Page 1

Page 2

SECTION : 0B

GENERAL INFORMATION

TABLE OF CONTENTS

SPECIFICATIONS 0B–1. . . . . . . . . . . . . . . . . . . . . . . . . .

TECHNICAL DATA 0B–1. . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE DIMENSIONS AND WEIGHTS 0B–5. . . . .

STANDARD BOLT SPECIFICATIONS 0B–7. . . . . . . .

MAINTENANCE AND REPAIR 0B–8. . . . . . . . . . . . . . .

MAINTENANCE AND LUBRICATION 0B–8. . . . . . . . . .

NORMAL VEHICLE USE 0B–8. . . . . . . . . . . . . . . . . . .

EXPLANATION OF SCHEDULED MAINTENANCE

SERVICES 0B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCHEDULED MAINTENANCE CHARTS 0B–10. . . .

OWNER INSPECTIONS AND SERVICES 0B–12. . . . .

WHILE OPERATING THE VEHICLE 0B–12. . . . . . . .

AT EACH FUEL FILL 0B–12. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

TECHNICAL DATA

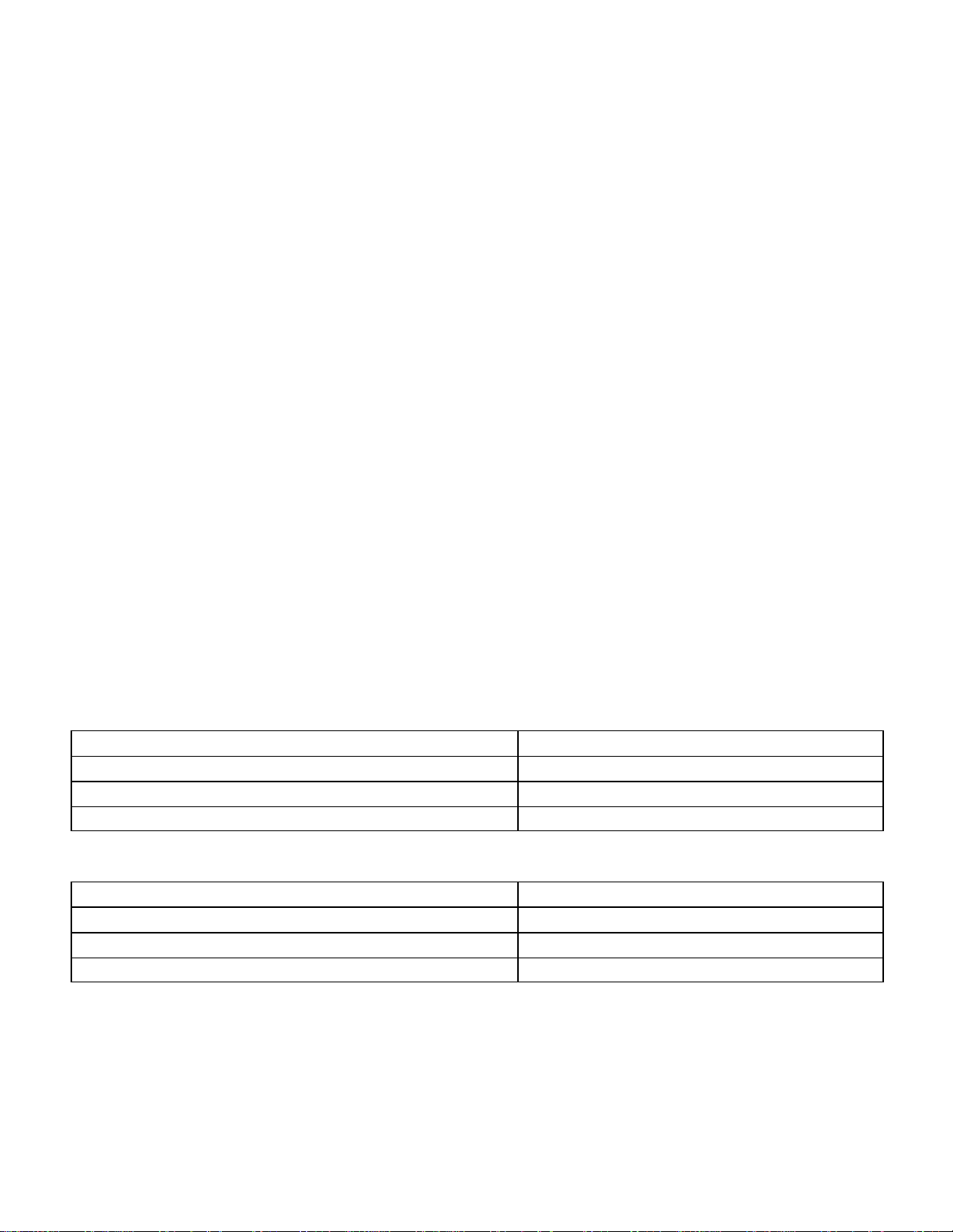

Performance – Manual Transaxle

AT LEAST MONTHLY 0B–12. . . . . . . . . . . . . . . . . . . . .

AT LEAST TWICE A YEAR 0B–12. . . . . . . . . . . . . . . .

EACH TIME THE OIL IS CHANGED 0B–13. . . . . . . .

AT LEAST ANNUALLY 0B–13. . . . . . . . . . . . . . . . . . . .

RECOMMENDED FLUIDS AND LUBRICANTS 0B–15

GENERAL DESCRIPTION AND SYSTEM

OPERATION 0B–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL REPAIR INSTRUCTIONS 0B–16. . . . . . .

GENERAL DESCRIPTION 0B–17. . . . . . . . . . . . . . . . . .

ON BOARD REFUELING VAPOR RECOVERY

SYSTEM 0B–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION 0B–20. . . . . . . . . . . . . . .

VEHICLE LIFTING PROCEDURES 0B–24. . . . . . . . .

Application 2.0L DOHC

Maximum Speed 195 km/h (122 mph)

Gradeability 0.446 (tan Ø)

Minimum Turning Radius 5.3 m (17 ft)

Performance – Automatic Transaxle

Application 2.0L DOHC

Maximum Speed 190 km/h (119mph)

Gradeability 0.668 (tan Ø)

Minimum Turning Radius 5.3 m (17 ft)

Page 3

0B – 2IGENERAL INFORMATION

Engine

Application 2.0L DOHC

Engine Type Dual Overhead Cam L–4

Bore 86 mm (3.4 in.)

Stroke 86 mm (3.4 in.)

Total Displacement 1 998 cm3 (121.9 in3)

Compression Ratio 9.5µ0.2:1

Maximum Power 96 kW (128.7 bhp)

(at 5,400 rpm)

Maximum Torque 184 NSm (135.7 lb–ft)

(at 4,400 rpm)

Ignition System

Application 2.0L DOHC

Ignition Type Direct Ignition System

Ignition Timing 8³ BTDC

Ignition Sequence 1–3–4–2

Spark Plug Gap 0.8 mm (0.031 in)

Spark Plug Maker Bosch

Spark Plug Type FR8LDC4

Clutch – Manual Transaxle

Application 2.0L DOHC

Type Single Dry Plate

Outside Diameter 225 mm (9.0 in.)

Inside Diameter 150 mm (5.9 in.)

Thickness 3.4 mm (0.13 in.)

Fluid Capacity Common Use; Brake Fluid

Manual Transaxle

Application 2.2L DOHC

Maker DWMC

Type or Model D–20

Gear Ratio: –

1st 3.545:1

2nd 2.158:1

3rd 1.478:1

4th 1.129:1

5th 0.886:1

Reverse 3.333:1

Final Drive Ratio 3.550:1

Oil Capacity 1.8L (2 qt)

* Puerto Rico only.

DAEWOO V–121 BL4

Page 4

GENERAL INFORMATION 0B – 3

Automatic Transaxle

Application 2.0L DOHC

Maker GM

Type or Model 4T40E

Gear Ratio: –

1st 2.957:1

2nd 1.623:1

3rd 1.000:1

4th 0.682:1

Reverse 2.143:1

Final Drive Ratio 3.910:1

Oil Capacity 11.5L (12 qt)

Brake

Application 2.0L DOHC

Booster Size: –

Single 228.6 mm (9 in.)

Master Cylinder Diameter 22.2 mm (0.87 in.)

Booster Ratio 5.0:1

Front Brake: –

Disc Type Ventilated

Disc Size 356 mm (14.0 in.)

Rear Brake: –

Disc: –

Disc Type Solid

Disc Size 32 mm (1.3 in.)

Fluid Capacity 0.5L (0.53 qt)

Tire and Wheel

Application 2.0L DOHC

Standard Tire Size 185/65R14

Temporary Tire Size T125/70D15

Standard Wheel Size 5.5JX14

Inflation Pressure at Full Load: –

185/65R14: ––

Front 30 psi

Rear 28 psi

T127/70D15 60 psi

DAEWOO V–121 BL4

Page 5

0B – 4IGENERAL INFORMATION

Steering System

Application 2.0L DOHC

Gear Type Power Rack and Pinion

Overall Gear Ratio: –

Manual Steering –

Power Steering 16:1

Wheel Alignment: –

Front: –

Total Toe–In (2 Occupants) –10′ to +10′

Caster: –

Power Steering 2³30′ to 3³30′

Camber –54′ to 6′

Rear: –

Total Toe–In (2 Occupants) –3′ to +17′

Camber –1³35′ to –5′

Oil Capacity 1.0L (1.1 qt)

Suspension

Application 2.0L DOHC

Front Type MacPherson Strut

Rear Type Compound Link

Fuel System

Application 2.0L DOHC

Fuel Delivery MPI

Fuel Pump Type Electric Motor Pump

Fuel Filter Type Cartridge

Fuel Capacity 52L (13.7 gal)

Lubricating System

Application 2.0L DOHC

Lubricating Type Forced Feed

Oil Pump Type Duocentric Rotor

Oil Filter Type Cartridge (Full Flow)

Oil Pan Capacity Including Oil Filter 3.8L (4.1 qt)

DAEWOO V–121 BL4

Page 6

GENERAL INFORMATION 0B – 5

Cooling System

Application 2.0L DOHC

Cooling Type Forced Water Circulation

Radiator Type Cross–flow

Water Pump Type Centrifugal

Thermostat Type Pellet Type

Coolant Capacity: –

Manual: 7.0L (7.4 qt)

Automatic: 7.0L (7.4 qt)

Electric System

Application 2.0L DOHC

Battery (55 AH, M/F) 630 Cold Cranking Amps

Alternator: 85 Amps

Starter (1.4 kW) No Load Test Minimum 40 Amps

Maximum 90 Amps

(at 12.2 volts)

VEHICLE DIMENSIONS AND WEIGHTS

Vehicle Dimensions – Manual and Automatic

Application 2.0L DOHC

Overall Length: –

4–Door Notchback 4 470 mm (176.0 in.)

4–Door Wagon 4 514 mm (177.7 in.)

5–Door 4 248 mm (167.2 in.)

Overall Width 1 700 mm (66.9 in.)

Overall Height: –

4–Door Notchback 1 425 mm (56.1 in.)

4–Door Wagon 1 432 mm (56.4 in.)

5–Door 1 425 mm (56.1 in.)

Overall Height: Overall Height:

4–Door Notchback 1 430 mm (56.2 in.)

4–Door Wagon 1 470 mm (58.0 in.)

5–Door 1 430 mm (56.2 in.)

Minimum Ground Clearance 151 mm (5.9 in.)

Wheel Base 2 570 mm (101.2 in.)

Tread: –

Front 1 464 mm (57.6 in.)

Rear 1 454 mm (57.2 in.)

DAEWOO V–121 BL4

Page 7

0B – 6IGENERAL INFORMATION

Vehicle Weights – 4 Door Notchback

Application 2.0L DOHC

Manual: –

Curb Weight: –

Standard 1 164 kg (2,566 lb)

Optional 1 233 kg (2,718 lb)

Gross Vehicle Weight 1 720 kg (3,792 lb)

Automatic: –

Curb Weight –

Standard 1 200 kg (2,645 lb)

Optional 1 269 kg (2,797 lb)

Gross Vehicle Weight 1 720 kg (3,792 lb)

Passenger Capacity 5

Vehicle Weights – 4 Door Wagon

Application 2.0L DOHC

Manual: –

Curb Weight: –

Standard 1 222 kg (2,694 lb)

Optional 1 291 kg (2,846 lb)

Gross Vehicle Weight 1 860 kg (4,101 lb)

Automatic: –

Curb Weight –

Standard 1 258 kg (2,773 lb)

Optional 1 327 kg (2,925 lb)

Gross Vehicle Weight 1 860 kg (4,101 lb)

Passenger Capacity 5

Vehicle Weights – 5 Door

Application 2.0L DOHC

Manual: –

Curb Weight: –

Standard 1 155 kg (2,546 lb)

Optional 1 224 kg (2,698 lb)

Gross Vehicle Weight 1 720 kg (3,792 lb)

Automatic: –

Curb Weight: –

Standard 1 191 kg (2,625 lb)

Optional 1 260 kg (2,778 lb)

Gross Vehicle Weight 1 720 kg (3,792 lb)

Passenger Capacity 5

Optional Weight: Air Conditioning, Power Steering, ABS, Sunroof, Airbag.

DAEWOO V–121 BL4

Page 8

GENERAL INFORMATION 0B – 7

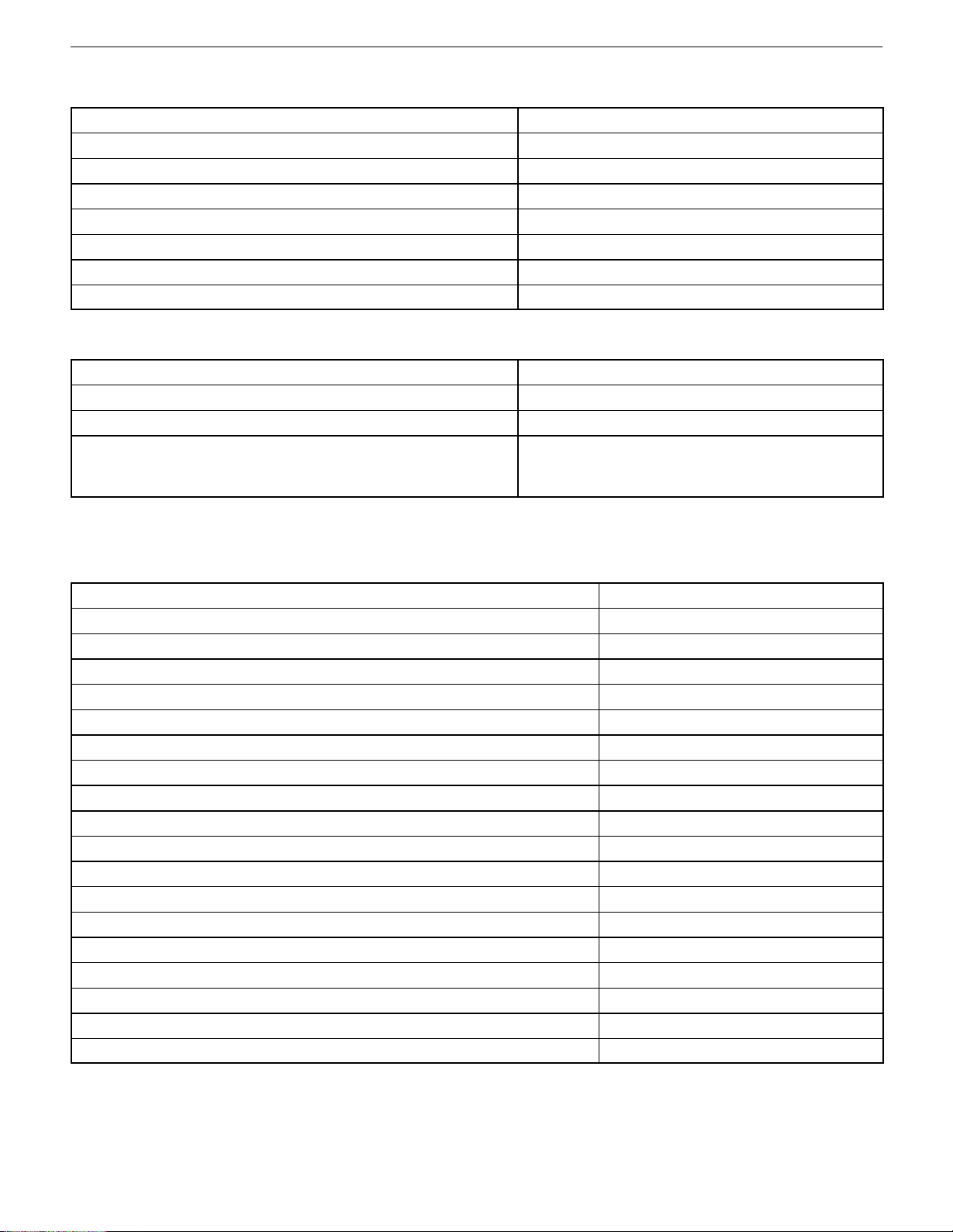

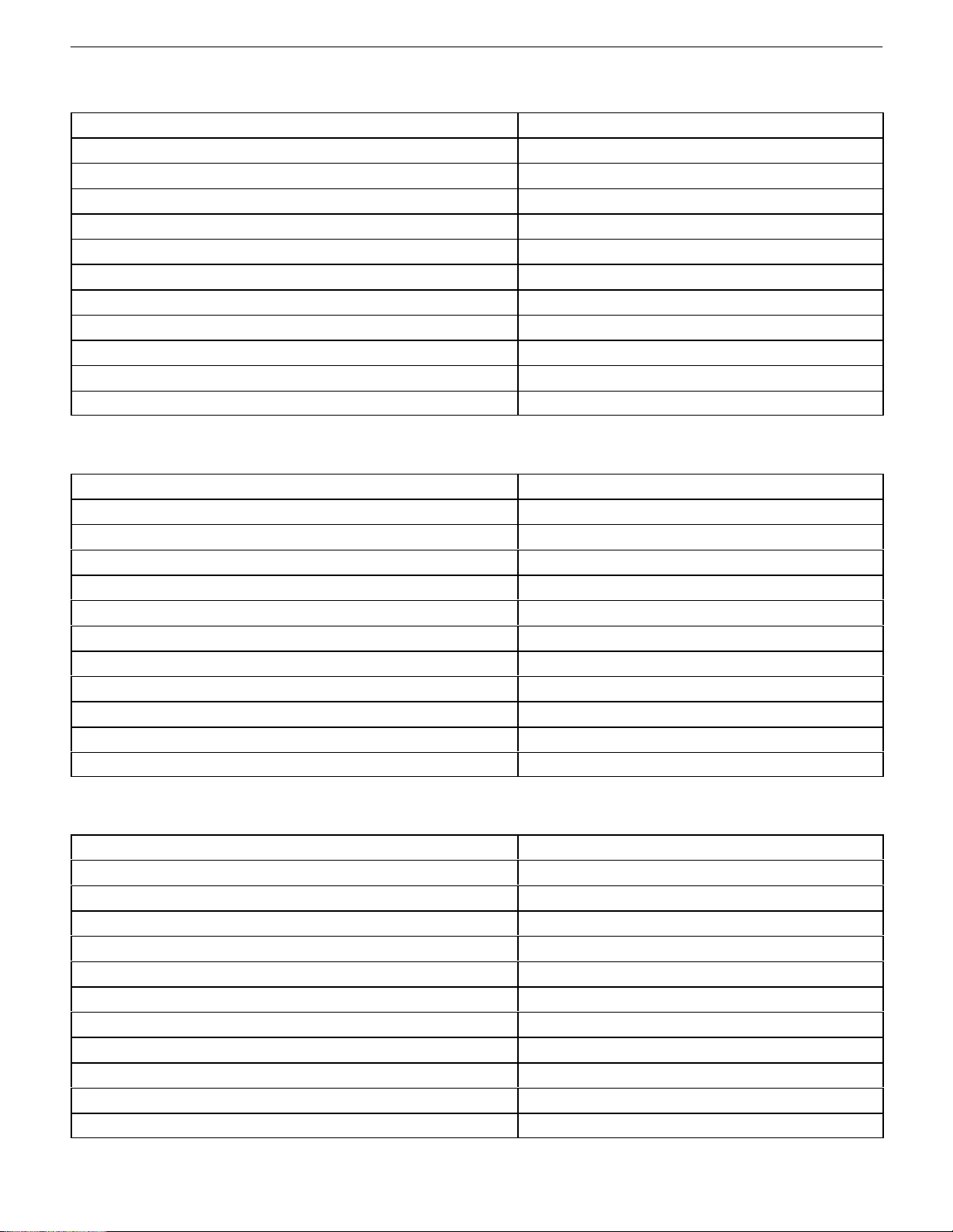

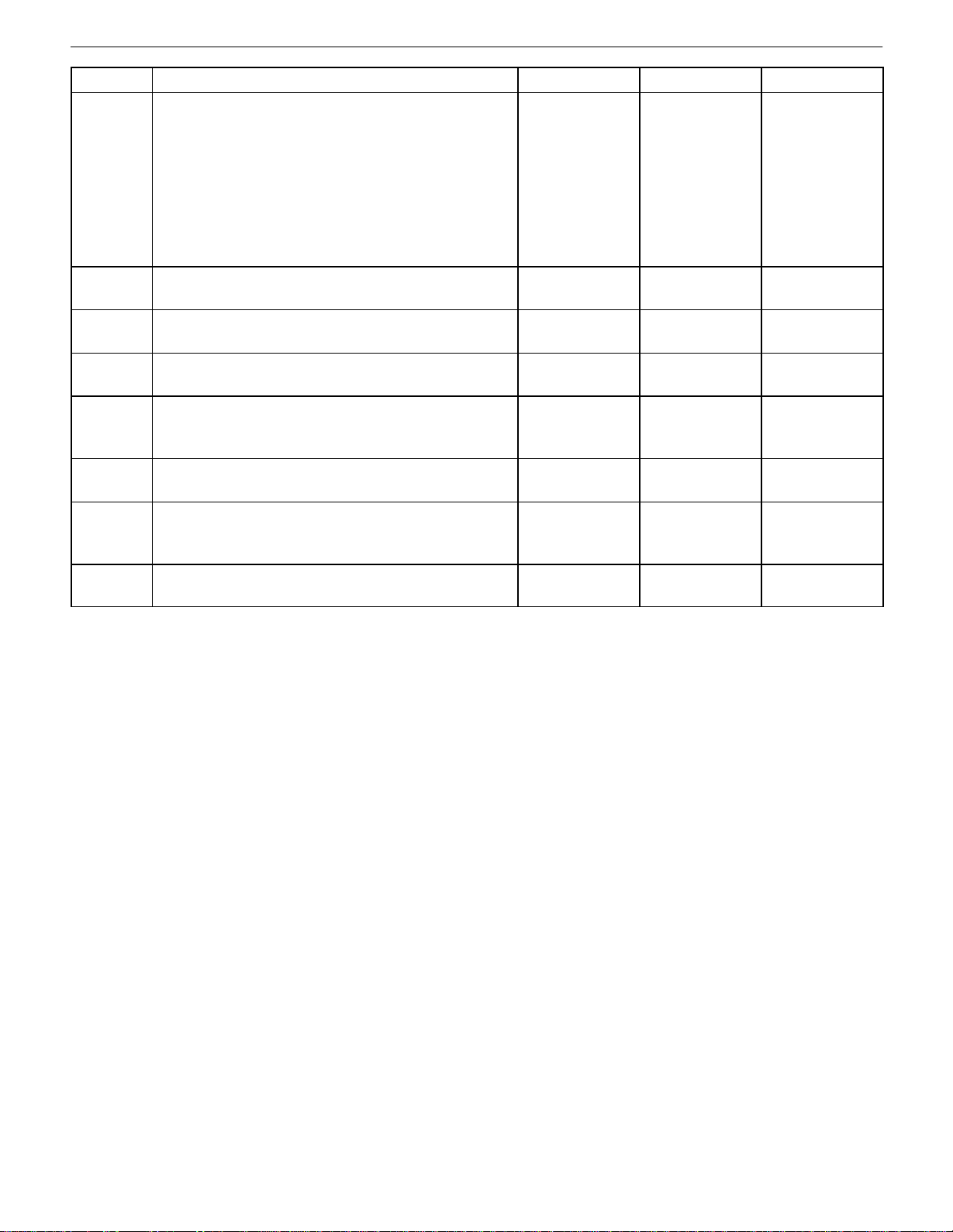

STANDARD BOLT SPECIFICATIONS

Bolt* 4T – Low Carbon Steel 7T – High Carbon Steel 7T – Alloy Steel

M6 X 1.0 4.1–8.1 NSm (36–72 lb–in) 5.4–9.5 NSm (48–84 lb–in) –

M8 X 1.25 8.1–17.6 NSm (72–156 lb–in) 12.2–23.0 NSm (108–204 lb–

in)

M10 X 1.25 20–34 NSm (15–25 lb–ft) 27–46 NSm (20–34 lb–ft) 37–62 NSm (27–46 lb–ft)

M10 X 1.5 19–34 NSm (14–25 lb–ft) 27–45 NSm (20–33 lb–ft) 37–60 NSm (27–44 lb–ft)

M12 X 1.25 49–73 NSm (36–54 lb–ft) 61–91 NSm (45–67 lb–ft) 76–114 NSm (56–84 lb–ft)

M12 X 1.75 45–69 NSm (33–51 lb–ft) 57–84 NSm (42–62 lb–ft) 72–107 NSm (53–79 lb–ft)

M14 X 1.5 76–115 NSm (56–85 lb–ft) 94–140 NSm (69–103 lb–ft) 114–171 NSm (84–126 lb–ft)

M14 X 2.0 72–107 NSm (53–79 lb–ft) 88–132 NSm (65–97 lb–ft) 107–160 NSm (79–118 lb–ft)

M16 X 1.5 104–157 NSm (77–116 lb–ft) 136–203 NSm (100–150 lb–ft) 160–240 NSm (118–177 lb–ft)

M16 X 2.0 100–149 NSm (74–110 lb–ft) 129–194 NSm (95–143 lb–ft) 153–229 NSm (113–169 lb–ft)

M18 X 1.5 151–225 NSm (111–166 lb–ft) 195–293 NSm (144–216 lb–ft) 229–346 NSm (169–255 lb–ft)

M20 X 1.5 206–311 NSm (152–229 lb–ft) 270–405 NSm (199–299 lb–ft) 317–476 NSm (234–351 lb–ft)

M22 X 1.5 251–414 NSm (185–305 lb–ft) 363–544 NSm (268–401 lb–ft) 424–636 NSm (313–469 lb–ft)

M24 X 2.0 359–540 NSm (265–398 lb–ft) 431–710 NSm (318–524 lb–ft) 555–831 NSm (409–613 lb–ft)

16–30 NSm (12–22 lb–ft)

* Diameter X pitch in millimeters

DAEWOO V–121 BL4

Page 9

0B – 8IGENERAL INFORMATION

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

NORMAL VEHICLE USE

The maintenance instructions contained in the maintenance schedule are based on the assumption that the vehicle will be used for the following reasons:

S To carry passengers and cargo within the limitation

indicated on the Tire Placard located on the edge of

the driver’s side door.

S To be driven on reasonable road surfaces and with-

in legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are further explained below. When the following maintenance

services are performed, make sure all the parts are replaced and all the necessary repairs are done before driving the vehicle. Always use the proper fluid and lubricants.

Drive Belt Inspection

When a separate belt drives the power steering pump, the

air conditioning compressor, and the generator, inspect it

for cracks, fraying, wear, and proper tension. Adjust or replace the belt, as needed.

Engine Oil and Oil Filter Change

API Classifications of Engine Oil

The International Lubricant Standardization and Approval

Committee (ILSAC) and American Petroleum Institute

classifies engine oils according to their performance quality. Always use oil rated API–SJ (ILSAC GF–II) or better.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel economy and cold weather operation. Lower viscosity engine

oils can provide better fuel economy and cold weather performance; however, higher temperature weather conditions require higher viscosity engine oils for satisfactory lubrication. Using oils of any viscosity other than those

viscosities recommended could result in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to ”Recommended Fluids and Lubricants”in this section.

DAEWOO V–121 BL4

Page 10

GENERAL INFORMATION 0B – 9

Fuel Micro–Filter Replacement

Replace the engine fuel filter every 48,000 km (30,000

miles).

The engine fuel filter is located on the center dash panel

near the brake booster.

Air Cleaner Element Replacement

Replace the air cleaner element every 48 000 km (30,000

miles).

Replace the air cleaner more often under dusty conditions.

Throttle Body Mounting Bolt Torque

Check the torque of the throttle body mounting bolts.

Tighten the throttle body mounting bolts to 17 NSm (13 lb–

ft) if necessary.

Spark Plug Replacement

Replace spark plugs with the same type.

– Type: AC Type FR8LDC4 (2.0L DOHC)

– Gap: 0.8 mm (0.031 in.) (2.0L DOHC)

Spark Plug Wire Replacement

Clean the w i res and inspect them for burns, cracks, or other damage. Check the wire boot fit at the direct ignition

system (DIS) module and at the spark plugs. Replace the

wires, as needed.

Brake System Service

Check the disc brake pads or the drum brake linings every

9,600 km (6,000 mi) or 6 months. Check the pad and the

lining thickness carefully. If the pads or the linings are not

expected to last another 9,600 km (6,000 mi), replace the

pads or the linings. Check the breather hole in the brake

fluid reservoir cap to be sure it is free from dirt and the passage is open.

Transaxle Service

The manual transaxle fluid does not require changing. For

automatic transaxles, refer to ”Scheduled Maintenance

Charts”in this section.

DAEWOO V–121 BL4

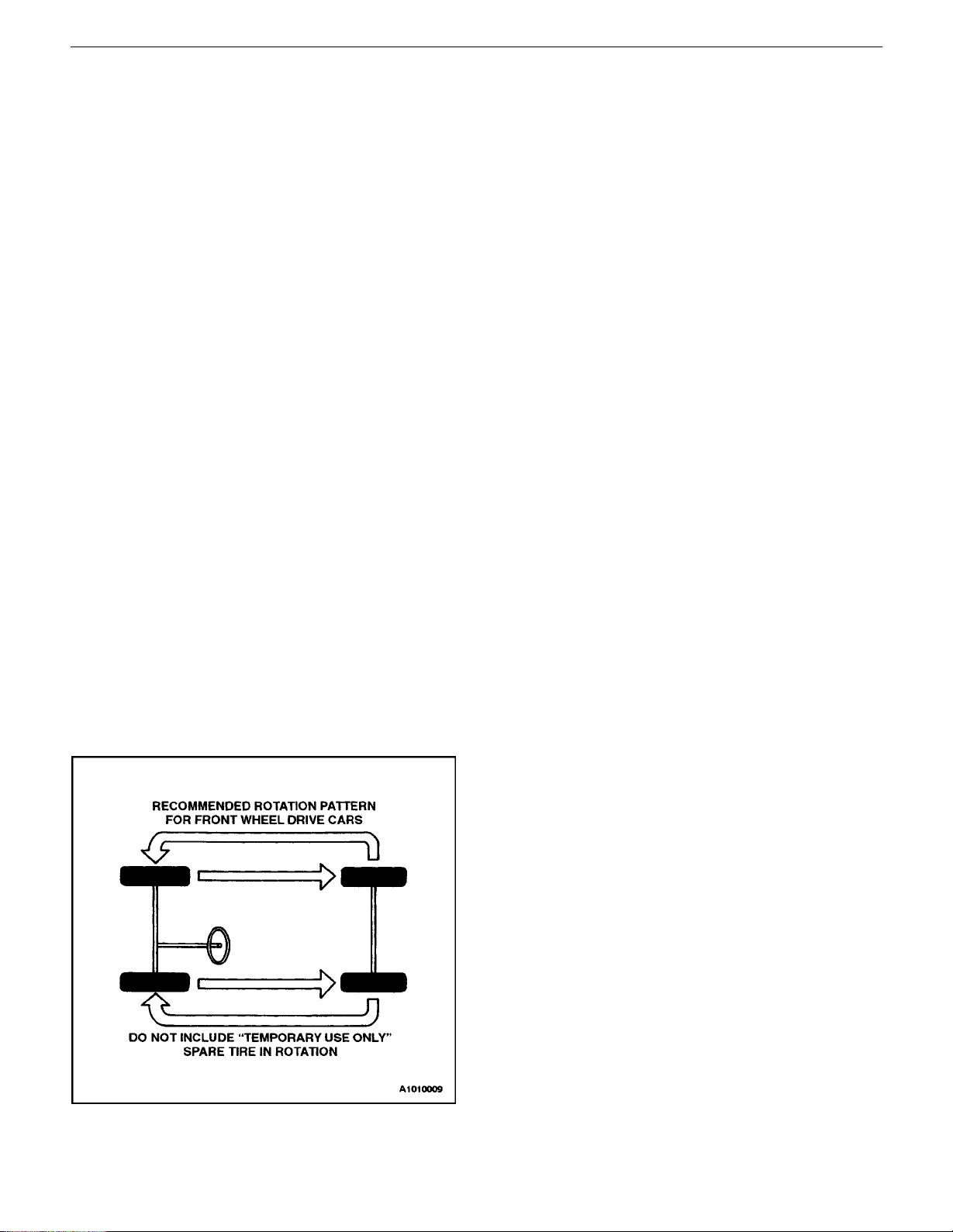

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To equalize

wear and obtain maximum tire life, rotate the tires. If irregular or premature wear exists, check the wheel alignment

and check for damaged wheels. While the tires and

wheels are removed, inspect the brakes. Refer to ”Each

Time The Oil Is Changed”in this section.

Page 11

0B – 10IGENERAL INFORMATION

belt)

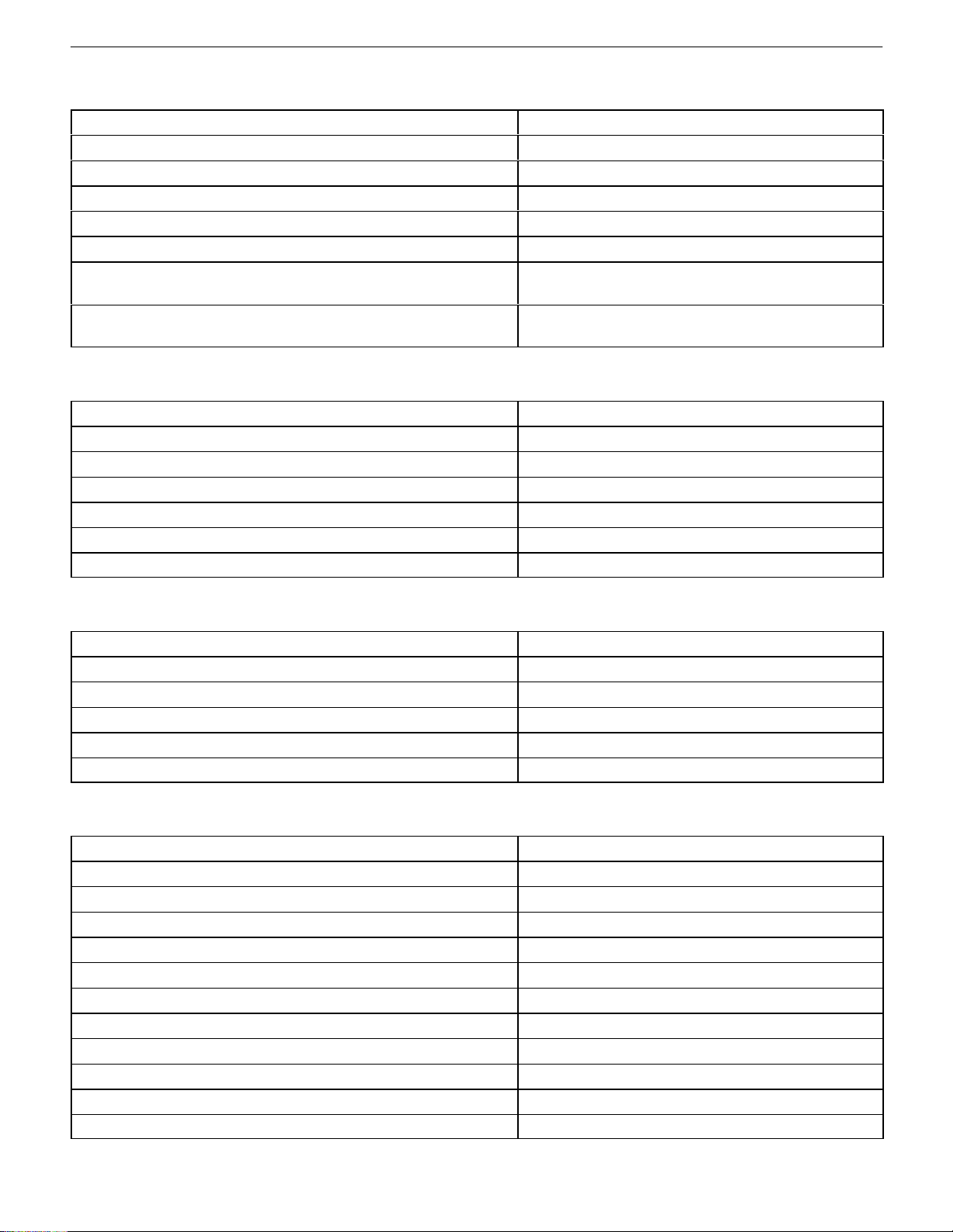

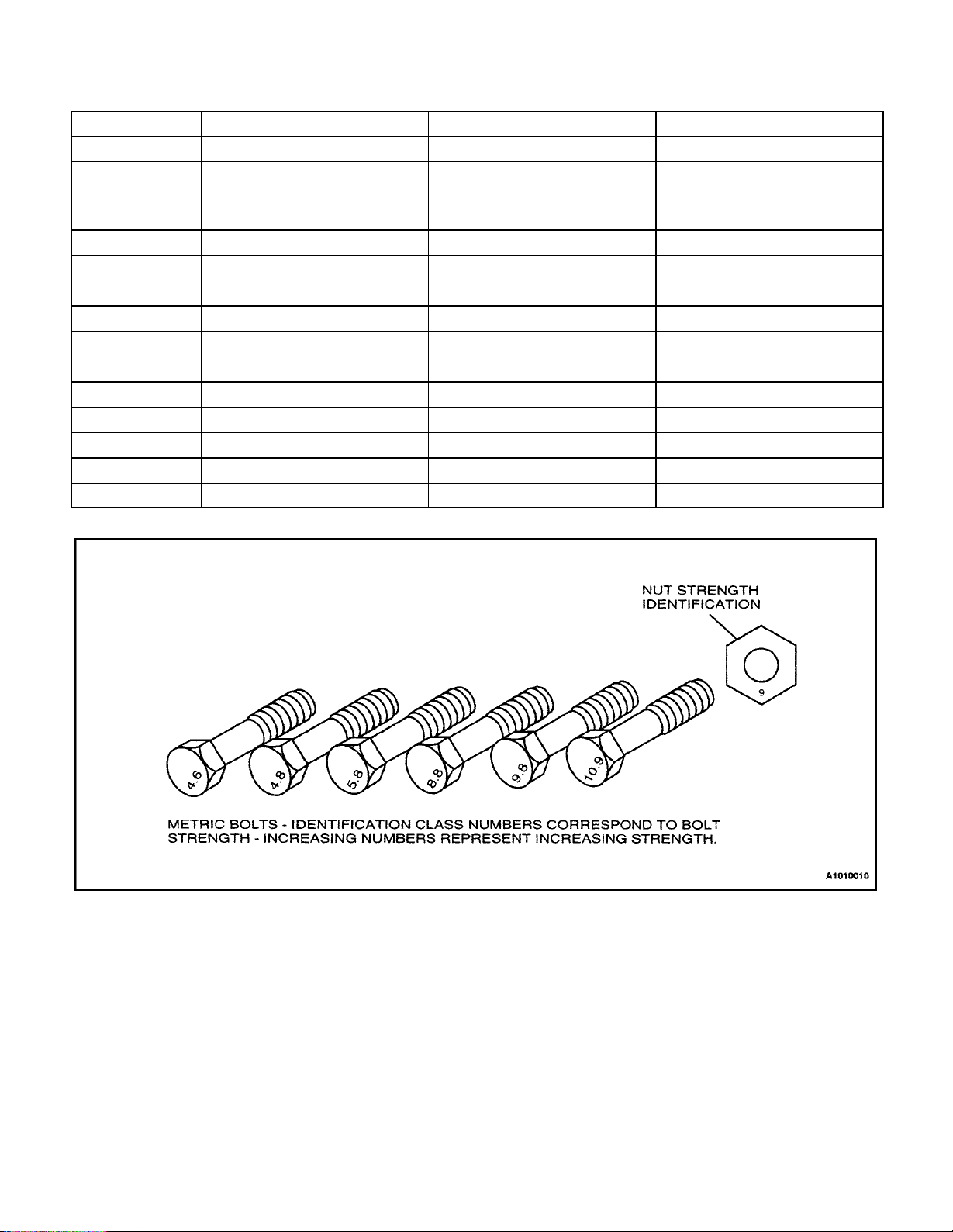

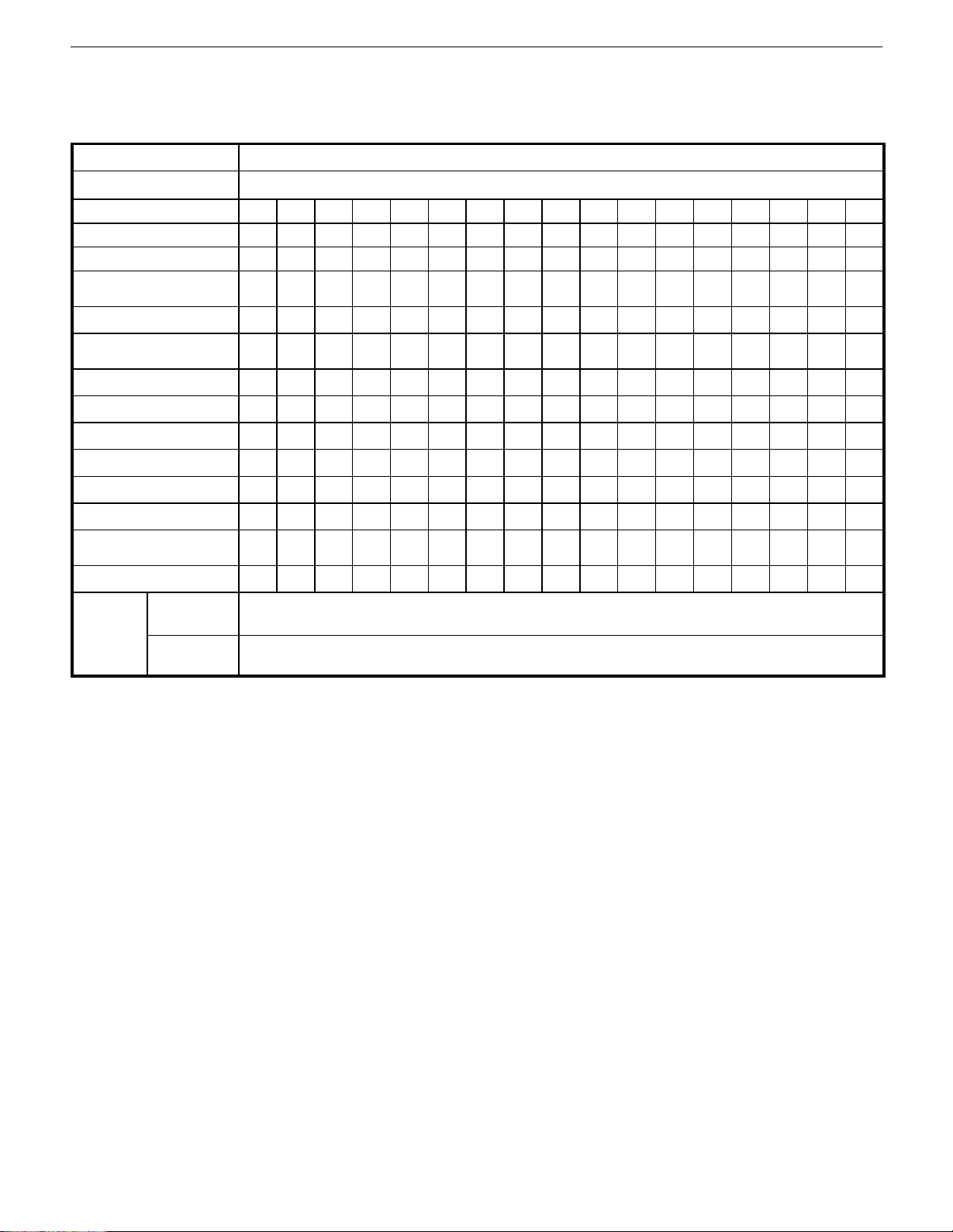

SCHEDULED MAINTENANCE CHARTS

Engine

Maintenance Item Maintenance Interval

Miles (Kilometers) or time inmonths, whichever comes first

x 1,000 miles

x 1,000 km

# Months

Drive belt (Generator and power

Steering)

Engine oil & engine oil filter (1)(3)

Cooling system hose & connections

Engine coolant (3)

Fuel filter

Fuel line and connections

Air cleaner element (2)

Ignition timing

Spark plugs

Evaporative emission canister &

vapor lines

PCV system

Camshaft

belt(Timimg

belt)

Out of Cali-

fornia

California

6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102

9.6 19.2 28.8 38.4 48 57.6 67.2 76.8 86.46 96 105.6 115.2 124.8 134.4 144 153.6 163.2

6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102

I I I I I

R R R R R R R R R R R R R R R R R

I I I I I I I I

I I I I R I I I I R I I I I R I I

R* R* R*

I* I* I* I* I* I* I* I*

I* I* I* I* R I* I* I* I* R I* I* I* I* R I* I*

I* I* I* I* I* I* I* I*

I* R I* R I* R

I* I* I*

I* I* I* I* I*

Replace every 72,000 miles (115,200 km)

Inspect every 60,000 miles (96,000 km) and 90,000 miles (144,000 km)

Replace every 102,000 miles (163,200 km)

Chart Symbols:

I – Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R – Replace or change.

(1) Change the engine oil every 3,000 miles (4,800 kilometers) or 3 months, whichever comes first, if the vehicle is operated

under any of the following conditions :

– Short–distance driving.

– Extensive idling.

– Driving on dusty roads.

(2) More frequent maintenance is required if driving under dusty conditions.

(3) Refer to ”Recommended Fluids And Lubricants”

Note : Check the engine oil and radiator coolant levels every week.

* : Replacement or inspection of these emissions components is recommended to be performed at the indicated intervals

however, the California Air Resources Board has determined that performing thesemaintenance items are not required

to maintained your vehicle emission warranty.

DAEWOO V–121 BL4

Page 12

GENERAL INFORMATION 0B – 11

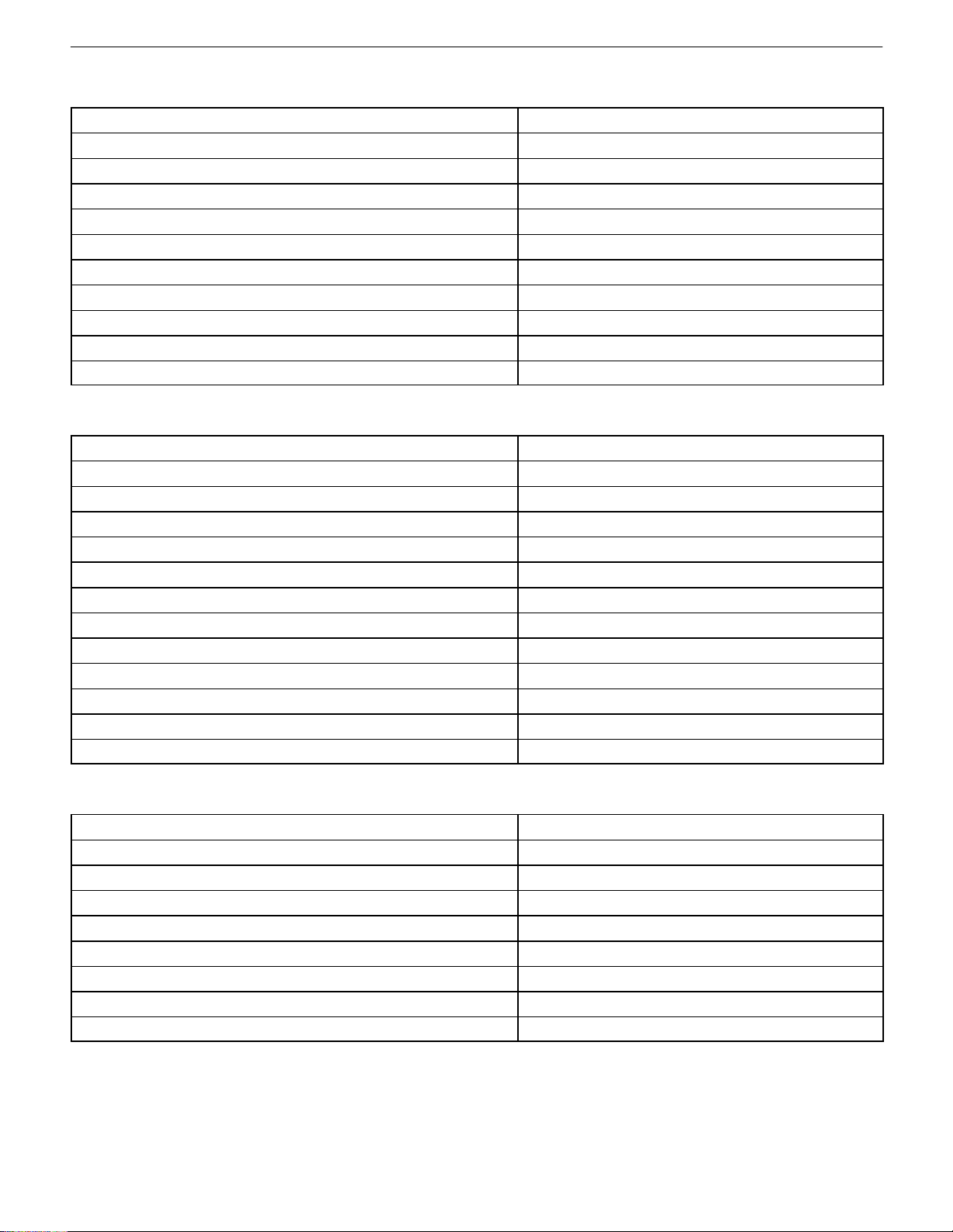

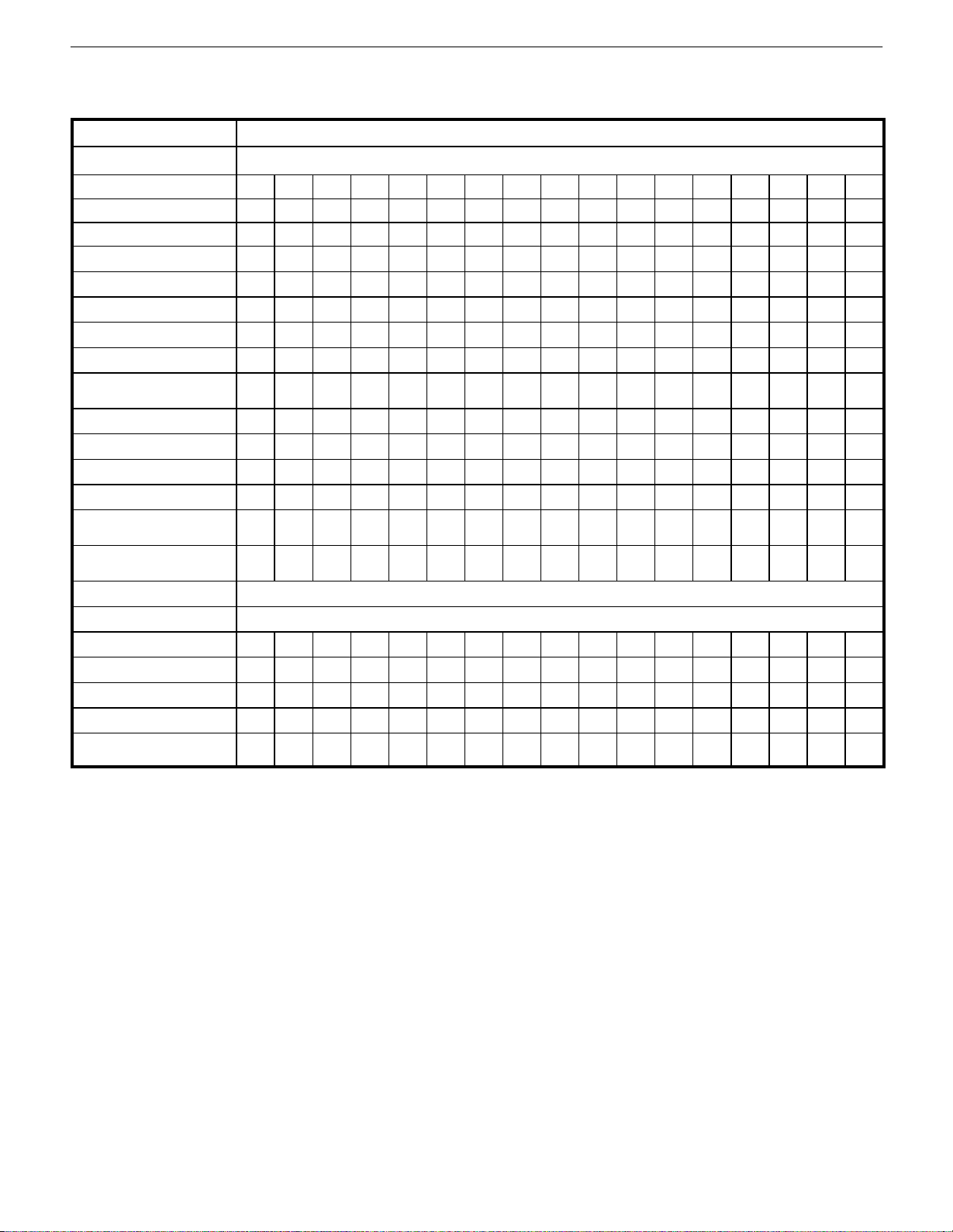

Chassis and Body

Maintenance Item Maintenance Interval

Miles (Kilometers) or time inmonths, whichever comes first

x 1,000 miles

x 1,000 km

# Months

Air Filter (A/C) (2)

Exhaust pipes & mountings

Brake/Clutch fluid (3)(5)

Brake pads & discs(6)

Parking brake

Brake line & connections (In-

cluding booster)

Rear hub bearing & clearance

Manual Transaxle Oil (3)

Clutch & brake pedal free play

Automatic transaxle fluid* (3) (7)

Chassis & underbody bolts &

nuts, tighten/secure

Tire condition & inflation pres-

sure

Wheel alignment (8)

Tire rotation

Steering wheel & linkage

Power steering fluid & lines*

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & hood

latch

6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102

9.6 19.2 28.8 38.4 48 57.6 67.2 76.8 86.46 96 105.6 115.2 124.8 134.4 144 153.6 163.2

6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102

R R R R R R R R R R R R R R R R R

I* I* I* I* I* I* I* I*

I I R I I R I I R I I R I I R I

I I I I I I I I I I I I I I I I

I I I I I I I

I I I I I I I I I I I I I I I I

I I I I I I I I

I I I I I I I I

I I I I I I I I I I I I I I I I I

I I I I R I I I

I I I I I I I I I I I I I I I I I

I I I I I I I I I I I I I I I I I

Inspect when abnormal condition is noted.

Rotate tires every 6,000 miles

I I I I I I I I I I I I I I I I I

I I I I I I I I

I I I I I I I I I I I I I I I I I

I I I I I I I I I I I I I I I I I

I I I I I I I I

Chart Symbols:

I – Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R – Replace or change.

(2) More frequent maintenance is required if driving under dusty conditions.

(3) Refer to”Recommended Fluids And Lubricants.”

(5) Change the brake/clutch fluid every 9,000 miles (14,400 kilometers) or 9months, whichever comes first, if the vehicle

is operated under any of the following conditions :

– Driving in hilly or mountainous terrain.

(6) More frequent maintenance is required if the vehicle is operated under any of the following conditions:

– Short–distance driving.

– Extensive idling or slow–speed driving in stop–and–go traffic.

– Driving on dusty roads.

(7) Change the automatic transaxle fluid every 50,000miles (80,000 kilometers) if the vehicle is operated under any of the

following conditions :

– Driving in hilly or mountainous terrain.

– Driving in heavy city traffic where the outside temperatures regularly reach 32³C (90³F) or higher.

– Driving a taxi, or police or delivery vehicles.

(8) If necessary, rotate and balance the wheels

Note : Check the engine oil and radiator coolant levels every week.

DAEWOO V–121 BL4

Page 13

0B – 12IGENERAL INFORMATION

* Replacement or inspection of these emissions components is recommended to be performed at the indicated intervals

however, the California Air Resources Board has determined that performing thesemaintenance items are not required

to maintained your vehicle emission warranty.

5. Add oil, if needed, to keep the oil level above the

OWNER INSPECTIONS AND

SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal travel, or repeated pulling to one side when braking. Also, if the

brake warning light goes on or flashes, something may be

wrong with part of the brake system.

MIN line and within the area labeled ”Operating

Range.” Avoid overfilling the engine, since this may

cause engine damage.

6. Push the indicator all the way back down into the

engine after taking the reading.

If checking the oil level when the oil is cold, do not run the

engine first. The cold oil will not drain back to the pan fast

enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank and

add coolant, if necessary. Inspect the coolant. Replace

dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid, if

necessary.

Exhaust System Operation

Be alert to any changes in the sound of the system or the

smell of the fumes. These are signs that the system may

be leaking or overheating. Have the system inspected and

repaired immediately.

Tires,Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the seats

at normal highway speeds. This may mean a wheel needs

to be balanced. Also, a pull to the right or the left on a

straight, level road may show the need for a tire pressure

adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn, has too

much free play, or if unusual sounds are noticed when

turning or parking.

Headlamp Aim

Take note of the light pattern occasionally. Adjust the

headlamps if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system may

indicate a problem. Have the system inspected and repaired immediately.

Engine Oil Level

Check the oil level and add oil, if necessary. The best time

to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for

the oil to drain back to the oil pan.

2. Pull out the oil level indicator (dipstick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level on it.

AT LEAST MONTHLY

Tire and Wheel Inspection and Pressure

Check

Check the tires for abnormal wear or damage. Also, check

for damaged wheels. Check the tire pressure when the

tires are cold (check the spare tire, unless it is a stowaway). Maintain the recommended pressures that are on

the tire placard that is on the driver’s side door.

Lamp Operation

Check the operation of the license plate lamp, the headlamps (including the high beams), the parking lamps, the

fog lamps, the taillamp, the brake lamps, the turn signals,

the backup lamps, and the hazardwarning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. W ater dripping from the air conditioning

system after use is normal. If you notice fuel leaks or

fumes, find the cause and correct it immediately.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to Section 6A, Pow-

er Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low fluid

level can indicate worn disc brake pads andmay need to

be serviced. Check the breather hole in the reservoir cover

that it is free from dirt and check for an open passage.

Clutch Pedal Free Travel

Check clutch pedal free travel and adjust, as necessary,

every 16,000 km (10,000 miles). Measure the distance

from the center of the clutch pedal to the outer edge of the

DAEWOO V–121 BL4

Page 14

GENERAL INFORMATION 0B – 13

steering wheel with the clutch pedal not pressed. Then,

measure the distance from the center of the clutch pedal

to the outer edge of the steering wheel with the clutch pedal fully pressed. The difference between the two values

must be greater than 130 mm (5.1 in.).

Weatherstrip Lubrication

Apply a thin film of silicone grease using a clean cloth.

EACH TIME THE OIL IS CHANGED

Automatic Transaxle Fluid

Refer to”Transaxle Fluid Level Checking Procedure”in-

Section 5A, 4T40E Automatic Transaxle.

Manual Transaxle

Check the fluid level and add fluid, as required. Refer

toSection 5B, Five–Speed Manual Transaxle.

Brake System Inspection

This inspection should be done when the wheels are removed for rotation. Inspect the lines and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. Inspect the disc brake pads for wear. Inspect the rotors for

surface condition. Also, inspect the drum brake linings for

wear and cracks. Inspect other brake parts, including the

drums, the wheels cylinders, the parking brake, etc., at the

same time. Check the parking brake adjustment. Inspect

the brakes more often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot and Seal Inspection

Inspect the front and the rear suspension and the steering

system for damaged, loose, or missing parts; signs of

wear; or lack of lubrication. Inspect the power steering

lines and the hoses for proper hookup, binding, leaks,

cracks and chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears, or leakage. Replace the

seals, if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic converter, if equipped). Inspect the body near the exhaust

system. Look for broken, damaged, missing, or out of

position parts, as well as open seams, holes, loose connections, or other conditions which could cause heat buildup in the floor pan or could let exhaust fumes seep into the

trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged or missing parts. Lubricate all linkage joints and

throttle cable joints, the intermediate throttle shaft bearing,

the return spring at the throttle valve assembly , and the accelerator pedal sliding face with suitable grease. Check

the throttle cable for free movement.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear, and proper tension. Adjust or replace the belts, as needed.

Hood Latch Operation

When opening the hood, note the operation of the secondary latch. It should keep the hood from opening all the

way when the primary latch is released. The hood must

close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belt Condition and

Operation

Inspect the belt system, including the webbing, the

buckles, the latch plates, the retractor, the guide loops and

the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare tire,

all the jacking equipment, and the tools must be securely

stowed at all times. Oil the jack ratchet or the screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood, the

fuel door, the rear compartment hinges and the latches,

the glove box and the console doors, and any folding seat

hardware.

Transaxle Neutral Switch Operation on

Automatic Transaxle

CAUTION : Adhere to the following precautions. Failuretodosocancauseinjuriesandpropertydamage.

S Firmly apply the parking brake and the regular

brakes.

S Do not use the accelerator pedal.

S Be ready to turn the ignition OFF if the vehicle

starts.

On automatic transaxle vehicles, try to start the engine in

each gear. The starter should crank only in P (PARK) and

in N (NEUTRAL).

Parking Brake and Transaxle P (PARK)

Mechanism Operation

CAUTION : To reduce the risk of personal injury or

property damage, be prepared to apply the regular

brakes if the vehicle begins to move.

Park on a fairly steep hillwith enough roomformovement

in the downhill direction. To check the parking brake, with

the engine running and the transaxle in N (NEUTRAL),

slowly remove foot pressure fromthe regular brake pedal

(until only the parking brake is holding the vehicle).

To check the automatic transaxle P (PARK) mechanism’s

holding ability, release all brakes after shifting the transaxle to P (PARK).

DAEWOO V–121 BL4

Page 15

0B – 14IGENERAL INFORMATION

Underbody Flushing

Flushing the underbody will remove any corrosive materials used for ice and snow removal and dust control. At

least every spring, clean the underbody. First, loosen the

sediment packed in closed areas of the vehicle. Then,

flush the underbodywith plainwater.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture to ensure proper freeze protection, corrosion

protection and engine operating temperature. Inspect the

hoses. Replace the cracked, swollen, or deteriorated

hoses. Tighten the clamps. Clean the outside of the radiator and the air conditioning condenser. Wash the filler cap

and the neck. Pressure test the cooling system and the

cap to help ensure proper operation.

DAEWOO V–121 BL4

Page 16

GENERAL INFORMATION 0B – 15

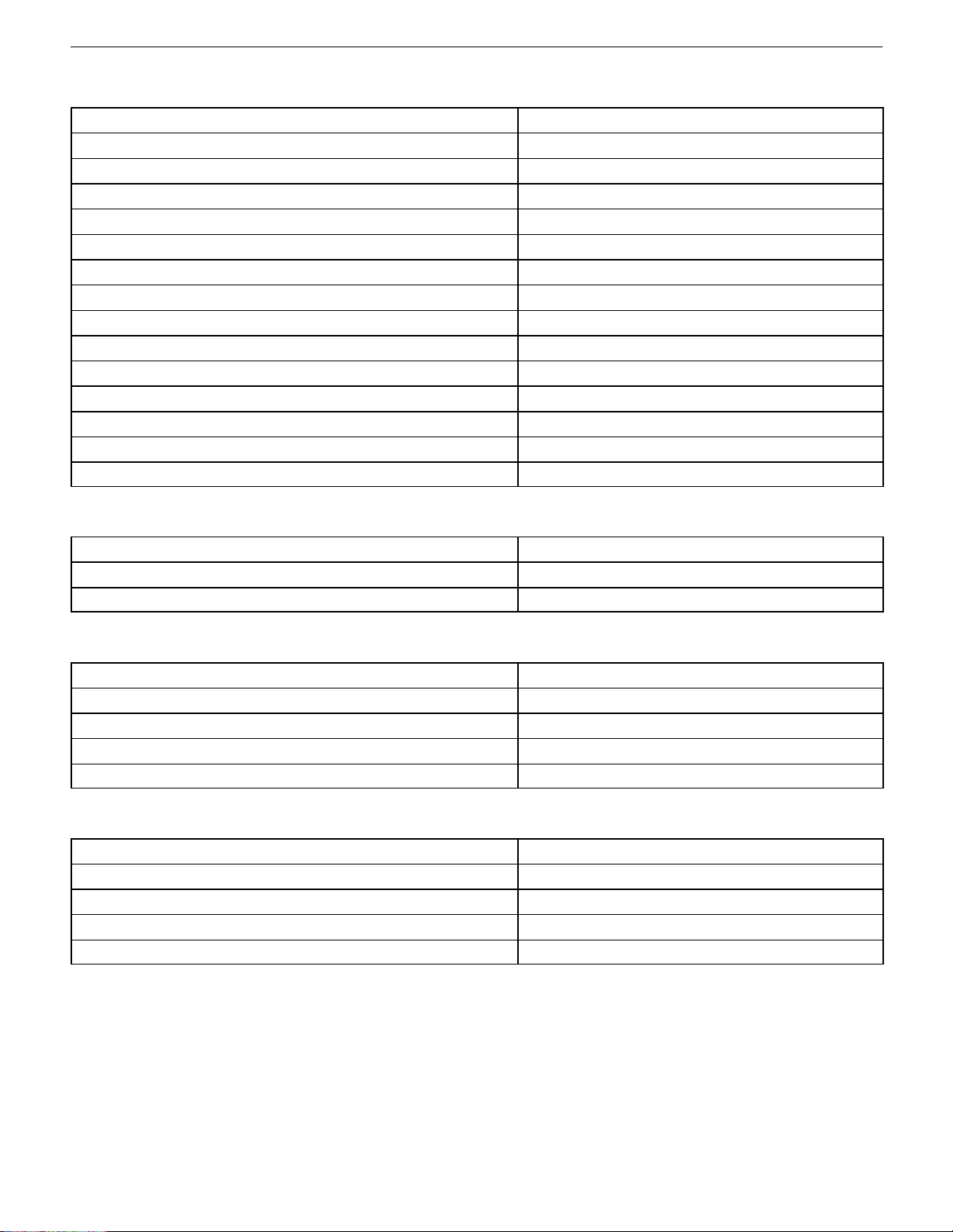

RECOMMENDED FLUIDS AND LUBRICANTS

USAGE CAPACITY FLUID/LUBRICANT

Engine Oil 3.8L (4.1 qt) ILSAC GF–II (API SJ) grade

SAE 5W––30, SAE 10W––30

Engine Coolant 7.0L (7.4 qt) Mixture of water and good quality ethylene glycol–

base antifreeze (year–round coolant)

Brake and Clutch Fluid 0.5L (0.5 qt) SSK–221 (DOT–3 and DOT–4 Fluid)

Power Steering System Fluid 1.0L (1.1 qt) DEXRON±–III, DEXRON± II–D

Automatic Transaxle 11.5L (12.2 qt) DEXRON±–III

Manual Transaxle 1.8L (2 qt) Manual Transaxle Fluid ( B0400075, SAE80 or eqi-

valent; Extremely cold area: SAE 75W)

Manual Transaxle Shift Linkage As needed Multipurpose–type grease meeting requirements

NLGI No. 1 or 2

Key Lock Cylinders As needed Silicone lubricant

Automatic Transaxle Shift Link-

age

Clutch Linkage Pivot Points As needed Engine oil

Floor Shift Linkage Points As needed Engine oil

Hood Latch Assembly

1. Pivots and Spring Anchor

2. Release Pawl

Hood and door hinges

Fuel door hinge

Rear compartment lid hinges

Weatherstripping As needed Silicone grease

As needed Engine oil

As needed

As needed Engine oil

1. Engine oil

2. Multipurpose–type grease meeting requirements NLGI No. 1 or 2

DAEWOO V–121 BL4

Page 17

0B – 16IGENERAL INFORMATION

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL REPAIR INSTRUCTIONS

If a floor jack is used, the following precautions are recommended:

S Park the vehicle on level ground, ”block” the front or

rear wheels, set the jack against the frame, raise

the vehicle and support it with chassis stands, and

then perform the service operation.

S Before performing the service operation, disconnect

the negative battery cable to reduce the chance of

cable damage and burning due to short–circuiting.

S Use a cover on the body, the seats, and the floor to

protect them against damage and contamination.

S Handle brake fluid and antifreeze solution with care

as they can cause paint damage.

S The use of proper tools, and the required special

tools where specified, is important for efficient and

reliable performance of the service repairs.

S Use genuine DAEWOO parts.

S Discard used cotter pins, gaskets, O–rings, oil

seals, lock washers and self–locking nuts. Prepare

new ones for installation. Normal functioning of the

vehicle’s components cannot be maintained if these

fasteners and seals are reused.

S Keep the disassembled parts to assist in reassemb-

ly.

S Keep attaching bolts and nuts separated, as they

vary in hardness and design depending on the position of the installation.

S Clean the parts before inspection or reassembly.

S Clean the oil parts, etc. Use compressed air to

make certain they are free of restrictions.

S Lubricate rotating and sliding faces of parts with oil

or grease before installation.

S When necessary, use a sealer on gaskets to pre-

vent leakage.

S Carefully observe all specifications for bolt and nut

torques.

When service operation is complete, make a final check

to be sure service was done properly and the problem was

corrected.

DAEWOO V–121 BL4

Page 18

GENERAL INFORMATION 0B – 17

GENERAL DESCRIPTION

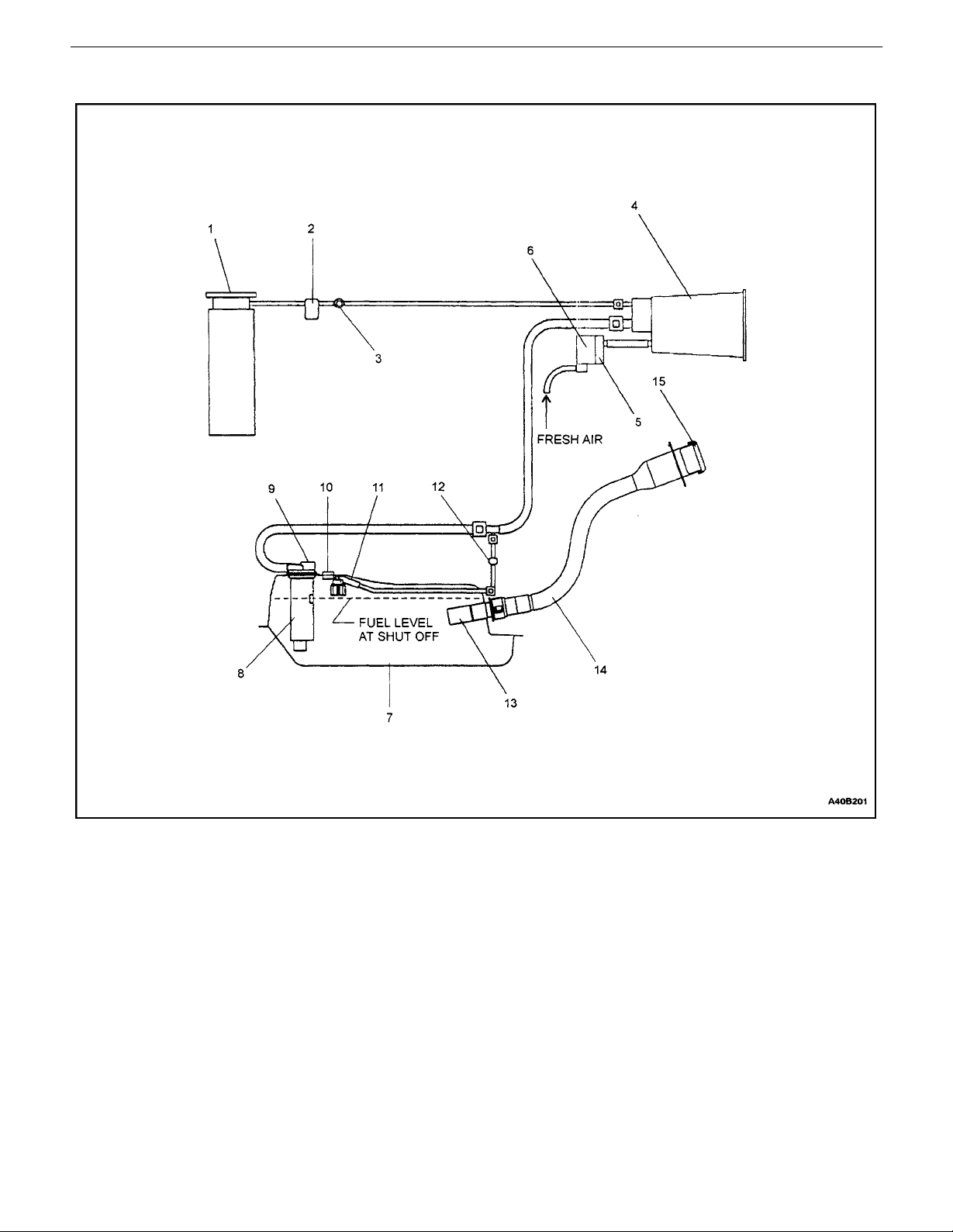

ON BOARD REFUELING VAPOR

RECOVERY SYSTEM

The NUBIRA 2.0 DOHC model is equipped with an On

Board Diagnostic Stage II (OBD–II) system to meet enhanced emission control requirements. Within this OBD–II

system, an On Board Refueling Vapor Recorvery (ORVR)

system has been developed and equipped to meet enhanced evaporative emission control requirements during

vehicle moving, parking, and refueling at gas stations. The

Daewoo ORVR system adopts one canister to collect both

evaporative vapors during the moving & parking as well as

refueling vapor. Collected vapor is consurmed by the engine through the intake manfold during vehicle operation.

The mechanism of Daewoo ORVR system to meet the

ORVR requirement is to create suction inside filler neck by

the aid of fuel flow through a reduced diameter section in

the filler pipe.

Therefore, Daewoo ORVR system adopts the so called

”Liquid Trap” or ”Liquid Seal” system that assures the long

term durability.

The Daewoo ORVR system provides nozzle compatibility

with conventional and stage II vapor recovery nozzle.

The Daewoo ORVR system has been designed to have

the following functional features.

S To collect refueling vapors and to route to canister.

S To provide nozzle compatibility with conventional

and stage II vapor recovery nozzles.

S To provide fill shut off signal.

S To prevent canister from liquid fuel during normal

driving and vehicle rollover.

S To provide fuel tank venting to canister during ve-

hicle operation.

S To protect fuel tank from over–pressure.

S To protect fuel vapor dome from overfill.

Any failures or malfunction of the ORVR system will be

identified by OBD–II system and warned through Malfunction Indicator Lamp (MIL) on the instrument cluster.

No special refueling procedures and mainternance on

ORVR system are required.

The Daewoo ORVR system and all fuel system components have been designed to prevent the electrostatic discharge phenomenon by adopting mitigation techniques

recommended in SAE J1645. Daewoo’s own test procedure (EDS–T–5005) is similar to SAE J1113.

DAEWOO V–121 BL4

Page 19

0B – 18IGENERAL INFORMATION

Schematic Of On Board Refueling Vapor Recovery System

1. Manifold (Intake)

2. Canister Purge Valve (Electronic Pwm Control)

3. Service Port

4. Integrated Fuel Vapor Storage Canister

5. OBD–II Valve (Solenoid)OBD–II Valve (Solenoid)

6. Air Filter

7. Fuel Tank (Steel)

8. Fuel Fill Vent Control Valve & Liquid–Vapor Dis-

criminator

9. Pressure Relief Valve

10. Tank Pressure Transducer (OBD–II)

11. Rollover Valve

12. 2–Way Check Valve

13. Check Valve

14. Fuel Filler Tube (Dynamic Seal During Fill)

15. Fuel Filler Cap (Pressure–Vacuum Relief)

DAEWOO V–121 BL4

Page 20

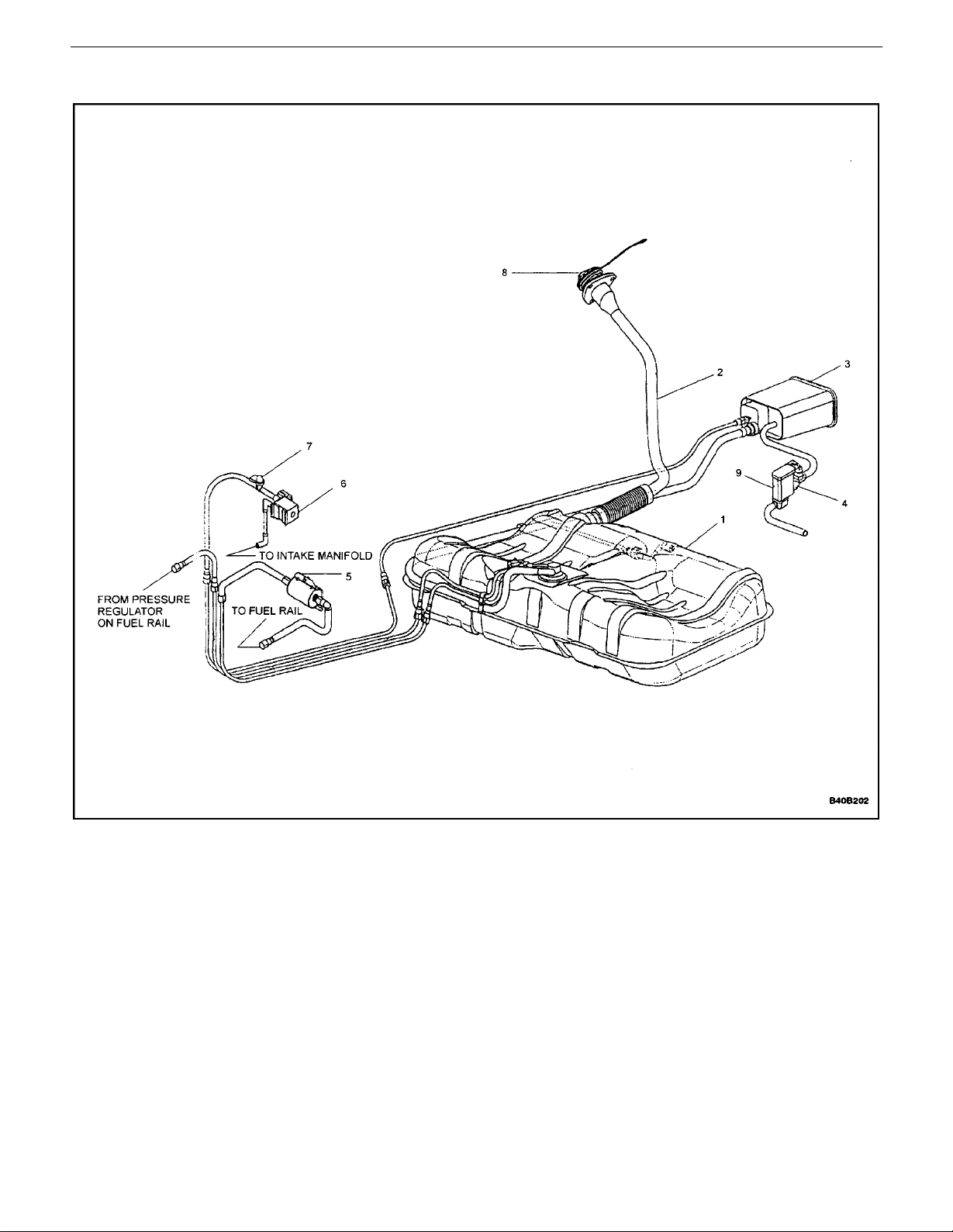

Component Locator

GENERAL INFORMATION 0B – 19

1. Fuel Tank

2. Filler Tube

3. Canister

4. OBD– II Valve

5. Fuel Filter

DAEWOO V–121 BL4

6. Purge Valve

7. Service port

8. Fuel Filler Cap

9. Air Filter

Page 21

0B – 20IGENERAL INFORMATION

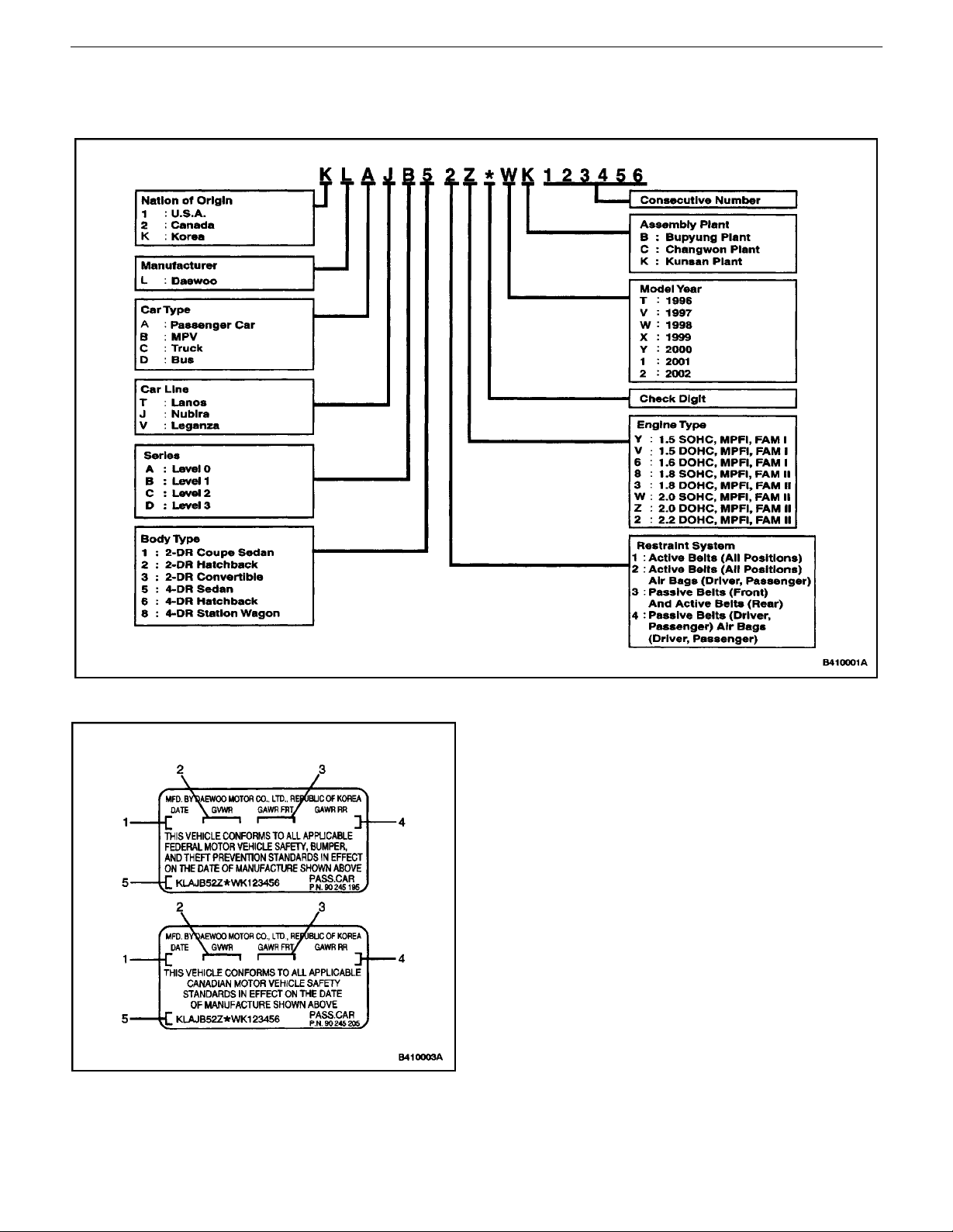

VEHICLE IDENTIFICATION

Passenger Car VIN

Certification plate

1. Production Date

2. Gross Vehicle Weight Rating

3. Gross Axle Weight Rating Front

4. Gross Axle Weight Rating Rear

5. Vehicle Identification Number

DAEWOO V–121 BL4

Page 22

GENERAL INFORMATION 0B – 21

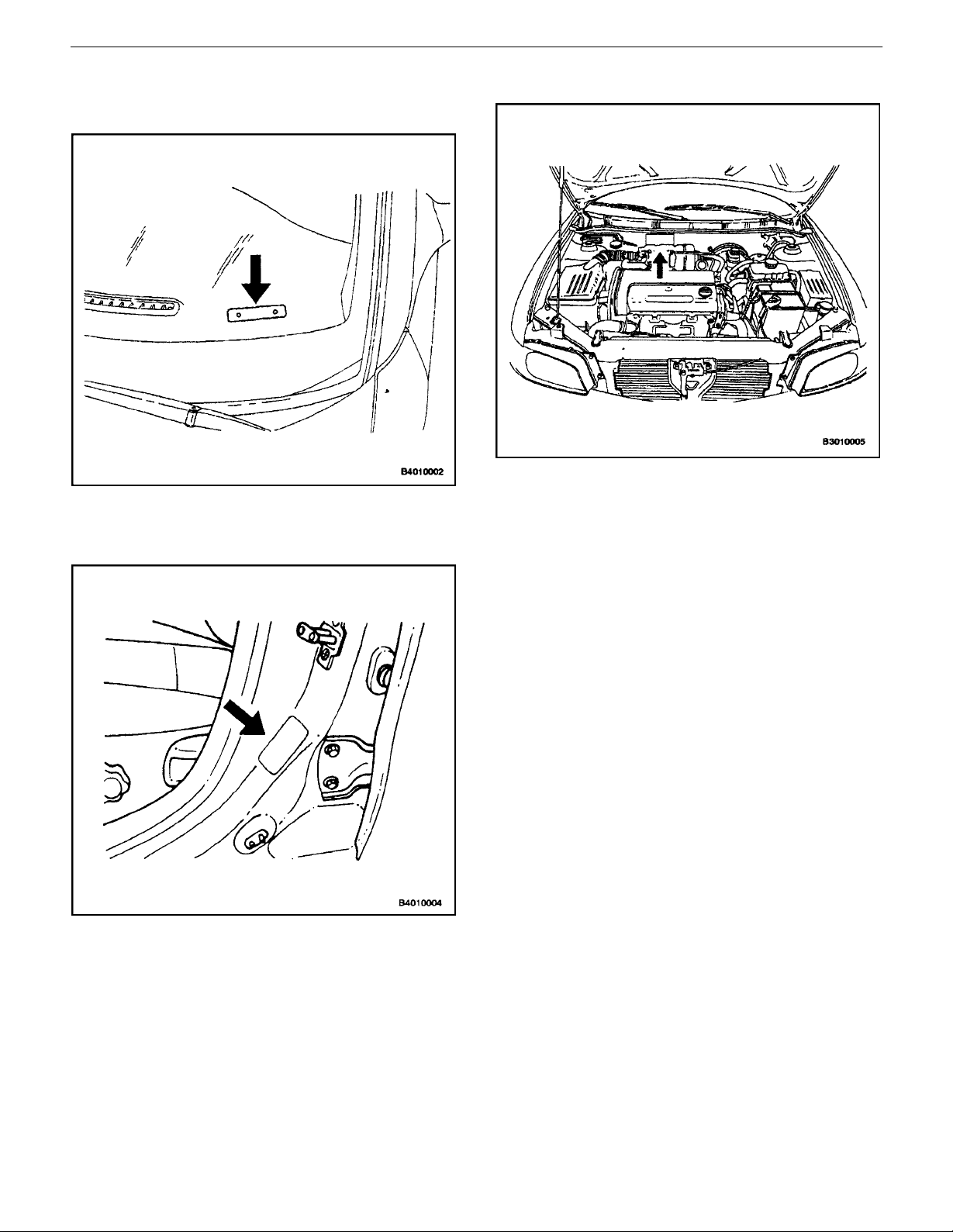

VIN Plate Location

The vehicle identification number (VIN) plate is attached

to the top of the driver’s side of the instrument panel.

Certification Label

The Certification Label is attached to the driver’s side B–

pillar near door strike.

Engraved VIN Location

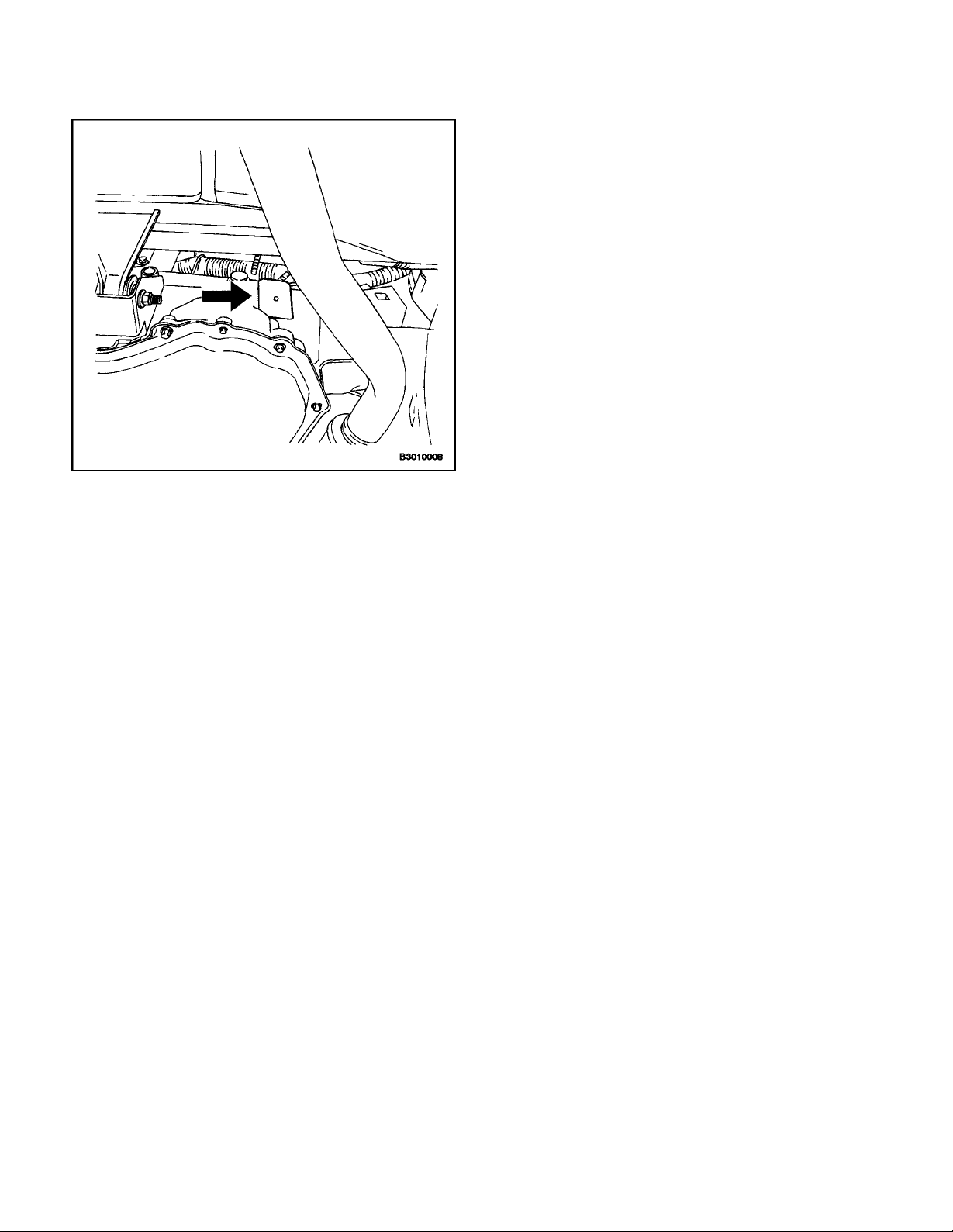

The vehicle identification number (VIN) is engraved in the

top of the bulkhead, next to the ABS module.

DAEWOO V–121 BL4

Page 23

0B – 22IGENERAL INFORMATION

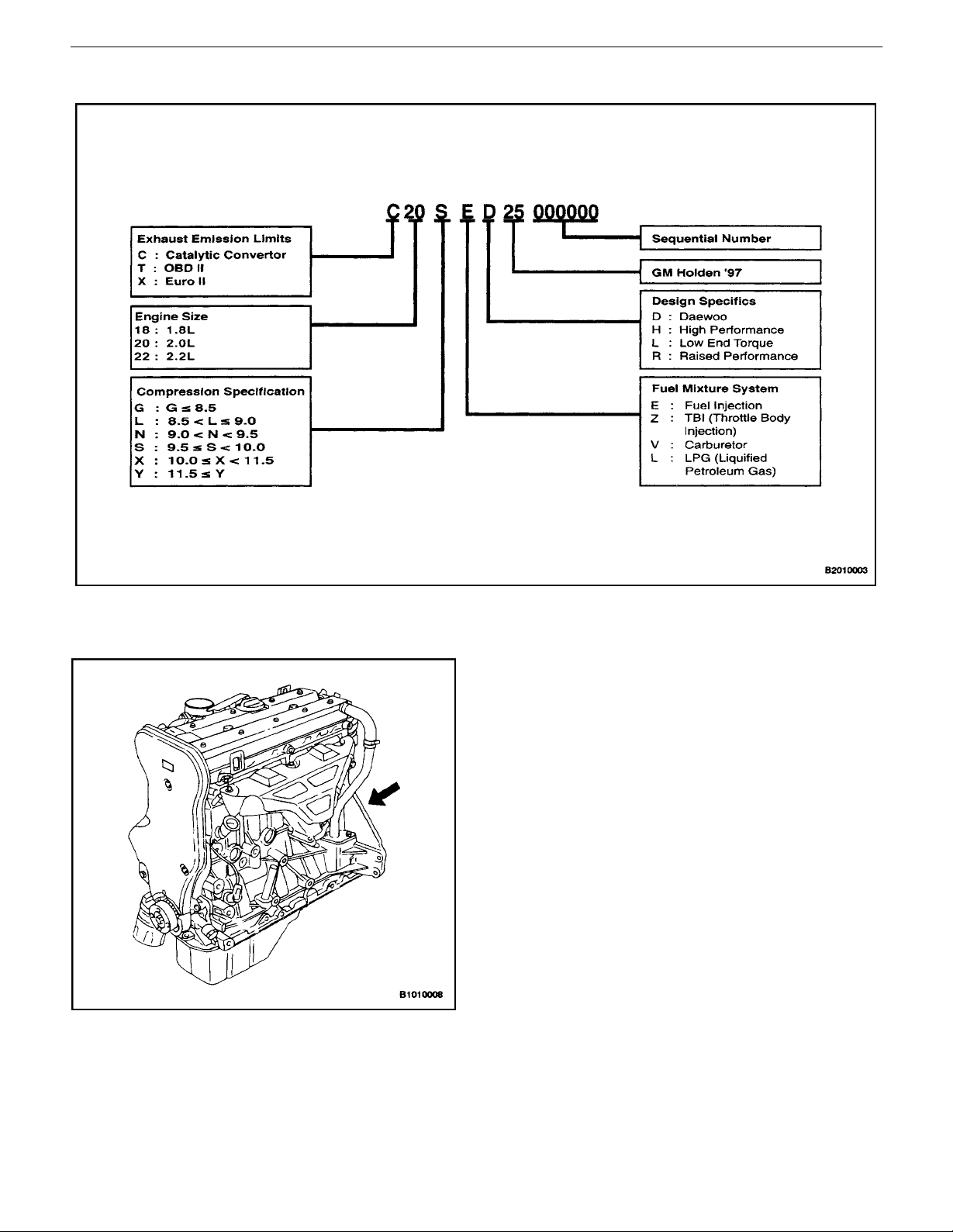

Engine Number – Family II (2.0L DOHC Engine)

Engine Number Plate Location – Family II

(2.0L DOHC Engine)

The engine number is stamped on the cylinder block under

the No. 4 exhaust manifold of the engine.

DAEWOO V–121 BL4

Page 24

GENERAL INFORMATION 0B – 23

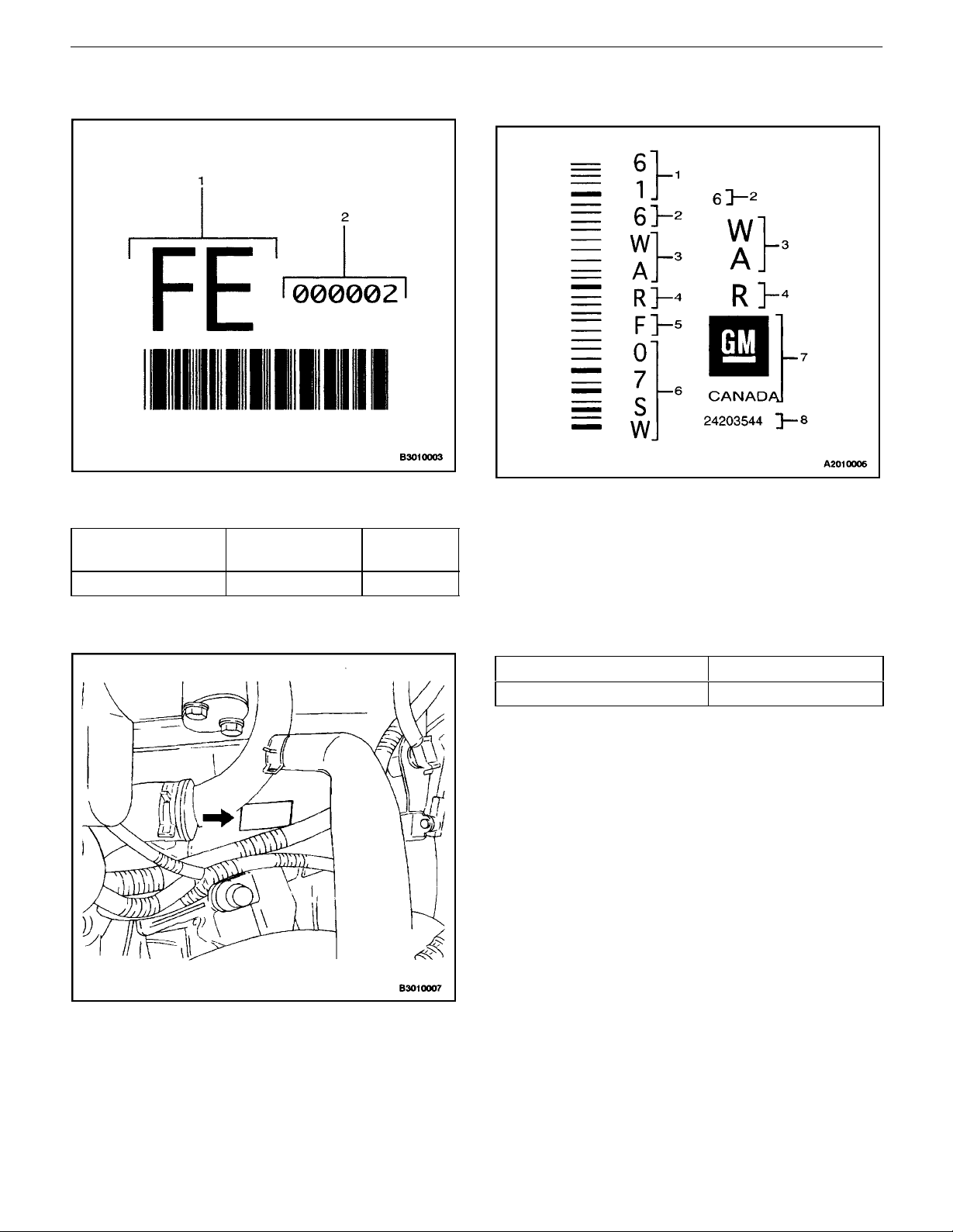

Manual Transaxle Identification Number

Plate

1. Identification Code

2. Sequential Number

Identification

Code

FE 2.0L DOHC 3.545 C/R

Engine Gear Ratio

Manual Transaxle Identification Number

Plate Location

Automatic Transaxle Identification Number

Plate

1. Assembly Plant (Windsor, Canada)

2. Model Year (1996)

3. Broadcast Code

4. Model Name (4T40E)

5. Update Level

6. Sequential Number

7. Manufacturer

8. Part Number

The manual transaxle identification number is attached to

the top of the transaxle case near the engine.

Identification Code Engine

7ZZR 2.0L DOHC

DAEWOO V–121 BL4

Page 25

0B – 24IGENERAL INFORMATION

Automatic Transaxle Identification Number

Plate Location

The automatic transaxle identification number plate is attached on the rear side of the transaxle near the bulkhead.

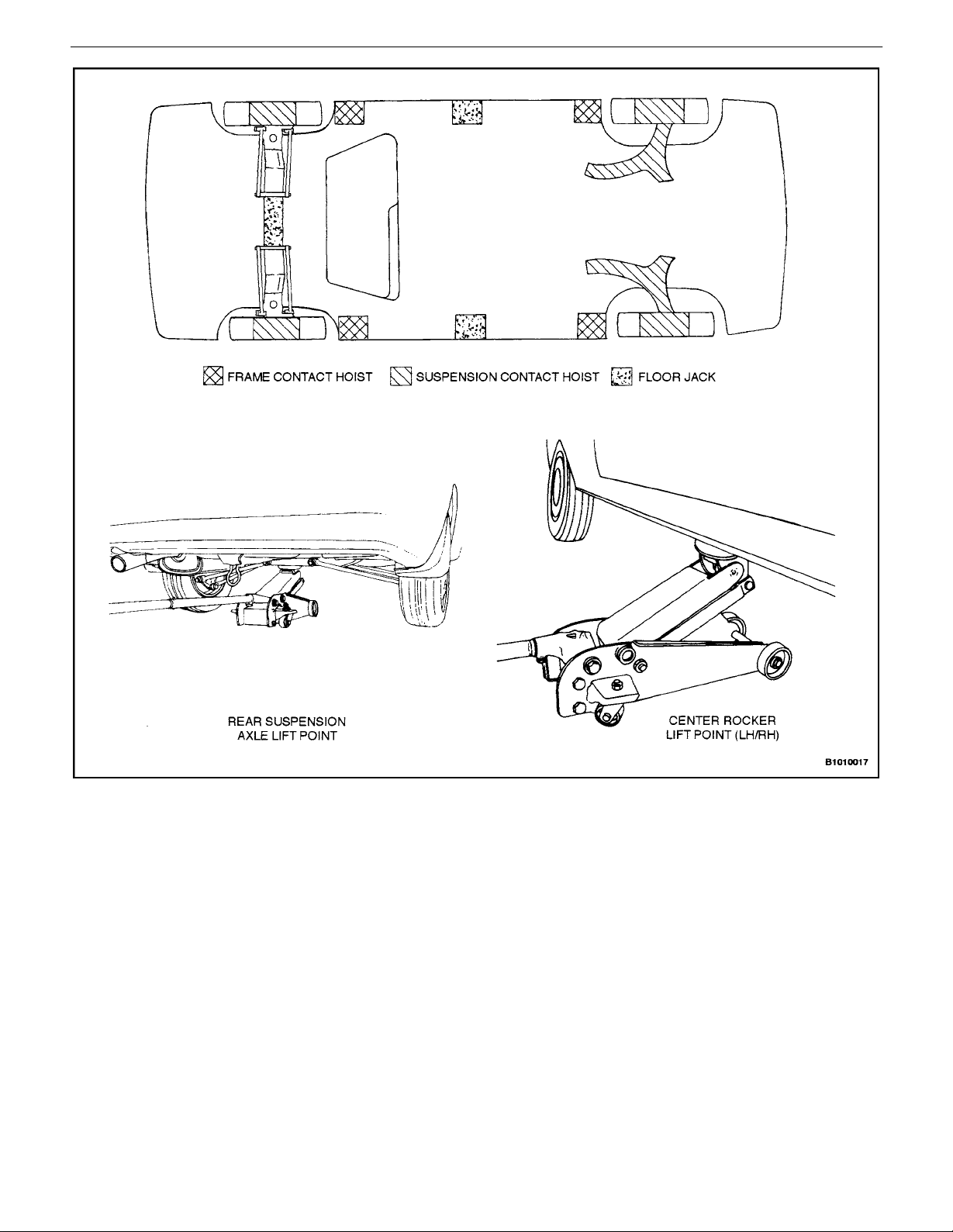

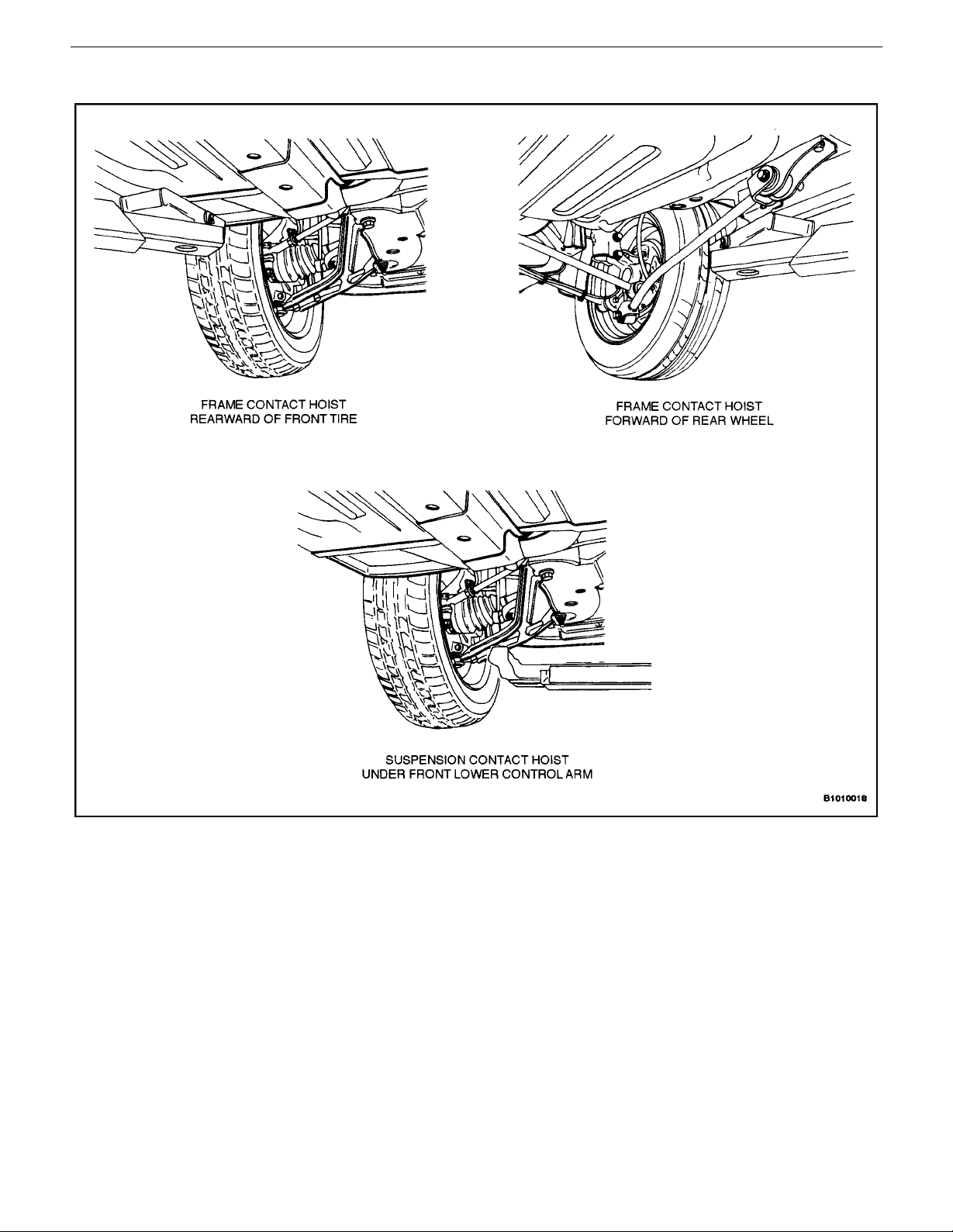

VEHICLE LIFTING PROCEDURES

Notice : To raise the vehicle, place the lifting equipment

only at the points indicated. Failure to use these precise

positions may result in permanent body deformation.

Many dealer service facilities and service stations are

equipped with automotive hoists that bear upon some

parts of the frame to lift the vehicle. If any other hoist method is used, use special care to avoid damaging the fuel

tank, the filler neck, the exhaust system, or the underbody .

DAEWOO V–121 BL4

Page 26

GENERAL INFORMATION 0B – 25

DAEWOO V–121 BL4

Page 27

0B – 26IGENERAL INFORMATION

Vehicle Lifting Points

DAEWOO V–121 BL4

Page 28

SECTION : 1A

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

DIAGNOSIS 1A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSION TEST 1A–1. . . . . . . . . . . . . . . . . . . . .

OIL PRESSURE TEST 1A–2. . . . . . . . . . . . . . . . . . . . .

OIL LEAK DIAGNOSIS 1A–3. . . . . . . . . . . . . . . . . . . . .

KNOCK DIAGNOSIS 1A–4. . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

COMPRESSION TEST

Important : Disconnect the Crankshaft Position Sensor

(CPS) connector to disable the fuel and the ignition systems.

Test the compression pressure for each cylinder. Low

compression pressure may be the fault of the valves or the

pistons. The following conditions should be considered

when checking the cylinder compression:

S The engine should be at normal operating tempera-

ture.

S The throttle must be wide open.

S All the spark plugs should be removed.

S The battery must be at or near full charge.

1. Place approximately three squirts of oil from a

plunger type oiler into each spark plug port.

2. Insert the engine compression gauge into each

spark plug port.

NOISE DIAGNOSIS 1A–8. . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 1A–11. . . . . . . . . . . . . . . . . .

CLEANLINESS AND CARE 1A–11. . . . . . . . . . . . . . . .

ON–ENGINE SERVICE 1A–11. . . . . . . . . . . . . . . . . . .

3. Crank test each cylinder with four to five compression strokes using the starter motor.

4. The lowest reading should not be less than 70% of

the highest reading. The compression gauge reading should not be less than 689 kPa (100 psi) for

any of the cylinders.

5. Examine the gauge readings obtained after the four

”puffs” per cylinder are obtained from cranking the

starter motor. The readings are explained in the

following descriptions:

S Normal Condition – Compression builds up quickly

and evenly to specified compression on each cylinder.

S Piston Rings Faulty – Compression is low on the

first stroke and tends to build up on following

strokes, but does not reach normal. The compression pressure improves considerably with the addition of oil into the cylinder.

S Valves Faulty – Low compression pressure on the

first stroke. The compression pressure does not

tend to build up on the following strokes. The compression pressure does not improve much with the

addition of oil into the cylinder.

Page 29

1A – 2IGENERAL ENGINE INFORMATION

OIL PRESSURE TEST

Step Action Value(s) Yes No

1 Is the oil pressure warning lamp on? Go to Step 2 System OK

2 Check the oil level in the crankcase.

Is the oil level low?

3 Add oil so that the oil level is up to the MAX mark on

the indicator.

Is the repair complete?

4 Check the idle speed.

Is the idle speed below the value specified?

5 Increase the idle speed.

Is the speed increased?

6 Inspect the oil pressure switch.

Is the oil pressure switch incorrect or malfunctioning?

7 Install a new oil pressure switch.

Is the repair complete?

8 Inspect the oil pressure gauge.

Is the oil pressure gauge incorrect or malfunctioning?

9 Install a new oil pressure gauge.

Is the repair complete?

10 Inspect the engine oil.

Is the engine oil in the crankcase diluted or of the improper viscosity?

11 Install new engine oil of the proper viscosity for the

expected temperatures.

Is the repair complete?

12 Inspect the oil pump.

Is the pump worn or dirty?

13 Replace the oil pump.

Is the repair complete?

14 Inspect the oil filter.

Is the oil filter plugged?

15 Install a new oil filter.

Is the repair complete?

16 Inspect the oil pickup screen.

Is the oil pickup screen loose or plugged?

17 Tighten or replace the oil pickup screen as neces-

sary.

Is the repair complete?

18 Inspect the oil pickup tube.

Are there any holes in the oil pickup tube?

19 Replace the oil pickup tube.

Is the repair complete?

825 rpm Go to Step 5 Go to Step 6

Go to Step 3 Go to Step 4

Go to Step 1

Go to Step 1

Go to Step 7 Go to Step 8

Go to Step 1

Go to Step 9 Go to Step 10

Go to Step 1

Go to Step 11 Go to Step 12

Go to Step 1

Go to Step 13 Go to Step 14

Go to Step 1

Go to Step 15 Go to Step 16

Go to Step 1

Go to Step 17 Go to Step 18

Go to Step 1

Go to Step 19 Go to Step 20

Go to Step 1

DAEWOO V–121 BL4

Page 30

Step NoYesValue(s)Action

20 Inspect the bearing clearances.

Are the bearing clearances more than the values

specified?

21 Replace the bearing, if necessary.

Is the repair complete?

22 Inspect the oil galleries.

Are the oil galleries cracked, porous, or plugged?

23 Repair or replace the engine block.

Is the repair complete?

24 Inspect the gallery plugs.

Are any of the gallery plugs missing or installed improperly?

25 Install plugs or repair, as necessary.

Is the repair complete?

26 Inspect the camshaft.

Is the camshaft worn or is there evidence of poor

machining?

27 Replace the camshaft.

Is the repair complete?

GENERAL ENGINE INFORMATION 1A – 3

Crankshaft

0.005 mm

(0.0001 in.)

Connecting

Rod

0.0019–0.070

mm

(0.0007–0.0025

in.)

Go to Step 21 Go to Step 22

Go to Step 1

Go to Step 23 Go to Step 24

Go to Step 1

Go to Step 25 Go to Step 26

Go to Step 1

Go to Step 27 System OK

Go to Step 1

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by visually finding the leak and replacing or repairing the necessary parts. On some occasions, a fluid leak may be difficult

to locate or repair. The following procedures may help you

in locating and repairing most leaks.

Finding the Leak:

1. Identify the fluid. Determine whether it is engine

oil,automatic transmission fluid, power steering

fluid, etc.

2. Identify where the fluid is leaking from.

1) After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2) Wait a few minutes.

3) You should be able to find the approximate loca-

tion of the leak by the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas

that are hard to reach.

4. If the leak still cannot be found, it may be necessary to clean the suspected area with a degreaser,

steam or spray solvent.

1) Thoroughly clean the area.

2) Dry the area.

3) Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4) After operating the vehicle, visually check the

suspected component.

5) If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method:

1. Clean the suspected area.

2. Apply an aerosol–type powder (such as foot powder) to the suspected area.

3. Operate the vehicle under normal operating conditions.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method:

A dye and light kit is available for finding leaks. Refer to the

manufacturer’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.

DAEWOO V–121 BL4

Page 31

1A – 4IGENERAL ENGINE INFORMATION

2. Operate the vehicle under normal operating conditions as directed in the kit.

3. Direct the light toward the suspected area. The

dyed fluid will appear as a yellow path leading to

the source.

Repairing the Leak:

Once the origin of the leak has been pinpointed and traced

back to its source, the cause of the leak must be determined in order for it to be repaired properly. If a gasket is

replaced, but the sealing flange is bent, the new gasket will

not repair the leak. The bent flange must be repaired also.

Before attempting to repair a leak, check for the following

conditions and correct them as they may cause a leak.

Gaskets:

S The fluid level/pressure is too high.

S The crankcase ventilation system is malfunctioning.

S The fasteners are tightened improperly or the

threads are dirty or damaged.

KNOCK DIAGNOSIS

Definition for Knock

Engine knock refers to the various types of engine noise.

Heavy knock is usually very loud and the result of broken

or excessively worn internal engine components. Light

S The flanges or the sealing surface is warped.

S There are scratches, burrs or other damage to the

sealing surface.

S The gasket is damaged or worn.

S There is cracking or porosity of the component.

S An improper seal was used, (where applicable).

Seals:

S The fluid level/pressure is too high.

S The crankcase ventilation system is malfunctioning.

S The seal bore is damaged (scratched, burred or

nicked).

S The seal is damaged or worn.

S Improper installation is evident.

S There are cracks in the component.

S The shaft surface is scratched, nicked or damaged.

S A loose or worn bearing is causing excess seal

wear.

knock is a noticeable noise, but not as loud. Light knock

can be caused by worn internal engine components.

Loose or broken external engine components can also

cause heavy or light knock.

Engine Knocks Cold and Continues for Two–Three Minutes and/or

Knock Increases with Engine Torque

Step Action Value(s) Yes No

1 Does the engine knock when it is cold and continue

for two to three minutes or does the knock increase

with torque?

2 Inspect the flywheel.

Is the flywheel contacting the splash shield?

3 Reposition the splash shield.

Is the repair complete?

4 Inspect the balancer and the drive pulleys.

Is either the balancer or the drive pulleys loose or

broken?

5 Tighten or replace the balancer or the drive pulleys.

Is the repair complete?

6 Inspect the piston–to–bore clearance.

Is the clearance more than the value specified?

7

8 Inspect the connecting rod.

9 Replace the connecting rod.

1. Rebore the cylinder and hone to size.

2. Replace the piston.

Is the repair complete?*

Is the connecting rod bent?

Is the repair complete?

0.030 mm

(0.001 in.)

Go to Step 2 System OK

Go to Step 3 Go to Step 4

Go to Step 1

Go to Step 5 Go to Step 6

Go to Step 1

Go to Step 7 Go to Step 8

Go to Step 1

Go to Step 9 System OK

Go to Step 1

* Cold engine piston knock usually disappears when the cylinder is grounded out. Cold engine piston knock, which disappears in about 1.5 minutes, is considered acceptable.

DAEWOO V–121 BL4

Page 32

GENERAL ENGINE INFORMATION 1A – 5

Heavy Knock Hot with Torque Applied

Step Action Value(s) Yes No

1 Is there a heavy knock when the engine is hot and

torque is applied?

2 Inspect the balancer and the pulley hub.

Is the balancer or the pulley hub broken?

3 Replace the broken balancer or the pulley hub.

Is the repair complete?

4 Inspect the torque converter bolts.

Are the bolts tightened to specified value?

5 Tighten the torque converter bolts.

Is the repair complete?

6 Inspect the accessory belts.

Are the belts too tight or nicked?

7 Replace and/or tension the belts to specifications as

necessary.

Is the repair complete?

8 Inspect the exhaust system.

Is the system grounded?

9 Reposition the system as necessary.

Is the repair complete?

10 Inspect the flywheel.

Is the flywheel cracked?

11 Replace the flywheel.

Is the repair complete?

12 Inspect the main bearing clearance.

Is the clearance more than the specified value?

13 Replace the main bearings as necessary.

Is the repair complete?

14 Inspect the rod bearing clearance.

Is the clearance more than the specified value?

15 Replace the rod bearings as necessary.

Is the repair complete?

45NSm(33 lb–

ft)

2.0 DOHC

0.015–0.040

mm

(0.00059–0.001

5 in.)

0.019–0.070

mm

(0.0007–0.0027

in.)

Go to Step 2 System OK

Go to Step 3 Go to Step 4

Go to Step 1

Go to Step 5 Go to Step 6

Go to Step 1

Go to Step 7 Step 8

Go to Step 1

Go to Step 9 Go to Step 10

Go to Step 1

Go to Step 11 Go to Step 12

Go to Step 1

Go to Step 13 Go to Step 14

Go to Step 1

Go to Step 15 System OK

Go toStep 1

DAEWOO V–121 BL4

Page 33

1A – 6IGENERAL ENGINE INFORMATION

Light Knock Hot

Step Action Value(s) Yes No

1 Is there a light knock when the engine is hot? Go to Step 2 System OK

2 Is detonation or spark knock evident? Go to Step 3 Go to Step 4

3 Check the engine timing and the fuel quality.

Was the problem found?

4 Inspect the torque converter bolts.

Are the bolts loose?

5 Tighten the torque converter bolts.

Is the repair complete?

6 Inspect the manifold.

Is there an exhaust leak at the manifold?

7 Tighten the bolts or replace the gasket.

Is the repair complete?

8 Check the rod bearing clearance.

Is the clearance within the specified value?

9 Replace the rod bearings as necessary.

Is the repair complete?

45 NSm (33 lb–

ft)

0.019–0.070

mm

(0.0007–0.0027

in.)

Go to Step 1

Go to Step 5 Go to Step 6

Go to Step 1

Go to Step 7 Go to Step 8

Go to Step 1

Go to Step 9 System OK

Go to Step 1

Knocks During Initial Start–Up But Lasts Only a Few Seconds

Step Action Value(s) Yes No

1 Does the engine knock during initial start–up but last

only a few seconds?

2 Check the engine oil.

Is the proper viscosity oil used in the crankcase?

3 Install oil of the proper viscosity for the expected

seasonal temperatures.

Is the repair complete?

4 Inspect the hydraulic lifters.

Is there evidence of hydraulic lifter bleed–down?

5 Clean, test and replace the lifters as necessary.

Is the repair complete?*

6 Inspect the crankshaft end clearance.

Is the clearance more than specified value?

7 Replace the crankshaft thrust bearing.

Is the repair complete?

8 Inspect the front main bearing clearance.

Is the clearance more than the specified value?

9 Replace the worn parts of the front main bearing.

Is the repair complete?

0.01 mm

(0.0039 in.)

2.0 DOHC

0.015–0.040

mm

(0.00059–0.001

5 in.)

Go to Step 2 System OK

Go to Step 4 Go to Step 3

Go to Step 1

Go to Step 5 Go to Step 6

Go to Step 1

Go to Step 7 Go to Step 8

Go to Step 1

Go to Step 9 System OK

Go to Step 1

* When the engine is stopped, some valves will be open. Spring pressure against the lifters will tend to bleed the lifter down.

Attempts to repair this should be made only if the problem is consistent.

An engine that is only operated for short periods between start–ups may have lifter noise that lasts for a few minutes. This

is a normal condition.

DAEWOO V–121 BL4

Page 34

GENERAL ENGINE INFORMATION 1A – 7

Knocks at Idle Hot

Step Action Value(s) Yes No

1 Does the engine knock at idle when hot? Go to Step 2 System OK

2 Inspect the drive belts.

Are the belts loose or worn?

3 Tension or replace the belts as necessary.

Is the repair complete?

4 Inspect the A/C compressor and the generator.

Is either the compressor or the generator faulty?

5 Replace the faulty A/C compressor or the generator.

Is the repair complete?

6 Inspect the valve train.

Are valve train components faulty?

7 Replace the faulty valve train components.

Is the repair complete?

8 Check the engine oil.

Is the proper viscosity oil used in the crankcase?

9 Install oil of the proper viscosity for the expected

seasonal temperatures.

Is the repair complete?

10 Inspect the piston pin clearance.

Is the clearance more than the specified value?

11 Replace the piston and the pin.

Is the repair complete?

12 Check the connecting rod alignment.

Is the alignment faulty?

13 Check and replace rods as necessary.

Is the repair complete?

14 Inspect the piston–to–bore clearance.

Is the clearance within the specified value?

15 Hone the bore and fit a new piston.

Is the repair complete?

16 Inspect the crankshaft balancer.

Is the balancer loose?

17 Torque or replace worn parts.

Is the repair complete?

18 Check the piston pin offset.

Is the offset at the specified value?

19 Install the correct piston.

Is the repair complete?

2.0L DOHC

0.014 mm

(0.0005 in.)

0.03 mm

(0.0012 in.)

0.5–0.7 mm

(0.019–0.027

in.)

Toward Thrust

Side

Go to Step 3 Go to Step 4

Go to Step 1

Go to Step 5 Go to Step 6

Go to Step 1

Go to Step 7 Go to Step 8

Go to Step 1

Go to Step 10 Go to Step 9

Go to Step 1

Go to Step 11 Go to Step 12

Go to Step 1

Go to Step 13 Go to Step 14

Go to Step 1

Go to Step 16 Go to Step 15

Go to Step 1

Go to Step 17 Go to Step 18

Go to Step 1

Go to Step 19 System OK

Go to Step 1

DAEWOO V–121 BL4

Page 35

1A – 8IGENERAL ENGINE INFORMATION

NOISE DIAGNOSIS

Main Bearing Noise

Step Action Value(s) Yes No

1 Are dull thuds or knocks heard with every engine

revolution?

2 Check the oil pump pressure.

Is the oil pump pressure low?

3 Inspect the crankshaft end play.

Is there excessive crankshaft end play?

4 Inspect the crankshaft journals.

Are the crankshaft journals out–of–round?

5 Inspect the belt tension.

Is there excessive belt tension?

6 Inspect the crankshaft pulley.

Is the crankshaft pulley loose?

0.1 mm

(0.0039 in.)

0.004 mm

(maximum)

(0.0006 in.)

Go to Step 2 System OK

Go toOil Pres-

sure Test

Go toCrank-

shaft Replace-

ment Proce-

dure

Go toCrank-

shaft Replace-

ment Proce-

dure

Go toTiming

Belt Replace-

ment Proce-

dure

Go toCrank-

shaft Replace-

ment Proce-

dure

Go to Step 3

Go to Step 4

Go to Step 5

Go to Step 6

System OK

Connecting Rod Bearing Noise Symptom

Step Action Value(s) Yes No

1 Is a knock noise heard under all engine speeds? Go to Step 2 System OK

2 Inspect the crankshaft connecting rod journal.

Is the crankshaft connecting rod journal worn?

3 Check the oil pump pressure.

Is the oil pump pressure low?

4 Inspect the crankshaft connecting rod journals.

Are the journals out–of–round?

5 Inspect the connecting rods.

Is there a misaligned connecting rod?

6 Inspect the connecting rod bolts.

Are the connecting rod bolts torqued properly?

Go toCrank-

shaft Replace-

ment Proce-

dure

Go toOil Pres-

sure Test

Go toCrank-

shaft Replace-

ment Proce-

dure

Go toPistons

and Rods Re-

placement Pro-

cedure

System OK Go toPistons

Go to Step 3

Go to Step 4

Go to Step 5

Go to Step 6

and Rods Re-

placement Pro-

cedure

DAEWOO V–121 BL4

Page 36

GENERAL ENGINE INFORMATION 1A – 9

Piston Noises

Step Action Value(s) Yes No

1 Are any of the following noises heard: a sharp double

knock when the engine is idling, a light ticking with

no load on the engine, or a ”slapping” noise when the

engine is cold?

2 Inspect the piston pin and the bushing.

Is the piston pin or the bushing worn or loose?

3 Inspect the piston.

Is the piston broken or cracked?

4 Inspect the connecting rods.

Is there a misaligned connecting rod?

5 Inspect the piston position.

Is the piston 180³ out of position?

Go to Step 2 System OK

Go toPistons

Go to Step 3

and Rods Re-

placement Pro-

cedure

Go toPistons

Go to Step 4

and Rods Re-

placement Pro-

cedure

Go toPistons

Go to Step 5

and Rods Re-

placement Pro-

cedure

Go toPistons

System OK

and Rods Re-

placement Pro-

cedure

DAEWOO V–121 BL4

Page 37

1A – 10IGENERAL ENGINE INFORMATION

Valve Mechanism or Valve Train Noises

Step Action Value(s) Yes No

1 Is a light tapping sound heard from the engine? Go to Step 2 System OK

2 Inspect the valve springs.

Are the springs weak or broken?

3 Inspect the valves.

Are the valves sticking or warped?

4 Inspect the valve lifters.

Are the valve lifters dirty, stuck or worn?

5 Inspect the camshaft lobes.

Are the camshaft lobes damaged or improperly machined?

6 Check the oil supply to the valve train.

Is the oil supply insufficient or poor?

7 Inspect the valve guides.

Are the valve guides worn?

8 Inspect the valve spring seat.

Is the valve spring seat incorrect?

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go toCamshaft

Replacement

Procedure

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go toCylinder

Head and

Valve Train

Components

Replacement

Procedure

Go to Step 3

Go to Step 4

Go to Step 5

Go to Step 6

Go to Step 7

Go to Step 8

System OK

DAEWOO V–121 BL4

Page 38

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many machined,

honed, polished and lapped surfaces with tolerances that

are measured in ten–thousandths of an inch. When any internal engine parts are serviced, care and cleanliness are

important. A liberal coating of engine oil should be applied

to friction areas during assembly, to protect and lubricate

the surfaces on initial operation. Proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard shop

practice even if not specifically stated.

Whenever valve train components are removed for service, they should be kept in order. They should be installed

in the same locations and with the same mating surfaces,

as when they were removed.

Battery cables should be disconnected before any major

GENERAL ENGINE INFORMATION 1A – 11

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other electrical parts.

ON–ENGINE SERVICE

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit, or

when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting

this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Notice : Any time the air cleaner is removed, the intake

opening should be covered. This will protect against the

accidental entrance of foreign material, which could follow

the intake passage into the cylinder and cause extensive

damage when the engine is started.

DAEWOO V–121 BL4

Page 39

SECTION : 1C

DOHC ENGINE MECHANICAL

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 1C–2. . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SPECIFICATIONS 1C–2. . . . . . . . . . . . . . . . .

FASTENER TIGHTENING

SPECIFICATIONS 1C–4. . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 1C–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS TABLE 1C–6. . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR 1C–8. . . . . . . . . . . . . . . . . . . .

UPPER END 1C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOWER END 1C–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR 1C–12. . . . . . . . . . . . . .

ON–VEHICLE SERVICE 1C–12. . . . . . . . . . . . . . . . . . . .

VALVE COVER 1C–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND GASKET 1C–14. . . . . . . . . . .

CAMSHAFTS 1C–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIMING BELT CHECK AND ADJUST 1C–27. . . . . . .

TIMING BELT 1C–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PAN 1C–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PUMP 1C–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MOUNT 1C–44. . . . . . . . . . . . . . . . . . . . . . . . .

INTAKE MANIFOLD 1C–46. . . . . . . . . . . . . . . . . . . . . .

EXHAUST MANIFOLD 1C–49. . . . . . . . . . . . . . . . . . . .

CAMSHAFT GEARS 1C–51. . . . . . . . . . . . . . . . . . . . . .

REAR TIMING BELT COVER 1C–53. . . . . . . . . . . . . .

ENGINE 1C–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PISTONS AND RODS 1C–63. . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 1C–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND VALVE TRAIN

COMPONENTS 1C–68. . . . . . . . . . . . . . . . . . . . . . . .

CRANKSHAFT 1C–77. . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKSHAFT BEARINGS AND

CONNECTING ROD BEARINGS –

GAUGING PLASTIC 1C–88. . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND GASKET 1C–91. . . . . . . . . . .

CRANKSHAFT 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . .

TIMING BELT 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PUMP 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PAN 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXHAUST MANIFOLD 1C–91. . . . . . . . . . . . . . . . . . . .

INTAKE MANIFOLD 1C–91. . . . . . . . . . . . . . . . . . . . . .

CAMSHAFTS 1C–91. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 40

1C – 2IDOHC ENGINE MECHANICAL

SPECIFICATIONS

ENGINE SPECIFICATIONS

Application Description (Manual and Automatic)

General Data:

Engine Type 4–Cylinder (in–line)

Displacement 1,998 cm3 (121.92 in3)

Bore Stroke 86 x 86 mm (3.38 in. x 3.38 in.)

Compression Ratio 9.6 µ0.2 :1

Firing Order 1–3–4–2

Cylinder Bore:

Diameter 85.995~86.485 mm (3.3856~3.4049 in.)

Out of Round (Maximum) 0.013 mm (0.0005 in.)

Taper (Maximum) 0.013 mm (0.0005 in.)

Piston:

Diameter 85.955–86.485 mm (3.384–3.404 in.)

Clearance to Bore 0.0100~0.0300 mm (0.00039~0.00110 in.)

Piston Protrusion 0.5 mm (0.019 in.) Maximum

Piston Taper 0.013 mm (0.0005 in.)

Piston Rings:

Ring, End Gap, Top Compression 0.3~0.5 mm (0.011~0.019 in.)

Ring, End Gap, Second Compression 0.3~0.5 mm (0.011~0.019 in.)

Piston Pin:

Diameter 20.9970~20.9985 mm (0.82665~0.82671 in.)

Pin Offset 0.8 mm (0.03 in.) Toward Thrust Side

Clearance: In Piston 0.0035~0.0140 mm (0.00013~0.00055 in.)

Clearance: In Rod Interference Fit in Rod

Length 61.5 mm (2.42 in.)

Camshaft:

Lift – Intake 10.0 mm (0.39 in.)

Lift – Exhaust 10.0 mm (0.39 in.)

End Play 0.040~0.144 mm (0.0015~0.0056 in.)

Bearing Journal OD 42.455~43.470 mm (1.6714~1.7114 in.)

Crankshaft:

Main Journal

Diameter (All)

Out of Round (Maximum) 0.003 mm (0.0001 in.)

Main Bearing Clearance (All) 0.015–0.061 mm (0.00059~0.00239 in.)

Crankshaft End Play 0.070~0.302 mm (0.0027~0.0118 in.)

Service Oversize Available in 2 sizes

57.974~57.995 mm (2.2824~2.2832 in.)

0.25 mm and 9.50 mm (0.0098~0.0196 in.)

DAEWOO V–121 BL4

Page 41

DOHC ENGINE MECHANICAL 1C – 3

Application Description (Manual and Automatic)

Connecting Rod Journal:

Diameter (All)

Out of Round (Maximum) 0.004 mm (0.00015 in.)

Rod Bearing Play 0.006~0.031 mm (0.00023~0.00122 in.)

Cylinder Head:

Valve Stem Protrusion 39.2~39.8 mm (1.54~1.56 in.)

V alve Guide Height 13.7–14.0 mm (0.54~0.57 in.)

Overall Height 134~0.025 mm (5.2755~0.0009 in.)

Minimum Overall Height After Machining 133.9 mm (5.27 in.)

Valve System:

Valve Lash Compensators Hydraulic

Seat Runout (Maximum, All) 0.03 mm (0.00118 in.)

Face Runout (Maximum, All) 0.03 mm (0.00118 in.)

Valve Stem Diameter

Intake

Exhaust 6.078~6.992 mm (0.2747~0.2752 in.)

Valve Diameter

Intake

Exhaust 29µ0.1 mm (1.1417µ0.0039 in.)

Valve Seat Width

Intake

Exhaust 1.7~2.2 mm (0.066~0.086 in.)

Valve Face Angle 44³~40³

Valve Guide Inside Diameter 6.000~6.012 mm (0.236~0.237 in.)

48.981~ 48.987 mm (1.9283~1.9286 in.)

6.998~7.012 mm (0.2755~0.2760 in.)

32µ0.1 mm (1.2598µ0.0039 in.)

1.0~1.5 mm (0.039~0.059 in.)

Oil Pump:

Gear Lash 0.10~0.20 mm (0.003~0.007 in.)

Outer Gear to Body 0.11~0.19 mm (0.004~0.007 in.)

Outer Gear to Crescent 0.40~0.50 mm (0.015~0.019 in.)

Inner Gear to Crescent 0.35~0.40 mm (0.013~0.015 in.)

End Clearance 0.030~0.10 mm (0.001~0.003 in.)

Sealants and Adhesives:

Rear Main Bearing Cap GE p/n RTV 159

Camshaft Carrier to Cylinder Head HN 1581 (Loctite± 515)

Oil Pan Bolts HN 1256 (Loctite± 242)

Oil Pump Bolts HN 1256 (Loctite± 242)

Oil Pan Pickup Tube Bolts HN 1256 (Loctite± 242)

Oil Gallery Plug HN 1256 (Loctite± 242)

Coolant Jacket Caps and Plugs (Freeze Plugs) HN 1756 (Loctite± 176)

Exhaust Manifold Studs/Nuts Anti–seize Compound (HMC Spec HN1325)

DAEWOO V–121 BL4

Page 42

1C – 4IDOHC ENGINE MECHANICAL

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb–Ft Lb–In

A/C Compressor Hose Assembly Bolt 33 24 –

Air Filter Housing Bolts 10 – 89

Automatic Tensioner Bolt 25 18 –

Auxiliary Catalytic Converter–to–Exhaust Manifold Nuts 40 30 –

Camshaft Bearing Cap Bolts, Intake and Exhaust 8 – 71

Camshaft Gear Bolt, Intake and Exhaust 50 + 60³+ 15³ 37 + 60³+ 15³ –

Camshaft Position Sensor Bolts 12 – 106

Connecting Rod Cap Bolts 36 + 45³+ 15³ 26 + 45³+ 15³ –

Coolant Bypass Housing and Mounting Bolts 15 11 –

Coolant Pump Retaining Bolts 25 18 –

Coolant Temperature Sensor 25 18 –

Crankshaft Bearing Cap Bolts 50 + 45³ + 15³ 37 + 45³ + 15³ –

Crankshaft Position Sensor Retaining Bolt 8 – 71

Crankshaft Pulley Bolts 20 15 –

Crankshaft Timing Belt Drive Gear Bolt 135+ 30³ +10³ 100+ 30³ +10³ –

Cylinder Head Bolts 25 + 90³ +90³

+ 90³

EI System Ignition Coil and EGR Mounting Bracket Bolts 25 18 –

Engine Block Lower Support Bracket/Splash Shield Bolts 35 26 –

Engine Mount Bracket Retaining Bolts and Nuts 55 41 –

Engine Mount Bracket–to–Engine Mount Retaining Bolts 60 44 –

Engine Mount Retaining Bolts 60 44 –

Engine–to–Intake Manifold Support Bracket Bolts 20 15 –

Evaporative Emission Canister Purge Solenoid Bracket Bolt 5 – 44

Exhaust Gas Recirculation Valve Bolts 20 15 –

Exhaust Manifold Heat Shield Bolts 8 – 71

Exhaust Manifold Retaining Nuts 15 11 –

Exhaust Pipe Support Bracket Bolts 40 30 –

Flexible Plate Bolts 65 48 –

Flywheel Bolts 65 + 30³ + 15³ 48 + 30³ + 15³ –

Front Muffler Pipe–to–Main Catalytic Converter Nuts 30 22 –

Fuel Rail Retaining Bolts 25 18 –

Front Timing Belt Cover Bolts, Upper and Lower 6 – 53

Generator–to–Intake Manifold and Cylinder Head Support

Bracket Bolts

Generator–to–Intake Manifold Strap Bracket Bolt, Upper and

Lower

Generator–to–Intake Manifold Support Bracket Bolts 35 26 –

Ignition Coil Mounting Bolts 10 – 89

Intake Manifold Retaining Nuts and Bolts 18 13 –

Intake Manifold Support Bracket Bolts 20 15 –

37 27 –

22 16 –

18 + 90³ +90³

+ 90³

–

DAEWOO V–121 BL4

Page 43

DOHC ENGINE MECHANICAL 1C – 5

Application Lb–InLb–FtNSm

Lower Block Support Bracket Bolts 35 26 –

Oil Pan Drain Plug 35 26 –

Oil Pan Flange–to–Transaxle Retaining Bolts 40 30 –

Oil Pan Retaining Bolts 10 – 89

Oil Pressure Switch 40 30 –

Oil Pump Bolts 10 – 89

Oil Pump Rear Cover Bolts 6 – 53

Oil Pump/Pick–up Tube Bolts 10 – 89

Oil Pump Retaining Bolts 10 – 89

Pulse Pick–up Sensor Disc 13 – 115

Rear Timing Belt Cover Bolts 7 – 62

Safety Relief Valve Bolt 30 22 –

Spark Plug Cover Bolts 8 – 71

Spark Plugs 20 15 –

Support Bracket Bolts 40 30 –

Thermostat Housing Mounting Bolts 15 11 –

Throttle Cable Bracket Bolts 8 – 71

Timing Belt Automatic Tensioner Bolt 25 18 –

Timing Belt Idler Pulley Bolt 25 18 –

Timing Belt Idler Pulley Nut 25 18 –

Transmission/Transaxle Bell Housing Bolts 75 55 –

Transmission/Transaxle Torque Converter Bolts 60 44 –

Valve Cover Bolts 8 – 71

DAEWOO V–121 BL4

Page 44

1C – 6IDOHC ENGINE MECHANICAL

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–653

Adapter

KM–135

Adapter

KM–805

Valve Guide Reamer

MKM–571–B

Gauge

J–28467–B

Engine Assembly Lift

Support

KM–412

Engine Overhaul Stand

J–36792

Crankshaft Rear Oil Seal

Installer

KM–348

Spring Compressor

DAEWOO V–121 BL4

Page 45

DOHC ENGINE MECHANICAL 1C – 7

KM–635

Crankshaft Rear Oil Seal

Installer

KM–427

Piston Pin Service Set

KM–340–0

Cutter Set

Includes: KM–340–7

Guide Drift

KM–340–13

Cutters

KM–340–26

Cutters

KM–470–B

Angular Torque Gauge

KM–498–B

Pressure Gauge

DAEWOO V–121 BL4

Page 46

1C – 8IDOHC ENGINE MECHANICAL

COMPONENT LOCATOR

UPPER END

DAEWOO V–121 BL4

Page 47

DOHC ENGINE MECHANICAL 1C – 9

1. Bolt

2. Spark Plug Cover

3. Oil Cap

4. Oil Cap Seal

5. Bolt

6. Valve Cover

7. Valve Cover Gasket

8. Value Lash Adjuster

9. Retainer

10. Valve Cab

11. Valve Spring

12. Valve Stem Seal

13. Valve Spring Seat

14. Valve Guide

15. Valve Spring Seat

16. Exhaust Seat

17. Intake Valve

18. Exhaust Valve

19. Bolt

20. Front Bearing Cap

21. Head Bolt

22. Bolt

23. Bearing Cap

24. EGR Adapter

25. EGR Adapter Gasket

26. Cylinder Head

27. Exhaust Manifold Gasket

28. Exhaust Manifold

29. Nut

30. Exhaust Manifold Heat Shield

31. Cylinder Head Gasket

32. Bolt

33. Thermostat Housing

34. Thermostat Housing Gasket

35. Stud

36. Sleeve

37. Plug

38. Bolt

39. Camshaft Position Sensor

40. Oil Gallery Plug

41. Exhaust Camshaft

42. Oil Seal Ring

43. Camshaft Gear

44. Washer

45. Camshaft Gear Bolt

46. Intake Camshaft

47. Intake Manifold Gasket

48. Intake Manifold

49. Throttle Body Gasket

50. Throttle Body

51. Nut

52. Exhaust Gas Recirculation Solenoid

DAEWOO V–121 BL4

Page 48

1C – 10IDOHC ENGINE MECHANICAL

LOWER END

DAEWOO V–121 BL4

Page 49

DOHC ENGINE MECHANICAL 1C – 11

1. Connecting Rod

2. Bearing

3. Connecting Rod Bolt

4. Piston Ring Set

5. Piston Pin

6. Piston

7. Engine Block

8. Sleeve

9. Water Jacket Cap

10. Bolt (Manual Transaxle)

11. Flywheel (Manual Transaxle)

12. Flexible Plate (Automatic Transaxle)

13. Bolt (Automatic Transaxle)

14. Clamp

15. Hose

16. Clamp

17. Engine Vent Pipe

18. Bolt

19. Gasket

20. Transaxle Input Shaft Bearing

21. Rear Main Seal

22. Crankshaft

23. Ignition Transmitter Disk

24. Bolt

25. Splash Pan

26. Oil Pan

27. Drain Plug

28. Seal Ring

29. Bolt

30. Sleeve

31. Gasket

32. Bolt

33. Oil Pump Cover

34. Ring Gear

35. Gear

36. Plug

37. Washer

38. Washer

39. Bypass Valve Plug

40. Special Screw

41. Seal

42. Oil Filter

43. Bypass Valve

44. Pressure Relief Valve Plunger

45. Pressure Relief Valve Spring

46. Washer