DAIKIN VRV-S INSTALLATION MANUAL

EDUS 39 - 606A - N

Installation of

Outdoor Units

AMERICAS

EDUS39-606A-N

Installation of

Outdoor Units

1. Center of Gravity..................................................................... 2

2. REFNET Pipe System ........................................................... 3

2.1 Layout Example ............................................................... 3

2.2 Field Refrigerant Piping ................................................... 4

2.3 REFNET Joints and Headers .......................................... 4

3. REFNET Pipe ........................................................................ 7

3.1 REFNET Joint (Branch Kit) ............................................. 7

3.2 REFNET Header(Branch Kit) ........................................... 7

4. Installation............................................................................... 9

4.1 Safety Considerations RXYMQ-M .................................... 9

4.2 Introduction ......................................................................11

4.3 Before Installation ............................................................11

4.4 Selection of Installation Location .....................................12

4.5 Refrigerant Piping Work ...................................................17

4.6 Example of connection ....................................................20

4.7 Airtight test and vacuum drying .......................................21

4.8 Electrical Wiring Work ......................................................22

5. Checks after Completion of Work ..........................................26

5.1 Caution for Refrigerant Leaks...........................................28

Installation of Outdoor Units 1

Center of Gravity EDUS39-606A-N

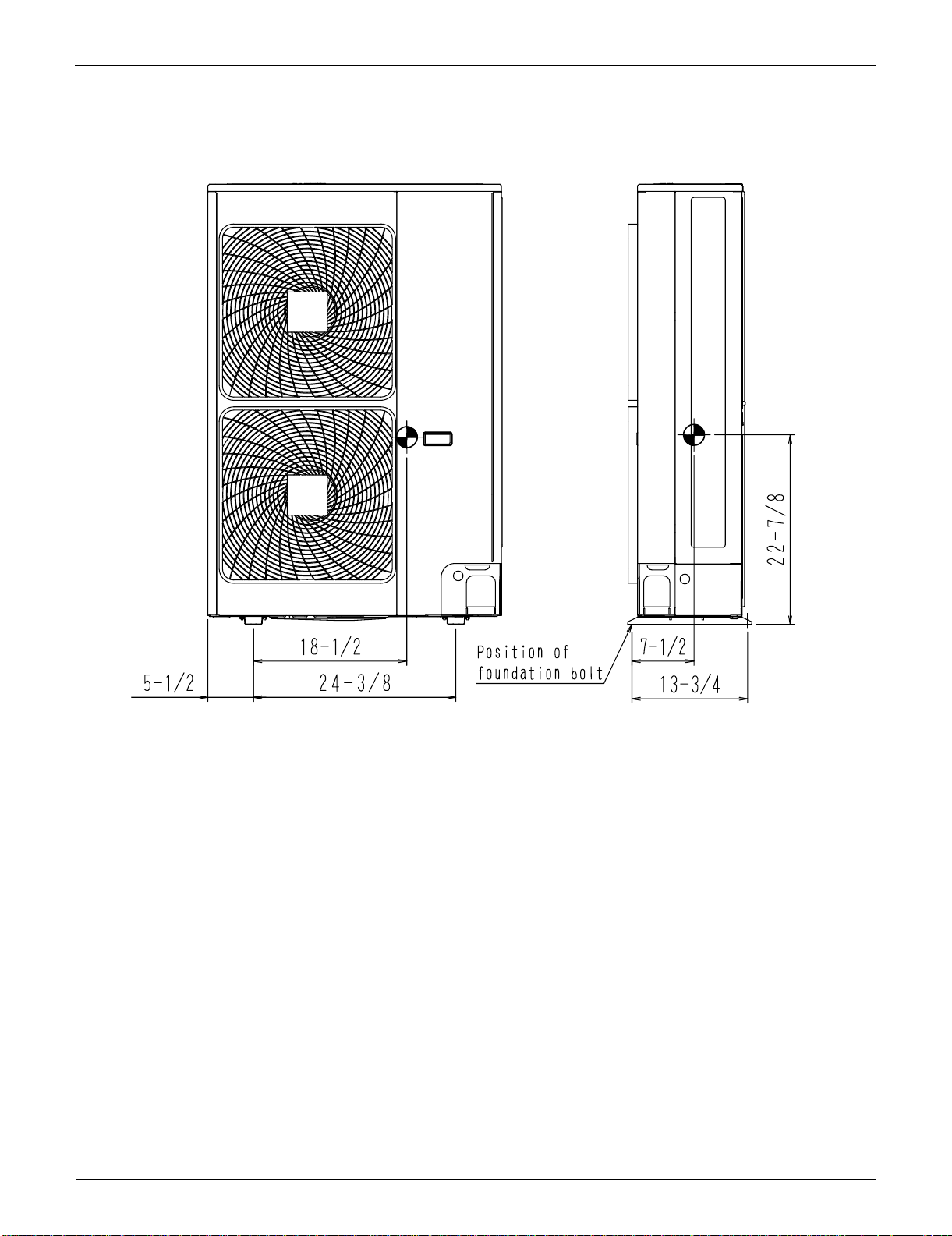

1. Center of Gravity

RXYMQ36/48MVJU

4D047387

2 Installation of Outdoor Units

EDUS39-606A-N REFNET Pipe System

2. REFNET Pipe System

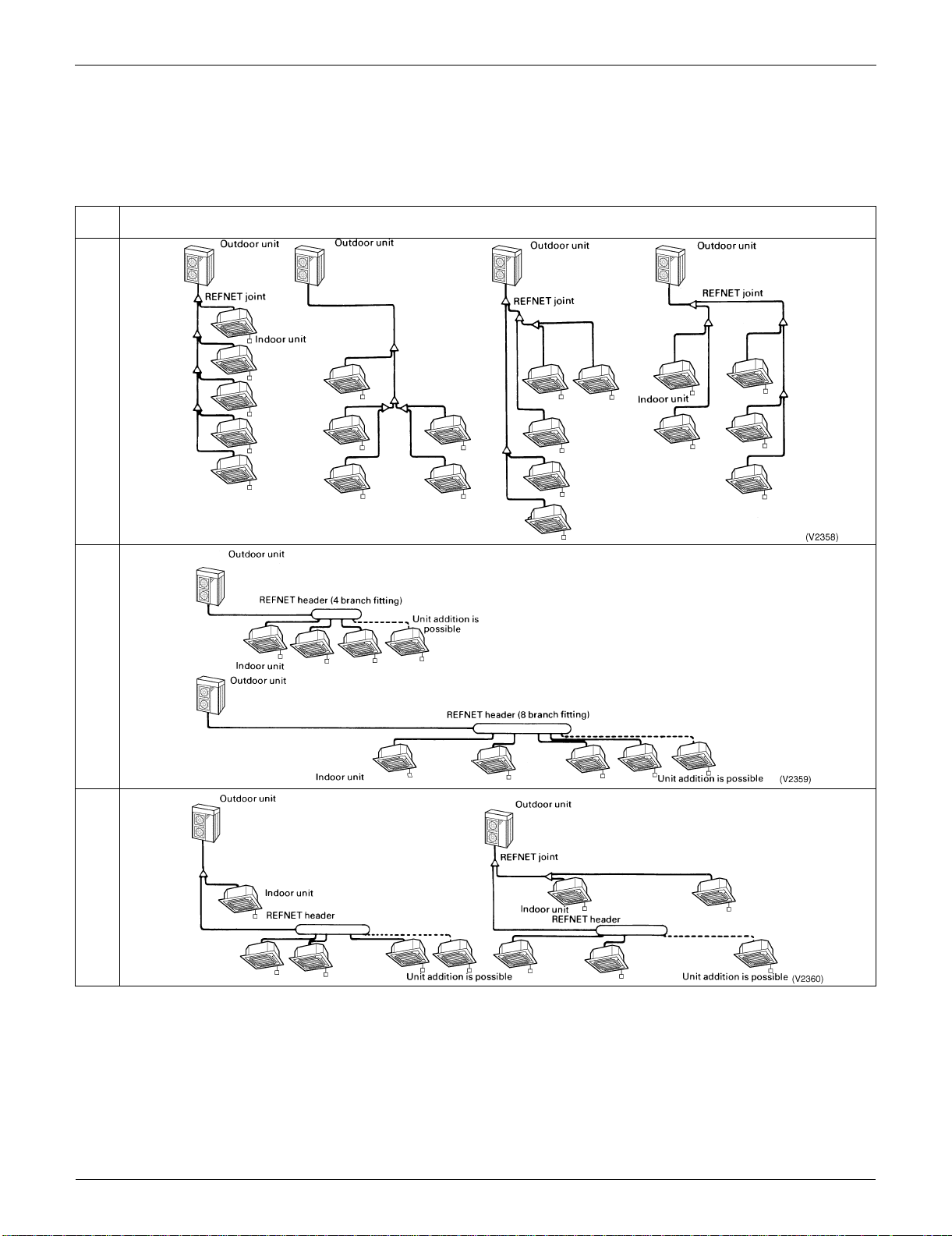

2.1 Layout Example

Use of the particular branch fitting appropriate to each individual unit type not only permits the pipes to be laid

with ease but also increases the reliability of the system as a whole.

Type of

fitting

Line branch fitting

(Pipes containing REFNET joints only)

Sample systems

Header branch fitting

(Piping consists of REFNET headers only)

and joints)

Mixed branch fittings

(Piping including both headers

Units can be added by connecting them directly to the REFNET header or REFNET joint. Further branches cannot be

included in the system below the REFNET header branch.

Notes

1. When the capacity ratio of the indoor system to the outdoor unit is more than 100% and when all the indoor units are

in operation at the same time then the rated capacity of each unit is somewhat reduced.

2. Special purpose REFNET pipe components must be used for all the pipe work

Installation of Outdoor Units 3

REFNET Pipe System EDUS39-606A-N

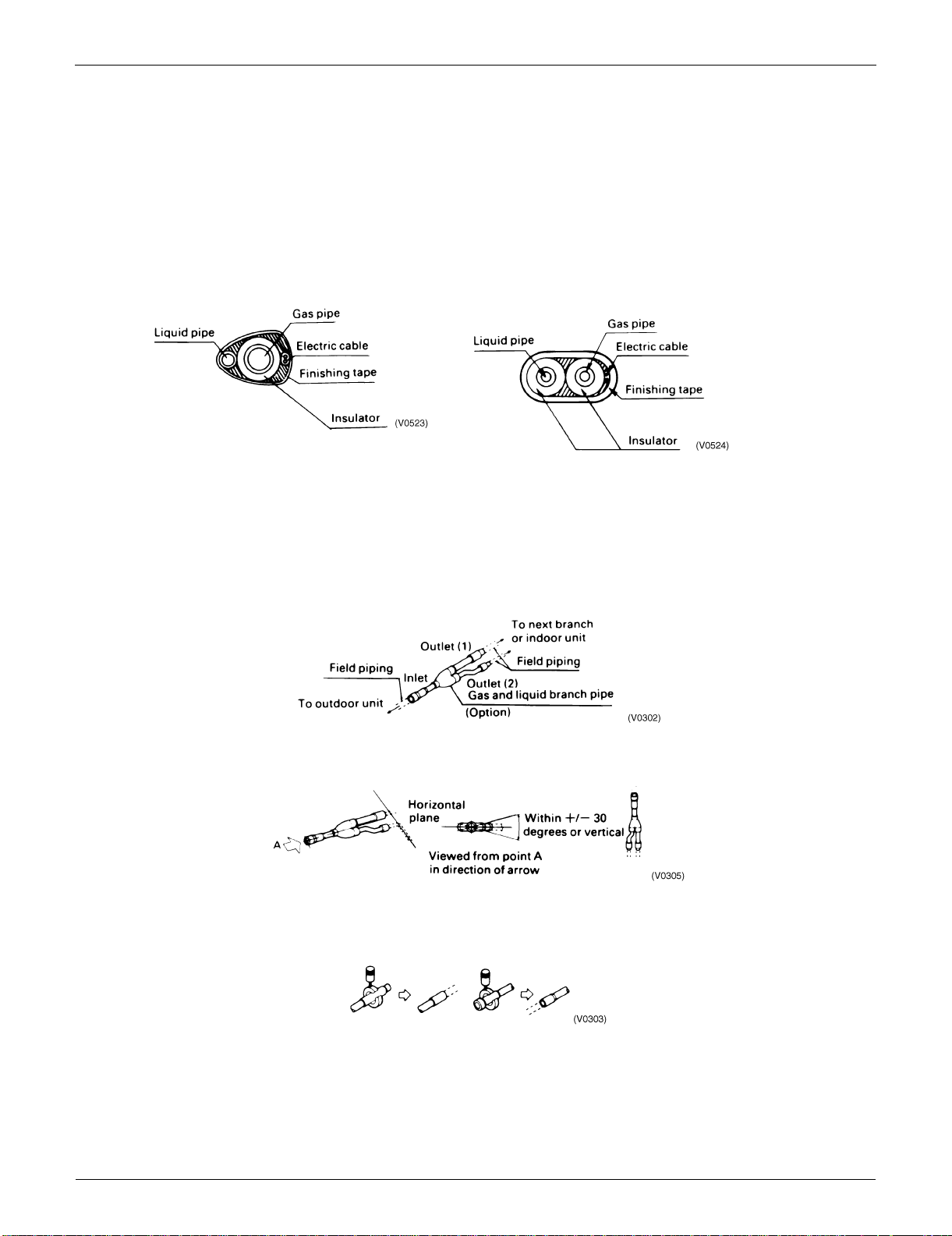

2.2 Field Refrigerant Piping

1. The following materials should be used for all refrigerant piping.

Materials: Deoxidized phosphorous seamless copper pipe or equivalent

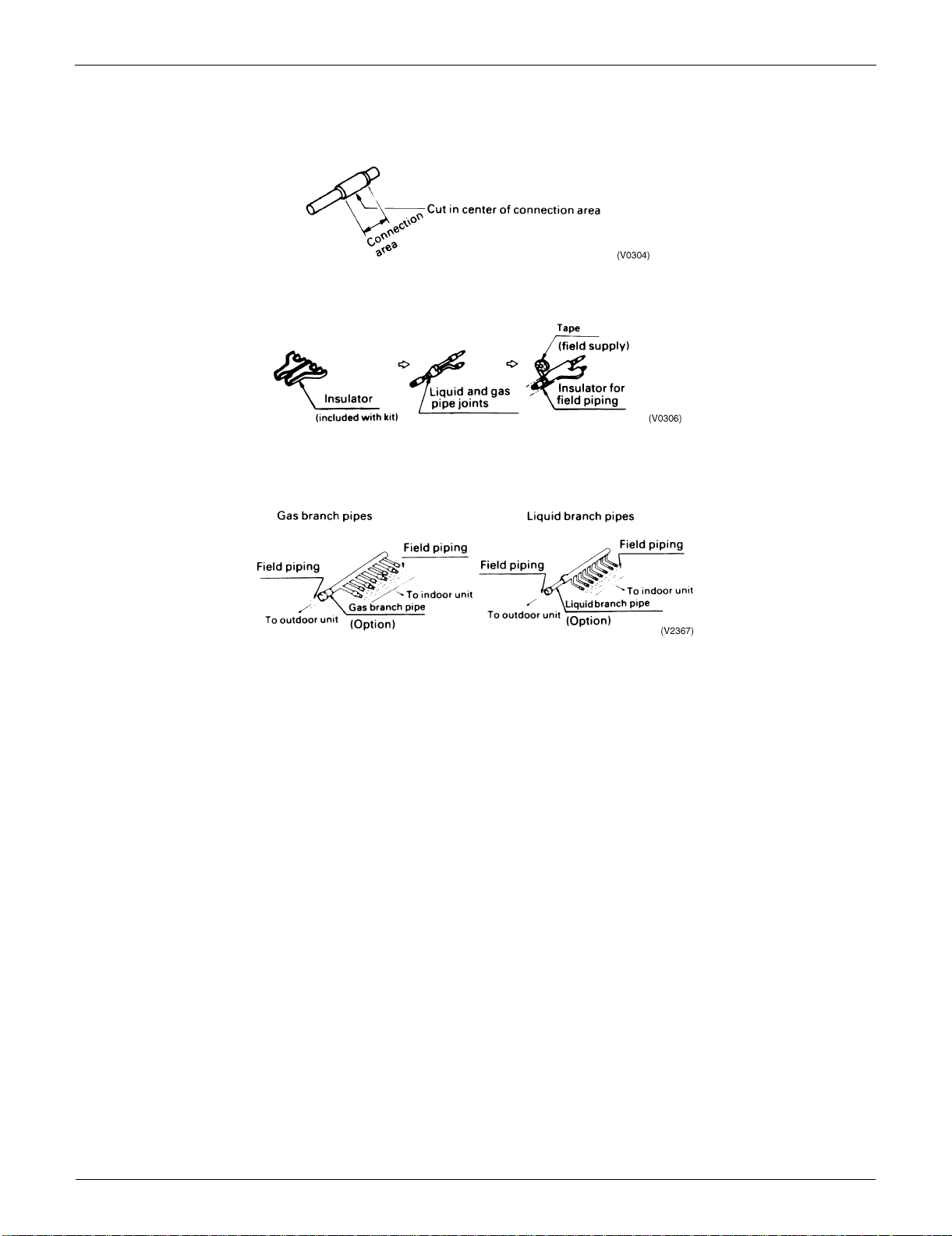

2. The tips for insulation

Both Gas, Liquid piping must be insulated.

Materials: Glass fiber or heat-resistant polyethylene foam.

Thickness: 1/2 inch (12.7 mm) or more

Heat resistance: Gas pipe : 250°F or more / Liquid pipe : 160°F or more

Insulation of single pipe only Insulation of both liquid and gas pipe

2.3 REFNET Joints and Headers

2.3.1 REFNET Joints

For gas and liquid branch pipes

Make sure that all branch pipes are fitted such that they branch either horizontally or vertically.

When the size of the selected field piping is different from that of branch pipe then the connecting section should be

cut with a pipe cutter as shown in the following figure.

4 Installation of Outdoor Units

EDUS39-606A-N REFNET Pipe System

When you are cutting an inlet or outlet pipe with a pipe cutter make sure that you make the cut in the center of the

connection area.

Branch pipes must be insulated in accordance with the handbook accompanying each kit.

2.3.2 REFNET Header

Installation of Outdoor Units 5

REFNET Pipe System EDUS39-606A-N

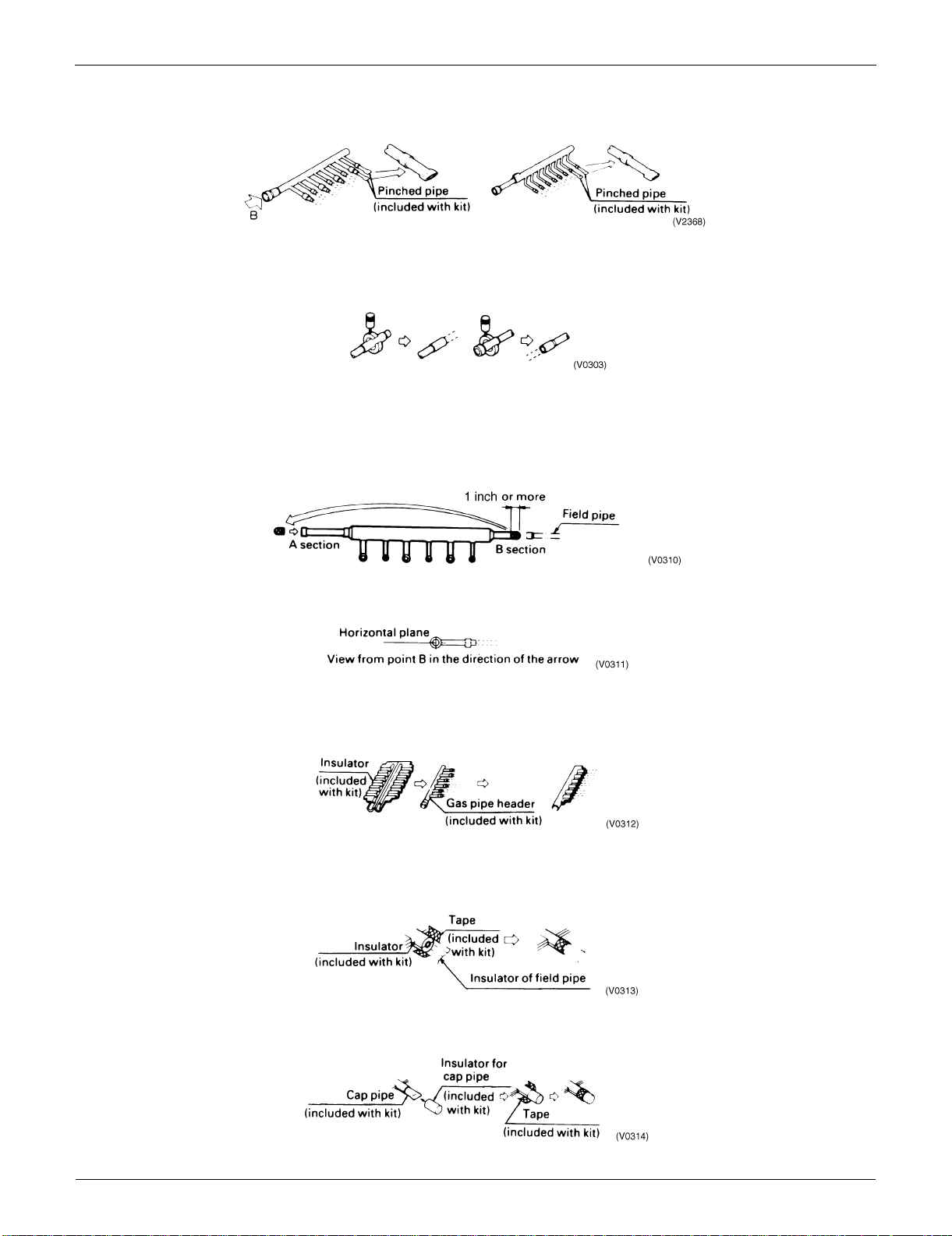

When the number of indoor units to be connected to the branch pipes is less than the number of branch pipes

available for connection then cap pipes should be fitted to the surplus branches.

When the size of the selected field piping is different from that of branch pipe, you must cut the connecting section

with a pipe cutter as shown in the following figure:

When field piping is connected to the B section of the inlet/outlet pipe on the outdoor unit side of the liquid pipe

header, cut the B section with a pipe cutter and connect it to the A section.

. Connect the flared section of the field pipe to the B section, as shown in the following figure:

Fit the branch pipe so that the branch lies in a horizontal plane.

The branch pipe must be insulated in accordance with the instruction manual accompanying each kit.

1. Insulate the header with insulator included in the kit.

2. Joints between insulators included in the kit and those already applied to the field piping should be sealed with the tape accompanying each kit.

3. Any cap pipes should also be insulated using the insulator provided with each kit and then taped as described above.

6 Installation of Outdoor Units

EDUS39-606A-N REFNET Pipe

3. REFNET Pipe

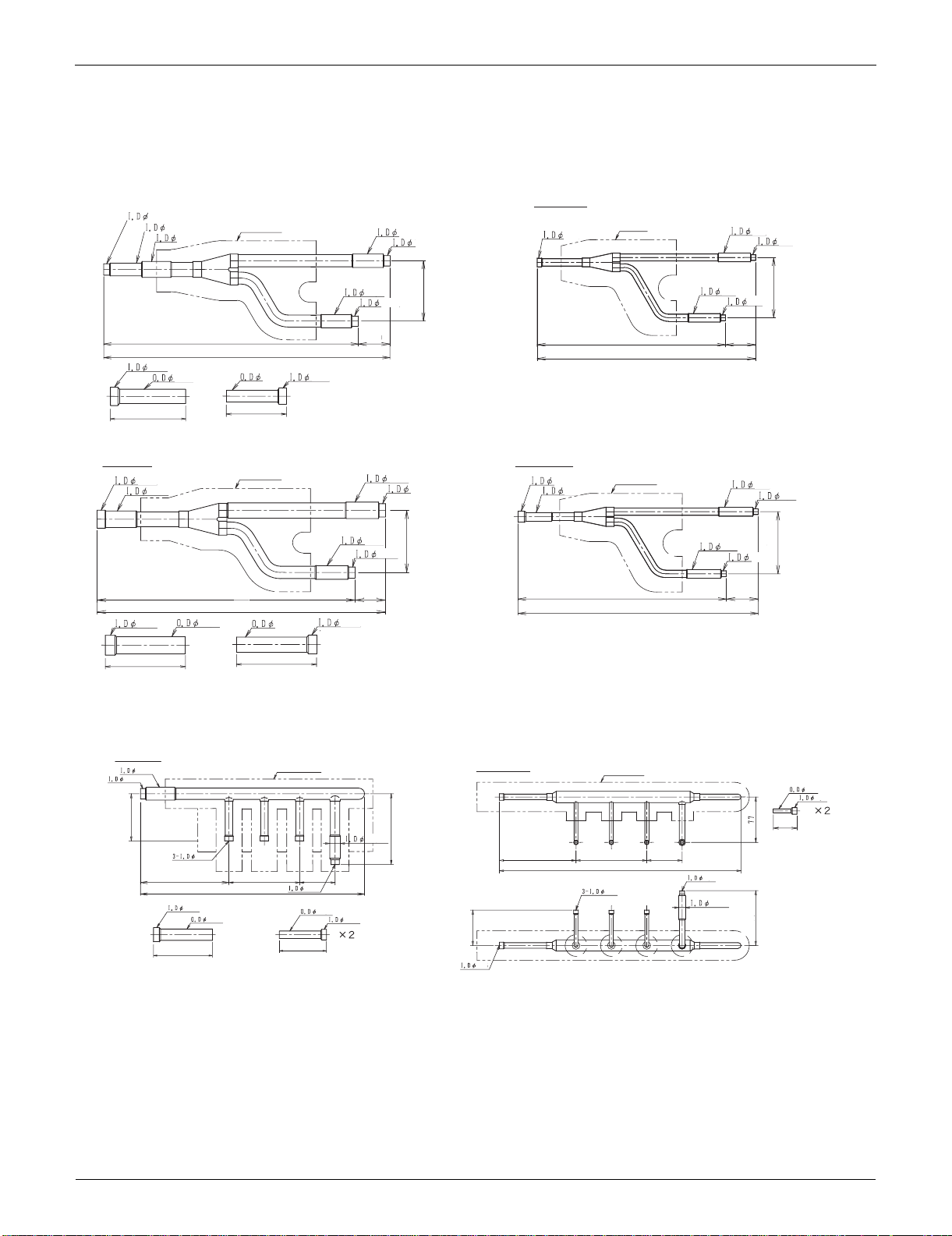

3.1 REFNET Joint (Branch Kit)

KHRP26M22T

Gas Side

1/2

5/8

3/4

Insulation

5/8

1/2

Liquid Side

3/8

Insulation

3/8

(unit:in)

1/4

5/8

1/2

13-1/3

1-1/2

15

7/8

3/4

4

5/8

3/4

3

KHRP26M33T

Gas Side

7/8

3/4

1

4

12-11/16

7/8

Insulation

14-1/4

5/8

1/2

1-1/2

3/4

7/8

4

3.2 REFNET Header(Branch Kit)

KHRP26M22H

Gas Side

3/4

5/8

3

1/2

6

7/8

4

15

3/4

2 x 2-1/2 = 5

Insulation

2-1/2

1/2

3

5/8

1/2

5/8

3

9-7/8

3/8

1-1/2

3

1/4

11-1/2

D3K03622C

Liquid Side

3/4

5/8

1/2

3/8

3

Liquid Side

5

6

5

2-1/2

3/8

Insulation

10-1/4

Insulation

2 x 2-1/2 = 5

16

1/4

3/8

1/4

3/8

3

1/4

1-1/2

11-13/16

D3K03623A

1-1/2

1/4

3/8

2-1/2

1/4

3/8

4

D3K03629B

Installation of Outdoor Units 7

REFNET Pipe EDUS39-606A-N

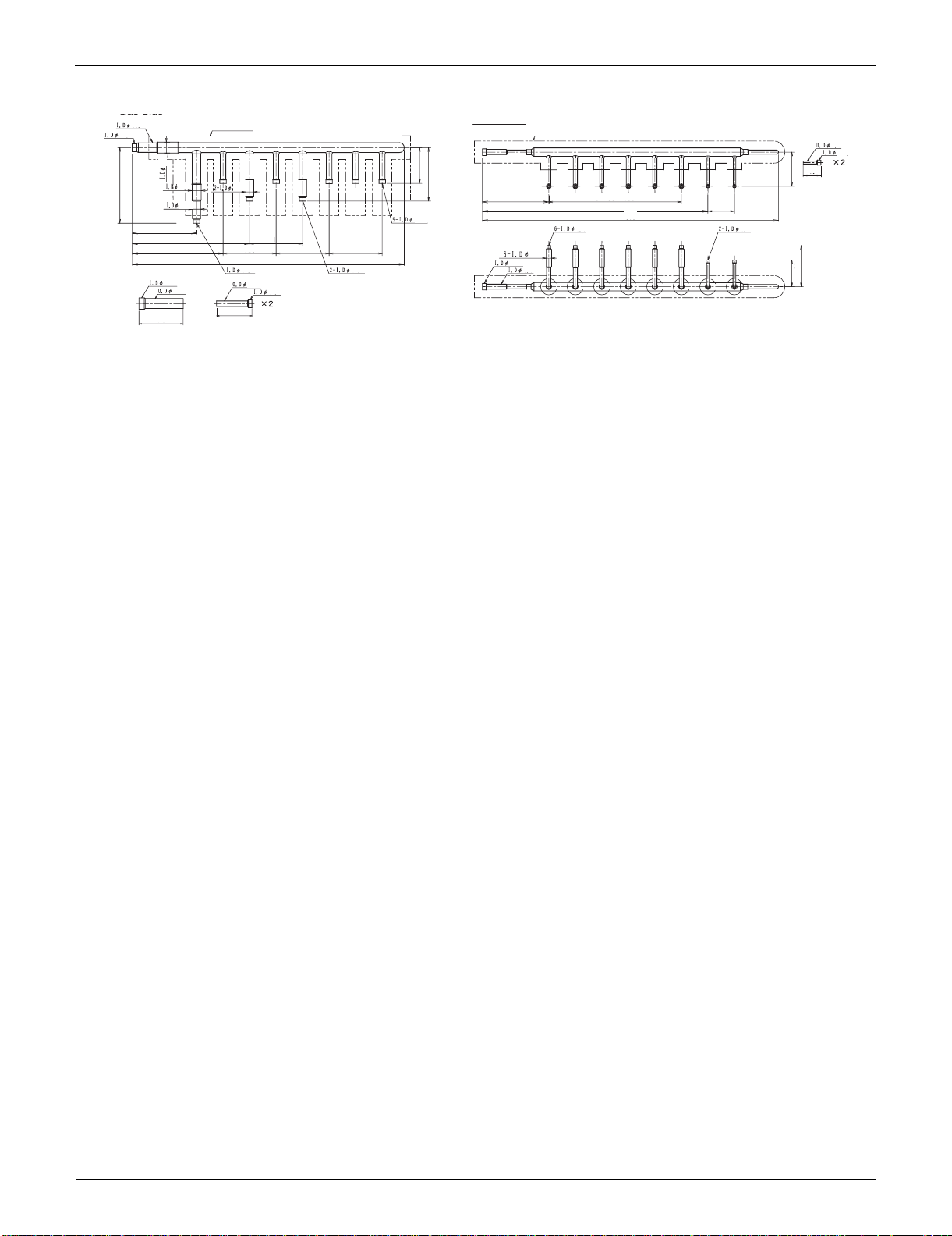

Gas Side

Li

Sid

KHRP26M33H

3/4

5/8

7/8

6-3/4

3/8

5/8

6

15

8

7/8

3/4

4

Insulation

5/8

3

quid

e

Insulation

3-1/4

4-3/4

6

1/2

5

5

24

1/2

1/2

5/8

2 x 2-1/2 = 5

5

1/2

3/8

1/2

3/8

5 x 2-1/2 = 12-1/2

26

26

2-1/2

1/41/4

3

2-1/2

1/4

3/8

1-1/2

3-3/4

D3K03630B

8 Installation of Outdoor Units

EDUS39-606A-N Installation

4. Installation

4.1 Safety Considerations RXYMQ-M

Please read these SAFETY CONSIDERATIONS carefully before installing air conditioning equipment, and be sure to install it

correctly. After completing installation, make sure the unit operations properly during startup operation.

Instruct the customer how to operate and maintain the unit.

Always use a licensed installer or contractor to install this product. Improper installation can result in water or refrigerant leakage,

electrical shock, fire, or explosion.

Meaning of danger, warning, caution and note symbols.

DANGER .............. Indicates an imminently hazardous situation which, if not avoided, results in death or serious injury.

WARNING ............ Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION ............. Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices that may cause property damage.

NOTE.................... Indicates a statement of company policy directly or indirectly related to the safety of personnell or pro-

tection of property.

DANGER

• Refrigerant gas is heavier air and replaces oxygen. A massive leak can lead to oxygen depletion, especially in basements, and an asphyxiation hazard can occur leading to serious injury or death.

• Do not ground units to water pipes, telephone wires or lightning rods because incomplete grounding could cause a

severe shock hazard resulting in severe injury or death, and to gas pipes because a gas leak could result in an explosion which could lead to severe injury or death.

• Do not install unit in an area where flammable materials are present due to risk of explosion resulting in serious injury

or death.

• Any abnormalities in the operation of the air conditioner such as smoke or fire could result in severe injury or death.

Turn off the power and contact your dealer immediately for instructions.

• If the refrigerant gas leaks during installation, ventilate the area immediately.

Refrigerant gas may produce toxic gas if it comes in contact with fire such as from a fan, heater, stove or cooking

sure to this gas could cause severe injury or death.

• After completing the installation work, check that the refrigerant gas does not leak.

Refrigerant gas may produce toxic gas if it comes in contact with fire such as from a fan, heater, stove or cooking device. Exposure to this gas can cause severe injury or death.

• Do not install the unit in an area where flammable materials are present due to risk of explosion resulting in serious

injury or death.

• Safely dispose of the packing materials.

Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries.

• Tear apart and throw away plastic packaging bags so that children will not play with them.

Children playing with plastic bags face danger of death by suffocation.

device. Expo-

WAR NING

• Perform installation work in accordance with this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in water leakage, electric shocks, fire or the unit falling.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injuries.

• Do not remove the front panel because some parts inside are dangerous to touch. In addition, some parts may be

damaged by touching. For checking and adjusting internal parts, contact your dealer.

• Carry out the specified installation work after taking account of strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is carried out by

qualified personnel according to local laws, regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

• Make sure that all wiring is secured, the specified wires are used, and no external forces act on the terminal connections or wires.

Improper connections or installation may result in fire.

• When wiring the power supply and connecting the remote controller wiring and transmission wiring, position the

wires so that the electric parts box lid can be securely fastened.

Improper positioning of the electric parts box lid may result in electric shocks, fire or the terminals overheating.

Installation of Outdoor Units 9

Loading...

Loading...