Page 1

1

Model

Model

Model

DH1715A

DH1715A

DH1715A

Dual

Dual

Dual

Channel

---

Channel

Channel

Regulated

Regulated

Regulated

Voltage/Current

Voltage/Current

Voltage/Current

User

User

User

’’’

sss

Power

Power

Power

Manual

Manual

Manual

Supply

Supply

Supply

hhh

uauaua

Company

Company

Company

DaDaDa

Electronic

ofofof

Electronic

Electronic

Instrument

Instrument

Instrument

ininin

Beijing

Beijing

Beijing

Page 2

2

Description

Description

Description

1. Operating Features

2. Operating Principle

3.

Structure Features

CONTENTS

CONTENTS

CONTENTS

4.

Applications

5.

Maintenance

6.

Completeness of the Instrument

7.

Storage

8.

Guarantee

Page 3

3

DESCRIPTION

Mode l

DH1715A-3

32V-2A

DH1715A-5

32V-3A

INPUT

Input P ower S upply

2 2 0V ± 10% 50Hz ± 5%

P ower D issipation (200VAC), R ate L oad

≤

300VA

OUTPUT

O utput

Vo

ltage (10-turn)

0-32V

T heor eti calValue ofVoltage resolution

5mV

O utput C urrent(1-turn)

0-2A

0-3A

CV FEATURE

Adj. Ratio

S ource E ffect (line regulation)(for 0-100%

change of output current)

1 × 10

-5

+1mV

L oad E ffect

1 × 10

-5

+2mV

R ipple and N oise(5Hz-1MHz) r.m.s

1mV

Typ

e.Value

of Temp. Coe.

2 × 10

-4

℃

R emote C ontrol ( C on trolVol t./O utput

Volt

.)

about 10V/32V

CC FEATURE

Adj. Ratio

Source Effect (line regulation)(for ± 10%

change of line volt)

2mA

L oad E ffect(load regulation) (for 0-100%

chang e of load resistance)

10mA

R ipple and N oise (5Hz-1mHz) r.m.s

1mA

R emote C ontrol ( C on.

Voltage/

Output C u r rent)

about 10V/2A 10V/3A

CV Mode

I

ndication

CC M ode

I

ndication

Operating

T

emperature Rang

0-40 ℃

R elative A mbient O perating H umidity R ange

20-90%RH

S torageTemperature and H umidity R ange

unforced air cooling

C ooling M ethod

positive or negative grounded

P olarity of O utput

V

oltage

DESCRIPTION

DESCRIPTION

The Model DH1715A Dual - Channel Regulated V oltage/Current Power Supply is an

automatic switching type of high accuracy CV/CC power supply with a 3

digits display

1/2

meter on the front panel.

The output voltage and the output current can be displayed by ON /OFF switch on the front

panel.

This instrument provides a preset circuit and an output switching circuit, the output switch is

an electronic type, which does not generate chattering and noise. When the output switch is

set to “ OFF ” state, the value indicated by the output voltmeter cor responds to the position of

the voltage setting knob so as to preset the voltage.

Press “ OUTPUT ” switch, the output voltage is available from “ OUTPUT ” terminal.

This instrument has function of the remote-controlled voltage. The input socket on the rear

panel is controlled remotely.

Please carefully read this instruction manual before use the power supply.

OPE

1.1.1.

OPE

OPE

RRR

ATING

ATING

ATING

FEATURES

FEATURES

FEATURES

Page 4

4

Continue:

Model

DH1715A-3

32V-2A

DH1715A-5

32V-3A

DC

VOLTMETER

Range Selection

Accuracy of Voltmeter

± (0.5%rdg + 3dgts, at 20 ± 2 ℃ and < 80%RH

Maximum Allowable Application

Voltage

DC AMMETER

Full Scale (Fixed Range)

Ammeter Accuracy(at20 ± 2 ℃ and<80%RH)

± 1rdg + 5dgts

Temperature Coe

.

(+400 × 10

-6

) / ℃ full- scale + the accuracy mentioned

above

Zero Drift

Not greater than 3dgts within 0-40 ℃

Input Fuse

2A

Output Fuse

Weight

≤ 8kg

External Dimensions

305(L) × 200(W) × 170(H)mm

Reliability of the Instrument

MTBF ( θ ) ≥ 5000 hours

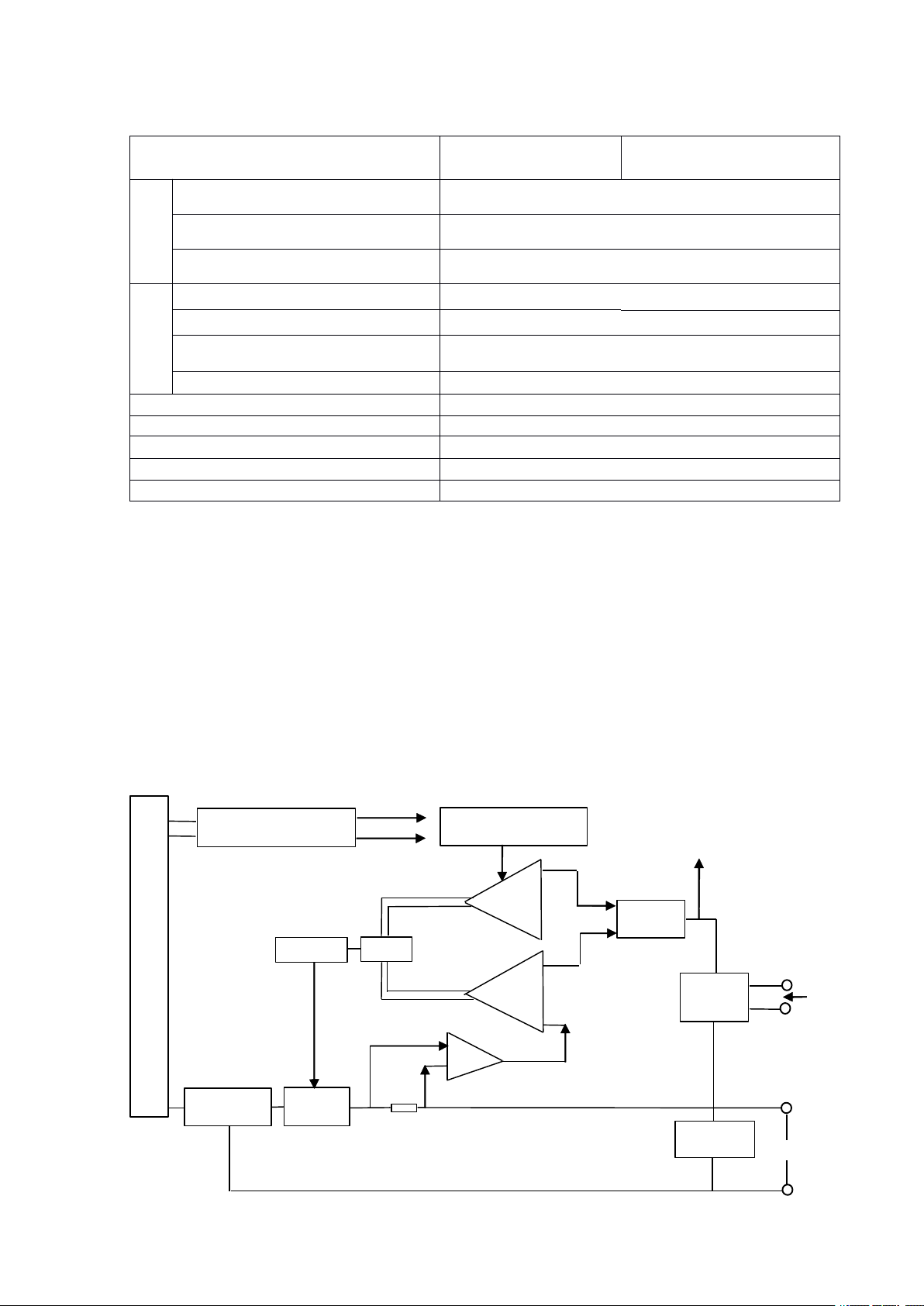

Remote

Control

Signal

Transformer

Relay Switching and

Aux. Supply Circuit

Output Switch Circuit

Reference

Voltage

DC

Remote

Control

Circuit

Voltage

Sampling

Control

Circuit

Rectify

and Filting

Series

Setting

Amplify

Gate

-

CC

Diff

Ampl

+

-

CV

Diff.

Ampl

+

A/D

Conv

AC

220V

Meter Circuit

Current

Sampling

Figure 1

OPE

2.2.2.

OPE

OPE

RRR

ATING

ATING

ATING

PRINCIPLE

PRINCIPLE

PRINCIPLE

The feature of this power supply is that the output voltage signal of constant V oltage circuit

and the output current signal of constant current circuit both are applied to the “ GATE ”

circuit at the same time. According to requirement of the load, the pow er supply is

determined to operate in the CV mode or in the CC mode, the automatic switching of the

regulated voltage and the regulated current can solve the problems of over — current

protection of the regulated power supply and the over — voltage protection of the regulated

current power supply.

CONTROL

CONTROL

CONTROL

CIRCUIT:

CIRCUIT:

CIRCUIT:

It is an adjustable reference voltage generator. The output current

and voltage depend on setting the reference voltage.

Page 5

5

2.1

2.1

2.1

Description

Description

Description

Constant

ofofof

Constant

Constant

Voltage

---

Voltage

Voltage

Mode

Mode

Mode

The reference output voltage circuit is applied to the negative input terminal of a CV error

amplifier, the error voltage from the voltage sampling resistor is applied to the positive input

terminal of the CV error amplifier. The error signals of both vol tages are compared each

other and via the gate circuit by amplify then applied to the base of a regulated tube. The

base current of the regulator tube is changed, then a stabilized output voltage can be obtained ,

the adjustment of the output voltage is re alized by setting the voltage potentiometer on the

front panel.

2.2

2.2

2.2

Description

Description

Description

Constant

ofofof

Constant

Constant

Current

---

Current

Current

Mode

Mode

Mode

The reference voltage from the control circuit is applied to the negative input terminal of a

CC error amplifier, the current signal from A/V conversion is applied to the positive input

terminal of the CC error amplifier. Both signals are compared each other and then amplified

to control the base voltage of the regulator tube to reach a stable current output.

CV/CC

2.3

CV/CC

CV/CC

2.3

2.3

Conversion

Conversion

Conversion

mode

---

CVCVCV

mode

mode

into

into

into

mode

CCCCCC

mode

mode

Setting CC potentiometer, a preset current value is provided as required, the resistor load is

reduced, the output current is increased. When the output current reaches the preset constant current value, the output voltage is reduced. When the power supp ly is power supply is

operating in the constant - current mode, even of the resistor load value is reduced to zero ( in

short circuit state), the output current can not be increased, it always keeps pre - setting value

constantly; that means this instrument can automatically be converted from constant - voltage

mode to constant current mode so as to protect the load from over - current. It is an automatic

CV/CC crossover system type of power supply.

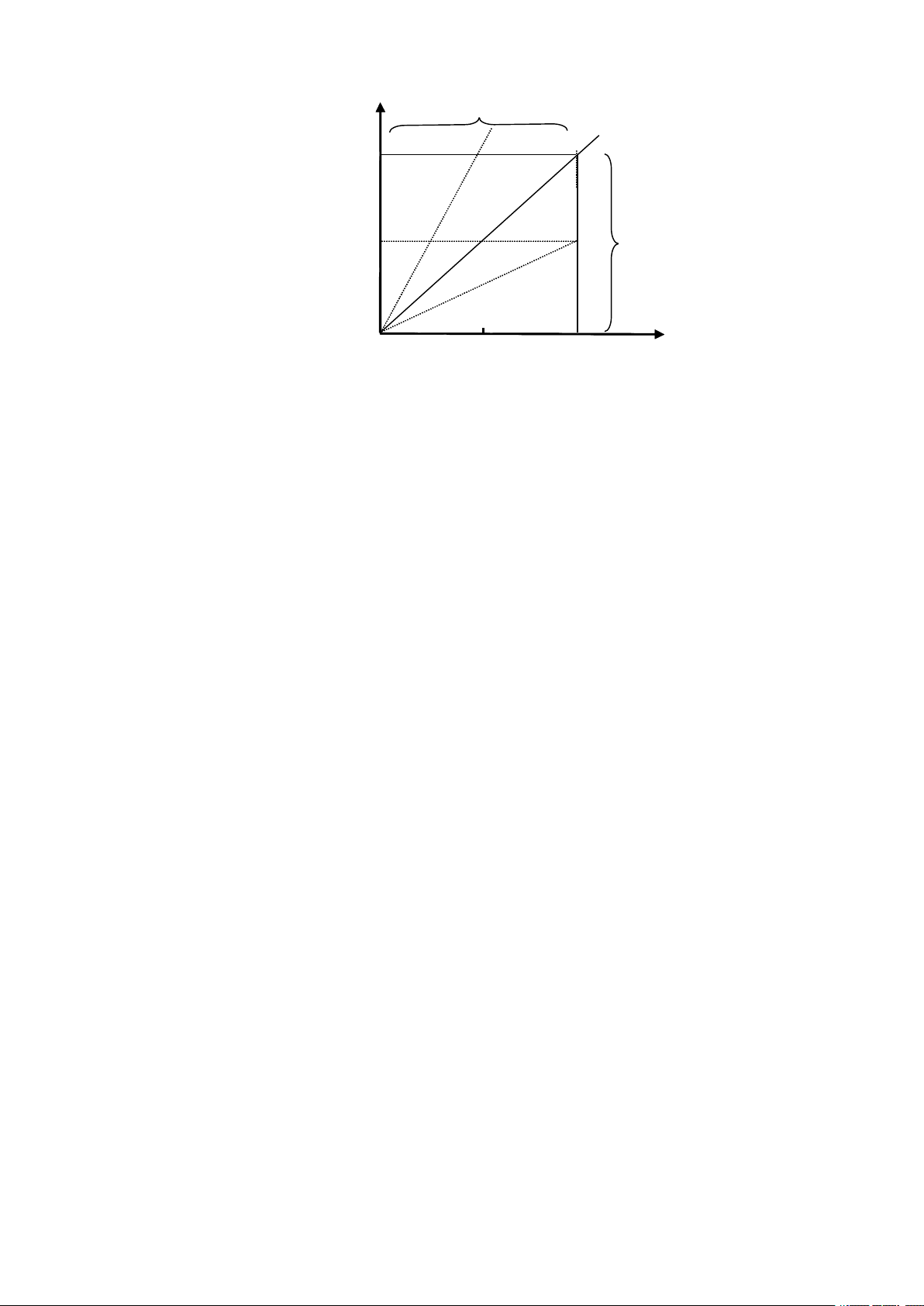

The Figure 2 shows operating points and operating domain related to the load lines. The

preset output voltage is

when RL=10 Ω

10V,

the limited current is 2A, the operating point in non--load is atA,

,

operating point B, and when RL=5 Ω , operating point is at C. The

operating point moves from C to D ,if the resistor load is reduced from RL=5 Ω to 2.5 Ω ,the

instrument operation is changed from the constant-voltage domain into the constant — current

domain. Point C is called “ Crossover Point ” owing to change modes.

Wen

the resistor load

(RL) is 2.5 Ω , the output voltage is I. RL=2 × 2.5=5V .

CC/CV

2.4

CC/CV

CC/CV

2.4

2.4

Conversion-Constant

Conversion-Constant

Conversion-Constant

Current

Current

Current

Mode

Mode

Mode

into

Constant-Voltage

into

into

Constant-Voltage

Constant-Voltage

Mode

Mode

Mode

Setting CV potentiometer, a preset value applied as required. When the output voltage

reaches the preset constant voltage value, then output current is reduced.

When the output current is 2A the resistor load is 0 Ω , operating point is E. While the resistor

load is increased to 2.5 Ω , the operating point moves from E to D. When the operating point

is increased to 5 Ω

,

the operating point moves from D to C. While the resistor load further is

increased to 10 Ω , the operating point moves from C to B. In this case, the instrument is

converted to the constant - voltage domain. When the resistor load is increased continuously

to an open circuit, the operating point moves from B to

A

. Generally, the voltage applied to

the load is not more than the preset voltage. The instrument can convert from the CC mode

to the

V

mode in order to protect the load. The point C serves as a crossover point.

Page 6

6

2.5

CC Mode

(RL<5 Ω )

I02A

1A

5V

10V

E0E

D

CBA

RL=2.5 Ω

RL=5 Ω

Load Line

RL=10 Ω

Figure 2

2.5

2.5

Output

Output

Output

Switching

Switching

Switching

Circuit

Circuit

Circuit

This instrument provides a special output switch, the output voltage can be preset as required

before the switch is unpressed. After the voltage is adjusted, press the switch. This switch is

an uncontacted electricity type of switch so it does not generatea mechanical spark,

protecting users’safety.

2.6

Digital

2.6

2.6

Digital

Digital

Display

Display

Display

Model TY – 43 digital meter adopts LED digital tube as display unit. At least, one or two

digits generated by the display may flicker. It is not caused by the wareform or noise of

output, w hile by characteristics of the A/D convert o

r.

When there is no input voltage, the display will be recovered to zero automatically. When the

input voltage, is inverse, “ - ” polarity will be displayed automatically. When the operating

voltage is

5V,

its input sensitivity is DC ± 199.9mV of full - scale.

STRUCTURE

3.3.3.

STRUCTURE

STRUCTURE

FEATURES

FEATURES

FEATURES

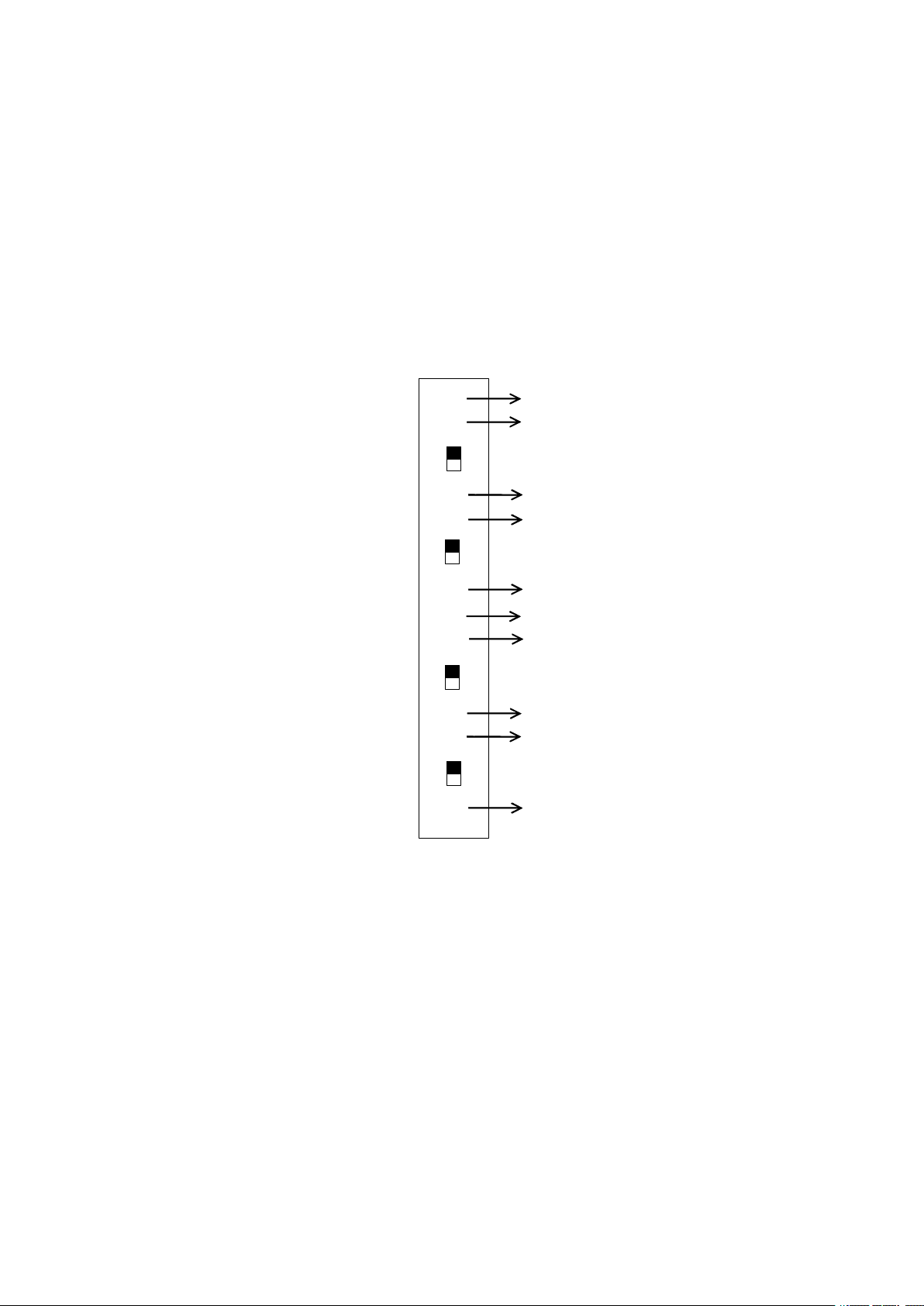

The instrument is designed symmetrically between left and right on the front panel. On the

upper side, there are two digital meters.

A

switch for output in the middle of the panel is

mounted. There are four knobs in line as voltage potentiometer of each c ircuit, and current

setting potentiometers for each way. The two external sockets are mounted in the middle or

lower part of the panel and at the bottom of the panel there are a pair of output binding posts

and a screw grounded with a short bar. When “ + ” or “ - ” to ground is needed, we can connect

the short bar.

At the lowest bottom of the instrument

’

s back, there are one power cord and two pairs of

input sockets for the remote - control signal corresponding to the two ways on the front panel.

There are L/R (local/remote control) and V/C (voltage/current control) operating selector

switches, respectively. The input fuses both are mounted on the rear panel of the instrument.

APPLICATIONS

4.4.4.

APPLICATIONS

APPLICATIONS

4.1

4.1

4.1

Before operation, should check L/R (local/remote control) selector whether on its right

position or mot, otherwise it doesn ’ t operate, generally it is atLposition.

4.2

4.2

4.2

Turn on the power supply, p ress the “ V ” button by adjusting the voltage setting

Page 7

7

potentiometer to a required voltage value and then press the “ OUTPUT ” button. While the

L

V

C

R

L

R

V

C

R

L

Lift

Voltage

Current

Remote

Local

Right

Voltage

Current

Remote

Local

Figure 3

voltage is available at the binding post, at the moment, the constant - voltage mode starts

operating. If the voltage value drops, in this case the instrument is in constant - current Mode,

should set the CC setting potentiometer to the extreme position clockwise.

4.3

4.3

4.3

Preset a constant – current point and set the output current of the unit. By above,

mentioned method, after the constant - voltage point is set, press the “ A ” button and output

terminal is shorted, turn on the “ OUTPUT ” switch. After the current setting potentiometer is

set to the required value.

To

keep the voltage position, turn off the “ OUTPUT ” switch and remove the short

bar,

connect the 1oad, press the “ OUTPUT ” switch, the instrument provides the required current

and voltage for the load.

4.4.4.

444

When turn off the power supply, first should turn off the “ OUTPUT ” switch, then turn off

the “ POWER ” switch.

4.5

4.5

4.5

Remote - Control CV Output

The output voltage can be controlled by an external voltage of 0 -

10V.

As the externa1 contro1 signal, its common termina1 is a “ + ” n output terminal.

4.5.1

4.5.1

4.5.1

Turn on the R/L (remote/loca1) selector switch to R position.

Turn on the V/C (voltage/current) selector switch to

4.5.2

4.5.2

4.5.2

Turn on the “ POWER ” switch and the “ OUTPUT ” switch, the external control voltage

V

position.

is applied through the jack on the rear panel of the unit. Adjust “ VOLTAGE ” switch of the

potentiometer to the extreme position clockwise, adjust the external control voltage so that

the output voltage becomes the desired voltage.

The relationships between the o u tput voltage (E o ) and the external control voltage

(El) is expressed as follows:

Page 8

8

Eo=1/10 E

Remote

Control Input

E

1

NOTE 2

R

L

NOTE 1

NOTE 4

NOTE 3

Figure 4

max

. E1.a (V)

Where Em: Maximum rated voltage (V)

El: External control voltage signal (V)

0V

≤ E1≤ <l0V

Term α is factor of 0-l which depends on the “ voltage ” setting potentiomet e

r.

Factor is 1

when “ VOLT AGE ” voltage setting potentiometer is set to the extreme positions clockwise.

Factor is 0 when both potentiometers are set to the extreme positions counterclockwise. It is

used to select the ratio of the output voltage (Eo) with respect to the external control voltage

signal (E1). Norma1ly, it is adjusted to the maximum vo1tage.

NOTE

NOTE

NOTE

1:1:1:

The vo1tage of the common line of the external control voltage signa1

(El) becomes that of the “ + ” output terminal.

NOTE

NOTE

NOTE

2:2:2:

The input impedance across remote control input jack is approximately

20K Ω . The ripple may be amplified and conveyed to the output loop circuit.

NOTE

NOTE

NOTE

3:3:3:

To

feed the external control vo1tage signal, a shielded cab1e (or a pair of stranded

wires) is used and the shielding wire is connected to the “ + ” output terminal. When the

wiring distance is very long, should prove a full protection against noise.

NOTE

NOTE

NOTE

4:4:4:

When the R/L (r e mote/local) switch is thrown to the

L

position, the output voltage

can be control1ed with the voltage setting potentiometer manually on the front panel.

NOTE

NOTE

NOTE

5:5:5:

Make sure that the output voltage is within the rated output voltage of the

instrument.

4.6

4.6

4.6

Remote Control Constant - Current Mode

The output current can be controlled by the external contro1 voltage signal

4.6.1

4.6.1

4.6.1

Turn on the V/C (voltage/current) selector switch to C position.

4.6.2

4.6.2

4.6.2

The external control voltage signal is ap p lied to the “ INPUT ” jack which is

on the rear panel of the instrument. Please note the po1arities of “ + ” and “ - ” .

4.6.3

4.6.3

4.6.3

Throw the R/ L - switch to R (remote control) position.

4.6.4

4.6.4

4.6.4

Turn on the power supply and output switch, then the output terminal is shorted, set the

current setting potentiometer mounted on the front panel to obtain the required output current

which is 10V at E2.

Output

The relationships between the external control voltage signa1 E

be expressed as fo1lows:

where: I

I0= 1/10. I

– Maximum rated current (A)

max

E

– External control voltage (V)

2

maxE2.

β ( A )

0(V) ≤ E2≤ 10(V)

and the output current I0can

2

Page 9

9

Range ofis β 0 – 1 which depends on the current setting potentiometer, when it is turned to

E1R

L

NOTE 2

NOTE 1

Figure 5

Remote

Control Input

Master

Remote

Control Input

the extreme position clockwise, 0 is

l,

while it is turned to the extreme position

counteclockwise, β is 0. Within the range of the factor, by adjusting the externa1 control

signal (E2) can performe r the proportional relation of the setting output current I o .

NOTE

NOTE

NOTE

1:1:1:

For wiring of the external control voltage signa1, use a shie1ded cable (or a pair of

stranded wires).

NOTE

NOTE

NOTE

2:2:2:

When the R/ L -switch is thrown to

L

(local) position, the output current can be

controlled by the current setting potentiometer on the front panel manually.

NOTE

NOTE

NOTE

3:3:3:

Pay attention to that the output current does not exceed the rated current, be sure

disconnect the short bar on the front panel.

Output

4.7

4.7

4.7

Series Operation

To

obtain a higher vo1tage, two or more instruments can be connected in series. In order to

eliminate potential difference among the chassis of units being due to connecting in series,

disconnect the ground bars of the units and connect the ground terminals together to the

same potential as required.

ATTENTION:

ATTENTION:

ATTENTION:

4.8

4.8

4.8

Paral1el Operation

The total series vo1tage should not exceed 2

00V.

In order to obtain a large output current, two or more instruments can be connected in parallel ,

then adjust their output voltage to the same voltage leve1.If differences of the output voltage

appears, the current initia1ly is fed

by

the unit which is set at the highest voltage. When the

load current becomes more, it wil1 be converted to constantcurrent operating mode, in this

case, the output voltage will be reduced. In this moment, the power supply with the higher

output voltage wi1l start operation . The tota1 output current of the instrument is the sum of

current of each unit.

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

1:1:1:

Pay attention that the output voltage of each unit does not exceed the rated v oltage .

2:2:2:

For the instrument, the output voltage setting is too

low,

the current of s everal

milliampers will flow in the reverse direction.

4.9

4.9

4.9

Parallel Operation of Single Unit

In order to increase current capacity, a master unit is used to control several slave units

remotely.

Method is the same as Section 4. 6 Remote – control CC Mode

The output of the master unit (power supply) is 0 – l0V controlled vo1tage. The slave units

are operating in remote – control constant – current mode

Page 10

10

4.9.1

Master E

1

Slave E3Slave E

2

R

RLLRRRL

Ground

Load

Figure 7

Remote

Control Input

Remote

Control Input

4.9.1

4.9.1

Each slave unit should be previously connected with the master unit in remote control

CC operation, and then adjust the current setting potentiometer to the extreme position,

making factor ɑ = 1. If differences of the slave unit appear, should trim the current setting

potentiometer.

4.9.2

4.9.2

4.9.2

Connect the output terminals of

all

units to the load, using wires of same gauge and the

same length.

Note that the current distribution may un unform unless the potential differ ent between the

“ + ” output terminals of the instruments and the “ + ” terminal of the load are the same. The

slave units are connected in paral1eI as shown in Fig. 6.

4.9.3

4.9.3

4.9.3

Throw R/L switch to R position . T he current setting potentiometer is set to the extreme

position

4.9.4

4.9.4

4.9.4

Turn on the “ OUTPUT ” switches of

4.9.5

4.9.5

4.9.5

Turn on the “ OUTPUT ” switch of the master unit and adjust the control voltage (<10V) .

NOTE

NOTE

NOTE

1:1:1:

All the parallel slave units must be the same typ es.

all

s1ave units.

4.10

4.10

4.10

Control Series Operation of Single Unit (Dual – tracking Power Supply Operating Mode) .

The instrument is connected in series and controlled

by

one master unit. The s1ave units can

be controlled to increase the output voltage of the setup (uppermost one of the instrument

Page 11

11

conne c ted in series operates as the master unit).

Rated V oltage

32V System

Coefficient A

32

4.10.1

4.10.1

4.10.1

the state of the output voltage controlled

Except that the master unit is operating in “ L ” (local) state,

by

the external voltage signal, that means the master

all

the slave units are in

unit’s R/L (r e mote/local) selector switch is thrown to “ L ” position, while the switch of the

slave unit is turned to “ R ” position. V/C (voltage/current) selector switch is th rown to “ V ”

position.

4.10.2

4.10.2

4.10.2

4.10.3

4.10.3

4.10.3

All the output terminals of the power supply are in series connection shown Fig8.

On the top of the Figure is a master unit. Resistor R1 is connected to “ + ” output

terminal of the uppermost unit and the remote – control input jack of the first slave unit.

Resistor R2 is connected between the remote contro1 “ – " input terminal of the first slave

unit and the remote – control “ + ” input jack Of the second s1ave unit.

4.10.4

4.10.4

4.10.4

The voltage setting potentiometer and current setting potentiometer are turned to the

extreme positions of each s1ave unit clockwise.

4.10.5

4.10.5

4.10.5

All the “ GROUND ” terminals of the instrument are connected to one common line

which is connected to a potential line as required.

4.10.6

4.10.6

4.10.6

Turn on both “ POWER ” and “ OUTUPUT ” switches of the master unit and the slave

unit.

NOTE:

NOTE:

NOTE:

( 2 ) Position of 1imiting current of

( 3 ) Calculation of resistors R

(1) For the remote – control operation, it is necessary to control the master unit only.

all

units must be preset previously.

).

1(R2

R

= E1/E

1

where: R1≥ 0 or E2≤ A/10 × E

R

(R2) external1y connected resistor (K Ω )

1

. x A – 10K Ω

2

1

El: Output vo1tage of the master unit (V)

E2: Output voltage of the slave unit 2 (V)

If E1=E2=E3,

then R

=R

1

2

(5) Maintenance of the Instrument

MAINTENANCE

555

...

MAINTENANCE

MAINTENANCE

5.1

5.1

5.1

Inspection

Inspect the instrument at regular intervals so that it maintains its intia1 performance for a

certain period.

5.2

5.2

5.2

Removing Dust and Dirt and Clean Treatment

When the panel has become

dirty,

wipe it 1ightly with a cloth moistured and a neutra1

soapsud, and then wipe it with a c lean dry c lo th. For c1eaning the inside of the instrument,

remove dust from the inside of the case and ventilation holes of the cover

by

using a

compressed air or the exhaust air of a vacuum cleaner. Be carefully when cleaning dust o f the

digital meter and always keeping it cleaning.

5.3

5.3

5.3

Adjustment and Calibration of the Meter

RVl: V oltmeter calibration potentiometer for voltage precision.

Page 12

12

RV2: Maximum voltage setting potentiometer

RV

2

RV

3

RV4RV

1

RV

5

RV

6

Figure 8

RV3: Maximum current setting potentiometer

RV4: Maximum current setting potentiometer for voltage presetting

RV5: Ammeter zero – setting potentiometer

RV6: Current meter calibration potentiometer for current precision

5.5.5.

444

Ca1ibration of V oltage Indication

(1) Connect a digital voltmeter with accuracy ≥ 0.05% to the output terminal.

Turn on “ OUTPUT ” switch, adjust the output voltage to 17.

50V.

(2) A djust potentiometer RV4 so that the digital meter indicates approximately the same

voltage.

5.5

5.5

5.5

Calibration of Ammeter

(1) Press

(2) Adjust potentiometer

A

button (ammeter) switch and turn off “ OUTPUT ” switch.

RVs

so that the digita1 meter shows

0A

(zero amperes)

(3) Connect an ammeter with accuracy ≥ 0. 2% to the output termina1, turn on

OUTPUT switch, and feed the current, after feeding the current for approximately 20 minutes ,

calibrate the output current with potentiometer RV6 so the indication on the digital meter is

the same as the standard ammeter.

5.6

5.6

5.6

Adjustment of Maximum Variable CV Range

(1) Press

V

(V oltmeter) switch and turn on “ OUTPUT ” switch.

(2) Turn voltage setting potentiometers to the extreme position clockwise, adjust

potentiometer

5.7

5.7

5.7

Adjustment of Maximum Variable CC Range.

RV

2,so that the output voltage becomes E

(maximum voltage) as specified.

0

(1) Connect an ammeter with approximate1y accuracy of 0.5% to the output terminal.

(2) Set the potentiometers to the extreme positions clockwise, adjust potentiometer

RV

3 so

that the output current becomes Io (maximum current), refer to tab1e 2.

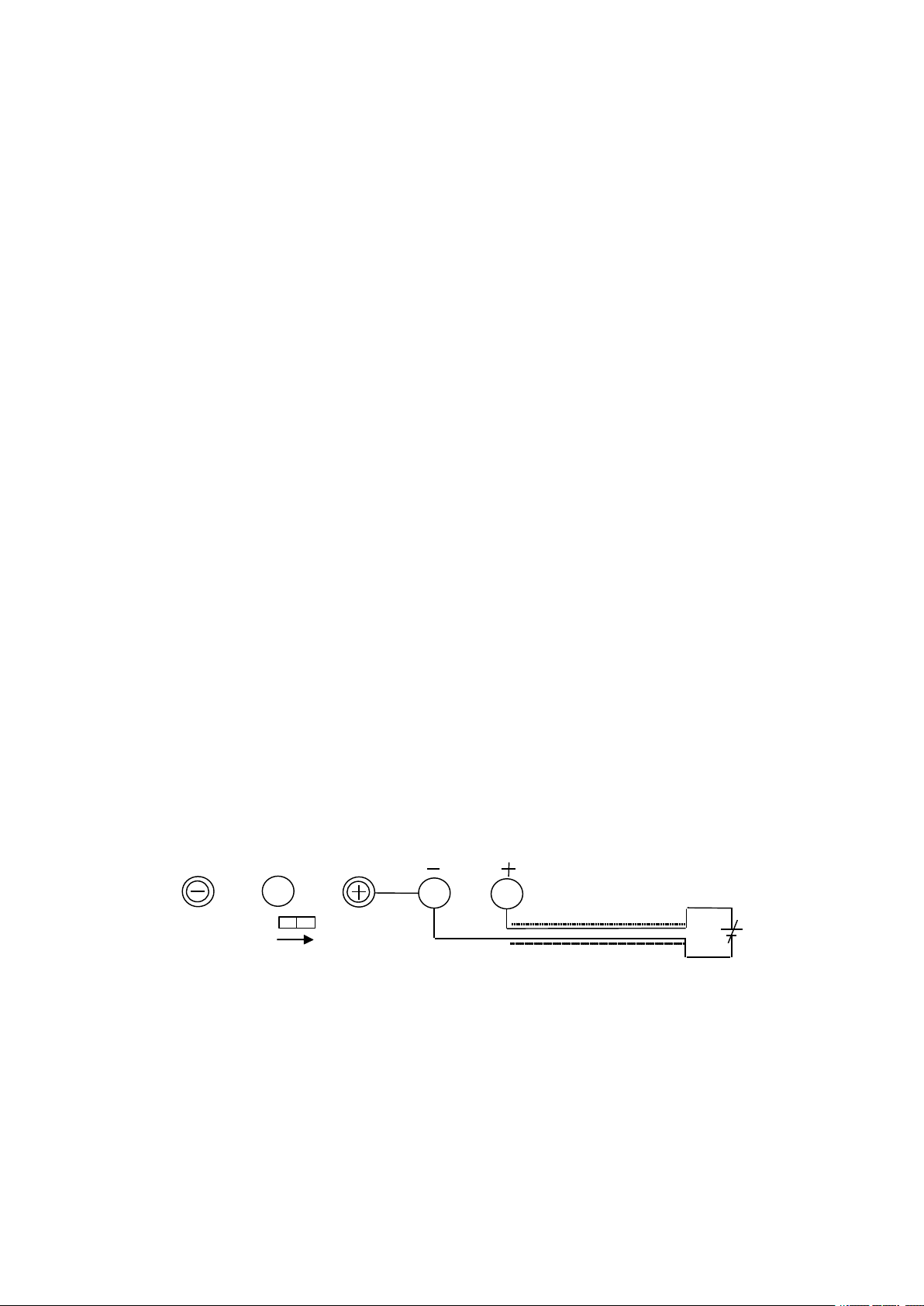

Rely turn on

Rely cut-off

0 E

Output voltage

0

Figure 8

5.5.5.

888

Calibration of Digital Meter

Press down the output switch, check the voltage accuracy in the subranges of

2V,

20V,

and

set RV1 to required secifications.

Page 13

13

Table 2.

Model

Adjustment

DH1715A-3

32V~2A

DH1715A-5

32V~3A

Calibrated. Standard Ammeter I

1

2A

3A

Max. V ariable CV Setting Range E

0 (max.)

33.3V

33.3V

Max. V ariable CV Setting Range I

0 (max.)

2.10A

3.15A

setting of Relay Switch Circuit

20V,10.5V

20V,10.5V

Mode

l

DH1715A-3

DH1715A-5

Specs of fuse

2A

2.5A

5.5.5.

999

Failure and Cause

5.9.1

5.9.1

5.9.1

Without V oltage Output

(1) The ± 15V Aux. P ower supply does not work.

(2) The Local/Remote (R/L) switch position is not correct.

(3) The output sw

5.5.5.

999

.2.2.2

The output voltage can not be set up to the required value.

(1) The CC point is turned to

i

tch is not turned on.

low,

it should be turned to higher.

(2) The output terminal has been shorted.

(3) On the PC boards Q

5.5.5.

999

...

333

Unstable Operation

or Q

1

may be damaged.

2

(1) ± 15V voltage of the aux. P ower supply does not stabilize.

(2) V

5.5.5.

or V

3

101010

Normal Operating V oltage of the Instrument

on the PC board does not operate normally

4

The “ + ” output terminal is a reference point when the instrument is measured.

5.5.5.

101010

.1.1.1

The voltage of the aux. power supply is ±

5.5.5.

101010

.2.2.2

The voltage of each measured point on the PC board .

V

=

6.

1v

2

15V.

REFV = 0~-10V

REFC = 0~-10V

CCAMP= 0~ - 10V

When operating in CV mode:

C.V = 0~4v C. c = +14V

When operating in CC m o de:

C.V = +l4v C. c = 0~4v

COMPLETENESS

666

...

COMPLETENESS

COMPLETENESS

The instrument suite includes:

(1) DHl715

A

(2) Cartridge fuse BGxP Φ 5x20

Input fuse

(3) Instrument Manual 2

STORAGE

777

...

STORAGE

STORAGE

The instrument should be save up in a ventilated room where the ambient temperature is 5 -

master unit

2A

THE

OFOFOF

INSTRUMENT

THE

THE

INSTRUMENT

INSTRUMENT

l

set

2

Page 14

14

45 ℃

,

RH ≤ 90% and dew is not allowed. These conditions are needed to protect the 1iquid

crystal display, in addition, keep the instrument from smoke, gas, acid, alkaline and other

corrosive materials, be sure not to place the instrument in high temperature and more dust

place so as to keep the instrument clean. After delivery within 18 months, if the users abide

by

the regulations of transpor t ation, storage and operation regu

l

ation, and the quality is

below the specification, our company take responsible for free repair or rep1ace a new one.

Loading...

Loading...