5-8

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

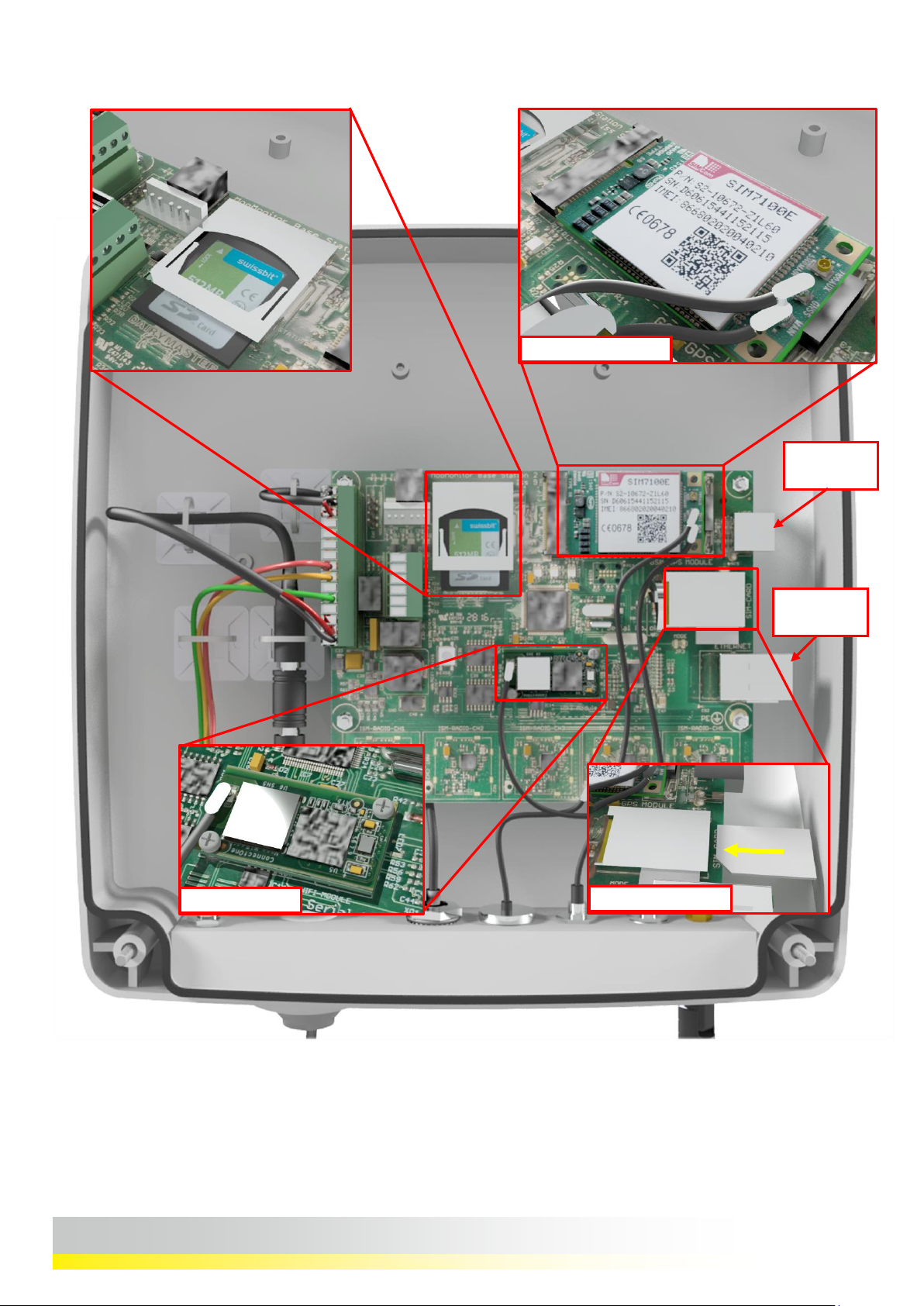

Figure 36 – Base Station PCB Components

SD Card Module

GPS GSM Module

WI-FI Module

Sim card Module

USB

Connector

CAT 6

Connection

5-9

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

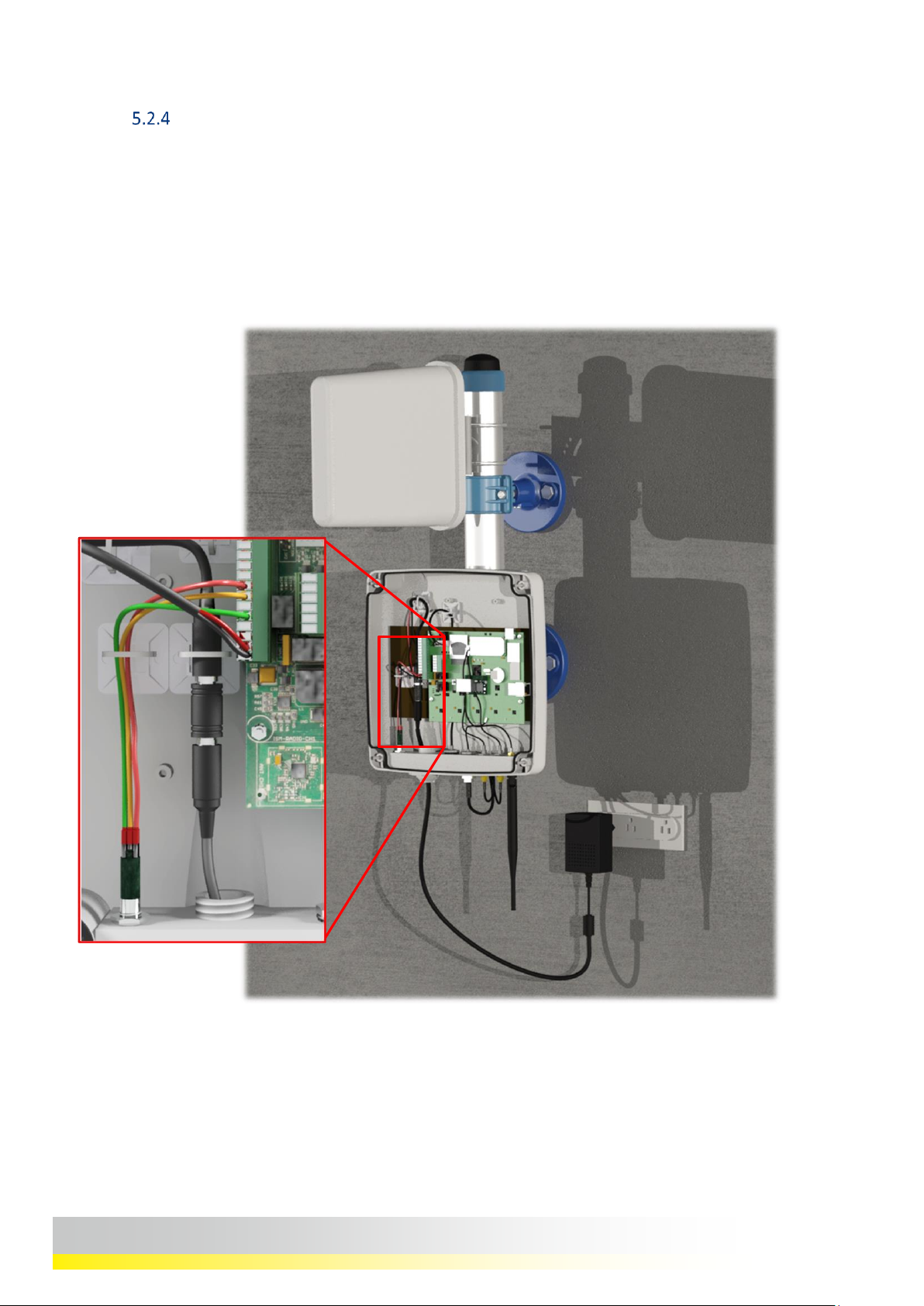

CAT 6 Connection to Basestation

Each Basestation is also fitted with a CAT 6 connection. In areas where WI-FI is

subject to disruption due to signal interference or other contributing factor the

installer may wish to install a CAT 6 cable connection onto the PCB board of the

base station.

Notes:

Dairymaster can provide a CAT 6 cable if require. This will need to be ordered

separately through the following part codes:

Description

Part Code

CAT6 LEAD (5M)

10401735

CAT6 LEAD (20M)

10401743

CAT6 LEAD (40M)

10401750

CAT 6 cable connected

into the connection

into the Basestation

Figure 37 - CAT 6 cable connected into the Basestation

5-10

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

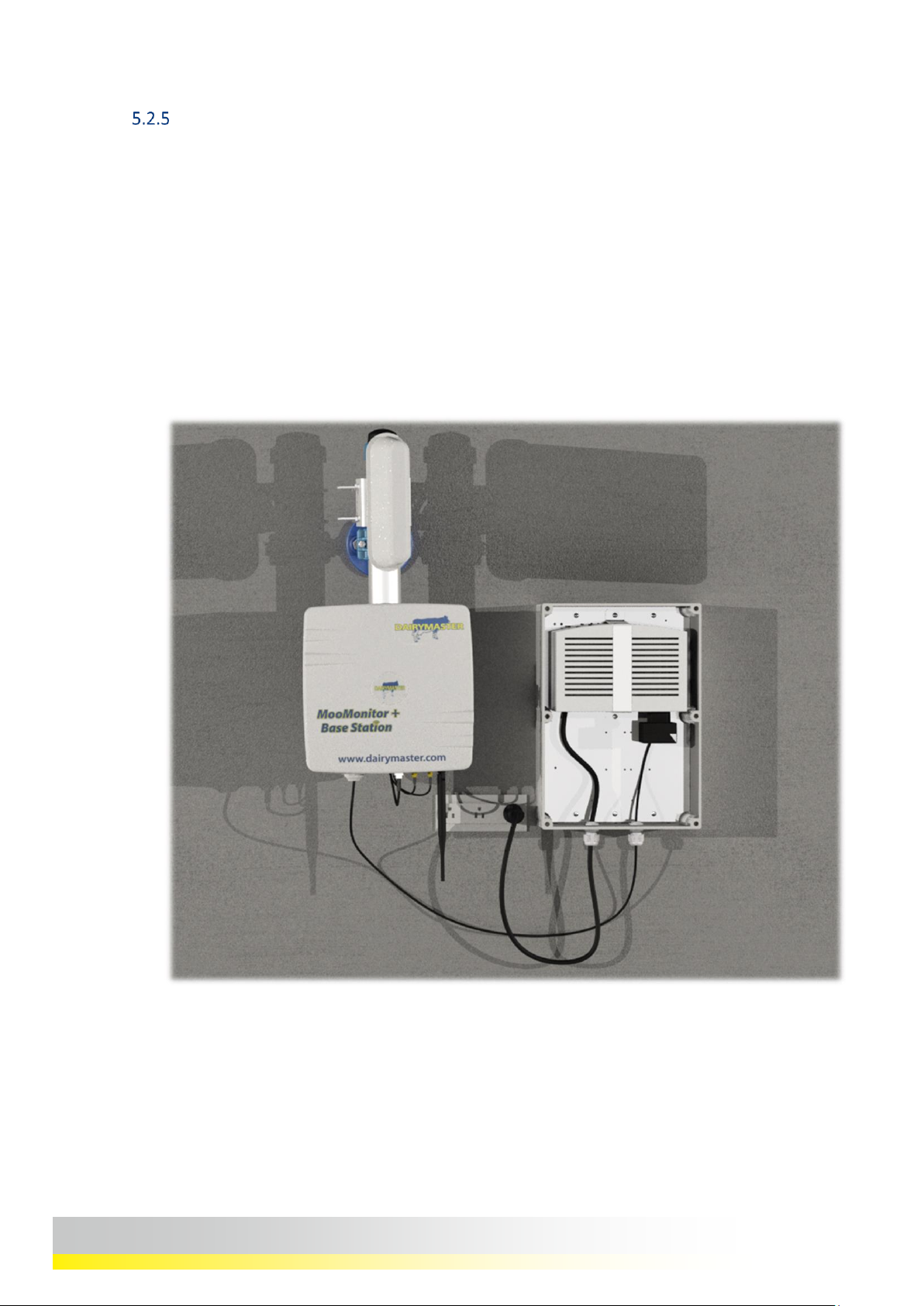

Basestation ISM Antenna Radio Frequencies

Each Base Station has a 5-way radio by default to allow for a wider spectrum to be

accommodated on site in the event of interference from an outside radio source

and selection of each of the radio channels is region dependant.

Figure 38 - Five Channel Radio is located on the Base Station PCB

Five Radio channels

Important Notes

There are five radio channels on the MooMonitor + PCB. These channels are

specific to the region of installation and are currently as follows:

ISM Radio Channel 3 = European Installation (countries within the EU &

UK).

ISM Radio Channel 4 = American Installation (Installations within the

USA).

ISM Radio Channel 5 = Australia & New Zealand.

Currently Radio channels 1 & 2 are currently not in use and should not be

connected to the ISM antenna unless specifically instructed to do so by

Dairymaster.

5-11

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Connecting the 12V DC Power Supply

The Base Station is provided with a 12V DC adapter which serves as the power

supply to the unit. This makes the unit exceptionally easy for the installer to fit.

The client’s electrical contractor must provide an electrical connection as

discussed in section 5.1

Route the electrical cable from the 12v DC adapter into the base station using the

large electrical gland at the base of the unit.

Figure 39 - View of the Electrical connection to the Base Station

using the 12V DC Adapter

5-12

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Installing a Voltage Regulator to the Base Station (USA installations only)

In situations where an unstable power supply is present to the basestation a voltage

regulator may be required.

The client’s electrical contractor must provide an electrical connection as

discussed in section 5.1

The voltage regulator is provided with a standard electrical socket and a 12V DC

adapter to connect the voltage regulator to the base station.

The installer would connect the basestation to the mains supply and plug the base

station directly into the voltage regulator. See Figure 40 &

Figure 40 – Typical view of Voltage Regulator installed with the Base Station

5-13

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Figure 41 – Typical view of Voltage Regulator installed with the Base Station

5-14

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

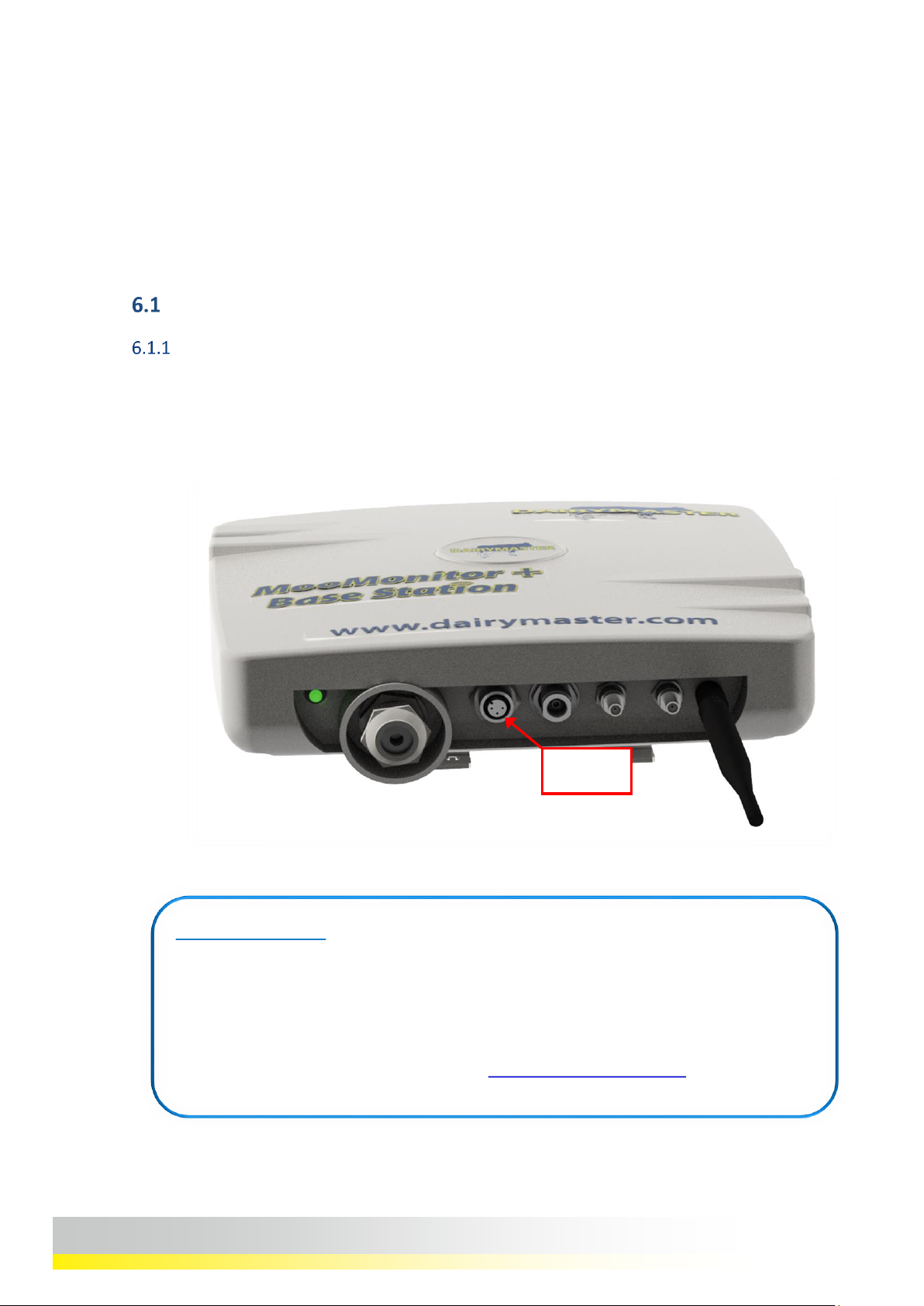

Basestation LED Power up

When the base station is powered up the LED located next to the base station

connections will light up. Depending on the connection type (Wifi, GSM or

Ethernet), the LED will have a different light sequence.

Connection Type

LED Sequence

Ethernet (LAN cable)

Stays on constant

Wifi

Flashes every 1 second

GSM (Mobile)

Flashes every 5 seconds

Figure 42 - LED located next to the connections on the base station

6-15

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6 Controls

The MooMonitor+ can be controlled and interfaced with in five ways.

1. Wi-Fi connection.

2. SMS commands

3. Dairymasters cloud based services.

4. MooMonitor+ Smartphone App

5. Through a USB to UART connection directly onto the base station PCB.

Installation Procedure

Configuring the base station using a USB to UART connection

Each base station can be configured using a physical connection onto the Base

Station PCB using the UART connection through USB. The installer will need a UART

to USB connection which will be provided by Dairymaster on request.

The UART cable is connected to the PCB as shown below.

Figure 43 – UART connection on the BaseStation

UART to

USB

Important Notes

For the moment configuration of the MooMonitor+ Basestation will be carried out

by the Dairymaster Global support team, and will be done remotely.

Installers should ensure that team viewer is installed on the local machine to

facilitate this.

Installers should contact Dairymaster at

software@dairymaster.ie

to arrange this.

6-16

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

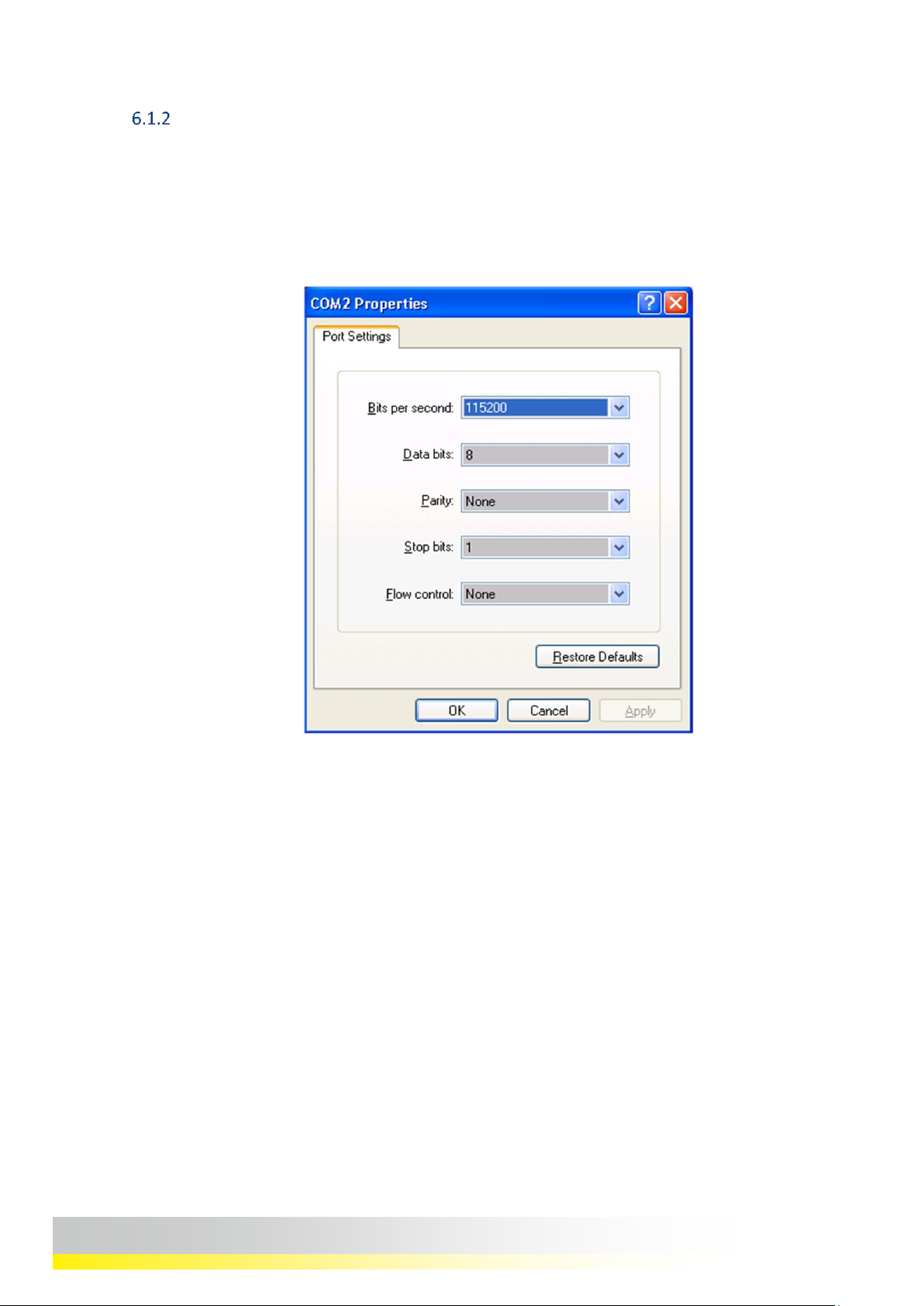

Configuring the base station using a UART connection

Once the connection to the board has been made the user will need to adjust the

com port settings on the pc to ensure that the PC and the MooMonitor base station

will communicate.

The com port settings can be accessed through My Computer\Control Panel\Device

Manager. Choose the appropriate USB comport and enter the following settings.

Once a connection has been established the user must use Hyper Terminal to

communicate with the base station. Hyper terminal is available online from a

number of sources.

Figure 44 – Com Port settings

6-17

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.1 Step 1: Accessing the base station using UART

When accessing the base station, it will display information about the base stations

current configuration and software version.

As per the Wi-Fi configuration options a value of 1 turns a feature on and a value of

turns a feature off.

As can be seen above the base station states the following information on boot up.

1. The Software version running on the device.

2. The device Address.

3. The Device ID

4. The Time

5. The number of records stored on the device.

6. Cloud connectivity active via mobile

7. Logging levels: The device is default is 1. The higher the level of logging

the more information that is logged.

8. Logging General: this logs general information about the device and is

used by Dairymaster for debugging or troubleshooting any issues a base

station may be having.

9. Log Wi-Fi: Device Logs are sent over the Wi-Fi

10. Log Mobile: Device Logs are sent over the GSM.

11. Radio Transmitters which are Active:

6.1.2.2 Step 2. Configuring the Farm ID and the base station ID

Once the base station has gone through its initial start-up process the device will be

ready for configuration. The installer will need to type in the installation password

into the install wizard and press enter to proceed.

Figure 45 – Step 1 UART Configuration

6-18

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

The password allows access to configure the device. The password is 1968.

To begin configuration, the installer will need to type ‘Install’ and hit Enter on the

keyboard.

For the installer to edit any given command, they will need to use the edit function.

This is done simply by pressing the numerical value on the key board as displayed

in window under the edit line.

Figure 46 – Password entry screen on using hyper terminal

The password is 1968.

Figure 47 – Configuring the base station identification using the

UART connection

Password entry

Items which can

be edited and

their numerical

values

Current values

Function

6-19

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

The installer will be prompted to enter a new value at this point. Press Enter on the

keyboard after a number is entered and check the new value has populated into the

FarmID or BasestationID value fields.

This procedure should be followed when entering any value to the system.

Notes:

1. The Farm ID is provided by Dairymaster. It is essential that the correct farm ID

is inputted.

2. Each MooMonitor is programmed to communicate with a specific farm ID only.

3. A MooMonitor with a different farm ID will not communicate with a base station

that does not have a corresponding farm ID.

4. The base station ID is used when multiple base stations exist on the one farm.

All base stations will have matching farm IDs but will need to have different Base

ID (Base station IDs)

Each MooMonitor will have a preferred base station to communicate with,

however if it cannot connect with its preferred base station, say station 1.

The monitor will connect to the next available station, say station 2 for example

if 2 stations exist on a farm or station 3, or 4 and so on.

To proceed with the next step press the greater-than (>) symbol on the keyboard

to move back a step press the less-than (<) symbol.

6-20

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.3 Step 3: Configuring the Wi-Fi using UART

This is the same procedure is as before: Pressing the numerical value on the key

board corresponding to the numbers displayed in window under the edit line.

Table 1 - Configurable Wi-Fi settings via UART

Edit

option

Description

Range

1

Wi-Fi enabled

0 = OFF, to 1 = ON

2

SSID

Sample SSID (Site dependant)

3

SSID password

Sample password (Site dependant)

4

Security type

0 = No Security

1 = WEP 64

2 = WEP 128

3 = WPA – PSK with TKIP encryption

4= WPA2 – PSK with TKIP or AES encryption

5= WPA - TKIP or AES encryption Enterprise with EAP – TLS

or PEAP-MSCHAPv2 (If CA parameter is empty returns

ERROR 222)

6 = WPA2 – AES Enterprise with EAP – TLS or PEAPMSCHAPv2 (If CA parameter is empty returns ERROR 222)

7 = EAP-MD5 and static WEP 64

8 = EAP-MD5 and static WEP 128

105 = WPA-TKIP Enterprise with EAP-TLS or

PEAP- MSCHAPv2. RADIUS Certification Verification will

be skipped.

106 = WPA2-AES Enterprise with EAP-TLS or PEAPMSCHAPv2. RADIUS Certification Verification will be

skipped.

5

Active FTP

0 = Active FTP Disabled

1 = Active FTP Enabled

6

Time Server Trys

Number of attempts to connect to Time server before a

reset is performed

Figure 48 - Configuring the Wi-Fi settings using UART

Items which can be

edited and their

numerical values

Items which can be

edited

6-21

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

7

Scan Access Point

This will scan and return any available Wifi Network Access

points within range

8

Test connection

(Shows the connection

status)

Not Connected, or Connected

Once a successful connection has been made the interface will display the strength

of the wireless connection and the ping test results for the connection.

It is advisable to ensure the strongest possible Wi-Fi signal and the lowest possible

ping time. A slow ping or poor signal can lead to loss of data.

To proceed with the next step, press the greater-than (>) symbol on the keyboard to

move back a step press the less-than (<) symbol.

Figure 49 – Wi-Fi connection established signal strength and ping

available for review via UART

Wi-Fi Status

Items which can be

edited and their

numerical values

Items which can be

edited

6-22

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.4 Step4: Configuring the GSM connection using UART

The base station can communicate to the cloud using a GSM connection.

Table 2 - Configurable GSM settings via UART

Edit

option

Description

Range

1

Mobile enabled

0 = OFF, to 1 = ON

2

APN

Sample live.vodafone.ie (provider dependant)

3

APN Username

Sample username (provider dependant)

4

APN Password

Sample password (provider dependant)

5

Service Centre

Sample +35387600000 (provider dependant)

6

Service Mobile

Dealer or Service agent number

7

Mobile 1

Customer Number 1

8

Mobile 2

Customer Number 2

To proceed with the next step press the greater-than (>) symbol on the keyboard

to move back a step press the less-than (<) symbol.

Important Note

1. The installer must ensure that an adequate 3G or 4G connection is

available on the farm and that the base station antenna is connected

with a strong mobile connection in the event that this is the base

stations only connection to the cloud based services.

2. The installer/dealer should inform the customer that data charges

may apply depending on the telecoms provider and a suitable data

plan will be required.

Figure 50 – configuration of the GSM connection

Items which can be

edited

Mobile Signal

Items which can be

edited and their

numerical values

6-23

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.5 Step 5: configuring the Cloud connection using UART

The cloud connection can be configured to use the mobile network or an available

Wi-Fi connection.

The base station will default to a Wi-Fi connection in the event of the mobile

connection being disabled.

Table 3 – Cloud connection setting via UART

To proceed with the next step press the greater-than (>) symbol on the keyboard

to move back a step press the less-than (<) symbol.

Edit

option

Description

Range

1

Cloud connection via

mobile

0 = OFF, to 1 = ON

2

Cloud polling interval

Interval at which the MooMonitor checks

on cloud services for updates.

Factory Default is 20 seconds.

Items which can be

edited and their

numerical values

Items which can be

edited

Figure 51 –Configuring the Cloud connections using UART

6-24

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.6 Step 6. Configuring the base station radio link using UART

Each base station has a 5 radios by default to allow a wider spectrum to be

accommodated on site in the event of interference from an outside radio source.

The ability to change radio channels and thereby radio frequencies will allow the

installer to ensure that any unwanted interference from signals at a similar

frequency will be avoided.

Table 4 – List of frequencies available through

Radio Transmitter

Frequency

Radio 1

868.0 MHz(EUROPE ONLY)

Radio 2

868.2772 MHz(EUROPE ONLY)

Radio 3

869.3 MHz(EUROPE ONLY)

Radio 4

914 MHz (USA ONLY)

Radio 5

915 MHz(USA ONLY)

Figure 53 – View of the PCB installed in the base station

The five radios are shown above.

Radio channels 1 to 5

going left to right

Figure 52 – Configuration of the radio channels using UART

Items which can be

edited and their

numerical values

Items which can be edited

and their numerical

values.

Note: When a radio is

active, the corresponding

IAP should also be active.

6-25

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

The same procedure can be followed when configuring the radios as in the previous

steps.

If the installer needs to activate another radio say Radio channel 1. They will need

to edit radio channel 1, by pressing 1 and following the screen prompts typing Y for

each of the prompts.

Once the new radio channel is active the installer will need to de-activate the old

radio channel. This is done by following the same procedures as outlined above.

Figure 54 – Configuring the radio station using the UART connection

Note: When a radio is

active, the corresponding

IAP should also be active.

Figure 55 - Configuring the radio station using the UART connection

6-26

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

If the installer needs to de-activate another radio say Radio channel 3, they will need

to edit radio channel 3 by pressing 3 and following the screen prompts typing N for

each of the prompts.

To proceed with the next step, press the greater-than (>) symbol on the keyboard

to move back a step press the less-than (<) symbol.

Note: When a radio is deactivated

then corresponding IAP should also

be deactivated.

Figure 56 - Configuring the radio station using the UART connection

6-27

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.1.2.7 Step 7: Configuring device logging using UART.

Each base station can be configured to create log files for its activity.

Logging should not be altered unless stated by a Dairymaster technical customer

support agent.

Logging level: this is defaulted to 1. The higher the level of logging the more

information that is logged.

Logging General: Logs general information about the device and is used by

Dairymaster for debugging or troubleshooting any issues a base station may be

having.

Log Wi-Fi: device logs are sent over the Wi-Fi

Log Mobile: Device logs are sent over the GSM.

Numerical

value

Logging

Range

1

Log Level

0 Logging OFF,

1 Logging ON.

2

Log General

0 Logging OFF,

1 Logging ON.

3

Log WI-FI

0 Logging OFF,

1 Logging ON.

4

Log Mobile

0 Logging OFF,

1 Logging ON.

The installer may configure device logging using the same procedures as in the

previous steps.

To proceed with the next step press the greater-than (>) symbol on the keyboard

to move back a step press the less-than (<) symbol.

Figure 57 – Configuring event logging using UART

Items which can be

edited and their

numerical values

6-28

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Once the event logging has been configured the device should be ready for normal

operation.

The installer will see a note appear stating the device is exiting install mode.

To proceed and complete the device configuration press the greater-than (>)

symbol on the keyboard to move back a step press the less-than (<) symbol.

The device will then begin populating the screen with device information and the

configuration is complete.

Figure 58 – Final screen on the UART configuration tool

6-29

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

MooMonitor+ Android App (Version 2.0)

App Overview

The MooMonitor+ Android App allows the User to interface with the MooMonitor+

system, giving them the ability to send and receive information from the devices

and get a real time view of the data collected for their animals.

The app will allow the user to carry out a range of functions from their Smartphone

such as the following:

Receive alerts for Cows that are Active/Suspect/Health Alert

View individual Cow Data

View Individual Cow Activity/Rumination/Feeding/Resting Graphs

Add events for the Cow such as Add Heat, Add Insemination, Add Calving

Date, etc.

Set up cows for Scheduled and Permanent Drafting

The MooMonitor+ App can be downloaded from the Google Play Store.

When the App has downloaded it will appear on the Smartphone home screen

(Figure 59).

Figure 59 – MooMonitor + App Icon

and typical home screen

6-30

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Launching the App

When launched for the first time the MooMonitor+ App will automatically redirect

you to the settings menu within the app.

Within the settings menu the app will require the user to enter the credentials

required to log into the system see Figure 60.

These credentials will be provided to the user by Dairymaster and consist of the

user name and password allocated to the specific user’s farm. Input your Username

and Password into the fields shown in Figure 60. The Username and Password will

be common amongst any device the user logs into.

Once the credentials have been entered and the Click Save to store the information.

Figure 60 - Settings Menu on the

Android App

Note

At this point you can also decide whether you wish to receive Push Notifications.

This option allows the App to send you a notification when an alert is triggered.

6-31

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

MooMonitor+ Android App User interface

Upon opening the app the Summary Screen will

appear.

This will give a summary of the 6 different alert lists

within the selected farm.

The number of cows in each group will be visible

below each alert icon.

The Basestation connectivity is also visible at the

top right of the screen

- Green: Connected

- Red: Disconnected

Heat Symbol

Displays all cows with increased activity on the farm including pregnant

Cows, Cows in Heat, Cows due to calve and cows that have had an AI or

a confirmed heat within the last 4 days.

Suspect Symbol

This is a list of the cows that are suspected to be in Heat. Their activity

levels have increased but they have not yet overcome the Activity

threshold. Farmers can identify these cows for further monitoring.

Behaviour Alert Symbol

The third symbol shows the cows that are displaying abnormal

behaviour such as a decrease in rumination, feed intake, activity,

increased resting etc.

High Activity Symbol

This Icon will show the cows that are showing high levels of activity and

therefore are identified as in heat. These cows will show factors such as

high activity levels, decreased rumination, etc.

Draft Symbol

Full list of cows in the herd. The number shown underneath signifies the

cows to be permanently drafted. Cows can be set up to draft by

choosing 0, 1 or 2 in this table.

Watch Symbol

This is the list of animals that have been marked for further monitoring

or treatment.

Figure 61 - Android App

Summary Screen

6-32

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.3.1 Animal Tables

Selecting any of the 6 alert icons will open up a tabulated list of the cows for that

alert. The table contains the information for each individual cow such as Cow ID,

Days in Milk (DIM), Last Heat, Last insemination (Last Insem), Number of

Inseminations (Num Insems) and the Group Number (Group). The drafting table

generates a different table which is outlined in section 6.2.3.2.

The colour codes at the left indicate the suitably of each cow for breeding. This is

assigned to each cow based on the information input into the system for each cow.

The colour code hint is accessed by selecting the help icon at the top right of the

screen which gives an explanation of each colour code (see below).

The information in the table can be sorted by each individual column by selecting

the column header at the top of the screen.

Summary Screen

This will show when the information was last updated or

currently being updated i.e. when the App last

downloaded information from the cloud. The current

status of the base station is also shown in this ribbon. The

user may search any known Cow ID by selecting the

search icon, entering the Cow ID and pressing on search.

Figure 62 - Tabulated list of Cows along with the Colour Code hint

6-33

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.3.2 Draft Table

The Draft table generates a list of all cows in the herd. The user can toggle between

the Permanent drafting list and the scheduled drafting list by selecting the

Scheduled or Permanent icon on the top ribbon.

The table contain information including Cow ID, Tag ID, draft pin, Group number

and if the cow is being weighed.

Figure 63 - Draft Table

6-34

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Figure 64 - Android App Options Menu

Android App Options Menu

On the Summary screen by sliding the screen

from left to right, the Options Menu will be

displayed see Figure 64.

This menu gives a list of eight different options

see Table 5.

Table 5 – Summary Screen Options

Option

Meaning

Farm Name

Allows the user to access other

farms if applicable.

Summary

Displays the Home Screen

Heat

Displays the Cows in Heat

Suspect

Displays the Suspect Cow List

Behaviour

Alert

Displays the Behaviour Alert List

High Activity

Displays the High Activity List

Draft

Displays all cows in the herd

Watch

Displays the cows on the Watch list

All

Shows a list of all cows on the farm

Assign MM+

Allows the user to assign a

MooMonitor+ to a cow.

Extras

Option

Meaning

Settings

Opens the Settings Menu

Scheduled

Draft

Displays cows on the Scheduled

Draft list

Batch

Selection

Allows the user to select any batch

of animals and add an event for

them animals

Herd Data

Display scatter graphs of individual

cows and performance against the

herd average.

Test Farm 1

Figure 65 – Android App Options

Menu (scrolled)

6-35

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Working with Multiple Farms

If the user has access to multiple farms, then they can switch farms by clicking on

the Farm Name in the options menu.

This will present them with a list of farms which they have access to see Figure 66.

Important Note

An important note for multi farm use is that each user should have a separate

login or each device should have a separate login.

Otherwise if two people are using the same login simultaneously on different

devices and one user switched farms then this could lead to undefined behaviour

for the second user.

Figure 66 - Android App Options Menu Farm Selection choosing Farm Menu

Test Farm 1

Test Farm 2

Test Farm 3

Test Farm 4

Test Farm 5

Test Farm 6

Test Farm 1

6-36

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Assigning a MooMonitor+

The user can assign a MooMonitor+ to a cow by selecting the Assign MM option in

the options menu.

Enter the Cow ID and the MooMonitor+ ID.

The Cow Id will be the number either

freeze branded onto the animal or the

number of the RF ID on the animal’s ear

tag (this is farm dependant).

The MooMonitor+ ID is the number

located on the rear of MooMonitor+

unit.

Figure 68 - Assign MooMonitor

Figure 67 – Location of the

MooMonitor + ID on the rear of tag

6-37

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Viewing Cow data

A cow’s individual data can be viewed by searching for the cow ID in the search bar,

by clicking into any of the six groups on the home screen and selecting any individual

cow or by selecting the All Cows list in the Options menu.

When the user clicks into an Individual Cow the screen will display the animal’s

information i.e. Cow ID, Last Heat, MooMonitor ID, Max. Activity, No of Heats, No.

of Inseminations, Lactation no. (see below).

By tapping on the cow summary at the top of the screen, the list of previous events

for that cow will appear instead. The user can toggle between both these

information screens.

By scrolling down it will also display the graphs associated with that cow (see

below).

The Daily & hourly Activity and Rumination Graph, the Rumination graph, resting

graph, feeding graph and Daily Activity Intensity graph will all be displayed.

To view another animal in the table simply swipe the screen left or right to show

the information for the next or previous cow on the list.

Figure 69 - Individual Cow

Summary

Figure 70 - Individual Cow

Summary Graphs

Figure 71 – Daily Activity

graph

6-38

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

The Activity and Runination Graphs display the Heat Alerts and Behaviour Alerts for that

specific animal.

The Red Bullseye denotes a heat

The Blue Bullseye denotes a Behaviour Alert.

The user can select any of these bullseye’s to view a summery of the information fo rthat

event.

Figure 72 - Daily Activity & Rumination Graph

6-39

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Adding Events

Users may add a number of events within the app which will assist the farmer to

organise the data generated by the MooMonitor+ system.

An event can be added by selecting the type of event at the bottom of the screen.

There are also other options such as Remove Collar from the cow, add the cow to

the Watch list, remove the cow from the watch list and remove that cow from the

system. By scrolling left to right more event options can be chosen.

There are a total of 12 different events that can be undertaken using the Android

App:

Remove Collar

Add Calved

Add DNB

Add Watch

Add Draft

Preg Check

Add Heat

Add BCS

Behaviour Alert

Add Insemination

Dry Off

Remove Animal

Figure 73 – Add Event Options

Figure 74 - Scroll left and right to view the full list of the options for each cow.

6-40

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.1 Add Heat Event

The user may at any time add an animal heat by pressing the Add Heat icon at the

bottom of the screen.

When an animal has a heat added they will be automatically added to the heats list.

1. The user will be prompted to Ignore or Confirm the heat alert.

2. The cow ID and the date of the heat event along with the time will

automatically be entered.

3. The time and date may be manually changed by the user if required.

4. Any comments the farmer may have can also be added.

5. Once the details have been entered the user will need to click the save icon

to store the information.

Figure 75 – Adding a Heat Event

6-41

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.2 Add Insemination event

The user may at any time add an animal insemination event by selecting the Add

Insem icon at the bottom of the screen.

1. The cow ID and the date of the insemination event along with the time will

automatically be entered.

2. The time and date maybe manually altered by the user if required.

3. The user will need to add in the siring animal ID to the app in the sire

dropdown menu. This list is generated by pressing the menu button on the

top right of the screen, entering the Sire ID, adding it to the list and pressing

save at the bottom of the screen. These sire ID’s will then appear on the

drop down menu in the Add Insemination screen.

4. Any comments the farmer may have can also be added.

5. Once the details have been entered the user will need to click the save icon

to store the information.

Figure 76 - Add insemination event

6-42

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.3 Adding a calving event

When a cow has calved the information of the event can be entered by selecting

the Calved icon at the bottom of the screen.

Information such as the CowID, the Date of the calving event, the difficulty of the

calving and no of calves, along with any comments the farmer may wish to add.

1. The cow ID and the date of the calving event along with the time will

automatically be entered.

2. The time and date maybe manually altered by the user if required.

3. The difficulty of the calving and number of calves may also be entered.

4. Any comments the farmer may have can also be added.

5. Once the details have been entered the user will need to click the save icon

to store the information.

Figure 77 – Add Calving Event

6-43

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.4 Add Drafting Event

It is now possible to add a drafting event for each animal. There is a range of drafting

options available to the user when drafting a cow.

Select the Add Draft symbol at the bottom of the cow summary screen. A list of

drafting options will appear on the screen. The cow can be set up for a Scheduled

Draft or Permanent Draft from this menu.

There also options to add that cow to the Watch list, draft the cow to Pin 1

permanently, Draft the cow to Pin 2 permanently and setting the draft to 0.

Figure 78 - Add Drafting Event

Figure 80 - Add Permanent Draft

Figure 79 - Add Scheduled Draft

6-44

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.5 Add Body Condition Score

The Body Condition Score of the animal can be added by selecting Add BCS at the

bottom of the cow information screen.

The Cow ID, Date & time will be populated automatically. The date and time can be

changed manually if required. The BCS for the cow is selected from the dropdown

menu. Any comments the user may have can be entered also.

Figure 81 - Add Body Condition Score

6-45

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.6 Add Dry Off Event

The user may add a Dry Off event by selecting the Dry Off icon at the bottom of the

screen.

1. The cow ID and the date of the dry off event will be automatically entered.

The user may enter a different date if they require.

2. Any comments the farmer may have can also be added.

Once the details have been entered the user will need to click the save icon to store

the information

Figure 82 - Add a Dry Off Event.

6-46

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.7 Add Do Not Breed (DNB) Event

In the event that an animal has genetic issues or is of poor health, the user may

select the animal for do not breed. At the bottom of the cow overview screen select

the DNB icon.

This means the animal can be excluded automatically from inseminations.

1. Enter the Start and Finish dates and times.

2. Any comments the farmer may have can be entered here.

3. Once the details have been entered the user will need to click the save icon

to store the information.

Figure 83 - Add Do Not Breed Event

6-47

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.8 Log a Pregnancy Check

The farmer can keep records of animal pregnancy checks and veterinary scans,

which will assist the farmer in building a profile of which animals struggle to get

pregnant.

1. The cow ID and the date of the event along with the time will automatically

be entered.

2. The result of the pregnancy check (Positive or Negative) will need to be

entered.

3. Any comments the farmer may have.

Figure 84 - Add Pregnancy Check Event

6-48

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

6.2.8.9 Adding a Behaviour Alert

A health event may be added for any animal by selecting the Behaviour Alert icon

at the bottom of the cow overview screen.

This will open up the Add Behaviour Event window on the Screen.

1. The cow ID and the start and end date and time of the behaviour event will

automatically be entered.

2. The start and end time and date maybe manually altered by the user if

requires.

3. The type of behaviour event must be selected from the illness dropdown list.

4. Any comments the farmer may have can also be added.

5. Once the details have been entered the user will need to click the save icon

to store the information.

Figure 85 – Adding a health event

6-49

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Batch Selection

The user may add an event to groups of animals at once by using the Batch Selection

feature on the Android App. The Batch Selection feature is accessed by selecting

the options menu at the top left of the home screen. Select Batch Selection at the

bottom of the settings list.

The Batch Selection screen will display a list of the various groups of animals in the

herd such as the Heat, Suspect, High Activity, Behaviour, Drafts & All Cow lists etc.

By selecting into any of these lists, the user can then select a number of cows from

the list by ticking the box next to each cow (Figure 86).

After selecting the cow ID’s, the user can add an event to the selected group of cows

by selecting one of the events on the scroll bar at the bottom of the screen

Figure 86 - Entering Batch Selection on the Android App

6-50

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Viewing Herd Data

The user can view individual herd scatter graphs to determine how each cow is

performing against the herd average. The graph compares Resting (y-axis) with

Rumination + Feeding (x-axis). Different groups can be selected from the dropdown

at the top right of the screen.

Select Herd Data from the settings menu. This will proceed to the Herd Analysis

screen. The herd graph will be displayed at the bottom of the screen.

By selecting any of the coloured dots on the

graph, the information for that animal will be

displayed at the top of the screen.

A chart of the cow’s Activity, Resting, Feeding

and Rumination performance against the

average performance of the herd will also be

shown.

Each cow is colour coded according to the colour

symbol assigned to them from the data which

has been inputted into the system (See section

6.2.3.1).

Figure 87 - Herd Analysis option on the Android App

Figure 88 - Chart Data displayed

for the individual Animal.

6-51

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

Individual Groups and specific dates can be selected by entering the dropdown

menu at the top right of the screen.

Figure 89 - - Choose from the list of groups for specific graphs to be displayed

6-52

INM12006 – MOOMONITOR + V3.0

Copyright Dairymaster 2015

View Basestation Status

The User may view the Basestation Status and information about the tags

communicating with the system.

To view the Basestation information, select the Basestation icon at the top right of

the home screen.

The system will show the number of collars which have communicated with the

Basestation in the last 24hrs and the collars which have been out of range for longer

than that period.

Figure 90 – View Basestation Status

Loading...

Loading...