Page 1

724 Robbins Road, Grand Haven, MI 49417 Phone: 616-842-7110 800-937-3253

Fax: 616-842-0859 800-846-3253

Web: www.dakecorp.com E-mail: customerservice@dakecorp.com

SB-250V Drill Press

OWNERS MANUAL

FOR YOUR OWN SAFETY AND

OPTIMUM OPERATION READ

INSTRUCTION MANUAL BEFORE

OPERATING DRILL PRESS

RETAIN THIS MANUAL FOR

FURTHER REFERENCE.

Model: SB-250V

4/1/14

Page 2

1

TABLE OF CONTENTS

• Model specifications, uncrating and installation page 2

• Safety Precautions page 3 - 4

• Controls page 5

• Basic tapping instructions and tips page 6

• Operation instructions basic page 7

• Tool removal page 8

• Table adjustments page 9

• Spindle depth and feed operation page 10

• Proper drill speeds for materials and bit diameter page 11

• Rapid range change rpm chart page 12

• Machine maintenance page 13

• Parts diagram and parts list page 14-18

• Troubleshooting matrix page 19

• Electrical warning page 20

• Electrical diagram page 21

Page 3

2

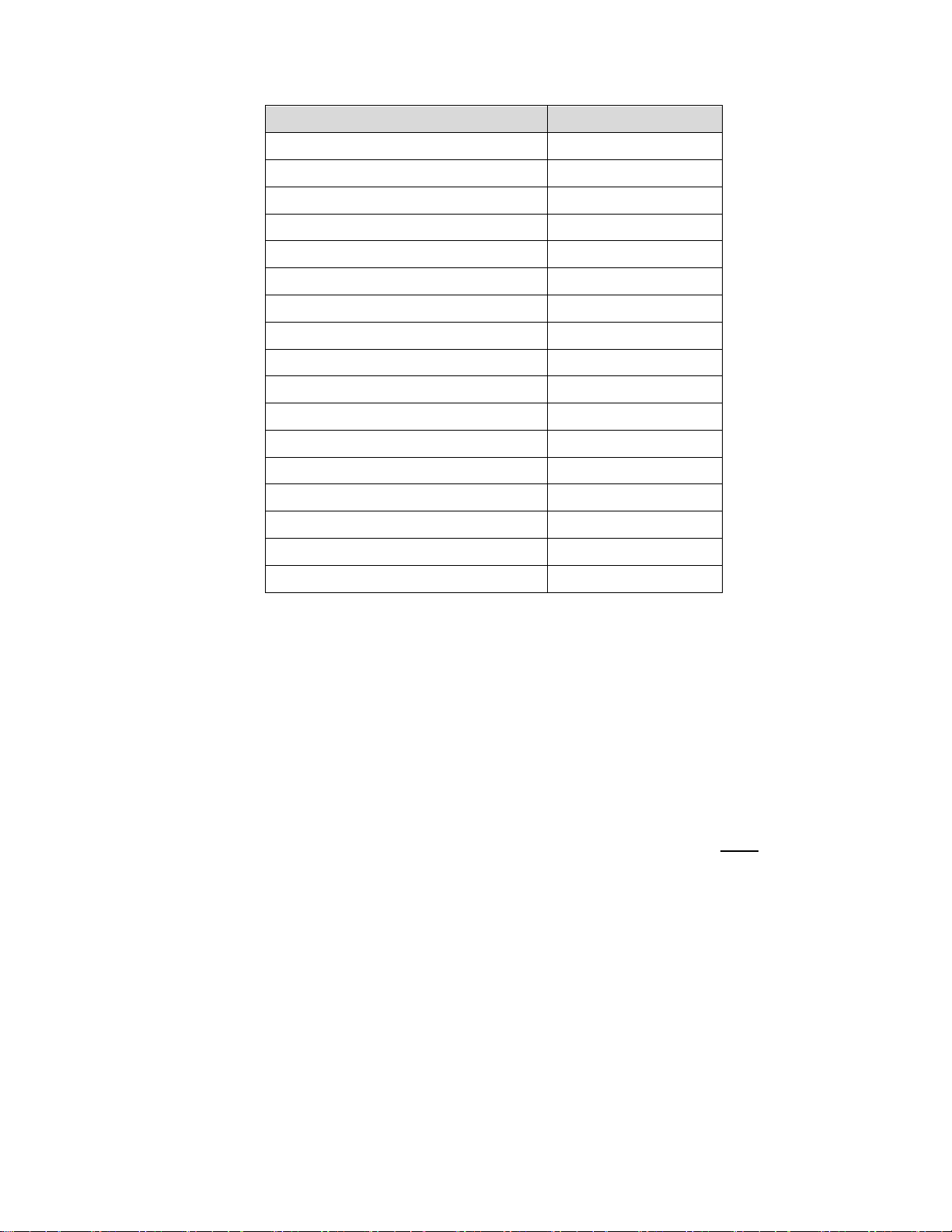

MODEL AND SPECIFICATIONS

Machine Specifications: Model SB-250V

Drill Type Floor

Max. Tap Capacity 3/4

Max. Drill Capacity 1”

Spindle Taper MT3

Spindle Travel 5”

Max. Work Diameter 18”

Speeds (Step Pulley) 9

Spindle Speed Range 68-1381

Column Diameter 3-5/8”

Table 14 x 14”

Base 23-1/2 x 15”

Spindle to Table 28-1/4”

Spindle to Base 49-1/8”

Motor 2 HP

Voltage 110V

Overall Height 71”

Weight 422 lbs.

Uncrating and installation

1. Location of the drill press should be in a well-lit area with correct power supply.

2. Carefully uncrate machine from crate. Inspect all packing as not to throw out

any parts or manuals.

3. When transporting the machine please use caution. If using a sling have

someone steady the machine while transporting it.

4. Install your drill press on a sturdy level floor surface. The machine must be

anchored to the floor. Machine is top heavy.

5. Connect appropriate power to the machine (see electrical diagram last page of

manual). Make sure circuit breakers are suitable for the machine. Consult local

codes for proper installation of machine. Always route power cables in a safe

manner away from traffic areas, damp areas, heat and moving parts.

6. After installing the drill press, use a degreasing product to clean off the anti-rust

oil which was applied at the factory. Then wipe machined surfaces with a light

coating of lubricant oil. (Way oil)

7.

Check for damaged parts. Before further use of the machine, a guard or other part that

is damaged should be replaced or repaired. Carefully check to determine that it will operate

Page 4

3

properly and perform its intended function. Check for alignment of moving parts, binding of

moving parts. Breakage of parts or mountings and any other conditions that affect its

operation.

SAFETY

1. Keep guards in place and in working order.

2. Remove adjusting key and wrenches. Be in the habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

3. Keep work area clean. Cluttered areas and benches invite accidents.

4. Do not use in dangerous environments. Do not use power tools in damp or wet

locations or expose them to rain. Keep work area well light.

5. Do not force tool. It will do the job better and safer at the rate for which it was

designed.

6. Use the right tool. Do not force the tool, or use the machine to do a job for which it was

not designed.

7. Wear proper apparel. No loose clothing, gloves, necktie, rings or other jewelry to get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering

to contain long hair.

8. Always use safety glasses. Also use face or dust mask if cutting operation is dusty.

9. Secure work. Use clamps or a vise to hold work. Do not hold part with hands.

10. Do not overreach. Keep proper footing and balance at all times.

11. Maintain tools with care. Keep tools sharp and clean for best and safest performance.

12. Disconnect drill press from power before servicing, when changing accessories such

as bits, cutter …etc.

13. Never stand on machine, or serious injury could occur.

14.

Never leave machine running unattended.

15.

Be sure drill bit or cutter tool is securely locked in the chuck. Do not hold part to be

machined in hand.

16.

Never place your fingers in a position where they could contact the drill or other cutting

tool if the work piece should unexpectedly shift.

17.

Never perform any operation by moving the head or table with respect to one another.

Do not switch machine on or start any operation before checking that the head and table

lock handles are clamped tight to column, and head and table support collars are correctly

positioned.

WARNING!!!

Extension cords and surge protectors are not recommended for this product.

Ground fault circuit interrupters (GFCI) should not be used. DO NOT TAMPER

WITH WIRING OR SETTINGS INSIDE THE FREQUENCY DRIVE.

Page 5

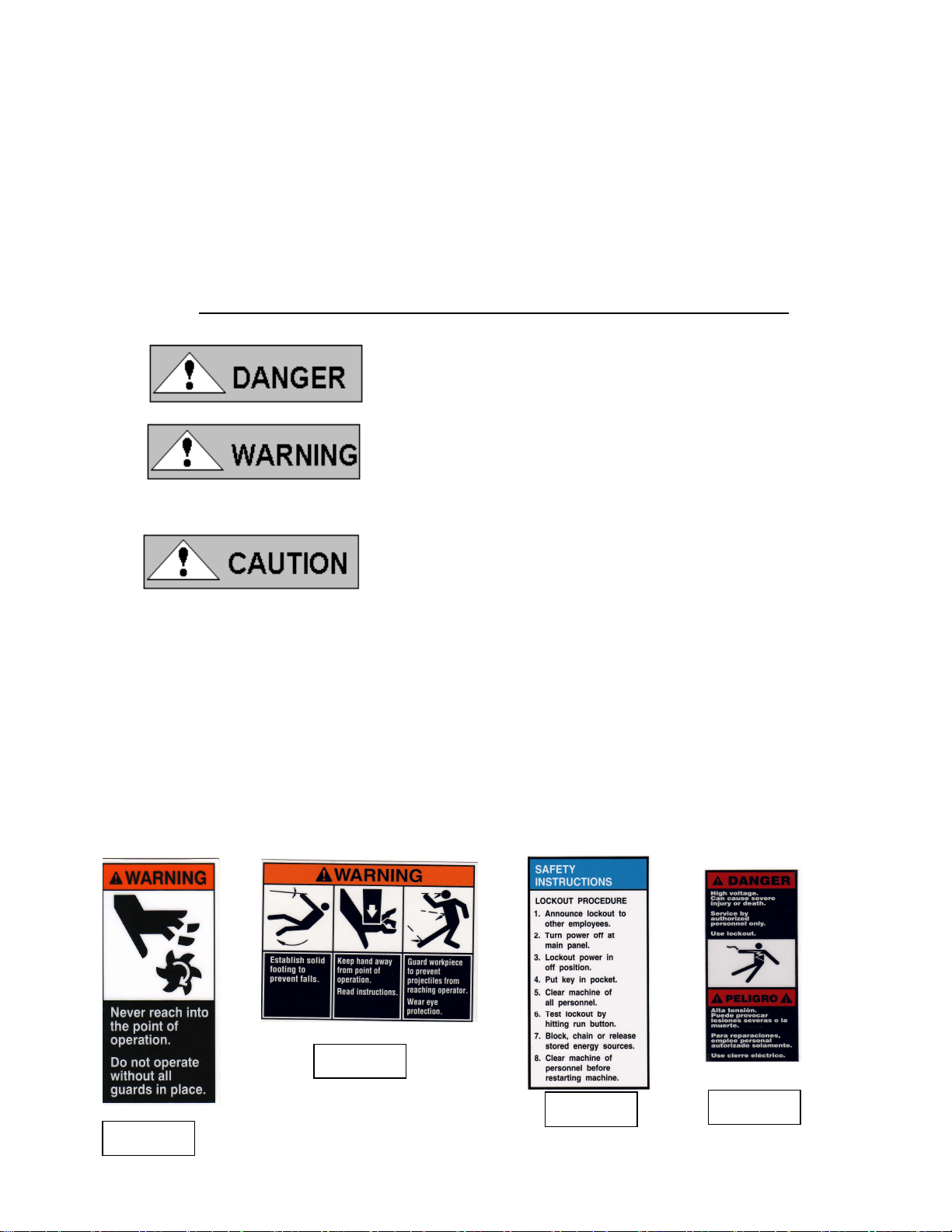

4

300168

82199

84605

84395

Do not open any cover or remove any guard without proper lockout of equipment.

Only a qualified electrician with proper PPE should perform electrical work on this

equipment.

Some components in this equipment may store electricity.

BEFORE USE, ALL SAFETY POINTS MUST BE READ AND UNDERSTOOD!

Operation of the drill press incorrectly, or in a dangerous

fashion can result in serious injury or death.

Operation of the drill press incorrectly, or in a

dangerous fashion can result in damage to machine or its

components and to the cutting tool.

Intend use:

The DRILL PRESS is designed to for drilling, boring

and tapping operations. Caution is required when

operating the drill press because it can be dangerous due to the high spindle

rotation speed. Operation hazards such as entanglement, shearing, ejection

parts ….etc. Guards such as pulley cover and chuck guard must in place and

working condition to prevent any hazard.

Please think about the safety warnings in the instruction manual before

operating the machine

Safety stickers

Page 6

5

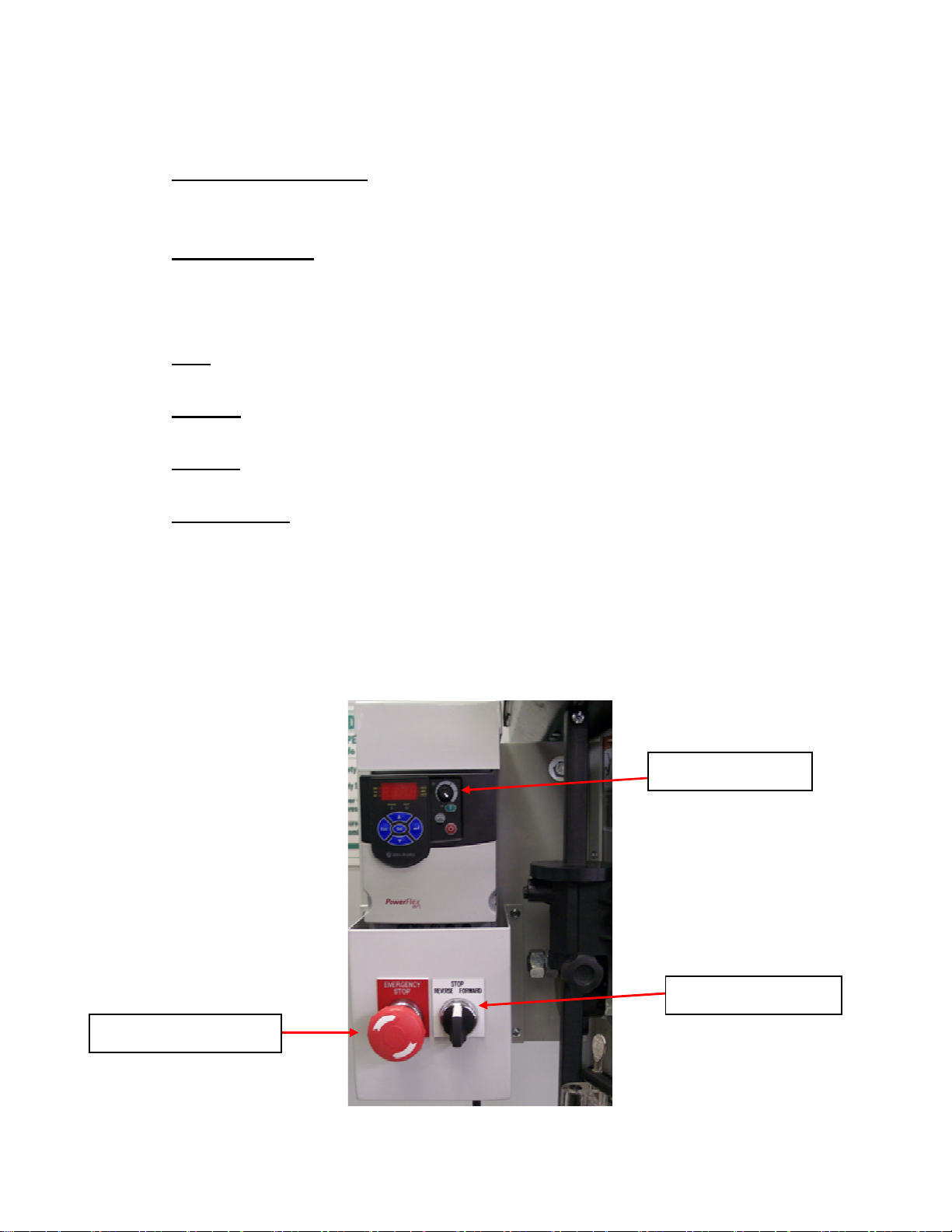

Familiarize yourself with the controls before operating.

Emergency stop button

When this is pressed the power to the motor and controls is disconnected. The

frequency drive stores energy this will remain lit for about 20 seconds.

Spindle direction

Turn the spindle direction switch to the desired direction forward, reverse or stop. If

the emergency stop button is pushed or if the power is lost you will have to move

this to stop (TO RESET) then to desired spindle direction.

Stop

This is used when you would like the spindle to stop.

Forward

This is used for standard drilling and tapping operations

Reverse

This is used for left hand tapping and to retract a tap during tapping operations.

Spindle speed

The black dial in the upper right hand corner controls the spindle speed. This will

change the speed in forward and reverse directions.

Warning!!!

Avoid stopping the motor under load or stalling the motor. This could damage

the electrical components.

Emergency stop button

Spindle speed dial

Spindle direction dial

Page 7

6

Tapping operations using the reverse feature

1.

Drill the initial hole on the drill press for accuracy of diameter. If the diameter

is 1/2 inch or larger, drill a pilot hole about half that diameter first.

2.

Make sure the hole has a large enough chamfer. If the chamfer is too small

the tap will work a little hard when starting the tapping operation.

3.

Select the tap type. Choose from a taper tap (recommended), plug tap or

bottoming tap. The taper tap has several chamfer threads forming a tapered

cone on the inserting end. The plug tap has fewer chamfer threads and a

bottoming tap only has a couple chamfer threads.

4.

Match the tap size. Use the specified tap size to thread the hole diameter.

Taps that are sold with drill bits are size matched for you. The taps

themselves may show the hole size they’re intended for, but it’s likely to be

given in metric notation. Use a conversion chart to match this with the inch

fractions measuring drill bits.

5.

Cut the threads. Lubricate the tap with tapping fluid. Start the drill press and

lower the tap gently into the hole to be threaded. It only takes a few seconds

to tap a hole. When the tap gets to the desired depth reverse the direction of

the spindle and the tap will work its way out. As long as it has been set up

properly, the chances are good for success.

Tips for tapping

Tapping is a skill. It takes practice to do it well and to not break taps. If you’re

new to tapping, practice on sample stock before tapping into your actual

project

Materials have differing requirements for drill speed and lubrication. Hole

depths and diameters may present additional drilling requirements. Refer to

material charts for drilling specifications.

Page 8

7

1. BASIC OPERATION (PROCEDURE)

Drill / Chuck Installation:

To show greater detail

Chuck guard is in the open position in POWER MUST BE OFF BEFORE

photos. CHUCK GUARD MUST IN MAKING ANY ADJUSTMENTS!

PLACE DURING OPERATION!

TURN POWER OFF! Before inserting

drill bits, chucks or arbors, always clean

out spindle hole and taper hole with a

clean cloth.

Open chuck jaws completely by turning

attached chuck key counter-clockwise

until the jaws are fully opened.

To install the chuck to the arbor tightly,

slide the chuck into the taper forcing it

into the spindle with by hand. Place a

block of wood on the table then lower the

spindle to make contact with the wood

and press the chuck tightly into the

spindles taper.

Install a taper shaft drill bit into the taper

the same way as you would the chuck. If

an adaptor is used it must fit the taper

correctly and the bit must fit snug in the

adaptor.

Installation of drill bits in the chuck:

A drill bit with a shaft of at least 1” long

should be used to allow correct chuck jaw

contact. If shaft length is less than 1” do

not insert bit as far into the chuck where it

allows jaw contact with drill flutes. Center

drill bit onto the chuck and tighten the

chuck securely with the chuck key.

Page 9

8

Note:

Correct: Jaws Incorrect: Jaws

contact drill shaft contact drill flutes

• Always use sharp, straight bits.

• Never use bits with turned down

shafts.

• Never exceed the maximum diameter

bit size for the machine.

• Always wear appropriate clothing

while operating the drill press.

• All guards and interlocks must be in

place when operating the machine.

Wedge removal tool

Tooling removal:

Before removing the chuck or bit from the

machine; be sure the spindle has come to

a complete stop and power is off. If needed,

rotate spindle by hand to align the spindle

and quill openings. Insert the wedge

removal tool, while supporting the tooling,

and tap the wedge to remove the tooling.

Work holding:

When drilling directly on table surface, it is recommended that a

piece of wood or plywood be clamped securely to table under the

work piece. This will minimize splintering or burring as the drill breaks

through. It will help minimize drill bit and table damage.

Clamp the work piece to the table whenever possible. The table has

“T” slots that allow for many different clamping configurations.

When part cannot be affixed to the table a drill vise that is bolted in

place is recommended.

Page 10

9

Table lock Table height adjustment:

Table height adjustment is

accomplished by loosening the clamp

Bolt, then adjusting the table with the

bracket handle to desired height. After

table is at working height, retighten

the clamp bolt securely.

Note: Keep table adjustment rack

clean from debris. Never attempt to

move table with clamp bolt tightened.

Table handle

Table tilting adjustment:

Using an adjustable or box wrench,

loosen table level lock bolt. Carefully tilt

the table to the degree needed, as shown

on the angle index scale located on the

table rotation point. Retighten nut

securely.

Note: Never tilt table if any material or

fixturing is on it. Only make adjustments

when table is free of loose articles.

Table swing adjustment:

To swing the table up to 360 degrees,

loosen the clamp release bolt and swing

table to the desired position. After the

table is in the correct position tighten

clamp release bolt securely.

Note: Never swing table if any material or

fixturing is on it. Only make adjustments

when table is free of loose articles.

Page 11

10

ZERO

POINTS

SPINDLE DEPTH AND FEED OPERATION

MANUAL FEED HANDLE POSITION

Depth setting

Loosen the depth locking handle by turning it counter clockwise. When this is loose

you can turn the depth gauge to the desired depth.

DEPTH LOCKING HANDLE

DEPTH LOCKING GAUGE

AUTO FEED HANDLE POSITION

Zigzag line is for auto feed depth operations

Straight line is for manual depth feed operations

After setting depth tighten the depth locking handle.

Manual feed operation

With the spindle in operation and the feed handle in the manual feed position pull

the feed handle down making contact with the work material.

Auto feed operation

With the spindle in operation, pull the feed handle out away from the drill press as

shown above (auto feed handle position). The spindle will begin to feed down. The

faster the spindle rotates the faster the spindle will feed down. The slower the

spindle rotates the slower the feed rate. If you want to stop the feed down

movement move the feed handle to the manual position and the spindle will go back

up to the starting position.

Page 12

11

The proper drill speed for a given drill bit size is as on following table:

Material

Type

Cast

Steel

Tool Steel Cast Iron Mild Steel Alum. &

Copper

SURFACE FEET PER MINUTE

s.f.m. s.f.m. s.f.m. s.f.m. s.f.m.

Drill Dia. 40 60 80 100 200

Inch

REVOLUTIONS PER MINUTE

1/16 2,445 3,665 4,890 6,110 12,225

1/8 1,220 1,835 2,445 3,055 6,110

3/16 815 1,220 1,630 2,035 4,075

1/4 610 915 1,220 1,530 3,055

5/16 490 735 980 1,220 2,445

3/8 405 610 815 1,020 2,035

7/16 350 525 700 870 1745

1/2 305 460 610 765 1,530

5/8 245 365 490 610 1,220

3/4 205 305 405 510 1,020

7/8 174 261 348 435 762

1 153 229 306 382 668

1-1/8 136 204 272 340 595

1-1/4 122 167 244 306 535

Page 13

12

Middle speed

High speed

Low speed / high torque

Range change handle

Adjustment handle

Rapid range change

With the motor running (NOT ON THE HIGHEST SPEED), push or pull the range

change handle and at the same time change the adjustment handle to the desired

range. See chart below for ranges.

SB-250V RPM Chart

High

Frequency

10 120 101 68

20 234 200 112

30 350 291 197

40 465 387 263

50 580 483 328

60 695 580 400

70 811 675 465

80 926 771 530

90 1042 865 585

100 1157 964 615

110 1270 1061 713

120 1381 1155 776

Speed Middle

Low speed

High Torque

Page 14

13

2. MAINTENANCE OF MACHINE

MAINTENANCE

1. On a regular basis blow out any dust that may accumulate inside

the motor. (Frequency depends on environment the machine is

in)

2. A coat of automotive wax applied to the table and column will help

to keep the surface clean.

3. All of the ball bearings are packed with grease at the factory. They

require no further lubrication.

4. Periodically lubricate the gear and rack table elevation

mechanism, the spindle splines and the rack (teeth on the quill).

5. After each use the machine should be cleaned. Weekly

lubrication of all sliding or moving parts with light weight or way oil

is recommended. For your own safely, turn switch “OFF” and

remove plug from power source outlet before maintaining or

lubricating your drill press.

BELT TENSION ADJUSTMENT

Proper belt tension is approx. 10 lbs. of pressure or deflection of about 1/2 “

Page 15

14

See page 18

Page 16

15

PARTS LIST for SB-250V

Item

No.

1 Nut 55 Spring

2 Spindle Pulley 301088 1 56 Clutch Claw

3

4 C-Ring 58 Pin

5 Ring 59 Gear- Clutch

6 Bearing 6203Z 300987 60 Pinion Shaft

7 Ring 61 Spring Cap Base

8 Bearing 62 Spring & Cap

9 Snap Ring 63 Nut

10 Pulley cover 30167 1 64 Gear Bevel

11 Head 65 Gear Bevel Base

68 Gear

12 Rubber Pad 66, 67 Key

13 Nut 69 C-Ring

Description SB-250V Qty.

Insert Pulley

302218 1 57 Clutch Claw Base

Shaft

Item No.

Description SB-250V Qty.

14 Nut 70

15

16 Quill 2.42" 301098 1 73

17 Seal 74

18 Bearing 75

19 Spindle 301099 1 76

20 Belt 301093 1 77

21 Snap Ring 78

22 Pulley 80

23 Set Screw 81

24 Spring 82

25 Ball 83

26 Bolt 84

27 Cover 86

28 Bearing 87

Bearing

301070 71

6006Z&6208Z

Nut 43938 1

Set Screw 302761 1

Can

Adjuster Rod 87391 1

Handle 554 1

Hinge Pin 87388 1

M14-2.0x150mm long 302757 1

1

Motor 300996 1

Motor Pulley 302749 1

Belt 302748 1

Hitch Pin 302760 1

Worm Shaft

Horizontal

Key

29

30 Washer 89

Button Head

88

Screw

Gear Bevel

Bearing

Page 17

16

Item

No.

Description SB-250V Qty.

Item No.

Description SB-250V Qty.

31

32 Bearing 91

33 Cover 92

34 Bolt 93

35 Bolt 94

36 Washer 95

37, 38,

39

40 Knob 98

41 Handle 99

42 Handle Base 100

43 Pin 100

44 Lock Screw 101

45 Scale Sleeve 301071 1 103

46 Clutch 104

47 Block 105

Worm shaft

90

vertical

Lock handle 97

Worm Shaft Base

Screw

Pulley holder

Spring

Bolt

Pulley 301089 1

Bearing

Spacer

Bearing

Handle washer 43632 3

Snap Ring

Nut Nylock 300827 1

Handle bolt 43317 1

Bolt 43330 1

Locknut 43937 1

48, 49 Pin 106

50 Hex Screw

51 Gear Box

52 Screw

53 Fixed Plate

54 C-Ring

110 Range Change Label 87402 1

107

108

109

Handle w/Ball 300702 1

Hinge Plate 87386 1

Motor Mounting Plate 87387 1

Adjuster Belt Tension 87390 1

Page 18

17

PEDISTEL PARTS BREAKDOWN

Item No.

1 Base 301040 8 Clamp Bolt 301049

2 Flange 301042 9 Clamp Bolt 301051

3 Spring Washer (4x) 13 mm 10 Table Arm 301052

4 Screw 300999 11

Description SB-250V

Item No.

Description SB-250V

Table

Bracket

301055

5 Column 301044 12 Worm 301056

6 Rack 301047 13 Collar 301057

7 Handle 301048 14

Feed Handle

301059

(3x)

Page 19

18

9.

8.

6.

ADDITIONAL PARTS LIST

Item # Part name Part # Qty.

1 Top cover 87377 1

2 Drive unit 302704 1

3 Name plate emergency stop 301904 1

4 Emergency stop button 716538 1

5 Back mounting plate 87378 1

6 Bracket 87382 1

7 Name plate reverse stop forward 302746 1

8 Selector Switch 302730 1

9 Switch mounting box 87379 1

Parts list

Parts list items not shown

1.

5.

2.

3.

7.

4.

Part

Part name

Cord set with plug 300529 1

Motor grommet 300540 1

Contact block N.O. 301782 2

Metal latch 301785 1

Cable 4 wire 302683 1

Hex bolt for mounting bracket 5/16-18 x 3/4 43314 2

washer for mounting bracket 5/16 flat 43632 2

Lock washer for mounting bracket 5/16 43644 2

Nut for mounting bracket 5/16-18 heavy 43911 2

Top mounting screws top bracket #10-24 x 1/2 43847 2

Nut for top mounting screws #10-24 43905 2

Screws self-tapping 43881 7

Connector cord 75151 2

Locknut conduit 1/2" 75257 2

number Quantity

Page 20

19

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy

Machine does not turn on Not plugged in Plug into proper receptacle

Frequency drive has error Clear error by turning off then back on

Too long or not correct extension

cord

Emergency stop button is activated Deactivate emergency button

Belt cover is operation Close belt cover

Noisy Operation Incorrect belt tension Adjust tension (page 8)

Loose Spindle or motor pulley

Spindle bearing worn Replace bearing

Chuck or Quill falls out Rust inhibitor, dirt, debris in or on

quill or spindle taper

Spindle does not move up or

down Belt broken or slipping

Debris in quill Clean quill and teeth

Feed depth adjustment is set see page 7 for adjustment

Spindle does not rotate Belt tension not tight enough Tighten belt tension page 8

Belt is broken or too worn Replace belt

Motor is not rotating Troubleshoot motor

Remove extension cord and plug directly

into receptacle

Check for wear or if pulley can be

tightened

Clean chuck and quill

Check belt for damage, Check for proper

belt tension page 8

Taper is slipping in spindle Clean chuck and quill

Page 21

20

ELECTRICAL WARNING

1. In the event of a malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock.

This machine is equipped with an electric cord having an equipment

grounding conductor. The proper plug must be used that is properly

installed and grounded in accordance with all local codes and

ordinances.

2. Do not modify the plug provided. If it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

3. Improper connection of the equipment grounding can result in a risk of

electric shock. The conductor with insulation having an outer surface that

is green with yellow stripes is equipment grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do not connect the

equipment grounding conductor to a live terminal.

4. Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt as whether the

machine is properly grounded.

5. It is not recommended to use an extension cord on this machine. If one

must be used, use only a grounded cord of proper size for machine and

length of run needed.

6. Repair or replace damaged or worn cords immediately.

Page 22

21

ELECTRICAL DIAGRAM

Loading...

Loading...