Page 1

刺绣机电脑

Computerized Control System for Embroidery

Machine

BECS-D19

Version: 2019-02

操作手册

USER’S MANUAL

Page 2

Page 3

Contents

Contents

Chapter 1 General Information .................................................................... 1

1.1 Warnings and Cautions ........................................................................................................1

1.2 Main Features ......................................................................................................................3

1.3 T echnical Specifications ......................................................................................................5

Chapter 2 Operation Guide .......................................................................... 6

2.1 Configuration and Direction of Control Panel .....................................................................6

2.2 Instructions of Control Panel ...............................................................................................6

2.3 Instructions of Main Screen .................................................................................................8

2.4 Notes on Menu Item Status ................................................................................................13

2.5 How to Input Number, Letter and Symbol ........................................................................13

2.6 How to Move Cursor .........................................................................................................14

2.7 Basic Embroidery Procedure .............................................................................................14

2.8 Normal Embroidery, Returning and Patch Embroidery ....................................................20

2.9 Relationship between Normal Embroidery, Idling and Positioning Idling ........................20

2.10 Embroidery Operation Bar and Turn Shaft Button ..........................................................21

2.11 Thread Breakage Detection and Patch Embroidery Switch .............................................21

2.12 Working Status .................................................................................................................22

Chapter 3 Disk Management ...................................................................... 23

3.1 Disk Selection ....................................................................................................................23

3.2 Pattern Preview ..................................................................................................................25

3.3 Single/Multiple Selection ..................................................................................................27

3.4 Pattern Input .......................................................................................................................28

BECS-D19 User’s Manual

I

Page 4

Contents

3.5 Pattern Output .................................................................................................................... 29

3.6 Directory Operation ........................................................................................................... 30

3.7 Delete Disk File (Including Pattern File and Directory) ................................................... 30

3.8 Disk Formatting ................................................................................................................. 31

Chapter 4 Memory Pattern Management .................................................... 33

4.1 Memory Pattern Management Interface and Other Instructions ....................................... 33

4.2 Select One or Several Patterns ........................................................................................... 37

4.3 Select Pattern for Embroidery ........................................................................................... 37

4.4 Pattern Preview .................................................................................................................. 37

4.5 Copy Memory Pattern ....................................................................................................... 39

4.6 Delete Memory Pattern ...................................................................................................... 41

4.7 Applique Pattern Setting .................................................................................................... 42

4.8 Satin Stitch Compensation ................................................................................................. 44

4.9 Edit Combined Pattern ....................................................................................................... 45

4.10 Devide Pattern ................................................................................................................. 47

4.11 Integrate Patterns ............................................................................................................. 47

4.12 Generate High-speed Pattern ........................................................................................... 48

4.13 Compile Combined Pattern ............................................................................................. 48

4.14 Generate Pattern by Parameters ....................................................................................... 49

4.15 Generate Pattern by Frame-moving ................................................................................. 50

4.16 Generate Outline Pattern from Normal Pattern ............................................................... 51

4.17 Copy Pattern of Varied Stitch Length .............................................................................. 52

4.18 Set Common Parameters ................................................................................................. 52

Chapter 5 Machine Parameter Management ............................................... 54

II

BECS-D19 User’s Manual

Page 5

Contents

5.1 Common Parameter Setting ...............................................................................................54

5.1.1 Pattern Direction .................................................................................................... 55

5.1.2 Rotating Angle ........................................................................................................ 55

5.1.3 Scaling .................................................................................................................... 55

5.1.4 Repetition Priority .................................................................................................. 56

5.1.5 Repetition Mode ..................................................................................................... 57

5.1.6 X-Y Repetitions ...................................................................................................... 57

5.1.7 X-Y Repetition Interval .......................................................................................... 57

5.1.8 Priority Mode ......................................................................................................... 57

5.2 Setting of Other Embroidery Parameters ...........................................................................57

5.2.1 Setting Procedure for Other Parameters ................................................................. 58

5.2.2 More Functions for Setting Other Parameters ........................................................ 60

5.3 Initialize Machine Parameters ...........................................................................................61

5.4 Machine Authorization Management ................................................................................61

5.4.1 Unlock/Change Administrator Password ............................................................... 62

5.4.2 Administrator Unlocks the Machine ...................................................................... 63

5.4.3 Administrator Saves and Recovers Optimized Parameters .................................... 64

5.4.4 Change Manufacturer Password ............................................................................. 64

5.4.5 Unlock Manufacturer Password ............................................................................. 64

5.4.6 Manufacturer Saves and Recovers Optimized Paremeters .................................... 64

5.5 Initialize Machine Parameters ...........................................................................................65

5.6 Save Machine Parameters to Disk .....................................................................................65

5.7 Read Machine Parameters from Disk ................................................................................65

5.8 Adjust XY Parameters of Servo Frame ..............................................................................65

BECS-D19 User’s Manual

III

Page 6

Contents

5.8.1 Set Parameters ........................................................................................................ 66

5.8.2 Inquire Driver Status .............................................................................................. 66

5.8.3 Save Driver Parameters .......................................................................................... 67

5.8.4 Recover Default Driver Parameters ....................................................................... 67

Chapter 6 Assistant Functions .................................................................... 68

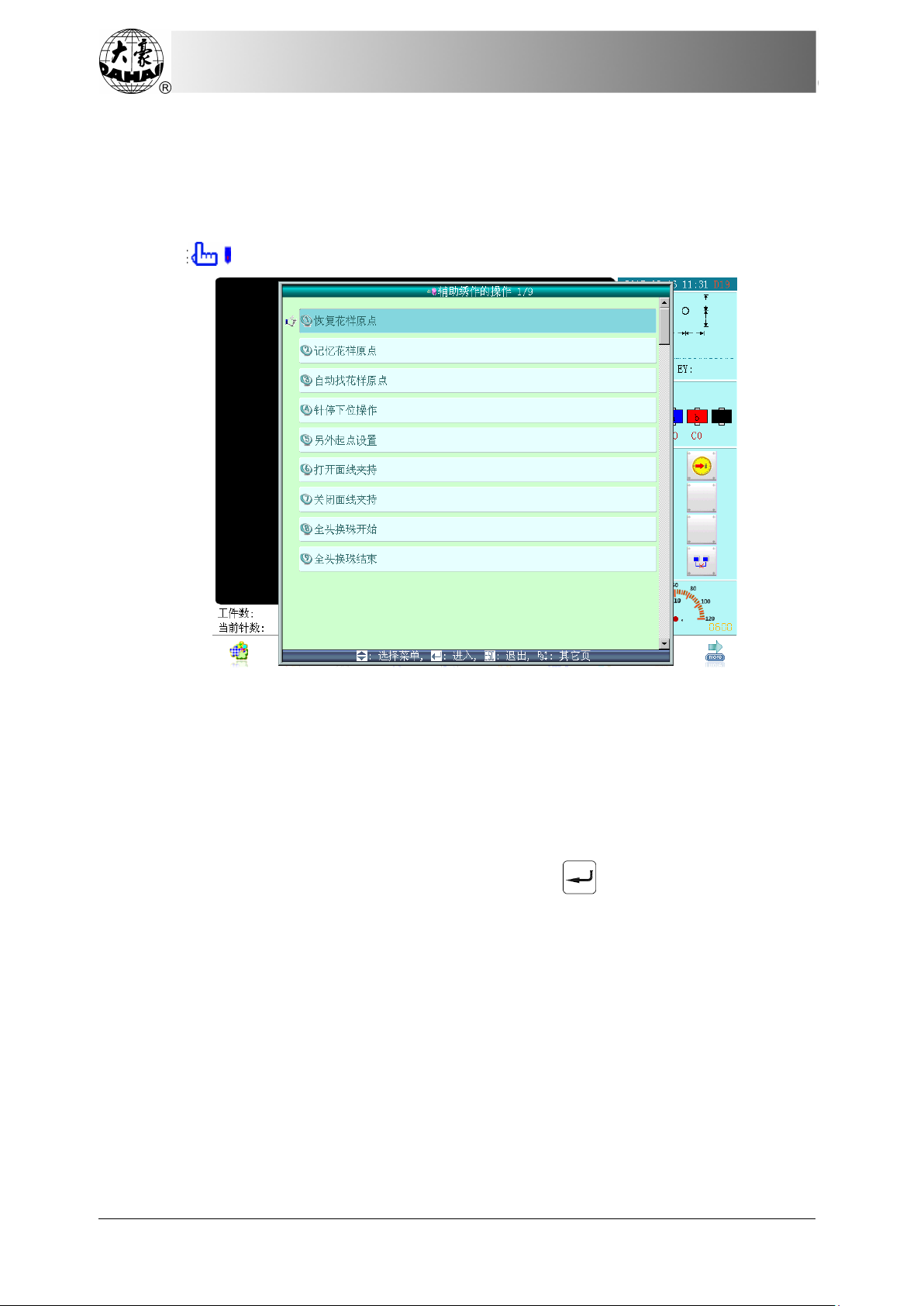

6.1 Assistant Embroidery Operation ........................................................................................ 68

6.1.1 Resume Pattern Origin ........................................................................................... 68

6.1.2 Save Pattern Origin ................................................................................................ 69

6.1.3 Pattern Origin Auto Search .................................................................................... 70

6.1.4 Needle Stops Down ................................................................................................ 70

6.1.5 Set another Start ..................................................................................................... 72

6.1.6 Set B Point .............................................................................................................. 72

6.1.7 Operation of Air Frame, Sequin and Coiling Devices ........................................... 74

6.1.8 Upper Thread Holding Operation .......................................................................... 74

6.2 Other Assistant Management Operation ............................................................................ 74

6.2.1 Check Embroidery Parameter ................................................................................ 75

6.2.2 Check Statistic Data ............................................................................................... 76

6.2.3 Frame Protection Setting/Frame Origin Setting ..................................................... 76

6.2.4 Frame Recovery ..................................................................................................... 77

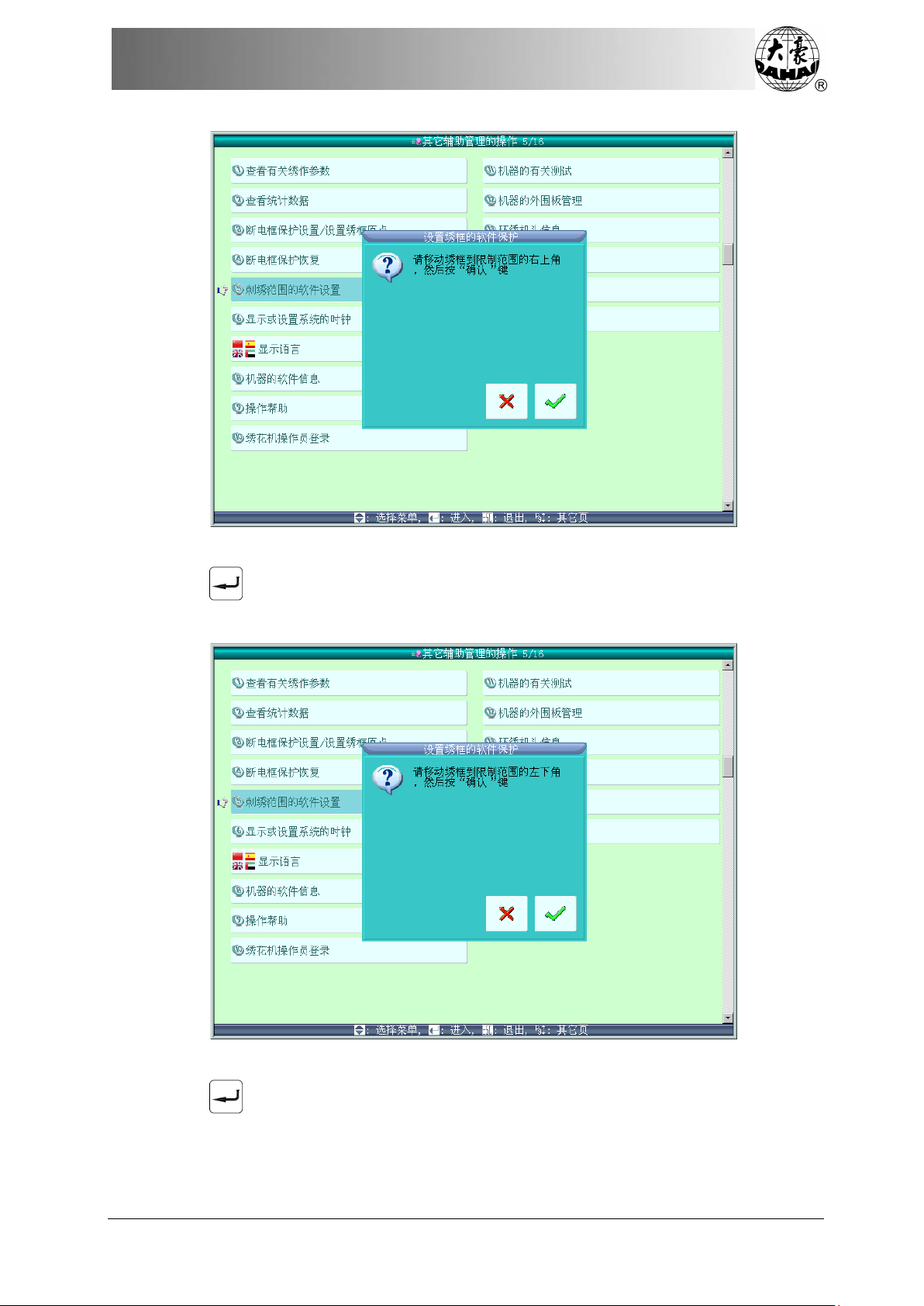

6.2.5 Set Embroidery Scope in Software ........................................................................ 78

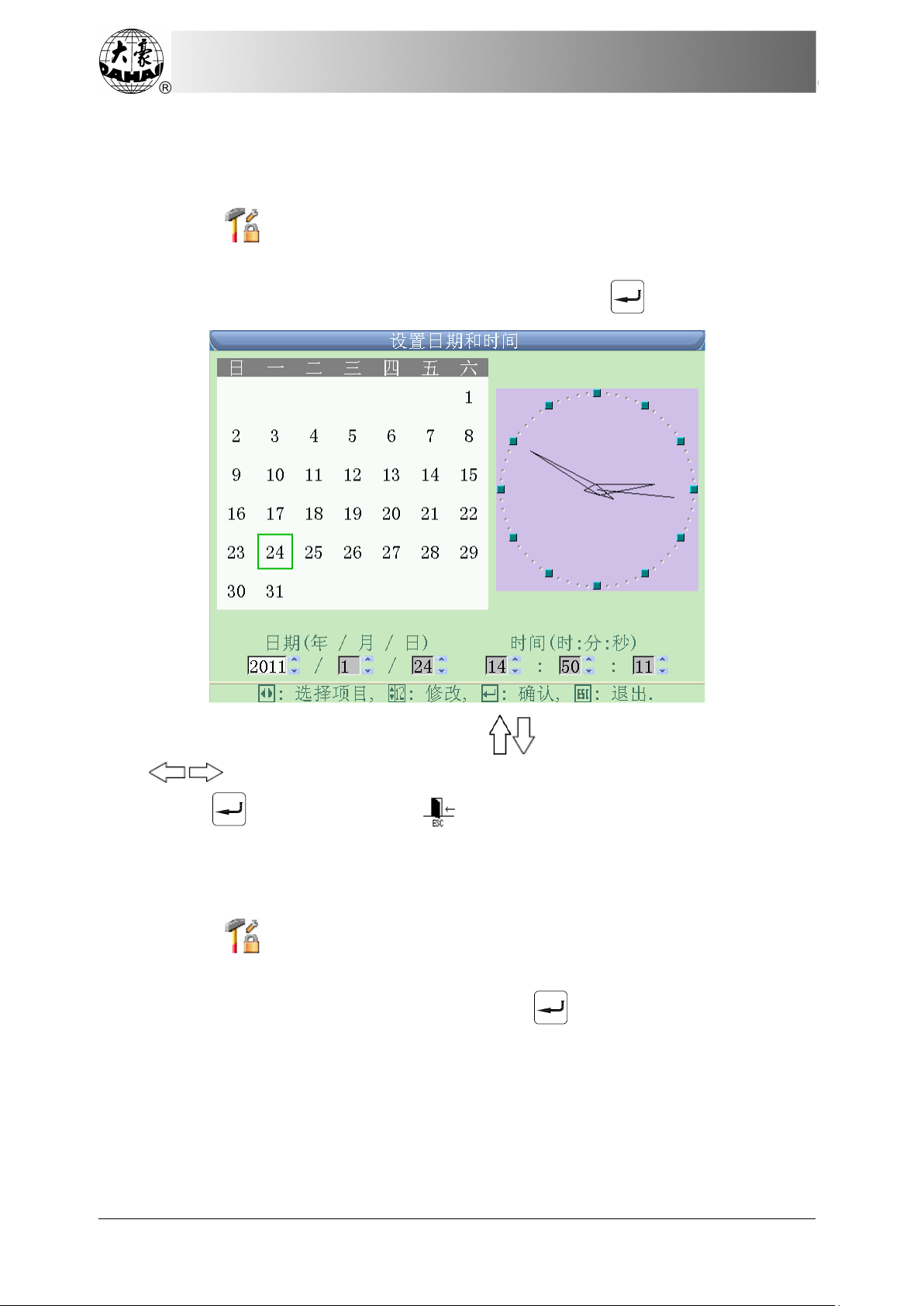

6.2.6 Set System Clock ................................................................................................... 80

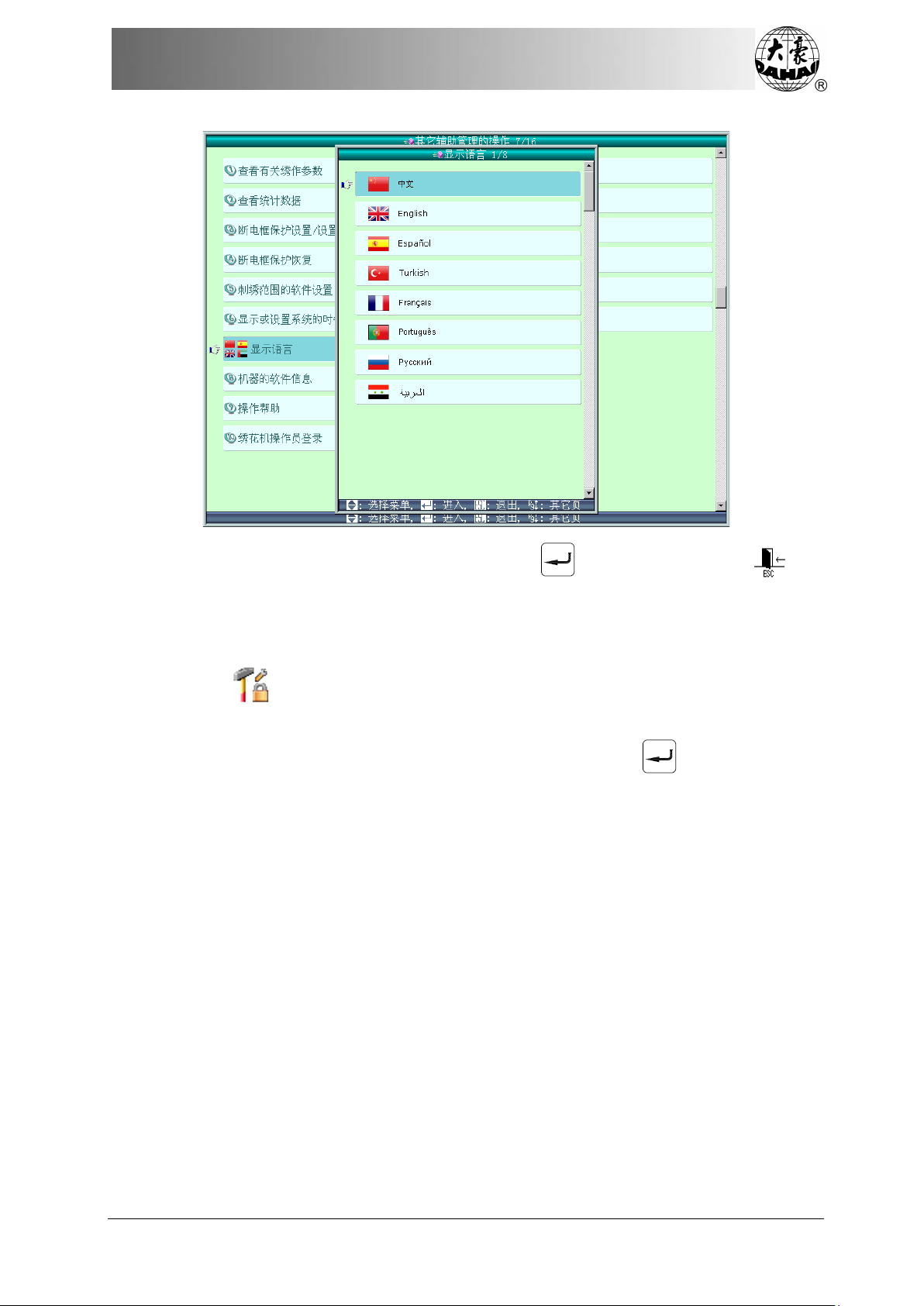

6.2.7 Select Language ..................................................................................................... 80

6.2.8 Machine Software Information .............................................................................. 81

6.2.9 Help ...................................................................................................................... 82

IV

BECS-D19 User’s Manual

Page 7

Contents

6.2.10 Machine T est ........................................................................................................ 82

Chapter 7 Other Operations........................................................................ 84

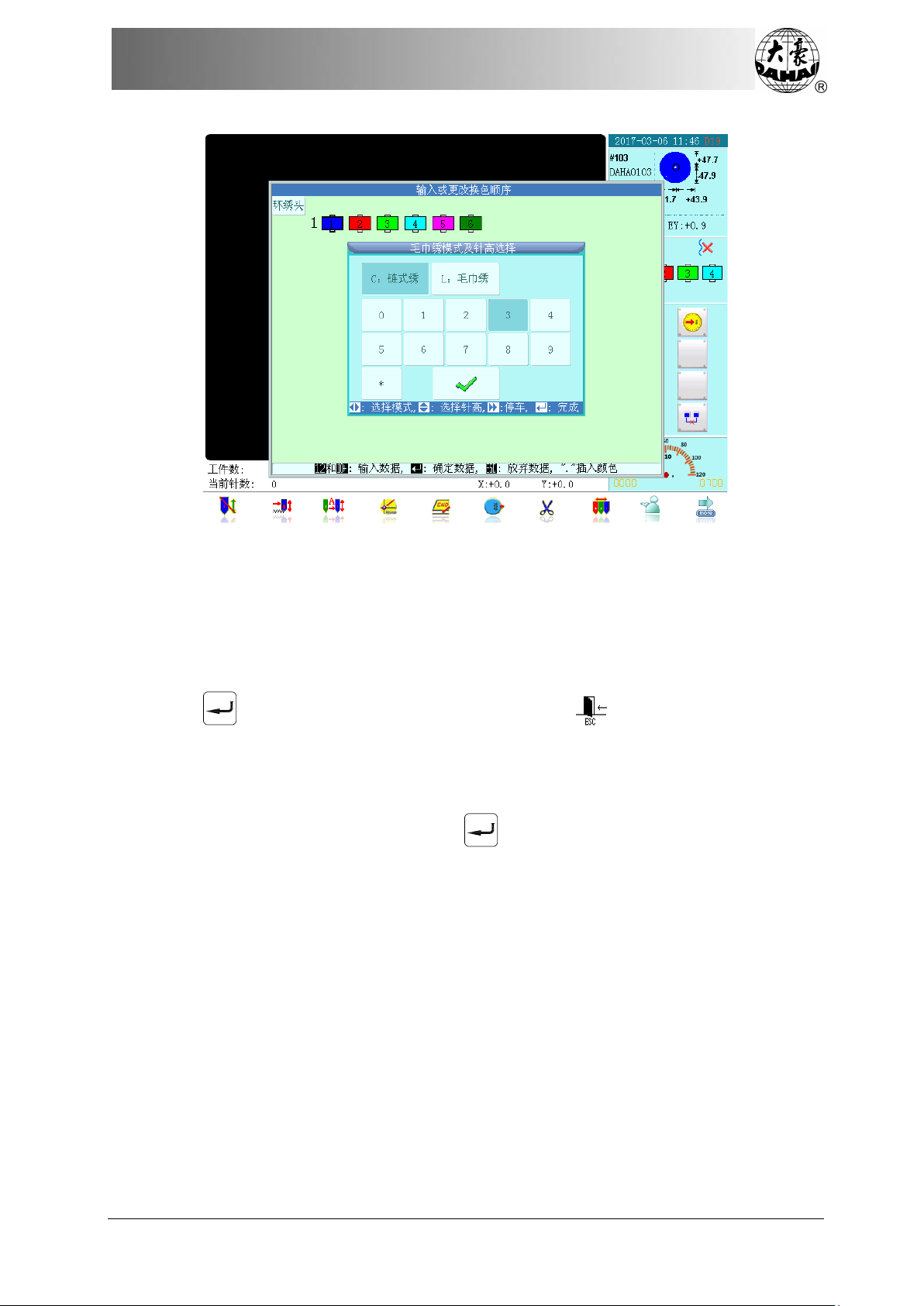

7.1 Color-changing Order Operation .......................................................................................84

7.1.1 Input and Repeat Color-changing Order ................................................................ 84

7.1.2 Modify Color-changing Order................................................................................ 85

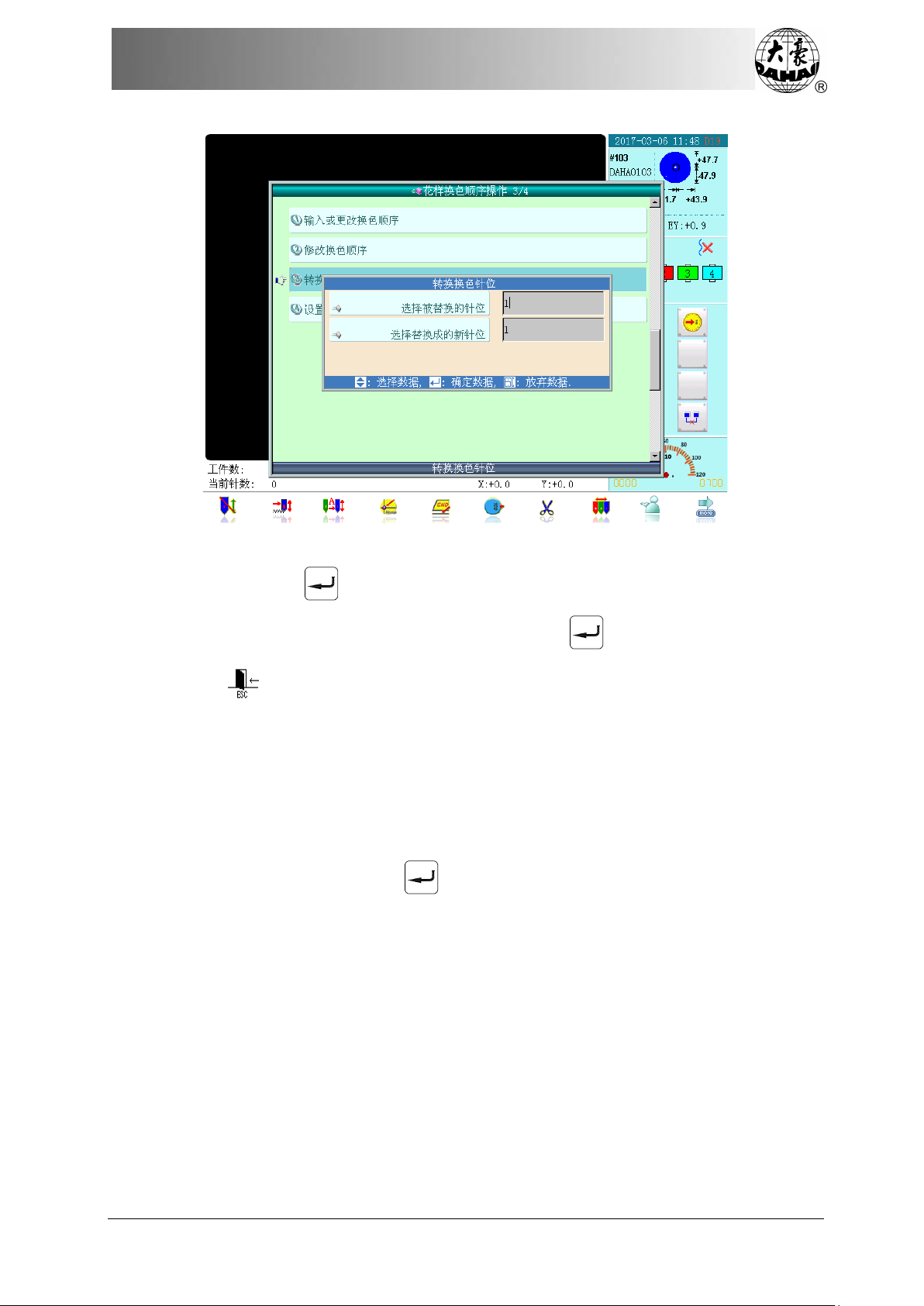

7.1.3 Replace Color-changing Needle Position ............................................................... 86

7.1.4 Set Pattern Display Color ....................................................................................... 87

7.2 Pattern Border Operation ...................................................................................................88

7.2.1 Check the Pattern Border Range ............................................................................ 89

7.2.2 Move the Frame along the Pattern Border ............................................................. 89

7.2.3 Generate Pattern from Pattern Outline ................................................................... 90

7.2.4 Generate Patch Position by Frame-moving, then Embroider ................................. 91

7.2.5 Embroider a Cross at Current Position ................................................................... 92

7.2.6 Embroider a Line from Frame-moving End to Start .............................................. 93

7.2.7 Embroider Along Outline of Current Pattern ......................................................... 94

7.2.8 Embroider Real Outline of Current Pattern ............................................................ 95

7.3 Positioning Idling ...............................................................................................................96

7.3.1 Positioning Idling by Forward Stitches .................................................................. 97

7.3.2 Positioning Idling by Backward Stitches ............................................................... 98

7.3.3 Positioning Idling by Next Color-changing Code .................................................. 98

7.4 Clear XY Displacements ...................................................................................................98

Chapter 8 Pattern Edit ...............................................................................100

8.1 Start Pattern Edit ..............................................................................................................100

8.2 Pattern Editing Operation ................................................................................................101

BECS-D19 User’s Manual

V

Page 8

Contents

8.2.1 Overview .............................................................................................................. 101

8.2.2 Document and View Operation ............................................................................ 102

8.2.3 Stitch Positioning and Editing Function............................................................... 102

Chapter 9 Letter Pattern Operation ........................................................... 104

9.1 Start Letter Pattern Operation .......................................................................................... 104

9.2 Input Letter String and Basic Parameters ........................................................................ 104

9.3 Save Letter Pattern ........................................................................................................... 109

Chapter 10 JF Type Sequin Embroidery ................................................... 111

10.1 Sequin Embroidery Introduction ................................................................................... 111

10.2 Embroider Sequin .......................................................................................................... 111

10.3 Input Sequin Pattern ...................................................................................................... 111

10.4 Sequin Embroidery Parameter Setting .......................................................................... 112

10.5 Manual Operation of Sequin Embroidery ..................................................................... 114

10.6 Sequin Applique ............................................................................................................ 115

Chapter 11 Instructions on Coiling, Taping and Zigzag Embroidery ....... 116

11.1 Function Introduction .................................................................................................... 116

11.2 Main Technical Specifications ....................................................................................... 116

11.3 Parameters and Settings ................................................................................................. 117

11.4 Related Operations of Special Embroidery ................................................................... 119

11.4.1 Shift between Flat Embroidery and Special Embroidery ................................... 119

11.4.2 M-axis Operation of Special Embroidery .......................................................... 121

11.4.3 Presser Foot Operation ....................................................................................... 121

11.5 Special Embroidery Debugging ..................................................................................... 122

VI

BECS-D19 User’s Manual

Page 9

Contents

11.6 Special Embroidery Procedure ......................................................................................122

11.7 Mechanical Device Category and Drive Mode of Special Embroidery ........................122

Chapter 12 Instructions on Loop Embroidery ...........................................125

12.1 Function Introduction ....................................................................................................125

12.2 Switch between Loop Embroidery Head and Flat Embroidery Head ...........................125

12.2.1 Head Switch ....................................................................................................... 125

12.2.2 Loop Embroidery Main Interface Introduction .................................................. 127

12.3 Loop Embroidery Procedure ..........................................................................................128

12.4 Parameters and Settings .................................................................................................128

12.5 Machine Debugging .......................................................................................................129

12.5.1 Thread Loosing Position Adjustment ................................................................. 130

12.5.2 Needle Height Adjustment ................................................................................. 131

12.5.3 Color-changing Position Adjustment ................................................................. 132

12.5.4 T est D-axis Motor ............................................................................................... 133

12.5.5 T ext H-axis Motor .............................................................................................. 133

12.5.6 Test Main Shaft of Chained Embroidery ............................................................ 134

12.5.7 Test Main Shaft Encoder of Chained Embroidery ............................................. 134

12.5.8 Test Trimming Motor of Chained Embroidery ................................................... 134

12.5.9 T est Thread Breakage Detection ........................................................................ 135

12.6 Manual Operation ..........................................................................................................136

12.7 Change Color-changing Order .......................................................................................136

12.8 Manual Switch of Loop Embroidery Head ....................................................................138

12.9 Mechanical Device and Drive Mode of Loop Embroidery ...........................................138

Appendix 1 Parameter Setting List ...........................................................140

BECS-D19 User’s Manual

VII

Page 10

Contents

Appendix 2 U Disk Operation Specification ............................................ 150

Appendix 3 Error List ............................................................................... 151

Appendix 4 Loop Embroidery Parameter List .......................................... 154

Appendix 5 Loop Embroidery Error List.................................................. 158

Appendix 6 Network Connection Instructions ......................................... 159

Note: changes of specifications will not be informed separately!

VIII

BECS-D19 User’s Manual

Page 11

Chapter 1 Gen er al In f ormation

Matters for Attention at Usage

cause serious injury.

work or in storage, in order to prevent electric shock or fire.

trouble to the machine.

security of person and property

insert or pull out the disk.

e will add appendix if necessary, and if there is any difference

between the manual and its appendix, the appendix will prevail.

Transportation and Carriage

Chapter 1 General Information

Thanks for using the Computerized Embroidery Control System produced

by Beijing Dahao Technology Corp., Ltd. User are recommended to read this

manual carefully, so as to operate the machine correctly and effectively. Besides,

user should keep at hand this manual for future use.

1.1 Warnings and Cautions

In order to reduce the danger of occurrence of fire, electronic shock and

personal injury at using this product, user shall strictly follow the basic security

prevention measures at below:

During the operation, do not try to open the machine box. The high

Danger

Forbidden

Forbidden

voltage contained in some parts can be deadly. Rotating parts may

Don’t expose the machine to humidity, dust, corrosive gas either at

Don’t store or operate the machine in vibrating area, which may cause

Caution

Caution

Caution

Caution

Caution

BECS-D19 User’s Manual

Please abide by all the warnings and safety requirements to ensure the

LCD is fragile item. Do not use hard materials to press on the screen.

Before plugging in, user has to pay attention to the direction of the

floppy disk and the U disk. Don’t insert with force when the direction

is wrong, or it may cause damage to floppy drive, disk, U disk and

USB port. When the indicator on floppy driver is on, please don’t

W

Don’t hold the cable when moving.

1

Page 12

Chapter 1 Gen er al In f ormation

security of person and property

lease load according to the

instruction on the box.

Installation

may cause fire or electronic shock.

inflammables.

Cable Connection

or the power socket used by the control box.

increase insulating capability.

grounding conductor

insulated terminal and

case is.

Operating

operate the machine when there is any damage on the

protection shell.

Make sure the configuration of power supply in normal. Use

-10%~10%.

be carried out again when problem is solved.

Caution

Compulsory

Caution

Caution

Caution

Forbidden

Forbidden

Caution

Please abide by all the warnings and safety requirements to ensure the

Overloading may cause collapse. P

Don’t block the vent on the device, nor plug up the machine, or it

Make sure the installation direction is correct.

Don’t expose the machine to humidity, corrosive gas and

Don’t test the insulation of the circuit loop.

Never try to connect overloading electronic device to the connector

Make sure the insulation cover of each cable is fine.

Caution

Caution

Caution

Danger

Forbidden

Communication cable and power cable should be separated.

All the cables should be well fixed. Don’t put any strength on cables.

Make sure the turning point of cable is well protected. Add pipes to

Please confirm that: The computerized control equipment involved in

this manual must be grounded. The equipmentshould use the wire with insulation having an outer surface that is

green, with or without yellow stripes. the cross-sectional area of the

wire shall not be less than 2mm2, and the grounding resistance

should be less than 10Ω. The equipment-grounding conductor must

be pressed crimping to the circular preconnected to the position where the grounding mark of the machine

Don’t

When machine is running, do not touch any running part.

Caution

stabilized voltage power supply when the voltage rebound is between

Caution

2

In case of warning, please check out the problem. Operation can only

BECS-D19 User’s Manual

Page 13

Chapter 1 Gen er al In f ormation

minutes time lag before the function can be used again.

Maintenance and Inspection

minute before opening the machine cover.

can not disassemble circuit boards.

If machine is inactive for a while, users must power on the machine

regularly (once in 2 or 3 days, more than an hour for each time).

If machine is inactive for a long time, users should have the machine

checked before power on.

Rejection

industrial electronic standards.

Caution

Warning

Caution

Caution

Caution

Caution

1.2 Main Features

The power supply has over-currency protection function. There is a 3

If you need to open the machine cover, cut out the power supply first.

Due to the capacitance after power off, operator must wait for one

Circuit boards can be damaged by static. Non-professional technician

Rejection should obey the rules and regulations set by national

1. LCD Displayer

It’s easy to learn and its beautiful screen makes work a joy.

2. Timing Turn-off of LCD Displayer

LCD will turn off automatically in case of no operation in 15 minutes (the time can be

changed in parameter setting). A touch of the screen or any key will reboot the LCD.

3. Super-large Memory Capacity

The memory space reaches 2M and up to 800 patterns can be stored, which can satisfy the

demands of various users for memory space.

4. Max. 2 Million Stitches for Single Pattern

Currently, the maximum number of stitches for single pattern is 2 million, with 1000 times

of automatic color-changing.

5. Multi-task Operation and Free Task Shift

During embroidering, user can input&output patterns, change and prepare the patterns to

be embroidered, and modify certain parameters at anytime. At the same time, user can shift

among tasks freely just by pressing the task-shifting key.

6. Separate Storage of Each Pattern’s Frequently Used Parameters and Color-changing Order

Frequently used parameters, color-changing (needle bar) order and needle bar colors of

each pattern can be stored separately. Work settings of each pattern will be recorded and user

can set and change the subsequent patterns while the previous pattern is under embroidering,

which will save time and improve work efficiency. What’s more important, this function is the

basis for the realization of centralized management via network.

7. Grouping Management of Parameters

Parameters can be divided into groups based on their functions and embroidery types. The

system can also save and recover the parameters used by technicians at end-user and the

BECS-D19 User’s Manual

3

Page 14

Chapter 1 Gen er al In f ormation

parameters used by the machine manufacturer. And for the machine with encryption function,

user can set password on the machine.

8. Pattern Input&Output via USB Disk

Except DOS, FDR and ZSK format floppy disk, users can use USB disk for data transfer.

USB disk supports DIR operation, which is easy for pattern management. For each directory,

system supports the storage of 400 patterns or the sub-directory operations. There is no

limitation on directory levels. Pattern formats like DSB, DST, ZSK and FDR can be loaded.

9. Input of Multiple Patterns

Both floppy and USB disks support input of multiple patterns under one directory.

10. Input of Pattern, Color-changing Order, etc. via Network

The system can be connected to network and user can input pattern, color-changing order,

applique, etc. via network.

11. Machine Network Function

A surveillance LAN can be built with connectors and linked to the factory LAN, which

can help realize network management, improve production efficiency and reduce possible

mistakes. It’s the best choice for enterprises to realize modern enterprise management. For

details, please refer to appendix 5.

12. Patch Embroidery (Applique)

This function can set as patch position the col or-changing code or stop code, and when the

machine embroiders to the patch position, it will halt and move out of frame for patching. Then,

user can pull the operation bar to return and continue embroidering.

13. Brake Adjustment

According to different characteristics of machines from different manufacturers, user can

adjust the parameter for brake process to have the main shaft to stop at the right position.

14. Embroidery Starting Point Memory

Each pattern’s embroidery starting point will be saved, and user need not search

embroidery starting point for the same pattern every time, which saves a lot of work.

15. Maintenance & Debugging Functions

These functions include: optical-electricity testing, main shaft rotation speed testing, main

shaft stop at any position and components testing. These functions can make it more

convenient to debug the machine or determine the faults at repairment.

16. Languages

The system supports Chinese, English, Spanish, Turkish and other languages.

17. Pattern Output

Pattern can be outputted and saved into floppy disk or USB disk. Adoption of TAJIMA’s

binary system enables user to enjoy the advantage of data transmitting through the World Wide

Web (other formats may not be transmitted directly).

18. Repetition Embroidery

The embroidery productivity of the machine can be increased by repetition embroidery,

which can also be used with cyclic embroidery.

19. Cyclic Embroidery

When cyclic embroidery function is activated, the machine automatically returns to the

4

BECS-D19 User’s Manual

Page 15

Chapter 1 Gen er al In f ormation

origin point and starts the same embroidery again after finishing one time. together with special

pattern-designing or repetition embroidery, work efficiency can be greatly improved.

20. Pattern Compiling

(1) Create new pattern by editing parameters of selected pattern

User can edit the scaling up/down rate, rotation angle, embroidery methods like normal

repetition or partial repetition in order to create a new pattern. Such new pattern can be used for

embroidery, output or other operations.

(2) Edit combination pattern

User can edit an existing combination pattern to create a new one and the new pattern can

be used for embroidery, output or other operations.

21. Letter Pattern

The system has 28 letter libraries. User can combine letters by various arrangements as

needed to generate letter patterns, which is very simple and esay.

22. Pattern Edit

By this function, user may insert, modify or delete certain stitch at certain point. New

patterns can be created by this function too.

23. Speed Adjustment

The highest speed for embroidery can be set in advance. During embroidery, speed will

change automatically when the needle interval changes.

24. Thread Trimm ing

Thread trimming can be manually controlled or operates automatically at the end of

embroidery process or color changing.

25. Thread Breakage Detection

In case of thread breakage or run-out of bobbin thread, machine stops and warning lights

start to blink.

26. Color Changing

At the color-changing position, either it can be manually operated, or the system will

operate color-changing automatically according to the pre-set order.

27. Special Embroidery

BECS-C16 has special embroidery functions (coiling, taping and Zigzag embroidery)

which can enrich the embroidery patterns.

1.3 Technical Specifications

1. Maximum Number of Patterns Saved in Memory: 800

2. Memory Capacity: 2M

3. Screeen Resolution: 800*600

4. Network Port Speed: 10Mbps

5. Data Transfer Method: floppy disk, USB disk, network

6. Control Precision: minimum stitch interval under control is 0.1mm

7. Needle Range: 0.1mm~12.7mm

BECS-D19 User’s Manual

5

Page 16

Chapter 2 Operation Guide

Chapter 2 Operation Guide

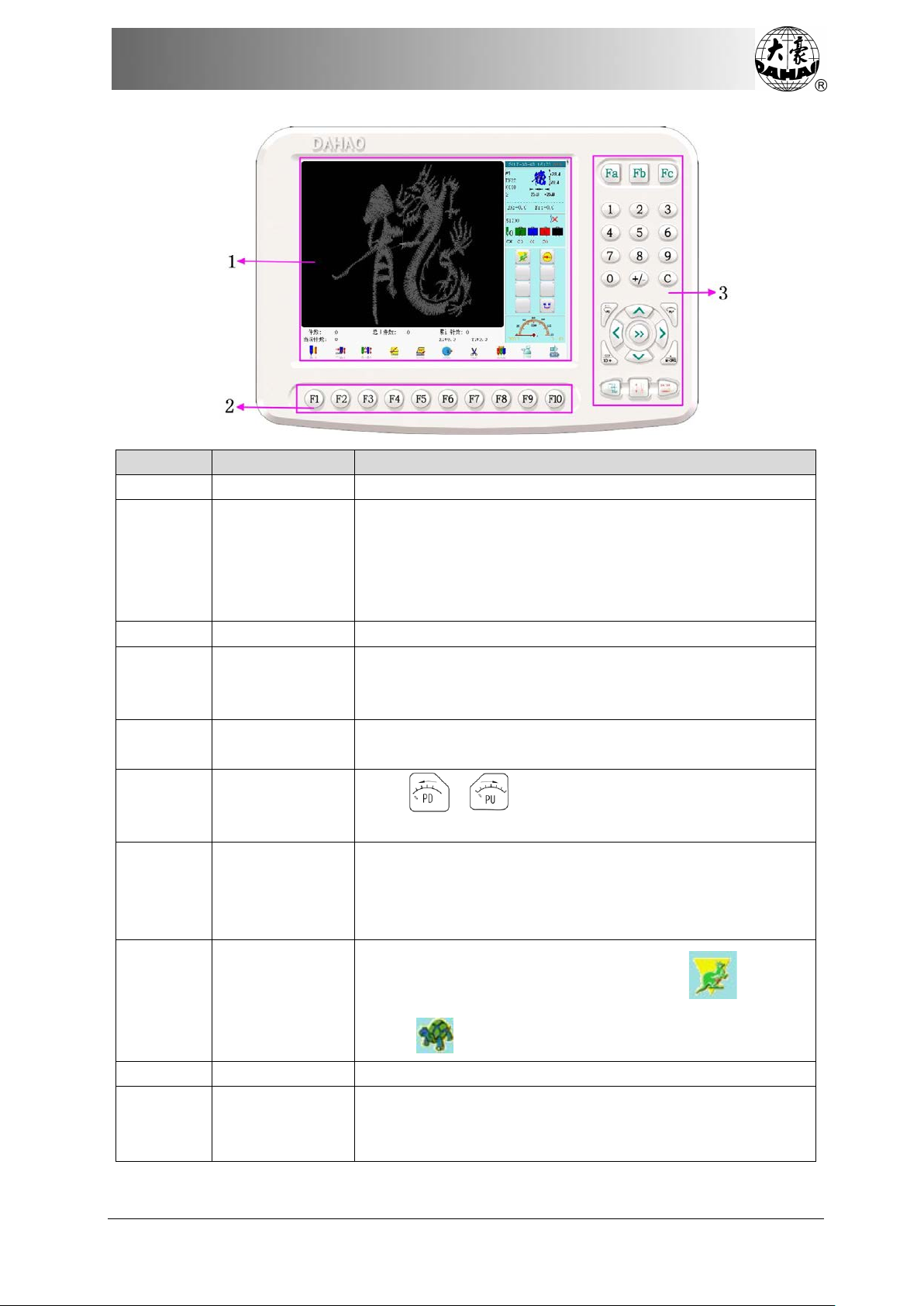

2.1 Configuration and Direction of Control Panel

A. Configuration of Control Panel

1. LCD

D19 adopts high-luminance LCD.

2. USB Interface

USB disk can be plugged in for data input/output. External floppy drive can also be

connected to the USB interface.

B. How to Use Floppy Disk

Floppy disk is external device and connected to the control panel via USB interface.

Please pay attention to the plug-in direction and don’t plug in with force. Otherwise, it may

casuse damage to the floppy dirve.

C. How to Use USB Disk

Please pay close attention to electrostatic phenomenon. Don’t forget to discharge the

metal structure or frame by hand before plugging in/out the USB disk.

USB disk features plug-in direction. Users should avoid plugging out during writing or

loading data, because it may result in loss of data. We highly recommend users to check the

data integrality on the computer before use.

Note: During the formatting process of USB disk, sudden power lost or plugging out may

damage the USB disk.

2.2 Instructions of Control Panel

The keys on the keyboard can be used along with LCD. If you want to operate any menu

item on the LCD, just press corresponding function key on the keyboard. The status of that key

will be shown on the screen.

6

BECS-D19 User’s Manual

Page 17

Chapter 2 Operation Guide

No.

Name

Description

1

LCD

This area displays the operation interface.

Press the function keys within this area to select functions.

(Note: If you press the key twice without interruption by

any other operation, the system will enter or exit the

page key.)

3 +/- Shift

Select negative or positive number.

Include such operations like pattern origin, needle stop at

down position, start elsewhere, sequin, quilting, special

embroidery

If user opens several interfaces, use this key to shift among

these interfaces in order.

to reduce or increase the current

embroidering speed respectively.

Operate by pressing direction keys. Combination of

included angle between two directions).

3

Confirm

Press this key to confirm certain operation.

nder ready status, user can make various preparations,

such as selecting pattern for embroidery, setting pattern

parameters, etc. before confirmation. Then press this key to

2

3

Function

Selection

Assistant

Operations

corresponding function in the main screen area, except the

3 Task Shift

3

3

3

3

Speed

Adjustment

Manual Frame

Movement

Manual

Frame-moving

Speed Shift

Confirm/Release

Embroidery

Press /

direction keys is permitted during manual movement (press

the nearby keys to move the frame along 45 degree of the

Press this key to shift between high speed ( ) and low

speed ( ).

U

BECS-D19 User’s Manual

7

Page 18

Chapter 2 Operation Guide

No.

Name

Description

key to releast the confirmation status and the system

3

Exit

Press this key to exit the current operation.

3

Page

Press this key to turn pages.

3

Number Keys

Used to select menu item or set parameters.

change from ready status ( ) into confirmation status

(

).

Or, under confirmation status, user can pull the bar at any

time to start embroidery. When machine stops, press this

changes from confirmation status ( ) into ready status

( ).

2.3 Instructions of Main Screen

Note: press to shift between the following two pages.

8

BECS-D19 User’s Manual

Page 19

Chapter 2 Operation Guide

No.

Display

Name

Description

Reference

1 Real Time

Tracking

Stitch forms or patterns are displayed in

this area.

2 Current Stitch

Information

The current stitch information is

displayed.

4 Pattern

Information

Information related to the embroidered

pattern is displayed.

5 Color-changing

Position

to make

shift)

Embroidery status (thread

6

Order and

Current Needle

Machine Status

Information (in

the order of left

to right, top to

bottom)

Frame-moving speed (low speed ,

high speed ; press

Main shaft status (running , stop in

position , not stop in position )

BECS-D19 User’s Manual

9

breakage , end of embroidery ,

color-changing , jump , pull bar

to stop )

Page 20

Chapter 2 Operation Guide

No.

Display

Name

Description

Reference

, none cyclic

embroidery (blank)

Assistant embroidery status/flat

al embroidery (flat

7

The set rotation speed and the actual

displayed.

3

If the main shaft fails to stop in position

, press this key

and the main shaft will arrive in

3

When the machine stops, press the key

moving” to move the

frame (e.g. in case of patching). Then

press this key and the frame will

the current design.

3

When the machine stops, press it to have

return to the

start point of the current design.

3 Machine

management

Press this key to enter into the interface

for machine parameter setting and

operations.

Chapter 5

3

Press this key to enter disk management

erface, for operations of floppy disk

and USB.

Chapter 3

3

Press this key to enter into pattern

management interface, to select pattern

for embroidery, input pattern to memory,

Main Shaft

Rotation Speed

Cyclic embroidery

embroidery/speci

embroidery , sequin , etc.)

Start elsewhere

Assistant embroidery mode

Network status (disconnected ,

connected , successful register )

rotation speed of the main shaft is

Main shaft

manual

adjustment

Go to stop

Go to start

parameter

management

point

point

Disk

after machine stops

position .

“Manual Frame-

automatically return to the stop point of

the frame automatically

int

Chapter 6

Pattern

management

10

Chapter 4

BECS-D19 User’s Manual

Page 21

Chapter 2 Operation Guide

No.

Display

Name

Description

Reference

display pattern, generate pattern, operate

letter pattern, etc.

3 Assistant

operations

Operations like pattern origin, needle

stop at down position, start elsewhere,

sequin, quilting, special embroidery, etc.

3

changing order menu, press

relative number to act color-changing.

3

After machine stops, user can press this

key to select trimming upper thread or

trimming bobbin thread.

In this status, press related needle

changing code, system stops the

hen you should act

hanging. Input the

position you need, pull bar to start

embroidering (manual start).

If you set machine to auto

changing, you should first set

current needle locates, system will act

changing according to this order.

changing code,

machine will stop automatically and

change to the needle position that

f you set auto

you set to manual start, pull bar to start.

auto start

3

embroidery

changing order

trimming

color-changing

manual start

Set color

Thread

Manual

When main shaft stops in position ,

press this key; after that, system goes to

the color-

position key to select a position. Pull bar

to start embroidering. When meeting the

colormachine automatically and

displays . T

manual color-c

Chapter 7

Auto

color-changing

manual start

Auto

color-changing

BECS-D19 User’s Manual

11

colorneedle color-changing order (press

in the main screen).

During embroidery, no matter where the

colorWhen you meet color-

already has been set. I

start, machine will start automatically; if

Page 22

Chapter 2 Operation Guide

No.

Display

Name

Description

Reference

3

System is now in normal embroidery

hen you pull bar to start

embroidery, the main shaft rotates and

ame moves along the pattern trace.

ull bar to go back, and machine will

hen machine

System is now in high speed idling

hen you pull bar to start

mbroidery, main shaft will not rotate

and the frame will move along the

hen you pull bar to go

back, main shaft will not rotate and the

frame will move back along the pattern

hen machine stops, press this

System is now in high speed idling

pull bar to stop, the frame goes to the

titch number decreases as well.

3

In embroidery preparation status, you

can make various preparations, such as

to select pattern, set parameter, etc.

Press this key and confirm, then

machine status is changed from

to confirmation

status. W

Normal

embroidery

fr

P

idle back at low speed. W

stops, press this key to shift to low speed

idling .

status. W

e

Low-speed

Idling

pattern trace. W

trace. W

key to change to high-speed idling

status .

status. Pull bar but main shaft and frame

don’t move and stitch number increases;

High speed

idling

Embroidery

preparation

status

12

real position of the current stitch. Pull

bar to back, main shaft and frame don’t

move. S

Pull bar to stop, the frame goes back to

the real position of current stitch. When

machine stops, press this key to change

to Embroidery Status 。

preparation status

status .

BECS-D19 User’s Manual

Page 23

Chapter 2 Operation Guide

No.

Display

Name

Description

Reference

In embroidery confirmation status, you

3

Press this key to enter interface for

manually changing machine head and

color-changing.

3 Special

mode

Press this key to enter interface for

3

Press this key to enter other auxilliary

nterfaces, like clock

setting and help.

3

Press this key to enter operation interface

3

Press this key to enter pattern border

3

Press this key to shift the pattern

Embroidery

confirmation

status

(embroidery

can be

cancelled)

Change

machine head

embroidery

Other assistant

management

Positioning

idling

can pull bar to embroider. When

machine stops, press this key to confirm

to cancel confirmation status and

return to preparation status .

manually shifting special embroidery.

management i

of positioning idling. Chapter 7

Chapter 6

Pattern border

operation

Change design

direction

operation interface. Chapter 7

direction.

2.4 Notes on Menu Item Status

If one menu item is labeled with the mark “ ” or “ ”, this menu item can not be

accessed and modified. On the contrary, if one menu item is labeled with the mark “ ” or “ ”,

this menu item can be accessed and modified. If there is a “ ”, then this menu item can be

modified only if the user relieves the password first.

2.5 How to Input Number, Letter and Symbol

For some menu items, press the key “ ” to enter setting interface (optional), press

“ ” to shift options, press “ ” to confirm.

At inputting number, press “ ” to input radix point, press “ ” to enter negative

number. If there are several digits or letters on one key, you can press the key continuously

BECS-D19 User’s Manual

13

Page 24

Chapter 2 Operation Guide

Input Pattern

Select Pattern

Auxilliary Operation

Confirm Embroidery

Pull Bar to Embroider

Cancel Embroidery

Manual Operation

until you get the number or letter you want. For example, press trice, then you can get

letter “I”. “ ” is used for shifting capital letters and small letters. “ ” is used for

deleting the last letter you typed in.

2.6 How to Move Cursor

The cursor of this controller is displayed as “ ”. You can press “ ” or

corresponding number keys to move the cursor to the intended item. Press “ ” or “ ” for a

while, the cursor will move consecutively among each item of the present operation interface.

2.7 Basic Embroidery Procedure

The machine embroiders based on the patterns in its memory. The following is the basic

procedure of embroidery.

①

②

③

④

⑤

A. Input Pattern

User can imput pattern through network, floppy disk or USB disk. Only under status,

can user transmit patterns by PC via network. For USB disk operation (including floppy disk),

press in the main screen to enter the “USB disk management” interface. You can also

14

⑦

⑥

BECS-D19 User’s Manual

Page 25

Chapter 2 Operation Guide

input patterns by pressing “ ” under the pattern management interface.

B. Select Pattern

If the pattern management interface is not opened, press in the main interface to

enter it. If the interface is opened but the current interface is about another function, press the

blue task shift key on the panel to enter the pattern management interface. Only under the

status of “ ”, can user choose pattern for embroidery.

1. After entering pattern management interface, press “ ” to select the

intended pattern for embroidery and then press (or ).

BECS-D19 User’s Manual

15

Page 26

Chapter 2 Operation Guide

2. If the pattern’s starting point has been saved, the hint “Move frame to start point”

will display after entering the main screen. Press “ ” and the frame will automatically

return to the start point.

C. Assistant Operation

After selecting the pattern for embroidery, the system will enter the main interface, where

user can make the assistant operation as needed before embroidery.

1. Set repetition, rotation, scaling and color-changing – press in oder to

enter the operation interface of pattern parameter and color-changing order.

2. Set applique embroidery - to enter pattern management interface, where user

can press to set applique following the hints.

3. Check the border, move freely along the border, embroider aong the boarder,

embroider a cross, embroider a line, embroider the pattern outline – press to enter

pattern border interface.

4. Automatically search pattern origin – press to enter assistant embroidery

interface. Please note: this function is to locate the pattern in the center of the frame as

preset by soft limit. To set soft limit area, press to enter other assistant

management operation.

5. Save pattern origin – in embroidery confirmation status, press to enter

16

BECS-D19 User’s Manual

Page 27

Chapter 2 Operation Guide

assistant embroidery interface. Please note: before using this function, user need preset

the origin of the frame. To set the frame origin, press to enter other assistant

management operation.

6. Set cyclic embroidery – press to enter system parameter management interface.

Move the cursor to “Assistant Embroidery Parameter” and select parameter B02 for

parameter setting of cyclic embroidery.

D. Embroidery Confirmation

1. Press after finishing assistant operation. Then press “ ” at the appearance of

the following hint window. Then (embroidery release) will change into

(embroidery confirmation), which indicates that the system has enter embroidery

confirmation status.

If user press “ ”, the system will remain in the embroidery release status. At

this time, even though user pulls the bar, the machine will not work and the system will

display the hint for user to confirm the embroidery.

2. Start elsewhere

After confirmation of embroidery, if needed, press to set another start point

following the hint. (Note: when embroidery starts, this setting is invalid.)

3. Set color-changing and starting method

Under the main interface, press the position where the icon (or , )

BECS-D19 User’s Manual

17

Page 28

Chapter 2 Operation Guide

locates to shift among (auto color-changing, auto start), (auto

color-changing, manual start), (manual color-changing, manual start).

4. Set normal embroidery or idling

Under the main interface, press the position where the icon (or , )

locates to shift among (normal embroidery), (low-speed idling) and

(high-speed idling).

E. Pull the Bar to Embroider

Operation bar (embroidery bar) is under the table.

1. Stop Status:

Pull the bar to right to start embroidery (including low-speed idling and

high-speed idling)

Pull the bar to left to return (including low-speed idling and high-speed idling)

2. Running Status

At normal embroidery, pulling the bar to the right end is to embroider slowly and

releasing the bar will resume the normal speed.

Pulling the bar to left is to stop embroidery (including low-speed idling and

high-speed idling).

F. Manual Operation

1. Manual trimming

When the machine stops, press in the main screen. Follow the prompt and

select a trimming mode (“trim upper & bobbin” or “trim bobbin”). Then press “ ”

to trim, or press “ ”to exit trimming operation.

2. Manual frame-moving

When the machine stops, press the keys (“ ”) to move the frame

in the corresponding direction. Press the neighboring two keys at the same time to move

the frame in the direction of the angle bisector. “ ” is the speed key for manual

frame-moving, to shift between (high speed) and (low speed).

3. Clear the frame coordinates

When the machine stops, press “ ” then press “ ” to clear the XY

displacements displayed in the main screen. The function can be used with manual

frame-moving.

18

BECS-D19 User’s Manual

Page 29

Chapter 2 Operation Guide

4. Manual color-changing

When the machine stops, you may type in needle position number in the main

screen. Then the head will move to the corresponding needle position automatically.

5. Turn the Main Shaft to 100°Manually

Usually the main shaft is needed to stop at 100° at color-changing, frame-moving

and beginning embroidery. The user can manually turn the main shaft to 100° when it

doesn’t reach there. Press “ ” in the main screen and then choose “ ” in the

followed prompt to carry out the function.

After the operation, the icon (main shaft not in the right position) will be

replaced by (main shaft in the right position).

6. Return to start point

In the main screen press and choose “ ” in the followed prompt. Then

the frame will return to the start point.

7. Return to stop point

Press in the main screen and choose “ ” in the followed prompt. Then

the frame will return to the stop point.

8. Positioning idling

Use this function after embroidery confirmation. Positioning idling enables the

machine to move to the designated position according to the user’s need without

embroidery. Press in the main screen then the user can set the needle number,

color-changing code, idling direction and stop code for forward or backward positioning

idling.

9. Needle stops at down position

This function is intended to quilt embroidering at replacing the fabric. Press

in the main screen and then the option “neddle stops down”. When pressing “ ”, the

needle will prick into the embroidery cloth and a prompt will appear. After releasing the

cloth (cloth has to be separated from the frame), move the frame to the designated

position and press “ ”. After this operation, the needle is still down. When the cloth

is placed on the frame again, press to turn the main shaft to 100º manually.

10. Manual operation of pneumatic frame, sequin and special embroidery

This function is functional for the machines that are equipped with pneumatic

frame, sequin and special embroidery devices. For such machines, press and

BECS-D19 User’s Manual

19

Page 30

Chapter 2 Operation Guide

then select the corresponding function item to enter the operation menu.

G. Embroidery Release

When the machine stops, press to display the hint window. Choose “ ” to change

(embroidery confirmation) into (embroidery release).

2.8 Normal Embroidery, Returning and Patch Embroidery

In embroidery confirmation status (the icon appears), push the switch of machine

head (which need perform normal embroidery) to the nor mal embroidery mode, and push the

switch of machine head that needn’t embroider to the down position, and then pull the

operation bar to right and release it to let the machine start normal embroidery. (When you pull

the bar to the right end and don’t release it, the machine will embroider at low speed.) During

the embroidery, pull the bar to left, the machine will stop.

After the machine stops, pull the operation bar to left and the frame will return to its last

position along original path. Pull the bar one time, the frame returns one stitch. Pull the bar

continuously and the frame will return one stitch after another continuously. After t he frame

returns 10 stitches continuously, the frame can return continuously even when you release the

bar. (This may be different for different machine types). When the frame returns continuously,

pull the bar to left again, the frame will stop returning.

The aim for returning is usually to perform patch embroidery. After the returning stops,

push the switch on machine head that need perform patch embroidery to go to the patch mode,

and then pull the operation bar to right and the machine head will start patch embroidery while

other heads remain inactive. When the frame goes to the point from which the frame returns,

other heads whose switches are in normal embroidering mode will start to embroider.

2.9 Relationship between Normal Embroidery, Idling and Positioning Idling

Functions like idling, returning, etc. are intended for the convenience of patching.

Low-speed idling, high-speed idling or positioning idling can be used as needed in embroidery.

In the status of idling, the returning function also has low-speed idling returning, high-speed

idling returning or positioning idling returning.

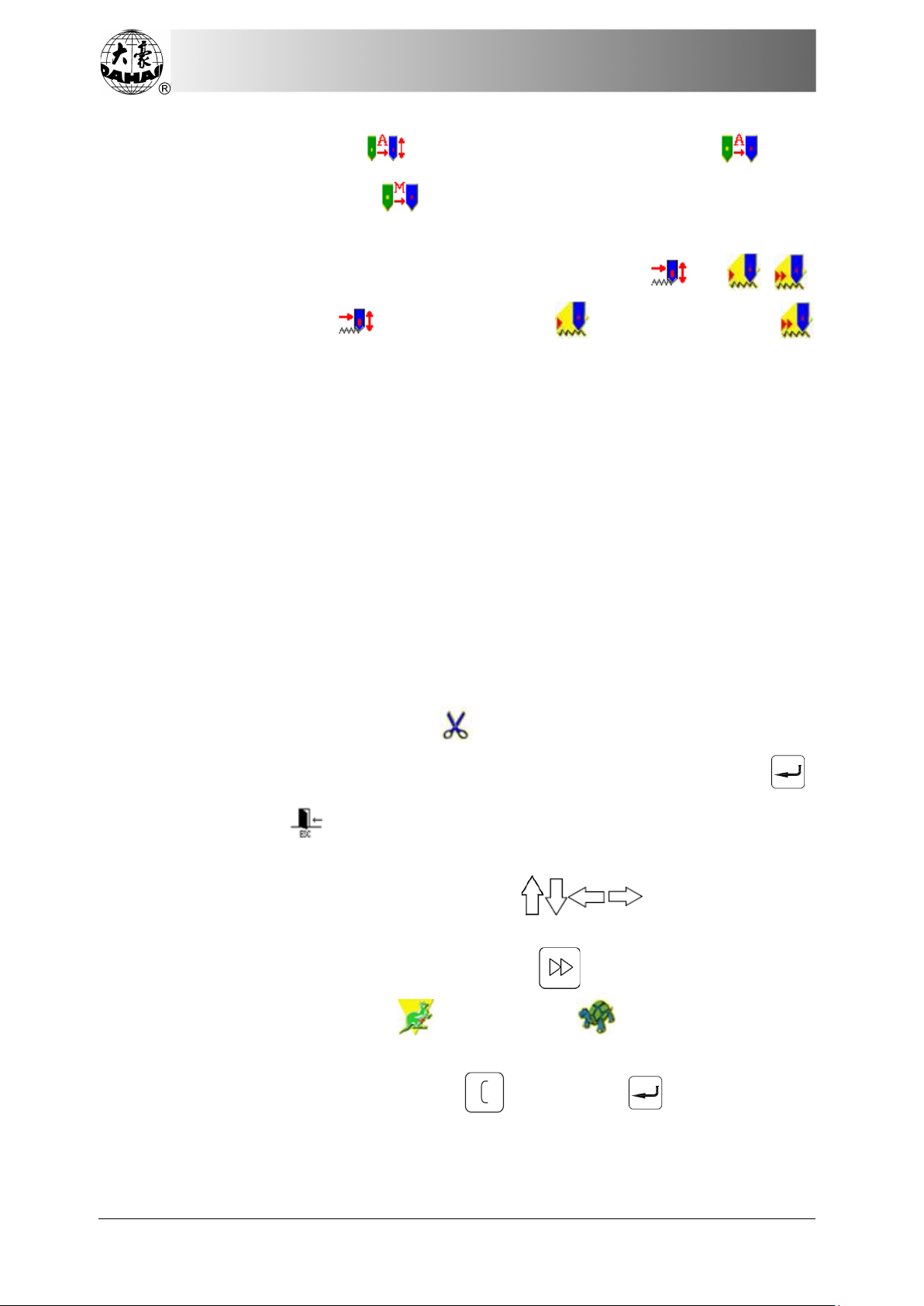

In the main screen, you may press “ ” (or “ ”, “ ”) to shift among “ ”

(normal embroidery), “ ” (low-speed idling) and “ ” (high-speed idling).

After user sets low-speed idling , the main shaft remains inactive when user pulls the

bar for normal embroidery, but the frame runs forward along the stitch trace. When user pulls

20

BECS-D19 User’s Manual

Page 31

Chapter 2 Operation Guide

bar for returning, the main shaft keeps inactive, but the frame returns along the stitch trace.

After user sets high-speed idling , the main shaft and frame remain inactive, the stitch

number increases. After user pulls the bar for halting, the frame moves directly to the actual

position of the current stitch number. When user pulls bar for returning, the main shaft and

frame keep inactive, but the stitch number decreases. After user pulls the bar for halting, the

frame returns directly to the actual position of the current stitch number.

The positioning idling can move the frame directly forward (or backward) to a designated

position, or to the latest color-change position, or even to the latest stop-code position. In the

main screen press and the user can select forward/backward positioning idling by

stitche number, color change code or stop code. After the system returns to the main screen,

user can pull the bar forward /backward to complete the positioning idling.

2.10 Embroidery Operation Bar and Turn Shaft Button

A. Embroidery operation bar (embroidery bar or operation bar, under the table)

Stop Status:

Pull the bar to right to start embroidery (including low-speed idling and

high-speed idling)

Pull the bar to left to return (including low-speed idling and high-speed idling)

Running Status:

Pulling the bar to the right end is to embroider slowly and r eleasing the bar will

resume the normal speed.

Pulling the bar to left is to stop embroidery.

B. Turn shaft button (on the operation bar case, at right side under the table)

Press the button to make the main shaft rotate one circle and stop at 100±2.5°.

2.11 Thread Breakage Detection and Patch Embroidery Sw itch

Based on different working principles, thread-breakage detection devices are divided into

three types: thread take-up spring type, thread winding wheel (chopper wheel) type and mixed

type.

For thread take-up spring type, it warns thread-breakage by detecting connection of

take-up spring and contact point. When thread breaks, the spring will close to the contact point.

In normal condition, this detection device reacts sensitively to upper thread breakage, but can

hardly detect bobbin thread run-out. In case you change the embroidery thread, or thread

tension changes, you need to adjust spring pressure between the take-up spring and contact

point. When the spring pressure is too large, there will be False Positive; when the spring

pressure is too small, there will be False Negative.

For thread winding wheel type, it judges thread-breakage by checking the winding wheel

angle. It reacts very sensitively in case of upper thread breakage; in most cases of bobbin

thread run-out, the consumption of upper thread will reduce, as a result, system will judge by

BECS-D19 User’s Manual

21

Page 32

Chapter 2 Operation Guide

statistic method and send out warning. Though it can almost avoid False Negative, it is not as

sensitive as the spring-type.

For the mixed type method, these two detection methods can complement each other with

their advantages, which results in sensitive and stabilized detecting effect.

No matter which method you use, there is one switch and one status light on each machine

head. There are three positions to switch but only two positions can be locked. When you

switch to the down position, status light does not shine, which means the head stops

embroidering. When you switch to the middle, status light is green, which means the head is

now in normal embroidery. In case of thread-breakage, machine stops and status light on that

particular head turns red. System automatically changes to patching mode on that head. If you

want to set a single head to patching mode manually, you can switch to the upper position,

which can not be locked. When you release the switch, it returns to the middle. Meanwhile,

status light on this head will turn red to indicate that patching mode is available on this head.

2.12 Working Status

The machine has three working statuses:

1. Preparation status

other preparation works;

2. Embroidery confirmation status - confirm the parameter settings to enter the

quasi-running status;

3. Embroidery running status - embroider the pattern.

How to shift among the above working statuses?

In preparation status ( is displayed), after selecting embroidery pattern from the

memory and setting the parameters, user needs press “ ” and “ ” to enter embroidery

confirmation status (

embroider, which means the machine is in embroidery running status ( is displayed).

In embroidery running status ( is displayed), pull the bar to left t o stop, and now the

- preset parameters; choose embroidery patterns and perform

is displayed). User should pull the embroidery bar to right to

machine is in embroidery confirmation status (pull the bar to right again and the machine goes

into embroidery running status).

In embroidery confirmation status ( is displayed), first press “ ” and then press

“ ” to release embroidery confirmation status. Now the machine enters preparation status

(

22

is displayed).

BECS-D19 User’s Manual

Page 33

Chapter 3 Disk Management

Chapter 3 Disk Management

In disk management interface, users can input the pattern data from disk to machine, and

vise versa; meanwhile, users can conduct some common disk managing actions, like erasing

file or catalogue, formatting disk, etc. Floppy disk (external device) and USB disk are both

supported. Users can save pattern data based on different types. The system recognizes formats

like DOS, FDR and ZSK. However, FDR and ZSK files are read only and cannot be deleted,

formatted and outputted. Pattern formats like DSB, DST and DSZ can be read. For data output,

pattern data will be saved as DSB format.

3.1 Disk Selection

Since the system supports more than one storage device, please choose the target disk.

A. Press in the main screen

B. System will display current disks. Press the icon of the intended disk and press

“ ” or to quit.

In this selelction window, all the storage devices will be displayed. Their information

includes the icons, words and numbers. The icon is the device type. means USB dis k and

means floppy disk. Words mean volume lable (if there is no volume lable, default words

will be used) and the numbers within the brackets mean the digital ID of the disk.

C. Enter Disk Management Interface

BECS-D19 User’s Manual

23

Page 34

Chapter 3 Disk Management

No.

Icon

Name

Description

1

File List

Display the pattern files and folders of the disk in

icons. It’s used to select files

2

Pattern Preview

Display the shape of selected pattern and its

information.

3

Single/Multiple

multiple-selection.

4

Select All

(only available under multiple-selection mode).

5

Pattern Input

Copy pattern from disk to memory

6

Pattern Output

Copy pattern from memory to disk

7

Previous

Directory

Return to the previous directory

8

Refresh Disk

Refresh current disk directory

9

Create New

Directory

Create new directory within the disk

10

File Deletion

Delete the seleted file

Press to turn page; press to turn the page of patterns.

Seletion

Shift between single-selection and

Select all items with the current directory

24

BECS-D19 User’s Manual

Page 35

Chapter 3 Disk Management

No.

Icon

Name

Description

11

Disk Formatting

Format current disk

12

Letter

Embroidery

Conduct letter embroidery

13

Help

Display the online help at the disk management

interface.

14

Current Browse

Path 15

Page Information

Display the current page and total page number

16

Memory

Capacity

Display the memory capacity and the remaining

space

17

Pattern Date

Only pattern file can be displayed

18

Pattern Stitch

Number

Display the stitich number (only available for

pattern file)

19

Object Name

Pattern file name or directory name

20

Object Icon

Icon represents the file type:

: directory

: DSB pattern

: DST pattern

3.2 Pattern Preview

1. In the disk management interface, press “ ” to select the pattern for

preview.

BECS-D19 User’s Manual

25

Page 36

Chapter 3 Disk Management

Pattern files and folders are shown by icon in the list. Each page contains 20 objects. If the

objects are more than 20 in current directory, please turn to another page to look for other

patterns. You can also use to find pattern in other pages. The selected object has

a blue frame.

2. Press to display as follows:

The system loads the data from the disk and displays the pattern’s image according to a

26

BECS-D19 User’s Manual

Page 37

Chapter 3 Disk Management

certain ratio. At the same time the pattern’s peripheral information and color-changing number

will be displayed.

Note: User can select more than one pattern for preview. For selecting more than one

pattern, please refer to chapter 3.3.

3.3 Single/Multiple Selection

Before preview, input and deletion of patterns, the target pattern has to be selected first.

The user can select one object or several objects at one time to improve efficiency.

1. Press “ ” to select objects

By default setting, the first object in the page is selected while others are not selected.

Press “ ” to select, and then the icon and word information of the selected

pattern will be showed within the blue square.

2. Single/multiple selection switch

When user selects the objects, the system is in single or multi-selection mode. In

single-selection mode, only one object can be selected and selecting another object will

automatically cancel the last selection. Press the switch key to shift between the two modes. In

multi-selection mode, user can select several objects. In the single selection mode the switch

key displays as , while in the multi-selection mode it displays as .

3. Select several objects for operation in order

In multiple-selection mode, user can press “ ” to select the object and then

press “ ” to confirm the selection, and repeat the same operation to make multiple

selections. If user need cancel any selection, move to the selected object and press “ ”

again to cancel.

BECS-D19 User’s Manual

27

Page 38

Chapter 3 Disk Management

4. Press to select all

The key is effective only in the multi-selection mode, where pressing this key will have all

the objects within the directory selected.

3.4 Pattern Input

To input pattern data from disk to the machine’s memory, the user has to select files from

one or more disks first, and then input the pattern number and name for the file to be saved.

1. Select one or more files in the disk;

2. Press and the system will require user to input the pattern number and name in

the memory;

3. Input the pattern number and name in the memory.

The system provides the minimum available pattern number as the default value, when

user enters the interface for inputting the pattern number and name in the memory. User can

28

BECS-D19 User’s Manual

Page 39

Chapter 3 Disk Management

use the keyboard to change the value. When several patterns are inputted at one time, the user

can only input the number of the first pattern.

At modifying the pattern number and name, the system will first change the pattern

number. After the modification, press “ ” and the system will automatically enter the item

for changing pattern name. Please input the name following the hints.

4. Press “ ” and the system will save the pattern data in memory.

3.5 Pattern Output

User can output pattern data from memory to the current disk.

1. Press

2. Select the pattern for output

The system displays the list of patterns saved in memory. User can select patterns for

output, and then press “ ”.

3. Input pattern number and name in the disk

BECS-D19 User’s Manual

29

Page 40

Chapter 3 Disk Management

System uses the pattern name in memory as the default name in disk. User can use the

keyboard to change the corresponding value.

The method of modification is the same as that in “Pattern Input”. User need press “ ”

to save the modification.

4. System will return to disk management interface and refresh the file list of the current

directory. At any previous step, user can press “ ” to quit.

3.6 Directory Operation

1. Enter the directory

Select the directory and press “ ”. System reads the item list of the directory and

refreshes the interface.

2. Return to previous directory

Press “ ” and system will return to previous directory and refresh the interface.

3. Create new directory

Press “ ” and system will display a dialogue box for user to input the name for the

new directory. Press “ ” to create the new directory and system will refresh the current

directory list.

3.7 Delete Disk File (Including Pattern File and Directory)

1. Select one or several objects for deletion (See 3.3)

30

BECS-D19 User’s Manual

Page 41

Chapter 3 Disk Management

2. Press

3. System will remind you to confirm the deletion

4. Press “ ” to delete and press “ ” to quit.

Note: If user chooses to select the directory for deletion, system will delete all the files

and sub-directory in this directory. If a file has the property of “only read” or “disk writeprotection”, the file will not be deleted.

3.8 Disk Formatting

1. Select the disk to be formatted (See 3.1)

2. Press “ ”

BECS-D19 User’s Manual

31

Page 42

Chapter 3 Disk Management

System will display the disk formatting box, where will be displayed the storage

information of the current disk, warning information for disk formatting and formatting process

bar as well as Start and Return button.

3. Press “ ”

System will begin to format the disk and show the speed with a process bar. After

formatting, the system will display a hint to show formatting success. Press the Return key to

return to the disk management interface.

Note: system will format the disk in DOS format.

32

BECS-D19 User’s Manual

Page 43

Chapter 4 Memory Pattern Management

Chapter 4 Memory Pattern Management

Memory pattern management includes embroidery pattern selecting, settings and transfer

and creation.

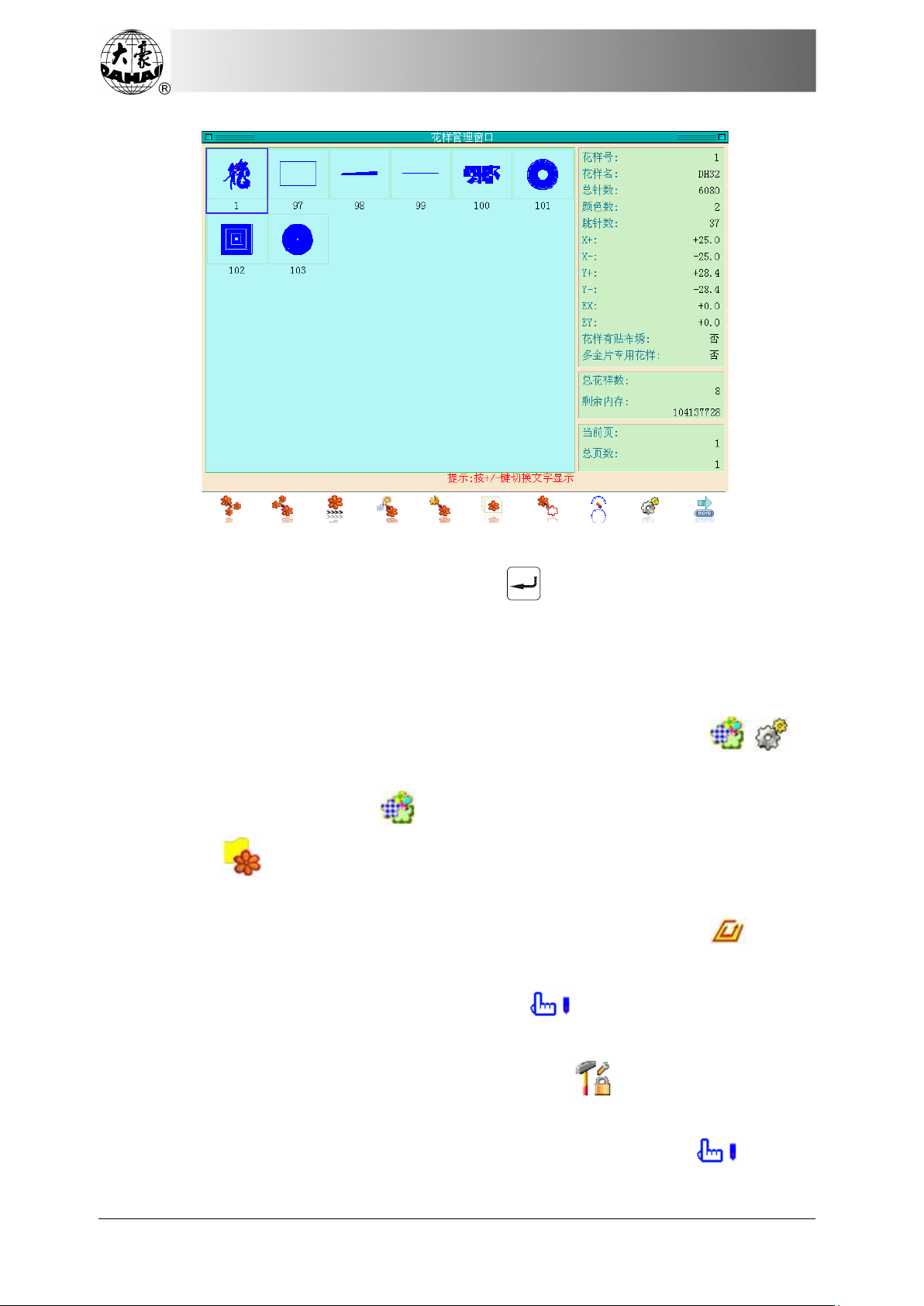

4.1 Memory Pattern Management Interface and Other Instructions

Press in the main interface to enter the memory pattern management interface.

The memory pattern management interface includes: pattern display area, information

area and function menu area. The pattern image display area can show 9 patterns at most;

beyond that, more pages will be needed. The function menu area is used for preview and order

setting.

BECS-D19 User’s Manual

33

Page 44

Chapter 4 Memory Pattern Management

34

BECS-D19 User’s Manual

Page 45

Chapter 4 Memory Pattern Management

No.

Icon

Name

Description

Pattern Amount and

Memory Information

Display the total number of patterns and the

memory information

Pattern Information

Display

Display the related information of selected

pattern

Browse Pattern

Display pattern files in the memory in icon,

mainly for the purpose of selection

Page Information

Display the current page number and total

number of pages

Select Pattern

In embroidery preparation status, press this

modifications

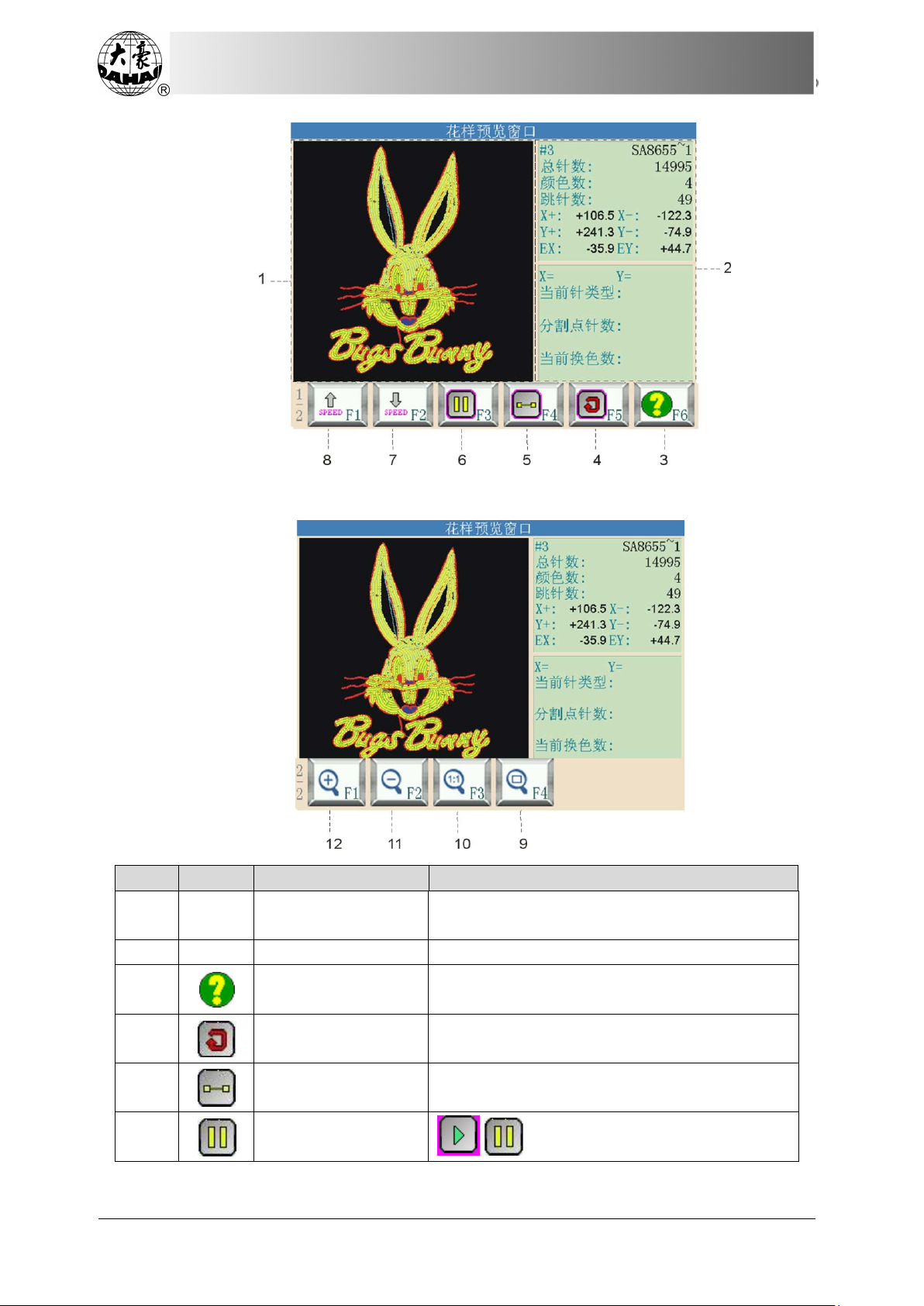

Pattern Preview

This key is used to view the details of the

analog display the pattern

Disk Operation

More disk operation, please see chapter 3

Copy Pattern

Press this key to enter pattern copying

interface

Edit Pattern

See chapter 8, how to edit selected or new

pattern

Press to shift among pages; press to shift page of patterns.

1

2

3

4

5

6

key to enter modification interface of pattern

parameters and the pattern will be used for

embroidery after confirming such

pattern, and to scale up/down, move or

7

8

9

BECS-D19 User’s Manual

35

Page 46

No.

Icon

Name

Description

10

Delete Pattern

Press this key to delete selected pattern

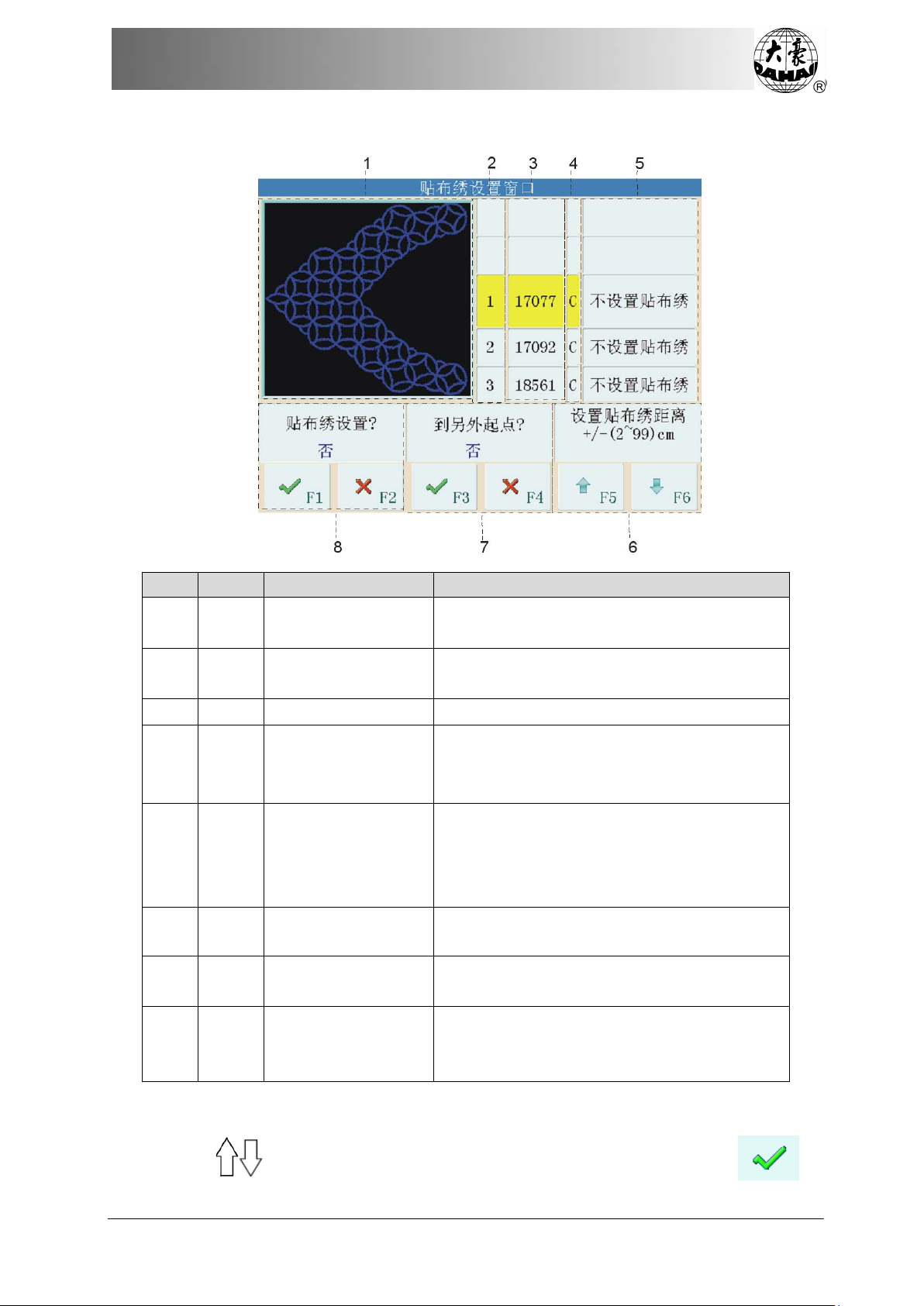

Appliqué Pattern

Setting

Press this key to enter appliqué pattern

setting

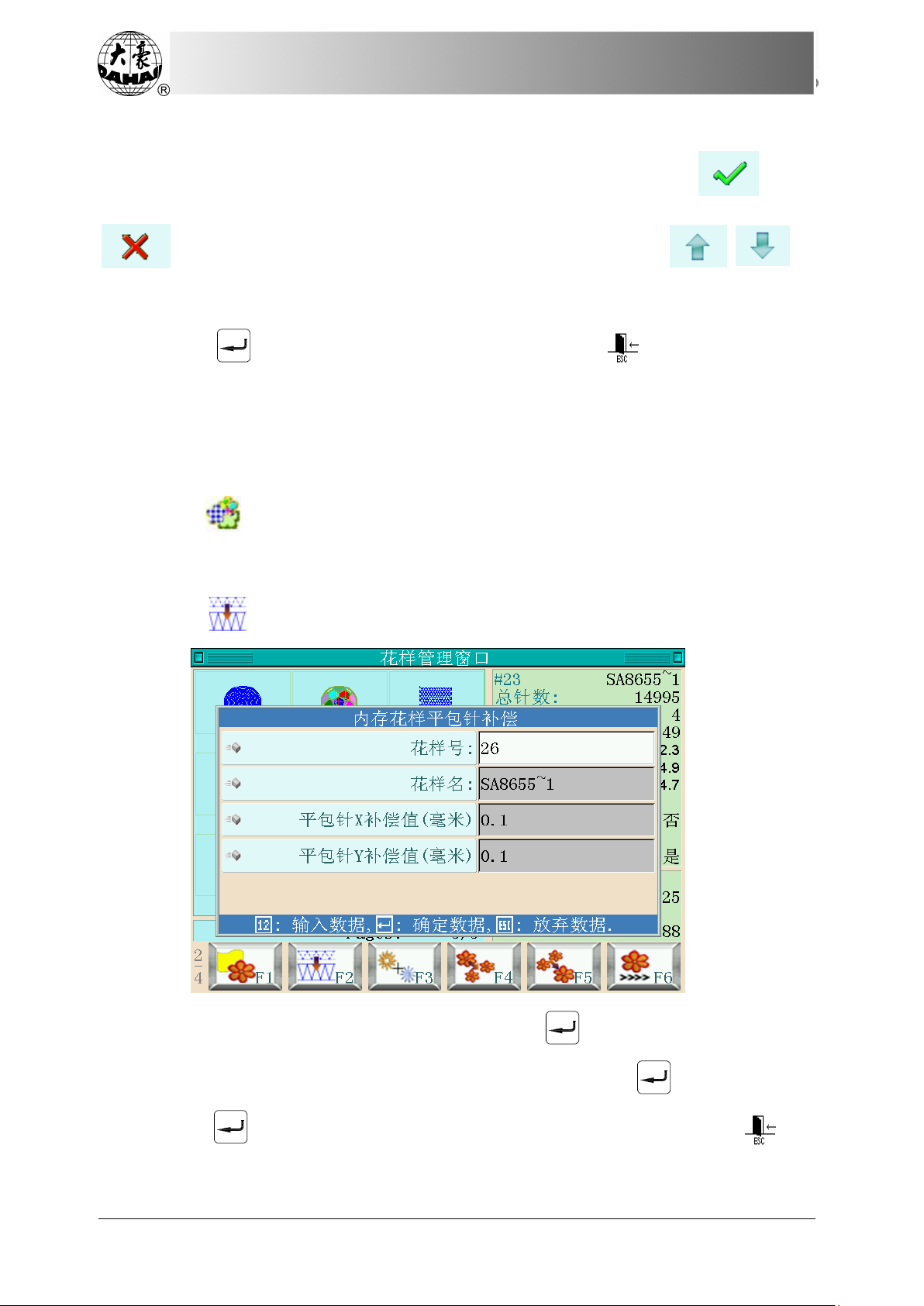

Satin Stitch

Compensation

Set the satin stitch compensation of the

memory pattern

Edit Combined Pattern

Press this key to enter edit interface of

combined pattern

Devide Pattern

Separate one pattern into two patterns

Integrate Patterns

Combine two patterns into one pattern

Generate High-speed

Pattern

Press this key to enter interface for

generating high-speed pattern

Generate Standard

Pattern

This function is used to generate standard

Generate Pattern by

Parameters

To generate pattern by embroidery

parameters

Generate Pattern by

Frame-moving

Press this key to enter the interface for

generating pattern by frame-moving

Generate Outline

Pattern

Press this key to enter the interface for

pattern

Copy Pattern with

Varied Stitch Length

Copy pattern according to the set stitch

length

Pattern Parameter

Operation

Press this key to enter pattern parameter

operation

Input Pattern from PC

Press this key to input pattern from PC

Letter Embroidery

Press this key to enter letter embroidery

operation (See chapter 9)

Help

Display the online help for pattern

management interface

Clear All Patterns

Press this key to clear all selected patterns

from memory

11

Chapter 4 Memory Pattern Management

12

13

14

15

16

17

18

19

20

Pattern from Combined

Pattern from Normal

pattern from combined pattern

generating outline pattern from normal

21

22

23

24

25

26

See the following specifications for each operation. Press the key “ ” to return to the

memory pattern management menu.

36

BECS-D19 User’s Manual

Page 47

Chapter 4 Memory Pattern Management

4.2 Select One or Several Patterns

Before any operation on patterns, you must select the target patterns. You can select one

pattern or select several patterns at a time to improve efficiency.

1. Press “ ” to select targets

By default, the first item in the page is the selected one. Press “ ” key or

directly use the pattern number key to select others. The icon and words of the selected target

appears within the blue squares.

During selection, if system is in multi-selection mode, user can select several objects.

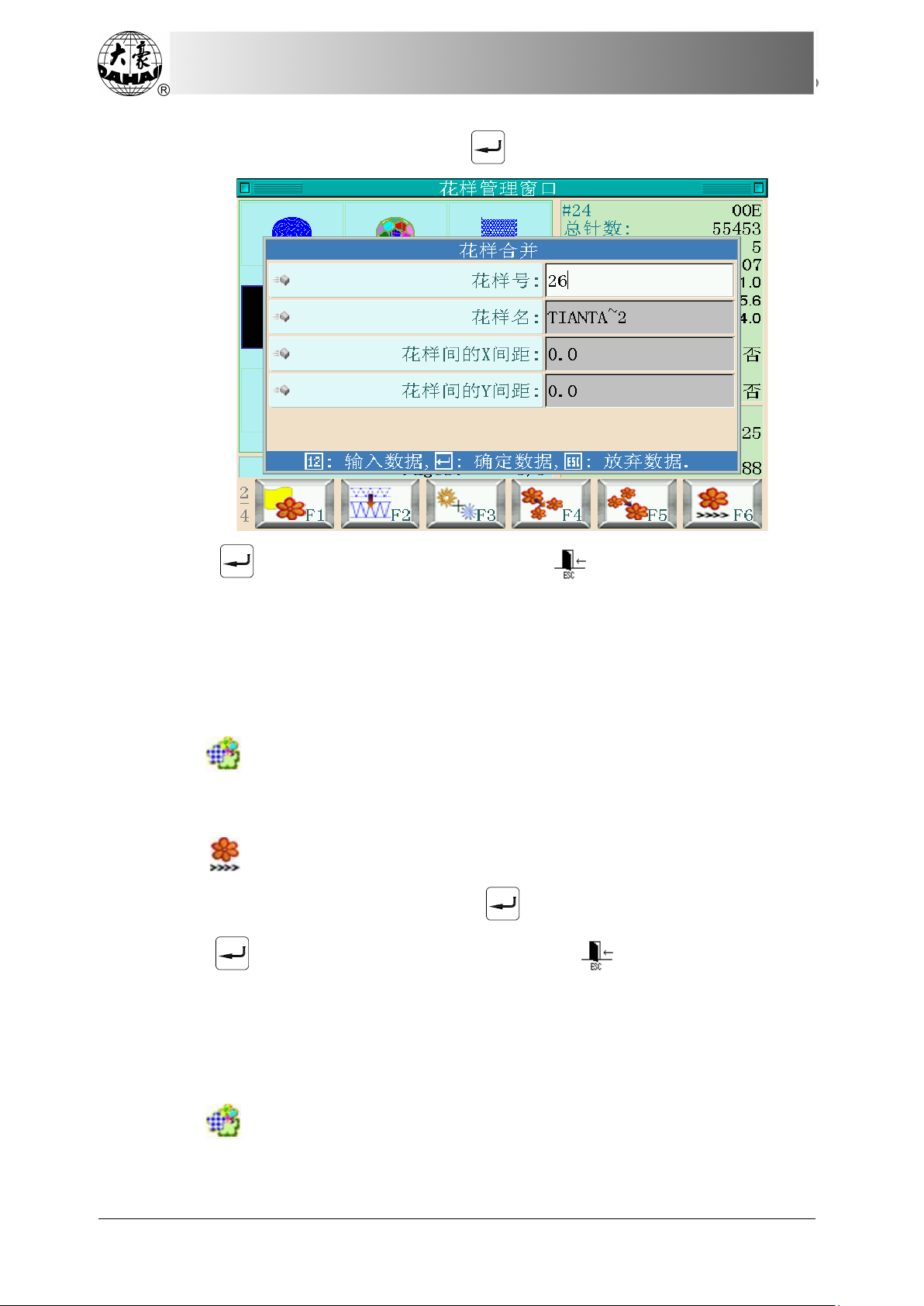

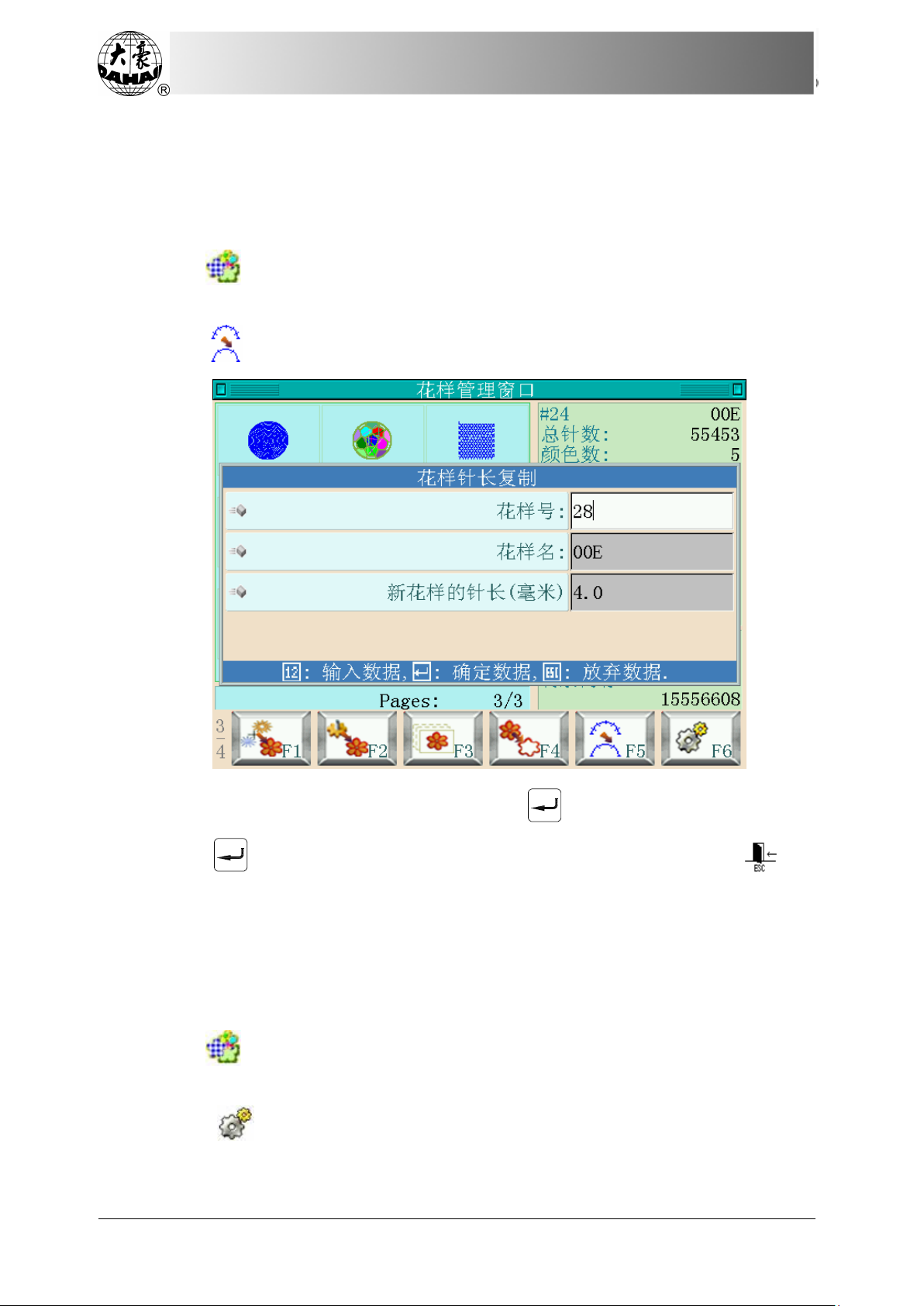

2. Select several patterns in order