Daewoo WP-811 Service Manual

S/M No: TWP811MEF0

Service Manual

Colour Television 66 Cm WIDE STEREO

CHASSIS : WP-811

MODEL :DTW - 28W2F

DTW - 2810F

Specifications

CRT

SYSTEM

MAIN VOLTAGE

POWER CONSUMPTION

SOUND OUTPUT

SPEAKER

ANTENNA IMPEDANCE

TUNING SYSTEM

TUNER

NUMBER OF PROGRAM

AUX. TERMINAL

REMOTE CONTROL

TELETEXT

OSD LANGUAGE

28" : W66ECK001X44

PAL / SECAM-B/K, PAL-I/I', SECAM-L/L', NTSC-3.58/4.43 (Play back)

230V AC, 50Hz

Stand-by mode : 2.0 Watts

Normal operating mode : 100 Watts

10 + 10 Watts, 10% THD at RF 60% mod. (1 kHz )

12W 8 ohm x 2 EA

75 ohm unbalanced input ( Din Standard )

Frequency Systhesize (FS) Tuning System

DT5-BF14D

100 program

21 pin EURO-SCART jack (AV input, TV output, RGB input)

21 pin EURO-SCART jack (AV input, S-VHS input)

RCA type AV input jack

Headphone jack (3.5 mm )

JACK AUDIO TERMINAL (AUDIO OUT L, R)

R-22D05(or R-23D05) with 2 "AAA" type batteries

TOP(5 Page memory) & FLOF(7 Page memory)

- West option : English, German/Dutch/Flemish, French, Italian, Spanish/Portuguese,

Swedish/Finnish/Danish, Hungarian, Rumanian, Turkish

- East option : Polish, Czech/Slovak, Rumanian, Servo-croat, German/Dutch/Flemish,

French, Estonian, Lettish

- West : English, German, French, Italian, Spanish, Nethelands, Swedish

- East : English, Russian, Polish, Rumanian, Czech, Hungarian

DAEWOO ELECTRONICS CO., LTD

http://svc.dwe.co.kr JUN.2000

TABLE OF CONTENTS

SAFETY INSTRUCTION .................................................................................................................. 2

SPECIFICATIONS ............................................................................................................................ 3

CIRCUIT BLOCK DIAGRAM ........................................................................................................... 4

ALIGNMENT INSTRUCTION ........................................................................................................... 5

SCHEMATIC DIAGRAM .................................................................................................................. 11

EXPLODED VIEW ............................................................................................................................ 13

PRINTED CIRCUIT BOARD ............................................................................................................ 15

SERVICE PARTS LIST .................................................................................................................... 16

APPENDIX (" Appendix is provided only by internet [http://svc.dwe.co.kr] ")

IC DESCRIPTION ............................................................................................................................. 1

IC DC VOLTAGE CHARTS .............................................................................................................. 18

1

SAFETY INSTRUCTION

WARNING

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can prodece potentially hazardous X-RAY RADIATION. To avoid such hazards,

the high voltage must not exceed the specified limit.

The nominal value of the high voltage of this receiver is

25-27kv at max beam current. The high voltage must

not, under any circumstances, exceed 30kv.

Each time a receiver require servicing, the high volt-

age should be checked. It is imprortant to use an accurate and reliable high voltage meter.

: Only competent service personnel may carry out work involving the testing or repair of this equipment

2. The only source of X-RAY Radiation in this TV receiver

is the picture tube. For continued X-RAY RADIATION

protection, the replacement tube must be exactly the

same type tube as specified in the parts list.

SAFETY PRECAUTION

1. Potentials of high voltage are present when this

receiver is operating. Operation of the receiver outside

the cabinet or with the back board removed involves a

shock hazard from the receiver.

1) Servicing should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high-voltage equipment.

2) Dischange the high potential of the picture tube

before handling the tube. The picture tube is highly

evacuated and if broken, glass fragments will be

violently expelled.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this have

special safety-related characteristics. These characteristics are often passed unnoticed by a visual

inspection and the X-RAY RADIATION protection

afforded by them cannot necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc. Replacement parts which have

these special safety characteristics are identified in

this manual and its supplements, electrical compo-

2. If any Fuse in this TV receiver is blown, replace it with

the FUSE specified in the Replacement Parts List.

3. When replacing a high wattage resistor ( oxide metal

film resistor ) in circuit board, keep the resistor 10mm

away from circuit board.

4. Keep wires away from high voltage or high temperature components.

5. This receiver must operate under AC230 volts, 50Hz.

NEVER connect to DC supply or any other power or

frequency.

nents having such features are identified designated

symbol on the parts list.

Before replacing any of these components, read the

parts list in this manual carefully. The use of substitute

replacement parts which do not have the same safety

characterisitics as specifide in the parts list may create

X-RAY Radiation.

2

SPECIFICATIONS

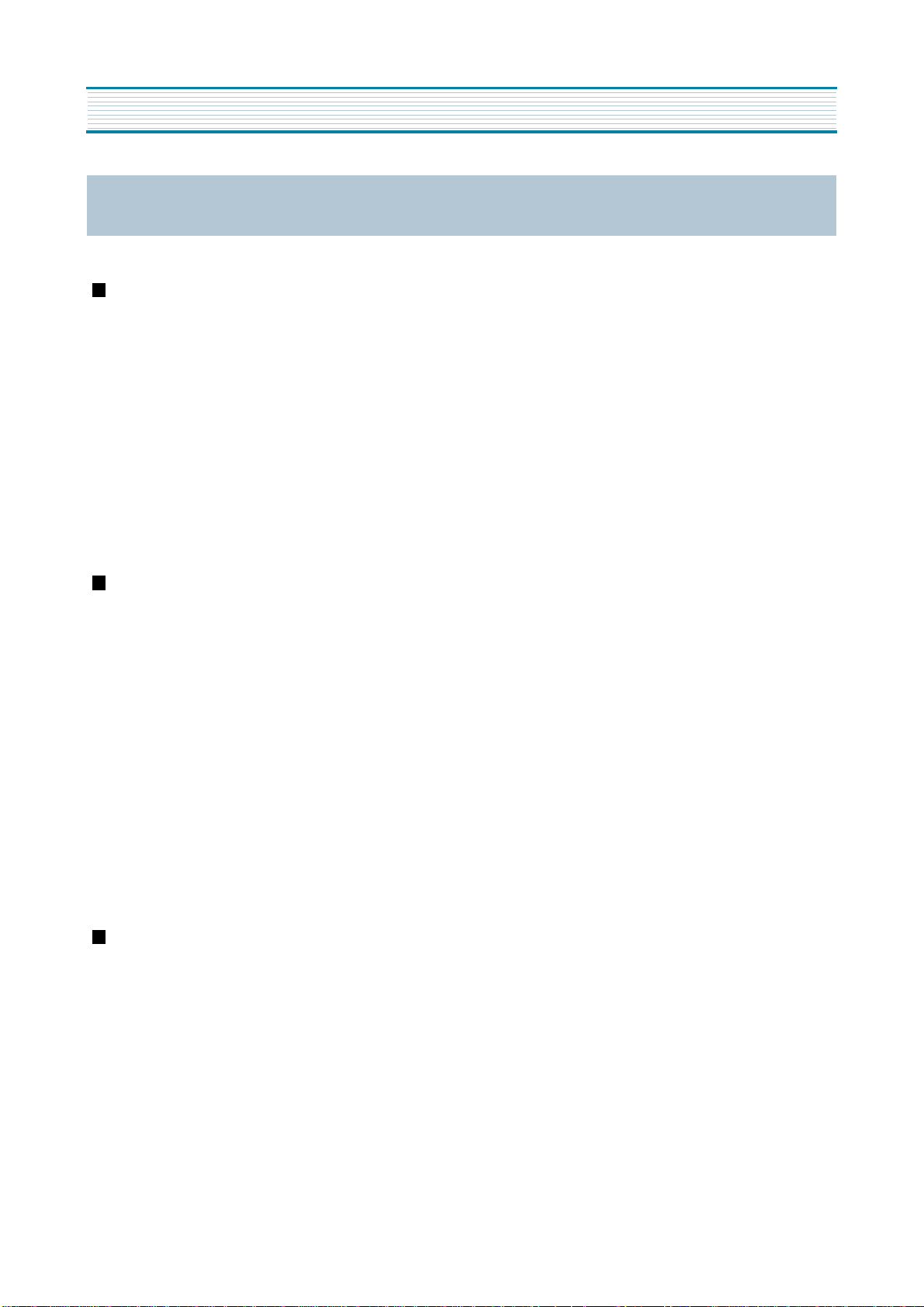

PIN Signal Designation Matching Value

1 Audio Out (linked with 3)

2 Audio In (linked with 6)

3 Audio Out (linked with 1)

4 Audio Earth

5 Blue Earth

6 Audio in (linked with 2)

7 Blue in

8 Slow (Function) Switching

9 Green Earth

10 NC

11 Green In

12 NC

13 Red Earth

14 Rapid(Blanking) Switching Earth

15 Red In, C In

16 Rapid(Blanking) switching

0.5Vrms, Imp < 1 k (RF 60% MOD)

0.5Vrms, Imp < 10 k

0.5Vrms, Imp < 1 k (RF 60% MOD)

0.5Vrms, Imp < 10 k (RF 60% MOD)

+

0.7Vpp 2dB, Imp 75

-

TV : 0-2V, PERI : 9.5 - 12V, Imp > 10 k

+

0.7Vpp 2dB, Imp 75

-

+

0.7Vpp 2dB, Imp 75

-

Logic 0 : 0 - 0.4V, Logic 1 : 1 - 3V, Imp 75

17 Video Earth

18 Rapid Blanking Earth

19 Video Out

20 Video In, Y In

21 Common Earth

+

1Vpp 2dB, Imp 75

-

+

1Vpp 2dB, Imp 75

-

3

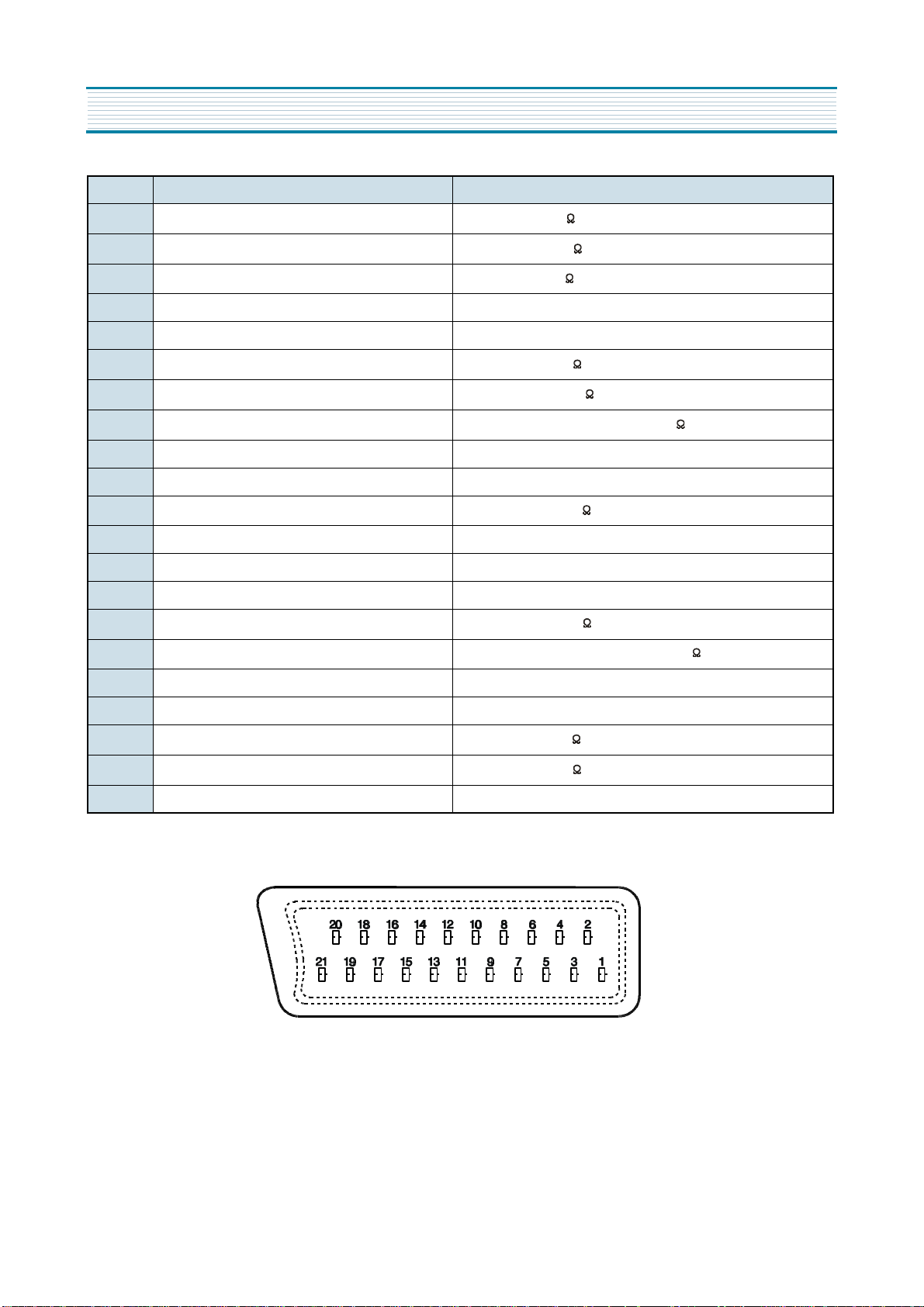

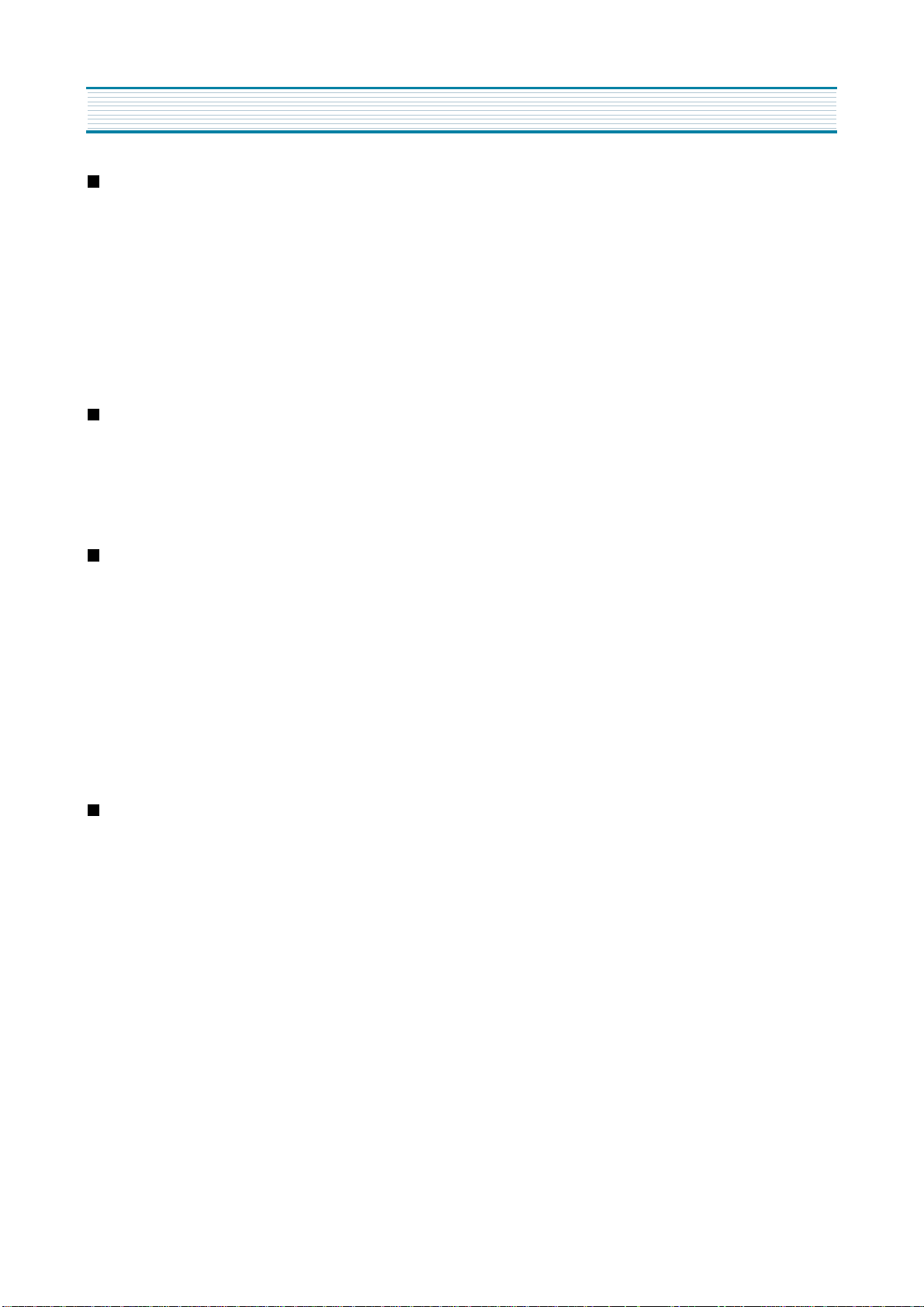

CIRCUIT BLOCK DIAGRAM

4

ALIGNMENT INSTRUCTIONS

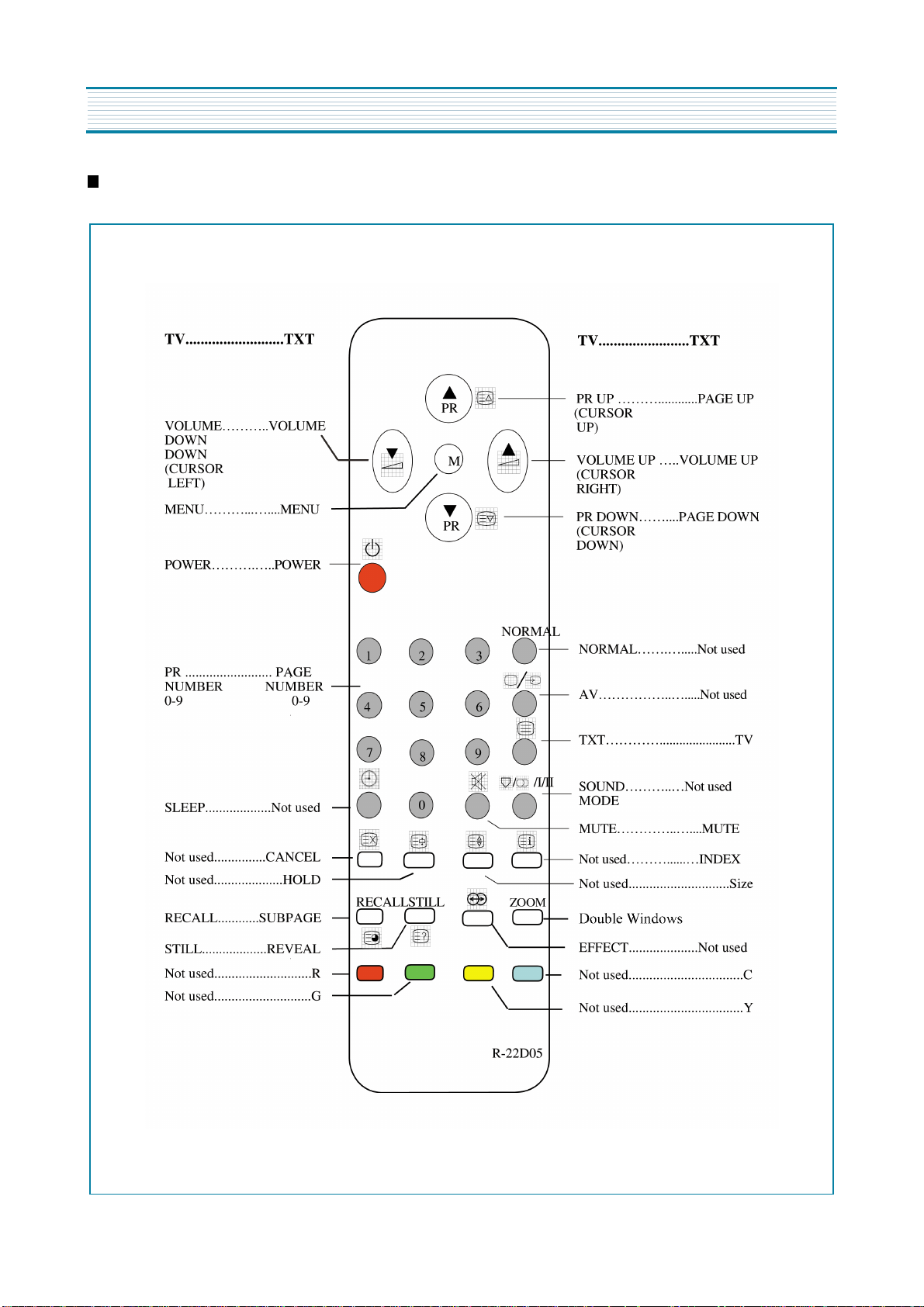

User Remocon

1. R-22D05

5

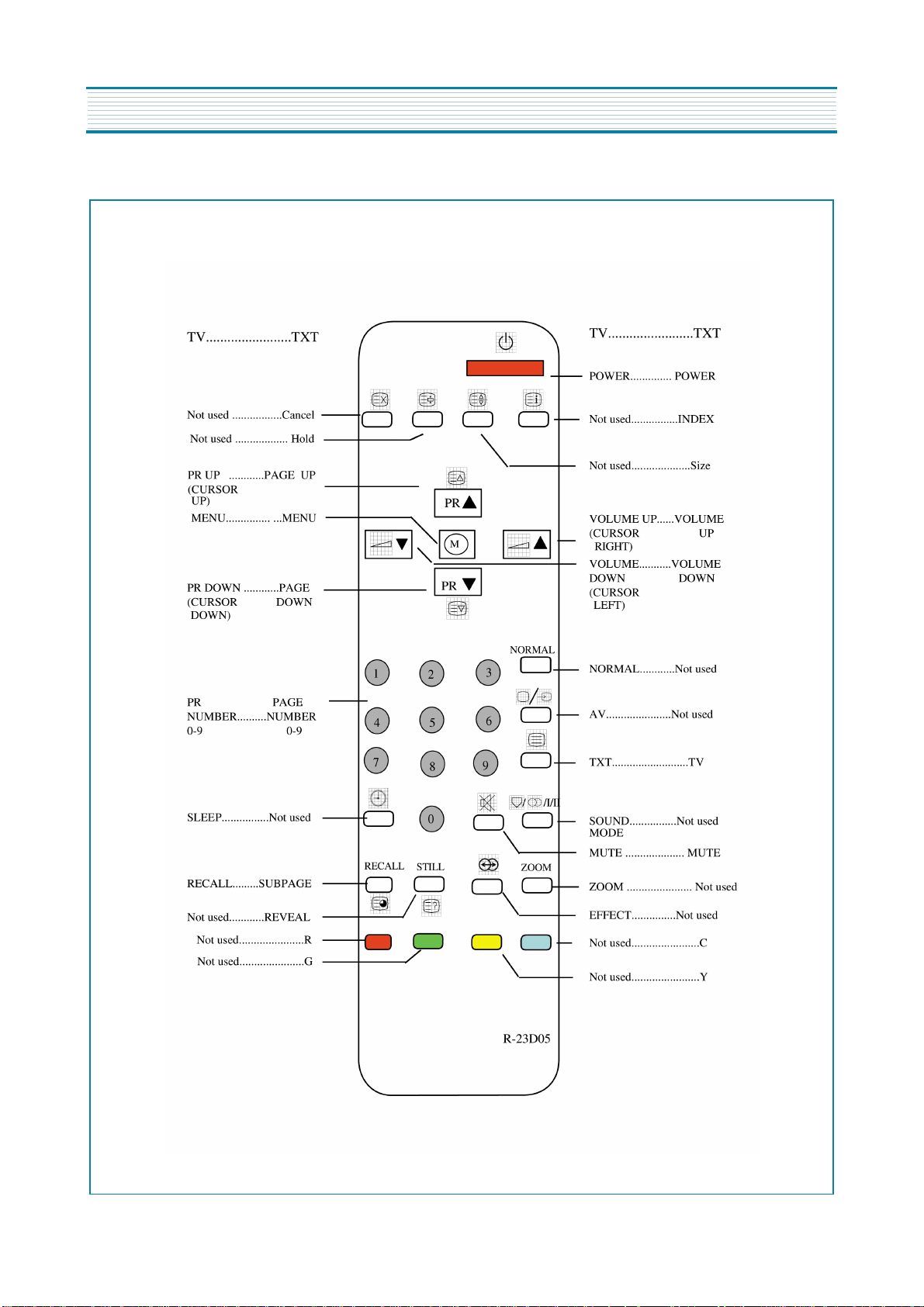

ALIGNMENT INSTRUCTIONS

2. R-23D05

6

ALIGNMENT INSTRUCTIONS

* How to Enter the “ Service Mode ” with user remocon.

1) Set the TV Pr 91

2) Sharpness “ MIN “ control.

3) Red, Green, Yellow buttons in regular sequency within 5 seconds after setting TV power off.

4) You can see the Menu of “ service mode “ on the screen.

5) The PR UP/DOWN buttons on the remote controller are used to move the selection bar up or down the Menus.

6) The VOL UP/DOWN buttons on the remote controller are used to adjust levels.

7) If you want to exit from “ Service Mode “ then power the TV off.

SVC v1

V. Slope

V. Center

V. Size

S. Curve

H. Center

H. Width

EW. Para

EW. Cor T

EW. CB

EW.Sym

R. b

G. b

B. b

R. d

G. d

B. d

G2

Sub Bri

DT

Wide

005

995

220

019

-190

510

382

028

500

021

370

311

311

330

315

330

330

021

048

Yes

- You can see the SVC Menu by OSD in TV set.

7

ALIGNMENT INSTRUCTIONS

AFT

Standard B/G, D/K, I and L

1) Set a Signal Generator with

- RF FREQUENCY = 38.9 MHz,

- RF OUTPUT LEVEL = 80 5dBuV

- Pattern = Color Bar

- System = PAL-B/G

2) Connect the Signal Generator RF Output to TP2 (Tuner IF Output).

There must be no signal input to the tuner.

3) Set the L109 to TP1(I101, #22) with DC Voltage to 2.5V 0.1V

+

-

+

-

AGC

1) Set a Pattern Generator with RF LEVEL 60 3dBuV, RF Frequency 210. 25MHz(10CH), Pattern Color Bar.

2) Connect a OSCILLOSCOPE PROBE to P101 (TUNER AGC INPUT).

3) Set the RBOI to P101(Tuner AGC Input) with DC Voltage to 2.8V 0.2V

+

-

+

-

SCREEN (G2)

1) Set a Pattern Generator with - RF Frequency : 210.25MHz (10CH)

- Pattern : RETMA

2) Select the “G2” in Menu

3) And a Horizontal Line will appear on the screen.

4) Adjust the SCREEN VOLUME on FBT barely to see the Horizontal Line.

5) Press the PR UP/DOWN keys to finish the SCREEN adjustment.

FOCUS

1) Apply a RETMA PATTERN signal.

2) Adjust the FOCUS VOLUME on FBT to obtain optimal resolution.

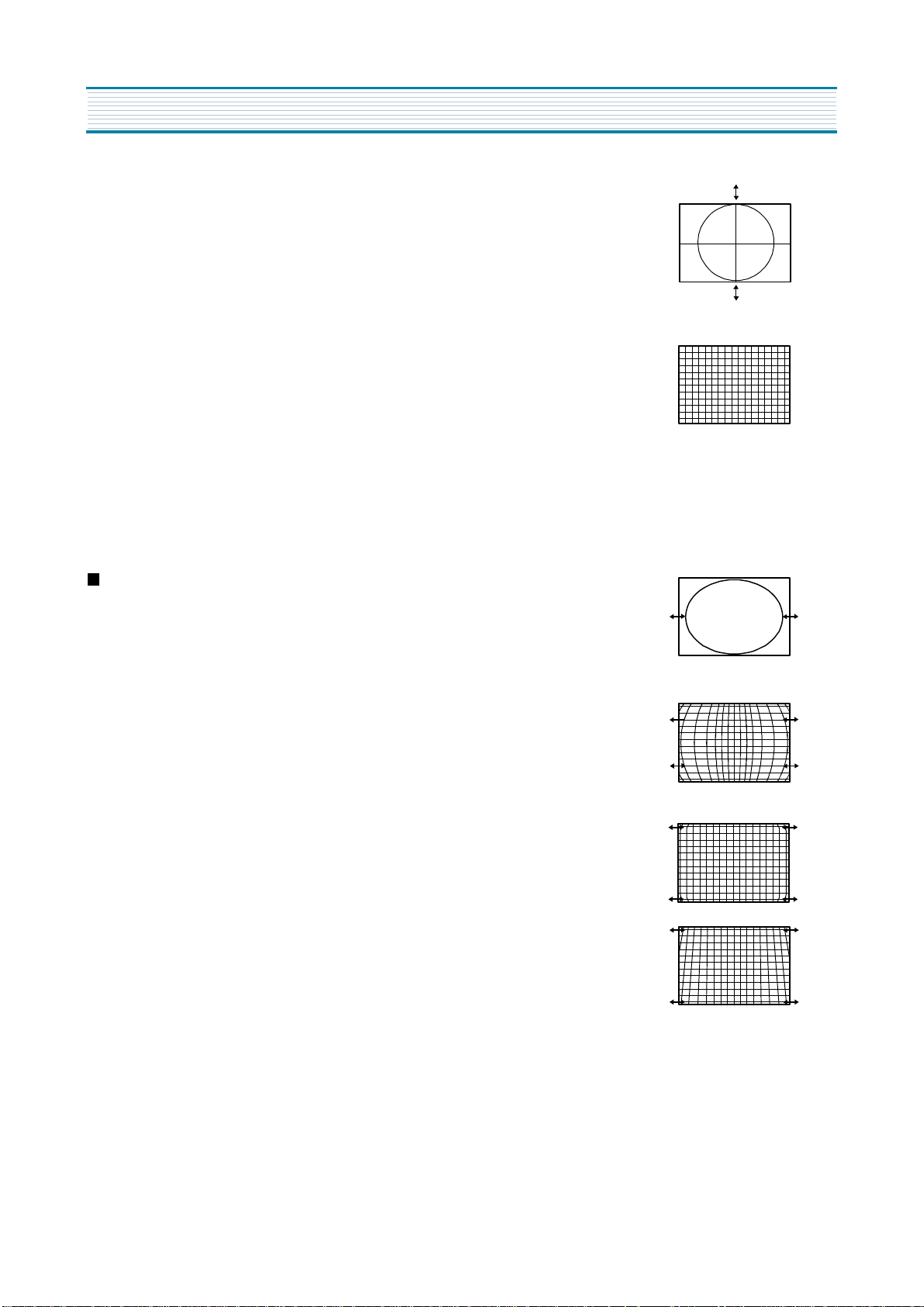

GEOMETRY

1. VERTICAL SLOPE ( Fixed : Adjust if need be )

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the higher semicircle and the lower semicircle to be the same, with the V.Slope

by volume Up/Down keys.

2. VERTICAL CENTER

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the center of the picture with the V.Center by volume Up/Down keys.

8

3. VERTICAL SIZE

* The VERTICAL CENTER adjustment has to be done in advance.

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the VERTICAL SIZE of the picture with the select V.size by

volume UP/DOWN keys.

4. VERTICAL S-CORRECTION ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the S-CORRECTION to obtain the same distance between

horizontal lines with the S.Curve by volume UP/DOWN keys.

5. HORIZONTAL CENTER

1) Apply a RETMA PATTERN Signal.

2) Adjust picture centering with the select H.Center by volume UP/DOWN keys.

ALIGNMENT INSTRUCTIONS

EW

1. WIDTH

1) Apply a RETMA PATTERN Signal.

2) Adjust the horizontal width to make a perfect circle with the select H.Width

by volume UP/DOWN keys.

2. PARA

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the vertical line to straight with the select E.W Para by volume

UP/DOWN keys.

3. CORNER ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the vertical line to straight with the select EW.Cor T by volume

UP/DOWN keys.

4. SYMMETRY ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the symmetrical balance to be suitable with the select EW Sym by

volume UP/DOWN keys.

9

ALIGNMENT INSTRUCTIONS

WHITE BALANCE

1. RGB Reference R

2

2. Beam Reference LOW ( 288, 301 : 10Cd/ )

HIGH ( 288, 301 : 10Cd/ )

m

m

2

3. Adjust G, B Gain with select Menu G,B of BIAS, DRIVE of select Menu so that R, G, B Bars

are on the center position of the analog meter. If R Analog meter is not on center, control

the Brightness +/- of user Remocon so as R Analog meter to be on the center position.

SUB BRIGHT

1. Pattern : Retma

2. Adjust the SUB BRIGHT with the select Sub Bri by volume UP/DOWN keys.

so that only H-Center parts of picture can be seen.

DOUBLE TEXT CENTER

1. Pattern : Pattern RED

2. Select Menu

3. Select DT in SVC menu time to see the Double Text Picture.

( Left : RF Picture, Right : Text Picture )

4. Change the Double Text control keys volume UP/DOWN keys so that the left edge of text

picture concur with the right edge of RF picture.

WIDE MODE

1. Locate the cursor on ‘Wide’ in SVC Menu.

2. ‘Yes’ changes the display to 16:9 mode.

3. ‘No’ change the display to 4:3 mode.

10

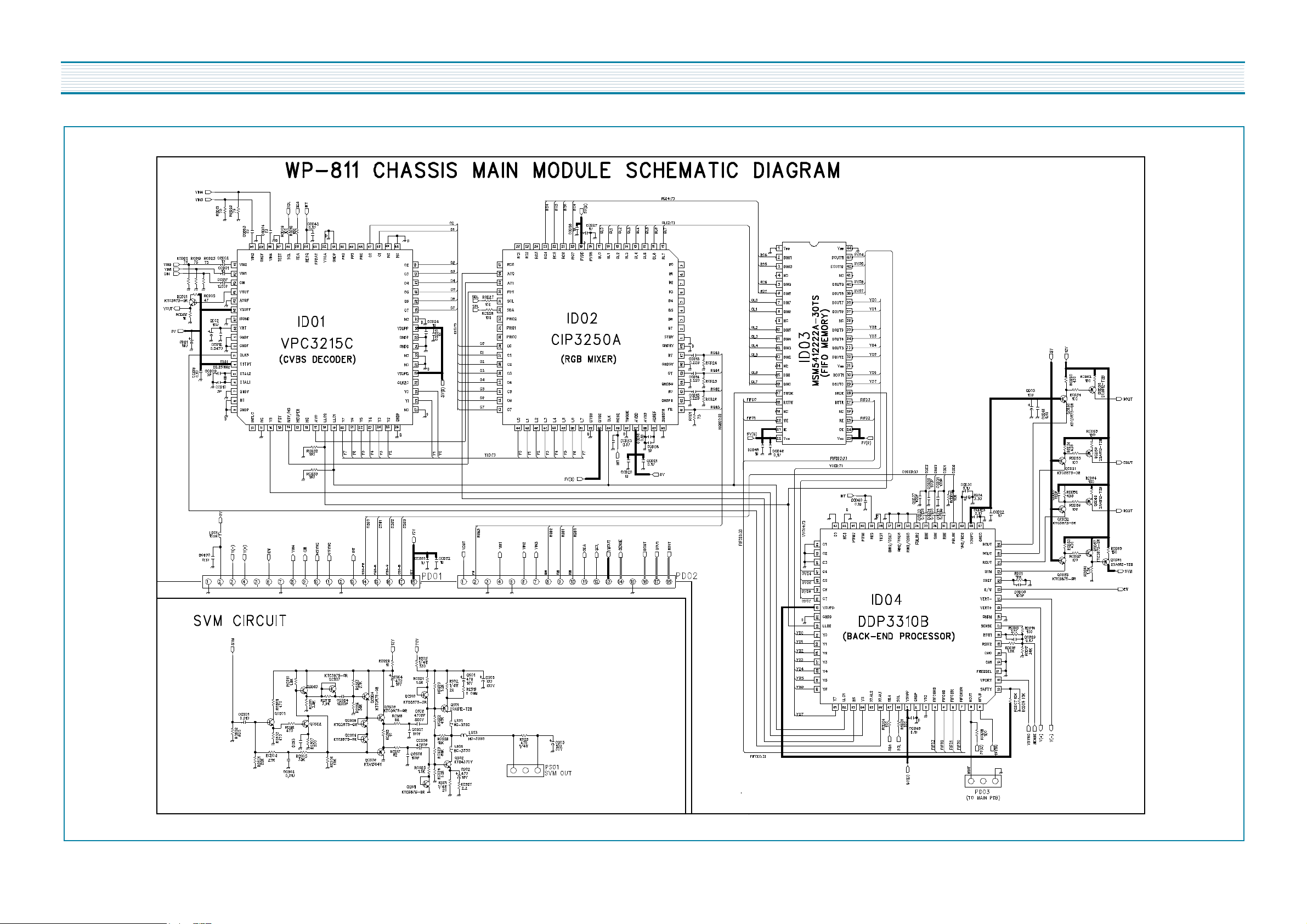

SCHEMATIC DIAGRAM

11

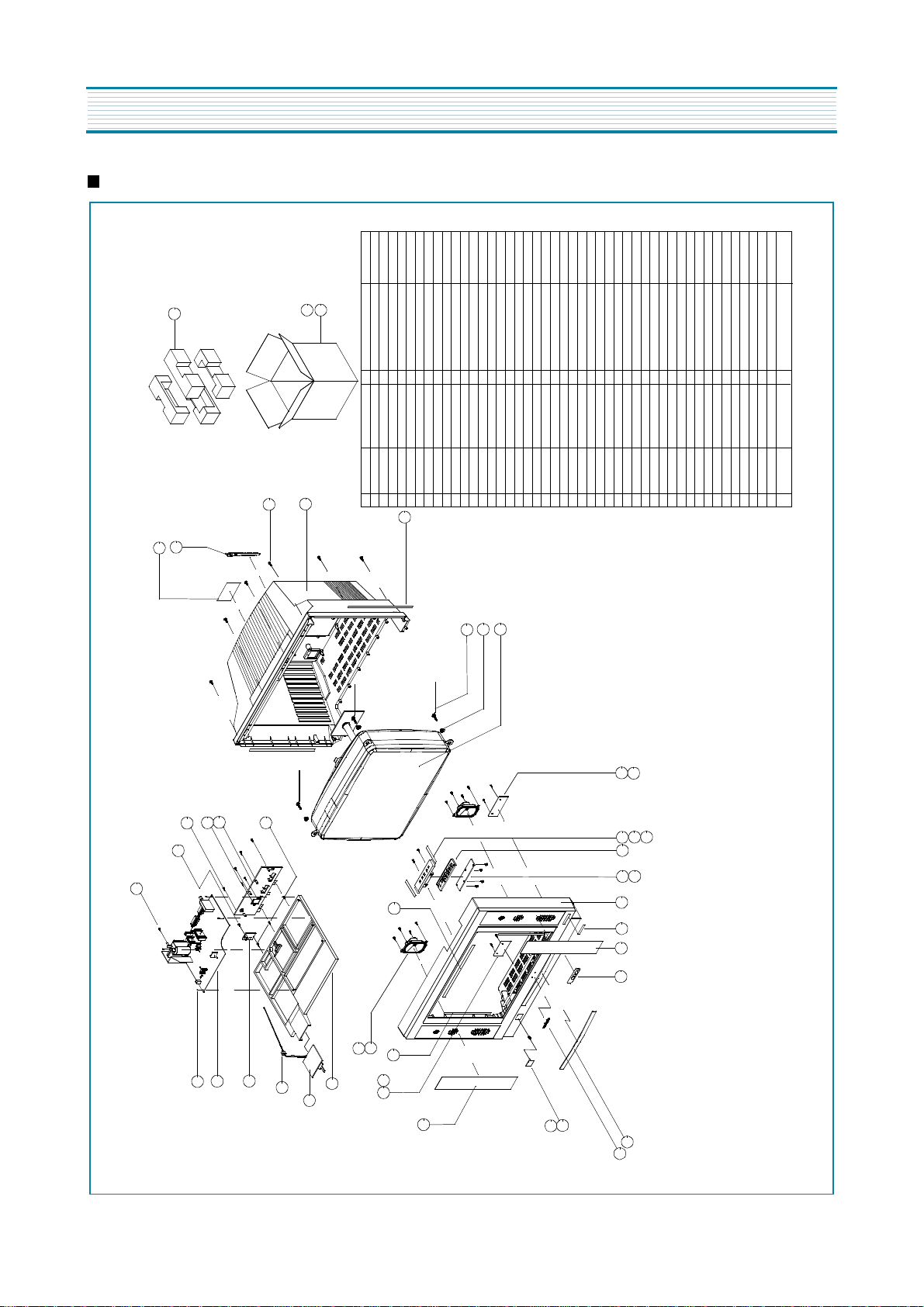

EXPLODED VIEW

DTW-28W2F

46

45

44

MATERIAL

FELT 400X20X0.7 4 CLOTH BLACK

TT2 TRS 4X14 MFZN BK 1 SCREW TAPPTITE

TT2 TRS 4X16 MFZN BK 1 SCREW TAPPTITE

TT2 WAS 3X12 MFZN BK 2 SCREW TAPPTITE

EPS 28W3 1

PE FOAM t0.5X1600X1270 1

DW-3 1

8 TT2 TRS 4X16 MFZN BK

W66ECK001X44

150ART P/E FILM (C/TV) 1

NYLON 66 BLK 5280N 1

SWRM+SK5 L=35 4

CR T2.0 4

FR HIPS GY (778A) 1

4 TT2 TRS 4X16 MFZN BK

FR HIPS BK 1 B/POWER PCB

NYLON66 UL/CSA 1 HOLDER AC CORD

TT2 TRS 4X14 MFZN BK 3

WP-811 1

FR HIPS BK 1

1 FR HIPS GY (778A) HOLDER CORD

TT2 TRS 4X16 MFZN BK

PVC T0.5 1

PC GY 1

SILVER DIA-CUTTING 1

SWPA PIE0.5 1

ABS GY (503A) 1

8 9 2

TT2 WAS 3X12 MFZN BK 4 7 ABS BK 1

HIPS GY (503A) 1

1

2 CLOTH 60X10X0.5 CLOTH BLACK

1

1

HIPS GY 1

FELT 180X10X1.5 2

HIPS GY (503A)

FELT 415X10X1.5 2

A1050P-H24 1

PS T0.5 28W2(L)

PS T0.5 28W2(R) 1

1

QTY

SCREW TAPPTITE

CLAMP CORD

PAD

BAG P.E.

BOX CARTON

7172401612

4858180700

4858215600

485805085K

46

45

44

2

43

43

CRT

SPEC PLATE

SCREW CRT FIX

WASHER RUBBER

4857817630

4859630260

4855415800

97P4602700

4856015820

4856215402

42

41

40

39

38

37

SCREW TAPPTITE

SCREW TAPPTITE

SCREW TAPPTITE 4 TT2 WAS 3X12 MFZN BK

PCB MAIN

TERMINAL ANT

7172401412

7172401612

7178301212

7172401612

36

35

34

33

97P2316600

7178301212

7172401412

4853529903

4853631102

4859803193

32

31

30

29

28

27

SPRING

SCREW TAPPTITE

SCREW TAPPTITE 2 TT2 WAS 3X12 MFZN BK

BUTTON POWER

MARK BRAND

SPEAKER

DECO AV

DECO SENSOR

FRAME MAIN PCB

4853817500

4855540600

48556174SD

4855933601

26

25

24

23

22

PREAMP PCB

7178301212

7172401612

4854856002

4856716000

18

21 1 20

19

17

16

SCREW TAPPTITE 2 TT2 TRS 4X16 MFZN BK

SCREW TAPPTITE 2 TT2 WAS 3X12 MFZN BK

SCREW TAPPTITE

AV JACK PCB

7178301212

7178301212

15

14

13

CLOTH BLACK

CLOTH BLACK

CTRL PCB

BUTTON

4854944601

12

11

DECO MARK

PANEL CTRL

4857818500

7172401612

4857821103

4857821101

4855930700

4852326302

8

6

5 1 4

10

PART NAME REMARKS

GRILL SPKR R/L

GRILL SPKR R/L

MASK FRONT

COVER BACK

4852534201

4852073102

4852155102

4852534200

PART CODE

3

2

1

NO

40

41

42

37

38

39

14

15

32

33

34

35

36

31

9

8

10

11

13

12

6

1

5

4

24

18

19

7

30

27

25

28

29

26

17

16

3

21

20

23

22

13

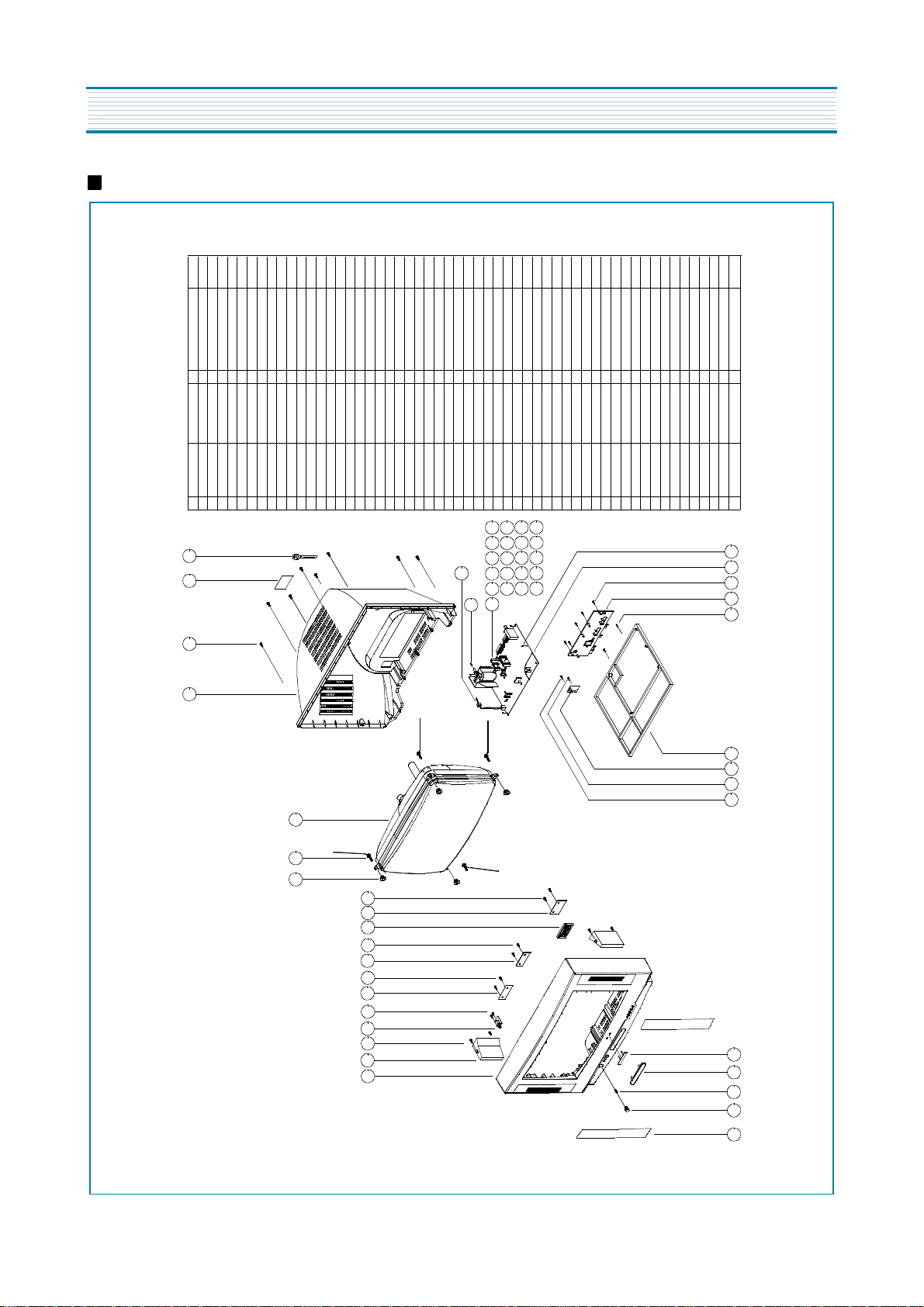

EXPLODED VIEW

DTW-2810F

1+8

1+52

28+52

24+28

26+52

24+26

23+24

23+52

1+15

1+10+11

1+6

1+4

1+2

Button

Switch

A/V Jack

PRE-AMP

TT2 TRS 4X16 MFZN BK SCREW TAPPTITE

NYLON 66 BLK 5280N

150ART P/E FILM(C/TV)

FR HIPS GY

1 NYLON 66 UL/CSA 97P2316600 HOLDER AC CORD

1

1 97P4602700

8

SPEC PLATE

CLAMP CORD

COVER BACK

4855415800

7172401612 1 4852154602

55

56

52

53

54

TT2 RND 3X10 MFZN 1

TT2 RND 3X10 MFZN

TT2 RND 3X8 MFZN

AL EX

1

1

HEAT SINK

SCREW TAPPTITE

4857027800

7174300811

50

51

TT2 RND 3X10 MFZN

AL EX

1 AL EX

1 AL EX

1

1

SCREW TAPPTITE

7174301011

49

1

SCREW TAPPTITE

HEAT SINK

HEAT SINK

HEAT SINK

SCREW TAPPTITE

4857026900

7174301011

4857026900

4857026900

7174301011

48

46

47

44

45

TT2 RND 3X8 MFZN 1 AL EX

AL EX BK

TT2 RND 3X8 MFZN

1

1 TT2 RND 3X8 MFZN

1

1

1 AL050P-H24 T=2

SCREW TAPPTITE

SCREW TAPPTITE

HEAT SINK

HEAT SINK

SCREW TAPPTITE

HEAT SINK

7174300811

4857025403

4857028205

7174300811

7174300811

43

4857031000

40

39

38

41

42

TT2 RND 3X8 MFZN

AL EXBK

PFC5000-0702

1

1 TT2 RND 3X8 MFZN

1 AL EX

1 TT2 RND 3X8 MFZN

SCREW TAPPTITE

7174300811

37

1 4857027534

1 AL EX

HEAT SINK

4857027910

36

2

HEAT SINK

SCREW TAPPTITE

SCREW TAPPTITE

HEAT SINK

CLIP FUSE

7174300811

4857027710

7174300811

4857415001

35

34

33

32

31

FR HIPS GY 1

T2S WAS 3X10 MFZN 4

WP-811

TT2 TRS 4X12 MFZNCK

1 T2S WAS 3X10 MFZN

1

5

TERM ANT

SCREW TAPPTITE

SCREW TAPPTITE

CHASSIS

SCREW TAPPTITE

7172401212

4853631002

7128301011

7128301011

26

27

30

29

28

52

TT2 TRS 4X12 MFZNCK

PC GY 1

PS SHEET T=0.4

SWPA PIE 0.5

HIPS GY

PHILIPS 28"WIDE

TT2 TRS 4X12 MFZNCK

SILVER DIA-CUTTING

FR HIPS BK

2 TT2 TRS 4X12 MFZNCK

SCREW TAPPTITE

7172401212

25

40 44 48

36

32 31

1

1

1 FR HIPS GY(778A)

1

1

HOLDER CORD

DECO SENSOR

SCREW TAPPTITE

FRAME M/PCB

MARK BRAND

SCREW TAPPTITE

7172401212

7172401212

4855526502

4853529903

4853817400

48556174SD

24

41 45 49

19

23

22

21

20

51

50

47

46

43

42 38 34

39

35

33 37

SWRM+SK5 L=35

1 4856716000

2

1

4

1

BUTTON POWER

GRILL

SCREW CRT FIX

CRT

SPRING

4854857903

4852530501

4856015820

15

16

18

17

14

30

53 56 55 54

CR T2.0

4

WASHER RUBBER

4856215402

13

T2S WAS 3X10 MFZN

HIPS GY 1

1

2

BUTTON

SUB-PCB

SCREW TAPPTITE

7128301011

4854929903

12

11

10

T2S WAS 3X10 MFZN

T2S WAS 3X10 MFZN 7128301011

T2S WAS 3X10 MFZN

2

1

2

1

2

SCREW TAPPTITE

SCREW TAPPTITE

SCREW TAPPTITE

SUB-PCB

SUB-PCB

48527160:9570151 : 9570151

7128301011

7128301011

9 8 7 6 5 4 3

2

1 HIPS GY

4 SWRM + SECC

1

SPKR SYSTEM

SCREW SPKR FIX

SUB-PCB

MASK FRONT

4856013600

4852072703

26

24 25 28 29 27

22 23

21

15 14 13

12 11

10

9

8

7

6

5

4

3

2

1

20

19 16

18

17

14

Loading...

Loading...