Page 1

S/M NO : PASP42B001

42” PLASMA PDP TV

PASP42B3D3S0

DPX-42D1NMSB

DPX-42D1

1

Page 2

CONTENS

1. Safety Precautions

2. Product Specification

2-1. DPX-42D1NMSB Product Specification

2-2. Available input signal

3. Block Diagram

3-1. Basic Block Diagram

3-2. Panel Block Diagram

4. A/V Block Diagram

5. Description of POWER PCB

5-1. Input/Output pin assignment & specification

5-2. Output specification

6. Service Mode

6-1. ENTERING METHODE OF SERVICE MODE

6-2. DEFAULT VALUE OF SERVICE MODE

7. Adjusting Method

7-1. Adjusting WHITE BALANCE

7-2 . POWER BOARD Adjustment

8. SOFTWARE UPGRADE Method

8-1. Preparation

8-2. UPGRADE Method

9. SET Disassemble/Assemble Method

9-1. Facts You Must Know When Disassembling/Assembling PDP SET

9-2. PCB Disassemble/Assemble

9-3. FRONT MASK & FILTER GLASS Disassemble/Assemble Method

10. Main PCB Trouble Diagnosis

10-1. VIDEO & JACK PCB Trouble Diagnosis

10-2. Sound Trouble Diagnosis

10-3. Key & IR Trouble Diagnosis

10-4. Remocone Trouble Diagnosis

11. TROUBLE SHOOTING

12. ASSEMBLY LIST

13. EXPLODED VIEW

14. Assemble Diagram

2

Page 3

1.Safety Precautions

(1) When moving or laying down a PDP Set, at least two people must be working. Avoid any impact

towards the PDP Set.

(2) Do not leave the broken PDP Set on for a long time. To prevent any further damages, after check the

broken Sets condition, make sure to turn the power (AC) off.

(3) When opening the BACK COVER, turn off the power (AC) to prevent electric shock. When a PDP

is on, high voltage and high current exist inside the Set.

(4) When loosening screws, check the connecting position and type of the screw. Sort out the screws

and store them separately. Because screws holding PCB are working as electric circuit

GROUNDING, make sure to check if any screw is missing when assembling.

(5) If you open the BACK COVER, you will see a Panel Gas Exhaust Tube . If this part is damaged,

entire PDP PANEL must be replaced. Therefore, when working, be careful not to dama ge this part.

(6) A PDP Set contains different kind of connector cables. When connecting or disconnecting connector

cables, check the direction and position of the cable beforehand.

(7) When disconnecting connectors, unplug the connectors slowly with care. Especially when

connecting/disconnecting FFC (film) cables or FPC cables, do not unplug the connectors too much

instantaneously or strongly, and always handle the cables with care.

(8) Connectors are designed so that if the number of pins or the direction does not match, connectors will

not fit. When having problem in plugging the connectors, make sure to check their kind, position, and

direction.

3

Page 4

2. Product Specification

2-1. DPD-42D1GMB Product Specification

1. GENERAL

1-1MODEL NO

1-2. CHASSIS NO

1-3. SCREEN SIZE

1-4. COUNTRY

1-5. RESOLUTION

1-6. REMOTE CONTROL

1-7. TUNING METHOD

2. ELECTRICAL

2-1. VIDEO INPUT

2-2. Component INPUT

2-3. PC INPUT

2-4. HDMI INPUT

2-5. TV INPUT

1) COLOR STANDARD

2) ANTENNA IN

3) RECEPTION CHANNEL

4) IF & SUBCARRIER

DPX-42D1NMSB

PASP42B3D3S0

42”(16:9)

South America

852(H) X 480(V)

DDR-2020C03

FS

COMPOSITE(NTST, PAL, SECAM, PAL-M/N,NTSC4.43) 2SETS

& S-VHS(50/60Hz) 1SET

1080 i, 720P, 480P , 480i, 576P, 576i

(Y, Pb/Cb, Pr/Cr COMPONENT SIGNAL) 2 SETS

15Pin D-Sub 1 SET (1280 x 1024 60Hz max.)

HDMI 1 SET

NTSC, PAL-M/N

ONE INPUT 75Ω Unbalanced (F-STANDARD)

VHF LOW : 48.25MHz ~ 160MHz. HIGH : 160MHz ~ 442MHz.

UHF : 442MHz ~ 801.28MHz

PIF : 45.25MHz(NTSC)

SIF : 41.25MHz (NTSC)

REMARKS P E C I F I C A T I O NI T E M

2-6. SOUND INPUT

2-7. SPEAKER OUTPUT

2-8. AUDIO OUTPUT

2-9. POWER REQUIREMENT

2-10. POWER CONSUMPTION

2-11. RS-232 /USB CONTROL

2-12. FUNCTIONS

1) SCALING

2) OSD

3) ETC

Component 2SETS, COMPOSITE 2SETS, PC 1 SET,

HDMI(DVI) 1 SET

10W(R) + 10W(L)

Audio Line Out 1 SET

AC 100V~240V, 50/60Hz

340W

RS-232 (FOR SYSTEM UPGRADE) ,

HDMI : Wide / Panorama / Zoom / 14:9 / 4:3

PC : Wide / 4:3 / 1:1

TV, A/V, Component : Wide / Panorama / Zoom, 14:9 / 4:3

4 LANGUAGES(ENGLISH, FRENCH, SPANISH, PORTUGUESE)

STILL, SLEEP MODE, PICTURE MODE, SOUND MODE,

TIMER, SCREEN MODE, Blue Screen, PANEL PROTECTION

(Screen Wiper & Pixel Shift)

4

Page 5

Product Specification

3. MECHANICAL

3-1. APPEARANCE

1) WITHOUT STAND

2) WITH STAND

3) CARTON BOX

3-2. WEIGHT

1) WITHOUT STAND

2) WITH STAND

4. OPTICAL

4-1. SCREEN SIZE

4-2. ASPECT RATIO

4-3. NUMBER OF PIXELS

4-4. DISPLAY COLOR

4-5. CELL PITCH

4-6. VIEWING ANGLE

WxHxD= 1,113.5 x 744 x 101.5 mm

WxHxD= 1,113.5 x 822 x 351 mm

WxHxD= 1,278 x 860 x 377 mm

29.5 Kg Net

38.5 Kg Net

42 inches(106.68 Cm)

16:9

852(H)X480(V)

16.77MILLION COLOR( RGB 8BIT)

1080㎛ x 1080㎛ x RGB

160DEGREE(VERTICAL/HORIZONTAL)

REMARKS P E C I F I C A T I O NI T E M

5. USERCONTROL &

ACCESSORIES

5-1 CONTROL BUTTON(SET)

5-2. REMOTE CONTROL

5-3. ACCESSORIES

CH+ / CH- / VOL+ / VOL- / AV

POWER, MUTE, TV, PC/HDMI, AV.SEL, SOURCE, MENU, EXIT,

CH-, CH+, VOL-, VOL+, ENTER, CH.ADD, AVC, PIC.SIZE,

PIC.MODE, MTS, S.MODE, PIP, P.INPUT, P.POSITION, P.SIZE,

P.SWAP, STILL, 0~9, +100, PRE-CH, SLEEP, KEY LOCK

REMOCON, USER MANUAL, POWER CORD,

BATTERY X 2(AAA SIZE)

5

Page 6

Product Specification

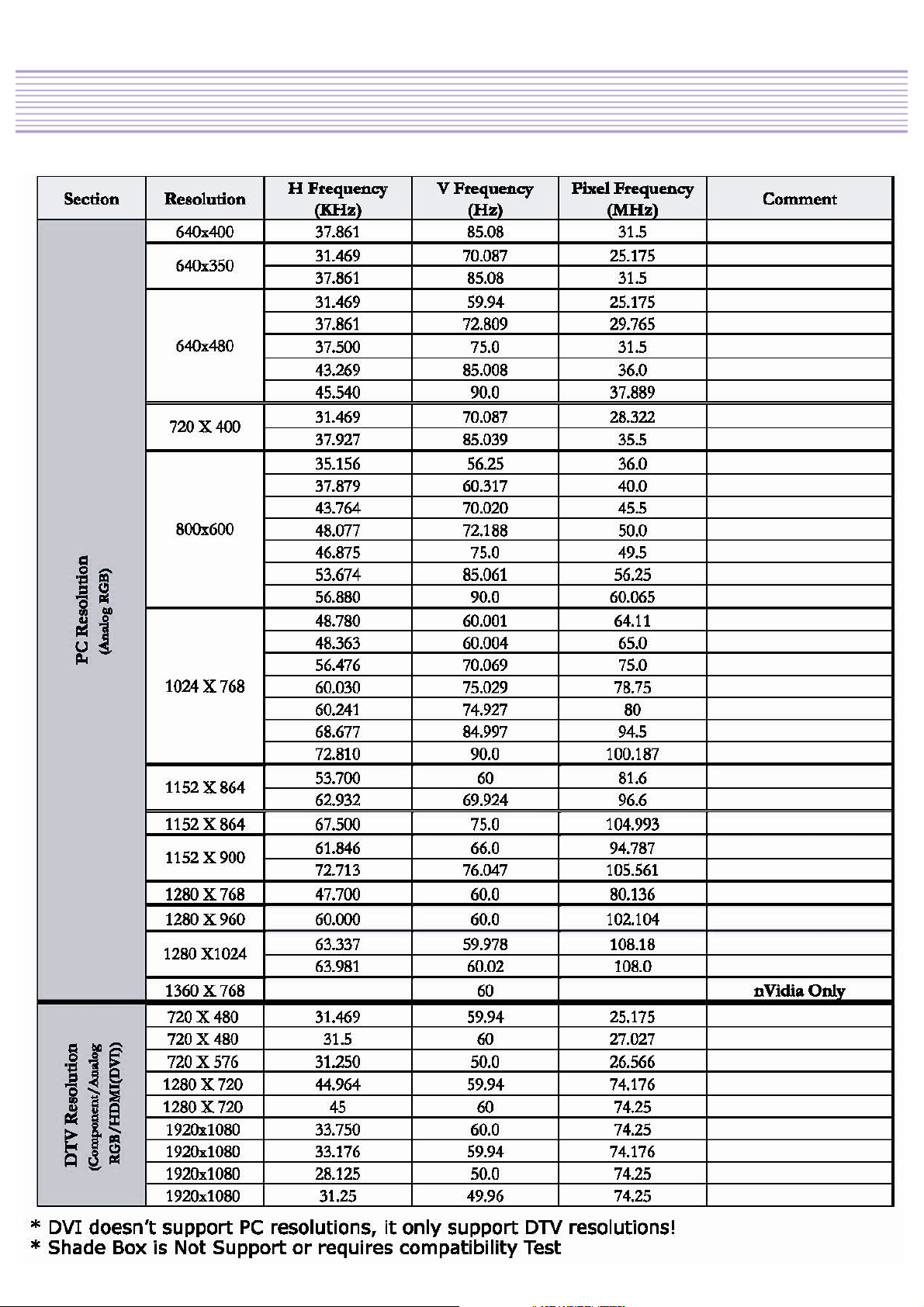

2-2. Available input signal

6

Page 7

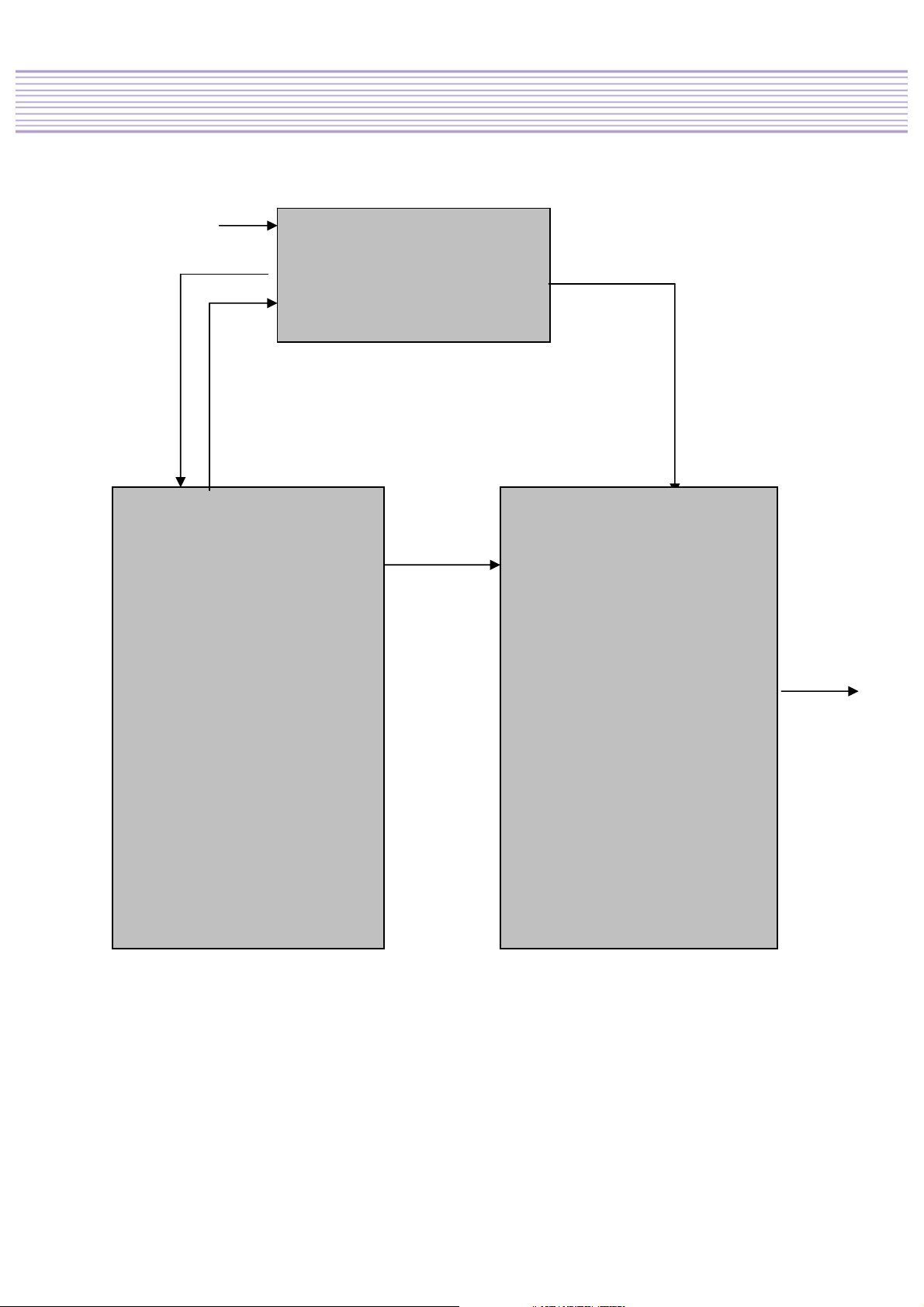

3. Block Diagram

3-1. Basic Block Diagram

AC INPUT

AC100~240V 50/60 Hz

M+7V

D+3.3V

A+12V

A+6V

POWER

MUTE

POWER

LVP

MAIN/AV BOARD PANEL

POWER BOARD

LVDS

OUT

Vs (170V ~ 190V)

Va (60V ~65V)

Vcc (+5v)

DISPLAY

7

Page 8

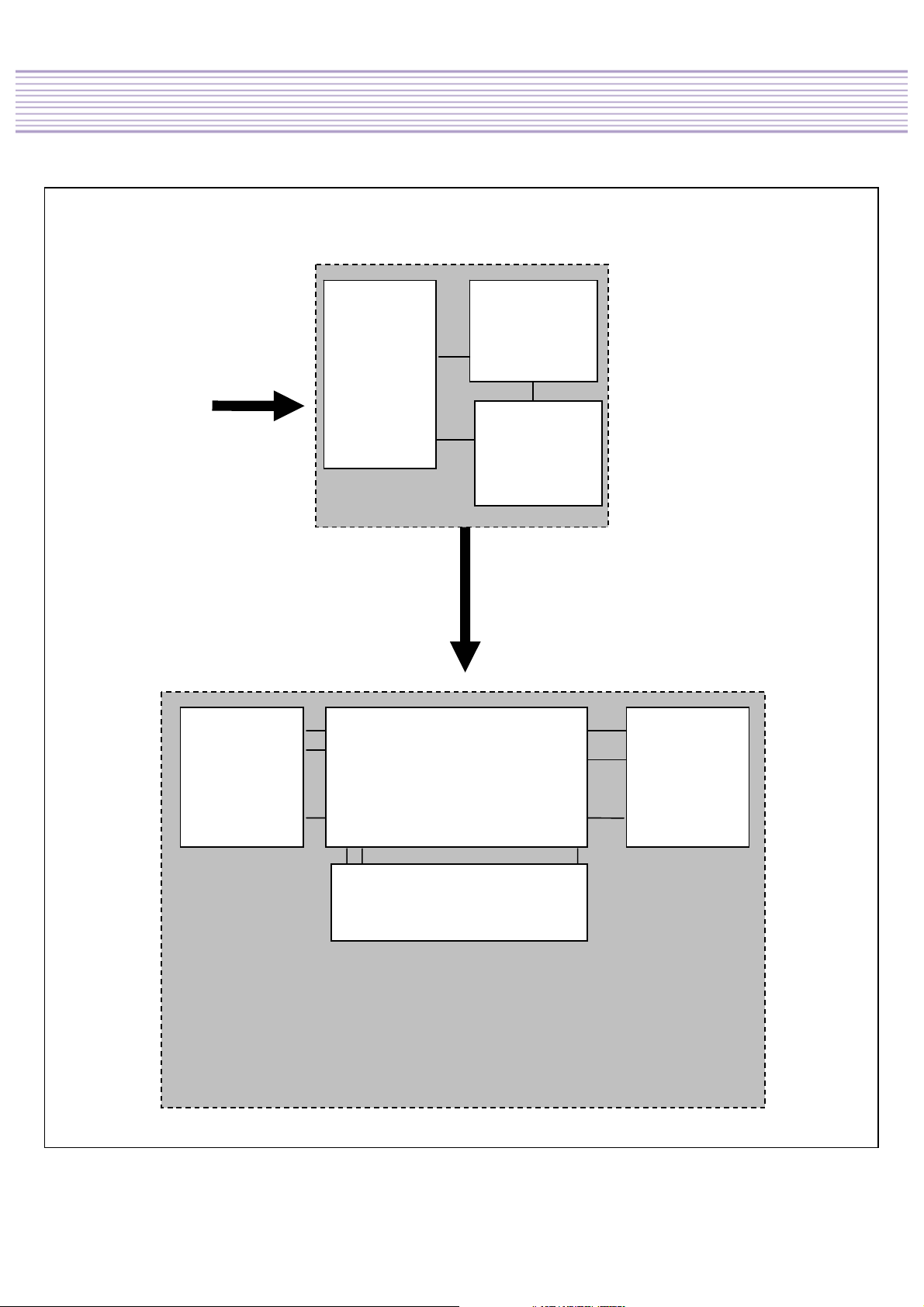

Block Diagram

3-2. Panel Block Diagram

Display Data

(LVDS Input)

RA+

RARB+

RBRC+

RCRD+

RDRCLK+

RCLK-

Input

Interface

Controller

Memory

Controller

Driver

Timing

Controller

Display Data

Driving

Scan

Driver

Color Plasma Display Panel

852 X 480 Pixels

Address Driver

Common

Sustain

Driver

8

Page 9

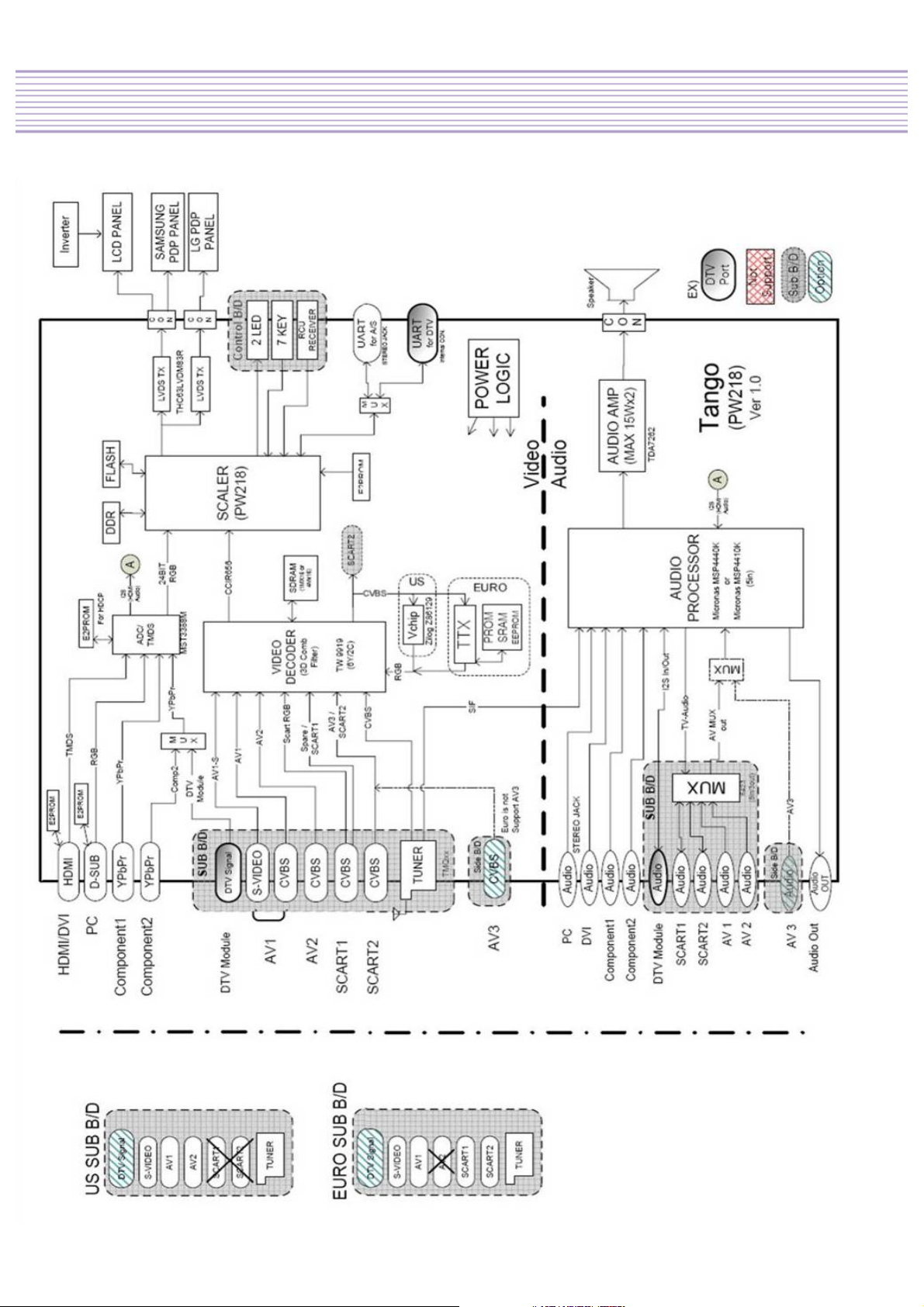

4. A/V Block Diagram

9

Page 10

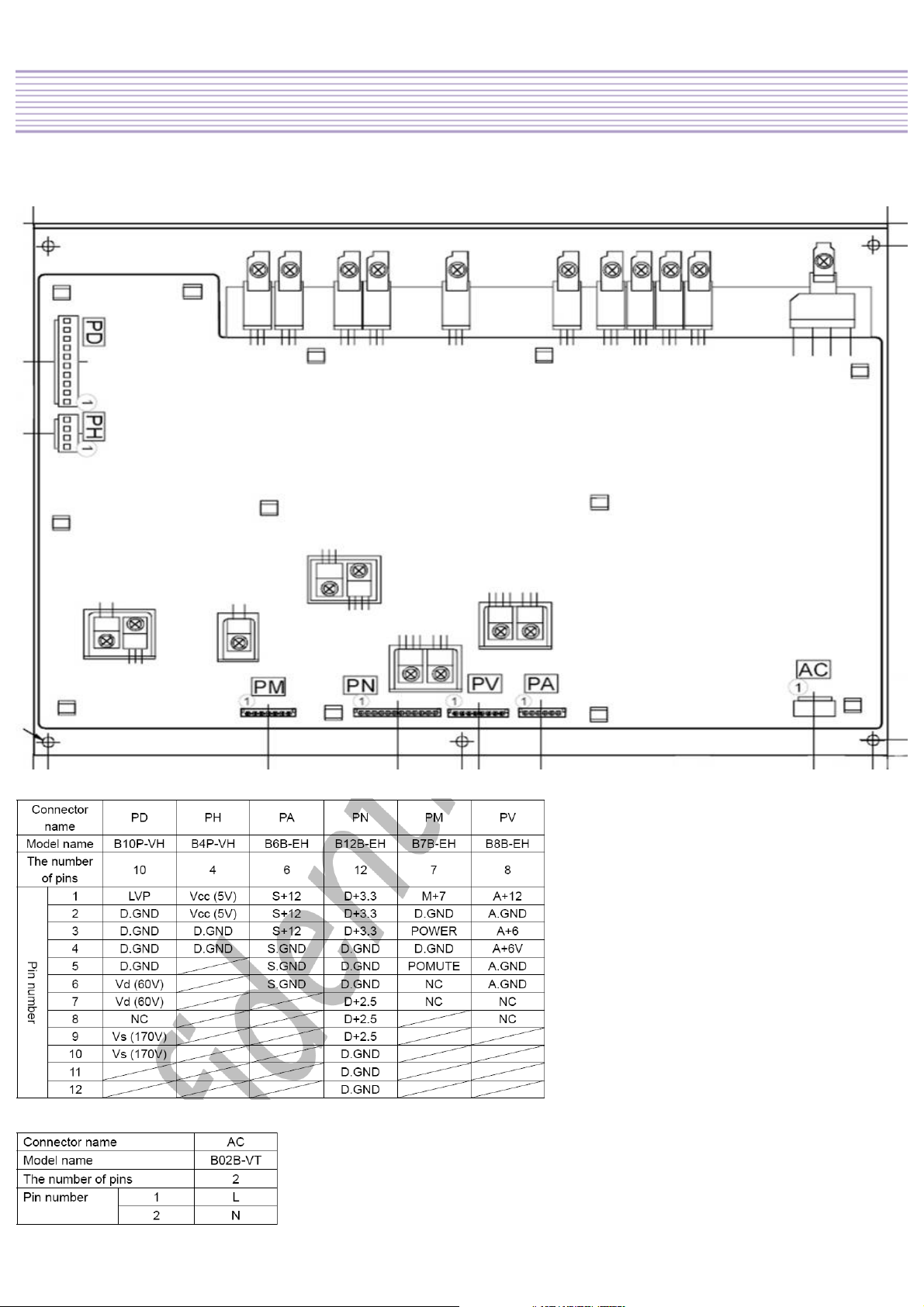

5. Description of POWER PCB

5-1. Input/Output pin assignment & specification

Output connector

Input connector

10

Page 11

5. Description of POWER PCB

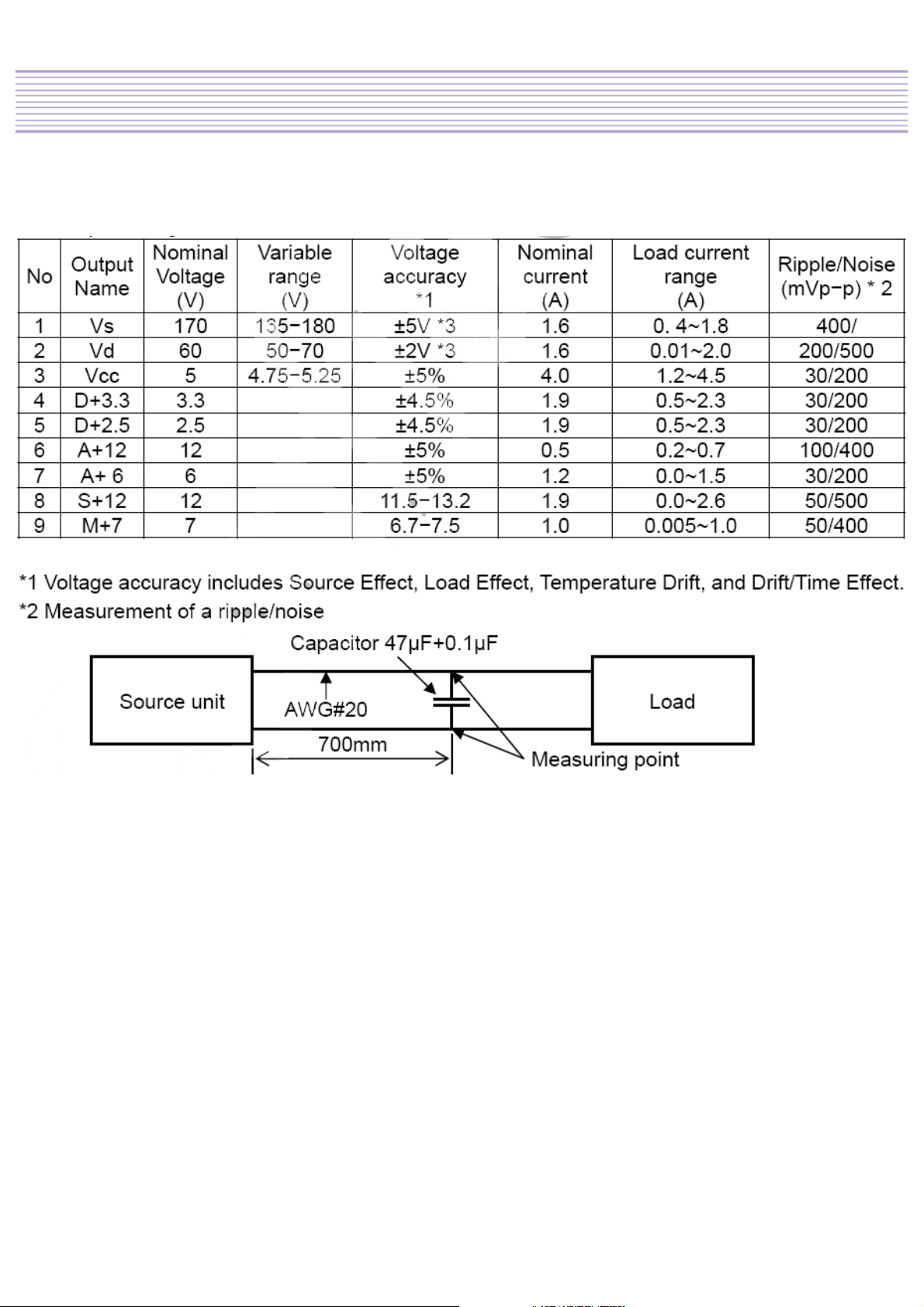

5-2. Output specification

Output Voltage & Load Condition

11

Page 12

6. Service Mode

6-1. ENTERING METHODE OF SERVICE MODE

1 => MUTE => (RECALL ) => MUTE BUTTON on the remote control

(You can exit from Service mode by press power button on the remote control)

6-2. DEFAULT VALUE OF SERVICE MODE

(1) DEFAULT VALUE OF Color Control

DPX-42D1NMSB(Default Value)

(2) Calibration Mode

Do not adjust.

(3) Option Table Mode

Do not adjust.

(4) Device Adjustment Mode

Do not adjust.

(5) Heat Run Mode

Heat Run.

(6) Version

100Sub Contrast123Sub Brightness

122Red Gain122Red Offset

100Green Gain117Green Offset

119Blue Gain127Blue Offset

-. Version: Tango-Tri_D2 Ver -.--

-. Release Day: MONTH/ DATE / YEAR

-. Release Time: HOUR/ MIN/ SEC

-. Panel used time: DATE/ HOUR/ MIN (PANEL USEDE TIME)

-. Panel Name: PDP_PI42_####_SD

(7) Reset

RESET TV.

12

Page 13

7. Adjusting Method

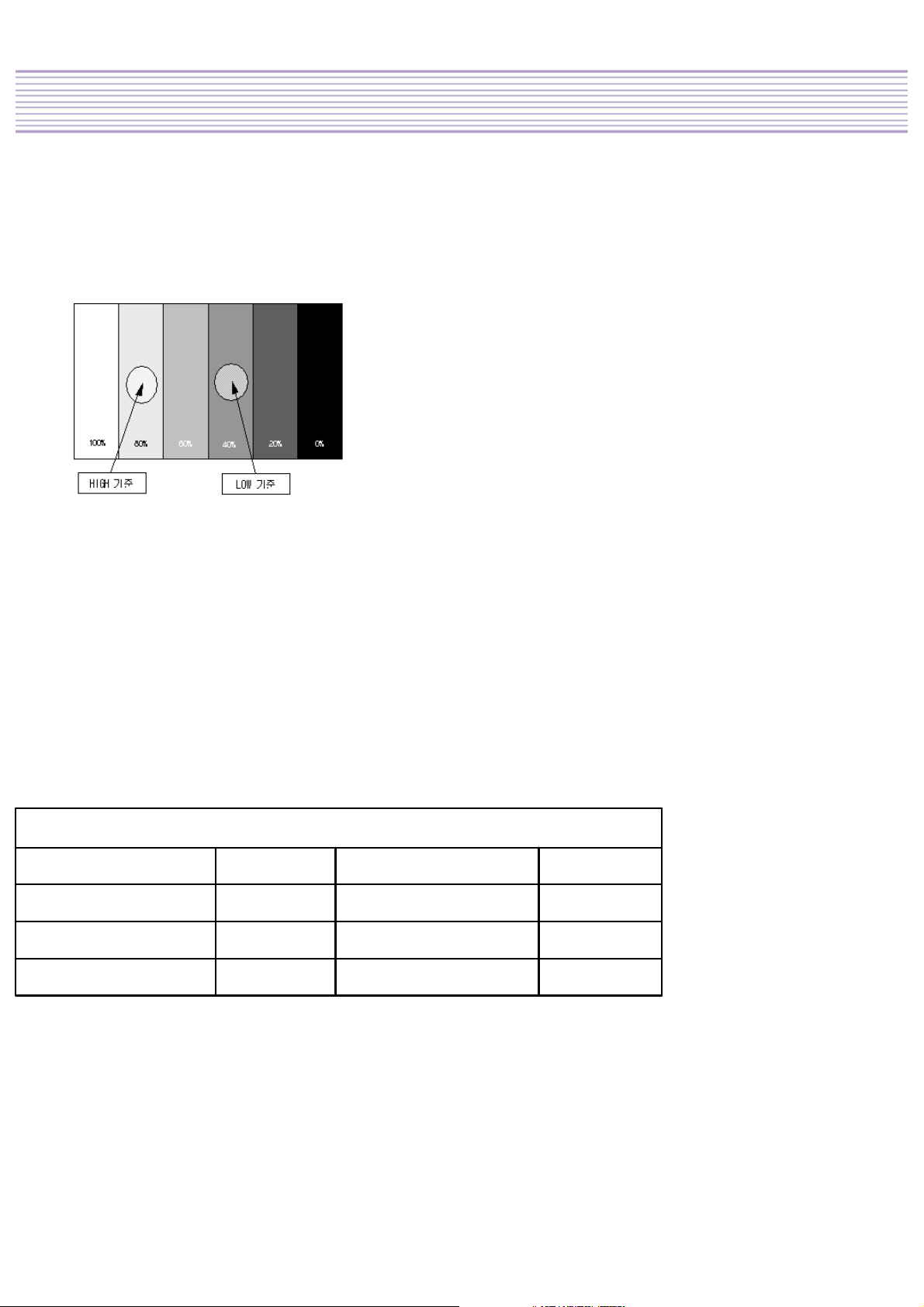

7-1. Adjusting WHITE BALANCE

(1) Input 5 STEP GRAY SCALE PATTERN to Video Input Terminal.

(2) Set the SCREEN MODE to NORMAL.

(3) Enter SERVICE MODE by inputting remote controllers [“1” => “MUTE” => “RECALL”=> “MUTE” BUTTON],

and then select “COLOR CONTROL” and check Default Values of SERVICE MODE Items.

(4) Attach WHITE BALANCE METER(FACTORY USE METER: CA-100) SENSOR to 80% Gray Scale part.

(5) Adjust WHITE BALANCE by varying R,G,B GAIN

-. Control R,G,B GAIN values so that the ranges are within Default Value10. If deviate from the range, classify the

SET disqualified.

-. Set color coordinate to x = 0.2800.01, y = 0.2900.01 and color temperature to above or equal to 10,000K.

(6) Attach WHITE BALANCE METERs SENSOR to 40% Gray Scale part.

(7) Adjust WHITE BALANCE by varying R,G,B BIAS-. Control R,G,B BIAS values so that the ranges are

within Default Value5. If deviate from the range, classify the SET disqualified.-. Set color coordinate to

x = 0.2800.01, y = 0.2900.01.

(8) Repeat above (4) ~ (7) until color coordinate is x=0.280, y=0.290. Attach WHITE BALANCE METERs SENSOR to

100% Gray Scale part. Control SUB CONTRAST so that LUMINANCE is above or equal to 140 Cd/m2.

(9) Press “Power” button and Exit SERVICE MODE.

DPX-42D1NMSB(Default Value)

100Sub Contrast123Sub Brightness

122Red Gain122Red Offset

100Green Gain117Green Offset

119Blue Gain127Blue Offset

13

Page 14

Adjusting Method

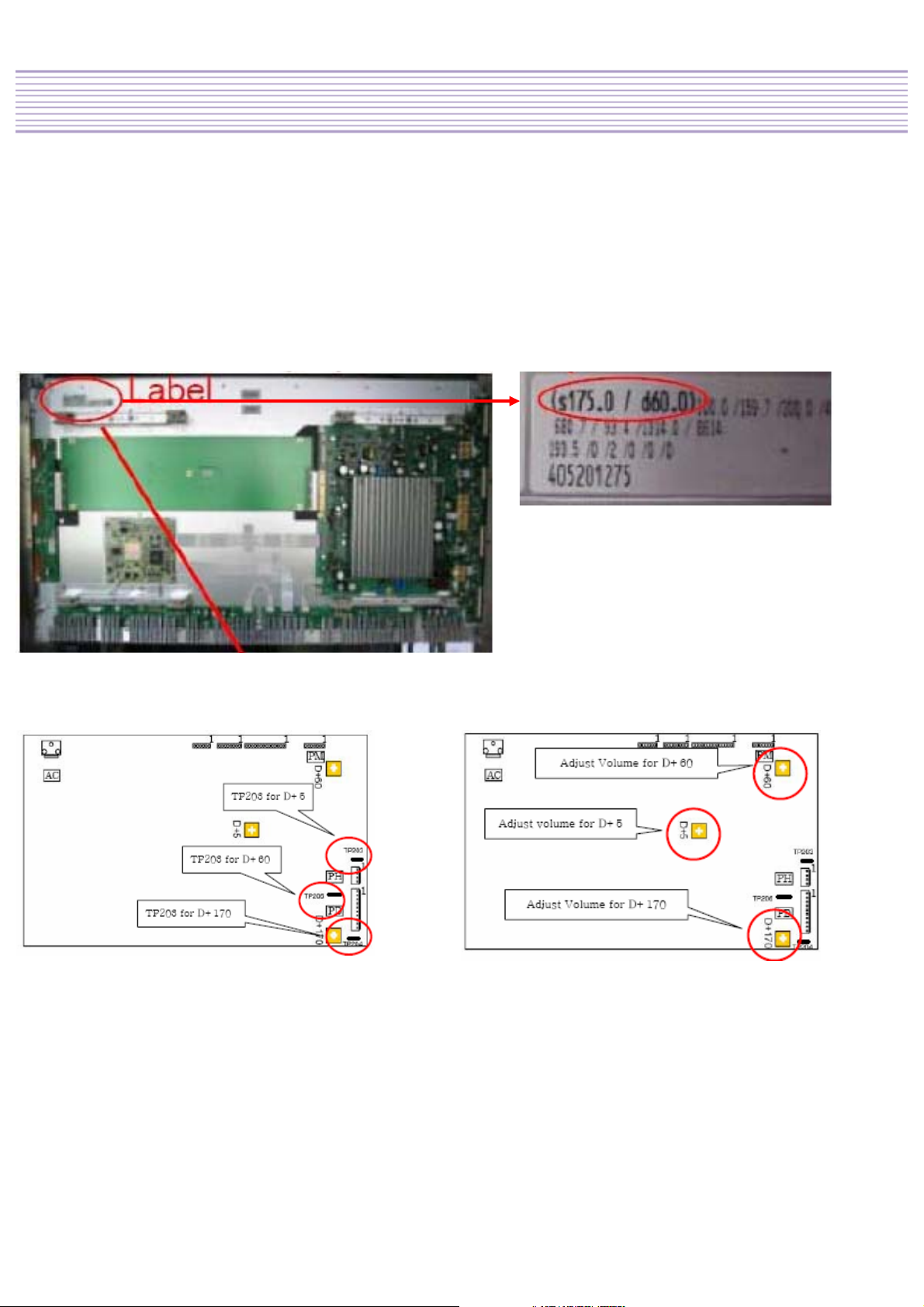

7-2 POWER BOARD Adjustment

(1) Turn On the PDP TV and Display Full white Pattern

(2) Check the Voltage Label

(3) Check the Voltage by using Multimeter each Test Point

(4) Adjust the each Voltage Very slowly, witted voltage at the label

Voltage Label

Test Point

Adjust Volume

14

Page 15

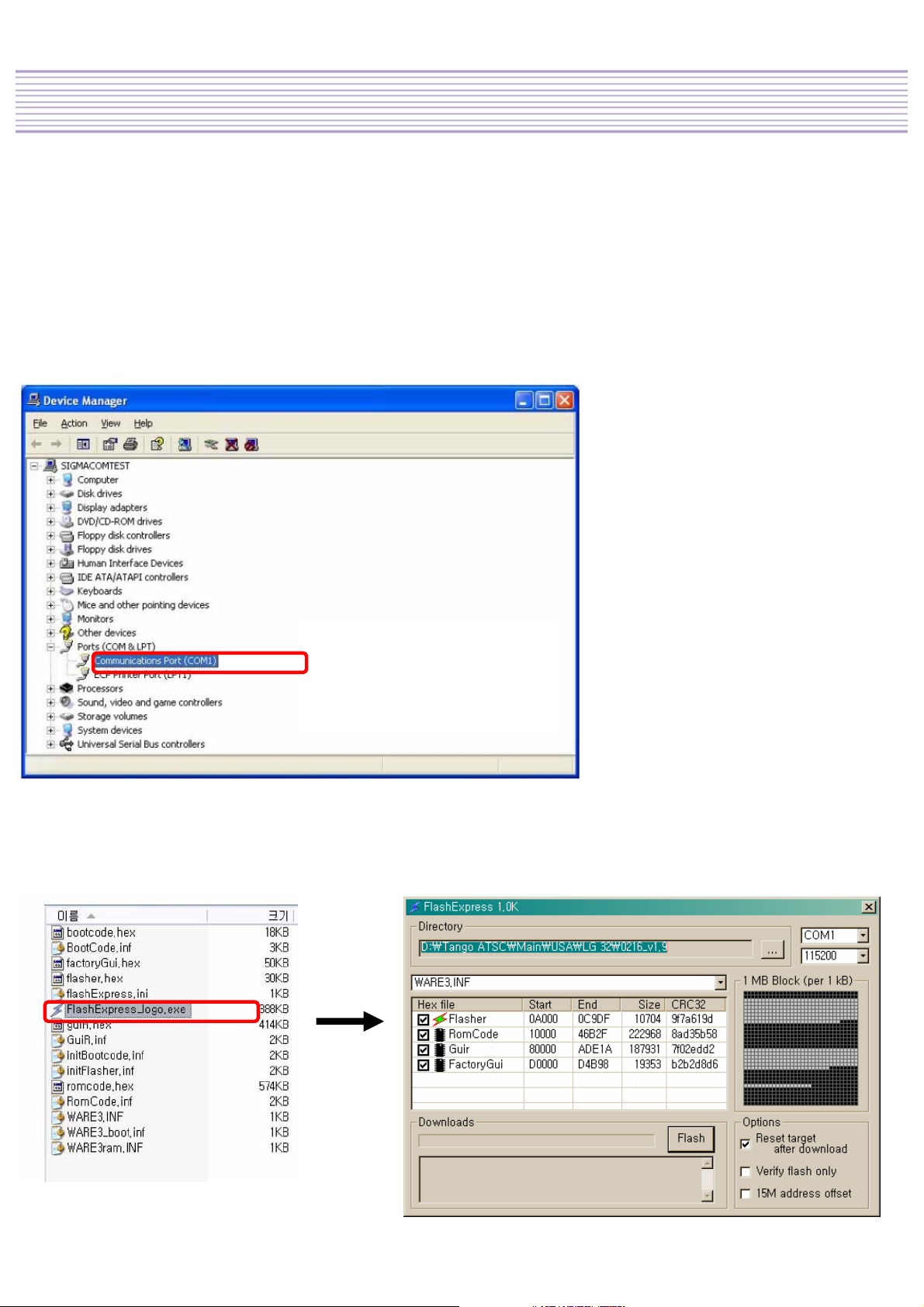

8. SOFTWARE UPGRADE Method

8-1. Preparation

(1) IBM PC with Serial Port (D-Sub 9 Type)

(with Windows98, Windows ME, Windows NT, Windows 2000, Windows XP)

(2) Update Cable (D-sub 9 pin mail to Phone Jack)

8-2. UPGRADE Method

(1) Check the com port is available. if com port is not available, you must install com port.

(2) Plug out power cable form PDP TV’s Power inlet.

(3) Connect phone jack to PDP TV’s upgrade port.

(4) Connect D-sub 9pin jack to computer com port.

(5) Run PC’s Flashexpress_nologo.exe

15

Page 16

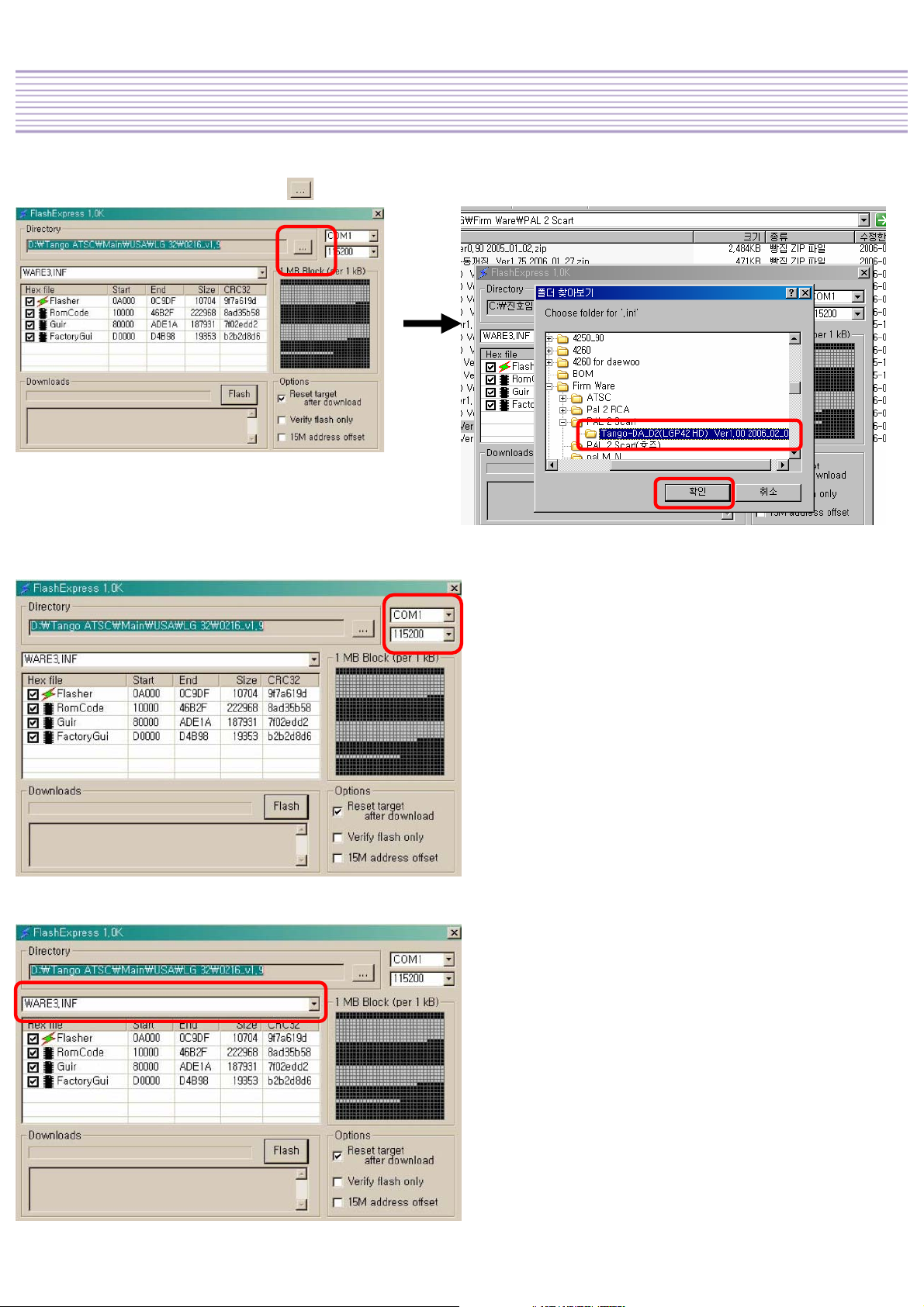

SOFTWARE UPGRADE Method

(6) Select Upgrade folder by pressing button and Select firmware folder

(7) Select COM port and baud rate(1152000)

(8) Select WARE3.INF.

16

Page 17

SOFTWARE UPGRADE Method

(9) Press the button and plug in power code to PDP’s power inlet.

(10) When all files Upgrade are complete, “Download successful” (below) will come out.

(11) Check Firmware Version and reset PDP TV.

* Reset method

1. Turn on the TV

2. Enter Service mode(1 -> Mute -> Recall -> Mute.)

3. Check Firmware Version. (Select “6. Version”)

4. Reset. (Select “7. Reset”)

17

Page 18

9. SET Disassemble/Assemble Method

9. SET Disassemble/Assemble Method

.9-1. Facts You Must Know When Disassembling/Assembling PDP SET

(1) The sheet must be clean, smooth and thick enough to reduce any impact which might occur while handling.

(2) BACK COVER can’ t be opened without separating the STAND from the PDP SET.

(3) BACK Shield Case can’ t be opened without separating the KEY PCB

(4) When disassemble PDP set. Do not disassemble Frame Main L/R screw, that may be cause of drop PDP Panel.

(5) When working with SET standing, be careful not to let screws or PCBs drop inside SET.

(6) Screws, connector cables, and other tools must be kept separately for reassemble.

9-2. PCB Disassemble/Assemble

(1) Detach BACK COVER

(2) Detach KEY PCB and then disassemble cable from KEY PCB.

(3) Detach LED-IR PCB and then disassemble cable from LED-IR PCB.

(4) Detach BCK SHIELD CASE L/R

(5) Detach POWER PCB

Disconnect cable from POWER PCB >>Unscrew POWER BOARD

(6) Detach VIDEO PCB

Disconnect cable from VIDEO PCB >>Unscrew VIDEO BOARD & TERMINAL

(7) Assembling procedure is in the reversing sequence of the disassembling procedure.

9-3. FRONT MASK & FILTER GLASS Disassemble/Assemble Method

(1) Detach BACK COVER.

(2) Detach KEY PCB and then disassemble cable from KEY PCB.

(3) Detach LED-IR PCB and then disassemble cable from LED-IR PCB.

(4) Detach BCK SHIELD CASE L/R.

(5) Unscrew the lower 4 screw and upper 4 screw at the PANEL BRACKET L/R

(6) Disassemble the PANEL from FRONT MASK.

(7) Detach the Retainer. (TOP, BOTTOM, LEFT, RIGHT)

When assemble Retainer. Must use new Gasket & new cushion tape.

(8) Detach FILTER GLASS.

(9) Assembling procedure is in the reversing sequence of the disassembling procedure.

(CAUTION) Before assemble

(1) Check front and back of FILTER GLASS. Make sure front is facing FRONT MASK’s external view.

(2) Be cautious of FILTER GLASS not being stained with dust or extraneous material. Clean FILTER GLASS with a clean

and soft cloth before assembling.

18

Page 19

10. Main PCB Trouble Diagnosis

10-1. VIDEO & JACK PCB Trouble Diagnosis

Check Start

Does “No signal”

screen appear?

YES

Is the signal input Jack

correctly connected?

YES YES

Does input source

(AV device) operate?

YES

Is input selection

in used mode?

NO

NO

Check the connection of

Jack (PDP or AV device)

NO

Check A/V Device

function

NO

Confirm input

selection

Is there a weak

discharge

on the screen?

YES

Is the LVDS Cable

correctly connected?

1. Check other PCBs

(DIGITAL,X/Y-SUS),

CONNECTION

2. Reassemble or change PA603

NO

NO

1. Confirm AC connection

2. Confirm Cable connection

of Power PCB

3. Reassemble or change

Power PCB

1. Confirm Cable connection

of Video PCB

2. Reassemble or

change Video PCB

10-2. Sound Trouble Diagnosis

Check Start

NO

Does screen appear?

YES

NO

Is the sound input Jack

correctly connected?

YES

NO

Does input source

(AV device) operate?

YES

1. Confirm AC connection

2. Confirm Cable connection

of Power PCB

3. Reassemble or change

Power PCB

Check the connection of

Jack (PDP or AV device)

Check A/V Device

function

Is the sound power Cable

correctly connected?

YES

Is the sound Cable

correctly connected?

YES

Change Video PCB

or speaker

YES

YES

Confirm

speaker power Cable

connection

Confirm

speaker cable

connection

19

Page 20

Main PCB Trouble Diagnosis

10-3. Key & IR Trouble Diagnosis

Check Start

1. Check the connection of

LED light is appear?

Dose PDP TV turn on

by use remocone?

YES

NO

NO

Key_LED_IR cable

2. Change the Key_LED_IR cable

3. Change IR_LED PCB

4. Change Video PCB

YES

1. Change IR_LED PCB

2. Change Video PCB

Check the KEY Lock

function

ON

Check A/V Device

function

OFF

1. Change KEY PCB

2. Change Video PCB

10-4. Remocon Trouble Diagnosis

Check Start

1. Check the connection of

LED light is appear?

YES

Is battery available?

NO

NO

2. Change the Key_LED_IR cable

3. Change IR_LED PCB

4. Change Video PCB

1. Change Battery

Key_LED_IR cable

YES

Change Remocon

20

Page 21

11. TROUBLE SHOOTING

11-1. Facts you must know when Trouble diagnosis or repairing

(1) Sets trouble diagnosis and repairing means Module Exchange. In other words, find out which PCB modules are not working and replace them with

normal PCB modules. Do not need to fix broken PCB modules in themselves.

(2) This TROUBLE SHOOTING list only contains representative and simple PCB trouble diagnosis and Module Exchange method. Therefore, if you find

Sets that are difficult to diagnose or to repair, contact Daew ooElectronics.

(3) Basic TROUBLE SHOOTING procedure Check Trouble Symptom Detach BACK COVER Trouble Diagnosis replace broken PCB module Adjust new

PCB module ( when replacing X-SUS, Y-SUS, POWER, VIDEOPCB, need Voltage adjustment) HEATRUN (for at least 30minutes, input TEST

PATTERN FULL WHITE), FUNCTION CHECK Repair Complete.

(4) Keep broken PCB modules separately for replacing with new PCB modules.

(5) Required equipments for trouble diagnosis- DIGITAL MULTIMETER (User Mode : measure DC VOLTAGE, measure DIODEVOLTAGE, SHORT-

OPEN TEST )- Screwdriver (or electric screwdriver), plastic adjusting tool

(6) Before assemble/disassemble PCBs, check to see if AC Switch is OFF.

(7) After the set is repaired, leave BACK COVER open for followings. Do HEATRUN for at least30 minutes by inputting SERVICE MODEs TEST

PATTERN (Refer to Service Manual 5.Service Mode) FULL WHITE. Check the screen condition and basic functions (remote control operation etc.).

(8) After BACK COVER is closed, redo HEATRUN for at least one hour by inputting FULLWHITE using SERVICE MODEs TEST PATTERN. Check the

screen condition and basic fun c tions.

21

Page 22

12. ASSEMBLY LIST

DiscriptionPart NamePart No.No

1P*200MMGND CABLEDDL32GND—4014

Qt'y

1PIONEER 42" B3 Panel, 218 AD board (SOUTH AMERICA)Main+A/D boardPASP42B3S3SD1

1PIONEER 42" B3 Panel, 218 AV board (SOUTH AMERICA)Main+A/V boardPASP42B3S3SV2

1T=1.6*100*20/2L, IR&LEDLED_IR BOARD PAS-SIG6LIXA3

1T=1.6*74*33.4/2L,KEYKEY BOARD PAS-SIG6KEYA4

2Built in speaker cable ass'yDD-SP1AS06-15

12P*460/1P*150MMNOISE FILTER ASS’YDD42NF024616

14P*6P*450MMPOWER 6P <--> 4PDD42NR04451S7

112P*(7+8)P*400/400MMPOWER 7P/8P <--> 12PDD42NR124018

130P*31P*500MMLVDS 31PD D 42CO 31501S9

114P*8P*6P*(500*600)MMKEY_LED_IR CABLEDD42CO1460110

16P*(2+2)P*600+700MMBuilt in speaker cableDD42CO0670111

14P*4P*450MMPANEL 4P CABLEDD42NR0445112

110P*10P*470MMPANEL 10P CABLEDD42NR1047113

1Mold/HIPS/3.5T/2ToneFont CoverDP4260M120A215

1Mold/ABS/3.5T/SilverSpeaker Grill-BDP4260M115A16

2Mold/ABS/2.0T/SilverSpeaker ElbowDP4260M113A17

1Mold/ABS/3.5T/Black/DWBack CoverDP4260M121A18

1Mold/ABS/BlackKnob ContlDL3280M181BA19

1Mold/ABS/Cr Knob StanbyDL3280M190CA20

21

1Mold/PAWindow IRDL3280M200A

1Mold/Acryl/1.2TWindow PlateDL3280M210A22

2AL/1.2TRetainer-HDP4280E310A23

2AL/1.2TRetainer-VDP4280E320A24

2EGI/PIO/1,OTPIO Panel Guide BracketDP4284P121A25

2EGIPIO Power BracketDP4211P122A26

4EGI/2.0TPIO SD PlateDP4281P123A27

2DiecastingMount Bracket-PDPDP4280D330A28

2EGI/2.0TStand Bracket PDP-BodyDP4280P340A29

1AL/0.8T/PIO/218/3SystemContl ShieldDP4286P352A30

1EGI/0.5TMain Shield-LDP4280P360A31

1EGI/0.5TMain Shield-RDP4280P370A32

1SPTE/0.5T/218/3SystemAv CoverDP4285P382A33

22

3ID∮5.1,L=75Retainer CoilDARC-434

2Sponge Form/5.0T*895L*8WTop Cushion DP4200R672A35

2Sponge Form/5.0T*520L*8WSide Cushion DP4250R672A36

21.5T*7W*540LGasket Retainer-VDP4260S651A37

21.5T*7W*945LGasket Retainer-HDP4260S652A38

11.5T*7W*565LGasket Av Cover DP4260S654A39

41.5T*7W*100LGasket MountDP4260S655A40

Page 23

ASSEMBLY LIST

Qt'yDiscriptionPart NamePart No.No

DP4260S653A41

11.5T*20W*600LGasket Shield

4Non-woven fabric/0.8T/15W*45LInsulation Sheet-SDP4200S654A42

1Non-woven fabric/0.8T/25W*440LInsulation Sheet-LDP4210S655A43

1EPS/30TPad Top/RDP4260S640A44

1EPS/30TPad Top/LDP4260S650A45

1EPS/30TPad Bottom/RDP4260S660A46

1EPS/30TPad Bottom/LDP4260S670A47

1PE/FormPad TopDP4260S647A48

1LDPE 0.5T*W1010*L960Poly BagDP5000S672A49

1PE/60*160*0.07Screw-Poly BagDP4210J923A50

1Vinyl/0.3T*W245*L360Accessory Bag999000001200 51

1Audio Video Jack Label/218/3SystemAV LabelDP4260B614C52

1Daewoo/MaxicoPacking BoxDP426-DW-0153

1Daewoo/Latin americaMark BrandP-MB-30-016054

142"/ABS/SilverStand CoverDP4260M171SA55

1Diecasting/AL/Black/90Stand ArmDP4290D180A56

1Diecasting/Al/4290Stand NeckDP4290E190A57

2Press/Al/4290Stand BracketDP4290E200A58

2Press/EGI/3.0TStand BaseDP4280P210A59

442"/40*20*3TStand Rubber-BDP4260TR673A60

Stand Rubber-ADP4260TR674A61

442"/40*20*6T

1DW2Stand B o x-O utDP4280B698A62

1DW2Stand B ox In-BDP4280B699A63

1DW2Stand Box In-ADP4280B700A64

1EnglishStand ManualP-MA-STD-11365

21WP+3*6Machine Screw 3SM00166

8S/W P/W-P+3*8Φ8Machine Screw 3SM01367

4P+4*6Machine Screw 4SM00668

16WP+4*8Machine Screw 4SM00269

1T/T-CT+WASHER+4*10Machine Screw 4SM00370

10S/W P/W-B+5*12Φ12Machine Screw 5SM01771

2T/T-BP+3*5Taptite Screw 3ST10272

4TWP+3*6 Taptite Screw 3ST10773

20TWP+3*8 Taptite Screw 3ST10874

23

11T/T-BP+3*8Taptite Screw 4ST10175

44T/T-BP+4*8Taptite Screw 4ST10476

43T/S-2B+4*10TaptiteScrew 4ST14077

11T/S-2B+4*10TaptiteScrew 4ST14078

4T*4*12Machine Screw 4SM01179

4S/W P/W-P+5*32Machine Screw 5SM20080

Page 24

ASSEMBLY LIST

Qt'yDiscriptionPart NamePart No.No

2S/W P/W P+5*16Machine Screw 5SM02581

2P+8*20Machine Screw 8SM00882

1PaperBack LabelPBL4260DAE-0183

1User manualMA-BDWP--3S184

1Power codeDPACC0000-10(EUROPE)85

2BatteryDPC9700000A(AAA)86

1Remote contro llerRE-BLSIDEWA187

88

PDP PANEL 42"-PIO B3DP42B3MF01

PDP PIONEER 42" B3 panel

1

24

Page 25

13. EXPLODED VIEW

25

Page 26

14. Assemble Diagram

26

Page 27

Assemble Diagram

27

Page 28

Assemble Diagram

28

Page 29

Assemble Diagram

29

Page 30

Assemble Diagram

30

Page 31

Assemble Diagram

31

Page 32

Assemble Diagram

32

Page 33

Assemble Diagram

33

Page 34

Assemble Diagram

34

Page 35

Assemble Diagram

35

Page 36

Assemble Diagram

36

Page 37

Assemble Diagram

37

Page 38

Assemble Diagram

38

Page 39

Assemble Diagram

39

Page 40

Assemble Diagram

40

Page 41

Assemble Diagram

41

Page 42

Assemble Diagram

42

Page 43

Assemble Diagram

43

Page 44

Assemble Diagram

44

Page 45

Assemble Diagram

45

Page 46

Assemble Diagram

46

Page 47

47

Page 48

Assemble Diagram

48

Page 49

Assemble Diagram

49

Page 50

Assemble Diagram

50

Page 51

Assemble Diagram

51

Page 52

Assemble Diagram

52

Page 53

Assemble Diagram

53

Loading...

Loading...