Daikin RXG09HVJU, FTXG09HVJU, RXG12HVJU, RXG15HVJU, FTXG12HVJU Engineeiring Data

...

EDUS04-906_b

H-Series

- Heat Pump -

EDUS04-906_b

Room Air Conditioners H-Series 1

Split-System

Room Air Conditioners

H-Series

1. Power Supply..............................................................................................2

2. Functions.....................................................................................................3

3. Specifications..............................................................................................4

4. Dimensions .................................................................................................6

5. Wiring Diagrams..........................................................................................7

6. Piping Diagrams..........................................................................................8

7. Capacity Tables ..........................................................................................9

7.1 Heat Pump ................................................................................................... 9

8. Operation Limit..........................................................................................15

9. Sound Level ..............................................................................................16

9.1 Measuring Location .................................................................................... 16

9.2 Octave Band Level ..................................................................................... 17

10.Electric Characteristics..............................................................................19

11.Installation Manual ....................................................................................20

11.1 Indoor Units................................................................................................ 20

11.2 Outdoor Units ............................................................................................. 33

12.Operation Manual......................................................................................40

13.Optional Accessories ................................................................................71

13.1 Option List .................................................................................................. 71

13.2 Installation Manual ..................................................................................... 72

Heat Pump

Quaternity

FTXG09HVJU

FTXG12HVJU

FTXG15HVJU

RXG09HVJU

RXG12HVJU

RXG15HVJU

Power Supply EDUS04-906_b

2 Room Air Conditioners H-Series

1. Power Supply

Note:

Power Supply Intake ; Outdoor Unit

Indoor Units Outdoor Units Power Supply

Quaternity

FTXG09HVJU RXG09HVJU

1

φ, 208-230V, 60HzFTXG12HVJU RXG12HVJU

FTXG15HVJU RXG15HVJU

EDUS04-906_b Functions

Room Air Conditioners H-Series 3

2. Functions

(1) Inverter POWERFUL operation can be used for COOLING, DRY COOLING, and HEATING.

(2) The function setting is cancelled as it is restarted automatically.(3) Temperature display 16~99°F (–9°C~37°C)

Category Functions

FTXG09/12/15HVJU

RXG09/12/15HVJU

Category Functions

FTXG09/12/15HVJU

RXG09/12/15HVJU

Basic

Function

Inverter (with Inverter Power Control) Health &

Clean

Air-Purifying Filter —

Operation Limit for Cooling (°FDB)

14~

109

Photocatalytic Deodorizing Filter —

Operation Limit for Heating (°FWB)

–4~

75

Air-Purifying Filter

with Photocatalytic Deodorizing Function

—

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Energy Saving During Operation Standby —

Compressor Oval Scroll Compressor — Deodorizing Filter for Streamer

Swing Compressor Flash Streamer Air-Purifying

Rotary Compressor — Air Filter (Prefilter)

Reluctance DC Motor Wipe-clean Flat Panel

Comfortable

Airflow

Power-Airflow Flap — Washable Upper Grille

Power-Airflow Dual Flaps Filter Cleaning Indicator (Remote Controller)

Wide-Angle Louvers Mold Proof Operation —

Vertical Auto-Swing (Up and Down) Mold Shock Operation —

Horizontal Auto-Swing (Right and Left) Mold Proof Stick

3-D Airflow Comfort Sleep Operation 2

Comfort Airflow Mode Fresh Air Supply Ventilation —

COOLING BREEZE Operation Home Leave Ventilation —

Comfort

Control

Auto Fan Speed Timer Weekly Timer —

Indoor Unit Quiet Operation 24-Hour ON/OFF Timer

Night Quiet Mode (Automatic) — Count Up-down ON/OFF Timer

OFF only

Outdoor Unit Quiet Operation (Manual) — Night Set Mode

INTELLIGENT EYE — Worry Free

“Reliability &

Durability”

Auto-Restart (after Power Failure)

2-Area INTELLIGENT EYE — Self-Diagnosis (Remote Controller) Display

Quick Warming Function Wiring Error Check —

Hot-Start Function

Anticorrosion Treatment of Outdoor Heat

Exchanger

Automatic Defrosting Flexibility Multi-Split / Split Compatible Indoor Unit —

Operation Automatic Operation H/P, C/O Compatible Indoor Unit —

Humidifying Operation — Chargeless

Drying Operation Either Side Drain (Right or Left)

DRY COOLING Operation Power Selection —

Programme Dry Function —

Low Temperature Cooling Operation

(5°F / -15°C)

—

Fan Only —

°F/°C changeover R/C temperature display

(factory setting : °F)

3

Air-Purifying Operation

Lifestyle

Convenience

New POWERFUL Operation (Non-Inverter) — Remote

Control

5-Rooms Centralized Controller (Option)

Inverter POWERFUL Operation

1

2

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Dry Keep

JP set

Priority-Room Setting —

Remote Control Adaptor

(Normal Open Contact) (Option)

Cooling / Heating Mode Lock —

HOME LEAVE Operation — DIII-NET Compatible (Adaptor) (Option)

ECONO Mode — Remote

Controller

Wireless

Indoor Unit ON/OFF Switch Wired —

Signal Reception Indicator

Multi-colored Indicator

Monitor Brightness Setting

Temperature & Humidity Level Information

Display (Remote Controller)

Childproof Lock

R/C with Back Light —

Note: : Included Functions

— : No Functions

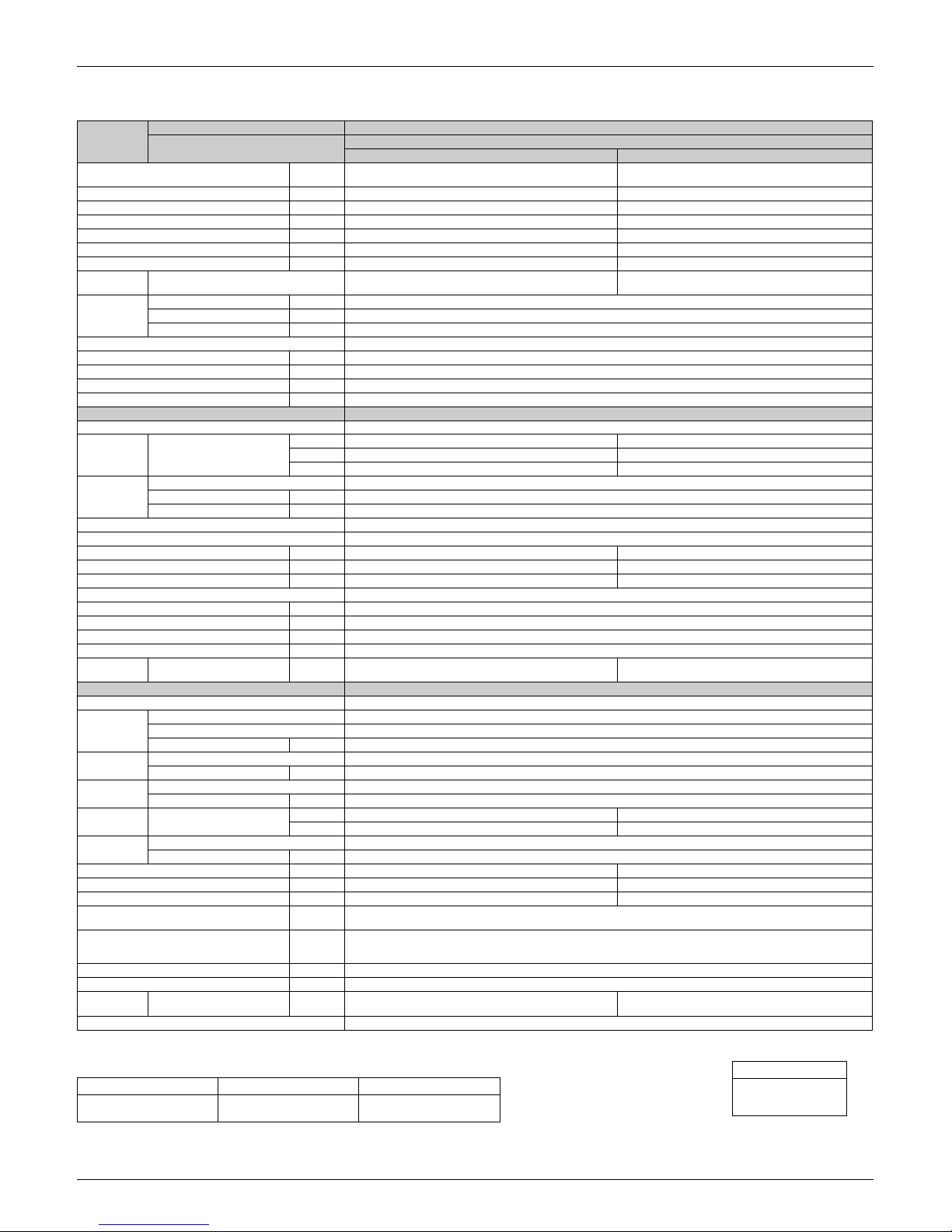

Specifications 60Hz 230V EDUS04-906_b

4 Room Air Conditioners H-Series

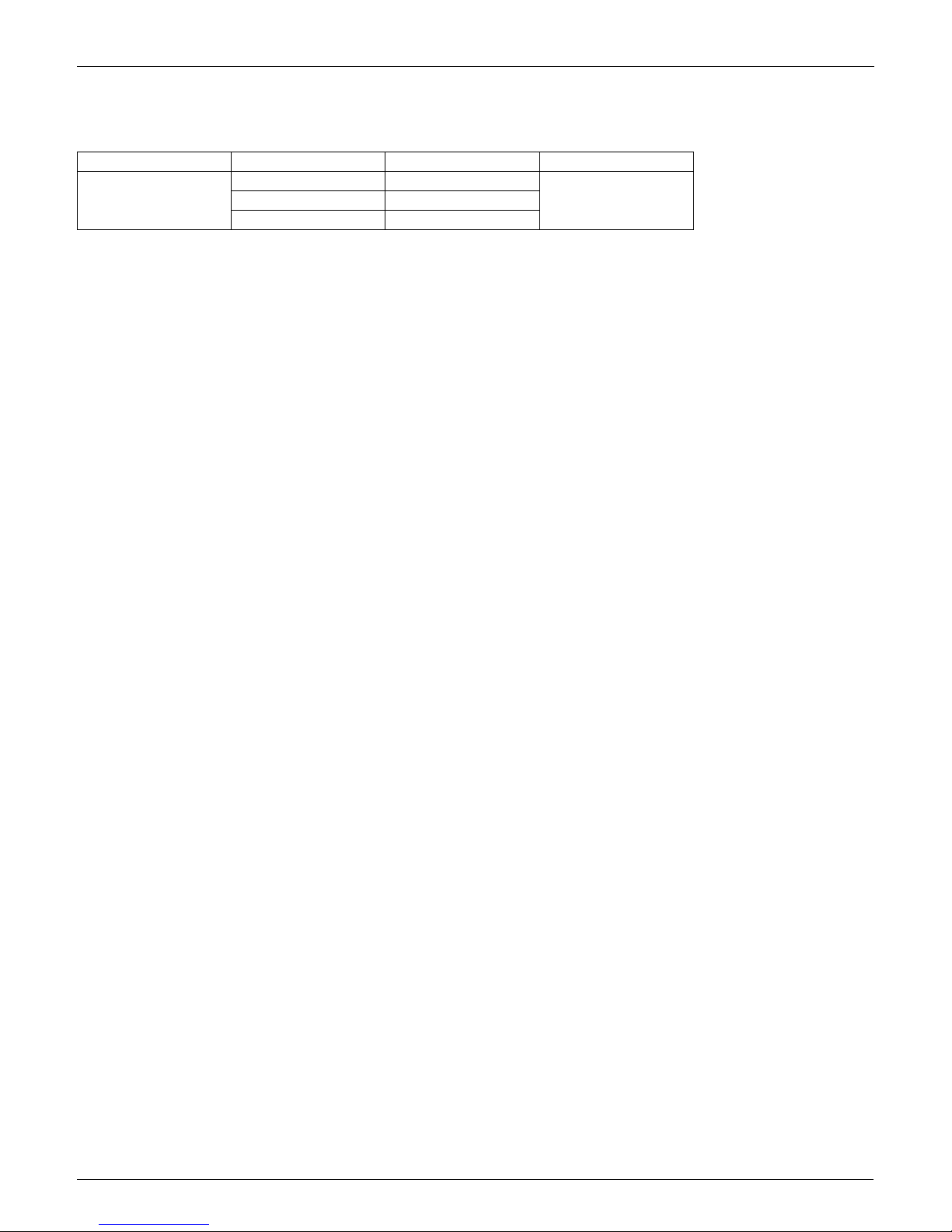

3. Specifications 60Hz 230V

Note:

The data are based on the conditions shown in the table below.

Models

Indoor Units FTXG09HVJU FTXG12HVJU

Outdoor Units

RXG09HVJU RXG12HVJU

Cooling Heating Cooling Heating

Capacity

Rated (Min.~Max.)

Btu/h 9,000 (5,300~12,300) 12,000 (4,400~18,000) 12,000 (5,300~15,700) 16,000 (4,400~19,100)

Moisture Removal Pt/h 3.3 — 4.1 —

Running Current (Rated) A 3.10 4.04 4.30 5.64

Power Consumption Rated

(Min.~Max.)

W 570 (250~900) 780 (220~1,900) 860 (260~1,300) 1,160 (220~2,100)

Power Factor % 80.0 84.0 87.0 89.5

EER (Rated)

Btu/h·W

15.8 — 14.0 —

COP (Rated) W/W — 4.51 — 4.04

Energy

Efficiency

SEER/HSPF 26.1 11.0 24.2 10.6

Piping

Connections

Liquid inch (mm) φ 1/4” (6.4 mmm) φ 1/4” (6.4 mmm)

Gas inch (mm) φ 3/8” (9.5 mm) φ 3/8” (9.5 mm)

Drain

inch (mm)

φ 11/16

” (17.5 mm)

φ 11/16

” (17.5 mm)

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length feet (m) 32 ft (10 m) 32 ft (10 m)

Max. Interunit Height Difference feet (m) 26 ft (8 m) 26 ft (8 m)

Chargeless feet (m) — —

Amount of Additional Charge of

Refrigerant

oz/ft — —

Indoor Units FTXG09HVJU FTXG12HVJU

Front Panel Color White White

Airflow Rate cfm (m³/min)

H 420 (11.9) 438 (12.4) 459 (13.0) 470 (13.3)

M 325 (9.2) 346 (9.8) 346 (9.8) 367 (10.4)

L 230 (6.5) 258 (7.3) 240 (6.8) 272 (7.7)

Fan

Type Cross Flow Fan Cross Flow Fan

Motor Output W 57 57

Speed Steps 5 Steps, Quiet and Auto 5 Steps, Quiet and Auto

Air Direction Control Right, Left, Horizontal and Downward Right, Left, Horizontal and Downward

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.12 0.14 0.14 0.15

Power Consumption (Rated) W 24 26 29 31

Power Factor % 87 80.7 90.1 89.9

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H×W×D) inch (mm) 12 × 35-1/16 × 8-1/4” (305 x 891 x 210 mm) 12 × 35-1/16 × 8-1/4” (305 x 891 x 210 mm)

Packaged Dimensions (H×W×D) inch (mm) 11 × 37-5/8 × 14-7/8” (279 x 956 x 378 mm) 11 × 37-5/8 × 14-7/8” (279 x 956 x 378 mm)

Weight Lbs (kg) 31 lbs (14 kg) 31 lbs (14 kg)

Gross Weight Lbs (kg) 38 lbs (17 kg) 38 lbs (17 kg)

Operation Sound H/M/L dBA 42 / 33 / 26 42 / 35 / 28 43 / 35 / 27 43 / 36 / 29

Outdoor Units RXG09HVJU RXG12HVJU

Casing Color Ivory White Ivory White

Compressor

Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Model 2YC36CXD 2YC36CXD

Motor Output W 1,100 1,100

Refrigerant

Oil

Type FVC50K FVC50K

Charge oz 13.5 13.5

Refrigerant

Type R-410A R-410A

Charge Lbs 3.1 3.1

Airflow Rate cfm (m³/min)

H 1,178 (33.4) 1,095 (31.0) 1,262 (35.7) 1,111 (31.5)

L————

Fan

Type Propeller Propeller

Motor Output W 60 60

Running Current (Rated) A 2.98 3.9 4.16 5.49

Power Consumption (Rated) W 546 754 831 1,129

Power Factor % 79.7 84.1 86.9 89.4

Dimensions (H×W×D) inch (mm)

22-3/8 × 31-5/16 ×11-1/4”

(568 x 795 x 286 mm)

22-3/8 × 31-5/16 ×11-1/4”

(568 x 795 x 286 mm)

Packaged Dimensions (H×W×D)

inch (mm) 25-3/16 ×36-7/16 ×14-7/8”

(568 x 795 x 286 mm

25-3/16 ×36-7/16 ×14-7/8”

(568 x 795 x 286 mm)

Weight Lbs(kg) 99 lbs (45 kg) 99 lbs (45 kg)

Gross Weight Lbs(kg) 104 lbs (32 kg) 104 lbs (32 kg)

Operation

Sound

H / L dBA 46 / — 46 / — 49 / — 48 / —

Drawing No. 3D062857 3D062858

Cooling Heating Piping Length

Indoor ; 80°FDB/67°FWB

Outdoor ; 95°FDB/75°FWB

Indoor ; 70°FDB/60°FWB

Outdoor ; 47°FDB/43°FWB

25ft (7.5 m)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/min×35.3

EDUS04-906_b Specifications 60Hz 230V

Room Air Conditioners H-Series 5

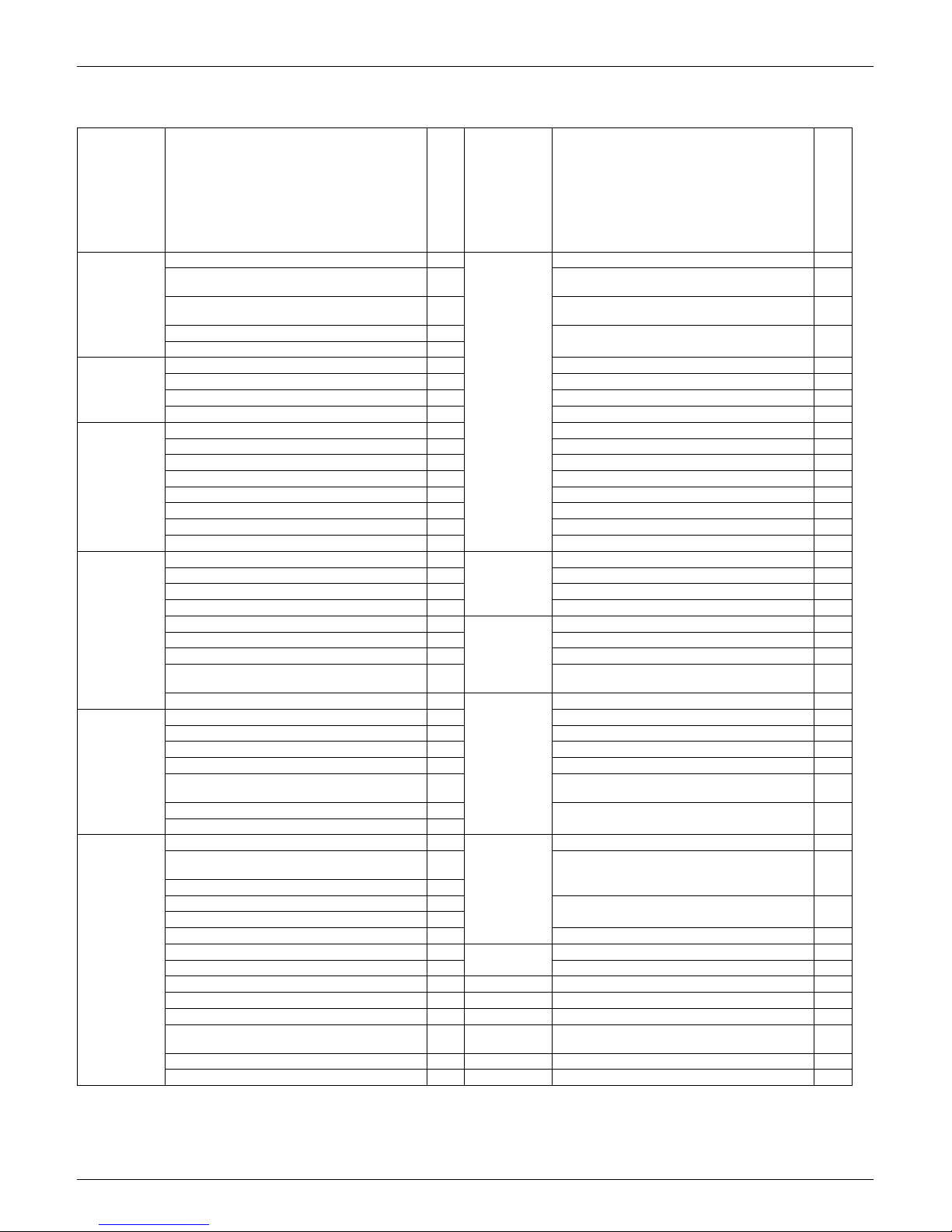

60Hz 230V

Note:

The data are based on the conditions shown in the table below.

Model

Indoor Units FTXG15HVJU

Outdoor Units

RXG15HVJU

Cooling Heating

Capacity

Rated (Min.~Max.)

Btu/h 15,000 (5,300~18,000) 18,000 (4,400~21,200)

Moisture Removal Pt/h 4.8 —

Running Current (Rated) A 5.64 6.36

Power Consumption Rated

(Min.~Max.)

W 1,160 (260~1,930) 1,320 (230~2,120)

Power Factor % 89.0 99.0

EER (Rated)

Btu/h·W

12.9 —

COP (Rated) W/W — 3.99

Energy

Efficiency

SEER/HSPF 21.0 10.0

Piping

Connections

Liquid inch (mm) φ 1/4” (6.4 mmm)

Gas inch (mm) φ 3/8” (9.5 mm)

Drain inch (mm) φ 11/16

” (17.5 mm)

Heat Insulation Both Liquid and Gas Pipes

Max. Interunit Piping Length feet (m) 32’ (10 m)

Max. Interunit Height Difference feet (m) 26’ (8 m)

Chargeless feet (m) —

Amount of Additional Charge of Refrigerant oz/ft —

Indoor Unit FTXG15HVJU

Front Panel Color White

Airflow Rate cfm (m³/min)

H 487 (13.8) 494 (14.0)

M 371 (10.5) 392 (11.1)

L 258 (7.3) 293 (8.3)

Fan

Type Cross Flow Fan

Motor Output W 57

Speed Steps 5 Steps, Quiet, Auto

Air Direction Control Right, Left, Horizontal, Downward

Air Filter Removable / Washable / Mildew Proof

Running Current (Rated) A 0.15 0.16

Power Consumption (Rated) W 33 35

Power Factor % 95.7 95.1

Temperature Control Microcomputer Control

Dimensions (H×W×D) inch (mm) 12 × 35-1/16 × 8-1/4” (305 x 891 x 210 mm)

Packaged Dimensions (H×W×D) inch (mm) 11 × 37-5/8 × 14-7/8” (279 x 956 x 378 mm)

Weight Lbs(kg) 31 lbs (14 kg)

Gross Weight Lbs(kg) 38 lbs (17 kg)

Operation

Sound

H/M/L dBA 45 / 37 / 29 44 / 38 / 31

Outdoor Unit RXG15HVJU

Casing Color Ivory White

Compressor

Type Hermetically Sealed Swing Type

Model 2YC36CXD

Motor Output W 1,100

Refrigerant

Oil

Model FVC50K

Charge oz 13.5

Refrigerant

Model R-410A

Charge Lbs 3.1

Airflow Rate cfm (m³/min)

H 1,262 (35.7) 1,195 (33.8)

L— —

Fan

Type Propeller

Motor Output W 60

Running Current (Rated) A 5.49 6.2

Power Consumption (Rated) W 1,127 1,285

Power Factor % 89.3 90.1

Dimensions (H×W×D) inch (mm)

22-3/8 × 31-5/16 ×11-1/4”

(568 x 795 x 286 mm)

Packaged Dimensions (H×W×D) inch (mm)

25-3/16 ×36-7/16 ×14-7/8”

(568 x 795 x 286 mm)

Weight Lbs (kg) 99

Gross Weight Lbs(kg) 104

Operation

Sound

H / L dBA 50 / — 50 / —

Drawing No. 3D062859

Cooling Heating Piping Length

Indoor ; 80°FDB/67°FWB

Outdoor ; 95°FDB/75°FWB

Indoor ; 70°FDB/60°FWB

Outdoor ; 47°FDB/43°FWB

25 ft (7.5 m)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/min×35.3

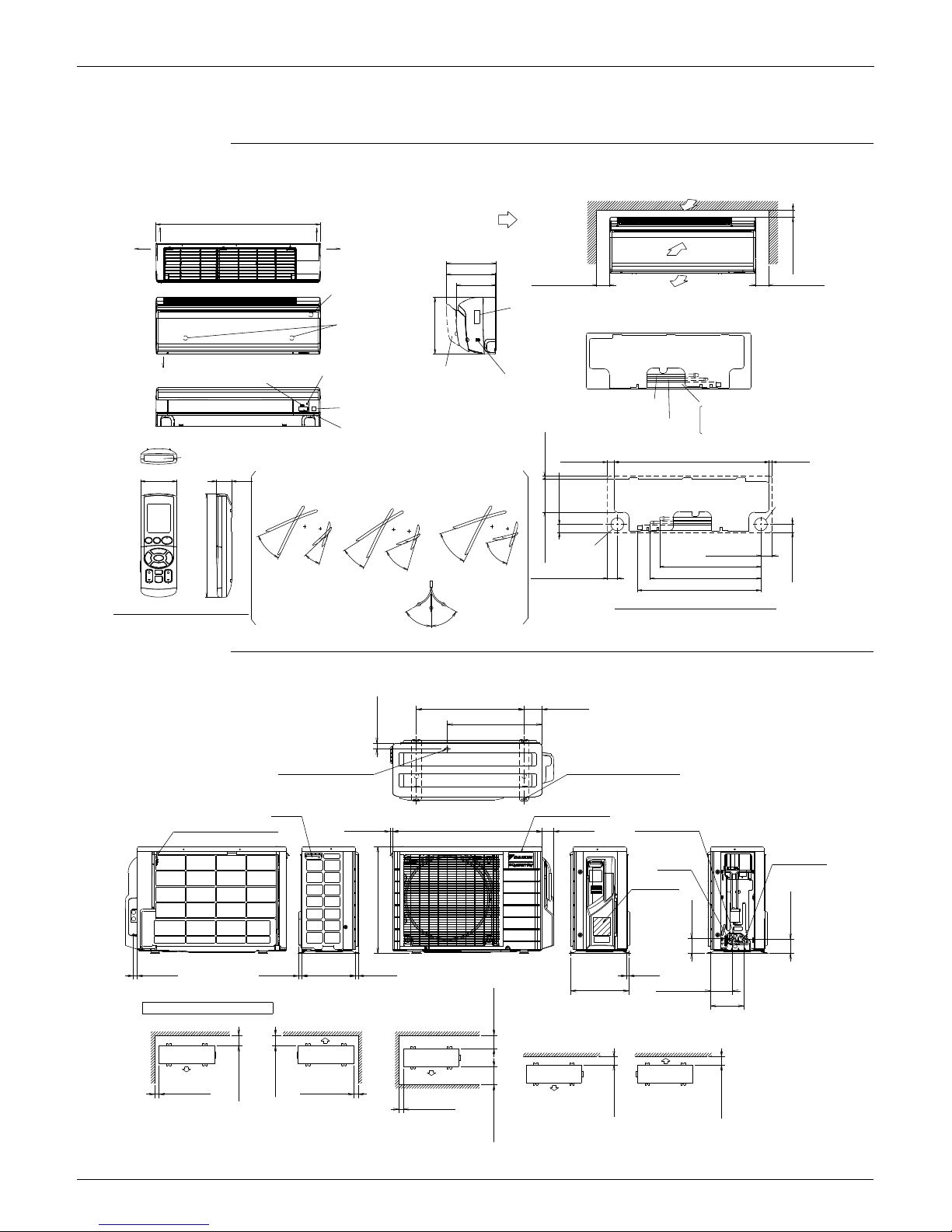

Dimensions EDUS04-906_b

6 Room Air Conditioners H-Series

4. Dimensions

FTXG09/12/15HVJU

RXG09/12/15HVJU

35-1/16(890)

45°

45

°

I.D. φ9/16(14)

CONNECTING PART

O.D. φ11/16(18)

TERMINAL BLOCK WITH EARTH TERMINAL

SIGNAL RECEIVER

55°

30°

25°

70°

APPROX.23-9/16(598)

1-7/16(37)

8-1/4(209)

10-3/4(273)

OPERATING STATE

12 (305)

10-13/16(275)

7-1/8(180.5)

33(838)

STANDARD LOCATIONS OF WALL HOLES

APPROX.25-13/16(655)

1-15/16(50)MIN.

9/16(15)

1-3/4(44.5)

1-3/16(30)MIN.

2-5/16(59.5)

1-15/16(50)MIN.

1-1/16(26.8)

2-1/2(63)

15°

15°

70°

55°

APPROX.21-9/16(548)

1-7/8(47)~2-3/8(60)

AIR FLOW (INDOOR)

1 - 3 / 4 (44.5)

9/16(14.5)

RIGHT/LEFT

(AUTOMATIC)

45°

55°

60°

20°

7-1/16(180)

(SPACE FOR

MAINTENANCE)

UP/DOWN (AUTOMATIC)

SIGNAL TRANSMITTER

WALL HOLE FOR

EMBEDDED PIPING

φ2-9/16(65) HOLE

COOLING

DRY COOLING

DRY

GAS PIPE φ3/8(9.5)Cut

WIRELESS REMOTE CONTROLLER

DRAIN HOSE

HEATING

ROOM TEMP.

THERMISTOR

RIGHT

REQUIRED SPACE

REAR

WALL HOLE

LIQUID PIPE φ1/4(6.4)Cut

AIR PURIFYING

(INDIVIDUAL OPERATION)

(SPACE FOR

PERFORMANCE)

GEAR CASE UNIT FIXED SCREWS

(INSIDE PANEL)

INCLUDING

MOUNTING PLATE

LEFT

(SPACE FOR

PERFORMANCE)

THE MARK (→) SHOWS PIPING DIRECTION

BOTTOM

BLADE ANGLE

(ARC447A3)

φ2-9/16(65)

HOLE

FRONT GRILL FIXED SCREWS

(INSIDE PANEL)

NAME

PLATE

MULTI-COLORED INDICATOR LAMP/

INDOOR UNIT ON/OFF SWITCH

(

)

TIMER LAMP

3D061002

(φ3/8 (9.5) CuT)

GAS STOP VALVE

3-1/8 (79)

31-5/16 (795)

19-7/8 (505)

1/2 (13)

4-5/8 (118)

1-15/16 (50)

OUTDOOR AIR THERMISTOR

1-15/16 (50)

2-15/16 (75)

1-15/16 (50)

5-7/8 (150)

BRAND NAME LABEL

(M8 OR M10)

4-HOLES FOR ANCHOR BOLTS

12-1/4 (311)

22-5/8 (574)

1-3/16 (29.5)

22-3/8 (569)

PORT

SERVICE

5-7/8 (150)

3-15/16 (100)

(φ1/4 (6.4) CuT)

STOP VALVE

LIQUID

11-1/4 (285)

HOSE FOR CONNECTION)

(I.Dφ5/8 (15.9)

DRAIN OUTLET

HANDLE

9/16 (15)

NAME PLATE

2-1/2 (63)

13/16 (20)

11-13/16 (300)

3-3/4 (95.5)

5/8 (15.7)

11/16 (17)

1-15/16 (50)

7 (178)

3-15/16 (100)

= LESS THAN 47-3/16 (1200)

WALL HEIGHT ON AIR OUTLET SIDE

MINIMUM SPACE FOR AIR PASSAGE

STOP VALVE COVER

IN CASE OF REMOVING

UNIT=INCH (mm)

(BASE PITCH)

3D062671A

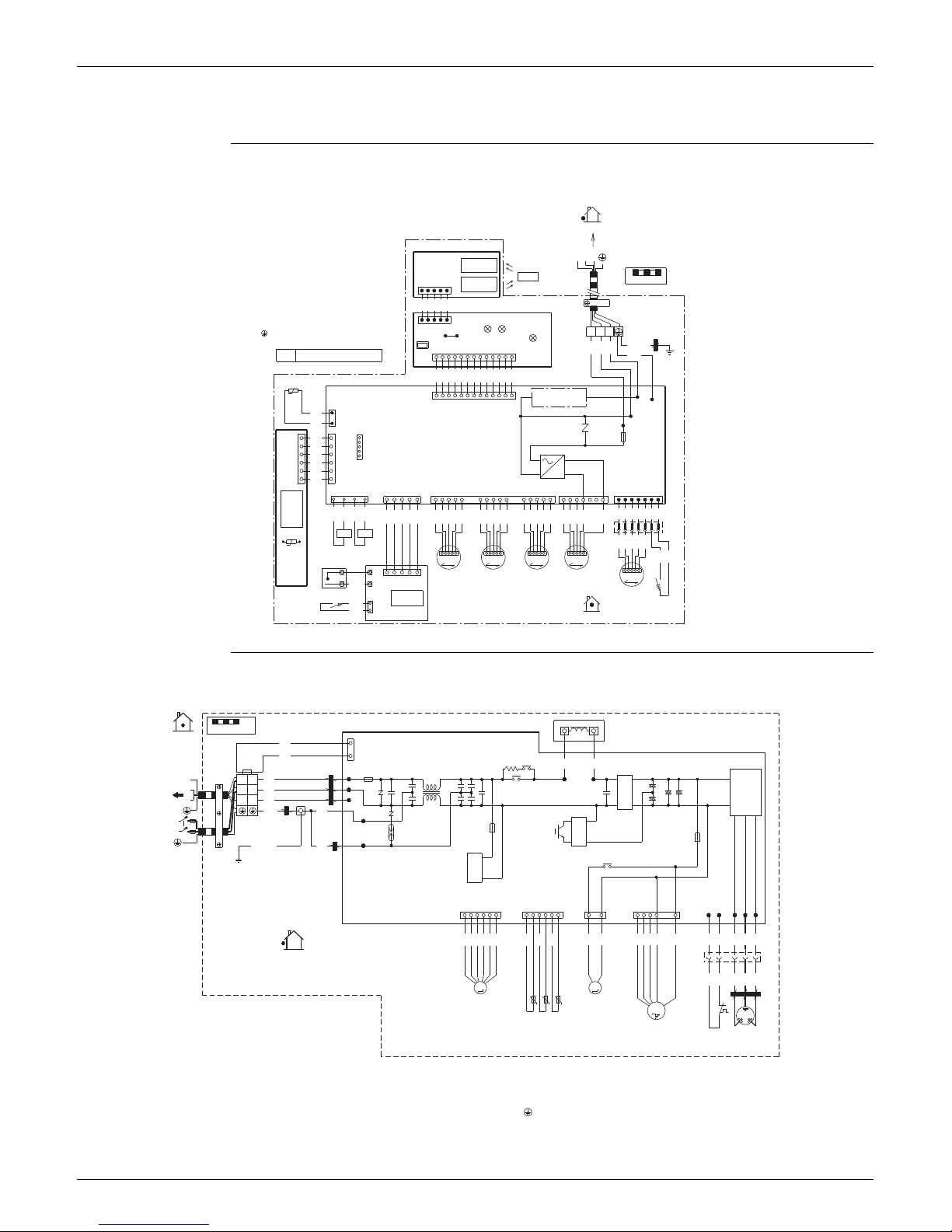

EDUS04-906_b Wiring Diagrams

Room Air Conditioners H-Series 7

5. Wiring Diagrams

FTXG09/12/15HVJU

RXG09/12/15HVJU

FIELD WIRING.

outdoor

R1T

t°

LED2

H2P

M

Y2S

indoor

TURNED OFF AND THEN BACK

RESTART AUTOMATICALLY IF

NOTE THAT OPERATION WILL

THE MAIN POWER SUPPLY IS

ON AGAIN.

CAUTION

SIGNAL

RECEIVER

MM

t°

R2T

Y1S

MULTI

MONITOR

H1P

SIGNAL

TRANSMITTER

LED3

H3P

M

6

RED

S51

5

+

1

BLK

S402

5

4

S1

7

M3S

BLK

JA

Z1C N=4

M2S

GRN

1

1

13

A5P

RED

BLK

S2C

BLK

BLK

RED

BLK

S21

6

S401

H2

HUMIDITY

SENSOR

BLK

1

GRN

S1C

S32

7

BLK

S91

BLK

HIGH VOLTAGE

UNIT

M1F

BLK

1

(16PIN)

ORG

M

JA

A4P

2

YLW

3

BLK

JUMPER

BLK

BLK

ORG

FG

/

BLK

BLK

TRANSMISSION

CIRCUIT

BLK

ORG

A3P

4

BLK

BLU

BLK

R1V

1

CN1

S41

1

-

H1

BLK

PNK

A1P

PNK

BLK

YLW

H3

S43

BLK

BLK

BLU

A2P

ORG

S57

BLK

2

1

BLK

BLK

1

PNK

S52

S1W

YLW

YLW

BLK

BLK

RED

BLK

YLW

RED

YLW

M1S

BLK

AN ADDRESS SETUP OF REMOTECONTROLLER

WHT

BLK

X1M

(H250V,T3.15A)

S403

BLU

BLK

S48

ORG

YLW

13

RED

BLK

STREAMER PART

-

PNK

WHT

BLK

HA

S56

WHT

RED

BLK

1

S46

BLK

M4S

WIRELESS

REMOTE

CONTROLLER

BLK

S58

1

BLU

YLW

ORG

BLU

YLW

BLK

BLU

BRN

BLK

BLK

GRN

: PROTECTIVE GROUND

3

F1U

: FLAME GROUND

: FUSE

: PILOT LAMP

: FAN MOTOR

: PRINTED CIRCUIT BOARD

R1T, R2T

: CONNECTOR

: OPERATION SWITCH

: TERMINAL STRIP

: SWING MOTORM1S~M4S

F1U

M1F

H2P, H3P

S1~S403, CN1

FG

X1M

S1W

: THERMISTOR

A1P~A5P

: MULTI MONITORH1P

: LIM IT SWITCH FOR PANELS1C

: LIM IT SWITCH FOR STREAMERS2C

: VARISTORR1V

: SOLENOID VALVE

Y1S, Y2S

: FERRITE COREZ1C

3D052768C

3

1

2

outdoor

L1R

DB1

NOTE

1. REFER TO THE NAMEPLATE FOR THE POWER REQUIREMENTS.

M

FIELD WIRING.

: PROTECTIVE GROUND

indoor

VW

IPM1

U

(CONDENSER)

BLU

FU1

W

R2T

V

BLK

E2

S70

WHT

X1M : TERMINAL STRIP

102°C

(OUTDOOR)

BLU

(DISCHARGE)

M1F

GRN/YLW

3

MRM20

BLU

YLW

3.15A

WHT

X1A : CONNECTOR

ORG

GRN/

YLW

HL1

6

HR1

3

RED

YLW

Z2C

N=3

WHT

M

Y1R

: REVERSING SOLENOIDE VALVE COIL

1

BLK

L1, L2 : LIVE

Q1L

1

YLW

W

4

R1T

R1T, R2T, R3T : THERMISTOR

MR4, MRM10

MRM20 : MAGNETIC RELAY

BLK

YLW

S80

OL1

Z1C

N=4

ORG

2

1

M1F : FAN MOTOR

U

BLU

PPL

2

PCB1 : PRINTED CIRCUIT BOARD

DB3

FU1, FU2, FU3 : FUSE

1

L2

1

Q1L : OVERLOAD PROTECTOR

X1M

S90

V1

3

M1C

WHT

YLW

S

BRN

3

1

GRN

Z3C

N=3

MRM10

3.15A

WHT

FU3

V2

U

1

RED

S45

MR4

SA1 : SURGE ARRESTER

FU2

Y1E

L1R : REACTOR

L

BLK

YLW

BLK

2

HN1

RED

V1, V2: VARISTOR

Y1E

: ELECTRONIC EXPANSION VALVE COIL

RED

E1

DB1, DB2, DB3 : DIODE BRIDGE

7

BRN

Z4C

N=2

L

DB2

RED

ORG

S20

M

PCB1

X1A

L

1

R3T

IPM1 : INTELLIGENT POWER MODULE

V

M1C : COMPRESSOR MOTOR

YLW

30A

OL2

6

SA1

YLW

BLK

Z1C, Z2C, Z3C, Z4C

: FERRITE CORE

HR2

Y1R

+

_

~

~

+

+

+

_

_

+

+

_

_

_

+

_

~

~

~

~

+

_

t° t° t°

1~

3D061486

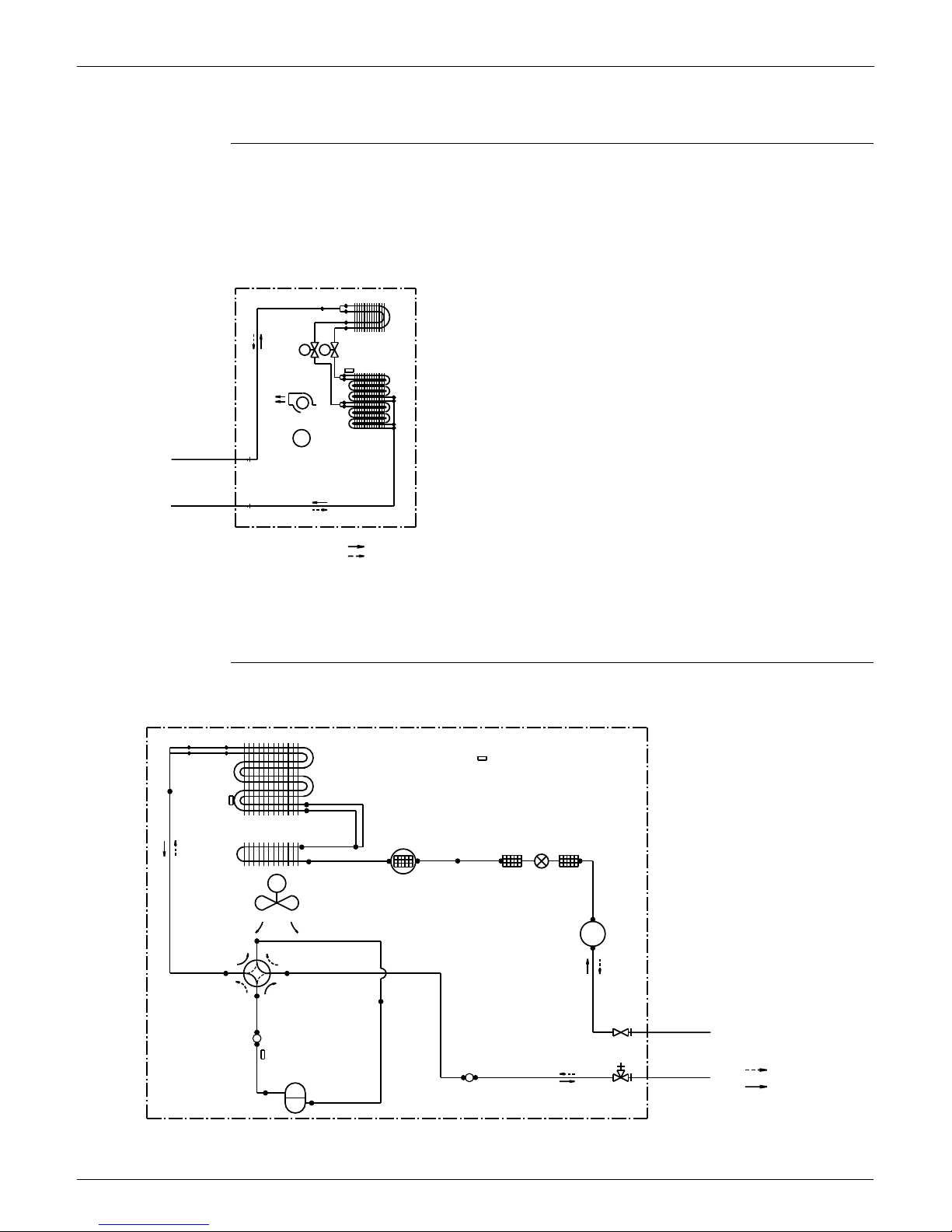

Piping Diagrams EDUS04-906_b

8 Room Air Conditioners H-Series

6. Piping Diagrams

FTXG09/12/15HVJU

RXG09/12/15HVJU

SV

SV

M

(UNDER DEHUMIDIFICATION

OPERATION)

FIELD PIPING

FAN MOTOR

HEATING

HEAT EXCHANGER

SINGLE UNION JOINT

HEAT EXCHANGER

REFRIGERANT FLOW

THERMISTOR

ON HEAT EXCH.

AT RATED VOLTAGE: CLOSED

SINGLE UNION JOINT

SOLENOID VALVE

1/ 4(6.4)CuT

FIELD PIPING

3/8(9.5)CuT

COOLING

1/4(6.4)CuT

CROSS FLOW FAN

INDOOR UNIT

3/8(9.5)CuT

4D061001

OUTDOOR TEMPERATURE

THERMISTOR

(7.9)CuT

FIELD PIPING

(7.9)CuT

COOLING

GAS STOP

VALV E

M

MOTOR

OPERATED

VALV E

OUTDOOR UNIT

FOUR WAY VALVE

ON : HEATING

1/2(12.7)CuT

(3/8(9.5)CuT)

HEAT EXCHANGER

3/8(9.5)CuT

(6.4)CuT

FILTER

(12.7)CuT

LIQUID STOP

VALV E

HEAT

EXCHANGER

THERMISTOR

HEATING

1/2(12.7)CuT

FAN MOTOR

(6.4)CuT

PROPELLER FAN

MUFFLER

WITH

FILTER

FIELD PIPING

1/4(6.4)CuT

1/4(6.4)CuT

MUFFLER

COMPRESSOR

AUXILIARY

HEAT EXCHANGER

DISCHARGE PIPE

THERMISTOR

1/4(6.4)CuT

(7.9)CuT

(1/4(6.4)CuT)

MUFFLER

3/8(9.5)CuT

MUFFLER

FILTER

REFRIGERANT FLOW

1/2(12.7)CuT

1/2

5/16

5/16

9/32(7.0)CuT

9/32(7.0)

CuT

9/32(7.0)CuT

5/16

(7.9)CuT

5/16

UNIT=INCH(mm)

1/4

1/4

3D062171A

EDUS04-906_b Capacity Tables

Room Air Conditioners H-Series 9

7. Capacity Tables

7.1 Heat Pump

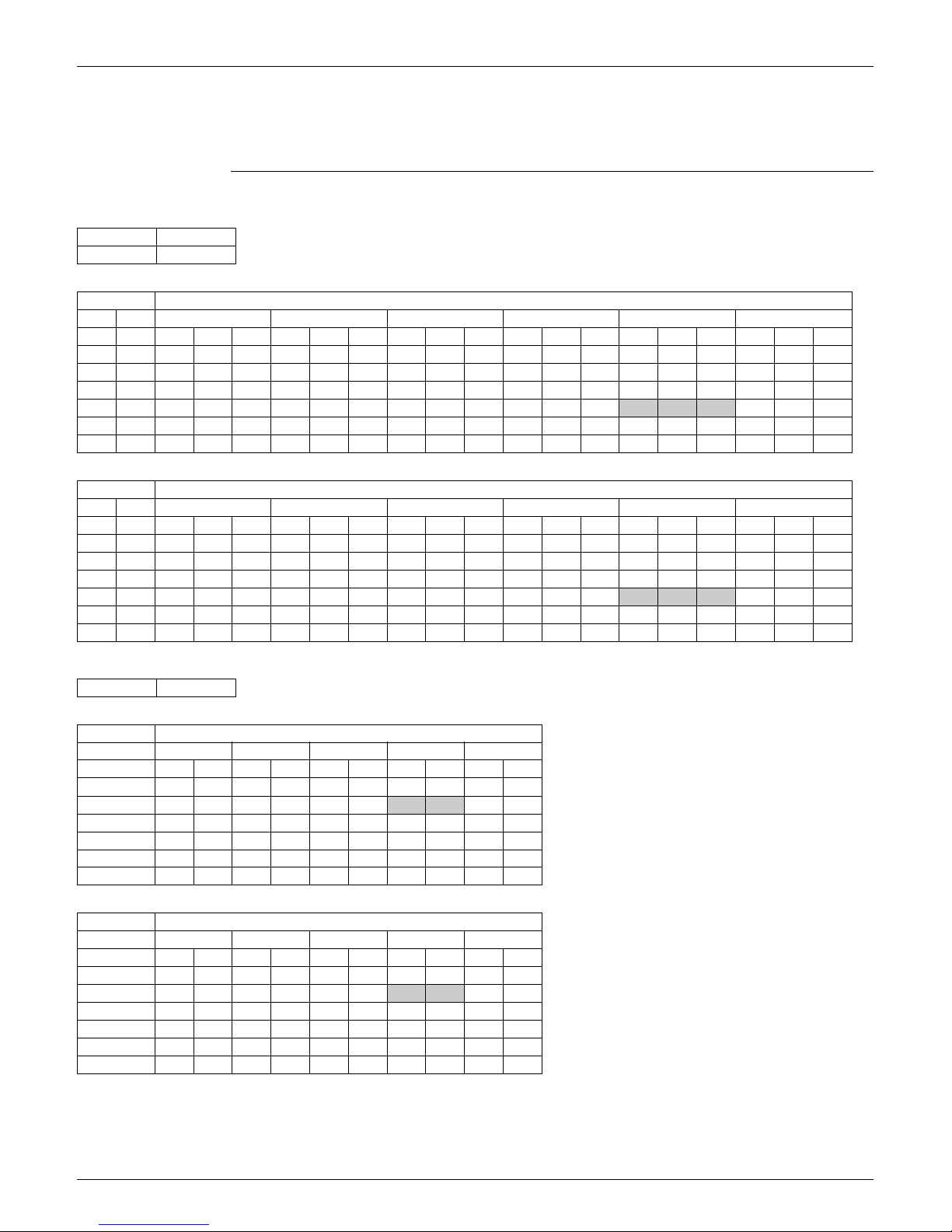

FTXG09HVJU + RXG09HVJU (60Hz 230V)

Cooling

Heating

AFR 11.9

BF 0.10

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CDB)

EWB EDB 20.0 25.0 30.0 32.0 35.0 40.0

°C °C TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

14.0 20 2.702.420.442.582.370.482.462.310.522.412.290.542.342.260.562.212.200.61

16.0 22 2.832.380.442.702.330.482.582.280.522.532.260.542.462.230.572.332.180.61

18.0 25 2.952.560.442.832.510.482.702.460.532.652.440.542.582.410.572.462.370.61

19.426.73.012.750.442.892.700.492.762.660.532.712.640.54

2.64 2.61 0.57 2.52 2.56 0.61

22.0 30 3.192.670.453.072.630.492.952.590.532.902.570.552.822.550.572.702.510.62

24.0 32 3.312.620.453.192.580.493.072.540.533.022.530.552.942.510.582.822.470.62

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FDB)

EWB EDB 68.0 77.0 86.0 89.6 95.0 104.0

°F °F TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

57.268.09.238.270.448.818.080.488.397.890.528.227.810.547.977.700.567.557.520.61

60.871.69.648.140.449.227.960.488.807.780.528.647.710.548.397.610.577.977.440.61

64.4 77.0 10.06 8.72 0.44 9.64 8.56 0.48 9.22 8.39 0.53 9.05 8.33 0.54 8.80 8.23 0.57 8.38 8.07 0.61

67.0 80.0 10.27 9.37 0.44 9.85 9.22 0.49 9.43 9.06 0.53 9.26 9.00 0.54

9.01 8.90 0.57 8.59 8.75 0.61

71.6 86.0 10.89 9.11 0.45 10.47 8.97 0.49 10.05 8.83 0.53 9.88 8.78 0.55 9.63 8.70 0.57 9.21 8.56 0.62

75.2 89.6 11.30 8.93 0.45 10.88 8.81 0.49 10.46 8.68 0.53 10.30 8.63 0.55 10.05 8.56 0.58 9.63 8.43 0.62

AFR 12.4

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CWB)

EDB -10.0 -5.0 0 6.1 10.0

°C TC PI TC PI TC PI TC PI TC PI

15.0 2.39 0.66 2.79 0.69 3.19 0.72 3.67 0.76 3.98 0.78

21.1 2.25 0.68 2.65 0.71 3.04 0.74

3.52 0.78 3.84 0.81

22.0 2.22 0.68 2.62 0.71 3.02 0.74 3.50 0.78 3.81 0.81

24.0 2.18 0.69 2.57 0.72 2.97 0.75 3.45 0.79 3.77 0.82

25.0 2.15 0.69 2.55 0.72 2.95 0.76 3.42 0.79 3.74 0.82

27.0 2.10 0.70 2.50 0.73 2.90 0.76 3.37 0.80 3.69 0.83

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FWB)

EDB 14.0 23.0 32.0 43.0 50.0

°F TC PI TC PI TC PI TC PI TC PI

59.0 8.15 0.66 9.52 0.69 10.88 0.72 12.52 0.76 13.58 0.78

70.0 7.67 0.68 9.03 0.71 10.38 0.74

12.01 0.78 13.10 0.81

71.6 7.57 0.68 8.94 0.71 10.30 0.74 11.94 0.78 13.00 0.81

75.2 7.44 0.69 8.77 0.72 10.13 0.75 11.77 0.79 12.86 0.82

77.0 7.34 0.69 8.70 0.72 10.07 0.76 11.67 0.79 12.76 0.82

80.6 7.17 0.70 8.53 0.73 9.89 0.76 11.50 0.80 12.59 0.83

Capacity Tables EDUS04-906_b

10 Room Air Conditioners H-Series

3D063098A

Symbols Note:

AFR : Airflow rate (m3/min.) 1. Ratings shown are net capacities which include a deduction for indoor fan

motor heat.

2. shows nominal (rated) capacities and power input.

3. TC, PI and SHC must be calculated by interpolation using the figures in

the above tables. (Figures outof the tables should not be used for

calculation.)

4. About SHC which are not mentioned on the table, please calculate them

with around values in direct proportion.

5. Capacities are based on the following conditions.

Corresponding refrigerant piping length : 25ft (7.5 m)

Level difference : 0ft

6. Airflow rate (AFR) and Bypass factor (BF) are tabulated above table.

7. Cooling capacity at -10 degrees Celsius / 14 degrees Fahrenheit.

BF : Bypass factor

EWB : Entering wet bulb temp. (°C) / (°F)

EDB : Entering dry bulb temp. (°C) / (°F)

TC : Total capacity (kW) / (kBtu/h)

SHC : Sensible heating capacity (kW) / (kBtu/h)

PI : Power input (kW)

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR

EWB EDB -10 (°CDB)

°C °C TC SHC PI

14.0 20 3.44 2.77 0.31

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR

EWB EDB 14 (°FDB)

°F °F TC SHC PI

57.2 68.0 11.75 9.44 0.31

EDUS04-906_b Capacity Tables

Room Air Conditioners H-Series 11

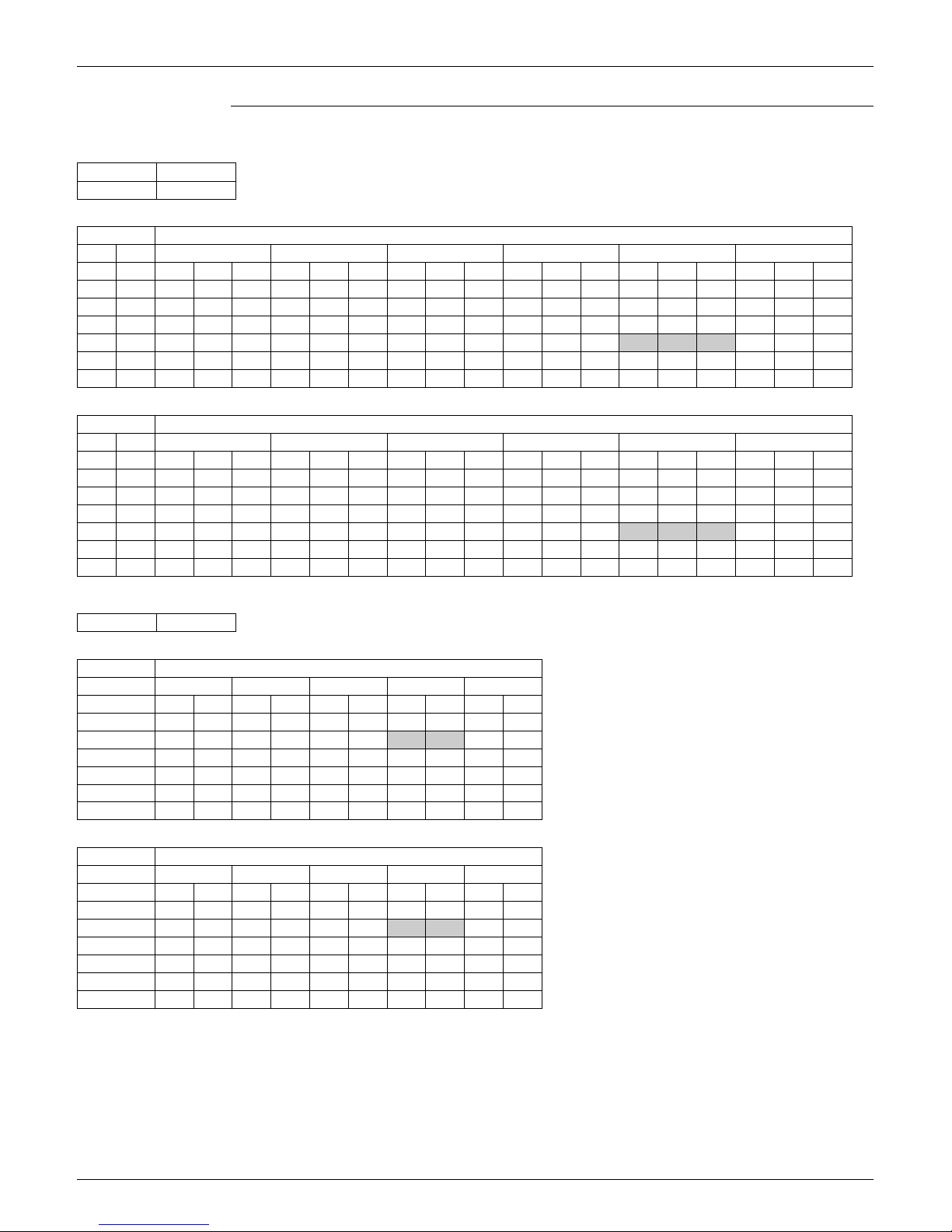

FTXG12HVJU + RXG12HVJU (60Hz 230V)

Cooling

Heating

AFR 13.0

BF 0.14

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CDB)

EWB EDB 20.0 25.0 30.0 32.0 35.0 40.0

°C °F TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

14.0 20 3.612.860.663.442.780.723.282.710.793.212.680.813.112.630.852.952.550.91

16.0 22 3.772.810.663.602.740.733.442.670.793.382.640.823.282.600.853.112.530.92

18.0 25 3.932.980.673.772.910.733.602.840.793.542.810.823.442.770.863.282.710.92

19.426.74.013.160.673.853.100.733.683.030.803.623.010.82

3.52 2.97 0.86 3.36 2.91 0.92

22.0 30 4.253.060.674.093.000.743.932.950.803.862.920.833.762.890.873.602.830.93

24.0 32 4.422.990.684.252.940.744.092.880.814.022.860.833.932.830.873.762.780.93

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FDB)

EWB EDB 68.0 77.0 86.0 89.6 95.0 104.0

°F °F TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

57.2 68.0 12.30 9.77 0.66 11.75 9.50 0.72 11.19 9.24 0.79 10.96 9.13 0.81 10.63 8.98 0.85 10.07 8.72 0.91

60.8 71.6 12.86 9.60 0.66 12.30 9.35 0.73 11.74 9.11 0.79 11.52 9.01 0.82 11.18 8.86 0.85 10.62 8.62 0.92

64.4 77.0 13.41 10.15 0.67 12.85 9.92 0.73 12.29 9.69 0.79 12.07 9.60 0.82 11.73 9.46 0.86 11.17 9.24 0.92

66.9 80.1 13.69 10.80 0.67 13.13 10.57 0.73 12.57 10.35 0.80 12.35 10.26 0.82

12.01 10.13 0.86 11.45 9.91 0.92

71.6 86.0 14.52 10.44 0.67 13.96 10.25 0.74 13.40 10.05 0.80 13.18 9.97 0.83 12.84 9.86 0.87 12.28 9.67 0.93

75.2 89.6 15.07 10.20 0.68 14.51 10.02 0.74 13.95 9.84 0.81 13.73 9.77 0.83 13.39 9.66 0.87 12.83 9.49 0.93

AFR 13.3

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CWB)

EDB -10.0 -5.0 0 6.1 10.0

°C TC PI TC PI TC PI TC PI TC PI

15.0 3.19 0.98 3.72 1.02 4.25 1.07 4.88 1.13 5.31 1.17

21.1 3.00 1.01 3.52 1.05 4.05 1.10

4.69 1.16 5.11 1.20

22.0 2.96 1.01 3.49 1.06 4.02 1.11 4.66 1.17 5.08 1.20

24.0 2.90 1.02 3.43 1.07 3.96 1.12 4.59 1.18 4.72 1.18

25.0 2.87 1.03 3.40 1.08 3.92 1.12 4.52 1.17 4.52 1.16

27.0 2.80 1.04 3.33 1.09 3.86 1.13 4.11 1.13 4.11 1.12

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FWB)

EDB 14.0 23.0 32.0 43.0 50.0

°F TC PI TC PI TC PI TC PI TC PI

59.0 10.88 0.98 12.69 1.02 14.50 1.07 16.65 1.13 18.12 1.17

70.0 10.22 1.01 12.03 1.05 13.83 1.10

16.00 1.16 17.45 1.20

71.6 10.10 1.01 11.91 1.06 13.72 1.11 15.90 1.17 17.33 1.20

75.2 9.89 1.02 11.70 1.07 13.51 1.12 15.66 1.18 16.11 1.18

77.0 9.79 1.03 11.60 1.08 13.38 1.12 15.41 1.17 15.41 1.16

80.6 9.55 1.04 11.36 1.09 13.17 1.13 14.01 1.13 14.01 1.12

Capacity Tables EDUS04-906_b

12 Room Air Conditioners H-Series

3D063099A

Symbols Note:

AFR : Airflow rate (m3/min.) 1. Ratings shown are net capacities which include a deduction for indoor fan

motor heat.

2. shows nominal (rated) capacities and power input.

3. TC, PI and SHC must be calculated by interpolation using the figures in

the above tables. (Figures out of the tables should not be used for

calculation.)

4. About SHC which are not mentioned on the table, please calculate them

with around values in direct proportion.

5. Capacities are based on the following conditions.

Corresponding refrigerant piping length : 25ft (7.5 m)

Level difference : 0ft

6. Airflow rate (AFR) and Bypass factor (BF) are tabulated above table.

7. Cooling capacity at -10 degrees Celsius / 14 degrees Fahrenheit.

BF : Bypass factor

EWB : Entering wet bulb temp. (°C) / (°F)

EDB : Entering dry bulb temp. (°C) / (°F)

TC : Total capacity (kW) / (kBtu/h)

SHC : Sensible heating capacity (kW) / (kBtu/h)

PI : Power input (kW)

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR

EWB EDB -10 (°CDB)

°C °C TC SHC PI

14.0 20 3.65 2.66 0.47

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR

EWB EDB 14 (°FDB)

°F °F TC SHC PI

57.2 68.0 12.45 9.08 0.47

EDUS04-906_b Capacity Tables

Room Air Conditioners H-Series 13

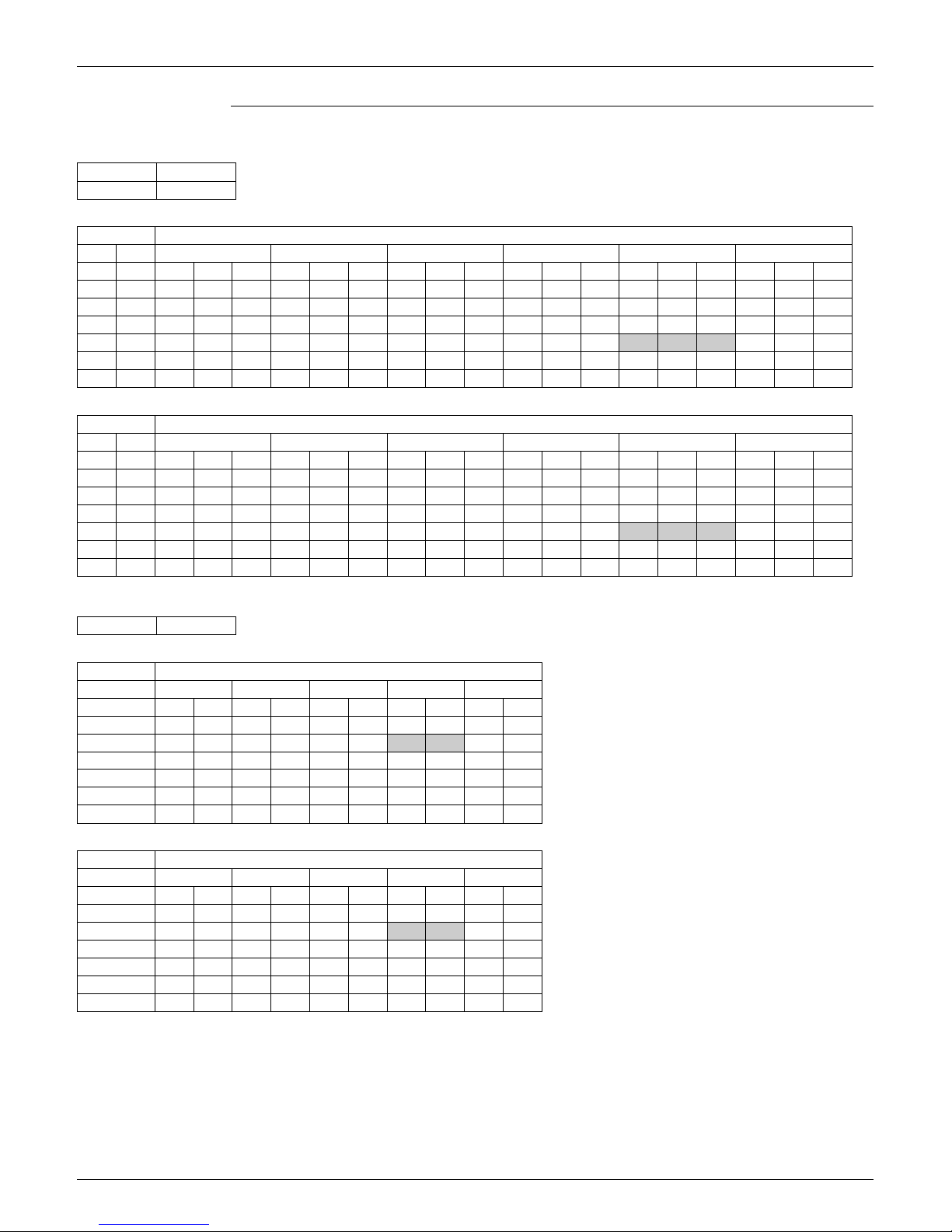

FTXG15HVJU + RXG15HVJU (60Hz 230V)

Cooling

Heating

AFR 13.8

BF 0.16

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CDB)

EWB EDB 20.0 25.0 30.0 32.0 35.0 40.0

°C °C TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

14.0 20 4.513.360.894.303.260.984.103.151.064.023.111.103.893.051.153.692.961.23

16.0 22 4.713.300.904.513.200.984.303.111.074.223.071.104.103.011.153.892.921.24

18.0 25 4.913.460.904.713.370.994.503.281.074.423.241.114.303.191.164.093.111.24

19.426.75.013.650.904.813.560.994.603.481.074.523.441.11

4.40 3.39 1.16 4.20 3.31 1.25

22.0 30 5.323.520.915.113.441.004.913.371.084.833.341.124.703.291.174.503.221.25

24.0 32 5.523.430.925.323.361.005.113.291.095.033.261.124.913.221.174.703.151.26

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FDB)

EWB EDB 68.0 77.0 86.0 89.6 95.0 104.0

°F °F TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI TC SHC PI

57.2 68.0 15.38 11.46 0.89 14.68 11.11 0.98 13.98 10.76 1.06 13.70 10.62 1.10 13.28 10.42 1.15 12.58 10.08 1.23

60.8 71.6 16.07 11.26 0.90 15.37 10.93 0.98 14.67 10.60 1.07 14.39 10.48 1.10 13.98 10.28 1.15 13.28 9.97 1.24

64.4 77.0 16.76 11.80 0.90 16.07 11.49 0.99 15.37 11.19 1.07 15.09 11.07 1.11 14.67 10.89 1.16 13.97 10.60 1.24

67.0 80.0 17.11 12.45 0.90 16.41 12.15 0.99 15.71 11.86 1.07 15.43 11.75 1.11

15.01 11.58 1.16 14.31 11.29 1.25

71.6 86.0 18.15 12.00 0.91 17.45 11.75 1.00 16.75 11.49 1.08 16.47 11.39 1.12 16.05 11.24 1.17 15.35 10.98 1.25

75.2 89.6 18.84 11.69 0.92 18.14 11.45 1.00 17.44 11.22 1.09 17.16 11.13 1.12 16.74 10.99 1.17 16.04 10.76 1.26

AFR 14.0

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR TEMPERATURE (°CWB)

EDB -10.0 -5.0 0 6.1 10.0

°C TC PI TC PI TC PI TC PI TC PI

15.0 3.59 1.11 4.19 1.16 4.78 1.22 5.50 1.28 5.98 1.33

21.1 3.37 1.15 3.97 1.20 4.56 1.25

5.28 1.32 5.62 1.34

22.0 3.34 1.15 3.93 1.21 4.53 1.26 5.24 1.33 5.41 1.32

24.0 3.26 1.16 3.86 1.22 4.46 1.27 4.97 1.31 4.97 1.28

25.0 3.23 1.17 3.82 1.22 4.42 1.28 4.76 1.28 4.76 1.26

27.0 3.15 1.18 3.75 1.24 4.33 1.29 4.33 1.23 4.33 1.20

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR TEMPERATURE (°FWB)

EDB 14.0 23.0 32.0 43.0 50.0

°F TC PI TC PI TC PI TC PI TC PI

59.0 12.25 1.11 14.29 1.16 16.32 1.22 18.76 1.28 20.39 1.33

70.0 11.51 1.15 13.54 1.20 15.57 1.25

18.02 1.32 19.19 1.34

71.6 11.38 1.15 13.42 1.21 15.45 1.26 17.89 1.33 18.45 1.32

75.2 11.13 1.16 13.17 1.22 15.20 1.27 16.97 1.31 16.97 1.28

77.0 11.01 1.17 13.04 1.22 15.08 1.28 16.23 1.28 16.23 1.26

80.6 10.76 1.18 12.79 1.24 14.76 1.29 14.76 1.23 14.76 1.20

Capacity Tables EDUS04-906_b

14 Room Air Conditioners H-Series

3D063100A

Symbols Note:

AFR : Airflow rate (m3/min.) 1. Ratings shown are net capacities which include a deduction for indoor fan

motor heat.

2. shows nominal (rated) capacities and power input.

3. TC, PI and SHC must be calculated by interpolation using the figures in

the above tables. (Figures out of the tables should not be used for

calculation.)

4. About SHC which are not mentioned on the table, please calculate them

with around values in direct proportion.

5. Capacities are based on the following conditions.

Corresponding refrigerant piping length : 25ft (7.5 m)

Level difference : 0ft

6. Airflow rate (AFR) and Bypass factor (BF) are tabulated above table.

7. Cooling capacity at -10 degrees Celsius / 14 degrees Fahrenheit.

BF : Bypass factor

EWB : Entering wet bulb temp. (°C) / (°F)

EDB : Entering dry bulb temp. (°C) / (°F)

TC : Total capacity (kW) / (kBtu/h)

SHC : Sensible heating capacity (kW) / (kBtu/h)

PI : Power input (kW)

Temp: Celsius / TC, SHC, PI: kW

INDOOR OUTDOOR

EWB EDB -10 (°CDB)

°C °C TC SHC PI

14.0 20 3.66 2.70 0.46

Temp: Fahrenheit / TC, SHC: kBtu / PI: kW

INDOOR OUTDOOR

EWB EDB 14 (°FDB)

°F °F TC SHC PI

57.2 68.0 12.49 9.21 0.46

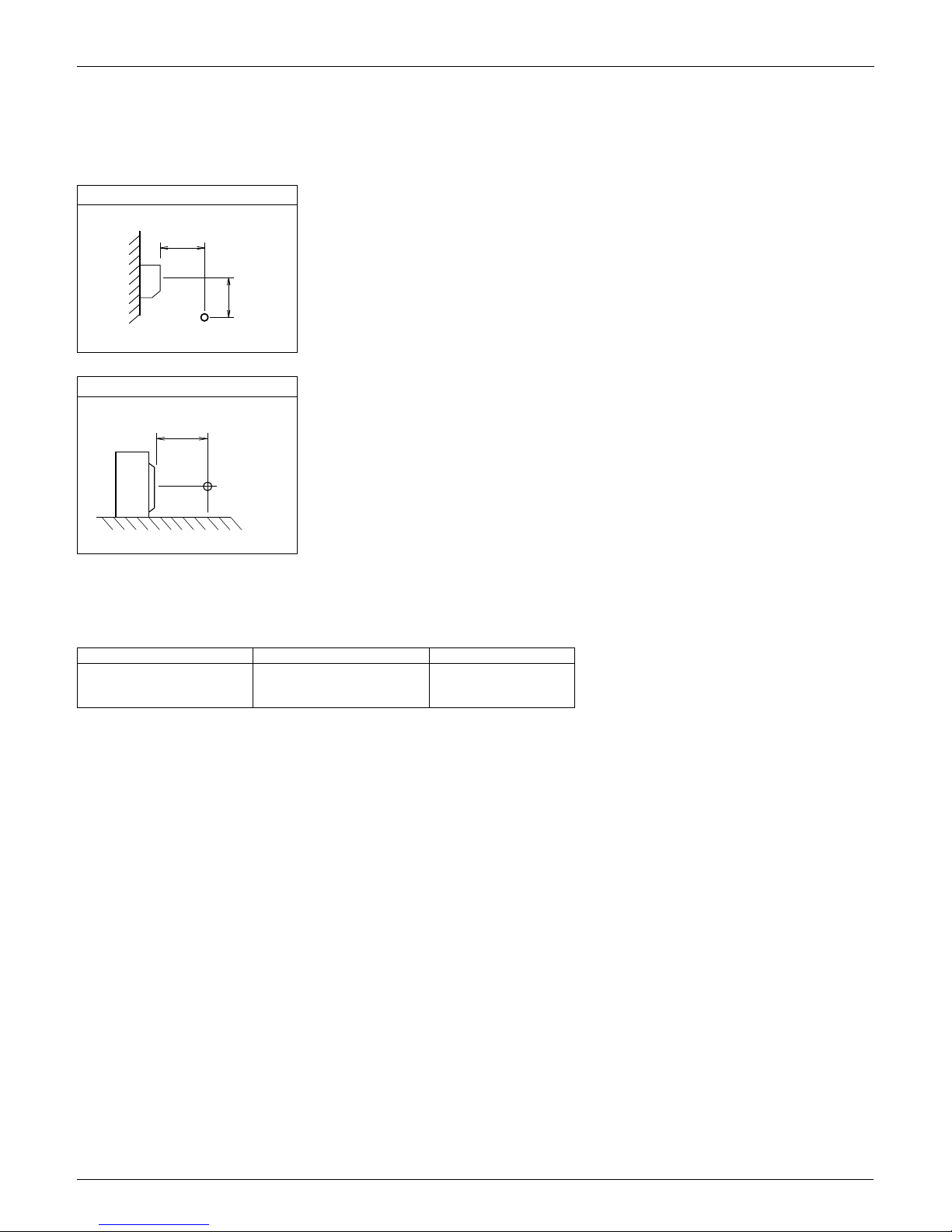

EDUS04-906_b Operation Limit

Room Air Conditioners H-Series 15

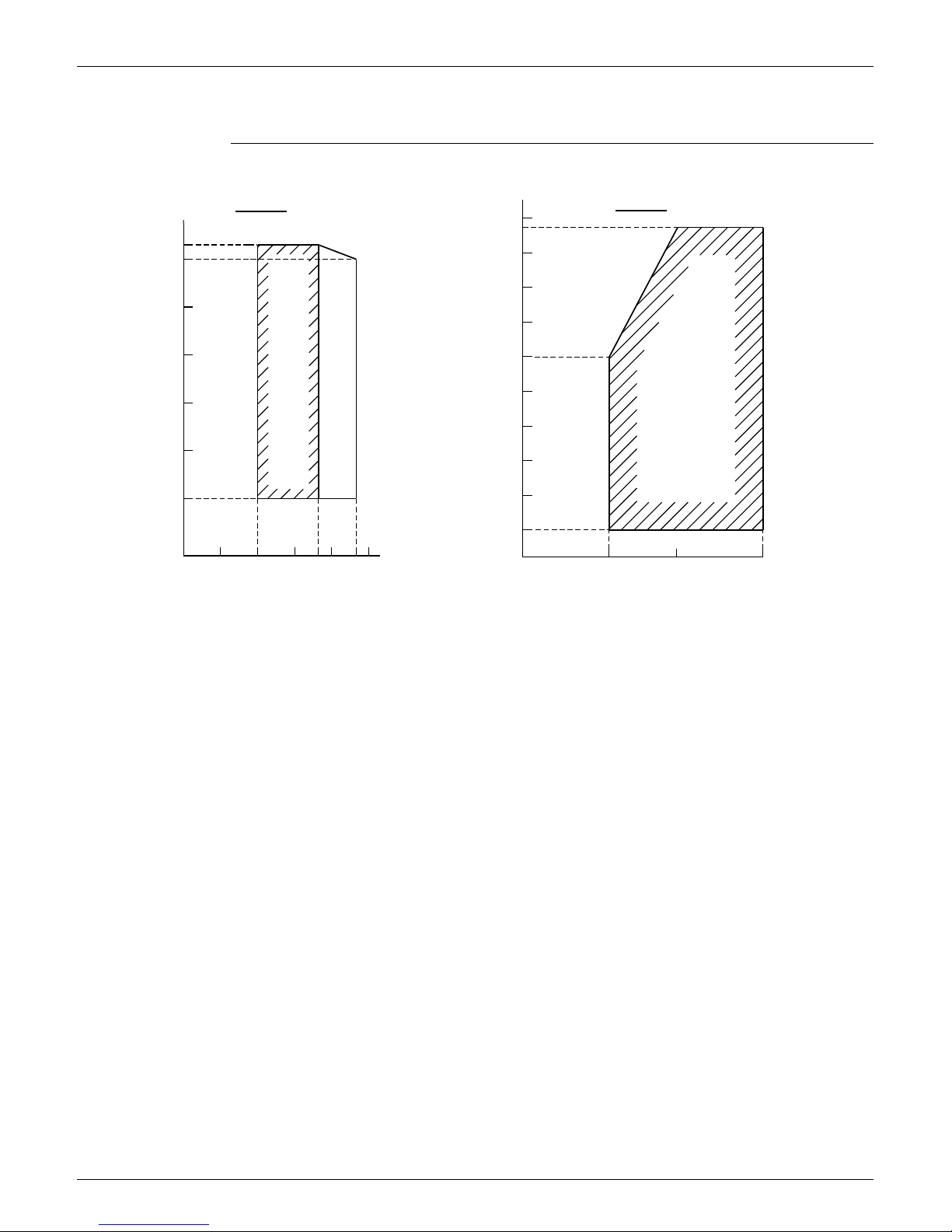

8. Operation Limit

RXG09/12/15HVJU

41

104

14

Heating

73.4

• Level difference

Continuous operation

-4

50

Outdoor temp. (°FWB)

68

50

68

(-4°FDB)

68

0ft

Outdoor temp. (°FDB)

• Air flow rate

High

77

778682.4

50

Cooling

5

75

32

Indoor temp. (°FDB)

Indoor temp. (°FWB)

25ft

14

32

109

86

Notes:

23

59

59

86

Pull-down period

Continuous operation

• Equivalent piping length

68

50

on the following conditions.

The graphs are based

3D063096

Sound Level EDUS04-906_b

16 Room Air Conditioners H-Series

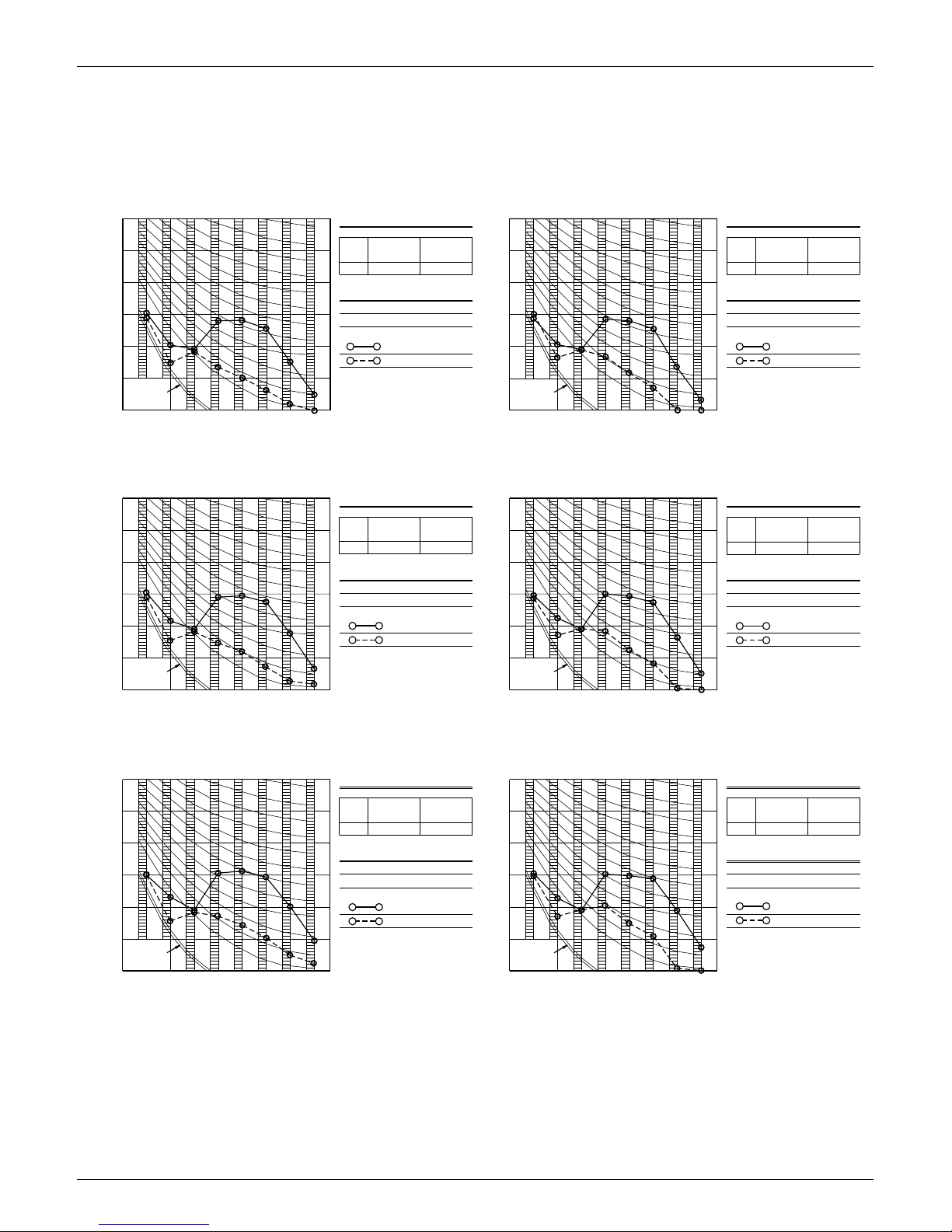

9. Sound Level

9.1 Measuring Location

Note:

1. Operation sound is measured in an anechoic chamber.

2. The data are based on the conditions shown in the table below.

Indoor Unit

Outdoor Unit

Cooling Heating Piping Length

Indoor ; 80°FDB/67°FWB

Outdoor ; 95°FDB/75°FWB

Indoor ; 70°FDB/60°FWB

Outdoor ; 47°FDB/43°FWB

16.4ft (5 m)

3.3ft

2.6ft

(R5162)

3.3ft

(R4796)

EDUS04-906_b Sound Level

Room Air Conditioners H-Series 17

9.2 Octave Band Level

9.2.1 Indoor Units

FTXG09HVJU

FTXG12HVJU

FTXG15HVJU

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OVER ALL ( dB )

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-60

NC-50

NC-40

NC-30

NC-20

60Hz 60Hz

208/230V 208/230V

SCALE

(H) (L)

42 26

60Hz 208/230V(H)

60Hz 208/230V(L)

STANDARD EXTERNAL STATIC PRESSURE

NC-60

NC-50

NC-40

NC-30

NC-20

60Hz

208/230V

SCALE

60Hz

208/230V

(H) (L)

A42 28

STANDARD EXTERNAL STATIC PRESSURE

60Hz 208/230V(H)

60Hz 208/230V(L)

208/230V 60Hz

208/230V 60Hz

Cooling Heating

3D063060

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-40

NC-20

NC-30

NC-60

NC-50

208/230V 60Hz

60Hz

(L)

208/230V

(H)

208/230V

2743

60Hz

SCALE

STANDARD EXTERNAL STATIC PRESSURE

60Hz 208/230V(H)

60Hz 208/230V(L)

Cooling Heating

STANDARD EXTERNAL STATIC PRESSURE

60Hz 208/230V(L)

60Hz 208/230V(H)

208/230V 60Hz

(L)

208/230V

60Hz

(H)

208/230V

A43 29

60Hz

NC-60

NC-30

NC-20

NC-40

NC-50

3D063061

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-50

NC-60

NC-40

NC-30

NC-20

(L)

208/230V

2945

(H)

208/230V

60Hz 60Hz

208/230V 60Hz

60Hz 208/230V(L)

60Hz 208/230V(H)

Cooling

STANDARD EXTERNAL STATIC PRESSURE

NC-50

NC-30

NC-60

NC-40

NC-20

(H)

208/230V

31

60Hz

(L)

208/230V

60Hz

44

208/230V 60Hz

STANDARD EXTERNAL STATIC PRESSURE

60Hz 208/230V(L)

60Hz 208/230V(H)

Heating

3D063080

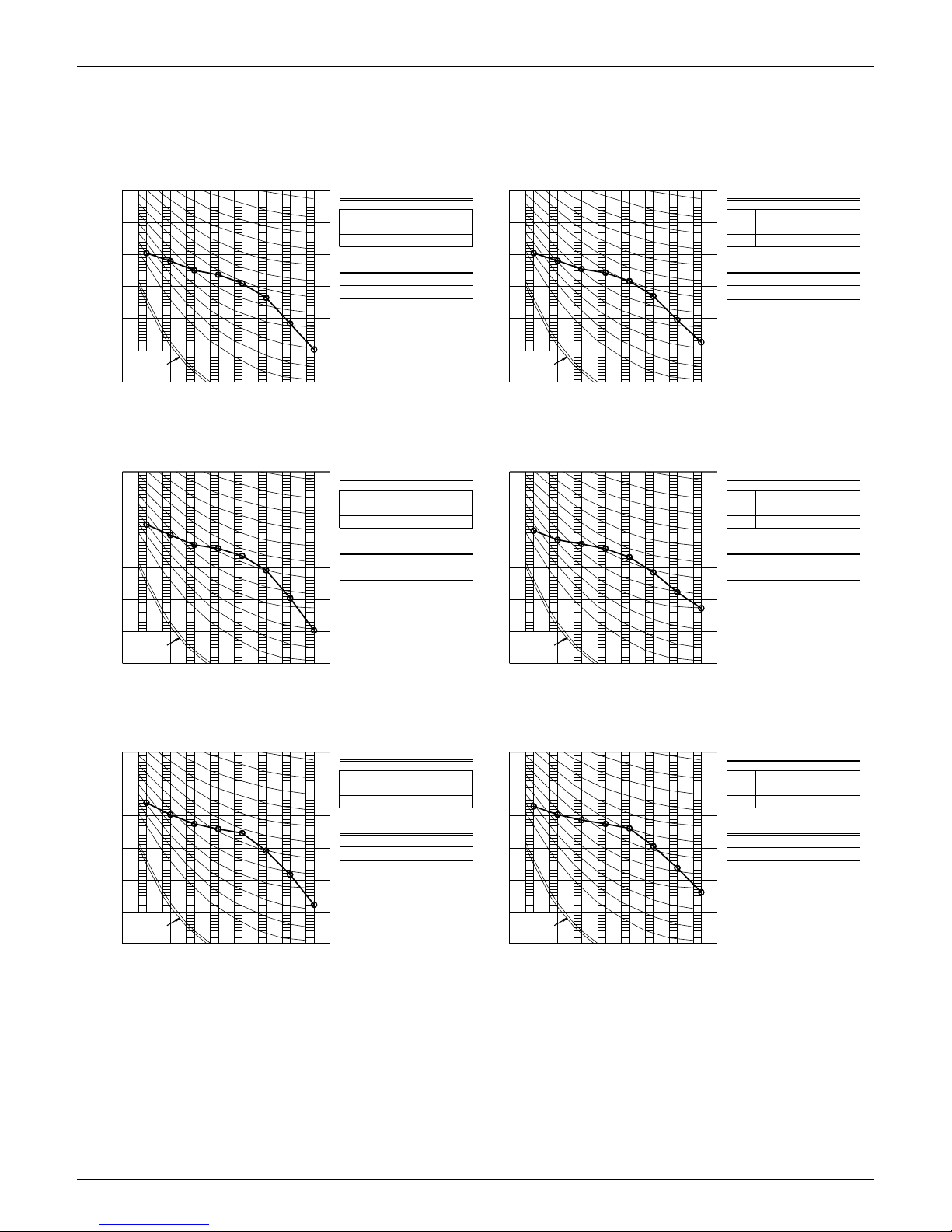

Sound Level EDUS04-906_b

18 Room Air Conditioners H-Series

9.2.2 Outdoor Units

RXG09HVJU

RXG12HVJU

RXG15HVJU

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

A

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-60

NC-30

NC-50

NC-20

NC-40

208-230V

60Hz

46

208-230V 60Hz

Cooling

NC-50

NC-40

NC-30

NC-20

NC-60

208-230V

60Hz

46

208-230V 60Hz

Heating

3D063010

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-60

NC-40

NC-50

NC-20

NC-30

60Hz

208-230V

49

208-230V 60Hz

Cooling

NC-20

NC-50

NC-60

NC-30

NC-40

48

60Hz

208-230V

208-230V 60Hz

Heating

3D063011

COOLING

NC-40

NC-30

NC-50

NC-60

NC-20

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

60Hz 208/230V

208/230V 60Hz

51

Cooling

208/230V

60Hz

NC-40

NC-30

NC-50

NC-60

NC-20

60Hz 208/230V

208/230V 60Hz

51

Heating

208/230V

60Hz

HEATING

3D047647A

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

70

60

20

30

50

40

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

63 125

OCTAVE BAND CENTER FREQUENCY (Hz

)

250 500 1000 2000 4000 8000

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

70

60

20

30

50

40

63

OCTAVE BAND CENTER FREQUENCY (Hz

)

125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL

dB

(

0dB=0.0002

μ

bar

)

THRESHOLD HEARING

APPROXIMATE

FOR CONTINUOUS

NOISE

POWER SOURCE

JIS STANDARD (JIS9612)

OPERATING CONDITIONS

OVER ALL ( dB )

SCALE

A

(

B.G.N IS ALREADY RECTIFIED

)

COOLING HEATING

NC-20

NC-50

NC-30

NC-60

NC-40

208-230V

50

60Hz

208-230V 60Hz

Cooling

NC-60

NC-30

NC-50

NC-20

NC-40

208-230V

60Hz

50

208-230V 60Hz

Heating

3D063012

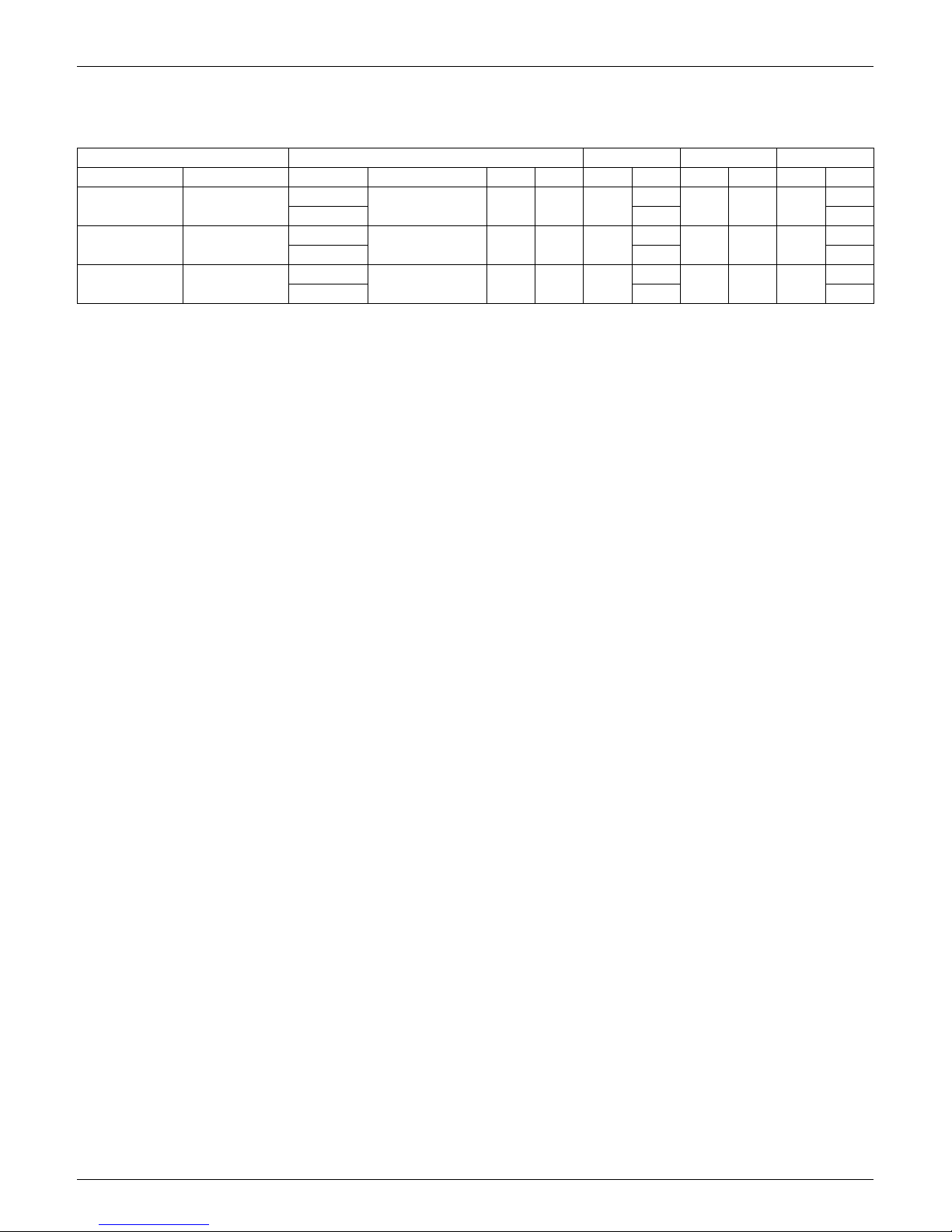

EDUS04-906_b Electric Characteristics

Room Air Conditioners H-Series 19

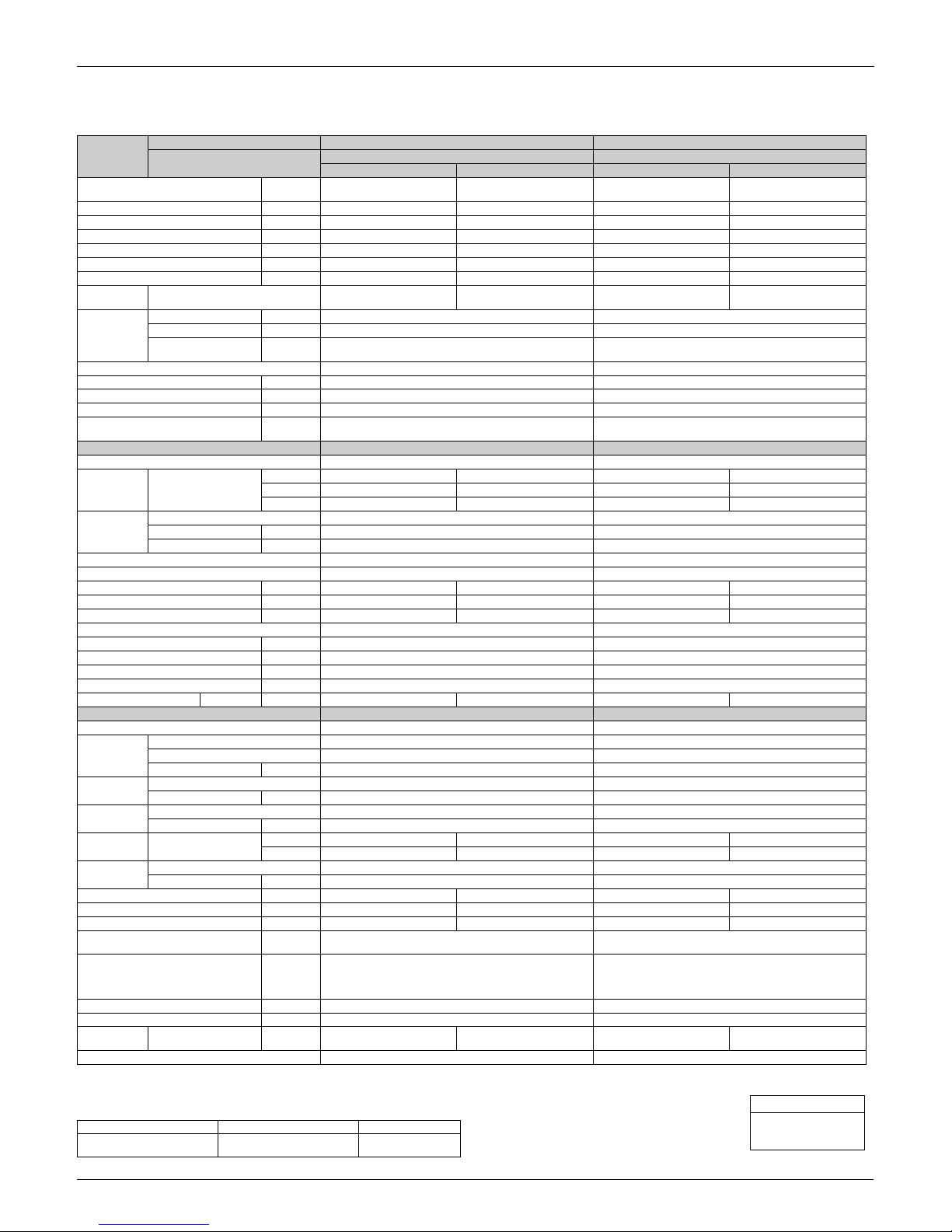

10.Electric Characteristics

3D063013

Representative Unit Combination Power Supply COMP OFM IFM

Indoor Unit Outdoor Unit Hz-Volts Voltage Range MCA MOP RHz RLA W FLA W FLA

FTXG09HVJU RXG09HVJU

60-208

MAX. 60Hz 253V

MIN. 60Hz 187V

14.5 15 29

2.3

60 0.10 57

0.13

60-230 2.1 0.12

FTXG12HVJU RXG12HVJU

60-208

MAX. 60Hz 253V

MIN. 60Hz 187V

14.5 15 43

3.7

60 0.13 57

0.15

60-230 3.3 0.14

FTXG15HVJU RXG15HVJU

60-208

MAX. 60Hz 253V

MIN. 60Hz 187V

14.5 15 54

5.1

60 0.13 57

0.17

60-230 4.6 0.15

Symbols: Note:

MCA : MIN. CIRCUIT AMPS (A) 1. RLA is based on the following conditions.

Indoor temp. : 80°FDB / 67°FWB (26.7°CDB / 19.4°CWB)

Outdoor temp. : 95°FDB (35°CDB)

2. Maximum allowable voltage variation between phases is 2%.

3. Select wire size based on the larger value of MCA.

4. Instead of fuse, use circuit breaker.

5. Be sure to install a ground leak detector. (One that can handle

higher harmonics.)

(This unit uses an inverter, which means that it must be used a

ground leak detector capable handling high harmonics in order to

prevent malfunctioning of the ground leak detector itself.)

MOP : MAX. OVERCURRENT PROTECTION (A)

RLA : RATED LOAD AMPS (A)

OFM : OUTDOOR FAN MOTOR

IFM : INDOOR FAN MOTOR

FLA : FULL LOAD AMPS (A)

W : FAN MOTOR RATED OUTPUT (W)

RHz : RATED OPERATING FREQUENCY (Hz)

Installation Manual EDUS04-906_b

20 Room Air Conditioners H-Series

11.Installation Manual

11.1 Indoor Units

Read these SAFETY CONSIDERATIONS for Installation

carefully before installing an air conditioner or heat pump.

After completing the installation, make sure that the unit

operates properly during the startup operation.

Instruct the customer on how to operate and maintain the unit.

Inform customers that they should store this Installation

Manual with the Operation Manual for future reference.

Always use a licensed installer or contractor to install this

product. Improper installation can result in water or refrigerant

leakage, electrical shock, fire, or explosion.

Meanings of DANGER, WAR N ING, CAUTION, and NOTE

Symbols:

DANGER .............. Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING ............ Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION ............. Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

NOTE .................. Indicates situations that may result in

equipment or property-damage

accidents only.

• Refrigerant gas is heavier than air and replaces oxygen.

A massive leak can lead to oxygen depletion, especially

in basements, and an asphyxiation hazard could occur

leading to serious injury or death.

• Do not ground units to water pipes, gas pipes,

telephone wires, or lightning rods as incomplete

grounding can cause a severe shock hazard resulting

in severe injury or death. Additionally, grounding to

gas pipes could cause a gas leak and potential

explosion causing severe injury or death.

• If refrigerant gas leaks during installation, ventilate

the area immediately. Refrigerant gas may produce

toxic gas if it comes into contact with fire. Exposure to

this gas could cause severe injury or death.

• After completing the installation work, check that the

refrigerant gas does not leak throughout the system.

• Do not install unit in an area where flammable

materials are present due to risk of explosions that

can cause serious injury or death.

• Safely dispose all packing and transportation

materials in accordance with federal/state/local laws

or ordinances. Packing materials such as nails and

other metal or wood parts, including plastic packing

materials used for transportation may cause injuries

or death by suffocation.

• Only qualified personnel must carry out the installation

work. Installation must be done in accordance with this

installation manual. Improper installation may result in

water leakage, electric shock, or fire.

• When installing the unit in a small room, take measures

to keep the refrigerant concentration from exceeding

allowable safety limits. Excessive refrigerant leaks, in

the event of an accident in a closed ambient space, can

lead to oxygen deficiency.

• Use only specified accessories and parts for

installation work. Failure to use specified parts may

result in water leakage, electric shocks, fire, or the

unit falling.

• Install the air conditioner or heat pump on a

foundation strong enough that it can withstand the

weight of the unit. A foundation of insufficient

strength may result in the unit falling and causing

injuries.

• Take into account strong winds, typhoons, or

earthquakes when installing. Improper installation

may result in the unit falling and causing accidents.

• Make sure that a separate power supply circuit is

provided for this unit and that all electrical work is

carried out by qualified personnel according to local.

state, and national regulations. An insufficient power

supply capacity or improper electrical construction

may lead to electric shocks or fire.

• Make sure that all wiring is secured, that specified

wires are used, and that no external forces act on the

terminal connections or wires. Improper connections

or installation may result in fire.

• When wiring, position the wires so that the terminal

box lid can be securely fastened. Improper

positioning of the terminal box lid may result in

electric shocks, fire, or the terminals overheating.

• Before touching electrical parts, turn off the unit.

• It is recommended to install a ground fault circuit

interrupter if one is not already available. This helps

prevent electrical shocks or fire.

• Securely fasten the outside unit terminal cover

(panel). If the terminal cover/panel is not installed

properly, dust or water may enter the outside unit

causing fire or electric shock.

• When installing or relocating the system, keep the

refrigerant circuit free from substances other than the

specified refrigerant (R-410A) such as air. Any

presence of air or other foreign substance in the

refrigerant circuit can cause an abnormal pressure

rise or rupture, resulting in injury.

EDUS04-906_b Installation Manual

Room Air Conditioners H-Series 21

• Do not change the setting of the protection devices. If

the pressure switch, thermal switch, or other

protection device is shorted and operated forcibly, or

parts other than those specified by Daikin are used,

fire or explosion may occur.

• Do not touch the switch with wet fingers. Touching a

switch with wet fingers can cause electric shock.

• Do not allow children to play on or around the unit to

prevent injury.

• Do not touch the refrigerant pipes during and

immediately after operation as the refrigerant pipes

may be hot or cold, depending on the condition of the

refrigerant flowing through the refrigerant piping,

compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the

refrigerant pipes. To avoid injury, give the pipes time

to return to normal temperature or, if you must touch

them, be sure to wear proper gloves.

• Install drain piping to proper drainage. Improper drain

piping may result in water leakage and property

damage.

• Insulate piping to prevent condensation.

• Be careful when transporting the product.

• Do not turn off the power immediately after stopping

operation. Always wait for at least 5 minutes before

turning off the power. Otherwise, water leakage may

occur.

• Do not use a charging cylinder. Using a charging

cylinder may cause the refrigerant to deteriorate.

• Refrigerant R-410A in the system must be kept clean,

dry, and tight.

(a) Clean and Dry -- Foreign materials (including

mineral oils such as SUNISO oil or moisture)

should be prevented from getting into the system.

(b) Tight -- R-410A does not contain any chlorine,

does not destroy the ozone layer, and does not

reduce the earth’s protection again harmful

ultraviolet radiation. R-410A can contribute to the

greenhouse effect if it is released. Therefore take

proper measures to check for the tightness of the

refrigerant piping installation. Read the chapter

Refrigerant Piping and follow the procedures.

• Since R-410A is a blend, the required additional

refrigerant must be charged in its liquid state. If the

refrigerant is charged in a state of gas, its

composition can change and the system will not work

properly.

• The indoor unit is for R-410A. See the catalog for

indoor models that can be connected. Normal

operation is not possible when connected to other

units.

• Remote controller (wireless kit) transmitting distance

can be shorter than expected in rooms with electronic

fluorescent lamps (inverter or rapid start types).

Install the indoor unit far away from fluorescent lamps

as much as possible.

• Indoor units are for indoor installation only. Outdoor

units can be installed either outdoors or indoors. This

unit is for indoor use.

• Do not install the air conditioner or heat pump in the

following locations:

(a) Where a mineral oil mist or oil spray or vapor is

produced, for example, in a kitchen.

Plastic parts may deteriorate and fall off or result in

water leakage.

(b) Where corrosive gas, such as sulfurous acid gas, is

produced.

Corroding copper pipes or soldered parts may result

in refrigerant leakage.

(c) Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of

the control system and cause the unit to

malfunction.

(d) Where flammable gas may leak, where there is

carbon fiber, or ignitable dust suspension in the air,

or where volatile flammables such as thinner or

gasoline are handled. Operating the unit in such

conditions can cause a fire.

• Take adequate measures to prevent the outside unit

from being used as a shelter by small animals. Small

animals making contact with electrical parts can

cause malfunctions, smoke, or fire. Instruct the

customer to keep the area around the unit clean.

• Install the power supply and control wires for the indoor

and outdoor units at least 3.5 feet away from televisions

or radios to prevent image interference or noise.

Depending on the radio waves, a distance of 3.5 feet may

not be sufficient to eliminate the noise.

• Dismantling the unit, treatment of the refrigerant, oil

and additional parts must be done in accordance with

the relevant local, state, and national regulations.

• Do not use the following tools that are used with

conventional refrigerants: gauge manifold, charge

hose, gas leak detector, reverse flow check valve,

refrigerant charge base, vacuum gauge, or refrigerant

recovery equipment.

• If the conventional refrigerant and refrigerator oil are

mixed in R-410A, the refrigerant may deteriorate.

• This air conditioner or heat pump is an appliance that

should not be accessible to the general public.

• As design pressure is 478 psi, the wall thickness of

field-installed pipes should be selected in accordance

with the relevant local, state, and national regulations.

Installation Manual EDUS04-906_b

22 Room Air Conditioners H-Series

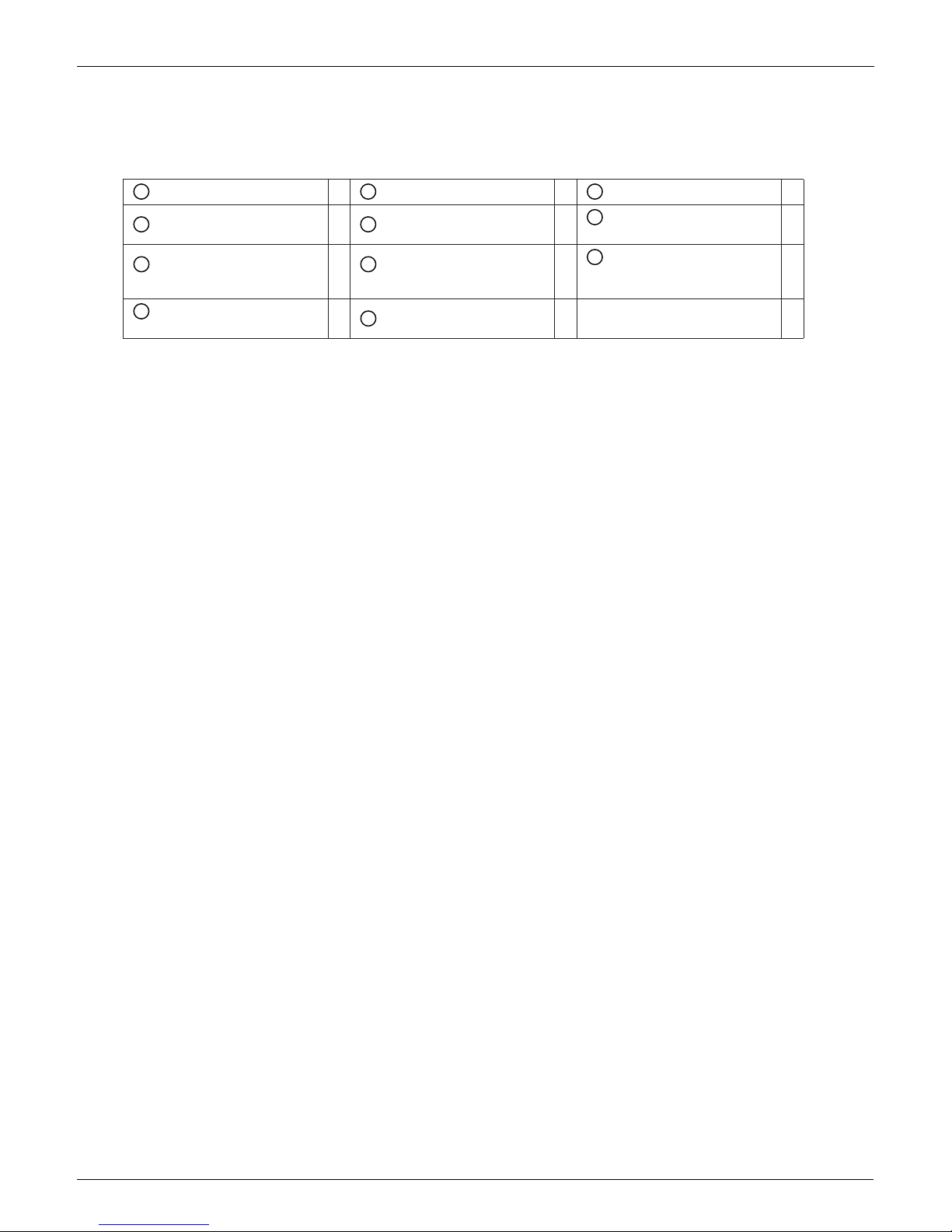

Accessories

Mounting plate

1

Wireless remote controller

1

Installation manual

1

Deodorizing filter for streamer

1

Remote controller holder

1

Mounting plate fixing screws

3/16” × 1”L (M4 × 25mm)

9

Titanium apatite photocatalytic

air-purifying filter

1

Dry batteries AAA. LR03

(alkaline)

2

Fixing screws for remote

controller holder

1/8” × 13/16”L (M3 × 20mm)

2

Indoor unit fixing screws

3/16” × 1/2”L (M4 × 12mm)

3

Operation manual

1

A

E

J

B

F

K

C

G

L

D

H

EDUS04-906_b Installation Manual

Room Air Conditioners H-Series 23

3

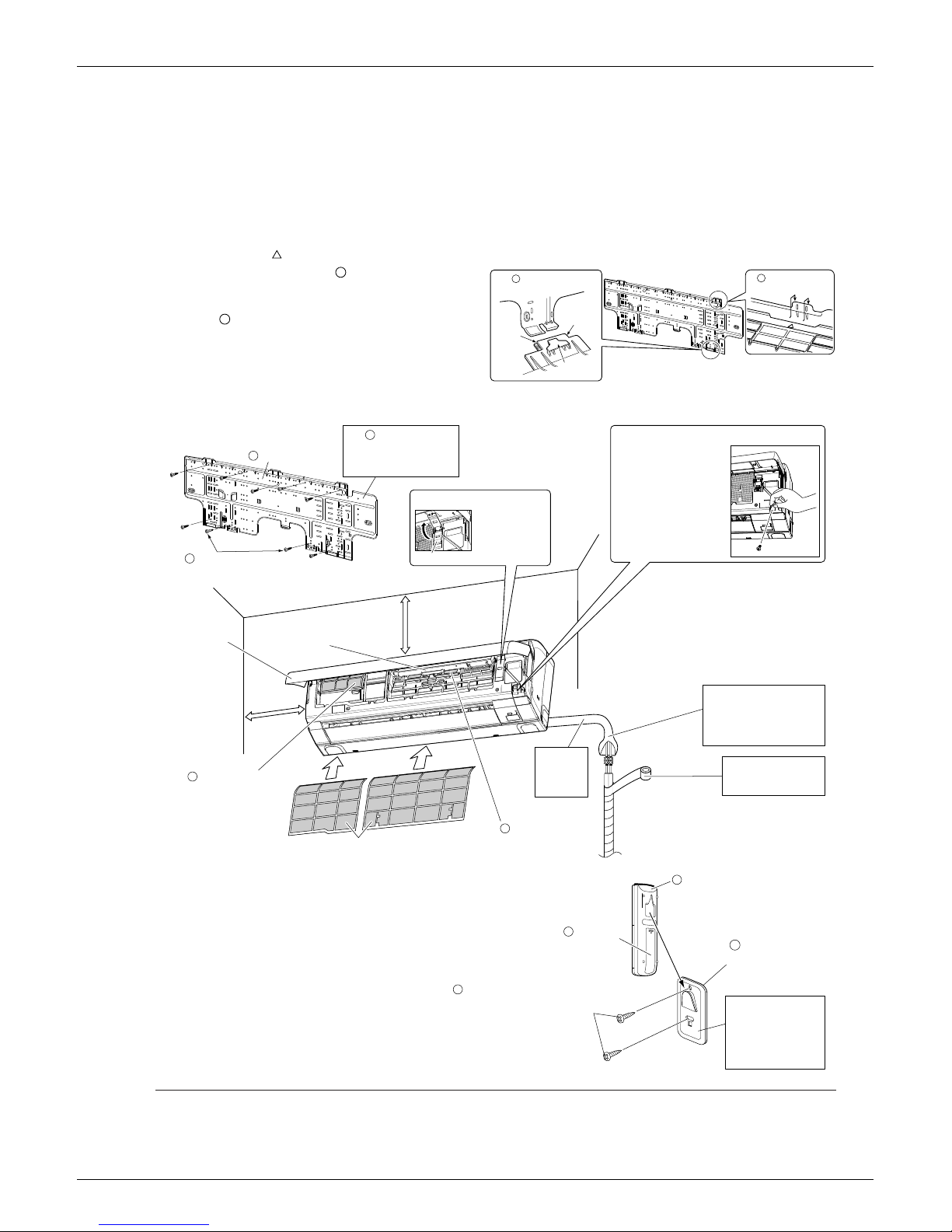

Indoor Unit Installation Drawings

1.

Removing and installing indoor unit.

• Installation method

1) Using the marks (3 locations) on top of the

indoor unit, attach the mounting plate hooks

onto the indoor unit.

2) Attach the tabs on the bottom frame onto the

mounting plate. If the tabs are not hooked onto

the plate, remove the front grille to hook them.

(Check to see if the tabs are hooked securely.)

• Removal method

Push up the mark part on the bottom of the front

grille, discharge the tabs, and then remove the unit

while lifting it up.

Ta b

Bottom

frame

Mark

(rear side)

A Mounting

plate

To remove the unit, push up the bottom of the bottom

frame with your fingers to free tabs.

(Mark parts (2 locations) on the bottom of the front grille.)

A Mounting

plate

A

A

F

Remote

controller holder

Fixing screws for remote

controller holder

1/8” × 13/16”L (M3 × 20mm) (2)

Wrap the insulation

pipe with the finishing

tape from bottom to top.

Install the

hose with a

downward

slope.

Cut thermal insulation pipe

to an appropriate length and

wrap it with tape, making

sure that no gap is left in the

insulation pipe’s cut line.

1-3/16” (30mm)

or more

from ceiling

1-15/16” (50mm)

or more from walls

(on both sides)

Mounting plate fixing

screws 3/16” × 1”L (M4 × 25mm) (9)

A

Mounting plate

The mounting plate

should be installed on a

wall which can support the

weight of the indoor unit.

Use when

opening the

front panel and

securing.

Supporting plate

Supporting plate

How to open the service lid

Front panel

Air filter

2)

1)

The service lid is

removable.

Opening the lid

1) Remove the screws

on the service lid.

2) Hold the knobs on the

service lid and pull

forward.

Before screwing the

remote controller

holder to the wall,

make sure that control

signals are properly

received by indoor unit.

C

Titanium apatite

photocatalytic

air-purifying filter

B

Deodorizing filter

for streamer

Hook

E

Wireless

remote controller

Set the

dry batteries

AAA. LR03

(alkaline)

G

L

The securing tape is applied.

Be sure to remove it before

installation.

A

K

Loading...

Loading...