Daewoo DMB-1822LH, DMB-1832LH, DMB-2122LH, DMB-2112LH User Manual

CONTENTS

1. SPECIFICATIONS.....................................................................................................2

2. CONFIGURATION.....................................................................................................4

3. OUTLINE AND DIMENSIONS .................................................................................5

4. INSTALLATION SECTION......................................................................................10

5. OPERATION ............................................................................................................26

6. WIRING DIAGRAM .................................................................................................41

7. REFRIGERANT CYCLE.........................................................................................45

8. CONTROL BLOCK DIAGRAM...............................................................................46

9. TROUBLE SHOOTING...........................................................................................48

10. PCB DRIVING DESCRIPTION ............................................................................54

11. KEY COMPONENTS OF ELECTRONIC CIRCUIT ...........................................76

12. DISASSEMBLY INSTRUCTIONS........................................................................80

1) Indoor Unit ........................................................................................................80

2) Outdoor Unit .....................................................................................................83

3) Exploded Diagram (Indoor Unit)......................................................................84

4) Exploded Diagram (Outdoor Unit)...................................................................92

5) Control Box Assembly......................................................................................96

6) Control Panel Assembly.................................................................................102

Contents

2

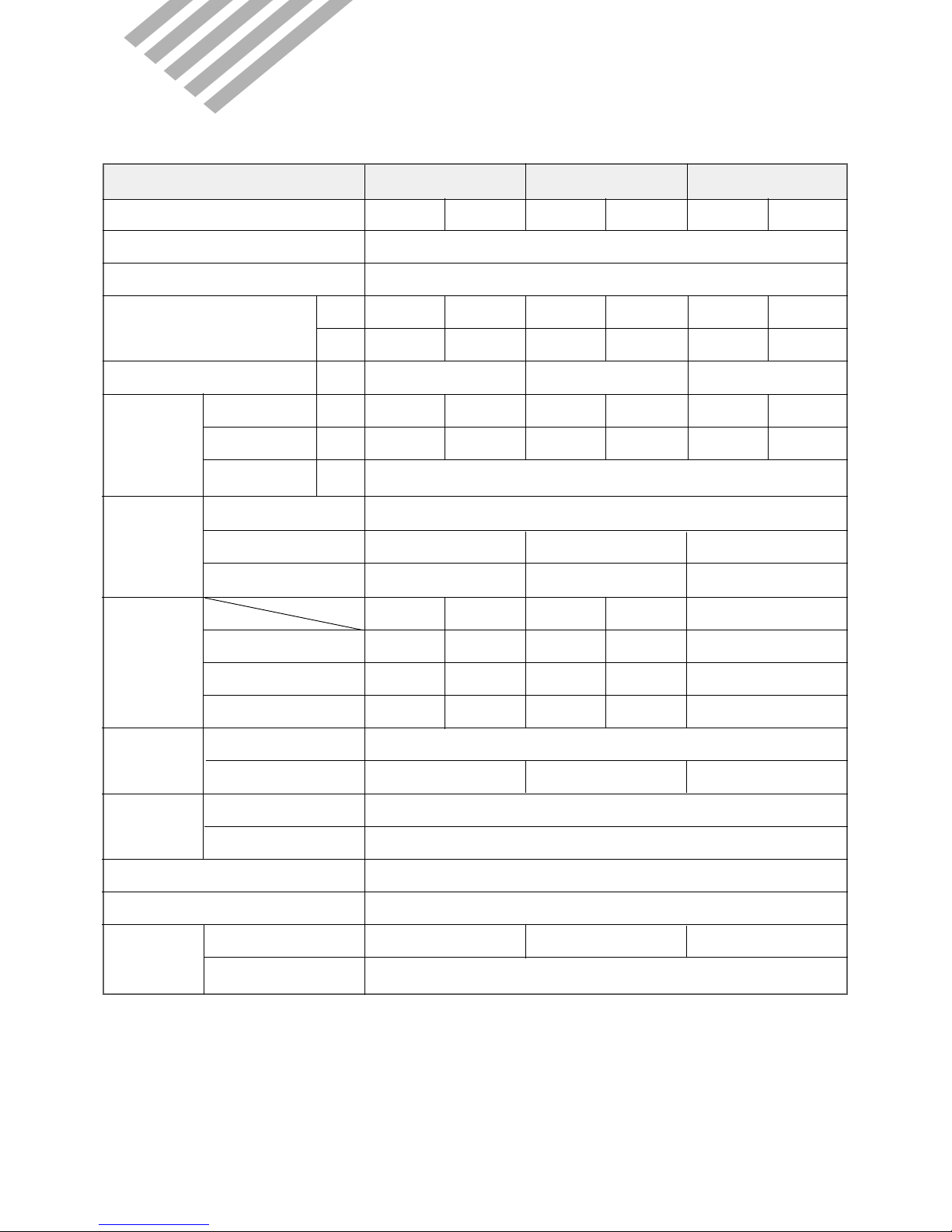

1. SPECIFICA

TIONS

MODEL

DMB-1822/1832LH (9K) DMB-1822/1832LH (9K) DMB-1822/1832LH (9K+9K)

Function

Class T

Power AC 220-240V, 50Hz

Capacity

Dehumidification 1.15 1.15 2.3

Running Current

Power Input

Starting Current 49 A

Type Rotary (DAEWOO : China)

Model RBB095M011

Capacitor 25uF/370VAC 25uF/370VAC

Type

Capacitor

Motor Model Number

Control Capillary

Charge Quality 750 g 750 g

Type Flare

OD (Liquid/Suction) 1/4" (6.35mm) / 3/8" (9.52mm)

Indoor Unit Dimension (W x H x D) 750 x 245 x 174

Outdoor Unit Dimensions (W x H x D) 800 x 615 x 325

Net Weight

Indoor Unit (kg) 7.00 7.00

Outdoor Unit (kg) 62.0

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

DSB-1822/1832LH

W

Btu/h

l/h

A

W

A

Cooling Heating Cooling Heating Cooling Heating

2637.6

9000

2637.6

9000

2637.6

9000

2637.6

9000

5275.3

18000

5275.3

18000

4.6

990

4.6

990

4.6

990

4.6

990

8.6

1880

8.5

1840

Indoor Unit

Cross flow fan

1.0uF 400VAC

YDK-8-4B(Xiangming)

Outdoor Unit

Propeller

fan

5+25uF 400VAC

A2919BA010(DMI)

Indoor Unit

Cross flow fan

1.0uF 400VAC

YDK-8-4B(Xiangming)

Outdoor Unit

Propeller

fan

5+25uF 400VAC

A2919BA010(DMI)

-

-

-

-

-

-

-

RBB095M011

-

3

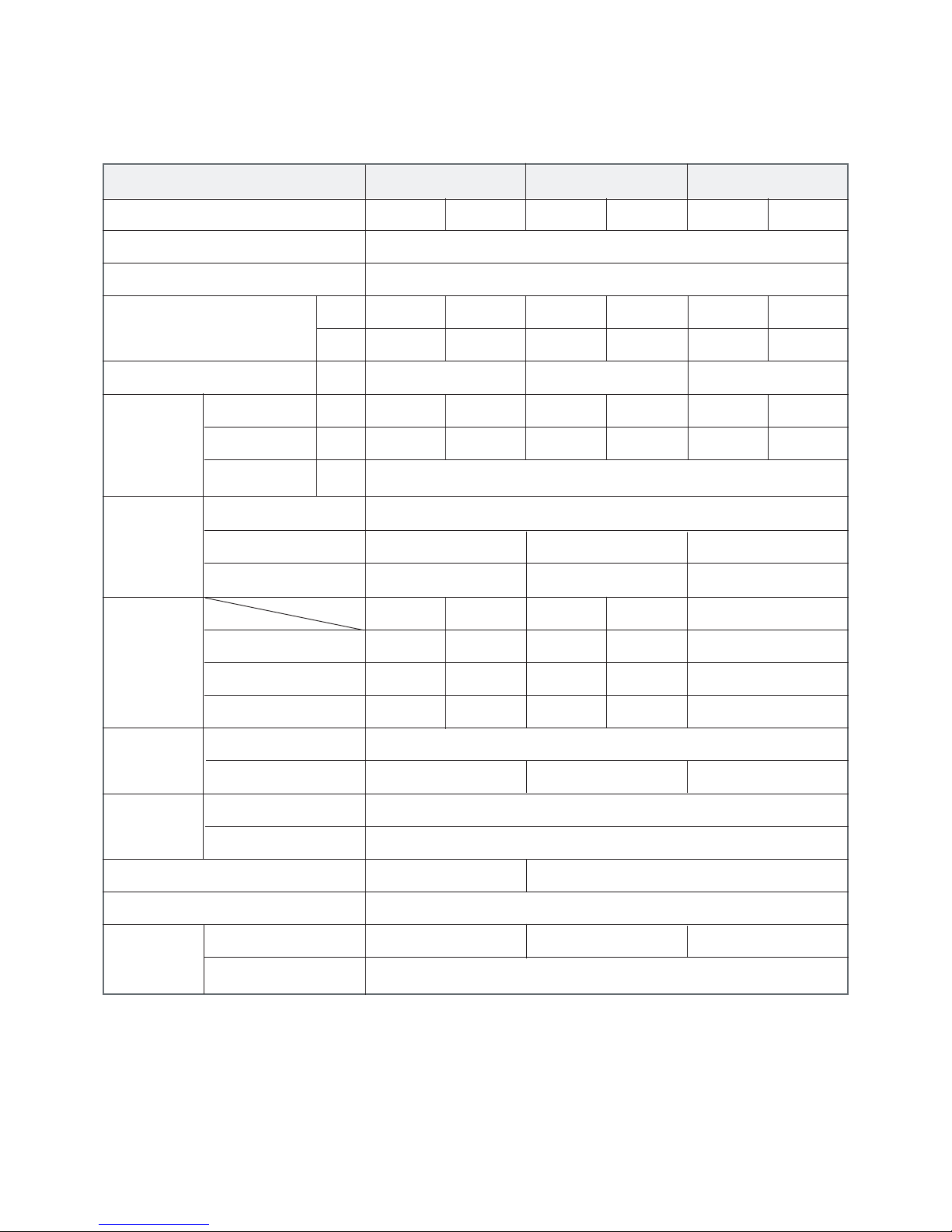

MODEL

DMB-2112/2122LH (9K) DMB-2112/2122LH (12K) DMB-2112/2122LH (9K+12K)

Function

Class T

Power AC 220-240V, 50Hz

Capacity

Dehumidification 1.15 2.10 3.25

Running Current

Power Input

Starting Current 49 A

Type Rotary (DAEWOO : China)

Model RCB120M001

Capacitor 25uF/370VAC 25uF/370VAC

Type

Capacitor

Motor Model Number

Control Capillary

Charge Quality 750 g 1150 g

Type Flare

OD (Liquid/Suction) 1/4" (6.35mm) / 3/8" (9.52mm)

Indoor Unit Dimension (W x H x D) 750 x 245 x 174

Outdoor Unit Dimensions (W x H x D) 800 x 615 x 325

Net Weight

Indoor Unit (kg) 7.00 9.3

Outdoor Unit (kg) 65.0

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

DSB-2112/2122LH

W

Btu/h

l/h

A

W

A

Cooling Heating Cooling Heating Cooling Heating

2637.6

9000

2637.6

9000

3516.8

12000

3516.8

12000

6154.4

21000

6154.4

21000

4.6

990

4.6

990

6.0

1300

6.0

1300

10.1

2200

10.1

2200

Indoor Unit

Cross flow fan

1.0uF 400VAC

YDK-8-4B(Xiangming)

Outdoor Unit

Propeller

fan

5+25uF 400VAC

A2919BA010(DMI)

Indoor Unit

Cross flow fan

1.0uF 400VAC

YDK-8-4B/A(Xiangming)

Outdoor Unit

Propeller

fan

5+25uF 400VAC

A2919BA010(DMI)

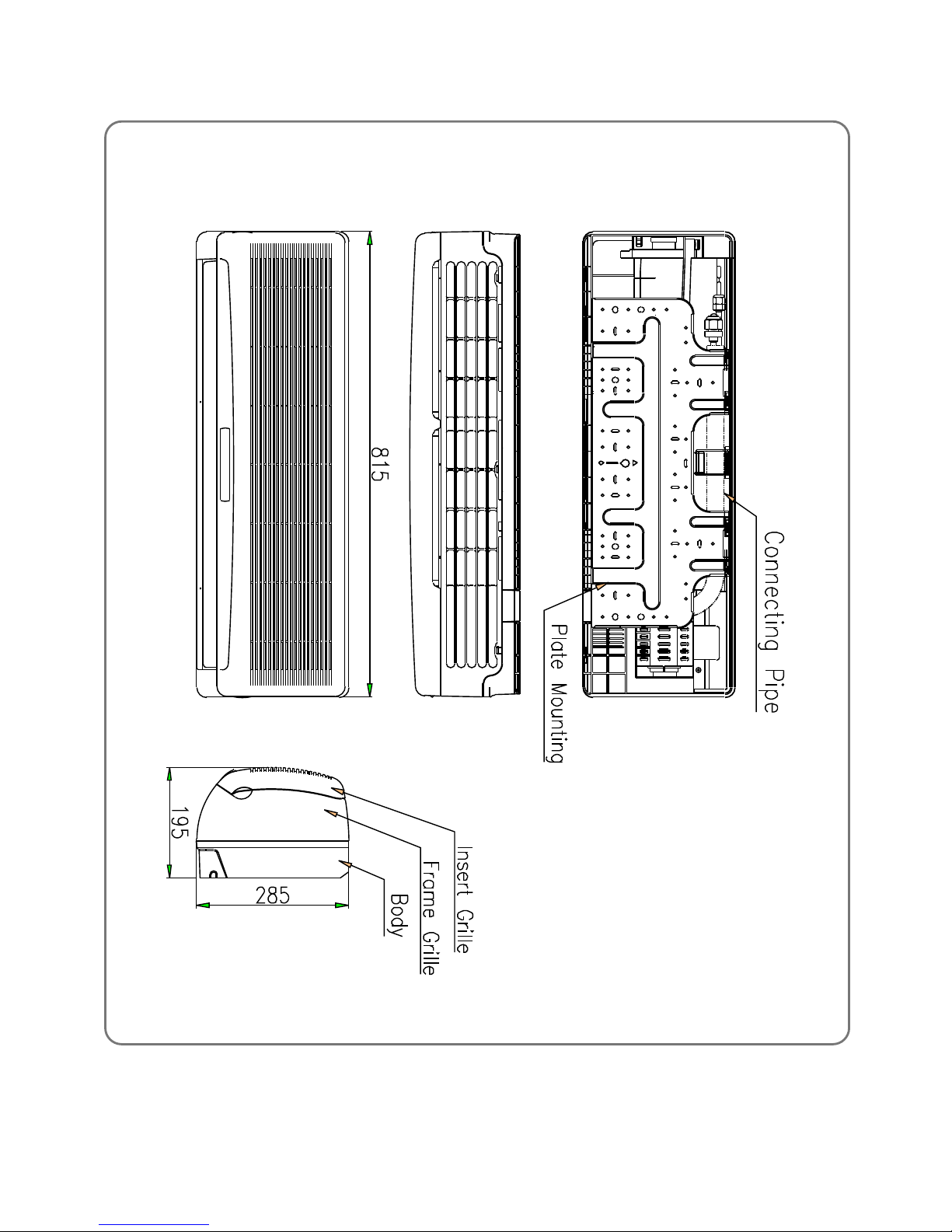

925 x 285 x 194 (815 x 285 x 195)

RBB095M011

-

-

-

-

-

-

-

-

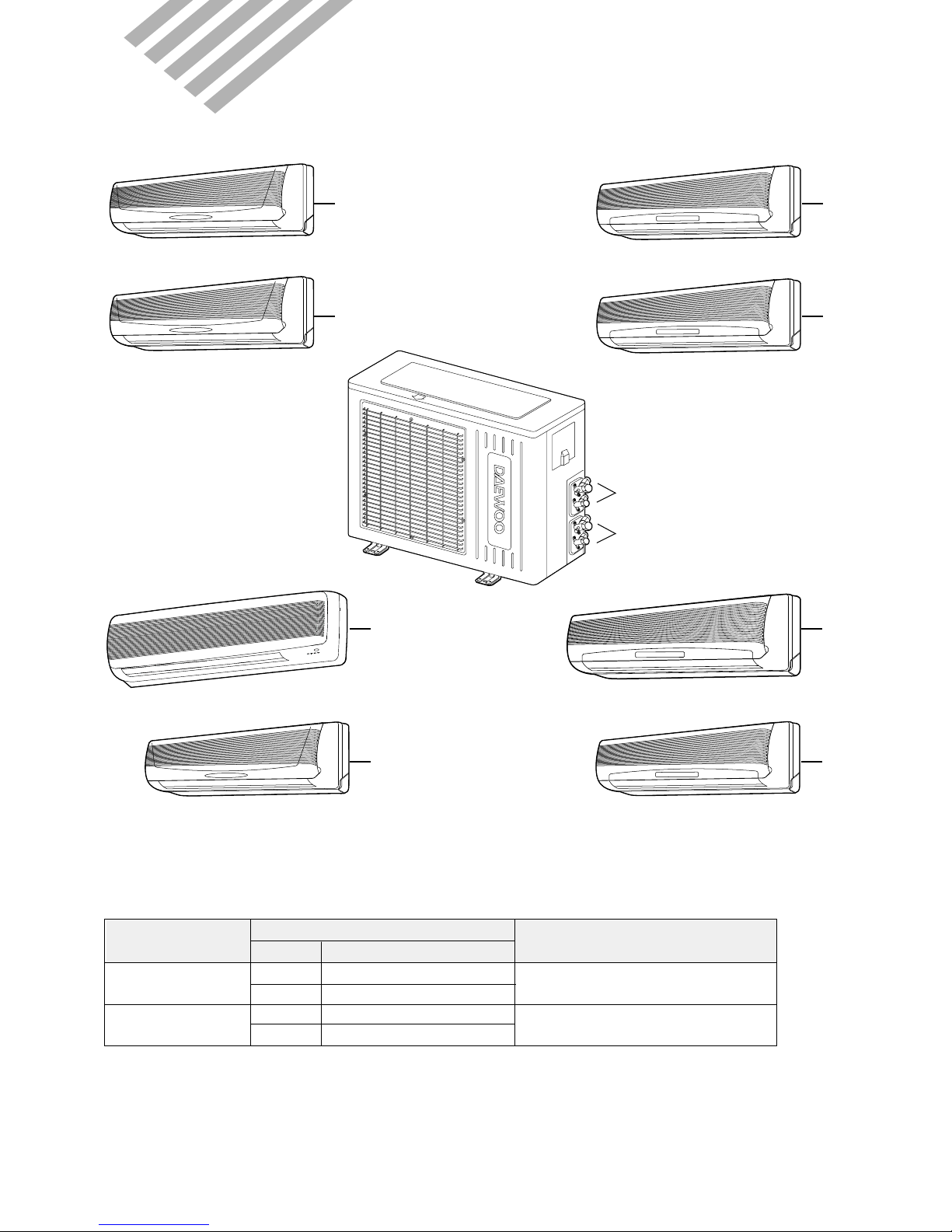

2. CONFIGURATION

4

* You should individually install and operate each A and B units in DMB-2112LH and DMB-2122LH.

* You can exchangeably install and operate each A and B unit in DMB-1822LH and DMB-1832LH.

Model

DMB-1822LH

DMB-1832LH

DMB-2112LH

DMB-2122LH

Indoor Unit Items

Unit Capacity

A 9000 Btu/h

B 9000 Btu/h

A 12000 Btu/h

B 9000 Btu/h

Reference

A & B units are the same

A & B units are different

A

B

A

B

(DMB-1822LH)

9K

9K

A

B

(DMB-2112LH)

12K

9K

A

B

(DMB-2122LH)

12K

9K

A

B

(DMB-1832LH)

9K

9K

5

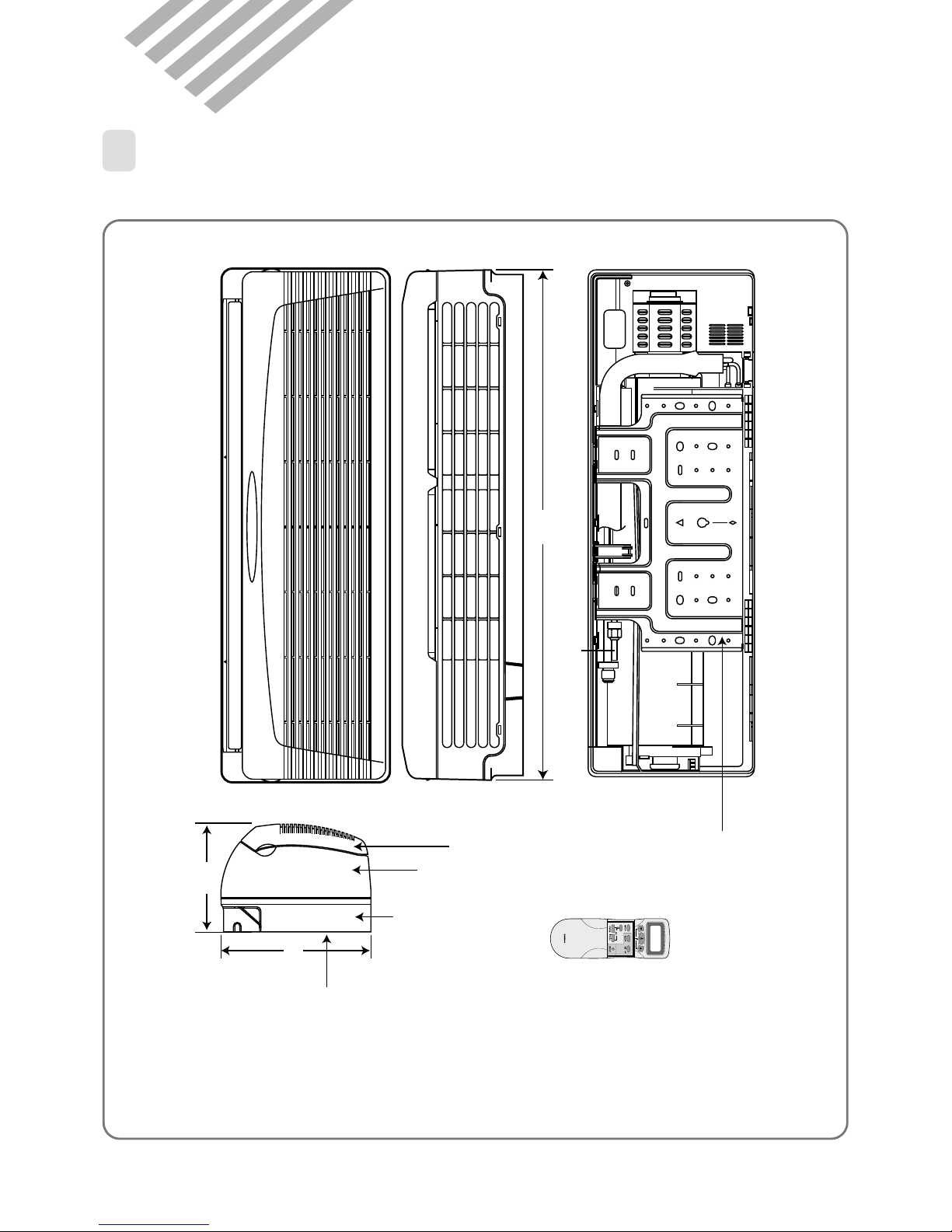

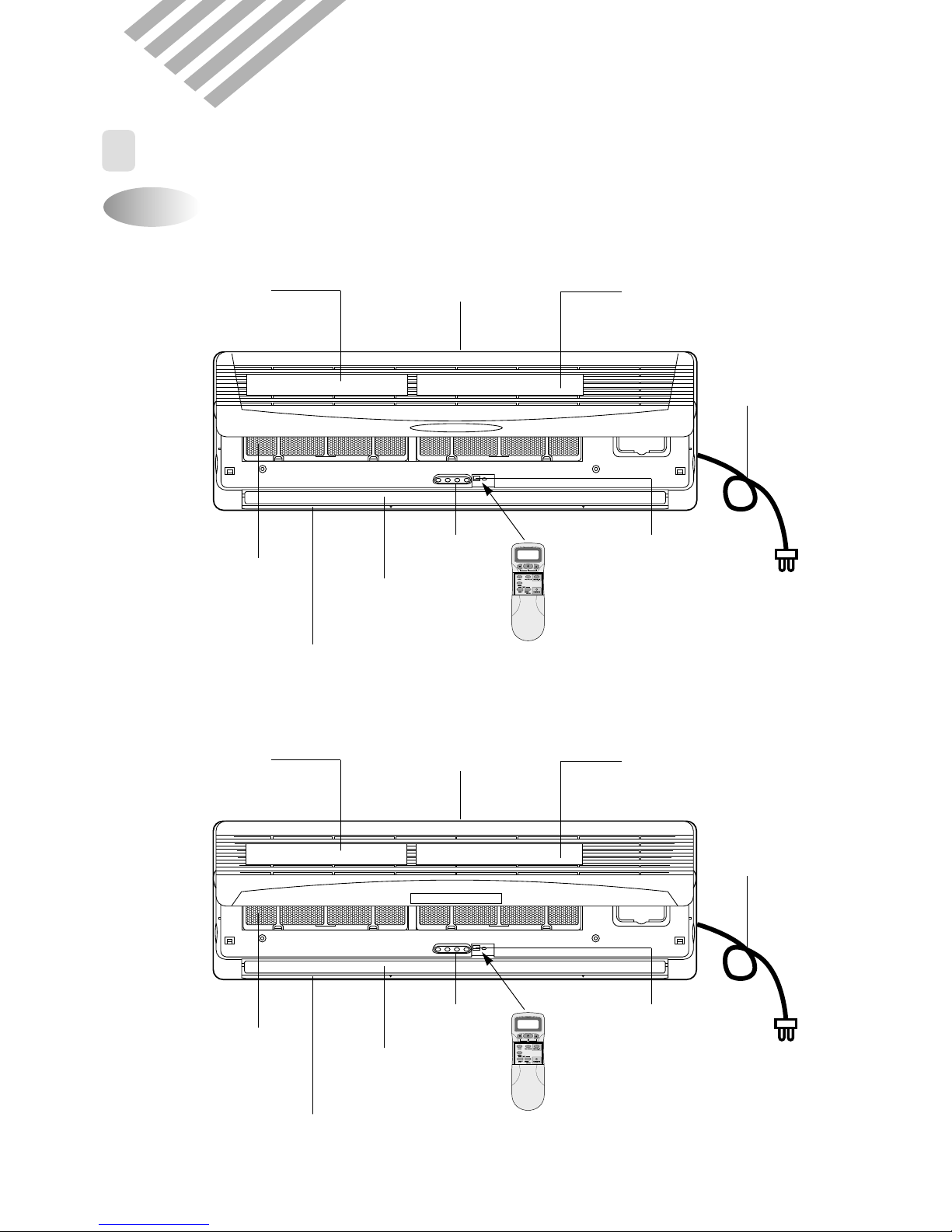

750

Plate Mounting

REMOCON

Connecting Pipe

Grille Insert

174

245

REMOTE CONTROLLER

Frame Grille

Body

Plate Mounting

3. OUTLINE AND DIMENSIONS

1

INDOOR UNIT

DMB-1822LH unit A & B, DMB-2112LH unit B (9000 BTU/h)

6

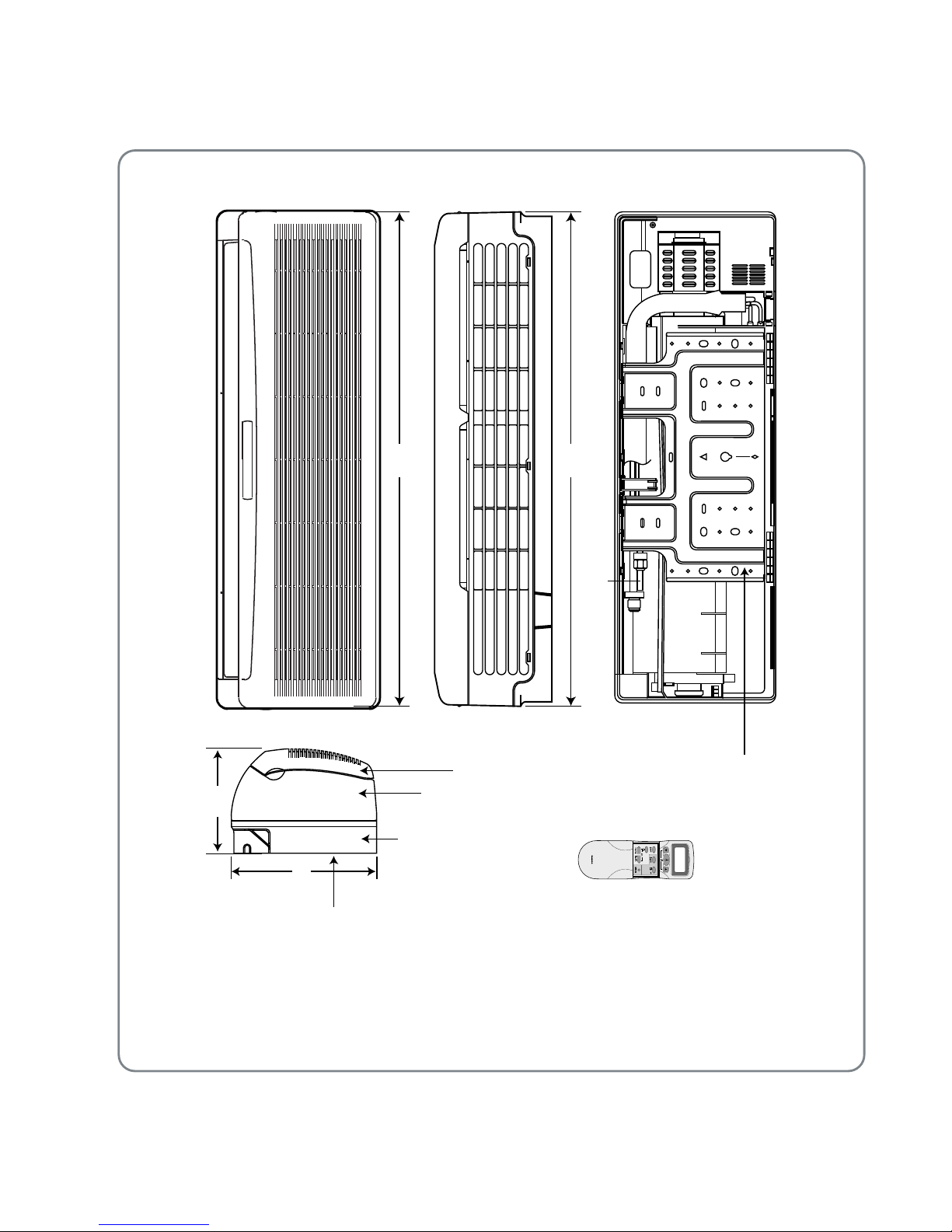

750

750

Plate Mounting

REMOCON

Connecting Pipe

Grille Insert

174

245

REMOTE CONTROLLER

Frame Grille

Body

Plate Mounting

DMB-1832LH unit A & B, DMB-2122LH unit B (9000 BTU/h)

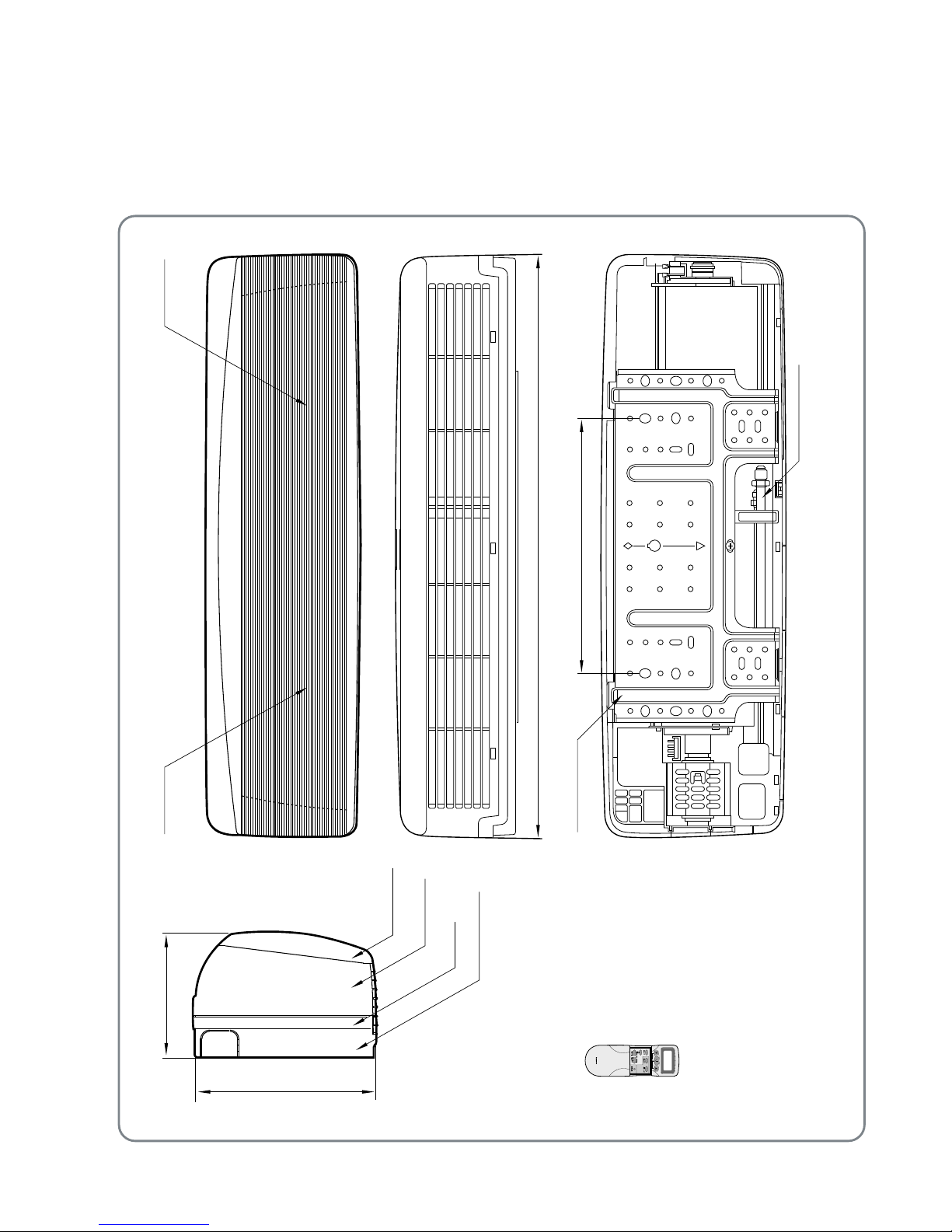

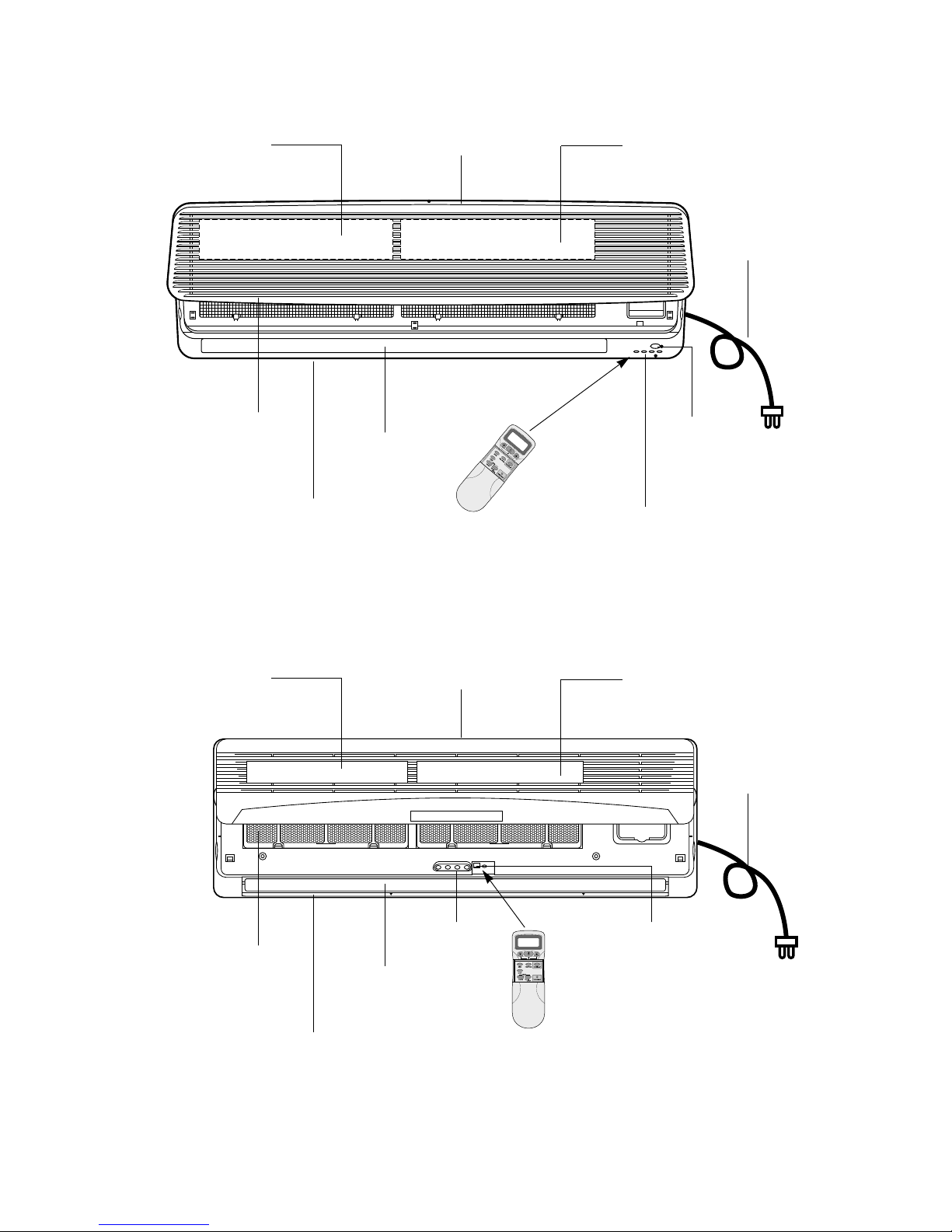

DMB-2112LH unit A (12000BTU/h)

7

REMOCON

Filter - L Filter - R

Grille Insert

Frame Grille

Body

Plate Mounting

Connecting Pipe

Plate Mounting

406

194

285

925

REMOTE CONTROLLER

8

DMB-2122LH unit A (12000BTU/h)

9

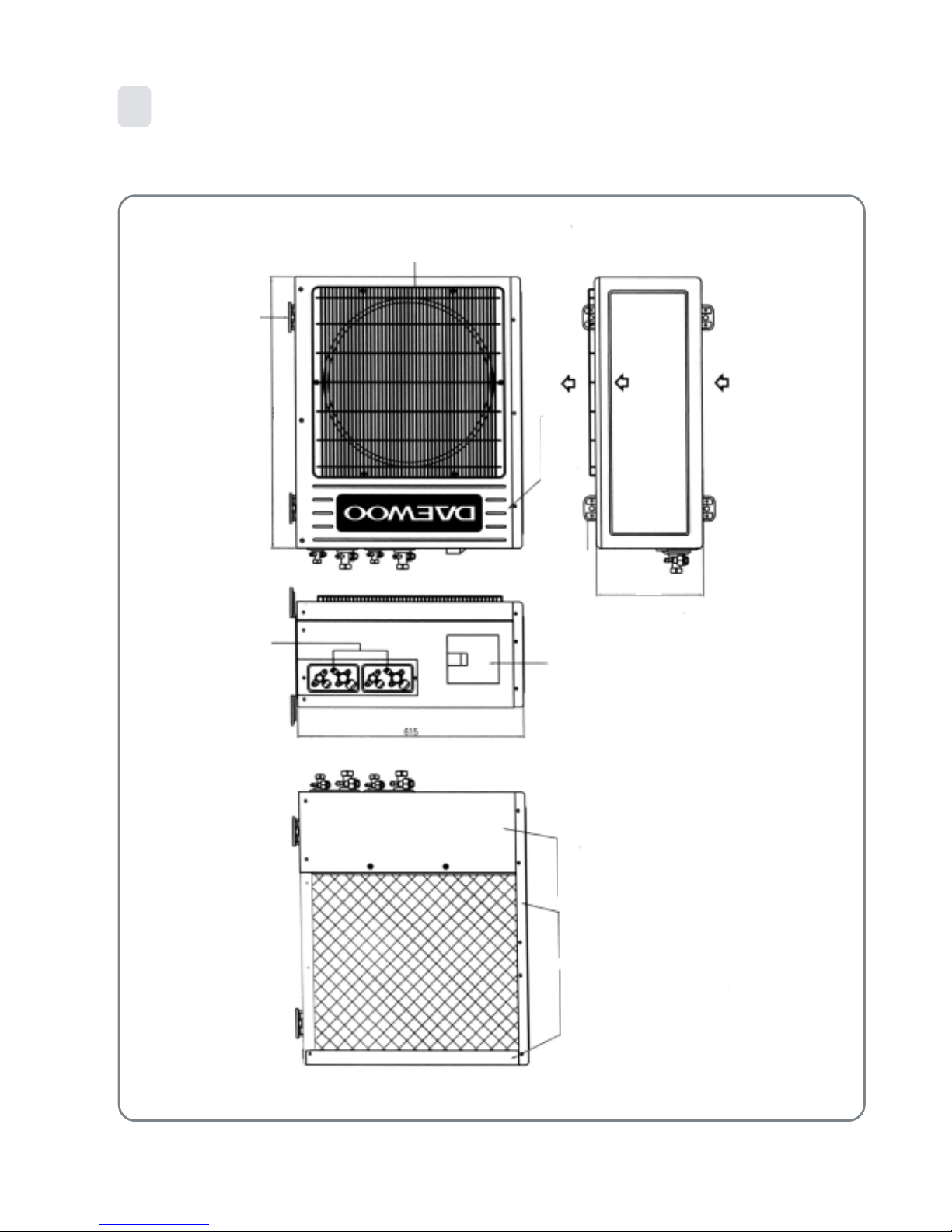

2

OUTDOOR UNIT

DMB-1822LH/1832LH/2112LH/2122LH

Inlet

Outlet

Outlet

Foot Cushion

800

Cabinet Front

Service Cover

Service Valve

Cabinet Side

Panel Top

Guide Support

Foot

325

10

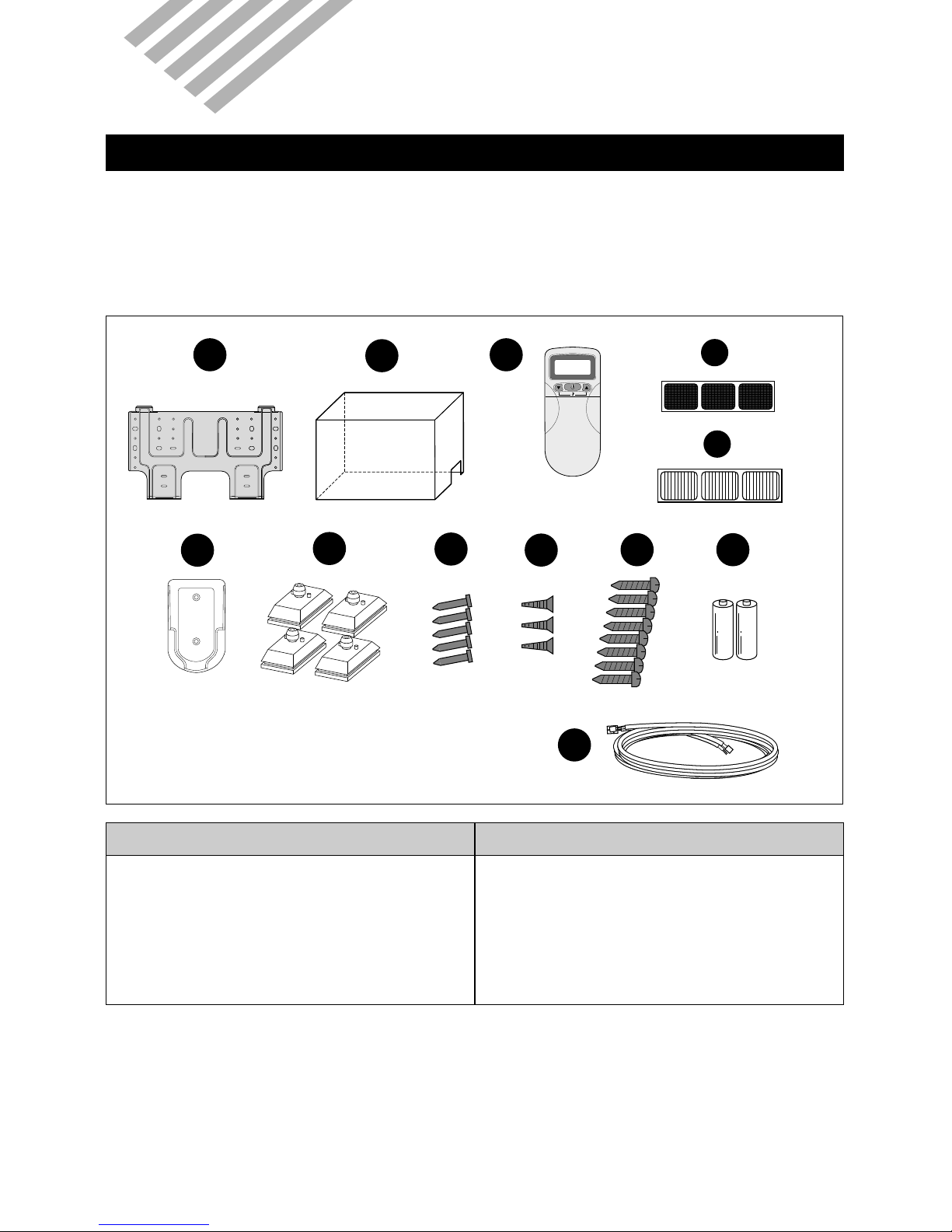

This Installation section explains how and where to connect this new air conditioner. Please read make sure all accessories are included as shown below and read manual thoroughly. This Installation section is provided to assist the person knowledgeable in air conditioner installation and should not be installed by anybody who is not thoroughly familiar

with this type of installation. Please contact a professional installer if necessary.

ACCESSORIES SUPPLIED WITH THE UNIT:

COPPER TUBING:

Copper tubing supplied is available at most dealers or A/C shops. Make sure the new copper tubing has the same

specifications and diameter as the original copper tubing and is as short as possible.

Note:

The remainders except for No. 2, 7, 11 are contained in the indoor boxes.

BASIC ACCESSORIES

1

2

8

6

7

9

3

10 11

4

No. Description Qty.

1 Wall Bracket 2

2 Outdoor Unit Cover 1

3 Remote Controller

4 Deodorizing Filter

5 Electrostatic Filter

2

2

2

6 Remote Holder 2

No. Description Qty.

7 Foot Cushion 4

8 Concrete Nails 10

9 Remote Holder Screws 6

10 Wall Bracket Screws 16

11

12 Signal connection cord 2

Battery 4

5

12

4. INSTALLATION SECTION

11

OPTIONAL A CCESSORIES

1 2

4

3

5 6

ACCESSORIES NOT SUPPLIED WITH THE UNIT:

No. Description Part No. Qty Material Size Remark

1 Drain Hose Extension 3103200400 2 ID19.6 X 2m PVC Pipe

2 Tape 2TQ1007502 2 PVC 75W X 0.1T X 25m

3 Copper Tubing Extension

3104402600 2

1/4" Copper Tube X L5M

Wrapped with

insulator tube

3104402910 2

3/8" Copper Tube X L5M

4 Insulator Plate 3103301010 2 F-US 225 X 120 X 5T

5 Putty 2221040001 2 80g

6 Connection Cord 3112716320 2 3P X 6m

7 Cable tie 3172400500 8 L200 x W4.08

8 Fixture tie mount 3112000300 8 L24.5 x W15.5 x H11.5 x ø6.6

9 Cap wall 3100900600 2 PP

97 8

12

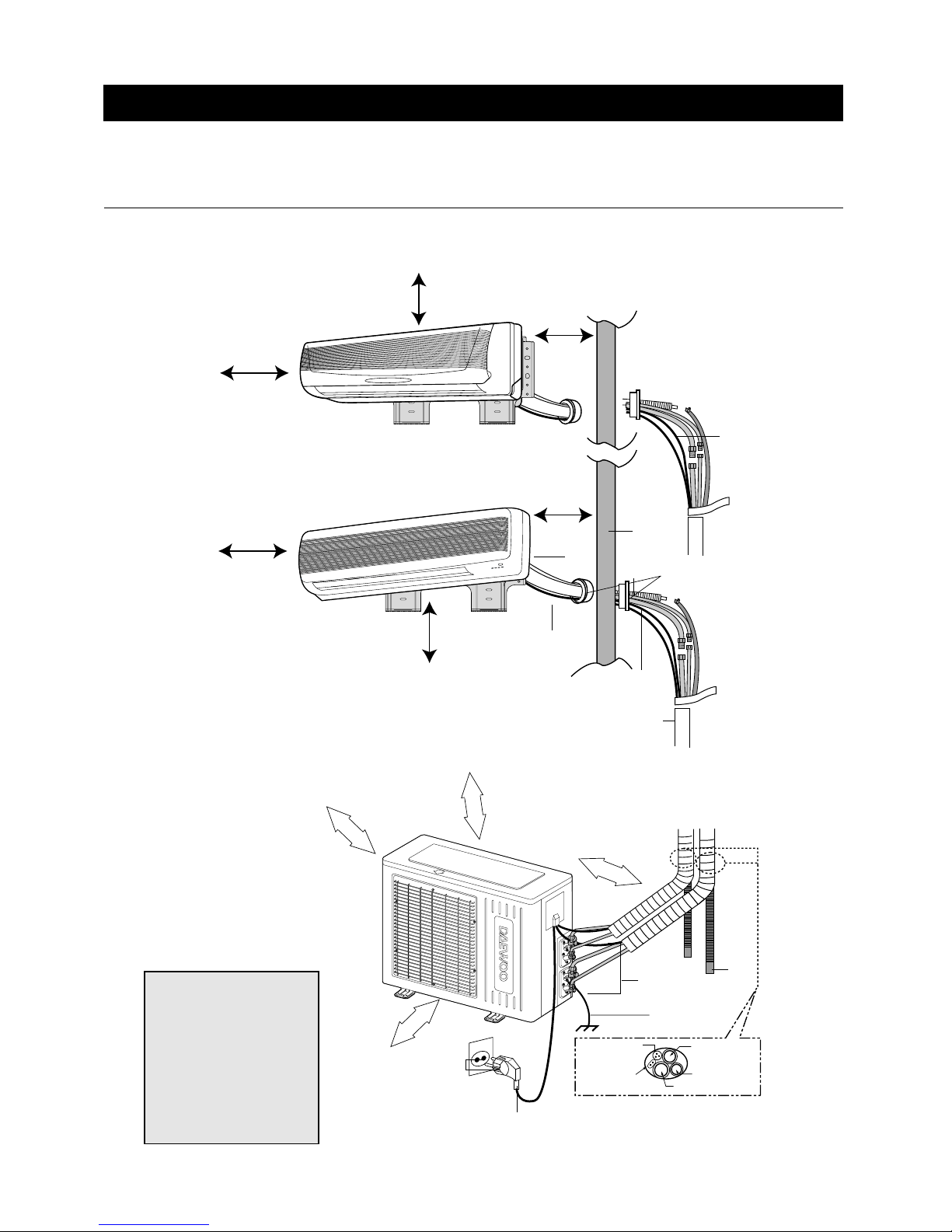

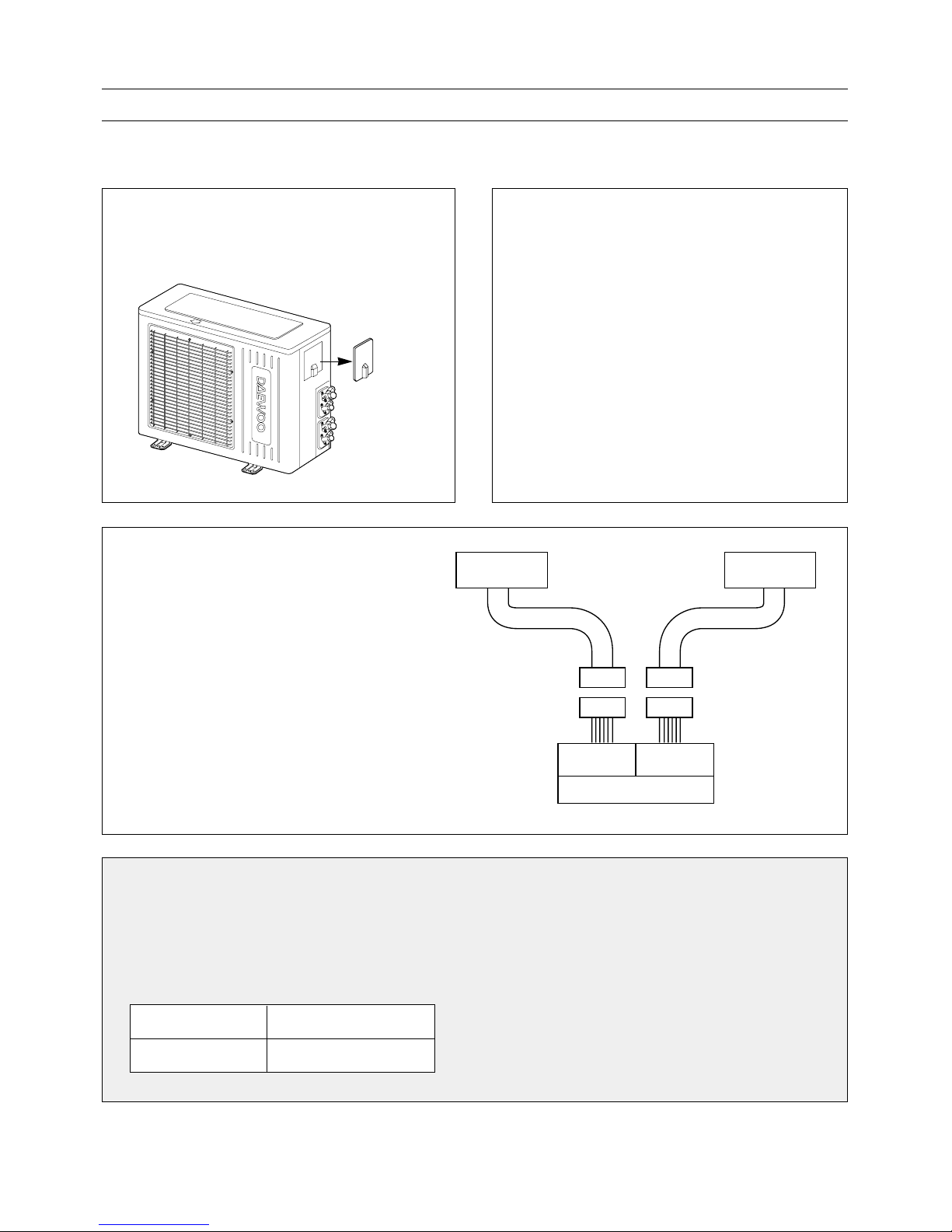

INSTALLATION DIAGRAM

Below is an overview for the connection of the Indoor unit to the Outdoor unit. The pages following will give detailed

instructions for full installation. Remember to read the complete Installation section and follow all the safety instructions

fully when installing the Indoor and Outdoor units.

OVERVIEW

This appliance must be installed according to national power supply acquirement.

NOTES:

• After installation it must be

possible for the user to

disconnect the power supply

plug.

•

If the AC outlet is a 3-pronged

type or other, have an

electrician install a new

outlet.

• Contanct service man when

replace the power cord set.

Drain

Hose

Ground Wire

(Not Supplied)

3/8" side piping

Signal Wire

1/4" side piping

Drain Hose

Wall

Wall

Cap

Drain

Hose

Pipes

(Not Supplied)

Signal wire

Wrap with

Tape

Copper

12000 BTU/h

or

9000 BTU/h

(9000BTU/h)

Tubing

At least 30cm

(11.8in) from unit

Maximum Height 7M (21Ft)

Maximum Length 15M (49Ft)

Any tube length between 7 and 15 meters must

be precharged with freon using the following calulation: (Length – 5) x 30 grams

Adding additonal tubing will decrease efficiency

60

cm

23.6

inches

cm

10

cm

3.9 inches

60

23.6

inches

70

cm

27.6

inches

AC Outlet

and Plug

Plug into 220V~240V

AC Outlet

(Not supplied)

10cm (3.95in)

from ceiling

30cm (11.8in) from

side wall

30cm (11.8in) from

side wall

10cm (3.95in) from

side wall

10cm (3.95in) from

side wall

Wall

Bracket

Connecting

cable

Connecting cable

(Not supplied)

13

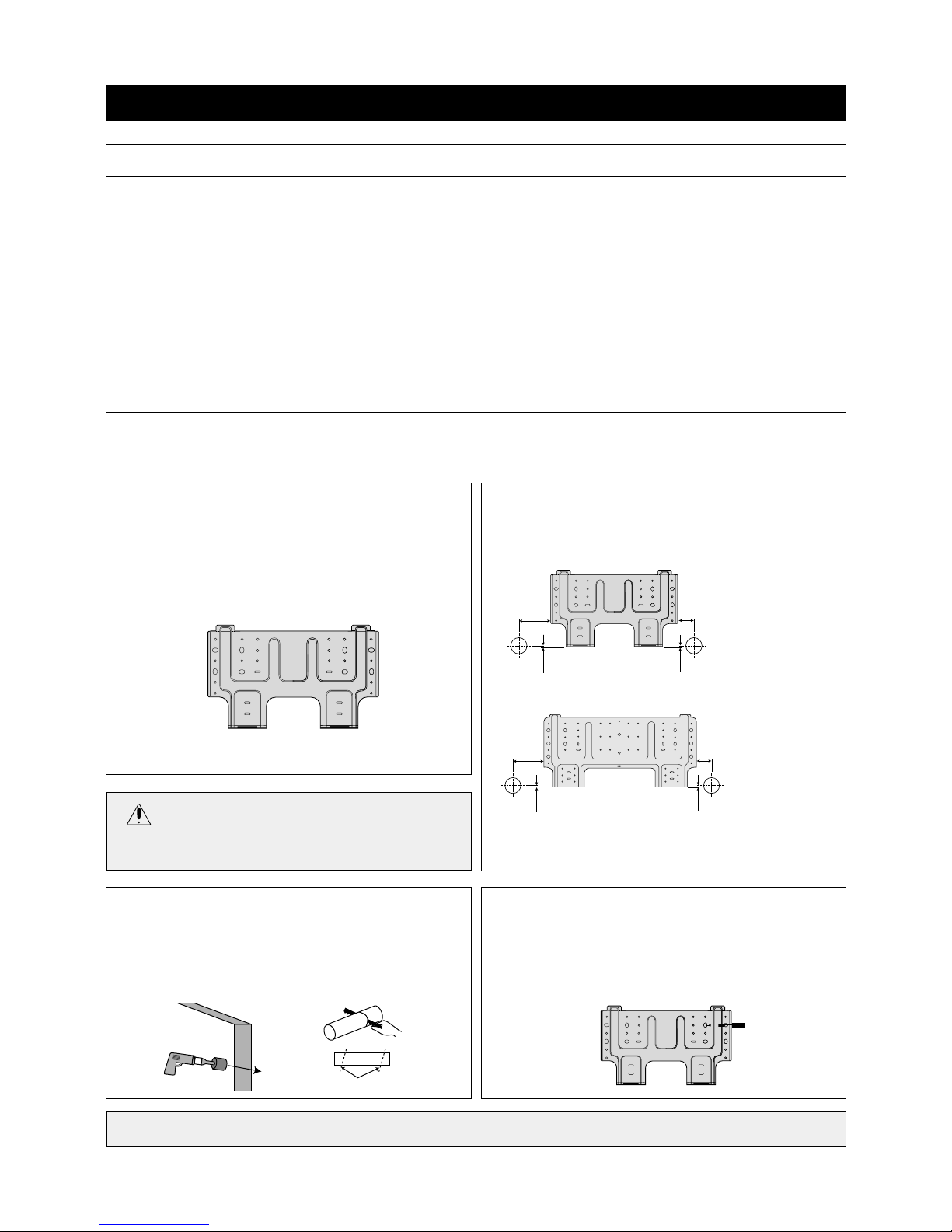

INSTALLATION

1. Determine the type of wall (sheetrock, concrete, etc.)

and make sure it is strong enough to hold indoor unit.

Select an approximate position for the unit, taking the

required distances away from walls/AC outlet into

consideration.

INDOOR UNIT

• Do not install the unit in an area with direct sunlight, near

heat sources (radiator, etc.), or an area where leakage of

flammable gas may be expected.

• Select a position in the room, high on the wall, where the

whole room can be uniformly cooled.

• Select a location that can hold the weight of the unit and

where the copper tubing, drain hose and Indoor to Outdoor

Wire have the shortest distance to the Outdoor unit.

• Make sure the Indoor unit is installed at least 10cm (3.95in)

away from the top and left side wall and at least 30cm

(11.8in) from AC outlet and right side wall (see Overview

figure on previous page).

OUTDOOR UNIT

• Do not install the unit in an area near heat sources,

exhaust fans, or an area where leakage of flammable gas

may be expected.

• Do not install the unit in a humid, damp or uneven location.

• Select a location that is well ventilated .

• Leave enough room around the unit for air intake, exhaust

and possible maintenance.

2. Determine if the hole is to be made at the left or right

hole location.

10 mm

10 mm

150 mm 60 mm

3. Using drill with hole-cutting attachment or equivalent, cut

a hole 65mm (2.56") in diameter. The hole should be

made at a slight downward slant to the outdoor side.

Measure the thickness from the inside to outside edges

and cut a PVC pipe at a slight angle 1/4" shorter than the

thickness of the wall and insert pipe in wall.

4. For sheetrock, wooden or similar wall, measure down

from the ceiling using a level or tape measure and attach

the wall bracket to the wall using 4 screws. If you are not

able to line up the holes with the beams, use toggle

bolts. Make sure the wall bracket is even and flush

against the wall.

Indoor Outdoor

Cut at slight angle

CAUTION

• Before making hole, make sure there are no studs, pipes,

electrical wiring or conduit directly behind the area to be cut.

For Concrete, or similar type wall, make holes into the wall and insert concrete nails instead of screws.

INST ALLING THE WALL BRACKET :

To install the wall bracket, follow the procedures below. One hole is required for the tubing and may be either on the left or right side.

SELECTING A SITE:

DMB-1812LH

(9000BTU/h)

DMB-1812LH

(12000BTU/h)

10 mm

10 mm

150 mm 60 mm

9000 Btu/h Class

12000 Btu/h Class

14

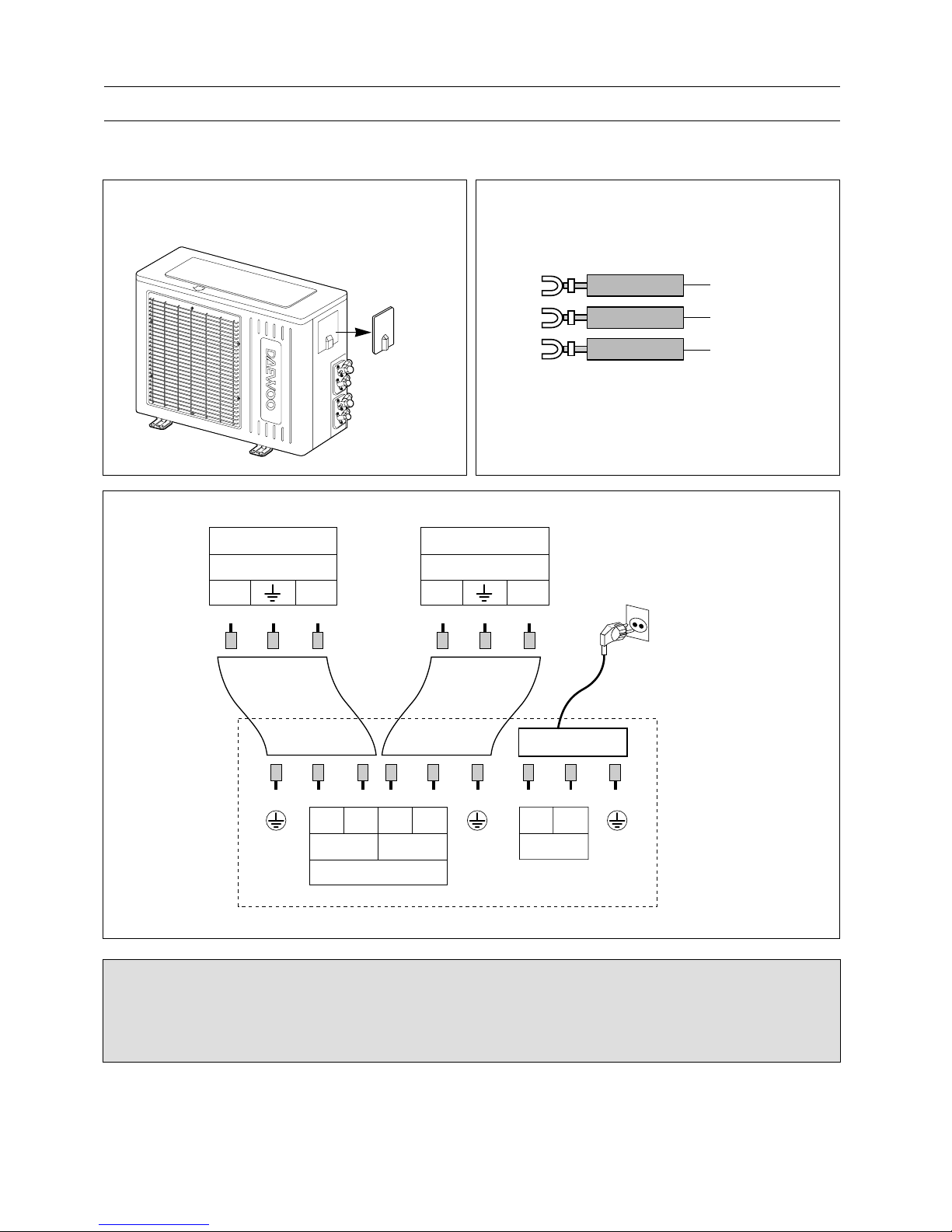

INSTALLING THE AC CONNECTION WIRE T O THE INDOOR UNIT FOR A C POWER SUPPLY

The AC Connection wire is used to supply AC from the outdoor unit to the indoor units. To install AC connection wire,

follow the procedures below.

NOTE:

• This appliance must be installed according to National power supply requirement.

• If the supply cord is damaged, it must be replaced by the manufacuturer or its service agent or a similarly

qualified person in order to avoid a hazard.

• Make sure the outdoor unit’s AC cord is not connected to AC connection wire.

• When connecting wires, make sure they are fully inserted and minimum copper wire is exposed. If they are

not, shorting, overheating, no operation, etc. may occur.

• Be sure to comply with local codes on running a wire from the indoor to the outdoor unit.

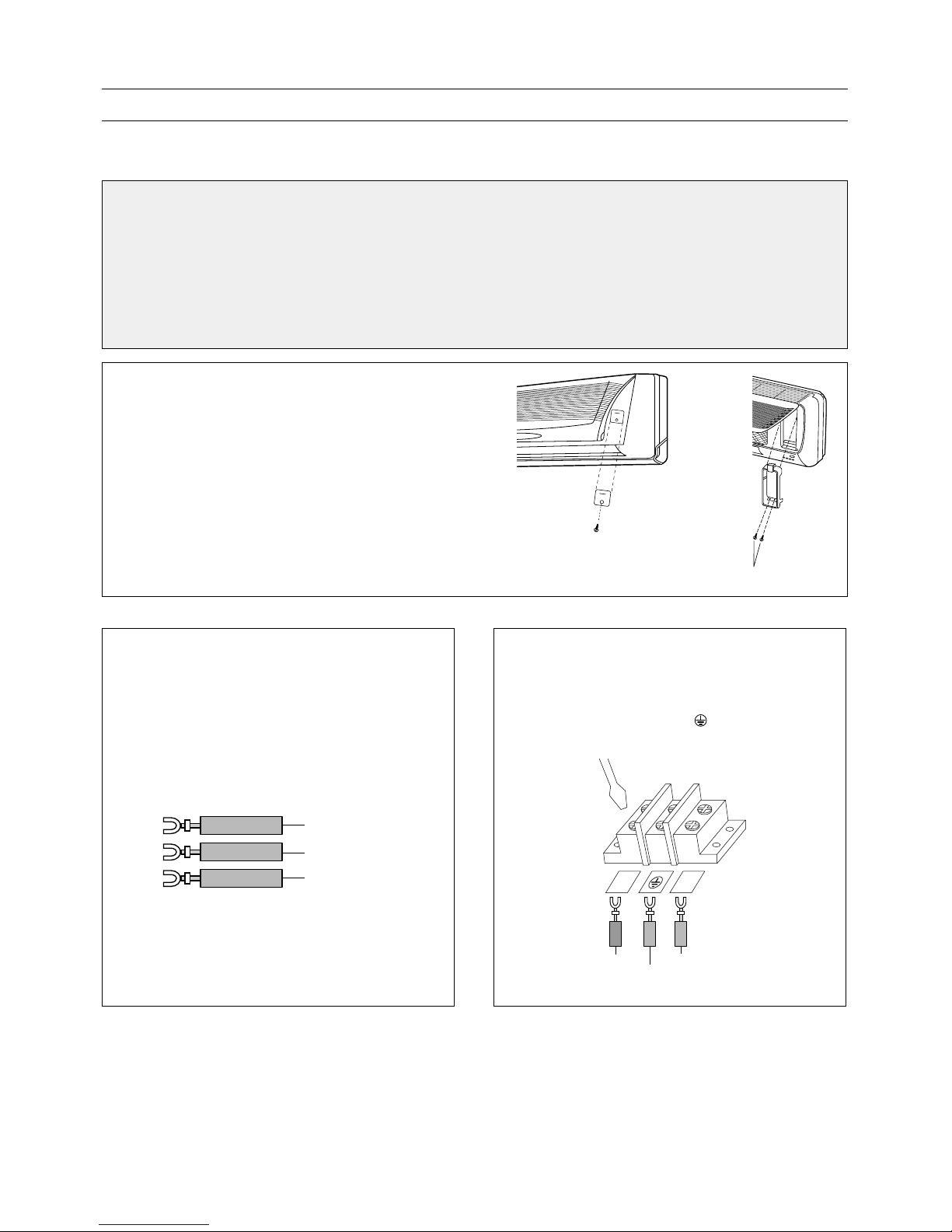

1. Open the connection cover on the indoor unit to access

the connection area.

Remove the Connection Cover.

• Loosen the screw fixed at the Connection Cover.

• Remove the Connection Cover.

2. Fish the AC connection wire from the rear of the

indoor unit through the front of the unit.

For easier connection, make sure enough wire

is pulled through the front. Use the wire as

shown below:

3. To connect wires, loosen the screw in the

Terminal Block and insert the correct wires like

following figure.

Connect the Brown wire to the “L” connection,

Yellow/Green wire to the “” connection and

the Blue wire to “N” connection.

Screw

Screw (Special screw)

Blue

Yellow/Green

Brown

L

N

Brown Blue

Yellow/Green

15

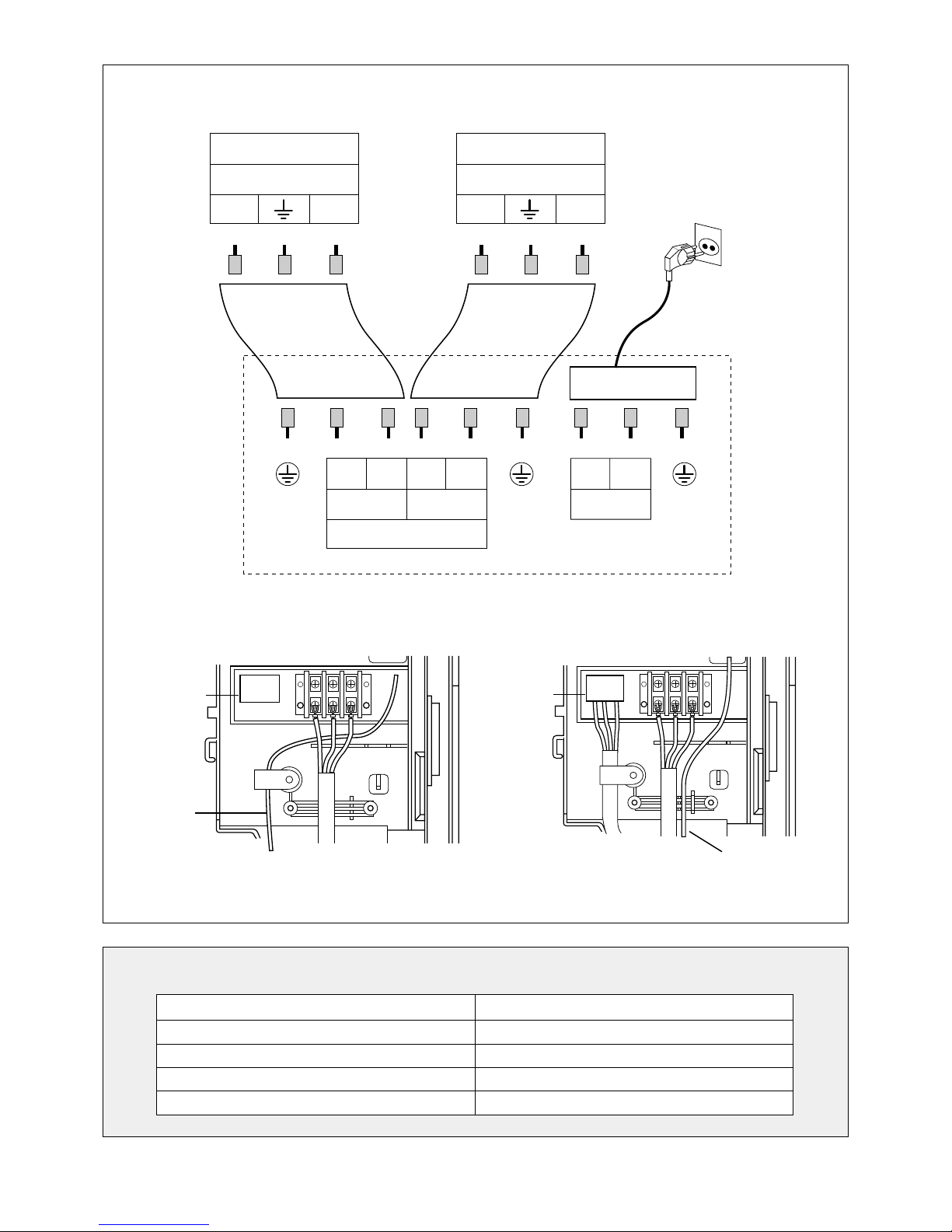

4. Connect the wires to the housing and terminals on the control board individually according to the outdoor uint

connection.

indoor terminal

Connection

Cable

Connection

Cable

not insert

plug

Unit A

LN

indoor terminal

Unit B

LN

L1 N1

Outdoor terminal

Outdoor

L2 N2

Unit A Unit B

Brn

Y/G Brn Blu Brn Blu Y/G Brn Blu Y/G

Y/G Blu Brn Y/G Blu

LN

Power

Terminals

Signal

++

<INDOOR UNIT (Control Box)><INDOOR UNIT (Control Box)>

(9000 Btu/h) (12000 Btu/h)

Terminals

Signal

++

NOTE: We want you to observe bellow recommended specifications.

Part Name

Power plug

Power cable

Circuit breaker

Connection cable

Recommended specifications

250V 10/16A

Flexible, H05RN-F above 2.0mm

2

15A

H05RN-F 0.5 or 0.75mm2 x 3P x 6m

16

Left

Tubing

2. Make sure the drain hose and copper tubing are

wrapped with the rubber insulation. Using the tape,

wrap the AC connection wire, copper tubing and drain

hose together.

MOUNTING (INDOOR UNIT)

The Indoor unit must be mounted before connecting the AC connection wire, drain hose and copper tubing. To mount,

follow the procedures below:

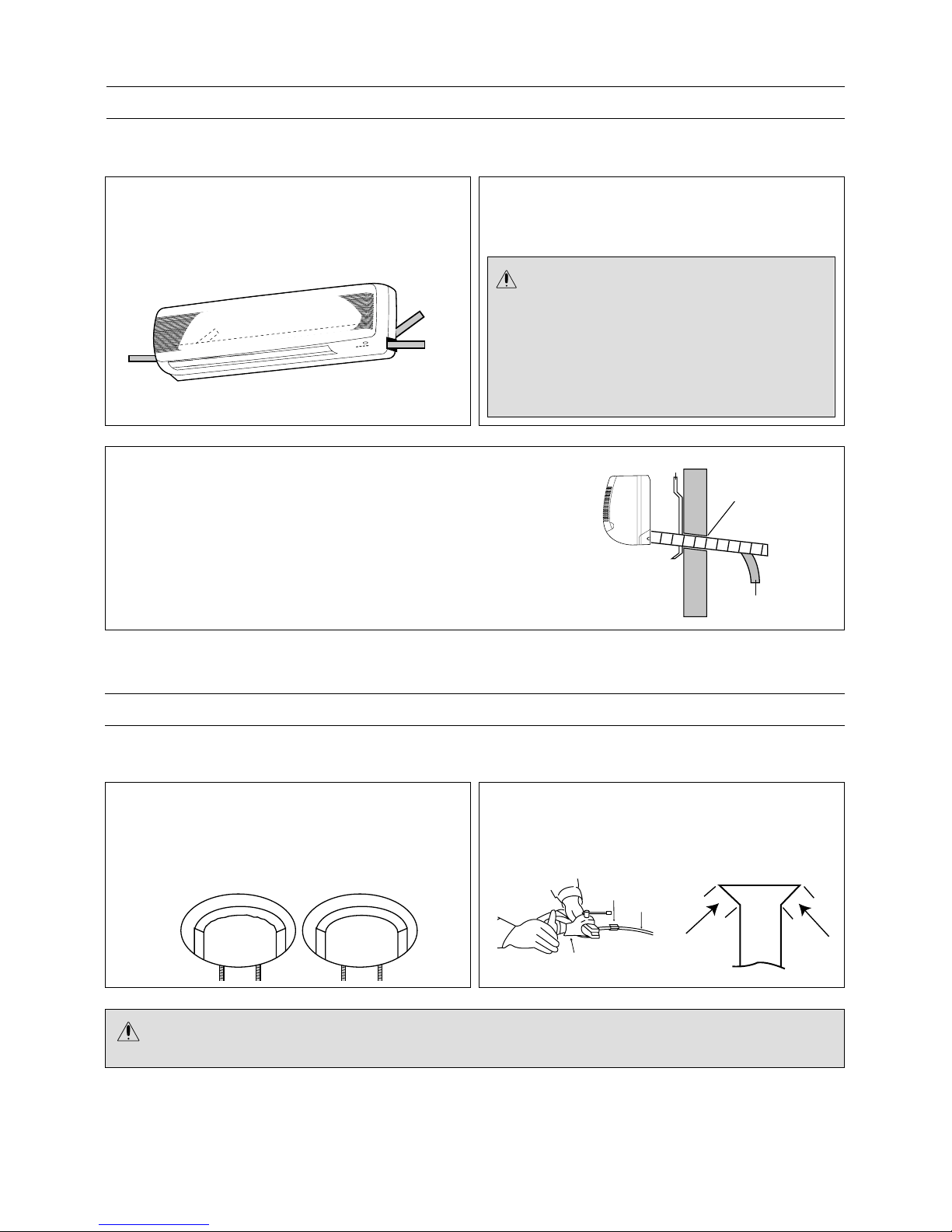

1. The tubing can be extended in 4 directions as shown

below. No cutting is necessary for left/rear and

right/rear tubing connections. If using left or right tubing connections, remove the plastic area with a hacksaw so pipes can go through.

CAUTION:

•

Make sure the outdoor unit’s AC cord is not

connected to AC power when performing these procedures.

• Be sure to comply with local codes on running a wire

from the indoor to the outdoor unit.

• DO NOT LET THE AC CONNECTION WIRE

COME IN DIRECT CONTACT WITH THE TUBING

OR HOSE!

3. Shape the tubing so it can easily go through the hole

in the wall. Push the AC connection wire, copper tubing and drain hose through the hole in the wall angling

downward. Situate the indoor unit on the wall bracket

by lifting the indoor unit slightly above the wall bracket

and then down so it is securely locked in place.

Wall Bracket

Insert Putty

Drain Hose

CAUTION:

• When using the tube reamer, hold the tube downward and make sure no copper scraps fall into the tubing.

2. Make a flare at the end of the copper tube with a flare

tool.

Make sure the inside surface and edges are smooth

and the sides are uniform length.

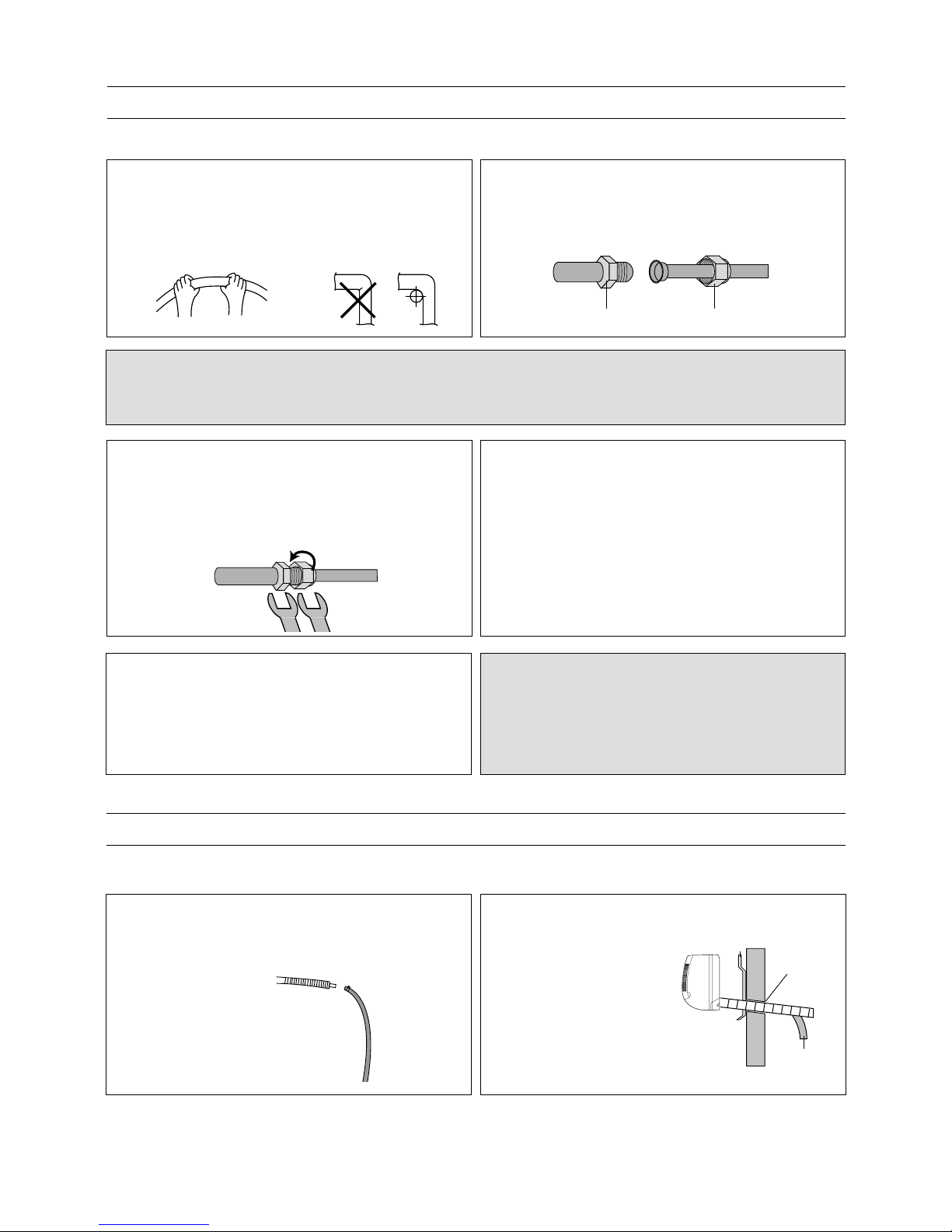

1. Cut the copper tube extension to the desired length

with a tube cutter. It is highly recommended that 1 foot

is added to the requested length. After cutting, deburring may be necessary (see below diagram). Perform

this with a tube reamer.

BEFORE AFTER

PREPARING THE COPPER TUBING (NOT INCLUDED)

A copper tubing extension (not included) may need to be cut. If this is the case, it will also have to be deburred and

flared as shown below:

Flare tool

Flare nut

Connection

pipe

Right

Tubing

Right/Rear

Tubing

Left/Rear

Tubing

17

1. Remove the flare nut stoppers from the inside unit.

Determine the location of the copper tubing and

where the bends will be. Gently bend the copper tubing, making sure to use big angles so no crimping will

occur. Try to do this on the first try as repeated bending may break or crimp the tubing.

2. Remove the plastic stoppers from the tubing. Connect

the large and small copper tubing to the respective

extension and rotate the flare nut with your finger until

a smooth match is made. Make sure the copper

extension has foam rubber (insulation) on it.

Flare Nutcoupler

CONNECTING COPPER TUBES

To connect the copper tubes, follow the procedures below:

NOTE:

When removing the flare nut stopper from the inside unit, confirm “Ping”, sounds because the mixed gas is charged in

the inside unit,

3. Once a smooth match is made, tighten the flare nut

using a wrench. Be very careful not to strip the

threads or flare nut. Repeat this process for the small

and large tubing. When tightening the flare nut, use

another wrench to securely hold the coupler from

twisting and possibly damaging the tubing.

4. Remove the flare nut stoppers from the outdoor unit’s

valves. Connect the larger copper tubing to the larger

valve on the outdoor unit. Connect the smaller copper

tubing to the smaller valve on the outdoor unit.

5. Perform a leak test on all copper tube connections. To

prevent heat loss and damage to walls from condensation, the copper tube connections coming from the

wall must be insulated. Do this by wrapping foam rubber or equivalent around the connection approximately 8mm thick so no copper tubing is exposed.

NOTES:

• As with all wiring and hookups on this unit, make sure

the AC plug on the the outdoor units are unplugged.

• Be very careful not to strip the threads or flare nut.

• When insulating the connections, use foam rubber or

equivalent.

1. Connect the drain hose extension to the drain hose

coming from the indoor unit by loosing the clamp on

the extension using a phillips screwdriver, attaching

the hoses together and then tightening the clamp.

2. Run the drain hose, slanted downward, outside. If the

drain pipe is exposed

indoors, make sure it is

thoroughly insulated so

condensation does not

ruin walls or furniture or

come in contact with the

AC connection or extension. Also, do not crease

or form a trap in the tubing.

Wall Bracket

Insert Putty

Drain Hose

CONNECTING THE DRAIN HOSE

To connect the drain hose, follow the procedures below:

18

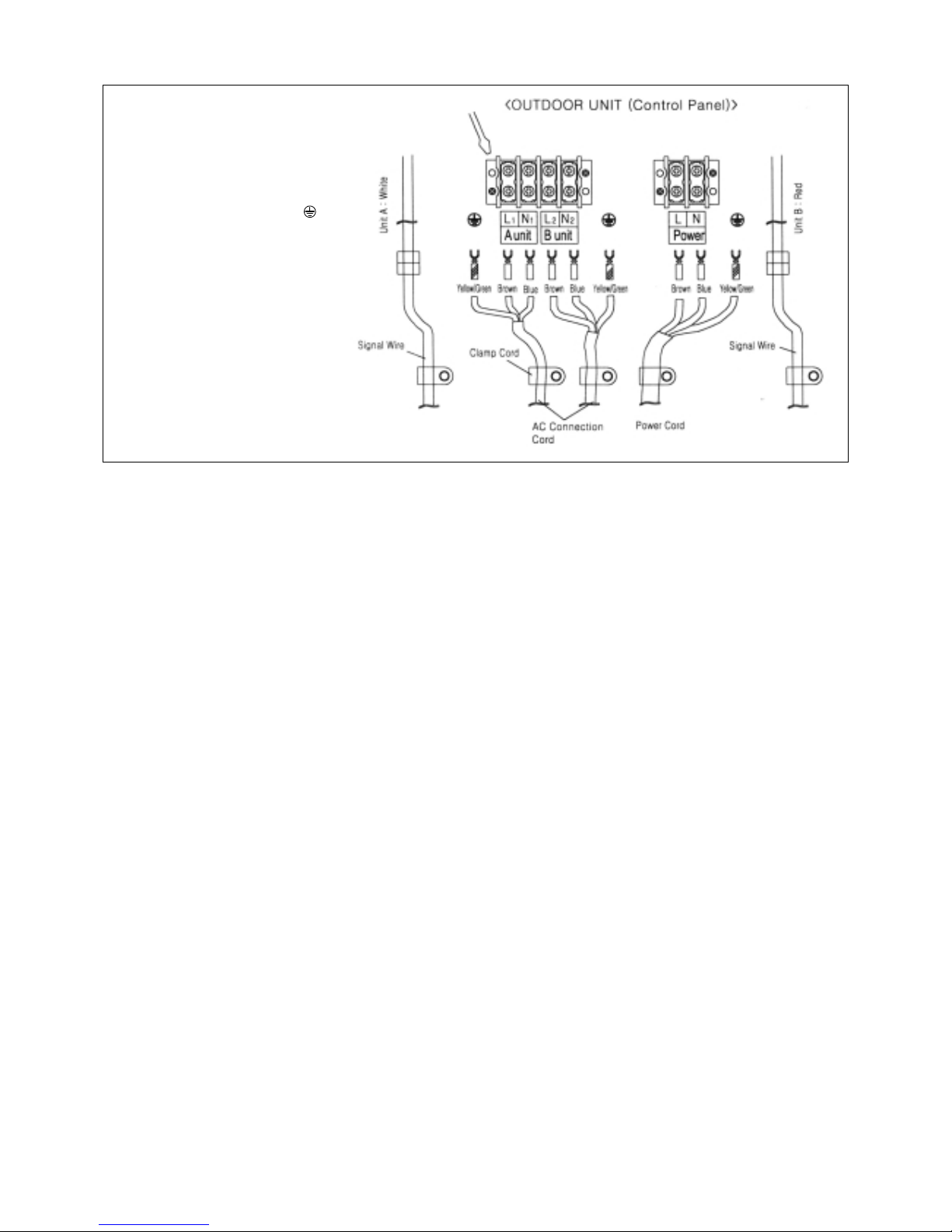

1. Remove the screw holding on the connection cover.

Remove the connection cover on the outdoor unit to

access the connection area.

3. Connect the wires to the housing and terminals on the control board individually as the following.

INSTALLING THE AC CONNECTION WIRE TO THE OUTDOOR UNIT FOR AC POWER SUPPLY

The AC connection wire is used to supply AC from the Indoor unit to the Outdoor unit. To install the AC connection wire,

follow the procedures below.

2. Route the AC connection wire into the opening on the

outdoor unit and through the wire holder. To connect

to the wire holder, loosen the screw on the wire holder, insert the wires through, then tighten the screw.

NOTES:

• Make sure the outdoor unit’s AC cord is not connected to AC power when connecting the indoor/outdoor wire.

• When connecting wires, make sure they are fully inserted and minimum copper wire is exposed. If they are not,

shorting, overheating, no operation, etc. may occur.

• Be sure to comply with local codes on running a wire from the indoor to the outdoor unit.

Yellow/Green

Blue

Brown

indoor terminal

Connection

Cable

Connection

Cable

not insert

plug

Unit A

LN

indoor terminal

Unit B

LN

L1 N1

Outdoor terminal

Outdoor

L2 N2

Unit A Unit B

Brn

Y/G Brn Blu Brn Blu Y/G Brn Blu Y/G

Y/G Blu Brn Y/G Blu

LN

Power

Connection

Cover

19

4. To connect wires, loosen the

screw in the Terminal Block and

insert the correct wires like

following figure.

Connect the Brown wire to the

“L” connection, the

Yellow/Green wire to the “”

connection, the Blue wire to the

“N” connection.

DMB-1822/1832/2112/2122LH

20

CONNECTING SIGNAL WIRES BETWEEN INDOOR UNITS AND OUTDOOR UNIT

The signal wires are used to inter-communicate indoor and outdoor’s signal, and attached to the indoor unit at first.

To install the signal wires to outdoor unit, follow the procedures below.

NOTE:

• Make sure the indoor & outdoor unit’s AC cord is not connected to AC power when connecting the signal

wires.

• When connecting wires, make sure they are fully inserted and minimum copper wire is exposed. If they are

not, shorting, overheating, no operation, etc. may occur.

• Be sure to comply with local codes on running a wire from the indoor to the outdoor unit.

• Must be careful to insert signal wire connectors where like color is like color.

1. Remove the screw holding on the connection

cover.

Remove the connection cover on the outdoor

unit to access the connection area.

3. Insert the indoor connector into the outdoor

connector from the PCB Board individually as

the following.

2. Route the indoor signal wire into the opening on

the outdoor unit and through the wire connector,

and insert the indoor connector into the outdoor

connector.

Connection

Cover

Indoor Unit A

White

Unit A

(White)

Unit B

(Red)

Outdoor PCB ASS'Y

White

Red

Red

Indoor Unit B

indoor unit A White – White

indoor unit B Red – Red

21

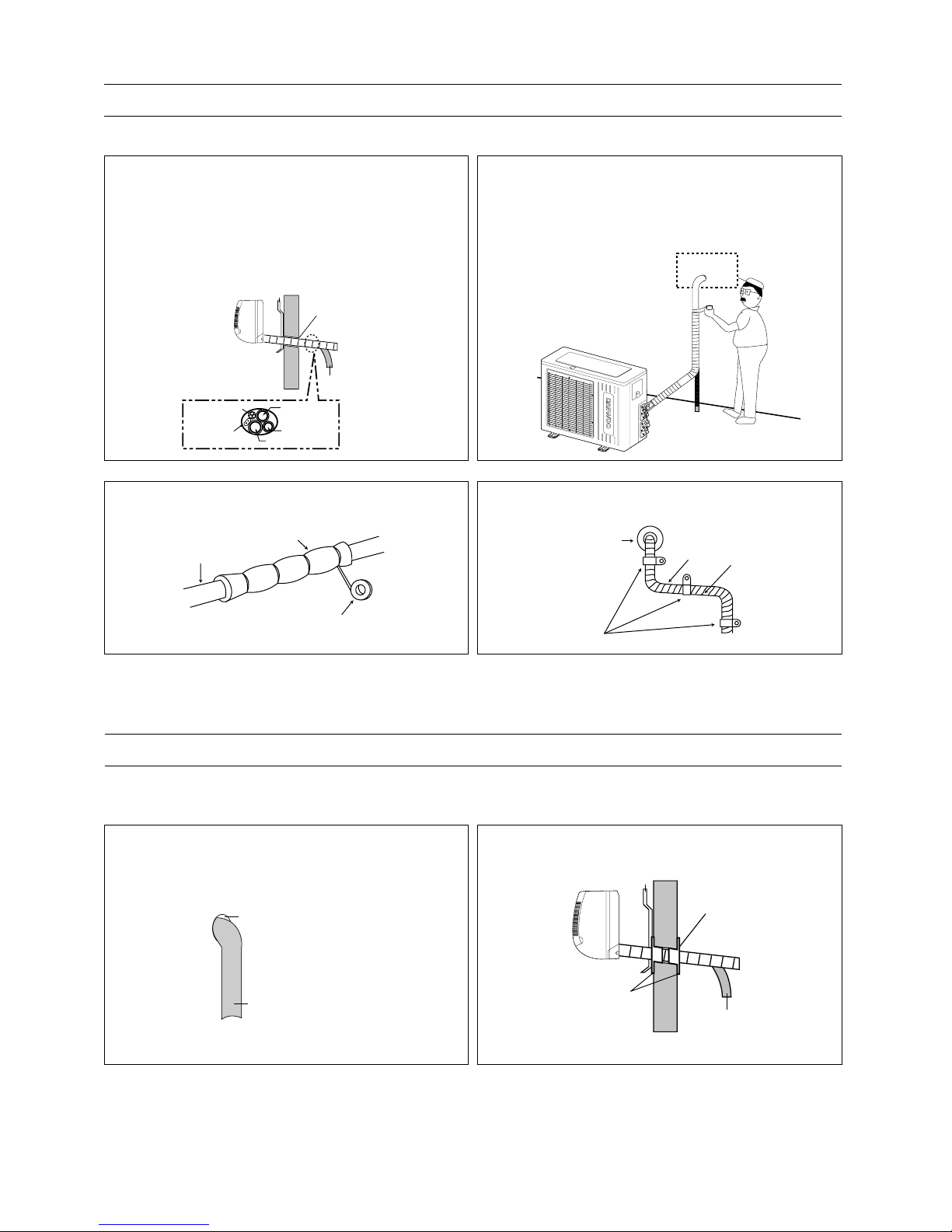

1. Tape the two copper tubes, drain hose (and the

electrical wiring if local codes permit) together with

the supplied tape. Make sure the electrical wiring

does not come in direct contact with the copper tubing or drain hose. Approximately 1 foot outside the

hole, let the drain hose out and separate from the

copper tubing and wiring.

Wall braket

Introduceti chit

Drain hose

2. Begin wrapping from the point the tubing comes out of

the outdoor unit and continue to the hole in the wall.

Leave no gaps or breaks and cover the entire length

of the tubing. As you wrap, overlap the previous turn

by half the width of the tape.

TAPING UP THE WIRE/TUBES/HOSE

After running the wire, hose and tubing outside, tape them up as shown below to insulate.

1. Apply the putty to any area on the outside hole that air

or rain can get into.

Apply Putty

Here

Tubing

2. After applying putty, insert the wall Cap at Indoor side

and Outdoor side.

Wall Bracket

Insert Putty

Wall Cap

(For DS-110R)

Drain Hose

APPLYING PUTTY AND INSERTING WALL CAP

After running the wires and tubing outside, putty should be inserted around the opening on the outside to protect against

rain, wind, etc. To apply putty, see below:

Indoor side Wall

Outdoor side

3. Wrap the piping joints with the insulator plate and fasten it with vinyl tape.

pipe

Insulator Plate

vinyl tape

4. After wrapping the connection pipe with tape, fasten it

to the outside wall with saddles, etc.

Saddle

(Not supplied)

Wall cap

Pipe

Tape

3/8" side piping

Connecting cable

Signal Wire

1/4" side piping

Drain Hose

22

AIR PURGING

Air and moisture remaining in the refrigerant system may create

adverse conditions as indicated below:

• pressure in the system rises.

• operating current rises.

• cooling efficiency drops.

• moisture in the refrigerant circuit may freeze and block capil

-

lary tubing.

• water may lead to corrosion of parts in the refrigerant system.

Therefore, the indoor unit and tubing between the indoor and

outdoor unit must be evacuated to remove moisture from the system.

AIR PURGING WITH VA CUUM PUMP (TEST R UN)

Confirm each tube (narrow and wide tubes) between the indoor

and outdoor units has been properly connected and all wiring

for the test run has been completed. Remove the valve caps

from the wide and narrow service valves on the outdoor unit.

Note that both narrow and wide tube service valves on the outdoor unit are kept closed at this stage (shipping position).

Leak Test

1. With the service valves on the outdoor unit remaining closed,

remove the threaded cover on the wide tube service port.

(Save for reuse.)

2. Attach a manifold valve (with pressure gauge) and dry nitrogen gas cylinder to this service port with charge hoses.

CAUTION:

Be sure to use a manifold valve for air purging. If it is not avail

-

able, use a stop valve for this purpose. The “Hi” knob of the

manifold valve must always be kept closed.

3. Pressurize the system to no more than 150 P.S.I.G. with dry

nitrogen gas and close the cylinder valve when the gauge

reading reaches 150 P.S.I.G. Next, test for leaks with liquid

soap.

Lo Hi

Pressure

Gauge

Manifold Valve

Outdoor Unit

Indoor Unit

Charge Hose

Nitrogen Gas

Cylinder

(Vertical

Position)

Evacuation

1. Attach the charge hose end described in the leak test

area to a vacuum pump to evacuate the air remaining

at the tubing and indoor unit.

Confirm the ÒLoÓ knob of the manifold valve is open.

Then, run the vacuum pump. The operation time for

evacuation varies with the tubing length and capacity of

the pump. The following table shows the amount of

time for evacuation:

2. When the desired vacuum is reached, close the ÒLoÓ knob

of the manifold valve and stop the vacuum pump.

Finishing the job

1. With a hex wrench, turn the narrow tube service valve

stem counter-clockwise to fully open the valve.

2. Turn the wide tube service valve stem counter-clockwise

to fully open the valve.

To avoid gas from leaking when removing the charge hose,

make sure the wide tube service valve is fully open and

Model

DMB-1822LH

DMB-1832LH

DMB-2112LH

DMB-2122LH

STANDARD

LENGTH(m)

INDOOR

UNIT

Change am't(g)

per 1m

5

A15

15

15

15

15

15

6

15

B

A

B

A

B

A

B

5

5

5

turned all the way out.

3. Loosen the charge hose connected to the wide tube ser

-

vice port slightly to release the pressure, then remove the

hose.

4. Replace the threaded cover on the wide tube service port

and fasten it securely. This process is very important to

prevent gas from leaking from the system.

5. Replace the valve caps at both wide and narrow service

valves and fasten them securely.

This completes air purging with a vacuum pump. The air

conditioner is now ready to test run..

If tubing length is less than

33 ft. (10 m)

10 min. or more

If tubing length is longer than

33 ft. (10 m)

15 min. or more

Required time for evacuation when 30 gal/h vacuum

pump is used

CAUTION:

CAUTION:

Freon Extra Charge

To avoid nitrogen entering the refrigerant system in a liquid

state, the top of the nitrogen gas cylinder must be higher than its bottom when you pressurize the system. Usually, the

cylinder is used in a vertical standing position.

4. Do a leak test of all joints of the tubing (both indoor and outdoor) and both wide and narrow service valves. Bubbles

indicate a leak. Be sure to wipe off the soap with a clean cloth.

5. After the system is found to be free of leaks, relieve the nitrogen pressure by loosening the charge hose connector at

the nitrogen cylinder. When the system pressure is reduced to normal, disconnect the hose from the cylinder.

Lo Hi

Pressure

Gauge

Manifold Valve

Outdoor Unit

Indoor Unit

Charge Hose

Vacuum

Pump

23

24

TEST RUN

Check that all tubing and wiring have been completed correctly. Check again that the wide and narrow tube service

valves are fully opened. Turn on the power and run the system.

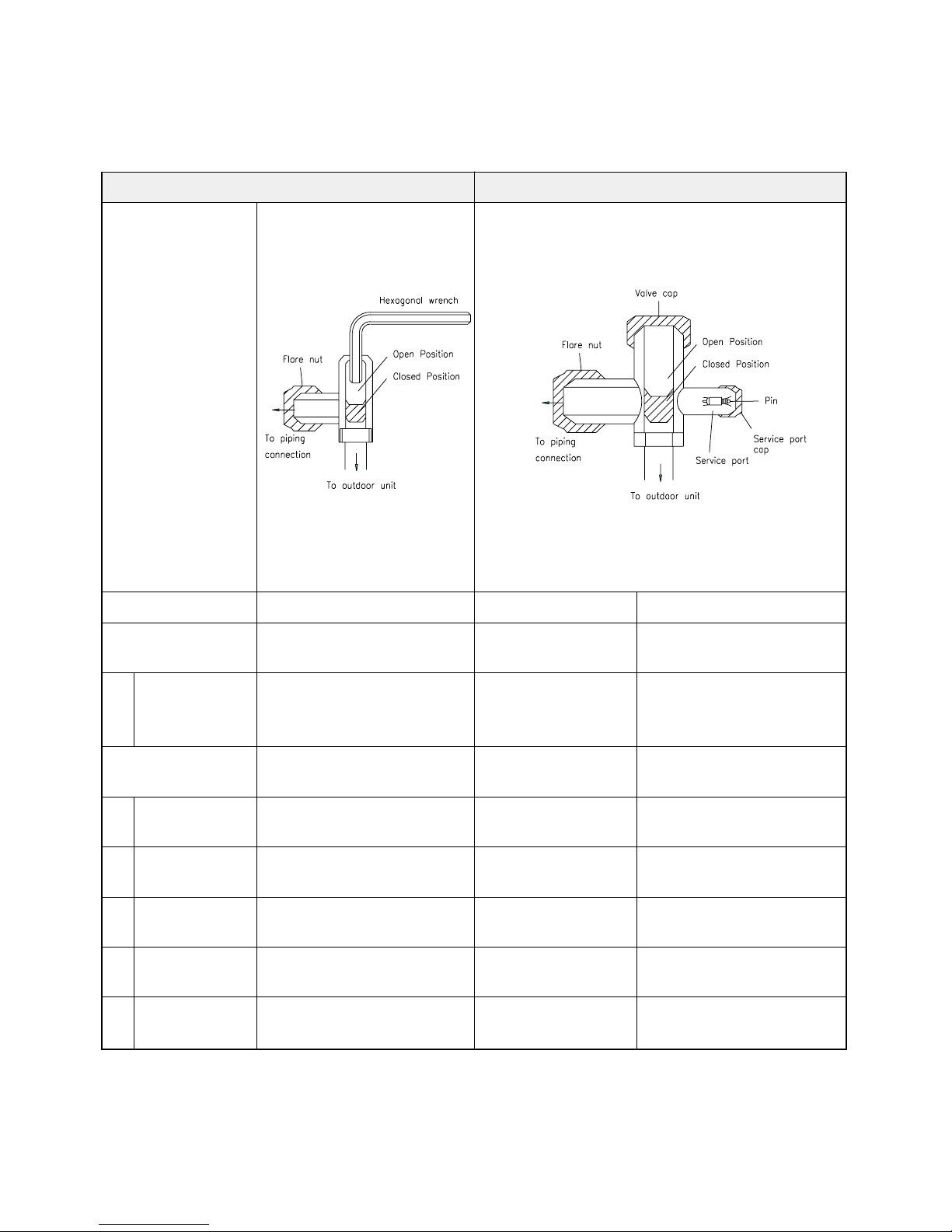

Service Valve Construction

• Valve Position Closed

The valve systems of both the wide and narrow tubes are turned all the way in. The unit is shipped from the factory in

this position and it is also used for Pump Down and Air Purging.

• Valve Position Fully Open

The valve stems of both the wide and narrow tubes are turned all the way out. This is normal operating and Test Run

position.

• Valve Position Half Open

With the narrow tube valve stem is turned to the halfway-down position. This position is used for pressure measurement and gas charging.

CAUTION:

When opening or closing the service valve stem, be sure to use a hex wrench.

PUMP DOWN

Pump Down means collecting all refrigerant in the outdoor unit without loss in refrigerant gas.

This is performed when the unit is to be relocated or the refrigerant circuit is serviced.

CAUTION:

Be sure to perform Pump Down procedure with the unit cooling mode.

Pump Down Procedure (execute the pump down of the unit A and unit B respectively)

1. Connect a low-pressure gauge manifold hose to the charge port on the wide tube service valve.

2. Open the wide tube service valve halfway and purge the air from the manifold hose using the refrigerant gas.

3. Close the narrow tube service valve (all the way in).

4. Turn on the unit’s operating switch and start the cooling operation.

5. When the low-pressure gauge reading becomes 1 to 0.5 kg/cm2 (14.2 to 7.1 psi), fully close the wide tube valve stem

and then quickly turn off the unit. At that time, Pump Down has been completed and all refrigerant gas will have been

collected in the outdoor unit.

3-W ay V alve

3-way valve(Liquid Side) 3-way valve(Gas Side)

Works Shaft position Shaft position Service port

Shipping Closed Closed Closed

(with valve cap) (with valve cap) (with cap)

1 Air purging Open Closed Open

(Installation) (counter-clockwise) (clockwise) (push-pin or with

vacuum pump)

Operation Open Open Closed

(with valve cap) (with valve cap) (with cap)

2 Pumping down Closed Open Open (connected

(Transfering) (clockwise) (counter-clockwise) manifold gauge)

3 Evacuation Open Open Open

(Servicing) (with charging cylinder)

4 Gas charging Open Open Open

(Servicing) (with charging cylinder)

5 Pressure check Open Open Open

(Servicing) (with charging cylinder)

6 Gas releasing Open Open Open

(Servicing) (with charging cylinder)

25

26

1

NAME AND FUNCTION OF PARTS

Indoor Unit

5. OPERA

TION

9000 BTU/h Class (DMB-1822LH unit A & B, DMB-2112LH unit B)

Electrostatic Filter

removes dust and

particles from the air

Deodorizing Filter

removes bad smells

from the air

Air Inlet

Remote

Controller

Receiver

Signal wire

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

removes dust and

prohibits germs.

Lamp

9000 BTU/h Class (DMB-1832LH unit A & B, DMB-2122LH unit B)

Electrostatic Filter

removes dust and

particles from the air

Deodorizing Filter

removes bad smells

from the air

Air Inlet

Remote

Controller

Receiver

Signal wire

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

removes dust and

prohibits germs.

Lamp

27

1 2 0 0 0 B TU / h Cla s s (DM B -2 1 1 2 LH u n it A )

Lamp

Electrostatic Filter

removes dust and

particles from the air

Deodorizing Filter

removes bad smells

from the air

Air Inlet

Remote

Controller

Receiver

Signal wire

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

removes dust and prohibits

germs.

1 2 0 0 0 B TU / h Cla s s (DM B -2 1 2 2 LH u n it A )

Electrostatic Filter

removes dust and

particles from the air

Deodorizing Filter

removes bad smells

from the air

Air Inlet

Remote

Controller

Receiver

Signal wire

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

removes dust and

prohibits germs.

Lamp

28

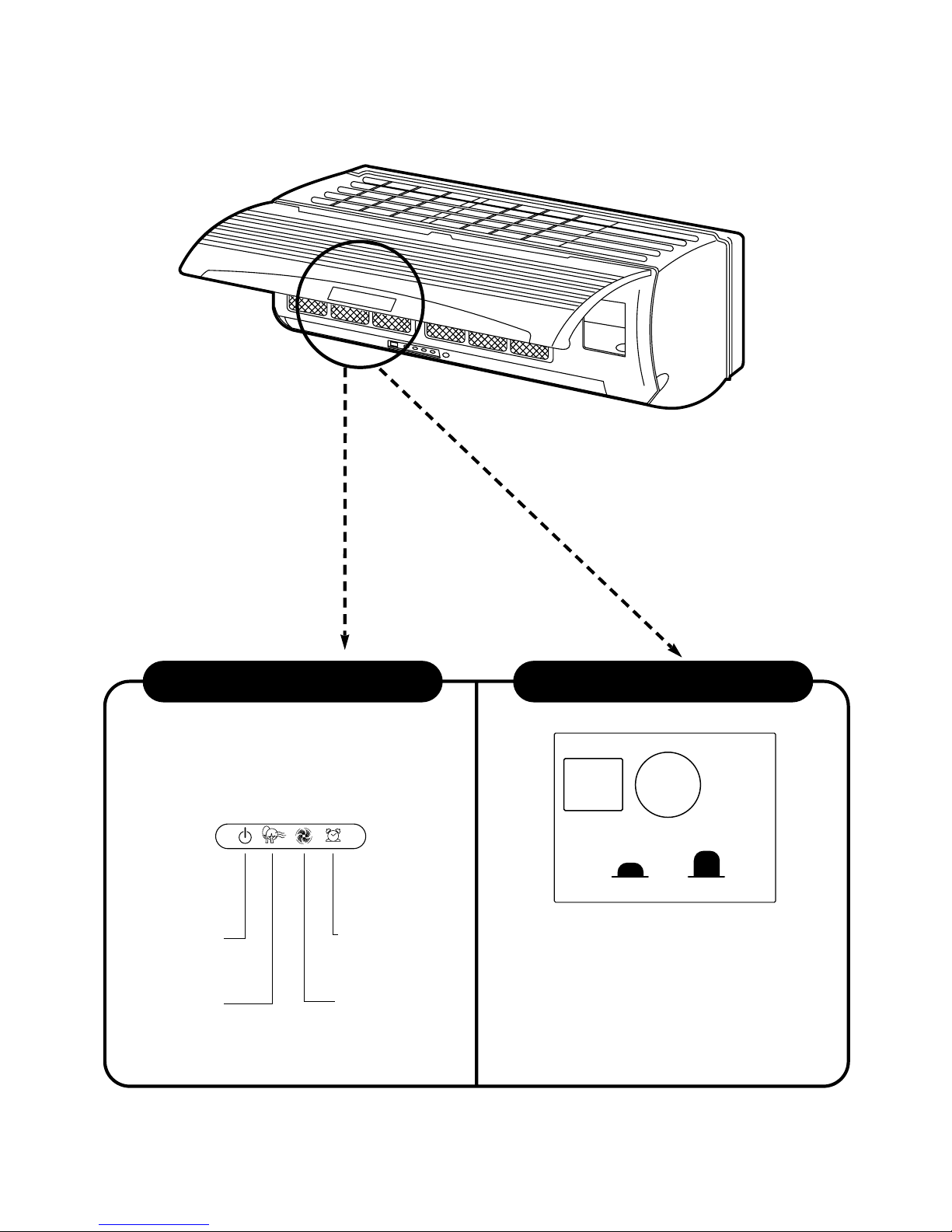

INDOOR UNIT (DMB-2112LH unit A (12000BTU/h))

■

Remote Control Signal Receiver

This place is the part to receive the signal if it receives

the signal, you can hear the signal “beep”.

■

When the remote controller is lost or outof-order, push the emergency button

(EMERGENCY) to operate by hand.

Open the front panel on emergency operating.

Remocon switch is usually used with remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights-on during the time

of reservation mode.

Quick (Red)

Lights-on during the time

of Quick Mode.

ON (Red)

Lights-on

during the operation

Air clean (Green)

Lights-on

during the operation

ON AIR

CLEAN

QUICK TIMER

EMERGENCY REMOTE

EMERGENCY REMOTE

29

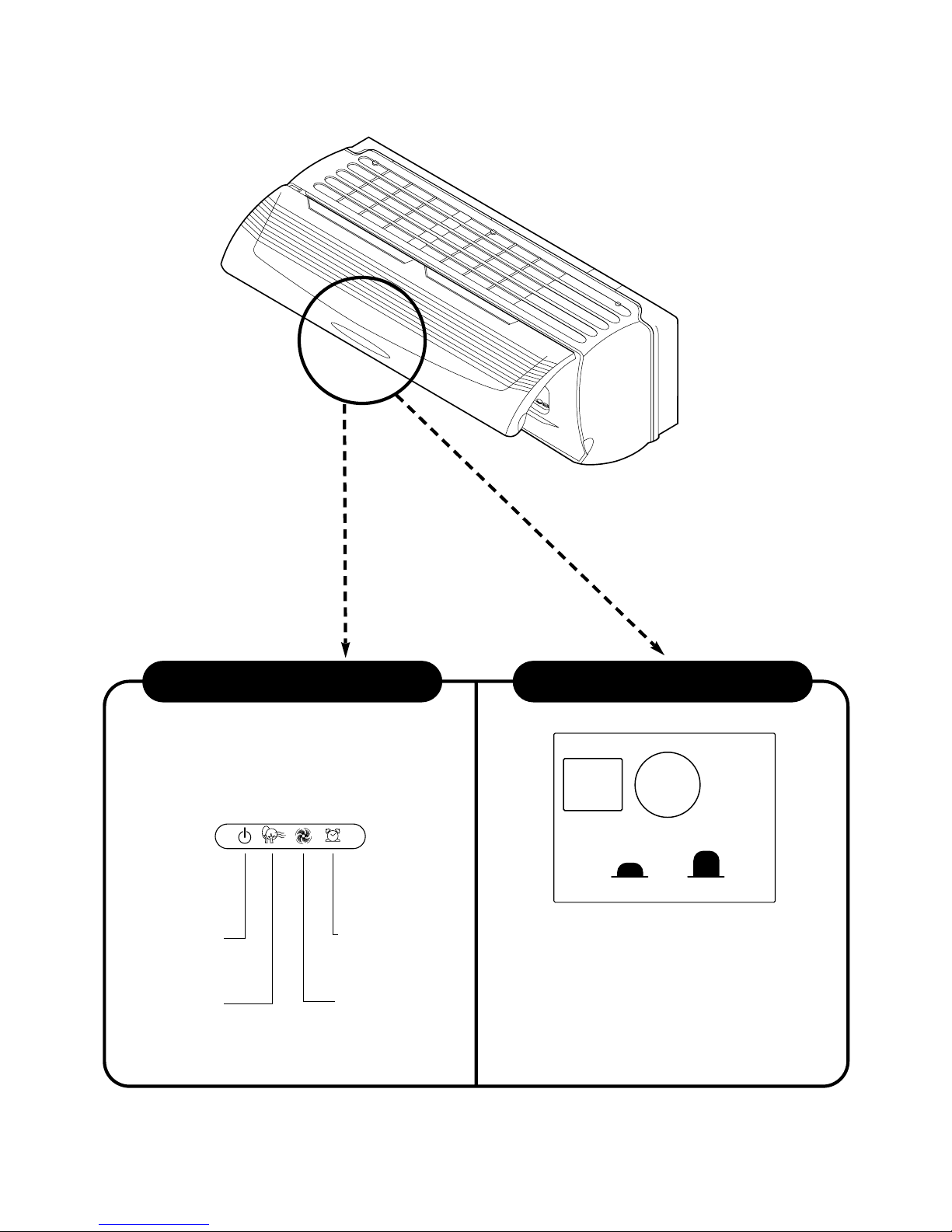

■

Remote Control Signal Receiver

This place is the part to receive the signal if it receives

the signal, you can hear the signal “beep”.

■

When the remote controller is lost or outof-order, push the emergency button

(EMR.) to operate by hand.

Open the front panel on emergency operating.

Remocon switch is usually used with remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights-on during the time

of reservation mode.

Quick (Red)

Lights-on during the time

of Quick Mode.

ON (Red)

Lights-on

during the operation

Air clean (Green)

Lights-on

during the operation

EMR. REMOCON

INDOOR UNIT (DMB-2122LH unit A (12000BTU/h))

30

■

Remote Control Signal Receiver

This place is the part to receive the signal if it receives

the signal, you can hear the signal “beep”.

■

When the remote controller is lost or outof-order, push the emergency button

(EMR.) to operate by hand.

Open the front panel on emergency operating.

Remocon switch is usually used with remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights-on during the time

of reservation mode.

Quick (Red)

Lights-on during the time

of Quick Mode.

ON (Red)

Lights-on

during the operation

Air clean (Green)

Lights-on

during the operation

EMR. REMOCON

INDOOR UNIT (DMB-1822LH unit A or B, DMB-2112LH unit B (9000BTU/h))

Loading...

Loading...