Page 1

Service Manual

S/N No. :

FEB. 2004

DAEWOO DAT CO., LTD.

Mini Component System

Model:

DVD Micro System

RD-400

()

Series

9CD8303000

JAN. 2005

series

only

Page 2

1. SAFETY PRECAUTIONS......................................................1/2

2. SPECIFICATIONS....................................................................3

3. LOCATION OF USERS CONTROLS....................................4/6

FRONT PANEL

REAR PANEL

DISPLAY

REMOTE CONTROLLER

4. CONNECTING TO EQUIPMENT...........................................7/8

CONNECTING TO TV

CONNECTING TO AUDIO & VIDEO

CONNECTING TO SPEAKER

CONNECTING TO RECORDING EQUIPMENT

5. FIRMWARE UPGRADE .....................................................9/10

6. TROUBLE SHOOTING GUIDE.........................................11/20

7. WAVEFORMS OF MAJOR CHECK POINT......................21/23

AUDIO OUT SIGNAL WAVEFORM

DAC OUTPUT SIGNAL WAVEFORM

OPTICALOUTPUT AUDIO DATASIGNALFORM

L/R CLOCKDATA WAVEFORM DURING NORMAL PLAY

SERIALDATA OUTPUT WAVEFORM DURING NORMALPLAY

Pr OUTPUT DATA WAVEFORM IN COMPONENT OUTPUT

Pb OUTPUT DATA WAVEFORM IN COMPONENT OUTPUT

Y OUTPUT DATAWAVEFORM IN COMPONENT OUTPUT

COMPOSITEOUTPUT DATA WAVEFORM IN MONITOR OUTPUT

S-VIDEO OUTPUT DATAWAVEFORM

8. INTERNAL BLOCK DIAGRAM OF ICs..........................24/28

9. BLOCK DIAGRAM...............................................................29

10. WIRING DIAGRAM...............................................................30

11. SCHEMATIC DIAGRAM..................................................31/35

MPEG Section

MPEG RF Section

I/A Section

FRONT Section

POWER Section

12. PRINTED CIRCUIT DIAGRAM........................................36/41

Front

Main

MPEG

13. EXPLODED VIEW AND MECHANICAL PARTS LIST ..42/43

MECHANICAL EXPLODED VIEW

MECHANICAL PARTS LIST

14. ELECTRICAL PARTS LIST......................................Appendix

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST [OPTION LIST]

Contents

DVDMICROSYSTEM

RD-400

()

Series

Page 3

1.SafetyPrecautions

WARNING

: TO PREVENT FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION :

TO REDUCE THE RISK IF ELECTRIC SHOCK, DO NOT

REMOVE COVER (OR BACK). NO USER SERVICEABLE PARTS

INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULTED "DANGEROUS VOLTAGE"

WITHIN THE PRODUCT'S ENCLOSURE THAT MAY BE

SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK TO PERSONS.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF IMPORTANT OPERATING AND MAINTENANCE

(SERVICING) INSTRUCTIONS IN THE LITERATURE

ACCOMPANYING THE APPLIANCE.

CAUTION

TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS POLARIZED AC

PLUG WITH AN EXTENSION CORD, RECEPTACLE OR OTHER OUTLET

UNLESS THE BLADES CAN BE FULLY INSERTED TO PREVENT BLADE

EXPOSURE.

LASER SAFETY

THIS UNIT EMPLOYS A LASER. ONLY QUALIFIED SERVICE PERSONNEL

SHOULD REMOVE THE COVER OR ATTEMPT TO SERVICE THIS DEVICE

DUE TO POSSIBLE EYE INJURY.

CAUTION :

USE OF ANY CONTROLS, ADJUSTMENTS, OR PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

CAUTION :

TO PREVENT ELECTRIC SHOCK, MATCH WIDE BLADE OF

PLUG TO WIDE SLOT, FULLY INSERT.

ATTENTION :

POUR EVITER LES CHOCS ELECTRIQUES, INTRODUIRE

LA LAME LA PLUS LARGE DE LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER JUSQU'AU FOND.

Important Safety Instructions

- All the safety and operating instructions should be read before

the appliance is operated.

- The safety and operating instructions should be retained for

future reference.

- All warnings on the appliance and in the operating instructions

should be adhered to.

- All operating and use instructions should be followed.

1. Water and Moisture - The appliance should not be used near

water - for example, near a bathtub, washbowl, kitchen sink,

laundry tub, in a wet basement, or near a swimming pool,

and the like.

2. Carts and Stands - The appliance

should be used only with a cart or

stand that is recommended by th

manufacturer.

3. An appliance and cart combination

should be moved with care. Quick

stops, excessive force, and uneven

surfaces may cause the appliance

and cart combination to overturn.

4. Wall or Ceiling Mounting - The appli-

ance should be mounted to a wall or

ceiling only as recommended by the manufacturer.

5. Ventilation - The appliance should be situated so that its

location or position does not interfere with its proper

ventilation. For example, the appliance should not be situated

on a bed, sofa, rug, or similar surface that may block the

ventilation openings; or, placed in a built-in installation, such

as a bookcase or cabinet that may impede the flow of air

through the ventilation openings.

6. Heat - The appliance should be situated away from heat

sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

7. Power Sources - The appliance should be connected to a

power supply only of the type described in the operating

instructions or as marked on the appliance.

8. Grounding or Polarization - The precautions that should be

taken so that the grounding or polarization means of an

appliance is not defeated.

9. Power - Cord Protection - Power-supply cords should be

routed so that they are not likely to be walked on or pinched

by items placed upon or against them, paying particular

attention to cords at plugs, convenience receptacles, and the

point where they exit from the appliance.

10.Protective Attachment Plug - If the appliance is equipped with

an attachment plug having overload protection. This is a

safety feature. See Instruction Manual for replacement or

resetting of protective device. If replacement of the plug is

required, be sure the service technician has used a

replacement plug specified by the manufacturer that has the

same overload protection as the original plug.

11.Cleaning - The appliance should be cleaned only as

recommended by the manufacturer.

12.Power Lines - An outdoor antenna should be located away

from power lines.

CAUTION

RISK OF ELECTRIC SHOCKS

DO NOT OPEN

PORTABLE CART

Figure 2

1

Page 4

1.SafetyPrecautions

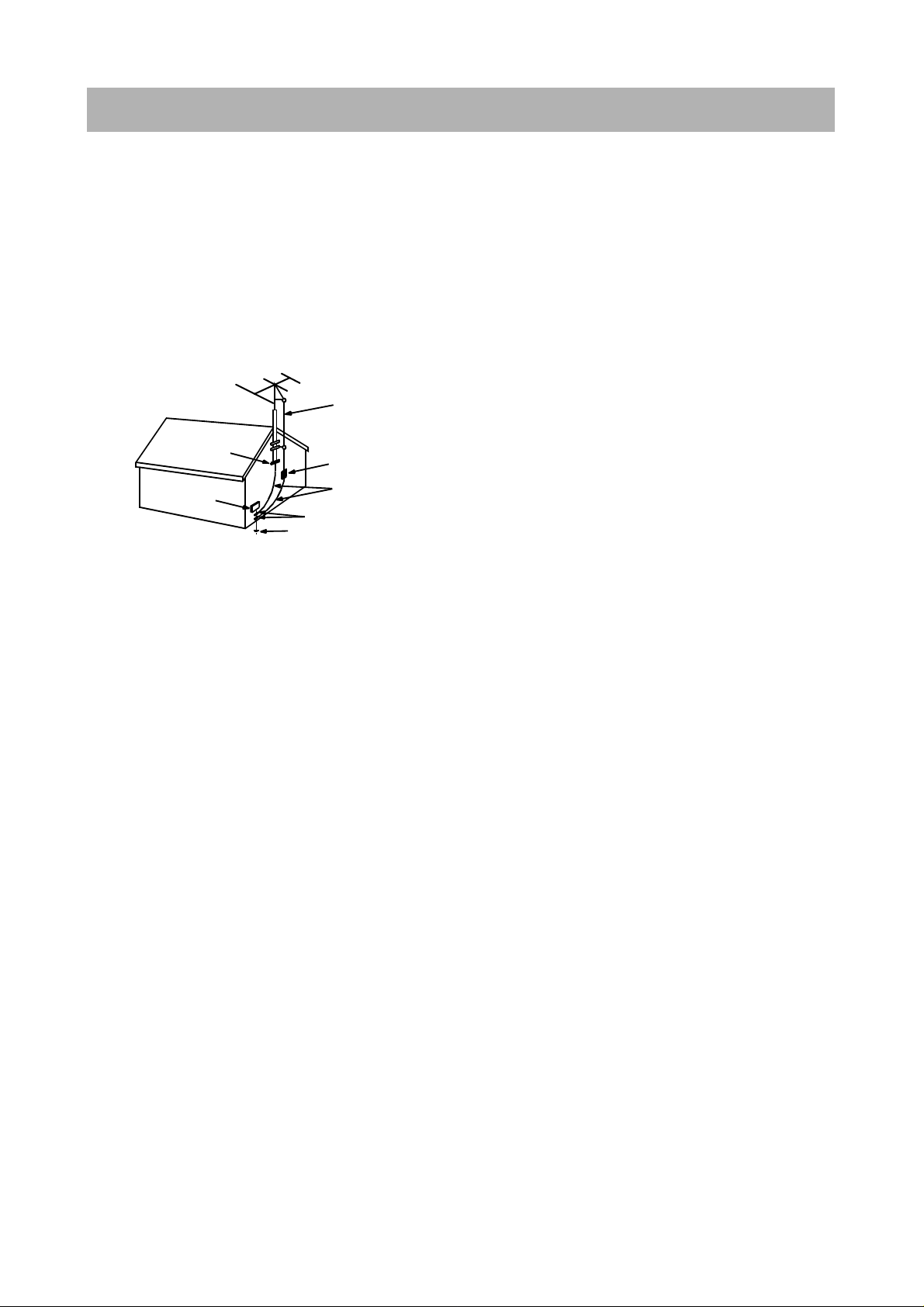

13.Outdoor Antenna Grounding - If an outside antenna is

connected to the receiver be sure the antenna system is

grounded so as to provide some protection against voltage

surges and built-up static charges. Article 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with

regard to proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna-dis

charge unit, size of grounding conductors,location of antennadischarge unit, connection to grounding electrodes and

requirements for the grounding electrode. See Figure 1.

14.Non-use Periods - The power cord of the appliance should be

unplugged from the outlet when left unused for a long period

of time.

15.Object and Liquid Entry - Care should be taken so that objects

do not fall and liquids are not spilled into the enclosure through

openings.

16.Damage Requiring Service - The appliance should be

serviced by qualified service personnel when:

a) The power-supply cord or the plug has been damaged; or

b) Objects have fallen, or liquid has been spilled into the

appliance; or

c) The appliance has been exposed to rain; or

d) The appliance does not appear to operate normally or

exhibits a marked change in performance; or

e) The appliance has been dropped, or the enclosure

damaged.

17.Servicing - The user should not attempt to service the

appliance beyond that described in the operating instructions.

All other servicing should be referred to qualified service

personnel.

ANTENNA DISCHARGE UNIT

(NEC SECTION 810-20)

ANTENNA LEAD

IN WIRE

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250 PART H)

GROUND CLAMP

ELECTRIC

SERVICE

EQUIPMENT

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

EXAMPLE OF ANTENNA

GROUNDING

NEC - NATIONAL ELECTRICAL CODE

2

Page 5

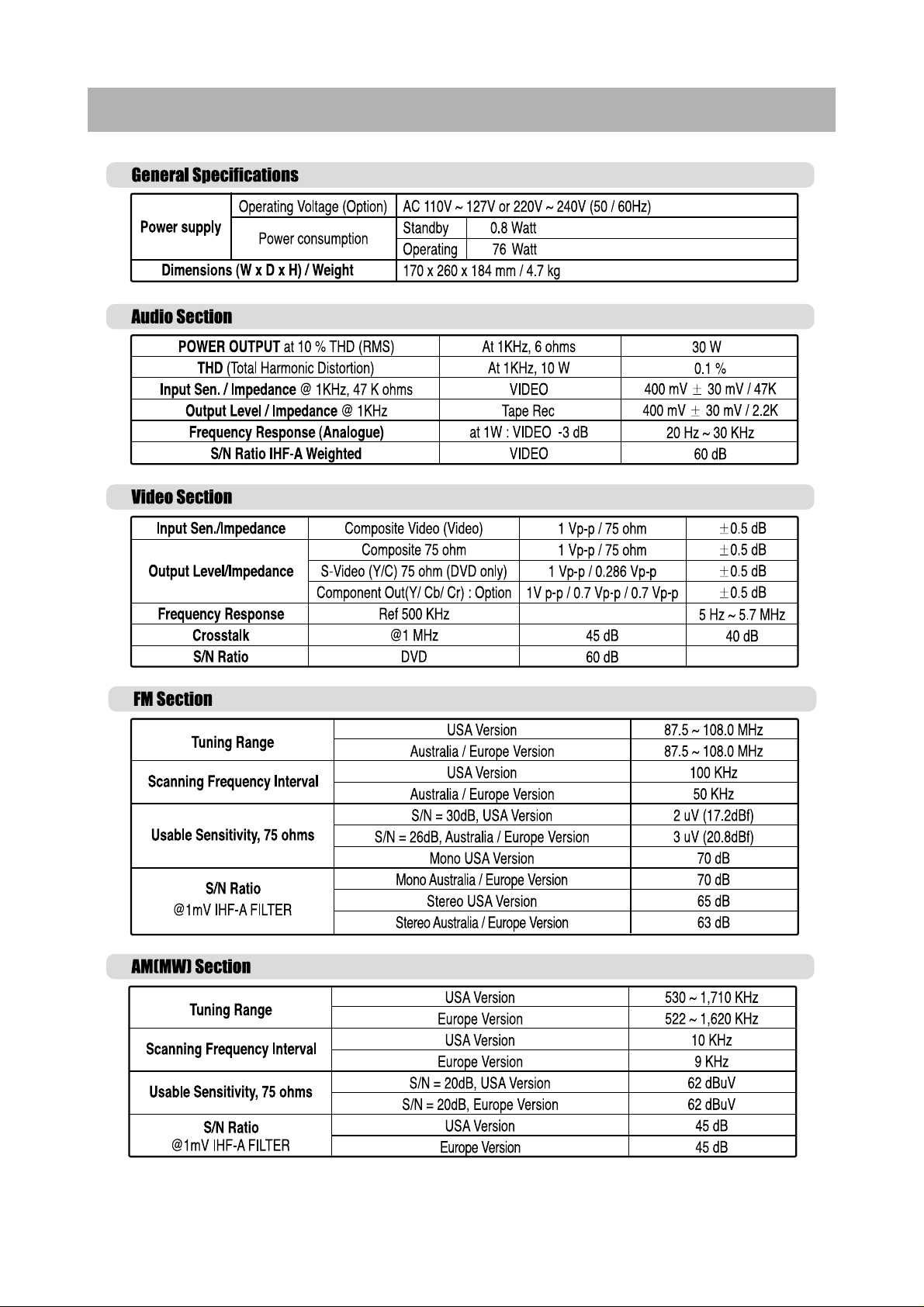

2. Specifications

3

Page 6

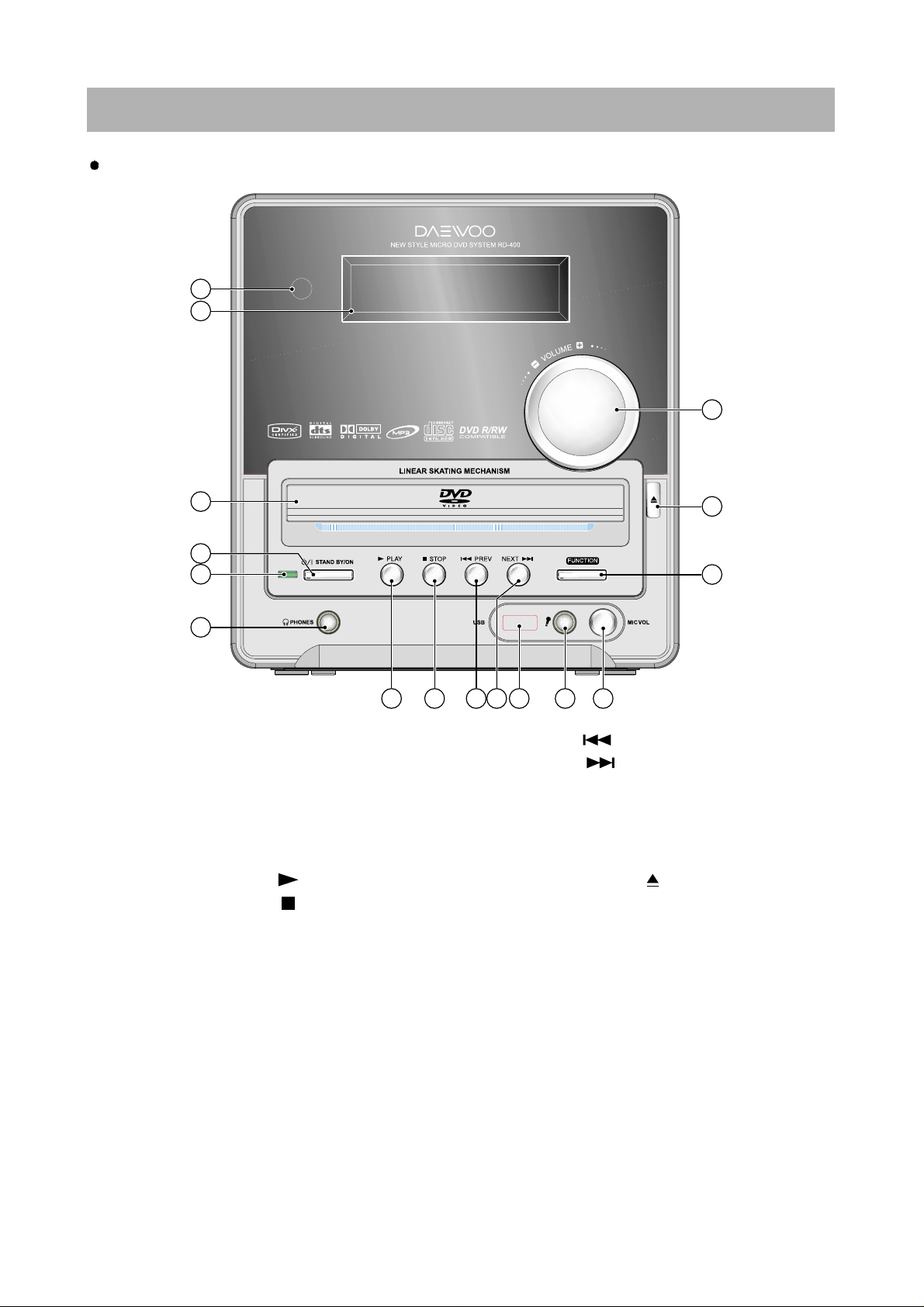

3.LocationofUsersControls

4

Front Panel

1. Remote Control Sensor

2. Display

3. DISC TRAY

4. STANDBY/ON button

5. STANDBY/ON LED lamp

6. PHONES jack

7. PLAY

()

button

8. STOP

()

button

9. PREV

()

button

10. NEXT

()

button

11. USB jack(Option)

12. Microphone jack

13. Mic. VOLUME Control

14. FUNCTION button

15. OPEN/CLOSE

()

button

16. MASTER VOLUME Control

1

2

3

5

6

4

7 8 11 12 13

15

14

16

9 10

Page 7

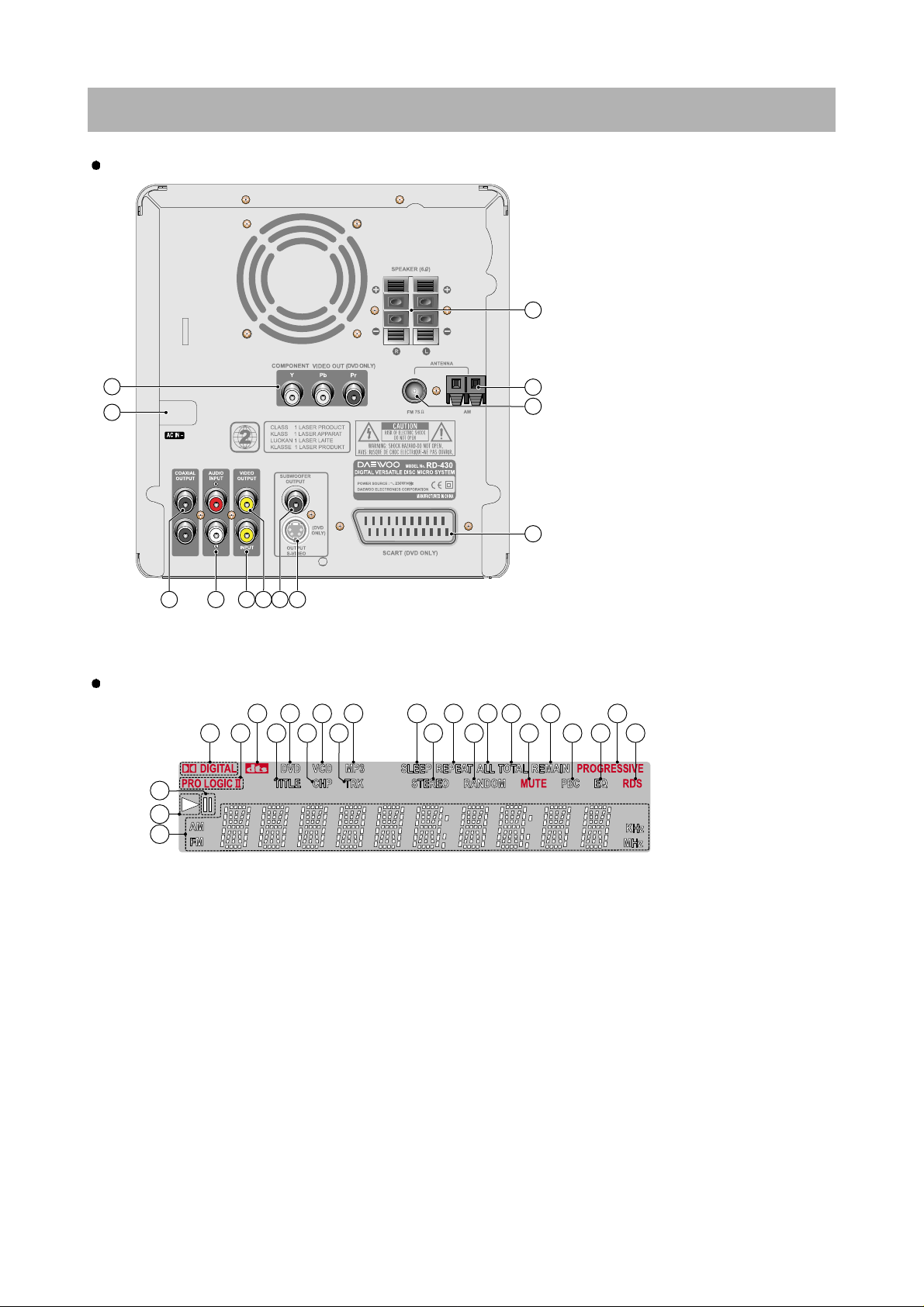

3.LocationofUsersControls

5

Rear Panel

Display

1 4 11 13 16 18 19 212 6 8

3 5 7 9 10 12 14 15 17 20

23

22

24

1. DOLBY DIGITAL indicator

2. Pro Logic II indicator

3. DTS indicator

4. TITLE indicator

5. DVD indicator

6. CHAPTER indicator

7. VCD indicator

8. TRACK indicator

9. MP3 indicator

10. SLEEP indicator

11. STEREO indicator

12. REPEAT indicator

13. RANDOM indicator

14. ALL indicator

15. TOTAL indicator

16. MUTE indicator

17. REMAIN ind icator

18. PBC(Playback Control) indicator

19.EQindicator

20. PROGRESSIVE indicator

21. RDS indicator

22. PAUSE indicator

23. PLAY indicator

24. Multi-Function Information Displaying Area

1. COMPONENT VIDEO OUTPUT

Y/Pb/Pr jacks (Optional)

2. Power cord

3. COAXIAL OUTPUT jack

4. AUDIO INPUT(R/L) jacks

5. VIDEO INPUT jacks

6. VIDEO OUTPUT jacks

7. SUBWOOFER OUTPUT

connectors : For Active subwoofer

speaker(User option)

8. S-VIDEO MONITOR OUT jack

9. FRONT SPEAKER connectors

10. AM(MW) ANTENNA connector

11. FM ANTENNAconnector

12. SCART jack

2

1

875 64

9

12

11

10

3

Page 8

6

3.LocationofUsersControls

Remote Controller

1. STANDBY/ON button

2. OPEN/CLOSE button

3. MUTE button

4. INPUT SELECTOR:DVD button/

TV SYSTEM(PAL/NTSC: DVD only) button

5. INPUT SELECTOR:VIDEO button

6. INPUT SELECTOR:TUNER button

7. FAST REVERSE(FR) ( ) button

8. FAST FORWARD(FF) ( ) button

9. SKIP PREV ( ) button

10. SKIP NEXT ( ) button

11. Direction ( ) buttons

12. Enter button

13. PLAY ( ) button

14. VOLUME( ) buttons

15. SETUP button

16. STOP( ) button

17. MENU/RETURN button

18. PAUSE/STEP button

19.GOTO/AUTOMEMORYbutton

20. PROGRESSIVE button

21. Number buttons(0~9)

22. CH-LEVEL button(Not Used)

23. DISPLAY/FM MODE button

24. A-B REPEAT button

25. REPEAT button

26. RANDOM/RDS MODE button

27. SLOW button

28. EQ button

29. SURROUND MODE button(Not Used)

30. ZOOM button

31. SLEEP button

32. SUBTITLE/MPX button

33. TITLE/PBC button

34. AUDIO/PTY SEARCH button

35. ANGLE/DIGEST button

ENTER

45

1

2 3

5

6

8

10

11

14

14

28

19

20

23

26

27

30

31

34

35

4

7

9

11

12

11

11

13

15

16

17

18

21

22

24

25

29

32

33

Page 9

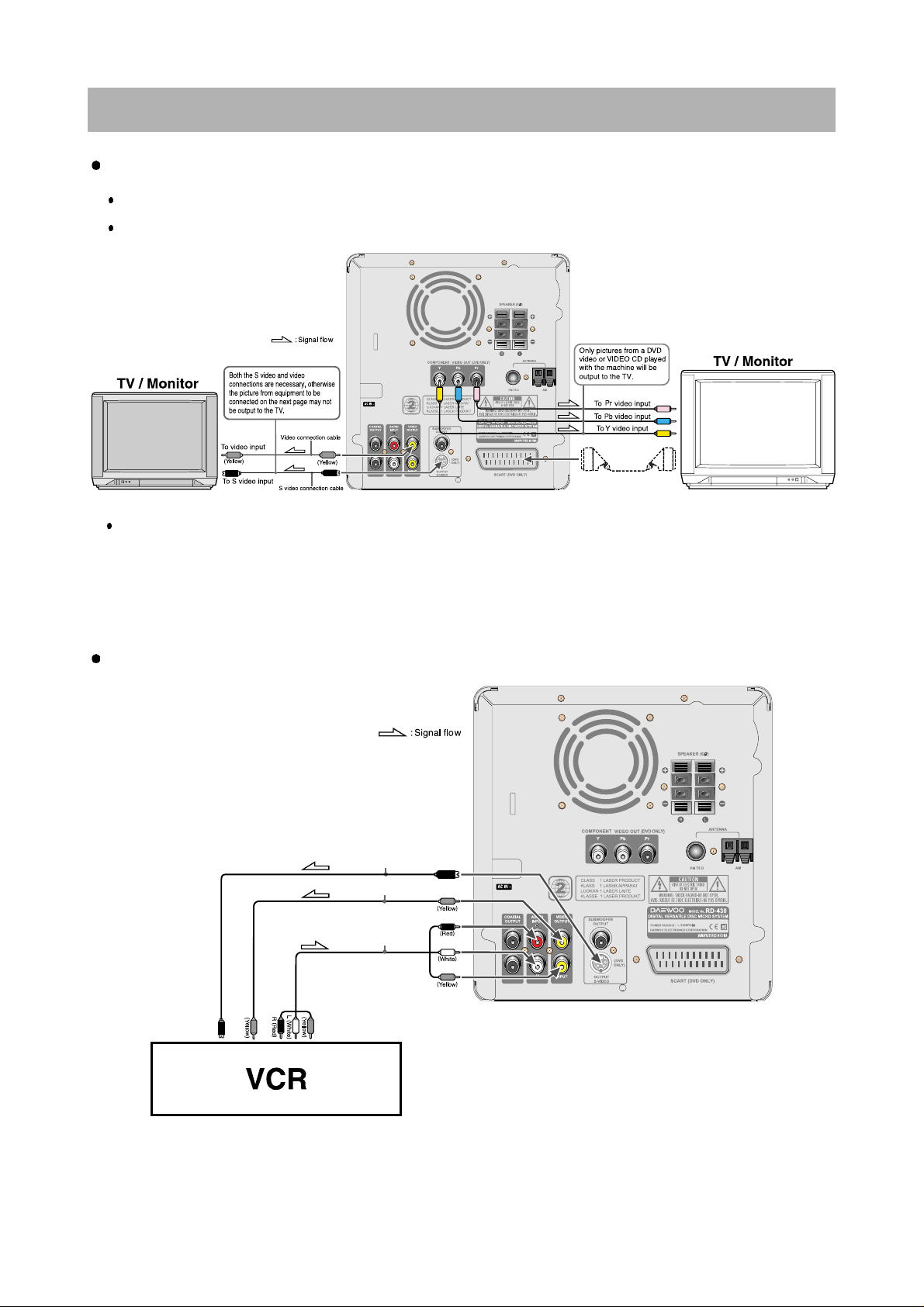

4.ConnectingtoEquipment

7

If the TV or monitor is equipped with an S video input, make the S video connection in addition to the normal video

connection. The S video connection will provide higher quality picture playback.

21-Pin SCART Cable(not included) to 21-pin SCART input terminal on TV

SCART Specification : Composite and Component Video output(DVD, Video)Audio L/R Output(DVD only)

Connecting to TV

Connecting to Audio & Video

for EU version: optional

Audio/Video connection cable

Video connection cable

To audio output

To S video input

To video output

To video output

S video connection cable

Page 10

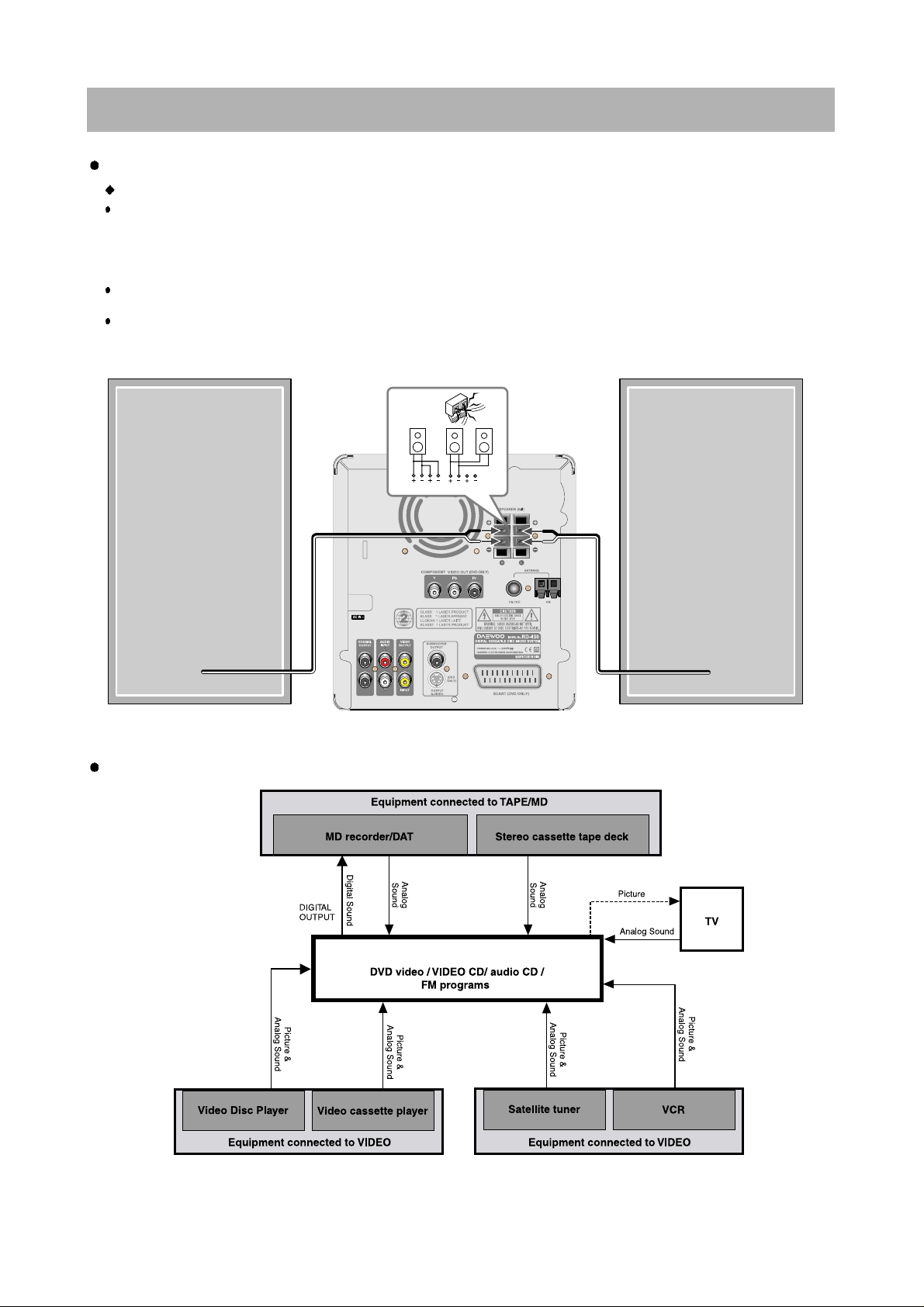

4.ConnectingtoEquipment

8

Connecting to Speaker

Connecting to Recoring Equipment

Before connecting

Thismachine is designed toreproduce optimum sound quality whenspeakers withthe specified impedance below

are connected. Please check the following information and choose speakers with appropriate impedance for the

connections.

Front speakers(L/R) : 6 ohms min. per speaker

To prevent damage tocircuits, never short-circuit the positive (+) andnegative (-) speakerwires.

Do not connect the speaker cable to the L and R connectors at the same time and do not connect more than one

speaker to the same speaker connectors.

Right speakerLeft speaker

R L

R L

NO!

NO!NO!

DVD Micro System

Page 11

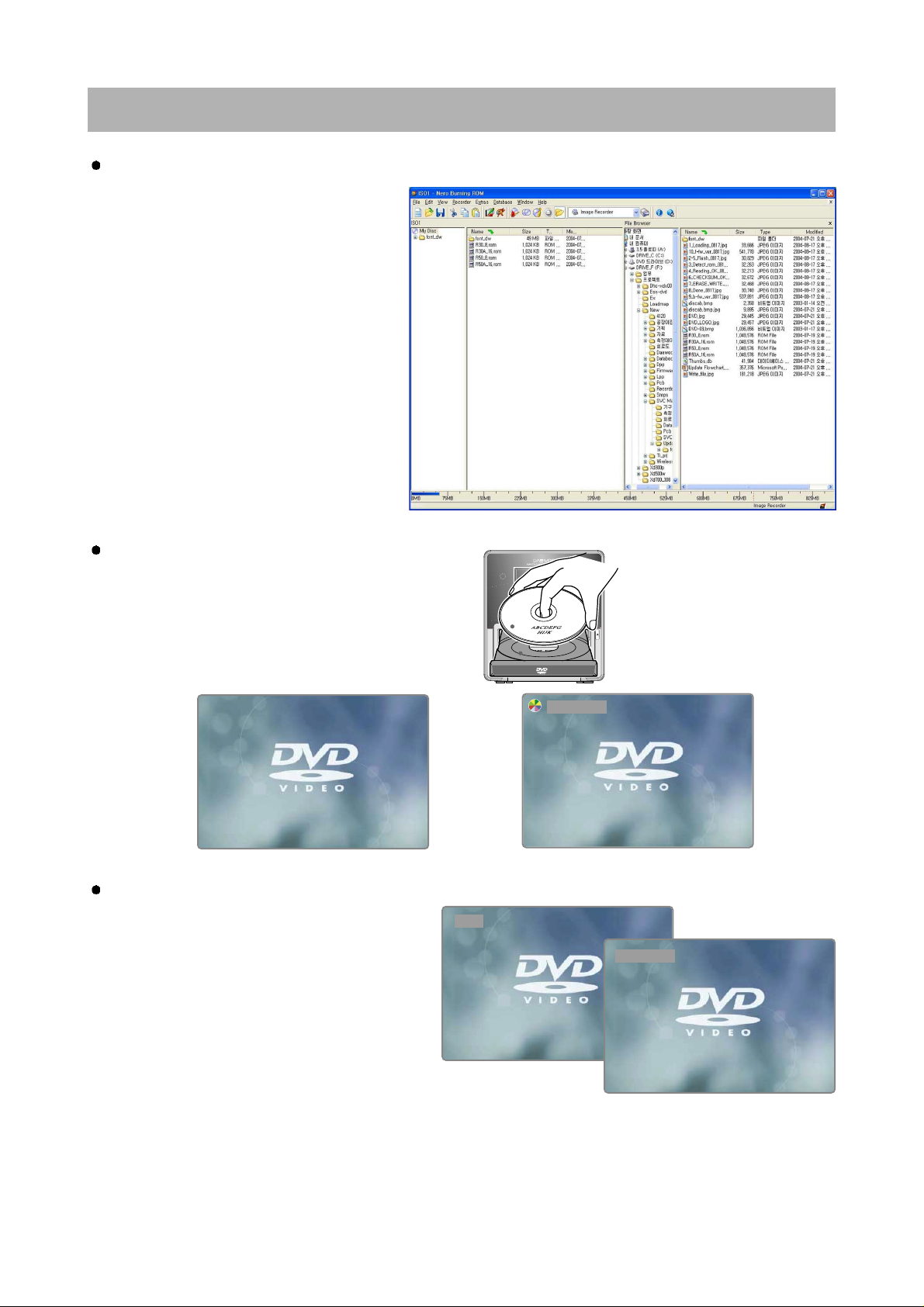

5.FirmwareUpgrade

Preparing the Firmware Upgrade

Activating the Firmware Upgrade

1. Write a disc to update file by

PC Writing Program.

2. A size of dummy folder is more than

10M bite. (ex : font_dw, attached picture)

3. Put firmware file in a disc.

1. Open the door of DVD receiver.

2. Insert the update disc into the disc tray.

3. Close the door, then DVD receiver reads the disc,

and update the firmware itself.

•

Basic Model : A400L_8.ROM

•

DivX Model : A400L_16.ROM

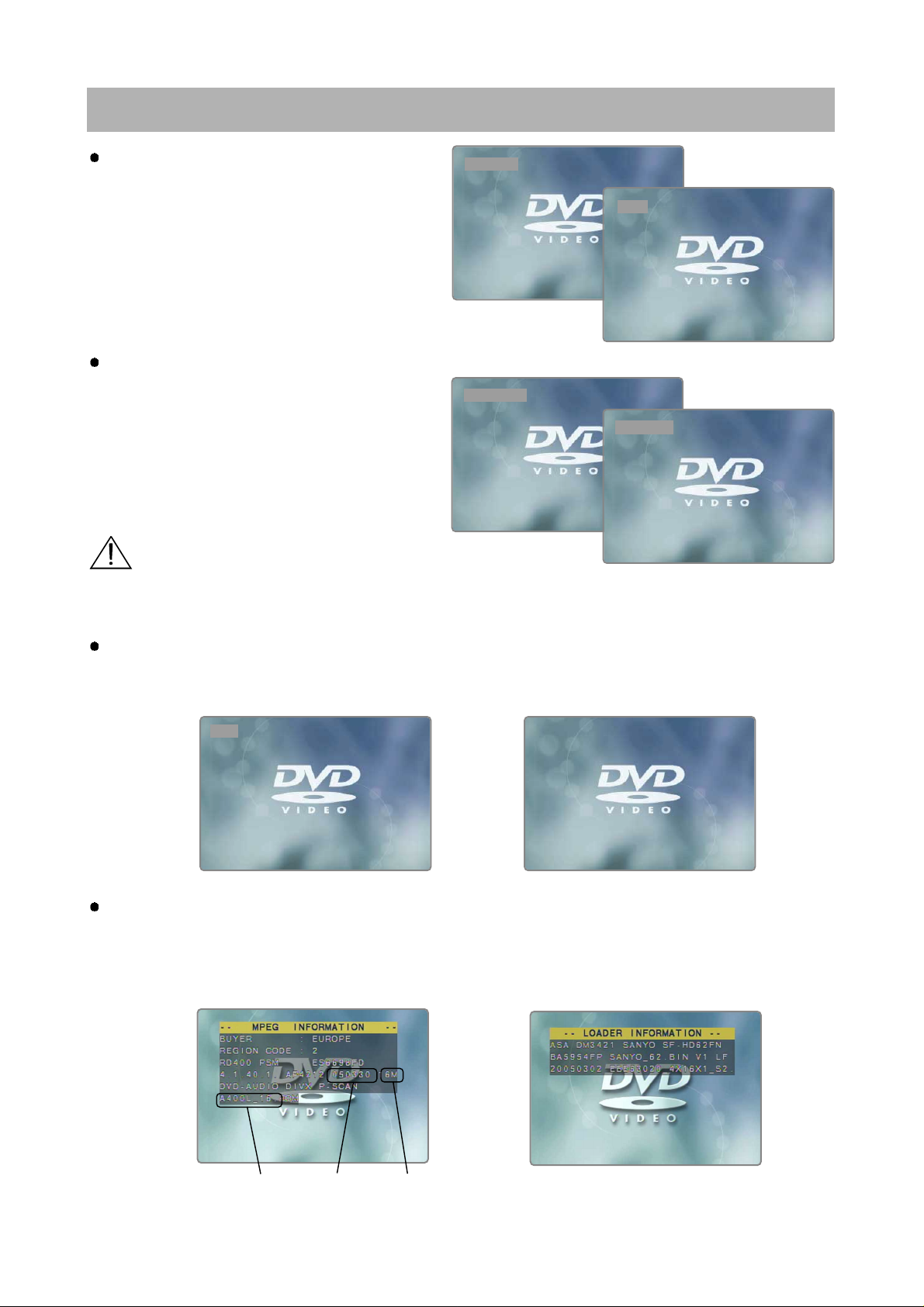

DISC LOADING

9

Starting Update.

1. Detect the update disc.(Lead Free)

2. Display for update ROM Version.

•

Basic Model : A400L_8.ROM

•

DivX Model : A400L_16.ROM

FLASH

A400L_16.ROM

Page 12

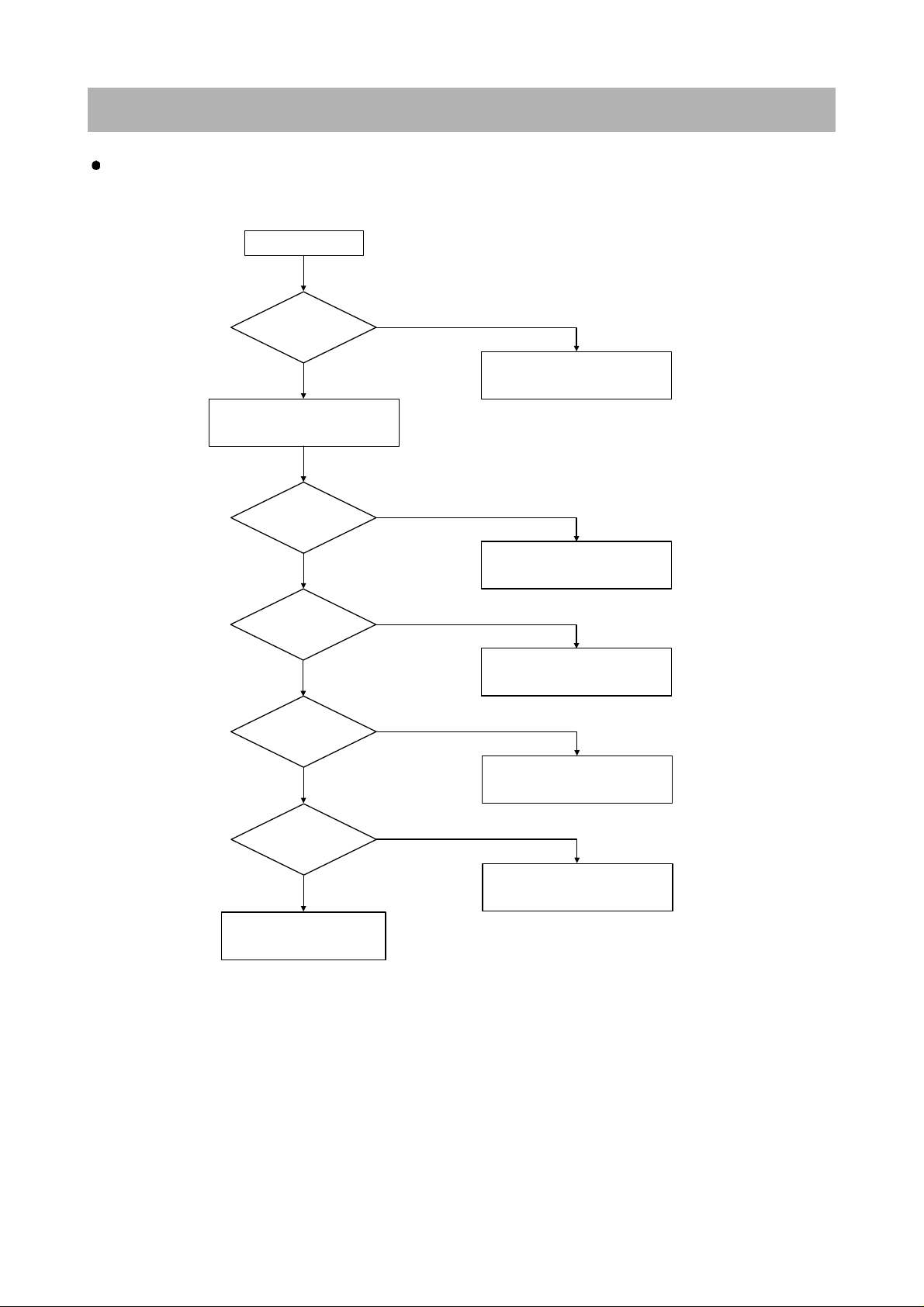

5.FirmwareUpgrade

Read the disc.

1. Automatically open the door, after read from disc.

2. Take a disc out of a tray

Completed Update.

1. Automatically power off (about 15 sec),after complete update.

2. Press POWER button, the System is working.

DONE

10

Check the Update Version.

1. Open the door of DVD receiver.

2. Press AUDIO button or SUBTITLE button.

•

AUDIO Button : Check for MPEG Firmware Version.

•

SUBTITLE Button : Check for Loader Firmware Version.

• While updating, if the door opened or closed by touch, or power button is pressed,

the Flash Memory will be damaged.

Caution

Firmware

Model

Firmware

Version

Flash

Size

READING OK

FLASH

CHECKSUM OK

ERASE/WRITE

Checksum check & Update new firmware.

Page 13

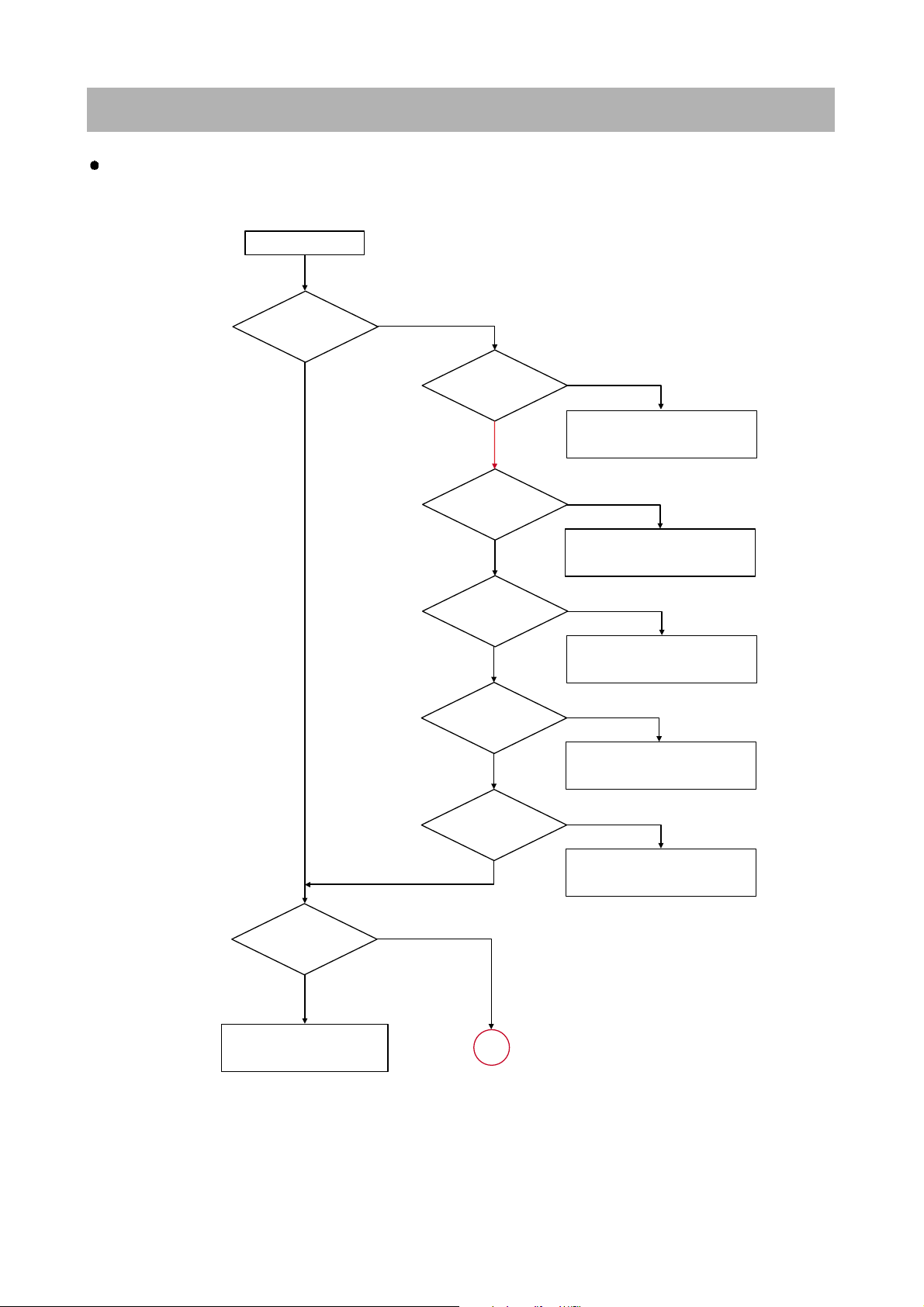

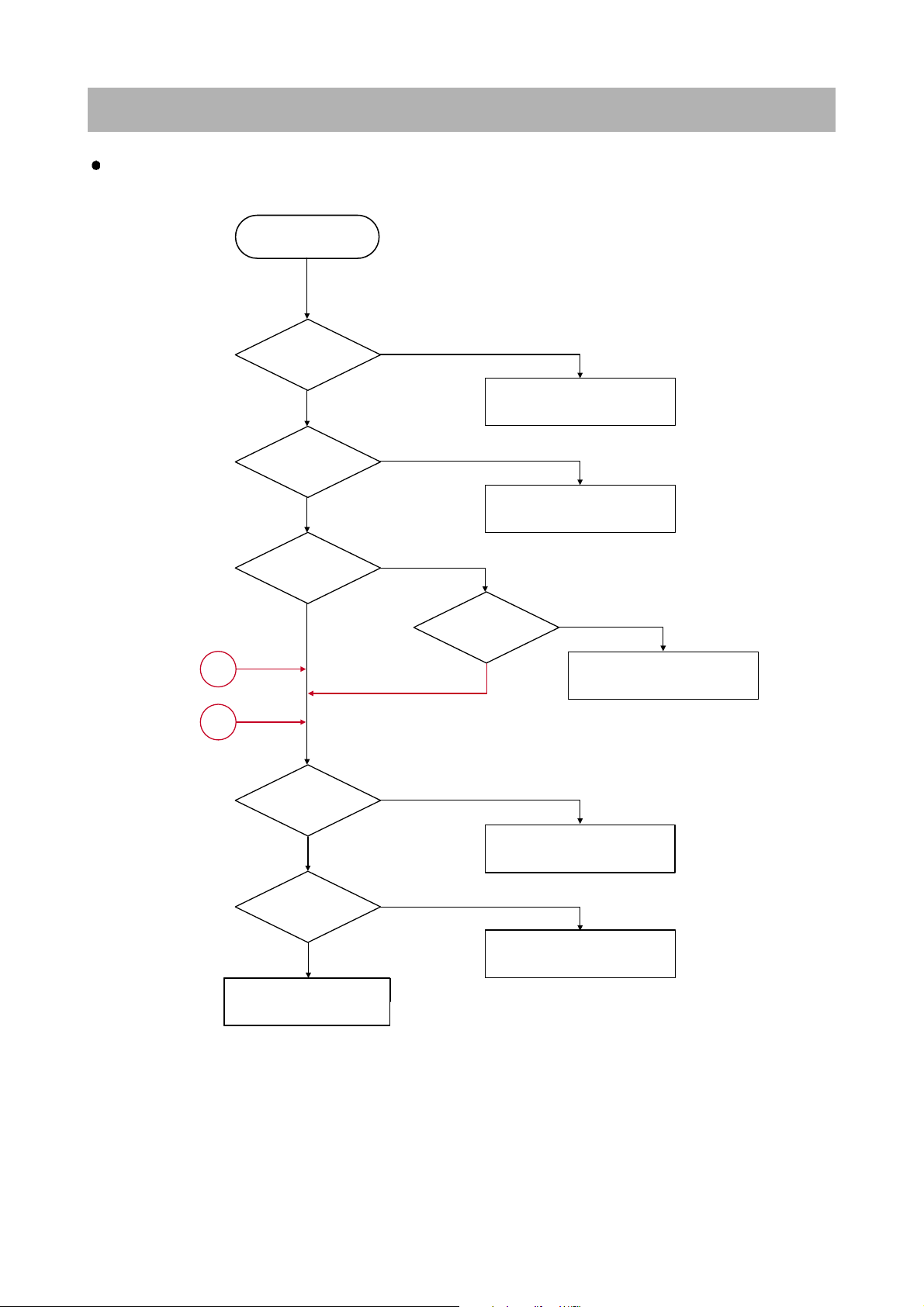

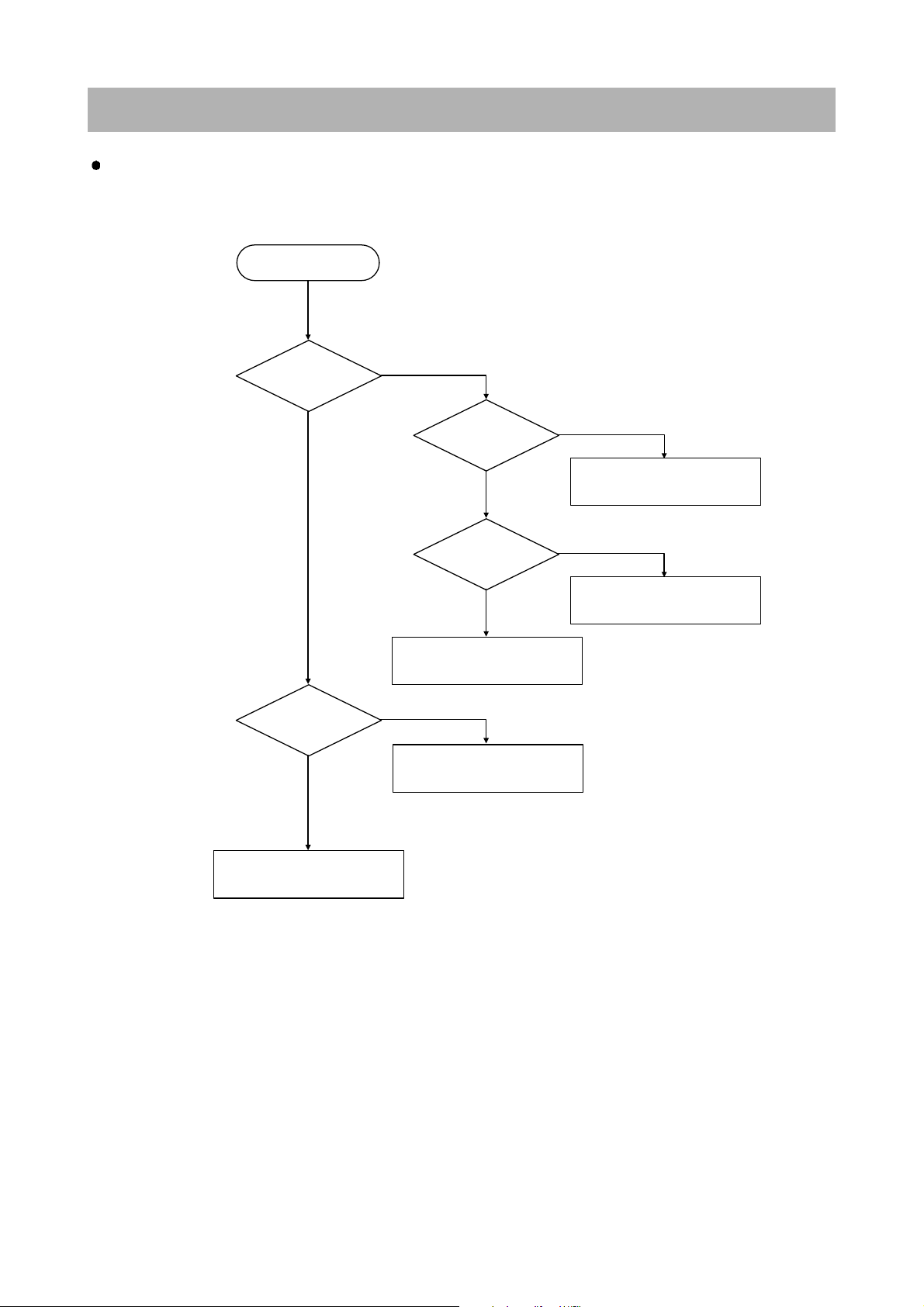

6.TroubleShootingGuide

11

START

1. BASIC OPERATING

Is Standby LED

on?

Check Power Supply Circuit.

Check Connection CN901, CN951.

No

Turn Power on.

Is Power on?

Yes

Check DVD Processor Circuit.

IC501 Block.

No

Does Initial

read work?

Yes

Check DVD Mechanism.

Check RF Circuit IC301.

No

Does It Play?

Yes

No

Check DVD Region.

Check RF Circuit IC301.

Yes

Does It Output

Audio?

No

Check Audio Section.

Yes

OK

Audio Part

Page 14

12

6.TroubleShootingGuide

START

1. INITIAL OPERATING

Is Standby

LED on?

No

Initial Operation OK.

Yes

Check OSC

waveform of

XC501.

Check I2C Line

of IC504.

Yes

Yes

Check interface

of VFD Driver

Yes

Is Power on?

Check Connection CN901/CN951.

Check Power Supply.

No

No

No

No

Yes

Check DVD Power Supply

Check Devices connected

I2C Line.

Check VFD Data Interface.

VFD_DATA/CLK.

Replace Front PCB Ass'y.

Check interface

of SDRAM

No

Check CLK of SDRAM.

Replace Flash Memory.

Is Power on?

1

No

Yes

Yes

Front Circuit

Page 15

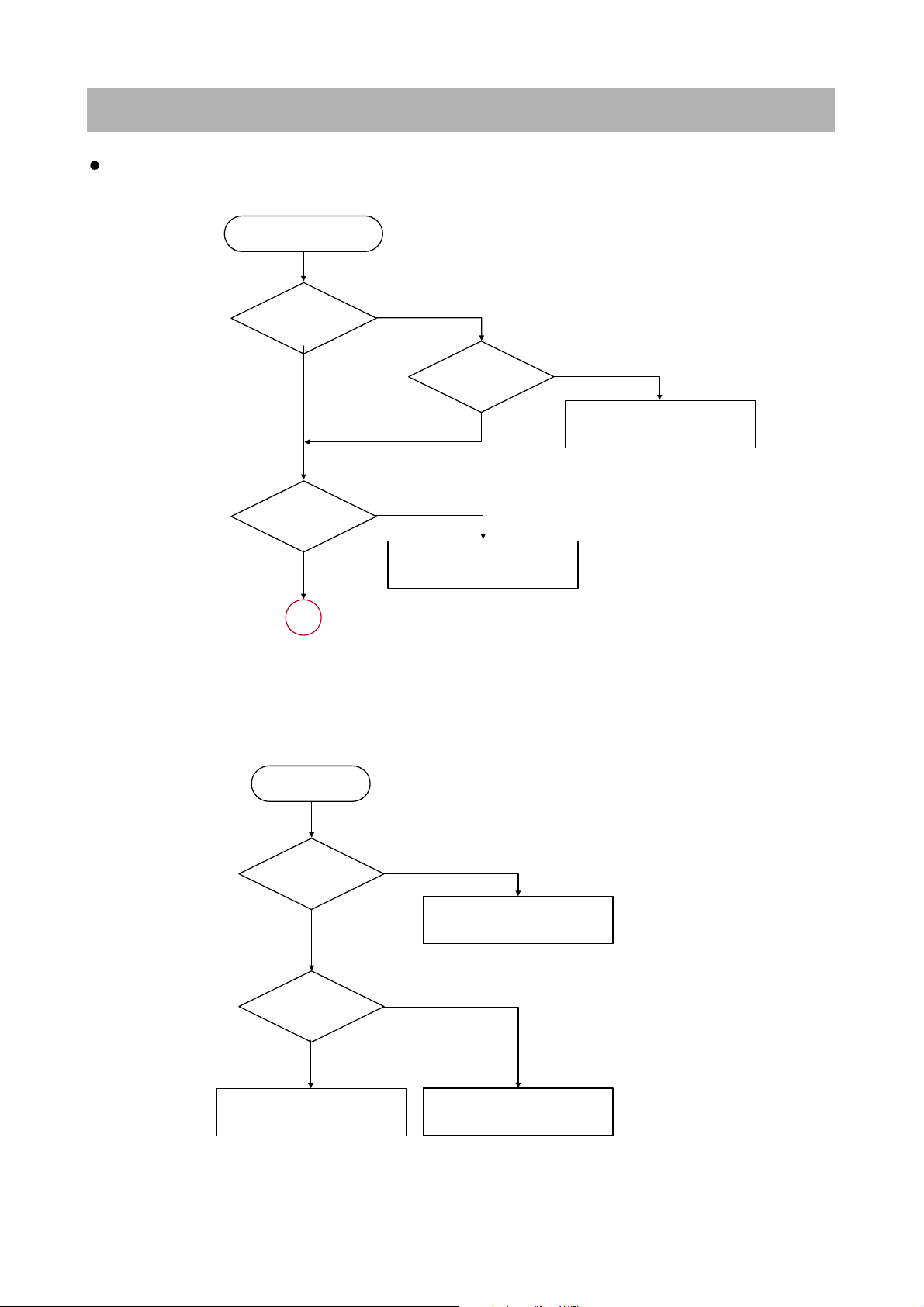

3. AUDIO Abnormal

Check if the I2S

Output of IC501

is ok?

Replace IC501.

No

Check if theI2S

Input of IC861

is ok?

Yes

Check Chip Resistor

HA861

Check if the

Output of IC861

is ok?

Yes

No

Yes

Yes

Yes

OK

Audio Abnormal of

DVD Function

Check if

suppled power

is ok?

Check Regulator Circuit.

IC904.

Yes

No

No

No

Check Regulator Circuit

IC902

No

Check Power Circuit

CE903, CE904

Check if

the Output of

IC871 is ok?

Check if

the Output of

IC841 is ok?

1

3

Video Output

Funtion

Digital Audio

Input Funtion

13

6.TroubleShootingGuide

Audio Part

Page 16

14

6.TroubleShootingGuide

3. AUDIO Abnormal

Check if the

Audio output of

IC401 is ok?

Check if the

Audio output of

IC421 is ok?

Check if the

Audio Input of

IIC401 is ok?

No

Yes

No

Check Audio In Line of J481

Check Regulator Circuit

IC902, 903

Yes

No

Yes

1

Audio Abnormal of Tuner

/Video Input Function

Audio Part

4. AUDIO LINE OUTPUT Abnormal

No

Yes

Yes

OK

Audio Abnormal

of H/P Output

Check if the

Output of IC811

is ok?

Check if the

Output of J701

is ok?

Check Regulator Circuit

IC902, 903

No

Check Audio Circuit

Page 17

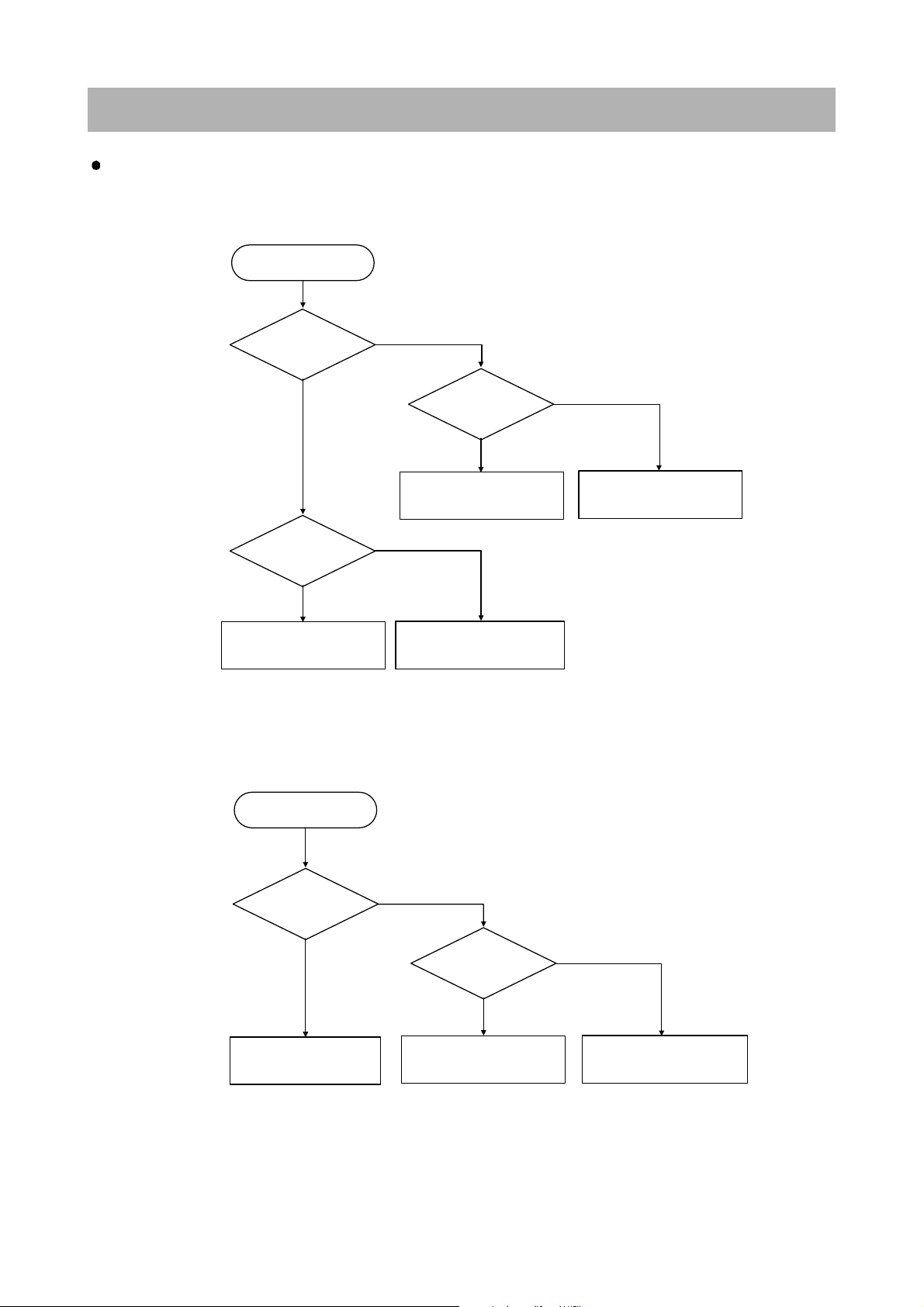

5. AUDIO CONTROL Abnormal

Yes

No

OK

Check Remote Receiver RM701

Yes

No

Replace IC501

Check if the

data of IC501

is ok?

Check Input

data of RMC

is ok?

Audio Abnormal of

Remote Control

6.TroubleShootingGuide

5. AUDIO CONTROL Abnormal

No

Yes

Check if the

data of IC501 is

ok?

No

Yes

OK

Audio Abnormal of

Volume Control

Check Encoder SW. VR701

Yes

No

Replace IC501

Check if the

I2C Waveform of

IC841 is ok?

Check between IC501 to IC841

Check Input

Data of Volume

is ok?

15

Audio Part

Page 18

6.TroubleShootingGuide

6. VIDEO OUTPUT Abnormal

Yes

Check if the

Output of IC501

is ok?

OK

VIDEO Abnormal of

Component

Check Setup

is ok?

Setting for RGB Mode.

Yes

No

Replace IC501

No

Check the

output of Jack

is ok?

Yes

No

Check Filter Circuit.

Check Crystal

is ok?

Yes

Replace Cystal, XC501.

No

16

Audio Part

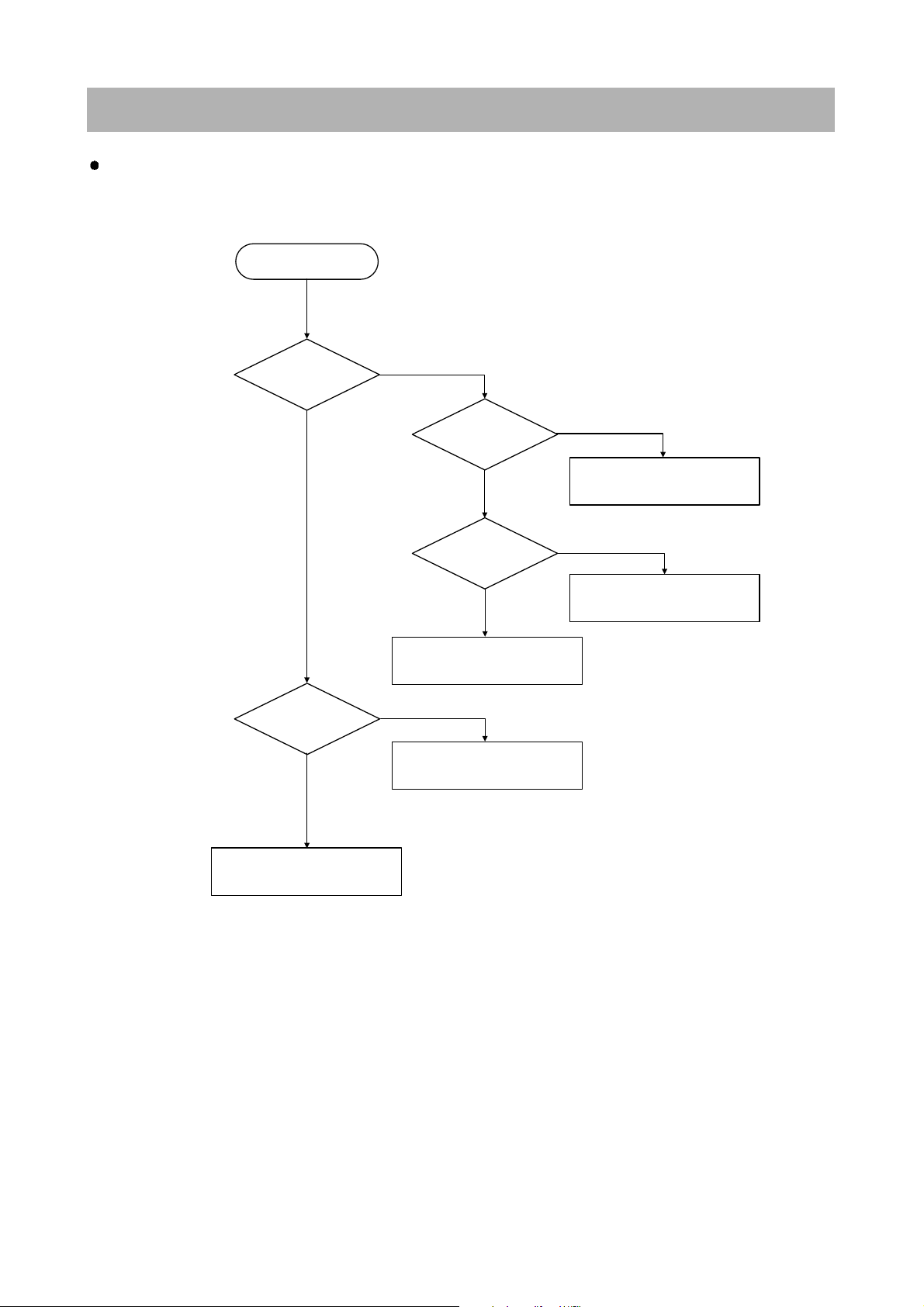

Page 19

6.TroubleShootingGuide

6. VIDEO OUTPUT Abnormal

Yes

Check if the

Output of IC501

is ok?

OK

VIDEO Abnormal

of S-VIDEO

Check Setup

is ok?

Setting for S-VIDEO Mode.

Yes

No

Replace IC501

No

Check the

output of Jack

is ok?

Yes

No

Check Filter Circuit.

Check Crystal

is ok?

Replace Crystal, XC501.

No

17

Audio Part

Page 20

6.TroubleShootingGuide

6. VIDEO OUTPUT Abnormal

Yes

Check if the

Output of IC501

is ok?

OK

VIDEO Abnormal of

Composite

Yes

Replace IC501

Check the

output of IC481

is ok?

No

No

Check the

output of Jack

is ok?

Yes

Yes

No

Check Filter Circuit.

Check Crystal

is ok?

Replace Crystal, XC501.

No

Check the

control of Select

is ok?

Check Power Supply Circuit.

Check Control Line between

IC510 : Pin12, 15

No

Replace IC481

Yes

18

Audio Part

Page 21

6.TroubleShootingGuide

7. MECHA CONTROL Abnormal

Yes

Check if the

data input of

IC501 is ok?

OK

Control Abnormal of

Open/Close

Yes

Replace IC501

Check the

output of IC303

pin 1,7 is ok?

No

No

Yes

Check VFD

data is ok?

Replace Front PCB Ass'y.

Check Connection CN701.

Check data waveforn of

VFD_DATA, CLK, CS

No

Check the

Supplied power

is ok?

Check Power Supply Circuit.

No

Replace IC303

Yes

19

Audio Part

Page 22

6.TroubleShootingGuide

7. MECHA CONTROL Abnormal

Yes

Check if the

data input of

IC501 is ok?

OK

Control Abnormal of

Disc Loading

Yes

Replace IC501

Check the

output of IC302

is ok?

No

No

Yes

Check VFD

data is ok?

Replace Front PCB Ass'y.

Check Connection CN701.

Check data waveforn of

VFD_DATA, CLK, CS

No

Check the

Supplied power

is ok?

Check Power Supply Circuit.

No

Replace IC302

Yes

Check the

interface data

is ok?

Check data between IC501.

No

Yes

20

Audio Part

Page 23

7.WaveformsofMajorCheckMethod

•

Audio Out Signal Waveform

•

DAC Output Signal Waveform

•

Optical Output Audio Data Signal waveform

•

PWM Output Waveform During Normal Play

•

Serial Data Output Waveform During Normal Play

21

Test Point : DVD Test Disc MDVD-W111 TRACK2 Color Bar

Page 24

•

Pr Output Data Waveform in Component Output

•

Pb Output Data Waveform in Component Output

•

Y Output Data Waveform in Component Output

7.WaveformsofMajorCheckMethod

Test Point : DVD Test Disc MDVD-W111 TRACK2 Color Bar

22

Page 25

•

Composite Output Data Waveform in Monitor Output

•

S-Video Output Data Waveform

7.WaveformsofMajorCheckMethod

Test Point : DVD Test Disc MDVD-W111 TRACK2 Color Bar

23

Page 26

8.InternalBlockDiagramofICs

•

74HC374

24

•

74HCU04

•

BA6287F

•

BU4052

Y

0

1

Y

2

2

COMMON

Y

3

Y

3

4

Y

1

5

INH

6

VEE

7

VSS

8

16

15

14

13

12

11

10

9

VDD

X

2

X1

X

X

0

X3

A

B

Y

0

B

Y

OUT / IN

INH

V

EE

X

OUT / IN

A

COMMON

Y2

Y3

Y1

X2

X1

X0

X3

Page 27

•

LD1117A

8.InternalBlockDiagramofICs

25

•

CS4340

•

FAN8024DB

•

LA7952

Page 28

8.InternalBlockDiagramofICs

26

•

ES6629FD/ES6698FD

•

M29W800DB

Page 29

8.InternalBlockDiagramofICs

27

PT2314

Page 30

8.InternalBlockDiagramofICs

28

•

PT6315

•

PT8311

Page 31

9.BlockDiagram

TUO WS

TUO ENI

L

TUO OEDIV

NI OIDUA

NI OEDIV

PMA CIM

CIM

R

EKAEPS

DFV

TUO OED

IV

TUO LATIGID

T

UO OEDIV-S

PMA FR

RE

VIRD ROTOM

REDOCED

DF9266SE

DF8966SE

1

05C

I

REFFUB TUO ENIL

RETREVNOC A

/D

NOITCNUF GOLAN

A

RETLIF SSAP WOL

REFFUB GOLANA

MARDS

ENOHPDAEH

SNART NIAM

SNART BUS

NI CA

1

03C

I

3066SE

HSALF

REFFU

B TUO

WS

PMA ENOHPDAEH

REVIRD DFV

29

Page 32

10.WiringDiagram

30

Page 33

11.SchematicDiagram

MPEG Section

DF8966SE

DF9266SE

105CI

31

Page 34

11.SchematicDiagram

MPEG RF Section

32

Page 35

11.SchematicDiagram

I/O Section

33

Page 36

11.SchematicDiagram

FRONT Section

34

Page 37

11.SchematicDiagram

KCOLB TP

POWER Section

35

Page 38

12.PrintedCircuitDiagram

36

FRONT [Top View]

Page 39

12.PrintedCircuitDiagram

37

FRONT [Bottom View]

Page 40

12.PrintedCircuitDiagram

38

MAIN [Top View]

Page 41

12.PrintedCircuitDiagram

39

MAIN [Bottom View]

Page 42

12.PrintedCircuitDiagram

40

MPEG [Top View]

Page 43

12.PrintedCircuitDiagram

41

MPEG [Bottom View]

Page 44

14.ExplodedViewandMechanicalPartsList

42

Page 45

14.ExplodedViewandMechanicalPartsList

43

Page 46

PCB MAIN Ass'y [9CDC074900] : RD400 MAIN

Loc. Part Code Part Name Description Remark

B801 9CD6596500 PCB MAIN 247X247X1.6T

CE811 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE812 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE813 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE814 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE815 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE816 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE817 CEXF1E100V C ELECTRO 25V RSS 10MF (5X11)

CE821 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE822 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE823 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE824 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE825 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE826 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE827 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE841 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11)

CE842 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11)

CE843 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11)

CE844 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11)

CE845 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE846 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE847 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE848 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11)

CE849 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE850 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE851 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE852 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE853 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE854 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE855 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE856 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE861 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE864 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE865 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE867 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11)

CE868 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11)

CE869 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE871 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11)

CE872 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE873 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE874 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE875 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE876 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE878 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE879 CEXF1H101V C ELECTRO 50V RSS 100MF (8X12)

CE880 CEXF1H101V C ELECTRO 50V RSS 100MF (8X12)

CE903 CEXF1V332V C ELECTRO 35V RSS 3300MF (16X31.5)

CE904 CEXF1V332V C ELECTRO 35V RSS 3300MF (16X31.5)

CE905 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE906 CEXF1E102V C ELECTRO 25V RSS 1000MF (12X22)

CE907 CEXF1E102V C ELECTRO 25V RSS 1000MF (12X22)

CE908 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE909 CEXF1H101V C ELECTRO 50V RSS 100MF (8X12)

CE910 CEXF1H101V C ELECTRO 50V RSS 100MF (8X12)

CE911 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE912 CEXF1E222V C ELECTRO 25V RSS 2200MF (13X25)

CE913 CEXF1H101V C ELECTRO 50V RSS 100MF (8X12)

CE914 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE915 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CM871 CMXM2A104J C MYLAR 100V 0.1MF J

CM872 CMXM2A104J C MYLAR 100V 0.1MF J

Page 1

Page 47

Loc. Part Code Part Name Description Remark

CM901 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CM902 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CM903 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CM904 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CM907 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CM908 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

CW861 9728811800 CONN WAFER 2.0MM PH-6A 6P

CN871 9736407800 CONN PIN 53095-1010 10PIN BASE

CN881 9736407800 CONN PIN 53095-1010 10PIN BASE

CW841 9728808800 CONN WAFER 2.0MM PH-3AW 3P

CW851 9CD6269000 CONN WAFER 52806-2510

CW901 9736408700 PIN WAFER 52075-1310

D902 DIN5402--- DIODE IN5402

D903 DIN5402--- DIODE IN5402

D904 DIN5402--- DIODE IN5402

D905 DIN5402--- DIODE IN5402

D906 DIN4001--- DIODE IN4001

D907 DIN4001--- DIODE IN4001

D908 DIN4001--- DIODE IN4001

D909 DIN4001--- DIODE IN4001

D910 DIN4001--- DIODE IN4001

D911 DKBPC806-- DIODE KBPC806

D912 DIN4001--- DIODE IN4001

D919 DIN4001--- DIODE IN4001

D920 DIN4001--- DIODE IN4001

D921 DIN4001--- DIODE IN4001

D922 DIN4001--- DIODE IN4001

HA861 HRTT8101J R ARRAY CHIP 1/10 100X4 OHM 1608

HC811 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC812 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC813 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC814 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC815 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC816 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC821 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC822 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC823 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC824 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC825 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC826 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC839 HCBK223KBA C CHIP CERA 50V X7R 0.022MF M 1608

HC841 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC842 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC843 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC844 HCBK272KBA C CHIP CERA 50V X7R 2700PF K 1608

HC845 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC846 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC847 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC848 HCBK272KBA C CHIP CERA 50V X7R 2700PF K 1608

HC849 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC850 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC851 HCBK331KBA C CHIP CERA 50V CH 330PF J 1608

HC852 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

HC853 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC854 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

HC855 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC856 HCBK331KBA C CHIP CERA 50V CH 330PF J 1608

HC863 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

HC864 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

HC866 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC867 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC868 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC871 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

Page 2

Page 48

Loc. Part Code Part Name Description Remark

HC872 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC873 HCQK100JBA C CHIP CERA 50V CH 10PF J 1608

HC874 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC875 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC876 HCQK100JBA C CHIP CERA 50V CH 10PF J 1608

HC877 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC878 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC902 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC903 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC904 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HD821 DZDS160--- DIODE SW CHIP KDS160

HD841 DZDS160--- DIODE SW CHIP KDS160

HD842 HRFT000-BA R CHIP 1/10 0 OHM 1608

HD871 DZDS160--- DIODE SW CHIP KDS160

HD901 DRLZ30B--- DIODE ZENER CHIP RLZ30B

HL863 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HQ811 TZRC111S-- TR CHIP KRC111S

HQ812 TZRC111S-- TR CHIP KRC111S

HQ813 TZRC111S-- TR CHIP KRC111S

HQ814 TZRC111S-- TR CHIP KRC111S

HQ815 TZRC231S-- TR CHIP KRC231S

HQ816 TZRA107S-- TR CHIP KRA107S

HQ820 TZRC231S-- TR CHIP KRC231S

HQ821 TZRC111S-- TR CHIP KRC111S

HQ823 TZRC111S-- TR CHIP KRC111S

HQ824 TZRC111S-- TR CHIP KRC111S

HQ825 TZRC231S-- TR CHIP KRC231S

HQ826 TZRA107S-- TR CHIP KRA107S

HQ871 TZTC3875S- TR CHIP KTC3875Y

HQ872 TZTC3875S- TR CHIP KTC3875Y

HQ873 TZRA107S-- TR CHIP KRA107S

HQ874 TZTC3875S- TR CHIP KTC3875Y

HQ875 TZRA107S-- TR CHIP KRA107S

HQ877 TZRC231S-- TR CHIP KRC231S

HR803 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR804 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR805 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR806 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR811 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR812 HRFT121JBA R CHIP 1/10 120 OHM J 1608

HR813 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

HR814 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

HR815 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

HR816 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

HR817 HRFT121JBA R CHIP 1/10 120 OHM J 1608

HR818 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR819 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR820 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR821 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR822 HRFT221JBA R CHIP 1/10 220 OHM J 1608

HR823 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR824 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR825 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR826 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR827 HRFT221JBA R CHIP 1/10 220 OHM J 1608

HR828 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR829 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR830 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR831 HRFT183JBA R CHIP 1/10 18K OHM J 1608

HR832 HRFT183JBA R CHIP 1/10 18K OHM J 1608

HR833 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR834 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR835 HRFT183JBA R CHIP 1/10 18K OHM J 1608

Page 3

Page 49

Loc. Part Code Part Name Description Remark

HR836 HRFT183JBA R CHIP 1/10 18K OHM J 1608

HR839 HRFT820JBA R CHIP 1/10 82 OHM J 1608

HR841 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR842 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR843 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR844 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR845 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR846 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR847 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR848 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR849 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR850 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR851 HRFT822JBA R CHIP 1/10 8.2K OHM J 1608

HR852 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR853 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR854 HRFT822JBA R CHIP 1/10 8.2K OHM J 1608

HR855 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR856 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR857 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR858 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR859 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR860 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR861 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR862 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR863 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR864 HRFT821JBA R CHIP 1/10 820 OHM J 1608

HR865 HRFT821JBA R CHIP 1/10 820 OHM J 1608

HR866 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR868 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR869 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR870 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR871 HRRT272JBA R CHIP 1/10 2.7K OHM J 1608

HR873 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR874 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR875 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR876 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR877 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR878 HRF4479JEA R CHIP 1/4W 4.7 OHM J 3216

HR879 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR880 HRFT182JBA R CHIP 1/10W 1.8K OHM J 1608

HR882 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR883 HRFT182JBA R CHIP 1/10W 1.8K OHM J 1608

HR884 HRF4479JEA R CHIP 1/4W 4.7 OHM J 3216

HR886 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR887 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR888 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR889 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR890 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR893 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR894 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR895 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR896 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR897 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR898 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR901 HRFT100JBA R CHIP 1/10 10 OHM J 1608

HR902 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR903 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR905 HRFT103JBA R CHIP 1/10 10K OHM J 1608

IC811 1BA4560F-- IC BA4560F

IC821 1NJM4558M- IC CHIP NJM4558M

IC841 1PT2314--- IC FUNCTION PT2314

IC851 1NJM4558M- IC CHIP NJM4558M

IC861 1CS4340--- IC CS4340 (DAC)

Page 4

Page 50

Loc. Part Code Part Name Description Remark

IC871 1STK433030 IC POWER STK433-030

IC902 1KIA7812AP IC REGULATOR KIA7812AP

IC903 1KIA7912AP IC KIA7912AP (MOLD)

IC904 1KA278R05- IC REGULATOR KA278R05PI

IC905 1KIA7805AP IC REGULATOR KIA7805AP

J871 9736323400 JACK SPEAKER SP024 B4, CJ9007-040

JW801 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW802 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW803 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW804 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW805 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW806 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW807 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW808 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW809 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW810 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW811 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW812 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW813 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW814 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW815 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW816 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW817 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW818 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW819 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW820 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW821 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW822 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW823 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW824 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW825 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW826 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW827 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW828 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW829 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW830 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW831 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW832 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW833 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW834 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW835 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW836 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW837 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW838 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW839 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW840 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW841 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW843 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW844 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW845 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW846 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW847 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW848 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW849 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW850 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW851 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW852 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW853 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW854 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW855 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW856 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW857 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW858 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

Page 5

Page 51

Loc. Part Code Part Name Description Remark

JW859 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW860 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW861 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW862 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW863 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW864 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW865 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW866 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW867 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW868 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW869 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW870 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW871 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW872 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW873 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW874 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW875 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW876 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW877 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW878 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW879 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW880 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW881 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW882 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW883 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW884 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW885 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW886 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW887 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW888 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW889 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW890 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW891 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW892 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW893 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW894 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW895 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW896 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW897 W581GY17J5 WIRE JUMPER AWG22 1/0.65 GY 17.5 AUTO

JW898 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

Q901 TZTA1273Y- TR KTA1273Y(A966Y) (KSA928A-Y)

R871 RD-4Z101J- R CARBON FILM 1/4W 100 OHM J

R872 RD-4Z101J- R CARBON FILM 1/4W 100 OHM J

PCB MPEG Ass'y [9CDC074800] : RD400 MPEG

Loc. Part Code Part Name Description Remark

B501 9CD6596600 PCB MPEG 212X160X1.6T

CE302 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE303 CEXF1C471V C ELECTRO 16V RSS 470MF (8X12)

CE304 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE305 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE306 CEXF1C471V C ELECTRO 16V RSS 470MF (8X12)

CE501 CEXF1C471V C ELECTRO 16V RSS 470MF (8X12)

CE502 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE503 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11)

CE504 CEXF1C471V C ELECTRO 16V RSS 470MF (8X12)

CE506 CEXF1C471V C ELECTRO 16V RSS 470MF (8X12)

CE508 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE509 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11)

CE510 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11)

CN502 9728828200 CONN AS UL1007 #22 6P 170MM TO HOUSING

CN501 9728828300 CONN AS FFC 25P P=1.0X170MM R

Page 6

Page 52

Loc. Part Code Part Name Description Remark

CW301 9CD6273500 CONN WAFER 52559-2492

CW302 9728810900 CONN WAFER 2.0MM PH-5A 5P

CW303 9728811800 CONN WAFER 2.0MM PH-6A 6P

CW501 9CD6269000 CONN WAFER 52806-2510

CW502 9736408600 CONN WAFER SMAW200-34

CW503 9728811800 CONN WAFER 2.0MM PH-6A 6P

HA501 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA502 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA503 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA504 HRTT8330J R ARRAY CHIP 1/10 33X4 OHM 1608

HA505 HRTT8330J R ARRAY CHIP 1/10 33X4 OHM 1608

HA506 HRTT8330J R ARRAY CHIP 1/10 33X4 OHM 1608

HA507 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA508 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA509 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA510 HRTT8100J R ARRAY CHIP 1/10 10X4 OHM 1608

HA511 HRTT8332J R ARRAY CHIP 1/10 3.3kX4 OHM 1608

HC301 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC302 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC303 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC304 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

HC305 HCQK121JBA C CHIP CERA 50V CH 120PF J 1608

HC306 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC307 HCQK681JBA C CHIP CERA 50V CH 680PF J 1608

HC308 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC309 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC310 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC311 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC312 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC313 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC314 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC315 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC316 HCBK473KBA C CHIP CERA 50V X7R 0.047MF M 1608

HC317 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC318 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC319 HCBK224KBA C CHIP CERA 50V X7R 0.22MF Z 1608

HC320 HCQK161JBA C CHIP CERA 50V CH 160PF J 1608

HC321 HCBK333KBA C CHIP CERA 50V X7R 0.033MF M 1608

HC322 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC323 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC324 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC325 HCBK472KBA C CHIP CERA 50V X7R 4700PF K 1608

HC326 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC327 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC328 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC329 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC330 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC331 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC332 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC333 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC334 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC335 HCQK821JBA C CHIP CERA 50V CH 820PF J 1608

HC338 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC339 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC341 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC501 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC502 HCQK200JBA C CHIP CERA 50V CH 20PF J 1608

HC503 HCQK200JBA C CHIP CERA 50V CH 20PF J 1608

HC504 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC505 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC506 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC507 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC508 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

Page 7

Page 53

Loc. Part Code Part Name Description Remark

HC509 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC510 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC511 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC512 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC513 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC514 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC515 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC516 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC517 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC518 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC519 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC520 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC521 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC522 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC523 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC524 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC526 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC527 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC528 HCBK272KBA C CHIP CERA 50V X7R 2700PF K 1608

HC529 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC530 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

HC531 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

HC532 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

HC533 HCBK153KBA C CHIP CERA 50V X7R 0.015MF M 1608

HC534 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC535 HCQK561JBA C CHIP CERA 50V CH 560PF J 1608

HC536 HCBK153KBA C CHIP CERA 50V X7R 0.015MF M 1608

HC537 HCQK561JBA C CHIP CERA 50V CH 560PF J 1608

HC538 HCBK153KBA C CHIP CERA 50V X7R 0.015MF M 1608

HC539 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC540 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC541 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC542 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC543 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC544 HCQK470JBA C CHIP CERA 50V CH 47PF J 1608

HC545 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC546 HCQK561JBA C CHIP CERA 50V CH 560PF J 1608

HC547 HCBK473KBA C CHIP CERA 50V X7R 0.047MF M 1608

HC550 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

HC552 HCBK472KBA C CHIP CERA 50V X7R 4700PF K 1608

HC555 HCBK472KBA C CHIP CERA 50V X7R 4700PF K 1608

HC556 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC557 HCBK105KBA C CHIP CERA 50V X7R 1MF K 1608

HC558 HCBK105KBA C CHIP CERA 50V X7R 1MF K 1608

HC559 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC560 HCBK105KBA C CHIP CERA 50V X7R 1MF K 1608

HC561 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC562 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC563 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC564 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

HC565 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC566 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC567 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC568 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC569 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC570 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC571 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC572 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC573 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC574 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC575 HRFT000-BA R CHIP 1/10 0 OHM 1608

HC576 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC577 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

Page 8

Page 54

Loc. Part Code Part Name Description Remark

HC578 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC579 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC580 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC581 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC582 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC583 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC584 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC585 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HD301 DZDS160--- DIODE SW CHIP KDS160

HD302 DZDS160--- DIODE SW CHIP KDS160

HD303 DZDS160--- DIODE SW CHIP KDS160

HD304 DZDS160--- DIODE SW CHIP KDS160

HD305 DZDS160--- DIODE SW CHIP KDS160

HD501 D1SR156--- DIODE RECTIFER 1SR156 4526 50V 1A

HD502 DZDS160--- DIODE SW CHIP KDS160

HL301 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL303 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL304 HLC399J03A CHIP COIL 3.9UH

HL305 HLC399J03A CHIP COIL 3.9UH

HL501 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL502 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL503 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL504 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL505 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL506 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL507 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL508 HLC104J01A COIL CHIP 120 OHM 100MHZ 2012

HL509 HLC229J02A COIL CHIP 2.2UH CHIP 1608

HL510 HLC229J02A COIL CHIP 2.2UH CHIP 1608

HL511 HLC229J02A COIL CHIP 2.2UH CHIP 1608

HL512 HLC229J02A COIL CHIP 2.2UH CHIP 1608

HL513 ?

HL514 ?

HQ301 T2SB1132T1 TR CHIP TR,2SB1132,SOT89EBC

HQ302 T2SB1132T1 TR CHIP TR,2SB1132,SOT89EBC

HQ303 TZRC111S-- TR CHIP KRC111S

HQ304 T2SK2731T1 FET CHIP TR, 2SK2731(30V,0.1A),FET

HQ305 T2SK2731T1 FET CHIP TR, 2SK2731(30V,0.1A),FET

HQ306 TZRC111S-- TR CHIP KRC111S

HQ501 TZRC107S-- TR CHIP KRC107S

HR301 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

HR302 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

HR304 HRFT123FBA R CHIP 1/10W 12K OHM F 1608

HR306 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR307 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR308 HRFT123JBA R CHIP 1/10 12K OHM J 1608

HR309 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR310 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR311 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR312 HRF2109JEA R CHIP 1/2W 1 OHM J 3216

HR313 HRF2109JEA R CHIP 1/2W 1 OHM J 3216

HR314 HRF2109JEA R CHIP 1/2W 1 OHM J 3216

HR315 HRF2109JEA R CHIP 1/2W 1 OHM J 3216

HR317 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR318 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR319 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR321 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR322 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR324 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR325 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR326 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR327 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR328 HRFT223JBA R CHIP 1/10 22K OHM J 1608

Page 9

Page 55

Loc. Part Code Part Name Description Remark

HR329 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR330 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR331 HRFT105JBA R CHIP 1/10 1M OHM J 1608

HR340 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR341 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

HR342 HRFT100JBA R CHIP 1/10 10 OHM J 1608

HR343 HRFT100JBA R CHIP 1/10 10 OHM J 1608

HR344 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR345 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR346 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR347 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR349 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR350 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR351 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR501 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR502 HRFT471JBA R CHIP 1/10 470 OHM J 1608

HR503 HRFT271JBA R CHIP 1/10 270 OHM J 1608

HR504 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR505 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR506 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR510 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR511 HRFT331JBA R CHIP 1/10 330 OHM J 1608

HR512 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR513 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR514 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR515 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR516 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR517 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR518 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR519 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

HR521 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR522 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR523 HRFT682JBA R CHIP 1/10 6.8K OHM J 1608

HR524 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR525 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

HR526 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR527 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

HR529 HRFT203JBA R CHIP 1/10 20K OHM J 1608

HR530 HRFT683JBA R CHIP 1/10 68K OHM J 1608

HR531 HRFT000-BA R CHIP 1/10 0 OHM J 1608

HR533 HRFT272JBA R CHIP 1/10 2.7K OHM J 1608

HR534 HRFT333JBA R CHIP 1/10 33K OHM J 1608

HR535 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR537 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR538 HRFT330JBA R CHIP 1/10 33 OHM J 1608

HR539 HRFT331JBA R CHIP 1/10 330 OHM J 1608

HR540 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR542 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR544 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR546 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR548 HRFT181JBA R CHIP 1/10 180 OHM J 1608

HR551 HRFT101FCA R CHIP 1/10 100 OHM J 2012

HR552 HRFT131FCA R CHIP 1/10W 130 OHM 2012

HR553 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR554 HRFT181JBA R CHIP 1/10 180 OHM J 1608

HR555 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR556 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR557 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR558 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR559 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR562 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR563 HRFT271JBA R CHIP 1/10 270 OHM J 1608

IC301 1ES6603S-- IC RF RFAMP IC, ES6603S

Page 10

Page 56

Loc. Part Code Part Name Description Remark

IC302 1FAN8024CD IC IC,MOTOR DRIVER

IC303 1BA6287F-- IC BA6287F DRIVER

IC304 1TL3472CD- IC OPAMP,TL3472

IC501 1ES6698FD- IC MPEG IC, MPEG DECODER ES6698FD

IC502 1L128168A- IC SDRAM M12L 128168A SDRAM(128M)

IC503 1M29W160EB IC FLASH M29W160DB FLASH(16M)

IC504 1M24C04MN- IC M24C04MN SOP

IC505 1LD1117A33 IC REGULATOR LD1117ADT33 DPAK

IC506 1LD1117A-R IC REGULATOR LD1117ADT-R DPAK

IC510 174HC374NS IC SN74HC374NSR SOP

IC511 174HC374NS IC SN74HC374NSR SOP

XC501 5XJ27M000E X-TAL 27MHZ 10 OHM 20PPM

PCB INOUT Ass'y [9CDC075000] : RD400 INOUT

Loc. Part Code Part Name Description Remark

B401 9CD6596700 PCB INOUT

CE401 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE402 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE403 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE404 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE421 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE422 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE423 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE424 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE425 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE426 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE441 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE442 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE443 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE444 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE445 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE446 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE455 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE456 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE457 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE458 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE459 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE460 CEXF1E220V C ELECTRO 25V RSS 22MF (5X11)

CE461 CEXF1E220V C ELECTRO 25V RSS 22MF (5X11)

CE462 CEXF1E220V C ELECTRO 25V RSS 22MF (5X11)

CE481 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X17)

CE482 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE483 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE484 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE485 CEXF1E221V C ELECTRO 25V RSS 220MF (8X12)

CE491 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CN101 9728828400 CONN AS FFC 13P P=1.25X220MM R

CN401 9736408500 CONN PIN CNSMH200-34

CW401 9CD6264500 CONN WAFER 52045-1345

HC401 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC402 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC403 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC404 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC405 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC406 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

HC407 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC408 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC421 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC422 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC441 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC442 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

HC443 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

Page 11

Page 57

Loc. Part Code Part Name Description Remark

HC455 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC456 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC457 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC458 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC459 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC461 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC462 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC481 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC482 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC483 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC484 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC491 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC494 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC495 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

HC496 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HQ441 TZRA107S-- TR CHIP KRA107S

HQ442 TZRA107S-- TR CHIP KRA107S

HQ443 TZRC107S-- TR CHIP KRC107S

HQ444 TZRC107S-- TR CHIP KRC107S

HQ455 TZTC3875S- TR CHIP KTC3875Y

HQ456 TZTC3875S- TR CHIP KTC3875Y

HQ457 TZTC3875S- TR CHIP KTC3875Y

HQ458 TZTC3875S- TR CHIP KTC3875Y

HQ459 TZTC3875S- TR CHIP KTC3875Y

HQ481 TZTC3875S- TR CHIP KTC3875Y

HQ482 TZTC3875S- TR CHIP KTC3875Y

HR401 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR402 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR403 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR404 HRFT183JBA R CHIP 1/10 18K OHM J 1608

HR405 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR406 HRFT183JBA R CHIP 1/10 18K OHM J 1608

HR407 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR408 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR409 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR410 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR411 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR412 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR413 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR414 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

HR415 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR416 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR421 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR422 HRFT563JBA R CHIP 1/10 56K OHM J 1608

HR423 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR424 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR425 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR426 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR427 HRFT101FBA R CHIP 1/10W 100 OHM 1608

HR428 HRFT101FBA R CHIP 1/10W 100 OHM 1608

HR441 HRFT101FBA R CHIP 1/10W 100 OHM 1608

HR442 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR443 HRFT471JBA R CHIP 1/10 470 OHM J 1608

HR444 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR445 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR446 HRFT152JBA R CHIP 1/10 1.5K OHM J 1608

HR447 HRFT471JBA R CHIP 1/10 470 OHM J 1608

HR449 HRFT222JBA R CHIP 1/10 2.2K OHM J 1608

HR450 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR451 HRFT101FBA R CHIP 1/10W 100 OHM 1608

HR455 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR456 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR457 HRFT391JBA R CHIP 1/10 390 OHM J 1608

Page 12

Page 58

Loc. Part Code Part Name Description Remark

HR458 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR459 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR460 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR461 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR462 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR463 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR464 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR465 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR466 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR467 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR468 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR469 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR470 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR471 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR472 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR473 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR474 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR475 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR476 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR477 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR478 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR481 HRFT101FBA R CHIP 1/10W 100 OHM 1608

HR482 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR483 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR484 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR485 HRFT750JBA R CHIP 1/10 75 OHM J 1608

HR486 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR487 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR488 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR489 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR490 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR498 HRFT221JBA R CHIP 1/10 220 OHM J 1608

IC401 1BU4052BCF IC BU4052

IC421 1NJM4558M- IC CHIP NJM4558M

IC441 1NJM4558M- IC CHIP NJM4558M

IC481 1LA7952--- IC SWITCH LA7952

IC491 EIC740404200 IC IC,INVERTER 74HCU04

J441 9736324801 JACK SCART 21P

J455 9736325200 JACK S-VIDEO C5026030 (S-VIDEO+RCA)

J481 9736327800 JACK RCA RCA-603EA-39

JW401 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW402 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW403 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW404 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW405 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW406 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW407 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW408 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW409 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW410 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW411 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW412 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW413 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW416 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW417 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW418 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW419 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW420 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW421 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW422 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW423 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW425 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW426 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

Page 13

Page 59

Loc. Part Code Part Name Description Remark

JW427 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW428 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW429 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW430 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW431 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW432 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW433 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW434 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW435 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW436 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW437 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW438 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW439 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW440 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW441 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW442 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW443 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW444 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW445 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW446 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW447 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW448 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW449 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW450 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

PCB FRONT Ass'y [9CDC075200] : RD400 FRONT

Loc. Part Code Part Name Description Remark

B701 9CD6596400 PCB FRONT 197X163X1.6T

CE701 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE702 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE703 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE704 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE705 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE706 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE707 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE751 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11)

CE752 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE753 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11)

CE754 CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11)

CE755 CEXF1H108V C ELECTRO 50V RSS 0.1MF (5X11)

CF701 5P1H101MF- FILTER CERA CFI 06B 1H 101MF

CF702 5P1H101MF- FILTER CERA CFI 06B 1H 101MF

CF703 5P1H101MF- FILTER CERA CFI 06B 1H 101MF

CW701 9736407900 CONN WAFER 52084-1010 10P BOTTOM

CW702 9736407900 CONN WAFER 52084-1010 10P BOTTOM

CW751 9728815800 CONN AS #26 UL2547 SHIELD 3P BOARD-IN 250MM

FL701 DHNV12SS29 VFD HNA-12SS29

HC701 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC702 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC703 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC704 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC705 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC706 HCBK104KBA C CHIP CERA 50V X7R 0.1MF Z 1608

HC707 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC708 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC751 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC752 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

HC753 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

HC754 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC755 HCBK103KBA C CHIP CERA 50V X7R 0.01MF M 1608

HC756 HCQK681JBA C CHIP CERA 50V CH 680PF J 1608

HD701 DZDS160--- DIODE SW CHIP KDS160

Page 14

Page 60

Loc. Part Code Part Name Description Remark

HD702 DZDS160--- DIODE SW CHIP KDS160

HD703 DZDS160--- DIODE SW CHIP KDS160

HD704 DZDS160--- DIODE SW CHIP KDS160

HD705 DZDS160--- DIODE SW CHIP KDS160

HD706 DZDS160--- DIODE SW CHIP KDS160

HD707 DZDS160--- DIODE SW CHIP KDS160

HD751 DZDS160--- DIODE SW CHIP KDS160

HQ701 TZRC231S-- TR CHIP KRC231S

HQ702 TZRC231S-- TR CHIP KRC231S

HQ703 TZRC231S-- TR CHIP KRC231S

HQ704 TZRC231S-- TR CHIP KRC231S

HQ705 TZRC231S-- TR CHIP KRC231S

HQ751 TZTC3875S- TR CHIP KTC3875Y

HQ752 TZTC3875S- TR CHIP KTC3875Y

HR701 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR702 HRFT100JBA R CHIP 1/10 10 OHM J 1608

HR703 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR704 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR705 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR706 HRFT823JBA R CHIP 1/10 82K OHM J 1608

HR707 HRF4221JEA R CHIP 1/4W 220 OHM J 3216

HR708 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR709 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR710 HRFT100JBA R CHIP 1/10 10 OHM J 1608

HR711 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR712 HRF4221JEA R CHIP 1/4W 220 OHM J 3216

HR713 HRF4221JEA R CHIP 1/4W 220 OHM J 3216

HR714 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR715 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR716 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR717 HRFT000-BA R CHIP 1/10 0 OHM 1608

HR718 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR719 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR720 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR751 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR752 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR753 HRFT101JBA R CHIP 1/10 100 OHM J 1608

HR754 HRFT391JBA R CHIP 1/10 390 OHM J 1608

HR755 HRFT393JBA R CHIP 1/10W 39K OHM J 1608

HR756 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR757 HRFT153JBA R CHIP 1/10 15K OHM J 1608

HR758 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HR759 HRFT153JBA R CHIP 1/10 15K OHM J 1608

HR760 HRFT104JBA R CHIP 1/10 100K OHM J 1608

HR761 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR762 HRFT223JBA R CHIP 1/10 22K OHM J 1608

HR763 HRFT182JBA R CHIP 1/10W 1.8K OHM J 1608

HR764 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

HR765 HRFT561JBA R CHIP 1/10 560 OHM J 1608

HR766 HRFT473JBA R CHIP 1/10 47K OHM J 1608

HR767 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

HR768 HRFT103JBA R CHIP 1/10 10K OHM J 1608

HR769 HRFT102JBA R CHIP 1/10 1K OHM J 1608

HZ701 DRLZ4R3B-- DIODE ZENER CHIP RLZ4.3B

HZ702 DRLZ4R3B-- DIODE ZENER CHIP RLZ4.3B

IC701 1PT6315--- IC DRIVER PT6315

IC702 1PT8311--- IC PSM PT8311

IC751 1NJM4558M- IC CHIP NJM4558M

J701 9736325300 JACK HTJ-035-18A(H/P)

J751 9736325300 JACK HTJ-035-18A(H/P)

JW701 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW702 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW703 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

Page 15

Page 61

Loc. Part Code Part Name Description Remark

JW704 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW705 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW706 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW707 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW708 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW709 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW710 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW711 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW712 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW713 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW714 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW715 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW716 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW717 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW718 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW719 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW720 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW721 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW722 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW724 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW725 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW726 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW727 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW728 W581GY1505 WIRE JUMPER AWG22 1/0.65 GY 15 AUTO

JW729 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW730 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW731 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW732 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW733 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW734 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW735 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW736 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW737 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW738 W581GY6095 WIRE JUMPER AWG22 1/0.65 SN 6 AUTO

JW739 W581GY1005 WIRE JUMPER AWG22 1/0.65 SN 10 AUTO

JW740 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW741 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO

JW742 W581GY7595 WIRE JUMPER AWG22 1/0.65 SN 7.5 AUTO

JW743 W581GY12J5 WIRE JUMPER AWG22 1/0.65 SN 12.5 AUTO