Daikin DPS012, DPS015, DPS004, DPS016, DPS018 Installation And Maintenance Manual

...

Installation and Maintenance Manual IM 1125-7

Group: Applied Air Systems

Part Number: IM 1125

Date: November 2015

Rebel™ Commercial Packaged

Rooftop Systems

Heating and Cooling

Models DPS003 – 028A

R-410A Refrigerant

MicroTech® III Unit Controller

Energy Recovery Wheel

3–6 tons

16–28 tons

Shown with Energy Recovery

7–15 tons

Shown with Energy Recovery

Table of ConTenTs

Introduction.............................................3

General Information .....................................3

Unit Nameplate......................................... 3

Hazard Identication Information ...........................3

Mechanical Installation ...................................4

Installer Responsibilities..................................4

Receiving Inspection ....................................4

Service Clearance ......................................4

Ventilation Clearance ....................................4

Overhead Clearance ....................................6

Roof Curb Assembly and Installation ........................6

Rigging and Handling ................................... 10

Unit Piping - Condensate Drain Connection.................. 12

Damper Assemblies ....................................12

Cabinet Weather Protection ..............................13

Installing Ductwork .....................................13

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pre-Construction ......................................15

Refrigeration System ....................................19

Piping System ........................................19

DPS 003–015 Component Description .....................21

DPS 016–028 Ton Component Description ..................27

VFD Compressor Operation – DPS 016–028 ................29

Variable Speed Scroll Compressor.........................33

Optional Modulating Hot Gas Reheat....................... 36

Modulating Hot Gas Reheat ............................. 36

Optional Electric Heat ...................................39

Electric Heater Design ..................................39

Optional Gas Heat ......................................40

Daikin Tubular Heater Series .............................40

Gas Furnace Design ...................................40

Gas Heating Capacity Data ..............................41

DPS 003–015 Sequence of Operation ...................... 48

DPS 016–028 Sequence of Operation .....................49

Start-Up Procedures.................................... 50

Operating Procedures ..................................51

DPS 003–015 (only) Ignition Control Module for

Staged Gas Furnace ...................................52

DPS 003–015 (only) Ignition Control Module for

Modulating Gas Furnace ................................53

DPS 003–015 (only) Gas Furnace Ignition and Control

Troubleshooting .......................................54

VB-1200 Trouble Shooting Guide..........................54

DPS 016–028 Gas Furnace Ignition Troubleshooting ..........60

Optional Hot Water Heat .................................65

Hot Water Heater Design ................................65

Optional Energy Recovery Wheel..........................66

System Description ....................................66

Optional Outdoor Air Monitor .............................69

Thermal Dispersion Airow Measurement Technology..........69

ECM Motor.............................................74

Table of ConTenTs

Unit Options ...........................................76

Economizer Enthalpy Control.............................76

External Time Clock ....................................76

Exhaust Fan Option ....................................76

Proof-of-Airow and Dirty Filter Switch...................... 76

Duct High Pressure Limit ................................76

Convenience Receptacle (Field Powered) ................... 77

Convenience Receptacle (Unit Powered) ...................77

Wiring Diagrams........................................78

Sequence of Operation ..................................90

Operating States ......................................90

Mechanical Cooling .................................... 91

Economizer ..........................................91

Preparing the Unit for Start Up ............................92

Pre-Start of Unit .......................................92

Spring Isolated Fans ...................................92

Servicing Control Panel Components ......................93

Power-Up ............................................93

Fan Start-Up..........................................93

Check, Test and Start Procedures .........................94

Economizer Start-Up ...................................94

Compressor Start-Up ...................................94

Set Up for Optimum Control .............................. 95

Air Balancing .......................................95

Energy Recovery Wheel................................. 96

Final Control Settings ...................................97

Final Control Settings ................................... 97

Maintaining Control Parameter Records ....................97

Maintenance ...........................................98

Performing Service Maintenance ..........................98

Planned Maintenance................................... 98

Unit Storage ..........................................98

Periodic Service and Maintenance.........................99

Refrigerant Charge....................................100

Servicing Refrigerant Sensors or Switches ............... 101

Servicing Optional Electric Heater .................... 101

Servicing the Compressor Ground Fault Interrupter ..........101

Phase Voltage Monitor (PVM) ...........................101

Cleaning Option E Coated Coils .........................102

Service and Warranty Procedures ........................103

Replacement Parts....................................103

Scroll Compressor ....................................103

In-Warranty Return Material Procedure ....................103

Warranty Registration Form.............................104

Quality Assurance Survey Report ........................108

Appendix – Keypad/Display Menu Structure................ 11 0

IM 1125-7 • REBEL ROOFTOPS 2 www.DaikinApplied.com

General Information

This manual provides general information about the “A”

vintage Daikin Rebel Commercial Packaged Rooftop Unit,

model DPS. In addition to an overall description of the unit,

it includes mechanical and electrical installation procedures,

commissioning procedures, sequence of operation information,

and maintenance instructions.

The MicroTech® III rooftop unit controller is equipped on

“A” vintage rooftop units. For a detailed description of the

MicroTech III components, input/output congurations, eld

wiring options and requirements, and service procedures,

see OM 1141. For operation and information on using and

programming the MicroTech III unit controller, refer to the

appropriate operation manual (see Table 1).

For a description of operation and information on using

the keypad to view data and set parameters, refer to the

appropriate program-specic operation manual (see Table 1).

InTroduCTIon

Unit Nameplate

The unit nameplate is located on the outside of the main

control box door. It includes the unit model number, serial

number, electrical characteristics, and refrigerant charge.

Hazard Identication Information

DANGER

Dangers indicate a hazardous situation which will result

in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations,

which can result in property damage, severe personal

injury, or death if not avoided.

InTroduCTIon

Table 1: Program Specic Unit Operation Literature

Rooftop unit control conguration

BACnet IP Comm Module IM 916

BACnet® Integration IM 917

LonWorks® Integration IM 918

DPS Unit Controller Discharge

Air Control (VAV or CAV)

Space Comfort Control (SCC)

Rebel Quick Start Guide OM 1164

Manual

bulletin number

OM 1141

Nomenclature (DPS 003–028)

DPS – 010 – A H H G 4

Daikin Packaged System

Nominal capacity

003 = 3 tons 016 = 16 tons

004 = 4 tons 018 = 18 tons

005 = 5 tons 020 = 20 tons

006 = 6 tons 025 = 25 tons

007 = 7.5 tons 028 = 28 tons

010 = 10 tons

012 = 12 tons

015 = 15 tons

CAUTION

Cautions indicate potentially hazardous situations,

which can result in personal injury or equipment damage

if not avoided.

Line voltage

2 = 208 volt power supply

3 = 230 volt power supply

4 = 460 volt power supply

5 = 575 volt power supply

Heat medium

Y = None (cooling only)

G = Natural gas heat

E = Electric heat

W = Hot water heat

Design vintage

A = Vintage 1

Cooling efciency

H = High (exceeds ASHRAE 92)

www.DaikinApplied.com 3 IM 1125-7 • REBEL ROOFTOPS

Unit style

C = Cooling only

H = Heat pump

M = Cooling-only microchannel

Installer Responsibilities

MeChanICal InsTallaTIon

MeChanICal InsTallaTIon

Service Clearance

CAUTION

Sharp edges on sheet metal and fasteners can cause

personal injury. This equipment must be installed,

operated, and serviced only by an experienced

installation company and fully trained personnel.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and all

applicable codes. It is the responsibility of the installer to

determine and follow the applicable codes.

Receiving Inspection

When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. If the unit has become dirty

during shipment (winter road chemicals are of particular

concern), clean it when received.

All units should be carefully inspected for damage when

received. Report all shipping damage to the carrier and le a

claim. In most cases, equipment is shipped F.O.B. factory and

claims for freight damage should be led by the consignee.

Before unloading the unit, check the unit nameplate to make

sure the voltage complies with the power supply available.

CAUTION

Location. Care should be taken for the installation

location to minimize snow drifts on the outdoor coil.

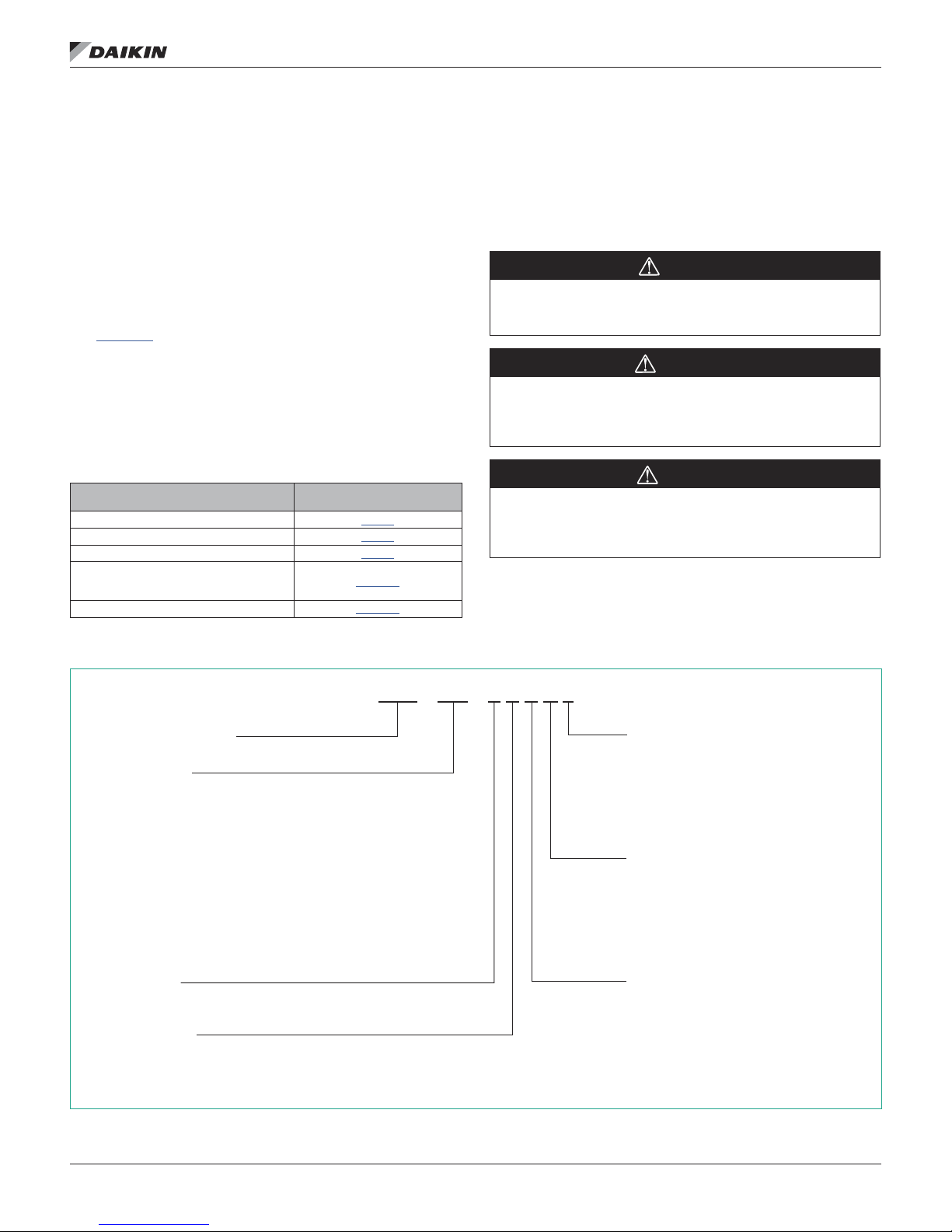

Allow service clearances as approximately indicated in Figure

1. Also, Daikin recommends providing a roof walkway to the

rooftop unit as well as along each side of the unit that provides

access to most controls and serviceable components.

Refer to NEC and local for minimum clearances around the

unit and control panel.

Ventilation Clearance

Below are minimum ventilation clearance recommendations.

The system designer must consider each application and

provide adequate ventilation. If this is not done, the unit may

not perform properly.

Unit(s) Surrounded by a Screen or a Fence:

1. The bottom of the screen or fence should be at least 1 ft.

(305 mm) above the roof surface.

2. The distance between the unit and a screen or fence

should be as described in Figure 1.

3. The distance between any two units within a screen or

fence should be at least 120" (3048 mm).

Unit(s) Surrounded by Solid Walls:

1. If there are walls on one or two adjacent sides of the unit,

the walls may be any height. If there are walls on more

than two adjacent sides of the unit, the walls should not

be higher than the unit.

2. The distance between the unit and the wall should be at

least 96" (2438 mm) on all sides of the unit.

3. The distance between any two units within the walls

should be at least 120" (3048 mm).

Do not locate outside air intakes near sources of contaminated air.

If the unit is installed where windy conditions are common,

install wind screens around the unit, maintaining the

clearances specied (see Figure 1). This is particularly

important to maintain adequate head pressure control when

mechanical cooling is required at low outdoor air temperatures.

IM 1125-7 • REBEL ROOFTOPS 4 www.DaikinApplied.com

Figure 1: Service Clearances

MeChanICal InsTallaTIon

Small Cabinet

003—006

Filter

Access

60.00

(1524 mm)

Plenum Discharge,

Electric Heat &

Supply Fan Access

Large Cabinet

016—028

Exhaust

Fan Access

Outdoor Air

Control

Panel

Access

Hood

50.00

(1270 mm)

48.00

(1219 mm)

21.00 (533 mm)

Gas

59.2"

(1504 mm)

36.00

(914 mm)

Medium Cabinet

007—015

Filter

Access

60.00

(1524 mm)

Supply Fan

Access

Exhaust

Fan Access

Outdoor Air

Control

Panel

Access

Hood

50.00

(1270 mm)

48.00

(1219 mm)

17.00 (431 mm)

Gas

59.2"

(1504 mm)

36.00

914 mm)

www.DaikinApplied.com 5 IM 1125-7 • REBEL ROOFTOPS

MeChanICal InsTallaTIon

Overhead Clearance

1. Unit(s) surrounded by screens or solid walls must have

no overhead obstructions over any part of the unit. For

heat pump models overhead obstructions could allow the

formation of dangerous ice cycles.

2. The area above the condenser must be unobstructed in

all installations to allow vertical air discharge.

3. The following restrictions must be observed for overhead

obstructions above the air handler section:

a. There must be no overhead obstructions above the

furnace ue, or within 9" (229 mm) of the ue box.

b. Overhead obstructions must be no less than 96"

(2438 mm) above the top of the unit.

c. There must be no overhead obstructions in the areas

above the outside air and exhaust dampers that are

farther than 24" (610 mm) from the side of the unit.

Roof Curb Assembly and Installation

WARNING

Mold can cause personal injury. Some materials such

as gypsum wall board can promote mold growth when

damp. Such materials must be protected from moisture

that can enter units during maintenance or normal

operation.

Locate the roof curb and unit on a portion of the roof that can

support the weight of the unit. The unit must be supported to

prevent bending or twisting of the machine.

If building construction allows sound and vibration into

the occupied space, locate the unit over a non-critical

area. It is the responsibility of the system designer to

make adequate provisions for noise and vibration in the

occupied space.

Install the curb and unit level to allow the condensate drain to

ow properly and allow service access doors to open and close

without binding.

The gasketed top surface of the curb seals against the unit

when it is set on the curb. These anges must not support

the total weight of the duct work. See Installing Ductwork on

page 13 for details on duct connections. It is critical that

the condensate drain side of the unit be no higher than the

opposite side.

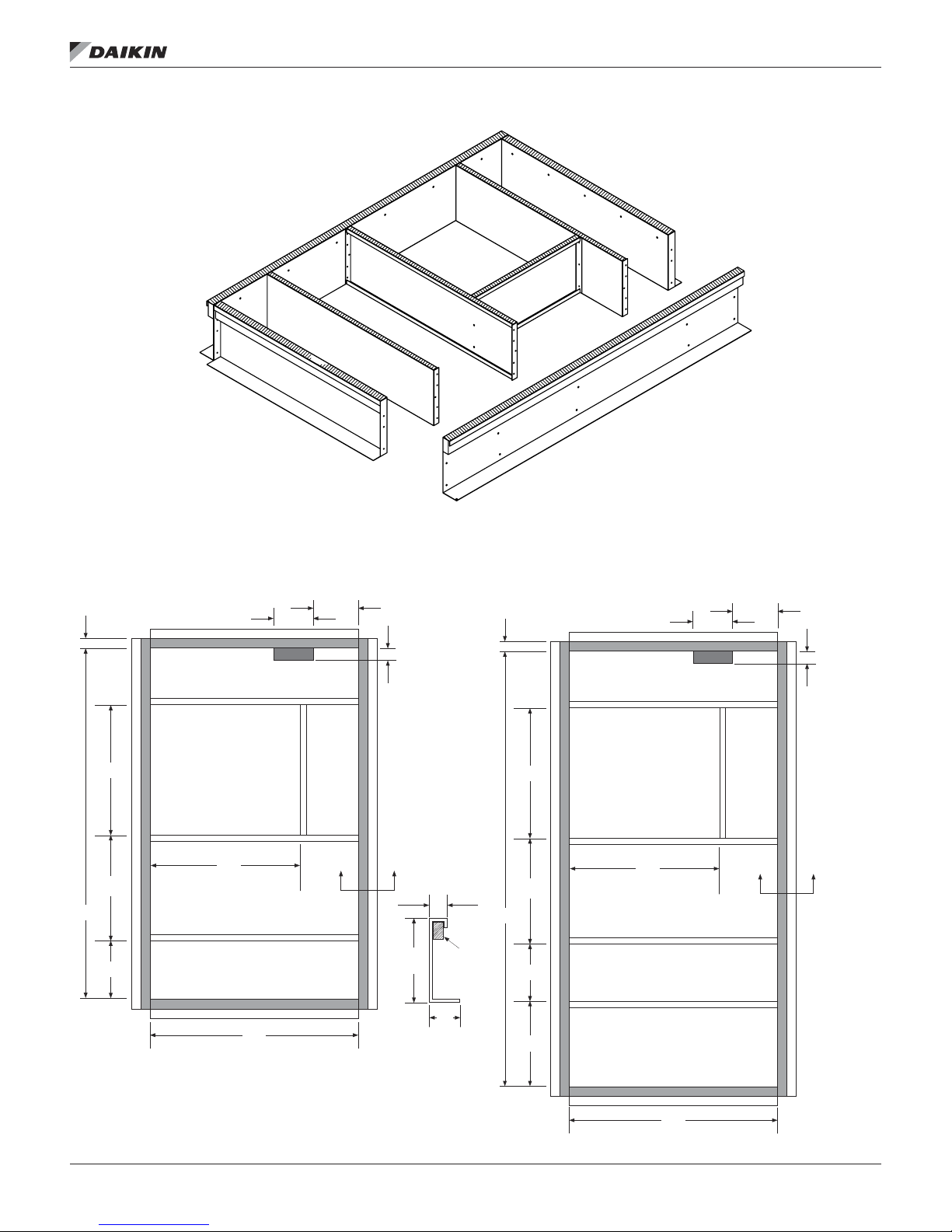

Assembly Instructions

Assembly of a typical roof curb is shown in Figure 2, Figure 3

on page 8 and Figure 4 on page 9.

1. Set curbing parts A thru G per dimensions shown over roof

opening or on a level surface. Note location of supply air

opening. Check alignment of all mating screw holes.

2. Screw curbing parts together using fasteners provided.

Leave all screws loose until curb is checked to be square.

3. Square entire curbing assembly and securely tighten all

screws.

4. Position curb assembly over roof openings. Curb must

be level within 0.25 inches from side to side and 1.50

inches over its length. Check that top surface of curb is

at with no bowing or sagging.

5. Weld curb assembly in place. Caulk all seams watertight.

Remove backing from 0.25 × 1.50 wide gasket and apply

to surfaces shown by crosshatching.

6. Check that electrical connections are coordinated.

IM 1125-7 • REBEL ROOFTOPS 6 www.DaikinApplied.com

Figure 2: Roof Curb Assembly (DPS 003—006)1

DPS 003–006 Roofcurb with ERW Certi ed Drawing

McQuay International certi es that its equipment will conform to this drawing and McQuay’s

published speci cations, subject to its published warranty. Purchaser must determine that the

equipment is t and suf cient for the job speci cations. No change to this drawing may be made

unless approved in writing by McQuay. www.DaikinMcQuay.com © 2012 McQuay International

Model: DPS

Date:

Unit Tag:

Units: Sheet: __ of __

DPS 003–006 Roofcurb with ERW Certi ed Drawing

McQuay International certi es that its equipment will conform to this drawing and McQuay’s

published speci cations, subject to its published warranty. Purchaser must determine that the

equipment is t and suf cient for the job speci cations. No change to this drawing may be made

unless approved in writing by McQuay. www.DaikinMcQuay.com © 2012 McQuay International

Model: DPS

Date:

Unit Tag:

Units: Sheet: __ of __

Curb Detail

A–A

2"×4"

Nailer

A A

2.0"

Typ.

14.0"

or

24.0"

4.0"

3.9

28.55

Inside

9.69

Inside

28.69

Inside

44.38

Inside

76.0

Inside

19.1

9.5

Inside

18.5

Supply

Opening

Return

Opening

Electrical

Entrance

47.05

2.0

3.9

6.4

LEFT SIDE

G

28.69

INSIDE

B

MeChanICal InsTallaTIon

BACK SIDE

D

9.84

INSIDE

SUPPLY AIR

A

H

RETURN AIR

E

F

28.76

INSIDE

C

61.50

RIGHT SIDE

FRONT SIDE

44.24

9.64

INSIDE

NOTE: 1. Check submittal drawing for gas/water/electrical/supply/return air opening

Horizontal above the roof gas connection only

Standard Roof Curb – Small Cabinet

2.0

9.5

Inside

19.1

Return

Opening

44.38

Inside

Supply

Opening

28.55

Inside

Roof Curb for ERW – Small Cabinet

57.5

Inside

3.9

6.4

Electrical

Entrance

3.9

28.69

Inside

www.DaikinApplied.com 7 IM 1125-7 • REBEL ROOFTOPS

9.69

Inside

A A

Curb Detail

14.0"

or

24.0"

A–A

2.0"

Typ.

4.0"

2"×4"

Nailer

Figure 3: Roof Curb Assembly (DPS 007–015)1

DPS 007–012 Roofcurb with ERW Certi ed Drawing

McQuay International certi es that its equipment will conform to this drawing and McQuay’s

published speci cations, subject to its published warranty. Purchaser must determine that the

equipment is t and suf cient for the job speci cations. No change to this drawing may be made

unless approved in writing by McQuay. www.DaikinMcQuay.com © 2012 McQuay International

Model: DPS

Date:

Unit Tag:

Units: Sheet: __ of __

DPS 007–012 Roofcurb with ERW Certi ed Drawing

McQuay International certi es that its equipment will conform to this drawing and McQuay’s

published speci cations, subject to its published warranty. Purchaser must determine that the

equipment is t and suf cient for the job speci cations. No change to this drawing may be made

unless approved in writing by McQuay. www.DaikinMcQuay.com © 2012 McQuay International

Model: DPS

Date:

Unit Tag:

Units: Sheet: __ of __

Curb Detail

A–A

2"×4"

Nailer

A A

2.0"

Typ.

4.0"

14.0"

or

24.0"

34.88

Inside

48.38

Inside

101.5

Inside

13.5

Inside

30.5

Inside

Supply

Opening

Return

Opening

Electrical

Entrance

20.0

24.25

2.0

3.4

6.9

8.8

MeChanICal InsTallaTIon

LEFT SIDE

BACK SIDE

A

SUPPLY

B

AIR

E

E

F

RETURN

AIR

FRONT SIDE

A

D

C

RIGHT SIDE

NOTE: 1. Check submittal drawing for gas/water/electrical/supply/return air opening

Horizontal above the roof gas connection only

Standard Roof Curb – Medium Cabinet

2.0

30.5

Inside

Supply

Opening

Electrical

Entrance

8.8

6.9

3.4

Roof Curb for ERW – Medium Cabinet

81.5

Inside

IM 1125-7 • REBEL ROOFTOPS 8 www.DaikinApplied.com

24.25

13.5

Inside

34.88

Inside

Return

Opening

48.38

Inside

A A

Curb Detail

14.0"

or

24.0"

A–A

2.0"

Typ.

4.0"

2"×4"

Nailer

Figure 4: Roof Curb Assembly (DPS 016–028)1

LEFT SIDE

B

RETURN

AIR

D

D

SUPPLY

AIR

E

MeChanICal InsTallaTIon

BACK SIDE

A

E

F

C

A

RIGHT SIDE

FRONT SIDE

NOTE: 1. Check submittal drawing for gas/water/electrical/supply/return air opening

2. Horizontal above the roof gas connection only

3. All dimensions in inches

Standard Roof Curb – Large Cabinet

Roof Curb for ERW – Large Cabinet

www.DaikinApplied.com 9 IM 1125-7 • REBEL ROOFTOPS

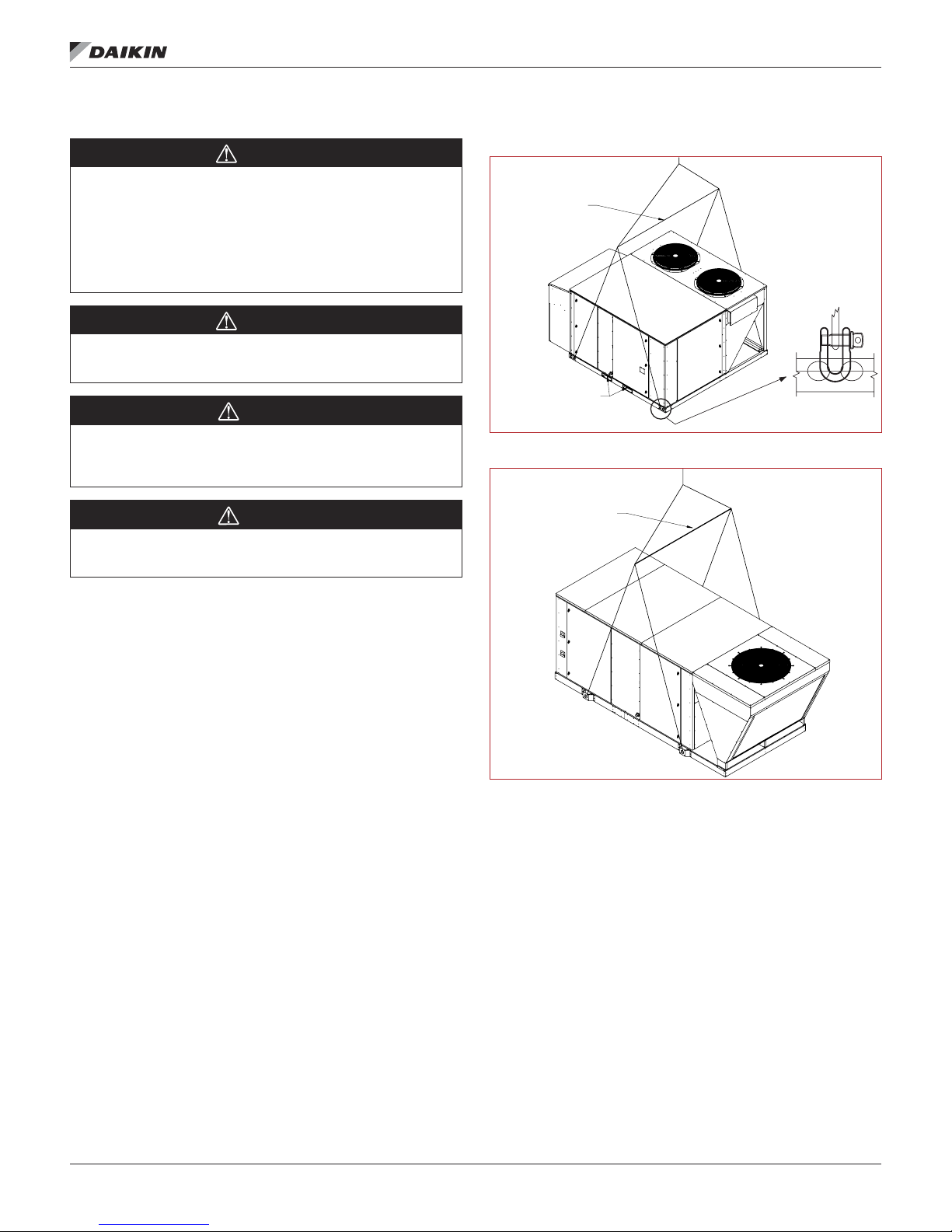

Rigging and Handling

WARNING

Only trained and qualified personnel should be allowed

to rig loads or operate load rated cranes and/or hoist

assemblies. Do not use a forklift to lift or maneuver the

unit. Failure to use a load rated crane or hoist assembly

to lift or maneuver the unit can cause severe personal

injury and property damage.

WARNING

Use all lifting points. Improper lifting can cause property

damage, severe personal injury, or death.

CAUTION

Lifting points may not be symmetrical to the center

of gravity of the unit. Ballast or unequal cable lengths

may be required.

Figure 5: Rigging Label 003–015

LIFT ONLY AS SHOWN

USE SPREADER BAR

REMOVE THE FORKLIFT

CHANNELS BEFORE

SETTING THE UNIT ON

THE ROOF CURB

Figure 6: Rigging Label 016–028

LIFT ONLY AS SHOWN

MeChanICal InsTallaTIon

CAUTION

Unit is equipped with fork slot reenforcement pieces.

These need to be removed before unit is set on the curb.

Rigging holes for shackles are integral on the unit base. Use

four independent lines, securing one end of a line to a

unit base lifting point and the other end of the line to an

associated spreader bar lifting point. Figure 5 and Figure 6

are examples of instruction labels shipped with each unit.

Use spreader bars to prevent damage to the unit cabinet. Avoid

twisting or uneven lifting of the unit. The cable length from the

bracket to the hook should always be longer than the distance

between the outer lifting points.

If the unit is stored at the construction site for an intermediate

period, take these additional precautions:

1. Support the unit well along the length of the base rail.

2. Level the unit (no twists or uneven ground surface).

3. Provide proper drainage around the unit to prevent

ooding of the equipment.

4. Provide adequate protection from vandalism, mechanical

contact, etc.

5. Securely close the doors.

6. Cover the supply and return air openings.

USE SPREADER BAR

IM 1125-7 • REBEL ROOFTOPS 10 www.DaikinApplied.com

MeChanICal InsTallaTIon

Table 2: Physical Data—Unit Weights DPS 003 through 028

Model

003 004 005 006 007 010 012 015

Weight (lbs.)

Base Weight

1

1000 1000 1025 1058 1600 1600 1600 1763

Heat pump 1030 1030 1058 1058 1660 1660 1660 1823

Electric Heat 45 45 45 45 100 100 100 100

Hot Water 2 Row 11 11 11 16.5 30 30 30 30

Hot Water 1 Row 32 32 32 20 31 31 31 31

Gas Heat 75 75 63 93 186 186 186 186

Hot Gas Re-heat 8 8 12 12 28 31 31 31

Economizer 163 163 163 163 308 308 308 308

High capacity coil 105 105 105 105 215 215 215 215

Energy Wheel Weight Adds (lbs.)

100% OA 160 160 160 160 300 300 300 300

Mixed Air 175 175 175 175 250 250 250 250

1. Includes standard cooling coil

Small Cabinet Medium Cabinet

Model

Base Weight (in lbs.) 2,465 2,575 2,700

Heat Pump — — — — —

Electric Heat 228

1-row 60

Hot Water Heat

Gas Heat

Hot Gas Reheat 30

Economizer 500

ERW – Small 350

ERW – Large 400

Indoor Fan

Indoor Fan Motors

Exhaust Fan 250

2-row 100

3-row 140

016 018 020 025 028

300 175

450 225

600 275

16" 100

20" 150

24" 260

1 36

1.5 41

2 40

3 69

5 84

7.5 11 5

10 128

15 211

20 225

Large Cabinet

Size 3–15 Fan Weights (lbs.)

12 (in) 87

14 (in) 91

16 (in) 115

18 (in) 87

20 (in) 91

22 (in) 115

Curb Weights (lbs.) 14" 24"

003—006 156 230

007—015 200 295

016—028 566 657

Table 3: Refrigerant Charge

Unit Size

3 10.5 12.9 12.0 14.4

4 11.1 13.5 12.6 15.0

5 15.3 18.2 16.8 19.7

6 15.3 18.2 16.8 19.7

7.5 11.0 17.3 26.0 31.2

10 34.0 39.8 40.0 45.8

12 34.0 39.8 40.0 45.8

15 37.0 43.8 42.0 47.8

16 37.0

18 37.0

20 37.0

25 35.5

28 35.5

Cooling Model Heat Pump Model

Standard Unit

Standard Unit

w/ MHGRH

Standard Unit

Consult Factory

Standard Unit

w/ MHGRH

www.DaikinApplied.com 11 IM 1125-7 • REBEL ROOFTOPS

Static Pressure (P)

Actuator

MeChanICal InsTallaTIon

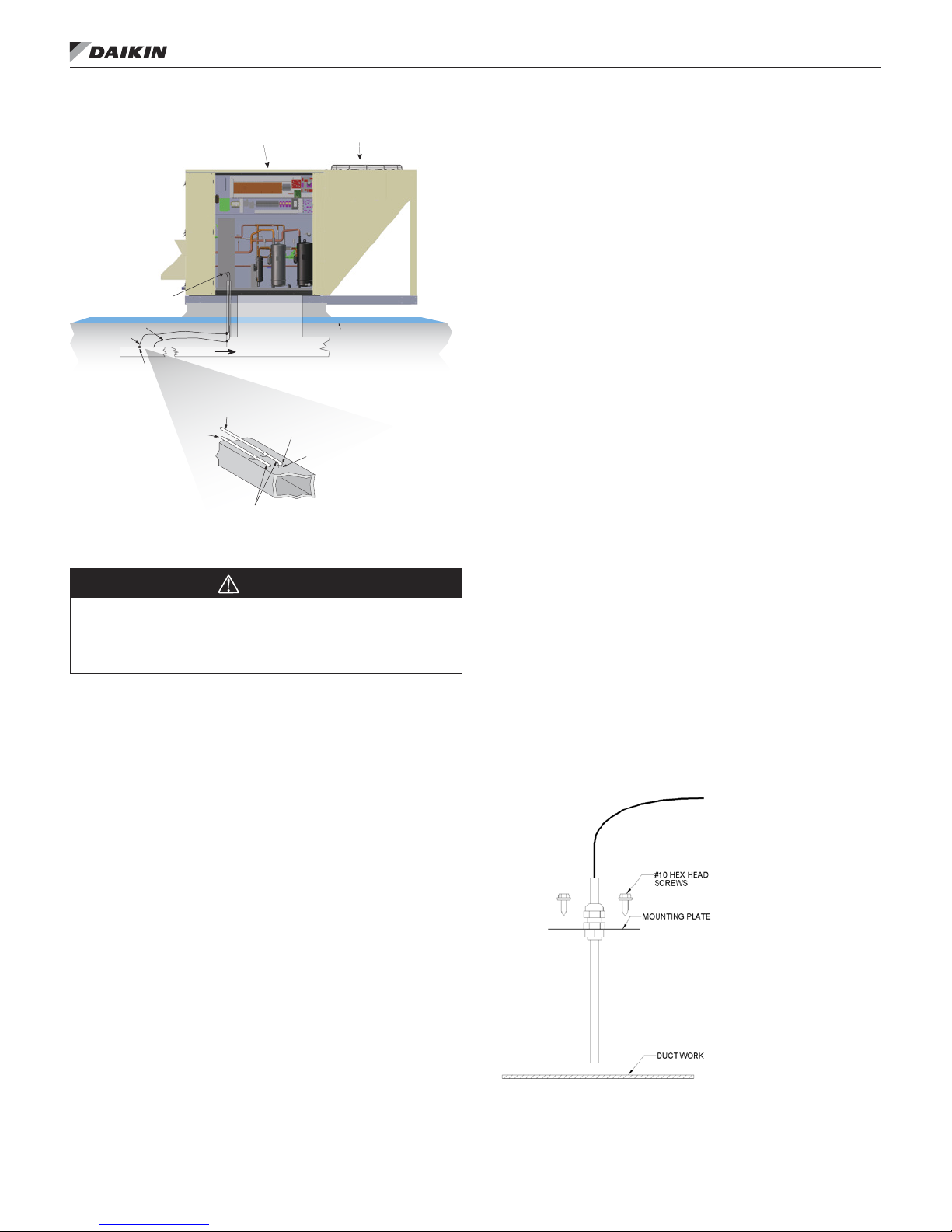

Unit Piping - Condensate Drain Connection

WARNING

Drain pans must be cleaned periodically. Material in

uncleaned drain pans can cause disease. Cleaning

should be performed by qualified personnel.

The unit is provided with a condensate drain connection, a 3/4"

male NPT for 003–015 units and a 1" male NPT for 016–028

units. For proper drainage, level the unit and drain pan side to

side and install a P-trap.

Figure 7 shows the layout of the condensate drain connection.

The distance from the drain pan outlet to the horizontal run of

the P-trap should be a distance of twice the static pressure in

the drain pan.

Example: If the static pressure as measured in the drain pan

is 1.5", then the distance between the drain outlet and the

horizontal run should be 3".

Draining condensate directly onto the roof may be acceptable;

refer to local codes. Provide a small drip pad of stone, mortar,

wood, or metal to protect the roof against possible damage.

If condensate is piped into the building drainage system, pitch

the drain line away from the unit a minimum of 1/8" per foot.

The drain line must penetrate the roof external to the unit.

Refer to local codes for additional requirements. Sealed drain

lines require venting to provide proper condensate ow.

Periodically clean to prevent microbial growth/algae buildup

from plugging the drain and causing the drain pan to overow.

Clean drain pans to prevent the spread of disease. Cleaning

should be performed by qualied personnel.

Damper Assemblies

The optional damper assemblies described in this section

are ordered with factory-installed actuators and linkages.

The following sections describe the operation and linkage

adjustment of the factory option.

Figure 8: Damper Assembly

Linkage

Figure 7: Condensate Drain Connection

at the Drain Pan

Economizer Dampers

As the single actuator modulates, the outside air dampers

open, the return air dampers close, and the exhaust air exits

the unit through the gravity relief dampers.

The economizer comes with manually adjustable linkage (Figure

8). The damper is set so that the crank-arm moves through

a 90-degree angle to bring the economizer dampers from full

open to full close. Mechanical stops are placed in the crank-arm

mounting bracket. Do not remove stops. Driving the crank-arm

past the stops results in damage to the linkage or damper.

Outdoor Air Dampers (0% to 30%)

These dampers are intended to remain at a xed position during

unit operation, providing fresh air quantities from 0 to 30% of the

total system airow, depending on the damper setting.

The damper position may be set at the unit controller keypad

(refer to OM 1141 for further detail). During unit operation, the

damper is driven to the position set at the unit controller. During

the OFF cycle, the damper is automatically closed.

IM 1125-7 • REBEL ROOFTOPS 12 www.DaikinApplied.com

MeChanICal InsTallaTIon

Cabinet Weather Protection

CAUTION

Transportation, rigging, or maintenance can damage

the unit’s weather seal. Periodically inspect the unit

for leakage. Standing moisture can promote microbial

growth, disease, or damage to the equipment and

building.

This unit ships from the factory with fully gasketed access

doors and cabinet caulking to provide weather resistant

operation. After the unit is set in place, inspect all door gaskets

for shipping damage and replace if necessary.

Protect the unit from overhead runoff from overhangs or other

such structures.

Installing Ductwork

WARNING

Mold can cause personal injury. Materials such as

gypsum wall board can promote mold growth when

damp. Such materials must be protected from moisture

that can enter units during maintenance or normal

operation.

On vertical-supply/vertical-return units, if a Daikin roof curb

is not used, the installing contractor should make an airtight

connection by attaching eld fabricated duct collars to the

bottom surface of the unit’s duct opening. Do not support the

total weight of the duct work from the unit.

Use exible connections between the unit and ductwork to

avoid transmission of vibration from the unit to the structure.

To minimize losses and sound transmission, design duct work

per ASHRAE and SMACNA recommendations.

Where return air ducts are not required, connect a sound

absorbing T or L section to the unit return to reduce noise

transmission to the occupied space.

Ductwork exposed to outdoor conditions must be built in

accordance with ASHRAE and SMACNA recommendations

and local building codes.

Table 4: AHRI CFM Ratings

Unit Size AHRI Rated CFM Unit Size AHRI Rated CFM

3 1140 15 4690

4 1550 16 Consult Factory

5 1810 18 Consult Factory

6 2310 20 7315

7.5 2885 25 8180

10 3850 28 8200

12 4620

Installing Duct Static Pressure Sensor Taps

For all VAV units, duct static pressure taps must be eld

installed and connected to the static pressure sensor 1 (SPS1)

in the unit. Sensor SPS1 is standard on VAV units and is

located in the main control panel.

Carefully locate and install the duct static pressure sensing

tap. Improperly locating or installing the sensing tap causes

unsatisfactory operation of the entire variable air volume

system. Below are pressure tap location and installation

recommendations. The installation must comply with local code

requirements.

1. Install a tee tting with a leak-tight removable cap in each

tube near the sensor tting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2. Use different colored tubing for the duct pressure (HI)

and reference pressure (LO) taps, or tag the tubes.

Daikin recommends 3/16" ID tubing.

3. Locate the duct pressure (HI) tap near the end of a long

duct to ensure that all terminal box take-offs along the

run have adequate static pressure.

4. Locate the duct tap in a nonturbulent ow area of the

duct. Keep it several duct diameters away from take-off

points, bends, neckdowns, attenuators, vanes, or other

irregularities.

5. Use a static pressure tip (Dwyer A302 or equivalent) or

the bare end of the plastic tubing for the duct tap. (If the

duct is lined inside, use a static pressure tip device.)

6. Install the duct tap so that it senses only static pressure

(not velocity pressure). If a bare tube end is used,

it must be smooth, square (not cut at an angle) and

perpendicular to the airstream (see Figure 10).

7. Locate the reference pressure (LO) tap near the duct

pressure tap within the building. If the tap is not connected

to the sensor, unsatisfactory operation will result.

8. Route the tubes through the curb and feed them into the

unit through the knockout in the bottom of the control

panel (see Figure 9). Connect the tubes to appropriate

barbed ttings (on SPS1) in the control panel. (Fittings

are sized to accept 3/16" ID tubing.)

Figure 9: Typical Wiring Chase, Size 007–015 shown

Field

Wiring

Block

Behind

Panel

Utility

Chase

www.DaikinApplied.com 13 IM 1125-7 • REBEL ROOFTOPS

MeChanICal InsTallaTIon

Figure 10: Duct Static Pressure Sensing Tubing Installation

Condenser Sec tion

Roof

Ductwork

(RemoteLocation)

Tubing Extends

Through Approx.3/16"

SPS1

LO Line

HI Line

Remote Sense Po int

To Sensor

LO Input

Main ControlPanel

To Sensor

HI Input

PressureSensing

Tubing

Rubber

Grommet

Installing Building Static Pressure Sensor Taps

CAUTION

Fragile sensor fittings. If you must remove tubing

from a pressure sensor fitting, use care. Do not use

excessive force or wrench the tubing back and forth to

remove or the fitting can break off and damage sensor.

If a unit has building static pressure control capability, you

must eld install and connect static pressure taps to the static

pressure sensor SPS2 in the unit. This sensor is located at the

bottom of the main control panel next to SPS1.

Carefully locate and install the two static pressure sensing

taps. Improper location or installation of the sensor taps causes

unsatisfactory operation. Below are pressure tap location and

installation recommendations for both building envelope and

lab, or “space within a space” pressure control applications.

The installation must comply with local code requirements.

3. Locate the building tap so it is not inuenced by any

source of moving air (velocity pressure). These sources

may include air diffusers or outside doors.

4. Route the building tap tube through the curb and feed

it into the unit through the knockout in the bottom of the

control panel (refer to Figure 9). Connect the 3/16" ID

tube to the (high) tting for sensor SPS2.

5. Locate the reference pressure (low) tap on the roof.

Keep it away from the condenser fans, walls, or anything

else that may cause air turbulence. Mount it high

enough above the roof so it is not affected by snow. Not

connecting the reference tap to the sensor results in

unsatisfactory operation.

6. Use an outdoor static pressure tip (Dwyer A306 or

equivalent) to minimize the adverse effects of wind.

Place some type of screen over the sensor to keep out

insects. Loosely packed cotton works well.

7. Route the outdoor tap tube out of the main control panel

through a small eld-cut opening in the upright. Seal the

penetration to prevent water from entering. Connect the

3/16" ID tube to the (low) tting for sensor SPS2.

Discharge Air Temperature Sensor

The discharge air temperature sensor must be installed in the

discharge air duct, downstream of the rooftop unit. Locate the

sensor in a location that closely approximates the average

duct temperature. To avoid the effects of radiation, the sensor

should not be in the line-of-sight of a gas furnace or electric

heater. Generally, locate sensor in the center of a duct wall,

5′ – 10′ from unit opening to allow for air mixing. Do not mount

down stream of VAV boxes or other dampers.

Installation: Drill 7/8" diameter hole in duct, insert sensor probe

and secure plate to duct with 2 – #10 screws. Be sure to apply

gasket or silicone sealant to back of mounting plate prior to

screwing plate to the duct to create an air-tight seal.

Figure 11: Discharge Air Temperature Sensor Installation

Building Pressurization Applications

1. Install a tee tting with a leak-tight removable cap in each

tube near the sensor tting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2. Locate the building pressure (high) tap in the area that

requires the closest control. Typically, this is a ground

level oor that has doors to the outside.

IM 1125-7 • REBEL ROOFTOPS 14 www.DaikinApplied.com

DANGER

Hazardous voltage. Can cause severe injury or

death.

Disconnect electric power before servicing equipment.

More than one disconnect may be required to deenergize the unit.

WARNING

Provide proper line voltage and phase balance.

Improper line voltage or excessive phase imbalance

constitutes product abuse. It can cause severe damage

to the unit’s electrical components.

WARNING

Electrical shock hazard. Can cause severe injury or

death.

Connect only low voltage NEC Class II circuits to

terminal block TB2.

DANGER

Overheating or failure of the gas supply to shut off can

cause equipment damage, severe personal injury or

death. Turn off the manual gas valve to the appliance before

shutting off the electrical supply.

eleCTrICal InsTallaTIon

eleCTrICal InsTallaTIon

Pre-Construction

The Rebel unit comes equipped with a Microtech III controller

and can be used for sites that are still under construction. The

following conditions must be met.

1. Ductwork has to be installed. The fan proving switch

and furnace might not run correctly without the specied

external static pressure

2. Filters must be installed.

3. Follow furnace commissioning instructions found in the

furnace section.

4. After substantial completion of the construction process

the unit is to be thoroughly cleaned. Special attention

should be paid to the indoor DX coil and the furnace.

Filters should be changed

5. Furnace operation, rate, and temperature rise should be

re-veried. See instructions found in the furnace section.

Lab Pressurization Applications

1. Install a “T” tting with a leak-tight removable cap in each

tube near the sensor tting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2. Use different colored tubing for the controlled space

pressure (high) and reference pressure (low) taps, or tag

the tubes.

3. Regardless whether the controlled space is positive or

negative with respect to its reference, locate the high

pressure tap in the controlled space (the setpoint can be

set between -0.2" and 0.2" wc).

4. Locate the reference pressure (low) tap in the area

surrounding the controlled space. Not locating the

reference tap to the sensor results in unsatisfactory

operation.

5. Locate both taps so they are not inuenced by any source

of moving air (velocity pressure). These sources may

include air diffusers or doors between the high and low

pressure areas.

6. Route the building tap tube between the curb and the

supply duct and feed it into the unit through the knockout

in the bottom of the control panel.

7. Connect the tube to the (high) tting for sensor SPS2.

www.DaikinApplied.com 15 IM 1125-7 • REBEL ROOFTOPS

eleCTrICal InsTallaTIon

Electrostatic Discharge (ESD)

Disconnect Power to the Rebel Rooftop Unit prior to

inspecting and/or repairing.

When inspecting/repairing Rebel Rooftop units the technician or

building owner must take precautions to ground themselves to

the unit. This will prevent them from damaging the circuit boards

mounted inside the inverter box and main control panel.

Electrostatic Discharge (ESD) can damage components in a

manner that is not always readably detectable. A static potential

can easily be generated on a person that reaches 25 kVolts. If

this potential is discharged into one of the unit’s circuit boards it

can degrade part of the current carrying conductors inside. This

is the conceptual equivalent of reducing 16 gage wires to 18.

The component will still operate initially, but will have a much

shorter life span due to overheating of the conductor.

In order to prevent ESD from the technician to the unit they

must both be at the same potential. First the technician must

ground themselves to the unit; this can be achieved by touching

any galvanized (not painted) section of the unit. The unit’s base

rail and refrigerant piping are both reliable options. The next

step is to attach a grounded wrist or ankle strap to the copper

tubing. This grounding strap must have direct contact with the

technician’s skin. Once this has been done the technician is free

to work on electrical components in side the unit.

Although ESD is partially dependent on humidity, at levels

above 50% it is a greatly reduced risk, good practices should

always be observed.

All Units

Wiring must comply with all applicable codes and ordinances.

The warranty is voided if wiring is not in accordance with these

specications.

According to the National Electrical Code, a disconnecting

means shall be located within sight of and readily accessible

from the air conditioning equipment. The unit can be ordered

with an optional factory mounted disconnect switch. This switch

is not fused. Power leads must be over-current protected at the

point of distribution. The maximum rated overcurrent protection

device (MROPD) value appears on the unit nameplate.

All units are provided with internal power wiring for single point

power connection. The power block or an optional disconnect

switch is located within the main control panel. Field power leads

are brought into the unit through knockouts in the bottom of the

main control panel (see Figure 9 and also Table 5). Refer to the

unit nameplate to determine the number of power connections.

NOTE: To wire entry points, refer to certied drawings for

dimensions.

Table 5: Recommended Field Power Wiring

Ampacity (MCA)

20 1 14 75

25 1 12 75

35 1 10 75

50 1 8 75

65 1 6 75

85 1 4 75

100 1 3 75

115 1 2 75

130 1 1 75

150 1 1/0 75

175 1 2/0 75

200 1 3/0 75

230 1 4/0 75

255 1 250 75

NOTE:

1. All wire sizes assu me separ ate conduit for ea ch set of pa rallel c onduc tors.

2. All wi re sizes based on NEC Table 310-16 for 75°C THW wire (copper). Cana dian

elect rical c ode wire ampacities may vary.

3. All wi re sizes as sume no vo ltage dr op for short power leads .

Number of Power

Wires Per Phase

Wire Gauge

Insulation

Temperature

Rating (°C)

IM 1125-7 • REBEL ROOFTOPS 16 www.DaikinApplied.com

eleCTrICal InsTallaTIon

WARNING

Provide proper line voltage and phase balance.

Improper line voltage or excessive phase imbalance

constitutes product abuse. It can cause severe damage

to the unit’s electrical components.

WARNING

Electrical shock hazard. Can cause severe injury or

death.

Connect only low voltage NEC Class II circuits to

terminal block TB2.

DANGER

Overheating or failure of the gas supply to shut off can

cause equipment damage, severe personal injury or

death. Turn off the manual gas valve to the appliance before

shutting off the electrical supply.

The preferred entrance for power cables is through the bottom

knockouts provided on the unit. If a side entrance is the only

option, a hole may be drilled in the stationary upright.

The minimum circuit ampacity (MCA) is shown on the unit

nameplate. Refer to Table 5 for the recommended number of

power wires.

Copper wire is required for all conductors. Size wires in

accordance with the ampacity tables in Article 310 of the

National Electrical Code. If long wires are required, it may be

necessary to increase the wire size to prevent excessive voltage

drop. Wires should be sized for a maximum of 3% voltage drop.

Supply voltage must not vary by more than 10% of nameplate.

Phase voltage imbalance must not exceed 2%. (Calculate the

average voltage of the three legs. The leg with voltage deviating

the farthest from the average value must not be more than

2% away.) Contact the local power company for correction of

improper voltage or phase imbalance.

The power source to the unit must be a balanced 3-phase power

supply, meaning that the voltage and impedance to the line is

matched. Under normal conditions, a balanced power supply

will result in balanced current phase-to-phase. Unbalanced

voltage and/or current (such as provided with an "Open Delta"

conguration), is likely to result in nuisance alarms, premature

failure of components and it will void equipment warranty.

A ground lug is provided in the control panel. Size the grounding

conductor in accordance with Table 250-95 of the National

Electrical Code.

In compliance with the National Electrical Code, a 115 V factory

mounted service receptacle outlet is provided. This outlet must

be powered by a eld connected 15 A, 115 V power supply.

Leads are brought into the unit through the bottom of the main

control panel.

Field Control Wiring

The Rebel rooftop units are available with the following eld

control connections:

• Space sensor.

• Space sensor with setpoint adjustment.

• Fan operation output.

• VAV box output.

• Remote alarm output.

• External discharge air temperature reset.

• Outdoor air damper minimum position adjustment.

Descriptions of these eld connections are included in the

MicroTech III Unit Controller Manual (OM 1141).

Start-up and service of this equipment must be performed

by trained and experienced technicians. It is highly

recommended that the initial start-up and future service be

performed by Daikin trained technicians who are familiar with

working on live equipment. A representative of the owner or the

operator of the equipment should be present during start-up to

receive instructions in the operation, care and adjustment of

the unit.

Before Start-Up

1. Notify inspectors or representatives who may be required to

be present during start-up of gas fuel equipment. These could

include the gas utility company, city gas inspectors, heating

inspectors, etc.

2. Review the equipment and service literature and become

familiar with the location and purpose of the furnace controls.

Determine where the gas and power can be turned off at the

unit and before the unit.

3. Determine that power is connected to the unit and available.

4. Determine that the gas piping, meter, and service regulator

have been installed, tested, and meet the equipment

requirements.

5. Determine that proper instruments will be available for the

start-up. A proper start-up requires the following: voltmeter,

manometer or gauges with ranges for both manifold pressure

and inlet gas pressure.

www.DaikinApplied.com 17 IM 1125-7 • REBEL ROOFTOPS

eleCTrICal InsTallaTIon

Table 6: 003–015 Electric Heat Data

kW Voltage Amps kW Voltage Amps

208 16.7

6

12

18

30

NOTE: 1. Maximum temperature rise equals 60ºF

230 15.1 230 90.4

475 7.3 475 43.8

575 6.0 575 36.1

208 33.3

230 30.1 230 135.6

475 14.6 475 65.6

575 12.0 575 54.2

208 50.0

230 45.2 230 N/A

475 21.9 475 87.5

575 18.1 575 72.3

208 83.3

230 75.3

475 36.5

575 30.1

1

208 99.9

36

208 149.9

54

208 N/A

72

Table 7: DPS 016–028 Electric Heat Data

KW Voltage Amps KW Voltage Amps

208 83.4

30

45

60

230 75.4 230 226.2

460 37.7 460 113.1

575 30.2 575 90.5

208 125.1

230 113.1 230 301.6

460 56.5 460 150.8

575 45.2 575 120.6

208 166.7

230 150.8 230 377.0

460 75.4 460 188.5

575 60.3 575 150.8

90

120

150

208 250.1

208 333.5

208 416.9

Table 8: Amp Draw Data

Unit

Size

(Tons)

3 7.7 7.0 3.5 — 45% 0.0 0.0 0.0 —

4 10.0 9.0 4.5 — 55% 0.0 0.0 0.0 — 0.0 0.0 0.0 — 1 0.9 0.8 0.4

5 11.9 10.8 5.4 — 68% 0.0 0.0 0.0 — 0.0 0.0 0.0 — 1 2.0 1.8 0.9

6 15.0 13.6 6.8 — 89% 0.0 0.0 0.0 — 0.0 0.0 0.0 — 1 2.0 1.8 0.9

7.5 11.9 10.8 5.4 — 68% 8.6 7.8 3.9 — 67.5 73.7 37.1 — 2 2.0 1.8 0.9

10 10.0 9.0 4.5 — 59% 17.5 15.8 7.9 — 93.1 84.2 42.1 — 2 2.0 1.8 0.9

12 15.0 13.6 6.8 — 89% 17.5 15.8 7.9 — 93.1 84.2 42.1 — 2 2.0 1.8 0.9

15 28.3 25.6 12.8 — 100% 17.5 15.8 7.9 — 93.1 84.2 42.1 — 2 2.0 1.8 0.9

16 47.0 42.5 22.9 20.5 — 0 0 0 0

18 47.0 42.5 22.9 20.5 — 0 0 0 0 1 8.0 8.0 4.0

20 47.0 42.5 22.9 20.5 — 0 0 0 0 1 8.0 8.0 4.0

25 47.0 42.5 22.9 20.5 — 39.1 35.4 18.6 15.4 1 8.0 8.0 4.0

28 47.0 42.5 22.9 20.5 — 39.1 35.4 18.6 15.4 1 8.0 8.0 4.0

NOTE: The inverte r compr esor is c ontro lled to have a s oft start and a n LRA <1.0

Horse

Power

NOTE: DPS 0 07–015 575 V Amp Draws: Compressor s and moto rs will b e run of f a 575 to 460V transformer. Motors will be nameplated at 46 0V.

Compressor 1 - Variable Compressor 2 - Fixed Compressor 1 Compressor 2

208 230 460 575 [%] 208 230 460 575 208 230 460 575 208 230 460 575

Supply Fan FLA (DPS 003–015) Exhaust Fan FLA (DPS 003–028) Supply Fan FLA (016–028)

208 230 460 kW 208 230 460 kW 208 230 460 575

1.3 3.1 2.8 1.4 1.0 3.1 2.8 1.4 1.0 — — — —

2.3 5 4.6 2.3 1.7 5 4.6 2.3 1.7 — — — —

3 — — — — — — — — 9.9 9.0 4.5 3.4

4 8.8 7.4 4.0 3.0 8.8 7.4 4.0 3.0 — — — —

5 — — — — — — — — 16.1 14.0 7.0 5.3

7.5 — — — — — — — — 25.0 21.6 10.8 8.2

8 13.5 12.2 6.1 6.0 — — — — — — — —

10 — — — — — — — — 33.0 28.0 14.0 11.0

15 — — — — — — — — 44.8 40.6 20.3 16.2

20 — — — — — — — — 61.0 50.0 25.0 20.0

EAF FL A are per motor. Some D PS 016– 028 units have (2) EAFs a nd motor s.

Compressor RLA Compressor LRA

0.0 0.0 0.0 — 1 0.9 0.8 0.4

See Note

See Note

Voltage Voltage Voltage

Condenser Fan

FLA Each

Qty 208 230 460Voltage Voltage Voltage Voltage

1 8.0 8.0 4.0

IM 1125-7 • REBEL ROOFTOPS 18 www.DaikinApplied.com

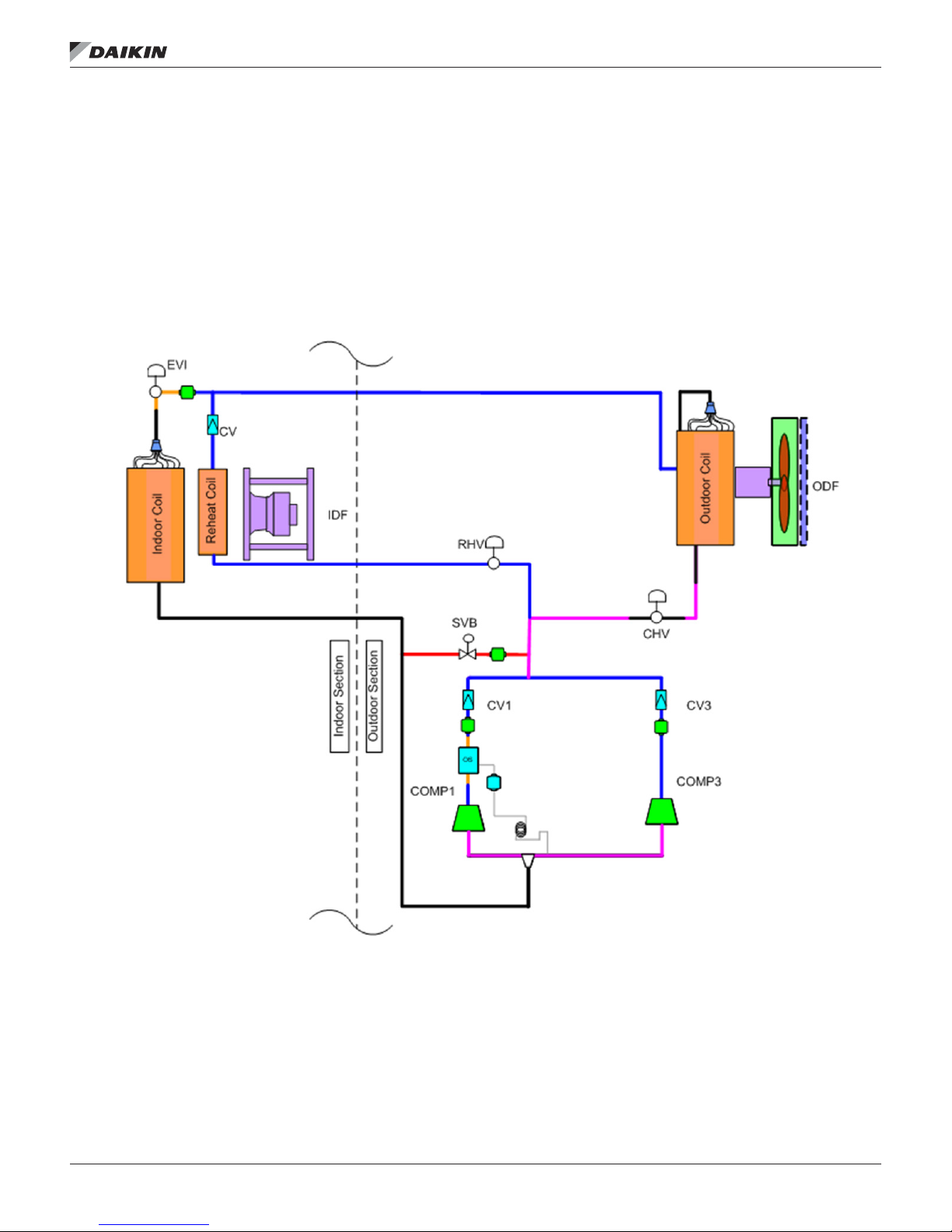

Piping System

The Rebel piping system varies signicantly between the

multiple possible congurations; heat pump, cooling only, and

modulating hot gas reheat. In spite of this multiplicity there

are some consistent characteristics. All units have a single

circuit with a single or tandem compressor. All units use

an electronic expansion valve (EVI) and a start-up by pass

solenoid valve (SVB).

Figure 12: Typical Refrigeration Circuit for Cooling Only Unit with

Modulating Hot Gas Reheat (DPS 007–015 shown)

refrIgeraTIon sysTeM

refrIgeraTIon sysTeM

www.DaikinApplied.com 19 IM 1125-7 • REBEL ROOFTOPS

refrIgeraTIon sysTeM

Figure 13: Typical Refrigeration Circuit for Heat Pump Unit with Modulating Hot Gas Reheat (DPS 007–015 shown)

Item Description

EVI

EVO

CV Check Valve, size 3-15 only

REC Refrigerant Receiver

IDF Indoor fan

ODF Outdoor fan

COMP1 Inverter compressor

COMP3

SVB Bypass solenoid valve

RHV Reheat step valve

SVR Receiver solenoid valve

CHV Condenser step valve

OVI

4WV 4-way heat pump valve

OS Oil separator, size 3-15 only

Indoor coil electronic

expansion valve

Outdoor coil electronic

expansion valve

Fixed speed compressor

(7½ thru 15 ton and 25-28

only)

Outdoor electronic

expansion valve

IM 1125-7 • REBEL ROOFTOPS 20 www.DaikinApplied.com

DPS 003–015 Component Description

refrIgeraTIon sysTeM

Variable Speed Compressor

A variable speed compressor (COMP1) is used on all DPS(H)

003–015. On small cabinet units (3–6 Tons) the variable speed

compressor will be the only one present. On medium cabinet

units (7–15 Tons) the variable speed compressor will be on the

left. The discharge of the variable speed compressor is located

on the side and the suction is located on the top.

These pipes can also be identied by recalling that suction

lines will always be larger than discharge lines. The side

discharge design is used to create a positively pressurized

crank case that returns oil to the scroll set even during low turn

down conditions.

Figure 14: Compressor Suction and Discharge on Medium

Cabinet (7.5T) Heat Pump (DPH)

Compressor Suction Line

Compressor Discharge Line

Receiver

Only Rebel Heat Pump units will have a receiver. Different

volumes of refrigerant are required inside the system during

Mechanical Cooling (or defrost) and Mechanical Heating.

This is the results of the charge in operating temperatures in

Cooling and Heating Mode. The receiver stores the excess

refrigerant upstream, in Cooling Mode, of the Indoor Expansion

Valve (EVI). Three refrigerant lines connect to the receiver.

In cooling mode the refrigerant leaves (Cooling Mode) the

receiver from the bottom connection on its way to the Indoor

Expansion Valve (EVI). The refrigerant enters the receiver

by the middle connection from the Outdoor Expansion Valve

(EVO). The top connection is linked to the Receiver Solenoid

Valve (SVR) and is used to bleed refrigerant vapor out of the

top of the vessel during the change over from Mechanical

Heating to Cooling Mode (or defrost).

In heating mode the refrigerant ow path will be reversed and

will enter the receiver at the bottom connection on its way from

EVI. The refrigerant will leave the receiver from the middle

connection towards EVO. The top connection will always

be a vapor bleed connected to SVR regardless of the units

operating mode.

Figure 16: Receiver on Medium Cabinet (7.5T) Heat Pump

(DPH)

Fixed Speed Compressor (7–15 Only)

The xed speed compressor (COMP3) is used on all medium

cabinet (7–15 Ton), DPS, units. This compressor will always be

located on the right and like the variable speed has the suction

line on the top of the dome entering the scrolls and a discharge

exiting from the side of the shell.

Figure 15: Compressor Tandem on Medium Cabinet

Variable Speed

Compressor

(COMP 1)

Fixed Speed

Compressor

(COMP 3)

“Vapor Bleed”

leading to SVR

Entering Receiver

from Outdoor Coil

(Cooling Mode)

Leaving Receiver

to EVI

(Cooling Mode)

www.DaikinApplied.com 21 IM 1125-7 • REBEL ROOFTOPS

refrIgeraTIon sysTeM

Oil Separator

All DPS(H) 003–015 units will have an oil separator on the

discharge line of the compressor. This device will remove

oil from the compressor discharge gas and return it to the

compressor suction line. The oil separator has three lines

entering it. The connection on the side of the compressor

is where the discharge gas enters. The hot gas continues

on to the Outdoor Coil from the connection on the top of the

separator. On the bottom is a small drain through which the

oil returns after separation to the compressor suction. The

refrigerant and oil path through the separator will not change

depending on Heating or Cooling Mode.

Figure 17: Oil Separator

Hot Gas

Entering

Outdoor Coil

Check Valve

All DPS 003–015 will have check valves on each of the

compressor discharge lines. On medium cabinet units

(7–15 Tons), two valves, one on each compressor, prevent

recirculation of refrigerant during part load conditions. On

small cabinet units (3–6 Tons) a single check valve prevents

migration of refrigerant into the scrolls during off cycles.

Figure 19: Discharge Line Check Valves on Large Cabinet

(7.5T) Heat Pump (DPH)

Y-Joint connecting

COMP1 and COMP2

Discharge

CAUTION!

Correct Orientation

Must Be Observed

Discharge Gas

from Compressor

Oil Drain into

Compressor

Suction Line

Figure 18: Secondary Oil Separator

Secondary

Oil Separator

Direction of

Compressor

Discharge Gas

IM 1125-7 • REBEL ROOFTOPS 22 www.DaikinApplied.com

refrIgeraTIon sysTeM

High Pressure Switch

All Rebel Units will have a high pressure switch on each

compressor. Medium cabinet units (7–15 Tons) will have an

HP1 switch on the variable speed compressor (COMP1) and a

HP3 on the xed speed compressor (COMP3). These switches

are normally closed devices that are brazed directly to the

refrigerant piping. When the pressure at the switch exceeds

580 PSIG the switch will open. This opening will interrupt the

control signal to the variable compressor drive or de-energize

the contactor coil on the xed speed compressor, both acts

will shut down the compressors and generate an alarm at the

MicroTech III keypad.

Figure 20: High Pressure Switch

High Pressure Switch

(HP1)

Four-Way Valve

The Four-Way Valve (4WV) also known as a Reversing Valve

is a component only used on Heat Pumps. This device is

used to direct the discharge gas from the compressor into the

outdoor coil (Heating Mode) or indoor coil (Cooing Mode). This

device is defaulted to cooling and when un-energized will direct

the discharge gas into the outdoor coil.

Figure 22: Four-Way Valve

Compressor Discharge Gas

Cooling Mode:

Suction Vapor from

Indoor Coil

Suction Vapor

to Compressor

Heating Mode:

Discharge Gas to

Indoor Coil

Refrigerant Screen

During manufacturing, service, and repair there is always the

potential for debris to accidentally enter the sealed refrigeration

system. Filter screens are positioned around the refrigerant

circuit to prevent any possible debris from entering critical

components; expansion valves, compressors, etc. These

screens are not bi-direction and must be installed in a specic

direction if replaced. Please be aware that these screens are

not desiccant lters and provide no moisture protection for

compromised systems.

Figure 21: Refrigerant Screen

Refrigerant Screen

Cooling Mode:

Discharge Gas to

Outdoor Coil

Heating Mode:

Suction Vapor from

Outdoor Coil

www.DaikinApplied.com 23 IM 1125-7 • REBEL ROOFTOPS

refrIgeraTIon sysTeM

By-Pass Solenoid Valve

The By-Pass Solenoid Valve (SVB) is used to “short-circuit”

the high pressure compressor discharge to the low pressure

suction side during start-up. This increases compressor

longevity by minimizing starting torque and inrush current.

Figure 23: By-pass Solenoid Valve

Short Circuit between

High Pressure Discharge

and Low Pressure Suction

By-Pass

Solenoid

Valve

Indoor Expansion Valve

The Indoor Expansion Valve (EVI) is a 12 VDC stepper motor

driven valve, used in heating and cooling mode. In cooling

mode EVI is used to expand the refrigerant entering the Indoor

Coil, operating as an evaporator, in much the same way as a

TXV on a conventional air conditioner. In heating mode the EVI

can operate in two different modes, congurable at the keypad.

When congured for Standard during heating mode the EVI

will modulate to fully open and remain in this position. When

congured for heating mode the EVI will modulate to maintain

the Subcooling Set-Point.

Figure 25: Indoor Expansion Valve

Indoor

Refrigerant

Temperature

Sensor (IRT)

Indoor

Expansion

Valve (EVI)

Receiver Solenoid Valve

The Receiver Solenoid Valve (SVR) is used to “bleed off”

refrigerant vapor from the top of the Receiver during pump

down or the transition between mechanical heating and

defrost. Cooling only units will not have this component, only

Heat Pumps .

Figure 24: Receiver Solenoid Valve

Receiver

Solenoid

Valve (EVI)

Vapor Bleed

from top of

Receiver to

Compressor

Suction

Outdoor Expansion Valve

The Outdoor Expansion Valve (EVO) is a 12 VDC stepper

motor driven valve, used in heating and cooling mode. Cooling

only units will not have this component, only Heat Pumps.

In heating mode the EVO is used to expand the refrigerant

entering the Outdoor Coil, which is now and evaporator,

in much the same way as a TXV on a conventional air

conditioner. In Cooling Mode the EVO can operate in two

different modes, congurable at the keypad. When congured

for Standard during Cooling Mode the EVO will modulate

to fully open and remain in this position. When congured

for Cooling Mode the EVO will modulate to maintain the

Subcooling Set-Point.

IM 1125-7 • REBEL ROOFTOPS 24 www.DaikinApplied.com

refrIgeraTIon sysTeM

Suction Pressure Transducer

The Suction Pressure Transducer (PTS) is a refrigerant

pressure sensor that screws onto a Schrader tting on the

suction line of the compressor deck. On single compressor

units (3–6T) this sensor is located on the suction line. On

tandem, two compressor units (7–15T), the PTS is located

upstream of the joint suction.

This sensor is used to ensure that the compressor does not

leave the operating envelope and is used to regulate the super

heat leaving the indoor coil and entering the compressor.

Discharge Pressure Transducer

The Discharge Pressure Transducer (PTD) is a refrigerant

pressure sensor that screws onto a Schrader tting on

the discharge line of the compressor system. On single

compressor units (3–6T) this sensor is located on the

discharge line. On tandem, two compressor units (7–15T), the

PTD is located down stream of the joint discharge.

This sensor is used to ensure that the compressor does not

leave the operating envelope and is used to regulate the

outdoor fan speed and maintain head pressure.

Discharge Refrigerant Temperature

All Rebel units will have a Discharge Refrigerant Temperature

Sensor (DRT1 / DRT3) on the discharge line of each

compressor. This sensor is attached the piping with a metal

clip and wrapped in insulation. The purpose of this device is to

increase compressor life by preventing it from running outside

of the operating envelope.

Outdoor Refrigerant Temperature

Only Rebel Heat Pumps units will have an Outdoor Refrigerant

Temperature Sensor (ORT). This sensor is used in Cooling

Mode when ClgEVOmethod is set to control subcooling. This

sensor is attached to the refrigerant piping upstream (Cooling

Mode) of the Outdoor Expansion Valve (EVO).

Figure 26: Outdoor Expansion Valve

Outdoor Expansion

Valve (EVI)

Outdoor

Refrigerant

Temperature

Sensor (ORT)

Defrost Temperature Sensor

Only Rebel Heat Pump, DPH, units will have a Defrost

Temperature Sensor (DFT). This sensor is used in Heating

Mode and Defrost Mode to determine the amount of frost

accumulated on the Outdoor Coil.

Suction Refrigerant Temperature

All Rebel units will have a Suction Refrigerant Temperature

Sensor (SRT). This sensor is located on the suction line. Unlike

DRT1 or 3 there is only one SRT for tandem compressor

units. This sensor is used to determine the suction super heat

entering the compressor and is the control input for the EVI in

cooling mode (EVO in heating mode).

Indoor Refrigerant Temperature

Only Rebel Heat Pump units will have an Indoor Refrigerant

Temperature Sensor (IRT). This sensor is used in Heating

Mode when htgEVImethod is set to control subcooling. This

sensor is attached to the refrigerant piping downstream

(Cooling Mode) of the Indoor Expansion Valve (EVI).

www.DaikinApplied.com 25 IM 1125-7 • REBEL ROOFTOPS

refrIgeraTIon sysTeM

Heating

The unit’s heating mode of operation is determined by the

control temperature and the heating setpoint temperature. The

unit enters the heating mode of operation by comparing the

control temperature to the heating setpoint.

The control temperature can be either the return temperature

or the space temperature.

The return temperature is typically used for VAV units and the

space temperature is typically used for CAV units.

The unit goes into the heating mode of operation when the

control temperature (return or space temperature) is below the

heating setpoint by more than ½ the deadband.

For example, a standard air conditioning unit with supplemental

gas, electric, or hot water heat with a heating setpoint of 68.0ºF

and a deadband of 1.0ºF would enter heating mode if the

control temperature reached 67.4ºF. When this takes place,

the heating mode of operation will begin and the 1st Stage of

heating operation will start.

Heat Pump

(DPS 003 –015 ton)

The heating mode of operations will be slightly different for heat

pump units. It is the manufacturer’s recommendation that all

Rebel heat pump units be purchased with supplemental gas,

electric, or hot water heat. When the control temperature drops

below the heating setpoint by half the deadband the unit will

energize the four way valve and initiate mechanical heating.

On heat pumps mechanical heating is the primary source of

heat and will always be the unit’s rst attempt to meet the

application’s load. After start-up the variable compressor

will ramp up to meet the DAT Setpoint. If the mechanical

heating capacity at the ambient conditions is capable of

meeting the building load the variable speed compressor will

stabilize at some value below its maximum speed. If the heat

pump’s capacity is insufcient at the ambient conditions the

supplemental (gas, electric, hot water) heat will be enabled and

gradually ramp/stage on to make up the capacity shortage.

If the combined capacity of the heat pump’s mechanical and

supplemental heating is greater than the building load the

supplemental supply will ramp/stage down. The unit will always

seek to operate with mechanical heating as much as possible.

Periodically during heating operations the unit will need to

enter defrost to remove frost build up from the outdoor coil.

During defrost mechanical heating will be unavailable and the

supplemental heat will ramp/stage up to meet the DAT set-point.

Defrost

(DPS 003 –015 ton)

Defrost is a temporary and infrequent period during normal

heating operations on Rebel heat pumps. The purpose of

defrost is to remove frost that has built up on the outdoor coil

during mechanical heating. In heating mode the outdoor coil

acts as an evaporator to “pull” heat out of the ambient air. As a

result the surface temperature of the outdoor coil is below the

ambient temperature and depending on conditions maybe below

freezing. During prolonged mechanical heating while the surface

temperature of the outdoor coil is below 32ºF frost will form.

The defrost operation is similar to mechanical cooling. In defrost

the four way valve will de-energize and the hot gas from the

compressor will be forced into the outdoor coil, rejecting heating

to the ambient, and melting any frost formed on the coil. To

speed up the melting process during a defrost cycle the OA

damper will close and the outdoor fan will de-energize. During

this period the supplemental (gas, electric, hot water) heat will

ramp/stage up to maintain the unit’s DAT Setpoint.

Rebel heat pump unit’s have demand based defrost control

and will operate in defrost only as long as necessary to remove

frost from the outdoor coil.

Charging

Rebel units have advanced charge management systems

that obsolete many common techniques for determining

over or under charged conditions. The charge management

system means that super heat and subcooling values will

oat to achieve the peak real time energy efciency possible

at current operating conditions (building load and ambient

temperature). Rebel units also use electronic expansion valves

that can not be adjusted manually. Refrigerant should never

be added or removed from the system based on the desire to

achieve an arbitrary subcooling value. It will always be Daikin's

recommendation that unit’s suspected of being over/under

charged have all of their refrigerant removed, leak tested with

nitrogen, and then re-charged based on the unit name plate.

Table 9: Refrigerant Charge

Unit Size

3C 10.5 12.9 12.0 14.4

3M 6.6 11.3

4C 11.1 13.5 12.6 15.0

4M 6.5 11.3

5 15.3 18.2 16.8 19.7

6 15.3 18.2 16.8 19.7

7.5 11.1 17.8 26.0 31.2

10 20.0 25.8 40.0 45.8

12 20.0 25.8 40.0 45.8

15 24.4 30.2 46.0 51.8

3C & 4C with n tube outdoor coils

3M & 4M with micro-channel outdoor coils

Cooling Model Heat Pump Model

Standard Unit

Standard Unit

w/ MHGRH

Standard Unit

Standard Unit

w/ MHGRH

IM 1125-7 • REBEL ROOFTOPS 26 www.DaikinApplied.com

DPS 016–028 Ton Component Description

refrIgeraTIon sysTeM

Variable Speed Compressor

A variable speed compressor (COMP1) is used on all DPS

016-028. On DPS 16–20 ton units, the variable speed

compressor will be the only one present, and be on the right.

The discharge of the variable speed compressor is located on

the top and the suction is located on the side.

These pipes can also be identied by recalling that suction

lines will always be larger than discharge lines. The side

suction design is used to cool the motor with cold refrigerant.

Figure 27: Compressor Suction and Discharge on DPS

025–028 units

Figure 28: High Pressure Switch

High Pressure Switch

Refrigerant Screen

During manufacturing, service, and repair there is always the

potential for debris to accidentally enter the sealed refrigeration

system. Filter screens are positioned around the refrigerant

circuit to prevent any possible debris from entering critical

components; expansion valves, compressors, etc. These

screens are not bi-direction and must be installed in a specic

direction if replaced. Please be aware that these screens are

not desiccant lters and provide no moisture protection for

compromised systems.

Fixed Speed Compressor (DPS 025–028 Only)

This compressor will always be located on the left and like the

variable speed has the suction line on the side of the dome

entering the scrolls and a discharge exiting from the top of the

shell.

High Pressure Switch

All Rebel Units will have a high pressure switch on each

compressor. HP1 switch is on the variable speed compressor

(COMP1) and HP3 is on the xed speed compressor

(COMP3). These switches are normally closed devices

that are brazed directly to the refrigerant piping. When the

pressure at the switch exceeds 580 PSIG the switch will open.

This opening will interrupt the control signal to the variable

compressor drive or de-energize the contactor coil on the xed

speed compressor, Both acts will shut down the compressors

and generate an alarm at the MicroTech III keypad.

Figure 29: Refrigerant Screen

Refrigerant Screen

www.DaikinApplied.com 27 IM 1125-7 • REBEL ROOFTOPS

refrIgeraTIon sysTeM

Indoor Expansion Valve

The Indoor Expansion Valve (EVI) is a 12 VDC stepper motor

driven valve. In cooling mode EVI is used to control the

superheat and expand the refrigerant entering the Indoor Coil,

operating as an evaporator, in much the same way as a TXV

on a conventional air conditioner.

Figure 30: Indoor Expansion Valve

Indoor

Expansion

Valve

Easy

Expansion

Valve

Access

Panel

Suction Pressure Transducer

The Suction Pressure Transducer (PTS) is a refrigerant

pressure sensor that screws onto a Schrader tting on the

suction line of the compressor deck. On single compressor

units (DPS 016–020) this sensor is located on the suction line.

On tandem, two compressor units (DPS 025–028), the PTS is

located upstream of the joint suction.

This sensor is used to ensure that the compressor does not

leave the operating envelope and is used to regulate the super

heat leaving the indoor coil and entering the compressor.

Discharge Pressure Transducer

The Discharge Pressure Transducer (PTD) is a refrigerant

pressure sensor that screws onto a Schrader tting on

the discharge line of the compressor system. On single

compressor units (DPS 016–020) this sensor is located on the

discharge line. On tandem, two compressor units (DPS 025–

028), the PTD is located downstream of the joint discharge.

This sensor is used to ensure that the compressor does not

leave the operating envelope and is used to regulate the

outdoor fan speed and maintain head pressure.

Discharge Refrigerant Temperature

All Rebel units will have a Discharge Refrigerant Temperature

Sensor (DRT1/DRT3) on the discharge line of each

compressor. This sensor is attached the piping with a metal

clip and wrapped in insulation. The purpose of this device is to

increase compressor life by preventing it from running outside

of the operating envelope.

Suction Refrigerant Temperature

All Rebel units will have a Suction Refrigerant Temperature

Sensor (SRT). This sensor is located on the suction line. Unlike

DRT1 or 3 there is only one SRT for tandem compressor

units. This sensor is used to determine the suction super heat

entering the compressor and is the control input for the EVI in

cooling mode.

Bypass Solenoid

The bypass solenoid (SVB) is used to “short circuit” the high

pressure compressor discharge to the low pressure suction

side during startup. This increases compressor life by reducing

the startup torque and inrush current.

IM 1125-7 • REBEL ROOFTOPS 28 www.DaikinApplied.com

VFD Compressor Operation – DPS 016–028

VFD compressor modulation is controlled by a Mobus® signal