Daitsu FSTD SLIM-01, FSTD SLIM-01-4T, FSTD SLIM-02, FSTD SLIM-02-4T, FSTD SLIM-03 Installation And Maintenance Manual

...Page 1

INSTALLATION AND MAINTENANCE MANUAL

FLOOR CEILING SLIM

FSTD SLIM - EC FLEX

Serie

FSTD SLIM - EC FLEX

Edition

R00

Models

FSTD SLIM-01

FSTD SLIM-02

FSTD SLIM-03

FSTD SLIM-04

FSTD SLIM-05

FSTD SLIM-01-4T

FSTD SLIM-02-4T

FSTD SLIM-03-4T

FSTD SLIM-04-4T

FSTD SLIM-05-4T

Page 2

INVESTING IN QUALITY, RELIABILITY & PERFORMANCE

ISO 9001 QUALITY

World Leading Design and Technology

Every product is manufactured to meet

the stringent requirements of the

internationally recognized ISO 9001

standard for quality assurance in design,

development and production.

Equipped with the latest air-conditioning test rooms

and manufacturing technology, we produce over

50,000 fan coil units each year, all conforming to the

highest international standards of quality and safety.

CE SAFETY STANDARDS

The Highest Standards of Manufacturing

All products conform to the Certificate

Europe directives (Machinery Safety,

Electromagnetic Compatibility and Low

Voltage), as required throughout the

European Community, to guarantee

correct standards of safety.

In order to guarantee the very highest standards and

performance, we manage every stage in the

manufacturing of our products. Throughout the

production process we maintain strict control,

starting with our extensive resources in research and

development through to the design and

manufacture of almost every individual component,

from molded plastics to the assembly of units and

controllers.

WEEE MARK

Quality Controlled from Start to Finish

All products conform to the “WEEE”

directive to guarantee correct standards

of environmental solutions.

Our highly trained staff and strict quality control

methods enable us to produce products with an

exceptional reputation for reliability and efficiency,

maintained over many years. As well as CE

certification and ISO 9001, several products ranges

have UL / ETL safety approval in the USA and Canada,

Eurovent performance and sound certification as

well as ROHS compliance for Europe, giving you the

confidence of knowing our company is the right

choice when selecting fan coil units.

Page 1 of 71

ALWAYS MAKE SURE THIS MANUAL REMAINS WITH THE UNIT. READ THIS MANUAL BEFORE PERFORMING ANY

OPERATION ON THE UNIT.

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 3

Page 2 of 71

Table of Contents

A. Technical Data ...................................................................................................................................................................... 5

General Description ........................................................................................................................................................ 5

General Specification ..................................................................................................................................................... 6

2-Pipe Systems ........................................................................................................................................................ 6

4-Pipe Systems ........................................................................................................................................................ 7

Coil Data ........................................................................................................................................................................ 8

2-Pipe Systems ........................................................................................................................................................ 8

4-Pipe Systems ........................................................................................................................................................ 8

Sound Power Data .......................................................................................................................................................... 9

Dimensions .................................................................................................................................................................. 14

Valve Information (Optional) ........................................................................................................................................ 15

B. Installation ......................................................................................................................................................................... 18

Safety Precautions ........................................................................................................................................................ 18

Installation and Location .............................................................................................................................................. 19

Front Panel Removal .................................................................................................................................................... 20

Electrical Connection .................................................................................................................................................... 20

Piping Connections ....................................................................................................................................................... 22

Valve and External Drain Pan Installation ..................................................................................................................... 23

C. Maintenance ...................................................................................................................................................................... 25

General Maintenance ................................................................................................................................................... 25

Regular Maintenance ................................................................................................................................................... 25

Filter Installation & Cleaning ........................................................................................................................................ 25

Fan Motor Assembly Maintenance ............................................................................................................................... 26

Water Fittings Interchange ........................................................................................................................................... 26

D. Control Specifications: Complete Function PCB – TOTAL Type Control .............................................................................. 27

I/O Port Definitions ...................................................................................................................................................... 27

Wiring Diagrams .......................................................................................................................................................... 28

Standard EC-TOTAL Type Control PCB .................................................................................................................... 28

Master-Slave Networking Wiring Diagram ............................................................................................................. 29

Configuration Settings .................................................................................................................................................. 30

Control Logics for 2-Pipe System ................................................................................................................................... 32

With Valve Configuration ....................................................................................................................................... 32

Without Valve Configuration ................................................................................................................................. 35

Control Logics For 4-Pipe System .................................................................................................................................. 37

Sleep Mode .................................................................................................................................................................. 39

Auto Fan Speed ............................................................................................................................................................ 39

Modulating Valve Control Under Energy Saving Mode ................................................................................................. 39

Buzzer .......................................................................................................................................................................... 39

Auto Restart ............................................................................................................................................................... 39

On/Off Switch On The Front Panel .............................................................................................................................. 40

Electric Heater Safety Switch ...................................................................................................................................... 40

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 4

Page 3 of 71

Low Temperature Protection of Indoor Coil in Winter ................................................................................................. 40

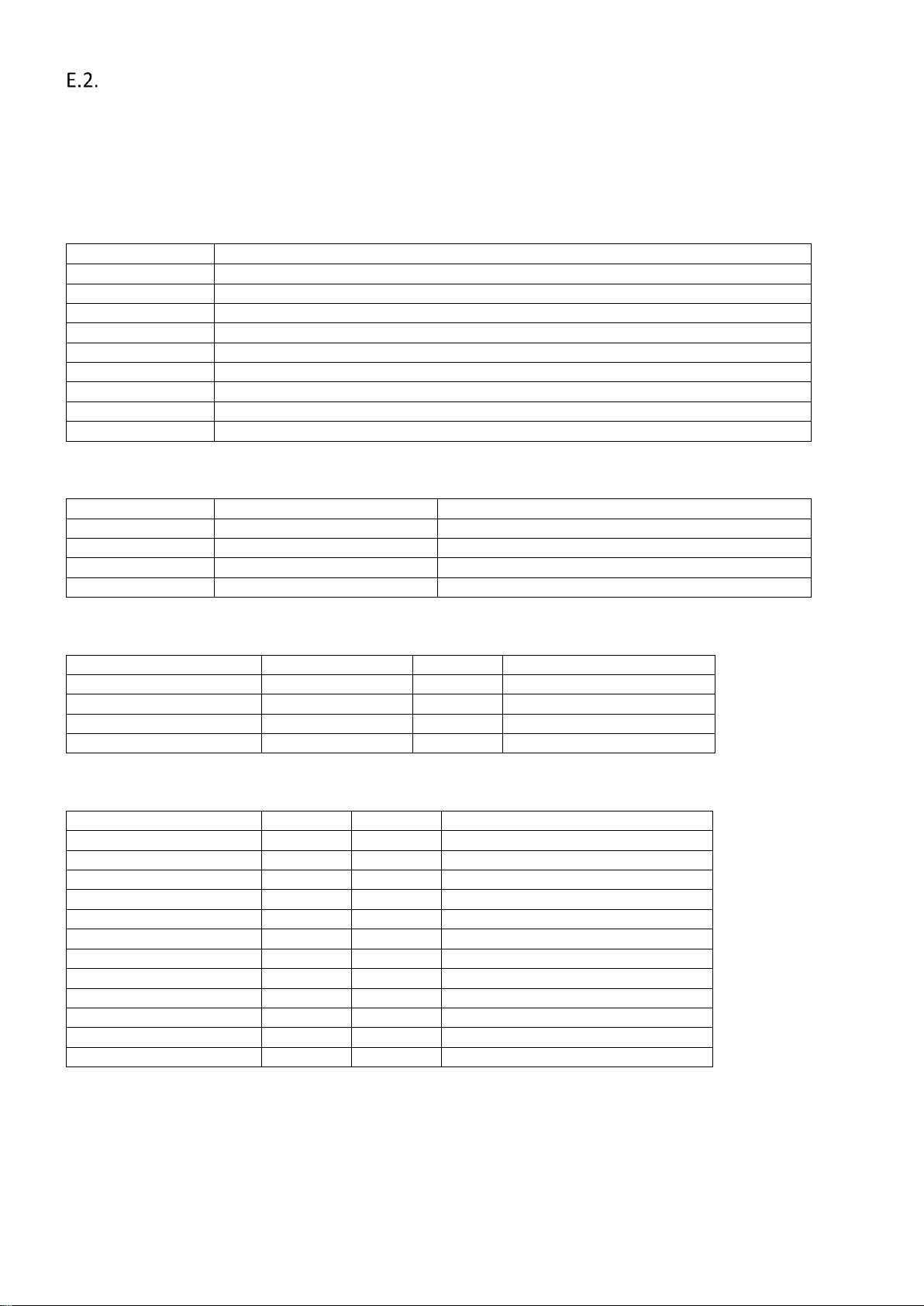

E. Networking System ............................................................................................................................................................ 41

Master-Slave Network .................................................................................................................................................. 41

Master Unit Control Settings .................................................................................................................................. 41

Master-Slave Network Setup ................................................................................................................................. 42

Master-Slave Communication Method ................................................................................................................... 44

Open Modbus protocol ................................................................................................................................................. 45

F. Control Specifications: Flexible Function PCB – FLEXI Type Control .................................................................................... 48

Features ........................................................................................................................................................................ 48

I/O Port Definitions ....................................................................................................................................................... 48

Onboard Configuration ................................................................................................................................................. 48

Wiring Diagrams ........................................................................................................................................................... 49

Standard EC-FLEXI Type Control PCB....................................................................................................................... 49

Control Logics Specification ........................................................................................................................................... 50

Unit Power On/Off ................................................................................................................................................. 50

Alarm Protection and Error Display ........................................................................................................................ 50

Drain Pump Operation ........................................................................................................................................... 50

Modulating Signal Input ......................................................................................................................................... 50

Electrical Heater Operation .................................................................................................................................... 50

Low Temperature Protection of Indoor Coil in Winter ............................................................................................ 50

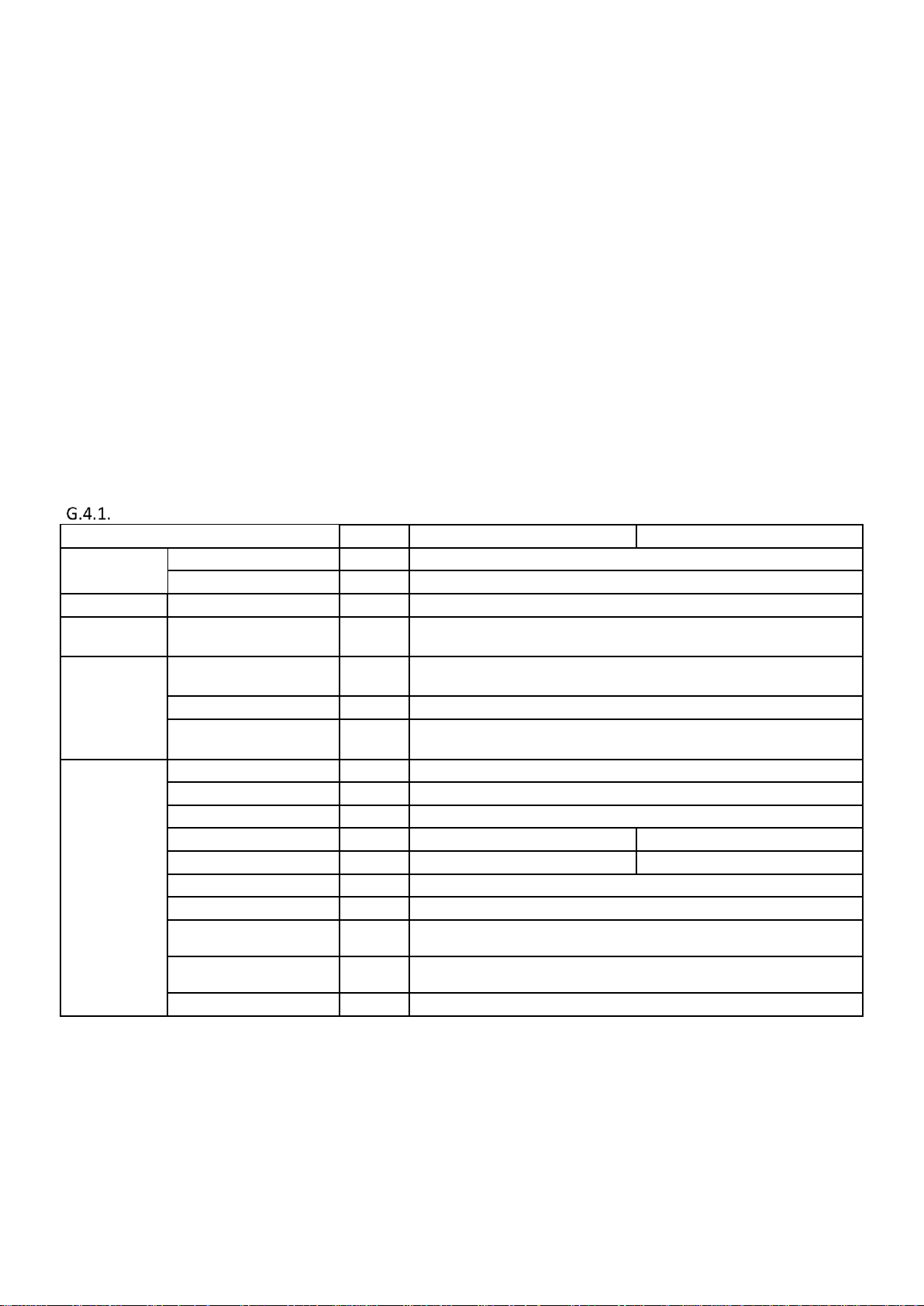

G. User Interface .................................................................................................................................................................... 51

Remote Handset for TOTAL Type Control ...................................................................................................................... 51

Wired Wall Pad Controller ............................................................................................................................................ 52

Thermostat for EC-FLEXI Type Control .......................................................................................................................... 56

LED display ............................................................................................................................................................ 56

Parameters setting ................................................................................................................................................ 57

AC/EC fan coil thermostat ............................................................................................................................................ 58

I/O table ................................................................................................................................................................ 59

Thermostat control specification ........................................................................................................................... 60

2-pipe thermostat control specification (Parameter 17=0) .................................................................................... 60

4-pipe thermostat control specification (Parameter 17=1) .................................................................................... 62

2-pipe +floor heating control specification (Parameter 17=2) ................................................................................ 64

MODBUS Communication Protocols for Thermostat ............................................................................................. 65

H. Sensor Resistance R-T Conversion Table ............................................................................................................................ 67

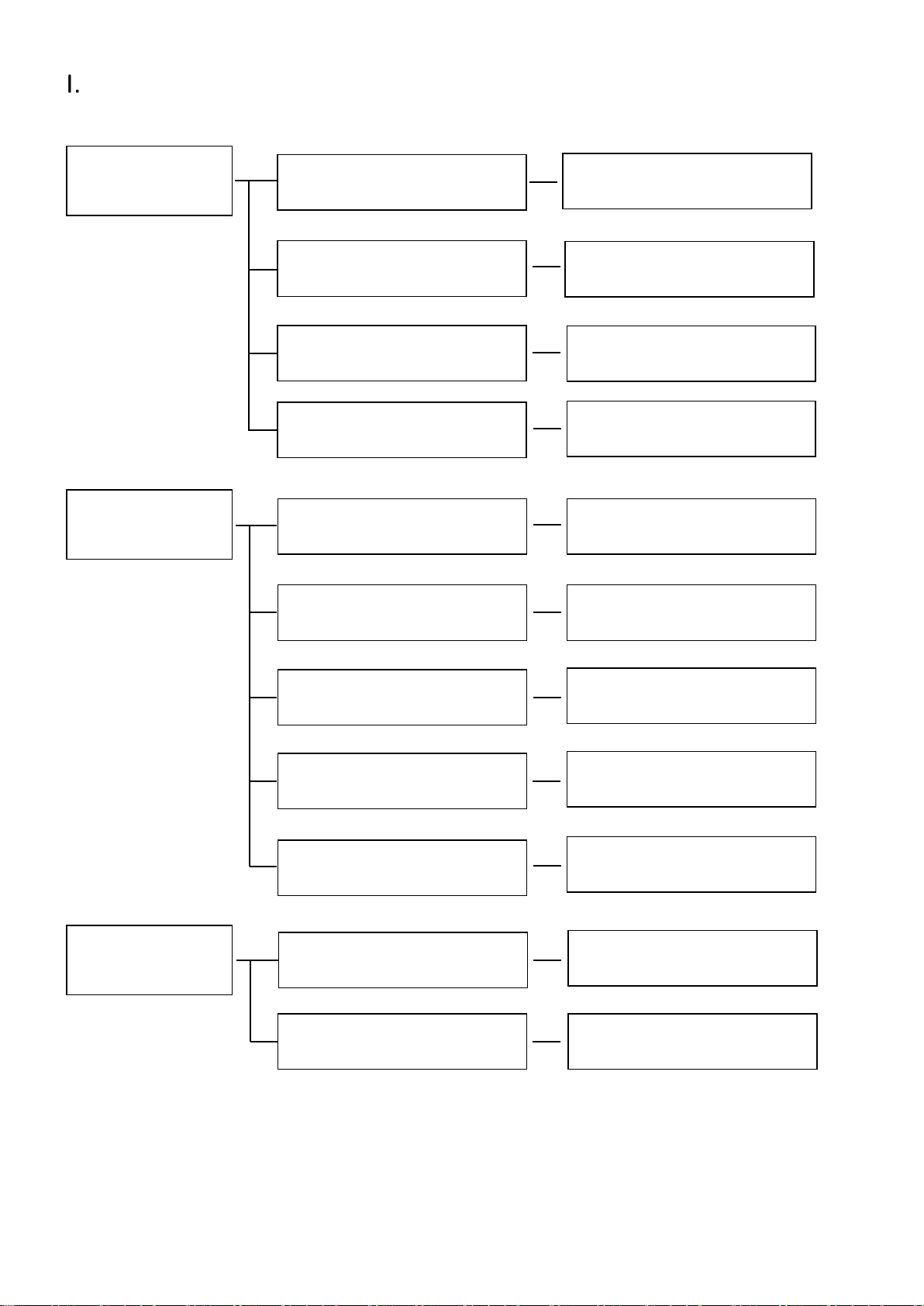

I. Troubleshooting .................................................................................................................................................................. 69

J. Accessories Descriptions ..................................................................................................................................................... 70

Electrical Heater ............................................................................................................................................................ 70

Auxiliary External Drain Pan .......................................................................................................................................... 71

Supporting Feet ............................................................................................................................................................. 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 5

Model Code Nomenclature

FSTD SLIM

-

01

-

4T

FLEX-

EC

EC

EC Motor Configuration

FLEX

Flexible function onboard PCB with zone

control functionality.

4T

Chilled/Hot Water, 4-Pipe

01 - 05

Unit Sizes. See General Specification

section A for cooling and heating

capacities

FSTD SLIM

Super Slim Universal Unit

Page 4 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 6

Page 5 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Technical Data

General Description

The product represents all-in-one solution for cooling, heating and dehumidification. It achieves high energy saving levels as it

can be combined with low-temperature heat generators such as heat pump, condensing boilers and solar collectors. With its

sophisticated temperature regulator, it guarantees thermal comfort in every season. It heats and cools extremely quickly and

once the desired temperature is reached it maintains it accurately and silently.

STRUCTURE

The bearing structure is made of galvanized sheet-steel with holes for attaching the structure to the wall/ceiling. The “V” type

drain pan is used in the unit which ensure the unit can be installed vertically and horizontally. Fire resistant insulation is fitted

internally to provide both thermal and acoustic insulation.

FASCIA

The RAL9010 fascia is made of steel-sheet with electrostatic coating which is resistant to rust, corrosion, chemical agents,

solvents, aliphatic compounds and alcohols.

AIR DELIVERY GRILLE

The air delivery grill is made from ABS, which color is RAL9010.

HEAT EXCHANGER

The heat exchanger is a highly efficient coil in which copper pipes and aluminum fins are fixed by mechanical expansion. Coil

connections are provided with an anti-torsion system, hand air vent and water purge valves.

Coils are tested at the pressure of 25 bar and recommended for operating at 8 bar.

Blower and Motor

The unit incorporates only specially designed and tested EC motors, allowing the blower wheel to provide optimum

performance in airflow-efficiency and quiet operation.

AIR FILTER

The air filter is made of ABS with Nylon filter. It is easy to removing and cleaning, which can be cleaned by rinsing with water

or by gently vacuuming it.

Microprocessor controls (EC-TOTAL type)

The PCB (printed circuit board) Modbus microprocessor controls functionality of the indoor fan motor, water valves (ON/OFF)

and electric heater (optional), to maintain room conditions at a user-defined set point. Temperature settings, fan speeds and

other control functions can be changed by either infrared handset or wired wall pad controller.

Electro-mechanical controls (EC-FLEXI type)

A 230VAC signal from the thermostat which working power is from L and N or from indoor room to terminal H/M/L supplies

power to limited PCB. When any of H/M/L is powered ON, the stepping motor is working and open the louver at maximum

position. When all of H/M/L is powered OFF, the stepping motor will close the louver. The condensate pump will run

continuously, as long as coil temperature is less than 15°C. Alarm notification and zone control function are available. 40VA

24vac transformer is equipped with unit optionally, which is used to supply 24Vac power to thermostat and modulating valve.

EC-TOTAL-version unit

EC-FLEXI-version unit

Thermostat-(optional)

Page 7

General Specification

FSTD SLIM-[Size]-EC

01

02

03

04

05

Unit Configuration

Configuration

2-pipe

Number Of Fan Blowers

1

2

Power Supply

(V/Ph/Hz)

230/1/50

220/1/60

Operation Control

~TOTAL: Complete function onboard PCB with integrated group control

functionality.

~FLEXI: Flexible function onboard PCB with zone control functionality.

Performance Data

Air

Air Flow

H

m3/hr

184

300

420

524

590 M 146

230

333

412

450 L 92

142

228

337

392

Cooling

Cooling

Capacity

H

kW

0.96

1.64

2.36

2.93

3.4 M 0.8

1.34

1.99

2.44

2.78

L

0.56

0.92

1.48

2.1

2.5

Sensible

Cooling

Capacity

H

0.7

1.17

1.66

2.07

2.39

M

0.57

0.94

1.38

1.71

1.92

L

0.39

0.63

1.01

1.46

1.73

FCEER

Rating

73.7

94.0

118.1

163.2

180.9

Class

D C C B B

Heating

Heating

Capacity

H

kW

1

1.66

2.34

2.93

3.36

M

0.84

1.36

1.98

2.45

2.75

L

0.58

0.94

1.47

2.1

2.47

Max. Electric Heater

Capacity

0.75

1.0

1.5

2.0

FCCOP

Rating

76.0

95.3

116.5

164.9

180.8

Class

D D C B B

Noise

Sound Pressure Level

dB(A)

39/33/28

43/37/3

1

45/41/34

47/41/35

49/45/38

Sound Power Level

48/42/37

52/46/4

0

54/50/43

56/50/44

58/54/47

Electrical

Fan Motor

Power

H

W

13

18.7

20.3

23

24 M 10

13.6

15.8

16

16.7 L 8

10

13

12

12.8

Fan Motor Running

Current @ H

A

0.13

0.162

0.176

0.2

0.21

Hydraulic

Cooling

Water Flow

Rate

H

L/h

164

281

405

501

582 M 137

229

341

418

475 L 96

157

254

360

428

Cooling

Pressure

Drop

H

kPa

2.9

9.6

22.2

12.6

18.9 M 2.2

6.8

16.6

9.3

13.4

L

1.18

3.6

10

7.2

11.25

Heating

Water Flow

Rate

L/h

170.9

284.6

401.6

501.9

576

144.3

233.2

339.2

419.7

472

100.1

161.2

252.8

359.9

423.2

Heating

Pressure

Drop

H

kPa

2.6

8.1

18.2

10.5

15.5

M

1.9

5.8

13.6

7.7

11. L 1

3.1

8.3

5.9

9.2

Water Content

L

0.44

0.73

1.03

1.32

1.61

Construction and Packing

Data

Water

Type

Socket (Threaded Female)

In

mm[in]

19.05 [3/4]

Out

Condensate Drainage

Connection

16 [5/8]

Dimensions

L

mm

740

940

1140

1340

1540

W

130

130

130

130

130 H 580

580

580

580

580

Net Weight

kg

19

22

25

28

31

a. Cooling mode (2-pipe):

b. Heating mode (2-pipe):

- Return air temperature: 27C DB/ 19C WB.

- Return air temperature: 20C.

- Inlet/ outlet water temperature: 7C/ 12C.

- Inlet/ outlet water temperature: 45C/ 40C.

2-Pipe Systems

Product range: FSTD SLIM-EC Super Slim Universal Fan Coil with EC Motor

FSTD SLIM~-EC Super Slim Universal Unit 2-pipe with EC Motor

Page 6 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 8

4-Pipe Systems

FSTD SLIM-[Size]-4T-EC

01

02

03

04

05

Unit Configuration

Configuration

4-pipe

Number Of Fan Blowers

1

2

Power Supply

(V/Ph/Hz)

230/1/50

220/1/60

Operation Control

~TOTAL: Complete function onboard PCB with integrated group control

functionality.

~FLEXI: Flexible function onboard PCB with zone control functionality.

Performance Data

Air

Air Flow

H

m3/hr

184

300

420

524

590 M 146

230

333

412

450 L 92

142

228

337

392

Cooling

Cooling Capacity

H

kW

0.95

1.6

2.27

2.85

3.3 M 0.8

1.31

1.92

2.37

2.7 L 0.56

0.89

1.43

2.04

2.43

Sensible Cooling

Capacity

H

0.68

1.12

1.6 2 2.31 M 0.56

0.9

1.33

1.65

1.87

L

0.38

0.61

0.97

1.41

1.68

FCEER

Rating

73.6

91.3

114.0

158.5

175.8

Class

D C C B B

Heating

Heating Capacity

H

kW

1.08

1.76

2.49

3.09

3.59

M

0.89

1.44

2.08

2.58

2.91 L 0.62

0.99

1.55

2.2

2.6

FCCOP

Rating

81.0

100.6

122.8

173.1

190.8

Class

D C C B B

Noise

Sound Pressure Level

dB(A)

39/33/28

43/37/31

45/41/34

47/41/35

49/45/38

Sound Power Level

48/42/37

52/46/40

54/50/43

56/50/44

58/54/47

Electrical

Fan Motor Power

H

W

13

18.7

20.3

23

24 M 10

13.6

15.8

16

16.7 L 8

10

13

12

12.8

Fan Motor Running Current @ H

A

0.13

0.162

0.176

0.2

0.21

Hydraulic

Cooling Water Flow

Rate

H

L/h

164

274

390

488

566 M 137

224

329

407

463 L 96

153

244

350

417

Cooling Pressure Drop

H

kPa

9.2

29.8

23

18.4

27.9 M 6.8

21.1

17.1

13.6

19.8 L 3.7

11.1

10.3

10.5

16.6

Hot Water Flow Rate

H

L/h

92

151

214

265

308 M 77

123

179

221

249

L

53

85

133

189

223

Heating Pressure Drop

H

kPa

8.8

28.8

67.6

17.3

26.5 M 6.4

20.3

49.9

12.7

18.5

L

3.5

10.9

30.3

9.7

15.4

Water Content – Chill Water

L

0.23

0.38

0.53

0.68

0.83

Water Content – Hot Water

0.115

0.19

0.265

0.34

0.415

Construction and

Packing Data

Water Type

Socket (Threaded Female)

Chilled Water

In

mm[in]

12.7 [1/2]

Out

Hot Water

In

Out

Condensate Drainage Connection

16 [5/8]

Dimensions

L

mm

740

940

1140

1340

1540 W 130

130

130

130

130 H 580

580

580

580

580

Net Weight

kg

19

22

25

28

31

a. Cooling mode (4-pipe)

b. Heating mode (4-pipe):

- Return air temperature: 27C DB/ 19C WB.

- Return air temperature: 20C.

- Inlet/ outlet water temperature: 7C/ 12C.

- Inlet/ outlet water temperature: 65C/ 55C.

Product range: FSTD SLIM-4T~-ECM Super Slim Universal Unit 4-pipe with EC Motor

FSTD SLIM-4T~-ECM Super Slim Universal Unit 4-pipe with EC Motor

Page 7 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 9

Coil Data

Model

Fin

height

(mm)

Fin

Length

(mm)

Fins per

Inch

No. of

Rows

Fin width

(mm)

No. of

Circuits

Tube Ø

(mm)

FSTD SLIM-01

300

301

12.7 2 44 2 9.52

FSTD SLIM-02

501

2

FSTD SLIM-03

701

2

FSTD SLIM-04

901

3

FSTD SLIM-05

1101

3

Model

Fin

height

(mm)

Fin

Length

(mm)

Fins per

Inch

No. of

Rows

Fin width

(mm)

No. of

Circuits

Tube Ø

(mm)

294

301

16.5

2

25.4 2 7

501

2

701

3

901

4

1101

4

Fin

height

(mm)

Fin Length

(mm)

Fins per

Inch

No. of

Rows

Fin width

(mm)

No. of

Circuits

Tube Ø

(mm)

294

301

16.5

1

12.7 1 7

501

1

701

1

901

2

1101

2

2-Pipe Systems

4-Pipe Systems

Cooling Coil

Page 8 of 71

FSTD SLIM-01-4T

FSTD SLIM-02-4T

FSTD SLIM-03-4T

FSTD SLIM-04-4T

FSTD SLIM-05-4T

Heating Coil

Model

FSTD SLIM-01-4T

FSTD SLIM-02-4T

FSTD SLIM-03-4T

FSTD SLIM-04-4T

FSTD SLIM-05-4T

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 10

Page 9 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

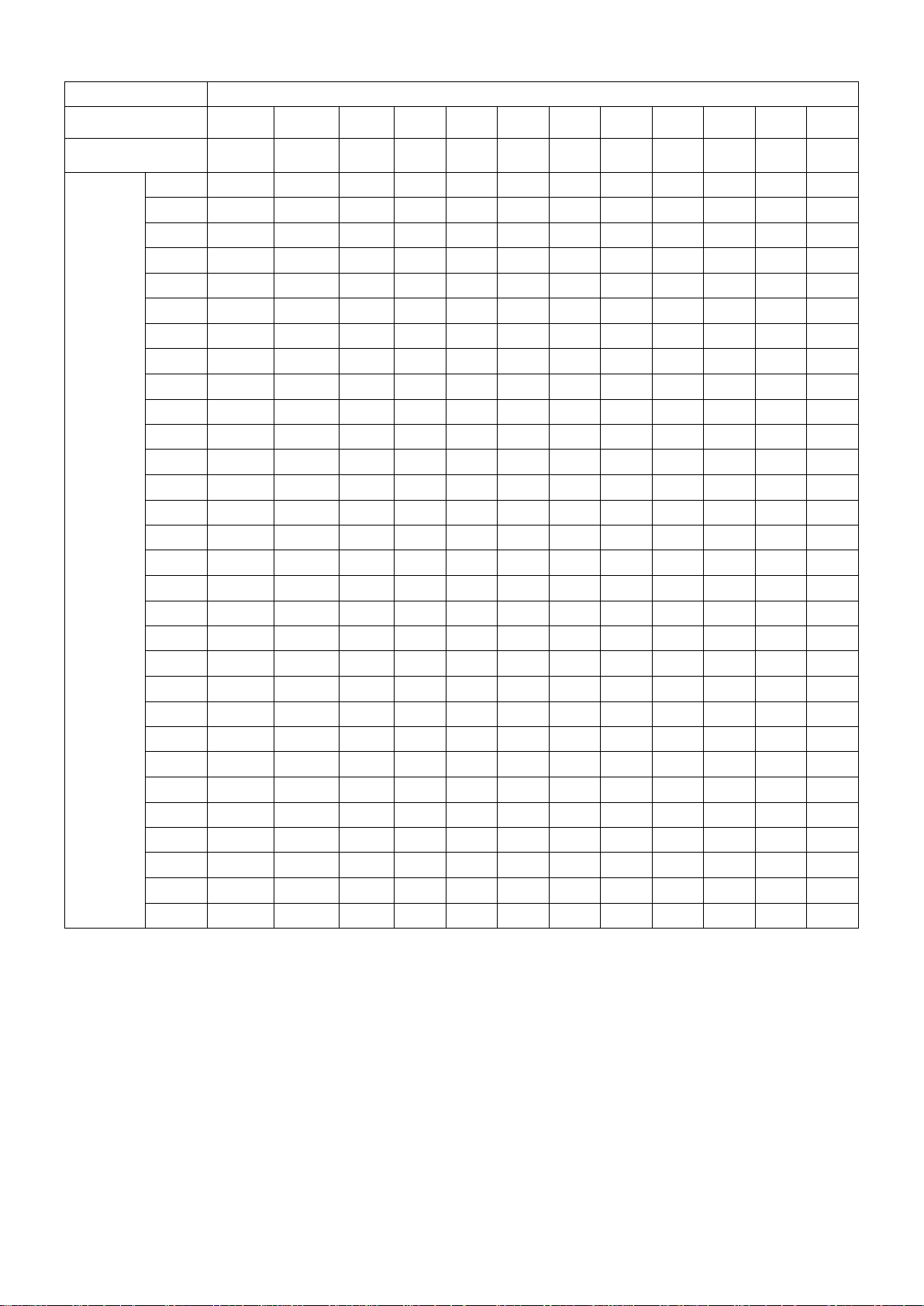

Sound Power Data

Model

FSTD SLIM-01

Speed

H(1200

RPM)

M(1000

RPM)

L(800

RPM)

500RPM

600RPM

700RPM

800RPM

900RPM

1000RPM

1100RPM

1200RPM

1300RPM

1400RPM

Sound Power dB(A)

50.2

44.2

38.1

27.4

30.2

33.8

38.1

41.2

44.2

47

50.2

52

54.5

Sound Po

wer in 1/3 Octave

-bands under ESP:0P

(dB)

20 Hz

13.8

15.7

8.8

12

10.1

11.4

8.8

12.2

15.7

9.2

13.8

14.4

15.6

25 Hz

13.6

12

13.6

12.7

10.5 7 13.6

12.5

12

7.3

13.6

13.2

12.7

31.5 Hz

7.4

10.7

10.8

8.1

6.4

3.1

10.8

5.7

10.7

6.5

7.4 7 5.5

40 Hz

3.8

9.2

14.5

4.6

3.5

3.2

14.5

2.6

9.2 9 3.8

3.5

13.6

50 Hz

8.2 6 10.1

6.9

5.4

7.1

10.1

10.4 6 9.8

8.2

13.2

14.6

63 Hz

9.2

5.6

3.3

5.2

3.4

3.3

3.3

5.2

5.6 8 9.2

12

10.9

80 Hz

11.7

4.5

0.5

-4.1

0.4

0.1

0.5 9 4.5

8.2

11.7

14.1

15.4

100 Hz

14.2

11.6

3.1

1.7

4.1

5.4

3.1

9.8

11.6

14.3

14.2

17.8

21

125 Hz

20.2

16.1

12.1

3.7

10.2

14.5

12.1

15.2

16.1

18.6

20.2

23

26

160 Hz

24.2

21.6

19.2

7.8

10.3

13.9

19.2

19

21.6

22.4

24.2

26.2

26.6

200 Hz

27

24.6

18.2

10.5

13

14.1

18.2

21.2

24.6

26.2

27

27.7

29.8

250 Hz

36.3

32.2

26.3

17.8

22.1

24.5

26.3

30.2

32.2

34

36.3

41

40.5

315 Hz

31

26.8

20.3

15.8

17.7

19.7

20.3

26.5

26.8

28.9

31

33.2

36.9

400 Hz

36.8

31.1

27

15.7

20

25.5

27

29.8

31.1

35.4

36.8

39.7

39.5

500 Hz

39.7

35.9

33.7

16.1

21.7

25.3

33.7

34

35.9

38

39.7

40.8

42.8

630 Hz

42.4

36.6

29.3

13.2

19.7

24.8

29.3

32.4

36.6

39.3

42.4

42.2

45.2

800 Hz

40.9

35.7

29.2

12

18.1

22.7

29.2

33.2

35.7

38.6

40.9

42.9

48.1

1000 Hz

42.3

36.2

26.7

12.6

18.6

23.7

26.7

33.6

36.2

39.7

42.3

45.2

48.8

1250 Hz

40.2

33.5

24.4

12.2

16

20.8

24.4

29.8

33.5

37.6

40.2

42.7

45.4

1600 Hz

37.4

30.5

22.1

13.6

14.8

17.7

22.1

27.4

30.5

34.4

37.4

40

42.8

2000 Hz

34.2

26.7

19.3

13.2

13.6

15.8

19.3

23.8

26.7

31.2

34.2

37.3

39.4

2500 Hz

32.5

25.1

18.9

14.3

14.7

17.9

18.9

21.9

25.1

29.4

32.5

35.5

38.2

3150 Hz

32.1

23.3

15.8

13.8

14

14.1

15.8

19.9

23.3

28

32.1

35.4

38.3

4000 Hz

27.2

18.8

14.5

13.8

14.1

14.1

14.5

16.3

18.8

23.5

27.2

30.6

34.1

5000 Hz

24.5

16.5

14.3

13.8

14

13.8

14.3

15

16.5

20.7

24.5

28.6

31.8

6300 Hz

19.4

14.8

13.7

13.5

13.4

13.6

13.7

13.8

14.8

16.8

19.4

23.1

26.7

8000 Hz

16

13.2

13

12.8

12.9

13

13

12.9

13.2

14.1

16

19.4

22.7

10000 Hz

13.3

12

11.8

11.2

11.4

11.6

11.8

11.6

12

12.2

13.3

15.2

17.7

12500 Hz

7.8

7.9

7.6

7.5

7.6

8.5

7.6

7.7

7.9

7.7

7.8

8.6

9.9

16000 Hz

11.7

11.2

9.9

7.6

8.7

11.3

9.9

10.6

11.2

11.7

11.7

12

12.5

Page 11

Page 10 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Model

FSTD SLIM-02

Speed

H(1200

RPM)

M(1000

RPM)

L(800

RPM)

500RPM

600RPM

700RPM

800RPM

900RPM

1000RPM

1100RPM

1200RPM

1300RPM

1400RPM

Sound Power dB(A)

52.2

46.2

40.1

29.4

32.2

35.8

40.1

43.2

46.2

49.0

52.2

54.0

56.5

Sound Power in 1/3 Octave

-bands under ESP:0Pa

(dB)

20.0 Hz

15.8

17.7

10.8

14.0

12.1

13.4

10.8

14.2

17.7

11.2

15.8

16.4

17.6

25.0 Hz

15.6

14.0

15.6

14.7

12.5

9.0

15.6

14.5

14.0

9.3

15.6

15.2

14.7

31.5 Hz

9.4

12.7

12.8

10.1

8.4

5.1

12.8

7.7

12.7

8.5

9.4

9.0

7.5

40.0 Hz

5.8

11.2

16.5

6.6

5.5

5.2

16.5

4.6

11.2

11.0

5.8

5.5

15.6

50.0 Hz

10.2

8.0

12.1

8.9

7.4

9.1

12.1

12.4

8.0

11.8

10.2

15.2

16.6

63.0 Hz

11.2

7.6

5.3

7.2

5.4

5.3

5.3

7.2

7.6

10.0

11.2

14.0

12.9

80.0 Hz

13.7

6.5

2.5

-2.1

2.4

2.1

2.5

11.0

6.5

10.2

13.7

16.1

17.4

100.0 Hz

16.2

13.6

5.1

3.7

6.1

7.4

5.1

11.8

13.6

16.3

16.2

19.8

23.0

125.0 Hz

22.2

18.1

14.1

5.7

12.2

16.5

14.1

17.2

18.1

20.6

22.2

25.0

28.0

160.0 Hz

26.2

23.6

21.2

9.8

12.3

15.9

21.2

21.0

23.6

24.4

26.2

28.2

28.6

200.0 Hz

29.0

26.6

20.2

12.5

15.0

16.1

20.2

23.2

26.6

28.2

29.0

29.7

31.8

250.0 Hz

38.3

34.2

28.3

19.8

24.1

26.5

28.3

32.2

34.2

36.0

38.3

43.0

42.5

315.0 Hz

33.0

28.8

22.3

17.8

19.7

21.7

22.3

28.5

28.8

30.9

33.0

35.2

38.9

400.0 Hz

38.8

33.1

29.0

17.7

22.0

27.5

29.0

31.8

33.1

37.4

38.8

41.7

41.5

500.0 Hz

41.7

37.9

35.7

18.1

23.7

27.3

35.7

36.0

37.9

40.0

41.7

42.8

44.8

630.0 Hz

44.4

38.6

31.3

15.2

21.7

26.8

31.3

34.4

38.6

41.3

44.4

44.2

47.2

800.0 Hz

42.9

37.7

31.2

14.0

20.1

24.7

31.2

35.2

37.7

40.6

42.9

44.9

50.1

1000.0 Hz

44.3

38.2

28.7

14.6

20.6

25.7

28.7

35.6

38.2

41.7

44.3

47.2

50.8

1250.0 Hz

42.2

35.5

26.4

14.2

18.0

22.8

26.4

31.8

35.5

39.6

42.2

44.7

47.4

1600.0 Hz

39.4

32.5

24.1

15.6

16.8

19.7

24.1

29.4

32.5

36.4

39.4

42.0

44.8

2000.0 Hz

36.2

28.7

21.3

15.2

15.6

17.8

21.3

25.8

28.7

33.2

36.2

39.3

41.4

2500.0 Hz

34.5

27.1

20.9

16.3

16.7

19.9

20.9

23.9

27.1

31.4

34.5

37.5

40.2

3150.0 Hz

34.1

25.3

17.8

15.8

16.0

16.1

17.8

21.9

25.3

30.0

34.1

37.4

40.3

4000.0 Hz

29.2

20.8

16.5

15.8

16.1

16.1

16.5

18.3

20.8

25.5

29.2

32.6

36.1

5000.0 Hz

26.5

18.5

16.3

15.8

16.0

15.8

16.3

17.0

18.5

22.7

26.5

30.6

33.8

6300.0 Hz

21.4

16.8

15.7

15.5

15.4

15.6

15.7

15.8

16.8

18.8

21.4

25.1

28.7

8000.0 Hz

18.0

15.2

15.0

14.8

14.9

15.0

15.0

14.9

15.2

16.1

18.0

21.4

24.7

10000.0 Hz

15.3

14.0

13.8

13.2

13.4

13.6

13.8

13.6

14.0

14.2

15.3

17.2

19.7

12500.0 Hz

9.8

9.9

9.6

9.5

9.6

10.5

9.6

9.7

9.9

9.7

9.8

10.6

11.9

16000.0 Hz

13.7

13.2

11.9

9.6

10.7

13.3

11.9

12.6

13.2

13.7

13.7

14.0

14.5

Page 12

Page 11 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Model

FSTD SLIM-03

Speed

H (1200RPM)

M 1000RPM)

L (800RPM)

800RPM

900RPM

1000RPM

1100RPM

1200RPM

1300RPM

1400RPM

Sound Power dB(A)

54.7

48.9

42.3

42.3

45.8

48.9

51.8

54.7

56.6

59.0

Sound Power in 1/3 Octave

-bands under ESP:0

Pa (dB)

20.0 Hz

10.0

6.8

7.6

7.6

8.6

6.8

11.4

10.0

1.5

8.6

25.0 Hz

7.2

4.1

6.5

6.5

3.8

4.1

8.4

7.2

5.2

7.2

31.5 Hz

8.2

3.0

-0.9

-0.9

0.1

3.0

-0.4

8.2

4.5

5.4

40.0 Hz

4.6

3.2

-0.1

-0.1

1.5

3.2

3.9

4.6

5.1

5.8

50.0 Hz

6.9

3.7

5.5

5.5

4.6

3.7

8.4

6.9

6.1

10.0

63.0 Hz

12.0

4.5

3.7

3.7

2.3

4.5

7.7

12.0

12.7

13.0

80.0 Hz

11.8

7.5

3.2

3.2

7.8

7.5

12.2

11.8

12.3

17.8

100.0 Hz

19.2

14.2

9.6

9.6

10.6

14.2

16.9

19.2

20.5

22.6

125.0 Hz

22.2

20.1

15.1

15.1

18.5

20.1

22.2

22.2

26.1

28.6

160.0 Hz

28.8

25.3

22.2

22.2

22.4

25.3

25.3

28.8

29.4

32.3

200.0 Hz

31.1

29.5

21.8

21.8

22.4

29.5

32.4

31.1

30.9

33.2

250.0 Hz

45.6

36.7

34.7

34.7

34.1

36.7

38.2

45.6

42.7

46.7

315.0 Hz

36.3

33.9

28.0

28.0

31.3

33.9

34.4

36.3

37.6

41.8

400.0 Hz

40.2

35.7

30.2

30.2

34.3

35.7

39.7

40.2

42.8

44.6

500.0 Hz

43.0

39.3

34.8

34.8

37.7

39.3

40.5

43.0

44.7

48.4

630.0 Hz

44.8

40.7

32.9

32.9

36.7

40.7

43.2

44.8

46.2

47.6

800.0 Hz

46.0

39.8

33.5

33.5

37.4

39.8

42.8

46.0

48.6

52.4

1000.0 Hz

48.0

41.6

34.0

34.0

38.8

41.6

44.9

48.0

49.7

52.0

1250.0 Hz

46.3

39.9

32.8

32.8

35.8

39.9

43.3

46.3

48.6

51.2

1600.0 Hz

43.2

36.5

29.1

29.1

32.7

36.5

39.8

43.2

45.5

48.2

2000.0 Hz

40.0

33.0

25.1

25.1

29.1

33.0

36.9

40.0

42.6

45.9

2500.0 Hz

38.5

31.3

23.7

23.7

27.2

31.3

35.0

38.5

41.4

44.3

3150.0 Hz

37.5

30.0

21.3

21.3

25.1

30.0

33.3

37.5

41.0

43.3

4000.0 Hz

34.1

26.0

19.0

19.0

22.4

26.0

29.7

34.1

37.7

40.5

5000.0 Hz

31.9

23.8

19.5

19.5

21.8

23.8

27.9

31.9

35.6

38.4

6300.0 Hz

27.0

21.0

18.2

18.2

19.1

21.0

22.9

27.0

30.6

34.0

8000.0 Hz

22.8

17.9

15.7

15.7

17.0

17.9

19.5

22.8

26.4

30.4

10000.0 Hz

18.9

15.5

13.9

13.9

14.9

15.5

16.3

18.9

21.4

24.8

12500.0 Hz

12.8

11.8

10.6

10.6

11.9

11.8

12.6

12.8

14.0

16.0

16000.0 Hz

13.0

11.2

8.3

8.3

17.8

11.2

13.6

13.0

13.0

13.1

Page 13

Page 12 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Model

FSTD SLIM-04

Speed

H (1200RPM)

M 1000RPM)

L (800RPM)

800RPM

900RPM

1000RPM

1100RPM

1200RPM

1300RPM

1400RPM

Sound Power dB(A)

55.1

49.8

42.9

42.9

46.6

49.8

52.8

55.1

57.3

59.8

Sound Power in 1/3 Octave

-bands under ESP:0Pa

(dB)

20.0 Hz

17.9

13.0

13.5

13.5

12.0

13.0

18.3

17.9

15.7

18.8

25.0 Hz

11.2

14.5

13.8

13.8

11.3

14.5

11.8

11.2

14.0

12.2

31.5 Hz

9.9

6.3

3.2

3.2

8.3

6.3

9.8

9.9

6.3

8.2

40.0 Hz

11.8

4.8

2.7

2.7

3.2

4.8

9.0

11.8

5.9

7.7

50.0 Hz

9.1

10.3

6.2

6.2

4.3

10.3

9.1

9.1

8.9

8.4

63.0 Hz

10.6

9.0

4.3

4.3

8.5

9.0

9.0

10.6

13.5

16.0

80.0 Hz

13.4

10.7

2.8

2.8

6.1

10.7

11.3

13.4

14.0

20.2

100.0 Hz

21.6

16.2

9.7

9.7

11.0

16.2

19.2

21.6

20.2

25.3

125.0 Hz

24.5

27.3

14.6

14.6

20.2

27.3

25.4

24.5

27.7

31.3

160.0 Hz

29.4

22.6

18.9

18.9

22.2

22.6

27.3

29.4

29.2

32.3

200.0 Hz

29.6

27.8

22.2

22.2

23.5

27.8

28.6

29.6

32.2

34.3

250.0 Hz

41.2

36.1

33.1

33.1

34.0

36.1

39.1

41.2

43.7

45.0

315.0 Hz

36.5

33.9

27.9

27.9

30.6

33.9

34.2

36.5

37.4

40.0

400.0 Hz

41.4

37.3

29.8

29.8

33.7

37.3

39.0

41.4

42.0

43.2

500.0 Hz

44.5

40.9

35.8

35.8

39.6

40.9

42.3

44.5

45.7

47.3

630.0 Hz

46.5

42.4

33.7

33.7

37.4

42.4

44.4

46.5

47.5

48.0

800.0 Hz

47.4

41.2

33.6

33.6

38.0

41.2

44.5

47.4

49.3

53.8

1000.0 Hz

47.2

41.8

33.7

33.7

38.5

41.8

45.1

47.2

50.5

52.1

1250.0 Hz

47.8

41.7

33.3

33.3

37.9

41.7

45.4

47.8

50.6

52.4

1600.0 Hz

43.6

37.9

29.5

29.5

34.1

37.9

40.8

43.6

46.1

49.4

2000.0 Hz

41.2

34.8

25.3

25.3

30.5

34.8

38.2

41.2

43.6

46.8

2500.0 Hz

38.9

32.4

23.2

23.2

28.2

32.4

36.1

38.9

42.2

45.1

3150.0 Hz

38.4

30.7

21.1

21.1

25.6

30.7

34.8

38.4

41.4

44.4

4000.0 Hz

34.8

27.3

18.4

18.4

22.3

27.3

31.3

34.8

38.4

41.7

5000.0 Hz

32.1

24.2

17.1

17.1

19.8

24.2

28.3

32.1

35.5

39.1

6300.0 Hz

27.6

19.8

15.8

15.8

17.0

19.8

23.3

27.6

31.0

35.6

8000.0 Hz

23.3

16.5

14.7

14.7

15.0

16.5

19.4

23.3

27.0

31.6

10000.0 Hz

18.0

13.5

12.8

12.8

13.0

13.5

14.8

18.0

21.4

25.8

12500.0 Hz

10.8

10.2

9.4

9.4

9.6

10.2

10.8

10.8

12.7

16.3

16000.0 Hz

18.9

18.6

16.8

16.8

17.7

18.6

19.1

18.9

19.7

20.6

Page 14

Page 13 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Model

FSTD SLIM-05

Speed

H

(1300RPM)

M

(1100RPM)

L

(900RPM)

600RPM

700RPM

800RPM

900RPM

1000RPM

1100RPM

1200RPM

1300RPM

1400RPM

Sound Power dB(A)

56.7

51.8

45.1

35.6

39.1

42.6

45.1

48.9

51.8

54.3

56.7

58.7

Sound Power in 1/3 Octave

-bands under ESP:

0Pa (dB)

20.0 Hz

15.9

15.7

16.3

23.2

17.9

10.8

16.3

14.5

15.7

15.2

15.9

14.6

25.0 Hz

14.2

7.0

9.5

16.2

16.2

12.3

9.5

10.9

7.0

14.3

14.2

10.9

31.5 Hz

10.9

6.5

2.9

5.2

9.5

8.0

2.9

6.8

6.5

8.7

10.9

10.9

40.0 Hz

8.6

6.2

4.1

4.9

6.3

5.4

4.1

7.5

6.2

5.0

8.6

9.5

50.0 Hz

7.9

10.3

8.4

10.3

6.2

12.3

8.4

10.7

10.3

7.6

7.9

10.9

63.0 Hz

12.9

11.3

4.7

2.9

5.0

6.9

4.7

4.3

11.3

13.8

12.9

14.8

80.0 Hz

16.6

11.9

8.3

1.5

3.2

3.4

8.3

9.8

11.9

14.6

16.6

15.6

100.0 Hz

22.7

19.2

17.8

16.8

16.9

18.1

17.8

19.1

19.2

20.1

22.7

26.3

125.0 Hz

28.4

24.6

23.3

18.4

17.0

22.6

23.3

30.7

24.6

24.5

28.4

29.7

160.0 Hz

29.9

28.6

23.7

14.5

18.9

22.3

23.7

23.6

28.6

29.7

29.9

33.2

200.0 Hz

31.6

30.5

26.1

21.6

23.0

23.9

26.1

30.2

30.5

29.2

31.6

32.8

250.0 Hz

42.9

37.7

32.2

24.6

30.2

32.2

32.2

36.7

37.7

40.6

42.9

45.4

315.0 Hz

38.9

35.6

30.1

26.5

27.5

29.8

30.1

32.9

35.6

36.8

38.9

40.2

400.0 Hz

44.4

40.5

34.0

25.8

31.0

33.9

34.0

36.4

40.5

41.1

44.4

43.8

500.0 Hz

44.6

41.0

36.6

25.5

30.2

34.6

36.6

38.4

41.0

42.6

44.6

46.5

630.0 Hz

45.9

43.3

36.0

23.8

28.8

32.9

36.0

40.8

43.3

45.8

45.9

47.4

800.0 Hz

49.2

43.8

35.8

24.1

27.9

32.4

35.8

39.8

43.8

46.2

49.2

52.1

1000.0 Hz

48.9

44.3

37.1

23.9

27.6

32.7

37.1

40.8

44.3

46.5

48.9

50.6

1250.0 Hz

48.2

43.6

36.3

22.7

26.8

31.9

36.3

39.9

43.6

45.9

48.2

50.3

1600.0 Hz

45.9

40.7

33.3

21.3

24.6

28.9

33.3

37.7

40.7

43.7

45.9

48.3

2000.0 Hz

43.1

37.3

28.4

19.1

20.5

25.1

28.4

33.5

37.3

40.4

43.1

45.0

2500.0 Hz

41.5

35.3

26.8

19.8

20.7

23.7

26.8

31.7

35.3

38.5

41.5

43.5

3150.0 Hz

40.3

33.9

24.5

18.1

18.6

21.4

24.5

29.5

33.9

37.0

40.3

42.6

4000.0 Hz

36.5

29.9

20.9

17.8

17.9

18.9

20.9

25.6

29.9

33.0

36.5

38.9

5000.0 Hz

33.5

26.8

19.6

17.7

17.4

18.6

19.6

22.8

26.8

30.3

33.5

36.2

6300.0 Hz

29.1

23.1

18.7

17.8

17.7

18.3

18.7

20.7

23.1

26.1

29.1

31.7

8000.0 Hz

25.3

21.5

17.9

17.1

17.0

17.5

17.9

19.2

21.5

22.6

25.3

28.0

10000.0 Hz

21.1

19.0

17.1

16.6

16.4

16.6

17.1

18.0

19.0

20.0

21.1

23.2

12500.0 Hz

17.7

17.4

16.1

15.4

15.6

15.1

16.1

16.8

17.4

17.9

17.7

17.9

16000.0 Hz

22.4

21.4

20.4

18.1

22.7

19.6

20.4

21.2

21.4

21.9

22.4

22.6

Page 15

Dimensions

MODEL

FSTD SLIM-01

FSTD SLIM-02

FSTD SLIM-03

FSTD SLIM-04

FSTD SLIM-05

L

740

940

1140

1340

1540

M

716

916

1116

1316

1516

N

433

633

833

1033

1233

(All dimensions in mm)

Page 14 of 71

300

R5

N

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 16

Valve Information (Optional)

Valve Code

(valve body + ON/ OFF

thermoelectric actuator)

Valve Body Dimensions (mm)

DN A B C D

SGS14HFCA-23010101

D20

(G3/4”)

56

47

22

63

Valve Code

(valve body + ON/ OFF

thermoelectric actuator)

Valve Body Dimensions (mm)

DN A B C D

SGS14HFCA-23010102

D20

(G3/4”)

56

88

50

104

3/4”

2-Way 3/4” Valve Body

3-Way 3/4” Valve Body

Page 15 of 71

Differential Pressure Chart

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 17

Page 16 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

2-Way 1/2" Valve Body

Valve Code

(valve body + ON/ OFF

thermoelectric actuator)

Valve Body Dimensions (mm)

DN A B C D

SGS14HFCA-23020101

D15

(G1/2”)

52

47

19.5

63

Differential Pressure Chart

Page 18

Actuator

Model

DR-16-230B

DR-16-24B

DR-15B-24B

Normal closed

Normal closed

Normal closed

Voltage

230Vac

24Vac

24Vac

Working force

90~125N

90~125N

90~125N

Time

4.5min

4.5min

4.5min

Power

3W

3W

3W

Full stroke

3.5mm

3.5mm

5.0mm

Imax

150mA

250mA

250mA

Wires

2-wire

2-wire

3-wire (red, blue, black)

Page 17 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 19

Page 18 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Installation

Safety Precautions

• When installing, performing maintenance or servicing Daitsu fan coil units observe the precautions

stated in this manual as well as those stated on the labels attached to the unit.

• Ensure all local and national safety codes, laws, regulations, as well as general electrical and

mechanical safety guidelines are followed for installation, maintenance and service.

• The appliance is for indoor use only.

• Ensure the correct power supply is provided.

• If the power supply cord is damaged, it must be replaced by qualified personnel.

• Installing and servicing fan coil unit should be performed by qualified service personnel only.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or persons lacking in experience and knowledge of the appliance, unless they

have been given supervision or instruction concerning it.

• User of this appliance is responsible for his/her own safety.

• Warranty shall be voided if installation instructions and safety precaution stated in this manual are

not observed.

• The unit should only be switched off by using the ON-OFF button on the control interface.

CAUTIONS

Before any service or maintenance operations turn off the mains electrical supply.

DO NOT turn OFF the main power supply when the unit is operating. Turn off the

unit BEFORE turning off the main power

Page 20

Page 19 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Installation and Location

The unit location should be established by the installation designer, services engineer or by a technically competent person

before installation. It should take into account the technical requirements as well as the relevant current laws and

regulations. The fan coil should be installed by a qualified company, also in accordance with the relevant laws and regulations

of the country of installation.

The fan coils are designed for exposed installation. All the models are designed to be floor free standing, wall mounted or

suspended from the ceiling. Installation should allow the treated air to circulate freely throughout the room and leave

sufficient space to access the unit, in order to carry out maintenance or servicing operations.

FOR FLOOR FREE STANDING

1. Open the top left and right covers to loosen the 8 screws.

2. Lift and remove the front panel.

3. Install the unit on the wall with ABS supporting feet.

4. Complete the hydraulic connection and check for leakage.

5. Complete the electrical connection as shown in the wiring

diagrams.

6. Remount the front panel, return air grille and filter.

FOR WALL-MOUNTED WITH BOTTOM RETURN

1. Open the top left and right covers to loosen the 8 screws

2. Lift and remove the front panel.

3. Keep a minimum clearance of 80mm from the floor.

4. Secure the mounting brackets to the wall, then suspend the unit

by the mounting brackets, as shown in figure.

5. Complete the hydraulic connection and check for leakage.

6. Complete the electrical connection as shown in the wiring

diagrams.

7. Remount the front panel, return air grille and filter.

FOR CEILING-MOUNTED

1. Open the top left and right covers to loosen the 8 screws.

2. Lift and remove the cover.

3. Secure the mounting brackets to the ceiling, then suspend the

unit by the mounting brackets. To correctly position flanges

and brackets, see the dimensional data.

4. Complete the hydraulic connection and check for leakage.

5. Complete the electrical connection as shown in the wiring

diagrams Make electrical connection as shown in the wiring

diagrams.

6. Remount the front panel, return air grille and filter.

Page 21

Page 20 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Front Panel Removal

Step 1: Unlock grill and remove the filter.

Step 2: Lift the front panel and remove it.

Electrical Connection

The fan coil comes fully wired and only requires connecting to the mains electricity supply and to any room controls.

Remove the front panel, then control box is shown below.

Connect the wires according to wiring diagram.

Page 22

Page 21 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

TOTAL-version unit

FLEXI-version unit

Thermostat-(optional)

Page 23

Piping Connections

1. Fan 2. Heat exchanger 3. Manual bleeds 4. Joint 5. Valve

The fan coils have been designed and made for installation in heating and air-conditioning systems.

The characteristics of the water fittings are given below:

Main pipes connection

The position of the water fittings may be reversed from left to right in the factory.

Page 22 of 71

Installation diagram of water connections

CONDENSATE DRAINAGE

For use in air-conditioning systems, the fan coils are fitted with a condensate-collecting tray to which a drainpipe can be

connected. Connect an insulated drainage pipe (inside ø 16 mm.) to the hole of the tray and direct it towards a suitable drain

Notes:

i. Check that the condensation flows out regularly into the tray.

ii. The drainage pipe should have a 2% slope towards the drain.

iii. Check all the joints for leaks.

iv. Apply heat-insulating material to the joints.

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 24

Valve and External Drain Pan Installation

3-Way 4 Port Valve 3/4”

2-Way Valve 1/2” for Cooling Coil

2-Way Valve 1/2” for Heating Coil

Hot Water Outlet 1/2”

Horizontal Drain Pan

Chilled Water Outlet 1/2”

Water Outlet 3/4”

Water Inlet 3/4”

Chilled Water Inlet 1/2”

Hot Water Inlet 1/2”

Horizontal type

Piping for 2-Pipe System

Page 23 of 71

Piping for 4-Pipe System

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 25

Page 24 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Vertical type

Piping for 2-Pipe System

Piping for 4-Pipe System

IMPORTANT

Gravity drainage may be converted into forced drainage by attaching the condensate drain pump available as an accessory.

Chilled Water Outlet 1/2”

Chilled Water Inlet 1/2”

Hot Water Inlet 1/2”

Vertical Drain Pan

2-Way Valve 1/2” for Heating Coil

Hot Water Outlet 1/2”

2-Way valve 1/2” for Cooling Coil

Vertical Drain Pan

Water Outlet 3/4”

Water Inlet 3/4”

3-Way 4 Port Valve 3/4”

Page 26

Page 25 of 71

Maintenance

General Maintenance

1. Installation and maintenance should be performed by qualified personnel who are familiar with local codes and regulations,

and are experienced with this type of appliance.

2. Confirm the unit has been switched OFF before installing or service.

3. Prevent damage and unexpected shutting down of the fan coil unit.

4. Check the cleanliness of the filter and replace or clean as required monthly.

5. Clean the coils with compressed air or water to remove dust, dirt or lint. They can be brushed with a soft brush or vacuumed

with a vacuum cleaner.

6. If the water coil is not being used during the winter season, it should be drained or an anti-freezing solution should be

added to the water circuit to avoid freezing.

Regular Maintenance

1. Inspect and clean the condensate drain pan to avoid any clogging of drainage by dirt, dust, etc. Inspect drainage piping to

ensure the proper condensate flow.

2. Check and clean the coil. Clean the coils with a low-pressure water jet or low pressure air.

3. Clean and tighten all the wiring connections.

4. Drain out the water in the system and check for buildup of mineral deposits.

Filter Installation & Cleaning

1. Unlock the grille, then remove the filter.

2. Clean the filter with a brush, or with warm water.

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 27

Page 26 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Fan Motor Assembly Maintenance

Step 1: Remove the front panel.

Step 2: Loosen screws on the mounting brackets. EC motor can be removed.

Step 3: Once finished with maintenance, remount the front panel.

Water Fittings Interchange

The unit is not easy to change water fitting position. Please make sure the side of the fitting when order. Factory will make it

according to the order instruction.

When water fitting is installed on the left (motor side), main pipes cannot be installed from bottom.

Page 28

Page 27 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

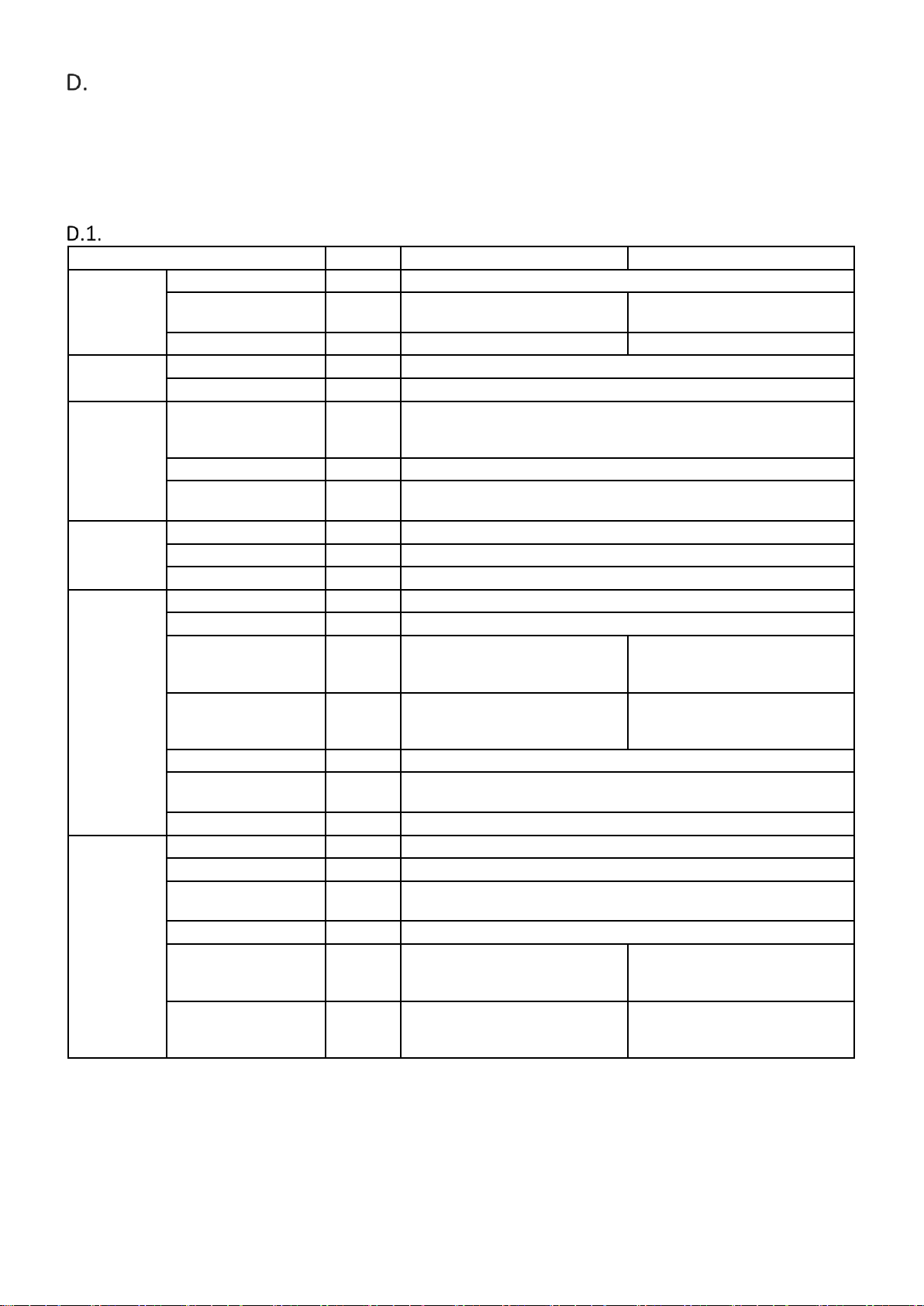

Control Specifications: Complete Function PCB – TOTAL Type Control

Abbreviations

Ts = Setting temperature

AUX1 = Hot water free contact

Tr = Room air temperature

AUX2 = Chilled water free contact

Ti1 = Chilled water coil temperature

MTV1 = Chilled water valve

Ti2 = Hot water coil temperature

MTV2 = Hot water valve

I/O Port Definitions

I/O

Code

2-Pipe

4-Pipe

Analogue

Input

Return air sensor

AI1

Return air temperature (Tr)

2-pipe coil circuit sensor

AI2

Chilled / hot water coil circuit

(Ti1)

Chilled water coil circuit

(Ti1)

Hot water Sensor

AI3

N/A

Hot water coil circuit (Ti2)

Input

LED display / IR receiver

X-DIS 1

Digital communication port to LED display / IR receiver board.

Wired wall pad

TTL1

Digital communication port to wired wall-pad board.

Digital input

Occupancy contact

ON/OFF

Window contacts: for remote ON/OFF (when DIPB SW1=1).

Economy mode contacts: for remote activation of economy mode (when DIPB

SW1=0).

Float switch

Float

Voltage-free (NC)

Electrical heater safety

switch

EH

Voltage-free (NC). The contact is closed before the EH is turned on.

Power input

Phase

L1

Power supply to the PCB and all the loads connected to the voltage outputs.

Neutral

N1

Power supply to the PCB and all the loads connected to the voltage outputs.

Earth

PE1

Power supply to the PCB and all the loads connected to the voltage outputs.

Voltage

output

Fan 1

CN4

Fan 1 driver

Fan2

CN5

Fan 2 driver

Valve1

MTV1

2-pipe coil circuit valve output –

chilled / hot water valve.

Voltage output (L)

4-pipe coil circuit valve output –

chilled water valve.

Voltage output (L)

Valve2

MTV2

Reserved

4-pipe coil circuit valve output – hot

water valve.

Voltage output (L)

Water pump

PUMP

Power supply to condensate pump. Voltage output (L)

Voltage of electrical

heater (Live)

L-EH

Voltage output (L), maximum 30A.

[See wiring diagram, cross check with supplier].

Stepping motor

CN1-2

Power supply to louver steeping motors. Voltage output (L)

Output

Auxiliary contact 2

AUX2

Cooling mode signal relay (NO). Voltage free contact.

Auxiliary contact 1

AUX1

Heating mode signal switch (NO). Voltage free contact.

Serial BUS port

CN3

Master-slave network serial connection OR

MODBUS / local PC host network serial connection.

24VAC power input

DA1

24VAC external power supply (modulating valve applications only).

Modulating valve 1

DA2

Connection to DC modulating valve

on 2-pipe coil circuit

- chilled / hot water.

Connection to DC modulating valve

on 4-pipe coil circuit

- chilled water.

Modulating valve 2

DA3

N/A

Connection to DC modulating valve

on 4-pipe coil circuit

- hot water.

Page 29

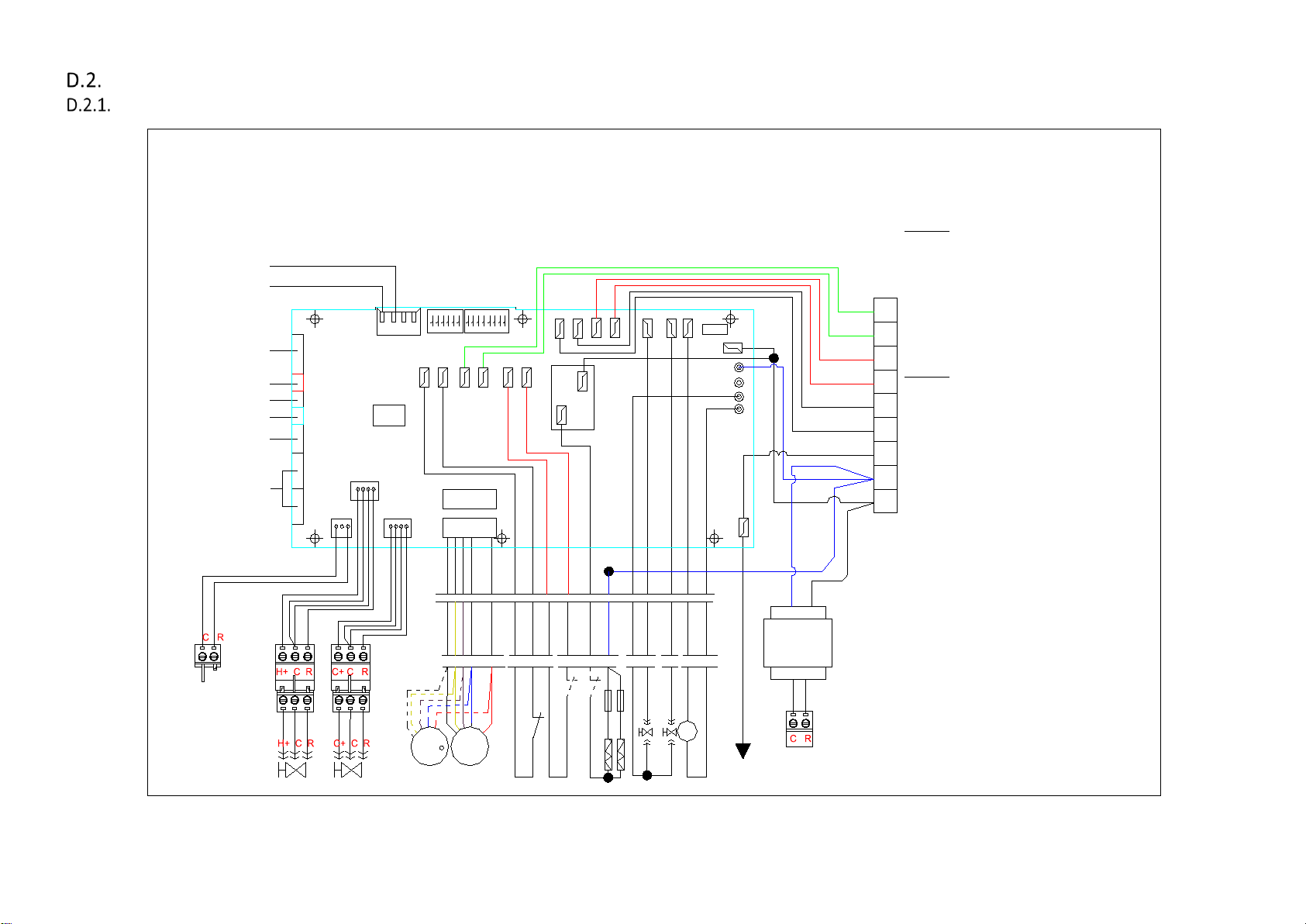

Wiring Diagrams

Standard EC-TOTAL Type Control PCB

NEXT UNIT

CN3

LED display/IR receiver

Renturn sensor (Tr)

2 pipe sensor (Ti1)

chilled /hot water

4-pipe coil circut sensor

(Ti2):hot water

Wired wall pad

Louver stepping motor

connectors

X-DISI

AI1

AI2

AI3

TTL1

CN2

CN1

24Vac Cooling/heating Modulate valve

DA3

DA1

485

A B A B

CPU

DA2

24Vac heating Modulate valve

EC-S1 Unit wiring scheme

GR

GR

RD

RD

WH

WH

YL/GR

BL

BK

24Vac/230Vac

FLOAT

CN4

CN5

EC mot r

S2

WH

GND

BLDC

BLDC

BR

OR

EC motor

VALVE1

AUX2

AUX1

AUX1

S1

ON/OFF

ON/OFF

BL

RD

RD

RY6

EH

GND

L-EH

BK/2.5

WH/2.5

OR

OR

RD

VALVE2

WH

PUMP

FUSE

L1

N

N

N

N

PE

GY

BL

BK

AUX2

BL

TR

Fuse

Fuse

Temp. switch2

Temp. switch1

PUMP

float control switch for pump

Electrical heater

IPA19-DL-EC-S1

DIPA-S1

SW1-5: set the unit address

SW6: set unit type :master or slave

Mode Configuration

SW7=0;SW8=0; unit operates in cooling/heating

PRO

SW7=0;SW8=1; unit operates in cooling/heating w/booster

EH

PRO

SW7=1;SW8=0 ; unit operates in cooling

SW7=1;SW8=1; unit operates in cooling with primary EH

A2 A2 A1 A1

DIPB-S2

SW1: Occupancy contact setting

SW2: Unit configuration setting: 0=2pipe system;

SW3:on/off valve configuration: 0= no valve 1=with valve

G

SW4:preheat setting:0=36C;1=28C

SW5: Fan1(CN4)configuration setting:0=Fan1 OFF;

N

SW6:Fan2(CN5)configuration setting: 0=Fan2 OFF;

L1

L \N----Power supply

VALVE1: 230V on/off valve output;

VALVE2: 230V on/off valve output;

WP: 230V condensate pump output;

AUX1:Voltage free contact; ON:unit in heating mode.

AUX2:Voltage free contact; ON:unit in cooling mode.

ON/OFF:Occupancy contact

CN1~2:Stepping motor output.

CN3:Serial BUS contact

CN4:Fan motor 1 output

CN5:Fan motor 2 output

TTL: Wired wall-pad.

AI1:Return air temperature sensor(Tr)

AI2:Indoor coil temperature sensor1 (Ti1)

AI3:Indoor coil temoeraturesensor 2 (Ti2)

X-DISI----LED receiver output

DA1-24VAC input for modulating valves.

DA2-modulating valve 1 output(0-10V modulating signal).

DA3-modulating valve 2 output(0-10V modulating signal).

1=4-pipe system;

1=Fan1 ON .

1=Fan1 ON .

Page 28 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 30

Master-Slave Networking Wiring Diagram

CN1

X-DISI

AI1

AI2

AI3

TTL1

wired wall-pad

4-pipe coil circuit sensor

2-pipe sensor (Ti1):

return air sensor (Tr)

LED display / IR receiver

chilled/hot water

(Ti2):hot water

louver stepping moter

connections

CN2

A B A B

S1

S2

FLOAT

EH2 EH1PR2PR1

AUX2

AUX1

HF

MF

LF

VALVE1

VALVE2

WP

CONNECT

GY

RD

WH

BK

BL

PUMP

L1N

G

A1

A1A2A2PROPRO

TERMINAL

WH

OR

BR

YL

BL

L

N

N

N

N

RY7

BK

BL

YL/GR

WH

WH

RD

RD

GR

GR

485

FUSE

FAN

cap

Electrical heater

1

N

2 3

RD

RD

FAN

cap

float control switch for pump

YL

YL

CN1

X-DISI

AI1

AI2

AI3

TTL1

wired wall-pad

4-pipe coil circuit sensor

2-pipe sensor (Ti1):

return air sensor (Tr)

LED display / IR receiver

chilled/hot water

(Ti2):hot water

louver stepping moter

connections

CN2

A B A B

S1

S2

FLOAT

EH2 EH1PR2 PR1

AUX2

AUX1

HF

MF

LF

VALVE1

VALVE2

WP

CONNECT

GY

RD

WH

BK

BL

PUMP

L1N

G

A1

A1A2A2

PROPRO

TERMINAL

WH

OR

BR

YL

BL

L

N

N

N

N

RY7

BK

BL

YL/GR

WH

WH

RD

RD

GR

GR

485

FUSE

FAN

cap

Electrical heater

1

N

2 3

RD

RD

FAN

cap

float control switch for pump

YL

YL

CN1

X-DISI

AI1

AI2

AI3

TTL1

wired wall-pad

4-pipe coil circuit sensor

2-pipe sensor (Ti1):

return air sensor (Tr)

LED display / IR receiver

chilled/hot water

(Ti2):hot water

louver stepping moter

connections

CN2

A B A B

S1

S2

FLOAT

EH2 EH1PR2PR1

AUX2

AUX1

HF

MF

LF

VALVE1

VALVE2

WP

CONNECT

GY

RD

WH

BK

BL

PUMP

L1

N

GA1

A1A2A2

PROPRO

TERMINAL

WH

OR

BR

YL

BL

L

N

N

N

N

RY7

BK

BL

YL/GR

WH

WH

RD

RD

GR

GR

485

FUSE

FAN

cap

Electrical heater

1

N

2 3

RD

RD

FAN

cap

float control switch for pump

YL

YL

B

A

Page 29 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Page 31

Page 30 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Configuration Settings

Note: 0 = OFF

1 = ON

SW1-SW5 Network address

setting

DIPA-S1

DIPB-S2

SW5/SW6 Fan Qty setting

SW5=0 Single fan application

SW6=1

SW5=1 Twin fans application

SW6=1

SW7/SW8 Operating mode

SW7=0 Cooling and heating modes available

SW8=0

SW7=0 Cooling and heating modes available,

SW8=1 with EH functioning as booster

SW7=1 Cooling mode only available

SW8=0

SW7=1 Cooling and heating modes available,

SW8=1 with EH functioning as primary

Master / Slave setting

SW6=1 Master

SW6=0 Slave

Preheat temperature setting

SW4=1 28

o

C

SW4=0 36

o

C

230VAC on/off valve setting

SW3=1 With valve

SW3=0 Without valve

2-pipe/4-pipe system configuration

SW2=1 4-pipe system

SW2=0

2-pipe system

PRO contact setting

SW1=1 Window contact (remote on/off)

When PROs closed for 10 minutes, unit

enters standby mode.

When PROs opened, unit resumes

operation.

SW1=0 Economy contact

When PROs closed, dead-band condition

is increased from “Tr=Ts+/-1” to “Tr=Ts+/-

4”.

Page 32

Page 31 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

Fan Coil Unit ON/OFF

There are 3 ways to turn the system on or off:

a) By the ON/OFF button on the remote handset or wired wall pad;

b) By the programmable timer on the handset or wired wall pad.

c) By the manual control button on fan coil unit.

Auto Restart

The system uses a non-volatile memory to save the present operation parameters when the system is turned off

or in case of system failure or cessation of power supply.

The restored parameter data-set depends on the type of user interface.

a) Handset only user interface:

When the power ON signal is received by the fan coil unit and no wired wall-pad is installed, the Mode, Fan Speed,

Set temperature will be the same as the handset setting before the last power OFF.

b) Wall-pad only OR wall-pad and handset user interface:

When the power ON signal is received by the fan coil unit and a wired wall-pad is installed, the Mode, Fan Speed,

Set temperature and Timer ON/OFF weekly program will be the same as the wall pad setting before the last power

OFF.

Page 33

Page 32 of 71

SK2019 FSTD-SLIM-EC-FLEX-001_01

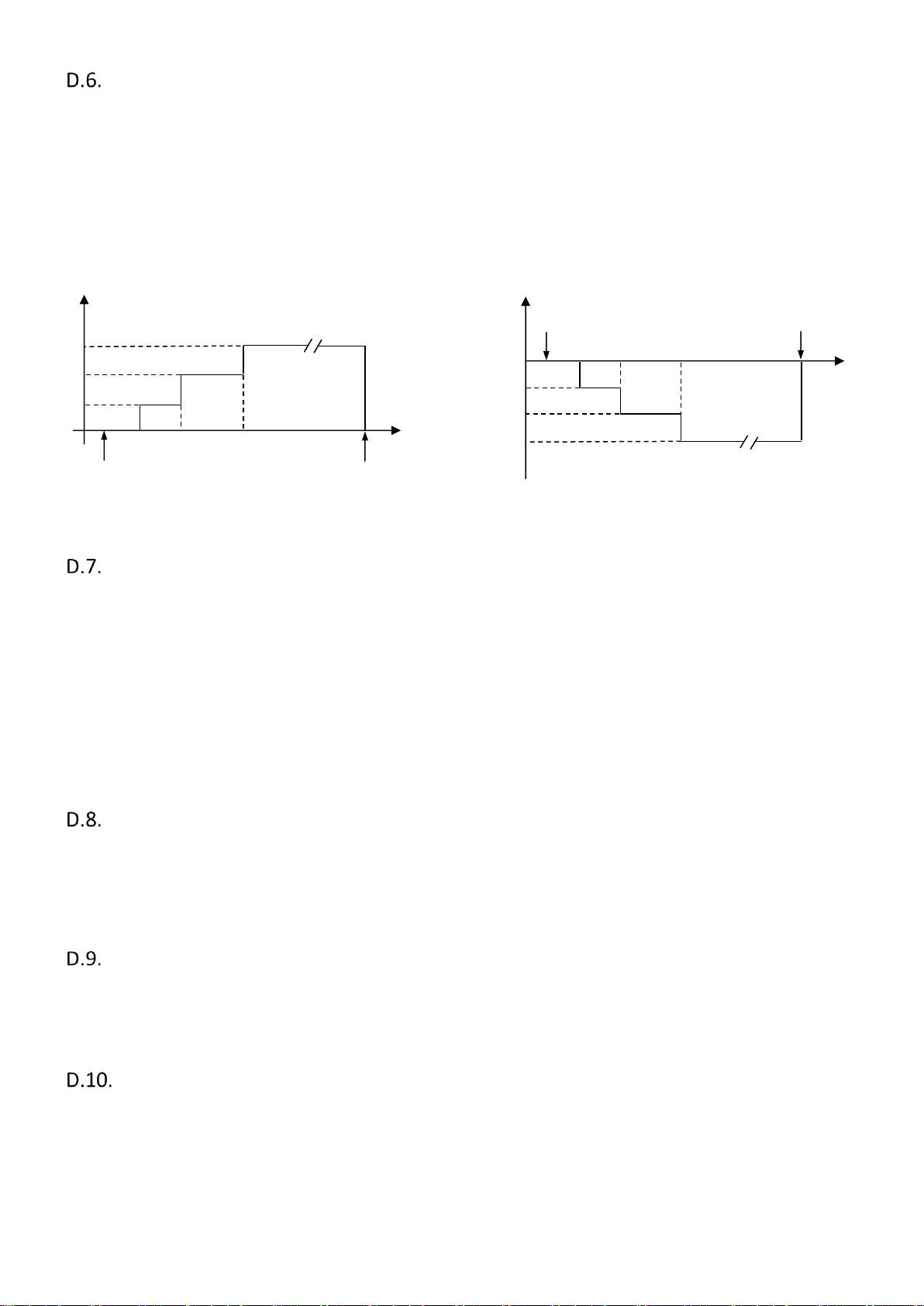

Control Logics for 2-Pipe System

With Valve Configuration

COOL MODE

a) MTV2, AUX1 and electric heater are always off.

b) If Tr ≥ Ts + 1ºC (or + 4ºC if economy contact is activated), then cool operation is activated and MTV1 and AUX2 are turned

on. Indoor fan runs at set speed.

c) If Tr < Ts, then cool operation is terminated and MTV1 and AUX2 are turned off. Indoor fan runs at set speed.

d) The range of Ts is 16 - 30ºC

e) Indoor fan speed can be adjusted to low, medium, high and auto.

f) When turned on, MTV1 requires 30 seconds before it is fully open.

g) When turned off, MTV1 requires 120 seconds before it is fully closed.