Page 1

Page 2

SECTION : 9T

IMMOBILIZER ANTI–THEFT SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T–1. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING

SPECIFICATIONS 9T–1. . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 9T–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS TABLE 9T–1. . . . . . . . . . . . . . . . . . .

DIAGNOSIS 9T–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMMOBILIZERANTI–THEFT SYSTEM 9T–2. . . . . . .

DTC 53 – PCM/ECM Immobilized Error 9T–2. . . . . . .

KEY STATUS ERRORS 9T–2. . . . . . . . . . . . . . . . . . . .

COMMUNICATION BETWEEN

IMMOBILIZER AND TEST EQUIPMENT 9T–3. . . .

MAINTENANCE AND REPAIR 9T–4. . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T–4. . . . . . . . . . . . . . . . . . . . .

KEY CODING PROCEDURE 9T–4. . . . . . . . . . . . . . .

ID CODE REPROGRAMMING 9T–4. . . . . . . . . . . . . .

TRANSPONDER 9T–5. . . . . . . . . . . . . . . . . . . . . . . . . .

DETECTION COIL 9T–5. . . . . . . . . . . . . . . . . . . . . . . . .

IMMOBILIZER CONTROL UNIT 9T–8. . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 9T–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMMOBILIZER SYSTEM 9T–10. . . . . . . . . . . . . . . . . .

ELECTRONICALLY CODED KEYS 9T–10. . . . . . . . .

DETECTION COIL 9T–10. . . . . . . . . . . . . . . . . . . . . . . .

IMMOBILIZER CONTROL UNIT 9T–10. . . . . . . . . . . .

SERIAL DATA LINK 9T–11. . . . . . . . . . . . . . . . . . . . . . . .

POWERTRAIN CONTROL MODULE

(PCM)/ENGINE CONTROL

MODULE (ECM) 9T–11. . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

Immobilizer Control Unit Mounting Bolts 4 – 35

Knee Bolster Mounting Bolts 22 16 –

SPECIAL TOOLS

SPECIAL TOOLS TABLE

Scan Tool

Page 3

9T – 2IIMMOBILIZER ANTI–THEFT SYSTEM

Unauthorized use of a scan tool could be a method of defeating the immobilizer anti–theft system. Therefore, cer-

DIAGNOSIS

IMMOBILIZERANTI–THEFT SYSTEM

The immobilizer anti–theft system requires diagnosis

when it is not possible to start the engine. If the no–start

condition occurs because of the immobilizer system, a

diagnostic trouble code (DTC) 53 should be set.

The immobilizer anti–theft system requires diagnosis

when it is not possible to start the engine. If the no–start

condition occurs because of the immobilizer system, a

diagnostic trouble code (DTC) 53 should be set.

tain scan tool procedures require the use of a password.

The following functions are password protected:

S Coding of an additional key.

S Deleting all key codes.

S Deletion of the immobilizer identification (ID) code.

S Deletion of the powertrain control module

(PCM)/engine control module (ECM) ID code.

The following functions do not require a password:

S Reading an ignition key to determine if the trans-

ponder is working or if a key is authorized.

S Reading the immobilizer ID code to verify that it

matches the PCM/ECM ID code.

DTC 53 – PCM/ECM Immobilized Error

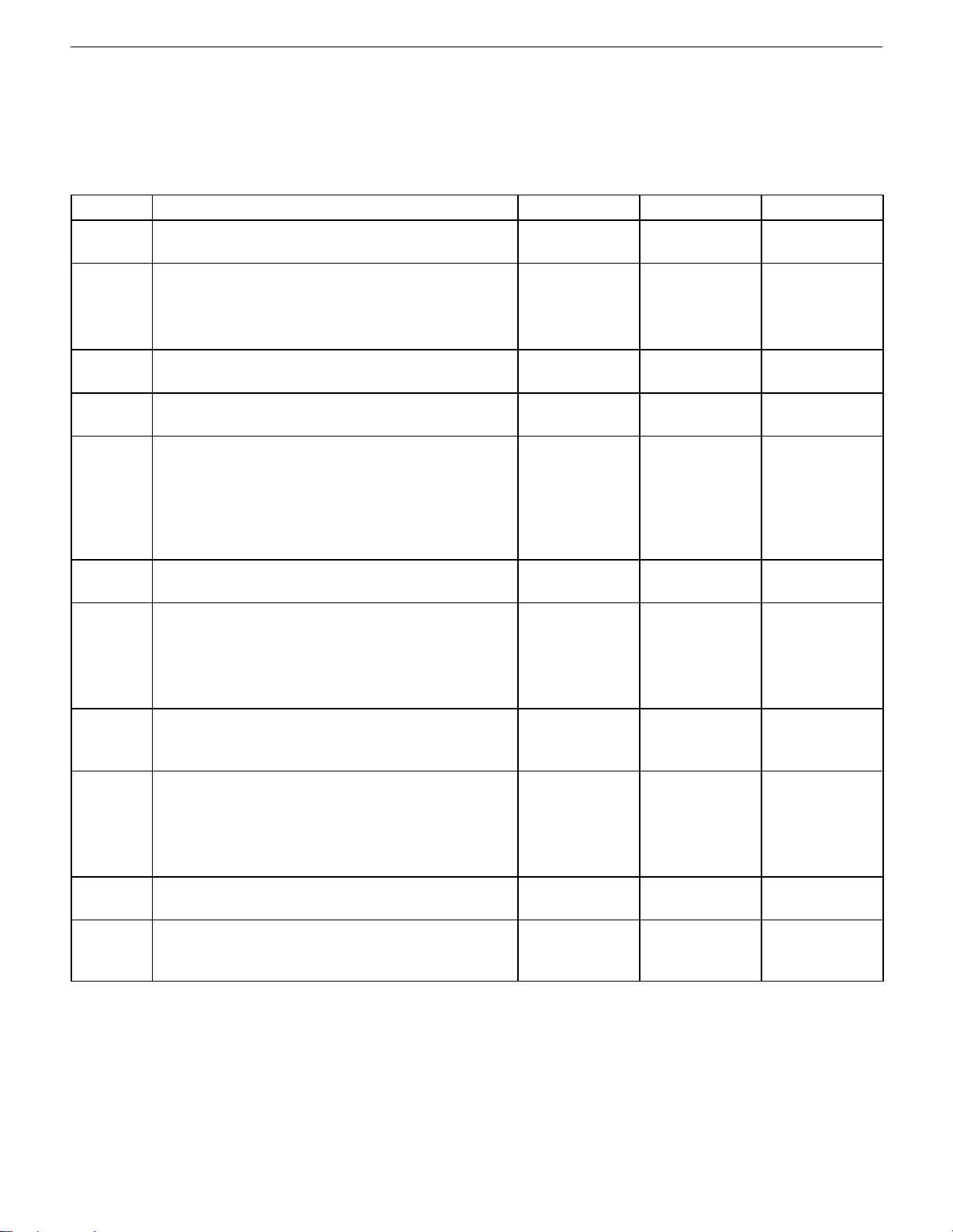

Step Action Value(s) Yes No

1 Connect the scan tool using the following procedure:

1. Insert the immobilizer data cartridge into the

scan tool.

2. Turn the ignition OFF.

3. Connect the scan tool to the data link connector DLC).

4. Turn the ignition ON, but do not start the engine.

Is communication established between the scan tool

and the immobilizer control unit?

2 Select SYSTEM DIAGNOSIS from the scan tool

menu.

Does the KEY STATUS message indicate POS NR

(position number) 00?

3 Read the IMMO & PCM/ECM ID–CODE message

that is displayed after requesting SYSTEM DIAGNOSIS.

Does the message ID–CODE DIFFERENT appear?

4 Check for an open serial data wire between the im-

mobilizer control unit and the powertrain control

module (PCM)/engine control module (ECM).

Is the circuit open?

5 Repair the open serial data wire between the PCM/

ECM and the immobilizer control unit.

Is the repair complete?

6

1. Replace the ECM.

2. Reprogram the identification (ID) code. Refer

to”ID Code Reprogramming” in this section.

Is the repair complete?

Go to Step 2 Go to ”Commu-

tween Immobi-

Go to ’Key

Status Errors”

Go to ”ID

Code Repro-

gramming”

Go to Step 5 Go to Step 6

System OK

System OK

nication Be-

lizer and Test

Equipment”

Go to Step 3

Go to Step 4

KEY STATUS ERRORS

The following KEY STATUS messages may be shown on

the scan tool after commanding SYSTEM DIAGNOSIS:

S IGNITION OFF STATUS. This message informs

the technician that the ignition is OFF during the

key coding process. Turn the ignition ON during key

coding, but do not start the engine.

DAEWOO V–121 BL4

Page 4

IMMOBILIZER ANTI–THEFT SYSTEM 9T – 3

S KEY IS OCCUPIED. Only five keys may be coded.

If a new key is desired, the previous key codes

must be deleted. Up to five keys may then be authorized.

S ALREADY AUTHORIZED. Key coding is being at-

tempted with a key that is already authorized.

S ERROR NO. 001, 002, 003. There is no commu-

nication between the transponder in the ignition key

and the detection coil. Follow the steps below to

diagnose the problem:

1. Try a different key. If a different key works, the

problem is in the original key.

2. If trying a different key results in the same error

message, replace the detection coil.

S INVALID KEY. The communication between the

immobilizer control unit and the key transponder

has not validated the key. Follow the steps below to

diagnose the problem:

1. Code the key. Refer to”Key Coding Procedure”in

this section.

2. If the same message is received after key coding,

check the connection of the detection coil.

3. If the detection coil is okay, replace the immobilizer.

Refer to”Immobilizer Control Unit” in this section.

S NO TRANSPONDER DETECTED. The fault may

be in ignition key transponder, the detection coil, or

the immobilizer. Follow the steps below to diagnose

the problem:

1. Try a different key. If a different key works, the

problem is in the original key.

2. If trying a different key results in the same error

message, check the connection of the detection

coil.

3. If the connection of the detection coil is okay, disconnect the detection coil and use an ohmmeter to

check for an open detection coil.

4. If the detection coil is not open, replace the immobilizer control unit. Refer to”Immobilizer Control Unit”

in this section.

COMMUNICATION BETWEEN

IMMOBILIZER AND TEST

EQUIPMENT

1. Connect the test equipment as described in theScan Tool Equipment Manual.

2. If communication between the scan tool and the

test equipment is unsuccessful, wait 30 seconds

and try again.

3. If communication is not successful on the second

try, turn the ignition OFF, and check the wire and

the connectors between the immobilizer control unit

terminal 3 and the data link connector (DLC).

4. If the wire and the connectors between the DLC

and the immobilizer control unit are OK, replace the

immobilizer control unit. Refer to ”Immobilizer Control Unit”in this section.

DAEWOO V–121 BL4

Page 5

9T – 4IIMMOBILIZER ANTI–THEFT SYSTEM

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

KEY CODING PROCEDURE

1. Install the immobilizer control unit cartridge in the

scan tool.

2. Turn the ignition OFF

3. Connect the scan tool.

4. Turn the ignition ON with the key to be coded.

5. Enter the four–digit password that enables service

personnel to use the scan tool for coding keys.

6. A lost key can be deleted only by deleting all keys

and reauthorizing the remaining keys as new keys.

If a key is lost, go to the next step. If no keys have

been lost but an additional key is desired, go to

Step 8.

7. Use the scan tool command DELETE ALL KEY

CODES.

8. Use the scan tool command AUTHORIZE ONE

ADDITIONAL KEY.

9. Repeat Steps 4, 5, and 6 until the immobilizer control unit has recorded all of the new keys or, after a

deletion, has reauthorized all of the remaining keys.

The immobilizer control unit can record a maximum

of five keys.

10. Return the system to the normal mode.

11. Turn the ignition OFF.

12. Turn the ignition ON.

13. Start the engine.

ID CODE REPROGRAMMING

Reprogram the identification (ID) code in the following situations:

1. An immobilizer control unit has been replaced.

2. An electronic control module (ECM) has been replaced.

If a valid key has been lost, refer to”Key Coding Procedure” in this section.

Reprogramming Procedure

1. Turn the ignition OFF. Reprogramming is not allowed while the engine is running.

2. Insert the immobilizer control unit cartridge into the

scan tool.

3. Turn the ignition ON, but do not start the vehicle.

4. Enter the four–digit password that enables service

personnel to use the scan tool for ID code reprogramming.

5. Use the scan tool to command RESET ID CODE.

DAEWOO V–121 BL4

Page 6

IMMOBILIZER ANTI–THEFT SYSTEM 9T – 5

6. Turn the ignition OFF and ON again, but do not

crank or start the engine. The powertrain control

module (PCM)/engine control module (ECM) will

reset the ECM ID code to match the new ID code

that was calculated and sent by the immobilizer

control unit when the ignition was first turned ON

after the reset command.

7. Return the system to the normal mode.

8. Turn the ignition OFF.

9. Turn the ignition ON.

10. Start the engine.

After reprogramming the ID code, the scan tool SYSTEM

DIAGNOSIS command can verify that the PCM/ ECM ID

code matches the immobilizer control unit ID code.

If the reprogramming procedure does not result in matching ID codes, check the electrical connectors for the serial

data wire between the immobilizer control unit and the

PCM/ECM.

TRANSPONDER

If a transponder is faulty, the ignition key must be replaced.

It is not possible to install a new transponder into a key.

DAEWOO V–121 BL4

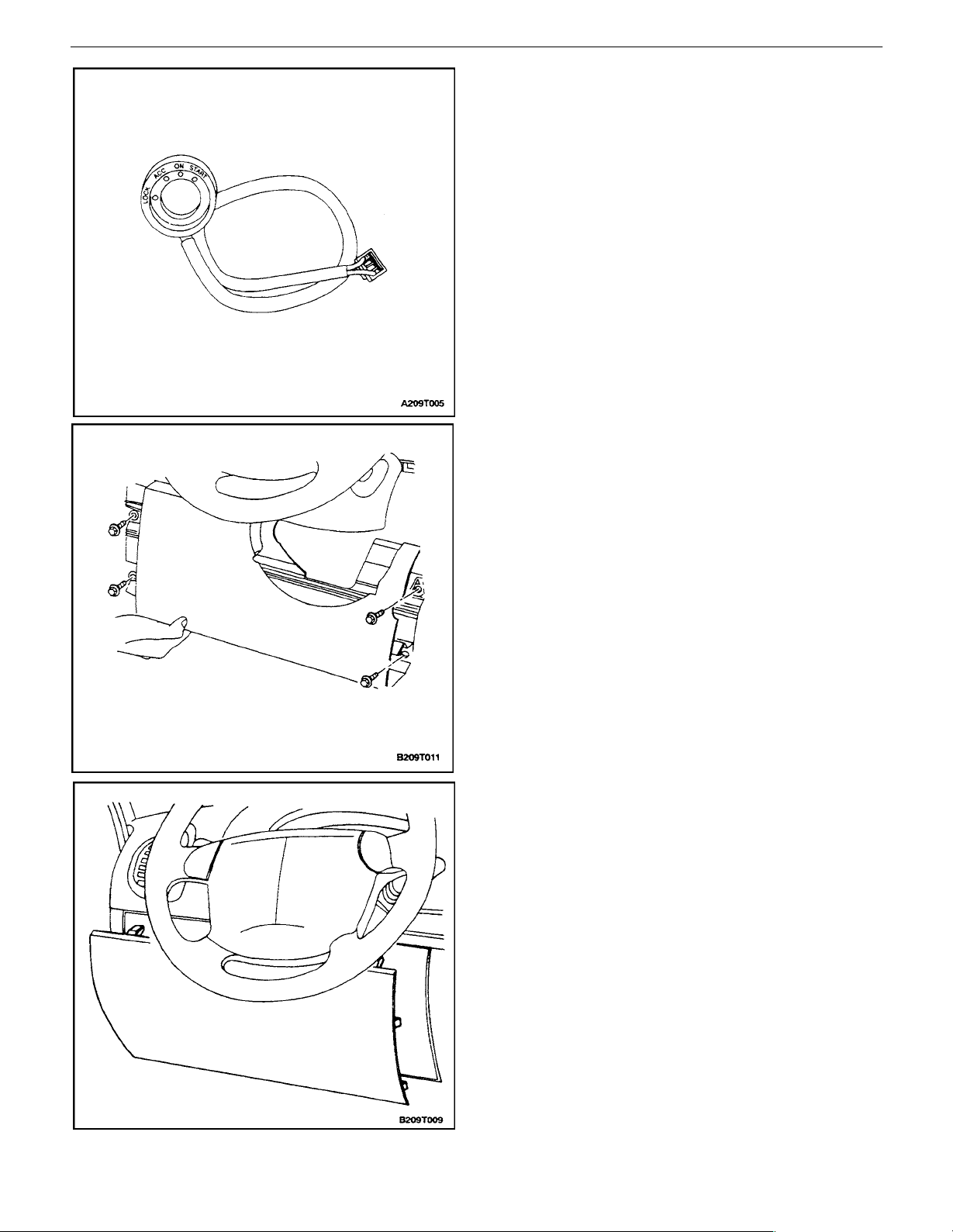

DETECTION COIL

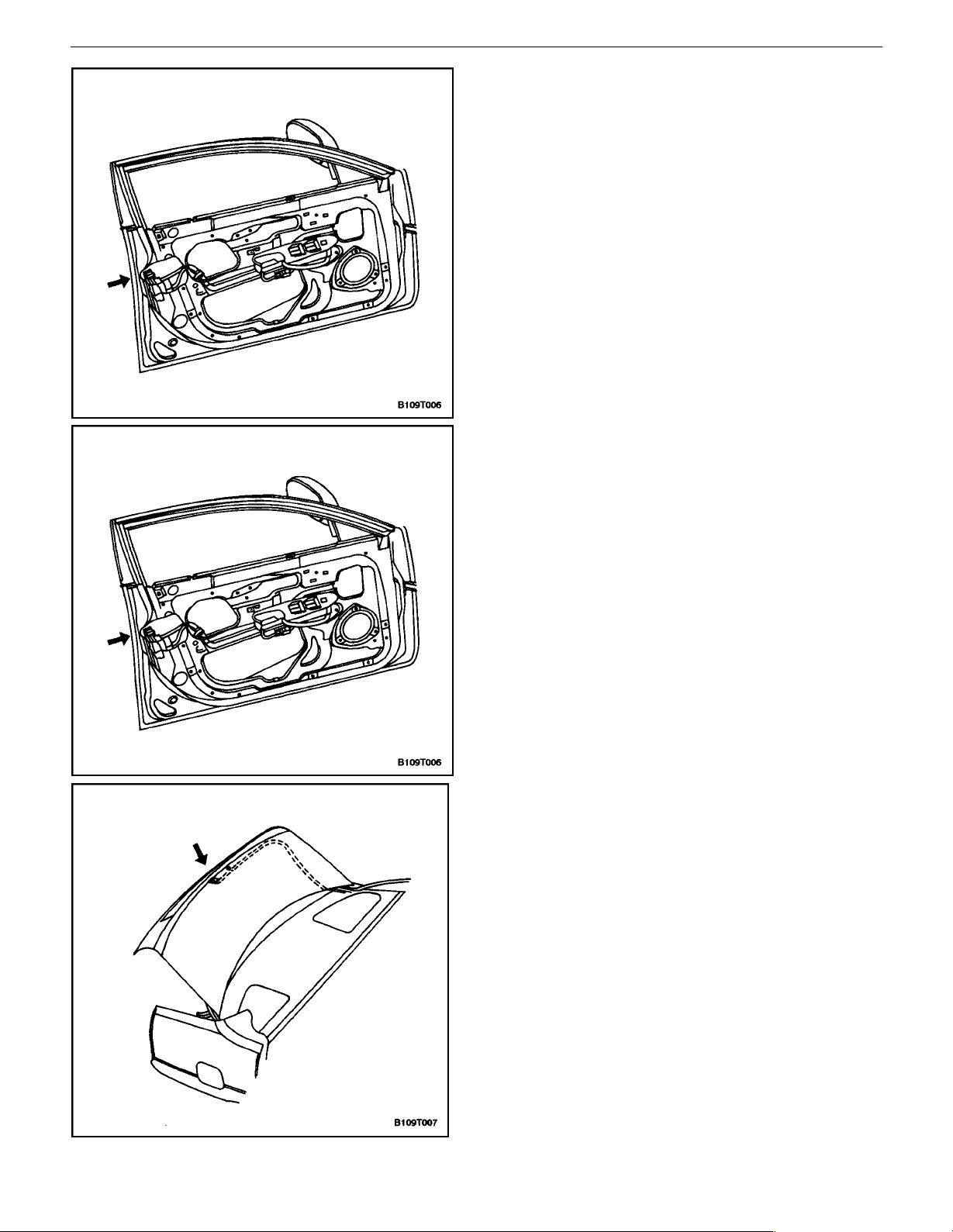

Removal Procedure

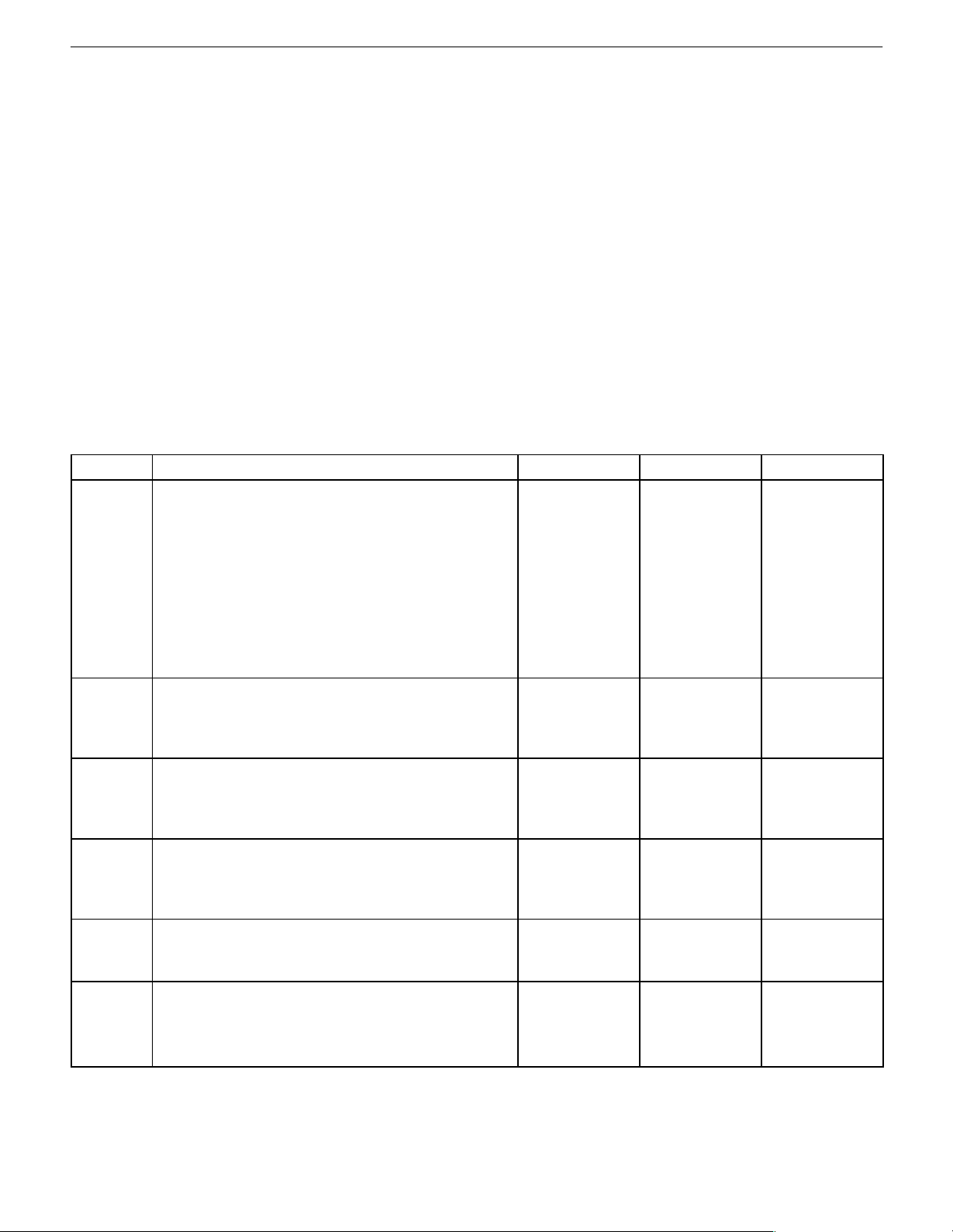

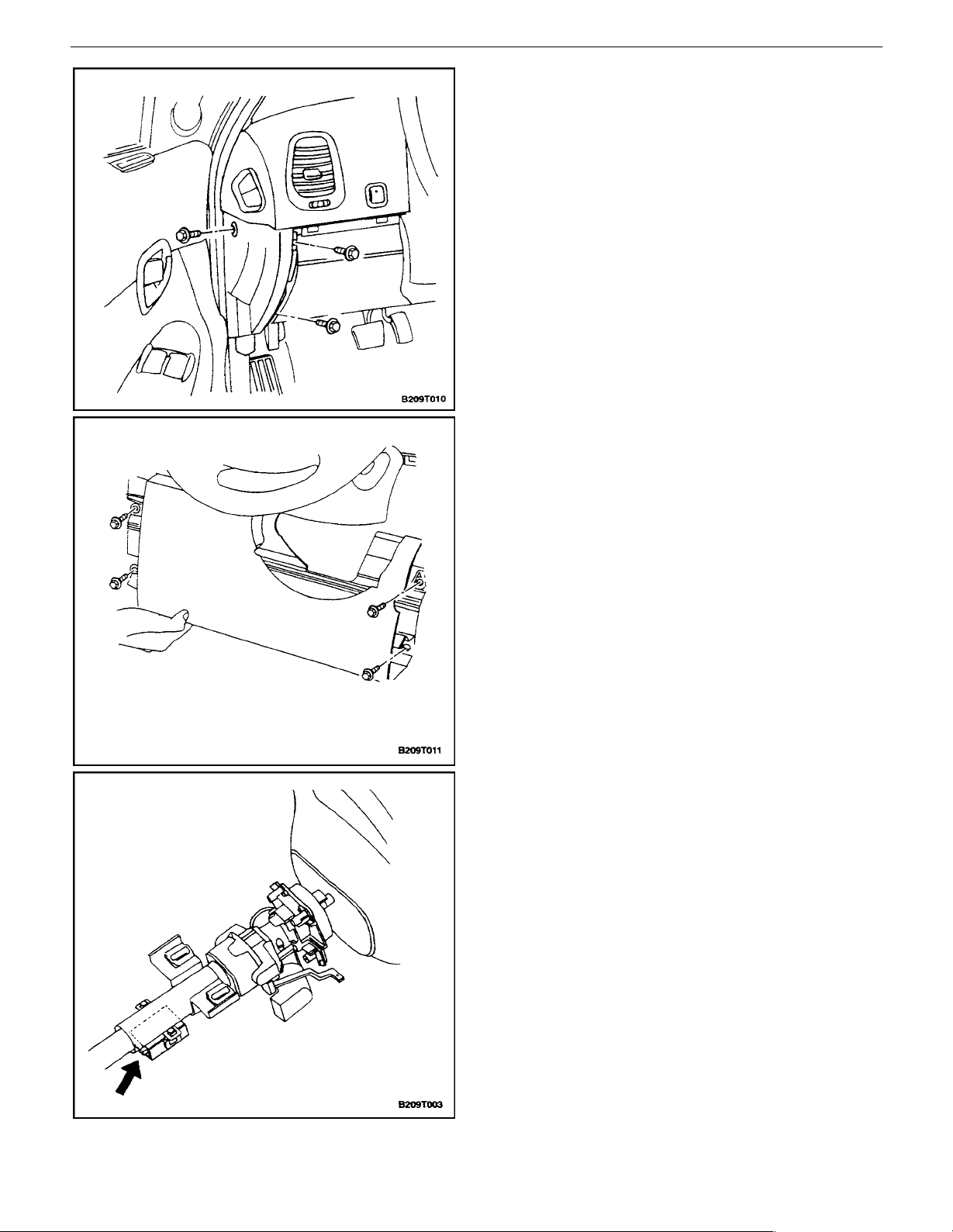

1. Carefully pull the knee bolster trim panel until it is

loose from its retaining clips.

Page 7

9T – 6IIMMOBILIZER ANTI–THEFT SYSTEM

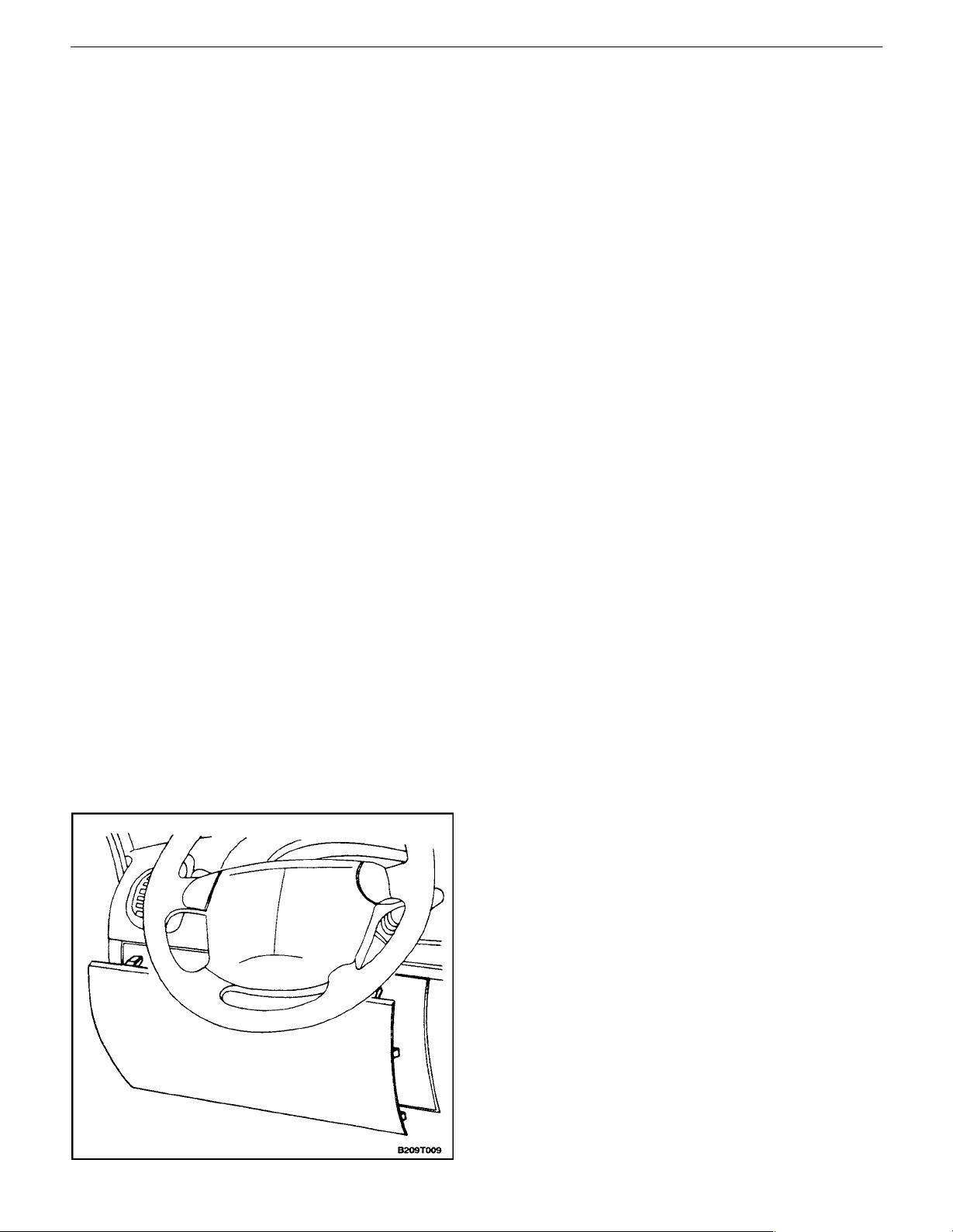

2. Slide the knee bolster trim panel upward and pull it

outward to remove it.

3. Remove the instrument panel side cover.

4. Remove the bolts and the knee bolster.

5. Remove the steering column lower cover. Refer

toSection 6E, Steering Wheel and Column.

6. Disconnect the two–pin connector from the immobilizer.

DAEWOO V–121 BL4

Page 8

IMMOBILIZER ANTI–THEFT SYSTEM 9T – 7

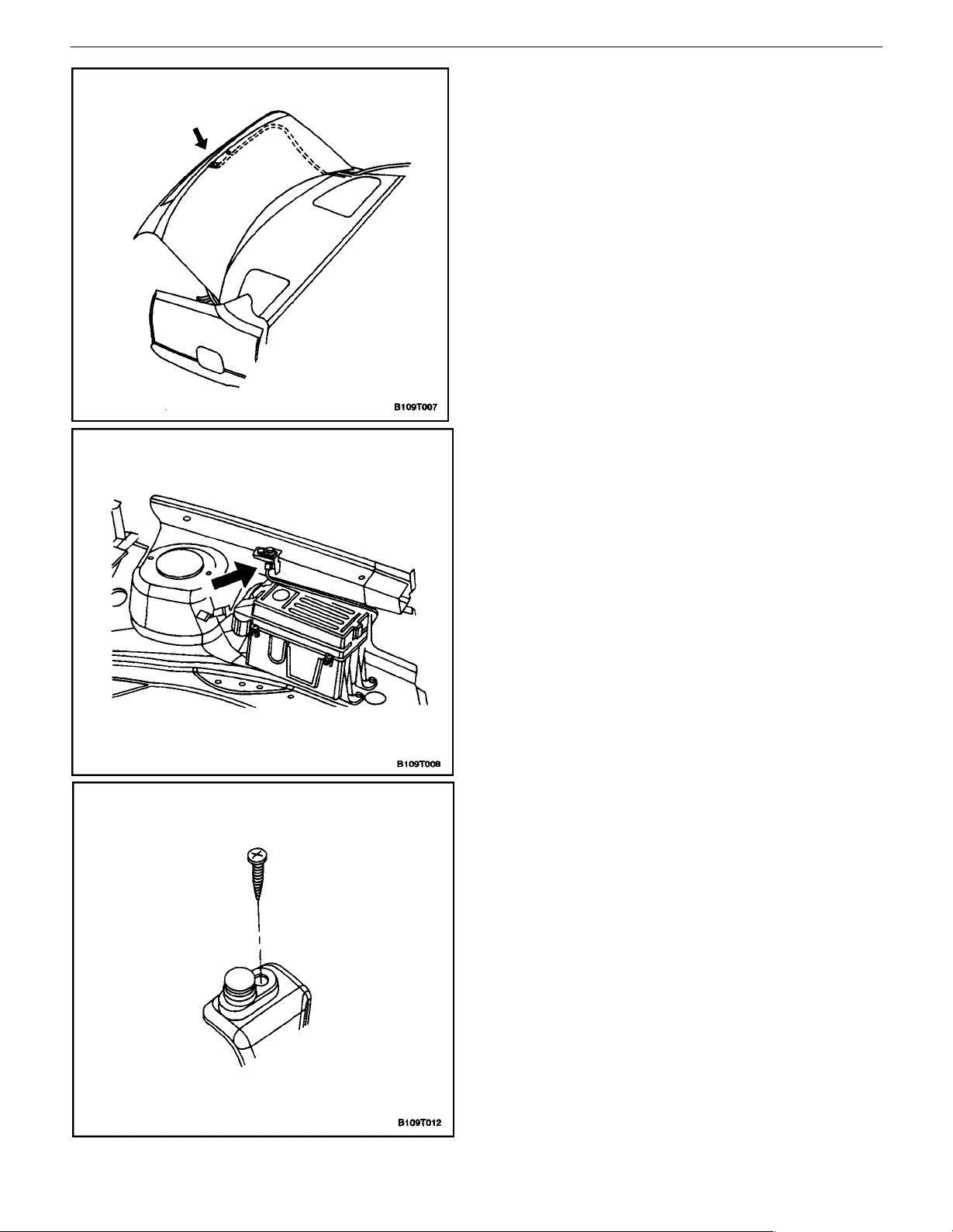

7. Pry the detection coil away from the lock cylinder. If

the detection coil will be replaced with a new one, it

does not matter if the key position trim ring is damaged during removal. A new trim ring is part of the

new detection coil.

Installation Procedure

1. Install the detection coil by pressing it onto the lock

cylinder until it snaps in place.

2. Connect the two–pin connector to the immobilizer.

3. Install the steering column lower cover. Refer to

Section 6E, Steering Wheel and Column.

4. Install the knee bolster with the bolts.

Tighten

Tighten the knee bolster mounting bolts to 22 NSm (16

lb–ft)

DAEWOO V–121 BL4

5. Install the instrument panel side cover.

6. Install the knee bolster trim panel.

Page 9

9T – 8IIMMOBILIZER ANTI–THEFT SYSTEM

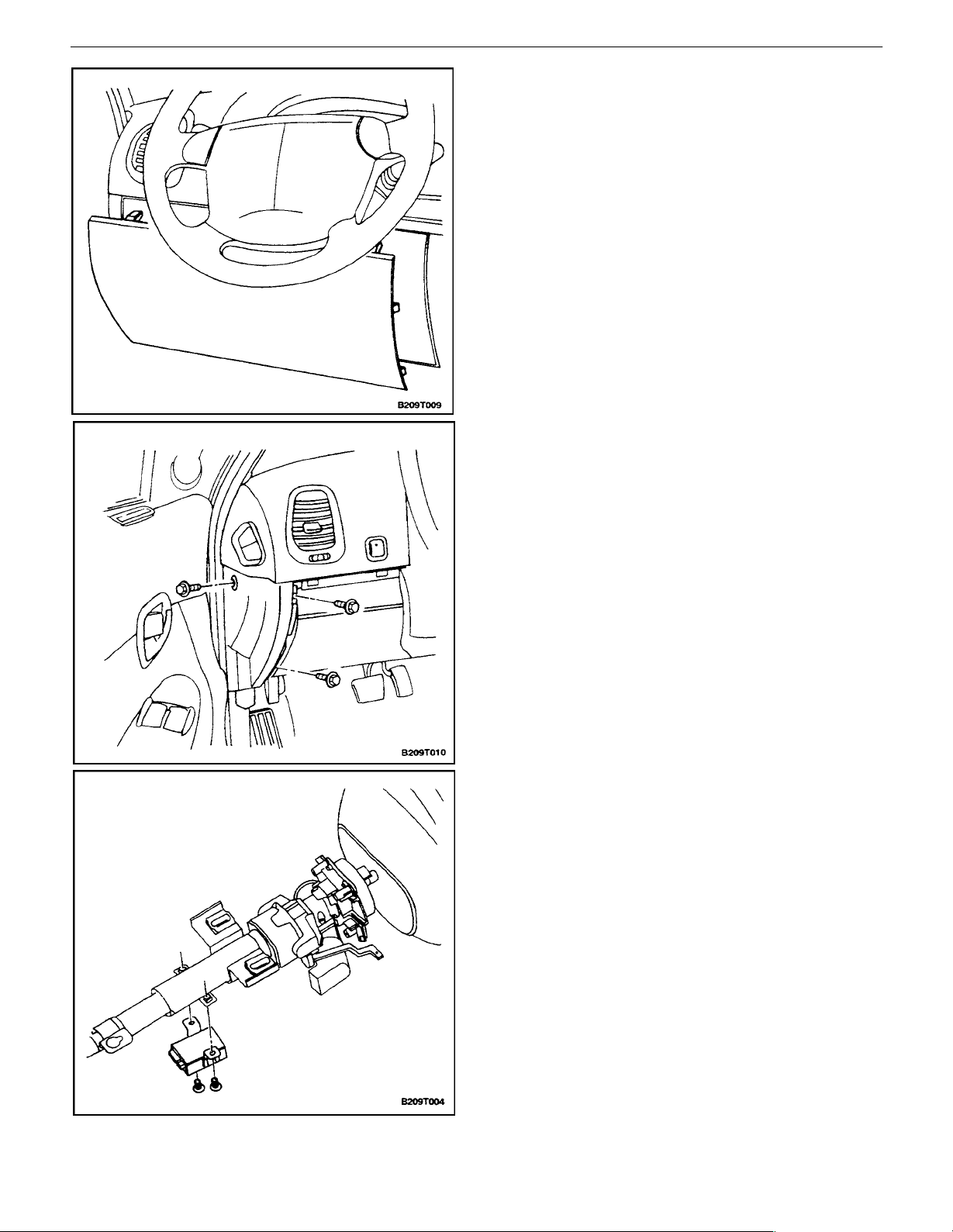

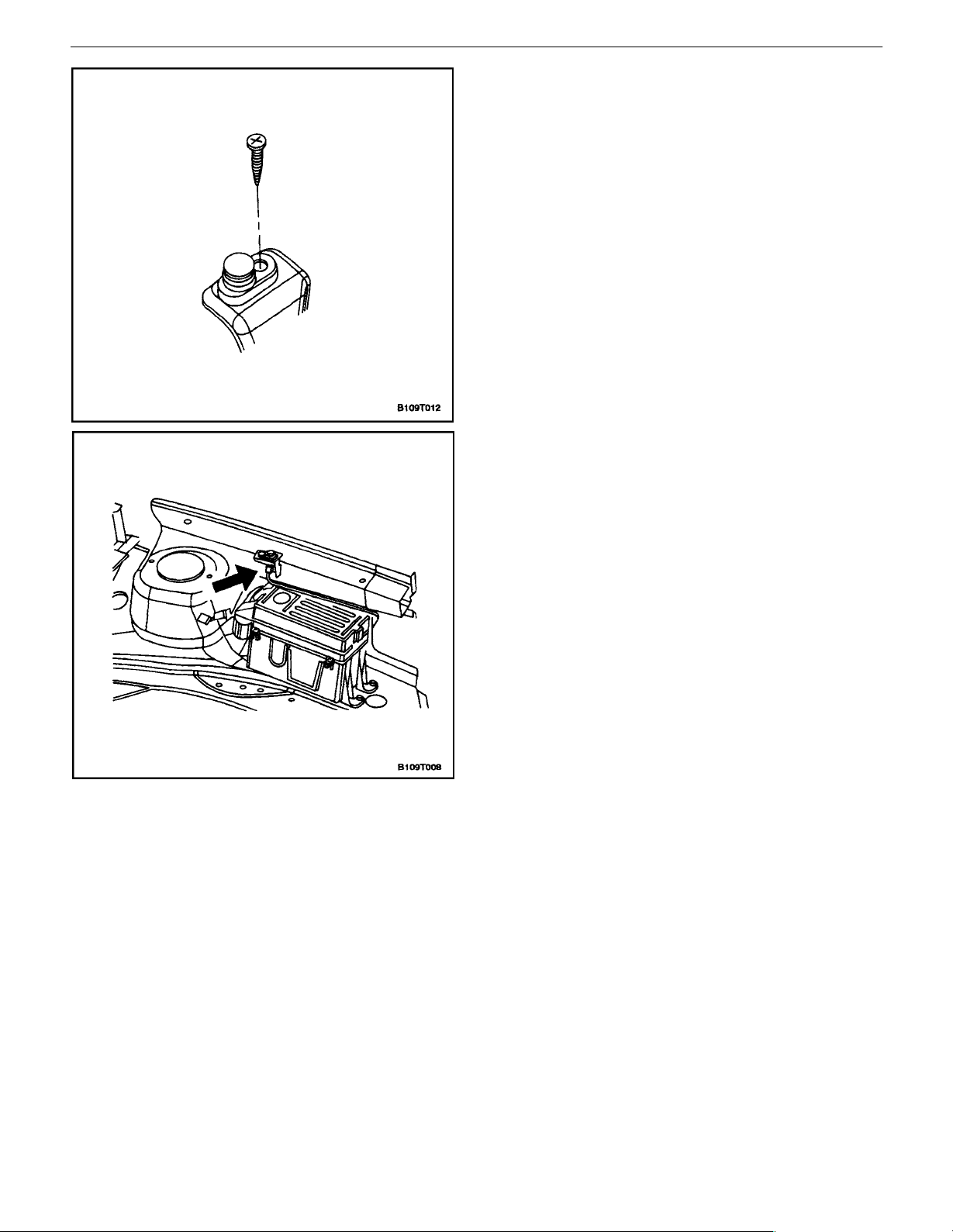

IMMOBILIZER CONTROL UNIT

Removal Procedure

1. Disconnect the negative battery cable.

2. Carefully pull the knee bolster trim panel loose from

its retaining clips.

3. Slide the knee bolster trim panel upward and pull it

outward to remove it.

4. Remove the instrument panel side cover.

5. Remove the bolts and the knee bolster.

6. Remove the bolts and the immobilizer control unit.

7. Disconnect the electrical connectors from the immobilizer control unit.

DAEWOO V–121 BL4

Page 10

IMMOBILIZER ANTI–THEFT SYSTEM 9T – 9

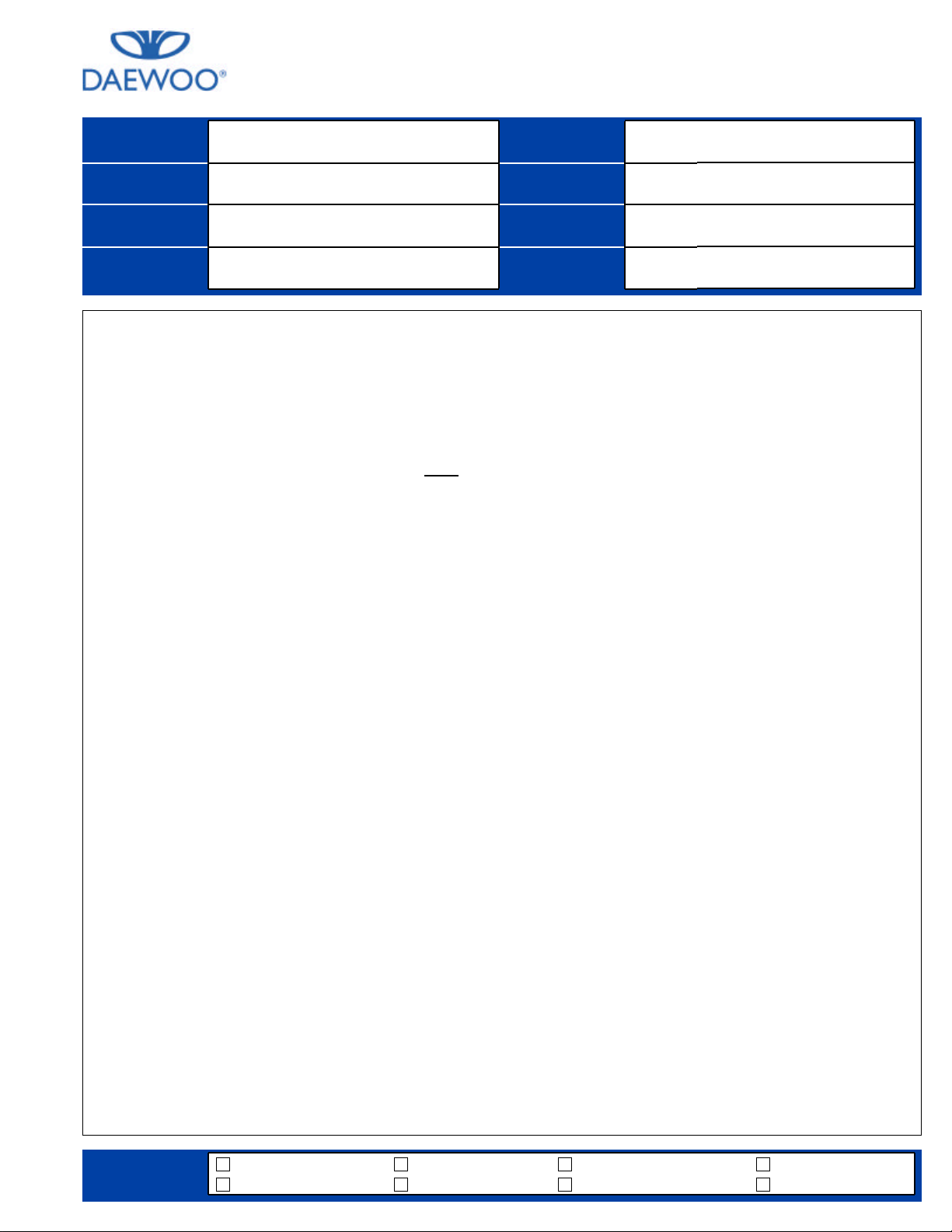

Installation Procedure

1. Connect the electrical connectors to the immobilizer

control unit.

2. Install the immobilizer control unit with the bolts.

Tighten

Tighten the immobilizer control unit mounting bolts to

4 NSm (35 lb–in).

3. Install the knee bolster with the bolts.

Tighten

Tighten the knee bolster mounting bolts to 22 NSm (16

lb–in).

4. Install the instrument panel side cover.

5. Install the knee bolster trim panel.

6. Connect the negative battery cable.

Important : After replacing the immobilizer, the keys must

be re–authorized using the key coding procedure. Refer

to”Key Coding Procedure” in this section. Also, the electronic control module (ECM) identification (ID) code must

be reset. Refer to”ID Code Reprogramming” in this section.

DAEWOO V–121 BL4

Page 11

9T – 10IIMMOBILIZER ANTI–THEFT SYSTEM

GENERAL DESCRIPTION

AND SYSTEM OPERATION

the radio–frequency signal. A release message is sent to

the powertrain control module (PCM)/engine control module (ECM) if the key is authorized.

New keys are coded by using a scan tool. Refer to in this

section.”Key Coding Procedure”

IMMOBILIZER SYSTEM

The purpose of the immobilizer system is to prevent the

vehicle from being stolen or driven by unauthorized users.

Users are authorized by an electronically coded key.

When the ignition is turned ON, the key is tested by the immobilizer system. While the key code is being read by the

immobilizer control unit, the engine can start and run with

any key that will turn the lock cylinder. The key code is read

and compared with key codes that have been stored in the

immobilizer control unit’s memory.

If a valid key is detected, the immobilizer control unit sends

a serial data release message to the powertrain control

module (PCM)/engine control module (ECM). Included in

the release message is an identification (ID) code which

assures that neither the immobilizer control unit nor the

PCM/ECM has been substituted to defeat the system.

If the PCM/ECM does not receive a release message within a specified time, or if the ID codes do not match, the

PCM/ECM performs the following actions:

S Disables the fuel injector circuit.

S Disables the fuel pump circuit.

S Disables the ignition coil.

S Sets diagnostic trouble code (DTC) 53.

The above conditions are maintained until the ignition is

turned OFF.

The immobilizer control unit system consists of the following components:

S Electronically coded keys.

S Detection coil.

S Immobilizer control unit.

S PCM/ECM.

S Instrument cluster indicator.

S A data link connector (DLC) to provide serial data

access for a scan tool.

DETECTION COIL

A detection coil is mounted at the ignition lock as an integral part of the key position trim ring. The wires to and from

the detection coil are connected to the immobilizer. When

the ignition is turned ON, the immobilizer energizes the

detection coil and the coil is coupled inductively to the

transponder in the ignition key. The immobilizer sends a

modulated signal to the detection coil. The signal is

changed by interaction with the internal transponder in the

ignition key. The immobilizer reads the signal from the

detection coil and determines whether the key is authorized.

IMMOBILIZER CONTROL UNIT

The immobilizer control unit is an electronic module in the

instrument panel which verifies the validity of an ignition

key when the ignition is turned ON.

To accomplish its purpose, the immobilizer control unit

performs the following actions:

S Learns and stores the codes of valid keys.

S Reads the radio frequency input from the ignition

key.

S Compares the received code with the codes of the

valid keys.

S Sends a release message to the powertrain control

module (PCM)/engine control module (ECM) if a

valid key has been presented.

S Calculates and transmits identification (ID) codes

within each release message.

S Controls the external relay which interrupts the

starter relay circuit.

S Controls the status indicator in the instrument clus-

ter.

S Monitors system faults.

S Supports system test functions.

A PCM/ECM for a vehicle without an immobilizer control

unit cannot be interchanged with a PCM/ECM that is used

with an immobilizer control unit system. The immobilizer

control unit and the PCM/ECM must have a matching ID

code. ID coding and key coding are accomplished by using

a scan tool.

ELECTRONICALLY CODED KEYS

Each valid ignition key has an internal transponder which

transmits a unique code. When a key is inserted into the

ignition lock, the transponder is inductively coupled to the

detection coil. The transponder interacts with the detection coil to generate an amplitude modulated modulated

signal which is conducted from the detection coil to the immobilizer control unit. The immobilizer control unit reads

Normal Operation

When the ignition is turned ON, the immobilizer control

unit tries to read the key code transmitted by the transponder in the ignition key.

If a valid key is detected, the immobilizer control unit sends

a release message to the PCM/ECM. The release message contains an ID code. Immobilization will be performed by the PCM/ECM if no release message is received, or if the ID code in the PCM/ECM does not match

the immobilizer control unit ID code.

If a non–valid key is detected, the release message is not

sent to the PCM/ECM.

When the driver turns the ignition OFF, the immobilizer

control unit switches to the active mode.

DAEWOO V–121 BL4

Page 12

IMMOBILIZER ANTI–THEFT SYSTEM 9T – 11

Data Link Connector (DLC)

When the ignition is ON, a scan tool can switch the immobilizer control unit to the data link connector (DLC) mode

for the purpose of diagnostics, key coding, or ID coding.

ID Code Handling

One of 65,535 possible ID codes is stored in the immobilizer control unit’s memory.

The ID code can be erased by using the scan tools’RESET

ID CODE command. When the immobilizer control unit

calculates a new ID code, the PCM/ECM ID code must be

reset to match the immobilizer control unit ID code. To reset the ID code, refer to ”ID Code Reprogramming.”

During diagnostic procedures, the ID code can be read for

comparison with the PCM/ECM ID code by using the scan

tool’s READ IMMOBILIZER CONTROL UNIT IDCODE

command.

SERIAL DATA LINK

Serial data can be exchanged between a scan tool, the

powertrain control module (PCM)/engine control module

ECM), and the immobilizer control unit.

The scan tool connection is the data link connector (DLC).

POWERTRAIN CONTROL MODULE

(PCM)/ENGINE CONTROL MODULE

(ECM)

When the powertrain control module (PCM)/engine con-

trol module (ECM) detects that the ignition is being turned

ON, the PCM/ECM waits for a release message from the

immobilizer control unit. If a release message is not received within a specified time, the PCM/ECM disables the

engine. The engine is also disabled if the identification (ID)

code transmitted by the immobilizer control unit does not

match the code stored in the PCM/ECM’s memory. Immobilization remains in effect until the ignition is turned OFF,

or until battery power is removed.

To prevent the vehicle from being driven, the PCM/ECM

applies the following strategy:

S The ignition module is put in a bypass mode.

S The PCM/ECM will not create an electronic spark

timing (EST) output. Therefore, no spark will be

generated by the ignition coil.

S The PCM/ECM will not enable the fuel pump.

S The PCM/ECM will not enable the fuel injectors.

S The PCM/ECM sets diagnostic trouble code (DTC)

53.

Serial data communication is transmitted on a single wire

between the immobilizer control unit and the PCM/ ECM.

During diagnostic procedures or ID code changing, a scan

tool is added to the communication system.

A PCM/ECM with an immobilizer control unit is not exchangeable with a PCM/ECM that does not have an immobilizer control unit.

DAEWOO V–121 BL4

Page 13

SECTION : 9T

REMOTE KEYLESS ENTRY AND

PERIMETER/ULTRASONIC ANTI–THEFT SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T–1. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING SPECIFICATIONS 9T–1.

SCHEMATIC AND ROUTING DIAGRAMS 9T–2. . . . .

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM (1 OF 2) 9T–2. . . . . . . . . . . . . . . . . . . . . . .

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM (2 OF 2) 9T–3. . . . . . . . . . . . . . . . . . . . . . .

CONTROL MODULE/RECEIVER CONNECTOR 9T–

4

WIRING HARNESS CONNECTORS 9T–4. . . . . . . . .

MAINTENANCE AND REPAIR 9T–5. . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T–5. . . . . . . . . . . . . . . . . . . . .

CONTROL MODULE/RECEIVER 9T–5. . . . . . . . . . . .

SIREN 9T–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT DOOR TAMPER SWITCH 9T–7. . . . . . . . . . .

REAR DECK LID TAMPER SWITCH 9T–7. . . . . . . . .

SPECIFICATIONS

HOOD OPEN SWITCH 9T–8. . . . . . . . . . . . . . . . . . . . .

PASSWORD PROGRAMMING 9T–10. . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 9T–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM 9T–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE LOCKING AND UNLOCKING 9T–11. . . . . .

SECURITY INDICATOR 9T–11. . . . . . . . . . . . . . . . . . . .

INTRUSION SENSING 9T–11. . . . . . . . . . . . . . . . . . . . .

SIREN 9T–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE LOCATOR 9T–12. . . . . . . . . . . . . . . . . . . . . .

AUTOLOCKING (SAFETY LOCK) 9T–12. . . . . . . . . .

CONTROL MODULE/RECEIVER 9T–12. . . . . . . . . . .

FAULT OR ALARM INDICATION 9T–12. . . . . . . . . . .

PANIC BUTTON 9T–12. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

Hood Open Switch Mounting Screw 8 – 71

Siren Bracket Mounting Bolt 22 16 –

Page 14

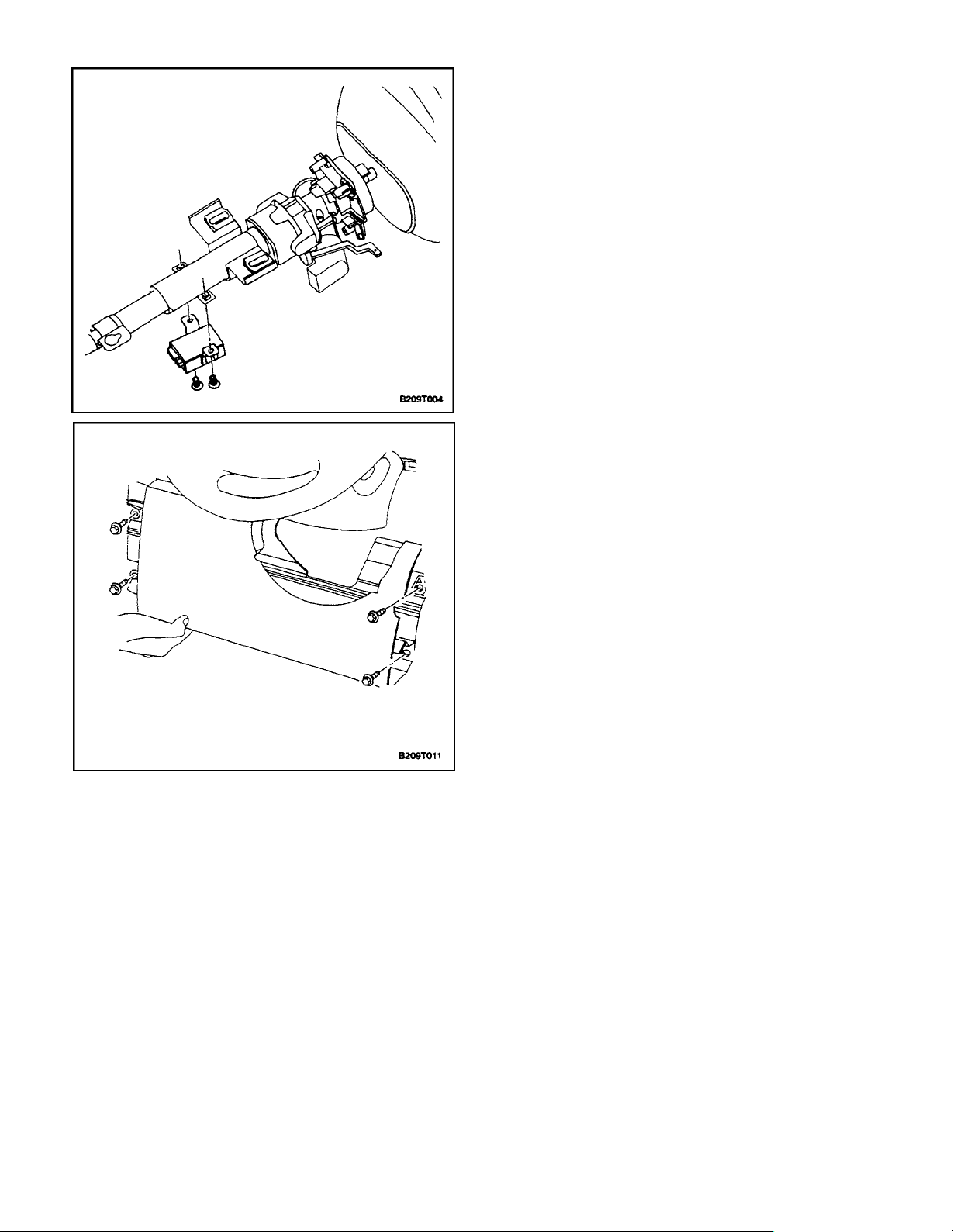

9T – 2IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

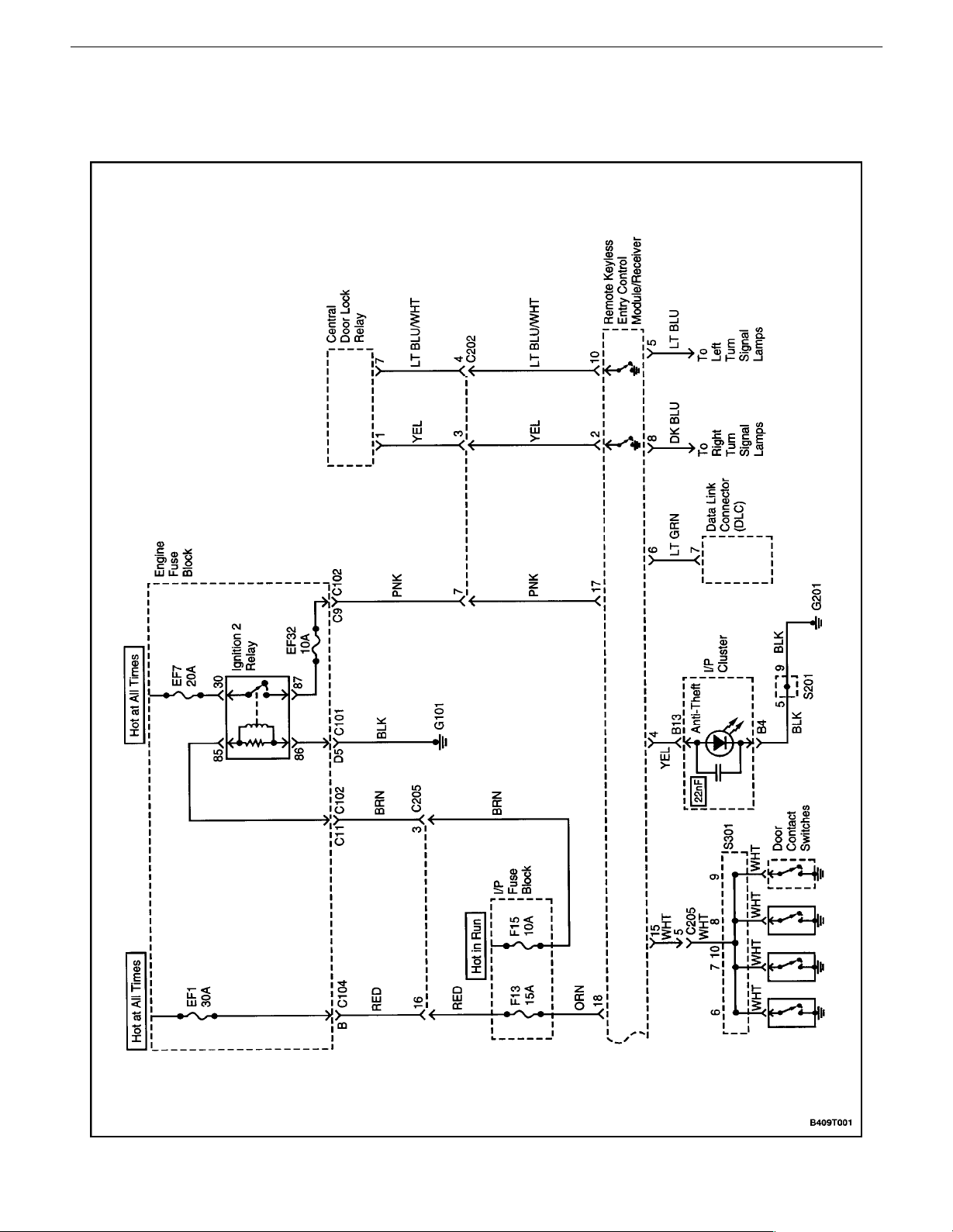

SCHEMATIC AND ROUTING DIAGRAMS

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM (1

OF 2)

DAEWOO V–121 BL4

Page 15

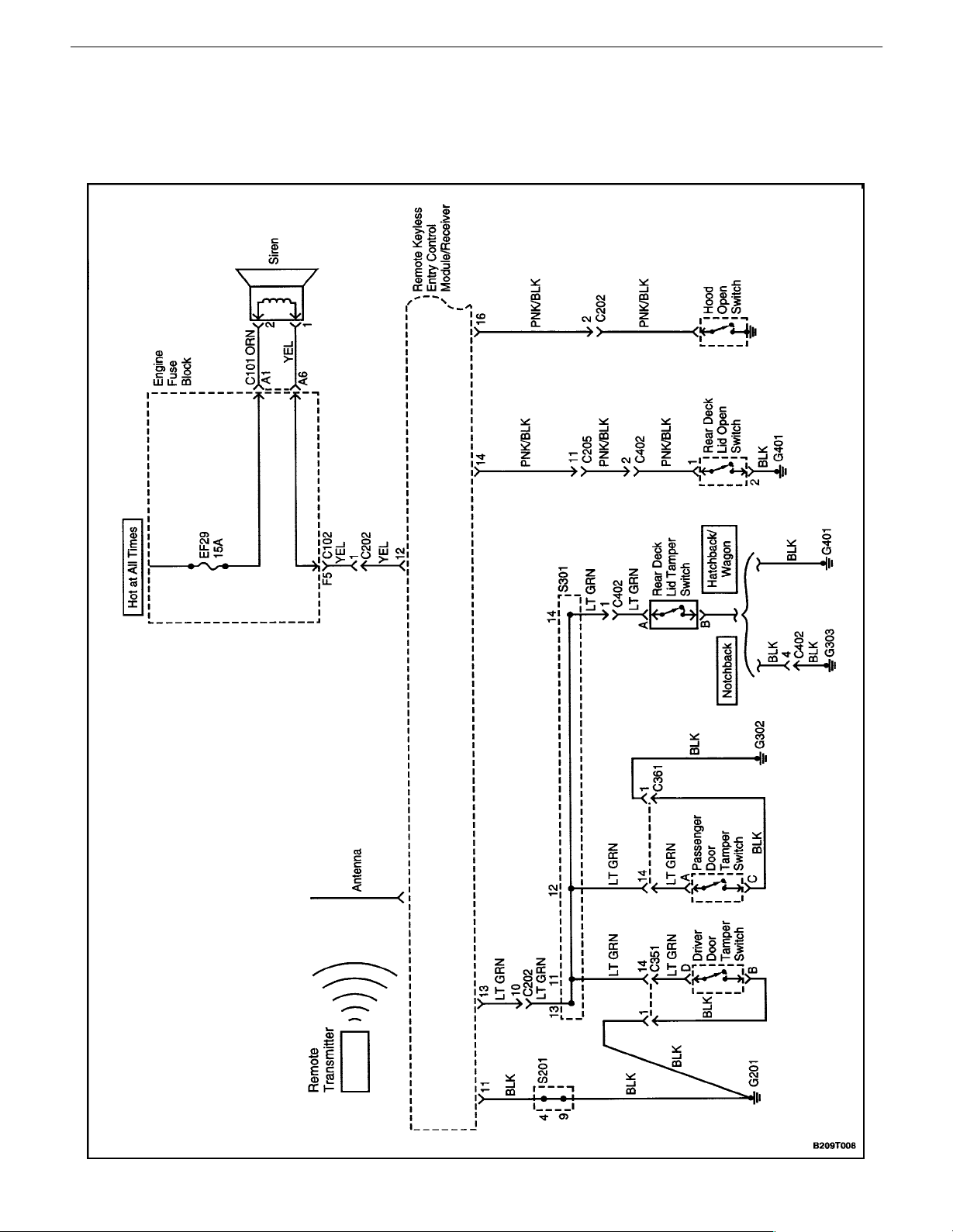

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T – 3

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM (2

OF 2)

DAEWOO V–121 BL4

Page 16

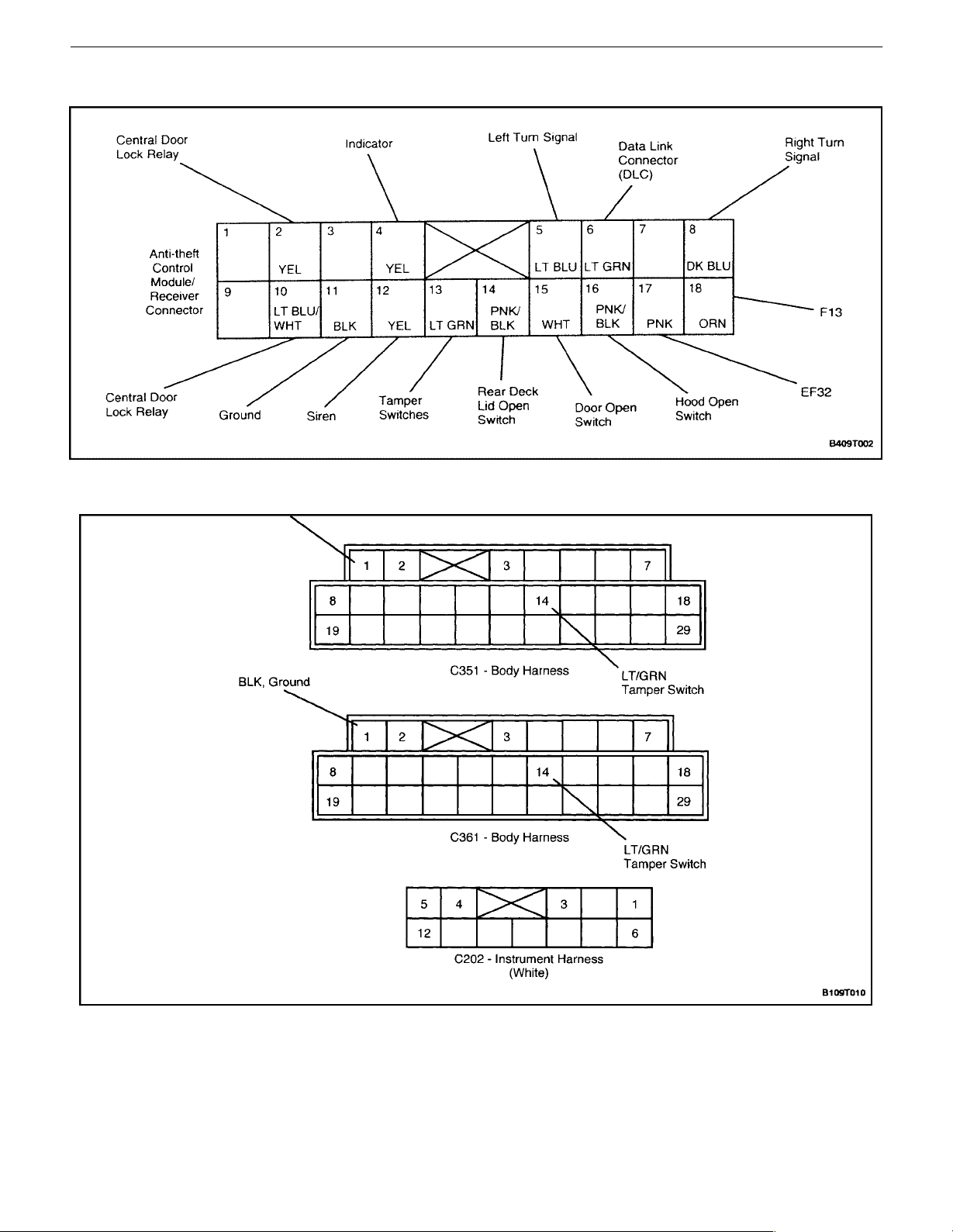

9T – 4IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

CONTROL MODULE/RECEIVER CONNECTOR

WIRING HARNESS CONNECTORS

DAEWOO V–121 BL4

Page 17

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T – 5

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

CONTROL MODULE/RECEIVER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove floor console left side forward trim panel.

Refer to Section 9G, Interior Trim.

3. Disconnect the control module/receiver electrical

connector.

4. Slide the control module/receiver toward the rear of

the vehicle and remove it.

Installation Procedure

1. Install the control module/receiver by sliding it onto

its bracket.

2. Connect the control module/receiver electrical connector.

3. Install the floor console left side forward trim panel.

Refer to Section 9G, Interior Trim.

4. Connect the negative battery cable.

DAEWOO V–121 BL4

SIREN

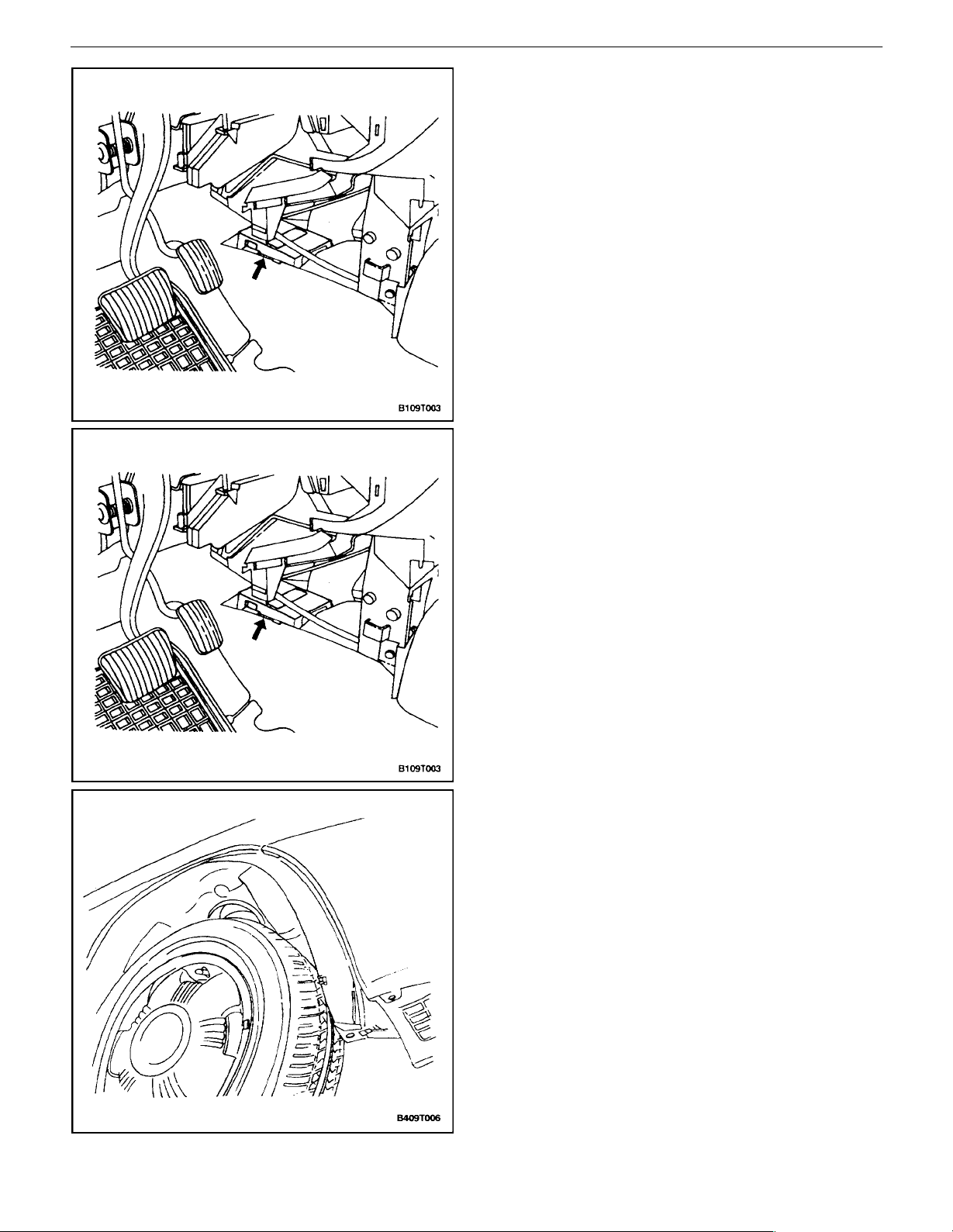

Removal Procedure

1. Remove several screws to boosen the forward half

of the right front wheel well splash shield.

Page 18

9T – 6IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

2. Remove the siren electrical connector.

3. Remove the siren bracket mounting bolt.

4. Remove the siren.

Installation Procedure

1. Install the siren on the siren bracket with the mounting screws.

Tighten

Tighten the siren bracket mounting bolts to 22 NSm

(16 lb–in).

2. Connect the siren electrical connector.

DAEWOO V–121 BL4

Page 19

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T – 7

FRONT DOOR TAMPER SWITCH

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front door trim panel. Refer to Section

9G, Interior Trim.

3. Disconnect the door tamper switch electrical connector.

4. Remove the front door lock and the integral door

tamper switch. Refer toSection 9P, Doors.

Installation Procedure

1. Install the front door lock and the integral door tamper switch. Refer toSection 9P, Doors.

2. Install the door tamper switch electrical connector.

3. Install the front door trim panel. Refer to Section

9G, Interior Trim.

4. Connect the negative battery cable.

DAEWOO V–121 BL4

REAR DECK LID TAMPER SWITCH

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the rear deck lid tamper switch electrical connector from the tamper switch.

3. Remove the rear deck lid tamper switch.

Page 20

9T – 8IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

Installation Procedure

1. Install the rear deck lid tamper switch.

2. Connect the rear deck lid tamper switch electrical

connector to the tamper switch.

3. Connect the negative battery cable.

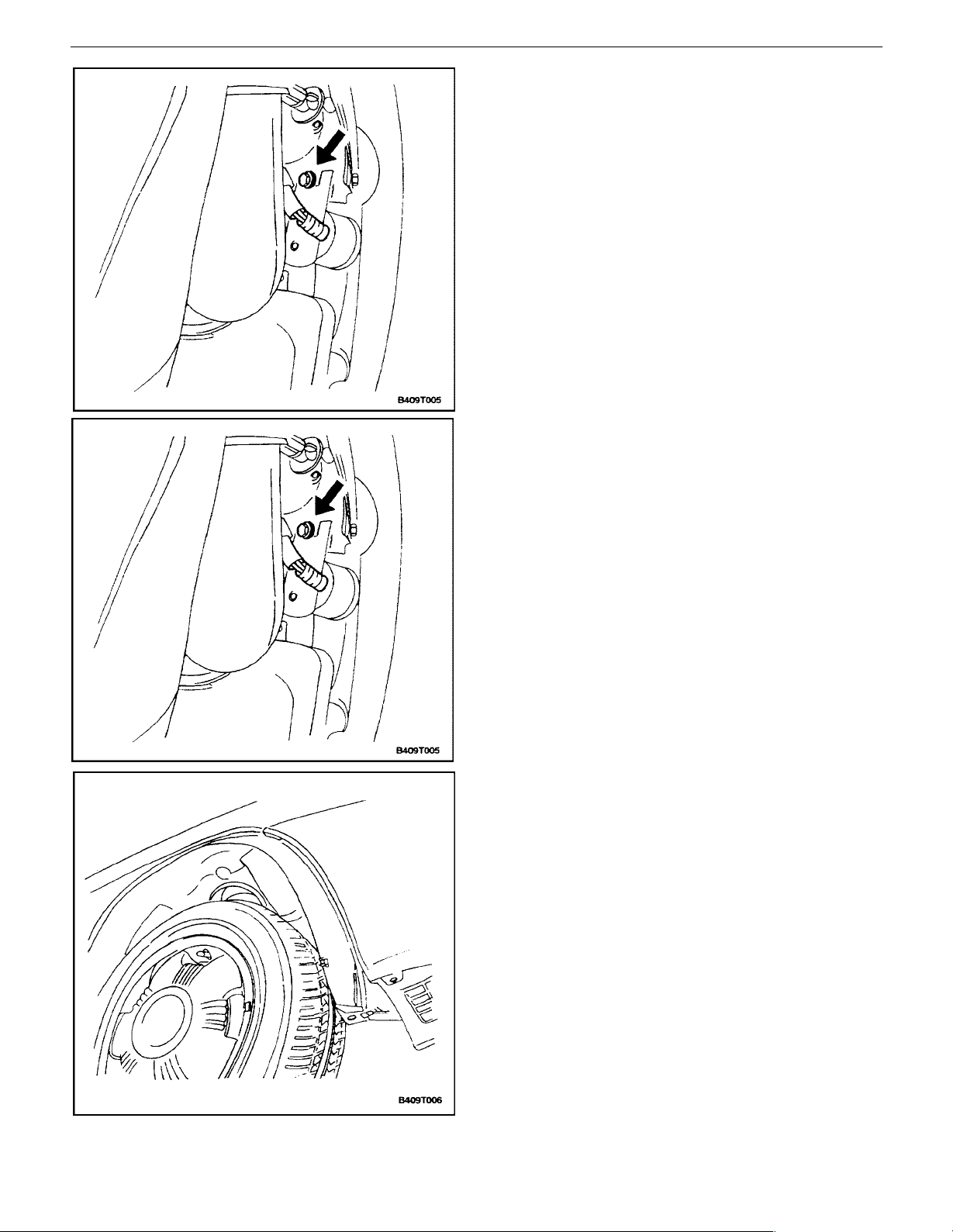

HOOD OPEN SWITCH

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the hood

open switch.

3. Remove the mounting screw from the hood open

switch.

4. Remove the hood open switch.

DAEWOO V–121 BL4

Page 21

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T – 9

Installation Procedure

1. Install the hood open switch with the mounting

screw.

Tighten

Tighten the hood open switch mounting screw to 8

NSm (71 lb–in).

2. Connect the electrical connector to the hood open

switch.

3. Connect the negative battery cable.

DAEWOO V–121 BL4

Page 22

9T – 10IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

PASSWORD PROGRAMMING

If a transmitter is lost or damaged, the control module/receiver must be re–programmed to communicate with a

new transmitter. The passwords recorded in the control

module/receiver should not be deleted when power is off

in the control module/receiver.

Each control module/receiver should be able to record five

passwords. The following method is used to record new

passwords in the control module/receiver:

1. Connect the scan tool to the assembly line diagnostic link (ALDL) connector.

2. Turn the ignition ON.

3. Delete the current passwords.

4. Send the programming mode message to the control module/receiver.

5. Press any button of the transmitter to generate a

data code including a password which will be recorded by the control module/receiver. The control

module/receiver sends a response message to the

scan tool to indicate that the first password has

been recorded.

6. Press any button of the transmitter to generate a

data code including a password which will be recorded by the control module/receiver. The control

module/receiver sends a response message to the

scan tool to indicate that the second password has

been recorded.

7. Press any button of the transmitter three more

times until the control module/receiver has responded that the third, fourth, and fifth passwords

have been recorded.

8. Turn the ignition OFF.

9. Disconnect the scan tool.

The control module/receiver automatically leaves the programming mode and switches to the normal operating

mode when either of the following conditions occurs:

S The scan tool is disconnected from the ALDL.

S Five passwords are recorded in the control module/

receiver.

DAEWOO V–121 BL4

Page 23

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T – 11

GENERAL DESCRIPTION

AND SYSTEM OPERATION

REMOTE KEYLESS ENTRY AND

ANTI–THEFT SYSTEM

The remote keyless entry and anti–theft system can per-

form the following functions:

S Remotely lock and unlock the vehicle doors with a

hand–held high–frequency transmitter.

S Sense intrusion into the vehicle through the doors,

the trunk, or the hood.

S Activate a warning to signal an intrusion.

S Help the driver find the vehicle in a parking area.

S Automatically re–lock the doors if a door or the

trunk is not opened within 30 seconds after the vehicle has been unlocked by the remote keyless

entry.

S Communicate serial data to a scan tool to help

diagnose system faults.

The remote keyless entry and anti–theft system consists

of the following components:

S Keyless entry and anti–theft control module/receiv-

er.

S Security indicator.

S Rear deck lid open switch.

S Rear deck lid tamper switch.

S Front door tamper switches.

S Door open switches.

S Central locking unit.

S Flashing turn signal lamps.

S Siren.

S Hood open switch.

REMOTE LOCKING AND UNLOCKING

The transmitter has a replaceable battery. The battery is

designed to last at least three years before replacement

is necessary.

SECURITY INDICATOR

There is a security indicator on the instrument panel. After

the LOCK button of the transmitter is pressed, the module

is placed in the armed mode, and the security indicator

flashes. The security indicator turns ON for 0.1 second

and OFF for 0.7 second. It then flashes at that frequency

until the control module/receiver is disarmed. If the vehicle

is equipped with an immobilizer, the security indicator is

connected to the immobilizer system instead of the keyless entry/anti–– theft system.

INTRUSION SENSING

The anti–theft function is armed if the transmitter sends

the LOCK message to the control module/receiver when

the ignition is OFF.

When the hood, the door, or the rear deck lid is opened,

the hood open switch, the door open switch, or the trunk

open switch will change its input to ground. The alarm will

be activated if the hood open sensor, the door open sensor, or the trunk open sensor changes its input to ground

before either of the following conditions occurs:

S An UNLOCK message is received from the trans-

mitter.

S The front door tamper switch or the rear deck lid

tamper switch indicates key operation by changing

its input to ground.

The alarm also will be activated if the ignition input is

changed to battery voltage before either of the following

conditions occurs:

S An UNLOCK message is received from the trans-

mitter.

S The front door tamper switch or the rear deck lid

tamper switch indicates key operation by changing

its input to ground.

The hand–held transmitter locks and unlocks the vehicle

doors by sending radio waves to the control module/receiver in the vehicle. The effective range of the transmitter

varies between 5 and 10 meters (approximately 16 to 32

feet), depending on whether or not objects such as other

vehicles are blocking the path of the radio waves.

The transmitter has a LOCK button and an UNLOCK button which only function when the ignition is OFF. Pressing

the UNLOCK button has the following effects:

S The doors are unlocked.

S The turn signal lamps flash twice.

S The control module is disarmed.

Pressing the LOCK button has the following effects:

S The doors are locked.

S The turn signal lamps flash once.

S The control module is armed.

DAEWOO V–121 BL4

SIREN

The remote keyless entry system is armed when the

LOCK message is received from the transmitter when the

ignition is OFF. When the system is armed, it will activate

the siren and flash the turn signals for 28 seconds if any

of the following conditions occurs:

S A door is opened without using the key (front door

open switch input is changed to ground).

S The rear deck lid is opened without using the key

trunk open switch input is changed to ground).

S The hood is opened while the anti–theft system is

armed (hood open switch input is changed to

ground).

S The ignition switch input is changed to battery volt-

age.

The siren is disarmed when any of the following conditions

occurs:

Page 24

9T – 12IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

S The door is opened with the key.

S The rear deck lid is opened with the key.

S The UNLOCK button or the LOCK button on the

remote transmitter is pressed within 2 seconds of

the beginning of the alarm. If the UNLOCK button

or the LOCK button is not pressed within 2 seconds

of the beginning of the alarm, the transmitter will

not stop the alarm.

VEHICLE LOCATOR

The remote keyless entry system assists the driver in locating the vehicle. When the vehicle is unlocked with the

remote control, the turn signals flash twice to indicate the

location of the vehicle. The duration of the flashes and the

length of time between flashes is used to indicate certain

vehicle conditions. Refer to ”Fault or Alarm Indication” in

this section.

AUTOLOCKING (SAFETY LOCK)

The remote keyless entry system features an autolocking

control. If the doors are unlocked with the remote transmitter when the control module/receiver is in the armed

mode, the doors are automatically re–locked after 30 sec-

onds unless any of the following events occur:

S The door is opened.

S The ignition switch is turned ON.

S The rear deck lid is opened.

S The hood is opened.

CONTROL MODULE/RECEIVER

The remote keyless entry control module/receiver is contained in the floor console. The module/receiver processes signals from the remote transmitter and the intrusion sensors, and it activates the alarm if an intrusion is

detected. The control module/receiver also has a selfdiagnostic function which will display trouble codes. In order to

display trouble codes, a scan tool must be connected to

the assembly line diagnostic link (ALDL) connector.

The control module/receiver will not communicate with

transmitters from other vehicles because there are over

four billion possible electronic password combinations,

and passwords are not duplicated. The control module/ receiver has an attached antenna to detect signals from the

transmitter.

FAULT OR ALARM INDICATION

When the UNLOCK button on the remote transmitter is

pressed, the control module/receiver will flash the parking

lamps to indicate information about the remote keyless

entry and anti–theft system.

Normal Condition: If there has not been an intrusion, and

no fault has been detected, the control module/receiver

will signal a normal condition when the UNLOCK button is

pressed. The parking lamps will flash twice for 0.5 second,

with a 0.5 second pause between flashes.

Fault Indication: If there is a fault in the remote keyless

entry and anti–theft system, the control module/receiver

will signal the fault when the UNLOCK button is pressed.

The parking lamps will flash twice for 1 second, with a 0.5

second pause between flashes.

Alarm Indication: If there has been an intrusion since the

last time the LOCK button was pressed, the control module/receiver will signal that there has been an intrusion

when the UNLOCK button is pressed. The parking lamps

will flash twice for 0.5 second, with a 1.5 second pause between flashes.

Alarm and fault information in the control module/receiver

will be erased the next time the controlmodule/receiver enters the armed condition after receiving a LOCK message

from the transmitter.

PANIC BUTTON

In addition to the LOCK and UNLOCK buttons on the

transmitter, there is the panic button. This button is used

to activate the siren if a threatening situation occurs while

the driver is approaching the vehicle. If the panic button is

held down for 2 seconds, the siren will be activated for 30

seconds, and the parking lights will flash during that time.

DAEWOO V–121 BL4

Page 25

TECHNICAL SERVICE BULLETIN

TECHNICAL SERVICE BULLETIN

Bulletin No.:

Model(s):

Date:

VIN Range:

TSB-003-01

All

May 18, 2001

All

Description:

Group:

Reference:

Prod. Dates:

Remote Keyless Entry Transmitter

Programming

Body

N/A

All

Remote Keyless Entry Transmitter Programming Information

The Daewoo Remote Keyless Entry System allows for the use of as many as five (5)

transmitters for each vehicle. Replacement Remote Keyless Entry System Transmitters must

first be programmed to a specific vehicle using the Scan 100 Scan Tool. This process is

completed using serial data communication between the Scan 100 Scan Tool and the Remote

Keyless Entry Control Unit and is the only method available for programming Transmitters.

Note: All Transmitters for a specific vehicle must be programmed at the same time.

Once the programming function of the Remote Keyless Entry System is

activated, any Transmitter (existing or new) that is not programmed (or

reprogrammed) during the programming procedure will no longer operate the

Remote Keyless Entry System of that vehicle.

This Technical Service Bulletin provides information concerning the programming procedure

for the Remote Keyless Entry Transmitter(s).

REMOTE KEYLESS ENTRY TRANSMITTER PROGRAMMING PROCEDURE:

Note: Ensure that the doors, hood and trunk / rear hatch are closed prior to starting

the programming procedure.

1. Connect the Scan 100 Scan Tool to the Data Link Connector (DLC).

2. Turn the Scan 100 Scan Tool “ON” by pressing the “POWER” Button, then wait for the

MAIN MENU screen to be displayed.

3. From the MAIN MENU screen, select “Diagnostics” by pressing #1 on the Key Pad.

4. From the MODEL YEAR screen, select the appropriate model year of the specific vehicle

by either scrolling down to the year and pressing “ENTER”, or by pressing the respective

item number on the Key Pad.

5. From the VEHICLE TYPE screen, select the specific vehicle model by either scrolling

down to the model name and pressing “ENTER”, or by pressing the respective item

number on the Key Pad.

6. From the SYSTEM SELECTION MENU screen, select “Body” by pressing #2 on the Key

Pad.

7. From the BODY SELECTION MENU screen, select “Coding” by pressing #2 on the Key

Pad.

Circulate To:

√

General Manager

√

Service Manager

√

Technician(s)

√

Service Advisor

√

Body Shop Manager

√

Parts Manager

Page 26

Description Page

8. From the CODING SYSTEM screen, select “Coding Only” by pressing #1 on the Key

Pad.

9. From the SECRET NUMBER OF CODINGS screen, enter four (4) zero's (0-0-0-0) in the

four (4) boxes labeled “1-2-3-4”.

10. From the CODING SYSTEM SELECT screen, select “Keyless Entry” by pressing #2 on

the Key Pad.

Note: A slight delay may occur and “PLEASE WAIT” may be displayed before the next

11. From the KEYLESS ENTRY CODING SYSTEM screen, select “Coding Transmitter” by

pressing #1 on the Key Pad.

12. When directed by the Scan 100 Scan Tool, press any Button on the first Transmitter to

be programmed.

CAUTION: Ensure that Transmitters from other vehicles in the immediate area are not

13. Continue programming Transmitters when directed by the Scan 100 Scan Tool until all

Transmitters have been programmed.

Remote Keyless Entry Programming

screen appears.

activated during this procedure.

2 of 2

Note: A maximum of five (5) Transmitters may be programmed to a vehicle.

14. Once all Transmitters have been programmed, press the “ESC” Button on the Key Pad.

The display will confirm the number of Transmitters programmed. If the number

displayed does not match the number of Transmitters programmed, repeat the procedure.

15. Turn the Scan 100 Scan Tool “OFF” by pressing the “POWER” Button, then disconnect it

from the Data Link Connector.

16. Wait approximately 10 seconds, then test the operation of each programmed Transmitter

to ensure it operates properly.

If additional information is needed regarding this procedure, please contact your District Parts

& Service Manager or the Daewoo Technical Assistance Center toll free at (877) 362-1234,

selection 1.

May, 2001

Page 27

SECTION : 9D

WIPERS/WASHER SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9D–1. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING SPECIFICATIONS 9D–1.

SCHEMATIC AND ROUTING DIAGRAMS 9D–2. . . . .

WIPERS AND WASHER SYSTEM (NOTCHBACK)9D

–2

WIPERS AND WASHER SYSTEM (HATCHBACK) 9D

–3

DIAGNOSIS 9D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WINDSHIELD WIPERS 9D–4. . . . . . . . . . . . . . . . . . . .

WINDSHIELD WASHER SYSTEM 9D–8. . . . . . . . . . .

REAR WINDOW WIPER (HATCHBACK AND

WAGON) 9D–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REAR WINDOW WASHER SYSTEM (HATCHBACK

AND WAGON) 9D–11. . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR 9D–12. . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9D–12. . . . . . . . . . . . . . . . . . . .

WINDSHIELD WIPER ARM 9D–12. . . . . . . . . . . . . . . .

SPECIFICATIONS

WINDSHIELD WIPER MOTOR 9D–12. . . . . . . . . . . . .

WINDSHIELD WIPER BLADE 9D–14. . . . . . . . . . . . . .

WINDSHIELD WIPER BLADE INSERT 9D–14. . . . .

WINDSHIELD WASHER RESERVOIR 9D–15. . . . . .

WINDSHIELD WASHER PUMP(S) 9D–17. . . . . . . . . .

WINDSHIELD WASHER NOZZLES 9D–18. . . . . . . . .

WINDSHIELD WASHER HOSES 9D–18. . . . . . . . . . .

REAR WINDOW WIPER ARM 9D–20. . . . . . . . . . . . .

REAR WINDOW WIPER MOTOR (HATCHBACK)9D–

20

REAR WINDOW WIPER MOTOR (WAGON) 9D–21.

REAR WINDOW WASHER NOZZLE (HATCHBACK) 9

D–22

GENERAL DESCRIPTION AND SYSTEM

OPERATION 9D–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WINDSHIELD WIPER SYSTEM 9D–24. . . . . . . . . . . .

WINDSHIELD WASHER SYSTEM 9D–24. . . . . . . . . .

REAR WINDOW WIPER/WASHER SYSTEM 9D–24

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

Front Wheel Well Splash Shield Bolts 1.5 – 13

Washer Fluid Reservoir Bolts 8 – 71

Wiper Arm Linkage Nut 5 – 44

Wiper Arm Nut 11 – 97

Wiper Motor Bolts 8 – 71

Page 28

9D – 2IWIPERS/WASHER SYSTEMS

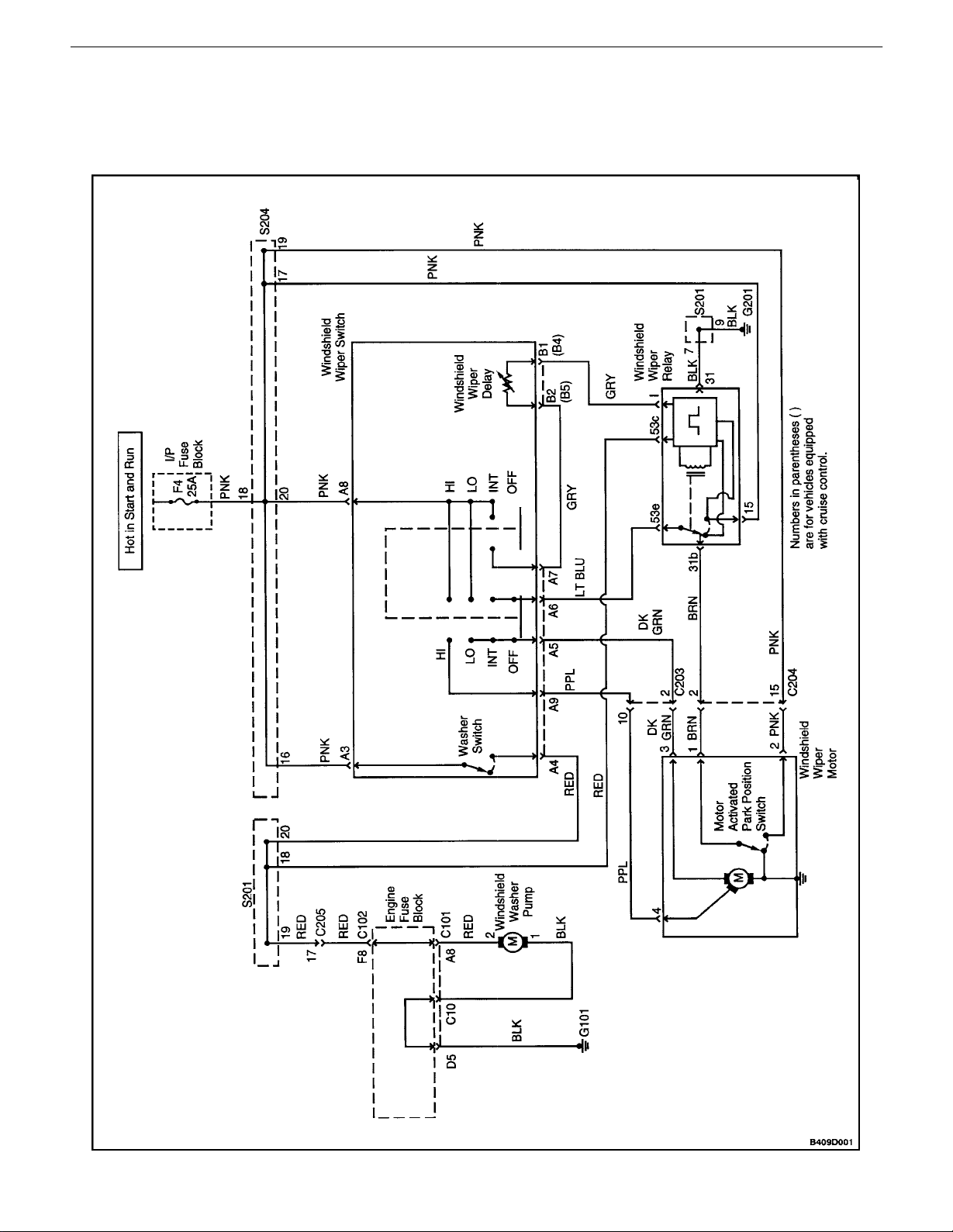

SCHEMATIC AND ROUTING DIAGRAMS

WIPERS AND WASHER SYSTEM (NOTCHBACK)

DAEWOO V–121 BL4

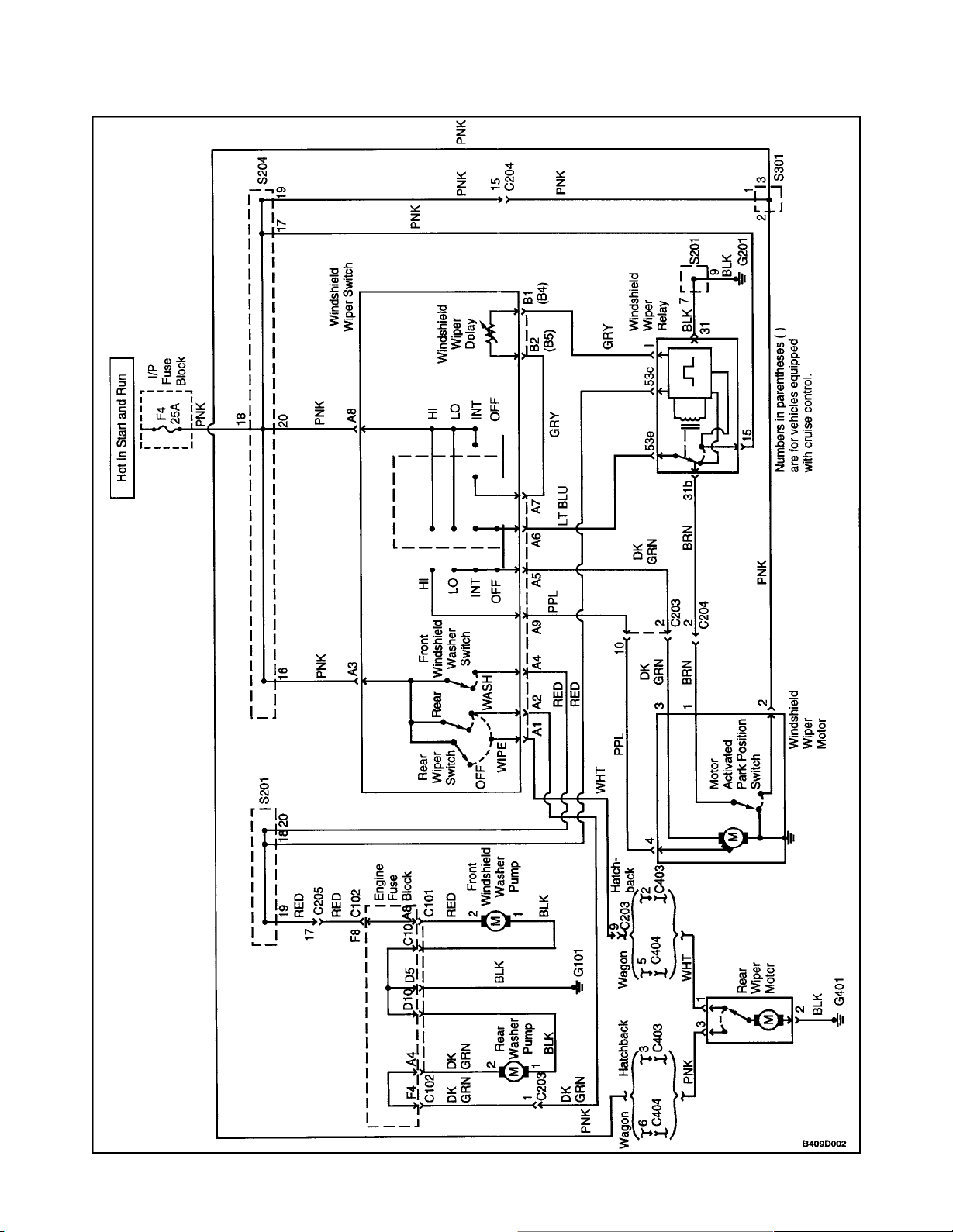

Page 29

WIPERS/WASHER SYSTEMS 9D – 3

WIPERS AND WASHER SYSTEM (HATCHBACK)

DAEWOO V–121 BL4

Page 30

9D – 4IWIPERS/WASHER SYSTEMS

DIAGNOSIS

WINDSHIELD WIPERS

Windshield Wipers Do Not Work At Any Speed

Step Action Value(s) Yes No

1 Check fuse F4.

Is fuse F4 blown?

2

3 Check the voltage at fuse F4.

4 Repair the open power supply circuit to fuse F4.

5

6 Replace the wiper motor.

7

8 Repair the open circuit between the wiper switch

9

10 Replace the wiper switch.

11 Repair the open circuit between the wiper switch and

1. Check for a short circuit and repair it, if necessary.

2. Replace the fuse.

Is the repair complete?

Is the voltage equal to the specified value?

Is the repair complete?

1. Disconnect the wiper motor connector.

2. Turn the ignition ON.

3. Turn the wiper switch to HI.

4. Check the voltage at the wiper motor connector

terminal 6.

Is the voltage equal to the specified value?

Is the repair complete?

1. The wiper switch is still disconnected.

2. Turn the ignition ON.

3. Check for battery voltage at the wiper switch

connector terminal A8.

Is the voltage equal to the specified value?

connector terminal A8 and fuse F4.

Is the repair complete?

1. The wiper switch is still disconnected.

2. Turn the wiper switch to HI.

3. Use an ohmmeter to check for continuity between wiper switch terminal A8 and A9.

Does the ohmmeter indicate the specified value?

Is the repair complete?

the wiper motor.

Is the repair complete?

11–14 v Go to Step 5 Go to Step 4

11–14 v Go to Step 6 Go to Step 7

11–14 v Go to Step 9 Go to Step 8

[ 0 W Go to Step 11 Go to Step 10

Go to Step 2 Go to Step 3

System OK

System OK

System OK

System OK

System OK

System OK

DAEWOO V–121 BL4

Page 31

WIPERS/WASHER SYSTEMS 9D – 5

Wipers Do Not Work On HI Speed, LO Speed OK

Step Action Value(s) Yes No

1

2 Replace the wiper motor.

3

4 Replace the wiper switch.

5 Repair the open circuit between wiper switch con-

1. Turn the ignition ON.

2. Turn the wiper switch to HI.

3. Check the voltage at the wiper motor connector

terminal 4.

Is voltage equal to the specified value?

Is the repair complete?

1. Disconnect the wiper switch.

2. Turn the wiper switch to HI.

3. Use an ohmmeter to check for continuity between wiper switch terminal A8 and A9.

Does the ohmmeter indicate the specified value?

Is the repair complete?

nector terminal A9 and wiper motor connector terminal 4.

Is the repair complete?

11–14 v Go to Step 2 Go to Step 3

System OK

[ 0 W Go to Step 5 Go to Step 4

System OK

System OK

Wipers Do Not Work On LO Speed, HI Speed OK

Step Action Value(s) Yes No

1

2 Replace the wiper motor.

3

4 Replace the wiper switch.

5 Repair the open circuit between wiper switch con-

1. Turn the ignition ON.

2. Turn the wiper switch to LO.

3. Check the voltage at the wiper motor connector, terminal 3.

Is the voltage equal to the specified value?

Is the repair complete?

1. Disconnect the wiper switch.

2. Turn wiper switch to LO.

3. Use an ohmmeter to check for continuity between wiper switch terminal A8 and A5.

Does the ohmmeter indicate the specified value?

Is the repair complete?

nector terminal A5 and wiper motor connector terminal 3.

Is the repair complete?

11–14 v Go to Step 2 Go to Step 3

System OK

[ 0 W Go to Step 5 Go to Step 4

System OK

System OK

DAEWOO V–121 BL4

Page 32

9D – 6IWIPERS/WASHER SYSTEMS

Wipers Do Not Work On Intermittent (INT), Other Speeds OK

Step Action Value(s) Yes No

1

1. Turn the ignition ON.

2. Use a voltmeter to test the voltage at wiper

relay connector terminal 15.

Is voltage equal to the specified value?

2 Repair the open circuit between the wiper relay con-

nector terminal 15 and fuse F4.

Is the repair complete?

3

1. Turn the ignition on.

2. Turn the wiper switch to INT.

3. Check the voltage at wiper relay connector terminal I.

Does the voltmeter indicate a voltage equal to the

specified value?

4 Check for an open circuit between wiper switch con-

nector terminal A7 and wiper relay connector terminal I.

Is there an open circuit?

5 Replace the wiper switch.

Is the repair complete?

6 Repair the open circuit between wiper switch con-

nector terminal A7 and wiper relay connector terminal I.

Is the repair complete?

7

1. Turn the ignition on.

2. Turn the wiper switch to INT.

3. Check for pulsing voltage at wiper switch connector terminal A6.

Does the voltmeter indicate a pulsating voltage

equal to the specified value?

8 Using an ohmmeter, check the resistance between

ground and the wiper relay connector terminal 31.

Is resistance equal to the specified value?

9 Repair the open ground circuit.

Is the repair complete?

10 Replace the wiper relay.

Is the repair complete?

11

1. Ignition ON.

2. Turn the wiper switch to INT.

3. Backprobe to check the voltage at the wiper

switch connector terminal A5.

Does the voltmeter indicate a pulsating voltage

equal to the specified value?

12 Replace the wiper relay.

Is the repair complete?

13 Repair the open circuit between the wiper switch and

the wiper relay.

Is the repair complete?

11–14 v Go to Step 3 Go to Step 2

System OK

11–14 v Go to Step 7 Go to Step 4

Go to Step 6 Go to Step 5

System OK

System OK

11–14 v Go to Step 11 Go to Step 8

[ 0 W Go to Step 10 Go to Step 9

System OK

System OK

11–14 v Go to Step 12 Go to Step 13

System OK

System OK

DAEWOO V–121 BL4

Page 33

WIPERS/WASHER SYSTEMS 9D – 7

Windshield Wipers Do Not Return To Park Position

Step Action Value(s) Yes No

1

1. Turn the ignition ON.

2. Check the voltage at the wiper motor connector

terminal 2.

Is the voltage equal to the specified value?

2 Repair the open circuit between the wiper motor

connector terminal 2 and fuse F4.

Is the repair complete?

3

1. Turn the wiper switch to HI.

2. While turning the wiper switch OFF, check the

voltage at the wiper motor connector terminal

1.

Is the specified voltage indicated when the wiper

switch is turned OFF?

4 Replace the wiper motor.

Is there an open circuit?

5

1. Disconnect the wiper relay.

2. Check continuity between wiper relay terminal

31b and 53e.

Does the ohmmeter indicate the specified value?

6 Repair the open circuit between the wiper motor and

the wiper relay.

Is the repair complete?

7 Replace the wiper relay.

Is the repair complete?

11–14 v Go to Step 3 Go to Step 2

System OK

11–14 v Go to Step 5 Go to Step 4

System OK

[ 0 W Go to Step 6 Go to Step 7

System OK

System OK

DAEWOO V–121 BL4

Page 34

9D – 8IWIPERS/WASHER SYSTEMS

WINDSHIELD WASHER SYSTEM

Windshield Washer Inoperative, Wipers Work OK

Step Action Value(s) Yes No

1 Activate the windshield washer switch.

Do the windshield wipers operate when the washer

switch is activated?

2

3 Replace windshield wiper switch.

4 Check the windshield washer fluid reservoir.

5 Fill the windshield washer fluid reservoir.

6 Check the windshield washer hoses and nozzles.

7 Repair the washer hoses and nozzles.

8

9 Repair the open circuit between the windshield

10 Use an ohmmeter to measure resistance between

11 Repair the windshield washer pump ground circuit.

12 Replace the windshield washer pump.

1. Turn the ignition ON.

2. While activating the washer switch, test the

voltage at windshield wiper switch connector

terminal A4.

Is voltage equal to the specified value?

Is the repair complete?

Is there washer fluid in the fluid reservoir?

Is the repair complete?

Are the windshield washer hoses and nozzles

clogged or damaged?

Is the repair complete?

1. Turn the ignition ON.

2. With the windshield washer activated, test the

voltage at the windshield washer pump.

Is the voltage equal to the specified value?

washer pump and the windshield wiper switch.

Is the repair complete?

ground and the windshield washer pump connector

terminal 1.

Is the resistance equal to the specified value?

Is the repair complete?

Is the repair complete?

11–14 v Go to Step 8 Go to Step 3

11–14 v Go to Step 10 Go to Step 9

[ 0 W Go to Step 12 Go to Step 11

Go to Step 4 Go to Step 2

System OK

Go to Step 6 Go to Step 5

System OK

Go to Step 7 Go to Step 8

System OK

System OK

System OK

System OK

DAEWOO V–121 BL4

Page 35

WIPERS/WASHER SYSTEMS 9D – 9

REAR WINDOW WIPER (HATCHBACK AND WAGON)

Diagnostic Aid

If the front wiper is operating correctly, it is not necessary to check the fuse or the power supply circuit. Begin the diagnostic

check at Step 5 of the table below.

Step Action Value(s) Yes No

1 Check fuse F4.

Is fuse F4 blown?

2

3

4 Repair the open power supply circuit for fuse F4.

5

6 Repair the open circuit between fuse F4 and rear

7 With the rear window wiper still disconnected, use

8 Repair the open ground circuit for the rear window

9

10 Replace the rear window wiper motor.

11

12 Repair the open circuit between fuse F4 and rear

1. Check for a short circuit and repair it, if necessary.

2. Replace the fuse.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F4.

Is the specified voltage available at fuse F4?

Is the repair complete?

1. Disconnect the rear window wiper motor electrical connector.

2. Turn the ignition ON.

3. Check the voltage at rear wiper motor connector terminal 3.

Does the voltage equal the specified value?

window wiper motor connector terminal 3.

Is the repair complete?

an ohmmeter to check continuity between rear wiper

motor connector terminal 2 and ground.

Does the ohmmeter indicate the specified value?

wiper motor.

Is the repair complete?

1. Turn the ignition ON.

2. Turn the rear window wiper to ON.

3. Check the voltage at rear window wiper motor

connector terminal 1.

Does the voltmeter indicate the specified value?

Is the repair complete?

1. Disconnect the rear window wiper switch electrical connector.

2. Turn the ignition ON.

3. Check the voltage at wiper switch connector

terminal A3 (PNK wire).

Does the voltmeter indicate the specified value?

window wiper switch connector terminal A3.

Is the repair complete?

11 – 14 v Go to Step 5 Go to Step 4

11 – 14 v Go to Step 7 Go to Step 6

[ 0 W Go to Step 9 Go to Step 8

11 – 14 v Go to Step 10 Go to Step 11

11 – 14 v Go to Step 13 Go to Step 12

Go to Step 2 Go to Step 3

System OK

System OK

System OK

System OK

System OK

System OK

DAEWOO V–121 BL4

Page 36

9D – 10IWIPERS/WASHER SYSTEMS

Step NoYesValue(s)Action

13

14 Repair the open circuit between terminal A1 of the

15 Replace the rear window wiper switch.

1. Connect an ohmmeter between terminals A1

and A3 of the rear window wiper switch.

2. Move the rear window wiper switch to the

WIPE position.

Does the ohmmeter indicate the specified value?

rear window wiper connector (WHT wire) and the

rear window wiper motor.

Is the repair complete?

Is the repair complete?

[ 0 W Go to Step 14 Go to Step 15

System OK

System OK

DAEWOO V–121 BL4

Page 37

WIPERS/WASHER SYSTEMS 9D – 11

REAR WINDOW WASHER SYSTEM (HATCHBACK AND

WAGON)

Step Action Value(s) Yes No

1 Check the washer fluid level.

Is there fluid in the washer reservoir?

2 Fill the washer reservoir.

Is the repair complete?

3 Verify that the hoses are not obstructed or leaking.

1. Disconnect the washer hose.

2. Blow through the washer hose toward the reservoir and also toward the nozzle.

Are the hoses obstructed or leaking?

4 Repair or replace the hoses.

Is the repair complete?

5 Check the function of the rear window wiper.

Does the rear window wiper function correctly?

6 Repair the rear window wiper.

Is the rear window wiper functioning correctly?

7

8 Repair the open or high–resistance ground connec-

9

10 Replace the rear window washer pump.

11

12 Repair the open circuit between terminal A2 (DK

13 Replace the rear window wiper switch.

1. Disconnect the electrical connector at the rear

window washer pump.

2. Use an ohmmeter to check continuity between

terminal 1 and ground.

Does the ohmmeter indicate the specified value?

tion.

Is the repair complete?

1. Turn the rear window washer ON.

2. Check the voltage at terminal 2 of the rear window washer pump connector (DK GRN wire).

Is the voltage equal to the specified value?

Is the repair complete?

1. Disconnect the rear window wiper switch.

2. Connect an ohmmeter between terminal A3

and terminal A2 of the rear window wiper

switch.

3. Observe the ohmmeter when the switch is

moved to the rear WASH position.

Does the ohmmeter indicate the specified value?

GRN wire) of the rear window wiper switch connector and terminal 2 (DK GRN wire) of the rear window

washer pump.

Is the repair complete?

Is the repair complete?

[ 0 W Go to Step 9 Go to Step 8

11 – 14 v Go to Step 10 Go to Step 11

[ 0 W Go to Step 12 Go to Step 13

Go to Step 3 Go to Step 2

System OK

Go to Step 4 Go to Step 5

System OK

Go to Step 7 Go to Step 6

Go to Step 7

System OK

System OK

System OK

System OK

DAEWOO V–121 BL4

Page 38

9D – 12IWIPERS/WASHER SYSTEMS

MAINTENANCE AND REPAIR

ON–VEHICLE SER VICE

WINDSHIELD WIPER ARM

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Open the hood.

2. Remove the cap to reveal the wiper arm nut, if nec-

essary.

3. Remove the nut from the wiper arm.

4. Pull the wiper arm off.

Installation Procedure

1. Install the wiper arm.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

2. Secure the wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 11 NSm (97 lb–in).

3. Install the wiper arm nut cap, if necessary.

4. Close the hood.

WINDSHIELD WIPER MOTOR

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the left–side portion of the cowl vent grille.

Refer to Section 9R, Body Front End.

3. Remove the nut and the washer that secure the

wiper arm linkage to the motor drive shaft.

DAEWOO V–121 BL4

Page 39

WIPERS/WASHER SYSTEMS 9D – 13

4. Pry the wiper arm linkage off the motor drive shaft.

5. Remove the nuts and reposition the engine coolant

reservoir.

6. Disconnect the electrical connector.

7. Remove the bolts and the wiper motor.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

1. Install the wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 8 NSm (71 lb–in).

2. Connect the electrical connector.

3. Press the wiper arm linkage onto the motor drive

shaft.

4. Install the wiper arm linkage to the motor drive shaft

with the washer and the nut.

Tighten

Tighten the wiper arm linkage nut to 5 NSm (44 lb–in).

5. Install the left side portion of the cowl vent grille.

Refer toSection 9R, Body Front End.

6. Connect the negative battery cable.

DAEWOO V–121 BL4

Page 40

9D – 14IWIPERS/WASHER SYSTEMS

WINDSHIELD WIPER BLADE

(Typical)

Removal Procedure

1. Rotate the wiper blade on the arm.

2. While pressing the retainer clip, slide the wiper

blade down the wiper arm and remove the blade.

Installation Procedure

1. Install the wiper blade by sliding it onto the arm until

the retainer clip engages.

WINDSHIELD WIPER BLADE INSERT

(Front Shown, Rear Similar)

Removal Procedure

1. Slide the insert out of the wiper blade.

DAEWOO V–121 BL4

Page 41

WIPERS/WASHER SYSTEMS 9D – 15

Installation Procedure

1. Slide the insert into the wiper blade.

WINDSHIELD WASHER RESERVOIR

(Typical)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

4. Disconnect the washer hose from the washer

pump.

5. Disconnect the reservoir pump electrical connector.

DAEWOO V–121 BL4

Page 42

9D – 16IWIPERS/WASHER SYSTEMS

6. Remove the bolts and the reservoir.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

1. Install the reservoir with the bolts.

Tighten

Tighten the washer fluid reservoir bolts to 8 NSm (71

lb–in).

2. Connect the reservoir pump electrical connector.

3. Connect the washer hose to the washer pump.

DAEWOO V–121 BL4

Page 43

WIPERS/WASHER SYSTEMS 9D – 17

4. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the front wheel well splash shield bolts to 1.5

NSm (13 lb–in).

5. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

6. Connect the negative battery cable.

WINDSHIELD WASHER PUMP(S)

(Typical)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

4. Disconnect the electrical connector.

5. Disconnect the washer hose from the washer

pump.

6. Remove the washer pump.

Installation Procedure

1. Install the washer pump.

2. Connect the washer hose to the washer pump.

3. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

4. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the front wheel well splash shield bolts to 1.5

NSm (13 lb–in).

5. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

6. Connect the negative battery cable.

DAEWOO V–121 BL4

Page 44

9D – 18IWIPERS/WASHER SYSTEMS

WINDSHIELD WASHER NOZZLES

Removal Procedure

1. Remove the cowl vent grille. Refer to Section 9R,

Body Front End.

2. Disconnect the washer hose from the nozzle.

3. Remove the nozzle from the cowl vent grille.

Installation Procedure

1. Install the nozzle onto the cowl vent grille.

2. Connect the washer hose to the nozzle.

3. Install the cowl vent grille. Refer to Section 9R,

Body Front End.

WINDSHIELD WASHER HOSES

(Typical)

Removal Procedure

1. Remove the cowl vent grille. Refer to Section 9R,

Body Front End.

2. Disconnect the windshield washer hose from the

washer nozzles.

DAEWOO V–121 BL4

Page 45

WIPERS/WASHER SYSTEMS 9D – 19

3. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

4. Remove the bolts and the screws and the front

wheel well splash shield.

5. Disconnect the washer hose from the washer reser-

voir.

6. Remove the washer hose.

Installation Procedure

1. Install the washer hose.

2. Connect the washer hose to the washer pump.

DAEWOO V–121 BL4

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

3. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the front wheel well splash shield bolts to 1.5

NSm (13 lb–in).

4. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

5. Connect the windshield washer hose to the washer

nozzles.

6. Install the cowl vent grille. Refer to Section 9R,

Body Front End.

Page 46

9D – 20IWIPERS/WASHER SYSTEMS

REAR WINDOW WIPER ARM

(Wagon Shown, Hatchback Similar)

Removal Procedure

1. Open the wiper arm access cap.

2. Remove the nut and the rear wiper arm.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

1. Install the rear wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 11 NSm (97 lb–in).

2. Close the wiper arm access cap.

REAR WINDOW WIPER MOTOR

(HATCHBACK)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

3. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Remove the bolts and the rear wiper motor.

5. Disconnect the electrical connector.

DAEWOO V–121 BL4

Page 47

WIPERS/WASHER SYSTEMS 9D – 21

Installation Procedure

1. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

2. Install the rear wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 8 NSm (71 lb–in).

3. Install the hatchback door lower garnish molding.

Refer toSection 9G, Interior Trim.

4. Install the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

5. Close the wiper arm access cap.

REAR WINDOW WIPER MOTOR

(WAGON)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

3. Remove the wiper motor exterior retaining clip and

nut from the tailgate.

4. Remove the tailgate lower garnish molding.

5. Disconnect the electrical connector and the washer

hose.

6. Remove the bolts and the rear wiper motor.

DAEWOO V–121 BL4

Page 48

9D – 22IWIPERS/WASHER SYSTEMS

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasteners to prevent premature corrosion.

1. Install the rear wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 8 NSm (71 lb–in).

2. Connect the electrical connector and the washer

hose.

3. Install the tailgate lower garnish molding.

4. Install the wiper motor nut and exterior retaining clip

to the tailgate.

5. Install the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

6. Connect the negative battery cable.

REAR WINDOW WASHER NOZZLE

(HATCHBACK)

Removal Procedure

1. Remove the hatchback door upper garnish molding.

Refer to Section 9G, Interior Trim.

2. Remove the washer hose from the nozzle.

3. Remove the nut and the washer nozzle.

DAEWOO V–121 BL4

Page 49

WIPERS/WASHER SYSTEMS 9D – 23

Installation Procedure

1. Install the washer nozzle with the nut.

2. Install the washer hose to the nozzle.

3. Install the hatchback door upper garnish molding.

Refer toSection 9G, Interior Trim.

DAEWOO V–121 BL4

Page 50

9D – 24IWIPERS/WASHER SYSTEMS

GENERAL DESCRIPTION

AND SYSTEM OPERATION

WINDSHIELD WIPER SYSTEM

The windshield wiper system consists of a wiper motor, a

linkage, a wiper arm and a blade, and a wiper/washer

switch. The windshield wiper circuit incorporates a selfparking device which consists of a worm gear and a cam

plate in order to keep the circuit engaged temporarily when

the switch is turned off. The wiper system is driven by a

permanent magnet–type motor. The windshield wiper motor is mounted on the bulkhead and is directly connected

to the windshield wiper linkage.

The windshield wiper motor has two speeds, LO and HI,

and also has intermittent wiper capability. The wiper

switch is an integral part of the wiper/washer switch. Windshield wiper operation is actuated through the lever on the

right side of the steering column.

WINDSHIELD WASHER SYSTEM

The windshield washer system is equipped with a washer

fluid reservoir, a washer fluid pump, hoses, nozzles, and

a wiper/washer switch. The windshield washer reservoir

is mounted behind the front left wheel well splash shield.

Attached to the reservoir is a washer pump, which pumps

fluid through the hoses to the two nozzles mounted on the

hood. The washer switch is an integral part of the wiper/

washer switch. Windshield washer operation is actuated

through the lever on the right side of the steering column.

REAR WINDOW WIPER/WASHER

SYSTEM

The rear window wiper system consists of a wiper motor,

a wiper arm, and a blade. The rear window wiper motor is

located inside the hatchback/tailgate door and is directly

connected to the rear window wiper. The rear window

washer system is equipped with a separate washer fluid

pump and hose. The hatchback has a hatch–mounted

rear window washer nozzle and on the wagon, the washer

nozzle is incorporated into the rear wiper motor. The rear

window washer reservoir is mounted behind the front left

wheel well splash shield. Attached to the reservoir is a

washer pump, which pumps fluid through a hose to the

rear washer nozzle.

DAEWOO V–121 BL4

Page 51

SECTION : 9N

FRAME AND UNDERBODY

TABLE OF CONTENTS

SPECIFICATIONS 9N–1. . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER TIGHTENING SPECIFICATIONS 9N–1.

MAINTENANCE AND REPAIR 9N–2. . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9N–2. . . . . . . . . . . . . . . . . . . . .

ALIGNMENT CHECKING 9N–2. . . . . . . . . . . . . . . . . . .

FLOOR PAN INSULATORS 9N–2. . . . . . . . . . . . . . . . .

ENGINE UNDER COVER 9N–3. . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 9N–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL BODY CONSTRUCTION 9N–5. . . . . . . . .

ENGINE UNDER COVERS 9N–5. . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

Engine Under Cover Screw 2 – 18

Front Fascia Splash Shield Screw 1.5 – 13

Page 52

9N – 2IFRAME AND UNDERBODY

MAINTENANCE AND REPAIR

ON–VEHICLE SER VICE

ALIGNMENT CHECKING

An accurate method of determining the alignment of the

underbody uses a measuring tram gauge. The tram gauge

set used to perform the recommended measuring checks

must include a vertical pointer.

Two types of measurements can be made with a tram

gauge: direct point–to–point measurements and measurements calculated on a horizontal plane (datum line)

parallel to the underbody. Point–to–point measurements

are generally taken on steering and suspension engine

compartment parts and simply require the vertical pointers

to be set equally.

For horizontal plane measurements, the vertical pointers

must be set as specified for each point to bemeasured.

Dimensions–to–gauge holes are measured to the center

of the holes and flush to the adjacent surface metal unless

otherwise specified. It is recommended that the diagonal

dimensions to the cross–body be checked on both sides

in order to verify the dimensional accuracy of the vehicle

underbody.

FLOOR PAN INSULATORS

The floor pan insulators have been designed for the higher

floor pan temperatures that result from the use of the catalytic converter in the exhaust system. Therefore, when

servicing a vehicle, it is essential that any insulators that

may have been disturbed or removed be reinstalled in the

original sequence and location. Also, if an insulator needs

to be replaced, use only the insulation specified for that

location on the floor pan.

When servicing or replacing interior insulators, observe

the following instructions.

S Install the insulators in the original position and se-

quence. Butt the pieces together in order to avoid

gapping or overlapping.

S If it is necessary to replace an insulator, use only

the specified insulation.

S Use the original part to determine the amount of

replacement material required and as a template for

cutting and fitting the new piece to the floor pan.

S When installing the insulator, do not enlarge any

cutouts or holes that are used for the attachment of

interior parts such as the instrument panel or the

floor console.

S Route the cross–body harness for interior parts

over the floor pan insulators. Clip it in the original

location.

S Do not apply spray–on deadeners or trim adhesives

to the top of the floor pan at the area directly over

the catalytic converter or the muffler.

Any insulator service repair or replacement should be the

same thickness, size, and location as the original installation in the vehicle.

DAEWOO V–121 BL4

Page 53

FRAME AND UNDERBODY 9N – 3

ENGINE UNDER COVER

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the screws and the front fascia splash

shield.

3. Remove the screws, the nuts, and the engine under

cover.

DAEWOO V–121 BL4

Installation Procedure

1. Install the engine under cover with the screws and

the nuts.

Tighten

Tighten the engine under cover nuts to 2 NSm (18

lbin).

2. Install the front fascia splash shield with the screws.

Tighten

Tighten the front fascia splash shield screw to 1.5

NSm (13 lb–in).

3. Lower the vehicle.

Page 54