Page 1

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

Page 2

§CONTENTS

SPECIFICATIONS---------------------------------------------------------------- 2

SAFETY INSTRUCTIONS°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 3

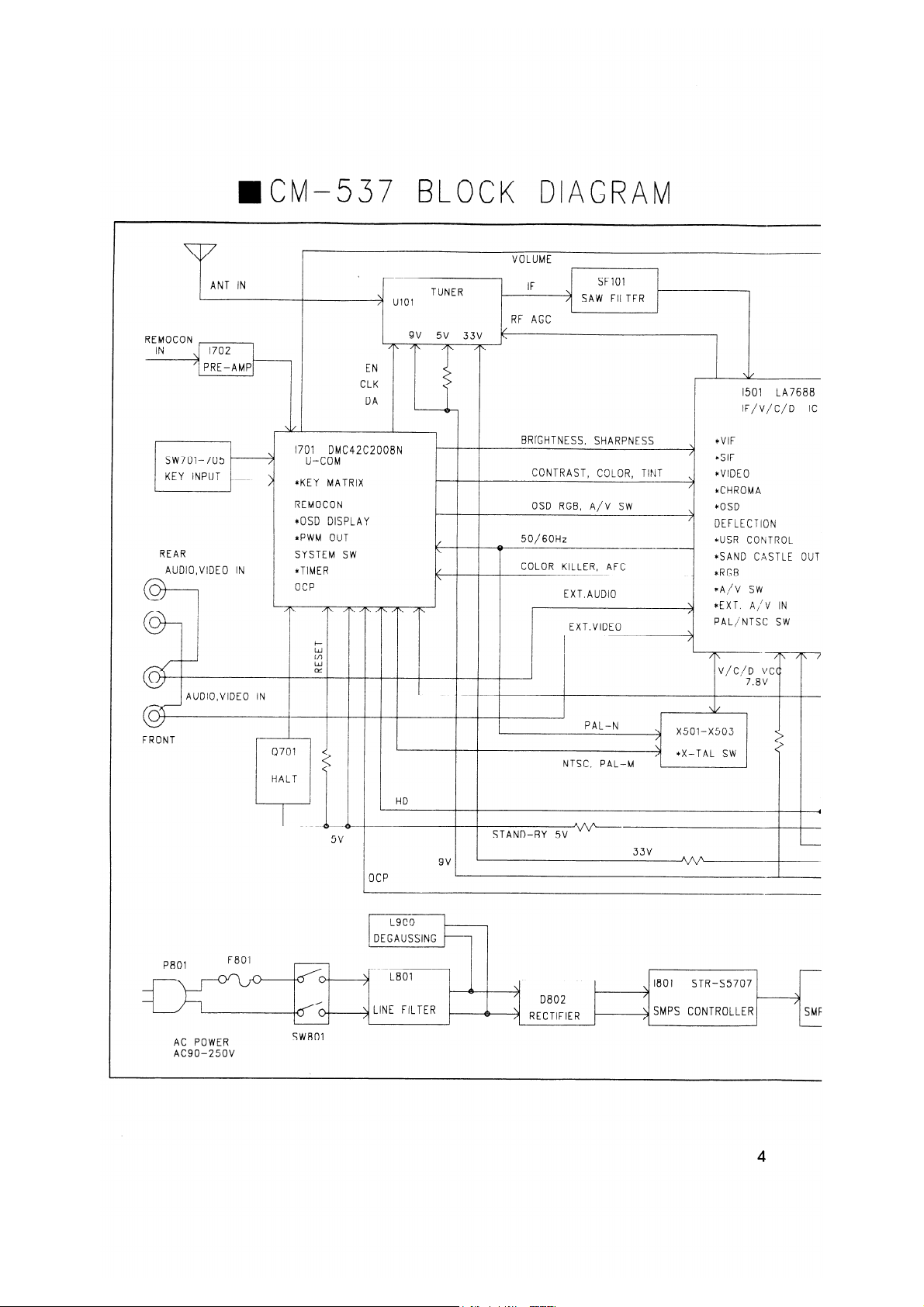

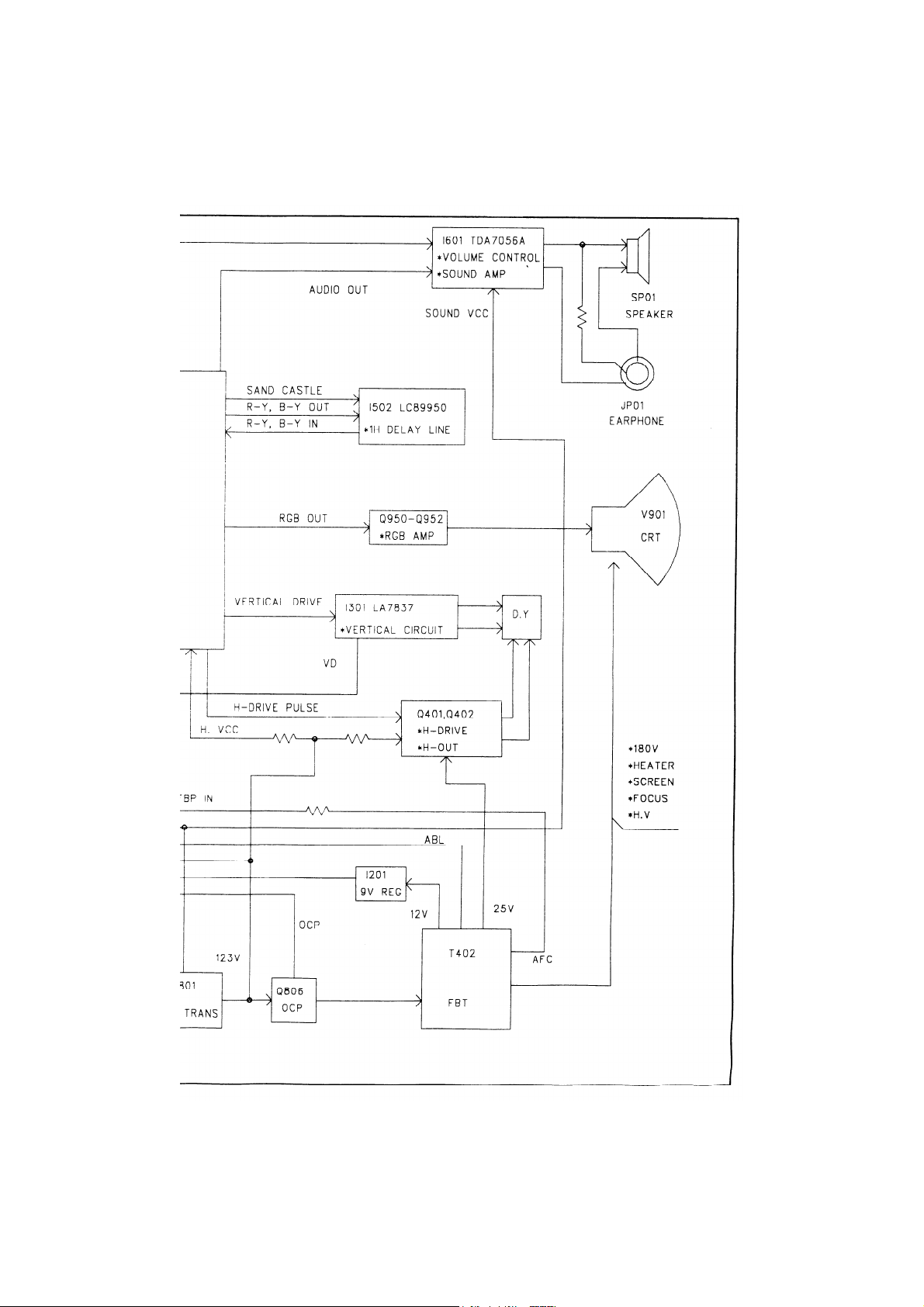

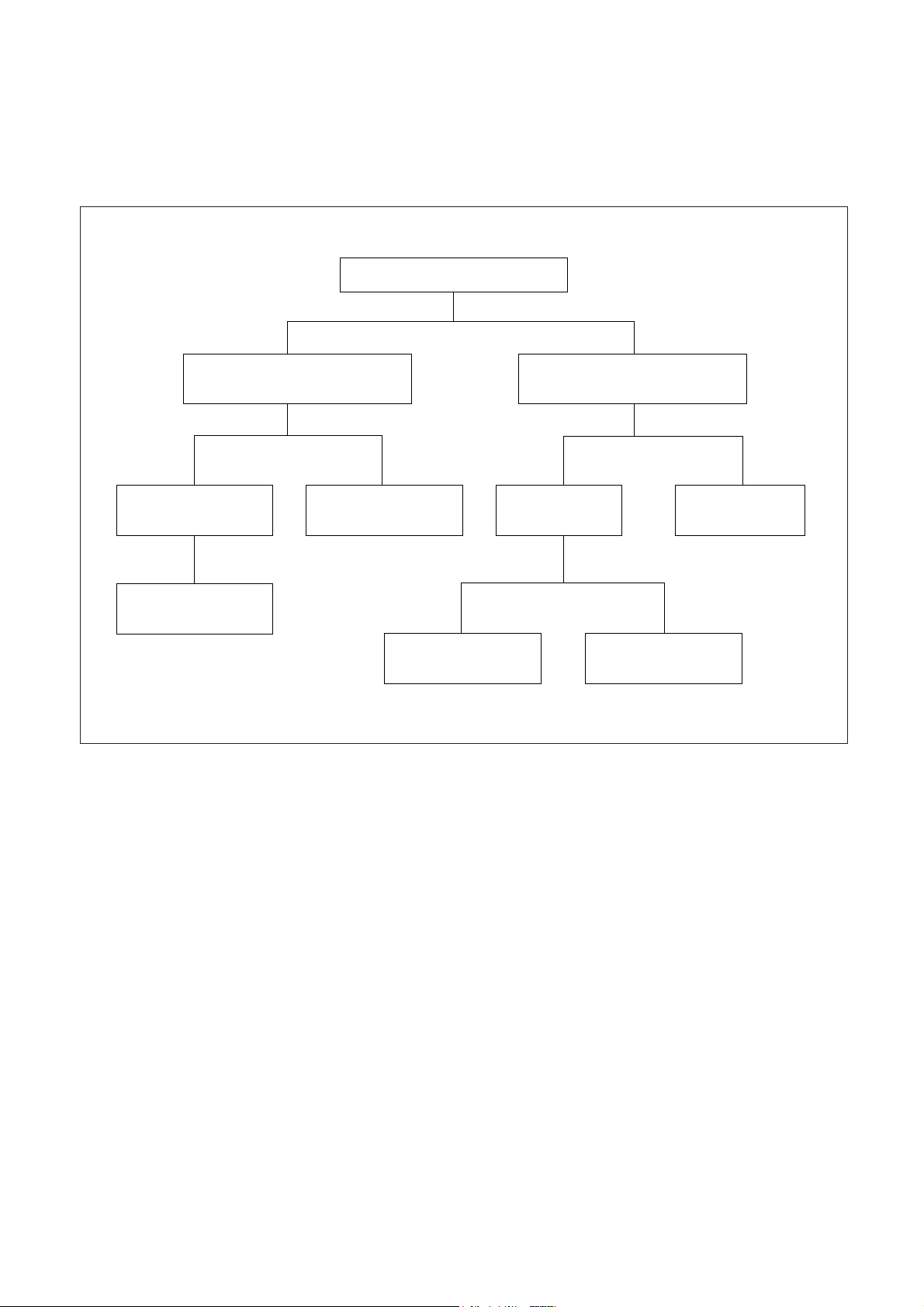

BLOCK DIAGRAM°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 4

GENERAL ALIGNMENT INSTRUCTIONS°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 6

DESCRIPTION OF THE CIRCUIT OPERATION°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 10

TROUBLE SHOOTING CHARTS°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 32

PRINTED CIRCUIT BOARDS °¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 40

REPLACEMENT PARTS LIST°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 41

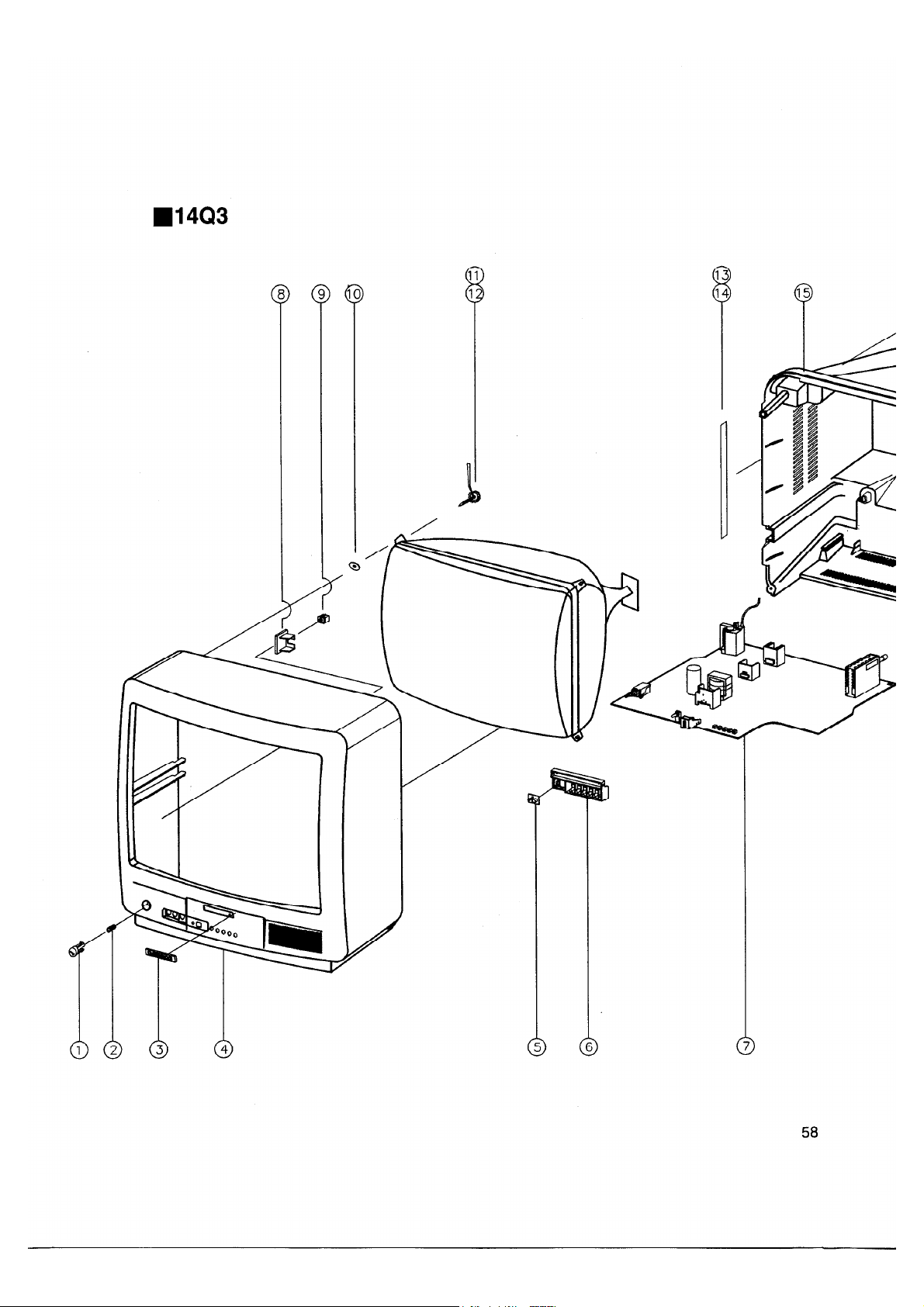

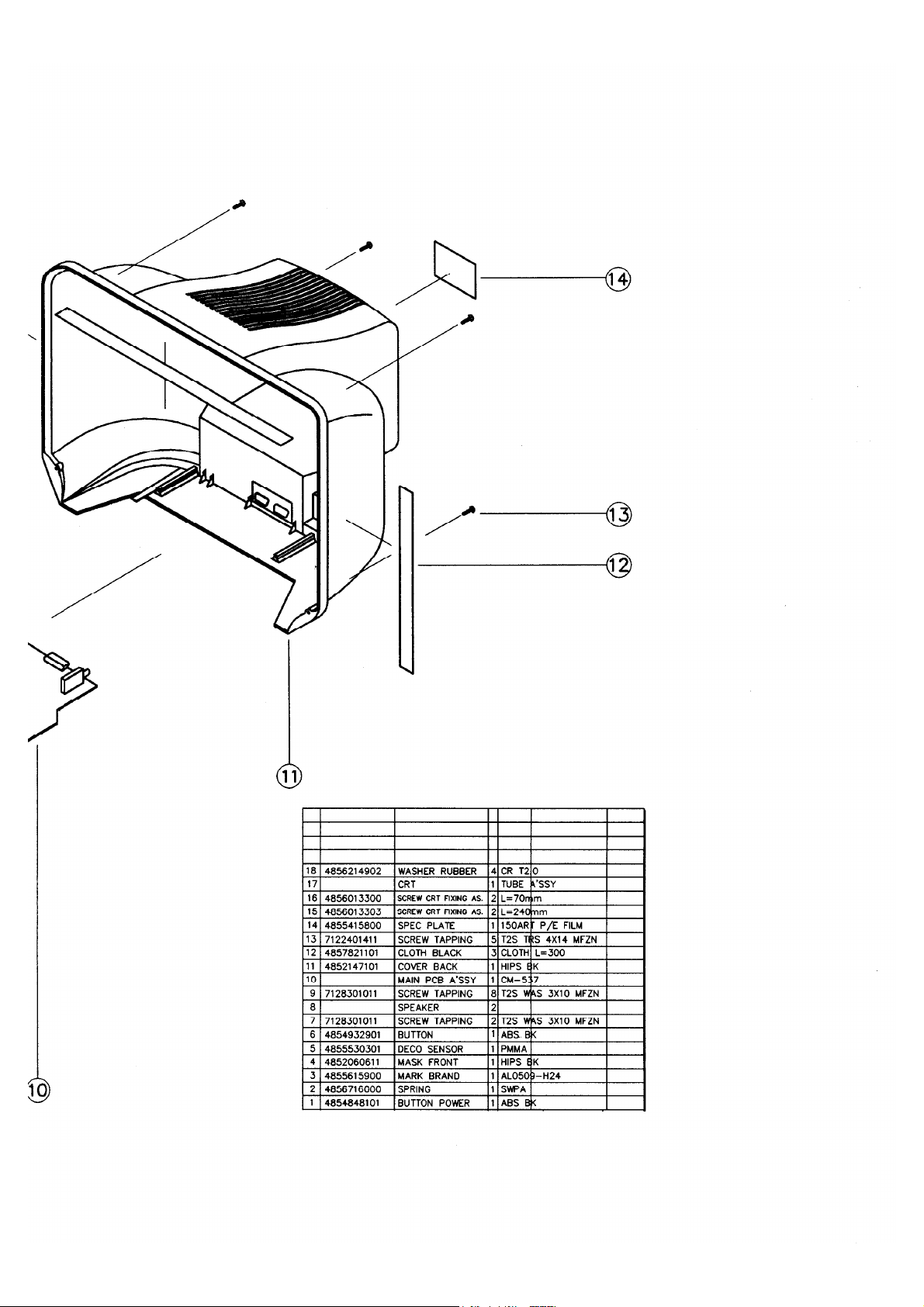

EXPLODED VIEW°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 54

CIRCUIT DIAGRAM°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶°¶ 64

1

Page 3

§ SPECIFICATIONS

CHASSIS CM-537

Receiving System NTSC/PAL-M/PAL-N

Main Voltage AC 100/220V, 50/60Hz

Power Consumption 60 Watts (14”) / 65 Watts (20”)

Sound Output 2.5W (16§ )

Antenna Impedance 75§ Unbalanced

Tuning System Frequency Synthesizer

Number of Memory 181 Channels

Channel

Reception Channel VHF TV LOW:CH2~6

HIGH:CH7~13

UHF TV CH14~CH69

CATV CH1~CH125

Remote Control Unit R-25C04

Screen Size 14” / 20”(diagonal)

Color Standard NTSC/PAL-N,M

Tuner Type Varactor Type with PLL

Aux. Terminal Input:Video,Audio

2

Page 4

§ SAFETY INSTRUCTIONS

10WATT

Good earth ground,

such as the water

pipe, conduit, etc.

1500 OHM

0.15MFD

AC VOLT METER

Place this probe

on each exposed

metallic part.

§ SAFETY PRECAUTION

WARNING: Service should not be attempted by anyone unfamiliar

with the necessary precaution on this receiver.

The following are the necessary precaution to be observed before

servicing.

1.Always discharge the picture tube anode to the CRT conductive

coating the picture tube. the picture tube is hightly evacuated

and if broken, glass fragments will be violently expelled. Use

shatterproofgoggles and keep picture tube away from the body

while handling.

2.When replacing chassis in the cabinet,always be certain that all

the protective devices are put back in place, such as;

nonmetallic control knobs, insulating covers, shields, isolation

resistor-capacitor network, etc

Plug the AC line cord directly into a AC outlet. Use an AC

voltmeter having 500 ohms per volt or more sensitivily in the

following manner.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 mfd,

AC type capacitor, between a known good earth ground( water

pipe, conduit etc) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm

resistor and 0.15 mfd capacitor.

Reverse the ac plug at the ac outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage measured

must not exceed 0.3 volts RMS. This corresponds to 0.2 milliamp,

AC. Any value exceeding this limit constitutes a potential shock

hazard and must be corrected immediately.

3.Before retuning the set to the customer, always perform an AC

leakage current check on the exposed metallic parts of the

cabinet, such as antennas, terminals, screwheads, metal

overlays, control shafts etc, to be sure the set is safe to operate

without danger of electrical shock.

§ PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special

safety-related characteristics. These characterictics are often

passed unnoticed by a visual inspection and the protection

afforded by them cannot necessarily be obtained by using

replacement components rated for higher volage, wattage,

etc.Replacement parts which have these special safety

characteristics are identified in this manual and its

§ SERVICE NOTES

1.When replacing parts or circuit boards, clamp the lead wires to

terminal before soldering.

2.When replacing a high wattage resistor(metal oxide film

resistor)in the circuit board keep the resistor min 1/2 inch away

from the circuit board.

supplements;electrical components having such features are

identified by shading on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in

this manual carefully. The use of substitute replacement parts

which do not have the same safety characteristics as specified in

the parts list may create shock, fire or other hazards.

3.Keep wires away form high voltage or high temperature

components.

3

Page 5

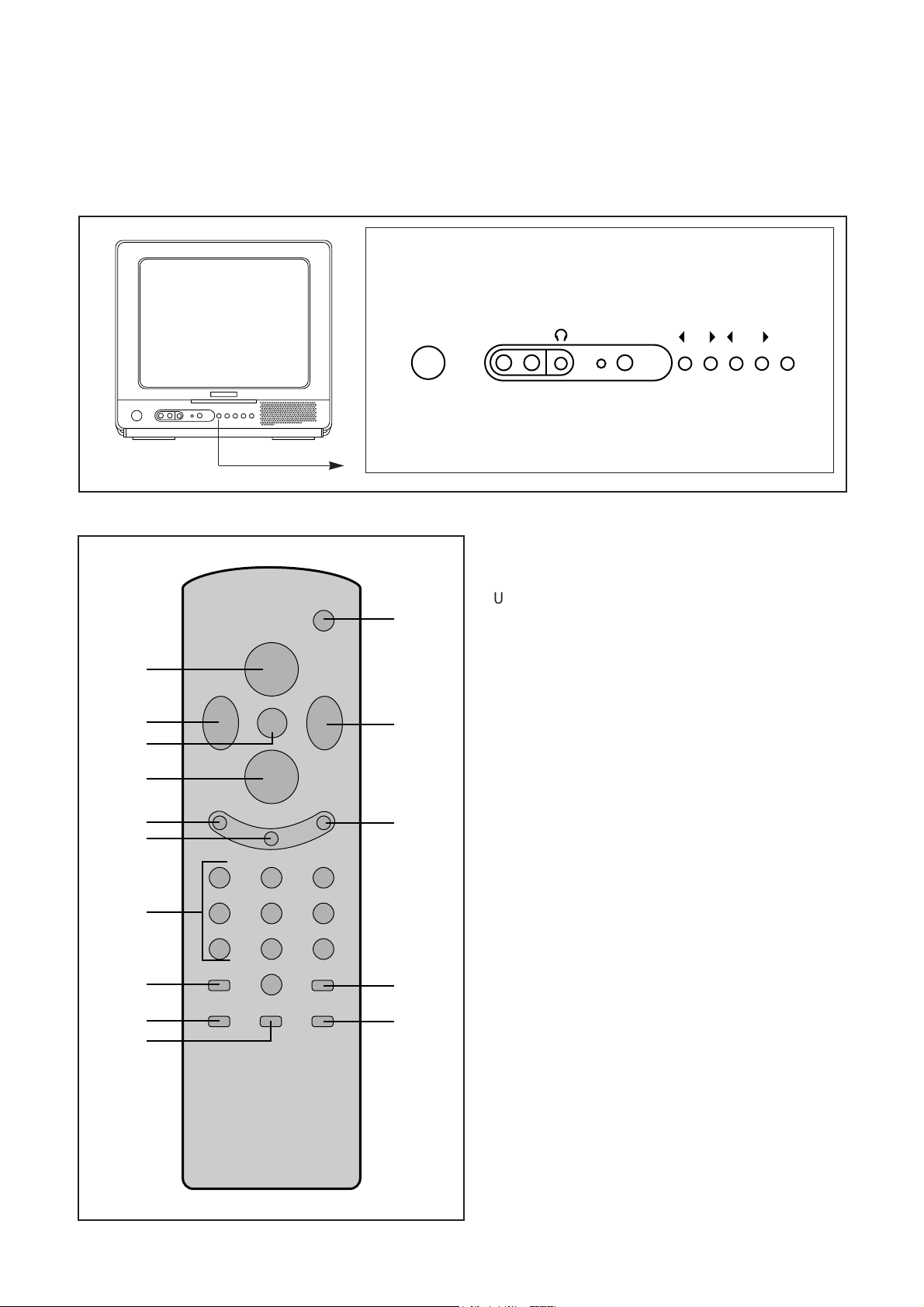

§ LOCATION OF CONTROLS

§ REMOTE CONTROL UNIT

POWER

2

3

VOL

¢‚

CH

¡ª

MENU

VOL

¢”

3

2

RECALL MUTE

5

CH

¡

ADD/ERA

6

123

8

9

456

789

SLEEP PREV.CH

0

TV/VIDEO AIR/CABLEAUTO.PICT

13

11

REMOTE CONTROLLER R-25C

MAIN POWER VIDEO AUDIO STAND-BY C H VOL MENU

1. POWER

Used to turn TV ON or OFF.

¡¡ªªCH¡¡

Â

Use these buttons to change channels on your

TV, or select items in the menu system.

¢¢‚‚

¢¢””

VOL

Use these buttons to change your TV’s

volume, to activate selections in the menu

system, or to change audio and video settings.

Use this button to turn TV’s menu system

on and off.

Press this button to display the channel

number

Use this button to add a channel to the TV’s

memory or erase the channel from memory.

Use to turn the TV’s sound on and off.

Use these buttons to change channels.

Use this button to program the TV to turn off

after a certain time.

Press this button to return to the previous

channel you were watching.

Press this button to return TV’s video

settings to their original level.

Use the button to set up your TV to receive

signals from an antenna (AIR) or a cable

system (CABLE)

Use the button to seiect TV or VIDEO mode.

1

3

7

10

12

2.

3.

4. MENU

5. RECALL

6. ADD/ERA

7. MUTE

8. 0-9

9. SLEEP

10. PREV.CH

11. AUTO.PICT.

12. AIR/CABLE

13. TV/VIDEO

5

Page 6

Page 7

Page 8

§ GENERAL ALIGNMENT INSTRUCTIONS

THIS RECEIVER IS TRANSISTORIZED. SPECIAL CARE MUST BE TAKEN WHEN SERVICING. READ THE FOLLOWING

NOTES BEFORE ATTEMPTING ALIGNMENT.

• Alignment requires an exact procedure and should be undertaken only when necessary.

• The test equipment specified or its equivalent is required to perform the alignment properly.The use of a

equipment which does not meet these requirements may result in improper alignment.

• Correct matching of the equipment is essential. Failure to proper matching will result in responses which

cannot represent the true operation of the receiver.

• The AC Power line voltage should be kept within from 110 to 220 volts while alignment.

• Do not attempt to connect or disconnect any wire while the receiver is in operation.

Make sure the power cord is disconnected before replacing any parts in the receiver.

TEST EQUIPMENTS.

DC POWER SUPPLY ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ 0V~30V/500mA Class.

RF PATTERN GENERATOR¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ PHILIPS PM-5518

DIGITAL MULTI METER ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ FLUKE 8050A

WHITE BALANCE TESTER ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ¡ƒ NITSUKI 2840

6

Page 9

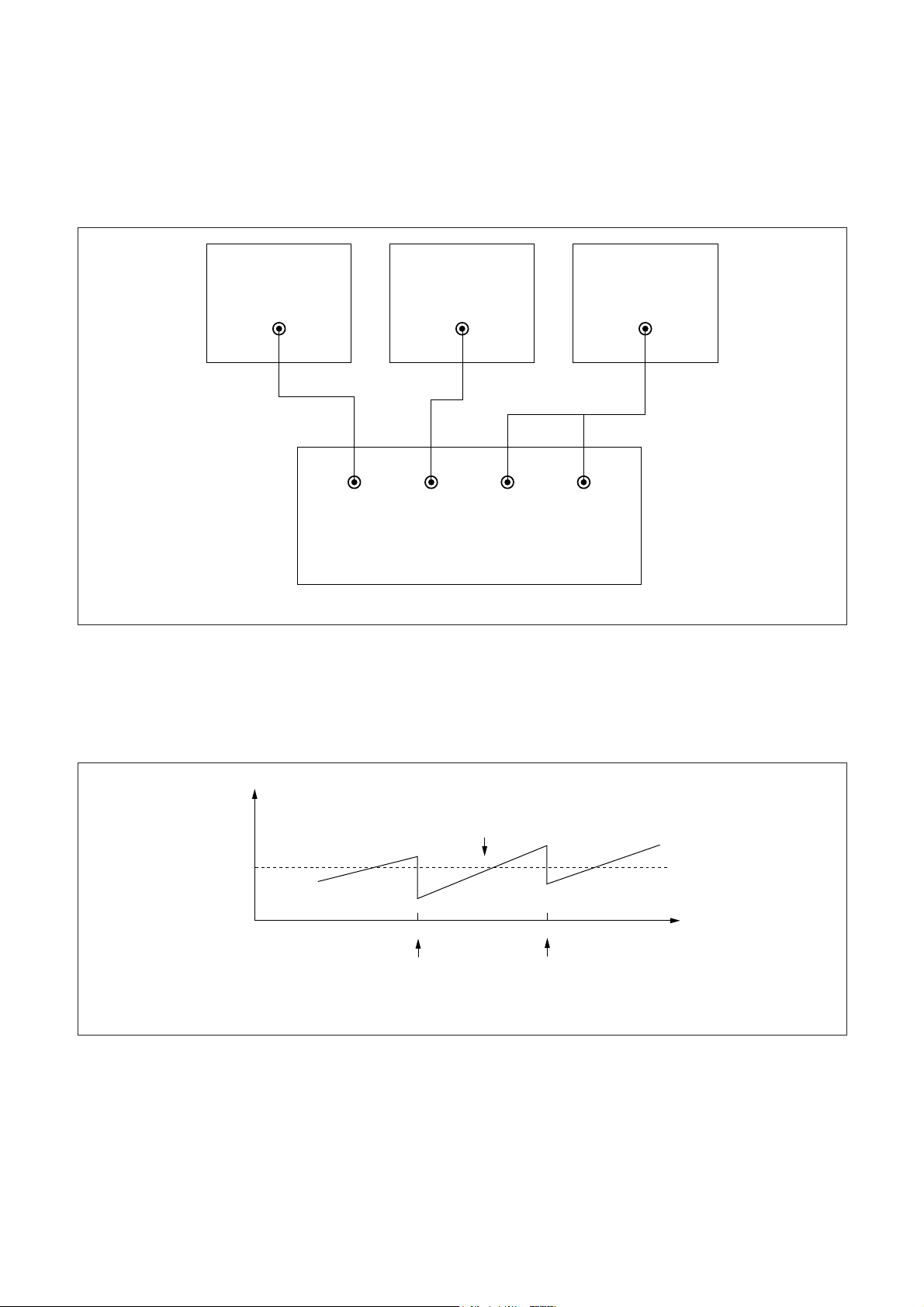

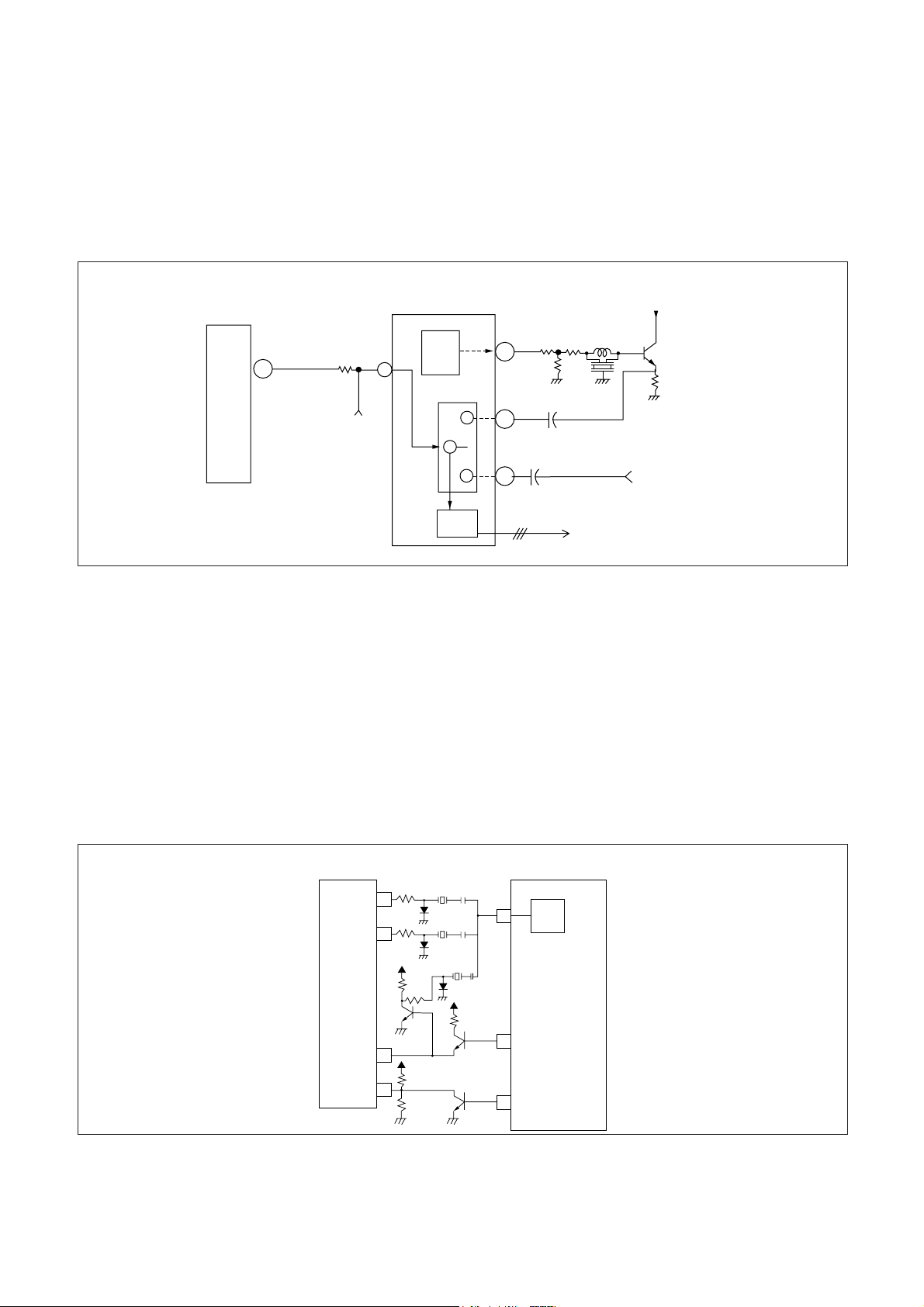

§ PIF VCO ADJUSTMENT

RF PATTERN

GENERATOR

PM-5518

DIGITAL MULTI

METER

DC POWER

SUPPLY

TP1

(L102)

TP3

(I501 #7)

TP4

(R701)

TP5

(I201)

[ADJUSTMENT SET]

(FIGURE 1)

[Measuring Instrument Connection]

1. Connect the 12V DC POWER SUPPLY to TP4 and TP5.

2. Set the frequency of RF PATTERN GENERATOR with COLOR BAR PATTERN signal to 45.75MHz,

and connect the RF output to TP1.

3. Connect the DIGITAL MULTI METER to TP3.

4. Adjust L506 so that the voltage of TP3 becomes 3.8V ± 0.1 Vdc within two DROP-POINTs (FIGURE 2).

V

adjust point

3.8V

core(L506) rotating

voltage drop points

(FIGURE 2)

§ SCREEN ADJUSTMENT

1. Push the 9D.SCR key of SERVICE REMOCON to obtain one line picture of screen.

2. Adjust the R,G,B Bias volume in order that the one line of screen may become white color.

7

Page 10

3. Adjust the SCREEN VOLUME of FBT in order that the one line of screen disappear.

4

1

1

4

1

4

4

1

5 3 1

1 3 5

4. Push the 9D.SCR key of SERVICE REMOCON again.

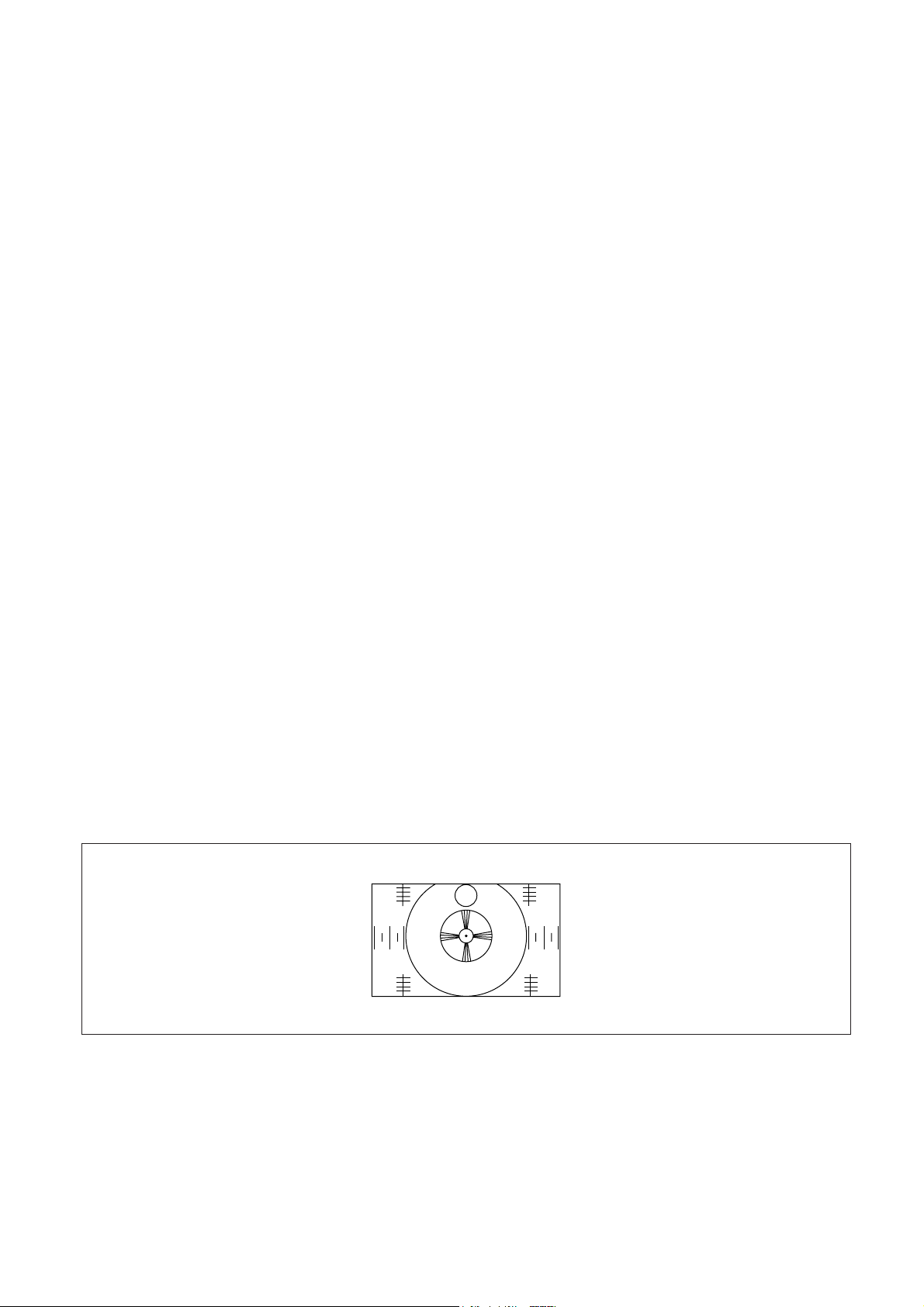

§ FOCUS ADJUSTMENT

1. Receive the RETMA pattern.

2. Adjust the FOCUS volume of FBT to obtain the most clear picture.

§ RF AGC ADJUSTMENT

1. Input the COLOR BAR SIGNAL of 65dB to the ANTENNA INPUT of TV SET

2. Set the user control to AUTO PICTURE ON.

3. Turn completely the RF AGC volume R101 counter-clockwise and turn it clockwise until AGC voltage 6.0V is

obtained.

4. If there is the BEA T with strong signal(95 dB over), re-adjust it.

§ VERTICAL CENTER ADJUSTMENT

1. Receive the RETMA PATTERN.

3. Set the user control to AUTO PICTURE ON.

4. Adjust the R302 so that the horizontal center of the PATTERN may meet with the mechanical center of CRT.

§ HORIZONTAL CENTER ADJUSTMENT

1.Receive the RETMA PATTERN.

2.Set the user control to AUTO PICTURE ON.

3. Adjust the R501 in order that the circle may put in the center position of the screen.

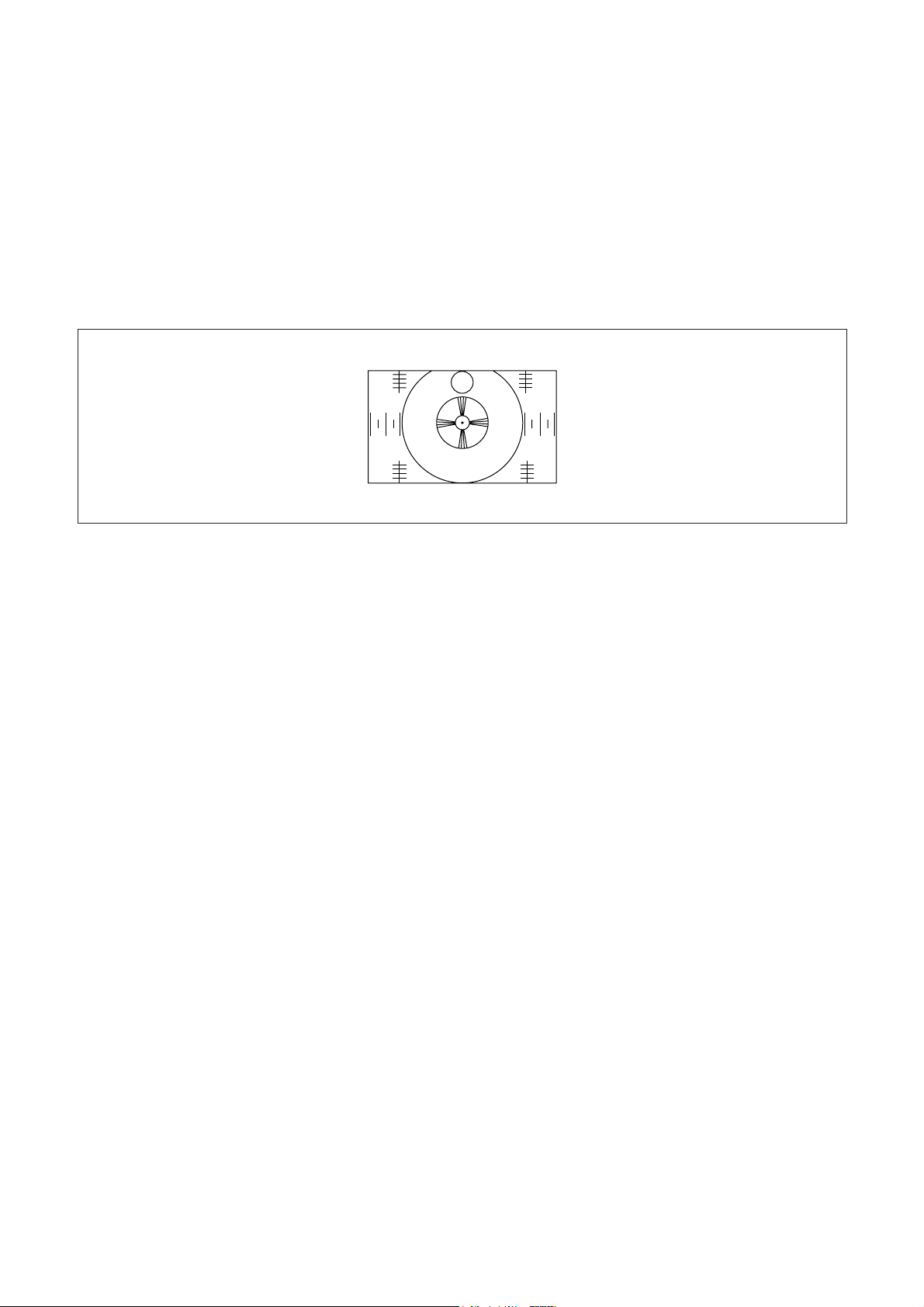

(FIGURE 3) VERTICAL and HORIZONTAL center Adjustmemt

8

Page 11

§ VERTICAL HIGHT ADJUSTMENT

4

1

1

4

1

4

4

1

5 3 1

1 3 5

1. Receive the RETMA PATTERN.

2. Set the user control to AUTO PICTURE ON.

3. Adjust the R301 so that the CENTER of circumference of big circle may meet with the upper and lower sides

of screen.

§ WHITE BALANCE ADJUSTMENT

1.Execute HEAT RUN of the TV SET over 30 minutes with SERVICE REMOCON.

2.Connect the signal output of WHITE BALANCE TESTER (Nitsuki 2840) to the ANTENNA (or VIDEO IN) input

of the TV SET. Stick and fix the SENSOR to the center position of CRT.

3. Adjust the R,G,B BIAS and G,B DRIVE VOLUME in order that R,G,B of the HIGH and LOW BEAM may meet

with the CENTER LED of each measuring instrument.

4. At this time, the memorized coordinates of the WHITE BALANCE TESTER, unless otherwise specified, use

following coordinates and color temperature (PAL:9600K 3~5ftL 265¡¿295 , NTSC: 10850K 3~5ftL 274¡¿289)

§ SUB-BRIGHT ADJUSTMENT

1. Receive the RETMA PATTERN.

2. Set the user control to AUTO PICTURE ON.

3. Turn the SUB-BRIGHT CONTROL VOLUME (R540) and adjust the gradation pattern as shown.

4. The status that the border between 15% and 20% can be distinguished.

9

Page 12

§ DESCRIPTION OF CIRCUIT OPERATION

§ FEATURE OF THE CM-537

•VIDEO, CHROMA, DEFLECTION in one-chip IC.

•Automatic switching of 3-SYSTEM(NTSC, PAL-M, PAL-N).

•FS(Frequency Synthesizer ) Tunning System.

•Function of LAST MEMORY against the electric failure (E2PROM:24LC028).

•Separation of PIF and SIF(SAW filter :DSW1013P)

•Minimization of Ringing by applying Ringing-less FBT(2001SPND)

•Auto-compensation of the vertical height level against the frequency change of AC power .

•OVER CURRENT PROTECTION Circuit.

•Elimination Circuit of POP NOISE.

§ OPERATION CHARACTERISTICS OF EACH BLOCK

A.¥-COM BLOCK

1. ¥-COM(DMC42C522N, I701) PIN DESCRIPTION/OPERATION

PIN NAME/(ABBREV) FUNCTION REMARK

1 NTSC-M 3-SYSTEM SWITCHING CMOS

(RCO/PWM14) PUSH PULL

2 PAL-M 3-SYSTEM SWITCHING CMOS

(R83) PUSH PULL

3 AC POWER DOWN MAIN POWER DOWN Detect input:active LOW CMOS

(R03/INT3) PUSH PULL

4 SD INPUT SYNC. signal INPUT H: signal detect

(RO2/INT2) L: no signal

5 REMOTE CONTROL REMOTE CONTROL signal input

INPUT REMOTE CONTROL IC : M50560-388GP/M50560-001

(R01/INT1TIM1) (CUSTOM CODE: 14H)

6 KEY RETURN IN 0 ·KEY MATRIX COLUMN 0

(R00/INT0/TIM0) ·HOLD MODE : WAKE-UP using INT1 PUSH PULL

7 Xin SYSTEM CLOCK : 4.1943 MHz

8 Xout

9 RESET SYSTEM RESET

10 KEY RETURN IN 1 KEY MATRIX COLUMN 1

(R82)

11 Vss GND

12 KEY RETURN IN 2 KEY MATRIX COLUMN 2

(R81)

13 KEY SCAN OUT 0 · KEY MATRIX ROW 0

& TIMER · Active HIGH when ON TIMER is set.

(R80)

10

Page 13

PIN NAME/(ABBREV) FUNCTION REMARK

14 Vdd +5V

15 KEY SCAN OUT 1 · KEY MATRIX COLUMN 1

& CLOCK · TUNER CLOCK & EEPROM CLOCK

(R23)

16 KEY SCAN OUT 2 · KEY MATRIX COLUMN 2

& DATA · TUNER DATA & EEPROM DATA

(R22)

17 ENABLE · TUNER ENABLE CMOS

(R20/PCL) PUSH PULL

18 AFC · AFC voltage from MAIN IC(LA7688) : DC 0 ~Vdd A/D CONV

(R21/AFC IN) CENTER : 2.5V 4BIT

19 OSC in

20 OSC out

21 /H-Sync · SYNC. signal for OSD H. position.

(HD) · 0~5V PULSE/Active LOW INPUT

· OSD CLOCK

22 /V-Sync · SYNC. signal for OSD V. position.

(VD) · 0~5V PULSE/Active LOW INPUT

23 R(R60/OSD R) · Active “HIGH” OUTPUT

24 G(R61/OSD G) · Dot pattern OF OSD

25 B(OSD B)

26 OSD Ys

27 50/60 IN · 3-SYSTEM SWITCHING CMOS

(R13) · 50Hz: LOW(PAL-N) , 60Hz: HIGH (PAL-M, NTSC-M)

28 /C.IDENT IN · 3-SYSTEM SWITCHING CMOS

(R12) · “LOW” (INPUT) signal detected with NO-COLOR.

29 OCP IN · OVER CURRENT PROTECTION INPUT: active HIGH CMOS

(R11) · TV POWER turns OFF when HIGH signal detected for

10ms.

· The u-COM observe this pin immediately after

POWER ON.

30 SCREEN OUT · HIGH signal OUTPUT indicating SCREEN adjustment. CMOS

(R10) · Goes HIGH when REMOCON KEY;9DH detected.

· Toggled when 9DH detected.

31 VIDEO MUTE OUT · Active LOW, Normal : HIGH CMOS

11

Page 14

PIN NAME/(ABBREV) FUNCTION REMARK

32 POWER · Active HIGH

· LOW state at initial condition (RESET). except

· Toggle LOW/HIGH when POWER KEY input is detected. HEAT-RUN mode

(LOW ¡ POWER OFF / HIGH ¡ POWER ON)

· Automatically turns to LOW when SLEEP TIMER

(count down) counts “0”.

· Automatically turns to LOW when the OFF TIMER is set

and the clock(TV) indicates OFF-TIME.

· Automatically turns to HIGH when the ON TIMER is set

and the clock (TV) indicates ON-TIME.

33 TV/VIDEO · TV: HIGH / VIDEO: LOW CMOS

(R31) · VIDEO MUTE(#31) is activated for a moment PUSH PULL

when this pin is togglled.

(VIDEO MUTE MODE needs OPTION diodes)

34 SOUND MUTE · Active HIGH, Normal : LOW CMOS

(R30) · HIGH out ¡ MUTE. PUSH PULL

· Following action make the TV set to be MUTE

for a moment.

1. Channel selecting

direct selecting, sequential channel selecting,

AUTO PROGRAM

2. POWER ON/OFF

· When MUTE KEY is detected following changes

are occurred for a moment.

1. VOLUME level ¡ LOW

2. SOUND MUTE(#34) ¡ HIGH

3. Color of OSD : GREEN ¡ RED

35 VOLUME · Active HIGH, PWM OUTPUT CMOS

(PWM82) · 64 STEP (2bit/step) VOLUME CONTROL

· Following action make the VOLUME level to “0”

(MUTE) for a moment.

1. Channel selecting

2. TV/VIDEO selecting

36 BRIGHTNESS · Active HIGH, PWM OUTPUT

(PWM81) · 64 step (2bit/step) BRIGHTNESS CONTROL

37 CONTRAST · Active HIGH, PWM OUTPUT

(PWM80) · 64 step (2bit/step) CONTRAST CONTROL

38 SHARPNESS · Active HIGH, PWM OUTPUT

(RC3/PWM63) · 64 step (2bit/step) SHARPNESS CONTROL

39 COLOR · Active HIGH, PWM OUTPUT

(RC2/PWM62) · 64 step (2bit/step) COLOR CONTROL

40 TINT · Active HIGH, PWM OUTPUT

(RC3/PWM63) · 64 step (2bit/step) TINT CONTROL

2.Function of LAST MEMORY

Always holds a previous DATA by saving the signal of the data,clock,enable on the E2PROM.

12

Page 15

33

10

14

8

1

µ-COM

(I701)

TV(H)

/VI(L)

SIF

Filter

I501

LA7688

VIDEO

DET

VIDEO

SWITCH

9V

R,G,B OUT

Q503

EXT.VIDEO

(JV01/JV02)

B. VIDEO BLOCK

17

21

41

1

2

27

28

I701

µ-COM

I501

LA7685J

NTSC-M

50/60

COLOR

/KILLER

PAL-M

VCO

X502

X503

Q506

9V

R766

R774

Q502

Q705

X501

7.6V

9V

1. TV/VIDEO SWITCHING

1) SWITCHING BLOCK DIAGRAM

2) CIRCUIT OPERATION

•After going out to the #8 of I501, the detected signals go into the #10 of I501through 4.5MHz BPF(Band Pass

Filter, Z502) : TV SIGNAL.

•The external VIDEO signals from JV01(or JV02) go into the #14 of I501 : VIDEO SIGNAL.

•Output pulse from the #33 of the ¥-COM(TV:HIGH, VIDEO:LOW) go into #1 of I501 through a buffer(Q504 and

Q507).

•According to the input pulse of the #1, TV/VIDEO switching circuit let out the video signals to the RGB generator

block inside I501.

2. OUTLINE AND OPERATION OF 3-SYSTEM AUTO SWITCHING

1) SWITCHING BLOCK DIAGRAM

2) CIRCUIT OPERATION

•If 50[Hz] detected. #21 of the I501 goes down to LOW level. This out goes into the Q506 (and #27 of the I701),

and then X501 oscillates (#1 and #2 of the I701 are deactivated.).

13

Page 16

¢¡PAL-N system

•If 60[Hz] detected, #21 of the I501 goes up to HIGH level and the system operates as PAL-M or NTSC-M.

¤ In the case that Base voltage of Q705 is LOW, the voltage driven from R766 and R774 is applied to the #28

of the I701.

¤ŁIn the case that Base voltage of Q705 is HIGH, according to the voltage change of the #28 of the I701, the

comparator in the I701 switch over the system.

(PAL-M¢¡NTSC-M, NTSC-M¢¡PAL-M)

•HIGH signal of the #1 of I701 makes X502 oscillates.(NTSC-M)

•HIGH signal of the #2 of I701 makes X503 oscillates.(PAL-M)

3) FREQUENCY CHARACTERISTICS OF EACH SYSTEM

COLOR VHF UHF

SCANNING

NUMBER

LINE

FREQUENCY

(Fh) (Fsc)

FIELD

FREQUENCY

CHROMINANCE

SUB CARRIER

NTSC M M 525line 15,734[Hz] 60[Hz] 3.579545[MHz]

PAL M M 525line 15,734[Hz] 60[Hz] 3.575611[MHz]

PAL M 625line 15,625[Hz] 50[Hz] 3.582056[MHz]

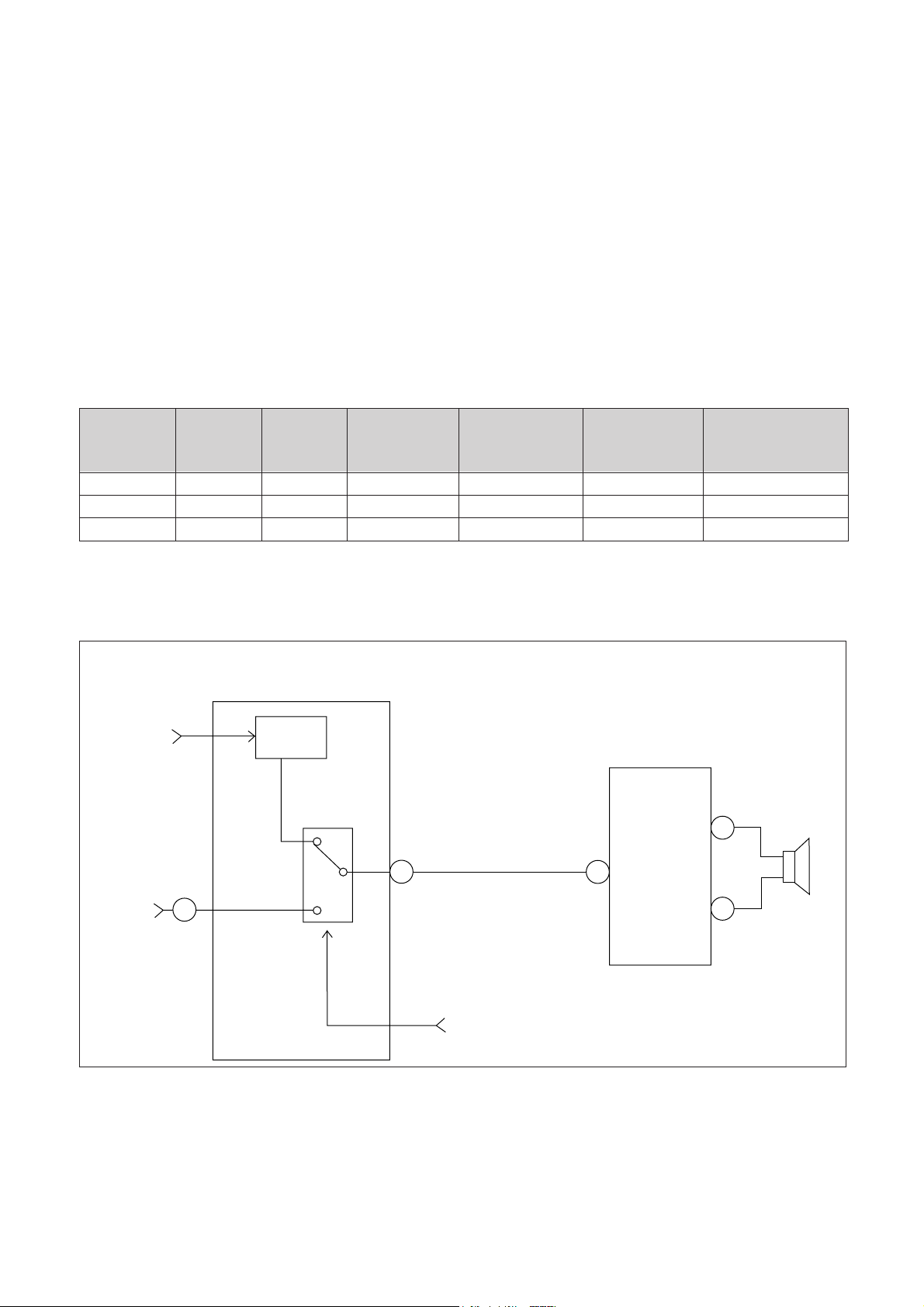

C. SOUND BLOCK

1. SOUND BLOCK DIAGRAM

I501

LA7688

FM

DET

AUDIO

SWITCH

51

I601

TDA7056A

6

3

8

EXT.

AUDIO

(JV01/JV02)

SIF

12

SP

from the µ-COM(#33)

2. EXPLANATION OF OPERATION

1) The TV audio signal is detected and goes into the audio switch in I501.

2) The external audio signal from JV01(or JV02) goes into the #12 of I501.

3) The audio switch in I501 alternates audio signals according to the TV/VIDEO control input from the I701.

4) The selected audio signal (#51 of I501) go into the #3 of I601.

14

Page 17

3.SOUND AMP IC

1 2 4 63 5 7 8 9

33V

From

#51

of I501

From

#35

of I701

N.C VP IN

S.GND

Volume OUT(+) P.GND OUT(–) N.C

TDA7056A

Earphone

Jack

SPEAKER

16 ohm

3W

SP01

1) BLOCK DIAGRAM

2) EXPLAINATION OF THE OPERATION

•The audio signal from the I501 goes into the #3 of the I601.

•I601 amplifies this audio signal correspond to the volume control signal from I701.

•The amplified audio signal from the #6 and #8 drives the speaker (s).

¡ AUDIO MUTE function is activated by the I701(SOFTWARE MUTE).

15

Page 18

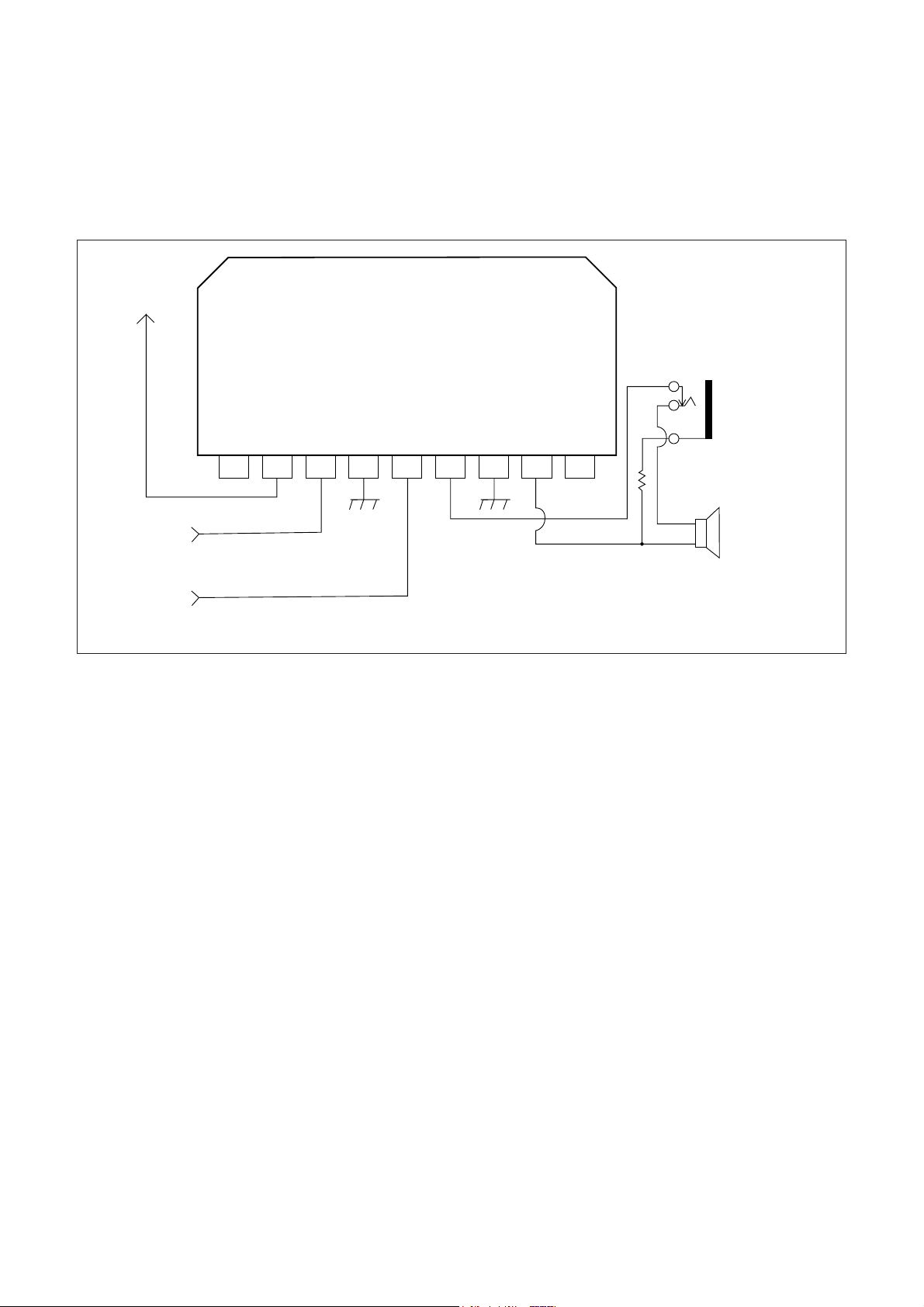

D. DEFLECTION BLOCK

Ramp

Generator

Vert. Drive

Vert. Out

THERMAL PROTECTION

Vert.

Trig.

Input

One

Shot

Multi

Vert.

Size

Control

S.W

Pump UP

+B1

9V

+

VERT.

TR1G.

1N

50/60

Hz

Vert. Height.

+B7

25V

+

+

+

10~20P

vert

center

DY

1 2 3 4 5 6 7 8

9

10 11 12 13

LA7837

This block can be separated into two parts, VERTICAL and HORIZONTAL.

Only the VERTICAL circuit is explained here, comprehensibly.

1. BLOCK DIAGRAM OF VERTICAL IC

# 1: B+ (12V)

# 2: VERTICAL TRIGGER INPUT

# 3: TIME CONSTANT & MUTE

# 4: VERTICAL HEIGHT CONTROL

# 5: 50/60[Hz] VERTICAL SIZE CONTROL SIGNAL

INPUT

# 6: RAMP WAVEFORM GENERATION

# 7: AC/DC FEEDBACK INPUT TO VERTICAL

# 8: POWER SUPPLY (VBB): 25V

# 9:PUMP UP OUTPUT

#10:OSC BLOCKING

#11:GND

#12:VERTICAL OUTPUT

#13:POWER SUPPLY FOR VERTICAL OUTPUT

16

Page 19

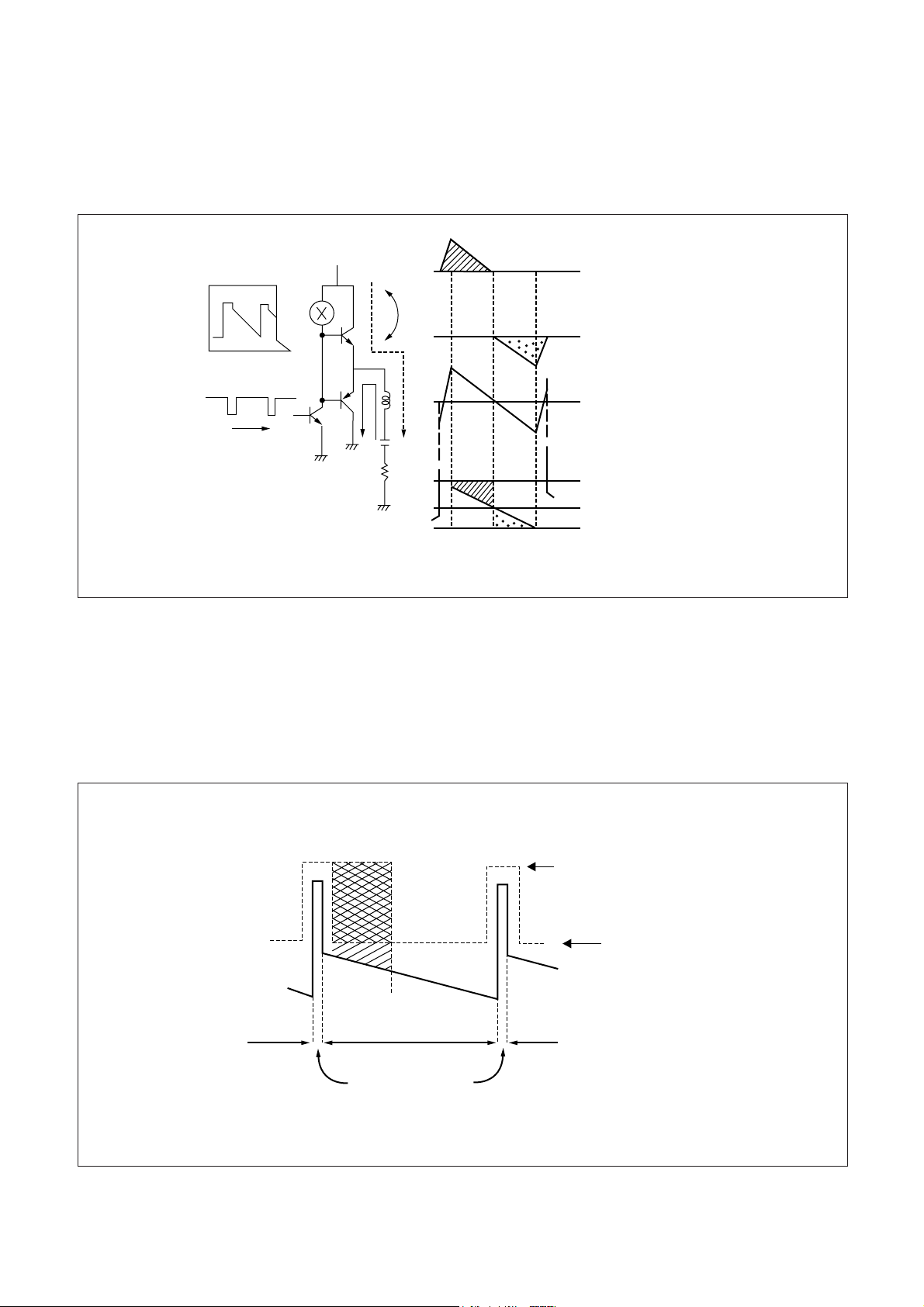

2. OPERATION OF VERTICAL

GND

(b) Q3 Collector

Current i1

GND

(c) Q4 Collector

Current i2

VCC (e)Emitter Voltage

1/2 VCC

GND

(d) Current of

Deflection coil

i1 + i2

GND

(a)

VCC

Q3

Q4

Q2

i2

i1

VCC1

VERTICAL OUTPUT WAVE

1) In the picture above, (a) shows a fixed Vcc, and (+)(-)current of deflection coil is (d) whichk is sum of (b) and

(c), and (e) shows EMITTER voltage of Q3,Q4.

2) Collector loss of Q3 is i1 Vce1 which is the product of obligue region of (b),(e).Collector loss of Q4 is product

of dot region of (c),(e).

3) To reduce collector loss of Q3,if bring down the voltage during scanning time as shown in the picture (b) ,

Vce1 become lower so that the loss diminish.

Diminish if Q3 Collector Loss

OUTPUT VOLTAGE

17

Blanking Time

Voltage

Sanning Time

Voltage

Page 20

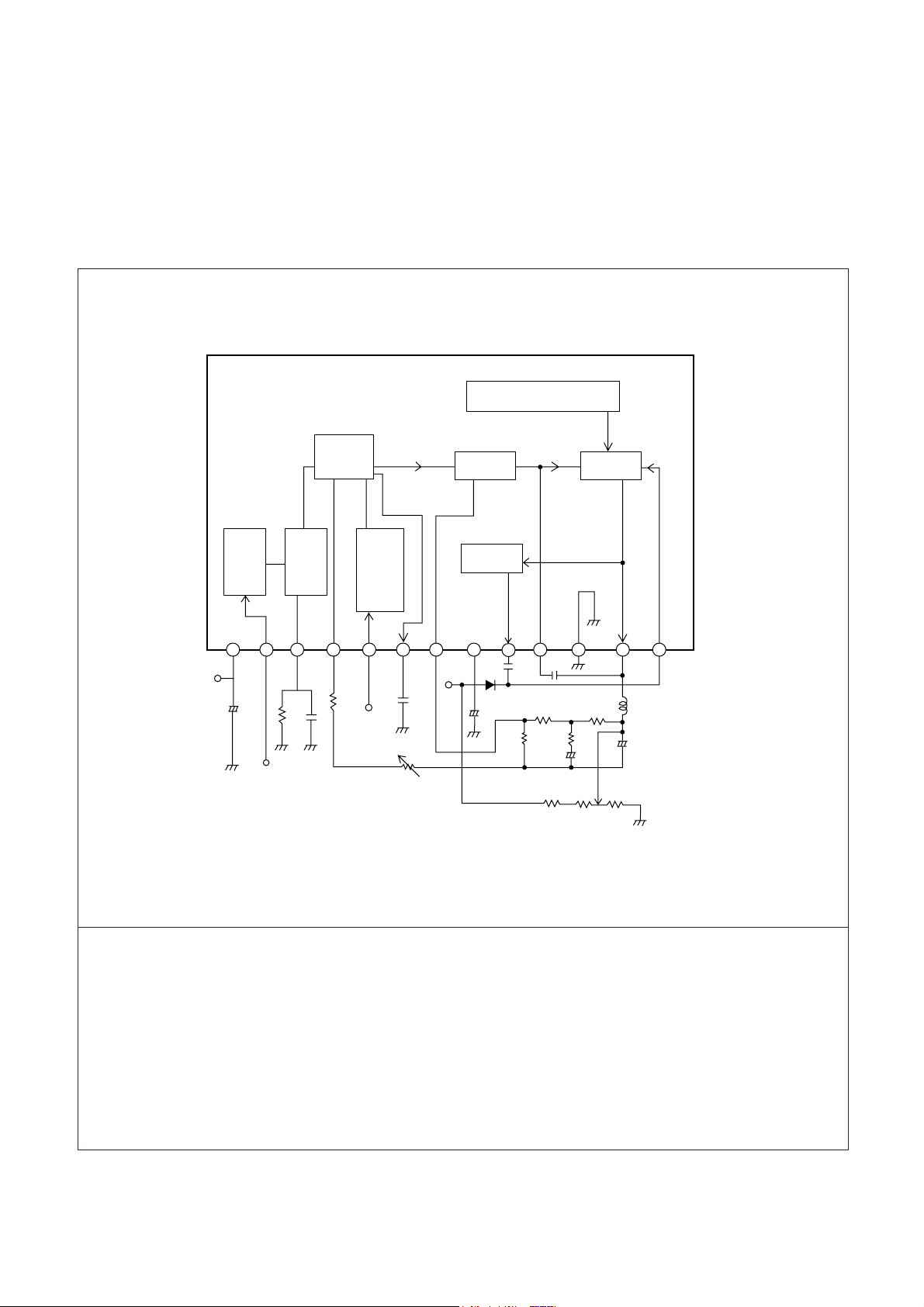

E. POWER BLOCK

INH-1

REF

OCP

REF

INH-2

REF

INH-3

REF

9

7

6

8

4

3

1

2

5

START UP

PRE REG OSC

T.S.D

OVP LATCH

V IN

INH

PROPOTIONAL

DRIVE

Tr2

R6

PNP +2Di

R7 R8 R9

Tr1

R4

R4

R3

R1

C1 C4 R5C2 C3R2

DIRVE

SINK

B

C

GND

OCP

SENS

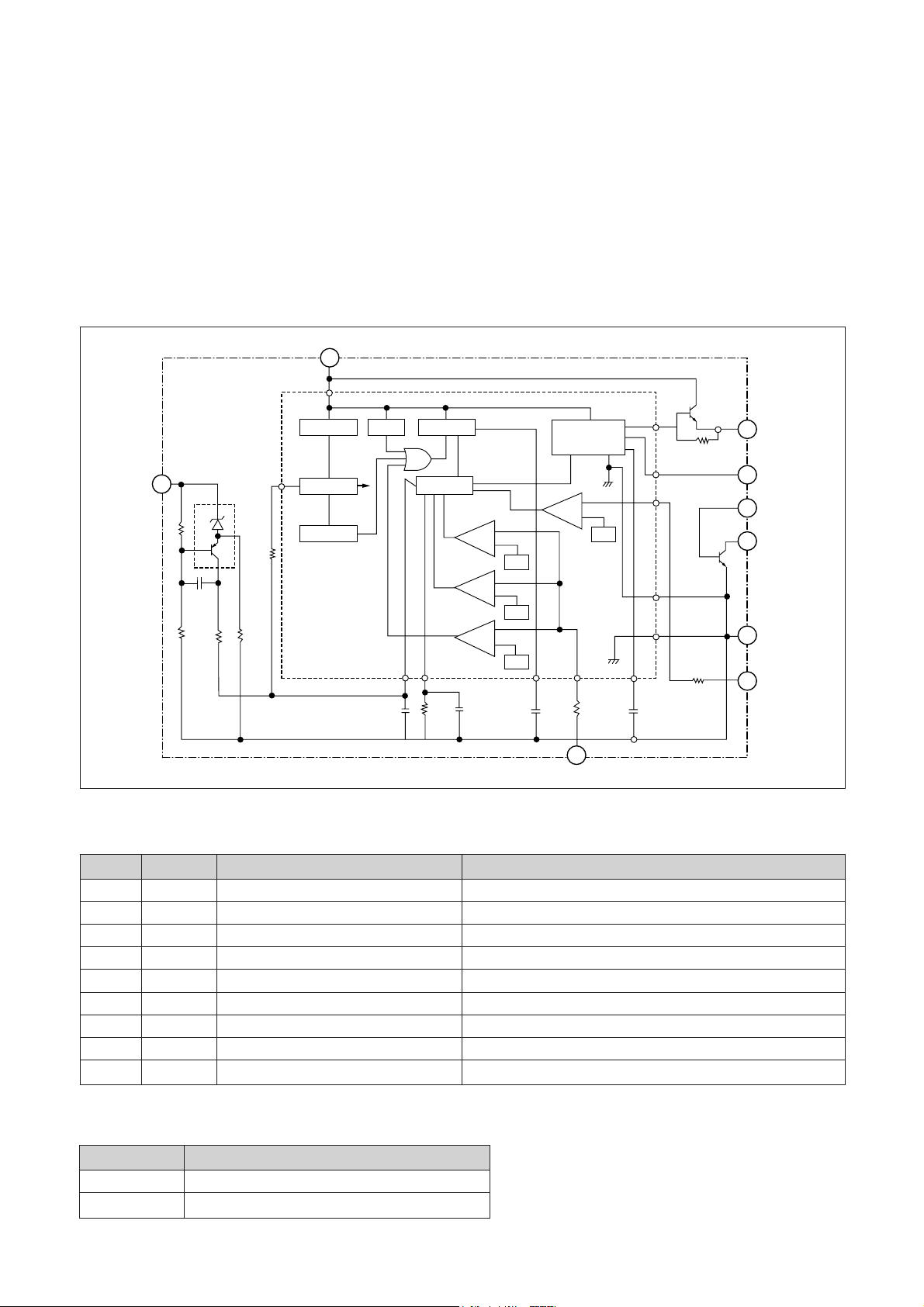

This chassis designed for free voltage(AC 100V ~ AC 220V ) power. power block contains power IC, SMPS

transformer and several passive components.

The power IC STR-S5707 has power transistor. oscillator circuit, voltage comparator circuit, thermal protection

circuit, OCP(over current protection) circuit insiude.

1.STR-S5707 BLOCK DIAGRAM

2.PIN DESCRIPTION

PIN NO SYMBOL NAME FUNCTION

1 C COLLECTOR POWER TRANSISTOR COLLECTOR

2 GND GROUND GROUND(POWER TRANSISTOR EMITTER)

3 B BASE POWER TRANSISTOR BASE

4 SINK SINK BASE CURRENT (Is) INPUT

5 OCP OVER CURRENT PROTECTION OVERCURRENT SENSING SIGNAL INPUT

6 INH INHIBIT / LATCH SYNC, OFF TIME/LATCH CIRCUIT CONTROL INPUT

7 F/B(SENS) FEED BACK(SENSING) INPUT CONSTANT VOLTAGE CONTROL SIGNAL INPUT

8 DRIVE DRIVE BASE DRIVE CURRENT (Id) OUTPUT

9 Vin Vin SUPPLY VOLTAGR FOR CONTROL CIRCUIT

3. OTHER FUNCTION

Symbol Function

OVP Built-in Overvoltage Protection Circuit

TSD Built-in Thermal Shutdown Circuit

18

Page 21

Rs(R803,R804)

Ln

L1

9

V

IN

2

GND

C806

D804

AC

IN

Fig .1 Start-up Circuit

1

Fig .2 V

IN Terminal Voltage Circuit Current VIN

IN

20mA

200µA

4.9V 7.5V8V

Vin

4. EXPLAINATION OF CIRCUIT OPERATION

1) VIN terminal, start-up circuit

A start-up circuit is to start and stop a operation of a control IC by detecting a voltage appearing at a VIN

terminal (pin-9). At start up of a power supply, when a voltage at the VIN terminal reaches to 8V by charging up

C806 by the function of a start-up resistor, Rs, a control circuit starts operating by the function of the start-up

circuit. As shown in Fig. 2, since a circuit current is suppressed 200§¸ maximum ( at V

IN = 7.5V ) until the

control circuit starts its operation.

After the control circuit starts its operation, power source is obtained by smoothing voltage appearing at L1

winding. Once the control circuit starts operating, as its voltage doesn’t reach the fixed voltage at once, V

IN

terminal voltage starts dropping. However, as a shut-down voltage is set low (at 4.9V), while VIN terminal

voltage reaches a shutdown voltage, L1 winding voltage reaches the fixed voltage earlier so that the control

circuit can continue on operating.

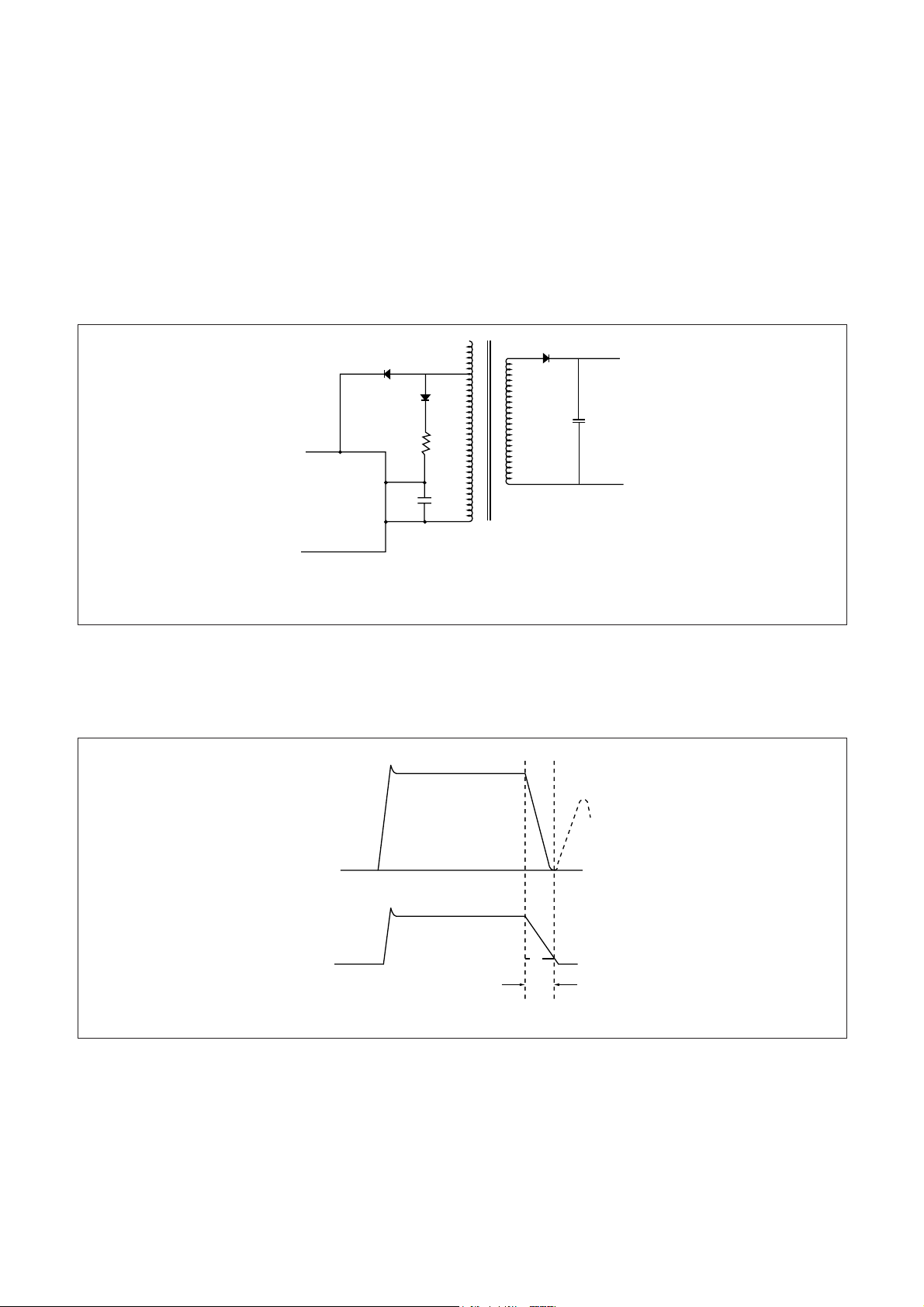

2) Osciliator, F/B terminal voltage (Pin #7)

A oscillator generates pulse signals which turns a power transistor on and off by making use of charge and

discharge of CI and C2 incorporated in the Hybrid IC.

Constant voltage control of a switch-mode power supply is performed by changing both ON- time and OFFtime except when the load is light (ex. remote control stand-by mode of TVs).

Fig. 4 shows how the oscillator works when the Hybrid IC independently operates (with no F/B nor INH

signals). When the power thransistor is on, C2 Is charged to the set voltage (approx 2.3V at Ta =25°C). On the

other hand, C1 starts charging up through R1 from almost 0V and the voltage across C1 increases in

accordance with the inclination determined by the product of C1 and R1. When the voltage across C1 reaches

approx. 0.75V (Tc=25°C). the output from the oscillator is reversed and the power transistor turns off. At the

same time C1 is quickly discharged by the function of a internal circuit of the oscillator and the voltage across it

decreases to almost 0V. When the power transistor turns off, C2 starts discharging through R2 and the voltage

across C2 decreases in accordance with the inclination derermined by the product of C2 decreases to about

1V. the output from the oscillator is reversed again and the transistor consequently turns on. The power

transistor continues turning on and off by repeating the above-mentioned operations.

19

Page 22

As the circuit in Fig. 3 shows, the ON-time is controlled by changing a current charged by C1, which is as the

R6

R7

PIN +2Di

Reg

Drive

Cfrcu1

R7 R8 R9

R1

R2

C1 C2

+

–

+

–

OSD

L1

COMP 1

COMP 2

VTH1

VTH2

INH

Tre

Fig 3 Oscillator Circuit Configulation

C2 ACROSS

Voltage

C1 ACROSS

Voltage

Osc.

Output

PTR

Fig 4 Operation Waveforms of Oscillator without F/B nor

INH Signal

1V

2.3V

0V

0V ON

OFF

0.75V

Fig 5 Operation Waveforms of Oscillator with F/B Signal

C2 ACROSS

Voltage

C1 ACROSS

Voltage

Osc.

Output

PTR

1V

2.3V

0V

0V

0.75V

result of that the detection winding (L1),which detects a change of voltage in a secondary side, connected to the

sensing terminal (Pin No. 7) has the current in accordance with an output signal from an output voltage

detection circuit (an error amplifier) built in. As an AC input voltage to the power supply gets the higher and a

load current the smaller, the current flowing to the SENS terminal gets the larger, and the ON-time gets the

shorter.

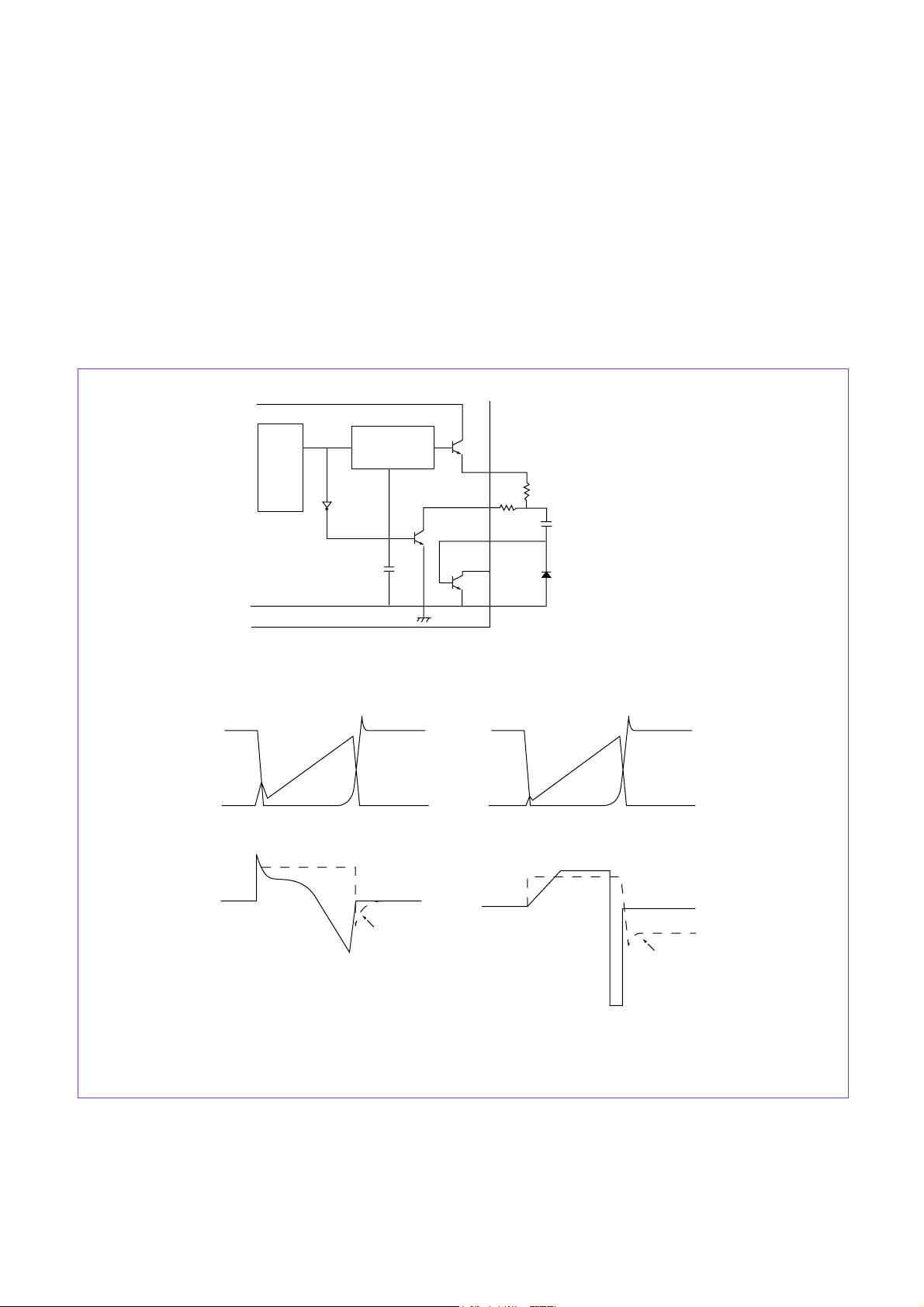

3) Function of INH terminal (Pin #6), control of OFF-time

Signal to the INH terminal is used as inputs to COMP.1 and COMP.2 inside of the control IC. A threshold voltage

of COMP.1 VTH1 is set at 0.75V (Ta=25°C) and an input signal to a drive circuit becomes almost 0V (the power

transistor is in OFF mode) when a voltage at the INH terminal reaches the VTH1. As long as the INH terminal

voltage does not get lower than VTH1. the power transistor sustains OFF mode. On the other hand, a threshold

voltage of COMP.2 VTH2, is set at 1.5V (Ta=25°C).When the INH terminnal voltage reaches VTH2, an output from

COMP.2 reverses and, as a result, C2 starts firing and a voltage across C2 drops to almost 0V in a moment. As

the result of this immediate discharge of C2, the OFF-time of the oscillator which has been determined by the

product of C2 and R2 (⁄ 55 ¥ sec) can be quicker up to approx. 2¥sec. As long as the INH terminal voltage

does not get lower than V

TH2, AVoltage across C2 stays at almost 0V and a output from the oscillator keeps the

power transistor being on. The relation between the INH terminal voltage and the function of the oscillator

described above is shown in Fig. 6 and Fig. 7

Osc.

Output

PTR

Fig .6 Operation Waveforms of INH Terminal(VTH1)

INH

Ter. Voltage

ON

OFF

TH1

V

20

Osc.

Output

PTR

C2 ACROSS

Voltage

Fig .7 Operation Waveforms of INH Terminal(VTH2)

2.3V

0V

INH

Ter. Voltage.

ON OFF

V

TH2

Page 23

9

VIN

6

INH

2

GND

C808

R807 L1

D805

D803

S1

+

Fig 8 Operation Circuit

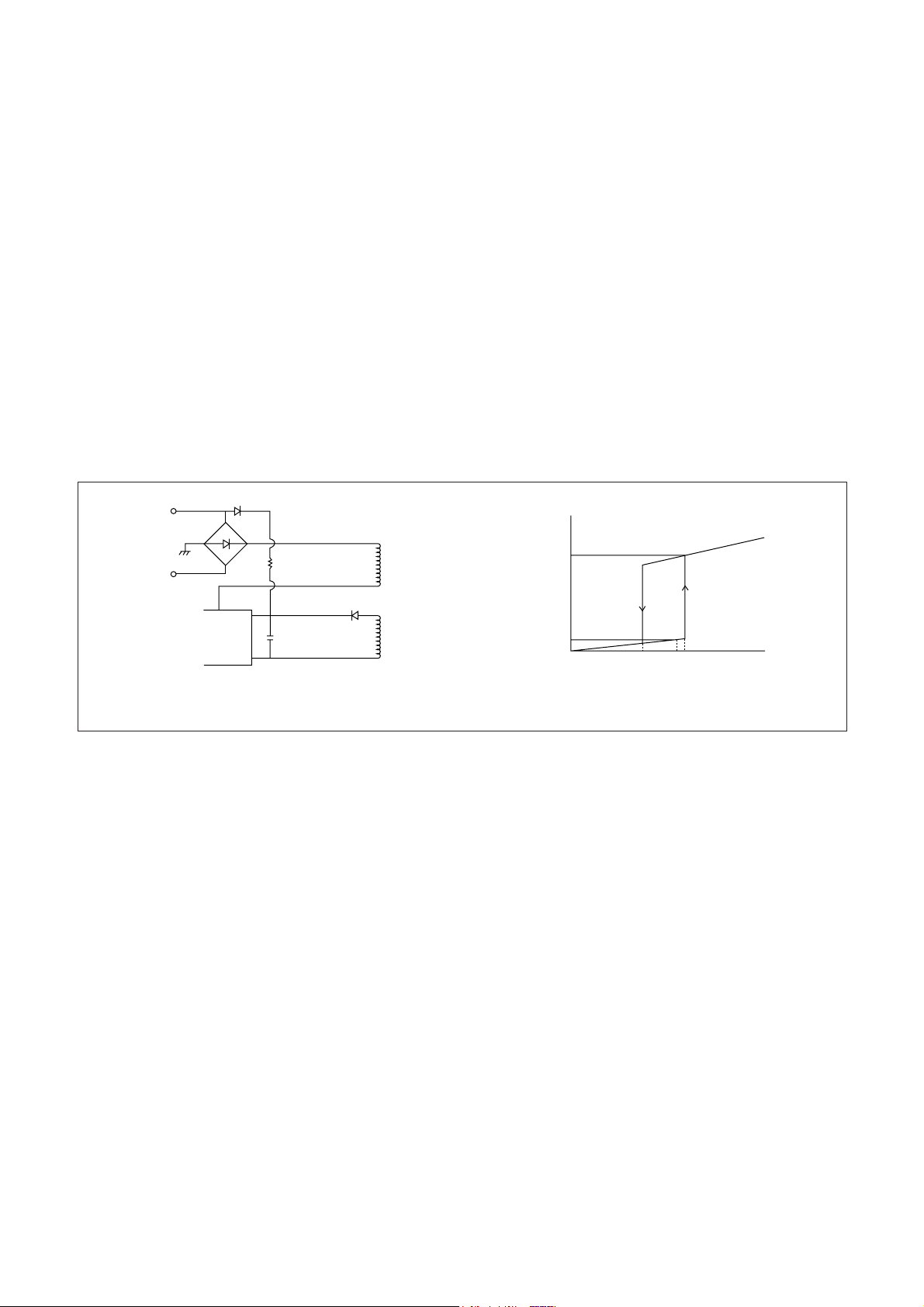

4) Quasi-resonant operation

0V

0V

Fig 9 Waveforms of VCE and VINH at Quasi-resonant Operation

VCE

INH Terminal

Voltage

tr

V

THI

By inputting a voltage signal which is synchronized with the energy discharge time of a secondary winding of a

transformer to the. INH terminal, quasi-resonant operation can be achieved. As shown in Fig. 8 , the voltage of

L1 winding which is synchronized. with the energy discharge time of a secondary winding. S1. shall be input to

the INH terminal through D805 and R807. Since V

TH2 is set at 1.5V typical, a voltage at the INH terminal. VINH,

shall be set at 2V.

Fig. 9 shows waveforms of VCE, Ic and VINH of the transistor, voltage across C808 in the oscillator as well as an

output from the oscillator when operating in quasi-resonant mode.

when the power transistor turns off and a voltage higher than VTH2 is applied to the INH terminal, C808

immediately discharges and then starts charging again. Even after the discharge of energy of a secendary

winding is completed, VINH does not immediately increases. When it gets lower than VTH2 after the time,tr, which

is determined by the production of internal impedance of the IC and CINH, has past, the transistor turns on.

21

Page 24

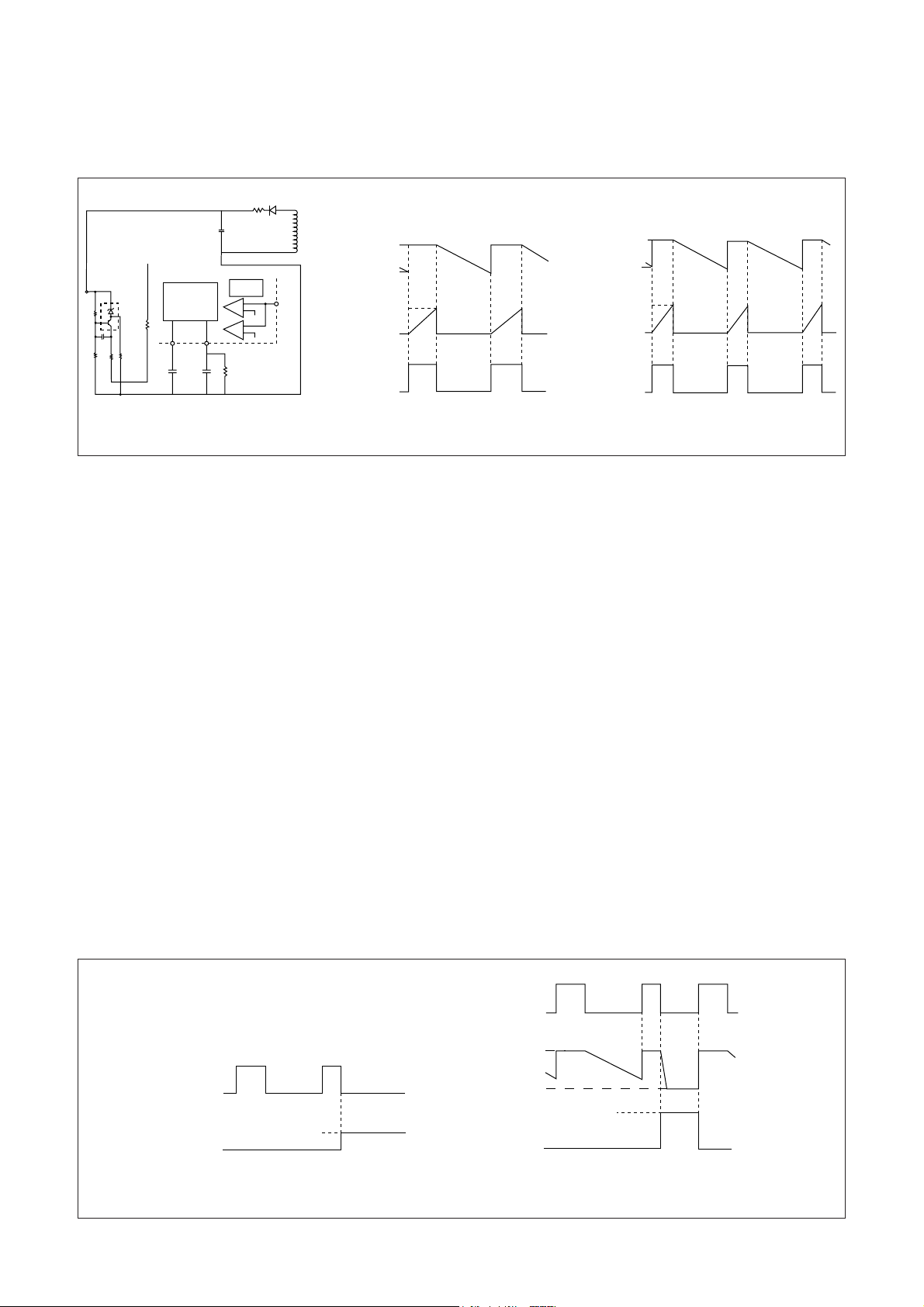

5) Drive circuit

OSC

Drive

R810

C805

D806

Fig .10 D806 and C805 function to reverse-blas between the base and the emitter

of the transistor during its off state.

Fig .10-1 Waveforms of Conventional

RCC Power Supply

Fig .10-2 Waveforms of power Supply

Using STR-S5707

VCE

IC

0

VCE

IC

0

V

BE

I

B

Reveres

bias

V

BE

I

B

Reveres

bias

The STR-S5707 applies the proportional drive system in order to minimize turn-on and satruration loss, and

storage time. In the conventional RCC system, turn-on loss and switching noise due to the surge current

appearing when the power transistor turns on are high as because the transistor is driven by the drive current

shown in Fig. 10-1. In addition, since is decreases linearly when the transistor turn off and a peak value of IB2 is

not large, the storage time is long and the VCE(sat) voltage is high, which results in large turn-off loss. The circuit

and the waveforms of the proportional drive system which is applied to the STR-S5707 in order to reduce these

switching loss and shorten the storage time are shown in Fig . 10 and Fig. 10-2 respectively.

22

Page 25

6) OCP (overcurrent protection) function

Drive

OSC

+

–

-1V

5.OCP

2.GND

R811

Fig 11 Overcurrent protection Circuit

Overcurrent protection is performed pulse by pulse by directly detecting collector current of the power transistor.

Configuration of the OCP circuit is shown in . Detecting voltage is set to -1V below a reference point of GND

(ground). In additlon, since the detecting voltage is set by a comparator, very stable characteristics against

temperature is achieved and drift of the detecting voltage against temperature change is almost 0V.

7) Latch circuit

It is a circuit which sustains an output from the oscillator low and stops operation of the power supply when

overvoltage protection (OVP) circuit and thermal shutdown (TSD) circuit are in operation. As the sustaining

current of the latch circult is 500¥A maximum when V

the off state as long as current of 500¥A minimum flows to V

prevent a malfunction to be caused by a noise and so on, delay time is provided by C1 incorporated in the IC

IN terminal voltage is 4V. the power supply circuit sustains

IN terminal from a start-up resistor. In order to

and, therefore, the latch circuit operates when the OVP of TSD circuit is in operation, of an external signal input

is provided. for about 10¥sec or longer.In addition, even after the latch circuit start operating, the constant

voltage regulator (Reg) circuit is in operation and the circuit current is at high level. As a result. V

voltage rapidly decreases. When VIN terminal voltage becomes lower than the shutdown voltage, VIN(OFF),

(4.9V typical), it starts in -creasing as the circuit current is below 500¥A. When it reaches the ON-state voltage.

V

IN(ON), (8V typical), VIN terminal voltage starts decreasing because the circult current increases again.

23

IN terminal

Page 26

when the latch cirguit is on. VIN terminal voltage increases and decreases with- in the range from 4.9V typical to

Fig 12 Typical VIN Terminal Voltage Waveform When Latch Circuit Is Operating

8V

(TYP)

VIN

4.9V

(TYP)

0

8V typical and is prevented from abnormally rising. Fig. 12 shows an example of VIN terminal voltage

waveform.Cancellation of the latch-is done by decreasing VIN terminal voltage below 3.3V. The power supply

can be restarted after disconnecting an AC input to the power supply once.

8) Thermal shutdown, circuit

It is a circuit to trigger the latch circuit when the frame temperature of the IC exceeds 150°C (typical). Although

the temperature is actually sensed at the control chip. It works against overheating of the power transistor as

the power transistor and the control IC are mounted on the same lead frame.

9) Overvoltage protection circuit

It is a circuit to trigger the latch circuit when V

IN terminal voltage exceeds 11V (typical). Although it basically

functions as protection of VIN terminal against overvoltage, since VIN terminal is usually supplied from the drive

winding of the transformer and the voltage is proportional to the output voltage, it also functions against the

overvoltage of secondary output which causes when the control circuit opens or in some other events.

24

Page 27

5.OCP (OVER CURRENT PROTECTION) CIRCUIT

+

C816

100µ

16V

R821

123 [V] LINE

1W 0.68(F)

R820

22K

1/4W

R823

8.2K

1/4W

C815

4.7µ

50V

Q806

KSA1013Y

R822

20K

1/4W

R826

20K

1/4W

D810

UZ-5.1

R824

22K

1/4W

I701 #29

(OCP)

FBT

A

C

B

This circuit is designed to protect the circuit from over current due to overload occurred at the rear of 132[V]

line.

1) CONFIGURATION OF OCP CIRCUIT

2) EXPLANATION OF THE OPERATION

¤ There is very little voltage drop at £ R821(1W 0.68) of 123 [V] line.

¤ŁIn case that the overload occurs at the rear of 123[V] line, the increase of the voltage drop at R821 bring

down the base voltage of the Q806 so as to drive the Q806

¤ØBecause of the overload at the rear of the R821, the voltage of the £ point decreases. And this makes Q806

turn on so that a voltage is applied to the #29 of I701.

¤ŒIn case that OCP operates by the #29 of the I701, the set is protected by power off (#32 of I701¡ LOW).

25

Page 28

F.IC BLOCK DIAGRAM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

SIF IN

RF AGC VR

APC1 FILTER

AUDIO FILTER

VCO

VCO

AFT OUT

COMP. VIDEO OUT

INT VIDEO IN

CONTRAST

EXT. AUDIO IN

SHARPNESS

EXT. VIDEO IN

GND

VIDEO OUT

COLOR

TINT

BRIGHTNESS

VERT. OUT

50/60

AFC

HOR. X-TAL

HOR. VCC

HOR. OUTPUT

FBP IN/BGP OUT

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

FM-DET OUT

AUDIO OUT

RF AGC OUT

IF GND

VIF INPUT

VIF INPUT

IF AGC

VIF VCC

SIF VCC

APC FILTER

X-TAL

X-TAL

VCC

DEMO OUTUT(R-Y)

DEMO OUTUT(R-Y)

ALC INPUT(R-Y)

ALC INPUT(B-Y)

R-OUT

G-OUT

B-OUT

BLACK STRETCH

OSD R

OSD G

OSD B

OSD Ys IN

X-TAL SW

FILTER-REF/

S-VHS SW

1.LA7688: VIF/SIF/VIDEO/CHROMA/DEFLECTION 1-CHIP IC

26

Page 29

2.µ-COM : DMC42C200N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

NTSC-M

PAL-M

AC DOWN DETECT

SD

REMOCON IN

KEY IN 0

KEY IN 1

KEY IN 2

KO 0

(TIMER)

KO 1

KO 2

(CLOCK)

(DATA)

ENABLE

AFC

TINT

COLOR

SHARP

CONTRAST

BRIGHT

VOLUME

/S.MUTE

(OPEN DRAIN)

/V.MUTE

(OPEN DRAIN)

TV/VIDEO

(OPEN DRAIN)

POWER

SCREEN OUT

(PUSE-PULL)

OCP IN

50/60 IN

C. IDENT IN

(PUSH PULL)

osd IN

OSD B

OSD G

OSD R

RCO/PWM14

R83

RO3/INT3

RO2/INT2

RO1/INTO/TIMI

ROO/INTO/TIMO

XIN

XOUT

/RESET

R82

GND

R81

R80

Vcc

R23

R22

R20/PCL

R21/AFC IN

OSC IN

OSC out

RC1/PWM60

RC2/PWM61

RC3/PWM62

PWM80

PWM81

PWM82

R30

R31

R32

R33

R10

R11

R12

R13

OSD Ys

OSD B

R61/OSD G

R60/OSD R

/VS

/HS

27

Page 30

3.LC89950 : CCD DELAY LINE

B-Y

IN

5

B-Y

OUT

3

RD

2

OUT

1

VSS

14

BGP

IN

13

VDD

12

VDD

6

R-Y

IN

7

4MHz

OUT

8

COMP

9

PC OUT

11

VCO IN

10

VSS

4

Ø1 Ø2

Ø1 Ø2

CLAMP

CLAMP

AUTO BIAS

AUTO BIAS

BGP

BGP

4MHz OSC.

DUTY Compensation

vco

CCD

254.5 BIT

CCD

254.5 BIT

CLOCK DRIVER

TIMING

1/256 COUNTER

(S&H.AMP)

(S&H.AMP)

Pump-up

BGP

BGP

Wave Forming

Phase comporator

28

Page 31

3.LOCAL KEY & OPTION SW

6

10

12

13

15

16

KEY IN 0

KEY IN 1

KEY IN 2

KEY -O 0

KEY -O 1

KEY -O 2

ROO/INTO/TIMO

R82

I701

R81

R80

R23

R22

CH –

CH +

AUTO-ON TV/VID

LANGUAGE

VOL – MENU

VOL +

29

Page 32

4.STR-S5707 : POWER IC

INH-1

REF

OCP

REF

INH-2

REF

INH-3

REF

9

7

6

8

4

3

1

2

5

START UP

PRE REG OSC

T.S.D

OVP LATCH

V IN

INH

PROPOTIONAL

DRIVE

Tr2

R6

PNP +2Di

R7 R8 R9

Tr1

R4

R4

R3

R1

C1 C4 R5C2 C3R2

DIRVE

SINK

B

C

GND

OCP

SENS

Internal Circuit Constants

R1 TON Adjustment Trimming Resistor R8 2.5KΩ C3 820pF

R2 TOFF Adjustment Trimming Resistor R9 35KΩ C4 0.01¥ F

R3 1.0KΩ C1 3300pF C5 1500pF

R4 100Ω C2 0.01¥ F

R5 85Ω

R6 Vs Adjustment Trimming Resistor

R7 14KΩ

Function of Terminal

Terminal symbol Description

1 C Collector Terminal

2 GND Ground Terminal

3 B base Terminal

4 SINK Sink Terminal

5 OCP Overcurrent Protection Terminal

6 INH Inhibit Terminal

Latch Terminal

7 SENS Sensing Terminal

8 DRIVE Drive Terminal

9V

IN VIN Terminal

1 2 3 4 5 6 7 8 9

Front

30

Page 33

5.LA7837 : VERTICAL IC

Power supply (+B1)

Vertical trigger input

Time constant

Vertcal height control

50/60Hz vertical size

control signal input

Ramp wavefom generation

AC/DC feedback input to

vertcal output section

Power supply (+B8)

Pump-up output

OSC blocking

GND

vertcal output

Power supply for vertical output

1 2 3 4 5 6 7 8 9 10 11 12 13

Vert

Ting

Input

One

Shot

Multi

Pump

Up

Vert.

Drive

Ramp

Generator

Vert.Size

Control

S.W.

Vert.

out

Thermal protection

31

Page 34

§

OK

OK

OK

OK

OK

OK

OK

NG

NG

NG

NG

NG

CHECK THE SPEAKER

CHECK THE VOLTAGE OF

PIN 2 OF I601

CHECK THE PIN 6 AND 8

OF I601 AT THAT

SOUND VOLUME MAX.

CHECK THE PIN 51 OF I501

CHECK AFT AND CHECK THE

PIN 52 VOLTAGE OF I501

CHECK/REPLACE Z501

REPLACE SPEAKER

CHECK/REPLACE

R606, I601

CHECK PIN 5 OF I601

CHECK/REPLACE I701

CHECK/REPLACE C604

REPLACE I501

TROUBLE SHOOTING CHARTS

¡ÆNO SOUND

¡ÆNO NO-SCREEN DISPLAY

CHECK/REPLACE R771, 772, 773

514, 587, C514, 515, AND 516

OK

CHECK/REPLACE I501

TURN OFF THE MAIN POWER SW

AND TURN ON THE TV SET AGAIN

CHECK THE WAVEFORM OF PIN 23, 24, 25, 26 OF I701

OK

CHECK THE WAVEFORM OF

CHECK/REPLACE I501, R759

NG

Q704

OK

CHECK THE WAVE FROM OF

NG

NG

PIN 21, 22 OF I701

REPLACE I701

CHECK/REPLACE

OK

Q704

32

Page 35

OK

OK

OK

OK

OK

OK

NG

NG

NG

NG

CHECK WAVEFORM OF PIN20 OF I501

MEASURE THE VOLTAGE

OF PIN 8, 13 OF I301

CHECK THE WAVEFORM

OF PIN 12, OF I301

CHECK THE CONNECTING

OF P401

CHECK/REPLACE D.Y

DISCONNECT D302 AND

MEASURE THE VOLTAGE

REPLACE I301

CHECK/REPLACE R318

CHECK/REPLACE T402

CHECK/REPLACE I501

§ OUT OF VERTICAL SIZE

CHECK THE VOLTAGE OF PIN 21 OF I501

N.B. : NTSC / PAL-M:H/PAL-N:L

OK

CHECK Q502

NG

OK

CHECK/REPLACE I301 REPLACE Q502

§ NO VERTICAL SCAN (ONE HORIZ. LINE RASTER)

NG

CHECK THE NTSC/PAL SW

OK

REPLACE I501

33

Page 36

OK

OK

OK

OK

NG

NG

CHECK THE VOLTAGE OF PIN

21 OF I501 (HIGH)

CHECK/REPLACE Q502 CHECK PIN 17 OF I501

REPLACE X501, C507

CHECK/REPLACE I701

CHECK/REPLACE I501

REPEAT ON COLOR (GENERAL) PROCESS

CHECK/REPLACE

I501

§ NO COLOR (GENERAL)

(PUSH THE REMOCON CONTROL BUTTON FOR COLOR MAX)

OK NG

RECEIVE A COLOR BAR SIGNAL

WITH PATTERN GENERATOR

CHECK THE CONTROL VOLTAGE OF I701 #39

CHECK THE COLOR/KILLER

VOLTAGE OF I501 #17

CHECK THE COMPOSIT VIDEO

SIGNAL ON #10 OF I501

CHECK/REPLACE I501

§ NO COLOR (AT PAL-N ONLY)

CHECK/REPLACE I701

NG

NG

CHECK/REPLACE R527, L502, Z502,

Q503, R525 AND R528

34

Page 37

OK

OK

OK

OK

NG

NG

NG

RECEIVE A COLOR BAR SIGNAL

WITH SIGNAL GENERATOR

WHETHER IS THE COLOR

NORMAL OR NOT?

CHECK I701 AND ANTENNA

CHECK/REPLACE

REPLACE I701

REPLACE D508

CHECK THE VOLTAGE OF PIN1

AND PIN 27 OF I701 (HIGH)

CHECK D508

CHECK/REPLACE X502 AND C508

CHECK/REPLACE I501

§ ON COLOR (AT PAL-M ONLY)

CHECK THE VOLTAGE OF PIN

21 OF I501 (HIGH)

OK

CHECK PIN 27 OF I701

(HIGH)

OK

CHECK THE PIN 2 OF

I701 (HIGH)

NG

OK

CHECK THE PIN 18 OF

I501 (LOW)

OK

CHECK THE CCD DELAY

LINE (I502)

§ ON COLOR (AT NTSC ONLY)

CHECK/REPLACE

NG

CHECK/REPLACE

Q502 AND I701

NG

CHECK/REPLACE Q702

C517, C518, R532

NG

CHECK PIN 22 AND 23

OF I501

NG

AND X401

OK

CHECK/REPLACE

I501

35

Page 38

OK

OK OK

OK

NG

NG NG

NG

OPEN THE SLIT OF TUNER IF OUTPUT AND

CONNECT TESTER LEADS TO PIF INPUT STAGE

(C101) AND EARTH MOMENTARILY

NOISE IS APPEARED OR NOT?

MEASURE THE VOLTAGE OF

EACH PIN OF I501

CHECK/REPLACE Z101

(SAW FILTER)

CHECK/REPLACE

I501

CHECK/REPLACE I501

AND PIF AGC

CIRCUIT

MEASURE THE

B+ VOLTAGE OF

TUNER

CHECK/REPLACE

+9V LINE

CHECK/REPLACE

TUNER

MEASURE THE VOLTAGE OF

AGC TERMINAL OF TUNER

(NORMAL: +3.0V~+7.6V)

§ NO RASTER (NOISE OR WEAK SOUND)

CHECK +9V/+7.6V LINE ON MAIN PCB

LOW OR ZERO

CHECK/REPLACE R202, I201

OK

CHECK/REPLACE D201, R201

§ NO PICTURE (RASTER REMAINS AND NO SOUND)

OK

CHECK/REPLACE

I501

OK

CHECK/REPLACE U101

36

Page 39

OK

OK

OK

OK

OK

OK

NG

NG

NG

HEATER ELEMENTS OF CRT

ARE LIGHTING OR NOT?

CHECK H.V AT

ANODE OF CRT

CHECK CONNECTOR

ASS' Y P401 AND PA501

CHECK/REPLACE I501

CHECK/REPLACE

T402

CHECK THE SUPPLY

VOLTAGE OF HEATER

CHECK/REPLACE

THE WIRING

PA501 AND P401

CHECK/REPLACE

R817 AND T402

CHECK/REPLACE HORIZ.

DRIVE TRANS(T401)

CHECK/REPLACE Q401/Q402

§ NO PICTURE (RASTER AND SOUND OK)

CHECK WHETHER THE BRIGHT & CONTRAST ARE

CONTROLLABLE OR NOT?

OK

NG

CHECK/REPLACE THE COMPOSITE

SIGNAL INPUT STAGE

AND VIDEO PARTS OF I501

OK

CHECK THE VCC VOLTAGE AT

#40 OF I501

OK

CHECK R, G, B SIGNAL

OUTPUT AND PA501

OK

CHECK/REPLACE +7.6V

LINE OF I501

§ NO RASTER (SOUND OK)

OK

CHECK/REPLACE THE

EACH PIN OF I501

OK

CHECK THE SIGNAL INPUT

CIRCUIT OF I501

NG

REPLACE THE SIGNAL

INPUT CIRCUIT

CHECK THE VOLTAGE OF

+185V ON CRT BOARD

NG

CHECK/REPLACE +185V

OK

REPLACE T402

37

Page 40

OK

OK

OK

OK

OK

NG

NG

NG

NG

CHECK THE PIN 14 OF I501

CHECK THE AV SIGNAL OF

AV JACK JV01 AND JV02

CHECK/REPLACE

C540, CA01, RV02,RA01

CHECK/REPLACE

I501

CHECK/REPLACE AV

JACK JV01 AND JV02

CHECK #33

OF I701

CHECK/REPLACE

I501

CHECK THE DC VOLTAGE AT

#1 OF I501

CHECK/REPLACE

I701

CHECK/REPLACE R555,

R556, R562 AND Z501

§ AV DOES NOT OPERATE (TV SIGNAL IS OK)

38

Page 41

OK

NG

OK

OK

OK

OK

OK

OK

NG

NG

(140V OR MORE)

NG

NG

NG(OV)

NG

CHECK FUSE F801

ON MAIN PCB

REPLACE THE FUSE

NEW FUSE ALSO OPENS

CHECK AND REPLACE

D802, I801

CHECK +123V LINE

ON MAIN PCB

CHECK 5.1V LINE OF

MAIN PCB

CHECK/REPLACE

D809 AND D704

CHECK/REPLACE +11V,

+9V AND +180V

CHECK/REPLACE Q801,

Q802 AND I802

CHECK/REPLACE I701

CHECK/REPLACE I501

CHECK/REPLACE HORIZ.

OUTPUT DRIVE CIRCUIT

CHECK/REPLACE

T801 AND I801

CHECK THE VOLTAGE

AT PIN 9 OF I801

CHECK/REPLACE

D827 AND Q827

CHECK/REPLACE I801

§ POWER FAILS TO TURN ON (NO RASTER, NO SOUND DOES NOT TURN ON)

39

Page 42

§ Replacement Parts List

✔ Caution:In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

A000 CORD POWER 4859901111 KKP-419CKLCE-2F(2.1ME) 1

A001 PCB MAIN 4859802096 330X246(330X246) 1

C101 C CERA CCZF1E103Z 25V F 0.01MF Z(AXIAL) 1

C103 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C106 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP 1

C107 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C108 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP 1

C112 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C116 C ELECTRO CEXF1E101V 25V RSS 100MF (6.3X11) TP 1

C117 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C121 C CERA CCZB1H102K 50V B 1000PF K (AXIAL) 1

C201 C CERA CCXB2H102K 500V B 1000PF K (TAPPING) 1

C202 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C203 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C204 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C207 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C208 C ELECTRO CEXF1E221V 25V RSS 220MF (8X11.5) TP 1

C301 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C302 C MYLAR CMXM2A103J 100V 0.01MF J (TP) 1

C303 C MYLAR CMXL1H105J 50V MEU 1MF J 1

C304 C ELECTRO CEXD1H109Q 50V RT 1MF (6.3X11) TP 1

C305 C CERA CZCH1H100J 50V CH 10PF J (AXIAL) 1

C306 C ELECTRO CEXF1H101V 50V RSS 100MF (8X11.5) TP 1

C307 C ELECTRO CEXF1E102V 25V RSS 1000MF (13X20) TP 1

C308 C MYLAR CMXM2A104J 100V 0.1MF J (TP) 1

C309 C CERA CCXB2H102K 500V B 1000PF K (TAPPING) 1

C310 C ELECTRO CEXF1V471V 35V RSS 470MF (10X20) TP 1

C401 C MYLAR CMYH3C602J 1.6KV BUP 6000PF J 1 14¡–ONLY

CMYH3C752J 1.6KV BUP 7500PF J 1 20¡–ONLY

C402 C CERA CCXB2H222K 500V B 2200PF K (TAPPING) 1

C403 C ELECTRO CEXF2C109V 160V RSS 1MF (6.3X11) TP 1

C404 C CERA CBZR1C152M 16V Y5R 1500PF M (AXIAL) 1

C405 C CERA CCXB3D271K 2KV B 270PF K (T) 1

C406 C ELECTRO CEXF2C109V 160V RSS 1MF (6.3X11) TP 1

C407 C MYLAR CMYE2D474J 200V PU 0.47MF J 1

C409 C MYLAR CMXM2A104J 100V 0.1MF J (TP) 1

C504 C ELECTRO CEXF1H338V 50V RSS 0.33MF (5X11) TP 1

C505 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C506 C ELECTRO CEXF1H478V 50V RSS 0.47MF (5X11) TP 1

C507 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C508 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C509 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C510 C MYLAR CMXM2A103J 100V 0.01MF J (TP) 1

C511 C MYLAR CMXM2A103J 100V 0.01MF J (TP) 1

C512 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C513 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C514 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C515 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C516 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C517 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C518 C MYLAR CMXM2A333J 100V 0.033MF J (TP) 1

C519 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP 1

C520 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C522 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

41

Page 43

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

C523 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP 1

C524 C ELECTRO CEXF1H478V 50V RSS 0.47MF (5X11) TP 1

C525 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C526 C CERA CCZB1H561K 50V B 560PF K (AXIAL) 1

C527 C CERA CCZB1H102K 50V B 1000PF K (AXIAL) 1

C528 C CERA CZSL1H510J 50V SL 51PF J (AXIAL) 1

C529 C CERA CZSL1H330J 50V SL 33PF J (AXIAL) 1

C530 C CERA CCZB1H561K 50V B 560PF K (AXIAL) 1

C533 C MYLAR CMXM2A104J 100V 0.1MF J (TP) 1

C534 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C536 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP 1

C537 C ELECTRO CEXF1E470V 25V RSS 47MF (5X11) TP 1

C538 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C539 C CERA CCZB1H102K 50V B 1000PF K (AXIAL) 1

C540 C ELECTRO CEXF1H339V 50V RSS 3.3MF (5X11) TP 1

C542 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C543 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C544 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C546 C CERA CCZB1H121K 50V B 120PF K (AXIAL) 1

C547 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP 1

C551 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C552 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C553 C CERA CCZF1E103Z 25V F 0.01MF Z (AXIAL) 1

C580 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C603 C MYLAR CMXM2A123J 100V 0.012MF J (TP) 1

C604 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C606 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C607 C MYLAR CMXM2A103J 100V 0.01MF J (TP) 1

C608 C CERA CCZF1H473Z 50V F 0.047MF Z (AXIAL) 1

C702 C ELECTRO CEXF1E101V 25V RSS 100MF (6.3X11) TP 1

C703 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C704 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C705 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C706 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C707 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C708 C CERA CZSL1H300J 50V SL 30PF J (AXIAL) 1

C709 C CERA CZCH1H160J 50V CH 16PF J (AXIAL) 1

C710 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

C711 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C712 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C713 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP 1

C714 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C715 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C716 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C717 C CERA CCZB1H102K 50V B 1000PF K (AXIAL) 1

C720 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C722 C CERA CCZB1H471K 50V B 470PF K (AXIAL) 1

C723 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C725 C CERA CCZB1H471K 50V B 470PF K (AXIAL) 1

C726 C CERA CCZB1H471K 50V B 470PF K (AXIAL) 1

C727 C CERA SEMI CBZF1H104Z 50V F 0.1MF Z (AXIAL) 1

C801 C LINE ACROSS CL1UC3104M WORLD AC250V 0.1UF M R.47 1

C802 C CERA CCYB3A472K 1KV B 4700PF K 1

C803 C CERA CCYB3A472K 1KV B 4700PF K 1

42

Page 44

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

C804 C ELECTRO CEYN2G181P 400V LHS 180MF (25X35) 1

C805 C ELECTRO CEXF1E221V 25V RSS 220MF (8X11.5) TP 1

C806 C ELECTRO CEXF1E221V 25V RSS 220MF (8X11.5) TP 1

C807 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP 1

C808 C CERA CCZB1H102K 50V B 1000PF K (AXIAL) 1

C809 C ELECTRO CEXF2A100V 100V RSS 10MF (6.3X11) TP 1

C810 C ELECTRO CEXF2C101V 160V RSS 100MF (16X25) TP 1

C811 C ELECTRO CEXF1C102V 16V RSS 1000MF (10X20) TP 1

C812 C CERA CBYB3D102K 2KV BL(N) 1000PF K 1

C813 C ELECTRO CEXF2C330V 160V RSS 33MF (13X20) TP 1

C814 C ELECTRO CEYF2C221V 160V RSS 220MF (18X35.5) 1

C815 C ELECTRO CEXF1H479V 50V RSS 4.7MF (5X11) TP 1

C816 C ELECTRO CEXF1E101V 25V RSS 100MF (6.3X11) TP 1

C817 C CERA CCXB2H102K 500V B 1000PF K (TAPPING) 1

C818 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C819 C ELECTRO CEXF2E470V 250V RSS 47MF (16X25) TP 1

C820 C CERA AC CH1FFF472M AC400V 4700PF F DE7150F 1

C822 C CERA AC CH1FFF472M AC400V 4700PF F DE7150F 1

C825 C CERA CCXB2H331K 500V B 330PF K (TAPPING) 1

C830 C CERA CBXB3D471K 2KV BL(N) 470PF K (T) 1

C950 C CERA CCXB3D102K 2KV B 1000PF K (TAPPING) 1

C951 C ELECTRO CEXF1H100V 50V RSS 10MF (5X11) TP 1

C953 C CERA CCZB1H221K 50V B 220PF K (AXIAL) 1

C954 C CERA CCZB1H271K 50V B 270PF K (AXIAL) 1

C955 C CERA CCZB1H221K 50V B 220PF K (AXIAL) 1

C956 C CERA CCZB1H271K 50V B 270PF K (AXIAL) 1

C957 C CERA CCZB1H221K 50V B 220PF K (AXIAL) 1

C958 C CERA CCZB1H271K 50V B 270PF K (AXIAL) 1

CA01 C ELECTRO CEXF1H109V 50V RSS 1MF (5X11) TP 1

D102 DIODE ZENER DMTZ5R1B-- MTZ 5.1-B (TAPPING) 1

D201 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D205 IC 1UPC574J-- UPC574J 1

D301 DIODE D1N4003--- 1N4003 (TAPPING) 1

D302 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D401 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D403 DIODE D1N4148--- 1N4148 (TAPPING) 1

D503 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D504 DIODE D1N4148--- 1N4148 (TAPPING) 1

D505 DIODE D1N4148--- 1N4148 (TAPPING) 1

D508 DIODE D1N4148--- 1N4148 (TAPPING) 1

D509 DIODE D1N4148--- 1N4148 (TAPPING) 1

D510 DIODE D1N4148--- 1N4148 (TAPPING) 1

D511 DIODE D1N4148--- 1N4148 (TAPPING) 1

D512 DIODE D1N4148--- 1N4148 (TAPPING) 1

D582 DIODE D1N4148--- 1N4148 (TAPPING) 1

D703 DIODE ZENER DUZ3R9B--- UZ-3.9B 1

D704 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D707 DIODE D1N4148--- 1N4148 (TAPPING) 1

D708 DIODE D1N4148--- 1N4148 (TAPPING) 1

D710 DIODE D1N4148--- 1N4148 (TAPPING) 1

D711 DIODE D1N4148--- 1N4148 (TAPPING) 1

D712 DIODE D1N4148--- 1N4148 (TAPPING) 1

D713 DIODE D1N4148--- 1N4148 (TAPPING) 1

D715 DIODE D1N4148--- 1N4148 (TAPPING) 1

43

Page 45

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

D716 DIODE D1N4148--- 1N4148 (TAPPING) 1

D717 DIODE D1N4148--- 1N4148 (TAPPING) 1

D718 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D719 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D720 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D721 DIODE D1N4148--- 1N4148 (TAPPING) 1

D801 VARISTOR DSVC471D14 SVC471D14A 1

D802 DIODE BRIDGE DPBS208GU- PBS208GU-CA 1

D803 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D804 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D805 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D806 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D807 DIODE D1N4003--- 1N4003 (TAPPING) 1

D808 DIODE DBYW95C--- BYW95C (TAPPING) 1

D809 DIODE DBYV95C--- BYV95C (TAPPING) 1

D810 DIODE ZENER DUZ5R1BM-- UZ-5.1BM 1

D812 DIODE D1N4937GP- 1N4937GP (TAPPING) 1

D827 DIODE ZENER DUZ7R5BM-- UZ-7.5BM 7.5V 1

D828 DIODE D1N4148--- 1N4148 (TAPPING) 1

DL01 LED DKLR114L-- KLR114L 1

F801 FUSE GLASS TUBE 5FSGB4022L

F801A CLIP FUSE 4857415001 PFC5000-0702 1

F801B CLIP FUSE 4857415001 PFC5000-0702 1

I201 IC REGULATOR 1KA7809--- KA7809 1

I301 IC 1LA7837--- LA7837 1

I301A HEAT SINK 4857027101 SPCC T1.0+SN 1

I301B SCREW TAPPTITE 7174301011 TT2 RND 3X10 MFZN 1

I501 IC VIDEO 1LA7688--- LA7688 1

I502 IC DELAY 1LC89950-- LC89950 1

I601 IC AUDIO 1TDA7056A- TDA7056A 1

I601A HEAT SINK 4857025400 A1050P-H24 T2.0 1

I601B SCREW TAPPTITE 7174301011 TT2 RND 3X10 MFZN 1

I701 IC MICOM 1DMC42C204 DMC42C2008-204 1

I703 IC MEMORY 124LC02B-- 24LC02B 1

I801 IC POWER 1STRS5707- STR-S5707 1

I801A HEAT SINK 4857024607 AL EX DG 1

I801B SCREW TAPPTITE 7174301011 TT2 RND 3X10 MFZN 1

I802 IC PHOTO COUPLER 1LTV817C-- LTV-817C 1

IL701 IC PREAMP 1TFMW5380- TFMW5380 1

J001 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J002 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J003 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J004 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J005 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J006 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J007 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J008 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J009 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J010 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J011 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J012 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J013 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J014 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J015 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

SEMKO TL 4A 250V MF51

1

44

Page 46

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

J016 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J017 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J018 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING Q-SERIES ONLY

J019 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J020 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J021 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J022 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J023 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J024 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J025 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J026 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J027 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J028 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J029 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J030 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J031 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J032 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J033 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J034 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J035 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J036 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J037 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J038 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J039 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J040 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J041 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J042 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J043 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J044 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J045 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J046 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J047 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J048 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J049 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J050 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J051 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J052 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J053 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J054 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J055 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J056 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J057 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J058 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J059 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J060 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J061 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J062 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J063 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J064 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J065 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J066 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J067 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J068 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J069 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

45

Page 47

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

J070 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J071 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J072 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J073 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J074 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J075 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J076 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J077 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J078 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J079 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J080 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J081 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J082 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J083 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J084 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J085 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J086 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J087 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J088 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J089 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J090 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J091 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J092 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J093 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J094 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J095 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J096 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J097 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J098 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J099 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J100 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J101 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J102 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J103 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J104 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J105 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J106 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J107 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J108 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J109 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J110 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J111 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J112 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J113 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING 14¡–ONLY

J114 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J115 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J116 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J117 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J118 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J119 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J120 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

J121 WIRE COPPER 85801065GY AWG22 1/0.65 TIN COATING

JP01 JACK EARPHONE 4859102130 YSC-1537 1

JV01 JACK PIN BOARD 4859109150 PH-JB-9615C 1

46

Page 48

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

JV02 JACK PIN BOARD 4859108350 YSC02P-4100-14A 1

L102 COIL CHOKE 58C9780027 TRF-1201B (0.97 UH) 1

L201 COIL PEAKING 5CPZ560K04 56UH K (AXIAL 10.5MM) 1

L402 COIL H-LINEARITY 58H0000020 L-76(76.5UH) 1 20¡–ONLY

L501 COIL PEAKING 5CPZ220K02 22UH K (AXIAL 3.5MM) 1

L502 COIL PEAKING 5CPZ150K02 15UH K (AXIAL 3.5MM) 1

L506 COIL VCO 58N0000S36 TRF-V003 1

L607 COIL BEAD 5MC0000100 MD-5 (HC-3550) 1

L701 COIL PEAKING 5CPZ560K02 56UH K (AXIAL 3.5MM) 1

L702 COIL PEAKING 5CPZ220K02 22UH K (AXIAL 3.5MM) 1

L801 FILTER LINE 5PLF302--- LF-302-801 1

L802 COIL BEAD 5MC0000100 MD-5 (HC-3550) 1

L804 COIL CHOKE 58C0000107 L-680 1

L805 COIL CHOKE 58C9430599 AZ-9004Y(94MH) 1

L901 COIL PEAKING 5CPZ820K02 82UH K (AXIAL 3.5MM) 1

P401 CONN WAFER 4859240020 YFW500-05 1

P601 CONN WAFER 485923162S YW025-03 (STICK) 1

P801 TERM PIN 4857417500 DA-IB0214(D2.3/DY PIN) 1

P802 CONN WAFER 4859242220 YFW800-02 1

P90 TERM PIN 4857417500 DA-IB0214(D2.3/DY PIN) 1

PA501 CONN AS 4850708N08 BIC-08T-25T+C-20T+ULW=400 1

PA601 CONN AS 4850703S11 YH025-03+YST025+USW=200 1

PA602 CONN AS 4850703S13 YH025-03+YST025+USW=500 1 T-SERIES ONLY

PA802 CONN AS 4850701S09 YFH800-01+YPT018+ULW=400 1

PWC1 CORD POWER AS 4859902910

PWC1A CONN WAFER 4859242220 YFW800-02 1

Q301 TR TKTC3198Y- KTC3198Y 1

Q401 TR TKTC3207-- KTC3207 (TP) 1

Q402 TR T2SD2499-- 2SD2499 1

Q502 TR TKTC3198Y- KTC3198Y 1

Q503 TR TKTC3198Y- KTC3198Y 1

Q504 TR TKTC3198Y- KTC3198Y 1

Q505 TR TKTC3198Y- KTC3198Y 1

Q506 TR TKTC3198Y- KTC3198Y 1

Q507 TR TKTC3198Y- KTC3198Y 1

Q508 TR TKTC3198Y- KTC3198Y 1

Q701 TR TKTA1266Y- KTA1266Y (TP) 1

Q702 TR TKTC3198Y- KTC3198Y 1

Q704 TR TKTC3198Y- KTC3198Y 1

Q705 TR TKTC3198Y- KTC3198Y 1

Q801 TR TKTC3198Y- KTC3198Y 1

Q802 TR TKTC3198Y- KTC3198Y 1

Q806 TR TKSA1013Y- KSA1013Y (TP) 1

Q807 TR TKTC3203Y- KTC3203-Y 1

Q808 TR TKTC3207-- KTC3207 (TP) 1

Q809 TR TKTC3198Y- KTC3198Y 1

Q810 TR TKTC3198Y- KTC3198Y 1

Q827 TR TKTD1414-- KTD1414 1

Q950 TR TKTC3229-- KTC 3229 1

Q951 TR TKTC3229-- KTC 3229 1

Q952 TR TKTC3229-- KTC 3229 1

R100 R CARBON FILM RD-AZ303J- 1/6 30K OHM J 1

R101 R SEMI FIXED RV5426223P RH0638C 22K OHM 1

R102 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

KKP419C+BL102NG+TUBE=2100

1

47

Page 49

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

R108 R CARBON FILM RD-AZ823J- 1/6 82K OHM J 1

R109 R CARBON FILM RD-2Z820J- 1/2 82 OHM J 1

R111 R CARBON FILM RD-AZ331J- 1/6 330 OHM J 1

R113 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R201 R FUSIBLE RF01Z229J- 1W 2.2 OHM J (TAPPING) 1

R202 R M-OXIDE FILM RS01Z479J- 1W 4.7 OHM J (TAPPING) 1

R203 R M-OXIDE FILM RS02Z240JS 2W 24 0HM J SMALL 1

R206 R M-OXIDE FILM RS02Z273JS 2W 27K OHM J SMALL 1

R301 R SEMI FIXED RV5426223P RH0638C 22K OHM 1

R302 R SEMI FIXED RV5426472P RH0638C 4.7K OHM B 1

R303 R CARBON FILM RD-AZ683J- 1/6 68K OHM J 1

R304 R CARBON FILM RD-AZ393J- 1/6 39K OHM J 1

R305 R CARBON FILM RD-AZ273J- 1/6 27K OHM J 1

R306 R CARBON FILM RD-AZ183J- 1/6 18K OHM J 1

R307 R CARBON FILM RD-AZ562J- 1/6 5.6K OHM J 1

R308 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R309 R CARBON FILM RD-AZ561J- 1/6 560 OHM J 1

R310 R CARBON FILM RD-2Z331J- 1/2 330 OHM J 1

R312 R M-OXIDE FILM RS01Z331J- 1W 330 OHM J (TAPPING) 1

R313 R CARBON FILM RD-2Z229J- 1/2 2.2 OHM J 1

R315 R CARBON FILM RD-AZ222J- 1/6 2.2K OHM J 1

R316 R CARBON FILM RD-AZ202J- 1/6 2K OHM J 1

R317 R CARBON FILM RD-AZ243J- 1/6 24K OHM J 1

R318 R FUSIBLE RF01Z309J- 1W 3 OHM J (TAPPING) 1

R401 R CARBON FILM RD-AZ561J- 1/6 560 OHM J 1

R402 R M-OXIDE FILM RS02Z153JS 2W 15K OHM J SMALL 1

R404 R CARBON FILM RD-4Z272J- 1/4 2.7K OHM J 1

R405 R M-OXIDE FILM RS02Z512JS 2W 5.1K OHM J SMALL 1

R406 R CARBON FILM RD-2Z154J- 1/2 150K OHM J 1 14¡–ONLY

RD-2Z124J- 1/2 120K OHM J 1 20¡–ONLY

R407 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R408 R M-OXIDE FILM RS01Z102J- 1W 1K OHM J (TAPPING) 1 20¡–ONLY

R409 R CARBON FILM RD-2Z153J- 1/2 15K OHM J 1

R410 R M-OXIDE FILM RS02Z512JS 2W 5.1K OHM J SMALL 1

R411 R CARBON FILM RD-4Z303J- 1/4 30K OHM J 1

R413 R M-OXIDE FILM RS02Z153JS 2W 15K OHM J SMALL 1

R414 R M-OXIDE FILM RS02Z153JS 2W 15K OHM J SMALL 1

R420 R CARBON FILM RD-4Z392J- 1/4 3.9K OHM J 1

R501 R SEMI FIXED RV5426103P RH0638C 10K OHM B 1

R503 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R504 R CARBON FILM RD-AZ752J- 1/6 7.5K OHM J 1

R505 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R506 R CARBON FILM RD-AZ472J- 1/6 4.7K OHM J 1

R507 R CARBON FILM RD-AZ472J- 1/6 4.7K OHM J 1

R514 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R517 R CARBON FILM RD-AZ391J- 1/6 390 OHM J 1

R519 R CARBON FILM RD-AZ433J- 1/6 43K OHM J 1

R520 R CARBON FILM RD-AZ154J- 1/6 150K OHM J 1

R525 R CARBON FILM RD-AZ471J- 1/6 470 OHM J 1

R527 R CARBON FILM RD-AZ331J- 1/6 330 OHM J 1

R528 R CARBON FILM RD-AZ561J- 1/6 560 OHM J 1

R531 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R532 R CARBON FILM RD-AZ332J- 1/6 3.3K OHM J 1

R533 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

48

Page 50

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

R535 R CARBON FILM RD-AZ823J- 1/6 82K OHM J 1

R538 R CARBON FILM RD-AZ331J- 1/6 330 OHM J 1

R539 R CARBON FILM RD-AZ332J- 1/6 3.3K OHM J 1

R540 R SEMI FIXED RV5426103P RH0638C 10K OHM B 1

R541 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R543 R CARBON FILM RD-AZ203J- 1/6 20K OHM J 1

R544 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R546 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R547 R CARBON FILM RD-AZ684J- 1/6 680K OHM J 1

R548 R CARBON FILM RD-AZ202J- 1/6 2K OHM J 1

R549 R CARBON FILM RD-AZ222J- 1/6 2.2K OHM J 1

R551 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R552 R CARBON FILM RD-AZ223J- 1/6 22K OHM J 1

R553 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R554 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R555 R CARBON FILM RD-AZ332J- 1/6 3.3K OHM J 1

R556 R CARBON FILM RD-AZ133J- 1/6 13K OHM J 1

R557 R CARBON FILM RD-AZ243J- 1/6 24K OHM J 1

R558 R CARBON FILM RD-AZ335J- 1/6 3.3M OHM J 1

R559 R CARBON FILM RD-AZ335J- 1/6 3.3M OHM J 1

R560 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R561 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R562 R CARBON FILM RD-AZ223J- 1/6 22K OHM J 1

R563 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R565 R CARBON FILM RD-AZ151J- 1/6 150 OHM J 1

R566 R CARBON FILM RD-AZ151J- 1/6 150 OHM J 1

R567 R CARBON FILM RD-AZ151J- 1/6 150 OHM J 1

R580 R CARBON FILM RD-AZ202J- 1/6 2K OHM J 1

R581 R CARBON FILM RD-AZ472J- 1/6 4.7K OHM J 1

R582 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R583 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R584 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R585 R CARBON FILM RD-4Z241J- 1/4 240 OHM J 1

R587 R CARBON FILM RD-AZ561J- 1/6 560 OHM J 1

R602 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R603 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R605 R CARBON FILM RD-2Z271J- 1/2 270 OHM J 1

R606 R FUSIBLE RF01Z109J- 1W 1 OHM J (TAPPING) 1

R701 R CARBON FILM RD-2Z241J- 1/2 240 OHM J 1

R702 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R703 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R704 R CARBON FILM RD-AZ473J- 1/6 47K OHM J 1

R705 R CARBON FILM RD-AZ101J- 1/6 100 OHM J 1

R706 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R707 R CARBON FILM RD-AZ101J- 1/6 100 OHM J 1

R708 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R709 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R711 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R712 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R713 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R714 R CARBON FILM RD-AZ471J- 1/6 470 OHM J 1

R715 R CARBON FILM RD-AZ392J- 1/6 3.9K OHM J 1

R716 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R717 R CARBON FILM RD-AZ472J- 1/6 4.7K OHM J 1

49

Page 51

LOC ITEM PARTS CODE DESCRIPTION NUMBER REMARK

R719 R CARBON FILM RD-AZ753J- 1/6 75K OHM J 1

R722 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R723 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R724 R CARBON FILM RD-AZ432J- 1/6 4.3K OHM J 1

R725 R CARBON FILM RD-AZ223J- 1/6 22K OHM J 1

R726 R CARBON FILM RD-AZ562J- 1/6 5.6K OHM J 1

R727 R CARBON FILM RD-AZ223J- 1/6 22K OHM J 1

R728 R CARBON FILM RD-AZ472J- 1/6 4.7K OHM J 1

R729 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R730 R CARBON FILM RD-AZ392J- 1/6 3.9K OHM J 1