Daewoo Q600 series Service Manual

SxS Refrigerator

Service Manual

CAUTION

PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS BOOK

BEFORE CHECKING OR OPERATING THE REFRIGERATOR.

2013. Dec.

1. Safety Warnings & Cautions

For your safety, please observe following items

◆ Please read [Cautions for Safety] carefully in advance and use the refrigerator correctly.

This indicates that death or

Serious injuries may occur

As a result of not observing

Warning

◆ Meaning of marking

this warning.

Don’t Disassemble.

Disconnect the power plug.

Do not install refrigerator in humid

environments.

◇ If electrical insulation were

weakened, it would cause electric

shock or fire outbreak.

Caution

Warning

This indicates that minor to

moderate injuries may occur

as a result of not observing

this warning.

Prohibited / Don’t try to do it.

Enforced / You should observe

instructions.

Before disposing of refrigerator,

remove the rubber packing of

the doors.

◇ Children can lock themselves

in the refrigerator and may be

suffocated.

When inserting the power plug,

the direction of the electrical cord

is downward.

◇ When the direction of cord is

inserted upward, it may be

damaged and causing short circuit

and overheat. then electric shock

or fire outbreak may occur.

When the power cord is damaged,

please make a call for a service.

◇ It may cause fire outbreak,

electric shock or short circuit.

When connecting the power

plug, make sure it is fastened

certainly.

◇ Electrical insulation will be

weakened and causing electric

shock or fire outbreak.

When you feel a combustible gas

leaking, air the area so that

the refrigerator does not exposed

to gas.

◇ A spark at an electrical contact

point may cause an explosion, fire

or burning damage.

1

Warning

Don’t hold the power plug with

a wet hand.

◇ It may cause electric

shock.

Be sure the power supply is 220V.

◇ Otherwise, a fire outbreak,

electric shock or disorder may

be caused.

The power plug or cable shall not

be pressed by the refrigerator or

other things.

◇ Damage may be caused,

followed by a fire outbreak.

Don’t let the power cord touched

by a heater.

Don’t use a branched electrical outlet.

◇ Multi-branched power

connection may cause abnormal

overheat and a fire outbreak.

◇ Use a single-connection

electrical outlet with rated 220V

or more.

Don’t use a damaged power cord

or plug or a loose outlet.

◇ They may cause short circuit and

overheat, so that electric shock or a

fire outbreak may occur.

When pulling off the electric plug,

avoid holding only the cable.

◇ The cable may be damaged,

causing electric shock or a

fire outbreak.

◇ Be sure to hold the power plug

to pull it off.

Don’t put a container filled with water

on it.

◇ Damaged cord may cause a fire

outbreak or electric shock.

◇ If the cord is damaged, stop

using it and ask for a change by the

service center.

Don’t spill water on the main body

or inside.

◇ Electrical insulation may be

deteriorated, causing electric shock

or a fire outbreak.

Don’t hold the door and pull it down.

◇ The refrigerator may fall down

or your hand may be squeezed

and harmed.

Never disassemble or modify it.

◇ A fire outbreak or malfunctioning

may occur.

◇ If water is spilt, insulation of the

electrical parts may be

deteriorated, causing short circuit,

electric shock or a fire outbreak.

Don’t adjust the shelf with food

on it.

◇ It may fall down to hurt you.

Don’t climb over the refrigerator.

◇ It may be overturned and

hurt you.

Don’t let the power cord pressed by

heavy things nor pull or bend it hard.

◇ Damaged coating may cause a

fire or electric shock.

Don’t use flammable spray nearby.

◇ Spark at a contact point may

cause a fire outbreak.

Don’t put combustible inside.

◇ Thinner, benzene, LP gas and

adhesive may catch fire or

cause explosion.

2

Don’t put medicine or academic

materials inside.

Warning

When the fuse is exchanged, use

one with the same capacity.

◇ Don’t put materials that strict

temperature control is needed for in

a domestic refrigerator.

When you put your hand in the

machine room at the rear bottom,

be sure to unplug the

power connection.

◇ Otherwise, electric shock or

burning may occur.

When changing the light inside, be

sure to disconnect the power.

◇ Electric shock may occur.

Caution

When changing the light inside,

wear gloves so that you may not to

be burned or hurt by a breaking.

When moving it, raise the

adjustment feet.

◇ Otherwise, fire may be caused.

Grounding shall not be onto a water

pipe, a gas pipe, a telephone line or

a lightening rod.

◇ Fire or electric shock may occur.

◇ For grounding, be sure to ask

the seller.

Solid grounding shall be made.

◇ Short circuit by a disorder may

cause electric shock.

◇ For grounding, be sure to ask

the seller.

Don’t eat odorous or

color-changed food.

◇ Long keeping even in the fridge

or Freezer may

spoil food.

◇ Otherwise, the floor may

be damaged.

◇ A protection cover shall be used

on a damage-prone floor.

Don’t put your hand under the

bottom of the refrigerator.

◇ If you do while cleaning, you

may get hurt on the sharp steel

sheet.

Don’t put your hand on the

compressor or the pipes at the

rear bottom.

◇ Those parts are hot while in or

right after operation and so they

may burn you.

Don’t put a bottle in the

Freezer.

◇ It may be broken and hurt you.

When moving it, hold the adjustment

feet and the rear upper part.

◇ When holding the rear upper

part, be careful not to let your

hand slip.

◇ If it slips, it may be hurt.

Don’t touch the food or containers

in the fridge or freezing

compartment with a wet hand.

◇ You may suffer from frostbite.

If it is not in use for long, unplug

the power cord.

◇ Otherwise, fire outbreak

may occur.

3

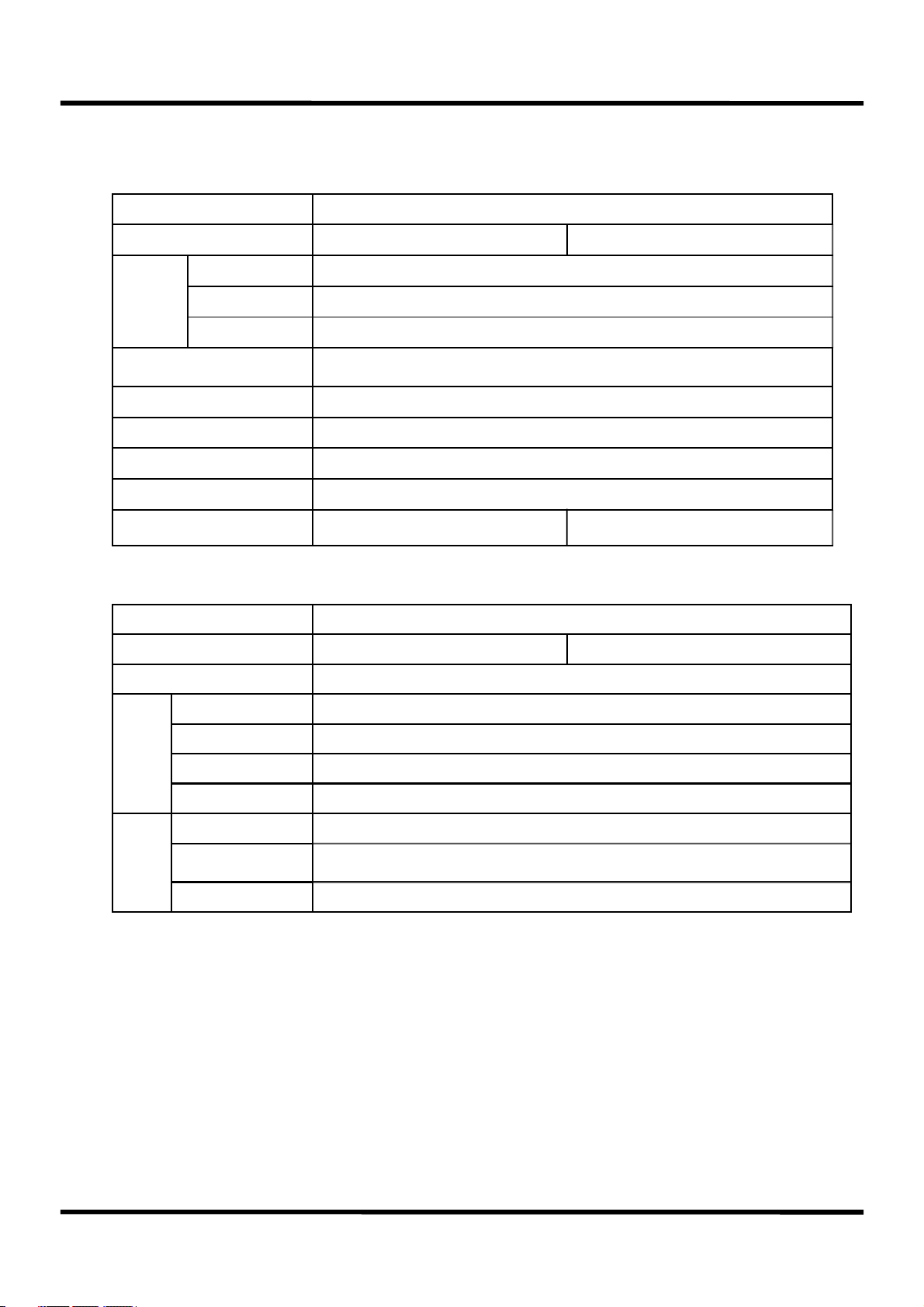

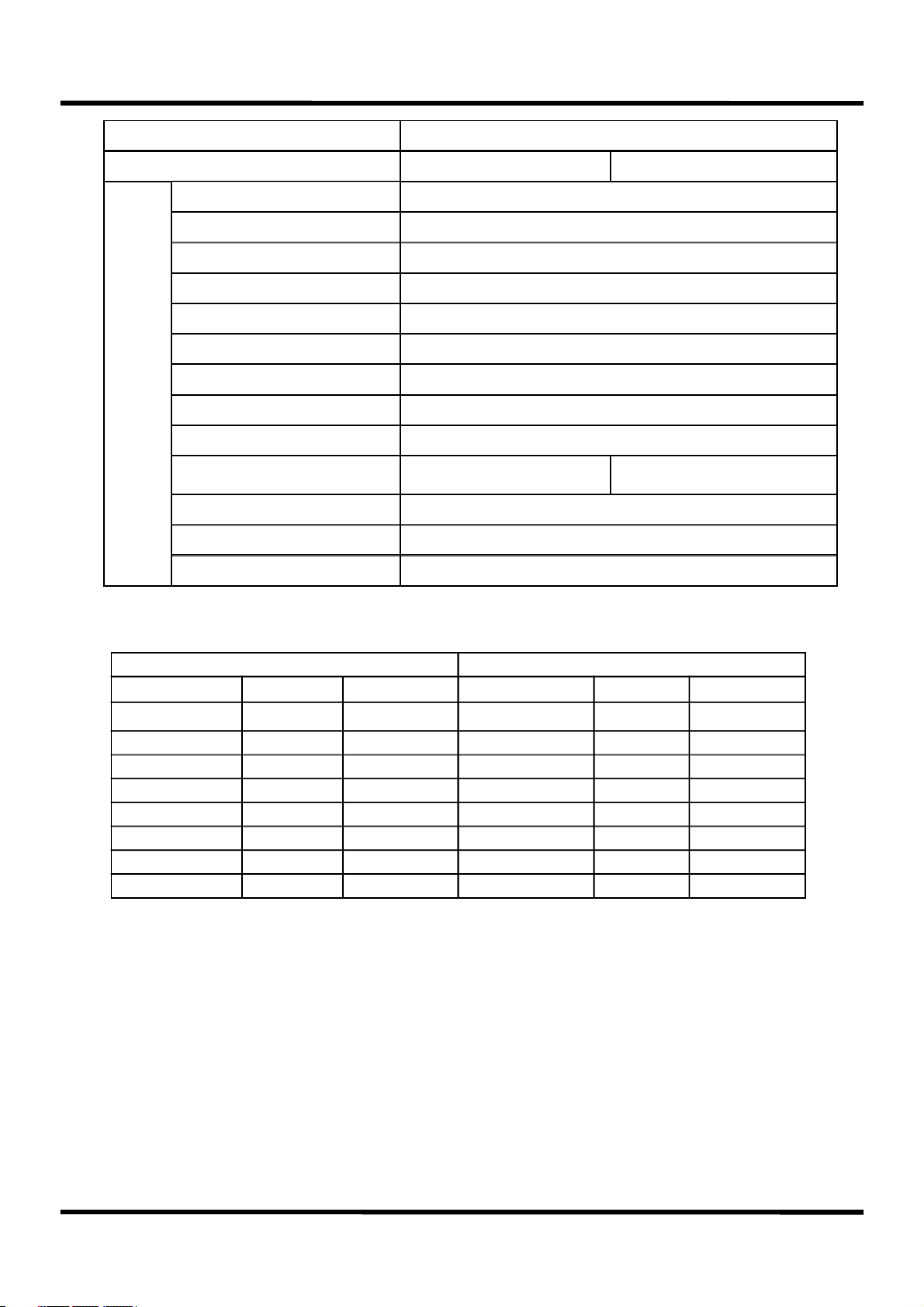

2. Product Specification

2-1. Product Specification

Items Product Specification

Model Name FRQ-19D... (Dispenser only ) FRQ-19F... ( Dispenser + H/bar )

Total Capacity 512ℓ

( Effective

Capacity

Freezing Compart. 4star: 134ℓ / 2star: 25ℓ

Fridge Compart. 353ℓ

External Size_mm

(WidthXDepthXHeight

Heating Device Rated Input 250 W

Refrigerator Kind Indirect cooling type

Cooling Media / Sealed Quant’y R600a ( 0.064kg ) or R-134a ( 0.160kg )

Climate Grade SN ~ T

Weight 97 kg 100 kg

912X795.8X1771

2-2. Electrical Part Specification

Items Product Specification

Model Name FRQ-19D... (Dispenser only ) FRQ-19F... ( Dispenser + H/bar )

Freezing Performance 4-Star

Evaporator FIN TYPE

Freezing

Parts

Condenser Forced circulation type

dryer MOLECULAR SIEVE XH-9

Capillary Tube IDΦ0.7 X 0.55t X L2,365

Defrost

ing

Parts

Defrosting Heater 250W

D-sensor (Type/

Return Temperature)

Temperature Fuse 250V / 10A / 77 (+0,-4)℃

PBN-43 / 13℃

4

Other

Electronic

Unit Spec.

Items Specification

Model Name FRQ-19D... (Dispenser only ) FRQ-19F... ( Dispenser + H/bar )

Main Fuse AC250V /12A

Home-bar Heater 230V / 10W (Control per RT & time)

Freezing Compart.(F) Fan Motor DC12V / Φ140

Condenser(C) Fan Motor DC12V / Φ150

Freezing Compart.(R) Damper DC12V

Switchable Room Damper -

Freezer Light LED ( DC12V / 1.20W )

Fridge Light LED ( DC12V / 1.69W )

Freez./Fridge Compart. Door Switch SP101B-2D1 (AC 250 V, 0.5A)

Home-bar Door Switch -

power cord AC250V 16A(VDE)

F / R-sensor N3RC-K32D / N3JC-K41A

ICING / FLOW-sensor N3JC-K35D-D94 / SH-F 110L

DC 12V / RS-D4

(REED S/W + MAGNET)

2-3. Controlled Temperature of the Freezing & Fridges

Freezer Fridge

Stage Display ON / OFF Stage Display ON / OFF

Weak -16 -12.0 / -16.0 Weak 8 9.4 / 9.9

Weak-to-medium1 -17 -14.8 / -18.8 Weak-to-medium1 7 8.5 / 8.9

Weak-to-medium2 -18 -15.8 / -19.8 Weak-to-medium2 6 7.4 / 7.9

Medium -19 -16.8 / -20.8 Medium 5 6.5 / 7.0

Medium-to-strong1 -20 -17.4 / -21.4 Medium-to-strong1 4 5.5 / 6.0

Medium-to-strong2 -21 -19.0 / -23.0 Medium-to-strong2 3 4.5 / 5.0

Strong -22 -22.0 / -26.0 Strong 2 3.5 / 3.9

Quick -22 - Quick 2 -

5

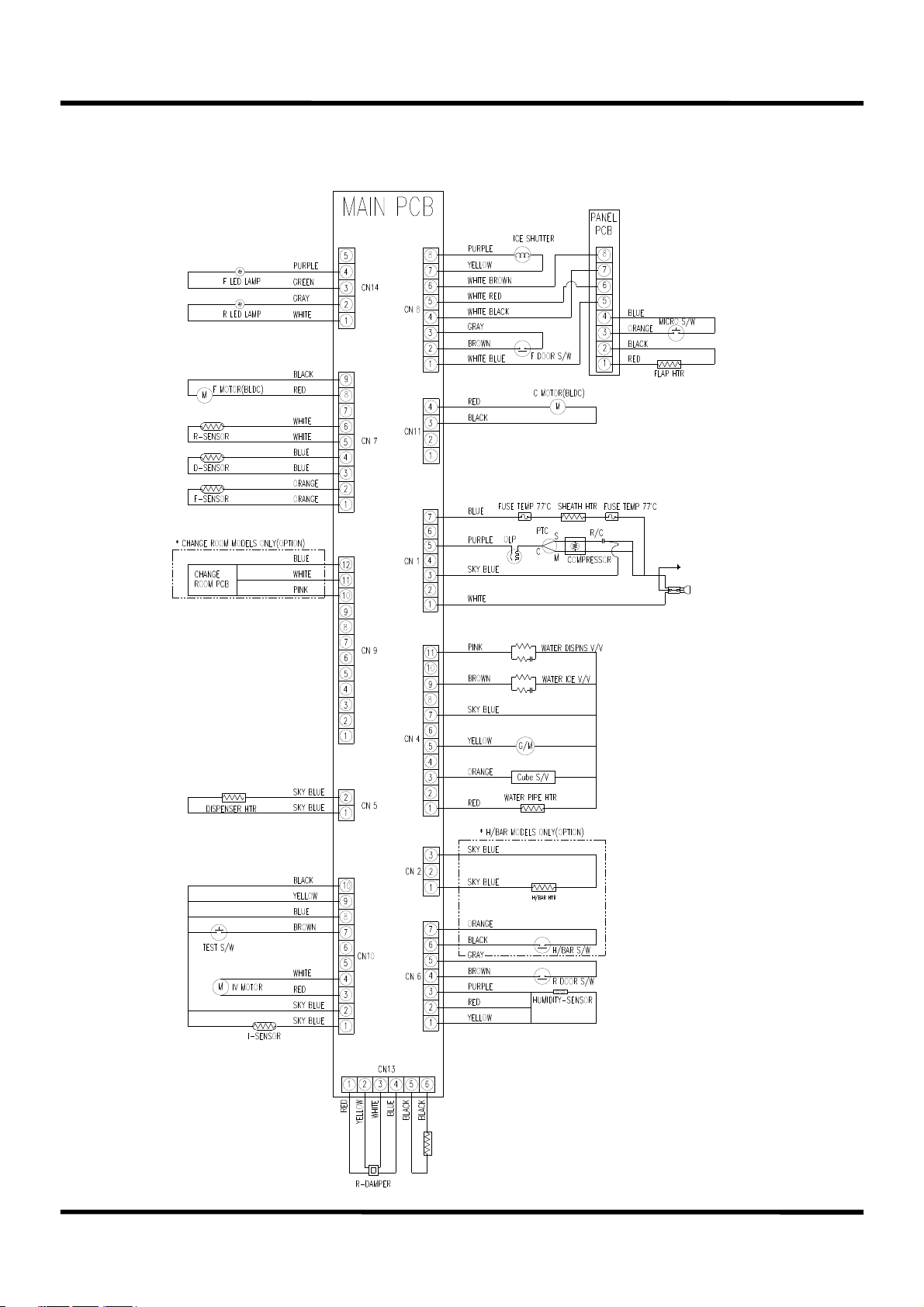

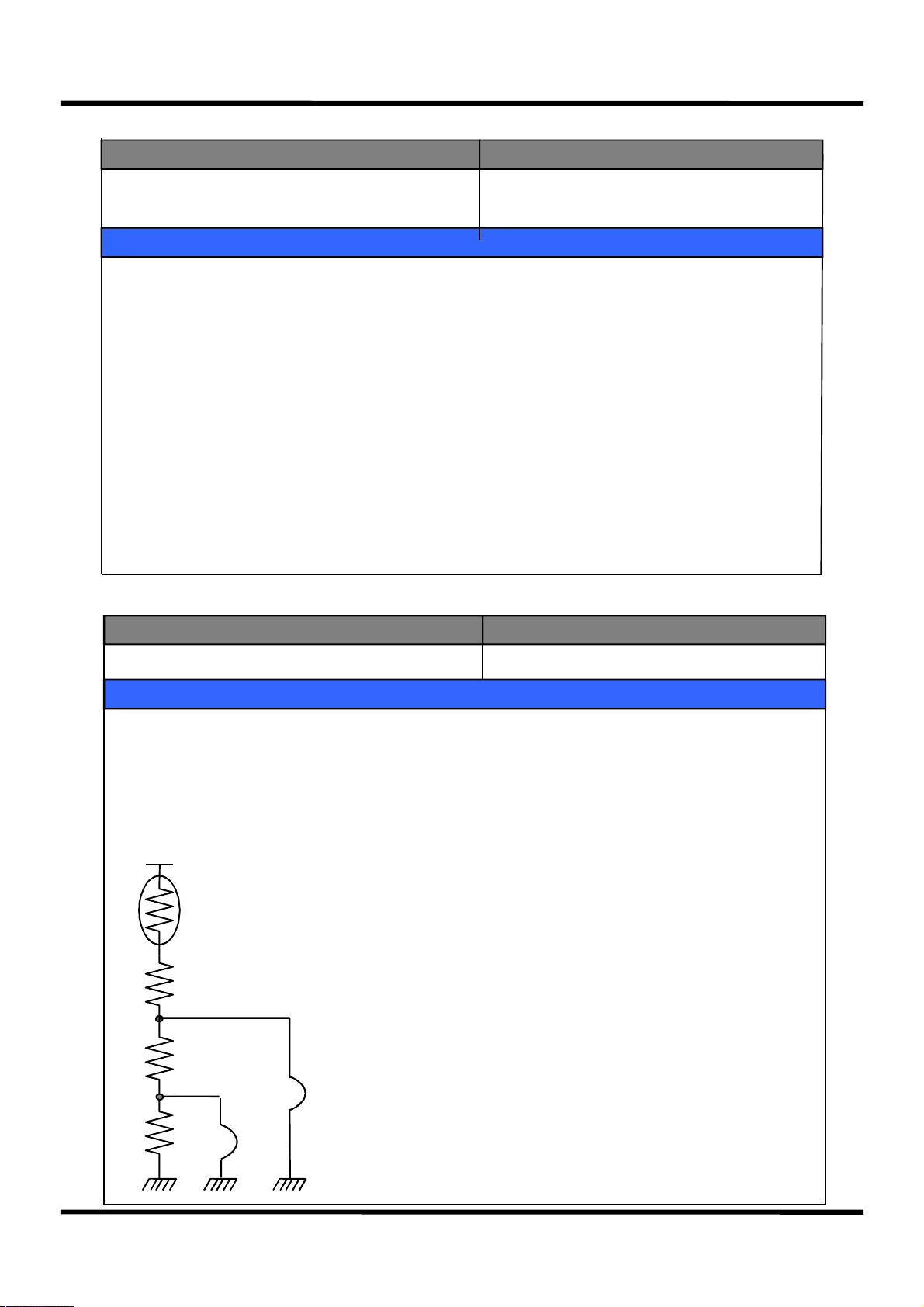

3. Wiring Diagram

3-1. Normal Compressor

6

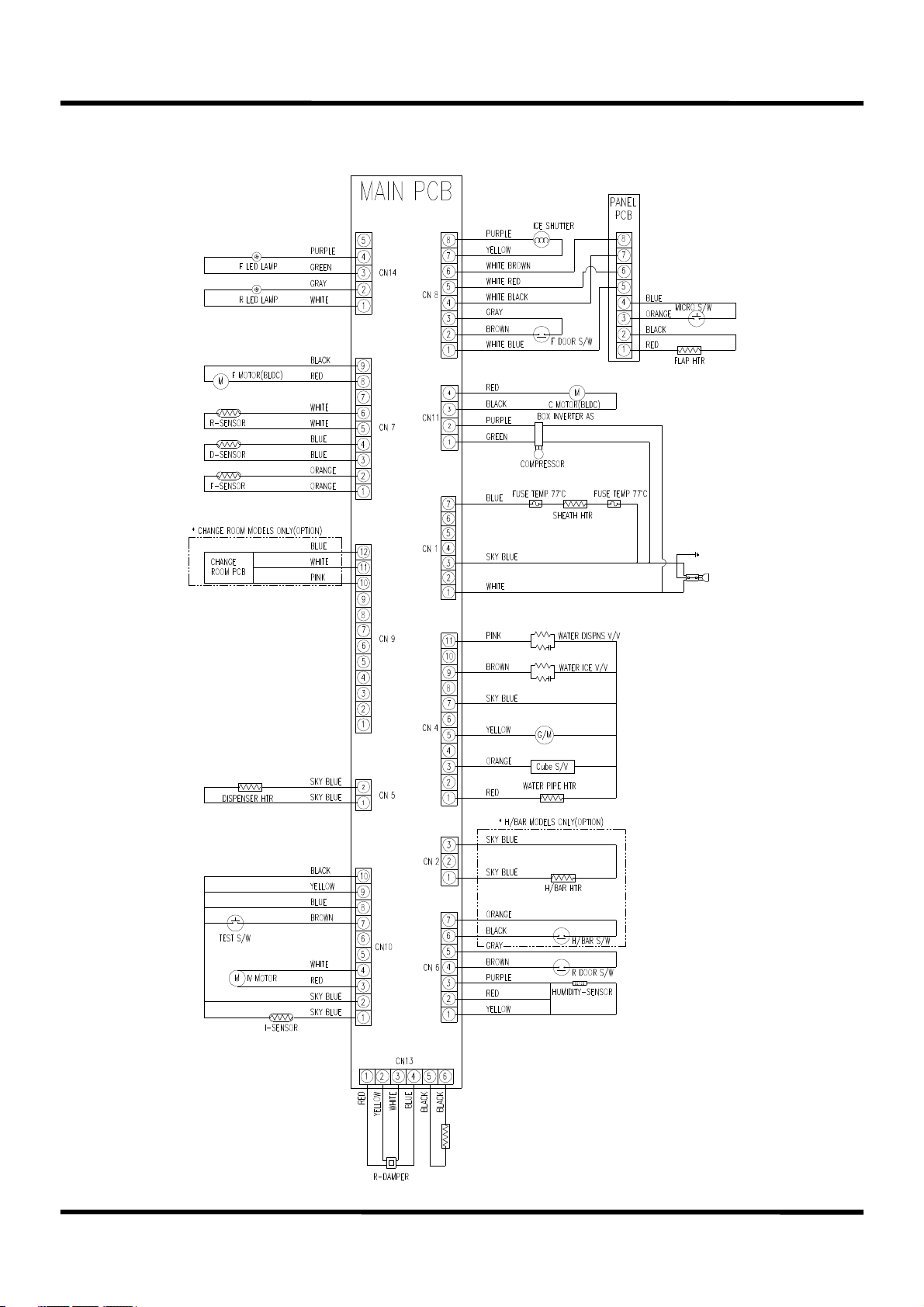

3-2. Inverter Compressor

7

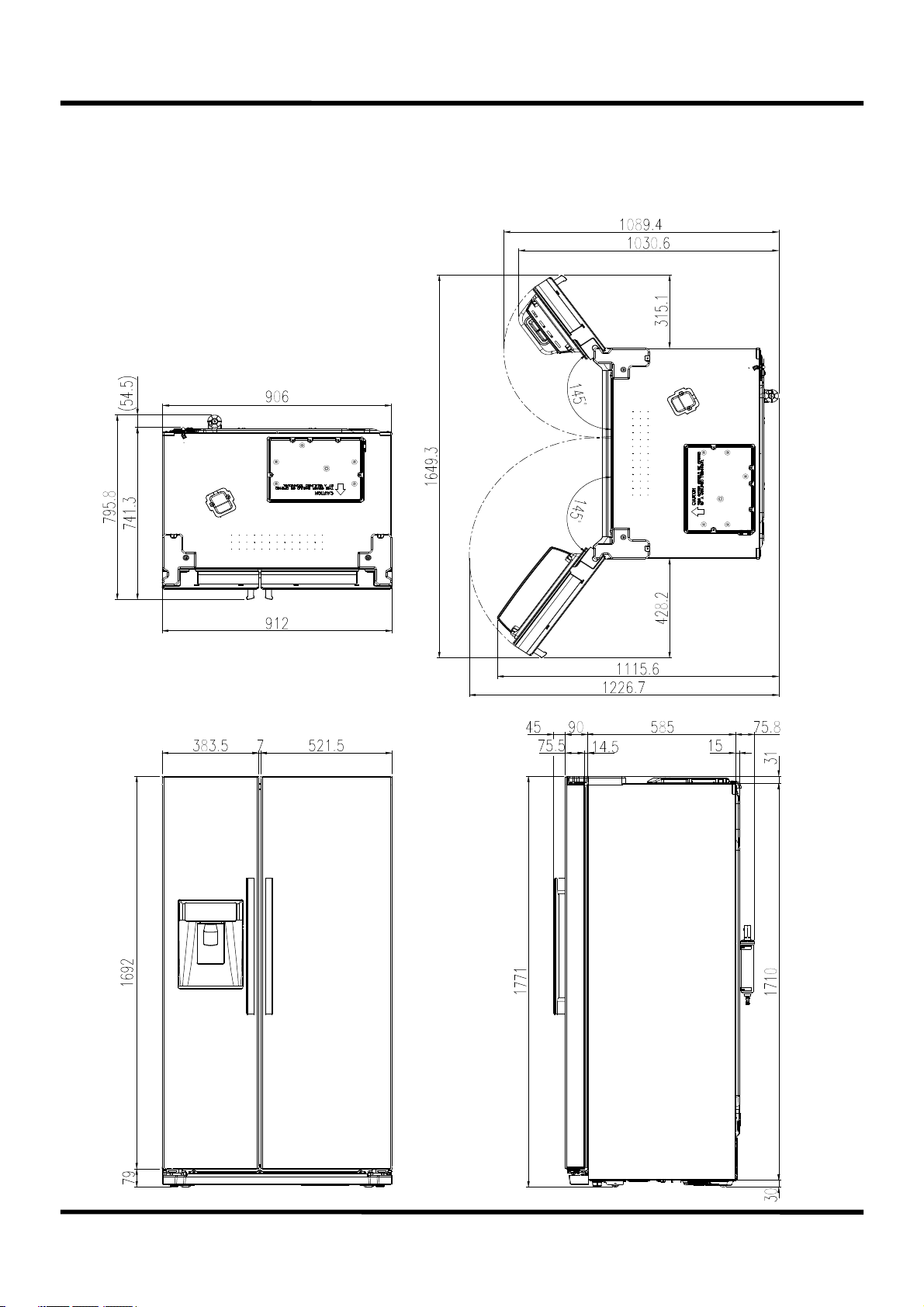

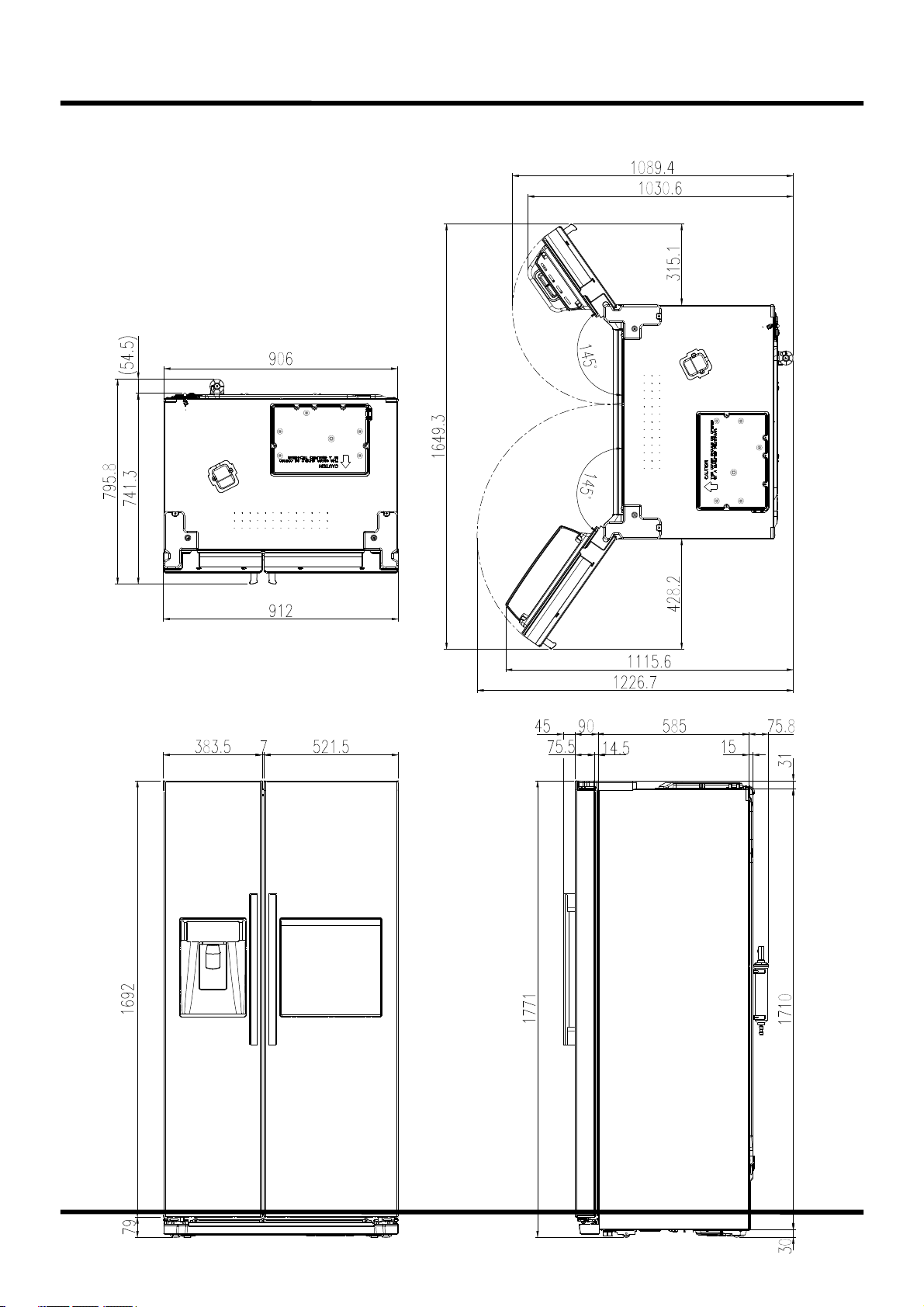

4. External Size and Names of the Refrigerator

4-1. FRQ-19D... (Dispenser only )

8

4-2. FRQ-19F... ( Dispenser + H/bar )

9

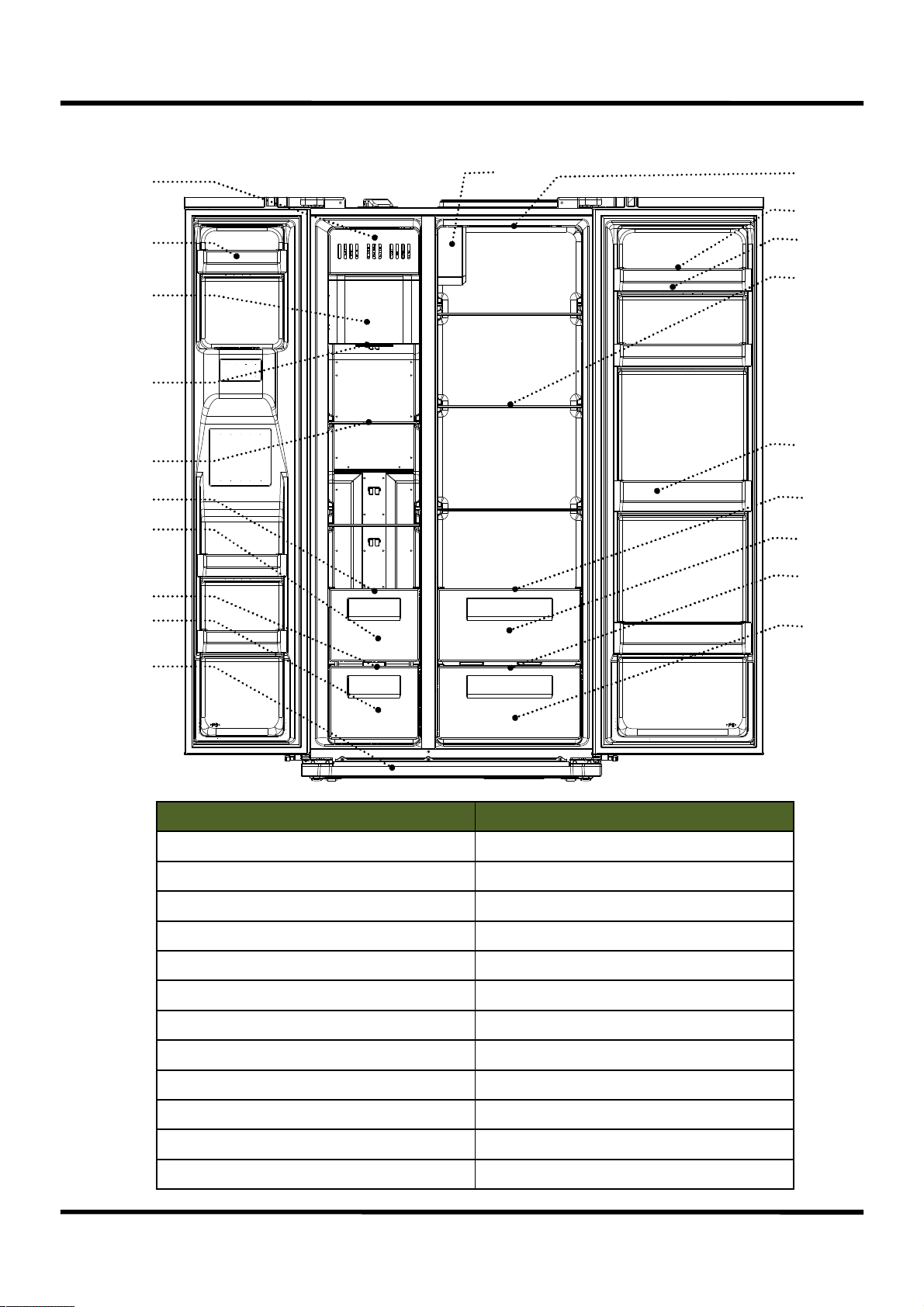

4-3. Part Name (FRQ-19D... )

2

1

3

4

5

6

7

8

9

13

14

20

11

15

12

16

17

18

19

10

Freezer Fridge

1. Freezer Pocket 11. Upper Fridge Pocket

2. Upper Ice Crusher Cover 12. Lower Fridge Pocket

3. Lower Ice Crusher Cover 13. Damper Cover

4. Freezer Internal Light 14. Fridge Internal Light

5. Freezer Shelf 15. Fridge Shelf

6. Dried Food Case Cover 16. Upper Vegetable Case Cover

7. Dried Food Case 17. Upper Vegetable Case

8. Meat/Fish Case Cover 18. Lower Vegetable Case Cover

9. Meat/Fish Case 19. Lower Vegetable Case

10. Front Cover 20. Egg Tray

10

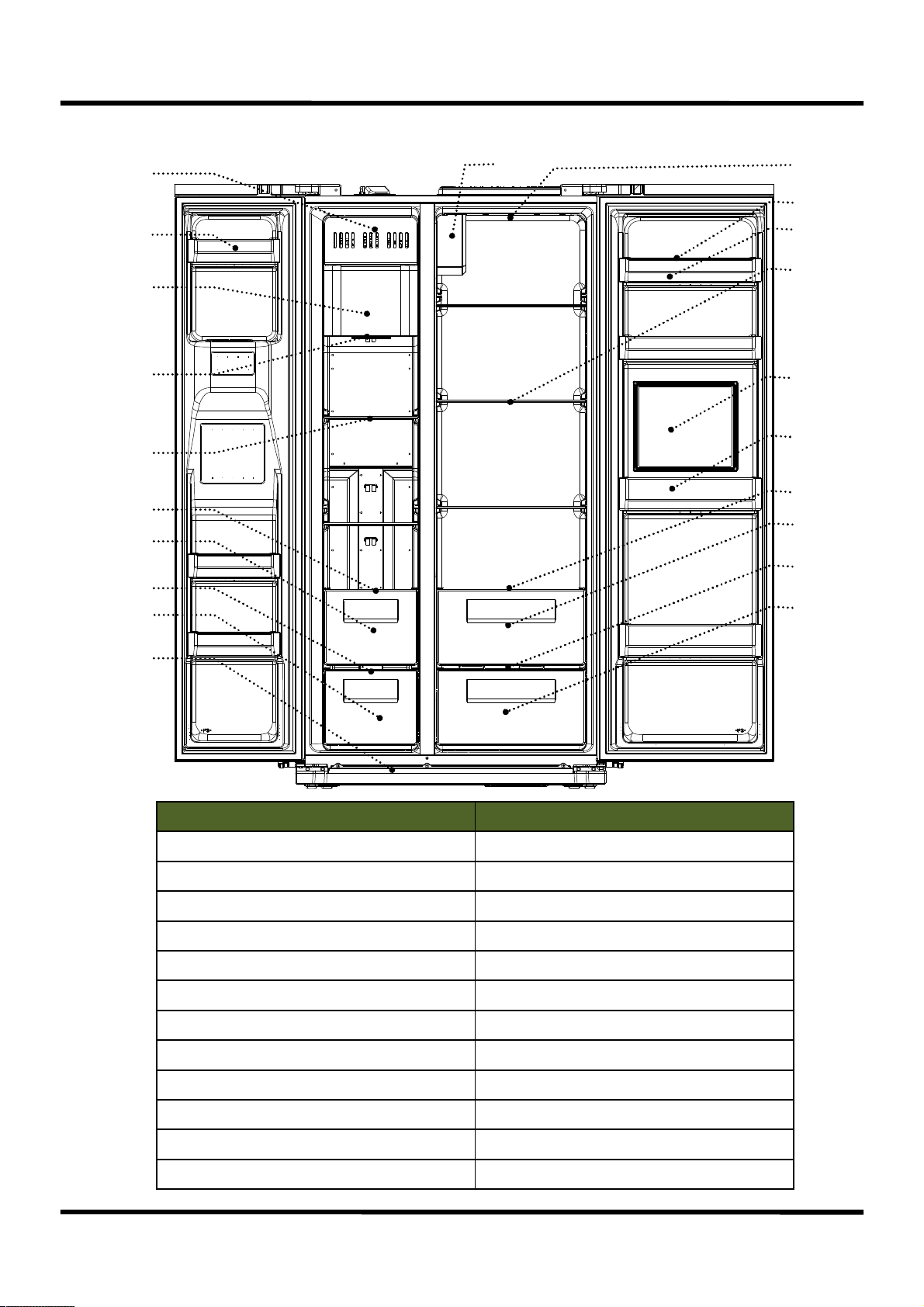

4-4. Part Name (FRQ-19F... )

1

2

3

4

5

6

7

8

9

13

14

21

11

15

20

12

16

17

18

19

10

Freezer Fridge

1. Freezer Pocket 11. Upper Fridge Pocket

2. Upper Ice Crusher Cover 12. Lower Fridge Pocket

3. Lower Ice Crusher Cover 13. Damper Cover

4. Freezer Internal Light 14. Fridge Internal Light

5. Freezer Shelf 15. Fridge Shelf

6. Dried Food Case Cover 16. Upper Vegetable Case Cover

7. Dried Food Case 17. Upper Vegetable Case

8. Meat/Fish Case Cover 18. Lower Vegetable Case Cover

9. Meat/Fish Case 19. Lower Vegetable Case

10. Front Cover 20. Home Bar

21. Egg Tray

11

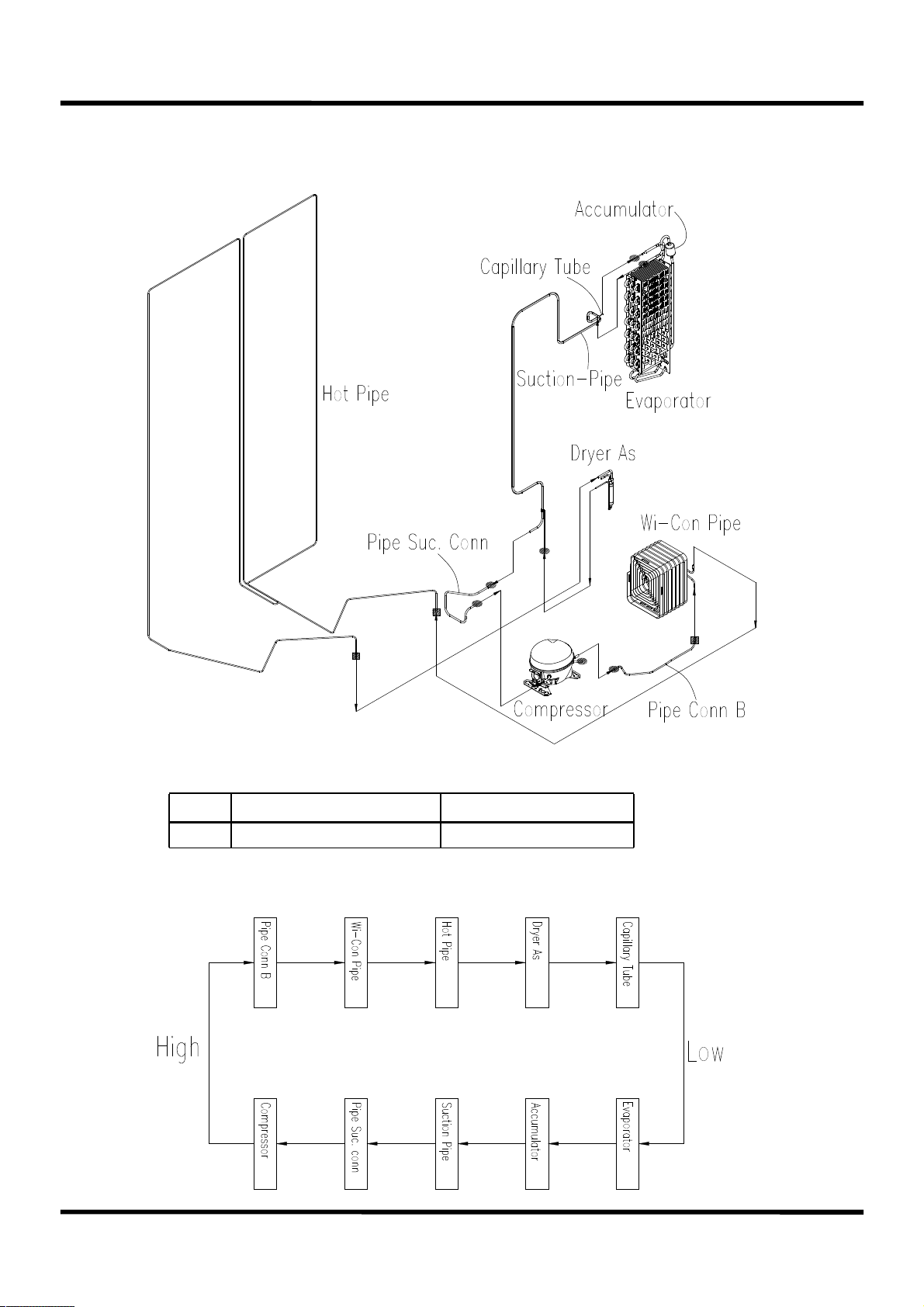

5. Refrigeration Cycle

▶ Welding Specification

●

■

▶ Refrigerent Flow

Copper Soldering (Ag 3%) 7 Points

Silver Soldering (Ag 30%)

3 Points

12

6. Functions & Usage of the Refrigerator

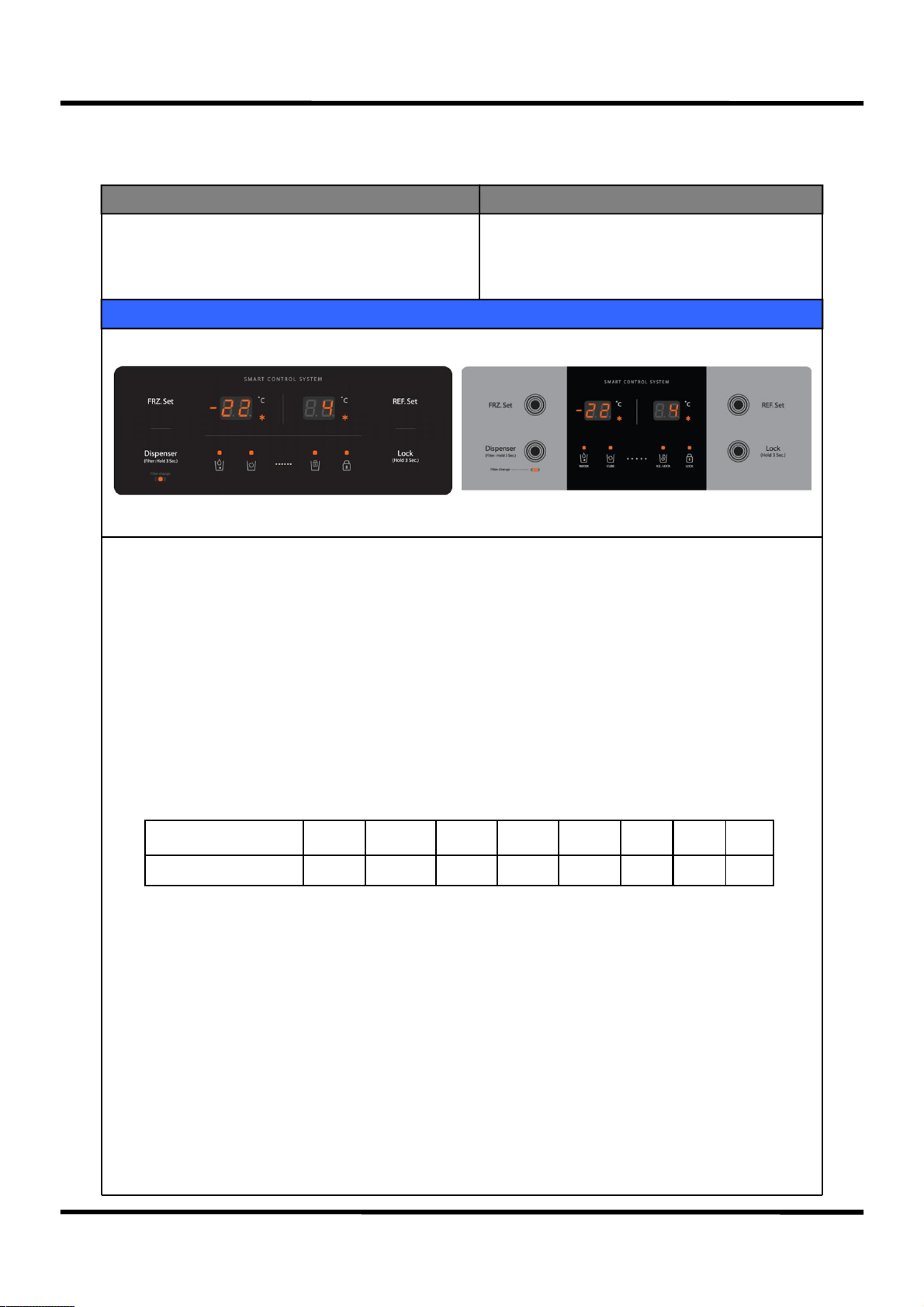

6-1. Display ( None crusher model )

Input Parts Control Object

1. F-PCB Button

2. Freezing Adjustment, Fridge Adjustment

3. lock Button

Contents

1. “Freezing Adjustment” Button

1) Press “Freezing Adjustment” Button to have it run in staged temperature adjustment (7 stages)

and quick freezing (max. limit 24 hours). In quick freezing running, “ * “ is on; otherwise, it is off.

2

) Initial default setup at the power connection is “medium” stage, with the setup temperature -19℃ displayed.

Order of display:

Medium(-19℃)→Medium-to-strong1(-20℃)→Medium-to-strong2(-21℃)→Strong(-22℃)

→Quick(-22℃)→Weak(-16℃)→Weak-to-medium1(-17℃)→Weak-to-medium2(-18℃)

3) When Quick freezing is chosen, “Quick Icon” flickers 6 times before it is lighted, with the setup

temperature displayed the same as in dial “Strong”.

4) Freezing Adjustment stages & displays

1.Display

Adjustment Stages W WM1 WM2 M MS1 MS2 S Q

Setup Temperature(℃) -16 -17 -18 -19 -20 -21 -22 -22

5) When Quick freezing is finished, Dial will automatically turn to “Medium(-19℃)”.

2. “Fridge Adjustment” Button

1) Press “Fridge Adjustment” Button to have it run in staged temperature adjustment (7 stages)

and quick fridge(max. limit 40 minutes). In quick freezing running, “ * “ is on; otherwise, it is off.

2) Initial default setup at the power connection is “medium” stage, with the setup temperature 2℃ displayed.

Order of display:

Medium(4℃)→Medium-to-strong(3℃)→Strong(2℃)→Quick(2℃)→Weak(8℃)→Weak-to-medium1(7℃)

→Weak-to-medium2(6℃)→Weak-to-medium3(5℃)

3) When Quick operation is chosen, “Quick Icon” flickers 6 times before it is lighted, with the setup

temperature displayed the same as in dial “Strong”.

13

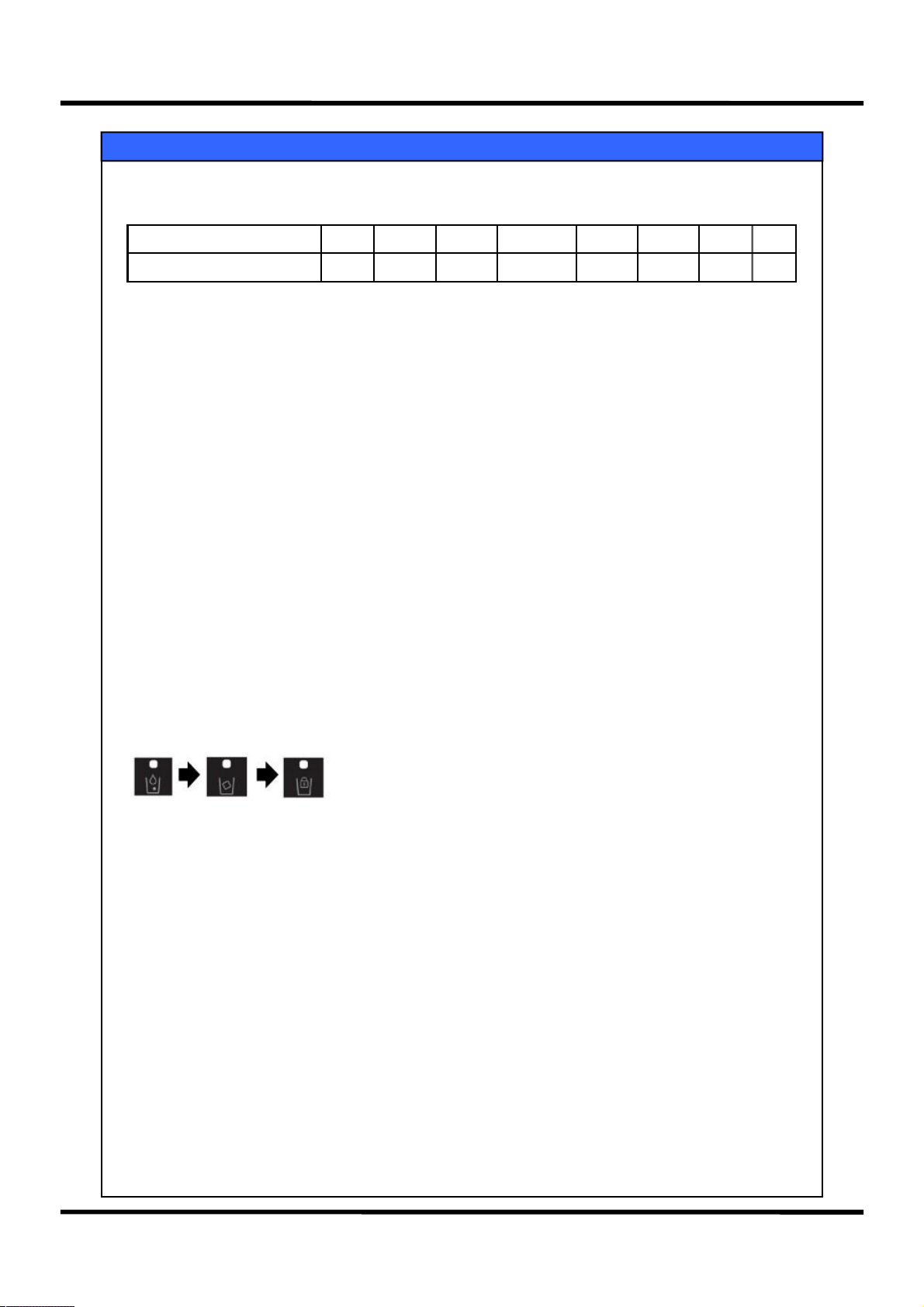

2. “Fridge Adjustment” Button

4) Fridge Adjustment stages & displays

Contents

Adjustment Stages

Setup Temperature(℃)

W WM1 WM2 WM3 M MS S Q

8 7 6 5 4 3 2 2

5) When Quick fridge is finished, Dial will automatically turn to “Medium(4℃)”.

3. “lock” Function Button

1) lock Setup

- Press “lock” button for 0.5 seconds to have the “lock Icon” On

- When “lock” is set up, no key input (including the dispense switch) is possible nor the buzzer will ring.

2) Cancel: Press the “lock” function button for 3 seconds to cancel the lock state.

4. Power Save Function

All LED will be turned off one minute after a final key input or a door closing

(with Lock LED and Water/Ice LED not included).

5. Dispenser select

Led above the icon will light up to indicate your selection.

1) 1st‘Dispenser’ button, water is available.

2) 2nd‘Dispenser’ button, cubed ice is available.

rd

3) 3

‘Dispenser’ button, dispenser lock.

14

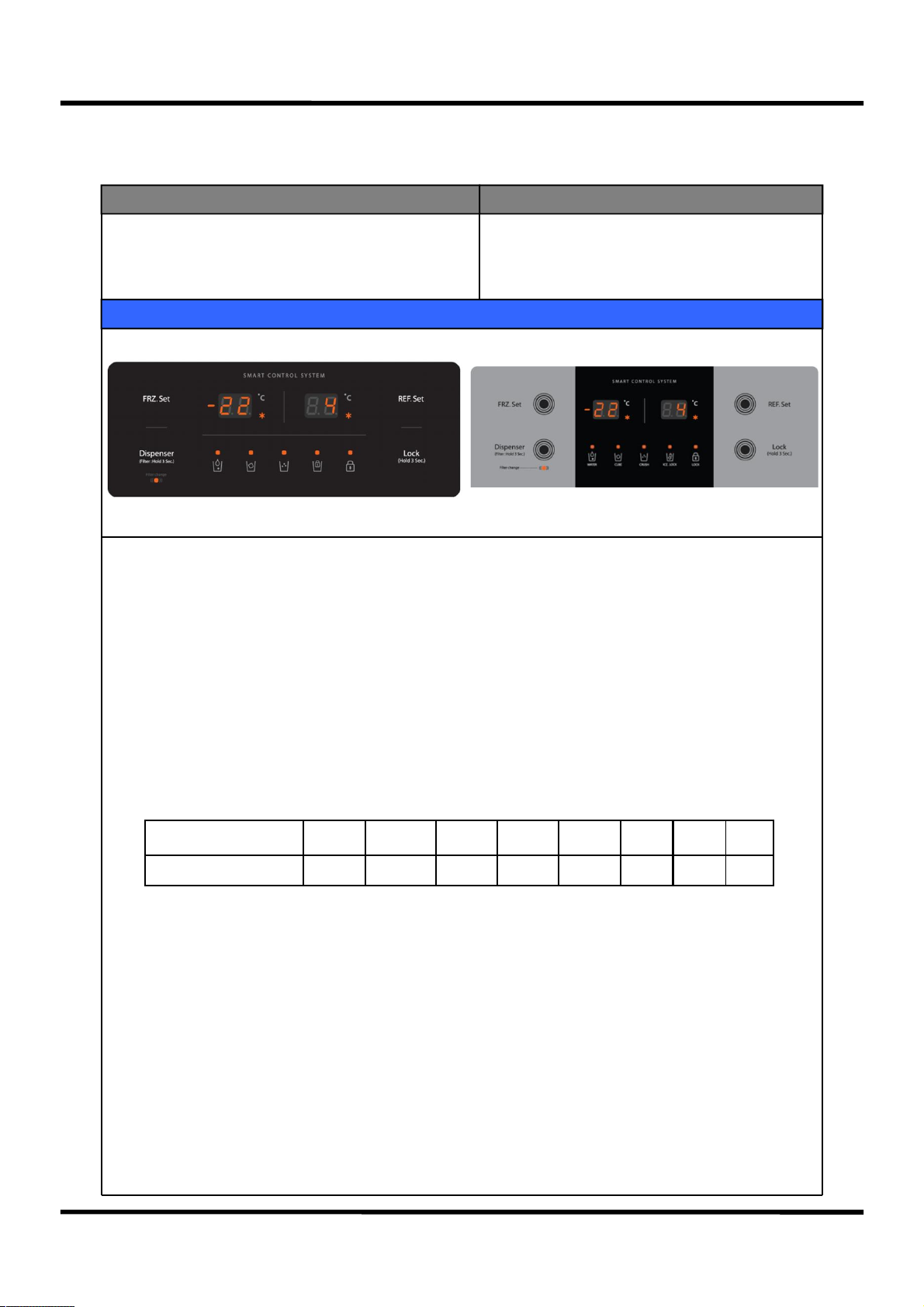

6-1. Display ( Crusher model )

Input Parts Control Object

1. F-PCB Button

2. Freezing Adjustment, Fridge Adjustment

3. lock Button

Contents

1. “Freezing Adjustment” Button

1) Press “Freezing Adjustment” Button to have it run in staged temperature adjustment (7 stages)

and quick freezing (max. limit 24 hours). In quick freezing running, “ * “ is on; otherwise, it is off.

2

) Initial default setup at the power connection is “medium” stage, with the setup temperature -19℃ displayed.

Order of display:

Medium(-19℃)→Medium-to-strong1(-20℃)→Medium-to-strong2(-21℃)→Strong(-22℃)

→Quick(-22℃)→Weak(-16℃)→Weak-to-medium1(-17℃)→Weak-to-medium2(-18℃)

3) When Quick freezing is chosen, “Quick Icon” flickers 6 times before it is lighted, with the setup

temperature displayed the same as in dial “Strong”.

4) Freezing Adjustment stages & displays

1.Display

Adjustment Stages W WM1 WM2 M MS1 MS2 S Q

Setup Temperature(℃) -16 -17 -18 -19 -20 -21 -22 -22

5) When Quick freezing is finished, Dial will automatically turn to “Medium(-19℃)”.

2. “Fridge Adjustment” Button

1) Press “Fridge Adjustment” Button to have it run in staged temperature adjustment (7 stages)

and quick fridge(max. limit 40 minutes). In quick freezing running, “ * “ is on; otherwise, it is off.

2) Initial default setup at the power connection is “medium” stage, with the setup temperature 2℃ displayed.

Order of display:

Medium(4℃)→Medium-to-strong(3℃)→Strong(2℃)→Quick(2℃)→Weak(8℃)→Weak-to-medium1(7℃)

→Weak-to-medium2(6℃)→Weak-to-medium3(5℃)

3) When Quick operation is chosen, “Quick Icon” flickers 6 times before it is lighted, with the setup

temperature displayed the same as in dial “Strong”.

15

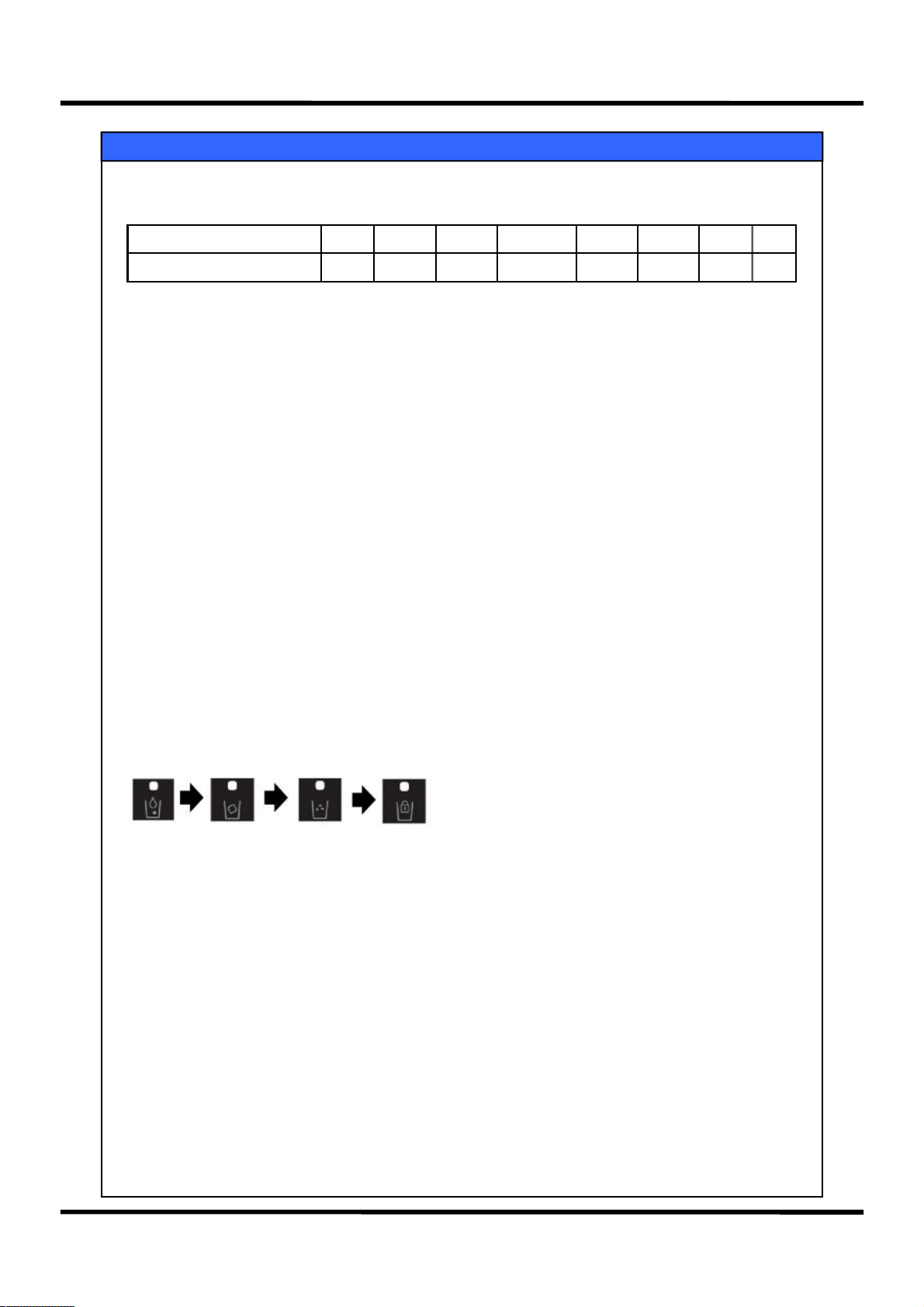

2. “Fridge Adjustment” Button

4) Fridge Adjustment stages & displays

Contents

Adjustment Stages

Setup Temperature(℃)

W WM1 WM2 WM3 M MS S Q

8 7 6 5 4 3 2 2

5) When Quick fridge is finished, Dial will automatically turn to “Medium(4℃)”.

3. “lock” Function Button

1) lock Setup

- Press “lock” button for 0.5 seconds to have the “lock Icon” On

- When “lock” is set up, no key input (including the dispense switch) is possible nor the buzzer will ring.

2) Cancel: Press the “lock” function button for 3 seconds to cancel the lock state.

4. Power Save Function

All LED will be turned off one minute after a final key input or a door closing

(with Lock LED and Water/Ice LED not included).

5. Dispenser select

Led above the icon will light up to indicate your selection.

1) 1st‘Dispenser’ button, water is available.

2) 2nd‘Dispenser’ button, cubed ice is available.

rd

3) 3

‘Dispenser’ button, crushed ice is available.

4) 4th‘Dispenser’ button, dispenser lock.

16

6-2. Freezer Temperature Adjustment

Input Parts Control Object

1. Freezer Temperature Adjustment Button

2. F-Sensor

1. Comp

2. F-Fan

Contents

1. Press the Freezer button to adjust the Freezer temperature.

Medium(-19℃)→Medium-to-strong1(-20℃)→Medium-to-strong2(-21℃)→Strong(-22℃)

→Quick(-22℃)→Weak(-16℃)→Weak-to-medium1(-17℃)→Weak-to-medium2(-18℃)

2. Comp and F-fan are controlled by Dial On / Off.

3. On / Off Diff of the Freezer: 4.0℃

Medium Off point of the Freezer : -20.8℃

4. Freezer Diff for each step

1) Weak → Weak-to-medium1 : 3.0 deg.

2) Weak-to-medium1 → Weak-to-medium2 → Medium : 1.0 deg.

3) Medium → Medium-to-strong1 : 0.6 deg.

4) Medium-to-strong1 → Medium-to-strong2 : 1.4 deg.

5) Medium-to-strong2 → Strong : 3.0 deg.

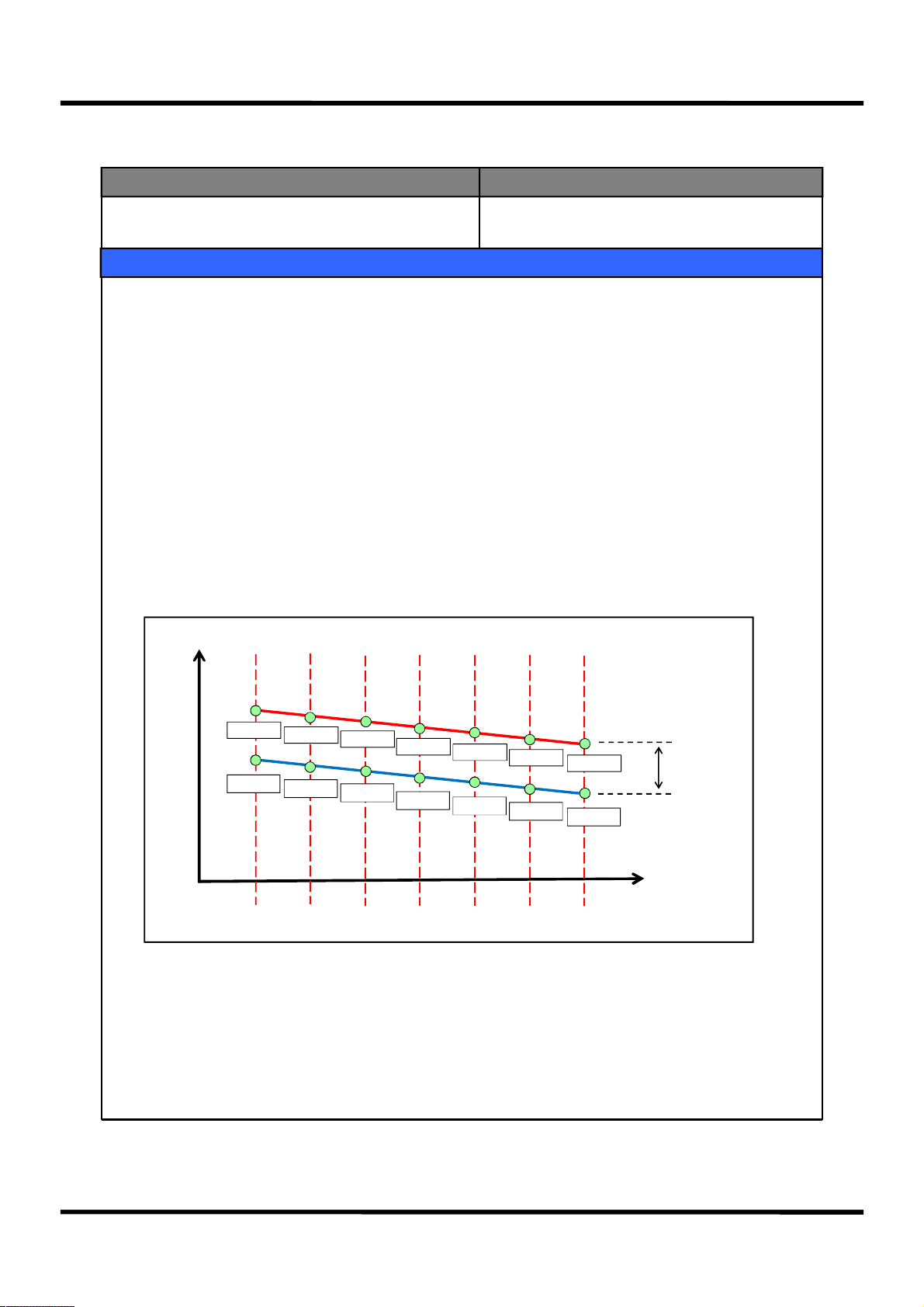

5. Control Point for each Dial (F-Sensor Detection Temperature)

temp.

-8.8 ℃

-13.3 ℃

-12.0 ℃

-16.3 ℃

-13.1 ℃

-17.2 ℃

-14.1 ℃

-18.2 ℃

-15.1 ℃

-19.1 ℃

-17.0 ℃

-20.9 ℃

-18.9 ℃

-22.8 ℃

ON Point

ON/OFF DIFF

OFF Point

MODE

Weak

(Weak to medium1,2)

Medium (Medium to strong1,2)

6. Quick Freezing

1) In Quick Freezing, it is run by ‘Strong’ dial of F-Dial for the limited time(24 hours).

2) When Quick Freezing is closed by the time limit or the F-Sensor is Off point, it is run with the ‘Medium’

dial value of the F-Dial.

3) During a Quick Freezing operation, defrosting cannot be started. If Quick Freezing is set up in defrosting,

Quick Freezing will be run after the defrosting.

Strong

17

6-3. Fridge Temperature Adjustment

Input Parts Control Object

1. Fridge Temperature Adjustment Button

2. R-Sensor

1. Comp

2. F-Fan

3. Damper

Contents

1. Press the Freezer button to adjust the setup temperature of the Freezer.

Medium(4℃)→Medium-to-strong(3℃)→Strong(2℃)→Quick(2℃)→Weak(8℃)→Weak-to-

medium1(7℃)→Weak-to-medium2(6℃)→Weak-to-medium3(5℃)

2. Comp and F-fan are controlled by the On / Off points of each Dial.

3. On / Off Diff of the Fridge: 0.5℃

Fridge “Medium” Off point: 5.5℃

4. Fridge Step Diff

1) Each Step Diff: 1 deg.

(At low room temperature (RT-S of 19℃ or less), Dial ‘Medium, Medium-to-strong, Strong’ will lower the On/Off

points by 1℃, while at high room temperature (RT-S of 41℃ of more), Dial ‘Medium, Medium-to-strong,

Strong’ will lower the On/Off points by 0.3℃.)

5. Prevention of Weak Cooling

1) When Weak Cooling is detected, Comp is turned on, regardless of F-Sensor.

2) When R-sensor reaches R-Damper Close point, Comp is controlled by the F-sensor and R-Damper is Close.

3) Weak Cooling detection point: R-Damper Close of each Mode + 7℃

4) Weak Cooling cancellation point: the same as the R-Damper Close point of each Mode

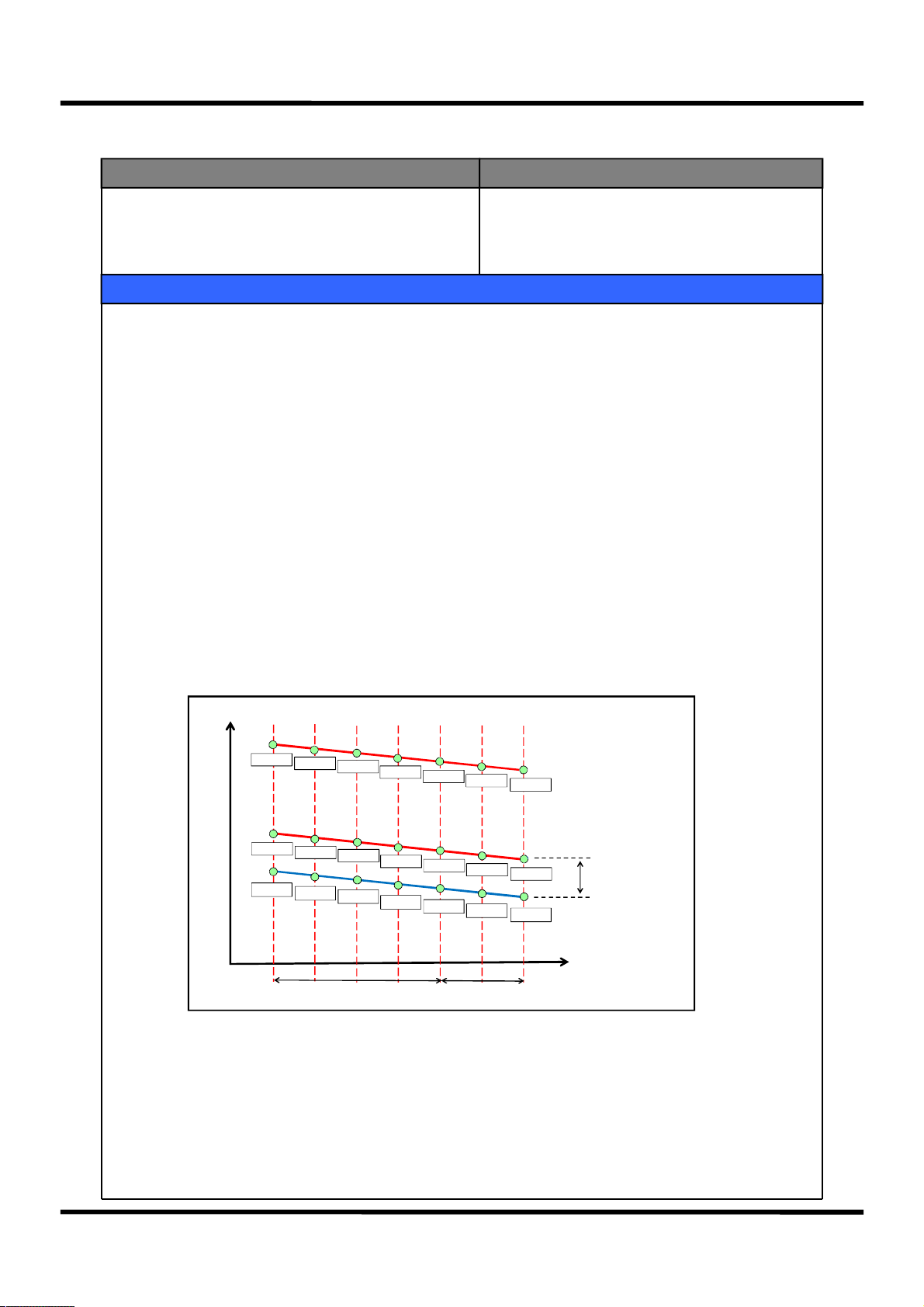

6. Control Point for each Dial (R-Sensor detection temperature)

temp.

16.5 ℃

15.5℃

9.9℃

9.4℃

Weak

14.5℃

8.9℃

7.9℃

8.5℃

7.4℃

STEP DIFF

(Weak to medium1,2,3)

13.5 ℃

7.0℃

6.5℃

12.5℃

6.0℃

5.5℃

Medium

11.5℃

5.0℃

4.5℃

STEP DIFF

Medium to strong

10.5℃

3.9℃

3.5℃

Strong

Week Cooling c heck

(OFF Point + 7.0 deg)

ON Point

ON/OFF DIFF

(0.5 deg)

OFF Point

MODE

7. Quick Fridge

1) In Quick Fridge, it is run in ‘Strong’ dial of the R-Dial for the limited time (40 minutes).

2) Until the R-sensor reaches the Overcooling Off point(-7deg.), R-Damper is open and F-Fan /

Comp are On.

3) After the Overheating Off point is reached, it is run by Dial “strong” On/Off points until 40

minutes of Quick Fridge is finished.

4) When the Quick Fridge is finished, it will turn to normal operation.

18

6-4. Fan Control at each Mode

Input Parts Control Object

1. R-Sensor

2. F-Sensor

1. F-Fan

2. C-Fan

Contents

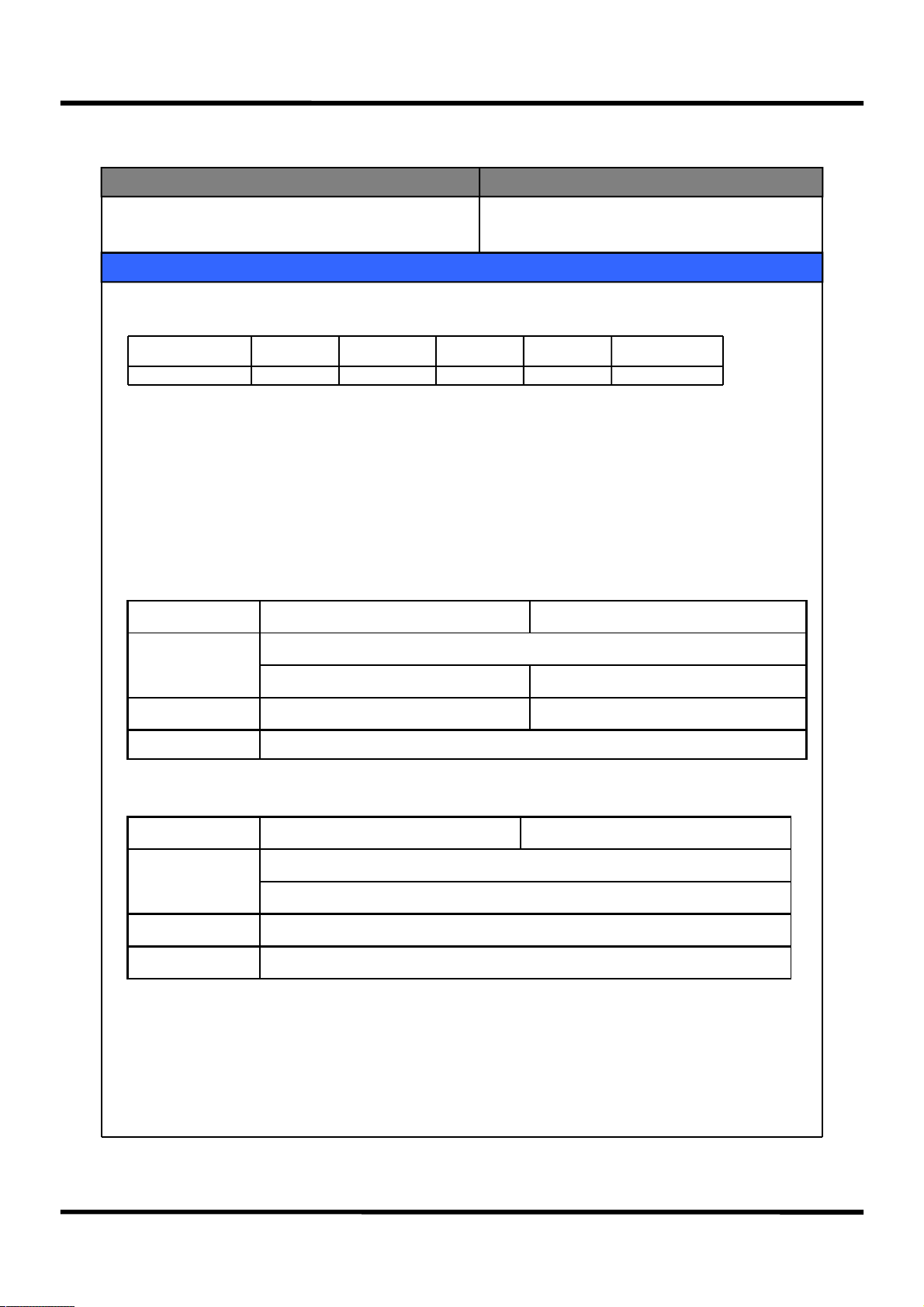

1. Fan RPM for each control Mode

1) F-Fan Motor voltage

Control Mode Normal Quick Freezing

F-FAN voltage 10V 12V 12V 13V 13V

Load

Response1

Load

Response2

RT-S 39℃ or more

● Normal Control ☞ Low operation mode with soft noise

● Load Response ☞ Operation mode when the temperature in the compartments is deemed escalating by

usage condition.

2. Load Response Mode

1) Purpose: To recover the temperature of the compartment escalated by overload or an opening of the

door.

2) Display Method: There is no separate display.

3) Conditions for Load Response1 startup and cancellation, and its control method

Freezer Load Response Fridge Load Response

Startup Condition

1. F/R-Door opening of 30 seconds or more

2. F/S On Point + 5deg. or more detected 2. R/S On Point + 5deg. or more detected

Cancel. Condition F-Sensor value < Off point R-Sensor value < Off point

Control Method Comp RPM is controlled to change to the next higher stage of RPM

4) Conditions for Load Response2 startup and cancellation, and its control method

Freezer Load Response Fridge Load Response

Startup Condition

Cancel. Condition Cancelled if the defrosting is started

Control Method Operation with Comp RPM being 3990

1. Load Response1 at RT-S 29 ℃ or less

2. When COMP has continuously operated for 6 hours

19

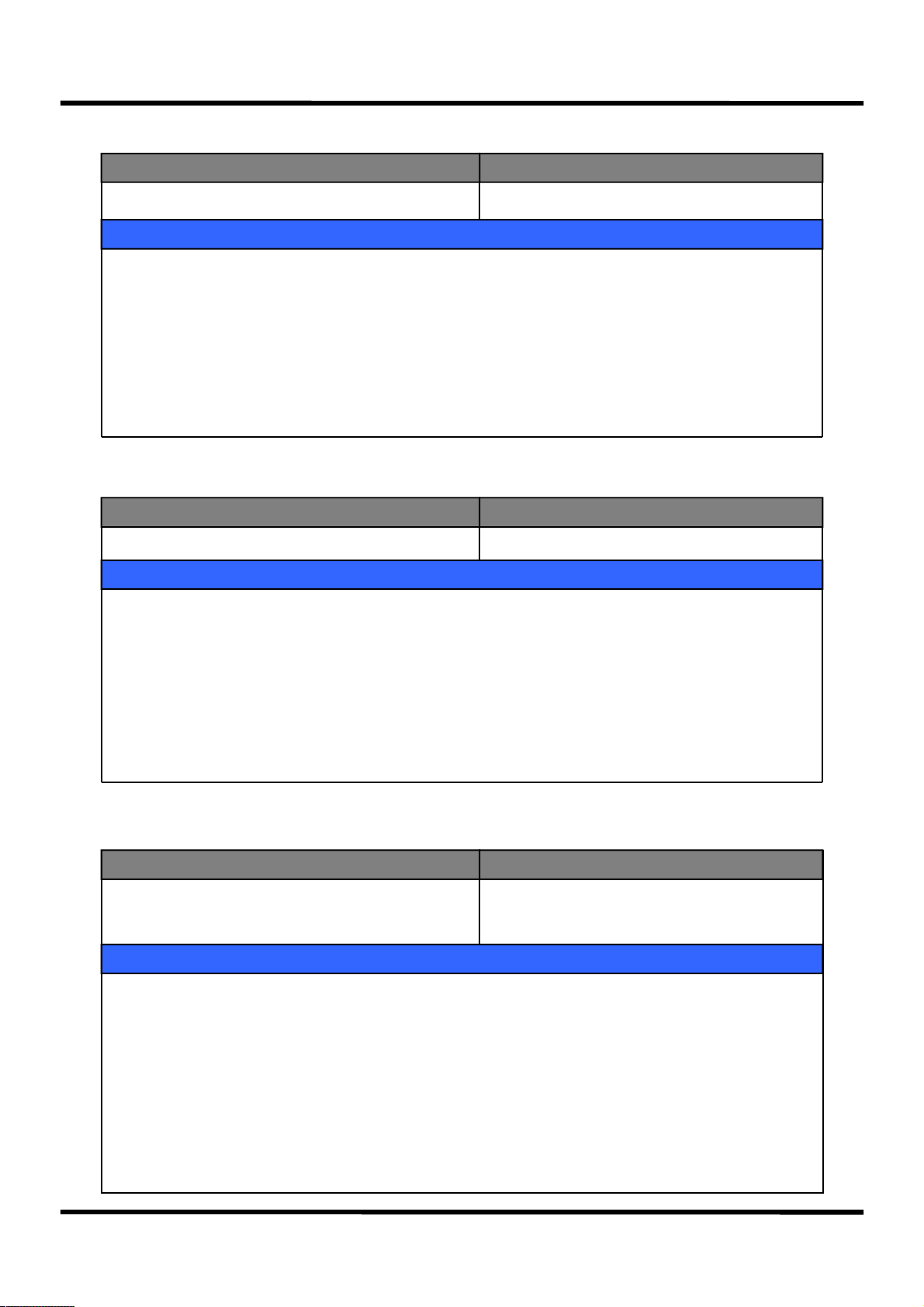

6-5. Defrosting

Input Parts

1. Accumulated Comp Operation Time

2. Time Lapse since a Comp On/Off

1. Comp

2. F-Fan

Control Object

3. Defrosting Heater

4. Damper

Contents

1. Defrosting Startup Condition

1) Accumulated Comp Operation Time: If it passes 8,10,12,~ 40 hours and, at the same time, various errors take place or

the accumulated F-Door Opening is 2 minutes or more, the defrosting will be started.

2) If the accumulated F/R-Door Opening time is 2 minutes or more and the operation rate in 2 hours is 85% or more, the

defrosting will be started.

3) Total (Comp On Time + Comp Off Time) time : If it is 50 hours, the defrosting will be started.

4) If accumulate Comp operation time is 24 hours, the defrosting will be started.

* Various Errors : R1, F1, D1, F3, RT/S, C1, Door error.

2. General Defrosting Procedure

1) Time limit is 50 minutes (Comp, F-fan operation)

Precool

Heater

Defrosting

2) When the lime limit of 50 minutes passes, F-Sensor < -27℃, or there is Error F3,

Precool will end.

* There is no Precool in a general Defrosting (but only in a power consuming mode).

1) When D-Sensor ≥ 13℃, Defrosting Heater will be Off.

2) When the Defrosting heater turns off by the time limit (60 minutes), there will be an

F3-Error.

3) If there is a D-Sensor Error, the Defrosting Heater will be on, with the time limit of 30 min.

4) Process Time Limit

① 30min.: At a D-Error, each heater is on for 30/10 min.

② 60min.: When defrosting starts at a normal control state, the time limit will be 60min.

1) Pause Time = 10min.

Pause

2) In the pause time, Defrosting Heater, Comp and F-Fan is off.

3) During the pause time, Comp is off regardless of the R-Sensor temperature.

Fan Delay

2) Immediately after the pause, only the Comp is on, with the Heater off.

3. Power consuming mode starting (Average operation rate before a Defrosting is 80% or less)

1) If D-Sensor ≥ 9℃, the Defrosting Heater will be off.

2) Pause time is 10min.

3) After a Precool mode is proceeded, Heater-on mode will start.

4. Electronic Unit Control State & Time Limit for Each Mode

Precool D-HTR Defrosting Pause Fan Delay

Comp On Off Off On/Off

F-Fan On Off Off Off

D-HTR Off On Off Off

Time Limit 50min. 60min. 10min. 5min.

20

1) Fan Delay Time = 5min.

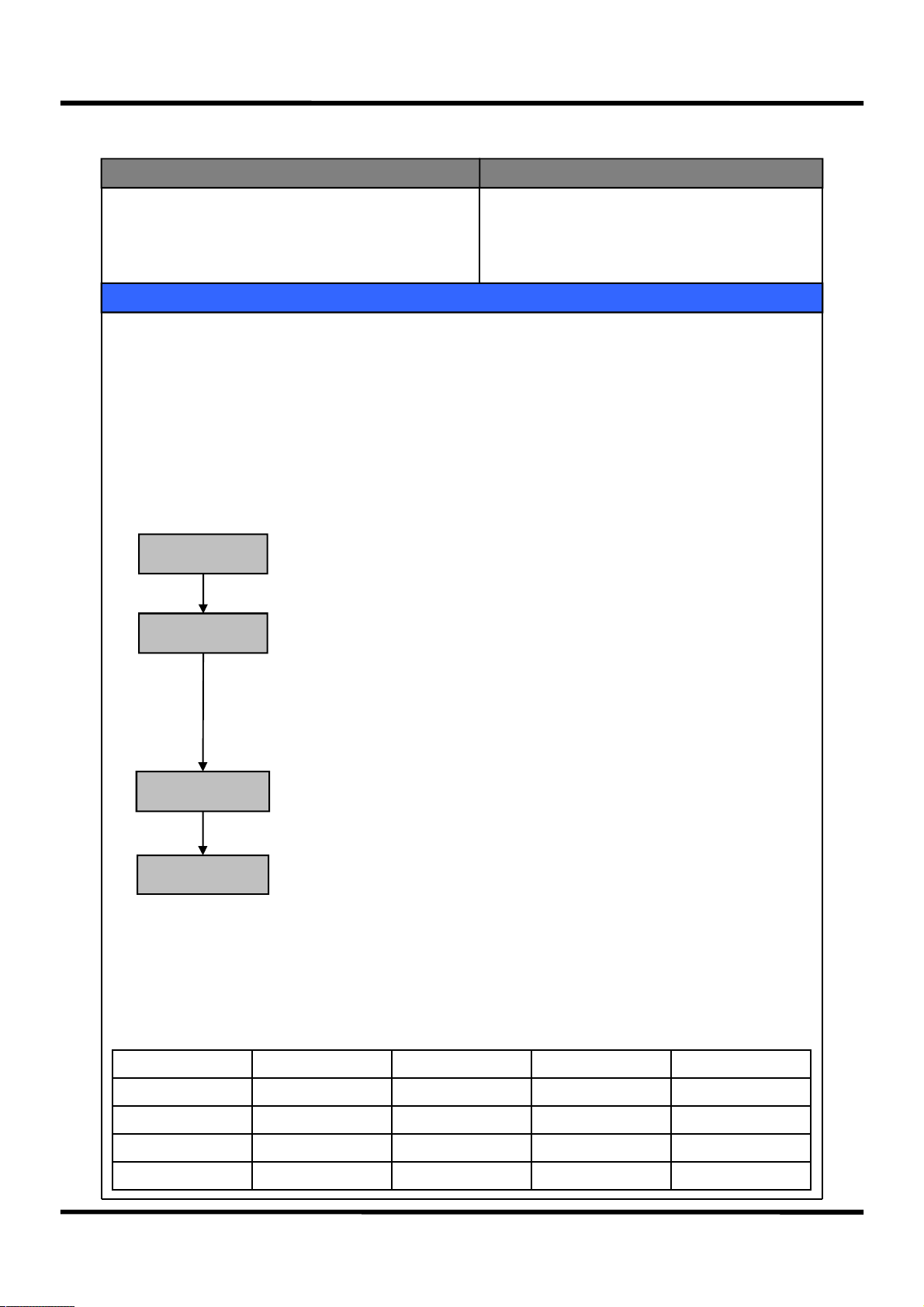

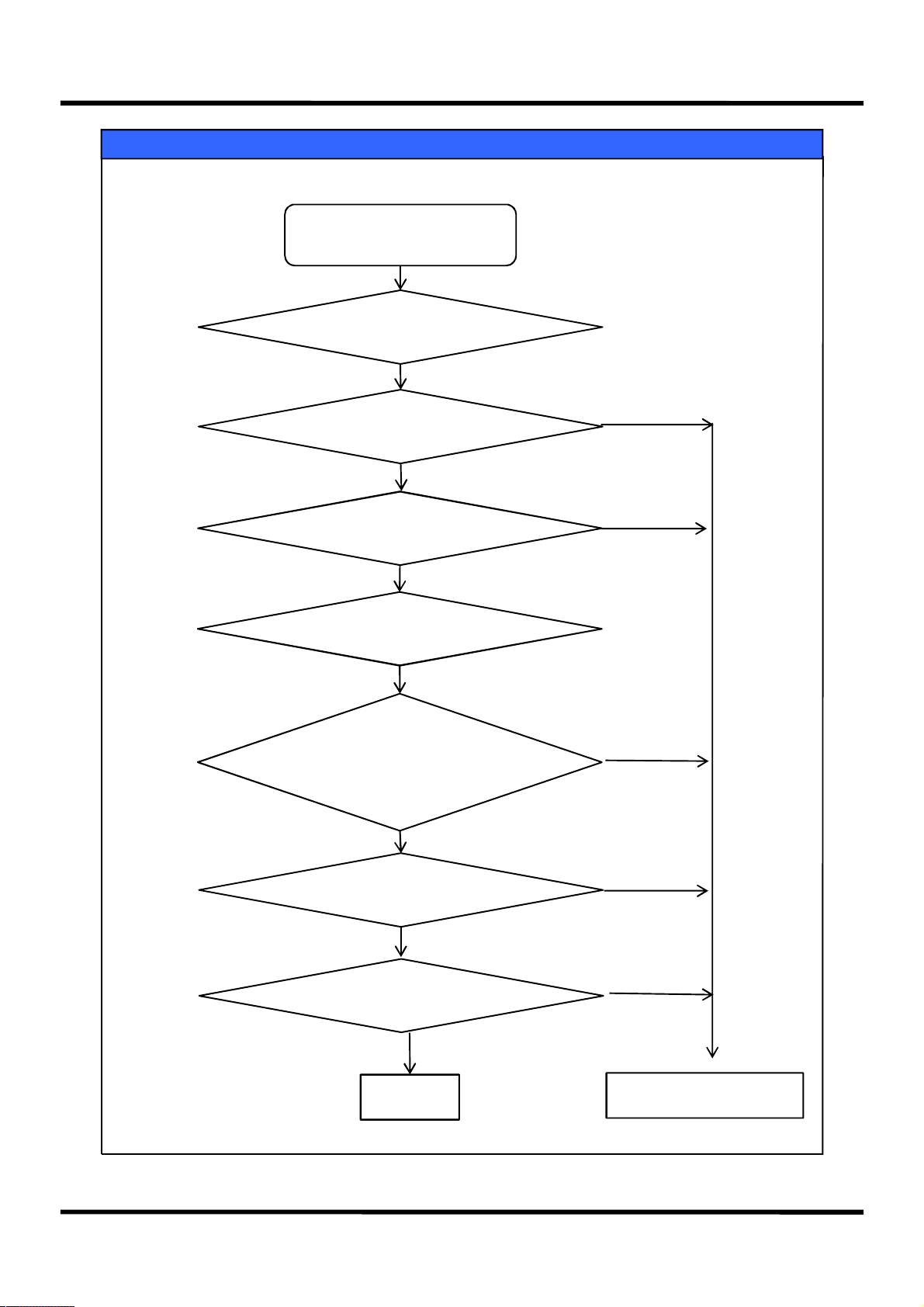

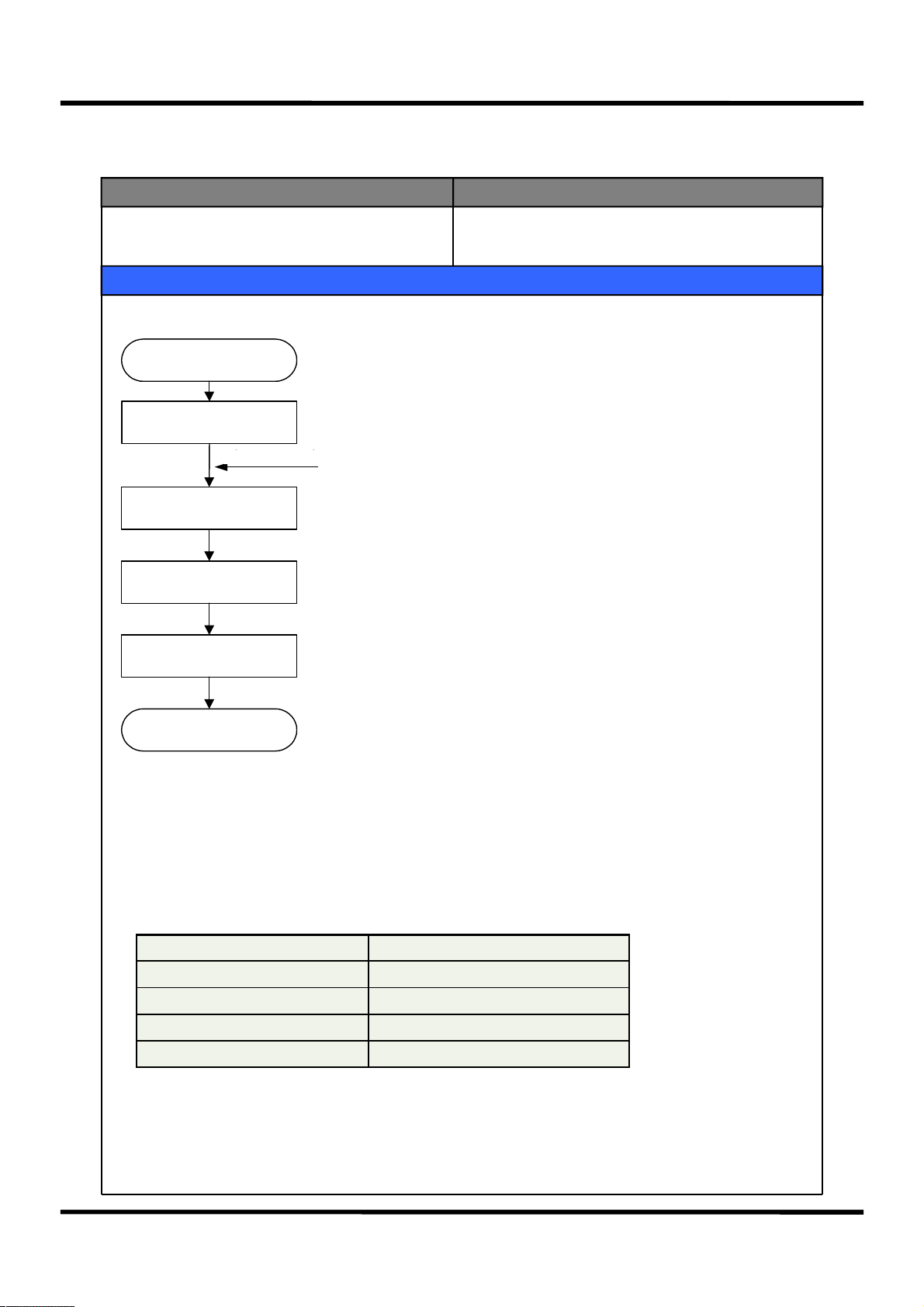

5. Defrosting Flow Decision

Contents

START

Comp. operation accumulated > 2 hours

YES

Total time(Comp On + Comp Off) > 50 hours

RT < 14℃ &

Total time(Comp On + Comp Off) > 24 hours

YES

Comp. operation accumulated > 8 hours

NO

(Comp. operation accumulated > 24 hours

NO

Any error ?

YES

YES

YES

Total F/R door open time > 2 min

END

21

YES

Defrost Mode Start

6-6 Initial Defrosting

Input Parts Control Object

1. D-Sensor

2. Initial Power Supply

Contents

1. If D-Sensor ≤ 3.5℃ when the initial power supply begins, Defrosting mode will start.

2. Defrosting is made per D-Sensor.

3. When in initial Defrosting, Comp is delayed by 6min.

1. Defrosting Mode

6-7 Short Circuit Operation

Input Parts Control Object

1.Front PCB

Contents

1. Starting: Press “Fridge Adjustment” + “Freezing Adjustment” 10 times in the “Locked” state.

2. Control Method: Comp & F/C-Fan continuous operation. R Damper Open

3. Operation Display: “Co” displayed at Error Display Mode (Refer to Error Display)

4. Cancellation: Automatically canceled 10 hr after starting

1. Electronic Units

6-8. Comp RPM Control ( Inverter compressor model only )

Input Parts Control Object

N/A

Contents

1. Comp RPM is changed per RT-Sensor & Set operation state

Temperature Condition

Normal Operation 1800 RPM 2550 RPM 3600 RPM 3990 RPM

Load Response1 2550 RPM 3600 RPM 3990 RPM 3990 RPM

Load Response2 3990 RPM 3990 RPM 3990 RPM 3990 RPM

Quick Operation 3600 RPM 3600 RPM 3600 RPM 3990 RPM

Short Circuit Operation 3990 RPM 3990 RPM 3990 RPM 3990 RPM

2. For 5 min. after an initial power supply, 1800RPM (lowest speed) operation

~29℃

29℃ ~ 35℃ 35℃ ~ 41℃ 41℃ ~

1.Comp

22

6-9. Prevention of Comp Re-start

Control ObjectInput Parts

N/A 1.Comp

Contents

1. For 6 min. after Comp is off, it will not re-start even though there is a Comp On condition occurring.

6-10. Time Shortening Function

Input Parts Control Object

1. Main PCB 1. Electronic Units

Contents

1. 1 min. Shortening: Click “Fast Key” of Main PCB.

2. 30 min. Shortening: Press “Fast Key” continuously and it will be shortened by 30 min. every 2.5 seconds

with a short buzzer beeping.

3. Usage Example: May be used to shorten unnecessary time.

(6 min. Pause function, Fan Delay function)

6-11. Buzzer Function

Input Parts Control Object

1. Front PCB Button

2. Door Switch

3. Initial Power Supply

Contents

1. Buzzer beeps as Front PCB is manipulated.

2. Buzzer beeps 3 sec. after an initial power supply.

3. Buzzer beeps at a power consuming mode forced Defrosting, short-circuit operation, A/S forced Defrosting.

1. Buzzer

4. Buzzer beeps when you press a button as you are fine-tuning the Freezer

/ Fridge.

5. Buzzer beeps every minute when a Door is open (for 5 min.).

23

6-12. Electronic Unit Delay Time

Control ObjectInput Parts

1.Comp On / Off

Contents

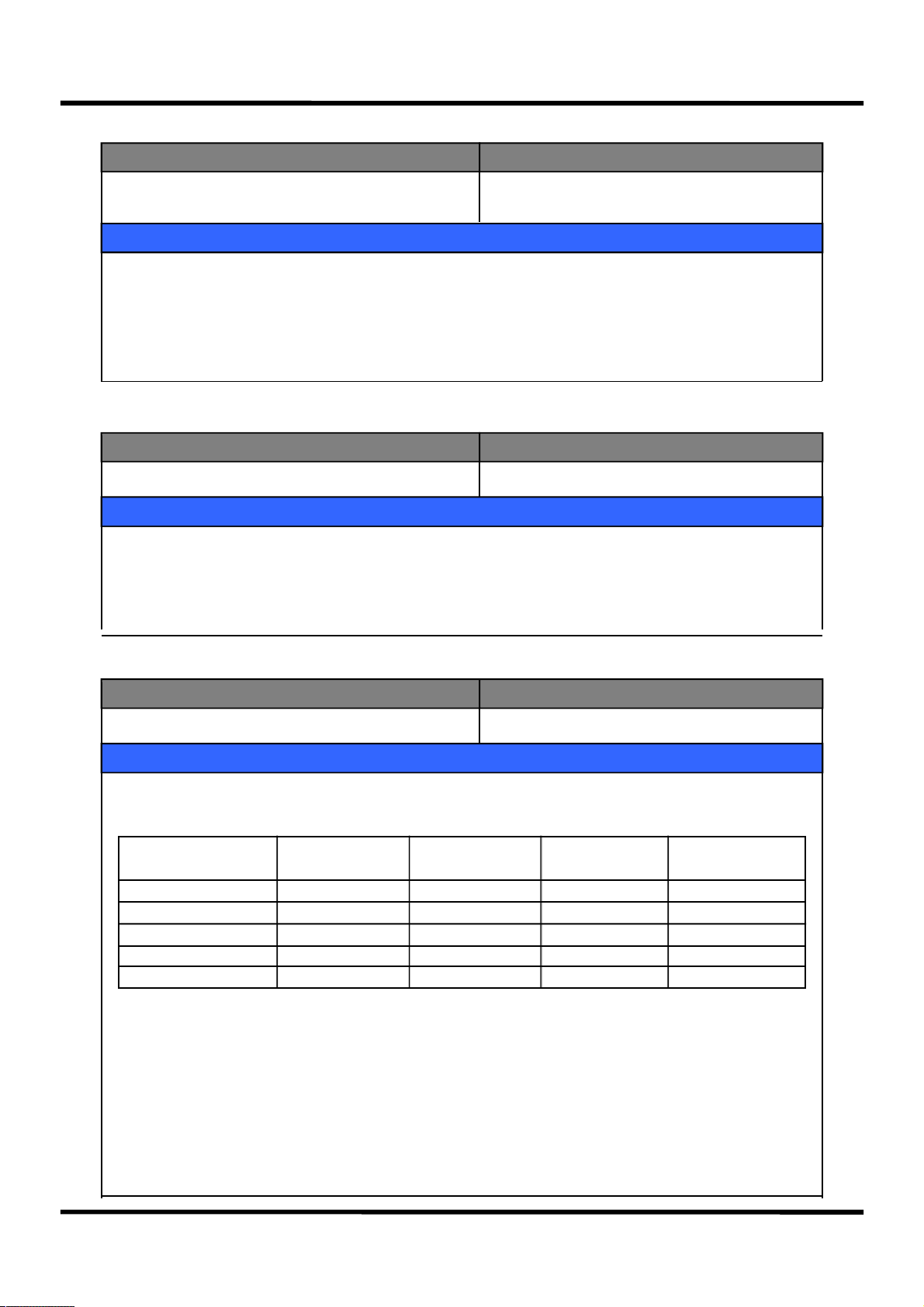

1. Comp / C-Fan / F-Fan

1) F-Fan Time Delay function at Comp On/Off (F-FAN on/off 1 min. after Comp on/off).

2) C-Fan : On 0.5 sec. after an On condition occurring

3) F-Fan : On 1.0 sec. after an On condition occurring

1.Comp

2.F/C-Fan

24

6-13. Internal Light Control Function

Control ObjectInput Parts

1. F Door

2. R Door

3. Home bar Door (option)

Contents

1. R Compartment Light Control

1) R Compartment Light is on/off immediately after a R Door Switch Open / Close signal detection.

2) But if opened state continues for 10 min. after a R Door Switch detects Opening, R Compartment light

will turn off even though there is no Close signal detected.

3) When opening is detected continuously for 1 hr. or more, “dr” Error is displayed and the functions related

to the Door Switch detection will be ignored.

2. F Compartment Light Control

1) F Compartment Light is on/off immediately after a F Door Switch Open / Close signal detection.

2) But if opened state continues for 10 min. after a F Door Switch detects Opening, F Compartment light

will turn off even though there is no Close signal detected.

3) When opening is detected continuously for 1 hr. or more, “dF” Error is displayed and the functions related

to the Door Switch detection will be ignored.

1. F/R Compartment Lights

3. R Compartment Light Control by Home Bar

1) R Compartment Light will be on/off immediately after a Home bar Door Switch Open/Close signal detection.

2) But if opened state continues for 10 min. after a Home bar Door Switch detects Opening, R Compartment

light will turn off even though there is no Close signal detected.

3) When opening is detected continuously for 1 hr. or more, “dH” Error is displayed and the functions related

to the Door Switch detection will be ignored.

25

6-14. DEMO Function

Input Parts Control Object

1. Fridge Button

2. Freezer Button

Contents

1. Starting

Press “fridge adjustment” button at the ”Locked State” and press “Choose Freezing” 5 times.

2. Control Method

1) Electronic units will all be off.

2) But if the Freezer and Fridge doors are open, the pertinent Fan will be on.

Door Open → Fan On , Door Close → Fan Off

3)

Display

Freezing and Fridge temperature Display for each stage → Quick Icon On → Water Icon On →

Cube Icon On → Ice Maker Lock Icon

3. Cancellation

1) Press Fridge Adjustment + Choose Freezing 5 times.

2) Reset Power Supply.

1. Comp

2. F-Fan

3. Heater

6-15. Weak Cooling Option

Control ObjectInput Parts

1. J1,J2 on the Main PCB

Contents

1. R-Sensor Off Point Adjustment (Maximum 3℃ down)

2. When weak cooling occurs, adjustment is made as following so as to make A/S easy.

1) Resistance(R36) : R-Sensor Standard Resistance at normal operation (31.4K)

2) Resistance(R37) : Standard Resistance 2K up by J1 cutting at weak cooling (1.5℃down)

3) Resistance(R38) : Standard Resistance 4K up by J1 & J2 cutting at weak cooling (3.0℃down)

R-SENSOR

R36

R36 = Medium OFF Point

R37

R36 + R37 = Medium OFF Point - 1.5 deg.

R36 + R37 + R38 = Medium OFF Point - 3.0 deg.

J1

1. R-Sensor “Medium” Off Point Standard Resistance

R38

J2

26

6-16. Automatic Ice Machine

Input Parts

N/A Automatic Ice Machine

1. Ice-making Flow

시작

START

제빙 MODE

Ice Making MODE

(급수대기상태)

(Water Supply stand by)

Ice Separation

이빙 MODE

MODE

Water Supply

급수 MODE

MODE

Contents

얼음이 만들어짐

▶

Ice is being made

Ice tray is twisted to separate ice cubes

▶

제빙명을 비틀어 얼음을 떨어뜨림

제빙명에 물을 공급함

▶

Water is supplied to ice tray

Control Object

Water Supply

급수확인 MODE

check MODE

Check if water is properly supplied

제대로 급수가 되었는지를 체크함

▶

RETURN

1) Press the Test S/W of the ice machine Ass’y for more than one second, to let the Test Mode proceed

(But 1. Test Mode starts from the Ice Separation mode

2. In Test S/W short circuit Error, the Test will run only once)

2) When the initial power is supplied, the ice machine horizontality balancing is made and the ice-making mode

begins

3) If it is cancelled, during a ice-making flow, after ice-making is paused, the process will start from the ice-

making mode

4) Water-supply hose HTR Control

RT-S Control Time

14℃ or less 30/30(On/Off)

14℃ ~ 28℃ 13/47(On/Off)

28℃ ~ 36℃ 25/35(On/Off)

36℃ or more 40/20(On/Off)

5) Water-supply Ready State

① Condition: When ice full is detected

② Operation: It proceeds only up to the ice-making mode of the ice-making flow (Ice Separation and water-

supply modes paused)

③ Cancellation: Automatically cancelled if normal

27

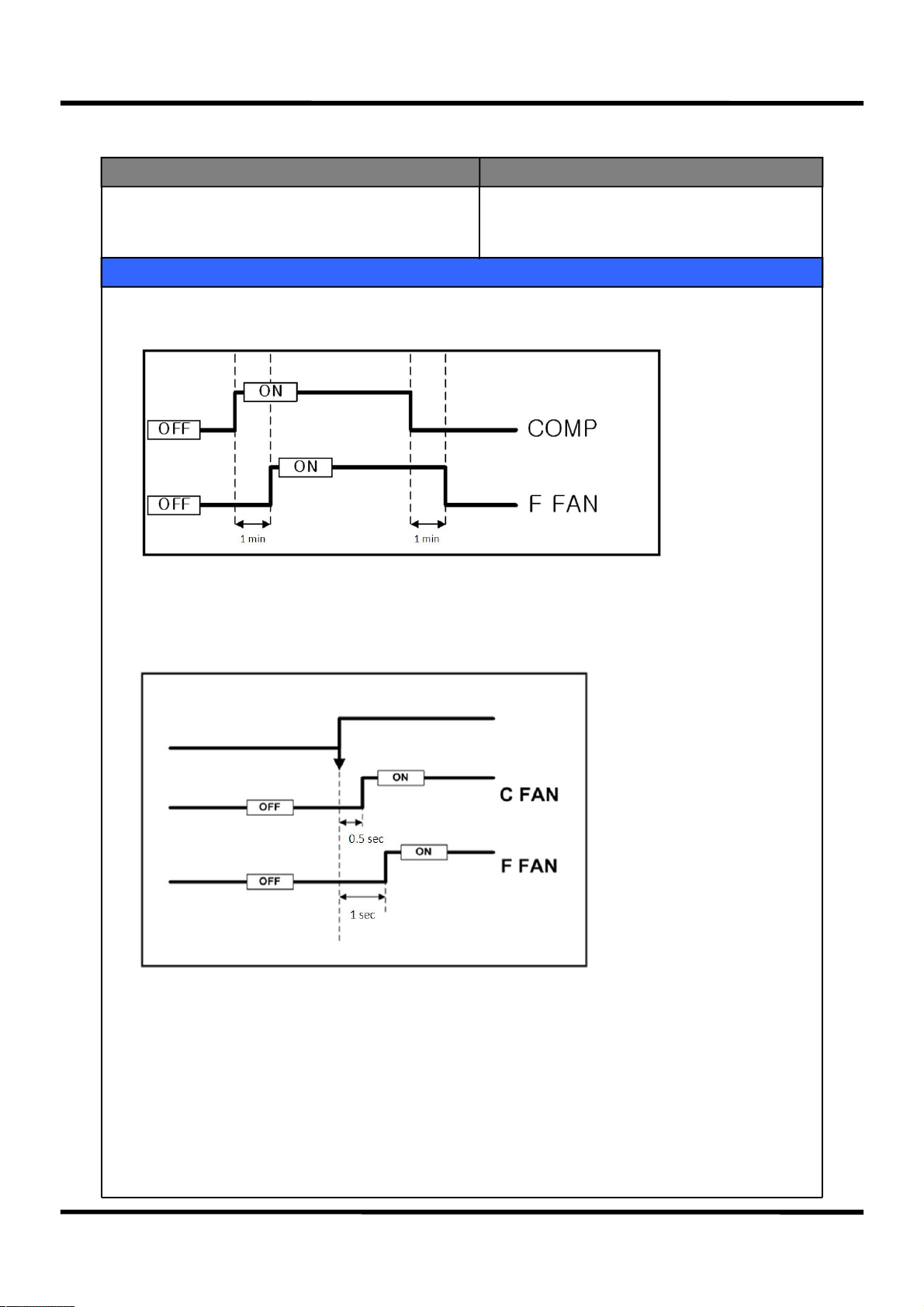

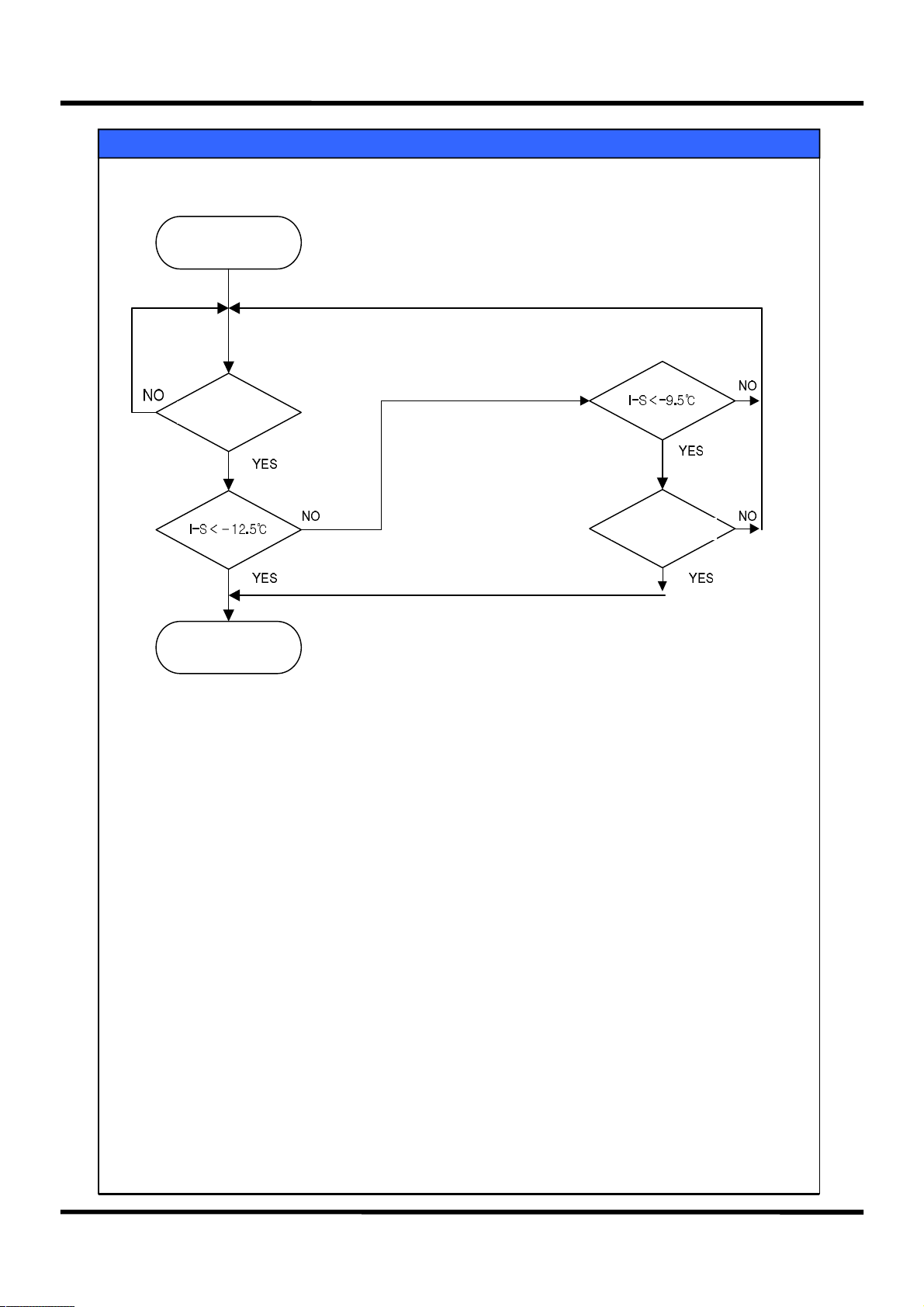

2. Ice-making Mode

START

70 min passed?

Contents

15 min passed?

Ice Separation

MODE

1) If I-S is -12.5℃ or lower after 70 min. lapsing, ice making is finished

2) If I-S is higher than -12.5℃ after 70 min. lapsing but it continuously maintains -9.5℃

or lower for 15 min, ice making is finished

3) If there is an I-Sensor Error, ice making is finished after 4.8hr lapsing

28

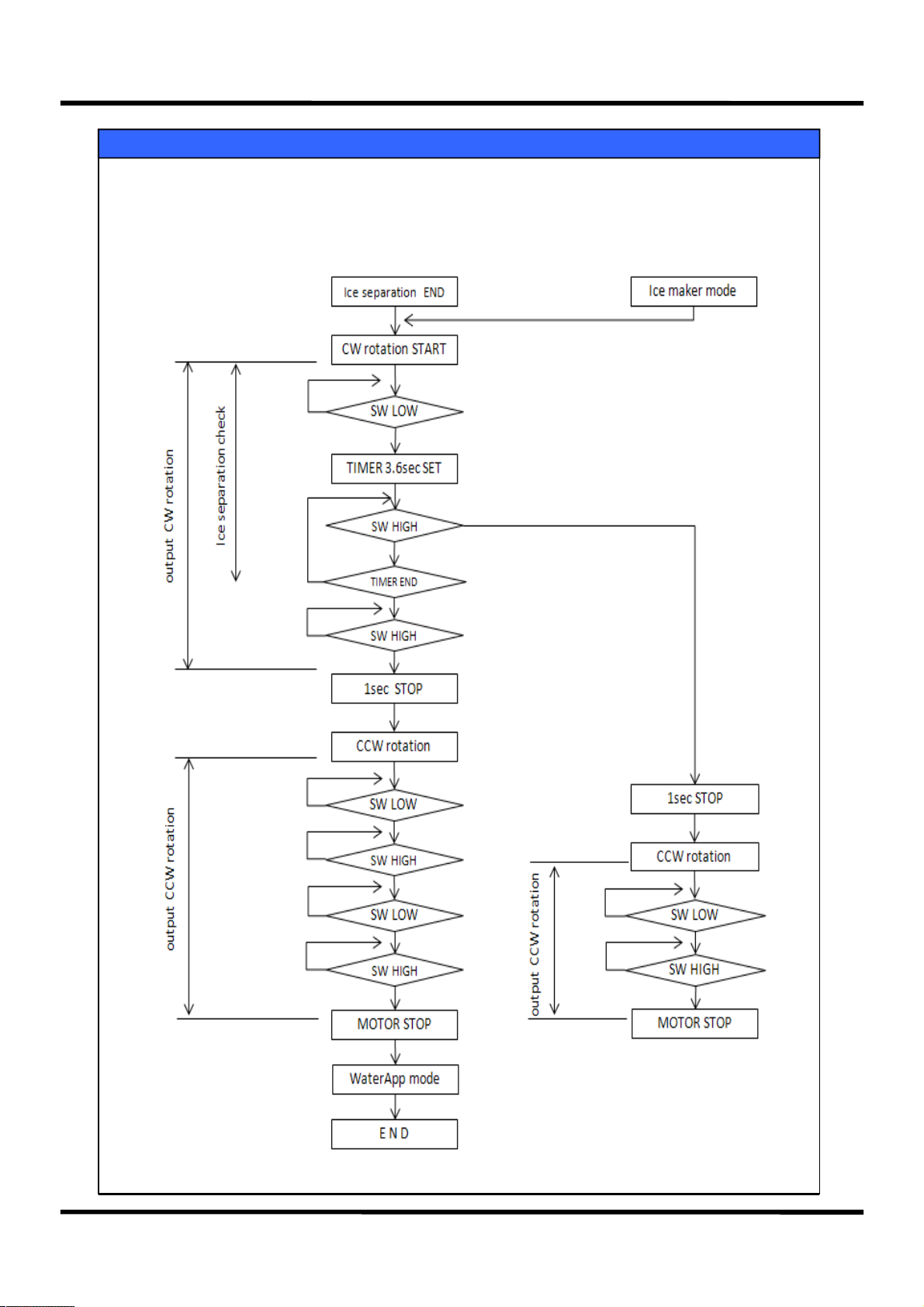

3. Ice Separation Mode

Contents

29

Loading...

Loading...