Daikin FTXA20A2V1BS, CTXA15A2V1B, FTXA20A2V1BT, FTXA25A2V1B, FTXA25A2V1BW Service Manual

...

Service manual

Split Stylish R32

CTXA15A2V1B(W)(S)(T)

FTXA20A2V1B(W)(S)(T)

FTXA25A2V1B(W)(S)(T)

FTXA35A2V1B(W)(S)(T)

FTXA42A2V1B(W)(S)(T)

FTXA50A2V1B(W)(S)(T)

RXA42A2V1B

RXA50A2V1B

RXA20A2V1B

RXA25A2V1B

RXA35A2V1B

Service manual

Split Stylish R32

English

Disclaimer

Disclaimer

The present publication is drawn up by way of information only and does not constitute an offer binding upon Daikin Europe N.V.. Daikin

Europe N.V. has compiled the content of this publication to the best of its knowledge. No express or implied warranty is given for the

completeness, accuracy, reliability or fitness for particular purpose of its content and the products and services presented therein.

Specifications are subject to change without prior notice. Daikin Europe N.V. explicitly rejects any liability for any direct or indirect damage, in

the broadest sense, arising from or related to the use and/or interpretation of this publication. All content is copyrighted by Daikin Europe N.V..

Service manual

2

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Table of contents

Table of contents

1 Troubleshooting 4

1.1 To display the error code on the user interface......................... 4

1.2 To reset the error code via remote controller ............................ 4

1.3 To reset the error code via outdoor unit .................................... 4

1.4 To perform a test run................................................................. 4

1.4.1 To perform a test run using the user interface............ 4

1.5 Error based troubleshooting ...................................................... 4

1.5.1 A1-00 – PCB abnormality ........................................... 4

1.5.2 A5-00 – Freeze-up protection / heating peak cut

control ......................................................................... 5

1.5.3 A6-00 – Indoor unit fan motor abnormality.................. 5

1.5.4 AH-00 – Streamer unit abnormality............................. 5

1.5.5 C4-00 – Indoor heat exchanger thermistor

abnormality ................................................................. 5

1.5.6 C9-00 – Room thermistor abnormality ........................ 5

1.5.7 CC-00 – Humidity sensor abnormality ........................ 6

1.5.8 CE-00 – Intelligent thermal sensor abnormality.......... 6

1.5.9 E1-00 – PCB defect .................................................... 6

1.5.10 E3-00 – High pressure switch abnormality ................. 6

1.5.11 E5-00 – Overheat of inverter compressor motor......... 7

1.5.12 E6-00 – Compressor startup defect ............................ 7

1.5.13 E7-00 – Fan lock abnormality ..................................... 8

1.5.14 E8-00 – Input overvoltage abnormality ....................... 8

1.5.15 EA-00 – Cooling/Heating switch abnormality .............. 8

1.5.16 F3-00 – Discharge pipe temperature stop

abnormality ................................................................. 8

1.5.17 F6-00 – Stop due to cooling high pressure ................. 9

1.5.18 F8-00 – System shutdown due to compressor

internal temperature abnormality ................................ 9

1.5.19 H0-00 – Current sensor abnormality ........................... 9

1.5.20 H3-00 – High pressure switch defect .......................... 10

1.5.21 H6-00 – Location detection sensor abnormality.......... 10

1.5.22 H8-00 – Compressor input abnormality ...................... 10

1.5.23 H9-00 – Outdoor air thermistor abnormality................ 11

1.5.24 J3-00 – Discharge pipe thermistor dislocation

abnormality ................................................................. 11

1.5.25 J6-00 – Outdoor heat exchanger thermistor

abnormality ................................................................. 11

1.5.26 L3-00 – Electrical component temperature

abnormality ................................................................. 11

1.5.27 L4-00 – Fin temperature increase abnormality ........... 11

1.5.28 L5-00 – Output over current abnormality .................... 12

1.5.29 P4-00 – Fin thermistor abnormality ............................. 12

1.5.30 U0-00 – Shortage of refrigerant .................................. 12

1.5.31 U2-00 – Main circuit voltage abnormality .................... 13

1.5.32 U4-00 – Indoor/outdoor transmission abnormality ...... 13

1.5.33 U5-00 – Transmission malfunction between indoor

unit and remote controller ........................................... 13

1.5.34 UA-00 – Indoor/outdoor combination abnormality ...... 13

1.6 Symptom based troubleshooting............................................... 15

1.6.1 Operation does not start ............................................. 15

1.6.2 Operation sometimes stops ........................................ 15

1.6.3 Operation starts but the unit does not cool/heat ......... 15

1.6.4 Operating noise and vibrations ................................... 15

1.6.5 Abnormal high pressure.............................................. 16

1.6.6 Abnormal low pressure ............................................... 16

1.6.7 Indoor fan starts operating but the compressor does

not operate.................................................................. 17

1.6.8 Operation starts and the unit stops immediately......... 17

1.6.9 Operation stops, unit cannot start for a while.............. 17

1.6.10 Unit discharges white mist .......................................... 17

1.6.11 Swing flap does not operate ....................................... 17

2 Components 18

2.1 4-way valve ............................................................................... 18

2.1.1 Checking procedures .................................................. 18

2.1.2 Repair procedures ....................................................... 19

2.2 Compressor................................................................................ 20

2.2.1 Checking procedures ................................................... 20

2.2.2 Repair procedures ....................................................... 22

2.3 Expansion valve ......................................................................... 23

2.3.1 Checking procedures ................................................... 23

2.3.2 Repair procedures ....................................................... 24

2.4 Front panel motor ....................................................................... 26

2.4.1 Checking procedures ................................................... 26

2.4.2 Repair procedures ....................................................... 26

2.5 High pressure switch .................................................................. 27

2.5.1 Checking procedures ................................................... 27

2.5.2 Repair procedures ....................................................... 27

2.6 Humidity sensor.......................................................................... 28

2.6.1 Checking procedures ................................................... 28

2.6.2 Repair procedures ....................................................... 28

2.7 Indoor unit fan motor .................................................................. 29

2.7.1 Checking procedures ................................................... 29

2.7.2 Repair procedures ....................................................... 29

2.8 Indoor unit PCB .......................................................................... 30

2.8.1 Checking procedures ................................................... 30

2.8.2 Repair procedures ....................................................... 31

2.9 Intelligent thermal sensor ........................................................... 33

2.9.1 Checking procedures ................................................... 33

2.9.2 Repair procedures ....................................................... 33

2.10 Inverter PCB ............................................................................... 34

2.10.1 Checking procedures ................................................... 34

2.10.2 Repair procedures ....................................................... 35

2.11 Main PCB ................................................................................... 35

2.11.1 Checking procedures ................................................... 35

2.11.2 Repair procedures ....................................................... 36

2.12 Outdoor unit fan motor ............................................................... 38

2.12.1 Checking procedures ................................................... 38

2.12.2 Repair procedures ....................................................... 39

2.13 Plate work................................................................................... 40

2.13.1 Outdoor unit ................................................................. 40

2.13.2 Indoor unit .................................................................... 42

2.14 Reactor ....................................................................................... 44

2.14.1 Checking procedures ................................................... 44

2.14.2 Repair procedures ....................................................... 45

2.15 Streamer unit .............................................................................. 45

2.15.1 Checking procedures ................................................... 45

2.15.2 Repair procedures ....................................................... 45

2.16 Swing flap motor......................................................................... 46

2.16.1 Main swing flap motor .................................................. 46

2.16.2 Secondary swing flap motor......................................... 47

2.17 Swing raster motor ..................................................................... 48

2.17.1 Checking procedures ................................................... 48

2.17.2 Repair procedures ....................................................... 49

2.18 Thermistors ................................................................................ 49

2.18.1 Refrigerant thermistors ................................................ 49

2.18.2 Other thermistors ......................................................... 51

2.19 Wifi control PCB ......................................................................... 51

2.19.1 Checking procedures ................................................... 51

2.19.2 Repair procedures ....................................................... 51

3 Third party components 52

3.1 Power supply.............................................................................. 52

3.1.1 Checking procedures ................................................... 52

3.1.2 Repair procedures ....................................................... 52

3.2 Refrigerant circuit ....................................................................... 53

3.2.1 Checking procedures ................................................... 53

3.2.2 Repair procedures ....................................................... 54

3.3 External factors .......................................................................... 55

3.3.1 Checking procedures ................................................... 55

3.3.2 Repair procedures ....................................................... 55

4 Maintenance 56

4.1 To clean the outdoor unit heat exchanger.................................. 56

4.2 To clean the indoor unit heat exchanger .................................... 56

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

3

1 Troubleshooting

4.3 To clean the air filters ................................................................ 56

5 Technical data 57

5.1 Detailed information setting mode............................................. 57

5.1.1 Detailed information setting mode: Indoor unit ........... 57

5.1.2 Detailed information setting mode: Outdoor unit......... 57

5.1.3 Detailed information setting mode: Remote controller 57

5.2 Wiring diagram .......................................................................... 58

5.2.1 Wiring diagram: Indoor unit......................................... 58

5.2.2 Wiring diagram: Outdoor unit ...................................... 59

5.3 Piping diagram .......................................................................... 61

5.3.1 Piping diagram: Indoor unit......................................... 61

5.3.2 Piping diagram: Outdoor unit ...................................... 62

5.4 Component overview................................................................. 64

5.4.1 Component overview: Indoor unit ............................... 64

5.4.2 Component overview: Outdoor unit ............................ 66

5.5 Field information report ............................................................. 68

5.6 Field settings ............................................................................. 71

5.6.1 To control heating only mode...................................... 71

5.6.2 To adjust target set temperature in heating operation 71

5.6.3 To control the indoor unit fan during thermostat off .... 71

5.6.4 To change auto restart ON to OFF ............................. 71

5.6.5 To control cooling mode only...................................... 71

5.7 Service tools.............................................................................. 72

1 Troubleshooting

1.1 To display the error code on the user interface

Prerequisite: Test run should be performed in accordance with the

operation manual of the indoor unit to make sure that all functions

and parts are working properly.

1 In cooling mode, select the lowest programmable temperature.

In heating mode, select the highest programmable temperature.

Test run can be disabled if necessary.

2 When the test run is finished, set the temperature to a normal

level. In cooling mode: 26~28°C, in heating mode: 20~24°C.

3 The system stops operating 3minutes after the unit is turned

OFF.

INFORMATION

▪ Even if the unit is turned OFF, it consumes electricity.

▪ When the power turns back on after a power break, the

previously selected mode will be resumed.

1.4.1 To perform a test run using the user interface

1 Press to switch the system on.

2 Press , and simultaneously.

3 Press , select and press .

Result: Test run operation will stop automatically after about

30minutes.

4 To stop operation sooner, press .

1.5 Error based troubleshooting

1 Hold for about 5seconds.

Result: blinks in the temperature display section.

2 Press repeatedly until a continuous beep is heard.

Result: The code is now displayed on the display.

INFORMATION

▪ A short beep and 2 consecutive beeps indicate non-

corresponding codes.

▪ To cancel the code display, hold the cancel

button for 5seconds. The code will also disappear from

the display if the button is NOT pressed within

1minute.

1.2 To reset the error code via remote controller

Prerequisite: Problem is solved.

1 Press the ON/OFF button of the remote controller to reset the

error.

1.3 To reset the error code via outdoor unit

Prerequisite: Problem is solved.

1 Perform a power reset to reset the error code.

1.4 To perform a test run

Prerequisite: Power supply MUST be in the specified range.

Prerequisite: Test run may be performed in cooling or heating

mode.

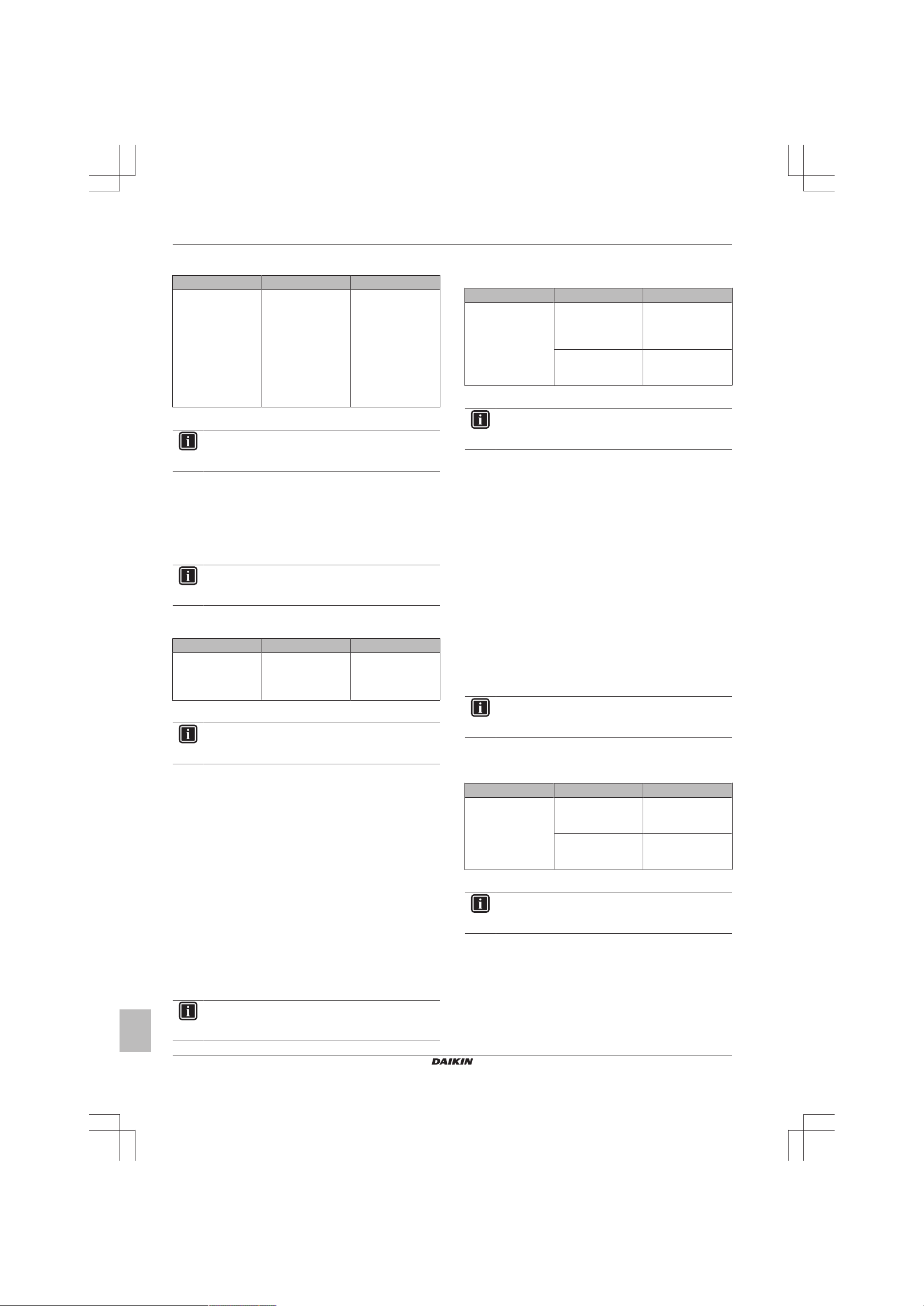

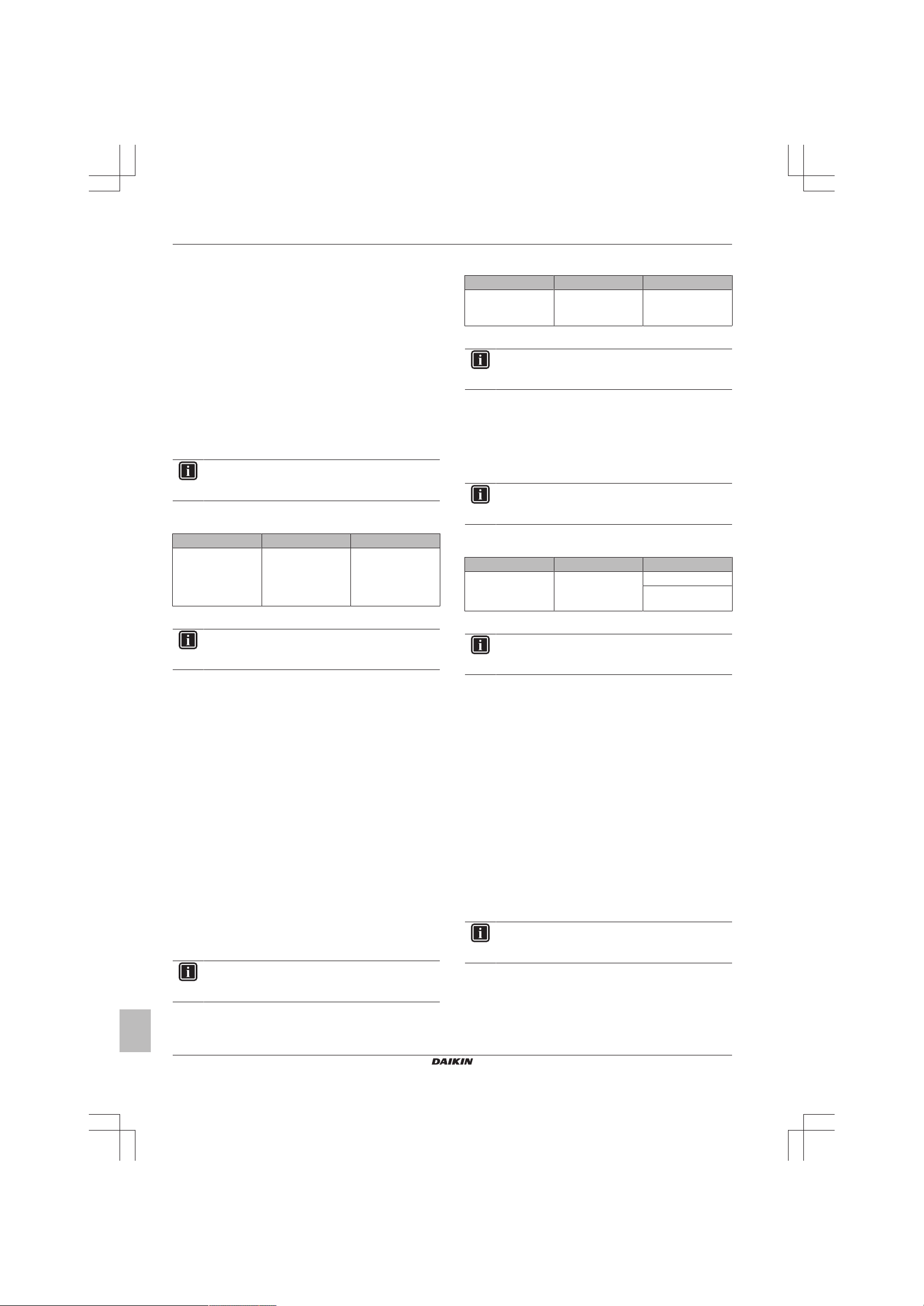

1.5.1 A1-00 – PCB abnormality

Trigger Effect Reset

The system CANNOT

set the internal

settings.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Check for improper combination of the indoor unit and the

outdoor unit. See the combination table in the Databook for

more information.

2 Perform a check of the power supply, connections, wiring,…

between the outdoor unit and the indoor unit. See "3.1Power

supply"on page52.

Possible cause: Faulty wiring between the outdoor unit and

the indoor unit.

3 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

4 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Power reset via

outdoor unit.

Service manual

4

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

1.5.2 A5-00 – Freeze-up protection / heating peak cut control

Trigger Effect Reset

During cooling

operation, indoor heat

exchanger

temperature is below

0°C (freeze‑up

protection control).

During heating

operation, indoor heat

exchanger

temperature is above

65°C (heating

peak‑cut control).

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Check for objects near the indoor unit that may block the

airflow. See "3.3External factors"on page55.

Possible cause: Airflow of the indoor unit is blocked.

2 Clean the air filter. See "4Maintenance"on page56.

Possible cause: Faulty or dirty air filter.

3 Clean the indoor unit heat exchanger. See "4Maintenance"on

page56.

Possible cause: Dirty indoor unit heat exchanger.

4 Perform a check of the indoor unit heat exchanger thermistor.

See "2.18Thermistors"on page49.

Possible cause: Faulty indoor unit heat exchanger

thermistor.

5 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Automatic reset when

temperature is within

range.

1.5.3 A6-00 – Indoor unit fan motor abnormality

Trigger Effect Reset

The rotation speed of

the fan motor is NOT

detected while the

output voltage to the

fan is at its maximum.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

2 Perform a check of the indoor unit fan motor. See "2.7Indoor

unit fan motor"on page29.

Possible cause: Faulty indoor unit fan motor.

Unit will stop

operating.

Power reset via the

outdoor unit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.4 AH-00 – Streamer unit abnormality

Trigger Effect Reset

Streamer unit starts

electric discharge

when operation starts

after approximately

90 to 180seconds.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the streamer unit. See "2.15 Streamer

unit"on page45.

Possible cause: Faulty streamer unit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will NOT stop

operating.

Manual reset via user

interface.

1.5.5 C4-00 – Indoor heat exchanger thermistor abnormality

Trigger Effect Reset

Refrigerant liquid

thermistor detects an

open or short circuit

during compressor

operation.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

INFORMATION

In case of preferential kWh rate, the indoor unit also needs

a power reset.

1 Perform a check of the refrigerant liquid thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty refrigerant liquid thermistor.

2 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Power reset via

outdoor unit.

1.5.6 C9-00 – Room thermistor abnormality

Trigger Effect Reset

Resistance value is

out of range.

Temperature

measured <–43.6°C

or >90°C.

Unit will stop

operating.

Automatic reset when

resistance is within

range.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

5

1 Troubleshooting

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the room thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty room thermistor.

2 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

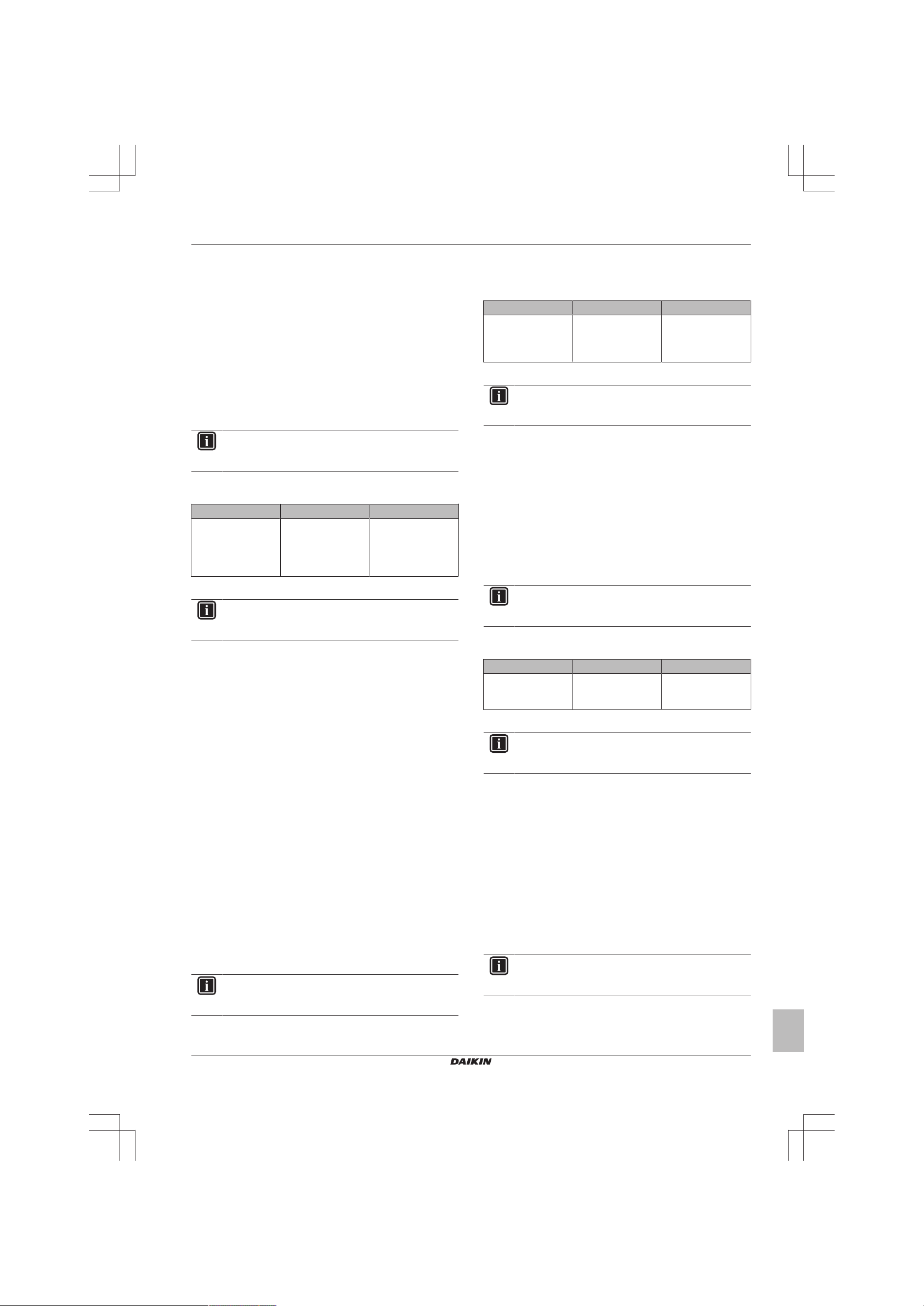

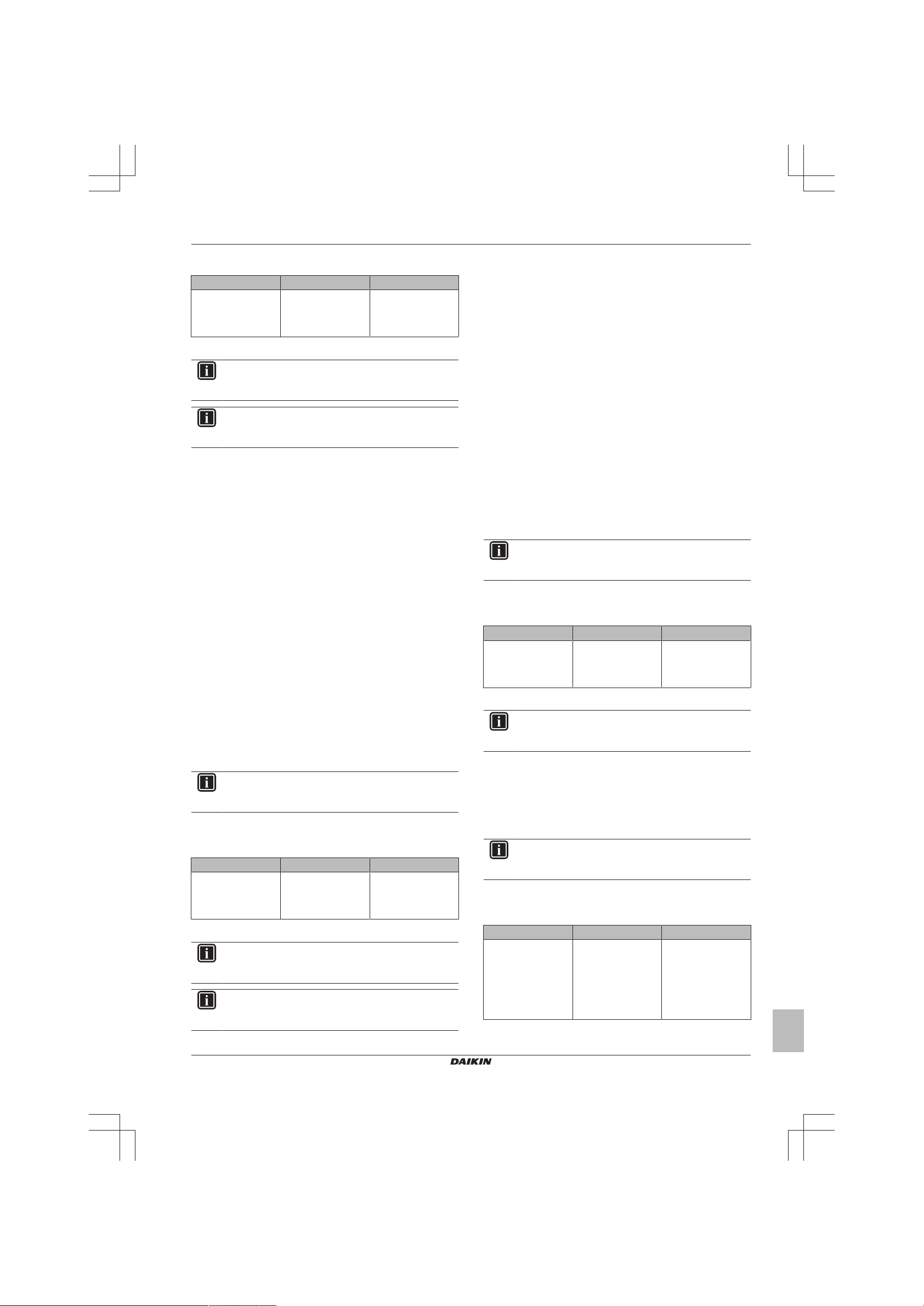

1.5.7 CC-00 – Humidity sensor abnormality

Trigger Effect Reset

▪ Disconnected

sensor

▪ Broken sensor

▪ Communication

error

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the humidity sensor. See "2.6 Humidity

sensor"on page28.

Possible cause: Faulty humidity sensor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.8 CE-00 – Intelligent thermal sensor abnormality

Trigger Effect Reset

▪ Disconnected

sensor

▪ Broken sensor

▪ Communication

error

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the intelligent thermal sensor. See

"2.9Intelligent thermal sensor"on page33.

Possible cause: Faulty intelligent thermal sensor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.9 E1-00 – PCB defect

Trigger Effect Reset

Main PCB detects

that EEPROM is

abnormal.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

INFORMATION

In case of preferential kWh rate, the indoor unit also needs

a power reset.

1 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

2 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

3 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

Power reset via

outdoor unit.

1.5.10 E3-00 – High pressure switch abnormality

Trigger Effect Reset

High pressure switch

opens due to

measured pressure

>41.7bar.

High pressure control

(measured pressure

>38bar) occurs 16

times within

300minutes.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the high pressure switch. See "2.5 High

pressure switch"on page27.

Possible cause: Faulty high pressure switch.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

3 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Unit will stop

operating.

Manual reset via user

interface.

Service manual

6

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

4 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

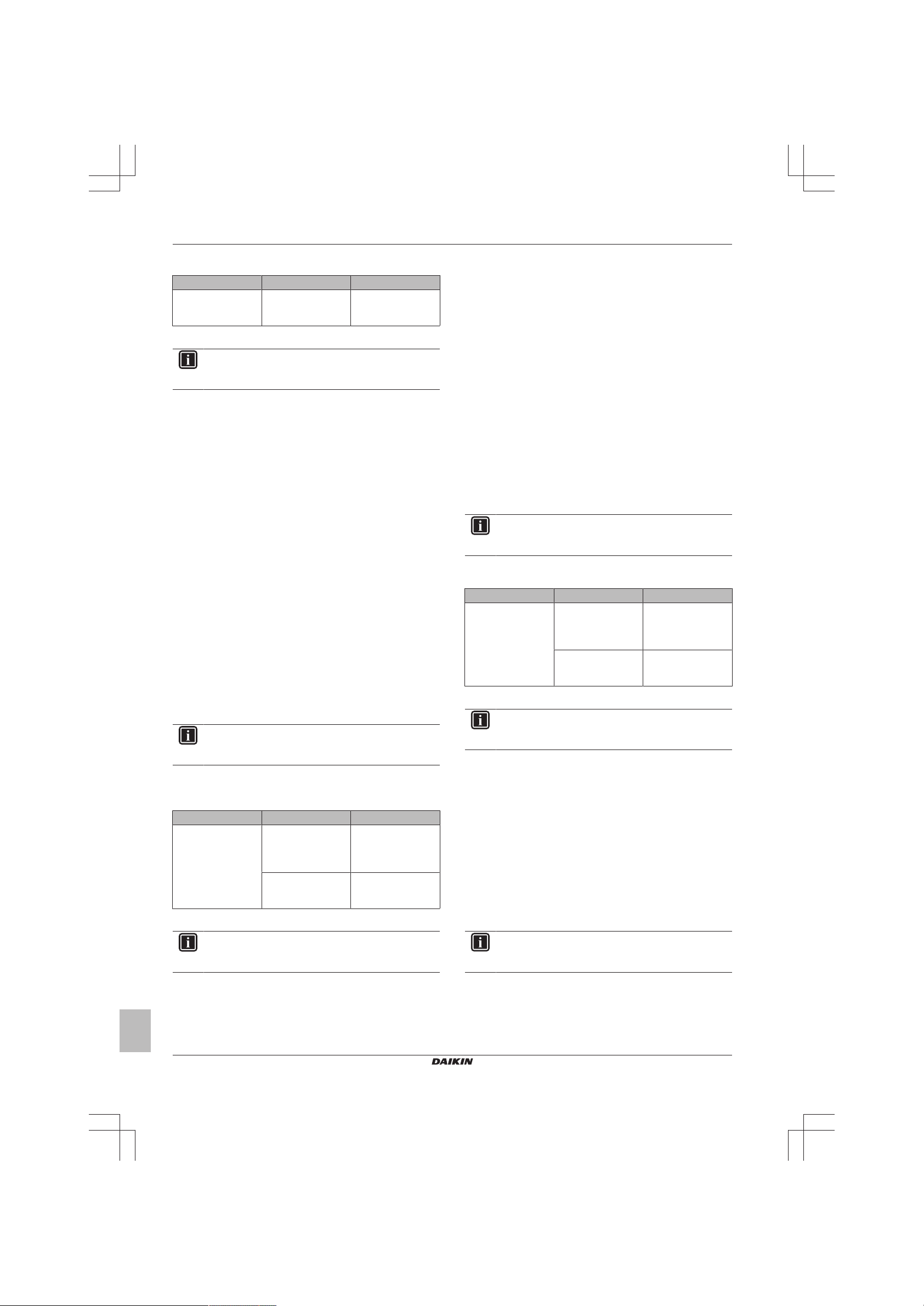

1.5.11 E5-00 – Overheat of inverter compressor motor

Trigger Effect Reset

Compressor overload

is detected.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the discharge pipe thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty discharge pipe thermistor.

2 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

3 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

4 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

5 Perform a check of the 4‑way valve. See "2.14-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

6 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

7 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

8 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

Unit will NOT stop

operating.

Automatic reset if the

unit runs without

warning for

60seconds.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.12 E6-00 – Compressor startup defect

Trigger Effect Reset

The motor rotor does

NOT rotate when the

compressor is

energized.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the discharge pipe thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty discharge pipe thermistor.

2 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

3 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

4 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

5 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

6 Perform a check of the 4‑way valve. See "2.14-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

7 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will NOT stop

operating.

Unit will stop

operating

Automatic reset after

a continuous run for

10minutes.

Manual reset via user

interface.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

7

1 Troubleshooting

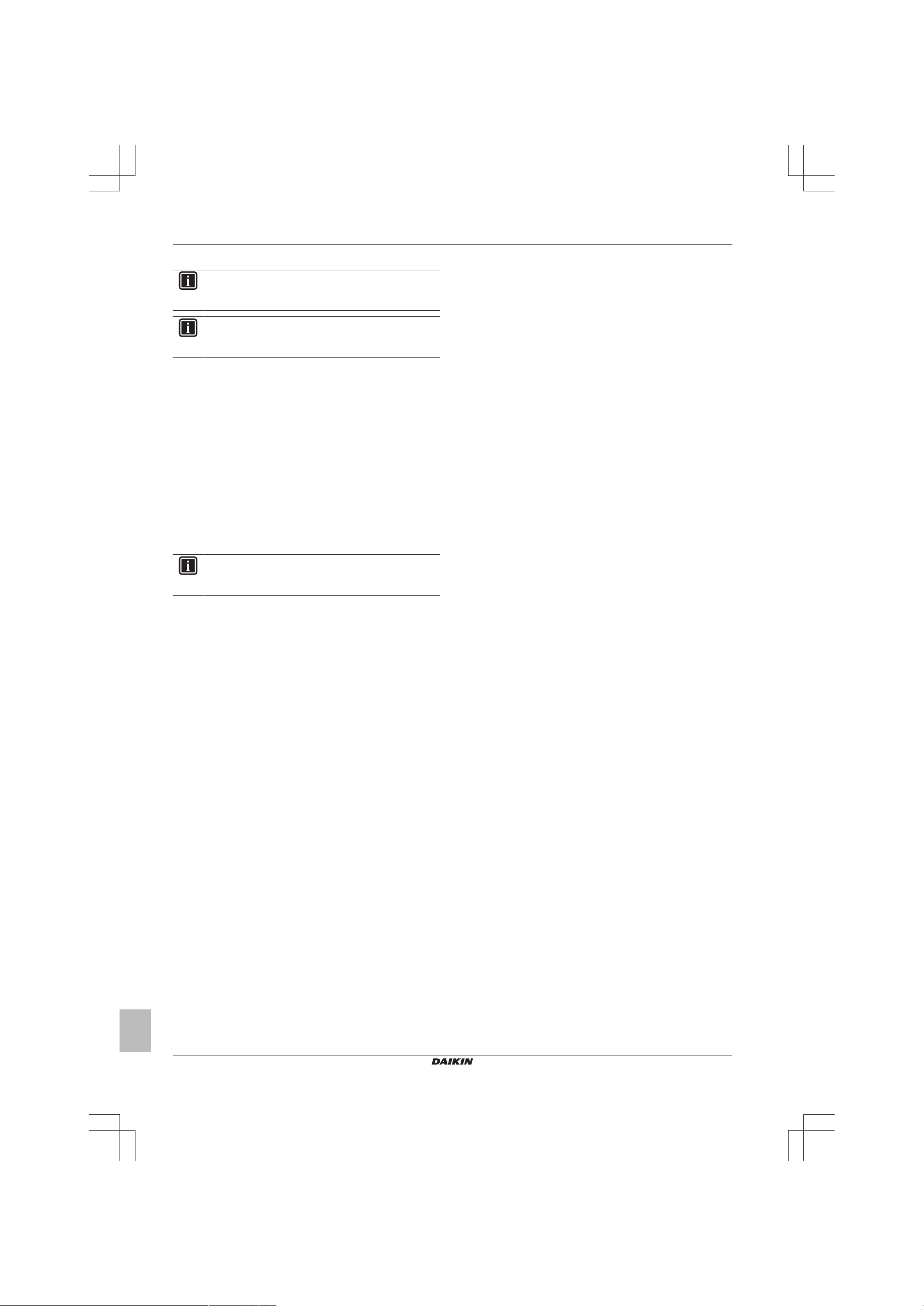

1.5.13 E7-00 – Fan lock abnormality

Trigger Effect Reset

Fan does NOT start

15~30seconds after

ON signal.

It can occur that the

error code is

triggered when the

fan motor is running

caused by a faulty

rotating sensor

signal.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

2 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.14 E8-00 – Input overvoltage abnormality

Trigger Effect Reset

Compressor running

current exceeds

standard value for

2.5seconds.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Check the outdoor temperature. See "3.3 External factors"on

page55.

Possible cause: Outdoor temperature is out of operation

range.

2 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

3 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

4 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.15 EA-00 – Cooling/Heating switch abnormality

Trigger Effect Reset

Room thermistor is

NOT functioning

within operation

range.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the 4‑way valve. See "2.14-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

3 Perform a check of the room thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty room thermistor.

4 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will NOT stop

operating.

If the error occurs too

soon: unit will stop

operating.

Automatic reset after

a continuous

operation of

10minutes.

Manual reset via user

interface.

1.5.16 F3-00 – Discharge pipe temperature stop abnormality

Trigger Effect Reset

Discharge pipe

thermistor detects a

too high temperature.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

Unit will NOT stop

operating.

If the error re-occurs

too soon: unit will

stop operating.

Automatic reset when

temperature drops

normal level.

Manual reset via user

interface.

Service manual

8

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

2 Perform a check of the 4‑way valve. See "2.14-way valve"on

page18.

Possible cause: Faulty 4‑way valve.

3 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

4 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

5 Perform a check of all refrigerant thermistors. See

"2.18Thermistors"on page49.

Possible cause: Faulty refrigerant thermistor(s).

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

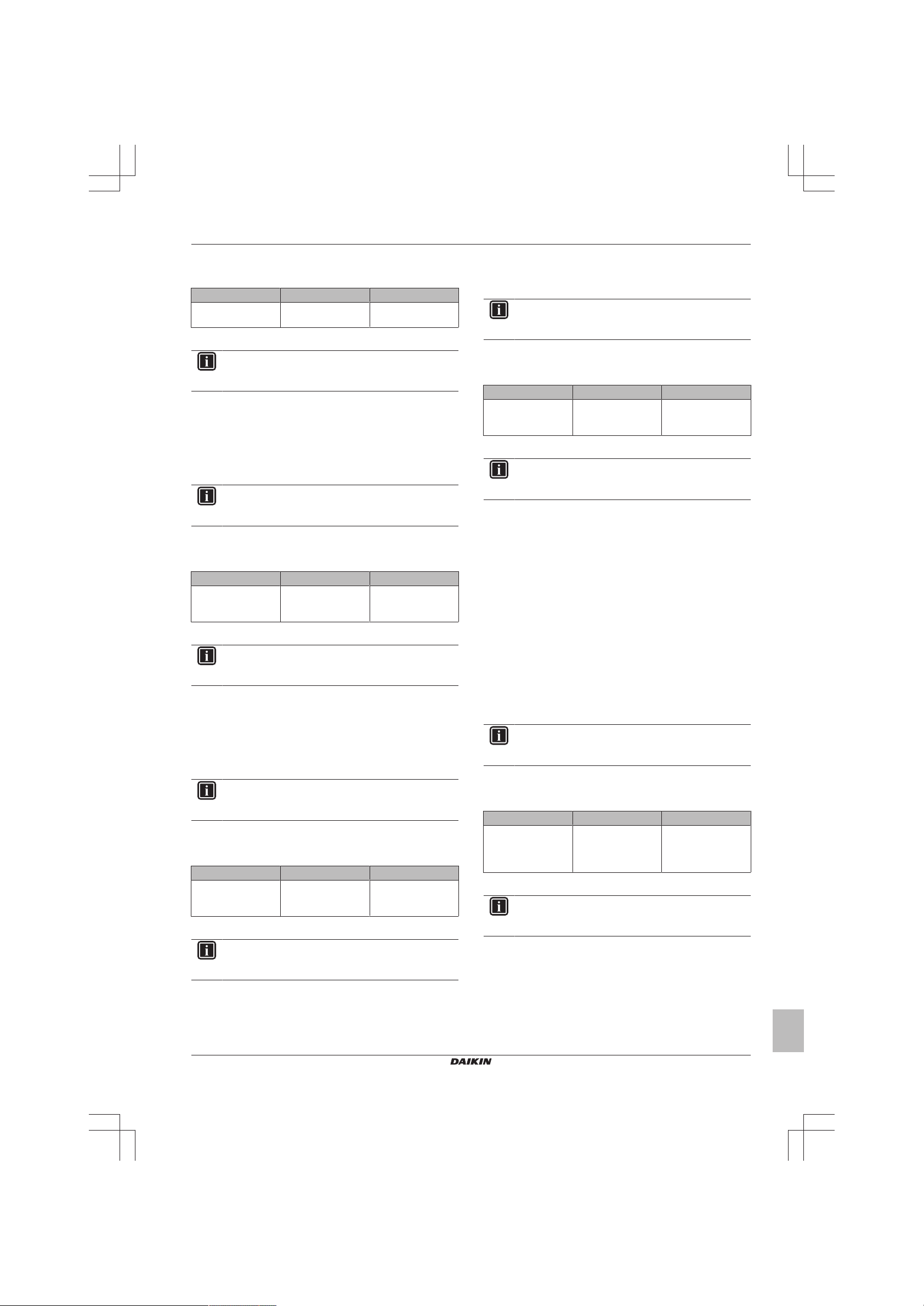

1.5.17 F6-00 – Stop due to cooling high pressure

Trigger Effect Reset

Outdoor heat

exchanger thermistor

measures

temperature

>60°C~65°C

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Clean the outdoor heat exchanger. See "4 Maintenance" on

page56.

Possible cause: Dirty outdoor heat exchanger.

2 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

3 Perform a check of the heat exchanger thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty heat exchanger thermistor.

4 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

5 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

6 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will NOT stop

operating.

Automatic reset when

temperature drops

below 50°C.

1.5.18 F8-00 – System shutdown due to compressor internal temperature abnormality

Trigger Effect Reset

Temperature

discharge pipe

thermistor exceeds

the determined limit.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

2 Perform a check of the discharge pipe thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty discharge pipe thermistor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.19 H0-00 – Current sensor abnormality

Trigger Effect Reset

Compressor voltage

(DC) is out of range

before start‑up.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

2 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

3 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

9

1 Troubleshooting

1.5.20 H3-00 – High pressure switch defect

Trigger Effect Reset

High pressure switch

is activated when

compressor is off.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the high pressure switch. See "2.5 High

pressure switch"on page27.

Possible cause: Faulty high pressure switch.

2 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

3 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

4 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

5 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.21 H6-00 – Location detection sensor abnormality

Trigger Effect Reset

Compressor fails to

start within

15seconds after the

compressor run

command signal is

sent.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Unit will NOT stop

operating.

If the error re-occurs

within 8minutes: unit

will stop operating.

Automatic reset after

a continuous

operation of

10minutes.

Manual reset via user

interface.

Possible cause: Faulty main PCB.

3 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

4 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

5 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.22 H8-00 – Compressor input abnormality

Trigger Effect Reset

DC voltage or current

sensor abnormality

based on the

compressor running

frequency and the

input current.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

2 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

3 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

4 Perform a check of the reactor. See "2.14 Reactor" on

page44.

Possible cause: Faulty reactor.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will NOT stop

operating.

If the error re-occurs

too soon: unit will

stop operating.

Automatic reset when

compressor runs

normally for

60minutes.

Manual reset via user

interface.

Service manual

10

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

1.5.23 H9-00 – Outdoor air thermistor abnormality

Trigger Effect Reset

Outdoor air thermistor

input is out of range.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the outdoor air thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty outdoor air thermistor.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.24 J3-00 – Discharge pipe thermistor dislocation abnormality

Trigger Effect Reset

Discharge pipe

thermistor input is out

of range.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the discharge pipe thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty discharge pipe thermistor.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

Unit will stop

operating.

Manual reset via user

interface.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.26 L3-00 – Electrical component temperature abnormality

Trigger Effect Reset

Switch box

temperature is too

high.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

2 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

3 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

4 Clean the outdoor heat exchanger. See "4 Maintenance" on

page56.

Possible cause: Dirty outdoor heat exchanger.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via

remote controller.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.25 J6-00 – Outdoor heat exchanger thermistor abnormality

Trigger Effect Reset

Outdoor heat

exchanger thermistor

input is out of range.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the heat exchanger thermistor. See

"2.18Thermistors"on page49.

Possible cause: Faulty heat exchanger thermistor.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Unit will stop

operating.

Manual reset via user

interface.

1.5.27 L4-00 – Fin temperature increase abnormality

Trigger Effect Reset

Radiating fin

thermistor measures

a too high

temperature.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

2 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Unit will stop

operating.

Manual reset via user

interface.

Service manual

11

1 Troubleshooting

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

3 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

4 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

5 Check that the silicon grease is applied properly on the

radiation fin of the outdoor unit PCB. Adjust if needed.

Possible cause: Silicon grease NOT applied properly on the

radiation fin.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.28 L5-00 – Output over current abnormality

Trigger Effect Reset

An output overcurrent

is detected by

checking the current

that flows in the

inverter DC section.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

2 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

3 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

4 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.29 P4-00 – Fin thermistor abnormality

Trigger Effect Reset

Radiating fin

thermistor input is out

of range.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of the inverter PCB. See "2.10 Inverter

PCB"on page34.

Possible cause: Faulty power module = inverter PCB.

2 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Manual reset via user

interface.

1.5.30 U0-00 – Shortage of refrigerant

Trigger Effect Reset

Refrigerant shortage

detected.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Perform a check of all refrigerant thermistors. See

"2.18Thermistors"on page49.

Possible cause: Faulty refrigerant thermistor(s).

2 Perform a check of the refrigerant circuit. See "3.2 Refrigerant

circuit"on page53.

Possible cause:

▪ Stop valve is closed,

▪ Clogged refrigerant circuit,

▪ Refrigerant circuit NOT charged correctly,

▪ Humidity in the refrigerant circuit,

▪ Non-condensables in the refrigerant circuit,

▪ Leaking refrigerant circuit.

3 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

4 Perform a check of the expansion valve. See "2.3 Expansion

valve"on page23.

Possible cause: Faulty expansion valve.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Automatic reset.

Power reset via

outdoor unit.

Service manual

12

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

1.5.31 U2-00 – Main circuit voltage abnormality

Trigger Effect Reset

Power supply

abnormality or instant

power failure is

detected.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

INFORMATION

In case of preferential kWh rate, the indoor unit also needs

a power reset.

1 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

2 Perform a check of the compressor. See "2.2Compressor" on

page20.

Possible cause: Faulty compressor.

3 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

4 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

5 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

6 Wait until the compressor restarts.

Possible cause:

▪ Momentary drop of voltage,

▪ Momentary power failure.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Power reset via

outdoor unit.

1.5.32 U4-00 – Indoor/outdoor transmission abnormality

Trigger Effect Reset

Communication

failure between

outdoor and indoor

unit.

Unit will stop

operating.

Power reset via

outdoor unit.

1 Check if the power supply is conform with the regulations. See

"3.1Power supply"on page52.

Possible cause:

▪ Faulty or disturbance of the power supply (imbalance

>10%),

▪ Power drop,

▪ Short circuit.

2 Perform a check of the power supply, connections, wiring,…

between the outdoor unit and the indoor unit. See "3.1Power

supply"on page52.

Possible cause: Faulty wiring between the outdoor unit and

the indoor unit.

3 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

4 Perform a check of the outdoor unit fan motor. See

"2.12Outdoor unit fan motor"on page38.

Possible cause: Faulty outdoor unit fan motor.

5 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

1.5.33 U5-00 – Transmission malfunction between indoor unit and remote controller

Trigger Effect Reset

Communication

failure between

indoor unit and user

interface.

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

1 Check for improper combination of the indoor unit and the

remote controller. See Business Portal for more information.

2 Check the wiring between the indoor unit and remote controller.

See "3.1Power supply"on page52.

Possible cause: Faulty wiring between the indoor unit and

remote controller.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Unit will stop

operating.

Automatic reset.

1.5.34 UA-00 – Indoor/outdoor combination abnormality

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

INFORMATION

In case of preferential kWh rate, the indoor unit also needs

a power reset.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Trigger Effect Reset

Signal transmission

between outdoor and

indoor unit

abnormality. Improper

combination of

outdoor and indoor

unit.

Unit will stop

operating.

Power reset via

outdoor unit.

Service manual

13

1 Troubleshooting

To solve the error code

INFORMATION

It is recommended to perform the checks in the listed

order.

INFORMATION

In case of preferential kWh rate, the indoor unit also needs

a power reset.

1 Check for improper combination of the indoor unit and the

outdoor unit. See the combination table in the Databook for

more information.

2 Perform a check of the power supply, connections, wiring,…

between the outdoor unit and the indoor unit. See "3.1Power

supply"on page52.

Possible cause: Faulty wiring between the outdoor unit and

the indoor unit.

3 Perform a check of the main PCB. See "2.11 Main PCB"on

page35.

Possible cause: Faulty main PCB.

4 Perform a check of the indoor unit PCB. See "2.8Indoor unit

PCB"on page30.

Possible cause: Faulty indoor unit PCB.

INFORMATION

If all procedures listed above have been performed and the

problem is still present, contact the helpdesk.

Service manual

14

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1.6 Symptom based troubleshooting

1 Troubleshooting

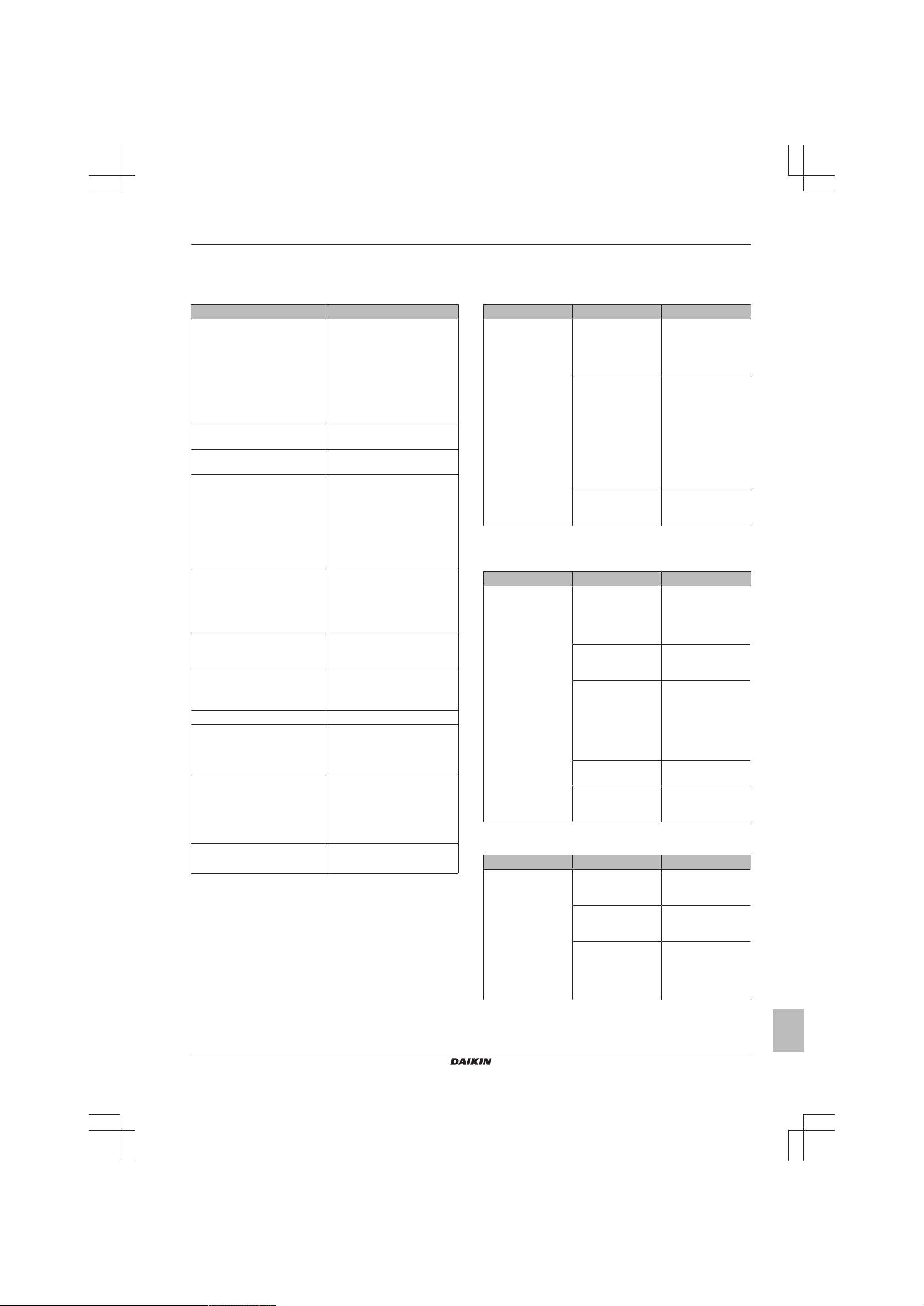

1.6.1 Operation does not start

Check Detail

When the operation lamp is off,

there is a power failure.

Check the power supply.

Check the type of the indoor unit. Is the indoor unit type compatible

Check the transmission between

indoor and outdoor

Check the outdoor temperature. ▪ Heating operation cannot be

When the operation lamp blinks,

there may be an error code,

activating the protection device.

Diagnose with remote controller

indication.

Check the remote controller

addresses.

Check the operation circuit. ▪ Is the thermal fuse blown.

Check high pressure switch. Not available

Check fan motor. ▪ Is the magnetic switch

Check compressor. ▪ Is the contact defective?

Check remote controller. ▪ Are the batteries LOW?

▪ Is the power supply breaker

ON?

▪ Do other electrical appliances

work?

▪ Is the rated voltage (± 10%) is

supplied?

▪ Check the insulation of the

electric system.

with the outdoor unit?

▪

used when the outdoor

temperature is 18°C WB or

higher.

▪ Cooling operation cannot be

used when the outdoor

temperature is below –

10°CDB.

See "1.5Error based

troubleshooting"on page4.

Are the address settings for the

remote controller and indoor unit

correct?

▪ Are wire size and wire

connections OK?.

defective?

▪ Is the overcurrent relay

defective?

▪ Is the protection thermostat

defective?

▪ Is the compressor itself

defective?

▪ Are there incorrect settings?

1.6.2 Operation sometimes stops

Symptom Check Detail

Operation sometimes

stops

Check the power

supply.

Check the outdoor

temperature.

Diagnose with remote

controller indication.

A power failure of 2 to

10 cycles stops air

conditioner operation.

(Operation lamp

OFF)

Heating operation

cannot be used when

the outdoor

temperature is

18°CWB or higher,

and cooling operation

cannot be used when

the outdoor

temperature is below

–10°CDB.

{Jesse Victoor,

12/01/2018

09:43:04: ???}

1.6.3 Operation starts but the unit does not cool/heat

Symptom Check Detail

Operation starts and

the unit does not

cool/heat

Check for wiring and

piping errors in the

connection between

the indoor unit and

outdoor unit.

Check for thermistor

detection errors.

Check for faulty

operation of the

electronic expansion

valve.

Diagnose with remote

controller indication.

Diagnose by service

port pressure and

operating current.

Not applicable

Check if the

thermistor is mounted

securely.

Set the unit to cooling

operation, and check

the temperature of

the liquid pipe to see

if the electronic

expansion valve

works.

Not applicable

Check for refrigerant

shortage.

1.6.4 Operating noise and vibrations

Symptom Check Detail

Operating noise and

vibrations

Check the output

voltage of the power

module.

Check the power

module.

Check the installation

condition.

{Jesse Victoor,

12/01/2018

09:41:35: ???}

{Jesse Victoor,

12/01/2018

09:41:35: ???}

Check if the required

spaces for installation

(specified in the

installation manual)

are provided.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

15

1 Troubleshooting

Symptom Check Detail

{Jesse Victoor,

12/01/2018

09:41:41: ????}

Check refrigerant

charge.

▪ Overcharge

▪ Air in the system

▪ Flushing noise, due

to refrigerant

shortage

1.6.5 Abnormal high pressure

In cooling mode

Check item Detail

Does the outdoor unit fan run

normally?

Is the outdoor unit heat

exchanger clogged?

Is there clogging before or after

the expansion valve (capillary)?

Is the High Pressure Switch

normal?

Is the outdoor unit installed under

such conditions that short circuit

easily occurs?

Is the piping length ≤5m? Visual inspection

Does air enter the refrigerant

system?

Is the refrigerant overcharged? Conduct refrigerant collection

In cooling mode

Check item Detail

Does the indoor unit fan run

normally?

Is the indoor unit heat exchanger

clogged?

Is the indoor unit installed under

such conditions that short circuit

easily occurs?

Is there clogging before or after

the expansion valve (capillary)?

Is the High Presure Switch

normal?

Is the minimum piping length

respected?

Does air enter the refrigerant

system?

Is the refrigerant overcharged? Conduct refrigerant collection

Visual inspection

Visual inspection

▪ Check if there is a temperature

difference before and after

expansion valve (capillary).

▪ Check if the main valve unit of

expansion valve operates (by

noise, vibration).

Check continuity by using a

tester.

Visual inspection

Conduct refrigerant collection

and vacuum drying, and then

add proper amount refrigerant.

and vacuum drying, and then

add proper amount refrigerant.

Visual inspection

Visual inspection

Visual inspection

▪ Check if there is a temperature

difference before and after

expansion valve (capillary).

▪ Check if the main valve unit of

expansion valve operates (by

noise, vibration).

Check continuity by using a

tester.

Visual inspection

Conduct refrigerant collection

and vacuum drying, and then

add proper amount refrigerant.

and vacuum drying, and then

add proper amount refrigerant.

1.6.6 Abnormal low pressure

Abnormally low pressure level is mostly caused by the evaporator

side. The following contents are provided based on field checking of

service engineer. Further, the number is listed in the order of degree

of influence.

In cooling mode

Check item Detail

Does the outdoor unit fan run

normally?

Is the indoor unit heat exchanger

clogged?

Is there clogging before or after

the expansion valve (capillary)?

Is the check valve clogged? Check if there is a temperature

Is the indoor unit installed under

such conditions that short circuit

easily occurs?

Is the refrigerant gas short? Conduct refrigerant collection

In cooling mode

Check item Detail

Does the outdoor unit fan run

normally?

Is the outdoor unit heat

exchanger clogged?

Is the outdoor unit installed under

such conditions that short circuit

easily occurs?

Is there clogging before or after

the expansion valve (capillary)?

Is the check valve clogged? after check valve. If YES, the

Is the refrigerant gas short? Conduct refrigerant collection

Visual inspection

Visual inspection

▪ Check if there is a temperature

difference before and after

expansion valve (capillary).

▪ Check if the main valve unit of

expansion valve operates (by

noise, vibration).

difference before and after check

valve. If YES, the check valve is

caught.

Visual inspection

and vacuum drying, and then

add proper amount refrigerant.

Visual inspection

Visual inspection

Visual inspection

▪ Check if there is a temperature

difference before and after

expansion valve (capillary).

▪ Check if the main valve unit of

expansion valve operates (by

noise, vibration).

check valve is caught.

and vacuum drying, and then

add proper amount refrigerant.

Service manual

16

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

1 Troubleshooting

1.6.7 Indoor fan starts operating but the compressor does not operate

Symptom Check Detail

Indoor fan starts

operating,

compressor does not

operate

Check power supply ▪ Check if the rated

voltage is supplied.

▪ Check the

insulation of the

electric system.

Check thermistor Connection witch

PCB, output.

Check PCB's HAP LED.

Check magnetic

switch

Check power

transistor

Check compressor Defective contact,

defective

compressor,

defective protection

thermostat.

Check operation

range

Is the outdoor

temperature within

the limit.

1.6.8 Operation starts and the unit stops immediately

1.6.10 Unit discharges white mist

Symptom Check Detail

Unit discharges white

mist

Check installation

conditions

Check heat

exchanger

Air filter Dirty air filter

Fan motor Defective fan motor

Humid site, dirty site,

oil mist

Dirty heat exchanger

1.6.11 Swing flap does not operate

Symptom Check Detail

Swing flap does not

operate

Check swing flap

motor

Check indoor unit

PCB

Some functions can

force the swing flap

into a fixed position,

although swing mode

is selected on the

remote controller.

This is not a unit

error, but a control

function to prevent

draft to the customer.

Connector connection

Symptom Check Detail

Operation starts and

the unit stops

immediately

Check refrigerant

charge

Check pressure

switch

Check fan motor ▪ Check magnetic

Check heat

exchanger

Check airflow Soiled air filter,

▪ Overcharge

▪ Air in the system

▪ Water in the

system

Not available

switch

▪ Operation

Soiled heat

exchanger,

obstruction.

obstruction,

installation space.

1.6.9 Operation stops, unit cannot start for a while

Symptom Check Detail

Operation stops, the

unit cannot start for a

while

Check compressor Overcurrent relay,

protection thermostat

Check power supply Low voltage, size of

power cable

Check high pressure

Check refrigerant

charge

Compressor delay

timer is counting.

▪ Air in the system

▪ Incorrect charge

▪ Water in the

system

▪ Obstruction in the

system

Wait for minimum 3

minutes.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

17

2 Components

2 Components

2.1 4-way valve

2.1.1 Checking procedures

INFORMATION

It is recommended to perform the checks in the listed

order.

To perform a mechanical check of the 4-way valve

Prerequisite: Turn OFF the unit via the user interface.

Prerequisite: Turn OFF the respective circuit breaker.

Prerequisite: Remove the required plate work, see "2.13 Plate

work"on page40.

1 Disconnect the 4‑way valve connector from the main PCB.

2 Turn ON the power of the unit.

INFORMATION

Default position of the 4‑way valve is Heating mode.

3 Activate Heating operation via the user interface.

Water temperature after plate

type heat exchanger of the

indoor unit:

Drops 4‑way valve is stuck in cooling

Rises Skip the next step of this

Does NOT rise/drop Perform the next step of this

4 Connect a manifold to one of the service ports of the refrigerant

circuit and check the pressure.

Refrigerant pressure

measured?

Yes Perform a position check of the

No Leaks may be found in the

CAUTION

To prevent damage due to liquid entering the compressor,

the steps below MUST ONLY be executed once.

CAUTION

Make sure you have a pressure difference of at least 6bar

between the high and low pressure when performing this

test.

5 Place a round permanent magnet on the core of the solenoid

valve and listen to the 4‑way valve.

Does the 4‑way valve switch? Action

Yes Perform an electrical check of the

Action

position. Replace the 4‑way

valve body, see "2.1.2Repair

procedures"on page19.

procedure.

procedure.

Action

4‑way valve, see "2.1.1Checking

procedures"on page18.

refrigerant circuit. Perform a

pressure test of the refrigerant

circuit, see "3.2.1Checking

procedures"on page53.

4‑way valve, see "2.1.1Checking

procedures"on page18.

Does the 4‑way valve switch? Action

No Replace the 4‑way valve body,

see "2.1.2Repair procedures"on

page19.

To perform an electrical check of the 4-way valve

1 First perform a mechanical check of the 4‑way valve, see

"2.1.1Checking procedures"on page18.

2 Activate Cooling operation via the user interface.

3 Measure the voltage on the 4‑way valve connector pins 1-3.

The measured voltage MUST be 220~240 V AC during

switching and 12VDC after switching of the 4‑way valve.

Is the measured voltage

correct?

Yes Skip the next step of this

No Perform the next step of this

4 Disconnect the 4‑way valve connector from the main PCB and

measure the voltage on the connector pins 1-3 of the connector

on the main PCB. The voltage MUST be 220~240VAC during

switching and 12VDC after switching.

Is the measured voltage on the

4‑way valve connector of the

main PCB correct?

Yes Replace the 4‑way valve coil, see

No Replace the main PCB, see

5 Disconnect the 4‑way valve connector from the main PCB and

measure the resistance of the 4‑way valve coil. The resistance

MUST be 1000~2000Ω.

Is the measured resistance

correct?

Yes Perform the next step of this

No Replace the 4‑way valve coil, see

6 De-activate Cooling and activate Heating operation via the user

interface.

7 Measure the temperature after the plate type heat exchanger.

Does the measured

temperature rise?

Yes Perform a position check of the

No Replace the main PCB, see

Action

procedure.

procedure.

Action

"2.1.2Repair procedures"on

page19.

"2.11Main PCB"on page35.

Action

procedure.

"2.1.2Repair procedures"on

page19.

Action

4‑way valve, see "2.1.1Checking

procedures"on page18.

"2.11Main PCB"on page35.

To perform a position check of the 4-way valve

1 First perform a mechanical check of the 4‑way valve, see

"2.1.1Checking procedures"on page18.

2 Slide a magnet over the front and rear side of the 4‑way valve

body. The magnet MUST be attracted in the positions a or b,

but NOT in positions c.

Service manual

18

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

2 Components

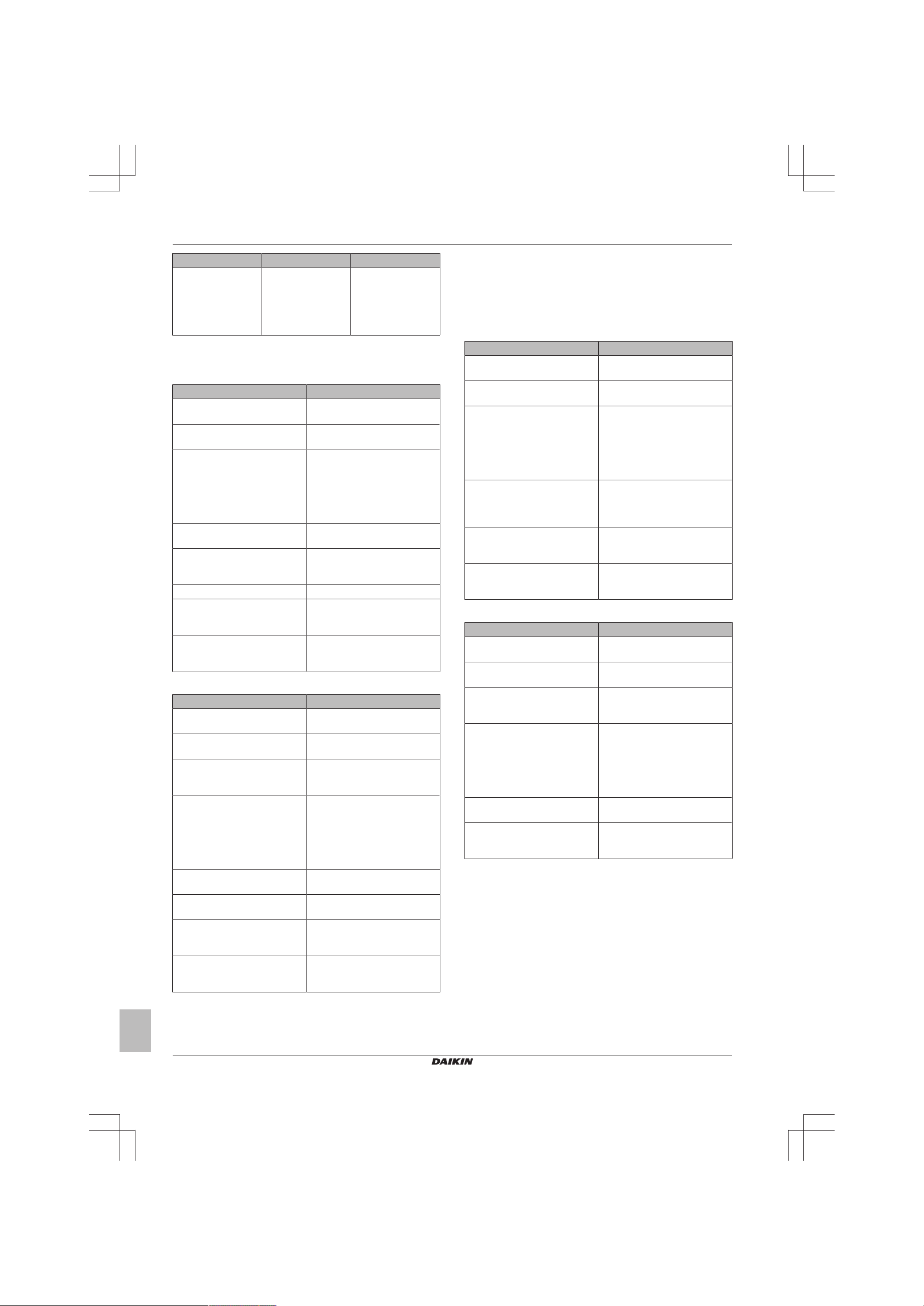

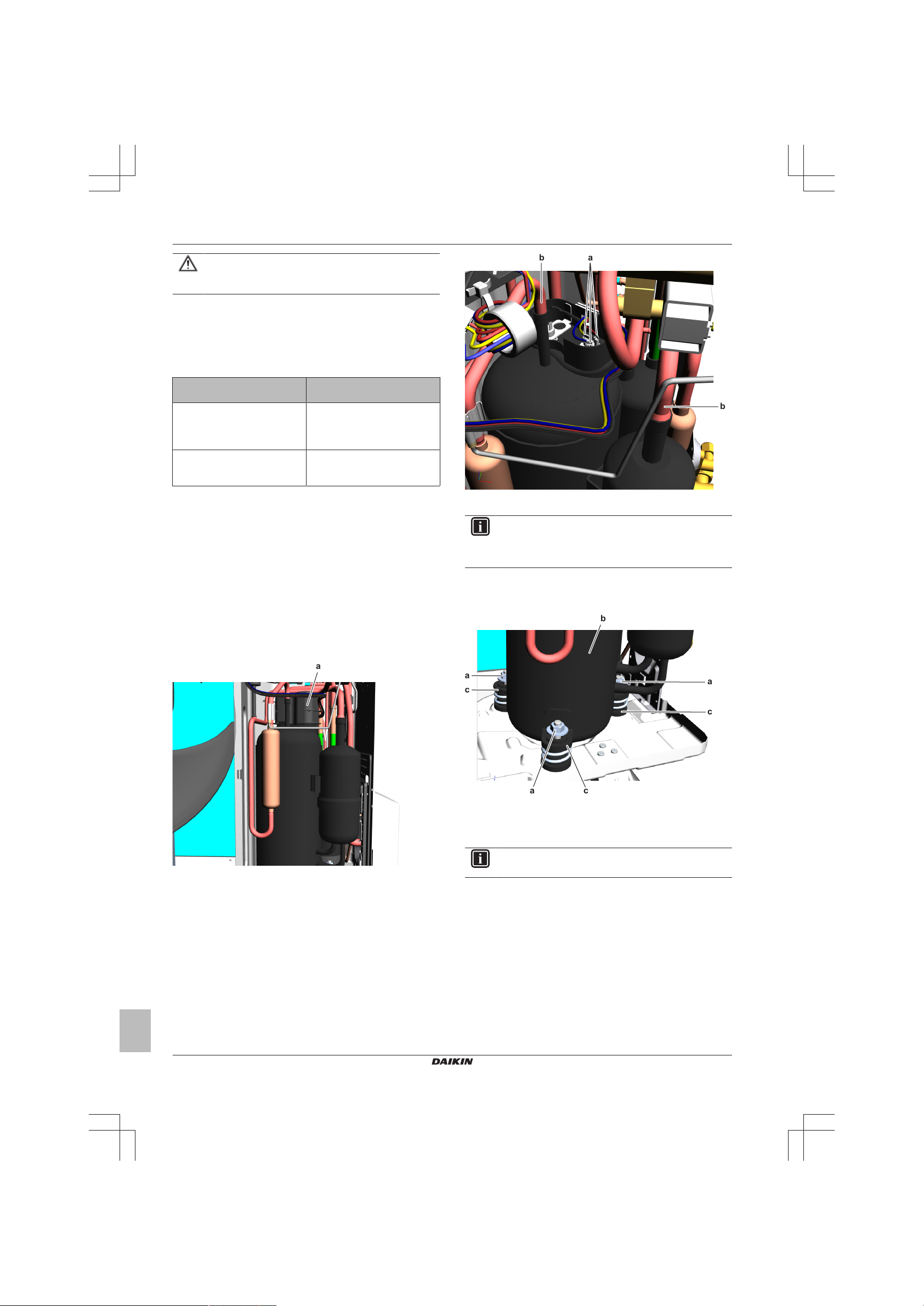

a a

b b

c c

c a b

cd a b a

a Screw

b 4‑way valve coil

c 4‑way valve body

2 Cut all tie straps that fix the 4‑way valve coil harness.

3 Disconnect the 4‑way valve coil connector from the main PCB.

4 To install the 4‑way valve coil, see "2.1.2Repair procedures"on

page19.

To remove the 4-way valve body

Prerequisite: Recuperate the refrigerant from the refrigerant circuit,

see "3.2.2Repair procedures"on page54.

1 Remove the 4‑way valve coil from the 4‑way valve body, see

"2.1.2Repair procedures"on page19.

2 Cut the 4‑way valve pipes using a pipe cutter.

a Magnet attracted

b Magnet attracted

c Magnet NOT attracted

Magnet is attracted in the

correct positions of the 4‑way

valve?

Yes The 4‑way valve is OK. Return to

No Replace the 4‑way valve body,

Action

the troubleshooting of the

specific error and continue with

the next procedure.

see "2.1.2Repair procedures"on

page19.

2.1.2 Repair procedures

To remove the 4-way valve coil

Prerequisite: Turn OFF the unit via the user interface.

Prerequisite: Turn OFF the respective circuit breaker.

Prerequisite: Remove the required plate work, see "2.13 Plate

work"on page40.

Prerequisite: If needed, remove any parts to create more space for

the removal of the 4‑way valve coil.

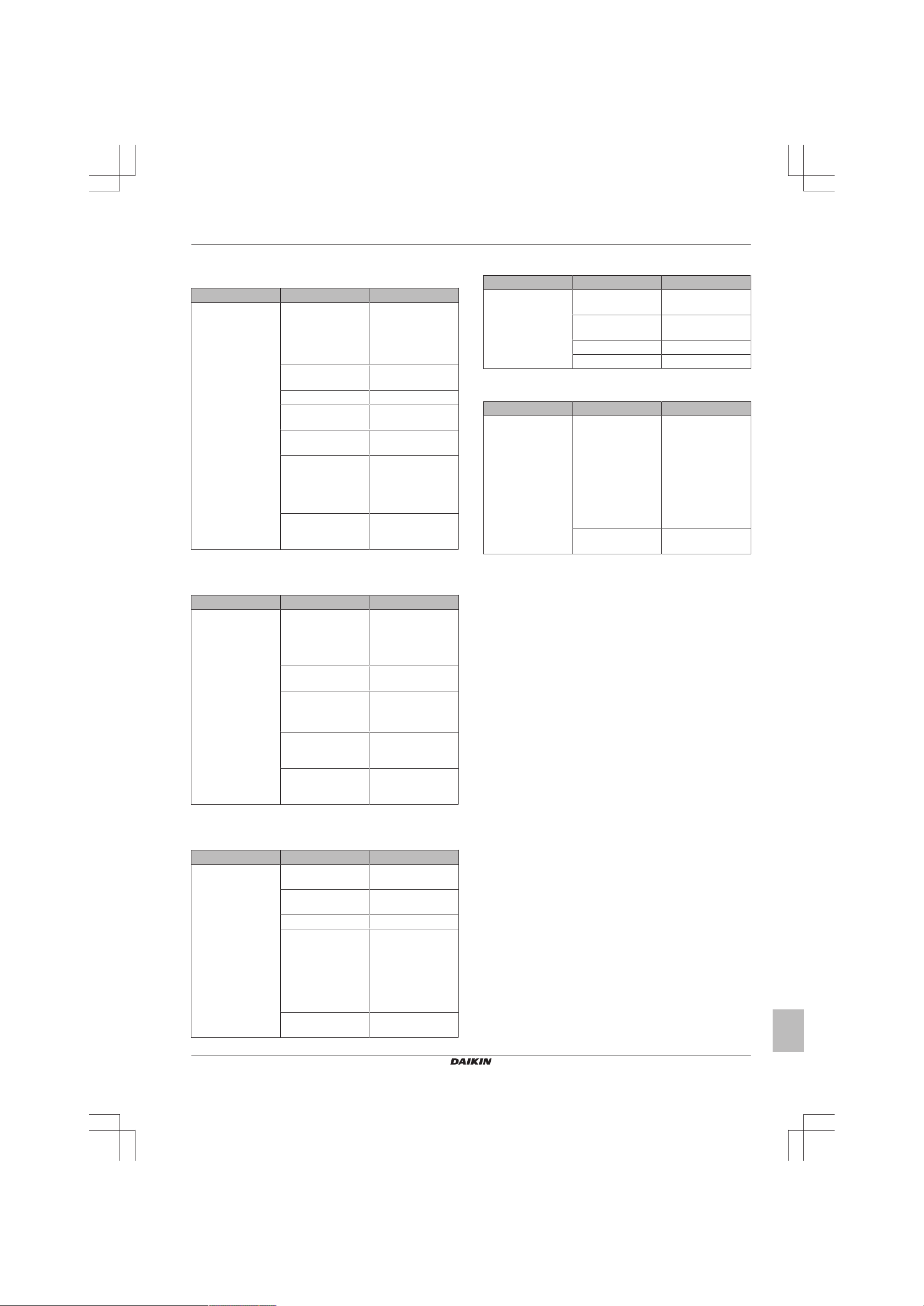

1 Remove the screw and remove the 4‑way valve coil from the

4‑way valve body.

a 4‑way valve pipe

b 4‑way valve

c Putty

d Insulation

3 Remove the 4‑way valve.

4 Keep the putty and the insulation for re-use.

5 To install the 4‑way valve body, see "2.1.2 Repair

procedures"on page19.

To install the 4-way valve body

1 Install the 4‑way valve in the correct location.

2 Wrap a wet rag around the 4‑way valve and solder the 4‑way

valve pipes to the 4‑way valve.

CAUTION

Overheating the valve will damage or destroy it.

(C)(F)TXA15~50A2V1B(W)(S)(T) + RXA42+50A2V1B +

RXA20~35A2V1B

Split Stylish R32

ESIE18-03 – 2018.09

Service manual

19

2 Components

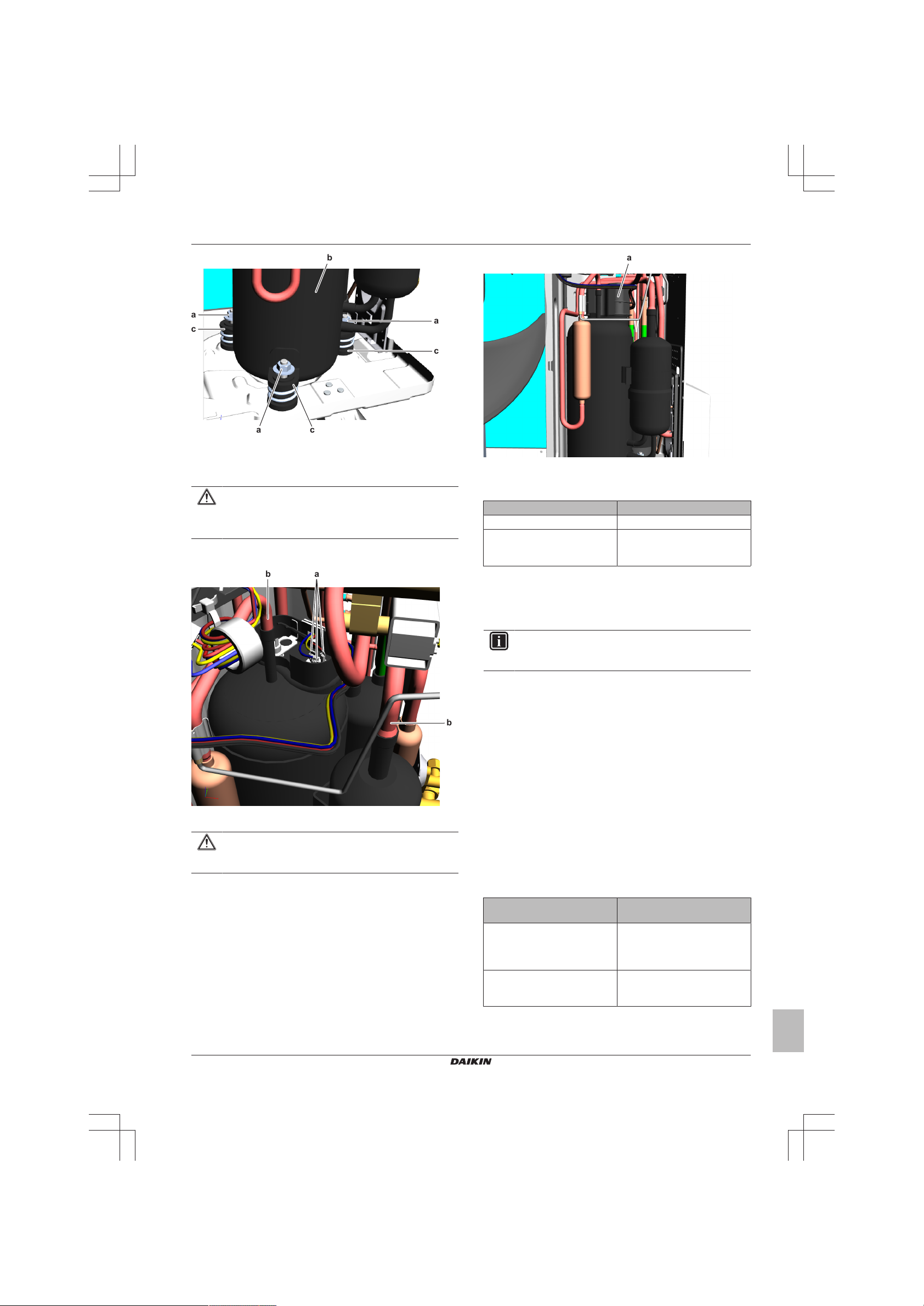

cd a b a

c a b

a

a

a 4‑way valve pipe

b 4‑way valve

c Putty

d Insulation

3 Install the putty and the insulation in their original location.

4 Install the 4‑way valve coil on the 4‑way valve body, see

"2.1.2Repair procedures"on page19.

5 Add refrigerant to the refrigerant circuit, see "3.2.2 Repair

procedures"on page54.

To install the 4-way valve coil

1 Install the 4‑way valve coil on the 4‑way valve body.

2.2 Compressor

2.2.1 Checking procedures

INFORMATION

It is recommended to perform the checks in the listed

order.

To perform a mechanical check of the compressor

Prerequisite: Turn OFF the unit via the user interface.

Prerequisite: Turn OFF the respective circuit breaker.

Prerequisite: Remove the required plate work, see "2.13 Plate

work"on page40.

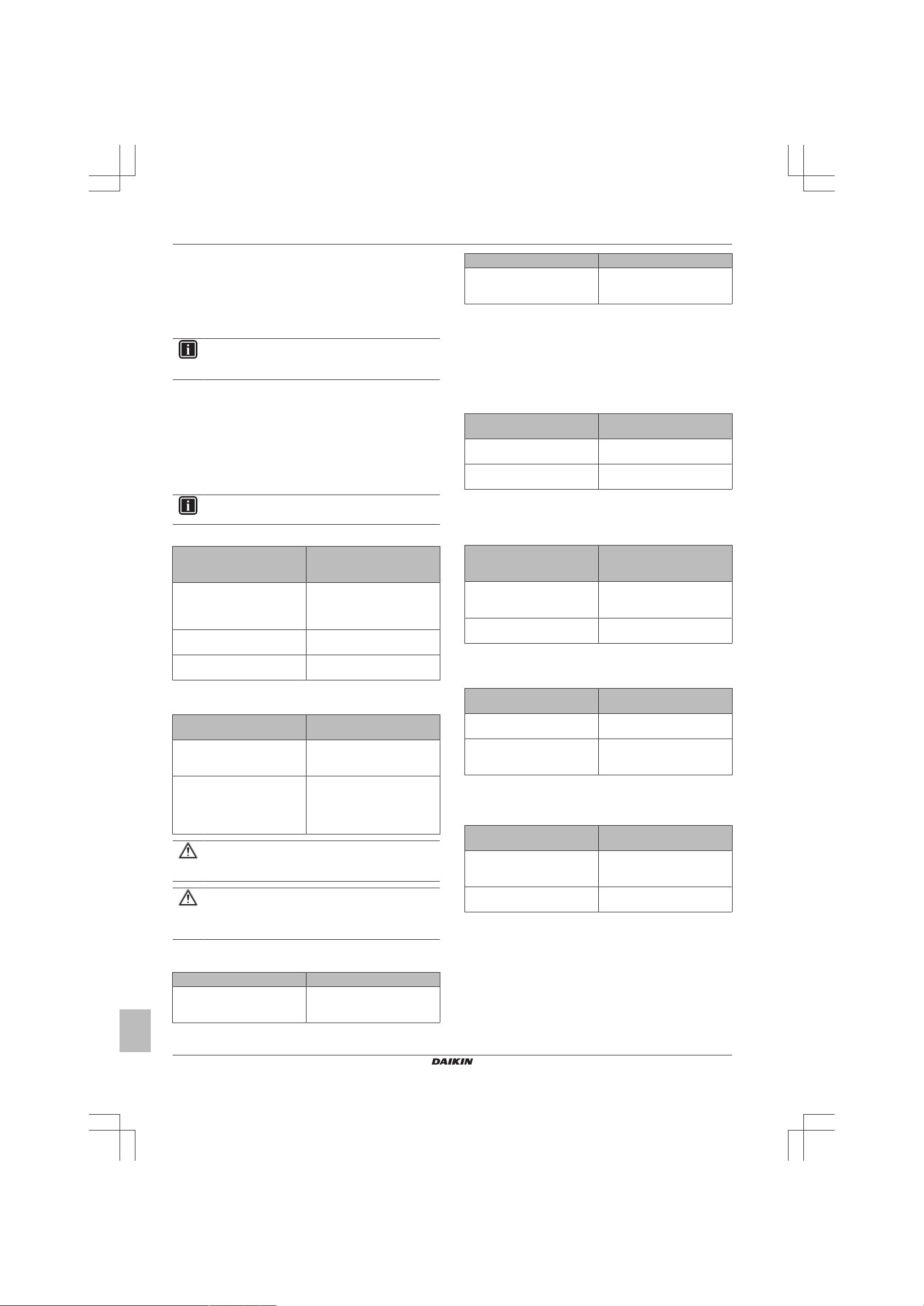

1 Open the compressor insulation.

2 Check the compressor dampers and piping for any damage.

a Screw

b 4‑way valve coil

c 4‑way valve body

2 Install and tighten the screw to fix the 4‑way valve coil.

3 Route the 4‑way valve coil harness towards the main PCB.

4 Connect the 4‑way valve coil connector to the main PCB.

WARNING

When reconnecting a connector to the PCB, do NOT apply

force, as this may damage the connector or connector pins

of the PCB.

5 Fix the 4‑way valve coil harness using new tie straps.

Is the problem solved? Action

Yes No further actions required.

No Return to the troubleshooting of

the specific error and continue

with the next procedure.

a Damper

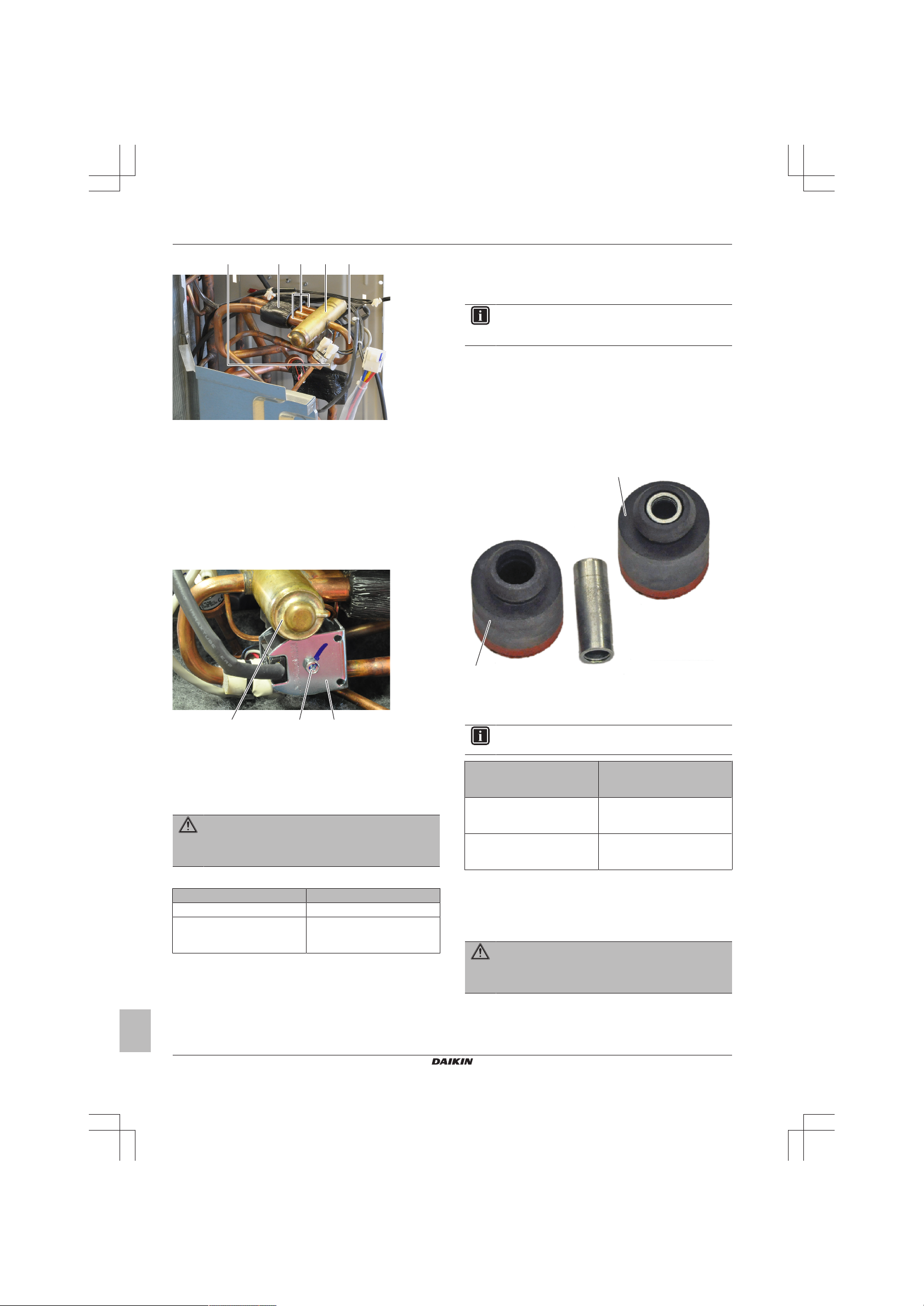

INFORMATION

The compressor dampers may look different.

Compressor dampers and

piping are in a good

condition?