DAK Americas 7000 User Manual

PDS-B92A 140303KH

DAK Americas

ISO 9001:2008

#10004457

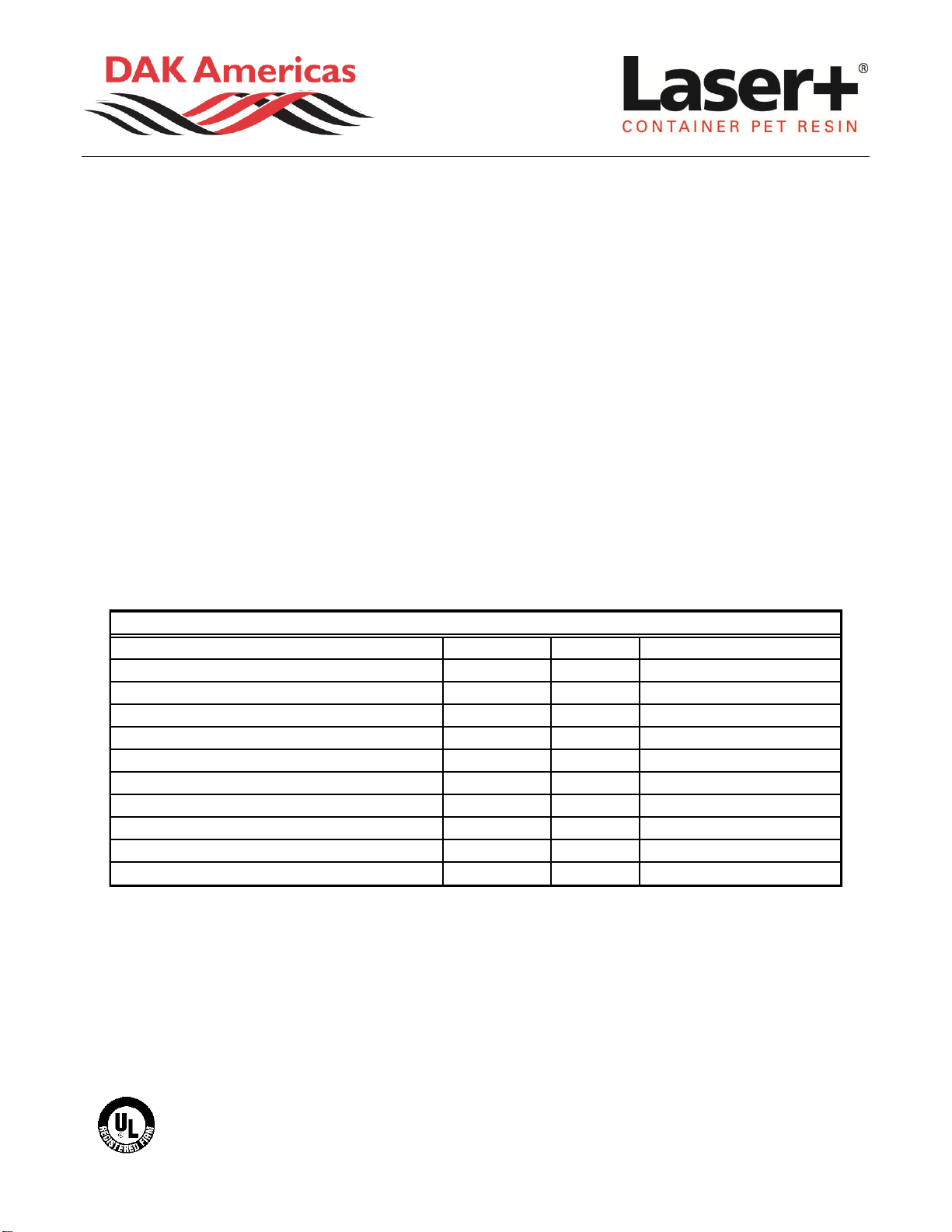

Property Value Unit Test Method

Intrinsic Viscosity

0.84 ± 0.02 dL/g DAK-QAR-SOP-0012

Color L* 67 min CIE DAK-QAR-SOP-0011

Color b*

- 4.5 ± 1.4 CIE DAK-QAR-SOP-0011

Acetaldehyde 2 max ppm DAK-QAR-SOP-0010

Moisture Content (as packaged) 0.25 max weight % DAK-QAR-SOP-0013

Fines (as packaged, +24 Mesh Size) 0.050 max weight % DAK-QAR-SOP-0014

Chip Size, nominal 30 chips / g DAK-QAR-SOP-0015

Crystallinity > 35 % DAK-QAR-SOP-0016

Partical Size, Shape (Spherical) 3.5 mm DAK-QAR-SOP-0017

Melting Point, nominal 242 ºC DAK-QAR-SOP-0016

Bulk Density 52 lb / ft³ DAK-QAR-SOP-0018

Laser+® 7000 (B92A) Product Information

polyethylene terephthalate resin

Product Description

Laser+® 7000 (B92A) polyethylene terephthalate (PET) resin is a copolymer formulated for conversion

to PET bottles by conventional single or two-stage processing technology.

Typical Properties

Bi-orientation of Laser+® 7000 (B92A) by injection/stretch blow molding provides optimal barrier and

mechanical properties, including superior stress crack resistance. It performs exceptionally well in the

manufacture of CSD bottles made from thick-wall preforms, where heatup rate and temperature profile

through the wall are important. DAK has reengineered Laser+® 7000 (B92A), improving acetaldehyde

(AA) performance without sacrificing intrinsic viscosity (IV), to meet increasing demand for CSD

applications. Laser+® 7000 (B92A) offers superior heat absorption and processing control, even at

higher blowing speeds. A slower crystallization rate enables high injection molding output.

Certification

Laser+® 7000 (B92A) is ideally suited for food packaging applications and is considered in compliance

with the Food and Drug Administration (FDA) Food Contact Notification (FCN) 000635, and Health

Canada Health Products and Food Branch (HPFB) file KS 06111304 for PET polymers.

Sales Specifications

These values represent the anticipated performance data for these polyester resins and intermediates; they are not intended to

be used as design data. We believe this information is the best currently available on the subject. It is offered as a possible

helpful suggestion in the experimentation you may care to undertake along these lines. It is subject to revision as additional

knowledge and experience is gained. DAK Resins makes no guarantee of results and assumes no obligation or liability

whatsoever in connection with this information. This publication is not a license to operate under, or intended to suggest

infringement of, any existing patents.

CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical

applications, see “DAK Medical Caution Statement”.

223 Wilmington W Chester Pike• Chadds Ford, PA 19317

1-888-738-2002 • fax: 610-558-7385 • www.dakamericas.com

DAK Americas LLC

Gateway Corporate Center, Suite 210

PDS-B92A 140303KH

DAK Americas

ISO 9001:2008

#10004457

Laser+® 7000 (B92A) Product Information

polyethylene terephthalate resin

Material Drying

Proper drying of polyethylene terephthalate (PET) is essential to produce a high quality part (container, film, etc.) with optimum

physical properties. PET is hygroscopic, meaning that when it is exposed to humid atmospheres, it will absorb moisture. In

PET the moisture is not only on the surface but diffuses slowly through the whole pellet and is firmly held by molecular

attraction. Before processing the PET, this moisture must be removed. Carefully controlled drying of all PET is an essential

requirement for optimum processing performance and final product properties. If drying is not carried out properly, to the

known requirements of the type of PET in use, then deficiencies in process and product will results. The deficiencies will be

impossible to remedy by later process changes. These defects arise in the injection molding or extrusion processes because

at PET melt temperature (250°-280° C) any water present causes hydrolytic degradation of the PET, almost instantaneously,

with the resultant loss in intrinsic viscosity (IV). Significant drops in IV cause loss of process control and reductions in end

product properties.

Drying of PET polymer involves the diffusion of absorbed moisture from the interior of the polymer chip to its surroundings and,

subsequently the removal of moisture from the bulk of polymer chips. Moisture removal can be achieved by heating the

polymer chip under dry air or vacuum. In an air drying system, heated dehumidified air flows up through a chip bed and

returns to the dehumidifier. The key requirements for a reliable drying process are:

Drying temperature: The ACTUAL chip temperature should achieve between 300° and 330° F measured at the dryer exit.

Dehumidified air temperature: Correctly designed equipment should operate at temperatures up to 340° F measured on entry

to the dryer hopper, with an absolute maximum of 350° F to prevent possible discoloration.

Dehumidified air dew point: This should not be allowed to rise above –34° F and should preferably be –40° F or lower,

measure after the desiccant bed. Always check the correct regeneration temperatures are being used.

Dehumidified air flow through the chip bed: Most dryers operate at around 1 CFM of airflow per 1lb/hr of PET chip as a

minimum requirement, with the airflow at the correct temperature and dew point.

Chip residence time (drying time): DAK recommends a chip residence time for Laser+® PET of not less than four hours and

preferably six hours. This is the theoretical drying time, which is calculated by dividing dryer capacity in lbs. by throughput in

lb./hr. Extended periods of high temperature can adversely affect the polymer processing conditions. In the event of a

stoppage for an extended period, dry polymer can be stored in the dryer-hopper by reducing the air temperature to 240° F (or

even lower).

Important Start-Up and Shut-Down Procedures:

Dryer Start-Up Conditions

When beginning to dry a “wet” load of pellets, start drying at reduced temperatures 135 to 150⁰C (275 to 300⁰F) for 2 hours

Raise the drying temperature to a maximum of 165⁰C (330⁰F) for a single stage drying system for the remaining start-up drying time

Dryer Running Conditions

Shutting Down Dryers

Note: When a stoppage occurs for an extended period of time, dry resin pellets may be stored in the drying vessel at a reduced air

temperature of 115⁰C (240⁰F). Drying of these pellets will not then be necessary, only increasing of the pellet temperature will be required to

restart the system.

(2-4 additional hours)

When running the injection molding machine, it is recommended to not exceed 170⁰C (340⁰F)

Absolute maximum drying condition is 175⁰C (350⁰F).

When higher operational temperatures are used, care should be taken if the machine stops production (idle time of 20+ minutes) to

reduce the drying temperature down to a maximum of 165⁰C (330⁰F) and preferred to be at or below 150⁰C (300⁰F).

Ensure pellet temperature is cooled to below 120⁰C (250⁰F) prior to shutting down process air blower

Time required to reduce the pellet temperature varies on ambient conditions, equipment configuration, and air flow capacity

If pellets reside in drying vessel above the recommended cooled pellet temperature, degradation can occur (IV loss and yellowing)

DAK Americas LLC

Gateway Corporate Center, Suite 210

223 Wilmington W Chester Pike• Chadds Ford, PA 19317

1-888-738-2002 • fax: 610-558-7385 • www.dakamericas.com

Loading...

Loading...