Daikin REYQ144PTJU, REYQ72PTJU, REYQ168PTJU, REYQ192PTJU, REMQ72PTJU Engineering Data

...

EDUS 39-802A-R2_a

AMERICAS

AMERICAS

AMERICAS

REYQ_PTJU

3 phase

208-230V

60Hz

EDUS39-802A-R2_a

REYQ-P Heat Recovery (208-230V) 1

REYQ-P

(3φ 208-230V 60Hz)

Heat Recovery

1. Specifications .............................................................................................. 2

2. Dimensions .................................................................................................5

3. Service Space .............................................................................................8

4. Piping Diagrams..........................................................................................9

5. Wiring Diagrams........................................................................................13

6. Field Wiring ...............................................................................................17

7. Electric Characteristics..............................................................................19

8. Capacity Tables (Reference Data)............................................................21

8.1 Cooling Capacity (REYQ-PTJU) ................................................................ 21

8.2 Heating Capacity (REYQ-PTJU) ................................................................ 29

8.3 Capacity Correction Factor......................................................................... 45

9. Operation Limits ........................................................................................53

10.Sound Levels ............................................................................................54

11.Accessories...............................................................................................55

EDUS39-802A-R2_a

2 REYQ-P Heat Recovery (208-230V)

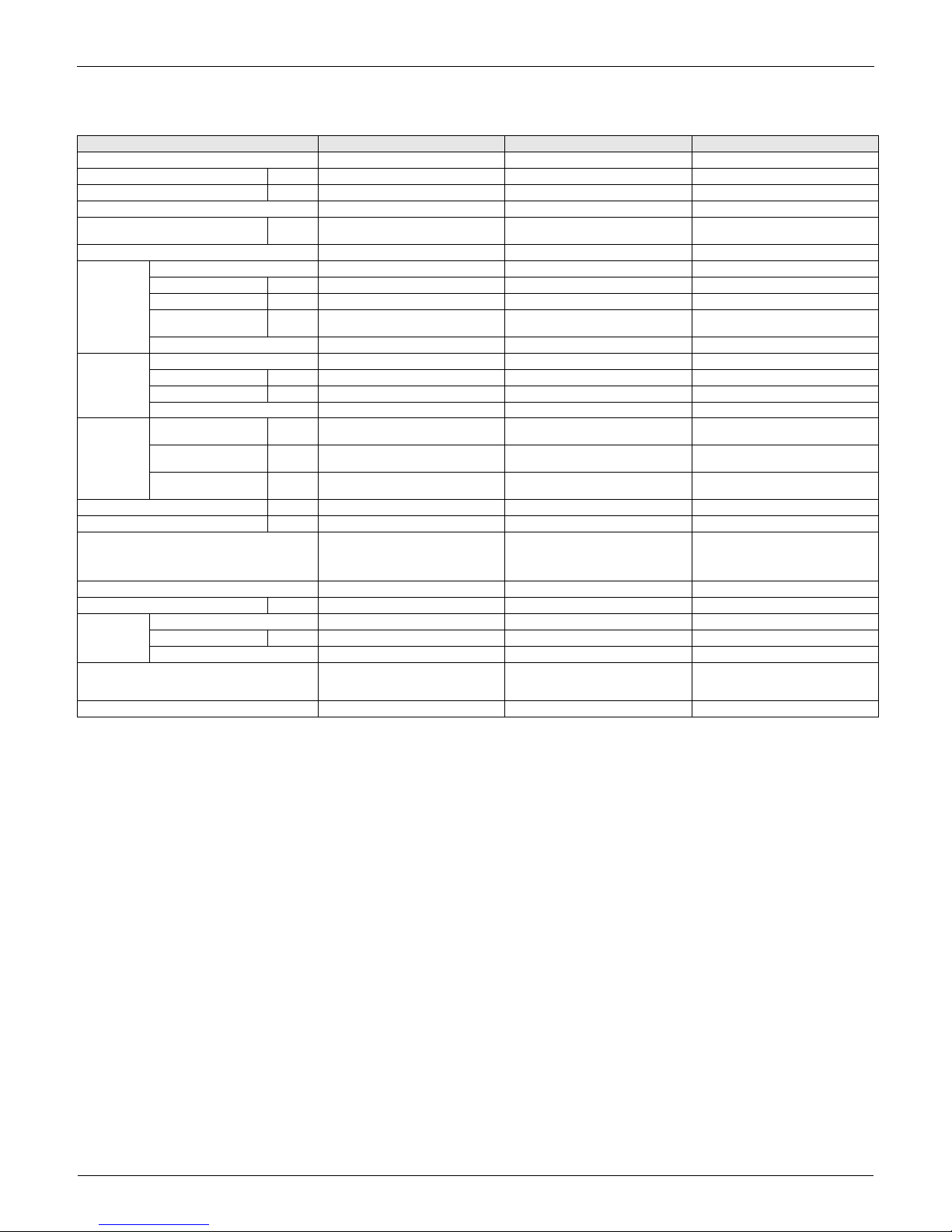

1. Specifications

Notes:

+1 Indoor temp. : 80°FDB or 67°FWB / outdoor temp. : 95°FDB / Equivalent piping length : 25 ft (7.5 m), evel difference: 0 ft.

+2 Indoor temp. : 70°FDB / outdoor temp. : 47°FDB or 43°FWB / Equivalent piping length : 25 ft (7.5 m), evel difference: 0 ft.

+3 Anechoic chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model Name REYQ72PTJU REYQ96PTJU REYQ120PTJU

Power Supply 3 Phase 60Hz 208V-230V 3 Phase 60Hz 208V-230V 3 Phase 60Hz 208V-230V

+1 Cooling Capacity Btu / h 72,000 96,000 120,000

+2 Heating Capacity Btu / h 81,000 108,000 135,000

Casing Color Ivory White (5Y7.5/1) Ivory White (5Y7.5/1) Ivory White (5Y7.5/1)

Dimensions: (H×W×D) in (mm)

66-1/8 × 51-3/16 × 30-1/8”

(1680 x 1300.2 x 765 mm)

66-1/8 × 51-3/16 × 30-1/8”

(1680 x 1300.2 x 765 mm)

66-1/8 × 51-3/16 × 30-1/8”

(1680 x 1300.2 x 765 mm)

Heat Exchanger Cross Fin Coil Cross Fin Coil Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type

Piston Displacement m

3

/h 7.88+10.53 13.34+10.53 13.34+10.53

Number of Revolutions r.p.m 3720, 2900 6300, 2900 6300, 2900

Motor Output×Number

of Units

kW (1.0+4.5) × 1 (2.2+4.5) × 1 (3.3+4.5) × 1

Starting Method Soft Start Soft Start Soft Start

Fan

Type Propeller Fan Propeller Fan Propeller Fan

Motor Output kW (0.35) × 2 (0.35) × 2 (0.35) × 2

Air Flow Rate cfm 6,700 6,700 7,410

Drive Direct Drive Direct Drive Direct Drive

Connecting

Pipes

Liquid Pipe in (mm)

φ 3/8” (9.5 mm) C1220T

(Brazing Connection)

φ 3/8” (9.5 mm) C1220T

(Brazing Connection)

φ 1/2” (12.7 mm) C1220T

(Brazing Connection)

Suction Gas Pipe in (mm)

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

φ7/8” (22.2 mm) C1220T

(Brazing Connection)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

High and Low Pressure

Gas Pipe

in (mm)

φ5/8” (15.8 mm) C1220T

(Brazing Connection)

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

Mass Lbs (kg) 730 (331 kg) 730 (331 kg) 730 (331 kg)

+3 Sound Level (Reference Value) dBA 58 58 60

Safety Devices

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

Defrost Method Deicer Deicer Deicer

Capacity Control % 20~100 14~100 14~100

Refrigerant

Refrigerant Name R-410A R-410A R-410A

Charge Lbs 22.7 23.4 23.8

Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Drawing No. 4D058609 4D058610 4D058611

EDUS39-802A-R2 Specifications

REYQ-P Heat Recovery (208-230V) 3

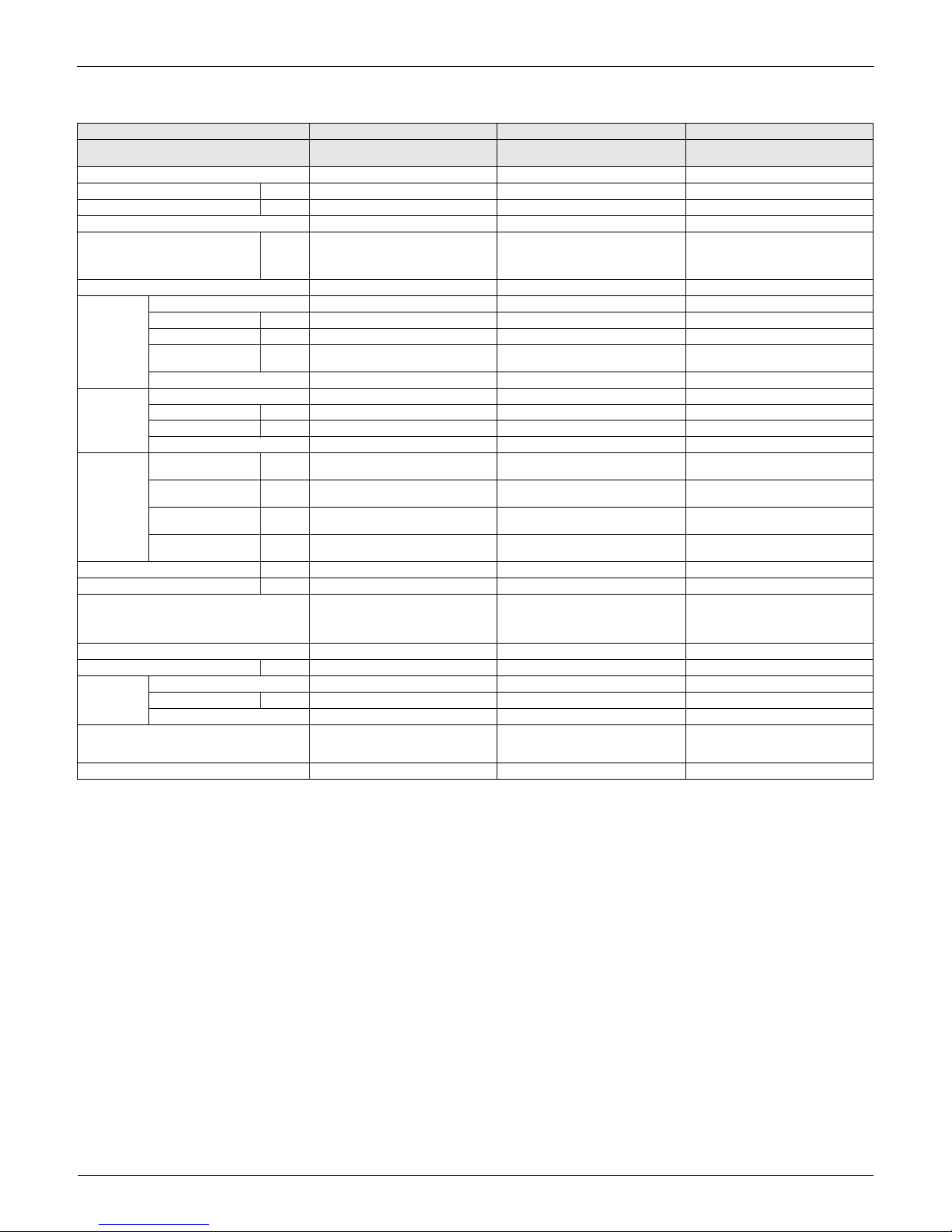

Notes:

+1 Indoor temp. : 80°FDB or 67°FWB / outdoor temp. : 95°FDB / Equivalent piping length : 25 ft (7.5 m), level difference: 0 ft.

+2 Indoor temp. : 70°FDB / outdoor temp. : 47°FDB or 43°FWB / Equivalent piping length : 25 ft (7.5 m), level difference: 0 ft.

+3 BHFP26P90U is necessary for the connection.

Concerning about the piping connection for each outdoor unit to the main line as shown above, use REFNET.

+4 Anechoic chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model Name (Combination Unit) REYQ144PTJU REYQ168PTJU REYQ192PTJU

Model Name (Independent Unit) —

REMQ72PTJU

REMQ96PTJU

REMQ72PTJU

REMQ120PTJU

Power Supply 3 Phase 60Hz 208V-230V 3 Phase 60Hz 208V-230V 3 Phase 60Hz 208V-230V

+1 Cooling Capacity Btu / h 144,000 168,000 192,000

+2 Heating Capacity Btu / h 162,000 189,000 216,000

Casing Color Ivory White (5Y7.5/1) Ivory White (5Y7.5/1) Ivory White (5Y7.5/1)

Dimensions: (H×W×D) in (mm)

66-1/8 × 51-3/16 × 30-1/8”

(1680 x 1300 x 765 mm)

66-1/8 × 36-5/8 × 30-1/8”

(1680 x 930 x 765 mm) +

66-1/8 × 36-5/8 × 30-1/8”

(1680 x 930 x 765 mm)

66-1/8 × 36-5/8 × 30-1/8”

(1680 x 930 x 765 mm) +

66-1/8 × 36-5/8 × 30-1/8”

(1680 x 930 x 765 mm)

Heat Exchanger Cross Fin Coil Cross Fin Coil Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type

Piston Displacement m

3

/h 16.90+16.90 16.90 + (10.53+13.34) 16.90 + (10.53+13.34)

Number of Revolutions r.p.m 7980, 7980 7980, (2900, 6300) 7980, (2900, 6300)

Motor Output×Number

of Units

kW (3.8+3.8) x 1 (4.7) × 1 + (2.2+4.5) × 1 (4.7) × 1 + (3.5+4.5) × 1

Starting Method Direct on Line Soft Start Soft Start

Fan

Type Propeller Fan Propeller Fan Propeller Fan

Motor Output kW 0.75 × 2 (0.75) × 1 + (0.75) × 1 (0.75) × 1 + (0.75) × 1

Air Flow Rate cfm 8,299 6,350+6,530 6,350+7,060

Drive Direct Drive Direct Drive3 Direct Drive

Connecting

Pipes

Liquid Pipe in (mm)

φ1/2” (12.7 mm) C1220T

(Brazing Connection)

φ5/8” (15.9 mm) C1220T

(Brazing Connection)

φ5/8” (15.9 mm) C1220T

(Brazing Connection)

Suction Gas Pipe in (mm)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

High and Low

Pressure Gas Pipe

in (mm)

φ 7/8” (22.2 mm) C1220T

(Brazing Connection)

φ 7/8” (22.2 mm) C1220T

(Brazing Connection)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

Pressure Equalizer

Tube

in (mm) —

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

Mass Lbs (kg) 747 lbs (229 kg) 450+560 lbs (204 + 254 kg) 450+560 lbs (204 + 254 kg)

+4 Sound Level (Reference Value) dBA 61 — —

Safety Devices

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

Defrost Method Deicer Deicer Deicer

Capacity Control % 10~100 9~100 7~100

Refrigerant

Refrigerant Name R-410A R-410A R-410A

Charge Lbs 24.5 18.1+19.8 18.1+20.1

Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Drawing No. 4D058612 4D060122 4D060123

+3

+3

+3

+3

+3

+3

EDUS39-802A-R2_a

4 REYQ-P Heat Recovery (208-230V)

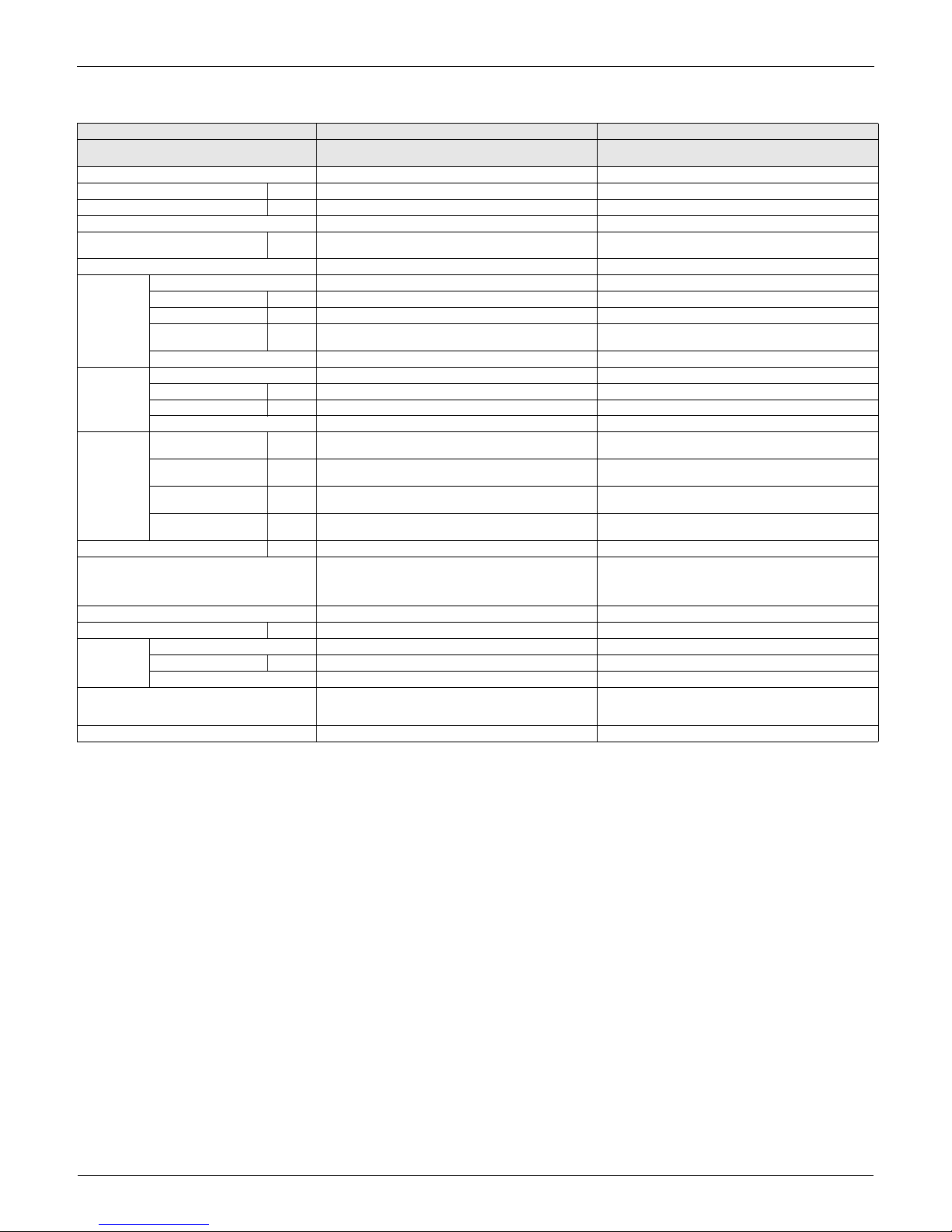

Notes:

+1 Indoor temp. : 80°FDB or 67°FWB / outdoor temp. : 95°FDB / Equivalent piping length : 25 ft (7.5 m), evel difference: 0 ft.

+2 Indoor temp. : 70°FDB / outdoor temp. : 47°FDB or 43°FWB / Equivalent piping length : 25 ft (7.5 m), evel difference: 0 ft.

+3 BHFP26P90U is necessary for the connection.

Concerning about the piping connection for each outdoor unit to the main line as shown above, use REFNET.

Model Name (Combination Unit) REYQ216PTJU REYQ240PTJU

Model Name (Independent Unit)

REMQ96PTJU

REMQ120PTJU

REMQ120PTJU

REMQ120PTJU

Power Supply 3 Phase 60Hz 208V-230V 3 Phase 60Hz 208V-230V

+1 Cooling Capacity Btu / h 216,000 240,000

+2 Heating Capacity Btu / h 243,000 270,000

Casing Color Ivory White (5Y7.5/1) Ivory White (5Y7.5/1)

Dimensions: (H×W×D) in (mm)

66-1/8 × 36-5/8 × 30-1/8” (1680 x 930 x 765 mm) +

66-1/8 × 36-5/8 × 30-1/8” (1680 x 930 x 765 mm)

66-1/8 × 36-5/8 × 30-1/8” (1680 x 930 x 765 mm) +

66-1/8 × 36-5/8 × 30-1/8” (1680 x 930 x 765 mm)

Heat Exchanger Cross Fin Coil Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type

Piston Displacement m

3

/h (10.53+13.34) × 2 (10.53+13.34) × 2

Number of Revolutions r.p.m (2900, 6300) × 2 (2900, 6300) × 2

Motor Output×Number

of Units

kW (2.2+4.5) × 1 + (3.5+4.5) × 1 (3.5+4.5) × 2

Starting Method Soft Start Soft Start

Fan

Type Propeller Fan Propeller Fan

Motor Output kW (0.75) × 1 + (0.75) × 1 (0.75) × 1 + (0.75) × 1

Air Flow Rate cfm 6,530+7,060 7,060+7,060

Drive Direct Drive Direct Drive

Connecting

Pipes

Liquid Pipe +3 in (mm)

φ5/8” (15.9 mm) C1220T

(Brazing Connection)

φ5/8” (15.9 mm) C1220T

(Brazing Connection)

Suction Gas Pipe +3 in (mm)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

φ1-3/8” (34.9 mm) C1220T

(Brazing Connection)

High and Low Pressure

Gas Pipe +3

in (mm)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

φ 1-1/8” (28.6 mm) C1220T

(Brazing Connection)

Pressure Equalizer

Tube

in (mm)

φ 3/4” ( 19.1 mm) C1220T

(Brazing Connection)

φ 3/4” (19.1 mm) C1220T

(Brazing Connection)

Mass Lbs (kg) 560+560 lbs (254 + 254 kg) 560+560 lbs (254 + 254 kg)

Safety Devices

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

High Pressure Switch,

Fan Driver Overload Protector,

Overcurrent Relay,

Inverter Overload Protector

Defrost Method Deicer Deicer

Capacity Control % 7~100 6~100

Refrigerant

Refrigerant Name R-410A R-410A

Charge Lbs 19.8+20.1 20.1+20.1

Control Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Installation Manual,

Operation Manual,

Connection Pipes, Clamps

Drawing No. 4D060124 4D060125

EDUS39-802A-R2 Dimensions

REYQ-P Heat Recovery (208-230V) 5

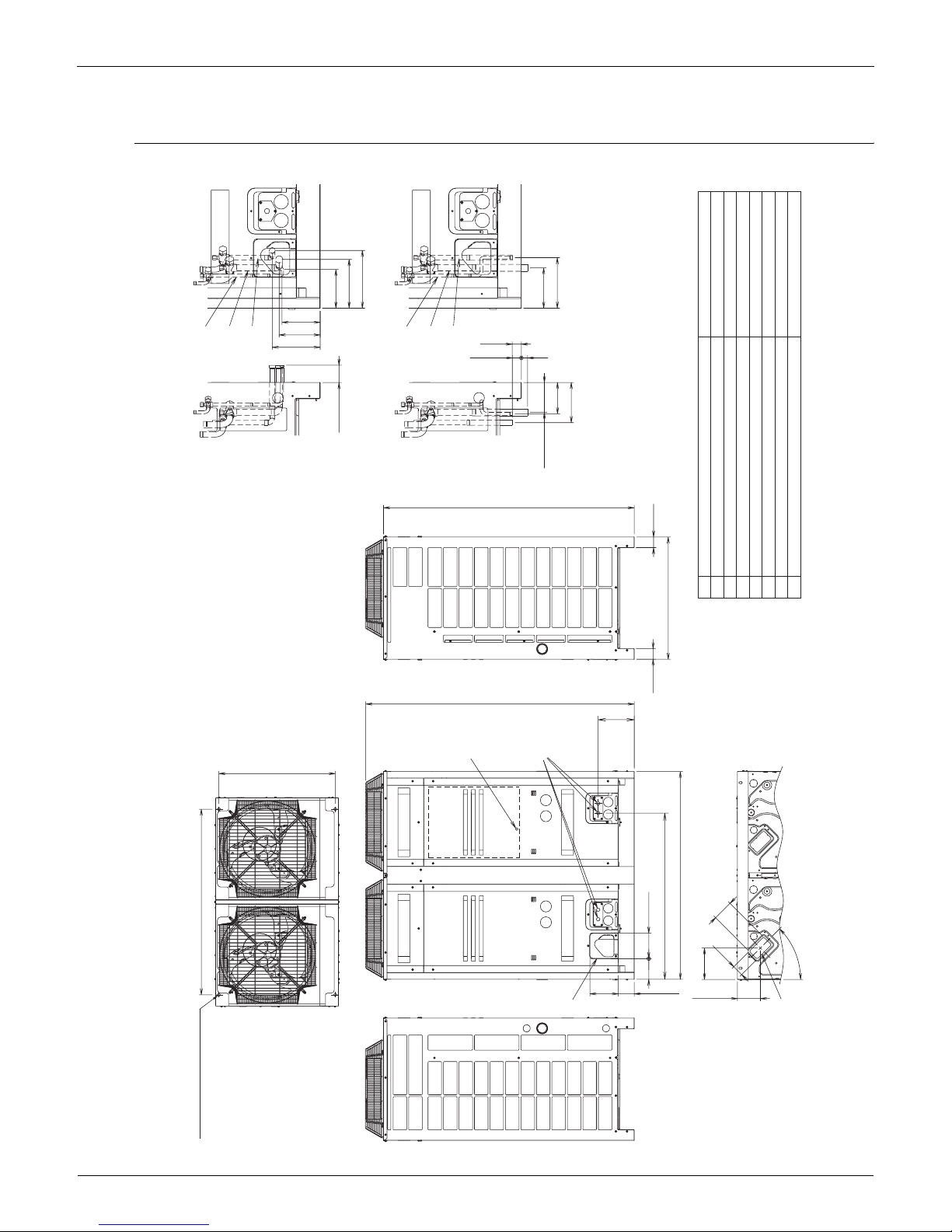

2. Dimensions

REYQ72, 96, 120, 144PTJU

[DETAIL FOR FRONT SIDE]

[DETAIL FOR BOTTOM SIDE]

*8-1/16

*9-1/2

*6-3/4

*7-7/8

*6-1/4

*2-13/16

*6-3/8

*8-5/16

*1

5-1/16

*6-9/16

*4-15/16

1-1/4

*1-7/16

*6-5/8

(Knock-out hole)

(Pitch of foundation bolt holes)

(Knock-out hole)

(Pitch of foundation bolt holes)

7-3/4

51-3/16

8-7/8

28-7/16~29

3-15/16

40-15/16

5-1/16

6-15/16

2-3/4

5-1/16

45°

5-11/16

45-3/4

66-1/8

(Foundation bolt hole)

4-9/16 × 7/8 Oblong holes

6-5/16

2-5/8 2-5/8

61-13/16

30-1/8

Notes)

1. For piping connection method (front and bottom sides), see the

installation manual.

2. High and low pressure gas pipe

φ 5/8 Brazing connection

...

REYQ72P

φ 3/4 Brazing connection

...

REYQ96, 120P

φ 7/8 Brazing connection

...

REYQ144PT

Gas pipe

φ 1-1/8 Brazing connection

...

RXYQ72PT

Suction gas pipe

φ 3/4 Brazing connection

...

REYQ72P

φ 7/8 Brazing connection

...

REYQ96P

φ 1-1/8 Brazing connection

...

REYQ120, 144PT

Liquid pipe

φ 3/8 Brazing connection

...

REYQ72, 96P

φ 1/2 Brazing connection

...

REYQ120, 144PT, RXYQ144PT

3. *shows the dimensions after fixing the accessory pipes.

7654321

No.

Pipe routing hole (bottom)

Pipe routing hole (front)

Power cord routing hole (front)

Grounding terminal

High and low pressure gas pipe connection port

Suction gas pipe connection port

Liquid pipe connection port

Parts name

See note 1.

See note 1.

φ 7/8

Inside of el. compo. box (M8)

See note 2.

See note 2.

See note 2.

Remarks

3D058618A

EDUS39-802A-R2_a

6 REYQ-P Heat Recovery (208-230V)

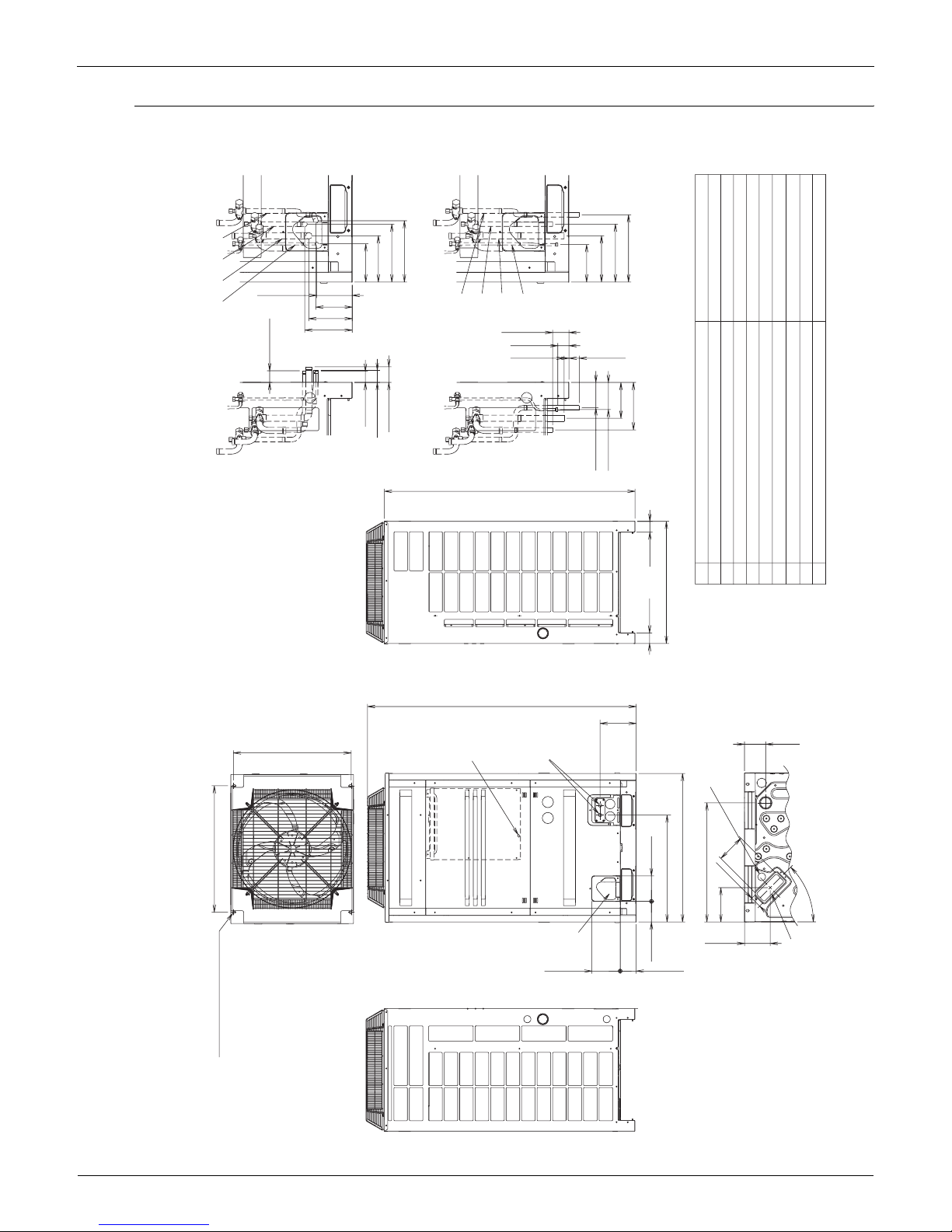

REMQ72, 96, 120PTJU

3

7

See note 2.

(Knock-out hole)

Suction gas pipe connection port

Power cord routing hole (front)

Pipe routing hole (bottom)

1

Liquid pipe connection port

Grounding terminal

(Pitch of foundation bolt holes)

Remarks

4

High and low pressure gas pipe connection port

9

(Pitch of foundation bolt holes)

2

See note 2.

5

φ 3/4 Brazing connection

8

Pressure equalizer pipe connection port

(Knock-out hole)

6

Parts name

See note 2.

No.

Pipe routing hole (front)

Pipe routing hole (bottom)

(Knock-out hole)

:

Pressure equalizer

pipe only.

6-5/16

6-15/16

45°

61-13/16

2-5/8

5-1/4

*7-13/16

*1-15/16

*5-13/16

*2-9/16

*6

*6-5/16

*1-7/8

*7-5/8

*9-1/2

[DETAIL FOR FRONT SIDE]

*1-15/16

*10-1/16

*7-1/8

6-5/16

2-3/4

8-7/8

31-3/16

*4-3/16

*2-11/16

*9-1/2

*4-7/16

*1-7/8

*11-1/16

*5-7/8

*4-7/16

*7-5/8

*13/16

[DETAIL FOR BOTTOM SIDE]

*7-13/16

8-7/16

66-1/8

3-15/16

29-3/8

7

26-3/8

28-7/16~29

5-1/16

36-5/8

4-9/16 × 7/8 Oblong holes

(Foundation bolt hole)

30-1/8

2-5/8

*6-1/8

Notes)

1. For piping connection method (front and bottom sides),

see the installation manual.

2. High and low pressure gas pipe

φ 3/4 Brazing connection

...

REMQ72P

φ 3/4 Brazing connection

...

REMQ96, 120P

Suction gas pipe

φ 3/4 Brazing connection

...

REMQ72P

φ 7/8 Brazing connection

...

REMQ96P

φ 1-1/8 Brazing connection

...

REMQ120P

Liquid pipe

φ 3/8 Brazing connection

...

REMQ72, 96P

φ 1/2 Brazing connection

...

REMQ120P

φ 1-15/16 See note 1.

See note 1.

See note 1.

φ 7/8

Inside of el. compo. box (M8)

3D058617

EDUS39-802A-R2 Dimensions

REYQ-P Heat Recovery (208-230V) 7

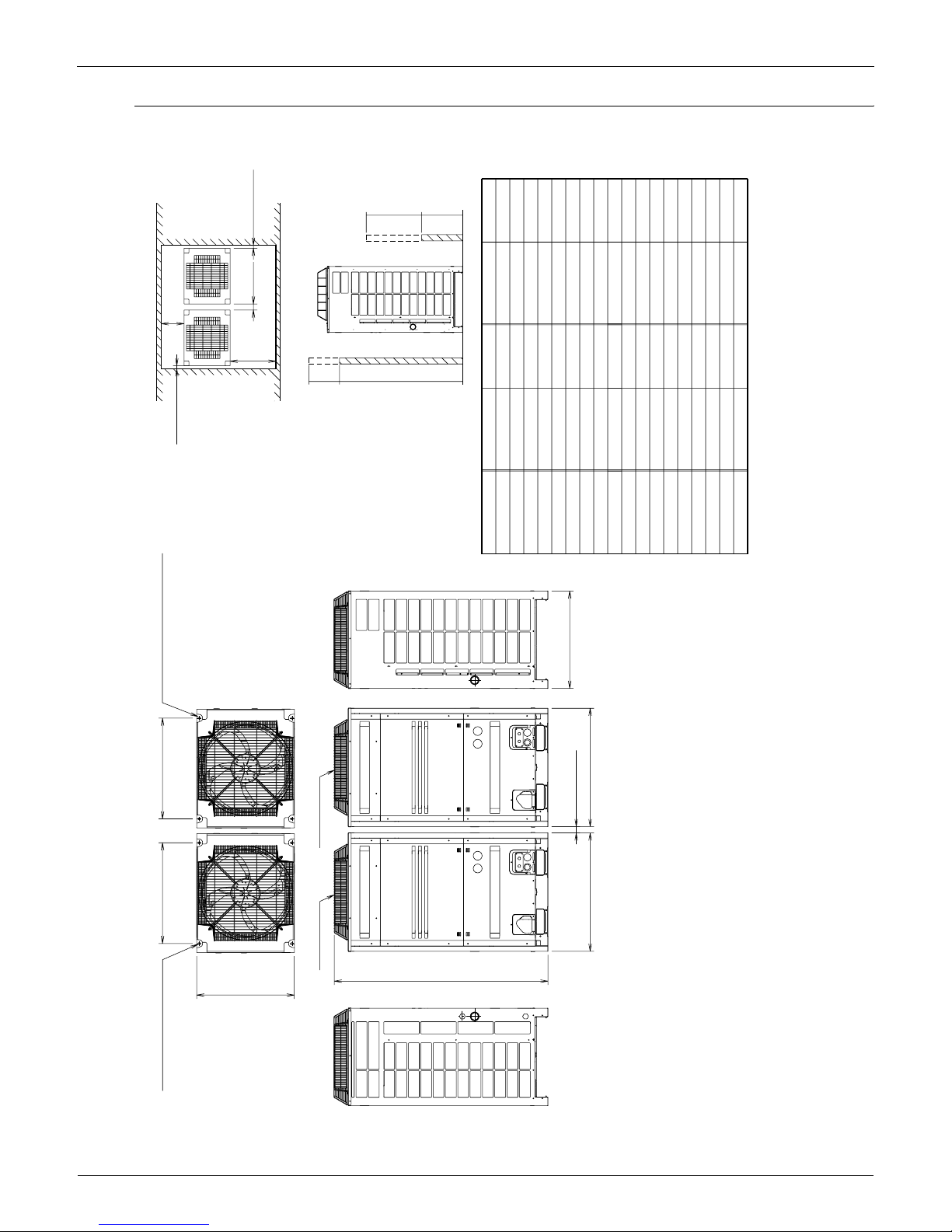

REYQ168, 192, 216, 240PTJU

Model Name

or more

Outdoor Unit 1

19-11/16

11-13/16 or more

< Suction side >

(Foundation bolt hole)

19-11/16 or more

59-1/16 h 2

< Front >

(Pitch of foundation

bolt holes)

(Pitch of foundation

bolt holes)

(Pitch of foundation

bolt holes)

Drawing No.

(Foundation bolt hole)

Outdoor Unit 2

Drawing No.

(Front)

3D058616

3D058616

3D058616

3D058617

3D058616

3D058617

3D058617

3D058617

3D058617

3D058617

3D058616

3D058616

3D058616

3D058616

3D058617

3D058617

3D058616

3D058617

RXYQ72PTJU

RXYQ96PYDN

REMQ120PYDN

REMQ72PTJU

REMQ120PTJU

RXYQ72PYDN

RXYQ120PYDN

RXYQ96PTJU

REMQ72PYDN

RXYQ72PTJU

REMQ96PYDN

REMQ72PTJU

RXYQ72PYDN

REMQ72PYDN

RXYQ120PTJU

REMQ72PYDN

RXYQ72PYDN

REMQ96PTJU

h 1

REMQ120PYDN

RXYQ120PTJU

RXYQ120PYDN

REMQ120PTJU

RXYQ72PYDN

RXYQ120PYDN

REMQ120PTJU

RXYQ120PTJU

RXYQ120PTJU

REMQ120PYDN

RXYQ96PYDN

REMQ72PYDN

REMQ96PTJU

REMQ96PYDN

REMQ120PYDN

RXYQ96PTJU

REMQ120PTJU

RXYQ120PYDN

REYQ216PYDN

REYQ240PTJU

RXYQ216PTJU

RXYQ168PTJU

REYQ168PYDN

RXYQ192PYDN

REYQ216PTJU

REYQ144PYDN

RXYQ192PTJU

REYQ192PYDN

REYQ240PYDN

RXYQ144PYDN

REYQ168PTJU

RXYQ240PYDN

RXYQ240PTJU

RXYQ168PYDN

REYQ192PTJU

RXYQ216PYDN

3D058616

3D058616

3D058616

3D058616

3D058616

3D058616

3D058616

3D058616

3D058616

3D058617

3D058617

3D058617

3D058617

3D058617

3D058617

3D058617

3D058617

3D058617

4-19/32×7/8-mm-Oblong holes

30-1/8

Outdoor Unit 1

36-5/8

25/32 or more

Outdoor Unit 2

25/32

66-1/8

31-3/16

Notes :

1. Heights of walls

Front : 59-1/16in

Suction side : 19-11/16in

Side : Height unrestricted

The installation space shown in this figure is based on the condition of cooling operation at the outdoor

air temperature of 95˚F.

The installation space of suction side shown above must be expanded in the following case.

· Design outdoor temperature becomes over 95˚F.

· Operating over Max. operating load (In case of causing a heavy heating load at indoor unit side)

2. If the above wall heights are exceeded then h2/2 and h1/2 should be added to the

front and suction side service spaces respectively as shown in the following figure.

3. When installing the units the most appropriate pattern should be selected from those shown above

in order to obtain the best fit in the space available always bearing in mind the need to leave enough room

for a parson to pass between units and wall and for the air to circulate freely.

(If more units are to be installed than are catered for in the above patterns your layout should take account

of the possibility of short circuits. )

4. The units should be installed to leave sufficient space at the front for the on site refrigerant piping work

to be carried out comfortably.

36-5/8

13/32 or more

28-7/16 ~ 29-1/32

4-19/32 × 7/8-mm-Oblong holes

31-3/16

13/32 or more

3D059677

EDUS39-802A-R2_a

8 REYQ-P Heat Recovery (208-230V)

3. Service Space

REYQ72, 96, 120, 144, 168, 192, 216, 240PTJU

3D058620

EDUS39-802A-R2 Piping Diagrams

REYQ-P Heat Recovery (208-230V) 9

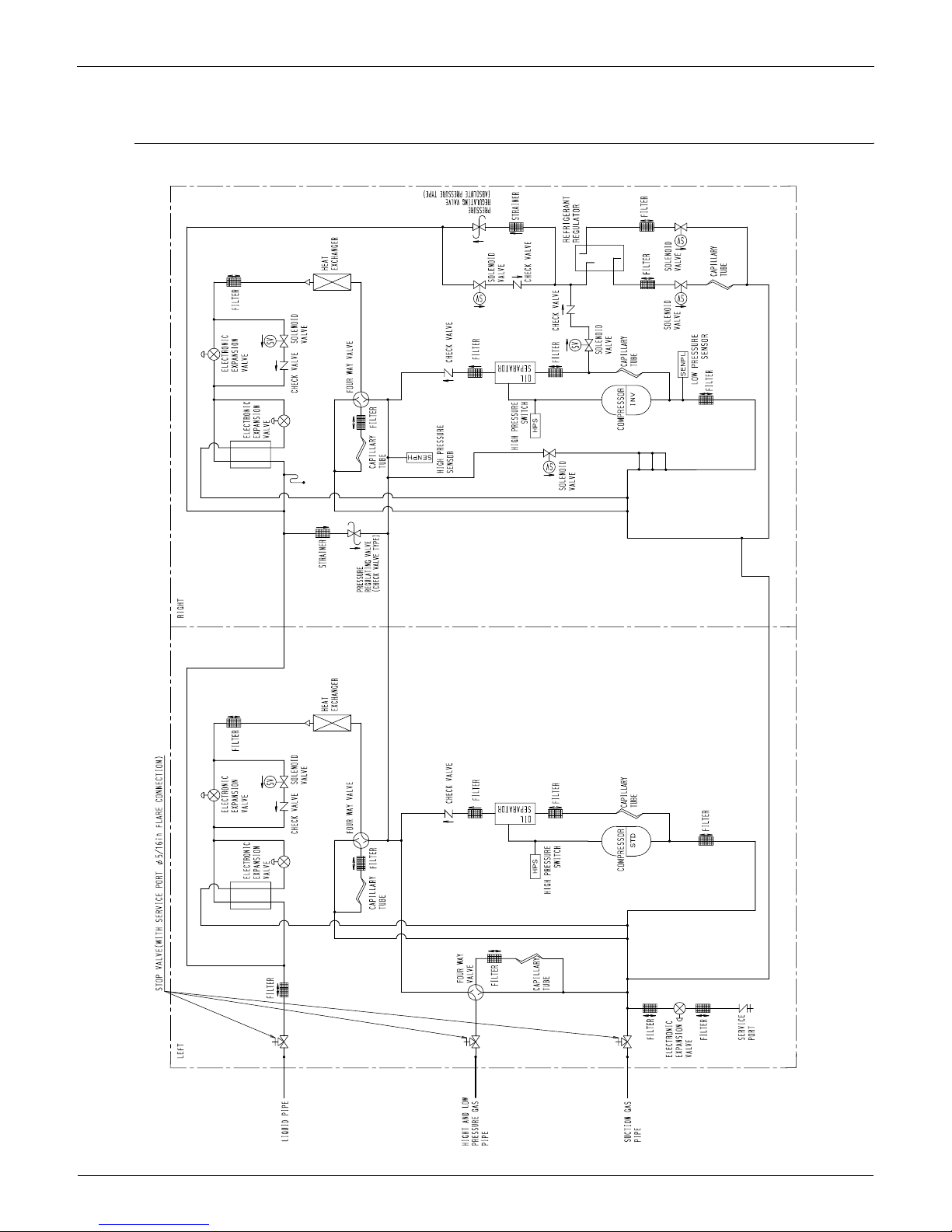

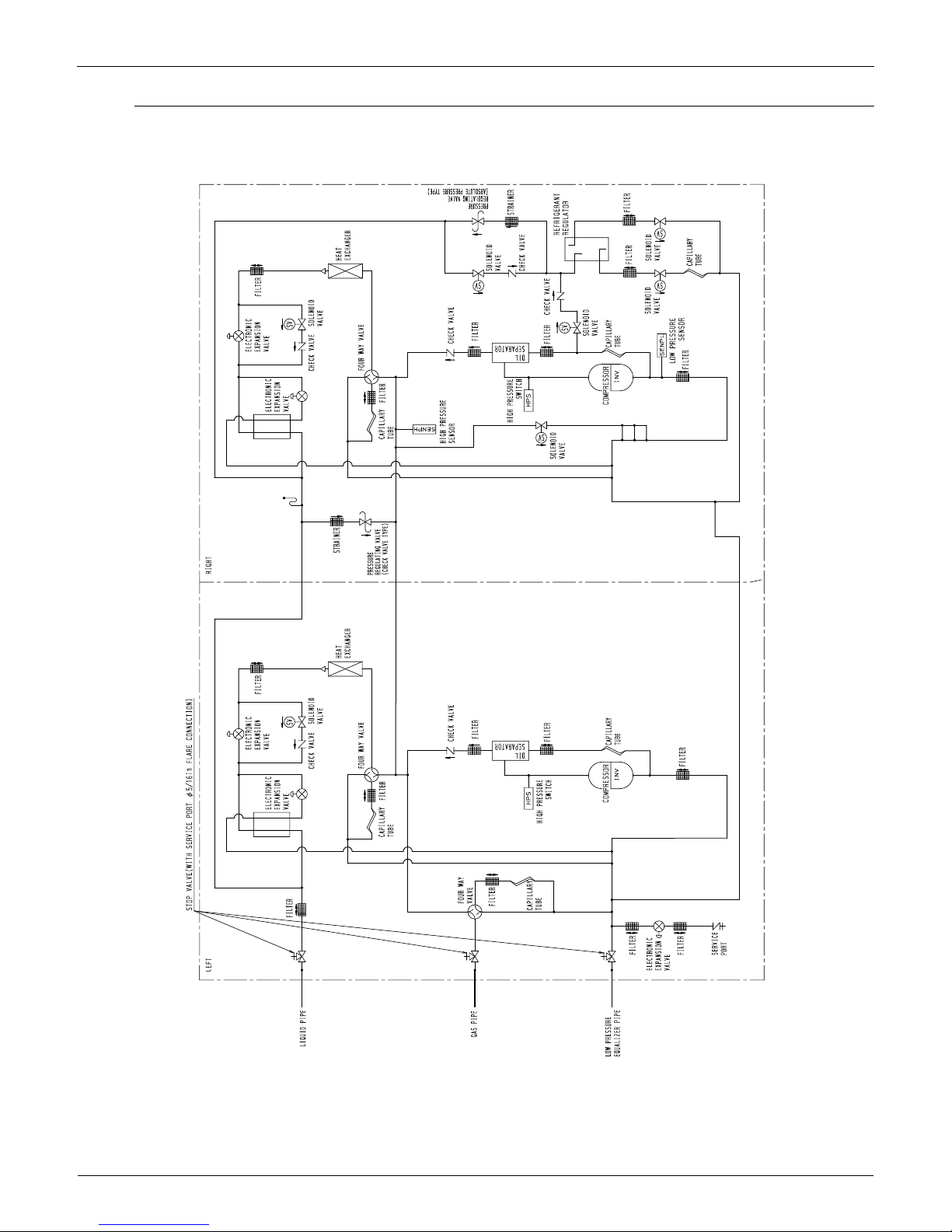

4. Piping Diagrams

REYQ72, 96, 120PTJU

3D058639A

EDUS39-802A-R2_a

10 REYQ-P Heat Recovery (208-230V)

REYQ144PTJU

3D058640

EDUS39-802A-R2 Piping Diagrams

REYQ-P Heat Recovery (208-230V) 11

REMQ72PTJU

3D058637A

EDUS39-802A-R2_a

12 REYQ-P Heat Recovery (208-230V)

REMQ96, 120PTJU

3D058638A

EDUS39-802A-R2 Wiring Diagrams

REYQ-P Heat Recovery (208-230V) 13

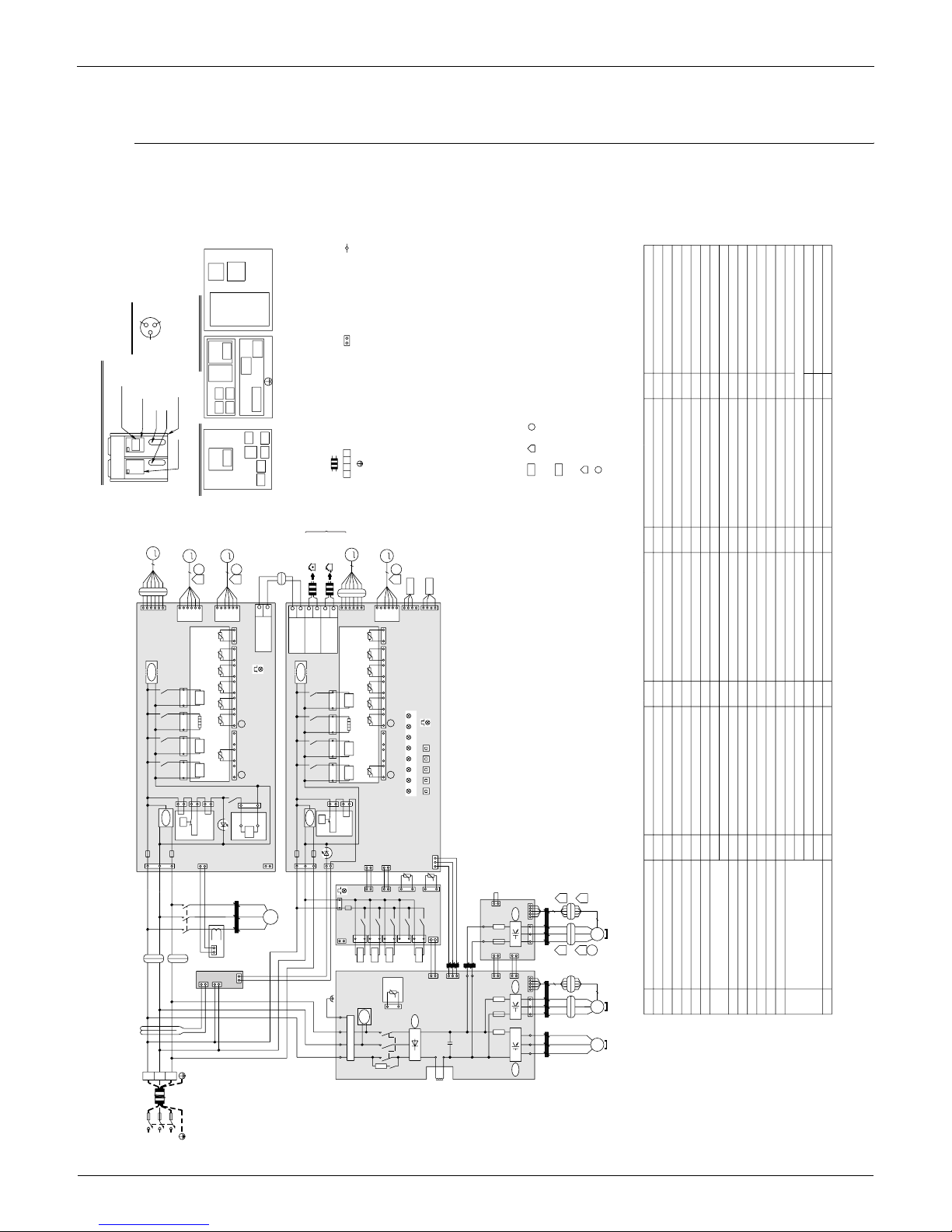

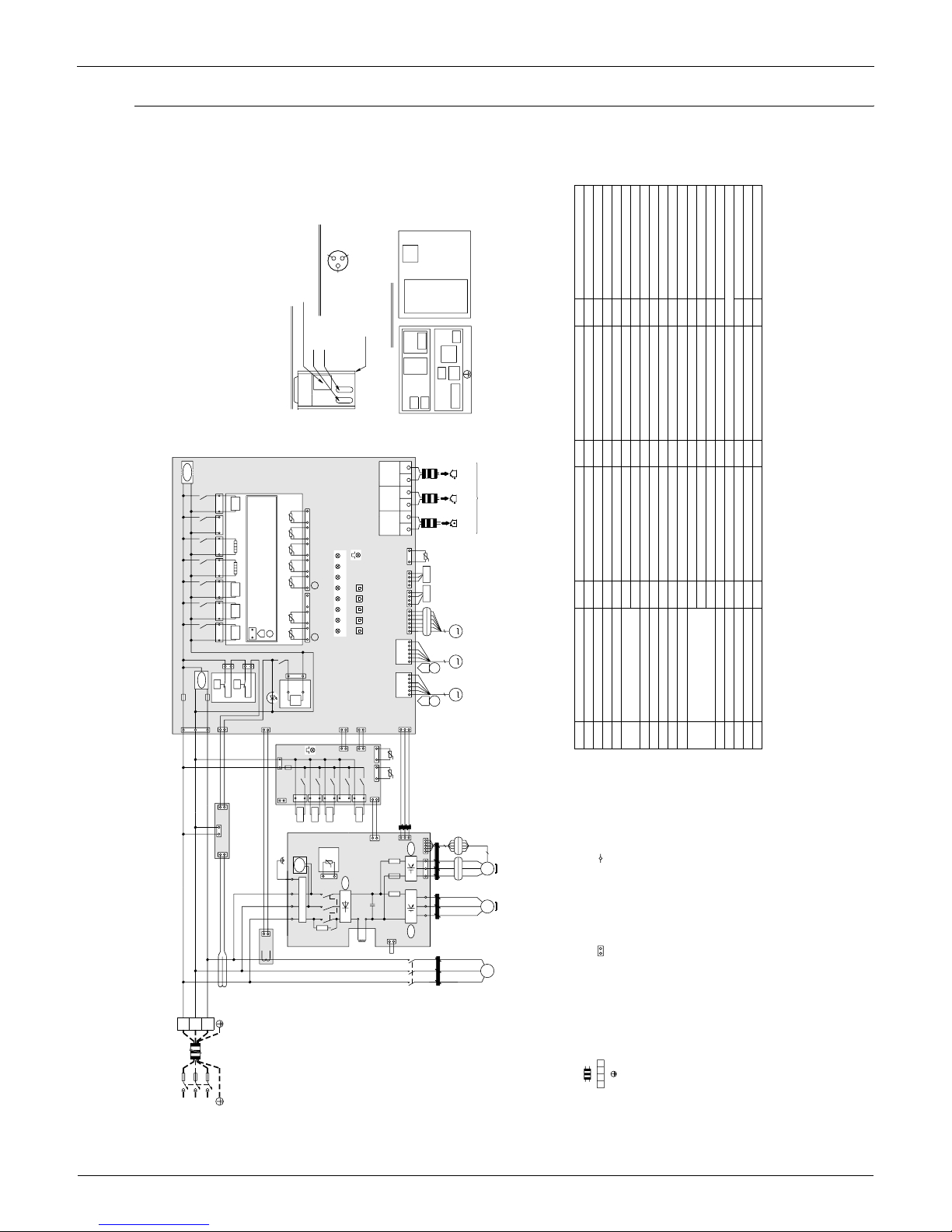

5. Wiring Diagrams

REYQ72, 96, 120PTJU

N=2Z4C

BS4

NOTE) 4

RED

M

Y3S

NOTE) 4

X5A

A2

K11R

X4A

BLU

F1U

R4T

A2P

A6P

P<

K11R

K1M

X3A

X2A

GRE

X9A

K2R

RED

WHT

BS2

208-230V 3~60Hz

5

K4R

R502

X16A

X1M

K3R

R14T

A4P

X8A

A6P

5

X28A

X2A

(BACK)

X3A

X1M

U

X31A

-

Q1RP

X6A

t˚

Z1C

N=4

5

TO

OUT/D UNIT

5

Y3E

F2

X21A

P1

3

BLU

K5R

5

X30A

t˚

K1R

BLK

WHT

X1A

X26A

X20A

t˚

M

M

H6P

U

V2R

BLK

H7P

t˚

X4A

H8P

L1R

X3A

K2M

M1C

LAYOUT OF M1C, M2C, M1F, M2F

F1U

P2

R10T

Y4S

R9T

M

K2M

BLK

V1CP

X15A

L1

Y10S

E2HC

X5A

Q1RP

X7A

P3

X37A

H1P

M1F

WHT

+

K7R

BLU

t˚

F1U

L3

X7A

K5R

R6T

X1M

K2M

t˚

5

K5R

WHT

Y6S

A5P

TO

MULTI UNIT

TO

MULTI UNITTOIN/D UNIT

A4P

WHT

X23A

X15A

RED

X29A

X8A

A3P

Y1E

M2F

X1A

R1T

Y4E

X7A

X3A

BLK

X1A

H4P

NOTE) 5

Y2S

X9A

HAP

WHT

F1

F2U

BLK

Y8S

H5P

t˚

BLK

V1R

R8T

S2NPL

X9A

X6A

RED

S1PH

R1

X1A

R2

R32T

X1A

outdoor

(F1)(F2)

WHT

RED

BLK

WHT

P<

F1U

Q1

S2PH

V

N3

F1

X11A

X7A

M2C

L1

K2M

X9A

M

3~

BLU

F1U

X3A

K3R

MS

3~

MS

3~

MS

3~

Y9S

RED

BLU

TERMINAL

OF M1C, M2C

X9A

HAP

A1

EL. COMPO. BOX(2)

A7P

A1P

Q2

t˚

T2A

N=1

5

HAP

F2

X8A

X22A

X2A

X1M

Z6C

N=4

L2

X1M

H3P

X4A

L2

+

t˚

R11T

RED

t˚

R12T

WHT

K84R

BLU

BS3

X21A

1

BLK

X37A

BS5

M

H2P

X5A

X3A

X4A

V1R

WHT

T1A

POWER SUPPLY

+

R15T

t˚

R13T

K8R

RED

BLU

WHT

(FRONT)

R1T

A5P

A7P

Y5E

indoor

(F1)(F2)

V

+

NOTE) 4

t˚

BS1

R7T

-

X12A

X18A

F2U

6

A2P

X2A

X1A

S1NPH

6

Y1S

t˚

X2A

E1HC

X10A

Q1

X18A

L1R

X30A

W

t˚

X15A

RED

X29A

X11A

642

X4A

X5A

EL. COMPO. BOX (1)

RED

BLU

RED

K1M

K8R

K6R

K5R

K5R

K3R

L1R

K4R

K11R

K5R

K84R

K11R

K7R

K3R

M1C, M2C

K2M

K1R

K2M

K2R

K1R

X1M

A3P

A1P

CONNECTOR FOR OPTIONAL PARTS

X7A

X9A

X37A

X6A

REDRED

R112

BLU

R2T

N=3Z3C

5

L3

ELECTRONIC EXPANSION VALVE (MAIN 2) (A3P)

THERMISTOR (SUB COOL HEAT EXC. GAS 2) (A3P)

SAFETY DEVICES INPUT (A1P) (A3P)

CURRENT SENSOR (A6P)

TERMINAL STRIP (POWER SUPPLY)

PRESSURE SWITCH (HIGH) (A3P)

CONNECTOR

ELECTRONIC EXPANSION VALVE (MAIN 1) (A1P)

CURRENT SENSOR (A7P)

PRESSURE SENSOR (LOW) (A1P)

POWER MODULE (A5P)

PRESSURE SENSOR (HIGH) (A1P)

POWER MODULE (A4P)

THERMISTOR (LIQUID 2) (A3P)

ELECTRONIC EXPANSION VALVE (SUBCOOL 1) (A1P)

PRESSURE SWITCH (HIGH) (A1P)

THERMISTOR (HEAT EXC. DEICER 2) (A3P)

THERMISTOR (HEAT EXC.LIQUID 2) (A3P)

TERMINAL STRIP (CONTROL) (A1P) (A3P)

DIODE BRIDGE (A4P)

SOLENOID VALVE (RMTO) (A2P)

SOLENOID VALVE (EV BYPASS 1) (A2P)

SOLENOID VALVE (RMTL) (A1P)

NOISE FILTER (WITH SURGE ABSORBER) (A4P)

SOLENOID VALVE (RMTT) (A2P)

ELECTRONIC EXPANSION VALVE (CHARGE) (A3P)

SOLENOID VALVE (HOT GAS) (A2P)

SOLENOID VALVE (RMTG) (A1P)

SOLENOID VALVE (EV BYPASS 2) (A3P)

SOLENOID VALVE (4 WAY VALVE) (PIPE) (A3P)

ELECTRONIC EXPANSION VALVE (SUBCOOL 2) (A3P)

SOLENOID VALVE (4 WAY VALVE) (HEAT EXC. 2) (A3P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (4 WAY VALVE) (HEAT EXC. 1) (A1P)

POWER SUPPLY (ADAPTOR) (A3P)

POWER SUPPLY (ADAPTOR) (A2P)

OPERATION OUTPUT (A2P)

X23A

Y2E

R31T

-

X12A

V1CP

X3A

X4A

V3R

WHT

t˚

t˚

X32A

X4A

WHT

X1A

Y5S

K1R

X5A

t˚

C1

Q2

MAGNETIC RELAY (M2C)

MAGNETIC RELAY (Y1S) (A1P)

MAGNETIC RELAY (Y9S) (A3P)

MAGNETIC RELAY (E2HC) (A3P)

MAGNETIC RELAY (Y3S) (A1P)

MAGNETIC RELAY (K2M) (A3P)

MAGNETIC RELAY (Y2S) (A1P)

MAGNETIC RELAY (Y4S) (A2P)

MAGNETIC RELAY (E1HC) (A1P)

MAGNETIC RELAY (Y6S) (A2P)

MAGNETIC RELAY (A4P)

MAGNETIC CONTACTOR (M1C) (A4P)

MOTOR (COMPRESSOR)

MAGNETIC RELAY (FOR OPTION) (A2P)

MAGNETIC RELAY (Y7S) (A2P)

MAGNETIC RELAY (CURRENT LIMITING) (A4P)

MAGNETIC RELAY (Y5S) (A2P)

MAGNETIC RELAY (Y10S) (A3P)

MAGNETIC RELAY (Y8S) (A3P)

REACTOR

X8A

K6R

F1U

E1HC

F1U, F2U

F1U

E2HC

C1

BS1~5

HAP

A6P

A3P

A7P

A5P

A1P

A2P

A4P

H1P~8P

R5T

Y7S

X7A

PHASE REVERSAL DETECT CIRCUIT (A1P) (A3P)

THERMISTOR (FIN) (A4P)

MOTOR (FAN)

THERMISTOR (LIQUID 1) (A2P)

THERMISTOR (HEAT EXC. GAS 1) (A1P)

RESISTOR (CURRENT LIMITING) (A4P)

SWITCHING POWER SUPPLY (A1P, A3P, A4P)

RESISTOR (CURRENT SENSOR) (A4P)

THERMISTOR (SUB COOL HEAT EXC. GAS 1) (A1P)

RESISTOR (CURRENT SENSOR) (A4P)

THERMISTOR (AIR) (A1P)

THERMISTOR (HEAT EXC. LIQUID 1) (A1P)

THERMISTOR (SUB COOL HEATE XC.LIQUID 1) (A1P)

THERMISTOR (HEAT EXC. DEICER 1) (A1P)

THERMISTOR (M1C DISCHARGE) (A1P)

THERMISTOR (SUCTION 2) (A3P)

THERMISTOR (M2C DISCHARGE) (A3P)

THERMISTOR (SUCTION 1) (A2P)

RESISTOR (CURRENT SENSOR) (A5P)

THERMISTOR (HEAT EXC. GAS 2) (A3P)

W

R32T

R31T

R4T

R8T

R502

Q1RP

R1

M1F, M2F

R1T

R5T

R7T

R6T

R2T

R2

PS

R11T

R10T

R1T

R9T

R112

WHT

PRINTED CIRCUIT BOARD (MAIN)

PRINTED CIRCUIT BOARD (SUB)

PRINTED CIRCUIT BOARD (INV, FAN)

PILOT LAMP (SERVICE MONITOR : ORANGE) (A1P)

[H2P] PREPARE, TEST-------------------FLICKERING

MALFUNCTION DETECTION---LIGHT UP

PRINTED CIRCUIT BOARD (CURRENT SENSOR)

PRINTED CIRCUIT BOARD (ELB)

FUSE (16A, DC450V) (A4P) (A5P)

PRINTED CIRCUIT BOARD (FAN)

FUSE (T, 3.15A, 250V) (A2P)

CAPACITOR

CRANKCASE HEATER (A1P)

FUSE (T, 3.15A, 250V) (A1P) (A3P)

PRINTED CIRCUIT BOARD (MAIN)

CRANKCASE HEATER (A3P)

PUSH BUTTON SWITCH

(MODE, SET, RETURN, TEST, RESET) (A1P)

PILOT LAMP (SERVICE MONITOR-GREEN) (A1P) (A2P) (A3P)

Y3S

Y6S

Y4E

Y5E

Y1S

Y8S

Y10S

Z1C~6C

Y9S

Y5S

Y2S

Y7S

Z1F

Y4S

S1NPH

V2R, V3R

Y3E

V1R

V1CP

R14T

T1A

S1PH

S2NPL

X1M

V1R

Y1E

R12T

R15T

X1A~X9A

S2PH

X1M

Y2E

T2A

R13T

L3A

X504A

X5A

X501A

1 1

P1

X2A

Z1F

PS

X1A

1 1

N1

E1

X502A

L1A

M2F

THIS DWG.

M1F

M2C

BOX (2)

BOX (1)

M1C

CASING

Z5C

L2A

Z2C

U

W

V

U

VW

PS

PS

NOTES)

1. THIS WIRING DIAGRAM IS APPLIED ONLY TO THE

OUTDOOR UNIT.

2. : FIELD WIRING.

3. : TERMINAL STRIP : CONNECTOR : TERMINAL

: PROTECTIVE EARTH (SCREW)

4. WHEN USING THE OPTIONAL ADAPTOR, REFER TO THE

INSTALLATION MANUAL OF THE OPTIONAL ADAPTOR.

5. FOR CONNECTION WIRING TO INDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-MULTI

TRANSMISSION Q1 · Q2, REFER TO THE INSTALLATION

MANUAL.

6. HOW TO USE BS1~5 AND DS1 · 2 SWITCH, REFER TO

"SERVICE PRECAUTION" LABEL ON EL. COMPO. BOX

COVER.

7. WHEN OPERATING, DON' T SHORTCIRCUIT THE

PROTECTION DEVICE (S1, 2PH).

8. , , SYMBOLS INDICATE COLORS OF EACH

PARTS AS SHOWN BELOW.

: IS CONNECTOR COLOR FOR PRINTED CIRCUIT

BOARD.

: IS CONNECTOR COLOR FOR COMPONENT.

: IS IDENTIFICATION COLOR FOR COMPONENT

LEAD WIRE.

9. COLORS BLK : BLACK RED : RED BLU : BLUE

WHT : WHITE.

*

*

*

*

*

*

***

3D058533D

EDUS39-802A-R2_a

14 REYQ-P Heat Recovery (208-230V)

REYQ144PTJU

X1A

X3A

F1U

A6P

X5A

X6A

L3A

X6A

K3R

A2P

Y2E

R2T

BLU

Q1

R502

(BACK)

M1C

Y3E

TERMINAL

OF M1C, M2C

BS3

(FRONT)

A2P

X5A

L2

M

L3

Z2C

X2A

C1

Y7S

-

BLU

L2A

X2A

Z5C

X37A

A5P

BLK

C1

M

X1M

6

K2M

A1P

X8A

K4R

Y6S

Z1C

N=4

BLK

P2

M

K5R

5

V

E1

S2PH

X4A

S2NPL

X501A

5

H4P

K1R

X3A

-

R1

M1F

Y8S

V1CP

K5R

X4A

R31T

R1T

RED

MS3~MS

3~

MS3~MS

3~

H1P

RED

R6T

X8A

TO

OUT/D UNIT

Q2

(BACK)

BS4

X5A

X11A

X6A

X4A

X2A

V2R

X2A

EL. COMPO. BOX (1)

X15A

Y2S

L1A

EL. COMPO. BOX (2)

t˚ t˚ t˚ t˚ t˚ t˚

t˚

F1U

X1M

POWER SUPPLY

5

R5T

Q1

X1A

t˚

X21A

X9A

R7T

X32A

X28A

Q2

K2R

BLU

X37A

+

A2

H2P

X4A

X20A

X1A

NOTE) 5

M

K1M

X9A

X7A

X501A

V1R

W

5

R10T

BS1

R15T

X8A

HAP

F1U

H6P

R1

K6R

Y5E

Y3S

A5P

L3

R1T

X20A

+

t˚

P<

outdoor

(F1) (F2)

P2

X23A

Y1S

X11A

X30A

Z4C

N=4

X1A

E1HC

R1T

R11T

A1P

Z3C

N=3

M2C

WHT

WHT

X29A

F1

X23A

indoor

(F1) (F2)

U

S1NPH

X2M

A4P

A3P

R12T

X2A

X15A

BLU

Y4E

RED

t˚

U

A3P

L1R

V2R

F1

BLK

L2

+

5

K1M

L1

X3A

R32T

5

X7A

Z6C

N=3

+

L3A

F1U

BLU

TO

MULTI UNIT

TO

MULTI UNIT

L2A

K3R

Y1E

A1

HAP

X29A

X7A

L1

X1M

BLK

WHT

RED

L3

BS5

X1M

X3A

X6A

L2R

X8A

WHT

BLK

F2

X28A

H5P

X21A

NOTE) 4

X7A

RED

X4A

NOTE) 4

R8T

V1CP

X9A

V3R

X9A

K84R

K2M

M2F

t˚

X5A

Y9S

R9T

X7A

X1M

L1A

-

5

X1M

P<

V

WHT

HAP

GRE

Y10S

BLK

X10A

X4A

M

K2M

R13T

F2

L2R

T2A

N=1

X16A

X3A

WHT

NOTE) 4

+

X2M

K7R

V

U

BLK

WHT

RED

W

V

U

BLK

WHT

RED

W

P1

E1

X9A

V3R

X30A

K7R

GRE

W

BLU

WHT

BLU

WHT

BLU

H7P

X502A

A6P

H8P

X22A

RED

R112

BLU

H3P

X15A

K1M, K2M

A4P, A5P

A6P

A2P

HAP

F1U

F1U

F1U, F2U

H1P~8P

BS1~5

K1R

E1HC, E2HC

C1

A1P

A3P

X18A

WHT

-

X7A

X1A

K6R

K2R

K7R

K3R

Q1RP

K5R

K5R

K5R

K11R

M1F, M2F

PS

M1C, M2C

K7R

K4R

K11R

K3R

L1R, L2R

R14T

208-230V 3~60Hz

F2U

K5R

+

Y4S

WHT

BLU

RED

X31A

BLK

R112

E2HC

R4T

L1R

L2

S1PH

X12A

X4A

Q1RP

K84R

Q1RP

K11R

TO

IN/D UNIT

F1U

X502A

R14T

R10T

R1T

R11T

R2T

R112, R502

R1T

R32T

R31T

R8T

R9T

R1

R4T

R7T

R5T

R12T

R13T

X3A

P1

R502

K1R

L1

Y5S

X1A

t˚ t˚ t˚ t˚ t˚ t˚ t˚

WHT

(FRONT)

RED

X11A

X18A

V1R

6

K11R

BS2

PUSH BUTTON SWITCH

(MODE, SET, RETURN, TEST, RESET)

CRANKCASE HEATER (A1P) (A3P)

PRINTED CIRCUIT BOARD (SUB 1)

PRINTED CIRCUIT BOARD (INV)

CAPACITOR (A4P) (A5P)

PILOTLAMP (SERVICE MONITOR : ORANGE)

[H2P] PREPARE, TEST-------------------FLICKERING

MALFUNCTION DETECTION---LIGHT UP

MAGNETIC RELAY (Y4S) (A2P)

PILOT LAMP (SERVICE MONITOR-GREEN) (A1P, A2P, A3P)

MAGNETIC RELAY (M1C) (M2C) (A4P) (A5P)

FUSE (16A, DC450V) (A4P) (A5P)

FUSE (T, 3.15A, 250V) (A2P)

PRINTED CIRCUIT BOARD (MAIN)

PRINTED CIRCUIT BOARD (ELB)

FUSE (T, 3.15A, 250V) (A1P) (A3P)

PRINTED CIRCUIT BOARD (SUB 2)

MAGNETIC RELAY (Y3S) (A1P)

K84R MAGNETIC RELAY (CURRENT LIMITING) (A4P) (A5P)

MAGNETIC RELAY (FOR OPTION) (A2P)

MOTOR (FAN)

MAGNETIC RELAY (Y10S) (A3P)

MAGNETIC RELAY (E1HC) (A1P)

MAGNETIC RELAY (Y5S) (A2P)

MAGNETIC RELAY (Y8S) (A3P)

PHASE REVERSAL DETECT CIRCUIT (A1P) (A3P)

MOTOR (COMPRESSOR)

SWITCHING POWER SUPPLY (A1P, A3P, A4P, A5P)

MAGNETIC RELAY (Y2S) (A1P)

MAGNETIC RELAY (Y6S) (A2P)

MAGNETIC RELAY (Y1S) (A1P)

REACTOR (A4P) (A5P)

MAGNETIC RELAY (Y7S) (A2P)

MAGNETIC RELAY (E2HC) (A3P)

MAGNETIC RELAY (Y9S) (A3P)

F2U

RED

BLU

WHT

S2NPL

V1R

Y2E

Y1S

Y4E

Y1E

V2R, V3R

V1CP

X1M

Y3E

X1M

R15T

X1A~X9A

T2A

S1PH, S2PH

S1NPH

Y5E

X2M

A4P

Y9S

Y7S

Y6S

Y4S

X37A

Y2S

Y8S

Y5S

Y10S

Z1C~6C

X7A

CONNECTOR FOR OPTIONAL PARTS

Y3S

X9A

SOLENOID VALVE (EV BYPASS 1)

SOLENOID VALVE (4 WAY VALVE-HEAT EXC. 1)

SOLENOID VALVE (RMTT)

POWER SUPPLY (ADAPTER) (A3P)

POWER SUPPLY (ADAPTER) (A2P)

SOLENOID VALVE (RMTL)

SOLENOID VALVE (EV BYPASS 2)

SOLENOID VALVE (HOT GAS)

SOLENOID VALVE (4 WAY VALVE-PIPE)

SOLENOID VALVE (RMTO)

NOISE FILTER (FERRITE CORE)

OPERATION OUTPUT (A2P)

Z1F NOISE FILTER (WITH SURGE ABSORBER) (A4P) (A5P)

SOLENOID VALVE (4 WAY VALVE-HEAT EXC. 2)

THERMISTOR (M1C DISCHARGE) (A1P)

THERMISTOR (SUB COOL HEAT EXC. GAS 1)

THERMISTOR (FIN) (A4P) (A5P)

THERMISTOR (HEAT EXC. LIQUID 1) (A1P)

THERMISTOR (HEAT EXC. DEICER 2) (A3P)

THERMISTOR (HEAT EXC. GAS 2) (A3P)

THERMISTOR (SUCTION 1) (A2P)

THERMISTOR (M2C DISCHARGE) (A2P)

THERMISTOR (SUB COOL HEAT EXC. GAS 2)

R6T THERMISTOR (SUB COOL HEAT EXC. LIQUID) (A1P)

THERMISTOR (AIR) (A1P)

THERMISTOR (LIQUID 1) (A2P)

RESISTOR (CURRENT SENSOR) (A4P) (A5P)

THERMISTOR (LIQUID 2) (A3P)

THERMISTOR (HEAT EXC. GAS 1) (A1P)

THERMISTOR (HEAT EXC. DEICER 1) (A1P)

RESISTOR (A4P) (A5P)

THERMISTOR (SUCTION 2) (A3P)

PRESSURE SENSOR (HIGH) (A1P)

SOLENOID VALVE (RMTG)

PRESSURE SENSOR (LOW) (A1P)

POWER MODULE (A4P) (A5P)

ELECTRONIC EXPANSION VALVE (SUBCOOL 2)

ELECTRONIC EXPANSION VALVE (CHARGE)

ELECTRONIC EXPANSION VALVE (SUBCOOL 1)

TERMINAL STRIP (CONTROL) (A1P) (A3P)

ELECTRONIC EXPANSION VALVE (MAIN 1)

TERMINAL STRIP (RELAY)

ELECTRONIC EXPANSION VALVE (MAIN 2)

THERMISTOR (HEAT EXC. LIQUID 2) (A3P)

CONNECTOR

DIODE BRIDGE (A4P) (A5P)

TERMINAL STRIP (POWER SUPPLY)

PRESSURE SWITCH (HIGH) (A1P) (A3P)

SAFETY DEVICES INPUT (A1P) (A3P)

CURRENT SENSOR (A6P)

Z1F

W

U

V

CASING

BOX (1)

M1C

THIS DWG.

BOX (2)

M2C

M2F M1F

1

PS

Z1F

1 1

1

PS

PS

PS

LAYOUT OF M1C, M2C, M1F, M2F

NOTES)

1. THIS WIRING DIAGRAM IS APPLIED ONLY TO THE

OUTDOOR UNIT.

2. : FIELD WIRING.

3. : TERMINAL STRIP : CONNECTOR : TERMINAL

: PROTECTIVE EARTH (SCREW)

4. WHEN USING THE OPTIONAL ADAPTOR, REFER TO THE

INSTALLATION MANUAL OF THE OPTIONAL ADAPTOR.

5. FOR CONNECTION WIRING TO INDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-MULTI

TRANSMISSION Q1 · Q2, REFER TO THE INSTALLATION

MANUAL.

6. HOW TO USE BS1~5 AND DS1 · 2 SWITCH, REFER TO

"SERVICE PRECAUTION" LABEL ON EL. COMPO. BOX

COVER.

7. WHEN OPERATING, DON' T SHORTCIRCUIT THE

PROTECTION DEVICE (S1, 2PH).

8. , , SYMBOLS INDICATE COLORS OF EACH

PARTS AS SHOWN BELOW.

: IS CONNECTOR COLOR FOR PRINTED CIRCUIT

BOARD.

: IS CONNECTOR COLOR FOR COMPONENT.

: IS IDENTIFICATION COLOR FOR COMPONENT

LEAD WIRE.

9. COLORS BLK : BLACK RED : RED BLU : BLUE

WHT : WHITE.

*

*

*

*

*

*

***

3D060077A

EDUS39-802A-R2 Wiring Diagrams

REYQ-P Heat Recovery (208-230V) 15

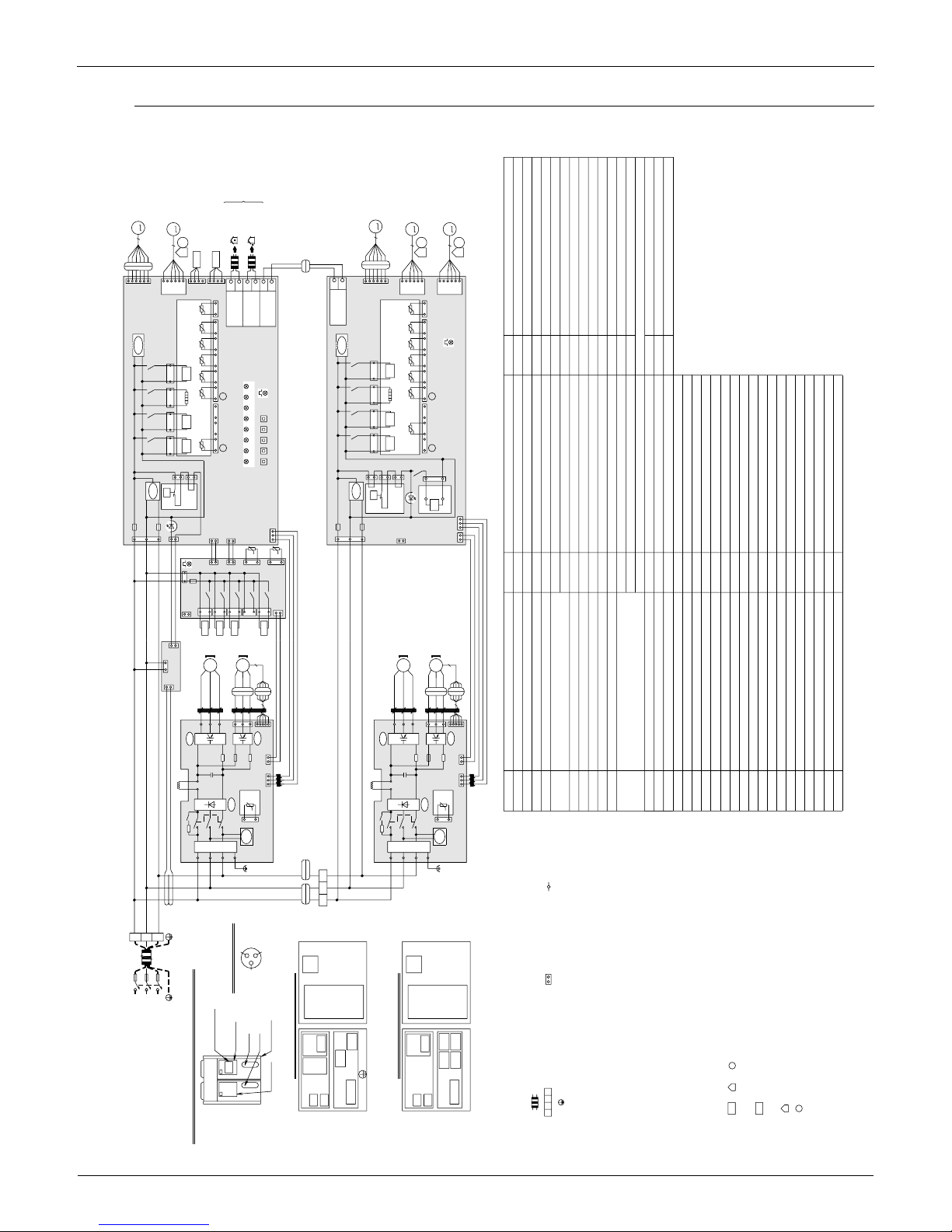

REMQ72PTJU

C1

5

K2M

+

X4A

A2P

F2U

WHT

V1CP

-

F1U

A3P

BLU

+

X504A

C1

X7A

5

RED

-

X2A

X1A

A1P

V2R

A4P

+

X28A

L2

L3

X1M

L1

Z1F

PS

PS

POWER SUPPLY

208-230V 3~60Hz

L1L2L3

WHT

RED

BLU

T2A

N=1

GRNWHTRED BLU

L1A L3A E1L2A

K1M

X2A

X3A

X1A

K84R

R1

R1T

V1R

t˚

t˚ t˚

t˚ t˚ t˚ t˚ t˚ t˚

BLK

BLK

L1R

P1

P2

F1UR112

X6A

V3R

X4A

R502

X502A

X501A

UWV

UWV

Z1C

N=4

RED

BLK

WHT

X1A

Z2C

RED

BLK

WHT

MS

3~

MS

3~

M1FM1C

Z3C

N=3

R9TR8T

X16A

X12AX11A

NOTE) 4

Y5S

NOTE) 4

Y8S

Y6S

Y7S

X9A

X1A

F1U

X7A

X8A

X4A

X5A

X3A K1R

K5R

K3R

K6R

K2R

X20A

X37A

X10A

X15A

HAP

Q1RP

X3A

X2A

K11R

K5R

K3R

K4R

K7R

X7A X9AX8A X11A X15A

Y2S Y3SY1S

E1HC

Y4S

: * IS CONNECTOR COLOR FOR PRINTED CIRCUIT BOARD.

: * IS CONNECTOR COLOR FOR COMPONENT.

: * IS DISCRIMINATION COLOR FOR COMPONENT LEAD WIRE.

***

R31T R2T R6TR5T R7TR4T

X30AX29A

1 1

H1P H2P H3P H4P H5P H6P H7P H8P

BS1 BS2 BS3 BS4 BS5

HAP

Q2F1 F2

TO

IN/D

UNIT

TO

OUT/D

UNIT

F1

X1M

TO

MULTI

UNIT

NOTE) 5

Q1

outdoor

(Q1) (Q2)

outdoor

(F1) (F2)

indoor

(F1) (F2)

F2

X3A

S2NPL

X18A

Y1E

M

X31A

5

t˚

R1T

X21A

S1NPH

X32A

X23A

5

BLU

WHT WHT

M

BLU

Y3E Y2E

5

BLK

X22A

M

BLK

LAYOUT OF M1C, M2C, M1F

V

U

TERMINAL OF M1C, M2C

W

M1F

EL. COMPO. BOX

CASING

M1C

(FRONT)

X2A

(BACK)

X1A

A2P A1P

A3P

X1M

A4P

L1R

X3A

X1M

EL. COMPO. BOX

NOTES)

1. THIS WIRING DIAGRAM IS APPLIED ONLY TO THE

OUTDOOR UNIT.

2. : FIELD WIRING.

3. : TERMINAL STRIP : CONNECTOR : TERMINAL

: PROTECTIVE EARTH (SCREW)

4. WHEN USING THE OPTIONAL ADAPTOR, REFER TO THE

INSTALLATION MANUAL OF THE OPTIONAL ADAPTOR.

5. FOR CONNECTION WIRING TO INDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-MULTI

TRANSMISSION Q1 · Q2, REFER TO THE INSTALLATION

MANUAL.

6. HOW TO USE BS1~5, REFER TO "SERVICE PRECAUTION"

LABEL ON EL. COMPO. BOX COVER.

7. WHEN OPERATING, DON' T SHORTCIRCUIT THE

PROTECTION DEVICE (S1PH, S2PH).

8. COLORS BLK : BLACK RED : RED BLU : BLUE

WHT : WHITE GRN : GREEN.

CONNECTOR FOR OPTIONAL PARTS

R6T

R9T

R7T

S2NPL

S1PH

R5T

R31T

R4T

T2A

R2T

R8T

S1NPH

V2R, V3R

V1CP

X1M

X3A

X1A, X2A

V1R

X9A

X7A

PRESSURE SENSOR (HIGH) (A1P)

PRESSURE SWITCH (HIGH) (A1P)

THERMISTOR (LIQUID) (A2P)

THERMISTOR (HEAT EXC. DEICER) (A1P)

THERMISTOR (HEAT EXC. LIQUID) (A1P)

THERMISTOR (SUB COOL HEAT EXC. LIQUID) (A1P)

PRESSURE SENSOR (LOW) (A1P)

CURRENT SENSOR (A4P)

THERMISTOR (SUB COOL HEAT EXC. GAS) (A1P)

THERMISTOR (SUCTION) (A2P)

THERMISTOR (HEAT EXC. GAS) (A1P)

THERMISTOR (M1C, M2C DISCHARGE) (A1P)

SAFETY DEVICES INPUT (A1P)

CONNECTOR (Y1E)

POWER MODULE (A3P)

TERMINAL STRIP (POWER SUPPLY)

POWER MODULE (A3P)

CONNECTOR (M1F)

OPERATION OUTPUT (A2P)

POWER SUPPLY (ADAPTOR) (A2P)

Z1F

Y5S

Z1C~3C

Y1S

Y4S

Y1E

Y3S

Y7S

Y6S

Y2E

Y8S

X1M

Y3E

Y2S

NOISE FILTER (WITH SURGE ABSORBER) (A3P)

ELECTRONIC EXPANSION VALVE (CHARGE) (A1P)

ELECTRONIC EXPANSION VALVE (MAIN) (A1P)

ELECTRONIC EXPANSION VALVE (SUBCOOL) (A1P)

SOLENOID VALVE (HOT GAS) (A2P)

SOLENOID VALVE (RMTL) (A1P)

SOLENOID VALVE (RMTG) (A1P)

TERMINAL STRIP (CONTROL) (A1P)

SOLENOID VALVE (RMTO) (A2P)

SOLENOID VALVE (EV BYPASS) (A2P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (4 WAY VALVE) (PIPE) (A1P)

SOLENOID VALVE (4 WAY VALVE) (HEAT EXC. ) (A1P)

SOLENOID VALVE (RMTT) (A2P)

MAGNETIC RELAY (Y3S) (A1P)

MAGNETIC RELAY (Y1S) (A1P)

MAGNETIC RELAY (Y8S) (A2P)

MAGNETIC RELAY (Y2S) (A1P)

MOTOR (COMPRESSOR)

MAGNETIC RELAY (FOR OPTION) (A2P)

REACTOR (A3P)

MAGNETIC RELAY (E1HC) (A1P)

MOTOR (FAN)

MAGNETIC RELAY (CURRENT LIMITING) (A3P)

MAGNETIC RELAY (Y4S) (A1P)

RESISTOR (A3P)

RESISTOR (CURRENT SENSOR) (A3P)

SWITCHING POWER SUPPLY (A1P, A3P)

PHASE REVERSAL DETECT CIRCUIT (A1P)

THERMISTOR (FIN) (A3P)

THERMISTOR (AIR) (A1P)

MAGNETIC RELAY (Y7S) (A2P)

A1P

A2P

A3P

A4P

BS1~5C1E1HC

F1U, F2U

F1U

F1U

H1P~8P

HAP

K1M, K2M

K1R

K2R

PRINTED CIRCUIT BOARD (MAIN)

PRINTED CIRCUIT BOARD (SUB)

PRINTED CIRCUIT BOARD (INV, FAN)

PRINTED CIRCUIT BOARD (ELB)

PUSH BUTTON SWITCH

(MODE, SET, RETURN, TEST, RESET) (A1P)

CAPACITOR

CRANKCASE HEATER (A1P)

FUSE (T, 3.15A, 250V) (A1P)

FUSE (T, 3.15A, 250V) (A2P)

FUSE (16A, DC450V) (A3P)

PILOT LAMP (SERVICE MONITOR : ORANGE) (A1P)

[H2P] PREPARE, TEST-------------------FLICKERING

MALFUNCTION DETECTION---LIGHT UP

PILOT LAMP (SERVICE MONITOR-GREEN) (A1P) (A2P)

MAGNETIC RELAY (M1C) (A3P)

MAGNETIC RELAY (Y5S) (A2P)

MAGNETIC RELAY (Y6S) (A2P)

K3R

K3R

K4R

K5R

K5R

K6R

K7R

K11R

K84R

L1R

M1C

M1FPSQ1RP

R1

R112, R502

R1T

R1T

P<

S1PH

3D058614

EDUS39-802A-R2_a

16 REYQ-P Heat Recovery (208-230V)

REMQ96, 120PTJU

A4P

Z4C

N=4

+

LAYOUT OF M1C, M2C, M1F

Y5S

V2R

A2P

X3A

WHT

Y2S

(FRONT)

X7A

X3A

K2M

V

Z1C

N=4

S2NPL

X1A

Y3S

X9A

X26A

X2A

X6A

(BACK)

R9T

X18A

WHT

Q2

X2A

T2A

N=1

X1A

M

3~

A5P

RED

MS

3~

MS

3~

R1T

X3A

P<

P<

Z3C

N=3

5

K2M

X20A

X7A

A2P

Y1E

P1

A3P

K1R

X1A

C1

F1

Y4S

K84R

5

K5R

M1F

X5A

K3R

M

X8A

F2

X31A

TO

IN/D

UNIT

TO

OUT/D

UNIT

X16A

6

M1C

X37A

S2PH

V1R

X4A

WHT

RED

BLU

A1

F1

RED

F1U

t˚

t˚ t˚ t˚

t˚

t˚ t˚ t˚ t˚

X10A

X15A

F2U

A1P

K2M

-

X1M

U

NOTE) 4

HAP

NOTE) 4

R1

A4P

+

P2

A2

V3R

K6R

K1M

A1P

TERMINAL OF M1C, M2C

A3P

+

M2C

X1M

X5A

BLK

TO

MULTI

UNIT

K2R

K2M

S1PH

WHT

Y8S

T1A X1A

X28A

X1A

R1T

X21A

-

K1R

A5P

V

3

WHT

4

X30A

E1HC

X4A

X2A

E2HC

X3A

Y6S

GRN

L1R

BLK

W

X3A

RED

Y1S

X1M

BLU

RED

U

2

1

R32TR31T R2T R6TR5T R7TR4T

BLK

Q1RP

X4A

t˚

X12A

F1U

X504A

W

BLK

5

6

F1UR112

R502

M1F

S1NPH

NOTE) 5

X1A

X32A

V1CP

R8T

X29A

Q1

outdoor

(Q1) (Q2)

outdoor

(F1) (F2)

indoor

(F1) (F2)

F2

L1R

X7A X9A X14AX8A X12AX11A X15A

EL. COMPO. BOX

X11A

K11R

K5R

K3R

K4R

K10R

K7R

K8R

NOTE) 4

BLU

Y7S

WHT

X2A

Z2C

RED

U

U

X502A

Z1F

L1A

EL. COMPO. BOX

1 1

X501A

W

BLK

W

L3A

H1P H2P H3P H4P H5P H6P H7P H8P

BS1 BS2 BS3 BS4 BS5

HAP

X23A

5

BLU

WHT WHT

M

BLU

Y3E

WHT

V

V

Y2E

5

BLK

X22A

M

BLK

X1M

L3L1L2

E1

CASING

M1C

M2C

PS

L2A

PS

POWER SUPPLY

208-230V 3~60Hz

L1L2L3

RED

NOTES)

1. THIS WIRING DIAGRAM IS APPLIED ONLY TO THE

OUTDOOR UNIT.

2. : FIELD WIRING.

3. : TERMINAL STRIP : CONNECTOR : TERMINAL

: PROTECTIVE EARTH (SCREW)

4. WHEN USING THE OPTIONAL ADAPTOR, REFER TO THE

INSTALLATION MANUAL OF THE OPTIONAL ADAPTOR.

5. FOR CONNECTION WIRING TO INDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-OUTDOOR

TRANSMISSION F1 · F2, OUTDOOR-MULTI

TRANSMISSION Q1 · Q2, REFER TO THE INSTALLATION

MANUAL.

6. HOW TO USE BS1~5, REFER TO "SERVICE PRECAUTION"

LABEL ON EL. COMPO. BOX COVER.

7. WHEN OPERATING, DON' T SHORTCIRCUIT THE

PROTECTION DEVICE (S1PH, S2PH).

8. COLORS BLK : BLACK RED : RED BLU : BLUE

WHT : WHITE GRN : GREEN.

CONNECTOR FOR OPTIONAL PARTS

R6T

R9T

R7T

V2R, V3R

V1CP

S2NPL

X1M

X3A

R1T

S1PH, S2PH

R5T

R31T, R32T

R4T

T1A

R2T

X1A, X2A

T2A

R8T

S1NPH

V1R

X9A

X7A

Z1F

Y5S

Z1C~4C

Y1S

Y4S

Y1E

Y3S

Y7S

Y6S

Y2E

Y8S

X1M

Y3E

Y2S

PRESSURE SENSOR (HIGH) (A1P)

SAFETY DEVICES INPUT (A1P)

PRESSURE SWITCH (HIGH) (A1P)

CONNECTOR (Y1E)

DIODE BRIDGE (A3P)

THERMISTOR (LIQUID) (A2P)

THERMISTOR (HEAT EXC. DEICER) (A1P)

THERMISTOR (FIN) (A3P)

TERMINAL STRIP (POWER SUPPLY)

THERMISTOR (HEAT EXC. LIQUID) (A1P)

THERMISTOR (SUB COOL HEAT EXC. LIQUID) (A1P)

PRESSURE SENSOR (LOW) (A1P)

CURRENT SENSOR (A5P)

CURRENT SENSOR (A4P)

THERMISTOR (SUB COOL HEAT EXC. GAS) (A1P)

THERMISTOR (SUCTION) (A2P)

THERMISTOR (HEAT EXC. GAS) (A1P)

THERMISTOR (M1C, M2C DISCHARGE) (A1P)

POWER MODULE (A3P)

CONNECTOR (M1F)

OPERATION OUTPUT (A2P)

POWER SUPPLY (ADOPTER) (A2P)

NOISE FILTER (WITH SURGE ABSORBER) (A3P)

ELECTRONIC EXPANSION VALVE (CHARGE) (A1P)

ELECTRONIC EXPANSION VALVE (MAIN) (A1P)

ELECTRONIC EXPANSION VALVE (SUBCOOL) (A1P)

SOLENOID VALVE (HOT GAS) (A2P)

SOLENOID VALVE (RMTL) (A1P)

SOLENOID VALVE (RMTG) (A1P)

TERMINAL STRIP (CONTROL) (A1P)

SOLENOID VALVE (RMTO) (A2P)

SOLENOID VALVE (EV BYPASS) (A2P)

NOISE FILTER (FERRITE CORE)

SOLENOID VALVE (4 WAY VALVE) (PIPE) (A1P)

SOLENOID VALVE (4 WAY VALVE) (HEAT EXC. ) (A1P)

SOLENOID VALVE (RMTT) (A2P)

MAGNETIC RELAY (Y3S) (A1P)

MAGNETIC RELAY (Y1S) (A1P)

MAGNETIC RELAY (Y8S) (A2P)

MAGNETIC RELAY (Y2S) (A1P)

MAGNETIC RELAY (CURRENT LIMITING) (A3P)

RESISTOR (CURRENT SENSOR) (A3P)

MAGNETIC RELAY (FOR OPTION) (A2P)

MAGNETIC RELAY (Y4S) (A1P)

SWITCHING POWER SUPPLY (A1P, A3P)

MAGNETIC RELAY (E1HC) (A1P)

REACTOR (A3P)

MAGNETIC RELAY (FOR OPTION) (A3P)

MAGNETIC RELAY (E2HC) (A1P)

MOTOR (FAN)

PHASE REVERSAL DETECT CIRCUIT (A1P)

THERMISTOR (AIR) (A1P)

RESISTOR (CURRENT SENSOR) (A3P)

MAGNETIC RELAY (Y7S) (A2P)

MOTOR (COMPRESSOR)

MAGNETIC RELAY (Y6S) (A2P)

A1P

A2P

A3P

A4P

A5P

BS1~5

C1

E1HC, E2HC

F1U, F2U

F1U

F1U

H1P~8P

HAP

K1M, K2M

K2M

K1R

K1R

PRINTED CIRCUIT BOARD (MAIN)

PRINTED CIRCUIT BOARD (SUB)

PRINTED CIRCUIT BOARD (INV, FAN)

PRINTED CIRCUIT BOARD (CURRENT SENSOR)

PRINTED CIRCUIT BOARD (ELB)

PUSH BUTTON SWITCH

(MODE, SET, RETURN, TEST, RESET) (A1P)

CAPACITOR

CRANKCASE HEATER (A1P)

FUSE (T, 3.15A, 250V) (A1P)

FUSE (T, 3.15A, 250V) (A2P)

FUSE (16A, DC450V) (A3P)

PILOT LAMP (SERVICE MONITOR : ORANGE) (A1P)

[H2P] PREPARE, TEST-------------------FLICKERING

MALFUNCTION DETECTION---LIGHT UP

PILOT LAMP (SERVICE MONITOR-GREEN) (A1P) (A2P)

MAGNETIC RELAY (M1C) (A3P)

MAGNETIC CONTACTOR (M2C)

MAGNETIC RELAY (K2M) (A1P)

MAGNETIC RELAY (Y5S) (A2P)

K2R

K3R

K3R

K4R

K5R

K5R

K6R

K7R

K8R

K10R

K11R

K84R

L1R

M1C, M2C

M1FPSQ1RPR1R112, R502

R1T

t˚

: * IS CONNECTOR COLOR FOR PRINTED CIRCUIT BOARD.

: * IS CONNECTOR COLOR FOR COMPONENT.

: * IS DISCRIMINATION COLOR FOR COMPONENT LEAD WIRE.

***

3D058512C

EDUS39-802A-R2 Field Wiring

REYQ-P Heat Recovery (208-230V) 17

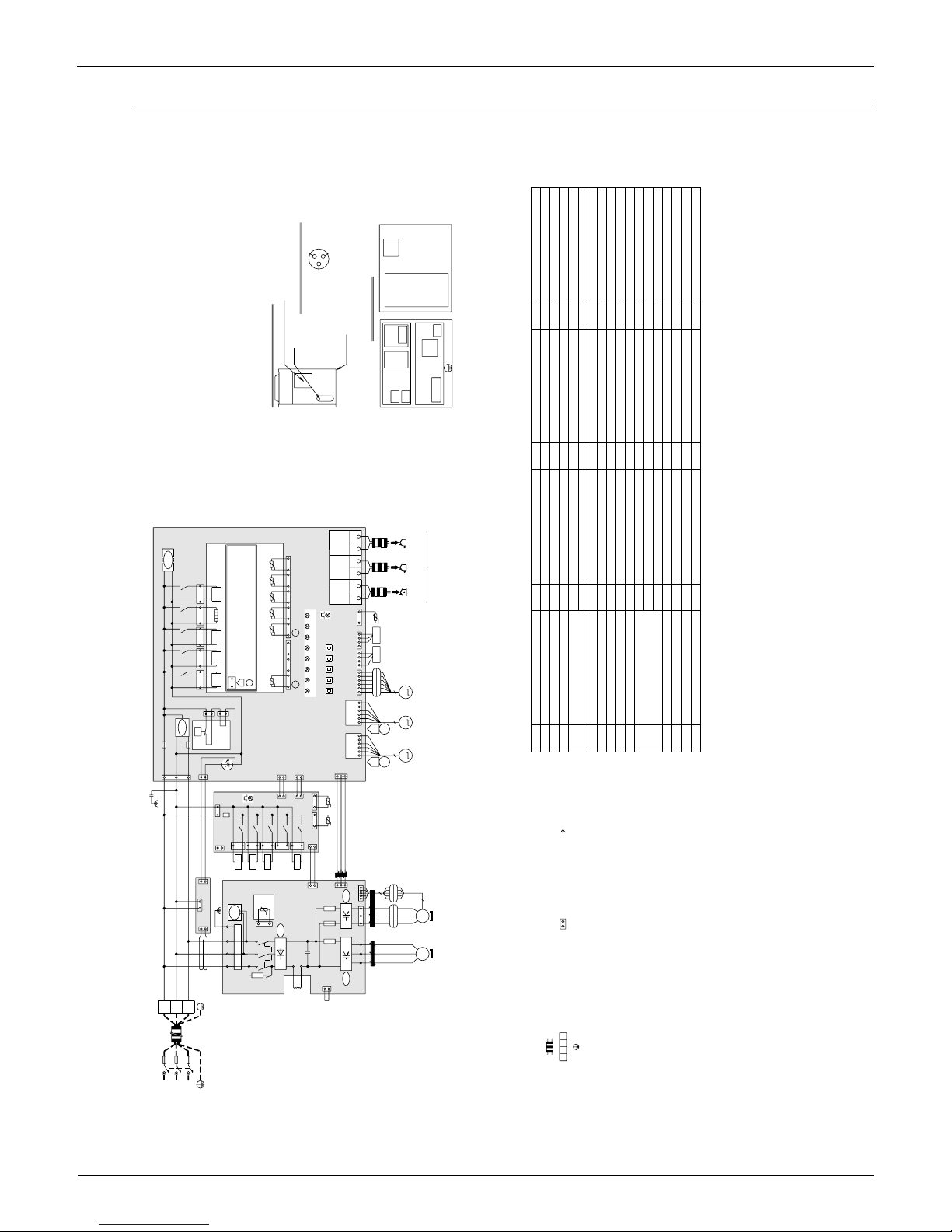

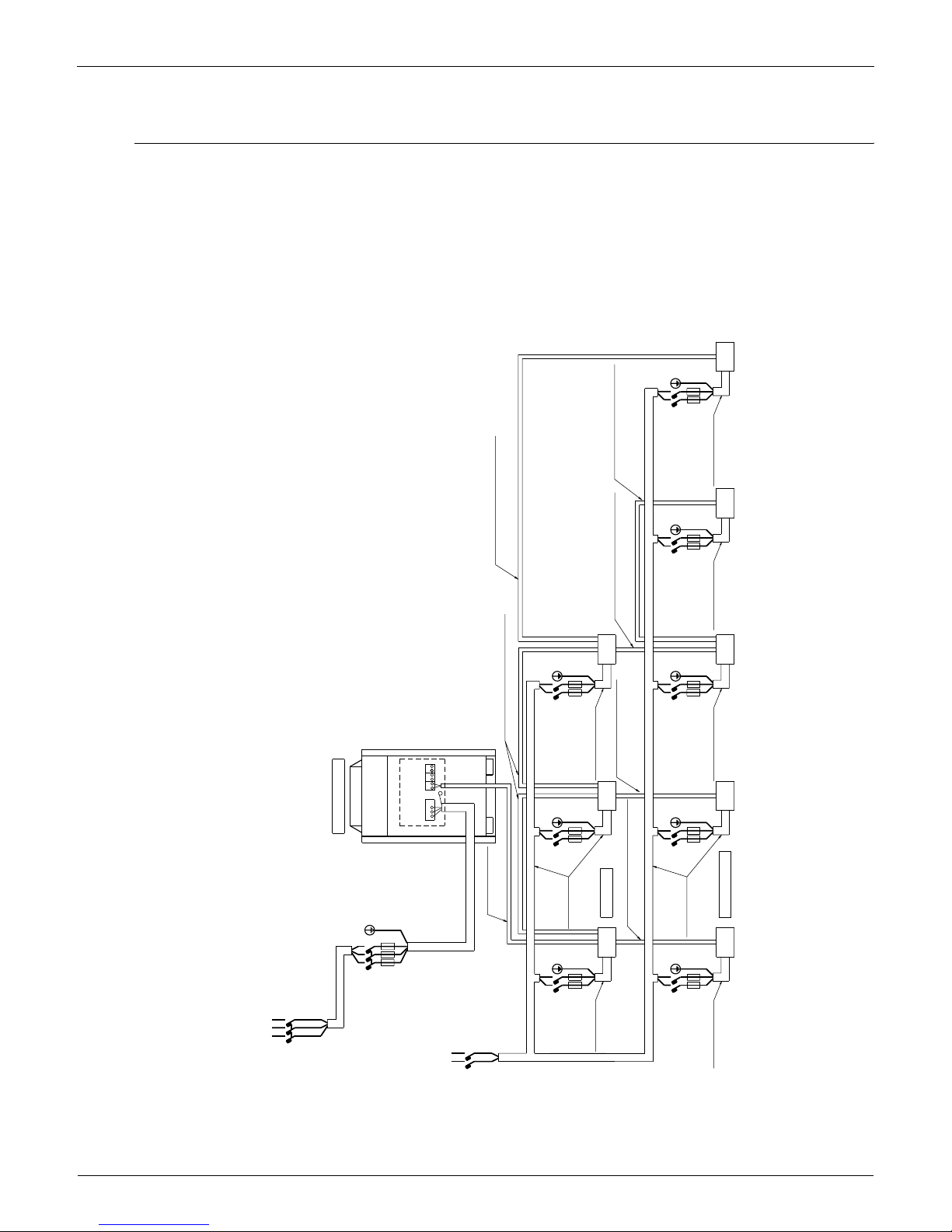

6. Field Wiring

REYQ72, 96, 120, 144PTJU

L1

COOLING ONLY UNIT

L2

SWITCH

L2

L1

POWER SUPPLY

L1

FUSE

L1

POWER SUPPLY

L1

MAIN

SWITCH

L2

MAIN

SWITCH

L2

FUSE

SWITCH

FUSE

SWITCH

L2 L1

FUSE

SWITCH

L2

L3

L3

OUTDOOR UNITS

2 WIRES CABLE

(POWER LINE)

2 WIRES CABLE

(POWER LINE)

INDOOR UNITS

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(TRANSMISSION LINE)

2 WIRES CABLE

(POWER LINE)

L2L1

FUSE

SWITCH

2 WIRES CABLE

(POWER LINE)

L2L1

SWITCH

2 WIRES CABLE

(POWER LINE)

L2L1

FUSE

FUSE

SWITCH

2 WIRES CABLE

(POWER LINE)

L2L1

FUSE

SWITCH

2 WIRES CABLE

(POWER LINE)

L2L1

FUSE

SWITCH

2 WIRES CABLE

(POWER LINE)

BS UNITS

Notes 1) All wiring, components and materials to be

procured on the site must comply with the

applicable local and national codes.

2) Use copper conductors only.

3) As for details, see wiring diagram.

4) Install ground fault circuit interrupter for safety.

5) All field wiring and components must be provided by licensed electrician.

6) Unit shall be grounded in compliance with the applicable local and

national codes.

7) Wiring shown are general points-of-connection guides only and are not

intended for or to include all details for a specific installation.

8) Be sure to install the switch and the fuse to the power line of each

equipment.

9) Install the main switch that can interrupt all the power souces in an

integrated manner because this system consists of the equipment utilizing

the multiple power sources.

10) If there exists the possibility of reversed phase, lose phase, momentary

blackout or the power goes on and off while the product is operating,

attach a reversed phase protection circuit locally.

Running the product in reversed phase may break the compressor and

other parts.

3D058622

Loading...

Loading...