8

9

Item Part Number Description Quantity

1 43450 Cap Screw 2

2 86827 Pillow Block 1

3 86830 Tension Screw 1

4 43447 Cap Screw 6

5a 86824 Wheel Slide – External piece 1

5b 86825 Wheel Slide Adjustment – Internal piece 1

6 86826 Rail Wheel Slide 2

7a 43922 Nut 1

7b 43638 Washer 1

8a 43452 Soc Cap Screw 3/8-16 x 1-3/4 4

8b 43632 Washer 5/16” flat 4

9 43591 Set Screw 3/8-16 x 1 1

10 86810 Guide Bar Holder 1

11 300832 Knob Assembly 1-1/2” 1

12 70287 Roll pin 2

13 43451 Cap Screw 2

Model 14-10 8

Page 9

5/13/07

2

4

6

11

14

13

5

4

3

12

1

7

9

8

10

Item Part Number Description Quantity

716749 Saddle Assembly - 1

1 87081 Table Top Base 1

2 87025 Table Lock 1

3 43939 Nut, Hex Jam, 7/16-20 1

4 44033 Pin, Dowel 4

5 87078 Rocker Rings 2

6 87077 Pointer, Rocker Ring 1

7 43449 Screw, Soc Set 4

8 43451 Screw, Soc Cap 2

9 300564 Cam Follower 1

10 43939 Nut, Hex Jam 7/16-20 1

11 43591 Pin, Spiral or Roll 2

12 86806 Insert, Contour Guide Insert 1

13 87034 Lower Guide Holder 1 x 1-5/8” x 1-9/16” 1

14 87033 Guide Bracket 4” x 4” x ¾” x 1” long 1

Model 14-10 9

Page 10

5/13/07

1

4

Item Part Number Description Quantity

1 87029 Guide Bar 1

2 86912 Upper guide stem 1

3 43545 Screw, Soc Cap 1-1/2-6 x 4 1/2 1

4 87028 Upper Guide Swivel 1

5 86808 Holder Contour Insert 1

6 86807A Insert Contour Guide ¼” Blade Carbide 1

6 86807B Insert Contour Guide ¼” Blade Brass 1

6 86806B Insert Contour Guide ½” Blade Brass 1

6 86806A Insert Contour Guide ½” Blade Carbide 1

7 87012 Blade Guard 1

8 43545 Screw, Soc Set #10-24 x ¼, Cup point 1

2

3

5

7

6

8

Model 14-10 10

Page 11

5/13/07

2

Item Part Number Description Quantity

1 300473 Pulley, Gearbox 1

77449 Key for Pulley 1

2 300522 V-Belt 1

3 86798 Motor mounting axle 1

43314 Screw, Hex cap 5/16-18 x 3/4 2

43632 Washer 5/16 inch flat 2

4 86800 Block, motor mounting 2

43450 Screw, Soc Cap 3/8-16 x 1-1/4 4

300597 Screw, Soc Set 1/4 – 20 x 1/4 2

5 300542 Pulley, Motor 1

77449 Key for Pulley 1

6 300485 Motor, Single Phase 1

300486 Motor, Three Phase 1

1

3

4

5

7

6

Model 14-10 11

Page 12

5/13/07

Model 14-10 12

Page 13

5/13/07

Item Part Number Description Quantity

716712 Gearbox Assembly 1

300472 Bearing, Seal 2

300490 Gasket, Gearbox 1

300491 Gasket, Gearbox 4

300589 Dowel Pin 3/16 x 1/2 2

43412 Screw, Soc Cap 16

43414 Screw, Soc Cap 6

43590 Screw, Soc Set 3

86820 Bearing Cover, Small/hole 2

86821 Bearing Cover, Small 2

86822 Gearbox Casting 1

86823 Cover, Gearbox 1

12 300666 Gear, Worm 40T Bronze 1

13 86784 80 Tooth Gear 1

14 300456 Worm, 4-Lead 1

15 300646 24 Tooth Gear 1

20 300454 Bearing, Gearbox 2

21 300448 Bearing, Gearbox 2

22 86785 Shaft, Main Drive 1

23 86781 Axle, Gearbox-Short 1

28 86783 Spacer, Gearbox 1-1/4 1

29 86786 Spacer, Gearbox 1

30 300449 Key, Woodruff #13 2

31 300451 Key, Woodruff #5 1

Electrical components

Description Part number

Contactor 460 volt 300715

contactor 230 volt 3 phase 300714

Contactor 220 volt 1 phase 300718

Contactor 110 volt 300717

Stop button 716539

Start button 716540

E-Stop button 716538

Model 14-10 13

Page 14

5/13/07

110 Volt Single Phase

Model 14-10 14

Page 15

220 Volt Single Phase

5/13/07

Model 14-10 15

Page 16

5/13/07

230 Volt Three Phase

Model 14-10 16

Page 17

460 Volt Three Phase

5/13/07

Model 14-10 17

Loading...

Loading...