Page 1

Service Manual

Washing Machine

Model: DWM-200C

DAEWOO ELECTRONICS CORP.

S/M No. : DW200C0001

http : //svc.dwe.co.kr Jul. 2004

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

Page 2

WASHING MACHINE

CCoonntteennttss

1. SPECIFICATIONS..................................................................................................... 2

2. EXTERNAL VIEW..................................................................................................... 3

3. PRINCIPLES OF OPERATION AND EXPLANATION OF FUNCTIONS................ 4

4. DIRECTION FOR DISASSEMBLY AND ASSEMBL Y..............................................8

5. TROUBLESHOOTING GUIDE.................................................................................11

6. EXPLODED VIEW AND PARTS LIST.....................................................................16

7. WIRING DIAGRAM..................................................................................................23

Page 3

2

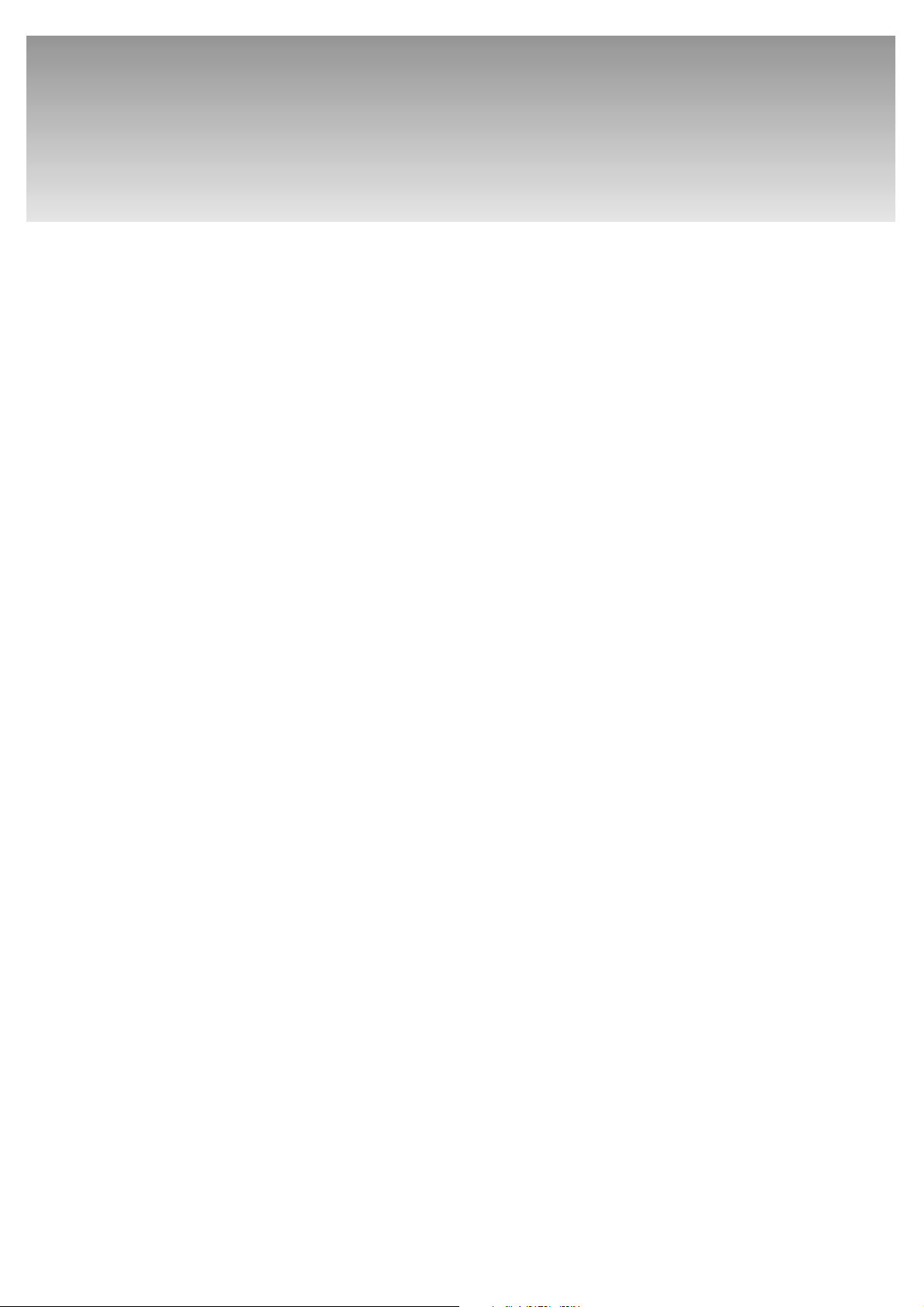

NO. ITEM SPECIFICATIONS

1 POWER VOLTAGE

SOURCE FREQUENCY 60Hz

2 POWER PUMP 610W

CONSUMPTION

NON PUMP 580W

3 DIMENSION NET : 924X542X1025, PACKED UP : 938X558X1040 (WXDXH)

4 MACHINE PUMP NET : 39kg, PACKED UP : 42.5kg

WEIGHT NON PUMP NET : 38kg, PACKED UP : 41.5kg

5 WASHING COURSE STRONG, NORMAL, SOFT

6 WATER LEVEL HIGH:90l, MEDIUM:80l, LOW:70l, SMALL:60

l

7 REVOLUTION WASH 100 rpm 100 rpm

PER MINUTE SPIN 1700 rpm 1400 rpm

8 TIMER WASH MAX. 15 min., Manual operation

SPIN MAX. 5 min., Manual operation

9 WASHER TYPE PULSATOR TYPE

10 SPIN TYPE CENTRIFUGALLY SEPARATED TYPE

11

MAXIMUM MASS

WASH 10.0 kg

OF TEXTILE SPIN 7.0 kg

12 WATER SUPPLY MANUAL

13 SPIN RINSE O

14 OUTLET OF DRAIN HOSE REAR

15 LINT FILTER O

POWER SOURCE

SUFFIX

EXPLANATION

NON PUMP PUMP

AC 127V 60Hz A AC 110V 60Hz T TP

AC 220V 50Hz N NP

AC 220V 60Hz L LP

AC 240V 50Hz M MP

AC 110/220V 50Hz D DP

AC 127/220V 60Hz S -

1. SPECIFICATIONS

NOTE : Explanation table for suffix of names.

AC 110V AC 220V AC 127/220V AC 110/220V AC 220V AC 240V AC 127V

50Hz 60Hz

650W

600W

Model Name Pump

DWM-XXXX N P

Power Source

Page 4

3

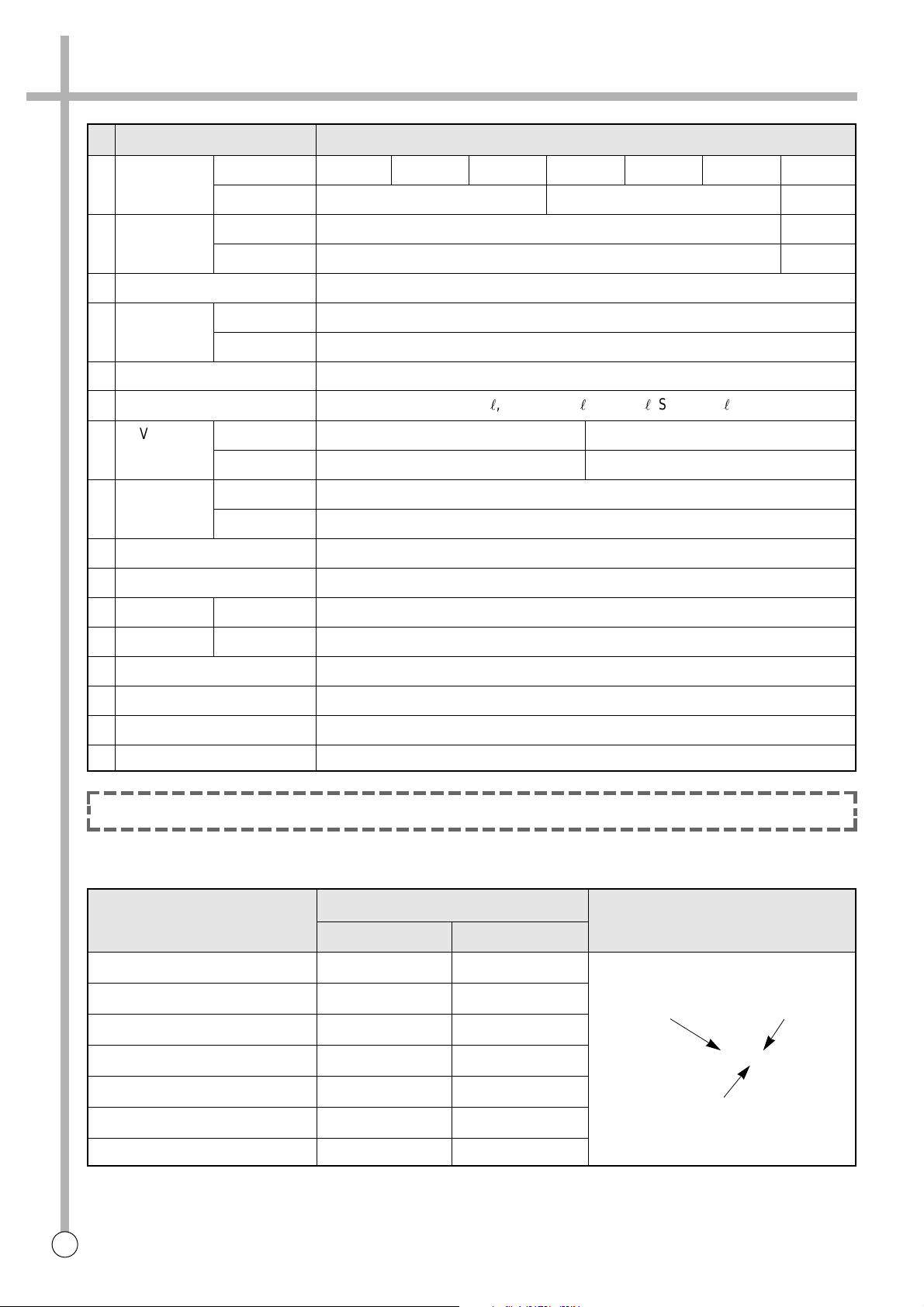

2. EXTERNAL VIEW

Structure Of The Washing Machine

Control Panel (Panel b Ass’y)

11

WASH TIMER

Use to select the desired time for washing or rinsing.

22

WASH ACTION

Use to select wash action. (“STRONG”, “NORMAL”,

“SOFT”)

33

LEVER WATER SUPPLY SELECTOR

Left : water supply in the WASH TUB.

Right : water supply in the BASKET SPIN.

44

INLET WATER

Connect inlet hose to supply water in the WASH

TUB or BASKET SPIN.

55

V ALVE SELECTOR

Select “WASH, RINSE” for washing and rinsing, and

“DRAIN” to drain the water.

(In case PUMP MODEL turn on the drain pump)

“OFF” to turn off the drain pump. (Only PUMP

MODEL)

66

SPIN TIMER

Used to select the desired time for spinning.

12 3 45 6

Page 5

4

WORK PRINCIPLE INSTRUCTION

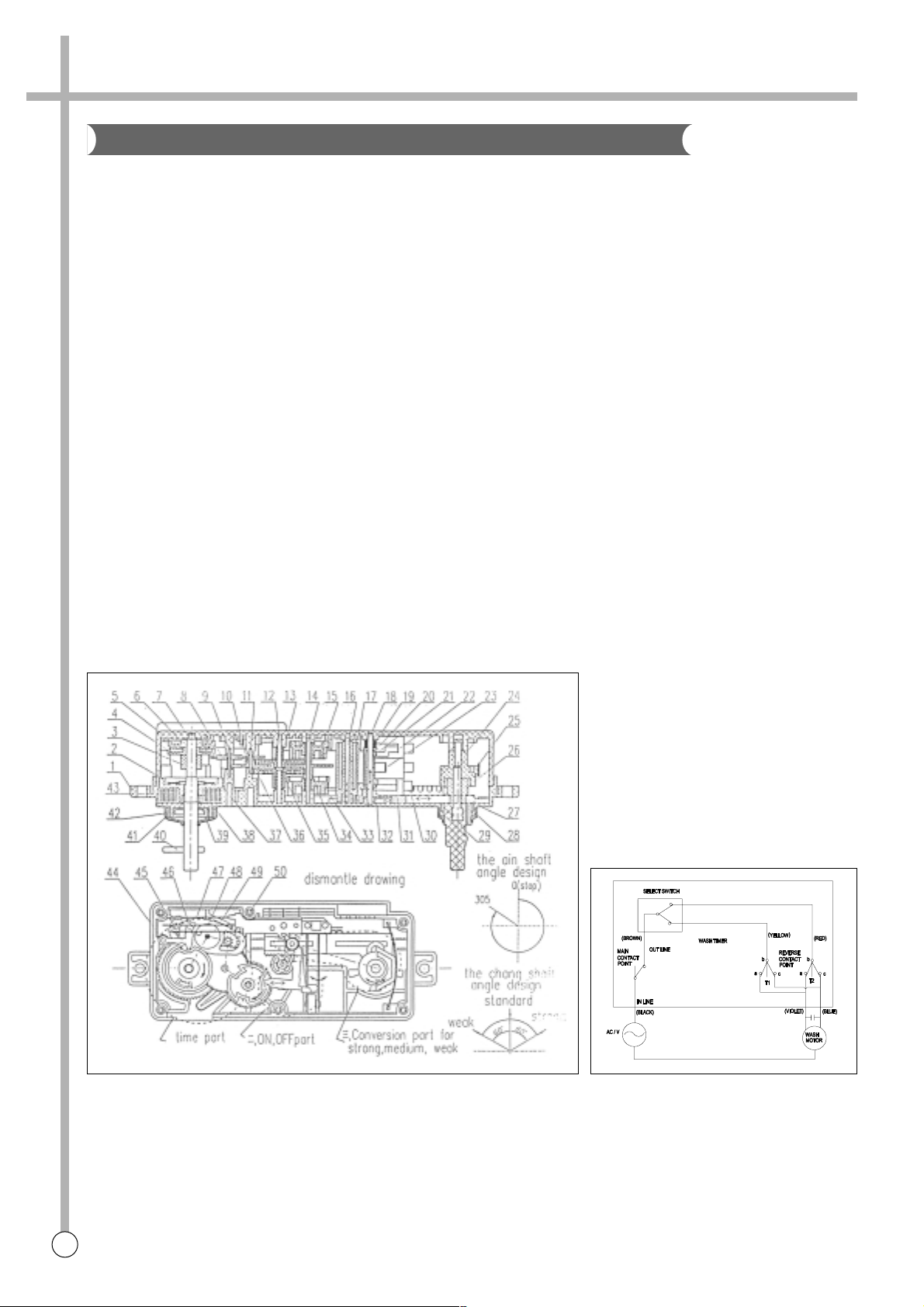

I. Time part

1. The extro force will make 7(main shaft), 4, 6(cam) and 37(first cam) rotate clockwise to a certain angle, then

43(spring) transmogrify and accumulate power, the both sides of 48, 49(reed) be contacted, move limitation of

8(sway slice) was released. When the force is released, 8(sway slice) swift by constant frequency. After gear

move by variety speed, 43(spring) mode 7(main shaft) can only rotate back by constant velocity.

2. A moment later , the gap in 6(buzzer cam) reach 46(adjustor), the 47, 48(reed) be contacted, begin to buzz, the

gap in 4 (main cam) reach 44(adjustor), the main circult disconnect, the movement of 8(sway slice) is limited,

cease to buzz, the timer stop working.

II. On, OFF part

15, 33(program cam), 21, 32(adjustor) move along with the surface of program cam, 22, 31(reed) swing with its

elasticity so as to ON and OFF freely.

III. Conversion part for strong, medium, weak.

When exact force add to 29(reversion shaft) 30(the program reversion panel) will glide by horizontal, due to the

three stage strong, medium, weak designed on the 30(program reversion panel), the 20(shaft cover) move by

vertical, which made 21, 32(adjustor) move by horizontal so that there will by three rate strong, medium, weak

can be chose 15, 33(program cam).

3. PRINCIPLES OF OPERATION AND EXPLANATION OF FUNCTIONS

Wash Timer

CIRCUIT DIAGRAM

Page 6

5

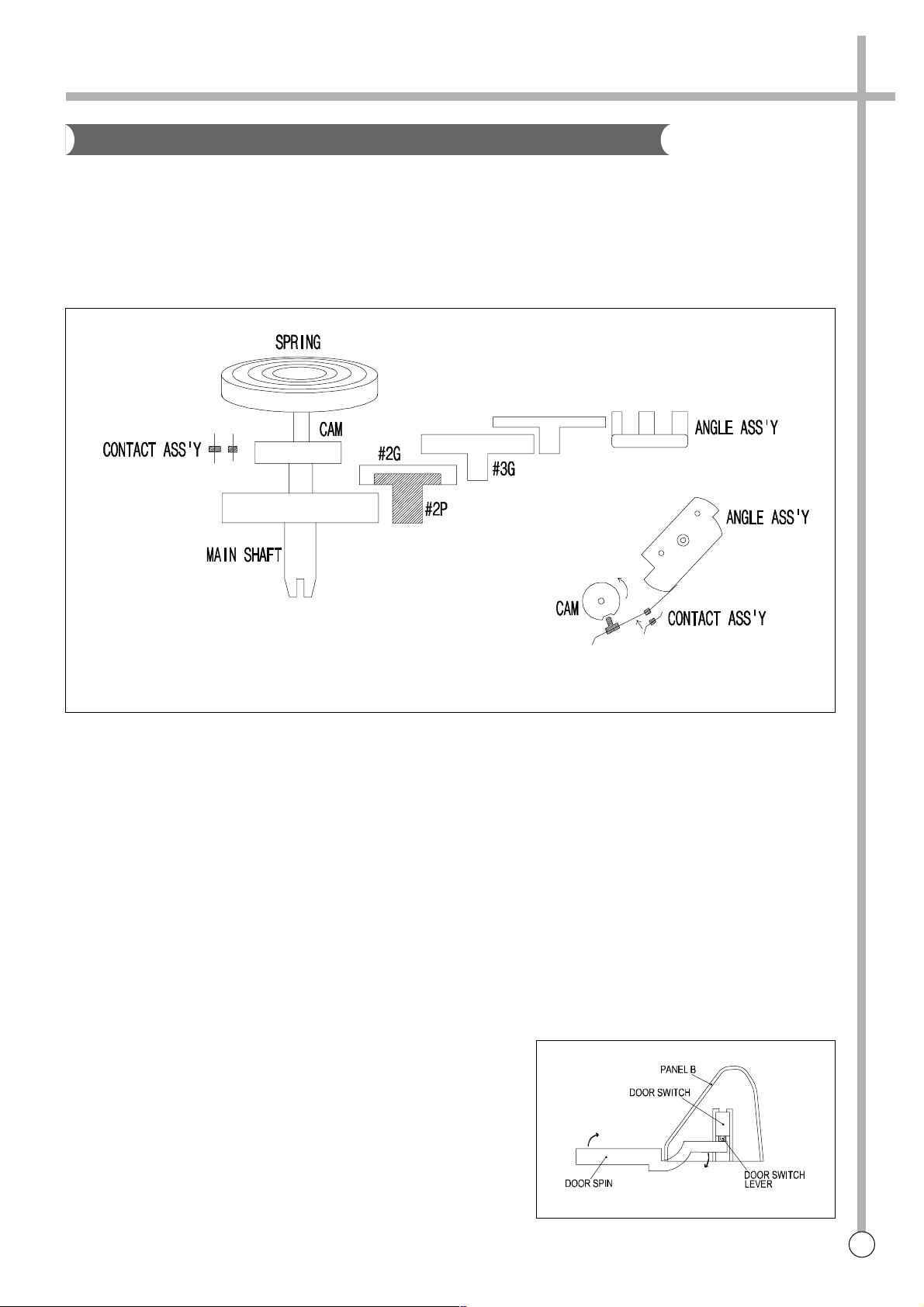

FUNCTION

The spin timer is the switch providing power to the SPIN MOTOR(DRAIN PUMP MOTOR) during the set spin dry

time, and is a spring-type time switch comes on turning and those contact points comes off after the set time.

STRUCTURE AND PRINCIPLE OF ACTIVATION

1) The main shaft turns due to the unwinding force when the spin timer is turned, the spring wound with that force

being delivered through each gear and the spring slowly unwinding at a speed finally controlled by the angle

assembly .

2) The contact point Turns ON and the assembly angle is set in motion which is in the CAM groove in the OFF

state, comes off the groove when the main shaft is turned to wind the spring. The contact point turns OFF,

return to CAM groove when the spring unwind completely.

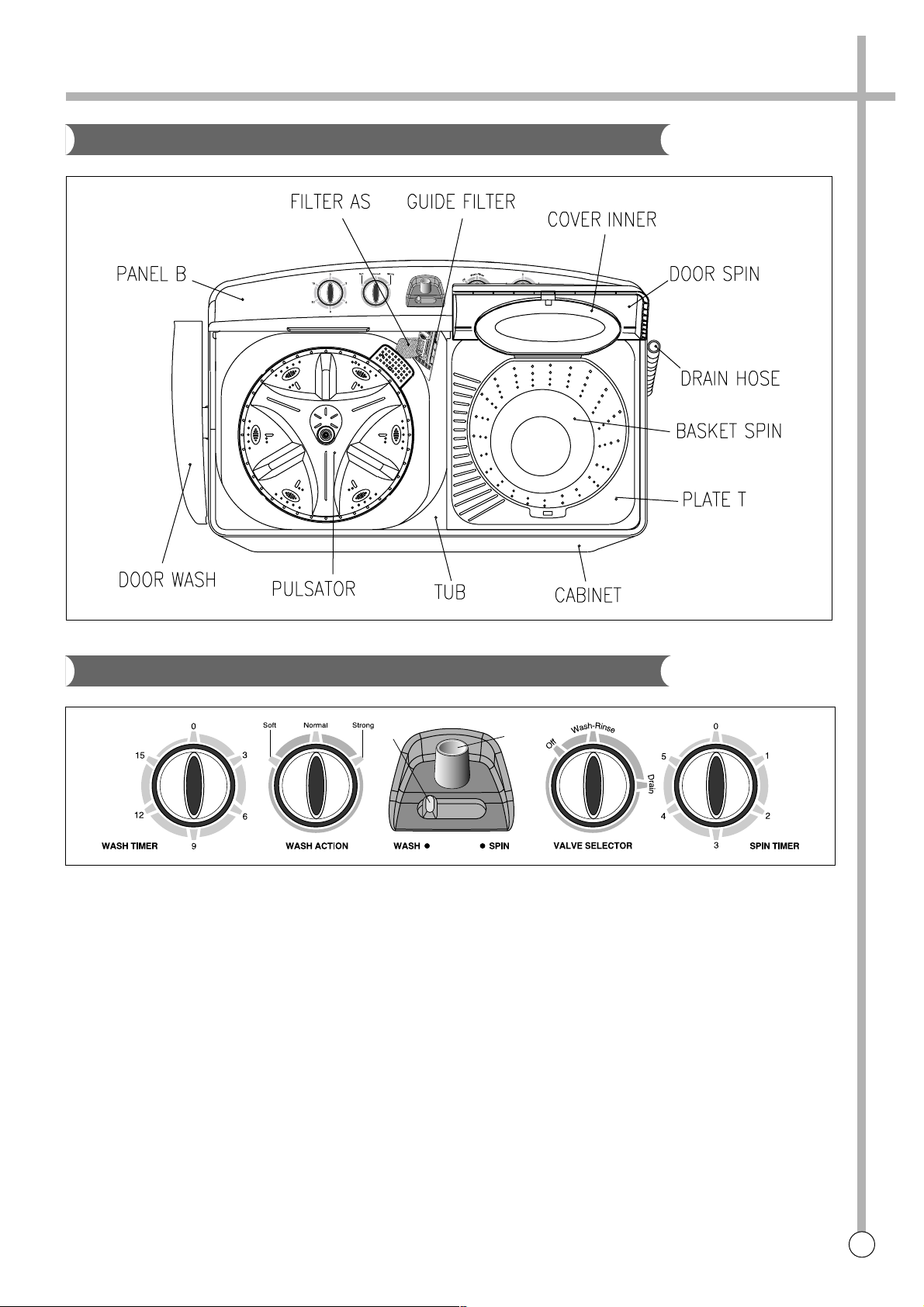

SAFETY DEVICE FOR BASKET SPIN

The BASKET SPIN is an apparatus which eliminates the water from the laundry through centrifugal separation

generated by rapid revolution(approximately 1,700rpm for 60Hz). Accordingly, there are a DOOR SWITCH to cut

off the power going into the DOOR SPIN is opened and a brake system to stop the rotating BASKET SPIN.

DOOR SWITCH

When the DOOR SPIN is opened during spinning, the DOOR

SWITCH LEVER which sites atopt the DOOR SPIN falls off the

contact, and cuts off the power going into the SPIN MOTOR.

Spin Timer

Page 7

6

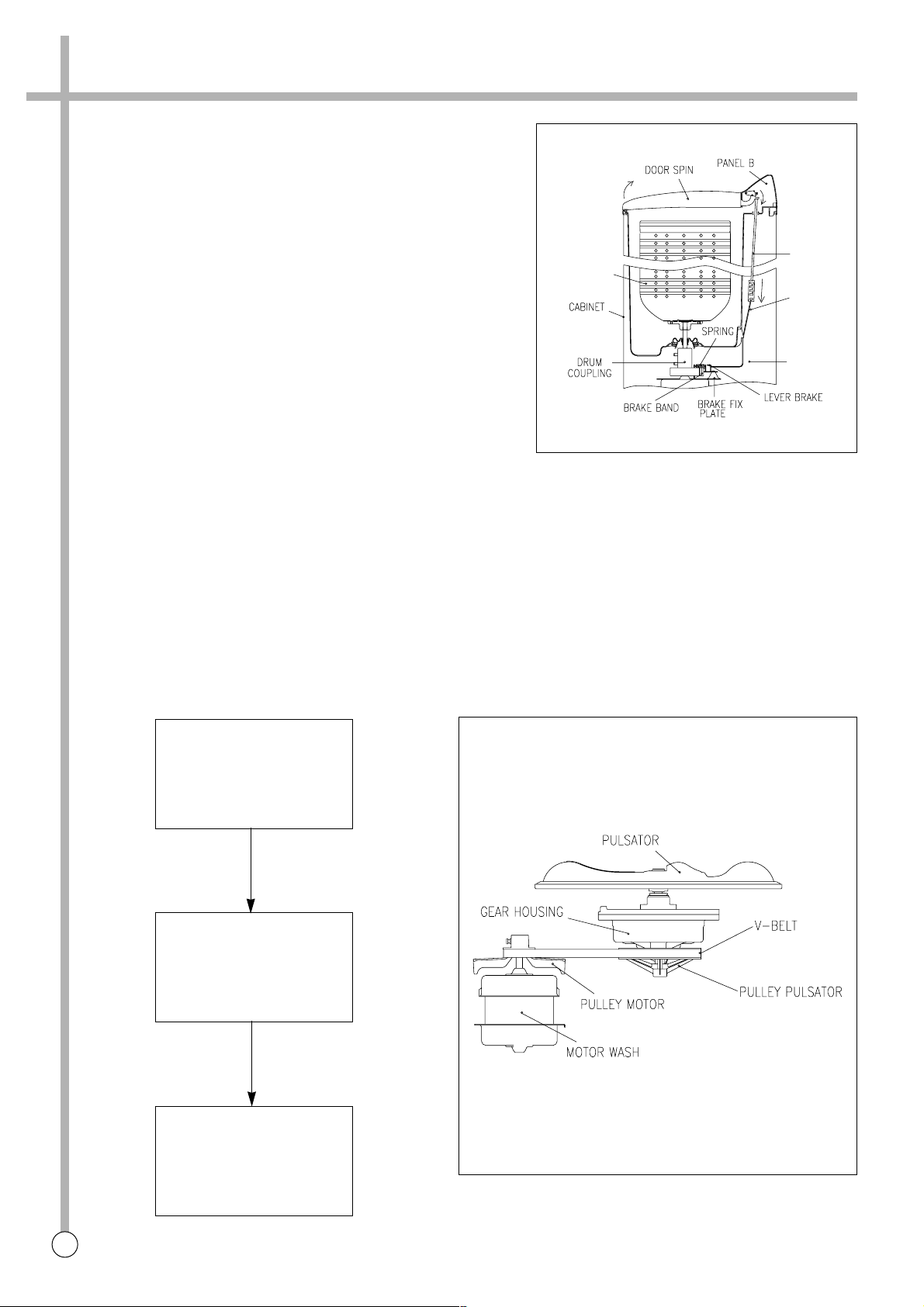

BRAKE SYSTEM

When the DOOR SPIN is opened, LINK BRAKE which connect to DOOR SPIN loosens. And then the BRAKE BAND

touches the DRUM COUPLING assembly and stops the BASKET SPIN as it is pulled by the SPRING in the BRAKE FIX

PLA TE assembly.

BRAKE BAND GAP CONTROL METHOD

The BAND BRAKE works best when the gap between it and

the DRUM COUPLING is about 2mm when the DOOR SPIN

is closed. The BASKET SPIN stops slowly if the gap between

the two is too narrow, the BASKET SPIN revolution is affected

and the PLA TE CONTROL WIRE may be adjusted to maintain the BRAKE BAND gap adequately.

WASH DECELERATOR ASSEMBLY

The initial deceleration following the activation of the WASH MOTOR takes place through the PULLEY MOTOR

and PULLEY PULSA TOR, and the secondary deceleration is done by the gear in the GEAR HOUSING which also

increases their revolution strength. This revolution speed and strength is delivered to the PULSATOR, which is

then able to cause water current that is strong yet soft so that wash loads are not damaged.

LINK BRAKE

BASKET SPIN

LINK WIRE

BRAKE WIRE

(INNER WIRE)

MOTOR WASH

About 1,700rpm(60Hz)

1,400rpm(50Hz)

PULLEY PULSATOR

About 600rpm(60Hz)

600rpm(50Hz)

PULSATOR

About 100rpm(60Hz)

100rpm(50Hz)

Page 8

7

GEAR HOUSING ASS’Y

The GRAR HOUSING ASSEMBL Y is a transmission device which turns the PULSATOR at 6:1 lowered speed

through the gear unit assembly which receives power at the GEAR SHAFT UNIT.

1) The two sides of the GEAR SHAFT UNIT are supported by the

OILLESS BEARING in the GEAR HOUSING ASSEMBLY .

2) The GEAR UNIT ASSEMBLY is connected to the GEAR

SHAFT 1 and GEAR SHAFT UNIT by the GEAR and GEAR

UNIT respectively .

3) The two sides of GEAR SHAFT 1 are supported by the OIL

SEAL and OILLESS BEARING in the GEAR HOUSING

ASSEMBL Y.

BELLOWS ASS’Y

The wrinkled rubber device on the botton of the BASKET SPIN is

called BELLOWS ASSEMBL Y.

It has a waterseal and a oilless metal inside to prevent leakage and so that the BASKET SPIN may work smoothly.

Much lint may be obtained depending upon the kind of clothes to

be washed and same of the lint may also be suck to the clothes.

To minimize this possibility, a lint filter is provide on the upper part

of the FIL TER OVERFLOW to filter the wash water.

Use of the lint filter during every wash is recommend.

CLEANING THE LINT FILTER

1) Remove the FILTER AS from the FILTER OVERFLOW by

pressing it downwards.

2) Turn the FILTER AS inside out, and wash the lint off with

water.

3) Return the FILTER AS it was, and fix the FILTER AS to the

FIL TER OVERFLOW.

STRUCTURE

Filter

Page 9

8

4. DIRECTION FOR DISASSEMBLY AND ASSEMBLY

1. Remove 3 screws on the P ANEL B.

3. Remove 5 screws and CONTROL LEVER

2. Remove KNOB, wash timer and spin timer on the

P ANEL B.

Ass’y Panel Back

4. Remove 4 screws on the COVER BACK. 5. Separate LINK BRAKE and ASSEMBLY BRAKE

WIRE.

Basket Spin

Page 10

9

9. Remove 1 screw on the CABINET. 10. Separate HARNESS AS connectors.

6. Remove bolt and nut on the upper side of the

DRUM COUPLING AS.

8. Lift up the BASKET SPIN.

7. Remove the PLA TE Ton the TUB.

Ass’y Base Under

Page 11

10

1 1. Remove a V-BELT from PULLEY MOT OR.

13. Remove 7 screws on the BASE UNDER ASSY.

15. Remove 3 bolts on the BASE UNDER, and

remove the WASH MOTOR.

12. Turn over the washing machine.

14. Remove 3 screws on the BRACKET MOTOR,

and remove the SPIN MOTOR.

16. Remove 1 screw on the FIXTURE PUMP. (In

case of pump model)

Page 12

5. TROUBLESHOOTING GUIDE

PROBLEM

Pulsator

does not

rotate.

CHECK POINT CAUSE SOLUTION

Pull out the power plug to repair and make sure that the Washing Machine has been properly

grounded.

NOTES

Concerning Wash

Is the Power properly connected? Reconnect the Power Cord.

Is there a whirring sound from the

Wash Motor when turned on?

Is the Condeser properly connected?

Motor does not start due to

opening the Condenser circuit

Is the Motor hot?

(In case there is Thermal Protector)

Is the Wiring good?

(Refer to the Wiring Diagram)

Is the contact of Wash Timer good? Defective Wash T imer

Defective Wash Motor

Power has been cut off by

the Thermal Protector.

Improper wiring

Reconnect the Condenser.

Replace Wash T imer

Replace Wash Motor

Reload with proper wash

load.

Wash restart when Motor

cools.

Reconnect the wiring

Pulsator

does not

rotate

smoothly .

Is the Wash Load appropriate?

Are the Pulsator and Motor

Pulleys securely assembled?

Does the V-Belt slip?

Are there impurities between the

Pulsator.

Revolution obstructed by

impurities

Remove impurities after

disassembling pulsator.

Defect of mechanical

assembly

Worn out V-Belt

Tighten the screws fixed on

the Pulleys.

Replace V-Belt

The wash load is more

than 8.0kg (160C) or

10.0kg (170C)

YES

NO

YES

NO

YES

NO

NO

NO

NO

YES

YES

NO

NO

YES

YES

YES

YES

YES

NO

11

Page 13

12

PROBLEM CHECK POINT CAUSE SOLUTION

PROBLEM CHECK POINT CAUSE SOLUTION

Concerning Spin

Keep the Door Spin closed

during spin.

The contact Door Switch is

open.

The Basket

Spin does

not rotate.

Is the Door Spin open?

Is there a whirring sound from the

Spin Motor when turned ON?

YES

Pulsator. only

rotates in one

direction.

Is the wiring of Wash condenser

properly connected?

Is the wiring of Wash Timer properly connected?

Improperly Wiring

Defective Wash timer Replace Wash Timer.

Reconnect the Wash

Timer.

Improper Connection Reconnect

YES

NO

NO

NO

There is

excessive

noise during

Washing

Are there strange noise from Tub

when the Pulsator rotate?

Pulsator improperly

assembled.

Something is in contact with

the Pulsator Pulley or Motor

Pulley or other rotating parts.

Adjust the parts so that

there are no impurities in

contact with rotating parts

Tighten the Pulsator fixing

screw.

Impurites between Pulsator

and tub

Remove impurities after disassembling Pulsator.

YES

NO

YES

NO

NO YES

Pulsator

does not

rotate

smoothly .

Does the Gear Housing Shaft

rotate properly when the Pulsator

has been disassembled?

Worn out the Serration

within the Pulsator.

Defective Gear Housing Replace Gear Housing As.

Replace Pulsator.

NO

YES

Page 14

13

PROBLEM

The Basket

Spin does

not rotate.

There are

strange

noise and

servere

vibration

during spinning.

CHECK POINT CAUSE SOLUTION

The Brake Band is touching

the Drum Coupling Assembly.

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

Brake wire is too long.

Assemble after loosening

LINK BRAKE and adjusting

downward.

BRAKE SPRING is broken. Replace Brake Spring.

Power has been cut off by

the Thermal Protector

Is the Motor hot? (In case there is

Thermal Protector)

Is the wiring good? (Refer to

Wiring Diagram)

Improper wiring Reconnect wiring

Is the Door Switch Lever properly

placed on the Door Spin?

Defective connection

Replace Door Switch or

reshape the Lever.

Is the Door Switch terminal properly connected?

Improper wiring Reconnect the terminal.

Is the Contact of Spin Timer good?

Defective Spin Timer Replace the Spin Timer.

Defective Spin Motor

Basket Spin does not balanced

due to wash load.

Basket Spin does not balanced

due to wash load.

Reload the clothes and

press down the Safety

Cover into Basket Spin.

Tighten the Bolt Drum

Coupling Assembly .

Is the assembly between the

Drum Coupling Assembly and

Spin Motor or Basket Spin loose?

Improper structural assembly

Is the Basket Spin itself well balanced?

Basket Spin unbalance

Replace Basket Spin.

Are clothes or the Safety Cover

stick out from Basket Spin?

Reload the clothes so they

are well balanced

Is the wash load well balanced?

Replace the Spin Motor.

Power restored when motor

cools.

YES

YES

NO

NO

YES

NO

NO

NO

YES

NO

The Waterseal or the oilless metal in the Bellows

Assembly worn out.

Replace Bellows Assembly.

Page 15

14

PROBLEM CHECK POINT CAUSE SOLUTION

There is leakage during

spinning.

Is the Bellows Assembly properly

assembled?

The Waterseal or the

Oilless Metal in the Bellows

Assembly is worn out.

Replace Bellows

Assembly .

Waterproofing not working

due to defective assembly .

Re-assemble

Bellows Assembly.

YES

NO

YES

YES

Basket Spin

does not

stop with the

Door Spin

open

The Brake Band touches the

Drum Coupling when the Door

Spin open.

Brake Band is worn out.

Defective

Door Switch

Is the electric connection of the

Door Switch good?

Replace

Door Switch

The contact of the Door

Switch does not open due

to deformity of the lever of

Door Switch.

Replace Door Switch or

reshape the lever of Door

Switch.

Replace Brake Band or

Brake Fix Assembly .

Brake wire is too short.

Replace after loosening

LINK BRAKE and adjusting

upward.

NO

NO

Concerning Drainage (Pump)

PROBLEM

Drainage is

not satisfactory

CHECK POINT CAUSE SOLUTIONPROBLEM CHECK POINT CAUSE SOLUTION

Is the height of the drainage area where

the Drain Hose hangs over 1m?

The Drain Hose is too high.

Hang the Drain Hose lower.

Are there impurities on the Drain

Strainer?

YES

NO

NO

Impurities are obstructing

drainage.

Remove out impurities on

the drain Strainer

Impurities are obstructing

drainage.

Are there impurities in the V alve

Housing or Inlet Joint?

Remove impurities or

replace V alve Housing or

Inlet Joint.

Impurities are blocking the

Drain Hose

Remove impurities

YES

YES

NO

Page 16

15

PROBLEM CHECK POINT CAUSE SOLUTION

Draining

does not

function during drain

selecting

Is the Drain Selector in the DRAIN

position

The position is fault.

Turn the Drain Selector to

DRAIN.

Is the pump Motor wiring properly

connected?

Defective Pump motor Replace Pump Motor

YES

NO

YES

Defective wiring Reconnect wiring

NO

Drain does

not function

during

Spinning.

Are the wiring of the Spin Timer

and the Pump Motor good?

Defective wiring Reconnect wiring

Is the Spin Timer’s contact good?

Defective Pump motor Replace Pump Motor

NO

YES

Defective Spin Timer Replace Spin Timer

NO

Concerning Drainage (Non Pump)

PROBLEM CHECK POINT CAUSE SOLUTION

NO

NO

Drainage is

not satisfactory .

Are there impurities on the Drain

Strainer?

Impurities are obstructing

drainage.

Are there impurities in the Valve

Housing or Inlet Joint?

Remove impurities or replace

Valve Housing or Inlet Joint

Impurities are blocking the

Drain Hose

Remove impurities

Impurities are obstructing

drainage.

Remove impurities on the Drain

Strainer

YES

YES

YES

Water keeps

draining during wash

Is the Drain Selector on the operation Panel at the DRAIN position?

There are impurities

between the V alve Housing

and V alve Bellows.

Remove impurities and

replace Valve Housing.

Mismanupilation

Turn Drain Selector to

WASH/RINSE position

NO

Page 17

16

6. EXPLODE VIEW AND PARTS LIST

14

4

3

1

5

6

7

8

9

11

10

15 16

12

1

3

2

2

13

Ass’y Panel Back

Page 18

17

ass’y panel

NO. PART NAME P ART CORD SPECIFICATION Q’TY REMARKS

1 DECO KNOB 361 1630400 ABS-TR 4.0

2 KNOB 3613404700 ABS 4.0

3 DECORAT OR PANEL 3611630500 ABS-TR 1.0

4 PANEL B 3614281900 HIPS 1.0

5 SCREW TAPPING 712240141 1 T2S TRS 4X14 MFZN 3.0

6 HOSE SPRAY 3613201201 PE-LD 1.0

7 LEVER W.S SELECT 3613702300 PP 1.0

8 BRACKET PANEL 3610607800 HIPS 1.0

9 TIMER WASH 361991 1900 DXT-15SF-201, KDW5A 1.0

10 LEVER CONTROL 3613701400 POM 1.0

1 1 TIMER SPIN 361991 1220 S-160MA 1.0

12 LINK V ALVE 3617804900 PP BAND W6 L=800 1.0

13 SWITCH COVER 3619045400 GSM-V16183A4 250V 16A 1.0

14 SCREW T APPING 7122401411 T2S TRS 4X14 MFZN 5.0

15 SWITCH SELECTOR 3619045800 GSM-V16181A4 1.0 PUMP MODEL

16 HARNESS DRAIN 3612790600 160CP SW DRAIN L=1100 1.0 PUMP MODEL

ACCESSORY ASS'Y

NO. PART NAME P ART CORD SPECIFICATION Q’TY REMARKS

1 COVER SAFETY 361 1419900 LDPE(DIA:286) 1.0

2 HOSE DRAIN O AS 3613224310

820MM, HANGER, NON CLAMP

1.0 NON PUMP

3 HOSE DRAIN O AS 3613218800 LD-PE/EVA L=1600 PUMP 1.0 PUMP MODEL

✔ Caution

:

In this Service Manual, some parts can be changed for improving, their performance without notice in the

parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service

Information Center (http://svc.dwe.co.kr).

Page 19

18

26

29

25

28

27

13

14

31

30

24

23

21

20

4

16

15

1

3

5

29

2

3

6

9

8

7

10

11

12

17

19

18

22

32

Ass’y Tub

Page 20

19

ass’y tub

NO. PART NAME P ART CORD SPECIFICATION Q’TY REMARKS

1 TUB 3618820100 PP 1.0

DOOR WASH

361 17AB100 HIPS 1.0

2 36117AAZ00 ABS-TR 1.0 OPTION

COVER DOOR WASH 3611425200 HIPS 1.0 OPTION

3619706800 PP 1.0

3 PULSAT OR AS 3619708100 PP, IMPELLER 1.0 OPTION

36197081 10 PP, NANO IMPELLER 1.0 OPTION

4 SPECIAL SCREW 3616002901 SUS 304(NON SLOCK) 1.0

5 BASE WATER SUPPLY 3610391700 PP 1.0

6 FILTER OVERFLOW 361 1906600 PP 1.0

7 FILTER AS 361 1904700 PP+POL YESTER 1.0

8 LEVER W.H 3613791000 PP 1.0

9 PIPE WATER LEVER 3614404600 EVA 1.0

10 BALANCER AS 3616105800 DWM-160C 1.0

1 1 SCREW TAPPING 7122401211 T2S TRS 4*12 MFZN 4.0

12 BASKET SPIN 3619103600 PP(J-360A) 1.0

13 BELLOWS 3616402800 NBR, H=65 1.0

14 FIXTURE BELLOWS 3612006300 PP 1.0

15 LINK BRAKE 3617804300 PP BAND W6 L=564 1.0

16 SPRING COVER 3615108810 HSW3 1.0

DOOR SPIN

361 17AB000 HIPS 1.0

17 36117AAY00 ABS-TR 1.0 OPTION

COVER DOOR SPIN 3611425100 HIPS 1.0 OPTION

18 PLA TE T 3614531300 PP 1.0

19 COVER INNER 3611419700 PP 1.0

20 RING O 4506H05050 CR 1.0

21 GEAR HOUSING ASS'Y 3617309100 6.0:1 1.0

22 SCREW T APPING 7122502011 T2S TRS 5X20 MFZN 5.0

23 PULLEY PULSA TOR 3618432600 FRPP 1.0

24 SPECIAL BOL T 3616008400 M6 SIDE-FIXING 1.0

25 PROTECTOR F.B 3618303500 NBR 1.0 PUMP MODEL

26 V ALVE CAP 4505F06013 PE-HD 1.0

27 SPRING V ALVE 4505C06022 SWC WR 1.0D 1.0

28 ROD V ALVE 3618504000 PP 1.0

29 BELLOWS V ALVE 4505C06041 NBR 1.0

30 INLET JOINT 3617505200 PP 1.0

31 CASE V ALVE

3611131500 PP 1.0 NON PUMP

3611139100 PP 1.0 PUMP MODEL

32 SCREW T APPING 7122502011 T2S TRS 4X14 MFZN 1.0

✔ Caution

:

In this Service Manual, some parts can be changed for improving, their performance without notice in the

parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service

Information Center (http://svc.dwe.co.kr).

Page 21

20

15

13

12

14

11

10

9

8

32

34

31

36

38

37

39

28

29

263527

16

24

20

22

21

23

18

5

2

1

4

3

6

7

30

25

33

40

41

17

19

43

42

Ass’y Main

Page 22

21

ass’y main

NO. PART NAME P ART CORD SPECIFICATION Q’TY REMARKS

1 ASSY CABINET PRCACA8100 DWM-200C 1.0

2 PLATE UPPER 3614525100 SGCC 0.6T 1.0

3 SCREW TAPPING 712240101 1 T2S TRS 4*10 MFZN 6.0

4 COVER BACK 3611419800 SECC 0.4T 1.0

5 SCREW TAPPING 7112400811 T1 TRS 4*8 MFZN 4.0

6 BASE UNDER 3610391800 PP 1.0

7 SCREW TAPPING 712240101 1 T2S TRS 4*10 MFZN 7.0

8 CUSHION SPOT 450M712010 PP 1.0

9 CUSHION MOTOR 450M712020 NR 3.0

3618961900

220~240V/50HZ,W1S35VD060

1.0 N(P)

3618949501

220~240V/50HZ,W1S42VD101

1.0 M(P)

10 MOTOR WASH

3618961600 110V/60HZ,W1S35ED060 1.0 T(P)

3618961800 220V/60HZ,W1S35UD060 1.0 L

3618961700 120V/60HZ,W1S35JD060 1.0 A

3618962000 W1S35GD060 1.0 D,S

1 1 SPECIAL SCREW 3616003100 M5X35 WASHER 3.0

12 PULLEY MOTOR AS

3618431700

PRESS(SGCC1.2T,D31),2.1MM

1.0 60HZ

3618431810 PRESS(SGCC1.2T,D38) 1.0 50HZ

13 WASHER PLAIN 7400108411 PW-1-8.4 MFZN 1.0

14 NUT HEX 739280001 1 M8*P1.25 MFZN 1.0

15 BEL T V 3616590900 A24, 200C 1.0

3618964800 AC 220~240V , 50HZ,PLASET 1.0 NP, MP

16 UNIT DRAIN PUMP AS 3618964900 AC 110V, 60HZ,PLASET 1.0 TP

3618952710 AC 110/220V, 50/60HZ 1.0 DP

17 FIXTURE PUMP 3612005700 PP 1.0 NP,MP,TP

18 SCREW T APPING 7112402011 T1 TRS 4X20 MFZN 1.0

19 HOSE DRAIN I 3613226400 PE-LD 1.0 NP,MP,TP

3618948200 9.7/5.2 400/440 CON-4P 1.0 L,N(P)

20 UNIT CAP ACITOR

3618948300 10.4/5.2 400/440 CON-4P 1.0 M(P)

3618948600 45.6/25 200/200 CON-4P 1.0 T(P)

3618950600 41.6/20.8 200/230 CON-4P 1.0 A

21 CAP ACITOR WASH 4508C1 1010 22.8+22.8UF 1.0 D(DUAL)

4509C1 1020 200V 20.8UF*2 1.0 S(DUAL)

22 CAP ACITOR SPIN 4509C1 1010 MF CAPACITOR 200V 20.8MF 1.0 D,S(DUAL)

23 HARNESS CONDENSER 3612706710 CONN A,B 1.0 D,S(DUAL)

361 1332100 T V ACTFK 2*0.75 2.3M GY 1.0

361 1331700 A V ACTFK 2*0.75 2.3M GY 1.0

361 1331310 VCTF 3*0.75 2.3M GY 1.0

361 1331630 H05VV-F 3*0.75 WH 1.0

361 1331650 H05VV-F 3*0.75 BK 1.0

24 CORD POWER AS 361 13311 10 VCTF 3*0.75 2.3M GY 1.0

361 1331810 H05VV-F 3*0.75 2.3M BK 1.0

361 1332100 VCTFK 2*0.75 2.3M GY 1.0

361 1331930 C SJT 3*18AWG 2.3M GY 1.0

361 1331700 A VCTFK 2*0.75 2.3M GY 1.0

361 1331700 FH05VV 3*0.75 2.3M BK 1.0

✔ Caution

:

In this Service Manual, some parts can be changed for improving, their performance without notice in the

parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service

Information Center (http://svc.dwe.co.kr).

Page 23

22

NO. PART NAME P ART CORD SPECIFICATION Q’TY REMARKS

25 COUPLING DRUM AS 3617001700 DWM-160C 1.0

26 DRUM COUPLING BOL T 3619401601

8X13 BOL T, SILOCK COA TING

2.0

27 SPECIAL BOL T AS 3616008000 6B-1-M8X12 2.0

28 BRAKE FIX PL T AS 4505C54000 2-WAY 1.0

29 BOL T HEX 7341500811 6B-1-5X8 MFZN 3.0

30 SPRING BRAKE 4507K53010 SWC D1.0 ZN8-C 1.0

31 ASS'Y BRAKE WIRE 3619201702 SUS WIRE+PE L260 1.0

32 SCREW T APPING 7122502011 T2 TRS 5X20 MFZN 3.0

3618949601 110V 60HZ W1D35EF001 1.0 T(P)

3618949201 220V 60HZ W1D35UF001 1.0 L

33 UNIT SPIN MOTOR 3618949401 220-240V 50HZ W1D35VF001 1.0 N(P), M(P)

3618950101 W1D35FF002 110/220V 50HZ 1.0 D, DUAL

3618950001 W1D35LF002 120/240V 60HZ 1.0 S, DUAL

34 BRACKET MOTOR SPIN 3610607700 PP 1.0

35 SCREW T APPING 7112503011 T1 TRS 5X30 MFZN 3.0

36 SPRING CUSHION 3615112700 SWC D=3.2 L=95 1.0

37 STOPPER 4506H14020 PE - HD 1.0

38 STOPPER LOWER 3615200800 PP 1.0

39 RUBBER DAMPING 4506H14030 NBR 1.0

3612757300 SINGLE PUMP 1.0 NP,TP,MP,AP ,LP

40 HARNESS ASS'Y

3612757220 SINGLE NON PUMP 1.0 N,M,T,L

3612756301 DUAL NORMAL 1.0 D,S

3612756401 DUAL PUMP 1.0 DP

41 HARNESS EARTH 3612757810 UL1015 AWG18 490 1.0

42 CABLE CLAMP 361 1202610 NYLON66 DA-5N 1.0

43 T APTITE SCREW 7272400811 TT3 TRS 4*8 MFZN 1.0

Page 24

23

7. WIRING DIAGRAM

SPIN TIMER

GN(GN/YW)

CAPACITOR

Hz

B

A

60

25.0

45.6

BK

WH

GN(GN/YW)

VOLTAGE(V~)

RATING

110

WH(BL)

BK(BR)

WH

BK

221

1

YW:YELLOWRD:RED

GN/YW:GREEN/YELLOW

GN:GREEN

5.2

50/60

10.4/9.7

60

41.6

20.8

50

5.2

10.4/9.7

WH:WHITE

PK:PINK

BK

BK

WASH TIMER

VT:VIOLET

BR:BROWN

PK

WH

RD

PK

WH

CAPACITOR

UNIT

220

120~

127

(EARTH)

220~

240

MOTOR

SPIN

WH

223

3

RD

PK

1

1

BK:BLACK

BL:BLUE

AB

PK

BL

2

2

BL

WH

443

3

VT VT

1

1

SAFETY S/W

RD

RD

1

1

BL

MOTOR

WASH

WH

WH

1

1

VT

3

3

VT

2

2

BL

BL

BK

1

1

VT

332

2

BL

BL

VT

BK

Single Voltage/Normal

VT

VT

WASH

VT

MOTOR

YW:YELLOWRD:RED

10.4/9.7

60

45.6

25.0

Hz

CAPACITOR

A

B

50/60

10.4/9.7

41.6

20.8605.2505.2

PK:PINK

WH:WHITE

GN/YW:GREEN/YELLOW

GN:GREEN

1

1

PUMP

DRAIN

220~

WH

110

BK(BR)

WH(BL)

GN(GN/YW)

VOLTAGE(V~)

RATING

BK

WH

BK

1

1

MOTOR

120~

127

GN(GN/YW)

(EARTH)

220

240

GN/YW

SPIN

RDWHPK

3

3

RD

2

2

WH

2

2

PK

1

1

GY

WH

2

GY2WH

RD

GY

2

3

3

2

1

GY

RD

BK

BK

RD

GY

BK

1

SPIN TIMER

1

1

RD

BL

VTVT

CAPACITOR

BL:BLUE

BK:BLACK

B

UNIT

PK

WH

3

3

PK

4

4

WH

VT:VIOLET

BR:BROWN

A

GY:GRAY

GN/YW

BL BL

221

1

WH

3

3

WH

NC

DRAIN S/W

NO

off

COM

SAFETY S/W

wash/rinse,drain

BL

BK

VT

WH

WH

BK

BK

3

3

BK

WASH TIMER

BL

VT

BK

BL

2

BL

211

BL

221

1

Single Voltage/Pump

Page 25

24

WH(BL)

BK(BR)

WH(BL)

BK(BR)

GN(GE)

20.8x2

127/220

EARTH

220

20.8

110~130

A

CONNECTOR

CAPACITOR

110~130

D

B

C

20.8

220

AS THE FIG.

VOLTAGE. THIS UNIT IS

OPTIMUM USE WITH YOUR

CHANGE VOLTAGE THE

C V ~ CONNECTOR PLUG

SET FOR IF YOU WANT TO

RATING

VOLTAGE(V~)

C V~

110/220

D V~

YR : YELLOW/RED

WN : WHITE/GREEN

WP : WHITE/PURPLE

RL : RED/BLUE

BW : BLUE/WHITE

GE : GREEN/YELLOW

YW : YELLOW

RW : RED/WHITE

GY : GRAY

BL : BLUE

WH : WHITE

BR : BROWN

BH

BK

SPIN

VT : VIOLET

PK : PINK

RD : RED

MOTOR

BK : BLACK

OR : ORANGE

GN : GREEN

GE

22

11

WH

BK

3

RL

3

1

RD

122

OR

RL

RD

OR

CAPACITOR

SPIN

B

BK BK

66445

PK

5

PK

WH

WH

1

1

PK PK

2

2

BH : BROWN/WHITE

CAPACITOR

A

WASH

WASH

MOTOR

FUSE

3

3

BW

2

2

BW

WP

1

1

WP

WNWN

4

4

VT

3

3

VT

WH

112

2

WH

YRYR

BR

7

7

RD

YW

5

566

BR

YW

RW

250V/6A

8

8

GY

BL

9

9

GY

BL

CAUTION

PLUG

CONNECTOR

CONNECTOR

SW VOLTAGE CHANGE 110V or 127V D

TIMER SPIN

RD

1

RL

1

OR

RD

1

1

WN

BL

SW VOLTAGE CHANGE 220V C

423GY75 6

BR

4

BR

RD

23GY75YW6

RW

WP

8 9

BK

1

8 9

SAFETY S/W

BL

NO COM

TIMER WASH

YR

4RL2 3 75BL6

BW

VT

8 9

BK

2

1

3

BL

VT

BK

1

2

3

VT

BL

BK

22.8x2

Dual Voltage/Normal

BW

FUSE

5

5

RD

RW

WASH

MOTOR

YK : YELLOW/BLACK

BH : BROWN/WHITE

KW : BLACK/WHITE

CONNECTOR

CAPACITOR

3

3

SPIN

MOTOR

20.8x2

A

C

B

D

110~130

20.8

220

WH : WHITE

110~130

20.8

220

BR : BROWN

BL : BLUE

VOLTAGE(V~)

RATING

110/220

SET FOR IF YOU WANT TO

OPTIMUM USE WITH YOUR

CHANGE VOLTAGE THE

VOLTAGE. THIS UNIT IS

C V ~ CONNECTOR PLUG

AS THE FIG.

C V~

D V~

127/220

EARTH

GN(GE)

BK(BR)

WH(BL)

GN : GREEN

OR : ORANGE

BK : BLACK

WH

WH(BL)

BK(BR)

22

2

2

RLRD

1

1

OR

RD OR RL

BK

11

RL : RED/BLUE

WP : WHITE/PURPLE

WN : WHITE/GREEN

YR : YELLOW/RED

RW : RED/WHITE

YW : YELLOW

GY : GRAY

WH

PUMP

GE : GREEN/YELLOW

BW : BLUE/WHITE

DRAIN

SPIN

CAPACITOR

RD : RED

PK : PINK

VT : VIOLET

B

BK

BK

6

6

WH

WH

BH

4

4

PK

BK PK

5

5

1

1

PK

PK

1

1

KW

2

2

KW

4

4

WHYK

2

2

YR

3

3

BH

YR

CAPACITOR

WASH

A

WN

BW

GY

556

6

GY

2

2

WP

1

1

WN

WP

BW

WH

WH

1

1

3

3

4

4

YR

223

3

VT

VTYR

250V/6A

8

8

GY

GY

YW

6

6

BR

YW

BR

779

9

DB

BL

BK

COM

NC(WASH/RINSE,DRAIN)

YW

SW VOLTAGE CHANGE 220V C

PLUG

CONNECTOR

CAUTION

CONNECTOR

RD

RL1GY

42 3

RD1OR

42 3

GY BR

RD

1

1

RD

TIMER SPIN

YR

SW VOLTAGE CHANGE 110V or 127V D

11

KW

1175 6

BR BL

9810

WN

7RW5 6

WP

10BH89

YR

BK12RL

1 2 3

12

COM

SAFETY S/W

BL

NO

BK

TIMER WASH

10

DRAIN S/W

7645

BL

WH

VT

8 9

BK

KW

11 12

GYRD

3

3

BK

21

12

RD GY

NO(OFF)

BK

VT

BL

2

131

2

3

BK

VT

BL

BK

22.8x2

Dual Voltage/Pump

Page 26

S/M No. : DW200C0001

DAEWOO ELECTRONICS CORP.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

PRINTED DATE: Jul. 2004

Loading...

Loading...