Daikin RXYQ5M, RXYQ12M, RXYQ16M, RXYQ8M, RXYQ10M Introduction Manual

...

technical data

Systems

Introduction

• Introduction

IIntroduction

Table of contents

1 Possible indoor units using R-410A..........................................................................2

2 Possible outdoor units using R-410A......................................................................3

Indoor unit capacity index.............................................................................................................................3

3 Nomenclature

Indoor units.............................................................................................................................................................4

Outdoor units ........................................................................................................................................................5

4 line-up..........................................................................................................6

5 technology ...............................................................................................7

6Main features

Creating maximum comfort......................................................................................................................10

Energy efficient solution..............................................................................................................................13

High reliability .....................................................................................................................................................16

Eco friendly...........................................................................................................................................................18

Easy and flexible design................................................................................................................................19

Simple and rapid installation.....................................................................................................................22

7Selection procedure

Selection procedure System based on cooling load..................................................................26

Capacity correction ratio .............................................................................................................................29

Refnet pipe system..........................................................................................................................................37

Refnet pipe selection .....................................................................................................................................39

• Systems • Introduction

1

• Introduction

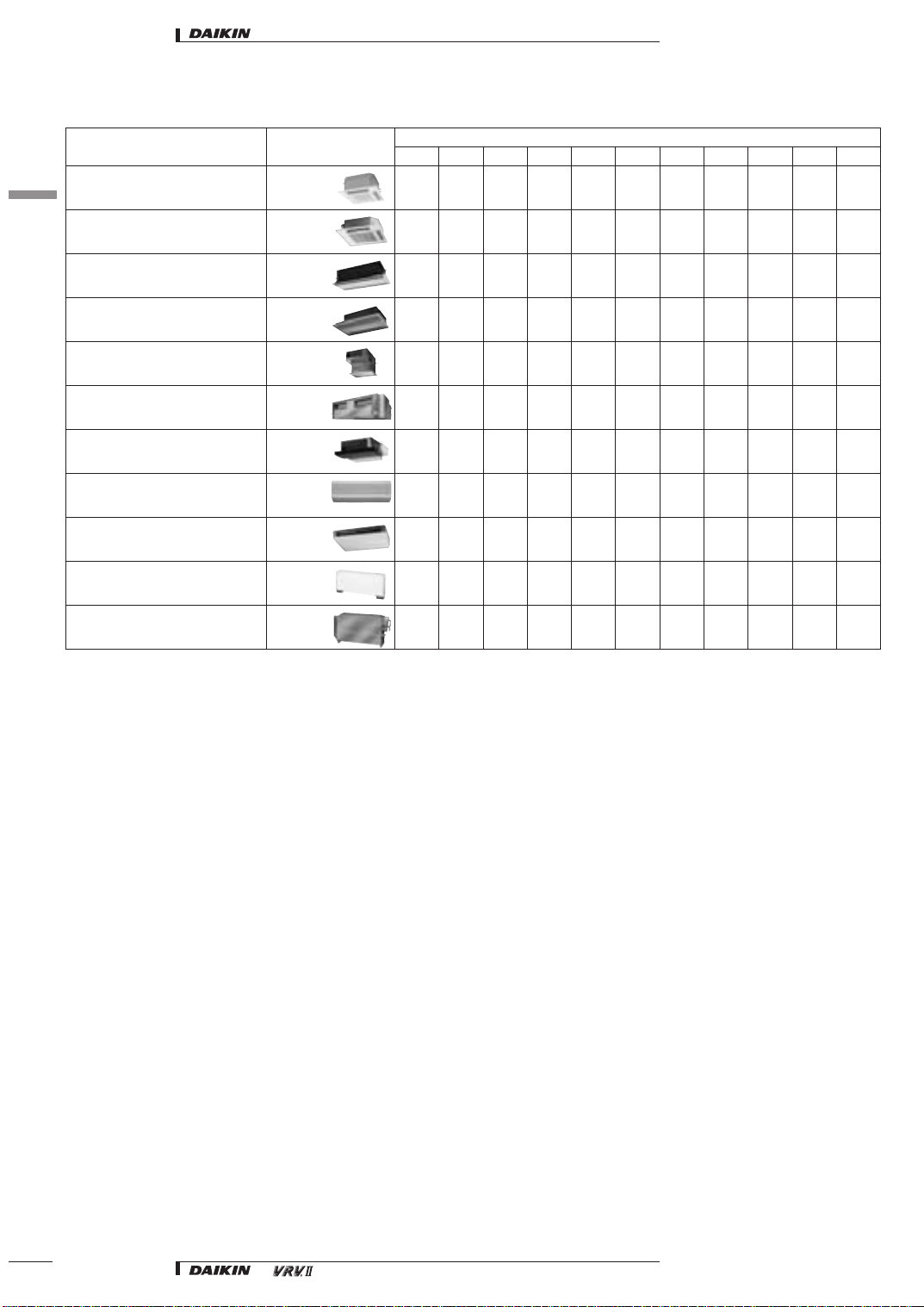

1 Possible indoor units using R-410A

Description Indoor unit

1

1

4-way blow ceiling mounted cassette (600 mm x 600 mm) FXZQ-MVE xxxxx

4-way blow ceiling mounted cassette FXFQ-M7V1B xxxxxxxxx

2-way blow ceiling mounted cassette FXCQ-M7V1B xxxxxxx x

Ceiling mounted corner cassette FXKQ-MVE x x x x

Concealed ceiling unit FXSQ-M7V1B xxxxxxxxx

Concealed ceiling unit (large) FXMQ-MVE xxxxxxxx

Concealed ceiling unit (small) FXDQ-M7V1B x x

Wall mounted unit FXAQ-MVE xxxxxx

Ceiling suspended unit FXHQ-MVE x x x

Floor standing unit FXLQ-MVE xxxxxx

Concealed floor standing unit FXNQ-MVE xxxxxx

20 25 32 40 50 63 80 100 125 200 250

Size

2

• Systems • Introduction

• Introduction

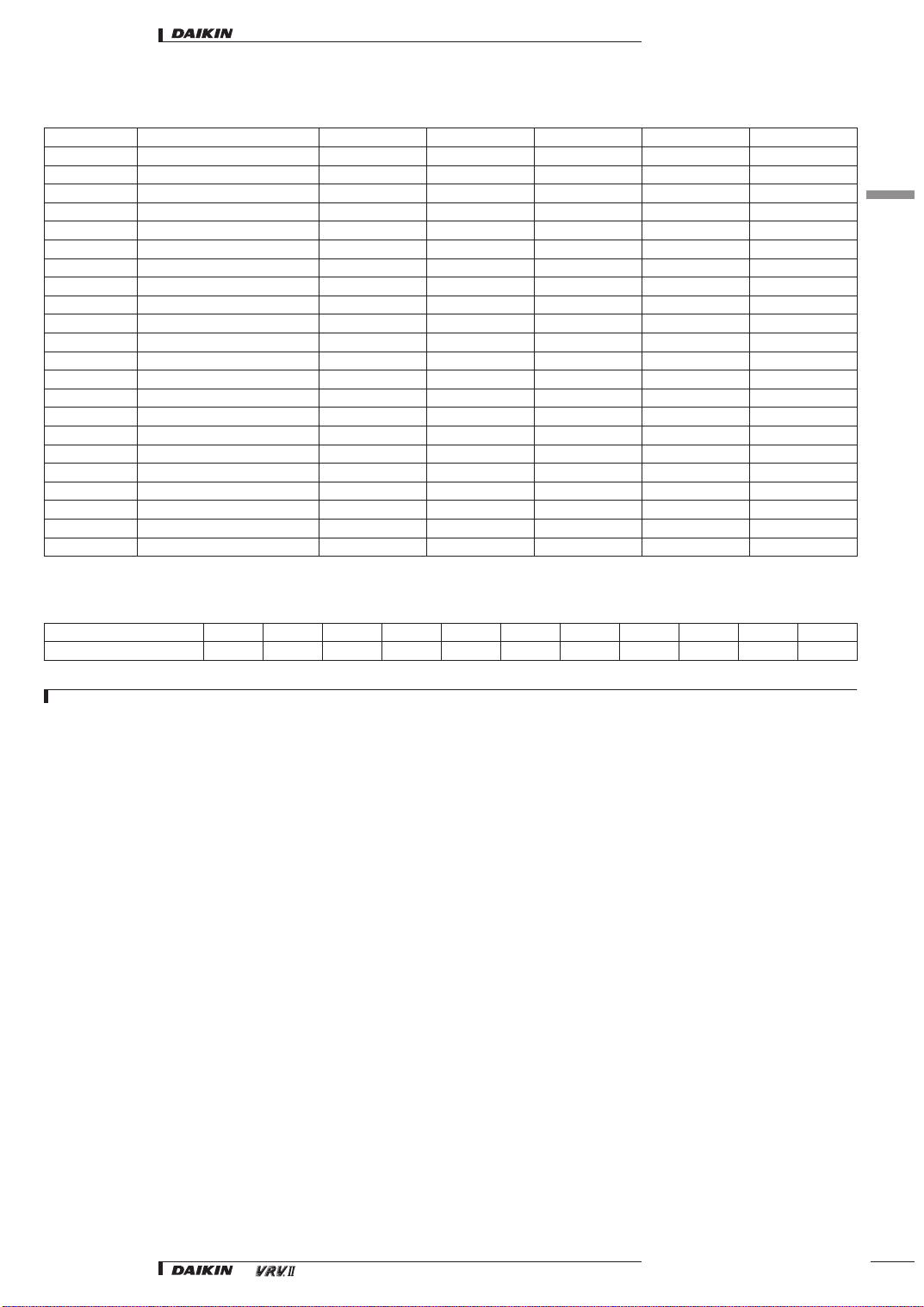

2 Possible outdoor units using R-410A

VRV II heat pump Fixed combinations Nr. of outdoors Nr. of compressors Nr. of connectable indoor units Minimum capacity index Maximum capacity index

RXYQ5M RXYQ5M 1 1 8 63 163

RXYQ8M RXYQ8M 1 2 13 100 260

RXYQ10M RXYQ10M 1 2 16 125 325

RXYQ12M RXYQ12M 1 2 20 150 390

RXYQ14M RXYQ14M 1 3 20 175 455

RXYQ16M RXYQ16M 1 3 20 200 520

RXYQ18M RXYQ8M + RXYQ10M 2 4 20 225 585

RXYQ20M RXYQ10M x 2 2 4 20 250 650

RXYQ22M RXYQ10M + RXYQ12M 2 4 22 275 715

RXYQ24M RXYQ10M + RXYQ14M 2 5 32 300 780

RXYQ26M RXYQ10M + RXYQ16M 2 5 32 325 845

RXYQ28M RXYQ12M + RXYQ16M 2 5 32 350 910

RXYQ30M RXYQ14M + RXYQ16M 2 6 32 375 975

RXYQ32M RXYQ16M x 2 2 6 32 400 1,040

RXYQ34M RXYQ10M x 2 + RXYQ14M 3 7 34 425 1,105

RXYQ36M RXYQ10M x 2 + RXYQ16M 3 7 36 450 1,170

RXYQ38M RXYQ10M + RXYQ12M + RXYQ16M 3 7 38 475 1,235

RXYQ40M RXYQ10M + RXYQ14M + RXYQ16M 3 8 40 500 1,300

RXYQ42M RXYQ10M + RXYQ16M x 2 3 8 40 525 1,365

RXYQ44M RXYQ12M + RXYQ16M x 2 3 8 40 550 1,430

RXYQ46M RXYQ14M + RXYQ16M x 2 3 9 40 575 1,495

RXYQ48M RXYQ16M x 3 3 9 40 600 1,560

2-1 Indoor unit capacity index

Model 20 25 32 40 50 63 80 100 125 200 250

Capacity index 20 25 31.25 40 50 62.5 80 100 125 200 250

1

2

NOTE

1e.g. Selected indoor units: FXCQ25 + FXFQ100 + FXMQ200 + FXSQ40

Connection ratio: 25 + 100 + 200 + 40 = 365

→

Possible outdoor unit: RXYQ12M

• Systems • Introduction

3

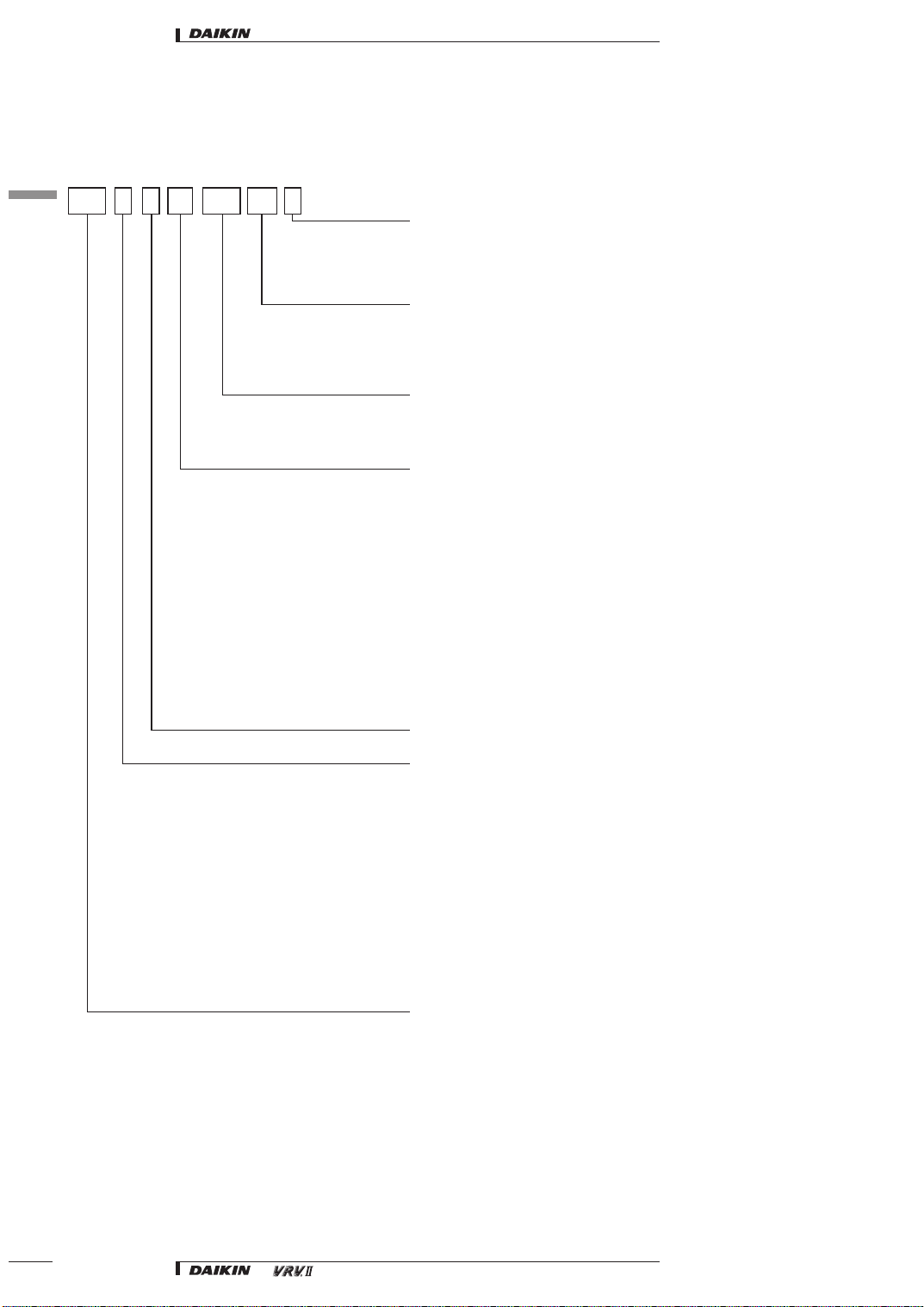

3 Nomenclature

3-1 Indoor units

1

3

• Introduction

V1M40S Q BFX

Special series for Europe (CE approved)*

Power supply symbol

V1: 1~, 230V, 50Hz

VE: 1~, 220-240V, 50Hz

M: Indicates major design category

M7: Indicates DENV production

Capacity Indication

Conversion to horsepower:

20: 0.8HP

25: 1HP

32: 1.25HP

40: 1.6HP

50: 2.0HP

63: 2.5HP

80: 3.2HP

100: 4HP

125: 5HP

200: 8HP

250: 10HP

* B is not mandatory for indoor units

Indicates use with ozone friendly refrigerant R-410A

Model name

Z: 4-way blow ceiling mounted cassette (600x600mm)

F: 4-way blow ceiling mounted cassette

C: 2-way blow ceiling mounted cassette

K: Ceiling mounted corner cassette

S: Concealed ceiling unit

D: Concealed ceiling unit (small)

M: Concealed ceiling unit (large)

H: Ceiling suspended unit

A: Wall mounted unit

L: Floor standing unit

LM: Concealed floor standing unit

Indicates that this is an INVERTER HEAT PUMP/COOLING ONLY

or a HEAT RECOVERY indoor unit

4

• Systems • Introduction

• Introduction

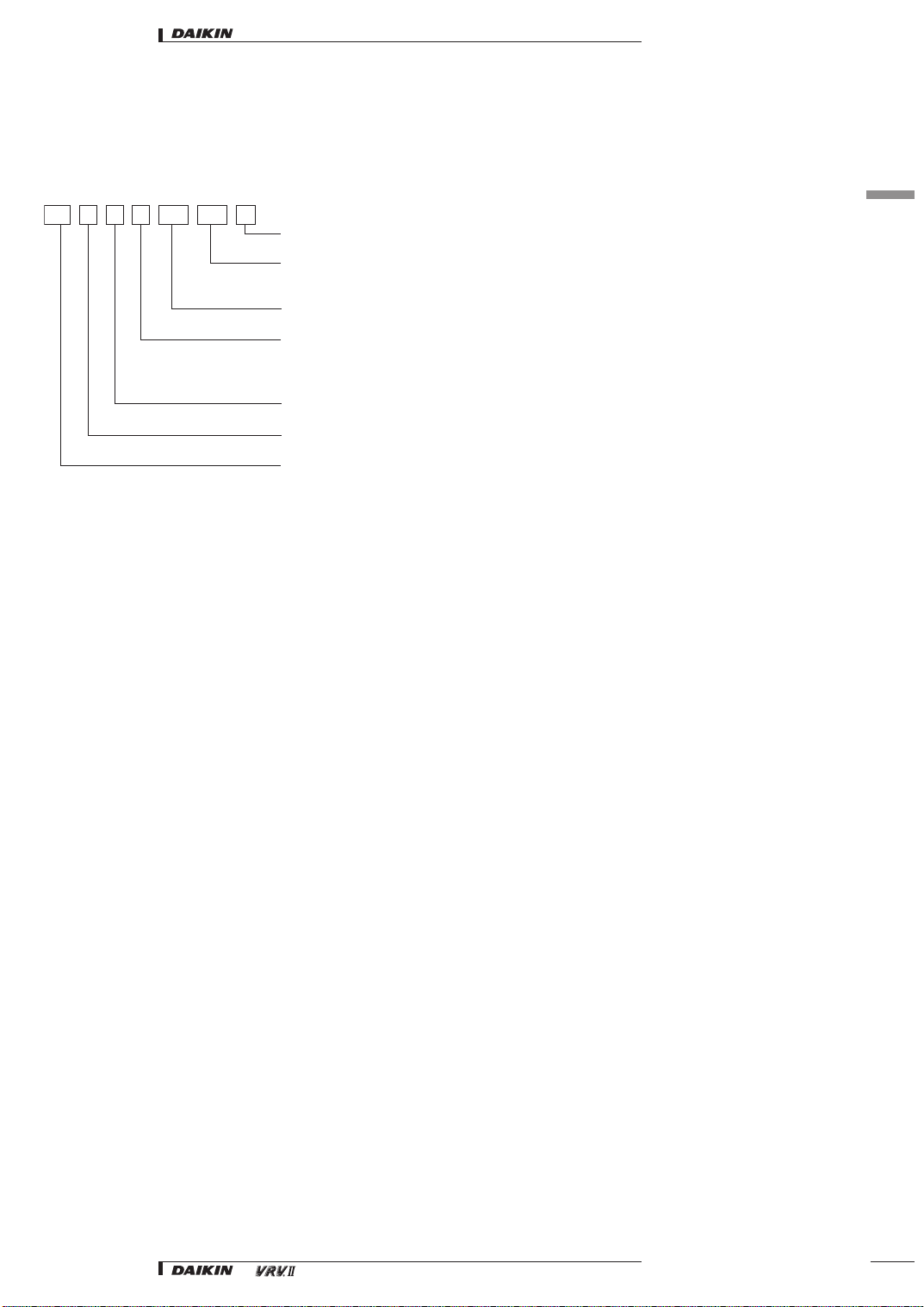

3 Nomenclature

3-2 Outdoor units

• VRVII heat pump

RX Y Q 8 M7 W1 B

1

3

Special series for Europe (CE approved)

Power supply symbol:

W1: 3N~, 400V, 50Hz

M7, M: indicates major design category (internal company symbol)

5: 5HP 12:12HP

8: 8HP 14:14HP

10: 10HP 16:16HP

Indicates the use of ozone friendly refrigerant R-410A

Indicates heat pump (year around)

RX: indicates that this is an INVERTER outdoor unit

• Systems • Introduction

5

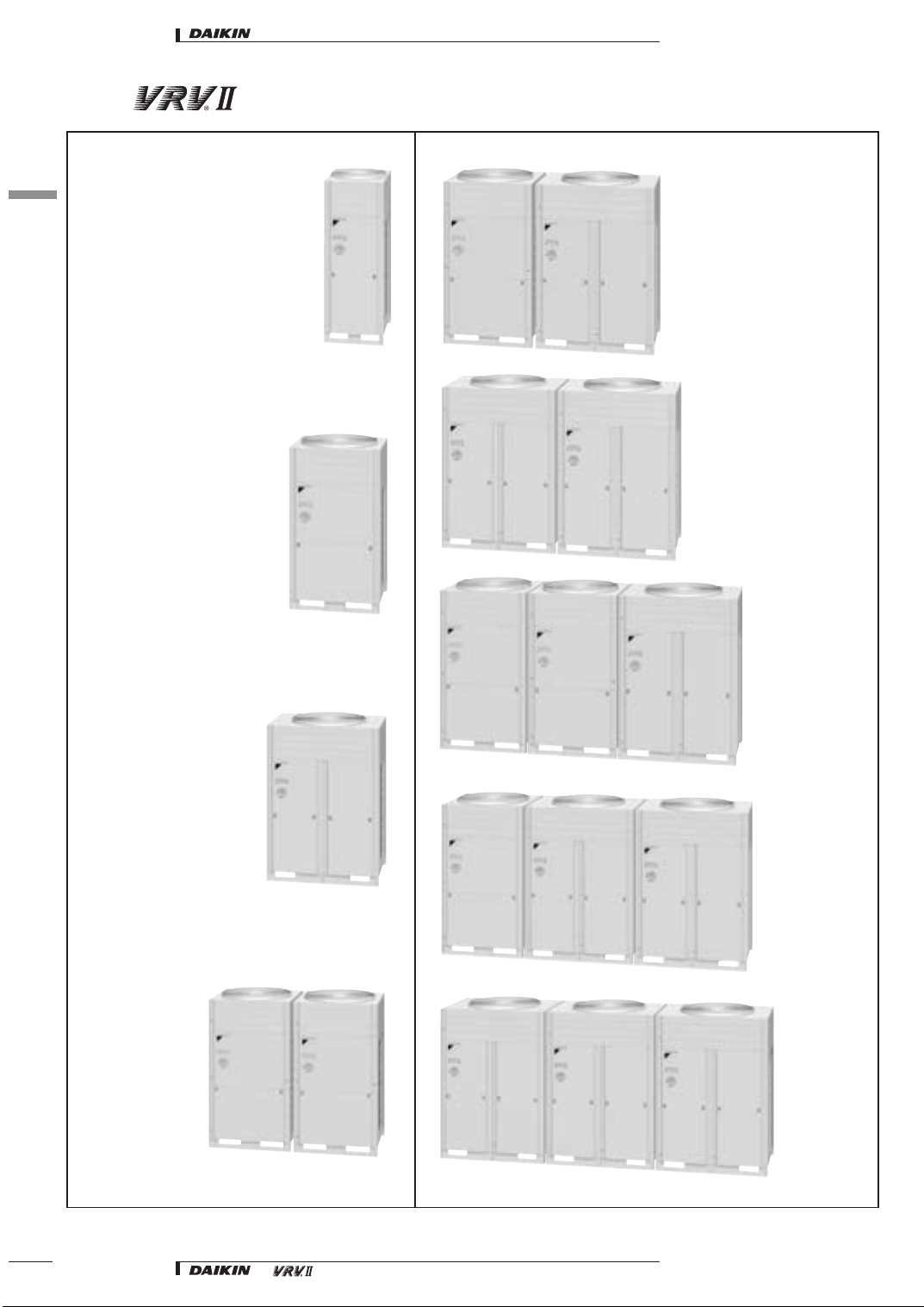

4 line-up

1

4

• Introduction

8-10HP

5HP

22-24-26HP

28-30-32HP

34-36HP

12- 14- 16 HP

38-40-42HP

18- 20HP

44-46-48HP

6

• Systems • Introduction

• Introduction

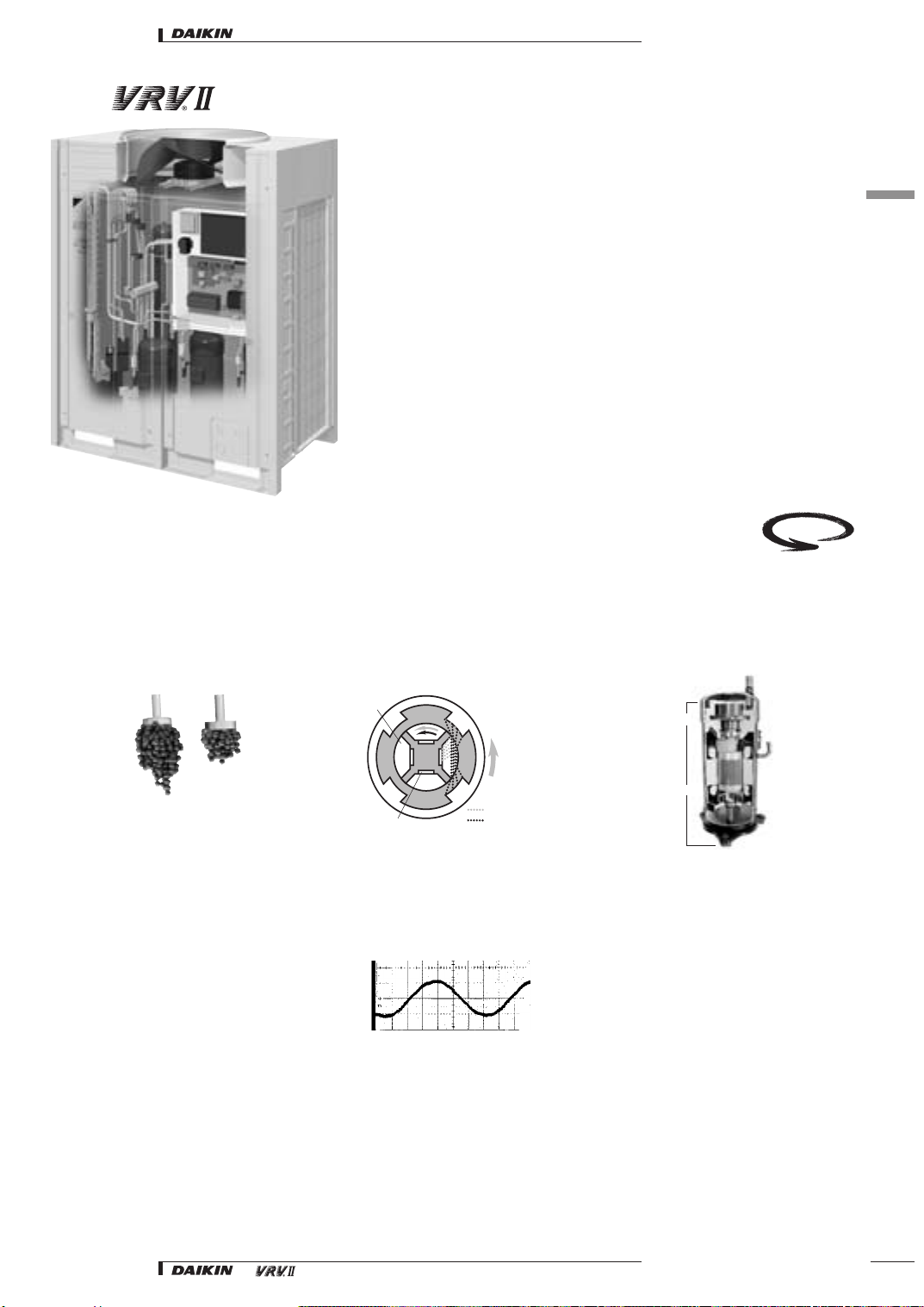

5 technology

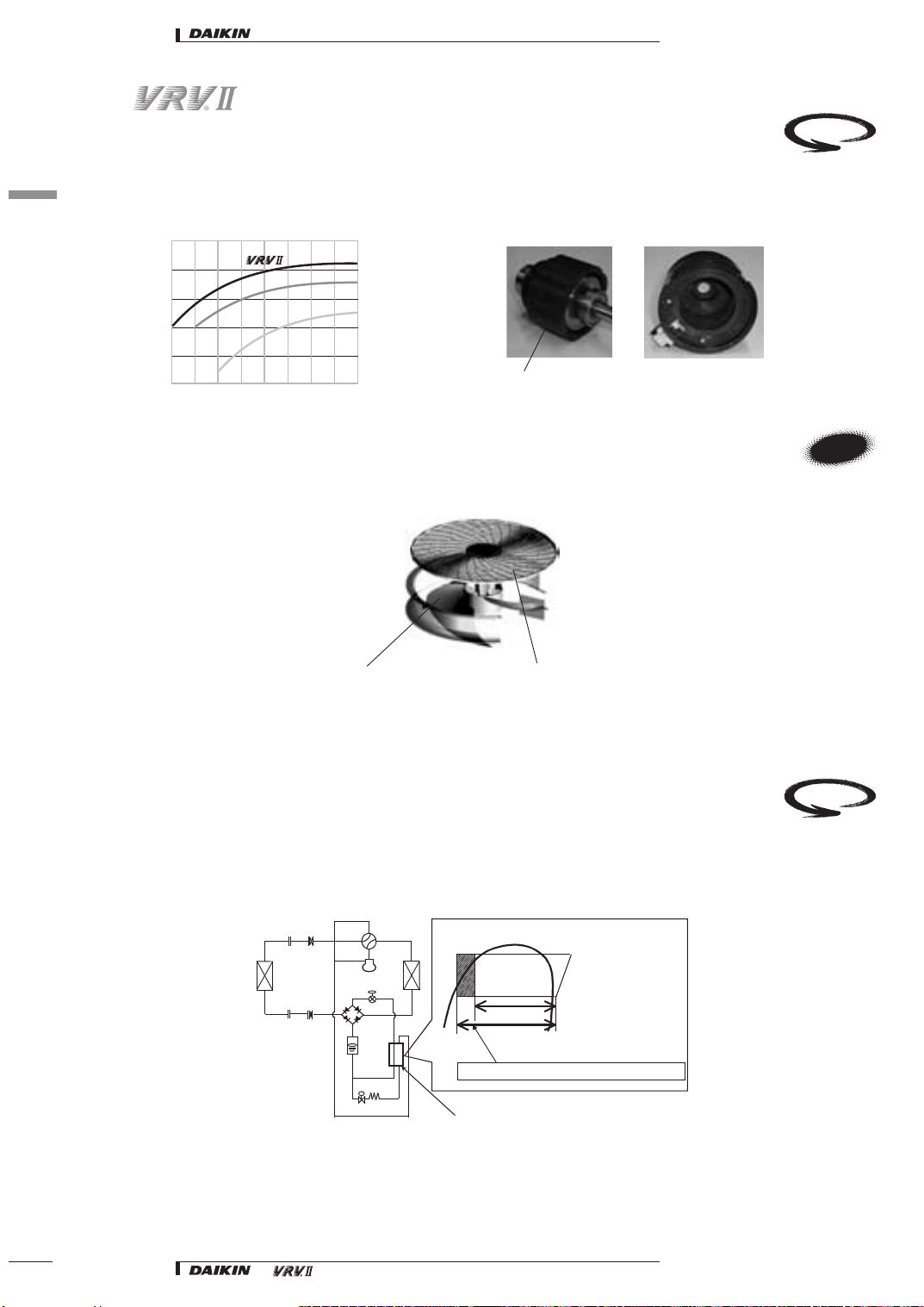

Reluctance brushless DC Compressor

The reluctance brushless DC motor provides significant increases in efficiency compared to conventional AC inverter motors, simultaneously using

2 different forms of torque (normal and reluctance torque) to produce extra power from small electric currents.

The motor comprises powerful neodymium magnets, that create the reluctance torque. These magnets ar approximately 12 times stronger than ferrite

magnets and make a major contribution to its energy saving characteristics.

Secret to raising energy-efficiency! Powerful neodymium magnets

First in the

industry

1

5

Neodymium magnet is

12 times more powerful

than the widely used

ferrite magnets

Ferrite magnet

Neodymium magnet

Sine Wave DC inverter

Optimizing the sine wave curve, results in smoother motor rotation and improved motor efficiency.

Iron

Neodymium magnet

N

N

S

S

NNNS

S

Rotating

Stator

Field

S

"Normal" torque

Reluctance torque

Low pressure side

High pressure side

Suction

Scroll

Reluctance

DC Motor

Discharge

• Systems • Introduction

7

• Introduction

5 technology

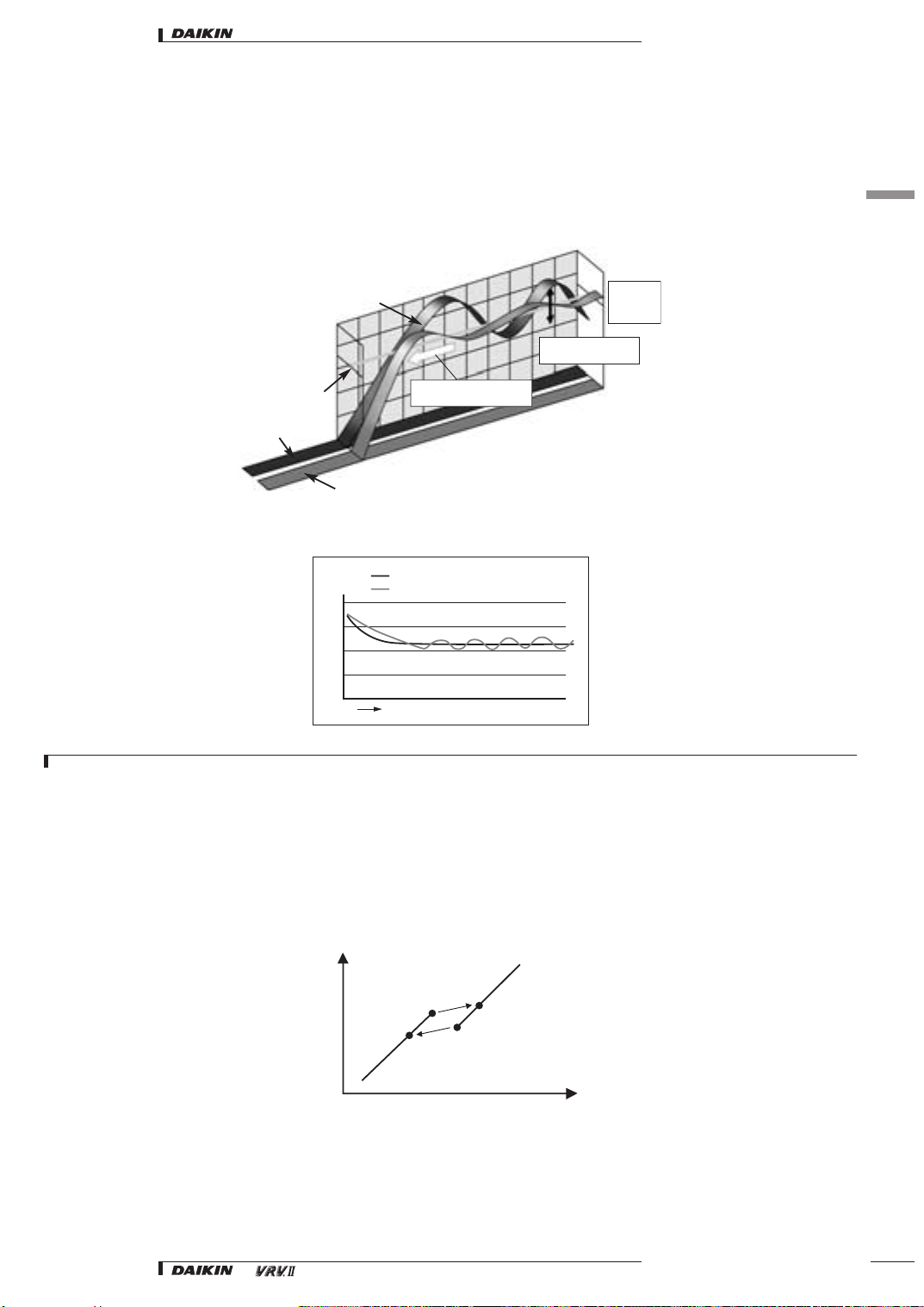

DC fan motor

1

The use of a DC fan motor offers substantial improvements in operating efficiency compared to conventional AC motors, especially during low speed

5

rotation.

First in the

industry

DC motor efficiency

(comparison with a conventional AC motor)

100

80

60

Efficiency (%)

40

20

0

20 0 300 400 500 600 700 800 900 1000

Aero fitting grill & aero spiral fan

DC motor

AC motor

Motor speed (rpm)

DC fan motor structure

magnet

N

These new features achieve a low noise fan with a large airflow, and realize a compact casing together with the compressor linking technology.

Aero spiral fan

Bending the fan blade

edge reduces turbulence,

resulting in less pressure

loss.

Aero fitting grille

New shape promotes a

spiral discharge airflow,

resulting in reduced

pressure loss.

W

E

e-Bridge circuit

Prevents accumulation of liquid refrigerant in the condenser. This results in more efficient use of the condenser surface under any circumstance and

leads in turn to better energy efficiency.

An increase in evaporative capacity systems from the newly developed refrigeration circuit, known as the SCe-bridge circuit, which adds super cooling

prior to the expansion cycle. By adopting this circuit, the COPs in both cooling and heating have been drastically improved.

Evaporative capacity can be

raised by taking super cooling

Current

Evaporative-capacity

Evaporative-capacity has been improved by adopting the SCe-Bridge Circuit.

SCe-Bridge Circuit

8

• Systems • Introduction

just before the electronic

expansion valve

By the SCe- bridge circuit,

cooling and heating attain the

improvement in COP

First in the

industry

• Introduction

5 technology

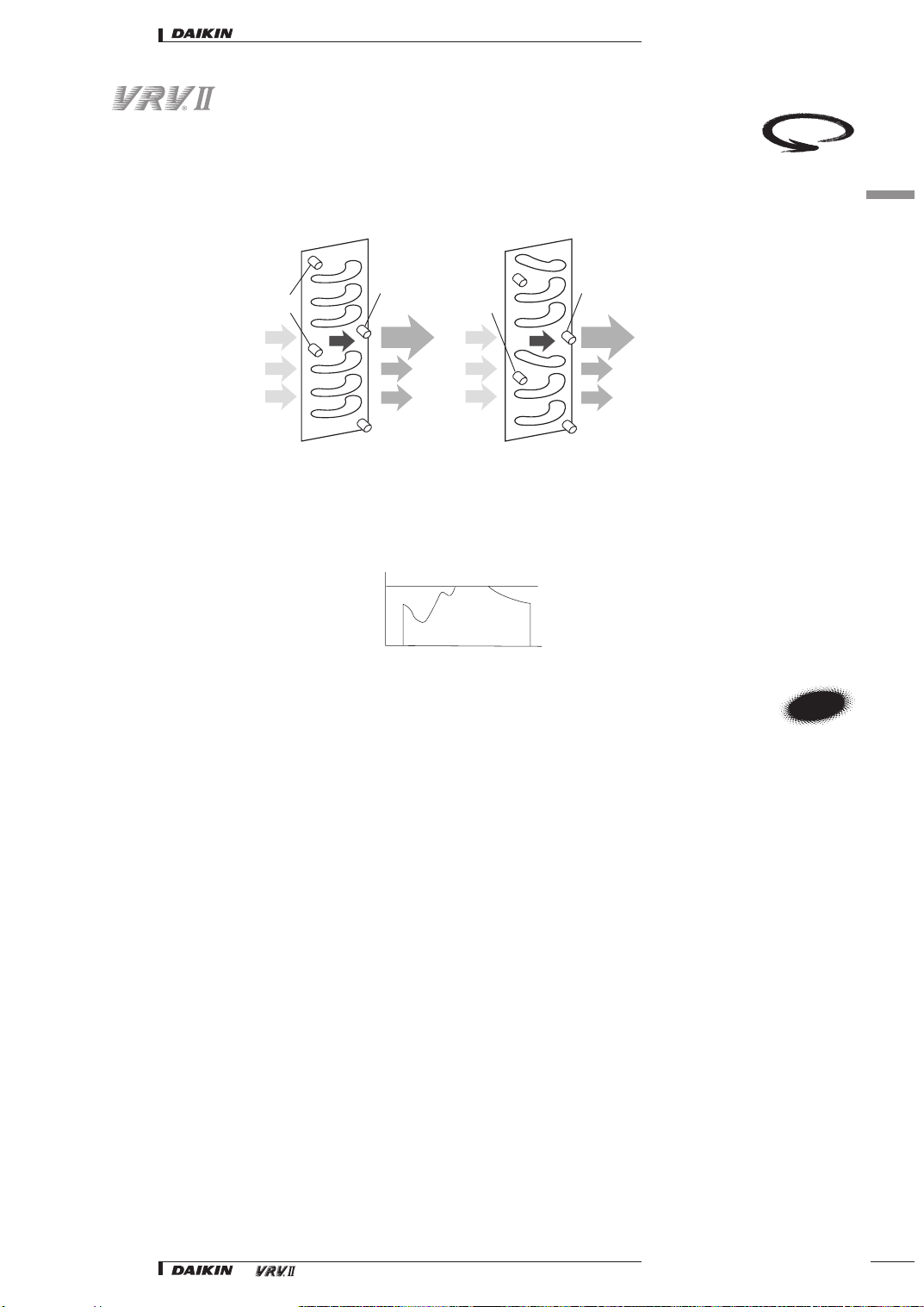

e-Pass heat exchanger

Optimization of the path layout of the heat exchanger prevents heat transferring from the overheated gas section towards the sub cooled liquid section

- a more efficient use of the heat exchanger.

First in the

industry

1

5

Current Model

out 45°C

in 85°C

27°C55°C

27°C

27°C

In cooling mode, the heat exchanger of the condensor is improved. This means an improvement of COP by 3%.

i-Demand function

The newly introduced current sensor minimizes the difference between the actual power consumption and the predefined power consumption.

Compact aero box

55°C

55°C

50°C

Power

consumption (KVV)

8:00

in 85°C

27°C43°C

27°C

27°C

12: 00 16: 00 20:00

Time

HD Typ e

out 45°C

37°C

60°C

55°C

N

W

E

Lower noise and savings in input power are achieved by stacking the inverter and control PCBs within a new and more compact ‘aero’ box.

• Systems • Introduction

9

• Introduction

6Main features

6-1 Creating maximum comfort

1

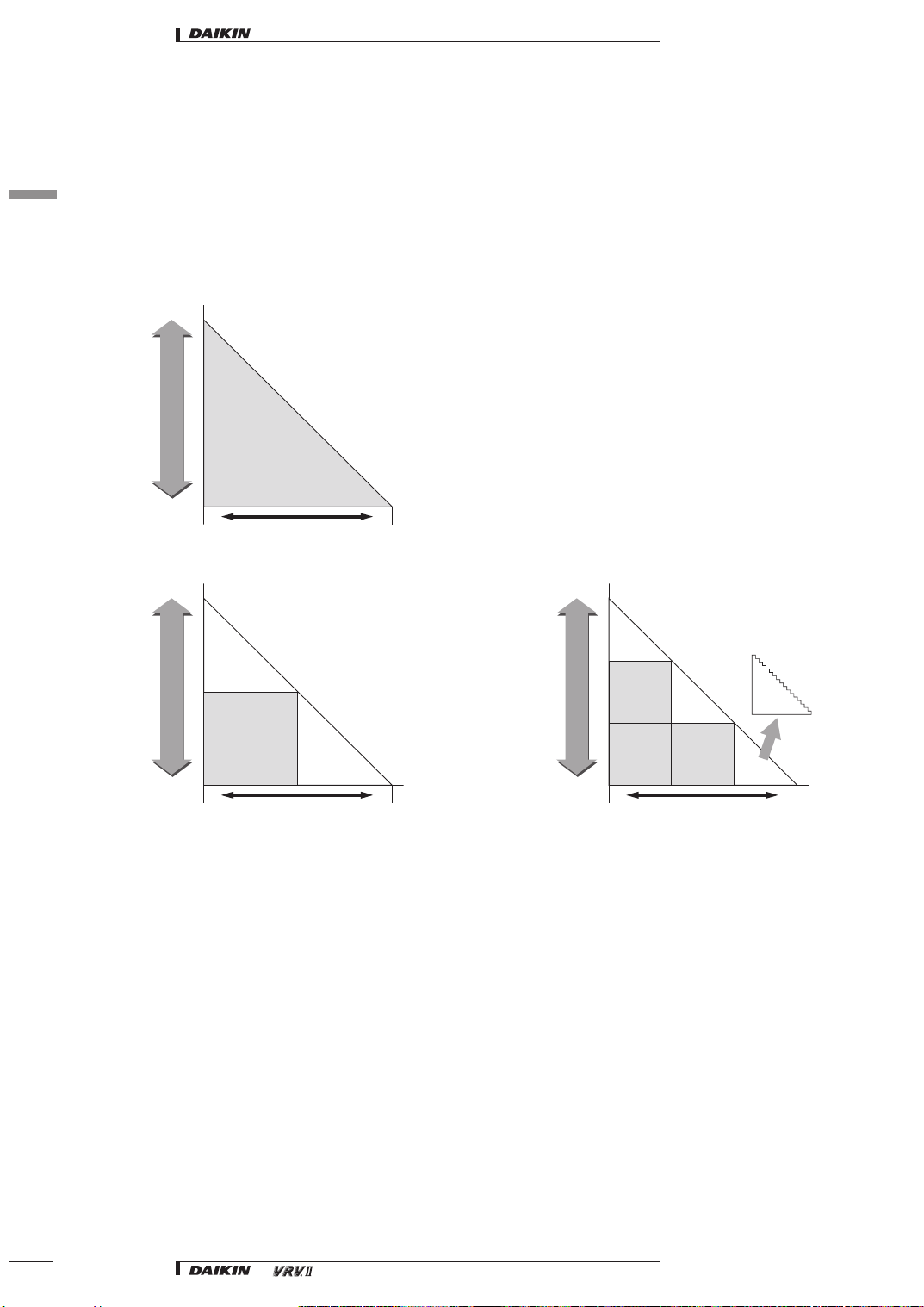

6-1-1 Inverter technology

6

The linear VRV system makes use of a variable Proportional Integral (PI) control system which uses refrigerant pressure sensors to give added control

over inverter and ON/OFF control compressors in order to abbreviate control steps into smaller units to provide precise control in both small and larger

areas.

This in turn enables individual control of up to 40 indoor units of different capacity and type at a ratio of 50~130 % in comparison with outdoor units

capacity. 5 HP outdoor units use inverter control compressors only.

5HP Outdoor Unit

100%

210Hz~52Hz

20 Steps

Compressor Capacity Control

Inverter

Control

24%

Large

8,10,12HP Outdoor Unit

100%

Nr. 1

Compressor

Inverter Control

Compressor Capacity Control

14%

Large

Nr. 2

Compressor

100% Operation

Load

210Hz~52Hz

+ Nr. 2 Compressor

29 Steps

Nr. 1

Compressor

Inverter Control

Load

Small

Small

14,16HP Outdoor Unit

100%

Nr. 1

Compressor

Inverter Control

Compressor Capacity Control

10%

Large

Nr. 3

Compressor

100% Operation

Nr. 2

Compressor

100% Operation

210Hz~52Hz

+ Nr. 2 + Nr. 3

Compressor

35 Steps

Nr. 1

Compressor

Inverter Control

Nr. 2

Compressor

100% Operation

Load

Inverter Control

210Hz~52Hz 20 steps

Nr. 1

Compressor

Inverter Control

Small

10

• Systems • Introduction

• Introduction

6Main features

6-1 Creating maximum comfort

6-1-2 Smart control brings comfort

An electronic expansion valve, using PID control, continuously adjusts the refrigerant volume in respond to load variations of the indoor units. The VRV

system thus maintains comfortable room temperatures at a virtually constant level, without the temperature variations typical of conventional ON/OFF

control systems.

Keeps temperature stable

Slow start-up

Set point

Non inverter AC

Inverter AC

The thermostat can control stable room temperature at ± 0.5°C from set point.

Startup time educedby about 1/3

s

t

a

e

p

e

R

Cooling

VRV series (Daikin PID controls)

On/off controlled air conditioner (2.5HP)

Large temperature difference

s

e

l

c

y

c

d

l

o

c

d

n

a

t

o

h

Smaller

temperature

difference

1

6

Suction air temp.

Time

NOTE

1 the graph shows the data, measured in a test room assuming actual heating load.

6-1-3 Less frequent start/stop cycle

• The technique adopted by Daikin, of regulating the capacity using multiple compressors clearly results in minimum switching losses and power surges

because of the overlap in capacity and frequency

• Since Daikin utilises small 5HP inverter compressors, the influence of harmonics is less than that generated by a single large compressor

• The use of multiple compressors by Daikin also ensures a 50 % standby facility

•Smaller compressors are cheaper and faster to replace

60%

Capacity

50%

30 116 30+on 116+on

65%

55%

Frequency

• Systems • Introduction

11

• Introduction

6Main features

6-1 Creating maximum comfort

1

6-1-4 PID control

6

Proportional Integral Derivative control with an automatic capacity balancing circuit:

– enables the use of lengthy piping up to 100 meters (actual length)

– consists of two control systems:

1Oil control system that controls the refrigerant oil volume to prevent it from raising or backing up in the pipes

2 Refrigerant flow stabilization mechanism: prevents refrigerant drift, caused by level difference of indoor units in the same system.

6-1-5 Operation control of small capacity indoor units

If the operating frequency is minimal, the refrigerant pressure and outdoor temperature are detected, the number of control steps are calculated, and

capacity of outdoor unit heat exchanger (refrigerant accumulates in coils) and air flow of outdoor unit fans (controls pole change of the two fans) are

controlled.

If operating a small-capacity indoor unit, the bypass valve is controlled (ON/OFF), with capacity control being executed at a minimum of 14% for a 5HP

outdoor unit (when operating one 20-class indoor unit), or a minimum of 8% for 8 and 10HP outdoor units (when operating one 20-class indoor unit.

Minimum Frequency

(5HP Outdoor Unit: 30Hz)

(8/10HP Outdoor Unit: 30Hz)

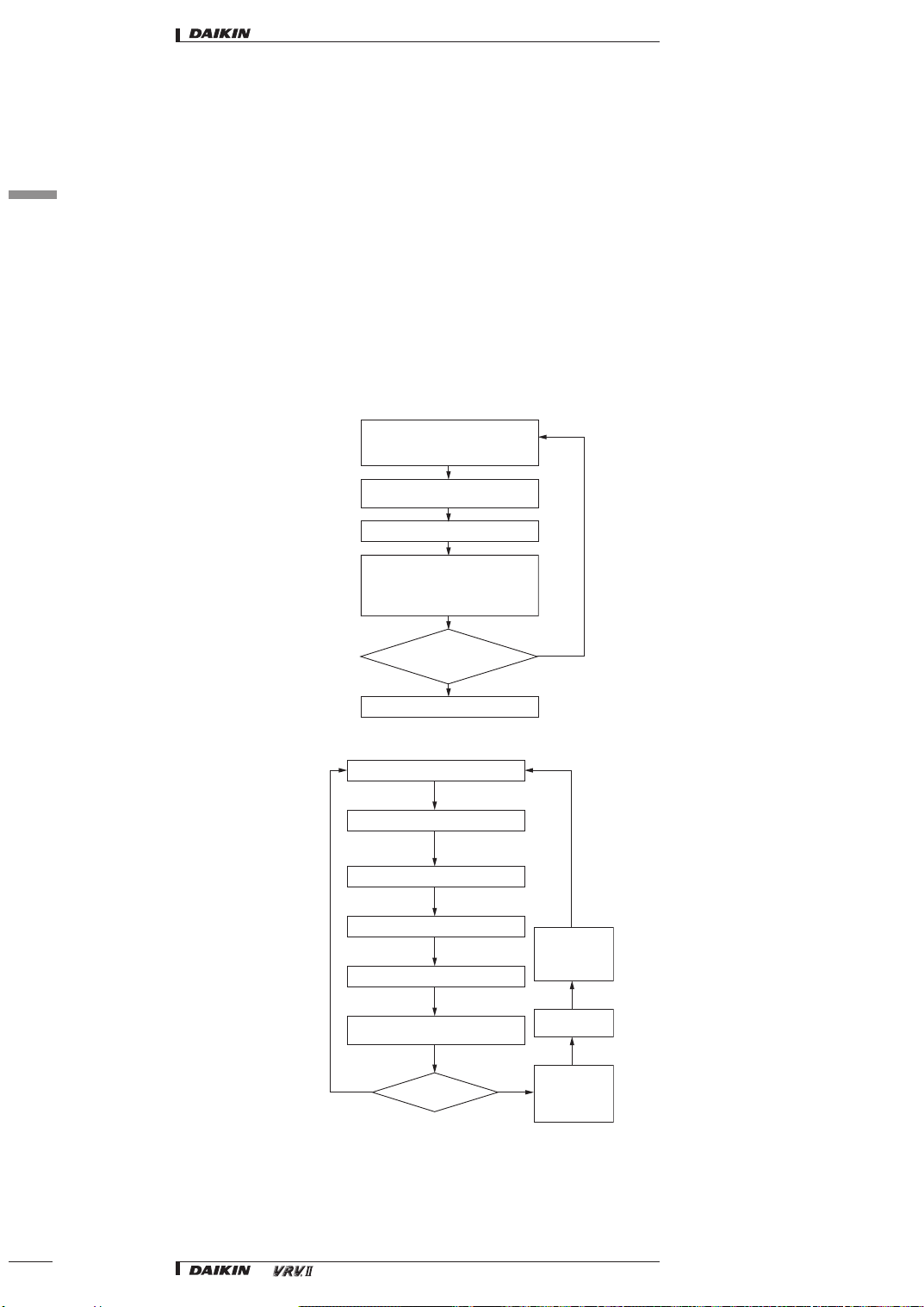

6-1-6 Control flow

Detection of Refrigerant Pressure and Outdoor

Operating Pressure Detection by Pressure Sensors

Calculation of Constant for Integral Control

Total capacity Decision by Multi-Variable P-Control

Temperature

Step Control Calculation

Capacity Control of Outdoor Unit

Heat Exchangers

Air Flow Control of Outdoor

Unit Fans

Are you operating a

small-capacity indoor unit?

Bypass Valve On/Off Control

Sampling Timer Count

Optimal Load Decision

Yes

Every T Seconds

Deviation (difference between

sensed pressure and desired value)

No

Outdoor Coil Capacity

Control Air Volume

Control by Outdoor

Unit Fan

12

Frequency Alteration of Inverter Compressor

On/Off of ON/OFF Compressor

No Yes

Minimum Frequency

• Systems • Introduction

Step Control

Calculation

Detection of

Refrigerant Pressure

and Outdoor

Temperature

Loading...

Loading...