Page 1

Service Manual

Model : DVR-1989D

DVR-1989D(KD)

DVR-1989D(BB)

DVR-1989D(GB)

DVR-1983D

DVR-1983D(KD)

DVR-1983D(BB)

DVR-1983D(GB)

DVR-1181D

DVR-1181D(KD)

DVR-1181D(BB)

DVR-1181D(GB)

D AEW OO ELECTRONICS CO., LTD.

Page 2

¡¡

‹

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have

been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order to verify

compliance with safety standards.

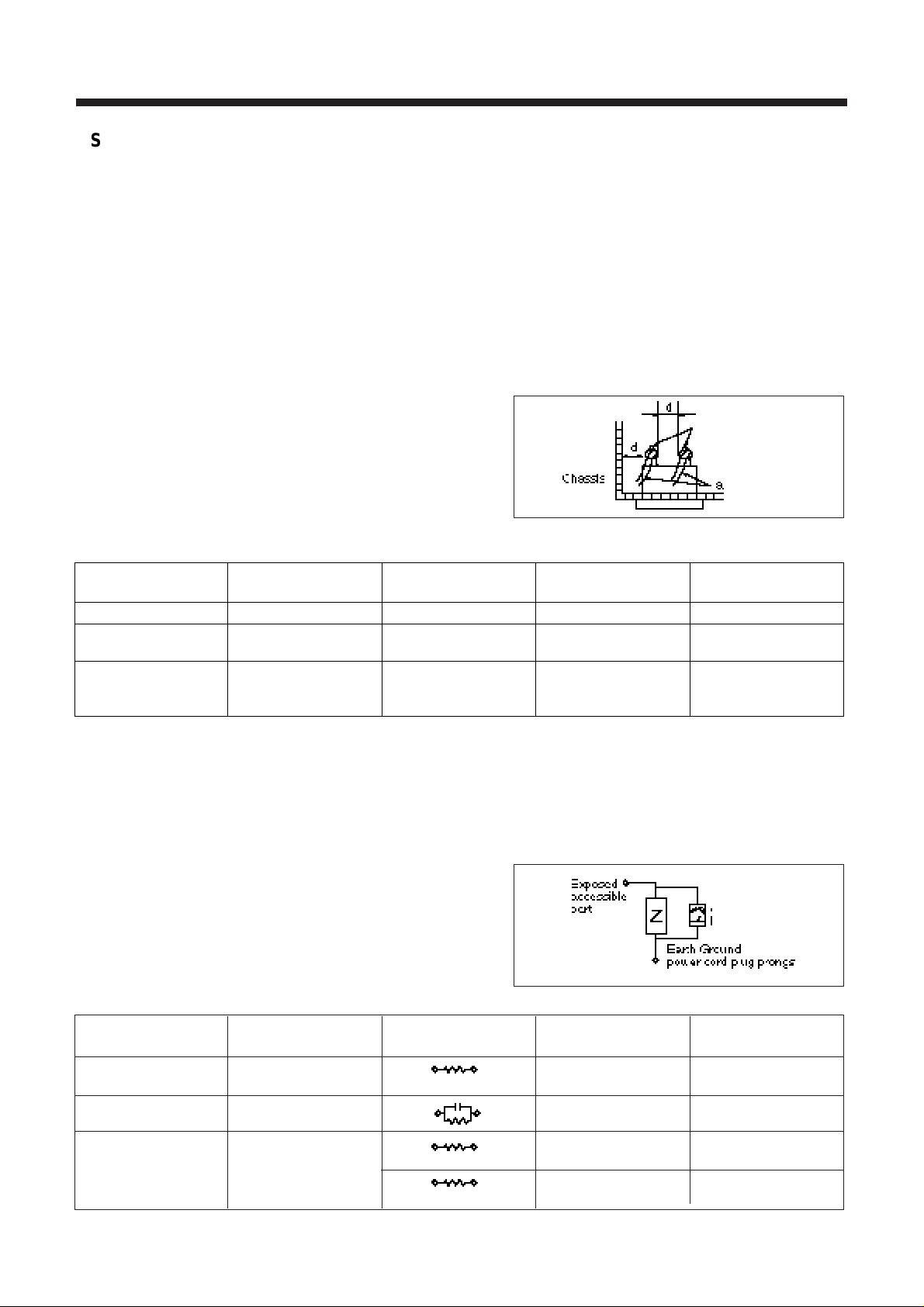

1. Insulation resistance test

1. Confirm the specified insulation resistance or greater between power cord plug prongs and e xternally e xposed parts of the 1.

1. set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.). 1.

1. See table below.

2. Dielectric strength test

1. Confirm specified dielectric strength or greater between power cord plug prongs and e xposed accessib le parts of the set

1. (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.). See

1. table belo w.

3. Clearance distance

1. When replacing primary circuit components, confirm specified 1. 1. 1.

1. clearance distance (d), (d') betw een soldered terminals, and between

1. terminals and surrounding metalic parts. See table below.

T able 1: Rating for selected areas

*Class ¥–model only.

Note: This table is unofficial and for reference only. Be sure to confirm the precise v alues for your particular country and locality .

4. Leakage current test

1.Confirm specified or lower leakage current between B (earth ground, power cord plug prongs) and externally exposed 1. 1. 1.

1. accessible.parts (RF terminals, antenna terminals, video and audo input and output terminals, microphone jacks, earphone

1. jacks etc.)

1. Measuring Method: (Pow er ON)

1. Insert load Z between B (earth ground, power cord plug prongs) and

1. exposed accessible parts. Use and AC voltmeter to measure across

1. both terminals of load Z.

1. See figure and following tab le .

T able 2: Leaka ge current ratings f or selected areas

Note : This table unofficial and for reference only. Be sure to confirm the precise values for your particular country

Note : and locality.

AC Line Voltage Region Insulation dielectric Clearance

Resistance Strengthe Distance (d), (d')

100V Japan 1M/500 V DC 1kV 1 minute ¡ˆ3 mm

110 to 130V USA & --- 900 V 1 minute ¡ˆ 3.2 mm

Canada

* 110 to 130 V Europe 10 M/500 V DC 4kV 1 minute ¡ˆ6 mm (d)

200 to 240 V Australia ¡ˆ‘ mm (d')

Primary circuit terminals

Fig.8

AC voltage

(high impedance)

AC Line Voltage Region Load Z Leakage Curent (i) Earth Ground

(B) to:

100V Japan i ¡´1mA rms Exposed accessible

parts

110 to 130 V USA & i ¡´0.5 mA rms Exposed accessible

Canada parts

110 to 130 V Europe i ¡´0.7 mApeak antenna earth

200 to 240 V Australia i ¡´2 mAdc terminals

i ¡´0.7 mApeak Other terminals

i ¡´ 2 mAdc Other terminals

1K ¥

1K ¥

1K ¥

1.5K ¥

1.5k¥

Page 3

SECTION 1. GENERAL

1111-1. IDENTIFICATION AND OPERATION OF CONTROLS 2

SECTION 2. ELECTRICAL ADJUSTMENT

1112-1. ALIGNMENT AND ELECTRICAL ADJUSTMENTS 5

1112-2. SERVO-LOGIC CIRCUIT ADJUSTMENT METHOD 6

1112-3. VIDEO CIRCUIT ADJUSTMENT METHOD 6

1112.4. AUDIO CIRCUIT ADJUSTMENT METHOD 10

SECTION 3. CIRCUIT DIAGRAM

1113-1. CONNECTION DIAGRAM 11

1113-2. POWER CIRCUIT 12

1113-3. SERVO/SYSCON CIRCUIT 13

1113-4. VIDEO CIRCUIT 14

1113-5. PRE-AMP CIRCUIT 15

1113-6. AUDIO CIRCUIT 16

11 3-7. LOGIC SW CIRCUIT (D VR-1181 SERIES) 17

11 3-8. LOGIC SW CIRCUIT (D VR-1383 SERIES) 18

11 3-9. LOGIC SW CIRCUIT (D VR-1989 SERIES) 19

SECTION 4. EXPLODED VIEWS AND PARTS LIST

1114-1. PACKING ASSEMBLY 20

1114-2. SET ASSEMBLY 21

1114-3. PANEL FRONT ASSEMBLY (DVR-1181 SERIES) 22

1114-4. PANEL FRONT ASSEMBLY (DVR-1383 SERIES) 23

1114-5. PANEL FRONT ASSEMBLY (DVR-1989 SERIES) 24

1114-6. MAIN CHASSIS ASSEMBLY 25

SECTION 5. COMPONENTS LOCATION GUIDE ON PCB (T OP VIEW)

1115-1. MAIN PCB AS 26

1115-2. FRONT PCB AS 27

1115-3. POWER PCB AS 28

SECTION 6. ELECTRICAL PARTS LIST

1116-1. STANDARD PART NUMBER CODING 29

SECTION 7. ELECTRICAL PARTS LIST

1117-1. ELECTRICAL PARTS LIST BY ASSEMBLIES 33

1

TABLE OF CONTENTS

Page 4

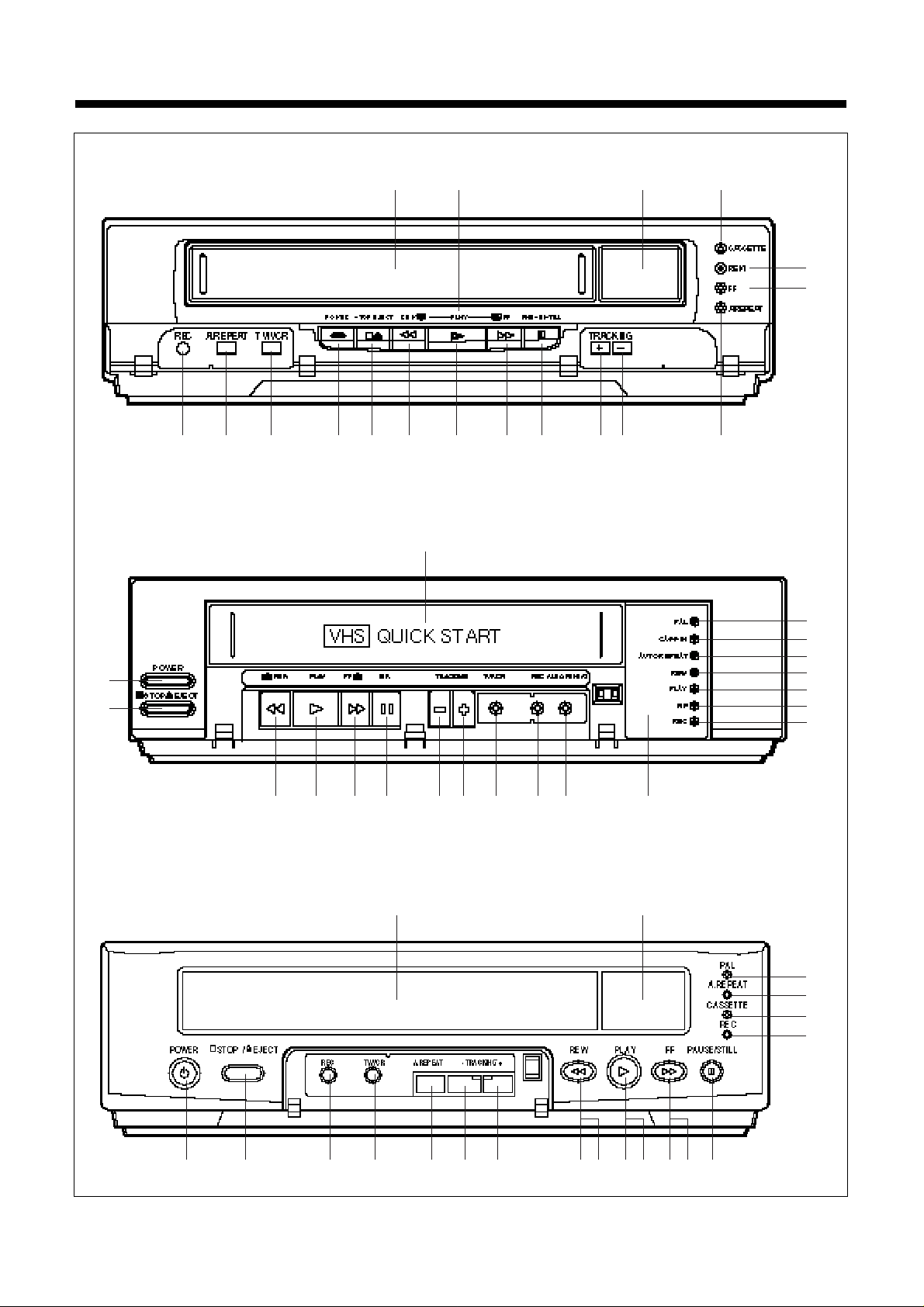

SECTION 1.

GENERAL

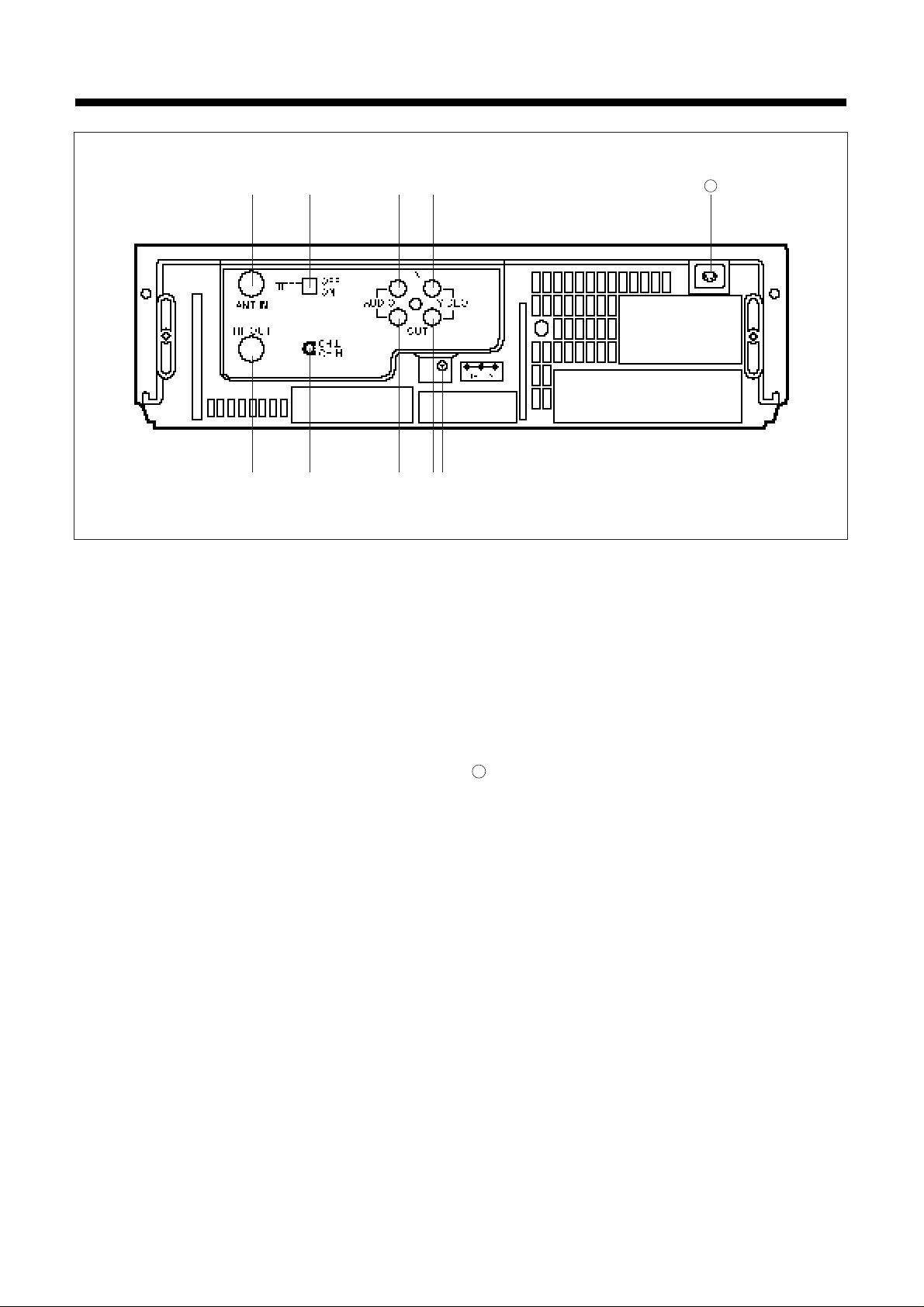

1.1 IDENTIFICATION AND OPERATION OF CONTR OLS

2

DVR-1181 SERIES

DVR-1383 SERIES

DVR-1989 SERIES

¤

¤Ł

¤ ¤ ¤ ¤ ¤Ł ¤º ¤Œ ¤ ¤ ¤ ¤ §æ

¤ı

§

¤Ø § ¤æ ¤

¤º ¤Œ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤æ

§ı

¤

§æ

§

§

§

¤ı

¤Ø

¤ ¤Ł ¤ ¤ ¤ ¤ ¤ ¤º§ ¤Œ§ ¤ § ¤

§ı

§æ

¤

¤ı

¤Ø ¤æ

Page 5

3

¤¤

Á

POWER Switch & LAMP

Turns VCR power on and off .

¤ŁSTOP/EJECT Button

In STOP mode this button makes a cassette come out of

compartment. In any other mode except STOP this button

operates STOP function.

¤ØCassette Compartment

When the cassette is inserted in this compar tment, the

cassette will automatically be ready for operation.

¤ŒPLAY Button

Push to playback the recorded tape .

¤ºREW Button

The REW Button serves a dual purpose. Press this

button to rewind the tape. When this button is pressed

during the playback mode, the picture will move quickly

backward as three times of playback speed. When this

button is pressed again, the picture will move quickly

backward as nine times of playback speed and you can

search for the desired part of program. When play button

is pressed, the recorder will return to the play back mode.

¤ FF Button

The FF Button serves a dual purpose. Push to fast forward the tape. When this button is pressed during the

playback mode, the picture will move quickly forward as

three times of playback speed. In this mode, when this

button in pressed again, the picture will move quickly

forward as nine times of playback speed and you can

search for the desired part of program. When play button

is pressed, the recorder will return to the playback mode.

¤ PA USE/STILL Button

In the recording mode, you can stop the operation of the

recorder temporarily. In the playback mode, a picture will

apear in the STILL mode. The STILL mode is released

automatically after 5 minutes, and will return to the PLAY

mode.

¤ RECORD Button

Push this button to record. If the safety tab has been

removed from the cassette, it will not be possible to

record, thereby preventing your recordings from accidentally erased.

¤ ¤ TRACKING + /

-

Buttons

Press one of the buttons to eliminate noise bars or black

streaks across the picture during playback.

¤æREMOTE Sensor

Receives signals from the Remote Controller.

¤ AUT O REPEAT Button

Press this button and the recorder will automatically

rewind the tape at the end of the signal and repeat the

playback continuously until the auto repeat button is

pressed again.

¤ TV/VCR Button

Press this button to select the TV or VTR mode.

¤ CASS-IN indicator lamp

Illuminates when a cassette tape is loaded.

¤ıREC lamp

Illuminates when REC button is pressed.

§ VCR lamp

Illuminates when VCR mode.

§æ AUT O REPEAT lamp

Illuminates when AUTO REPEAT button is pressed.

§ REW lamp

Illuminates when REW button is pressed.

§ PLAY lamp

Illuminates when the play, still, auto repeat button is

pressed.

§ F.F lamp

Illuminates when FF button is pressed.

§ıPAL lamp

This lamp is lit up in PAL MODE.

N.B : When this button is pressed, all other control keys

are inoperable until AUTO REPEAT is pressed

again

Page 6

4

§ ANT IN Terminal

Connect a TV aerial to this terminal.

§ RF OUTPUT Terminal

Connect to the aerial terminal of a TV receiver with the RF

Cable (provided.)

§łTEST SIGNAL SWITCH

In test signal mode, you can check channel accordance of

the TV and VCR.

§øRF OUTPUT CHANNEL ADJUSTMENT SCREW

In video playback mode, you can adjust more accurately

the RF OUTPUT for obtaining clean picture.

§œAUDIO IN SOCKET (PHONO)

§ßVIDEO IN SOCKET (PHONO)

§ AUDIO OUT SOCKET (PHONO)

§ VIDEO OUT SOCKET (PHONO)

§ DC JACK

Connect this Jack to DC Source (DC 12V)

31

POWER CORD

Connect this cord into the AC outlet.

§ §ł §œ §ß

31

§ §ø § § §

Page 7

5

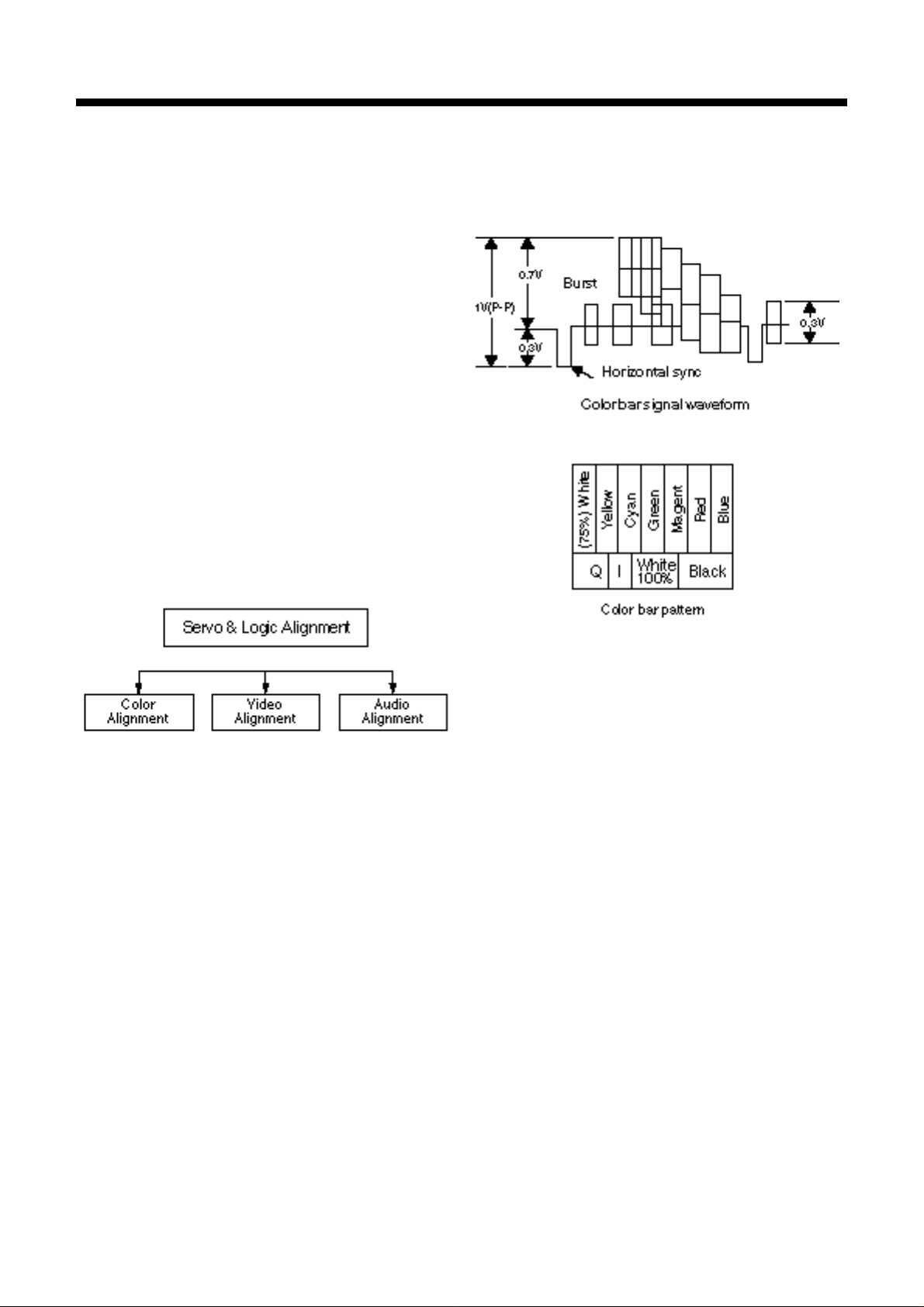

For these adjustment, use the equipment mentioned below

and proceed by using the alignment tape and video signal.

Instrument and T ools Required

1. Color TV receiver .

2. Oscilloscope having 10 MHz or more bandwidth.

3. Color-bar generator.

4. Frequency counter.

5. VTVM.

6. VOM (20 Kµ/V).

7. Audio oscillator .

8. Audio attenuator.

Signal Level and Input and Output Impedance

Requirement

1. Video input: Negative sync., 1Vp-p standard composite

1. video signal, 75Ω.

2. Video output: Same as above.

3. Audio input: Line - 10dBs, 47KΩ.

4. Audio output: -5dBs, 10KΩor less.

Adjustment Sequence

The VCR should be adjusted in the sequence shown below.

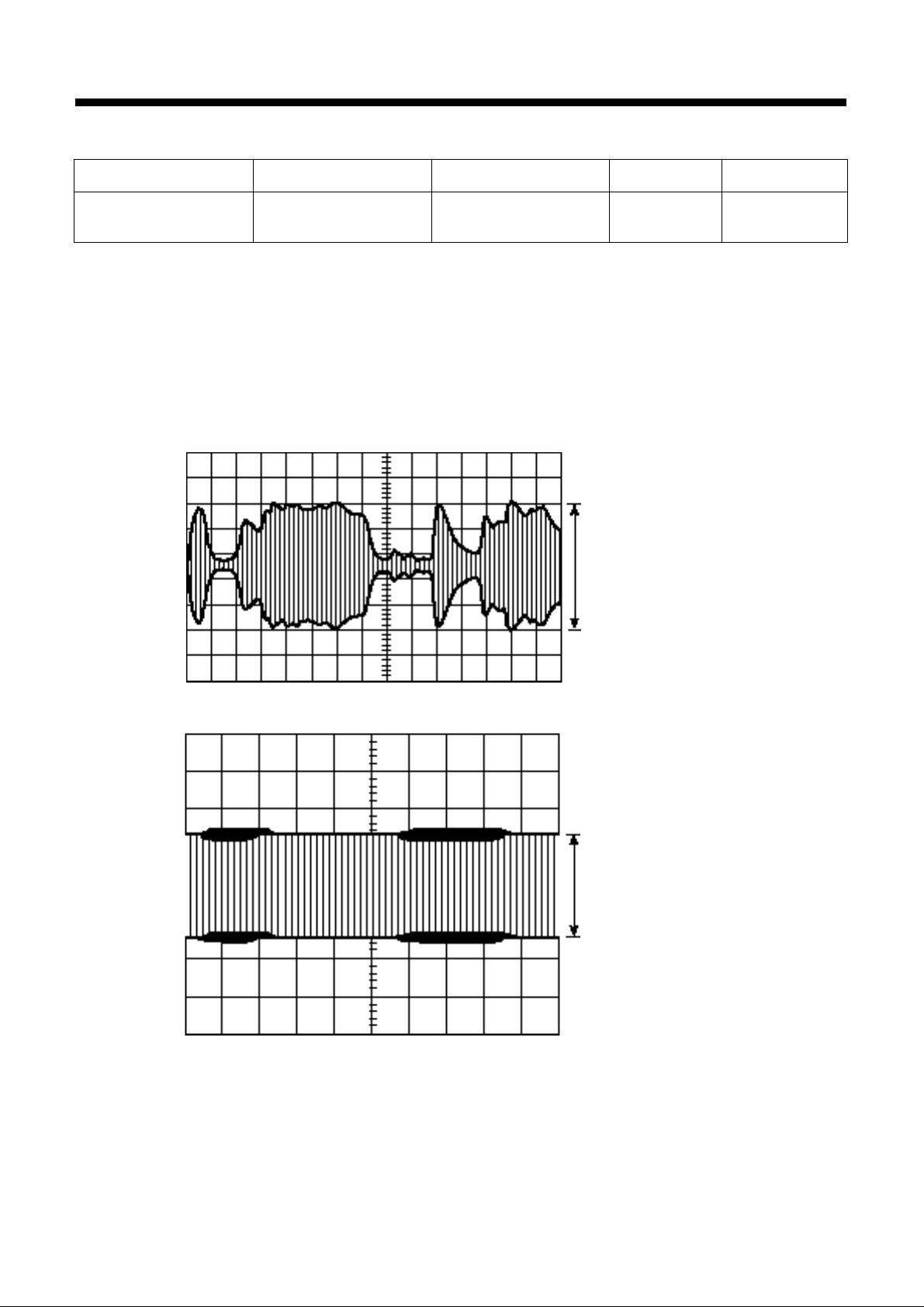

The suitable output waveform of the color-bar signal

generator is shown below.

SECTION 2.

ELECTRICAL ADJUSTMENTS

2-1. ALIGNMENT AND ELECTRICAL ADJUSTMENT

Page 8

6

2-2. SERVO-LOGIC CIRCUIT ADJUSTMENT METHOD

1. VIDEO HEAD SWITCHING POSITION

1) Play back the test tape .

2) Set the oscilloscope in the CHOP mode connect the CH1 to SW pulse PT01 2 PIN the CH2 to TP396 with CH1 triggering.

3) Adjust RV501 for the positive trigger until 6.5H¡ 0.5H cycles before the vertical SYNC pulse.

2-3. VIDEO CIRCUIT ADJUSTMENT METHOD

1. E E VIDEO LEVEL

1) Feed the color bar signal to the line input terminal. And set for the stop (EE) mode.

2) Connect the oscilloscope to TP395 and trigger the scope with a composite SYNC signal at TP313 .(COMP.SYNC.)

3) Adjust the oscilloscope so that it can display a wa veform of approx. 2H.

4) Adjust RV395 to obtain 0.5¡ 0.02 Vp-p between SYNC TIP and 100% white le v el.

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV501

PT01 3 PIN

Oscilloscope Play DP-1

TP396

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV395 TP395 Oscilloscope EE ƒ¡

0.5¡ 0.02Vp-p

Page 9

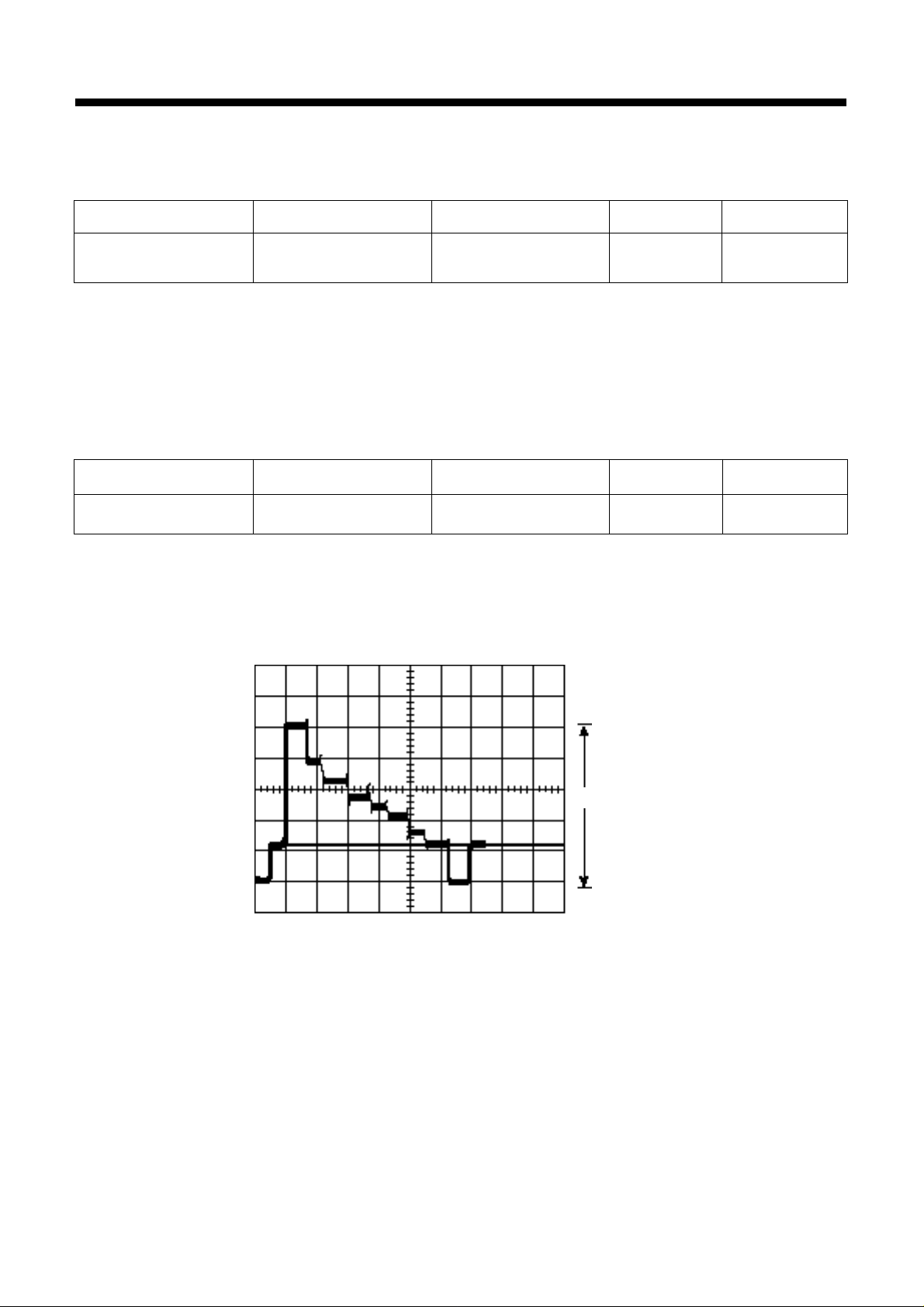

2. PLAYBACK Y-SINGAL OUTPUT LEVEL

1) Playback the test tape (Color Bar Signal).

2) Connect the oscilloscope to TP396 and trigger the scope will a composite SYNC signal at TP313.

1) Adjust the scope so that it can display a wa v eform of approx. 2H.

3) Adjust RV396 to optain 2.0VP¡ 0.2 Vp-p between the SYNC TIP and 100% white le v el.

3. SYNC TIP FREQUENCY

1) Set the unit to stop mode without video signal. (Jack of video line input is shorted with ground).

2) Conncet the frequency counter to TP391.

3) Adjust RV391 until the SYNC TIP frequency becomes 3.80 MHz ¡ 0.1 MHz.

7

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV396 TP396 Oscilloscope PB DP-1

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV391 TP391 Oscilloscope REC. ƒ¡

2.0¡ 0.2Vp-p

Horizontal 10¥ s/div

V ertical 0.5V/div.

Page 10

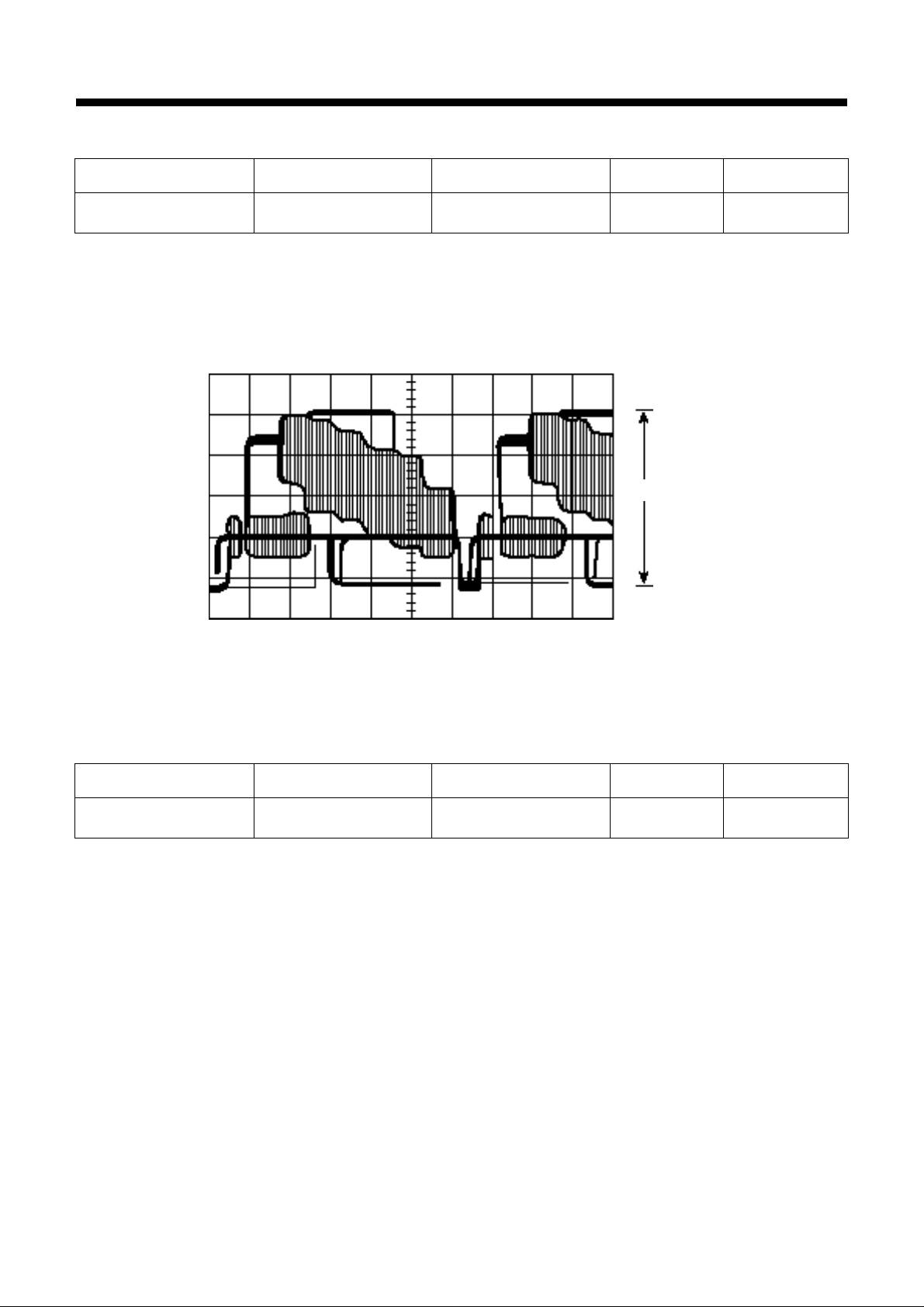

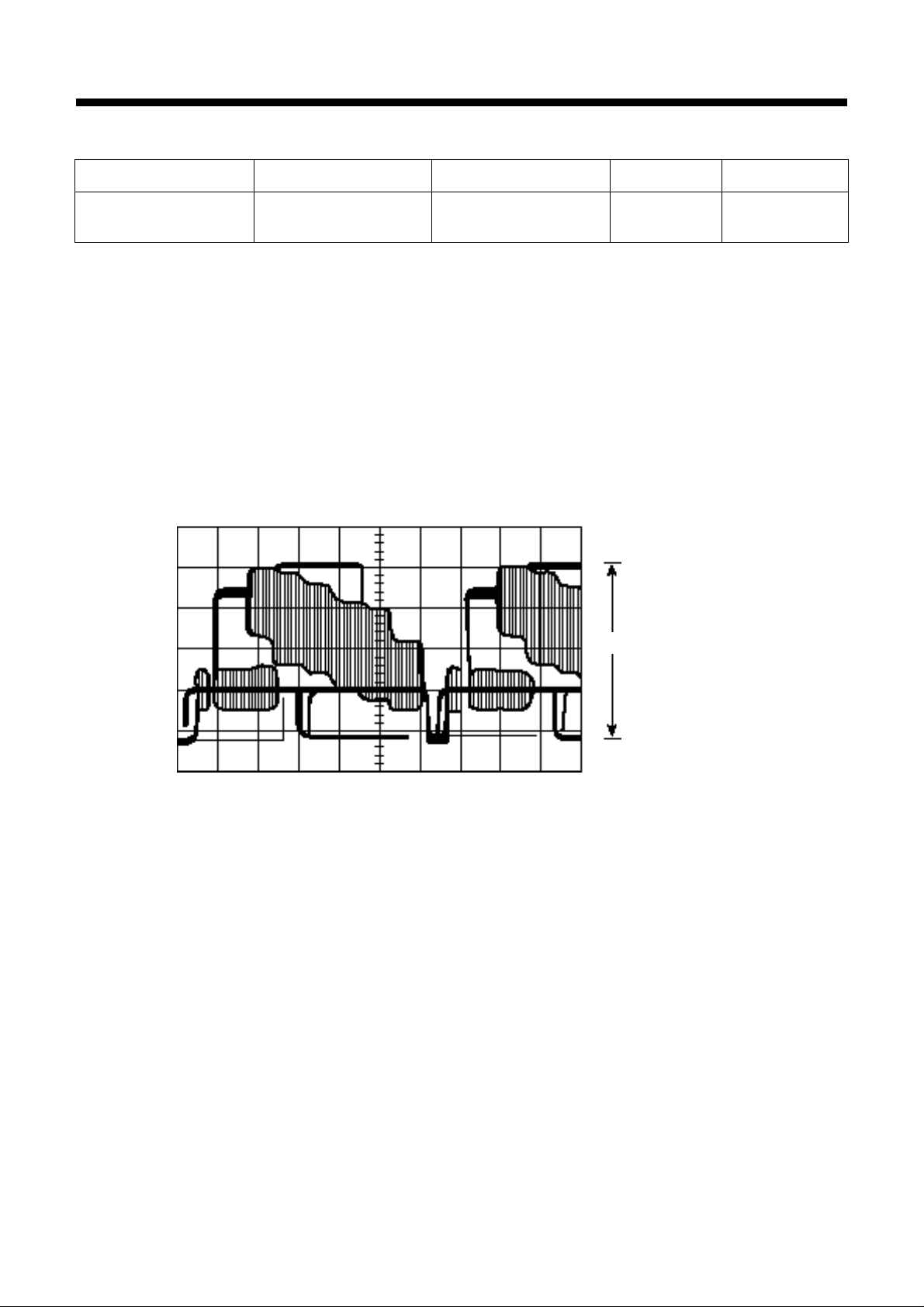

4. LUMINANCE AND COLOR RECORD CURRENT

1) Input Color bar signal in 'video line in'.

2) Make every adjustment in REC mode.

3) Connect CH. 1 of oscilloscope to TP399 and TP GND and CH. 2 TP313 (C.SYNC), and then trigger the scope with an

external signal.

4) Adjust RV491 Until the color record current level (RED REFERENCE) becomes 100¡ 5mVp-p.

5) Connect CH. 1 of oscilloscope to TP399 and TP GND and CH. 2 TP313 (C.SYNC), and then trigger the scope with an

external signal.

6) Adjust RV399 Until the Luminance level becomes 300¡ 10mVp-p.

8

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV339

TP399 Oscilloscope REC. Blank T ape

TV491

Color Record Current

a:100mVp-p¡ 5mVp-p

Y Record Current

b:300mVp-p¡ 10mVp-p

Page 11

5. FM DEVIATION

1) Confirm that the adjustment for the playbac k Y-Signal output lev el has been made corretly.

2) Feed the color bar signal to the line terminal, and set the VCR to the record mode.

3) Connect the oscilloscope to TP396 and trigger the scope with a composite sync signal (TP313).

4) Record the color bar signal for a f e w min ute and pla ybac k it. Then confirm that the pla ybac k Y-signal output lev el is

4) 2.0¡ 0.2 Vp-p.

5) If the playback y signal output level is not 2.0 ¡ 0.2 Vp-p, the adjust as f ollo ws .

5-1) Set the VCR in the record mode.

5-2) Turn the variable RV392 a little.

5-3) Record the color bar signal f or a f e w min ute and pla ybac k it.

5-4) Confirm the playback Y signal output is 2.0 ¡ 0.2Vp-p.

5-5) Repeat from step until the playbac k Y-signal output lev el becomes 2.0¡ 0.2Vp-p between the sync. TIP and 100% white

level.

9

Adj. Location Chec king Point Measuring Equipment Mode Test T ape

RV332 TP399 Oscilloscope REC.

DP-1 Color Bar

Blank Tape

2.0¡ 0.2Vp-p

Horizontal 10¥ s/div

V ertical 0.5V/div.

Page 12

10

2-4. AUDIO CIRCUIT ADJUSTMENT METHOD

1. PLAYBACK OUTPUT LEVEL

1) Connect the audio level meter to the audio line output jack.

2) Play back the test tape .

3) Adjust RV291 until the audio level meter reads -5¡ 1.5dBs play back output.

2. PLAYBACK OUTPUT FREQUENCY CHARA CTERISTIC

1) Playback the Test tape, and confirm that the playback output le v el at 7 KHz is within 0 ¡ 3 dB as referenced to the 1 KHz 1) 1)

playback output le vel.

3. BIAS CURRENT ADJUSTMENT AND OSCILLATION FREQUENCY CHECKING

1) Supply the signal in the OPEN mode

2) Conncet the positive lead of the VTVM to TP201 and negativ e lead to TP202.

3) Set the VCR in recording mode.

4) Confirm the frequency counter display is 70 KHz¡ 10% and adjust RV292 until VTVM reads 2.3 mVrms

4. RECORD-PLAYBACK FREQUENCY RESPONSE

1) Connect the audio signal generator to the audio line input jack, and the audio level meter to the audio line output jac k

2) Record referene audio signal of the 400 Hz and 10 KHz (SP) audio signal at -20 dBs .

3) Check to insure that 10 KHz playbc k output level is within -1¡ 3 dB as referenced to the 400 Hz pla ybac k output level.(SP)

4) If the difference between 10 KHz and 400 Hz playback output le v el is more than +1 dB , increase the bias current more than

4) 2.3mVms, and if the difference is less than -3 dB , reduce the bias current less than 2.3 mVrms .

5. RECORD-PLAYBACK OUTPUT LEVEL

1) Connect the audio signal generator to the audio line input jack.

2) Record and playback the input of the audio reference signal 1 KHz, -10 dBs.

3) Confirm that play output lev el is -5¡ 3dBs as ref erenced to the pla ybac k output level

Adj. Location Measuring Point Measuring Equipment Condition of Adj. Test Tape

Checking Audio Line Out A udio Le v el Meter PLAY Mode

1KHz, 0dBm

6KHz, 0dBm

Adj. Location Measuring Point Measuring Equipment Condition of Adj. Test Tape

RV291 Audio Line Out A udio Le v el Meter PLAY Mode DN-1

Adj. Location Measuring Point Measuring Equipment Condition of Adj. Test Tape

Checking Audio Line Out

Audio Lev el Meter

REC. Play Blank Tape

Audio Signal Generator

Adj. Location Measuring Point Measuring Equipment Condition of Adj. Test Tape

Checking Audio Line Out

Audio Lev el Meter

REC. Play Blank Tape

Audio Signal Generator

Adj. Location Measuring Point Measuring Equipment Condition of Adj. Test Tape

RV292 TP201, TP202 Frequency Counter REC. Mode Blank T ape

Page 13

3-1. CONNECTION DIAGRAM

11

SECTION 3.

CIRCUIT DIA GRAM

Page 14

3-2. POWER CIRCUIT

12

Page 15

3-3. SERVO/SYSCON CIRCUIT

13

Page 16

3-4. VIDEO CIRCUIT

14

Page 17

3-5. PRE-AMP CIRCUIT

15

Page 18

3-6. AUDIO CIRCUIT

16

Page 19

3-7. LOGIC SW CITRCUIT (DVR-1181 SERIES)

17

Page 20

3-8. LOGIC SW CITRCUIT (DVR-1383 SERIES)

18

Page 21

3-9. LOGIC SW CITRCUIT (DVR-1989 SERIES)

19

Page 22

4.1. PACKING ASSEMBLY

20

SECTION 4.

EXPLODED VIEWS AND PAR TS LIST

1 97P5027800 BO X CAR TON 1 SW-4

2 97P4915100 PAD TOP/BOTTOM 1 EPS

3 97P4802400 POLY BAG FOR SET 1 HD-PE 0.05

4 97P0424100 CO VER ACCESSORY

5 97P9527502 MANUAL OWNERS 1 ART PARER

6 97P1R30D00 REMOCON HANDSET AS 1 VR-430S/N

7 47P7500001 BATTERY 1 AAM 1.5V

8 97P8804202 CABLE CONNECTOR 1 HP-504(P AL-TYPE)

Page 23

4-2. SET ASSEMBLY

21

NO. PART CODE PART NAME Q'TY DESCRIPTION REMARK

1 97PB166500 CHASSIS MAIN AS 1

2 97PB166600 PANEL FR ONT AS 1

3 97P1812800 DOOR F/L 1 PC

4 97P3033600 SPRING F/L DOOR 1 SWPB

5 97P0449500 COVER T OP 1 SECC T=0.7

6 7003400812 SCREW MACHINE 4 BIN 4¡¿8 MFZN BK 4 FIX

7 97P0449600 COVER BO TTOM 1 SECC T=0.5

8 7624301211 SCREW TAPPING 5 T2S RND 3¡¿10 MFZN 5 FIX

Page 24

4-3. PANEL FROT ASSEMBLY (DVR-1181 SERIES)

22

NO. PART CODE PART NAME Q'TY DESCRIPTION REMARK

1 97P0308900 PANEL FRONT 1 HI-PS HI-425

2 97P1812700 DOOR FRONT 1 HI-PS HI-425

3 97P1812800 DOOR F/L 1 3022R

4 97P1610100 WINDOW REMO 1 RMMA HI-855M

5 97P1327700 KNOB FUNCTION 1 ABS ABS-780,HF-3

6 97P1707200 INDICATORFUNCTION 1 GPPS GP-125,150

7 97P1707300 INDICATOR PO WER 1 GPPS GP-125,150

8 97P1707400 INDICATOR PLAY 1 GPPS GP-125,150

9 97P0942200 PLATE FUNCTION-R 1 PVC T0.5

10 97P0942300 PLATE FUNCTION-L 1 PVC T0.5

11 97P3033600 SPRING DOOR F/L 1 SWPB

12 97P3022200 SPRING DOOR 1 SUS

Page 25

4-4. PANEL FROT ASSEMBLY (DVR-1383 SERIES)

23

NO. PART CODE PART NAME Q'TY DESCRIPTION REMARK

1 97P0310200 PANEL FRONT 1 HI-425

2 97P1611900 WINDOW FRONT 1 HI-855M

3 97P1814200 DOOR FRONT 1 HI-425

4 97P0952100 PLATE FUNCTION-1 T0.5

5 97P0952200 PLATE FUNCTION-2 1 T0.5

6 4857920400 DOOR LOCK 1

7 97P1708100 INDICATOR PLAY 1 GP-125,150

8 97P1331000 KINOB STOP/EJECT 1 ABS-780,HF-380

9 97P1708100 KNOB POWER 1 GP-125,150

10 97P3033600 SPRING DOOR F/L 1

11 97P1813900 DOOR F/L 1 ABS-780,HF-380

12 97P1331100 KNOB FUNCTION-1 1 ABS-780, HF-380

13 97P1331200 KNOB FUNCTION-2 1 ABS-780, HF-380

Page 26

4-5. PANEL FROT ASSEMBLY (DVR-1989 SERIES)

24

NO. PART CODE PART NAME Q'TY DESCRIPTION REMARK

1 97P1816000 DOOR FRONT 1 HI-PS

2 97P0960500 PLATE FUNCTION 1 PVC

3 4857920400 LOCK DOOR 1 TCB-1488MW

4 97P1614200 WINDOW REMOCON 1 PC DARK SMOG

5 97P1710000 INDICATOR 1 GPPS MILKY

6 97P1339800 KNOB FUNCTION 1 1 ABS NATURAL

7 97P1339900 KNOB FUNCTION 2 1 ABS

8 97P1339700 KNOB P/F 1 ABS

9 97P1813900 DOOR F/L 1 ABS

10 97P3033600 SPRING F/L DOOR 1 SWPB 5088N

11 97P2334300 HOLDER DOOR F/L 1 HI-PS(HB)

12 97P0312200 PANEL FRONT 1 HI-PS(HB)

Page 27

4-6. MAIN CHASSIS ASSEMBLY

25

NO. PART CODE PART NAME Q'TY DESCRIPTION REMARK

1 97P0607600 CHASSIS MAIN 1 HI-PS HI-425*HB) BLK

2 97P0800600 LEG 2 SVR80 BLK

3 97P2422700 BRKT EARTH 4 SECC T=1.0

4 97PB179600 DECK AS 1

5 7124401211 SOCREW TAPPING 3 T2S RND 4¡¿12 MFZN 4 FIX

6 7124301211 SCREW TAPPING 1 T2S RND 3¡¿12 MFZN FIX

7 97PB168100 PCB PRE AMP AS 1

8 7278300811 SCREW TAPPTITE 2 TT3 WAS 3¡¿8 MFZN 7 FIX

9 97P2436900 BRKET POWER 1 SECC T+1.0

10 97PB168000 POWER PCB AS 1

11 97P4406300 RADITOR TR 1 AL

12 7624301011 SOCREW TAPPING 1 T2S RND 3¡¿10 MFZN 10 FIX

13 7624301011 SOCREW TAPPING 2 T2S RND 3¡¿12 MFZN 11 FIX

14 7273401011 SOCREW TAPPING 2 T2S RND 4¡¿12 MFZN 10 FIX

15 7124401211 SOCREW TAPPING 3 T2S RND 4¡¿12 MFZN 9 FIX

16 97P2316600

HOLDER POWER CORD

1 NYLON66 BLK

17 97P0708000 BOARD ANT 1 HI-PS (HB)

18 97P0949100 PLATE ANT BD 1 PVC T=0.5

19 7125300811 SCREW TAPPING 1 T2S RND 3¡¿8 MFZN JACK FIX

20 97PB167900 PCB MAIN AS 1

21 97P2811800 SPACE E 5 EVA

22 97P2421000 BRKT RF CON 1 SECC T=1.0

23 7624301011 SCREW TAPPING 1 T2S RND 3¡¿12 MFZN 20 FIX

24 7124301211 SCREW TAPPING 1 T2S RND 3¡¿12 MFZN 20 FIX

25 97P0942500 PLATE SHI DRUM 1 ET T=0.4

26 97PB168200 PCB FRONT AS 1

27 97P2328500 HOLDER LED 1 ABS

28 97P2315000 HOLDER LED 1 HI-PS

Page 28

5-1. PCB MAIN AS

PT01 TP313 TP396 TP391 TP399 TP201 TP202 TP395 RV501

RV393 R V392 RV391 RV395 RV399 R V491 RV396 RV292 RV291

PT01 TP313 TP396 TP391 TP399 TP201 TP202 TP395 RV501

RV393 RV392 R V391 RV395 R V399 RV491 RV396 RV292 RV291

26

SECTION 5.

COMPONENTS LOCATION GIDE ON PCB

Page 29

27

LOC POS

C201 I2

C202 J2

C203 J2

C204 I2

C205 J2

C206 J2

C207 J2

C208 K2

C209 K2

C210 I1

C211 J2

C212 J1

C213 K1

C216 K2

C217 K2

C218 I2

C219 I1

C406 J3

D503 H2

C220 J1

C221 I1

C222 I2

C223 J1

C301 K5

C302 J5

C303 J5

C304 J5

C305 J5

C306 I5

C307 I5

C308 I5

C309 I5

C310 J5

C311 I5

C312 K4

C313 J4

C314 K4

C315 J4

C316 J4

C317 K4

C318 J4

C319 J3

C320 J4

C321 I4

C322 H3

C323 H4

C324 H4

C325 H3

C328 I6

C329 I6

C330 J6

LOC POS

C331 J6

C332 J6

C333 J6

C334 I5

C336 F6

C337 F6

C339 G6

C401 I4

C402 H4

C403 I4

C404 J4

C405 I4

C407 H4

C408 H4

C409 H4

C411 H4

C412 G3

C416 K6

C419 F3

C430 H3

C432 H3

C433 G2

C501 C2

C502 C1

C503 E1

C504 D6

C506 C7

C508 B4

C509 B4

C505 B7

C505 B7

C516 C4

C519 C4

C522 F7

C525 D2

C527 D2

C533 E4

C540 E2

C547 D4

C601 C7

C602 D7

C603 D3

C604 D3

C605 D3

DZ501 H2

DZ601 D7

DZ602 E7

D301 D5

D302 I5

D303 F5

D304 E5

LOC POS

D305 F5

D501 D1

D502 D1

D507 E6

D506 D5

D601 D3

D603 E7

IC201 J2

IC301 H5

IC302 J4

IC501 C3

IC502 C1

IC503 C6

IC601 D7

IC602 D4

L201 K1

L202 H1

L205 K2

L301 J5

L302 J4

L303 J4

L305 I6

L306 I6

L307 J6

L308 J6

L401 J3

L402 G3

PJ01 G7

PJ01 G7

PJ201 I2

PJ301 F5

PJ601 E3

PT01 E4

P202 I2

P302 I6

P501 E7

P502 D5

P503 D1

P602 E5

Q201 J1

Q301 H6

Q302 J5

Q303 J5

Q304 K5

Q305 J5

Q307 J4

Q308 I6

Q309 I6

Q311 F6

Q312 F6

Q501 D6

LOC POS

Q502 B3

Q503 E2

Q504 E1

Q507 G1

Q508 H1

Q509 H1

Q512 H1

Q513 H1

Q514 E5

RF101 I7

RV291 K2

RV292 I2

RV931 G6

RV392 G6

RV396 K6

RV395 H6

RV399 J6

RV491 J6

RV501 D2

R201 I2

R202 J2

R203 J2

R204 I2

R205 J2

R206 J2

R207 J2

R208 K2

R209 K2

R210 K2

R212 K2

R214 J1

R220 J1

R221 K2

R222 K2

R301 J6

R302 J5

R303 J5

R304 K5

R305 K5

R306 K5

R307 I5

R308 J5

R309 J5

R310 K4

R311 J4

R312 K4

R313 K4

R314 I3

R315 I4

R316 I6

R317 H6

LOC POS

R318 G5

G319 F5

R320 I6

R321 I6

R322 I6

R323 I6

R324 I6

R325 I6

R326 I6

R327 H7

R328 G7

R329 F6

R330 G6

R331 E6

R337 F5

R338 F4

R356 H6

R401 I4

R402 J4

R403 H4

R404 H4

R405 H3

R406 G3

R407 H5

R408 H5

R501 E1

R502 E1

R503 D1

R504 C1

R505 B2

R506 C1

R507 B1

R508 C1

R509 C2

R512 B7

R513 B6

R514 B7

R517 C6

R518 C6

R519 C6

R521 C5

R522 D5

R525 D5

R526 C5

R529 C4

R530 C4

R531 C4

R532 B4

R533 B4

R534 B3

R537 E4

LOC POS

R542 D4

R543 D4

R547 E2

R548 C2

R554 H1

R555 E6

R556 H1

R557 H1

R601 E3

R602 E3

R604 E3

R605 E3

R606 D3

R607 E3

R608 E3

R609 E3

R610 D7

R611 D7

R613 D3

R614 D4

R615 D4

TP201 I2

TP202 I2

TP313 E3

TP391 I6

TP395 J5

TP396 F6

TP399 I6

T201 I1

X401 I4

X423 G3

X424 H2

X601 D3

Page 30

5-2. PCB FRONT AS

DVR-1181 SERIES FRONT PCB

DVR-1383 SERIES FR ONT PCB

DVR-1989 SERIES FR ONT PCB

28

Page 31

29

LOC

C701

DL701

DL703

DL704

DL705

DL706

RM701

R705

R706

R707

R708

R709

R710

R711

R712

R713

R714

R715

R716

R717

R718

R719

RM701

P701

SW701

SW702

SW703

SW704

SW705

SW706

SW707

SW708

SW709

SW710

SW711

SW712

POS

I7

D7

J7

J7

J7

I7

I7

I6

I6

D6

D6

D6

C6

F6

C6

E6

E6

G6

G6

G6

G6

F6

I7

J6

D6

E6

C6

B6

F6

B6

E6

G6

G6

I6

H6

H6

LOC

C701

L701

DL702

DL703

DL704

DL705

DL706

DL707

DL708

DL709

P701

RM701

R701

R702

R703

R704

R705

R706

R707

R708

R709

R710

R711

R712

R713

R714

R715

R716

R717

R718

R719

R721

SW701

SW702

SW703

SW704

SW705

SW706

SW707

SW708

SW710

SW711

SW712

POS

H4

I4

A4

I5

I5

I5

I4

I4

I4

A4

J4

H4

J4

J4

J4

J4

I4

I4

B4

B4

F4

G4

D4

G4

C4

C4

D4

E4

F4

E4

D4

F4

A4

A4

F4

G4

C4

G4

C4

D4

F4

D4

E4

LOC

C701

DL701

DL702

DL703

DL706

DL707

DL708

R701

RM701

P701

R702

R703

R704

R705

R706

R707

R708

R709

R710

R711

R712

R713

R714

R715

R716

R717

R718

R719

R721

SW701

SW702

SW703

SW704

SW705

SW706

SW707

SW708

SW709

SW710

SW711

SW712

POS

I2

H1

B1

J2

J2

H1

I1

J1

I2

I1

I1

H1

I1

J2

J2

B1

B1

C1

E1

F1

D1

G1

I1

I1

G1

G1

F1

G1

I1

B1

B1

D1

E1

H1

D1

H1

I1

J1

D1

F1

F1

DVR-1181 SERIES D VR-1383 SERIES DVR-1989 SERIES

Page 32

30

5-3. PCB POWER ASSEMBLY

LOC

C801

C802

C803

C804

C805

C807

C811

C812

C813

C815

C816

C817

C818

C819

C820

C830

DZ801

DZ802

DZ803

POS

A1

D1

D2

E2

E1

E2

I1

I1

E2

E2

F1

G2

H1

H1

G1

G1

G1

D1

D1

LOC

DZ804

D801

D802

D803

D804

D805

D806

D807

D808

D809

F801

F802

F803

F804

L801

Q801

Q803

Q806

Q808

POS

D1

C1

I1

C1

E2

F1

G1

G1

D1

A1

D1

D1

G1

A2

F2

F2

H2

H2

G1

LOC

Q809

R801

R802

R803

R804

R805

R806

R807

R809

R810

R811

R812

R813

R814

R815

R816

T801

POS

E2

E2

G2

G2

F2

F2

H1

H1

H2

H2

I2

I2

H1

A2

H1

C2

I1

Page 33

6-1. STAND ARD PART NUMBER CODING

ƒUFixed Resistor Coding

ƒUSemi-Fixed Resistor Coding

31

SECTION 6.

ELECTRICAL PAR TS LIST

6-1-1. RESISTOR CODING

Type of Resistor

C Composition Resistor

D Carbon Resistor

F Fusible Resistor

k Ceramic Resistor

N Metal Film Resistor

S Metal-Oxide Film

Resistor

W Wire Wound Resistor

X Cement Resistor

Y Chip Resistor

Rated Wattage

Code Wattage

-A 1/6 W

-B 1/8 W

-4 1/4 W

-2 1/2 W

01 1 W

02 2W

Value

Example

478 0.47Ω

479 4.7Ω

471 470Ω

472 4.7Ω

473 47Ω

Distance

Code Distance

A 2.5 mm

B 5.0 mm

C 7.5 mm

D 10.0 mm

E 12.5 mm

F 15.0 mm

G 17.5 mm

H 20.2 mm

J 22.0 mm

k 25.0 mm

X

Auto lnsertion

Z

Auto lnsertion

T olerance

Symbol Tolerance

F ¡ 1%

G ¡ 2%

J ¡ 5%

K ¡ 10%

M ¡ 20%

N ¡ 30

%

Pin Length Value Knob Type

(Same as Fixed Type)

Material Shape Knob Codeodod

VERTICAL

WITH 1 11

CARBON FILM 1

WITHOUT 2 12

HORIZONTAL

WITH 3 13

WITHOUT 4 14

VERTICAL

WITH 1 21

METAL GRAZE 5

WITHOUT 2 22

HORIZONTAL

WITH 3 23

WITHOUT 4 24

VERTICAL

WITH 1 51

CARBON SOLID 5

WITHOUT 2 52

HORIZONTAL

WITH 3 53

WITHOUT 4 54

VERTICAL

WITH 1 61

CERMIET 6

WITHOUT 2 62

HORIZONTAL

WITH 3 63

WITHOUT 4 64

Page 34

ƒUNormal

ƒUTemperature Compensation

32

T ype

Code Tpye

A Aluminum

B Barrier Layer

C Ceramic

E Electrolytic

L Line Across

M Mylar

S Styrol

N Metalized P oly ester

Q Mica

Oil

T T antal

Distance

Code Voltage

0J 6.3V

1A 10V

1C 16V

1D 20V

1E 25V

1V 35V

1G 40V

1H 50V

1J 63J

2A 100V

2B 125V

2C 160V

2D 200V

2E 250V

Distance Value (Same As Fixed

(Same As Fixed (Same As Fix ed Resistor)

Resistor) Resistor)

Shape or

Characteristic

Characteristic

Capacitance Temperature

Coefficient (ppm/¡ ) Coefficient(ppm/¡ )

A +100 F ¡ 15

B +30 G ¡ 30

C +0 H ¡ 60

H -30 J ¡ 120

L -80 K ¡ 250

P -150 L ¡ 500

R -220 M ¡ 1000

S -330 N ¡ 2500

T -470

U -750

V -1000

SI +350~

-1000

6-1-2. CAPA CITOR CODING

Distance Voltage Value Tolerance

(Same As Fixed (Same As Normal) (Same As Fixed (Same As Fixed

Resistor) Resistor) Resistor)

Page 35

33

6-1-3. FUSE CODING

Type

F Fiber

G Glass Tube

L Lead Type

Glass Tube

T Temperature

W Wire

C Ceramic

P Plastic

Type

1 AC125V

2 AC250V

3 125/250V

Size

A MF41 4.6¡¿16

B MF51 5.2¡¿20

C MF60 6.3¡¿30

D MF61 6.3¡¿31.8

E MF01 10.3¡¿38.1

F MF04 14.3¡¿50.8

G MF05 20.5¡¿76.2

Regulation Value Characteristics

(Same as Fixed

Resistor)

Page 36

34

C201 CMXM2A223J C MYLAR 100V 0.022 MF J TAPING

C202 CEXE1H478A C LELCTRO RS 50V .47MF 5¡¿11

C204 CCZB1H102K C CERA HIKB 50V 1000PF K A¡¿IAL

C205 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C206 CEXE1H100A C ELECTRO RS 50V 10MF 5¡¿11

C207 CMXM2A103J CMYLAR 100V 0.01MF J TAPING

C208 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C209 CEXE1C470A C ELECTRO RS 16V 47MF 6.3¡¿11

C210 CEXE1E220A C ELECTRO RS 25V 22MF 5¡¿11

C211 CEXE1C 470A C ELECTRO RS 16V 47MF 6.3¡¿11

C212 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C213 CMXM2A183J C MYLAR 100V 0.018MF J TAPING

C216 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C217 CMXM2A103J C MYLAR 100V 0.018MF J TAPING

C218 CCXB2H221K C CERA HIKB 500V 220PF K TAPING

C219 CBZR1C472M C CERA Y5R 16V 4700PF M A¡¿IAL

C220 CMXM2A682J C MYLAR 100V 6800PF J TAPING

C222 CMXM2A473J C MYLAR 100V 0.04MF J TAPING

C223 CEXE1E101A C ELECTRO RS 25V 100MF 8¡¿11.5

C301 CEXE1A470A C ELECTRO RS 10V 47MF 5¡¿11

C302 CXSL1H470J C CERA SL 50V 47PF J

C303 CXSL1H470J C CERA SL 50V 180PF J

C304 CZSL1H390J C CERA SL 50V 39PF J A¡¿IAL

C305 CXSL1H390J C CERA SL 50V 56PF J TAPING

C306 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C307 CCZB1H391K C CERA HIKB 50V 390PF K A¡¿IAL

C308 CZSL1H470J C CERA SL 50V 47PF J A¡¿IAL

C309 CZSL1H569K C CERA (AXIAL) SL 50V 82PF J

C310 CXSL1H820J C CERA SL 50V 82PF J

C311 CEXE1H100A C ELECTRO RS 50V 10MF 5¡¿11

C312 CEXE1H100A C ELECTRO RS 50V 10MF 5¡¿11

C313 CEXE1H100A C CERA HIKB 50V 100PF K A¡¿IAL

C317 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C318 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C319 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C320 CEXE1H338A C ELECTRO RS 50V 0.33MF 5¡¿11

C321 CXSL1E223J C CERA Y5V 25V 0.022MF Z A¡¿IAL

C322 CEXE1A101A C ELECTRO RS 10V 100MF 6.3¡¿11

C323 CCZF1H104Z C CERA HIKF 50V 0.1MF 6.3¡¿11

C324 CEXE1A101A C ELECTRO RS 10V 100MF 6.3¡¿11

C325 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C326 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C327 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C328 CZSL1H150J C CERA SL 50V 15PF J A¡¿IAL

C329 CXSL1H620J C CERA 50V SL 62 PF J TAPING

C330 CXSL1H620J C CERA SL 50V 160PF J TAPING

C331 CXSL1H620J C CERA SL 50V 180PF J

C332 CZSL1H200J C CERA SL 50V 20PF J A¡¿IAL

C333 CBZP1C103M C CDER SEMI Y5S 16V 0.01MF M A¡¿IAL

C334 CBZY1E223Z C CERA Y5V 25V 0.022MF Z A¡¿IAL

C335 CEXEO J471A C ELECTRO RS 6.3V 470MF 10¡¿12.5

C336 CEXE1A470A C ELECTRO RS 10V 47MF 5¡¿11

C337 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C338 CEXE1A470A C ELECTRO RS 10V 47MF 5¡¿11

C339 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C348 CCZF1H104Z C CERA SEMI Y5S 50V 0.1MF M A¡¿IAL

C352 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C354 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C355 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C401 CMXM2A223J C MYLAR 100V 0.022MF J TAPING

C402 CBPIC103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C403 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C404 CMXM2A473J C MYLAR 100V 0.047MF J TAPING

C405 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C406 CXSL1H750J C CERA SL 50V 75PF J

C407 CEXE1H109A CELECTRO RS 50V 1JMF 5¡¿11

C408 CEXE1H109A CELECTRO RS 50V 1JMF 5¡¿11

C409 CBZY1E223Z C CERA Y5V 25V 0.022MF Z A¡¿IAL

C411 CMXM2A473J C MYLAR 100V 0.047MF J TAPING

C412 CBZY1E223Z C CERA SEMI Y5V 16V 0.01MF M A¡¿IAL

C415 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C416 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C419 CZSL1H200J C CERA SL 50V 20PF J A¡¿IAL

C430 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C431 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

C481 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C482 CEXE0J221A C ELECTRO RS 6.3V 220MF 8¡¿11.5

C483 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

PCB MAIN AS (979C15300)

6-2. ELECTRICAL PART LIST BY ASSEMBLIES

Page 37

35

C484 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C485 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C501 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C502 CXEX1A470A C ELECTRO RS 10V 47MF 5¡¿11

C503 CXXF1H102Z C CERA HIKF 50V 1000PF Z TAPING

C504 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C505 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C506 CEXE1H109A C ELECTRO RS 50V 1MF 5¡¿11

C507 CMXM2A223K C MYLAR 100V 0.022MF K TAPING

C508 CMXM2A223K C MYLAR 100V 0.022MF K TAPING

C509 CEXE1J479A C ELECTRO RS 63V 4.7MF 5¡¿11

C510 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C516 CCXF1H102Z C CERA HIKF 50V 1000PF Z TAPING

C519 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C522 CEXE1C470A C ELECTRO RS 16V 47MF 6.3¡¿11

C523 CCZF1H470A C ELECTRO RS 50V 47MF 8¡¿11.5

C525 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C527 CEXE1C470A C ELECTRO RS 16V 47MF 6.3¡¿11

C528 CEXE1A470A C ELECTRO RS 10V 47MF 5¡¿11

C534 CEXE1E101A C ELECTRO RS 25V 100MF 8¡¿11.5

C529 CCZF1H470A C ELECTRO RS 50V 47MF 8¡¿11.5

C532 CMXM2A103K C MYLAR 100V .01MF K TAPING

C533 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

C535 CXSL1H201J C CERA HIKF 50V 0.1MF Z A¡¿IAL

C537 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C538 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C539 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C541 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C547 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C549 CBZP1C104M C CERA SEMI Y5S 16V 0.1MF M A¡¿IAL

C601 CEXE1E220A C ELECTRO RS 25V 22MF 5¡¿11

C602 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C603 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C604 CZSL1H120J C CERA SL 50V 12PF J A¡¿IAL

C605 CZSL1H120J C CERA SL 50V 12PF J A¡¿IAL

C606 CCZB1H101K C CERA HIKF 50V 1000PF K A¡¿IAL

DZ501 DZZ9R1BM-- DIODE ZENER UZ-9.1BM AUTO

DZ601 DZZ9R1BM-- DIODE ZENER UZ-9.1BM AUTO

DZ602 DZZ9R1BM-- DIODE ZENER UZ-9.1BM AUTO

D301 DZN4148-- DIODE 1N4148 AUTO 52MM

D302 DZN4148-- DIODE 1N4148 AUTO 52MM

D303 DZN4148-- DIODE 1N4148 AUTO 52MM

D304 DZN4148-- DIODE 1N4148 AUTO 52MM

D481 DZN4148-- DIODE 1N4148 AUTO 52MM

D482 DZN4148-- DIODE 1N4148 AUTO 52MM

D483 DZN4148-- DIODE 1N4148 AUTO 52MM

D501 DZN4148-- DIODE 1N4148 AUTO 52MM

D502 DZN4148-- DIODE 1N4148 AUTO 52MM

D503 DZN4148-- DIODE 1N4148 AUTO 52MM

D504 DZN4148-- DIODE 1N4148 AUTO 52MM

D507 DZN4148-- DIODE 1N4148 AUTO 52MM

D601 DZN4148-- DIODE 1N4148 AUTO 52MM

D602 DZN4148-- DIODE 1N4148 AUTO 52MM

D603 DZN4148-- DIODE 1N4148 AUTO 52MM

IC201 1LA7391A-- IC VIDEO LA7391A

IC301 1MSM7401RS IC MSM7401RS

IC481 1DBL2036-- IC VIDEO DBL2036

IC501 13GK1864SS IC MICOM 13GK1864SS

IC502 1MC4558C-- IC OP AMP MC4558C

IC503 1DBL358--- IC DBL358 DUAL OP-AMP

IC601 1DBL2018C- IC DRIVER DBL2018-C

IC602 1MN1280R-- IC MN1280R

L201 5CPX103J-- COIL PEAKING 10MH 5MM J RADIAL

L202 5CPX471J-- COIL PEAKING 470UN J RADIAL

L203 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

L205 5CPZ229M02 COIL PEAKING 2.2UH 3.5MM M (LAL02TB)

L301 5CPZ330M02 COIL PEAKING 33UH 3.5MM K (LAL02TB)

L303 5CPZ101K02 COIL PEAKING 100UH 3.5MM K (LAL02TB)

L304 5CPZ101K02 COIL PEAKING 100UH 3.5MM K (LAL02TB)

L305 5CPZ330K02 COIL PEAKING 33UH 3.5MM K (LAL02TB)

L306 5CPZ330K02 COIL PEAKING 33UH 3.5MM K (LAL02TB)

L308 5CPX271J-- COIL PEAKING 270UH J RADIAL

L312 5CPZ101K02 COIL PEAKING 100UH 3.5MM K (LAL02TB)

L401 5CPZ330K02 COIL PEAKING 33UH 3.5MM K (LAL02TB)

L402 5CPZ150K02 COIL PEAKING 15UH 3.5MM K (LAL02TB)

L419 5CPZ330K02 COIL PEAKING 33UH 3.5MM K (LAL02TB)

L501 5CPX271J-- COIL PEAKING 270UH J RADIAL

Q201 TZTC3202Y- TR KTC3202Y (AUDIO) (1959Y)

Q301 TZRC104M-- TR KRC104M AUTO

Q302 TZTA1266Y- TR KTA1266Y- (AUTO) (1015Y)

Q303 TZTA1266Y- TR KTA1266Y- (AUTO) (1015Y)

Q305 TZRC104M-- TR KRC104M AUTO

Q306 TZTA1266Y- TR KTA1266Y- (AUTO) (1015Y)

Q307 TZTC3198Y- TR KTC3198Y- (1815Y) (AUTO)

Q308 TZTC3198Y- TR KTC3198Y- (1815Y) (AUTO)

Q309 TZTC3198Y- TR KTC3198Y- (1815Y) (AUTO)

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Page 38

36

Q311 TZTA1266Y- TR KTA1266Y- (AUTO) (1015Y)

Q312 TZRC104M-- TR KRC104M AUTO

Q315 TZTC3198Y- TR KTC3198Y- (1815Y) (AUTO)

Q501 TZRC104M-- TR KRC104M AUTO

Q502 TZTC3198Y- TR KTC3198Y- (1815Y) (AUTO)

Q503 TZTA1266Y- TR KTA1266Y- (AUTO) (1015Y)

Q504 TZSR2001-- TR KSR2001 (AUTO)

Q506 TZSR2001-- TR KSR2001 (AUTO)

Q507 TZRC104M-- TR KRC104M AUTO

Q508 TZSR2001-- TR KSR2001 (AUTO)

Q509 TZTC3205Y- TR KSR2001 (AUTO)

Q511 TZTC3205Y- TR KSR2001 (AUTO)

Q512 TZRC104M-- TR KRC104M AUTO

Q513 TZTA1273Y- TR KTA1273Y(966Y)

Q514 TZRC104M-- TR KRC104M AUTO

RF101 97P7206400 MODULATOR RF MCB8-UG3621 (D Series)

97P7207600 MODULATOR RF MCB8-UZ3619 (D(KD) Series)

97P7209400 MODULATOR RF MCB8-VI23A (D(BB) Series)

RV291 RV5426103E R SEMI FIXED H10K-5¡¿3-6Y-PC-GS

RV292 RV5426103E R SEMI FIXED H10K-5¡¿3-6Y-PC-GS

RV391 RV5426203E R SEMI FIXED RH 0638C-20K OHM

RV392 RV5426203E R SEMI FIXED RH 0638C-20K OHM

RV395 RV5426203E R SEMI FIXED RH 0638C-20K OHM

RV396 RV5426203E R SEMI FIXED RH 0638C-20K OHM

RV399 RV5426102E R SEMI FIXED H10K-5¡¿3-6Y-PC-GS

RV491 RV5426203E R SEMI FIXED RH 0638C-20K OHM

RV501 RV5426203E R SEMI FIXED RH 0638C-20K OHM

R201 RD-AZ100J- R CARBON FILM 1/6 10 OHM J

R202 RD-AZ151J- R CARBON FILM 1/6 150 OHM J

R204 RD-AZ393J- R CARBON FILM 1/6 39K OHM J

R205 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R206 RD-AZ334J- R CARBON FILM 1/6 330K OHM J

R207 RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

R208 RD-AZ475J- R CARBON FILM 1/6 4.7M OHM J

R209 RD-AZ183J- R CARBON FILM 1/6 18K OHM J

R210 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R211 RD-AZ153J- R CARBON FILM 1/6 15K OHM J

R213 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R214 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R215 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R218 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R219 RD-AZ123J- R CARBON FILM 1/6 12K OHM J

R220 RD-AZ519J- R CARBON FILM 1/6 5.1 OHM J

R221 RD-AZ563J- R CARBON FILM 1/6 56K OHM J

R222 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R223 RD-AZ103J- R CARBON FILM 1/6 1K OHM J

R225 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

R301 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R302 RD-AZ512J- R CARBON FILM 1/6 5.1K OHM J

R303 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

R304 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R305 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R306 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R307 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R308 RD-AZ681J- R CARBON FILM 1/6 680 OHM J

R309 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R310 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R311 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R312 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R313 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R314 RD-AZ112J- R CARBON FILM 1/6 1.1K OHM J

R315 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R316 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R317 RD-AZ113J- R CARBON FILM 1/6 13K OHM J

R319 RD-AZ333J- R CARBON FILM 1/6 33K OHM J

R320 RD-AZ181J- R CARBON FILM 1/6 180 OHM J

R321 RD-AZ911J- R CARBON FILM 1/6 910 OHM J

R322 RD-AZ333J- R CARBON FILM 1/6 33K OHM J

R323 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R324 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R325 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R326 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R327 RD-AZ132J- R CARBON FILM 1/6 1.3K OHM J

R328 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R329 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R330 RD-AZ750J- R CARBON FILM 1/6 75 OHM J

R331 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R337 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

R338 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R353 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R356 RD-AZ273J- R CARBON FILM 1/6 27K OHM J

R401 RD-AZ105J- R CARBON FILM 1/6 27K OHM J

R402 RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

R403 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R404 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R405 RD-AZ271J- R CARBON FILM 1/6 270 OHM J

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Page 39

37

R406 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

R407 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R408 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R409 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

R421 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

R481 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R484 RD-AZ821J- R CARBON FILM 1/6 18K HM J

R485 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R486 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R487 RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

R489 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R501 RD-AZ752J- R CARBON FILM 1/6 7.5K OHM J

R502 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R503 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

R504 RD-AZ912J- R CARBON FILM 1/6 9.1K OHM J

R505 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R506 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R507 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R508 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R509 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R510 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R511 RD-AZ752J- R CARBON FILM 1/6 7.5K OHM J

R512 RD-AZ474J- R CARBON FILM 1/6 470 OHM J

R513 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R514 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R516 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R517 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R518 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R519 RD-AZ474J- R CARBON FILM 1/6 470K OHM J

R520 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R521 RD-AZ182G- R CARBON FILM 1/6 1.8K OHM J

R522 RD-AZ182G- R CARBON FILM 1/6 1.8K OHM J

R523 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R524 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R525 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R526 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R527 RD-AZ153J- R CARBON FILM 1/6 15K OHM J

R528 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R529 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R530 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R531 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R532 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R533 RD-AZ752J- R CARBON FILM 1/6 7.5K OHM J

R534 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R535 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R536 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R537 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R540 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R542 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R543 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R544 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R546 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R547 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R548 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

R551 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R554 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R555 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

R556 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R557 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R601 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R602 RD-AZ912J- R CARBON FILM 1/6 9.1K OHM J

R603 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

R604 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R605 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R606 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

R607 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R608 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R609 RD-AZ473J- R CARBON FILM 1/6 47K OHM J

R610 RD-AZ399J- R CARBON FILM 1/6 3.9K OHM J

R611 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R613 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R614 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R615 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

T201 5604020001 COIL BIAS OSC DEO-004

U301 97P6541203 PCB MAIN 284¡¿170¡¿1.6T(1080)

X401 5XE4R4336B

CRYSTAL QUARTZ

HC-49/U 4.433619MHZ 15PPM

X424 97P7002500 DELAY LINE 2H COMB MS-31PC-22K

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Page 40

38

C801 CLYL2E104M C LINE ACROSS 250V 0.1MF M S,O,V

C802 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C803 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

C804 CEXF1V103M C ELECTRO RSS 35V 3300MF 18¡¿35.5

C805 CEXE1E472A C ELECTRO RS 25V 4700MF 22¡¿40

C807 CEXE1E470A C ELECTRO RS 25V 47MF 6.3¡¿11

C811 CEXE1E470A C ELECTRO RS 25V 47MF 6.3¡¿11

C812 CEXE1E470A C ELECTRO RS 25V 47MF 6.3¡¿11

C815 CEXE1E470A C ELECTRO 47µ/25V

C816 CEXE1E470A C ELECTRO 47µ/25V

C818 CEXE1E470A C ELECTRO 47µ/25V

C819 CEXE1E470A C ELECTRO 47µ/25V

C820 CEXE1E470A C ELECTRO 47µ/25V

DZ803 DZA105R1L- DIODE ZENER MA 1051L (5R1)

DZ804 DZZ6R88M-- DIODE ZENER UZ-6.88M AUTO

D801 DZZ5R6BM- UZ-5.6M AUTO

D802 D1N4003--- DIODE 1N4003

D803 D1N4003--- DIODE 1N4003

D804 D1N4003--- DIODE 1N4003

D805 D1N4003--- DIODE 1N4003

D806 D1N4003--- DIODE 1N4003

D808 D1N4003--- DIODE 1N4003

D809 D1N4003--- DIODE 1N4003

ET01 8-UH033OBK TUBE SHRINK AWG8 D=3.3MM BK UL

ET02 8-UH033OBK TUBE SHRINK AWG8 D=3.3MM BK UL

F023 97P6901111 CORD POWER AS KKP-419C-BSP3-1/2HTO0.2

P0A 4859901111 CORD POWER KKP-419C KLCE-2F (2.1ME)

P0B 4857416500

TERM MALE W/MTD

BSP3-1/2H T0.2 SN-3

F801 5F2GB5012L

FUSE GLASS TUBE

BS/VDE TL 500MA 250V MF51

F801A 97P460160P CLIP FUSE PFC5000-0202

F801B 97P460160P CLIP FUSE PFC5000-0202

F802 5FSGB2022L

FUSE GLASS TUBE

SEMKO TL 2A 250V MF51

F802A 97P460160P CLIP FUSE PFC5000-0202

F802B 97P460160P CLIP FUSE PFC5000-0202

F803 5FSGB2022L

FUSE GLASS TUBE

SEMKO TL 2A 250V MF51

F803A 97P460160P CLIP FUSE PFC5000-0202

F803B 97P460160P CLIP FUSE PFC5000-0202

F804 5FSGB2022L

FUSE GLASS TUBE

SEMKO TL 2A 250V MF51

F804A 97P460160P CLIP FUSE PFC5000-0202

F804B 97P460160P CLIP FUSE PFC5000-0202

JA801 97P6304700 JACK DC HECO749-01-010

L801 5PLF302--- FILTER LINE LF-302-801

Q801 TZTC3205Y- TR ROUTE KTC3205Y (2236Y)

Q803 T2SD1273P- TE CSD1273-P

J010 2SD1273P

Q806 T2SD1273P- TR OUTE KTC3205Y (2236Y)

Q808 T2SD1273P- TE CSD1273-P

J010 2SD1273P

Q809 TZSR1001-- TR KSR1001 (AUTO)

R801 RD-4Z152J- R CARBON FILM 1/4 1.5K OHM J

R802 RD-4Z121J- R CARBON FILM 1/4 120 OHM J

G005 5043CX120ROJ SELL 1/4 120 OHM J

R803 RD-2Z122J- R CARBON FILM 1/2 1.2K OHM J

R804 RD-4Z121J- R CARBON FILM 1/4 120 OHM J

R805 RD-AZ202G- R CARBON FILM 1/6 2K OHM J

R806 RD-AZ222G- R CARBON FILM 1/6 2.2K OHM J

R807 RD-AZ472G- R CARBON FILM 1/6 4.7K OHM J

R809 RD-AZ331G- R CARBON FILM 1/6 330 OHM J

R810 RD-AZ331G- R CARBON FILM 1/6 330 OHM J

R811 RD-AZ121G- R CARBON FILM 1/6 120 OHM J

R812 RD-AZ123G- R CARBON FILM 1/6 12K OHM J

R813 RD-AZ331G- R CARBON FILM 1/6 330 OHM J

R814 RD-AZ821G- R CARBON FILM 1/6 820 OHM J

R816 RD-AZ201G- R CARBON FILM 1/6 200 OHM J

T801 57P2057154 TRANS POWER TPW-1181D

U801 97P6541202 PCB POWER 266.5¡¿246¡¿1.6T(1181D)

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

7-1-2. PCB POWERAS. (97B185300)

Page 41

39

7-1-3. PCB PRE-AMPAS (97PB185400)

CA01 CEXE1A470A C CELECTRO RS 10V 47MF 5¡¿11

CA02 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA03 CXSL1H620J C CERA 50V SL 62PF J TAPING

CA04 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA05 CCZB1H331K C CERA HIKB 50V 330PF K A¡¿IAL

CA07 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA08 CZSL1H270J C CERA SL 50V 27PF J A¡¿IAL

CA09 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA10 CXSL1H309C C CERA SL 50V 3PF C

CA13 CCZB1H331K C CERA HIKB 50V 330PF K A¡¿IAL

CA16 CXSL1H331J C CERA 50V SL 330PF J TAPING

CA18 CCZB1H331K C CERA HIKB 50V 330PF K A¡¿IAL

CA19 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA20 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA21 CEXE1A470A C CELECTRO RS 10V 47MF 5¡¿11

CA22 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA23 CEXE1H487A C CELECTRO RS 50V 0.47MF 5¡¿11

CA24 CCZF1H104Z C CERA HIKF 50V 0.1MF Z A¡¿IAL

CA25 CXCH1H560J C CERA CH 50V 56PF J TAPING

CA26 CCZB1H331K C CERA HIKB 50V 330PF K A¡¿IAL

CA27 CXCH1H560J C CERA CH 50V 56PF J TAPING

CA28 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA29 CBZP1C103M C CERA SEMI Y5S 16 0.01MF M A¡¿IAL

CA30 CCZB1H331K C CERA HIKB 50V 330PF K A¡¿IAL

CA01 DZN4148--- DIODE 1N4148 AUTO 52MM

ICA01 1LA7376--- IC VIDEO LA7376 (PREAMP)

LA01 5CPZ101K02 COIL PEARING 100UH 3.5MM K (LAL02TB)

LA02 5CPZ100K02 COIL PEARING 10UH 3.5MM K (LAL02TB)

LA03 5CPZ181K02 COIL PEARING 180UH 3.5MM K (LAL02TB)

LA04 5CPZ560K02 COIL PEARING 56UH 3.5MM K (LAL02TB)

LA05 5CPZ330K02 COIL PEARING 33UH 3.5MM K (LAL02TB)

LA06 5CPX221J-- COIL PEAKING 220UH J RADIAL

LA08 5CPX681J-- COIL PEAKING 680UH 5MM J RADIAL

LA09 5CPZ101K02 COIL PEARING 100UH 3.5MM K (LAL02TB)

QA01 TZTC3198Y- TR KTC3198Y-(1815Y)(AUTO)

QA02 TZTC3198Y- TR KTC3198Y-(1815Y)(AUTO)

QA03 TZTA1266Y- TR KTA1266Y-(AUTO)(1015Y)

QA05 TZST2002-- TR KSR2002(AUTO)

R536 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R537 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R540 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

QA06 TZTC3198Y- TR KTC3198Y-(1815Y)(AUTO)

QA07 TZTC3198Y- TR KTC3198Y-(1815Y)(AUTO)

QA08 TZTC3198Y- TR KTC3198Y-(1815Y)(AUTO)

RA01 RD-AZ122J- R CARBON FILM 1/6 1.2K OHM J

RA02 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA03 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA04 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RA05 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RA06 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RA07 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RA08 RD-AZ561J- R CARBON FILM 1/6 560 OHM J

RA09 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA10 RD-AZ152J- R CARBON FILM 1/6 1.5K OHM J

RA11 RD-AZ391J- R CARBON FILM 1/6 390 OHM J

RA12 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J

RA13 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA14 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RA15 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RA16 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RA19 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RA20 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA21 RD-AZ271J- R CARBON FILM 1/6 270 OHM J

RA22 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA23 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

RA25 RD-AZ622J- R CARBON FILM 1/6 6.2K OHM J

RA26 RD-AZ153J- R CARBON FILM 1/6 15K OHM J

RA27 RD-AZ392J- R CARBON FILM 1/6 3.9K OHM J

RA30 RD-AZ682J- R CARBON FILM 1/6 6.8K OHM J

RA31 RD-AZ203J- R CARBON FILM 1/6 20K OHM J

RA32 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

RA33 RD-AZ302J- R CARBON FILM 1/6 3K OHM J

RA34 5CPX228M-- COIL PEAKING 0.22µ H 5MM J

UA01 976541204 PCB PREAMP 115.2¡¿41.2¡¿1.6T(1080)

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Page 42

40

7-1-4. PCB FRONT AS (97PB186000)/D VR-1181 SERIES

C701 CBZP1C103M C CERA SEMI Y5S 16V 0.01MF M A¡¿IAL

DL701 DSLR34MC3- LED SLR34VC3 (GREEN)

DL703 DSLR34MC3- LED SLR34VC3 (GREEN)

DL704 DSLR34MC3- LED SLR34VC3 (RED)

DL705 DSLR34MC3- LED SLR34VC3 (GREEN)

DL706 DSLR34MC3- LED SLR34VC3 (RED)

RH701 1DHR38----

IC UNIT R/RECEIVER

DHR38 (FO=38KHZ) PREAMP

R705 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R706 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R707 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R708 RD-AZ161J- R CARBON FILM 1/6 160 OHM J

R709 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R710 RD-AZ361J- R CARBON FILM 1/6 360 OHM J

R711 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R712 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R713 RD-AZ161J- R CARBON FILM 1/6 160 OHM J

R714 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R715 RD-AZ361J- R CARBON FILM 1/6 360 OHM J

R716 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R717 RD-AZ112J- R CARBON FILM 1/6 1.1K OHM J

R718 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R719 RD-AZ432J- R CARBON FILM 1/6 4.3K OHM J

SW701 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW702 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW703 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW704 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW705 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW706 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW707 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW708 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW709 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW710 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW711 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW712 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

U701 97P6541205 PCB FRONT 298¡¿197¡¿1.6T/3 (1080)

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Page 43

41

7-1-5. PCB FRONT AS (97PC11320)/D VR-1383 SERIES

C701 CCXF1H103Z C CERA HIKF 50V 0.01MF Z

DL701 DSLR34MC3- LED SLR34VC3 (GREEN)

DL702 DSLR34MC3- LED SLR34MC3 (GREEN)

DL703 DSLR34MC3- LED SLR34MC3 (GREEN)

DL704 DSLR34VC3- LED SLR34VC3 (RED)

DL706 DSLR34VC3- LED SLR34VC3 (RED)

DL707 DSLR34MC3- LED SLR34MC3 (GREEN)

DL708 DSLR34MC3- LED SLR34MC3 (GREEN)

DL709 DDL1LRE--- LED DL-1LRN

JW701 97P880C115

CONN AS (LUG AS

) 4.2D ONE TYPE 150MM

PJ701 97P8807808 CONN AS (Y7808) MAIN-FRONT (11P-11P)

P701 97P6291298

CONN ANGLE WAFER

WIBP-11R-20T

RM701 1DHR38----

IC UNIT R/RECEIVER

DHR38 (FO=38KHZ) PREAMP

R701 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R702 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R703 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R704 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R705 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R706 RD-AZ331J- R CARBON FILM 1/6 330 OHM J

R707 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R708 RD-AZ161J- R CARBON FILM 1/6 160 OHM J

R709 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R710 RD-AZ361J- R CARBON FILM 1/6 360 OHM J

R711 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R712 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R713 RD-AZ161J- R CARBON FILM 1/6 160 OHM J

R714 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R715 RD-AZ361J- R CARBON FILM 1/6 360 OHM J

R716 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R717 RD-AZ112J- R CARBON FILM 1/6 1.1K OHM J

R718 RD-AZ332J- R CARBON FILM 1/6 3.3K OHM J

R719 RD-AZ112J- R CARBON FILM 1/6 1.1K OHM J

R721 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW701 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW702 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW703 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW704 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW705 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW706 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW707 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW708 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW709 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW711 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

SW712 5S50101290 SW TACT SKHVBD, 1C-1P, HLN/T5.0-A

U701 97P6541210 PCB UNION 300¡¿164¡¿1.6T(128N)

LOC PART CODE PART NAME PART DESCRIPTION LOC PART CODE PART NAME PART DESCRIPTION

Loading...

Loading...