Page 1

Service Manual

TV/VCR IN ONE BOARD

CHASSIS : CN-140

NTSC-M SYSTEM

MODEL : DVN-14F6N

DVN-20F6N

DAEWOO ELECTRONICS CO., LTD.

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

Page 2

CONTENTS

Specifications .................................................................................................. 1

Satety Checking After Servicing .................................................................... 2

1. Insulation resistance test

2. Dielectric strength test

3. Clearance distance

4. Leakage current test

Important Service Notes ................................................................................. 3

1. X-RAY radiation precaution

2. Safety precaution

3. Product safety notice

4. Service notes

General Adjustment ........................................................................................ 4

1. General

2. Vertical height adjustment

3. Focus adjustment

4. RF AGC adjustment

5. High voltage check

6. X-RADIATION protection circuit test

7. White valance adjustment

8. Convergence magnet assembly positioning

Leadless(chip) Instruction &

Cleaning and rubrication of deck mecanism ................................ 7

1. Leadless(chip) component removal instruction

2. Leadless(chip) component identification

3. Cleaning and rubrication of deck mechanism

Mechanical disassembly(DECK) .................................................................... 9

1. Top view

2. Bottom view

3. F/L mechanism view

4. General removal view

5. Mechanical checks/Gear alignment

6. Tention checks

Mechanical Adjustments ............................................................................... 22

Shape & Equipment of DVN-14/20F6N ......................................................... 24

1. DVN-14F6N/DVN-20F6N

2. Panel view

3. Remote controller

Electrical Adjustments ................................................................................... 29

1. Servo

2. Audio

3. Video

Page 3

Signal Flow ..................................................................................................... 35

1. Video & Audio

2. Power circuits

3. Deflection circuits

4. U-COM circuits

5. Channel selection and memory

6. Servo/Syscon circuit operation

7. Normal audio circuit operation

8. Video circuit operation

Important IC

¡¡flfl

s Operation .............................................................................. 43

1. IY03(LA7411)

2. IY02(LC89960)

3. IY01(LA7423A)

4. IU01(BA7790LS)

5. IN05(BA6209)

6. IN03(MC4558C)

7. I503(TC4066BP)

8. I301(TA8445K)

9. IN01(Syscon:TMP91C642AN-3178)

10. I701(Timer:M37267M6-101SP)

11. I501(Chroma IC:M52335SP-600)

Important Signal WaveForms ....................................................................... 80

Troubleshooting According to

Cause & Symptom ................................................................................. 83

1. Power supply unit

2. Vertical, horizontal unit

3. Servo/Syscon unit

4. Video unit

5. Audio unit

Electrical Parts List ..................................................................................... 100

1. Standard part number coding

2. Parts list

Block Diagram ............................................................................................. 128

Connection Diagram ................................................................................... 129

Schematic Diagram ..................................................................................... 130

Printed Circuit Boards ................................................................................ 135

Exploded View ............................................................................................. 138

Page 4

Format : VHS standard

Playback System : 2 rotary heads, helical

scanning system

Luminance : FM azimuth

recording

Color Signal :Converted

sub-carrier

phase shift

recording

Video Signal System : NTSE-type color signal'

Audio Track : 1 track

Tape Width : 12.65 mm (1/2 inch)

Tape Speed : (SP) : 33.35 mm/s (1.5/16 ips)

(LP) : 16.67mm/s (21/32 ips)

(SLP) : 11.12 mm/s (7/16 ips)

Maximum Recording Time

: (SLP) : 480min. with T-160

Videocassette

Power Source : 120V AC, 60Hz

Power Consumption : (14") : 60W

(20") : 75W

Input Level : Video : VIDEO IN jack(RCA)

1.0Vp-p, 75Ω unbalanced

Audio : AUDIO IN jack (RCA)

-3.8dBm. over 100K OHM

unbalanced

TV Tuner : VHF input CH2-CH13

Cable channels

"A" - "W"

75Ω unbalanced

UHF input CH14-CH 69

Video Horizontal

Resolution : More than 220 lines

Audio Frequency : SP : 100 Hz-10KHz

LP : 100Hz-7KHz

SLP : 100Hz-5KHz

Signal-to-Noise Ratio : Video : better than 43 dB (SP)

Audio : better than 36 dB (with TV)

Operating Temperature : 5°C-40°C

Weight : (14") : 17Kg/(20") : 25Kg

Dimensions : (14") : 379x402

x369

(20") : 498x495x464

Provided Accessories : Remote control unit

Picture Tube : (20"/14") A48JLL40x02

A34JLL40x01

Sound Output Power : Above 1.2W non distortion/

SPEAKER

* Design and apecifications are subject to change without

notice. our legal obligations.

■■

SPECIFICATIONS

1

Page 5

2

• Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have

been returned to original positions. Afterwards, perform the following tests and confirm the specfied values in order to verify compliance with safety satandards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of

the set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks,

etc.). See table below.

2. dielectric strength test.

Confirm specified dielectric or strength or greater between power cord plug prongs and exposed accessible parts of the

set(RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks,

etc.) See table below.

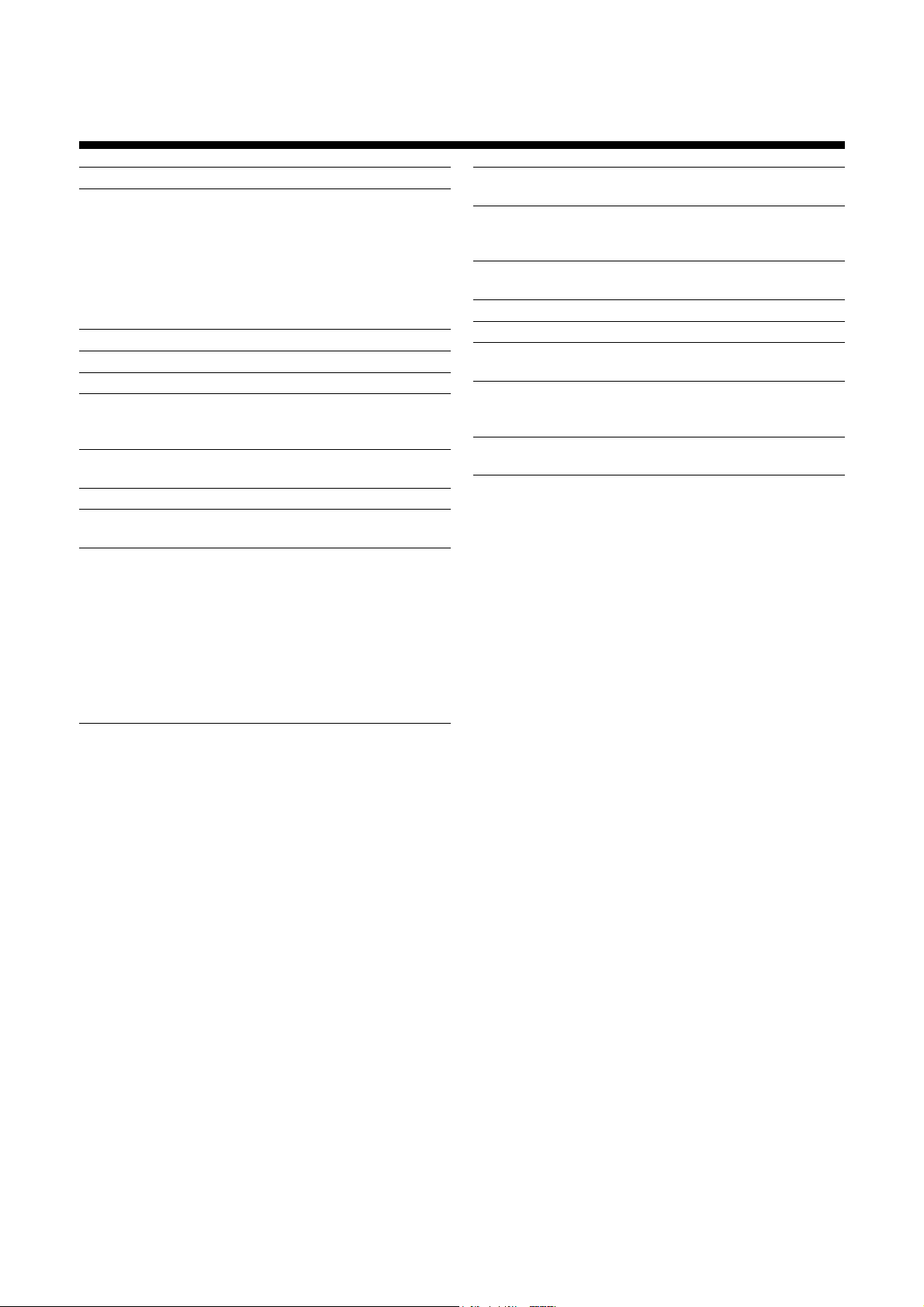

3. Clearance distance

When replacing primary circuit components, confirm

speckfied clearance distance (d), (d") between soldered

terminals, and between terminals and surrounding metalic

parts. see table below.

Table 1 : Rating for selected areas

Note : This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and

locality.

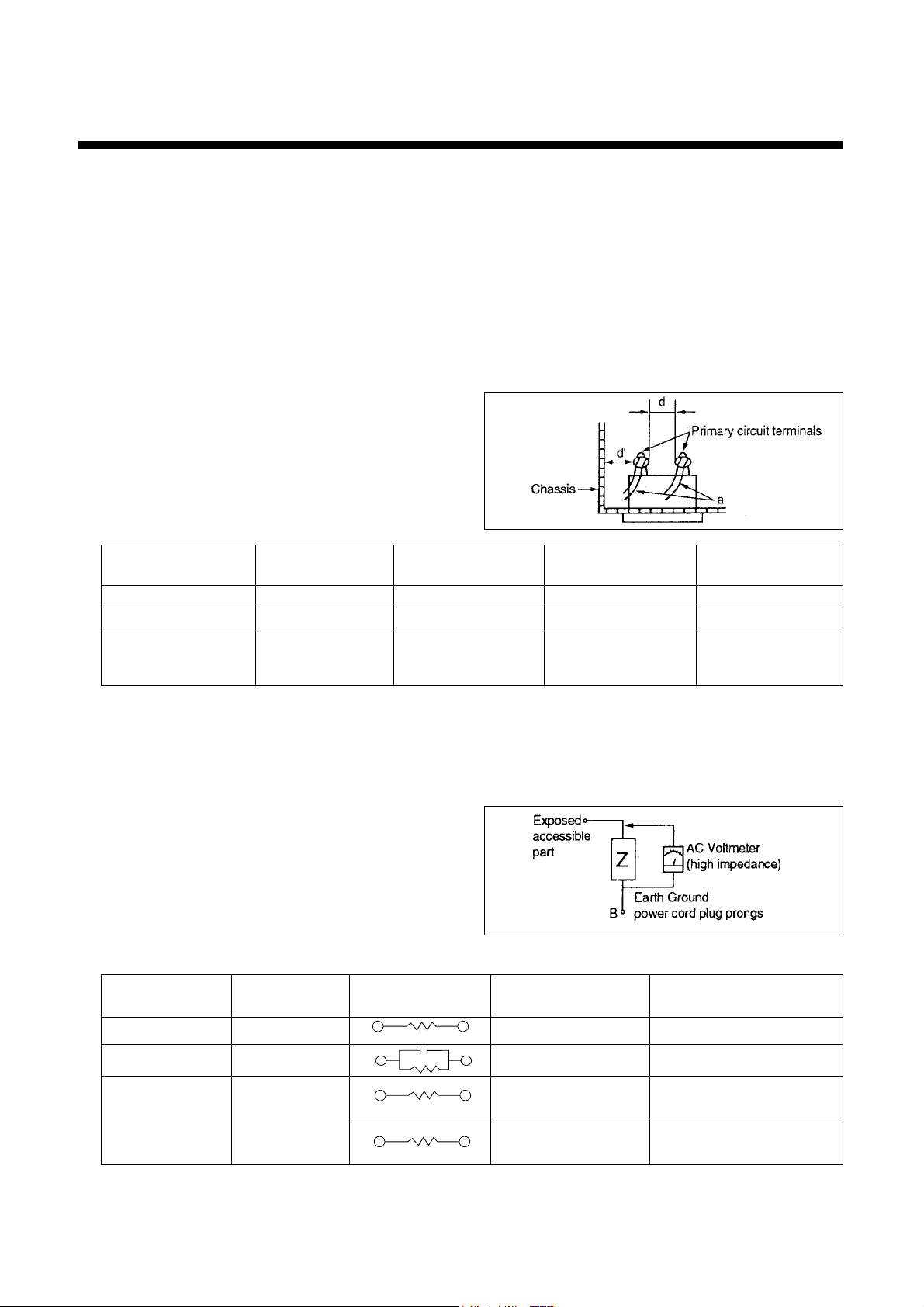

4. Leakage current test

confirm specified or lower leakage current between B (earth ground, power cord plug prongs) and externally exposed

accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use and AC voltmeter to measure across both terminals of load Z.

See figure and following table.

Table 2 : Leakage current ratings for selected areas

Note : This table unofficial and for reference only. Be sure to confirm the precise values for your particular coyntry and

locality.

AC Line Voltage Region

Insulation Dielectric Clearance

Resistance Strength Distance (d), (d')

100V Japan ≥1MΩ500 V DC 1kV 1 minute ≥3 mm

110 to 130V USA & Canada --- 900V 1 minute ≥3.2mm

≥6mm(d)

* 100 to 250V South America ≥10 MΩ/500 V DC 4 kV 1 minute ≥8mm(d')

(z:Power cord)

AC Line Voltage Region Load Z Leakage Current (i)

Earth Ground

(B) to :

100V Japan i ≤ 1mA rms Exposed accessible parts

110 to 130 V USA & Canada i ≤ 0.5 mA rms Exposed accessible parts

100 to 130 V South America

i ≤ 0.7 mA peak

Antenna earth terminals

i ≤ 2mA dc

200 to 250 V

i ≤ 0.7 mA peak

Other terminals

i ≤ 2mA dc

Fig. 1

Fig. 2

1kΩ

2kΩ

50kΩ

1.5kµF

1.5kΩ

Page 6

1. X-RAY RADIATION PRECAUTION

1)Excessive high voltage can produce potentially hazardous X-RAY RADIATION to avoid such hazards, the

high voltage must not be above the specified limit. The

nominal value of the high voltage of this receiver is

24.4kv (27.5kv) at zero beam current (mininum

brighrness) under a 120V AC power source. The high

voltage must not, under any circumstance, exceed 27kv

(28.5kv). Each time a receiver requires servicing, the

high voltage should be checked following the HIGH

VOLTAGE CHECK procedure on page 4 of this manual.

It is recommend as parts of the servuce record. It is

important to use an accurate and reliable high voltage

meter.

2) This receiver is equipped with X-RADITION PROTECTION circuit which prevents the receiver from producing

an excessively high voltage even of the B+ vlotage

increases abnormally. Each time the receiver is serviced,

X-RADIATION PROTECTION circuit must be checked to

determine that the circuit is properly functioning, following

the X-RADIATION PROTETION CIRCUIT CHECK procedure on page 4 of this manual.

3) The only source of X-RAY RADIATION in this TV receiver is the picture tube. For continued X-RAY RADIATION

PROTECTION, the replacement tube must be exactly

the same type tube as specified in the parts list.

4) Some parts in the receiver have special safety-related

characteristics for X-RAY RADIATION PROTECTION.

for continued safety, parts replacement should be undertaken only after referring to the PRODUCT SAFETY

NOTICE below.

2. SAFETY PRECAUTION

WARNING : Service should not be attempted by anyone

unfamiliar with the necessary precautions on this receiver.

The following are the necessary precaution to be observed

before servicing.

1) Since the chassis of this receiver has hazardous potential to ground whenever to receiver is plugged in (floating

chassis), an isolation transformer must be used during

service to avoid shock hazard.

2) Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube.

The picture tube is highly evacuated and if broken, glass

fragments will be violently expelled. Use shat-ter-proof

goggles and keep picture tube away from the body while

handling.

3) When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

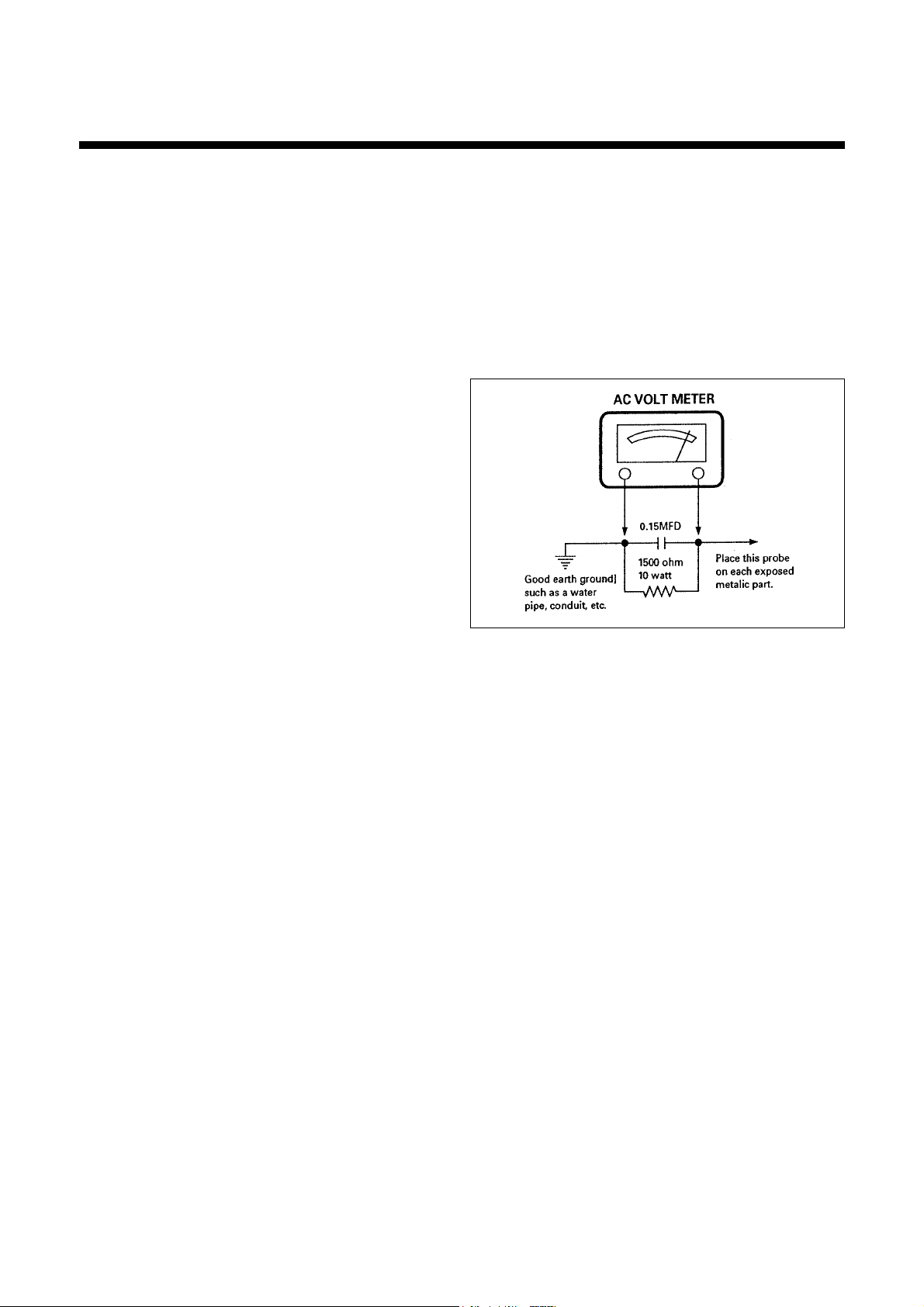

4) Before returning the set to the customer, always perform

an AC leakage curent check on the exposed metallic

parts of the cabinet, such as antennas, terminals, screwheads, metal overlays, control shafts etc. to be sure the

set is safe to operate without danger of electrical shock.

(Plug the AC line cord directly into a 120V AC outlet do

not use a line isolation transformer during this check).

Use an AC voltmeter having 5000 ohms per volt or more

sensitivity in the following manner.

Connect at 1500 ohm watt resistor, paralleled by a 0.15

mfd, AC type capacitor, between a known good earth

ground (water pipe, conduit, etc.) and the exposed metalic

parts, one at a time. Measure the AC voltage across the

combination of 1500 ohm resistor and o.15 mfd capacitor.

Reverse the AC plug at the AC output and repeat AC voltage measurements for each exposed metallic part. Voltage

messured much not exceed 0.3 volts RMS. this corresponds to 0.2 milliamp AC. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected

immediately.

3. PRODUCT SAFETY NOTICE

many electrical and mechanical parts in this chassis have

special safety-related characteristics. These characteristics

are often passed unnoticed by a visual inspection and the

protection afforded by them cannot necessarily be obtained

by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special

safety characteristics are identified in this manual and its

supplements; electrical components having such features

are identified by shading on the schematic diagram and the

parts list.

Before replacing ant of these componrnts, read the parts list

in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as

specified in the parts list may create X-ray radiation or other

hazards.

4. SERVICE NOTES

1) Which replacing parts or circuit boards, clamp the lead

wires to terminals before soldering.

2) When replacing a high wattage resistor (metal oxide film

resistor) in the circuit board, keep the resistor min 1/2 inch

away from circuit board.

3) Keep wires away from high voltage or high temperature

components.

■■

IMPORTANT SERVICE NOTES

3

Page 7

4

1. GENERAL

In the majority of cases, color television will need only slight

touch-up adjustment upon installation. Check the basic

characteristics such as height, focus and sub-bright.

Observe the picture for good black and white details without

objectionable color shading. If color shading is evident,

demagnetize the receiver. If color shading still persists, perfor purity and convergence adjustments. this should be all

that is necessary to achieve optimum receive performance.

2. VERTICAL HEIGHT ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness and contrast control for a good picture.

3) Adjust vertical height control (R304) for approximately

one half inch over scan at top and bottom of picture

screen.

3. FOCUS ADJUSTMENT

1) Tune in an active channel.

2) Adjust brightness, sharpness and contrast controls for a

good picture, sharp scanning lines and/or sharp picture.

4. RF AGC ADJUSTMENT

1) Tune in an active channel.

2) Using the attenuator, apply the signal of 60dBµV to the

Antena input terminal

3) Turn RF AGC control (R106) so that it is 1.0V±0.3V

lower than maximum voltage.

5. HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked verify

that the receiver is operating within safe and efficient design

limitations as specified :

1) Operate Receiver for at least 15 minutes at 100-140V

AC line.

2) Set brightness, sharpness, contrast and color controls to

minimum position (Zero beam).

3) Connect an accurate high voltage meter to CRT anode.

The reading should be as follows.

If a correct reading connot be obtaines, check circuitry for

malfunctioning components.

6. X-RADIATION PROTECTION CIRCUIT TEST

When service has been performed on the horizontal deflection system, high voltage system or B+ system, the X-RADIATION PROTECTION circuit must be tested for proper

operation as follows:

1) Operate receiver for at least 15 minutes at 120V AC line.

2) Confirm high voltage protector when R409 of power

PCB is connected to 30kΩ(1/4w) in parallel.

3) If high voltage protector is operated, remove 30kΩ(1/4w)

and confirm whether high voltage protector is still on.

4) Confirm normal operation on sound and video when

R410 is shorted.

7.WHITE VALANCE ADJUSTMENT

1) Receive MONOSCOPE PATTERN signal.

2) Set the each BIAS VR (VR903, VR904, VR905) and

DRIVE VR(VR901, VR902) to center position and Minimize SCREEN using SCREEN VR on the side of FBT.

3) Open LEVER SW(S901) of CRT PCB.

4) Make straight and horizontal line by pushing service

key(V/H) on the SERVICE remocon.

5) Turn the SCREEN VR slowly until first color is brightened and turn the concerned BIAS VR to the anticlockwise until that line's color is diappeared.

6) Turn the SCREEN VR slowly again until another color is

brightened and turn the concernde BIAS VR to the anticlockwise until that line's color is diappeared.

7) Turn the SCREEN VR slowly again until third color is

brightened and turn the concerned BIAS VR to the anticlockwise until that line's color is diappeared.

8) Adjust the BIAS VR to become white concerned line by

turning the BIAS VR in concerned with step 4-6, and 4-7

to clock direction (to be brightened).

9) Although you did step 4-5, 4-6, 4-7,

If it is not bright each step's color but bright first color,

stop turn the SCREEN VR at the position which color is

hardly to be seen, and concerned BIAS VR to clock

direction (to be brightened).

10) Turn LEVER SW(S901) of CRT PCB on.

11) Let the straight and horizontal line to be disappeared by

pushing service key(V/H) on the SERVICE remocon.

12) Set CONTRAST to maximize and set BRIGHT to

become center, and adjust WHITE BALANCE using R's

and B's DRIVE VR.

13) Inspect TRACKING of WHITE BALANCE by varying

CONTRAST and BRIGHT.

If you need to inspect again, Repeat step 4-5 to 4-9.

NOTE :

1. When performing any adjustments to resistor controls

and transformers use non-metallic screw driver or TV

alignment tools.

2. Before performing adjustments TV set must be on at

least 15 minutes.

■■

GENERAL ADJUSTMENT

DVN-14F6N 24KV~26KV

DVN-20F6N 26KV~28KV

Page 8

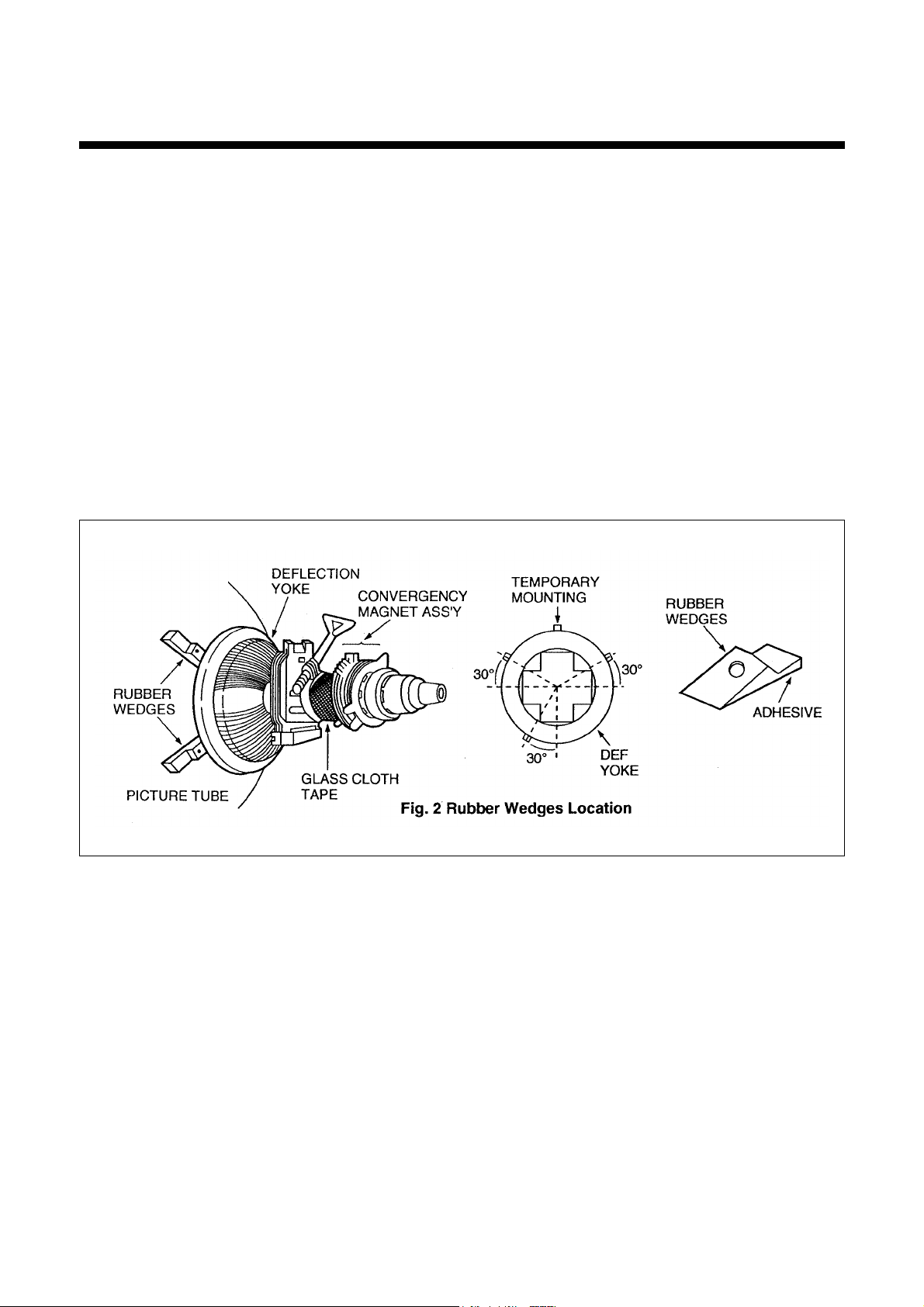

8. CONVERGENCE MAGNET ASSEMBLY

POSITIONING

Convergence magnet assembly and rubber wedges need

mechanical positioning following the figure 2.

8-1. COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjustments, the

receiver should be operated for at least 15 minutes.

1) Demagnetize the picture tube using a degaussing coil.

2) Vary the CONTRAST and BRIGHTNESS controls to

maximum.

3) Adjust RED and BLUE Bias controls (RJ04 and RJ24) to

provide only a green raster. Adjust the GREEN BIAS

control (RJ13) if necessary.

4) Loosen the clamp screw holding the yoke, and slide the

yoke backward to provid vertical green belt (zone) in the

picture screen.

5) Remove the Rubber Wedges.

6) Rotate and spread the tabs of the purity magnet (see figure 2) around the neck of the picture tube until the green

belt is in the center of the screen. At the same time, center the raster vertically.

7) Move the yoke slowly forward until a uniform green

screen is obtained. Tighten the clamp screw of the yoke

temporarily.

8) check the purity of the red and blue raster by adjusting

the BIAS controls.

9) Obtain a white raster, referring "CRT GRAT SCALE

ADJUSTMENT" on the CRT board.

10) Proceed with convergence adjustment.

5

Page 9

6

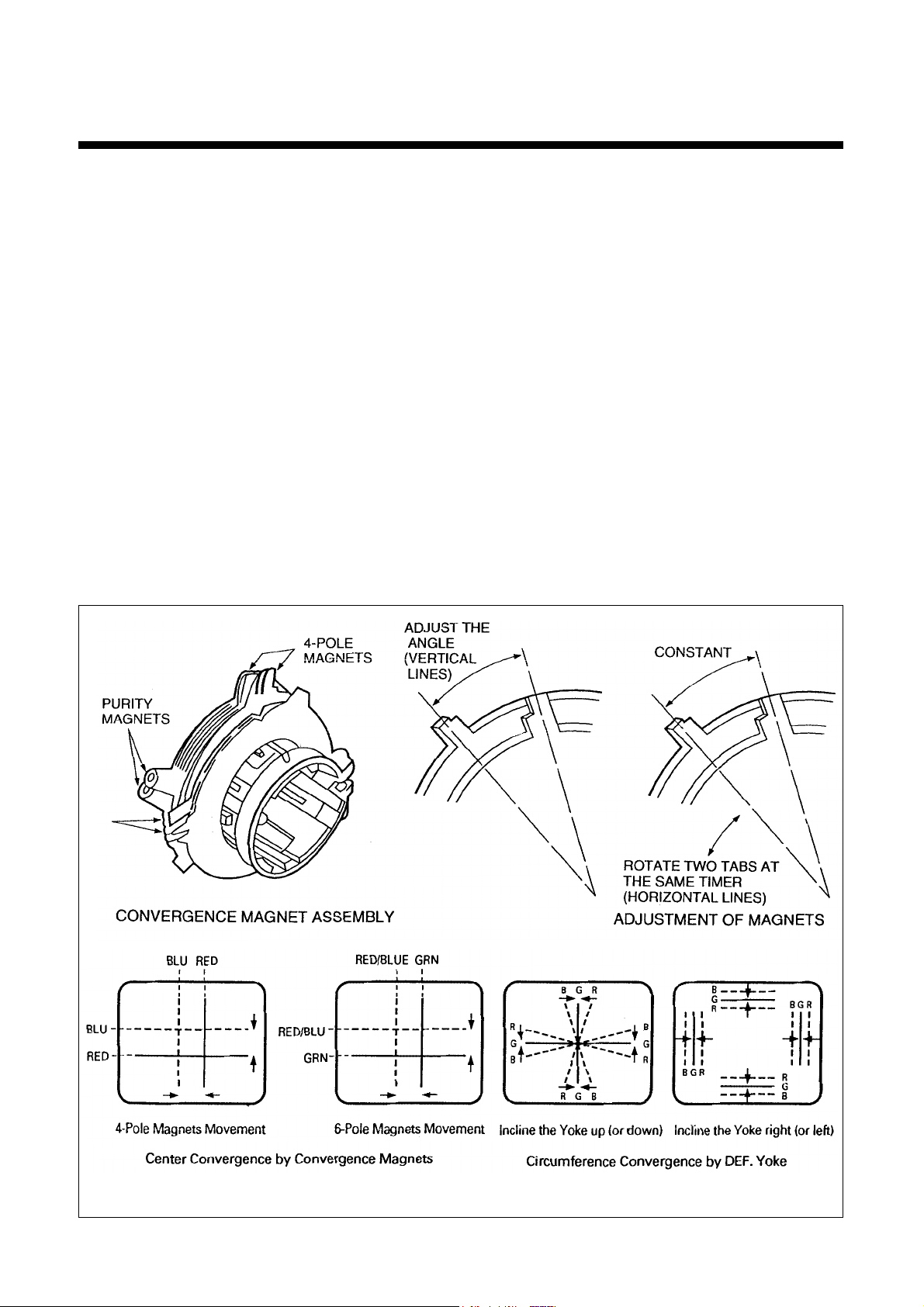

8-2. CONVERGENCE ADJUSTMENTS

NOTE : Before attempting any convergence adjustments,

the receiver should be operated for at least 15 minutes.

A. CENTER CONVERGENCE ADJUSTMENT

1) Receive crosshatch pattern with a crosshatch signal

generator.

2) Adjust the BRIGHTNESS and CONTRAST Controls for

a good picture.

3) Adjust two tabs of the 4-Pole Magnets to change the

angle between them (See Fig 3) and supertmpose red

and blue vertical lines in the center area of the picture

screen. (See Fig. 4)

4) Turn both tabs at the same time keeping their angles

constant to superimpose red and blue horizontal lines at

the center of the screen. (See Fig. 4)

5) Adjust two tabs of 6-Pole Magnets to superimpose

red/blue line with green one. Adjusting the angle affects

the vertical lines and rotating both magnets affects the

horizontal lines.

6) Repeat adjustments 3) 4) 5) keeping in mind red, green

and blue movement, because 4-Pole Magnets and 6Pole Magnets interact and make dot movement complex.

B. CIRCUMFERENCE CONVERGENCE ADJUSTMENT

NOTE : This adjustment requires Rubber Wedge Kit.

1) Loosen the clamping screw of deflection yoke to allow to

yoke to tilt.

2) Place a wedge as shown on figure 2 temporarily. (Do not

remove cover paper on adhesive part of the wedge).

3) Tilt front of the deflection yoke up or down to obtain better convergence in circumference. (See Fig. 4) Push the

mounter wedge into the space between picture and the

yoke to hols the yoke temporarily.

4) Place other wedge into bottom space and remove the

cover paper to stick.

5) Tilt front of the yoke right or left to obtain better convergence in circumference. (See Fig. 4).

6) Hold the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to hold the yoke.

7) Detach the temporarily mounted wedge and put it in

another upper space. Stick it on picture tube to fix the

yoke.

8) After placing three wedges, recheck overall convergence.

Tighten the screw furmly to hold the yoke tightly in place.

9) Stick 3 adhesive tapes on wedges as shown in figure 2.

Fig. 3

Fig. 4 Dot Movement Pattern

Page 10

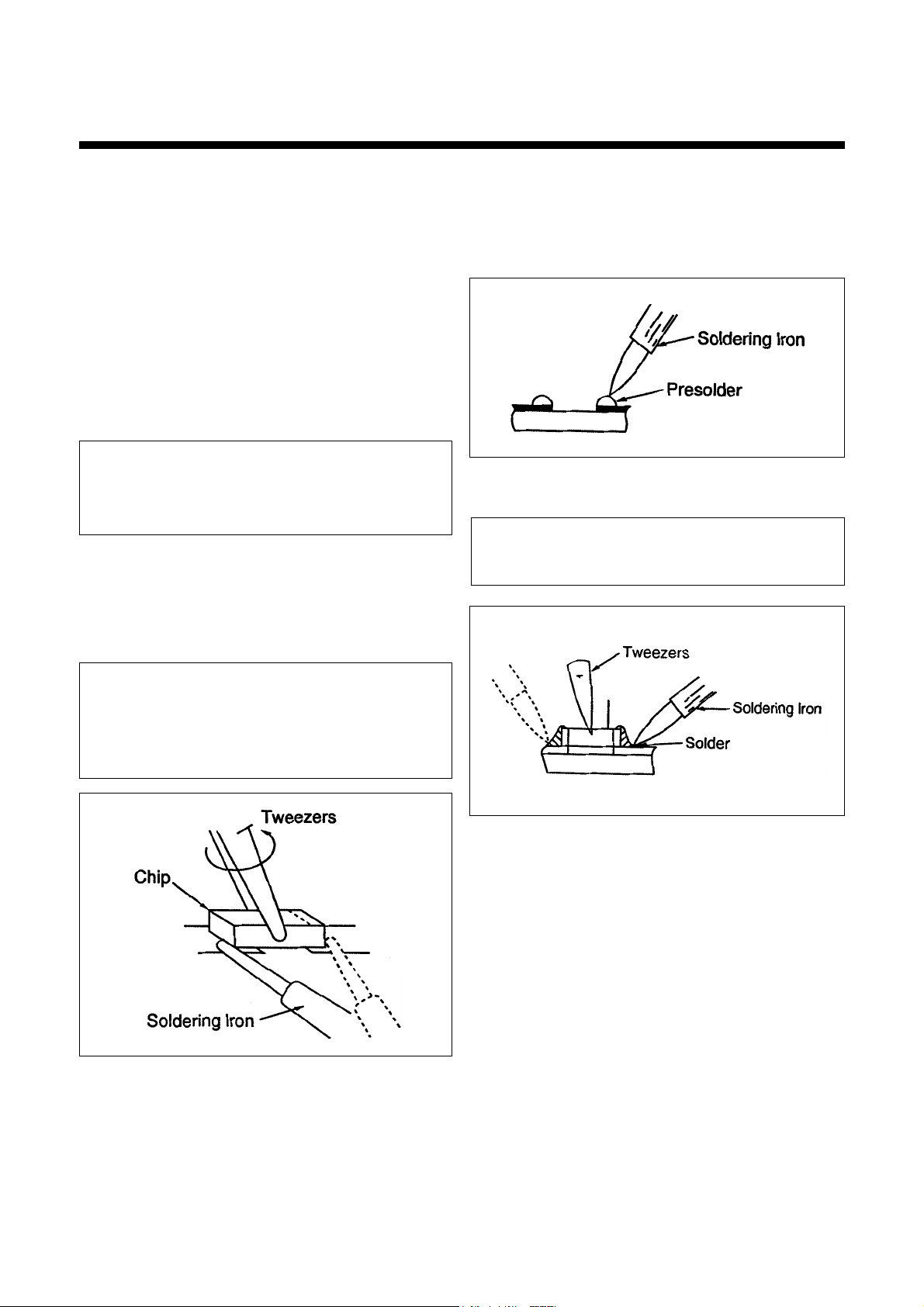

1-3. Installing the Leadless (chip) Component

1) Presolder the contact points of the circuit board.

2) Press the part downward with tweezers and solder

both electrodes as show below.

■■

LEADLESS(CHIP) INSTRUCTION

7

Note :

Do not glue the replacement leadless component to

the circuit board.

1-1. Preparation for replacement

a. Soldering Iron

Use a pencil-type soldering iron that uses less than 3o

watts.

b. Solder

Eutectic solder (Tin 63%, Lead 37%) is recom mened.

c. Soldering time

Do not apply heat more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before installation.

(130°C~150°C, for about two minutes).

1-2. Removing the leadless component (Resistors,

Capacitors)

.Grasp the leadless component body with tweezers and

alternately apply heat to both electrodes. When the sol- der

on both electrodes is melted, remove leadless component

with a twisting motion.

1.LEADLESS(CHIP) COMPONENT REMOVAL INSTRUCTION

• The following procedures are recommended for the replacement of the leadless components used in this unit.

Note :

a. Leadless component must not be reused after

removal.

b. Excessive mechanical stress and rubbing of the

component electrode must be avoided.

Note :

a. Do not attempt to lift the component off the board

until the component is completely disconnected

from the board by a twisting action.

b. take care not to break the copper foil on printed

board.

Page 11

8

• Cracked Chipped component Body

• Cracked Separated Solder Joints

• Peeling end Terminations Fractured Leads

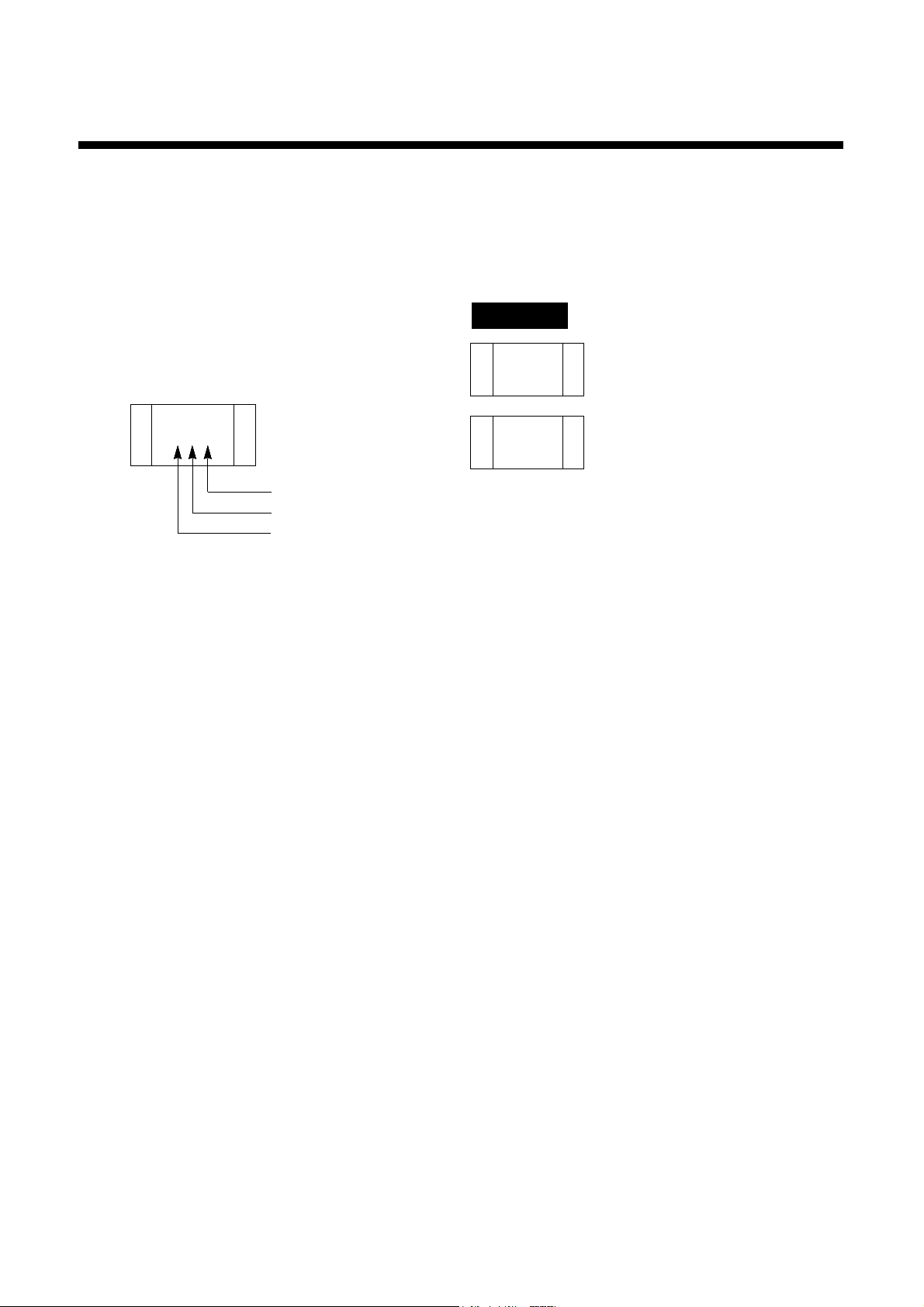

2-2. S.M.D (Surface Mounted Devices) Identification

1) Chip Resistor Identification

* Standard chip Resistor code

2) Chip Capacitor Identification

There is no identification of chip capacitor

REMARK Leadless (CHIP) components are identified on

schematic by means of "(C)" adjacent to symbol numbers.

• Rejection of Solder from copper Pads or Component

• Foreign Matter on Copper Pads

• Sloder Bridges

2.LEADLESS (CHIP) COMPONENT IDENTIFICATION

2-1. Check the followings before S. M. D Troubleshooting

XXX

MULTIPLIER (0-9)

2nd SIG. DIGHT (0-9)

1st SIG. DIGHT (1-9)

Examples

123

470

= 12x103(1000) = 12000Ω

= 12KΩ

= 47x 10°(1) = 47Ω

A. cleaning the Tape Transport System

The following parts should be cleaned after every 500

hours of use.

•TENSION POLE

• S-GUIDE POST

• FE HEAD

• S-SLANT POLE

• VIDEO HEAD/DRUM

• T-SLANT POLE

• T-GUIDE ROLLER

• AC HEAD/AE HEAD

• T-CUIDE POST

• CAPSTAN SHAFT

• PINCH ROLLER

NOTE : After cleaning with alcohol, allow the parts to dry

thoroughly before using a cassette tape.

B. Cleaning the Drive System

The following parts should be cleaned after every 500

hours of use.

• REEL TABLE

• T MAIN BRAKE

• S MAIN BRAKE

• T MAIN BRAKE

• CAPSTAN FLYWHEEL/PULLEY

• REEL PULLEY

C. Lubrication points

The following parts should be cleaned and lubricated

after every 500 hours of use. apply one (1) or two (2)

drops of oil. Refer to the "Replacement Parts List" for the

stock number of the recommended oil.

• S REEL TABLE POST

• T REEL TABLE POST

• IDLER PULLEY

CLEANING AND LUBRICATION OF DECK MECANISM IN DVN-14/20F6N

Cleaning and Lubrication

Page 12

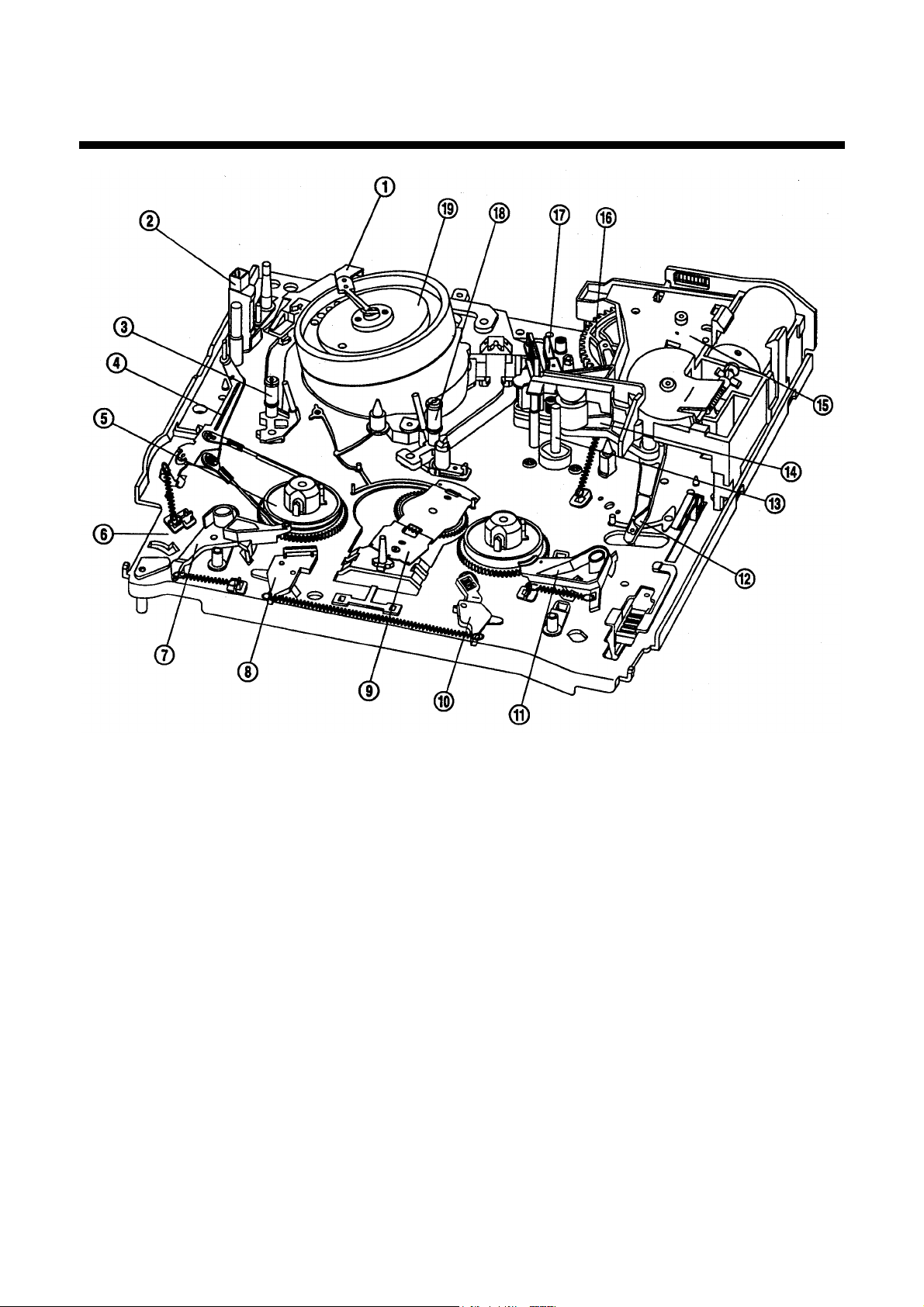

■■

MECHANICAL DISASSEMBLY(DECK)

9

1. Earth Bracket Ass'y

2. FE Head

3. S-Slant Pole Ass'y

4. Tension Lever Ass'y

5. Reel Table

6. Main Base Ass'y

7. S-Sub Brake Ass'y

8. S-Main Brake Ass'y

9. Idler Plate Total Ass'y

10.T-Main Brake Ass'y

11.T-Sub Brake Ass'y

12.Relay Lever

13.Capstan Motor

14.Pinch Lever Total Ass'y

15.L/C Bracker Total Ass'y

16.Cam Gear

17.AC Head Total Ass'y

18.T-Slant Pole Ass'y

Fig. 9- tape Transport Mechanism Identification (Top View)

1.TOP VIEW

Page 13

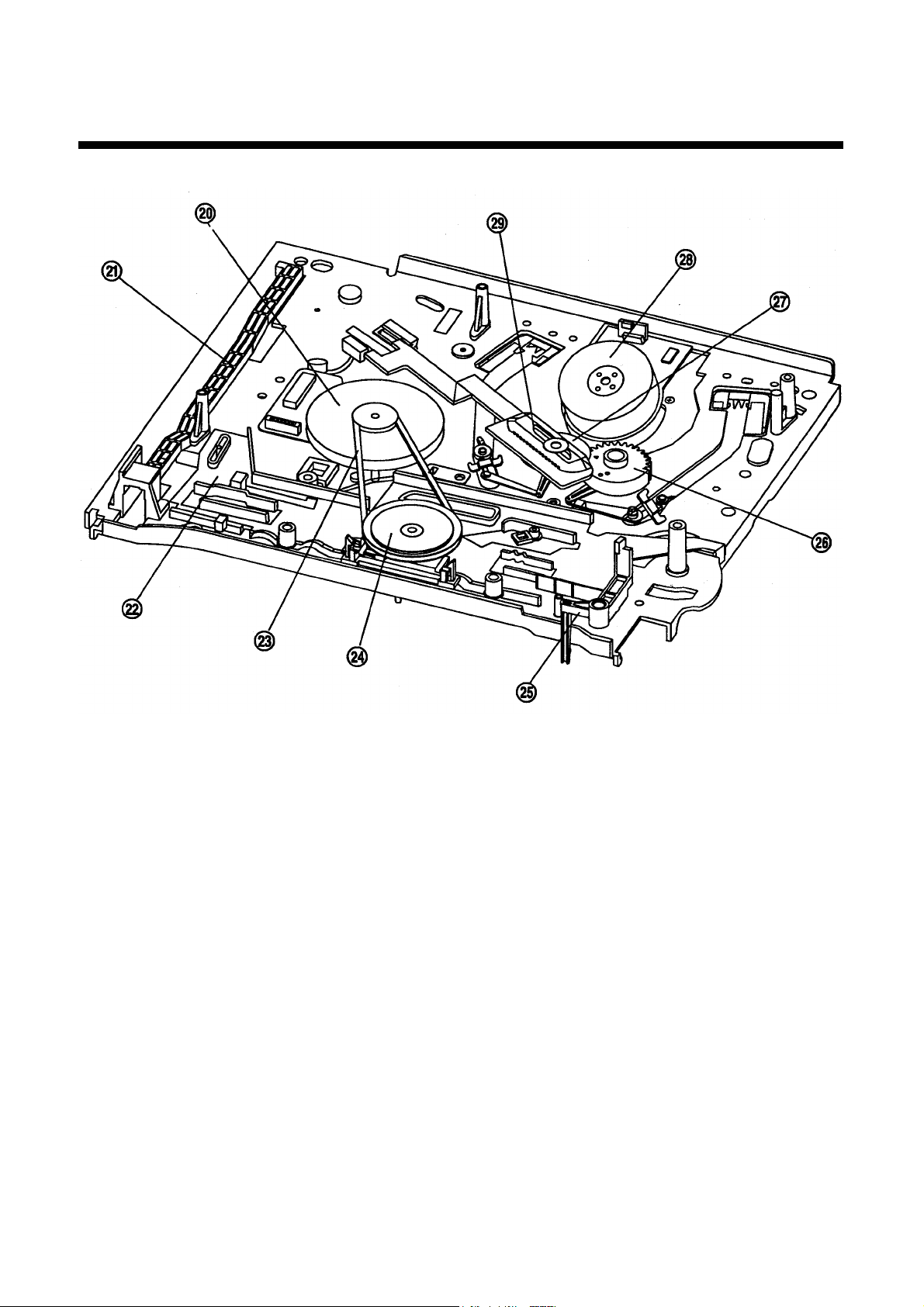

10

20.Capstan Motor

21.F/L Rack

22.Connect Plate

23.Reel Belt

24.Reel Gear Total Ass'y

25.Record Safety Lever

26.Loading Lever L

27.Loading Lever R

28.Drum Total Ass'y

29.Loading Rack

Fig. 10- Tape Transport Mechanism Identification (Bottom View)

2.BOTTOM VIEW

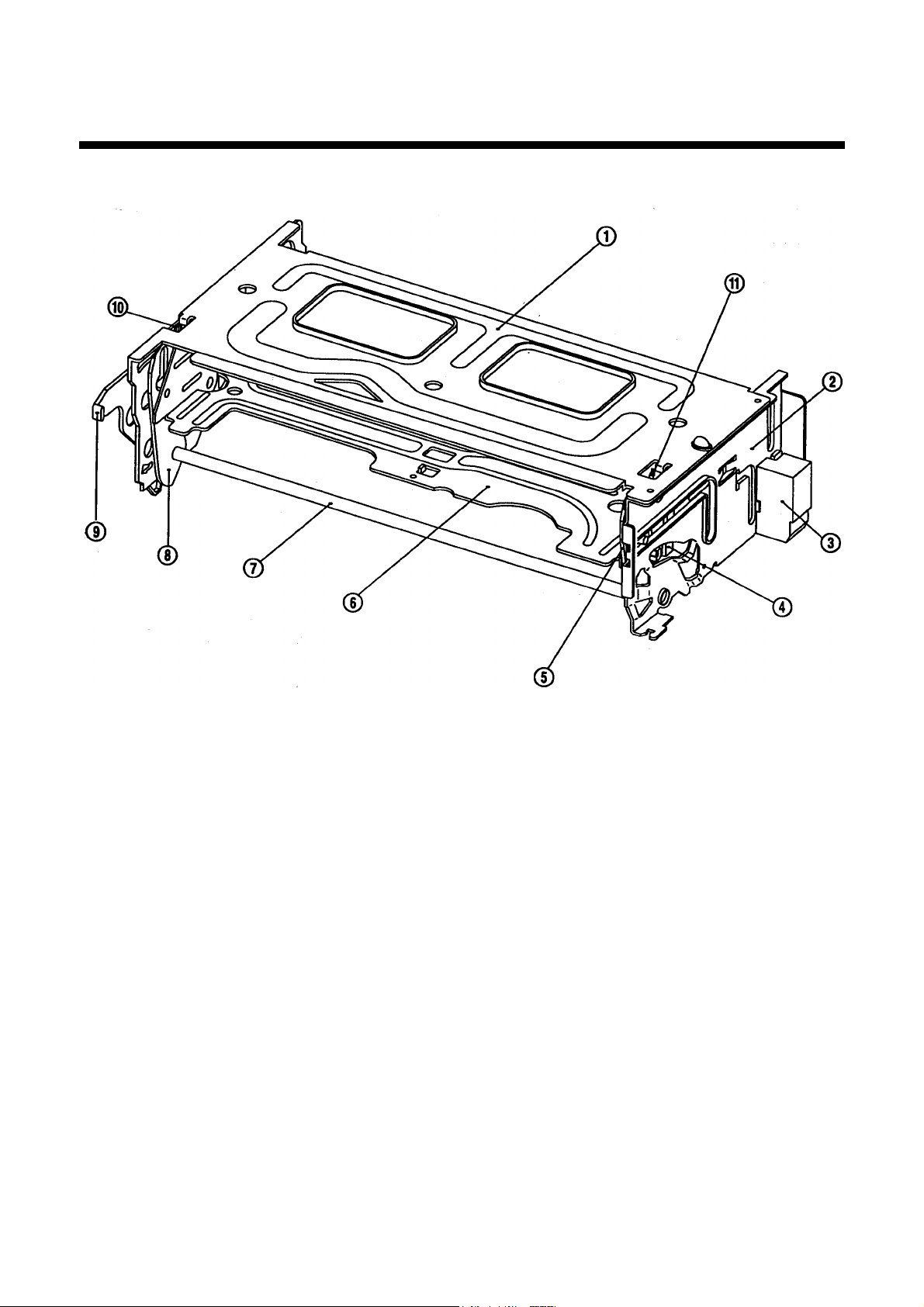

Page 14

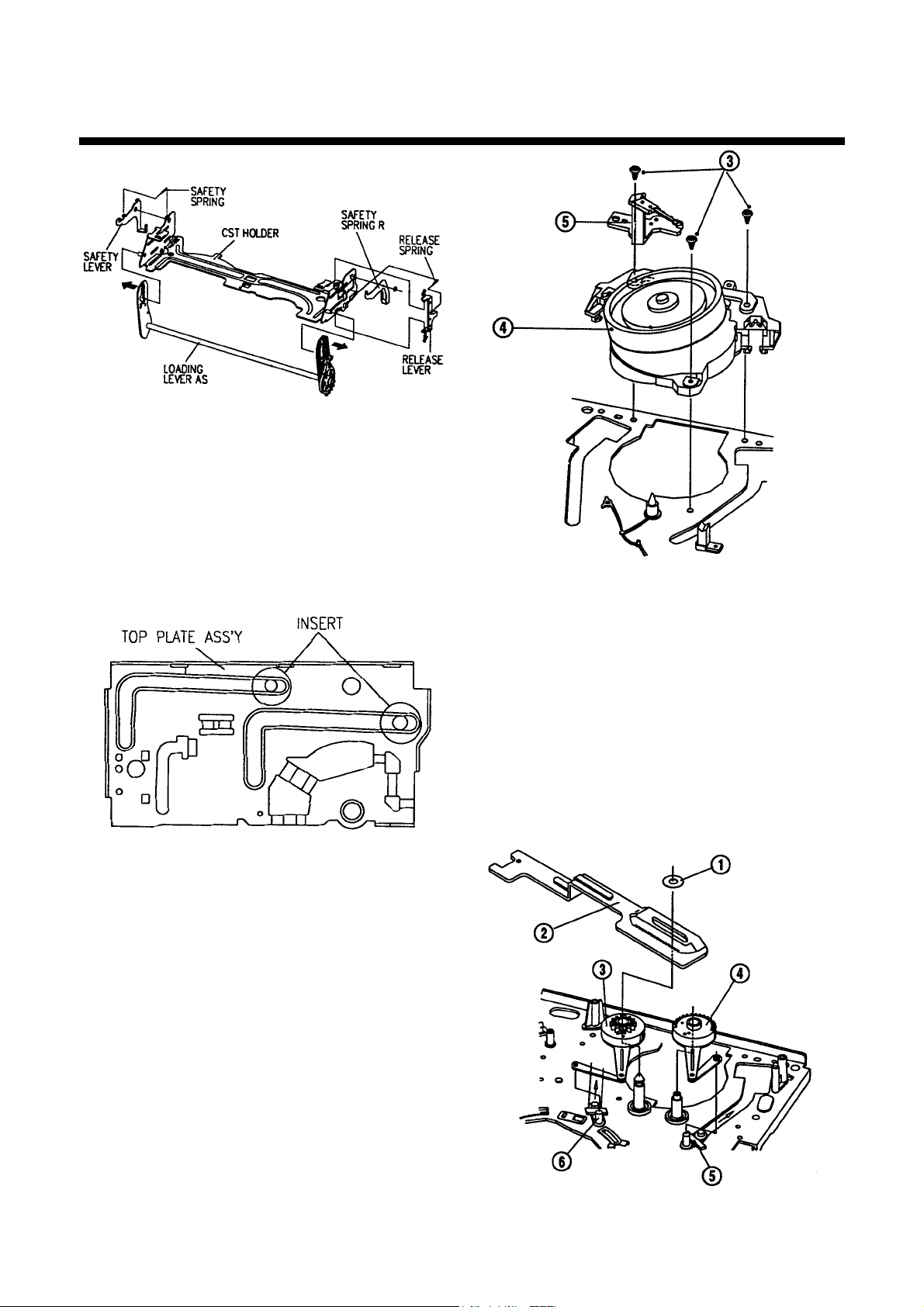

11

1. Top Plate Ass'y

2. F/L Bracket R

3. Prism Cap

4. Release Lever

5. Loading Lever R

6. CST Holder Ass'y

7. Loading Shaft

8. Loading Lever L

9. Door opener

10.Safety Lever

11.Safety Lever R

Fig. 11- Front Loading Mechanism Identification (Top view)

3.F/L MECANISM VIEW

Page 15

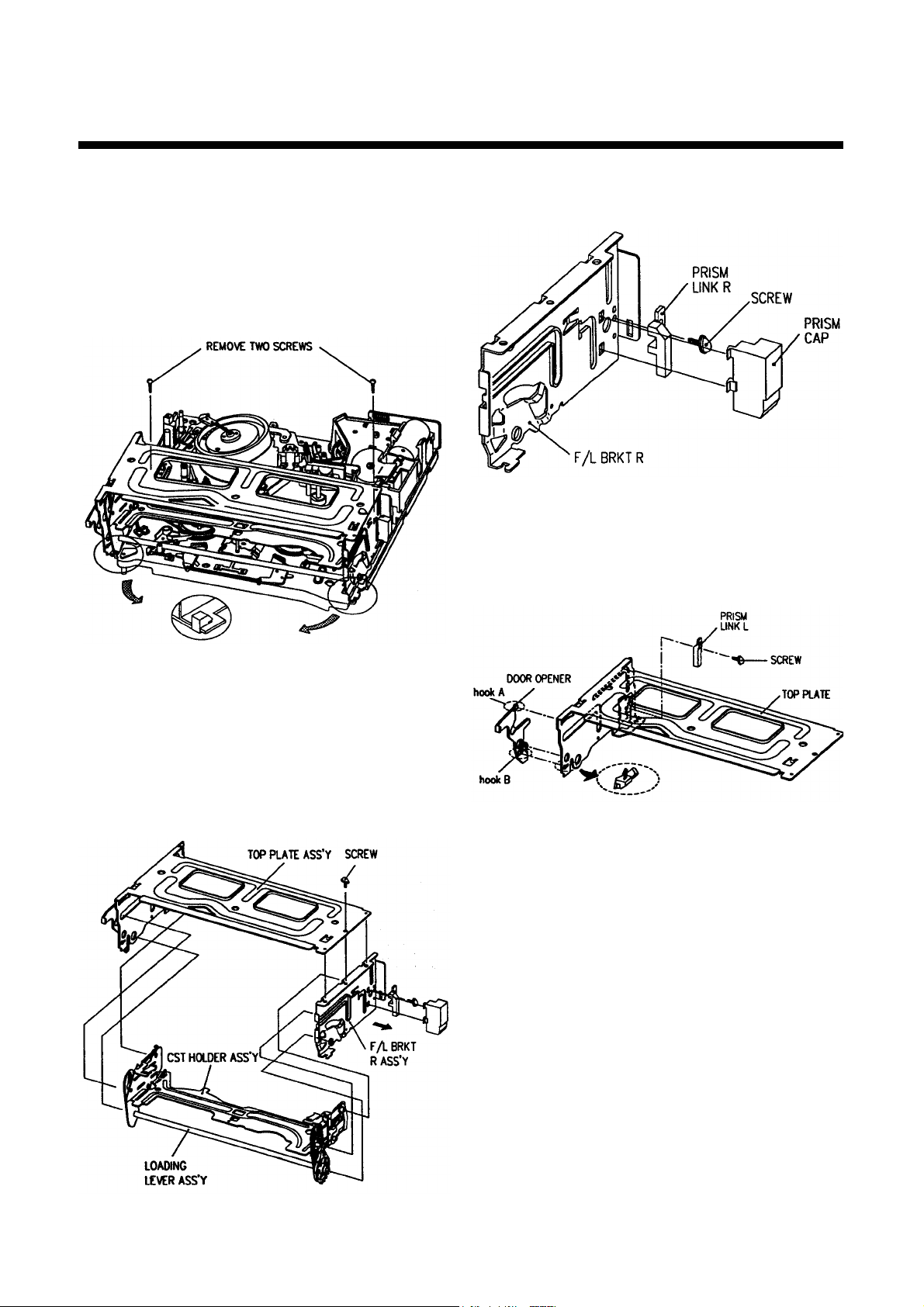

4. General removal view

Front Loading Mechanism Removal (Fig. 12)

NOTE :

The front loading mechanism must be in the eject position

to remove it.

1. Remove two (2) screw holding the Front Loading Mech-

anism.

2. Lift the rear of the cassette loading mechanism (hole

parts for screw) to separate it from the Main Base.

Front Loading Mechanism disassembly

(Fig. 13~17)

1. Remove the front loading mechanism.

2. Remove one(1) screw holding the F/L bracket R and

move the F/L bracket R in the direction of arrow to separate it from the top plate and the cassette holder

assembly.

3. Remove the cassette holder assembly (Fig. 13)

4. Remove the prism cap and remove one (1) screw hold-

ing the prism link R and remove the prism link R from the

F/L bracket R (Fig. 4)

5. Remove one (1) screw holding the prism link L (Fig. 15).

6. Release hook B by pushing it in the direction of the

arrow and remove the door opener (Fig. 15).

7. Press the linked section of the loading lever assembly in

the direction of the arrow and remove the loading lever

assembly (Fig. 16)

8. Remove the safety spring between the safety lever and

the cassette holder (Fig. 16)

9. Remove the release spring between the release lever

and the safety lever R (Fig. 16)

12

Fig. 12- Front Loading Mechanism Removal

Fig. 14- F/L Brkt Disassembly

Fig. 15- Top Plate Disassembly

Fig. 13- front loading mechanism disassembly

Page 16

NOTE :

Reassemble the cassette loading mechanism using the

reverse procedures. Confirm that the two (2) bosses on the

left side of the cassette holder are inserted into the groove

in the left side of the top plate. Insert the two (2) bosses on

the right side into the F/L bracket R (Fig. 17)

Replacement of the Drum Assembly/Earth

Bracket (fig. 18)

1. Remove three (3) screw (3).

2. Remove the earth bracket (5).

3. Carefully lift drum assembly (4) from the deck mechanism taking care not to damage or touch the video

heads.

NOTE :

After reassembling the assembly, confirm that the tape runs

smoothly and confirm all tape path adjustment procdures in

the "Mechanical Adjustment" section of this service publication.

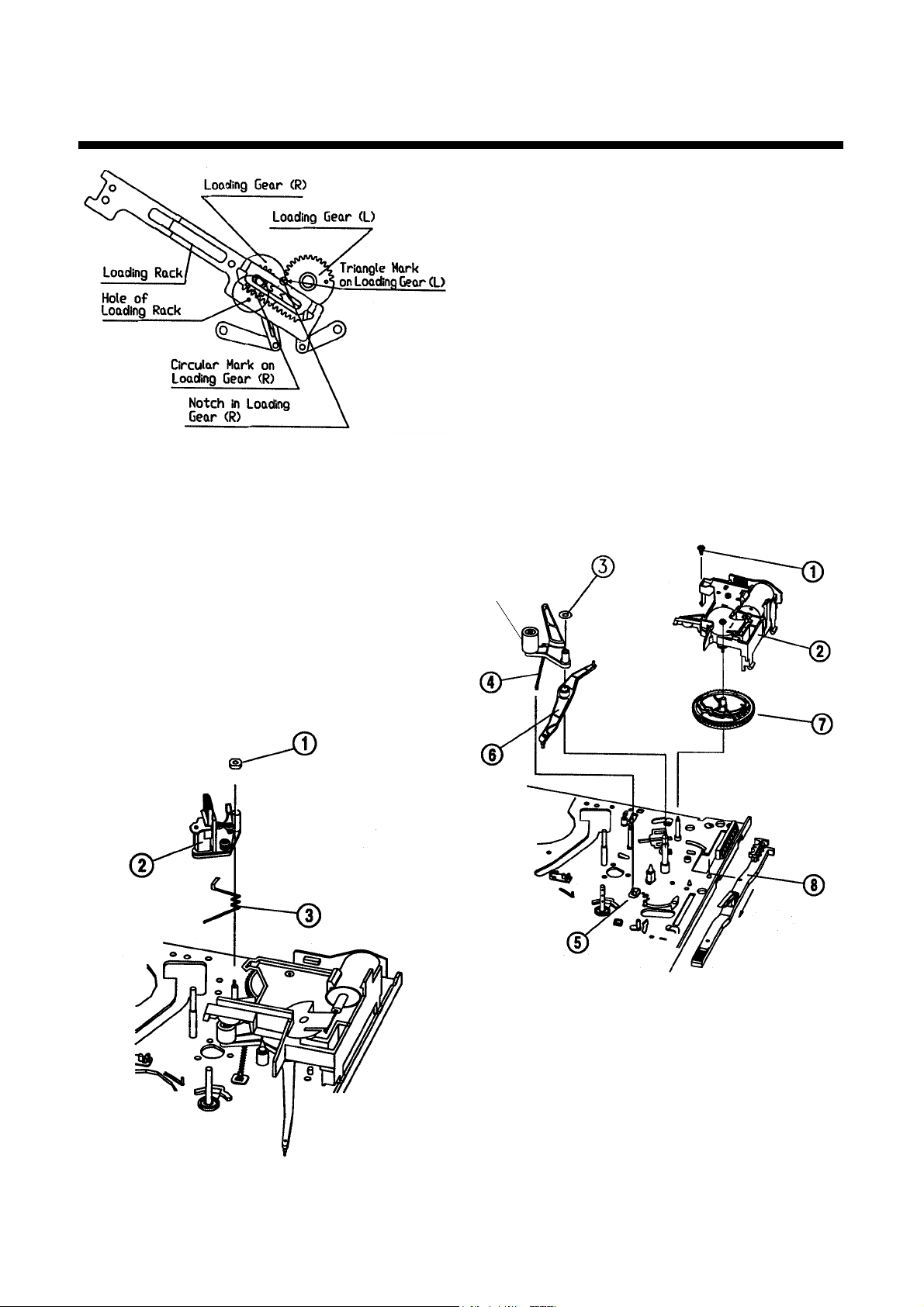

Reel belt, Loading Rack, Loading Gears, and

S/T Slant Pole Removal (Fig. 19, 20)

1. Turn the Deck Mechanism upside down and remove the

reel belt.

2. Remove one (1) poly washer ① and remove the loading

rack (2).

3. Remove Right and left loading gears ③ and ④.

4. Remove the S and T slant poles ⑤ and ⑥ by pulling

them in the direction of the arrow.

NOTE :

• Take care not to get grease on the guide rollers.

• When reinstalling, realign the gears as shown in Fig 20.

13

Fig. 16- Loading Lever Ass'y Disassembly

Fig. 17- F/L Brkt R

Fig. 18- Replacement of the Drum total Ass'y and Earth Brkt Ass'y

Fig. 19- Reel belt, Loading Rack, Loading Gears, S/T slant pole

Removal

Page 17

A/C Head Assembly Removal (Fig. 21)

1. Remove one (1) nut hex from the A/C head assembly ①

(Fig. 21)

2. Remove the A/C head assembly ② and remove the A/C

head spring ③ from the A/C head assembly ②.

NOTE :

After reinstalling, perform all A/CHead adjustment procedures and all tape path alignment procedures in publication.

Perform the "Audio Bias Level Adjustment" in the "Electrical

Adjustment" section of this service manual.

L/C Bracket Assembly removal (Fig. 22)

1. Remove one (1) screw ① from the L/C bracket assembly ②and remove the L/C bracket assembly ② from the

deck mechanism (Fig. 22)

NOTE :

When reassembling, refer to Fig. 23 for alignment instructions.

Replacement of Pinch Lever Total Assembly

Removal

(Fig. 22)

1. Remove one (1) washer ③.

2. Unhook the pinch spring ④ from the main base ⑤ and

remove the pinch lever total assembly ⑥.

NOTE :

Take care not to get oil on the outside surface of the pinch

roller ⑩.

14

Fig. 20- Loading Gears/Loading Rack Alignment

Fig. 21- A/C Head Assembly Removal

Fig. 22- Replacement of L/C Bracket Total Assembly/Pinch

Lever Total Assembly/cam Gear/Relay Lever/F/L Rack

⑩

Page 18

Cam Gear, and F/L Rack Removal (fig. 22)

1. Remove the cam gear ⑦ form the deck mechanism.

2. Remove the relay lever ⑥ from the main base ⑤.

3. Remove the F/L rack ⑧ from the deck mechanism.

NOTE :

When reassembling, align the assembly as shown in Fig.

23 & 24.

S/T Main & Sub Brakes Removal (Fig. 25)

1. Unhook the main brake spring ① from the T main brake

lever ③.

2. Disconnect the main brake lever assembly ② and T

main brake lever ③ from the main base ⑧.

3. Unhook the s sub brake spring ④ from the main base

and disconnect the s sub brake lever assembly ⑤ from

the main base ⑧.

4. Unlook the T sub brake spring ⑥ from the main base

and disconnect the T sub brake lever assembly ⑦ from

the main base ⑧.

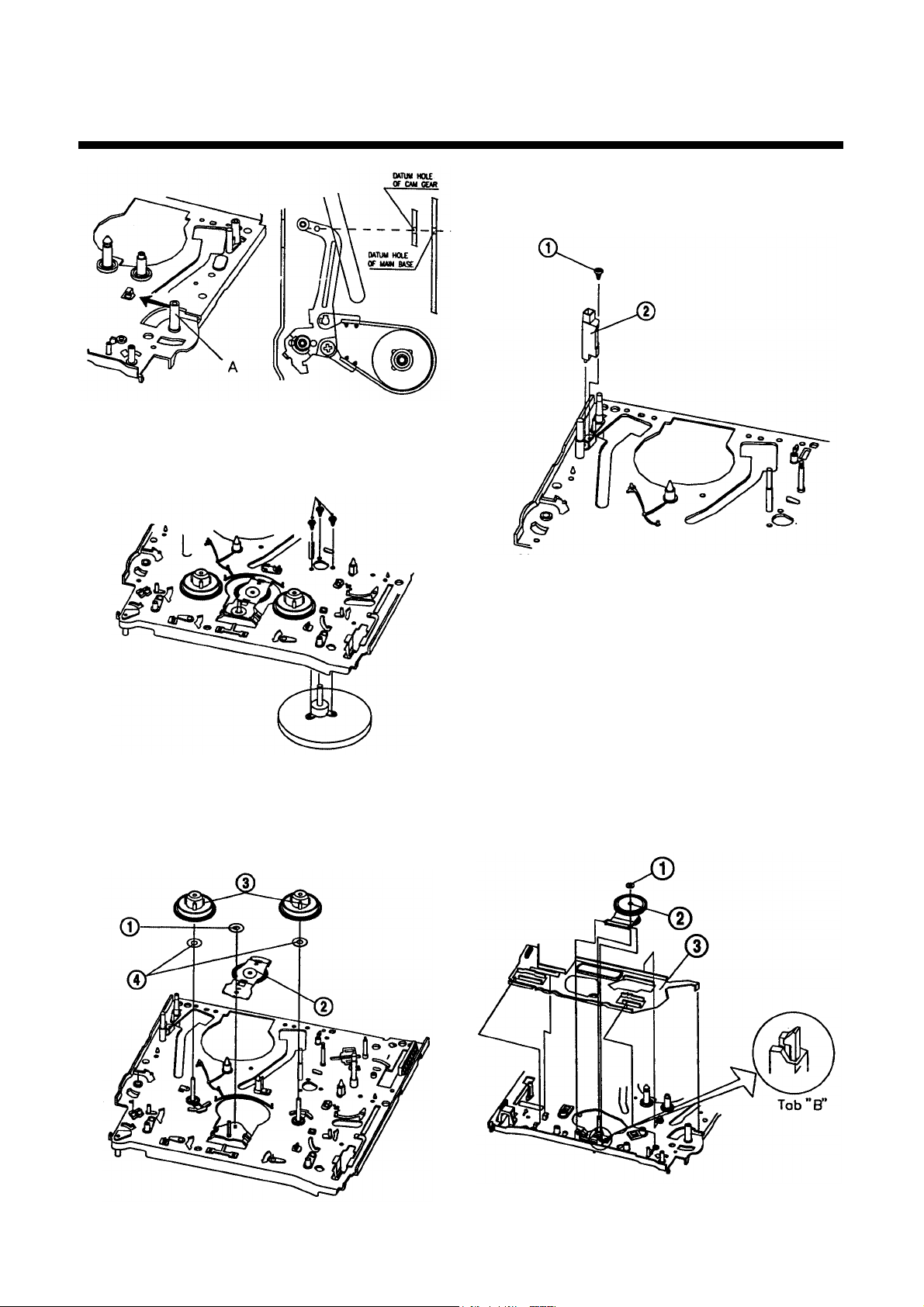

Tension Band Assembly Removal (Fig. 26, 27)

1. Remove the tension spring ② from the main base ①

(Fig. 26)

2. Turn the deck mechanism upside down (fig. 27) is facing

down (fig. 27)

NOTE :

• After reassembling, adjust the position of the tension pole

as shown in fig. 28.

• Avoid getting grease or oil on the felt section of the band

brake.

15

Fig. 23- L/C Bracket Assembly Alignment

Fig. 25- Main Plate Removal

Fig. 26- Tension Band Assembly Removal (1)

Fig. 24- Cam Gear/F/L Rack Alignment

Page 19

Capstan Motor Removal (Fig. 29)

Remove three (3) screws and remove the capstan motor.

Idier Plate/Reel Table Removal (fig. 30)

1. Remove one ① polywasher ① from the idler plate ②

and remove the idier plate ② from the main base.

2. Remove the reel tables ③ and the two ② polysliders ④

from the deck mechanism.

FE Head Removal (fig. 31)

Remove one (1) screw (1) and lift the FE head (2) from the

main base.

Reel Gear Total Ass'y and Connect Plate

Removal

(fig. 32)

1. Turn the deck mechanism upside down and remove one

① polywasher ①.

2. Release the tab "B" of the main base and part the reel

gear total ass'y ② from the main base.

3. Push the connect plate ③ to the left direction and separate it from the main base.

NOTE :

• When removing the connect plat with the the F/L rack

installed, take care not to damage/bend the connect plate.

• When assembling or disassembling, take care not to get

oil or grease on the reel belt.

16

Fig. 27- Tension Band Assem-

bly Removal (2)

Fig. 28- Tension Band Assem-

bly Alignment With

Main Base

Fig. 31- FE Head Removal

Fig. 32- Reel gear total ass'y and Connect Plate Removal

Fig. 29-Capstan Motor Removal

Fig. 30- Idler Hate/Reel Table Removal

Page 20

Some disassembly is required to access the adjustment locations. Refer to the "Disassembly Selection" in this publication

for disassembly instructions.

Caution : Use an isolation transformer when servicing.

5. Mechanical Checks/Gear Alignment (fig. 1, 2, 3, 4, 5)

When mechanical problems occur or when reassembling parts in this mechanism, be sure to confirm the following instructions to confirm the following:

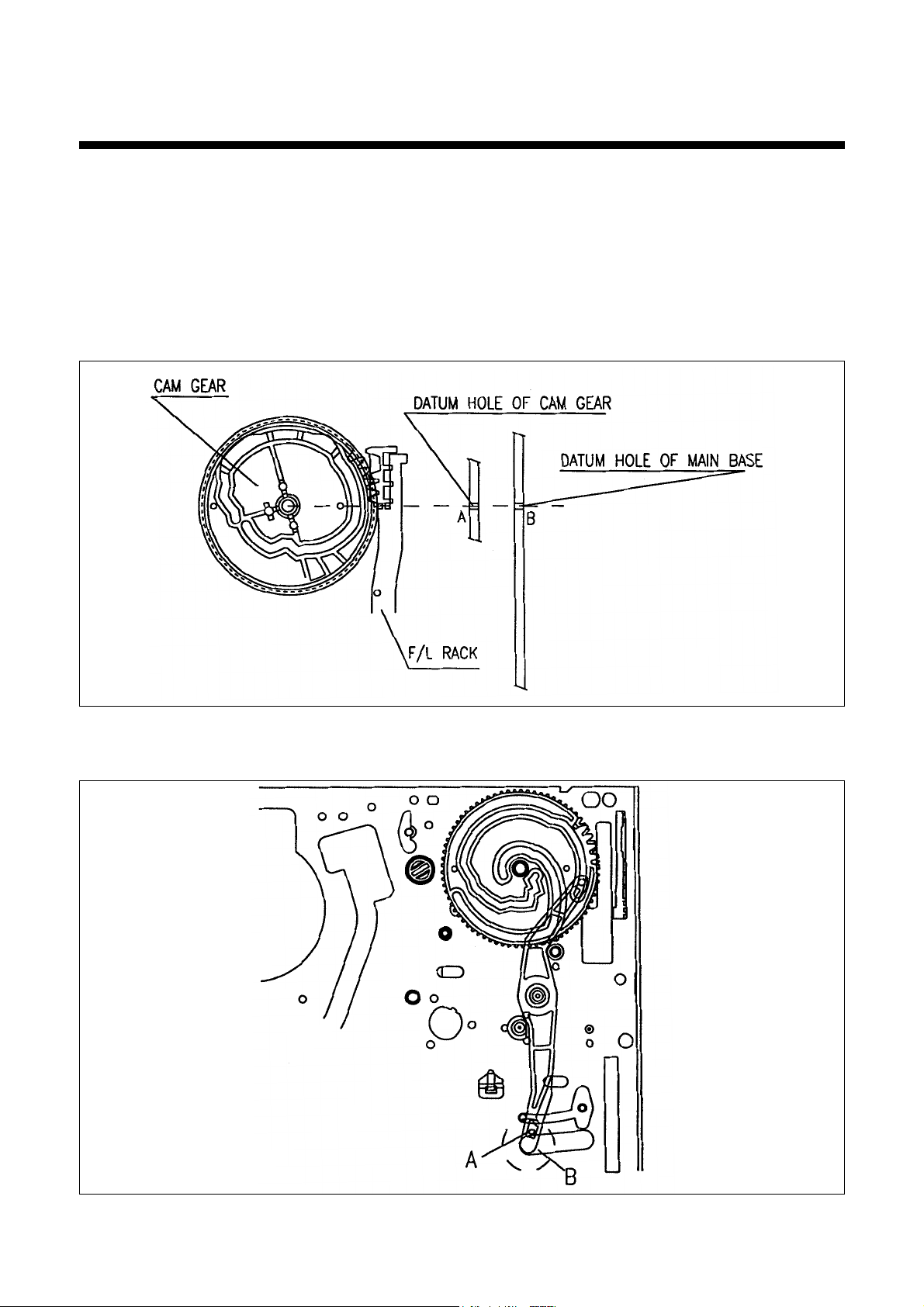

1. Make sure that the datum hole of the cam gear "A" is aligned with the hole "B" in the main base in the EJECT mode

(fig. 1)

2. Make sure that the part of the relay lever "A" which is assembled with CONNECT PLATE is fully rotated up to the left and

of the hole "B" (Fig. 2)

17

Fig. 1– Mechanical Checks/Cam Gear and F/L Alignmen

Fig. 2- Mechanical Checks/relay Lever and Cam Gear Alinment

Page 21

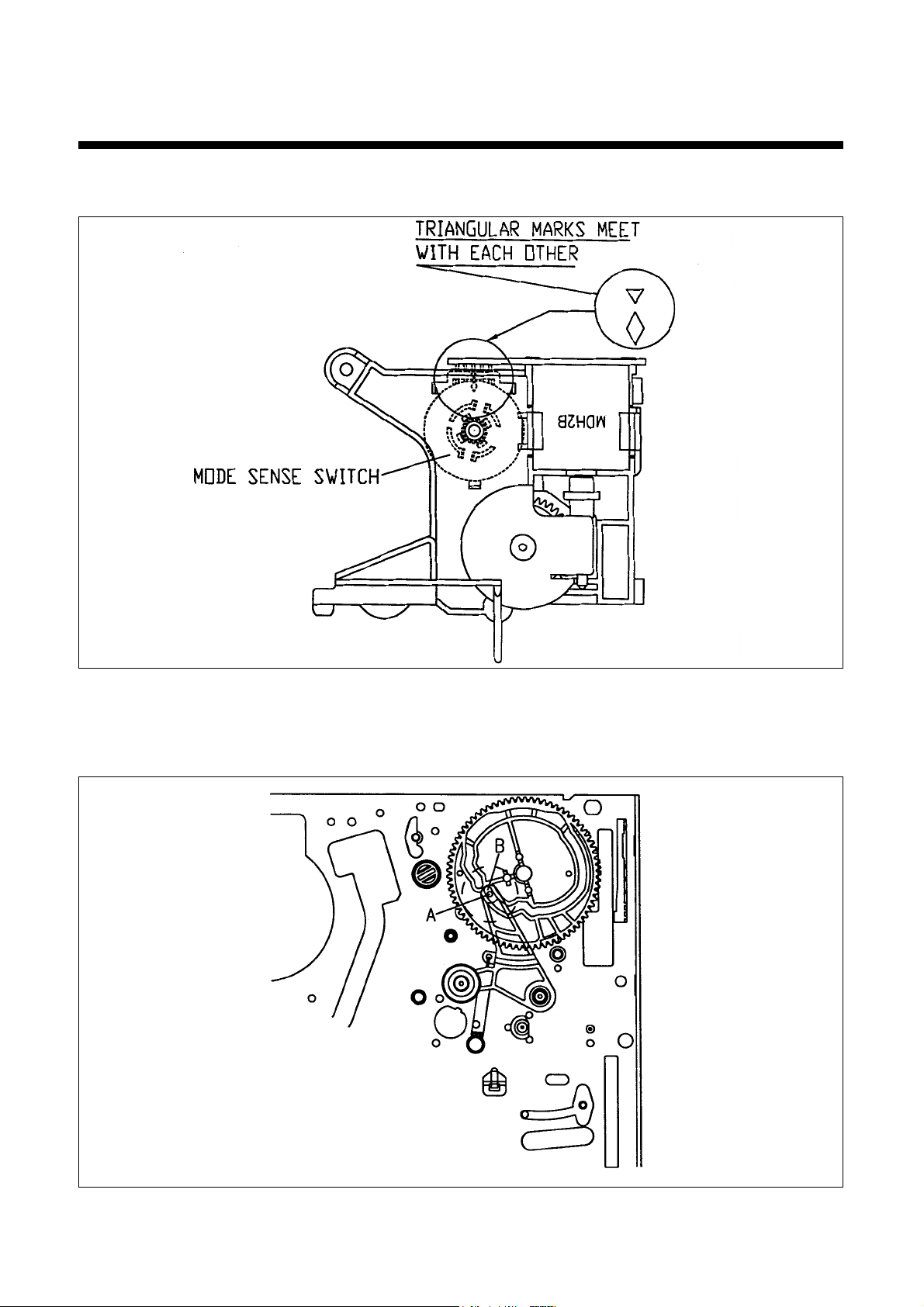

3. There are two (2) triangular marks on the mode sense switch. When installing the L/C bracket assembly on the main

base, confirm that the two (2) triangular marks aligned with each other in the EJECT mode (Fig. 3)

4. Make sure that the boss "A" of the Pinch Lever Total Ass'y is positioned at the point "B" of the cam gear in EJECT mode

(fig. 4).

18

Fig. 3 - Mechanical checks/Mode Sense S/W Alignment

Fig. 4 – Mechanical Checks/Pinch Lever and Cam Gear Alignment

Page 22

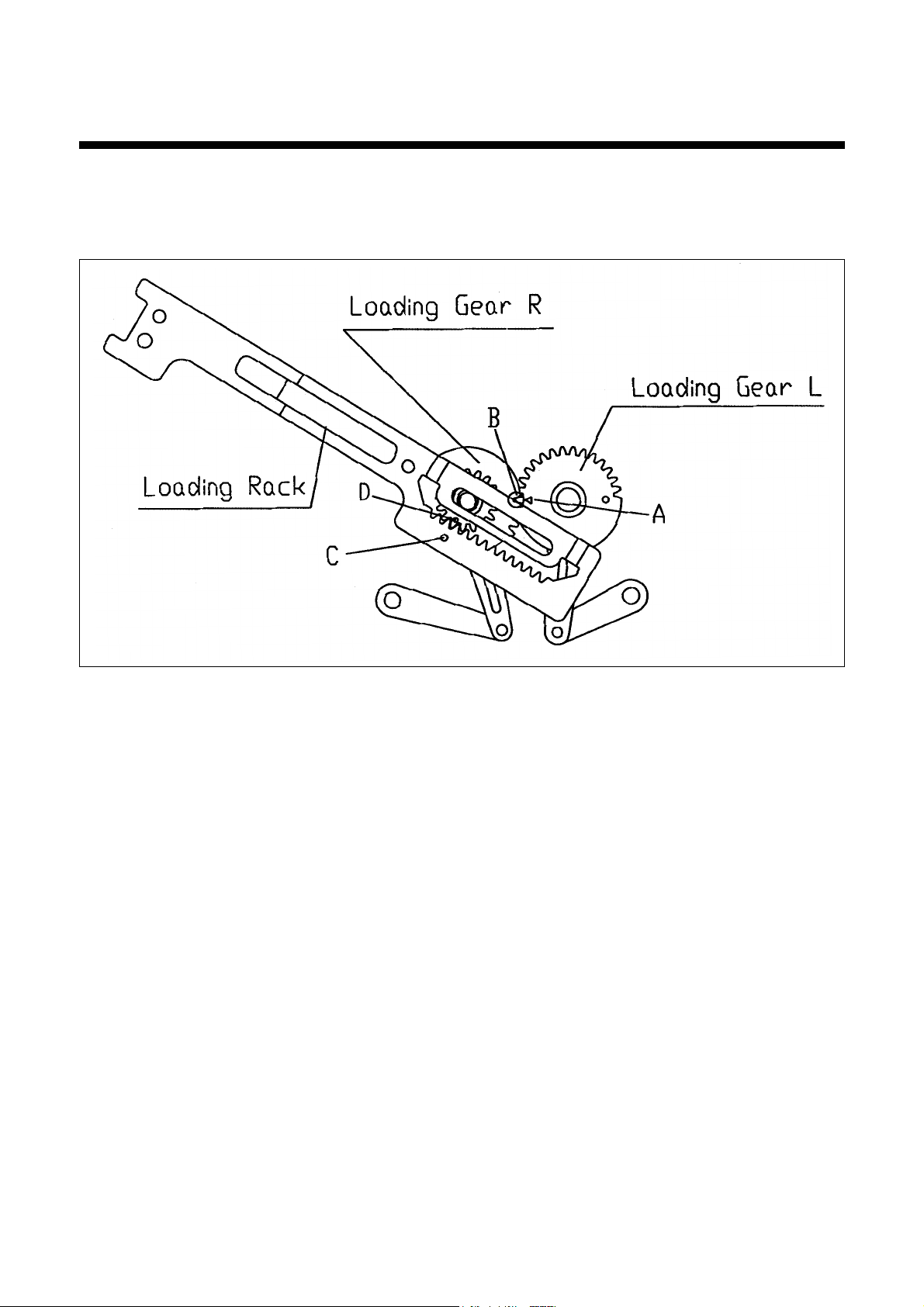

5. Confirm that the triangular mark "A" on the Loading Gear L Ass'y is aligned with the notch "B" in the Loading Gear R

Ass'y in EJECT mode (Fig. 5)

6. Make sure that the teeth of the Loading Rack are aligned with the those of the Loading Gear R so that hole "C" of the

Loading Rack aligns with the circulr mark "D" on the Loading Gear R (fig. 5)

19

Fig. 5- Mechanical Checks/Loading Loading Rack and Loading Gear Alignment

Page 23

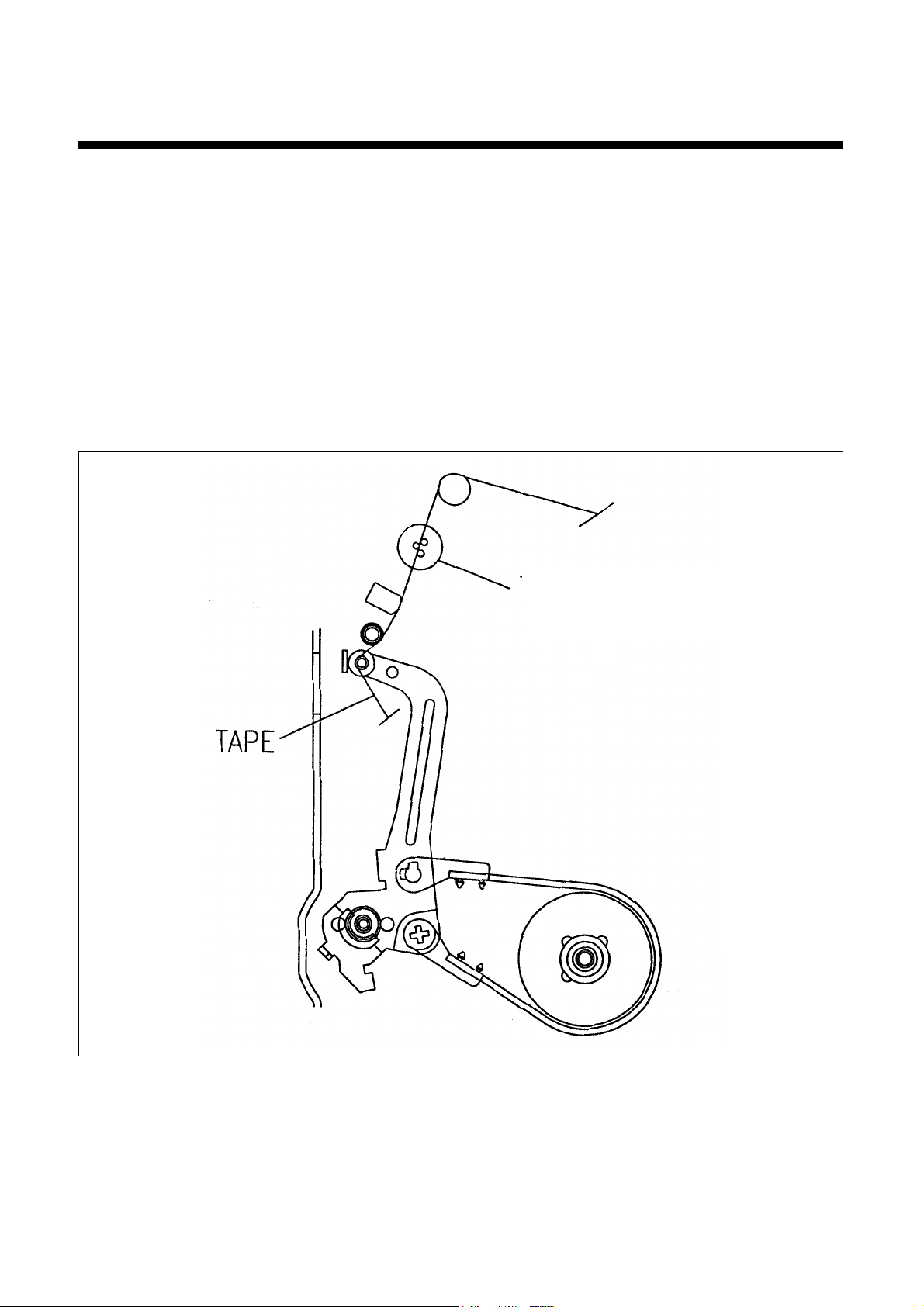

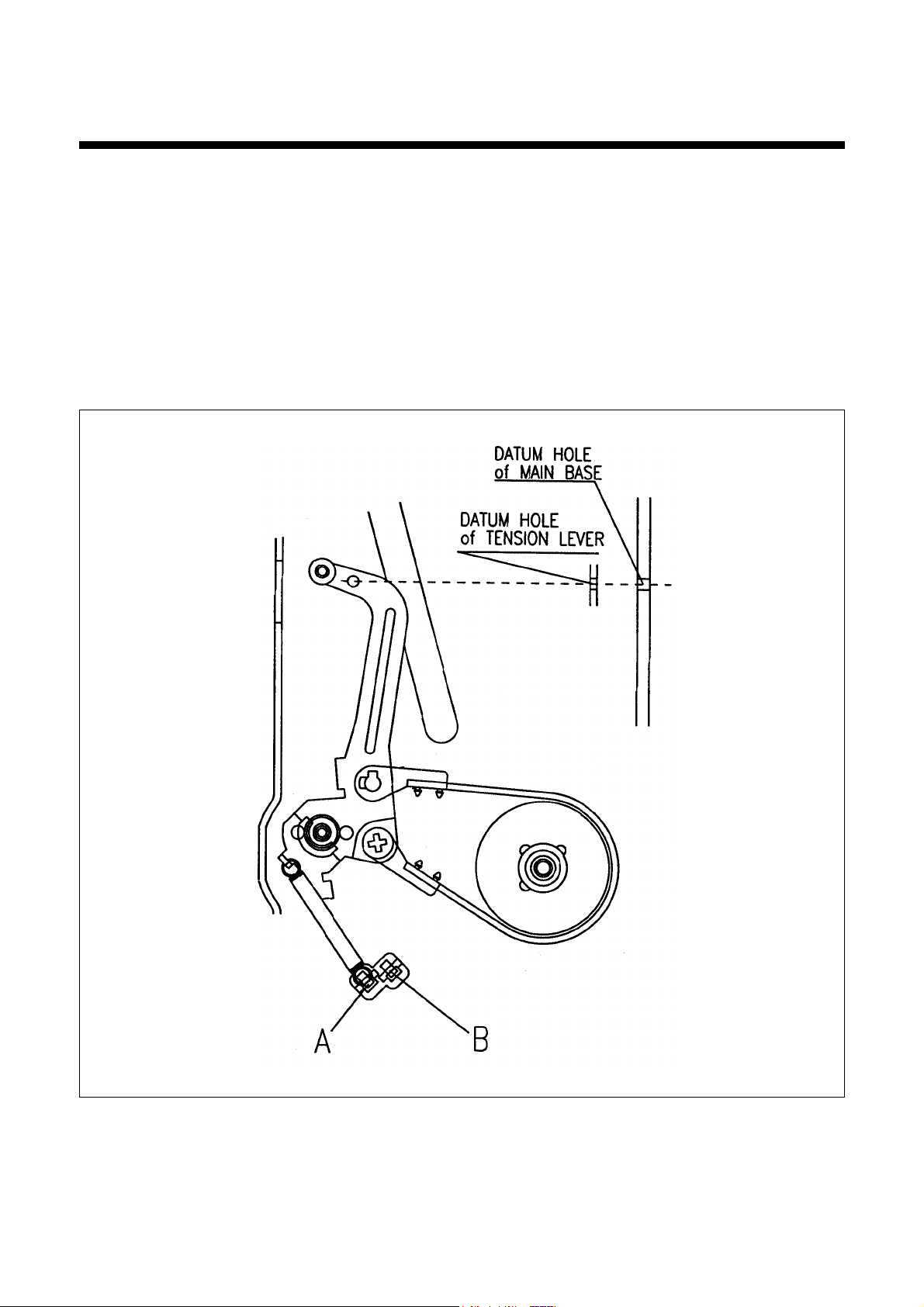

6. Tension checks

Back Tension Measurement /Adjustment (fig. 6, 7)

1. Confirm that the position of the tension pole is correctly positioned. If not, refer to the "Tension Pole Position Adjustment

Procedures"

2. Play back a T-120 tape from the beginning for about 20 seconds (wait until tape transporting system comes to be stable).

3. Insert the Tensiometer on the tape path (fig. 6) and measure the back tension. the measured result must meet the specification (25-33gr).

4. If the result is not within the specification, adjust the tension spring (If the measured result exceeds the specification,

locate the spring on the hook "A". If the value does not reach the specification, locate the spring on the hook "B".) and

repeat the step 1 thru 3 of "Tension Pole Position Adjustment" (fig. 7).

NOTE :

• Make sure that all of the three probes of the Tensiometer are on contact with the tape, but not with any other parts of the

Deck mechanism.

• It is recommended that the measurement should repeated at least three times to guarantee an accurate reading.

20

Fig. 6 - Back Tension Measurement/Adjustment

TENSIOMETER

PROBE

Page 24

Operating the VCR Without a Cassette Tape

1. Remove the cassette Loading Mechanism.

2. By hand revolve the worm counterclockwise 7-8 times until pole base loading process starts automatically.

3. Then PLAY mode appears. If you want ANOTHER mode, Press the desired button.

4. If the mechanism is in the desired mode, remove the Power.

Tension Pole Position Adjustment

1. Make the mode PLAY without a cassette loaded. Refer to "Operating the VCR Without a Cassette Tape".

2. Confirm that the datum hole of the tension lever is coincident with that of the main base.

3. If the above confirmation is not satisfying, turn Band Brake Cap clockwise or counterclockwise until the two holes are

coincident with each other.

21

Fig. 7- Tension Pole Position Adjustment

Page 25

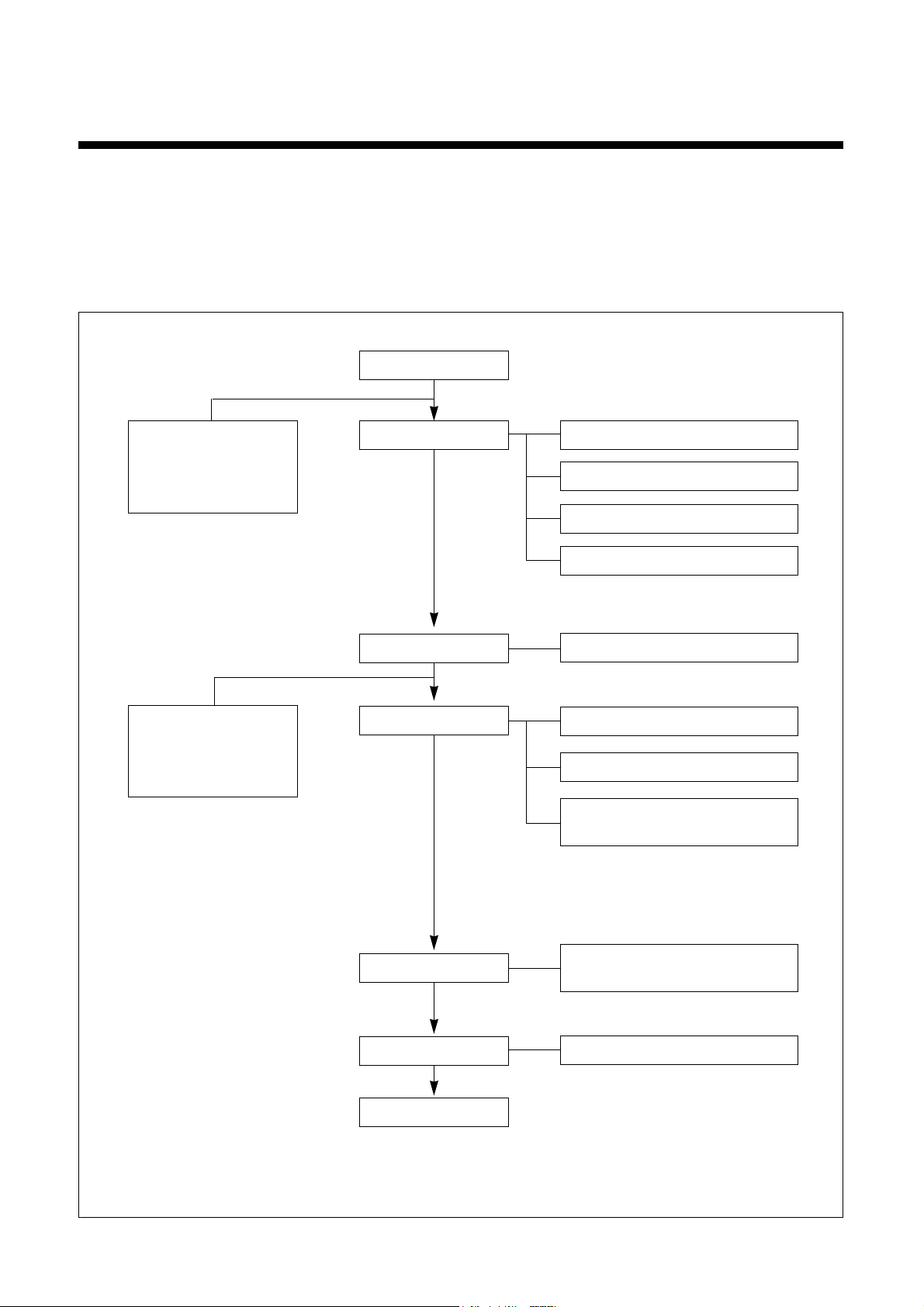

Tape Path Alignment Procedures

The tape transporting system is precisely aligned at the factory and under the normal circumstances will not require adjustment. However, if noise appears in the playback picture, it can be considered that the tape damage occured or the tape

path has been changed, readjustment of the tape path is necessary.

ADJUSTMENT FLOW FOR THE TAPE TRANSPORTING SYSTEM

22

■■

MECHANICAL ADJUSTMENTS

CLEANING

PATH ROUGH ADJ. S GUIDE ROLLER HEIGHT ADJ.

• DRUM TOTAL ASS'Y

• A/C HEAD ASS'Y

• PINCH LEVER

TOTAL ASS'Y

• S-POLE BASE ASS'Y

• T-POLE BASE ASS'Y

• TENSION LEVER

ASS'Y

A/C HEAD HEIGHT ADJ.

PG(PHASE GENERATOR)

ENTRANCE ENVELOPE

EXIT ENVELOPE WAVEFORM

SP, EP

ENTRANCE & EXIT ENVELOPE

WAVEFORM FINE ADJ,

• X-POSITION ROUGH ADJ.

• ENTRANCE & EXIT ENVELOPE

WAVEFORM FINE ADJ.

• REVIEW PLAY

CHANGE

CHANGE

AUDIO TILT, HEIGHT

AZIMUTH ADJ.

S GUIDE POST FLANGE

T GUIDE ROLLER HEIGHT ADJ.

LINEARITY ADJ.

PATH PRE-ADJ.

AUDIO ADJ.

TRACKING

X-POSITION ADJ.

Table. 8 Flow Chart of Tape Path Alignment

Page 26

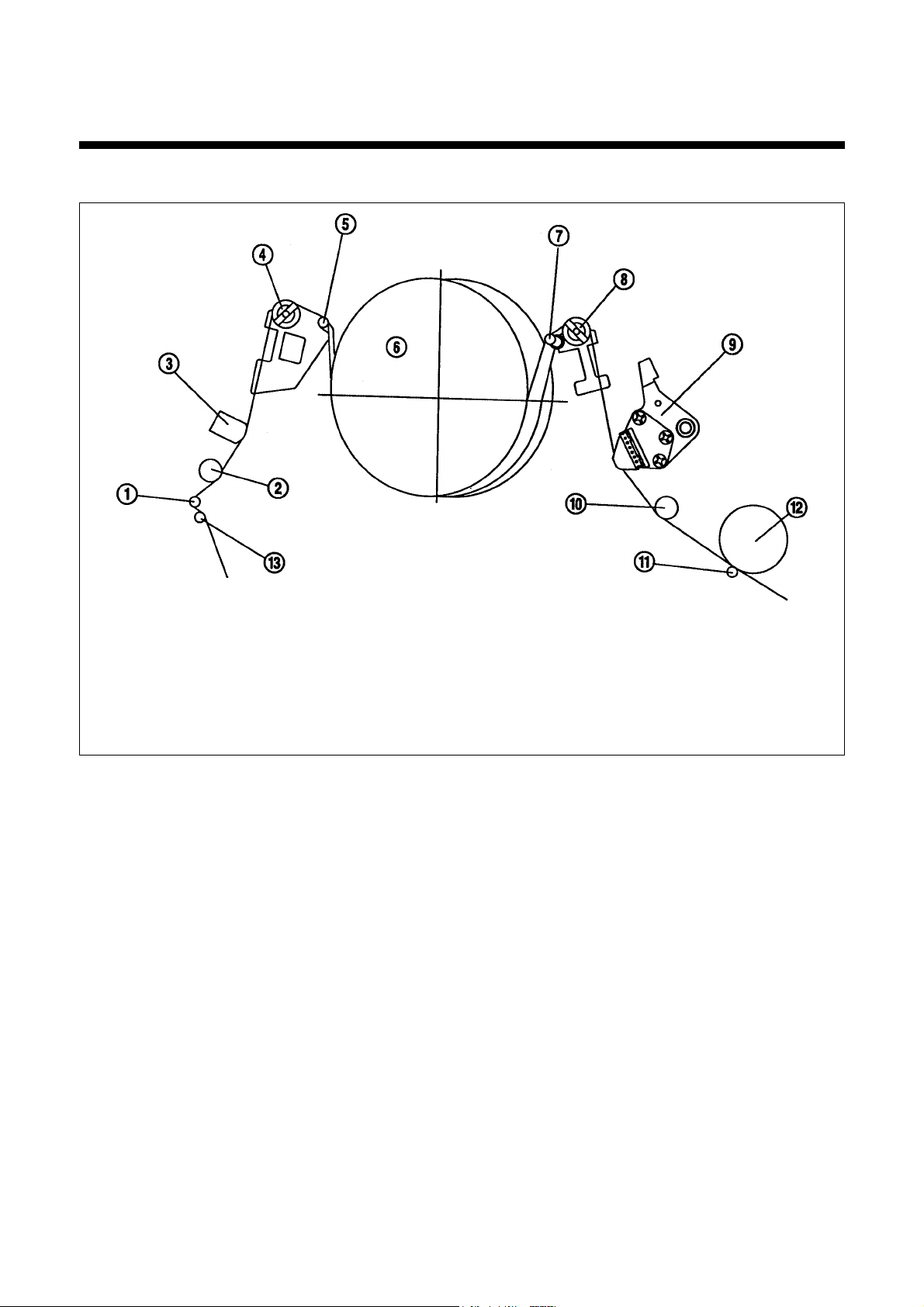

23

THE SCHEMATIC DIAGRAM OF TAPE TRANSPORTING SYSTEM

① TENSION POLE

② S-GUIDE POST

③ FE HEAD

④ S-GUIDE ROLLER(P2

)

⑤ S-SLANT POLE

⑥ DRUM

⑦ T-SLANT POLE

⑧ T-GUIDE ROLLER(P

3)

⑨ A/C HEAD

⑩ T-GUIDE POST

⑪ CAPSTAN SHAFT

⑫ PINCH ROLLER

⑬ VERTICAL POST

Page 27

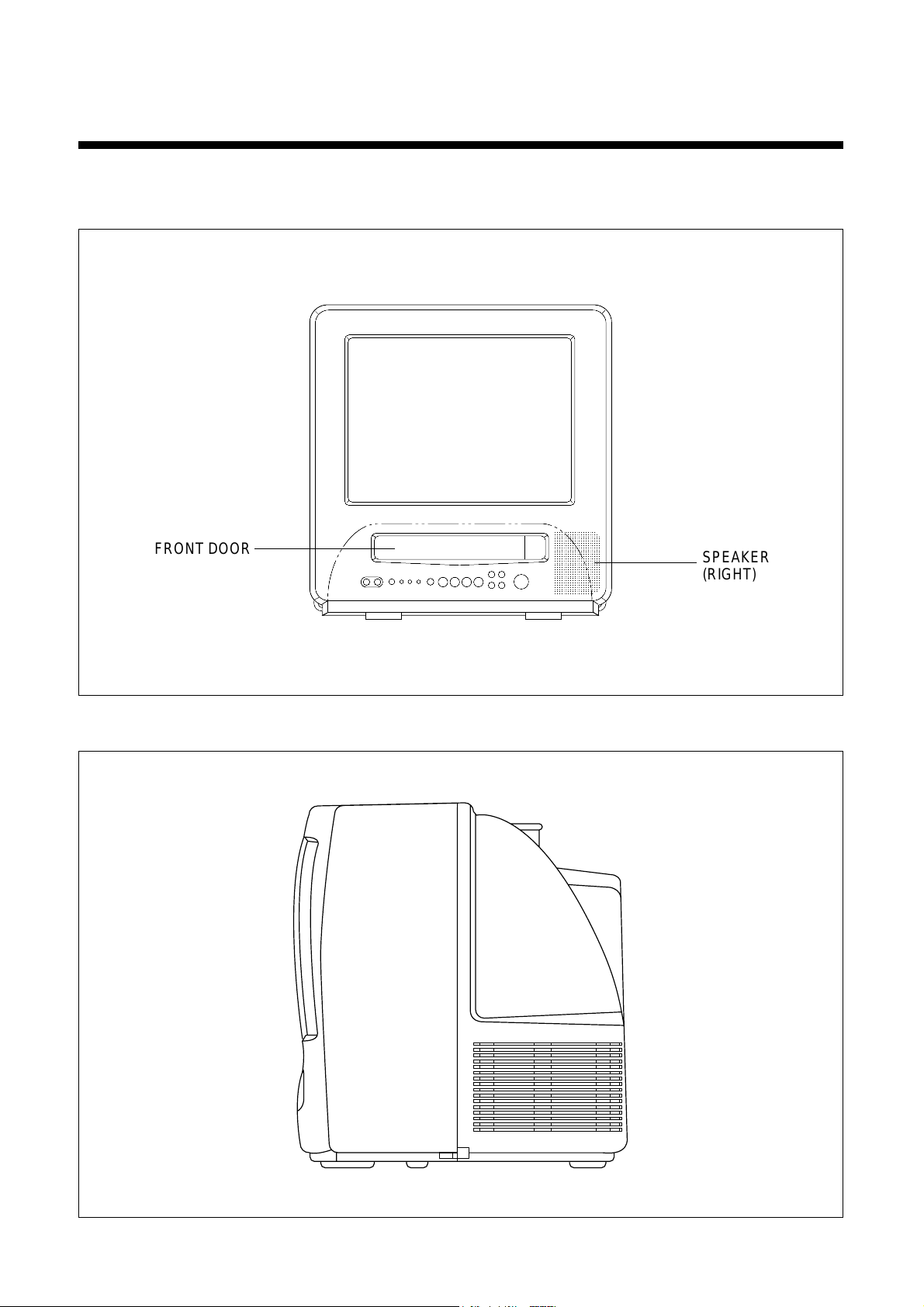

24

■■SSHHAAPPEE && EEQQUUIIPPMMEENNTT OOFF DDVVNN--1144//2200FF66NN

1. DVN-14F6N/DVN-20F6N

1-1. FRONT OF TV/VCR

1-2. SIDE OF TV/VCR

SPEAKER

(RIGHT)

FRONT DOOR

Page 28

25

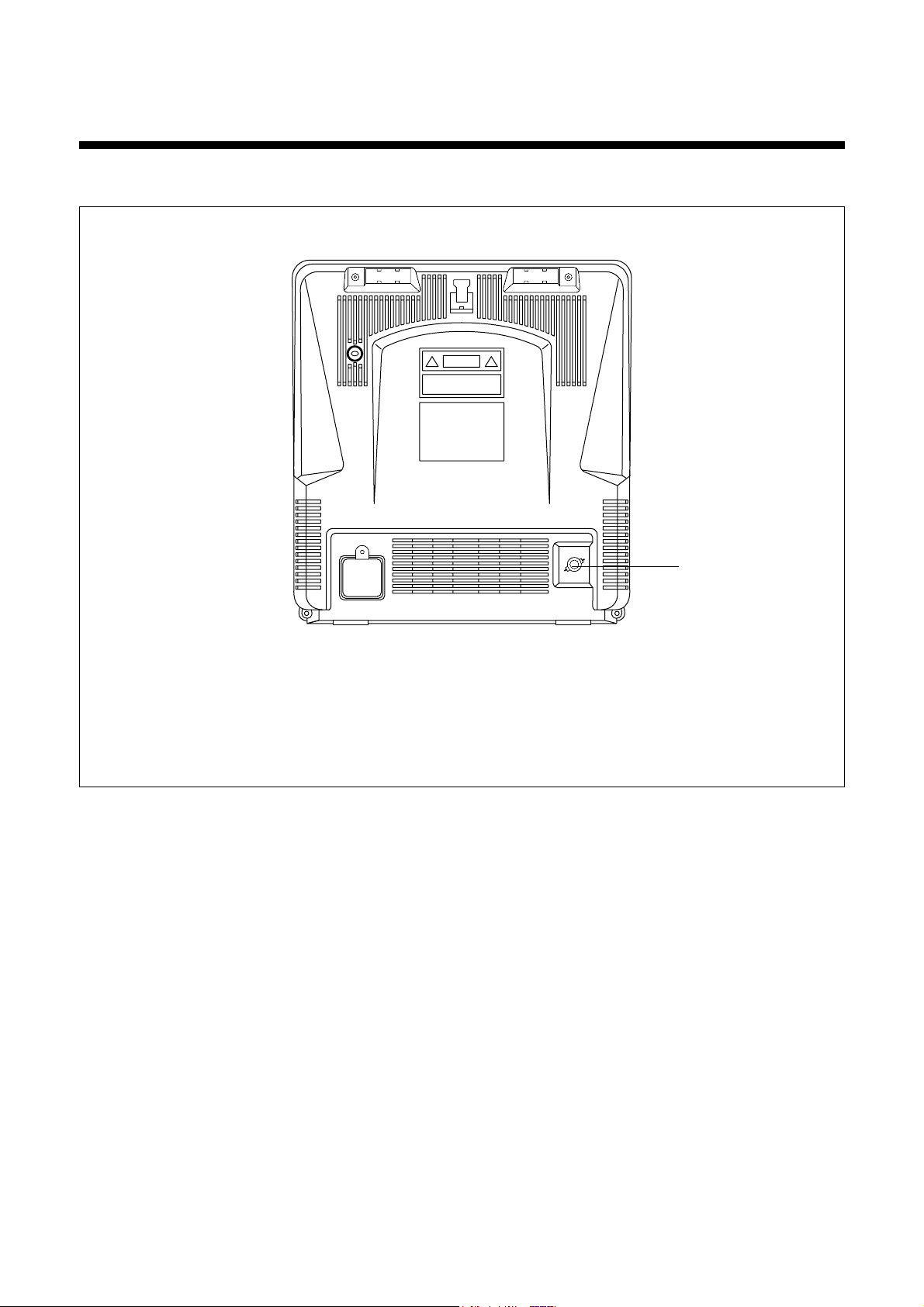

1-3. REAR OF TV/VCR (DVN-14F6N ONLY)

VHF Input

connect VHF antenna to this terminal.

VHF INPUT

* Rear of TV/VCR's Shape of DVN-20F6N is

similar to DVN-14F6N'S

Page 29

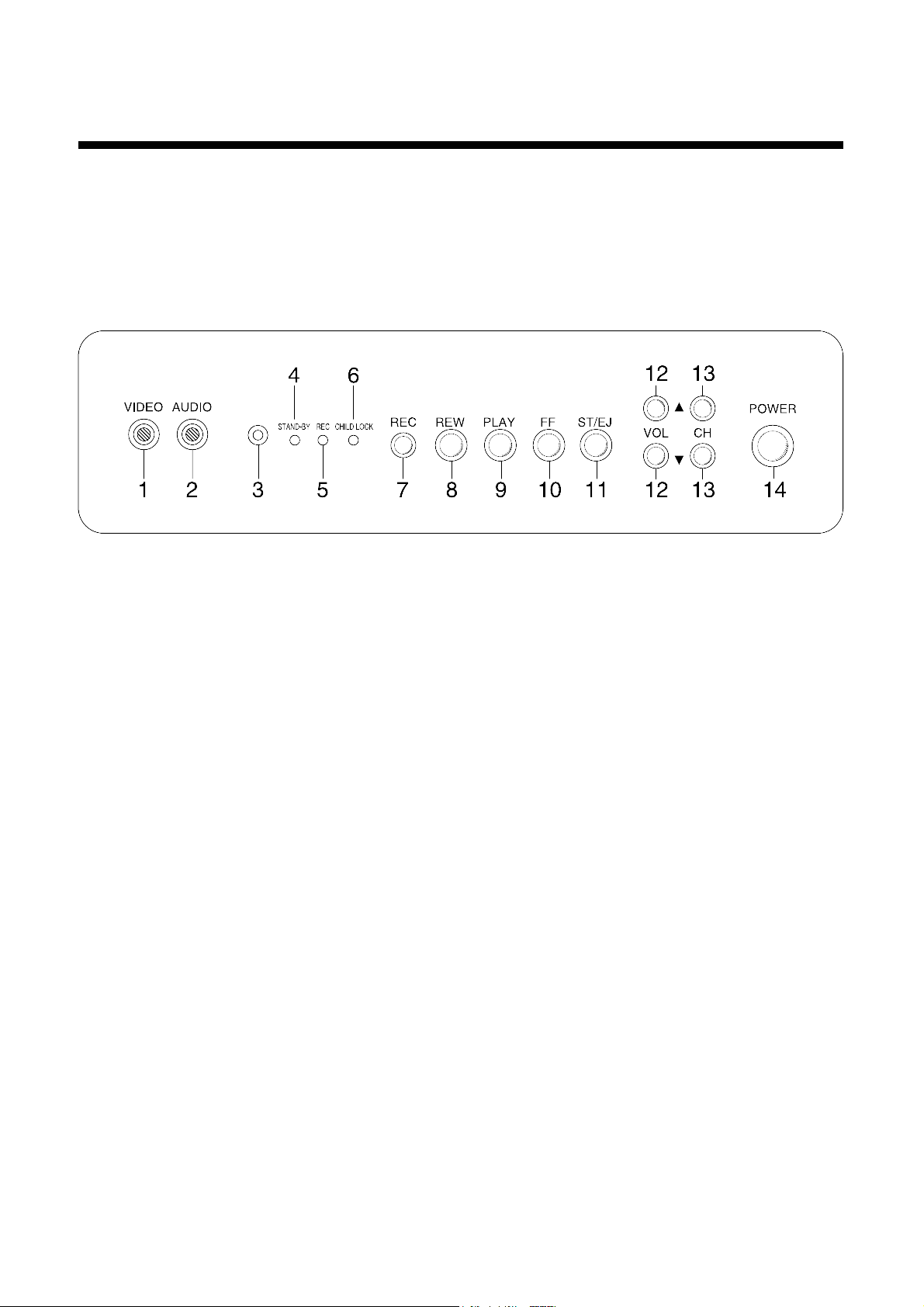

2. PANEL VIEW

2-1. FRONT PANEL

The section below summarizes the buttons, controls, and terminals that you will use with your TV.

Your TV/VCR's front Panel

Below you will find short descriptions of the buttons and indicators on the front panel. These are used following functions.

1 VIDEO IN jack

Use this jack to receive a video signal from another A/V component.

2 AUDIO IN jack

Use this jack to receive an audio signal from another A/V component.

3 Remote control receiver

This receiver receives a signal from your remote control. Do not block it.

4 STAND-BY (red) indicator

This indicator lights up when the power is off.

5 REC (Green) indicator

this indicator blinks when recording and lights up when set for timer recording.

6. CHILD LOCK (Yellow) indicator

This indicator lights up when the child lock is set.

7. REC button (record)

Press this button to begin recording. Press repeatedly to set a recording time using One-Touch Recording (OTR).

8 REW button (rewind)

Use this button to rewind the tape.

9 PLAY button

Press this button to begin normal playback of a tape.

10 FF button (fast forward)

Use this button to "fast forward" a tape.

11 ST/EJ button (stop/eject)

Press this button when a tape is moving to stop the tape. Press this button when the tape is stopped to eject it.

12▼▼VOL▲▲buttons (volume)

Use these buttons to change your TV/VCR's volume.

13▼▼CH▲▲buttons (channel)

Use these buttons to change channels on your TV/VCR. You will also use these buttons to adjust the tracking.

14 Power button

Use this button to turn your TV on or off.

26

Page 30

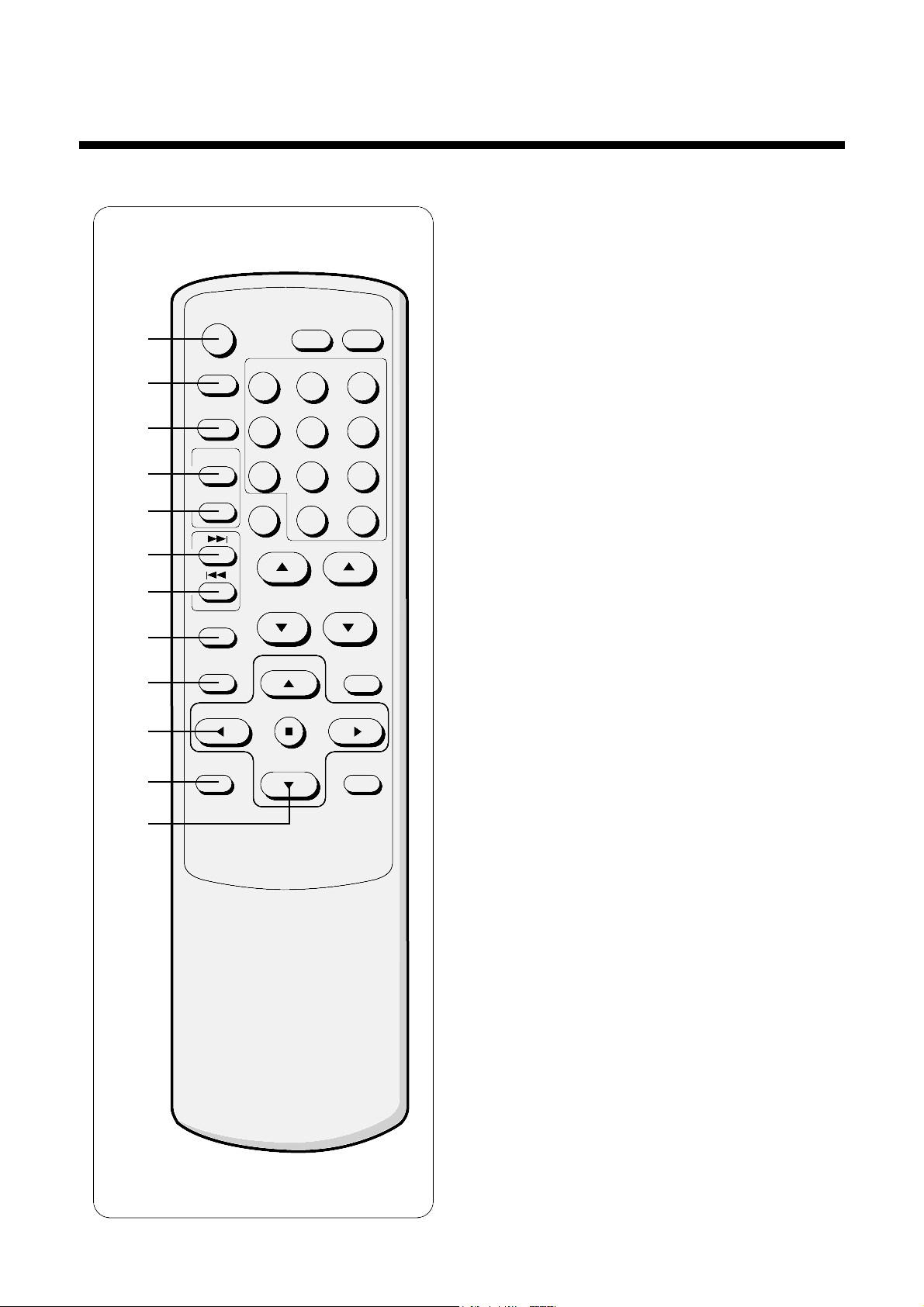

3. Remote controller (DVN-14F6N/20F6N)

1 POWER

Use this button to turn your TV/VCR on or off.

2 TV/CATV

Use the button to set up your TV/VCR to receive signals

from an antenna (TV) or a cable system (CATV).

3 TV/LINE

Use this button to select between viewing the signal

coming from the antenna terminal (TV) or the signal

coming from the A/V jacks (LINE).

4 RESET

Press this button to reset the counter to 0:00:00.

5 O STOP

Press this button to automatically rewind the tape to the

0:00:00 point.

6 VISS

▶▶▶▶

Press this button to find the next index mark on a tape

and begin playing.

7 VISS

◀◀◀◀

Press this button to find the most recent index mark on a

tape and begin playing.

8 REC ON/OFF

Use this buttin to enable or disable timer recording.

9 MENU

press this button to turn the on-screen menu system on

and off.

10 REW (rewind)

Use this button to rewind the tape or to change items in

the menu system.

11 REC/OTR

Press this button to begin recording.

Press repeatedly to set a recording time using OneTouch Recording (OTR).

12 PAUSE/STILL

Press to temporarily stop the tape during recording or

playback, or to move the cursor in the menu system.

27

1 2 3

4 5 6

7 8 9

SLEEP 0

STOP//EJECT

100

MUTE RECALL

TV/CATV

POWER

TV/LINE

RESET

COUNTER

0 STOP

REC ON/OFF

MENU

REC/OTR SPEED

CLEAR

PAUSE/STILL

PLAY

VOL/V-LOCK CH/TRK

FFREW

VISS

REMOTE CONTROLLER R-35A01

1

2

3

4

5

6

7

8

9

10

11

12

Page 31

13 MUTE

Use to turn the TV/VCR's sound on and off.

14 RECALL

Press this button to display the current time, the counter,

channel number or other status items.

15 Number buttons (0-9)

Use these buttons to change channels or select menu

items.

16 100

Use this button if you wish to view a channel greater than

99.

17 SLEEP

Use this button to program the TV/VCR to turn off after a

certain time.

18 CH/TRACKING

Use these buttons to change channels on your TV or to

adjust the tracking of a video tape during playback.

19 VOL/V-LOCK

Press to adjust the volume of the TV/VCR. You can also

use these button to eliminate video noise when displaying a still frame.

20 CLEAR

Press this button to erase timer recording settings.

21 PLAY

Press this button to begin normal playback of a tape, or

to move the cursor in the menu system.

22 FF (fast forward)

Use this button to "fast-forward" a tape or to change

items in the menu system.

23 SPEED

Use this button to select the SP, LP, or SLP tape speed.

23 STOP/EJECT

Press this button when a tape is moving to stop the tape

; press it when the tape is stopped to eject it. Also use

this button to activate items in the menu system.

28

1 2 3

4 5 6

7 8 9

SLEEP 0

STOP//EJECT

100

MUTE RECALL

TV/CATV

POWER

TV/LINE

RESET

COUNTER

0 STOP

REC ON/OFF

MENU

REC/OTR SPEED

CLEAR

PAUSE/STILL

PLAY

VOL/V-LOCK CH/TRK

FFREW

VISS

REMOTE CONTROLLER R-35A01

13

14

15

16

17

18

19

20

21

22

23

24

Page 32

Location of Adjustment Parts Observation Waveform

MAIN PCB Horizontal Axis : S/DIV

Vertical Axis : CH1 : H/SW, CH2 : ENVELOPE

1. SERVO

1-1) X-path and P2, P3 Adjustment

Adjustment Procedure

1. Preparation

1) Set the AUTO TRACKING to OFF using REMOCON.

2) Play back the Test tape (Color Bar)

3) Set the oscilloscope to the CHOP mode. Connect CHI to the H/W (PY09) and CH2 to the ENVELOPE (PY09) and

trigger the scope with the signal from CH1.

2. Adjustment

1) Adjust CORN SCREW to position to maximize the width of the ENVELOPE pluse.

2) Adjust P2 to position which the edge of ENVELOPE signal has equal degree to the body of ENVELOPE signal.

Adjusting P3 is same to P2's.

3. Remark

1) After adjusting, press stop button to eject the tape.

2) Insert the tape into deck to confirm Autotracking.

3) If Normal screen is showed up as soon as it is start to play, adjustment becomes good.

If not, Adjust repeatedly to operate autotracking.

4) To know P2, P3, and CORN SCREW, refer from 'The schematic diagram of tape transporting system' on page 23

■■

ELECTRICAL ADJUSTMENTS

29

Item Mode Adjustment parts Check point Test equipments Test tape Input signal

X-path PLAY CORN SCREW PY09 Oscilloscope DN-1

P2, P3

P2, P3

DECK A'S

MAIN PCB

PY09

PY05

Y/C

BOARD

⊕RN90

Page 33

30

1-2) PLAYBACK PHASE Adjustment

• Adjustment Procedure

1. Preparation

1) Play back the Test tape (Color Bar).

2) Connect scope's connector to PY 09

3) Set the Oscilloscope to the chop mode.

Connect CH1 to the H/SW(PY09) and CH2 to the V-OUT(PY09) and trigger the scope with the signal from CH1.

2. Adjustment

1) Adjust RN90 to position the rising edge of SW PULSE at 6.5H from the V-SYNC.

Mode Adjustment parts Check point Test equipments Test tape Input signal

Play RN90 RY05 Oscilloscope DN-1

Location of Adjustment Parts Observation Waveform

MAIN PCB Horizontal Axis : 100µS/DIV

Vertical Axis : CH1 : SW30, CH2:V.OUT

DECK A'S

PY09

PY05

Y/C

BOARD

⊕RN90

Page 34

31

2. AUDIO

2-1) AUDIO CIRCUIT ADJUSTMENT METHOD

• Adjustment Procedure

1. Preparation

1) Set REC BAIS to ON mode using REMOCON. (then, front pannel's REC LED will be lighted up.)

2) Supply the signal in the OPEN mode.

3) Connect the Audio level meter to RC HEAD 10Ω (on solder side).

2. Adjustment

1) Adjust RU57 to obtain [3.0]mVrms.

3. Adjustment Inspection Standard : [3.0 ± 0.1mVrms]

• If you don't have Service Remocon, You can set this rec mode by inserting a tape (with record top) and pushing rec

button.

Item Mode Adjustment parts Check point Test equipments Test tape Input signal

Audio

REC RU57 RC HEAD 10Ω Audio level meter Blank tape

Record Bias

Location of Adjustment Parts Observation Waveform

MAIN PCB Horizontal Axis :

Vertical Axis :

RC HEAD

DECK A'S

MAIN PCB PARTS SIDE

PY09

PY05

Y/C

BOARD

⊕RU57

Page 35

32

2-2) Audio Azimuth Adjustment

• Adjustment Procedure

1. Preparation

1) Set the VCR to the PLAY mode

2) Set the Scope connector to the P602.

3) Adjust first screw on the plate under the AC head to maximize scope's signal width.

2. Adjustment Inspection standard : [Maximum Point]

Item Mode Adjustment parts Check point Test equipments Test tape Input signal

Audio Azimuth

PLAY AC HEAD'S P602 Signal GEN. DN-2 7KHz

Adjustment

SCREW Osilloscope MONO Bar

Location of Adjustment Parts Observation Waveform

MAIN PCB Horizontal Axis : 0.1mS/DIV

Vertical Axis : 0.1V/DIV

MAIN PCB PARTS SIDE

PY09

PY05

Y/C

BOARD

P602

···

RC HEAD

DECK A'S

Page 36

33

3. VIDEO

3-1) Y NOISE REDUCTION

• Adjustment Procedure

1. Preparation

1) Supply the MULTI BURST signal to the VIDEO IN JACK.

2. Adjustment

1) Set the VCR to the STOP(EE) MODE.

2) Set the Oscilloscope to the chop mode.

Connect CH1 to the V-OUT(RY09) and CH2 to the CNR TP(RY05) and trigger the scope with the signal from CH1.

3) Adjust RY34 to the 3.58MHz Y component of MULTI BURST signal becomes less than [20]mVp-p.

Location of Adjustment Parts Observation Waveform

Y/C PCB Horizontal Axis : 10µS/DIV

Vertical Axis : 20 mV/DIV

Y/C PCB SOLDER SIDE

PY05

IY03 IY01

IY02

⊕RY34

Mode Adjustment parts Check point Test equipments Test tape Input signal

EE RY 34 PY05, PY09 Oscilloscope Multi Burst

Signal gen. with 3.58 MHz

PAY01 PAY02

CH-2 (PY05YNR)

Horizontal:10µs/DIV

Vertical:20mv/DIV

Page 37

34

3-2) COLOR NOISE REDUCTION

• Adjustment Procedure

1. Preparation

1) Supply the Color bar signal to the VIDEO LINE IN JACK.

2) Supply 5V to RY05.

2. Adjustment

1) Set the VCR to the STOP(EE) Mode.

2) Set the Oscilloscope to the chop mode.

Connect CH1 to the V-OUT(RY09) and CH2 to the YNR TP (RY05) and trigger the scope with the signal from CH1.

3) Adjust RY91 until Color signal becomes minimum.

Location of Adjustment Parts Observation Waveform

Y/C PCB Horizontal Axis : 10µS/DIV

Vertical Axis : 50 mV/DIV

Mode Adjustment parts Check point Test equipments Test tape Input signal

EE RY 91 PY09 Signal gen. Color Bar

Oscilloscope

CH-2(PY09(NR)

Horizontal:10µs/DIV

Vertical:50mv/DIV

Y/C PCB SOLDER SIDE

PY05

PY09

IY03 IY01

IY02

⊕RY91

PAY01 PAY02

Page 38

1. VIDEO & AUDIO

1-1. FROM RF TO COMPOSITE VIDEO

When the TIMER IC (I701) selects a certain channel from antenna, CLOCK, DATA, and ENABLE of I701 signals are

inputted to the TUNER.

So, TUNER(U101) tunes up a certain channel frequency by means of PLL circuit operation and output IF (Intermediate

Frequency) signal.

This IF signal through Q103, PRE-AMP stage, and SAW FILTER is inputted to I501 #8 and #9, and it is optimized by

VCO and AFT.

As the result of these operations, COMPOSITE VIDEO SIGNAL comes from pin 51 of I501.

Because 4.5MHz sound frequency in the COMPOSITE VIDEO SIGNAL is eliminated by Z102 TRAP, only video signal

in the COMPOSITE VIDEO SIGNAL is inputted to pin 45 of I501 and 4.5MHz sound frequency is inputted to pin 48 of

I501 through Z103 FILTER.

1-2. COMPOSITE VIDEO SIGNAL

This CHASSIS includes three video signals. One is from RF(above mentioned), another is from A/V, and the third is from

PLAY MODE.

Switching IC I503 controls these three final video signal.

Once one of the two signals(TV video signal from pin 45 of I501 and A/V video signal from pin 42 of I501) is selected, the

selected signal is from pin 43 of I501 and it is inpitted to pin 1 of I503.

Another video signal from PLAY MODE is inputted to pin 4 of I503.

Also, One of the two signals(video signal from pin 1 of I503 and video signal from PLAY MODE) is selected, and the

selected signal is transmitted to pin 2 and pin 3 of I503.

Final video signal is inputted to pin 22 of I701 to detect CAPTION SIGNAL and it is also inputted to pin 38(C INPUT), pin

(Y INPUT), pin 44(SYNC INPUT).

And R-Y signal is from pin 23, G-Y signal is from pin 24, B-Y signal is from pin 22, -Y signal is from pin 22, and those

color difference signals are sent to CRT BOARD.

In CRT BOARD, those color difference signals are mixed and amplified by color difference drive method.

1-3. AUDIO SIGNAL

This CHASSIS includes three audio signals. One is from RF(above mentioned), another is from A/V, and the third is

from PLAY MODE.

Switching IC I503 also controls these three audio signal.

TV Audio signal from pin 3 of I501 is inputted to pin 8 of I503.

A/V audio signal from A/V JACK is inputted to pin 11 of I503 and outputted to pin 9, pin 10.

So, that audio signal is inputted to pin 16 of IU01.

Audio signal from PLAY MODE is inputted to pin 2 of IU01.

One of the two audio signals(audio signal from PLAY MODE, audio signal from A/V mode) is selected and outputted to

pin 22 of IU01 and inputted to pin 1 of I501.

Audio signal to be inputted pin 1 of I501 and controlled volume is outputted to pin 4 of I501.

That audio signal is inputted to pin 3 of I601(SOUND AMP), and amplified by I601 and outputted to pin 5 of I601.

Finally that audio signal goes into SPEAKER.

■■

SIGNAL FLOW

35

Page 39

36

SWITCHING TABLE OF I503

MODE RF

A/V PLAY TOGGLE

PIN (EE)

5 L L H VIDEO

6 H L L AUDIO

12 L H H AUDIO

13 H H L VIDEO

* The input signal is transmitted to putput port when switching port

is at logically high state.

(Top View)

Page 40

37

2. Power circuit (Power supply circuit)

2-1. Abstract And Function

It selects SMPS(SWITCHING MODE POWER SUPPLY) which is possible to put in from AC 108V~132V/60Hz with

SANKEN Ic STR-S5707 and supply the stable voltage which each circuit needs.

The voltage which electric resources circuit supplies is followed.

2-2. I801 STRS-5707

1) BLOCK DIAGRAM

NO.SUPPLY ELECTRIC

SOURCE SUPPLY CIRCUIT APPLICATION

RESOURCES

TRANS SECOND RECTIFIED

FBT

FBT B

+

1 DC 125V VOLTAGE

PIF

For channel

D814 selecting(33V)

2

DC 12V REGULATOR IC

SERVO circuit

For driving DRUM,

(MOTOR 12V) I805(PQ12RF11) CAPSTAN MOTOR

TUNER For channel selecting(9V, 5V)

3

DC 12V REGULATOR IC IF AMP circuit IF amp. circuit(9V), V/SIF(5V)

(ON/OFF 12V) I804(PQ12RF11) AUDIO circuit For driving AUDIO I/O circuit

VIDEO circuit For driving VIDEO, ANALOG circuit

4

DC 6.0V REGULATOR IC SERVO, TIMER IC For driving SYSCON, TIMER,

(EVER 5.3V) I803(KIA7806) SYSCON IC circuit SERVO circuit

TRANS SECOND

5 DC 14V RECTIFIED VOLTAGE AUDIO circuit AUDIO AMP. B

+

D813

6 DC 9V

REGULATOR IC

DEFLECTION circuit

VERTICAL IC B

+

I806 (KIA7809) H. VCC

SENS

7

PNP

R6

R7 R8 R9

+2D

R1

VIN

9

START UP

PRB RBG

T.S.D

OVP

C1

R2

LA TCH

OSC

C2

PROPOTONAL

OCP

C4

INH

DRIVE

R5

6

C3

R3

R4

Trl

Tr2

8

4

3

1

2

5

DRIVD

SINK

B

C

GND

OCP

Page 41

38

2) Function of Each Termiinal

3) Other Function

4) Internal Circuit Constant

No. of Terminal Symbol Description Function

1 C Collector Terminal Collector of TRr(Power Transistor)

2 GND Ground Terminal Ground(Emitter of PTr)

3 B Base Terminal Base of PTr

4 SINK Sink Terminal Base Current (IS) Input

5 OCP Overcurrent Protection Terminal Overcurrent Sensing Signal Input

6 INH

Inhibit Terminal Off Time Synchronizing

Latch Terminal Latch Circuit Operation Signal Input

7 SENS Sensing Terminal Constant Voltage Control Signal Input

8 DRIVE Drive Terminal Base Drive Currnet(ID) Output

9 VIN VIN Terminal Control Circuit Power Supply Input

Symbol Function

OVP Built-in Overvoltage Protecton circuit

TSD Built-In Thermal Shutdown Circuit

R1 T ON Adjustment Trimming Resistor R7 14KΩ C4 0.01µF

R2 T OFF Adjustment Trimming Resistor R8 2.5K C5 1500pF

R3 1.0kΩ R9 35kΩ

R4 100Ω C1 3300pF

R5 85Ω C2 0.01µF

R6 Vs Adjustment Trimming Resistor C3 820pF

Page 42

39

2-3. SMPS BASIC OPERATING DESCRIPTION

1) Power supply block circuit

2) Initially starting operation

– When AC power supply is put in at first, the voltage which rectifies this.happens on the both Blocks of C806

This voltage flows through R806 and is the circuit which searchs the voltage of I801 Vin TERMINAL (PIN No.#9) and

starts or stops operating I801.

– Turning on the power supply, CTRL circuit starts operating by the funtion of START circuit, when it is charged to C807

through starting resistance R806 and Vin terminal voltage goes to 8V (TYP.)

– According to the multiplication(PRODUCT) of starting resistance R806 and C807, time is decided which CTRL citcuit

starts operating after putting AC input voltage. So, if the value of C807 is too high, It could be late for I801 to start.

– When CTRL circuit starts operating and the voltage of DRIVE wound wire (pin no #3) of T801 TRANS is up, I801

starts operating after rectification of D808 and C807.

– When the voltage of detect wound wire(pin no #4) T801 TRANS increases and is rectified through D807 and C809

and DC 32V is put in I801 sense(pin no #7), TRANS secondary voltage is established.

– When MAIN TR of power IC is off, energy which is charged to the primary is transtmitted through TRANS secondary

rectification DIODE.

PWC1

R804

2.2M(COMP)

1/2W

F801

AC 125V 4A

C801

O.1U(M)

AC250V

Z801

SVC2710

VARISTOR

L801

TLF-472BE

D802-D805

:1S1888

C802-C805

4700P 500V

R803

1 OHM 7W

CEMENT

R812

120K

1/2W

R806

36K

2W

89

10

11

12

13

14

16

15

7

6

5

4

3

2

1

R819

2.2

1/4W

R833

4.7K

1/4W

R807

18 1W

DR

S

B

C

E

OCP

1801

STR-S5707

Vin

SENSE

START UP

1

1

7

6

3

2

1

3

4

4

PRE REA

T.S.D

DSC

REF

OCP

R1

C1

C2

R2 C4

C3

PROPORTION

ORIVE

DVP

LATCM

D810

BYV950

240(*200)

1/4W

R832

R809

0.27(F)

2W

R816

1K

1/4W

C822

1500P

50V

C824

4700P

AC400V

C823

3900P

630VPL

L803

MD-5

C808

220U

25V

R815

1.8K

1/4W

R813

100K

1/4W

C807

220U

25V

C809

10U

100V

D807

BYV95C

123V

15V

15V

8.5V

D811

BYV95C

D812

BYV95C

D813

BYW95C

D814

BYW95C

C827

1000P(HIKR)

2KV

T810

TSM-4242A3

C810

470U

16V

C812

470U

25V

C814

470U

25V

C828

0.01U

C815

100U

160V

D809

BYV95C

D808

BYV95C

D803

C803

D805

C805

D802

C802

D804

C804

C806

330U(LWF)

200V

Page 43

40

3. DEFLECTION CIRCUIT

Vertical, Horizental drive pulses are out of M52335ASP(I501). This vertical drive pulses are connected to

Vertical Drive IC TA8445K(I301) and drive vertical deflection coils. This horizental deflection drive pulses by

driving horizental output circuits drive horizental deflection coils and supply 26.5v, 180v, high voltage 25kV,

focus voltage and screen voltage by driving FBT.

4.

u-COM CIRCUITS.

Timer IC is M37267MX(I701) made by Mitsubish. Syscon receives the signal from user's remocon and it

becomes to be serial-communication CLOCK/S DATA IN/S DATA OUT signal. Timer IC selects channel

with CLOCL /DATA /EN and receives the functions to control TV and VCR drivings(OSD, VOL CTRL, TV

ON/OFF), such as brightness, contrast, color, tint, sharpness, video signal, volume, caption and program

recording.

5.

CHANNEL SELECTION AND MEMORY

Selecting operation chosen by user is made up when PLL DATA, PLL CLOCK, PLL ENABLE are put out from

u-com and is put in to Tuner. u-com put out data to memory IC 24LC01B(I702) to memorize final channel,

volume condition, video condition, memorized channel.

Page 44

41

6.

SERVO/SYSCON CIRCUIT OPERATION

1) summary

•

When power supply is supplied to TV/VCR, Servo-Syscon 1 Chip IC confirms the driving condition of DECK

by checking CAM SW from DECK. And it gets capstan Motor worked and is operated as initial Mode. This

is ready for receiving the serial data from timer IC after proper operating according to the driving condition

of Deck and the existence of tape or not.

•

When Syscon IC received recording signal, playback signal and so on by receiving of pussing button and

using remote control inform Timer IC what button (remote sensor) is pressed as a serial data, Timer IC operates properly on each mode.

•

After making Deck be in proper condition in each mode by driving L/C motor according to each mode, it drives the drum motor and capstan motor to make the head spin and the tape move. Drum and capstan

servo are operated in order to obtain clear screen condition.

• The special feature of Drum servo system helps to keep the constant speed and phase of it and to prevent the

screen sway up/down.

By comparing with D-FG signal from Drum Motor and referencesignal of Syscon IC to keep the constant

speed, the difference value is put out to DPWM to drive Drum Motor.

By comparing with D-PG signal from Drum Motor and reference signal of Syscon IC (playback Mode) to

keep the constant phase, the difference value and speed difference are put out to D-PWM.

•

Capstan servo system keeps the constant speed and phase of tape. It prevents the trembling sound and the

flow of the Noise band on screen. And it prevents a lot of Noise on screen by malfunction of Tracking.

•

In order to keep the constant speed, It's put out to C-PWM from caption Motor, DC-amplified in power curcuit

and gets caption Motor drived.

•

By comparing with CTL signal from CTL Head connected with the lower section of A/C Head and the

refeence signal of Syscon IC, the value and speed difference are put out to C-PWM.

2) VCR MODE IN NORMAL CONDITION

(1) EJECT :

MODE that a casstte come out of compartment.

(2) STAND-BY :

MODE that a cassette is unloading.

(3) STOP :

MODE that a casstte is loading.

(4) FF :

Fast Forward MODE that moves the tape forward in STOP mode

(5) REW :

REWind MODE that moves the tape reversely in STOP mode

(6) REC :

RECord MODE that records video and audio signal on tapes.

(7) PAUSE :

record PAUSE MODE that makes recording stop.

(8) PLAY :

MODE that plays the record tape

(9) STILL :

play STILL MODE that playback is paused

(10) CUE & REV :

MODE that search the screen right or reversely.

7. NORMAL AUDIO CIRCUIT OPERATION

1. REC Mode

The signal put in to IU01 #16, is amplified at LINE AMP through ALC circuit in the IC. It is put out to speaker

through #22. At the same time it is put out from #21 through High-Frequency compensation circuit by reso

nance block.

After the signal goes through the REC AMP, it's modulated to AM by frequency 70KHz, is recorded on a tape

through R/P Head.

2. PB Mode

After the signal picked up at the HEAD is put in to pin #2 and performs to amplify and equalize frequency at

each mode, it is supplied to OUTPUT #1 SW in IC.

The signal is chosen as normal by Sound Ouptut control, is put in to LINE AMP again and is amplified. Then,it's

put in to TV.

8. VIDEO CIRCUIT OPERATION

1. EE mode

VIDEO input signal is input to #31 of IY01 (LA7423A) and output to #28 of IY01 after it's multiplied 2 times at AGC and

VIDEO AMP.

The signal is connected to VIDEO output terminal.

41

Page 45

4242

2. REC mode

•

Signal is put in to #31 of IY01(LA7423A), and it is seperated into Luminance and Chroma within IC.FM modulated

luminance signal is put in to #34 and low-frequency transformed color signal is put in to #14.

After passing through REC EQ, circuit for adjusting REC characteristics, FM modulated signal is put in to

IY03(LA7411)#8 and color signal put out to #11 is put in to IY03 #3.

•

The signal put in to #7, #8 of IY03(LA7411) is recorded on the tape by HEAD through AGC and REC CUR

RENT AMP.

3. PB Mode

•

In case of SP, the signals on #17, #20 of IY03(LA7411) are amplified to 60dB respectively by V.SW, put out

to #7 IY03 and put in to #4 IY01(LA7423A)

•

FM signal put in to #14 of IY01 is demodulated at FM DEMODULATIOR after passing through FM EQ.

within IC and put in to Y/C MIXER after passing through 3.0MHz LPF to eliminate color signal component.

•

While FM signal put in to #14 of IY01 is passing through 1.3MHz LPF. Only low-frequency transformed color

signal passes.

The color signal is converted to 3.58MHz at Main CONVERTER and is put in to Y/C MIXER after it's

amplified to 6dB and goes through ACC/BURST EMPHASIS. Y/C signal is put out to #28.

VIDEO OUT

HA SW REC "H"

7.1M LPF

41

IY02 8

LC89960

IH CCD IC

REC EQ R/T

R/T

VIDEO IN

31 28

IY01

LA7423A

Y/C PROCESS IC

9111718

IY03

LA7411

814

PRE-AMP

IC

715

14

Page 46

■ IY03 (LA7411)

1. Case Outline : DIP-24S (300mil) Plastic Package

2. Application : VHS format VTR Record and Playback Head Amplifiers

3. Maximum Ratings at Ta = 25°C

4. Operating conditions at Ta = 25°C

5. Electrical Characteristics at Ta = 25°C

43

■■

IMPORTANT IC'S OPERATION

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage VCC max 7.0 V

Allowable power dissipation Pd max Ta ≦ 6.5°C 700 mW

Operating temperature Topg -10 to +65 °C

Storage temperature Tstg -40 to +150 °C

Parameter Symbol Conditions Ratings Unit

Recommended supply voltage VC 5.0 V

Operating supply voltage range VCC opg 4.80 to 5.50 V

Parameter Symbol

In- Out

Conditions min typ max Unit

-put -put

T1 T2

PB mode T12:5.0V T10:OPEN EP/ SW30

T4:OPEN (PB) SP MUTE

Current dissipation I CCP The current flowing

0141822mA

into pins 12

Voltage gain

L CH1 GVP 1 T17A T7A

Vi = 38mVpp. f = 1MHz

0

56.5 59.5 62.5 dB

H CH2 GVP 2 T20A 2.5

Voltage gain difference △GVP 1 GVP1-GVP2 -1 0 1 dB

Input conversion CH1 VNIN 1 T17A T7A VOUT/GVP1.2 0

1.1 1.5

µVrms

noise distortion CH2 VNIN2 T20A after 1.1MHz LPF 2.5

Frequency CH1 △V fp 1 T17A T7A Vi=38mVpp. f=7MHz 0

characteristics CH2 △Vfp 2 T20A V OUT/GVP1.2 2.5 -2.5 1 dB

output ratio

Second harmonic CH1 V HDP 1 T17A T7A Vi=38mVpp. f=4MHz 0 -40 -35 dB

distortion CH2 VHDP 2 T20A (8M component)/ 2.5

(4M component)

Vi=38mVpp

output ratio

Maximum output level

CH1 V OMP 1 T17A T7A f=1MHz 0 1.0 1.2 Vpp

CH2 V OMP 2 T20A The output level when 2.5

the third harmoinic

is-30dB.

Page 47

44

6. Pin Function Table

No Pin-function Type DC voltage(V) Input/Output configuration Remarks

1 HA (EP/SP)

2 RF-SW

(REC-MUTE)

3 H-SYNC

4 REC-H PB O

REC 5

5 ENV DET PB See attached

OUT sheet

REC 0

6 GND

2 2

7 PB-OUT PB 2.3

REC-C-IN REC 3.6

8 REC-Y-IN

REC 3.6

1kΩ

100kΩ 1.6V

HA

COMP

20kΩ

80kΩ

1.2V

H.SYNC

COMP

20kΩ

80kΩ

1.6V

REC/PB

COMP

100Ω

20kΩ

1kΩ

50kΩ

3.2V

1.0V

RF

COMP

RECMUTE

COMP

VCC

100Ω

25kΩ

5kΩ

300Ω

PB OUT

REC

C IN

5kΩ

100Ω

EP

SP

HCH

ON

LCH

OFF

1.6V

Syac

H

L

REC

PB

1.5V

2.0V

SW30 REC MUTE

1.0V 3.2V

Page 48

45

No Pin-function Type DC voltage(V) Input/Output configuration Remarks

9 AGC-FLT

PB 0

REC 1.6

10 REC-CUR

ADJ2

PB 2.5

REC 2.5

11 REC-CUR PB 4.5

ADJI

REC 5.0

12 VCC

13 REC-BIAS

PB 0

REC 1.7

14 REC-OUT

PB 0

REC 4.2

16 PB Amp

19 2'nd Filt

PB 2.0

REC 3.6

100

1k

5k

1k

100

10k

20k

500

VCC

COMP

From

REC

ACC

COMP

16.7k

1.5k

3.3k

1.6k

10k

100

VCC

4V : +3.5dB

2.5V : ±0dB

(OPEN)

1V : -6dB

Page 49

46

No Pin-function Type DC voltage(V) Input/Output configuration Remarks

PIN MODE STOP REC PLAY REW/FWD REV/FF PAUSE STILL

10000000

2 0 0 0 0 1.4 1.4 1.4

30000000

4 0 5.2 0 0 0.5 0 0

5 0.9 0 0.9 2.4 2.5 1.6 2.1

60000000

7 2.3 3.5 2.3 2.3 2.3 2.3 2.3

80000000

9 0 1.6 0 0 0 0 0

10 2.6 .2.6 2.6 2.6 2.6 2.6 2.6

11 5.1 4.3 5.1 5.2 5.2 5.2 5.2

12 5.1 5.2 5.1 5.2 5.2 5.2 5.2

13 0 1.7 0 0 0 0 0

14 0 4.2 0 0 0 0 0

15 5.2 5.2 5.2 5.2 5.2 5.2 5.2

16 2.1 3.8 2.1 2.1 2.1 2 2.1

17 0.7 0.7 0.7 0.7 0.7 0.7 0.7

18 0 4.2 0 0 0 0 0

19 2.1 3.8 2.1 2.1 2.1 2.1 2.1

20 0.7 0.9 0.7 0.7 0.7 0.7 0.7

21 0 4.2 0 0 0 0 0

22 0 0 0 0 0 0 0

23 0 0 0 0 0 0 0

24 0 0 0 0 0 0 0

17 PB-L-IN

20 PB-H-IN PB 0.7

REC 0

18 PB-L-SW

21 PB-H-SW

PB 0

REC 4.2

15

23 NC

24

REC ON

REC ON

VCC

PB ON

ON resistance

4 to 6Ω

VIDEO PREAMP IC LA7411

7. Pin Operation

Page 50

47

■■

IY02 (LC89960)

1. Overview

The SANYO LC89960 is a 1H delay line for NTSC television systems.

Only an external low-pass filter is required to implement a 1H delay line.

2. Features

• Single 5V power supply.

• 1H delay signal can be obtained with low-pass filter and 3.58MHz clock input.

• Minimum number of external components required because of timing generator, bias generator, output Amp, on

chipped.

• The phase of output signal is reversed to the phase of input signal.

3. Functions.

• 905 stage CCD shift register.

• Timing generator and clock driver for CCD.

• Auto-bias citcuit.

• Sync tip clamp circuit.

• Sample and hold circuit and output Amp.

• 4fsc clock generator with PLL circuit.

• VCO (4fsc) output circuit.

4. Absolute Maximum Ratings

Items Symbol Unit Min. max. Conditions

supply voltage VDD V -0.3 +6.0 Ta = 25°C

Operating Temperature TOPR °C -10 +60

Storage Temperature TSTG °C -55 +150

Allowable Power : Dissipation PD mW - 450 Ta = 25°C

PIN MODE STOP REC PLAY REW/FWD REV/FF PAUSE STILL

1 2.2 2.2 2.2 2.2 2.2 2.2 2.2

2 2.5 2.5 2.5 2.5 2.5 2.5 2.5

30000000

42222222

50000000

60000000

70000000

8 1.2 1.2 1.2 1.2 1.2 1.2 1.2

9 5.2 5.2 5.2 5.2 5.2 5.2 5.2

10 2.1 2.1 2.1 2.1 2.1 2.1 2.1

11 2.1 2.1 2.1 2.1 2.1 2.1 2.1

12 5.2 5.2 5.2 5.2 5.2 5.2 5.2

13 9.4 9.4 9.4 9.4 9.4 9.4 9.4

14 0 0 0 0 0 0 0

Y/C CCD IC LC89960

5.Pin Operation

Page 51

■■

IY01 (LA7423A)

1. Case Outline : DIP-36S(400mil) Plastic Package

2. Application : VHS VTR Video signal Processor (Y/C single-chip)

3. Maximum Ratings at Ta = 25°C

48

PIN MODE STOP REC PLAY REW/FWD REV/FF PAUSE STILL

1 0 0 4.8 0 4.8 0 4.8

2 2.4 2.4 1.9 2.4 2 2.4 2

3 3 3 3.2 3 3.1 3 3.1

4 2.3 2.3 4.7 2.3 4.7 2.3 4.7

5 2.3 2.3 4.7 2.3 4.7 2.3 4.7

6 3.1 3.1 3 3.1 3 3.1 3

7 0 0 3.6 1.8 3.6 1.8 3.6

8 3.1 3.1 3.1 3.1 3.1 3.1 3.1

9 2.1 2.1 2.1 2.1 2.1 2.1 2.1

10 0 0 0 0 0 0 0

11 1.1 1.1 1.1 1.1 1.1 1.1 1.1

12 2.5 2.5 2.5 2.5 2.5 2.5 2.5

13 2.5 2.5 2.5 2.6 2.5 2.6 2.5

14 2.5 2.5 3.3 2.5 3.3 2.5 3.3

15 2.1 2.1 2.1 2.3 2.1 2.3 2.1

16 2.1 2.1 2.1 2.1 4.6 2 5

17 3.9 3.9 3.8 3.9 3.8 3.9 3.8

18 2.8 2.8 2.7 2.8 2.7 2.8 2.7

19 2.7 2.7 2.7 2.7 2.7 2.7 2.7

20 2.7 2.7 2.7 2.7 2.7 2.7 2.7

21 1.9 1.9 1.9 1.9 1.9 1.9 1.9

22 2 2 2 2 2 2 2

23 1.6 1.6 1.6 1.6 1.6 1.6 1.6

24 5.1 5.1 5.1 5.1 5.1 5.1 5.1

25 4.2 4.2 4.2 4.2 4.2 4.2 4.2

26 0 0 0 0 0 0 0

27 5.1 5.1 5.1 5.1 5 5.1 5

28 1.8 1.8 1.8 1.8 1.7 1.8 1.8

29 0 0 0 0 0 0 0

30 2.7 2.7 2.7 2.7 2.7 2.7 2.7

31 3 3 3.5 3 3.5 3 3.5

32 1.5 1.5 1.8 1.5 1.7 1.5 1.6

33 0 0 0 0 0 0 0

34 3.1 3.1 3.7 3.1 4.6 3.1 4.6

35 0 0 3.6 0 3.6 0 3.6

36 5.2 5.2 3.7 5.2 3.7 5.2 3.7

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage VCC max 7.0 V

Allowable power dissipation Pd max Ta ≦ 65°C 1070 mW

Operating temperature Topg -10 to + 65 °C

Storage temperature Tstg -40 to + 150 °C

Y/C 1CHIP IC LA 7423

4. Pin Operation

Page 52

No Pin-function Type voltage(V) Signal waveform Input/Output configuration Remarks

5. IY01 (LA7423A : Y/C PROCESS IC)

49

SYNC-DET

-OUT

1DC

S-DET-OUT

REC-Y REC = 2.4V

2

MADE. DE.

PB = 2.0V

EMPH-OUT

REC = 3.0V

3 CLAMP

PB = 3.2V

EMPH-OUT REC = 2.1V

4

R/P CTL PB = 4.4V

REC = 2.1V

5 MAIN-EMPH

-FILT

PB = 4.4V

REC = 3V

6 NL FILT

PB = 3V

Page 53

50

No Pin-function Type voltage(V) Signal waveform Input/Output configuration Remarks

SP 0~1.5 [V]

7 MODE-CTL LP 1.5~3.2 [V]

EP 3.2~5.0 [V]

REC = 3V

8 VCA-FILT DC

PB = 3V

REC = 2.2V

9 VCA-IN

PB = 2.2V

10 GND 0V

REC = 1.0V

11 CCD DRIVE

PB = 1.0V

PIC-CTL REC = 3V SOFT : 2.0~2.5V

HARD : 2.6V~3.2V

12

EDIT

PB = 3V EDIT when over 3.5V

Page 54

51

No Pin-function Type voltage(V) Signal waveform Input/Output configuration Remarks

REC = 2.5V

13 NC-CTL

under 1.5V N.C OFF

2.0~3.0V N.C CTL

PB = 2.5V

over 3.8V Y/CMix

OFF (N.C. Center)

REC C-OUR REC =2.4V

14

PB-YC-IN PB = 3.2V

Y-FM

+Low Chroma

AGC-TC 1 REC = 2.4V

15

BALANCER PB = 2.3V

REC-APC- REC = 2.3V

16 FILT

TRICK-H PB = over 3.5V

(SP Mode)

REC = 3.8V

17 VXO-IN

PB = 3.8V

REC = 2.3V

18 XO-OUT

PB = 2.4V

Page 55

No Pin-function Type voltage(V) Signal waveform Input/Output configuration Remarks

REC = 2.8V

19 SLD-FILT

PB = 2.8V

AFC/APC

REC =2.8V

20

FILT

PB = 2.8V

REC = 1.9V

XO mode

when over 3.5V

21 C-OUT

PB = 1.9V

ANR ON

when over 3.5V

Color = 1.9V

22 KILL-FILT

Killer = 3.1V

REC = 1.7V

23 CNR-CD-IN

PB = 1.7V

CNR OFF

when over 2.5V

24 VCC-2 5.0V D.C

52

Page 56

53

No Pin-function Type voltage(V) Signal waveform Input/Output configuration Remarks

25 REG = 4.2 4.2V D.C

26 SYNC OUT

1.75V when CNR

mode

27 VCC-1

28 VIDEO OUT

29

QV. QH INS.

CHARA INS

30 ROT-PLS