Daikin UATYQ250MCY17, UATYQ350MCY17, UATYQ450MCY17, UATYQ550MCY17, UATYQ600MCY17 Installation manuals

...

INSTALLATION

Installation Manual

Rooftop Package Units

English

MANUAL

Installationshandbuch

Kompaktanlage Für Dachmontage

Manuel D’installation

Conditionneurs D’air En Toiture

Installatiehandboek

Compactsysteem Voor Dakmontage

Manual De Instalación

Unidades Del Conjunto Del Tejado

Manuale Di Installazione

Unità A Pacchetto Per Installazione Sul Tetto

Manual De Instalação

Unidades De Conjuntos De Telhado

Deutsch

Français

Nederlands

Español

Italiano

Português

Model:

UATYQ250MCY17

UATYQ350MCY17

UATYQ450MCY17

UATYQ550MCY17

UATYQ600MCY17

UATYQ700MCY17

UATYQ900MCY17

Руководство По Установке

Компактные Установки Для Кондиционирования

Воздуха, Монтируемые На Крыше Здания

Instrukcja instalacji

Urządzenia dachowe (typu „rooftop”)

Kurulum kılavuzu

Çatı Tipi Ambalaj Üniteleri

Installationsmanual

Paketenheter för Takovansidor

(Applicable to certified models only)

IM-5RTBR-0710(9)-DAIKIN (DENV)

Part No.: R08019035377I

Русский

Polski

Türkçe

Svenska

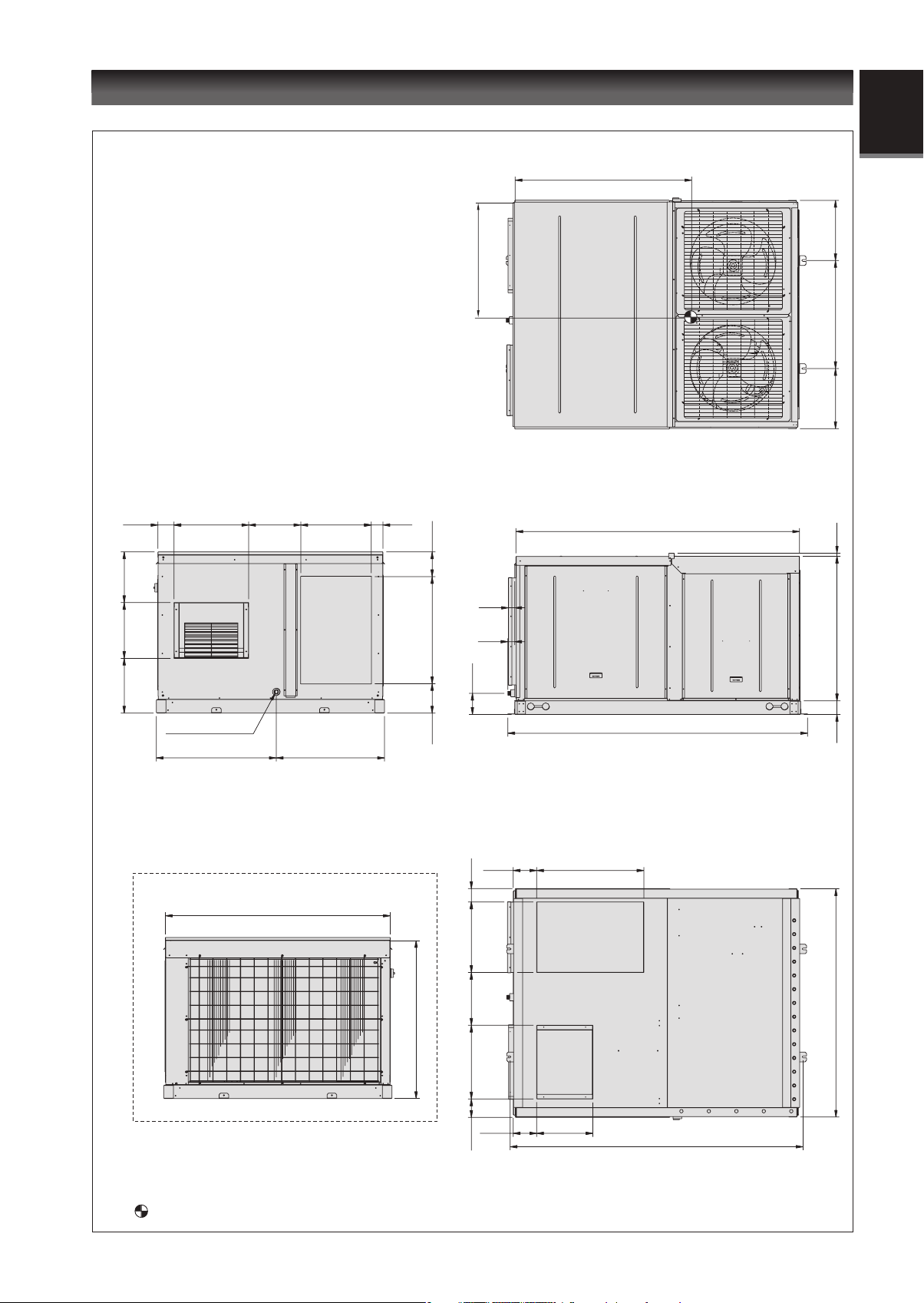

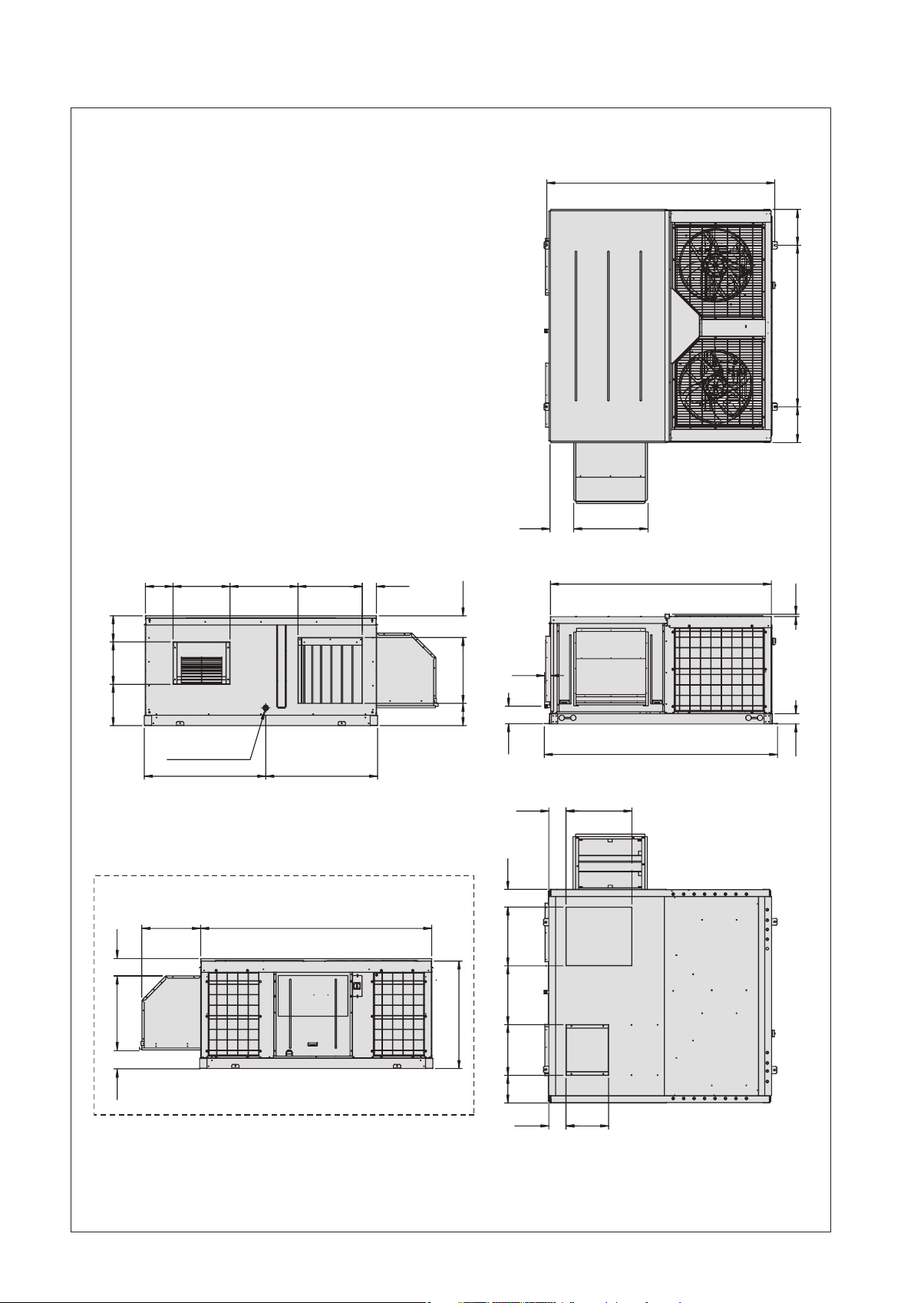

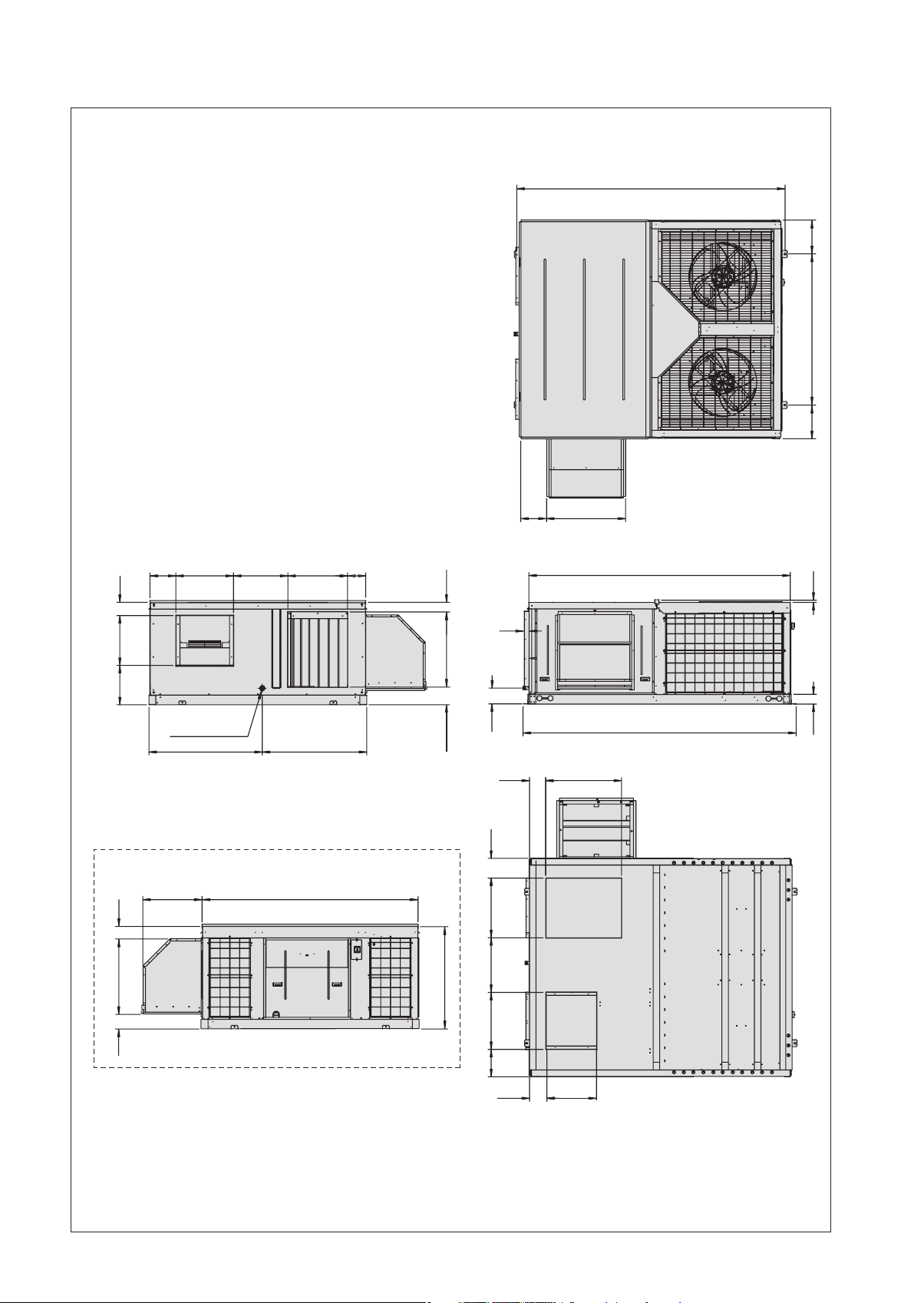

OUTLINE AND DIMENSIONS

Model: UATYQ250

117

544

379

513

85

180

850

ENGLISH

All dimensions are in mm

1275

437

Original Instruction

786

437

2063

22

369

405

398

Back view of the unit:

SUPPLY AIR

DRAIN PIPE Ø 1"

FOR HORIZONTAL DISCHARGE

872

1638

RETURN

AIR

788

1150

779

214

45

51

154

171 779

97

513384537133

VERTICAL

SUPPLY

VERTICAL

RETURN

AIR

AIR

2181

98 1052

1660

CENTER OF GRAVITY

171

408

2131

FOR VERTICAL DISCHARGE

1

Model: UATYQ250 WITH ECONOMIZER OPTION

All dimensions are in mm

437786437

808191

117

398 405 369

Back view of the unit:

544

SUPPLY AIR

DRAIN PIPE ø 1"

FOR HORIZONTAL DISCHARGE

522

379

513 85

RETURN AIR

788872

1638

OUTDOOR AIR

180779

214

154

97

513384537

51

171

OUTDOOR AIR

779

VERTICAL

RETURN AIR

2063

2181

22

1052

98

2

223 672 277

1150

133

171

1660

VERTICAL

SUPPLY

AIR

408

2131

FOR VERTICAL DISCHARGE

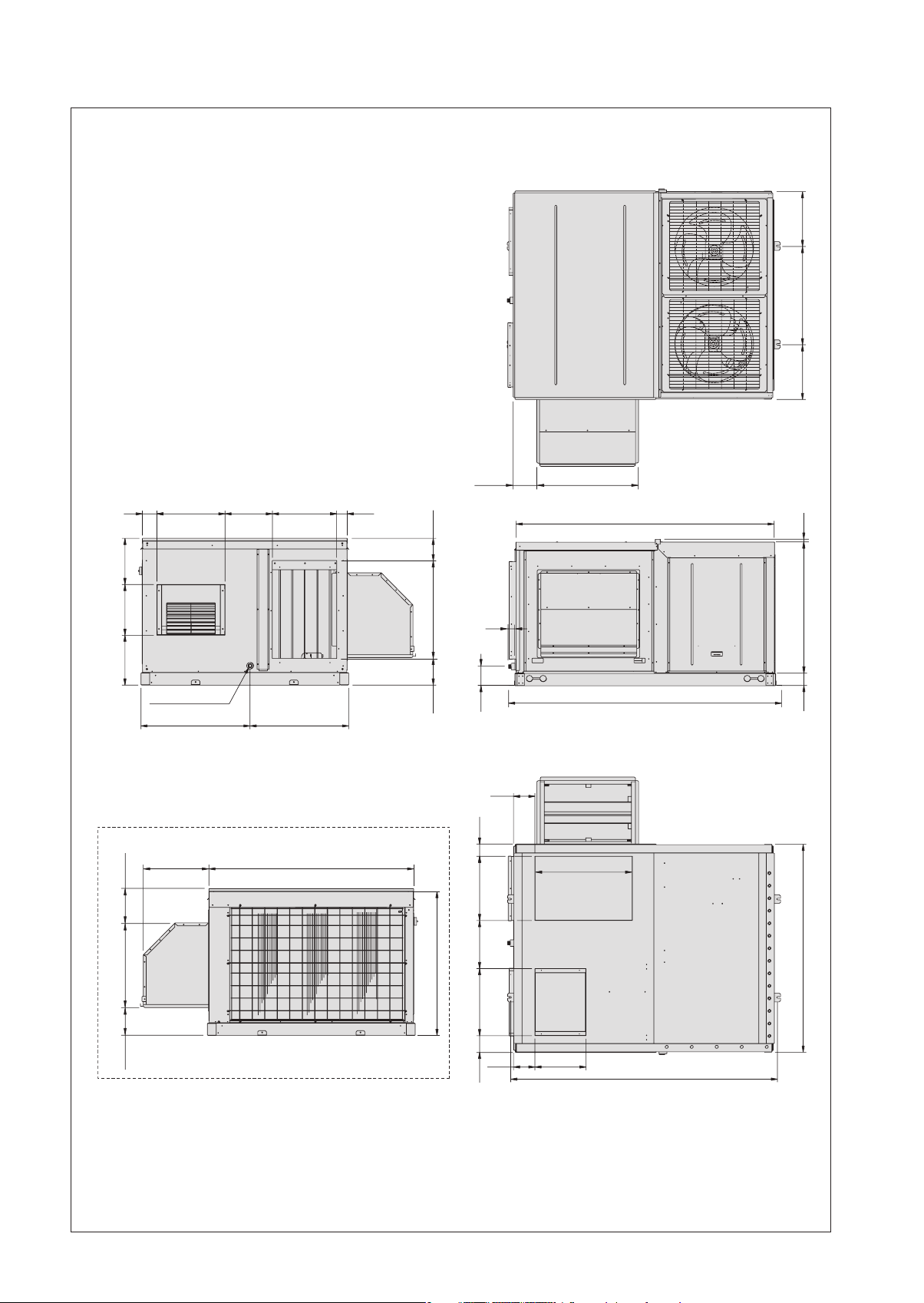

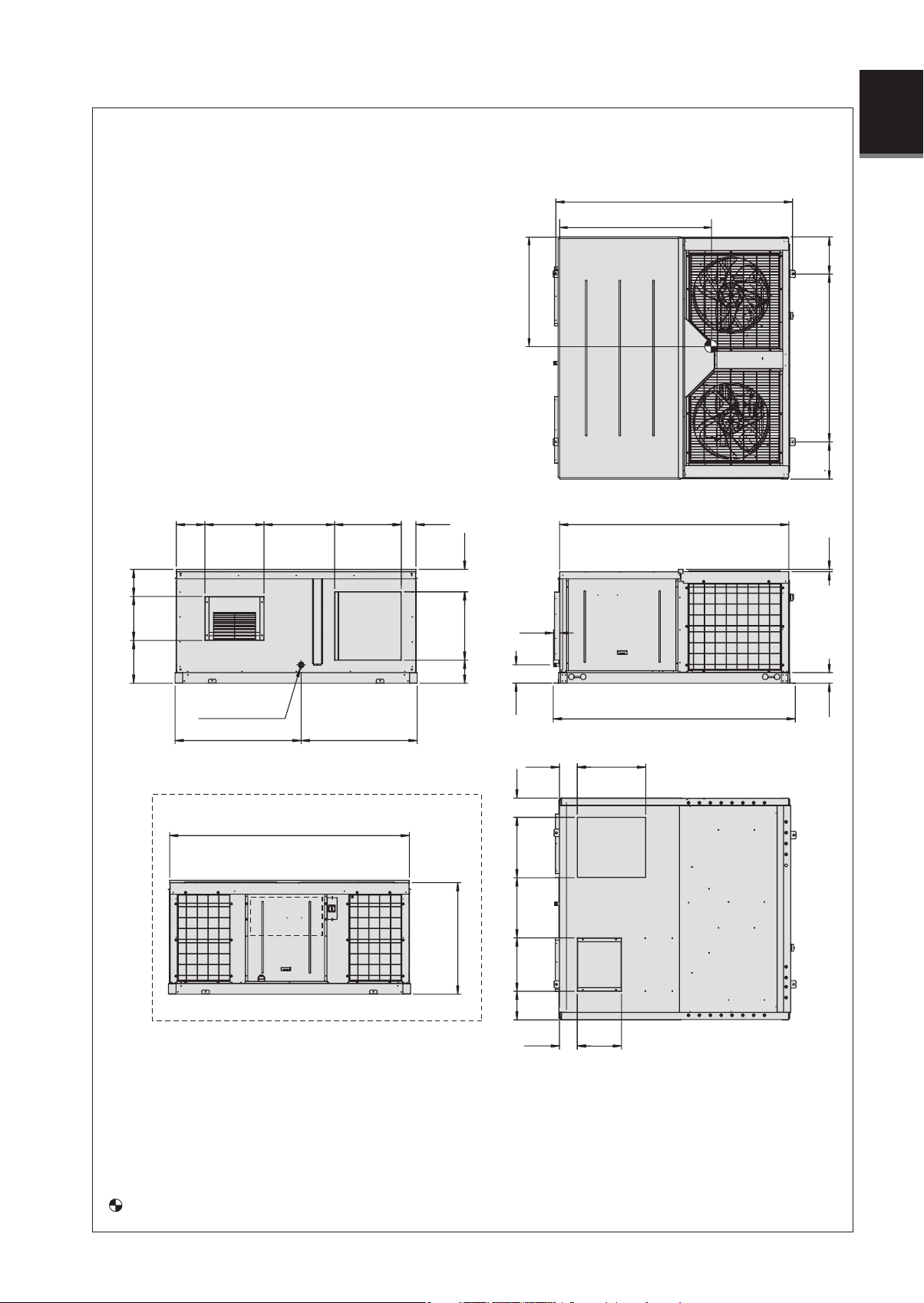

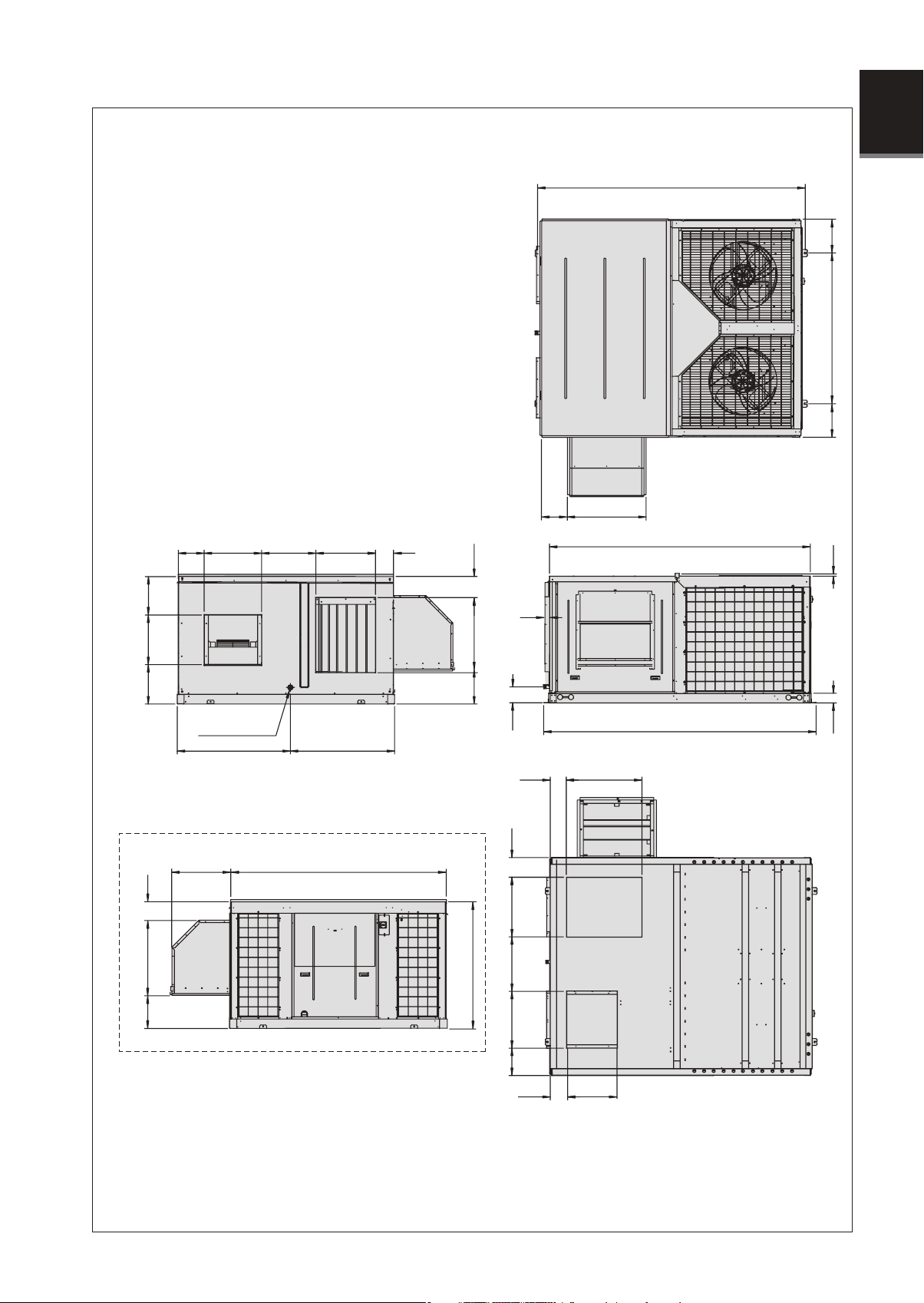

Model: UATYQ350

265

544

651

614

136

207

1000

1410

All dimensions are in mm

2180

2113

ENGLISH

342

1546

342

22

250

405

395

Back view of the unit:

SUPPLY AIR

DRAIN PIPE ø 1"

FOR HORIZONTAL DISCHARGE

1161

2209

CONTROL

BOX

RETURN

AIR

1070

1028

630

213

168

187

614613538280

58

164

630

VERTICAL

RETURN

AIR

VERTICAL

SUPPLY

AIR

2230

99

CENTER OF GRAVITY

407164

FOR VERTICAL DISCHARGE

3

Model: UATYQ350 WITH ECONOMIZER OPTION

All dimensions are in mm

2180

342

1546

342

265

544

250

405395

SUPPLY AIR

DRAIN PIPE ø 1"

1161 1069

FOR HORIZONTAL DISCHARGE

Back view of the unit:

562

166

651

RETURN AIR

2209

136614

OUTDOOR AIR

207

630

213

168

187

614

58

223

164

709

630

OUTDOOR AIR

VERTICAL

RETURN AIR

2113

2230

22

99

4

710

175

CONTROL

BOX

1028

613

538

280

164

VERTICAL

SUPPLY AIR

407

FOR VERTICAL DISCHARGE

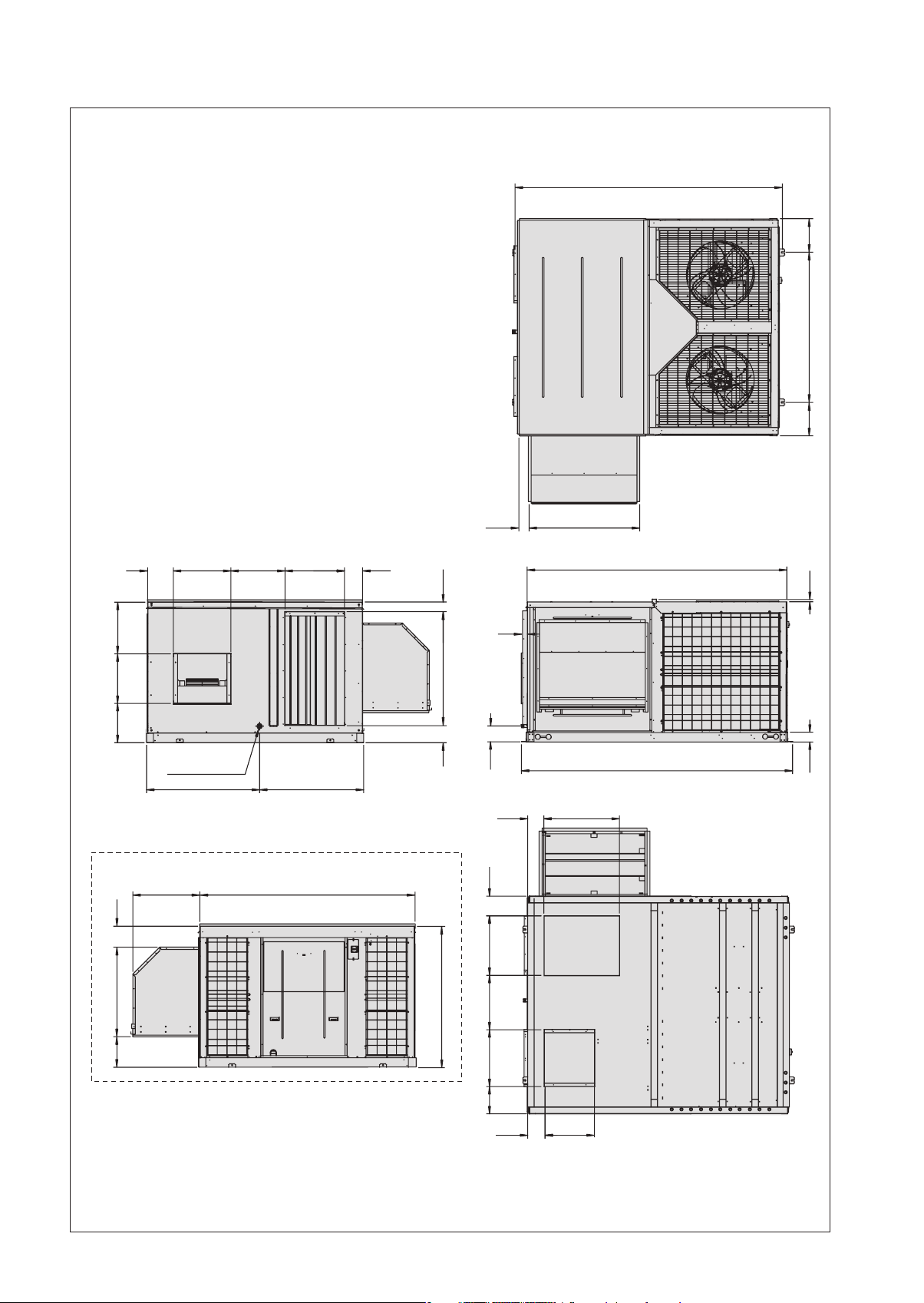

Model: UATYQ450

265 544 651 614 136

235630

1000

1385

All dimensions are in mm

2180

2113

ENGLISH

342

1546342

22

328405395

DRAIN PIPE ø 1"

Back view of the unit:

SUPPLY AIR

RETURN

AIR

1161 1069

FOR HORIZONTAL DISCHARGE

2209

CONTROL

BOX

264

1130

168

187614613538280

58

164

630

VERTICAL

RETURN

AIR

VERTICAL

SUPPLY

AIR

2230

99

CENTER OF GRAVITY

407164

FOR VERTICAL DISCHARGE

5

Model: UATYQ450 WITH ECONOMIZER OPTION

All dimensions are in mm

2180

342

1546

342

544265

328405

SUPPLY AIR

395

DRAIN PIPE ø 1"

1161 1069

FOR HORIZONTAL DISCHARGE

Back view of the unit:

562

207

614651

RETURN AIR

2209

136

OUTDOOR AIR

235

630

264

168

187

614

223

58

709

630164

OUTDOOR AIR

VERTICAL

RETURN AIR

2113

2230

22

99

6

710237

CONTROL

BOX

1130

613

538

280

164

VERTICAL

SUPPLY

AIR

407

FOR VERTICAL DISCHARGE

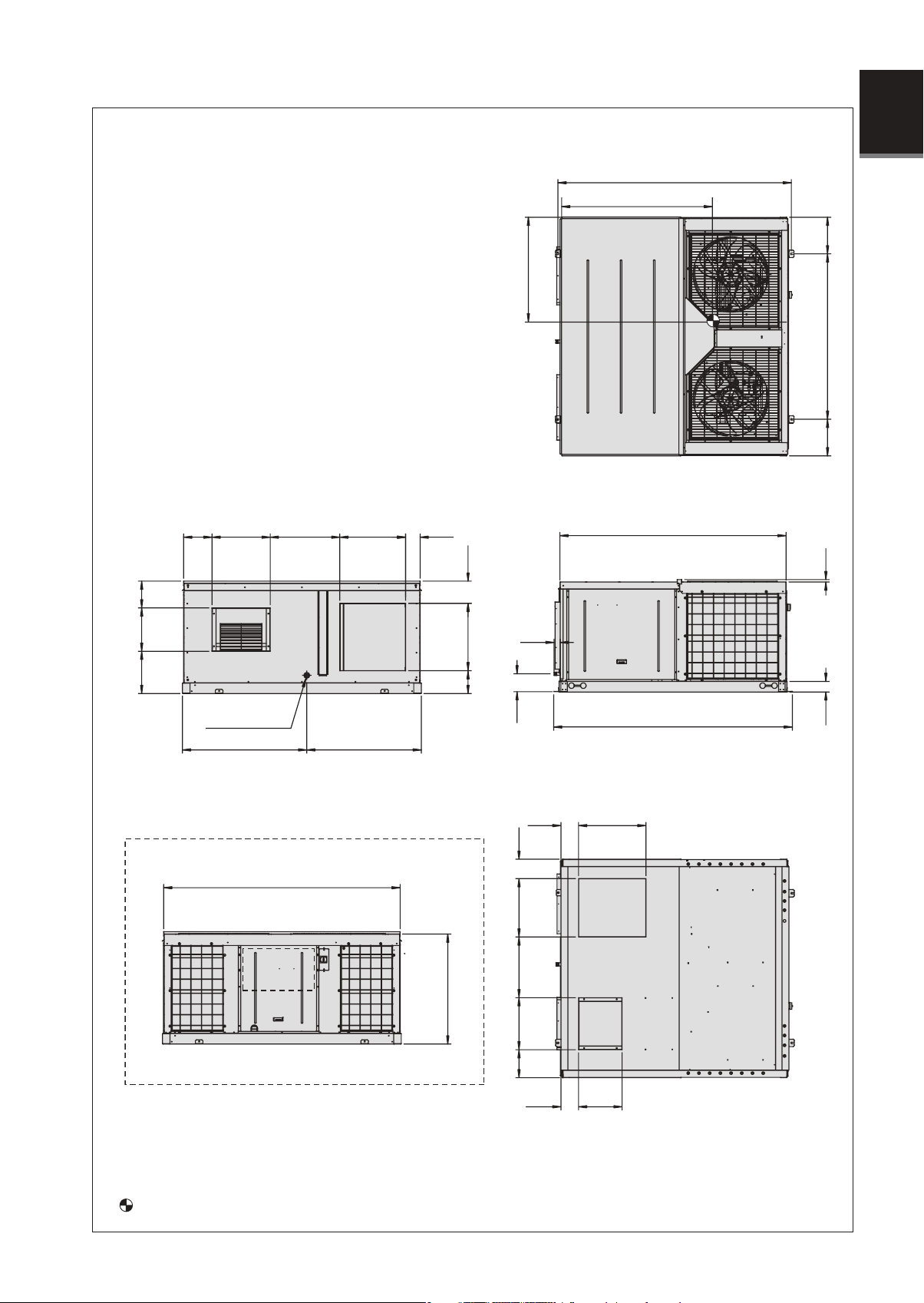

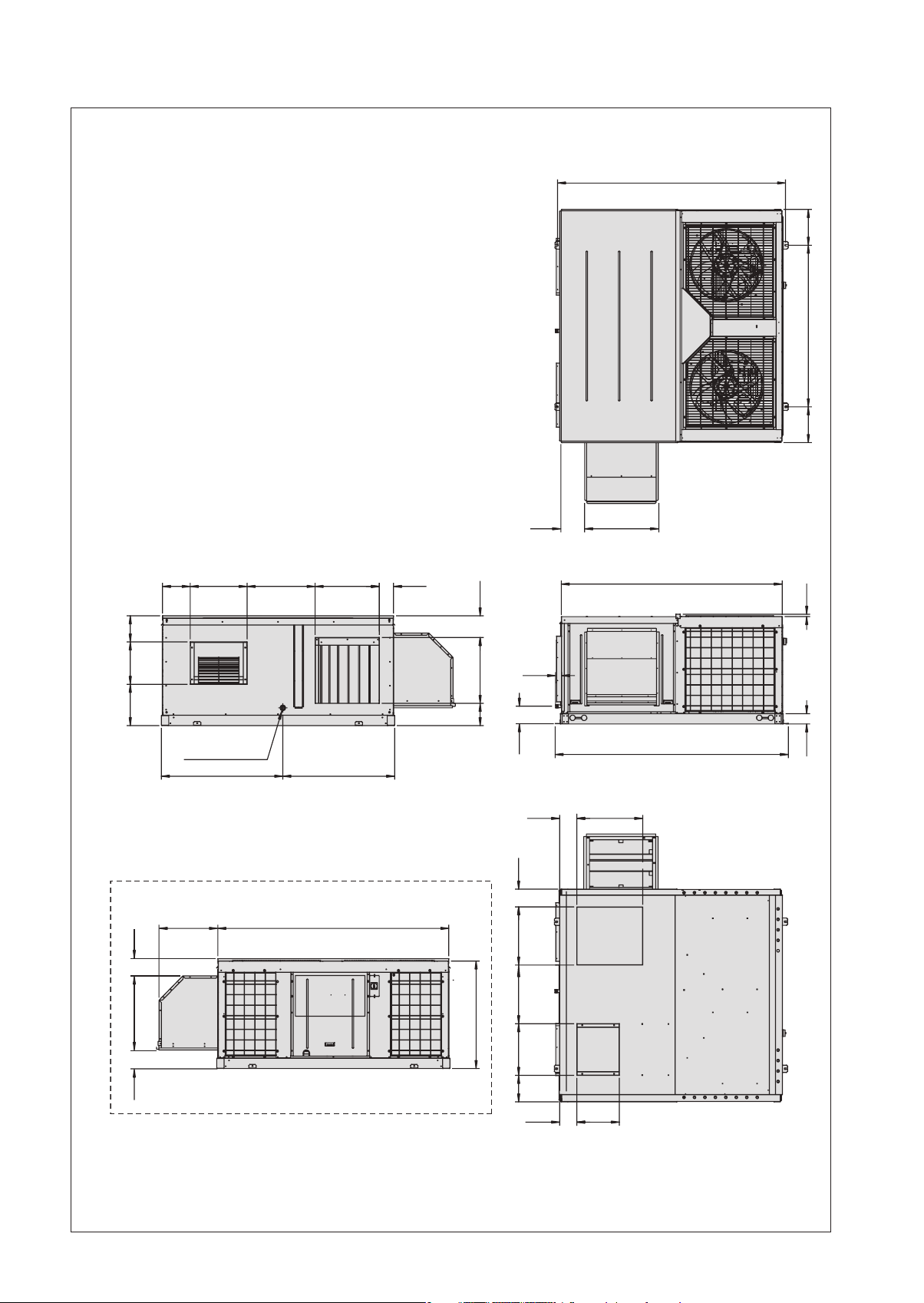

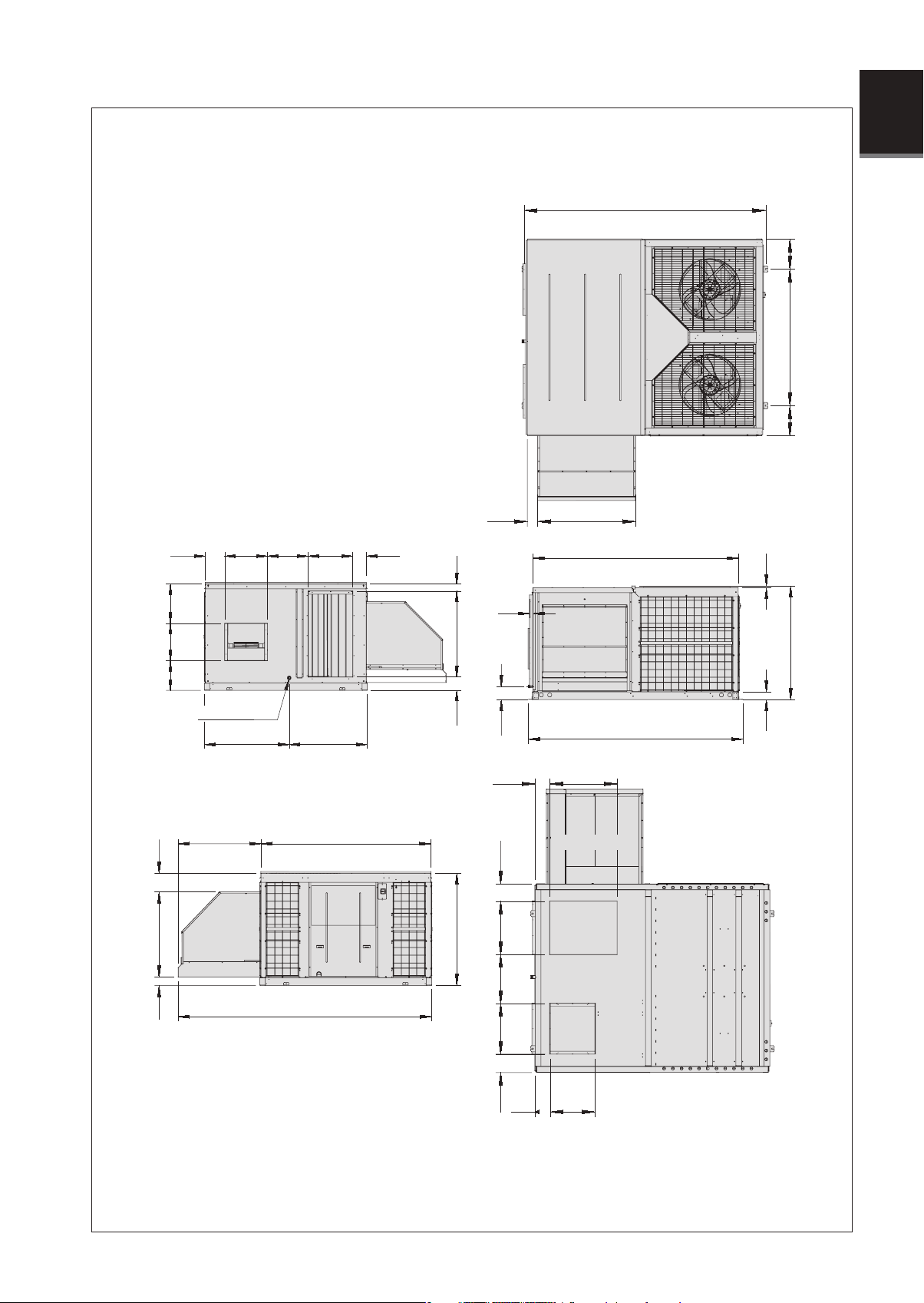

Model: UATYQ550/600/700/900

268 586 558 610 187

509405

RETURN

AIR

All dimensions are in mm

ENGLISH

2739

1735

342

1000

1547342

2670

23

48

BC

SUPPLY AIR

DRAIN PIPE ø 1"

1162 1069

FOR HORIZONTAL DISCHARGE

Back view of the unit:

2209

CONTROL

BOX

168

172

201610560581281

A

770

VERTICAL

RETURN

AIR

VERTICAL

SUPPLY AIR

509 179

FOR VERTICAL DISCHARGE

2789

99

Model (UATYQ) 550 600 700 900

A 1048 1302 1454 1454

B 770 770 1176 1176

C 182 322 182 182

CENTER OF GRAVITY

7

Model: UATYQ550 WITH ECONOMIZER OPTION

All dimensions are in mm

2739

342

1547

342

268

586

134509

SUPPLY AIR

405

DRAIN PIPE ø 1"

1161

FOR HORIZONTAL DISCHARGE

Back view of the unit:

607

128

771

149

558

610

RETURN AIR

1069

2209

CONTROL

BOX

187

OUTDOOR AIR

96

770

182

1048

168

201

610560

581

281

48

172

179

269

806

770

OUTDOOR AIR

VERTICAL

RETURN AIR

VERTICAL

SUPPLY

AIR

509

2670

2789

23

99

8

FOR VERTICAL DISCHARGE

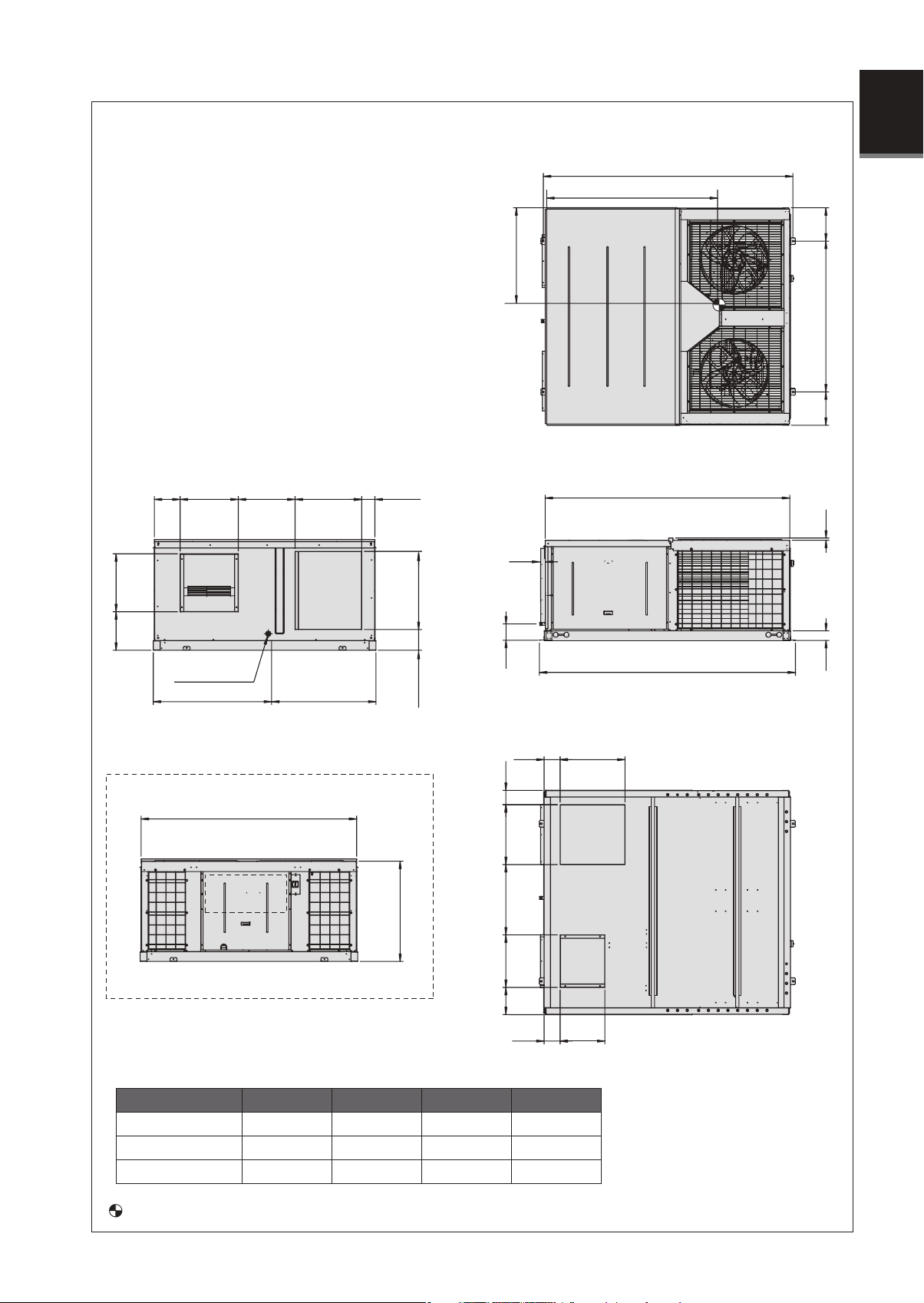

Model: UATYQ600 WITH ECONOMIZER OPTION

268

586

All dimensions are in mm

2739

342

1547

342

269

610558

187

210

806

2670

23

ENGLISH

387

509

SUPPLY AIR

405

DRAIN PIPE ø 1"

1161

FOR HORIZONTAL DISCHARGE

Back view of the unit:

607

187

771

344

RETURN AIR

1069

2209

CONTROL

BOX

OUTDOOR AIR

770

322

1302

168

201

610560

581

48

770172

OUTDOOR AIR

VERTICAL

RETURN AIR

VERTICAL

SUPPLY

AIR

2789

99

281

179

509

FOR VERTICAL DISCHARGE

9

Model: UATYQ700 WITH ECONOMIZER OPTION

All dimensions are in mm

2739

342

1547

342

586268

539

509405

Back view of the unit:

216923

SUPPLY AIR

DRAIN PIPE ø 1"

1161

FOR HORIZONTAL DISCHARGE

693

610558

RETURN AIR

1069

2209

CONTROL

BOX

187

OUTDOOR AIR

96

1176

182

102

168

201

610

48

1140

770172

OUTDOOR AIR

VERTICAL

RETURN AIR

2670

2789

23

99

10

315

1454

560

581281

179

VERTICAL

SUPPLY

AIR

509

FOR VERTICAL DISCHARGE

Model: UATYQ900 WITH ECONOMIZER OPTION

268

586 558 610 187

118 1109

2739

2670

All dimensions are in mm

342 1547 342

ENGLISH

405 509 540

106 1107 241

SUPPLY AIR

RETURN AIR

DRAIN PIPE ø 1"

1161 1069

FOR HORIZONTAL DISCHARGE

1092 2209

CONTROL

3311

BOX

OUTDOOR AIR

182 1176 96

1454

48

168

172 770

OUTDOOR AIR

RETURN AIR

SUPPLY AIR

581 560 610 201281

2789

1477

99 23

179 509

FOR VERTICAL DISCHARGE

11

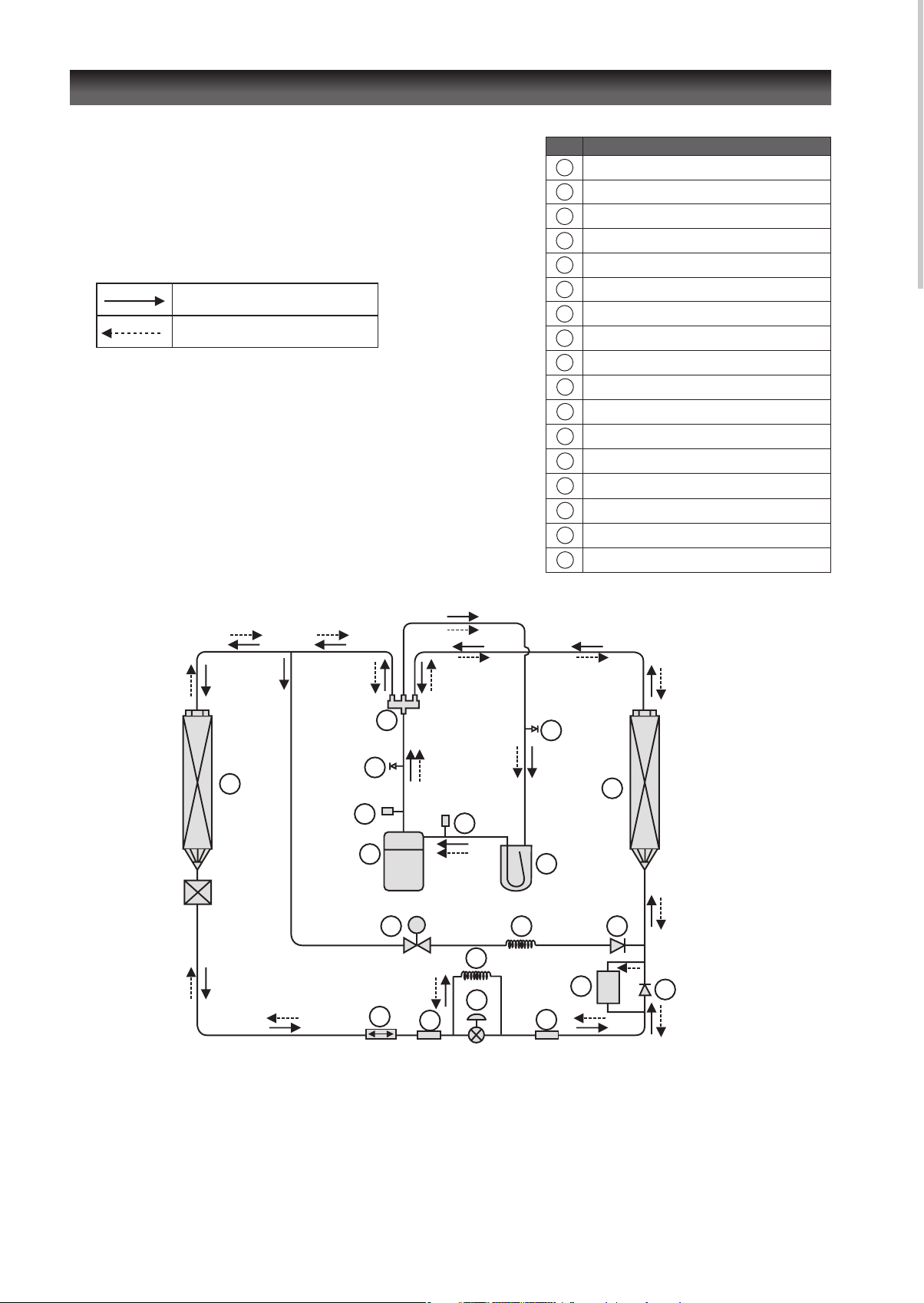

REFRIGERANT CIRCUIT DIAGRAM

Model: UATYQ 250, 350, 450, 550, 600, 700 & 900

Cooling Operation

Heating Operation

No Item Description

1

Compressor

2

High Pressure Switch

3

Access Valve

4

4 - Ways Valve

5

Filter Drier

6

Electronic Expansion Valve

7

Strainer

8

Accumulator

9

Low Pressure Switch

10

Solenoid Valve

11

Bypass Capillary Tube

12

Indoor Heat Exchanger

13

Outdoor Heat Exchanger

14

Check Valve 1

15

Check Valve 2

16

Compensator

17

Capillary Tube

13

4

3

2

1

10 11 14

5

9

17

6

7

3

12

8

16

7

15

Note: (a) UATYQ350, 450, 550, 600, 700 & 900 consists of 2 circuits in the system.

(b) Item no. 15 & 16 are applicable for UATYQ350 only.

(c) Item no. 17 is applicable for UATYQ700 & UATYQ900 only.

12

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air

conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for

commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

ENGLISH

ENGLISH

IMPORTANT

Important information

regarding the

refrigerant used

This product contains

fluorinated greenhouse

gases. Do not vent gases

into the atmosphere.

Refrigerant type:

R410A

(1)

GWP

value:

2087.5

(1)

GWP =

global warming potential

The refrigerant quantity

is indicated on the unit

name plate. Periodical

inspections for

refrigerant leaks may

be required depending

on European or local

legislation. Please

contact your local dealer

for more information.

NOTICE

In Europe, the greenhouse

gas emissions of the total

refrigerant charge in the

system (expressed as tonnes

CO2-equivalent) is used to

determine the maintenance

intervals. Follow the

applicable legislation.

Formula to calculate

the greenhouse gas

emissions:

GWP value of the refrigerant

× Total refrigerant charge [in

kg] / 1000

WARNING

Installation and maintenance should be performed by qualified persons who are familiar

n

with local code and regulation, and experienced with this type of appliance.

All field wiring must be installed in accordance with the national wiring regulation.

n

Ensure that the rated voltage of the unit corresponds to that of the name plate before

n

commencing wiring work according to the wiring diagram.

The unit must be GROUNDED to prevent possible hazard due to insulation failure.

n

All electrical wiring must not touch the refrigerant piping, or any moving parts of the fan

n

motors.

Confirm that the unit has been switched OFF before installing or servicing the unit.

n

n

Disconnect from the main power supply before servicing the air conditioner unit.

n

DO NOT pull out the power cord when the power is ON. This may cause serious electrical

shocks which may result in fire hazards.

n

Keep the air-conditioner units, power cable and transmission wiring, at least 1m from TVs

and radios, to prevent distorted pictures and static. (Depending on the type and source

of the electrical waves, static may be heard even when more than 1m away).

n

The equipment is not intended for use in a potentially explosive atmosphere.

CAUTION

Please take note of the following important points when installing.

Do not install the unit where leakage of flammable gas may occur.

n

If gas leaks and accumulates around the unit, it may cause fire ignition.

Ensure that drainage piping is connected properly.

n

If the drainage piping is not connected properly, it may cause water leakage.

Do not overcharge the unit.

n

This unit is factory pre-charged.

Overcharge will cause over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service or installation.

n

Unsecured panels will cause the unit to operate noisily.

Sharp edges and coil surfaces are potential locations which may cause injury

n

hazards.

Avoid from being in contact with these places.

n

Before turning off the power supply, set the remote controller’s ON/OFF switch to

the “OFF” position to prevent the nuisance tripping of the unit. If this is not done, the

unit’s fans will start turning automatically when power resumes, posing a hazard to

service personnel or the user.

n

Do not operate any heating apparatus too close to the air conditioner unit.

n

Do not use joined and twisted wires for incoming power supply.

Disposal Requirement:

Dismantling of the unit, treatment of the refrigerant, oil and other parts must be done in accordance with the applicable

legislation.

13

INSTALLATION OF THE UNIT

Location For Installation

A

Install the unit in such way that air discharged by the unit cannot be drawn in again (as in the case of short circuit of

l

discharge air). Allow sufficient space for maintenance around the unit.

When two or more units are installed in a location, they must be positioned such that one unit will not be taking the

l

discharge air from another unit.

Ensure that there is no obstruction of air flow into or out of the unit. Remove obstacles which block air intake or air

l

discharge.

The location must be well ventilated, so that the unit can draw and distribute plenty of air.

l

The unit is recommended to install in:-

l

A place capable of bearing the weight of the unit and isolating noise and vibration.

–

A place where has adequate drainage.

–

A place where the unit will not be buried in snow.

–

A place where air inlet and outlet ports are not exposed to strong wind.

–

A place where the air discharge and operating sound level will not annoy the neighbours.

–

The location where it is not accessible by general public.

–

To install the unit with economizer kit, follow the recommendations given in part (B) (iii) under chapter “OPTIONAL

ü

ACCESSORY” in this manual.

CAUTION

Do not install the unit at altitude over 2000m.

Duct Construction

B

This unit are equipped with supply and return air openings. Duct connection to the unit should be made with duct

l

flanges and secured directly to the air openings with flexible duct connectors to avoid normal noise transmission.

To prevent air leakage, all duct seams should be sealed.

l

Ducts in the spaces that not air-conditioned must be insulated.

l

Ducts exposed to the outside must be weather proofed.

l

Ducts that entering building through the roof, the entering should be sealed with weather stripping to prevent rain,

l

sand, dust etc., from entering the building.

Correct size of filter must be installed at the return air duct.

l

14

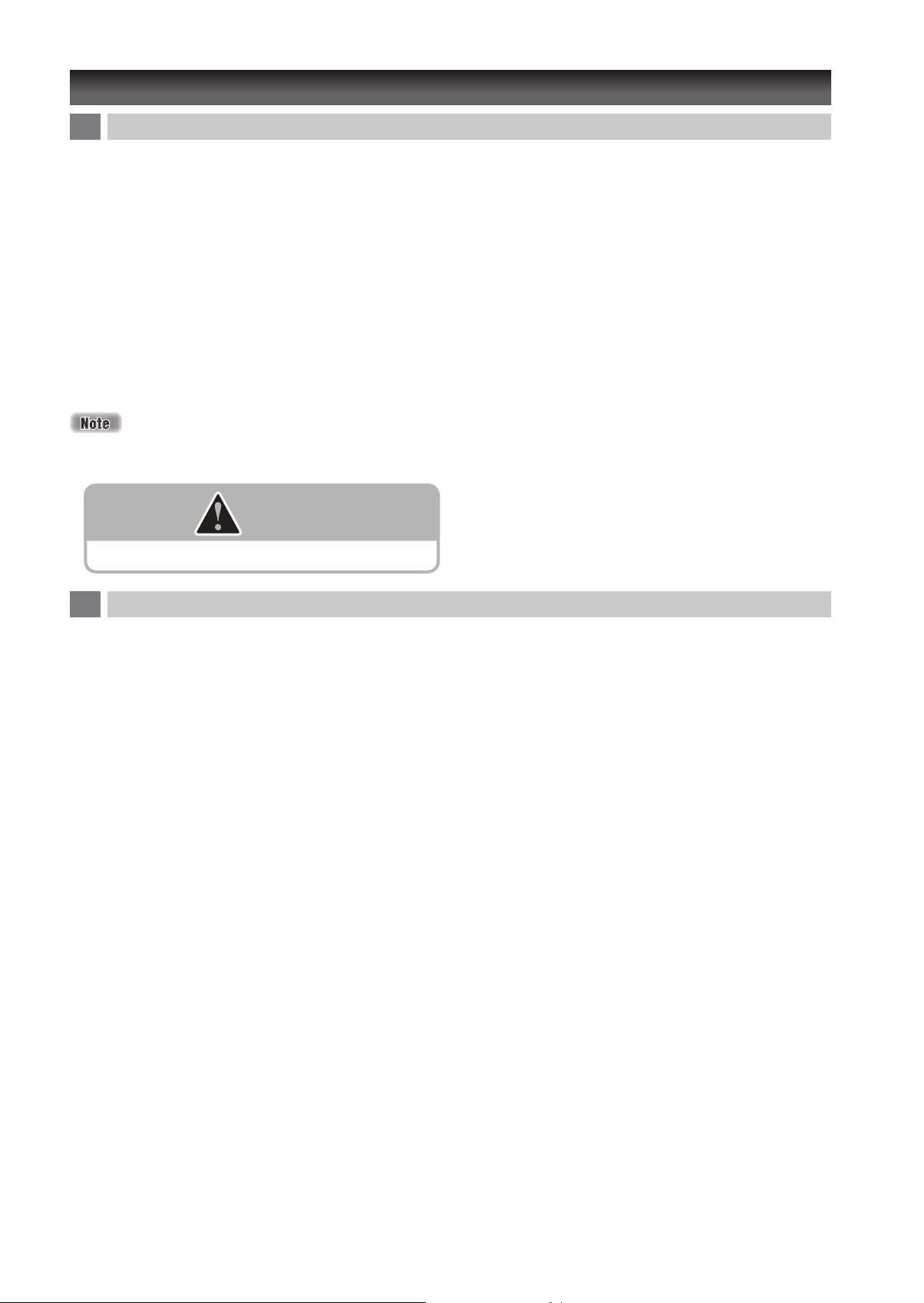

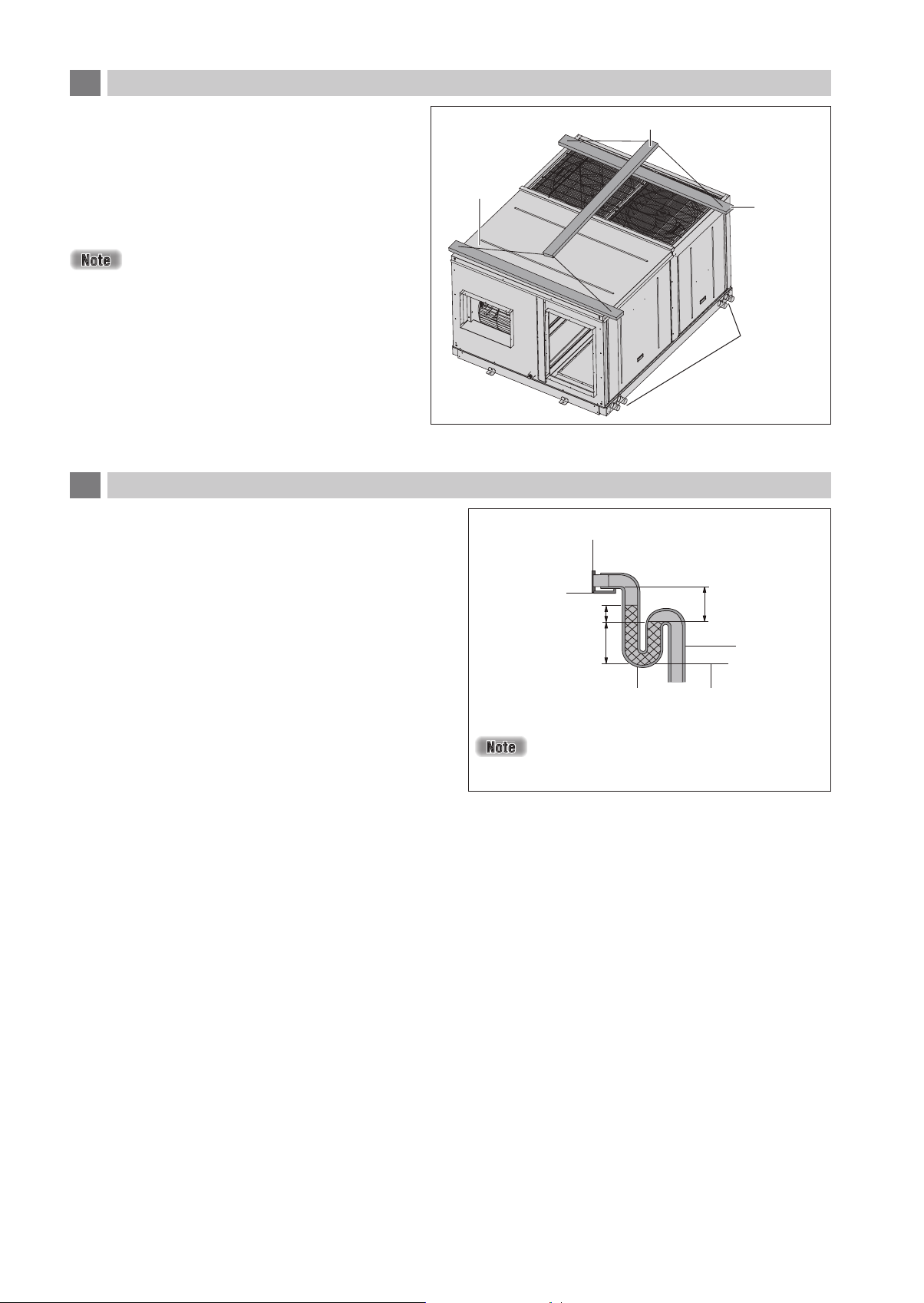

Unit Support (For down throw unit only)

C

The figure shows the use of the roof curb for mounting

l

these units.

The curb should be sealed and fixed to the roof by

l

weather stripping. A suggested means of sealing the

unit and roof curb as shown in the right.

Recommended roof curb dimension is shown below.

l

P

Q

SECTION X-X

Unit

Seal with tar

Roof deck

ENGLISH

Roof curb

A

C

Y

DEFG

S

H

IKL

X

B

Z

X

R

Z

J

Y

M

N

25

T

SECTION Y-Y

Model

(UATYQ)

A 355 355 355

B 1506 2081 2081

C 840 700 840

D 315 410 625

E 315 410 462

F 0 0 190

G 314 287 248

H 0 131 131

I 607 600 646

J 322 544 495

K 540 682 676

L 042 51

M 300 300 300

N 141 141 141

O 1784 1807 2365

P 300 300 300

Q 481 477 590

R 1469 1998 1998

S 20 41.5 41.5

T 20 41.5 41.5

250 350/450 550/600/700/900

Note: All dimensions are in mm

O

SECTION Z-Z

52

15

Unit Lifting

D

l

Holes at 4 corners of the unit base are used for unit

lifting purpose.

l

The spreader bar shall be slightly wider than the

unit width.

l

The insulation should be added at 4 corners of the

chain to prevent the damage of the panel when

lifting.

Unit shown in diagram is UATYQ250.

ü

Other models will follow the same method in lifting.

ü

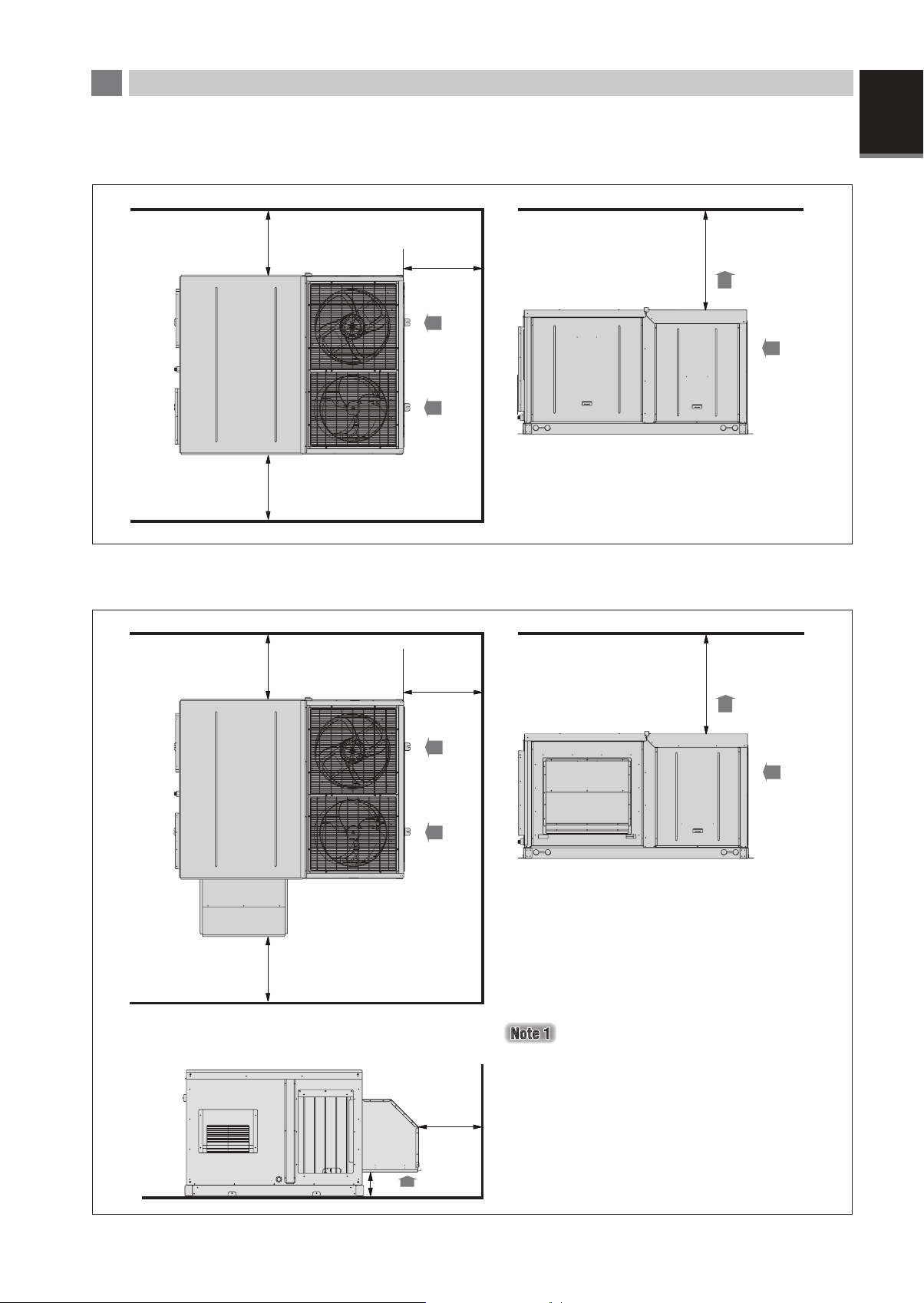

Drain Piping

E

A 1" MPT condensate drain fitting is provided. The drain

l

pipe can be led out at the front side.

The drain pipe must be provided with a trap on the

l

outside of the unit and also installed at an incline for

proper drainage, as shown in the right.

To prevent condensate formation and leakage, provide

l

the drain pipe with insulation to safeguard against

sweating.

Upon completion of piping work, check that there is no

l

leakage and that the water drains off properly.

Lifting beam

Chain

The drain piping should have a drain trap.

C

A

A ≥ 70mm

B ≥ 2C

C ≥ 2 X ESP

Drain trap

The drain pipe should

extend below this level.

Spreader

bar

Lifting

holes for

shackle

(4 corners)

B

Drain piping

ESP = External Static Pressureü

Drain trap for condensate

16

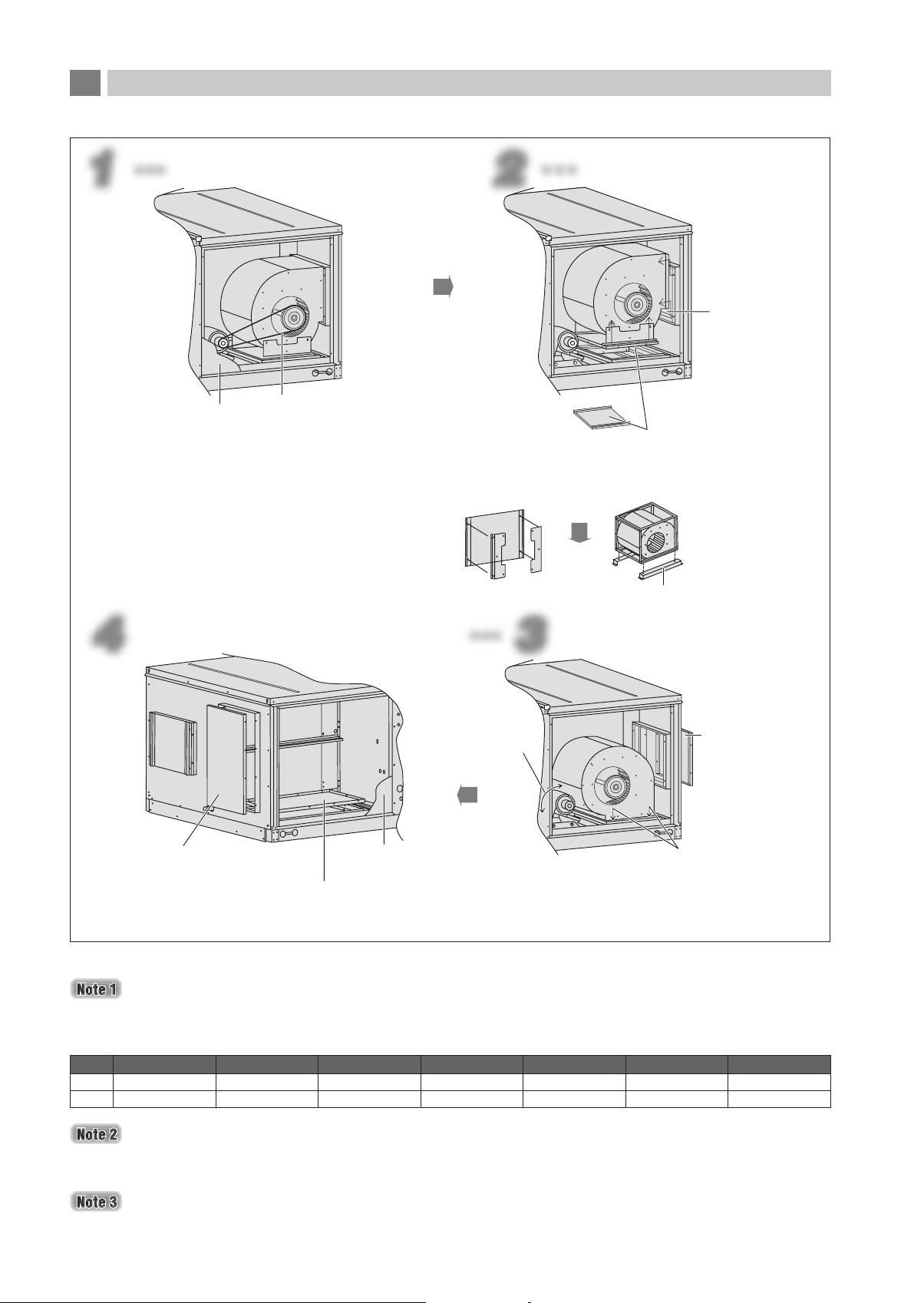

Space Required Around Unit

F

Refer diagram below for the space required around the unit. Note that:-

All dimensions shown are in mm.

l

All space value shown are minimum clearance required for the unit.

l

Unit shown in the diagram is UATYQ250. Other models shall follow the same clearance.

l

ENGLISH

Blower & motor

service

Air filter

service

Evaporator coil

service

Additional space or clearance is required when economizer kit is installed. Whenever the unit is equipped with

economizer kit, the space required around the unit with economizer kit shall follow the diagram below:-

Blower & motor

service

Electrical control

1200

circuit service

1200

Electrical control

1200

circuit service

Condenser

air inlet

Compressor service

1200

Condenser

air inlet

1200

Condenser

air outlet

Condenser

air outlet

3000

3000

Air filter

service

Evaporator coil

& economizer

kit service

Air filter for economizer

kit service

1200

Compressor service

X

X : No obstacles and no accumulation of snow or

water shall be allowed in this area.

1200

Fresh air

inlet

17

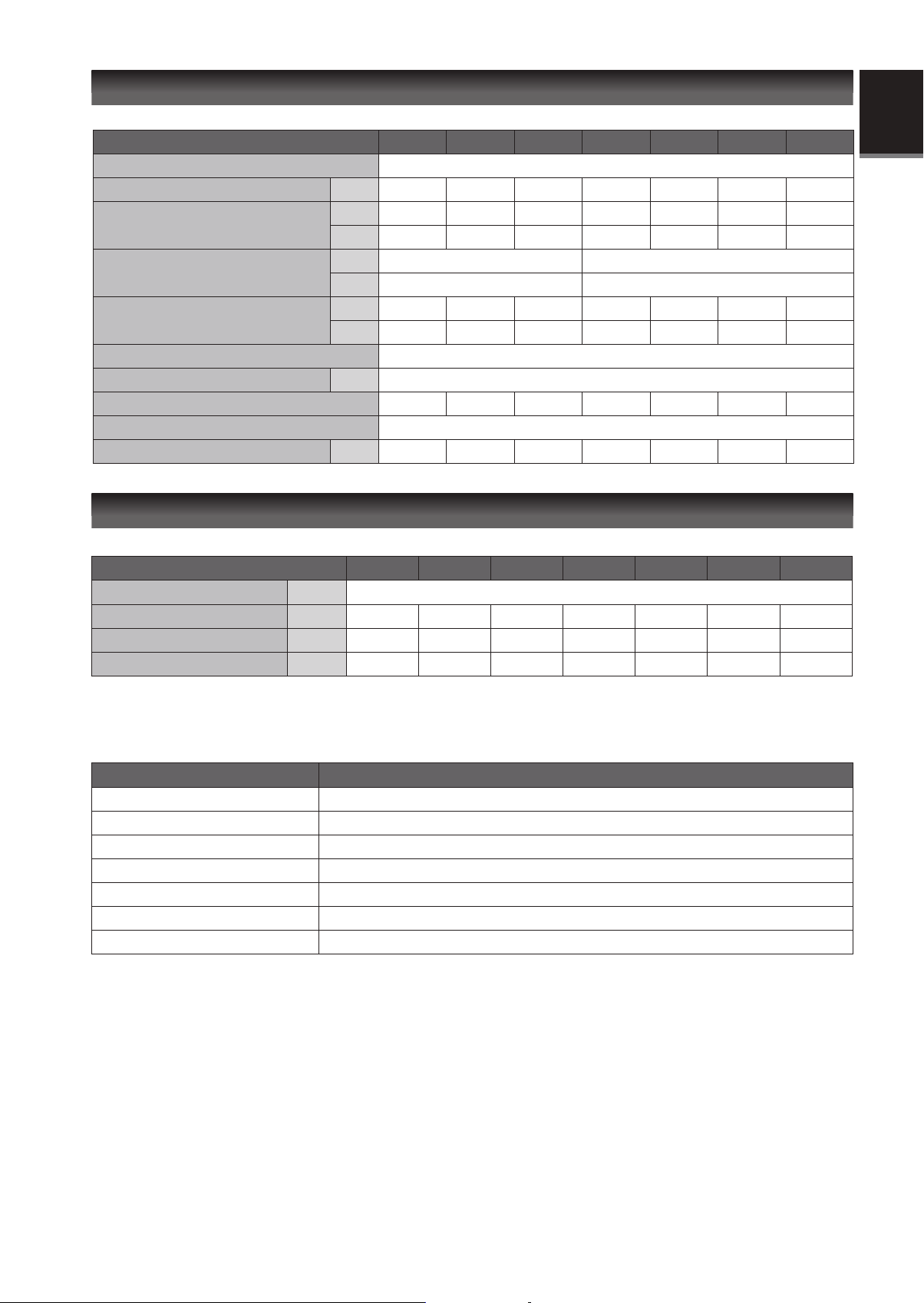

Unit Conversion

G

In the case of converting standard unit to downthrow unit, follow the steps as stated below:

UATYQ250, 350, 450, 550, 600, 700 & 900

1 1

ÑÑÑ

Remove the

side panel

Remove the

Pulley Belt

ÇÇÇ

2 2

For UATYQ250:

The two side plates are screwed

on the blower support as shown

ÉÉÉ

3 344

Remove screws

at both sides

Detached

blower

Detached the

blower support

For UATYQ250, 350, 450, 550, 600, 700 & 900

The two downflow structure

are screwed to blower

Cover the

horizontal supply

Install back the pulley

belt. Adjust the belt

tension by moving the

motor base.

Cover the horizontal

return opening with the

cover and screw tightly.

Refer Note 2.

Install back the pulley belt. Adjust the belt tension. Lastly, install back the side panel. Refer Note 1.

For downthrow conversion, belt length need to be changed.

For unit with standard pulley, belt length = a mm

Shaft to shaft distance for downthrow, C-C = b mm

UATYQ250 UATYQ350 UATYQ450 UATYQ550 UATYQ600 UATYQ700 UATYQ900

a 1432 1457 1382 1500 1500 1500 1500

b 425 430 345 420 420 440 445

Unscrew the vertical return

cover from the base panel

Lastly, install back the side panel.

Remove the side

panel at return side

Turn the blower to face bottom.

Screw at both sides.

opening with the

blower support

that detached

from the blower

and screw tightly.

Refer Note 2.

Sealant such like gasket (field supply) shall be placed in between the metal cover and flange. Besides that, weather-proof

silicone shall be applied on all the joints, screw holes and gaps to ensure water-tight condition.

Refer Engineering Data Book for blower curve and technical data of variable pitch pulley.

18

PHYSICAL DATA

Heat Pump (R410A)

Model

Refrigerant R410A

Refrigerant charge kg 6.1 5.8/5.8 7.2/7.2 8.7/8.7 10.4/10.4 11.6/11.6 11.6/11.6

Evaporator air flow

External static pressure

Condenser air flow

Control Wired Rooftop Controller

Control wire length (Standard/Max) : Size m : mm

Compressor (Type/Quantity) Scroll/1 Scroll/2 Scroll/2 Scroll/2 Scroll/2 Scroll/2 Scroll/2

Air filter (Type/Quantity) Washable Saranet/2

Air filter dimension (Length x Width x Thickness) mm 880 x 467 x 4 1126 x 385 x 4 1126 x 435 x 4 1497 x 392 x 4 1497 x 495 x 4 1497 x 595 x 4 1497 x 595 x 4

mmAq 15 21

UATYQ250 UATYQ350 UATYQ450 UATYQ550 UATYQ600 UATYQ700 UATYQ900

CFM 3300 4300 5650 6700 7300 8300 9600

L/S 1557 2029 2667 3162 3445 3917 4531

Pa 147 206

CFM 8230 6000/6000 6050/6050 6450/6450 10100/10100 10600/10600 10600/10600

L/S 3884 2831/2831 2855/2855 3044/3044 4767/4767 5003/5003 5003/5003

2

15 / 100 : 3

ELECTRICAL DATA

Heat Pump (R410A)

Model

Power supply V/Ph/Hz 380-415/3N~/50

Max continuous current (Comp) A 26 17/17 19/19 26/26 28/28 29/29 40.0/40.0

Full load current (FLA, Comp) A 21 12/12 15/15 21/21 22/22 25/25 34.0/34.0

Locked rotor current (LRA, Comp) A 111 74/74 101/101 111/111 118/118 118/118 174.0/174.0

UATYQ250 UATYQ350 UATYQ450 UATYQ550 UATYQ600 UATYQ700 UATYQ900

ENGLISH

The equipment fulfils the requirements in EN 61000-3-11 and is subject to conditional connection to the mains. It may

be connected in consultation with the supply authority. The equipment may only be connected to a mains supply with

a system impedance of less than the value stated in table below. The system impedance in the interface point may be

obtained from the supply authority.

Model Maximum impedance (Z

UATYQ250 0.22

UATYQ350 0.23

UATYQ450 0.21

UATYQ550 0.21

UATYQ600 0.21

UATYQ700 0.21

UATYQ900 0.20

If the mains supply has a higher system impedance, short voltage dips may appear when the equipment is started or

during operation. This may influence or disturb the operation of other apparatuses, e.g. flickering lamps, especially those

connected to the same supply mains.

max

), ohm

19

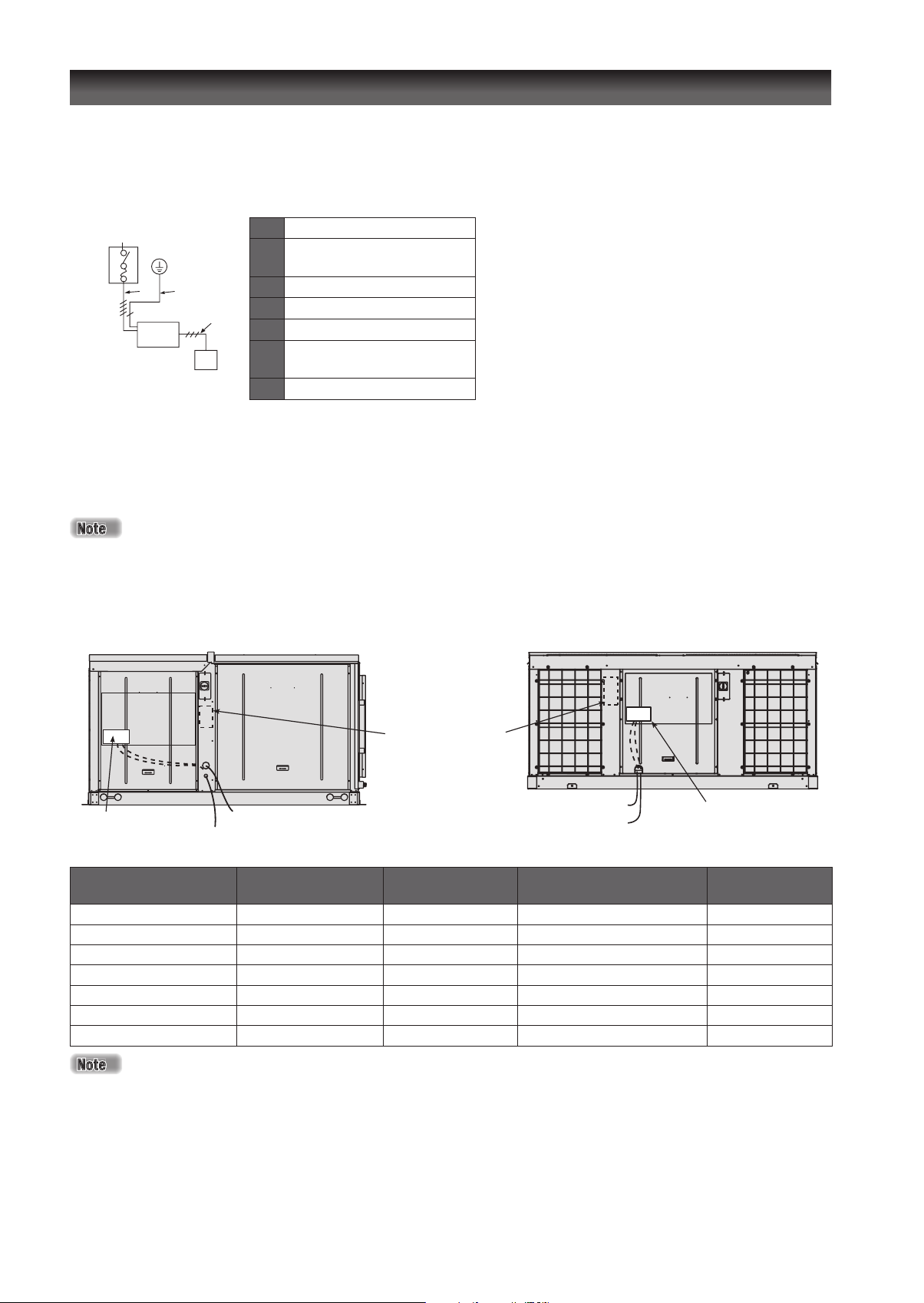

WIRE CONNECTION

All electrical work must be carried out by qualified electrician and accordance with local supply requirement and

l

associate regulation.

Method for connecting electric wire

Before connecting the wire, consult the electric power company of jurisdiction.

1. The entire wiring diagram of unit

a

a

b

PE

c

g

d

f

e

2. Wiring connection to unit

Route the power supply wires and control wire through the knockout holes or cable holes in the unit.

Remove the service panels and connect the units power supply wires to terminal block inside the control box, as

shown.

Make use of push releasable cable ties which are located at the bottom of control box to hold the power supply wires

properly.

Power supply

Main switch/fuse

b

(field supply)

c

Power supply wiring for unit

d

Unit

e

Remote control

Connection wiring for unit &

f

remote controller

g

Earth

While installing the circuit breaker onto the unit, make sure that the screws do not damage the components (e.g. coil)

inside the unit.

The switch box also can be installed without attaching to the unit.

The knockout holes are only available in UATYQ250; UATYQ350, UATYQ450, UATYQ550, UATYQ600, UATYQ700 & UATYQ900

comes with a power cable hole.

UATYQ250 UATYQ350, 450, 550, 600, 700 & 900

CONTROL

BOX

Recommended

CONTROL

BOX

switch box position

Terminal block

Power cable (seal off the knockout

Control wire

holes after installation)

Power cable

Control wire

Terminal block

Wiring Example And Selection Of Circuit Breaker

Model

Power cable

(mm2)

Breaker

capacity (A)

Over current

protection switch (A)

Earth cable

(mm2)

UATYQ250 432 32 4

UATYQ350 640 40 6

UATYQ450 10 40 40 10

UATYQ550 10 50 50 10

UATYQ600 16 63 63 16

UATYQ700 25 80 80 25

UATYQ900 35 100 100 35

A main switch or other means for disconnection, having a contact separation in all poles, must be incorporated in fixed

wiring in accordance with local and national legislation.

The unit is to be wired directly from an electrical distribution board either by a circuit breaker (preferred) or HRC fuse.

ü

Fix the power supply wiring to control module. Connect control wiring to control terminal block through the control

ü

box’s hole.

Earth wiring must be connected.

ü

The power supply cord must be equivalent to H07RN-F which is the minimum requirement, and to be used in protective

ü

tube.

There must be an all pole disconnection in the supply mains with a contact separation of at least 3mm.

ü

20

WARNING

n

Before working in this unit, isolate it from the power supply.

n

Electrical wiring to this unit and the remote controller shall be installed in accordance with the appropriate requirement of

the local wiring code.

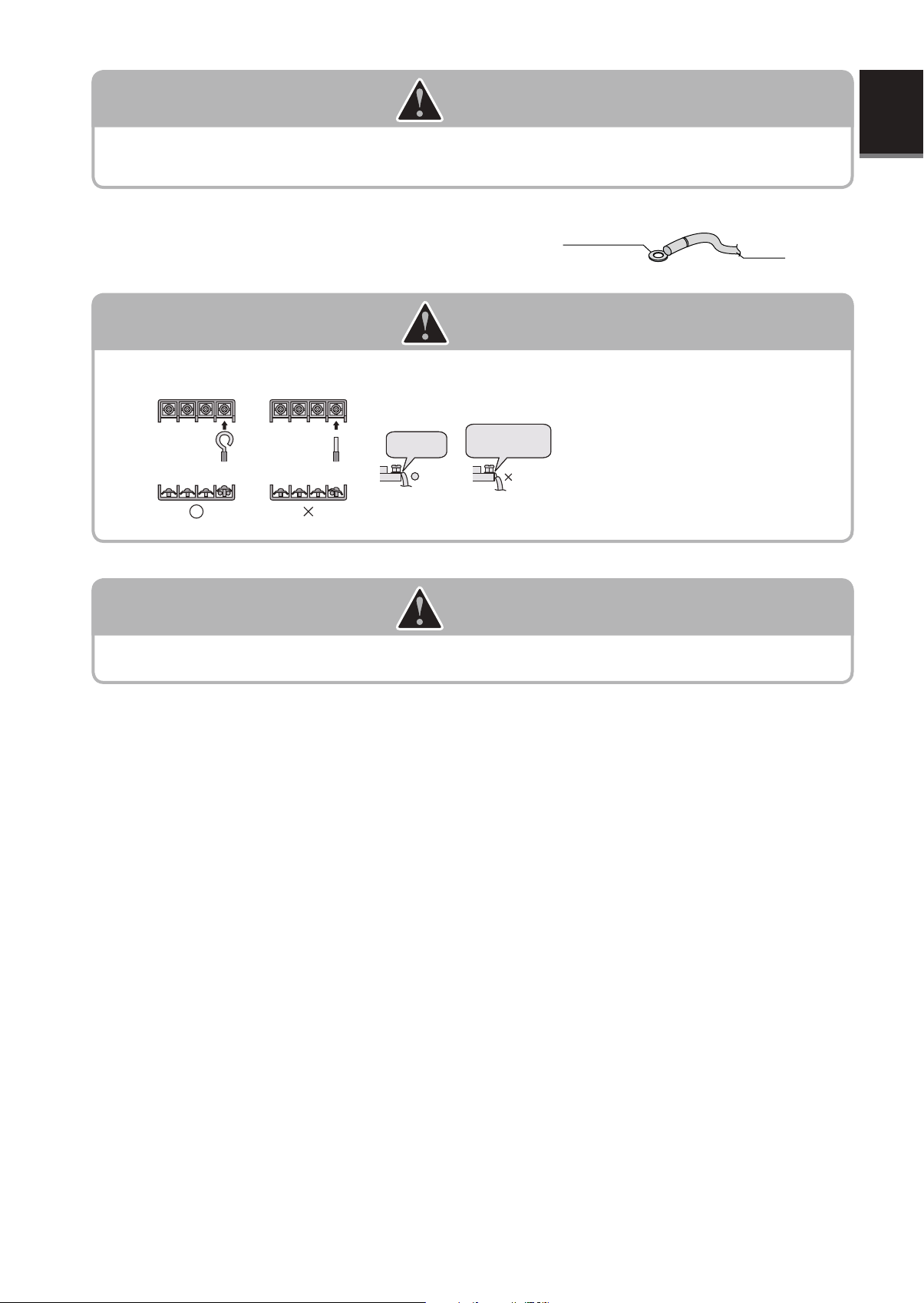

Observe the notes mentioned below when wiring to the terminal

block. Precautions to be taken for power supply wiring.

(Use a round crimp-style terminal for connection to the terminal

block. In case it cannot be used due to unavoidable reasons, be sure

Round crimp-style

terminal

Stranded wire

to observe the following instruction.)

CAUTION

When connecting the connection wires to the terminal block using a single core wire, be sure to perform curling.

Problems with the work may cause heat and fires.

Excessive strip length

may cause electrical

shock or leakage.

Wrong

Stripping wire at terminal block

Strip wire end

to this point.

Good

Pull the wire and make sure that it does not disconnect. Then fix the wire in place with a wire stop.ü

ENGLISH

WARNING

Transmission wire must be routed at least 50mm away from the power cable.

n

Transmission wire should be a shielded wire.

n

21

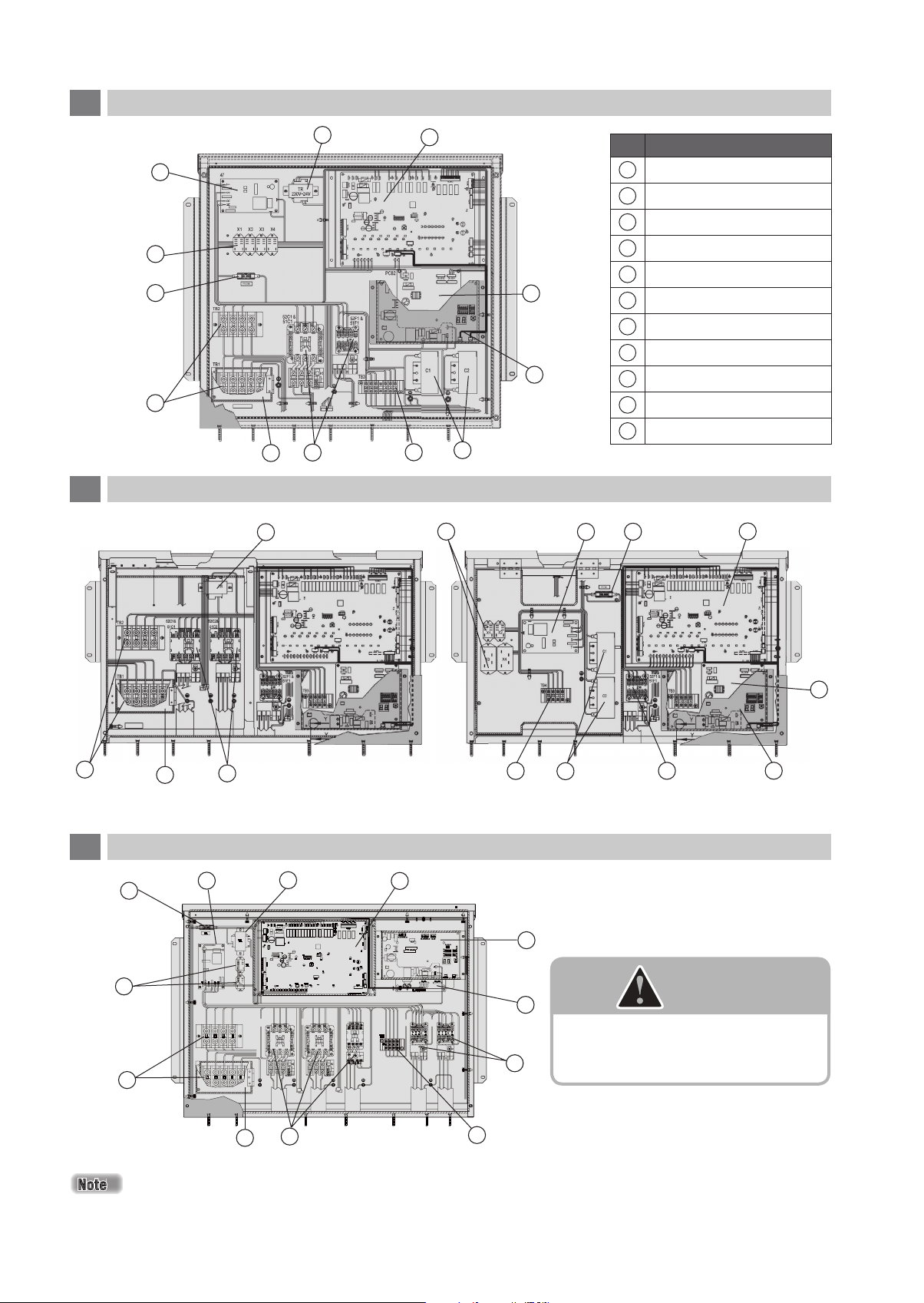

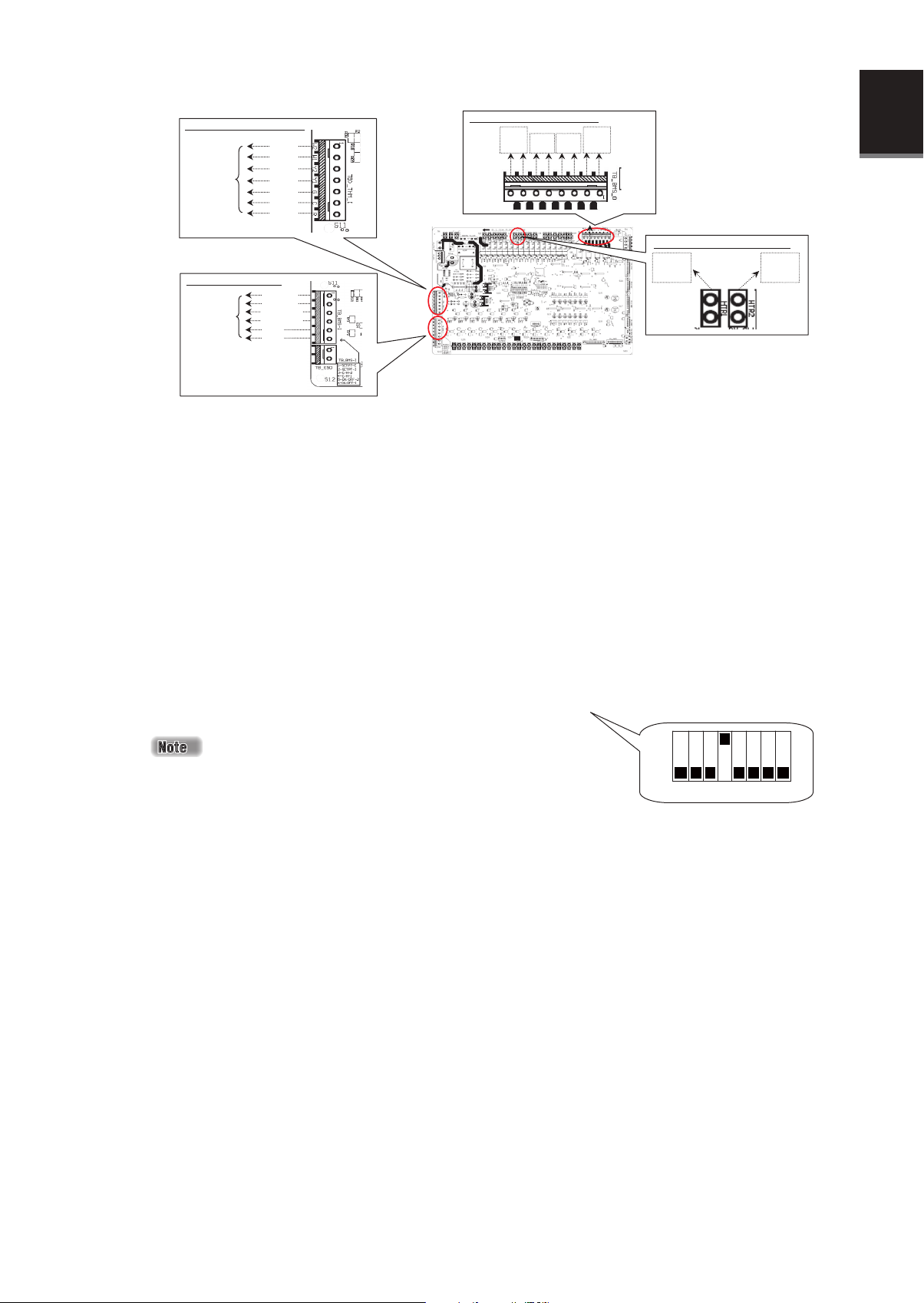

Arrangement of terminal blocks and components for controller are shown as below:

Control Module UATYQ250

A

5

6

8

7

10

Control Module UATYQ350/450/550

B

9

9

4

1

2

11

7

3

6

No. Item Description

Controller Main Board

1

EXV Controller Board

2

Capacitor

3

Contactor

4

Phase Protector

5

Relay

6

Terminal Block

7

Fuse

8

Transformer

9

Terminal Block Cover

10

Economizer Controller Board

11

5

8

1

7

10

4

(Bottom Layer) (Top Layer)

Control Module UATYQ600/700/900

C

8

6

7

5

2

7

9

1

3

11

4

11

WARNING

2

Unless the main supply switch is turned off,

4

the terminal block (TB1) will remain Live

when the isolator is turned off.

10

4

7

Item 11 (Economizer Controller Board) shall be used together with the economizer kit which is provided separately as

the accessory.

22

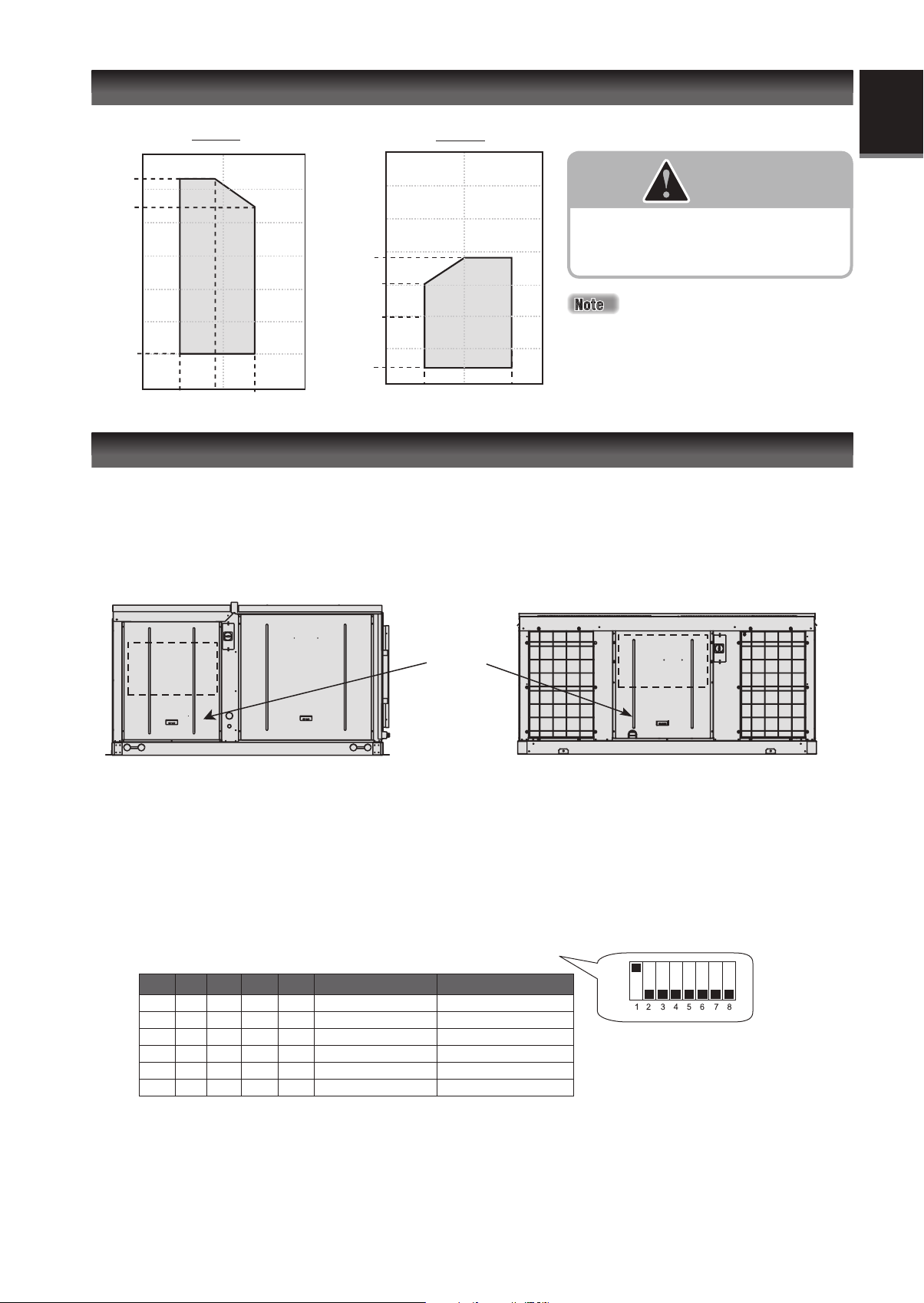

OPERATING RANGE

Ensure the operating temperature is within the allowable range, as stated in diagram below:

Cooling

52

50

43

40

30

20

10

0

Outdoor DB temperature (°C)

-10

10 20

14

19

Indoor WB temperature (°C)

23 30

20

18

10

0

-10

-15

Outdoor WB temperature (°C)

-20

10 30

Indoor DB temperature (°C)

Heating

15

CAUTION

The use of the air conditioner outside the range

of working temperature and humidity can

result in serious failure.

Refer Operating Range for unit with

economizer option in part (E) (vi) in chapter

“OPTIONAL ACCESSORY”.

20

27

DB = Dry Bulb

WB = Wet Bulb

CONTROL OPERATION GUIDE

The unit is equipped with a controller main board, and a wired remote controller is connected to the controller main

board.

All the setting in the unit is preset by the manufacturer. It is not recommended to change the setting unless necessary or

mentioned below.

a) Remote Controller Location

The remote controller is located on a metal bracket behind the service panel. It is packed together with installation

man

ual.

UATYQ250 UATYQ350, 450, 550, 600, 700 & 900

ENGLISH

CONTROL

BOX

Remove

panel

CONTROL

BOX

b) LED Display (Controller Main Board)

The LED will blink when power up the unit.

c) LCD Display (Remote Controller)

During normal operations, the LCD displays compressor on/off status, mode, set temperature and so on. Refer to

Operating Manual for the details of operation guide. The LCD will display the main screen upon power-up. When

malfunctioning occur, a pop-up message will appear on the LCD with backlight blinking and ‘beep’ sound.

d) Optional Configurations

The controller main board can be used as the interface for thermostat control and BMS system.

(i) Thermostat control (TB_THM-I)

To use this control, set Dip Switch Setting: SW1-ON (default is OFF).

ü

Follow the method below for thermostat control inputs:

ü

ON

G Y1 Y2 W1 W2 Mode Operation

0 0 0 0 0 - Unit off

OFF

1 0 0 0 0 Fan Indoor fan on

X 1 0 X X Cool 1 stage compressor

X 1 1 X X Cool 2 stage compressor

X 0 X 1 0 Heatpump/Heater 1 stage compressor

X 0 X 1 1 Heatpump/Heater 2 stage compressor

Remark: X = Don’t care.

23

Refer table below for installation recommendations:

ü

Input Rated voltage Rated current Wire size

G

Y1

Y2

W1

W2

When the controller main board is configured as thermostat control, the remote controller is used for monitoring

ü

24V AC 5mA AWG18~22

purpose only.

Unit needs to be restarted (power off and on) whenever dip switch setting is changed.

ü

(ii) BMS control (TB_BMS-I)

To use this control, set Dip Switch Setting: SW3 - ON (default is OFF) and panel parameter G8 to ‘1’ (default is ‘0’).

ü

ON

G8 = Control Type

ü

0 = Panel

1 = BMS

OFF

1 2 3 4 5 6 7 8

2 = DEC

For TB_BMS-I, there are 3 control inputs:

ü

unit on/off; operating mode (cool-0/heat-1); and set point (4~20mA).

Refer below table for installation recommendations:

ü

Input TB_BMS-I Rated voltage Rated current Wire size

On/O 24V AC 5mA

AWG18~22Operating mode 24V AC 5mA

Cool/Heat set point - 4~20mA

When the controller main board is configured as BMS control, the remote controller is used for monitoring

ü

purpose only.

Unit needs to be restarted (power off and on) whenever dip switch setting is changed.

ü

(iii) Dry contact output (TB_BMS-O)

For TB_BMS-O, there are 4 monitoring outputs: error alarm; output1; output2; and defrost signal.

ü

Refer

ü

ü

table below for installation recommendations:

Input TB_BMS-O Rated voltage Rated current (A) Wire size

Alarm output (AL) 230V AC/125V AC/30V DC 1/3/3

Output1 (O1) 230V AC/125V AC/30V DC 2/3/3

Output2 (O2) 230V AC/125V AC/30V DC 3/3/3

Defrost signal (DFRT) 230V AC/125V AC/30V DC 4/3/3

AWG18~22

The output signals will vary depending on the configuration of controller main board, whether it is thermostat

control or BMS con

trol.

(1) For thermostat control, the outputs are indicated as shown in the table below.

Thermostat input

(SW1-ON)

G Y1 Y2 W1 W2 (AL) (O1) (O2) (DFRT)

0000 0 X X X 0 0 X

1000 0 X X X 0 1 X

X10X X X X X 1 0 X

X11X X X X X 1 0 X

X0X1 0 X X X 1 1 X

X0X1 1 X X X 1 1 X

XXXX X 1 X 1 X X X

XXXX X X 1 X X X 1

ERROR DEFROST Alarm output Output1 Output2

Remark: X = Don’t care.

(2) For BMS control, the outputs are indicated as shown in the table below.

BMS input

(SW3-ON)

ON/OFF

00 XXXX00X

01 XXXX01X

10 XXXX10X

11 XXXX11X

XX X1X1XXX

XX XX1XXX1

OPERATING

MODE

COOL/HEAT

SET POINT

ERROR DEFROST

Alarm

output

(AL) (O1) (O2) (DFRT)

Output1 Output2

Remark: X = Don’t care.

Defrost

signal

Defrost

signal

24

The diagram below shows the position for terminal blocks in the controller main board which are used for

thermostat control and BMS system. Beside that, the output pins for auxilliary electrical heater are shown as well.

Thermostat Control (TB_THM-l)

Connect to

third party

controller

BMS System (TB_BMS-l)

Connect to

BMS

System

(iv)

Auxilliary Electrical Heater Output (HTR1 and HTR2)

There are two output pins (HTR1 and HTR2) on controller main board, which are used to energize the heater

ü

inputs

(G, Y1, Y2, W1, W2)

Thermostat control

Supply

24V AC

Voltage

set

Heat

point

Cool/

Heat

Cool/

select

mode

off

on/

Unit

Dry Contact Outputs (TB_BMS-O)

Alarm

Output

1 (O1)

Output

2 (O2)

output

(AL)

Controller Main Board

Defrost

signal

(DFRT)

Heater Output (HTR1 and HTR2)

Connect to

heater

contactor

Connect to

heater

contactor

contactor. The contactor must be selected accordingly to avoid any safety issue(s).

The heater shall be installed in accordance with local and national legislation. It must comply with EN60335-2-40.

ü

Thermal fuse(s) shall be installed on the heater to eliminate any danger or damage on the heater/unit. This is

ü

especially critical when there is any malfunction happen to controller main board or blower.

The heater shall be in a safe location, whereby no risk of damage could be happen on the unit.

ü

Use non-flammable duct for the unit that is installed with heater

ü

Use different power supply for electrical heater and install a circuit breaker for each of the heater.

ü

Maximum temperature in the unit must not exceed 60°C. Temperature measurement shall be taken during the

ü

installation or commisioning in order to ensure the temperature not exceed this value.

Select the proper safety device or thermal protector accordingly.

ü

The heater shall never be installed inside the unit. The recommended location for the heater is inside the supply

ü

duct, whereby the distance of the heater is sufficient to ensure the temperature inside the unit does not exceed

60°C.

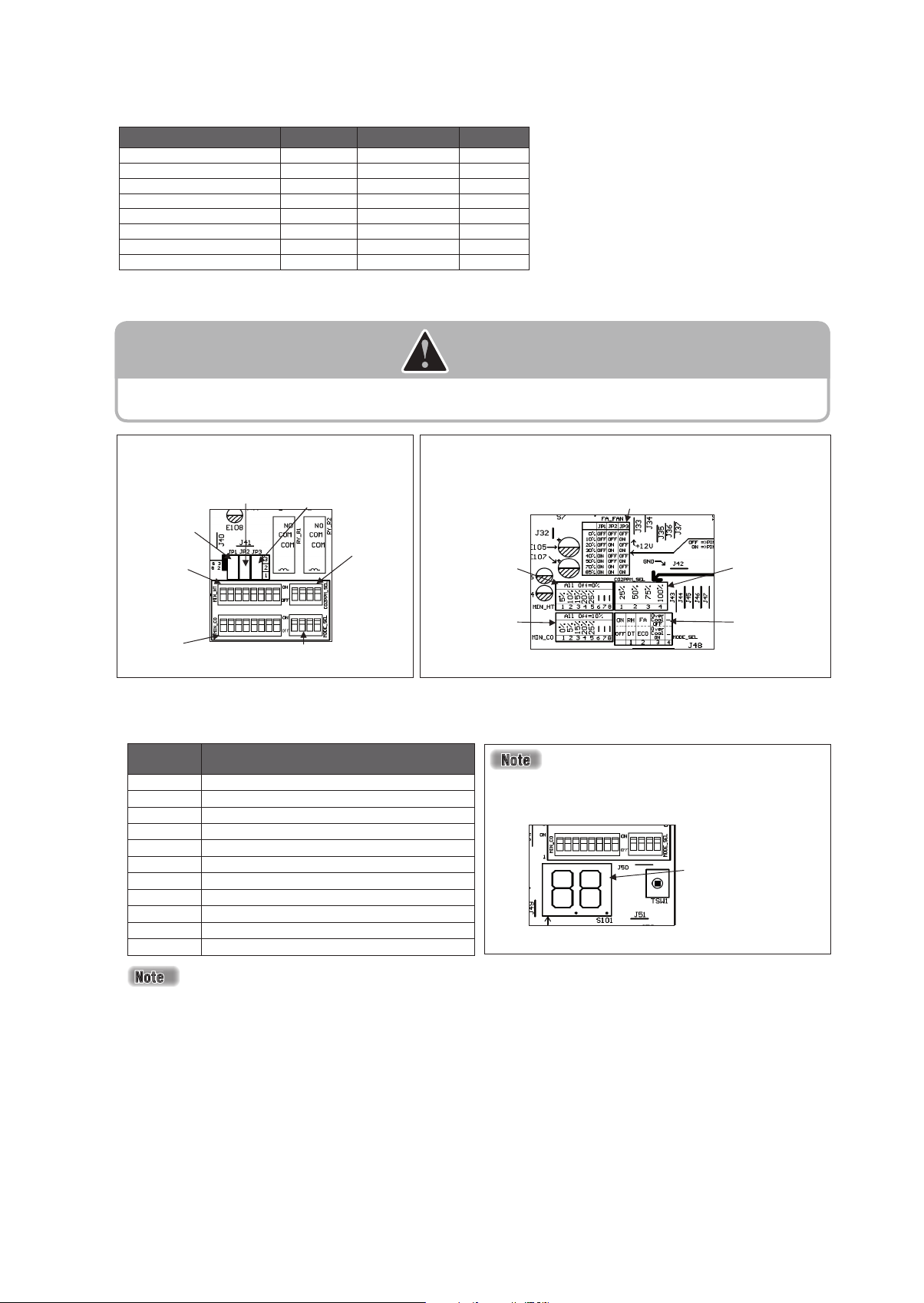

(v) Economizer control

Ensure the economizer kit has been incorporated with rooftop unit before activate the economizer function in

ü

the controller main board. Else, error will occur.

To activate economizer function, set Dip Switch Setting: SW4 - ON (default is OFF) in the controller main board

ü

and panel parameter G6 to ‘1’ (default is ‘0’).

ON

ENGLISH

G6 = Economizer control

0 = disable

OFF

12345 867

1 = enable.

In economizer controller board, there are 4 dip switches and 3 shunt jumpers which provide flexible selection

ü

based on different requirements:

– Dip Switch 1: Minimum fresh air opening setting in heating mode, where by the selection of different pins will

give different opening setting. SW1: 5%, SW2: 10%, SW3: 15%, SW4: 20%, SW5: 25%, SW6/7/8:

no function, Default: 0% (no selection, all OFF).

– Dip Switch 2: Minimum fresh air opening setting in cooling mode, where by the selection of different pins will

give different opening setting. SW1: 0%, SW2: 5%, SW3: 15%, SW4: 20%, SW5: 25%, SW6/7/8:

no function, Default: 10% (no selection, all OFF).

– Dip Switch 3: CO2 PPM level threshold value selection, where by the selection of different pins will give different

value setting. SW1: 25%, SW2: 50%, SW3: 75%, SW4: 100%, Default: 0% (no selection, all OFF).

– Dip Switch 4: Type of operation, which include the following selection:-

SW1: OFF = Differential temperature operation (default), ON = No function at this moment.

SW2: OFF = Economizer mode (default), ON = Fresh air mode.

SW3: OFF = Overcooled protection is activated (default), ON = Overcooled protection is not

activated.

25

Shunt jumper 1, 2 and 3: Minimum fresh air opening setting in fan mode, where by the selection of different pins

will give different opening setting. Let name the shunt jumper 1 = JP1, shunt jumper 2 = JP2 and shunt jumper 3

= JP3; refer the table below for different fresh air opening selection:-

Fresh air opening (%) JP1 JP2 JP3

0 (default) OFF OFF OFF

10 OFF OFF ON

20 OFF ON OFF

30 OFF ON ON

40 ON OFF OFF

50 ON OFF ON

70 ON ON OFF

85 ON ON ON

Legend: OFF = Short pin 2 and pin 3

ON = Short pin 1 and pin 2

CAUTION

Dip Switch 1, 2 and 3 allow only 1 pin selection. Multiple pins selection will cause error and the operation will go back to

default setting. While Dip Switch 4 allow multiple pins selection.

Location of dip switches and shunt jumpers

Indication on the economizer controller board:

in the economizer controller board:

Shunt jumper 2

Shunt jumper 1

Dip Switch 1

Dip Switch 2

There are two LEDs in economizer controller board, which are green LED and red LED. Green LED will blink when

ü

Shunt jumper 3

Dip Switch 4

Dip Switch 3

Indication for the

means of selection

for Dip Switch 1.

Indication for the

means of selection

for Dip Switch 2.

Indication for the means of selection for shunt

jumper 1, 2 and 3.

Indication for the

means of selection

for Dip Switch 3.

Indication for the

means of selection

for Dip Switch 4.

economizer controller board is powered-up. Red LED will blink when error(s) occur. Refer the table below for

error codes and their meaning:-

Error

Code

F0 Fresh air actuator faulty/ malfunction

F1 Return air actuator faulty/ malfunction

F2 Communication error

F3 CO

F4 CO2 sensor open

F5 Fresh air RH sensor short

F6 Fresh air RH sensor open

F7 Return air RH sensor short

F8 Return air RH sensor open

F9 Activation of actuator protection

FA Multiple pins selection in Dip Switch 1, 2 or 3

Fault

sensor short

2

The error codes will be shown on the seven segment

display on the economizer controller board.

Seven segment display

26

When error(s) occur and the faults persist, please call your authorized local dealer/ serviceman for

troubleshooting. However, all the errors occur in economizer controller board will not affect the normal

operation of rooftop unit.

SERVICE AND MAINTENANCE

Note is valid for Turkey only: The lifetime of our products is ten (10) years

SERVICE OF THE FILTER

Remove any dust adhering to the filter by using a vacuum cleaner or wash in lukewarm water (below 40°C) with neutral

ü

cleaning detergent.

Rinse the filter well and dry before placing it back onto the unit.

ü

Do not use gasoline, volatite substances or chemicals to clean the filter.

ü

Clean the filter at least once every 2 weeks. Or more frequently if necessary.

ü

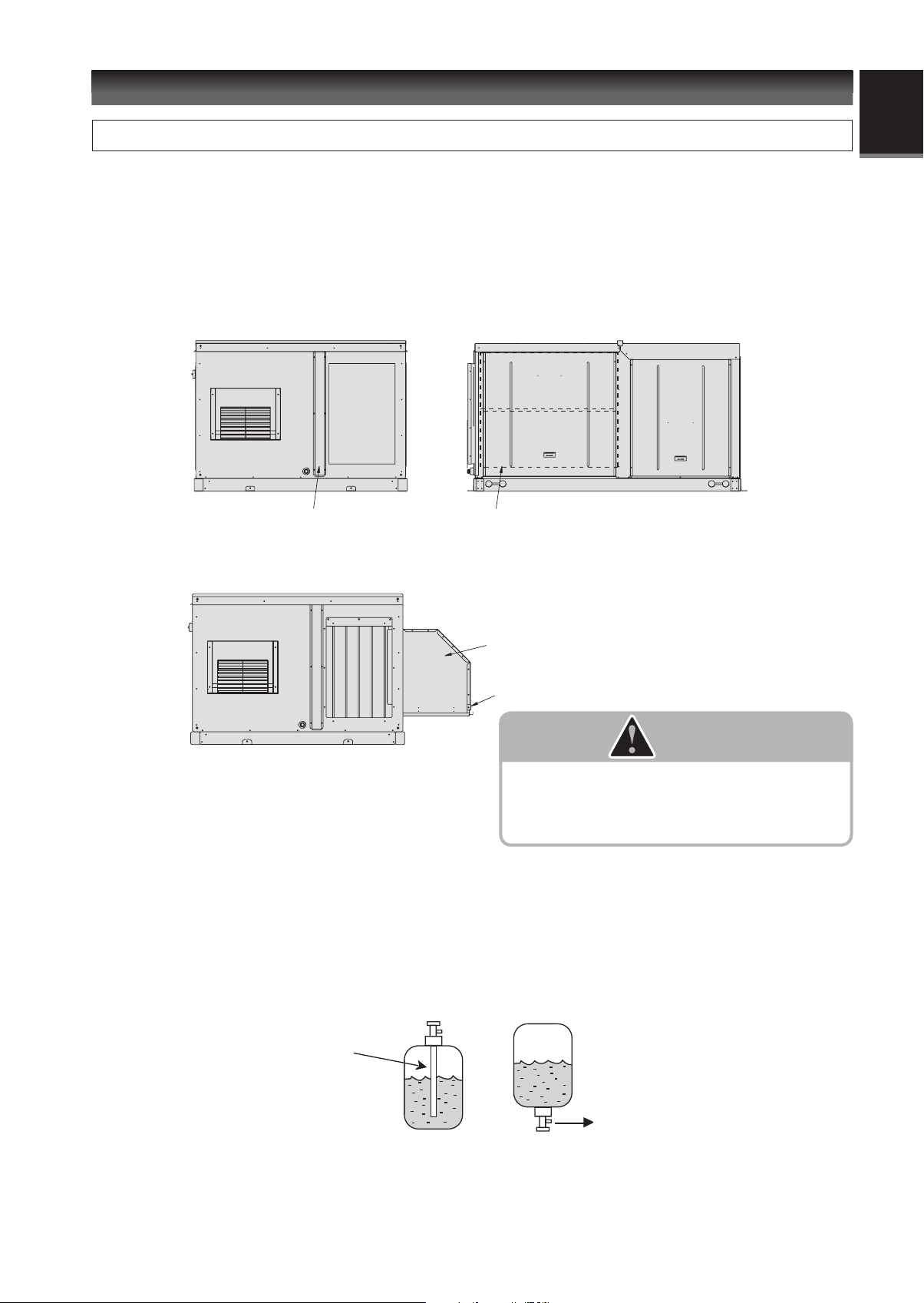

Filter Position

The filters are mounted in front of the indoor heat exchanger.

Unit shown in the diagram is UATYQ250. Other models shall follow the same method.

Remove filter cover for filter service. Alternatively, remove side panel for filter service.

For unit which is installed together with economizer kit, there is one additional filter which is mounted at the bottom

side of rain hood. Unit shown in the diagram is UATYQ250 + economizer kit (field installed). Other models shall follow the

same method.

ENGLISH

Rain hood (field installed)

Remove filter cover on the rain hood for filter

service.

CAUTION

Ensure the filter is placed properly and the filter cover is

fastened with screws tightly after the service to avoid water

leaking. If necessary, weather-proof sealant shall be applied

in order to ensure water-proof finishing on the filter cover

and rain hood.

VACUUMING AND CHARGING

The rooftop package units are factory pre-charged with sufficient refrigerant. However, there may be a need for charge

recovery during service and maintenance works. Therefore, some precautions must be taken to ensure optimum and

trouble-free system operation:

(i) The system should be throughly vacuumed to ensure no incompressible gas and moisture in the system.

(ii) Use a vacuum pump for R410A exclusively. Using the same vacuum pump for different refrigerants may damage the

vacuum pump or the unit.

(iii) The refrigerant should never be released directly into the environment.

(iv) When charging R410A, ensure that only liquid is being withdrawn from the cylinder or can.

Dip-pipe

Invert cylinder

without dip-pipe

Liquid

withdrawal

27

Normally, the R410A cylinder or can is equipped with a dip-pipe for liquid withdrawal. However, if the dip-pipe

is not available, invert the cylinder or can so as to withdraw liquid from the valve at the bottom.

CAUTION

R410A must be charged as liquid. Usually R410A cylinder is equipped with a dip-pipe for liquid withdrawal. If there is no

n

dip-pipe, the cylinder should be inverted so as to withdraw liquid R410A from the valve.

Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit thoroughly and then charge the

n

unit with fresh R410A according to the amount recommended in the specification.

TROUBLESHOOTING

For any enquiries on spare part please contact your authorized dealer. If any malfunction of the air-conditioner

unit is noted, check the following fault conditions and causes for some simple troubleshooting tips.

Problem Causes Action

Unit does not run.

Compressor does not

operate in 3 min after

unit has started.

Air flow is low.

Compressor operate

continuously.

No cool air delivered

during cooling cycle,

or no hot air delivered

during heating cycle.

On heating cycle, no air

delivered (UATYQ250).

Or, the delivered air

is not warm enough

(UATYQ350/450/550/

600/700/900).

Power failure.

l

Fuse blown or circuit breaker

l

tripped.

Power supply wiring phase incorrect.

l

Protection against frequent starting.l

Filter is filled with dust and dirt.

l

There are some obstacles at the air

l

inlet or outlet of the units.

Dirty air filter.

l

Temperature setting is too low (for

l

cooling).

Temperature setting is too high (for

l

heating).

Temperature setting is too high (for

l

cooling).

Temperature setting is too low (for

l

heating).

Unit is in defrosting cycle.l

Press the [ON/OFF] after

l

power restore.

Replace fuse or reset

l

circuit breaker.

Modify the wiring phase.

l

Wait for 3 min for the

l

compressor to start.

Clean the filter.

l

Remove obstacles.

l

Clean the air filter.

l

Reset the temperature.

l

Set the temperature

l

lower.

Set the temperature

l

higher.

Wait for a while.

l

(It will be resumed after

defrosting.)

If the fault persists, please call your authorized local dealer/serviceman.

28

Loading...

Loading...