Daikin FTX12NMVJU, FVXS12NVJU, FVXS15NVJU, RXL09QMVJU, RXL12QMVJU Service Manual

...

Service

Manual

SiUS091601EA

Inverter Pair

Wall Mounted Type FTX-N/U Series

Floor Standing Type FVXS-V Series

Duct Connected Type FDMQ-R Series

[Applied Models]

Inverter Pair : Heat Pump

SiUS091601EA

Introduction .......................................................................................1

1. Safety Cautions...........................................................................................2

1.1 Warnings and Cautions Regarding Safety of Workers................................. 2

1.2 Warnings and Cautions Regarding Safety of Users..................................... 4

2. Icons Used ..................................................................................................7

3. Revision History ..........................................................................................8

Part 1 General Information ...............................................................9

1. Applicable Models .....................................................................................10

2. Functions...................................................................................................11

Part 2 Specifications....................................................................... 13

1. Specifications ............................................................................................14

Part 3 Printed Circuit Board Connector Wiring Diagram................ 21

1. Indoor Unit.................................................................................................22

1.1 FTX09/12NMVJU ....................................................................................... 22

1.2 FTX15NMVJU ............................................................................................ 24

1.3 FTX18/24UVJU .......................................................................................... 26

1.4 FVXS09/12/15NVJU................................................................................... 28

1.5 FDMQ12/18/24RVJU ................................................................................. 30

2. Wireless Remote Controller Receiver .......................................................32

2.1 BRC082A43 ............................................................................................... 32

3. Wired Remote Controller...........................................................................33

3.1 BRC1E73 ................................................................................................... 33

4. Outdoor Unit..............................................................................................34

4.1 RXL09QMVJU............................................................................................ 34

4.2 RXL12QMVJU(9) ....................................................................................... 36

4.3 RXL15QMVJU............................................................................................ 38

4.4 RXL18/24UMVJU ....................................................................................... 39

5. Optional Adaptor .......................................................................................42

5.1 BRP072A43 Wireless LAN Adaptor ........................................................... 42

5.2 KRP067A41/KRP980B2 Remote Control PC-board Set............................ 42

Part 4 Functions and Control .......................................................... 43

1. Common Functions ...................................................................................44

1.1 Temperature Control .................................................................................. 44

1.2 Frequency Principle.................................................................................... 44

2. Functions for FTX, FVXS Series ...............................................................46

2.1 Airflow Direction Control............................................................................. 46

2.2 COMFORT AIRFLOW Operation ............................................................... 49

2.3 Fan Speed Control for Indoor Unit ............................................................. 50

2.4 Program Dry Operation .............................................................................. 51

2.5 Automatic Cooling/Heating Changeover .................................................... 52

i Table of Contents

SiUS091601EA

2.6 Thermostat Control..................................................................................... 53

2.7 NIGHT SET Mode ...................................................................................... 54

2.8 ECONO Operation .................................................................................... 55

2.9 INTELLIGENT EYE Operation ................................................................... 56

2.10 POWERFUL Operation .............................................................................. 57

2.11 Clock Setting .............................................................................................. 58

2.12 WEEKLY TIMER Operation ....................................................................... 59

2.13 Other Functions.......................................................................................... 65

3. Functions for FDMQ Series.......................................................................66

3.1 Fan Speed Control for Indoor Unit ............................................................. 66

3.2 Program Dry Operation .............................................................................. 67

3.3 Clock and Calender Setting (With BRC1E73) ............................................ 68

3.4 Schedule Timer Operation (With BRC1E73).............................................. 70

3.5 Drain Pump Control.................................................................................... 73

3.6 Hot Start Control (In Heating Operation Only)............................................ 75

3.7 Other Functions.......................................................................................... 76

4. Thermistor Functions ................................................................................77

5. Control Specification .................................................................................78

5.1 Mode Hierarchy .......................................................................................... 78

5.2 Frequency Control...................................................................................... 78

5.3 Controls at Mode Changing/Start-up.......................................................... 80

5.4 Discharge Pipe Temperature Control......................................................... 82

5.5 Input Current Control.................................................................................. 83

5.6 Freeze-up Protection Control ..................................................................... 84

5.7 Heating Peak-cut Control ........................................................................... 84

5.8 Outdoor Fan Control................................................................................... 85

5.9 Liquid Compression Protection Function.................................................... 85

5.10 Defrost Control ........................................................................................... 86

5.11 Electronic Expansion Valve Control ........................................................... 87

5.12 Malfunctions ............................................................................................... 90

Part 5 Remote Controller ................................................................91

1. Applicable Remote Controller ...................................................................92

2. ARC466A21 ..............................................................................................93

3. ARC466A37 ..............................................................................................95

4. ARC480A8 ................................................................................................97

5. BRC082A43 ..............................................................................................98

6. BRC1E73 ................................................................................................ 100

Part 6 Service Diagnosis ............................................................... 106

1. General Problem Symptoms and Check Items .......................................108

2. Troubleshooting with LED .......................................................................109

2.1 Indoor Unit................................................................................................ 109

2.2 Outdoor Unit ............................................................................................. 110

3. Service Diagnosis ................................................................................... 111

3.1 ARC480 Series......................................................................................... 111

Table of Contents ii

SiUS091601EA

3.2 ARC466 Series......................................................................................... 114

3.3 BRC1E73 ................................................................................................. 117

3.4 BRC082A43 ............................................................................................. 119

4. Error Codes and Description...................................................................123

5. Troubleshooting for FTX, FVXS Series...................................................124

5.1 Indoor Unit PCB Abnormality ................................................................... 124

5.2 Freeze-up Protection Control/Heating Peak-cut Control .......................... 126

5.3 Indoor Fan Motor (DC Motor) or Related Abnormality ............................. 128

5.4 Thermistor or Related Abnormality........................................................... 132

5.5 Low-voltage Detection or Over-voltage Detection.................................... 133

5.6 Signal Transmission Error (Between Indoor Unit and Outdoor Unit)........ 135

5.7 Unspecified Voltage (Between Indoor Unit and Outdoor Unit) ................. 137

6. Troubleshooting for FDMQ Series ..........................................................138

6.1 Indoor Unit PCB Abnormality ................................................................... 138

6.2 Drain Level Control System Abnormality.................................................. 139

6.3 Indoor Fan Motor (DC Motor) or Related Abnormality ............................. 140

6.4 Indoor Fan PCB Abnormality.................................................................... 142

6.5 Humidifier or Related Abnormality............................................................ 143

6.6 Thermistor or Related Abnormality........................................................... 144

6.7 Remote Controller Thermistor Abnormality .............................................. 145

6.8 Low-voltage Detection or Over-voltage Detection.................................... 146

6.9 Signal Transmission Error (Between Indoor and Outdoor Unit) ............... 148

6.10 Signal Transmission Error (Between Indoor Unit and Remote Controller)

................................................................................................................. 150

6.11 Signal Transmission Error (Between MAIN/SUB Remote Controllers) .... 151

6.12 Mismatching of Indoor Unit and Outdoor Unit .......................................... 152

7. Troubleshooting for Outdoor Unit............................................................153

7.1 Outdoor Unit PCB Abnormality................................................................. 153

7.2 OL Activation (Compressor Overload) ..................................................... 154

7.3 Compressor Lock ..................................................................................... 157

7.4 DC Fan Lock ............................................................................................ 158

7.5 Input Overcurrent Detection ..................................................................... 159

7.6 Four Way Valve Abnormality.................................................................... 161

7.7 Discharge Pipe Temperature Control....................................................... 163

7.8 High Pressure Control in Cooling ............................................................. 165

7.9 System Shutdown due to Temperature Abnormality in the Compressor

................................................................................................................. 167

7.10 Compressor Sensor System Abnormality ................................................ 168

7.11 Position Sensor Abnormality .................................................................... 169

7.12 Thermistor or Related Abnormality (Outdoor Unit)................................... 172

7.13 Electrical Box Temperature Rise.............................................................. 174

7.14 Radiation Fin Temperature Rise .............................................................. 176

7.15 Output Overcurrent Detection .................................................................. 178

7.16 Signal Transmission Error on Outdoor Unit PCB ..................................... 180

8. Check ......................................................................................................181

8.1 Thermistor Resistance Check .................................................................. 181

8.2 Indoor Fan Motor Connector Check......................................................... 182

8.3 Power Supply Waveform Check............................................................... 184

iii Table of Contents

SiUS091601EA

8.4 Electronic Expansion Valve Check........................................................... 184

8.5 Four Way Valve Performance Check ....................................................... 185

8.6 Inverter Unit Refrigerant System Check................................................... 185

8.7 Inverter Analyzer Check........................................................................... 186

8.8 Rotation Pulse Check on the Outdoor Unit PCB ...................................... 189

8.9 Installation Condition Check..................................................................... 190

8.10 Discharge Pressure Check....................................................................... 190

8.11 Outdoor Fan System Check ..................................................................... 191

8.12 Main Circuit Short Check.......................................................................... 191

8.13 Power Module Check ............................................................................... 194

Part 7 Trial Operation and Field Settings ..................................... 197

1. Pump Down Operation............................................................................198

2. Forced Cooling Operation .......................................................................199

3. Trial Operation ........................................................................................202

4. Field Settings for FTX, FVXS Series.......................................................206

4.1 Temperature Display Switch .................................................................... 206

4.2 When 2 Units are Installed in 1 Room...................................................... 207

4.3 Jumper and Switch Settings..................................................................... 209

5. Field Settings for FDMQ Series ..............................................................210

5.1 How to Change the Field Settings............................................................ 210

5.2 Overview of Field Settings........................................................................ 213

5.3 MAIN/SUB and Address Setting for Wireless Remote Controller ............ 214

6. Field Settings for Outdoor Unit................................................................217

6.1 Facility Setting (cooling at low outdoor temperature) ............................... 217

6.2 Drain Pan Heater...................................................................................... 218

7. Silicone Grease on Power Transistor/Diode Bridge................................ 219

Part 8 Appendix ............................................................................. 220

1. Piping Diagrams......................................................................................221

1.1 Indoor Unit................................................................................................ 221

1.2 Outdoor Unit ............................................................................................. 223

2. Wiring Diagrams......................................................................................226

2.1 Indoor Unit................................................................................................ 226

2.2 Outdoor Unit ............................................................................................. 231

3. Operation Limit........................................................................................236

Table of Contents iv

SiUS091601EA

Introduction

1. Safety Cautions...........................................................................................2

1.1 Warnings and Cautions Regarding Safety of Workers................................. 2

1.2 Warnings and Cautions Regarding Safety of Users..................................... 4

2. Icons Used ..................................................................................................7

3. Revision History ..........................................................................................8

1 Introduction

SiUS091601EA Safety Cautions

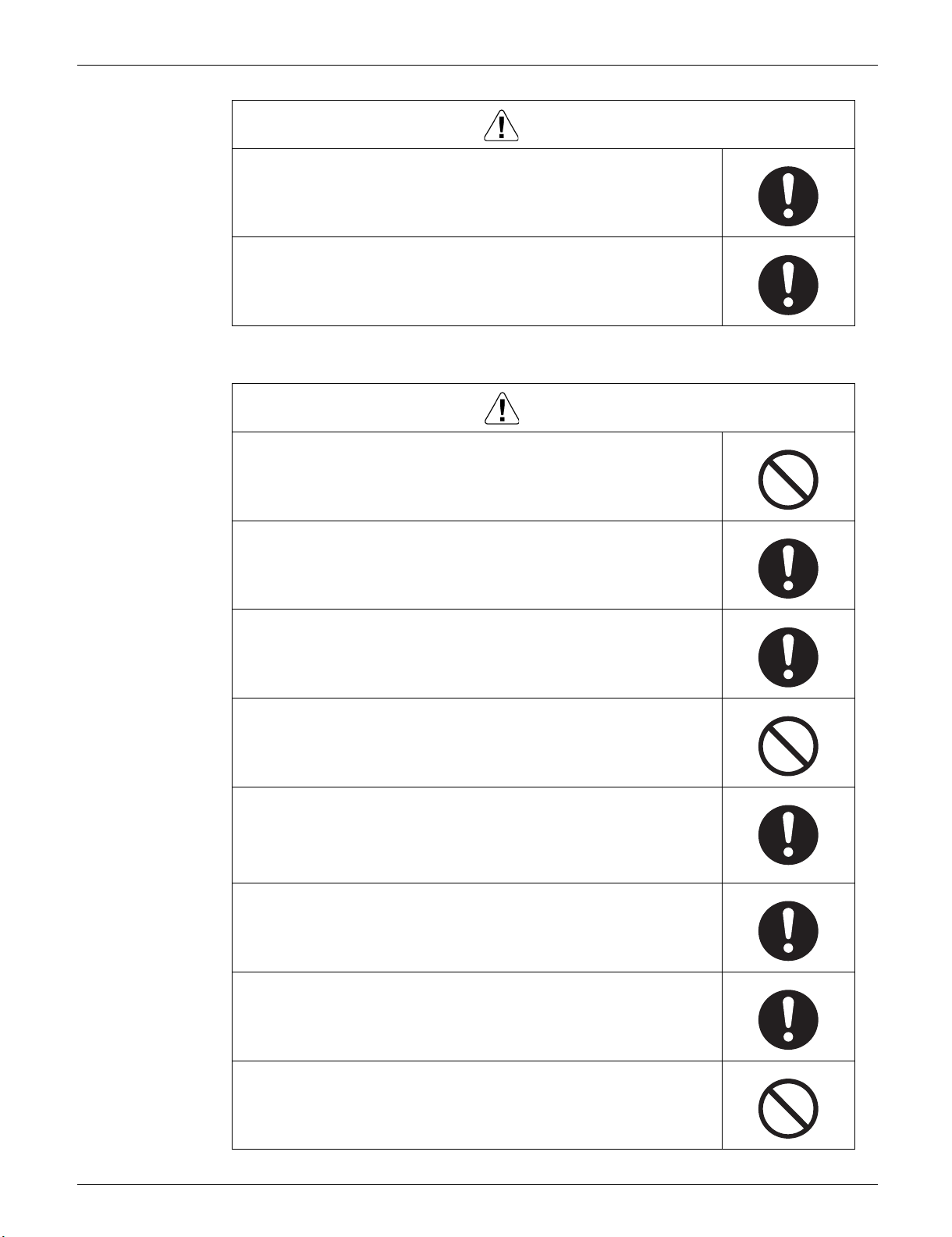

Warning

1. Safety Cautions

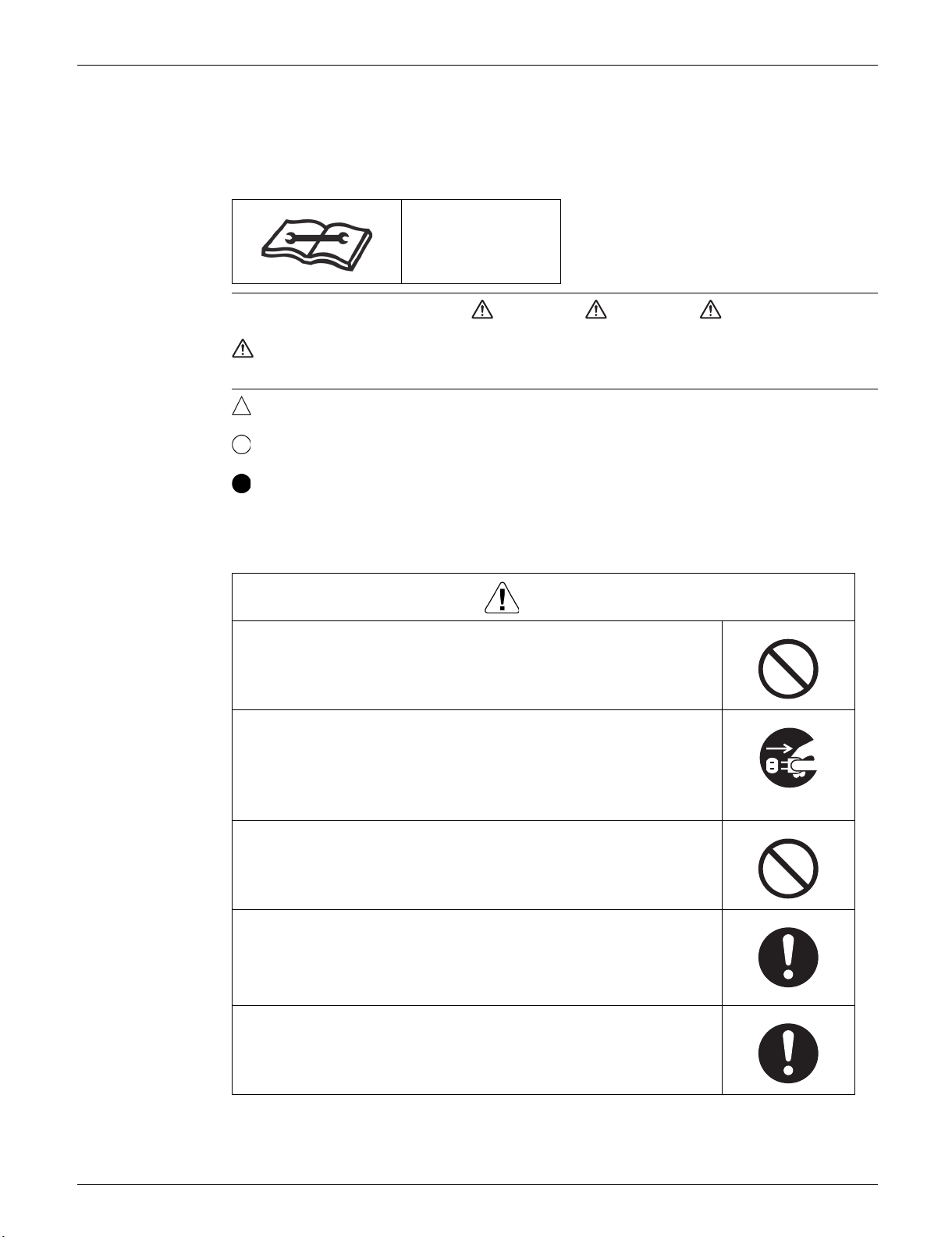

Be sure to read the following safety cautions before conducting repair work.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment

operates normally, and explain the cautions for operating the product to the customer.

This manual is for the

person in charge of

maintenance and

inspection.

Caution Items The caution items are classified into Warning and Caution. The Warning items are

especially important since death or serious injury can result if they are not followed closely. The

Caution items can also lead to serious accidents under some conditions if they are not

followed. Therefore, be sure to observe all the safety caution items described below.

Pictograms This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown in the illustration or near the symbol.

1.1 Warnings and Cautions Regarding Safety of Workers

Do not store equipment in a room with fire sources (e.g., naked

flames, gas appliances, electric heaters).

Be sure to disconnect the power cable from the socket before

disassembling equipment for repair.

Working on equipment that is connected to the power supply may cause

an electrical shock.

If it is necessary to supply power to the equipment to conduct the repair or

inspect the circuits, do not touch any electrically charged sections of the

equipment.

If refrigerant gas is discharged during repair work, do not touch the

discharged refrigerant gas.

Refrigerant gas may cause frostbite.

When disconnecting the suction or discharge pipe of the

compressor at the welded section, evacuate the refrigerant gas

completely at a well-ventilated place first.

If there is gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it

may cause injury.

If refrigerant gas leaks during repair work, ventilate the area.

Refrigerant gas may generate toxic gases when it contacts flames.

Introduction 2

Safety Cautions SiUS091601EA

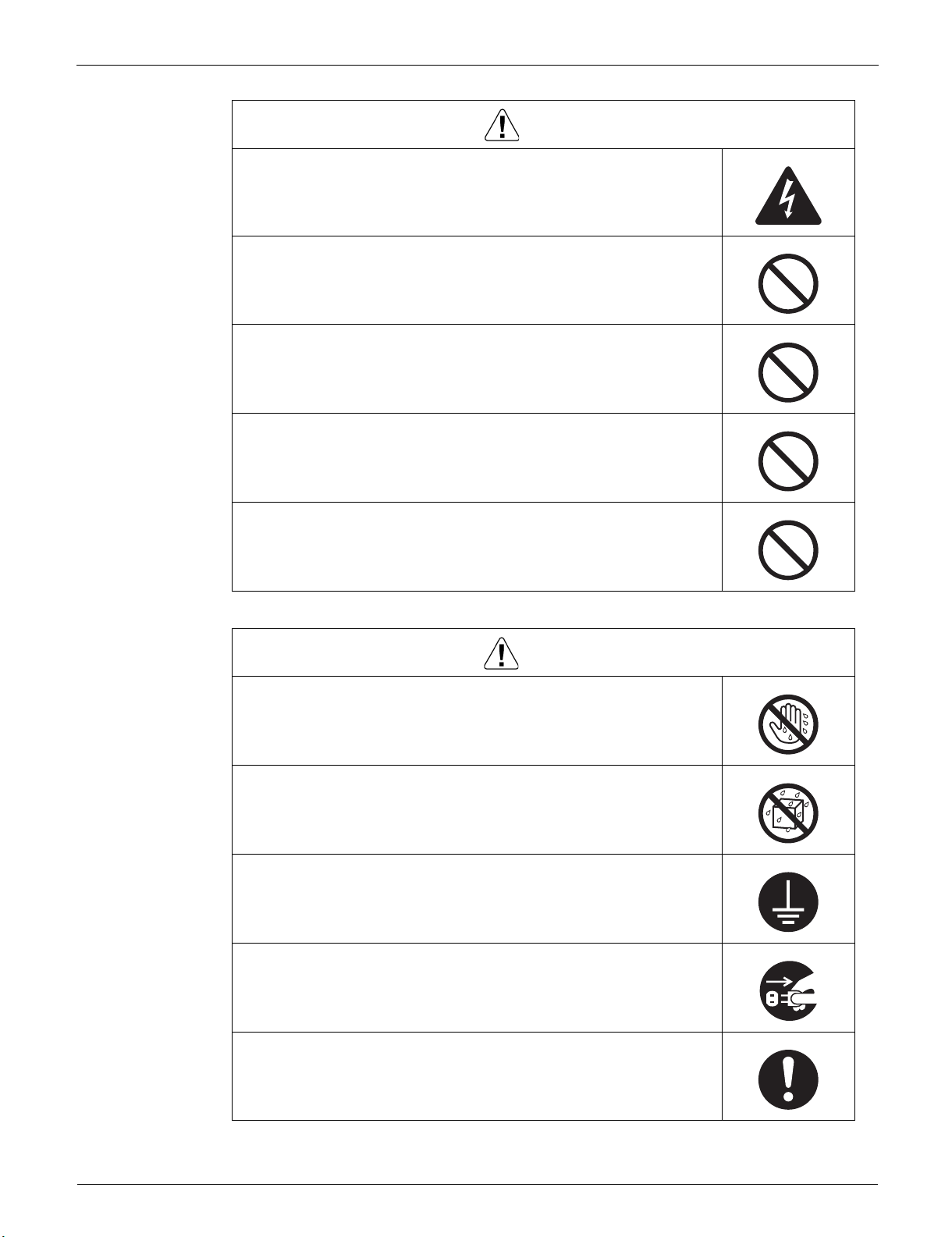

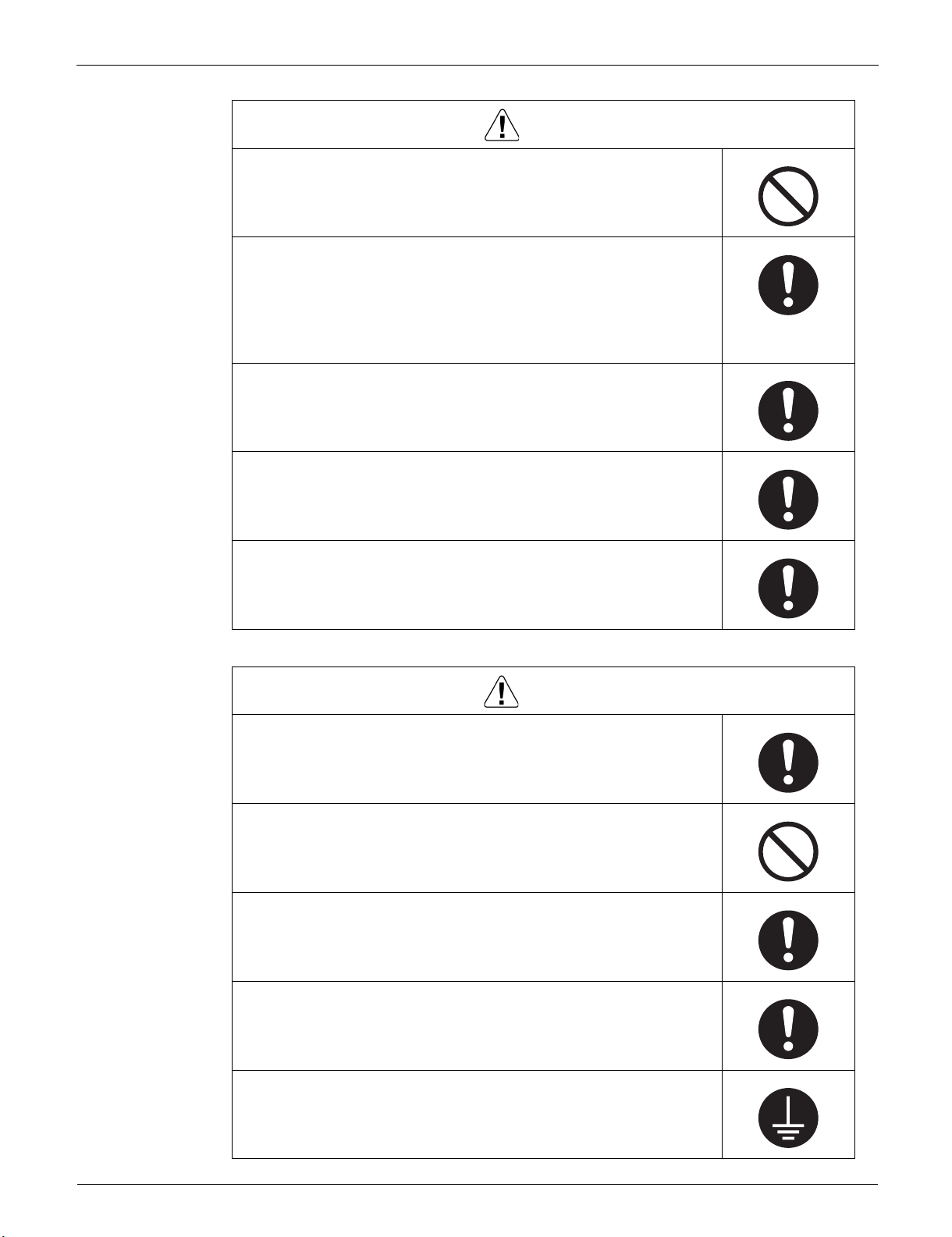

Caution

Warning

Be sure to discharge the capacitor completely before conducting

repair work.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

A charged capacitor may cause an electrical shock.

Do not turn the air conditioner on or off by plugging in or

unplugging the power cable.

Plugging in or unplugging the power cable to operate the equipment may

cause an electrical shock or fire.

Be sure to wear a safety helmet, gloves, and a safety belt when

working in a high place (more than 2 m (6.5 ft)).

Insufficient safety measures may cause a fall.

In case of R-32 / R-410A refrigerant models, be sure to use pipes,

flare nuts and tools intended for the exclusive use with the R-32 /

R-410A refrigerant.

The use of materials for R-22 refrigerant models may cause a serious

accident, such as a damage of refrigerant cycle or equipment failure.

Do not mix air or gas other than the specified refrigerant (R-32 /

R-410A / R-22) in the refrigerant system.

If air enters the refrigerant system, an excessively high pressure results,

causing equipment damage and injury.

Do not repair electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner with water.

Washing the unit with water may cause an electrical shock.

Be sure to provide an earth / grounding when repairing the

equipment in a humid or wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable

when cleaning the equipment.

The internal fan rotates at a high speed, and may cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

3 Introduction

SiUS091601EA Safety Cautions

Caution

Warning

Be sure to check that the refrigerating cycle section has cooled

down enough before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

Conduct welding work in a well-ventilated place.

Using the welder in an enclosed room may cause oxygen deficiency.

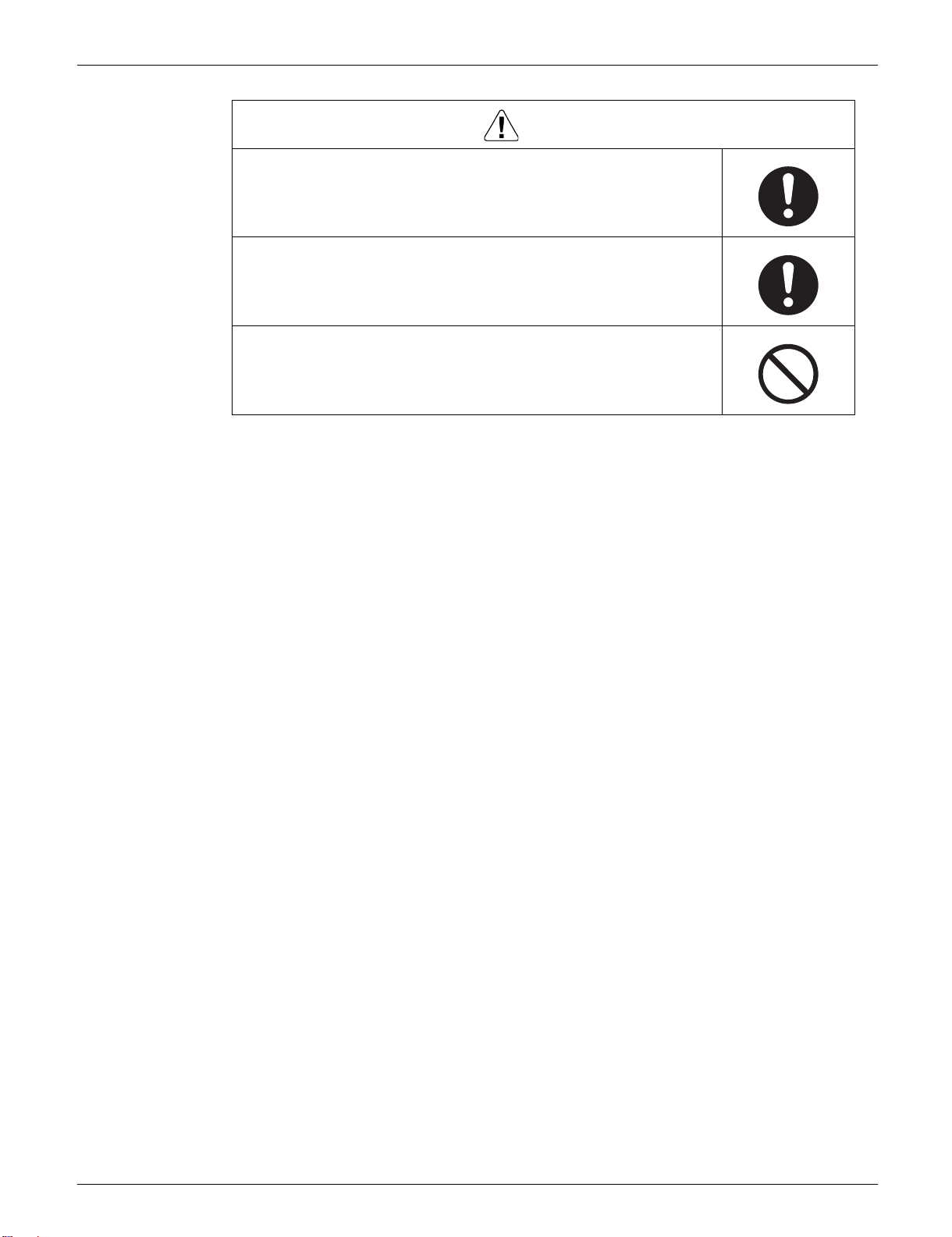

1.2 Warnings and Cautions Regarding Safety of Users

Do not store the equipment in a room with fire sources (e.g., naked

flames, gas appliances, electric heaters).

Be sure to use parts listed in the service parts list of the applicable

model and appropriate tools to conduct repair work. Never attempt

to modify the equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires are scratched or have deteriorated,

be sure to replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the

same power outlet with other electrical appliances, since it may

cause an electrical shock, excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and

follow the local technical standards related to the electrical

equipment, the internal wiring regulations, and the instruction

manual for installation when conducting electrical work.

Insufficient power circuit capacity and improper electrical work may cause

an electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and

outdoor units.

Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

When wiring between the indoor and outdoor units, make sure that

the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may

cause an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cables may cause an electrical shock or fire.

Placing heavy items on the power cable, or heating or pulling the power

cable may damage it.

Introduction 4

Safety Cautions SiUS091601EA

Caution

Warning

Do not mix air or gas other than the specified refrigerant (R-32 /

R-410A / R-22) in the refrigerant system.

If air enters the refrigerant system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leaking point and

repair it before charging the refrigerant. After charging the

refrigerant, make sure that there is no leak.

If the leaking point cannot be located and the repair work must be

stopped, be sure to pump-down, and close the service valve, to prevent

refrigerant gas from leaking into the room. Refrigerant gas itself is

harmless, but it may generate toxic gases when it contacts flames, such

as those from fan type and other heaters, stoves and ranges.

When relocating the equipment, make sure that the new installation

site has sufficient strength to withstand the weight of the

equipment.

If the installation site does not have sufficient strength or the installation

work is not conducted securely, the equipment may fall and cause injury.

Check to make sure that the power cable plug is not dirty or loose,

then insert the plug into a power outlet securely.

If the plug is dusty or has a loose connection, it may cause an electrical

shock or fire.

When replacing the coin battery in the remote controller, be sure to

dispose of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Installation of a leakage breaker is necessary in some cases

depending on the conditions of the installation site, to prevent

electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if parts and wires are mounted and connected

properly, and if connections at the soldered or crimped terminals

are secure.

Improper installation and connections may cause excessive heat

generation, fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

A corroded installation platform or frame may cause the unit to fall,

resulting in injury.

Check the earth / grounding, and repair it if the equipment is not

properly earthed / grounded.

Improper earth / grounding may cause an electrical shock.

5 Introduction

SiUS091601EA Safety Cautions

Caution

Be sure to measure insulation resistance after the repair, and make

sure that the resistance is 1 M or higher.

Faulty insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage may cause water to enter the room and wet the furniture

and floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

Introduction 6

Icons Used SiUS091601EA

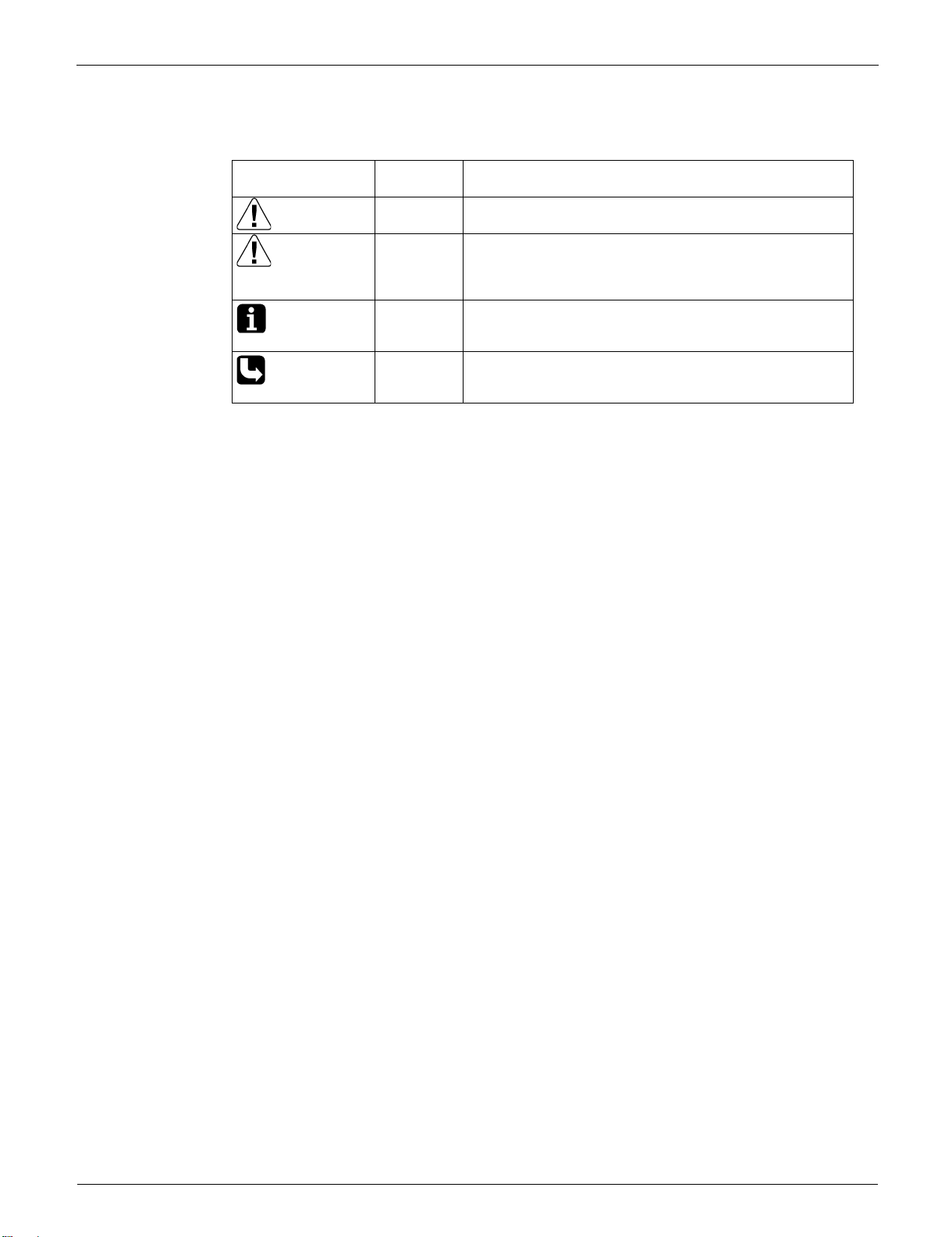

2. Icons Used

The following icons are used to attract the attention of the reader to specific information.

Icon Type of

Information

Warning Warning is used when there is danger of personal injury.

Warning

Caution Caution is used when there is danger that the reader,

Caution

Note Note provides information that is not indispensable, but

Note

Reference Reference guides the reader to other places in this binder

Reference

Description

through incorrect manipulation, may damage equipment,

lose data, get an unexpected result or have to restart (part

of) a procedure.

may nevertheless be valuable to the reader, such as tips

and tricks.

or in this manual, where he/she will find additional

information on a specific topic.

7 Introduction

SiUS091601EA Revision History

3. Revision History

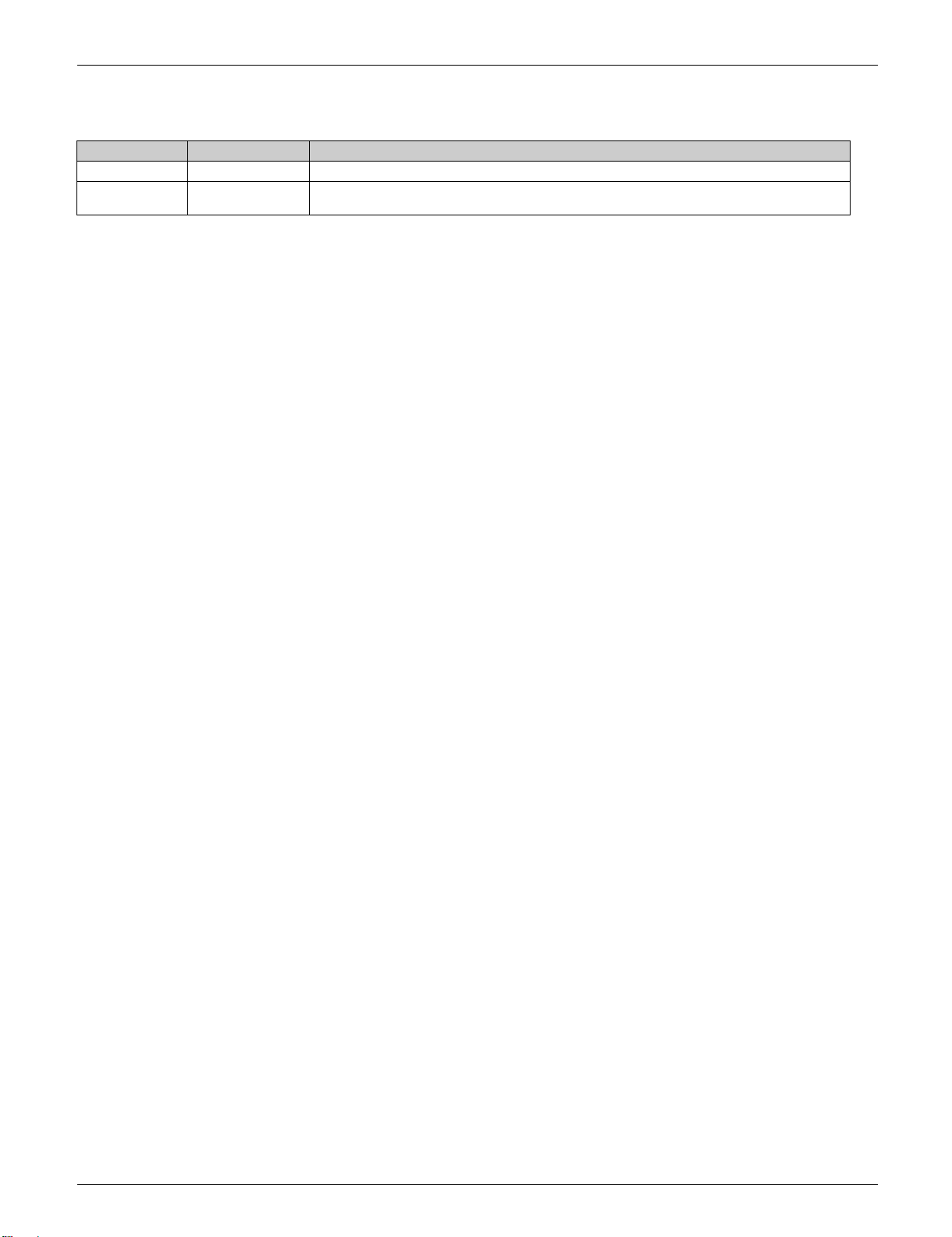

Month/Year Version Revised contents

02 / 2016 SiUS091601E First edition

10 / 2019 SiUS091601EA

Model addition :

FTX18/24UVJU, FDMQ12/18/24RVJU, RXL12QMVJU9, RXL18/24UMVJU

Introduction 8

SiUS091601EA

Part 1

General Information

1. Applicable Models .....................................................................................10

2. Functions...................................................................................................11

9 Part 1 General Information

SiUS091601EA Applicable Models

1. Applicable Models

Indoor Unit

FTX09NMVJU

FTX12NMVJU

FTX15NMVJU

FTX18UVJU

FTX24UVJU

Outdoor Unit

RXL09QMVJU

RXL12QMVJU

RXL12QMVJU9

RXL15QMVJU

RXL18UMVJU

RXL24UMVJU

FVXS09NVJU

FVXS12NVJU

FVXS15NVJU

FDMQ12RVJU

FDMQ18RVJU

FDMQ24RVJU

Part 1 General Information 10

Functions SiUS091601EA

2. Functions

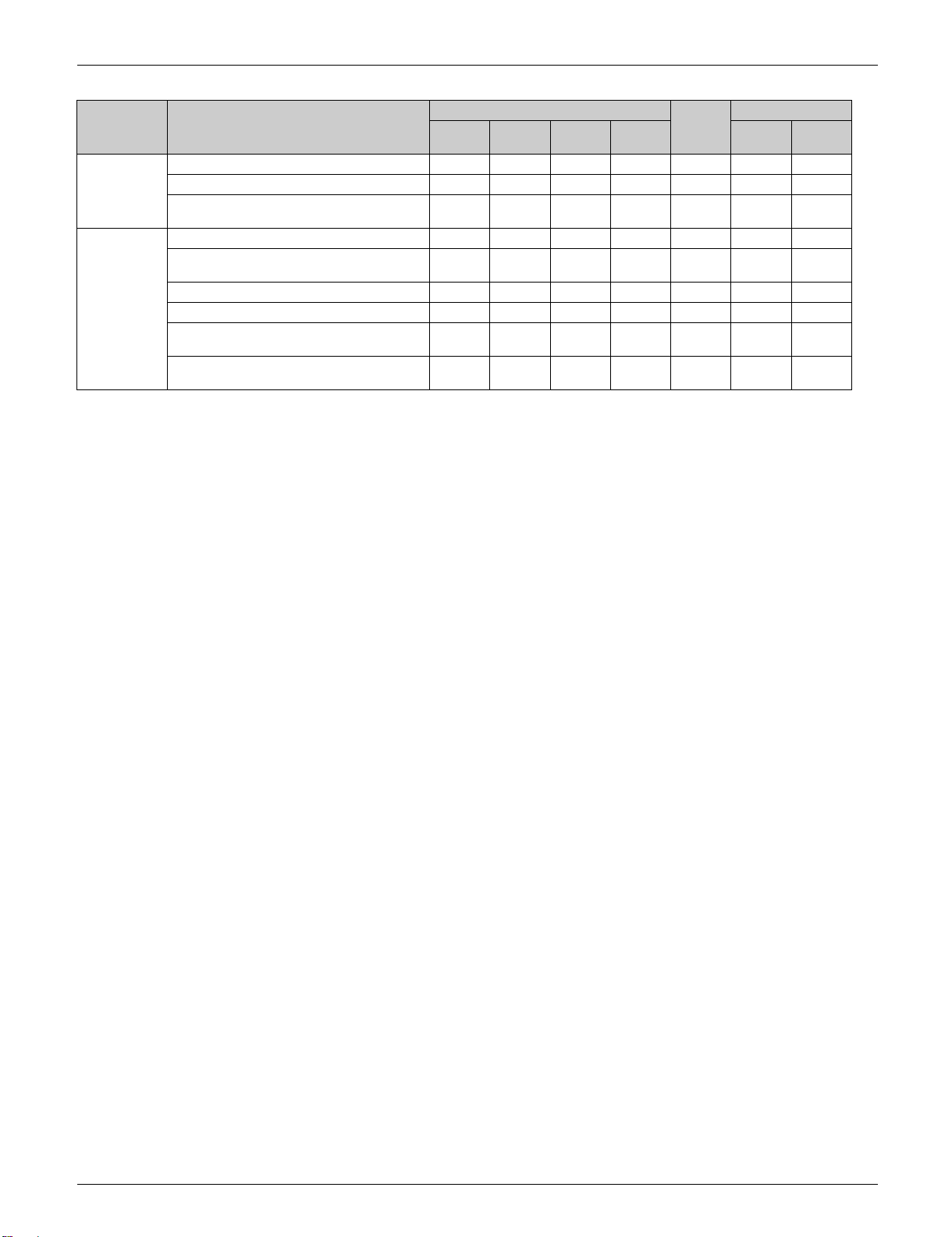

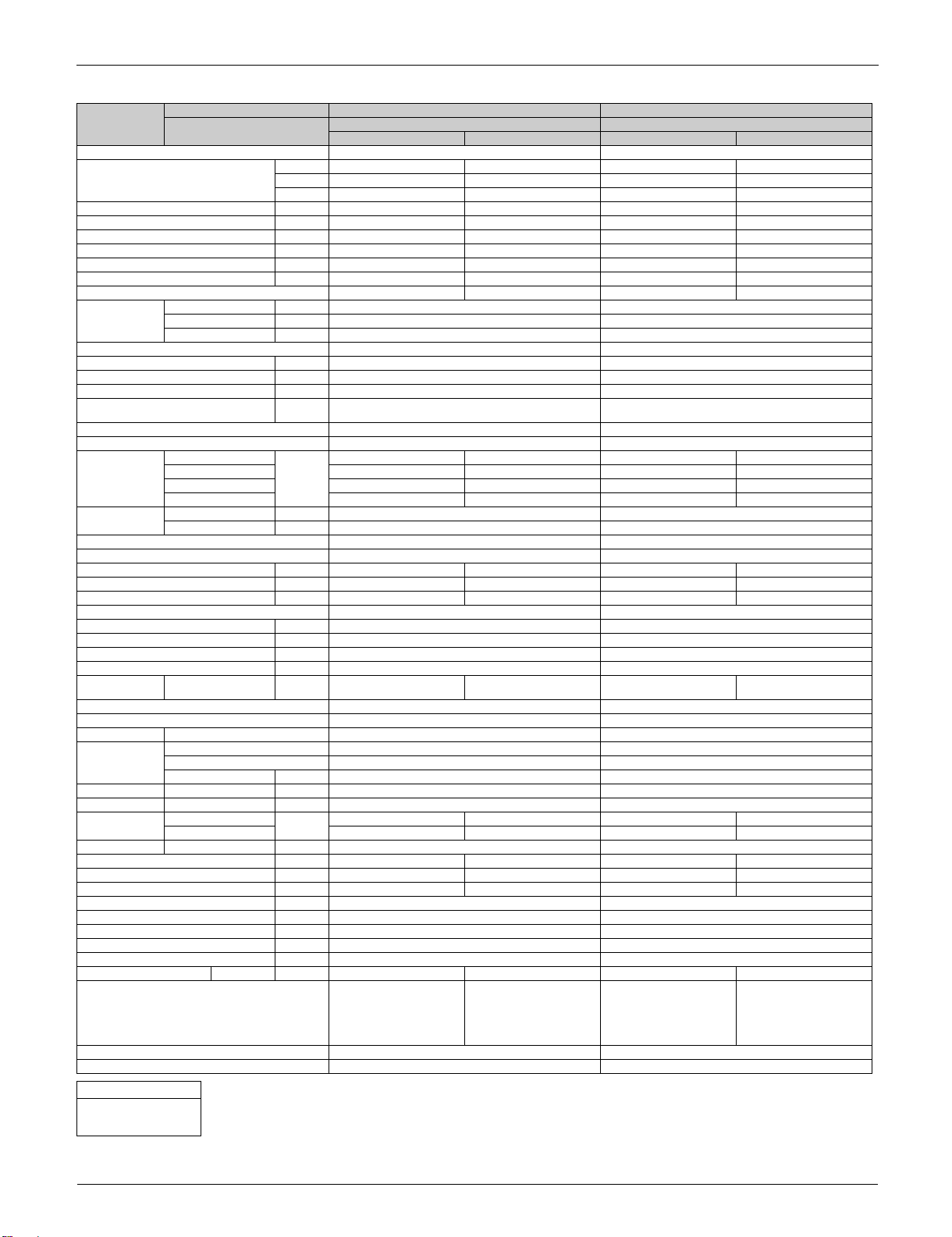

Category Functions FTX

09 12 15 18/24

Basic

Function

Compressor Swing compressor

Comfortable

Airflow

Comfort

Control

Operation Automatic cooling/heating changeover

Lifestyle

Convenience

Health and

Cleanliness

Remote

Control &

Timer

Inverter (with inverter power control)

Operation limit Refer to page 236

PAM control

Standby electricity saving 1 ————

Reluctance DC motor

Power-airflow flap (horizontal blade) —— ——

Power-airflow dual flaps (horizontal blades) — — ———

Wide-angle louvers (vertical blades) ——

Auto-swing (up and down) ——

Auto-swing (right and left) — — — ———

3-D airflow — — — ———

COMFORT AIRFLOW operation ———

Auto fan speed —

Switchable fan speed 5 steps 5 steps 5 steps 5 steps 5 steps 3 steps 3 steps

Indoor unit quiet operation ——

OUTDOOR UNIT QUIET operation

(manual)

INTELLIGENT EYE operation

(auto energy saving)

2 selectable temperature sensors ————— —

Quick warming function —

Hot-start function

Automatic defrosting

Program dry operation

Fan only

Inverter POWERFUL operation ——

ECONO operation ——

Indoor unit ON/OFF switch ——

Emergency operation switch — —————

Signal receiving sign —

Titanium apatite deodorizing filter ——

Air filter (prefilter) ——

Wipe-clean flat panel ——

Silver ion anti-bacterial drain pan —————

Filter cleaning indicator —————

WEEKLY TIMER operation — — — ——

Schedule timer ————— —

24-hour ON/OFF TIMER — — — —

72-hour ON/OFF TIMER — —————

Count up-down ON/OFF timer ———

Off timer (turns unit off after set time) ————— —

Setpoint auto reset ————— —

Setpoint range set ————— —

NIGHT SET mode ——

Remote controller with back light —

DIII-NET compatible (adaptor) Option Option Option Option Option Option Option

Wireless LAN connection Option Option Option Option Option — —

—————

——— ———

FVXS

Wired

R/C

FDMQ

Wireless

R/C

2

11 Part 1 General Information

SiUS091601EA Functions

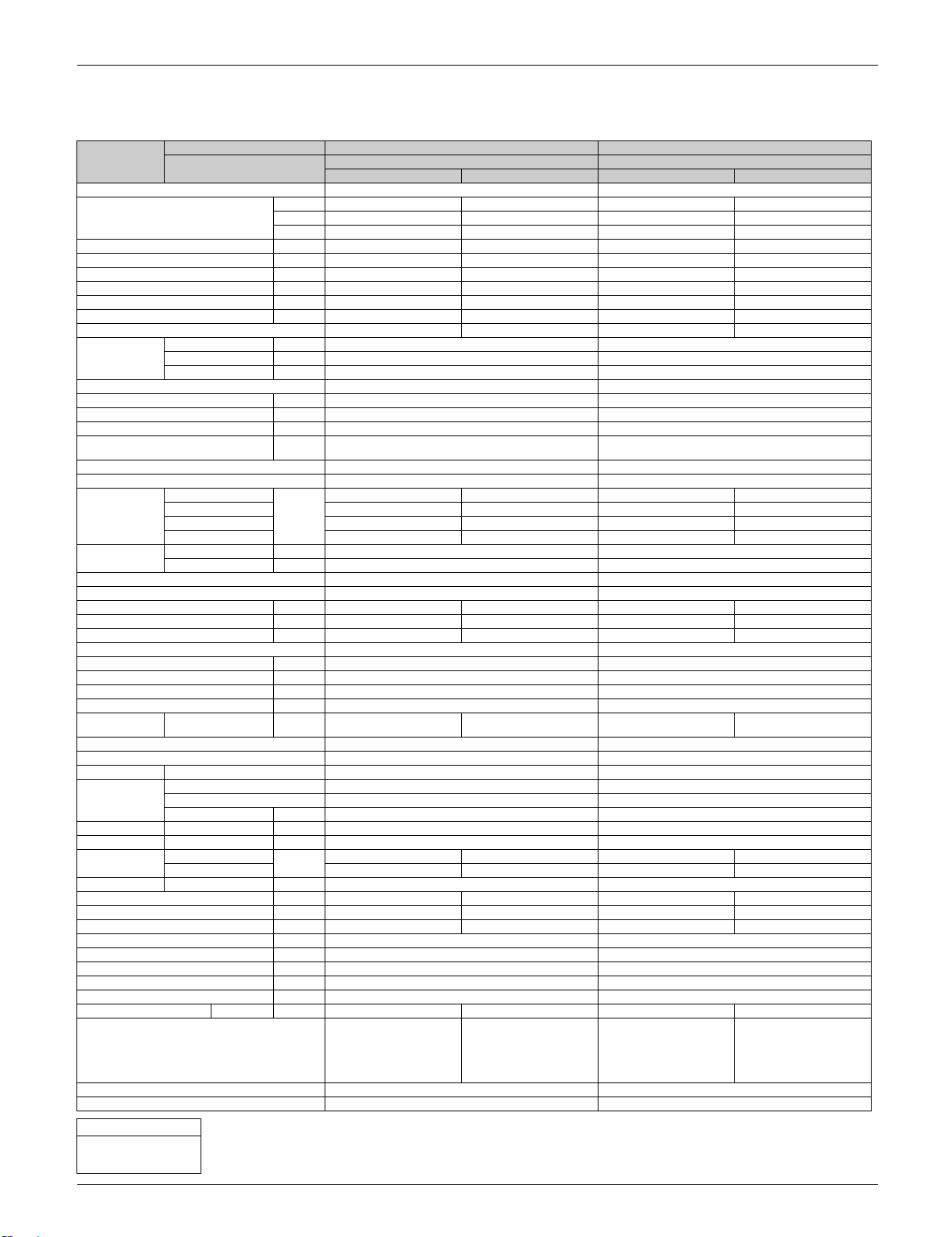

Category Functions FTX

09 12 15 18/24

Worry Free

(Reliability &

Durability)

Work &

Servicing

: Available 1: Not available with RXL12QMVJU9

— : Not available 2: Receiving sound only

Auto-restart (after power failure)

Self-diagnosis (R/C, LED)

Anti-corrosion treatment of outdoor heat

exchanger

Multi-split/split type compatible indoor unit — — — —

Chargeless 32.8 ft.

Drain pump —————

Either side drain (right or left) ———

Low temperature cooling operation –4°F 3

°F/°C changeover R/C temperature display

(factory setting: °F)

3: Below 50°F (10°C):

(10m)

(–20°C)

Below 14°F (–10°C):

32.8 ft.

(10m)

–4°F 3

(–20°C)

32.8 ft.

(10m)

–4°F 3

(–20°C)

Needs setting on outdoor unit.

09/12/15 class cutting jumper on the main PCB

18/24 class switch on the service monitor PCB

Need to install the air direction adjustment grille.

32.8 ft.

(10m)

–4°F 3

(–20°C)

FVXS

32.8 ft.

(10m)

–4°F 3

(–20°C)

FDMQ

Wired

R/C

32.8 ft.

(10m)

–4°F 3

(–20°C)

Wireless

R/C

32.8 ft.

(10m)

–4°F 3

(–20°C)

—

(°F only)

Part 1 General Information 12

SiUS091601EA

Part 2

Specifications

1. Specifications ............................................................................................14

13 Part 2 Specifications

SiUS091601EA Specifications

1. Specifications

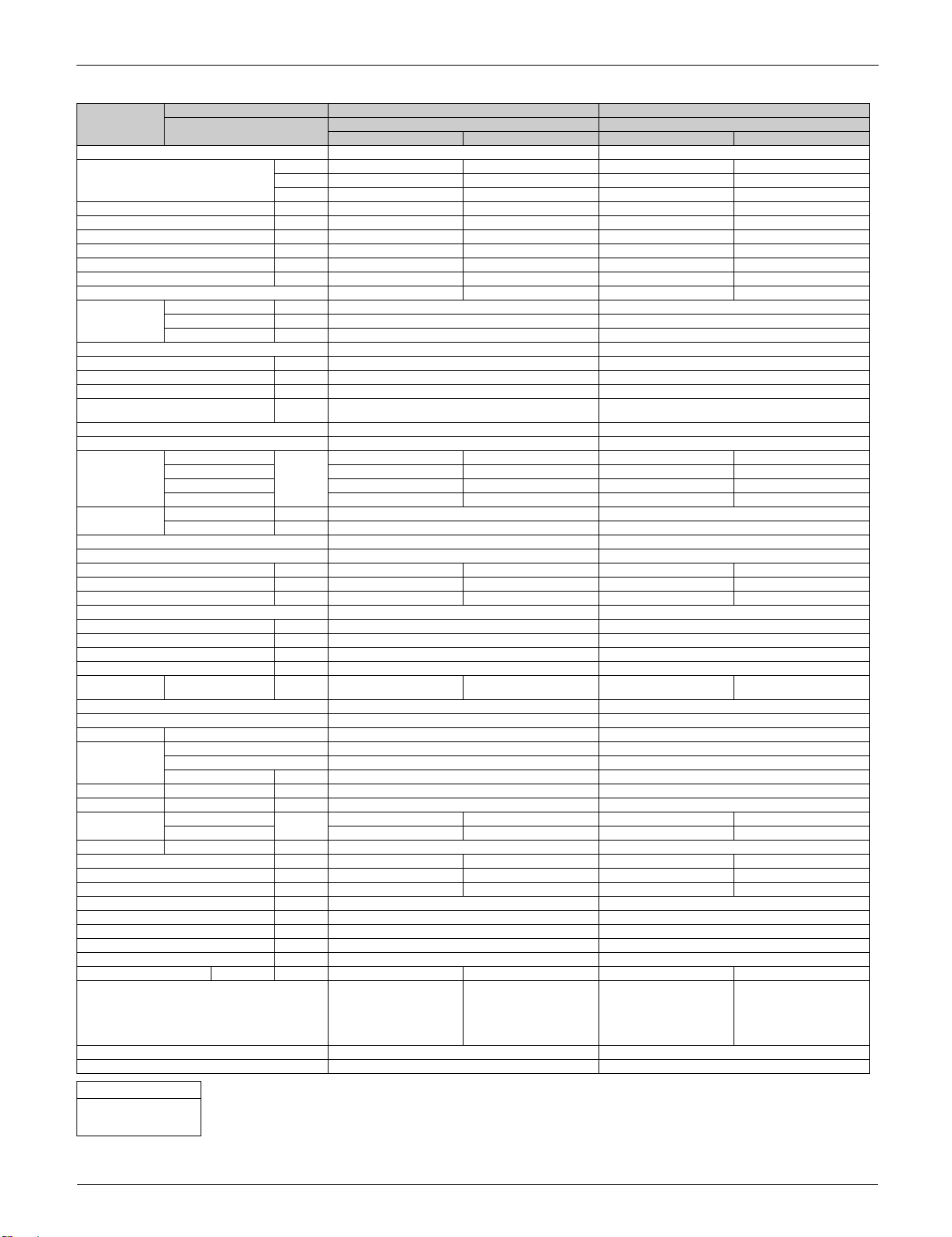

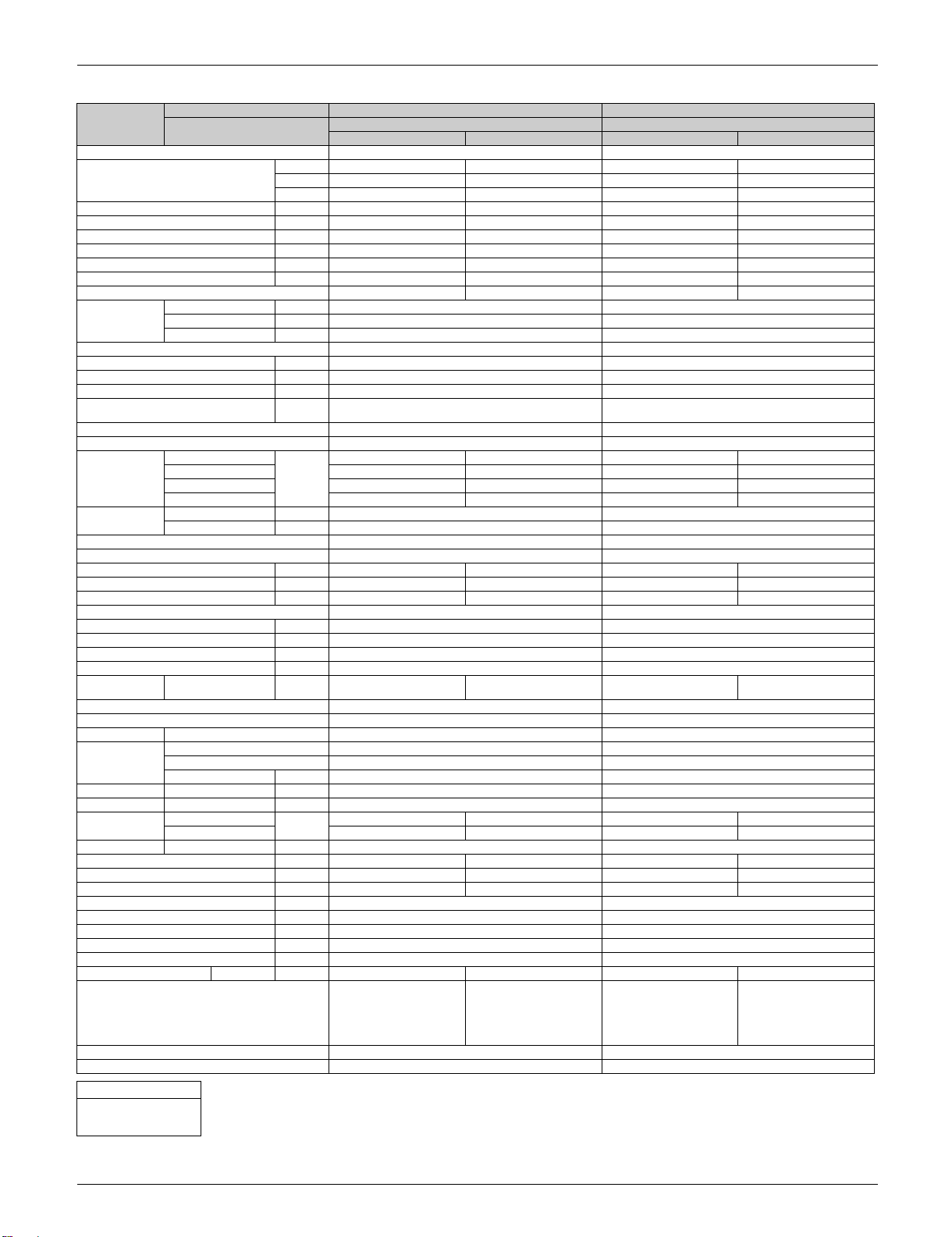

Model Indoor Unit FTX09NMVJU FTX12NMVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity Rated (Min. ~ Max.) kW 2.64 (1.30 ~ 3.20) 3.20 (1.30 ~ 4.70) 3.20 (1.30 ~ 3.90) 4.00 (1.30 ~ 5.50)

Moisture Removal gal/h 0.32 — 0.45 —

Running Current (Rated) A 3.76 - 3.40 3.95 - 3.57 4.36 - 3.94 5.10 - 4.61

Power Consumption Rated (Min. ~ Max.) W 720 (250 ~ 1,180) 760 (230 ~ 1,440) 870 (280 ~ 1,390) 1,025 (240 ~ 1,660)

Power Factor (Rated) % 92.1 - 92.1 92.6 - 92.6 96.0 - 96.0 96.7 - 96.7

COP Rated (Min. ~ Max.) W/W 3.66 (5.20 ~ 2.70) 4.20 (5.64 ~ 3.26) 3.68 (4.64 ~ 2.80) 3.90 (5.42 ~ 3.30)

EER Rated (Min. ~ Max.) Btu/h·W 12.5 (17.6 ~ 9.2) 14.3 (19.1 ~ 11.1) 12.5 (15.7 ~ 9.6) 13.3 (18.3 ~ 11.3)

SEER / HSPF 20.0 12.5 20.0 12.0

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length ft (m) 65-5/8 (20) 65-5/8 (20)

Max. Interunit Height Difference ft (m) 49-1/4 (15) 49-1/4 (15)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of

Refrigerant

Indoor Unit FTX09NMVJU FTX12NMVJU

Front Panel Color White White

Airflow Rate H

Fan Type / Motor Output W Cross Flow Fan / 21 Cross Flow Fan / 28

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A 0.25 - 0.23 0.23 - 0.21 0.28 - 0.25 0.25 - 0.23

Power Consumption (Rated) W 28 - 28 25 - 25 31 - 31 28 - 28

Power Factor (Rated) % 53.8 - 52.9 52.3 - 51.8 53.2 - 53.9 53.8 - 52.9

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-1/4 × 30-5/16 × 8-3/4 (285 × 770 × 223) 11-1/4 × 30-5/16 × 8-3/4 (285 × 770 × 223)

Packaged Dimensions (H × W × D) in. (mm) 14-3/16 × 32-11/16 × 12 (360 × 831 × 305) 14-3/16 × 32-11/16 × 12 (360 × 831 × 305)

Weight (Mass) Lbs (kg) 18 (8) 18 (8)

Gross Weight (Gross Mass) Lbs (kg) 24 (11) 25 (12)

Sound Pressure

Level

Outdoor Unit RXL09QMVJU RXL12QMVJU

Casing Color Ivory White Ivory White

Heat Exchanger Fin / Spec. Tube Waffle Fin (PE) / 7 mm Hi-XD Tube Waffle Fin (PE) / 7 mm Hi-XD Tube

Compressor Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Refrigerant Oil Type / Charge oz (L) FVC50K / 12.4 (0.375) FVC50K / 21.5 (0.650)

Refrigerant Type / Charge Lbs (kg) R-410A / 2.09 (0.95) R-410A / 2.09 (0.95)

Airflow Rate H

Fan Type / Motor Output W Propeller / 18 Propeller / 20

Running Current (Rated) A 3.51 - 3.17 3.72 - 3.36 4.08 - 3.69 4.85 - 4.38

Power Consumption (Rated) W 692 - 692 735 - 735 839 - 839 997 - 997

Power Factor (Rated) % 94.8 - 94.9 95.1 - 95.1 98.9 - 98.9 98.9 - 99.0

Starting Current A 3.95 4.94

Dimensions (H × W × D) in. (mm) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284)

Packaged Dimensions (H × W × D) in. (mm) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407)

Weight (Mass) Lbs (kg) 60 (27) 70 (32)

Gross Weight (Gross Mass) Lbs (kg) 71 (32) 80 (36)

Sound Pressure Level H dB(A) 49 49 50 50

Conditions Based on

Drawing No. C: 3D101720 C: 3D101721

Notes SL: The quiet fan level of the airflow rate setting. SL: The quiet fan level of the airflow rate setting.

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL09QMVJU RXL12QMVJU

Btu/h 9,000 (4,400 ~ 10,900) 10,900 (4,400 ~ 16,000) 10,900 (4,400 ~ 13,300) 13,600 (4,400 ~ 18,800)

kcal/h 2,270 (1,120 ~ 2,750) 2,750 (1,120 ~ 4,040) 2,750 (1,120 ~ 3,350) 3,440 (1,120 ~ 4,730)

Liquid in. (mm) 1/4 ( 6.4) 1/4 ( 6.4)

Gas in. (mm) 3/8 ( 9.5) 3/8 ( 9.5)

Drain in. (mm) 5/8 ( 16.0) 5/8 ( 16.0)

oz/ft

(g/m)

M 297 (8.4) 328 (9.3) 311 (8.8) 321 (9.1)

L 244 (6.9) 251 (7.1) 247 (7.0) 258 (7.3)

SL 141 (4.0) 215 (6.1) 145 (4.1) 219 (6.2)

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL

Model 1YC23AUXD 2YC36PXD

Motor Output W 790 1,100

SL 865 (24.5) 777 (22.0) 865 (24.5) 777 (22.0)

cfm

(m³/min)

dB(A) 43 / 36 / 30 / 19 43 / 36 / 29 / 25 45 / 37 / 30 / 19 45 / 37 / 30 / 26

cfm

(m³/min)

Cooling Heating Cooling Heating

0.21 (20) 0.21 (20)

417 (11.8) 403 (11.4) 434 (12.3) 413 (11.7)

1,105 (31.3) 922 (26.1) 1,144 (32.4) 1,006 (28.5)

Indoor ; 80°FDB (26.7°CDB)

/ 67°FWB (19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 80°FDB (26.7°CDB)

/ 67°FWB (19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

Piping Length: 25 ft (7.5 m)

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Part 2 Specifications 14

Specifications SiUS091601EA

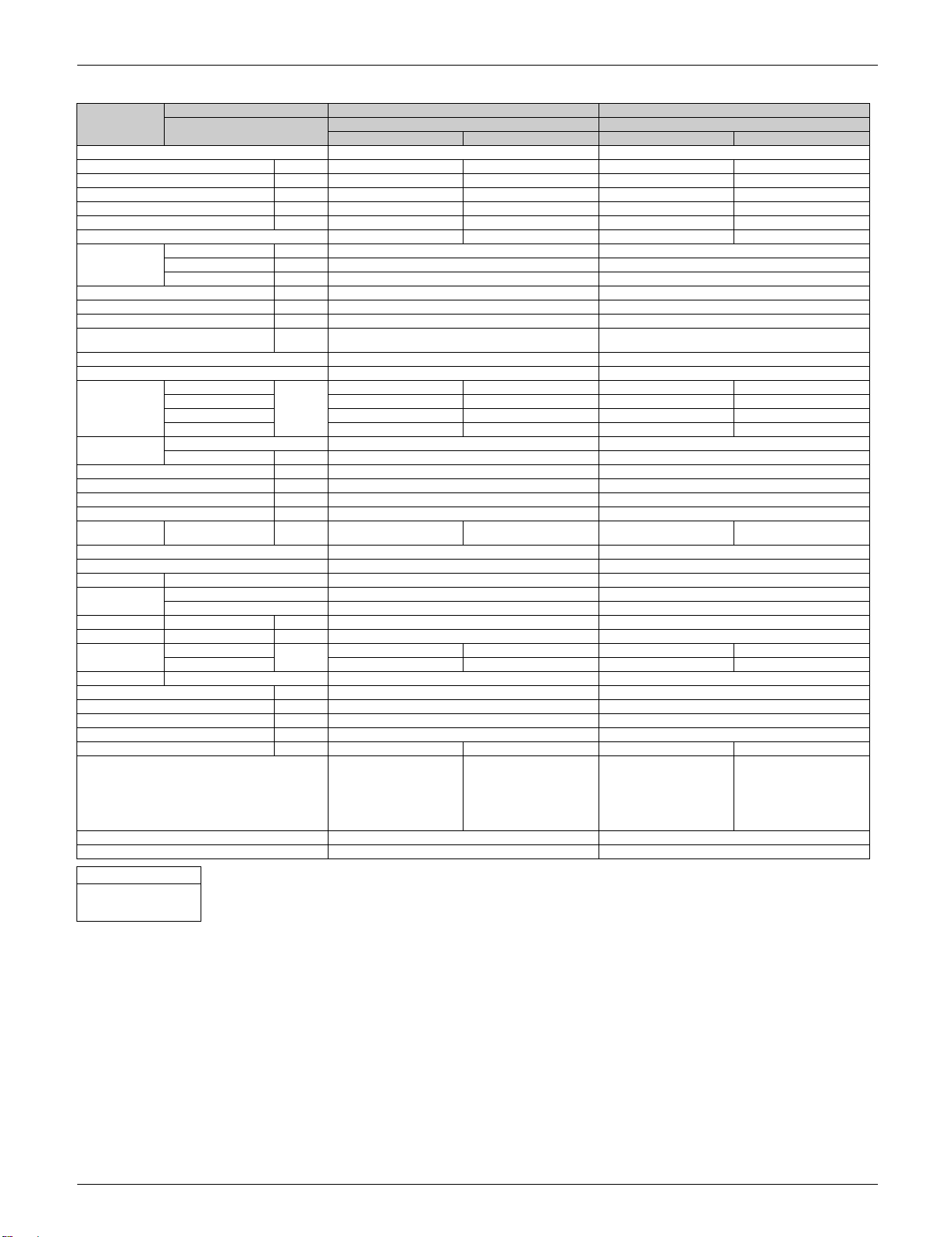

Model Indoor Unit FTX12NMVJU FTX15NMVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity Rated (Min. ~ Max.) kW 3.20 (1.30 ~ 3.90) 4.00 (1.30 ~ 5.50) 4.40 (1.70 ~ 5.40) 5.35 (1.70 ~ 7.20)

Moisture Removal gal/h 0.45 — 0.63 —

Running Current (Rated) A 4.36 - 3.94 5.10 - 4.61 5.92 - 5.35 6.81 - 6.16

Power Consumption Rated (Min. ~ Max.) W 870 (280 ~ 1,390) 1,025 (240 ~ 1,660) 1,150 (290 ~ 1,630) 1,340 (390 ~ 2,310)

Power Factor (Rated) % 96.0 - 96.0 96.7 - 96.7 93.5 - 93.5 94.6 - 94.6

COP Rated (Min. ~ Max.) W/W 3.68 (4.64 ~ 2.80) 3.90 (5.42 ~ 3.30) 3.82 (5.86 ~ 3.30) 4.00 (4.36 ~ 3.12)

EER Rated (Min. ~ Max.) Btu/h·W 12.5 (15.7 ~ 9.6) 13.3 (18.3 ~ 11.3) 13 (20 ~ 11.3) 13.7 (14.9 ~ 10.6)

SEER / HSPF 20.0 12.0 20.0 13.0

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length ft (m) 65-5/8 (20) 98-1/2 (30)

Max. Interunit Height Difference ft (m) 49-1/4 (15) 65-5/8 (20)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of

Refrigerant

Indoor Unit FTX12NMVJU FTX15NMVJU

Front Panel Color White White

Airflow Rate H

Fan Type / Motor Output W Cross Flow Fan / 28 Cross Flow Fan / 33

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A 0.28 - 0.25 0.25 - 0.23 0.23 - 0.21 0.25 - 0.23

Power Consumption (Rated) W 31 - 31 28 - 28 33 - 33 38 - 38

Power Factor (Rated) % 53.2 - 53.9 53.8 - 52.9 69.0 - 68.3 73.1 - 71.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-1/4 × 30-5/16 × 8-3/4 (285 × 770 × 223) 11-5/8 × 39 × 10-3/8 (295 × 990 × 263)

Packaged Dimensions (H × W × D) in. (mm) 14-3/16 × 32-11/16 × 12 (360 × 831 × 305) 14-9/16 × 42-1/2 × 15-3/8 (370 × 1,080 × 390)

Weight (Mass) Lbs (kg) 18 (8) 27 (12)

Gross Weight (Gross Mass) Lbs (kg) 25 (12) 37 (17)

Sound Pressure

Level

Outdoor Unit RXL12QMVJU9 RXL15QMVJU

Casing Color Ivory White Ivory White

Heat Exchanger Fin / Spec. Tube Waffle Fin (PE) / 7 mm Hi-XD Tube Waffle Fin (PE) / 7 mm Hi-XD Tube

Compressor Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Refrigerant Oil Type / Charge oz (L) FVC50K / 21.5 (0.650) FVC50K / 21.5 (0.650)

Refrigerant Type / Charge Lbs (kg) R-410A / 2.09 (0.95) R-410A / 3.20 (1.45)

Airflow Rate H

Fan Type / Motor Output W Propeller / 20 Propeller / 71

Running Current (Rated) A 4.08 - 3.69 4.85 - 4.38 5.69 - 5.14 6.56 - 5.93

Power Consumption (Rated) W 839 - 839 997 - 997 1,117 - 1,117 1,302 - 1,302

Power Factor (Rated) % 98.9 - 98.9 98.9 - 99.0 94.4 - 94.5 95.4 - 95.5

Starting Current A 4.94 6.81

Dimensions (H × W × D) in. (mm) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320)

Packaged Dimensions (H × W × D) in. (mm) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407) 31-7/8 × 41-9/16 × 18-1/4 (810 × 1,056 × 464)

Weight (Mass) Lbs (kg) 70 (32) 108 (49)

Gross Weight (Gross Mass) Lbs (kg) 80 (36) 123 (56)

Sound Pressure Level H dB(A) 50 50 50 55

Conditions Based on Indoor ; 80°FDB

Drawing No. C: 3D123801 C: 3D101716

Notes SL: The quiet fan level of the airflow rate setting. SL: The quiet fan level of the airflow rate setting.

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL12QMVJU9 RXL15QMVJU

Btu/h 10,900 (4,400 ~ 13,300) 13,600 (4,400 ~ 18,800) 15,000 (5,800 ~ 18,400) 18,300 (5,800 ~ 24,600)

kcal/h 2,750 (1,120 ~ 3,350) 3,440 (1,120 ~ 4,730) 3,780 (1,460 ~ 4,640) 4,600 (1,460 ~ 6,190)

Liquid in. (mm) 1/4 ( 6.4) 1/4 ( 6.4)

Gas in. (mm) 3/8 ( 9.5) 1/2 ( 12.7)

Drain in. (mm) 5/8 ( 16.0) 5/8 ( 16.0)

oz/ft

(g/m)

M 311 (8.8) 321 (9.1) 505 (14.3) 554 (15.7)

L 247 (7.0) 258 (7.3) 431 (12.2) 470 (13.3)

SL 145 (4.1) 219 (6.2) 367 (10.4) 399 (11.3)

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL

Model 2YC36PXD 2YC36PXD

Motor Output W 1,100 1,100

SL 865 (24.5) 777 (22.0) 1,762 (49.9) 1,585 (44.9)

cfm

(m³/min)

dB(A) 45 / 37 / 30 / 19 45 / 37 / 30 / 26 45 / 41 / 36 / 33 45 / 41 / 37 / 33

cfm

(m³/min)

Cooling Heating Cooling Heating

0.21 (20) 0.21 (20)

434 (12.3) 413 (11.7) 593 (16.8) 653 (18.5)

1,144 (32.4) 1,006 (28.5) 2,044 (57.9) 2,044 (57.9)

(26.7°CDB) / 67°FWB

(19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 80°FDB

(26.7°CDB) / 67°FWB

(19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

Piping Length: 25 ft (7.5 m)

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

15 Part 2 Specifications

SiUS091601EA Specifications

Model Indoor Unit FTX18UVJU FTX24UVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity Rated (Min. ~ Max.) Btu/h 18,000 (9,000 ~ 21,600) 21,600 (9,000 ~ 28,000) 21,200 (9,000 ~ 25,800) 24,000 (9,000 ~ 32,000)

Power Consumption Rated (Min. ~ Max.) W 1,440 (570 ~ 1,930) 1,809 (540 ~ 3,080) 1,696 (580 ~ 2,360) 2,132 (570 ~ 3,800)

Power Factor (Rated) % 96 97 96 97

COP (Min. ~ Max.) W/W — 3.50 (4.88 ~ 2.66) — 3.30 (4.62 ~ 2.46)

EER (Min. ~ Max.) Btu/h·W 12.50 (15.80 ~ 11.20) — 12.50 (15.50 ~ 10.90) —

SEER / HSPF 20.30 10.30 20.00 10.30

Piping

Connections

Max. Interunit Piping Length ft (m) 98-1/2 (30) 98-1/2 (30)

Max. Interunit Height Difference ft (m) 65-5/8 (20) 65-5/8 (20)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of

Refrigerant

Indoor Unit FTX18UVJU FTX24UVJU

Front Panel Color (Munsell No.) White (N-95) White (N-95)

Airflow Rate H

Fan Type Cross Flow Fan Cross Flow Fan

Dimensions (H × W × D) in. (mm) 13-3/8 × 41-5/16 × 10-1/4 (340 × 1,050 × 261) 13-3/8 × 41-5/16 × 10-1/4 (340 × 1,050 × 261)

Packaged Dimensions (H × W × D) in. (mm) 13-1/2 × 45-1/2 × 17 (342 × 1,160 × 429) 13-1/2 × 45-1/2 × 17 (342 × 1,160 × 429)

Weight (Mass) Lbs (kg) 33 (15) 33 (15)

Gross Weight (Gross Mass) Lbs (kg) 42 (19) 44 (20)

Sound Pressure

Level

Outdoor Unit RXL18UMVJU RXL24UMVJU

Casing Color Ivory White Ivory White

Heat Exchanger Fin / Spec. Tube Waffle Fin (PE) / 7 mm Hi-XD Tube Waffle Fin (PE) / 7 mm Hi-XD Tube

Compressor Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Refrigerant Oil Type / Charge oz (L) FVC50K / 31.75 (0.900) FVC50K / 31.75 (0.900)

Refrigerant Type / Charge Lbs (kg) R-410A / 3.53 (1.60) R-410A / 3.53 (1.60)

Airflow Rate H

Fan Type Propeller Propeller

Dimensions (H × W × D) in. (mm) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320)

Packaged Dimensions (H × W × D) in. (mm) 31-7/8 × 41-1/2 × 18-1/4 (810 × 1,056 × 464) 31-7/8 × 41-1/2 × 18-1/4 (810 × 1,056 × 464)

Weight (Mass) Lbs (kg) 130 (59) 130 (59)

Gross Weight (Gross Mass) Lbs (kg) 137 (62) 137 (62)

Sound Pressure Level dB(A) 54 / — 55 / — 55 / — 55 / —

Conditions Based on Indoor ; 80.0°FDB

Drawing No. C: 3D123803A C: 3D123803A

Note SL: The quiet fan level of the airflow rate setting. SL: The quiet fan level of the airflow rate setting.

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL18UMVJU RXL24UMVJU

Liquid in. (mm) 1/4 ( 6.4) 1/4 ( 6.4)

Gas in. (mm) 1/2 ( 12.7) 5/8 ( 15.9)

Drain in. (mm) 5/8 ( 16) 5/8 ( 16)

oz/ft

(g/m)

M 484 (13.7) 583 (16.5) 494 (14.0) 572 (16.2)

L 385 (10.9) 431 (12.2) 350 (9.9) 445 (12.6)

SL 360 (10.2) 399 (11.3) 328 (9.3) 403 (11.4)

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL

Model 2YC63AAXD 2YC63AAXD

SL 1,907 (54.0) 2,134 (60.4) 1,907 (54.0) 2,134 (60.4)

cfm

(m³/min)

dB(A) 46 / 41 / 36 / 33 48 / 42 / 35 / 32 51 / 44 / 37 / 34 48 / 42 / 37 / 34

cfm

(m³/min)

Cooling Heating Cooling Heating

0.32 (30) 0.32 (30)

583 (16.5) 713 (20.2) 643 (18.2) 699 (19.8)

2,417 (68.5) 2,361 (66.9) 2,417 (68.5) 2,361 (66.9)

(26.7°CDB) / 67.0°FWB

(19.4°CWB)

Outdoor ; 95.0°FDB

(35°CDB) / 75°FWB

(23.9°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70.0°FDB

(21.1°CDB) / 60.0°FWB

(15.6°CWB)

Outdoor ; 47°FDB

(8.33°CDB) / 43.0°FWB

(6.11°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 80.0°FDB

(26.7°CDB) / 67.0°FWB

(19.4°CWB)

Outdoor ; 95.0°FDB

(35°CDB) / 75°FWB

(23.9°CWB)

Piping Length: 25 ft (7.5 m)

(21.1°CDB) / 60.0°FWB

(8.33°CDB) / 43.0°FWB

Piping Length: 25 ft (7.5 m)

Indoor ; 70.0°FDB

(15.6°CWB)

Outdoor ; 47°FDB

(6.11°CWB)

Part 2 Specifications 16

Specifications SiUS091601EA

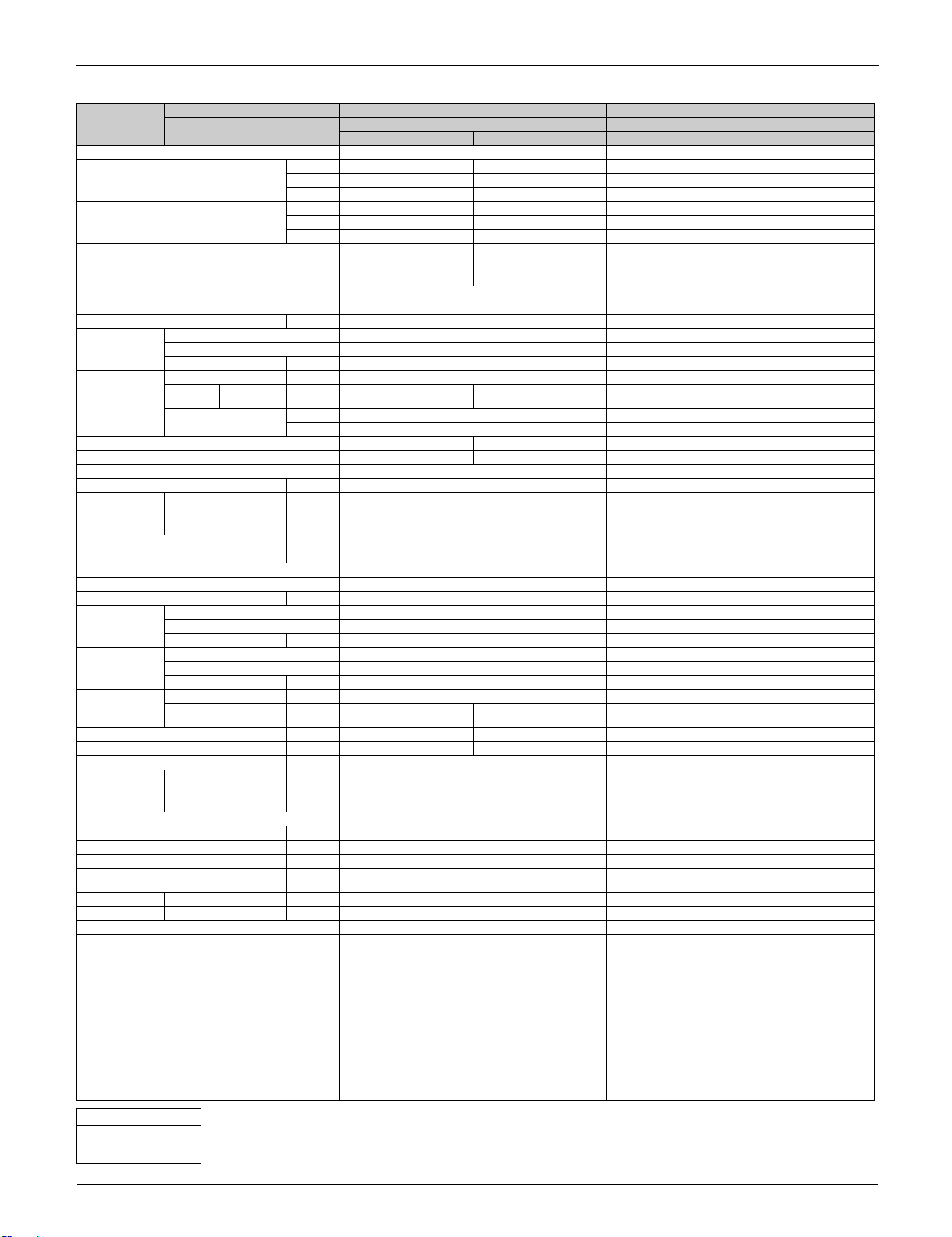

Model Indoor Unit FVXS09NVJU FVXS12NVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity Rated (Min. ~ Max.) kW 2.64 (1.30 ~ 3.00) 2.95 (1.30 ~ 4.20) 3.00 (1.30 ~ 3.60) 3.80 (1.30 ~ 5.00)

Moisture Removal gal/h 0.32 — 0.45 —

Running Current (Rated) A 3.75 - 3.39 3.67 - 3.32 4.20 - 3.80 4.69 - 4.24

Power Consumption Rated (Min. ~ Max.) W 720 (250 ~ 820) 720 (240 ~ 1.390) 850 (270 ~ 1,350) 950 (250 ~ 1,570)

Power Factor (Rated) % 92.3 - 92.3 94.3 - 94.3 97.3 - 97.3 97.4 - 97.4

COP Rated (Min. ~ Max.) W/W 3.66 (5.20 ~ 3.66) 4.10 (5.42 ~ 3.02) 3.52 (4.80 ~ 2.66) 4.00 (5.20 ~ 3.18)

EER Rated (Min. ~ Max.) Btu/h·W 12.5 (17.6 ~ 12.4) 14 (18.3 ~ 10.3) 12.0 (16.3 ~ 9.1) 13.7 (17.6 ~ 10.9)

SEER / HSPF 20.0 11.7 20.0 11.4

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length ft (m) 65-5/8 (20) 65-5/8 (20)

Max. Interunit Height Difference ft (m) 49-1/4 (15) 49-1/4 (15)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of

Refrigerant

Indoor Unit FVXS09NVJU FVXS12NVJU

Front Panel Color White White

Airflow Rate H

Fan Type / Motor Output W Turbo Fan / 12.3 Turbo Fan / 13.4

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A 0.14 - 0.13 0.15 - 0.14 0.14 - 0.13 0.15 - 0.14

Power Consumption (Rated) W 15 - 15 17 - 17 15 - 15 17 - 17

Power Factor (Rated) % 51.5 - 50.2 54.5 - 52.8 51.5 - 50.2 54.5 - 52.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 23-5/8 × 27-9/16 × 8-1/4 (600 × 700 × 210) 23-5/8 × 27-9/16 × 8-1/4 (600 × 700 × 210)

Packaged Dimensions (H × W × D) in. (mm) 27-3/8 × 30-15/16 × 11 (696 × 786 × 280) 27-3/8 × 30-15/16 × 11 (696 × 786 × 280)

Weight (Mass) Lbs (kg) 31 (14) 31 (14)

Gross Weight (Gross Mass) Lbs (kg) 40 (18) 40 (18)

Sound Pressure

Level

Outdoor Unit RXL09QMVJU RXL12QMVJU

Casing Color Ivory White Ivory White

Heat Exchanger Fin / Spec. Tube Waffle Fin (PE) / 7 mm Hi-XD Tube Waffle Fin (PE) / 7 mm Hi-XD Tube

Compressor Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Refrigerant Oil Type / Charge oz (L) FVC50K / 12.4 (0.375) FVC50K / 21.5 (0.650)

Refrigerant Type / Charge Lbs (kg) R-410A / 2.09 (0.95) R-410A / 2.09 (0.95)

Airflow Rate H

Fan Type / Motor Output W Propeller / 18 Propeller / 20

Running Current (Rated) A 3.61 - 3.26 3.52 - 3.18 4.06 - 3.67 4.54 - 4.10

Power Consumption (Rated) W 705 - 705 703 - 703 835 - 835 933 - 933

Power Factor (Rated) % 93.9 - 94.0 96.0 - 96.1 98.8 - 98.9 98.8 - 98.9

Starting Current A 3.76 4.54

Dimensions (H × W × D) in. (mm) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284)

Packaged Dimensions (H × W × D) in. (mm) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407)

Weight (Mass) Lbs (kg) 60 (27) 70 (32)

Gross Weight (Gross Mass) Lbs (kg) 71 (32) 80 (36)

Sound Pressure Level H dB(A) 49 49 50 50

Conditions Based on Indoor ; 80°FDB

Drawing No. C: 3D101722 C: 3D101724

Notes SL: The quiet fan level of the airflow rate setting. SL: The quiet fan level of the airflow rate setting.

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL09QMVJU RXL12QMVJU

Btu/h 9,000 (4,400 ~ 10,200) 10,100 (4,400 ~ 14,300) 10,200 (4,400 ~ 12,300) 13,000 (4,400 ~ 17,100)

kcal/h 2,270 (1,120 ~ 2,580) 2,540 (1,120 ~ 3,610) 2,580 (1,120 ~ 3,100) 3,270 (1,120 ~ 4,300)

Liquid in. (mm) 1/4 ( 6.4) 1/4 ( 6.4)

Gas in. (mm) 3/8 ( 9.5) 3/8 ( 9.5)

Drain in. (mm) 13/16 ( 20.0) 13/16 ( 20.0)

oz/ft

(g/m)

M 230 (6.5) 244 (6.9) 237 (6.7) 258 (7.3)

L 169 (4.8) 177 (5.0) 173 (4.9) 184 (5.2)

SL 145 (4.1) 155 (4.4) 159 (4.5) 166 (4.7)

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL

Model 1YC23AUXD 2YC36PXD

Motor Output W 790 1,100

SL 865 (24.5) 777 (22.0) 865 (24.5) 777 (22.0)

cfm

(m³/min)

dB(A) 38 / 32 / 26 / 23 38 / 32 / 26 / 23 39 / 33 / 27 / 24 39 / 33 / 27 / 24

cfm

(m³/min)

Cooling Heating Cooling Heating

0.21 (20) 0.21 (20)

290 (8.2) 311 (8.8) 300 (8.5) 332 (9.4)

1,105 (31.3) 922 (26.1) 1,144 (32.4) 1,006 (28.5)

(26.7°CDB) / 67°FWB

(19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 80°FDB

(26.7°CDB) / 67°FWB

(19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

Piping Length: 25 ft (7.5 m)

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

17 Part 2 Specifications

SiUS091601EA Specifications

Model Indoor Unit FVXS12NVJU FVXS15NVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity Rated (Min. ~ Max.) kW 3.00 (1.30 ~ 3.60) 3.80 (1.30 ~ 5.00) 4.40 (1.70 ~ 5.00) 5.28 (1.70 ~ 7.00)

Moisture Removal gal/h 0.45 — 0.63 —

Running Current (Rated) A 4.20 - 3.80 4.69 - 4.24 6.06 - 5.48 7.00 - 6.33

Power Consumption Rated (Min. ~ Max.) W 850 (270 ~ 1,350) 950 (250 ~ 1,570) 1,200 (320 ~ 1,560) 1,400 (340 ~ 2,190)

Power Factor (Rated) % 97.3 - 97.3 97.4 - 97.4 95.2 - 95.2 96.2 - 96.2

COP Rated (Min. ~ Max.) W/W 3.52 (4.80 ~ 2.66) 4.00 (5.20 ~ 3.18) 3.66 (5.30 ~ 3.20) 3.76 (5.00 ~ 3.20)

EER Rated (Min. ~ Max.) Btu/h·W 12.0 (16.3 ~ 9.1) 13.7 (17.6 ~ 10.9) 12.5 (18.1 ~ 11.0) 12.9 (17.1 ~ 11.0)

SEER / HSPF 20.0 11.4 20.0 11.3

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length ft (m) 65-5/8 (20) 98-1/2 (30)

Max. Interunit Height Difference ft (m) 49-1/4 (15) 65-5/8 (20)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of

Refrigerant

Indoor Unit FVXS12NVJU FVXS15NVJU

Front Panel Color White White

Airflow Rate H

Fan Type / Motor Output W Turbo Fan / 13.4 Turbo Fan / 23.3

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A 0.14 - 0.13 0.15 - 0.14 0.19 - 0.17 0.21 - 0.19

Power Consumption (Rated) W 15 - 15 17 - 17 27 - 27 34 - 34

Power Factor (Rated) % 51.5 - 50.2 54.5 - 52.8 68.3 - 69.1 77.8 - 77.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 23-5/8 × 27-9/16 × 8-1/4 (600 × 700 × 210) 23-5/8 × 27-9/16 × 8-1/4 (600 × 700 × 210)

Packaged Dimensions (H × W × D) in. (mm) 27-3/8 × 30-15/16 × 11 (696 × 786 × 280) 27-3/8 × 30-15/16 × 11 (696 × 786 × 280)

Weight (Mass) Lbs (kg) 31 (14) 31 (14)

Gross Weight (Gross Mass) Lbs (kg) 40 (18) 40 (18)

Sound Pressure

Level

Outdoor Unit RXL12QMVJU9 RXL15QMVJU

Casing Color Ivory White Ivory White

Heat Exchanger Fin / Spec. Tube Waffle Fin (PE) / 7 mm Hi-XD Tube Waffle Fin (PE) / 7 mm Hi-XD Tube

Compressor Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Refrigerant Oil Type / Charge oz (L) FVC50K / 21.5 (0.650) FVC50K / 21.5 (0.650)

Refrigerant Type / Charge Lbs (kg) R-410A / 2.09 (0.95) R-410A / 3.20 (1.45)

Airflow Rate H

Fan Type / Motor Output W Propeller / 20 Propeller / 71

Running Current (Rated) A 4.06 - 3.67 4.54 - 4.10 5.87 - 5.31 6.79 - 6.14

Power Consumption (Rated) W 835 - 835 933 - 933 1,173 - 1,173 1,366 - 1,366

Power Factor (Rated) % 98.8 - 98.9 98.8 - 98.9 96.1 - 96.0 96.7 - 96.7

Starting Current A 4.54 6.79

Dimensions (H × W × D) in. (mm) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320)

Packaged Dimensions (H × W × D) in. (mm) 24-3/4 × 32-11/16 × 16 (629 × 830 × 407) 31-7/8 × 41-9/16 × 18-1/4 (810 × 1,056 × 464)

Weight (Mass) Lbs (kg) 70 (32) 108 (49)

Gross Weight (Gross Mass) Lbs (kg) 80 (36) 123 (56)

Sound Pressure Level H dB(A) 50 50 50 55

Conditions Based on

Drawing No. C: 3D123806 C: 3D101718

Notes SL: The quiet fan level of the airflow rate setting. SL: The quiet fan level of the airflow rate setting.

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL12QMVJU9 RXL15QMVJU

Btu/h 10,200 (4,400 ~ 12,300) 13,000 (4,400 ~ 17,100) 15,000 (5,800 ~ 17,100) 18,000 (5,800 ~ 24,000)

kcal/h 2,580 (1,120 ~ 3,100) 3,270 (1,120 ~ 4,300) 3,780 (1,460 ~ 4,300) 4,540 (1,460 ~ 6,020)

Liquid in. (mm) 1/4 ( 6.4) 1/4 ( 6.4)

Gas in. (mm) 3/8 ( 9.5) 1/2 ( 12.7)

Drain in. (mm) 13/16 ( 20.0) 13/16 ( 20.0)

oz/ft

(g/m)

M 237 (6.7) 258 (7.3) 325 (9.2) 357 (10.1)

L 173 (4.9) 184 (5.2) 275 (7.8) 300 (8.5)

SL 159 (4.5) 166 (4.7) 233 (6.6) 251 (7.1)

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL

Model 2YC36PXD 2YC36PXD

Motor Output W 1,100 1,100

SL 865 (24.5) 777 (22.0) 1,762 (49.9) 1,585 (44.9)

cfm

(m³/min)

dB(A) 39 / 33 / 27 / 24 39 / 33 / 27 / 24 44 / 40 / 36 / 32 45 / 40 / 36 / 32

cfm

(m³/min)

Cooling Heating Cooling Heating

0.21 (20) 0.21 (20)

300 (8.5) 332 (9.4) 378 (10.7) 417 (11.8)

1,144 (32.4) 1,006 (28.5) 2,044 (57.9) 2,044 (57.9)

Indoor ; 80°FDB (26.7°CDB)

/ 67°FWB (19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 80°FDB (26.7°CDB)

/ 67°FWB (19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

/ 75°FWB (24°CWB)

Piping Length: 25 ft (7.5 m)

Indoor ; 70°FDB (21°CDB) /

Piping Length: 25 ft (7.5 m)

60°FWB (15.6°CWB)

Outdoor ; 47°FDB

(8.3°CDB) / 43°FWB

(6°CWB)

Part 2 Specifications 18

Specifications SiUS091601EA

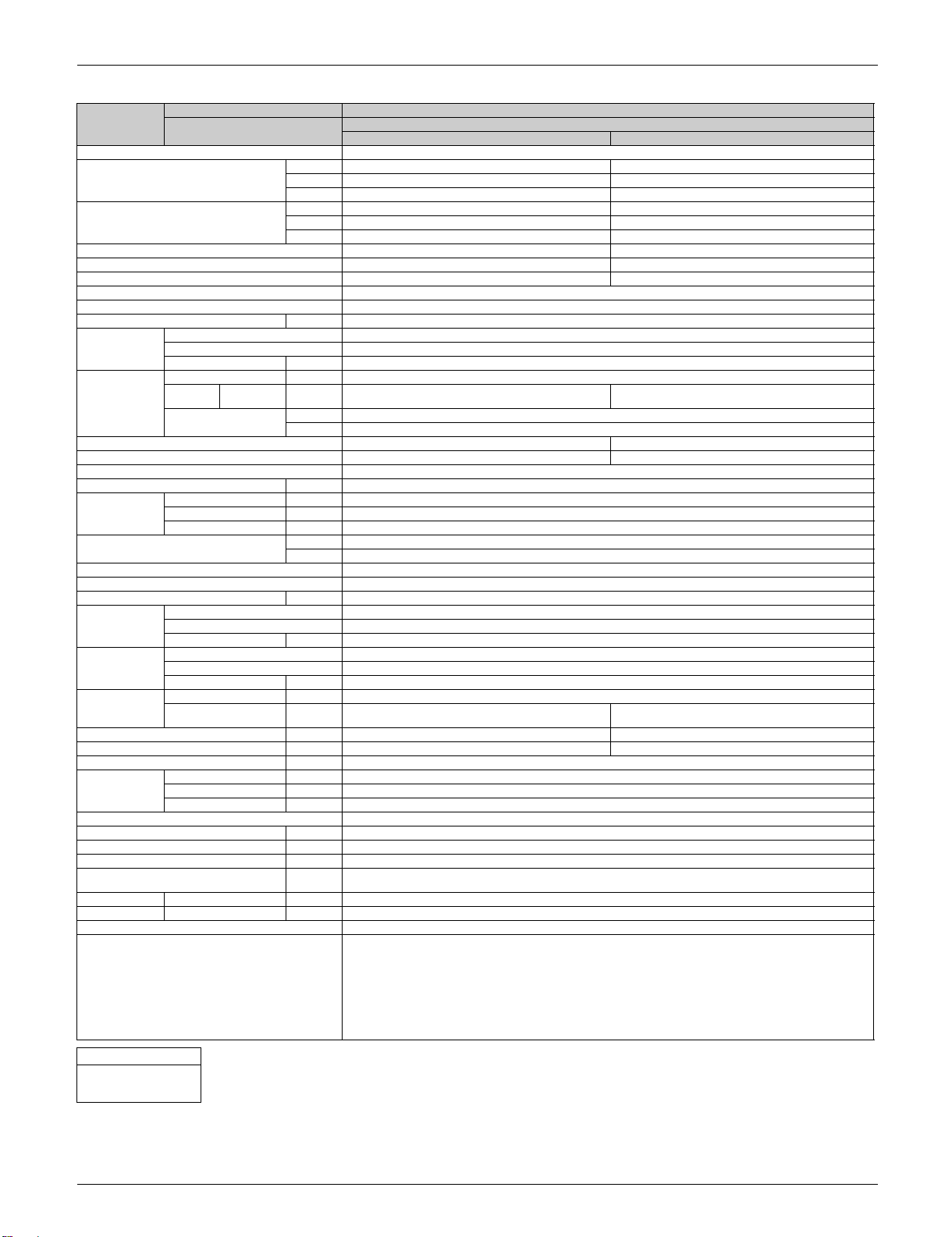

Model Indoor Unit FDMQ12RVJU FDMQ18RVJU

Power Supply 1 , 60 Hz, 208 - 230 V 1 , 60 Hz, 208 - 230 V

Capacity (Min. ~ Max.)

4

Capacity

3, 4

COP (Min. ~ Max.) — 3.70 (4.62 ~ 2.40) — 3.80 (5.28 ~ 2.78)

EER (Min. ~ Max.) 11.7 (14.4 ~ 9.9) — 12.7 (15.8 ~ 11.7) —

SEER / HSPF 18.0 10.8 19.4 10.3

Indoor Unit FDMQ12RVJU FDMQ18RVJU

Casing Color ——

Dimensions (H × W × D) in. (mm) 9-5/8 × 27-9/16 × 31-1/2 (245 × 700 × 800) 9-5/8 × 39-3/8 × 31-1/2 (245 × 1,000 × 800)

Coil Type Cross Fin Coil Cross Fin Coil

Fan Type / Motor Output W Sirocco Fan / 130 Sirocco Fan / 230

Sound Pressure Level 33 33 35 35

Sound Power Level 47 47 49 49

Air Filter — 6— 6

Weight (Mass) / Gross Weight (Gross Mass) Lbs (kg) 64 (29) / 71 (32) 82 (37) / 88 (40)

Piping

Connections

Remote Controller

(Option)

Outdoor Unit RXL12QMVJU9 RXL18UMVJU

Casing Color Ivory White Ivory White

Dimensions (H × W × D) in. (mm) 21-5/8 × 26-9/16 × 11-3/16 (550 × 675 × 284) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320)

Coil Type Cross Fin Coil Cross Fin Coil

Compressor Model 2YC36PXD 2YC63AAXD

Fan Type / Motor Output W Propeller / 20 Propeller / 76

Sound Pressure Level dB(A) 50 50 54 55

Sound Power Level dB(A) 62 62 66 67

Weight (Mass) / Gross Weight (Gross Mass) Lbs (kg) 70 (32) / 80 (36) 130 (59) / 137 (62)

Piping

Connections

Safety Devices Fuse Fuse

Max. Interunit Piping Length ft (m) 65-5/8 (20) 98-1/2 (30)

Max. Interunit Height Difference ft (m) 49-1/4 (15) 65-5/8 (20)

Chargeless ft (m) 32-13/16 (10) 32-13/16 (10)

Amount of Additional Charge of Refrigerant oz/ft

Refrigerant Oil Type / Charge oz (L) FVC50K / 12.4 (0.375) FVC50K / 31.75 (0.900)

Refrigerant Type / Charge Lbs (kg) R-410A / 2.09 (0.95) R-410A / 3.53 (1.60)

Drawing No. C: 3D123805 C: 3D123805

Notes 1 Indoor temp.: 80.0°FDB (26.7°CDB), 67.0°FWB

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL12QMVJU9 RXL18UMVJU

kW 3.18 (1.91 ~ 3.87) 1 3.99 (1.85 ~ 4.98) 2 5.16 (2.64 ~ 5.92) 1 6.33 (2.64 ~ 7.33) 2

Btu/h 10,800 (6,500 ~ 13,200) 1 13,600 (6,300 ~ 17,000) 2 17,600 (9,000 ~ 20,200) 1 21,600 (9,000 ~ 25,000) 2

kcal/h 2,720 (1,640 ~ 3,330) 1 3,430 (1,590 ~ 4,280) 2 4,440 (2,270 ~ 5,090) 1 5,440 (2,270 ~ 6,300) 2

kW — 2.52 — 4.28

Btu/h — 8,600 — 14,600

kcal/h — 2,170 — 3,680

Rows × Stages × Fin per inch 3 × 26 × 18 3 × 26 × 18

Face Area ft² (m²) 1-15/16 (0.178) 3-1/8 (0.288)

Airflow

Rate

External Static

Pressure

Liquid in. (mm) 1/4 (6.4) (Flare) 1/4 (6.4) (Flare)

Gas in. (mm) 3/8 (9.5) (Flare) 1/2 (12.7) (Flare)

Drain in. (mm) I.D. 1 (25) / O.D. 1-1/4 (32) I.D. 1 (25) / O.D. 1-1/4 (32)

Rows × Stages × Fin per inch 2 × 24 × 17 2 × 32 × 18

Face Area ft² (m²) 3-11/16 (0.342) 7-1/16 (0.658)

Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Motor Output W 1,100 1,920

Airflow Rate cfm

Liquid in. (mm) 1/4 (6.4) (Flare) 1/4 (6.4) (Flare)

Gas in. (mm) 3/8 (9.5) (Flare) 1/2 (12.7) (Flare)

Drain in. (mm) I.D. 5/8 (16) I.D. 5/8 (16)

H / M / L cfm

(m³/min)

inH

Pa 50 (150 - 30) 5 50 (150 - 50) 5

Wired BRC1E73 BRC1E73

Wireless BRC082A43 BRC082A43

(m³/min)

(g/m)

O 0.20 (0.60 - 0.12) 5 0.20 (0.60 - 0.20) 5

2

Cooling Heating Cooling Heating

392 / 332 / 275

(11.1 / 9.4 / 7.8)

1,144 (32.4) 1,006 (28.5) 2,418 (68.5) 2,361 (66.9)

0.21 (20) 0.32 (30)

(19.4°CWB) / Outdoor temp.: 95.0°FDB (35.0°CDB) /

Equivalent piping length: 25 ft (7.6 m) / Level difference: 0

2 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.:

47.0°FDB (8.3°CDB), 43.0°FWB (6.1°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

3 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.:

17.0°FDB (-8.3°CDB), 15.0°FWB (-9.4°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

4 Capacities are net, including a deduction for cooling

(an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable in 13 stages by

remote controller.

6 Air filter is not standard accessory, but please mount it

in the duct system of the suction side. Select its dust

collection efficiency (gravity method) 50% or more.

392 / 332 / 275

(11.1 / 9.4 / 7.8)

675 / 572 / 473

(19.1 / 16.2 / 13.4)

1 Indoor temp.: 80.0°FDB (26.7°CDB), 67.0°FWB

(19.4°CWB) / Outdoor temp.: 95.0°FDB (35.0°CDB) /

Equivalent piping length: 25 ft (7.6 m) / Level difference: 0

2 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.:

47.0°FDB (8.3°CDB), 43.0°FWB (6.1°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

3 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.:

17.0°FDB (-8.3°CDB), 15.0°FWB (-9.4°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

4 Capacities are net, including a deduction for cooling

(an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable in 11 stages by

remote controller.

6 Air filter is not standard accessory, but please mount it

in the duct system of the suction side. Select its dust

collection efficiency (gravity method) 50% or more.

675 / 572 / 473

(19.1 / 16.2 / 13.4)

19 Part 2 Specifications

SiUS091601EA Specifications

Model Indoor Unit FDMQ24RVJU

Power Supply 1 , 60 Hz, 208 - 230 V

Cooling Capacity (Min. ~ Max.)

4

Heating Capacity

3, 4

COP (Min. ~ Max.) — 3.80 (5.38 ~ 2.66)

EER (Min. ~ Max.) 12.5 (15.8 ~ 11.4) —

SEER / HSPF 18.6 10.0

Indoor Unit FDMQ24RVJU

Casing Color —

Dimensions (H × W × D) in. (mm) 9-5/8 × 39-3/8 × 31-1/2 (245 × 1,000 × 800)

Coil Type Cross Fin Coil

Fan Type / Motor Output W Sirocco Fan / 230

Sound Pressure Level 40 40

Sound Power Level 54 54

Air Filter — 6

Weight (Mass) / Gross Weight (Gross Mass) Lbs (kg) 82 (37) / 88 (40)

Piping

Connections

Remote Controller

(Option)

Outdoor Unit RXL24UMVJU

Casing Color Ivory White

Dimensions (H × W × D) in. (mm) 28-15/16 × 34-1/4 × 12-5/8 (735 × 870 × 320)

Coil Type Cross Fin Coil

Compressor Model 2YC63AAXD

Fan Type / Motor Output W Propeller / 76

Sound Pressure Level dB(A) 55 55

Sound Power Level dB(A) 67 67

Weight (Mass) / Gross Weight (Gross Mass) Lbs (kg) 130 (59) / 137 (62)

Piping

Connections

Safety Devices Fuse

Max. Interunit Piping Length ft (m) 98-1/2 (30)

Max. Interunit Height Difference ft (m) 65-5/8 (20)

Chargeless ft (m) 32-13/16 (10)

Amount of Additional Charge of Refrigerant oz/ft

Refrigerant Oil Type / Charge oz (L) FVC50K / 31.75 (0.900)

Refrigerant Type / Charge Lbs (kg) R-410A / 3.53 (1.60)

Drawing No. C: 3D123805

Notes 1 Indoor temp.: 80.0°FDB (26.7°CDB), 67.0°FWB (19.4°CWB) / Outdoor temp.: 95.0°FDB (35.0°CDB) / Equivalent

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Outdoor Unit RXL24UMVJU

kW 6.21 (2.64 ~ 7.03) 1 7.02 (2.64 ~ 8.09) 2

Btu/h 21,200 (9,000 ~ 24,000) 1 24,000 (9,000 ~ 27,600) 2

kcal/h 5,340 (2,270 ~ 6,050) 1 6,050 (2,270 ~ 6,960) 2

kW — 4.69

Btu/h — 16,000

kcal/h — 4,030

Rows × Stages × Fin per inch 3 × 26 × 18

Face Area ft² (m²) 3-1/8 (0.288)

Airflow

Rate

External Static

Pressure

Liquid in. (mm) 1/4 (6.4) (Flare)

Gas in. (mm) 5/8 (15.9) (Flare)

Drain in. (mm) I.D. 1 (25) / O.D. 1-1/4 (32)

Rows × Stages × Fin per inch 2 × 32 × 18

Face Area ft² (m²) 7-1/16 (0.658)

Type Hermetically Sealed Swing Type

Motor Output W 1,920

Airflow Rate cfm

Liquid in. (mm) 1/4 (6.4) (Flare)

Gas in. (mm) 5/8 (15.9) (Flare)

Drain in. (mm) I.D. 5/8 (16)

H / M / L cfm

(m³/min)

inH

Pa 50 (150 - 50) 5

Wired BRC1E73

Wireless BRC082A43

(m³/min)

(g/m)

O 0.20 (0.60 - 0.20) 5

2

piping length: 25 ft (7.6 m) / Level difference: 0

2 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.: 47.0°FDB (8.3°CDB), 43.0°FWB (6.1°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

3 Indoor temp.: 70.0°FDB (21.1°CDB) / Outdoor temp.: 17.0°FDB (-8.3°CDB), 15.0°FWB (-9.4°CWB) / Equivalent

piping length: 25 ft (7.6 m) / Level difference: 0

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable in 11 stages by remote controller.

6 Air filter is not standard accessory, but please mount it in the duct system of the suction side. Select its dust

collection efficiency (gravity method) 50% or more.

Cooling Heating

798 / 678 / 558

(22.6 / 19.2 / 15.8)

2,418 (68.5) 2,361 (66.9)

0.32 (30)

798 / 678 / 558

(22.6 / 19.2 / 15.8)

Part 2 Specifications 20

SiUS091601EA

Part 3

Printed Circuit Board

Connector Wiring Diagram

1. Indoor Unit.................................................................................................22

1.1 FTX09/12NMVJU ....................................................................................... 22

1.2 FTX15NMVJU ............................................................................................ 24

1.3 FTX18/24UVJU .......................................................................................... 26

1.4 FVXS09/12/15NVJU................................................................................... 28

1.5 FDMQ12/18/24RVJU ................................................................................. 30

2. Wireless Remote Controller Receiver .......................................................32

2.1 BRC082A43 ............................................................................................... 32

3. Wired Remote Controller...........................................................................33

3.1 BRC1E73 ................................................................................................... 33

4. Outdoor Unit..............................................................................................34

4.1 RXL09QMVJU............................................................................................ 34

4.2 RXL12QMVJU(9) ....................................................................................... 36

4.3 RXL15QMVJU............................................................................................ 38

4.4 RXL18/24UMVJU ....................................................................................... 39

5. Optional Adaptor .......................................................................................42

5.1 BRP072A43 Wireless LAN Adaptor ........................................................... 42

5.2 KRP067A41/KRP980B2 Remote Control PC-board Set............................ 42

21 Part 3 Printed Circuit Board Connector Wiring Diagram

SiUS091601EA Indoor Unit

FG

S32

S26

H3 H2 H1

S6

S200

2P399175-9

FU1

V2

S403

1. Indoor Unit

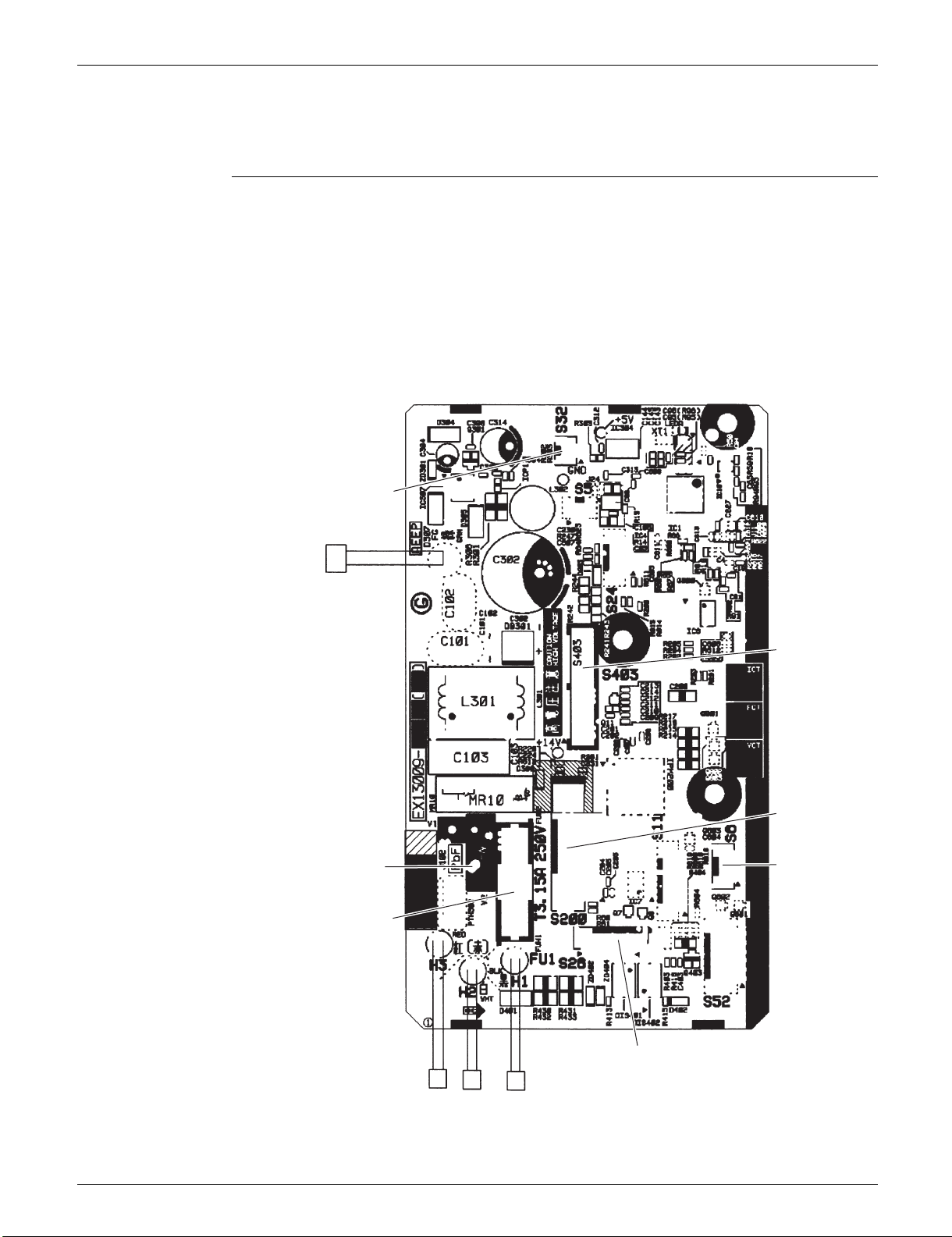

1.1 FTX09/12NMVJU

Control PCB

(PCB1)

1) S6 Connector for swing motor (horizontal blade)

2) S26 Connector for display/signal receiver PCB (PCB2)

3) S32 Connector for indoor heat exchanger thermistor (R2T)

4) S200 Connector for DC fan motor

5) S403 Connector for adaptor PCB (option)

6) H1, H2, H3, FG Connector for terminal strip

7) FU1 Fuse (3.15 A, 250 V)

8) V2 Varistor

Part 3 Printed Circuit Board Connector Wiring Diagram 22

Indoor Unit SiUS091601EA

Note

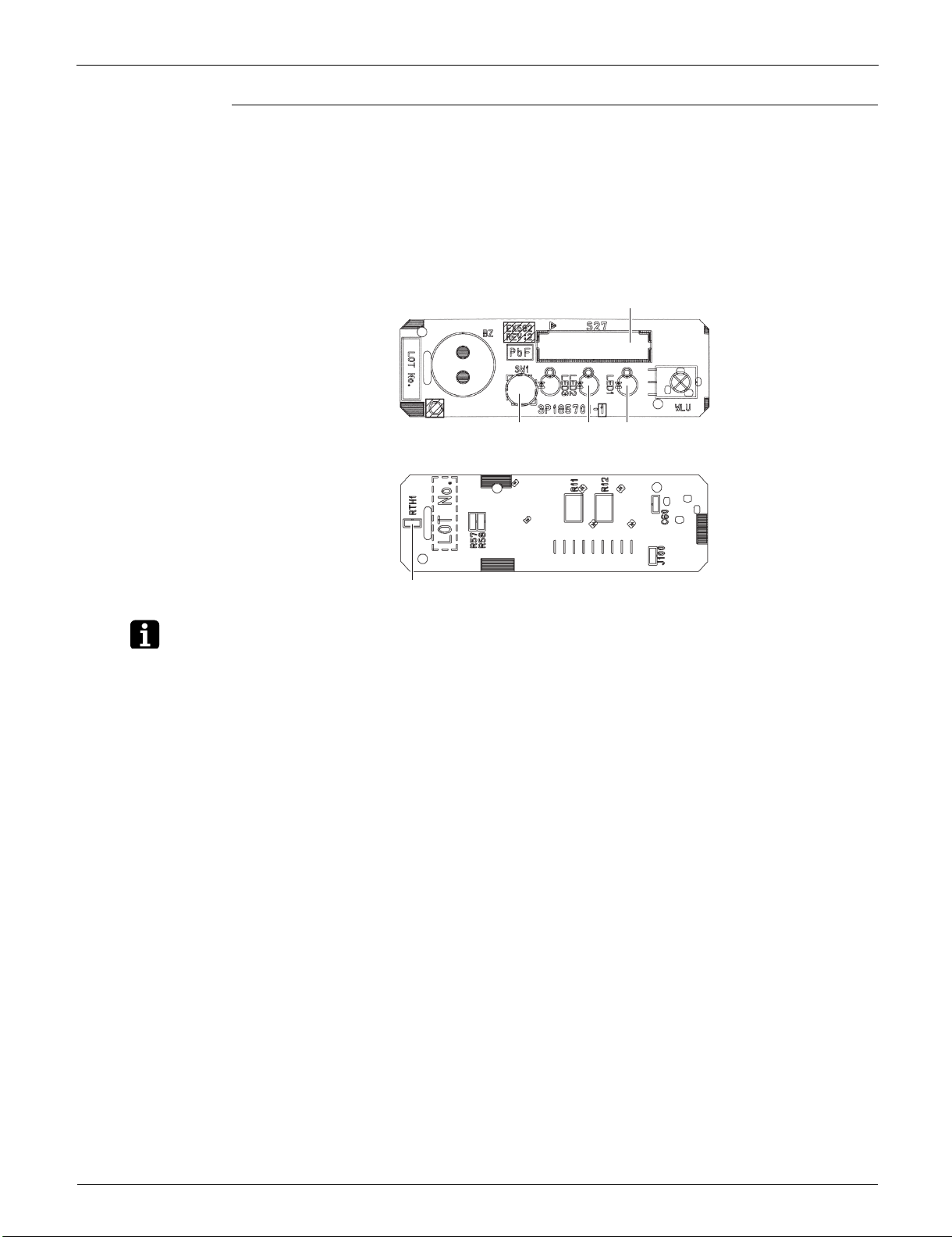

Display/Signal

Receiver PCB

(PCB2)

1) S27 Connector for control PCB (PCB1)

2) SW1 (S1W) Indoor unit ON/OFF switch

(Forced cooling operation ON/OFF switch)

Refer to page 199 for details of forced cooling operation.

3) LED1 (H1P) LED for operation (green)

4) LED2 (H2P) LED for timer (yellow)

5) RTH1 (R1T) Room temperature thermistor

S27

SW1 LED2 LED1

(Solder side)

# LED3 is not mounted.

RTH1

3P185701-4

The symbols in the parenthesis are the names on the appropriate wiring diagram.

23 Part 3 Printed Circuit Board Connector Wiring Diagram

SiUS091601EA Indoor Unit

S26

S900

3P380931-1

S6

S32

S200

S403

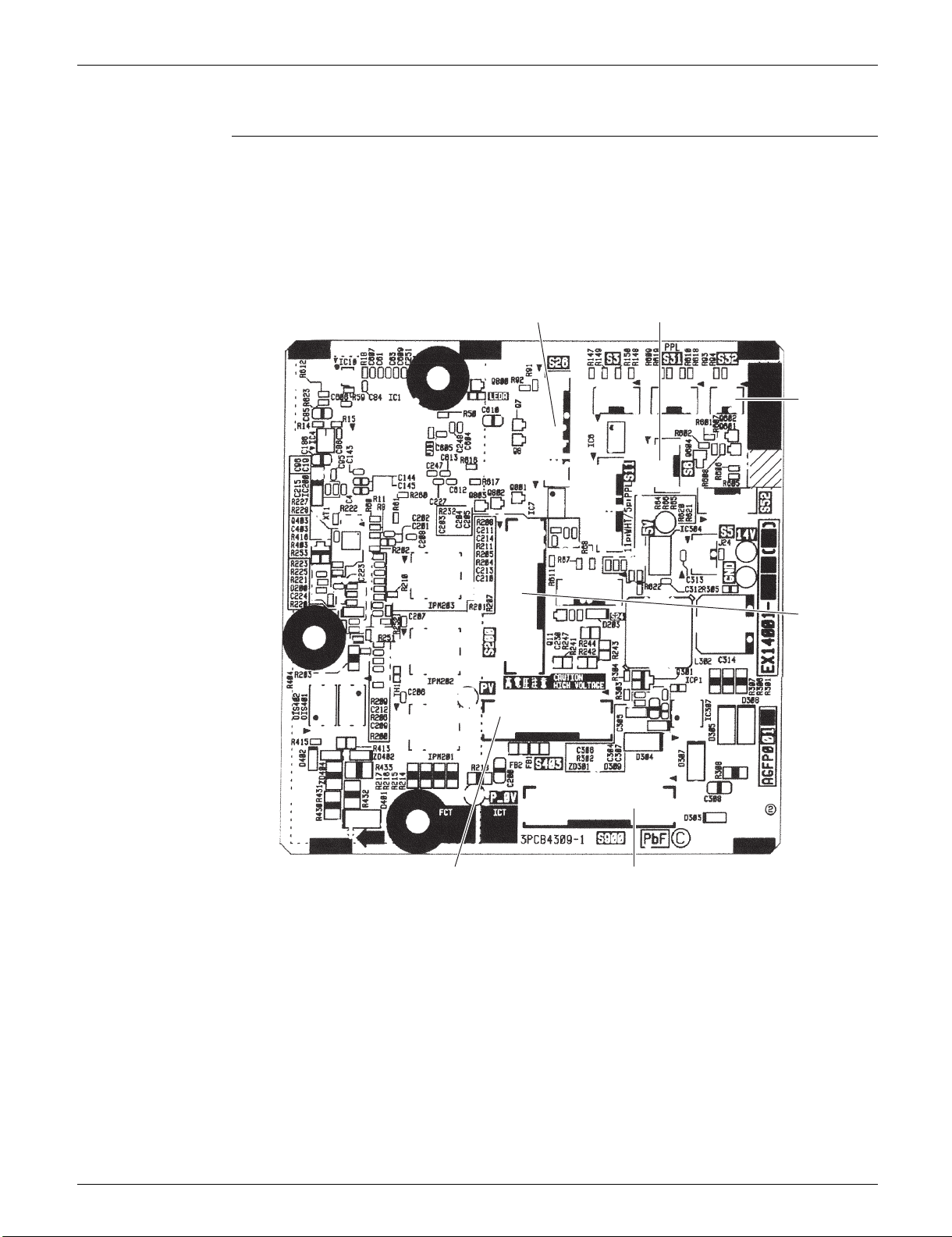

1.2 FTX15NMVJU

Control PCB

(PCB2)

1) S6 Connector for swing motor (horizontal blade)

2) S26 Connector for display/signal receiver PCB (PCB3)

3) S32 Connector for indoor heat exchanger thermistor (R2T)

4) S200 Connector for DC fan motor

5) S403 Connector for adaptor PCB (option)

6) S900 Connector for filter PCB (PCB1)

Part 3 Printed Circuit Board Connector Wiring Diagram 24

Indoor Unit SiUS091601EA

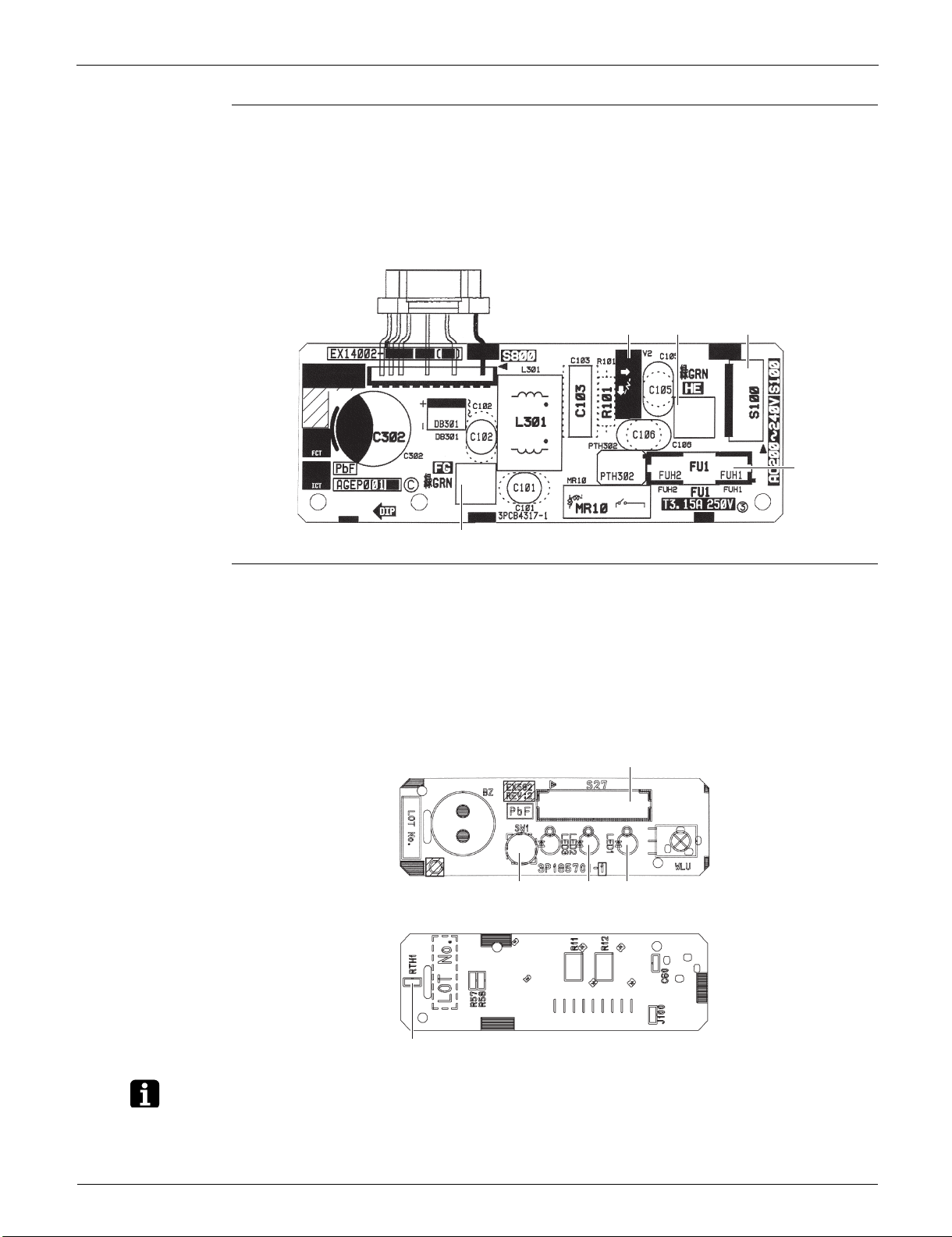

Note

Filter PCB (PCB1)

1) S100 Connector for terminal strip

2) S800 Connector for control PCB (PCB2)

3) FG, HE Connector for ground

4) FU1 Fuse (3.15 A, 250 V)

5) V2 Varistor

S800

V2 HE S100

FU1

Display/Signal

Receiver PCB

(PCB3)

FG

1) S27 Connector for control PCB (PCB2)

2) SW1 (S1W) Indoor unit ON/OFF switch

(Forced cooling operation ON/OFF switch)

Refer to page 199 for details of forced cooling operation.

3) LED1 (H1P) LED for operation (green)

4) LED2 (H2P) LED for timer (yellow)

5) RTH1 (R1T) Room temperature thermistor

SW1 LED2 LED1

# LED3 is not mounted.

(Solder side)

3P380932-1

S27

RTH1

3P185701-4

The symbols in the parenthesis are the names on the appropriate wiring diagram.

25 Part 3 Printed Circuit Board Connector Wiring Diagram

Loading...

Loading...