Page 1

1

CONTENTS

RUN AND CHECK UP....................................................................................................................................................2

WHERE TO INSTALL.....................................................................................................................................................3

INSTALLATION..............................................................................................................................................................3

INDOOR UNIT

DIMENSIONS OF INDOOR UNIT [DTA-240LH]......................................................................................... 4

INDOOR UNIT INSTALLATION....................................................................................................................5

REFRIGERANT PIPE CONNECTION..........................................................................................................6

AIR PURGE...................................................................................................................................................6

REFRIGERANT SUPPLEMENT...................................................................................................................7

LEAK CHECKUP...........................................................................................................................................7

PIPE INSULATION AND ISOLATION...........................................................................................................7

DRAIN HOSE INSTALLATION .....................................................................................................................8

DRAINAGE TEST..........................................................................................................................................9

INDOOR UNIT WIRE CONNECTION.........................................................................................................10

OUTDOOR UNIT

OUTDOOR UNIT WIRE CONNECTION.....................................................................................................11

CHECKUP GROUNDING ...........................................................................................................................12

FRONT PANEL

FRONT PANEL INSTALLATION ................................................................................................................13

OWNER’S MANUAL.....................................................................................................................................................14

Page 2

RUN AND CHECK UP

2

Before the installation is carried out completely, check these out.

• Pipe connection and gas leaks

• Electric wiring and isolation treatment of drain pipes

• Drainage system and insulation treatment of drain pipes

• Grounding wire connection

Wire Remote Controller

1. Turn on the air conditioner. (If you can see the present temperature on the LCD of the wire remote controller, it means

the power supply is correctly connected.)

2. Set the mode 'Auto' and check if the outdoor unit is working properly.

(The outdoor unit runs 30 seconds after the first operation.)

3. Press the Fan Dir. button and check if regulating the angle of Flap is normal.

4. Complete the operation.

If any error occurs, ERR is shown on the wire remote controller.

Wireless Remote Controller

1. Turn on the air conditioner.(If you can see the present temperature on the LCD of the wire remote controller, it means

the power supply is correctly connected.)

2. Set the mode 'Auto' and check if the outdoor unit is working properly.(The outdoor unit runs 30 seconds after the first

operation.)

3. Complete the operation.

Page 3

WHERE TO INST ALL

3

Cautions before installation

• Read this manual thoroughly before you attempt to install the air conditioner.

• Drilling work through the ceiling must be done before installation.

• After installation, be sure to take a dry run and check if the machine is working properly.

• To avoid possible personal injury or property damage, be sure that installation will be done by instructed employees.

• In case that installation in those places as below is inevitable, contact an authorized company.

- Where the oily vapor or wheat flour is around

- Where the lubricating oil(such as cutting oil) is around

- Where inflammable gas flows in and remains.

- Where corrosive gas is produced or flows in and remains

- Where ducts are restricted to be installed

- Where surroundings of installation is not ordinary

Indoor Unit

• Where the unit can be sufficiently held up and no vibration is felt.(must receive the weight of more than 150kg)

• Where around the air inlet and outlet is clear.

• Where condenser water can be easily let out, and connecting pipes to the outdoor unit is easy.

• Where heat or vapor around the unit is clear(must be far away from kitchen or other heat sources)

• Where ceiling and floor is at a distance of lower than 3m.

• Where the unit can stand level with floor.

Outdoor Unit

• Out of rain or direct rays of the sun and well-ventilated

• Where not to bar the way

• Where the noise and heated air wouldn't disturb neighbourhood or animals and plants.

• Not to be installed on the outside railings of window or outside wall.

(to avoid possible personal injury and no after service available)

• Where pipes or wires can be easily connected to the unit.

• Where grounding is easy.

• Where installation distance is maintained long enough.

Page 4

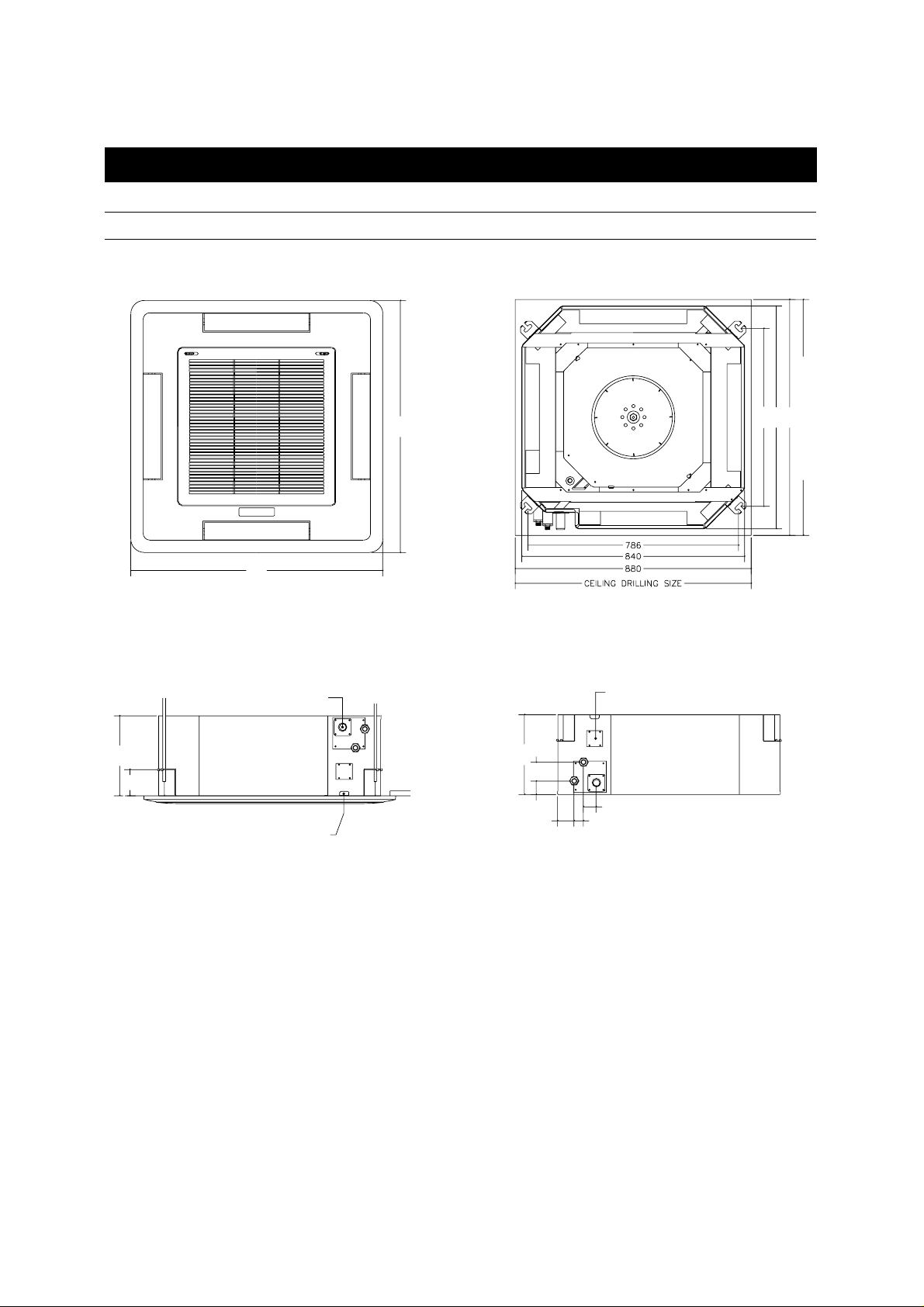

4

INDOOR UNIT

664

940

250

250

7050

98

940

61.5 34.7

48

DRAIN OUTLET

DRAINAGE CHECKUP HOLE

POWER CORD

CONNECTING HOLE

840

880

CEILING DRILLING SIZE

DIMENSIONS OF INDOOR UNIT [DTA-240LH]

Page 5

5

1. Drill a hole with a depth of 880mm where the indoor

unit will be installed.

• Before carrying out installation, be cautious of the direction of drainage pipes and refrigerant pipes.

3. Bring the product fixing bolt together with nut and

washer as the figure shows.

• But the space for a hanger bracket to be inserted

must be secured.

4. Insert the hanger bracket between the fixed nuts on

the ceiling Suspension Bolt and hang the indoor unit.

2. Drill a hole through the ceiling or ceiling rest and insert the base bolt.

• In case that the bolt for supporting ceiling is over

1.5M, vibration isolation is needed.

Vibration isolating device is not included in product.

INDOOR UNIT INSTALLATION

5. Tighten the nuts and fix the indoor unit completely. 6. Select where to put the indoor unit, considering the

enough space the front panel can be fit in.

Product's level surface must be considered and adjust the level, and then fix the product.

Concrete

Anchor Bolt

for fixing product

Suspension Bolt

20

0~5mm

Suspension Bolt

nuts

Product fixing bracket

880

880

overhead

side

NUT

SPRING WASHER

BOLT

PLANE WASHER

Page 6

6

REFRIGERANT PIPE CONNECTION

AIR PURGE

If there is air or nitrogen gas which isn't to be condensed in the pipes, outflow pressure rise, power loss, condenser heating, and air conditioner deterioration might occur, and therefore air purge is essential.

Air purge is supposed to use the pulsometer pump, and can also use additional refrigerant in the unit.

• Refrigerant pipe connection

After finishing connecting the refrigerant piping,

check any refrigerant leak and wrap it with insulation

material, and cover it again with vinyl tape.

Tighten the flare nuts with torque rule.

1. Connect the pipes of indoor/outdoor units.

In carrying out this work, tighten the flare nut 4 rather

loosely.(screwable with hand)

2. Remove the cap nuts 8, 9, 10, and tighten the cap

nut 7 1~2 seconds after screwing it with a angle of 90

counterclockwise with hexagon wrench. In doing this

work, tight the flare nut 4 completely.

3. Press the nut 6 2~3 times(1 time/3 sec.) and vacuum

the air in the service valve completely.

4. Open the gas/liquid side service valves fully with use

of hexagon wrench.

Warning

• Use two spanners in connecting the union to the flare

nut.

• Do not bend the pipes more than twice and work on

the longer radius.

• Do not remove the cap on the flare until the clamping

is done.

INDOOR OUTDOOR

Page 7

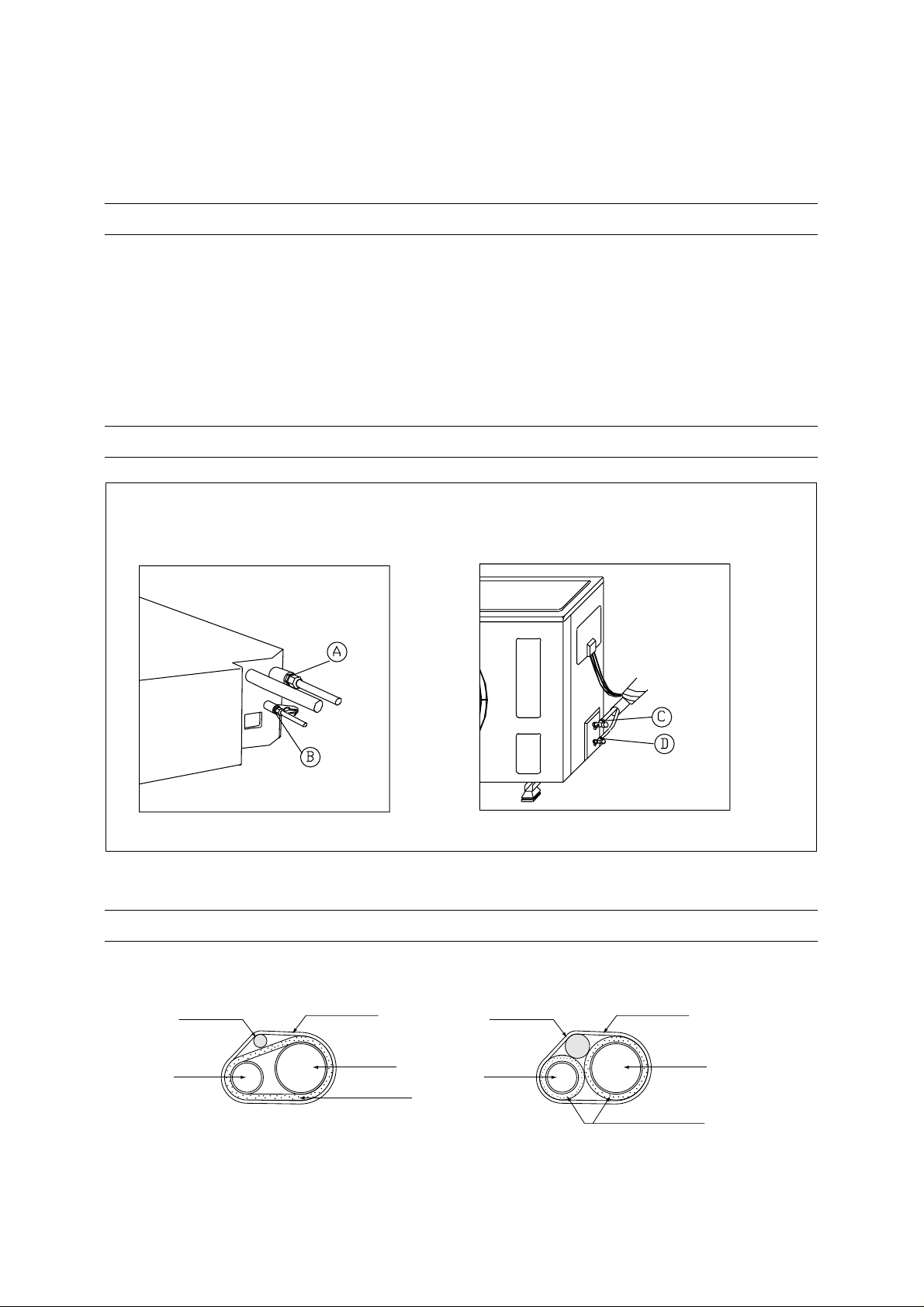

Indoor Unit

To check up gas leak, the end of flare nut

on A, B part.

Outdoor Unit

valve on C, D part

7

REFRIGERANT SUPPLEMENT

In case that the length of the refrigerant pipe is over 5m, refrigerant must be supplemented.(max.20m)

But the amount of the supplementary refrigerant is variable according to installing condition, so check the condition before supplementing refrigerant.

This work must be carried out by qualified employees.

• In case that vertical length is over 10m, install an oil trap on the gas pipes.

PIPE INSULATION AND ISOLATION

To prevent vapor from forming inside the pipes, insulate each pipe with heat-resisting polyethylrne resin.

Following figure shows how to insulate and isolate the refrigerant pipes correctly.

LEAK CHECKUP

ELECTRIC WIRE

PIPE LIQUID

FINISHING TAPE

PIPE GAS

ELECTRIC WIRE

PIPE LIQUID

FINISHING TAPE

PIPE GAS

PIPE INSULATION

PIPE INSULATION

(X) (O)

Page 8

8

DRAIN HOSE INSTALLATION

1. Drain hose connection

In case that the drain hose is connected, bonding

work is necessary for preventing leaks, and then

make it immovable with fixing stuff such as adhesive

band.(adhesive band is not included in product)

• outside diameter of drain hose connecting hole is

32mm

2. Insulating treatment

Insulating treatment must be carried out for the condenser water not to leak out from drain pipes.

Be sure there is no gap between the product and

hose.

• Inside diameter of flexible hose connecting hole is

32mm.

• In case that outside temperature and humidity is

high, make the insulating material by 10~30mm.

3. Supporting and connecting pipes

To let out the condenser water, drain pipes must be

at down-slope.

In case that drain pipes are not at down-slope, problems such as reverse flow of condenser water might

occur.

If the pipe is long, a rest that can support the pipe

needs to be installed.(to be worked within 1~1.5M)

4. Horizontal extension of pipe is impossible.

In case that drain hose is above the connecting hole,

it must be connected up to the hole at a right angle

within 30cm crossways from the product. Height of

the drain hose is at a right angle within 600mm from

the drain hose connecting hole.

Warning!

After connecting the flexible hose to the drain hose connecting hole, connecting the hose up at a right angle is

restricted.

outside diameter of

drain hose connecting

hole is 32mm

Drain hose

connecting hole

Insulation

Flexible

hose

main

body

bonding

work

adhesive band

(not included in

product)

drain

pipe

Main

body

pipe rest

pipe rest

down-slope(over 1/100)

elbow

25A VP

flexible hose

drain pipe

(with down-slope)

drain hose

connecting

hole

horizontal extension within

30cm is not impossible

within

60cm

overhead side

Page 9

9

DRAINAGE TEST

1. Remove the two bolts from checkup unit on the side

of drain pipe and detach the checkup cover.

2. Pour the prepared water inside the checkup unit.

• In case of failing to pour the water inside the checkup unit, water might overflow the product.

3. Check if the draining is normal.

pumping/draining

--->Checking drainage is available during turn-off,

cooling and heating.

4. Reinstall the checkup cover.

Page 10

10

INDOOR UNIT WIRE CONNECTION

DTA-240LH

3113544330

Page 11

11

OUTDOOR UNIT WIRE CONNECTION

OUTDOOR UNIT

Page 12

12

Attachments for grounding are not included in product.

1. Select proper place to install the grounding bar.

• For grounding, wet and solid ground is preferred to one covered with sand or pebbles.

• Select the place far away from gas/water pipes, telephone lines, underground cables, or other structures.

• The grounding must be carried out at least 2m from a lightening rod.

• A ground wire for telephone is not to be used for air conditioner.

2. Wrap the rest part of the pipe connected to the outdoor unit with the isolation tape and complete the grounding.

3. Install green or yellow ground wire.

• In case the ground wire is too short, extend the wire, wrapping the extended part with the isolation tape.

Don't bury the connected part.

• Fix the ground wire using a clamp.

In case the ground bar is installed where people pass, it must be fastened tight.

4. Connect the ground wire to the terminal plate on the outdoor unit.

CHECKUP GROUNDING

Page 13

13

FRONT PANEL INSTALLATION

1. Detach the inlet grille from the front panel. 2. Fasten two fixing screws for front panel diagonally to

the indoor unit by one third of each.

• Piping side mark of front panel must be fit together

with that of main body.

3. After fastening two screws, rotate the front panel to

be fixed on the edge of the key hole and fasten the

other two screws to be fixed completely.

4. Connect the cable of front panel to the PCB as the

figure shows.

5. Fasten the control box cover as the front panel

installed.

6. Close the front grille and fasten the fixing studs.

Control

bow cover

Page 14

BEFORE USE

14

Care and maintenance................................................................................................................................................15

Names of parts.............................................................................................................................................................16

Indoor Unit/Outdoor Unit......................................................................................................................................16

Wire remote controller..........................................................................................................................................17

Wireless remote controller...................................................................................................................................18

Replacing remote controller battery.....................................................................................................................19

How to use the wire remote controller......................................................................................................................20

Cool mode............................................................................................................................................................20

Heat mode............................................................................................................................................................20

Dehumidifier mode...............................................................................................................................................21

Fan mode.............................................................................................................................................................21

Auto mode............................................................................................................................................................21

Quick mode..........................................................................................................................................................22

Timer mode..........................................................................................................................................................22

Sleep mode..........................................................................................................................................................23

Fan direction/Fan speed controlling.....................................................................................................................23

How to use the wireless remote controller ..............................................................................................................24

Cool mode............................................................................................................................................................24

Heat mode............................................................................................................................................................24

Dehumidifier mode...............................................................................................................................................25

Fan mode.............................................................................................................................................................25

Auto mode............................................................................................................................................................25

Quick mode..........................................................................................................................................................26

Timer mode..........................................................................................................................................................26

Sleep mode..........................................................................................................................................................27

Fan speed controlling...........................................................................................................................................27

Cleaning the air filter...................................................................................................................................................28

Problems/Possible causes.........................................................................................................................................29

Specification ................................................................................................................................................................30

Page 15

15

CARE AND MAINTENANCE

Clean the casing and front of the indoor unit with a vacuum brush or wipe with a clean damp cloth.

• NEVER USE Solvents, harsh chemicals or hot water to clean the unit.

• Some metal edges on the unit are sharp. Be careful when cleaning or handling.

• Internal parts in the outdoor unit may need cleaning or routine maintenance from time to time. Consult your local ser-

vice center for more details.

AFTER THE SEASON:

• Operate the fan, then dry the indoor unit.

• Shut off the indoor unit and then unplug it from the wall.

• Clean the air filters.

• Cover the outdoor unit with the supplied cover; this is very important to protect this unit.

BEFORE THE SEASON:

• Make sure the air filters are clean.

• Make sure the inlet and outlet on the indoor and outdoor units are not blocked by obstructions.

• Make sure the unit is grounded. Consult a serviceman for help.

PRECAUTIONS:

• Do not use this unit for animal or plant storage.

• In a lightning or thunder storm, immediately unplug it from the wall.

warning

• Make sure the AC cord is unplugged and the unit is off before cleaning.

• Do not use water on the unit to clean it. This is a shock hazard and the unit can be damaged.

Page 16

16

INDOOR UNIT

Remote Controller Receiving

Part and Indicator

Heat Mode Indicator

• lit on during heating.

Remote Controller

Receiving Part

Cool mode Indicator

• lit on during cooling, fanning,

or dehumidifying.

Filter cleaning indicator

• shows when to clean the filter.

NAMES OF PARTS

Inlet Outlet

OUTDOOR UNIT

OUTDOOR UNIT AIR IN

- If there is any obstacle in front of

the grille, the efficiency of the unit

can be lowered.

OUTDOOR UNIT AIR OUT

SERVICE VALVES(GAS TUBE)

SERVICE VALVES(LIQUID TUBE)

CAUTION

• Do not install the outdoor unit on

unstable place like outside wall of

building or outside of balcony. In

case of falling, it may cause serious

trouble and damage.

Page 17

17

WIRE REMOTE CONTR OLLER

WIRE REMOTE CONTROLLER OPERATION INDICATOR

Power button

Mode button

Fan Speed button

Fan Direction button

Operation Indicator

Temperature Button

Timer button

(Enter/Cancel button)

Filter Reset button

Sleep button

Reservation Time Up button

Reservation Time Down button

Fan Mode Indicator

Dehumidifier Mode Indicator

Heat Mode Indicator

Filter Cleaning Indicator

Fan Dir.

Indicator

Cool Mode Indicator

Quick Mode Indicator

Auto mode Indicator

Fan Speed Indicator

Temperature Indicator

Timer Mode(Time) indicator

Sleep mode indicator

Page 18

18

MODE

SLEEP

ON/OFF

TIMER

ENTER/

CANCEL

FAN SPEED

Operation Indicator

Displays information

pertaining to unit.

Timer Enter/Cancel Button

Press to enter a timer setting or

to cancel timer setting

Timer On/Off Button

Press to set the unit off or on time.

(0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8,

10, 12, 16, 20, 24hr)

Mode Button

Press to cycle through the modes

(Auto/Quick/Cool/Fan/Dehumidifier/

Heat)

Sleep Button

Press to set the unit for the

sleep mode.

On/Off Button

Press to turn the unit on or off.

Temperature Buttons

Fan Speed Button

Press to select the fan speed

(Auto, High " ", Middle " ",

Low " ", Natural).

Cover

Slide down to access most

of the remote buttons.

Slide down further to

access the battery

compartment.

AUTO

WIRELESS REMOTE CONTR OLLER

WIRELESS REMOTE CONTR OLLER OPERATION INDICATOR

Mode Indicators (Auto/Quick/Cool/Fan/Dehumidifier/Heat)

Lights to indicate the mode selected.

Timer Indicators (Include sleep)

Lights to indicate the timer function mode.

Temperature & Reservation Time lndicator

Lights to indicate the temperature or time.

Nantural Indicator

Lights to indicate the

speeds simulating a breeze.

Fan Indicators

Lights to indicate

the fan speed.

AUTO

Page 19

19

1. Lift the cap by pressing hard and pulling it in direction

of the arrow on the cap.

3. Close the cap by pushing it to the direction of the arrow.

2. Put the battery in to the direction of + and - inside of the

remote controller. Be sure the direction of + and -.

REPLACING REMOTE CONTROLLER B ATTERY

+–

+–

Page 20

20

• Cool mode

• Heat mode

• Dehumidifier mode

• Fan mode

• Auto mode

• Quick mode

• Timer mode

• Sleep mode

• Fan direction/Fan speed controlling

COOL MODE

• NOTES!

When the present temperature goes down to the desired temperature, the air conditioner retains the desired temperature, repeating cooling and fanning automatically.

• Press the Power Button and

turn the power on.

• Press the button till is

shown and the

Cool Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

HEAT MODE

• NOTES!

When the present temperature goes up to the desired temperature, the air conditioner retains the desired temperature, repeating heating and fanning automatically.

• Press the Power button and

turn the power on.

Defrosting Mode

During the Defrosting Mode, in case that outdoor temperature is low and humidity is high, the outdoor unit gets

covered with frost and it deteriorates the heating function. During the Defrosting mode, pre-heating mode is applied until temperature of the outdoor unit pipe goes up to proper temperature.

During the Defrosting Mode, indoor unit doesn't work.

• Press the button till is

shown and the

Heat Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

HOW TO USE THE WIRE REMOTE CONTROLLER

Page 21

21

DEHUMIDIFIER MODE

• NOTES!

During the Dehumidifier Mode, Cool Mode indicator on the front panel gets lit on.

During the Dehumidifier Mode, Fan speed is automatically set on "Low".

• Press the power button and

turn the power on.

• Press the button till is

shown and the

Dehumidifier Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

AUTO MODE

• NOTES!

With Auto Mode applied, cooling, heating, or dehumidifying is automatically set into run.

• Press the power button and

turn the power on.

• Press the button till is

shown and the Auto Mode

starts.

• Yon can freely set the temperature between 24~28°C and the

temperature is set by 1°C with

each time the button pressed.

FAN MODE

• NOTES!

During the Fan Mode, Cool Mode Indicator on the front panel gets lit on.

During the Fan Mode, temperature isn't able to be set.

During the Fan Mode, pleasant air comes out insteand of cool/heal air.

• Press the power button and turn the power on.

• Press the button till is shown and the

Fan Mode starts.

Page 22

22

QUICK MODE

• Notes!

With Quick Mode applied, cooling or heating is set to work more swiftly.

During Quick Mode, cooling or heating is automatically set.

During Quick Mode, temperature or fan speed isn't able to be set.

• Press the power button and turn the power on.

• Press the button till is shown and the

Quick Mode starts.

TIMER MODE

• Notes!

When the reservation time is over, the air conditioner is running under the previously selected mode.

• Notes!

When the reservation time is over, the running mode stops.

Timer On is available only

when the air conditioner isn't

running.

Timer Off is available only

when the air conditioner is

running.

• Press the button and select

timer mode.

• Press the button and set the

reservation time.

• Reservation time can be set in

the order of 0.5, 1, 1.5, 2, 2.5, 3,

4, 5, 6, 8, 10, 12, 16, 20, 24 hr.

• Press the button and select

timer mode.

• Press the button and set the

reservation time.

• Reservation time can be set in

the order of 0.5, 1, 1.5, 2, 2.5, 3,

4, 5, 6, 8, 10, 12, 16, 20, 24 hr.

How to cancel the reservation,

With the reservation time set, press the button and the reservation is canceled.

'Timer' on the Timer Mode(Time) indicator disappears.

Page 23

23

SLEEP MODE

• Notes!

When Sleep Mode starts, 'SLEEP 4.0 HOUR’ is shown on the Sleep mode indicator.

Operation is turned off 4 hours after the Sleep Mode is applied.

Sleep Mode is not working during Fan Mode and Quick Mode.

Sleep Mode is available only when

the air conditioner is turned on.

• Press the button and the Sleep Mode starts.

FAN SPEED CONTROLLING

By pressing the button, Fan Speed can be regulated

as below.

•

During Auto, Cool, Heat and Dehumidifier Mode

:

Auto-> Low-> Middle-> High-> Natural

• During Quick Mode: 'High' fan speed Only

• During Fan Mode:

Low-> Middle-> High-> Natural

• With Auto Fan Speed applied, fan speed can be au-

tomatically regulated according to temperature.

How to cancel the mode,

Press the button again and the reservation is canceled.

FAN DIRECTION CONTROLLING

By pressing the button, Fan Direction can be regulated.

• To make the angle of FLAP half open, press the button, and to make it fully open, press the button twice.

Pressing the button once more changes it "Middle",

and by pressing the button again, it is set on

"Narrow".

Narrow

→ Middle → Wide → Middle

→

Narrow

Middle

Wide

Page 24

24

• Cool mode

• Heat mode

• Dehumidifier mode

• Fan mode

• Auto mode

• Quick mode

• Timer mode

• Sleep mode

COOL MODE

• NOTES!

When the present temperature goes down to the desired temperature, the air conditioner retains the desired temperature, repeating cooling and fanning automatically.

• Press the Power Button and

turn the power on.

• Press the button till is

shown and the

Cool Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

HEAT MODE

• NOTES!

When the present temperature goes up to the desired temperature, the air conditioner retains the desired temperature, repeating heating and fanning automatically.

• Press the Power button and

turn the power on.

Defrosting Mode

During the Defrosting Mode, in case that outdoor temperature is low and humidity is high, the outdoor unit gets

covered with frost and it deteriorates the heating function. During the Defrosting Mode, pre-heating mode is applied until temperature of the outdoor unit pipe goes up to proper temperature.

During the Defrosting Mode, indoor unit doesn't work.

• Press the button till is

shown and the

Heat Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

HOW TO USE THE WIRELESS REMOTE CONTROLLER

Page 25

25

DEHUMIDIFIER MODE

• NOTES!

During the Dehumidifier Mode, Cool Mode indicator on the front panel gets lit on.

During the Dehumidifier Mode, Fan speed is automatically set on "Low".

• Press the power button and

turn the power on.

• Press the button till is

shown and the

Dehumidifier Mode starts.

• Yon can freely set the temperature between 18~32°C and the

temperature is set by 1°C with

each time the button pressed.

AUTO MODE

• NOTES!

With Auto Mode applied, cooling, heating, or dehumidifying is automatically set into run.

• Press the power button and

turn the power on.

• Press the button till is

shown and the Auto Mode

starts.

• Yon can freely set the temperature between 24~28°C and the

temperature is set by 1°C with

each time the button pressed.

FAN MODE

• NOTES!

During the Fan Mode, Cool Mode Indicator on the front panel gets lit on.

During the Fan Mode, temperature isn't able to be set.

During Fan Mode, pleasant air comes out instead of cool air.

• Press the power button and turn the power on.

• Press the button till is shown and the

Fan Mode starts.

Page 26

26

QUICK MODE

• Notes!

With Quick Mode applied, cooling or heating is set to work more swiftly.

During Quick Mode, cooling or heating is automatically set.

During Quick Mode, temperature or fan speed isn't able to be set.

• Press the power button and turn the power on.

• Press the button till is shown and the

Speedy Mode starts.

TIMER MODE

• Notes!

When reservation time is set, 'TIMER' is shown on the Temperature & Reservation Time indicator.

The range of reservation time is from 30min. to 24hr.

Timer On is available only when the air conditioner is turned off.

When the reservation time is over, the air conditioner is running under the previously selected mode.

• Notes!

When the reservation time is over, the running mode stops.

Timer On is available only

when the air conditioner isn't

running.

• Press the button and set the

reservation time.

• Reservation time can be set

in the order of 0.5, 1, 1.5, 2,

2.5, 3, 4, 5, 6, 8, 10, 12, 16,

20, 24 hr

• Press the button to input the

setting into memory while

'TIMER' is blinking on the

Temperature & Reservation

Time indicator.

Timer Off is available only

when the air conditioner is

running.

• Press the button and set the

reservation time.

Reservation time can be set

in the order of 0.5, 1, 1.5, 2,

2.5, 3, 4, 5, 6, 8, 10, 12, 16,

20, 24 hr

• Press the button to input the

setting into memory while

'TIMER' is blinking on the

Temperature & Reservation

Time indicator.

How to cancel the reservation,

During the Timer Mode, press the button and the reservation is canceled.

'Timer' on the Temperature & Reservation Time indicator disappears.

Page 27

27

SLEEP MODE

• Notes!

When Sleep Mode starts, '4 HOUR OFF' is shown on the display.

Operation is turned off 4 hours after the Sleep Mode is applied.

Sleep Mode is not working during Fan Mode and Qucik Mode.

Sleep Mode is available only when the air

conditioner is turned on.

• Press the button and the Sleep Mode starts.

How to cancel the mode,

Press the button again and the reservation is canceled.

FAN SPEED CONTROLLING

By pressing the button, Fan Speed can be regulated as below.

•

During Auto, Cool, Heat and Dehumidifier Mode

: Auto-> Low-> Middle-> High-> Natural

• During Quick Mode: 'High' fan speed Only

• During Fan Mode:

Low-> Middle-> High-> Natural

• With Auto Fan Speed applied, fan speed can be automatically regulated according to temperature.

Page 28

28

1. For your safety, disconnect the plug or turn off the

main power supply switch before cleaning.

2. To take the air filter out, loosen the fixing studs on

each side of air inlet and open the front grille.

3. Use a vacuum cleaner or soft brush to clean it.

In case that the air filter is heavily polluted, rinse it

using water heated below 40°C and commercially

available neutral detergent.

Dry the air filter in the shade, avoiding the direct rays

of the sun.

4. In assembling, fix the air filter in and close the front

grille, and then fasten the fixing studs.

5. Finishing cleaning the air filter, press the Filter Reset

button on the wire remote controller.

Notes!

• The products of our company let you know when to

clean the air filter, with automatic sensor.

• When it's time to clean the air filter, the indicator

on the wire remote controller gets lit on.

• It is desirable to clean the air filter more than once a

month.

• It could deteriorate the efficiency of air conditioner

not to clean the air filter.

CLEANING THE AIR FIL TER

Page 29

29

PROBLEMS/POSSIBLE CAUSES

Problems

• The air conditioner isn't

working at all.

• You can't regulate the

temperature.

• Air does blow out, but

when cool/hot air doesn't

come out.

• You can't set the fan

speed.

• The wireless remote controller isn't working.

• Strange sound from the

air conditioner

• Dew forms around the air

outlet.

• Cool/Heat Mode Indicator

is blinking.

Possible Causes

• Isn't the power switch blocked?

• Isn't the Fuse cut off?

• Hasn't the power gone off?

• Is the remote controller working nor-

mally?

• Isn't the Fan or Quick Mode applied?

• Isn't the Fan Mode applied?

• Isn't the air filter clogged?

• Is there any obstacle around the

outdoor unit?

• Isn't the air conditioner affected by

the direct rays of the sun?

• Isn't the air conditioner turned on after being turned off?

• Isn't the desired temperature higher

or lower than present temperature?

• Isn't the Quick Mode or Dehumidifier

Mode applied?

• Isn't the battery low?

• Is it clear near the remote controller

receiving part on the indoor unit?

• Has the air conditioner been turned

on long enough to work normally?

• Is the humidity in the room normal?

Troubleshooting

• Turn on the main supply switch

again.

• Replace the fuse with one which

meets standard requirements.

• Check out other electric appliances.

• Check out if the battery polarity is ac-

curate and replace it with new one.

• Temperature is not supposed to be

set during Fan/Quick Mode.

• Try Cool/Heat Mode.

• Clean the air filter following the air fil-

ter maintenance.

• Heat exchange isn't working normally. Remove the obstacles.

• Window shade is needed.

• Don't worry. In case that the air con-

ditioner is turned on right after being

turned off, for the protection of air

conditioner, the outdoor unit doesn't

work for 3 minutes.

• Regulate proper desired temperature.

• In this case, fan speed is set automatically, so you don't need to regulate it.

• Replace the battery with new one.

• Remove the obstacles.

• The change in the sound could be

caused by a change in the current of

cooling gas according to modes,

which is normal.

• Dew could be formed by the moisture

in the air. Wipe it with a dry towel.

• Please contact the authorized service

center or appliance distributor you

purchased.

Page 30

30

SPECIFICATION

MODEL DTA -240LH

Type Thru-the-Ceiling cassette Cool/Heat air conditioner

Power Supply Single phase AC 220V/60Hz

Conditions By JIS C9812

Cooling capacity 24000 Btu/h

Heating capacity 24000 Btu/h

Power Consumption (Cooling/Heating) 2700W / 2400W

Operating Current (Cooling/Heating) 13A / 12A

Refrigerant R22, 1.8Kg

Net Weight (Indoor/Outdoor) 36kg / 61kg

Dimensions of Units (Indoor/Outdoor) 840mm x 840mm x 250mm / 872mm x 675mm x 325mm

Dimensions of Front Grille 940mm x 940mm x 30mm

Operating

Operating

Indoor side (Heating Mode) min 21˚C ~ max 32˚C (min 15°C ~ max 27°C)

Condition

Outdoor side (Heating Mode) min 21˚C ~ max 54˚C (min -2°C ~ max 24°C)

Design and specification are subject to change without notice for product improvement.

S/N: 3113909110

Page 31

MODEL #:

DTA-240LH

Made in Korea

INSTALLATION AND

OWNER'S MANUAL

Loading...

Loading...