Page 1

Phone: 800.937.3253

www.dakecorp.com

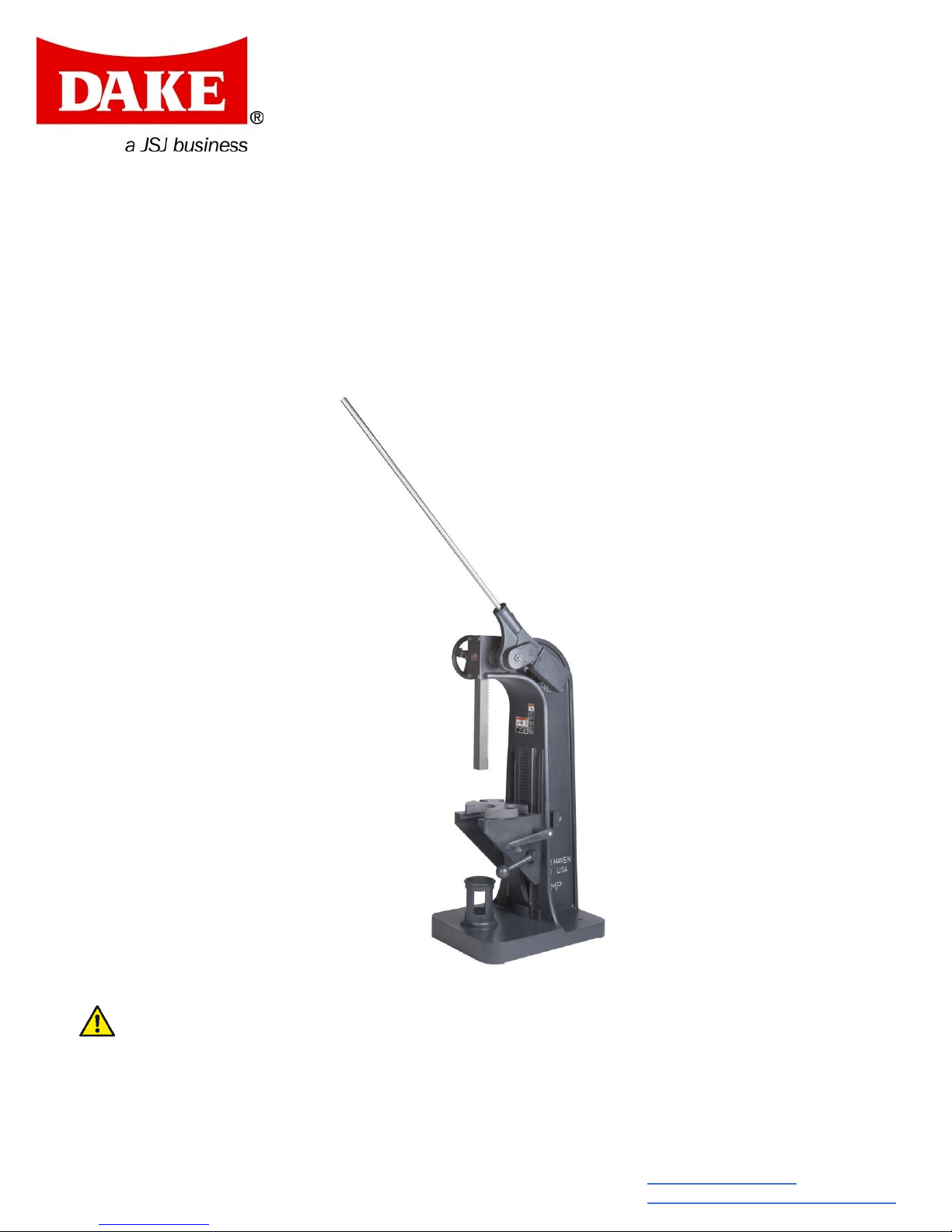

DAKE RATCHET LEVER ARBOR PRESS

Model 4M

INSTRUCTIONAL MANUAL

WARNING!

Read and understand all instructions and responsibilities before operating. Failure to follow

safety instructions and labels could result in serious injury.

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

Fax: 800.846.3253

customerservice@dakecorp.com

Page 2

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

TABLE OF CONTENTS

DAKE STANDARD LIMITED WARRANTY ............................................................ 2

RETURN & REFUND POLICY .............................................................................. 3

SPECIFICATIONS ................................................................................................ 4

SAFETY ................................................................................................................ 4

HANDLE POSITION .................................................................................... 5

OPERATION ......................................................................................................... 5

MAINTENANCE .................................................................................................... 5

LUBRICATION ............................................................................................. 5

EXPLODED VIEW & PARTS LIST ........................................................................ 6

EXPLODED PARTS VIEW ........................................................................... 6

PARTS LIST ................................................................................................ 7

ORDERING INFORMATION ................................................................................. 7

1 REV062018

Page 3

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

DAKE STANDARD LIMITED WARRANTY

Finished Machines

Dake warrants to the original purchaser the finished machine manufactured or distributed by it to be free

from defects in material and workmanship under normal use and service within 1 year (12 months) from

the delivery date to the end user.

Parts & Couplings

Dake warrants to the original purchaser the component part or coupling manufactured or distributed by it

to be free from defects in material and workmanship under normal use and service within 30 days from

the delivery date to the end user.

The standard limited warranty includes the replacement of the defective component part or coupling, at

no cost to the end user.

Warranty Process

Subject to the conditions hereinafter set forth, the manufacturer will repair or replace any portion of the

product that proves defective in materials or workmanship. The manufacturer retains the sole right and

option, after inspection, to determine whether to repair or replace defective equipment, parts or

components. The manufacturer will assume ownership of any defective parts replaced under this

warranty.

All requested warranty claims must be communicated to the distributor or representative responsible for

the sale. Once communication has been initiated, Dake Customer Service must be contacted for

approval:

Phone: (800) 937-3253

Email: customerservice@dakecorp.com

When contacting Dake, please have the following information readily available:

- Model #

- Serial #

- Sales Order #

Purchasers who notify Dake within the warranty period will be issued a Case number and/or a Return

Material Authorization (RMA) number. If the item is to be returned per Dake’s request, the RMA number

must be clearly written on the exterior packaging. Any item shipped to Dake without an RMA will not be

processed.

Warranty Exceptions:

The following conditions are not applicable to the standard limited warranty:

(a) Part installation or machine service was not completed by a certified professional, and is not

in accordance with applicable local codes, ordinances and good trade practices.

(b) Defects or malfunctions resulting from improper installation or failure to operate or maintain

the unit in accordance with the printed instructions provided.

(c) Defects or malfunctions resulting from abuse, accident, neglect or damage outside of prepaid

freight terms.

(d) Normal maintenance service or preventative maintenance, and the parts used in connection

with such service.

(e) Units and parts which have been altered or repaired, other than by the manufacturer or as

specifically authorized by the manufacturer.

(f) Alterations made to the machine that were not previously approved by the manufacturer, or

that are used for purposes other than the original design of the machine.

2 REV062018

Page 4

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

RETURN & REFUND POLICY

Thank you for purchasing from Dake! If you are not entirely satisfied with your purchase, we are here to

help.

Returns

All Dake manufactured / distributed machines, parts and couplings include a 30-day return option. These

policies are valid from the date of final shipment to the end user.

To be eligible for a return, the item must be unused and in the same condition as received.

All requested warranty claims must be communicated to the distributor or representative responsible for

the sale. Once communication has been initiated, Dake Customer Service must be contacted for

approval:

Phone: (800) 937-3253

Email: customerservice@dakecorp.com

Once the return request has been approved by Customer Service, a representative will supply a Return

Material Authorization (RMA) number. The returned item must have the provided RMA number clearly

marked on the outside packaging. Any item received without an RMA number clearly visible on the

packaging will not be processed.

An RMA number can only be provided by the Dake Customer Service team and must be obtained prior

to the return shipment.

Refunds

Once the item has been received and inspected for damages, a representative will notify the requestor

referencing the provided RMA number.

If the return is approved, a refund will be issued to the original method of payment, less a 20% restocking

fee. The restocking fee may be waived if an order is placed at the time of return with like-value

merchandise.

Transportation costs are the responsibility of the end user and will not be credited upon return approval.

Any item that is returned after the initial 30 days or has excessive/obvious use will not be considered for

a full refund.

3 REV062018

Page 5

Dake Corporation

Model

4M

Largest arbor

5-1/4”

Number

902006

Capacity over table

26”

Capacity

5 tons

Capacity over table plate

24-1/2”

Leverage ration

55:1

Base length

21-1/2”

Ram size

2 x 2 x 23”

Base width

24”

Max diameter work

20”

Height

58”

Throat

10”

Weight

1045 lbs

Carefully read all safety

This machine is intended to

Under no circumstances

Label Part No. 300168

Label Part No.

Label Part No.

87130

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

SPECIFICATIONS

SAFETY

This is the safety alert symbol. When you see this symbol on your press be alert to the

potential for personal injury.

Employer is responsible to perform a hazard/PPE assessment before work activity.

79979

Follow recommended precautions and safe operating practices.

messages in these

instructions and on your

press safety signs. Keep

safety labels in good

condition. Replace missing or

damaged safety labels.

4 REV062018

be operated by one person.

This person should be

conscious of the press ram

movement not only for

themselves but also for

persons in the immediate

area of the machine.

increase the leverage ratio

of the press by using a

longer handle or by placing

a pipe over the handle.

Never hammer on top of the

ram.

Page 6

HANDLE POSITION

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

CAUTION: NEVER PULL THE PRESS HANDLE PAST THE HORIZONTAL POSITION!

To avoid personal injury and damaging the press only pull until the handle is horizontal, then

return the handle back up as far as it allows before bringing the handle back down. This ensures

that the pawl fully engages with the gear teeth to prevent tooth damage and gear slippage that

can cause harm to the machine and worker. Examples above show the ideal minimum and

maximum handle positions.

OPERATION

Handwheel: The handwheel (item 15) can be turned to raise or lower the ram to and from the

workpiece without exerting force on the workpiece.

Handle: The handle (item 23) can be used to lower the ram to exert force onto the workpiece.

See safety instructions for more information on handle position.

MAINTENANCE

LUBRICATION

• Keep all working parts of the press well-oiled for easier operation.

• Keep a light film of oil over the entire surface of the ram to prevent rust.

5 REV062018

Page 7

EXPLODED VIEW & PARTS LIST

EXPLODED PARTS VIEW

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

6 REV062018

Page 8

Item

Part Name

Part Number

Qty

1

Frame

295

1

2

Mandrel Catcher

254

1

3

Table Pinion

271

1

4

Table Pinion Shaft

291

1

5

Table Crank

270

1

6

Table Pawl Handle

266

1

7

Table Pawl Shaft

287

1

8

Table Pawl

265

1

9

Spring (1/2” x 2”)

302436

1

10

Table Plate Assembly

701227

1

11

Hex Cap Screw (1/2”-13 x 1-3/4”)

43350

4

12

Label – Made in U.S.A.

76936

1

13

Ram Cap

296

1

14

Ram Cap Shim (.015”)

252

6

15

Handwheel

257

1

16

Ram Cap Shim (.008”)

251

2

17

Hex Cap Screw (3/8”-16 x 2”)

43333

1

18

Ram

253

1

19

Table

262

1

20

Hand Brake Stud

223A

1

21

Handbrake Clamp

215

1

22

Handbrake

214

2

23

Handle

283

1

24

Hex Jam Nut (1/2”-13)

43940

1

25

Flat Washer (1/2”)

43634

1

26

Compound Rest Pin

280

1

27

Headless Set Screw (1/2”-13 x 1-1/2”)

43608

1

28

Pawl

297

1

29

Spindle

256

1

30

Table Stud

282

2

31

Table Washer

279

2

32

Table Spring

281

2

33

Hex Cap Screw

53759

2

34

Table Clamp

267

1

35

Hex Nut (1-8)

43922

2

36

Headless Set Screw (3/8”-16 x 5/8”)

43589

4

37

Lever Weight

258

1

38

Pawl Pin

255

1

39

Retaining Ring

67955

1

40

Warning Label – Pinch Point

87130

1

41

Warning Label – Tipping

79979

1

42

Warning Label – Ganged

300168

1

PARTS LIST

Dake Corporation

724 Robbins Road

Grand Haven, MI 49417

www.dakecorp.com

Please contact factory for current prices.

ORDERING INFORMATION

Parts are available for direct purchase from Dake or through a distributor. When placing a parts

order, you will need to provide the part number, name of part, and model number. All parts

shipped F.O.B. Factory in Grand Haven, MI.

7 REV062018

Loading...

Loading...