Service Manual

Color Television

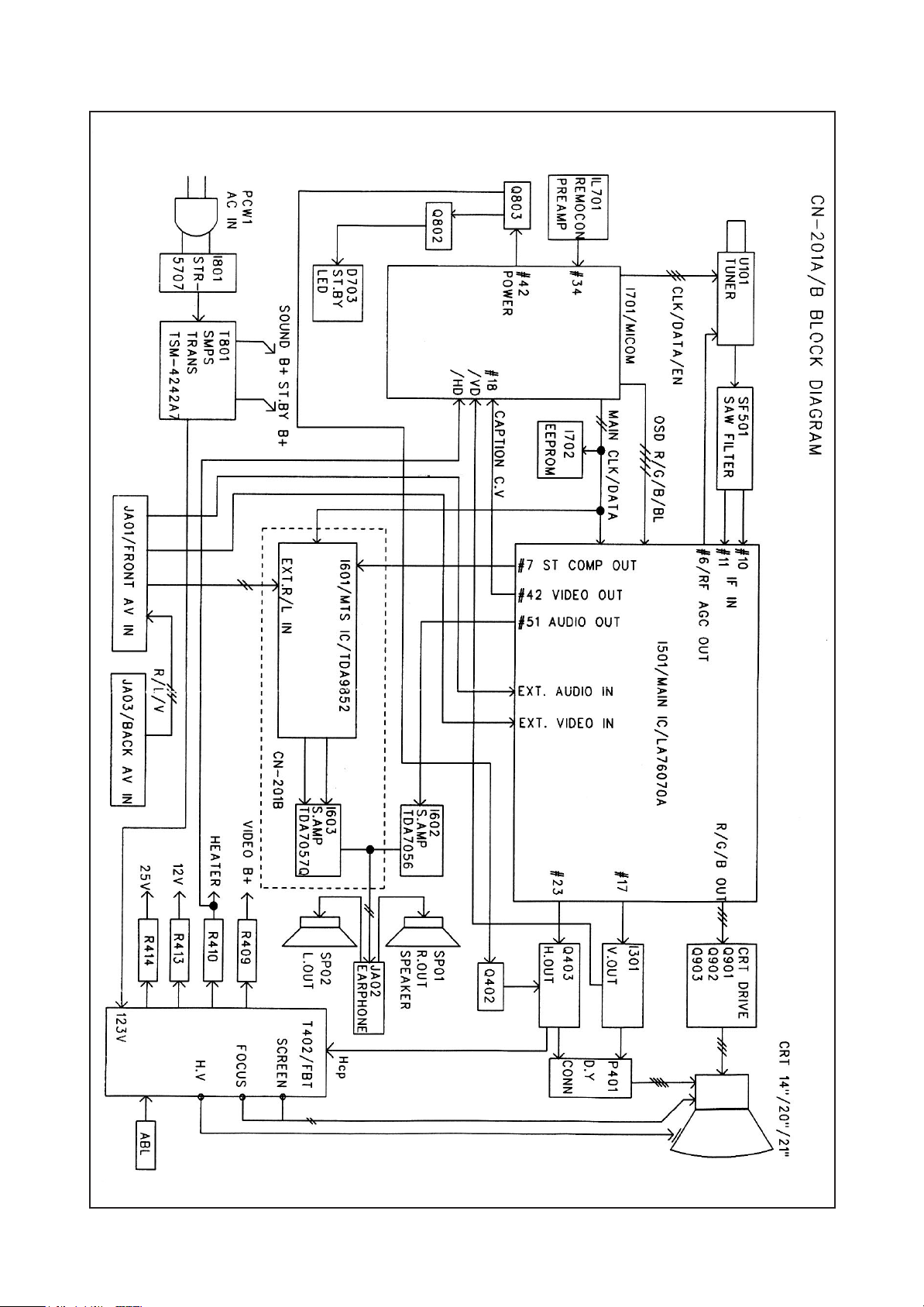

CN-201A/B

CHASSIS

MODEL:DTQ-14Q1FS, DTQ-14Q2TS

DTQ-14Q3FS, DTQ-14T1AS

DTQ-14T2FS, DTQ-20Q1FS

DTQ-20Q2FS, DTQ-20Q3FS

DTQ-20T1AS, DTQ-20T2AS

DTQ-20T1FS, DTQ-20T2FS

DTQ-20T3FS, DTQ-21T1FS

DTQ-21T2FS, DTQ-21T5FS

DTQ-21T9FS, DTQ-20T1FC

:

NTSC-M SYSTEM

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CO., LT D .

FEATURES

FS (Frequency Synthesizer) Tuning System

CATV Ready

High Focus Minineck CRT

ELECTRICAL SPECIFICATIONS

POWER INPUT

AC90V - AC250V 50/60Hz

DTQ-20T1FC : 120V 60HZ ONLY

POWER RATING

14” Model 60W

20” MONO Model 70W

20” ST Model 80W

21” ST Model 80W

INTERMEDIATE FREQUENCIES

PICTURE IF CARRIER FREQUENCY 45.75MHz

SOUND IF CARRIER FREQUENCY 41.25MHz

COLOR SUB CARRIER FREQUENCY 42.17MHz

AUDIO OUTPUT RATING MONO(2W) ST(3W+3W)

SPEAKER 3W 16ohm

ANTENNA INPUT IMPEDANCE VHF/UHF 75 ohm UNBALANCED

TUNING RANGES

VHF 2 THRU 13

UHF 14 THRU 69

CATV 1 THRU 125

CONTENTS

Safety Precautions 3

Control View 6

Important Service Notes 8

Block Diagram 9

General Adjustments 10

Operation Charaeteristic of Power Block 14

Trouble Shooting Charts 22

Description of Semiconductors 28

Printed Circuit Board Diagram 32

Exploded Views 33

Schematic Diagram with Waveforms 50

Parts List 51

Option List 65

2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO VIDEO PRODUCTS

DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY. NEVER

CAUTION

PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER S APPROVAL.

UNAUTHORIZED MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT MAY

LEAD TO YOUR BEING LIABLE FOR ANT RESULTING PROPERTY DAMAGE OR USER

INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE THOROUGHLY

FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS AND SERVICING

GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS AND

INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C.

LINE SHOCK.

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK SHOULD

BE MADE OF THE FOLLOWING:

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS TO AVOID

POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER SUPPLY

CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER ORIGINAL DESIGN.

BE SURE, THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT

BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS,

SOLDER SPLASHES OF SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL

LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION TO PARTS AND

COMPONENTS, FOR FRAYED LEADS, DAMAGED INSULATION (INCLUDING A.C. CORD),

AND REPLACE IF NECESSARY. FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND

DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A RESISTOR

RATED AT 1 WATT OR MORE. LEAD TENSION AROUND PROTRUDING METAL

SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF RESISTOR,

CAPACITORS, ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES. DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE SPECIFIED OR MAKE

UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE STE ALWAYS PERFORM AN A.C. LEAKAGE TEST ON

ALL EXPOSED METALLIC PARTS OF THE CABINET. (THE CHANNEL SELECTOR KNOB,

ANTENNA TERMINALS, HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL SHOCK.

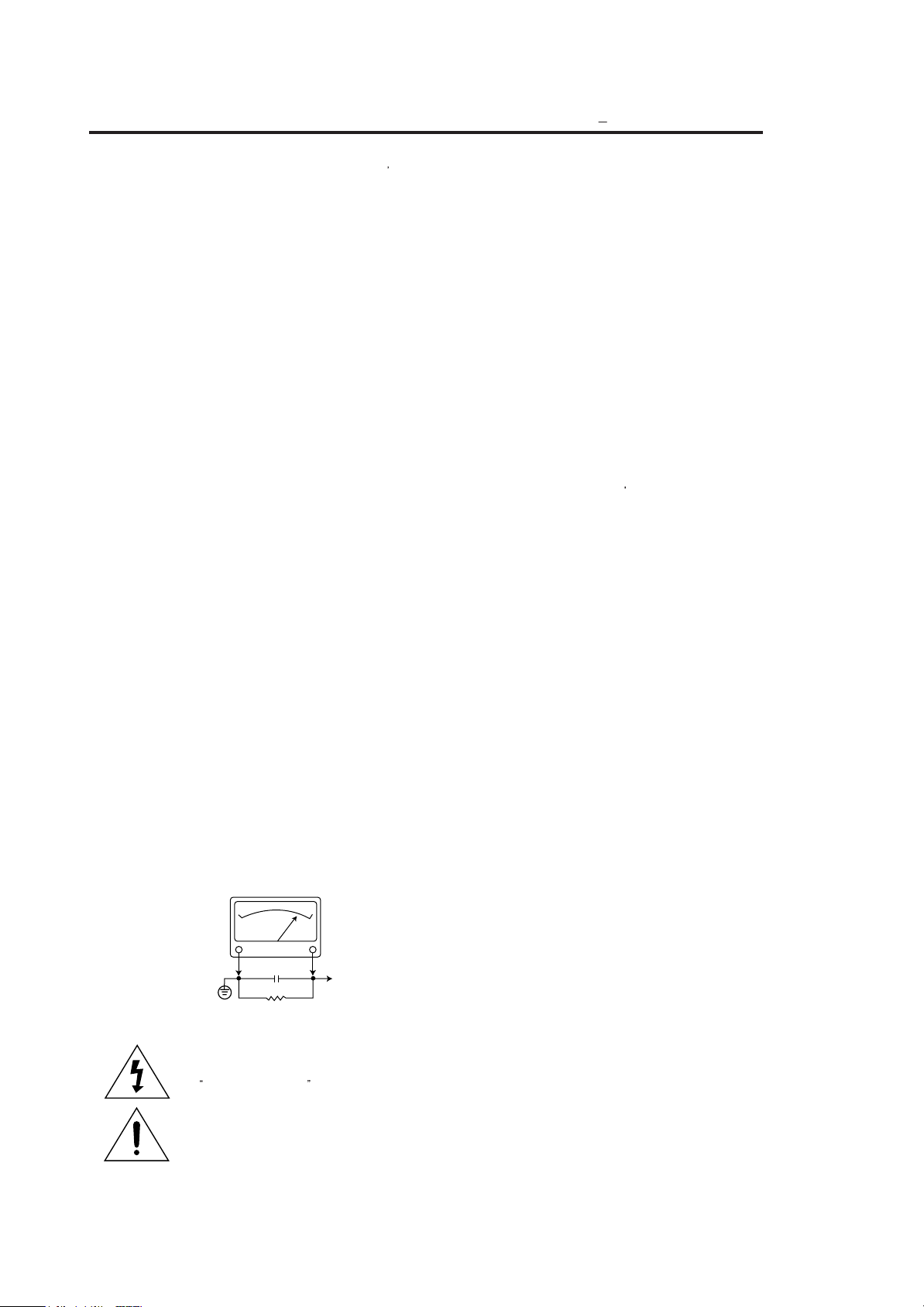

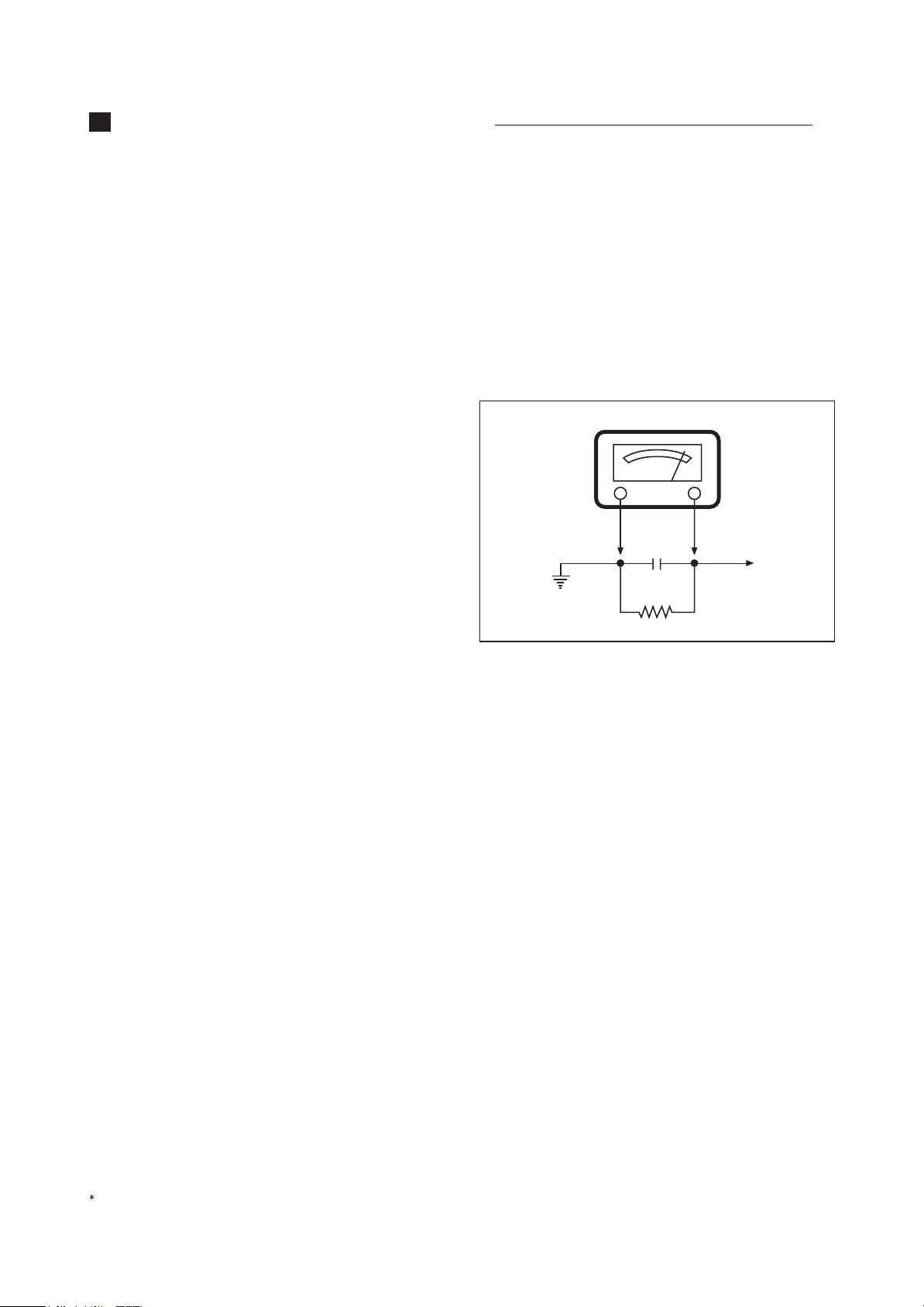

ISOLATION TRANSFORMER DURING THIS TEST

HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER :

CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150V A.C.

TYPE CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND (WATER POPE,

CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME. MEASURE

THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500 OHM RESISTOR AND .15

MFD CAPACITOR. REVERSE THE A.C. PLUG AND REPEAT A.C. VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST

NOT EXCEED .75 VOLTS R.M.S THIS CORRESPONDS TO 0.5 MILLIAMP A.C. NAY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK HAZARD AND MUST BE

CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

:

SAFETY CHECKS

SUBJECT:FIRE & SHOCK HAZARD

A.C. VOLTMETER

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE, CONDUIT, ETC.

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

DANGEROUS VOLTAGE THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL

TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION ON SERVICE LITERATURE.

0.15µF

1500 OHM

10WATT

DO NOT USE A LINE

USE AN A.C. VOLTMETER,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER

2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE IS NO

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A PRODUCT WITH

6. REFER TO HV, B + AND SHUTDOWN ADJUSTMENT PROCEDURES DESCRIBED IN THE

SUBJECT : IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRAL IMPLOSION

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO INSTALLATIONS

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING. THE

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT,

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON SLOPING SHELF

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO THE

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH HAS NOT

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS, EXPLAIN THAT A

950ART94

1009

THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN

CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT

EMIT X-RAYS WHEN THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER

VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE

SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, AMY PRODUCE RADIATION IN

EXCESS OF DESIRABLE LEVELS.

DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN COLOR SETS. ALWAYS REINSTALL THEM.

RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE

CHECKED PERIODICALLY AGAINST A REFERENCE STANDARD. SUCH AS THE ONE

AVAILABLE AT YOUR DISTRIBUTOR.

POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY TIME A COLOR CHASSIS IS

SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND DOWN WHILE MONITORING

THE HIGH VOLTAGE WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING CORRECTLY. WE

SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST

PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A

STANDARD SERVICING PROCEDURE, AND THAT THE HIGH VOLTAGE READING BE

RECORDED ON EACH CUSTOMER

A PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID BEING UNNECESSARILY CLOSE

TO THE PICTURE TUBE AND THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE

PRODUCT LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCESSIVE

VOLTAGE.

APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE USED).

PROTECTION SYSTEM. BUT CARE SHOULD BE TAKEN TO AVOID DAMAGE DURING

INSTALLATION. AVOID SCRATCHING THE TUBE. OF SCRATCHED REPLACE IT.

FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN THE PATH OF

HEATED AIR FLOW.

WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A

FACTOR, ETC.

CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER

COVERINGS WHICH MIGHT OBSTRUCT VENTILATION.

MUST FOLLOW THE FACTORY APPROVED MOUNTING INSTRUCTIONS. A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE

EQUIVALENT THICKNESS IN SPACERS)TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS MUST NOT TOUCH ANY

PARTS OR WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

OR A TILTED POSITION, UNLESS THE PRODUCT IS PROPERLY SECURED.

CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP PILE CARPETS.

BEEN LISTED BY UNDERWRITERS LABORATORIES. INC. FOR USE WITH THEIR

SPECIFIC MODEL OF TELEVISION RECEIVER OR GENERICALLY APPROVED FOR USE

WITH T.V.S OF THE SAME OR LARGER SCREEN SIZE.

FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

S INVOICE.

3

Product safety servicing guidelines for color

television receivers

A.C. VOLTMETER

CAUTION :

way. Unauthorized modifications will not only void the

warranty, but may lead to your being liable for any

resulting property damage or user injury.

Service work should be performed only after you are

thoroughly familiar with all of the following safety checks

and servicing guidelines. To do otherwise, increases the

risk of potential hazards and injury to the user.

Do not attempt to modify this product in any

SAFETY CHECKS

After the original service problem has been corrected, a

check should be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a

way as to avoid possibility of adjacent component

shorts. This is especially important on those chassis

which are transported to and from the repair shop.

2. Never release a repair unless all protective devices

such as insulators, barriers, covers, shields, strain

reliefs, and other hardware have been reinstalled per

original design.

3. Soldering must be inspected to discover possible cold

solder joints, frayed leads, damaged insulation

(including A.C. cord), solder splashes or sharp solder

points. Be certain to remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration

to parts and components, and replace if necessary

follow original layout, lead length and dress.

5. No leads or components should touch a receiving tube

or a resistor rated at 1 watt or more. Lead tension

around protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof

resistors, capacitors, etc. must be replaced with exact

factory types. Do not use replacement components

other than those specified or make unrecommended

circuit modifications.

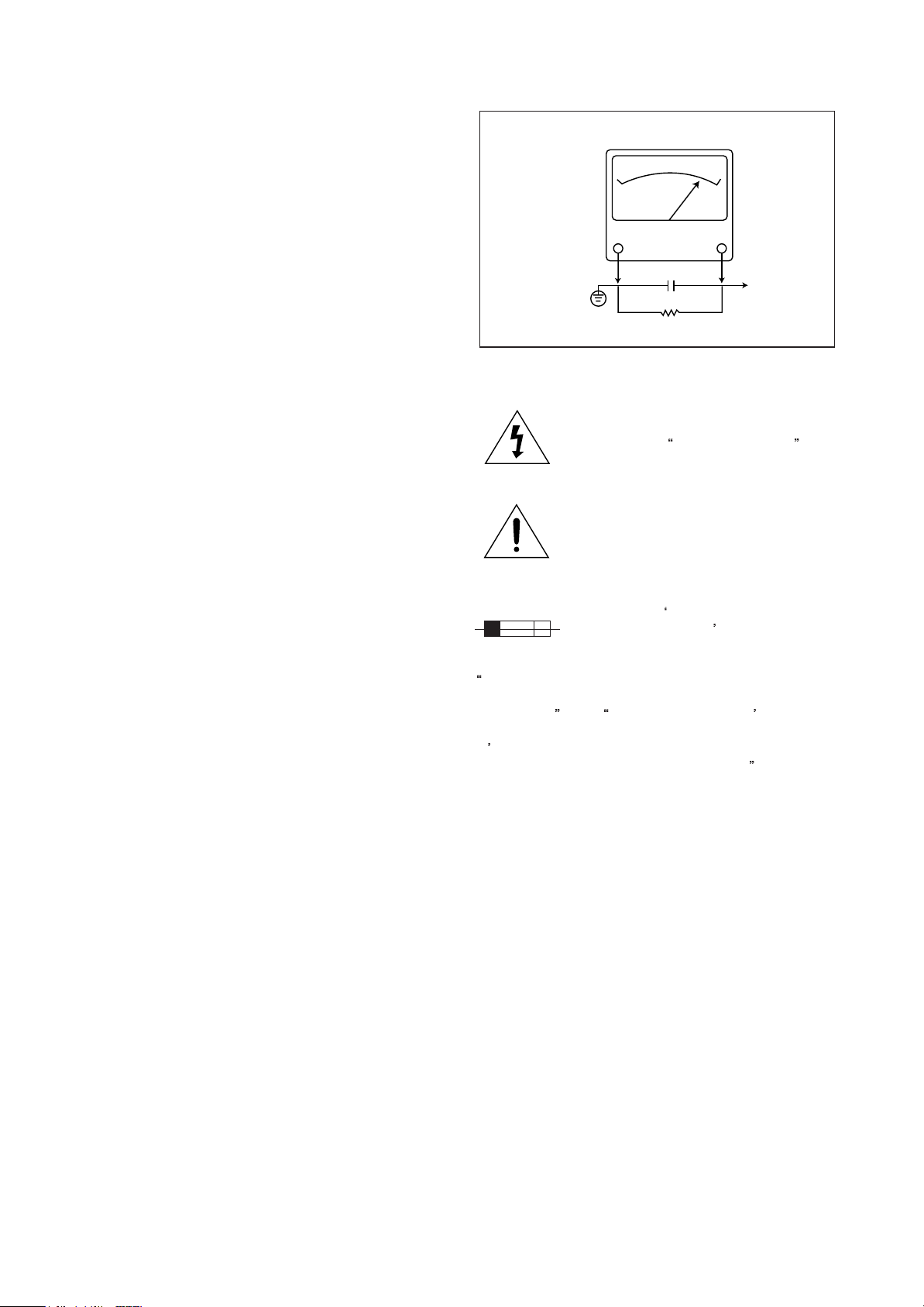

7. After re-assembly of the set always perform an A.C.

leakage test on all exposed metallic parts of the

cabinet, (the channel selector knob, antenna terminals,

handle and screws) to be sure the set is safe to operate

without danger of electrical shock. Do not use a line

isolation transformer during this test. Use an A.C.

voltmeter, having 5000 ohms per volt or more

sensitivity, in the following manner : connect a 1500

ohm 10 watt resistor, paralleled by a 15 mfd. 150V A.C.

type capacitor between a known good earth ground

(9water pipe, conduit, etc.) and the exposed metallic

parts, one at a time. Measure the A.C. voltage across

the combination of 1500 ohm resistor and 0.15 MFD

capacitor. Reverse the A.C. plug and repeat A.C.

voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.75 volts R.M.S.

This corresponds to 0.5 milliamp A.C. Any value

exceeding this limit constitutes a potential shock hazard

and must be corrected immediately.

Good earth ground,

such as the water

pipe, conduit, etc.

0.15µF

••

1500 OHM

10WATT

Place this probe

on each exposed

metal part.

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the service personnel to the presence

of uninsulated

may be of sufficienty magnitude to

constitute a risk of electric shock.

The exclamation point within an equilateral

triangle is intended to alert the service

personnel to the presence of important

safety information in service literature.

Fuse symbol is printed on pcb adjacent to

the fuse, with

FUSE AS MARKED

explained in the service manual with the

following wording or equivalent.

CAUTION : FOR CONTINUED PROTECTION AGAINST

FIRE HAZARD, REPLACE ONLY WITH SAME TYPE 4A,

125V FUSE

PROTECTION PERMANENTE CONTRE LES RISQUES

D

INCENDIE, REMPLACER UNIQUEMENT PAR UN

FUSIBLE DE MEME TYPE ET DE 4A, 125V

and ATTENTION: AFIN D ASSU UNE

dangerous voltage that

RISK OF FIRE REPLACE

. The symbol is

.

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service

personnel cover the subject of X-rays in current T.V.

receivers is the picture tube. However, this tube does

not emit X-rays when the high voltage is at the factory

specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may

cause a failure of the picture tube or high voltage

supply and, under certain circumstances, may produce

radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must

be used. Degaussing shields also serve as X-ray shield

in color sets. Always re-install them.

3. It is essential that the serviceman has available an

accurate and reliable high voltage meter. The

calibration of the meter should be checked perio dically against a reference standard. Such as the one

available at your distributor.

4. When the high voltage circuitry is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be run up and down while monitoring the high voltage

4

with a meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly. We suggest that you and your service

organization review test procedures so that voltage

regulation is always checked as a standard servicing

procedure. And that the high voltage reading be recorded

on each customer

5. When troubleshooting and making test measurements

in a receiver with a problem of excessive high voltage,

avoid being unnecessarily close to the picture tube and

the high voltage compartment.

Do not operate the chassis longer than is necessary to

locate the cause of excessive voltage.

6. Refer to HV, B+and Shutdown adjustment procedures

described in the appropriate schematic and

diagrams(where used).

s invoice.

SUBJECT : IMPLOSION

1. All direct viewed picture tubes are equipped with an

integral implosion protection system, but care should be

taken to avoid damage during installation. Avoid

scratching the tube. If scratched, replace it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER

INSTALLATION

1. Never install any receiver in closed-in recess,

cubbyhole or closely fitting shelf space over, or close to

heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as : Outdoor

patio installations where dew is a factor. Near steam

radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear

venting. The customer should also avoid the use of

decorative scarves or other coverings which might

obstruct ventilation.

4. Wall and shelf mounted installations using a

commercial mounting kit, must follow the factory

approved mounting instructions. A receiver mounted to

a shelf or platform must retain its original feet(or the

equivalent thickness in spacers) to provide adequate

are flow across the bottom, bolts or screws used for

fasteners must not touch and parts or wiring. Perform

leakage test on customized installations.

5. Caution customers against the mounting of a receiver

on sloping shelf or a tilted position, unless the receiver

is properly secured.

6. A receiver on a roll-about cart should be stable on its

mounting to the cart. Caution the customer on the

hazards of trying to roll a cart with small casters across

thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand

which has not been listed by underwriters laboratories,

inc. For use with their specific model of television

receiver or generically approved for use with T.V.

the same or larger screen size.

s of

5

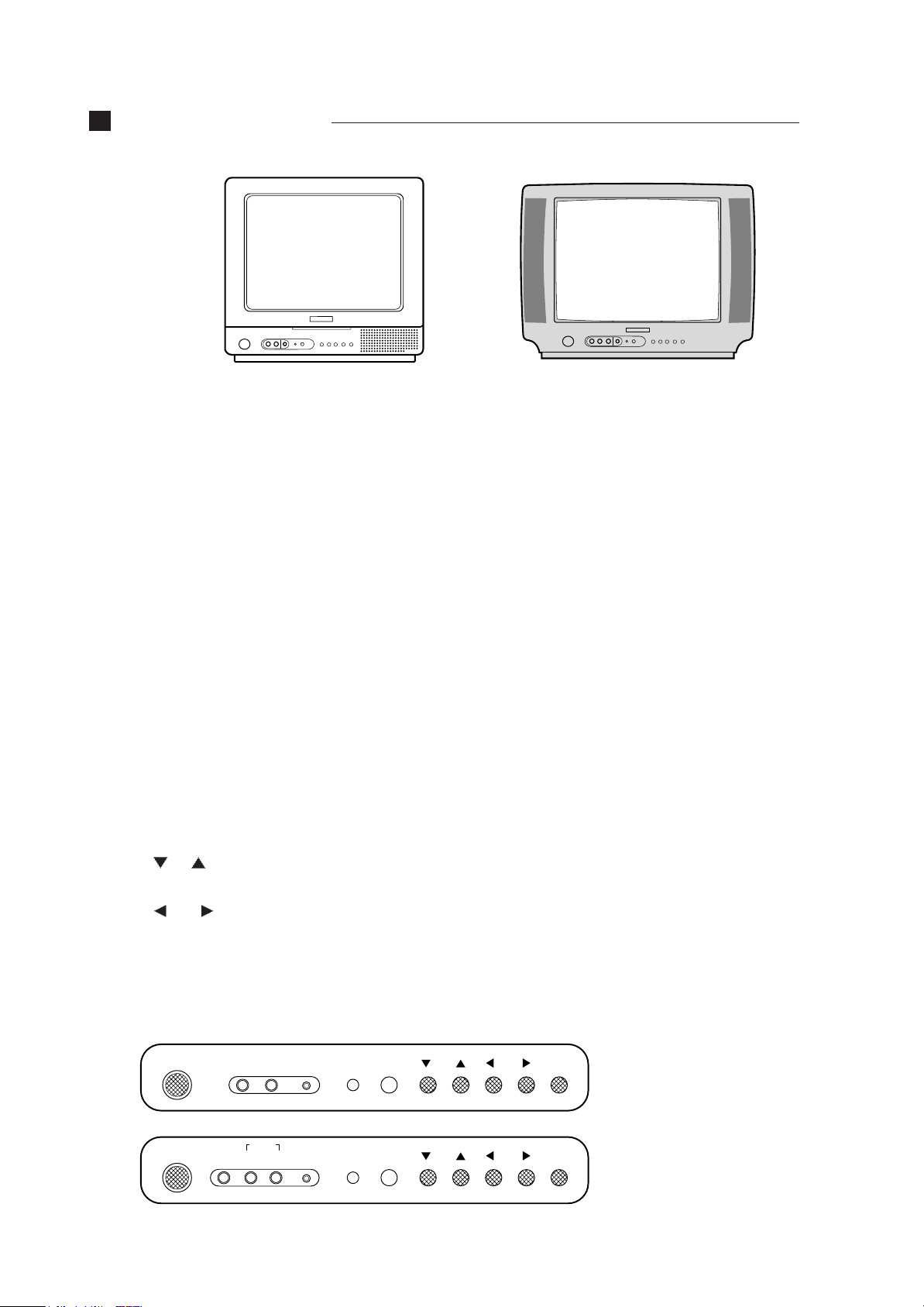

CONTROL VIEW

MONO MODEL

STEREO MODEL

Overview of Your Equipment

Your TV comes with a remote control. The section below summarizes the buttons, controls, and terminals that you

will use with your TV.

Your TV's Front Panel

1 POWER

Use this button to turn your TV on or off.

2 VIDEO IN jack

Use this jack to receive a video signal from another A/V component.

3 AUDIO IN jack

MONO MODEL use this jack to receive an audio signal from another A/V component. But, STEREO MODEL use

this jack to receive audio L/R signal from another A/V component.

4 EARPHONE IN jack

Use this jack to receive a audio signal from your TV.

5 STAND-BY (red) indicator

This indicator lights up when the power is off.

6 Remote control receiver

This receiver receives a signal from your remote control. Don’t block it.

7 CH

Use these buttons to change channels on your TV, or to select items in the menu system.

8 VOL

Use these buttons to change your TV’s volume, to activate selections in the menu system, or to change audio and

video settings.

9 MENU

Use this button to turn the TV’s menu system on and off.

MONO MODEL

POWER VIDEO AUDIO

STEREO MODEL

POWER VIDEO

AUDIO

L R

EARPHONE

EARPHONE

STAND-BY

STAND-BY

CH

CH

VOL

VOL

MENU

MENU

6

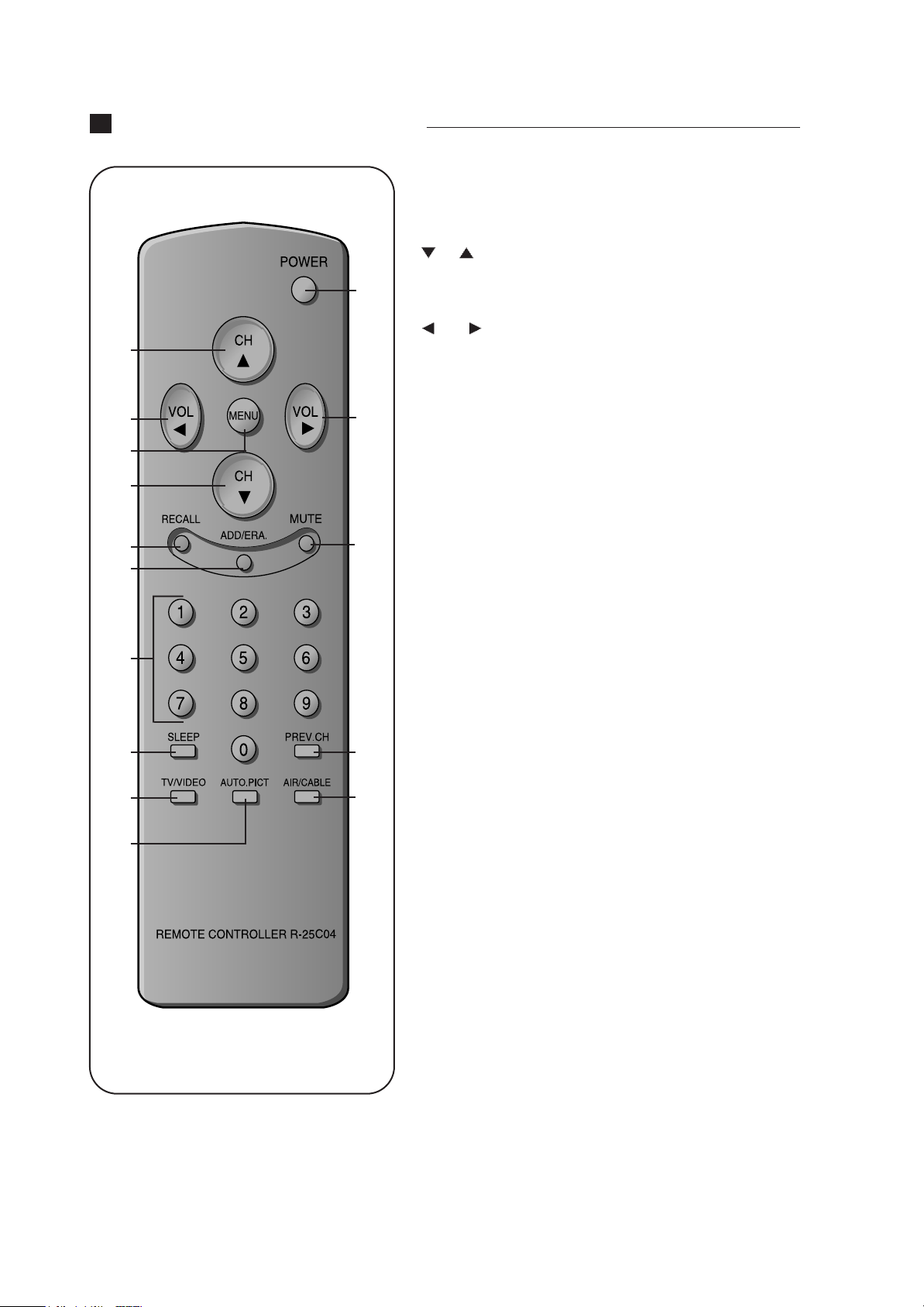

REMOTE CONTROL UNIT

1 POWER

2 CH

1

3 VOL

2

Use this button to turn your TV on or off.

Use these buttons to change channels on your TV, or select items in

the menu system.

Use these buttons to change your TV's volume, to activate selections

in the menu system, or to change audio and video settings.

3

4

2

5

6

8

9

11

12

4 MENU

3

5 RECALL

6 ADD/ERA.

7

7 MUTE

8 0-9

9 SLEEP

10PREV. CH

10

13

11 TV/VIDEO

Use this button to turn the TV's menu system on and off.

Press this button to display the channel number.

Use this button to add a channel to the TV's memory or erase the

channel from memory.

Use to turn the TV's sound on and off.

Use these buttons to change channels.

Use this button to program the TV to turn off after a certain time.

Press this button to return to the previous channel you were watching. If you have set Favorite Ch, this key operates to Favorite function.

Use this button to select TV or VIDEO mode.

12 AUTO. PICT

Press this button to return the TV's video settings to their original

level.

13 AIR/CABLE

Use the button to set up your TV to receive signals from an antenna

(AIR) or a cable system (CABLE).

7

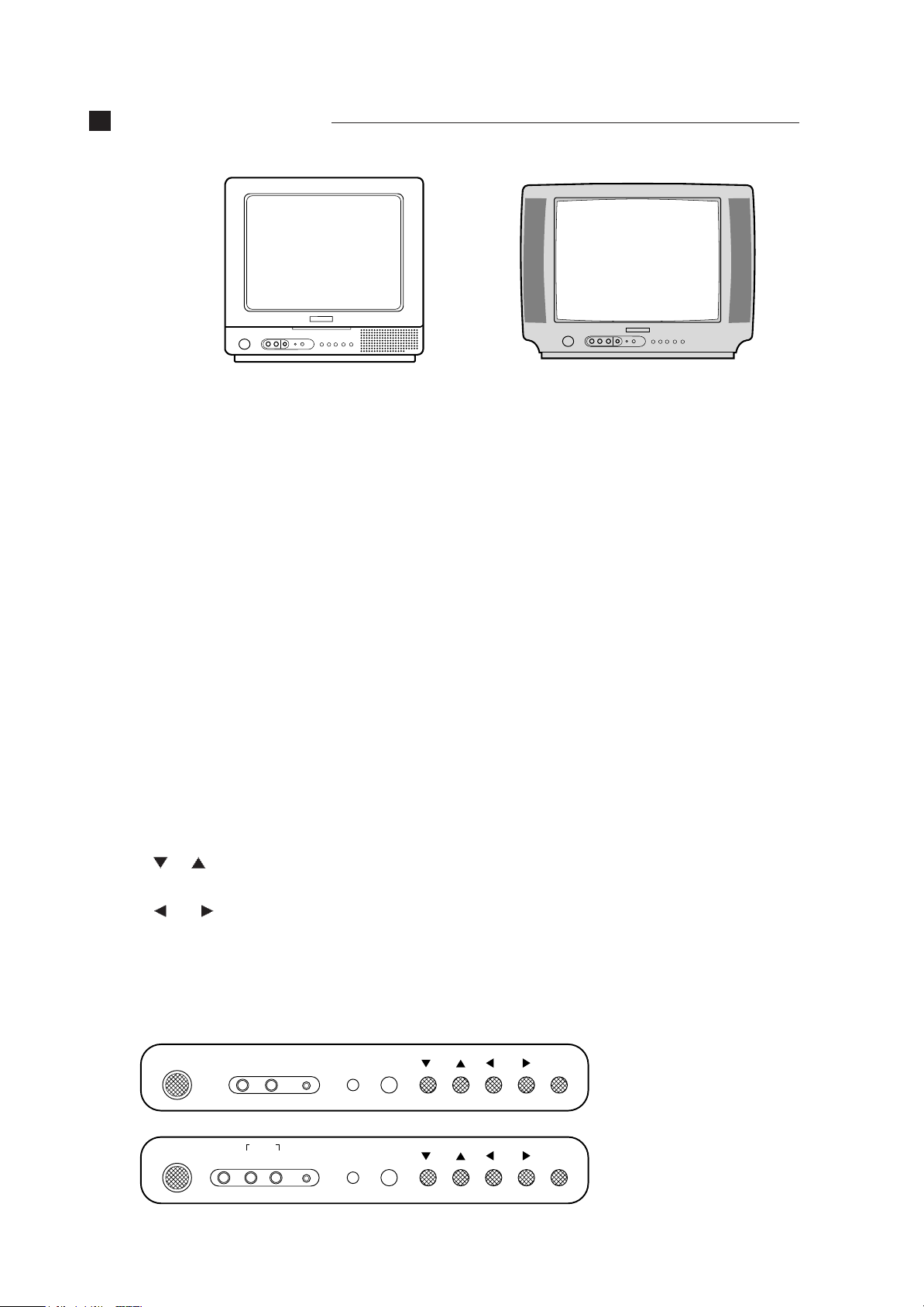

CONTROL VIEW

MONO MODEL

STEREO MODEL

Overview of Your Equipment

Your TV comes with a remote control. The section below summarizes the buttons, controls, and terminals that you

will use with your TV.

Your TV's Front Panel

1 POWER

Use this button to turn your TV on or off.

2 VIDEO IN jack

Use this jack to receive a video signal from another A/V component.

3 AUDIO IN jack

MONO MODEL use this jack to receive an audio signal from another A/V component. But, STEREO MODEL use

this jack to receive audio L/R signal from another A/V component.

4 EARPHONE IN jack

Use this jack to receive a audio signal from your TV.

5 STAND-BY (red) indicator

This indicator lights up when the power is off.

6 Remote control receiver

This receiver receives a signal from your remote control. Don’t block it.

7 CH

Use these buttons to change channels on your TV, or to select items in the menu system.

8 VOL

Use these buttons to change your TV’s volume, to activate selections in the menu system, or to change audio and

video settings.

9 MENU

Use this button to turn the TV’s menu system on and off.

MONO MODEL

POWER VIDEO AUDIO

STEREO MODEL

POWER VIDEO

AUDIO

L R

EARPHONE

EARPHONE

STAND-BY

STAND-BY

CH

CH

VOL

VOL

MENU

MENU

6

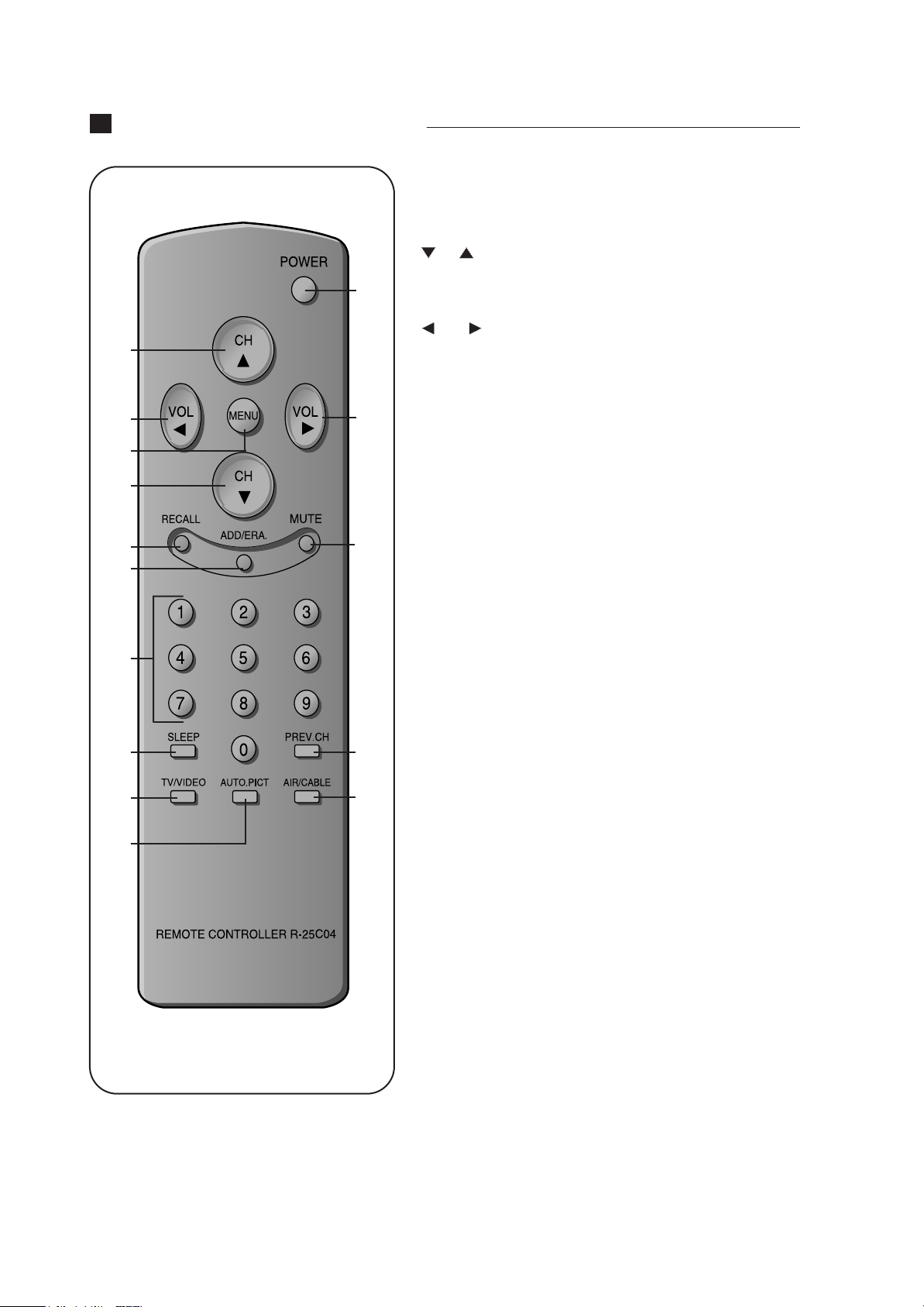

REMOTE CONTROL UNIT

1 POWER

2 CH

1

3 VOL

2

Use this button to turn your TV on or off.

Use these buttons to change channels on your TV, or select items in

the menu system.

Use these buttons to change your TV's volume, to activate selections

in the menu system, or to change audio and video settings.

3

4

2

5

6

8

9

11

12

4 MENU

3

5 RECALL

6 ADD/ERA.

7

7 MUTE

8 0-9

9 SLEEP

10PREV. CH

10

13

11 TV/VIDEO

Use this button to turn the TV's menu system on and off.

Press this button to display the channel number.

Use this button to add a channel to the TV's memory or erase the

channel from memory.

Use to turn the TV's sound on and off.

Use these buttons to change channels.

Use this button to program the TV to turn off after a certain time.

Press this button to return to the previous channel you were watching. If you have set Favorite Ch, this key operates to Favorite function.

Use this button to select TV or VIDEO mode.

12 AUTO. PICT

Press this button to return the TV's video settings to their original

level.

13 AIR/CABLE

Use the button to set up your TV to receive signals from an antenna

(AIR) or a cable system (CABLE).

7

IMPORTANT SERVICE NOTES

1. X-RAY RADIATION PRECAUTION

1) Excessive high voltage can produce potentially

hazardous X-RAY RADIATION. To avoid such hazards,

the high voltage must not be above the specified limit.

The nominal value of the high voltage of this receiver is

24.4kv at zero beam current (minimum brightness)

under a 120V AC power source. The high voltage must

not, under any circumstances, exceed 27kv (28.5kv).

Each time a receiver requires servicing, the high

voltage should be checked following the HIGH

VOLTAGE CHECK procedure on page 6 of this

manual. It is recommended as a parts of the service

record. It is important to use an accurate and reliable

high voltage meter.

2) This receiver is equipped with X-RADIATION

PROTECTION circuit which prevents the receiver from

producing an excessively high voltage even if the

B+voltage increases abnormally. Each time the

receiver is serviced, X-RADIATION PROTECTION

circuit must be checked to determine that the circuit is

properly functioning, following the X-RADIATION

PROTECTION CIRCUIT CHECK procedure on page 6

of this manual.

3) The only source of X-RAY RADIATION in this TV

receiver is the picture tube. For continued X-RAY

RADIATION protection, the replacement tube must be

exactly the same type tube as specified in the parts list.

4) Some parts in this receiver have special safety-related

characteristics for X-RAY RADIATION protection. For

continued safety, parts replacement should be

undertaken only after referring to the PRODUCT

SAFETY NOTICE below.

2. SAFETY PRECAUTION

WARNING

: Service should not be attempted by anyone

unfamiliar with the necessary precaution on this receiver.

The following are the necessary precaution to be

observed before servicing.

1) Since the chassis of this receiver has hazardous

potential to ground whenever the receiver is plugged in

(floating chassis), an isolation transformer must be

used during servicing to avoid shock hazard.

2) Always discharge the picture tube anode to the CRT

conductive coating the picture tube. The picture tube is

highly evacuated and if broken, glass fragments will be

violently expelled. Use shatterproof goggles and keep

picture tube away from the body while handling.

3) When placing chassis in the cabinet, always be certain

that all the protective devices are put back in place,

such as; nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4) Before returning the set to the customer, always

perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas,

terminals, screw-heads, metal overlays, control shafts

etc. to be sure the set is safe to operate without

danger of electrical shock. Plug the AC line cord

directly into a 120V AC outlet (do not use a line isola-

Minimum brightness

tion transformer during this check). Use an AC

voltmeter having 5000 ohms per volt or more sensitivity in the following manner.

Connect at 1500 ohm 10 watt resistor, paralleled by a

0.15 mfd. AC type capacitor, between a known good

earth ground (water pipe, conduit etc.) and the exposed

metallic parts, one at a time. Measure the AC voltage

across the combination of 1500 ohm resistor and 0.15

mfd capacitor. Voltage measured must not exceed 0.3

volts RMS. This corresponds to 0.2 millliamp. AC. Any

value exceeding the limit constitutes a potential shock

hazard and must be corrected immediately.

AC VOLT METER

0.15MFD

Place this probe

on each exposed

metallic part.

Good earth ground

such as d water

pipe, conduit, etc.

1500 ohm

10watt

3. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have

special safety-related characteristics. These

characteristics are often passed unnoticed by a visual

inspection and the protection afforded by them cannot

necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual and its

supplements; electrical components having such features

are identified by shading on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute

replacement parts which do not have the same safety

characteristics as specified in the parts list may create Xray radiation or other hazards.

4. SERVICE NOTES

1) When replacing parts or circuit boards, clamp or bend

the lead wires to terminals before soldering.

2) When replacing a high wattage resistor (metal oxide

film resistor) in the circuit board, keep the resistor min

1/2 inch away form circuit board.

3) Keep wires away from high voltage or high temperature

components.

8

9

GENERAL ADJUSTMENTS

1. GENERAL

In the majority of cases, all color televisions will need only

slight touch-up adjustment upon installation. Check the

basic characteristics such as height, focus and sub- basic

characteristics such as height, focus and sub- bright.

Observe the picture for good black and white details

without objectionable color shading. If color shading is

evident, demagnetize the receiver. If color shading still

persists, perform purity and convergence adjustments.

This should be all that is necessary to achieve Optimum

receiver performance.

2. SCREEN ADJUSTMENT

1) Turn on TV

2) Press the S2 key of Service Remocon to make the One

Horizontal Line

3) Adjust the Screen adj. VR of FBT so that the One

Horizontal Line may be cut off.

4) Press the S2 key of Servic Remocon to be normal.

3. FOCUS ADJUSTMENT

1) Receive the Retma Pattern.

2) Adjust the FOCUS adj. VR to optain the clearest

picture.

4. HORIZONTAL CENTER ADJUSTMENT

1) Receive the Retma Pattern.

2) Press the S6(59H) key of Service Remocon, select

H.Phase, then adjust step so that the L/R Width of

picture be alike.

3) Press the RECALL key to store.

4) Initial value of D.P : 5

7. X-RADIATION PROTECTION CIRCUIT TEST

When service has been performed on the horizontal

deflection system, high voltage system or B+system. the

X-RADIATION protection circuit must be tested for proper

operation as follows:

1) Operate receiver for at least 15 minutes at 120V AC

line.

2) Adjust all customer controls for normal picture and

sound.

3) Short R411(X-RAY Short test), and remove short clip.

4) If the operation of horizontal osc. does not stop in step

The circuit must be repaired, before the set is returned

to the customer.

8. White balance ADJUSTMENT

1) Press the S8 key of SERVICE REMOCON, select W/B

2) Adjust the R/G/B BIAS of Low BEAM in order that the

R/G/B BIAS of Low BEAM may meet with coordinates.

3) Adjust the R/B DRIVE of High BEAM in order that the

R/B DRIVE of High BEAM may meet with coordinates.

4) Confirm the LOW BEAM, HIGH BEAM alternately.

5) Press the RECALL key to store.

9. SUB-BRIGHTNESS ADJUSTMENT

1) Receive the Retma Pattern.

2) Press the S9(5CH) key of Service Remocon, adjust

Bright in order that the gradation pattern may set 18%.

3) Press the RECALL key to store.

4) Initial value of D.P :25

5. VERTICAL CENTER ADJUSTMENT

1) Receive the Retma Pattern.

2) Press the S6(59H) key of Service Remocon, select

V.DC, then adjust V.DC so that the horizontal line of

RETMA PATTERN’S center may meet with the

mechanical CENTER of CRT.

3) Press the RECAL key to store.

4) Initial value of D.P:35

6. VERTICAL HIGHT ADJUSTMENT

1) Receive the Retma Pattern.

2) Press the S6(59H) key of Service Remocon, select

V.Size, then adjust V.Size so that the center of

circumference of big circle may meet with the upper

and lower sides of the screen.

3) Press the RECALL key to store.

4) Initial of value of D.P :35

10

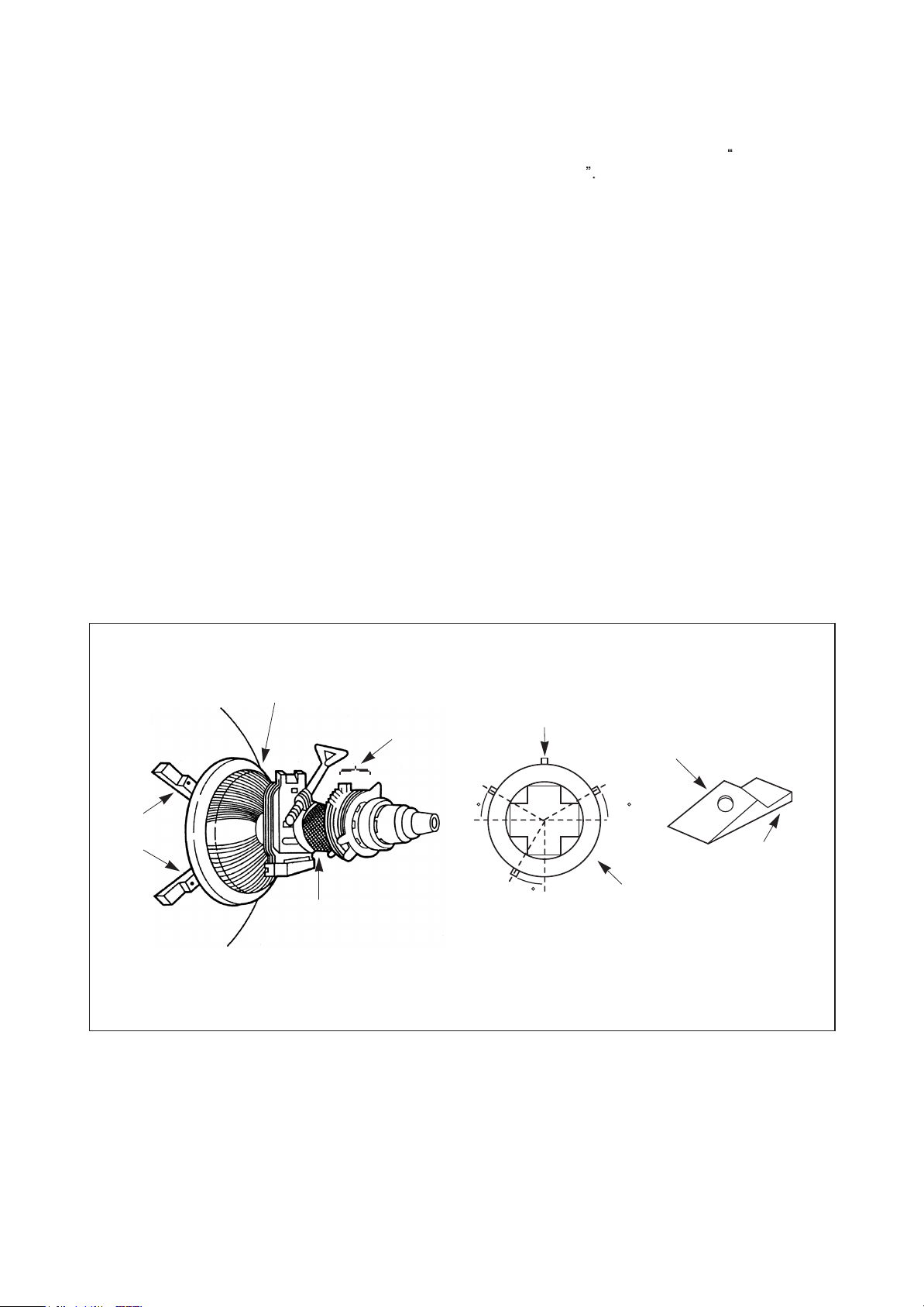

10. CONVERGENCE MAGNET ASSEMBLY

POSITIONING

If Convergence magnet assembly and rubber wedges

need mechanical positioning follow figure 2.

10-1. COLOR PURITY ADJUSTMENT

NOTE

1) Demagnetize the picture tube with a degaussing coil.

2) Adjust the CONTRAST and BRIGHTNESS controls to

3) Adjust RED and BLUE Bias controls Service Remocon

4) Loosen the clamp screw holding the yoke, and slide the

5) Remove the Rubber Wedges.

6) Rotate and spread the tabs of the purity magnet (See

7) Move the yoke slowly forward until a uniform green

: Before attempting any purity adjustments, the

receiver should be operated for at least 15

minutes.

maximum

to provide only a green raster. Adjust the GREEN BIAS

control Service Remocon if necessary.

yoke backward to provide vertical green belt(zone)in

the picture screen.

figure 2) around the neck of the picture tube until the

green belt is in the center of the screen. At the same

time, center the raster vertically.

screen is obtained. Tighten the clamp screw of the yoke

temporarily.

8) Check the purity of the red and blue raster by adjusting

the BIAS controls.

9) Obtain a white raster, referring to

ADJUSTMENT

10) Proceed with convergence adjustment.

White Bodance

RUBBER

WEDGES

PICTURE TUBE

DEFLECTION

YOKE

GLASS CLOTH

TAPE

CONVERGENCE

MAGNET ASS'Y

TEMPORARY

MOUNTING

30 30

30

Fig. 2 Rubber Wedges Location

RUBBER

WEDGES

ADHESIVE

DEF.

YOKE

11

10-2. CONVERGENCE ADJUSTMENTS

NOTE

: Before attempting any purity adjustments, the

receiver should be operated for at least 15

minutes.

A. CENTER CONVERGENCE ADJUSTMENT

1) Receive crosshatch pattern with a crosshatch signal

generator.

2) Adjust the BRIGHTNESS and CONTRAST Controls for

a good picture.

3) Adjust two tabs of the 4-Pole Magnets to change the

angle between them (See Fig. 3) and superimpose red

and blue vertical lines in the center area of the picture

screen. (See Fig. 4)

4) Turn both tabs at the same time keeping their angles

constant to superimpose red and blue horizontal lines

at the center of the screen. (See Fig. 4)

5) Adjust two tabs of 6-Pole Magnets to superimpose

red/blue line with green on top of each other. Adjusting

the angle affects the vertical lines and rotating both

magnets affects the horizontal lines.

6) Repeat adjustments 3), 4), 5) keeping in mind red,

green and blue movement, because 4-Pole Magnets

and 6-Pole Magnets interact and make dot movement

complex.

B. CIRCUMFERENCE CONVERGENCE ADJUSTMENT

: This adjustment requires Rubber Wedge Kit.

NOTE

1) Loosen the clamping screw on deflection yoke to allow

the yoke to tilt.

2) Place a wedge as shown in figure 2 temporarily. (Do

not remove cover paper on adhesive part of the

wedge.)

3) Tilt front of the deflection yoke up or down to obtain

better convergence in circumference. (See Fig. 4) Push

the mounting wedge into the space between picture

and the yoke to hold the yoke temporarily.

4) Place other wedge into bottom space and remove the

cover paper to stick.

5) Tilt front of the yoke right or left to obtain better

convergence in cicumference. (See Fig. 4)

6) Hold the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to hold the yoke.

7) Detach the temporarily mounted wedge and put it in

another upper space. Stick it on picture tube to fix the

yoke.

8) After placing three wedges, re-check overall

convergence. Tighten the screw firmly to hold the yoke

tightly in place.

9) Stick 3 adhesive tapes on wedges as shown in figure32.

4-POLE

PURITY

MAGNETS

MAGNETS

4DJUST THE

ANGLE

(VERTICAL

CONSTANT

LINES)

ROTATE TWO TABS AT

THE SAME TIME

CONVERGENCE MAGNET ASSEMBLY

BLUE

BLUE

RED

RED

RED/BLUE

GRN

RED/BLUE

Fig. 3

GRN

B G R

R

G

B

R G B

(HORIZONTAL LINES)

ADJUSTMENT OF MAGNET

B

G

R

B

G

R

BGR

4-Pole Magnets Movement 6-Pole Magnets Movement Incline the Yoke up(or down) Incline the Yoke right(or left)

Center Convergence by Convergence Magnets Circumference Convergence by DEF. Yoke

BGR

R

G

B

Fig. 4 Dot Movement Pattern

12

11. APC DET & PLL Tunning ADJUSTMENT

1) Receive the signal of RF 100% Full Color bar 85dBuV.

2) Press the S5(58H) key of Service Remocon, then execute Auto adj Start.

3) Confirm the OSD of Auto adj. OK.

4) If it was Auto adj. NG, Receive the signal of adjacent channel, then perform Auto adj. Start again.

5) Press the RECALL key to store. (Initial value of D.P APC:30, PLL:40)

12. RF AGC ADJUSTMENT

1) Receive the attenuate signal of RF 100% Full Color Bar 60dBuV.

2) Connect Scope to TP101(OR P101).

3) Press the S5 key of Service Remocon, select RF AGC.D, then adjust the maximum voltage of Scope to attenuate 1V.

(Initial value of the maximum voltage : About 7V)

For example if initial maximum voltage is 7V, adjust it to 6V

4) Press the RECALL key to store. (Initial value of D.P :25)

13). Stereo/Sap ADJUSTMENT

1) Receive the ZENITH MTS signal of 1KHz(OR 3KHz)CH.

2) Press the S10(5D) key of Service Remocon, select Auto Off, then execute Auto on.

3) Press the RECALL key to store.

4) Slect L ONLY OR R ONLY Channel, then confirm stereo Seperation.

If you have only User Remocon, A way of using is as follows;

1) Press the 1 key

2) Press the MUTE key

3) Press the RECALL Key

4) Press the MUTE key then the Service mode will appear.

5) Use the CH buttons to select the mode you wish to adjust.

1 MUTE RECALL MUTE

13

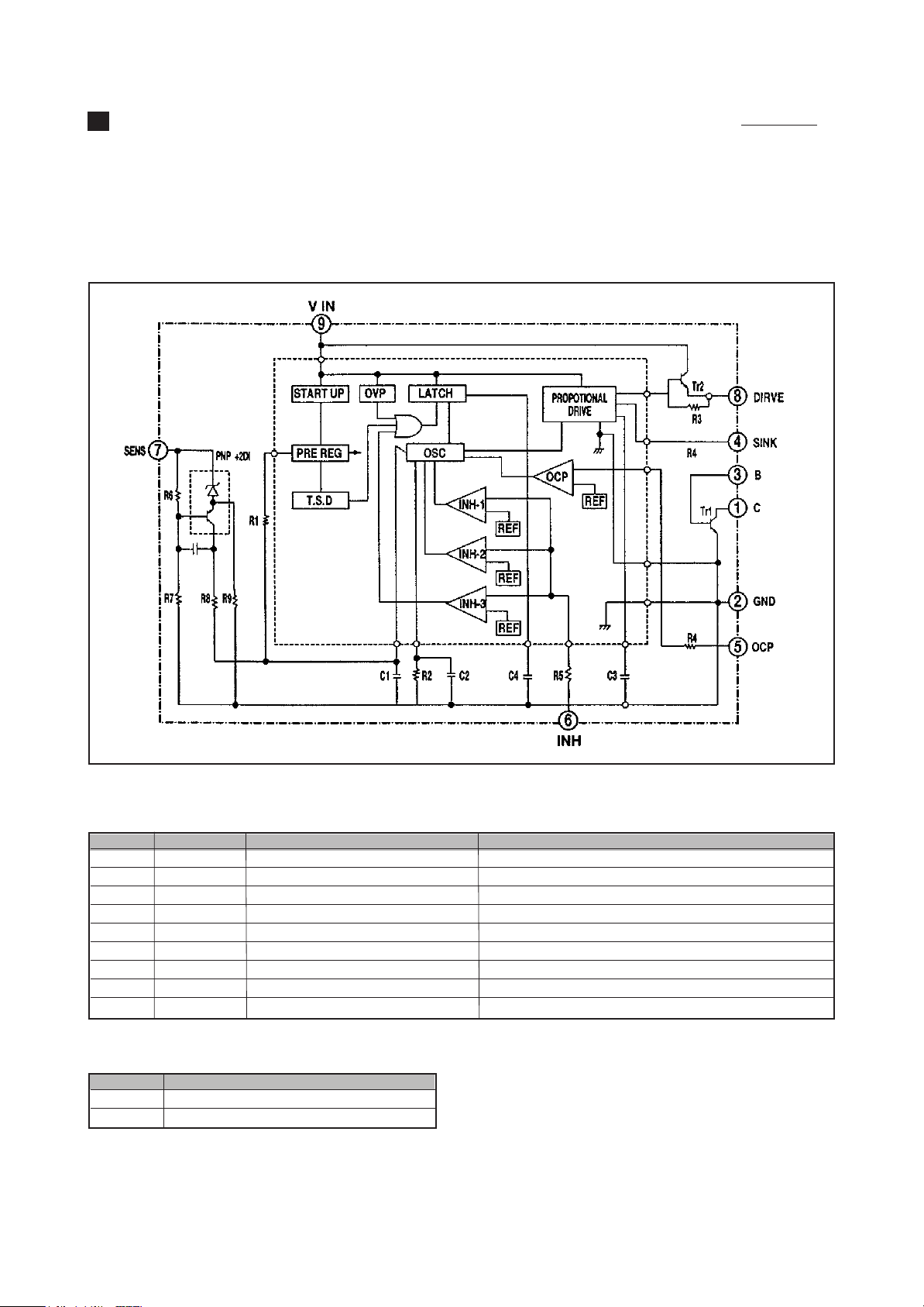

OPERATION CHARACTERISTICS OF POWER BLOCK(I801)

This chassis designed for free voltage(AC 100V ~ AC 220V) power. power block contains power IC, SMPS

transformer and several passive components.

The power IS STR-S5707 has power transistor. oscillator circuit, voltage comparator circuit, thermal protection

circuit, OCP(over current protection)circuit inside.

1. STR-S5707 BLOCK DIAGRAM

2. PIN DESCRIPTION

PIN NO SYMBOL NAME FUNCTION

1 C COLLECTOR POWER TRANSISTOR COLLECTOR

2 GND GROUND GROUND(POWER TRANSISTOR EMITTER)

3 B BASE POWER TRANSISTOR BASE

4 SINK SINK BASE URRENT(Is) INPUT

5 OCP OVER CURRENT PROTECTION OVERCURRENT SENSING SIGNAL INPUT

6 INH INHIBIT/LATCH SYNC, OFF TIME/LATCH CIRCUIT CONTROL INPUT

7 F/B(SENS) FEED BACK(SENSING)INPUT CONSTANT VOLTAGE CONTROL SIGNAL INPUT

8 DRIVE DRIVE BASE DRIVE CURRENT(Id)OUTPUT

9 Vin Vin SUPPLY VOLTAGE FOR CONTROL CIRCUIT

3. OTHER FUNCTION

Symbol Function

OVP Built-in Overvoltage Protection Circuit

TSD Built-in Thermal Shutdown Circuit

14

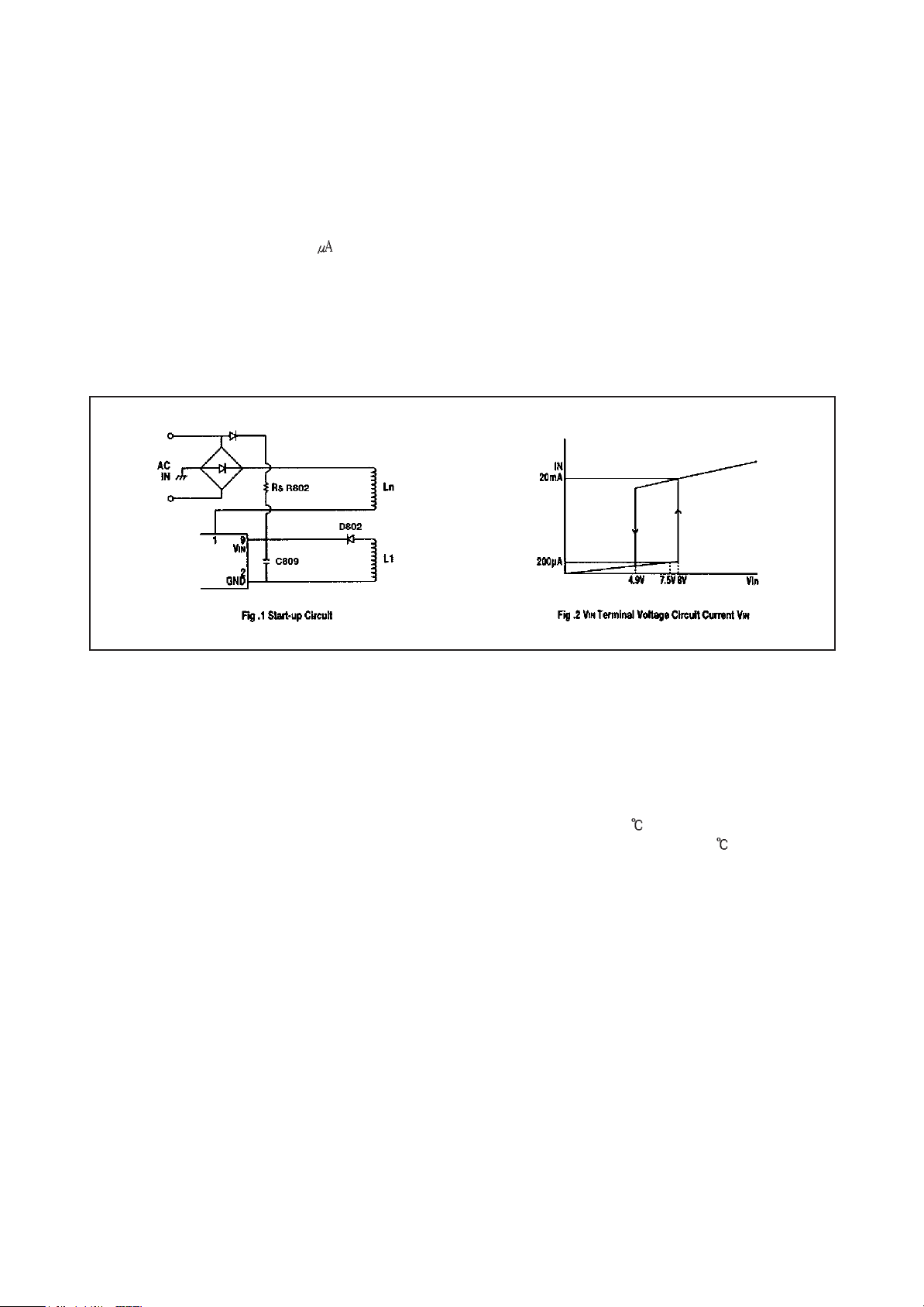

4. EXPLANA TION OF CIRCUIT OPERATION

1) VINterminal, start-up circuit

A Start-up circuit is to start and stop a operation of a control IC by detecting a voltage appearing at a VINterminal(pin-

9).At start up of a power supply, when a voltage at the VINterminal reaches to 8V by charging up C809 by the function

of a start-up resistor, Rs, a control circuit starts operating by the function of the start-up circuit. As shown in Fig. 2, since

a circuit current is suppressed 200 maximum (at VIN= 7.5V) until the control circuit starts its operation.

After the control circuit starts its operation, power source is obtained by smoothing voltage appearing at L1 winding.

Once the control circuit starts operating, as its voltage doesn’t reach the fixed voltage at once, VINterminal voltage

starts dropping. However, as a shut-down voltage is set low(at 4.9V), while VINterminal voltage reaches a shutdown

voltage, L1 winding voltage reaches the fixed voltage earlier so that the control circuit can continue on operating.

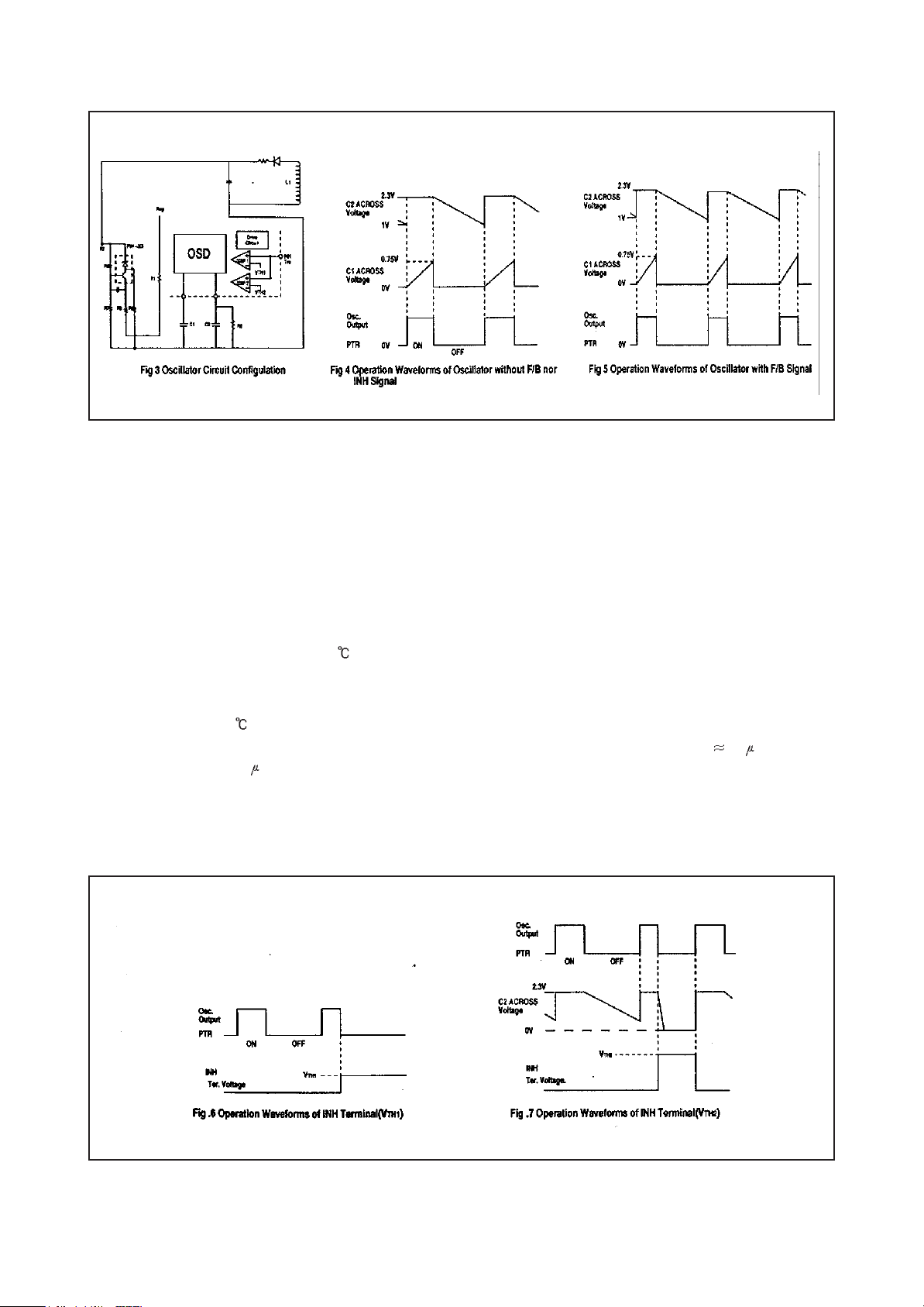

2) Oscillator, F/B terminal voltage (Pin #7)

A oscillator generates pulse signals which turns a power transistor on and off by making use of charge and discharge of

C1 and C2 incorporated in the Hybrid IC.

Constant voltage control of a switch-mode power supply is performed by changing both ON-time and OFF-time except

when the load is light (ex. remote control stand-by mode of TVs).

Fig. 4 shows how the oscillator works when the Hybrid IC independently operates (with no F/B nor INH signals). When

the power thransistor is on, C2 Is charged to the set voltage (approx 2.3V at Ta = 25 ). On the other hand, C1 starts

charging up through R1 from almost OV and the voltage across C1 reaches approx. 0.75V (Tc = 25 ). the output from

the oscillator is reversed and the power transistor turns off. At the same time C1 is quickly discharged by the function of

a internal circuit of the oscillator and the voltage across it decreases to almost OV. When the power transistor turns off,

C2 starts discharging through R2 and the voltage across C2 decreases with the inclination determined by the product of

C2 decreases to about 1V. the output from the oscillator is reversed again and the transistor consequently turns on. The

power transistor continues turning on and off by repeating the above-mentioned operations.

15

As the circuit in Fig. 3 shows, the ON-time is controlled by changing a current charged by C1, which is as the result of

that the detection winding (L1), which detects a change of voltage in a secondary side, connected to the sensing

terminal (Pin No. 7) has the current in accordance with an output signal from an output voltage detection circuit (an error

amplifier) built in. As an AC input voltage to the power supply gets the higher and a load current the smaller, the current

flowing to the SENS terminal gets the larger, and the ON-time gets the shorter.

3) Function of INH terminal (Pin #6), control OFF-time

Signal to the INH terminal is used as inputs to COMP.1 and COMP.2 inside of the control IC.A threshold voltage of

COMP.1 V

is in OFF mode) when a voltage at the INH terminal reaches the V

lower than V

set at 1.5V (Ta = 25 ). When the INH terminal voltage reaches V

TH

is set at 0.75V (Ta = 25 ) and an input signal to a drive circuit becomes almost OV (the power transistor

1

TH

. As long as the INH terminal voltage does not get

1

TH

. the power transistor sustains OFF mode. On the other hand, a threshold voltage of COMP.2 V

1

TH

, an output from COMP.2 reverses and, as a

2

TH

2

, is

result, C2, the OFF-tim of the oscillator which has been determined by the product of C2 and R2 ( 55 sec) can be

quicker up to approx. 2 sec. As long as the INH terminal voltage does not get lower than V

TH

, A Voltage across C2

2

stays at almost 0V and a output from the oscillator keeps the power transistor being on. The relation between the INH

terminal voltage and the function of the oscillator described above is shown in Fig. 6 and FIg. 7

16

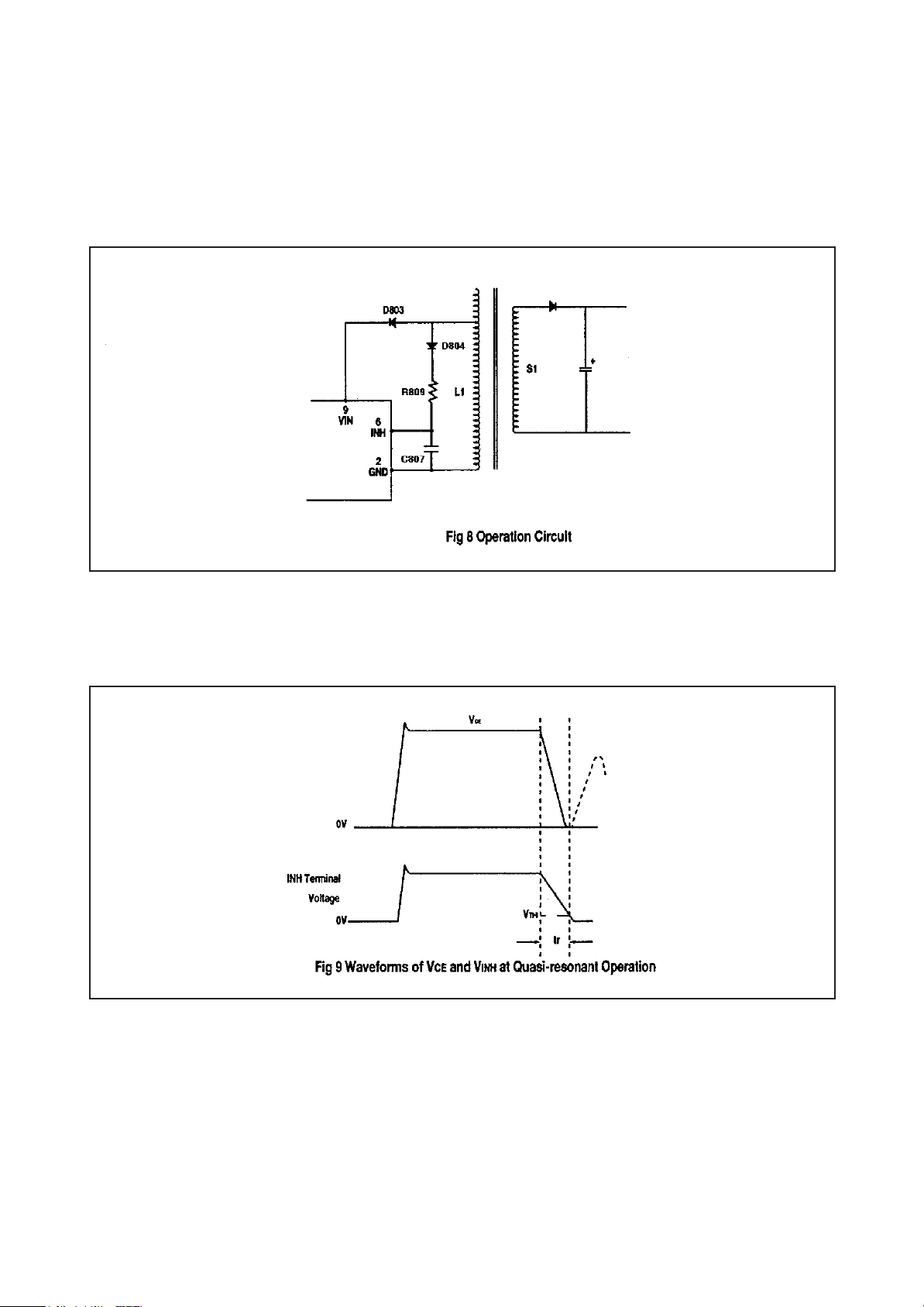

4) Quasi-resonant operation

By inputting a voltage signal which is synchronized with the energy discharge time of a secondary winding of a

transformer to the. INH terminal, quasi-resonant operation can be achieved. As shown in Fig. 8, the voltage of L1

winding which is synchronized. with the energy discharge time of a secondary winding. S1. shall be input to the INH

terminal through D804 and R809. Since V

TH

is set at 1.5V typical, a voltage at the INH terminal. V

2

INH

, shall be set at

Fig. 9 shows waveforms of VCE, Ic and V

INH

of the transistor, voltage across C807 in the oscillator as well as an output

from the oscillator when operating in quasi-resonant mode.

when the power transistor turns off and a voltage than V

and then starts charging again. Even after the discharge of energy of a secondary winding is completed, V

immediately increases. When it gets lower than V

impedance of the IC and C

INH

, has past, the transistor turns on.

TH

is applied to the INH terminal, C807 immediately discharges

2

INH

does not

TH

after the time,tr, which is determined by the production of internal

2

17

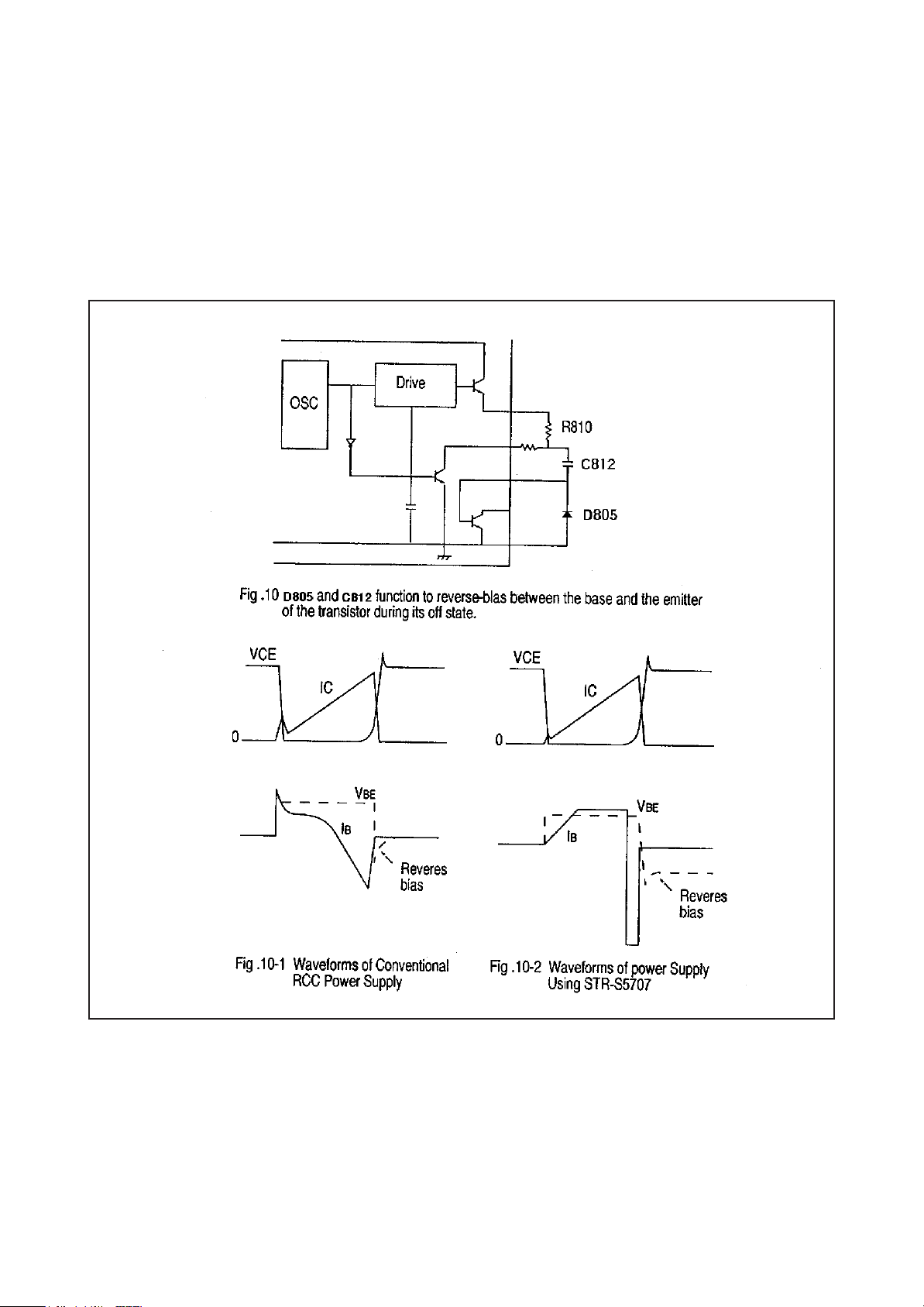

5) Drive circuit

The STR-S5707 applies the proportional drive system in order to minimize turn-on and saturation loss, and storage

time. In the conventional RCC system, turn-on loss and switching noise due to the surge current appearing when the

power transistor turns on are high as because the transistor is driven by the drive current shown in FIg. 10-1. In

addition, since is decreases linearly when the transistor turn off and a peak value of l

long and the V

CE

voltage is high, which results in large turn-off loss. The circuit and the waveforms of the proportional

(

SAT

)

B

is not large, the storage time is

2

drive system which is applied to the STR-S5707 in order to reduce these switching loss and shorten the storage time

are shown in Fig. 10-2 respectively.

18

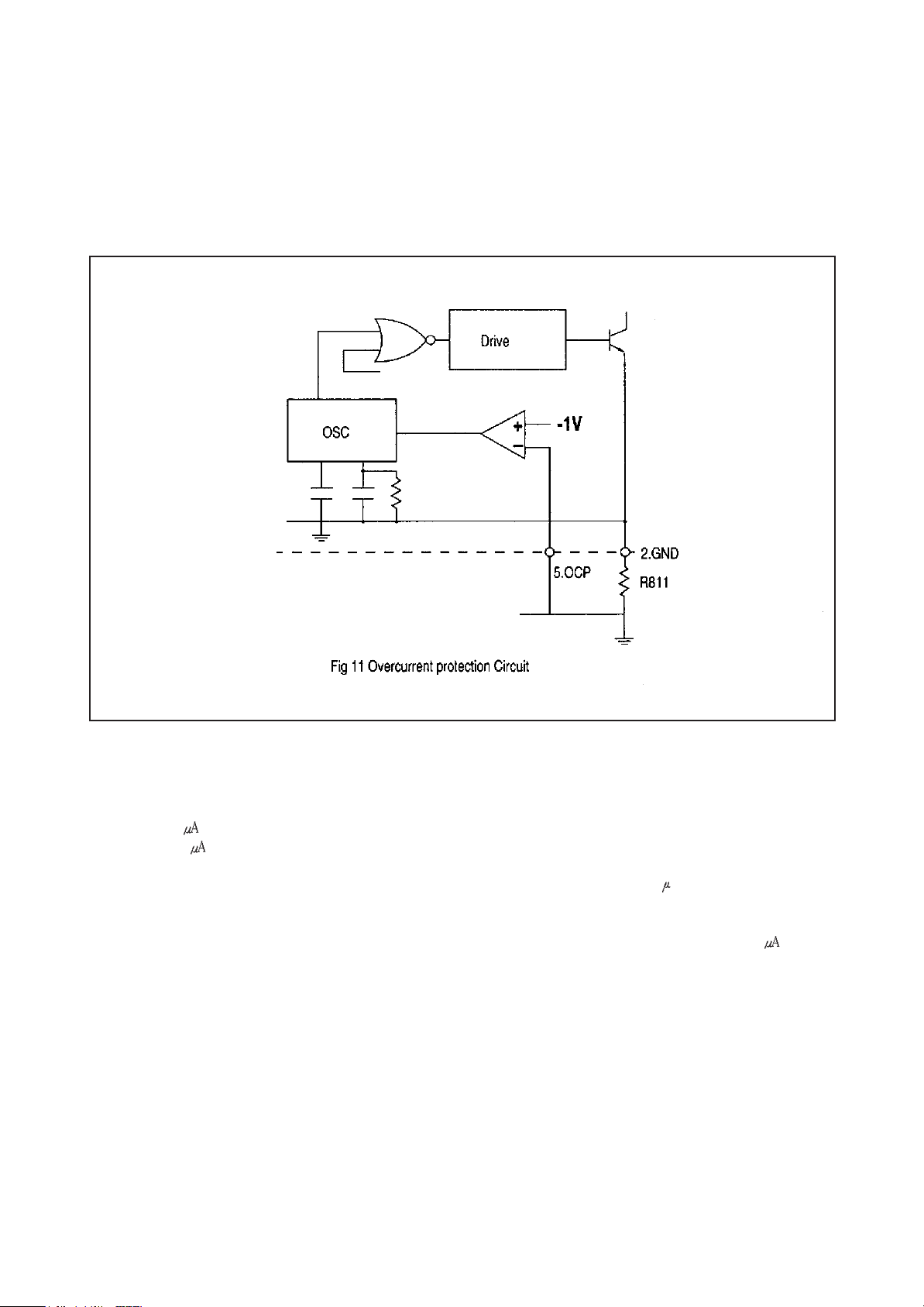

6) OCP (overcurrent protection)function

Overcurrent protection is performed pulse by directly detecting collector current of the power transistor.

Configuration of the OCP circuit is shown in. Detecting voltage is set to-1V below a reference point of GND (ground). In

addition, since the detecting voltage is set by a comparator, very stable characteristics against temperature is achieved

and drift of the deteting voltage against temperature change is almost OV.

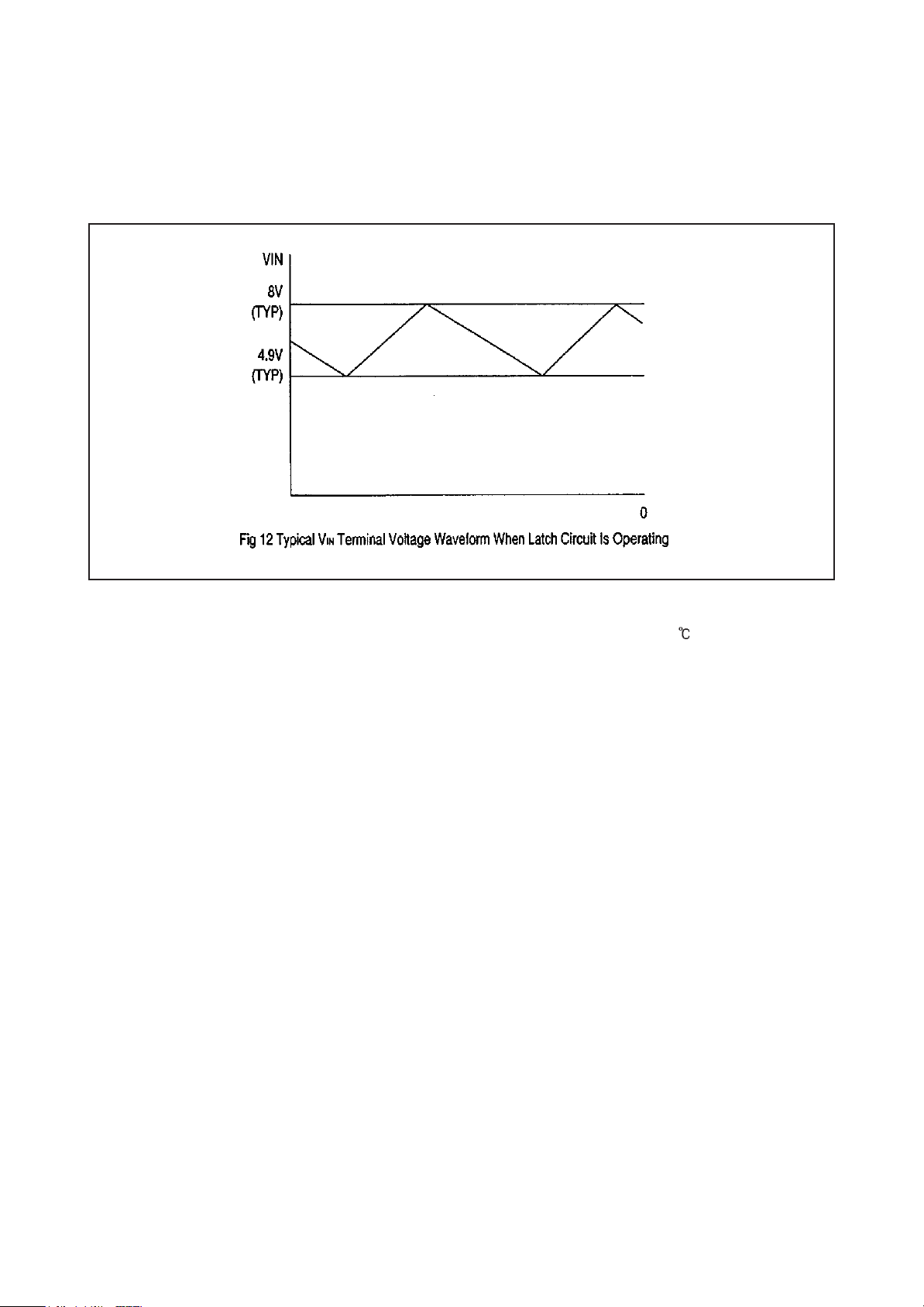

7) Latch circuit

It is a circuit which sustains an output from the oscillator low and stops operation of the power supply when overvoltage

protection (OVP) circuit and thermal shutdown (TSD) circuit are in operation. As the sustaining current of the latch

circuit is 500 maximum when VINterminal voltage is 4V. the power supply circuit sustains the off state as long as

current of 500 maximum flows to VINterminal from a start-up resistor. In order to prevent a malfunction to be caused

by a noise and so on, delay time is provided by C1 incorporated in the IC and, therefore, the latch circuit operates when

the OVP of TSD circuit is in operation, of an external signal input is provided. for about 10 sec or longer. In addition,

even after the latch circuit start operating, the constant voltage regulator (Reg) circuit is in operation and the circuit

current is at high level. As a result. VINterminal voltage rapidly decreases. When V

than the shutdown voltage, V

reaches the ON-state voltage. VIN(ON), (8V typical), V

IN

(OFF), (4.9V typical), it starts in-creasing as the circuit current is below 500 . When it

terminal voltage starts decreasing because the circuit current

IN

terminal voltage becomes lower

IN

increases again.

19

when the latch circuit is on. VINterminal voltage increases and decreases with-in the range from 4.9V typical to 8V

typical and is prevented from abnormally rising. Fig. 12 shows an example of VINterminal voltage waveform.

Cancellation of the latch-is done by decreasing VINterminal voltage below 3.3V. The power supply can be restarted

disconnecting an AC input to the power supply once.

8) Thermal shutdown, circuit

It is a circuit to trigger the latch circuit when the frame temperature of the IC exceeds 150 (typical). Although the

temperature is actually sensed at the control chip. lt works against overheating of the power transistor as the power

transistor and the control IC are mounted on the same lead frame.

9) Overvoltage protection circuit

lt is a circuit to trigger the latch circuit when Vin terminal voltage exceeds 11V (typical). Although it basically functions as

protection of Vin terminal against overvoltage, since Vin terminal is usually supplied from the drive winding of the

transformer and the voltage is proportional to the output voltage, it also functions against the overvoltage of secondary

output which causes when the control circuit opens or in some other events.

20

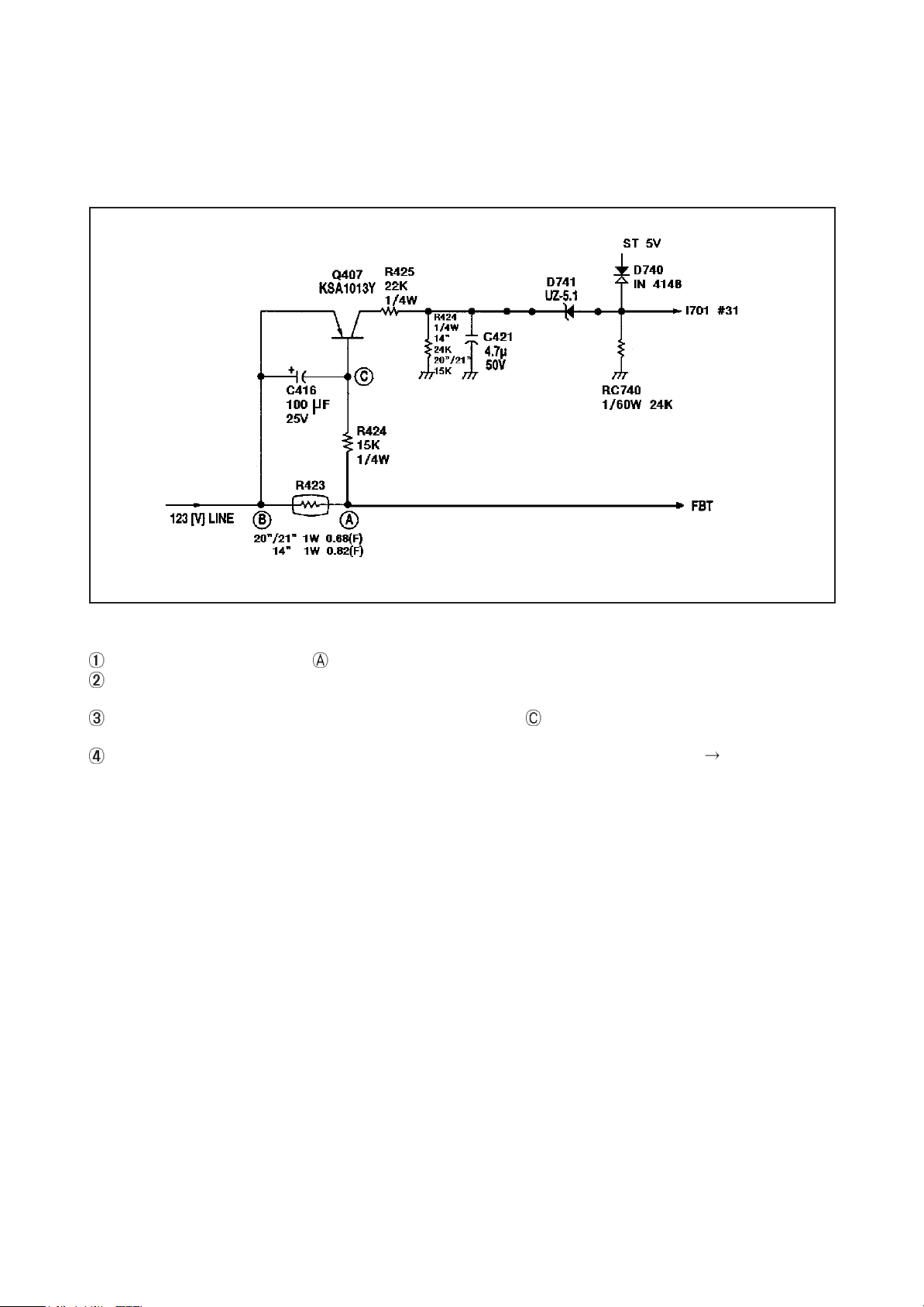

5. OCP (OVER CURRENT PROTECTION) CIRCUIT

This circuit is designed to protect the circuit from over current due to overload occurred at the rear of 123[V] line

1) CONFIGURATION OF OCP CIRCUIT

2) EXPLANATION OF THE OPERATION

There is very little voltage drop at R423 of 123[V] line.

In case that the overload occurs at the rear of 123[V] line, the increase of the voltage drop at R423 bring down the base

voltage of the Q407 os as to drive the Q407

Because of the overload at the rear of the R423, the voltage of the point decreases. And this makes Q407 turn on

so that a voltage is applied to the #31 of l701.

In case that OCP operates by the #31 of the l1701, the set is protected by power off (#42 of l1701 LOW).

21

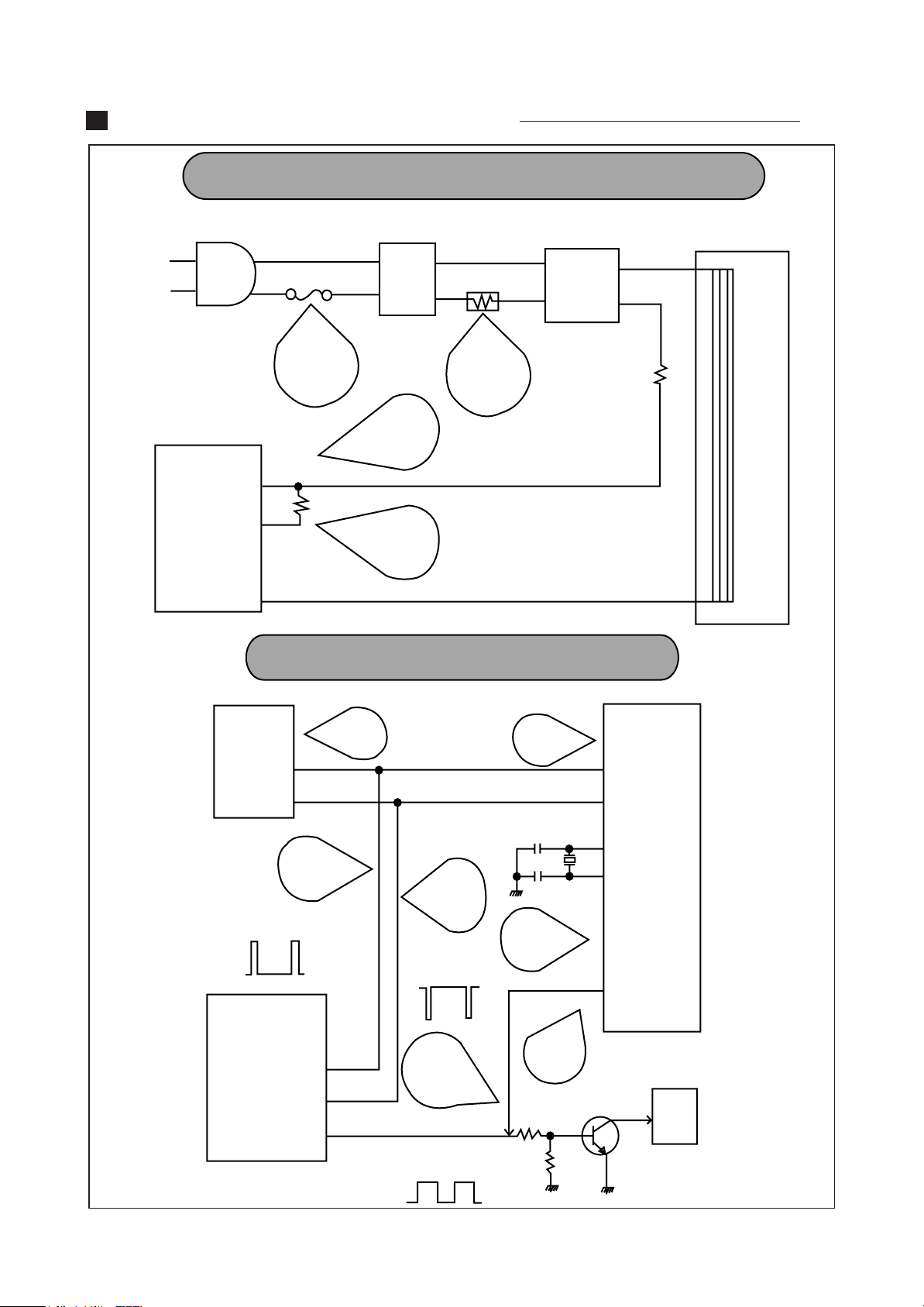

TROUBLE SHOOTING CHART S

NO POWER (NO OUTPUT SECOND POWER)

I801

VIN 9

SENS 7

COLEECTO R 1

CHECK

F801

250V A

L801

LINE

FIL TER

CHECK

R801

R CEMENT

CHECK

SUPPLY

VOLTAGE

CHECK

FEED BACK

INPUT

D801 +

PBS208GU

R802

DON'T OPERATE POWER ON

T801

SMPS

TRANS

I1702

VDD 8

CLK 6

DATA 5

CHECK

CLOCK

PULSE

ST-BY: OV

POER ON:

I501

H. VCC 21

BUS 43

INTERFAC E 44

H. OUT 23

CHECK

DC 5V

CHECK

DATA

PULSE

ST-BY: 5V

POWER ON

CHECK

H-OUT

PUSLE

ST-BY: OV

POWER ON:

CHECK

DC 5V

CHECK

DC 5V

CHECK

VOLT.

RC401

X701

I701

1 EE-CLK

3 M-CLK

4 M-DATA

10

11

12 VDD

16 RESET

42 POWER

ST-BY: L

POWER ON: H

T401

22

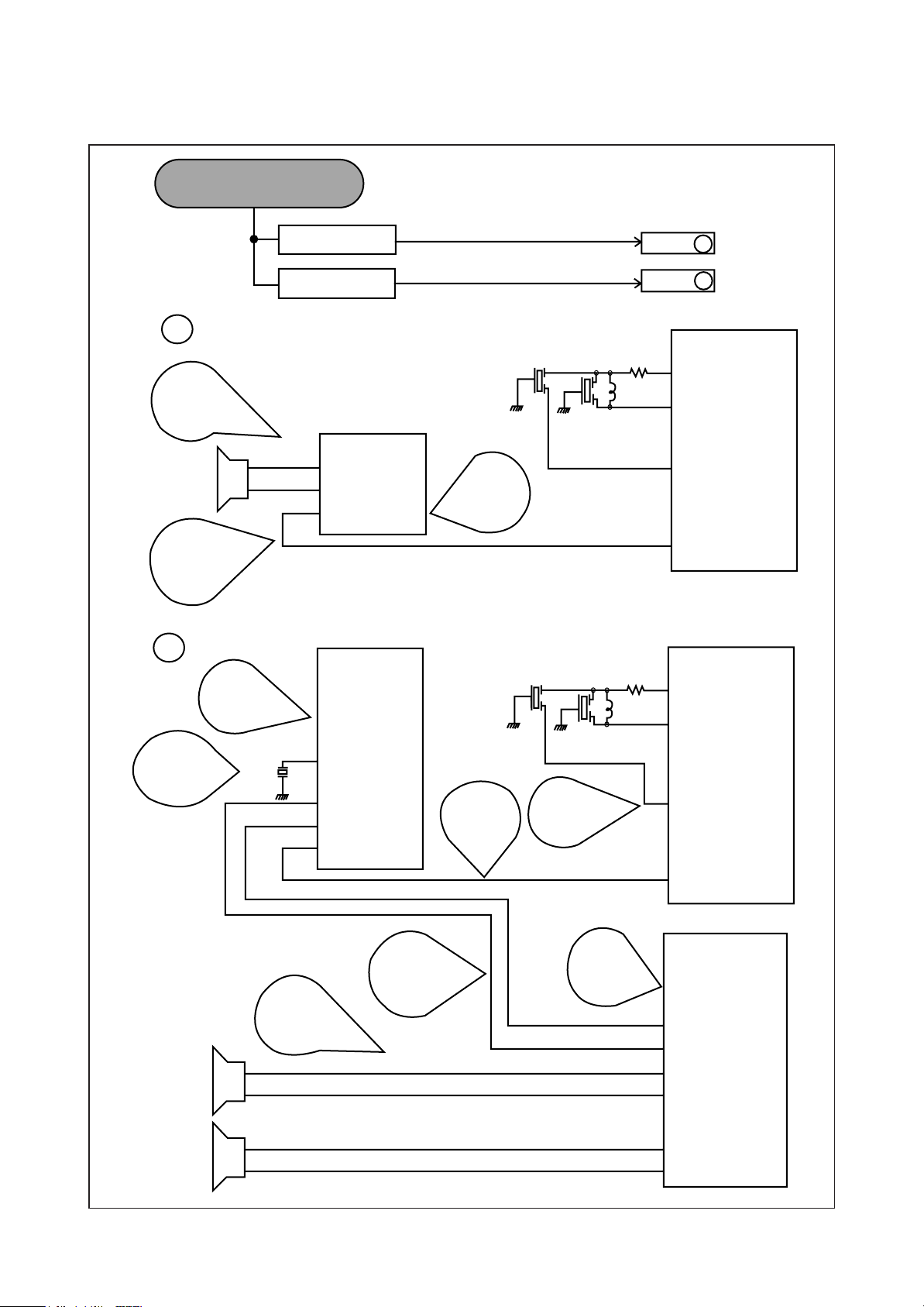

NO PICTURE

CHECK THE WAVE FORM OF

U101 #IF

A

CHECK

VIDEO SIGN AL

4.6V

2.6V

2Vp-p

1.6V

4.6V

Z502

3Vp-p

RC539

L505

BRIGHT

CONTRAST

OK

NO

I501

45 VIDEO OUTPUT

47 INTERNAL

VIDEO INPUT

42 SELECT

VIDEO OUTPUT

32 ABL

33 ACL

30 R OUTPUT

29 G OUTPUT

28 B OUTPUT

CHECK

R/G/B SIGN AL

4

CHECK

7.4V LINE

GOTO

GOTO

T 402

A

B

HEATER

180 V

ABL

RC549

CHECK

HEATER

VTG 6.3Vms

D405

D402

CHECK

180V

LINE

CC511

0.1MF

B

CHECK

DC 5V, 9V

33V LINE

SF 501

SAW FILTER

CHECK

RF AGC OUTPUT

VTG

DC 5V - 8V

U101

IF

5V

9V

33V

AGC

CL

DA

EN

I501

11

10

6 RF AGC

OUTPUT

I702

5 DATA

6 CLK

CHECK

CLK, EN, DATA

SIGNAL

I701

5 T-CLK

6 T-DATA

7 M-EN

23

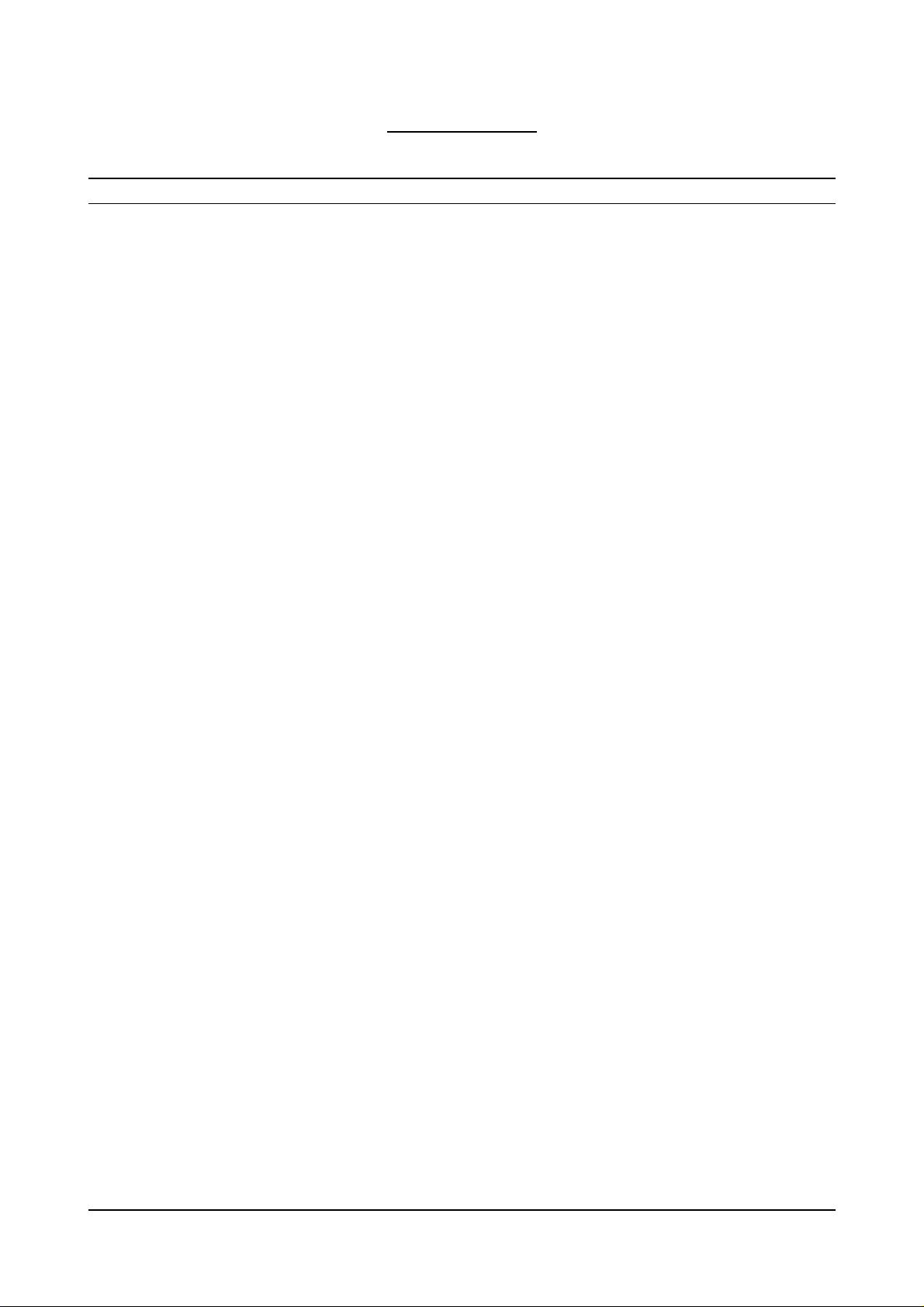

NO SOUND

C

CHECK

AUDIO

OUTPUT

SIGNAL

CHECK

AUDIO

INPUT

SIGNAL

D

CHECK

DC 9V

MONO MODEL

STEREO MODEL

I602

8 -A-OUT

6 +A-OUT

3 A-IN

I601

23

2

CHECK

SOUND B+

DC 12V

Z503 Z502

Z2

Z1 RC1

RC539

L505

L1

GOTO

GOTO

C

D

45 VIDEO OUTPUT

47 INTERNAL

VIDEO INPUT

49 SOUND IF

INPUT

51 AUDIO OUTPUT

45 VIDEO OUTPUT

I501

I501

CHECK

RESONATOR

Z601

CHECK

AUDIO

OUTPUT

SIGNAL

30 CES

1 OUT L

42 OUT R

24 COMP IN

CHECK

R/L-INPUT

SIGNAL

CHECK

INPUT

COMP

SIGNAL

CHECK

SOUND IF

SIGNAL

CHECK

SOUND B+

DC 12V

47 INTERNAL

VIDEO INPUT

49 SOUND IF

INPUT

7 AUDIO OUTP UT

I603

3

4 R-IN

2 L-IN

8 +R-OUT

11 -L-OUT

13 +L-OUT

24

CH DON'T STOP

E

CHECK

DC 5V, 9V

33V LINE

CHECK INPU T SI GN AL

CONDITIO NS

SF 501

SAW FILTER

CHECK

RF AGC OUTPUT

VTC

DC 5V - 8V

U101

IF

5V

9V

AGC

CL

DA

GOOD

BAD

I501

11

10

6 RF AGC

OUTPUT

CHECK

VCO

2

3

COIL

L501

CHECK

CLK, EN, DATA

SIGNAL

GOTO

LOSS OF SIGNL OR

E

WEEK SIGNAL

I702

5 DATA

6 CLK

I701

5 T-CLK

6 T-DATA

33V

NO COLOR

4.6V

1.6V

3Vp-p

EN

CHECK

VIDEO

SIGNAL

CHECK

R/G/B

SIGNAL

FILTER

BRIGHT

CONTRAST

I501

40 COLOR

42 SELECT

VIDEO OUTPUT

32 ABL

33 ACL

30 R OUTPUT

29 G OUTPUT

28 B OUTPUT

15

4

X501

7 M-EN

CHECK

7.4V LINE

CHECK

CRYSTAL

25

NO VERTICAL DEFLECTION

I301

CHECK

V.OUT

SUGBAK

INV 5

OUTPUT 2

VCC 6

V.D.Y

CHECK

OUTPUT

CHECK

DC 25V

17 V.OUT

CHECK

SYNK

SIGNAL

37 SYNC

26

ON SCREEN DISPLAY DOES NOT OPERATE

CHECK

FOR,60Hz

/ VS

/ HS

CHECK

FOR, 15, 734Hz

19

20

10

IC701

21

22

23

24

11

OSC CHECK

R

G

B

BL

R, G, B, BL

CHANGE

IF OSD DOES NOT

OPERATE, CHANGE

IC701

REMOTE CONTROL DOES NOT OPERATE

lL701

REMOCON

SENSOR

GND 5V OUT

CHECK

WAVEFORM

IC701

34

27

DESCRIPTION OF SEMICONDUCTORS

LA76070 (BUS CONTROL, VIF/SIF/Y/C/DEF)

I501 LA76070A

BUS CONTROL, VIF/SIF/Y/C/DEF

28

PIN ASSIGN OF IC LC864728V(I701)

OUTPUT

NOTE) XT is used 32.768 KHZ X-TAL

29

PIN ASSIGN OF IC TDA 7057Q (I603)

2 X 3 W sterei BTL audio output amplifier

PINNING

SYMBOL PIN DESCRIPTION

SGND1 1 signal ground 1

Vi(1) 2 vollage input 1

Vp 3 positive supply voltage

Vi(p) 4 voltage input 2

SGND2 5 signal ground 2

n.c. 6 not connected

n.c. 7 not connected

OUT2+ 8 positive output 2

PGND2 9 power ground 2

OUT2- 10 negative output 2

OUT1- 11 negative output 1

PGND1 12 power ground 1

OUT1+ 13 positive output 1

PIN ASSIGN OF IC LA7841 (I301)

30

PIN ASSIGN OF IC TDA 9852 (I601)

I2C-bus Controlled BTSC stereo/SAP decoder and audio processor

PINNING

SYMBOL

SDIP42 QFP44

OUTL 1 40 output, left channel

LDL 2 41 input loudness, left channel

VIL 3 42 input volume, left channel

EOL 4 43 output effects, left channel

C

V

AV

REF

5 44 automatic volume control capacitor

6 1 reference voltage 0.5Vcc

LIL 7 2 input line control, left channel

AVL 8 3 input automatic volume control, left channel

SOL 9 4 output selector, left channel

LOL 10 5 output line control, left channel

C

TW

C

TS

C

W

C

S

11 6 capacitor timing wideband for dbx

12 7 capacitor timing spectral for dbx

13 8 capacitor wideband for dbx

14 9 capacitor spectral for dbx

VEO 15 10 variable emphasis output for dbx

VEI 16 11 variable emphasis input for dbx

C

C

C

NR

M

DEC

17 12 capacitor noise reduction for dbx

18 13 capacitor mute for SAP

19 14 capacitor DC-decoupling for SAP

GND 20 - ground

AGND - 15 analog ground

DGND - 16 digital ground

SDA 21 17 serial data input/output(l2C-bus)

SCL 22 18 serial clock input(l2C-bus)

V

CC

23 19 supply voltage

COMP 24 20 composite input signal

V

C

C

C

C

CAP

P

1

P

2

PH

ADJ

25 21 capacitor for electronic filtering of supply

26 22 capacitor for pilot detector

27 23 capacitor for pilot detector

28 24 capacitor for phase detector

29 25 capacitor for filter adjustment

CER 30 26 ceramic resonator

C

MO

C

SS

31 27 capacitor DC-decoupling mono

32 28 capacitor DC-decoupling stereo/SAP

LOR 33 29 output line control, right channel

SOR 34 30 output selector, right channel

AVR 35 31 input automatic volume control, right channel

LIR 36 32 input line control, right channel

C

PS

2

C

PS

1

37 33 capacitor 2 pseudo function

38 34 capacitor 1 pseudo function

EOR 39 35 output effects, right channel

VIR 40 36 input volume, right channel

LDR 41 37 input loudness, right channel

OUTR 42 38 output,right channel

n.c 43 39 not connected

PINS

DESCRIPTION

31

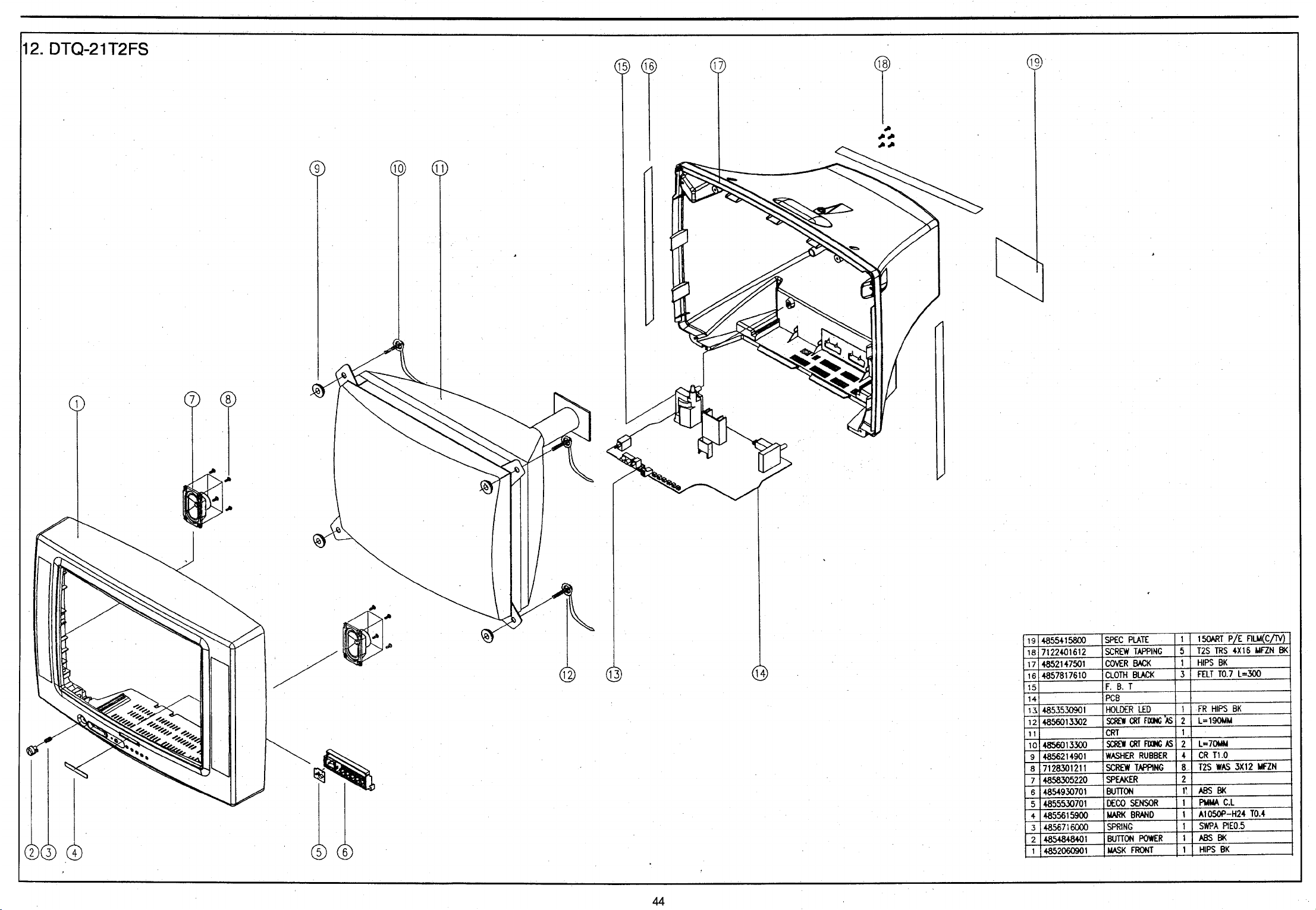

51

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

ZZ100 48B3225C04 TRANSMITTER REMOCON R-25C04

ZZ110 PTACPWJ591 ACCESSORY AS DTQ-20T1FS

30 486A716200 BATTERY AAA

40 4859000240 ADAPTER 2P15A 300V(D=4.0)

50 4850A00650 TRANS ANT MATCHING IMT-060 (CAPRISTOR OUT) B

60 4850A02510 ANT ROD S3BW216B (L=600 MM)

10000 48586054K1 MANUAL INSTRUCTION DTM-2082CW

M821 4858213800 BAG INSTRUCTION L.D.P.E T0.05X250X400

ZZ120 PTBCSHJ596 COVER BACK AS DTQ-21T1FS

M211 4852147001 COVER BACK HIPS BK

M541 4855415800 SPEC PLATE 150ART P/E FILM (C/TV)

M591 4855930923 DECO TERM PVC T0.2

M781 4857817612 CLOTH BLACK FELT T0.7 L=250

ZZ130 PTPKCPJ596 PACKING AS DTQ-21T1FS

10 6520010100 STAPLE PIN 18M/M J D O

20 6520010200 STAPLE PIN #3417

M641 6520010100 STAPLE PIN 18M/M J D O

M801 485804763B BOX CARTON DW-3A

M811 4858179000 PAD EPS 21T1

M821 4858261100 BAG P.E LDPE T0.02X1200X1000000

ZZ131 58G0000110 COIL DEGAUSSING DC-2080

ZZ132 48519A5210 CRT GROUND AS 2101H-1015-1P

ZZ140 PTCACAJ596 CABINET AS DTQ-21T1FS

M191 4851926801 BUTTON CTRL AS 4932801+5530201

M201A 4856013301 SCREW CRT FIXING AS 30X140 YL

M201B 4856214902 WASHER RUBBER CR T2.0

M201C 4856013303 SCREW CRT FIXING AS 30X250 YL

M211A 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

M211B 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

M481 4854848001 BUTTON POWER ABS BK

M481A 4856716000 SPRING SWPA PIE0.5

M561 48556159SS MARK BRAND SILVER ETCHING DIA-CUTTIN

M681 4856812001 TIE CABLE NYLON66 DA100

M781 4857821204 CLOTH BLACK FELT 220X12XT2

SP01A 7128301011 SCREW TAPPING T2S WAS 3X10 MFZN

SP02A 7128301011 SCREW TAPPING T2S WAS 3X10 MFZN

V901 4859608761 CRT A51JSW41X01 P00

ZZ200 PTFMSJJ596 MASK FRONT AS DTQ-21T1FS

M201 4852060402 MASK FRONT HIPS BK

ZZ202 PTSPPWJ591 SPEAKER AS DTQ-20T1FS

PA601 4850703S51 CONN AS YH025-03+35098+ULW=300

PA602 4850703S53 CONN AS YH025-03+35098+ULW=500

SP01 4858306810 SPEAKER 3W 16 OHM F2035C03-3

SP02 4858306810 SPEAKER 3W 16 OHM F2035C03-3

A001 4859812792 PCB MAIN 246X330 S1B

C101 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C102 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C103 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C104 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C301 CMXB1H103J C MYLAR 50V EU 0.01MF J (TP)

C302 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C303 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

52

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

C304 CEXF1V471V C ELECTRO 35V RSS 470MF (10X20) TP

C305 CEXF1H101V C ELECTRO 50V RSS 100MF (8X11.5) TP

C307 CXSL2H100D C CERA 500V SL 10PF D (TAPPING)

C308 CMXL1J104J C MYLAR 63V MEU 0.1MF J

C309 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C310 CEXF1E102V C ELECTRO 25V RSS 1000MF (13X20) TP

C311 CEXD1H229Q C ELECTRO 50V RT 2.2MF (6.3X11) TP

C401 CCXB2H222K C CERA 500V B 2200PF K (TAPPING)

C402 CEXF1H220V C ELECTRO 50V RSS 22MF (5X11) TP

C403 CCYB3A103K C CERA 1KV B 0.01MF K

C404 CMYH3C722J C MYLAR 1.6KV BUP 7200PF J

C405 CEXF2C109V C ELECTRO 160V RSS 1MF (6.3X11) TP

C406 CMYE2D474J C MYLAR 200V PU 0.47MF J

C407 CEXF2E100V C ELECTRO 250V RSS 10MF (10X20) TP

C408 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C409 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C410 CEXF1C222V C ELECTRO 16V RSS 2200MF (13X25) TP

C411 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C412 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C413 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C414 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C415 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C416 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C417 CEXF2C101V C ELECTRO 160V RSS 100MF (16X25) TP

C420 CCXB2H271K C CERA 500V B 270PF K (TAPPING)

C421 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C444 CCXB3D271K C CERA 2KV B 270PF K (T)

C501 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C503 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C507 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C508 CMXB1H473J C MYLAR 50V 0.047MF J (TP)

C510 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C511 CMXB1H333J C MYLAR 50V EU 0.033MF J (TP)

C513 CEXF1H108V C ELECTRO 50V RSS 0.1MF (5X11) TP

C514 CEXF1H108V C ELECTRO 50V RSS 0.1MF (5X11) TP

C515 CEXF1H108V C ELECTRO 50V RSS 0.1MF (5X11) TP

C517 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C518 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C519 CMXB1H333J C MYLAR 50V EU 0.033MF J (TP)

C520 CMXM2A102J C MYLAR 100V 1000PF J (TP)

C522 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

C524 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C531 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C532 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C533 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C537 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C542 CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

C543 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C544 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

53

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

C601 CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

C602 CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

C603 CMXL1J154J C MYLAR 63V MEU 0.15MF J

C605 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C606 CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

C607 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C608 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C609 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C610 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C611 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C612 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C613 CMXL1J473J C MYLAR 63V MEU 0.047MF J

C614 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C615 CMXL1J104J C MYLAR 63V MEU 0.1MF J

C616 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C618 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C619 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C620 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C621 CMXL1J474J C MYLAR 63V MEU 0.47MF J

C622 CMXL1J224J C MYLAR 63V MEU 0.22MF J (TP)

C623 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C624 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C625 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C626 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C627 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C628 CMXB1H153J C MYLAR 50V EU 0.015MF J (TP)

C629 CMXB1H153J C MYLAR 50V EU 0.015MF J (TP)

C630 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C632 CMXL1J154J C MYLAR 63V MEU 0.15MF J

C633 CMXL1J334J C MYLAR 63V MEU 0.33MF J (TP)

C634 CMXL1J334J C MYLAR 63V MEU 0.33MF J (TP)

C636 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C637 CMXL1J104J C MYLAR 63V MEU 0.1MF J

C640 CMXB1H223J C MYLAR 50V EU 0.022MF J (TP)

C641 CMXB1H223J C MYLAR 50V EU 0.022MF J (TP)

C704 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C706 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C708 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C709 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C711 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C801 CL1UC3104M C LINE ACROSS WORLD AC250V 0.1UF M R.47

C802 CCXF3A472Z C CERA 1KV F 4700PF Z (T)

C803 CCXF3A472Z C CERA 1KV F 4700PF Z (T)

C804 CEYN2G221P C ELECTRO 400V LHS 220MF (35X30)

C805 CH1BFE222M C CERA AC U/C/V AC400V 2200PF

C806 CBYB3D152K C CERA 2KV BL (N) 1500PF

C807 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C808 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C809 CEXF1E331V C ELECTRO 25V RSS 330MF (10X12.5)TP

54

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

C810 CCXB3A471K C CERA 1KV B 470PF K (T)

C811 CCXB3A471K C CERA 1KV B 470PF K (T)

C812 CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

C813 CCXB3D102K C CERA 2KV B 1000PF K (TAPPING)

C814 CEYF2C101V C ELECTRO 160V RSS 100MF (16X25)

C815 CCXB3A102K C CERA 1KV B 1000PF K (TAPPING)

C816 CEXF1E102V C ELECTRO 25V RSS 1000MF (13X20) TP

C817 CCXB3A102K C CERA 1KV B 1000PF K (TAPPING)

C818 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C819 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C820 CCXB3A102K C CERA 1KV B 1000PF K (TAPPING)

C888 CH1BFE222M C CERA AC U/C/V AC400V 2200PF

C889 CCXF3A472Z C CERA 1KV F 4700PF Z (T)

C901 CBXB3D102K C CERA 2KV BL(N) 1000PF K (T)

C908 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

CA01 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CA02 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

CAC01 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CAC02 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CC101 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC102 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC504 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC505 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC509 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC511 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CC512 HCQK160JCA C CHIP CERA 50V CH 16PF J 2012

CC516 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC523 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC530 HCQK561JCA C CHIP CERA 50V CH 560PF J 2012

CC534 HCQK470JCA C CHIP CERA 50V CH 47PF J 2012

CC535 HCQK220JCA C CHIP CERA 50V CH 22PF J 2012

CC536 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC538 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC539 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC544 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC601 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC602 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC604 HCBK822KCA C CHIP CERA 50V X7R 8200PF K 2012

CC617 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC631 HCBK822KCA C CHIP CERA 50V X7R 8200PF K 2012

CC701 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

CC702 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

CC703 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC705 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC707 HCBK333KCA C CHIP CERA 50V X7R 0.033MF K 2012

CC710 HCQK221JCA C CHIP CERA 50V CH 220PF J 2012

CC712 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC713 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC714 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

55

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

CC715 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC716 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CC717 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CC718 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012

CC722 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

Loc Item Code Item Name Description

CC726 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

CC902 HCQK271JCA C CHIP CERA 50V CH 270PF J 2012

CC903 HCQK271JCA C CHIP CERA 50V CH 270PF J 2012

CC904 HCQK271JCA C CHIP CERA 50V CH 270PF J 2012

CC908 HCQK102JCA C CHIP CERA 50V CH 1000PF J 2012

D101 DUZ9R1BM-- DIODE ZENER UZ-9.1BM 9.1V

D102 DUZ5R1BM-- DIODE ZENER UZ-5.1BM

D103 DUZ33B---- DIODE ZENER UZ-33B

D104 DUZ9R1BM-- DIODE ZENER UZ-9.1BM 9.1V

D301 D1N4003--- DIODE 1N4003 (TAPPING)

D401 NBYD33GT-- DIODE BYD33G-T

D402 NBYD33GT-- DIODE BYD33G-T

D403 NBYD33GT-- DIODE BYD33G-T

D404 NBYD33GT-- DIODE BYD33G-T

D405 NBYD33GT-- DIODE BYD33G-T

D406 D1N4148--- DIODE 1N4148 (TAPPING)

D407 DUZ7R5BM-- DIODE ZENER UZ-7.5BM 7.5V

D408 D1N4148--- DIODE 1N4148 (TAPPING)

D409 DUZ9R1BM-- DIODE ZENER UZ-9.1BM 9.1V

D412 DBY228---- DIODE BY228 (TAPPING)

D501 DUZ9R1BM-- DIODE ZENER UZ-9.1BM 9.1V

D504 D1N4148--- DIODE 1N4148 (TAPPING)

D601 DUZ8R2BM-- DIODE ZENER UZ-8.2B (8.2V)

D701 DUZ3R9B--- DIODE ZENER UZ-3.9B

D703 DKLR114L-- LED KLR114L

D740 D1N4148--- DIODE 1N4148 (TAPPING)

D741 DUZ5R1BM-- DIODE ZENER UZ-5.1BM

D801 DPBS208GU- DIODE BRIDGE PBS208GU-CA

D802 D1N4937GP- DIODE 1N4937GP (TAPPING)

D803 D1N4937GP- DIODE 1N4937GP (TAPPING)

D804 D1N4937GP- DIODE 1N4937GP (TAPPING)

D805 D1N4937GP- DIODE 1N4937GP (TAPPING)

D806 DPR3005G-- DIODE PR3005G

D807 DPR1505G-- DIODE PR1505G

D808 DPR1505G-- DIODE PR1505G

D809 DUZ6R2BM-- DIODE ZENER UZ-6.2BM 6.2V

D810 D1N4148--- DIODE 1N4148 (TAPPING)

D901 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

F801 5FKGB4022R FUSE GLASS TUBE KS MF51 4A 250V NR

F801A 4857415001 CLIP FUSE PFC5000-0702

F801B 4857415001 CLIP FUSE PFC5000-0702

I301 1LA7841--- IC VERTICAL LA7841

I301 PTB2SW7101 HEAT SINK ASS`Y 1LA7841--- + 7174301011

I301A 4857027101 HEAT SINK SPCC T1.0+SN

56

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

I301B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

I501 1LA76070A- IC VIDEO PROCESSOR LA76070A

I601 1TDA9852-- IC AUDIO PROCESSOR TDA9852

I603 1TDA7057Q- IC AUDIO AMP TDA7057Q

I603 PTC2SW6109 HEAT SINK ASS`Y 1TDA7057Q- + 7174301011

I603A 4857026109 HEAT SINK AL EX

I603B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

I701 1LC8645G79 IC MICOM LC864728V-5G79

I702 124LC02B-- IC MEMORY 24LC02B

I801 1STRS5707- IC POWER STR-S5707

I801 PTA2SW6107 HEAT SINK ASS`Y 1STRS5707- + 7174301211

I801A 4857026107 HEAT SINK AL EX

I801B 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

I802 1LTV817C-- IC PHOTO COUPLER LTV-817C

IL701 1TFMW5380- IC PREAMP TFMW5380

J001 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J002 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J004 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J005 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J006 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J007 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J008 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J009 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J010 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J011 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J012 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J013 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J014 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J015 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J017 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J019 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J020 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J021 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J022 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J023 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J024 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J025 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J026 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J027 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J028 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J029 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J030 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J031 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J032 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J033 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J034 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J035 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J036 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

57

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

J037 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J038 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J040 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J041 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J042 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J043 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J044 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J045 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J046 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J047 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J049 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J050 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J051 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J052 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J053 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J055 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J058 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J060 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J101 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J102 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J103 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J301 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J302 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J303 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J305 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J306 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J310 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J402 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J403 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J404 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J405 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J408 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J409 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J410 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J411 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J501 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J502 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J503 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J504 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J505 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J506 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J507 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J509 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J601 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J602 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J603 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J604 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J605 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J606 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

58

PARTS LIST

(DTQ-21T1FS)

Loc Item Code Item Name Description

J607 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J608 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J609 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J610 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J615 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J701 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING