Page 1

Page 2

SPECIFICATIONS............................................................................................................................... 5

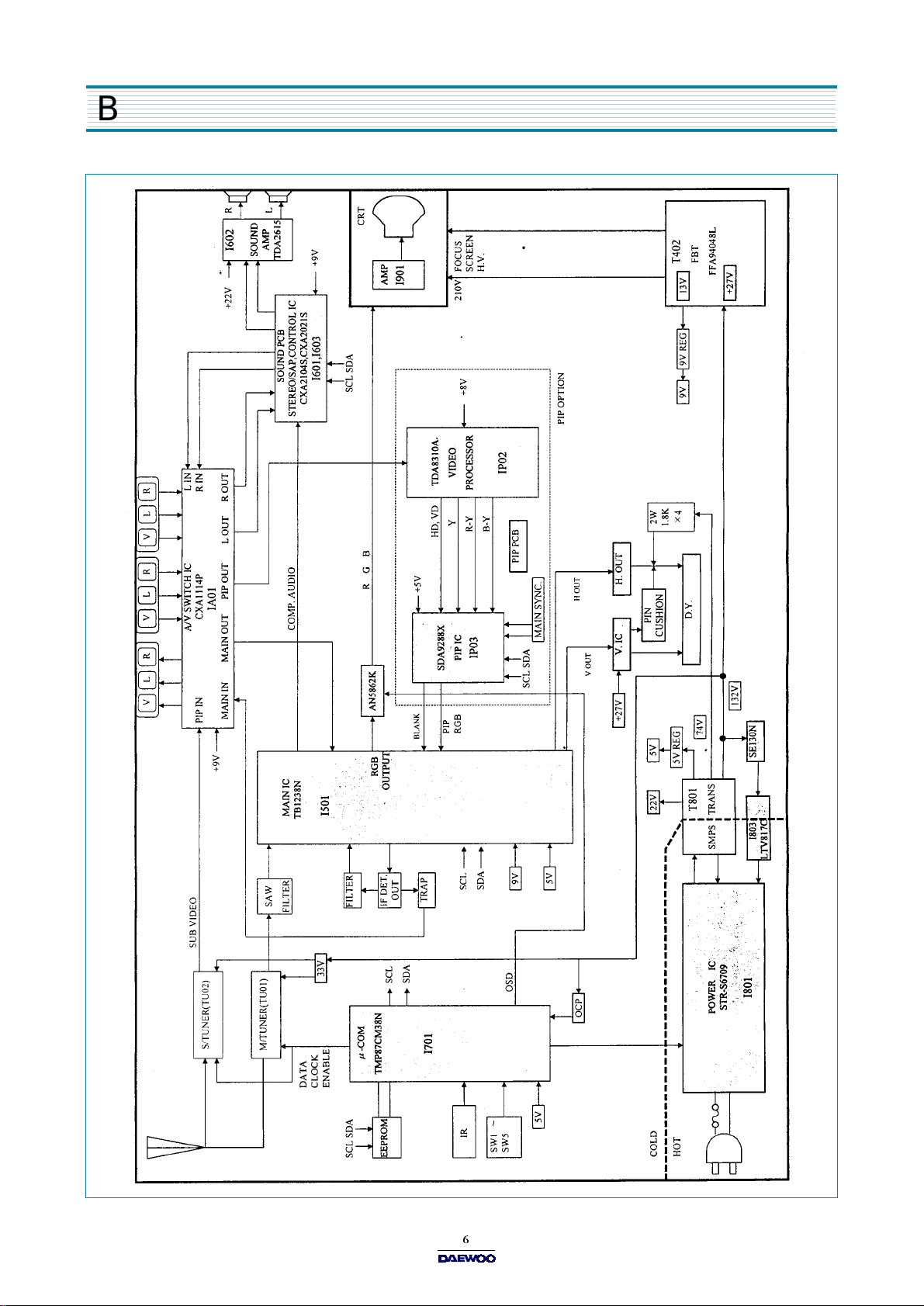

BLOCK DIAGRAM .............................................................................................................................. 6

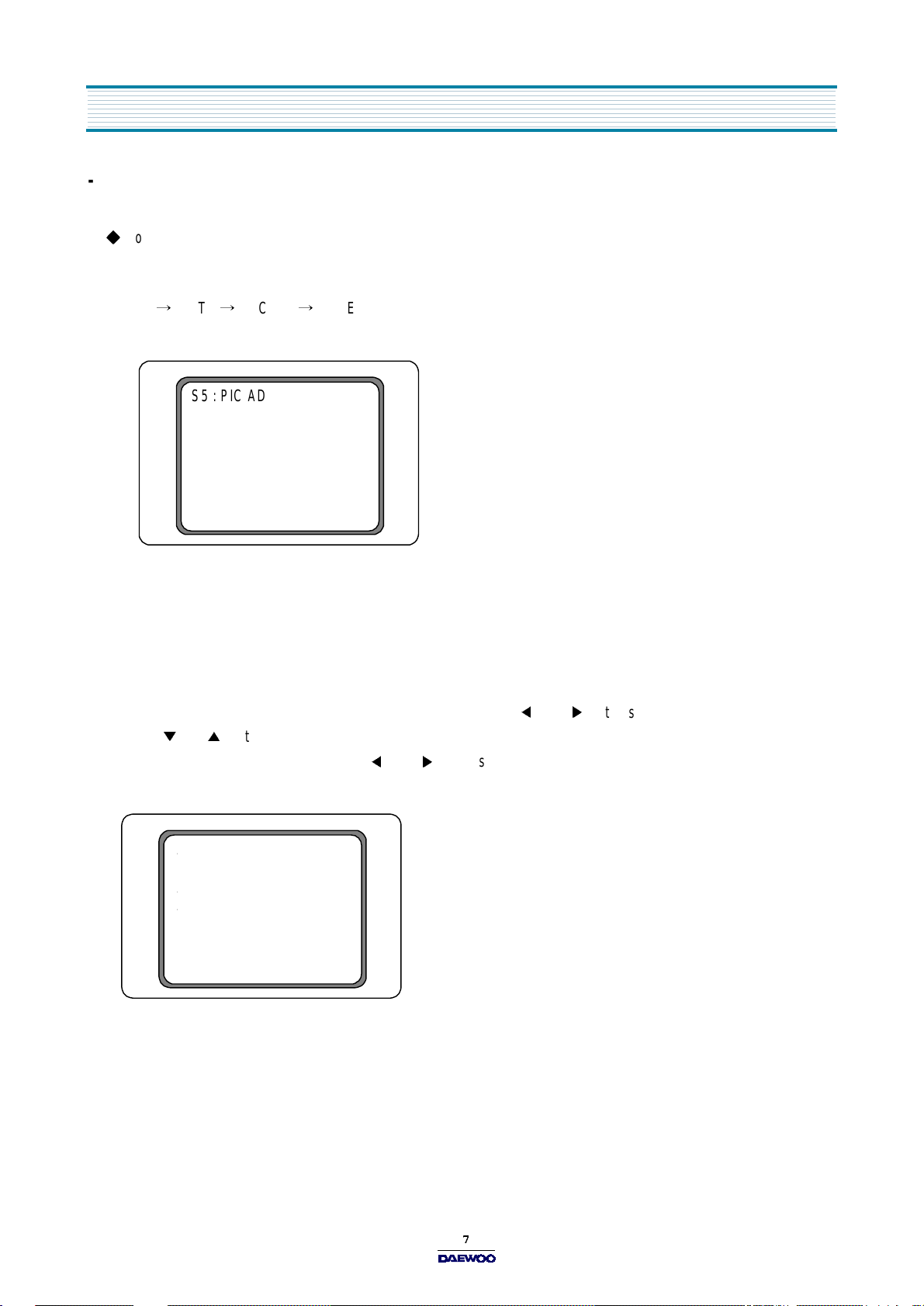

1. SERVICE MODE ADJUSTMENT ................................................................................................................ 7

2. VCO/AGC ADJUSTMENT ........................................................................................................................... 7

3. PIP VIDEO GAIN ADJUSTMENT................................................................................................................ 7

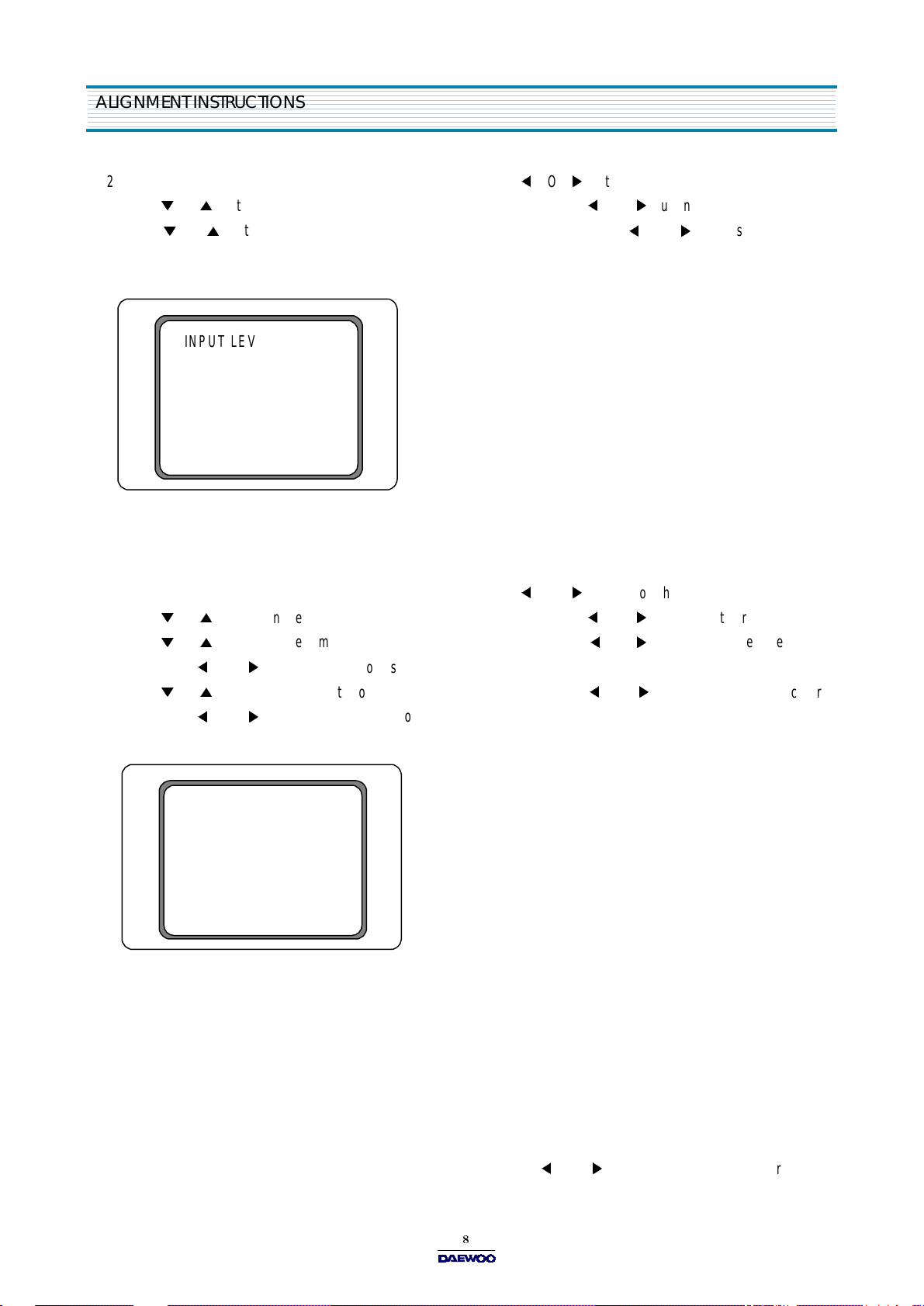

4. SOUND INPUT LEVEL ADJUSTMENT....................................................................................................... 7

ALIGNMENT INSTRUCTIONS............................................................................................................ 7

1. STEREO ADJUSTMENT ............................................................................................................................ 8

2. FOCU S A D J U S T M E NT .. ....... .. ... ...... ... .. ....... .. .. ....... ... .. ....... .. .. .............. .. ... ...... ... .. ....... .. .. ....... .................... 8

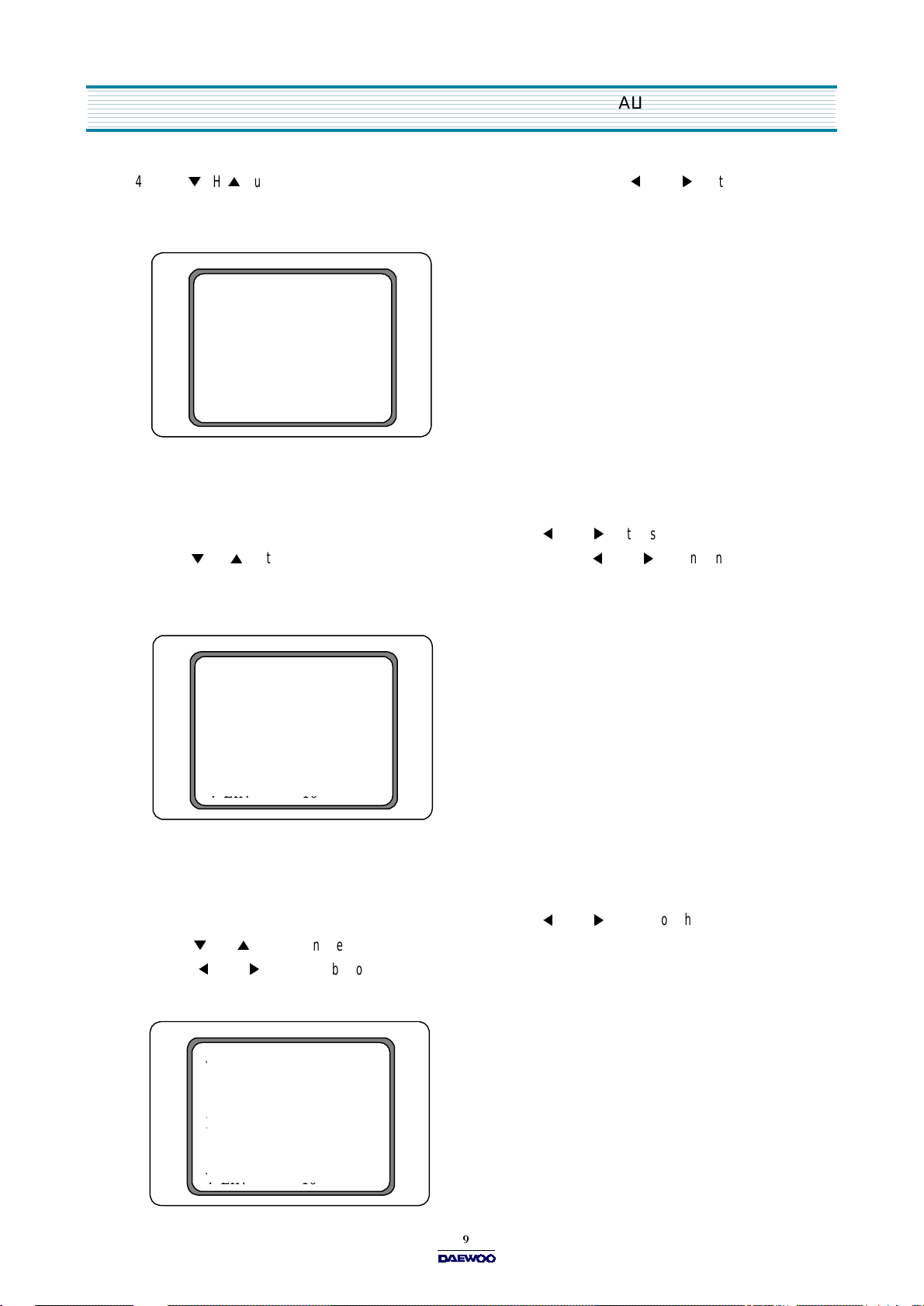

3. GEOMETRY 8

4. WHITE BALANCE ADJUSTMENT.............................................................................................................. 10

5. SUB-BRIGH T A D J U S T M E N T....... .. .............. .. .. ....... ... .. ....... .. .. ....... .. ... ............. ... .. ....... .. .. ....... ... ................. 11

6. PIP DATA ADJUSTMENT............................................................................................................................ 11

IC DESCRIP TIO N .... ... ......... ... ......... ... ... ......... ... ......... ... ......... ... ... ......... .. ......... ... ......... ... ... .. ............... 16

TROUBLE SHOOTING CHARTS. ....................................................................................................... 24

1.NO POWER.................................................................................................................................................. 24

2. NO PIP. ....... .. .. .............. .. .. ....... ... .. ....... .. .. ....... .. ... ....... .. .. ....... .. ... ...... ... .. ....... .. .. ....... .................................... 26

3. NO PIC T U R E.. .. ....... ... .. .............. .. .. ....... .. ... ...... ... .. ....... .. .. ....... ... .. ....... .. .. ....... .. ... ....... .. ............................... 27

4. NO SO U N D..... .. ... ....... .. .. ....... .. ... ...... ... .. ....... .. .. ....... ... .. ....... .. .. ....... .. ... ....... .. .. ....... .. ... ................................. 28

IC DC VOLTAGE CHARTS................................................................................................................. 29

EXPLODED VIEW ............................................................................................................................... 32

ELECTRICAL PARTS LIST................................................................................................................. 34

A DIFFERENCE PARTS LIST BETWEEN.......................................................................................... 46

PCB LAYOUT...................................................................................................................................... 61

Page 3

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO - VIDEO PRODUCTS

CAUTION

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER°ØS APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANT

RESULTING PROPERTY DAMAGE OR USER INJU RY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS AND

SERVICING GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF

POTENTIAL HAZARDS AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION

FROM A.C. LINE SHOCK.

: DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY.

SAFETY CH EC K S

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK SHO ULD BE M AD E OF TH E FO LLO W ING :

SUBJECT:FIRE & S HOCK HAZAR D

1. BE SURE THAT ALL COM PONENTS ARE POSITIONED IN SUCH A WAY AS

TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS

ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE, THAT THE SAFETY PURPOSE OF THE

POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPE CTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS, SOLDER SPLASHES OF SHARP SOLDER POINTS. BE CERTA IN TO R EM O VE ALL LOO S E FORE IGN PAR TI C LES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIO RATION TO

PARTS AND COMPONENTS, FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD), AND REPLACE IF NECESSARY. FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A

RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND PROTRUDING METAL SURFACES M UST BE AVOIDED.

6. ALL CRITICAL COM PONENTS SUCH AS FUSES, FLAMEPROOF RESISTOR,

CAPACITORS, ETC. MUST B E REPLACED WITH EXACT FACTO RY TYPES.

DO N OT USE REPLA CEM ENT C OM PO NENTS OTH ER TH AN THO SE SP ECIFIED OR MAKE UNRECOMM ENDED CIRCUIT MO DIFICATIONS.

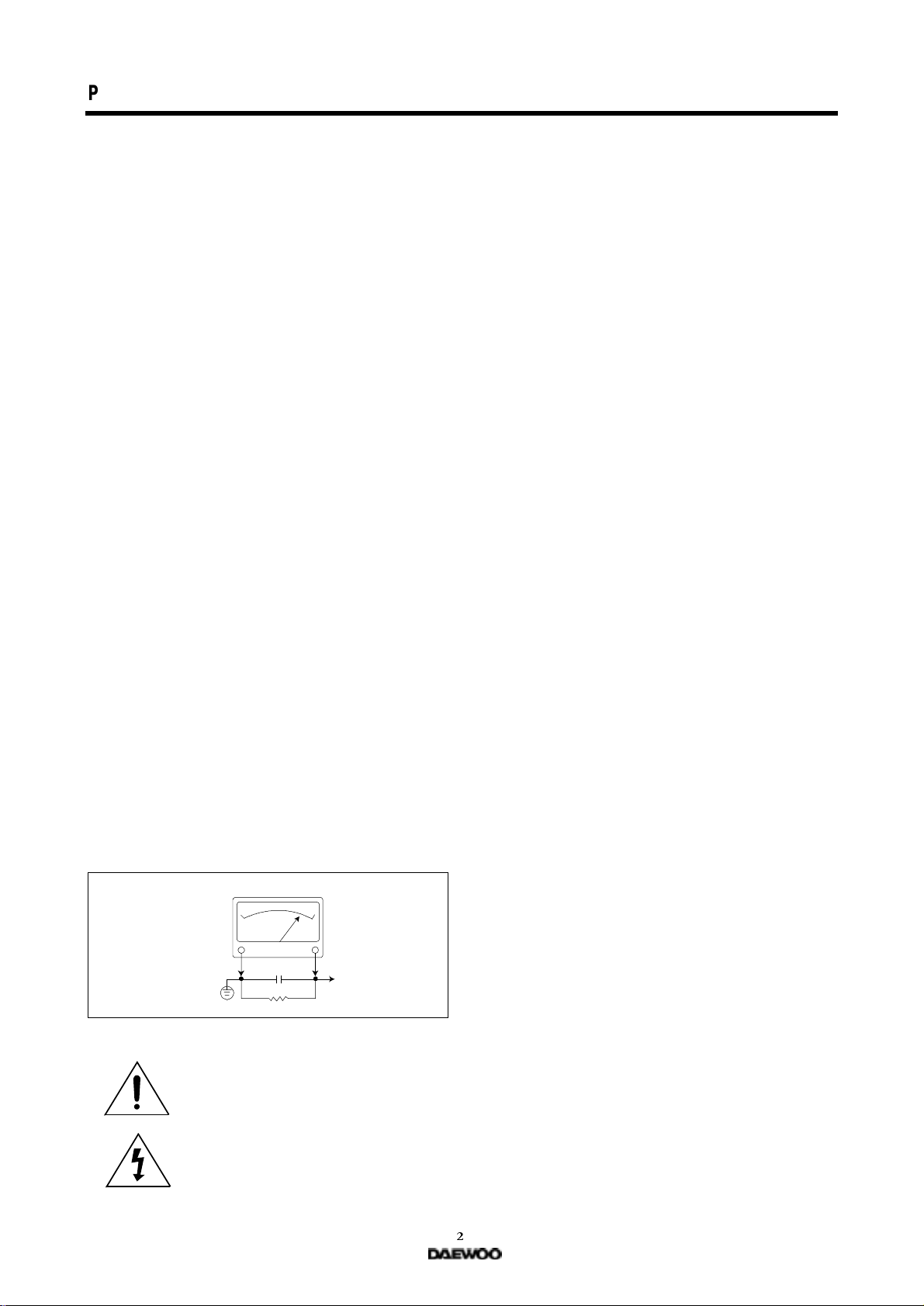

7. AFTER RE-ASSEM BLY OF THE STE ALWAYS PERFORM AN A.C. LEAKAGE

TEST O N ALL EXPO SED METALLIC PARTS OF TH E CABINET. (TH E CHA NNEL SELECTOR KNOB, ANTENNA TERMINALS, HANDLE AND SCREWS) TO

BE SUR E THE S ET IS SAFE TO OP ER ATE W ITHOUT DAN GE R O F ELE CTRICAL SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING

THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VO LT OR

M OR E SENSITI V ITY, IN THE FO LLOW ING M ANN E R : C ONN ECT A 15 00 OH M

10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150V A.C. TYPE CAPACITOR BETW EEN A KNO WN GOOD EARTH GROUND (WATER POPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500 OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG AND

REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC

PART. VOLTAGE MEASURED MUST NOT EXCEED .75 VOLTS R.M.S THIS

CORRESPONDS TO 0.5 MILLIAMP A.C. NAY VALUE EXCEEDING THIS LIMIT

CONSTITUTES A POTENTIAL SHOCK HAZARD AND MUST BE CO RRECTED

IMMEDIATELY.

A.C. VOLTMETER

0.15 uF

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE, CONDUIT, ETC.

1500 OHM

10WATT

PLACE THIS PROBE

ON EACH EXPOSED

METAL PAR T

SUBJEC T : GRA PHIC SY MBO LS

THE LIGHTNING FLASH WITH ARR OWH EAD SYM BO L,

WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SE RVICE PER SONN EL TO THE PR ESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A R ISK O F ELEC TRIC SH O C K.

THE EXCLAMATION POINT W ITHIN AN EQUILATERAL

TRIANGLE IS INTE NDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT

SAFETY INFORM ATION ON S ERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL

SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE.

HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE PROPER VALUE IS

GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE

SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, AMY PRODUCE RADIATION IN EXC ES S O F D ESIRA BLE LEVE LS.

2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED.

DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN CO LOR SETS.

ALWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRATIO N OF THE

METER SHOULD BE CHECKED PERIODICALLY AGAINST A REFERENCE

STANDARD. SUCH AS THE ONE AVAILABLE AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE

IS NO P OS SIBILITY O F AN X-RADIATION PR O BLEM . EVER Y TIME A C OLO R

CHASSIS IS SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND

DOWN WHILE MONITORING THE HIGH VOLTAGE WITH A METER TO BE

CERTAIN THAT THE HIGH VOLTAGE DOES NOT EXCEED THE SPECIFIED

VALUE AND THAT IT IS REGULATING CORRECTLY. WE SUGGEST THAT

YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES

SO THAT VOLTAGE REGULATIO N IS ALWAYS CHECKED AS A STANDARD

SERVICING PROCEDURE, AND THAT THE HIGH VOLTAGE READING BE

RECORDED ON EACH CUSTOMER°ØS INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A

PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID

BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND THE HIGH

VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT LONGER THAN IS

NECESSARY TO LOCATE THE CAUSE OF EXCESSIVE VOLTAGE.

6. REFER TO HV, B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE

USED).

SUBJECT : IMPLOSION

1. ALL DIR ECT VIEW ED PICTURE TU BES AR E EQUIPPED WITH AN INTEGR A

IMPLOSION PR O TEC TION SYS TEM. BUT CA R E SHO UL D B E TAKEN TO

AVOID DAMAGE DURING INSTALLATION. AVOID SCRATCHING THE

TUBE. OF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR

CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN

THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS

WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT W HERE DRAPERIES MAY OBSTRUCT REAR VENTING.

THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE

SCARVES OR OTHER COVERINGS WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL

MOUNTING KIT, MUST FOLLOW THE FACTORY APPROVED MOUNTING

INSTRUCTIONS. A PRODUCT MOUNTED TO A SHELF OR PLATFORM MUST

RETAIN ITS ORIGINAL FEET (OR THE EQ UIVA LENT T HIC KNESS IN SPACERS)TO PROVIDE ADEQUATE AIR FLOW ACROSS THE BOTTOM, BOLTS

OR SCREWS USED FOR FA STENERS MUST NOT TOUCH ANY PARTS OR

WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIO NS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PRO PERLY SECU RED .

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS THRESHO LDS OR

DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH

HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES. INC. FOR

USE WITH THEIR SPECIFIC MODEL OF TELEVISION RECEIVER OR

GENERICALLY APPROVED FOR USE WITH T.V.S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SING LE

OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO HOME AND

FAM ILY.

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR COLOR TELEVIS ION RECEIVERS

CAUTION : Do not attempt to modify this product in any way. Unautho riz ed mo d if ic a tio n s will n o t o n ly v oid the w arran ty, b u t may le a d to

your being liable for any resulting property damage or user injury.

Service work should be performed only after you are thoroughly

fam iliar w ith a ll of th e fo llow ing sa fety che cks and servicing guidelines. To do otherwise, increases the risk of potential hazards and

injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check should be made of the following:

SUBJECT : FIRE & SHOCK HAZAR D

1. Be sure that all components are positioned in such a way as to

av oid po ssib ility of adja cen t com ponent shorts. This is especially

important on those chassis which are transported to and from the

repair shop.

2. Never release a repair unless all protective devices such as insulators, barriers, covers, shields, strain reliefs, and other hardware

have been reinstalled per original design.

3. Soldering m us t be ins pecte d to dis co ve r poss ible cold solder join t s,

frayed leads, damaged insulation (including A.C. cord), solder

splashes or sharp solder points. Be certain to remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration to parts

and components, and replace if necessary follow original layout,

lead length and dress.

5. No leads or components should touch a receiving tube or a resistor

rated at 1 watt or more. Lead tension around protruding metal surfaces must be avoided.

6. All critical componen ts such as fuses, flam eproof resistors, capacitors, etc. must be replaced with exact factory types. Do not use

replacement components other than those specified or make

unrecommended circuit m odifications.

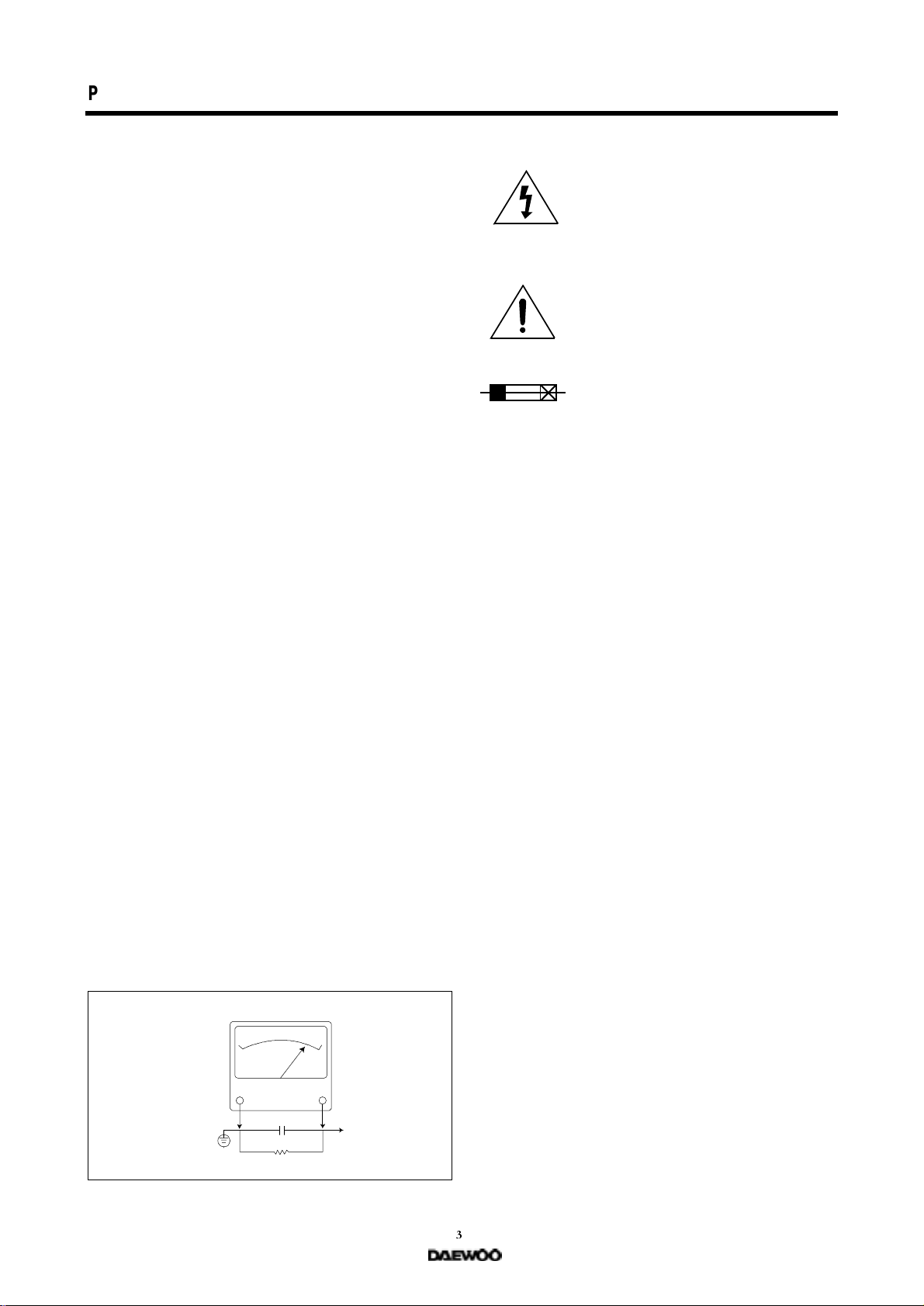

7. After re-assembly of the set always perform an A.C. leakage test

on a ll ex po sed m eta llic pa rts o f th e ca bine t, (th e ch a nne l sele cto r

knob, antenna terminals, handle and screws) to be sure the set is

safe to operate without danger of electrical shock. D o not use a

line isolation transformer during this test. Use an A.C. voltmeter,

having 5000 ohms per volt or more sensitivity, in the following

manner : connect a 1500 ohm 10 watt resistor, paralleled by a 15

mfd. 150V A.C. type capacitor between a known good earth

ground (9water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the A.C. voltage across the combination of

1500 ohm resistor and 0.15 M FD capacitor. Reverse the A.C . plug

and r ep ea t A .C . v o ltag e m ea s u reme nt s fo r e a ch ex p os ed m e ta llic

part. Voltage measured must not exceed 0.75 volts R.M.S. This

corresponds to 0.5 milliamp A.C. Any value exceeding this limit

constitu tes a potential shock hazard and must be corrected immediately.

A.C. VO LTMETER

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to alert

the service personnel to the presence of uninsulated “dangerous voltage” that may be of sufficienty magnitude to constitute a risk of electric

shock.

The exclamation point within an equilateral triangle is intended to alert the service personnel

to the presen ce of im porta nt safe ty inform ation

in s ervice literature.

Fuse symbol is printed on pcb adjacent to the

fuse, w ith “RIS K O F FIR E R EP LAC E FU SE AS

MARKED”. The symbol is explained in the service manual with the following wording or equivalent.

“CAUTION :

FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH SAME TYPE (6.3A, 250V)” and

ATTENTION

“

: AFIN D’ASSU UNE PROTECTION PERMANENTE

CONTRE LES RISQUES D’INCENDIE, REMPLACER UNIQUEMENT PAR UN FUS IBLE DE MEME TYPE ET DE ”6.3A, 250V”.

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service personnel cover

the subject of X-rays in current T.V. receivers is the picture tube.

However, this tube does not emit X-rays when the high voltage is

at the factory specified level. The proper value is given in the applicable schematic. Operation at higher voltages may cause a failure

of the picture tube or high voltage supply and, under certain circumstances, may produce radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must be used.

Degaussing shields also serve as X-ray shield in color sets.

Alw a y s re -ins ta ll them.

3. It is essential that the serviceman has available an accurate and

reliable high voltage meter. The calibration of the meter should be

checked perio - dically against a reference standard. Such as the

one available at your distributor.

4. When the high voltage circuitry is operating properly there is no

po ss ib ility o f a n X -ra d iatio n pr ob lem. Ev ery tim e a c olo r c ha s sis is

serviced, the brightness should be run up and down while m onitoring the high voltage with a meter to be certain that the high voltage

does not exceed the specified value and that it is regulating correctly. We suggest that you and your service organization review

test procedures so that voltage regulation is always checked as a

standard servicing procedure. And that the high voltage reading be

recorded on each customer’s invoice.

5. When troubleshooting and making test measurements in a

receiver with a problem of excessive high voltage, avoid being

unnecessarily close to the picture tube and the high voltage compartment.

Do not operate the chassis longer than is necessary to locate the

cause of excessive voltage.

6. Refer to HV, B+and Shutdown adjustment procedures described in

the appropriate schematic and diagram s(where used).

Good earth ground,

such a s the water

pipe, conduit, etc.

0.15 uF

1500 OHM

10WATT

Place this probe

on each exposed

metal part.

Page 5

SUBJEC T : IMPLOSION

1. All direct viewed picture tubes are equipped with an integral implosion protection system, but care should be taken to avoid damage

during installation. Avoid scratching the tube. If scratched, replace

it.

2. Use only recommended factory replacement tubes.

SUBJEC T : TIPS ON PRO PER INSTALL ATION

1. Never install any receiver in closed-in recess, cubbyhole or closely

fitting shelf space over, or close to heat duct, or in the path of

heated air flow.

2. Avoid conditions of high humidity such as : Outdoor patio installations where dew is a factor. Near steam radiators where steam

leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The

customer should also avoid the use of decorative scarves or other

coverings which might obstruct ventilation.

4. Wall and shelf mounted installations using a comm ercial mounting

kit, must follow the factory approved mounting instructions. A

receiver mounted to a shelf or platform must retain its original

feet(or the equivalent thickness in spacers) to provide adequate

are flow across the bottom, bolts or screws used for fasteners

must not touch and parts or wiring. Perform leakage test on customized installations.

5. Caution customers against the m ounting of a receiver on sloping

shelf or a tilted position, unless the receiver is properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to

the cart. Caution the customer on the hazards of trying to roll a cart

with small casters across thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand which has not

been listed by underwriters laboratories, inc. For use with their

specific model of television receiver or generically approved for

use with T.V.’s of the same or larger screen size.

Page 6

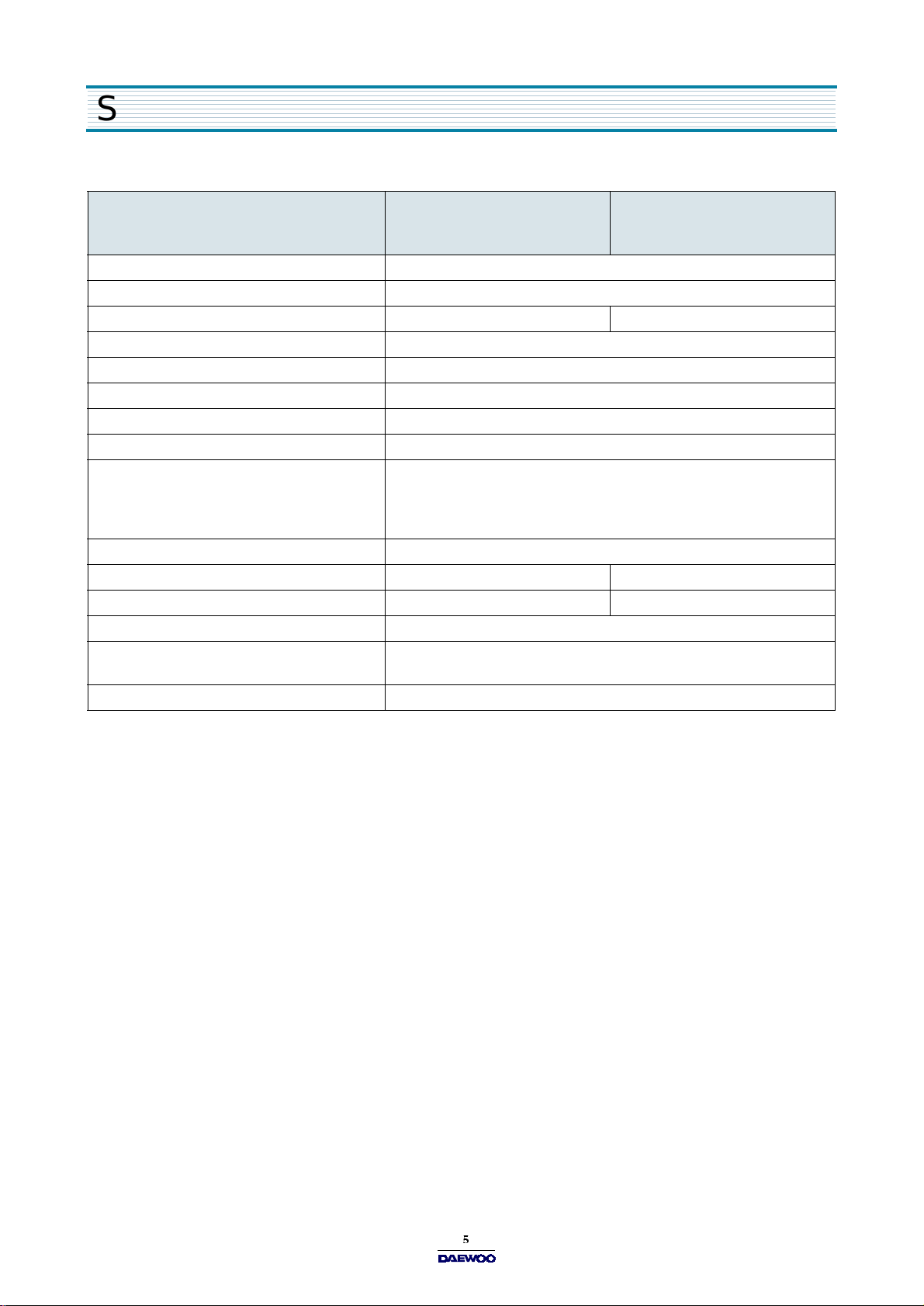

SPECIFICATIONS

DTH-25G1FST

MODEL

TV STANDARD NTSC/PAL-M/PAL-N

MAINS VO LTAG E 100~250V AC, 50/60Hz

POWER C ONSU MPTION 110W 120W

SOUND OUTPUT 5W+5W

SPEAKER 7W 8Ohm(2EA)

ANTEN NA IMP EDAN CE 75 ohm unbalanced

TUNIN G SYSTEM Frequency Synthesize Tuning System

MEM O RY CH AN NEL 181 Channels

RECEPTION CHANNEL UNIT VHF TV LOW : CH2 - CH6

REMOTE CONTROL UNIT R-23B04

SCRE EN SIZE 25” Diagonal 29” Diagonal

WEIGH T 35Kg 42Kg

TUNER TYPE Varactor Type with PLL

AUX. TERM INAL(IN PUT) Front : Video, Audio(L/R)

AUX. TERM INAL(OUTPUT) Rear : Video, Audio( L/R)

DTH-25G1FSP

DTH-25G1FS

HIGH : CH7 - CH1 3

CH1, CH14 - CH125

U H F T V CH 1 4 - CH6 9

Rear : Video, A udio(L/R)

DTH-29G1FST, DTH-29G3FST

DTH-29G1FSP, DTH-29G3FSP

DTH-29G1FS, DTH-29G3FS

Page 7

BLOCK D IAGR AM

Page 8

ALIGNME NT INSTRU CTIO NS

- ALIGNMENT BY USER REMOCON

1. SERVICE MODE ADJUSTMENT

How to enter into Service Mode.

1) Direct the remote control to the reception w indow of TV.

2) Push button of rem ote control in sequence.

MUTE RECALL MUTE

1

3) Then, the screen will appear as follows.

S5 : PIC ADJ

S5 : PIC ADJ

S6 : GEOMETRY

S7 : PIP ADJ

S6 : GEOMETRY

S8 : R GB ADJ

S7 : PIP ADJ

S9 : DP ADJ

S10 : P/S ADJ

S8 : RGB ADJ

S11 : AUTO PIC

TO EXIT : POW ER OFF

S9 : DP ADJ

When you select a item , its turns into the green.

How to memorize the adjusted settings in service mode; Must press RECALL button the state which the screen is

displaying each of service menus after all adjustments are com pleted each of all service menu.

2. VCO/AGC ADJUSTMENT

1) Receive the COLOR BAR signal. (INPUT LEVEL : 60 dBuV)

2) Select the S10 of service mode to display items, then press the

3) Press

4) It will start auto adjustment if you press

5) After adjustment, the “ VCO O K *** ” or “ AGC O K *** ” OSD w ill be displayed.

CH buttons on the rem ote control to select VCO or AGC

VOLbuttons.

VCO

VCO

AGC

AGC

VCO31

S MANUAL

VCO31

S MANUAL

VOLbuttons on the remote control.

3. PIP VIDEO GAIN ADJUSTMENT

1) Turn ON the PIP and receive the COLO R BAR PATTE RN.

2) Turn the volume R128 to set 1Vp-p on TP1.

4. SOUND INPUT LEVEL ADJUSTMENT

1) Receive the 100% mod. MON O. Signal.

Page 9

ALIGNMENT INS TR UCTIO NS

2) Select the S10 of service mode to display items, then press the VOLbuttons on the remote control.

3) Press

4) Press

become 490m V (+20mV/-5mV).

5) Press the REC ALL button of remote control to store.

CH buttons on the remo te co ntrol to select S MANUAL and press VOL buttons on the remo te control.

CH buttons on the remote control to select INPU T LE VEL and pressVOLbuttons to set T P2

INPUT LEVEL 15

INPUT LEVEL 15

WIDEBAND 23

WIDEBAND 23

SPECTRAL 32

SPECTRAL 32

5. STEREO AD JUS TMENT

1) Receive the Zenith M TS signal of 1KHz CH(L only).

2) Connect scope at T P2 to verify R out correspondent.

3) Select the S10 of service mode to display items, then press the VOLbuttons on the remote control.

4) Press

5) Press

6) Adj us t with

7) Press

8) Adj us t with

9) Press the RECA LL button on the remote control to store.

CH buttons on the remo te co ntrol to select S MANUAL and press VOL buttons on the remo te control.

CH buttons on the remote control to select WIDEBAND and pressVOLButtons on the remote con trol.

VOLbuttons till the Rout(scope) become minim um .

CH buttons on the remote control to select SPE CTRAL and pressVOLButtons on the remote con trol.

VOLbuttons till the Rout(scope) become minim um .

INPUT LEVEL 15

INPUT LEVEL 15

WIDEBAND 23

SPECTRAL 32

WIDEBAND 23

SPECTRAL 32

6. FOCUS ADJUSTMENT

1) Receive the RETM A PATTER N signal.

2) Adjust the FOC US VOLU ME of FBT to obtain the clearest picture

7. GEOM ETRY

7-1. VERT ICAL CENT ER AD JUST MEN T

1) Receive the RETM A PATTER N signal.

2) Set the user control A UTO PICTUR E to STANDAR D m ode.

3) Select the S6 of service mode to display items, then press the VOLbuttons on the remote control.

Page 10

ALIG NMENT INSTRUCTIONS

4)Press CH buttons on the remote control to select V CE N T ER and press VOL buttons on the remote

control to adjust the horizontal line of RETM A PATTER N S center m ay m e et with the mechan ical CENT ER of CRT.

5) Press the RECA LL button on the remote control to store.

V CENTER 05

V CENTER 05

V SIZE 31

H CENTER 18

V SIZE 31

H CENTER 18

V LIN 10

VS COR 09

GEO ADJ ON

V LIN 10

7-2. VERTICAL SIZE ADJUSTME NT

1) Receive the R ETM A PATTERN signal.

2) Set the user control AUTO P ICTU RE to STANDAR D m ode.

3) Select the S6 of service mode to display items, then press the VOLbuttons on the remote control.

4) Press

CH buttons on the remote control to select V SIZE and press VOL buttons on the remote control

to adjust the CENTE R OF CIR CUM F ER E N CE of big circle may meet w ith the upper and Lower sides of screen.

5) Press the RECA LL button on the remote control to store.

V CENTER 05

V CENTER 05

V SIZE 31

H CENTER 18

V SIZE 31

H CENTER 18

V LIN 10

VS COR 09

GEO ADJ ON

V LIN 10

7-3. VERTICAL LINEARITY ADJUSTMENT

1) Receive the R ETM A PATTERN signal.

2) Set the user control AUTO P ICTU RE to STANDAR D m ode.

3) Select the S6 of service mode to display items, then press the

4) Press

5) Adjust

CH buttons on the remote control to select V LIN,VS CO R

VOL buttons to be round center circle of R ETM A PATTERN

6) Press the RECA LL button on the remote control to store.

V CENTER 05

V CENTER 05

V SIZE 31

H CENTER 18

V SIZE 31

VOLbuttons on the remote control.

H CENTER 18

V LIN 10

VS COR 09

GEO ADJ ON

V LIN 10

Page 11

ALIG NMENT INSTRUCTIONS

7-4. HORIZONTAL CENTER ADJUS TMENT

1) Receive the R ETM A PATT E R N signal.

2) Set the user control AUTO P ICTU RE to STANDAR D m ode.

3) Select the S6 of service mode to display items, then press the

4) Press

CH buttons on the rem ote control to select H C EN TE R and press VOL buttons on the remote

control to adjust the left and right W IDTH of RE TM A PATTE R N becom e sym m etrical.

5) Press the R ECALL button on the remote control to store.

V CENTER 05

V CENTER 05

V SIZE 31

H CENTER 18

V SIZE 31

H CENTER 18

V LIN 10

VS COR 09

GEO ADJ ON

V LIN 10

VOLbuttons on the remote control.

7-5. HORIZONTAL WIDTH ADJUSTMENT

Receive the RE TMA PATTERN signal.

Set the user control A U TO PICTU RE to STANDAR D m ode.

Adjust R 406 in order to set the left and right end of RETMA PATTERN on point 5.

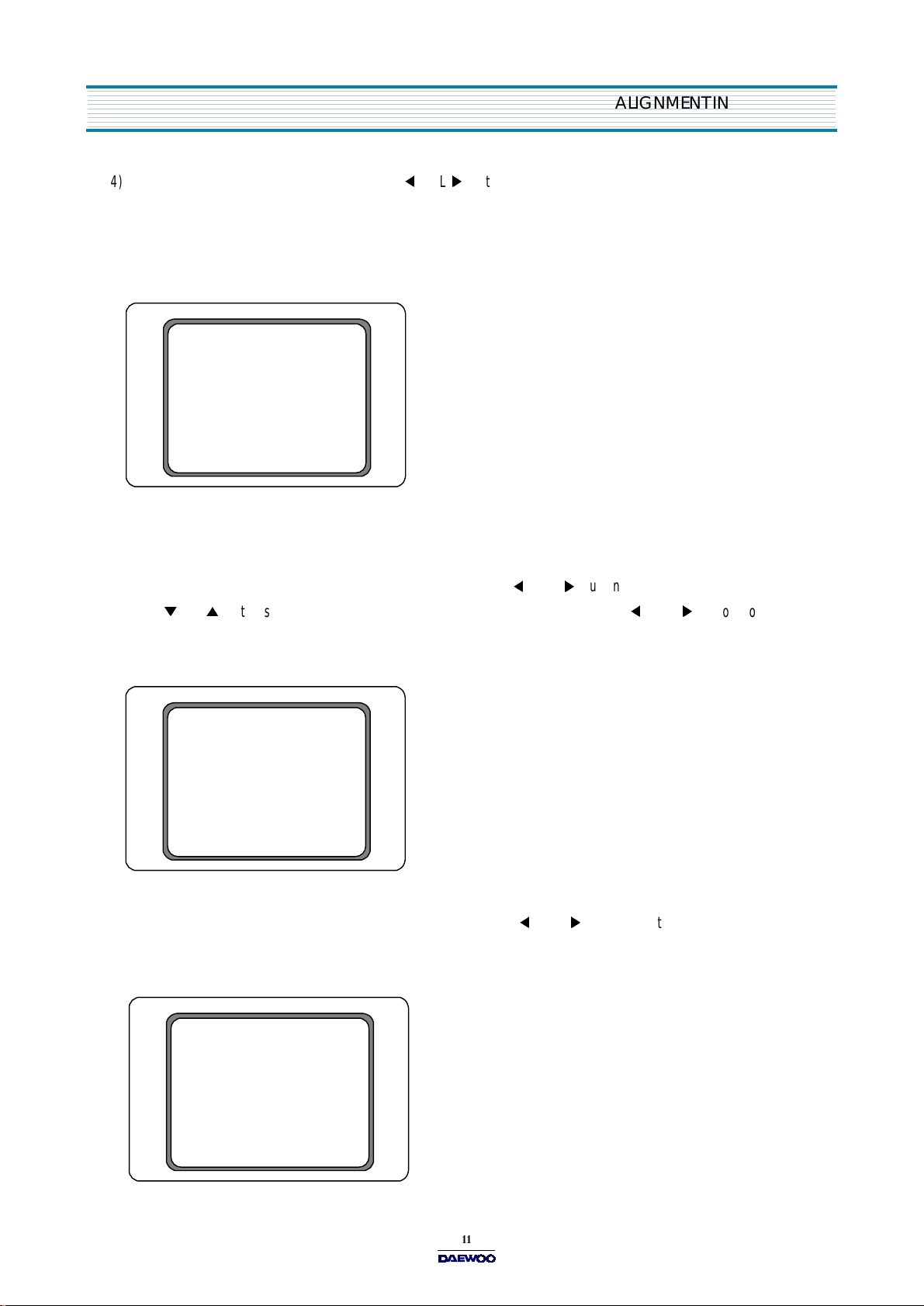

7-6. SIDE PINCUSHION ADJUSTMENT

1) Receive the R ETM A PATTERN signal.

2) Set the user control AUTO P ICTU RE to STANDAR D m ode.

3) Select the S11 of service mode to display items, then press the

4) Press

CH buttons on the remote control to select S G PATTERN 8 and press VOL buttons on the

VOLbuttons on the rem ote control.

rem o te co ntrol to selec t SG PATTE R N 2 o f SG PATTE R N 8

5) Adjust R 4 09 in order to set the second line from right side becom e straight.

6) After PO WER O FF /ON readjust H O R IZON TAL WIDTH with R406.

STANDARD

STANDARD

SOFT

SOFT

STRONG

MUSIC

STRONG

MOVIE

SG PATTERN 8

MUSIC

STANDARD

SOFT

STRONG

MUSIC

MOVIE

SG PATTERN 2

MOVIE

8. WHITE BALANCE ADJUSTMENT

1) Execute HEAT RUN of the TV set over 30 minutes.

2) Connect the signal output of white balance tester(Nitsuki 2840) to the ANTENN A(or VIDEO IN) input of theTV SET.

Stick and fix the SENSOR to the center position of CRT.

3) Select the S8 of service mode to display items, then press the

VOLbuttons on the remote control.

Page 12

ALIG NMENT INSTRUCTIONS

4) Adjust the R.G.B BIAS and G.B DRIVE, with VOLbuttons, in order that R.G.B of the High and Low BEAM may

meet with the CENTE R LED of each measuring instrument.

5) At this time, the memorized coordinates of the white balance tester, unless otherwise specified, use above coordinates

and color temperature(9600

6) Press the R E C ALL button on the remote control to store.

G DR IVE 0 61

G DRIVE 061

B DRIVE 070

B DRIVE 070

R CUT 127

B CUT 060

G CUT 087

K 265X295).

°

9. SUB-BRIGHT ADJUSTMENT

1) Receive the R ETM A PATTERN signal.

2) Set the user control AUTO P ICTU RE to STANDAR D m ode.

3) Select the S9 of service mode to display items, then press the VOLbuttons on the remote control.

4) Press

control to adjust Sub bright level in order that the gradation pattern may serve 18% of BRIGHT NESS.

5) Press the RECA LL button on the remote control to store.

CH buttons on the remote control to select BRIGHTNESS and press VOL buttons on the rem ote

DP ADJUST

DP ADJUST

BRIGNTNESS 32

CONTRAST 14

BRIGNTNESS 32

CO L O R 20

CONTRAST 14

TINT 45

COLOR 20

TINT 45

10. PIP DATA ADJUSTMENT

1) Select the S7 of service mode to display items, then press the VOLbuttons on the remote control.

2) Adjust PIP sub data.(TINT : 057, Y DE LAY : 00, SYN C D ELAY : 15, VSIDEL : 06, VSPDE L : 00)

3) Press the RECA LL button on the rem ote control to store.

PIP TIN T 057

PIP TINT 057

H POS 146

V POS 032

H POS 146

Y DELAY 00

V POS 032

SYNC DELAY 15

VSIDEL 06

Y DELAY 00

VSPDEL 00

SYNC DELAY 15

Page 13

ALIGNMENT INSTRUC TIONS

- ALIGNMENT BY SERVICE REMOCON

1. VCO/AGC ADJUSTMENT

1) Receive the COLOR BAR signal. (INPUT LEVEL : 60 dBuV)

2) Press S10 button on the SVC remote control to display MENU .

3) Press CH buttons on the SVC remote control to select V CO or AGC

4) It w ill start auto adjustm ent if you press

5) After adjustment, the “VCO O K ***” or “AG C O K ***” OSD will be displayed.

VOLkey

2. PIP VIDEO GAIN ADJUSTMENT

1) Turn ON the PIP and receive the COLOR B AR PAT TER N .

2) Turn the volume R 128 to set 1Vp-p on TP1.

3. SOUND INPUT LEVEL ADJUSTMENT

1) Receive the 100% m od. M ON O . Signal.

2) Press S10 button on the SVC remote control to display M ENU

3) Press CH buttons on the SVC remote contro l to select S MAN UAL and press VOL buttons on the SVC

rem ote co ntrol

4) Press

become 490m V (+20mV/-5mV).

5) Press the RECA LL button of SVC remote control to store.

CH buttons on the SVC remote control to select IN PU T LE VE L and pressVOL button s to s et TP2

4. STEREO AD JUS TMENT

1) Receive the Zenith MTS signal of 1KHz CH (Lonly).

2) Connect scope at T P2 to verify R out correspondent.

3) Press S10 button on the SVC remote control to display MENU.

4) Press

rem ote co ntrol

5) Press CH buttons on the SVC remote control to select W IDEBA ND and pressVOL Buttons

6) Ad just with

7) Press

8) Ad just with

9) Press the R EC ALL button on the S VC remote control to store.

CH buttons on the SVC remote control to select S M AN U A L and press VOL buttons on the SVC

VOLbuttons till the Rout(scope) become minimum.

CH buttons on the SVC remote control to select SPECTRAL and pressVOL Buttons

VOLbuttons till the Rout(scope) become minimum.

5. SCREEN ADJ U STME NT

1) Receive the RETM A PATTE RN signal.

2) Obtain horizontal line pressing S 2 button on the SVC remote control.

3) Adjust the SCR EE N V O LUME of FBT in order to the horizontal line of screen disappear.

4) Press the S2 button on the SVC remote control.

6. FOCUS ADJUSTMENT

1) Receive the R ETM A PATTERN signal.

2) Adjust the FO C US V O LU M E of FBT to obtain the clearest picture.

Page 14

7. GEOM ETRY

7-1. VERTICAL CENTER ADJUSTMENT

1) Receive the RETMA PATTER N signal.

2) Set the user control A U TO PICTU R E to STANDARD mode.

3) Press S6 button on the SVC remote control to display MENU

4) Press

SVC remote control to adjust the horizontal line of RETMA PAT TERN S center may m eet with the mechanical

CE N T E R o f CR T.

5) Press the RECA LL button on the SVC remote control to store.

7-2. VERTICAL SIZE ADJUSTMENT

1) Receive the R ETMA PATTERN signal.

2) Set the user control A UTO PICTURE to STANDA RD mode.

3) Press S6 button on the SVC remote control to display MENU

4) Press

CENTE R O F C IRCU M F ER ENCE of big circle may m eet with the upper and Lower sides of screen.

5) Press the R E C ALL button on the SVC remote control to store.

CH buttons on the SVC remote control to select V CE NT ER and press VOL buttons on the

CH buttons on the SVC remote control to select V SIZE and press VOL buttons to adjust the

ALIG NMENT INSTRUCTIONS

7-3. VERTICAL LINEARITY ADJUSTMENT

1) Receive the RET MA PATTERN signal.

2) Set the user control AUTO PICTU RE to STANDAR D m ode.

3) Press S6 button on the SVC remo te control to display M E NU

4) Press

5) Ad just

6) Press the R E CALL button on the SVC remote control to store.

CH buttons on the SVC remote control to select V LIN,VS CO R

VOL buttons to be round center circle of RETMA PATTE RN

7-4. HORIZONTAL CENTER ADJUSTM ENT

1) Receive the RETM A PATTE RN signal.

2) Set the user control AU TO PICTU R E to STANDAR D mode.

3) Press S6 button on the SVC remote control to display ME NU

4) Press

SVC remote control to adjust the left and right W IDTH of RETMA PATTERN becom e sym metrical.

5) Press the R ECALL button on the SVC remote control to store.

CH buttons on the SVC rem ote control to select H CEN TE R and press VOL buttons on the

7-5. HORI ZONT AL WI DTH ADJUST ME NT

1) Receive the R E TM A PATTERN signal.

2) Set the user control A UTO PICTURE to STAN DAR D mode.

3) Adjust R406 in order to set the left and right end of RETMA PATTERN on point 5.

Page 15

ALIGNMENT INSTRUC TIONS

7-6. SIDE PINCUSHION ADJUSTMENT

1) Receive the R ETMA PATTERN signal.

2) Set the user control A UTO PICTURE to STAND ARD mode.

3) Press S11 button on the SVC remote control to display ME N U

4) Press

on the SVC remote control to select SG PATTERN 2 of SG PATTERN 8

5) Adjust R409 in order to set the second line from right side becom e straight.

6) After POW ER O FF/ON readjust HO RIZONTAL WIDTH w ith R406.

CH buttons on the SVC remote control to select S G PATT ERN 8 and press VOL buttons

7-8. WHITE BALA NC E ADJUS TME NT

1) Execute HEAT RUN of the set over 30 minutes pressing S1 button on the SVC remote control .

2) Connect the signal output of white balance tester(NIT S U KI 2840) to the antenna input of the TV SET. S tick

and fix the SENSO R to the center position of CRT.

3) Press S8 button of SVC rem ote control and adjust the R .G.B BIAS and G .B DR IVE, with

order that R .G.B of the High and Low BE A M may m eet with the C EN TER LED of each measuring instrument.

4) At this time, the m em orized coordinates of the w hite balance tester, unless otherwise specified, use above

coordinates and color temperature(9600

5) Press the RECALL button on the SVC remote control to store

K 265X295).

°

VOLkey, in

7-9. SUB-BRIGHT ADJUSTMENT

1) Receive the R E TM A PATTERN signal.

2) Set the user control A UTO PICTURE to STAN DAR D mode.

3) Choose BRIGHTNESS of MENU pressing S9 button on the SVC remote control .

4) Press

BRIGHTNESS.

5) Press the R EC ALL button on the SVC remote control to store

SVC Remote Control

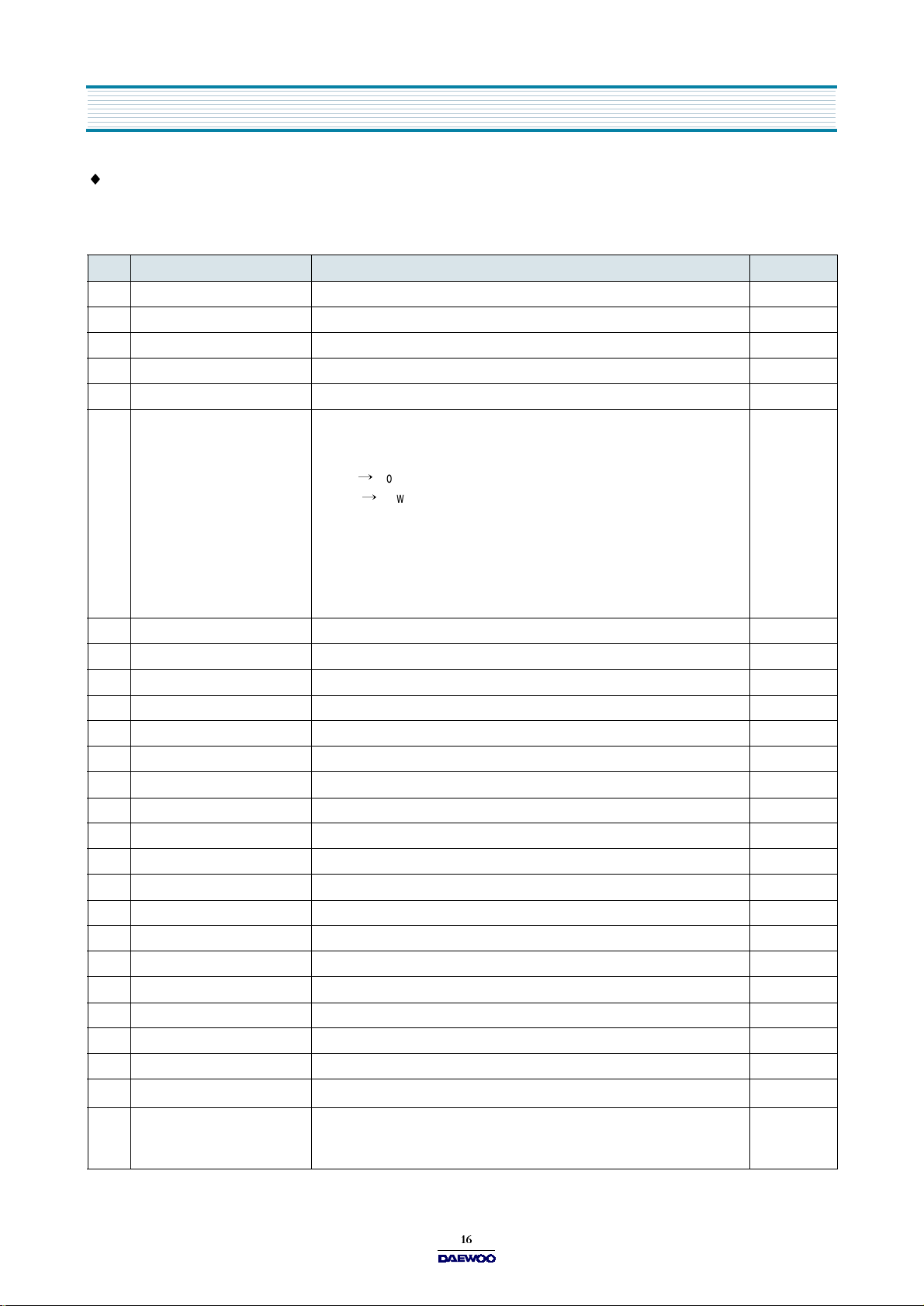

1) S1 KEY : heat run mode(ON/OFF)

2) S2 KEY : screen voltage adjust mode(ON/OFF)

3) S3 KEY : sound test mode

4) S4 KEY : picture test mode

5) S5 KEY : m ain IC bus data adjust m ode

- AGC : AG C adjust(0 ~ 63)

- VCO : VCO adjust(0 ~ 127)

- TOF : 3.58MH z BPF select(RF:1, VID EO :0).

- TRAP : 3.58MHz TRAP ON/OFF(ON:1, O FF:0).

- AFC G : AFC Gain select(norm al:00, 1/3:01, X3 at VBLK:10, OFF:11).

- WPS : White Peak Suppressor select(ON:0, OFF:1).

- V AGC : Vertical AGC speed select(normal:0, X3:1).

- SW VIDEO : VIDEO input select(TV:00, EXT:01, TV Y/C:10, EXT Y/C:11).

- ABL G : ABL G ain select(-0.12V:00, -0.37V:01, -0.64V:10, -0.74:11).

VOLbutton to adjust Sub bright level in order that the gradation pattern m ay serve 18% of

Page 16

- ABL S : ABL S tart point select(-0.01V:00, -0.11V:01, -0.3V:10, -0.45V:11).

- 60H : vertical frequency of VIDEO B LUE BACK select.

- RGB : PIP CONTRAST adjust(0 ~ 63)

- SW38 : VIDEO variation (ON:0, OFF:1).

6) S6 KEY : geometry adjust mode

- V CEN TER : V CENTER adjust(0 ~ 7)

- V SIZ E : V SIZE adjust(0 ~ 63)

- H CENTER : H CENTER adjust(0 ~ 32)

- V LIN : VERTICAL LINERITY adjust(0 ~ 15)

- VS COR : V-S CORRECTION adjust(0 ~ 15)

7) S7 KEY : PIP item adjust mode

- PIP TINT : PIP TINT adjust(0 ~ 127)

- H POS : PIP HOR IZONTAL POSITION adjust(0 ~ 255)

- V POS : PIP VERTICAL POSITION adjust(0 ~ 255)

- Y D ELAY : PIP Y D ELAY adjust(0 ~ 7)

- SYNC DELAY : PIP SYNC. DELAY(0 ~ 15)

- VSIDEL : VERTIC AL SYNC . DELAY adjust(INSET SIGNAL, 0 ~ 32)

- VSPDEL : VERTICAL SYNC. DE LAY adjust(PARENT SIGNAL, 0 ~ 32)

8) S8 KEY : WHITE BALANCE adjust mode

- G DRIVE : 0 ~ 127

- B DRIVE : 0 ~ 127

- R BIAS : 0 ~ 255

- G BIAS : 0 ~ 255

- B BIA S : 0 ~ 255

9) S9 KEY : DP adjust mode

- BRIGHT : 0 ~ 63

- CONTRAST : 0 ~ 15

- COLOR : 0 ~ 63

- TIN T : 0 ~ 63

10) S10 KEY : VCO, AG C Auto adjust, SOUN D adjust

- VCO : VCO Auto adjust

- AGC : AGC Auto adjust

- S MAN U A L : SOUND adjust mode

INPUT LEVEL : SO UND input level adjust(0 ~ 15)

•

W IDEBA ND : STERE O SE PARATION RATIO(300Hz) adjust(0 ~ 63)

•

SPEC TR AL : STE R EO S EPARATION RATIO(3KHz) adjust(0 ~ 63)

•

11) S11 KEY : AUTO PICTURE, AUTO SOUND BUS DATA setting m ode

- STANDAR D : CON 52, BRI 32, SHA 48, CO L32

- SOFT : CON 32, BRI 32, SHA 48, CO L30

- STRON G : CO N 60, BRI 32, SHA 52, COL38

- MUSIC : TREBLE 50, BASS 50

- MOVIE : TR EBLE 36, BASS 48

- TEST PATTERN 8 : TEST PATTERN(8 MO DE)

12) S12 KEY : O U T OK

ALIG NMENT INSTRUCTIONS

Page 17

IC DESCRIPTION

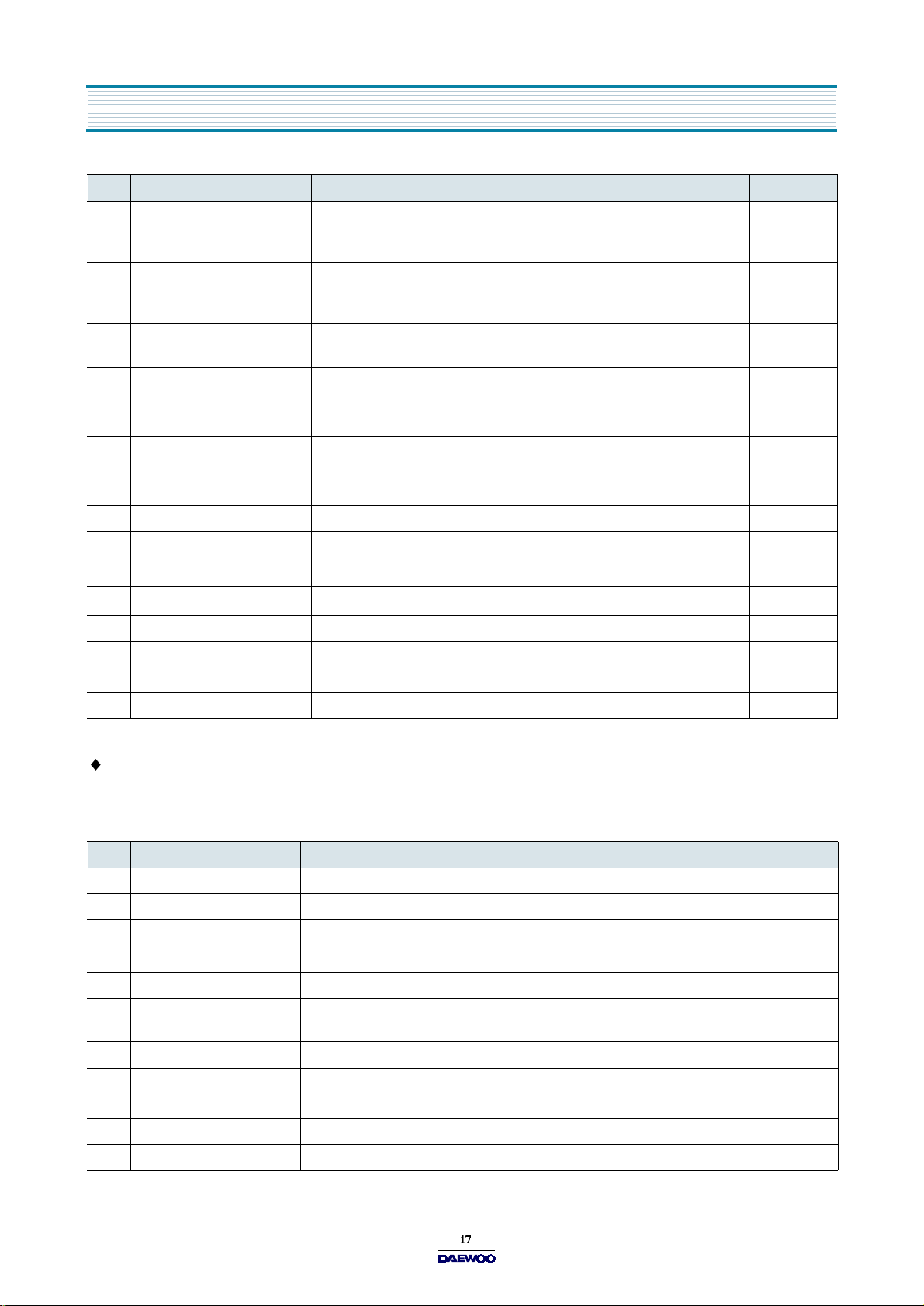

I701

♦

- TMP87CM38N (M-com)

1. Pin Description

PIN NAME FUNCTIO N REMARK

1 VSS Ground

2 TINT TINT control output

3 P41(PWM0) Ground

4 P42(PWM1) Ground

5 P43(PWM2) Ground

6 P OWE R - Ac tiv e H igh

- Low state at initial condition(RESET)

- Toggle Low/High when power key input is detected.

Lo w

Power OFF

Hig h

Power ON

- Autom atically turns to Low when S leep Timer(count down) counts ”0”

- Autom atically turns to Low when the OFF TIMER is set and the clock

(TV ) ind ica te s O FF - TIME .

- Autom atically turns to High when the ON TIMER is set and the clock

(TV ) ind ica te s O N-TIME.

- Autom atically turns to Low when A uto Power OFF.

7 KEY OUT KEY OUTPUT

8 KEY OUT KEY OUTPUT

9 KEY OUT KEY OUTPUT

10 ID Timer/coun ter input

11 P51(SI1/S CL1/PWM 9) G round

12 P52(SO 1/SDA1) Ground

13 P53(SCK 1/IN T2/TC1/A INO) Ground

14 P54(AIN1) Ground

15 KEY IN KEY INPUT

16 KEY IN KEY INPUT

17 OC P Over Current P rotect

18 M A FT AFT input

19 C.V OUT Test video signal output

20 KEY IN KEY INPUT

21 VSS G round

22 OS D R R output

23 OS D G G output

24 OS D B B output

25 OS D Y

26 H SY NC - Sync. Signal for H or_position

S

Focus signal output

- 0 ~ 5V pu lse

- Detect input-Active Low

Page 18

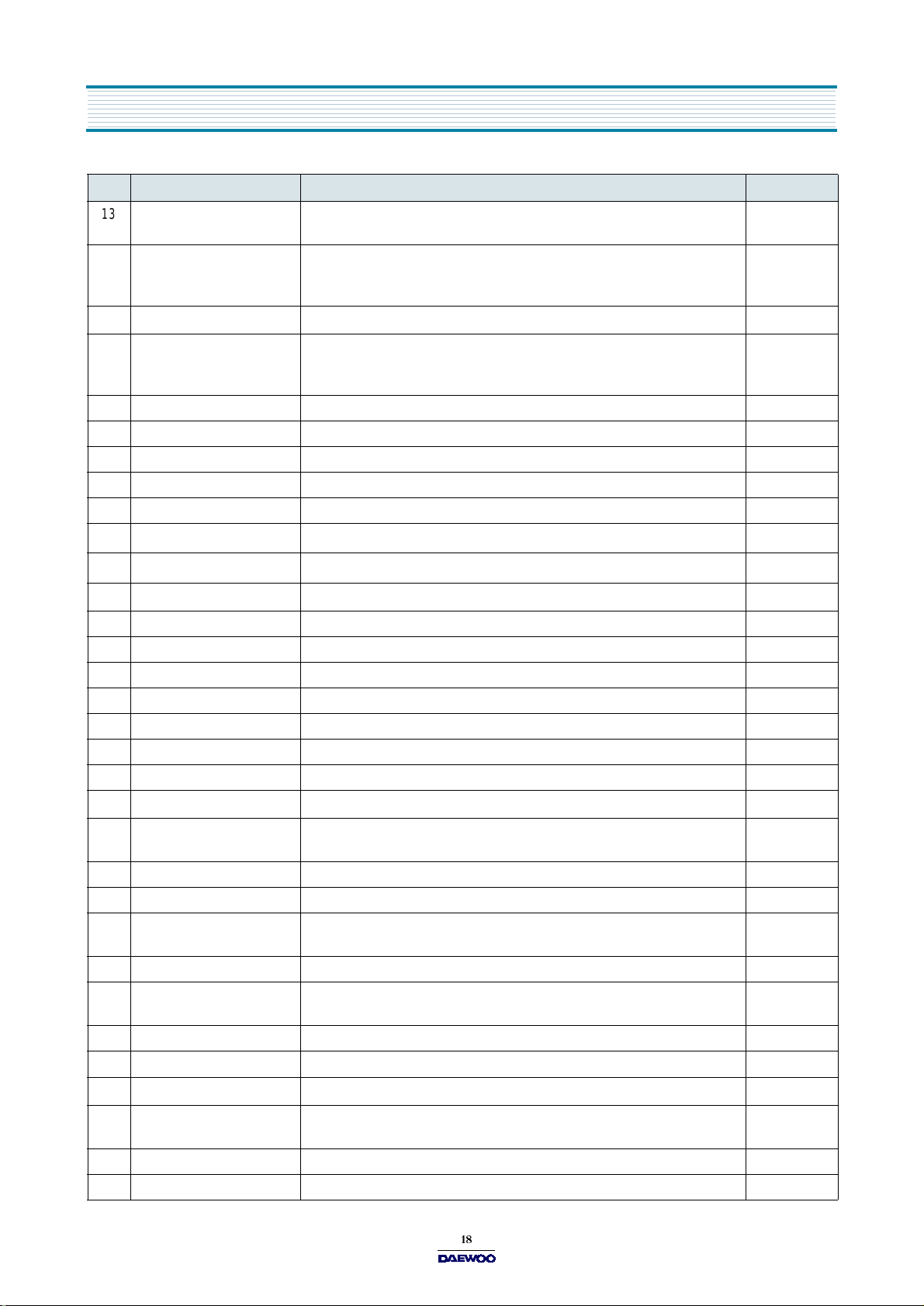

IC DESCRIPTION

PIN NAME FUNCTIO N REMARK

27 V SY NC - Sync. Signal for Vertical position

- 0 ~ 5V pu lse

-Detect input-Active Low

27 V SY NC - Sync. Signal for Vertical position

- 0 ~ 5V pu lse

-Detect input-Active Low

2829OSC1

OSC2

30 GN D Ground

3132X IN

X OU T

33 RESET - SYSTEM Reset(Hardware Reset) input term inal

34 50/60H z 50/60H z

35 IR IN REM O TE C ONT RO L signal input terminal

36 M S D Time r coun ter input

37 SC L

38 SD A

39 P34(SCL0)/P57 Ground

40 P35(SDA0)/P32(INT4) Ground

41 S M UT E Sound mute

42 VD D +5V

O S D os c illa to r

8MHz X-TAL input/output

- Ac tiv e Lo w

2

I

C bus serial clock input/output

2

I

C bus serial data input/output

I501

♦

- TB1238N(IF + VCD PRO CESS OR )

1. Pin Description

PIN NAM E FUNCTION REMARK

1 De-Emphasis The term inal to be connected with capacitor for deemphasis.

2 Audio O utput N.C

3IF V

(9V) The term inal for Vcc of PIF circuit.

CC

4 AFT Output The term inal for AFT output and Self-adj. Output.

5 IF G ND The te r mina l fo r GND o f P IF c irc u it.

67IF In p u t

The term inal for IF signal input.

IF In p u t

8 RF AGC The term inal for RF AGC output (open collector Output).

9 IF AGC The term inal to be connected with an IF AG C filter.

10 APC Filter T he term inal to be connected with APC filter for chrom a dem odulation.

11 Xtal The term inal to be connected with a 4.433619M Hz Xtal oscillator.

12 Y /C GND Th e te rmin a l fo r G ND o f Y /C c ircu it.

Page 19

IC DESCRIPTION

PIN NAM E FUNCTION REMARK

13 Ys/Ym. The term inal for switching of analog RG B M ode and fast

half tone.

14

Analog R Input

15

Analog G Input

16

Analog B Input

17 RG B V

18

R Output

19

G Output

20

B Output

(9V ) The te rmina l for V cc o f RGB c ircuit (TE X T circ uit).

CC

21 A B C L The te r mina l fo r A BL /AC L c o n tro l.

22 V. Ram p The terminal to be connected with a capacitor to make V Ramp signal.

23 V. NFB The term inal for input of V.sawteeth signal feedback.

24 V. Output The term inal for output of vertical drive signal.

25 V. AG C The term inal to be connected with a capacitor for V. AG C.

26 SCL

27 SDA

28 H. V

(9V) The term inal for Vcc of deflection circuit.

CC

29 S ID/CW OU T The terminal for PAL/NTSC ID output and SE CAM ID input.

30 FBP Input The term inal for FBP Input.

31 SYNC O utput The terminal for composite sync. Output(open collector output).

32 H. Output The term inal for output of horizontal drive signal.

33 DEF G ND The terminal for GND of deflection circuit.

34 SCP O utput N.C

35 Video output The term inal for Video Switch output.

36 Dig. V

(5V ) The te rmina l for V

DD

3738SECAM .B-Y Input

SECAM .R-Y Input

39 Y Input The term inal for Y input.

40 H . A F C T he te r mina l to b e c o n ne c te d w ith H . A F C filter.

41 EXT. Video/Y

Input

42 Dig. G N D The terminal for GND of digital block.

43 TV Input The term inal for input of com posite video signal from PIF Det.

44 BLACK Det The terminal to be connected with Black Det. filter.

45 EXT. C Input The terminal for input of chroma signal from TVs ext.jack.

46 Y/C V

(5V) The term inal for Vcc of Y/C circuit.

CC

47 IF Det. Output The terminal for output of composite video signal and SIF signal detected

48 LOOP Filter The term inal to be connected with loop filter for IF PLL.

49 VCO GN D The term inal for GND of VCO and SIF circuit.

The term inal for analog RGB signals input.

The term inals for RGB signals output.

The term inal for input of I

The term inal for input/output of I

2

C bus clock.

of digital block.

DD

2

C bus data.

N.C

The term inal for input of com posite signal or Y signal from

TVs ext. jack.

Output.

in IF circ u it.

Page 20

IC DESCRIPTION

PIN NAME FUNCTION REMARK

49 VCO GN D The term inal for GND of VCO and SIF circuit.

5051VCO

VCO

52 VCO V

53 Limiter Input/

H.Correction

54 Rip p le Filte r Th e t e rmina l to b e c o n n e c ted with a c a p a c it o r to s ta b iliz e

55 EXT Audio Input The term inal for input of audio signal from T Vs ext.jack.

56 FM DC NF The terminal for FM D C N egative Feedback and AGC Filter for L-SECAM.

IP 02

♦

(9V) The terminal for Vcc of IF V CO and SIF.

CC

Th e te rmin a l to be c o n ne c te d w ith a tan k c o il for IF V CO.

The term inal for SIF signal input and H.curve correction.

The performance of SIF injection-lock circuit.

- TDA8310A(IC PIP)

1. GENE RAL DESCRIPTION

The TDA8310A is an alignment-free PAL/NTSC color processor for Picture-in-P icture (P IP) applications.

The main difference betw een the TDA 8310 and the TDA 8310A is that the vision IF amplifier as been omitted in

the TDA8310A. Therefore, the circuit contains an input signal selector, a PAL/NTSC color decoder, horizontal and

vertical synchronization and an RG B/YUV switch.

The input signal selector has 2 CVBS inputs. One of the inputs can be switched betw een CVBS and Y/C and the

circuit can automatically detect whether the incoming signal is CVBS or Y/C.

The output signals for the PIP processor are;

Luminance signal

Color difference signals (U and V)

Horizontal and vertical synchronization pulses.

The RGB /YUV switch can select between tw o RG B or YUV sources, e.g. betw een the PIP processor and the SCART

input signal.

The supply voltage for the IC is 8V. It is available in a 52-pin SDIP package.

2. FEATURES

Video switch with 2 CVBS inputs. One input can be switched between CVBS and Y/C and the circuit

can automatically detect w hether the incoming signal is C VBS or Y/C

* Intergrated chrominance trap and bandpass filters(autom atically calibrated)

* Intergrated luminance delay line

* Autom atic PAL/NTSC decoder which can decode all standards available in the world

* Horizontal PLL with an alignm ent-free horizontal oscillator

* vertical count-down circuit

* Low dissipation (560m W )

* Small amount of peripheral components compared with com petition ICs.

Page 21

IC D ESCRIPTION

3. Pin Description

SYMBOL PIN DESCRIPTIO N SYMBOL PIN DESCRIPTION

R2 1 N.C R/ 27 Read /write selection input

G2 2 N.C HUE 28 HUE control input

B2 3 N.C i.c. 29 N.C

IDENT 4 Color standard identification output INT B 30 Internal bias

BLANK 5 N.C GND 2 31 G round 2 (0V)

B 6 N.C CVBSsw 32 CVBS positive/negative modulation

control switch input

G 7 N.C n.c 33 N.C

R 8 N.C n.c 34 N.C

SYSTsw 9 C VBS /system switch D EC

BG

35 Bandgap decoupling

R1 10 N.C V OU T 36 Vertical sync output pulse

G1 11 N .C PH 1LF 37 Phase 1 loop filter

B1 12 N.C GN D 3 38 Ground 3 (0V)

BLANK1 13 N.C H OU T 39 Horizontal sync output pulse

CLAM P 14 C lamping pulse input SAN D 40 N .C

DEC

FT

CHROMA

CVBS

15 Decoupling filter tuning V

16 N.C X TAL1 42 4.4336MHz crystal

I

17 External CVBS /Y input X TAL2 43 3.5820MHz crystal for PAL-N

EXT

P2

41 Supply voltage 2 (+8V)

GND 1 18 Ground 1 (0V ) XTAL3 44 3.5756MHz crystal for PAL-M

V

P1

CVBS

DEC

DIG

19 Supply voltage 1 (+8V) XTAL4 45 3.5795MHz crystal for N TSC

20 Internal CVBS input PLL 46 PLL color filter

INT

21 Decoupling digital supply rail CHROMAO47 N.C

i.c. 22 N.C SEC AM 48 SE CAM reference output

LOGIC2 23 N.C Y 49 Y output

LOGIC1 24 N.C B-Y 50 B-Y output

COLO R2 25 N.C R -Y 51 R-Y output

COLO R1 26 N.C B LAN K2 52 Blanking/insertion input 2 (PIP)

Page 22

IC DESCRIPTION

I601

♦

- CXA2104S(US AUDIO MULTIPLEXING DECODER )

1. PIN DESCRIPTIO N

SYMBOL PIN DESCRIPTION

R OU T 1 TV OU T right channel output pin.

L OUT 2 TV OUT left channel output pin.

SDA 3 Serial data I/O pin.

SCL 4 S erial clock I/O pin.

D.GND 5 Digital block ground.

MAIN IN 6 Input the (L+R) signal from M AIN OU T (pin 7)

MAIN OUT 7 (L+R) signal output pin.

PCIN T1

PCIN T2

PLINT 10 Pilot cancel circuit loop filter integrating pin.

COM PIN 11 Audio m ultiplexing signal input pin.

VGR 12 Band gap reference output pin.(connect a 10

IREF 13 Set the filter and VCO reference current.

GND 14 A nalog block GND .

SAPTC 15 Set the time constant for the SAP carrier detection circuit.

Vcc 16 Supply voltage pin.

SUBO U T 17 (L-R) signal output pin.

STIN 18 Input the (L-R) signal from S UB OUT (pin 17).

NOISETC 19 Set the time constant for the noise detection circuit.(connect a 47

SAPOUT 20 SAP FM detector output pin.

SAPIN 21 Input the (SAP ) signal from SAPOUT (pin 20).

VE 22 Variable de-emphasis integrating pin.(connect a 2700pF capacitor and a 3.3k

VEW G T 23 W eight the variable de-em phasis control effective value detection circuit.

VETC 24 Determine the restoration tim e constant of the variable de-emphasis control

VEOU T 25 Variable de-emphasis output pin.(connect a 4.7

VCAIN 26 VCA input pin.

VCATC 27 Determine the restoration time constant of the VCA control effective value D etection circuit.

VCAWG T 28 W eight the VCA control effective value detection circuit.(connect a 1

N.C 29 N.C

SOUT 30 N.C

89Stereo block PLL loop filter integrating pin.

GND.)

between this pin and GN D.)

Effective value detection circuit.

resistor in series between this pin and G ND.)

µ

F capacitor between this pin and G ND .)

µ

F Capacitor Between this pin and

Ω

Resistor in series

µ

F non-polar capacitor between Pins 25 and 26.)

µ

F capacitor And a 3.9kΩ

Page 23

IC D ESCRIPTION

IA 01

♦

- CXA1114P(AUDIO VIDEO SWITCH COMPATIBLE W ITH I

2

C BUS)

1. PIN DESCRIPTION

SYMBOL PIN DESCRIPTION

BIAS 1 Build up Vcc/2 that becomes the internal bias reference.

VIDEO 1 IN

VIDEO 2 IN

PIP IN

TV IN

Vcc 3 Power supply pin.

GND(AUDIO)

GND(DIGITAL)

GND(VIDEO)

AU DIO 1 IN (L )

AU DIO 1 IN (R )

AU DIO 2 IN (L )

AUDIO 2 IN(R)

TV AUDIO IN(L)

TV AUDIO IN(R)

AU DIO 3 IN (L )

AUDIO 3 IN(R)

TV AUDIO OUT(L)

TV AUDIO OUT(R)

MONITOR OUT(L)

MONITOR OUT(R)

AUDIO OUT(L)

AUDIO OUT(R)

SCL 21

SDA 22

TV VIDEO OUT

PIP O UT

MONITOR OUT

2

4

Video 1,2 and PIP, TV input pins.

6

28

5

2427Audio, digital and video GND pins.

7

8

9

10

Input pins for 1,2,3 audio, the TV audio and their respective L and R channels.

13

14

11

N.C

12

15

16

Output pins for MO NITOR audio, the TV audio and their respective L and R channels.

19

20

17

N.C

18

2

SCL (Serial Clock Line) of I

SDA (Serial D ata Line) of I

23

2526Output pins for TV video, PIP and MO NITOR.

C bus standards.

2

C bus standards.

I901

♦

- TDA6103Q (Triple video output amplifier)

1. FEATURES

High bandwidth : 7.5MHz typical;60V (peak-to-peak value)

•

High slew rate : 1600V/µs

•

simple application w ith a variety of colour decoders

•

Only one supply voltage needed

•

Internal protection against positive appearing Cathode-Ray Tube(CRT) flashover discharges

•

One non-inverting input w ith a low m inimum input voltage of 1V

•

Thermal protection

•

Controllable sw itch-off behaviour.

•

Page 24

2. PIN DESCRIPTIO N

SYMBOL PIN DESCRIPTIO N

V

I1

V

I2

V

I3

GND 4 Ground

V

IP

V

DD

V

OC3

V

OC2

V

OC1

I602

♦

- TDA2615(HI-FI A UDIO AM PLIFIER)

1. FEATURES

Requires very few external com ponents

•

No sw itch-on/switch-o ff clicks

•

Input mute during switch-on and switch-off

•

Low offset voltage between output and ground

•

Excellent gain balance of both amplifiers

•

Hi-fi in accordance with IEC268 and DIN45500

•

Short-circuit proof and thermal protected

•

Mute possibility.

•

IC DESCRIPTION

1 Inverting input 1

2 Inverting input 2

3 Inverting input 3

5 non-inverting input

6 Supply voltage

7 Cathode output 3

8 Cathode output 2

9 Cathode output 1

2. PIN DESCRIPTION

SYMBOL PIN DESCRIPTION

-IN V1 1 non-inverting input 1

MU TE 2 mute input

1/2VP/GND 3 1/2 supply voltage or ground

OUT1 4 Output 1

-VP 5 Supply voltage (negative)

OUT2 6 Output 2

+V P 7 S u p p ly v o lta g e ( p os it iv e )

INV1,2 8 Inverting input 1 and 2

-IN V2 9 non-inverting input 2

Page 25

TROUBLE SHOOTING CHARTS

1. NO POWER

Page 26

TROUBLE SHOOTING CHARTS

Step Check Point

Condition

Remark

Yes No

1 Check fuse next step Replace fuse 250V 6.3A

2 Check bridge diode next step Replace D801

3 Check DC Voltage(8V over) next step C heck/replace R802,R 804,R805

4 Check ripple voltage(1.5V under) next step Check/replace C809

5 Check voltage #1 (T801) next step Check D802~D804,

replace I801

6 Check 132V dc next step Check /replaceY801,I806,

Q802,R818,Q801,D 806

7 Check 33V dc next step Check/replace R 416,D103 C heck tuner

8 Check voltage #17 (I701) next step Check/replace R 403,R404,

R405

9 Check voltage (132Vdc) next step Check/replace Q401,R401

10 Check voltage #28,#36 (I501) next step Check/replace

R206,D203,I805

11 Check voltage #32 (I501) next step Check RC422,R426,Q402 4V

12 Check Voltage of C405(+) next step Check /replace R410,R411,

R412,R421

167.4Vrms

0.6V under

#28 : 9V

#36 : 5V

13 Check Q403 Collector next step Check/replace

Q403,D401,D402,D 403

14 Heater voltage is 6.3Vrms? next step C heck/replace R915,R 916

15 Check 210Vdc next step Check/replace R 417,D410

16 Check voltage #9 (I506 ) next step Replace I506 9V

17 Check 13Vdc next step Check/replace R 419,D406

18 Check 26.5Vdc Replace/replace R 418,D407

112 0V

Page 27

TROUBLE SHOOTING CHARTS

2. NO PIP

Step C heck Point

Condition

Yes No

1 Check voltage(5V,9V,33V) next step

2 Check SDA,SCL next step Check/replace R C104, I701, TU01, RC103

3 Check #6 of IA01 next step Check/replace QC102, QC103

4 Check #20 of IP02 next step Check/replace RCA38, RA27, CP10, IA01

5 Check 8V,5V(PP02) next step Check/replace R P04, DP01, IP 01

6 Check SDA,SCL(PP01) next step Check/replace I701, QCP02, QCP03, IP03

7 Check R,G,B ,BL(PP02) next step Check/replace Q C P06, IP 03, QCP07, QCP08

8 Check HD,VD(PP02) Check/replace RC706, R C 705

Check/replace R 101, D101, L102, L105,

R107, D103, R416, R102

Remark

Page 28

3. NO PICTURE

TROUBLE SHOOTING CHARTS

Step Ch eck Point

Remark

Yes No

1 Waveform is fig.2 next step Check/replace TU01

2 Check 33V next step Check/replace R107, D103, R416, R102

3 Check 5V next step Check/replace R101, D101

4 Check 9V next step Check/replace L102, L105

5 Check signal pulse next step Check/replace RC104, I701, TU01

6 Check signal pulse next step Check/replace RC103, I701, TU01

7 Check AGC voltage Check/replace I501 0~7.0 Vdc

Condition

Page 29

TROUBLE SHOOTING CHARTS

4. NO SOUND

Step Check Point

Condition

Yes No

1 Check waveform next step Replace RC125, Z205, I501

2 Check waveform next step Replace I501

3 Check waveform PM 01 C O M P next step Check/replace QC 602

4 Check RI,LI of PM 01 next step Check/replace I601

5 Check RO,LO of PM01 next step Check/replace I601, IA01

6 Check SCL,SDA of PM 01 next step Check/replace I601, I603

7 Check Rin,Lin of PM 01 next step C heck/replace I602, I603

8 Check #2 of I602 next step Check/replace QC601

9 Vcc is 22V ? next step Check/replace D610, D 814, R820, L811

10 Check sound output. Max:5W+5W Replace I602

Remark

Page 30

IC DC VOLTAGE C HARTS

Input signal

•

- video : color BAR(PM 5518), PAL-N(60dB

-Audio : 100% M OD . 1khz sine wave

-external input : not connected

User's control condition

•

- PICTURE : STAN DARD M ODE

- SOUND : BASS,TREBLE, BALANCE ---- CENTER

M T S --- - M O NO

VO L U ME ----- 22 STE P

Line Voltage

•

- AC 220V, 60H z

All the Voltage in each point are measured with multim eter

•

I501 (TB1238N )

♦

V)

µ

PIN NO

V(DC)

PIN NO

V(DC)

PIN NO

V(DC)

PIN NO

V(DC)

I701 (TM P87C M38N )

♦

PIN NO

V(DC)

PIN NO

V(DC)

PIN NO

V(DC)

12 3 4 5 6 7 8 9 10111213141516

4.9 3.6 8.7 2.8 0 0.6~3.2 2.0 4.7 4.2 2.0 0 0.2 2.8 2.8 2.8

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

8.8 3.0 3.0 3.0 5.8 4.2 5.0 1 1.8 4.3 4.3 9.0 3.5 1.4 4.3 1.5

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

0 1.4 2.8 4.8 2.6 2.6 2. 9 6.9 1.6 0 3. 1 2.2 2.7 5.1 3.6 4 .7

49 50 51 52 53 54 55 56

0 7 .9 7 .9 8.7 0.1 5.7 0 4

12 3 4 56 78 9 10 111213141516

0 2.8 0 0 0 4.9 5.0 0 5 5 0 0 0 0 5 5

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

0 2.8 0 5 0 0 0 0 0 4.2 4.5 5 5 0 0

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

5 5 4.5 4.3 4.3 4.3 0 0 0 5

I901 (TDA 6103Q )

♦

PIN NO

V(DC)

1 23456 7 89

2.8 2.8 2.8 0 2.8 211.6 112.9 119.1 114.1

Page 31

IC DC VOLTAGE CHARTS

I402

♦

PIN NO

V(DC)

I301

♦

PIN NO

V(DC)

I801(TA8427K)

♦

PIN NO

V(DC)

IP02(TDA8310A)

♦

PIN NO

V(DC)

PIN NO

V(DC)

PIN NO

V(DC)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

0.7 0.7 0.7 0.2 0.3 - - - 7.6 - - - - - 3.4 - 0 0

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

7.1 3.6 1.8 - - - - - 0 2 .5 - 5.9 0 0 - - 6 .5 0

37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

0 0 0.4 - 0 2.8 2 1.3 1.3 5.1 - - 2 .9 0 0 -

1 2 3 4 5 6 7 8 9101112

0 1.9 1.4 10.9 27.6 27 26.9 8.4 0.5 14.3 3.2 0

12345 6 7

0 14.1 28.4 0.9 0.8 27.6 1.9

12345678 9

277.8 0 0.5 0.7 1.3 0 0.2 1.3 8.3

IP03(SDA9288X)

♦

PIN NO

V(DC)

PIN NO

V(DC)

I806(P CL)

♦

PIN NO

I601(C XA2104S)

♦

PIN NO

V(DC)

PIN NO

V(DC)

12345678910111213141516

-3.42.4-4.800004.91.70--00

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

- - - 0.4 4.2 4 .2 - - 0 0 .2 0 2 .5 4 .8 2.9 4 .5 2 .9

V(DC)

4.1 4 .1 4.3 4 .3 0 4 4 4 .1 3.9 5.2 4.1 1.3 1.3 0 0

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

8.5 4 .1 4.1 3 .1 4.0 4.1 4.1 4.1 1.7 4.1 4.1 1.7 4.0 - -

12 3 456

0 - 8.4 4.9 73.2 73.7

1234 5 6 7 89101112131415

Page 32

I602(T DA2615)

♦

IC DC VOLTAGE CH ARTS

PIN NO

V(DC)

I603(C XA2021S)

♦

PIN NO

V(DC)

PIN NO

V(DC)

I506(A N5862K)

♦

PIN NO

V(DC)

IA01(CXA1114P )

♦

PIN NO

V(DC)

PIN NO

V(DC)

4.5 4 .4 8 .8 4.4 0 4.4 4.5 4.5 4.5 4.5 - - 4.5 4.5

4.5 4 .5 - - 4.5 4.5 4.2 4.2 4.4 0 4.4 4 .4 0 4.4

1 23456 7 8 9

11.5 23 11.6 11.6 0 11.6 11.6 23.1 11.5

14.52345 6 7 8 9 10 11

4.2 0 4.3 4.3 4.3 4.3 4.3 3 .9 4.3 1.7 4.3

12 13 14 15 16 17 18 19 20 21 22

4.3 1.6 4.3 4.3 4.2 4.3 4.3 4.3 4 .3 8.6 4.2

12345678910111213

3.1 3.0 3.0 0 3.2 3.1 0 3.2 8.7 0 0 0 0

1234567891011121314

15 16 17 18 19 20 21 22 23 24 25 26 27 28

♦

PIN NO

♦

I102

V(DC)

TR

LOCA

E(Vdc)

C(Vdc)

B(Vdc)

1 23456 7 8 9

4.4 4.4 6.8 - 0 3.3 8.7 - 6.6

Q401 Q 402 Q403 Q 404 Q406 Q 801

131.8 0 0 0 0 8.3

0 22 131.1 17.5 23.0 69.5

131.3 0.5 0 0.6 0.1 7.6

Page 33

ELECTRICAL PARTS LIST

DTH-29G1FST

LOC PART CODE PART NAM E DESCRIPTION

ZZ100 48B3523B 04 TR ANS M ITTER RE M OC ON R -23B04

ZZ110 PTACPWJ68 AC CESSO RY AS D TH-29G1FS T

30 4850Q 00910 BATTERY R 03/NN

40 48586870S1 M A NU AL INSTR U CTION D TH -29G3FS T

M821 4858213800 BA G INSTR UC TION L.D.P.E T0.05X250X400

ZZ120 PTBCSHJ68 CO VE R BACK AS D TH-29G1FS T

M211 4852150410 COV ER BAC K FR HIPS BK

M781 4857817630 CLOTH BLACK FELT T0.7 L=400

M783 4857817610 CLOTH BLACK FELT T0.7 L=300

ZZ130 PTPKCPJ63 PACKING AS D TH-29G1FST

M641 6520010100 STAPLE PIN 18M/M J D O

M681 4856812400 BAND 18M M X 3M

M801 485805225K BOX CA RTON D W -3

M811 4858183900 PAD EPS 29G1

M822 4858215600 BA G P.E PE FO AM T0.5X1550X127 0

ZZ131 48519A4210 CRT G R OUND N ET 2901H -1015-2P

ZZ132 58G0000094 CO IL DEG AU SSING D C -2901

ZZ140 PTCACAJ63 CABINET AS DTH-29G 1FST

M191 4851929610 BUTTON CTRL 4936410+553390 0

M191A 7128301212 SCR EW TAPPING T2S WAS 3X 12 M FZN B K

M201A 4856015820 SCR EW CR T FIX SW RM +SK5 L=35

M201B 4856215402 WAS HE R RU BBE R CR T2.0

M211A 7122401612 SCR EW TAP P ING T2S TRS 4X16 MFZN BK

M211C 7122401612 SCR EW TAPPING T2S T RS 4X16 MFZN BK

M351 4853526000 HO LD ER D EG AU SS NYLO N 66

M481 4854851901 BUTTON POWE R ABS BK

M481A 4856716000 SPR ING SWPA P IE0.5

M561 48556174SD MARK B R AND SILVER DIA-CUTTING

M781 4857821102 CLOTH BLACK FELT 340X10X T1.68

SP01A 7122401412 SCREW TAPPING T 2S TR S 4X1 4 MFZN BK

V901 4859618263 CRT A68KTB 191X006 M16

ZZ200 PTFMSJJ638 MASK FR ONT A S DTH-29G 1FST

M201 4852064901 MASK FRO N T H IPS BK

ZZ202 PTSPPWJ63 SP EAKER AS DTH-29G1FS T

P601A 4850704S31 CONNEC TO R YH025-04+35098+U LW= 800

SP01 4858310810 SP EAK ER 7W 8 O HM F2250C -2141

SP02 4858310810 SP EAK ER 7W 8 O HM F2250C -2141

ZZ290 PTMPMSJ63 PCB M AIN M A NUA L AS DTH-29G1FS T

10 2193102005 SO LDE R BA R SN:PB= 63:47 S63S-1320

20 2193011101 SOLDE R W IRE R S 60-1.2 1.6A

30 2291050615 FLU X SO LDE R D F-2012U

40 2291050301 FLU X SO LVENT IM-1000

50 2291140501 WAX C O VER

90 2291051001 FLU X KILLER KFT-7

LOC PART CODE PART NAME DESCRIPTION

C307 CE YF1E332V C ELEC TRO 25V R SS 3300M F (16X31.5)

C408 CM YH 3C822J C MY LAR 1.6K V BU P 8200P F J

C409 CM YH 3C822J C MY LAR 1.6K V BU P 8200P F J

C410 CM YE 2G273J C MY LAR 400V PU 0.027MF J

C423 CM YB2G 514K C M YLAR 400V EU 0.51MF K

C426 CE YD1H 689V C ELEC TR O 50V RUB 6.8MF (16*35.5)

C645 CE XF1V222V C ELEC TRO 35V R SS 2200M F 16X3 1.5

C803 CL1JB3104M C LINE ACR O SS AC250V 0.1MF M ECQ -UV W RL

C805 CH 1AEE 472M C CER A AC 2.5KV 4700P F M K H D E1307

C806 CH 1AEE 472M C CER A AC 2.5KV 4700P F M K H D E1307

C809 CE YN2W 471P C ELEC TR O 450V LHS 470M F (35X50)

C812 CM YH 3C222J C MY LAR 1.6K V BU P 2200P F J

C815 CEYN2D221T C ELECTRO 200V FWS 220M F (22X30)

C818 CH 1AEE 472M C CER A AC 2.5KV 4700P F M K H D E1307

C820 CE XF1V332V C ELEC TRO 35V R SS 3300M F 18X3 5.5

C824 CCYR3A102K C C ERA HIKR 1KV 1000PF K 125C

C826 DDSA452T05 VARISTOR DSA-452T-U05A

C827 CH 1AEE 472M C CER A AC 2.5KV 4700P F M K H D E1307

C903 CH 1BFE472M C CERA AC AC 400V 4700PF M U /C/V

C908 4SG 0D0010 SPARK GA P S -23 900V-1.5KV

C909 4SG 0D0010 SPARK GA P S -23 900V-1.5KV

C910 4SG 0D0010 SPARK GA P S -23 900V-1.5KV

D401 DB Y228---- DIODE BY228 (TAPPING)

D402 DB Y228---- DIODE BY228 (TAPPING)

D403 DR GP 30J--- DIODE RGP3 0J

D801 PTB1S W5801 HEAT SINK ASS`Y DD 5SBA60-- + 71 74301011

D801 DD 5SBA 60-- D IOD E BRIDG E D5SBA 60

D801A 4857015801 HEAT SINK SPCC -SN T1.0

D801B 7174301011 SCREW TAPPTITE TT2 RN D 3X1 0 MFZN

D808 PTZ2SW5200 HEAT SINK A SS `Y DFM LG16S -- + 7174300811

1 DFMLG 16S-- DIODE FML-G16S

0000A 4857025200 HEAT SINK S PCC T1.0 DG

0000B 7174300811 SCR EW TAPPTITE TT2 RND 3X8 MFZN

D814 DR GP 30J--- DIODE RGP3 0J

DF01 DKLR 114L-- LE D KLR114L

DP05 DMTZ9R1C-- DIODE ZENER MTZ 9.1-C (TAPPING)

F801 5FKG B6323L FUSE GLA SS TU BE KS MF51 6.3A 125/250V TL

I101 1PAPDW---- IC AMP MODUL E PAPD W

I102 1LA7510--- IC IF LA7510

I301 PTA2SW6111 HEAT SINK ASS `Y 1TA8427K -- + 7174300811

I301 1TA8427K-- IC TA8427K

I301A 4857026111 HE AT S INK AL EX BK

I301B 7174300811 SCREW TAPPTITE TT2 RN D 3X8 M FZN

I401 PT Q1SW3300 HEAT SINK ASS`Y 1KA7809--- + 717430 0811

Page 34

ELE CTRICAL PARTS LIST

LOC PART CODE PART NAM E DESCRIPTION

1 1KA 7809--- IC R E GULATOR KA 7809

0000A 4857013300 HEAT SINK C SPCC T 1.0 SN-3

0000B 7174300811 SC R EW TAPPTITE TT2 RN D 3X 8 MFZ N

0000D 4856215200 WASHER SPCC

I4 02 1 EW --- ---- IC HYBRID E/ W

I501 1TB1238N-- IC VIDEO TB 1238N

I502 1KA7805--- IC REG U LATO R KA 7805

I506 1AN5862K-- IC AN5862K

I602 PT D2SW6401 HE AT S INK ASS`Y 1TDA 2615-- + 7174300811

I602 1TDA2615-- IC AMP TDA2615

I602A 4857026401 HEAT SINK AL EX (BK)

I602B 7174300811 SCREW TAP PTITE TT2 RND 3X8 MFZN

I602C 4856815900 CLA MP WIRE EGI T0.4+PV C CO ATING

I602D 7128261011 SC REW TAPPING T2S WAS 2.6X10 MFZN

I701 1TMP873580 IC MICO M TMP87C M38N -3580

I702 1CAT24C16P IC E E PROM CAT24C1 6P

I801 PT G2SW6500 HEAT SINK ASS`Y 1STRS 6709- + 7174300811

I801 1STRS6709- IC P O WER ST R-S6709

I801A 4857026500 HEAT SINK AL EX

I801B 7174300811 SCREW TAP PTITE TT2 RND 3X8 MFZN

I802 1SE130N--- IC SE 130N

I803 1LTV817C-- IC PHOTO C OUP LE R LTV-817C

I804 1KA7805--- IC REG U LATO R KA 7805

I805 1K1A7809-- IC REGULATOR KIA7809

I806 1PCLDW---- IC HYB R ID PCLD W

I901 PTA2SW5400 HE AT S INK ASS `Y 1TDA6103Q- + 7174300811

I901 1TDA6103Q- IC VIDEO TDA6103Q

I901A 4857025400 HEAT SINK A1050P-H24 T2.0

I901B 7174300811 SCREW TAP PTITE TT2 RND 3X8 MFZN

IF01 1TFM W 5380- IC PREAMP TFMW53 80

IP01 1K A7805--- IC REG ULATO R KA 7805

JA01 4859109250 JAC K PIN BOA RD PH-JB-9614A

JA02 4859108450 JAC K PIN BOA RD YSC03P-4120-14A

JA03 4859109250 JAC K PIN BOA RD PH-JB-9614A

L109 58N 0000040 CO IL VCO TRF-V007

L402 58W0000018 C OIL W IDTH TLN-2092

L403 58H 0000039 CO IL H-LINEARITY TRL-200D

L404 58C 7070085 CO IL CHOKE TLN-3062A

L801 5PLF 3143G- FILTER LINE LF-3143 G

L810 58C 9430599 CO IL CHOKE AZ-9004Y(94MH )

M351 4853530901 HO LD ER LED P.P

M371A 4853747800 RETA P C B NYLON 66

M681 4856813600 HO LD ER W IRE NYLO N 66 DAW H-13NA

M701 4857236500 SH IELD CO VE R ET(DG) T0.25

M792 4857913302 RUBB ER CUSHION FR RUB BER SPO NGE

LOC PART CODE PART NAME DESCRIPTION

MD01 4850M 01810 M O DU LE RF PH-RF-9504

P102A 4850704S05 CO NN EC TO R YH025-04+YS T025+ ULW= 600

P401A 4850703S20 CO NN EC TO R YH025-03+YS T025+ ULW= 400

P402 4859238620 CONN WAFER YP W500-02

P403 4859240120 CONN W AFER YFW500-06

P501A 4850707S01 CONNEC TO R YH025-07+YST 025+ U LW =200

P801 PTW AS W2910 CO RD PO W E R ASS `Y 48599 01111+ HO US ING

PW000 4859901111 CORD P OWER KKP-419C KLCE-2F (2.1ME)

P807A 4850701S07 CONNEC TO R YFH800-01+YPT 018+ U LW =500

PM01 4859280820 CON N WAFER TAC-L13X-A1

PP01 4859280120 CONN WAFER TAC-L05X-A1

PP02 4859280520 CONN WAFER TAC-L10X-A1

Q402 TKTC3208-- TR KTC 3208

Q403 PTN2S W 4502 HEAT SINK ASS`Y T 2SD255 3-- + 7174301011

Q403 T2SD2553-- T R 2SD2553

Q403A 4857024502 HEAT SINK AL E X

Q403B 7174301011 SCREW TAPPTITE TT2 RN D 3X1 0 MFZN

Q403C 4856215200 WAS HER SP CC

Q404 PT12SW4502 HEAT S INK AS S`Y TKTD 2058Y- + 7 174301011

1 TKTD2058Y- TR KTD 2 058-Y

0000A 4857024502 HEAT SINK A L EX

0000B 7174301011 SCR EW TAPPTITE TT2 RND 3X1 0 MFZN

0000C 4856215200 WAS HE R SPCC

Q801 T2SC4793-- T R 2SC 4793

Q802 TT1P42C--- TR T1P 42C

R409 DR 320K---- TH ER M ISTOR R-320K

R801 DJ140M 290L PO SISTOR J503P53D140M290L

R802 RX 10T159J- R CEM E NT 10W 1.5 OHM J TRIPO D

R806 RX 10T159J- R CEM E NT 10W 1.5 OHM J TRIPO D

R811 RM 02Y158J- R M ETAL FLAT 2W 0.15 OHM J

SCT1 4859302830 SOCK ET C RT ISH-02S

SF101 5PM 3271K-- FILTER SAW M3271K

SW801 5S40202080 S W PUSH PS 3-22 (PCB)

T401 5TD0000018 TRANS D R IVE TH D -120

T402 50H0000189 FBT FFA94048L

T402A 7128301212 SCR EW TAPP ING T2S WA S 3X12 M FZN BK

T801 50M5345A7J TRA NS SMP S TSM-5345A7

TU01 4859718530 TUNER VARACTOR TELH9-087A

TU02 4859718830 TUNER VARACTOR TMAH2-010A

UT01 4859003750 PLUG PH ON E AS PLUG +C ABL E 1365AW G26 =15 0B

UT02 4859003750 PLUG PH ON E AS PLUG +C ABL E 1365AW G26 =15 0B

X701 5XE8R 0000E CRY STAL QU ART Z HC-49/U 8.000000MH Z 30PP M

Y801 5SC0101325 S W RELAY HR-CR7 DC12V

Z801 DSVC471D 14 VARISTOR SVC471 D14A

Z802 DSVC471D 14 VARISTOR SVC471 D14A

Page 35

ELE CTRICAL PARTS LIST

LOC PART CODE PART NAM E DESCRIPTION

ZZ200 PTM PJ2J638 P CB CH IP MOU NT B AS DTH-29G 1FST

CC101 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC102 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC105 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC110 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC114 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC115 HC FK104ZC A C CH IP CER A 50V Y5V 0.1MF Z 2012

CC116 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC118 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC121 HC BK 102KCA C CH IP CER A 50V X7R 1000PF K 2012

CC122 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC124 HC TAF100MB C CH IP TAN TAL 16V 10MF M 3216

CC125 HC Q K510JCA C CHIP C E RA 50V CH 51PF J 2012

CC126 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC128 HC BK 392KCA C CH IP CER A 50V X7R 3900PF K 2012

CC129 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC131 HC Q K470JCA C CHIP C E RA 50V CH 47PF J 2012

CC202 HC TAF109MB C CH IP TAN TAL 16V 1MF M 3216

CC203 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC205 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC206 HC Q K101JCA C CHIP C E RA 50V CH 100PF J 2012

CC207 HC Q K470JCA C CHIP C E RA 50V CH 47PF J 2012

CC214 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC234 HC TAF109MB C CH IP TAN TAL 16V 1MF M 3216

CC314 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC420 HC BK 472KCA C CH IP CER A 50V X7R 4700PF K 2012

CC428 HC Q K200JCA C CHIP C E RA 50V CH 20PF J 2012

CC430 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC436 HC BK 102KCA C CH IP CER A 50V X7R 1000PF K 2012

CC501 HC BK 472KCA C CH IP CER A 50V X7R 4700PF K 2012

CC502 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC503 H CQK 110JCA C CH IP CER A 50V CH 11PF J 2012

CC504 HC FK104ZC A C CH IP CER A 50V Y5V 0.1MF Z 2012

CC505 HC FK104ZC A C CH IP CER A 50V Y5V 0.1MF Z 2012

CC506 HC FK104ZC A C CH IP CER A 50V Y5V 0.1MF Z 2012

CC507 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC510 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC514 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC646 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC704 HC BK 102KCA C CH IP CER A 50V X7R 1000PF K 2012

CC705 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC706 HC Q K200JCA C CHIP C E RA 50V CH 20PF J 2012

CC707 HC Q K200JCA C CHIP C E RA 50V CH 20PF J 2012

CC710 HC BK 103KCA C CH IP CER A 50V X7R 0.01MF K 2012

CC713 HC Q K101JCA C CHIP C E RA 50V CH 100PF J 2012

LOC PART CODE PART NAME DESCRIPTION

CC715 HC TAJ478MB C CHIP TANTAL 35V 0.47MF M 3216

CC716 HC QK240JC A C CH IP CERA 50V C H 24PF J 2012

CC717 HC QK240JC A C CH IP CERA 50V C H 24PF J 2012

CC718 HC BK103KC A C CH IP CERA 50V X7R 0.01MF K 2012

CC720 HC BK103KC A C CH IP CERA 50V X7R 0.01MF K 2012

CC801 HC BK103KC A C CH IP CERA 50V X7R 0.01MF K 2012

CC901 HC QK150JC A C CH IP CERA 50V C H 15PF J 2012

CC902 HC QK150JC A C CH IP CERA 50V C H 15PF J 2012

CC911 HC QK100D CA C C H IP CERA 50V CH 10P F D 2012

CCA02 HC TAF100MB C CH IP TANTAL 16V 10MF M 3216

CCA09 HC TAF109MB C CH IP TANTAL 16V 1MF M 3216

CCA10 HC TAF109MB C CH IP TANTAL 16V 1MF M 3216

CCA15 HC BK102KC A C CH IP CERA 50V X7R 1000PF K 2012

CCA16 HC BK102KC A C CH IP CERA 50V X7R 1000PF K 2012

CCA20 HCQK101JCA C CHIP CE RA 50V CH 1 00P F J 2012

CCA21 HCQK101JCA C CHIP CE RA 50V CH 1 00P F J 2012

IA01 1CX A 1114ME IC CH IP SW ITCH A/V CXA1114M

JC001 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC002 HRF8101JEA R CH IP 1/8 100 OHM J 3216

JC003 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC008 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC009 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC010 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC013 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC015 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC016 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC017 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC018 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC019 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC020 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC021 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC022 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC023 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC024 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC025 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC026 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC028 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC030 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC031 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC032 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC034 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC035 HR FT000-CA R CH IP 1/10 0 OHM 2012

JC036 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC038 HR F8000-EA R CH IP 1/8 0 OHM 3216

JC039 HR F8000-EA R CH IP 1/8 0 OHM 3216

Page 36

ELECTRICAL PARTS LIST

LOC PART CODE PART NAM E DESCRIPTION

JC040 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC041 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC044 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC045 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC046 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC048 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC051 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC052 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC053 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC055 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC056 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC057 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC060 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC061 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC064 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC067 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC068 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC069 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC070 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC071 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC073 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC074 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC076 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC077 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC078 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC079 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC081 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC083 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC084 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC086 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC088 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC091 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC093 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC094 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC095 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC096 HRFT000-CA R C HIP 1/10 0 OHM 2012

JC097 H RF8000-EA R CH IP 1/8 0 OHM 3216

JC098 H RF8000-EA R CH IP 1/8 0 OHM 3216