Page 1

S/M No. : VTG7J3DET0

Service Manual

Video Cassette Recorder

ALL T -MECHA (Hi-Fi/MONO)

Model: (PAL/SECAM MODELS)

D VST7C3/4C3/2C3 Series

D VST7E3/4E3/2E3 Series

D VST7M3/4M3/2M3 Series

D VST7J3/4J3/2J3 Series

D VST7D3/4D3/2D3 Series

D VST7T3/4T3/2T3 Series

D VST7W3/4W3/2W3 Series

D VST7L3/4L3/2L3 Series

DVST7L3

DVST7E3

2

DVST7C3

DVST7B3

D AEW OO ELECTR ONICS CO., LTD.

http : //svc.dwe .co.kr

Apr . 2002

Page 2

TABLE OF CONTENTS

SAFETY&PRECAUTIONS................................................................................................ 2

EXTERNAL VIEWS......................................................................................................... 4

FRONT VIEWS FUNCTION.................................................................................................................... 4

REAR VIEWS FUNCTION...................................................................................................................... 6

ELECTRICAL ADJUSTMENT............................................................................................ 7

SPECIFICATIONS ......................................................................................................... 8

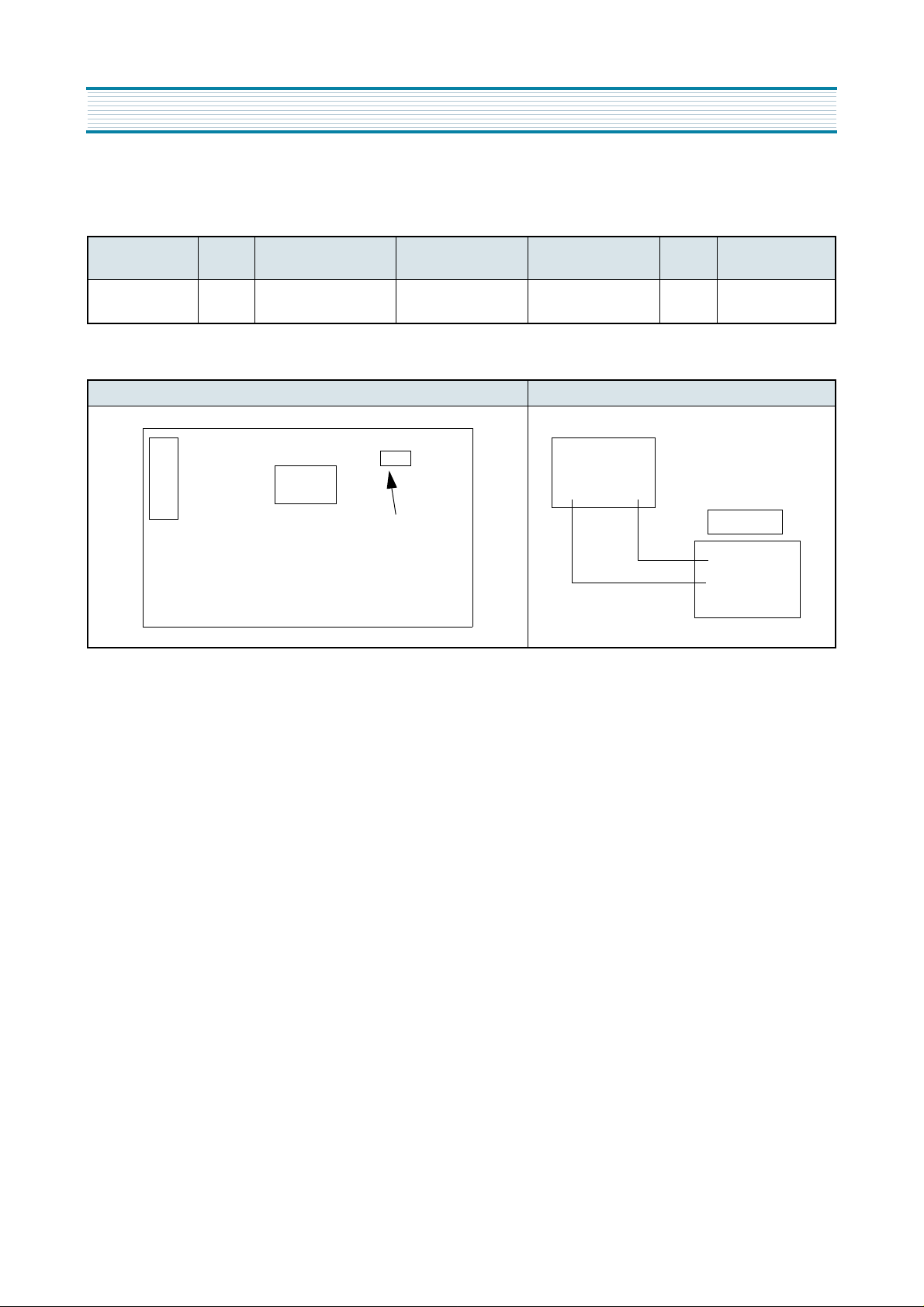

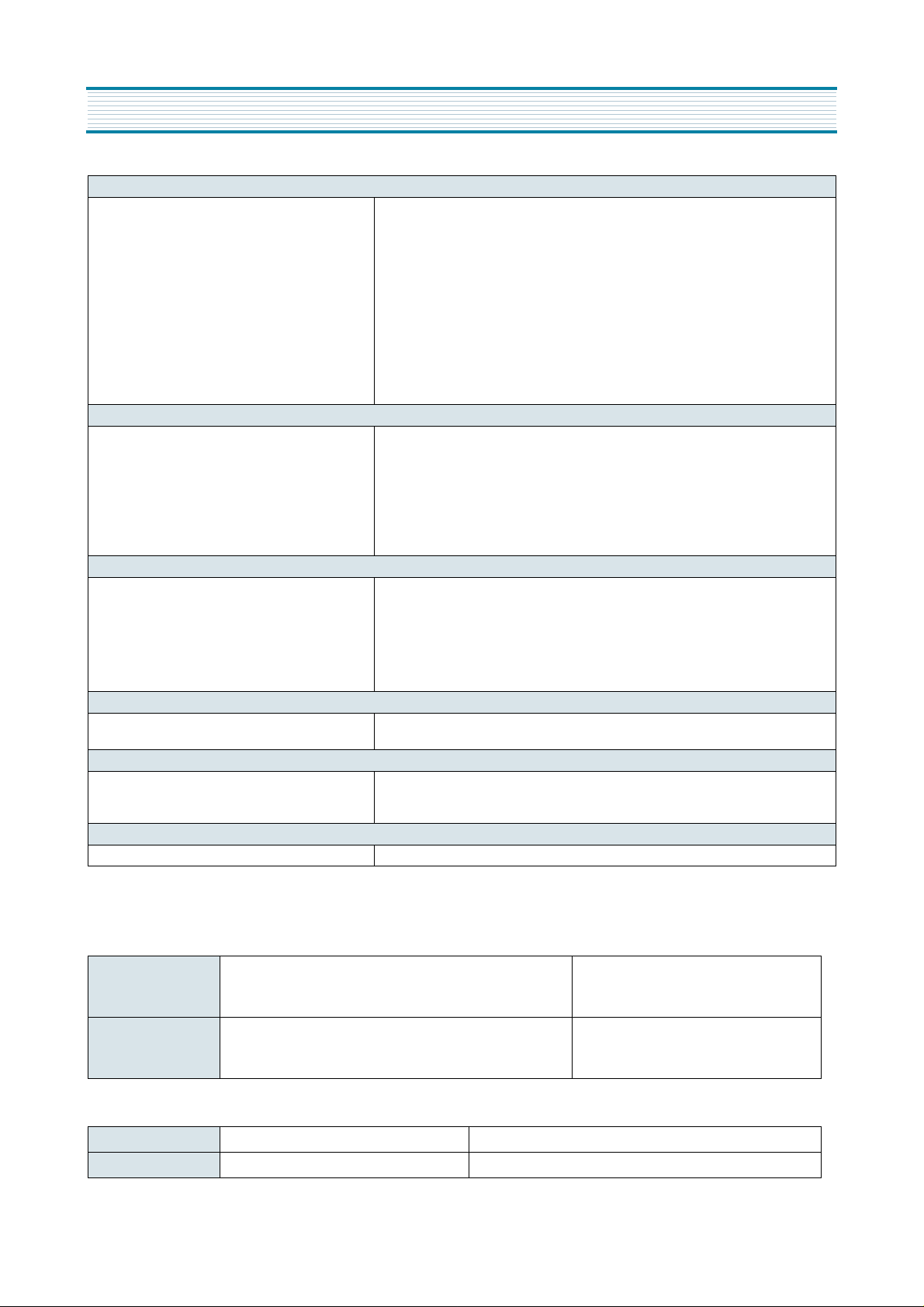

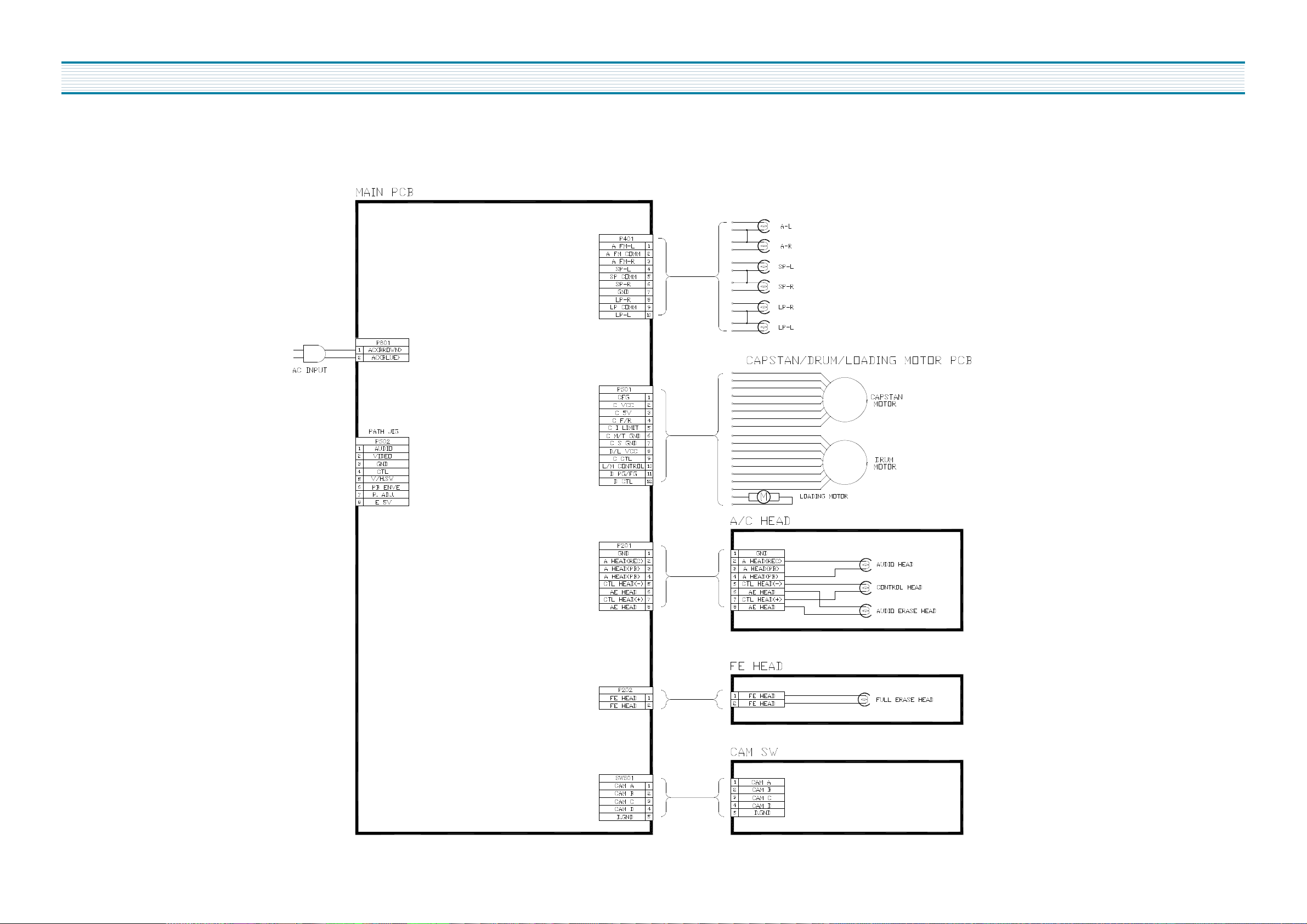

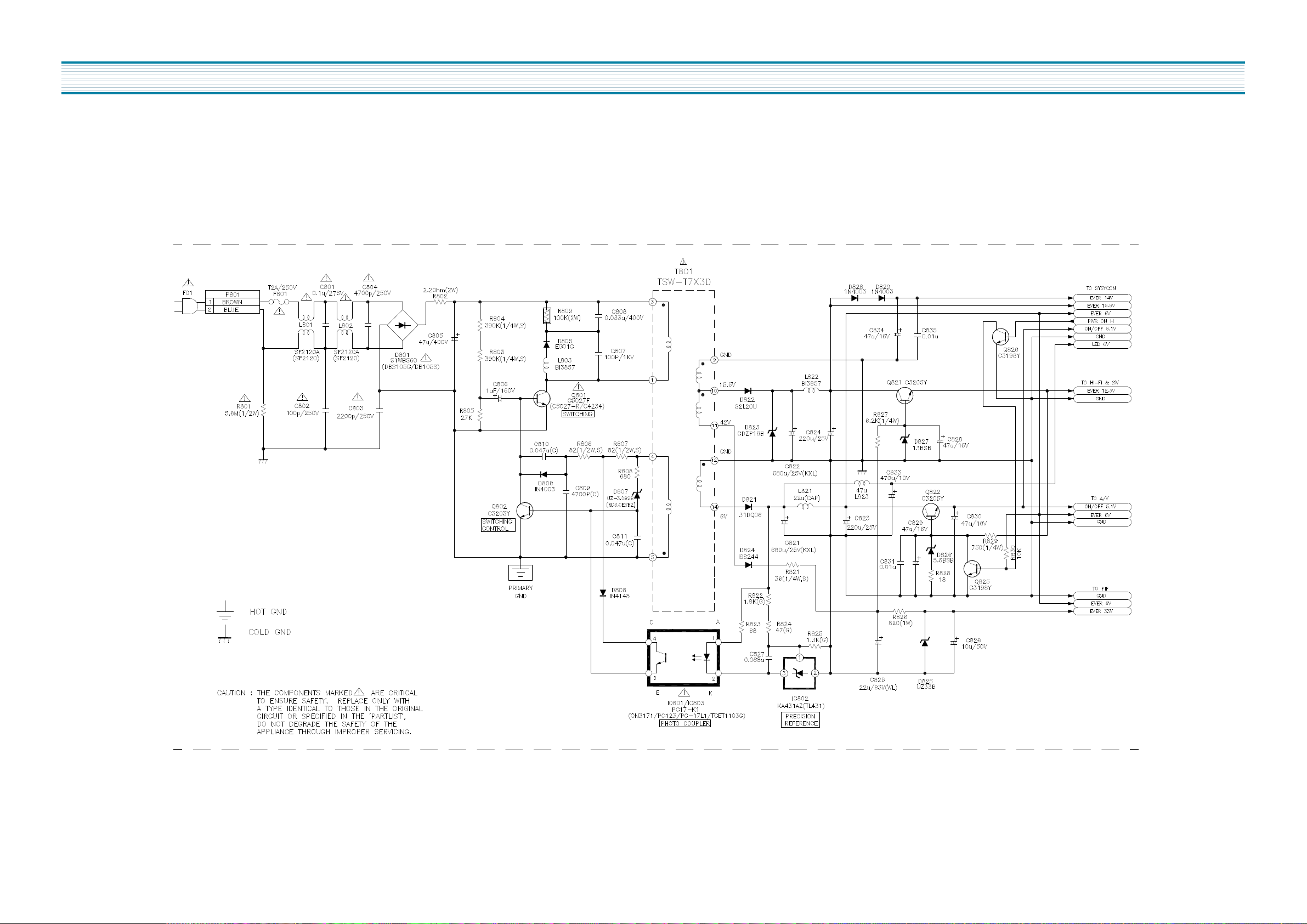

CIRCUIT INFORMATION............................................................................................... 9

INTERCONNECT WIRING DIAGRAM..................................................................................................... 9

POWER CIRCUIT DIAGRAM................................................................................................................. 10

POWER BLOCK DIAGRAM.................................................................................................................. 12

SYSCON CIRCUIT DIAGRAM............................................................................................................... 13

SERVO & SYSCON BLOCK DIAGRAM.................................................................................................. 15

A/V & SECAM COLOR CIRCUIT DIAGRAM........................................................................................... 16

VIDEO PLAYBACK/RECORD PATH FOR PAL.......................................................................................... 18

HIFI & SW CIRCUIT DIAGRAM.............................................................................................................. 19

PIF CIRCUIT DIAGRAM........................................................................................................................ 21

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW............................................ 23

PCB MAIN.......................................................................................................................................... 23

DISASSEMBLY ............................................................................................................. 24

PACKING ASS’Y ................................................................................................................................. 24

FRONT PANEL ASSEMBLY ................................................................................................................... 25

INSTRUMENT DISASSEMBLY ................................................................................................................. 29

ELECTRICAL PARTS LIST ............................................................................................... 30

PCB MAIN AS .................................................................................................................................... 30

1

Page 3

SAFETY & PRECAUTIONS

SAFETY CHECK AFTER SERVING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screw, parts and wires

have been returned to original positions. Afterwards, perform the following tests and conform the specified values in order

to verify compliance whit safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance between power cord plug prong and externally exposed parts of the set

(RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

is

greater than values given in table 1 below.

2. Dielectric strengthen test

Confirm specified dielectric strengthen between power cord

plug prongs and exposed accessible parts of the set

(RF terminals, antenna terminals, video and audio input output

terminals, microphone jack, ear phone jacks, etc.)

is greater than values given table 1.

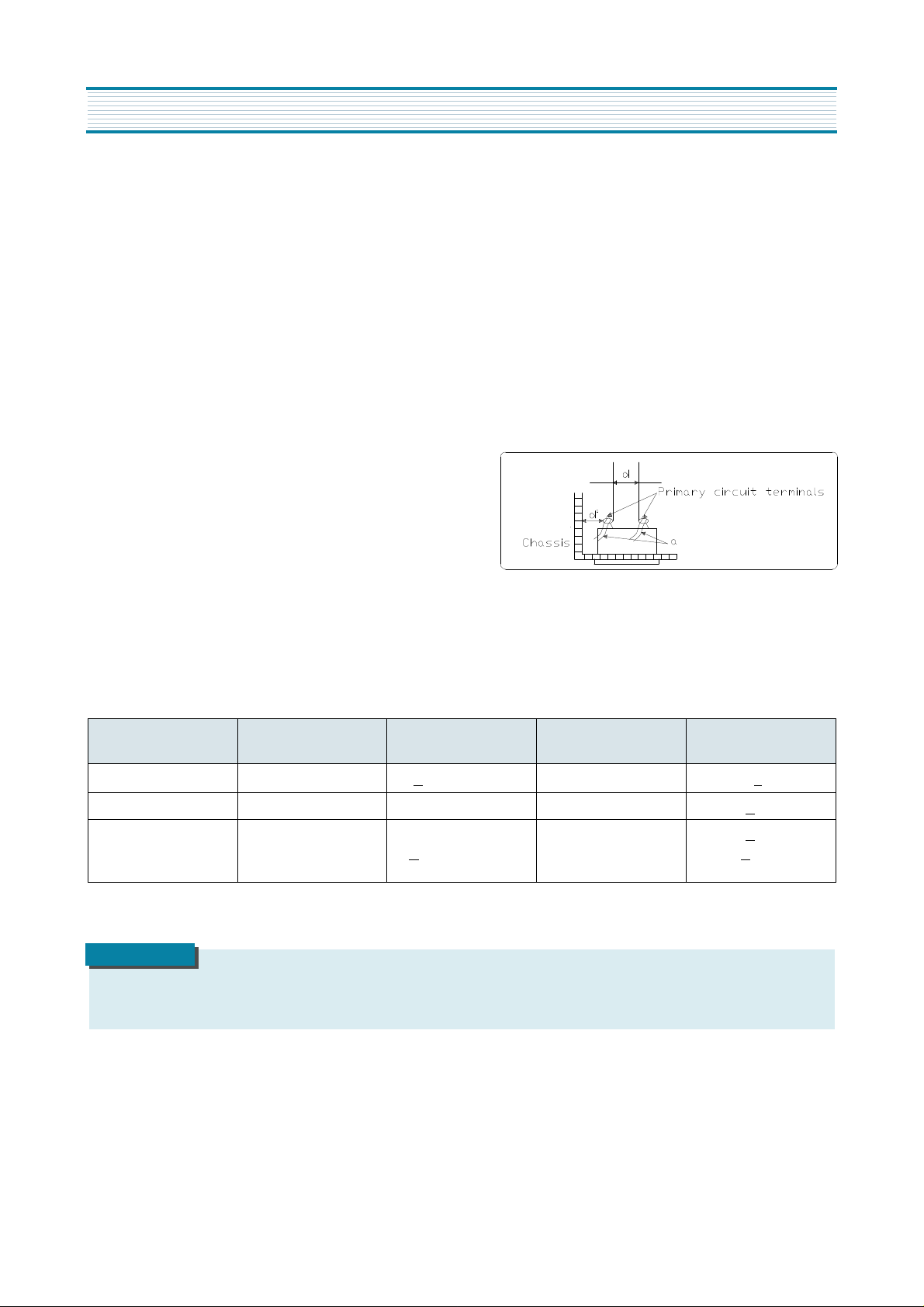

3. Clearance distance

When replacing primary circuit component, confirm specified clearance distance (d), (d

and between terminals and surrounding metallic parts. See table below.

Rating for selected areas

AC Line Voltage Region

100V Japan

110 to 130V

* 110 to 130V

200 to 240V

* : Class model only

USA & Canada

Latin America

Europe

Australia

Insulation

Resistance

>1MΩ

/500V DC

- 900V AC 1min.

>10MΩ

/500V DC 4kV AC 1min.

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values for your

particular country and locality

Dielectric

Strength

1kV AC 1min.

’

) between soldered terminals,

Clearance

Distance(d),(d)

>

3

>

3.2

>

6(d)

>

8(d')

(a :Power cord)

2

Page 4

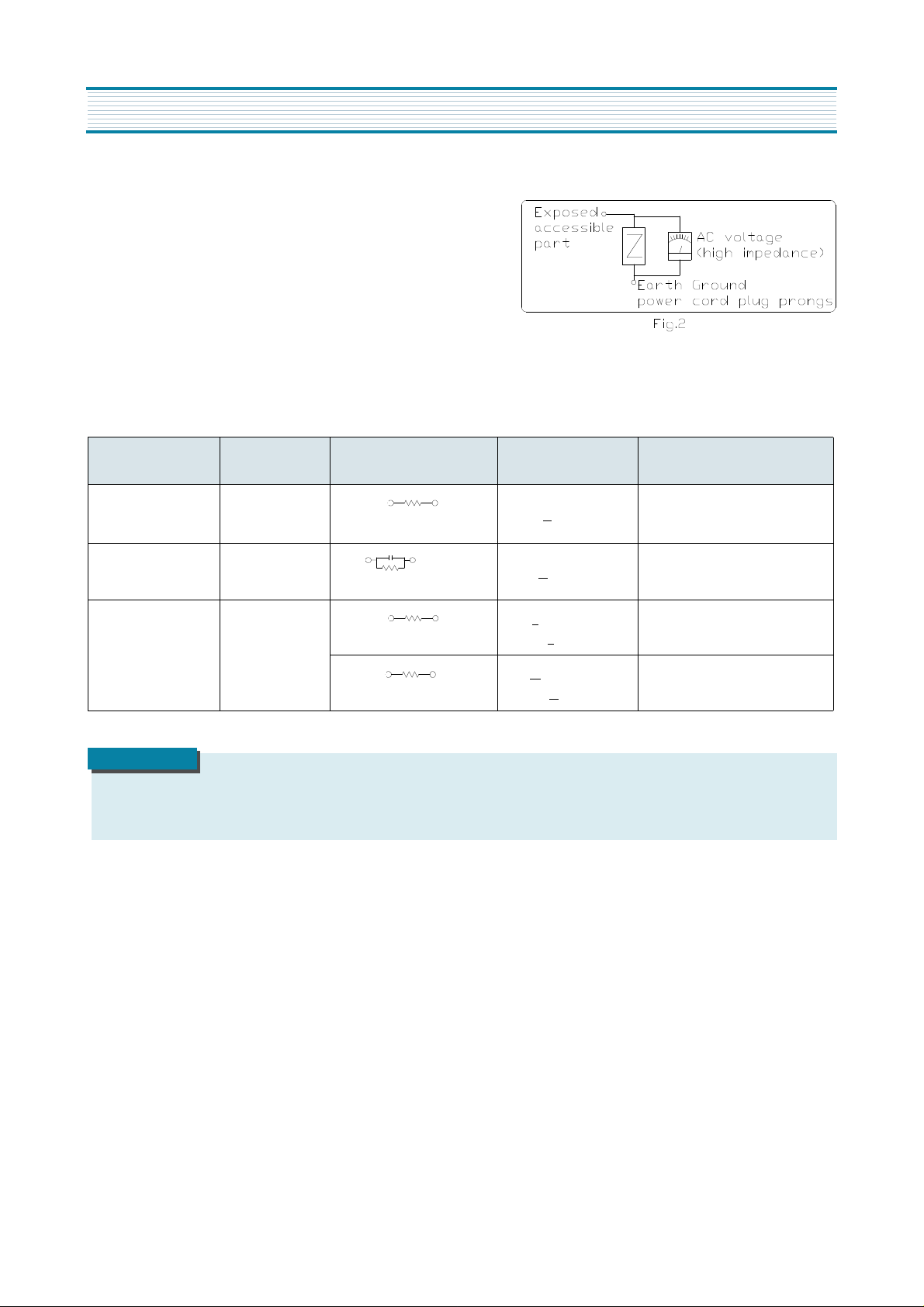

4. Leakage current test

Confirm specified or lower leakage current between B(earth

ground, power cord plug prongs) and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input

output terminals, microphone jacks, earphone jacks, etc.)

Measuring method:(Power ON) Insert load Z between B(earth

ground, power cord plug prongs) and exposed accessible parts.

Use on AC voltmeter to measure across both terminals of load Z.

See figure2 and following table.

Leakage current ratings for selected are as

SAFETY & PRECAUTIONS

AC Line Voltage Region Load Z

100V Japan

1k

Ω

110 to 130V USA &Canada

110 to 130V

200 to 240V

Europe

Australia

1k

2k

50k

15kmF

Ω

Ω

Ω

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values

for your particular country and locality.

Leakage Cur-

rent(i)

i

<

1 mArms

i

<

0.5mArms Exposed accessible parts

i

<

0.7mA peak

i

<

2mAdc

i

<

0.7mA peak

i <

1mAdc

Clearance Distance(d),(d’)

Exposed accessible parts

Antenna earth terminals

Other terminals

3

Page 5

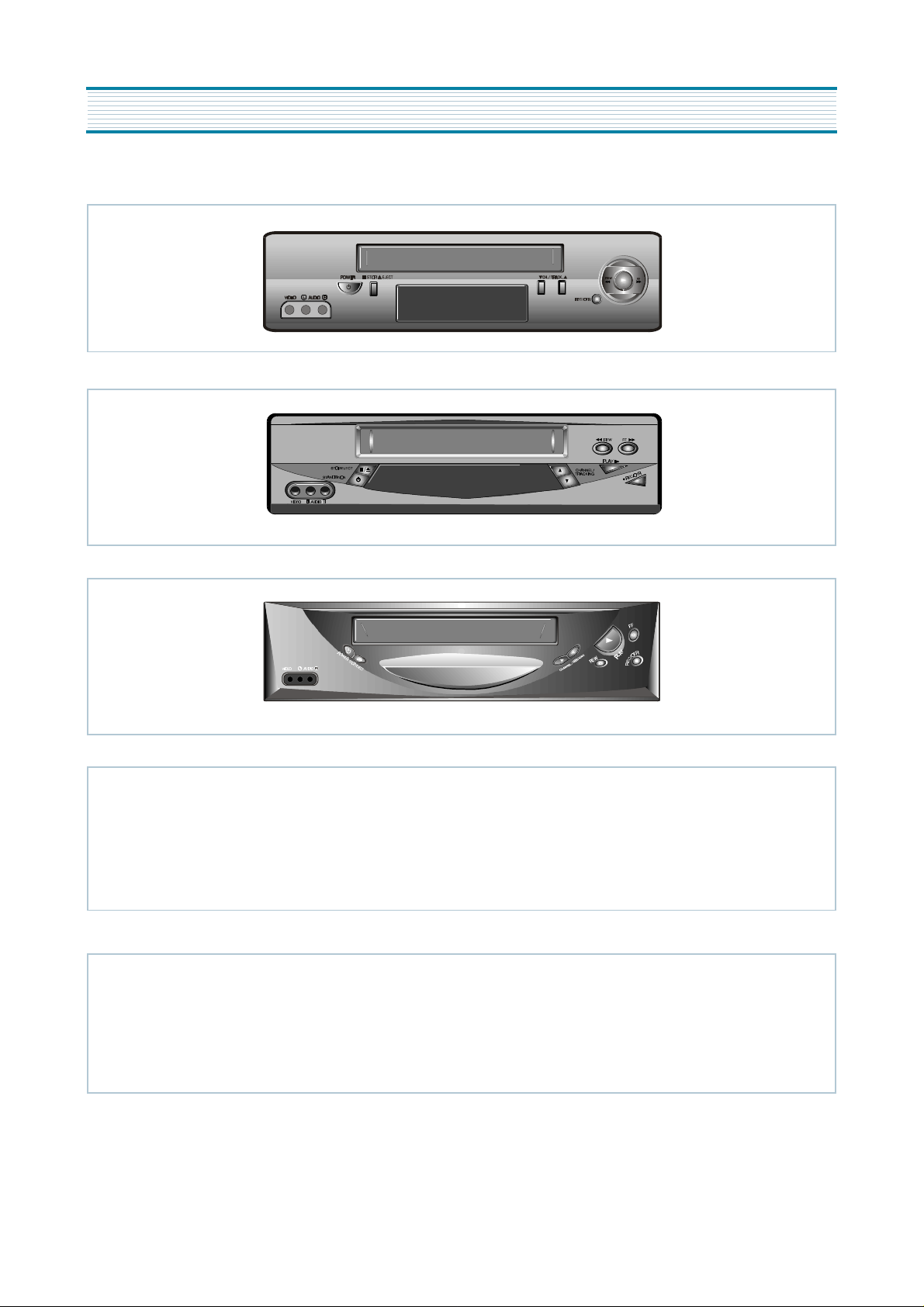

EXTERNAL VIEWS

1. FRONT VIEWS FUNCTION

DVST7C3 FRONT VIEW

DVST7E3 FRONT VIEW

DVST7L3 FRONT VIEW

DVST7M3 FRONT VIEW

4

Page 6

DVST7J3 FRONT VIEW

DVST7D3 FRONT VIEW

EXTERNAL VIEW

DVST7B3 FRONT VIEW

DVST8T3 FRONT VIEW

DVST8W3 FRONT VIEW

POWER REWIND / REVIEW

STOP / EJECT FAST FORWARD / CUE

RECORD PLAY BACK

FRONT VIDEO/AUDIO INPUT JACK CHANNEL UP / DOWN

5

Page 7

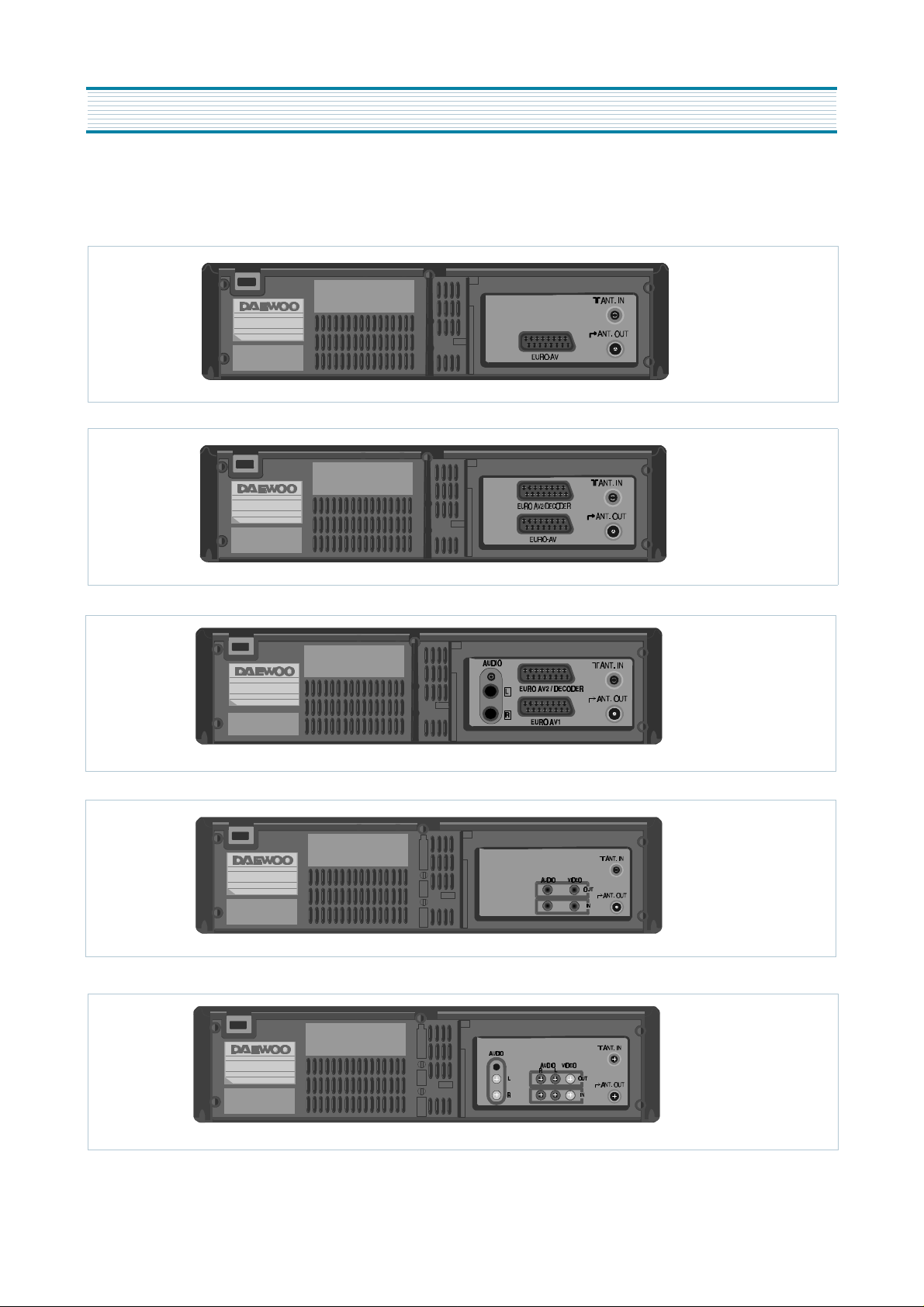

EXTERNAL VIEWS

2. REAR VIEWS FUNCTION

MONO 1 SCART TYPE REAR VIEW

MONO 2 SCART TYPE REAR VIEW

HI-FI 2 SCART TYPE REAR VIEW

MONO RCA TYPE REAR VIEW

HI-FI RCA TYPE REAR VIEW

6

Page 8

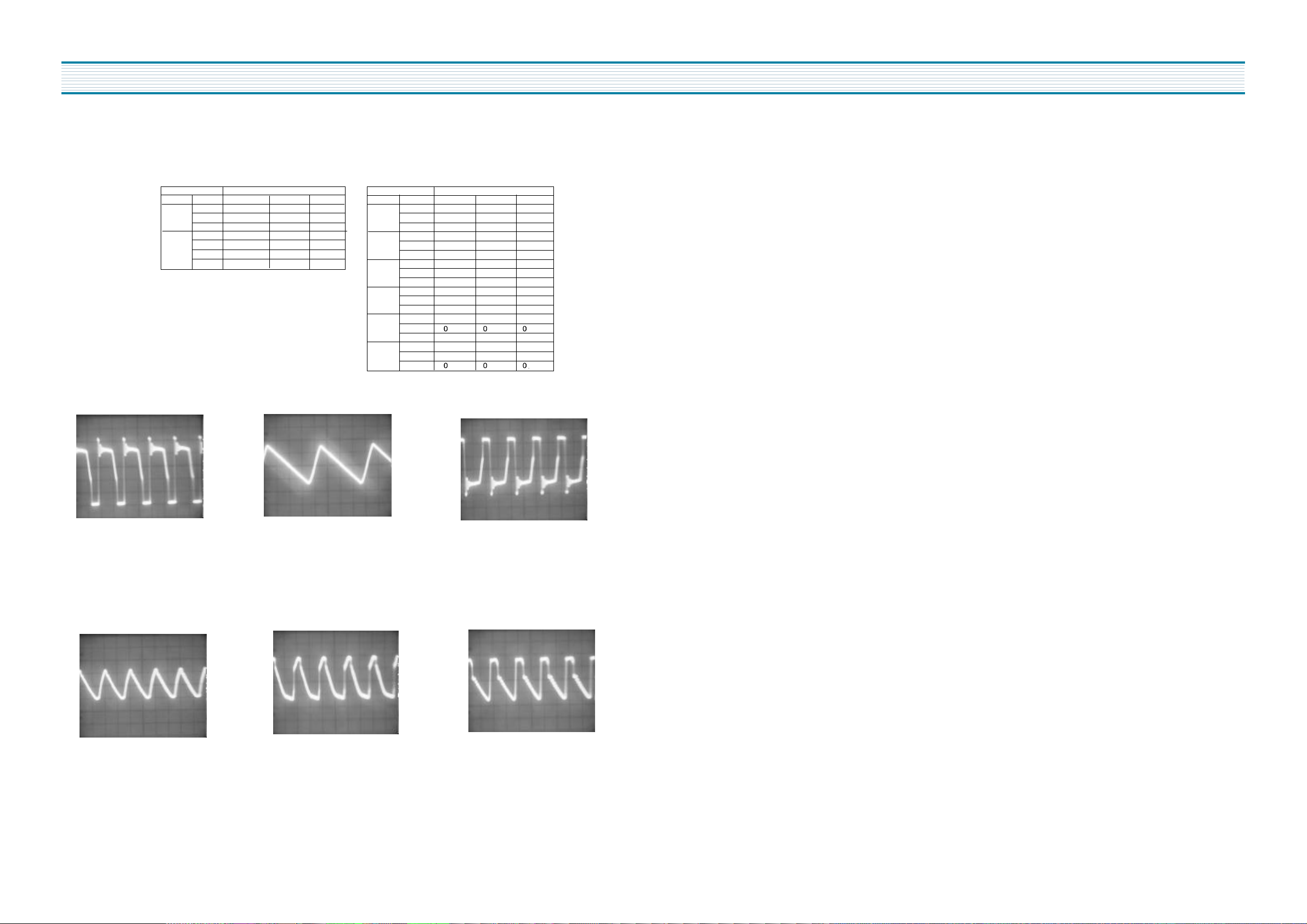

ELECTRICAL ADJUSTMENT

1. PLAYBACK PHASE

ITEM MODE

6.5H

ADJUSTMENT

PCB : MAIN - TOP VIEW

PLAY [REC] BUTTON

TMI

BLOC

ADJUSTMENT

POINT

CHECK POINT

PIN 4 & PIN 5

OF P502

TEST

EQUIPMENT

OSCILLOSCOPE DP-2 NO SIGNAL

TEST

TAPE

ADJUSTMENT PARTS MEASURING POINT

P502

PREAMP

TO PATH JIG

OSCILLOSCOPE

CH1 CH2

INPUT

SIGNAL

PATH JIG

ADJUSTMENT PROCEDURE

1. Play back the test tape. (DP-2)

2. Set the oscilloscope to the CHOP mode. Connect CH1 to the SW PULSE (PIN 4 of P502)

3. Connect CH2 to the ENVE signal (PIN5 of P502)

4. Insert PATH JIG and press "REC" button on the remote control.

5. Check the position of the V-sync from the rising edge of the SW pulse.

(Standard : 6.5H ± 0.5H)

7

Page 9

SPECIFICATIONS

GENERAL

Power Requirement

Power Consumption

Temperature

Operating position

Dimensions (W x H x D)

Weight

Format

Tape Width

Tape Speed

Maximum Recording Time with full-size cassette

VIDEO

Signal system

Recording system

Input

Output

Signal-to-Noise ratio

Horizontal resolution

AUDIO

Recording system

Input

Output

Frequency Range

Signal to Noise Ratio

Audio Distortion

TUNER

Tuning system

RF Output

TIMER

Memory programmable

Back up time

Clock exactness

ACCESSORIES

Provided Accessories Remote control unit, RF Cable, Battery

AC 230V, 50Hz

Max. 17W (in REC mode)

5×C ~ 35×C (Operating)

-20×C ~ 60×C

Horizontal only

360 x 90 x 288 (mm)

Approx. 3.85 Kg

VHS standard

12.65mm

(SP) : 23.39mm/sec

(LP) : 11.70mm/sec

(SP) :240min, with E-240 video cassette

(LP) :480min, with E-240 video cassette

PAL/SECAM colour and CCIR monochrome signals, 625 lines/50 fields

Rotary two-head helical scan with a slant double-azimuth combination video

head

1.0Vp-p, 75ohms, unbalanced

1.0Vp-p, 75ohms, unbalanced

45dB (Rhode & Schwarz noise meter) with NETTETE IMAGE control at center position

240 lines with NETTETE IMAGE control at center position

Longitudinal track

-8dBm, (CENELEC standard),more than 47 k-ohms, unbalanced

-6dBm, (CENELEC standard), less than 1k-ohms, unbalanced(100k-ohms,

load)

100Hz to 8,000Hz

More than 38dB

Less than 3% (SP)

Voltage synthesized tuner Programmable V/S 99CH (Hyper band)

UHF channel 21~69 (52)

99 CH

Less than 1 Hour

In accordance with the exactness of power supply frequency (50Hz)

*

Design and specification can be subjected to change without notice.

CHANNEL COVERAGE

SECAM-L

SYSTEM

CHANNEL

PAL, SECAM-B/G, PAL-I/I

PAL, SECAM-B/G, D/K, HYPER BAND

VHF Ch 2~12

UHF Ch 21~69

CATV Ch X,Y,Z S1~S41

INPUT/OUTPUT JACK TYPE

Model

Jack Type

EUROPE Asia, South Africa, Australia

SCART Type RCA Jack (Phone Jack)

PAL-I

UHF Ch 21~69

8

Page 10

CIRCUIT INFORMATION

1. INTERCONNECT WIRING DIAGRAM

9

Page 11

CIRCUIT INFORMATION

2. POWER CIRCUIT DIAGRAM

10

Page 12

CIRCUIT INFORMATION

POWER MODE

LOC. PIN EE PLAY REC.

IC802 1 2.46 2.46 2.46

2 4.81 4.83 4.82

3 0 0 0.01

IC801 1 5.88 5.89 5.89

/803 2 4.81 4.83 4.83

3 0.25 0.25 0.25

4 3.1 3.1 3.1

POWER MODE

LOC. PIN EE PLAY REC.

Q801 E 0 0 0

B -0.12 -0.11 -0.72

C 323 323 323

Q802 E 0 0 0

B 0.25 0.26 0.17

C 0.12 0.11 0.17

Q821 E 12.58 12.6 12.6

B 13.2 13.2 13.2

C 15.6 15.36 15.4

Q822 E 5.2 5.19 5.2

B 5.89 5.89 5.89

C 5.97 5.97 5.96

Q825 E 0 0 0

B

C 5.89 5.89 5.89

Q826 E 0 0 0

B 0.73 0.73 0.73

C

1. T801 PIN 1 X : 0.1KV DIV

Y : 5uS DIV

4. IC801 PIN3 X : 0.5V DIV

Y : 5uS DIV

2. T801 PIN 3 X : 2V DIV

Y: 2mS DIV

5. IC801 PIN 4 X: 2V DIV

Y : 5uS DIV

3. T801 PIN4 X: 5V DIV

Y: 5uS DIV

6. Q801 base X: 0.5V DIV

Y : 5uS DIV

11

Page 13

3. POWER BLOCK DIAGRAM

CIRCUIT INFORMATION

12

Page 14

CIRCUIT INFORMATION

4. SYSCON CIRCUIT DIAGRAM

13

Page 15

CIRCUIT INFORMATION

SYSCON MODE

LOC. PIN EE PLAY REC.

IC501

2 2.63 2.61 2.61

3 4.64 4.97 4.96

4 2.3 0 2.2

5 1.8 0 2.1

6 4.74 5.04 5.1

7 1.4 2.28 1.13

8 0.01 4.73 0.01

9 1.9 1.85 0.14

10 0.04 0.01 0.01

1

12 1.63 1.58 1.57

13 5.2 0.01 0.01

14 5.2 5.2 5.18

15 2.6 2.6 2.6

16 5.2 5.2 5.2

17 2.82 0 0

18 0 2.61 2.6

19 2.61 0 2.6

20 0 5.23 0

21 0 0 5.13

23 0.78 0.79 0.8

24 0.78 0.79 0.8

25 0.87 0.01 0.87

26 0.87 0.87 0.87

27 0.87 0.87 0.87

28 0.87 0.87 0.87

29 0.87 0.87 0.87

30 0.87 0.87 0.01

31 1.41 0.03 1.4

32 5.05 0.05 0.07

33 0.76 0.02 0.77

34 5.25 5.25 5.23

35 000

36 1.54 1.52 1.53

37 5.2 5.25 5.1

38 2.32 2.32 2.31

39 0 0.01 2.6

40 0 0.01 0.11

41 0 0 0.12

42 5.23 5.23 5.1

43 5.25 5.23 5.23

44 1.8 1.9 1.7

45 5 5 4.9

46 0.01 0 0.12

47 1.8 1.86 1.7

48 0.01 0 0.12

49 0.02 0 0

50 1.9 1.97 1.7

51 3.3 3.3 3.2

52 1.9 1.97 2.1

53 5.25 5.25 5.25

54 2.23 2.23 2.23

55 1.92 1.97 1.75

56 1.9 1.98 1.87

58 4.48 0.33 4.49

59 5.21 5.21 0

60 4.82 4.8 4.84

61 4.96 4.8 4.91

SYSCON MODE

LOC. PIN EE PLAY REC.

62 0.01 0.03 0

63

64 5.18 0 5.18

65 5.18 0.01 5.18

66 0.04 0.01 0.12

67 0 5.2 0

68 0 0.01 0

69 0 0 0.12

70 5.17 5.17 5.15

71 5.04 5.01 5.01

72 5.01 5.01 5.01

73 0.12 0.14 0.08

74 0.3 2.58 0.09

75 0.03 0 0.09

76 0 2.5 2.57

77 0 2.6 2.72

78 1.33 0 0.09

79 0 0 5 0 5

80 5.02 0 5 0 5

81 1.6 0.01 1.58

82 5.21 0 0

83 4.55 5.01 5.01

84 5.01 5.01 5.19

85 0.01 0.01 0

86 5.21 0.01 0

87 4.23 2.49 2.48

88 0 0.01 0

89 0 0.01 1.51

90 0.01 1.28 1.28

91 2.58 2.58 2.58

92

93

94 2.6 2.6 2.28

95 2.56 2.56 2.89

96 2.56 2.56 2.56

97 2.57 2.59 2.57

98 5.01 5.01 5.01

99 5.22 5.21 5.2

100 0 0.01 0

SYSCON MODE

LOC. PIN EE PLAY REC.

IC502

5 4.96 4.85 4.9

6 4.96 4.88 4.9

8 5.22 5.22 5.2

SYSCON MODE

LOC. PIN EE PLAY REC.

Q501 E 2.82 3.06 2.81

B 2.12 2.35 2.11

C 0.01 0.01 0.02

2.6 2.6 2.6

<-> <->

<->

<->

1. IC501 PIN97 X: 1V DIV

CTL AMP OUT Y : 5mS DIV

4. IC501 PIN 77 X : 1V DIV

CAPSTAN PWM Y : 5uS DIV

7. IC501 PIN 56 X : 0.5V DIV

EDS IN Y: 20uS DIV

2. IC501 PIN 89 X : 0.5V DIV

DRUM FG Y :0.5ms DIV

5. IC501 PIN61 X: 1V DIV

SERIAL CLK Y: 0.1mS DIV

3. IC501 PIN 87 X: 1V DIV

CAPSTAN FG Y : 0.5mS DIV

6. IC501 PIN60 X : 1V DIV

SERIAL DATA Y : 0.1mS DIV

14

Page 16

5. SERVO & SYSCON BLOCK DIAGRAM

CIRCUIT INFORMATION

15

Page 17

CIRCUIT INFORMATION

6. AV & SECAM COLOR CIRCUIT DIAGRAM

16

Page 18

CIRCUIT INFORMATION

A/V MODE

LOC. PIN EE PLAY REC.

IC301 1 5.09 0.1 0.78

2 0.03 0.03 0.84

3 2.29 2.28 2.55

4 0.33 0.17 0.62

5 2.28 2.27 2.49

6 2.29 2.28 2.27

7 2.28 2.28 2.28

8 2.28 2.28 2.28

9 2.28 2.28 2.25

10 2.29 2.28 2.28

11 2.4 2.4 2.4

12 0.02 0.02 0.02

13 2.29 2.28 2.27

14 0.05 0.04 0.04

15 2.29 2.28 2.27

16 5.16 0.18 5.15

17 2.29 2.28 2.27

18 5.15 5.121 5.14

19 4.21 4.16 4.13

20 0.02 0.02 0.02

21 3.32 1.99 3.32

22 3.2 3.17 3.2

23 3.2 3.2 3.2

24 5.16 5.13 5.16

25 0.16 3.3 0.15

26 1.42 1.67 1.42

27 2.1 2.1 2.04

28 4.2 4.16 4.17

29 2.79 2.74 2.81

30 0.02 0 0.02

32 5.07 4.91 4.97

33 2.12 2.03 2.11

34 1.57 1.57 1.57

35 2.1 2.09 2.1

36 3.48 3.45 3.59

37 1.69 1.66 1.72

38 2.04 2.01 2.08

39 9.5 9.47 9.48

40 0.02 0.02 0.02

41 0.02 0.02 0.02

42 5.16 5.13 5.15

43 2.23 2.44 2.23

44 0.06 4.21 0.04

45 2.27 2.28 2.29

46 2.42 2.67 2.43

47 4.15 4.15 4.16

48 1.89 1.89 1.88

49 2.94 3.16 2.94

50 1.95 1.95 1.93

51 0.02 0.02 0.02

52 1.94 1.95 1.92

53 1.35 2.34 2.18

54 1.94 1.95 1.92

55 5.17 5.17 5.14

56 2.17 2.31 2.16

57 2 2.15 2

58 1.98 1.98 1.98

59 2.93 2.95 2.92

60 1.43 1.58 1.43

61 1.57 1.86 1.58

62 0 0.07 0.07

A/V MODE

LOC. PIN EE PLAY REC.

63 1.19 1.02 1.21

64 0.02 0.02 0.02

65 0.85 1.92 0.86

66 0.06 1.45 0.07

67 4.49 0.35 4.49

68 5.05 5.07 5.05

69 5 5.01 5.01

70 0.01 2.61 2.6

71 1.73 1.68 1.67

72 5.12 5.1 5.11

73 2.2 2.06 2.2

74 2.3 2.6 2.31

75 2.22 0.69 2.23

76 2.22 0.76 2.23

77 1.7 1.52 1.6

78 2.66 3.37 2.67

79 2.02 1.96 2.52

80 0.95 0.96 4.53

81 1.15 1.14 1.15

82 0.02 0.02 0.02

83 0.45 1.35 1.28

84 1.39 2.26 1.13

85 0.39 0.02 0.66

86 0.2 0.27 1.63

87 1.93 1.96 4.35

88 1.93 1.95 4.33

89 1.93 1.95 4.33

90 1.93 1.96 4.35

91 5.14 5.12 5.12

92 0.02 0.02 0.02

93 1.94 0.74 0.73

94 1.94 0.74 0.73

95 1.94 0.74 0.73

96 1.95 0.74 0.73

97 0 0.02 0.02

98 2.29 2.29 2.43

99 2.29 2.29 2.43

100 2.29 2.29 2.56

SECAM COLOR MODE

LOC. PIN EE PLAY REC.

IC361 1 2.58 2.58 2.55

2 2.39 2.4 2.4

3 3.6 3.59 3.63

4 2.67 2.66 2.64

5 0.02 0 0.01

6 0.38 3.72 0.49

7 0.02 0.02 0.03

8 0.02 0.02 0.03

9 3.13 3.13 3.12

10 4.83 4.83 4.79

11 1.96 1.95 2

12 2.2 1.99 2.28

13 3.98 3.98 3.99

14 2.61 2.61 2.58

15 3.1 2.6 3.13

16 3.18 3.18 3.19

17 0 5.23 0

18 0.14 2.1 0.15

19 2.27 2.27 2.3

20 1.9 2.95 1.93

21 2.04 2.32 2.03

22 0.9 0 0.01

23 5.15 5.14 5.13

24 5.15 5.14 5.13

25 2.26 2.21 2.27

26 2.26 2.21 2.24

27 4.85 4.9 4.84

28 4.66 4.65 4.64

29 0.39 0.35 0.39

30 1.83 1.83 1.83

A/V MODE

LOC. PIN EE PLAY REC.

Q201 E 0.02 0.02 0.02

B 0.03 0.03 0.84

C 5.11 0.1 0.77

Q203 E 3.51 0.1 0.89

B 3.43 0.04 1.64

C 5.04 0.04 4.83

Q204 E 0 0.02 -14.24

B 0 0.7 -19.43

C 5.11 0.03 1.05

Q205 E 0.14 0.02 -14.15

B 0 0.71 -18.87

C 0.02 0.02 0.02

Q206 E 5.16 5.16 5.16

B 5.16 4.46 5.15

C 1.81 5.12 -19.1

Q207 E 5.97 5.97 5.91

B 5.96 5.96 5.11

C 5.34 0.02 5.07

Q208 E 0 0 0

B 0 0 0.68

C 5.96 5.96 0.02

Q301 E 2.14 2.13 2.15

B 2.78 2.76 2.76

C 5.16 5.15 5.15

Q305 E 1.4 1.32 1.4

B 2.03 2.3 2.06

C 5.17 5.17 5.16

Q330 E 2.73 2.01 2.73

B 2.05 2.67 2.05

C 0 0.12 0

Q331 E 2.06 2.32 2.06

B 2.73 2.98 2.72

C 5.17 5.17 5.16

1. IC301 PIN78 X: 0.1V DIV

RECY-FM Y : 10uS DIV

2. IC301 PIN21 X: 0.1V DIV

REC COLOR(PAL) Y:20uS DIV

5. IC301 PIN21 X: 0.1V DIV

PB COLOR(SCM) Y : 20uS DIV

8. IC301 PIN50 X: 0.2V DIV

VIDEO INPUT(REC) Y : 20uS DIV

11. IC301 PIN43 X: 0.1V DIV

Y-DLY OUT(REC) Y : 20us DIV

3. IC301 PIN25 X: 0.1V DIV

PB COLOR(PAL) Y: 20uS DIV

6. IC301 PIN3 X : 1V DIV

C.SYNC Y : 20uS DIV

9. IC301 PIN79 X : 0.1V DIV

PB ENVE Y : 2mS DIV

12. IC301 PIN74 X: 0.1V DIV

DEEMPHA OUT (PB) Y:20uS DIV

4. IC301 PIN25 X: 0.1V DIV

REC COLOR (SCM)Y :20uS DIV

7. IC301 PIN58 X: 0.2V DIV

REC SECAM Y: 20uS DIV

10. IC301 PIN43 X : 0.1V DIV

Y-DLY OUT(PB) Y 20uS DIV

13. IC301 PIN65 X: 0.5V DIV

VIDEO OUT(REC) Y : 20uS DIV

17

Page 19

7-1. VIDEO PLAYBACK PATH FOR PAL

CIRCUIT INFORMATION

7-2. VIDEO RECORD PATH FOR PAL

18

Page 20

CIRCUIT INFORMATION

8. HIFI & SW CIRCUIT DIAGRAM

19

Page 21

HIFFI BLOCK DIAGRAM

CIRCUIT INFORMATION

HIFI&SW MODE

LOC. PIN EE PLAY REC.

IC251 1 0.00 0.00 0.00

2 3.90 3.90 3.90

3 3.90 3.90 3.90

4 0.00 0.00 0.00

5 0.00 0.00 0.00

6 3.90 3.91 3.91

7 3.90 3.90 3.90

8 3.90 3.90 3.90

9 3.90 3.90 3.90

10 3.90 3.90 3.90

11 3.90 3.90 3.90

12 0.06 0.00 0.00

13 3.90 3.90 3.90

14 0.00 0.00 0.00

15 0.00 0.00 0.00

16 4.62 4.62 4.64

17 4.62 4.64 4.64

18 0.00 0.00 0.00

19 4.62 4.62 4.64

20 4.62 4.62 4.64

21 4.62 4.61 4.64

22 3.90 3.90 3.90

23 3.91 3.92 3.92

24 3.92 3.92 3.92

25 3.92 3.94 3.92

26 0.82 0.84 0.84

27 0.00 0.00 0.00

28 3.88 3.88 3.90

29 3.92 3.91 3.92

30 0.82 0.00 0.82

31 3.92 0.82 3.92

32 3.92 3.94 3.92

33 3.92 3.92 3.92

34 2.58 3.92 3.92

35 0.06 12.58 4.34

36 0.64 0.64 4.32

37 0.64 0.64 4.34

38 0.00 0.64 4.28

39 0.00 0.00 0.00

40 5.18 0.00 5.10

41 0.94 5.20 0.94

42 4.75 0.94 4.74

43 4.86 4.81 4.81

44 1.98

1.97

1.97

HIFI&SW MODE

LOC. PIN EE PLAY REC.

IC601 1 5.13 5.14 5.13

2 5.16 5.16 5.15

3 5.16 5.16 5.13

4 5.15 5.15 5.14

5 5.16 5.14 5.16

6 0 0.01 0.01

7 0.01 0.01 0.01

8 0.01 0.01 0.01

9 12.19 0.01 12.26

10 12.19 12.23 12.26

11 0.01 0.01 0.01

12 5.16 5.15 5.15

13 5.14 5.14 5.13

14 5.16 5.17 5.13

15 5.14 5.15 5.13

16 12.32 12.35 12.38

LOC. PIN EE PLAY REC.

Q601 E 12.5 12.58 12.59

B 12.5 0.06 12.57

C 0.04 12.57 0.05

Q602 E 0.01 0.01 0.02

B 0 5.16 0

C 12.5 0.06 12.58

Q603 E 0.01 0.01 0.02

B

C 0.04 12.38 0.05

Q670 E 2.28 2.85 2.28

B 1.59 2.16 1.59

C 0.01 0.01 0.01

Q671 E 1.91 1.74 1.91

B 1.22 1.04 1.22

C 0.01 0.01 0.01

1 IC251 PIN2 X : 0.1V DIV

IF A.IN LEFT Y : 0.5mS DIV

3. IC 251 PIN16 X: 0.5V DIV

A.OUT LEFT Y : 0.5mS DIV

2. IC251 PIN3 X: 0.5V DIV

IF A.IN RIGHT Y : 0.5mS DIV

4. IC251 PIN 17 X : 0.5V DIV

A.OUT RIGHT Y: 0.5mS div

20

Page 22

9. PIF CIRCUIT DIAGRAM

CIRCUIT INFORMATION

21

Page 23

CIRCUIT INFORMATION

PIF MODE

LOC. PIN EE PLAY REC.

IC051 1 5.02 0.00 5.02

2 1.52 0.07 1.52

3 1.52 0.00 1.52

4 0.00 0.00 0.02

5 2.44 0.07 2.44

6 2.27 0.07 2.32

7 0.06 0.07 0.3

8 0.00 0.07 0.02

9 0.00 0.07 0.02

10 0.00 0.00 0.02

11 5.07 0.00 5.07

12 4.83 4.83 4.83

13 4.84 4.76 4.77

14 2.52 0.05 2.54

15 2.54 0.07 2.56

16 2.51 0.08 2.52

17 0.10 0.08 0.32

18 0.08 0.08 0.30

19 5.08 0.00 5.08

20 0.00 0.00 0.02

21 0.02 0.00 0.36

22 5.22 0.00 5.22

23 0.00 0.00 0.00

24 0.00 0.00 0.00

25 0.00 0.00 0.02

26 1.40 0.00 1.42

27 1.40 0.00 1.42

28 0.00 0.00 0.00

29 0.00 0.00 0.02

30 2.56 0.04 2.58

31 0.00 0.04 2.56

32 5.08 0.00 0.00

33 2.53 0.00 5.08

34 0.00 0.00 2.53

35 2.56 0.00 0.00

36 0.00 0.00 2.56

37 0.00 0.00 0.00

38 0.00 0.00 0.00

39 0.00 0.00 0.00

40 0.00 0.00 0.00

41 0.00 0.00 0.00

42 2.60 0.00 2.26

43 2.56 0.04 2.56

44 0.00 0.00 0.00

PIF MODE

LOC. PIN EE PLAY REC.

IC151 1 0.02 0.01 0.02

2 2.66 2.68 2.64

3 2.66 2.70 2.66

4 0.02 0.00 0.02

5 0.00 0.00 0.00

6 4.83 4.75 4.71

7 4.87 4.83 4.76

8 5.22 5.26 5.20

9 4.84 4.86 4.80

10 0.02 0.00 0.02

11 2.30 2.31 2.28

12 2.30 2.32 2.28

13 1.32 1.00 0.98

14 0.00 0.00 0.01

15 5.24 5.26 5.20

16 3.16 3.12 3.07

17 2.60 2.62 2.57

18 4.80 4.84 4.77

19 5.24 5.26 5.20

20 5.18 5.21 5.14

21 0.02 0.00 0.02

22 3.80 3.82 3.77

23 5.20 5.24 5.18

24 5.24 5.26 5.20

PIF MODE

LOC. PIN EE PLAY REC.

Q001 E 0.002 0.002 0.002

B 0.01 0.01 0.012

C 5.86 5.86 5.86

Q002 E 5.86 5.86 5.86

B 5.82 5.86 5.8

C 0.012 0.012 0.018

1 IC 151 PIN 2 X : 0.5V DIV

2 FSC IN Y : 2uS DIV

3. IC051 PIN 43 X: 0.2V DIV

MONO IN Y : 0.5mS DIV

2. IC151 PIN16 X: 0.5V DIV

PDC V.IN Y : 20uS DIV

4. IC051 PIN 2 X :0.1V DIV

SIF IN Y : 0.5mS DIV

22

Page 24

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW

PCB MAIN

23

Page 25

DISASSEMBLY

1. PACKING ASS’Y

24

Page 26

DISASSEMBLY

2. FRONT PANEL ASSEMBLY

DVST7J3 SERIES

DVST7C3 SERIES

25

Page 27

DVST7D3 SERIES

DISASSEMBLY

DVST7L3 SERIES

26

Page 28

DISASSEMBLY

DVST7B3 SERIES

DVST7E3 SERIES

27

Page 29

DVST7M3 SERIES

DISASSEMBLY

28

Page 30

DISASSEMBLY

3. INSTRUMENT DISASSEMBLY

3-1. SET TOTAL

29

Page 31

ELECTRICAL PARTS LIST

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

“

2

” is a recommendable part for essential stock.

1. PCB MAIN AS

LOC. PART-CODE PART-NAME PART-DESC. REMARK

01 PVACPSS119 ACCESSORY AS DVST7L1S-AQ

DP01 97P95600S0 MANUAL OWNERS SECAM-L MODEL

DP02 97P881RP10 CABLE RF PAL 1.0M

DP03 97P0424100 COVER ACCESSORY LD-PE T0.1

02 PVPKCPD929 PACKING AS DV-K241DZ-RG/D

CP01 97P4930000 PAD FRONT/BACK EPS

CP02 97P4808500 POLY BAG FOR SET 800X800XT0.5 PE-FOAM

CP03 97P5051920 BOX CARTON 409X352X147

CP04 47P4502201 LABEL SERIAL A ART PAPER 2EA ALL MODEL

CP05 6520010020 STAPPLE M20

03 PVMCASS147 CHASSIS MAIN AS DVST7L3S-AQ

A001 97P0611300 CHASSIS MAIN HIPS

A0011 97P0800602 LEG PLASTOMER

A002 97P93400S0 LABEL SPEC PE FILM (SECAM-L MODEL)

A040 97P0478400 COVER TOP SECC T0.5 PCM

A041 7173401212 SCREW TAPPTITE TT2 BIN 4X12 BK

A060 97P0478600 COVER BOTTOM SECC T0.4

A061 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

D008 97P882T912 CABLE SCART SCART-SCART 9P 1.2M

D100 97P1R2TAA2 REMOCON HANDSET AS VR-F2TA

M01 97PP324300 PANEL FRONT AS T8L1DY

M021 7173401211 SCREW TAPPTITE TT2 BIN 4X12 MFZN

M022 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

M1000 PVDKARSB60 VCR DECK AS(T50) DRS-B600 NON

A0100 97SA332200 MAIN BASE AS T4.5-MECHA

A011 97P93B2102 LABEL CD(DECK) PAPER(13X56) ALL MODEL

A0200 97SA316500 S SLANT POLE AS T-MECHA

A0300 97SA316600 T SLANT POLE AS T-MECHA

A0400 97S8103000 MOTOR CAPSTAN DMVCMC-09D

A0401 97S3102000 SCREW TAPPTITE TT2 BIN-P 2.6X7 MFZN

A0600 97SA320500 AC HEAD AS T-MECHA

B0610 97SA326800 HEAD A/C HVMXA1101A(ALPS)

A0601 7004300511 SCREW MACHINE RND 3X5 MFZN

A1000 97SA316800 L LOADING AS T-MECHA

A1100 97SA316900 R LOADING AS T-MECHA

A1200 97S2709510 RACK LOADING SECC T1.2

A1201 7008301911 SCREW MACHINE WAS M3*19 MFZN

A1400 97S0904310 PLATE CONNECT-H SECC T1.0

A1500 97SA319410 REEL BRKT TOTAL AS T2-MECHA

A1501 7274300511 SCREW TAPPTITE TT3 RND 3X5 MFZN

A1700 97S5500400 BELT REEL CR68

A1800 97S2623200 LEVER RELAY SECC T1.2

A1900 97S2709600 RACK FL PBT(DY4410GF) NATURAL

A2000 97S2708200 GEAR CAM DERLIN 100

A2100 97SA317150 PINCH LEVER TOT AS T-MECHA

LOC. PART-CODE PART-NAME PART-DESC. REMARK

B1910 97SA481050 PINCH ROLLER AS D15(DAEJIN D2.6*D7*T4.5)

A2200 97SA318050 LC BRKT AS T5-MECHA

B2040 97P885X146 CONN AS A/C HEAD(6P) SHIELD

A2201 7274300611 SCREW TAPPTITE TT3 RND 3X6 MFZN

A2400 97SA317310 IDLER PLATE TOT AS T2-MECHA

A2401 97S3108200 POLYWASHER D2.6XD6.0XT0.5

A2600 97S2909400 TABLE REEL POM(F20-03) BLACK

A2700 97SA317200 TENSION LVR TOT AS T-MECHA

A2800 97SA317400 S BRAKE AS T-MECHA

A2900 97SA317510 T BRAKE AS T2-MECHA

A3000 97S8023700 HEAD FE HVFHP0042A

A3001 7274300811 SCREW TAPPTITE TT3 RND 3X8 MFZN

AD001 97PA285801 DRUM PRICE AS CYS-T610C

AD002 7004300511 SCREW MACHINE RND 3X5 MFZN

AD003 97P88F0B23 CABLE FFC 1.25K 11P 235MM

AF001 97SA261040 F/L AS T5-MECHA

AF002 7274300511 SCREW TAPPTITE TT3 RND 3X5 MFZN

AN002 2291131304 GREASE DELUXE 5221G(NAM-YOUNG)

PW01 97P69DB900 CORD POWER AS EU LP-21 YFH800 1.7M

Z001 PVMPMSS147 PCB MAIN MANUAL AS DVST7L3S-AQ

AM01 2193100801 SOLDER WIRE SN:PB=63:37 3PI(NO FLUX)

AM02 2193011100 SOLDER WIRE 60 SNA 1.2D

AM03 2291050305 FLUX LIQUID RF-800KN

AM04 2291050306 FLUX THINNER RF-800ADD

AM05 2291140501 WAX COVER

AM06 97P93B2101 LABEL CD(PCB) PAPER(13X48) ALL MODEL

B001 97P0720400 BOARD ANT HI-PS(HB)

B001A 7175300812 SCREW TAPPTITE TT2 FLT 3X8 MFZN BK

C801 CL2EE3104M C LINE ACROSS AC 275V 0.1MF M PCX2 335M

C802 CH1TFB101K C CERA AC 4.0KV 100PF K AD AC250V

C803 CH1TFE222M C CERA AC 4.0KV 2200PF M AD AC250V

C804 CH1CEE472M C CERA AC 2.5KV 4700PF M DE AC250V

C805 CEXF2G470V C ELECTRO 400V RSS 47MF 16X25

C821 CEXK1E681L C ELECTRO 25V 680UF KXL

C822 CEXK1E681L C ELECTRO 25V 680UF KXL

D821 DSB360---- DIODE SCHOTTKY SB360

D822 DRGP20D--- DIODE RGP20D

H501 10RC356VF4 IC UNIT R/RECE1VER ORC0356VF4(38KHZ)

H502 DLDVST7X3D LED DISPLAY DVST7X3D

IC803 1K1010HE01 IC PHOTO COUPLER K1010HE01

JK601 97P6313300 JACK DOUBLE SCART DSAM-9621

JK605 97P6314900 JACK PIN DPAM-9825

JK606 97P6316000 JACK PIN DPAE-9930

L801 5PLFSF212A FILTER LINE SF-2120A

L802 5PLFSF212A FILTER LINE SF-2120A

2

2

2

2

2

2

2

30

Page 32

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

M401 97P0478200 CASE SHI PREAMP ET T0.4

M801 97P0974300 PLATE EARTH-P ET T=0.4

P201 97P62Y1318 CONN WAFER DVW250 PLUG 2.5MM 8P

P202 97P62T14B2 CONN HOUSING TMC-EX-B1 RECEP 2.0MM 2P

P401 97P62G06DA CONN HOUSING GF120 FPC 1.25MM 10P

P501 97P62T152C CONN B/B TMC-JP PLUG 2.0MM 12P

P502 97P6269200 CONN WAFER 00-8283-0812-00000

P801 97P62Y02X2 CONN WAFER YFW800 STR 10MM 2P

Q801 TKSC5027FR TR KSC5027FR

R802 RW02B229J- R WIRE WOUND 2W 2.2 OHM J

R809 RS02F104JS R M-OXIDE FILM 2W 100K OHM J SMALL

R826 RS01F821J- R M-OXIDE FILM 1W 820 OHM J

RF101 97P7615400 TUNER 3 IN 1 SSTBI-SLQ1

S501 97P0S02500 SENSOR REEL RPI-303N

S502 97P0S02500 SENSOR REEL RPI-303N

SW501 5S10104100 SW MODE MMS00402ZMB0

SW510 5SD0101100 SW DETE MXS00921MPC0

T801 57M8282301 TRANS SMPS TSW-T7X3D

X051 5XJ18R4LAE CRYSTAL QUARTZ HC-49/S 18.43200MHZ 30PP

X501 5XJ17R7LAD CRYSTAL QUARTZ HC-49/S 17.73447MHZ 25PPM

Z0011 PVMPJ1S147 PCB MAIN CHIP AS DVST7L3S-AQ

C007 HCQK101JBA C CHIP CERA 50V CH 100PF J 1608

C012 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C014 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C017 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

C018 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

C051 HCQK390JBA C CHIP CERA 50V CH 39PF J 1608

C052 HCQK209CBA C CHIP CERA 50V CH 2PF C 1608

C053 HCQK209CBA C CHIP CERA 50V CH 2PF C 1608

C056 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C058 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C060 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C157 HCBK563KCA C CHIP CERA 50V X7R 0.056MF K 2012

C161 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

C202 HCBK122KBA C CHIP CERA 50V X7R 1200PF K 1608

C203 HCBK122KBA C CHIP CERA 50V X7R 1200PF K 1608

C206 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C212 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C239 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C251 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C252 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C253 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C254 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C255 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C256 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C257 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C258 HCFH474ZCA C CHIP CERA 25V Y5V 0.47MF Z 2012

C263 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

C266 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

C267 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

C268 HCBK392KBA C CHIP CERA 50V X7R 3900PF K 1608

C269 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

2

2

2

2

LOC. PART-CODE PART-NAME PART-DESC. REMARK

C271 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

C277 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

C281 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C282 HCBK122KBA C CHIP CERA 50V X7R 1200PF K 1608

C285 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C286 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C293 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C301 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

C303 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C306 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C307 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

C308 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C310 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

C311 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C312 HCBK822KBA C CHIP CERA 50V X7R 8200PF K 1608

C314 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C315 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C316 HCQK561JBA C CHIP CERA 50V CH 560PF J 1608

C317 HCQK131JBA C CHIP CERA 50V CH 130PF J 1608

C328 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C333 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C335 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C339 HCQK131JBA C CHIP CERA 50V CH 130PF J 1608

C340 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

C341 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C342 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C363 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C379 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C384 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C404 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C506 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C510 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

C511 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C514 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

C515 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C516 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C519 HCBK272KBA C CHIP CERA 50V X7R 2700PF K 1608

C521 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C524 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C525 HCQK201JBA C CHIP CERA 50V CH 200PF J 1608

C528 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C529 HCFH104ZBA C CHIP CERA 25V Y5V 0.1MF Z 1608

C531 HCQK150JBA C CHIP CERA 50V CH 15PF J 1608

C532 HCQK150JBA C CHIP CERA 50V CH 15PF J 1608

C536 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C612 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C613 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C614 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C615 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C616 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C625 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C626 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

31

Page 33

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

C627 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C628 HCFH223ZBA C CHIP CERA 25V Y5V 0.022MF Z 1608

C630 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C631 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C632 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C633 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C634 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C635 HRFS000-BA R CHIP 1/16 0 OHM 1608

C640 HCQK201JBA C CHIP CERA 50V CH 200PF J 1608

C692 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C693 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C694 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C695 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C696 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C697 HCQK330JBA C CHIP CERA 50V CH 33PF J 1608

C809 HCBK472KCA C CHIP CERA 50V X7R 4700PF K 2012

C810 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

C811 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

C827 HCFH683ZBA C CHIP CERA 25V Y5V 0.068MF Z 1608

2

2

2

2

2

2

2

2

2

C831 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

D801 DDBS105G-C DIODE BRIDGE DBS105G CHIP

IC051 1MSP3417DG IC NICAM MSP3417D-QG3

IC151 1LC74793-- IC VPS LC74793JM

IC251 1TDA9605H- IC HI-FI TDA9605H

2

2

IC301 1LA71750M- IC A/V 1 CHIP LA71750M

IC361 1LA70100M- IC SECAM-L LA70100M

IC501 168KT85ATS IC MICOM M37760M8H-1E6GP

IC502 14ATM24D08 IC EPROM ATM24D08

IC503 1PT6955--- IC DRIVER PT6955 24TP(LED DR)

L607 HLX1210001 BEAD CHIP TB201209Z121

L608 HLX1210001 BEAD CHIP TB201209Z121

L611 HLX1210001 BEAD CHIP TB201209Z121

Q305 T2SC2412KB TR CHIP 2SC2412K-T146-BR

Q330 T2SA1037KB TR CHIP 2SA1037AKT146-R

Q331 T2SC2412KB TR CHIP 2SC2412K-T146-BR

R056 HRFS562JBA R CHIP 1/16 5.6K OHM J 1608

R202 HRFS334JBA R CHIP 1/16 330K OHM J 1608

R203 HRFS181JBA R CHIP 1/16 180 OHM J 1608

R205 HRFS752JBA R CHIP 1/16 7.5K OHM J 1608

R206 HRFS273JBA R CHIP 1/16 27K OHM J 1608

R211 HRFS512JBA R CHIP 1/16 5.1K OHM J 1608

R251 HRFS335JBA R CHIP 1/16 3.3M OHM J 1608

R256 HRFS680JBA R CHIP 1/16 68 OHM J 1608

R257 HRFS242JBA R CHIP 1/16 2.4K OHM J 1608

R258 HRFS680JBA R CHIP 1/16 68 OHM J 1608

R259 HRFS242JBA R CHIP 1/16 2.4K OHM J 1608

R260 HRFS680JBA R CHIP 1/16 68 OHM J 1608

R261 HRFS242JBA R CHIP 1/16 2.4K OHM J 1608

R262 HRFS680JBA R CHIP 1/16 68 OHM J 1608

R263 HRFS242JBA R CHIP 1/16 2.4K OHM J 1608

R266 HRFS333JBA R CHIP 1/16 33K OHM J 1608

R270 HRFS333JBA R CHIP 1/16 33K OHM J 1608

LOC. PART-CODE PART-NAME PART-DESC. REMARK

R271 HRFS470JBA R CHIP 1/16 47 OHM J 1608

R302 HRFS822JBA R CHIP 1/16 8.2K OHM J 1608

R304 HRFS202JBA R CHIP 1/16 2K OHM J 1608

R308 HRFS102JBA R CHIP 1/16 1K OHM J 1608

R309 HRFS155JBA R CHIP 1/16 1.5M OHM J 1608

R310 HRFS155JBA R CHIP 1/16 1.5M OHM J 1608

R320 HRFS471JBA R CHIP 1/16 470 OHM J 1608

R323 HRFS682JBA R CHIP 1/16 6.8K OHM J 1608

R324 HRFS202JBA R CHIP 1/16 2K OHM J 1608

R327 HRFS332JBA R CHIP 1/16 3.3K OHM J 1608

R328 HRFS104JBA R CHIP 1/16 100K OHM J 1608

R349 HRFS101JBA R CHIP 1/16 100 OHM J 1608

R350 HRFS331JBA R CHIP 1/16 330 OHM J 1608

R366 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R377 HRFS154JBA R CHIP 1/16 150K OHM J 1608

R380 HRFS202JBA R CHIP 1/16 2K OHM J 1608

R381 HRFS302JBA R CHIP 1/16 3K OHM J 1608

R402 HRFS393JBA R CHIP 1/16 39K OHM J 1608

R404 HRFS363JBA R CHIP 1/16 36K OHM J 1608

R405 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R505 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R506 HRFS472JBA R CHIP 1/16 4.7K OHM J 1608

R510 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R511 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R515 HRFS222JBA R CHIP 1/16 2.2K OHM J 1608

R517 HRFS102JBA R CHIP 1/16 1K OHM J 1608

R518 HRFS182JBA R CHIP 1/16 1.8K OHM J 1608

R519 HRFS101JBA R CHIP 1/16 100 OHM J 1608

R520 HRFS561JBA R CHIP 1/16 560 OHM J 1608

R521 HRFS561JBA R CHIP 1/16 560 OHM J 1608

R525 HRFS104JBA R CHIP 1/16 100K OHM J 1608

R527 HRFS273JBA R CHIP 1/16 27K OHM J 1608

R529 HRFS201JBA R CHIP 1/16 200 OHM J 1608

R534 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R536 HRFS103JBA R CHIP 1/16 10K OHM J 1608

R539 HRFS431JBA R CHIP 1/16 430 OHM J 1608

R547 HRFS332JBA R CHIP 1/16 3.3K OHM J 1608

R550 HRFS472JBA R CHIP 1/16 4.7K OHM J 1608

R555 HRFS820JBA R CHIP 1/16 82 OHM J 1608

R606 HRFS750JBA R CHIP 1/16W 75 OHM J 1608

R611 HRFS750JBA R CHIP 1/16W 75 OHM J 1608

RJ001 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ041 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ042 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ043 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ201 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ202 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ203 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ241 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ242 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ501 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ502 HRF8000-EA R CHIP 1/8 0 OHM 3216

32

Page 34

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

RJ503 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ504 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ541 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ543 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ604 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ605 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ606 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ644 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ648 HRFS000-BA R CHIP 1/16 0 OHM 1608

RJ649 HRFS000-BA R CHIP 1/16 0 OHM 1608

Z0012 PVMPJRS147 PCB MAIN RADIAL AS DVST7L3S-AQ

C004 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7

C013 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C015 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C016 CEXF1H228A C ELECTRO 50V RSM 0.22MF (4X7)

C055 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C057 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C059 CEXF1H339A C ELECTRO 50V RSM 3.3MF 4X7

C061 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C063 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C064 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C065 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C066 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C068 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C151 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C152 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C154 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C158 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7

C201 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C204 CEXF1C220A C ELECTRO 16V RSM 22MF (5X7)

C205 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C208 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7

C210 CEXF1C220A C ELECTRO 16V RSM 22MF (5X7)

C213 CEXF1H478A C ELECTRO 50V RSM 0.47MF 4X7

C214 CEXF1C330A C ELECTRO 16V RSM 33MF (6.3X7) TP

C219 CEXF1C220A C ELECTRO 16V RSM 22MF (5X7)

C222 CMXM2A183J C MYLAR 100V 0.018MF J (TP)

C223 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7

C225 CMXM2A333J C MYLAR 100V 0.033MF J (TP)

C259 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C260 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C261 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C262 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C264 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C265 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C270 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C272 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C273 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C274 CEXF1H229A C ELECTRO 50V RSM 2.2MF (4X7) TP

C275 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C276 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C278 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

2

LOC. PART-CODE PART-NAME PART-DESC. REMARK

C279 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C283 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C291 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C292 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C302 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C304 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C305 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C309 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C313 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C318 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C319 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C320 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C322 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C325 CEXF1H478A C ELECTRO 50V RSM 0.47MF 4X7

C327 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C330 CEXF1H478A C ELECTRO 50V RSM 0.47MF 4X7

C331 CEXE1C100F C ELECTRO "RMB 16V 10MF(SRA-BP,NS)"

C332 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C334 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C336 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C338 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C362 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C365 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C370 CEXF1H478A C ELECTRO 50V RSM 0.47MF 4X7

C373 CEXF1H478A C ELECTRO 50V RSM 0.47MF 4X7

C375 CMXM2A222J C MYLAR 100V 2200PF J (TP)

C376 CMXM2A222J C MYLAR 100V 2200PF J (TP)

C377 CEXF1H229A C ELECTRO 50V RSM 2.2MF (4X7) TP

C378 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C401 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C402 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C403 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C501 CEXF1A471V C ELECTRO 10V RSS 470MF (8X11.5) TP

C502 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C504 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C508 CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

C512 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C513 CEXF1C100A C ELECTRO 16V RSM 10MF 5X7

C522 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C526 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C530 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C535 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C538 CEXF1A471V C ELECTRO 10V RSS 470MF (8X11.5) TP

C611 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C618 CEXF1A471V C ELECTRO 10V RSS 470MF (8X11.5) TP

C620 CEXF1A471V C ELECTRO 10V RSS 470MF (8X11.5) TP

C806 CEXF2C109V C ELECTRO 160V RSS 1MF (6.3X11) TP

C807 CBXB3A101K C CERA SEMI 1KV RR 100PF K

C808 CMXL2G333K C MYLAR 400V MEU 0.033MF K

C823 CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

C824 CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

C825 CEXK1J220L C ELECTRO 63V 22UF KXL

2

2

33

Page 35

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

C826 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) TP

C828 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C829 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C830 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

C833 CEXF1A471V C ELECTRO 10V RSS 470MF (8X11.5) TP

C834 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) TP

F801 5FWPS2022L FUSE PLASTIC TUBE "WRL 2A 250V TL LT-5, SR-5"

IC802 1KA431AZ-- IC REGULATOR KA431AZ

L001 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L002 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L051 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L052 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L053 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L201 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L202 5CPX820J-- COIL PEAKING 82UH J (RADIAL)

L203 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L250 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L251 5CPX101J2T COIL PEAKING 100UH(BRN-BRN)

L301 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L302 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L303 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L304 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L365 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L401 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L501 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L502 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L503 5CPX680J2T COIL PEAKING 68UH(BLU-BLK)

L504 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L601 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L821 56C220K695 COIL CHOKE(CAP TYPE) 22UH K (CAP TYPE) 9X11.1

L823 5CPX470J2T COIL PEAKING 47UH(YEL-BLK)

Q001 TZRC104M-- TR KRC104M AUTO

Q002 TZTA1273Y- TR KTA1273Y(966Y)

Q201 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q203 TZTC3202Y- TR KTC3202Y (AUTO)(1959Y)

Q204 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q205 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q206 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q207 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q208 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q301 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q501 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q601 TZSR2001-- TR KSR2001 (AUTO)

Q602 TZRC104M-- TR KRC104M AUTO

Q603 TZRC104M-- TR KRC104M AUTO

Q670 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q671 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q802 TZTC3203Y- TR KTC3203Y (2120Y)

Q821 TZTC3205Y- TR KTC3205Y (2236Y)

Q822 TZTC3205Y- TR KTC3205Y (2236Y)

Q825 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

Q826 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) (AUTO)

2

2

2

LOC. PART-CODE PART-NAME PART-DESC. REMARK

SW502 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW503 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW504 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW505 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW506 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW507 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW508 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

SW509 5S50101Z97 SW TACT THVV952GBA 9.5M AUTO

X301 5XE4R433TB CRYSTAL QUARTZ HC-49/U 4.433619MHZ 15PPM

Z0013 PVMPJAS147 PCB MAIN AXIAL AS DVST7L3S-AQ

AM31 2TM1456000 TAPE MASKING SI-602

AM31A 2TM110620R TAPE MASKING SI-600N RED

AM31B 2TM1106200 TAPE MASKING SI-600N

C002 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C005 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C054 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C062 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C067 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C153 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C159 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C160 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C209 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C220 CCZB1H391K C CERA 50V B 390PF K (AXIAL)

C321 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C323 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C324 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C326 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C329 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C337 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C361 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C368 CCZF1H104Z C CERA HIKF 50V 0.1MF Z AXIAL

C369 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C371 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C372 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C503 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C505 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C507 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C509 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C517 CCZB1H102K C CERA 50V B 1000PF K (AXIAL)

C518 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C520 CBZF1E223Z C CERA SEMI 25V Y5V 0.022MF Z

C523 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C527 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C537 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C690 CCZB1H331K C CERA 50V B 330PF K (AXIAL)

C691 CCZB1H331K C CERA 50V B 330PF K (AXIAL)

C835 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

D001 DZN4148--- DIODE 1N4148 AUTO 52MM

D003 DZN4003--- DIODE IN4003

D004 DZN4003--- DIODE IN4003

D301 DZN4148--- DIODE 1N4148 AUTO 52MM

D503 DZN4148--- DIODE 1N4148 AUTO 52MM

34

Page 36

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

D506 DZN4148--- DIODE 1N4148 AUTO 52MM

D509 DZN4148--- DIODE 1N4148 AUTO 52MM

D510 DZN4148--- DIODE 1N4148 AUTO 52MM

D515 DZN4148--- DIODE 1N4148 AUTO 52MM

D516 DZN4148--- DIODE 1N4148 AUTO 52MM

D517 DZN4148--- DIODE 1N4148 AUTO 52MM

D518 DZN4148--- DIODE 1N4148 AUTO 52MM

D519 DZN4148--- DIODE 1N4148 AUTO 52MM

D520 DZN4148--- DIODE 1N4148 AUTO 52MM

D521 DZN4003--- DIODE IN4003

D522 DZN4003--- DIODE IN4003

D523 DZN4003--- DIODE IN4003

D524 DZN4148--- DIODE 1N4148 AUTO 52MM

D525 DZN4003--- DIODE IN4003

D526 DZN4003--- DIODE IN4003

D603 DZUZ5R6BSB DIODE ZENER UZ-5.6BSB(5.46-5.70V)

D604 DZUZ5R6BSB DIODE ZENER UZ-5.6BSB(5.46-5.70V)

D627 DZUZ5R6BSB DIODE ZENER UZ-5.6BSB(5.46-5.70V)

D628 DZUZ5R6BSB DIODE ZENER UZ-5.6BSB(5.46-5.70V)

D629 DZN4148--- DIODE 1N4148 AUTO 52MM

D630 DZN4148--- DIODE 1N4148 AUTO 52MM

D631 DZN4148--- DIODE 1N4148 AUTO 52MM

D805 DZEG01C--- DIODE EG01C

D806 DZN4003--- DIODE IN4003

D807 DZUZ3R0BSB DIODE ZENER UZ-3.0BSB(3.01-3.22V)

D808 DZN4148--- DIODE 1N4148 AUTO 52MM

D823 DZGDZP16B- DIODE ZENER GDZP16B1

D824 D1SS244--- DIODE 1SS244

D825 DZUZ33BSB- DIODE ZENER UZ-33BSB(30.32-31.38V)

D826 DZUZ5R6BSB DIODE ZENER UZ-5.6BSB(5.46-5.70V)

D827 DZUZ13BSB- DIODE ZENER UZ-13BSB(12.59-13.16V)

D828 DZN4003--- DIODE IN4003

D829 DZN4003--- DIODE IN4003

JP005 85801060TA WIRE COPPER 0.6X52MM TAPING

JP014 85801060TA WIRE COPPER 0.6X52MM TAPING

JP016 85801060TA WIRE COPPER 0.6X52MM TAPING

JP018 85801060TA WIRE COPPER 0.6X52MM TAPING

JP019 85801060TA WIRE COPPER 0.6X52MM TAPING

JP020 85801060TA WIRE COPPER 0.6X52MM TAPING

JP036 85801060TA WIRE COPPER 0.6X52MM TAPING

JP037 85801060TA WIRE COPPER 0.6X52MM TAPING

JP038 85801060TA WIRE COPPER 0.6X52MM TAPING

JP045 85801060TA WIRE COPPER 0.6X52MM TAPING

JP047 85801060TA WIRE COPPER 0.6X52MM TAPING

JP051 85801060TA WIRE COPPER 0.6X52MM TAPING

JP053 85801060TA WIRE COPPER 0.6X52MM TAPING

JP061 85801060TA WIRE COPPER 0.6X52MM TAPING

JP063 85801060TA WIRE COPPER 0.6X52MM TAPING

JP073 85801060TA WIRE COPPER 0.6X52MM TAPING

JP075 85801060TA WIRE COPPER 0.6X52MM TAPING

JP077 85801060TA WIRE COPPER 0.6X52MM TAPING

JP078 85801060TA WIRE COPPER 0.6X52MM TAPING

2

LOC. PART-CODE PART-NAME PART-DESC. REMARK

JP085 85801060TA WIRE COPPER 0.6X52MM TAPING

JP088 85801060TA WIRE COPPER 0.6X52MM TAPING

JP102 85801060TA WIRE COPPER 0.6X52MM TAPING

JP103 85801060TA WIRE COPPER 0.6X52MM TAPING

JP104 85801060TA WIRE COPPER 0.6X52MM TAPING

JP107 85801060TA WIRE COPPER 0.6X52MM TAPING

JP108 85801060TA WIRE COPPER 0.6X52MM TAPING

JP113 85801060TA WIRE COPPER 0.6X52MM TAPING

JP114 85801060TA WIRE COPPER 0.6X52MM TAPING

JP115 85801060TA WIRE COPPER 0.6X52MM TAPING

JP118 85801060TA WIRE COPPER 0.6X52MM TAPING

JP126 85801060TA WIRE COPPER 0.6X52MM TAPING

JP127 85801060TA WIRE COPPER 0.6X52MM TAPING

JP134 85801060TA WIRE COPPER 0.6X52MM TAPING

JP137 85801060TA WIRE COPPER 0.6X52MM TAPING

JP160 85801060TA WIRE COPPER 0.6X52MM TAPING

JP161 85801060TA WIRE COPPER 0.6X52MM TAPING

JP215 85801060TA WIRE COPPER 0.6X52MM TAPING

JP221 85801060TA WIRE COPPER 0.6X52MM TAPING

JP228 85801060TA WIRE COPPER 0.6X52MM TAPING

JP234 85801060TA WIRE COPPER 0.6X52MM TAPING

JP235 85801060TA WIRE COPPER 0.6X52MM TAPING

JP236 85801060TA WIRE COPPER 0.6X52MM TAPING

JP237 85801060TA WIRE COPPER 0.6X52MM TAPING

JP250 85801060TA WIRE COPPER 0.6X52MM TAPING

JP251 85801060TA WIRE COPPER 0.6X52MM TAPING

JP252 85801060TA WIRE COPPER 0.6X52MM TAPING

L151 5CPZ569K02 COIL PEAKING 5.6UH K (AXIAL 3.5MM)

L311 5CPZ100K02 COIL PEAKING 10UH K (AXIAL 3.5MM)

L340 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L341 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L342 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L602 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L604 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L605 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L606 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L609 RD-AZ301J- R CARBON FILM 1/6 300 OHM J

L610 RD-AZ301J- R CARBON FILM 1/6 300 OHM J

L612 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L613 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L803 5PB13857-- COIL BEAD BI3857(AXIAL)

L822 5PB13857-- COIL BEAD BI3857(AXIAL)

R004 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R005 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R006 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R009 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R010 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R051 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R052 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R054 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R055 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

R152 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

2

35

Page 37

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

R153 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

R154 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R155 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R201 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R204 RD-AZ113J- R CARBON FILM 1/6 11K OHM J

R209 RD-AZ123J- R CARBON FILM 1/6 12K OHM J

R210 RD-AZ563J- R CARBON FILM 1/6 56K OHM J

R214 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R215 RD-AZ911J- R CARBON FILM 1/6 910 OHM J

R216 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R217 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R218 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R219 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R225 RD-AZ101J- R CARBON FILM 1/6 100 OHM J

R226 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R227 RD-AZ181J- R CARBON FILM 1/6 180 OHM J

R228 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R229 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R230 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R231 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R232 RD-AZ183J- R CARBON FILM 1/6 18K OHM J

R240 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R241 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R264 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R265 85801060TA WIRE COPPER 0.6X52MM TAPING

R267 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R268 RN-AZ3902F R METAL FILM 1/6 39K OHM F

R269 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R272 RD-AZ821J- R CARBON FILM 1/6 820 OHM J

R273 RD-AZ821J- R CARBON FILM 1/6 820 OHM J

R274 RD-AZ821J- R CARBON FILM 1/6 820 OHM J

R275 RD-AZ821J- R CARBON FILM 1/6 820 OHM J

R276 RD-AZ183J- R CARBON FILM 1/6 18K OHM J

R277 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R278 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R301 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R303 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R305 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R306 RD-AZ362J- R CARBON FILM 1/6 3.6K OHM J

R307 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R312 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

R313 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

R314 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R315 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R316 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R317 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R318 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R319 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R321 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R322 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R325 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R326 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

LOC. PART-CODE PART-NAME PART-DESC. REMARK

R329 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R330 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R331 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R362 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R401 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R403 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R501 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R502 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R503 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R504 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R509 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R512 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R513 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R514 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R516 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R522 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R523 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R524 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R526 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R528 RD-AZ201J- R CARBON FILM 1/6 200 OHM J

R530 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R531 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R532 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R533 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R535 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R537 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R538 RD-AZ912J- R CARBON FILM 1/6 9.1K OHM J

R540 RN-AZ103F- R METAL FILM 1/6 10K OHM F

R541 RN-AZ103F- R METAL FILM 1/6 10K OHM F

R542 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R543 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R544 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R545 RD-AZ121J- R CARBON FILM 1/6 120 OHM J

R546 RD-AZ121J- R CARBON FILM 1/6 120 OHM J

R549 RD-AZ474J- R CARBON FILM 1/6 470K OHM J

R551 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R552 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R553 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R554 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R601 RD-AZ153J- R CARBON FILM 1/6 15K OHM J

R602 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

R603 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

R604 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R605 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R607 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R608 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R609 RD-AZ153J- R CARBON FILM 1/6 15K OHM J

R610 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R612 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R613 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R614 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R615 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

2

2

36

Page 38

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

R618 RD-AZ470J- R CARBON FILM 1/6 47 OHM J

R619 RD-AZ470J- R CARBON FILM 1/6 47 OHM J

R670 RD-4Z751J- R CARBON FILM 1/4 750 OHM J

R671 RD-4Z751J- R CARBON FILM 1/4 750 OHM J

R677 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R678 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R801 RC-2Z565KP R CARBON COMP 1/2 5.6M OHM K

R803 RD-4Z394JS R CARBON FILM 1/4 390K OHM J SMALL

R804 RD-4Z394JS R CARBON FILM 1/4 390K OHM J SMALL

R805 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R806 RD-2Z820JS R CARBON FILM 1/2 82 OHM J SMALL

R807 RD-2Z820JS R CARBON FILM 1/2 82 OHM J SMALL

R808 RD-AZ681J- R CARBON FILM 1/6 680 OHM J

R821 RD-4Z360JS R CARBON FILM 1/4 36 OHM J SMALL

R822 RD-AZ182G- R CARBON FILM 1/6 1.8K OHM G

R823 RD-AZ680J- R CARBON FILM 1/6 68 OHM J

R824 RD-AZ470G- R CARBON FILM 1/6 47 OHM G

R825 RD-AZ132G- R CARBON FILM 1/6 1.3K OHM G

R827 RD-4Z622J- R CARBON FILM 1/4 6.2K OHM J

R828 RD-AZ180J- R CARBON FILM 1/6 18 OHM J

R829 RD-4Z751J- R CARBON FILM 1/4 750 OHM J

R830 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

UM01 97P65304MA PCB MAIN 330X246X1.6T(DVST7X3D)

Z0014 PVMPJVE068 PCB MAIN J/V ONLY AS "DVST7X3D-AL/I(304MA,HIFI)"

JP002 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP003 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP004 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP006 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP007 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP008 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP009 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP010 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP015 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP021 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP022 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP023 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP024 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP025 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP026 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP027 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP028 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP029 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP030 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP031 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP032 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP033 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP034 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP035 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP039 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP040 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP041 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP042 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

2

2

2

2

LOC. PART-CODE PART-NAME PART-DESC. REMARK

JP043 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP044 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP052 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP055 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP056 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP057 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP058 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP059 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP060 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP065 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP066 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP067 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP068 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP069 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP070 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP071 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP072 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP074 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP076 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP079 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP080 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP081 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP084 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP086 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP087 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP089 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP090 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP091 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP092 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP093 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP094 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP096 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP097 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP098 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP099 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP100 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP101 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP105 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP106 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP109 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP110 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP111 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP112 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP117 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP119 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP120 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP121 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP122 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP123 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP128 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP130 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP131 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

37

Page 39

ELECTRICAL PARTS LIST

LOC. PART-CODE PART-NAME PART-DESC. REMARK

JP133 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP135 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP138 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP139 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP140 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP141 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP142 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP146 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP147 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP148 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP150 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP152 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP153 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP154 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP155 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP156 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP158 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP159 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP162 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP163 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP165 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP166 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP167 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP168 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP169 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP170 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP171 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP172 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP173 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP174 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP175 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP177 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP178 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP179 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP180 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP181 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP182 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP183 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP184 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP185 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP189 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP190 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP191 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

LOC. PART-CODE PART-NAME PART-DESC. REMARK

JP192 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP193 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP194 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP195 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP196 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP197 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP198 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP199 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP200 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP201 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP202 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP203 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP204 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP205 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP206 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP207 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP208 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP209 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP210 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP211 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP212 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP213 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP214 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP218 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP219 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP220 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP222 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP223 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP224 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP225 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP226 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP227 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP230 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP231 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP240 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP242 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP243 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP244 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP246 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP247 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP248 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JP249 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

38

Page 40

Loading...

Loading...