Page 1

FILE NO. SM-CTV-O-056

COLOR TELEVISION

SERVICE MANUAL

MODEL NO.

PF2720/PF2730

PF3220/PF3230

CHASSIS NO. CH-16CD

Please read this manual carefully before service.

Page 2

SERVICE MANUAL

TABLE OF CONTENTS

SAFETY INSTRUCTIONS AND MAINTENANCE

X-Ray Radiation Precaution ..............................................................................................1

Safety Precaution................................................................................................................1

Product Safety Notice.........................................................................................................2

Maintenance ......................................................................................................... 3

SPECIFICATIONS..........................................................................................................4

KEY ICS AND ASSEMBLIES.................................................................................4

.....................................1

SYSTEM BLOCK DIAGRAMS

Structure Block Diagram....................................................................................................5

Block Diagram for Supply Voltage System.....................................................................6

...............................................................................5

SERVICE DATA...............................................................................................................7

Technical Data of Key ICs..................................................................................................7

Service Data of Key ICs.....................................................................................................22

Waveforms of Key Points...................................................................................................29

ADJUSTMENTS..............................................................................................................37

Set-up Adjustments.............................................................................................................37

Circuit Adjustments.............................................................................................................40

Service Mode and Bus Data..............................................................................................41

TROUBLESHOOTING FLOW CHARTS.........................................................47

APPENDIX

1. Circuit Diagrams

2. Printed Circuit Board Diagrams

3. Final Wiring Diagrams

4. Exploded Views

2

Page 3

SAFETY INSTRUCTIONS AND MAINTENANCE

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION

PRECAUTION”, “SAFETY PRECAUTION”AND “PRODUCT SAFETY NOTICE

INSTRUCTIONS BELOW.

”

X-RAY RADIATION PRECAUTION

1. The EHT must be checked every time the TV is serviced to ensure that the CRT does not emit

X-ray radiation as result of excessive EHT voltage. The maximum EHT voltage permissible in

any operating circumstances must not exceed the rated value. When checking the EHT, use

the High Voltage Check procedure in this manual using an accurate EHT voltmeter.

2. The only source of X-RAY radiation in this TV is the CRT. The TV minimizes X-RAY radiation,

which ensures safety during normal operation. To prevent X-ray radiation, the replacement

CRT must be identical to the original fitted as specified in the parts list.

3. Some components used in this TV have safety related characteristics preventing the CRT from

emitting X-ray radiation. For continued safety, replacement component should be made after

referring the PRODUCT SAFETY NOTICE below.

4. Service and adjustment of the TV may result in changes in the nominal EHT voltage of the

CRT anode. So ensure that the maximum EHT voltage does not exceed the rated value after

service and adjustment.

SAFETY PRECAUTION

WARNING: REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY.

1. The TV has a nominal working EHT voltage. Extreme caution should be exercised when

working on the TV with the back removed.

1.1 Do not attempt to service this TV if you are not conversant with the precautions and

procedures for working on high voltage equipment.

1.2 When handling or working on the CRT, always discharge the anode to the TV chassis before

removing the anode cap in case of electric shock.

1.3 The CRT, if broken, will violently expel glass fragments. Use shatterproof goggles and take

extreme care while handling.

1.4 Do not hold the CRT by the neck as this is a very dangerous practice.

2. It is essential that to maintain the safety of the customer all power cord forms be replaced

exactly as supplied from factory.

3. Voltage exists between the hot and cold gro und when the TV is in operation. Install a suitable

isolating transformer of beyond rated overall power when servicing or connecting any test

equipment for the sake of safety.

1

Page 4

SERVICE MANUAL

4. When replacing ICs, use specific tools or a static-proof electric iron with small power (below

35W).

5. Do not use a magnetized screwdriver when tightening or loosing the deflection yoke assembly

to avoid electronic gun magnetized and decrement in convergence of the CRT.

6. When remounting the TV chassis, ensure that all guard devices, such as nonmetal control

buttons, switch, insulating sleeve, shielding cover, isolating resistors and capacitors, are

installed on the original place.

7. Replace blown fuses within the TV with the fuse specified in the parts list.

8. When replacing wires or components to terminals or tags, wind the leads around the terminal

before soldering. When replacing safety components identified by the international hazard

symbols on the circuit diagram and parts list, it must be the company-approved type and must

be mounted as the original.

9. Keep wires away from high temperature components.

PRODUCT SAFETY NOTICE

CAUTION: FOR YOUR PROTECTION, THE FOLLOWING PRODUCT SAFETY NOTICE

SHOULD BE READ CAREFULLY BEFORE OPERATING AND SER VICING THIS TV SET.

1. Do not slap or beat the cabinet or CRT, since this may result in fire or explosion.

2. Never allow the TV sharing a plug or socket with other large-power equipment. Doing so may

result in too large load, thus causing fire.

3. Do not allow anything to rest on or roll over the power cord. Protect the power cord from being

walked on, modified, cut or pinched, particularly at plugs.

4. Do not place any objects, especially heavy objects and lightings, on top of the TV set. Do not

install the TV near any heat sources such as radiators, heat registers, stove, or other

apparatus that produce heat.

5. Service personnel should observe the SAFETY INSTRUCTIONS in this manual during use

and servicing of this TV set. Otherwise, the resulted damage is not protected by the

manufacturer.

6. Many electrical and mechanical components in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the X-ray radiation protection afforded by them cannot necessarily be obtained by using

replacements rated at higher voltages or wattage, etc. Components which have these special

safety characteristics in this manual and its supplements are identified by the international

hazard symbols on the circuit diagram and parts list. Before replacing any of these

components read the parts list in this manual carefully. Substitute replacement components

which do not have the same safety characteristics as specified in the parts list may create

X-ray radiation.

2

Page 5

SERVICE MANUAL

Safety Symbol Description

The lightning symbol in the triangle tells you that the voltage inside this product may

be strong enough to cause an electric shock. Extreme caution should be exercised

when working on the TV with the back removed.

This is an international hazard symbol, telling you that the components identified by

the symbol have special safety-related characteristics.

FDA This symbol tells you that the critical components identified by the FDA marking have

special safety-related characteristics.

UL This symbol tells you that the critical components identified by the UL marking have

special safety-related characteristics.

MAINTENANCE

1. Install the TV set on a stable and level surface. Do not place the set near or over a radiator or

heat register, or where it is exposed to direct sunlight.

2. Do not install the TV set in a place exposed to rain, water, excessive dust, mechanical

vibrations or impacts.

3. Allow enough space (at least 10cm) between the TV and wall or enclosures for proper

ventilation.

4. Slots and openings in the cabinet should never be blocked by clothes or other objects.

5. Please power off the TV set and disconnect it from the wall immediately if any abnormal

condition are met, such as bad smell, belching smoke, sparkling, abnormal sound or no

picture/sound/raster. Hold the plug firmly when disconnecting the power cord.

6. Unplug the TV set from the wall outlet before cleaning or polishing it. Use a dry soft cloth for

cleaning the exterior of the TV set or CRT screen. Do not use liquid cleaners or aerosol

cleaners.

3

Page 6

SERVICE MANUAL

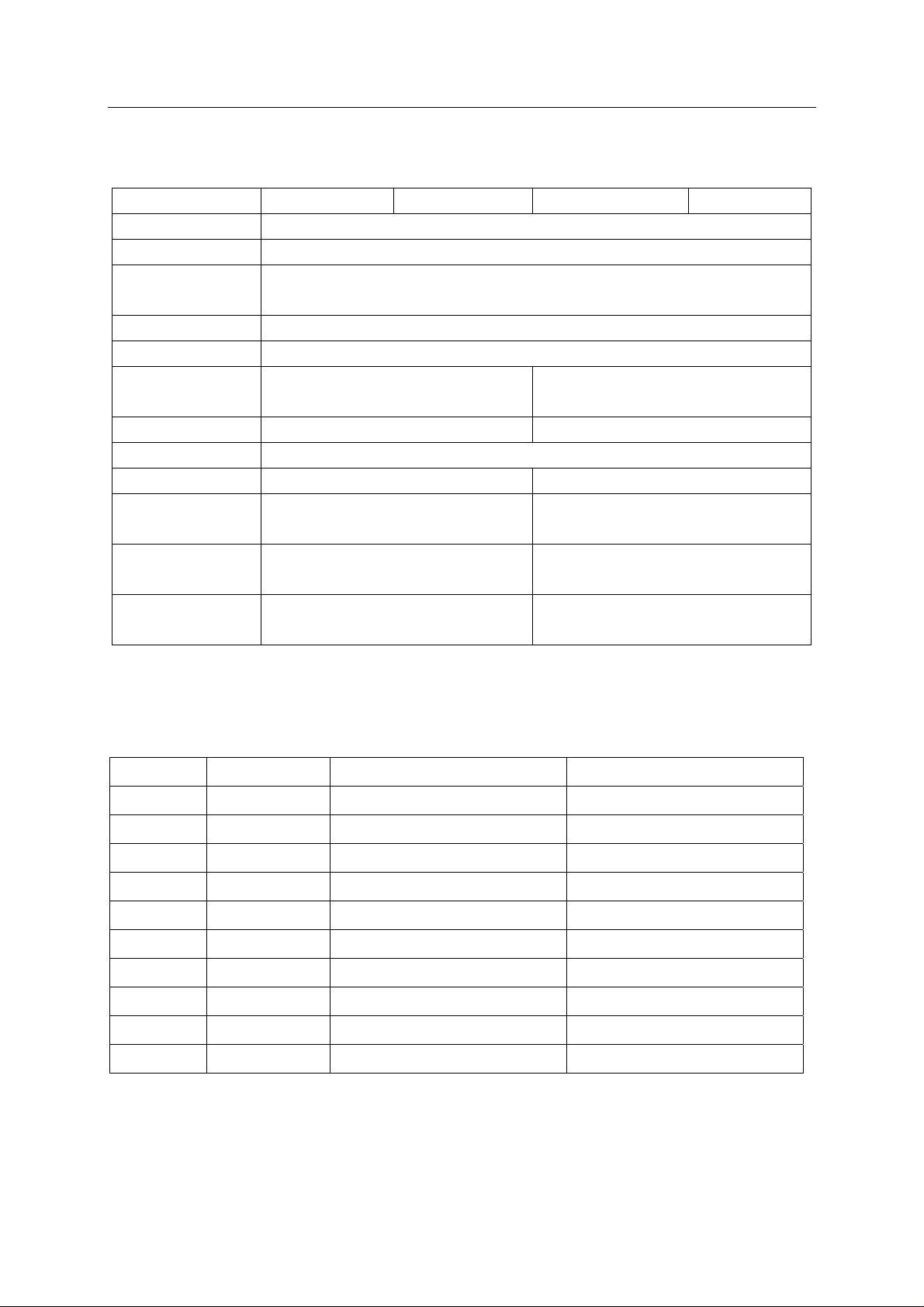

SPECIFICATIONS

MODEL PF2720 PF2730 PF3220 PF3230

Television System NTSC-M

Channel Coverage VHF 2-13, UHF 14~69

Cable TV Coverage

Channels Preset 181

Antenna Input 75 ohm (unbalanced)

Screen Dimensions

Audio Output 5W+5W 5W+5W

Power Source ~120Vac 60Hz

Unit Weight 97.9lbs. ( 44.5kg) 156lbs. ( 71kg)

Unit Dimensions

Packaged

Dimensions

Power

Consumption

Hyper Band (AA~ZZ, AAA, BBB)/Ultra Band (65~94, 100~125)

21.26x 15.94 in

29.09x22.83x19.29 in.

739x580x490mm

33.07x26.38x23.43in.

840x670x595mm

Mid Band (A-8~A-1, A~I)/Super Band (J~W)

25.20x 18.82 in

540x405 mm

135W 170W

640x478 mm

33.70x26.34x22.05 in.

856x669x560mm

40x30.55x27.76in.

1016x776x705mm

KEY ICS AND ASSEMBLIES

Table 1 Key ICs and Assemblies

Serial No. Position No. Model No. Function Description

1 N201 TDA937X UOC

2 N202 AT24C16 EEPROM

3 NB01 MSP3440G-B8 BTSC

4 N401 TDA8350 Vertical output circuit

5 N361 TDA8944J Sound power amplifier

6 N901 TA1219AN

7 N902 TC90A49P

8 NY01 TDQ6108JF

9 A101 TDQ-6F2-M

10 IC801 STR-G8626

TV/AV switch circuit

COMB filter

Video amplifier

Tuner

Power supply circuit

4

Page 7

SYSTEM BLOCK DIAGRAMS

Structure Block Diagram

SERVICE MANUAL

45V

V

5

Page 8

SERVICE MANUAL

Block Diagram for Supply Voltage System

6

Page 9

SERVICE MANUAL

SERVICE DATA

Technical Data of Key ICs

TDA937X (N201)

UOC

1. General Description

The various versions of the TDA937X PS/N2

series combine the functions of a video

processor together with a μ-Controller and

US Closed Caption decoder. The ICs are

intended to be used in economy television

receivers with 90° and 110° picture tubes.

The ICs have supply voltages of 8V and 3.3V

and they are mounted in an S-DIP 64

envelope.

The features are given in the following feature

list. The differences between the various ICs

are given in the table on page 4.

2. Features

TV-signal processor

• Multi-standard vision IF circuit with

alignment-free PLL demodulator

• Internal (switchable) time-constant for the

IF-AGC circuit

• A choice can be made between versions with

mono intercarrier sound FM demodulator and

versions with QSS IF amplifier.

• The mono intercarrier sound versions have a

selective FM-PLL demodulator which can be

switched to the different FM sound

frequencies (4.5/5.5/6.0/6.5 MHz).

The quality of this system is such that the

external band-pass filters can be omitted.

• Source selection between ‘internal’ CVBS and

external CVBS or Y/C signals

• Integrated chrominance trap circuit

• Integrated luminance delay line with

adjustable delay time

• Picture improvement features with peaking

(with variable positive/negative overshoot

ratio), black stretching and Dynamic Skin

Tone Control

• Integrated chroma band-pass filter with

switchable centre frequency

• Only one reference (12 MHz) crystal

required for the μ-Controller, Teletext- and

the colour decoder

• PAL/NTSC colour decoder with automatic

search system

• Internal base-band delay line

• RGB control circuit with ‘Continuous Cathode

Calibration’, white point and black level offset

adjustment so that the colour temperature of

the dark and the light parts of the screen can

be chosen independently.

• Linear RGB or YUV input with fast blanking

for external RGB/YUV sources. The

Text/OSD signals are internally supplied from

theμ-Controller/Teletext decoder

• Contrast reduction possibility during

mixed-mode of OSD and Text signals

• Horizontal synchronization with two control

loops and alignment-free horizontal oscillator

• Vertical count-down circuit

• Vertical driver optimized for DC-coupled

vertical output stages

• Horizontal and vertical geometry processing

• Horizontal and vertical zoom function for 16 :

9 applications

• Horizontal parallelogram and bow correction

for large screen picture tubes

• Low-power start-up of the horizontal drive

circuit

7

Page 10

3.Pin

SERVICE MANUAL

8

Page 11

4.Block Diagram

SERVICE MANUAL

9

Page 12

SERVICE MANUAL

5.Refer to Table 2 about Functions and Service Data of the IC's Each Pin.

10

Page 13

SERVICE MANUAL

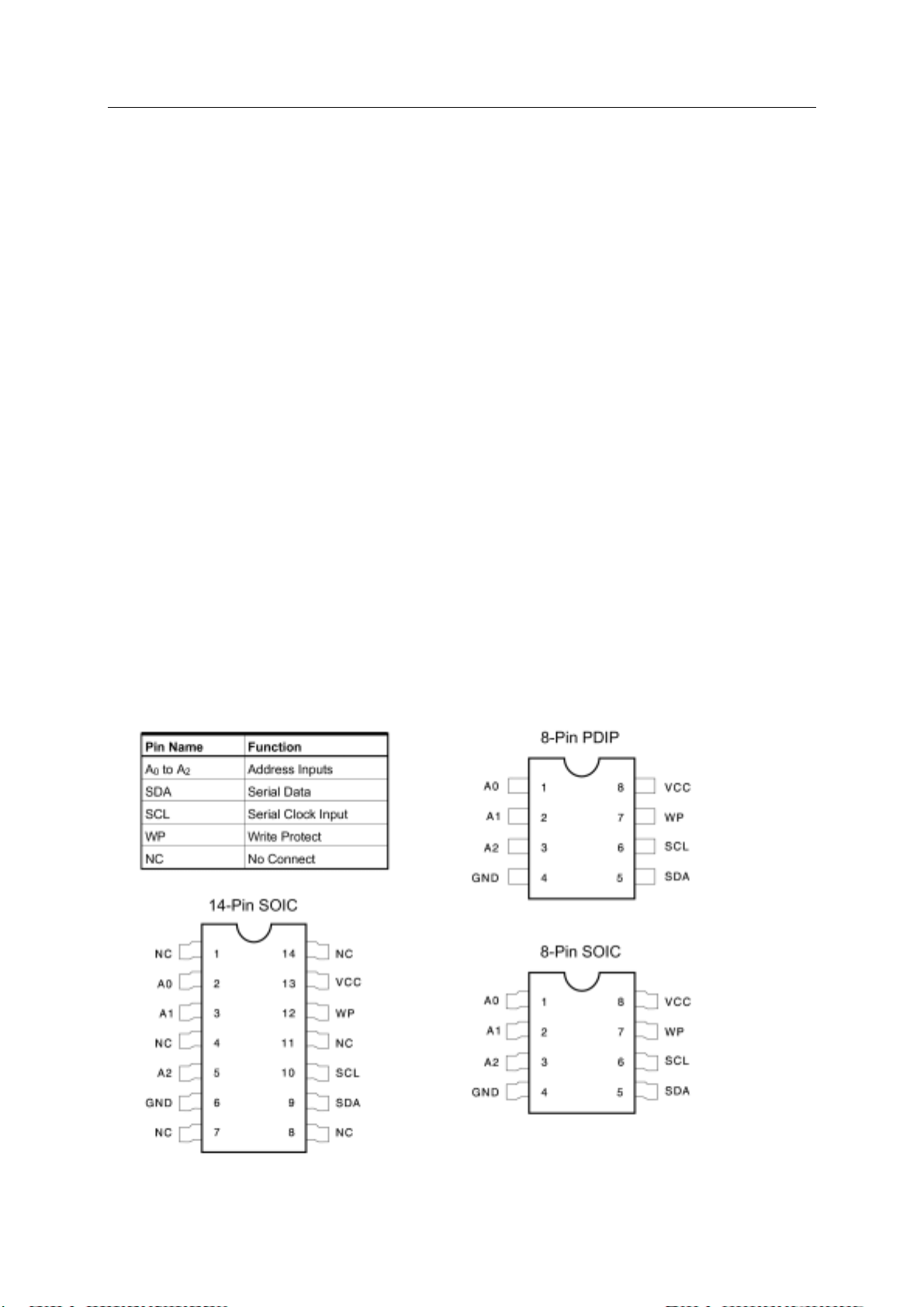

AT24C16 (N202)

EEPROM

1. Features

·Low Voltage and Standard Voltage Operation

5.0 (V

2.7 (V

2.5 (V

1.8 (V

= 4.5V to 5.5V)

CC

= 2.7V to 5.5V)

CC

= 2.5V to 5.5V)

CC

= 1.8V to 5.5V)

CC

·Internally Organized 128 x 8 (1K), 256 x 8 (2K),

512 x 8 (4K),1024 x 8 (8K) or 2048 x 8 (16K)

·2-Wire Serial Interface

·Bidirectional Data Transfer Protocol

·100 kHz (1.8V, 2.5V, 2.7V) and 400 kHz (5V)

Compatibility

·Write Protect Pin for Hardware Data Protection

·8-Byte Page (1K, 2K), 16-Byte Page (4K, 8K,

16K) Write Modes

·Partial Page Writes Are Allowed

·Self-Timed Write Cycle (10 ms max)

·High Reliability

Endurance: 1 Million Cycles

Data Retention: 100 Years

·Automotive Grade and Extended Temperature

Devices Available

·8-Pin and 14-Pin JEDEC SOIC and 8-Pin PDIP

Packages

2.Description

The AT24C01A/02/04/08/16 provides

1024/2048/4096/8192/16384 bits of serial

electrically erasable and programmable read

only memory (EEPROM) organized as

128/256/512/1024/2048 words of 8 bits each.

The device is optimized for use in many

industrial and commercial applications where low

power and low voltage operation are essential.

The AT24C01A/02/04/08/16 is available in space

saving 8-pin PDIP, 8-pin and 14-pin SOIC

packages and is accessed via a 2-wire serial

interface. In addition, the entire family is

available in 5.0V (4.5V to 5.5V), 2.7V (2.7V to

5.5V), 2.5V (2.5V to 5.5V) and 1.8V (1.8V to

5.5V) versions.

Pin Configurations

11

Page 14

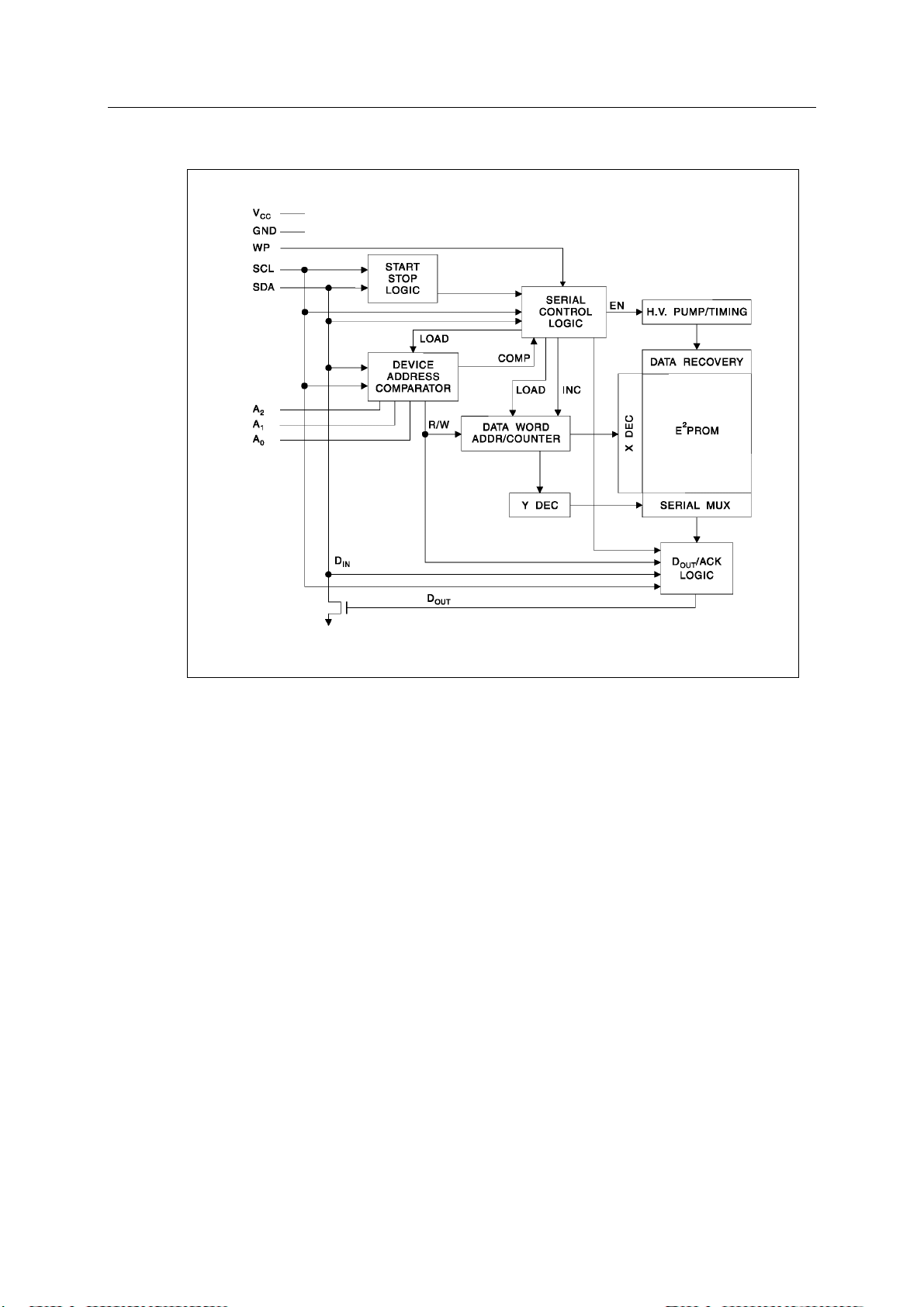

3.Block Diagram

SERVICE MANUAL

Fig.6

4.Refer to Table 3 about Functions and Data of the IC’ s Pins.

12

Page 15

SERVICE MANUAL

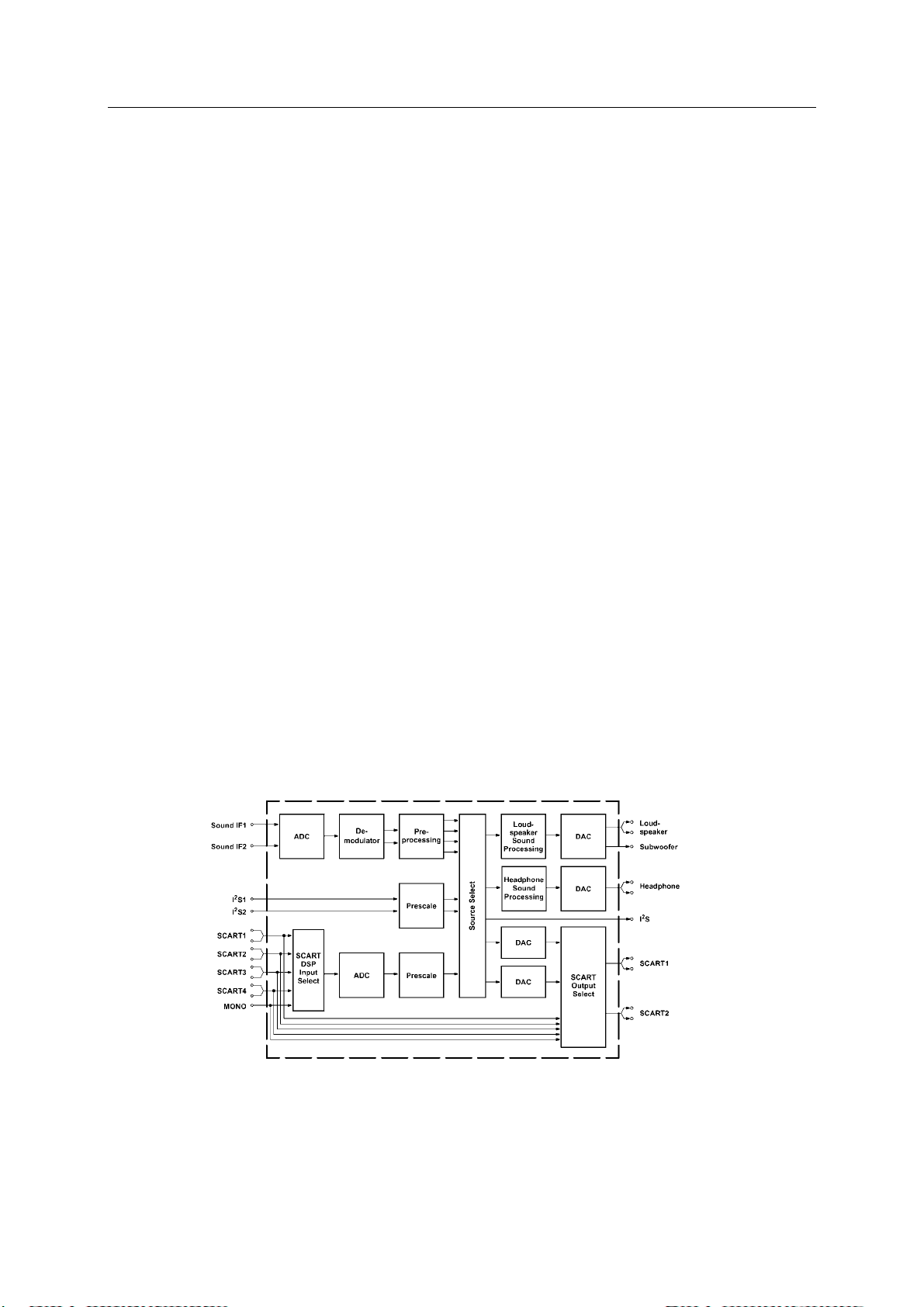

MSP3440G-B8 (NB01)

Multistandard Sound Processor Family

Release Note: Revision bars indicate significant

changes to the previous edition. The hardware

and software description in this document is

valid for the MSP34X0G version B5 and

following versions.

1. Introduction

The MSP34X0G family of single-chip

Multistandard Sound Processors covers

the sound processing of all analog

TV-Standards worldwide, as well as the

NICAM digital sound standards. The full TV

sound processing, starting with analog sound

IF signal-in, down to processed analog AF-out,

is performed on a single chip. Figure 7 shows

a simplified functional block diagram of the

MSP34X0G.

This new generation of TV sound processing

ICs now includes versions for processing the

multichannel television sound (MTS) signal

conforming to the standard recommended by

the Broadcast Television Systems Committee

(BTSC). The DBX noise reduction, or

alternatively MICRONAS Noise Reduction

(MNR) is performed alignment free

2. Block Diagram

Other processed standards are the Japanese

FM-FM multiplex standard (EIA-J) and the FM

Stereo Radio standard.

Current ICs have to perform adjustment

procedures in order to achieve good stereo

separation for BTSC and EIA-J.

The MSP34X0G has optimum stereo

performance without any adjustments.

All MSP34X0G versions are pin and

software downward-compatible to the

MSP34X0D. The MSP34X0G further simplifies

controlling software. S tandard selection

requires a single I

The MSP34X0G has built-in automatic

Functions: The IC is able to detect the actual

sound standard automatically (Automatic

Standard Detection). Furthermore, pilot levels

and identification signals can be evaluated

internally with subsequent switching between

mono/stereo/bilingual; no I

necessary (Automatic Sound Selection).

The ICs are produced in submicron CMOS

technology.

The MSP34X0G is available in the following

packages: PLCC68, PSDIP64, PSDIP52, PQFP80

and PLQFP64.

2

C transmission only.

2

C interaction is

Fig. 7 Simplified Functional Block Diagram of the MSP34X0G

3. Refer to Table 4 about Functions and Service Data of MSP34X0G’s Each Pins.

13

Page 16

SERVICE MANUAL

I

(

set

)

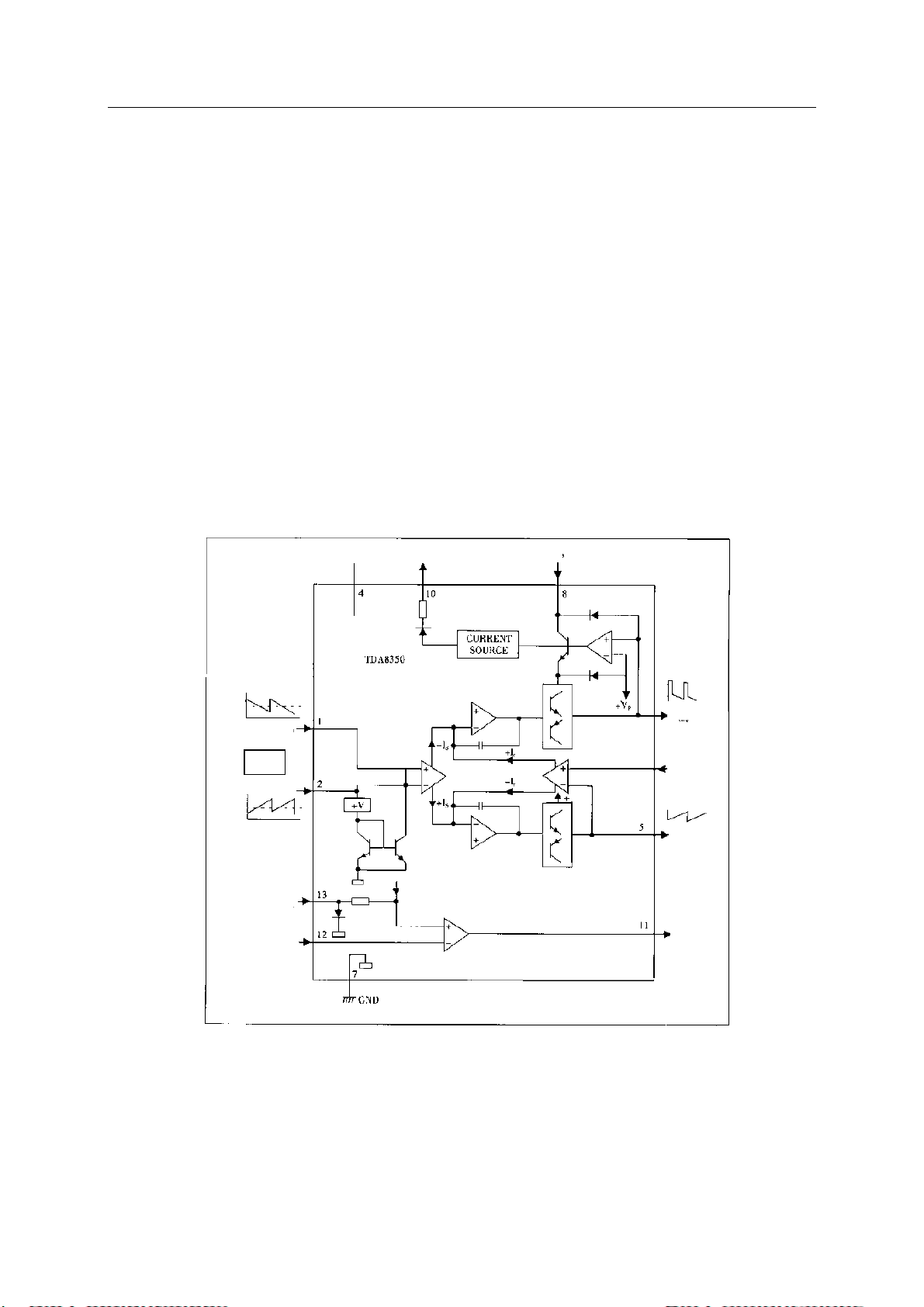

TDA8350 (N401)

DC-coupled Vertical Deflection and East-West Output Circuit

1. Features

·Few external components

·Highly efficient fully DC-coupled vertical output

bridge circuit

·Vertical fl yback switch

·Guard circuit

·Protection against:

-short-circuit of the output pins

-short-circuit of the output pins to Vp

3. Block Diagram

V

V

+V

·High EMC immunity due to common mode

inputs

·Temperature (thermal) protection

·East-West output stage with one single

conversion resistor.

2. General Description

The TDA8350Q is a power circuit for use

in 90° and 110° colour deflection systems

for field frequencies of 50 to 120 Hz. The

circuit provides a DC driven vertical

deflection output circuit, operating as a

highly efficient class G system and an

East-West driver for sinking the diode

modulator current.

V

I

I

+V

I

VP

-V

I

I

I

Fig. 8

4. Refer to Table 5 about Functions and Service Data of TDA8350Q’s Pins.

V

V

V

V

14

Page 17

TDA8944J (N361)

Audio Power Amplifier

SERVICE MANUAL

1. General Description

The TDA8944J is a dual-channel audio power

amplifier with an output power of

2 ´ 7 W at a n 8 W load and a 12 V supply. The

circuit contains two Bridge Tied Load

(BTL) amplifiers with an all-NPN output stage and

standby/mute logic. The TDA8944J

comes in a 17-pin DIL-bent-SIL (DBS) power

package. The TDA8944J is

printed-circuit board (PCB) compatible with all

other types in the TDA894x family.

One PCB footprint accommodates both the mono

and the stereo products.

3.Block Diagram

2. Features

Few external components

Fixed gain

Standby and mute mode

No on/off switching plops

Low standby current

High supply voltage ripple rejection

Outputs short-circuit protected to ground,

supply and across the load

Thermally protected

Printed-circuit board compatible

Pinning

Fig.10 Pin configuration.

5. Refer to Table 6 about Functions and Service Data of TDA8944J's Pins.

15

Page 18

SERVICE MANUAL

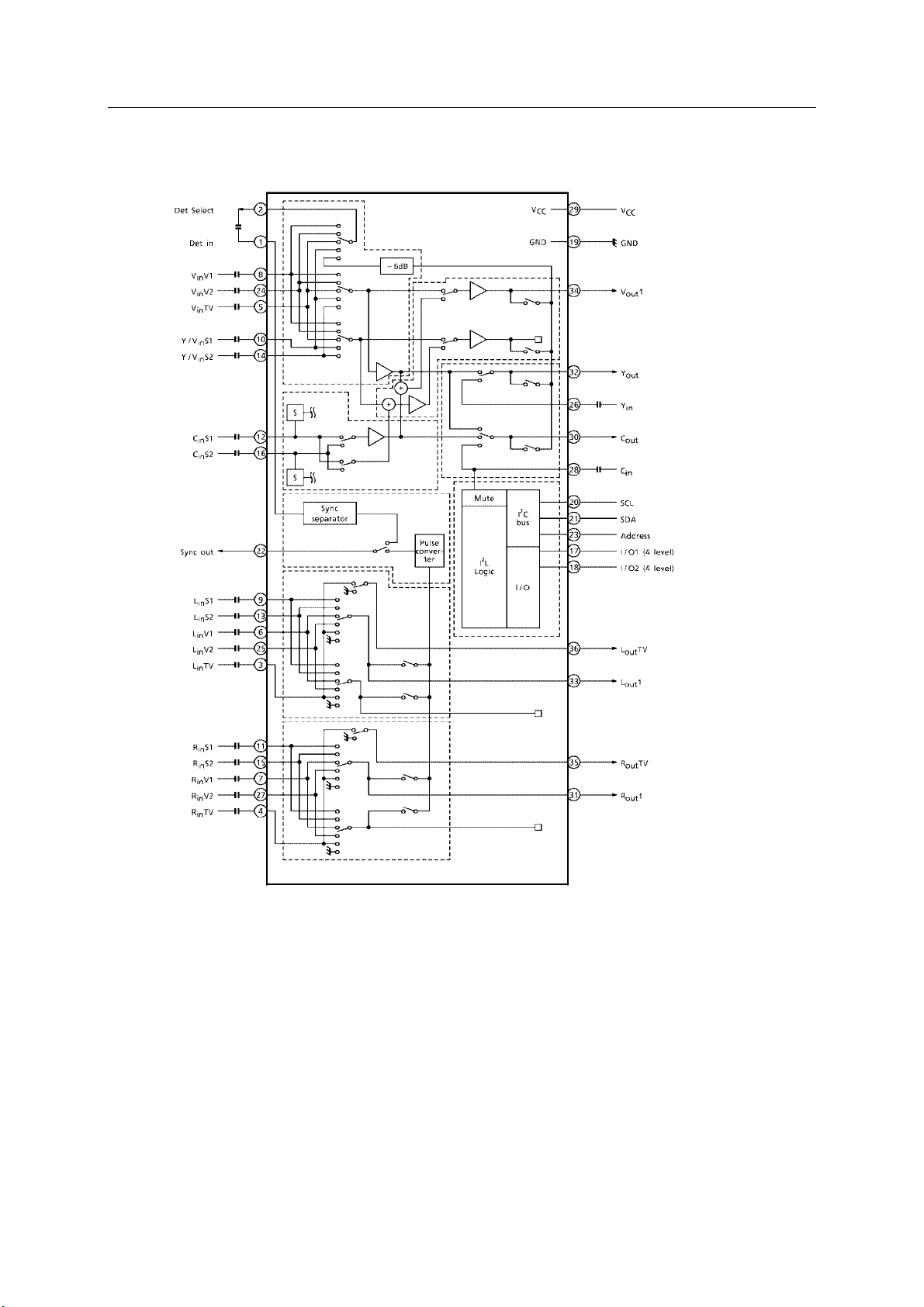

TA1219AN (N901)

Audio/Video Switching IC for TVs

The TA1219AN is an audio/video switching IC for TV Sets.

Conforming to I2C bus standards, it allows you to

perform various switching operations through the bus

lines by using a microcomputer. Furthermore, since the

presence of a signal on its sync signal output pin can be

determined by a microcomputer , it is possible to check

each input/output channel (self-diagnosis).

This IC has the same pin assignments as the TA1218AN

(SDIP42), a 2-channel output version of the TA1219AN, so

these chips are pin compatible on pins 3 to 20 and 23 to

40 in TA1218AN.

1. Features

2

·I

C bus control

·Video: 5-channel inputs and 1-channel outputs (2 channels conforming to S system)

·Audio: 5-channel inputs and 2-channel outputs

·Self-diagnostic function

·ADC inputs based on European 21-pin standards

·ADC inputs based on S1/S2 terminal standards

·Switchable subaddress

16

Page 19

2. Block Diagram

SERVICE MANUAL

Fig.11

3. Refer to Table 7 about Functions and Service Data of TA1219AN’s Pins.

17

Page 20

SERVICE MANUAL

3. Pin Assignment

2. Block Diagram

Fig.14

4. Refer to Table 8 about Fu nctions and Service Data of TC90A49P’s Pins.

TC90A49P (N902)

COMB Filter

1. Features

TV format : NTSC (3.58), PAL, M-PAL, and N-

PAL

Dynamic comb filter

Vertical edge enhancement circuit

PLL 8 × multiplier circuit

Internal 8-bit 4 fsc AD converter

Internal 8-bit precision 8 fsc DA converter (2 ch)

Sync tip clamp circuit

Internal 4H-line memory

2

I C bus interface

Package : DIP 20-pin and SOP 24-pin

5 V single power supply

18

Page 21

TDA6108JF (NY01)

Triple Video Output Amplifier

SERVICE MANUAL

1. Features

·Typical bandwid th of 9.0 MHz for an output

signal of 60 V (peak-to-peak value)

·High slew rate of 1850 V/µS

·No external components required

·Very simple application

·Single supply voltage of 200 V

·Internal reference voltage of 2.5 V

·Fixed gain of 51

·Black-Current Stabilization (BCS) circuit

·Thermal protection.

3. Ordering Information

Number

TDA6108JF DBS9MPF

Name Description Version

Plastic DIL-bent-SIL medium power package with

fin; 9 leads

2. General Description

The TDA6108JF includes three video

output amplifiers in one plastic

DIL-bent-SIL 9-pin medium power

(DBS9MPF)package (SOT 111-1), using

high-voltage DMOS technology, and is

intended to drive the three cathodes of a

colour CRT directly. To obtain maximum

performance, the amplifier should be used

with black-current control.

Package Type

SOT111-1

4. Block Diagram

Fig.15

5. Refer to Table 8 about Functions and Service Data of TDA6108JF’s Pins

.

19

Page 22

SERVICE MANUAL

STR-G8626 (IC801)

The Series STR-G 86626/5653/F6654 is specifically designed to satisfy the requirements for increased

integration and reliability in off-line quasi-resonant flyback converters. The series incorporates a

high-precise error amplifying control and drive circuit with discrete avalanche-rated power MOSFET,

featuring fewer external components, small-size and standard power supply.

Covering the power range from below 25 watts up to 300 watts for 100/115/230 VAC inputs, and up to

150 watts for 85 to 265 VAC universal input, these devices can be used in a range of applications,

from battery chargers and set top boxes, to televisions, monitors, and industrial power supply units.

Cycle-by-cycle current limiting, under-voltage lockout with hysteresis, over-voltage protection, and

thermal shutdown protects the power supply during the normal overload and fault conditions.

Low-current startup and a low-power standby mode selected from the secondary circuit completes

a comprehensive suite of features. The series is provided in a five-pin overmolded SIP style package,

affording dielectric isolation without compromising thermal characteristics.

1. Features

Flyback Operation with Quasi-Resonant Soft Switching for Low Power Dissipation and EMI

Rugged Avalanche-Rated MOSFET

Soft drive circuit MOSFET

Adjustable MOSFET switching speed

Choice of MOSFET Voltage and Rds(on)

Full Over-Current Protection (no blanking)

Under-Voltage Lockout with Hysteresis

Over-Voltage Protection

Direct Voltage Feedback

Low Start-up Current (100 Amax)

Low-Frequency, Low-Power Standby Operation

Overmolded 5-Pin Package

2. Circuit Block Diagram

Fig. 16

20

Page 23

SERVICE MANUAL

3. Pin Configuration and Functions

Fig.17

3.1) Pin function for STR-G5653/8626

Pin No. Symbol

1 D MOSFET drain

2 S MOSFET source

3 GND Ground

4 VIN Supply voltage input for control circuit

5 OCP/FB Over-current protection detection signal/ voltage-limiting signal input

Function Description

3.2) Pin function for STR-F6654

Pin No. Symbol

1 OCP/FB Over-current protection detection signal/ voltage-limiting signal input

2 S MOSFET source

3 D MOSFET drain

4 VIN Supply voltage input for control circuit

5 GND Ground

4. Refer to Table 9 about Functions and Service Data of the IC’s Pins.

Function Description

21

Page 24

SERVICE MANUAL

SERVICE DATA OF KEY ICs

Table 2 Functions and Service Data of TDA9379 (N201)’s Pins

Pin

No.

1 Port 1.3 or Counter/Timer 1 input 0.8

2 Port 1.6 or I2C-bus clock line 4 6.5 6.0

3 Port 1.7 or I2C-bus data line 4 6.5 6.0

4 Port 2.0 or Tuning PWM output 1.128 13.1 10.2

5 Port 3.0 or ADC0 input or PWM0 output 0.36

6 Port 3.1 or ADC1 input or PWM1 output 3.29 1.64 1.64

7 Port 3.2 or ADC2 input or PWM2 output 3.29 1.67 1.67

8 Port 3.3 or ADC3 input or PWM3 output 4.91 7.8 7.3

Digital ground for µ-Controller core and

9

periphery

Port 0.5 (8 mA current sinking capability for

10

direct drive of LEDs)

Port 0.6 (8 mA current sinking capability for

11

direct drive of LEDs)

Analog ground of Teletext decoder and digital

12

ground of TV-processor

13 Internally connected 2.285

14 2nd supply voltage TV-processor (+8V) 8.1 1.2 1.4

Functions Description

Reference

Voltage (V)

0 0 0

0 7.2 6.99

4.17 7.7 7.3

0 0 0

Digital Multimeter

Positive

Resistance (20KΩ)

∞ ∞

∞ ∞

∞

Negative

Resistance (20KΩ)

0

Supply voltage of digital circuit of

15

TV-processor

16 Phase-2 filter 3.49

17 Phase-1 filter 3.81

18 Ground 3 for TV-processor 0 0 0

19 Bandgap decoupling 3.96

Automatic Volume Levelling (90° versions) /

20

E-W drive output (110° versions) /

Decoupling sound demodulator (QSS version

21

in AM/FM mode)

22 Vertical drive B output 2.3

23 Vertical drive A output 1.85

24 IF input 1 1.85

25 IF input 2 3.82

26 Reference current input 3.75

27 Vertical sawtooth capacitor 1.36 4.75 4.73

28 Tuner AGC output 1.87

29 Audio deemphasis or SIF input 1 1.87

4.96

0.78

2.3

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

(Continued)

22

Page 25

SERVICE MANUAL

30 Decoupling sound demodulator or SIF input 2 0 0 0

31 Ground 2 for TV processor 2.32

32 Narrow band PLL filter or AGC sound IF 0

Automatic Volume Levelling / sound IF input /

33

subcarrier reference output / audio

34 Deemphasis 0.75

35 Horizontal output 2.60

36 Flyback input/sandcastle output 1.47 9.8 9.75

37 External audio output / QSS intercarrier out 2.43

38 EHT/overvoltage protection input 2.75

39 IF-PLL loop filter 8.1 1.2 1.35

40 IF video output / selected CVBS output 4

41 Supply voltage TV processor 0 0 0

42 CVBS/Y input 3.9

43 C input 1.55

Audio output/AM audio output

44

(volume controlled)

45 2nd RGB / YUV insertion input 1.67

46 2nd R input / V (R-Y) input / PR input 2.5

47 2nd G input / Y input 2.5

48 2nd B input / U (B-Y) input / PB input 2.5

49 Beam current limiter input 1.87

50 Black current input / V-guard input 5.8

51 Red output 2.63 3.1 3.0

52 Green output 2.47 3.1 3.0

53 Blue output 2.69 3.1 3.0

Analog supply of Teletext decoder and digital

54

supply of TV-processor (3.3 V)

55 OTP programming voltage 0 0 0

56 Digital supply to core (3.3 V) 3.28 0.67 0.65

57 Oscillator ground supply 0 0 0

58 Crystal oscillator input 1.58

59 Crystal oscillator output 1.67

60 Reset 0 0 0

61 Digital supply to periphery (+3.3 V) 3.28 0.67 0.65

62 Port 1.0 or external interrupt 1 input 0 12.9 11.9

63 Port 1.1 or Counter/Timer 0 input 0 7.3 7.1

64 Port 1.2 or external interrupt 0 input 4.59 18.7 18.8

3.1 11.2 10.9

4.44

3.27 0.67 0.65

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

23

Page 26

SERVICE MANUAL

Pin

No.

1

2

3

4

5

6

7

8

Functions Description

Address input 0

Address input 0

Address input 0

Common ground 0

Serial data 4

Serial clock input 4.2

Write protect 0

Supply voltage 4.9

Table 3 Functions and Service Data of AT 24C16 (N202)’s Pins

Table 4 Functions and Service Data of MSP3440(N606M)’s Pins

Pin

No.

Function Description

1 NC

2 NC

3 NC

4 NC

5 ADR-SEL

6 STANDBYQ

7 I2C-DC

8 I2C-DA

9 NC

10 NC

11 NC

12 NC

13 NC

14 NC

15 NC

16 DVSUP

17 DVSS

18 NC

19 NC

20 RESETQ

21 NC

22 NC

23 VREF2

24 DACM-R

25 DACM-L

26 NC

Reference Voltage

(V)

Reference Voltage

(V)

0.00 15.32 5.3

2.57 13.41 5.51

0.00 15.32 5.57

0.00 15.32 5.58

5.03 8.62 4.54

5.03 8.63 4.54

3.8 6.98 4.44

3.9 6.98 4.44

2.5 15.32 6.24

2.82 15.32 6.24

2.5 15.32 6.24

0.27 15.32 5.29

0.2 15.32 5.59

0.1 15.32 5.59

0.1 15.32 5.59

5.04 8.6 4.54

0.00 0.00 0.00

0.00 15.32 5.31

0.00

5 15.04 5.24

0.00 3.54 3.54

0.00 3.52 3.52

0.00 0.00 0.00

2.03 3.52 3.52

2.04 3.54 3.54

1.41 3.6 3.6

Digital Multimeter

Positive Resistance

(20KΩ)

0 0

0 0

0 0

0 0

6.37 6.4

6.37 6.44

0 0

3.03 3.02

Digital Multimeter

Positive Resistance

(20KΩ)

∞ ∞

Negative Resistance

(20KΩ)

Negative

Resistance (20KΩ)

(Continued)

24

Page 27

SERVICE MANUAL

27 NC

28 NC

29 GND

30 SC1-OUT-R

31 SC1-OUT-L

32 CAPL-A

33 AHVSUP

34 CAPL-M

35 AHVSS

36 ABNDC

37 NC

38 NC

39 NC

40 NC

41 SC1-IN-L

42 SC1-IN-R

43 VREFTOP

44 NC

45 AVSS

46 AVSUP

47 ANA-IN1+

48 ANA-IN149 ANA-IN2+

50 TESTEN

51 XTAL-IN

52 XTAL-OUT

3.81 13.8 5.92

3.79 13.8 5.91

0.00 0.00 0.00

3.8 12.8 5.91

3.79 12.8 5.92

7.28

8.26

6.53

∞ 6.04

∞ 4.59

∞ 6.04

0.00 0.00 0.00

3.74

3.77

3.77

3.77

∞ 6.02

∞ 6.1

∞ 6.1

∞ 6.1

3.77 ∞ 6.1

3.77 ∞ 6.1

3.77 ∞ 6.1

2.61 1.63 1.63

3.77 19.42 6.1

0 0.00 0.00

5.13 8.62 4.53

1.52 15.3 5.27

1.52 15.3 5.26

0.00 15.3 5.27

0.00 0.00 0.00

2.49 14.79 5.27

2.49 14.63 5.3

Table 5 Functions and Service Data of TDA8350Q-N6 (N401)’s Pins

Digital Multimeter

Pin No. Function Description

Reference

Voltage (V)

Positive Resistance

(20KΩ)

Negative

Resistance (20KΩ)

1 Vertical drive input (positive) 2.33 8.82 5.8

2 Vertical drive input (negative) 2.28 8.83 5.83

3 Feedback input 8.52 5.74 4.71

4 Supply voltage 17.23 7.92 4.2

5 Output 1 8.5 5.83 4.71

6 Not connected 0.00 ∞ ∞

7 Ground 0.00 0.00 0.00

8 Pump supply voltage input 49.31 ∞ ∞

9 Output 2 0.00 5.87 4.7

10 Guard output 0.2 8.64 5.88

11 Pincushion output 0.07 9.79 5.24

12 Pincushion input (negative) 2.43

13 Pincushion input (positive) 2.91

25

∞

∞

6.97

6.88

Page 28

Table 6 Functions and Service Data of TDA8944J (N361)’s Pins

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Functions Description

Negative loudspeaker terminal 1

Ground channel 1

Supply voltage channel 1

Positive loudspeaker terminal 1

Not connected

Positive input 1

Not connected

Negative input 1

Negative input 2

Mode selection input (standby,

mute, operating)

Half supply voltage decoupling

(ripple rejection)

Positive input 2

Not connected

Negative loudspeaker terminal 2

Ground channel 2

Supply voltage channel 2

Positive loudspeaker terminal 2

Table 7 Functions and Service Data of TA1219AN (DS01)’s Pins

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Function Description

Get Select

Get Select

Lin TV

Rin TV

Vin TV

LinTV1

RinTV1

VinTV1

LinS1

Y/Vins1

RinS1

CinS1

LinS2

Y/VinS2

SERVICE MANUAL

Digital Multimeter

Reference Voltage

(V)

7.98 ∞

0 0

14.9 5.8

7.3 ∞

0 ∞

7.3 ∞

0 ∞

7.4 ∞

7.3 ∞

0 7.8

7.6 ∞

7.3 ∞

0 ∞

7.3 ∞

0 0

14.8 3.5

7.3 ∞

Positive Resistance

(20KΩ)

Digital Multimeter

Reference

Voltage(V)

Positive

Resistance(20K

Ω)

6.54 7.88

3.69 7.99

5.12 7.49

5.11 7.55

5.13 7.52

5.12 7.63

5.12 7.63

5.13 7.52

5.12 7.64

5.09 7.5

5.1 7.64

0.00 0.00

5.08 7.64

5.13 7.62

Negative Resistance

(20KΩ)

∞

0

7.7

∞

∞

∞

∞

∞

∞

8.9

∞

∞

∞

∞

0

3.5

∞

Negative

Resistance(20 KΩ)

5.77

5.73

5.89

5.91

5.89

5.89

5.89

5.89

5.89

5.89

5.88

0.00

5.87

5.87

26

Page 29

SERVICE MANUAL

RinS2

15

CinS2

16

I/01

17

I/02

18

GND

19

Scl

20

SDA

21

Sync out

22

Address

23

VinV2

24

LinTV2

25

Yin

26

RinV2

27

Vin

28

Vcc

29

Cout

30

Rout1

31

Yout

32

Lout1

33

Vout1

34

RoutTV

35

LoutTV

36

Table 8 Functions and Service Data of TC90A49P (N902)’s Pins

Pin

No.

ADC and DAC analog power supply.

1

ADC bias voltage. Stabilize by attaching a 0.01µF

2

capacitor.

ADC input range D upper limit voltage. Stabilize

3

by attaching a 0.01µF capacitor.

ADC input. Inputs 1.0 Vp-p video signal. Sync tip

4

clamp is performed.

ADC input range D lower limit voltage. Stabilize by

5

attaching a 0.01µF capacitor.

ADC and DAC logic power supply.

6

Logic and internal DRAM GND (digital).

7

Internal DRAM power supply

8

2

C BUS SDA

I

9

2

C BUS SCL

I

10

Shipment test mode switch or I2C bus setting

11

reset pin.

Y signal comb function ON / OFF switch.

12

Functions Description

5.11 7.62

5.12 7.66

7.3 7.98

0.02 7.9

0.00 0.006.98

3.5 6.98

3.77 6.98

0.02 7.88

0.00 0.00

5.11 7.53

5.1 7.64

5.1 7.76

5.1 7.64

5.09 7.76

5.86 5.45

3.46 0.2

3.95 7.43

3.48 0.2

3.96 7.43

4.06 0.2

3.95 7.39

3.95 7.46

Digital Multimeter

Reference

Voltage (V)

4.98 0.55 0.54

1.41 ∞ ∞

3.15 0.64 0.63

2.14 ∞ ∞

1.84 0.497 0.49

4.98 0.55 0.55

0 0 0

4.98 0.55 0.55

4.12 6.39 6.44

4.25 6.4 6.45

0 0 0

0 0

Positive Resistance

(20KΩ)

Negative Resistance

5.86

5.64

5.43

5.44

0.00

4.47

4.46

5.45

0.00

5.81

5.82

5.82

5.82

5.6

4.1

0.2

5.46

0.2

5.46

0.2

5.48

5.48

(20KΩ)

0

(Continued)

27

Page 30

SERVICE MANUAL

Clock input pin.

13

Connect the APC filter in the 8 fsc PLL circuit

14

PLL power supply

15

ADC, DAC, and PLL GND (analog).

16

Outputs chrominance signal.

17

DAC output range D upper limit voltage.

18

DAC output range D lower limit voltage

19

Outputs luminance signal.

20

2.54 ∞ ∞

0 ∞ ∞

4.98 0.55 0.55

0 0 0

2.25 ∞ ∞

3.14 0.57 0.57

1.84 0.42 .043

2.16 ∞ ∞

Table 9 Functions and Service Data of TDA6108JF (NY01)’s Pins

Pin

No.

1 G inverting input 1.81 3.03 2.99

2 R inverting input 1.91 3.1 3.0

3 B inverting input 2.0 3.03 2.99

4 Ground 0 0 0

5 Black level current input 3.33 ∞ ∞

6 Supply voltage 196.7 ∞ ∞

7 B output 152.5 ∞ ∞

8 R output 157.5 ∞ ∞

9 G output 159.9 ∞ ∞

Functions Description

Reference Voltage

(V)

Table 10 Functions and Service Data of STR-G8626 (IC801)’s Pins

Pin

No.

1 D 146.3

2 S 0 0 0

3 GND 0 0 0

4 Vin 31.96

5 DCP/FB 1.72 0.699 0.166

Functions Description

Reference Voltage

(V)

Digital Multimeter

Positive Resistance

(20KΩ)

Digital Multimeter

Positive Resistance

(20KΩ)

∞ ∞

∞ ∞

Negative Resistance

(20KΩ)

Negative Resistance

(20KΩ)

28

Page 31

Waveforms of Key Points

SERVICE MANUAL

N201’s Pin2

N201’s Pin3

29

Page 32

SERVICE MANUAL

N201’s Pin22

N201’s Pin32

30

Page 33

SERVICE MANUAL

N201’s Pin33

N201’s Pin34

31

Page 34

SERVICE MANUAL

N201’s Pin38

N201’s Pin42

32

Page 35

SERVICE MANUAL

N201’s Pin43

N201’s Pin59

33

Page 36

SERVICE MANUAL

NB01’s Pin47

NB01’s Pin52

34

Page 37

SERVICE MANUAL

N401’s Pin5

N401’s Pin9

35

Page 38

SERVICE MANUAL

N401’s Pin11

36

Page 39

SERVICE MANUAL

ADJUSTMENTS

Set-up Adjustments

●The following adjustments should be made when a complete realignment is required or a new

CRT is installed. Perform the adjustments in order as follows.

1. Color purity

2. Convergence

3. White Balance

Note:

The purity/convergence magnet assembly and rubber wedges need mechanical positioning.

Refer to Fig. 18.

1. Color Purity Adjustment

Note:

Before attempting any purity adjustment, the TV should be operated for at least 15 minutes.

1) Demagnetize the CRT and cabinet using a degaussing coil.

2) Set the brightness and contrast to maximum.

3) Receive the green raster test pattern.

4) Loosen the clamp screw holding the deflection yoke and slide it backward or forward to display

vertical green belt (zone) on the screen.

5) Remove the rubber wedge.

6) Rotate and spread the tabs of the purity magnet around the neck of the CRT until the green belt

is on the center of the screen.

7) Slowly move the deflection yoke forward or backward until a uniform green screen is obtained.

Tighten the clamp screw of the yoke temporarily.

8) Check purity of the red and blue raster.

Fig. 18

Yoke

37

Page 40

SERVICE MANUAL

Fig. 19

2. Convergence Adjustment

Note:

Before attempting any convergence adjustment, the TV should be operated for at least 15

minutes.

●Center convergence adjustment

1) Receive the crosshatch test pattern.

2) Set the brightness and contrast properly.

3) Adjust two tabs of the 4-pole magnet to change the angle between them and red and blue

vertical lines are superimposed on the center area of the screen.

4) Turn both tabs at the same time keeping the angle constant to superimpose red and blue

horizontal lines on the center of the screen.

5) Adjust two tabs of 6-pole magnet to superimpose red/blue line and green line. Adjusting the

angle affects the vertical lines and rotating both magnets affects the horizontal lines.

6) Repeat steps 3)~5) keeping in mind red, green and blue movement. 4-pole magnet and 6-pole

magnet interact each other, resulting in complicating and dot movement.

●Circumference convergence adjustment

1) Loosen the clamping screw of the defection yoke slightly to allow it to tilt.

2) Temporarily put a wedge as shown in Fig.18. (Do not remove cover paper on adhesive part of

the wedge.)

3) Tilt front of the deflection yoke up or down to obtain better convergence in circumference.

Push the mounted wedge into the space between the CRT and yoke to fix th e yoke temp orarily.

4) Put other wedge into bottom space and remove the cover paper to stick.

5) Tilt front of the deflection yoke right or left to obtain better convergence in circumference.

6) Keep the deflection yoke position and put another wedge in either upper space. Remove cover

paper and stick the wedge on the CRT to fix the yoke.

7) Detach the temporarily mounted wedge and put it in another upper space. S tick it on the CRT to

fix the yoke.

8) After fixing three wedges, recheck overall convergence.

38

Page 41

SERVICE MANUAL

Tighten the screw firmly to fix the yoke and check if the yoke is fixed.

9) Stick three adhesive tapes on wedges as shown in Fig. 18.

4-pole Magnet Movement 6-pole Magnet Movement

Center Convergence by Convergence Magnets

Incline the Yoke Up (or Down) Incline the Yoke Right (or Left)

Circumference Convergence by DEF Yoke

Fig.20

Circuit Adjustments

1. General Description

All adjustments are thoroughly checked and corrected before the TV outgoing. Therefore the TV

should operate normally and deliver proper color pictures upon installation. However, several

minor adjustments may be required depending on the particular location where the TV is

operated.

This TV is shipped completely in carton. Carefully take out the TV from the carton and remove

all packing materials. Connect the power cord into a 120V AC, 60Hz two-pin power outlet. Turn

on the TV. Check and ad just all the customer controls such as brightness, contrast and color to

obtain natural color pictures.

2. Automatic Degaussing

39

Page 42

SERVICE MANUAL

A degaussing coil is mounted around the CRT so that external degaussing after moving the TV

is generally unnecessary, providing it is properly degaussed upon installation. The degaussing

coil operates in about 1 second after power on. If the set is moved or faced to a different

direction, the power switch must be switched off for at least 30 minutes in order that the

automatic degaussing circuit operates properly. Should the chassis or parts of the cabinet

become magnetized to cause poor color purity, use an external-degaussing coil. Slowly move

the degaussing coil around the screen, the sides and front of the TV and slowly withdraw the coil

to a distance of about 2m before unplug it. If color shading still exists, perform the Color Purity

Adjustment and Convergence Adjustment procedures.

3. Supply Voltage Adjustment

Caution: +B voltage has close relation to high voltage. To avoid X-ray radiation, +B voltage

should be +145V.

1) AC power supply to 120±2V.

2) Connect a digital voltmeter to two pins of C820, and then turn on the TV.

3) Receive Philips test pattern.

4) The voltmeter should be read 145±1.5V.

4. High Voltage Inspection

Caution: No high voltage adjustment should be done in the chassis.

1) Connect a precise high voltmeter to the second anode of the CRT.

2) Turn on the TV and set the brightness and contrast to minimum (i.e. set beam current of the

CRT to zero).

3) The high voltage tested should be 29±1KV (For 29” CRTs) or 31±1KV (for 34” CRTs).

4) Set the brightness to minimum or maximum, and ensure high voltage not beyond limitation of

32KV (for Samsung and LG 29” CRTs), 33 KV(for Daewoo and Toshiba 29” CRTs ) or 35KV (for

34” CRTs).

5. Focus Adjustment

1) Use the remote control to set the contrast to maximum and the brightness,color to medium.

2) Set H. V. lines near center of Philips pattern to thinnest with the FCB on the FBT. After finishing

adjustment,ensure that no poor focusing exists near the center or around of the frame.

Before Adjusting After Adjusting

40

Page 43

SERVICE MANUAL

Service Mode and Bus Data

1. How to Enter the Service Mode with the Remote Control

1) Decrease volume to 0.

2) Press the MUTE button on the remote control and VIDEO button on the TV at the same time.

3) Adjust the TV with the MENU SELECT buttons on the remote control.

4) Press the button on the remote control to quit the Service mode.

2. Bus Data

Symbol Adjustment Description

S0

OP1 190

OP2 15

OP3

1

Option bit 1(See “Option Set”)

Option bit 2(See “Option Set”)

Option bit 3(See “Option Set”)

S1

S2

S3

OP4 221

OP5

OP6

OP7

OP8

PAR

BOW Set to optimum Bow correction

HSH Set to optimum Horizontal shift

EWW Set to optimum East-west width adjustment

EWP Set to optimum East-west pincushion correction

UCR Set to optimum Upper corner correction

LCR Set to optimum Lower corner correction

EWT Set to optimum East-west Trapezoidal correction

VSL Set to optimum Half vertical output

VAM Set to optimum Vertical amplitude

SCL Set to optimum Vertical linearity

VSH Set to optimum Vertical shift

VOF Set to optimum Vertical position of character

CCV Set to optimum Vertical position of CCD

HOF Set to optimum Horizontal position of character

CCHF Set to optimum Horizontal position of CCD

VX 25

RED Set to optimum Red gun cutoff voltage

GRN Set to optimum Green gun cutoff voltage

WPR Set to optimum Red gun drive voltage

WPG Set to optimum Green gun drive voltage

WPB Set to optimum Blue gun drive voltage

140

111

191

101

Set to optimum Parallelogram correction

Option bit 4(See “Option Set”)

Option bit 5(See “Option Set”)

Option bit 6(See “Option Set”)

Option bit 7(See “Option Set”)

Option bit 8(See “Option Set”)

(Continued)

41

Page 44

SERVICE MANUAL

S5

S6

S7

S8

S9

S4

YDFN 7 Luminance delay

TOP Set to optimum Video automatic gain control

VOL 31 UOC volume control

IFFS 1 Picture intermediate frequency

HDOL 13 Cathode drive voltage

HD-B 3 Brightness of blue back

AGC 2 Automatic gain control velocity

VG2B 32

FEAT 57 See “Option Set”.

FEAT1 56 See “Option Set”.

TRE1 100 Treble Max.

TRE2 50 Treble Mid.

BAS1 60 Bass Max.

BAS2 30 Bass Mid.

1CON 80 Contrast in Normal mode

1BRI 50 Brightness in Normal mode

1COL 50 Color in Normal mode

1SHP 50 Sharpness in Normal mode

2CON 100 Contrast in Movie mode

2BRI 40 Brightness in Movie mode

2COL 60 Color in Movie mode

2SHP 60 Sharpness in Movie mode

3CON 100 Contrast in Sports mode

3BRI 60 Brightness in Sports mode

3COL 40 Color in Sports mode

3SHP 40 Sharpness in Sports mode

PP H 0

IFOF Set to optimum IF offset

VENH 1 Vertical enhancement

COR 3 Coring

VOLA 70 Volume 25

VOLB 80 Volume 50

VOLC 90 Volume 75

VOLD 100 Volume 100

WFRA 70 Woofer 25

WFRB 80 Woofer 50

WFRC 90 Woofer 75

WFRD 100 Woofer 100

SAGC 0 Sound AGC

LOUD 40 1KHz(or 2KHz) sound AGC

SCOT 107 AV output volume

(Continued)

42

Page 45

SERVICE MANUAL

SAV

Notes:

① “5”or “6”will be displayed before the data depending on signal frequency (50Hz or 60Hz)

② The data sheet may differ dependent on different models.

③ The data sheet may differ dependent on different CRTs for the same model.

3. Option Set

Bit Item Description Default

OP1

OP2

OP3

SCIN 61 AV input volume

FMIN 63 Sound frequency modulation

WOCF 15 Woofer Mid.

CON1 100 Contrast Max.

CON2 50 Contrast Min.

BRI1 Set to optimum Brightness Max.

BRI2 Set to optimum Brightness Min.

COL1 100 Color Max.

COL2 50 Color Min.

SHP1 80 Sharpness Max.

SHP2 40 Sharpness Min.

during geometric data adjustment.

0 TA1343N

1 MSP3440G

2 IDENT_TXT12

3 COMB_FILTER

4 OP_X_RAY

5 UOC_SVM

6 TDA9859

7 SOUND_CHIP

0 TV_29_21

1 VCHIP

2 CCD

SOUND_EFFE

3

CT

OP-ZOOM-DE

4

LE-LINE

5 0

6 0

7 OP-LOGO

0 BLUE_BACK

1 VM_OSD

2 TILT

WOOFER_ON

3

OFF

Sound processor TA1343N: 1→Yes, 0→No

MSP3440G: 1→Yes, 0→No

1→TXT12 IDENT detection, 0→SL IDENT detection

TC90A49P: 1→Yes, 0→No

X-Ray protection: 1→Yes, 0→No

TDA9379-VM: 1→Yes, 0→No

Sound processing chip TDA9859: 1→Yes, 0→No

Sound processing chip: 1→Yes, 0→No (PWM control)

Definition of UOC pin: 1→29”, 0→21”

V-chip: 1→Yes, 0→No

Closed Caption: 1→Yes, 0→No

Audio options: 1→Yes, 0→No

ZOOM detection:1→No, 0→Yes

User LOGO display: 1→Yes under no signal condition,

0→No

Blue back under no signal condition: 1→Yes, 0→No

1→Dependent on OSD MENU, 0→Independent on

OSD

Tilt: 1→Yes, 0→No

Super woofer: 1→Yes, 0→No

(Continued)

0

1

1

1

1

1

0

1

1

1

1

1

0

0

1

0

0

0

43

Page 46

SERVICE MANUAL

OP4

OP5

OP6

OP7

4 WOOFER_VOL

5 0

6 0

7 OP-TIMER

0 ENGLISH

1 PORTUGUESE

2 FRENCH

3 SPANISH

MSP3440G

4

-AVC

MSP3440G-

5

MDB

MSP3440G-

6

TONE

MSP3440G

7

_GAIN

0 PAL_M_N

Power-on

1

degaussing

2 AV_STEREO

16:9 16 : 9: 1→Yes, 0→No

3

4 LOCK_MENU

5 BSCREEN

6 WOOFER_MAI

N

7 CHANNELLAB

EL

0 FMWS

1 FSL

2 OSO

3 YPRPB

4 VG2_MODE

5 SYNC_Y

6 QSS

7 0

0 AV2

1 AV3

2 AV4

3 SVHS1

4 SVHS4

5 DVD

LAST_SOURCE Turn-on mode after power-on: 1 → TV, 0 → Last

6

Super woofer volume control: 1→Yes, 0→No

TIMER: 1→Yes, 0→No

English: 1→Yes, 0→No

Portuguese: 1→Yes, 0→No

French: 1→Yes, 0→No

Spanish: 1→Yes, 0→No

Auto volume control: 1→Yes, 0→No

MDB: 1→Yes, 0→No

Five equalizer: 1→Yes, 0→No

Frequency gain enhancement: 1→1KHz, 0→2KHz

PAL M /PAL N: 1→Yes, 0→No

1→4 seconds, 0→Every

AV Stereo: 1→Yes, 0→No

LOCK_MENU 1→Yes, 0→No

Black screen when changing channels: 1→Yes, 0→

No

Woofer available on main channel1(343): 1→Ye s, 0→

No

Channel label: 1→Yes, 0→No

FM-PLL window: 1→Large, 0→Small

Vertical sync: 1→60%, 0→Noise detector

Switch off: 1→Overscan, 0→Undefined

YPbPr selection: 1→Yes, 0→No

VG2 adjustment: 1→UOC H, 0→UOC I

DVD sync separately: 1→Yes, 0→No

1→QSS, 0→FM

AV2: 1→Yes, 0→No

AV3: 1→Yes, 0→No

AV4: 1→Yes, 0→No

SVHS1: 1→Yes, 0→No

SVHS4: 1→Yes, 0→No

DVD: 1→Yes, 0→No

program source

(Continued)

0

0

1

0

1

1

1

0

1

1

0

0

1

1

0

0

0

1

1

1

1

1

0

1

1

1

1

1

1

1

1

0

44

Page 47

SERVICE MANUAL

7 STANDBY

OP8

FEA

T

FEA

T1

Notes:

0 VM

1 LOCK

2 IDENT_MODE

COLOR

3

MATRIX

4 FORF 0

5 FORS

6 CHILD_LOCK

7 SPEAKER

0 BKS Black level stretch 1

1 0 0

2 0 0

3 DSK Skin tone correction 1

4 COR0 1

5 COR1

6 SVM0 0

7 SVM1

0 0

1 0

2 VAM0

3 VAM1

4 RPO0

5 RPO1

6 0

7 0

① The option data in the above table may differ depending on models, UOC chips and CRTs

used.

② It is required to check if the data comply with the function requirements of your TVs.

For example:

③ For PF2720 and PF3220 models, OP1 is set to 158, OP7 to 175 and OP8 to 100 when using

TDA9375 or OP1 is set to 158, OP7 to 175 and OP8 to 100 when using TDA9379.

For PF2730 and PF3230 models, OP1 is set to 158, OP7 to 191 and OP8 to 101 when using

TDA9375 or OP1 is set to 190, OP7 to 191 and OP8 to 101 when using TDA9379.

Standby mode after power-on: 1→Standby, 0→The

same as last power-off mode

Velocity modulation: 1→Yes, 0→No

Lock used for identifying detection: 1→Yes, 0→No

Lock handle: 1→TXT12 | Lock; 0→TXT12 & Lock

Matrix: 1→USA; 0 →Japan

F/S 00→AUTO 60 01→60 FORCED

10→AUTO LAST 11→AUTO 50

Child lock: 1→Yes, 0→No

Speaker On/Off: 1→Yes, 0→No

Dynamic coring: 00→Off 11→Max.

TDA9379 VM delay 00→50 01→70

10→90 11→Spare

TDA9379 VM amplitude: 00→OFF 01→0.8V

10→1.2V 11→1.8V

Over pulse/preset pulse 00(1:1) 01(1:1.25)

10(1:1.5) 11(1:1.8)

1

1

0

0

0

1

1

0

1

0

0

0

0

1

1

1

0

0

45

Page 48

SERVICE MANUAL

TROUBLESHOOTING FLOW CHARTS

1.Power On/Off

1.1 The power indicator lights but with no raster and sound

1.2 The SMPS has no voltage output.

46

Page 49

SERVICE MANUAL

1.3 The SMPS is always in the Standby mode.

2. Control System

2.1 The power indicator lights, but the CPU cannot enter the Operation mode after poweron again.

2.2 Channel number remains unchanged during auto program.

47

Page 50

3. Video Signal Processor

3.1 No color

SERVICE MANUAL

3.2 The color is abnormal.

4. Horizontal/Vertical Scan Circuit

4.1 No raster

48

Page 51

SERVICE MANUAL

4.2 Raster is displayed as a horizontal bright line on the screen.

4.3 The field amplitude of raster is not enough.

4.4 East-west pincushion distortion

49

Page 52

5. Audio System

5.1 No sound but with picture

SERVICE MANUAL

50

Page 53

6. Video System

SERVICE MANUAL

6.1 No picture

51

Page 54

APPENDIX 1: Circuit Diagram for PF2720/PF2730 (1)

Page 55

APPENDIX 2: Circuit Diagram for PF2720/PF2730 (2)

Note: VM board for PF2730 only

Page 56

APPENDIX 3: Circuit Diagram for PF3220/PF3230 (1)

Page 57

APPENDIX 4: Circuit Diagram for PF3220/PF3230 (2)

Note : VM Board for Pf3230 only

Page 58

APPENDIX 4: Main PCB Layout for PF2720/PF2730/PF3220/PF3230

Page 59

APPENDIX 6: AV PCB Layout for PF2720/PF2730/PF3220/PF3230

Page 60

APPENDIX 7: Auxiliary PCBs Layout for PF2720/PF2730/PF3220/PF3230 (3)

CRT RGB PCB

VM PCB

Power PCB

Page 61

APPENDIX 8: Final Wiring Diagram for PF2720

Remote Sensor PCB AssemblyRemote Sensor PCB Assembly

Key PCB AssemblyKey PCB Assembly

KK05KK05 KK04KK04

KK06KK06

TV/AVTV/AV

P+P+

XPK01XPK01

KK03KK03

P-P-

MENUMENU

KK01KK01

KK02KK02

V-V-

V+V+

Side-set AV PCB AssemblySide-set AV PCB Assembly

Wired Connector XPK01 Wired Connector XPK01

SpeakerSpeaker

XS805XS805

Power Switch PCB AssemblyPower Switch PCB Assembly

Wired Connector XE03 Wired Connector XE03

CPC01CPC01

XE03XE03

SpeakerSpeaker

Wired Connector XP205 Wired Connector XP205

--

++

From power cordFrom power cord

From degaussing coilFrom degaussing coil

CN803CN803

Power PCB AssemblyPower PCB Assembly

CN804CN804

CN801CN801

CN804 Cord PlugCN804 Cord Plug

Wired Connector XS800 Wired Connector XS800

CN801CN801

CN802CN802

CN502CN502

To deflection yokeTo deflection yoke

Wired Connector CPC01 Wired Connector CPC01

Main PCB AssemblyMain PCB Assembly

CN207CN207

CN361CN361

--

++

CN805CN805

GrayGray

To CRT's ground binding wireTo CRT's ground binding wire

CN103CN103

CN102CN102

CN101CN101

CN805 Cord PlugCN805 Cord Plug

CN501CN501

1

1

RedRed

WhiteWhite

XPY03 Cord PlugXPY03 Cord Plug

GND1GND1

GND2GND2

VG2VG2

XPY03XPY03

XPY01XPY01

CRT RGB PCB AssemblyCRT RGB PCB Assembly

Y0

Y0

XP

XP

r

r

to

to

c

c

onne

onne

C

C

d

d

re

re

Wi

Wi

AV PCB AssemblyAV PCB Assembly

Page 62

APPENDIX 9: Final Wiring Diagram for Pf2730

Remote Sensor PCB AssemblyRemote Sensor PCB Assembly

Key PCB AssemblyKey PCB Assembly

KK06KK06

KK05KK05 KK04KK04

P-P-

P+P+

TV/AVTV/AV

XPK01XPK01

KK03KK03

KK01KK01

KK02KK02

V-V-

MENUMENU

V+V+

Side-set AV PCB AssemblySide-set AV PCB Assembly

Wired Connector XPK01Wired Connector XPK01

SpeakerSpeaker

XS805XS805

Power Switch PCB AssemblyPower Switch PCB Assembly

Wired Connector Xe03 Wired Connector Xe03

CPC01CPC01

XE03XE03

SpeakerSpeaker

Wired Connector XP205 Wired Connector XP205

--

++

From power cordFrom power cord

From degaussing coilFrom degaussing coil

CN803CN803

Power PCB AssemblyPower PCB Assembly

CN804CN804

CN801CN801

CN801CN801

CN802CN802

nector CN804 Wired Con

nector CN804

CN806CN806

Wired Con

Wired Connector XS800 Wired Connector XS800

Wired Connector VDP03Wired Connector VDP03

CN502CN502

To deflection yokeTo deflection yoke

Wired Connector CPC01 Wired Connector CPC01

Main PCB AssemblyMain PCB Assembly

CN207CN207

CN206ACN206A

CN206CN206

CN103CN103

--

++

CN361CN361

From VM PCB's VDP02A (9379 CMOS chip )Wired Connector From VM PCB's VDP02A (9379 CMOS chip )Wired Connector

From VM PCBs VDP02 (9375 CMOS chip )Wired Connector From VM PCBs VDP02 (9375 CMOS chip )Wired Connector

CN102CN102

CN101CN101

Wired Connector CN805 Wired Connector CN805

CN805CN805

Wired Connector XPY03 Wired Connector XPY03

GrayGray

To CRT's Ground Binding WireTo CRT's Ground Binding Wire

RedRed

GND1GND1

GND2GND2

VG2VG2

XPY03

XPY03

CRT RGB PCB AssemblyCRT RGB PCB Assembly

CN501CN501

WhiteWhite

XPY01XPY01

VDP04VDP04

VM PCB AssemblyVM PCB Assembly

VD

P03VDP03

XPY01 Cord PlugXPY01 Cord Plug

AV PCB AssemblyAV PCB Assembly

VDP02VDP02

Page 63

APPENDIX 10: Exploded View for PF2720/PF2730

3

9

2

12

1

4

10

11

12

5

10

11

8

13

10

7

6

20

19

18

17

16

15

14

plasticene

13

Tapping screw M6X35W

12

Tapping screw 4X20BAHCh

11

10

Tapping screw 4X16BTHCh

9

Washer

8

C-UL label

7

Real label

6

Admonition label

5

Distance clip

Back cover

4

Front cover assembly

3

2

CRT assembly

Chassis assembly

1

Serial

No.

Parts

4

6

4

4

1

1

1

1

1

1

1

1

Quantity

Page 64

APPENDIX 11: Final Wiring Diagram for Pf3220

Remote Sensor PCB AssemblyRemote Sensor PCB Assembly

Key PCB AssemblyKey PCB Assembly

KK05KK05

KK06KK06

KK04KK04

P-P-

P+P+

TV/AVTV/AV

XPK01XPK01

KK03KK03

KK01KK01

KK02KK02

V-V-

V+V+

MENUMENU

Side-set AV PCB AssemblySide-set AV PCB Assembly

Wired Connector XPK01 Wired Connector XPK01

SpeakerSpeaker

XS805XS805

Power Switch PCB AssemblyPower Switch PCB Assembly

Wired Connector XE03 Wired Connector XE03

CPC01CPC01

XE03XE03

SpeakerSpeaker

Wired Connector XP205 Wired Connector XP205

--

++

Wired Connector CPC01 Wired Connector CPC01

--

++

Wired Connector XS800 Wired Connector XS800

From power cordFrom power cord

From degaussing coilFrom degaussing coil

C

C

N801

CN803CN803

CN801CN801

804 Wired Connector CN

804

N801

Main PCB AssemblyMain PCB Assembly

CN802CN802

CN361CN361

Power PCB AssemblyPower PCB Assembly

To CRT's Ground WireTo CRT's Ground Wire

Wired Connector CN

CN207CN207

CN804CN804

CN502CN502

To Deflection YokeTo Deflection Yoke

CN103CN103

CN102CN102

CN101CN101

Wired Connector CN805 Wired Connector CN805

CN805CN805

CN501CN501

RedRed

WhiteWhite

AV PCB AssemblyAV PCB Assembly

Wired Connector XPY03 Wired Connector XPY03

GrayGray

GND1GND1

GND2GND2

Wired Connector XPY01 Wired Connector XPY01

VG2VG2

XPY03XPY03

XPY01XPY01

CRT RGB PCB AssemblyCRT RGB PCB Assembly

Page 65

APPENDIX 12: Final Wiring Diagram for Pf3230

Remote Sensor PCB AssemblyRemote Sensor PCB Assembly

Key PCB AssemblyKey PCB Assembly

KK05KK05

KK06KK06

KK04KK04

P-P-

P+P+

TV/AVTV/AV

XPK01XPK01

KK03KK03

KK01KK01

KK02KK02

V-V-

MENUMENU

V+V+

Side-set AV PCB AssemblySide-set AV PCB Assembly

Wired Connector XPK01Wired Connector XPK01

SpeakerSpeaker

XS805XS805

Power Switch PCB AssemblyPower Switch PCB Assembly

Wired Connector XE03 Wired Connector XE03

CPC01CPC01

XE03XE03

SpeakerSpeaker

Wired Connector XP205Wired Connector XP205

--

++

From power cordFrom power cord

From degaussing coilFrom degaussing coil

CN803CN803

Power PCB AssemblyPower PCB Assembly

CN801CN801

CN801CN801

CN802CN802

CN806CN806

Wired Connector XS800Wired Connector XS800

Wired Connector VDP03 Wired Connector VDP03

Wired Connector CPC01Wired Connector CPC01

Main PCB AssemblyMain PCB Assembly

CN361CN361

From VM PCBs VDP02A (9379 CMOS chip )Wired Connector From VM PCBs VDP02A (9379 CMOS chip )Wired Connector

--

++

Wired Connector CN804 Wired Connector CN804

CN804CN804

Wired Connector CN805

Wired Connector CN805

CN502CN502

To deflection yokeTo deflection yoke

CN206ACN206A

CN207CN207

CN206CN206

CN103CN103

From VM PCBs VDP02 (9375 CMOS chip )Wired Connector From VM PCBs VDP02 (9375 CMOS chip )Wired Connector

CN102CN102

CN101CN101

CN805CN805

graygray

To CRT's Ground Binding WireTo CRT's Ground Binding Wire

CN501CN501

RedRed

WhiteWhite

VDP04VDP04

VM PCB AssemblyVM PCB Assembly

VDP03VDP03

VDP02VDP02

Wired Connector XPY03Wired Connector XPY03

GND1GND1

GND2GND2

AV PCB AssemblyAV PCB Assembly

XPY03XPY03

VG2VG2

XPY01XPY01

Wired Connector XPY01Wired Connector XPY01

CRT RGB PCB AssemblyCRT RGB PCB Assembly

Page 66

APPENDIX 13: Exploded View for PF3220/PF3230

or

or

or

20

Soldering agent

Tin solder

19

18

Q04-3 white nitro magnetic paint

Tapping screw 4X20BAHCh

17

Tapping screw 4X16BTHCh

16

C-1 notched washer

15

I hexagon nut A and B M8

14

Washer

13

C-UL label

12

Real label

11

C-UL label

10

9

Real label

Admonition label

8

Admonition label

7

6

Distance clip

Wire clip

5

Back cover

4

Front cover assembly

3

2

CRT assembly

Chassis assembly

1

Serial

No.

Parts

8

4

8

4

8

1

1

1

1

1

1

1

2

1

1

1

1

Quantity

Loading...

Loading...