Daikin RXYQ72-408TATJU, RXYQ144TAYDU, RXYQ72TAYDU, RXYQ120TAYDU, RXYQ168TAYDU Service Manual

...

Service

Manual

SiUS341615E

RXYQ72-408TAYDU

RXYQ72-408TATJU

Heat Pump 60 Hz

ED Reference

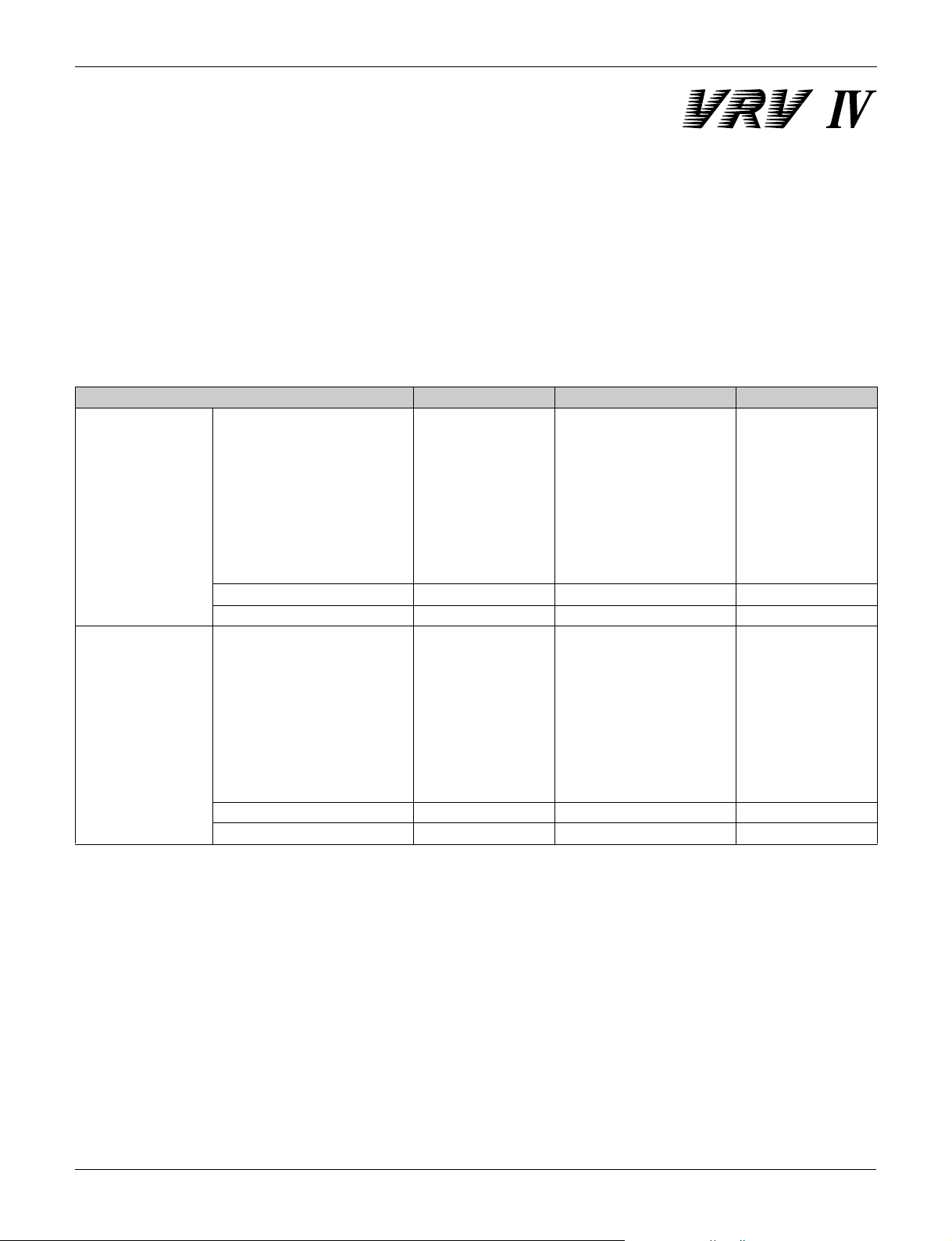

For items below, please refer to Engineering Data.

Item Model ED No. Page

VRV indoor unit

Specifications

Outdoor-air processing unit FXMQ-MF EDUS39-900A-F10 4

Energy recovery ventilator VAM-G EDUS711116A 2

VRV indoor unit

Option list

Outdoor-air processing unit FXMQ-MF EDUS39-900A-F10 32

Energy recovery ventilator VAM-G EDUS711116A 61

SiUS341615E

RXYQ-TA Series

Heat Pump

R-410A 60 Hz

FXFQ-T

FXFQ-P

FXZQ-M

FXUQ-P

FXEQ-P

FXDQ-M

FXMQ-PB

FXMQ-M

FXHQ-M

FXAQ-P

FXLQ-M, FXNQ-M

FXTQ-TA

FXFQ-T

FXFQ-P

FXZQ-M

FXUQ-P

FXEQ-P

FXDQ-M

FXMQ-PB

FXMQ-M

FXHQ-M

FXAQ-P

FXLQ-M, FXNQ-M

FXTQ-TA

EDUS391400-F14

EDUS391000-F1

EDUS391300-F9

EDUS391437-F15

EDUS391533-F16

EDUS39-600-F2

EDUS391503-F4

EDUS39-900A-F11

EDUS39-600-F5

EDUS391100-F6

EDUS391502-F7

FXTQ-TA Air Handling Unit

EDUS391400-F14

EDUS391000-F1

EDUS391300-F9

EDUS391437-F15

EDUS391533-F16

EDUS39-600-F2

EDUS391503-F4

EDUS39-900A-F11

EDUS39-600-F5

EDUS391100-F6

EDUS391502-F7

FXTQ-TA Air Handling Unit

2-4

2-3

2-3

3-4

3-5

3-4

3-5

3

3

2-3

4-7

4-5

43

40

48

36

27

30

43

25

32

43

28

47

i Table of Contents

SiUS341615E

1. Safety Cautions......................................................................................... vii

1.1 Warnings and Cautions Regarding Safety of Workers................................vii

1.2 Warnings and Cautions Regarding Safety of Users.....................................ix

2. Icons Used ................................................................................................ xii

Part 1 General Information ..............................................................1

1. Model Names of Indoor/Outdoor Units........................................................2

1.1 Indoor Unit.................................................................................................... 2

1.2 Outdoor Unit ................................................................................................. 2

1.3 Air Treatment Equipment ............................................................................. 3

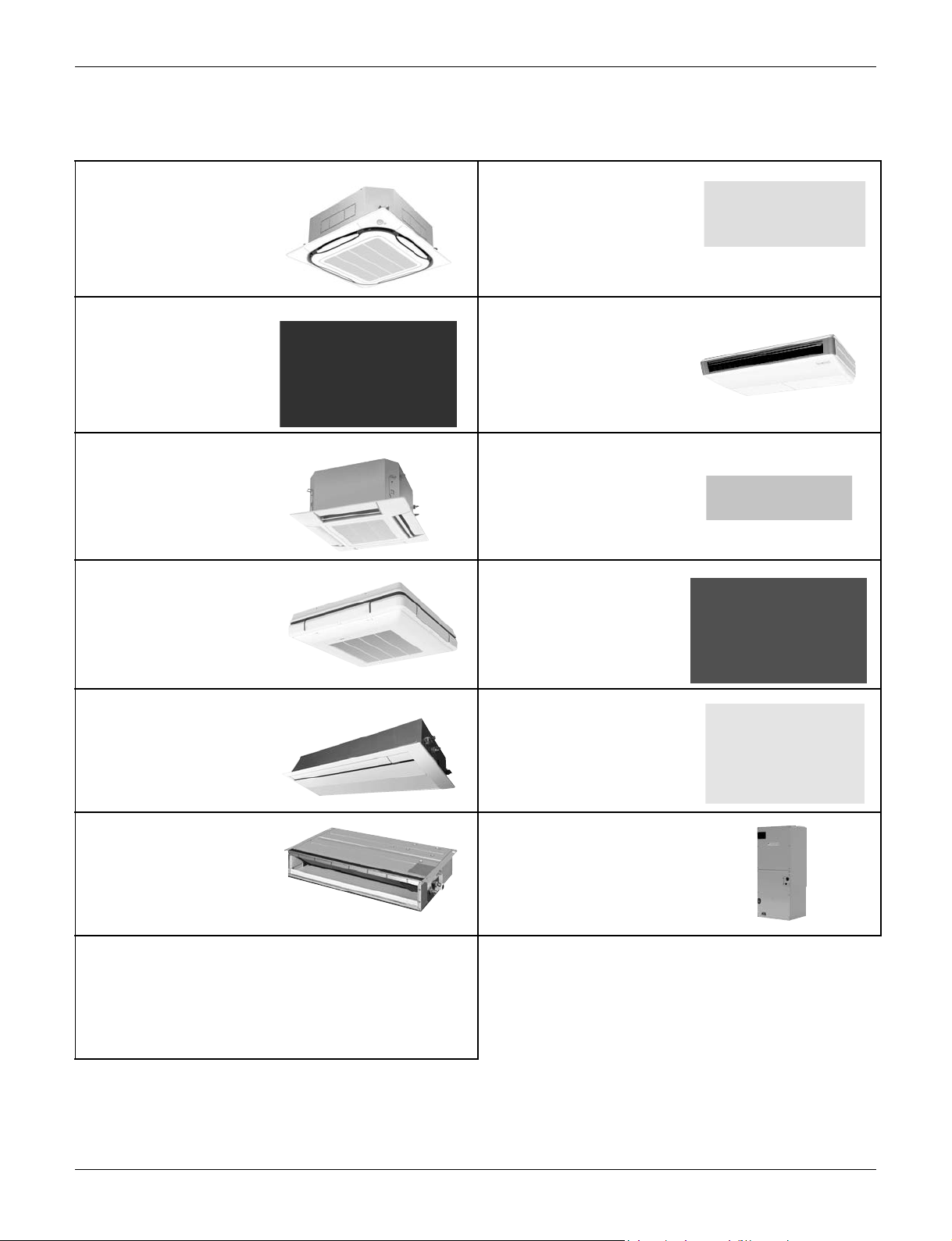

2. External Appearance...................................................................................4

2.1 Indoor Unit.................................................................................................... 4

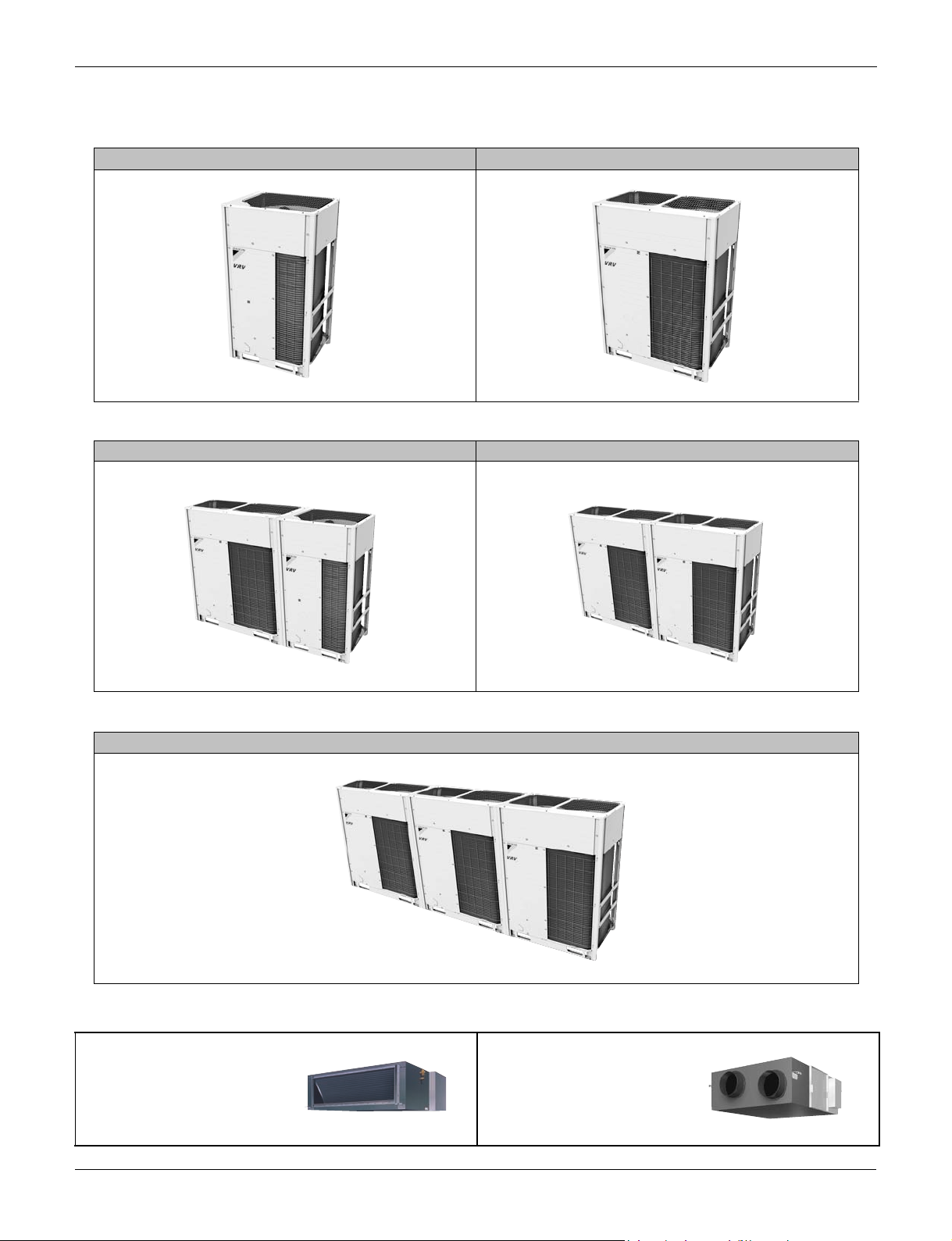

2.2 Outdoor Unit ................................................................................................. 5

2.3 Air Treatment Equipment ............................................................................. 5

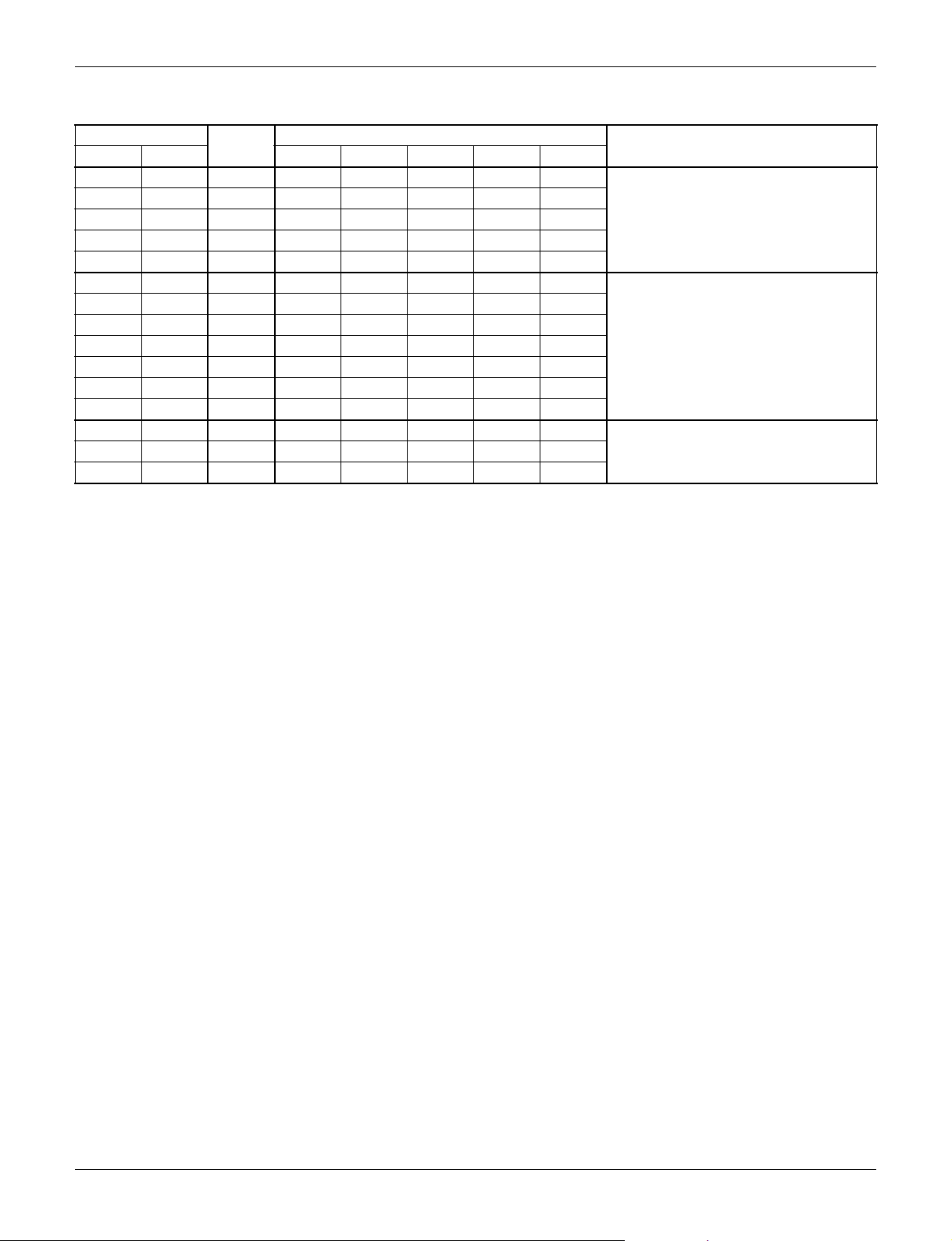

3. Combination of Outdoor Units.....................................................................6

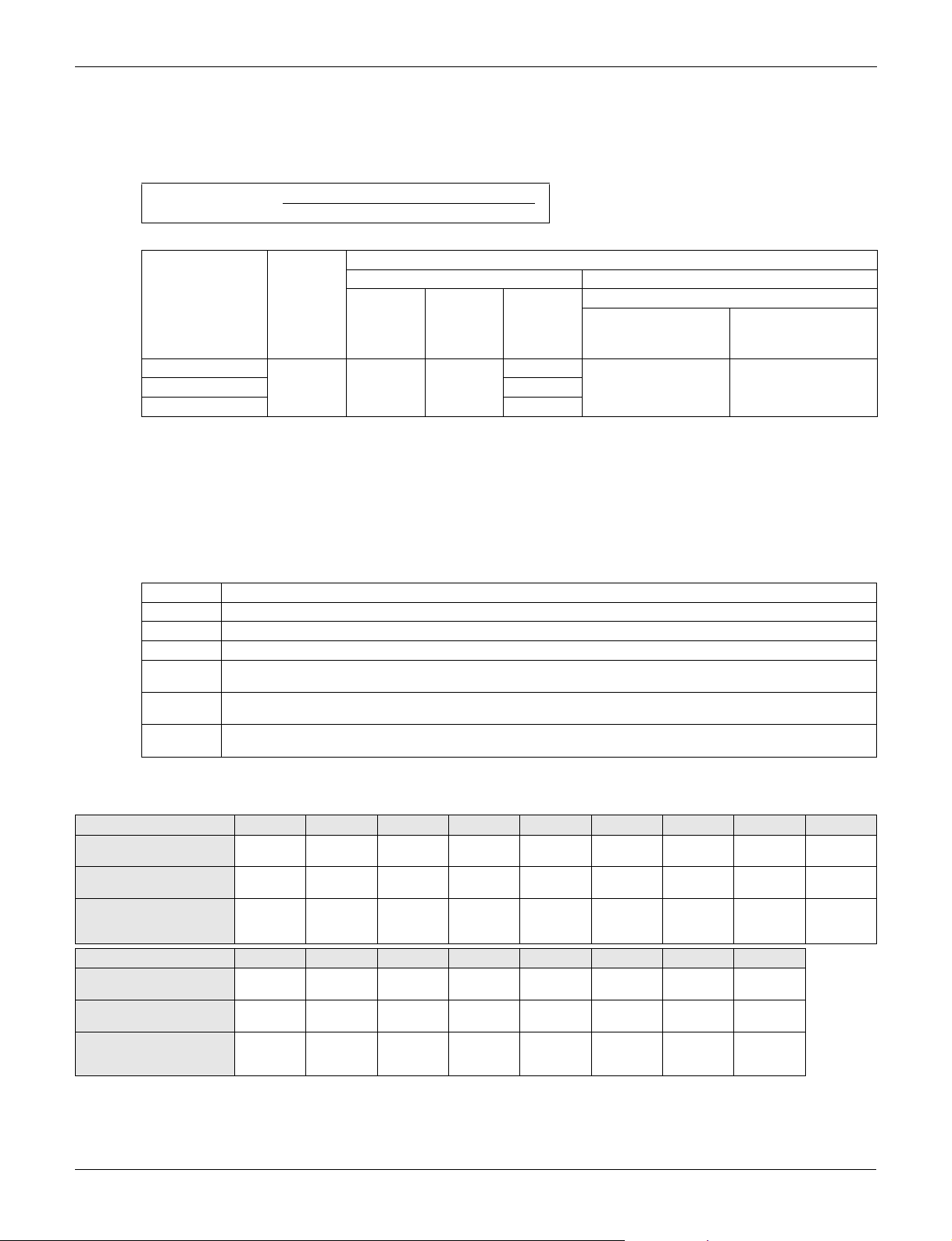

4. Capacity Range...........................................................................................7

4.1 Combination Ratio........................................................................................ 7

4.2 Outdoor Unit Combinations .......................................................................... 7

Part 2 Refrigerant Circuit ................................................................ 8

1. Refrigerant Circuit .......................................................................................9

1.1 Outdoor Unit ................................................................................................. 9

1.2 Indoor Unit.................................................................................................. 15

1.3 Outdoor-Air Processing Unit....................................................................... 17

2. Functional Parts Layout ............................................................................18

2.1 RXYQ72TAYDU ......................................................................................... 18

2.2 RXYQ96/120TAYDU .................................................................................. 19

2.3 RXYQ144/168TAYDU ................................................................................ 20

2.4 RXYQ72TATJU .......................................................................................... 21

2.5 RXYQ96/120TATJU ................................................................................... 22

2.6 RXYQ144/168TATJU ................................................................................. 23

3. Refrigerant Flow for Each Operation Mode...............................................24

3.1 RXYQ72TAYDU, RXYQ72TATJU.............................................................. 24

3.2 RXYQ96/120TAYDU, RXYQ96/120TATJU................................................ 28

3.3 RXYQ144/168TAYDU, RXYQ144/168TATJU............................................ 32

Part 3 Remote Controller ............................................................... 36

1. Applicable Models.....................................................................................37

2. Names and Functions ...............................................................................38

2.1 BRC1E73 ................................................................................................... 38

2.2 Wireless Remote Controller ....................................................................... 40

3. MAIN/SUB Setting.....................................................................................41

3.1 BRC1E73 ................................................................................................... 41

3.2 Wireless Remote Controller ....................................................................... 42

4. Centralized Control Group No. Setting......................................................43

Table of Contents ii

SiUS341615E

4.1 BRC1E73 ................................................................................................... 43

4.2 Wireless Remote Controller ....................................................................... 45

4.3 Group No. Setting Example........................................................................ 46

5. Service Mode ............................................................................................47

5.1 BRC1E73 ................................................................................................... 47

Part 4 Functions and Control......................................................... 49

1. Operation Flowchart (Outdoor Unit) ..........................................................51

2. Stop Control ..............................................................................................52

2.1 Stop due to Error........................................................................................ 52

2.2 When System is in Stop Mode ................................................................... 52

2.3 Slave Unit Stops during Master Unit Operation.......................................... 52

3. Standby Control ........................................................................................53

3.1 Restart Standby.......................................................................................... 53

3.2 Crankcase Heater Control .......................................................................... 53

4. Startup Control..........................................................................................54

4.1 Startup Control in Cooling .......................................................................... 54

4.2 Startup Control in Heating .......................................................................... 55

5. Basic Control.............................................................................................56

5.1 Normal Operation ....................................................................................... 56

5.2 Compressor Capacity Control .................................................................... 57

5.3 Operating Priority and Rotation of Compressors........................................ 58

5.4 Compressor Step Control ........................................................................... 59

5.5 Electronic Expansion Valve Control ........................................................... 59

5.6 Step Control of Outdoor Fans .................................................................... 60

6. Protection Control .....................................................................................61

6.1 High Pressure Protection Control............................................................... 61

6.2 Low Pressure Protection Control................................................................ 62

6.3 Discharge Pipe Protection Control ............................................................. 63

6.4 Compressor Body Protection Control......................................................... 63

6.5 Inverter Protection Control ......................................................................... 64

6.6 Heating Operation Prohibition .................................................................... 65

7. Special Control..........................................................................................66

7.1 Pump Down Residual Operation................................................................ 66

7.2 Outdoor Unit Rotation................................................................................. 66

7.3 Oil Return Operation .................................................................................. 68

7.4 Defrost Operation ....................................................................................... 70

7.5 Drain Pan Heater (Option).......................................................................... 70

8. Outline of Control (Indoor Unit) .................................................................71

8.1 Operation Flowchart ................................................................................... 71

8.2 Set Temperature and Control Temperature ............................................... 73

8.3 Remote Controller Thermistor.................................................................... 75

8.4 Thermostat Control..................................................................................... 77

8.5 Drain Pump Control.................................................................................... 80

8.6 Control of Electronic Expansion Valve ....................................................... 82

8.7 Freeze-up Prevention................................................................................. 83

iii Table of Contents

SiUS341615E

8.8 List of Swing Flap Operations .................................................................... 85

8.9 Hot Start Control (In Heating Only) ............................................................ 86

8.10 Louver Control for Preventing Ceiling Dirt.................................................. 87

8.11 Heater Control (Except FXTQ-TA Models)................................................. 88

8.12 Heater Control (FXTQ-TA Models)............................................................. 89

8.13 3 Step Thermostat Processing (FXTQ-TA Models).................................... 92

8.14 Fan Control (Heater Residual) (FXTQ-TA Models).................................... 93

8.15 Interlocked with External Equipment (FXTQ-TA Models)........................... 93

Part 5 Field Settings ......................................................................95

1. Field Setting from Remote Controller........................................................96

1.1 Wired Remote Controller ............................................................................ 96

1.2 Wireless Remote Controller ....................................................................... 98

1.3 Simplified Remote Controller...................................................................... 99

1.4 Setting Contents and Code No. for Indoor Units...................................... 100

2. Field Settings for Outdoor Unit................................................................118

2.1 Function Setting ....................................................................................... 118

2.2 Settings by DIP Switches ......................................................................... 120

2.3 Settings by BS Buttons............................................................................. 123

2.4 Normal Mode ............................................................................................ 125

2.5 Monitor Mode (Mode 1) ............................................................................ 126

2.6 Setting Mode (Mode 2)............................................................................. 140

3. Test Operation ........................................................................................157

3.1 Checks before Test Operation ................................................................. 157

3.2 Checkpoints.............................................................................................. 157

3.3 Check Work Prior to Turn Power Supply ON ........................................... 158

3.4 Turn Power ON ........................................................................................ 159

Part 6 Service Diagnosis.............................................................. 160

1. Symptom-based Troubleshooting ...........................................................163

1.1 Indoor Unit Overall ................................................................................... 163

1.2 With Optional Infrared Floor Sensor......................................................... 166

2. Service Check Function ..........................................................................167

2.1 Wired Remote Controller .......................................................................... 167

2.2 Wireless Remote Controller ..................................................................... 169

2.3 Error Codes and Descriptions .................................................................. 171

2.4 Error Codes - Sub Codes ......................................................................... 173

3. Troubleshooting by Error Code...............................................................174

3.1 External Protection Device Abnormality................................................... 174

3.2 Indoor Unit PCB Abnormality ................................................................... 176

3.3 Drain Level Control System Abnormality.................................................. 177

3.4 Fan Motor Lock, Overload........................................................................ 179

3.5 Indoor Fan Motor Abnormality.................................................................. 182

3.6 Overload/Overcurrent/Lock of Indoor Fan Motor...................................... 186

3.7 Blower Motor Not Running ....................................................................... 187

3.8 Indoor Fan Motor Status Abnormality....................................................... 188

Table of Contents iv

SiUS341615E

3.9 Low Indoor Airflow.................................................................................... 189

3.10 Swing Flap Motor Abnormality ................................................................. 190

3.11 Power Supply Voltage Abnormality .......................................................... 192

3.12 Blower Motor Stops for Over/Under Voltage ............................................ 193

3.13 Electronic Expansion Valve Coil Abnormality, Dust Clogging .................. 194

3.14 Drain Level above Limit ............................................................................ 195

3.15 Capacity Determination Device Abnormality ............................................ 196

3.16 Transmission Abnormality between Indoor Unit PCB and Fan PCB........ 197

3.17 Blower Motor Communication Error ......................................................... 199

3.18 Thermistor Abnormality ............................................................................ 200

3.19 Combination Error between Indoor Unit PCB and Fan PCB .................... 201

3.20 Blower Motor HP Mismatch...................................................................... 202

3.21 Indoor Blower Does Not Have Required Parameters to Function............ 203

3.22 Remote Sensor Abnormality .................................................................... 204

3.23 Humidity Sensor System Abnormality ...................................................... 205

3.24 Infrared Presence/Floor Sensor Error ...................................................... 206

3.25 Remote Controller Thermistor Abnormality .............................................. 211

3.26 Outdoor Unit Main PCB Abnormality ........................................................ 212

3.27 Current Leakage Detection ...................................................................... 213

3.28 Missing of Leakage Detection Core ......................................................... 214

3.29 Actuation of High Pressure Switch ........................................................... 215

3.30 Actuation of Low Pressure Sensor ........................................................... 217

3.31 Inverter Compressor Motor Lock.............................................................. 219

3.32 Compressor Damage Alarm..................................................................... 221

3.33 Outdoor Fan Motor Abnormality ............................................................... 223

3.34 Electronic Expansion Valve Coil Abnormality........................................... 226

3.35 Discharge Pipe Temperature Abnormality ............................................... 228

3.36 Wet Alarm................................................................................................. 230

3.37 Refrigerant Overcharged .......................................................................... 232

3.38 Harness Abnormality (between Outdoor Unit Main PCB and

Inverter PCB)............................................................................................ 233

3.39 Outdoor Fan Motor Signal Abnormality .................................................... 234

3.40 Thermistor Abnormality ............................................................................ 235

3.41 High Pressure Sensor Abnormality .......................................................... 237

3.42 Low Pressure Sensor Abnormality........................................................... 239

3.43 Inverter PCB Abnormality......................................................................... 241

3.44 Reactor Temperature Rise Abnormality ................................................... 243

3.45 Inverter Radiation Fin Temperature Rise Abnormality ............................. 244

3.46 Inverter Compressor Instantaneous Overcurrent ..................................... 245

3.47 Inverter Compressor Overcurrent............................................................. 247

3.48 Inverter Compressor Startup Abnormality ................................................ 249

3.49 Transmission Error between Inverter PCB and

Outdoor Unit Main PCB............................................................................ 252

3.50 Power Supply Voltage Imbalance ............................................................ 254

3.51 Reactor Temperature Abnormality ........................................................... 256

3.52 Inverter Radiation Fin Temperature Abnormality ..................................... 257

3.53 Field Setting after Replacing Outdoor Unit Main PCB Abnormality or

Combination of PCB Abnormality............................................................. 259

v Table of Contents

SiUS341615E

3.54 Refrigerant Shortage ................................................................................ 260

3.55 Reverse Phase, Open Phase................................................................... 261

3.56 Power Supply Insufficient or Instantaneous Abnormality ......................... 262

3.57 Check Operation not Executed ................................................................ 265

3.58 Transmission Error between Indoor Units and Outdoor Units.................. 266

3.59 Transmission Error between Remote Controller and Indoor Unit............. 269

3.60 Transmission Error between Outdoor Units ............................................. 270

3.61 Transmission Error between Main and Sub Remote Controllers ............. 276

3.62 Transmission Error between Indoor Unit and

Outdoor Unit in the Same System............................................................ 277

3.63 Improper Combination of Indoor Unit and Outdoor Unit,

Indoor Unit and Remote Controller........................................................... 278

3.64 Incorrect Electric Heater Capacity Setting................................................ 283

3.65 Address Duplication of Centralized Controller.......................................... 284

3.66 Transmission Error between Centralized Controller and Indoor Unit ....... 285

3.67 System not Set yet ................................................................................... 288

3.68 System Abnormality, Refrigerant System Address Undefined ................. 289

4. Check ......................................................................................................291

4.1 High Pressure Check ............................................................................... 291

4.2 Low Pressure Check ................................................................................ 292

4.3 Superheat Operation Check..................................................................... 293

4.4 Power Transistor Check ........................................................................... 295

4.5 Refrigerant Overcharge Check................................................................. 296

4.6 Refrigerant Shortage Check..................................................................... 297

4.7 Vacuuming and Dehydration Procedure .................................................. 298

4.8 Thermistor Check ..................................................................................... 299

4.9 Pressure Sensor Check ........................................................................... 302

4.10 Broken Wire Check of the Relay Wires .................................................... 303

4.11 Fan Motor Connector Check (Power Supply Cable) ................................ 304

4.12 Fan Motor Connector Check (Signal Cable) ............................................ 304

4.13 Electronic Expansion Valve Coil Check ................................................... 305

Part 7 Appendix............................................................................ 306

1. Wiring Diagrams......................................................................................307

1.1 Outdoor Unit ............................................................................................. 307

1.2 Indoor Unit................................................................................................ 313

1.3 Air Treatment Equipment ......................................................................... 320

Table of Contents vi

Safety Cautions SiUS341615E

1. Safety Cautions

Be sure to read the following safety cautions before conducting repair work.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment

operates normally, and explain the cautions for operating the product to the customer.

Caution Items The caution items are classified into Warning and Caution. The Warning items are

especially important since death or serious injury can result if they are not followed closely. The

Caution items can also lead to serious accidents under some conditions if they are not

followed. Therefore, be sure to observe all the safety caution items described below.

Pictograms This symbol indicates the item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates the prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates the action that must be taken, or the instruction.

The instruction is shown in the illustration or near the symbol.

1.1 Warnings and Cautions Regarding Safety of Workers

Warning

Do not store the equipment in a room with fire sources (e.g. naked flames,

gas appliances, electric heaters).

Be sure to disconnect the power cable from the socket before

disassembling equipment for repair.

Working on equipment that is connected to the power supply may cause an

electrical shock.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If refrigerant gas is discharged during repair work, do not touch the

discharged refrigerant gas.

Refrigerant gas may cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at

the welded section, evacuate the refrigerant gas completely at a wellventilated place first.

If there is gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it may

cause injury.

If refrigerant gas leaks during repair work, ventilate the area.

Refrigerant gas may generate toxic gases when it contacts flames.

vii

Be sure to discharge the capacitor completely before conducting repair

work.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

A charged capacitor may cause an electrical shock.

SiUS341615E Safety Cautions

Warning

Do not turn the air conditioner on or off by plugging in or unplugging the

power cable.

Plugging or unplugging the power cable to operate the equipment may cause

an electrical shock or fire.

Be sure to wear a safety helmet, gloves, and a safety belt when working

in a high place (more than 2 m (6.5 ft)).

Insufficient safety measures may cause a fall.

In case of R-32 and R-410A refrigerant models, be sure to use pipes, flare

nuts and tools intended for exclusive use with R-32 and R-410A

refrigerant.

The use of materials for R-22 refrigerant models may cause a serious accident,

such as damage to the refrigerant cycle or equipment failure.

Do not mix air or gas other than the specified refrigerant (R-32, R-410A,

R-22) in the refrigerant system.

If air enters the refrigerating system, excessively high pressure results, causing

equipment damage and injury.

Caution

Do not repair electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner with water.

Washing the unit with water may cause an electrical shock.

Be sure to provide an earth/grounding when repairing the equipment in a

humid or wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when

cleaning the equipment.

The internal fan rotates at a high speed, and may cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

viii

Safety Cautions SiUS341615E

Caution

Be sure to check that the refrigerating cycle section has cooled down

enough before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

Conduct welding work in a well-ventilated place.

Using a welder in an enclosed room may cause oxygen deficiency.

1.2 Warnings and Cautions Regarding Safety of Users

Warning

Do not store the equipment in a room with fire sources (e.g. naked flames,

gas appliances, electric heaters).

Be sure to use parts listed in the service parts list of the applicable model

and appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires are scratched or have deteriorated, be

sure to replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same

power outlet with other electrical appliances, since it may cause an

electrical shock, excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and follow

the local technical standards related to the electrical equipment, the

internal wiring regulations, and the instruction manual for installation

when conducting electrical work.

Insufficient power circuit capacity and improper electrical work may cause an

electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and

outdoor units.

Make the connections securely and route the cable properly so that there is no

force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

ix

SiUS341615E Safety Cautions

Warning

When wiring between the indoor and outdoor units, make sure that the

terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cables may cause an electrical shock or fire.

Placing heavy items on the power cable, or heating or pulling the power cable

may damage it.

Do not mix air or gas other than the specified refrigerant (R-32, R-410A,

R-22) in the refrigerant system.

If air enters the refrigerating system, excessively high pressure results, causing

equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leakage and repair it

before charging the refrigerant. After charging the refrigerant, make sure

that there is no leakage.

If the leakage cannot be located and the repair work must be stopped, be sure

to pump-down, and close the service valve, to prevent refrigerant gas from

leaking into the room. Refrigerant gas itself is harmless, but it may generate

toxic gases when it contacts flames, such as those from fan type and other

heaters, stoves and ranges.

When relocating the equipment, make sure that the new installation site

has sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength or if the installation work

is not conducted securely, the equipment may fall and cause injury.

Check to make sure that the power cable plug is not dirty or loose, then

insert the plug into a power outlet securely.

If the plug is dusty or has a loose connection, it may cause an electrical shock

or fire.

When replacing the coin battery in the remote controller, be sure to

dispose of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Caution

Installation of a leakage breaker is necessary in some cases depending

on the conditions of the installation site, to prevent electrical shocks.

x

Safety Cautions SiUS341615E

Caution

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections may cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

A corroded installation platform or frame may cause the unit to fall, resulting in

injury.

Check the earth/grounding, and repair it if the equipment is not properly

earthed/grounded.

Improper earth/grounding may cause an electrical shock.

Be sure to measure insulation resistance after the repair, and make sure

that the resistance is 1 MΩ or higher.

Faulty insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage may cause water to enter the room and wet the furniture and

floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

xi

SiUS341615E Icons Used

2. Icons Used

The following icons are used to attract the attention of the reader to specific information.

Icon Type of

Information

Warning A Warning is used when there is danger of personal injury.

Warning

Caution A Caution is used when there is danger that the reader, through

Caution

Note A Note provides information that is not indispensable, but may

Note:

Reference A Reference guides the reader to other places in this binder or

Description

incorrect manipulation, may damage equipment, loose data, get

an unexpected result or has to restart (part of) a procedure.

nevertheless be valuable to the reader, such as tips and tricks.

in this manual, where he/she will find additional information on a

specific topic.

xii

SiUS341615E

Part 1

General Information

1. Model Names of Indoor/Outdoor Units........................................................2

1.1 Indoor Unit.................................................................................................... 2

1.2 Outdoor Unit ................................................................................................. 2

1.3 Air Treatment Equipment ............................................................................. 3

2. External Appearance...................................................................................4

2.1 Indoor Unit.................................................................................................... 4

2.2 Outdoor Unit ................................................................................................. 5

2.3 Air Treatment Equipment ............................................................................. 5

3. Combination of Outdoor Units.....................................................................6

4. Capacity Range...........................................................................................7

4.1 Combination Ratio........................................................................................ 7

4.2 Outdoor Unit Combinations .......................................................................... 7

1 General Information

SiUS341615E Model Names of Indoor/Outdoor Units

1. Model Names of Indoor/Outdoor Units

1.1 Indoor Unit

Capacity Range (ton) 0.6 0.8 1 1.25 1.5 2 2.5 3 3.5 4 4.5 5 6 8 Power

Capacity Index 7.5 9.5 12 15 18 20 24 30 36 42 48 54 60 72 96

Ceiling Mounted Cassette

(Round Flow with Sensing) Type

Ceiling Mounted Cassette

(Round Flow) Type

4 Way Ceiling Mounted

Cassette (2'×2') Type

4-Way Blow CeilingSuspended Type

One Way Blow Cassette TypeFXEQ07P09P12P15P18P—24P————————

Slim Ceiling Mounted Duct Type

Ceiling Mounted Duct Type

(Middle and High Static Pressure)

Ceiling Mounted Duct Type FXMQ —————————————72M96M

Ceiling Suspended Type FXHQ — — 12M — — — 24M — 36M ——————

Wall Mounted Type FXAQ 07P 09P 12P — 18P — 24P ————————

Floor Standing Type FXLQ

Concealed Floor Standing Type

Air Handling Unit FXTQ —

FXFQ07T09T12T15T18T—24T30T36T—48T————

FXFQ—09P12P—18P—24P30P36P—48P————

FXZQ07M09M12M15M18M—————————— VJU9

FXUQ—————18P24P30P36P——————

FXDQ07M09M12M—18M—24M————————

FXMQ

07PB 09PB 12PB 15PB 18PB

07M—————————————— VJU9

—09M12M—18M—24M———————— VJU

07M—————————————— VJU9

FXNQ

—09M12M—18M—24M———————— VJU

09TA 12TA

—

18TA

—

24PB 30PB 36PB

—

24TA 30TA 36TA 42TA 48TA 54TA 60TA

—

48PB 54PB

———

——VJUA(D)

Supply,

Standard

VJU

VJU

VJ : 1 phase, 208/230 V, 60 Hz

U(VJU

): Standard Symbol

1.2 Outdoor Unit

Capacity Range (ton) 6 8 10 12 14 16 18 20

Capacity Index 72 96 120 144 168 192 216 240

Heat Pump

Capacity Range (ton) 22 24 26 28 30 32 34

Capacity Index 264 288 312 336 360 384 408

Heat Pump

YD : 3 phase, 460 V, 60 Hz

TJ : 3 phase, 208/230 V, 60 Hz

U(TJU

): Standard Symbol

460 V RXYQ- 72TA 96TA 120TA 144TA 168TA 192TA 216TA 240TA YDU

208/230 V

460 V RXYQ- 264TA 288TA 312TA 336TA 360TA 384TA 408TA YDU

208/230 V

RXYQ- 72TA 96TA 120TA 144TA 168TA 192TA 216TA 240TA TJU

RXYQ- 264TA 288TA 312TA 336TA 360TA 384TA 408TA TJU

Power Supply,

Standard

Power Supply,

Standard

General Information 2

Model Names of Indoor/Outdoor Units SiUS341615E

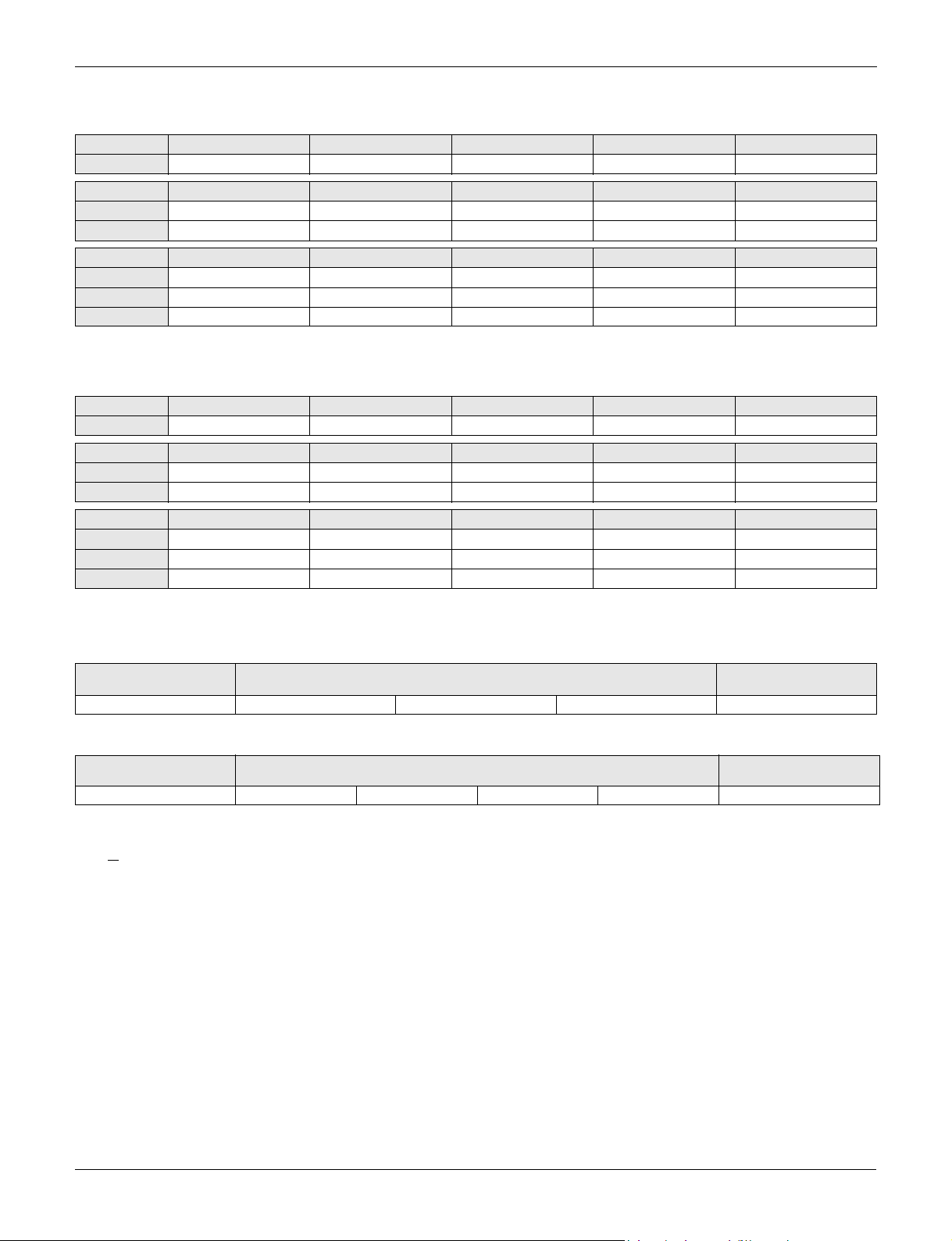

1.2.1 Combination of Outdoor Units (Heat Pump 460 V)

RXYQ-TAYDU

Model name RXYQ72TAYDU RXYQ96TAYDU RXYQ120TAYDU RXYQ144TAYDU RXYQ168TAYDU

Outdoor unit 1 RXYQ72TAYDU RXYQ96TAYDU RXYQ120TAYDU RXYQ144TAYDU RXYQ168TAYDU

Model name RXYQ192TAYDU RXYQ216TAYDU RXYQ240TAYDU RXYQ264TAYDU RXYQ288TAYDU

Outdoor unit 1 RXYQ72TAYDU RXYQ96TAYDU RXYQ120TAYDU RXYQ120TAYDU RXYQ144TAYDU

Outdoor unit 2 RXYQ120TAYDU RXYQ120TAYDU RXYQ120TAYDU RXYQ144TAYDU RXYQ144TAYDU

Model name RXYQ312TAYDU RXYQ336TAYDU RXYQ360TAYDU RXYQ384TAYDU RXYQ408TAYDU

Outdoor unit 1 RXYQ144TAYDU RXYQ168TAYDU RXYQ120TAYDU RXYQ96TAYDU RXYQ96TAYDU

Outdoor unit 2 RXYQ168TAYDU RXYQ168TAYDU RXYQ120TAYDU RXYQ120TAYDU RXYQ144TAYDU

Outdoor unit 3 — — RXYQ120TAYDU RXYQ168TAYDU RXYQ168TAYDU

1.2.2 Combination of Outdoor Units (Heat Pump 208/230 V)

RXYQ-TATJU

Model name RXYQ72TATJU RXYQ96TATJU RXYQ120TATJU RXYQ144TATJU RXYQ168TATJU

Outdoor unit 1 RXYQ72TATJU RXYQ96TATJU RXYQ120TATJU RXYQ144TATJU RXYQ168TATJU

Model name RXYQ192TATJU RXYQ216TATJU RXYQ240TATJU RXYQ264TATJU RXYQ288TATJU

Outdoor unit 1 RXYQ72TATJU RXYQ96TATJU RXYQ120TATJU RXYQ120TATJU RXYQ144TATJU

Outdoor unit 2 RXYQ120TATJU RXYQ120TATJU RXYQ120TATJU RXYQ144TATJU RXYQ144TATJU

Model name RXYQ312TATJU RXYQ336TATJU RXYQ360TATJU RXYQ384TATJU RXYQ408TATJU

Outdoor unit 1 RXYQ144TATJU RXYQ168TATJU RXYQ120TATJU RXYQ96TATJU RXYQ96TATJU

Outdoor unit 2 RXYQ168TATJU RXYQ168TATJU RXYQ120TATJU RXYQ120TATJU RXYQ144TATJU

Outdoor unit 3 — — RXYQ120TATJU RXYQ168TATJU RXYQ168TATJU

1.3 Air Treatment Equipment

Outdoor-Air Processing Unit

Series Model Name

FXMQ 48MF 72MF 96MF VJU

Energy Recovery Ventilator (VAM Series)

Series Model Name

VAM 300G 470G 600G 1200G VJU

VJ : 1 phase, 208/230 V, 60 Hz

U(VJU

) : Standard Symbol

Power Supply,

Standard

Power Supply,

Standard

3 General Information

SiUS341615E External Appearance

2. External Appearance

2.1 Indoor Unit

Ceiling mounted cassette (Round flow with sensing) type

FXFQ-T

Shown with BYCQ125B-W1

Ceiling mounted cassette (Round flow) type

FXFQ-P

Shown with BYCP125K-W1

4 way ceiling mounted cassette (2’×2’) type

FXZQ-M

Shown with BYFQ60B8W1U

4-way blow ceiling-suspended type

FXUQ-P

Ceiling mounted duct type

FXMQ-M

Ceiling suspended type

FXHQ-M

Wall mounted type

FXAQ-P

Floor standing type

FXLQ-M

One way blow cassette type

FXEQ-P

Slim ceiling mounted duct type

FXDQ-M

Ceiling mounted duct type (Middle and high static pressure)

FXMQ-PB

Concealed floor standing type

FXNQ-M

Air handling unit

FXTQ-TA

General Information 4

External Appearance SiUS341615E

2.2 Outdoor Unit

Single Outdoor Unit

Double Outdoor Unit

RXYQ192TA RXYQ216/240/264/288/312/336TA

RXYQ72TA

RXYQ96/120/144/168TA

Triple Outdoor Unit

RXYQ360/384/408TA

2.3 Air Treatment Equipment

Outdoor-air processing unit

FXMQ-MF

Energy recovery ventilator

(VAM series)

VAM-G

5 General Information

SiUS341615E Combination of Outdoor Units

3. Combination of Outdoor Units

System capacity

ton HP 72 96 120 144 168

67.51 O

8101 O

10 12.5 1 O

12 15 1 O

14 17.5 1 O

16 20 2 OO

18 22.5 2 OO

20 25 2 OO

22 27.5 2 OO

24 30 2 OO

26 323.5 2 OO

28 35 2 OO

30 37.5 3 OOO

34 42.5 3 OOO

Note: 1 For multiple connection, the outdoor unit multi connection piping kit (separately sold) is required.

Number

of units

Module

Outdoor Unit Multi Connection Piping Kit

BHFR22P100U

BHFR22P151U32 40 3 OO O

1

—

General Information 6

Capacity Range SiUS341615E

4. Capacity Range

4.1 Combination Ratio

Combination ratio =

Type

Single outdoor units

Triple outdoor units 130%

Total capacity index of the indoor units

Capacity index of the outdoor units

Min.

combination

ratio

50% 200% ∗1 130%

Types of connected indoor units Type of connected air treatment equipments

When using

only FXDQ,

FXMQ-PB,

FXAQ

When using

only FXTQ,

or at least one

FXFQ07 or

FXFQ09

Max. combination ratio

Other indoor

unit models

200% ∗1

FXMQ-MF

When FXMQ-MF is only

connected

100% 100% ∗2Double outdoor units 160% ∗1

When FXMQ-MF and

indoor units are

connected

Notes: ∗1. If the operational capacity of indoor units is more than 130%, low airflow operation is enforced in all the

indoor units. Refer to the table below.

∗2. When outdoor-air processing units (FXMQ-MF) and standard indoor units are connected, the total

connection capacity of the outdoor-air processing units (FXMQ-MF) must not exceed 30% of the capacity

index of the outdoor units. And the connection ratio must not exceed 100%.

Indoor unit fan tap setting

Indoor units fan speed limitation related to connection capacity and outdoor air temperature for energy saving.

Default value = 0

Value [2-34] Indoor unit fan tap setting

0 Fan speed is limited to L tap when indoor units capacity ≥ 130%.

1 In heating mode, fan speed is limited to L tap when indoor units capacity ≥ 130%.

2 Fan speed follows a setting of the remote controller (not limited by indoor units connection capacity).

3

4

5

Fan speed is limited to L tap when outdoor air temperature goes down to below 29.5°C (85.1°F). It returns to remote

controller setting when outdoor air temperature goes up to over 32.5°C (90.5 °F).

Fan speed is limited to L tap when outdoor air temperature goes down to below 23.5°C (74.3°F). It returns to remote

controller setting when outdoor air temperature goes up to over 26.5°C (79.7°F).

Fan speed is limited to L tap when outdoor air temperature goes down to below 19.3°C (66.7°F). It returns to remote

controller setting when outdoor air temperature goes up to over 22.3°C (72.1°F).

4.2 Outdoor Unit Combinations

Capacity Range 6 ton 8 ton 10 ton 12 ton 14 ton 16 ton 18 ton 20 ton 22 ton

RXYQ

Max. Number of

Connectable Indoor Units

Total Capacity Index of

Indoor Units to be

Connected ∗1

Capacity Range 24 ton 26 ton 28 ton 30 ton 32 ton 34 ton 36 ton 38 ton

RXYQ

Max. Number of

Connectable Indoor Units

Total Capacity Index of

Indoor Units to be

Connected ∗1

72TAYDU

72TATJU

12 16 20 25 29 33 37 41 45

36~93

(144)

288TAYDU

288TATJU

49 54 58 62 64 64 64 64

144~374

(461)

Note: ∗1. Values inside brackets are based on connection of indoor units rated at maximum capacity, 200% for single

outdoor units, 160% for double outdoor units, and 130% for triple outdoor units.

7 General Information

96TAYDU

96TATJU

48~124

(192)

312TAYDU

312TATJU

156~405

(499)

120TAYDU

120TATJU

60~156

(240)

336TAYDU

336TATJU

168~436

(538)

144TAYDU

144TATJU

72~187

(288)

360TAYDU

360TATJU

180~468

(468)

168TAYDU

168TATJU

84~218

(336)

384TAYDU

384TATJU

192~499

(499)

192TAYDU

192TATJU

96~249

(307)

408TAYDU

408TATJU

204~530

(530)

216TAYDU

216TATJU

108~280

(346)

432TAYDU

432TATJU

216~561

(561)

240TAYDU

240TATJU

120~312

(384)

456TAYDU

456TATJU

228~592

(592)

264TAYDU

264TATJU

132~343

(422)

SiUS341615E

Part 2

Refrigerant Circuit

1. Refrigerant Circuit .......................................................................................9

1.1 Outdoor Unit ................................................................................................. 9

1.2 Indoor Unit.................................................................................................. 15

1.3 Outdoor-Air Processing Unit....................................................................... 17

2. Functional Parts Layout ............................................................................18

2.1 RXYQ72TAYDU ......................................................................................... 18

2.2 RXYQ96/120TAYDU .................................................................................. 19

2.3 RXYQ144/168TAYDU ................................................................................ 20

2.4 RXYQ72TATJU .......................................................................................... 21

2.5 RXYQ96/120TATJU ................................................................................... 22

2.6 RXYQ144/168TATJU ................................................................................. 23

3. Refrigerant Flow for Each Operation Mode...............................................24

3.1 RXYQ72TAYDU, RXYQ72TATJU.............................................................. 24

3.2 RXYQ96/120TAYDU, RXYQ96/120TATJU................................................ 28

3.3 RXYQ144/168TAYDU, RXYQ144/168TATJU............................................ 32

Refrigerant Circuit 8

Refrigerant Circuit SiUS341615E

1. Refrigerant Circuit

1.1 Outdoor Unit

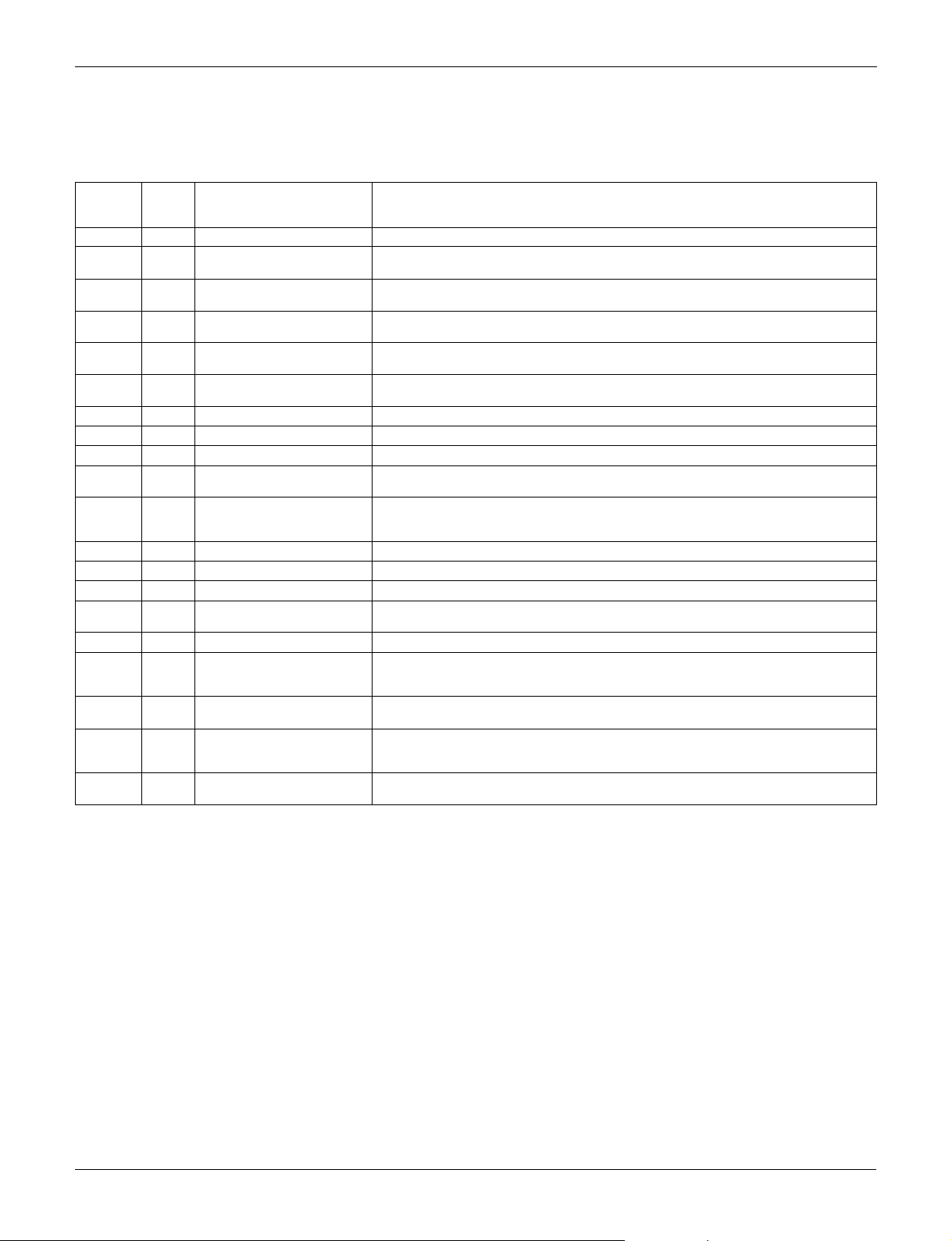

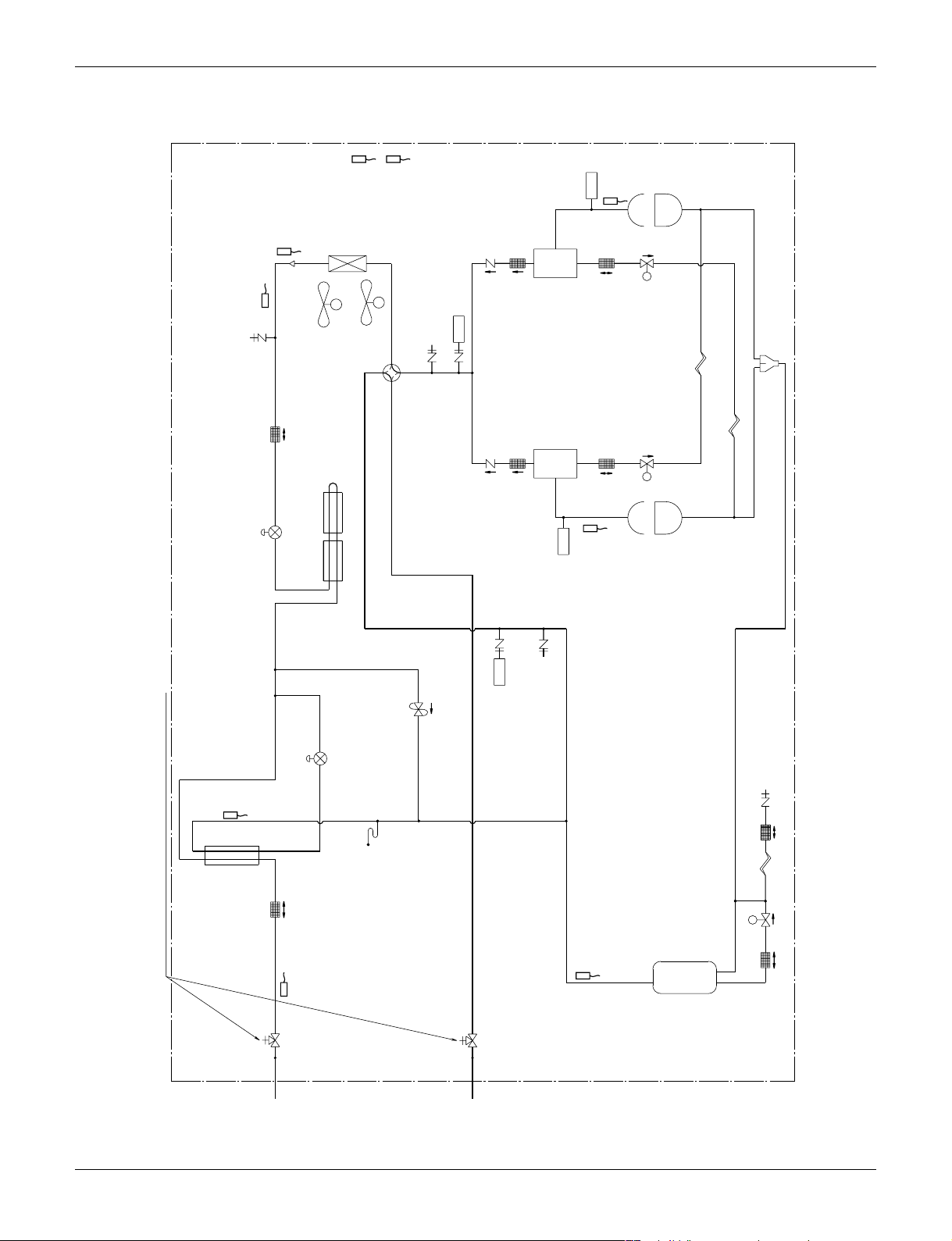

1.1.1 RXYQ72TAYDU, RXYQ72TATJU

No. in

piping

diagram

(1) M1C Inverter compressor Inverter driven compressor is operated in multi-steps according to Te.

(2) M1F Inverter fan

(3) Y1E

(4) Y2E

(5) Y1S

(6) Y2S

(7) Y3S Solenoid valve (Oil return) Used to control the amount of oil from the oil separator to the compressor.

(8) S1NPH High pressure sensor Used to detect high pressure.

(9) S1NPL Low pressure sensor Used to detect low pressure.

(10) S1PH High pressure switch

(11) — Pressure regulating valve

(12) — Subcooling heat exchanger Used to subcooling liquid refrigerant from the electronic expansion valve.

(13) — Capillary tube Used to return the refrigerating oil separated through the oil separator to the compressor.

(14) R1T Thermistor (Outdoor air) Used to detect outdoor air temperature, correct discharge pipe temperature, and others.

(15) R21T Thermistor (Discharge pipe)

(16) R3T Thermistor (Accumulator inlet) Used to detect gas pipe temperature at the accumulator inlet.

(17) R4T

(18) R5T

(19) R6T

(20) R7T

Electric

symbol

Name Function

Electronic expansion valve

(Main)

Electronic expansion valve

(Injection)

Solenoid valve

(Four way valve)

Solenoid valve

(Accumulator oil return)

Thermistor (Heat exchanger

liquid pipe)

Thermistor (Subcooling heat

exchanger liquid pipe)

Thermistor (Subcooling heat

exchanger gas pipe)

Thermistor

(Heat exchanger deicer)

Because the system is an air heat exchange type, the fan is operated at 10-step rotation

speed by using the inverter.

Fully open during cooling operation.

PI control is applied to keep the outlet superheated degree of subcooling heat exchanger

constant.

Used to switch the operation mode between cooling and heating.

Used to return oil from the accumulator to the compressor.

In order to prevent the increase of high pressure when an error occurs, this switch is

activated at high pressure of 4.0 MPa (580 psi) or more to stop the compressor operation.

This valve opens at a pressure of 4.0 MPa (580 psi) for prevention of pressure increase,

thus resulting in no damage of functional parts due to the increase of pressure in

transportation or storage.

Used to detect discharge pipe temperature, make the temperature protection control of

compressor, and others.

This detects temperature of liquid pipe between the air heat exchanger and main

electronic expansion valve. Used to make judgements on the recover or discharge

refrigerants to the refrigerant regulator.

This detects temperature of liquid pipe between the main electronic expansion valve and

subcooling heat exchanger.

This detects temperature of gas pipe on the evaporation side of subcooling heat

exchanger. Used to exercise the constant control of superheated degree at the outlet of

subcooling heat exchanger.

Used to detect liquid pipe temperature of air heat exchanger.

9 Refrigerant Circuit

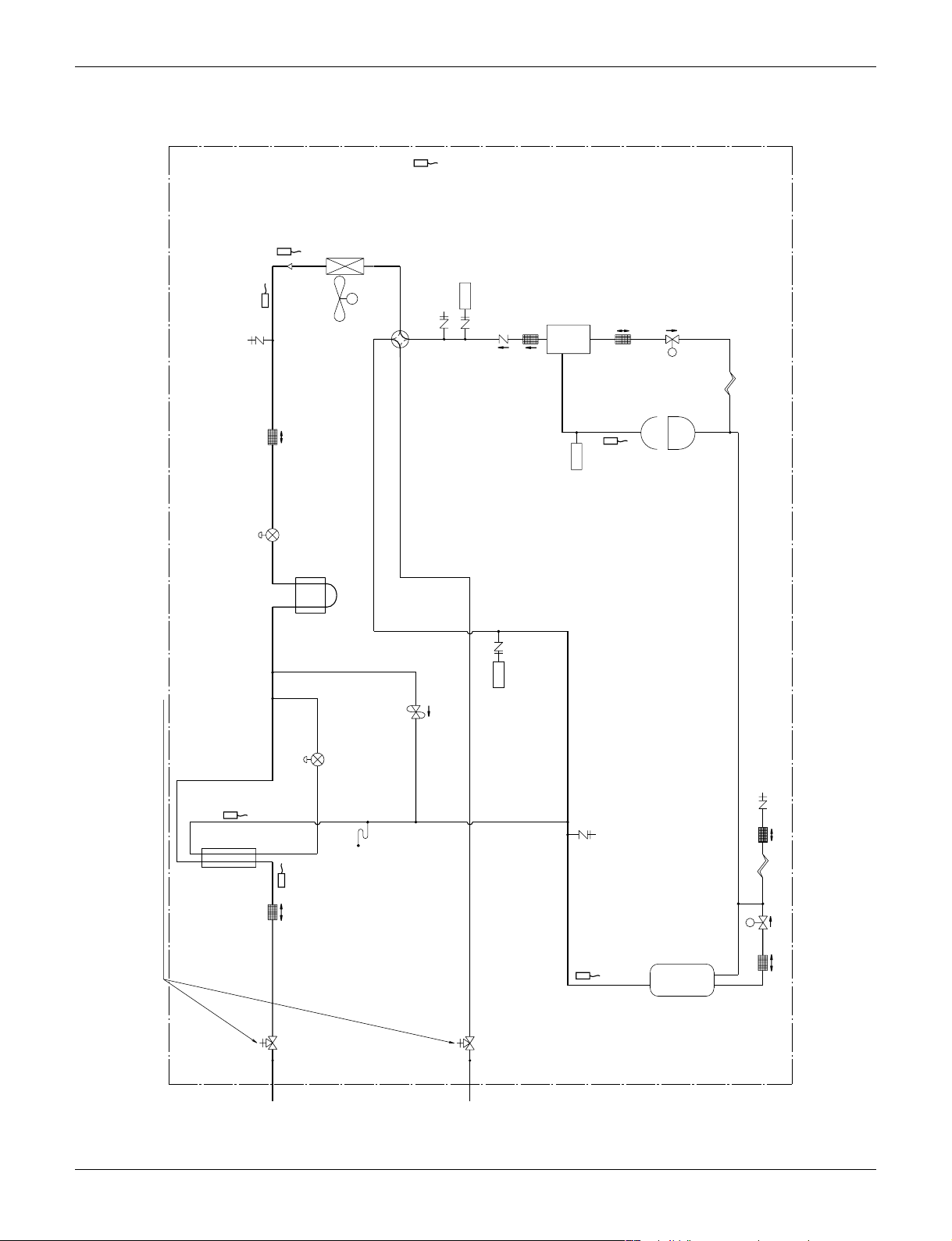

SiUS341615E Refrigerant Circuit

(3)

Electronic

(17)

valve

expansion

(20)

Fan

(2)

Heat sink

Heat exchanger

M

(5)

(14)

Four way valve

sensor

High pressure

(8)

S1NPH

C: 3D085567A

Oil

separator

Filter

Check valve

(10)

S1PH

switch

High pressure

(15)

Filter

(7)

Solenoid valve

SV

M1C

Compressor

(1)

Capillary tube

(13)

(19)

(12)

Double tube

heat exchanger

Stop valve (With service port φ5/16 in. (7.9mm) flare connection)

pipe

Liquid

(18)

Filter Filter

valve

Electronic

expansion

(4)

Fusible

plug

valve

Pressure

regulating

(11)

Gas

pipe

S1NPL

sensor

Low pressure

(9)

(16)

Accumulator

port

Charge

tube

Capillary

SV

FilterFilter

(6)

valve

Solenoid

Refrigerant Circuit 10

Refrigerant Circuit SiUS341615E

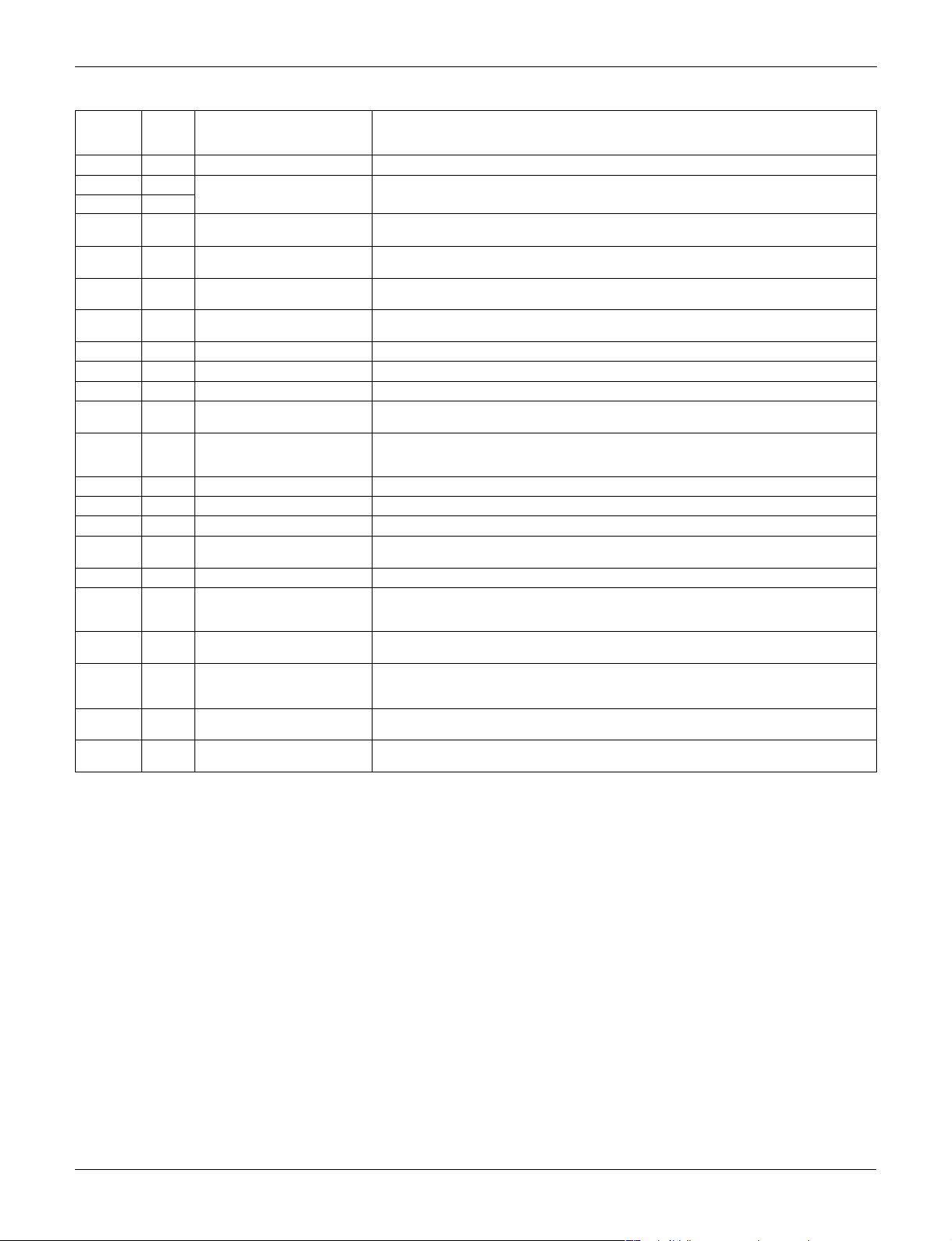

1.1.2 RXYQ96/120TAYDU, RXYQ96/120TATJU

No. in

piping

diagram

(1) M1C Inverter compressor Inverter compressor is operated in multi-steps according to Te.

(2) M1F

(3) M2F

(4) Y1E

(5) Y2E

(6) Y1S

(7) Y2S

(8) Y3S Solenoid valve (Oil return) Used to control the amount of oil from the oil separator to the compressor.

(9) S1NPH High pressure sensor Used to detect high pressure.

(10) S1NPL Low pressure sensor Used to detect low pressure.

(11) S1PH High pressure switch

(12) — Pressure regulating valve

(13) — Subcooling heat exchanger Used to subcooling liquid refrigerant from the electronic expansion valve.

(14) — Capillary tube Used to return the refrigerating oil separated through the oil separator to the compressor.

(15) R1T Thermistor (Outdoor air) Used to detect outdoor air temperature, correct discharge pipe temperature, and others.

(16) R21T Thermistor (Discharge pipe)

(17) R3T Thermistor (Accumulator inlet) Used to detect gas pipe temperature at the accumulator inlet.

(18) R4T

(19) R5T

(20) R6T

(21) R7T

(22) R8T

Electric

symbol

Name Function

Inverter fan

Electronic expansion valve

(Main)

Electronic expansion valve

(Injection)

Solenoid valve

(Four way valve)

Solenoid valve

(Accumulator oil return)

Thermistor (Heat exchanger

liquid pipe)

Thermistor (Subcooling heat

exchanger liquid pipe)

Thermistor (Subcooling heat

exchanger gas pipe)

Thermistor

(Heat exchanger deicer)

Thermistor

(Compressor body)

Because the system is an air heat exchange type, the fan is operated at 10-step rotation

speed by using the inverter.

Fully open during cooling operation.

PI control is applied to keep the outlet superheated degree of subcooling heat exchanger

constant.

Used to switch the operation mode between cooling and heating.

Used to return oil from the accumulator to the compressor.

In order to prevent the increase of high pressure when an error occurs, this switch is

activated at high pressure of 4.0 MPa (580 psi) or more to stop the compressor operation.

This valve opens at a pressure of 4.0 MPa (580 psi) for prevention of pressure increase,

thus resulting in no damage of functional parts due to the increase of pressure in

transportation or storage.

Used to detect discharge pipe temperature, make the temperature protection control of

compressor, and others.

This detects temperature of liquid pipe between the air heat exchanger and main

electronic expansion valve. Used to make judgements on the recover or discharge

refrigerants to the refrigerant regulator.

This detects temperature of liquid pipe between the main electronic expansion valve and

subcooling heat exchanger.

This detects temperature of gas pipe on the evaporation side of subcooling heat

exchanger. Used to exercise the constant control of superheated degree at the outlet of

subcooling heat exchanger.

Used to detect liquid pipe temperature of air heat exchanger.

Detects compressor surface temperature, this switch is activated at surface temperature

of 120°C (248°F) or more to stop the compressor operation.

11 Refrigerant Circuit

SiUS341615E Refrigerant Circuit

(15)

C: 3D085598A

(4)

Electronic

(20)

(18)

valve

expansion

(21)

Fan

(2)

Heat sink

Electronic

(5)

Heat exchanger

M

Fan

(3)

valve

expansion

(6)

M

Four way valve

sensor

(9)

High pressure

S1NPH

Oil

separator

Filter

Check valve

Filter

(8)

Solenoid valve

SV

(14)

Capillary tube

valve

Pressure

regulating

S1NPL

sensor

Low pressure

(10)

S1PH

switch

High pressure

(11)

(16)

M1C

Compressor

(1)

(22)

(12)

port

Charge

FilterFilter

(13)

Double tube

heat exchanger

Stop valve (With service port φ5/16 in. (7.9mm) flare connection)

pipe

Liquid

Filter Filter

(19)

plug

Fusible

Accumulator

Gas

(17)

pipe

tube

Capillary

(7)

SV

valve

Solenoid

Refrigerant Circuit 12

Refrigerant Circuit SiUS341615E

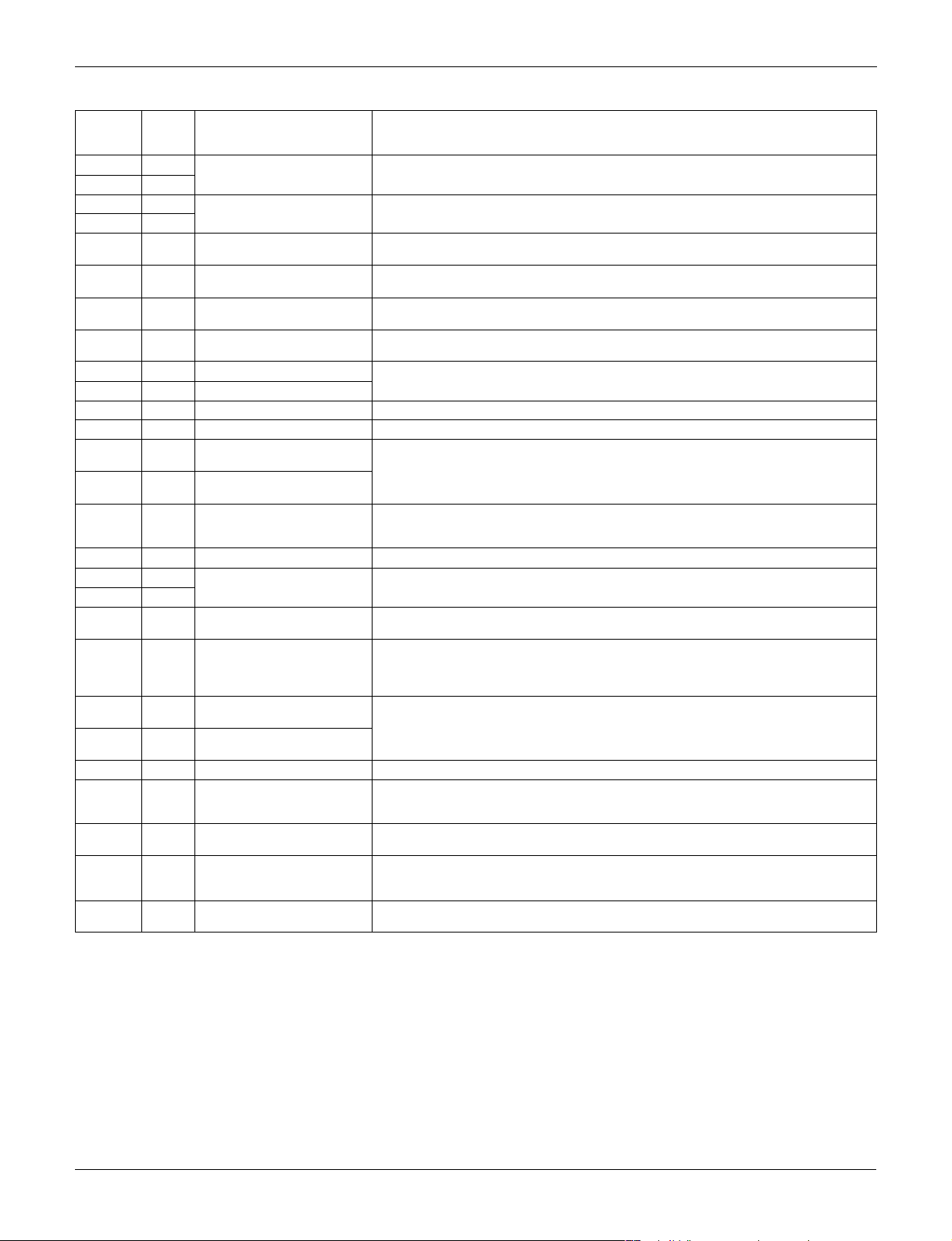

1.1.3 RXYQ144/168TAYDU, RXYQ144/168TATJU

No. in

piping

diagram

(1) M1C

(2) M2C

(3) M1F

(4) M2F

(5) Y1E

(6) Y2E

(7) Y1S

(8) Y2S

(9) Y3S Solenoid valve (Oil return 1)

(10) Y4S Solenoid valve (Oil return 2)

(11) S1NPH High pressure sensor Used to detect high pressure.

(12) S1NPL Low pressure sensor Used to detect low pressure.

(13) S1PH

(14) S2PH

(15) — Pressure regulating valve

(16) — Subcooling heat exchanger Used to subcooling liquid refrigerant from the electronic expansion valve.

(17) —

(18) —

(19) R1T

(20) R1T

(21) R21T

(22) R22T

(23) R3T Thermistor (Accumulator inlet) Used to detect gas pipe temperature at the accumulator inlet.

(24) R4T

(25) R5T

(26) R6T

(27) R7T

Electric

symbol

Name Function

Inverter compressor Inverter compressor is operated in multi-steps according to Te.

Inverter fan

Electronic expansion valve

(Main)

Electronic expansion valve

(Injection)

Solenoid valve

(Four way valve)

Solenoid valve

(Accumulator oil return)

High pressure switch

(For M1C compressor)

High pressure switch

(For M2C compressor)

Capillary tube Used to return the refrigerating oil separated through the oil separator to the compressor.

Thermistor (Outdoor air)

(A1P)

Thermistor

(Radiation fin) (A3P)

Thermistor

(M1C discharge pipe)

Thermistor

(M2C discharge pipe)

Thermistor (Heat exchanger

liquid pipe)

Thermistor (Subcooling heat

exchanger liquid pipe)

Thermistor (Subcooling heat

exchanger gas pipe)

Thermistor

(Heat exchanger deicer)

Because the system is an air heat exchange type, the fan is operated at 10-step rotation

speed by using the inverter.

Fully open during cooling operation.

PI control is applied to keep the outlet superheated degree of subcooling heat exchanger

constant.

Used to switch the operation mode between cooling and heating.

Used to return oil from the accumulator to the compressor.

Used to control the amount of oil from the oil separator to the compressor.

In order to prevent the increase of high pressure when an error occurs, this switch is

activated at high pressure of 4.0 MPa (580 psi) or more to stop the compressor operation.

This valve opens at a pressure of 4.0 MPa (580 psi) for prevention of pressure increase,

thus resulting in no damage of functional parts due to the increase of pressure in

transportation or storage.

Used to detect outdoor air temperature, correct discharge pipe temperature, and others.

RXYQ144/168TATJU only

• Used for outdoor unit fan speed control.

• Used for inverter radiation fin temperature control.

• Used for pressure difference control.

Used to detect discharge pipe temperature, make the temperature protection control of

compressor, and others.

This detects temperature of liquid pipe between the air heat exchanger and main

electronic expansion valve. Used to make judgements on the recover or discharge

refrigerants to the refrigerant regulator.

This detects temperature of liquid pipe between the main electronic expansion valve and

subcooling heat exchanger.

This detects temperature of gas pipe on the evaporation side of subcooling heat

exchanger. Used to exercise the constant control of superheated degree at the outlet of

subcooling heat exchanger.

Used to detect liquid pipe temperature of air heat exchanger.

13 Refrigerant Circuit

SiUS341615E Refrigerant Circuit

(19)

C: 3D085568A

(24)

(27)

(3)

switch

(20)*

Heat

exchanger

M

M

Fan

Fan

Check valve

sensor

High pressure

(11)

(4)

Four way valve

S1NPH

(13)

Filter

Oil

separator

(7)

(21)

S1PH

High pressure

(1)

(9)

M1C

Compressor

SV

valve

Solenoid

(17)

tube

Capillary

(18)

valve

Electronic

expansion

(26)

(5)

Heat sink

valve

Electronic

expansion

Fusible

(6)

plug

(15)

valve

Pressure

regulating

Check valve

(12)

Filter

S1NPH

sensor

Low pressure

Oil

(14)

switch

High pressure

separator

S2PH

(22)

Filter Filter

(10)

(2)

Solenoid

valve

SV

M2C

Compressor

tube

Capillary

∗ The radiation fin thermistor (20) is located near the electrical component box.

port

Charge

Filter

tube

Capillary

(16)

Double tube

heat exchanger

Stop valve (With service port φ5/16 in. (7.9mm) flare connection)

Filter Filter

(23)

Accumulator

SV

(8)

valve

Solenoid

Filter

(25)

pipe

Liquid

Gas

pipe

Refrigerant Circuit 14

Refrigerant Circuit SiUS341615E

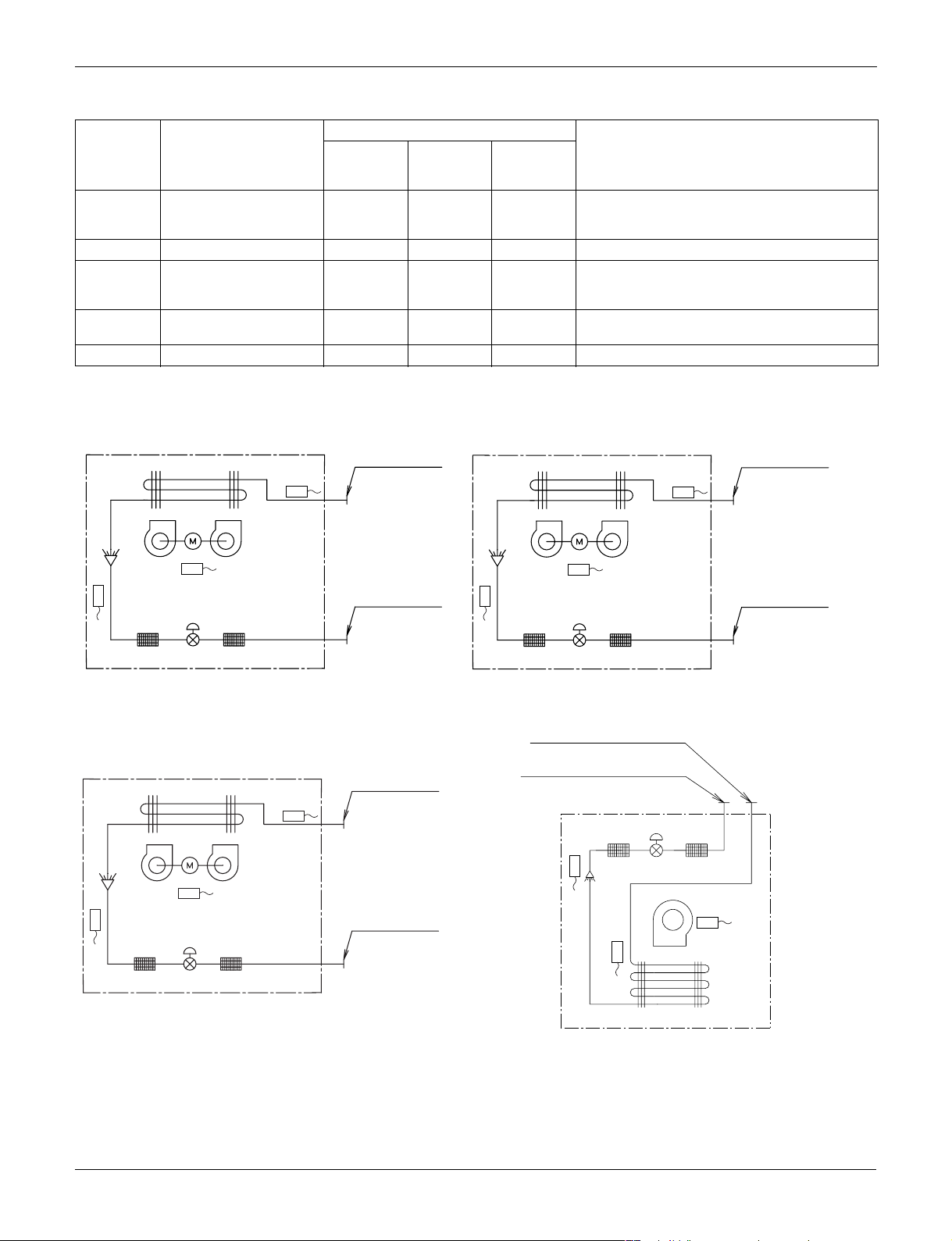

1.2 Indoor Unit

Symbol

No. in piping

diagram

(1)

Electronic expansion

valve

Name

(2) Suction air thermistor R1T R1T R1T (∗1) Used for thermostat control.

(3) Liquid pipe thermistor R2T R2T R2T

(4) Gas pipe thermistor R3T R3T R3T

(5) Discharge air thermistor — R4T — Used for discharge air temperature control.

∗1. R1T is for remote controller thermistor or optional remote sensor.

FXFQ-T, FXFQ-P, FXHQ-M FXZQ-M

Except

FXMQ-PB,

FXMQ-PB FXTQ-TA

FXTQ-TA

Y1E Y1E Y1E

Function

Used for gas superheated degree control while

in cooling or subcooled degree control while in

heating.

Used for gas superheated degree control while

in cooling or subcooled degree control while in

heating.

Used for gas superheated degree control while

in cooling.

Gas piping

connection port

(4)

Indoor heat exchanger

Fan

(3)

Filter Filter

(2)

(1)

Liquid piping

connection port

C: 4D024460M

FXUQ-P, FXEQ-P, FXMQ-M, FXAQ-P, FXLQ-M,

FXNQ-M

Gas piping

connection port

(4)

Indoor heat exchanger

Fan

(3)

(2)

Liquid piping

connection port

Indoor heat exchanger

(3)

Filter Filter

FXDQ-M

Gas piping connection port

Liquid piping connection port

Fan

(2)

(1)

(3)

Filter

(4)

(1)

(4)

Filter

(2)

Fan

Gas piping

connection port

Liquid piping

connection port

C: 4D040157B

Filter Filter

(1)

C: 4D034245P

Indoor heat exchanger

C: 4D043864N

15 Refrigerant Circuit

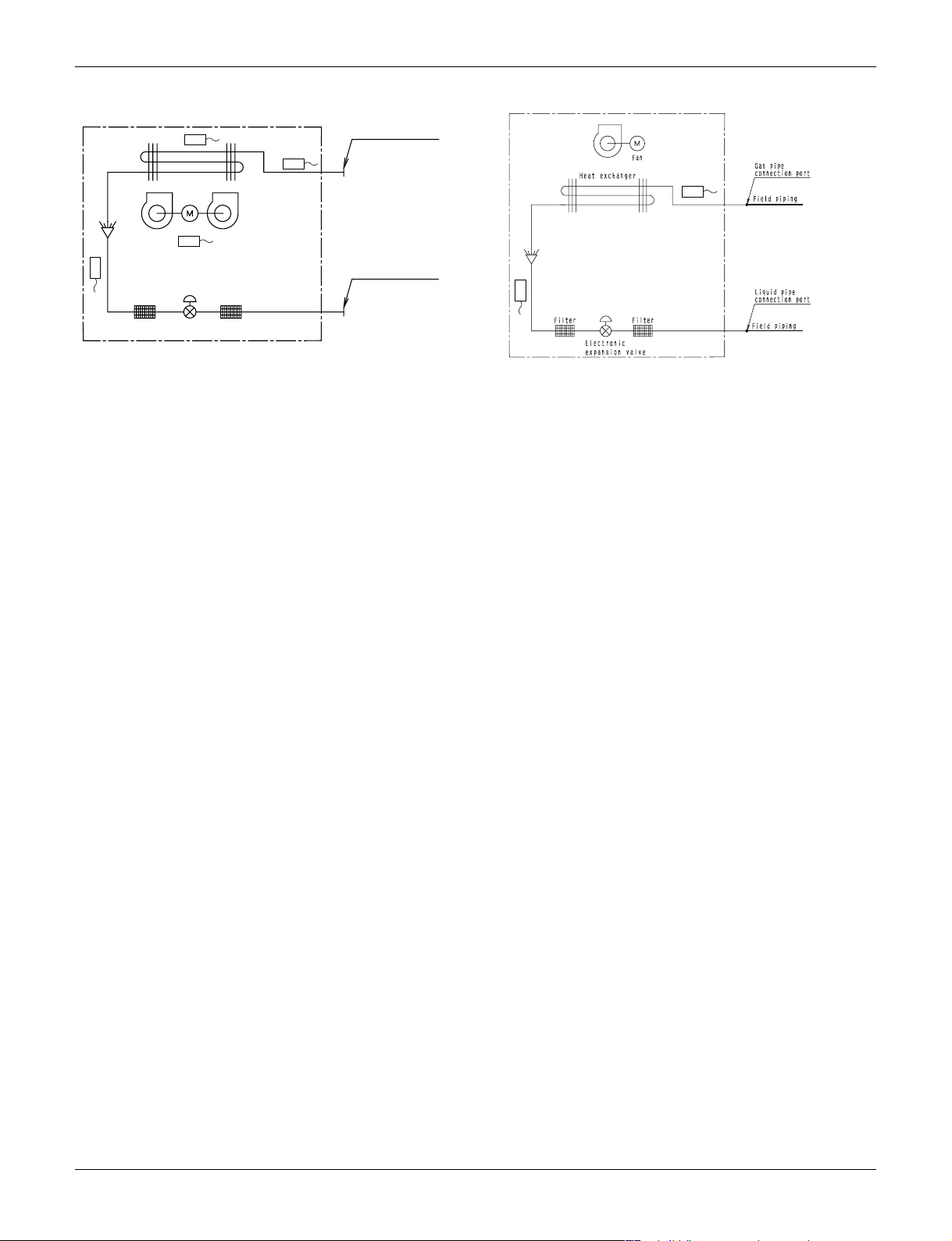

SiUS341615E Refrigerant Circuit

FXMQ-PB FXTQ-TA

Gas piping

(5)

(4)

connection port

Indoor heat exchanger

(3)

Filter Filter

Fan

(2)

(1)

Liquid piping

connection port

C: 4D034245P

(4)

(3)

(1)

C: 4D068194

Refrigerant Circuit 16

Refrigerant Circuit SiUS341615E

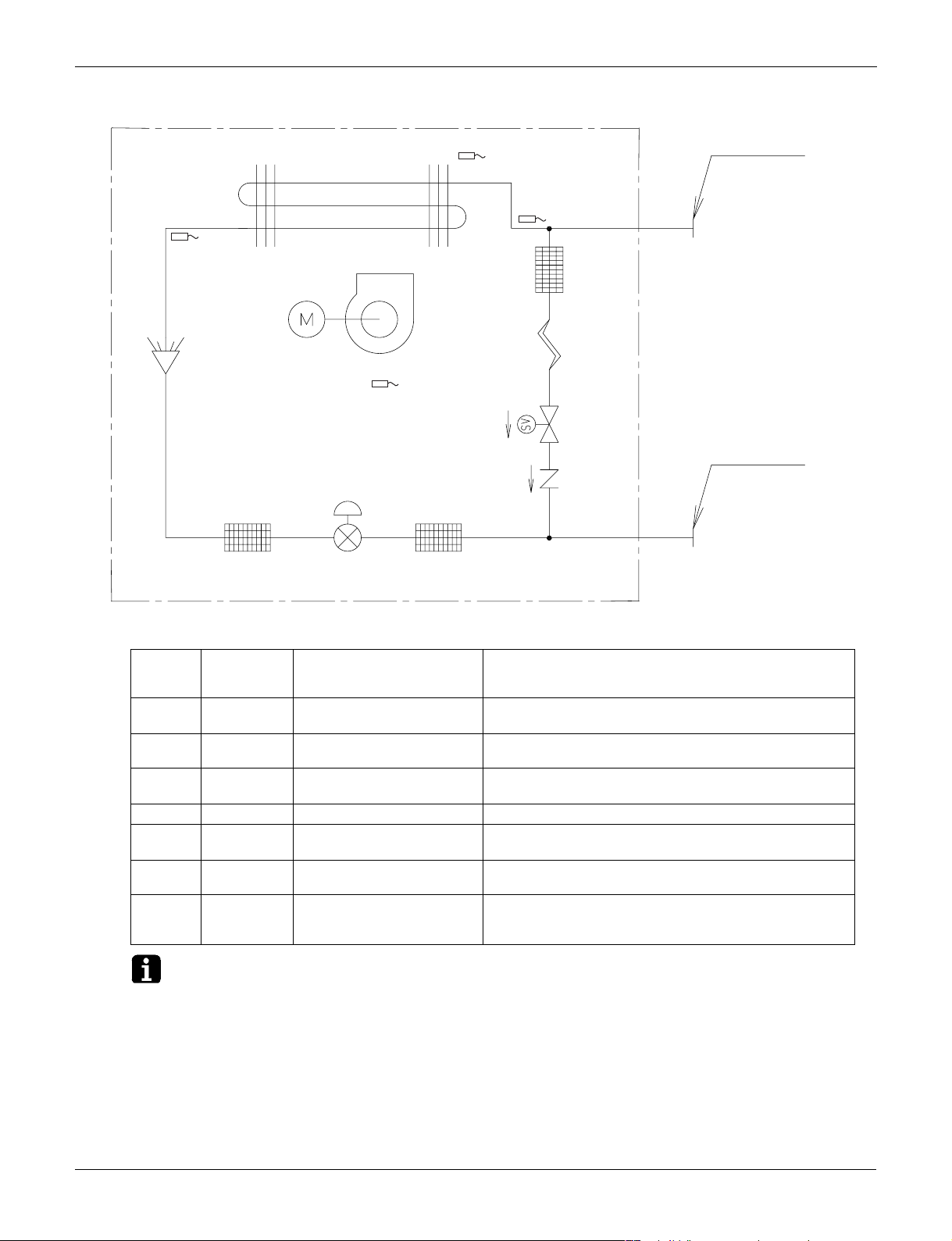

1.3 Outdoor-Air Processing Unit

Gas pipe

connection port

(5)

Heat exchanger

(7)

(6)

Filter

Capillary

tube

Solenoid

valve

Check

valve

Distributor

Fan

(4)

(1)

Filter

Electronic

expansion valve

No. in

piping

diagram

Electric

symbol

Name Function

(1) Y1E Electronic expansion valve

(2) Y1S Solenoid valve

(3) — Capillary tube

(3)

(2)

Filter

Used to control the flow rate of refrigerant, and make the

SH control (∗1) while in cooling.

Used to bypass hot gas while in heating with thermostat

OFF. Closed while in cooling.

Used to reduce pressure from high to low in bypassing hot

gas.

(4) R1T Suction air thermistor Used to turn ON or OFF the thermostat.

(5) R2T Liquid pipe thermistor

(6) R3T Gas pipe thermistor

Used to control the opening degree of electronic expansion

valve under the SC control (∗2).

Used to control the opening degree of electronic expansion

valve under the SH control.

Used to control the electronic expansion valve opening and

(7) R4T Discharge air thermistor

thermostat ON/OFF so as to keep the discharge air

temperature at the set temperature.

Liquid pipe

connection port

C: 4D018650D

Note: ∗1. SH control: Superheated control of heat exchanger outlet

∗2. SC control: Subcooling control of heat exchanger outlet

17 Refrigerant Circuit

Loading...

Loading...